A kind of wear-resistant liner and its preparation method

A technology of wear-resistant lining board and lining board, applied in the field of wear-resistant lining board and its preparation, wear-resistant lining board, can solve the problem of high cost, and achieve the effect of improving strength, low cost, and dispersion strengthening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

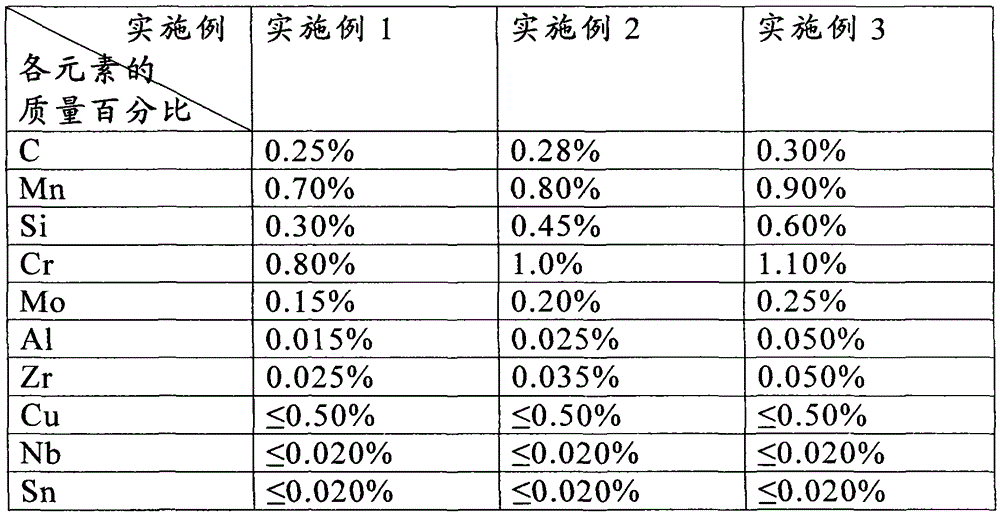

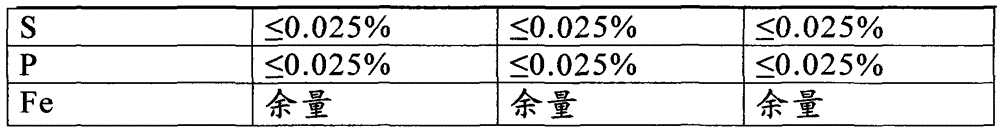

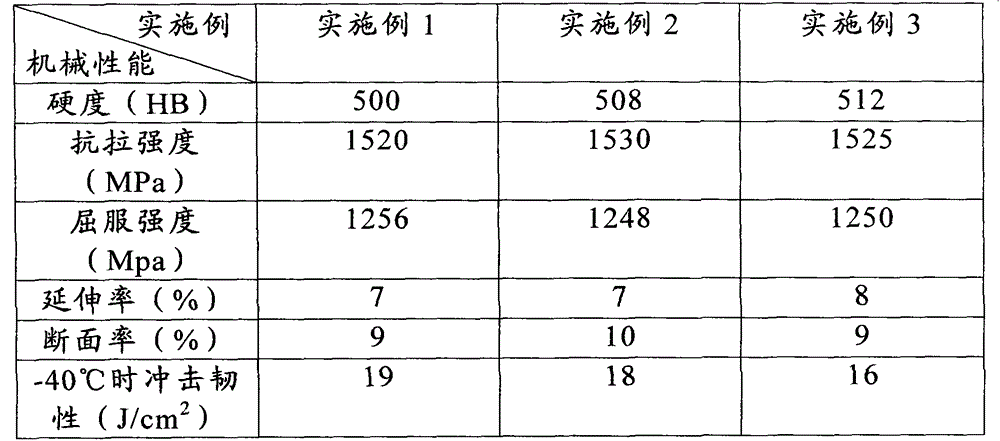

[0042] Determine the composition and mass percentage of the wear-resistant liner according to Example 1 of Table 1. The composition and mass percentage of the wear-resistant liner have a certain impact on the mechanical properties of the liner, and its preparation process has an impact on the final wear-resistant The mechanical properties of the liner also have a greater influence.

[0043] Prepare the wear-resistant liner as follows:

[0044] Raw material preparation: prepare raw materials according to the composition elements and mass percentages of the wear-resistant lining plate described in Example 1 in Table 1.

[0045] Casting: smelting the above-mentioned prepared raw materials and pouring molding at a temperature of 1520°C to obtain a forming liner.

[0046] Riser cutting: Preheat the above forming liner at 350°C for 3 hours, then heat cut and plan.

[0047] Heat treatment: The surface of the above-mentioned heat-planed liner is polished, then normalized when the te...

Embodiment 2

[0049] Prepare the wear-resistant liner as follows:

[0050] Preparation of raw materials: Prepare raw materials according to the composition elements and mass percentages of the wear-resistant lining plate described in Example 2 in Table 1. Casting: smelting the above-mentioned prepared raw materials and pouring molding at a temperature of 1525°C to obtain a molding liner.

[0051] Riser cutting: Preheat the above-mentioned forming liner at 400°C for 4 hours, then heat cut and plan.

[0052] Heat treatment: The surface of the formed liner after the above-mentioned hot planing is polished, and then normalized when the temperature is raised to 980 ° C, and the temperature is kept for 3 hours after normalizing. Quenching is carried out when the temperature is 940°C. After quenching, it is kept for 2 hours, and then it is taken out of the furnace and air-cooled. Temper at a temperature of 210°C, and keep warm for 3 hours after tempering to obtain a finished wear-resistant linin...

Embodiment 3

[0054] Prepare the wear-resistant liner as follows:

[0055] Preparation of raw materials: Prepare raw materials according to the composition elements and mass percentages of the wear-resistant lining plate described in Example 3 in Table 1. Casting: smelting the above-mentioned prepared raw materials and pouring molding at a temperature of 1530°C to obtain a forming liner.

[0056] Riser cutting: Preheat the above-mentioned forming liner at 480°C for 4 hours, then heat cut and plan.

[0057] Heat treatment: The surface of the above-mentioned hot-planed liner is polished, then normalized when the temperature is raised to 990°C, and kept for 4 hours after normalizing. Quenching is carried out when the temperature is 950°C. After quenching, it is kept for 3 hours, and then it is taken out of the furnace and air-cooled. Temper at a temperature of 220°C, and keep warm for 4 hours after tempering to obtain a finished wear-resistant lining.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com