High-strength and high-plasticity dual-phase steel and manufacturing method thereof

A production method and high plasticity technology, applied to dual-phase steel with high strength and high plasticity and its production field, can solve the problems of no high plasticity, easy strip deviation, poor forming and welding performance, etc. Alloying element content, effect on assuring formability and weldability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The principles and features of the present invention are described below, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

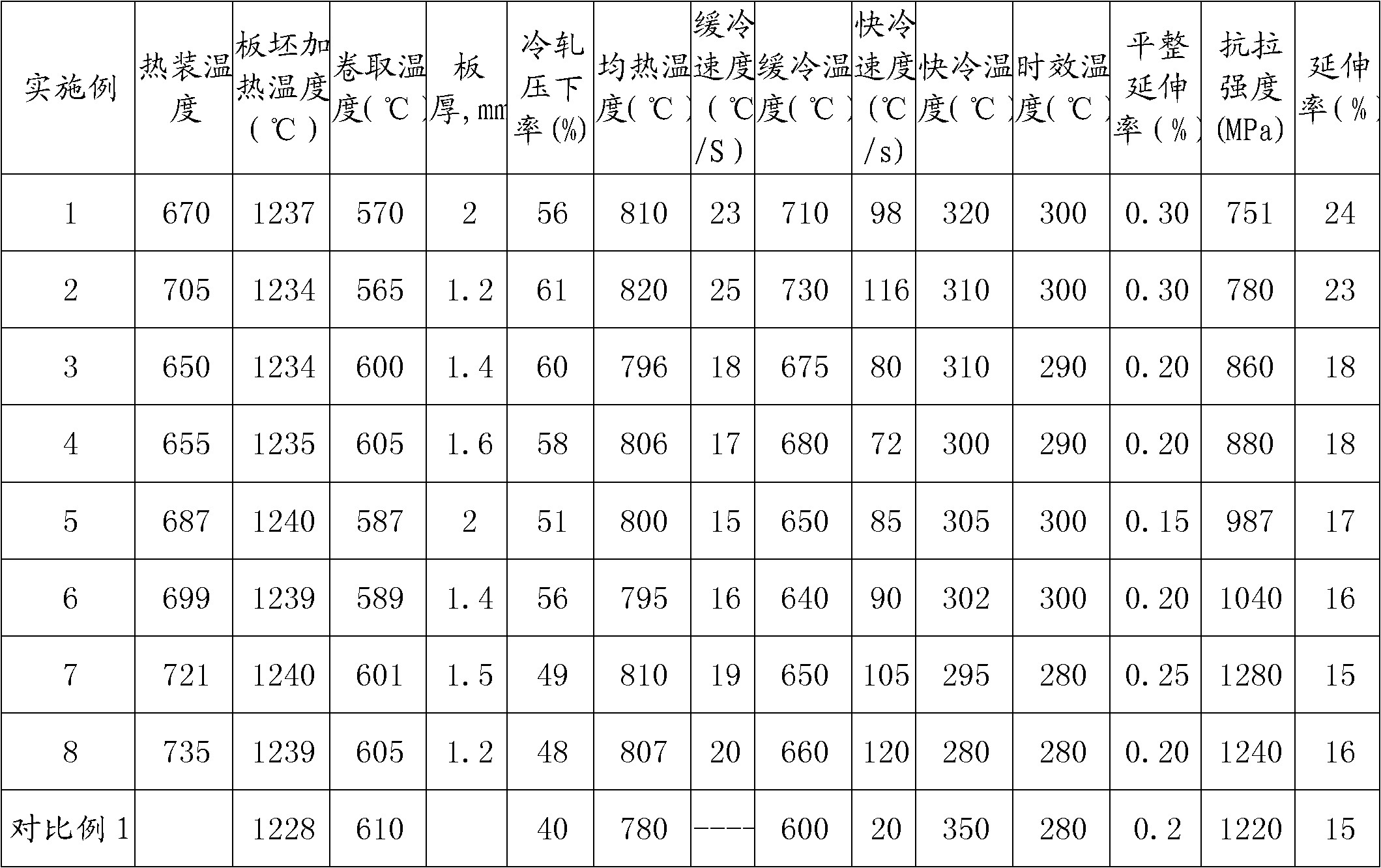

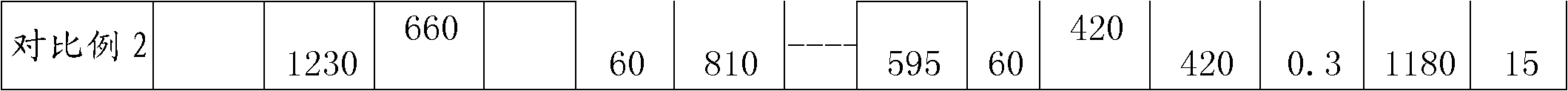

[0022] The invention improves the strength of the steel through multiple strengthening mechanisms such as phase transformation strengthening, dispersion strengthening and fine-grain strengthening, and introduces epigenetic ferrite into the ferrite plus martensite structure, and controls the epigenetic ferrite To improve the plasticity of the steel, to obtain ferrite, epitaxial ferrite and martensite with additional dispersion strengthening particles and other organizational characteristics, the tensile strength is 700-1200MPa and the elongation El is 12-25% high strength Duplex steel.

[0023] Design principle of the present invention is as follows:

[0024] The strength and plasticity of dual-phase steel mainly depend on the ferrite and martensite in the stru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com