Separation technology capable of solving mineral derichment problem in grinding and classification system

A classification system and mineral technology, applied in the field of sorting process, can solve the problems of mineral anti-enrichment, anti-enrichment, etc., and achieve the effect of reducing the amount of ore, reducing the load, and reducing the energy consumption of the mill

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

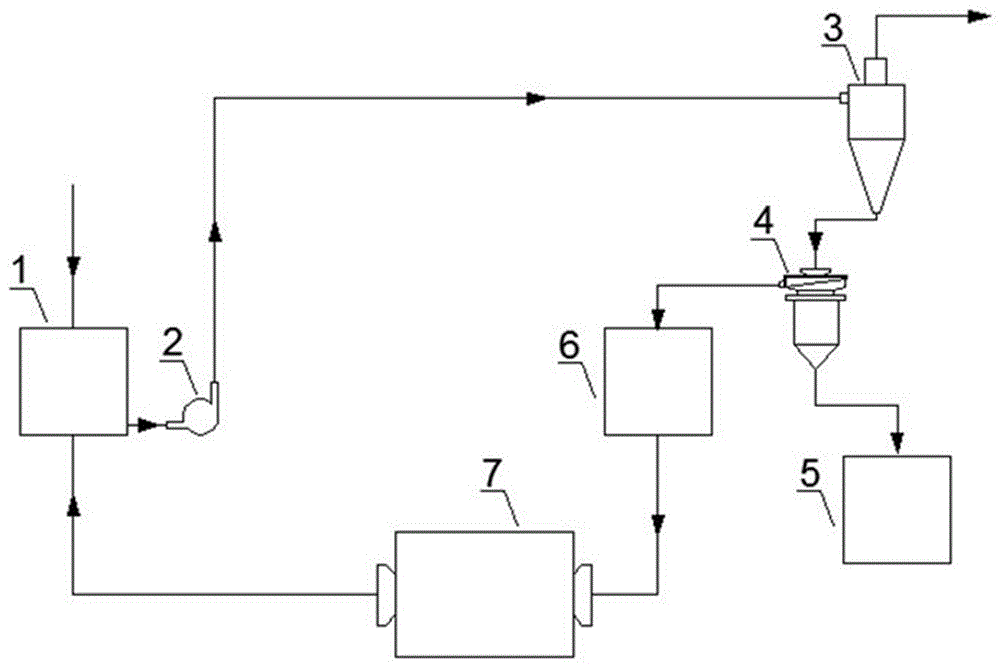

[0024] Example: such as figure 1 Shown is a schematic diagram of the sorting process structure to solve the problem of mineral anti-enrichment in the grinding and grading system, including: ore feeding box 1, ore feeding pump 2, cyclone 3, sorting equipment 4, concentrate tank 5, Concentrating equipment 6 and mill 7, the upper-level process pulp and the ore discharge of mill 7 are fed into the ore feeding box 1, and are lifted into the cyclone 3 through the ore feeding pump 2, and the overflow of the cyclone 3 The stream product enters the lower process, the underflow product of the cyclone 3 enters the sorting equipment 4, the sorting equipment 4 can get the concentrate product and enters the concentrate tank 5, and the tailings (joint organism) are fed into the concentration equipment 6, and the concentration equipment 6 The overflow is fed into the lower process, and the underflow product of the concentration equipment 5 is fed into the mill 7.

[0025] In this embodiment,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com