Method for manufacturing nickel-based high-temperature alloy forge piece

A technology of nickel-based superalloy and manufacturing method, applied in the field of forging technology, can solve the problems of unguaranteed product quality and steel consumption, and achieve the effects of improving quality and grade, reducing production cost and reducing large consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The following gives specific implementations of the method for manufacturing a nickel-based superalloy forging of the present invention in conjunction with the accompanying drawings, but the implementation of the present invention is not limited to the following embodiments.

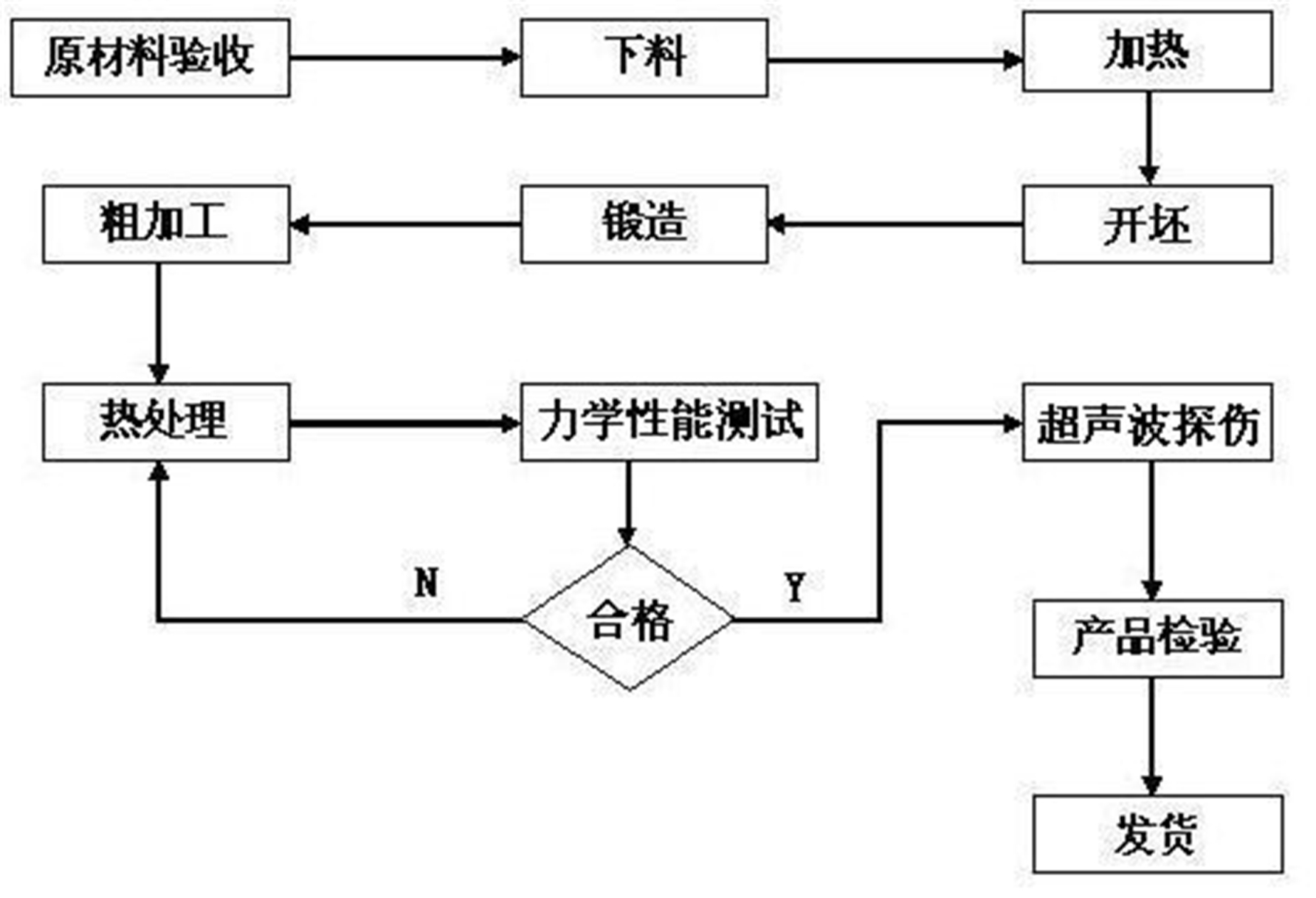

[0049] See attached figure 1 . A method for manufacturing nickel-based high-temperature alloy forgings includes the following steps:

[0050] (1) Raw material inspection

[0051] Raw material inspection of nickel-based superalloys, including re-inspection of chemical composition (according to TLV952011) and inspection of steel ingot surface.

[0052] (2) Cutting

[0053] Use a sawing machine or a chopper to cut with heat.

[0054] (3) Heating

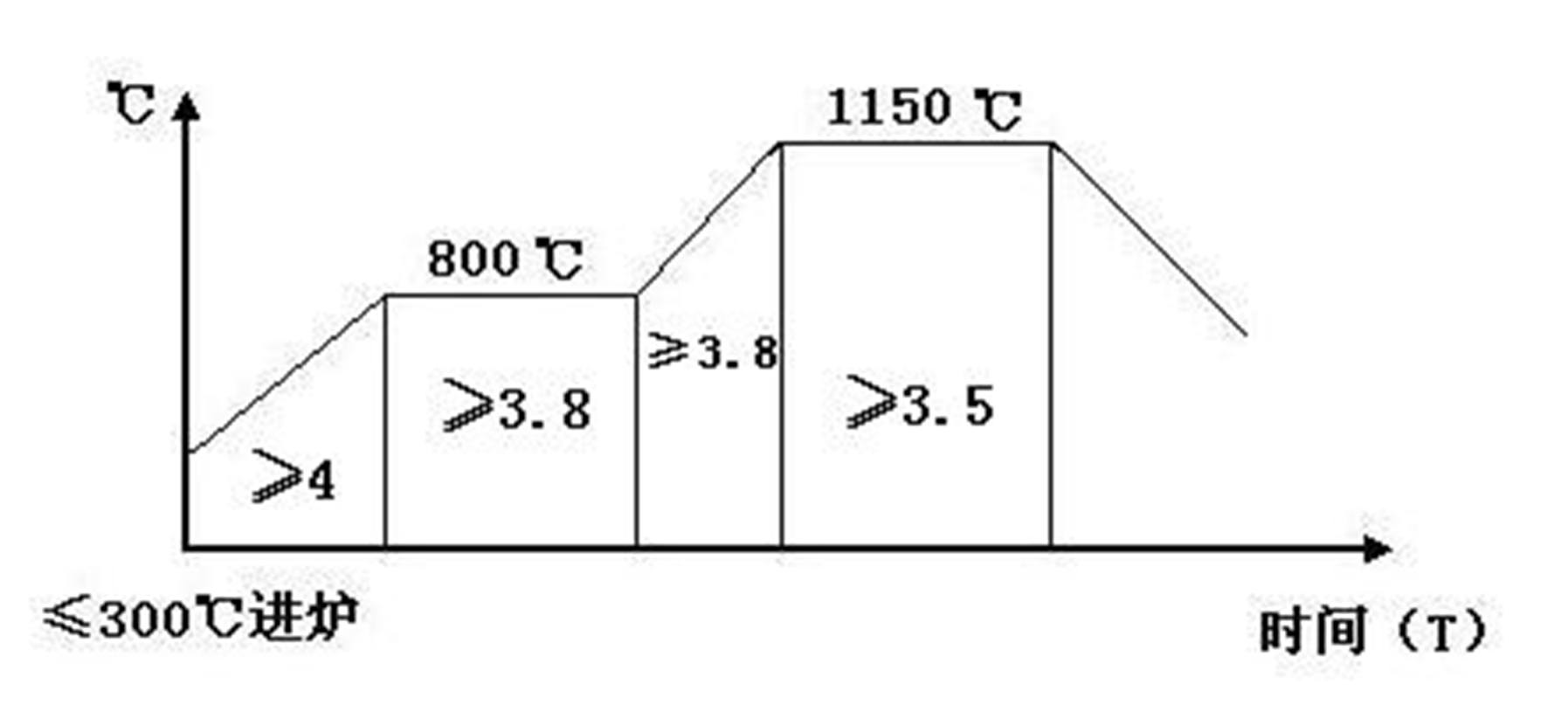

[0055] Heating the steel ingot, the processing steps are (see attached image 3 "The heating specification drawing of nickel-based superalloy"):

[0056] ① Heat the steel ingot to ≤300℃ into the furnace, and slowly heat it to 800℃ for 4 hours;

[0057] ②Heat insulation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com