Patents

Literature

6825results about How to "Raise the grade" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

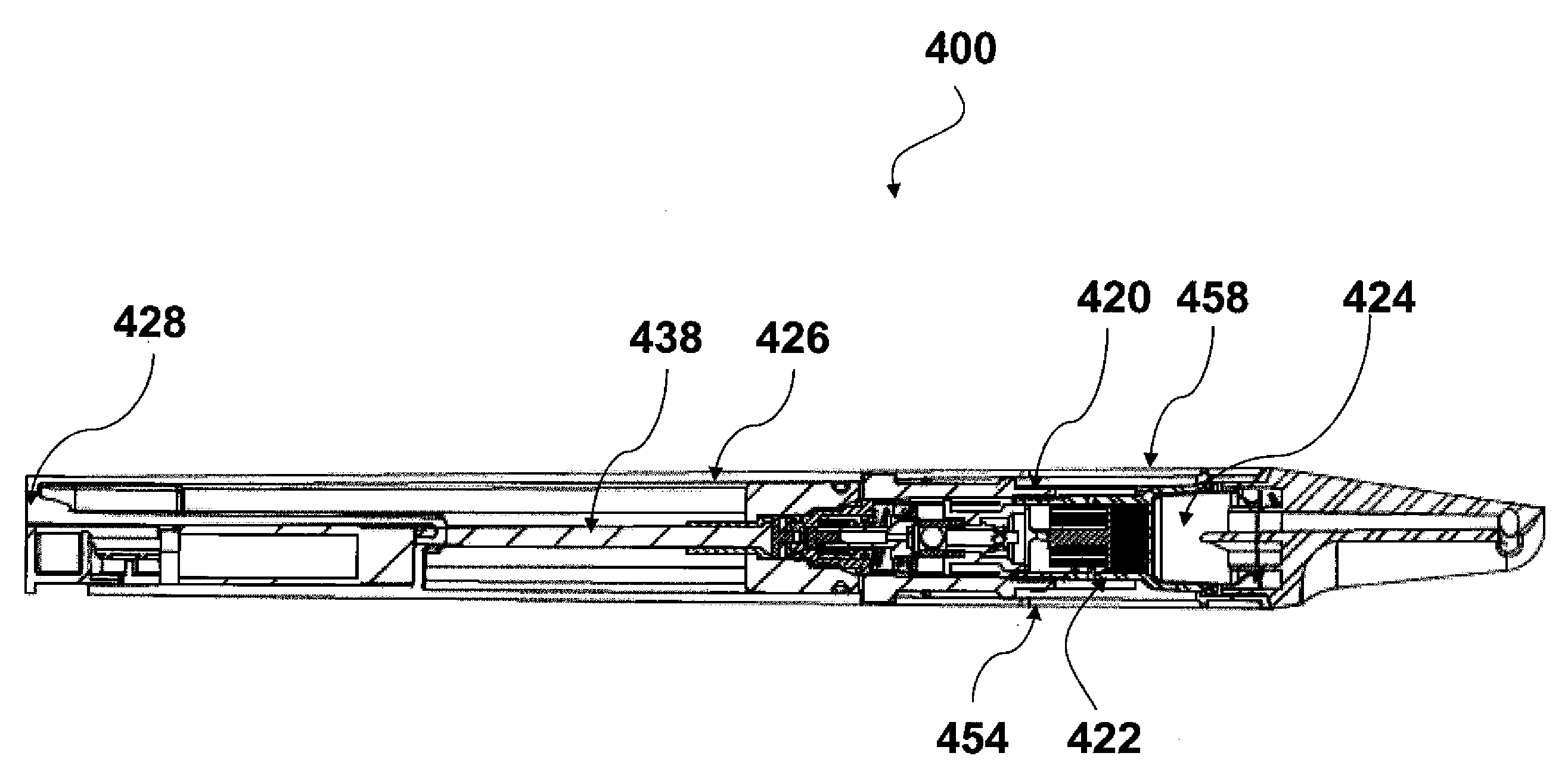

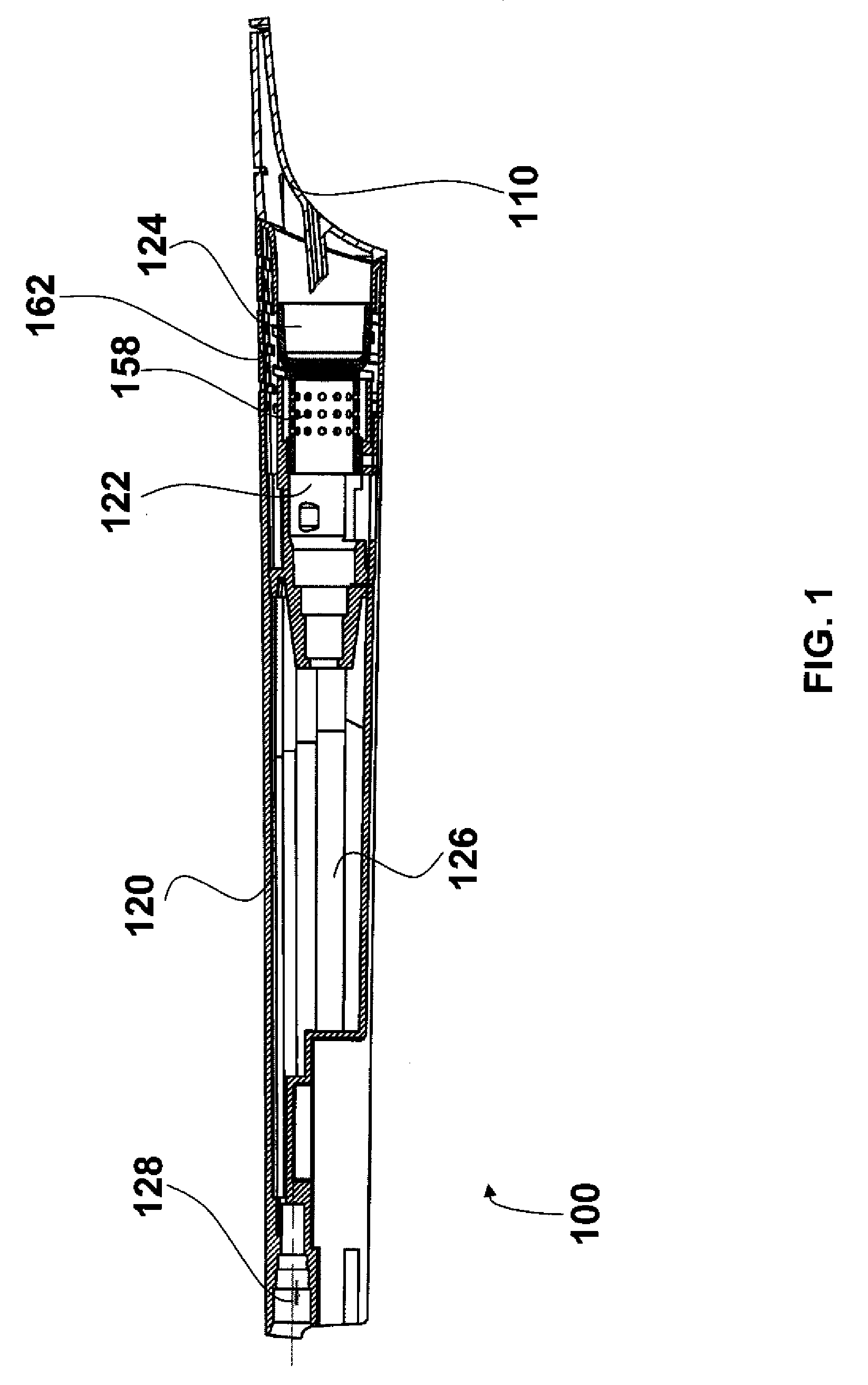

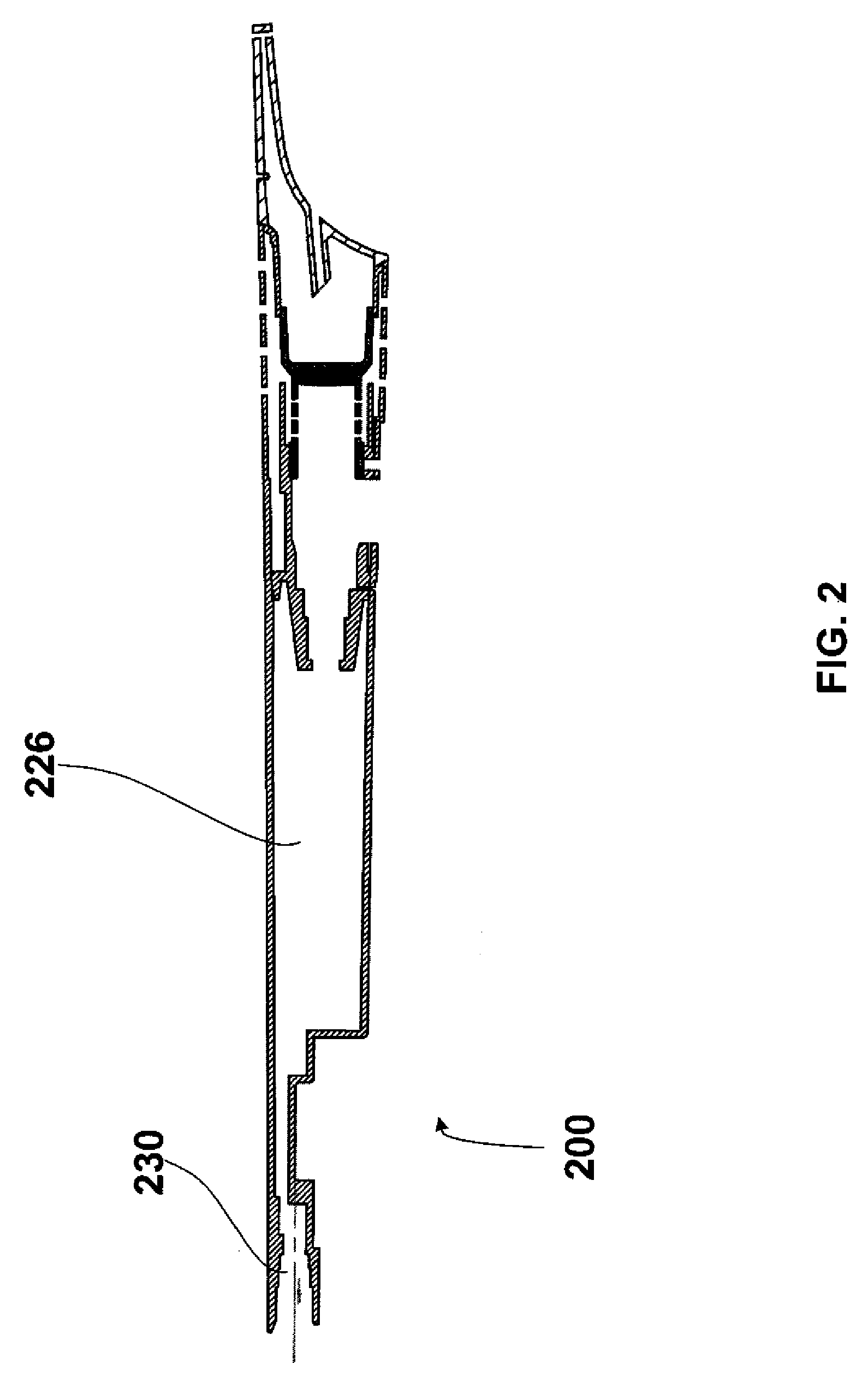

Aerosol devices and methods for inhaling a substance and uses thereof

ActiveUS20090151717A1Test may passRaise the gradeCigar manufactureSynthetic resin layered productsAnalyteChemical compound

Devices, cartridges, and method are described herein for emulating smoking wherein a device generates an aerosol for inhalation by a subject by heating a viscous material that can have a tactile response in the mouth or respiratory tract, while reducing Hoffman analytes and mutagenic compounds delivered to the user as compared to a common tobacco cigarette.

Owner:JLI NAT SETTLEMENT TRUST

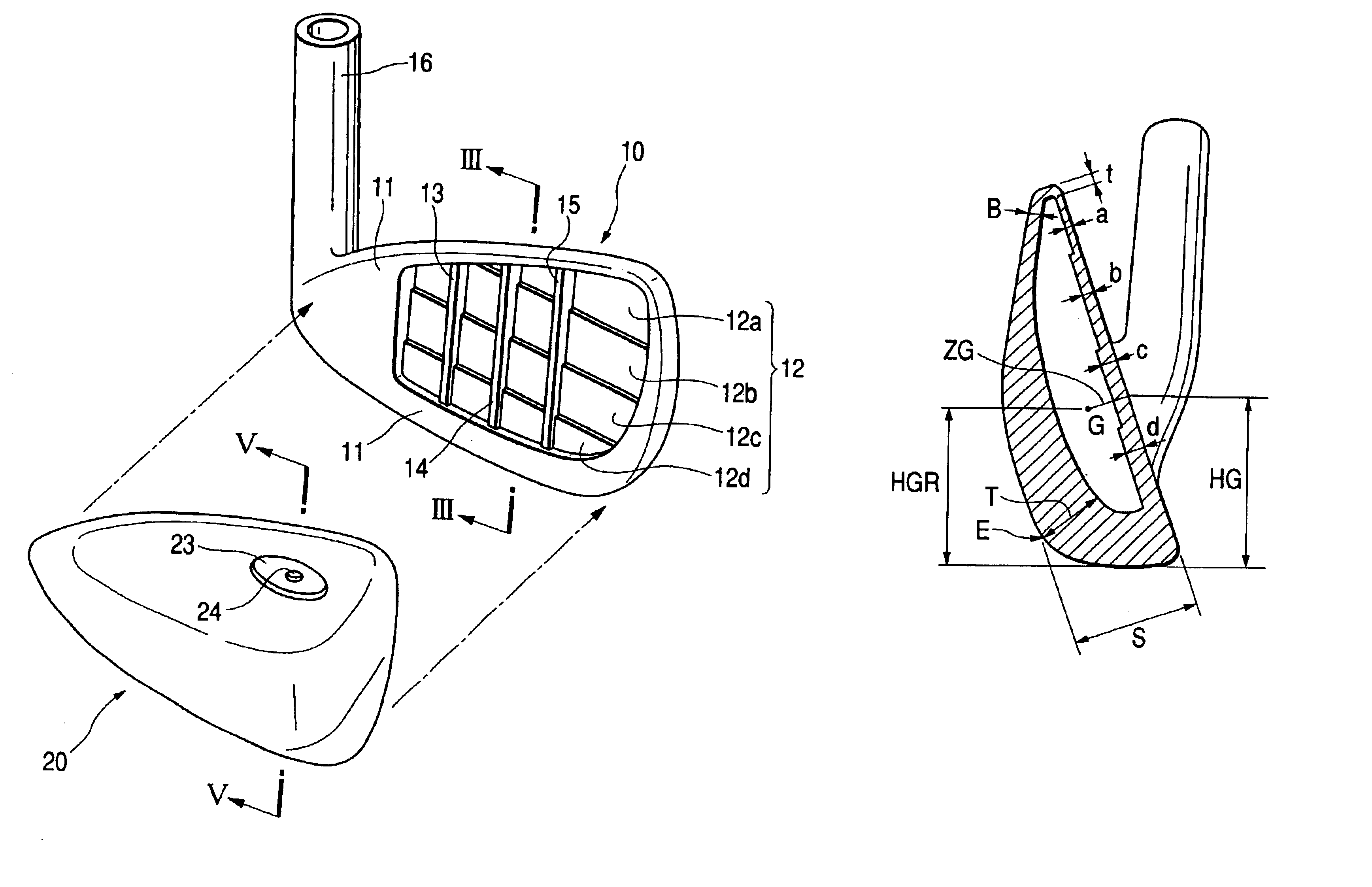

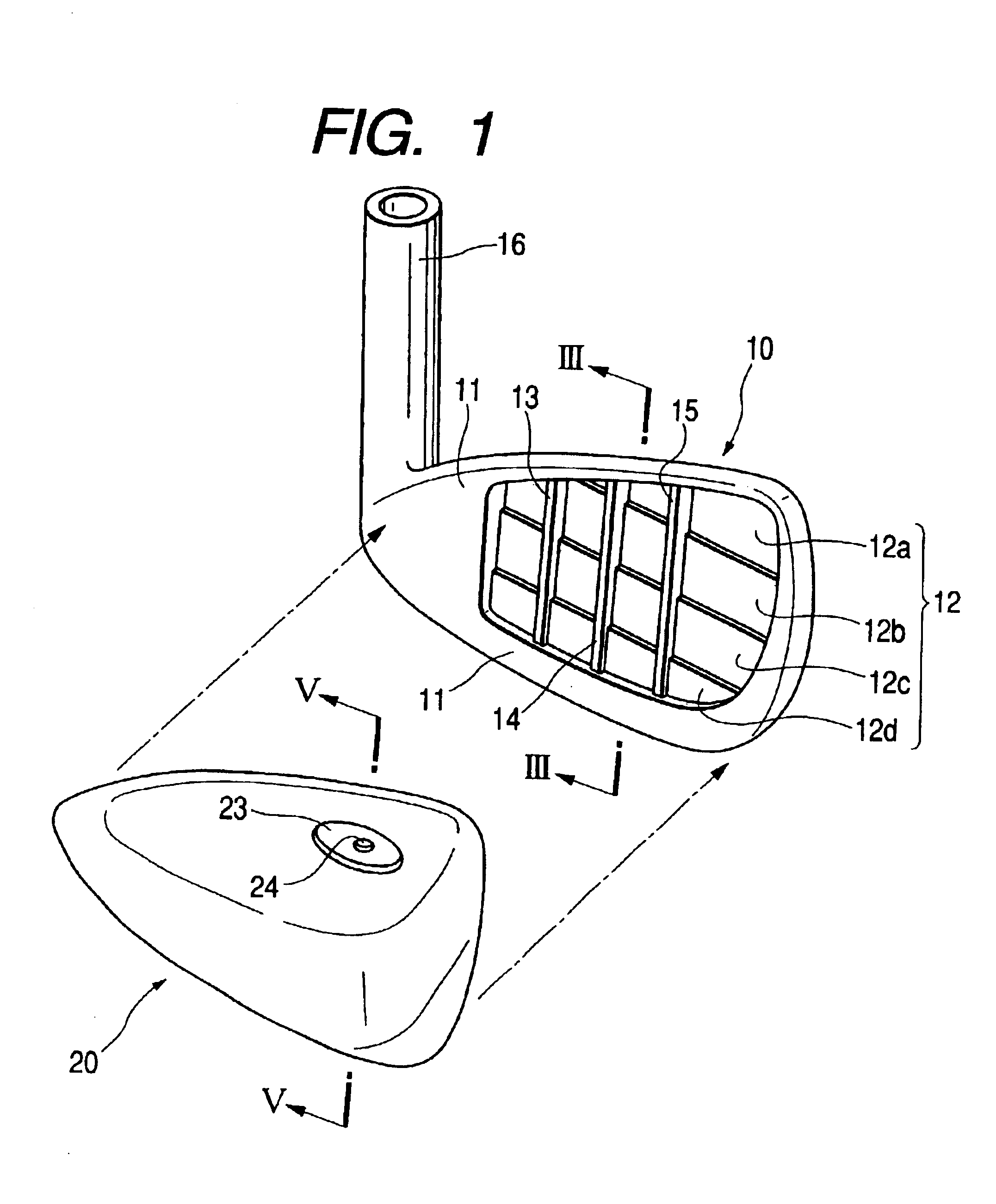

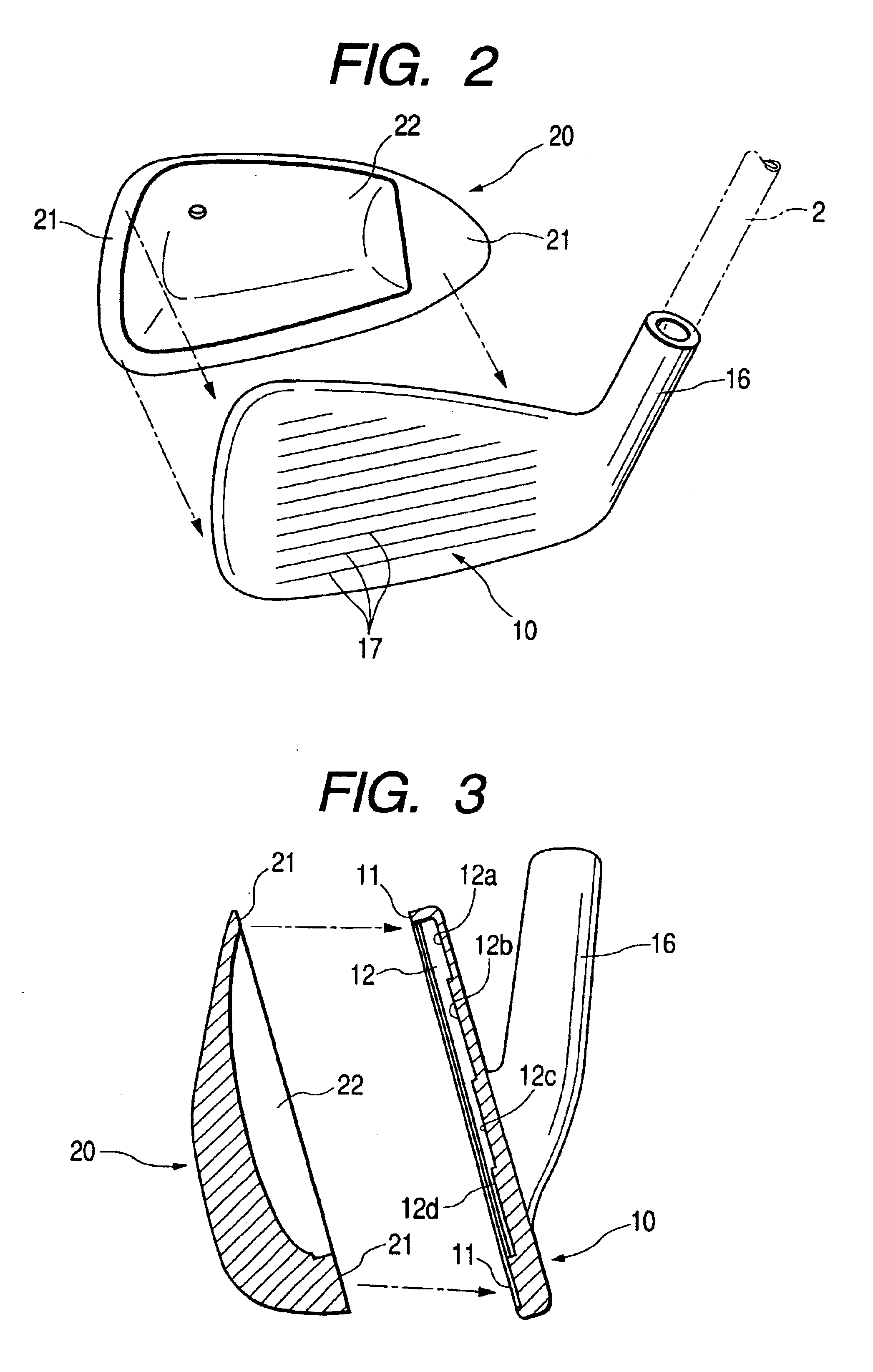

Golf club set

InactiveUS6780123B2Efficient use ofIncrease the number ofGolf clubsRacket sportsGravity centerEngineering

Owner:BRIDGESTONE SPORTS

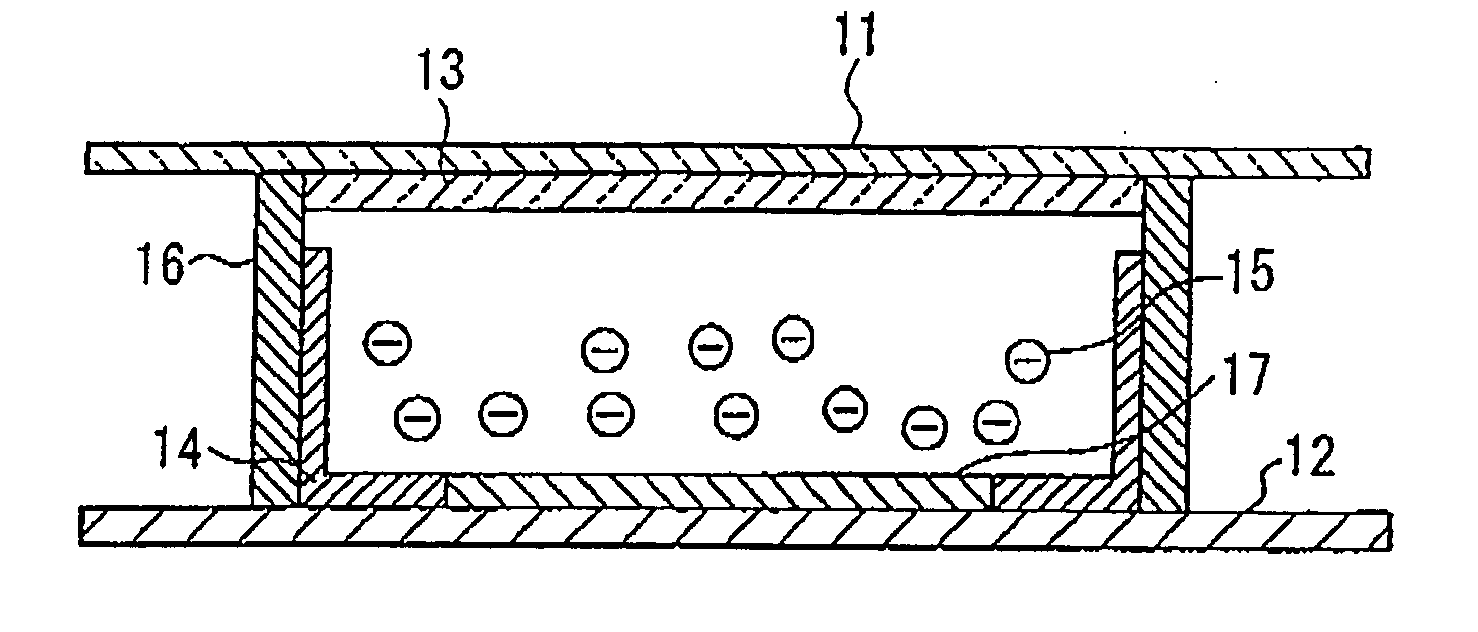

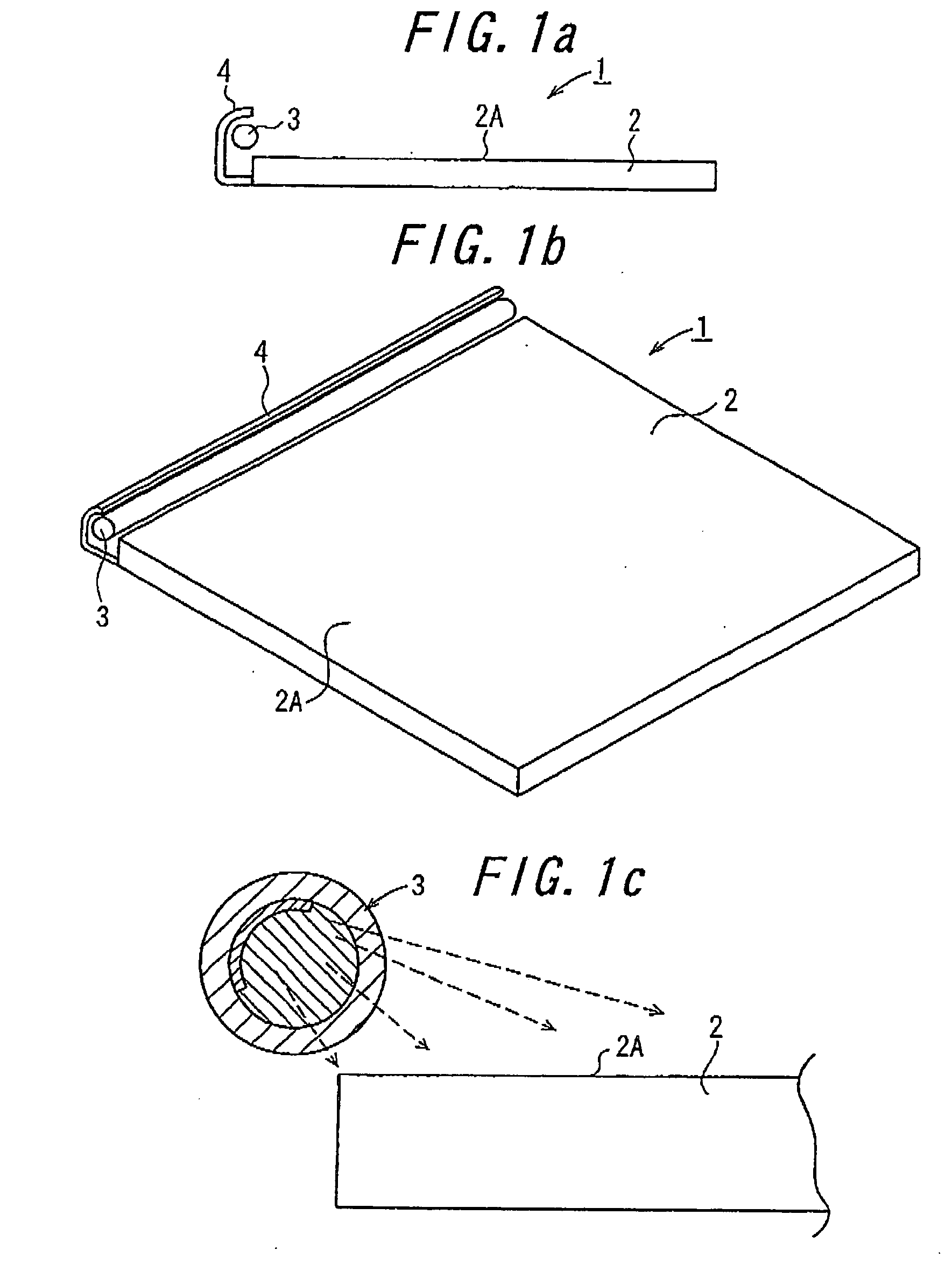

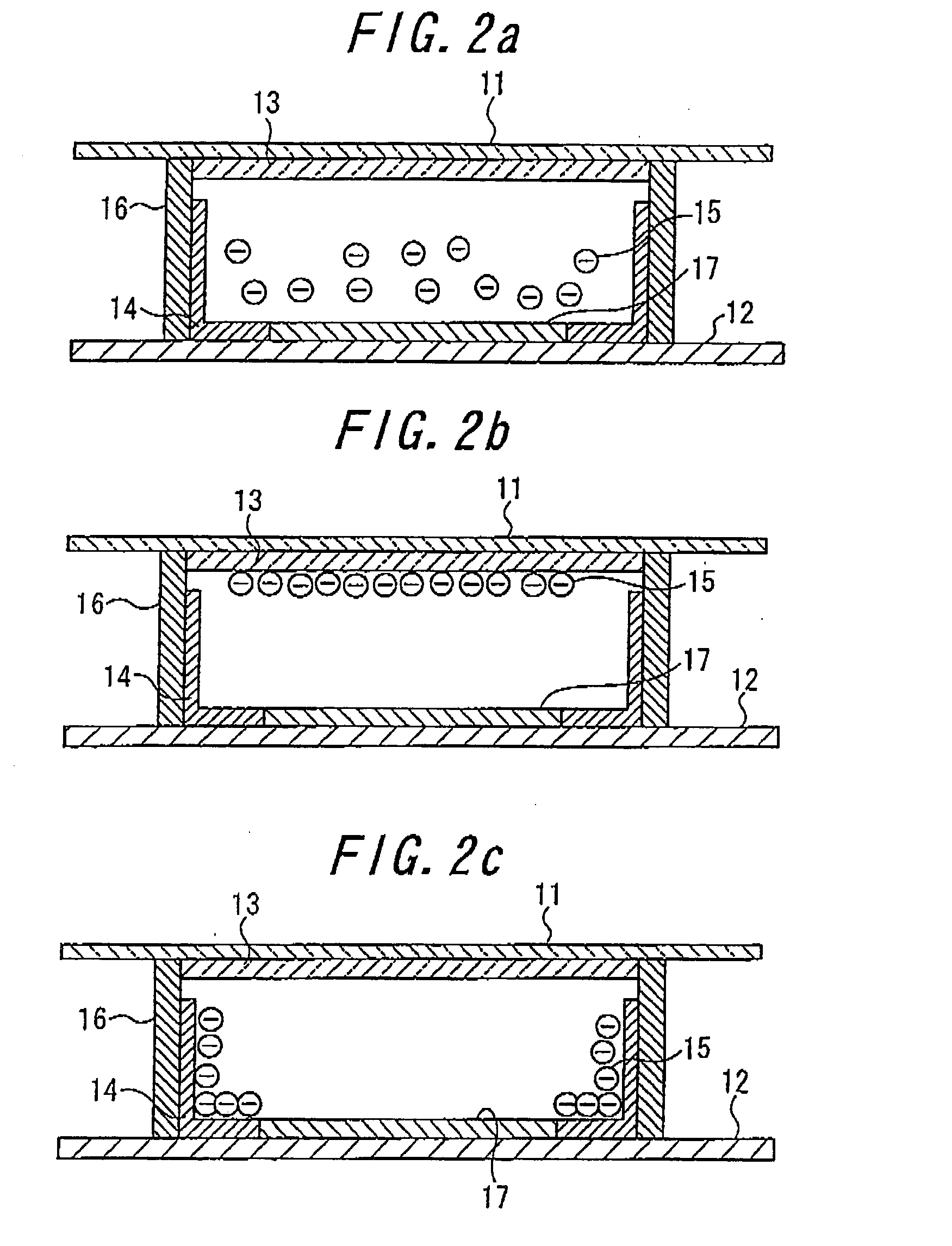

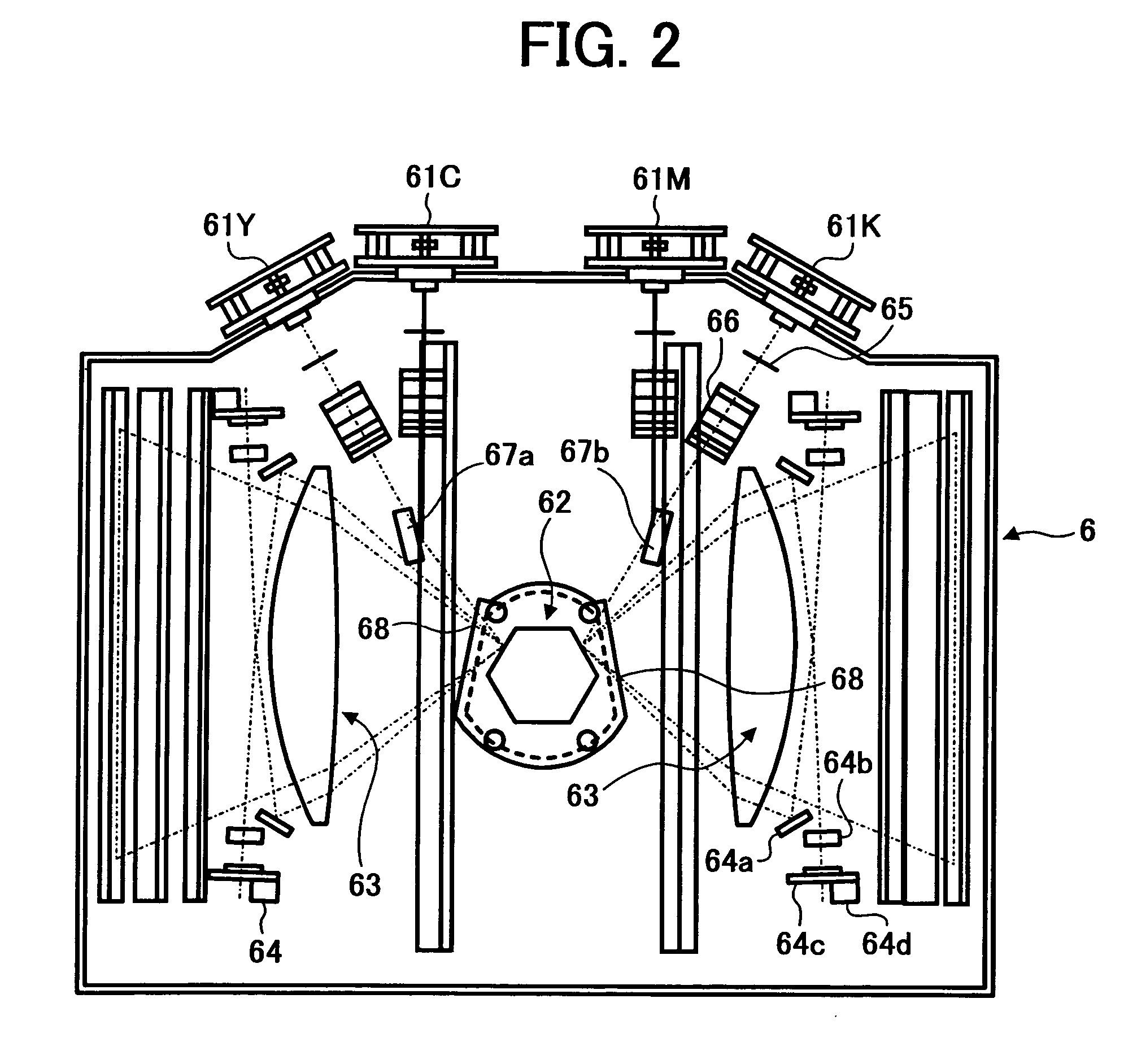

Image display

InactiveUS20060087489A1Excellent in image visibilityEasy constructionStatic indicating devicesNon-linear opticsComputer scienceLight emission

An image display device constructed by: an image display means for displaying an image by moving chargeable particles arranged between electrodes by means of a voltage applied to the electrodes; and a light emission means for emitting a light to an image display surface of the image display means (first aspect of the invention). Moreover, an image display device which has an image display panel, in which two or more groups of particles or liquid powders having different colors and different charge characteristics are sealed between opposed two substrates, at least one of two substrates being transparent, and, in which the particles or the liquid powders, to which an electrostatic field produced by a pair of electrodes provided on one substrate or both substrates respectively is applied, are made to move so as to display an image, characterized in that a color filter is arranged to an outer surface or an inner surface of a transparent substrate of the image display panel so as to perform a color displaying (second aspect of the invention).

Owner:BRIDGESTONE CORP

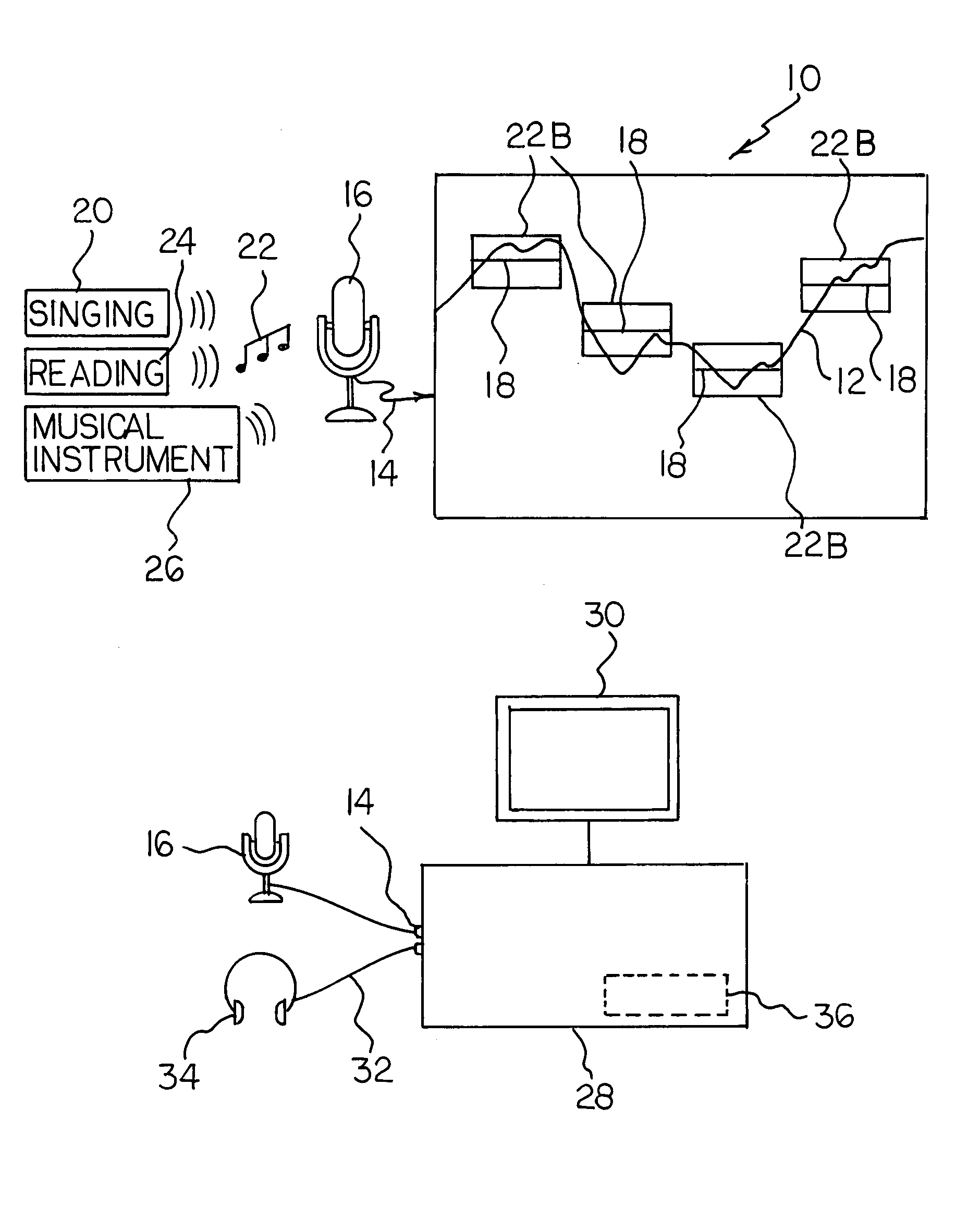

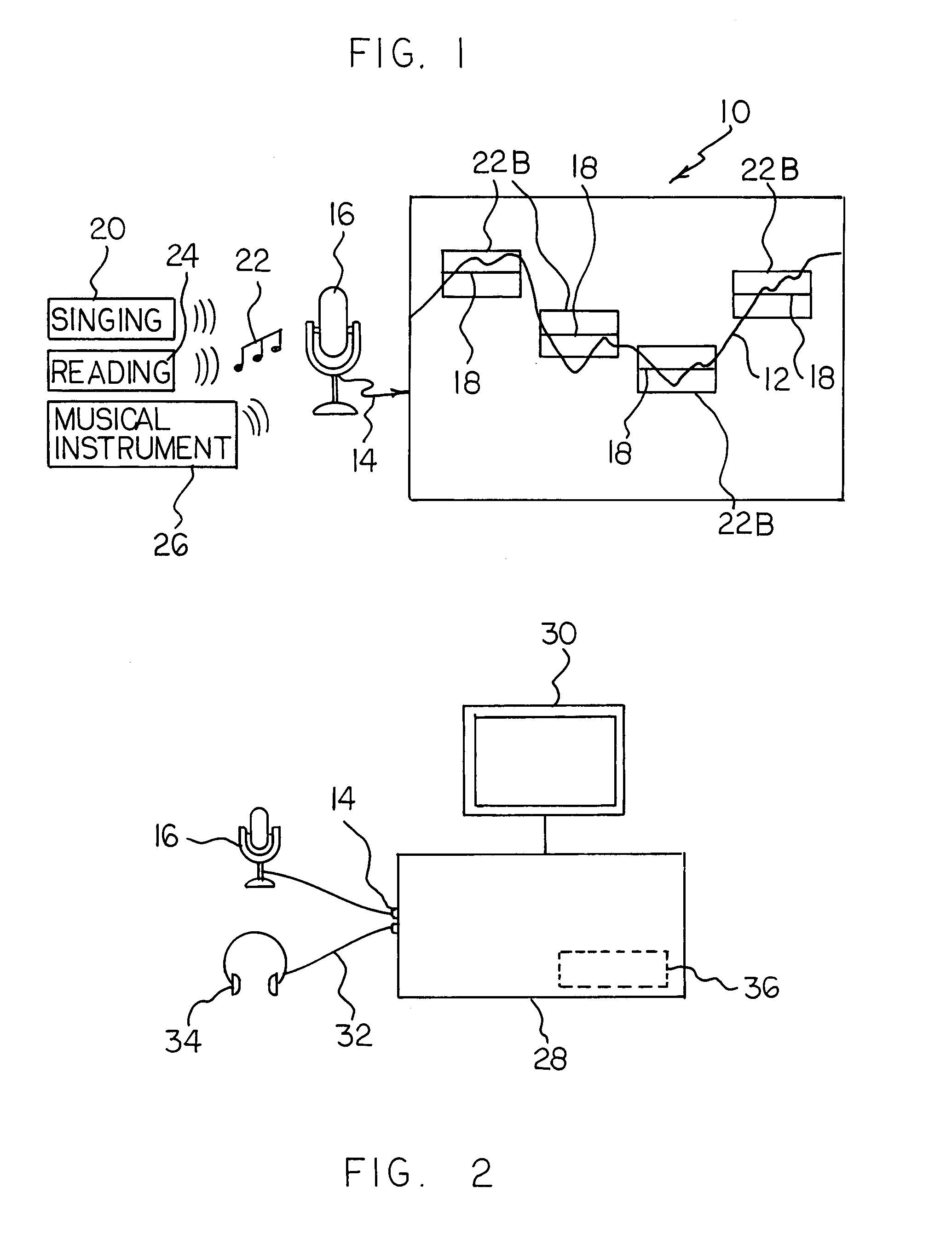

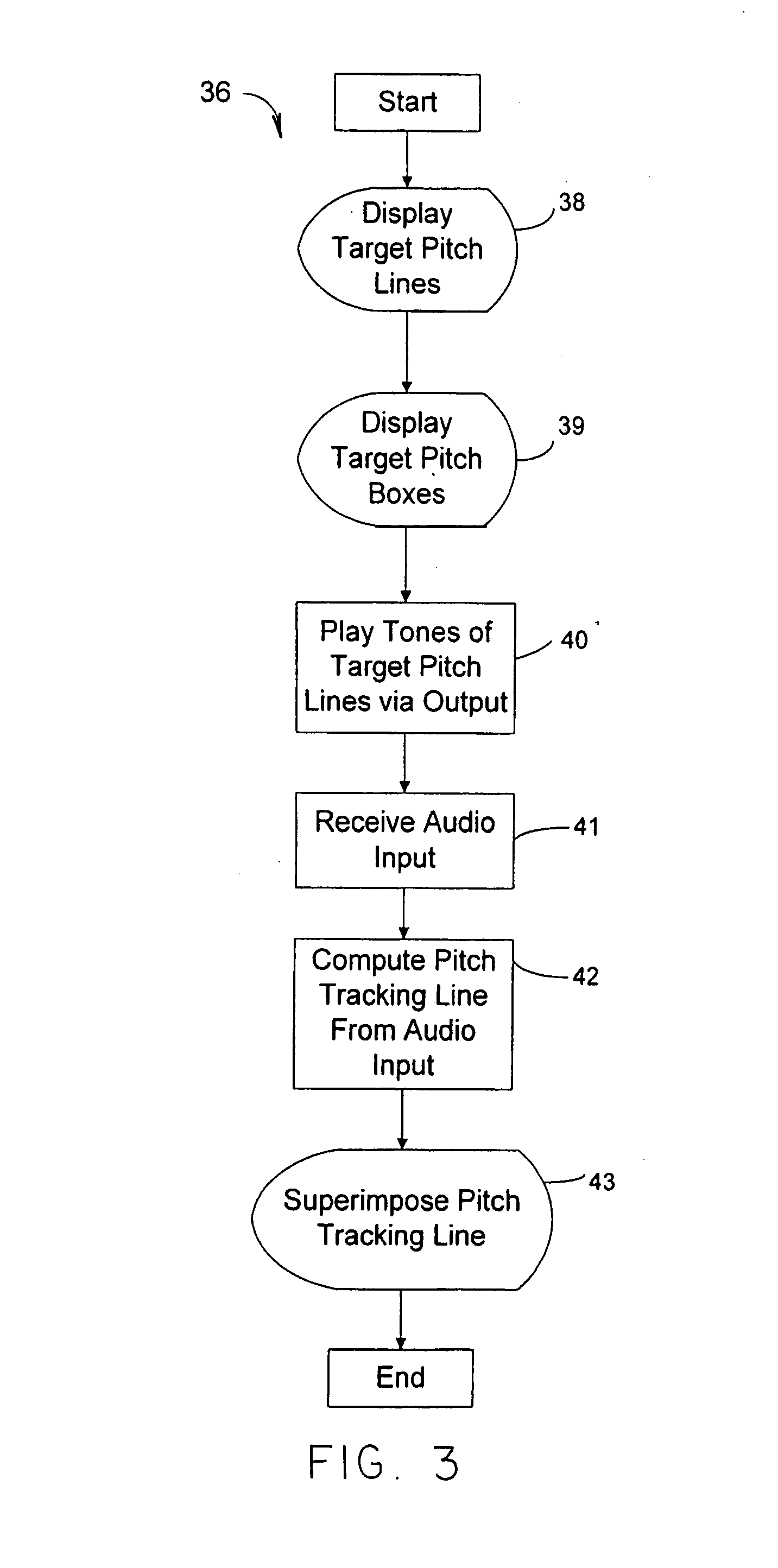

Computer-aided learning system employing a pitch tracking line

ActiveUS7271329B2Facilitate human to control pitch of their voiceFacilitates a human to control the rhythm of their voiceGearworksMusical toysDisplay deviceComputer-aided

A computer-aided learning system to facilitate a human to control the pitch and rhythm of their voice. In a preferred embodiment for learning how to sing a song in tune, a display provides visual, real-time depiction of the singer's actual pitch compared to the “target” pitch they should be singing, thereby allowing the singer to interactively raise or lower the pitch of their voice.

Owner:ELECTRONICS LEARNING PRODS

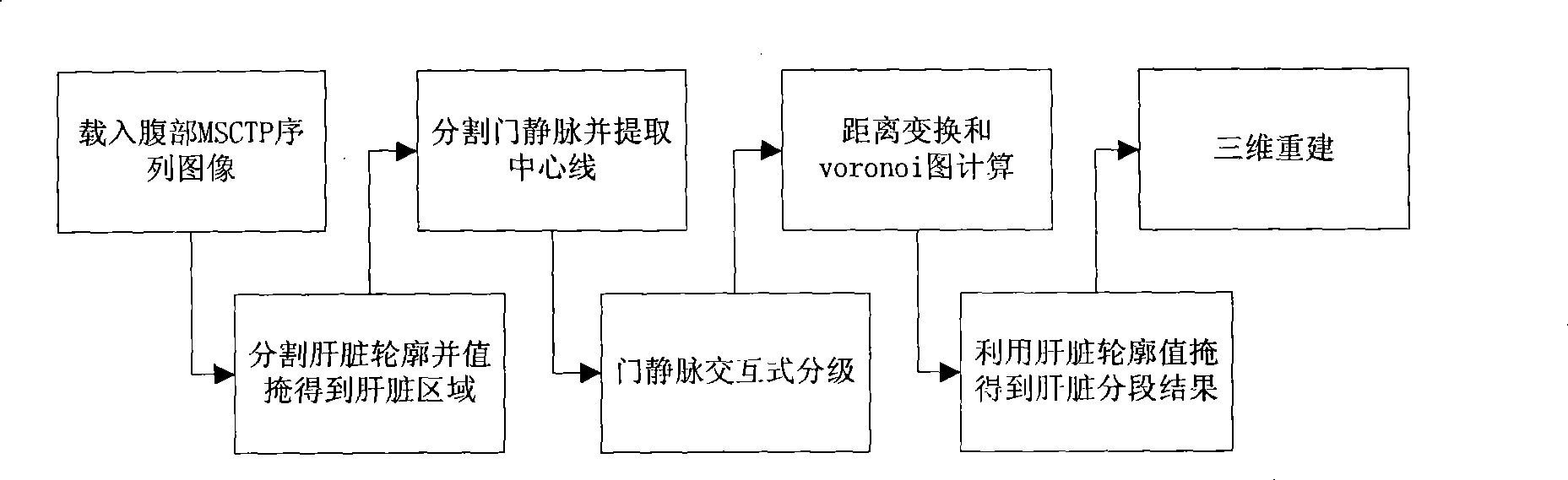

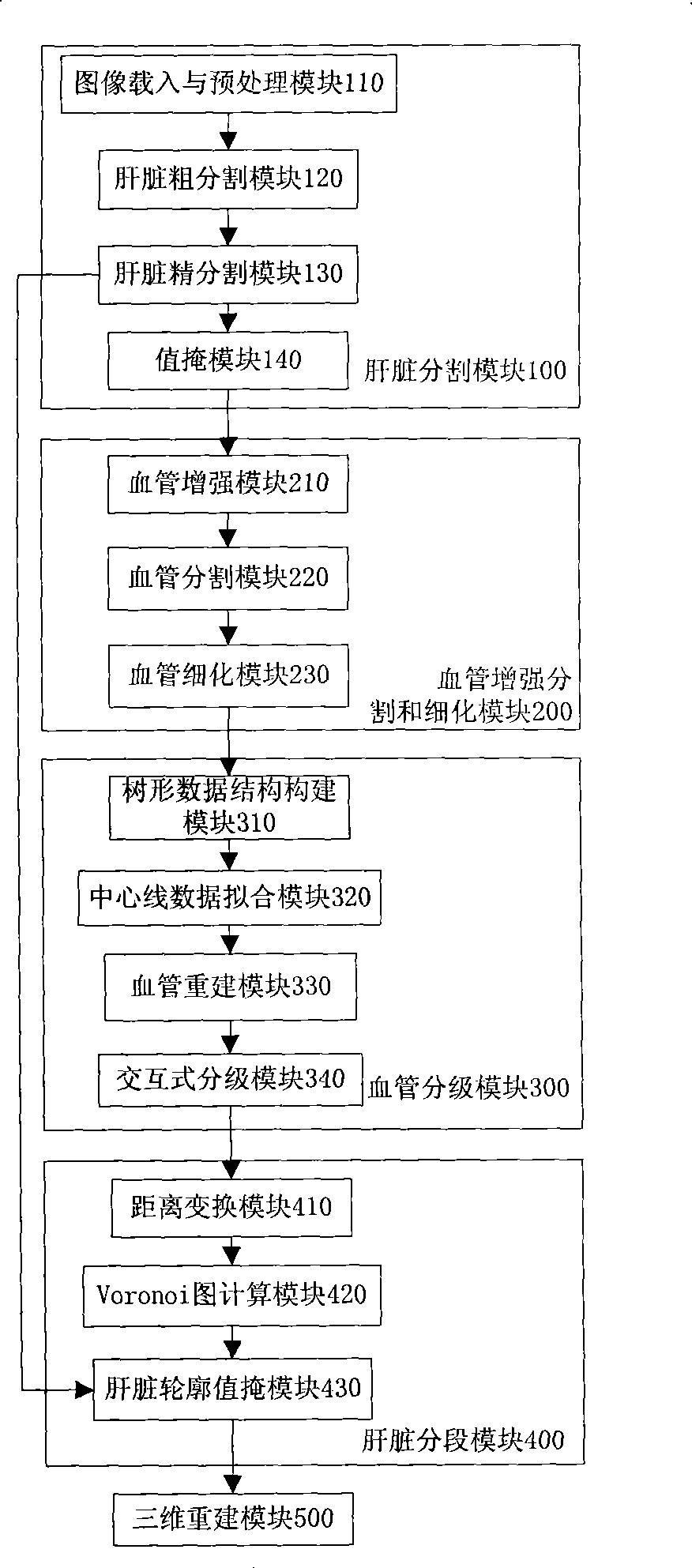

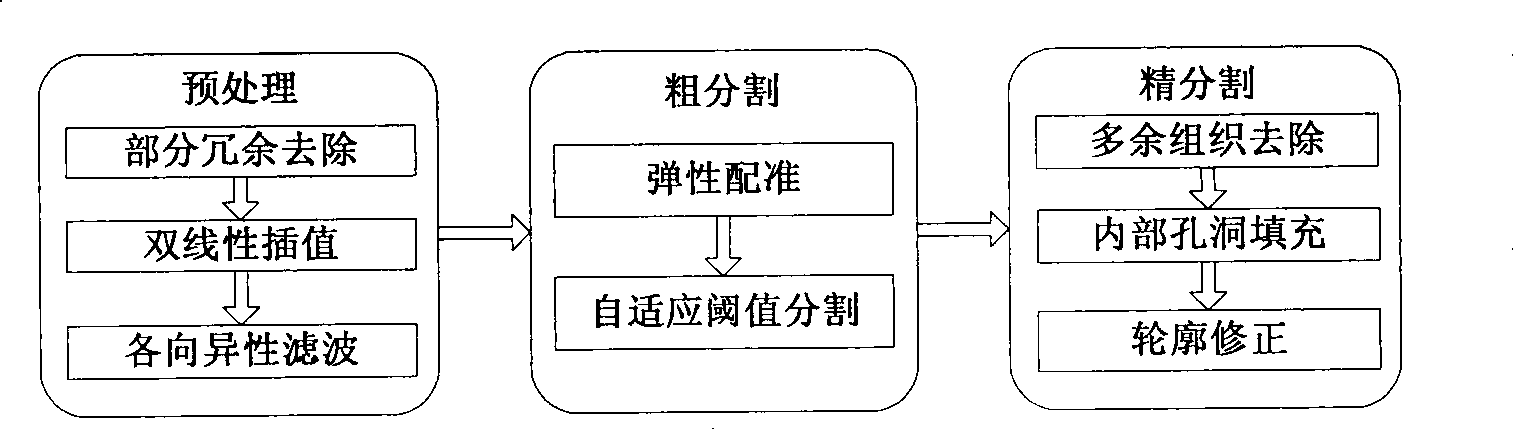

Liver subsection method based on CT image and system thereof

InactiveCN101425186AReduce noiseAvoid blurImage analysisComputerised tomographsPre treatmentThinning

The invention discloses a liver division method based on a CT image, which comprises the following steps: firstly, an MSCTP artery sequence image and a hepatic portal vein sequence image of the abdomen are pretreated, and the outline of the liver is automatically divided to obtain the liver image; secondly, a multi-scale filtering method based on a Hessian matrix is used for strengthening blood vessels, a dividing method such as region enlargement, and the like is used for dividing the hepatic portal vein, and a three-dimensional topology thinning method is used for picking up the central line of the hepatic portal vein; the blood vessels are identified mutually in classification; distance change and Voronoi arithmetic are then used for calculation, and the outline of the liver is used for covering values to obtain division results; the three-dimensional liver division results are finally reconstructed. The system comprises a liver division module, a blood vessel strengthening dividing and a thinning module, a blood vessel classifying module, a liver dividing module and a three-dimensional reconstructing module. The invention can reduce noise as well as avoid the vagueness of the boundary of the liver, effectively and exactly divides the outline of the liver, improves the division quality of the hepatic portal vein tree, and realizes accurate and rapid division of the liver.

Owner:HUAZHONG UNIV OF SCI & TECH

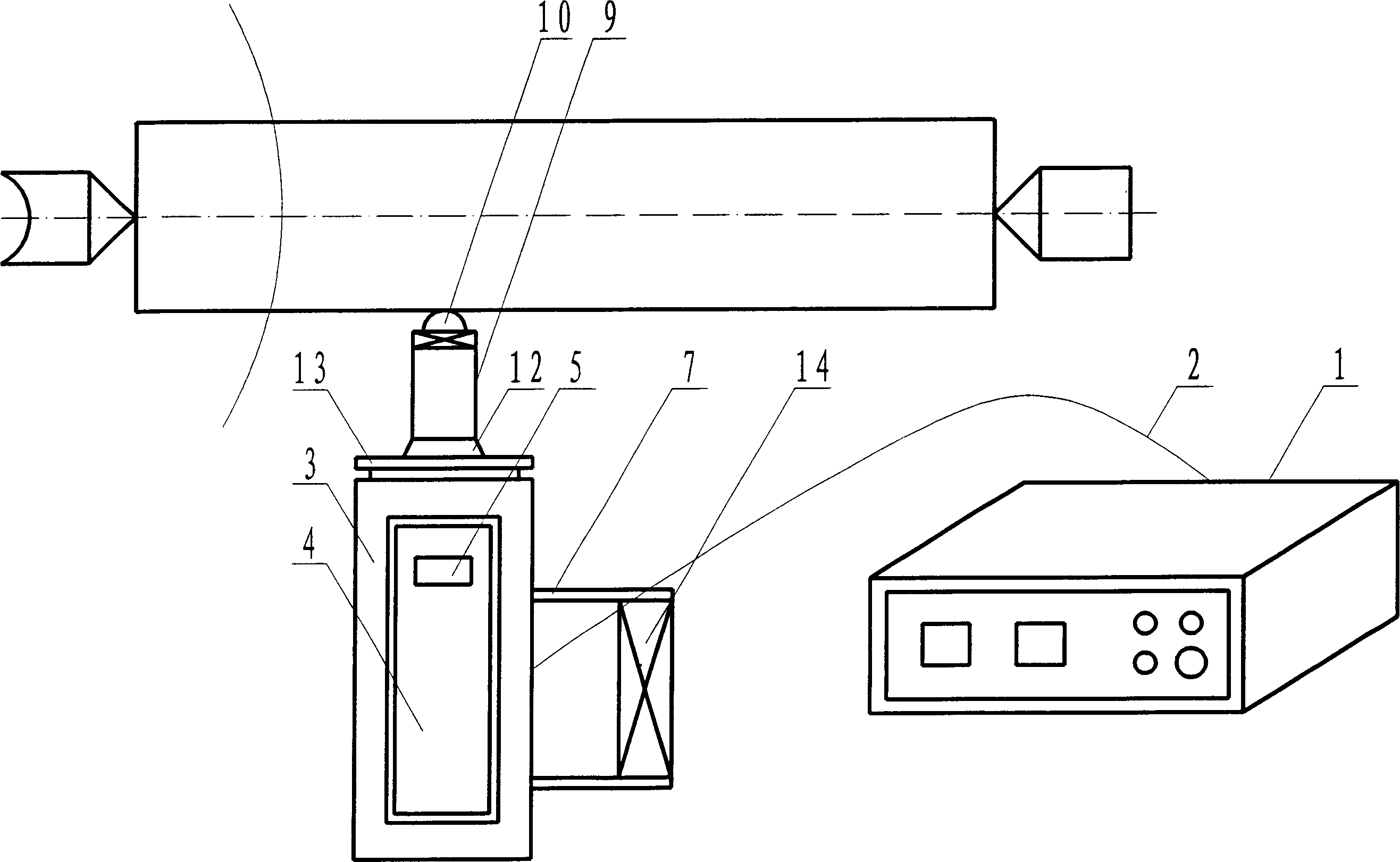

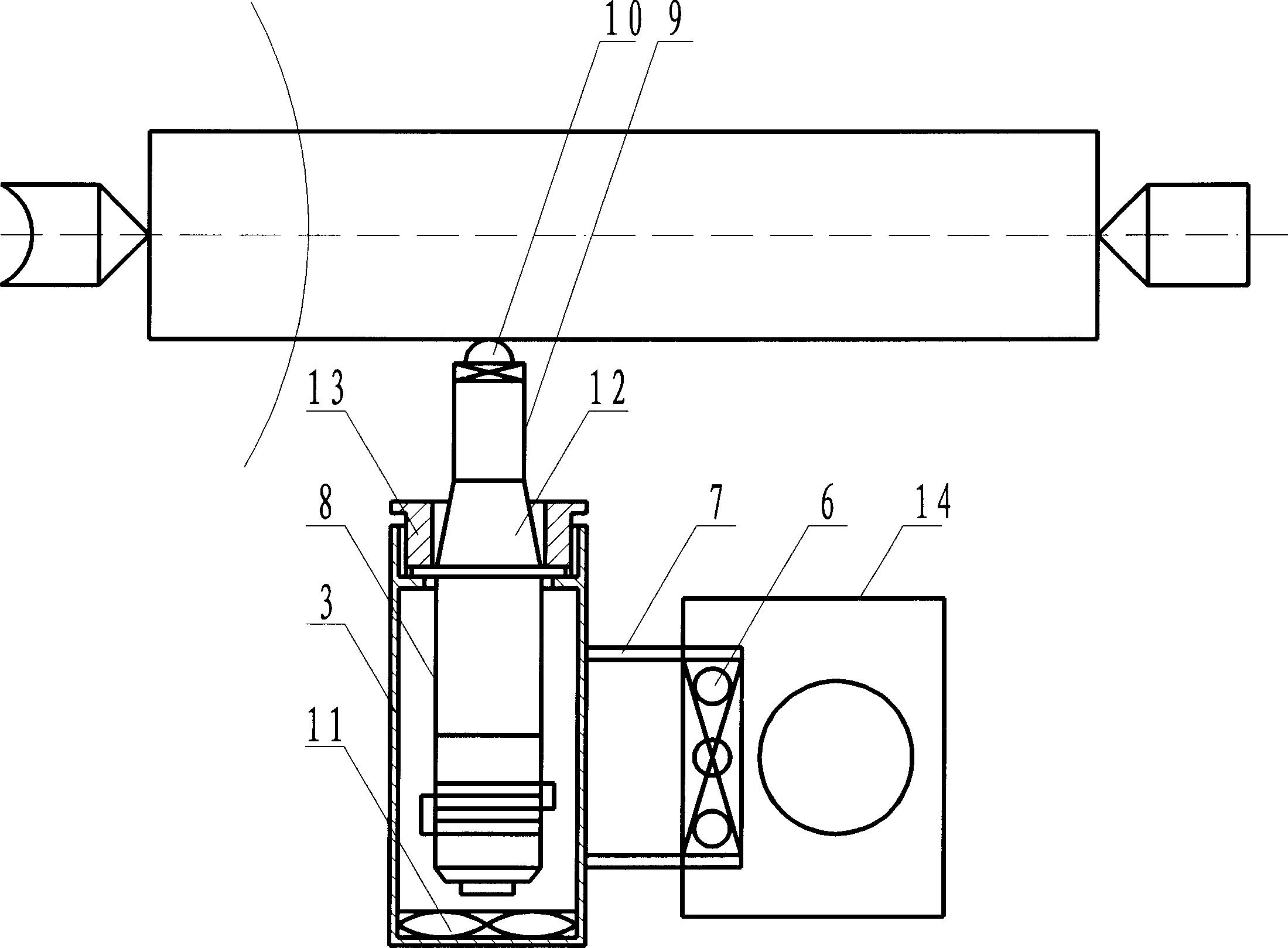

Ultrasonic metal surface processing device

ActiveCN1690231AIncrease productivityReduce investmentMechanical vibrations separationElectricityTransducer

The invention provides a ultrasonic working device for metallic surface, which comprises ultrasonic generator and ultrasonic working device linked together by cable conductor. The ultrasonic generator is existing device, and ultrasonic working device comprises shell which is equipped with spring connected to checkout gear for pressure one side and to briquette the other side besides with checkout gear for pressure and display for pressure, checkout gear for pressure, display for pressure, briquette, spring, piezoelectric ceramic transducer equipped in the shell and connected tight to one end of the half-wavelength complex varying amplitude pole by screw, half-wavelength complex varying amplitude pole whose outlet connected tight to tool caput by screw, tool caput and draught fan equipped on other end of the shell. Producing with the device for metallic surface can reduce the processing cost rapidly and effectively, simplify the productive technology, and advance the productive efficiency, as a result, it takes on a nice extendable and applicable value.

Owner:SHANDONG HUAWIN ELECTRICAL & MECHANICAL TECH

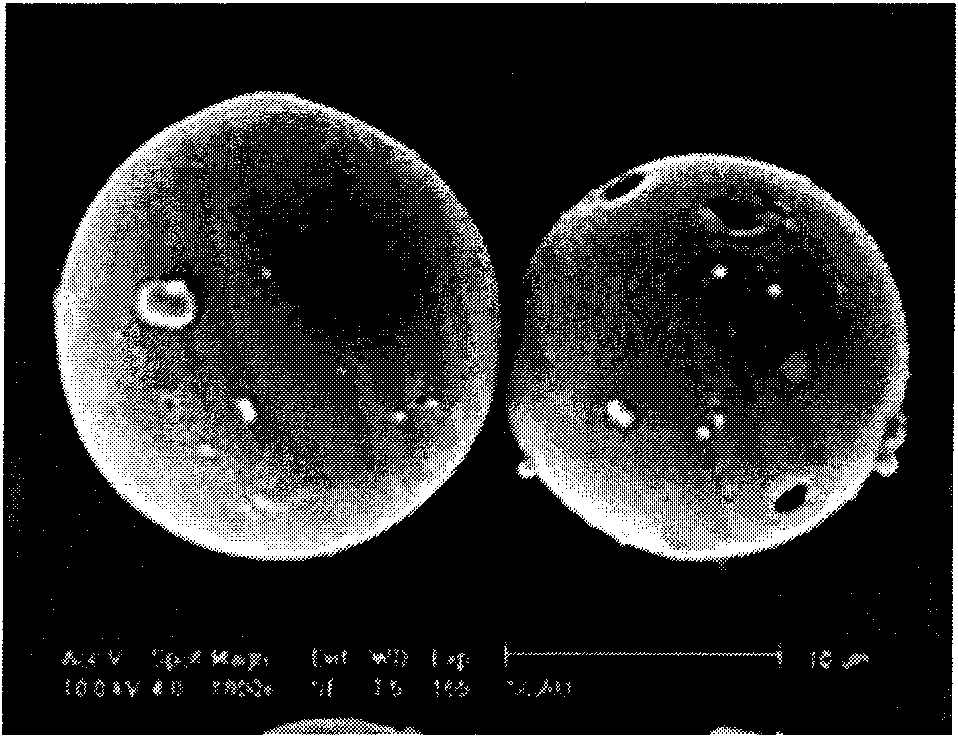

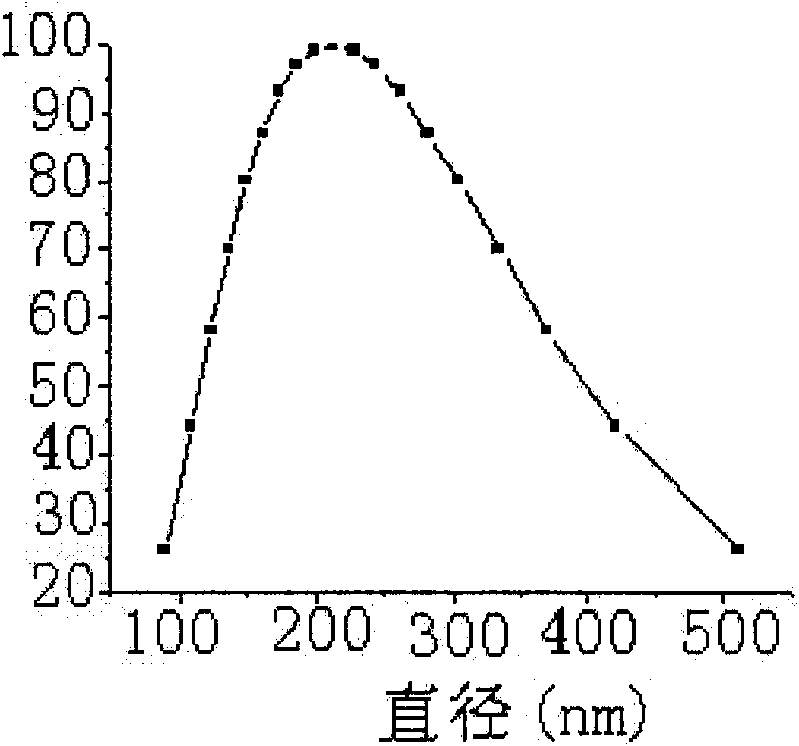

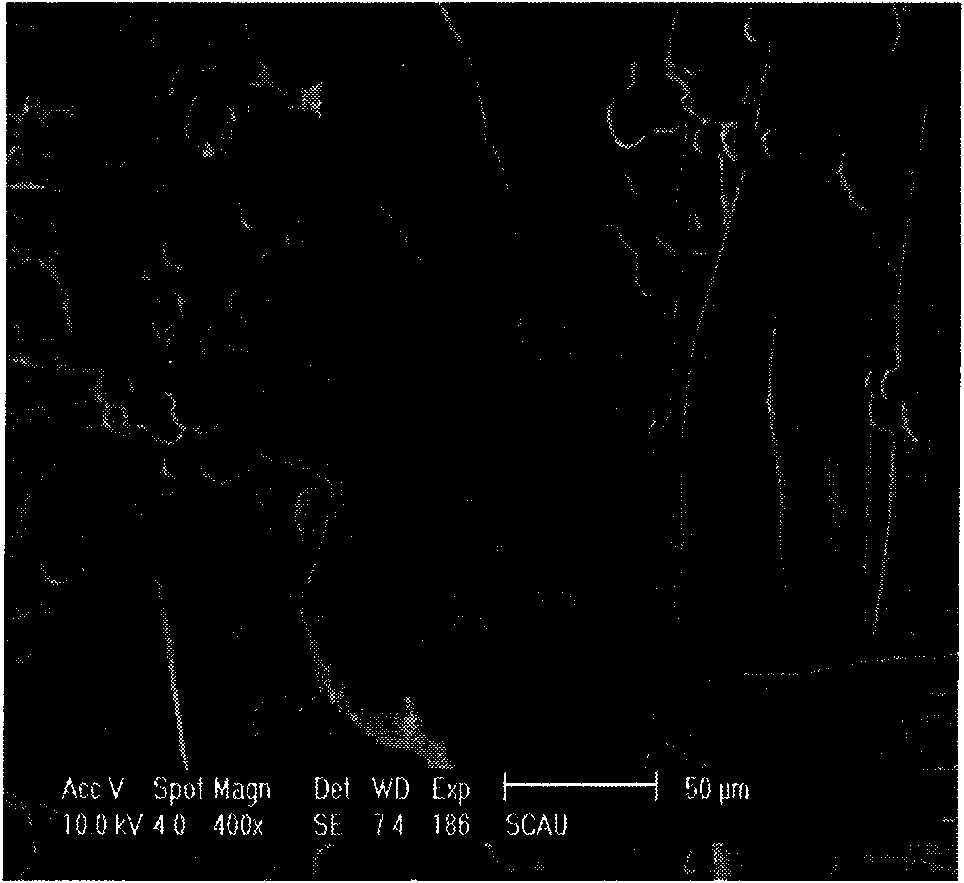

Blumea oil microcapsule textile composite finishing agent and use thereof

InactiveCN101591859AStir wellSmall particle sizeFibre treatmentMicroballoon preparationCross-linkChemical Linkage

The invention discloses a blumea oil microcapsule textile composite finishing agent and use thereof. Gelatin or acacia of natural polymers is used the main ingredient of a wall material, the blumea oil serving as a Chinese medicinal material is used as a core material, and complex coacervation is adopted to prepare an blumea oil microcapsule aqueous emulsion; a shrink-resistance crosslinker and a catalyst are added to be combined with the blumea oil microcapsule aqueous emulsion into a multifunctional blumea oil microcapsule textile composite finishing agent; researches on the use of blumea oil microcapsules in textile finishing are carried out; and a novel cross linked graft method is used to perform the microcapsule finishing of textiles to form chemical bonds between the microcapsules and the textiles though the shrink-resistance crosslinker and free formaldehyde molecules in 2D resin further participate in a cross-linking and curing reaction as a microcapsule curing agent, so the textiles achieve a long lasting antibacterial and health-care function, a shrink-resistance function and low formaldehyde release content performance.

Owner:SOUTH CHINA AGRI UNIV

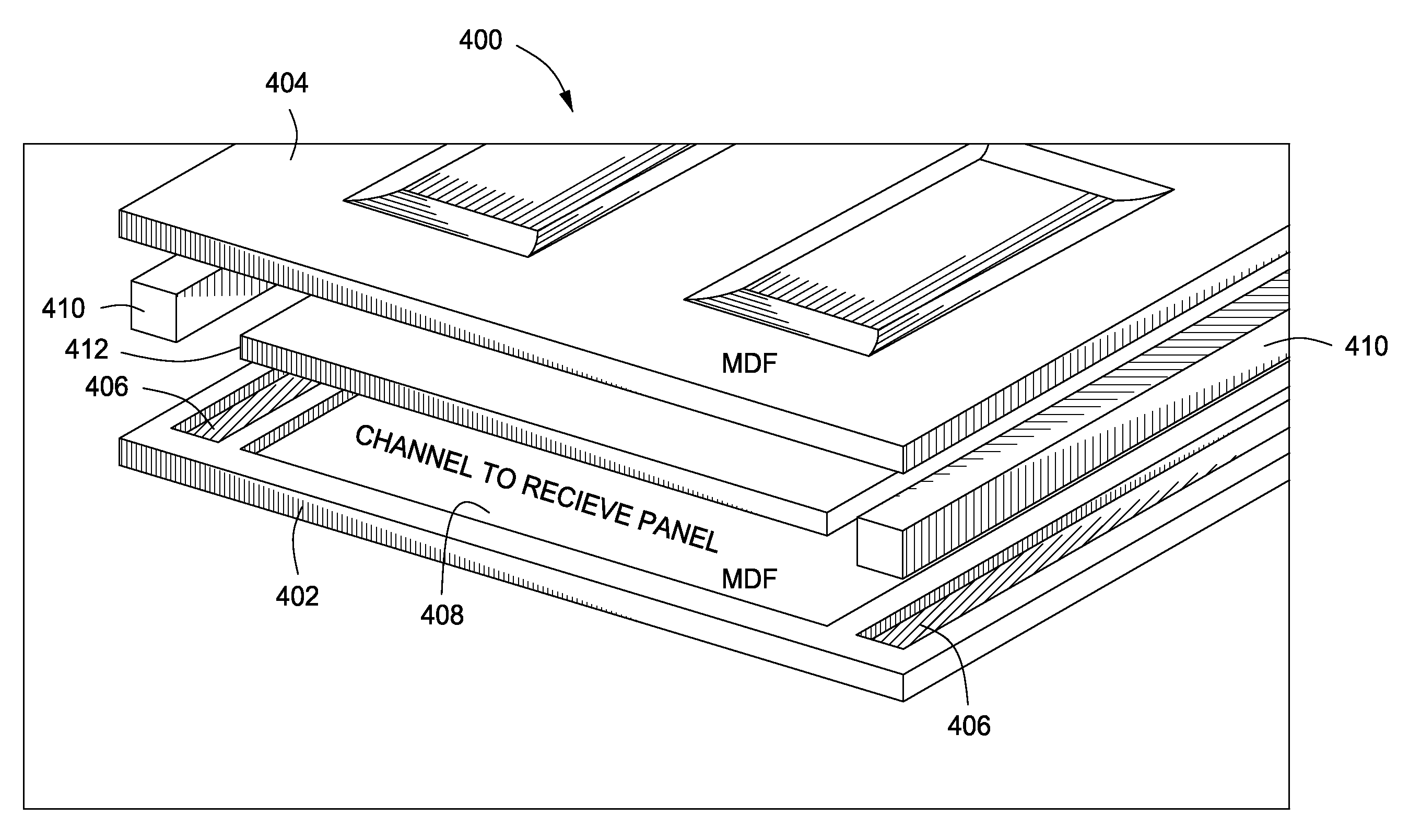

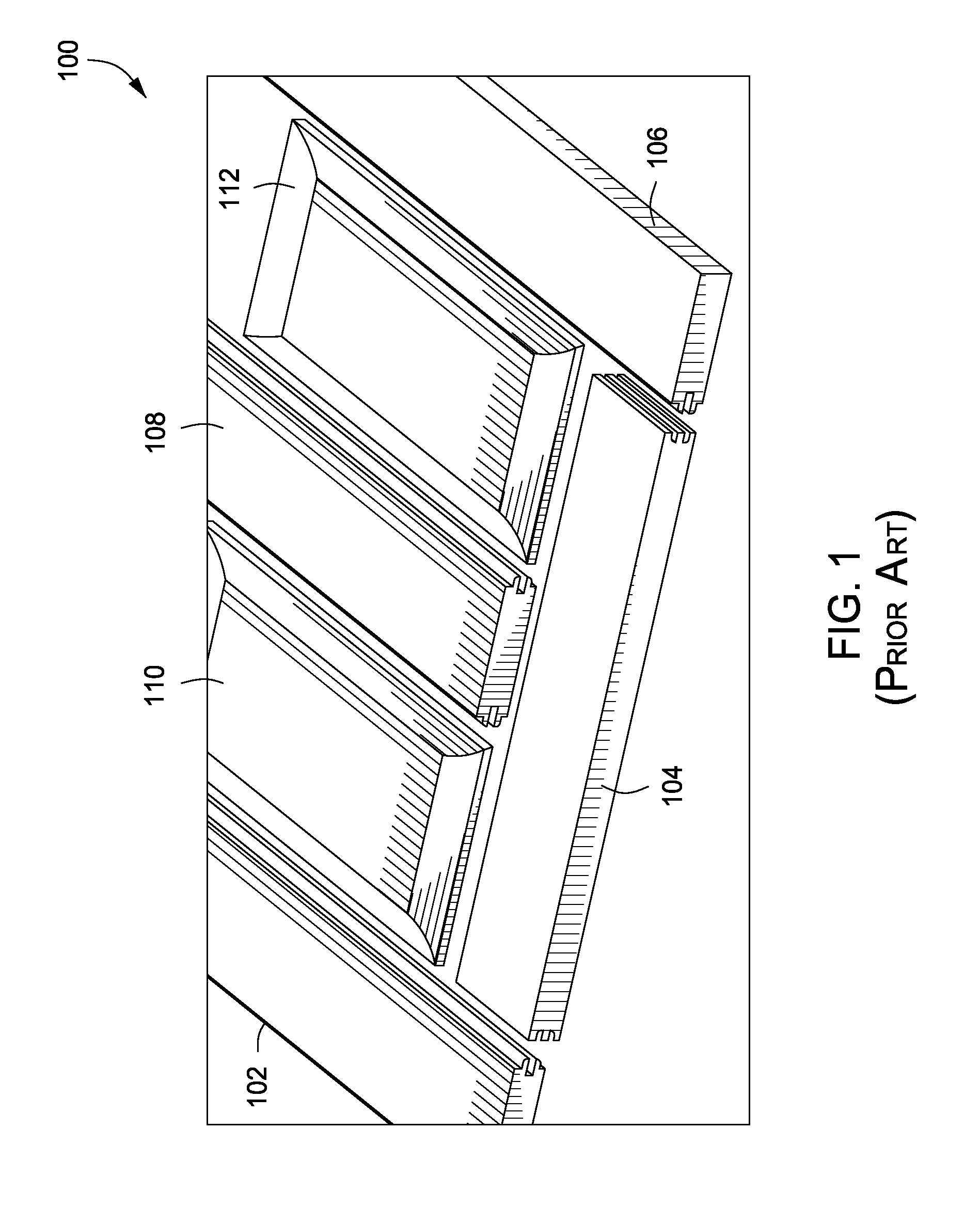

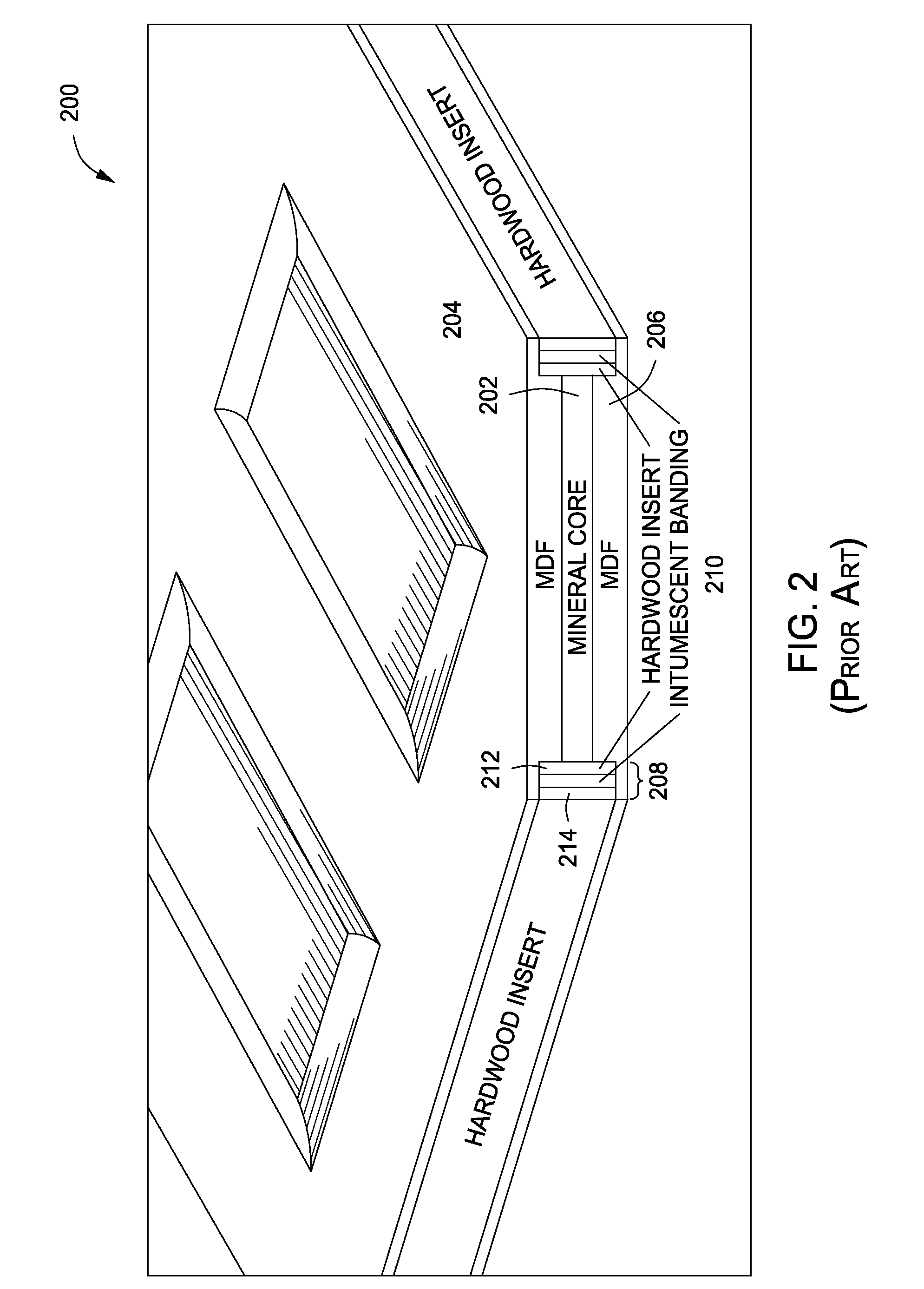

System, Method and Apparatus for Producing Fire Rated Doors

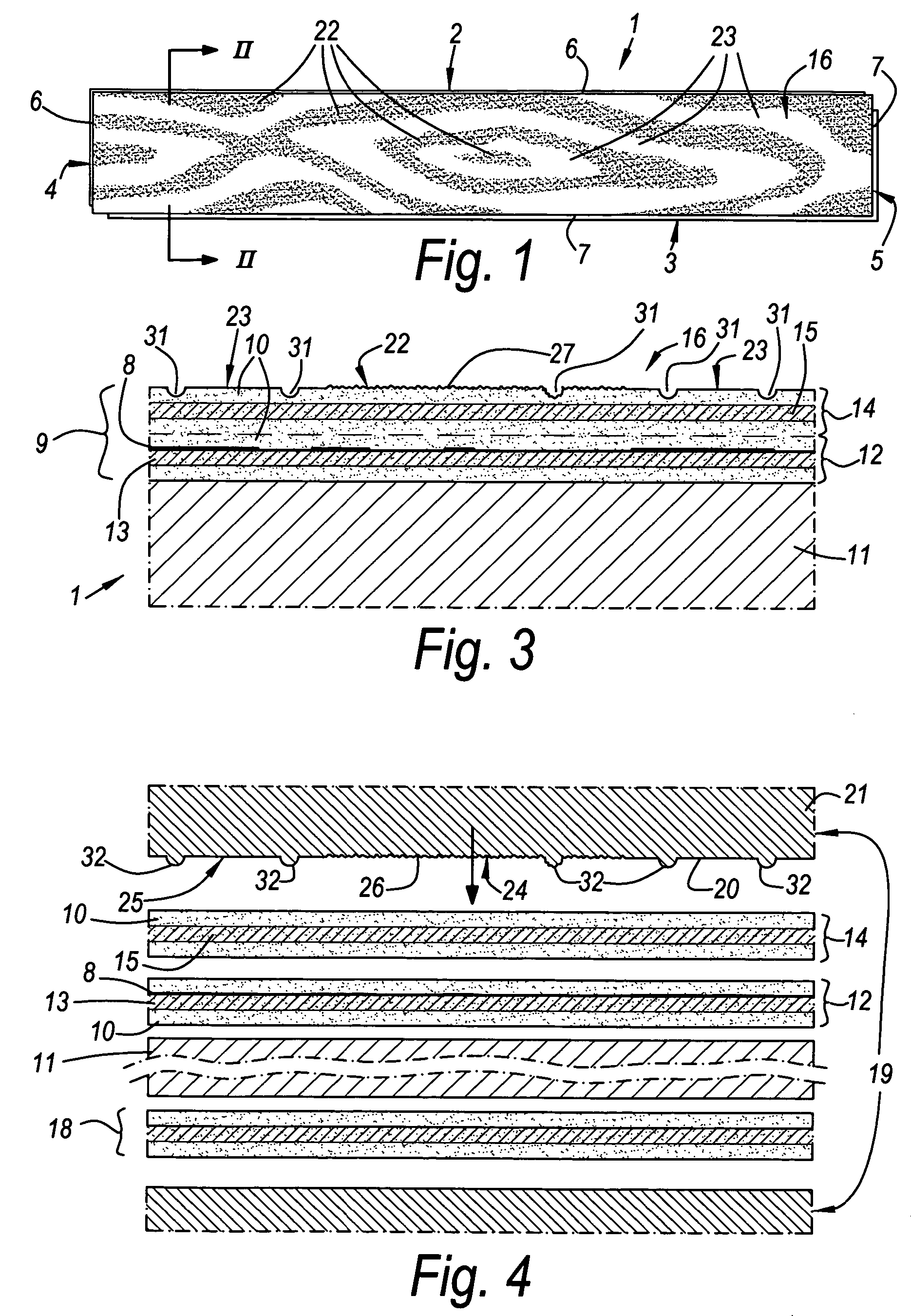

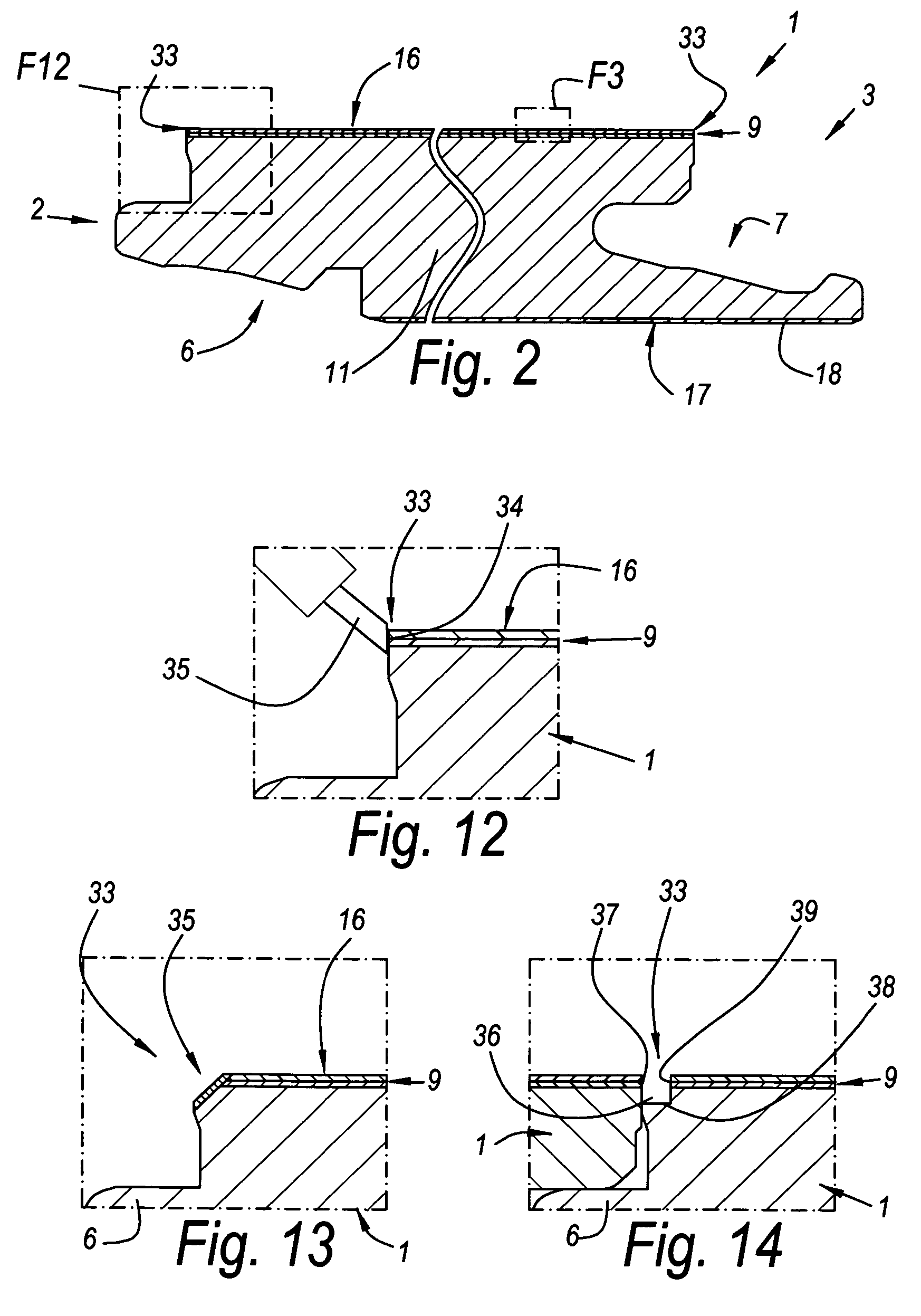

ActiveUS20070193220A1High strengthRaise the gradeFireproof doorsDoor leavesEngineeringUltimate tensile strength

The present invention provides a system, method and apparatus for producing fire rated doors having added strength, better finishing and low cost manufacturing flexibility. The fire rated doors are made from two panels “sandwiched” together. An optional interior layer (e.g., fire resistant material, lead sheeting, steel or Kevlar) can be added between the door panels for various purposes. Splines, stiles or sticks are inserted in longitudinal channels in the door panels to provide assistance in aligning the door panels and greater hardware holding strength. An intumescent banding material concealed by a banding material around the perimeter of the door seals the door within its frame during a fire. The door design and the automated manufacturing process provide greater design choice, reduced cost and faster fabrication.

Owner:POLYMER WOOD TECH

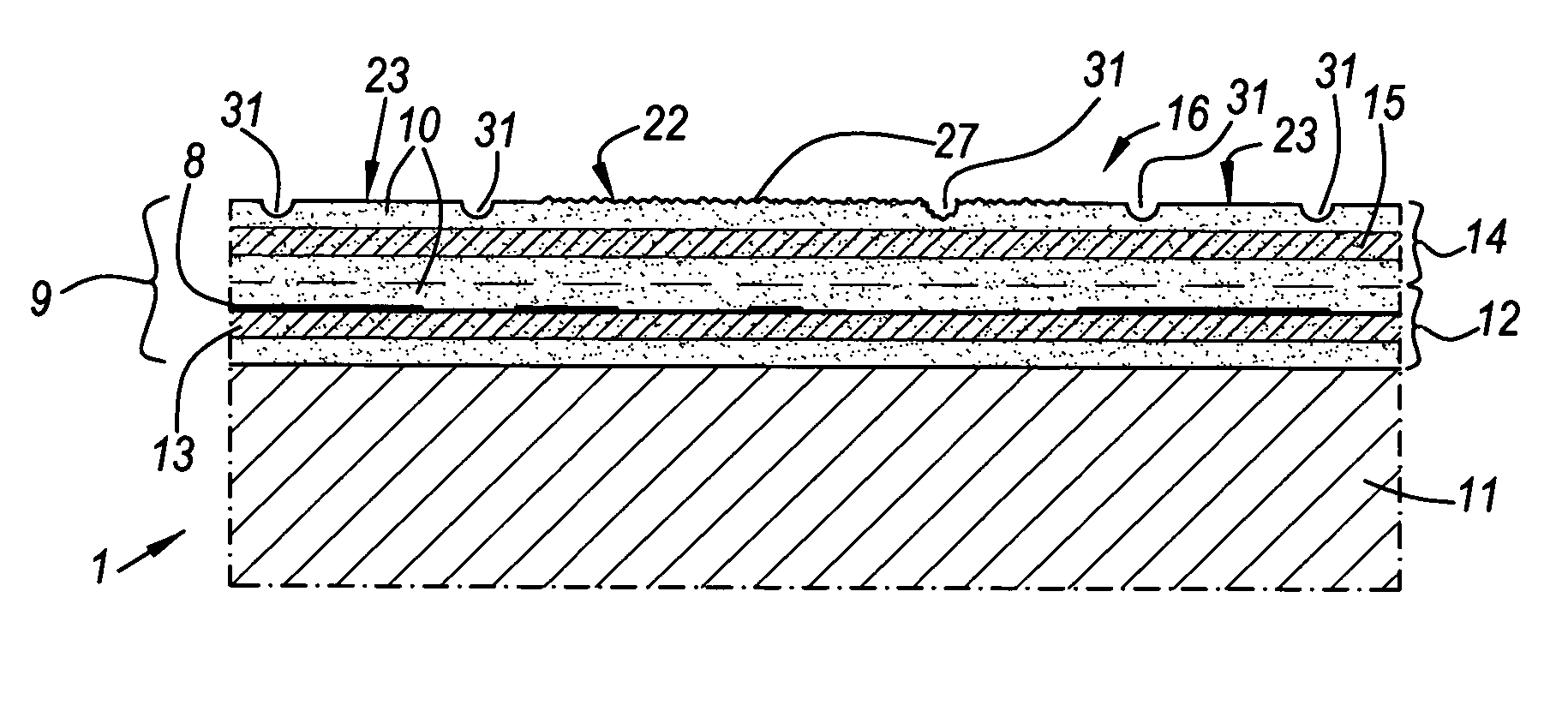

Floor panel and method for manufacturing a floor panel

ActiveUS8153234B2Easy to distinguishFlexible and inexpensiveDecorative surface effectsLayered productsFace sheetCivil engineering

Owner:FLOORING IND LTD

Trilaminar co-extrusion thermal contraction resin film, manufacturing method and application method thereof

InactiveCN101318392AReduce pollutionReduce packaging costsWrappers shrinkageSynthetic resin layered productsThermal contractionPuncturing

The invention discloses a three-layer coextrusion heat shrinkage resin film, a production method and an application method. The-three layer coextrusion heat shrinkage resin film is produced by taking PE(LDPE, HPPE, LLDPE, mPE), EVA, PP, PA and EVOH resins as the main materials which are matched with a functional master batch and adopting a production method of one-step huffing. The largest transverse and longitudinal shrinking rates of the product can reach 60 percent and 85 percent; the largest shrinking force of the product can reach 2.0N / cm. The shrinking rate and the shrinking force of the product can be controlled and adjusted by controlling various technical parameters to lead a package to be firm and endurable. The packaged objects are pertinently led to reach the anti-rust, anti static, illumination-resistance, anti-aging, anti-puncturing, anti-low-temperature, anti-isolation, anti-bacteria and anti-degradation effects and the like by adjusting the material composition and mixture ratio of each layer. The three-layer coextrusion heat shrinkage resin film is used for replacing the traditional paper box wrappage to reduce the packaging cost. The mechanical properties are good, the pertinence is strong, the materials are saved; when the three-layer coextrusion heat shrinkage resin film is used, the shrinking temperature is low, the power is saved and the packaging cost is saved, thus effectively reducing the production cost and having extremely high application value.

Owner:大连华诺塑胶科技有限公司

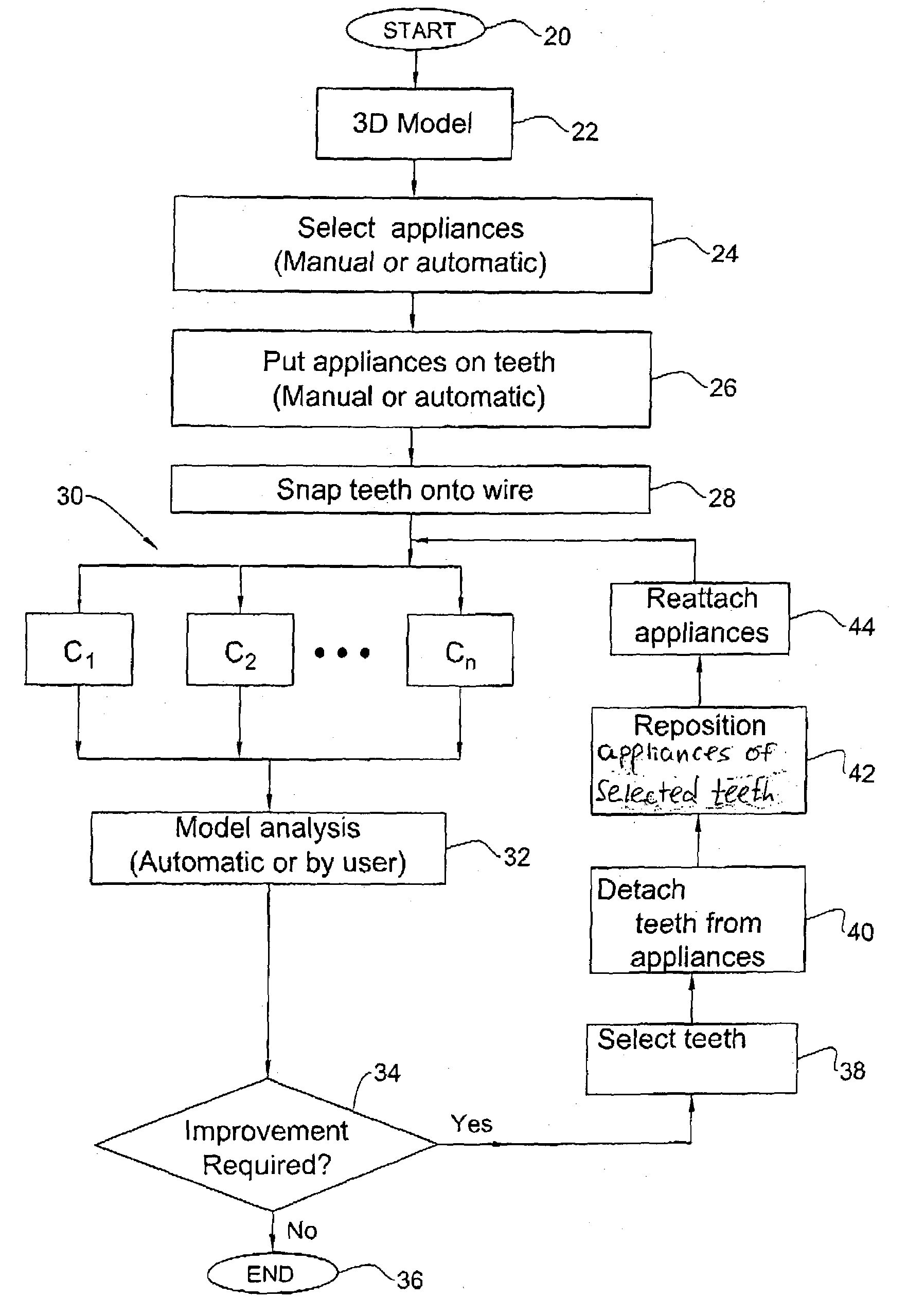

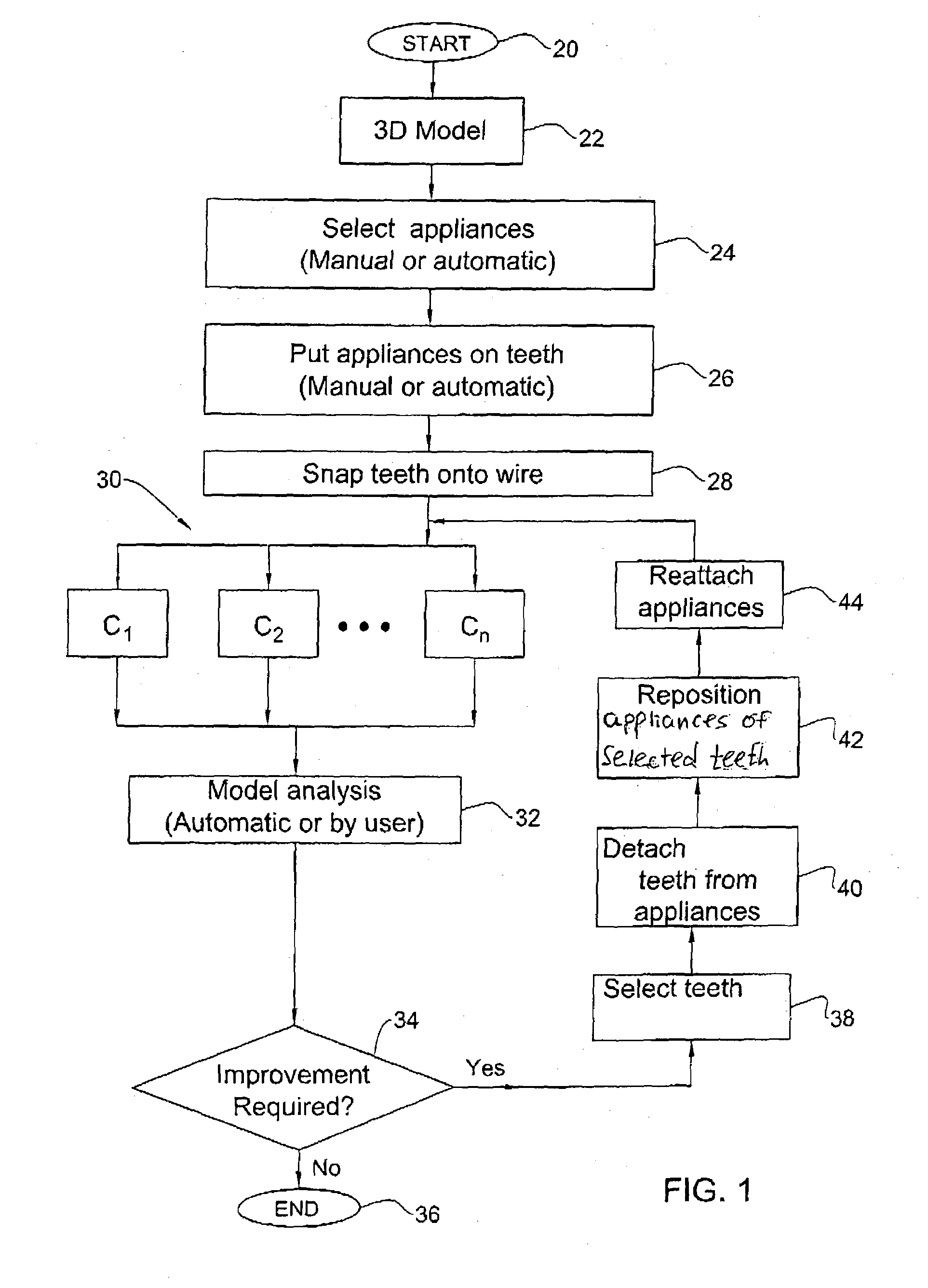

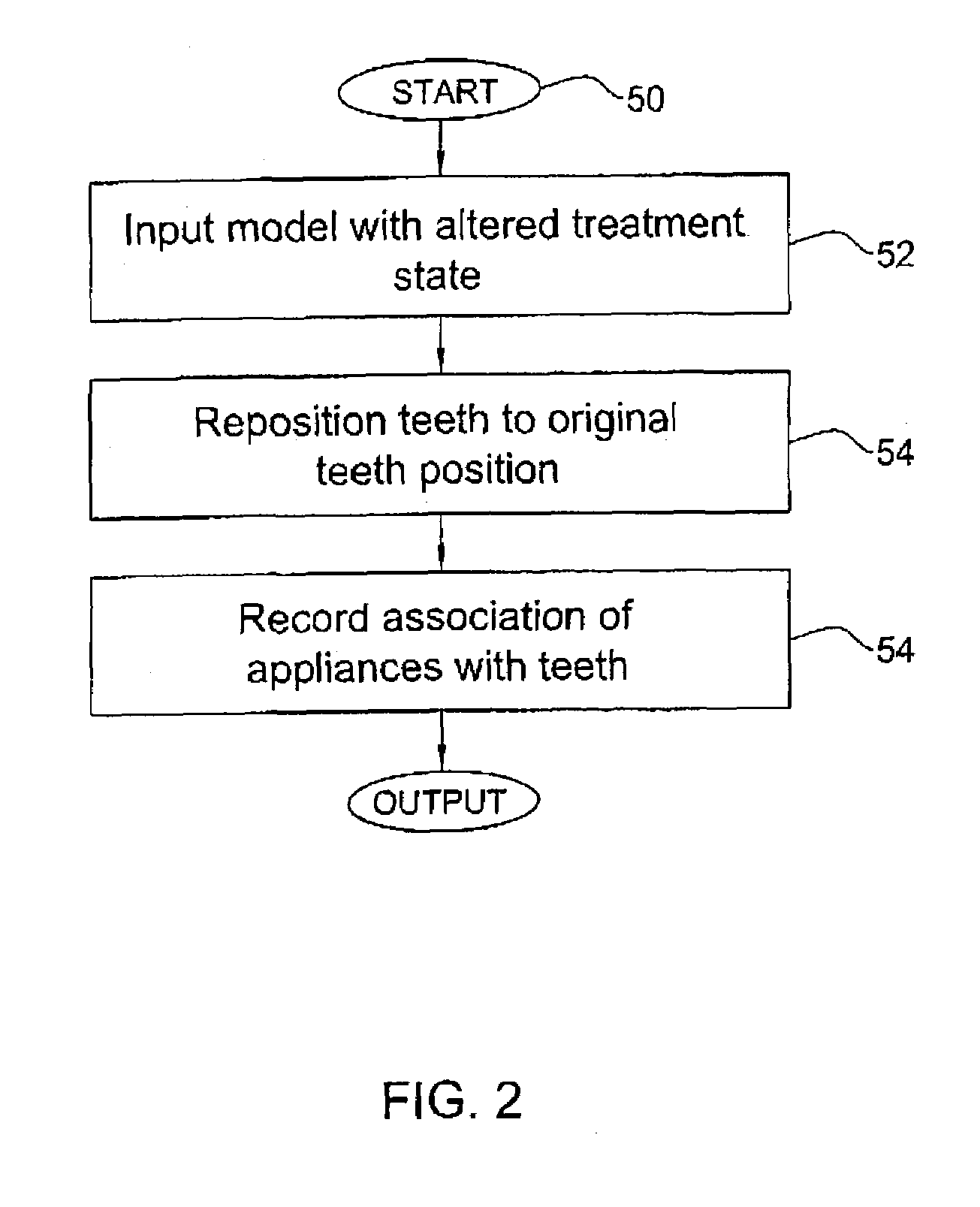

Method and system for assessing the outcome of an orthodontic treatment

A virtual orthodontic treatment method and a system thereof, the method comprising the following: providing a virtual diagnostic setup model of teeth of at least one jaw of an individual, associating each teeth in said model with its corresponding virtual orthodontic appliance to obtain a first composite model and repositioning teeth into an initial treatment state according to pre-defined appliances-dependent rules. In the initial treatment state, selecting one or more teeth and reassociating the teeth with their corresponding virtual orthodontic appliance by changing the position of the appliance corresponding to the selected tooth thereby causing repositioning of the teeth according to the appliance-dependence rules. An altered treatment state is obtained, yielding a better grade, according to one or more systems for grading an orthodontic model, as compared to the grade of the initial treatment state.

Owner:ALIGN TECH

Method for recycling copper, nickel, chromium, zinc and iron from plating sludge

The invention relates to a method for recycling copper, nickel, chromium, zinc and iron from plating sludge, belonging to the technical field of chemical engineering and metallurgy. The method comprises the following steps: acid leaching, vulcanizing for separation and enrichment, hot-pressure leaching, extracting for separation, hot-press oxidizing chromium, purifying chromium solution, extracting ferric chloride and the like. The method has obvious advantages of strong adaptability to different kinds of plating sludge, high utilization of metal resources, high value-added content of product,less process waste residue, thorough deintoxication and the like.

Owner:YANGZHOU NINGDA NOBLE METAL CO LTD

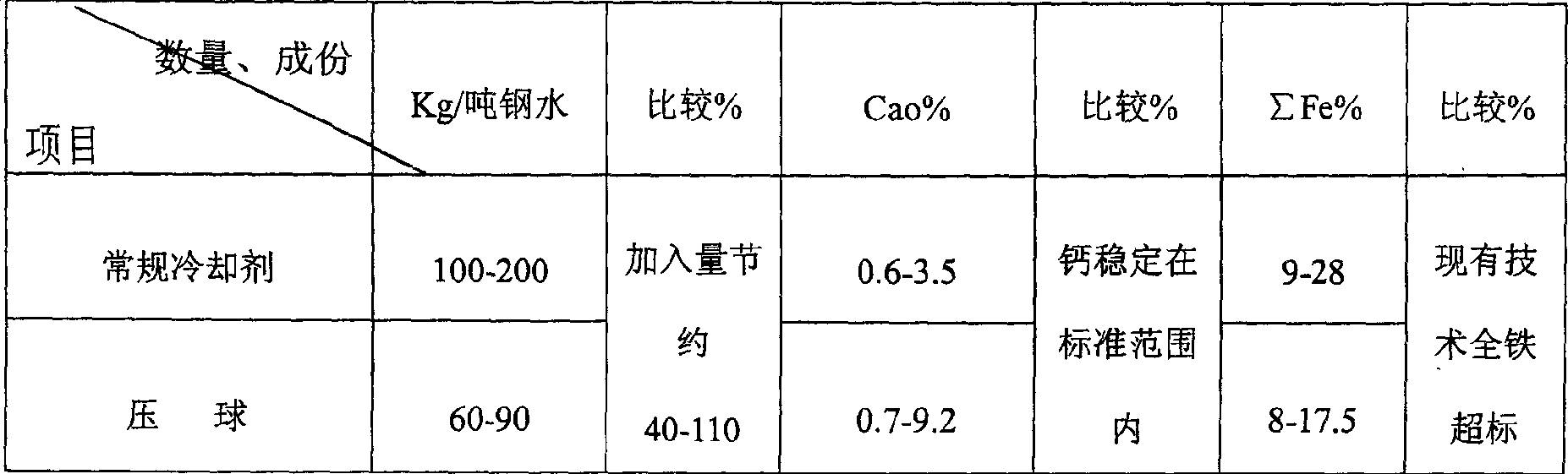

Molten iron vanadium-extracting calcium-controlling coolant and process therefor

The invention relates iron melt improving vanadium content and controlling calcium content cooling agent and the technology, specially relates the cooling agent of adjusting the proportion of cooling agent to stabilize calcium content in vanadium slag and the technology. The technology comprises the 56-60wt% iron scale, 30-40wt% iron concentrate powder containing vanadium, and 5-10wt% anchoring agent. The method stabilizes the calcium content and iron content in vanadium slag, and effectively solves the problems of great fluctuation of vanadium slag composition and superstandard calcium and iron. By controlling the thermoregulation material to meet the requirements of the improving vanadium temperature and calcium oxide content, the method improves the vanadium slag grade and extraction rate. The invention possesses the following characteristics: 1 shortening the converting time; 2 improving the vanadium slag grade and extraction rate, and stabilizing the calcium oxide content; 3 reducing the iron loss.

Owner:HEBEI LUANHE IND GROUP

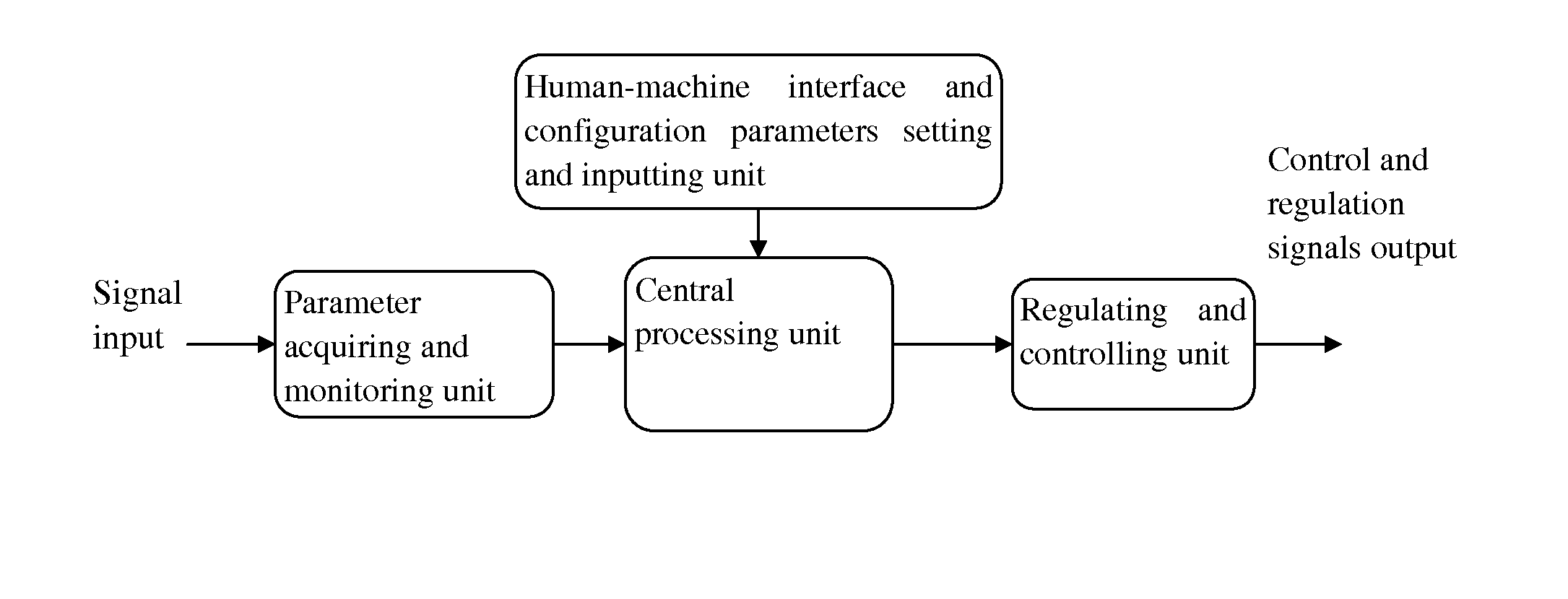

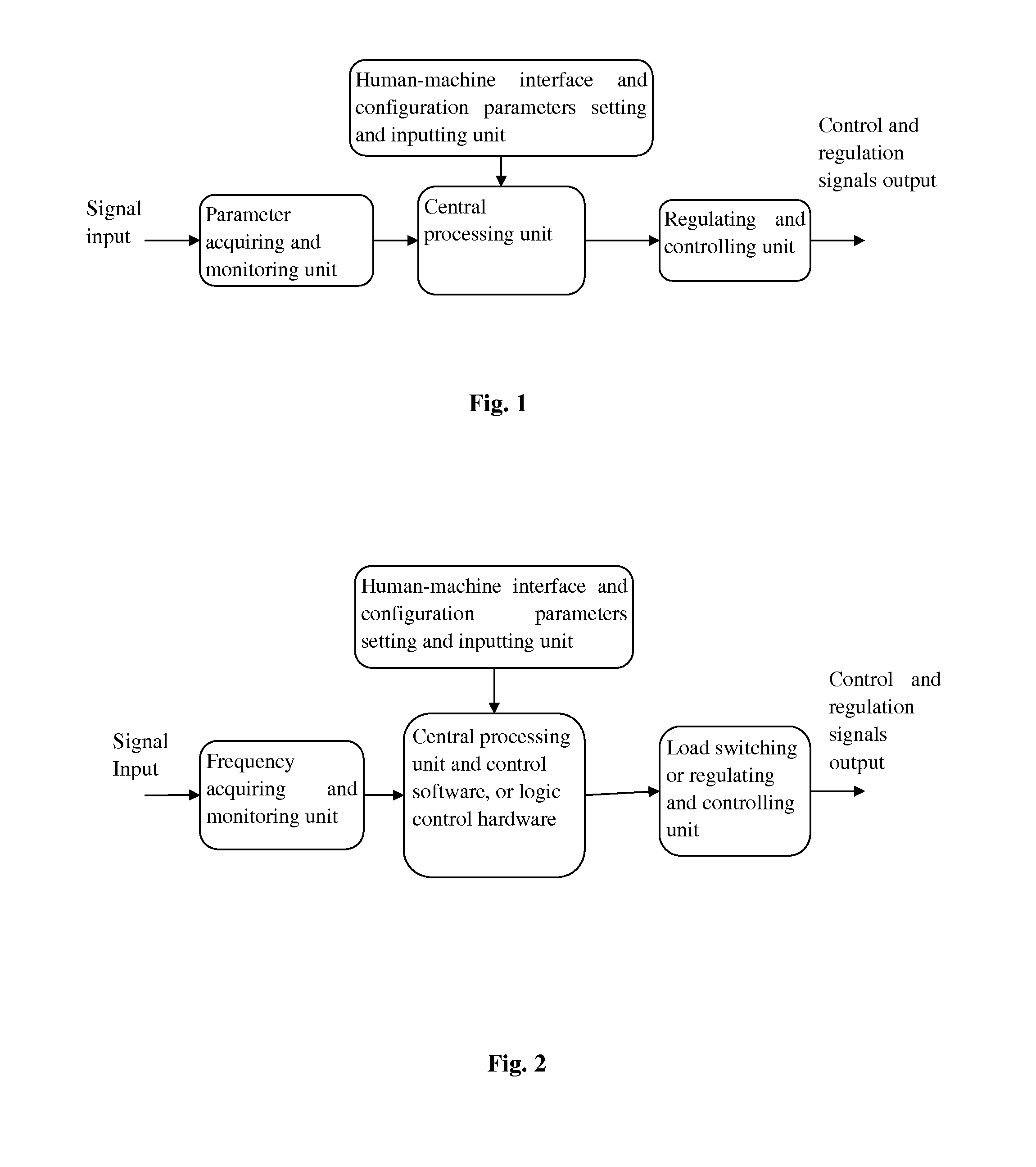

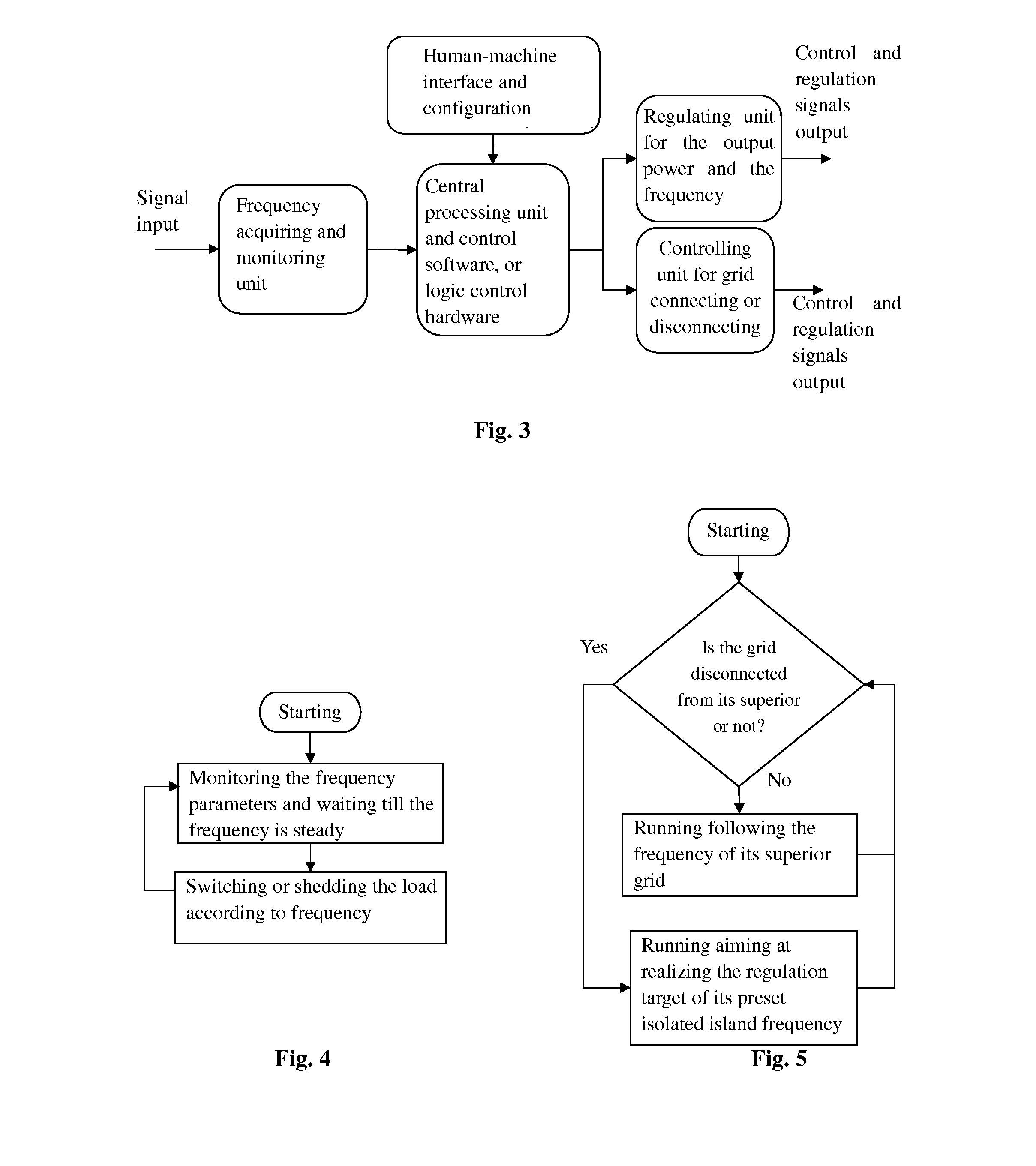

Device and method for self-healing control of a multi-level power grid

InactiveUS20140025217A1Long durationLower gradeMechanical power/torque controlLevel controlSelf-healingSupply energy

A device and method for self-healing control of multi-level power grid system are provided in the present invention. The requirements to be satisfied by the present invention are that: realizing interaction and balance between power supplies and loads; controlling and coordinating cooperation coordination and cooperation between various distributed power supplies, micro-grids in multi-levels and their main grids; automatically distinguishing an on-grid state or an isolated island state of a locale grid; and guaranteeing energy supply to the maximum. The device for self-healing control of multi-level power grid is connected in one or more levels of power grids of the multi-level power grid system, and the device includes: a parameter acquiring and monitoring unit, a central processing unit, a human-machine interface and configuration parameter setting and inputting unit, and a regulating and controlling unit. Using frequency as an information carrier to characterize the connection state and the area coverage and grids levels included in the power system, the device enables the loads and the power supplies in the power grid system to distinguish the states of their localized grids by themselves, and performs to perform automatic switching or regulating according to preset strategies. Using frequency as information tie, the device balances supply and demand of power by self-adjustment between the power supplies and the loads in the system, and guarantees the automatic balance and stabilization of the power grid system both in the on-grid state and in the isolated island state.

Owner:ZHUHAI UNITECH POWER TECH CO LTD

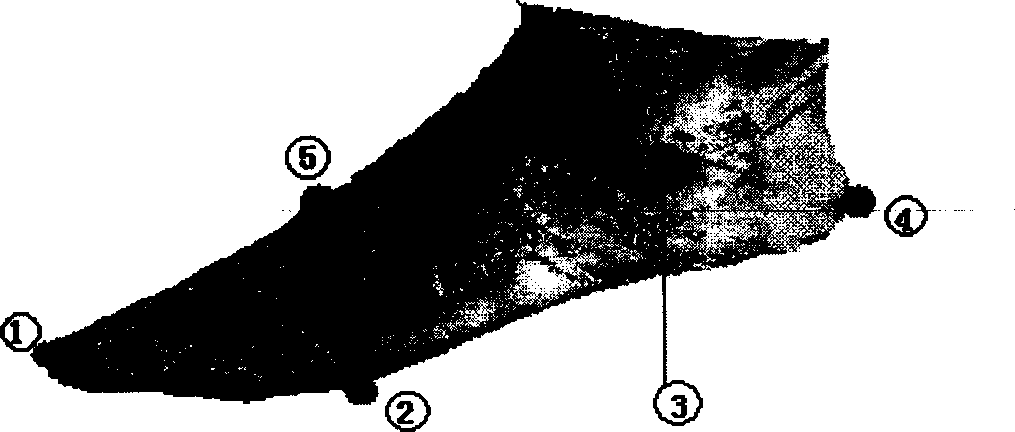

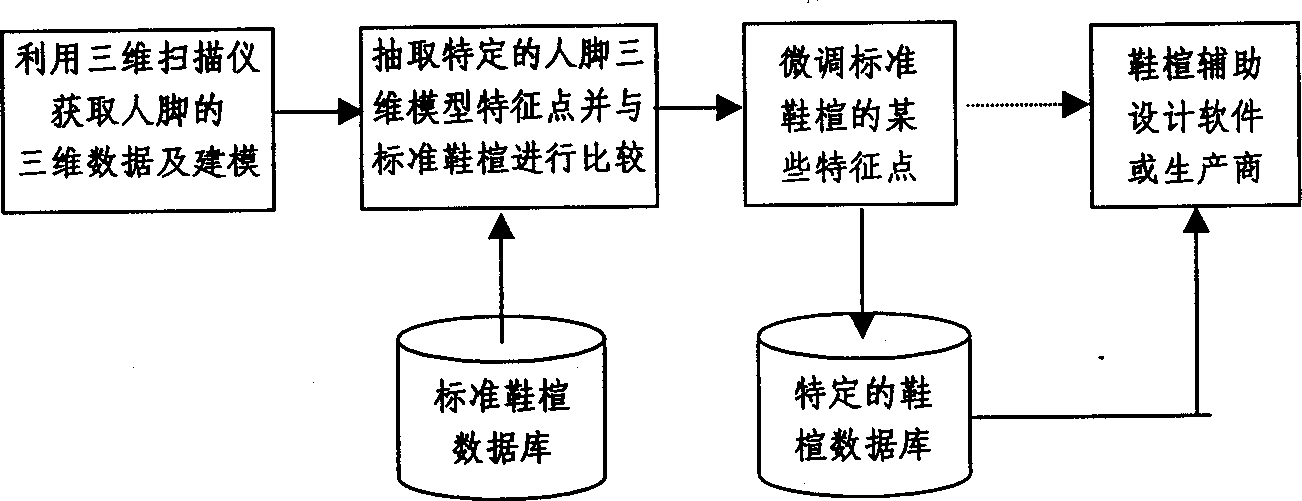

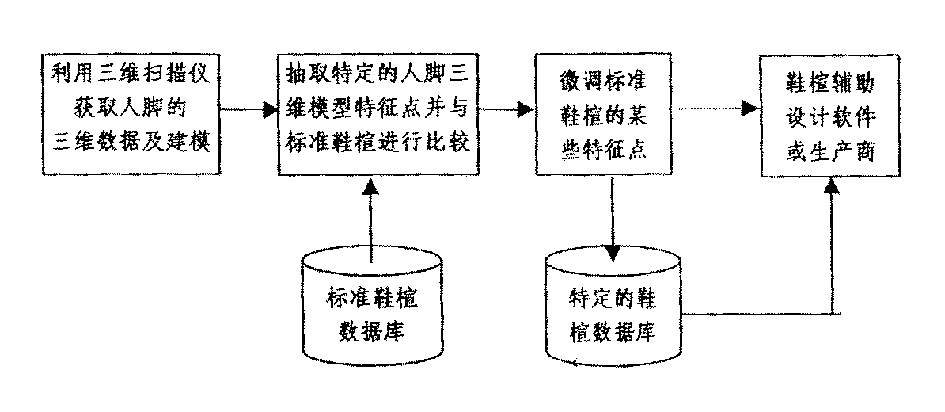

Personalized shoe tree mold designing method

InactiveCN1348731AEnsure a high degree of coordinationChange the traditional conceptFoot measurement devicesLastingFoot typePersonalization

The present invention discloses method of designing shoe tree model with specific individuality, in said method, 3D scanner is utilized to obtain 3D data of foot and then makes model according to theobtained data, then compare the model with standard shoe tree model and regulates the model to form specific shoe tree model which fits the foot shape of specified customer. The shoe made with the invented shoe tree possesses individuality and is comfort to wear.

Owner:ZHEJIANG UNIV

Blast-furnace smelting method for vanadium titano-magnetite

InactiveCN101775451ARaise the gradeReduce tons of iron slagBlast furnace detailsMagnetiteBlast furnace smelting

The invention discloses a blast-furnace smelting method for vanadium titano-magnetite. The method is realized in a way that: vanadium titano-magnetite accounts for 30-60% of ferrous burden which is fed into a blast furnace, and the burden comprises 40-65% of agglomerate, 30-50% of pellet and 5-10% of lump ore; the diacidic basicities CaO / SiO2 of agglomerate, pellet and blast-furnace slag are respectively controlled at 1.6-2.5, 0.6-1.0 and 1.05-1.20; the content of MgO in blast-furnace slag is controlled at 7.5-9.0%; by adding two batches of ore and three batches of coke and using the charging operation of the development center, manganese oxide ore or sintered manganese ore powder, and fluorite are incorporated into injection coal and injected into the blast furnace along with the coal powder; and thus, the content of MnO in the slag and the content of CaF2 in the slag are respectively controlled at 1.0-4.5% and 0.50-2.0%, and the oxygen-enrichment percentage of the blast furnace is controlled at 2.0-4.0%. Compared with the smelting blast furnace using the same quality and structure of the burden, the comprehensive coke ratio of the invention is reduced by 20-50kg per ton of iron, the content of TFe in the slag is reduced by 50%, and the comprehensive cost per ton of iron is reduced by 30-50 yuan. The invention has wide prospects for popularization and application.

Owner:CENT SOUTH UNIV

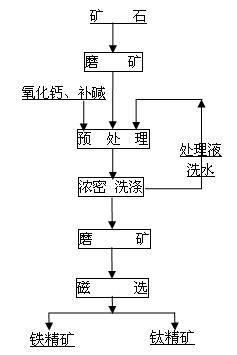

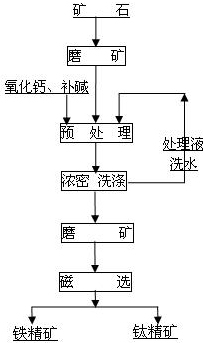

Beneficiating method for ilmenite

ActiveCN102181626AIncrease alkali concentrationHigh in ironBlast furnace detailsProcess efficiency improvementMagnetiteIlmenite

The invention discloses a beneficiating method for ilmenite, relating to a method for preparing titanium concentrate and iron concentrate by beneficiating crude ilmenite. The method is characterized in that: a beneficiating process of the method orderly comprises the following steps of: (1) grinding the crude ilmenite; (2) performing alkaline leaching pretreatment under the conditions of heating, oxygenating and pressurizing; (3) filtering pulp which is subjected to the alkaline leaching pretreatment; (4) washing filter residue and grinding; and (5) performing magnetic separation to obtain the titanium concentrate and the iron concentrate. In the method provided by the invention, the characteristic of iron and titanium compact symbiosis and the isomorphism occurrence characteristic of vanadium are damaged from the source of vanadium titano-magnetite by adopting the pretreatment process, so that mineral transformation of the vanadium titano-magnetite is realized, dissociation on lattice layers of titanium and iron is realized, high-quality iron concentrate and titanium concentrate with lower iron content are obtained through grinding and the magnetic separation process, an alkaline medium used in the pretreatment can be recycled, and the process has a small influence on environment and a bright application prospect.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

Low grade fluorite and barite flotation separation method

A low grade fluorite and barite flotation separation method uses waterglass as the inhibitor for silicious mineral and calcium carbonate mineral; uses oleic acid as the collector for fluorite and barite; and uses starch, sodium sulphate, hydrochloric acid and sodium hexametaphosphate as the inhibitor for barite mineral. The invention can perform flotation separation of low grade fluorite and barite effectively; under the condition that the given fluorite grade is 33.92%-40.41%, and the barite grade is 34.67%-35.33%, by mixing, flotation and separation, can achieves the fluorite concentrate with grade of above 95% and recovery rate of 75.5%-78.5%, and the barite concentrate with grade of 92.3%-93.27% and recovery rate of 75.2%-79.73%.

Owner:GUANGXI UNIV

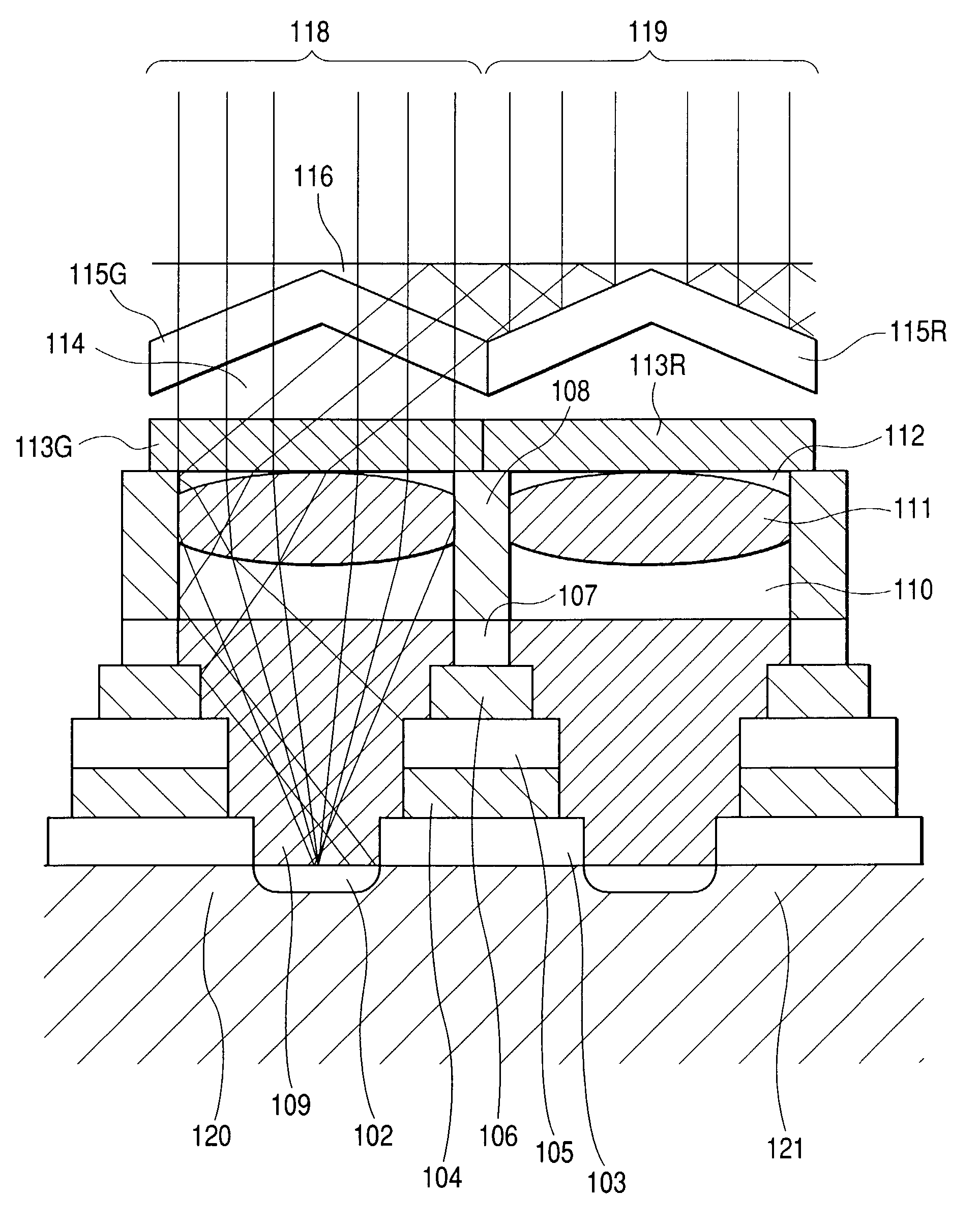

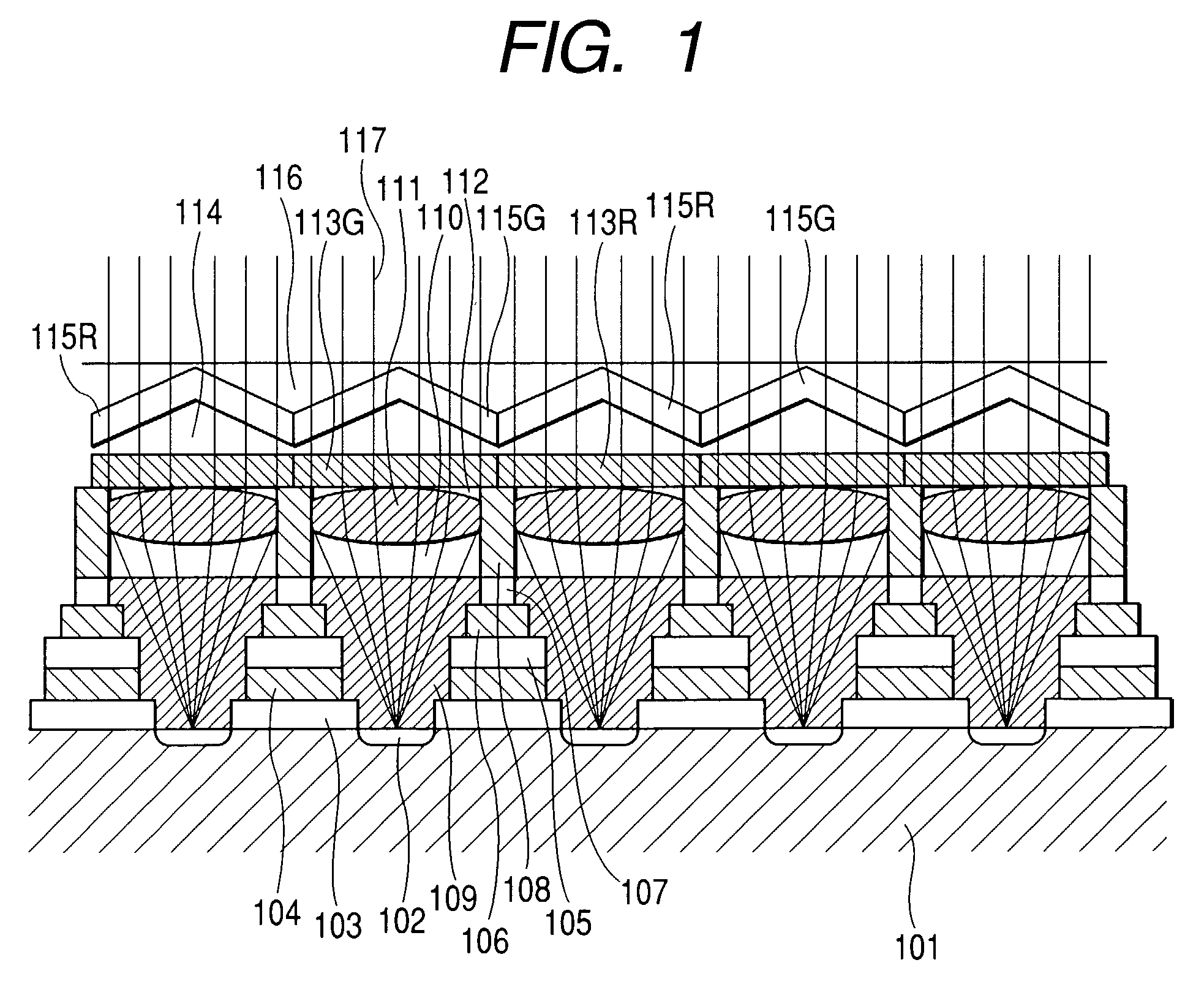

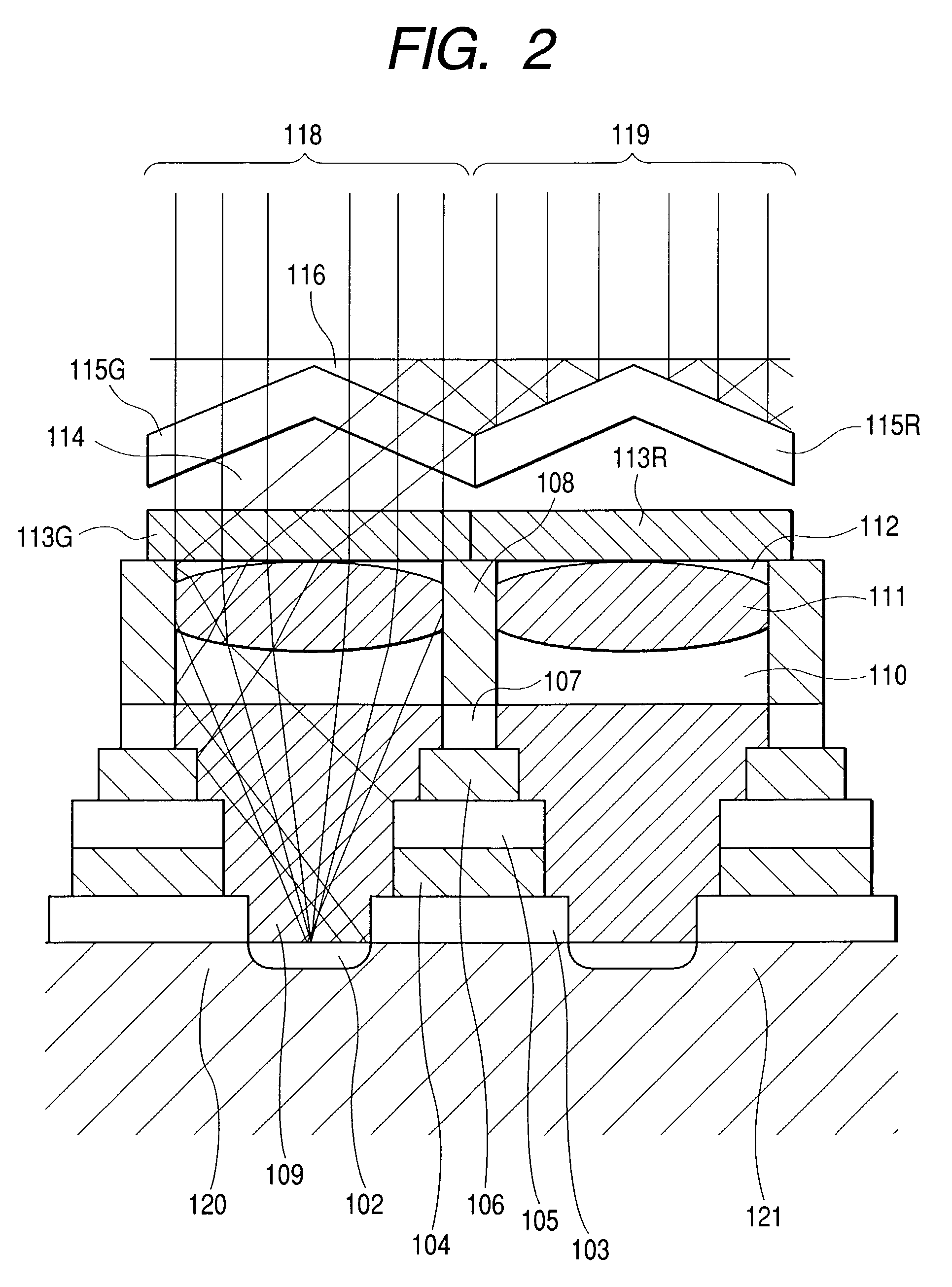

Image pickup apparatus containing light adjustment portion with reflection of a portion of light onto adjacent pixels

InactiveUS7110034B2Raise the gradeLess moiréTelevision system detailsTelevision system scanning detailsPhotoelectric conversionTransmitted light

An image pickup apparatus comprises a plurality of photoelectric conversion areas, and a light adjustment area including a first transmission portion for transmitting light which is provided in association with a first photoelectric conversion area included in the plurality of photoelectic conversion areas and a second transmission portion for transmitting light which is provided in association with a second photoelectric conversion area included in the plurality of photoelectric conversion areas. The light adjustment area is configured to cause a part of light incident on the second transmission portion to be incident on the first transmission portion.

Owner:CANON KK

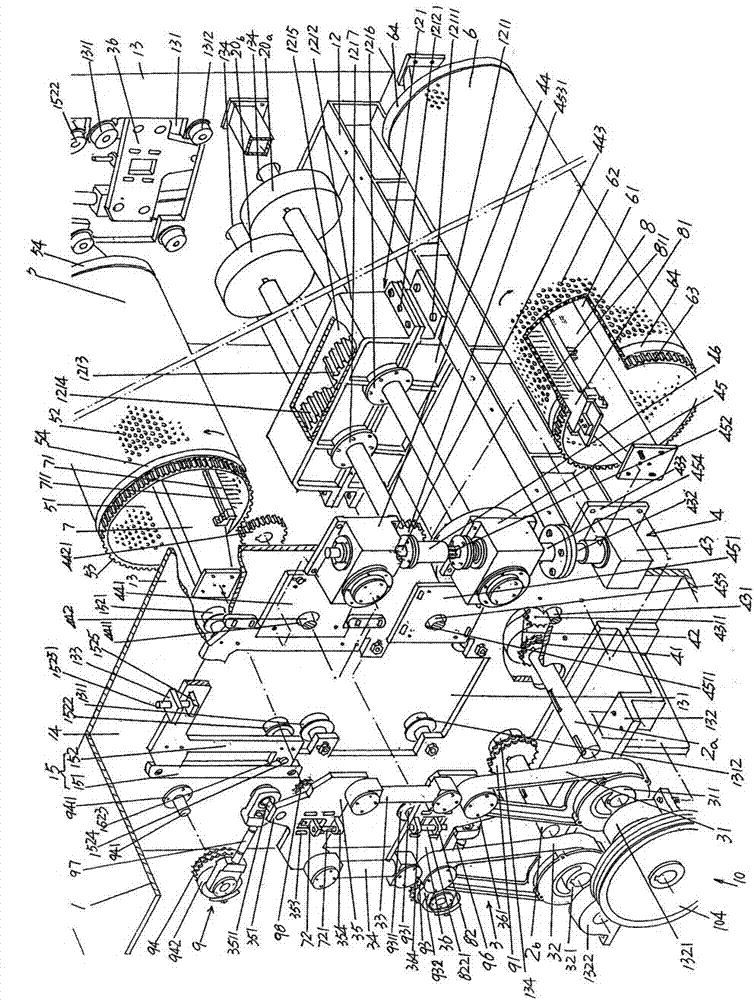

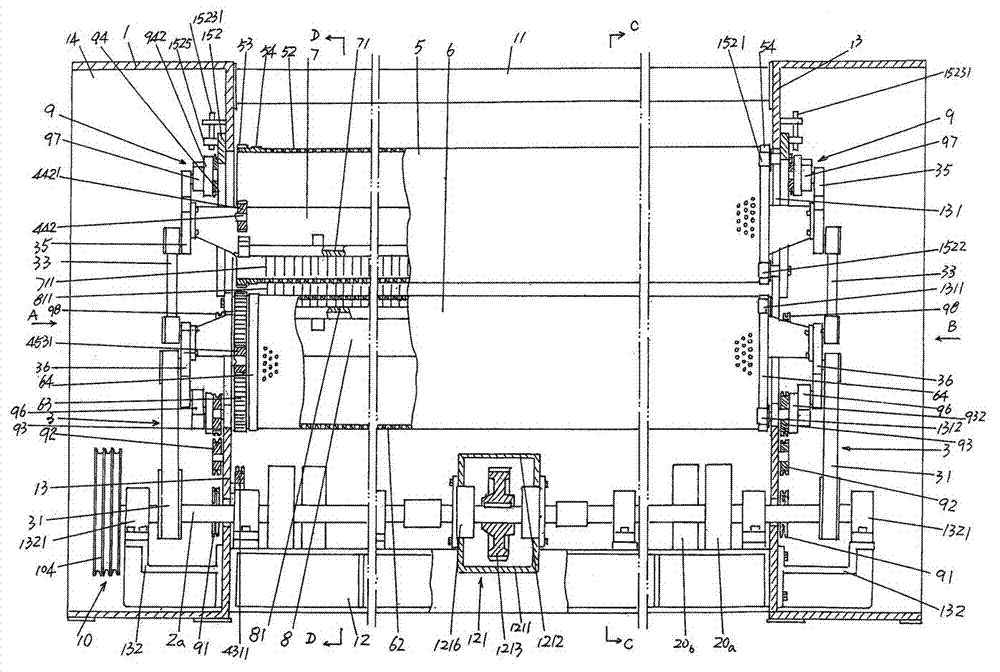

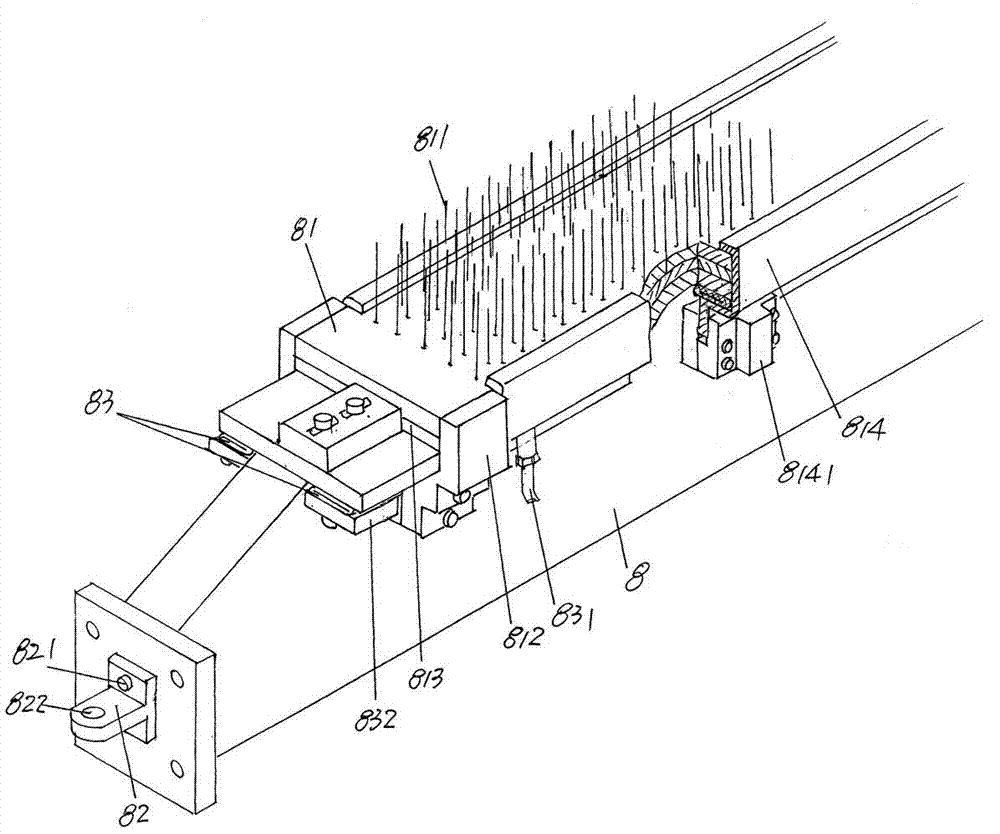

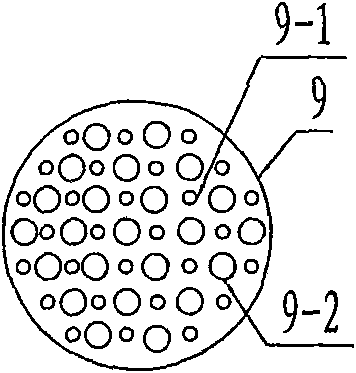

Roller type needling machine

ActiveCN102808290BSaving zero draftGuaranteed zero draftNeedling machinesNeedle penetrationWall plate

A drum-type needling machine belongs to the field of non-woven machinery. It includes a pair of chassis, a needle beam is set on the chassis wallboard of the pair of chassis to penetrate into the relief cavity, and a transmission box is arranged in the middle of the lower cross frame of the chassis; the first and second main shafts are supported between the pair of chassis; a pair of Connecting rod mechanism; roller driving mechanism, connected with the first main shaft; upper roller and lower roller, supported between a pair of chassis, cooperate with the roller driving mechanism; upper needle beam and lower needle beam, fixed on the middle part of the upper needle beam Needle board, the upper needle board is arranged with upper needles, the lower needle board is fixed in the middle of the lower needle beam, and the lower needle board is arranged with lower needles; a pair of connecting rod swing traction mechanisms are arranged in the chamber of a pair of chassis, It is connected with the link mechanism in the box cavity and is also connected with the second main shaft in transmission; the power transmission mechanism arranged on the case is connected with the first main shaft in transmission. Advantages: It helps to improve production efficiency, shorten the process flow, save energy consumed by needle looms; improve the grade of non-woven products.

Owner:CHANGSHU FEILONG NON WOVEN MACHINERY

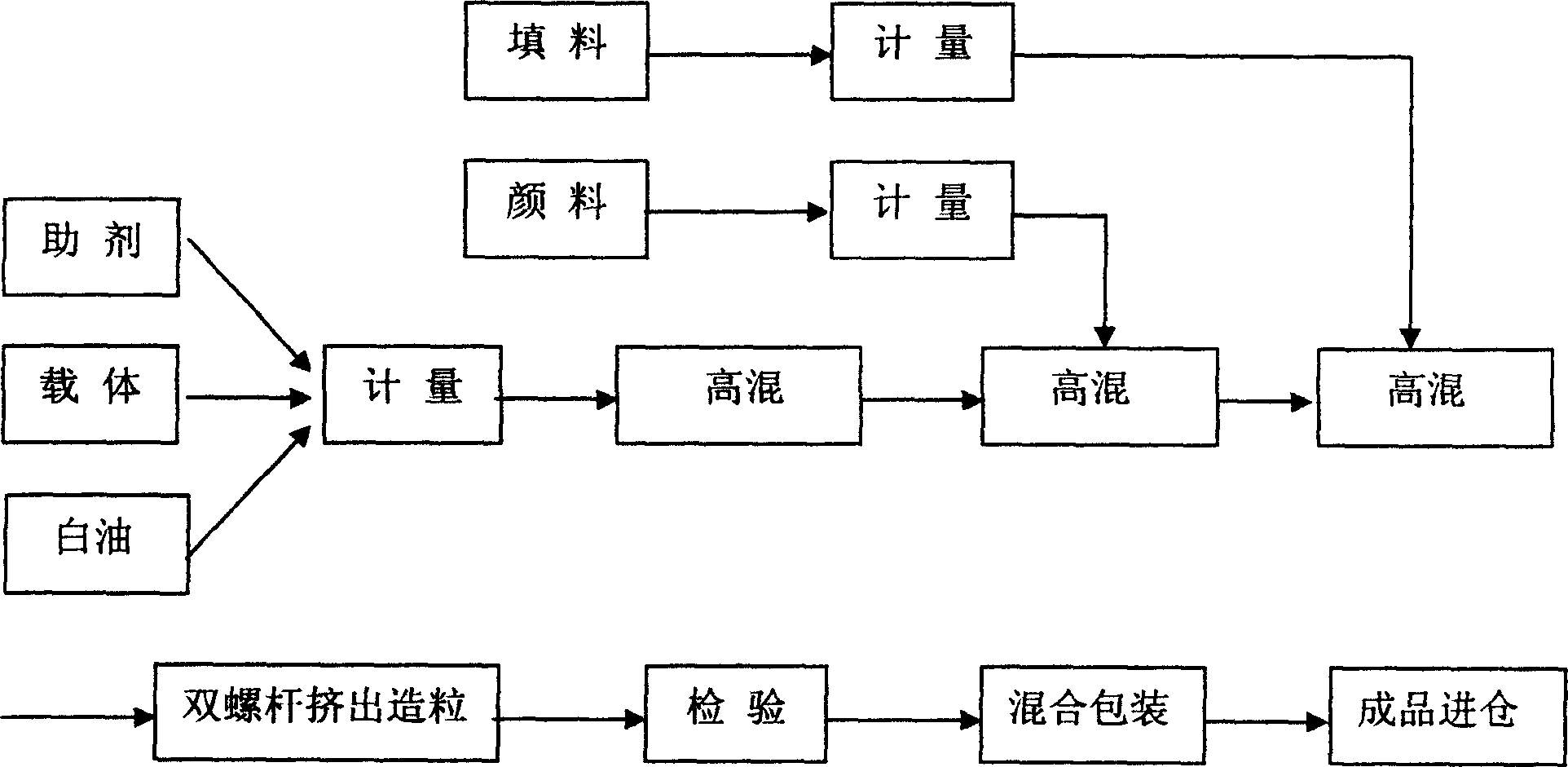

Natural-like multifunctional color batch and use thereof

The present invention features that the color concentrate is prepared with main carrier resin A, matched carrier resin X, compatizer, pigment, inorganic stuffing, antistatic agent, light stabilizer, antioxidant and pigment lubricating dispersant. The main carrier resin an and the matched carrier resin X, which has obviously different compatibility and smelting behavior from that of the basic resin B in the product, may constitute alloy carrier resin. The said materials may be altered to result in various decoration effects.

Owner:GUANGDONG SHENGHENGCHANG CHEM IND

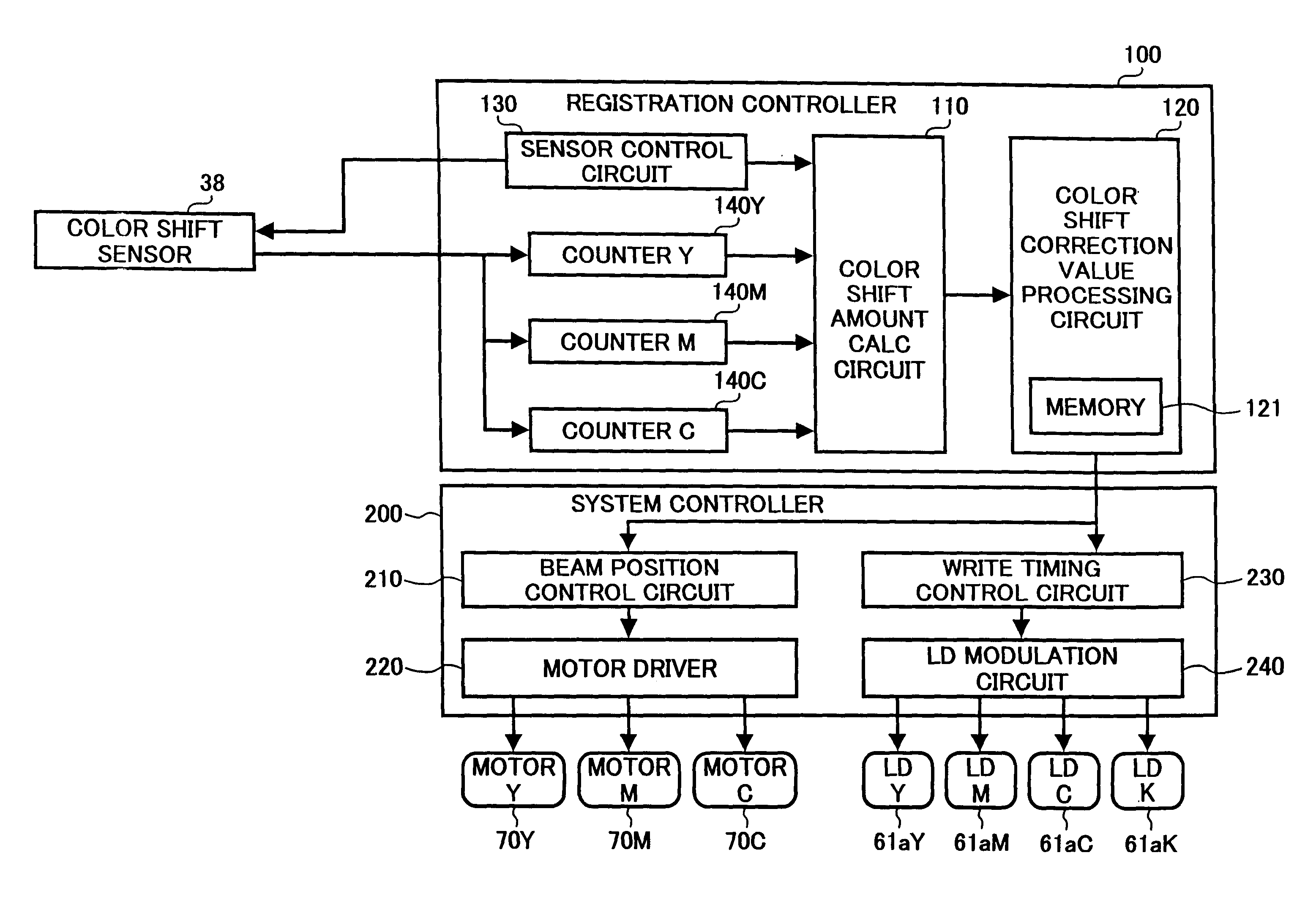

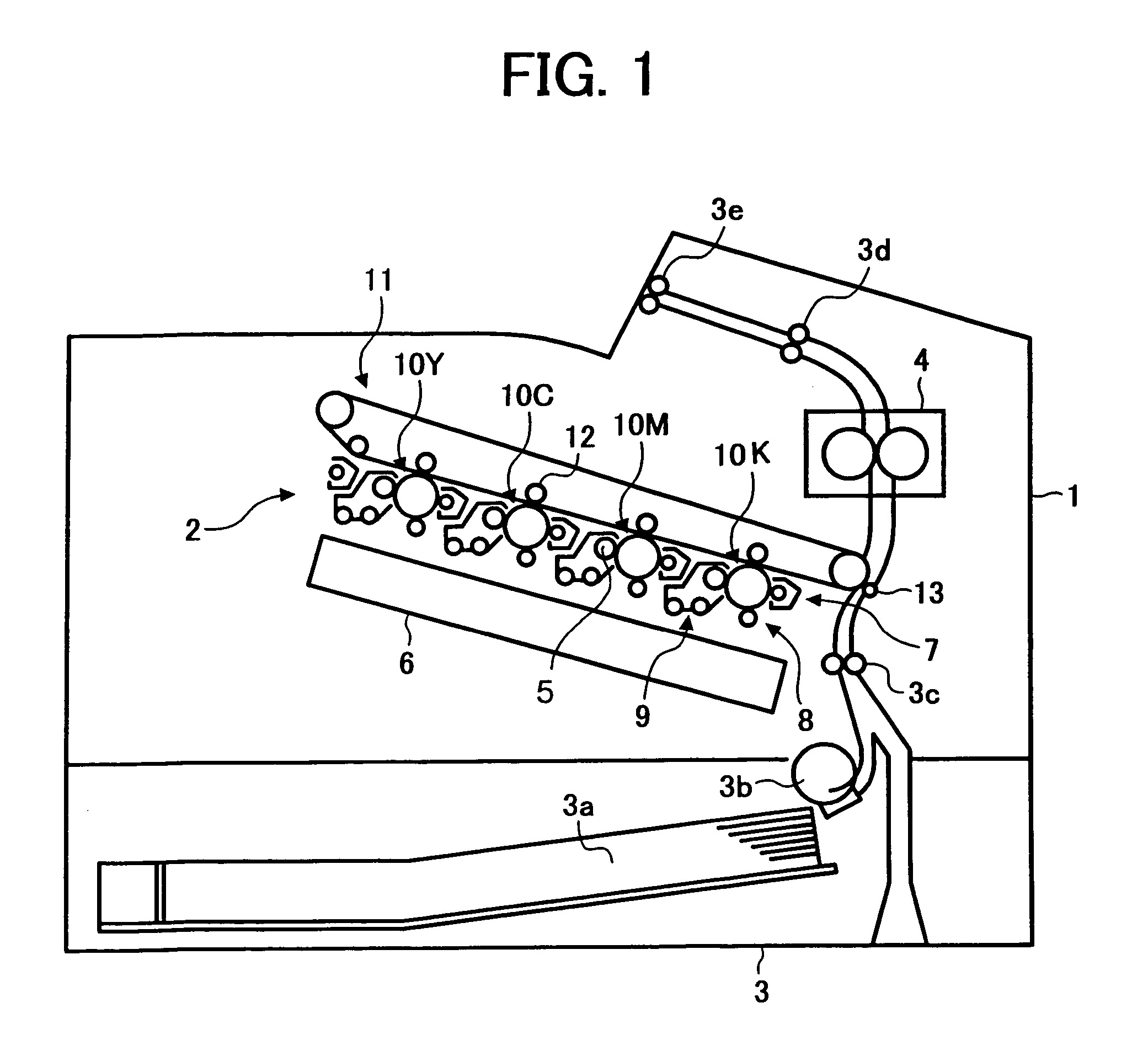

Color shift correcting method, optical writing device and image forming apparatus

InactiveUS20040100550A1True colorLow costElectrographic process apparatusPrintingColor imageColor shift

A color shift correcting method for correcting a color shift due to misregistration of images in different colors, where a multi-color image is formed by developing latent one-color images written onto respective image carriers by an optical writing device, and directly or indirectly transferring developed one-color images onto a movable element, said method comprising the step of: adjusting a position at which one of said image carriers is irradiated with an optical beam in a sub-scanning direction to correct said color shift while said optical beam is irradiated from said optical writing device onto said image carriers to develop the latent one-color images.

Owner:RICOH KK

Processing process of woven fabric with one-way quick moisture conducting composite structure

The invention discloses a processing process of a woven fabric with a one-way quick moisture conducting composite structure. The process comprises a design process and a weaving process, wherein the design process comprises the steps of: establishing a one-way quick moisture conducting model and designing an organization structure; and the weaving process comprises the steps of: selecting and weaving warp and yarn raw materials by the moisture conducting principle of the established fabric moisture conducting model. The invention can be used for designing and weaving the woven fabric with a one-way quick moisture conducting composite structure, and moisture conducting and quick drying series functional fabrics are a great trend of the future consumer market and have wide development prospect.

Owner:杭州新天元织造有限公司

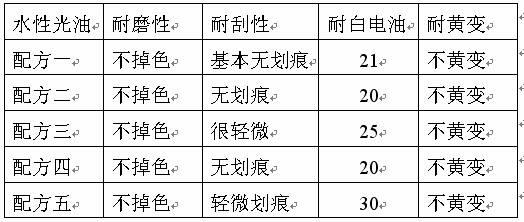

Water-based matte touch gloss oil and preparation method thereof

The invention discloses a water-based matte touch gloss oil and a preparation method thereof. The water-based matte touch gloss oil is prepared from the following raw materials in percentage by mass: 65-80% of water-based polyurethane dispersion, 10-20% of modified acrylic elastic emulsion, 1-3% of flatting agent, 3-5% of coupling agent, 3-5% of hand touch wax slurry, 1-3% of matting agent, 0.1-0.5% of defoamer, 0.5-2% of hand touch scratch-resistant agent, and 0-3% of water. The water-based matte touch gloss oil prepared from the materials is low in matte degree, and employs water as a diluent and contains no organic solvent or heavy metal; and the water-based matte touch gloss oil is natural and soft in color and luster without whiting, and good in color reveal property. Furthermore, the water-based matte touch gloss oil is suitable for surface coating treatment of high-quality paper, so that the coated paper feels like cotton, silk and velvet, and the paper finished product is good in matte degree and high in white gasoline resistance; the level of product packaging is greatly improved; and the water-based matte touch gloss oil is mainly applied to leatherette paper, imitation leather, calendered paper and some coated paper.

Owner:GUANGDONG YINGKE GRP CO LTD

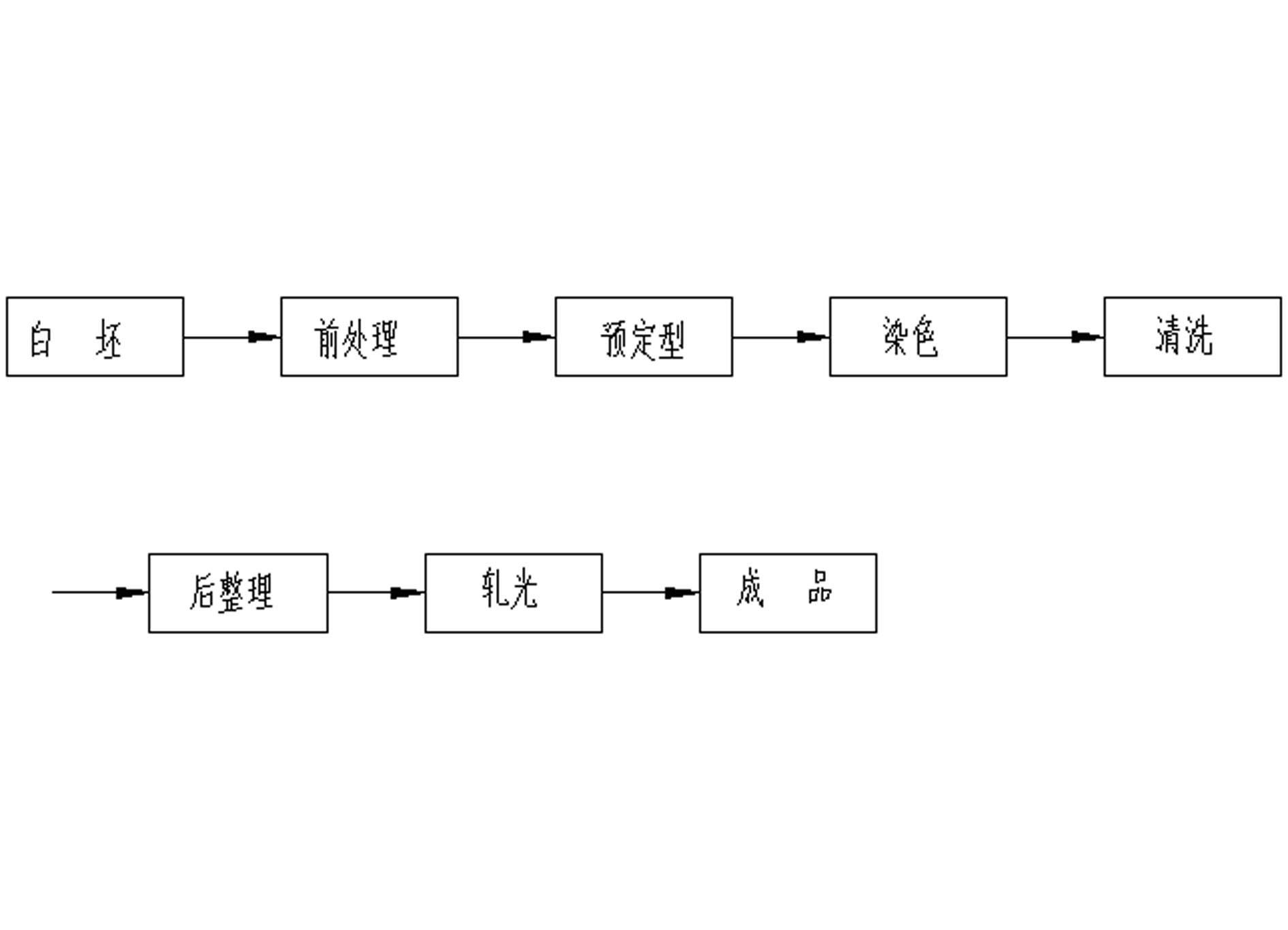

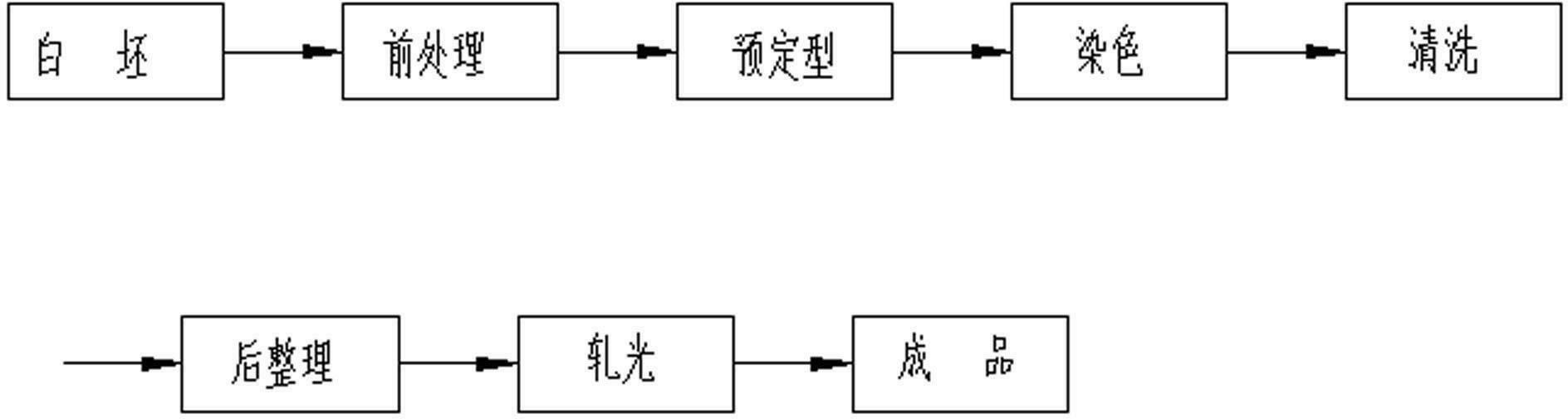

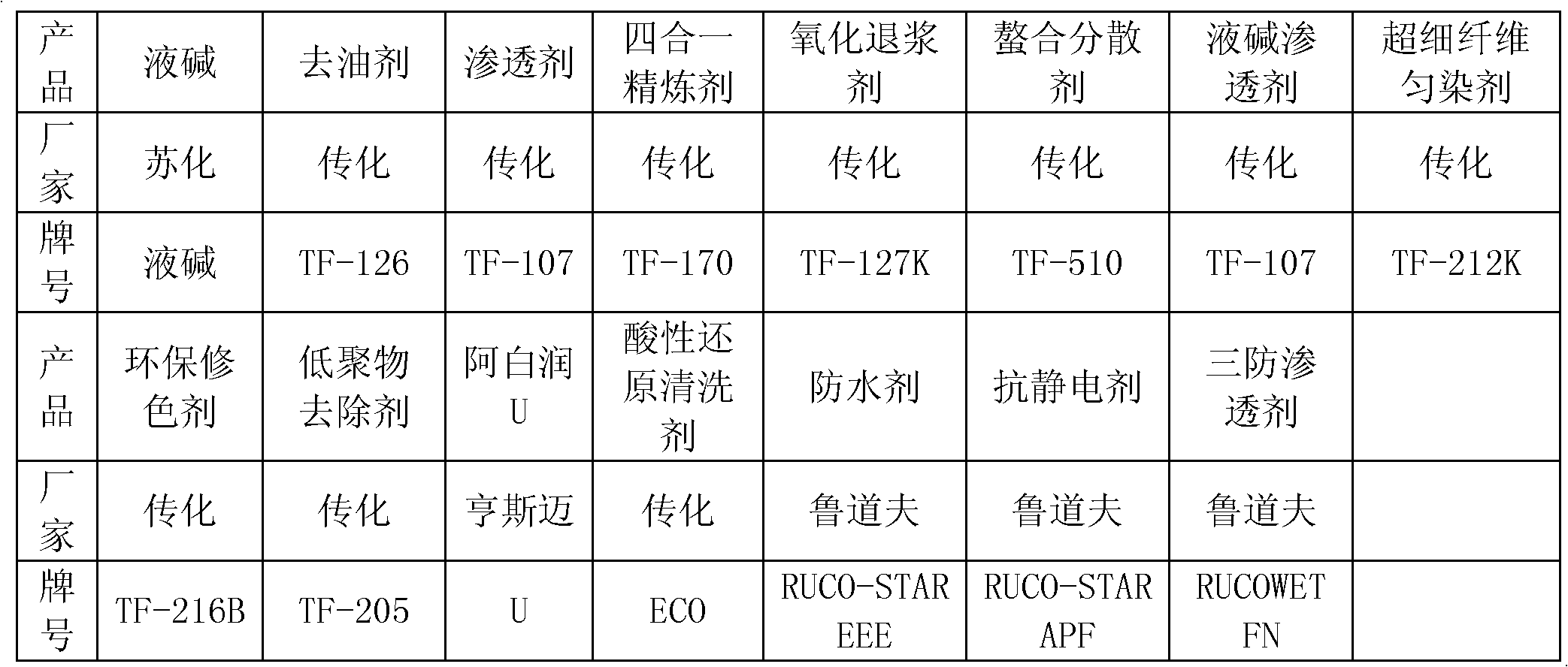

Novel dyeing and finishing processing technology of micro polyester fabric

ActiveCN102628211AReduce wrinklesReduce staining and chafingHeating/cooling textile fabricsDry-cleaning apparatus for textilesEnvironmental resistanceDisperse dye

The invention relates to a novel dyeing and finishing processing technology of a micro polyester fabric. The novel dyeing and finishing process disclosed by the invention is characterized by comprising the following steps of: (1) pretreatment, namely carrying out cold rolling and stacking processing comprising three stages, namely cold stacking, hot alkali treatment and high efficiency washing, on polyester gray fabric; (2) presetting, namely carrying out high temperature tentering and presetting on a pretreated fabric white body by utilizing a setting machine; (3) dyeing, namely dyeing the preset fabric white body by adopting superfine fiber leveling agent; and (4) cleaning, namely carrying out cleaning post-processing on the dyed fabric to remove disperse dyes which are not set after fibres are dyed. According to the novel dyeing and finishing processing technology disclosed by the invention, an environment-friendly and low-energy-consumption cold rolling and stacking pretreatment technology is used for carrying out pretreatment on the micro polyester fabric, on one hand, desizing effect is good and good dyeing and finishing processing conditions are provided for dyeing, and on the other hand, crease mark of the fabric can be effectively reduced; meanwhile, a formula of a dyeing process additive can be adjusted, albafluid U is added to reduce fabric dyeing scratch, and dyeing defects can be prevented from being caused.

Owner:SHENGHONG GRP CO LTD

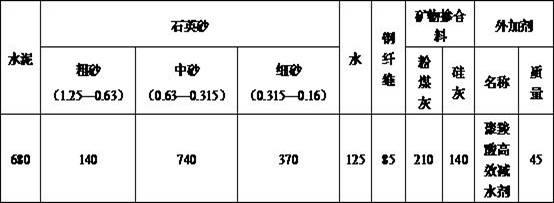

High-strength active powder concrete and preparation method

InactiveCN102320789AImprove performanceImprove uniformityCeramic shaping apparatusDry mixingWater reducer

The invention discloses a cement-based composite material - high-strength active powder concrete which comprises the following raw materials by weight: 40-55 parts of quartz sand, 25-30 parts of cement, 0-10 parts of fly ash, 0-7 parts of silica fume, 1-4 parts of steel fibers, 1-2 parts of water reducers, and 2-7 parts of water; in the components, the particle size of quartz sand is less than 1.25 mm, wherein the weight content of SiO2 is 97%. The mixing preparation comprises the following steps: weighing quartz sand and steel fibers according to the mixing ratios, adding into a stirring pot, performing dry mixing for 2 min; weighing cement and a special composite admixture according to the mixing ratios, adding into the stirring pot, performing dry mixing with quartz sand and steel fibers for 2 min; finally adding the high-efficient water reducer and water together, stirring for 6 min; after the stirring of the concrete, blanking and molding. The concrete of the invention has ultrahigh strength, low brittleness, high durability, and high compactness, brings into better play of the excellent performance of the active powder concrete, and reaches the purposes of less maintenance or free of maintenance, and prolongation of structure service life.

Owner:SICHUAN SOUTHWEST JIAOTONG UNIV RAILWAY DEV

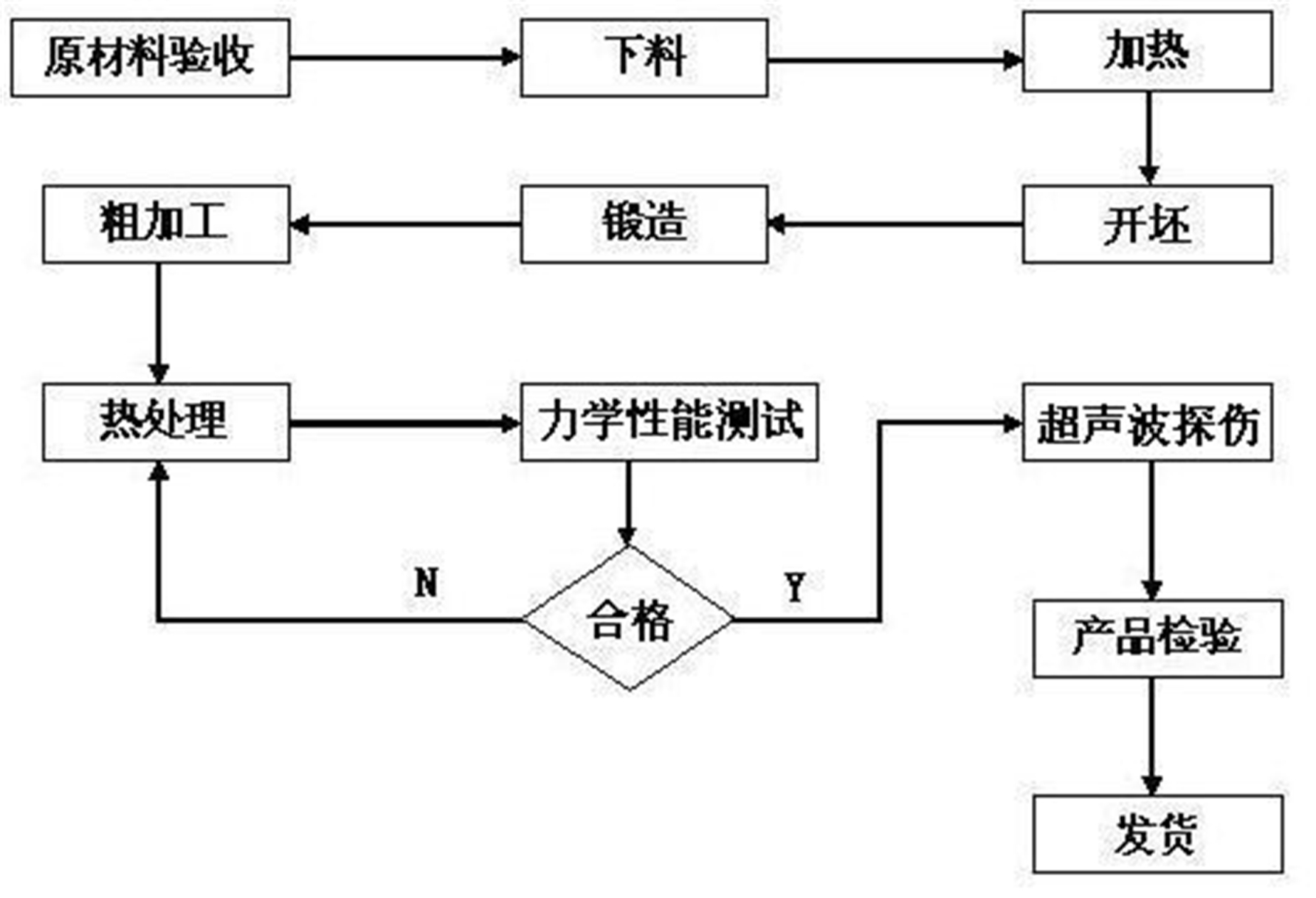

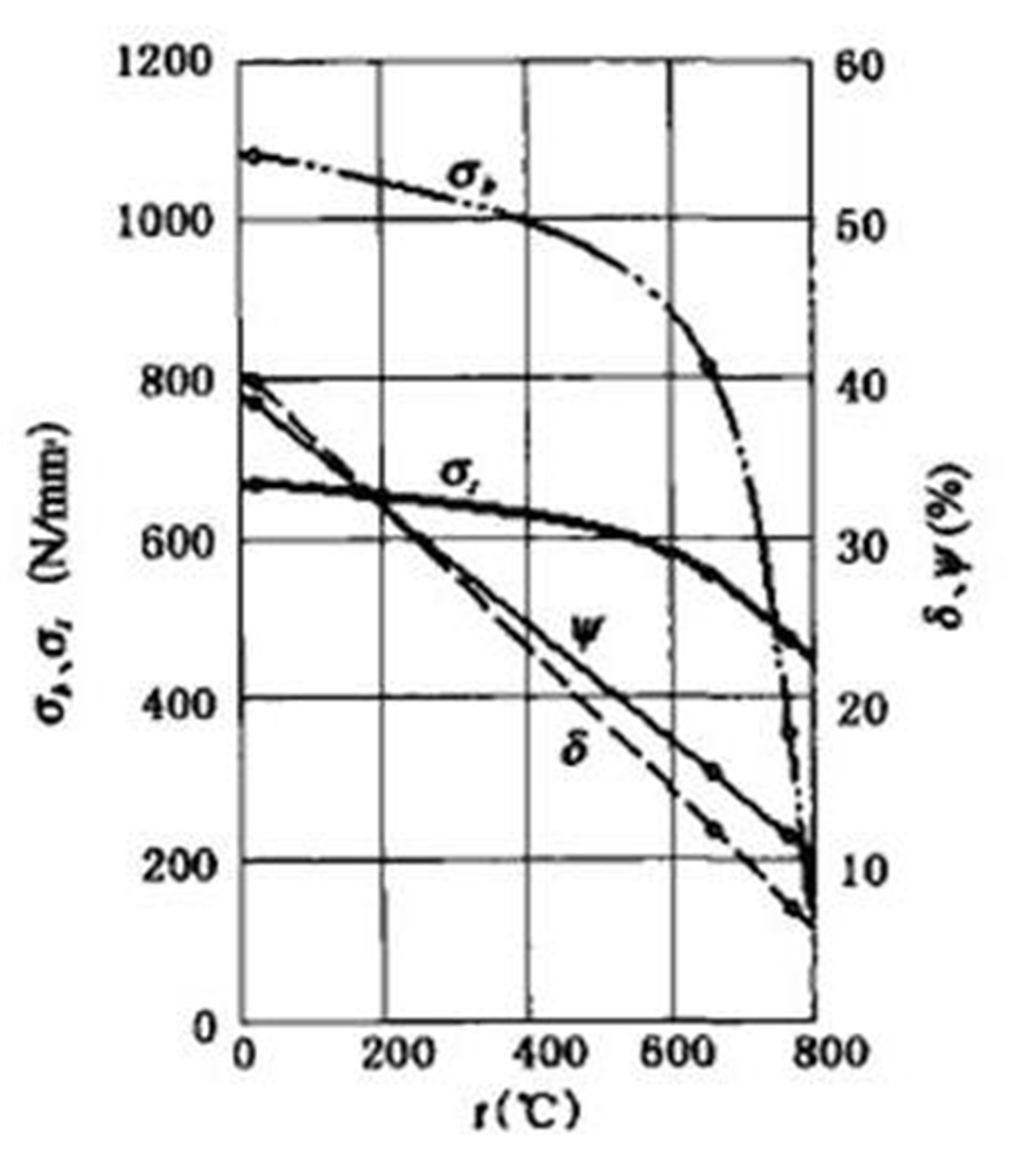

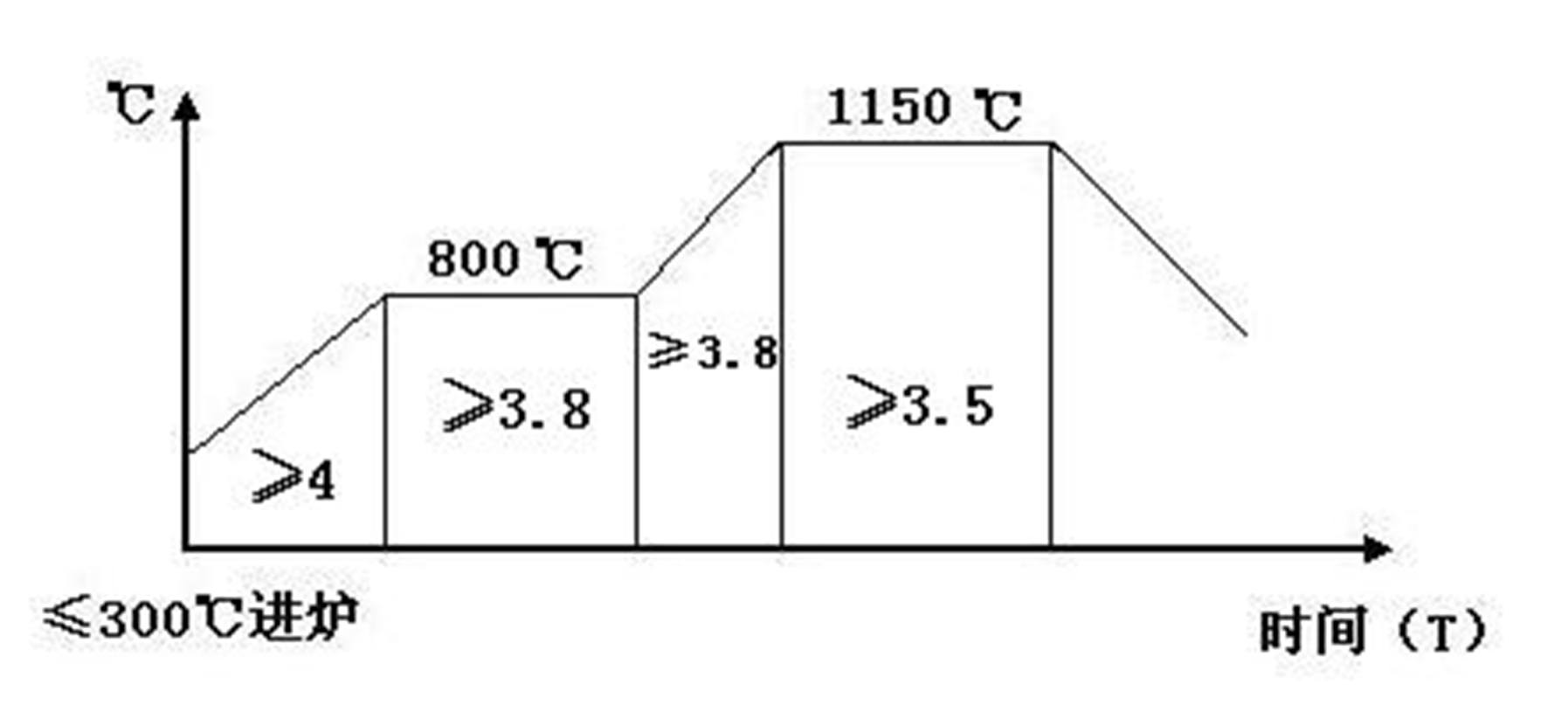

Method for manufacturing nickel-based high-temperature alloy forge piece

InactiveCN102357633AImprove competitivenessReduce mass consumptionMetal-working apparatusChemical compositionForging

The invention relates to the technical field of forge process, and provides a method for manufacturing a nickel-based high-temperature alloy forge piece. The method comprises the following steps of: (1) inspecting nickel-based high-temperature alloy raw materials, including re-inspection of chemical components and inspection of steel ingot surface; (2) blanking by adopting a sawing machine sawing method or a chopper hot chopping method; (3) heating the steel ingot; (4) cogging and performing forge deformation treatment; (5) performing last but one heating number forging and last heating number forging; (6) rough processing; (7) heat treating; (8) testing mechanical performance; (9) detecting faults with ultrasonic wave; and (10) inspecting products. According to the manufacturing method provided by the invention, home-made manufacture of nickel-based high-temperature alloy forge pieces achieves a success, utilization of China to the nickel-based high-temperature alloy is broken through, and the quality and grade of products of China can be improved, the requirement of domestic market for high-quality valve rods and valve discs of a steam turbine, seal rings in various specifications and critical parts in aerospace field can be fulfilled, and the competitive capability of native enterprises in the international market can be improved.

Owner:上海宏钢电站设备铸锻有限公司

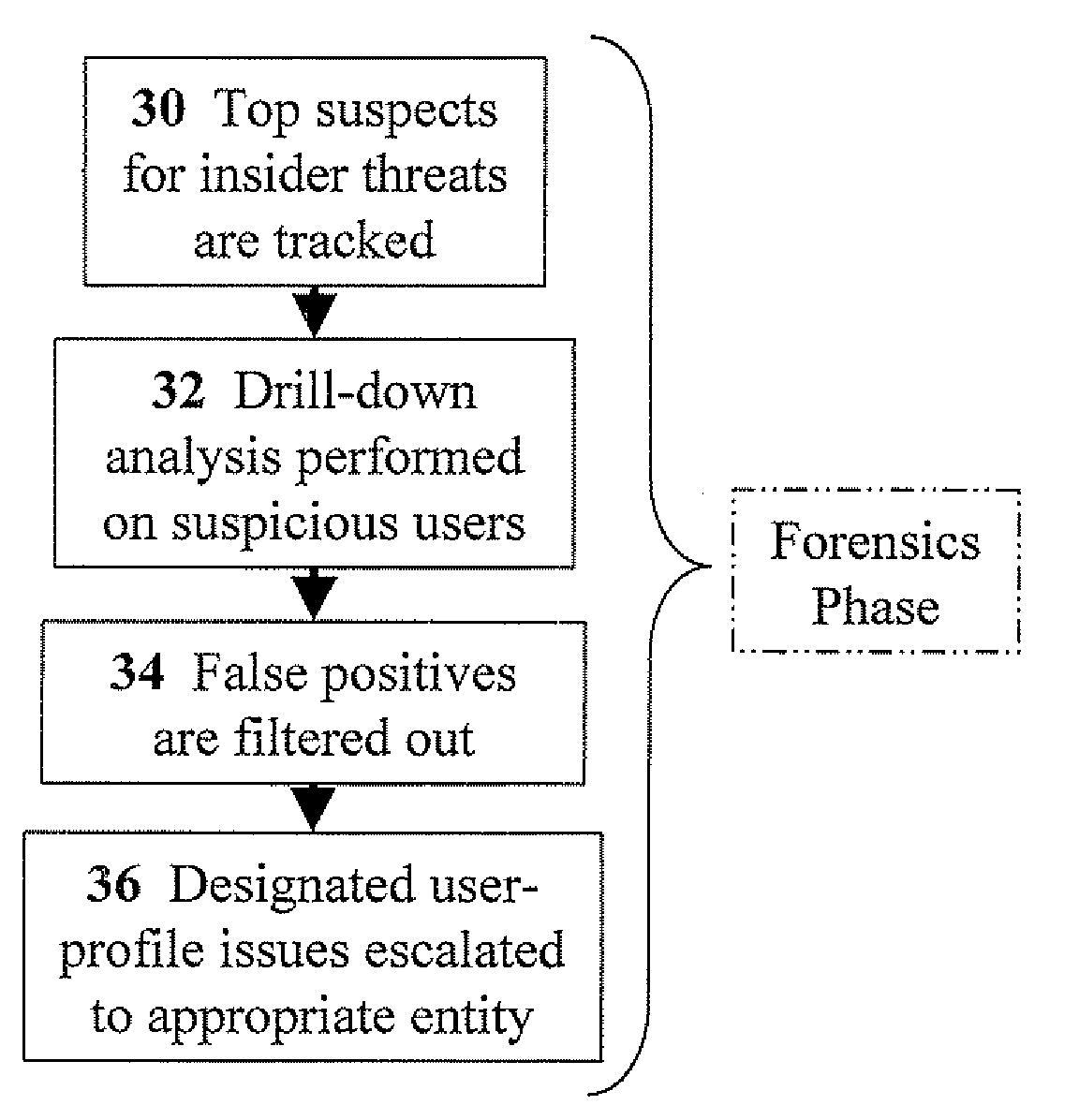

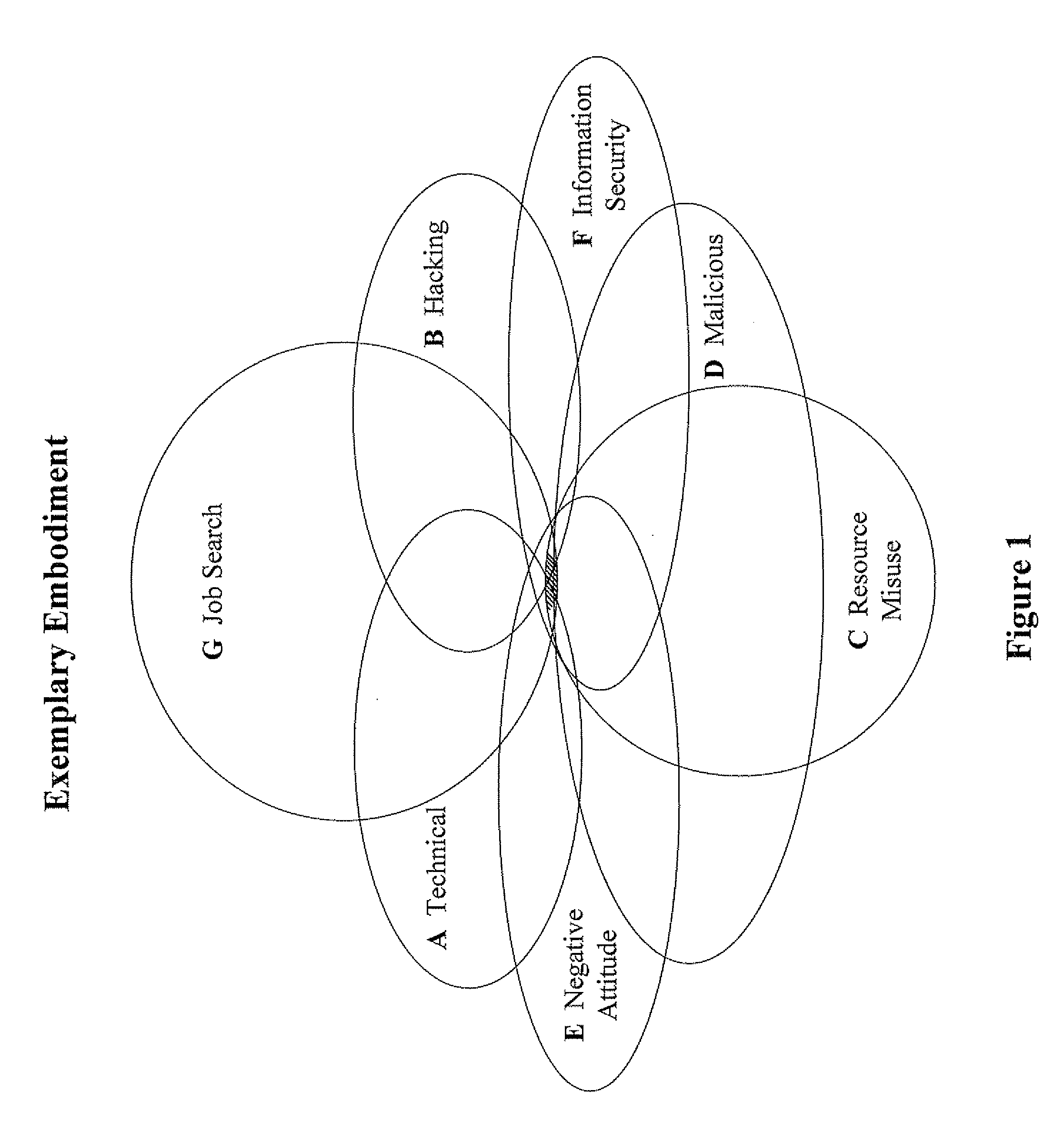

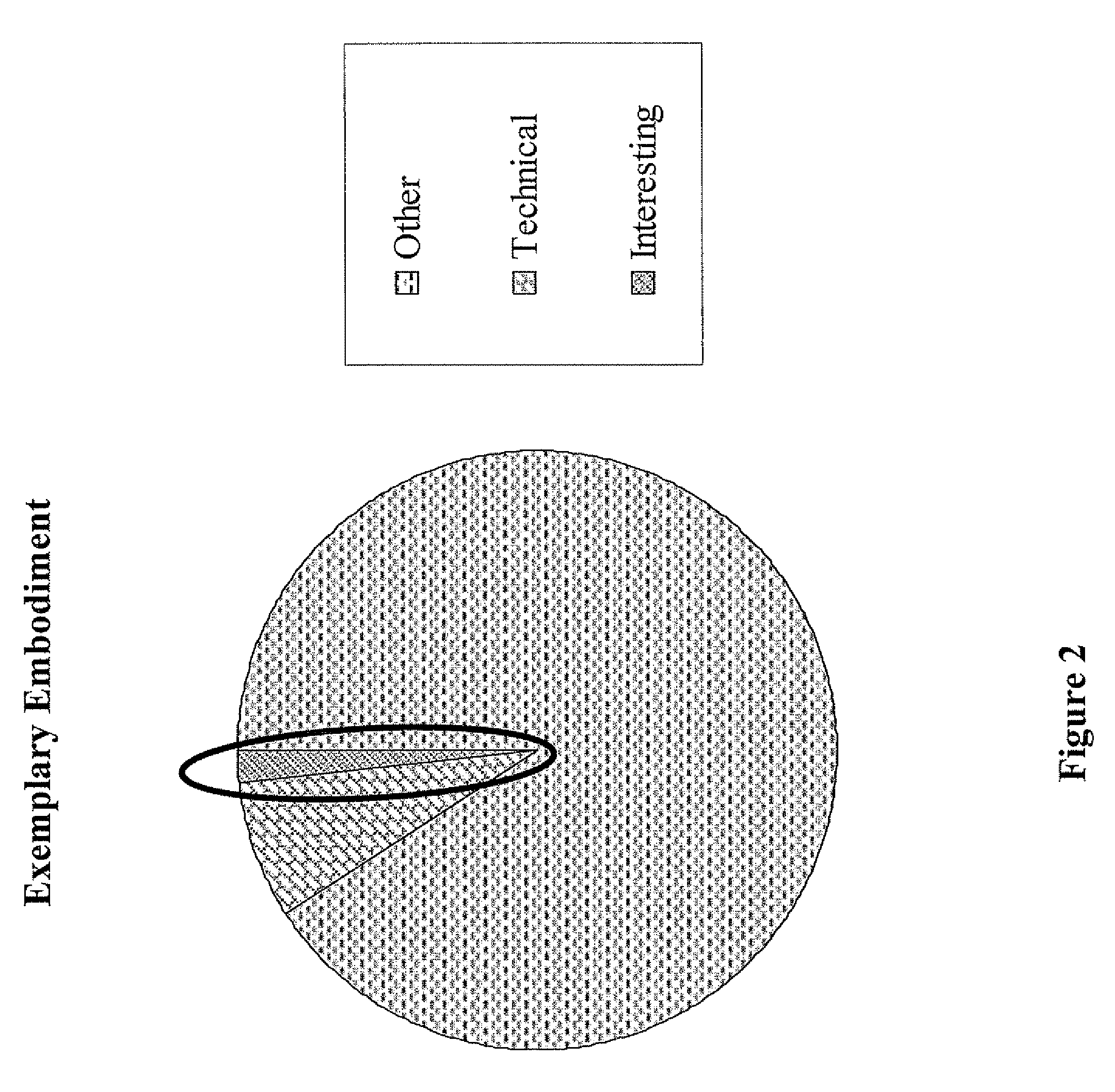

Methods for user profiling for detecting insider threats based on internet search patterns and forensics of search keywords

ActiveUS20100169971A1Improve the level ofImprove practicalityMemory loss protectionError detection/correctionStatistical analysisThe Internet

Disclosed are methods for user profiling for detecting insider threats including the steps of: upon a client application sending a request for a link, extracting at least one search keyword from a search session associated with the request; classifying the link into at least one classification; determining whether at least one classification is a monitored classification; capturing search elements of search sessions associated with the monitored classification; acquiring usage data from the search elements to create a user profile associated with a user's search behavior; and performing a statistical analysis, on a search frequency for the monitored classification, on user profiles associated with many users. Preferably, the method includes: designating a profile as suspicious based on the statistical analysis exceeding a pre-determined threshold value, wherein the pre-determined threshold value is based on an expected search frequency for the profile and each respective grade for at least one risk-assessment dimension.

Owner:CHECK POINT SOFTWARE TECH LTD

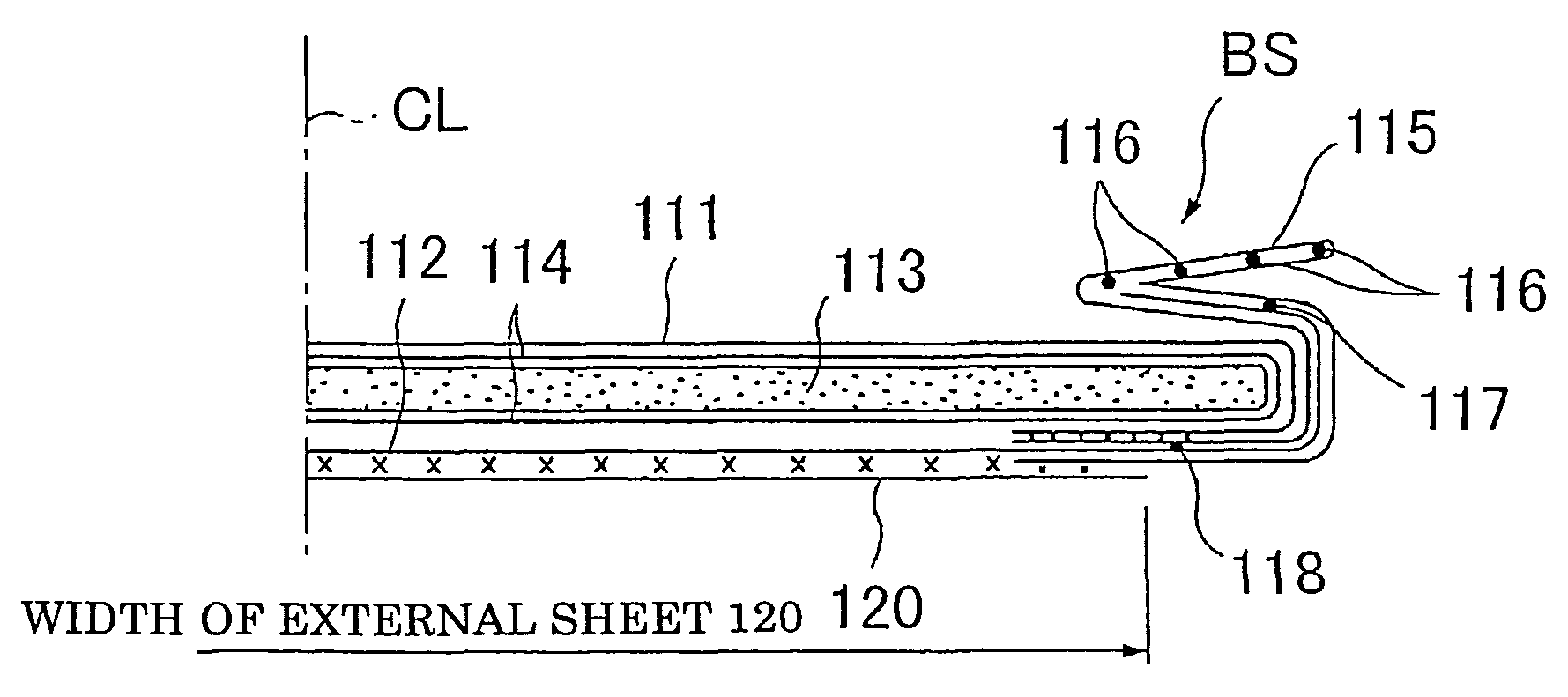

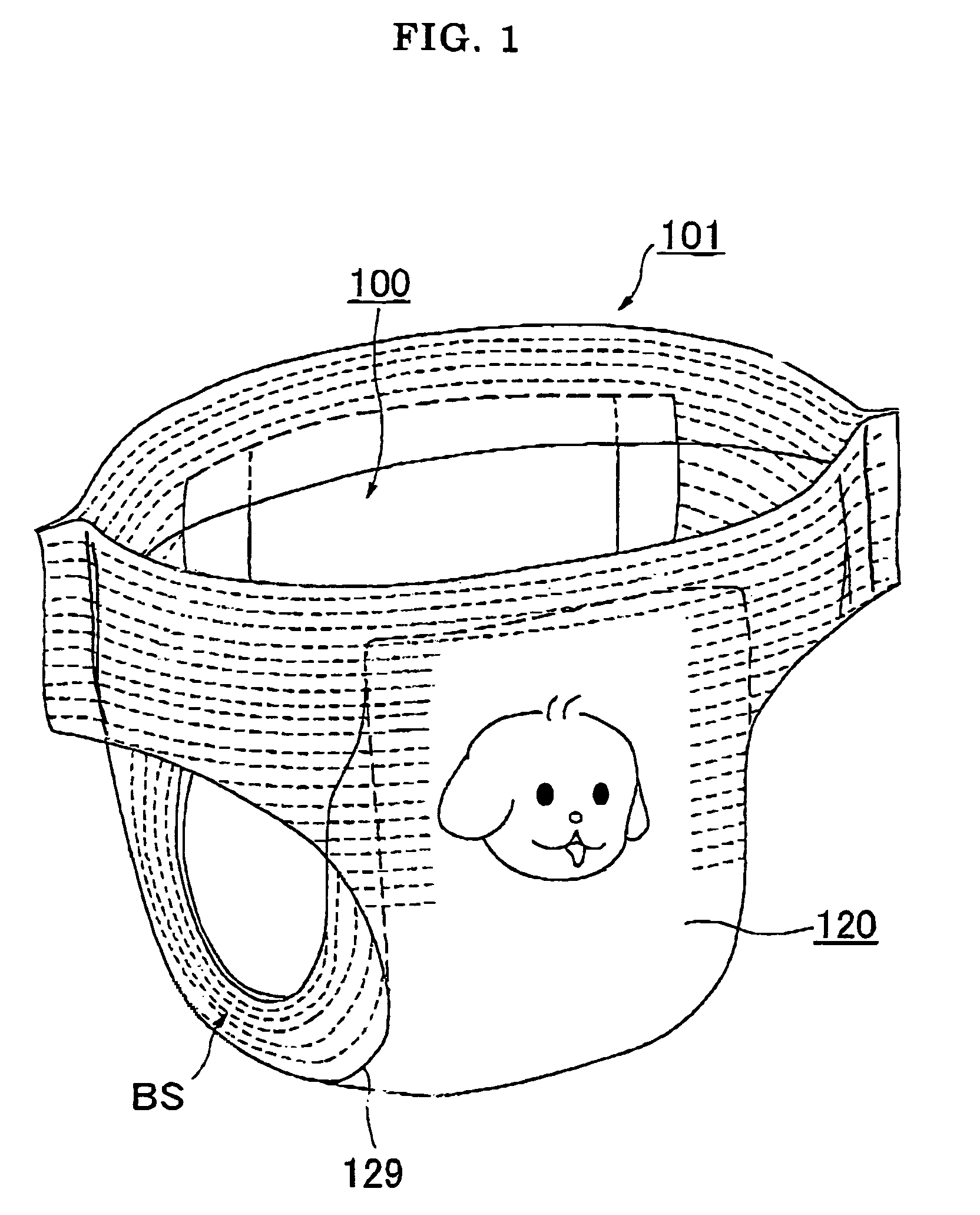

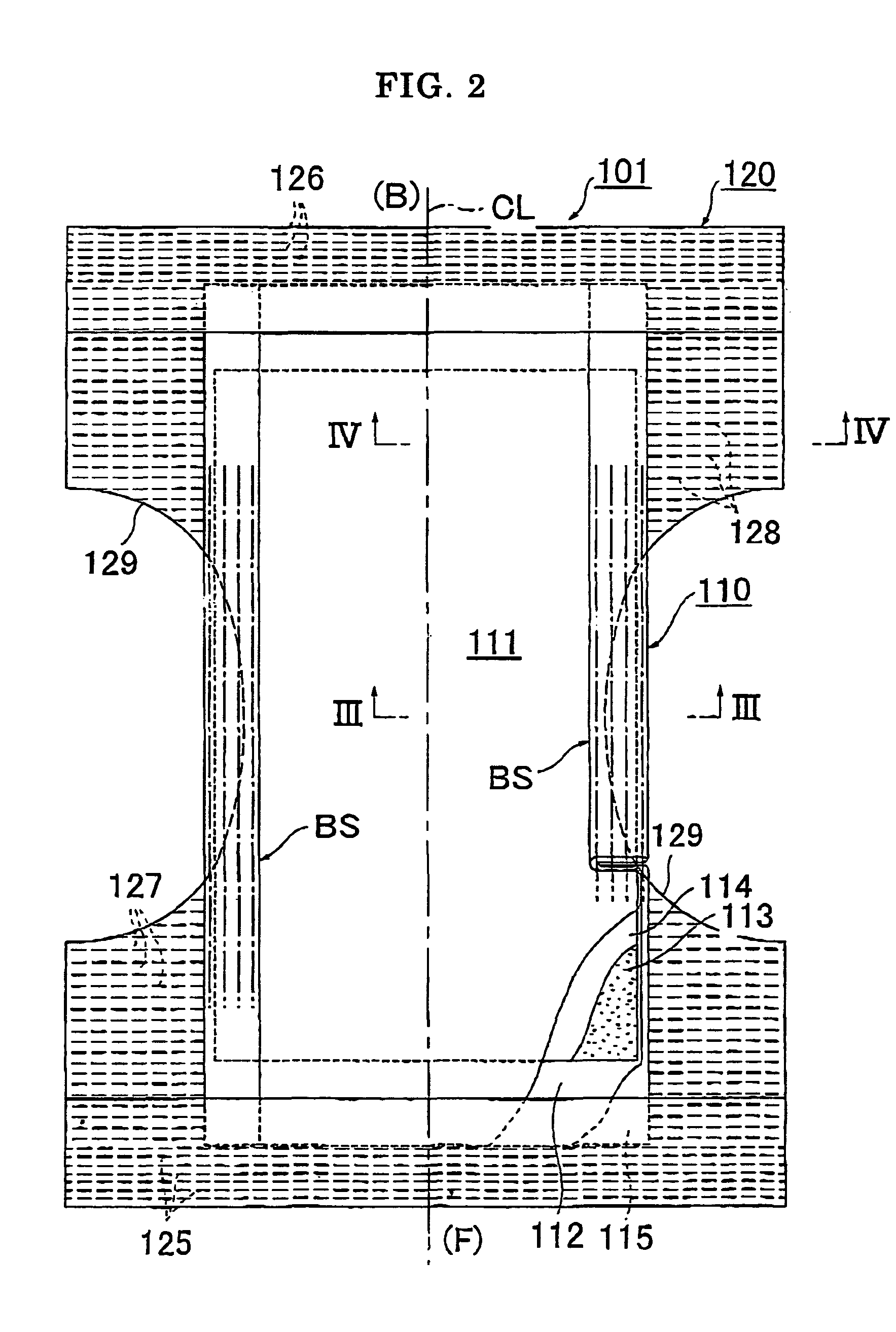

Disposable diaper with spaced elastic leg openings for improved appearance

InactiveUS7727214B2Sufficient fitting propertyGood appearanceBaby linensTamponsDisposable diaperEngineering

A disposable diaper having a neat appearance. The diaper 101 includes: a liquid-permeable top sheet 111 which covers a use surface side; a leakage preventing sheet 112 which covers a non-use surface side; an absorbent body 113 interposed between the top sheet and the leakage preventing sheet; and an external sheet 120 disposed on an outer surface side of the leakage preventing sheet, wherein three-dimensional gathers BS are formed along leg surrounding portions, and leg cut-out portions of the external sheet which form leg openings are located in a portion of the minimum width of a crotch portion, at a position nearer to a central side than places outward by 5 mm from rising start points of the three-dimensional gathers BS.

Owner:DAIO PAPER CORP

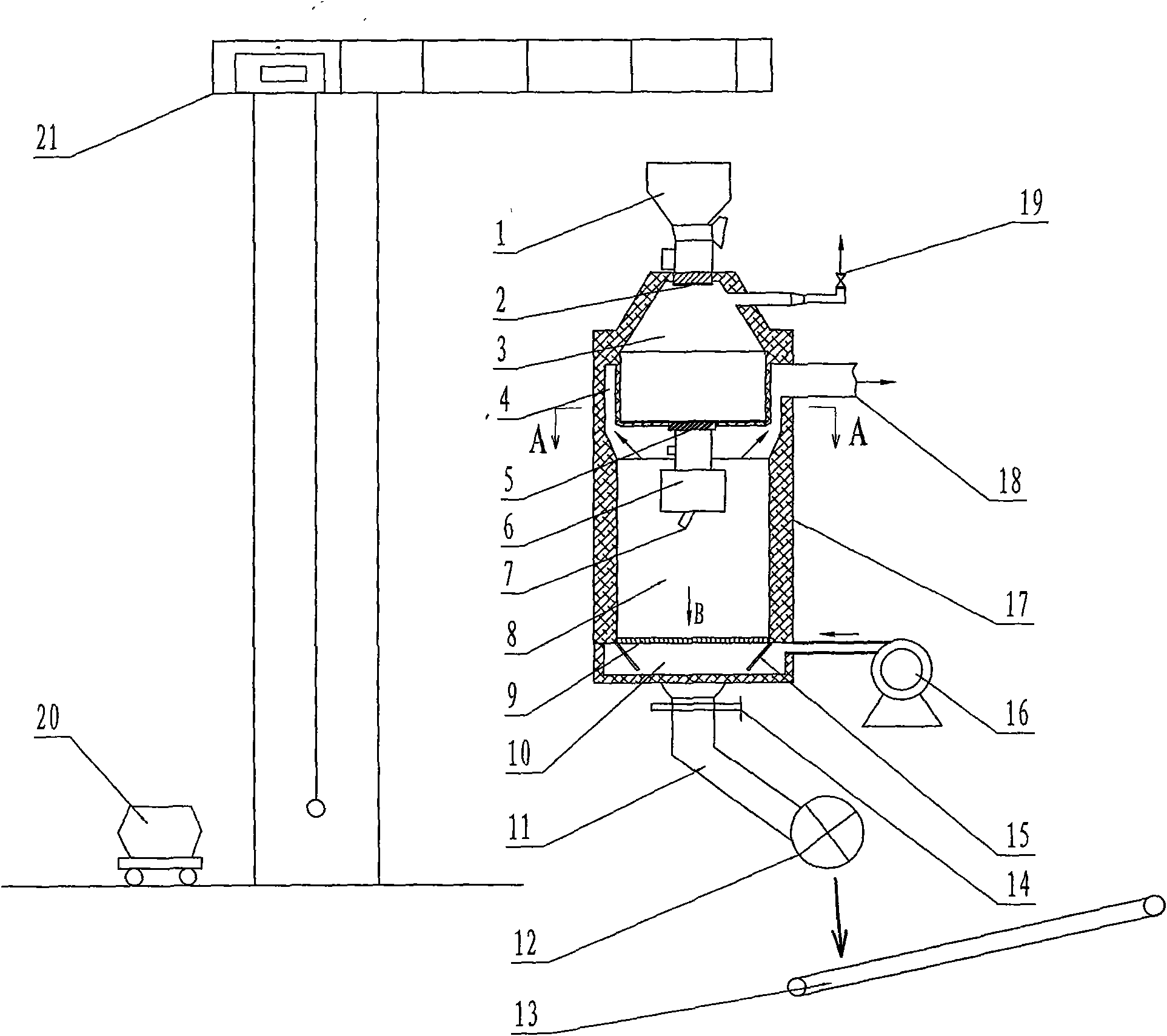

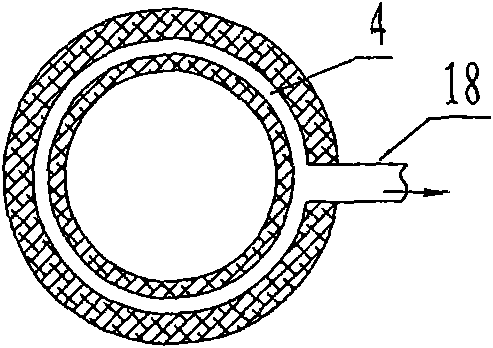

Vertical sinter ore cooling machine capable of efficiently recycling sensible heat of sinter ores

InactiveCN101576351AReduce heat transfer temperature differenceRaise the gradeIncreasing energy efficiencyHandling discharged materialGas solidMaterials science

The invention discloses a vertical sinter ore cooling machine capable of efficiently recycling the sensible heat of sinter ores, which pertains to the technical field of sintering equipment and is used for preventing air leak in the cooling course of sinter ores and effectively recycling the sensible heat of the sinter ores. The technical proposal of the invention is that: the cooling machine consists of a feeding part, a cooling part and a conveying part; the cooling part comprises a vertical closed body, a hot wind pipeline, a blower, as well as a hopper, an upper sealing valve, a pre-storing chamber, a lower sealing valve, a heat exchanging chamber, a wind distributing board, an isopiestic wind chamber and a discharging channel which are in sequence arranged on the body from top to bottom; an annular wind chamber is arranged between the pre-storing chamber and the heat exchanging chamber; the annular wind chamber is communicated with the hot wind pipeline; the isopiestic wind chamber is communicated with the blower; and wind shields and ore falling openings are distributed evenly on the wind distributing board . The vertical sinter ore cooling machine has the following advantages of: 1. an air leak rate near to 0; 2. improved gas-solid heat exchange efficiency of the cooling machine; 3. raised quality of the recycled hot air; and 4. being beneficial to increasing the utilization rate of exhaust-heat boilers. Based on the advantages, the vertical sinter ore cooling machine is expected to be used commonly as an upgraded replacement of the existing sinter cooling machine.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com