21MnCrMoS steel used for heavy truck transmission gear and manufacturing method for 21MnCrMoS steel

A technology for transmission gears and heavy-duty trucks, which is applied in the field of alloy steel and 21MnCrMoS gear steel, which can solve the problems of low product market competitiveness, high alloy and manufacturing costs, and achieve high market competitiveness and promotion value, low cost, The effect of preventing the growth of austenite grains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

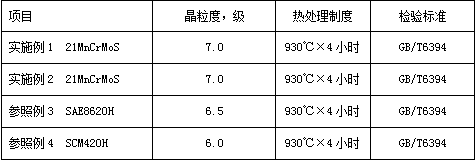

Examples

Embodiment Construction

[0029] Below in conjunction with embodiment the present invention is described in further detail.

[0030] 1. The manufacturing method of 21MnCrMoS gear steel bars is characterized in that the production process route with the manufacturing specification of φ50mm-φ120mm is as follows: the smelting raw materials are configured according to the chemical element composition of the steel, and the pretreated molten iron and the preferred steel scrap are added in sequence→ Primary smelting in electric furnace→refining in LF furnace→vacuum degassing in VD furnace→continuous casting of 300×340mm continuous casting slab→slow cooling of slab→slab shot blasting→heating in continuous heating furnace→high pressure water descaling→continuous rolling→bar slowing Cold→ultrasonic flaw detection + surface flaw detection and other inspections-warehousing. These include the steelmaking process and the rolling process.

[0031] Described steelmaking process:

[0032] 1) The pretreated molten iro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com