Manufacture method of extremely-thick steel plate for hydropower station through continuous-cast billet

A technology of extra-thick steel plate and manufacturing method, which is applied in metal rolling and other directions, can solve the problems of high strength of steel plate, high and low temperature impact toughness, etc., and achieve high strength, good weldability of weld seam, uniform and stable low temperature impact toughness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

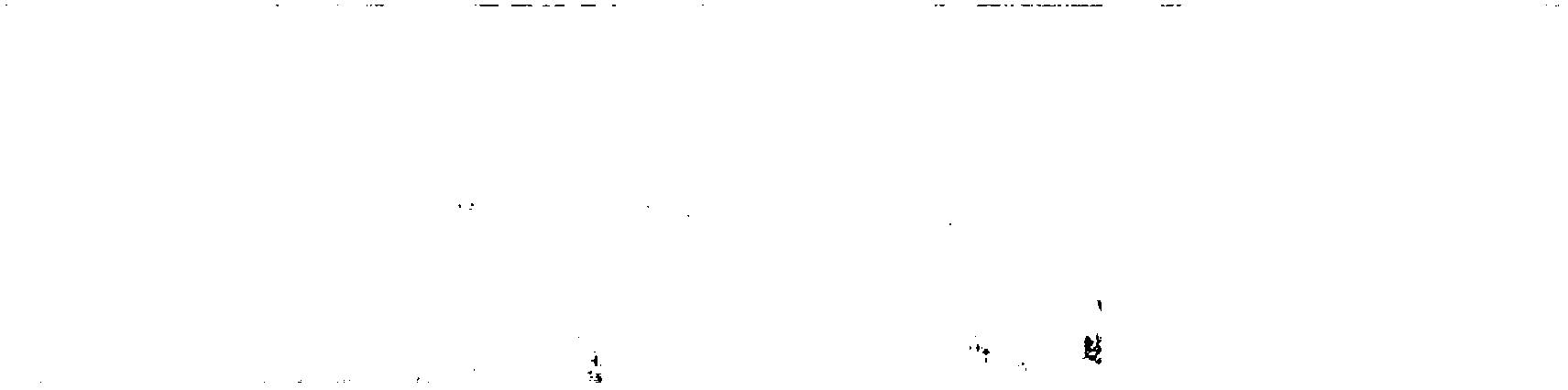

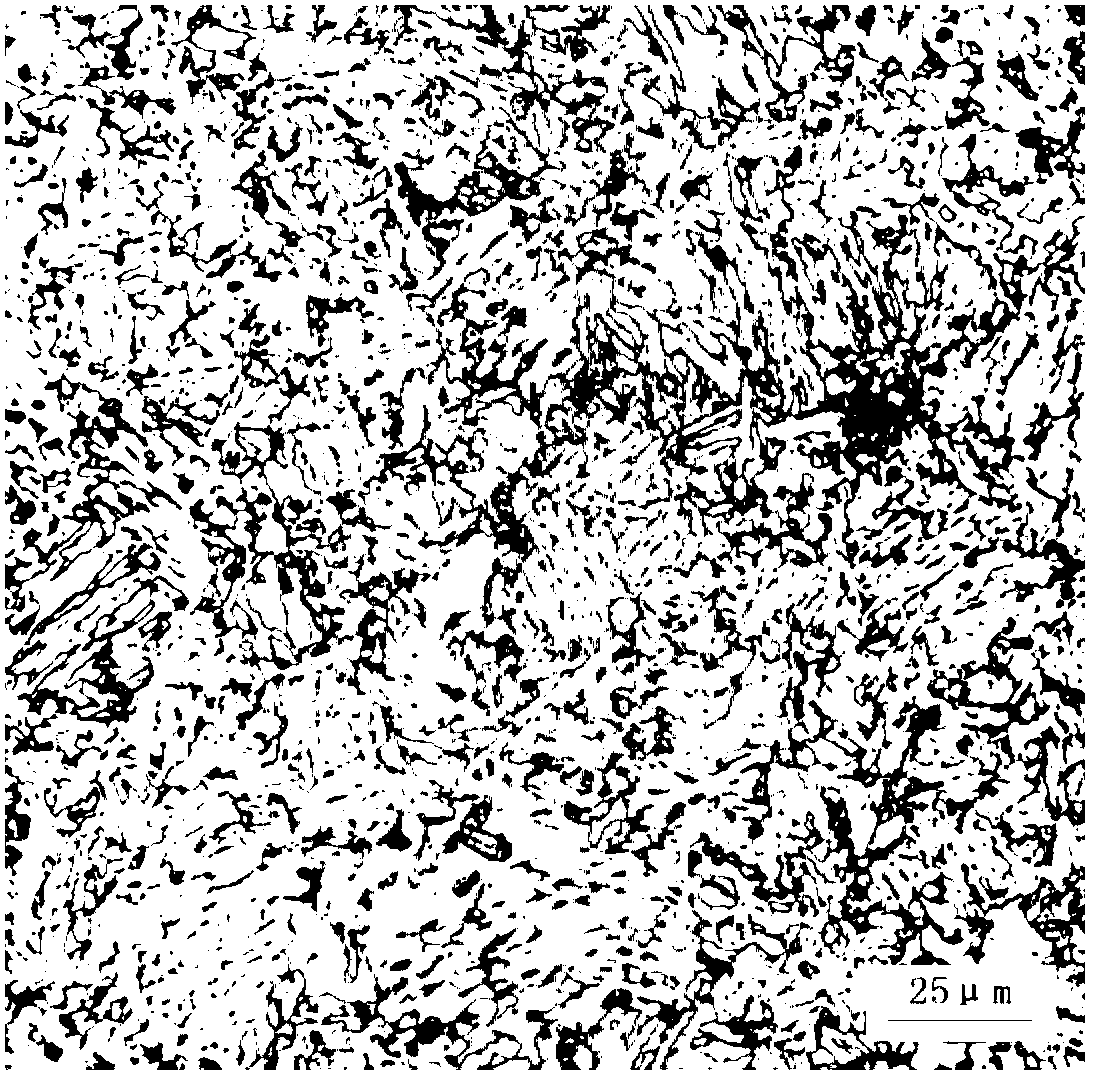

[0036] 400mm specification continuous casting slab is used to produce 110mm specification hydropower steel. Continuous casting adopts dynamic soft reduction technology, and the weight percentage of the chemical composition of the slab is: C: 0.078%, Si: 0.22%, Mn: 1.26%, P: 0.009%, S: 0.001%, Ni: 1.05%, Mo: 0.36 %, B: 0.001%, V: 0.042%, the balance is Fe; Ceq is 0.42%, Pcm is 0.20% (where: Ceq = C+Mn / 6+Si / 24+Ni / 40+Cr / 5+Mo / 4+V / 14, Pcm = C+Si / 30+Mn / 20+Cu / 20+Ni / 60+Cr / 20+Mo / 15+V / 10+5B). Attached is the low-magnification photo of the 400mm thick continuous casting slab figure 1 As shown, the segregation grade is ≤ grade 1 of class C, and the porosity is ≤ grade 1.0. The slab heating temperature is 1230°C, in the furnace for 320min, and the furnace temperature is 1200°C. 19MPa high-pressure water is used for descaling before rolling, the rolling start temperature is 1170°C, the reduction rate of each pass is within 15% to 20%, the final rolling temperature is 990°C, the thicknes...

Embodiment 2

[0042] Example 2 On the basis of Example 1, a 400 mm thick steel billet is used to manufacture a 150 mm thick steel plate, and the compression ratio of the steel plate is further reduced. Continuous casting adopts dynamic soft reduction technology, and the weight percentage of the chemical composition of the slab is: C: 0.083%, Si: 0.23%, Mn: 1.30%, P: 0.009%, S: 0.002%, Ni: 1.10%, Mo: 0.38 %, B: 0.0013%, V: 0.043%, the balance is Fe; Ceq is 0.43%, and Pcm is 0.21%. Attached is the low-magnification photo of the 400mm thick continuous casting slab Figure 5 As shown, the segregation grade is ≤ grade 1 of class C, and the porosity is ≤ grade 1.0. The slab heating temperature is 1240°C, in the furnace for 330min, and the furnace temperature is 1200°C. Before rolling, 19MPa high-pressure water is used for descaling. The rolling start temperature is 1170°C. The reduction rate of each pass is within 15% to 20%. The final rolling temperature is 1000°C. 2.67. The steel plate ente...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| percent by volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com