Patents

Literature

537results about How to "Guaranteed welding effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-strength cold-rolled hot-galvanized precipitation reinforced steel and manufacturing method thereof

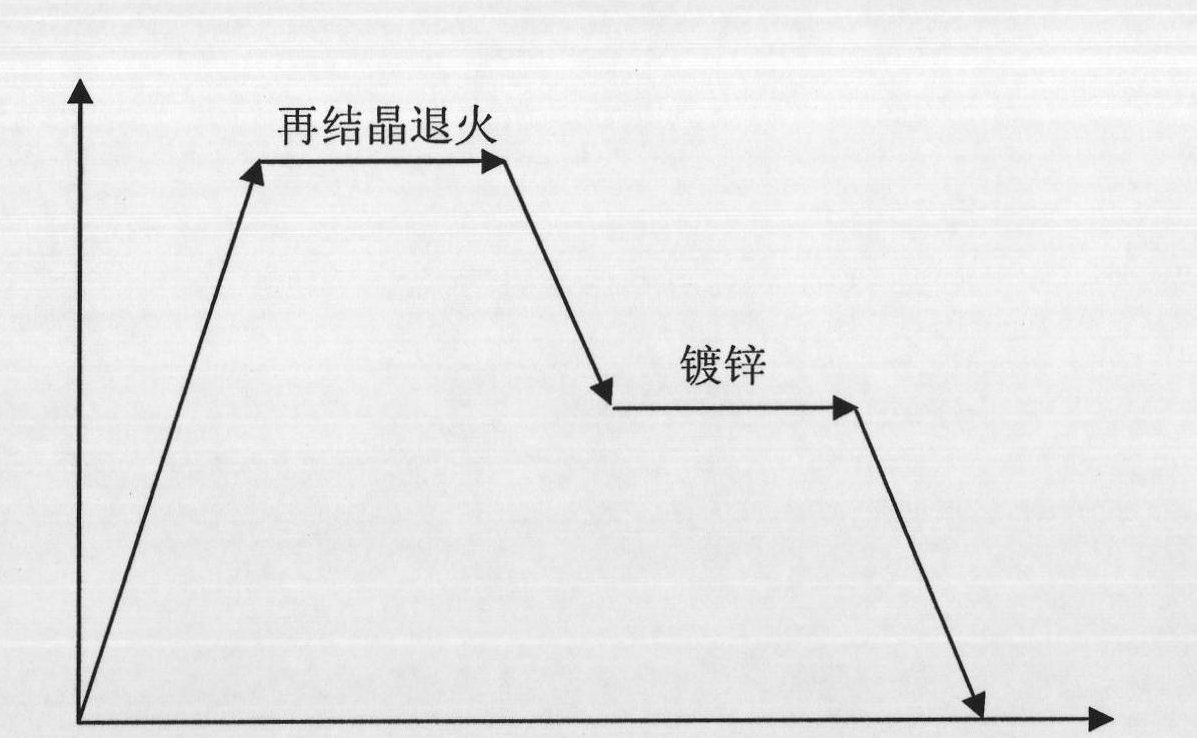

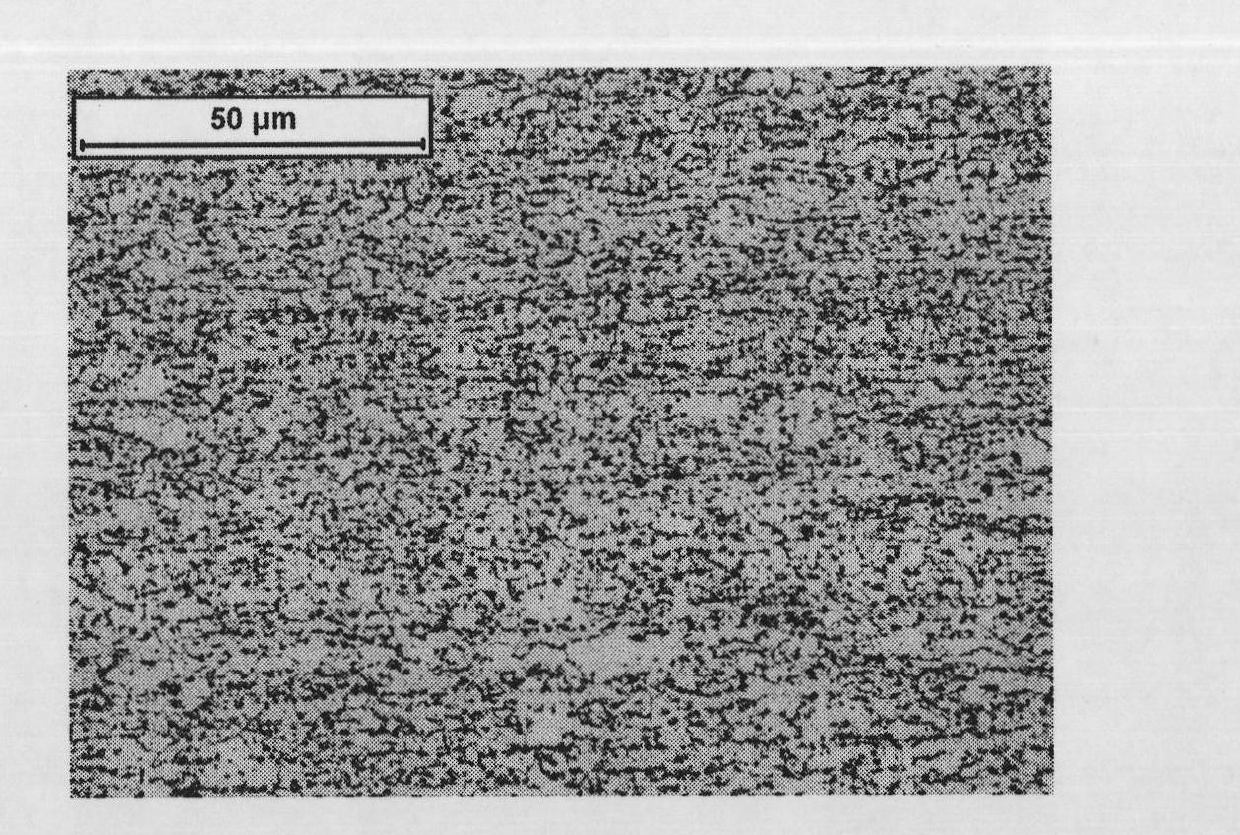

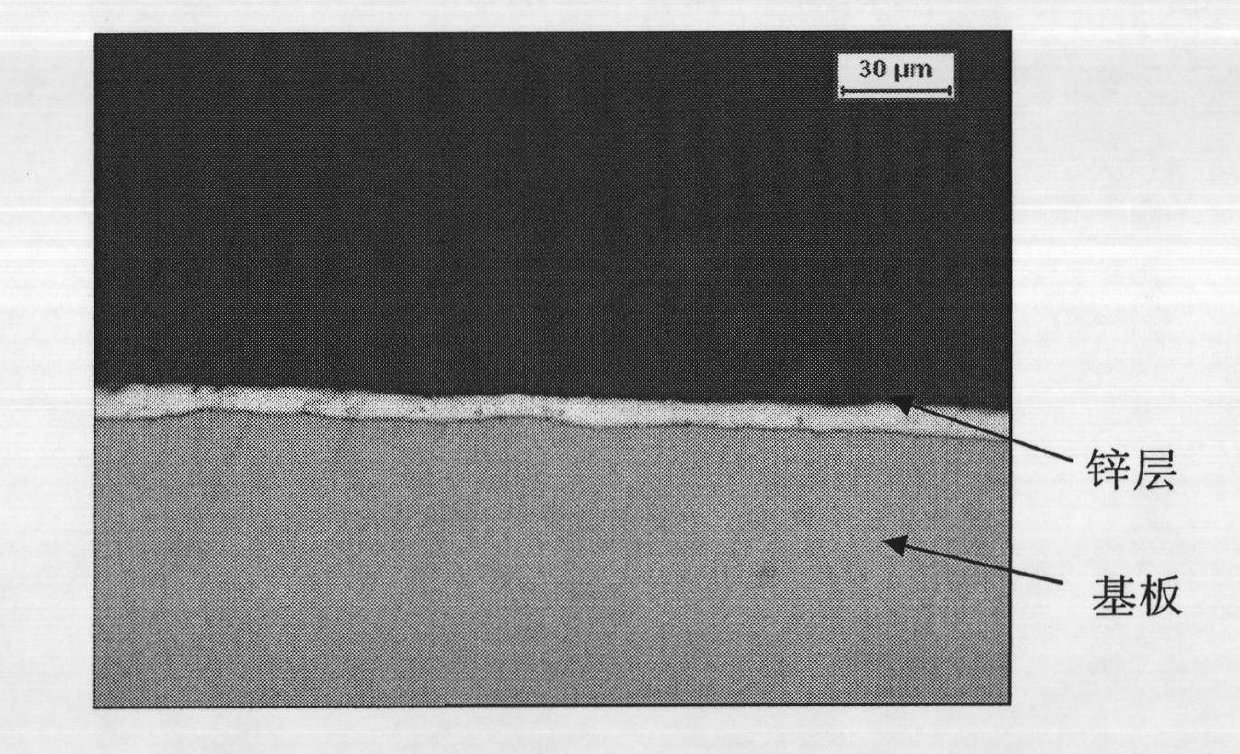

ActiveCN102199723AGood welding performancePremium surface qualityTemperature control deviceMetal rolling arrangementsSheet steelImpurity

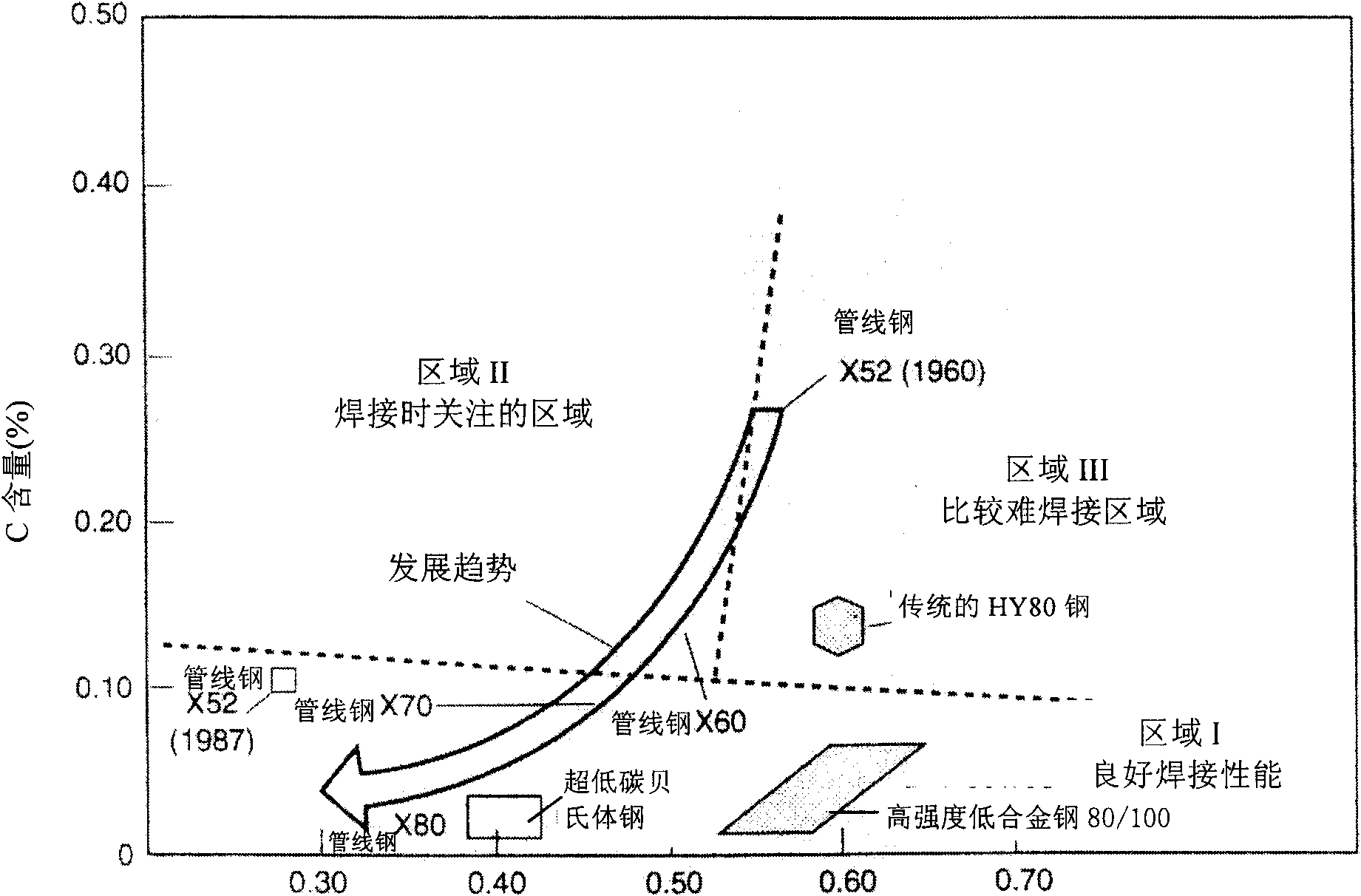

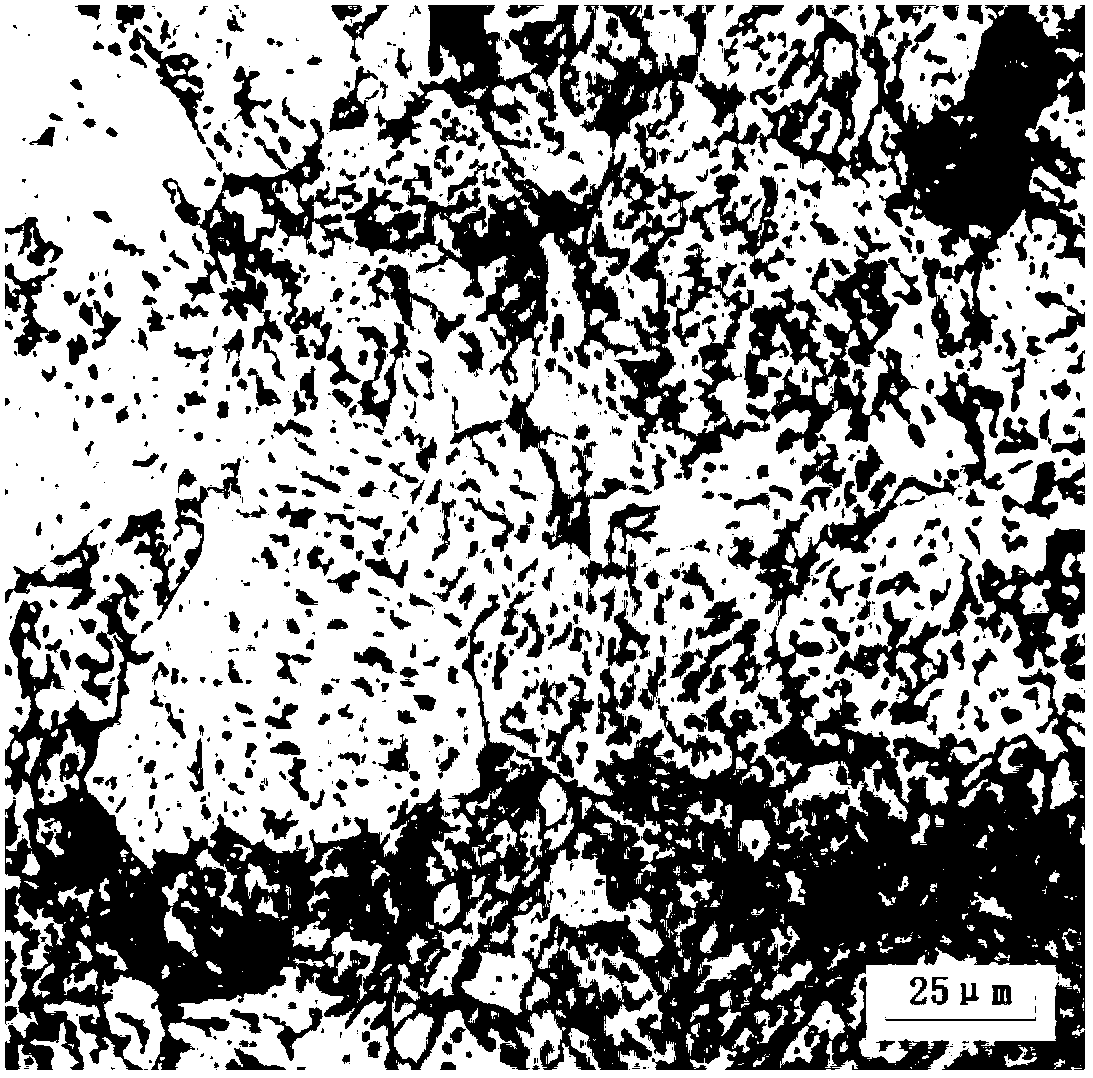

The invention discloses a high-strength cold-rolled hot-galvanized precipitation reinforced steel plate and a manufacturing method thereof. The steel plate comprises the following components: 0.09 to 0.12 weight percent of C, less than or equal to 0.05 weight percent of Si, 0.8 to 1.8 weight percent of Mn, less than or equal to 0.02 weight percent of P, less than or equal to 0.01 weight percent of S, less than or equal to 0.008 weight percent of N, 0.02 to 0.06 weight percent of Al, 0.05 to 0.08 weight percent of Nb and Ti and the balance of Fe and inevitable impurities. The microstructure ofthe steel plate is ferrite and second phase particles, wherein the diameter of the second phase particles is about less than 6 mu m, the yield strength is 500 to 600MPa, the tensile strength is 570 to 710MPa, and the total coefficient of elongation is over 14 percent (80 gauge length and transverse stretching). The hot-galvanized steel plate has high welding performance and surface quality and can be widely used in automotive structural membranes.

Owner:BAOSHAN IRON & STEEL CO LTD

Marine 40kg heat mechanical control rolling thick plate steel and manufacturing method thereof

InactiveCN101781737ASimple configuration of ingredientsReduce manufacturing costThick plateChemical composition

The invention discloses a TMCP-type F40 steel with excellent low-temperature toughness and a manufacturing method thereof. The TMCP-type F40 steel comprises the following chemical components in percentage by weight: 0.010-0.12 percent of C, 0.3-2.0 percent of Mn, less than 0.6 percent of Si, less than 0.0030 percent of S, less than 0.015 percent of P, 0.010-0.120 percent of Nb, 0.005-0.030 percent of Ti, less than 0.120 percent of V, less than 0.060 percent of Al, less than 0.60 percent of Mo, less than 1.2 percent of Cu, less than 1.5 percent of Ni, less than 1.2 percent of Cr, less than 0.0040 percent of B, less than 0.01 percent of Ca, 0.003-0.010 percent of N, 0.001-0.006 percent of O, less than 0.0001 percent of Mg, and the balance of Fe and other inevitable impurities. The manufacturing method comprises the steps of smelting by a revolving furnace or an electric furnace, external refining, casting, slabs reheating as well as rolling control and cooling control. The product has excellent toughness, intensity and welding performance.

Owner:BAOSHAN IRON & STEEL CO LTD

Manufacture method of extremely-thick steel plate for hydropower station through continuous-cast billet

ActiveCN103014283AUniform and stable impact toughnessMeet welding performance requirementsMetal rolling arrangementsDie castingQuenching

The invention provides a manufacture method of an extremely-stick steel plate for a hydropower station through a continuous-cast billet, and belongs to the technical field of production of continuous-cast steel plates. The manufacture method comprises the technological processes of continuous casting, rolling, cooling after rolling, austenite quenching, subcritical quenching and high-temperature tempering, thus a composite-phase structure of ferrite, acicular ferrite, small granular bainite and small residual bainite can be formed in the core part of the steel plate after the high-temperature tempering. The manufacture method has the advantages that the extremely-thick steel is given the same performance as the thin steel plate under the combination and organizational control of heat treatment process based on the smaller proportion; and compared with the methods of die casting and forging, the manufacture method provided by the invention is simple, convenient, easy to carry out and high in yield, and reduces the producing cost.

Owner:SHOUGANG CORPORATION

Cold rolled coil strapping steel having tensile strength of 940MPa or more, and production method thereof

InactiveCN103352165ALow costReduce energy consumption and pollutionFlexible elementsProcess efficiency improvementAlloy elementStrapping

Cold rolled coil strapping steel having a tensile strength of 940MPa or more comprises 0.10-0.22wt% of C, 0.8-1.5wt% of Mn, 0.01-0.03wt% of Si, 0.020wt% or less of P, 0.020wt% or less of S, 0.020-0.070wt% of Als, and the balance Fe and residual elements. The cold rolled coil strapping steel has the advantages of no containment of alloy elements comprising Nb, Ti or V, low cost, small energy consumption and pollution, simple operation, and suitableness for the large-batch industrial production, and follows low carbon and environmental protection ideas. The strapping steel has a tensile strength of 940MPa or more, an elongation rate of 9% or more, and an alternating bending frequency of 4 or more (R=2.5mm), has no brittle fracture layering phenomenon, and has a flexibility of 25.4mm / 2.4m or less and a camber of 2.0mm / m or less.

Owner:武汉钢铁有限公司

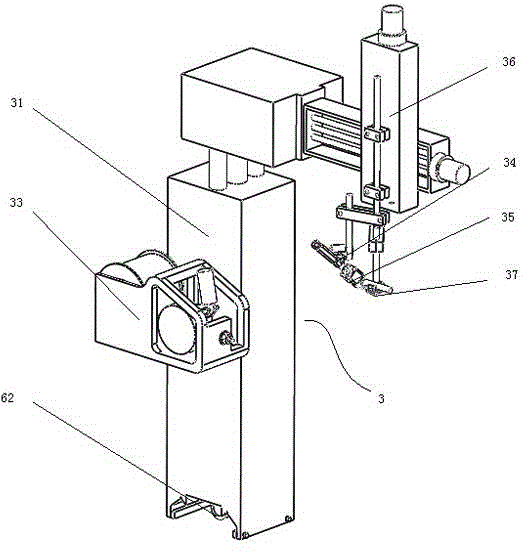

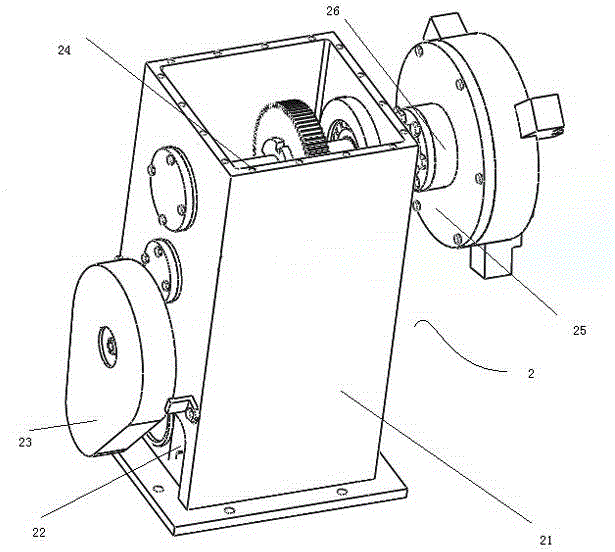

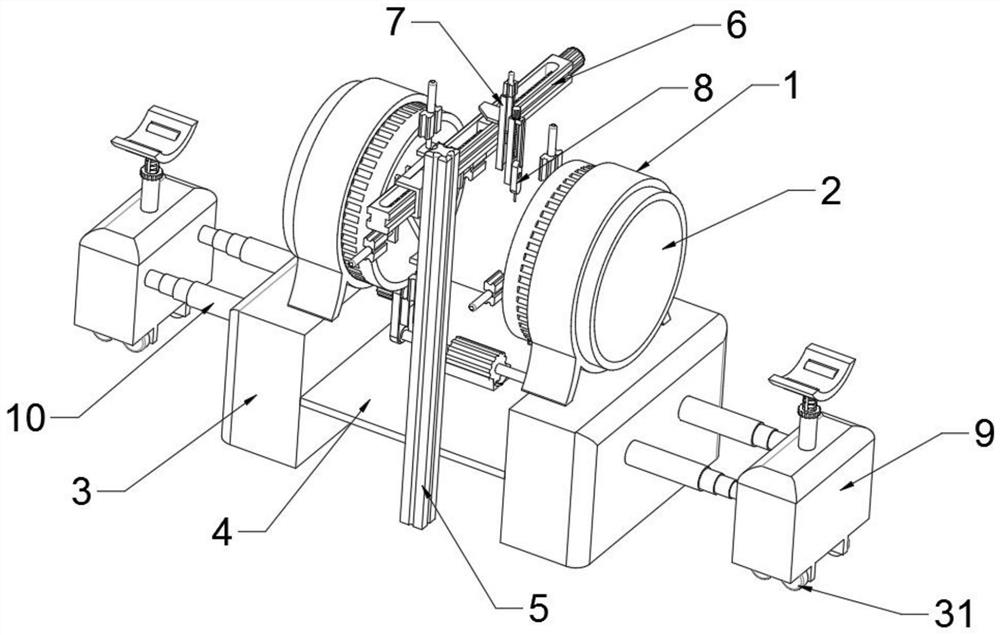

Automatic assembly machine of round capacitor

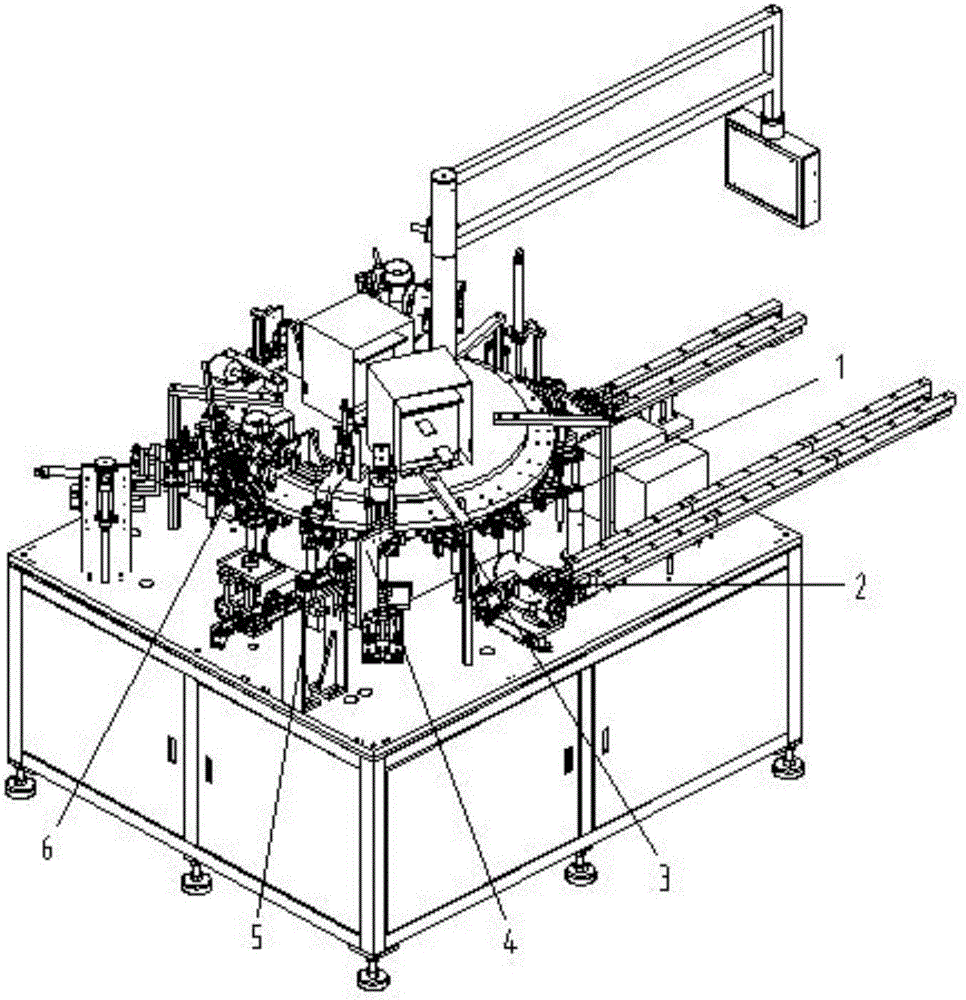

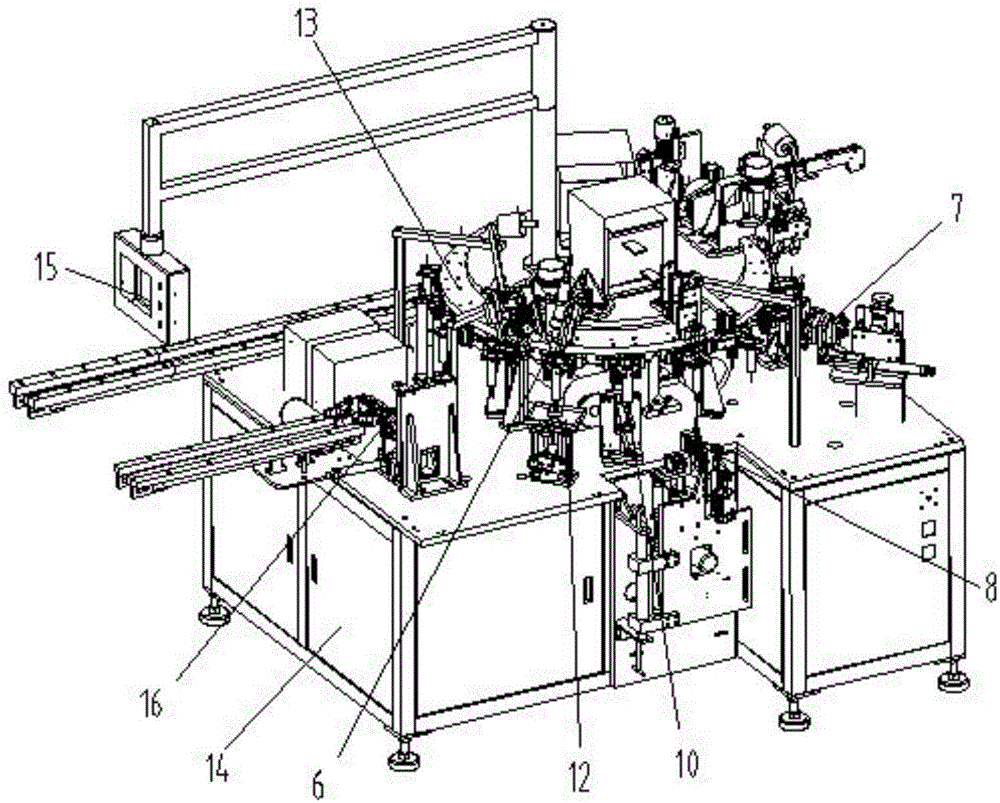

ActiveCN106847558ARealize automatic flipImprove welding efficiencyTerminal applying apparatusCapacitanceDistribution control

The invention relates to the field of capacitor processing equipment, in particular to an automatic assembly machine of a round capacitor. The machine includes a power distribution control box, a rotary plate and an operation screen, wherein the rotary plate and the operation screen are arranged above the power distribution control box through a bracket and communicated with the power distribution control box; clamps are uniformly arranged along a circle under the rotary plate; a feeding device, a positioning detection device, an upper tin-wire feeding device, a polarity detection device, a first tin-wire welding device, a capacitor turnover device, a lower tin-wire feeding device, a second tin-wire welding device and a discharging device are arranged in sequence on the outer side of the rotary plate in the clockwise direction and connected with the power distribution control box. The automatic assembly machine of the round capacitor has the advantages that automatic operation is adopted from feeding to discharging, the processing accuracy and processing efficiency of the round capacitor are greatly improved, and a large amount of working time is saved.

Owner:天长市中发电子有限公司

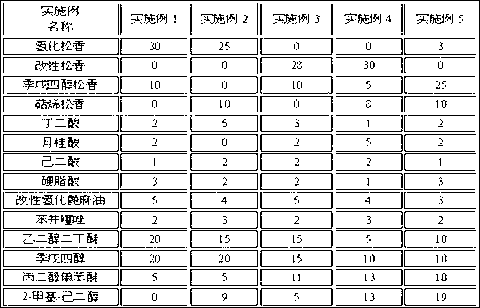

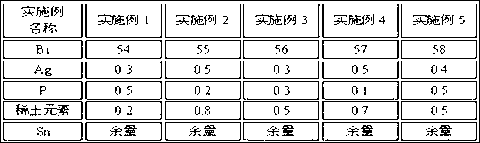

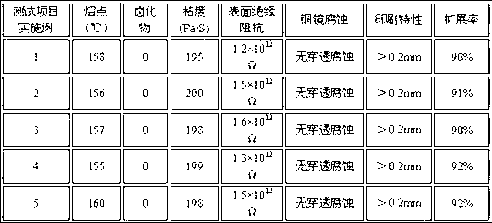

Low-temperature halogen-free lead-free solder paste

InactiveCN102990242AStir wellLow melting pointWelding/cutting media/materialsSoldering mediaRare-earth elementSlag (welding)

The invention relates to a low-temperature halogen-free lead-free solder paste. The solder paste is mixed by Sn-Ag-Bi-based lead-free solder powder added with P or rare earth elements and a rosin-based soldering flux. The soldering flux is basically composed of, by weight, 30-45% of rosin resin, 2-10% of an organic acid activator, 3-5% of a thixotropic agent, 2-5% of a corrosion inhibitor, 3-5% of a surfactant and the balance solvents. The solder paste has the advantages that the welding temperature is low, slag is reduced, and the solder paste is suitable for manual welding and printing welding with poor thermal shock resistance.

Owner:郴州金箭焊料有限公司

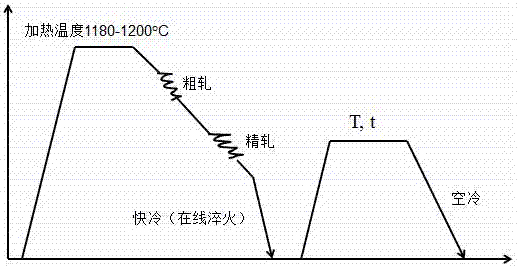

Method for producing niobium-contained HRB400 grade reinforcing steel

InactiveCN101007316AGuaranteed welding effectGuaranteed mechanical propertiesTemperature control deviceMetal rolling arrangementsChemical compositionNiobium

A method of produce containing niobium HRB400 reinforcement which process flow includes: electric furnace smelting, refining, billet casting, casting blank solidification and cooling, putting it into heating-furnace, hot-rolling, air cooling, sizing and hoping. The characteristics are: control the chemical composition range of molten steel (weight%): Ceq <= 0.45%, C: 0.18 ~ 0.24%, Si: 0.40 ~ 0.65%, Mn: 1.00~ 1.50%, Nb: 0.03 ~ 0.045% , S: <= 0.045%, P: <= 0.045%, V: 0 ~ 0.035%; little billet casting tandem rolling art parameters: casting blank continuous casting aligning temperature >=950DEG C, casting blank heating temperature is 1100 ~ 1250 degree C, soakage temperatures is 1150 ~ 1230 degree C, cut temperature is 1050~1100 DEG C, free air-cooling mode. The method can be used to produce Nb microalloy and Nb,V composite microalloying HRB400 reinforcement which Ceq(carbon equivalent) <=0.45wt.%, and has high intensity, seismic behavior and weldability in the electric furnace- continuous casting-tandem rolling process.

Owner:广州工业投资控股集团有限公司

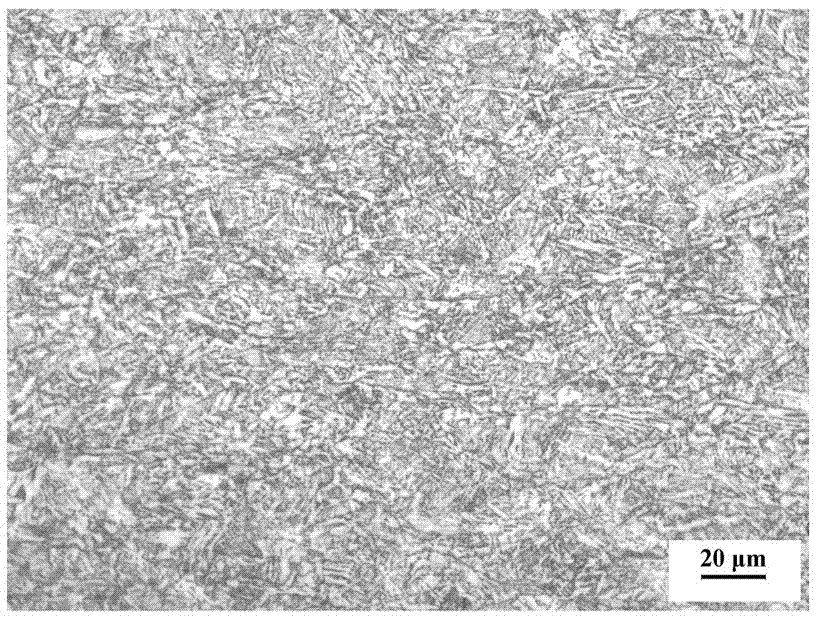

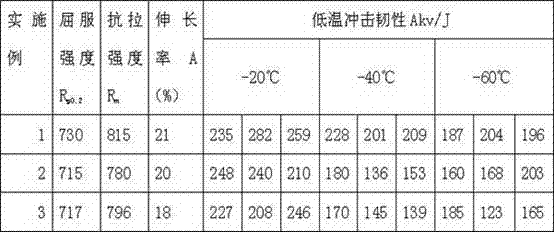

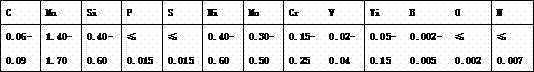

Easy-to-weld ultra-thick steel plate with high strength and high toughness suitable for minus 60 DEG C and manufacturing method thereof

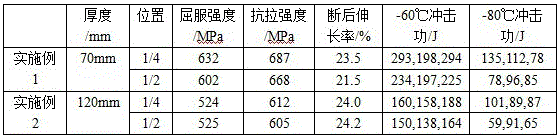

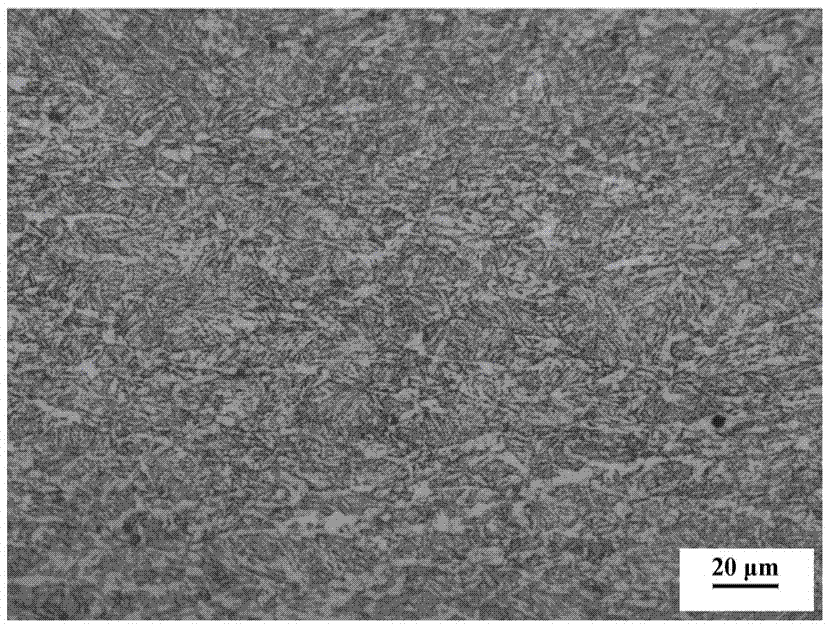

The invention relates to an easy-to-weld ultra-thick steel plate with high strength and high toughness suitable for minus 60 DEG C. The steel plate comprises the chemical ingredients of 0.05% to 0.10% of C, 0.2% to 0.3% of Si, 1.3% to 1.6% of Mn, 0.02% to 0.04% of Al, 0.03% to 0.05% of Nb, 0.03 to 0.05% of V, 0.1% to 0.3% of Cr, 0.1% to 0.4% of Ni, 0.1% to 0.3% of Mo, 0.1% to 0.3% of Cu, 0.01% to 0.02% of Ti, 0% to 0.015% of P, 0% to 0.002% of S, and 0% to 0.007% of N; the carbon equivalent is not larger than 0.43, and Pcm is not larger than 0.20. According to the steel plate, the thickness ranges from 70 mm to 120 mm, the yield strength is 460 MPa or more, and under the temperature of minus 60 DEG C, both the Charpy impact energy at the position, with the thickness one quarter that of the thickness of the steel plate, of the steel plate and the Charpy impact energy at the position, with the thickness one half that of the thickness of the steel plate, of the steel plate are larger than or equal to 100 J. The easy-to-weld ultra-thick steel plate with high strength and high toughness is made through the steps of KR hot metal pretreatment, converter smelting, ladle furnace refining, RH vacuum degassing, continuous casting, slow cooling, casting blank heating, rolling, straightening, pile slow cooling, quenching, tempering and the like.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

Steel plates for 355MPa-level easy-to-weld ocean platform and production process of steel plates

The invention belongs to the technical field of constructional steel for ships and ocean engineering and in particular relates to steel plates for a 355MPa-level easy-to-weld ocean platform and a production process of the steel plates. Two steel plates of which the thickness specifications are [6-40]mm and [40-60]mm are comprised, wherein the steel plate with the thickness specification of [6-40]mm comprises the following chemical components in percentage by mass: 0.10-0.15 percent of C, 0.20-0.50 percent of Si, 1.20-1.50 percent of Mn, not more than 0.015 percent of P, not more than 0.005 percent of S, 0.020-0.050 percent of Nb, 0.010-0.050 percent of V, 0.008-0.020 percent of Ti, 0.015-0.055 percent of Als, not more than 0.43 percent of Ceq, not more than 0.23 percent of Pcm and the balance of Fe and inevitable impurities; and the steel plate with the thickness specification of [40-60]mm comprises the following chemical components in percentage by mass: 0.10-0.15 percent of C, 0.20-0.50 percent of Si, 1.30-1.60 percent of Mn, not more than 0.015 percent of P, not more than 0.005 percent of S, 0.030-0.060 percent of Nb, 0.020-0.060 percent of V, 0.008-0.020 percent of Ti, 0.015-0.055 percent of Als, not more than 0.12 percent of Nb+V+Ti, not more than 0.43 percent of Ceq, not more than 0.23 percent of Pcm and the balance of Fe and inevitable impurities. According to the production method, the steel plates for the easy-to-weld ocean platform are produced by adopting low Ceq, low Pcm, Nb as well as V and Ti microalloy components and a normalizing heat treatment process and are lower in production cost, even in mechanical property and favorable in welding property.

Owner:JIGANG GRP

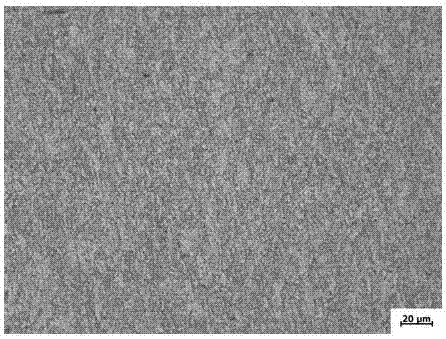

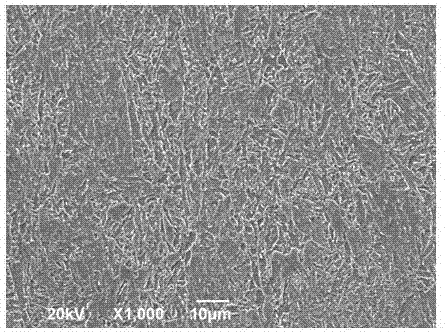

Steel plate with low welding crack sensitivity and manufacturing method thereof

InactiveCN105441790AReduce manufacturing costGood welding performanceTemperingUltimate tensile strength

The invention relates to a steel plate with low welding crack sensitivity and a manufacturing method thereof. The steel plate is composed of, by weight, 0.03%-0.09% of C, 0.20%-0.60% of Si, 1.40%-1.80% of Mn, 0-0.020% of P, 0-0.005% of S, 0.15%-0.45% of Cr, 0.03%-0.06% of Nb, 0.006%-0.04% of Ti, 0.015%-0.04% of Als, 0.0008%-0.003% of B, 0-0.04% of As, 0-0.03% of Sn, 0-0.005% of N, 0-0.003% of O, 0-0.0002% of H, and the balance Fe and inevitable impurities. By the adoption of the technologies of controlled rolling, relaxation and quick cooling, the heat treatment procedure of quenching and tempering or the heat treatment procedure of tempering or the like is not needed, the ultrafine bainite plate is obtained, and working procedure cost is reduced while strength, toughness and welding performance are guaranteed.

Owner:SGIS SONGSHAN CO LTD

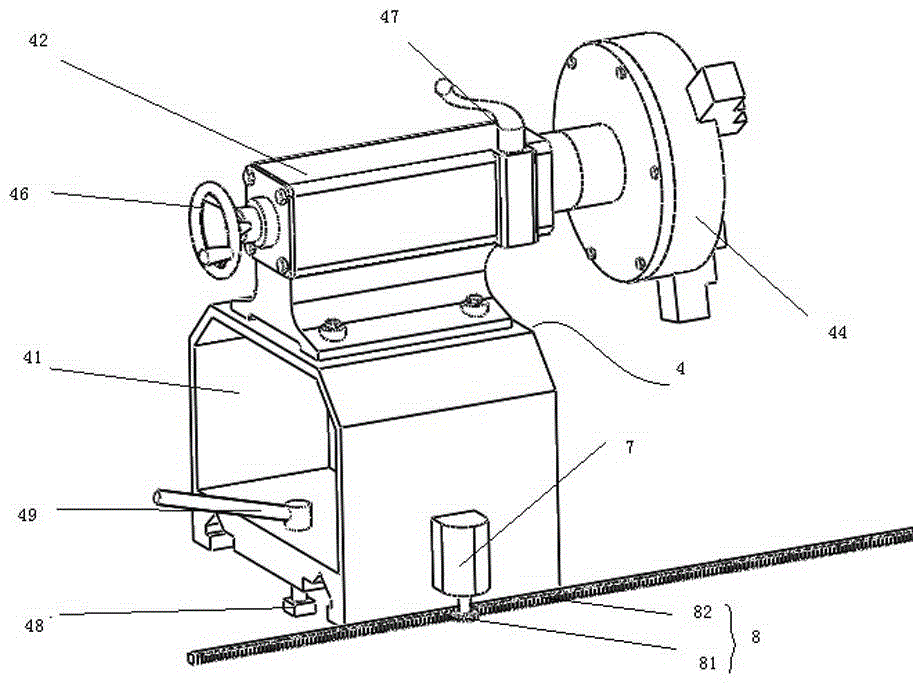

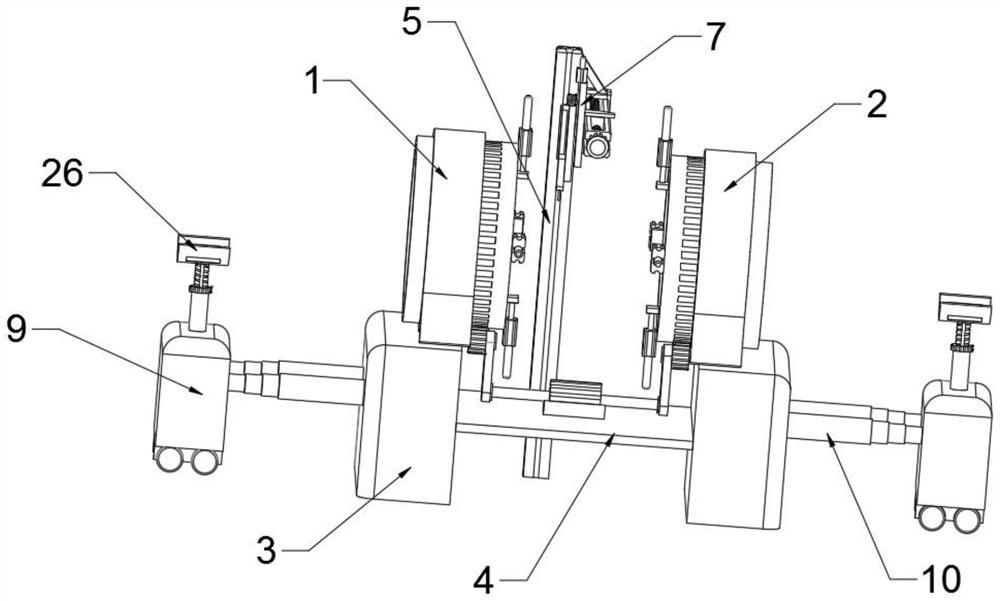

Welding machine tool

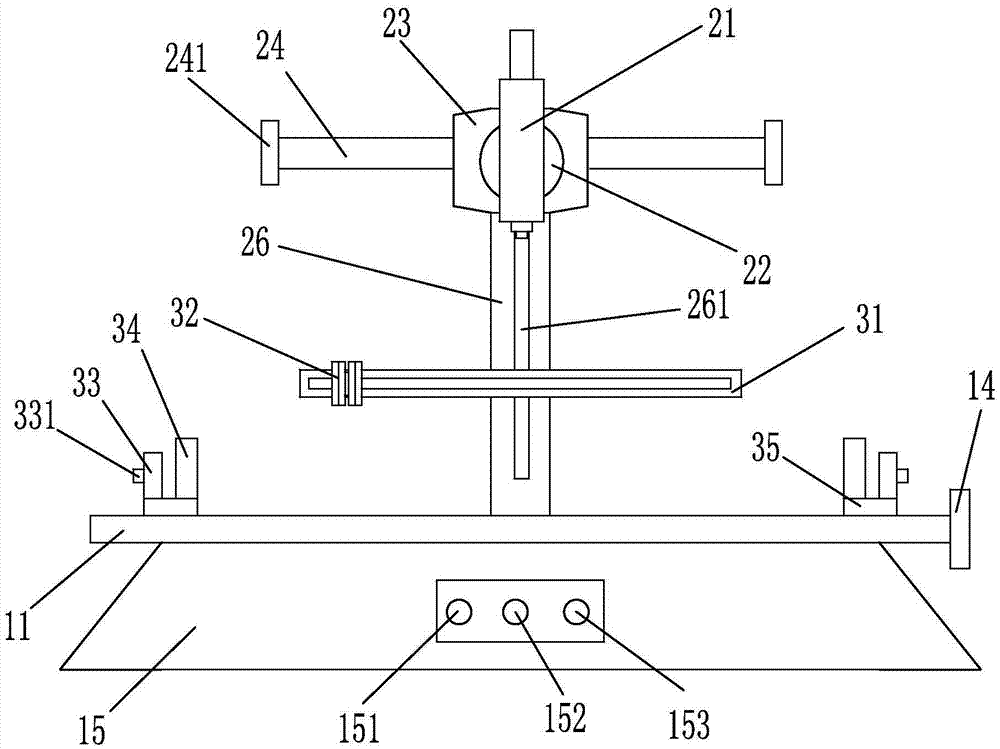

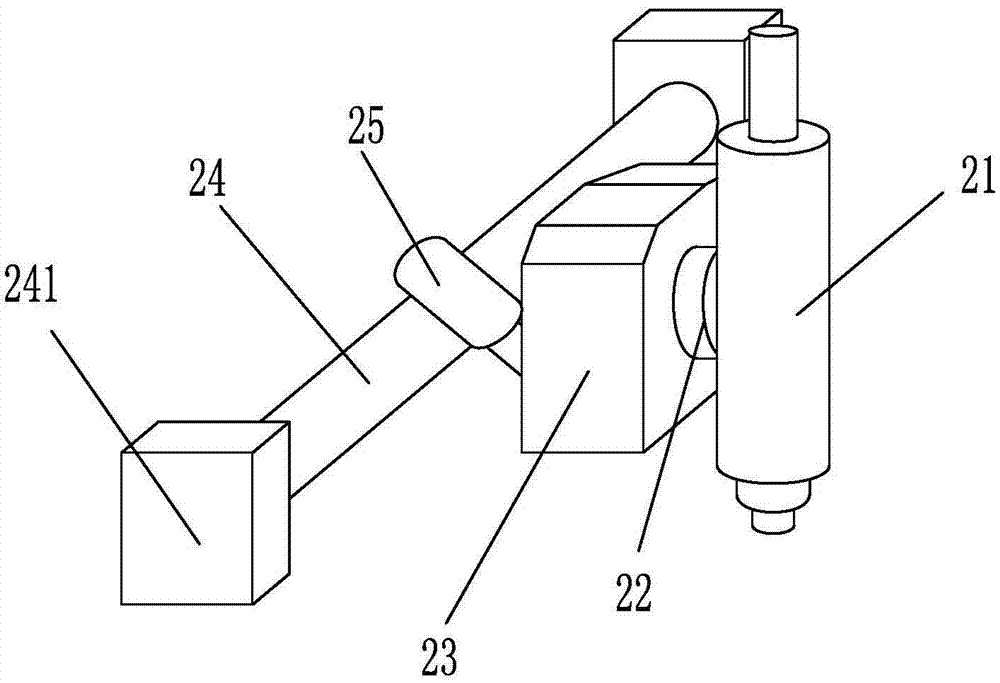

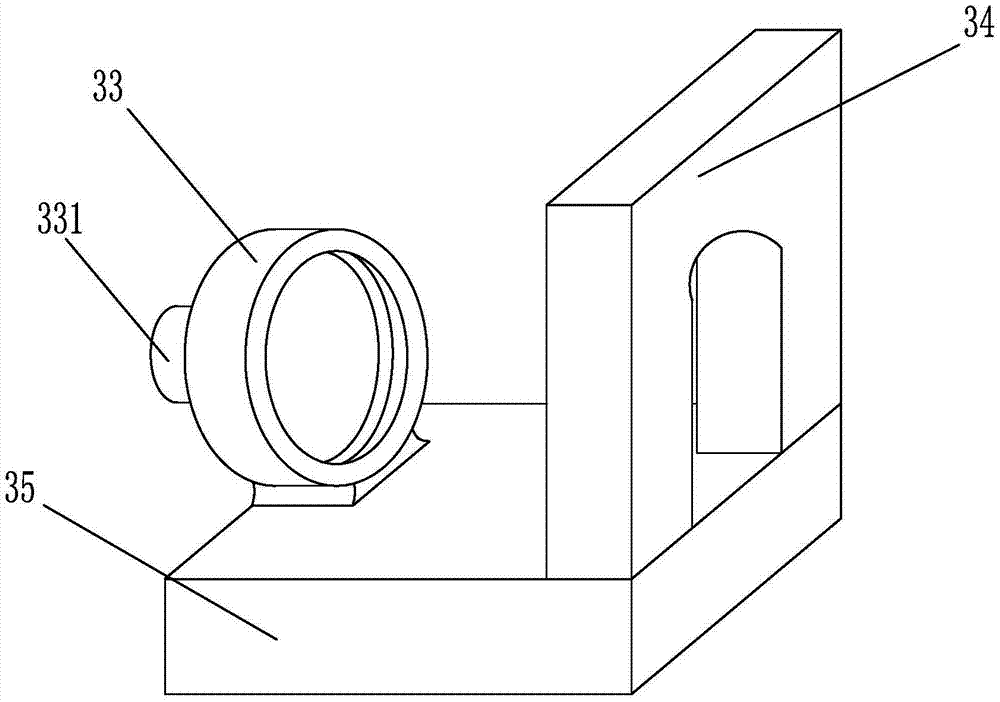

ActiveCN104690458AUniform supportGuaranteed stabilityWelding/cutting auxillary devicesArc welding apparatusControl systemEconomic benefits

The invention discloses a welding machine tool. The welding machine tool comprises a machine tool body and a control system; a main spindle box, a tail base mechanism and a welding mechanism for performing the welding operation are arranged on the machine tool body; the control system is connected with the main spindle box, the welding mechanism and the tail base mechanism, the welding mechanism is arranged between the main spindle box and the tail base mechanism; the main spindle box is fixed on the machine tool body, and the welding mechanism and the tail base mechanism are glided along the length direction of the machine tool body. The welding machine tool has variable functions, and not only can satisfy spot welding, simple linear welding and simple arc welding but also the welding of spiral vanes with different length requirements; the welding machine tool is simple in mechanism, convenient to operate, and high in efficiency; the welding machine tool has very big economic benefit and is worth to be popularized.

Owner:HOHAI UNIV CHANGZHOU

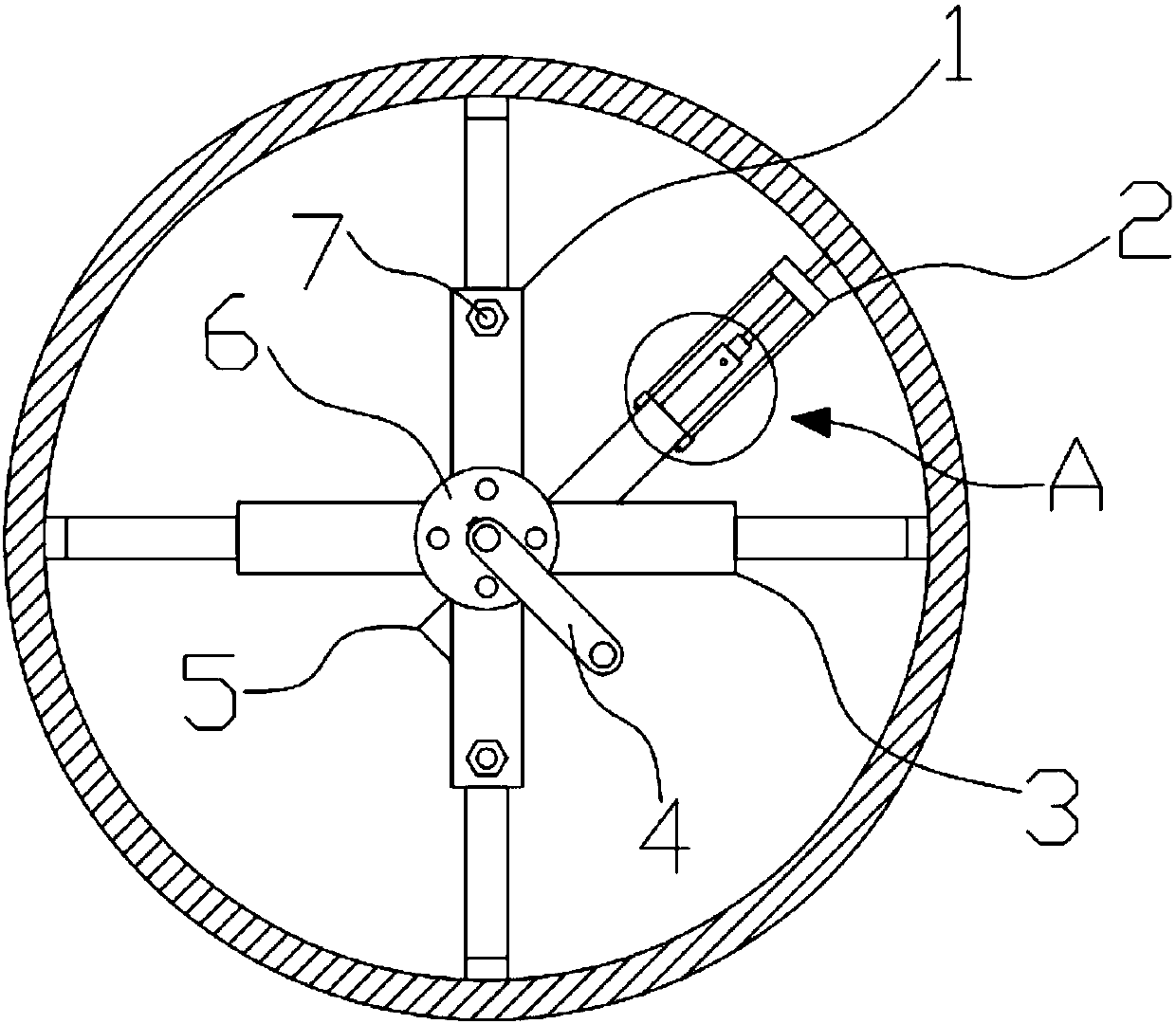

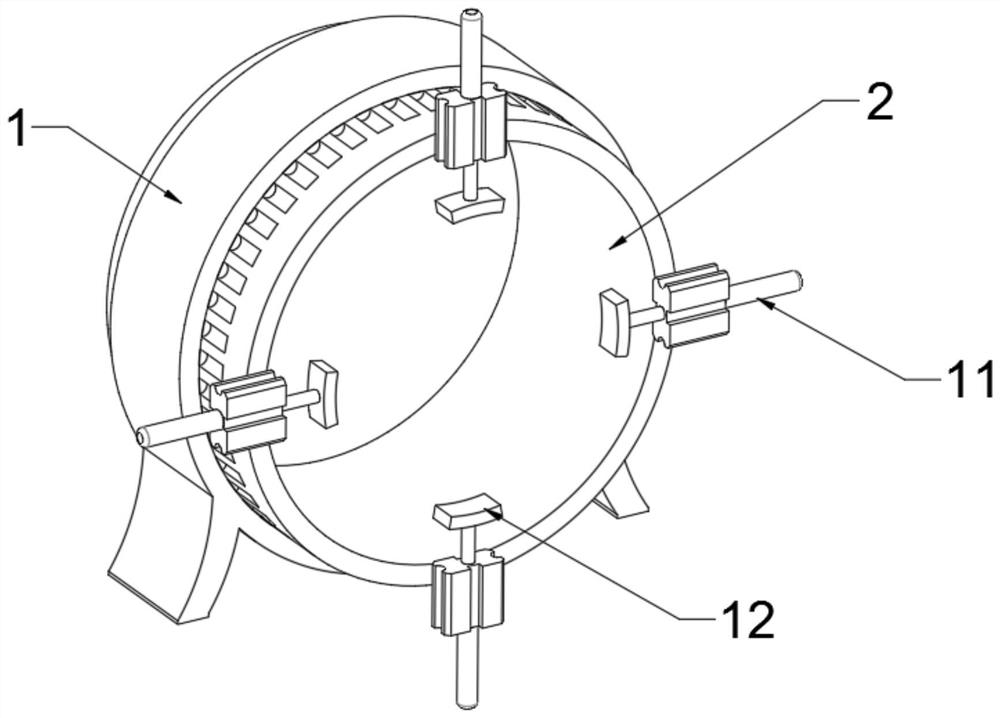

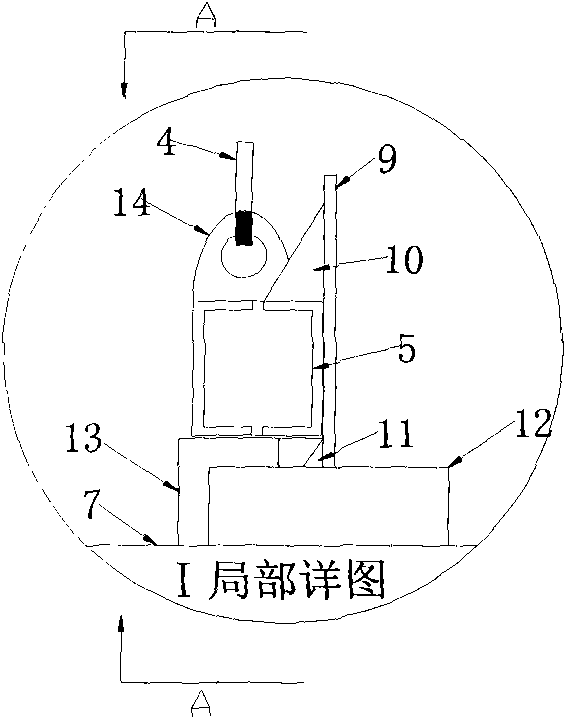

Large pipeline inner wall welding tool

InactiveCN107553023AImprove practicalityEasy to fixWelding/cutting auxillary devicesAuxillary welding devicesArchitectural engineeringInstalled base

The invention discloses a large pipeline inner wall welding tool. The large pipeline inner wall welding tool comprises a rotating shaft, two vertical supporting rods, two transverse supporting rods and a supporting arm, wherein a fixed disc and two installing bases are rotationally connected to the rotating shaft in sequence, a fixed sleeve is fixed to one end of the rotating shaft, and the otherend of the rotating shaft penetrates through the fixed disc to be fixedly provided with a curved bar; and the vertical supporting rods are fixed to the two ends of one installing base separately, thetransverse supporting rods are fixed to the two ends of the other installing base separately, the bottom of the supporting arm is fixed to the fixed sleeve, and a welding rod clamping base is installed at the top end of the supporting arm. According to the large pipeline inner wall welding tool, the rotating shaft can be fixed at the axis of a pipeline through the transverse supporting rods and the vertical supporting rods, the transverse supporting rods and the vertical supporting rods are each of a telescopic structure and can adapt to pipelines which are different in size, and the practicability of the device is improved; and manual welding operation is simulated, the welding effect is guaranteed, welding rods are attached to the inner wall of the pipeline all the time, and therefore continuous welding can be conducted, and the welding efficiency is high.

Owner:WUXI ZHIGURUITUO TECH SERVICE CO LTD

Method for producing J55-grade steel for petroleum casing based on electric furnace sheet billet continuous casting an rolling process

InactiveCN1884787AHigh strengthImprove toughnessDrilling rodsTemperature control deviceChemical compositionSolderability

The invention relates to a method for producing J55 steel used in oil sleeve, based on furnace sheet blank continuous casting rolling process, wherein the invention uses electric furnace to smelt, refine, continuously cast the sheet blank and, and solidifies the casting blank, to feed it to rolling heating or uniformly heating furnace, then removes scales with high-pressure water, hot rolls, laminated cools, and coils. The chemical components of steel water comprises (wt %): C in 0.15-0.22%, Si <=0.45%, Mn in 0.70-1.60%, P<=0.025%, S<=0.020%, Nb<=0.06% and Ti<=0.035%. The invention can make C content between 0.15-0.22wt percent, to produce the J55 steel as Nb and Ti alloy, with high strength, high flexibility and welding property.

Owner:GUANGZHOU PEARL RIVER STEEL & IRON

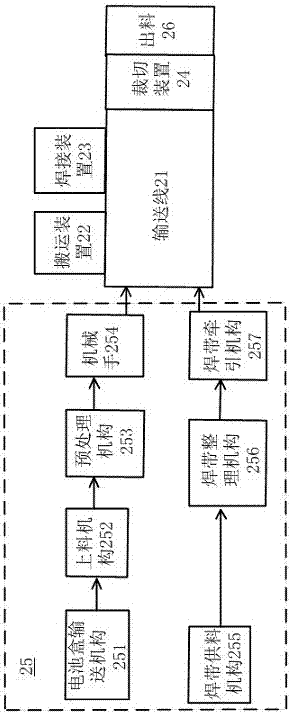

Cell series welding system

InactiveCN106881546ASave stringing processLow costFinal product manufactureWelding/cutting auxillary devicesEngineeringOn cells

The invention relates to a series welding system on a whole, in particular to a cell series welding system. The cell series welding system is used for series welding treatment on cells. The cell series welding system mainly can comprise a conveying line, a carrying device and a welding device. The conveying line is used for conveying the cells. Welding strips are placed on a main grid line of the cells. The carrying device is used for stacking bus bars on the welding strips on the cells. The welding device is used for welding the bus bars and the welding strips to the cells. The cell series welding system is simple in structure, effectively improves efficiency, reduces the labor cost and guarantees the welding effect on the cells.

Owner:WUXI AUTOWELL TECH

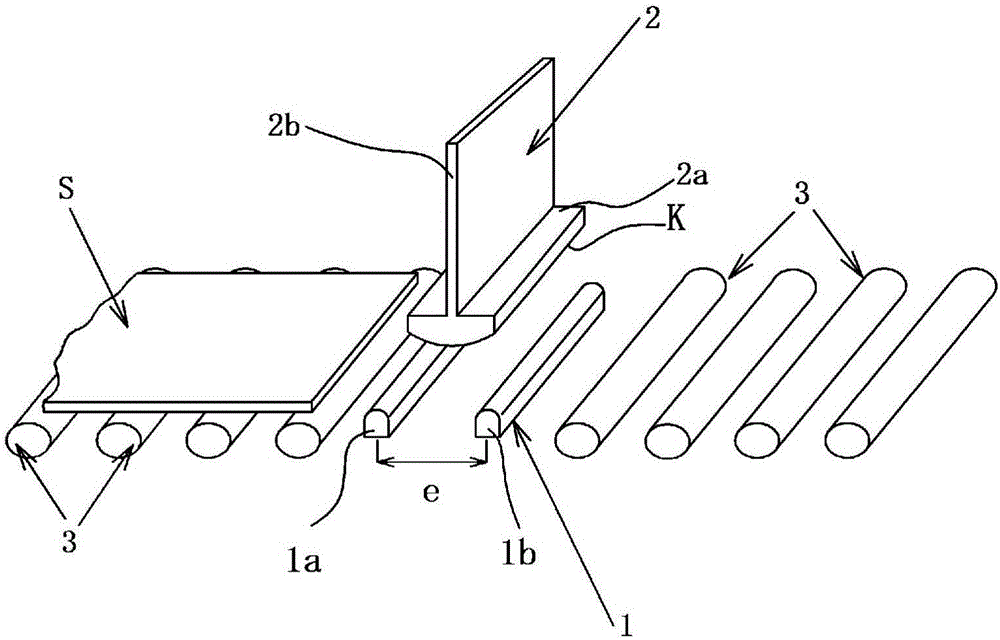

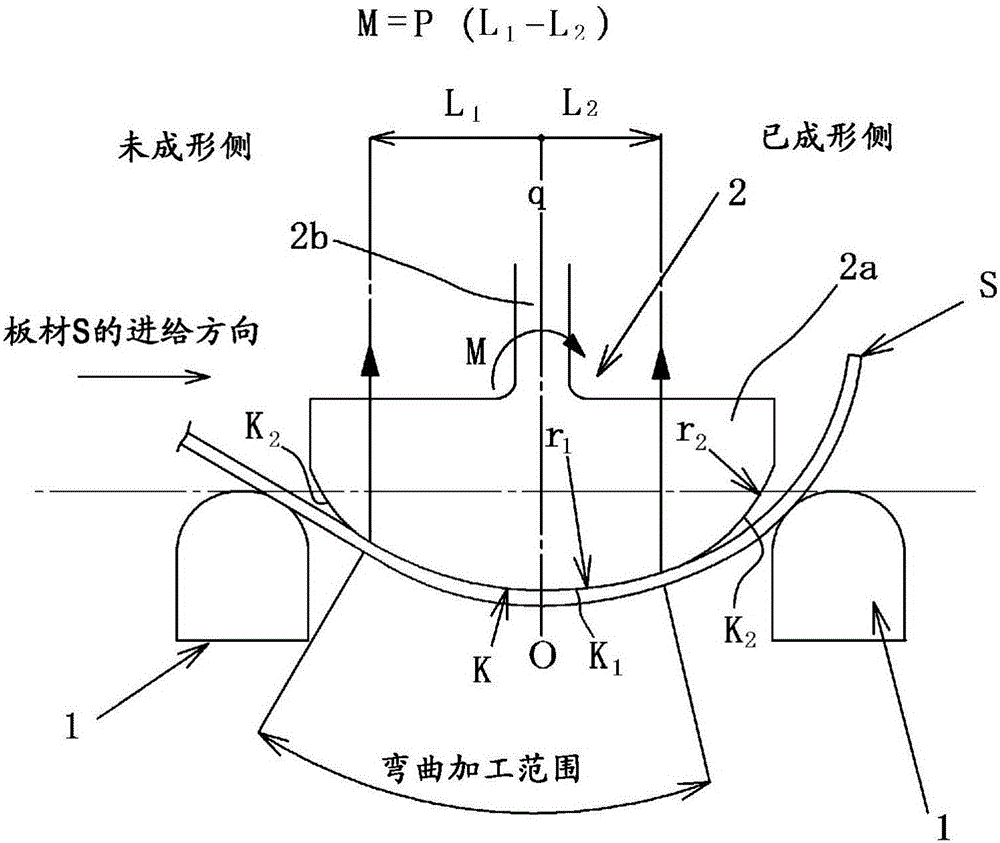

Die for bending-press forming

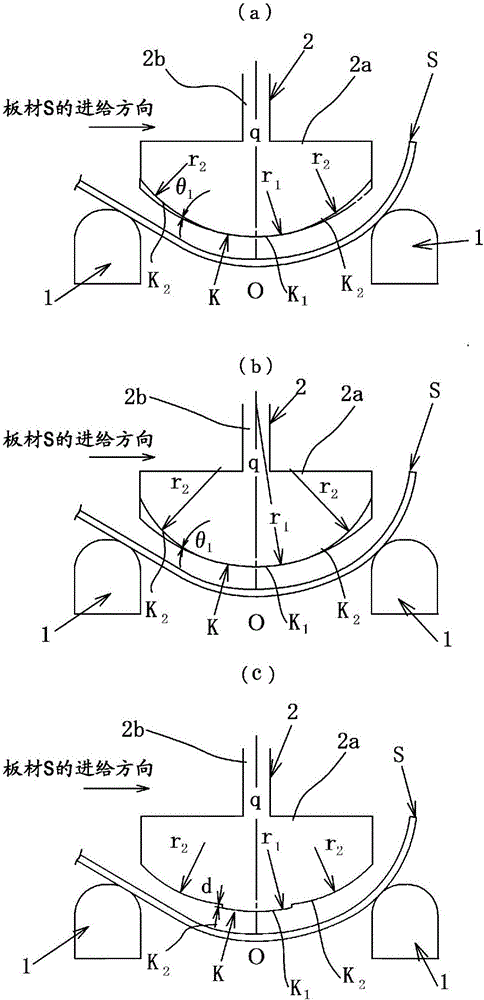

[Problem] To propose a die for bending-press forming whereby the effects of bending moments are small and a high-roundness cylinder can be obtained. [Solution] In this die for bending-press forming, said die comprising a left / right pair of die blocks (1) that support a sheet material (S) at two points and a punch (2) that can move toward and away from the die blocks (1) and bends the sheet material (S) sandwiched between the die blocks (1) and the punch (2) by successively applying pressure thereto in the width direction thereof, the punch (2) comprises the following: a punch head (2a) that has a working surface (K) that directly contacts the sheet material (S) and applies pressure thereto so as to give the sheet material (S) a concave shape; and a punch support (2b) that is attached to the punch head (2a) so as to be held thereby and supports said punch head (2a). The center (O) of the working surface (K) of the punch head (2a) coincides with the central axis (q) of the punch support (2b), and the shape of said working surface (K) is a non-uniform circular arc, the radius thereof in the widthwise middle thereof being the maximum radius thereof.

Owner:JFE STEEL CORP

Welding machine applicable to production and processing of aluminium profiles

InactiveCN105436767AEasy to adjustEasy to clean centrallyWelding/cutting auxillary devicesAuxillary welding devicesAluminiumEngineering

The invention discloses a welding machine applicable to production and processing of aluminium profiles. The welding machine comprises a working platform, a welding mechanism and a fixing mechanism, wherein the welding mechanism and the fixing mechanism are arranged on the working platform; a cutting plate is arranged on the working platform; cleaning through holes are formed in the cutting plate; the welding mechanism comprises a welding machine head, a rotary device and a moving device; the welding machine head is fixed on the rotary device; the rotary device comprises a rotary table and a moving machine base; the moving device comprises a moving rod, an elastic rod and a fixed support rod; the upper end of the fixed support rod is connected with the moving rod; the moving rod is connected with the elastic rod; the elastic rod slides left and right along the moving rod; the elastic rod is fixedly connected with the moving machine base; and the fixing mechanism comprises an upper material clamping device and lower material clamping devices. According to the welding machine disclosed by the invention, the applicability is good; the working stability of the welding machine is improved, and the welding effect of the welding machine is ensured; the whole process is convenient for operation and obvious in effect; and the welding efficiency is improved.

Owner:嵊州市银河铝业有限公司

Wear-resistant and corrosion-resistant surfacing material

InactiveCN104942477AGuaranteed wear and corrosion resistanceGuaranteed welding effectWelding/cutting media/materialsSoldering mediaFerrosiliconCorrosion resistant

The invention discloses a wear-resistant and corrosion-resistant surfacing material. The wear-resistant and corrosion-resistant surfacing material for a flux-cored wire comprises a steel strip and powder; the wear-resistant and corrosion-resistant surfacing material for a welding electrode comprises a core wire and the powder; the powder is prepared from the following components by weight: 4-8 parts of marble, 0-15 parts of feldspar, 4-14 parts of rutile, 0-4 parts of titanium dioxide, 0-10 parts of fluorite, 0.5-5 parts of mid-carbon ferromanganese, 3-6 parts of atomized ferrosilicon, 42-55 parts of chromium metal, 7-12 parts of molybdenum powder, 12-18 parts of nickel powder, 5.5-8 parts of ferroniobium, 0-8 parts of iron powder, 1-2.5 parts of ferrotitanium, and 0.5-2 parts of rare earth; the thickness of the steel strip is 0.3-0.61 mm; the filling amount of the powder is 28-35 percent of the total amount; the core wire is made from any one of H08A, H0Cr24Ni13 and 0Cr18Ni9Ti; the weight part ratio of the core wire to the powder is (40-65) to (35-60).

Owner:宋焯

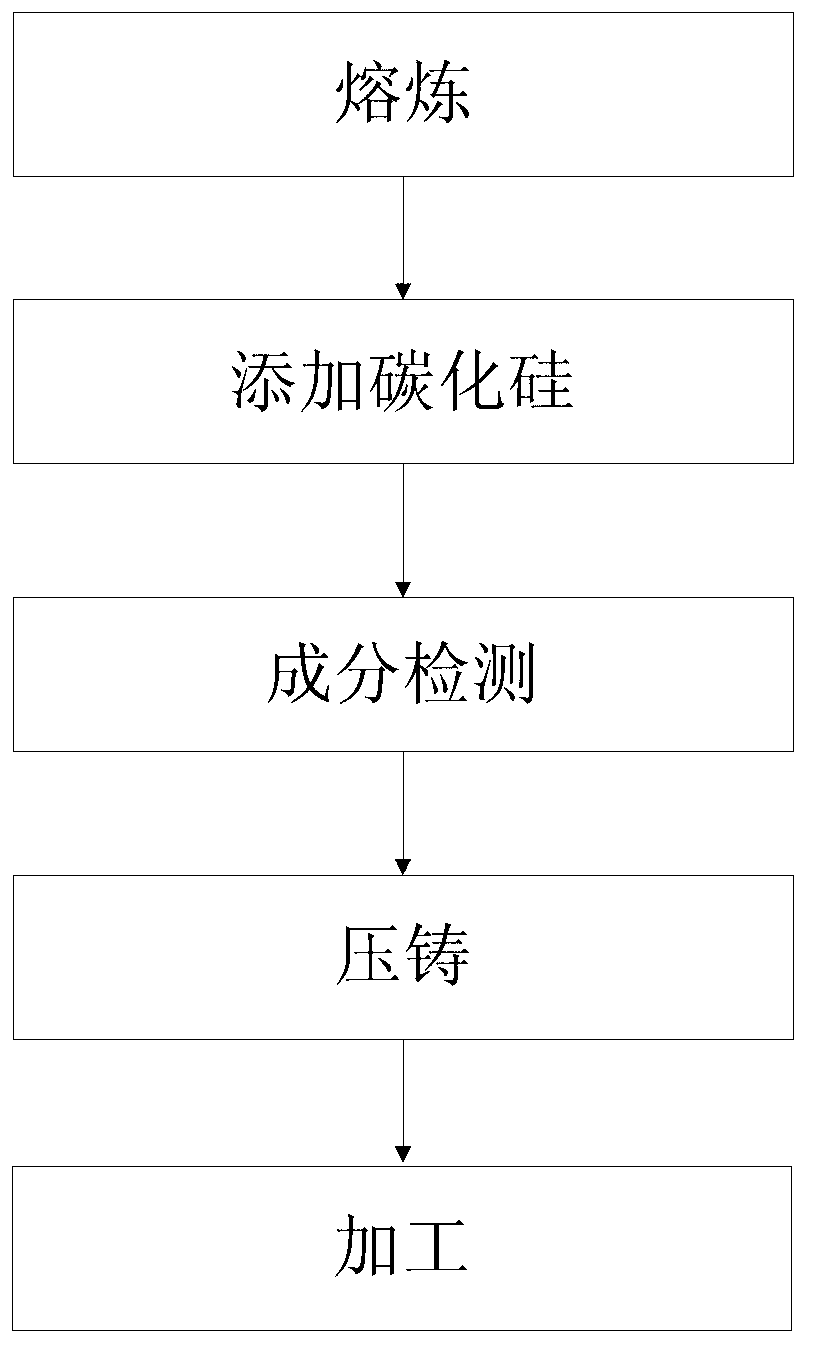

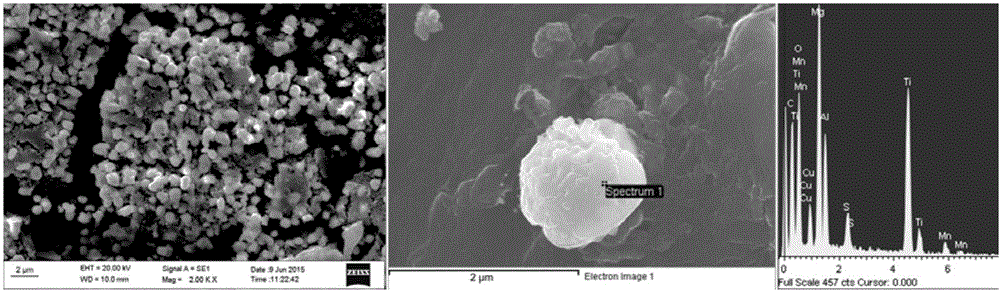

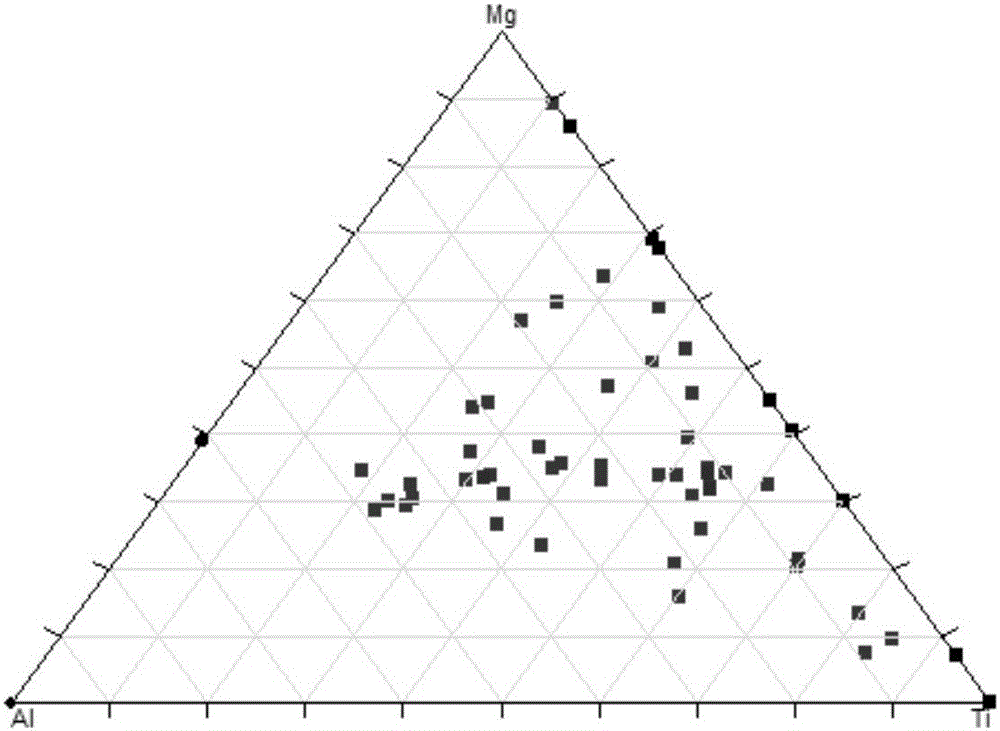

Preparation method of nanoscale silicon carbide magnesium alloy material

ActiveCN103320631AGuaranteed CorrosionGuaranteed ductilityTransportation and packagingMetal-working apparatusManganeseHardness

The invention provides a preparation method of a nanoscale silicon carbide magnesium alloy material. The nanoscale silicon carbide magnesium alloy material is prepared by uniformly dispersing and distributing a light nanoscale silicon carbide material through particle fine treatment in the magnesium alloy material. The nanoscale silicon carbide magnesium alloy material comprises the following components in percentage by weight: 1-1.5% of nanoscale silicon carbide, 10-11.5% of aluminum, 1.1-1.8% of zinc, 0.05-0.2% of manganese, less than or equal to 0.2% of inevitable impurities, and the balance of magnesium. According to the preparation method of the nanoscale silicon carbide magnesium alloy material provided by the invention, higher solid solubility is formed in a magnesium alloy substrate by means of characteristics of high hardness and wear resistance and the like of nanoscale silicon carbide, so that the stretching and compressing yield strength is enhanced while the welding performance, corrosion resistance and malleability of the nanoscale magnesium alloy material are ensured.

Owner:SUZHOU RICHMOND ADVANCED MATERIAL TECH TRANSFER CO LTD

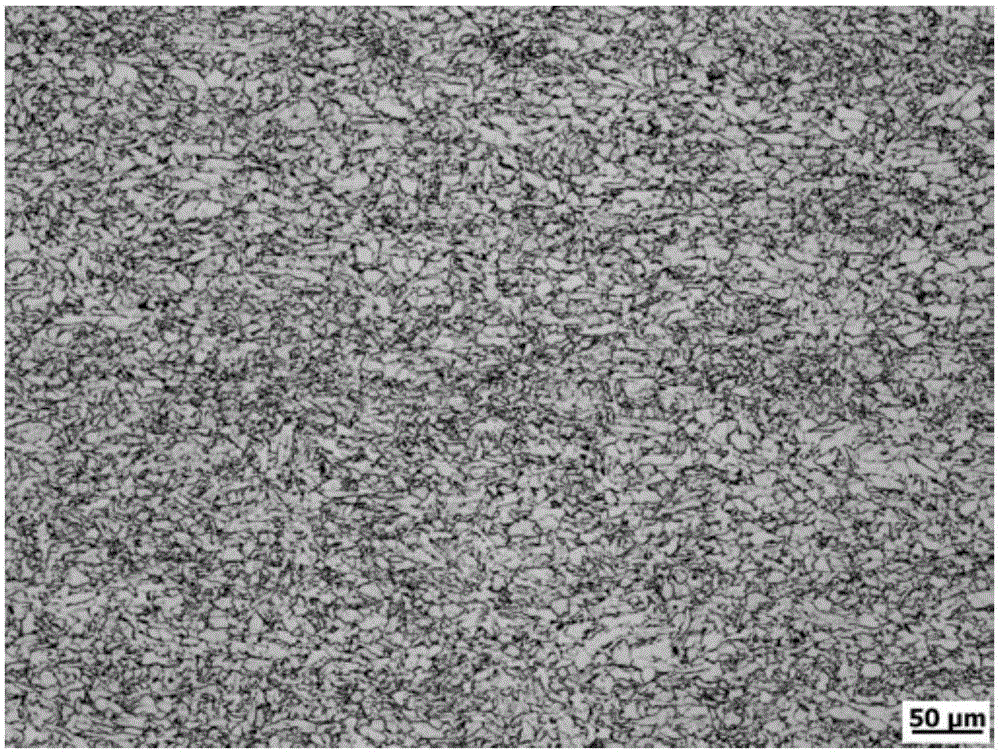

Oxide-enhanced high heat input welding steel plate

ActiveCN105714193AIncreased welding heat inputReasonable control of proportional relationshipHeat-affected zoneImpurity

The invention relates to an oxide-enhanced high heat input welding steel plate. The steel plate comprises the following chemical components in percentage by weight: C less than or equal to 0.10%, Si less than or equal to 0.20%, 1.20-1.80% of Mn, 0.01-0.10% of Ti, Alt less than or equal to 0.01%, 0.001-0.005% of Als, 0.0005-0.0030% of Mg, N less than or equal to 0.006%, 0.0010-0.0050% of O and the balance of Fe and part alloy elements and unavoidable impurities. The steel plate disclosed by the invention has the advantages that the proportion relationship among the elements of Ti, Al, Mg, O and N is reasonably controlled to ensure that a large number of TiOx-MgAl2O4 composite oxide particles with the size of 0.2-2.0 micrometers are formed in the steel plate, so that the welding heat input that the steel plate can bear is increased to 600-1000kJ / cm and the impact energy of the welding heat-affected zone at the temperature below 60 DEG C can be guaranteed to be greater than or equal to 100J.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE

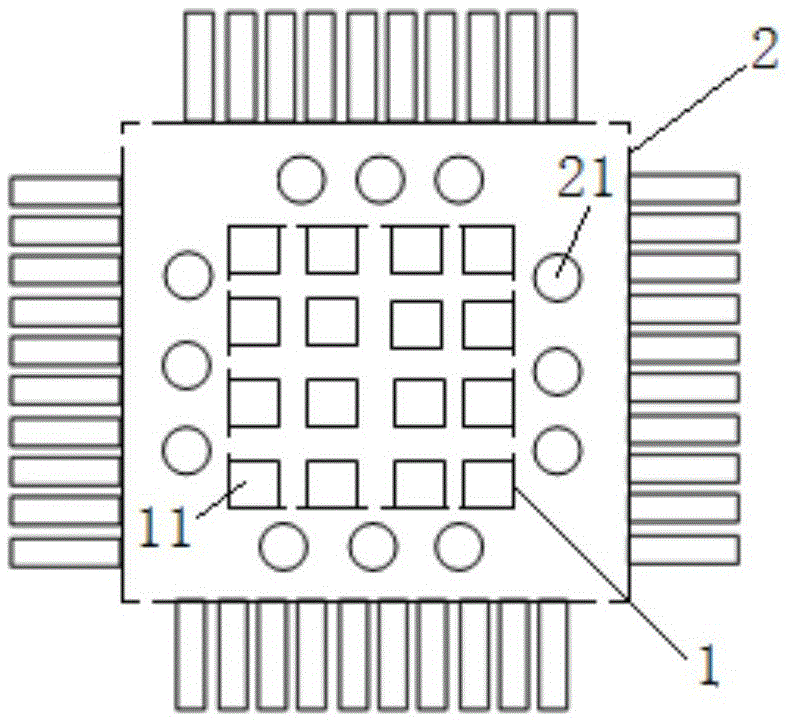

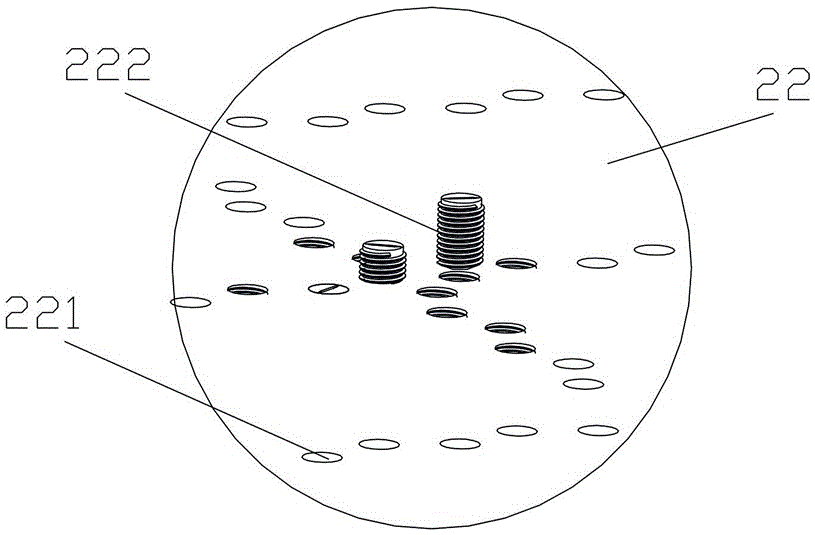

Heat-conducting bonding pad and package structure of QFP chip with heat-conducting bonding pad

InactiveCN105552048AReduce areaReduce in quantitySemiconductor/solid-state device detailsSolid-state devicesElectrical conductorHeat conducting

The invention provides a heat-conducting bonding pad and a package structure of a QFP chip with the heat-conducting bonding pad. The heat-conducting bonding pad comprises a bonding pad region and a peripheral region, wherein the bonding pad region is provided with a plurality of bonding pad parts which are arranged in an array; and gaps are formed among the bonding pad parts. The bonding pad parts of the heat-conducting bonding pad are arranged in the array and are isolated from one another, and the area of the bonding pad parts is greatly reduced, so that, on one hand, the escape path of a gas generated by soldering flux pyrolysis in a solder paste in a high-temperature welding process is shortened; and on the other hand, the gaps between the adjacent bonding pad parts provide channels for escape of the gas; the gas can timely escape; the area and the quantity of bubbles are effectively reduced; the condition that the chip has enough heat radiating area is ensured; and the heat radiating effect is improved. Meanwhile, the effective area of a conductor formed by the bonding pad is increased, so that the grounding impedance of the chip is reduced; and the reliability of the chip is improved. The welding effect of the heat-conducting bonding pad is improved; and excessive floating of the chip is avoided, so that the welding reliability of peripheral pins is improved.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

Manufacturing method of tin-copper double-layer electroplated steel plates

The invention discloses a manufacturing method of tin-copper double-layer electroplated steel plates. The technical scheme of the invention is as follows: the method comprises the following steps: carrying out rust removal on a cold rolled thin steel sheet, cleaning the cold rolled thin steel sheet, activating the cold rolled thin steel sheet by using dilute acid, carrying out chemical nickel dipping on the surface of the cold rolled thin steel sheet, sequentially carrying out electrocoppering and electrotinning on the surface of the cold rolled thin steel sheet, and carrying out soft melting, hardening, soda cleaning, chromate cathodic passivating, cleaning and blow-drying on the cold rolled thin steel sheet, so that a finished product is obtained. The method disclosed by the invention is simple in process and low in production cost, and the prepared tin-copper double-layer electroplated steel plate has excellent weldability and corrosion resistance.

Owner:WUHAN IRON & STEEL (GROUP) CORP

Production method for low-yield-ratio high-strength medium-thickness steel plate

The invention discloses a production method of a low-yield ratio high-strength medium-thick steel plate. The chemical composition mass percentage of the steel is C=0.06-0.09, Si=0.2-0.4, Mn=1.3-1.8, Al=0.02-0.05, Cr=0.30~0.40, Nb≤0.05, Ti=0.015~0.025, Mo≤0.30, B≤0.0010, P<0.02, S<0.005, CEQ<0.45, Pcm<0.22, the process steps include rolling and heat treatment. The method of the present invention is used for rolling low-yield ratio high-strength medium-thick steel plates, especially high-strength steel medium-thick plates with a yield strength of 550 MPa for construction machinery, and finally obtains tempered strips through quenching and tempering process or TMCP+tempering process. The plate with bainite structure has a yield strength of more than 550MPa, a tensile strength of more than 680MPa, a yield ratio of less than 0.9, an elongation after fracture of more than 17%, and a full-thickness V-notch Charpy impact energy of more than 140J at -20°C. . And excellent performance after welding.

Owner:HUNAN VALIN XIANGTAN IRON & STEEL CO LTD

Arc automatic welding machine

InactiveCN111730165AGuaranteed fitNo offset actionSoldering auxillary devicesRotation - actionEngineering

The invention relates to the technical field of welding, in particular to an arc automatic welding machine. The machine comprises two symmetric cylinder frame bodies, rotating cylinders are arranged in the cylinder frame bodies in a fit manner, the rotating cylinders are rotatably connected with the cylinder frame bodies, the sides, close to each other, of the two rotating cylinders are provided with clamping assemblies, a driving assembly for driving the two rotating cylinders to rotate at the same time is arranged on the bearing plate, one side of the bearing plate is fixedly provided with avertical supporting frame, a transverse arm is fixedly connected to the upper end of the vertical supporting frame, a welding head is arranged on one side of a sliding rail, the welding head is connected with the sliding rail through a vertical moving assembly, the machine can be used for welding operation of arcs and pipelines, according to needs, a welding head is adjusted, the adjusting freedom is higher, the machine can adapt to different conditions, meanwhile, two parts used for welding are rotated synchronously, welding effect is ensured, for a long pipeline, an auxiliary supporting assembly is mounted, auxiliary supporting is carried out on the premise of not affecting the rotation action, the welding effect is ensured, and the deviation appearing in the welding process can be avoided.

Owner:段旭东

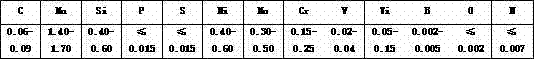

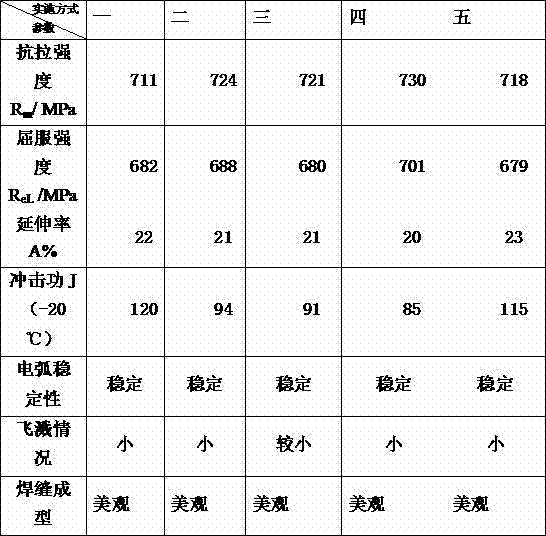

700MPa low-alloy high-strength welding wire for heavy machinery and use method thereof

ActiveCN102873465AGuaranteed welding effectAvoid crackingArc welding apparatusWelding/cutting media/materialsGas metal arc weldingAlloy

The invention provides a low-alloy high-strength welding wire suitable for heavy machinery. The low-alloy high-strength welding wire is characterized in that the strength of a deposited metal is more than 700MPa, the elongation is greater than 16% and the impact energy is more than 47J at minus 20 DEG C.; the welding wire has the advantages of stable electric arc, relatively small spatter and beautiful welding seam forming during use. Chemical components (by mass percent, %) of the welding wire with gas metal arc welding are as follows: 0.06-0.09% of C, 0.40-0.60% of Si, 1.40-1.70% of Mn, 0.4-0.6% of Ni, 0.30-0.50% of Mo, 0.15-0.25% of Cr, 0.02-0.04% of V, 0.05-0.15% of Ti, 0.002-0.005% of B, less than or equal to 0.015% of S, less than or equal to 0.015% of P, less than or equal to 0.0025% of O, less than or equal to 0.0070% of N, and the balance of Fe and inevitable impurities. Ar +20% CO2 argon-rich gas protection is adopted by the welding wire for welding, so that the deposited metal has high low-temperature toughness under the conditions of as-welded and post-welding heat treatment.

Owner:山东索力得焊材股份有限公司

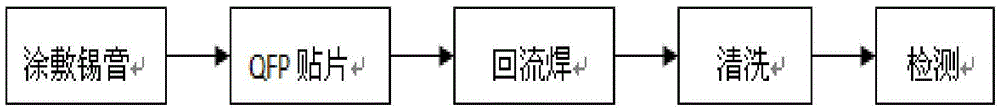

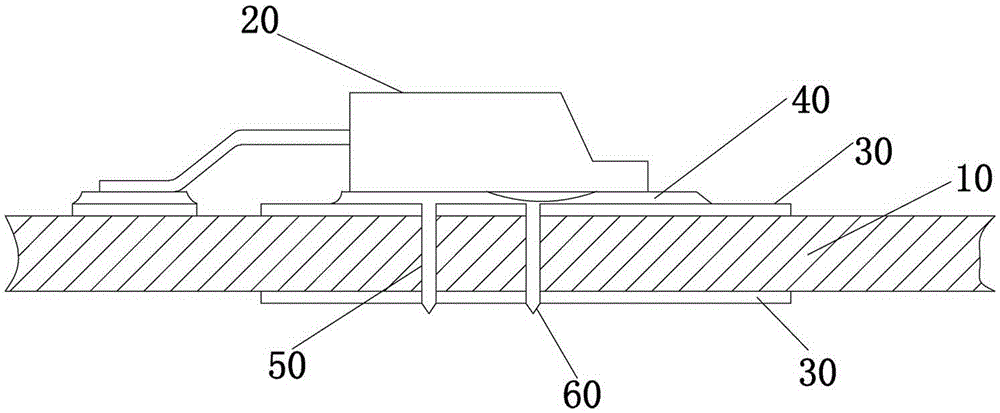

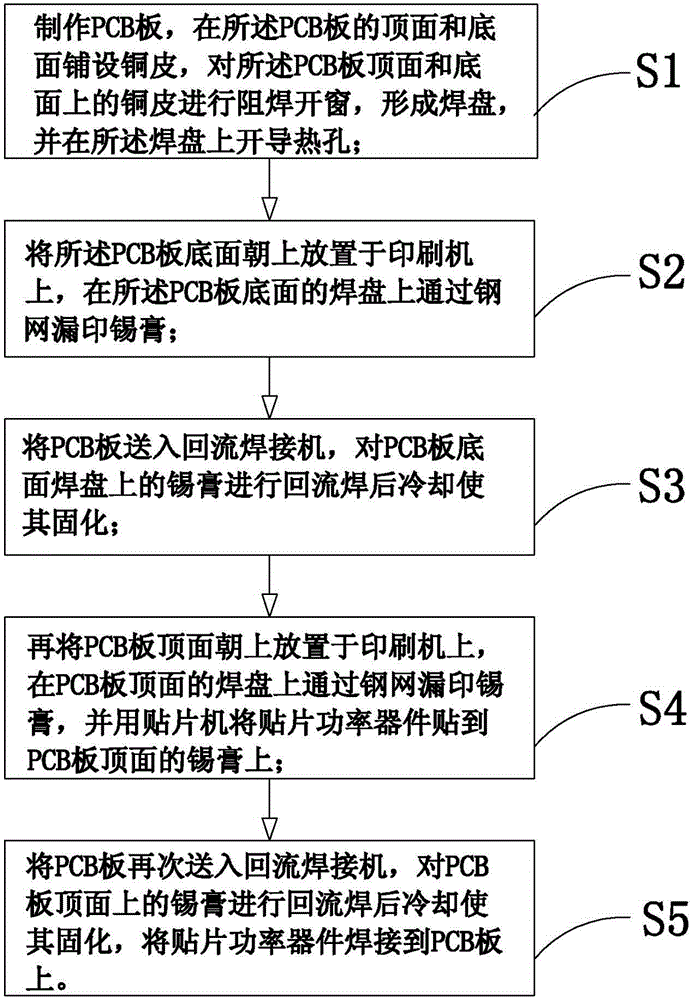

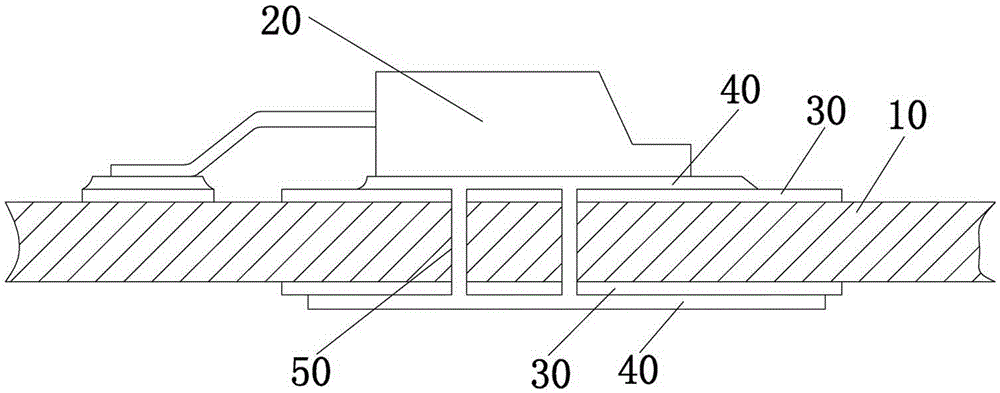

Printed circuit board manufacturing method and printed circuit board

InactiveCN105338757AGuaranteed smoothGuaranteed welding effectPrinted circuit assemblingSolder maskCopper

The invention discloses a printed circuit board manufacturing method and a printed circuit board. The method includes the following steps of manufacturing the PCB, lining the top face and the bottom face of the PCB with copper sheets, conducting solder mask opening on the copper sheets of the top face and the bottom face of the PCB to form weld discs, forming heat conduction holes in the weld discs, putting the PCB on a printing machine with the bottom face facing upwards, conducting solder paste skip printing on the weld disc on the bottom face of the PCB through a steel screen, putting the PCB on the printing machine with the top face facing upwards, conducting solder paste skip printing on the weld disc on the top face of the PCB through the steel screen, attaching a chip power device to solder paste of the top face of the PCB through a chip mounter, sending the PCB into a backflow welding machine, cooling and solidifying solder paste on the top face of the PCB after backflow welding, and welding the chip power device to the PCB. The welding effect of the chip power device and the smoothness of the bottom face of the PCB are ensured.

Owner:SHENZHEN VMAX POWER

Method for preparing welding wire made of nickel base alloy

ActiveCN103949805AEasy to processImprove antioxidant capacityWelding/cutting media/materialsSoldering mediaHydrogenSlag

The invention relates to a method for preparing a welding wire made of nickel base alloy. The welding wire comprises the following components by mass percent: 0.4-0.45% of C, 1.0-1.5% of Mn, 0.15-1.2% of Si, less than or equal to 0.025% of P, less than or equal to 0.02% of S, 28-30% of Cr, 49-51% of Ni, less than or equal to 0.1% of Co, less than or equal to 0.1% of Mo, less than or equal to 0.1% of Ti, less than or equal to 0.1% of Al, 4.0-5.0% of W and the balance of Fe. The method for preparing the welding wire comprises the steps of smelting the alloy, remelting electro-slag, carrying out hot forging and cogging down, carrying out hot rolling and annealing, carrying out acid pickling, polishing, carrying out cold drawing and removing hydrogen, wherein a CaF2, Al2O3 or CaO slag system is adopted in the step of remelting the electro-slag. The thinner welding wire can be prepared by the method for preparing the welding wire made of the nickel base alloy, the performances of the welding wire meet the requirements, and the welding wire is high in yield.

Owner:JIANGSU TOLAND ALLOY

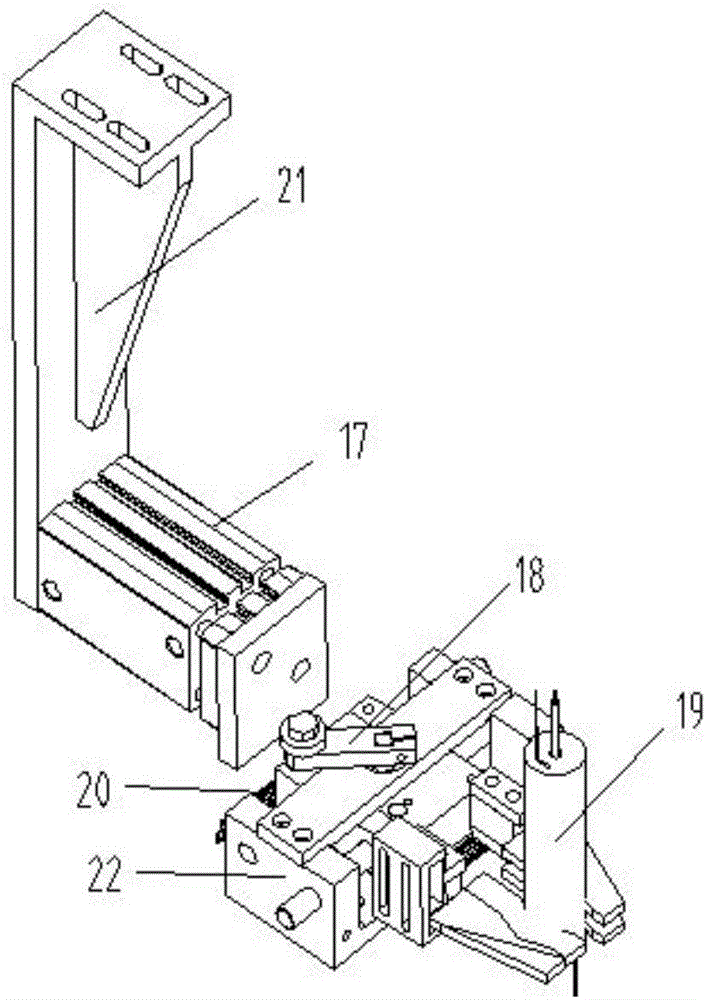

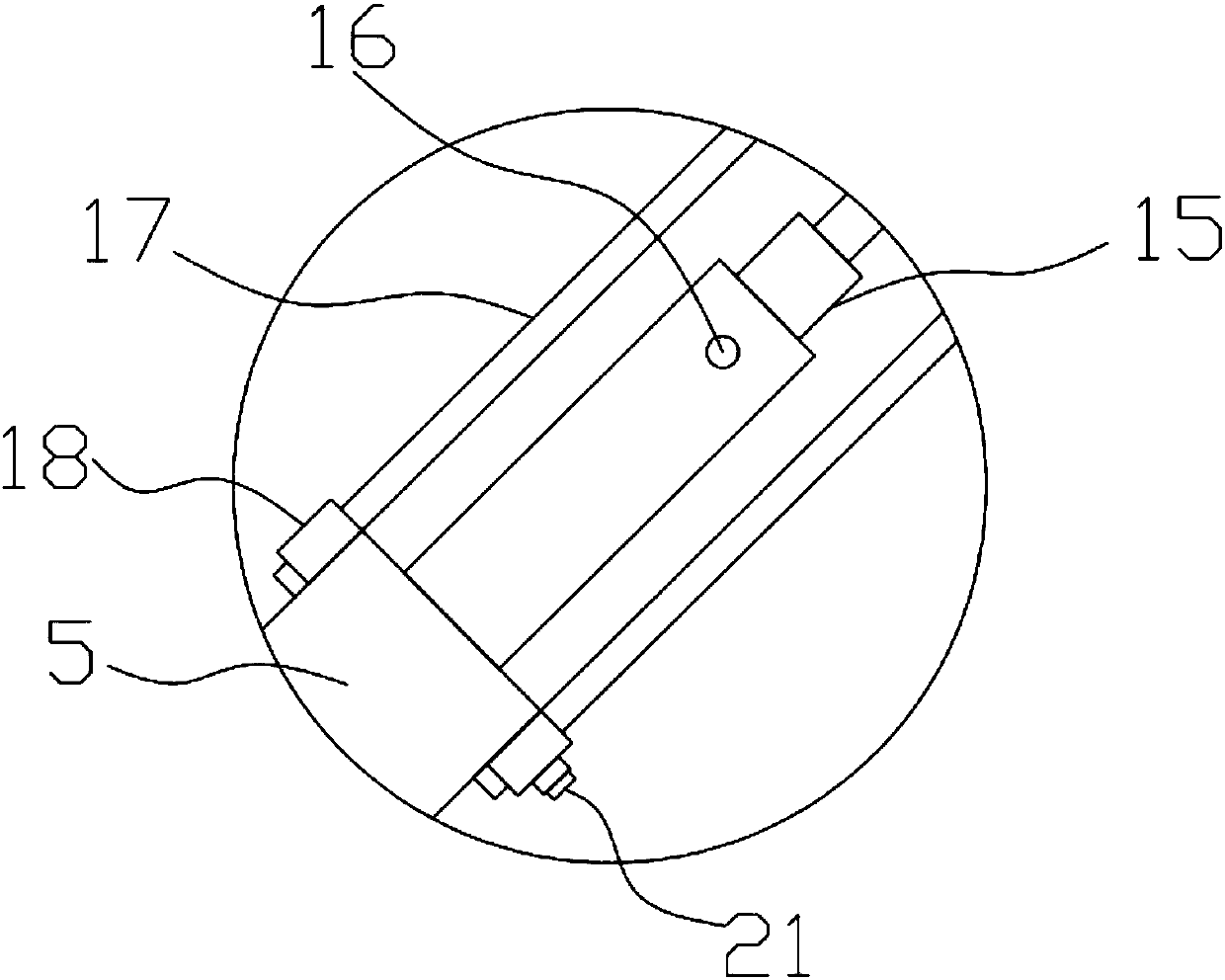

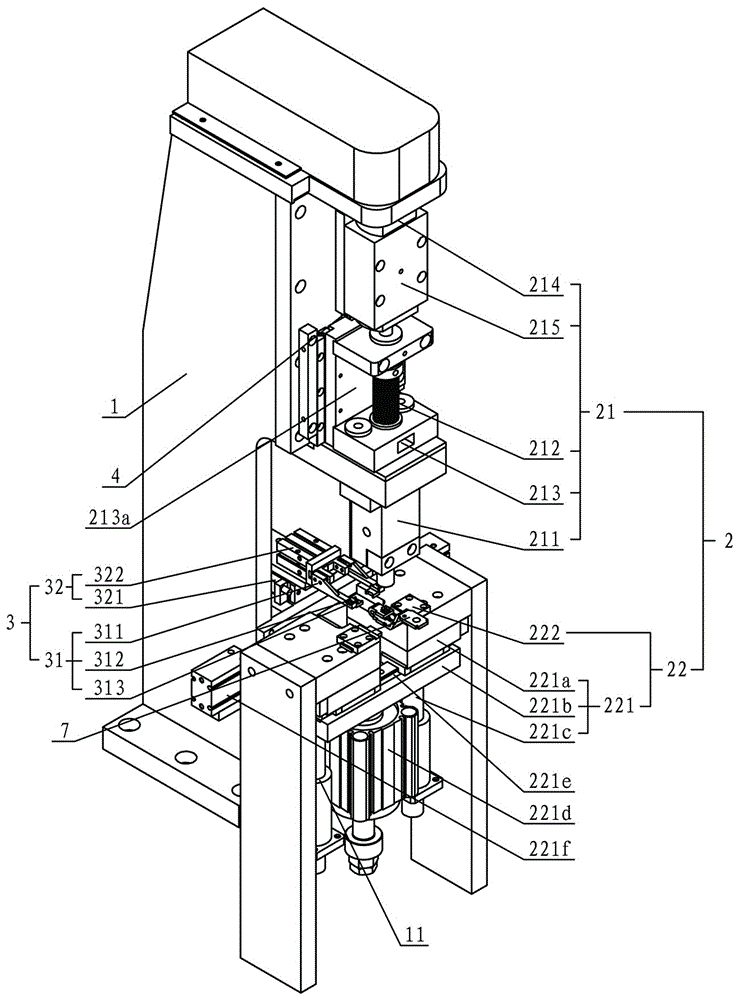

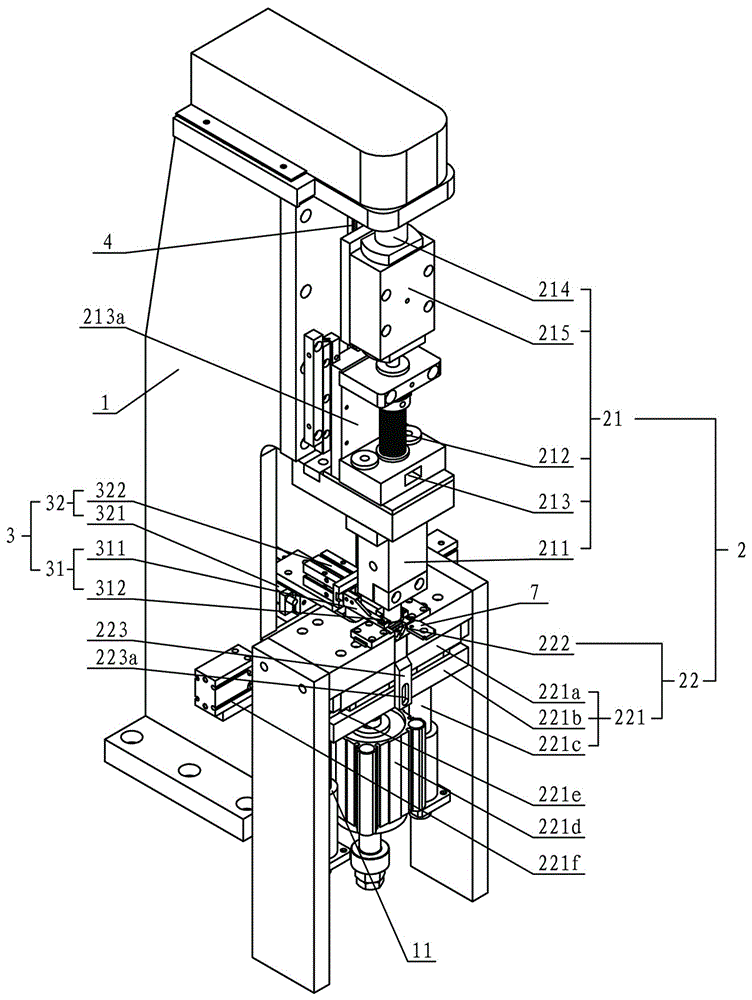

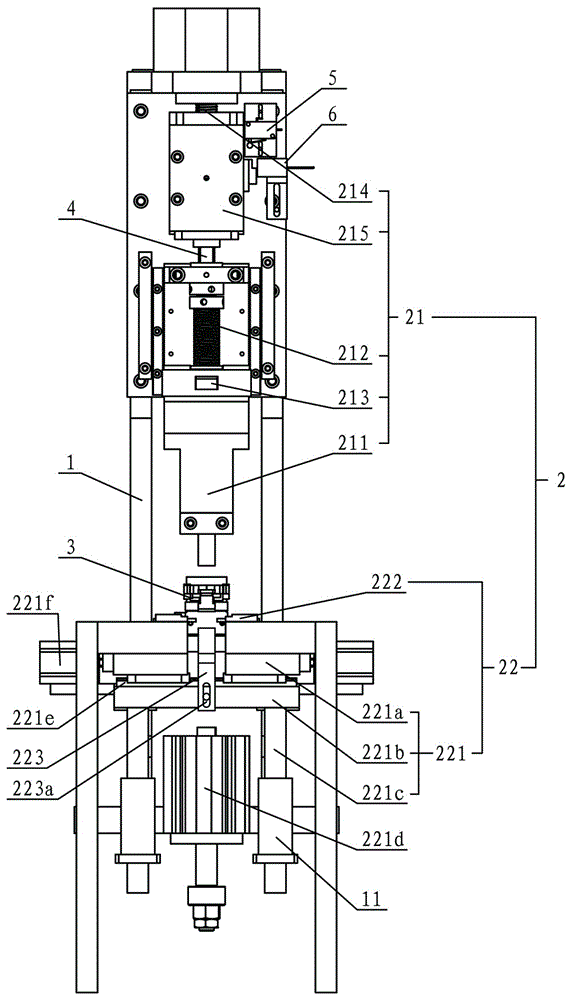

Servo welding head assembly

InactiveCN105750780AGuaranteed welding effectReasonable structureWelding/cutting auxillary devicesAuxillary welding devicesEngineeringSpot welding

The invention discloses a servo welding head assembly. In order to be matched with a workpiece with a large structure, the servo welding head assembly is provided with a lower welding head set which can move up and down. The lower welding head set ascends to be matched with the height wherein the workpiece is located, and therefore the servo welding head assembly can be flexibly matched with workpieces with different structures. In addition, lower welding heads stretch into the middle of the workpiece from the two sides, matching is conducted according to specific workpiece shapes, the lower welding heads and upper welding heads above the lower welding heads are matched, a silver point on the upper portion of the workpiece can be well subjected to spot welding, the upper welding heads and the lower welding heads directly make contact from the up-and-down contact surfaces of the silver point and the workpiece for spot welding, and the servo welding head assembly can adapt to workpieces with complex structures; the structure of the lower welding head set which can ascend and descend up and down and a positioning mechanism which can move front and back are both beneficial for the purpose that the workpiece with the large structure moves to the position in front of the servo welding head assembly without being blocked, the structure is reasonable, and the servo welding head assembly can be suitable for welding more workpieces.

Owner:WENZHOU TIANJI ROBOT AUTOMATION

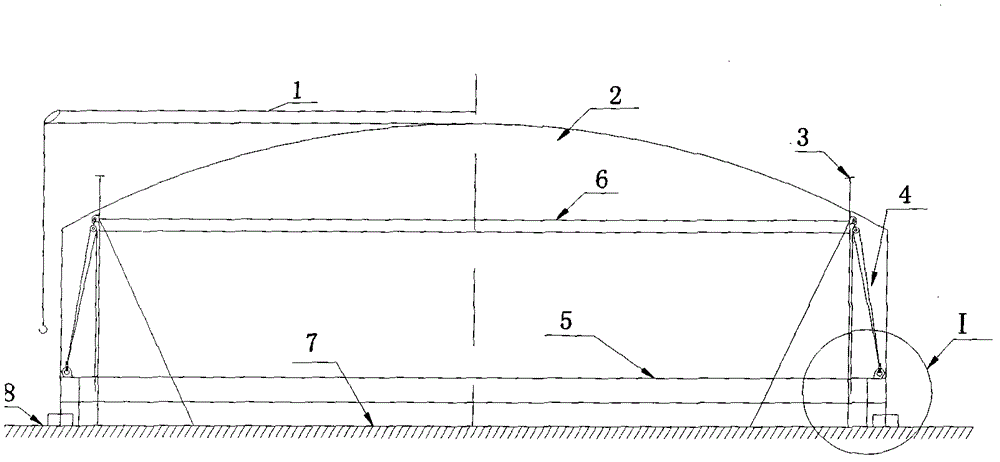

Inversing method of inner side clustering hoop of vertical storage tank

InactiveCN102720386ALow costReduce working at heightsBulk storage containerWork in processInverse method

The invention discloses an inversing method of an inner side clustering hoop of a vertical storage tank. The reversing method comprises the steps of: lifting a tensioning packing temporarily fixed at the lower part of a wall board by using holding poles with hoisting inverted chains to ensure that a precast tank top and a first ring of wall board to ascend to a preset height together with the tensioning packing, installing and welding a second ring of wall board, wherein the holding poles are uniformly arranged on the inner side of the storage tank; and then releasing the tensioning packing to descend to the lower part of the second ring of wall board for tensioning and fixing, lifting the second ring of wall board by using the hosting inverted chains on the inner-side clustering hoop until the final ring of wall board is installed and welded. All construction tools used in the invention can be repeatedly used during the construction of the storage tanks with various specifications except for the tensioning ring, semi-finished product materials are sent to the near side of an equipment foundation by needing a small crane by adopting an inner-side clustering inversing method, residual works are completed by using a crane jib on the top of the storage tank, the holding poles and the inverted chains. Compared with the prior art, the inversing method has the advantages of saving a large quantity of automobile machine teams, and greatly reducing cot; and meanwhile, the more the quantity of the storage tanks is, the larger the saved cost is.

Owner:QINGDAO INSTALLATION & CONSTR +1

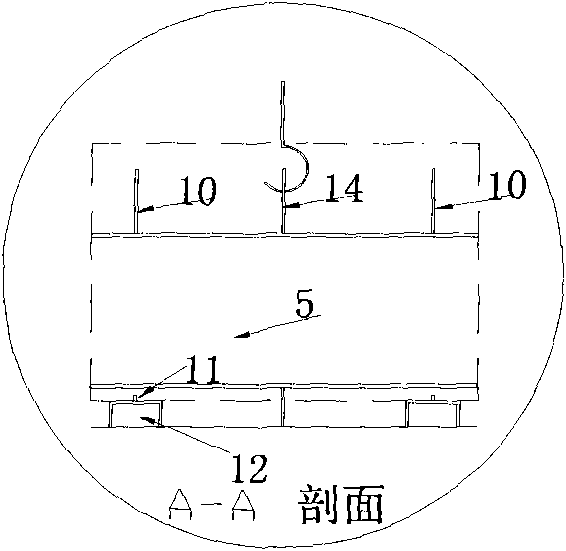

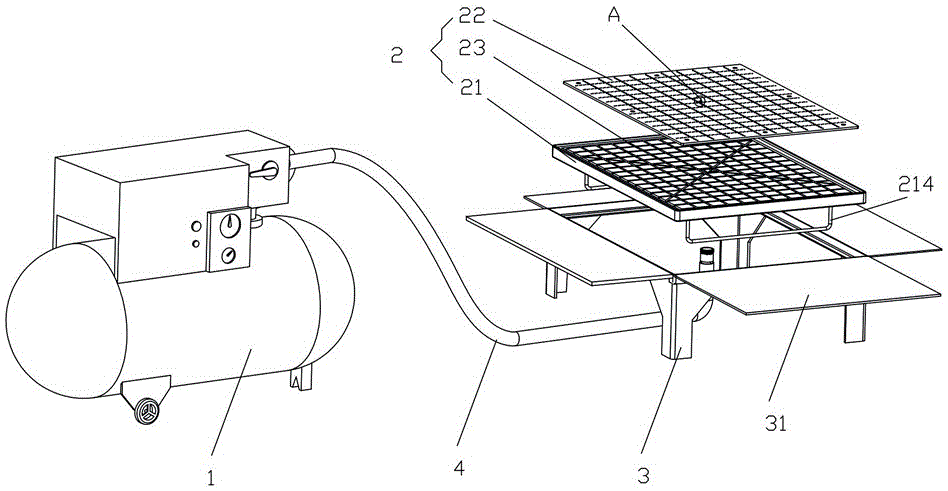

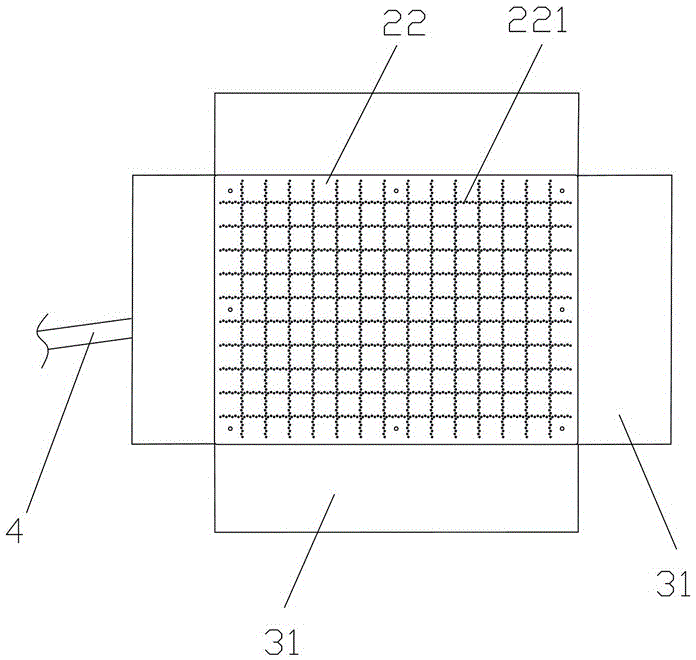

Negative-pressure adsorption welding device and negative-pressure adsorption welding method

InactiveCN106141519ANot prone to distortionImprove flatnessWelding/cutting auxillary devicesAuxillary welding devicesEngineeringWelding deformation

The invention discloses a negative-pressure adsorption welding device which comprises a negative-pressure producing assembly and negative-pressure adsorption plate assemblies; the negative-pressure adsorption plate assemblies comprise a bottom negative-pressure adsorption plate assembly and a top negative-pressure adsorption plate assembly; negative-pressure adsorption chambers are formed between the negative-pressure plate assemblies and the adsorption plate assemblies; the negative-pressure production assembly communicates with the negative-pressure adsorption chambers for extracting air in the negative-pressure adsorption chambers to form vacuum negative pressure; a plurality of negative-pressure adsorption holes are formed in the adsorption plate assemblies for fixing to-be-welded parts onto the adsorption plate assemblies in a negative-pressure adsorption manner to carry out welding operation when vacuum negative pressure is formed in the negative-pressure adsorption chambers. The invention further discloses a negative-pressure adsorption welding method. The negative-pressure adsorption welding device is reasonable in design, is convenient and quick to operate, is small in welding deformation and is capable of reducing working cost and improving working efficiency.

Owner:株洲天瑞精密钣金有限公司

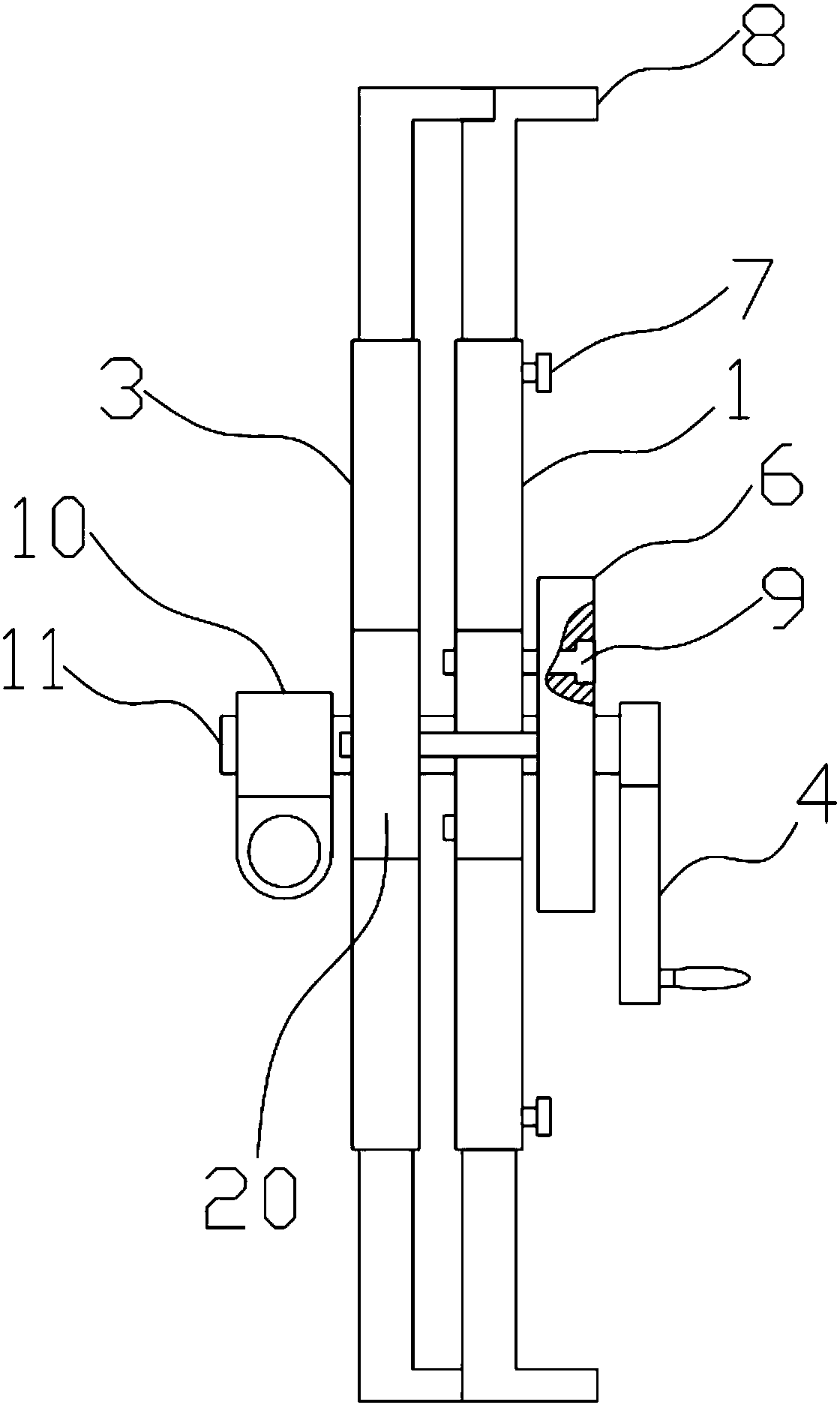

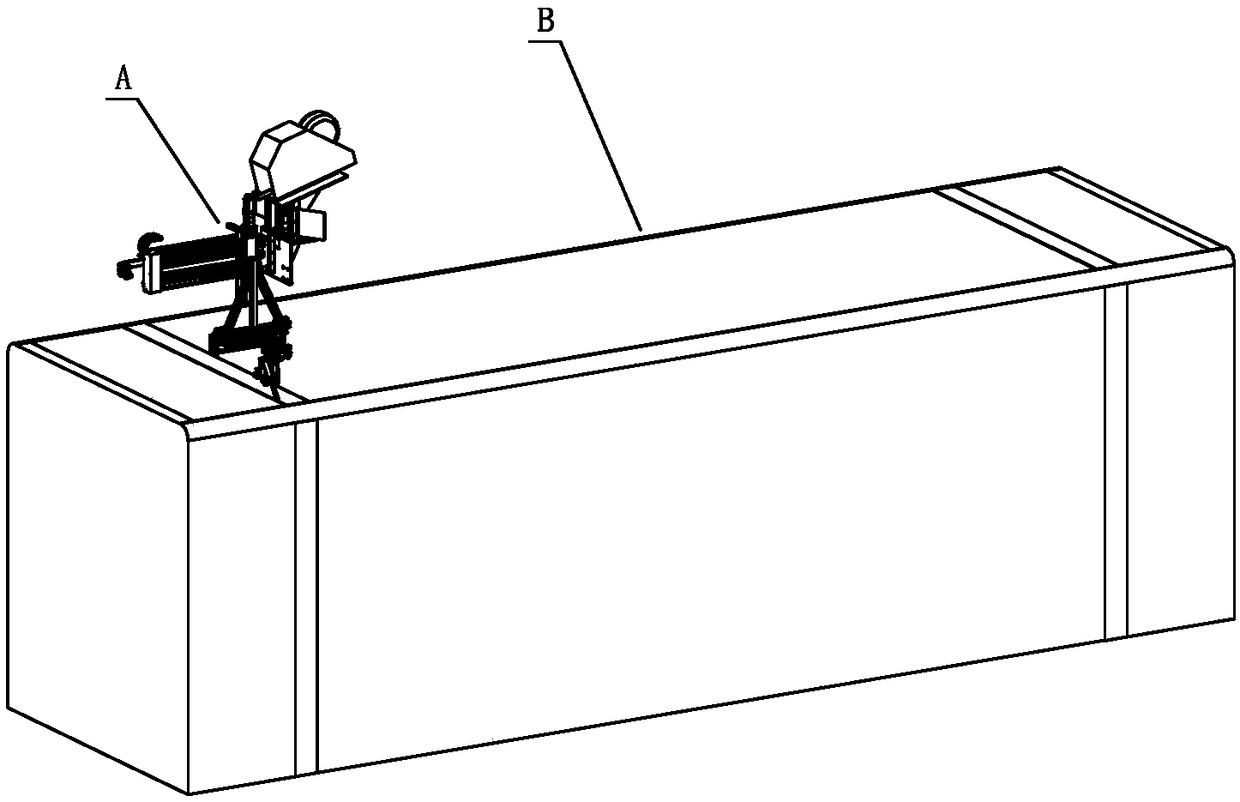

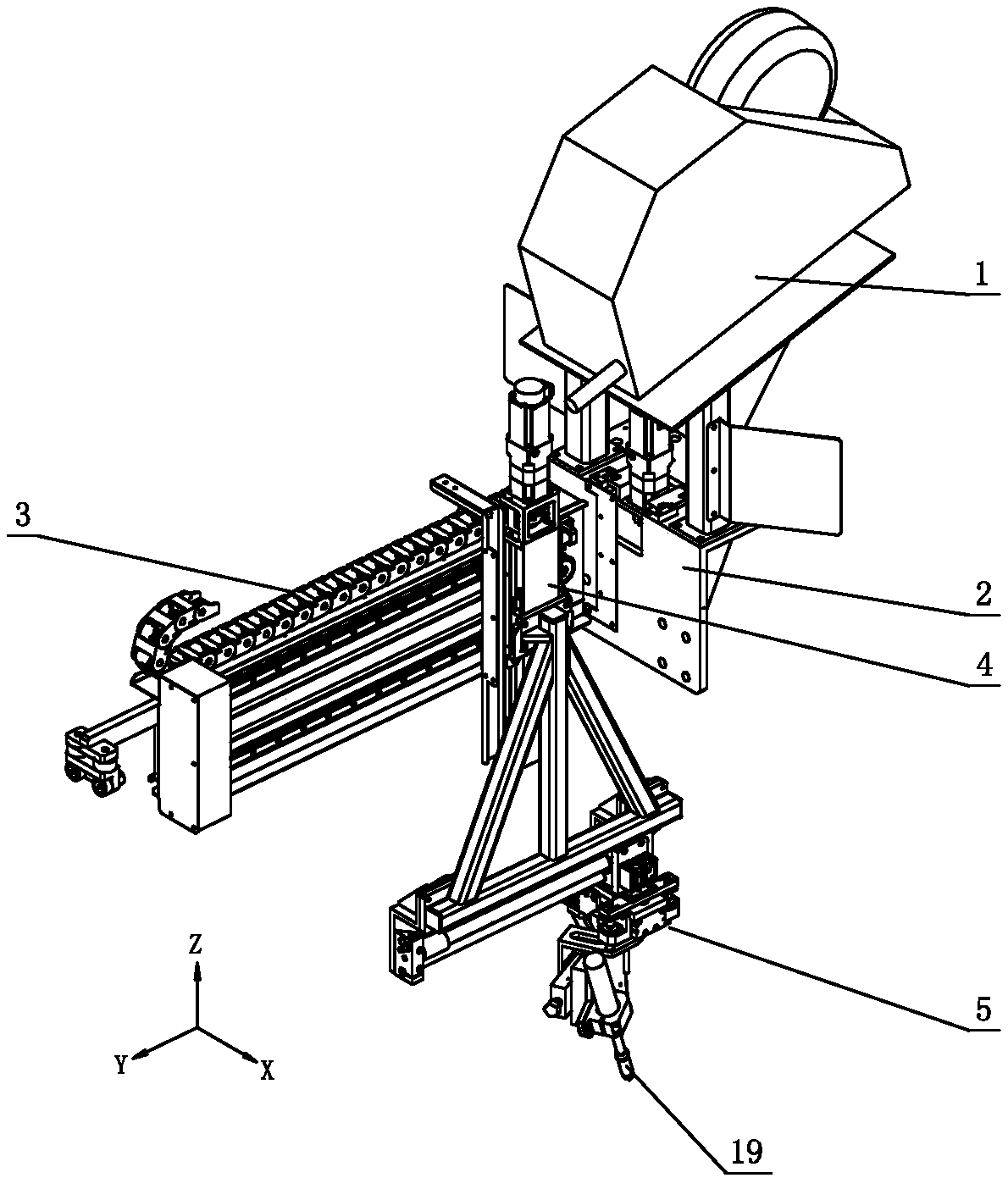

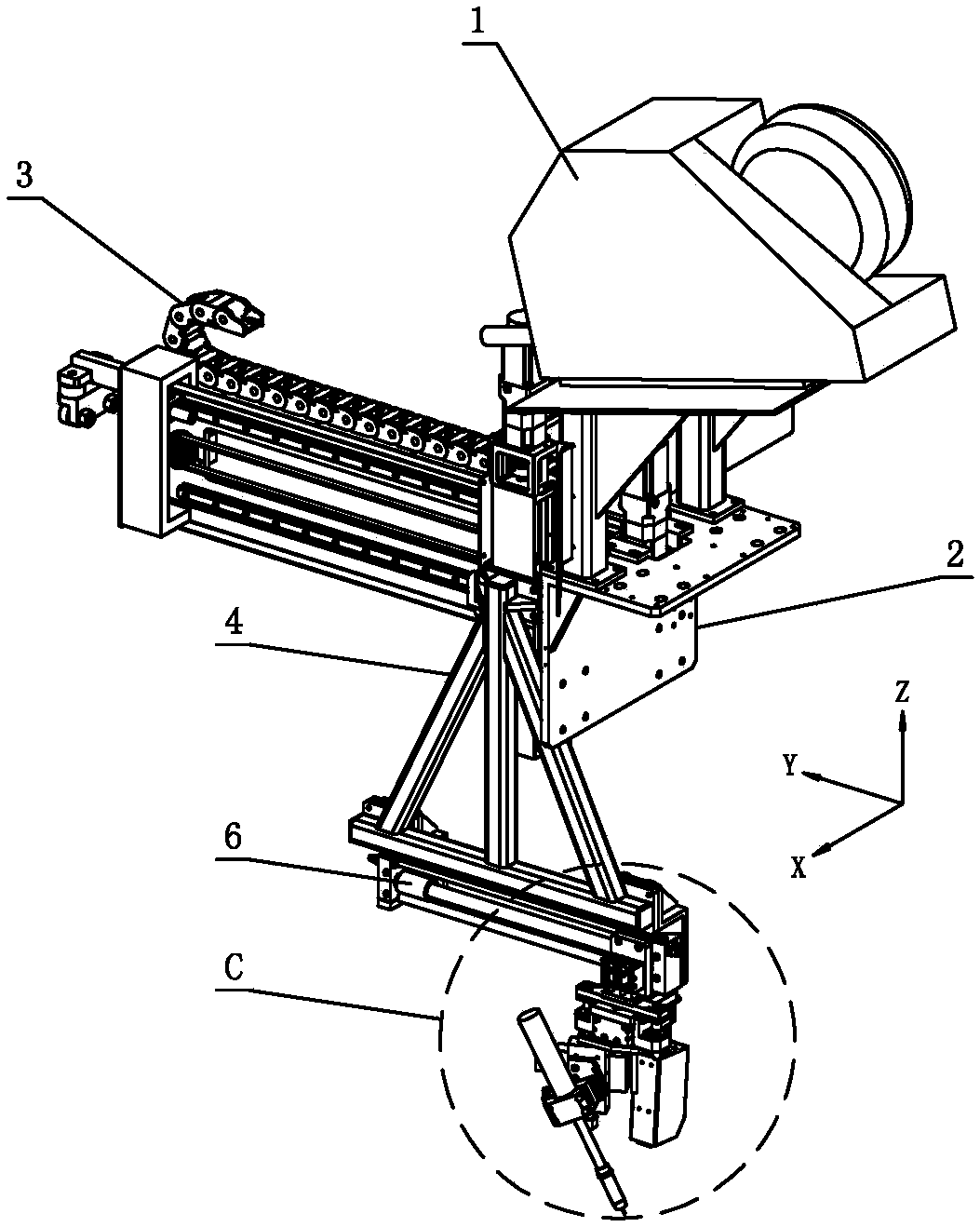

Three-axis real-time tracking welding device capable of conducting rotary symmetric welding

ActiveCN108356458ALow costSimple structureWelding/cutting auxillary devicesAuxillary welding devicesDrive shaftEngineering

A three-axis real-time tracking welding device capable of conducting rotary symmetric welding comprises a welding gun, a laser tracking device, an axial driving mechanism used for driving the weldinggun and / or the laser tracking device to move along the X axis and / or Y axis and / or Z axis relative to an equipment body, and a rotation mechanism at least used for driving the welding gun to rotate ina positioning manner so as to switch the welding angle. The rotation mechanism comprises an air cylinder support assembly connected with the axial driving mechanism, the air cylinder support assemblyis provided with a rotation air cylinder, the welding gun is connected with a drive shaft of the rotation air cylinder, and the rotation air cylinder drives the welding gun to rotate in a positioningmanner. The laser tracking device is relatively fixedly connected with the air cylinder support assembly. The welding gun and / or the laser tracking device are / is arranged on the rotation mechanism. The rotation mechanism is arranged on the axial driving mechanism and integrally moves along the X axis and / or Y axis and / or Z axis under the action of the axial driving mechanism. The three-axis real-time tracking welding device can meet different welding angle requirements, and at least one device can be omitted by adjusting different welding angles.

Owner:GUANGDONG LXD ROBOTICS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com