A solid gas-shielded welding wire for high-strength and high-toughness pipeline steel

A gas-shielded welding wire, high-strength and high-toughness technology, applied in the direction of welding medium, welding equipment, welding/cutting medium/material, etc., to achieve good low-temperature impact toughness and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment A1-A5

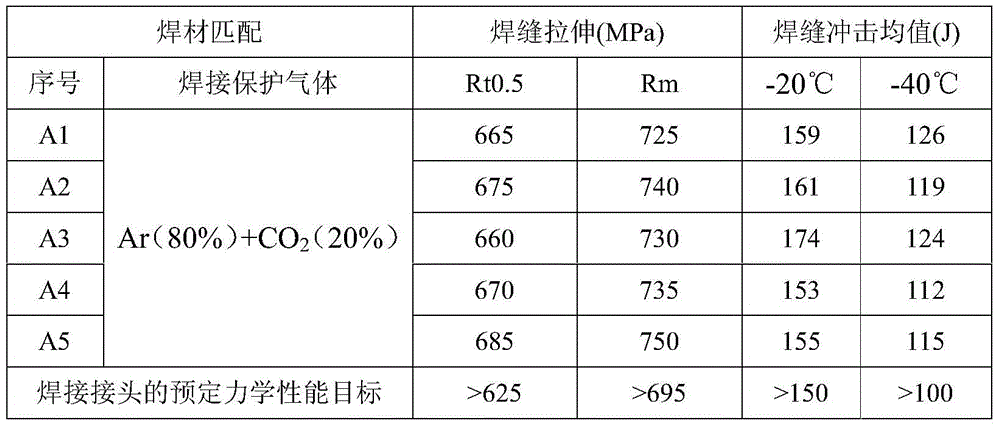

[0027] Welding wire steel was smelted in a vacuum induction furnace, and processed into a solid gas-shielded welding wire with a diameter of 1.4mm through forging, hot rolling, annealing, drawing, copper plating, winding and other processes. Show.

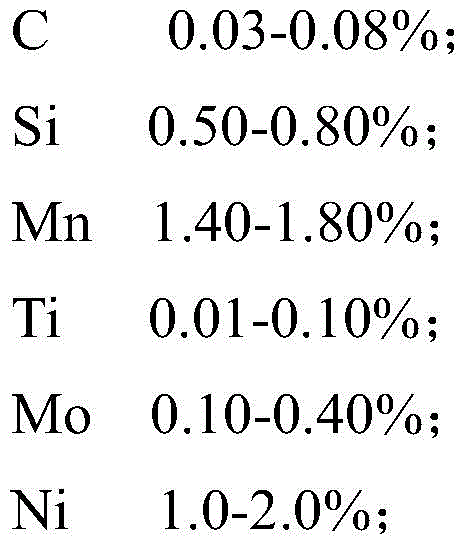

[0028] Table 1 lists the mass percentage ratios of the chemical elements in Examples A1-A5 of this case.

[0029] Table 1. (wt%, the balance is Fe and other unavoidable impurities)

[0030] serial number

C

Si

mn

Ti

Mo

Ni

C+Mn / 10

CE*

A1

0.034

0.78

1.77

0.018

0.38

1.06

0.211

0.476

A2

0.052

0.61

1.68

0.056

0.25

1.43

0.220

0.477

A3

0.063

0.66

1.61

0.078

0.21

1.58

0.224

0.479

A4

0.069

0.54

1.53

0.092

0.18

1.71

0.222

0.474

A5

0.078

0.51

1.42

0.033

0.12

1.98

0.220

0.471

[0031] Note*: CE=C+Mn / 6+(Ni+Cu) / 15+(Cr+Mo+V) / 5

[0032] Using Ar (80%) +...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com