Patents

Literature

2734 results about "Slow cooling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

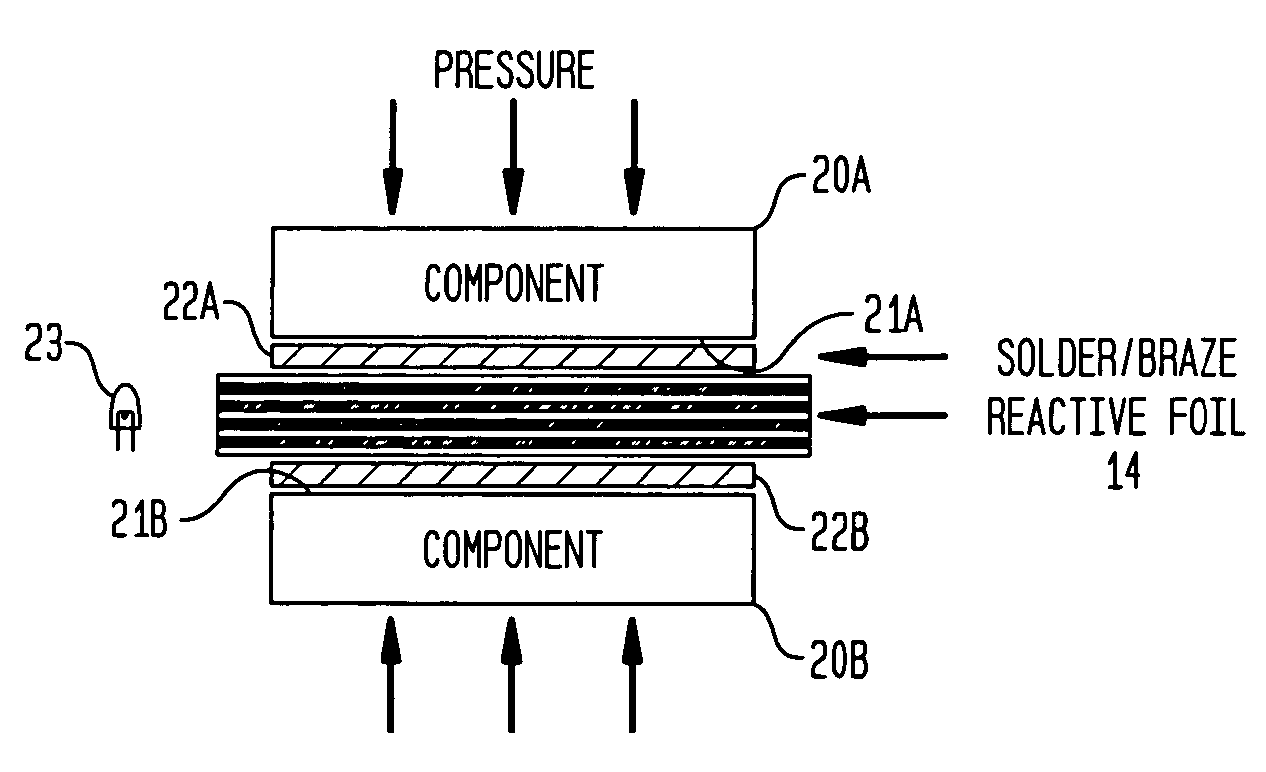

Nanostructured soldered or brazed joints made with reactive multilayer foils

InactiveUS20050051607A1Reduce coolingImprove microstructureExothermal chemical reaction heat productionVacuum evaporation coatingRoom temperatureSlow cooling

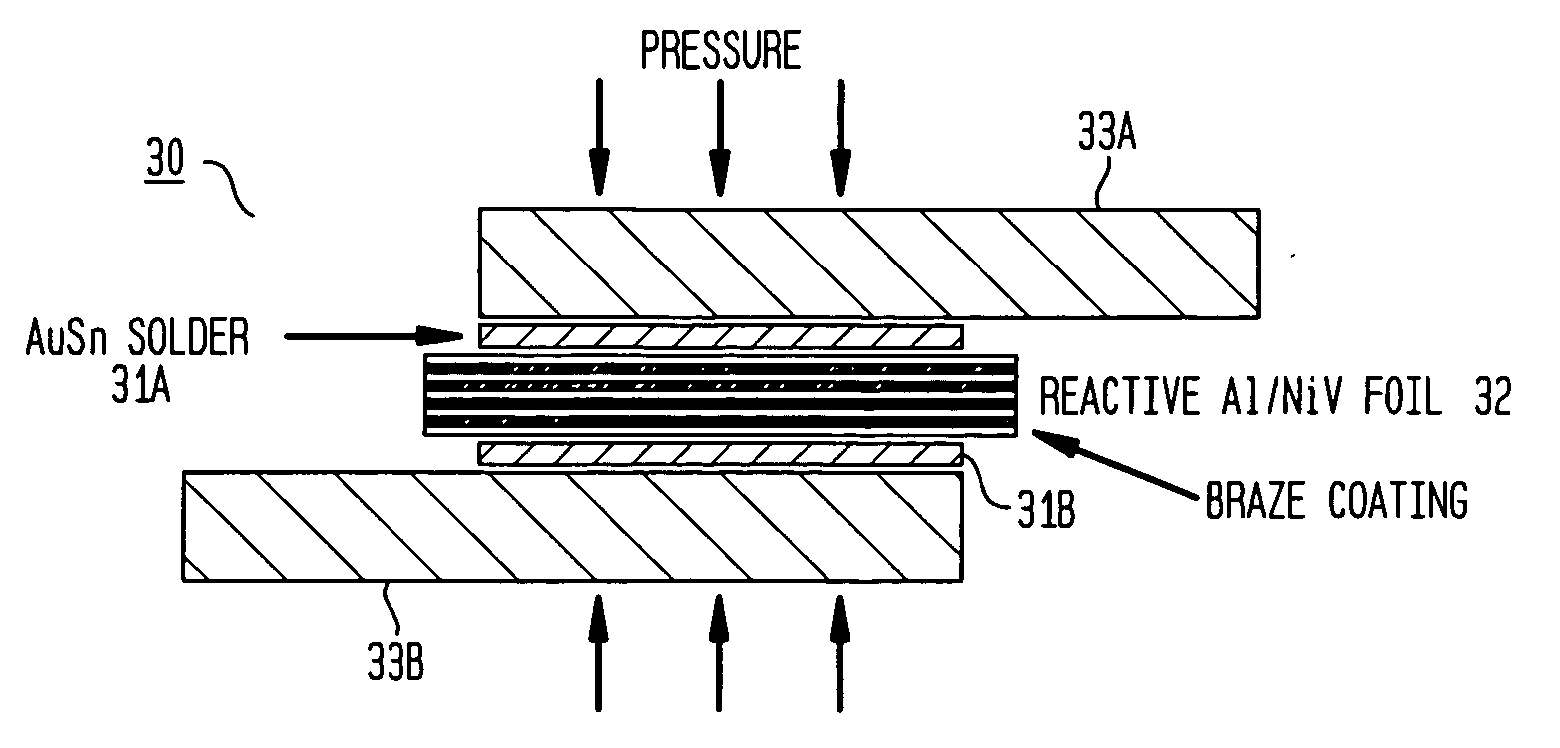

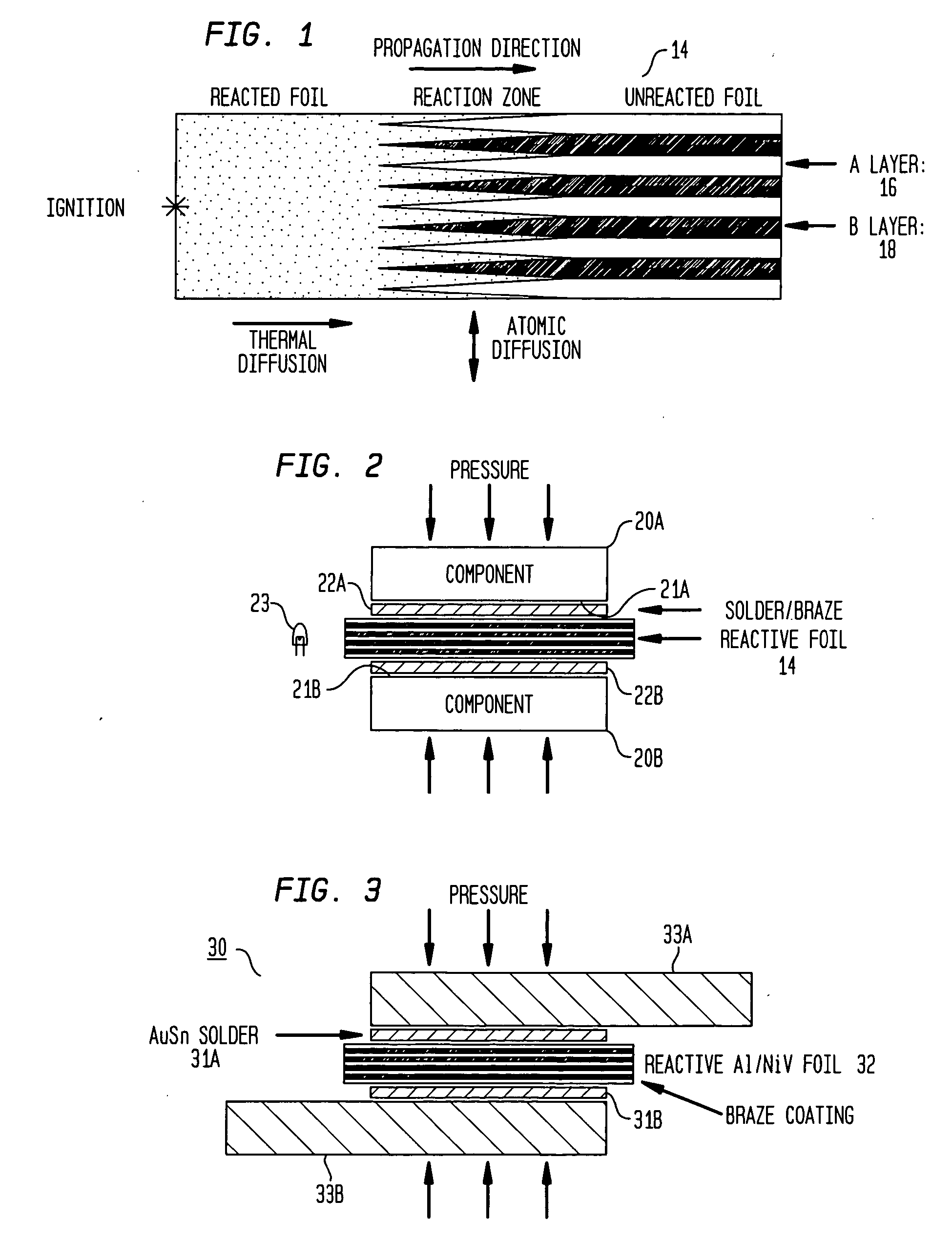

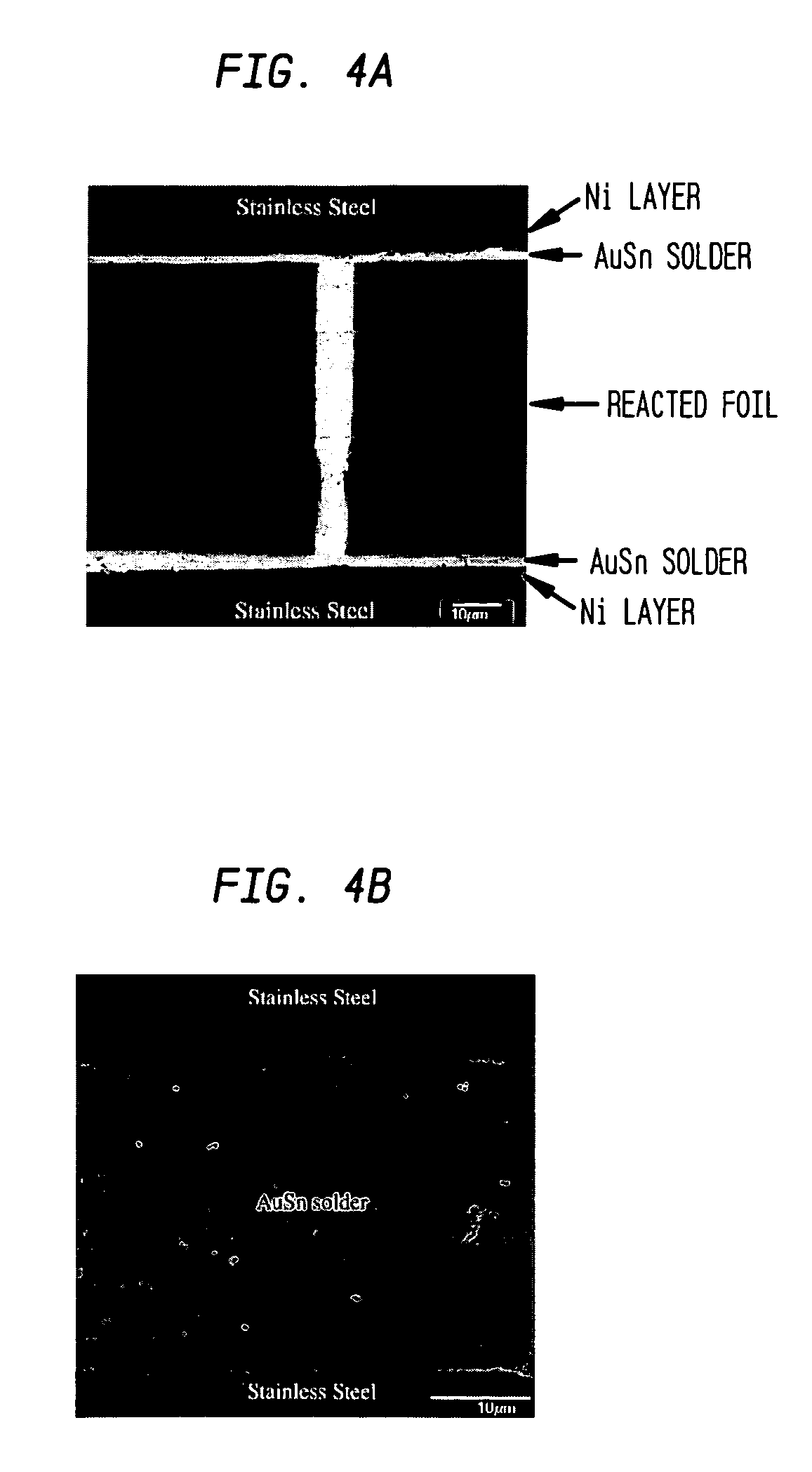

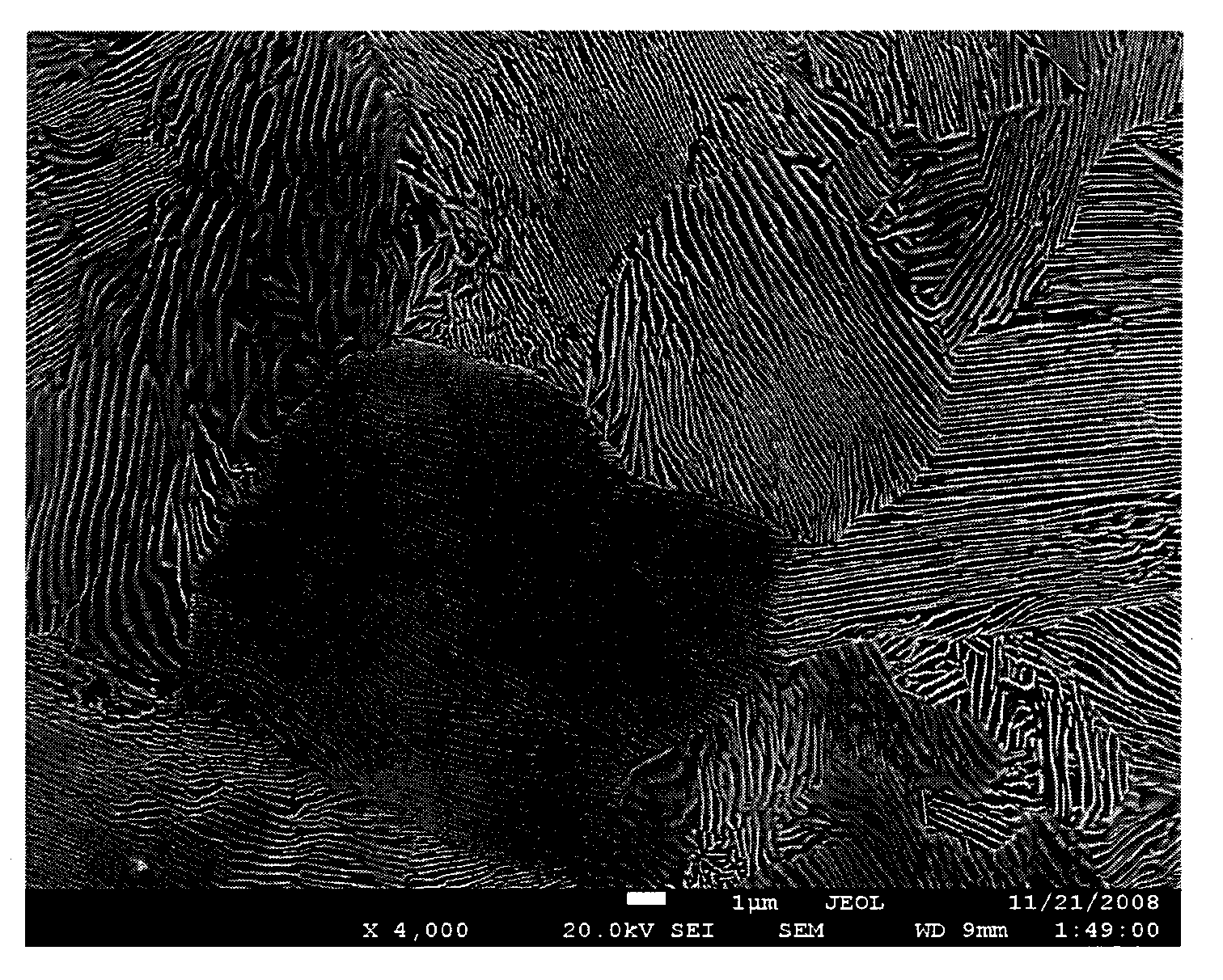

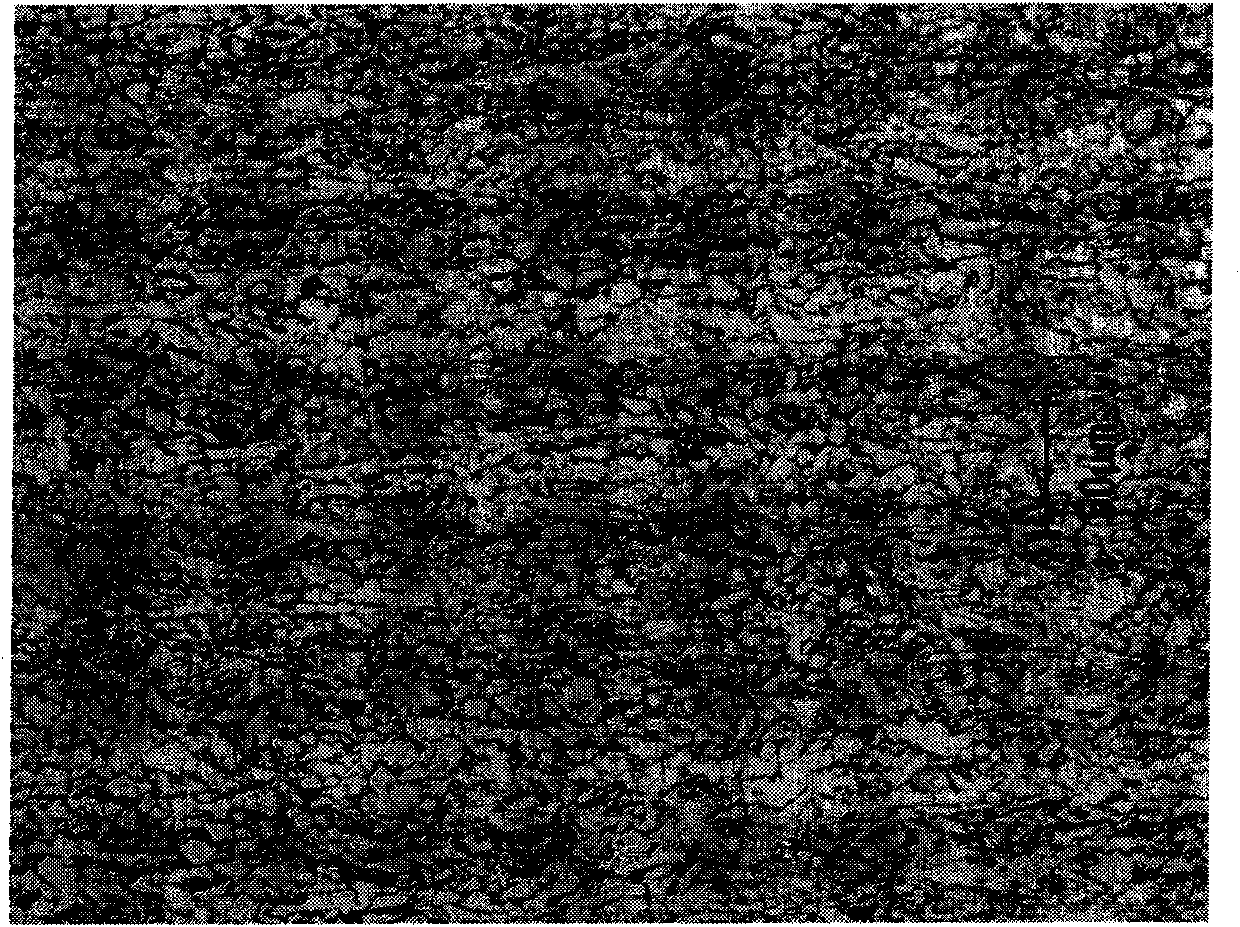

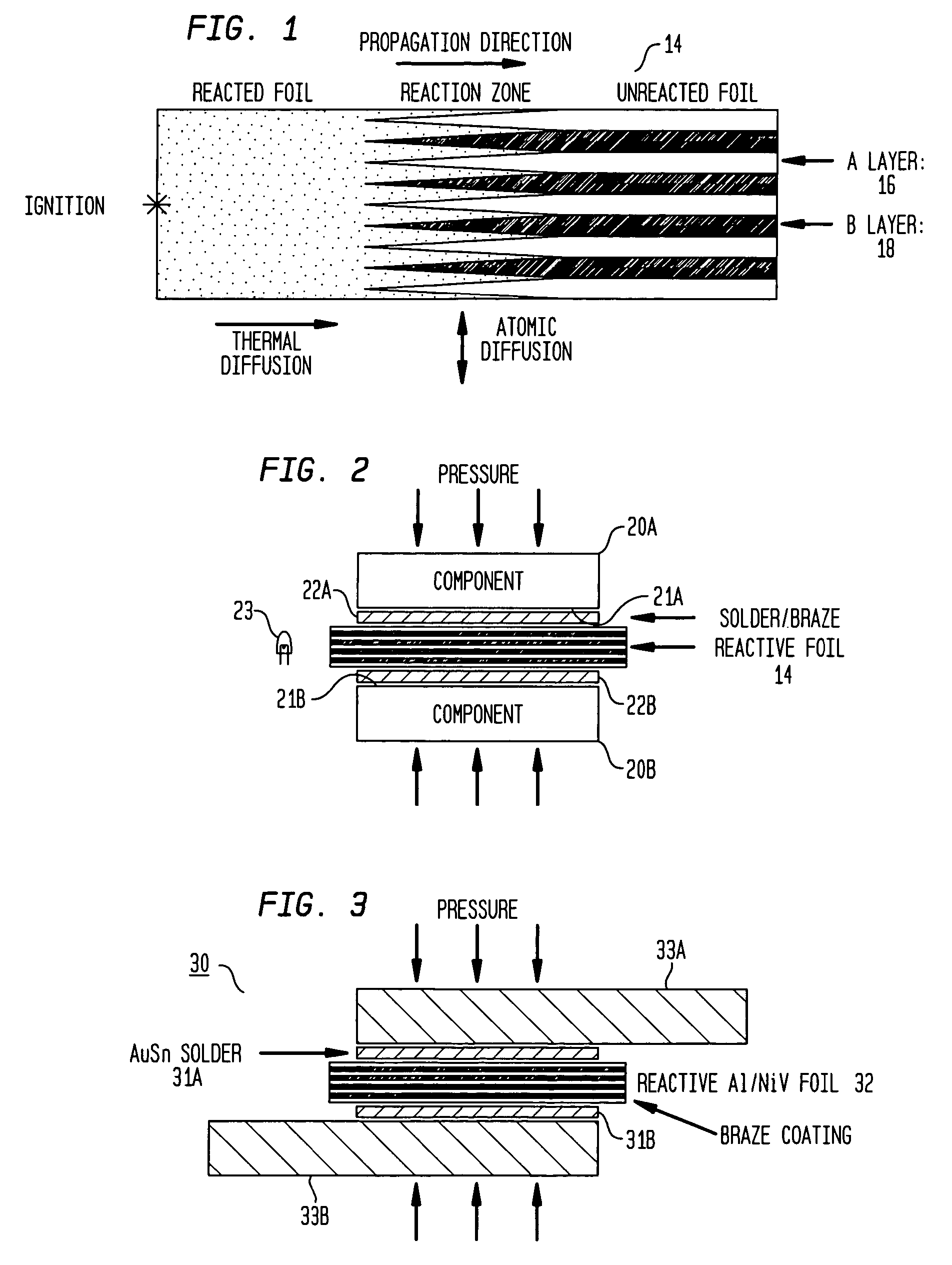

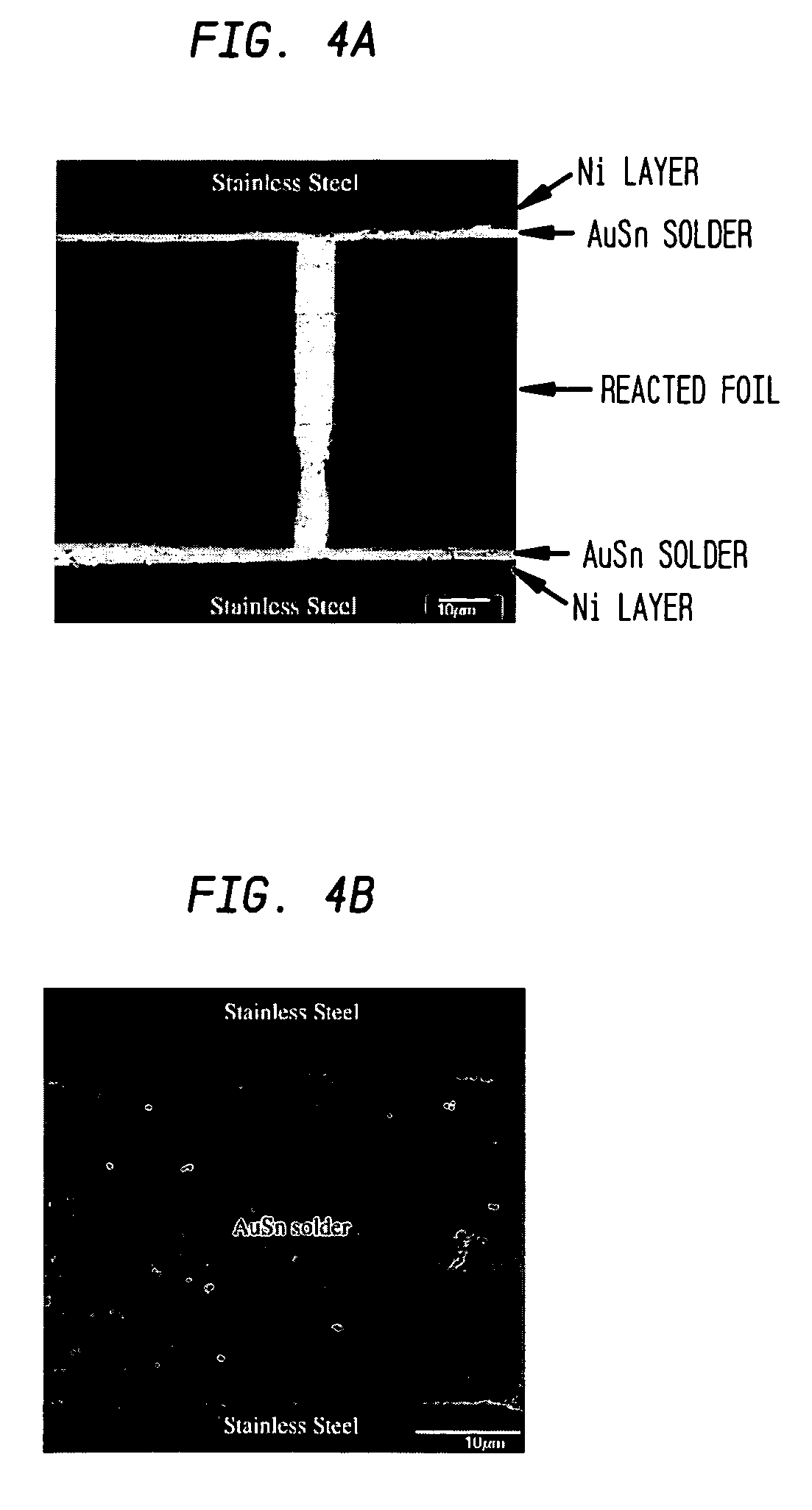

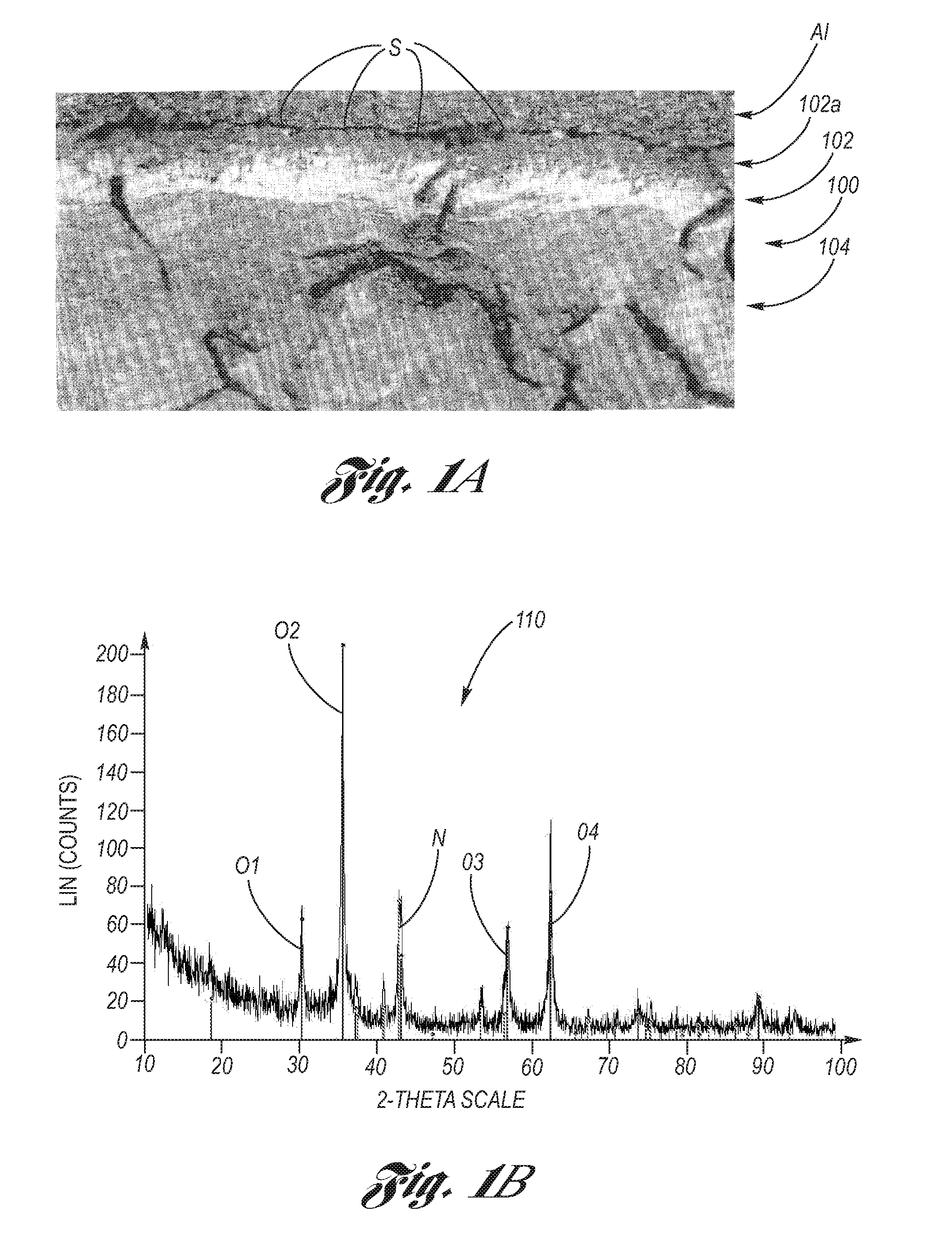

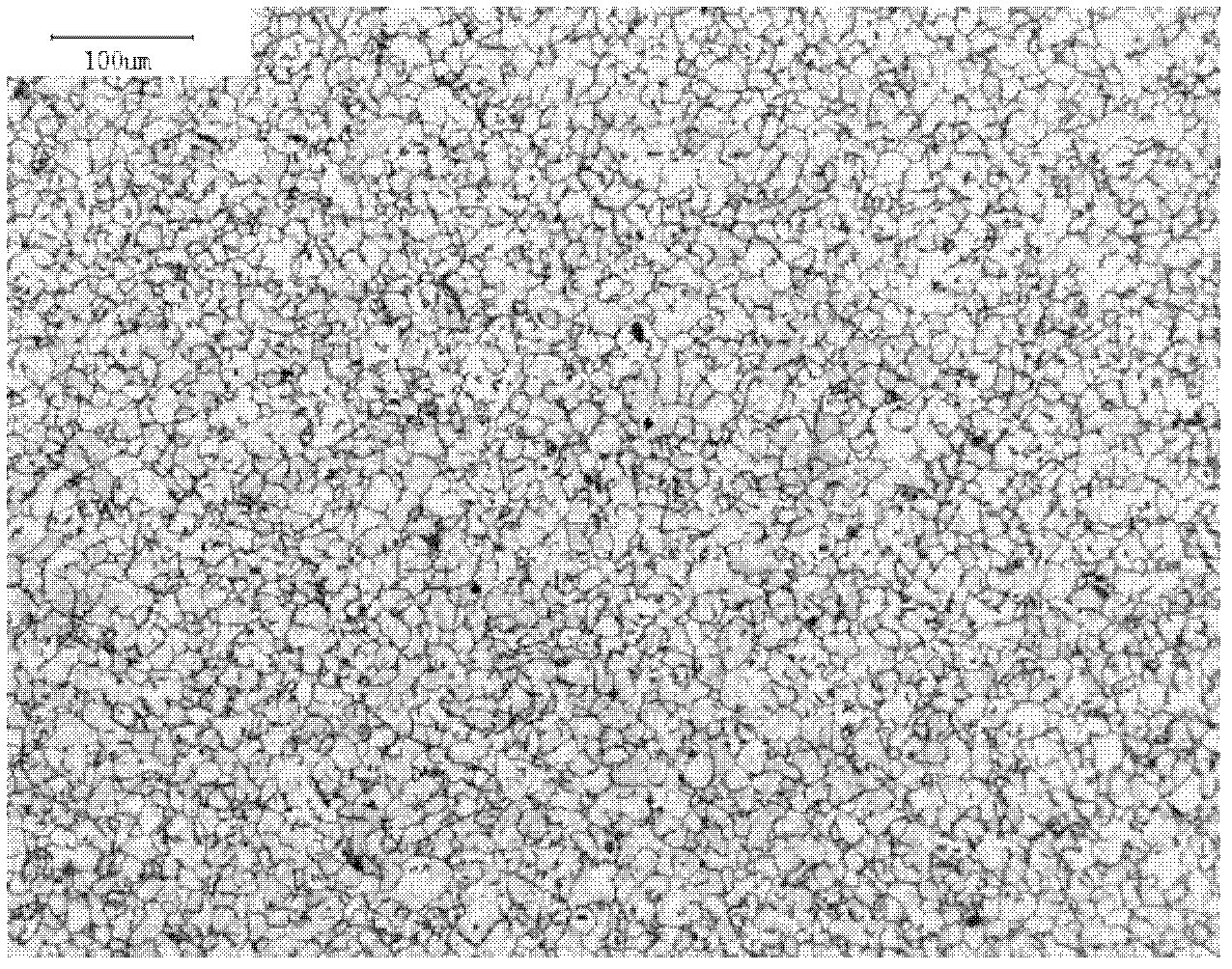

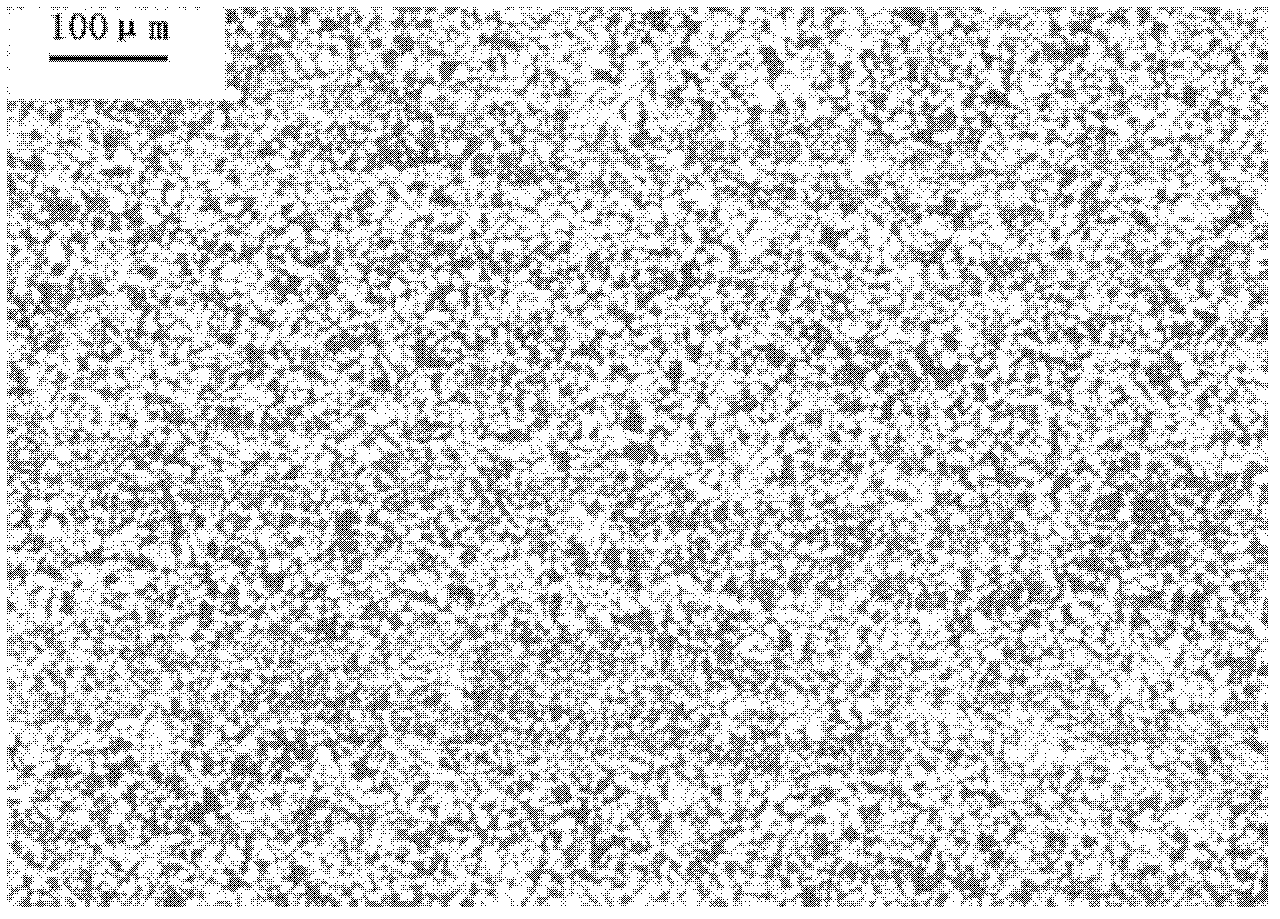

Self-propagating formation reactions in nanostructured multilayer foils provide rapid bursts of heat at room temperature and therefore can act as local heat sources to melt solder or braze layers and join materials. This reactive joining method provides very localized heating to the components and rapid cooling across the joint. The rapid cooling results in a very fine microstructure of the solder or braze material. The scale of the fine microstructure of the solder or braze material is dependant on cooling rate of the reactive joints which varies with geometries and properties of the foils and components. The microstructure of the solder or braze layer of the joints formed by melting solder in a furnace is much coarser due to the slow cooling rate. Reactive joints with finer solder or braze microstructure show higher shear strength compared with those made by conventional furnace joining with much coarser solder or braze microstructure. It is expected that the reactive joints may also have better fatigue properties compared with conventional furnace joints.

Owner:THE JOHN HOPKINS UNIV SCHOOL OF MEDICINE

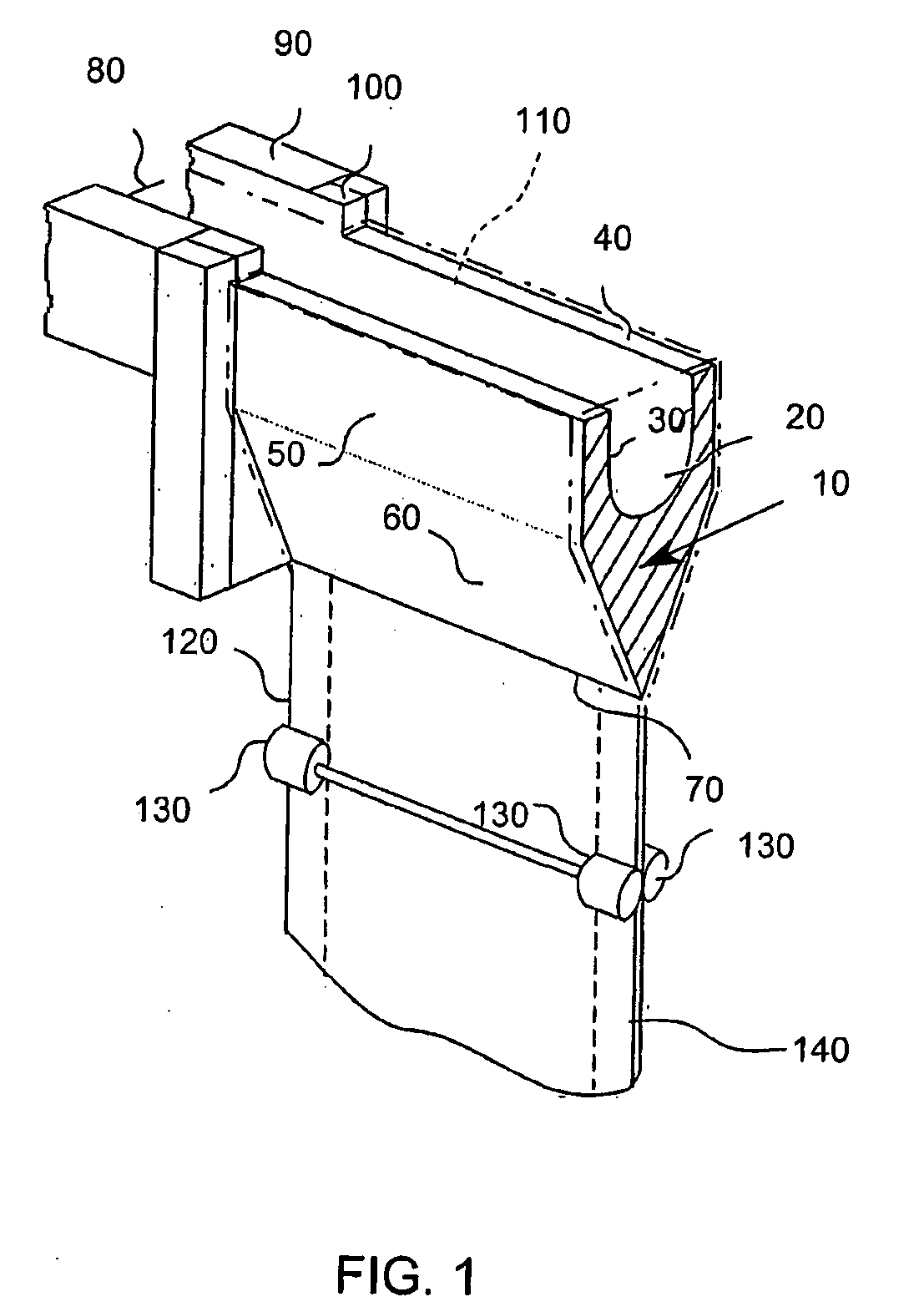

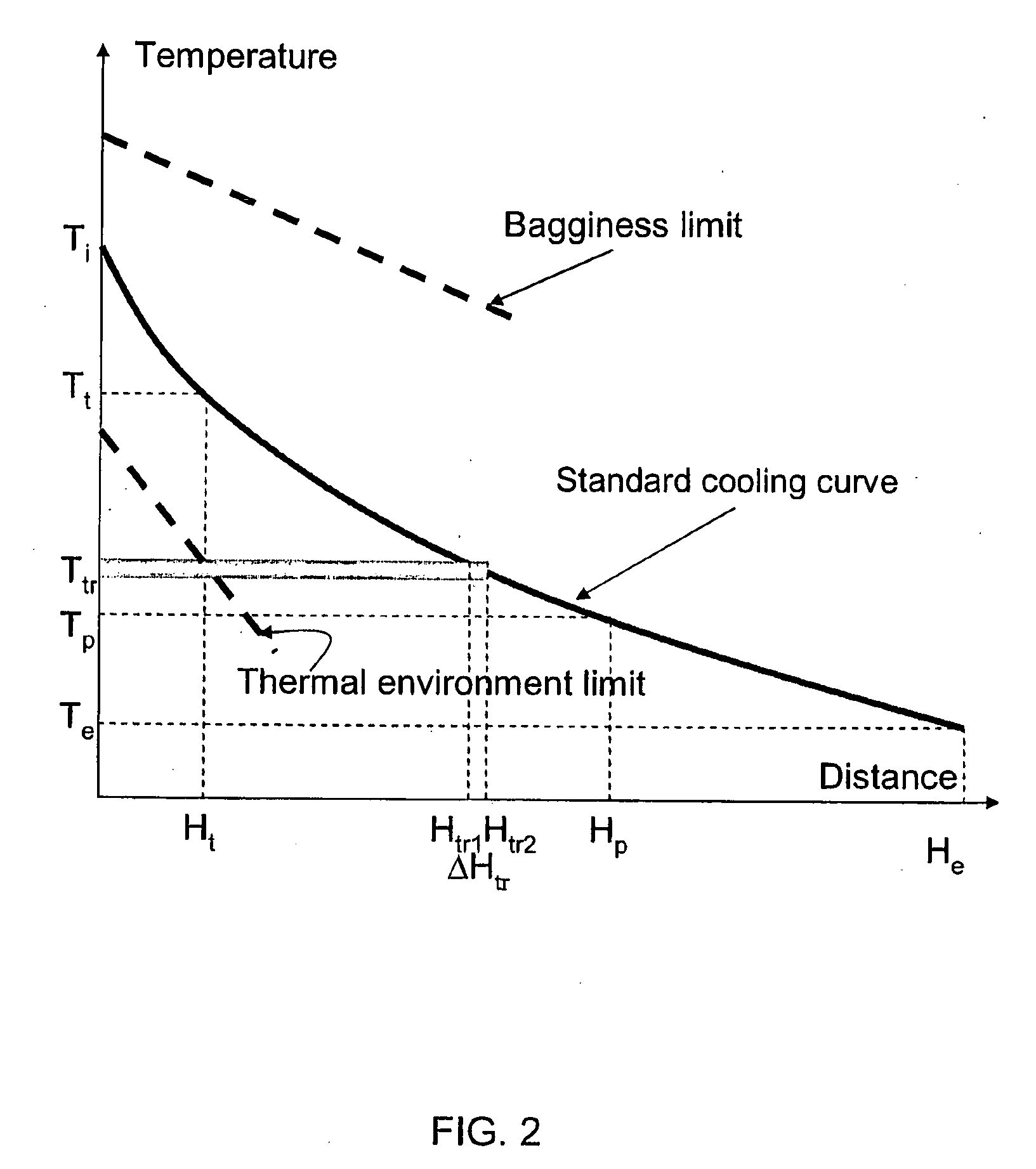

Method of making a glass sheet using controlled cooling

InactiveUS20090100873A1Increase rate increaseHigh trafficGlass drawing apparatusGlass forming apparatusFluid phaseEngineering

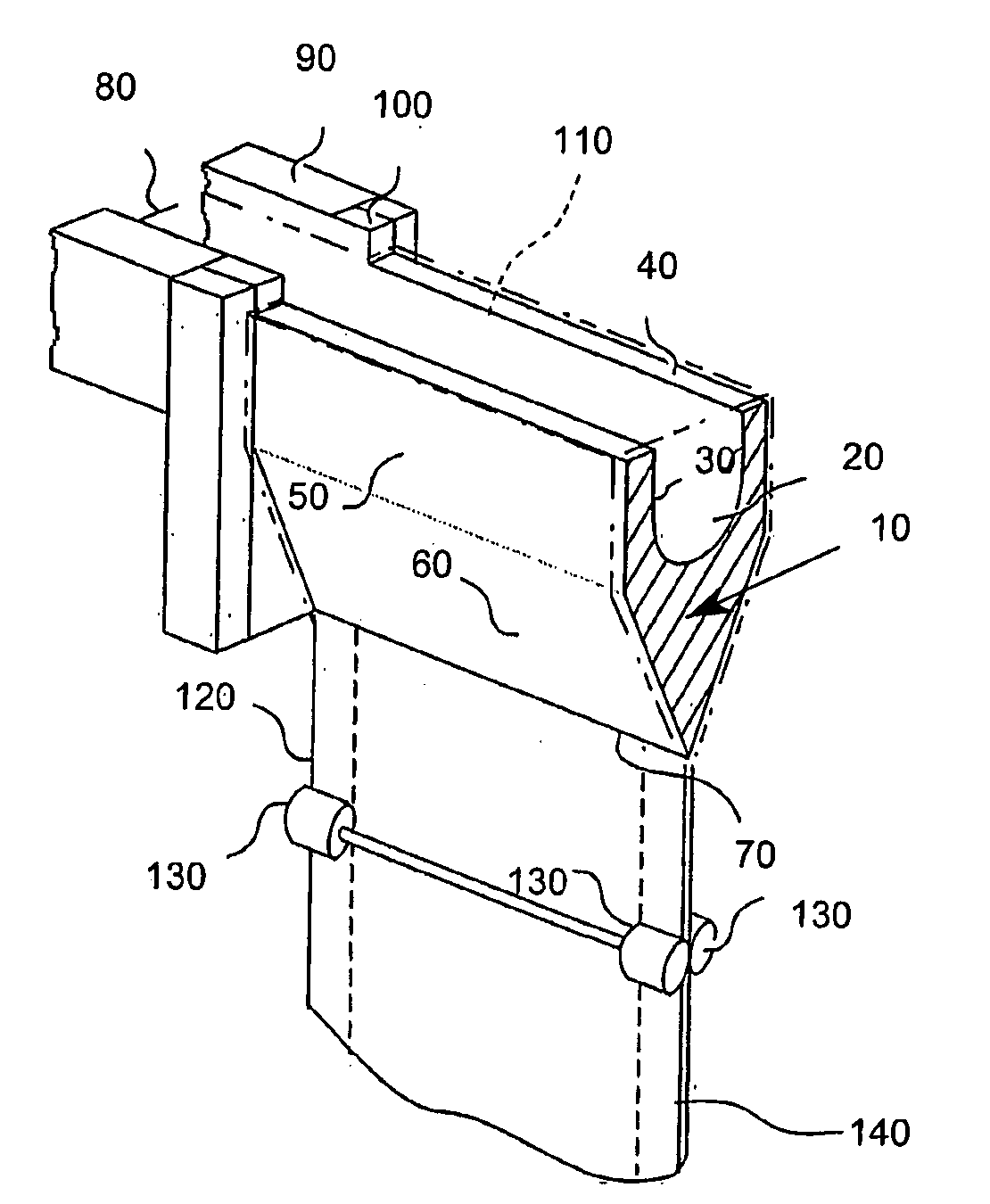

Methods of drawing glass sheet via a downdraw process are provided. In certain aspects, the methods utilize rapid cooling below the root (70) of the forming apparatus (10). Such rapid cooling can, for example, facilitate the use of glass having a liquidus viscosity less than about 100,000 poise. In other aspects, the methods utilize slow cooling between the viscosities of 1011 poises and 1014 poises. Such slow cooling can facilitate the production of glass substrates which exhibit low levels of compaction. In further aspects, substrates are removed from the glass sheet at elevated temperatures which can facilitate increases in the production rates of downdraw machines. In still further aspects, rapid cooling below the root, slow cooling between the viscosities of 1011 poises and 1014 poises, and / or substrate removal at elevated temperatures are combined. Such combinations can facilitate economically effective utilization of downdraw equipment.

Owner:CORNING INC

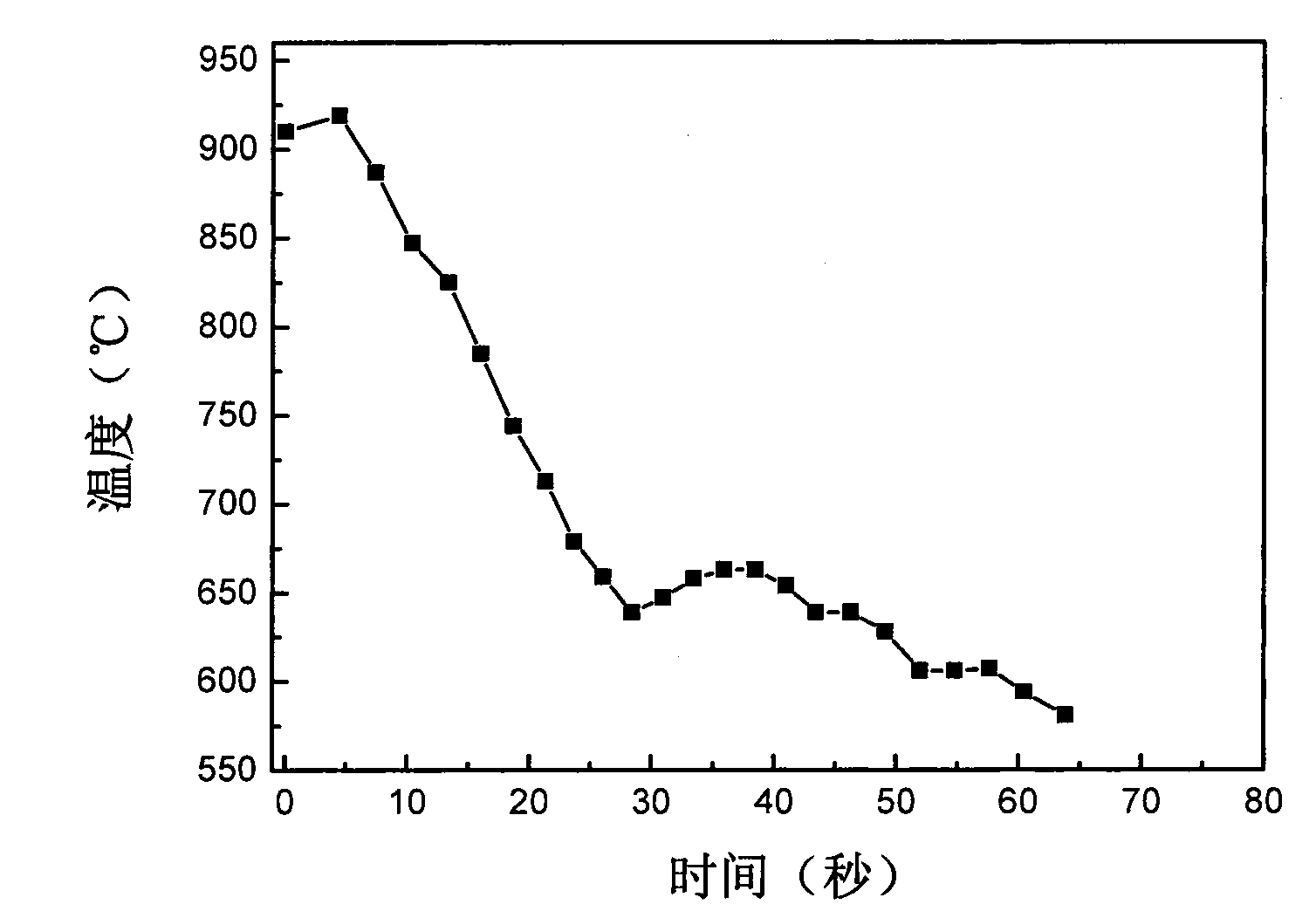

High carbon steel wire rod and preparation method thereof

ActiveCN101649416AImprove mechanical propertiesLess alloying elementsTemperature control deviceManufacturing convertersWire rodTemperature control

The invention relates to a high carbon steel wire rod with tensile strength of more than 1,200 MPa and surface shrinkage of more than 35 percent and a preparation method thereof. The high carbon steelwire rod comprises the base components of C, Si, Mn, Cr and the like, selective components of Ni, Cu, Al, B, Ti, Nb, Mo and the like, and the balance of Fe and impurities. The preparation method comprises the following procedures of smelting, casting, rolling and cooling control sequentially, wherein the rolling-starting temperature of the rolling procedure is controlled between 1,000 DEG C and 1,100 DEG C, the spinning temperature is 870-930 DEG C, the cooling controlling procedure is carried out by adopting Steyr cooling control, rapid cooling is adopted before the phase change and at the earlier stage of the phase change, and the slow cooling is adopted at the later stage of the phase change. The high carbon steel wire rod has excellent mechanical performance, less alloy elements and low cost; and meanwhile, the preparation method is realized by only less adjusting the prior production process of the high carbon steel wire rod without nearly adding any production cost.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE

Leadless easy cutted brass ally material and its manufacturing method

An easily cutted lead-free brass alloy is prepared from Cu (60-62 wt.%), Bi (0.5-2.2), Al (0.01-0.1), Sn (0.5-1.6), P (0.04-0.15) and Zn (rest) through heat treating at 460-600 deg.C for 30 min-4 hr, and slow cooling at speed lower than 70 deg.C / hr.

Owner:SAN ETSU METALS

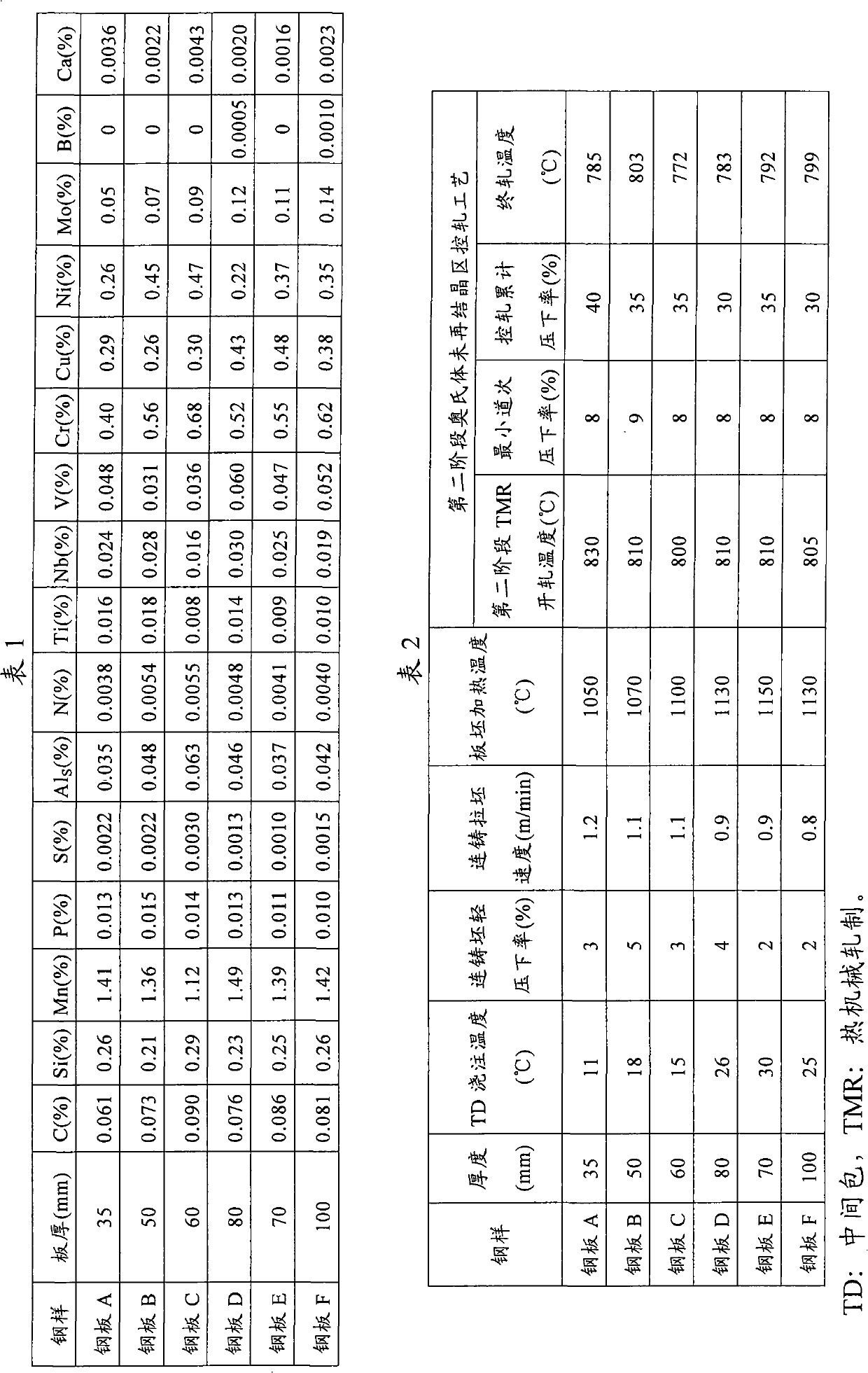

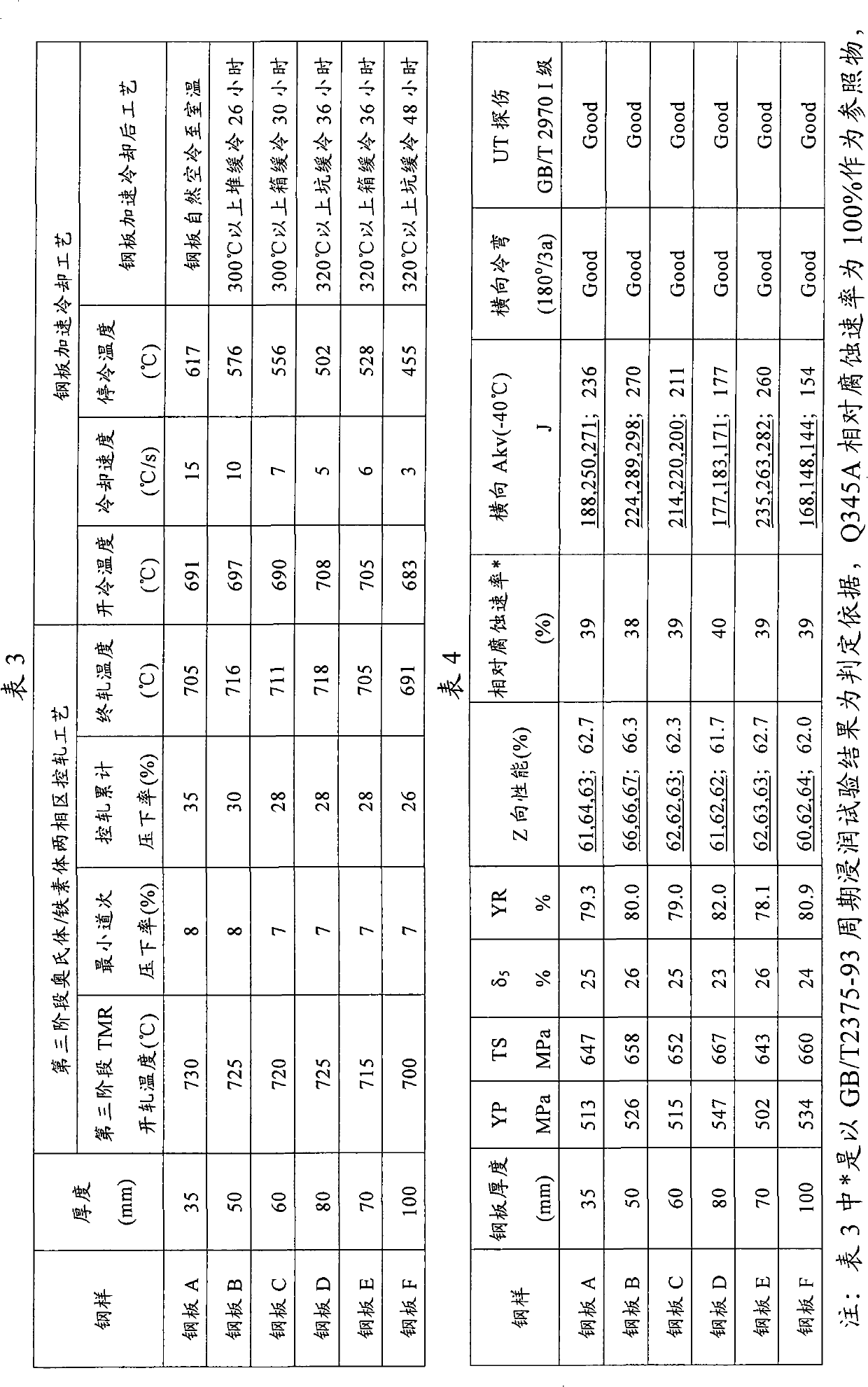

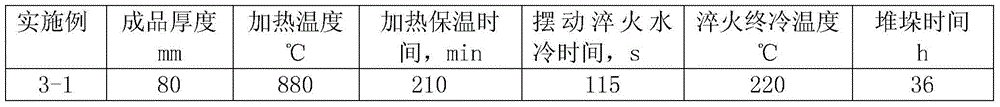

Weather resistant thick steel plate and manufacturing method thereof

A weather resistant thick steel plate comprises, by weight, 0.06%-0.9% of C, not more than 0.30% of Si; 1.10%-1.50% of Mn, not more than 0.015% of P, not more than 0.003% of S, 0.035%-0.065% of Als, 0.25%-0.50% of Cu, 0.20%-0.50% of Ni, 0.40%-0.70% of Cr, 0.50%-0.15% of Mo, 0.008%-0.018% of Ti, 0.030%-0.060% of V, 0.015%-0.030% of Nb, not more than 0.0055% of N, 0.001%-0.004% of Ca, 0.0004%-0.0010% of selectively added B, and the balance of Fe and unavoidable impurities. The manufacturing method includes deep desulfurization of molten iron, converter smelting, LF, RH, continuous casting, on-line finishing of slabs, cut-to-length torch cutting of slabs, heating, TMCP, and slow cooling of steel plates. The obtained weather resistant thick steel plate has balanced strong toughness and strong plasticity, low yield ratio, atmospheric corrosion resistance, excellent weldability and fatigue resistance, and is especially applicable to non-coating high-rise building structures and bridge structures.

Owner:BAOSHAN IRON & STEEL CO LTD

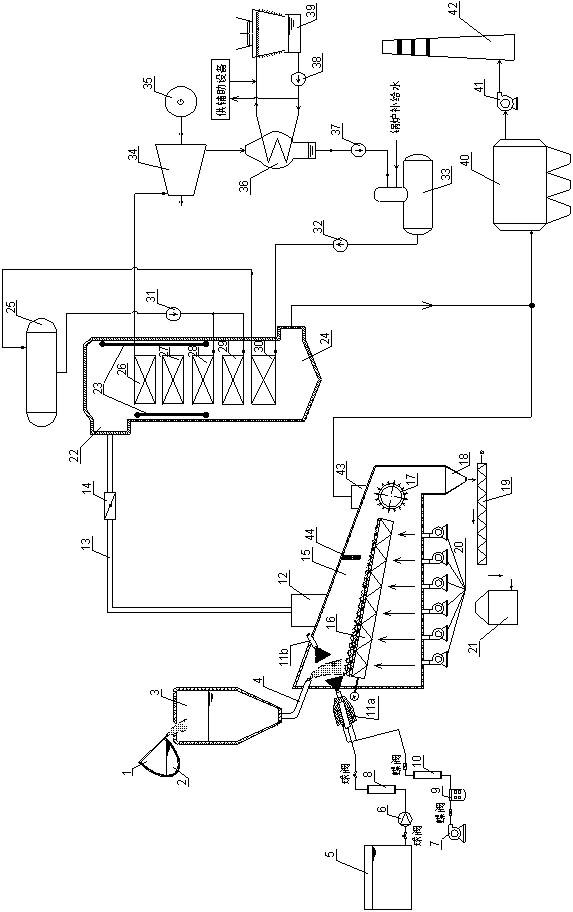

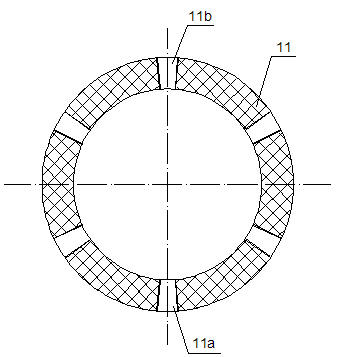

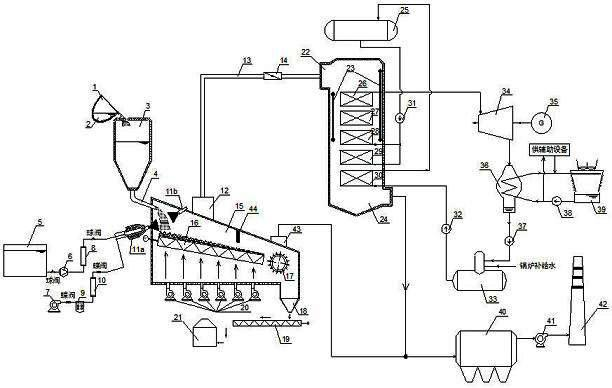

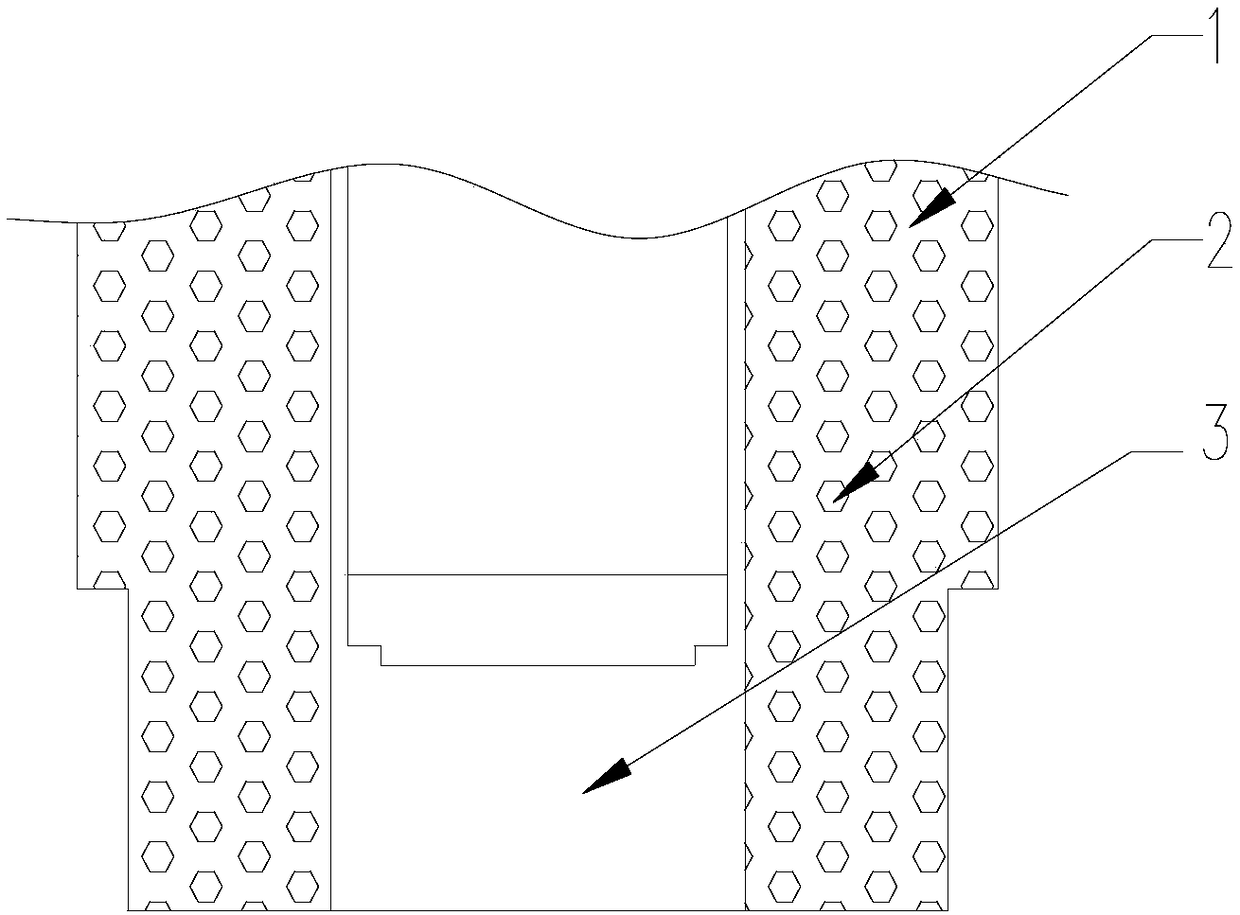

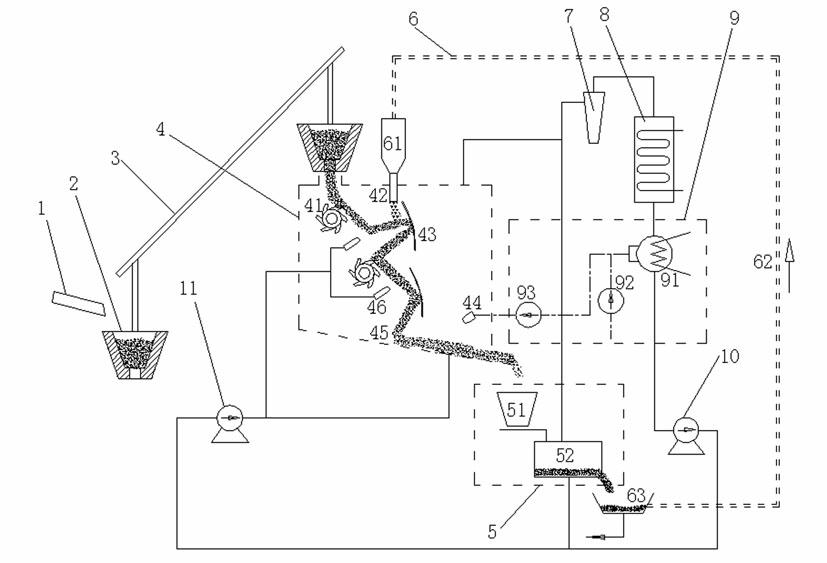

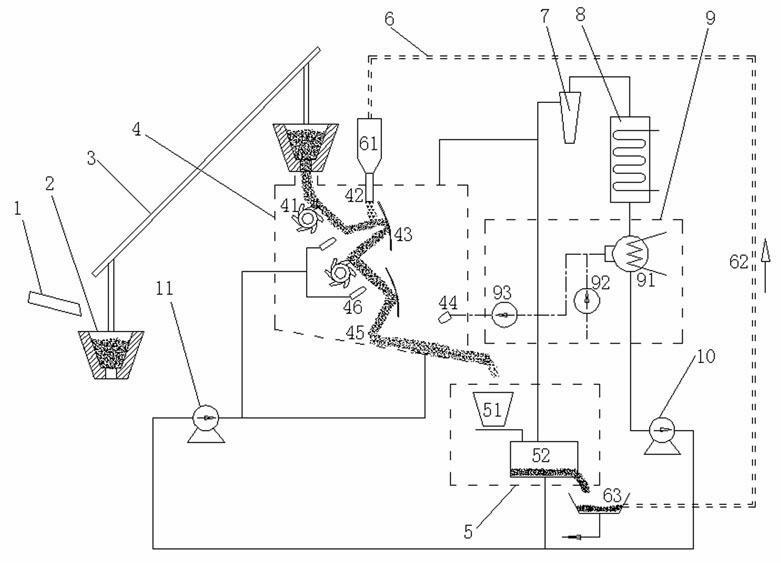

Melting furnace slag quenching dry type granulation and sensible heat recovery generating system and method using same

ActiveCN102433401AReduce cooling air volumeReduce power consumptionIncreasing energy efficiencyRecycling and recovery technologiesSlagHigh pressure water

The invention provides a melting furnace slag quenching dry type granulation and sensible heat recovery generating system and a method using the same and belongs to the technical field of steel metallurgy furnace slag treatment and complementary energy recovery. The melting furnace slag quenching dry type granulation and sensible heat recovery generating system provided by the invention comprisesa slag-receiving device, a high-pressure water-air pulverization furnace slag quenching and granulating device, a furnace slag slow-cooling device, a sensible heat recovery generating device and a waste gas purification treatment device. According to the invention, the melting furnace slag is quenched and granulated by utilizing the high-pressure water-air pulverization device, so that the melting furnace slag is rapidly cooled to be in a glassy state; and then through a water-cooled type vibration grid plate, the melting furnace slag in the glassy state is further subjected to heat exchange with cold air so as to facilitate the subsequent recovery of the sensible heat. By the system provided by the invention, the melting furnace slag is quenched and granulated, and the high-temperature sensible heat resource of the furnace slag is sufficiently recovered and is used for generation on the basis that the water activity quality of the furnace slag is not influenced.

Owner:NANJING KESEN KENEN ENVIRONMENT & ENERGY

Polyester DTY fiber and preparation method thereof

ActiveCN108385186AHigh molecular weightNarrow molecular weightSpinning head liquid feederFilament/thread formingFiberThermal insulation

The invention relates to polyester DTY fiber and a preparation method thereof. The preparation method comprises: metering a modified polyester melt, extruding, cooling, oiling, and winding to preparethe polyester POY fiber. According to the present invention, during the cooling, the longitudinal height is maintained, and the cross section area of the slow cooling chamber is increased while the plate surface temperature of the spinning plate is maintained by using the thermal insulation method; the material of the fiber is the modified polyester, the molecular chain of the modified polyester comprises a terephthalic acid chain segment, an ethylene glycol chain segment and a diol chain segment having the branched chain, the structure formula of the diol chain segment having the branched chain is defined in the specification, R1 and R2 are respectively and independently selected from straight chain alkylidene with a carbon atom number of 1-3, R3 is selected from alkyl with a carbon atomnumber of 1-5, and R4 is selected from alkyl with a carbon atom number of 2-5; the chromatic aberration [delta]E of the prepared fiber is less than 0.200; and the preparation process is simple and reasonable, and the obtained fiber has excellent performance.

Owner:JIANGSU HENGLI CHEM FIBER

Production process for intelligent temperature adjusting steel rail with laser cladding layer and heat insulation coating

InactiveCN102146563AHigh hardnessHigh Yield Stress LimitRailsMetallic material coating processesTemperature stressAlloy

The invention discloses a production process for an intelligent temperature adjusting steel rail with a laser cladding layer and a heat insulation coating. The production process comprises the following steps of: (1) cladding the laser cladding of one layer or superposed inner and outer two-layer structures in thickness of 0 to 4 millimeters on the surface of the steel rail by adopting the laser cladding technology, wherein the laser cladding layer consists of mixed powder formed by mixing alloy powder and ceramic powder comprising oxide powder or / and nickel clad oxide powder in a certain ratio; (2) performing slow cooling treatment on the surface of the steel rail; (3) moderately performing surface treatment and drying treatment on the surface of the steel rail; and (4) coating a functional coating with corrosion resistance, abrasion resistance, heat insulation performance, heat dissipation and cooling performances and intelligent temperature adjustment function at normal temperatureon the surface of the steel rail. The steel rail has corrosion resistance, abrasion resistance and good electric conductivity, the cost of the steel rail can be saved, and the service life of the steel rail is long; and the steel rail can insulate heat and reduce temperature, the temperature stress of the steel rail can be greatly reduced, and the safety of train transport is improved.

Owner:张昆

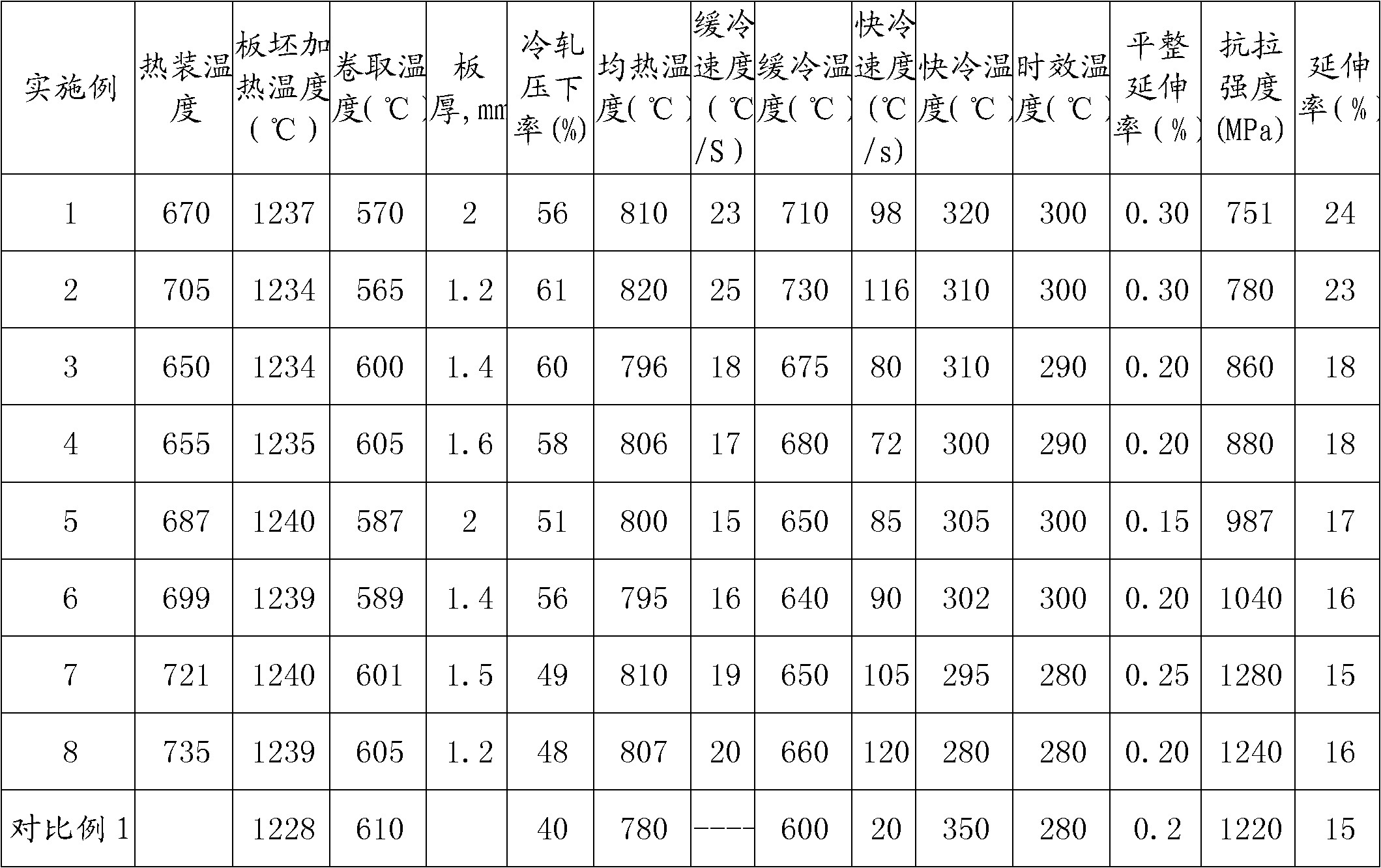

High strength cold-rolled plate with excellent formability and production method thereof

The invention provides a high strength cold-rolled plate with excellent formability, containing: no more than 0.0040% of C, 0.02-0.15% of Si, 0.20-1.00% of Mn, 0.02-0.09% of P, 0.015-0.06% Ti, 0.01-0.05% of Nb, and the rest being Fe. The production method comprises: smelting, continuous casting, hot-rolling, cold rolling and continuous annealing, wherein the heating temperature of the hot-rolled billet is 1170-1270 DEG C, the finishing temperature of hot-rolling is 850-960 DEG C, and the coiling temperature is 650-760 DEG C; the cold rolling reduction percent is 60-82%; the annealing temperature is 760-880 DEG C, the thermal insulation time is 60-210s, the slow-cooling segment temperature is 630-700 DEG C, and the fast-cooling exit temperature is 300-500 DEG C; and the levelling elongationrate is 0.5-1.0%. The high strength steel plate containing phosphorus of the invention has the features of low carbon, microalloying and purity. The steel added with a certain amount of Nb and Ti hashigher plasticity. Using relevant rolling and annealing technique, the indexes of performance of the steel achieves the demand of high strength automobile stamping parts.

Owner:ANGANG STEEL CO LTD

Nanostructured soldered or brazed joints made with reactive multilayer foils

InactiveUS7361412B2Reduce coolingImprove microstructureExothermal chemical reaction heat productionVacuum evaporation coatingRoom temperatureSlow cooling

Self-propagating formation reactions in nanostructured multilayer foils provide rapid bursts of heat at room temperature and therefore can act as local heat sources to melt solder or braze layers and join materials. This reactive joining method provides very localized heating to the components and rapid cooling across the joint. The rapid cooling results in a very fine microstructure of the solder or braze material. The scale of the fine microstructure of the solder or braze material is dependant on cooling rate of the reactive joints which varies with geometries and properties of the foils and components. The microstructure of the solder or braze layer of the joints formed by melting solder in a furnace is much coarser due to the slow cooling rate. Reactive joints with finer solder or braze microstructure show higher shear strength compared with those made by conventional furnace joining with much coarser solder or braze microstructure. It is expected that the reactive joints may also have better fatigue properties compared with conventional furnace joints.

Owner:THE JOHN HOPKINS UNIV SCHOOL OF MEDICINE

Micro-alloying steel for oil gas transport seamless pipeline and its preparation method

InactiveCN101186994AElimination of abnormal tissueImprove toughnessTemperature control deviceForeign matterChemical composition

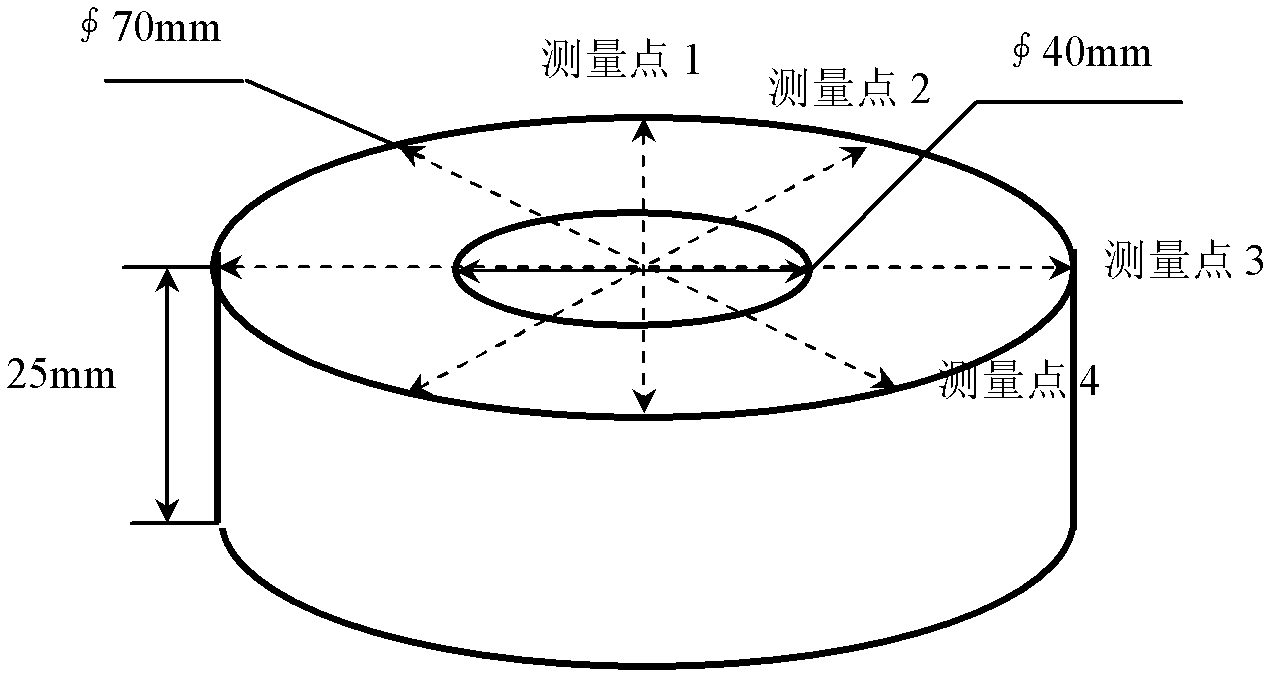

The invention discloses micro-alloying seamless pipeline steel and process for preparation. According to weight percentage, the range of the chemical components of the invention includes that C holds 0.08% to 0.20%, Si is equal to or less than 0.04%, Mn takes 0.60% to 1. 50%, S is equal to or less than 0.015%, P is equal to or less than 0.025%, Al is equal to or less than 0.04%, Ti is equal to or less than 0.04%, H is equal to or less than 2.5*10-4%, O is equal to or less than 25*10-4%, the rest is Fe and unavoidable foreign matters. The process for preparation comprises technique steps, including smelting, refining, continuous casting, hot rolling and slow cooling. Round steel with the size of phi 70 to 150 millimeters can be produced by the process for preparation. The seamless pipeline steel of the invention has perfect anti-sulphide stress corrosion (SSC resistance) capability and anti-HIC property. The pipeline steel which can substitute for welding pipe can be utilized in the filed of oil pipeline and the like, and the invention increases the reliability of material and adaptability of variety, in particular being adaptable for the low submarine temperature and corrosion-resistant environment and for manufacture of thick-walled tubes.

Owner:LAIWU IRON & STEEL GRP

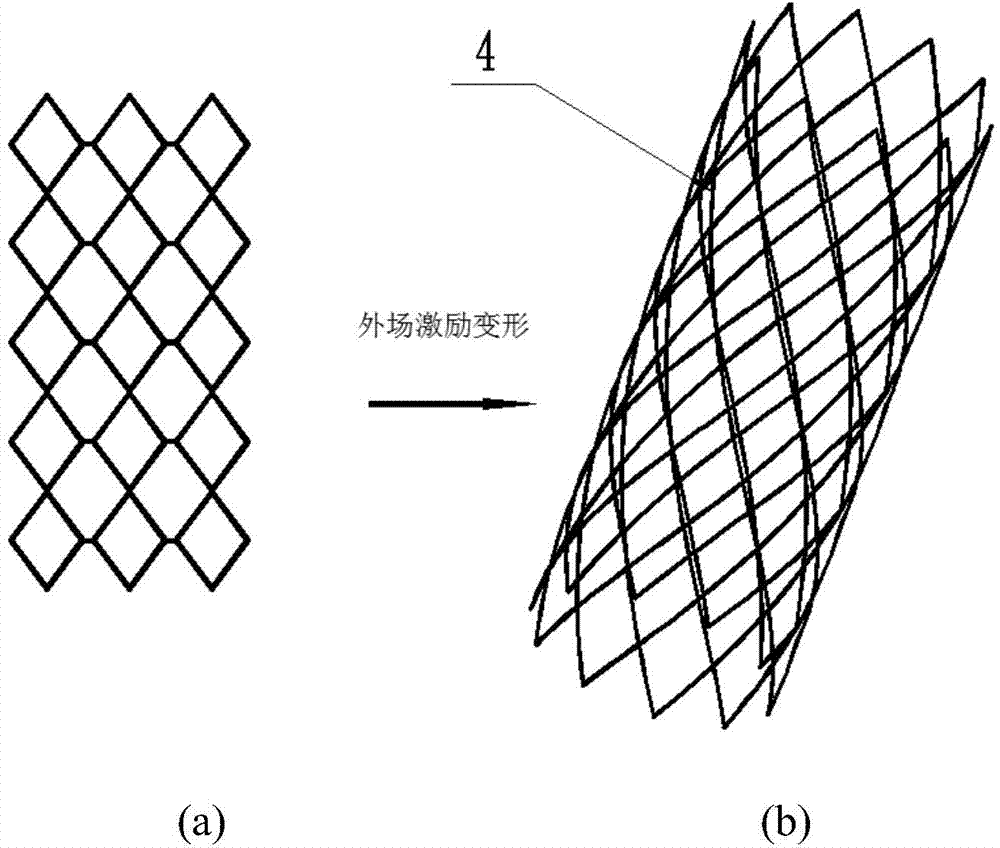

Method for forming artificial vascular stent through 4D printing

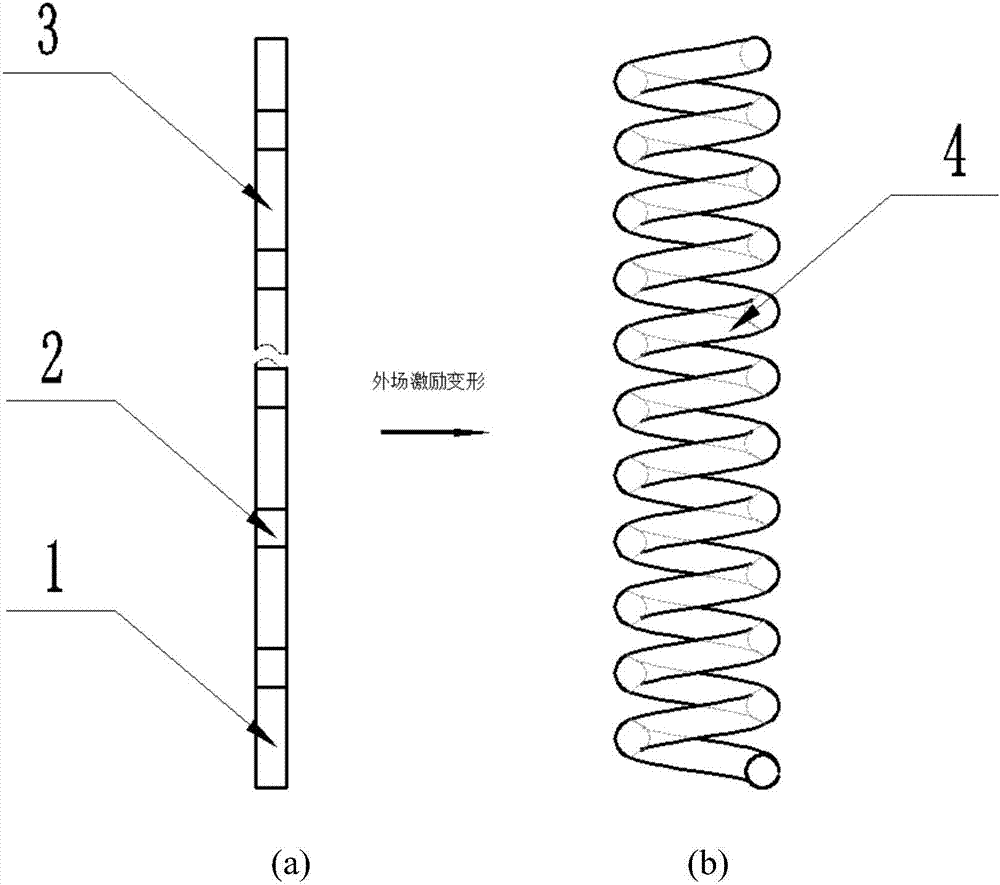

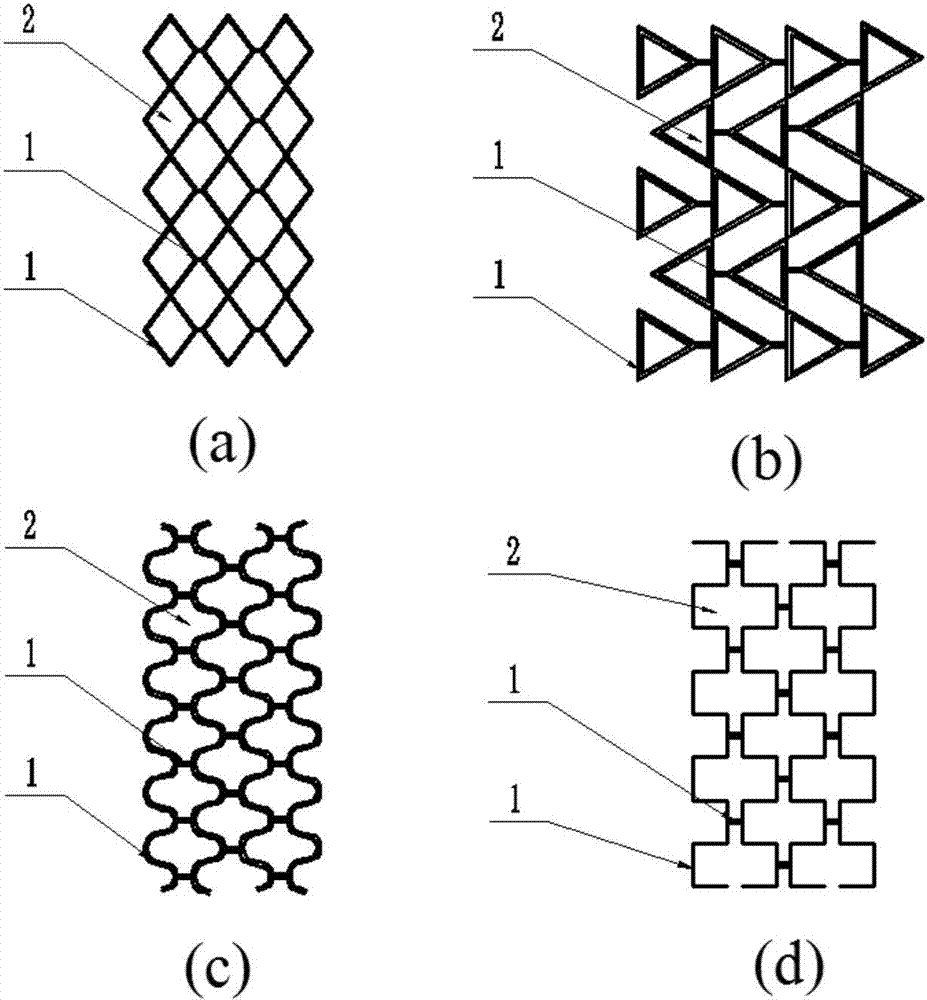

ActiveCN104116578AFast preparationSimplify molding manufacturing equipmentStentsBlood vesselsMetallic materialsAlloy

The invention discloses a method for forming an artificial vascular stent through 4D printing. The method comprises the following steps that (1) shape memory polymers or shape memory alloy serves as a transformable material unit, polymer materials or metal materials serve as a base body material unit, and an initial vascular stent configuration is designed; (2) the transformable material unit and the base body material unit are printed into a needed original 3D configuration with a direct fusion forming method, or a laser area selective fusion forming mode or a micro jet molten drip electromagnetic constraint forming mode is selected as a shape memory alloy printing forming mode to manufacture the vascular stent; (3) heat preservation and slow cooling are conducted on the original 3D configuration or the vascular stent obtained in the step (2); (4) performance tests are conducted on the formed vascular stent so that the vascular stent can meet using requirements, and thus the 4D printing forming of the artificial vascular stent is completed, wherein the performance tests include the mechanics performance test, the incentive transformation test and the medical performance test.

Owner:XI AN JIAOTONG UNIV

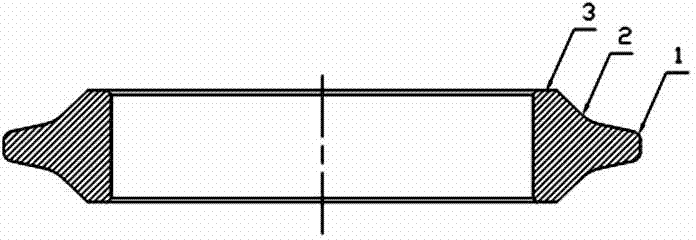

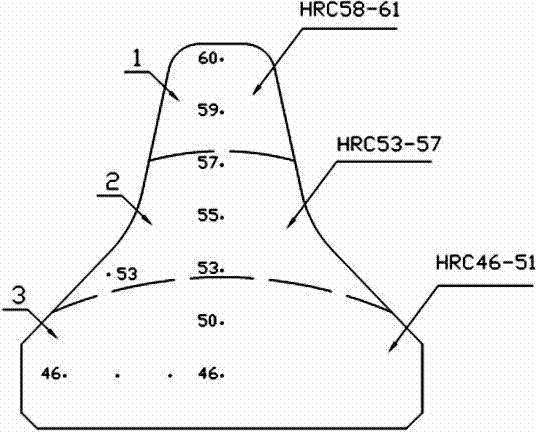

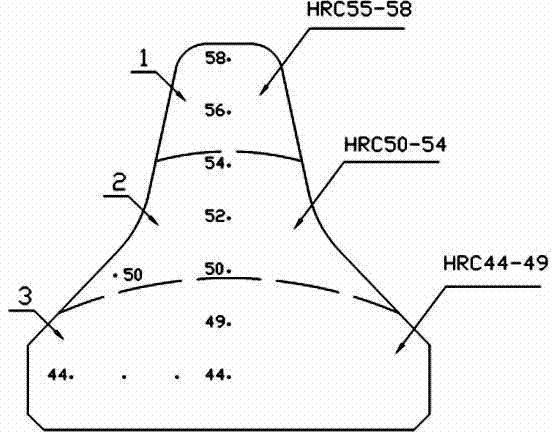

Disk-shaped roller cutter ring and manufacture method thereof

ActiveCN102517502AGuaranteed hardenabilityImprove toughnessFurnace typesHeat treatment furnacesMedium frequencyHardness

The invention discloses a disk-shaped roller cutter ring with high hardness, good toughness and excellent comprehensive performance. The disk-shaped roller cutter ring comprises the following ingredients of: 0.46-0.56% of C, 0.80-1.20% of Si, 0.20-0.65% of Mn, 5.00-5.80% of Cr, 1.15%-1.55% of Mo, 0.85-1.40% of V and the balance Fe and impurities, wherein the content of P is no more than 0.02%, and the content of S is no more than 0.01%; and the overall hardness of the cutter ring is HRC55-61 (Rockwell Hardness C55-61), or the hardness is of graded distribution, i.e. the hardness of a working edge area is HRC55-61, the hardness of a transition surface area is HRC50-57, and the hardness of a step assembly surface area and an inner ring is HRC44-51. A preparation method of the disk-shaped roller cutter ring comprises the following steps of: smelting the raw materials in an electric furnace; carrying out electroslag remelting; preforging; carrying out die forging; carrying out slow cooling; annealing; carrying out rough machining to obtain a disk-shaped roller cutter ring rough blank; carrying out high-temperature vacuum hardening and two-time high-temperature tempering on the cutter ring rough blank; carrying out low-temperature destressing treatment; carrying out fine finishing to obtain the cutter ring with the overall hardness of HRC55-61, wherein the cutter ring with the overall hardness of HRC55-61 is applicable to the tunneling of a hard rock formation by a shield tunneling machine; or carrying out medium-frequency induction tempering treatment prior to the low-temperature destressing treatment to obtain the cutter ring with graded-distribution hardness, wherein the cutter ring with the graded-distribution hardness is applicable to the tunneling of a rock formation with an upper soft part and a lower hard part.

Owner:ZHUZHOU HARD ALLOY GRP CO LTD

Method and system for recovering high-temperature sensible heat of molten blast furnace slag

ActiveCN102162016ADoes not affect activityImprove waste heat qualityIncreasing energy efficiencyDischarge devicesSlagSlow cooling

The invention discloses a method and a system for recovering high-temperature sensible heat of molten blast furnace slag. The system comprises a blast furnace slag runner, a slag hopper, a slag hopper lifting mechanism, a quenching unit, a slow cooling unit, a cold slag particle circulation unit, a cyclone dust collector, a waste heat boiler, a condensing unit, a circulating fan, and a booster fan. The method for recovering waste heat comprises the following steps of: crushing and quickly cooling the molten blast furnace slag in the quenching unit in a composite way of a rotary crushing wheel, high-pressure cold air, a slag trap, cold slag particles and cooling water, and fully exchanging heat with solidified blast furnace slag in the slow cooling unit by using cooling air; and allowing high-temperature air which comes out of the quenching unit and the slow cooling unit to enter the waste heat boiler and performing heat exchange, transforming into steam or electric power and then outputting. The subsequent utilization of blast furnace slag and the waste heat recovery efficiency are synchronously considered, condensed water is recycled, finished slag does not contain water or only contains a small amount of water, the granulation effect of the slag is better, and the contradiction between intermittent slagging and continuous heat production of blast-furnace ironmaking is resolved.

Owner:HANGZHOU BOILER GRP CO LTD

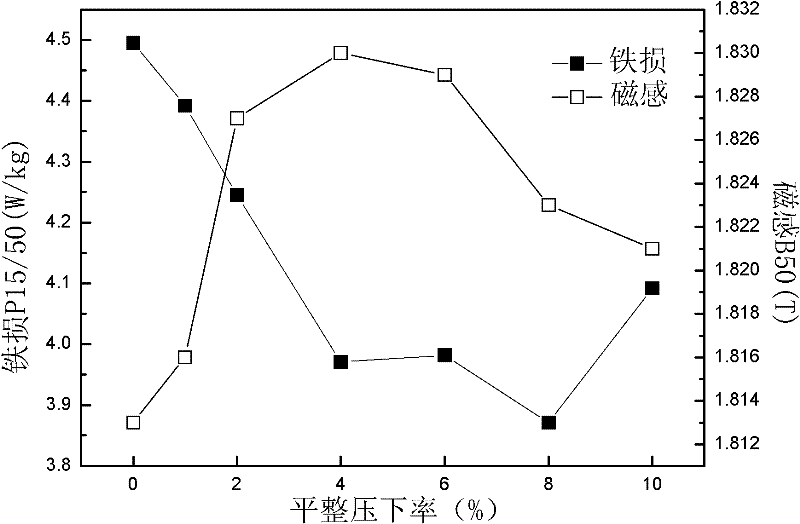

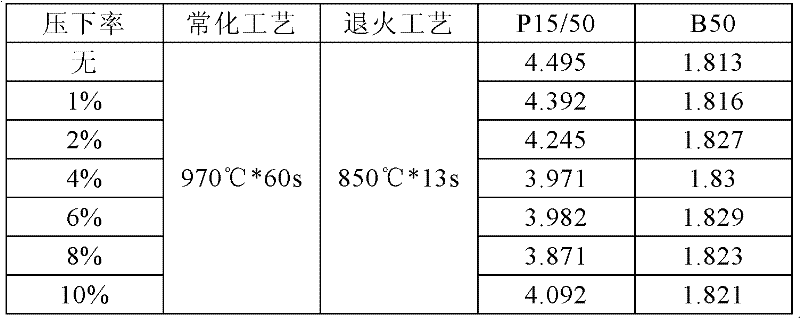

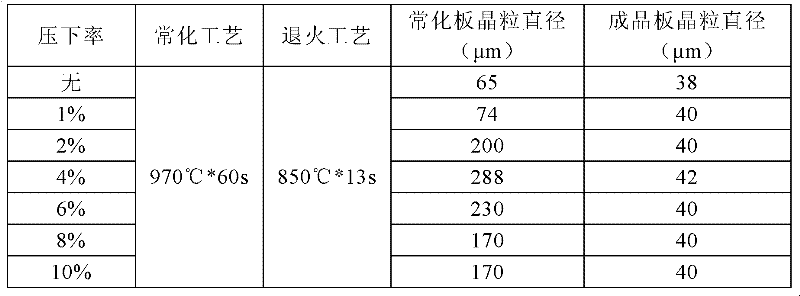

Method for preparing non-oriented silicon steel with high magnetic induction

ActiveCN102453837AHigh magnetic inductionGuaranteed iron lossInorganic material magnetismMetal rolling arrangementsReduction ratioSlow cooling

Owner:BAOSHAN IRON & STEEL CO LTD

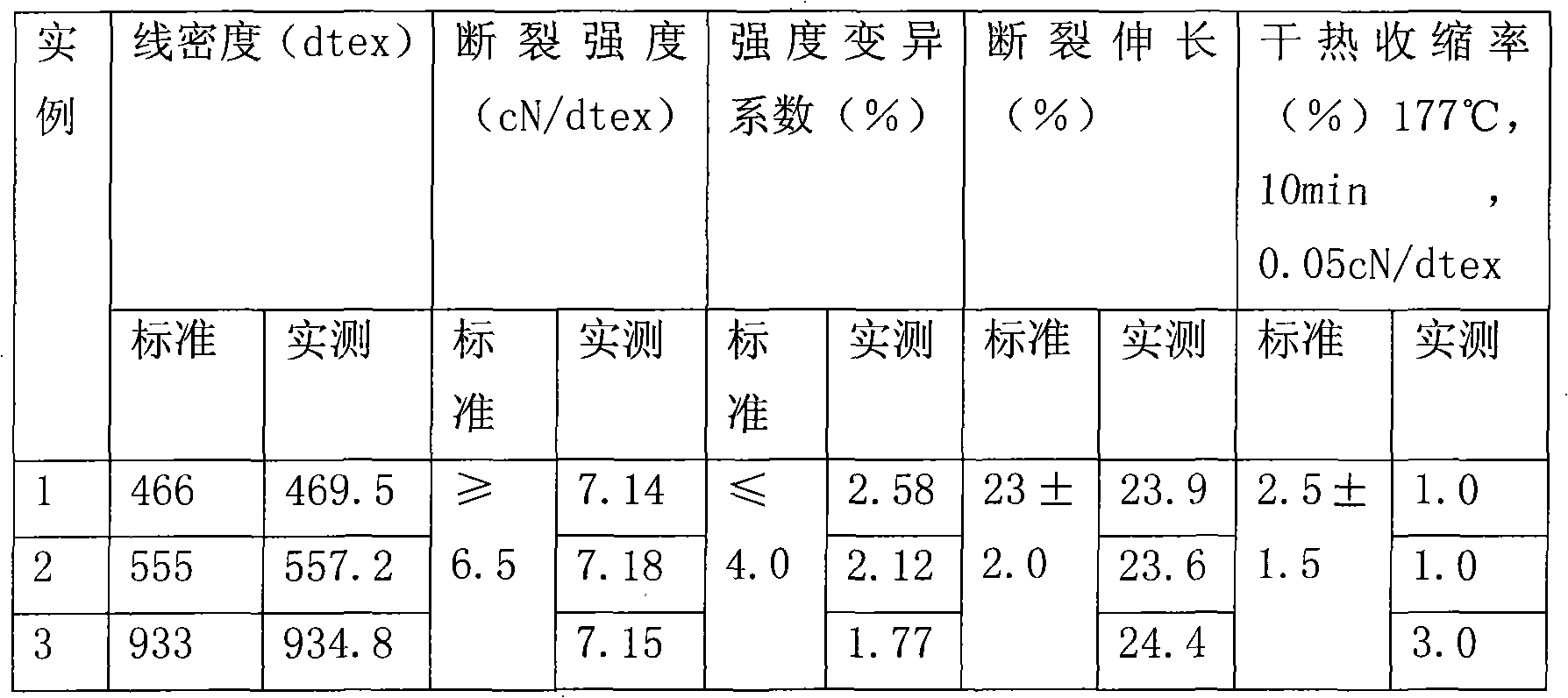

Manufacturing method of high-strength, high-modulus and low-shrinkage polyester industrial yarn

ActiveCN102797054AGuaranteed positionAvoid stretching unevenlyFilament/thread formingMonocomponent polyesters artificial filamentYarnFiber

The invention discloses a manufacturing method of a high-strength, high-modulus and low-shrinkage polyester industrial yarn. The manufacturing method comprises the processes of preparation of a highly viscous melt polyester raw material, metering, spinning, cooling, oil applying, drawing, heat shaping and winding formation; the cooling comprises slow cooling, precooling, cooling in an air free zone and air blast cooling in sequence; the precooling part uses a driven hollow-out successive annular strip. Through the introduction of a precooling device, irregularity caused by tow shaking due to move-down of a curing point of a fiber is reduced, the linear density deviation is controlled within a lower range, and orientation and crystallization of an as-spun fiber are reduced, so that the high-strength, high-modulus and low-shrinkage polyester industrial yarn is obtained; and the high-strength, high-modulus and low-shrinkage polyester industrial yarn has the advantages of high breaking tenacity, high initial modulus, low linear density deviation, low breaking elongation and lower dry-heat shrinkage rate and can be used for preferably satisfying requirements on application.

Owner:JIANGSU HENGLI CHEM FIBER

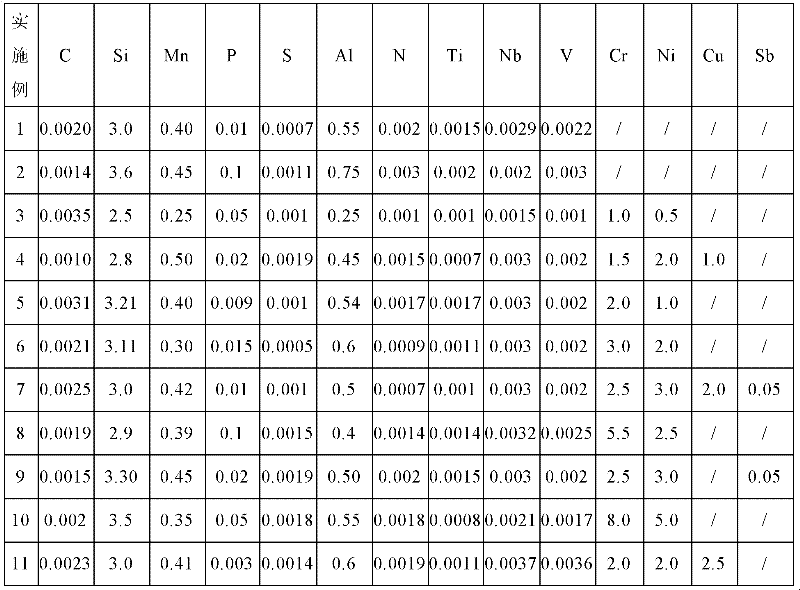

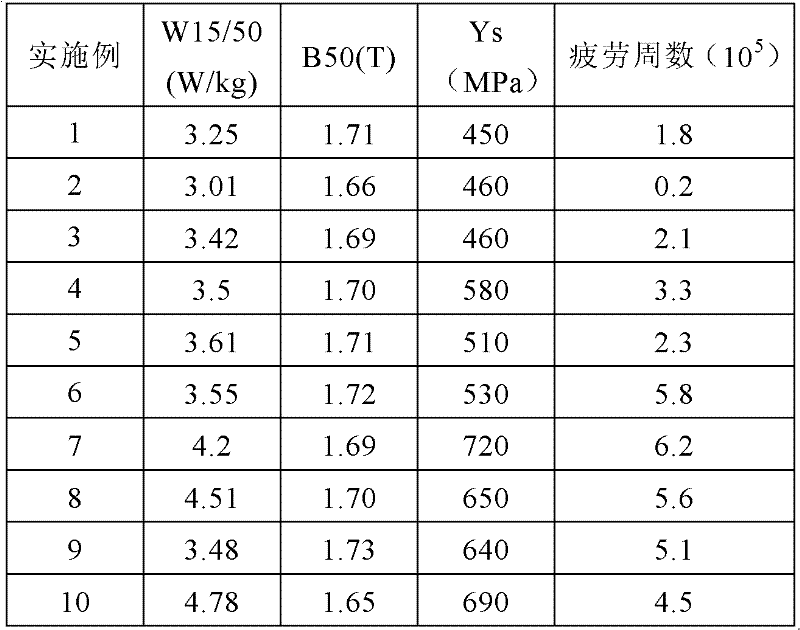

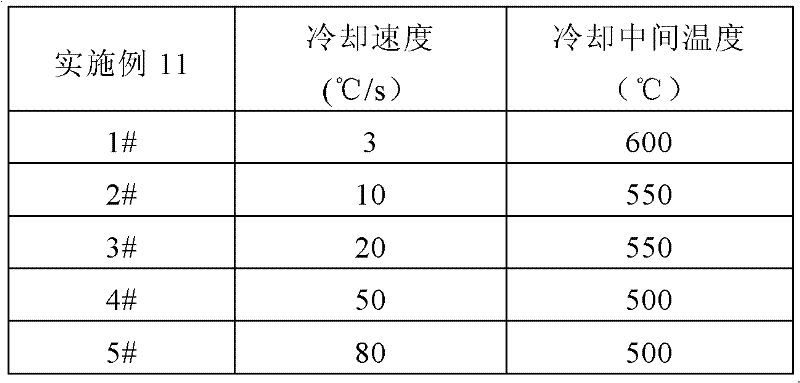

High-strength non-oriented electrical steel with high magnetic induction and manufacturing method thereof

InactiveCN102453838AHigh strengthSolve the problem of difficult rollingReduction rateElectrical steel

High-strength non-oriented electrical steel with high magnetic induction and a manufacturing method thereof. The method comprises the following steps of: 1) smelting and casting, wherein the electrical steel comprises the following components by weight: not more than 0.0040% of C, 2.50-4.00% of Si, 0.20%-0.80% of Al, 1.0-8.0% of Cr, 0.5-5.0% of Ni, not more than 0.50% of Mn, not more than 0.30% of P, not more than 0.0020% of S, not more than 0.0030% of N, not more than 0.0030% of Ti, not more than 0.010% of Nb, not more than 0.010% of V, not more than 0.010% of C+S+N+Ti, and the balance of Fe; smelting, RH vacuum treatment, casting; 2) hot rolling; 3) normalization at a temperature of 850-950 DEG C for 0.5-3 min, slow cooling to 650-750 DEG C with a speed of 5-15 DEG C / s, rapid cooling to below 100 DEG C with a speed of 20-70 DEG C; 4) pickling and cold rolling with a total reduction rate of not less than 70%; 5) annealing at 800-1000 DEG C for 5-60 seconds, slow cooling to 650-750 DEG C with a speed of 3-10 DEG C / s, rapid cooling to below 100 DEG C with a speed of 20-70 DEG C. The method of the invention produces non-oriented electrical steel with both high strength and high-efficient magnetic properties without the increase of manufacturing difficulties.

Owner:BAOSHAN IRON & STEEL CO LTD

A method for manufacturing high-strength, high-modulus, low-shrinkage polyester industrial yarn

ActiveCN102797054BReduce disturbanceReduce the temperatureFilament/thread formingMonocomponent polyesters artificial filamentYarnFiber

The invention discloses a manufacturing method of a high-strength, high-modulus and low-shrinkage polyester industrial yarn. The manufacturing method comprises the processes of preparation of a highly viscous melt polyester raw material, metering, spinning, cooling, oil applying, drawing, heat shaping and winding formation; the cooling comprises slow cooling, precooling, cooling in an air free zone and air blast cooling in sequence; the precooling part uses a driven hollow-out successive annular strip. Through the introduction of a precooling device, irregularity caused by tow shaking due to move-down of a curing point of a fiber is reduced, the linear density deviation is controlled within a lower range, and orientation and crystallization of an as-spun fiber are reduced, so that the high-strength, high-modulus and low-shrinkage polyester industrial yarn is obtained; and the high-strength, high-modulus and low-shrinkage polyester industrial yarn has the advantages of high breaking tenacity, high initial modulus, low linear density deviation, low breaking elongation and lower dry-heat shrinkage rate and can be used for preferably satisfying requirements on application.

Owner:JIANGSU HENGLI CHEM FIBER

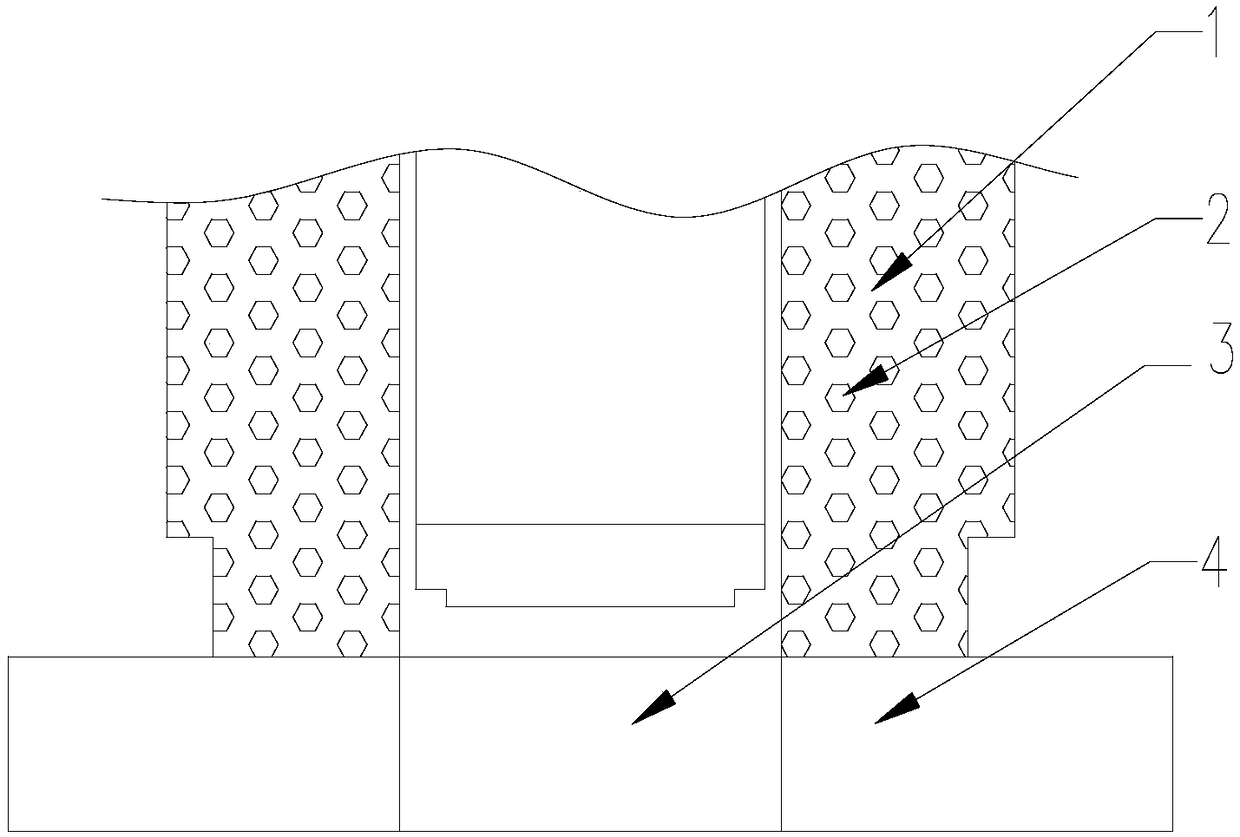

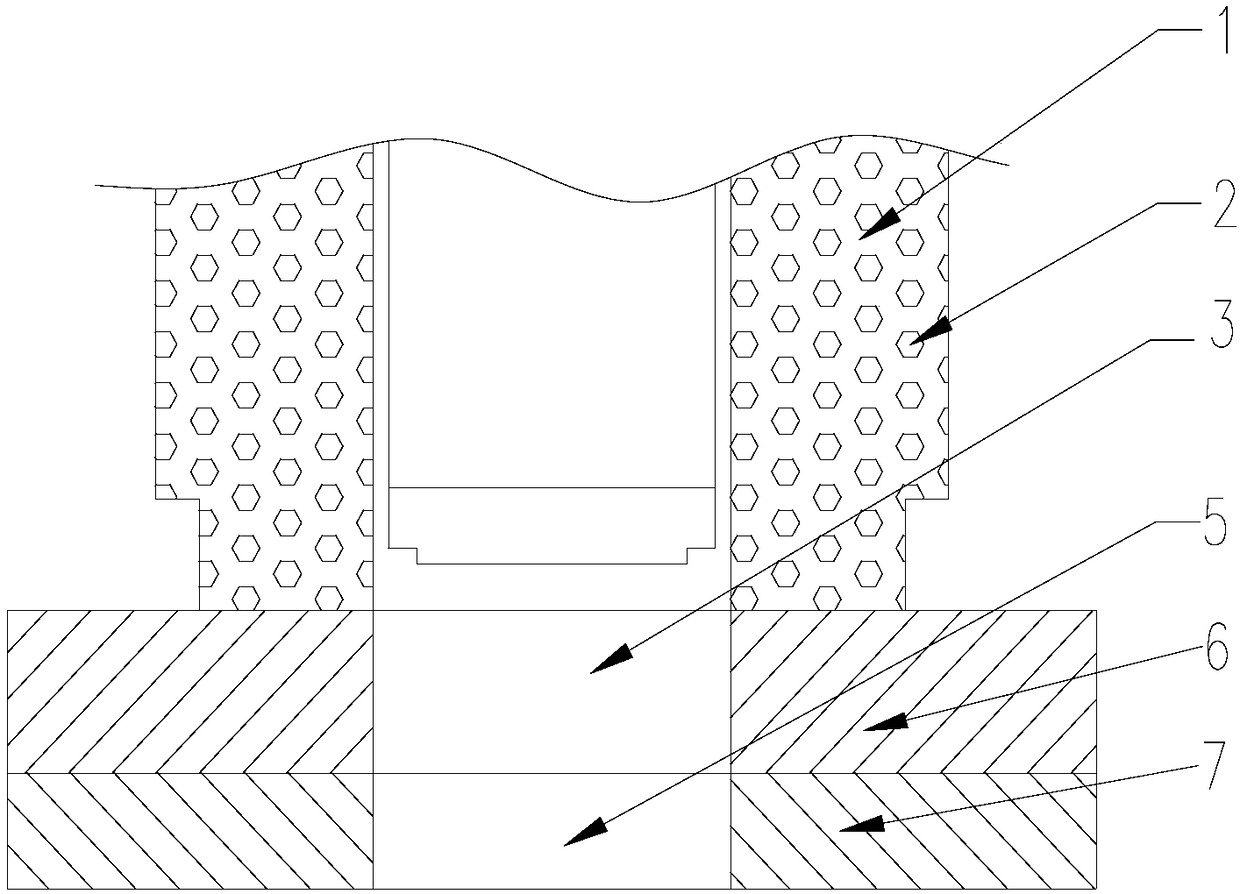

Salt Bath Ferritic Nitrocarburizing of Brake Rotors

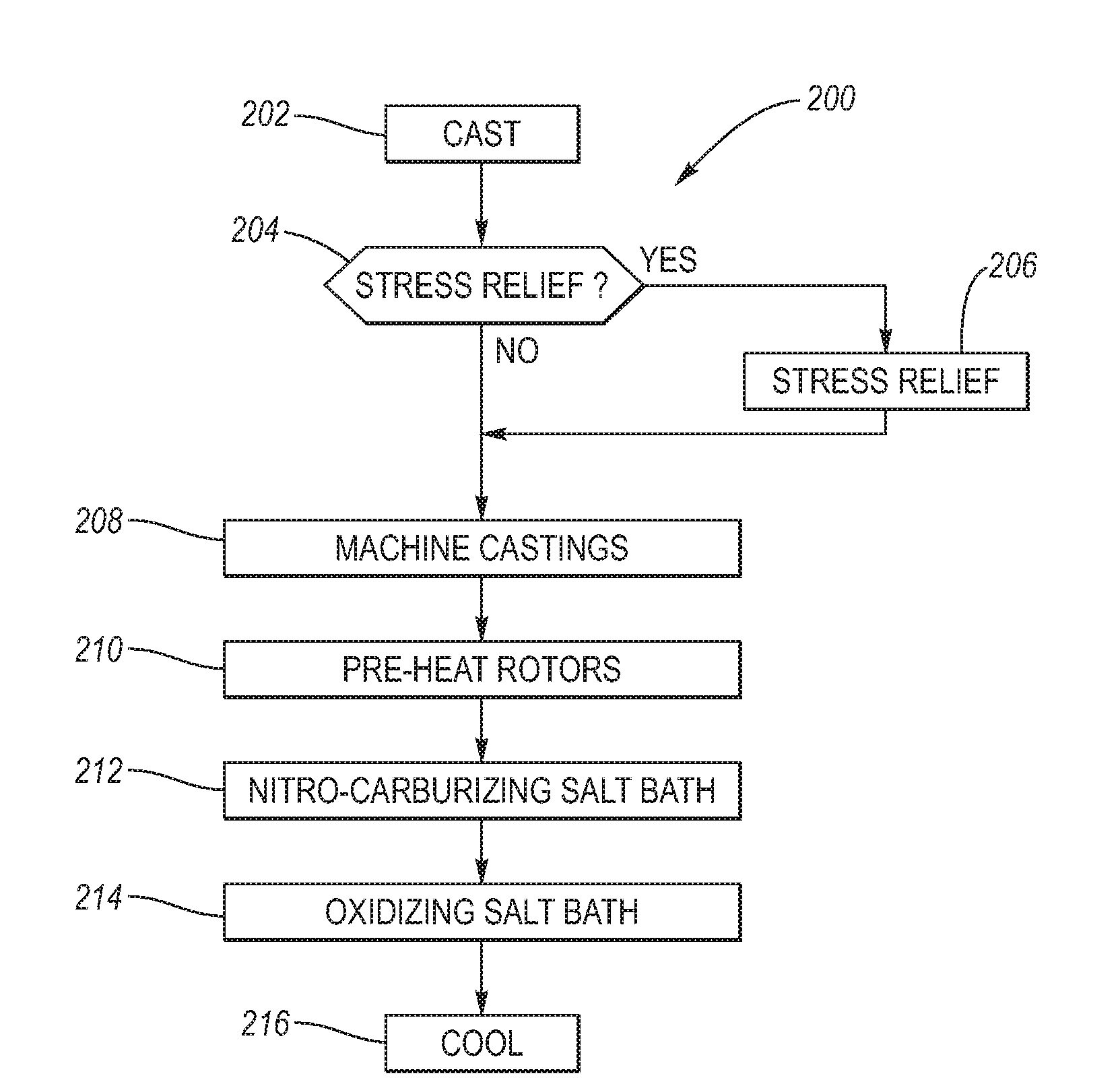

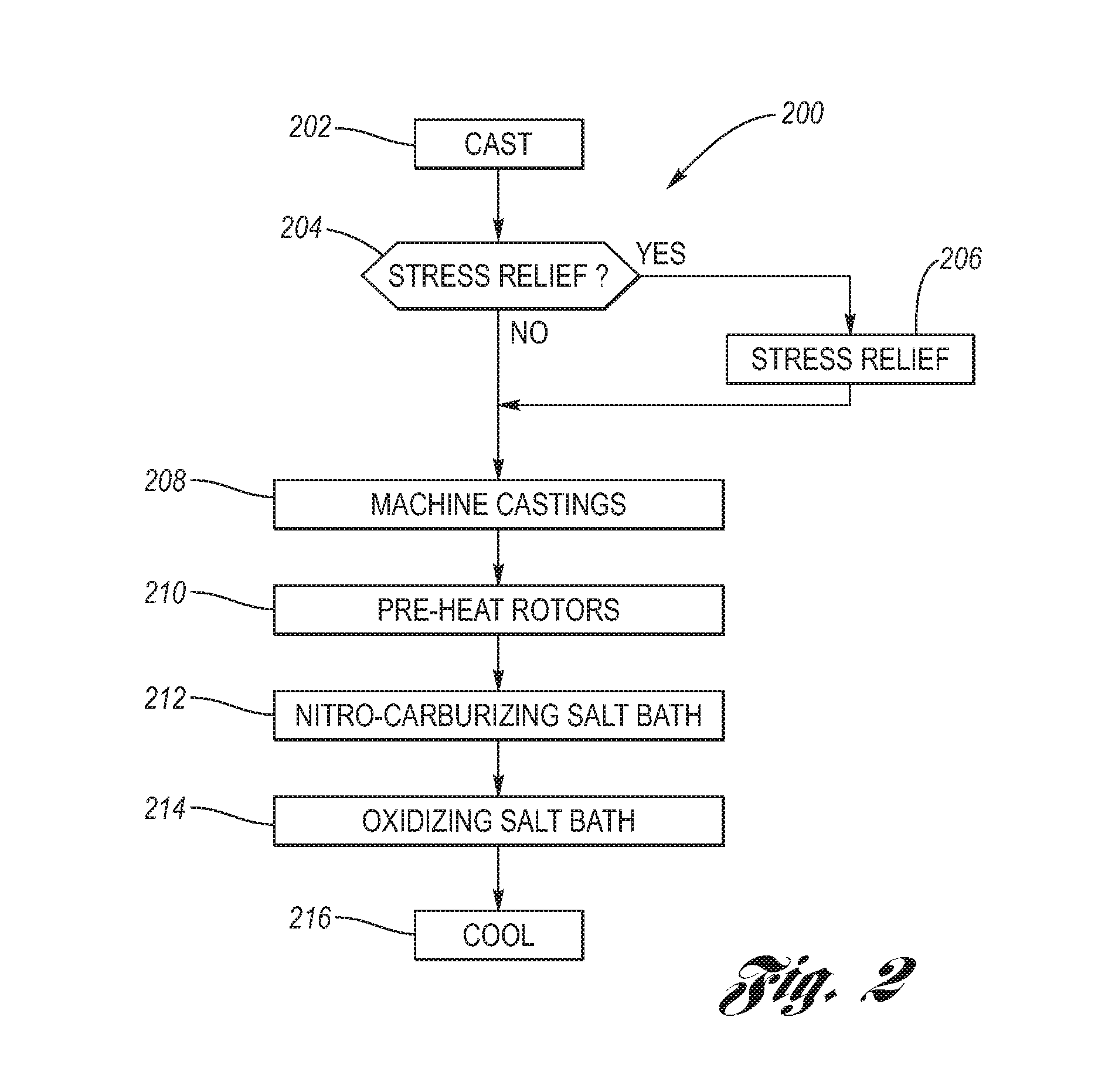

ActiveUS20080000550A1Absence of distortionProvide resistanceBraking discsSolid state diffusion coatingRoom temperatureNitrogen

Ferritic nitrocarburized surface treatment of cast iron brake rotors providing oxidation resistance, good braking performance and absence of distortion. Machined brake rotors are pre-heated, then immersed into a high temperature molten nitrocarburizing salt bath for a first predetermined dwell time. After removing the brake rotors from the nitrocarburizing salt bath, the brake rotors are directly immersed into an oxidizing salt bath at a lower temperature than the nitrocarburizing salt bath so that the brake rotors are thermally quenched. After a predetermined second dwell time in the oxidizing salt bath, the brake rotors are removed therefrom and further cooled to room temperature, either by water application thermal quenching or slow cooling in air. A fixture provides stable holding the brake rotors with a minimum of contact during placement in the salt baths.

Owner:KOLENE +1

Low-deformation gear steel and manufacturing method thereof

The invention relates to low-deformation gear steel. The gear steel comprises the following chemical components in percentage by weight: 0.10 to 0.30 percent of C, 0.15 to 0.25 percent of Si, 0.60 to 0.90 percent of Mn, less than or equal to 0.030 percent of P, 0.010 to 0.035 percent of S, 0.85 to 1.25 percent of Cr, 0.15 to 0.35 percent of Mo, 0.020 to 0.050 percent of Al, less than or equal to 0.20 percent of Cu, 0.0100 to 0.0250 percent of N, and the balance of Fe and inevitable impurities. A manufacturing method for the steel comprises the following steps of: performing primary smelting in an electric furnace, refining steel ladles, degassing in vacuum, and bulling the ladles at the temperature of between 1550 and 1570 DEG C; performing continuous casting with superheat degree of 20 to 40 DEG C at the speed of 0.6 to 2.10m / min, and performing slow cooling or hot charging on the continuously cast bloom in a slow cooling pit; cooling the steel billet to the temperature of less than 700 DEG C at a preheating section, preserving the heat at a heating section I of 880 to 980 DEG C, then preserving the heat at a heating section II of 950 and 1200 DEG C, preserving the heat at a soaking section of 1180 and 1220 DEG C, and performing external rolling, wherein the total heating time is 195 to 210 minutes, and the temperature difference between the two sides of the square billet is less than or equal to 30 DEG C; and discharging the steel billet out of the furnace, wherein the rolling start temperature is 1155 to 1200 DEG C, and the final rolling temperature is more than 950 DEG C.

Owner:宝钢特钢有限公司

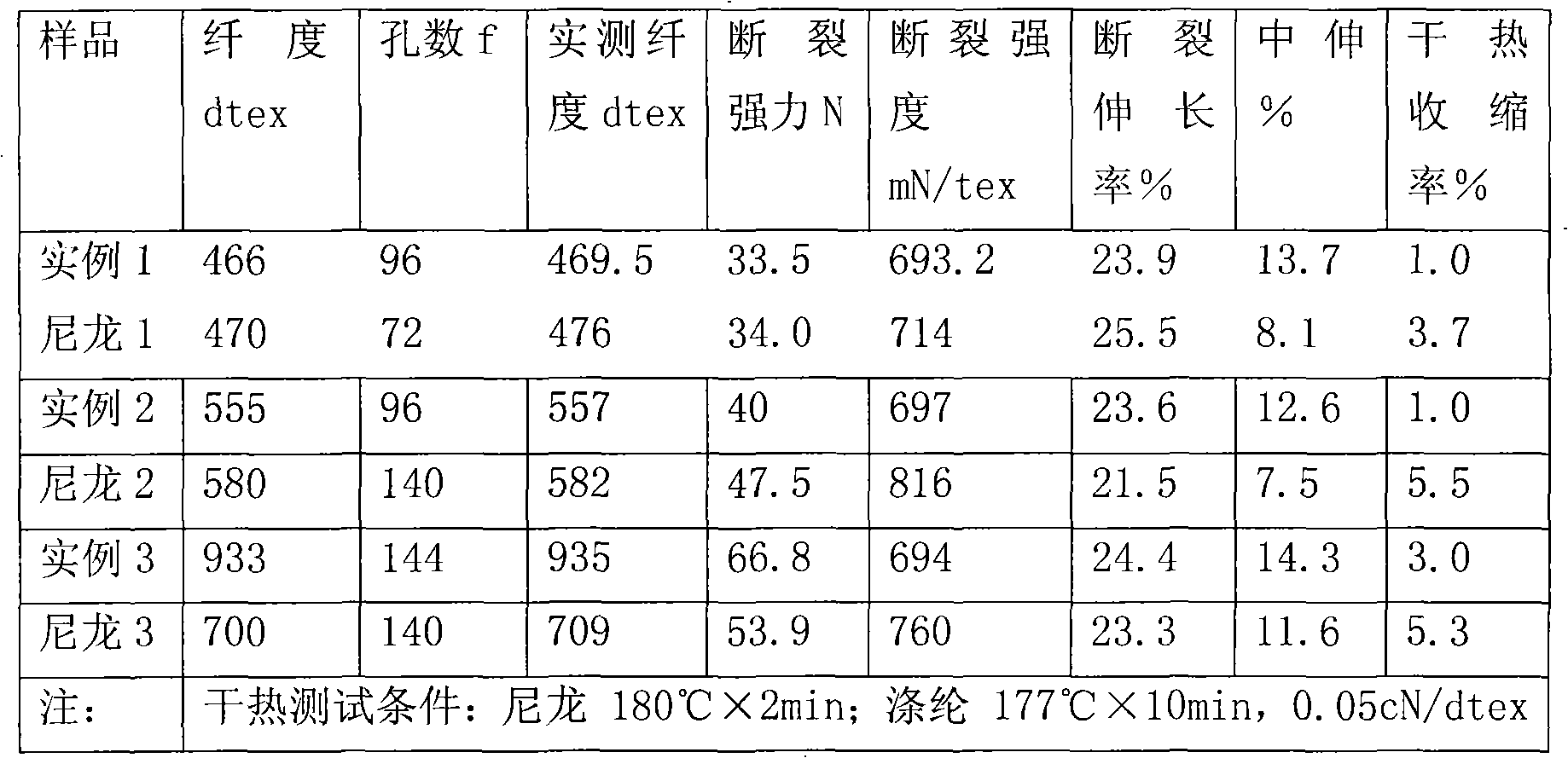

Process for producing polyester industrial fiber for processing safe air bag of automobile

ActiveCN101634052AHeat resistantAging resistantArtificial filament heat treatmentMelt spinning methodsPolyesterEngineering

The invention relates to a process for producing a polyester industrial long fiber for processing a safe air bag of an automobile, which sequentially comprises the following steps: A. processing a polyester slice with high viscosity: enabling the viscosity of the polyester slice to reach 1.0-1.1dl / g; B. melting and spinning: transmitting the polyester slice after solid phase polymerization to a spinning screw rod extruder, melting in a spinning screw rod, entering a spinning assembly by a metering pump and extruding from a fiber spray plate with a diameter of 190 mm to 220 mm to spin fusant, , then heating by a slow cooling heater, carrying out cooling for molding by a side-molding blowing device and then entering a spinning passage; C. stretching and winding: oiling the surface of a fiber and carrying out second-grade high-speed stretching with the total stretching multiple being 5.0 to 5.8, carrying out high-temperature loosing thermoforming at 230 DEG C-250 DEG C and carrying out winding for molding in the range of the winding process speed of 2,500-3,000 m / min to prepare a finished product. The fiber for the safe air bag, which is produced by the process, can completely replace a nylon 66 fiber, is used for spinning terylene safe air bag fabrics and greatly reduces the processing cost.

Owner:ZHEJIANG HAILIDE NEW MATERIAL

Preparation method of nylon powder for selective laser sintering

ActiveCN104497323ADestroy the regularity of the shapeRegular shapeSelective laser sinteringOrganic solvent

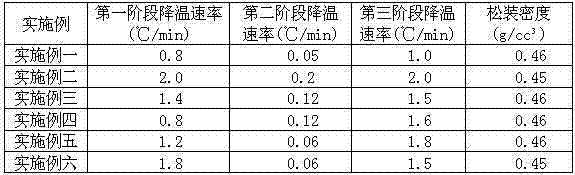

The invention provides a preparation method of nylon powder for selective laser sintering. The preparation method comprises the steps of adopting a precipitation method, and finally separating out solid powder through the processes of dissolution, cooling and precipitation. The method is characterized by being carried out under the condition of the presence of an organic solvent, wherein the cooling process is carried out in three phases, and rapid cooling is carried out to achieve a temperature which is 10 DEG C below than the separation temperature in the first phase; slow cooling is carried out to achieve the separation temperature in the second phase; rapid cooling is carried out to achieve a normal temperature in the third phase. The method is simple and feasible, low in cost, and capable of preparing the nylon powder with regular morphology, good part performance and suitable for SLS sintering.

Owner:HUNAN FARSOON HIGH TECH CO LTD

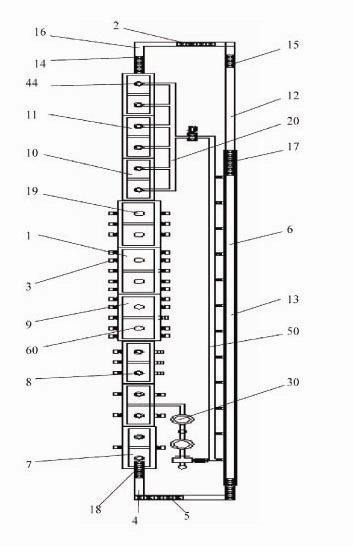

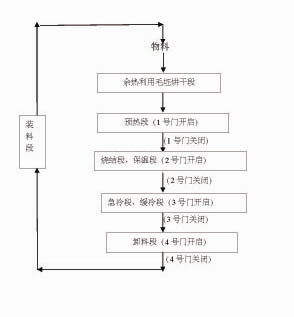

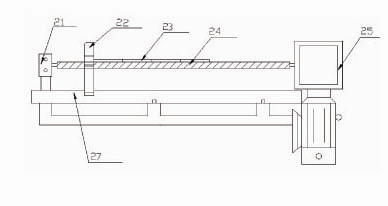

Fully-closed industrial microwave high-temperature roller continuous sintering kiln

InactiveCN102042749AConsistent shrinkageGood size consistencyMaintainance of heating chambersFurnace typesEnvironmental resistanceEngineering

The invention discloses a closed microwave high-temperature sintering roller kiln, in particular a tunnel roller kiln with length of 10 to 50meters, and hearth sectional area of 0.06 to 0.3m<2>. The kiln comprises a main kiln body, a microwave transmission system, a turning channel mechanism, a roller power system, and a kiln door interlocking opening and closing system; the main kiln body is formed by connecting a water draining section, a preheating section, a sintering section, a heat preservation section, a quick cooling section, and a slow cooling section in turn; the turning channel mechanism is mainly formed by a material loading and unloading section and a residual-heat utilization blank drying section and comprises a turning channel, a turning channel roller, and a power system; the power system can poke a pushing plate from the outlet of the main kiln body onto the turning channel and feed the pushing plate into the inlet of the main kiln body through the residual-heat utilization blank drying section; and an inner roller for transmitting the material pushing plate, which is driven by the roller power system, is arranged on the bottom of an inner cavity of the main kiln body. The closed microwave high-temperature sintering roller kiln saves energy and reduces consumption and is environmental-friendly, the shrinkage of the sintered products is consistent and the sintered products have high size consistency, the yield is high, the production efficiency is high and the production cost is low.

Owner:湖南航天有限责任公司

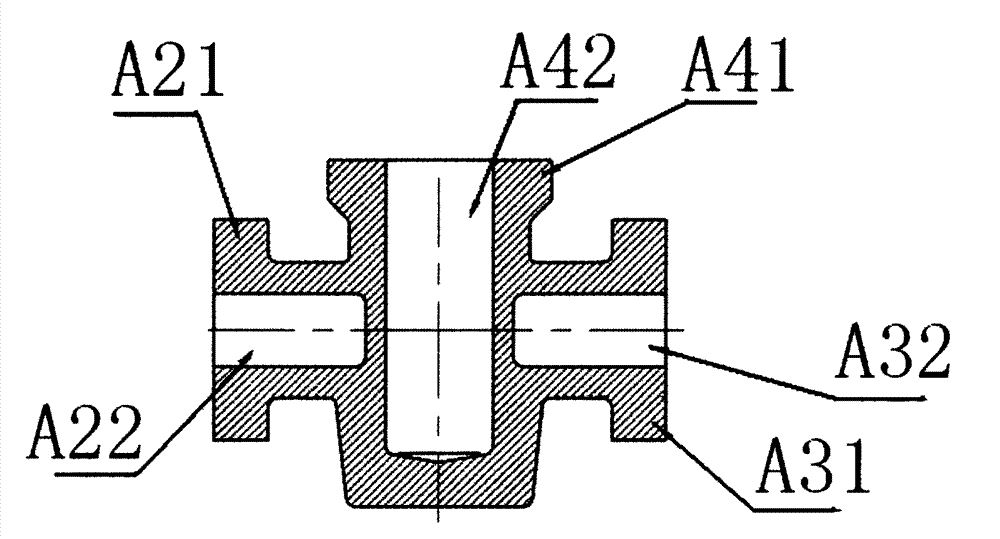

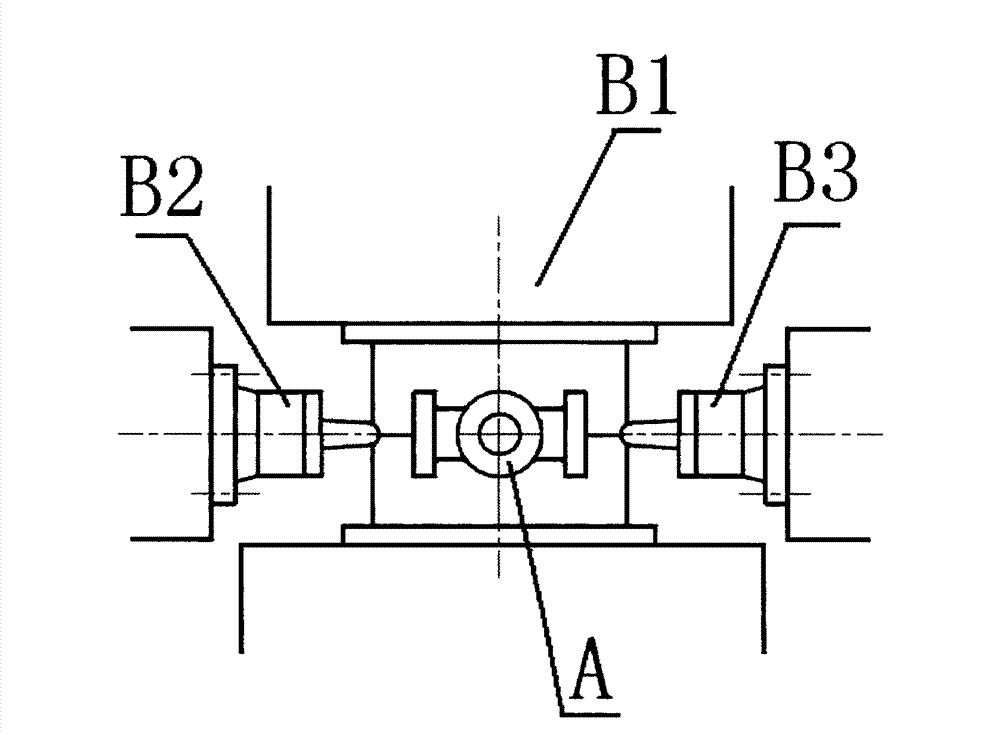

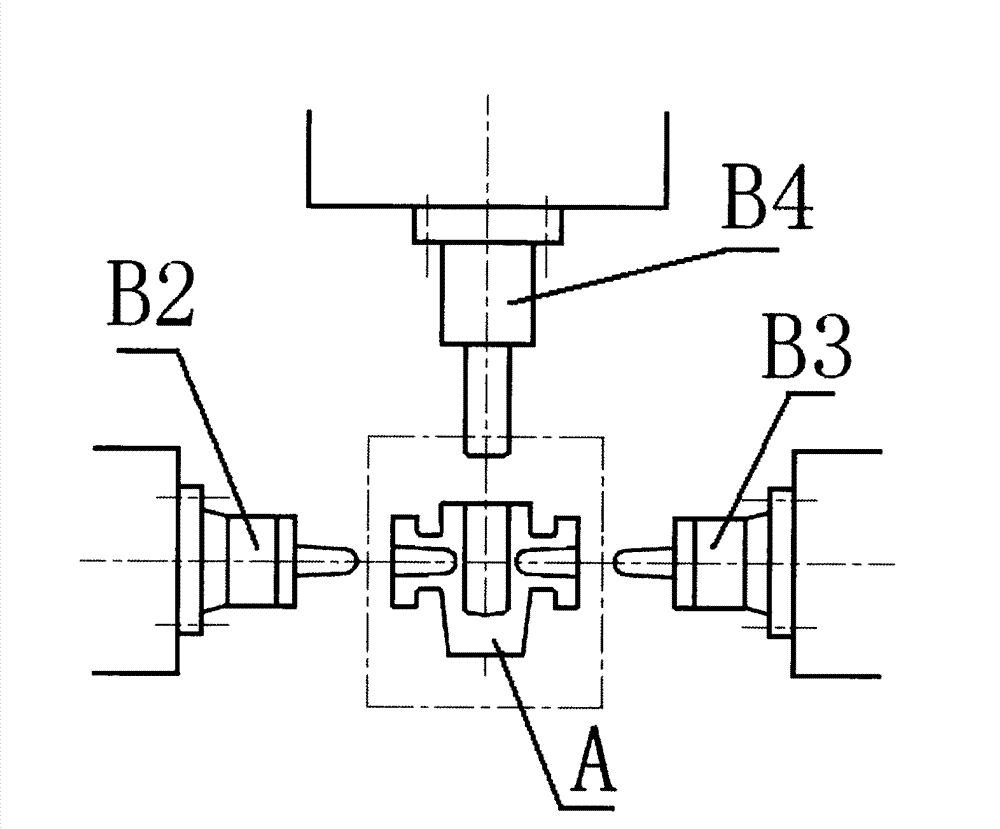

Full-closed multi-way integral die-forging forming process for large-size valve bodies

ActiveCN102873239AIncrease profitImprove machine efficiencyValve arrangementsMetal-working apparatusFiberEngineering

The invention discloses a full-closed multi-way integral die-forging forming process for large-size valve bodies. The full-closed multi-way integral die-forging forming process is characterized by sequentially including steps of blanking, heating, descaling, making blanks, multi-way die-forging forming, heat insulating and slow cooling. The step of multi-way die-forging forming includes that hydraulic systems of a back press, a left press and a right press are communicated mutually and apply force jointly to squeeze workpieces from all sides in a closed manner so as to complete die-forging forming of integral structures of valve bodies. By the full-closed multi-way integral die-forging forming process for the large-size valve bodies, the integral structures, including three-way flanges and three-way inner bores, of the valve bodies, can be finished by one die-forging process, a process of residue flash removal is omitted, defects of the prior art are overcome, utilization rate of raw materials is increased by at least 20% effectively, machining efficiency is increased by at least 60%, full-fiber die-forging forming of metal is also realized, comprehensive mechanical performance of products is improved, and product quality is guaranteed.

Owner:JIANGSU LONGSHENG DRILLING MACHINERY MFG

Continuous annealing method of DC01 steel plate with low yield and high tensile strength for automobiles

The invention relates to a continuous annealing method of DC01 steel plate with low yield and high tensile strength for automobiles, belonging to the field of metallic materials processing. The chemical composition of the steel plate is as follows by mass percentage: 0.02-0.04% of C, 0.2-0.35% of Mn, less than or equal to 0.03% of Si, less than or equal to 0.010% of P, less than or equal to 0.010% of S, 0.02-0.06% of Als, 0.0020-0.0050%of N, and the rest being Fe. The hot rolling parameter is as follows: heating temperature at 1250+ / -30 DEG C; finishing temperature at 930+ / -20 DEG C; coiling temperature at 730+ / -20 DEG C; cold rolling reduction ratio being controlled at 75-85%; soaking time for 50-100s; annealing temperature at 780+ / -20 DEG C; outlet temperature of the slow-cooling section at 675+ / -20 DEG C; outlet temperature of the rapid-cooling section at 400+ / -20 DEG C; overaging temperature at 350+ / -20 DEG C; and level elongate ratio being 0.9+ / -0.3%. The generated steel plate has the advantages of low yield strength, high tensile strength, fine formability, high product quality and considerable economic benefit.

Owner:SHOUGANG CORPORATION

High strength low yield ratio welding structure steel and production method thereof

The invention belongs to welded structural steel with high strength and low yield ratio and a production method thereof, aiming at solving the defects that a steel plate or a steel coil with the specification smaller than 25mm can only be produced, the process is long, and the like. The invention adopts the measures that the welded structural steel contains chemical components by weight that: 0.04-0.10 percent of C, 0.60-2.00 percent of Si, 1.50-2.50 percent of Mn, less than or equal to 0.030 percent of P, less than or equal to 0.010 percent of S, 0.20-0.50 percent of Cu, 0.40-0.80 percent of Cr, 0.35-0.80 percent of Ni, 0.0008-0.0030 percent of B, and at least three of the following components: less than or equal to 0.60 percent of Mo, 0.015-0.060 percent of Nb, 0.030-0.120 percent of V, less than or equal to 0.030 percent of Ti, less than or equal to 0.040 percent of Als and less than or equal to 0.010 percent of Zr, and the rest is Fe and unavoidable impurities; and meanwhile, Mn and Cr also need to satisfy the condition that Mn and Cr are equal to 2.20-2.80 percent, and the welding cold crack sensitivity coefficient Pcm is equal to C plus Si / 30 plus (Mn plus Cu plus Cr) / 20 plus Mo / 15 plus Ni / 60 plus V / 10 plus 5B and is less than or equal to 0.30 percent; the production method comprises the following steps of heating a steel billet, rough rolling, finishing rolling, relaxing and laminar cooling, and the laminar cooling comprises the following steps of slow cooling, quick cooling and natural cooling to room temperature.

Owner:武钢集团有限公司

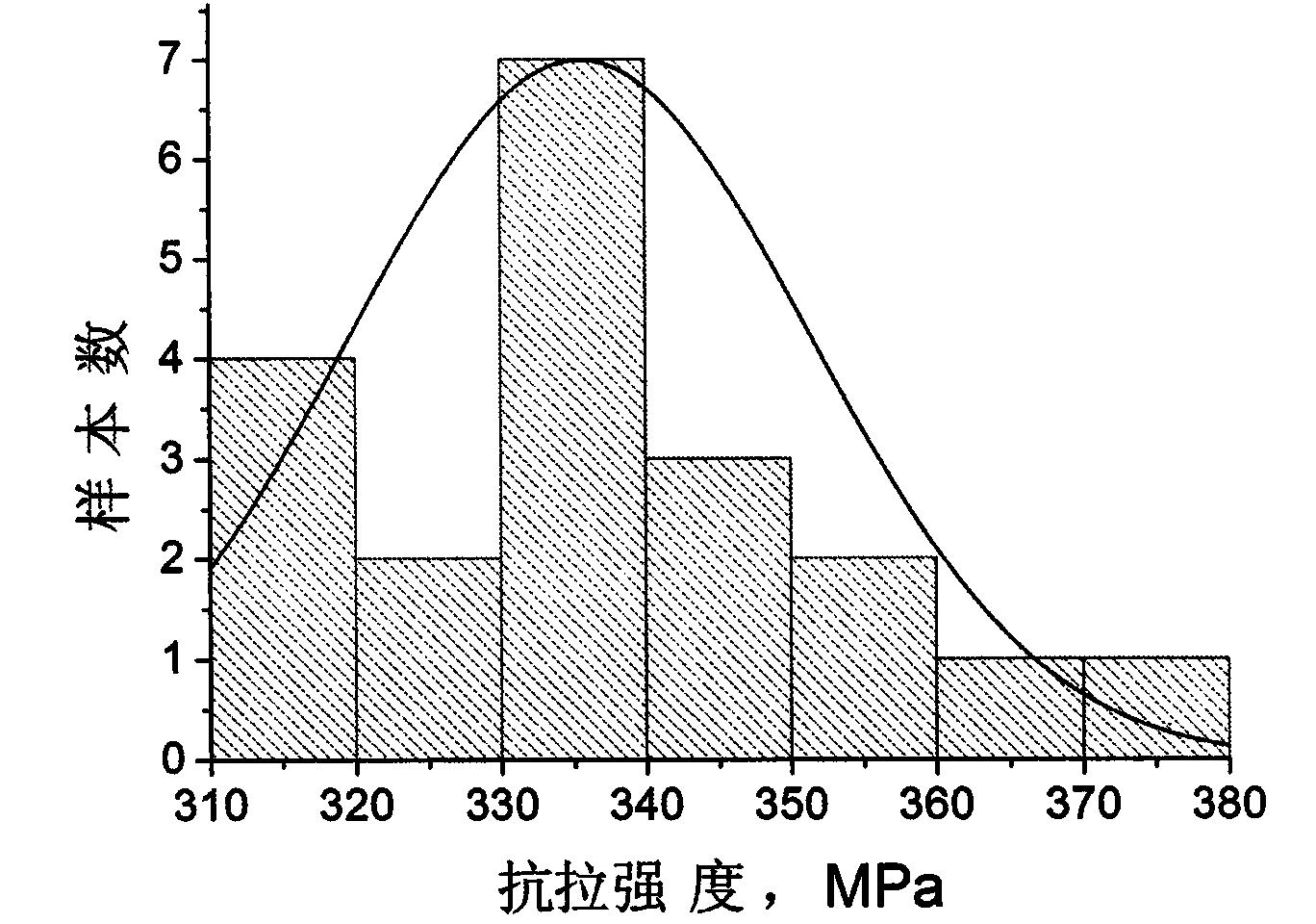

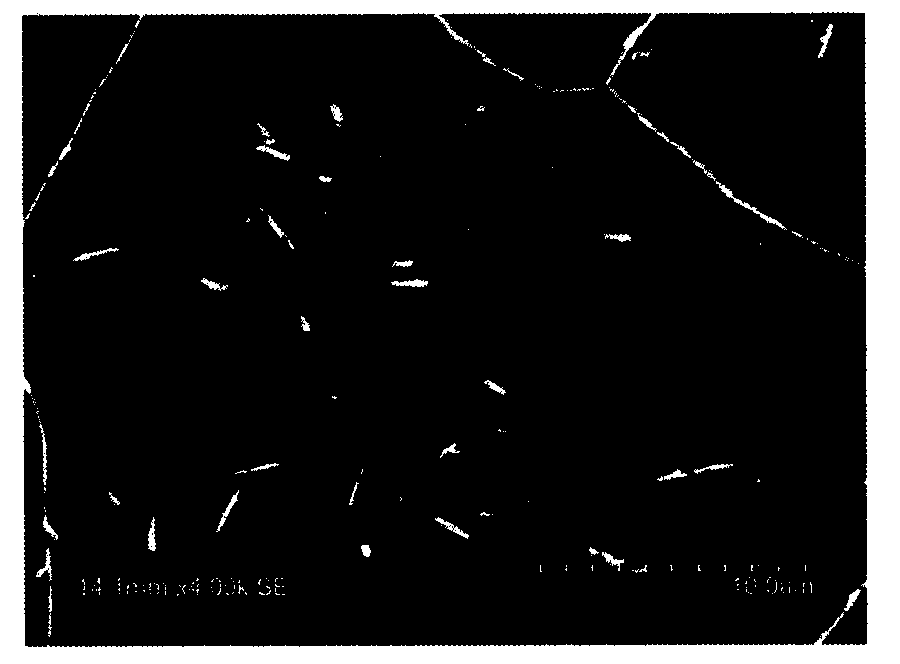

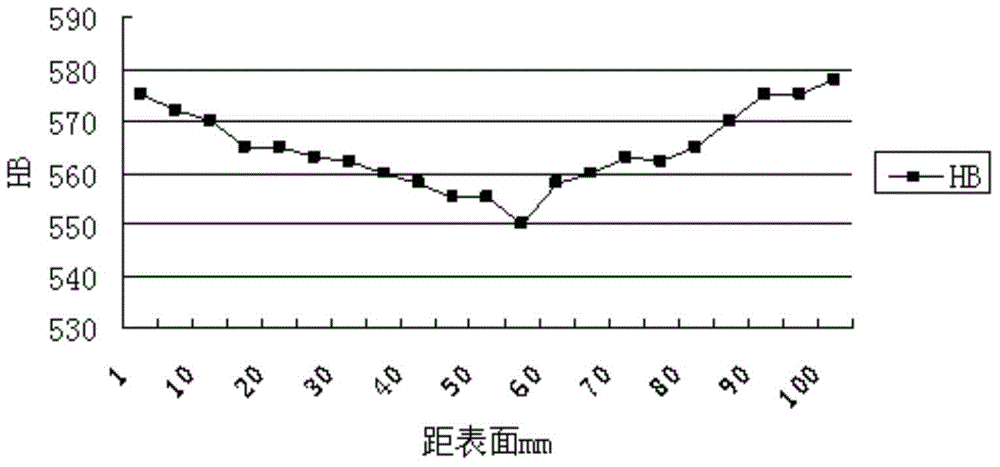

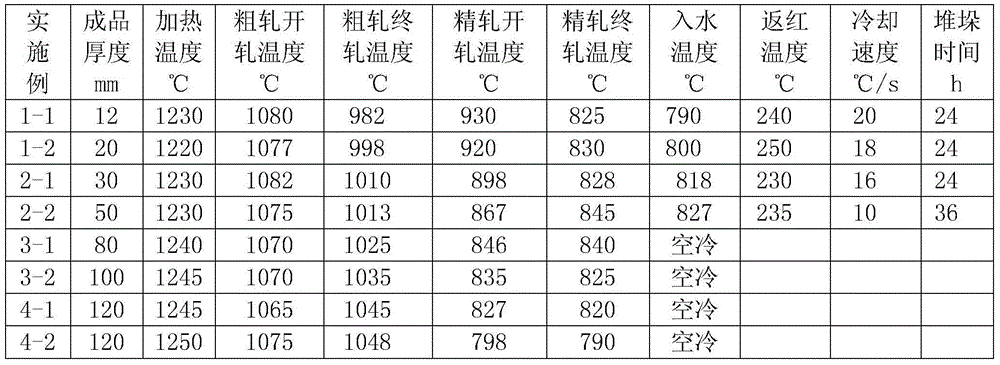

High-strength abrasion-resisting steel plate and production method thereof

The invention provides a high-strength abrasion-resisting steel plate and a production method thereof. The chemical components of the high-strength abrasion-resisting steel plate include, by weight, 0.25-0.30% of C, 0.3-0.5% of Si, 0.40-1.00% of Mn, 0.6-1.2% of Cr, 0.15-0.4% of Mo, 0.01-0.03% of Nb, smaller than or equal to 0.50% of Ni, smaller than or equal to 0.50% of Cu, 0.0005-0.0022% of B, 0.025-0.04% of Ti, 0.020-0.045% of Als, smaller than or equal to 0.015% of P and smaller than or equal to 0.005% of S, wherein Ti / N is greater than or equal to 3.4. During refining, molten steel [N] is controlled to be smaller than or equal to 0.0080%, [O] is controlled to be smaller than or equal to 0.0020%, it is ensured that the effective boron content is 0.0010-0.0020%, and stacking for slow-cooling is performed for 48 hours or more after continuous casting. Two-stage rolling control is adopted, the finish rolling temperature at the first stage is 980-1050 DEG C, out-line quenching is conducted on plate blanks with the thickness greater than 50 mm at the second stage, swinging is performed at the low-pressure section of a quenching machine, on-line quenching is conducted on plate blanks with the thickness smaller than or equal to 50 mm, and residual heat is utilized to perform self tempering. The high-strength abrasion-resisting steel plate has lower carbon and manganese contents and good weldability, the surface hardness is greater than 550 HB, and the toughness at the low temperature of -40 DEG C is greater than 30 J, and the maximum thickness can be up to 120 mm.

Owner:ANGANG STEEL CO LTD

High-strength and high-plasticity dual-phase steel and manufacturing method thereof

Owner:SHOUGANG CORPORATION

Processing method of high-strength low-shrinkage nylon 6 fine denier filament

InactiveCN102181951ALow dry heat shrinkageArtificial filament heat treatmentStretch-spinning methodsBreaking strengthNitrogen

The invention discloses a processing method of a high-strength low-shrinkage nylon 6 fine denier filament, belonging to the technical field of nylon filament processing. The method comprises the following steps: preparing materials: adding the nylon 6 slices into a bin of nitrogen protective gas to obtain a material to be melted; melting: introducing the material to be melted into a screw extruder for melting to obtain a melt; forming: introducing the melt from the upper part of a spinning box, and ejecting from a spinneret orifice of a spinneret plate to obtain a filament bundle; cooling: introducing the filament bundle into a slow-cooling area for slow cooling, forming through side-blowing air cooling, and further cooling through a channel; oiling and pre-interlacing: oiling the cooling-formed filament bundle through an oil lip or oil wheel, and pre-interlacing; drafting: feeding the filament bundle to be drafted through a feeding roller, drafting through a heat roller, and then performing relax-type setting to obtain the drafting-set filament; and re-interlacing and re-oiling: re-interlacing and re-oiling the drafting-set filament before packaging to obtain the high-strength low-shrinkage nylon 6 fine denier filament. The method can adapt to different purposes of products, and can be applied to the occasions having rigorous requirements on the breaking strength and dry heat shrinkage.

Owner:CHANGSHU POLYESTER

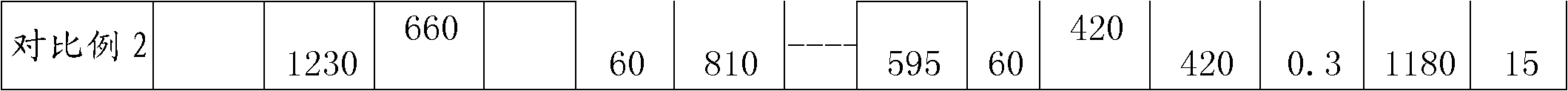

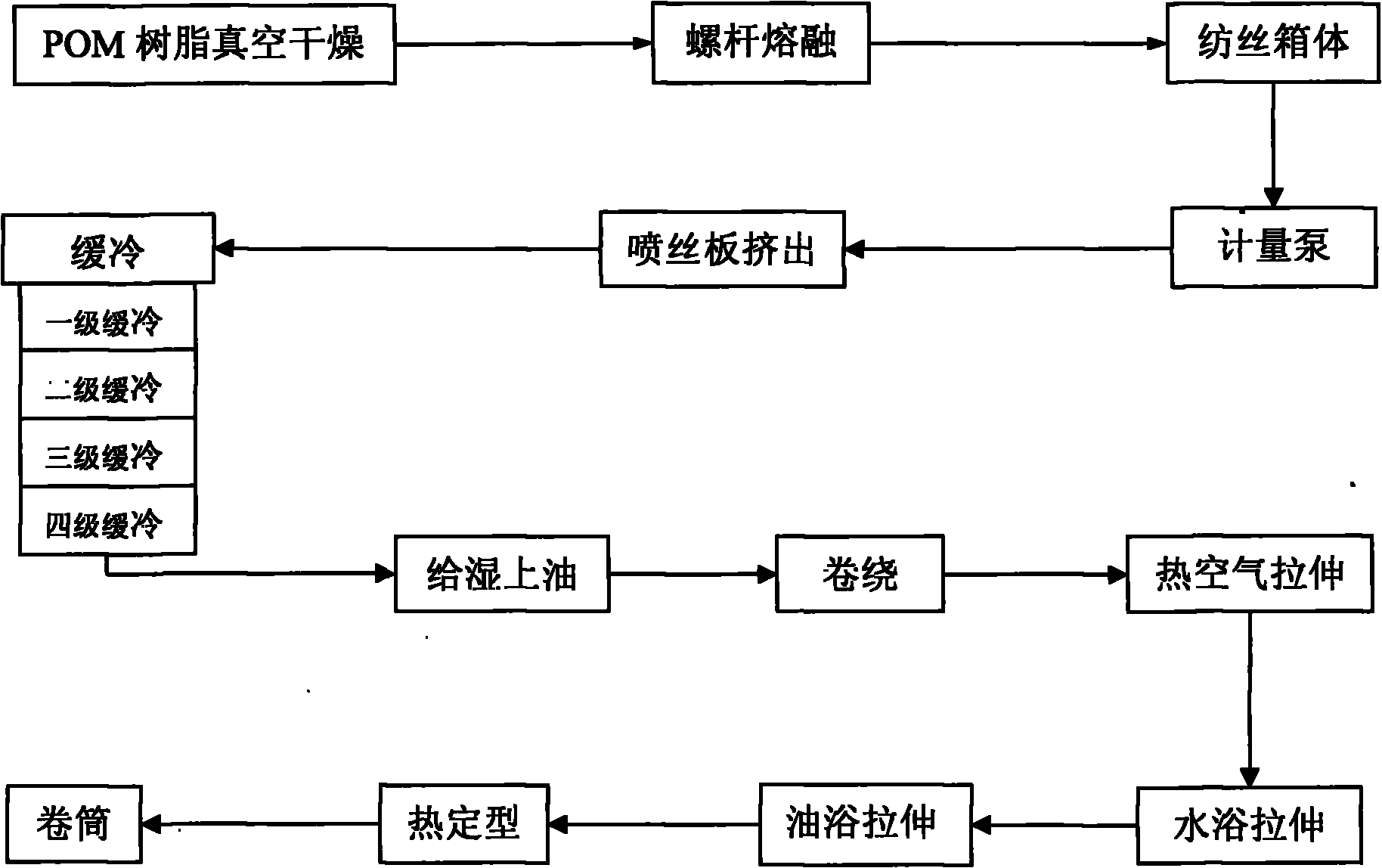

Novel preparation technology of polyoxymethylene fiber

InactiveCN101792938AStable structureReduce swellingArtificial filament heat treatmentStretch-spinning methodsFiberSolvent

The invention relates to a novel preparation technology of polyoxymethylene fiber, in particular to the novel preparation technology of the polyoxymethylene fiber via multi-stage slow cooling and three-stage drawing with different media, which comprises the following steps: vacuum-drying polyoxymethylene granular materials, heating and melting via a screw extruder, melting and extruding by a spinneret, leading small melt flow to pass through the multi-stage slow cooling, carrying out high-speed traction, passing through a moistening and oiling cluster, winding, then obtaining as-spun fiber, carrying out hot air drawing and two times of drawing with different types of solvent, then carrying out hot molding and finally preparing the polyoxymethylene fiber. The novel prepration technology can solve the problems of matching between the multiple sections of atmosphere and temperature and the spinning process control and the control of the drawing with multiple media and make up for the deficiencies that the single atmosphere and temperature and the single medium drawing of the prior art lead the structure to be difficult to stable and uniform.

Owner:DONGHUA UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com