Patents

Literature

413 results about "Solid gas" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Solid to Gas. The process which is used to convert solid to gas is known as sublimation. It diverts the flow of instinctual energy and solid converts into gas without passing through the liquid stage. Only some compounds like solid carbon dioxide can go through the process at normal atmospheric pressure.

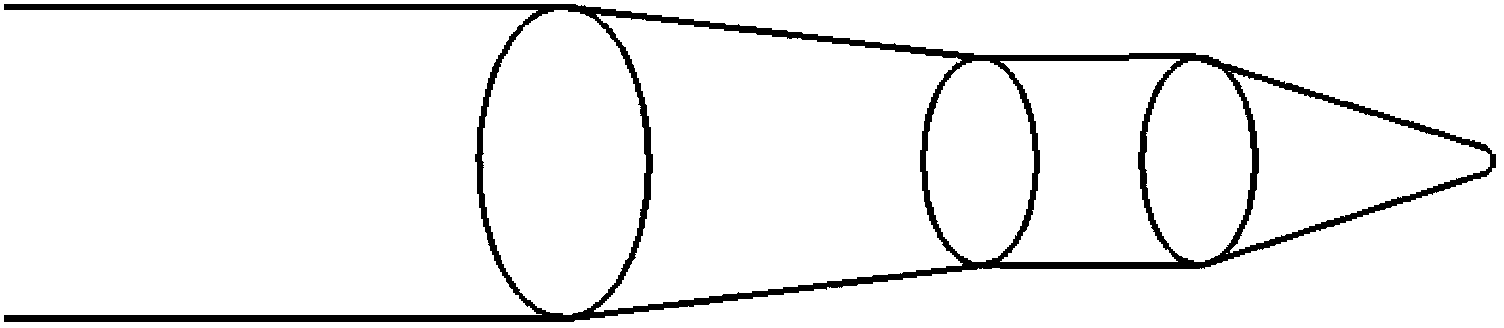

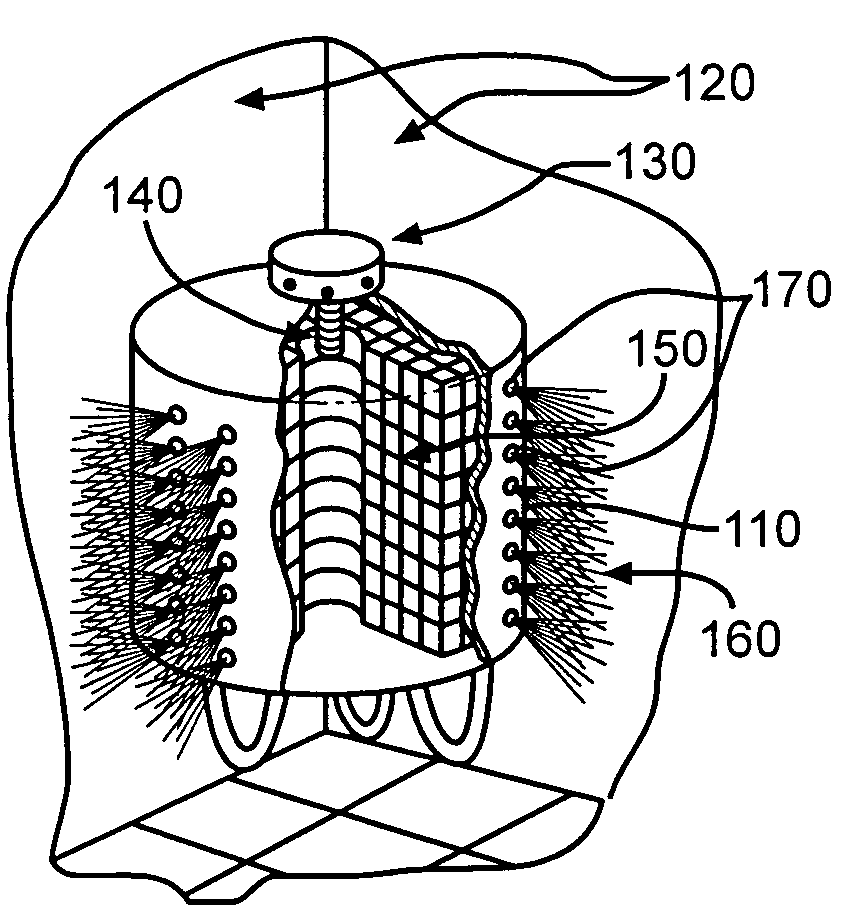

Method and apparatus for producing high efficiency fibrous media incorporating discontinuous sub-micron diameter fibers, and web media formed thereby

InactiveUS6315806B1Increase distanceReduce resistanceFilament/thread formingLoose filtering material filtersMean diameterFiber

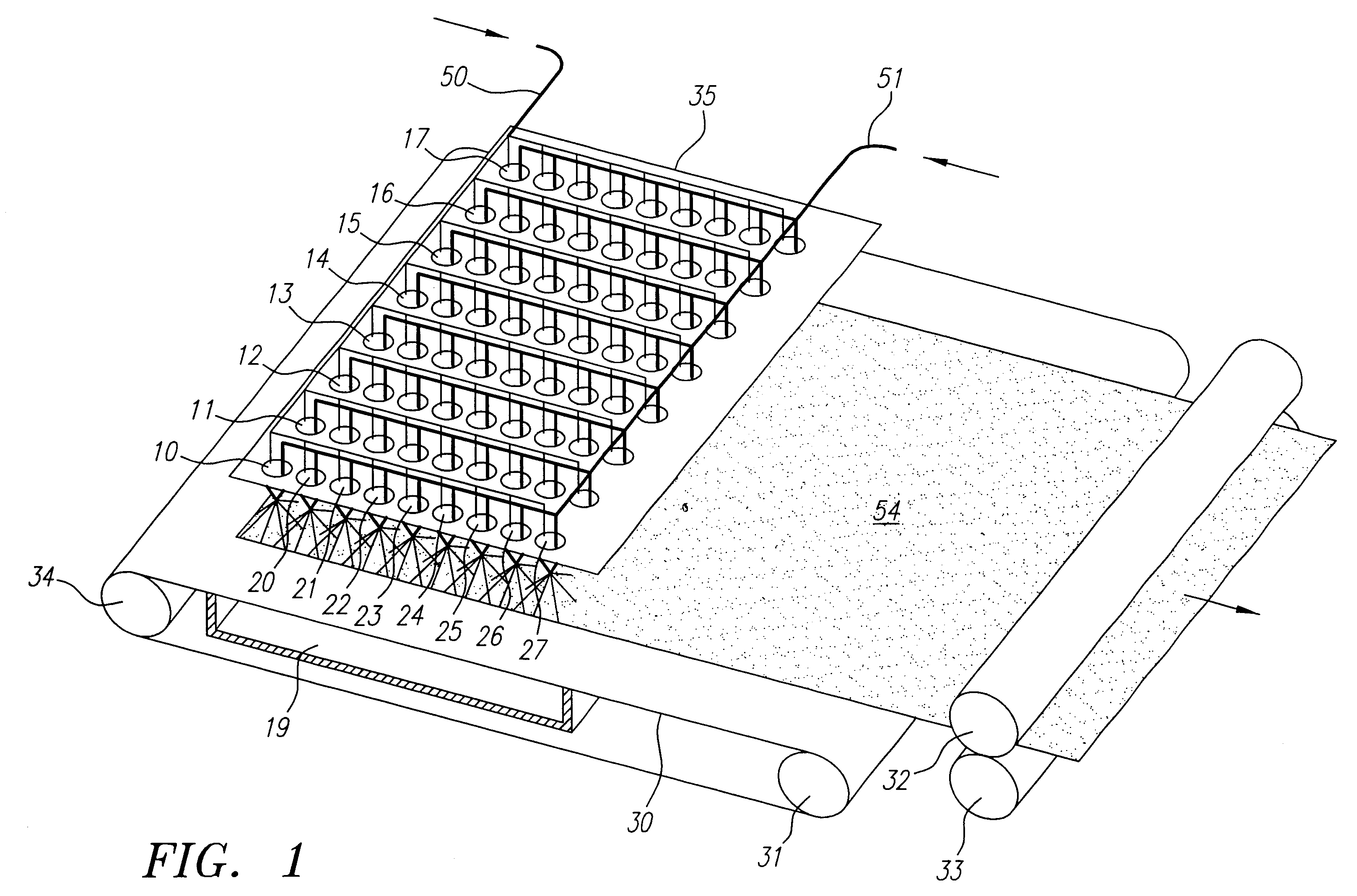

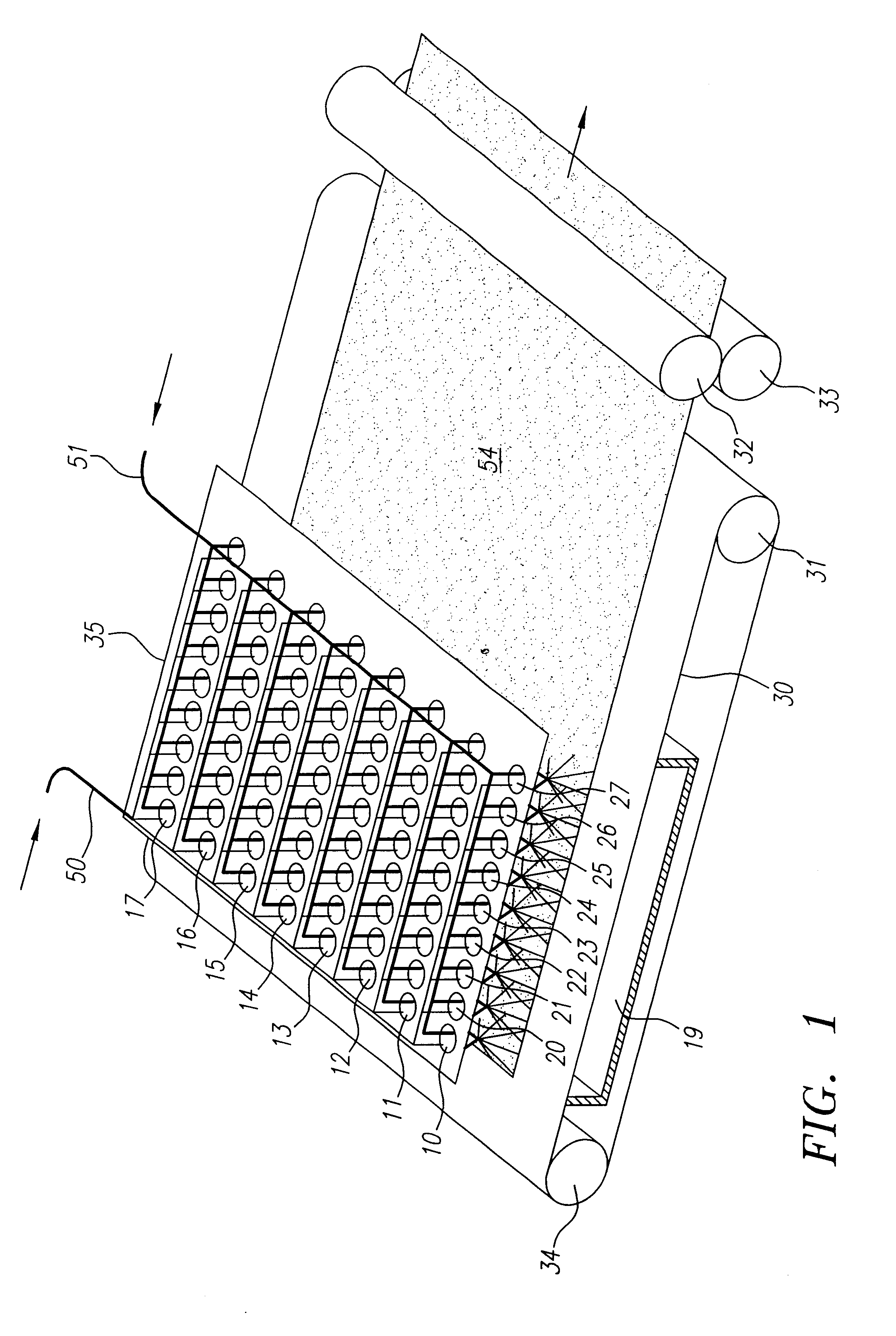

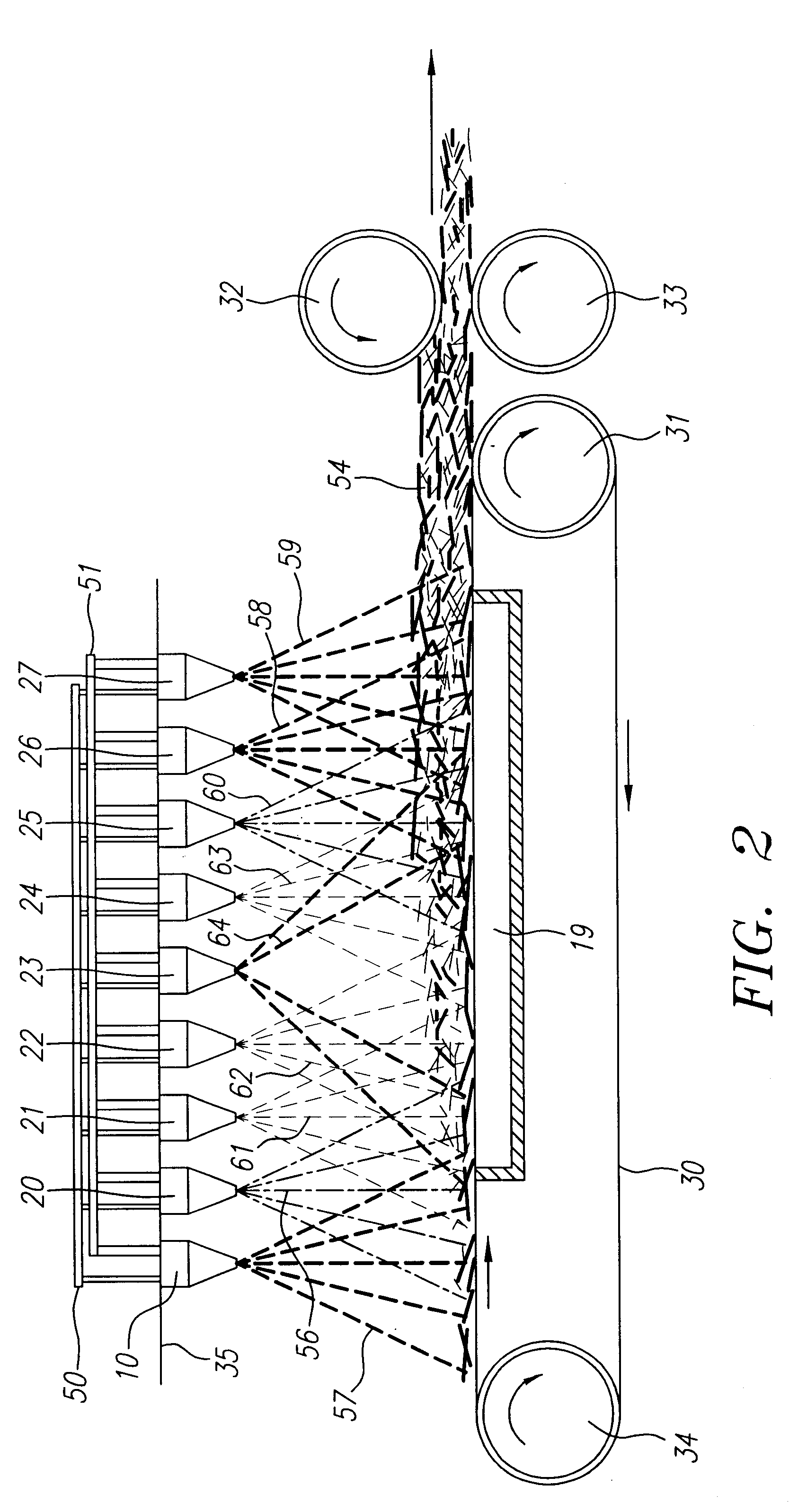

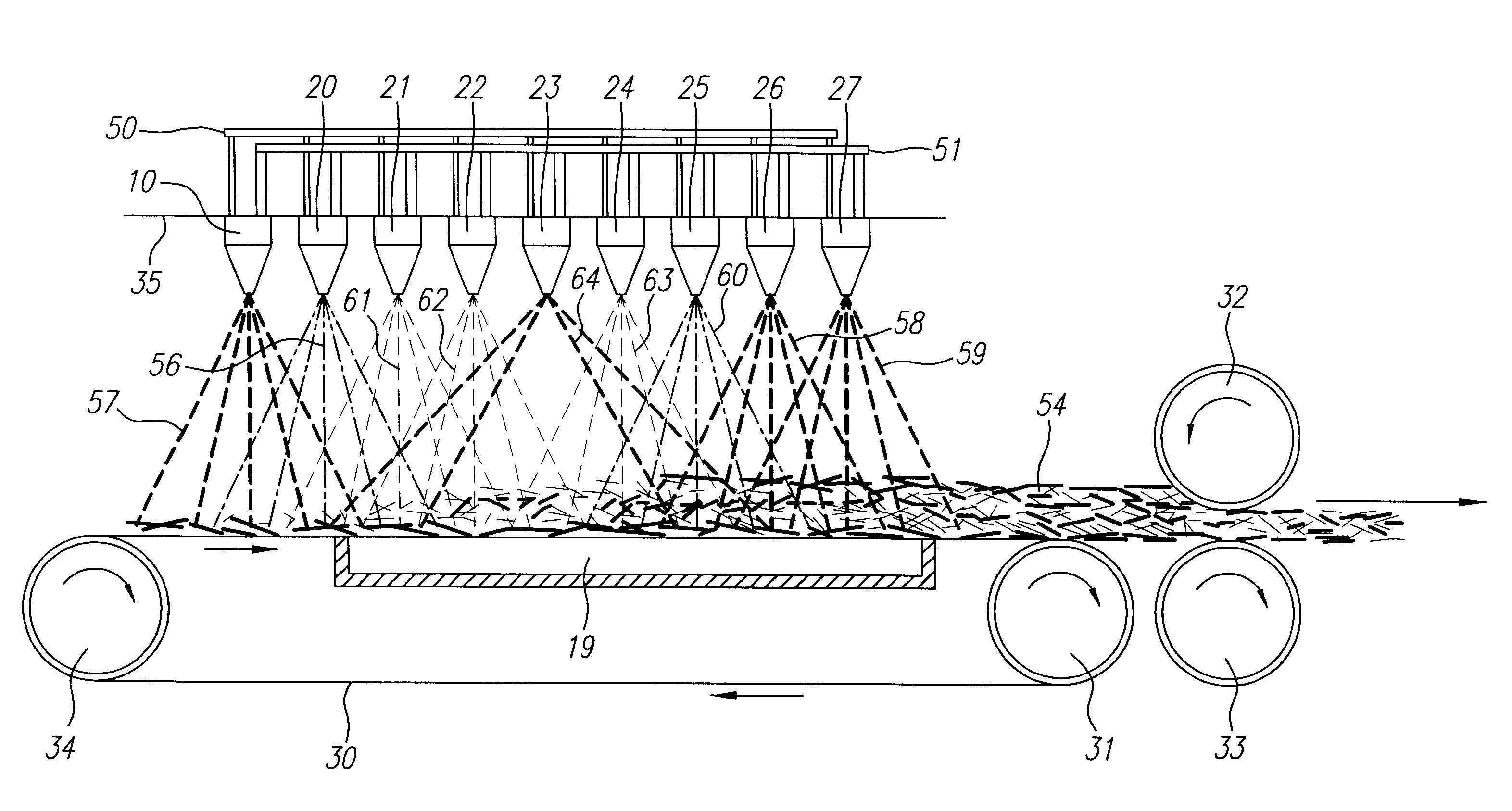

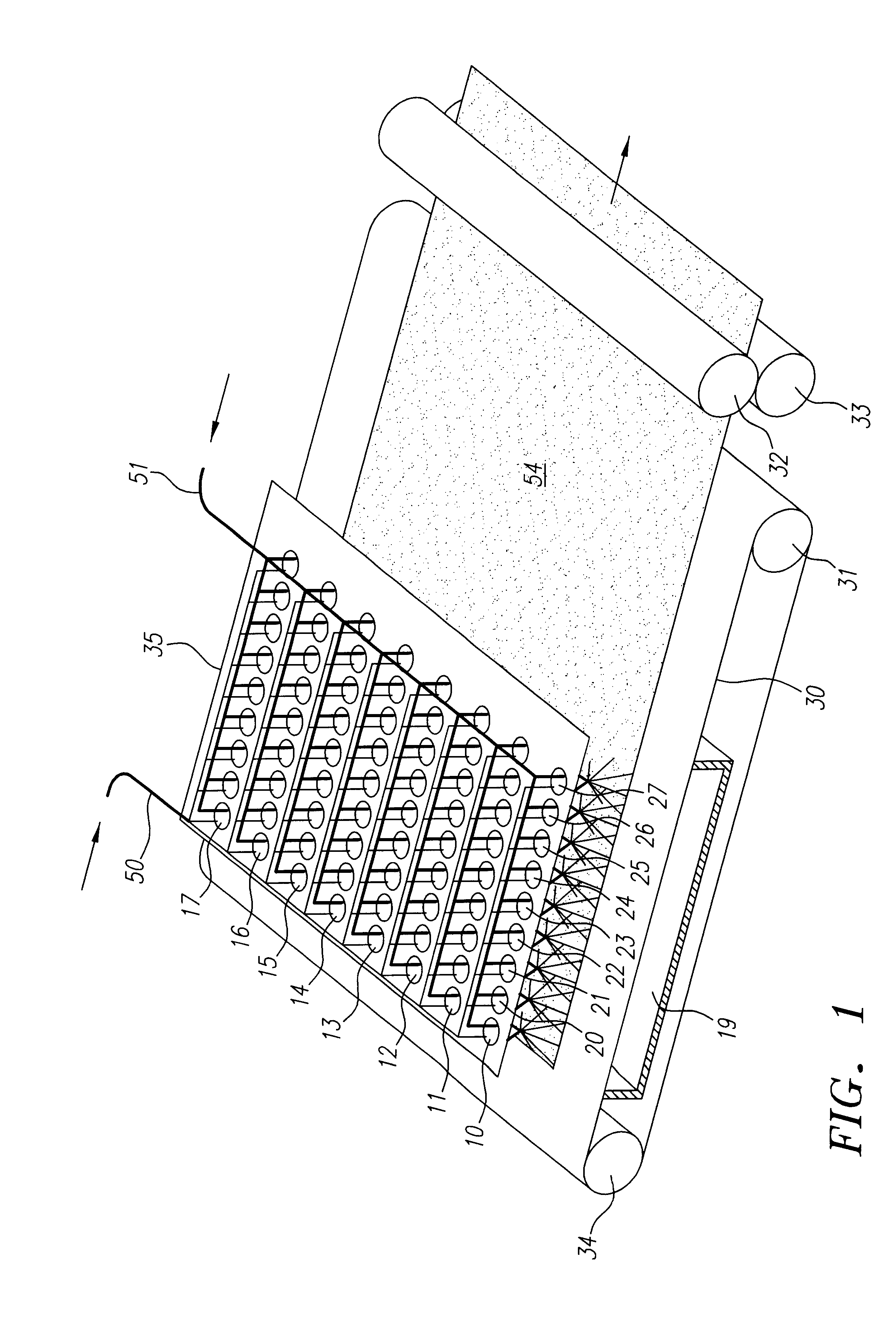

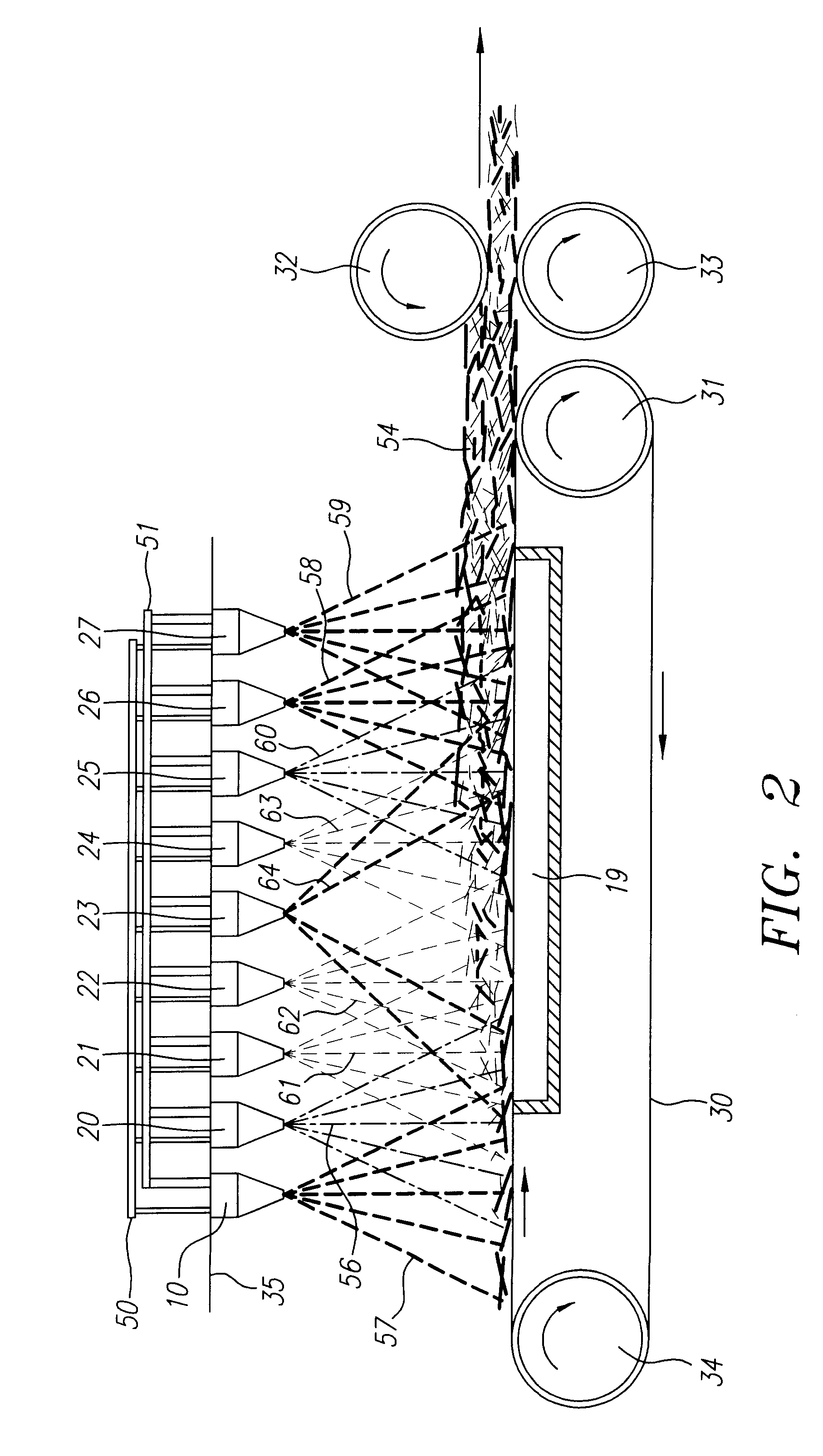

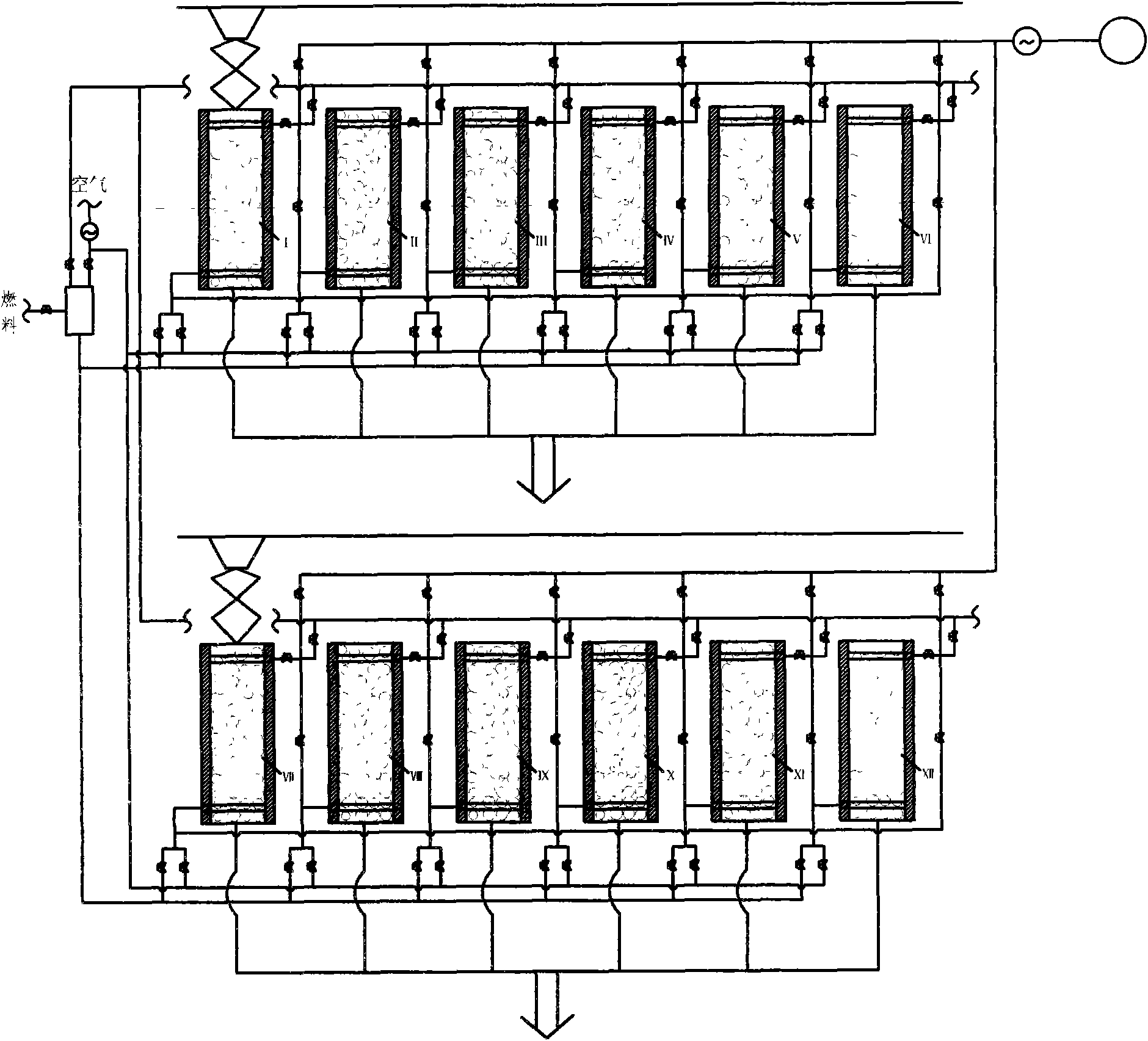

A composite filtration medium web of fibers containing a controlled dispersion of a mixture of sub-micron and greater than sub-micron diameter polymeric fibers is described. The filtration medium is made by a two dimensional array of cells, each of which produces a single high velocity two-phase solids-gas jet of discontinuous fibers entrained in air. The cells are arranged so that the individual jets are induced to collide in flight with neighboring jets in their region of fiber formation, to cause the individual nascent fibers of adjacent jets to deform and become entangled with and partially wrap around each other at high velocity and in a localized fine scale manner before they have had an opportunity to cool to a relatively rigid state. The cells are individually adjusted to control the mean diameters, lengths and trajectories of the fibers they produce. Certain cells are adjusted to generate a significant percentage of fibers having diameters less than one micron diameter, and which are relatively shorter in length and certain other cells are adjusted to generate a significant percentage of structure-forming reinforcing fibers having diameters greater than one micron diameter which are relatively longer in length. By employing appropriate close positioning and orientation of the cells in the array, the sub-micron fibers are caused to promptly entangle with and partially wrap around the larger reinforcing fibers. The larger fibers thereby trap and immobilize the sub-micron diameter fibers in the region of formation, to minimize the tendency of sub-micron diameter fibers to clump, agglomerate, or rope together in flight. Also, the larger fibers in flight are made to form a protective curtain to prevent the sub-micron fibers from being carried off by stray air currents.

Owner:THE PROCTER & GAMBLE COMPANY

Method and apparatus for producing high efficiency fibrous media incorporating discontinuous sub-micron diameter fibers, and web media formed thereby

InactiveUS6183670B1Increase collisionImprove compactionFilament/thread formingAuxillary shaping apparatusMean diameterFiber

A composite filtration medium web of fibers containing a controlled dispersion of a mixture of sub-micron and greater than sub-micron diameter polymeric fibers is described. The filtration medium is made by a two dimensional array of cells, each of which produces a single high velocity two-phase solids-gas jet of discontinuous fibers entrained in air. The cells are arranged so that the individual jets are induced to collide in flight with neighboring jets in their region of fiber formation, to cause the individual nascent fibers of adjacent jets to deform and become entangled with and partially wrap around each other at high velocity and in a localized fine scale manner before they have had an opportunity to cool to a relatively rigid state. The cells are individually adjusted to control the mean diameters, lengths and trajectories of the fibers they produce. Certain cells are adjusted to generate a significant percentage of fibers having diameters less than one micron diameter, and which are relatively shorter in length and certain other cells are adjusted to generate a significant percentage of structure-forming reinforcing fibers having diameters greater than one micron diameter which are relatively longer in length. By employing appropriate close positioning and orientation of the cells in the array, the sub-micron fibers are caused to promptly entangle with and partially wrap around the larger reinforcing fibers. The larger fibers thereby trap and immobilize the sub-micron diameter fibers in the region of formation, to minimize the tendency of sub-micron diameter fibers to clump, agglomerate, or rope together in flight. Also, the larger fibers in flight are made to form a protective curtain to prevent the sub-micron fibers from being carried off by stray air currents.

Owner:THE PROCTER & GAMBLE COMPANY

Method and system using liquid dielectric for electrostatic power generation

InactiveUS20060077762A1Not easy to wearImprove uniformityMechanical recordingRecord information storageEngineeringElectret

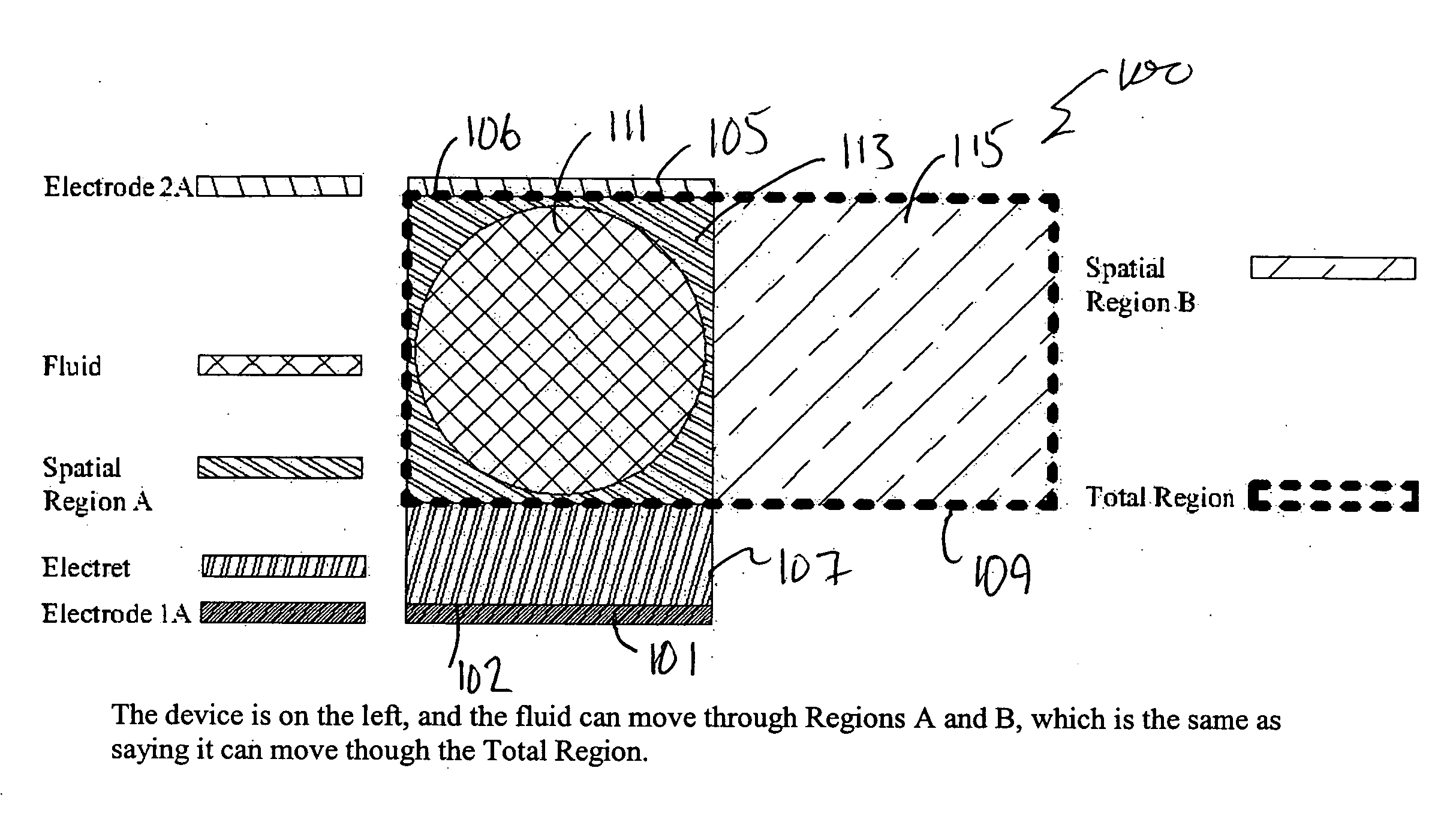

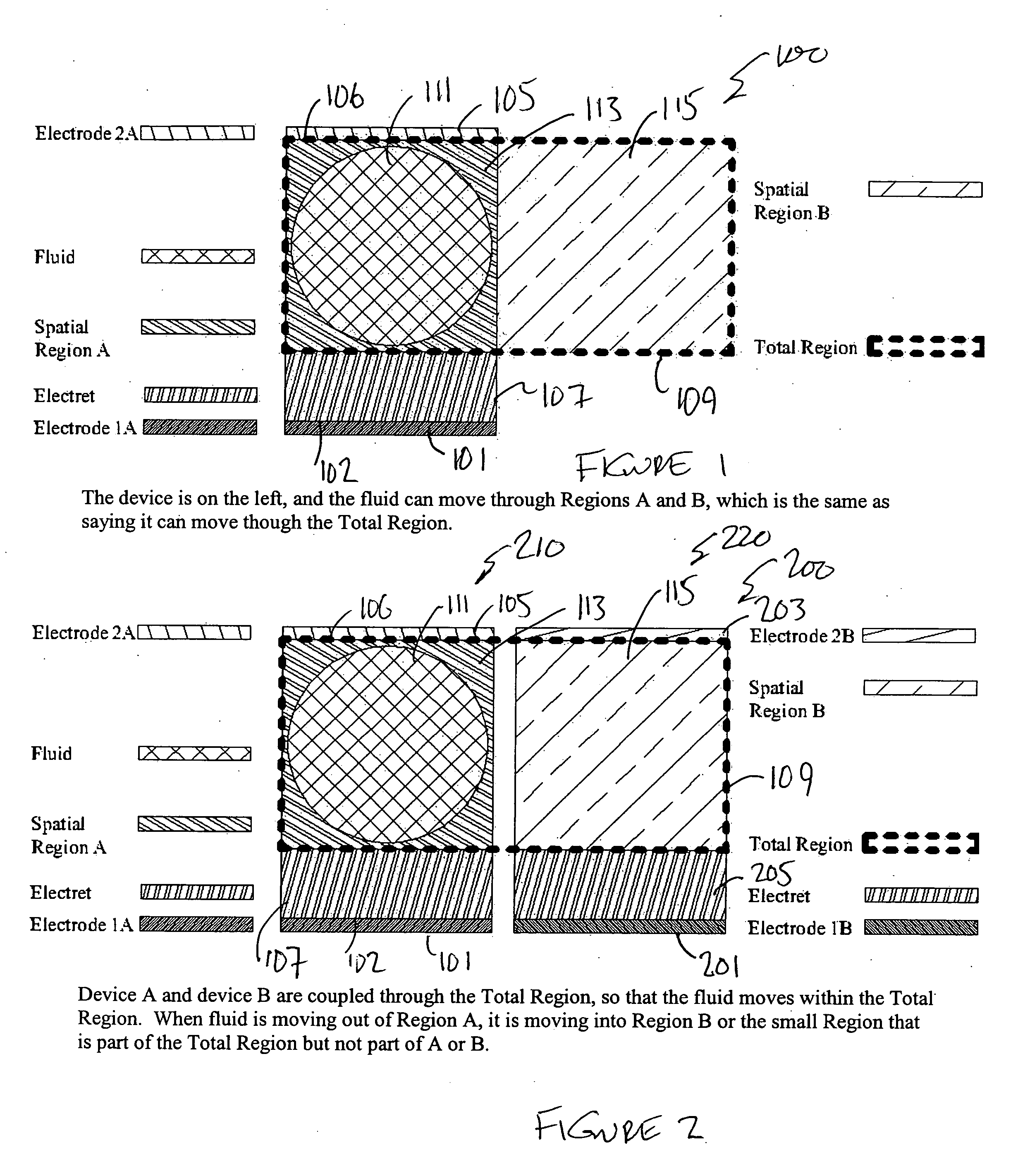

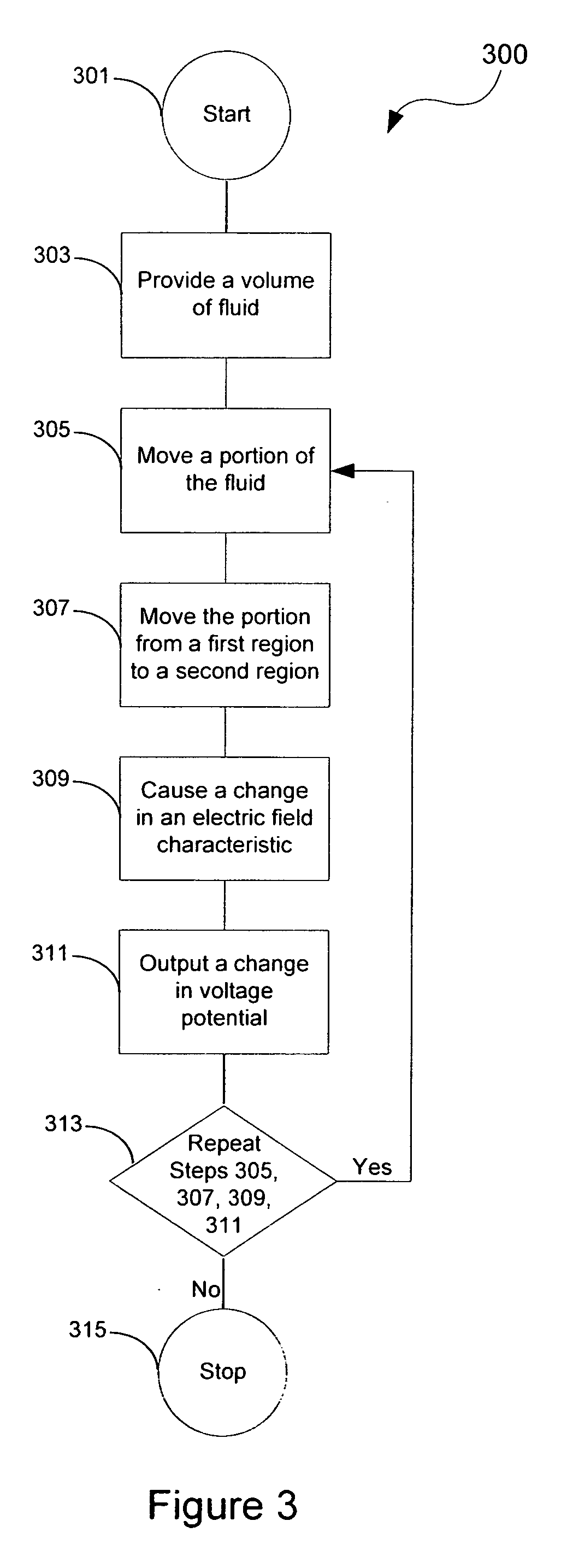

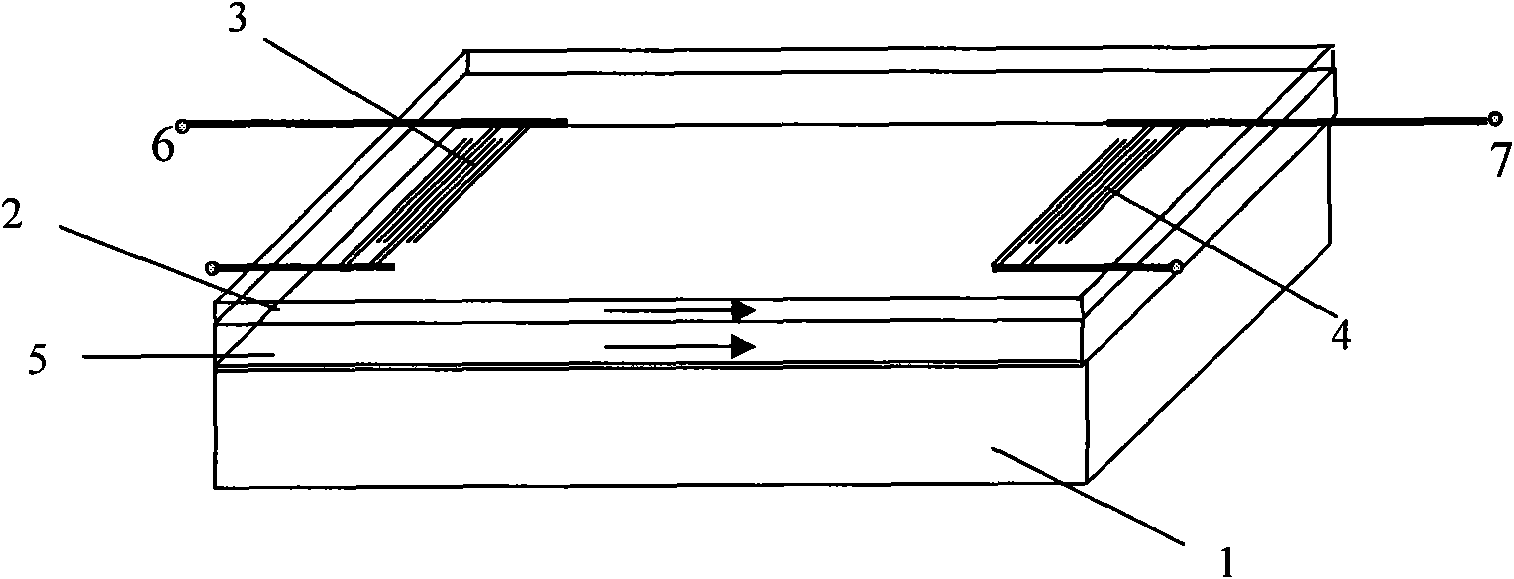

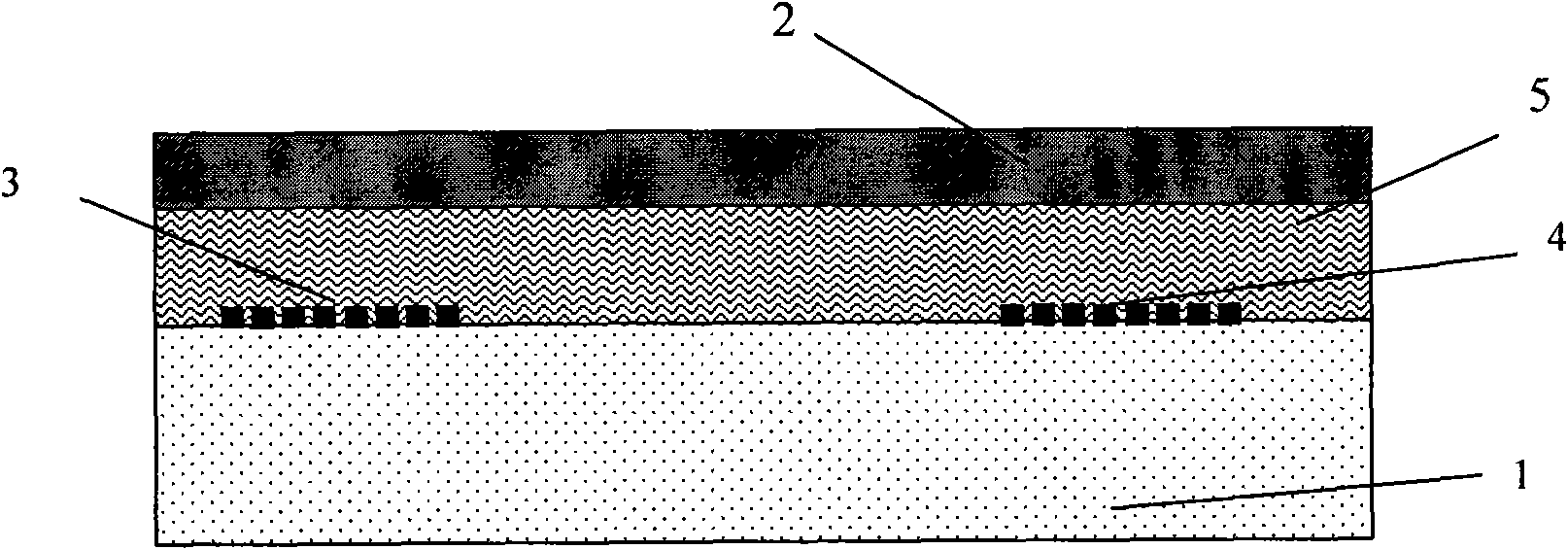

A system and method for generating power. The system has a first electrode member comprising a first region and a second electrode member comprising a second region. Preferably, the second electrode member is coupled to the first electrode member. An electret is coupled between the first electrode member and the second electrode member. The system has a spatial region provided between the first region of the first electrode member and the second region of the second electrode member. A volume of fluid (e.g., liquid, liquid and solids, gas and liquid, solids and gases) is provided between the first region and the second region and is adapted to move between the first region and the second region to cause a change in an electric field characteristic within a portion of the spatial region by the movement of at least a portion of the fluid within the portion of the spatial region to generate a change in voltage potential between the first electrode and the second electrode.

Owner:CALIFORNIA INST OF TECH

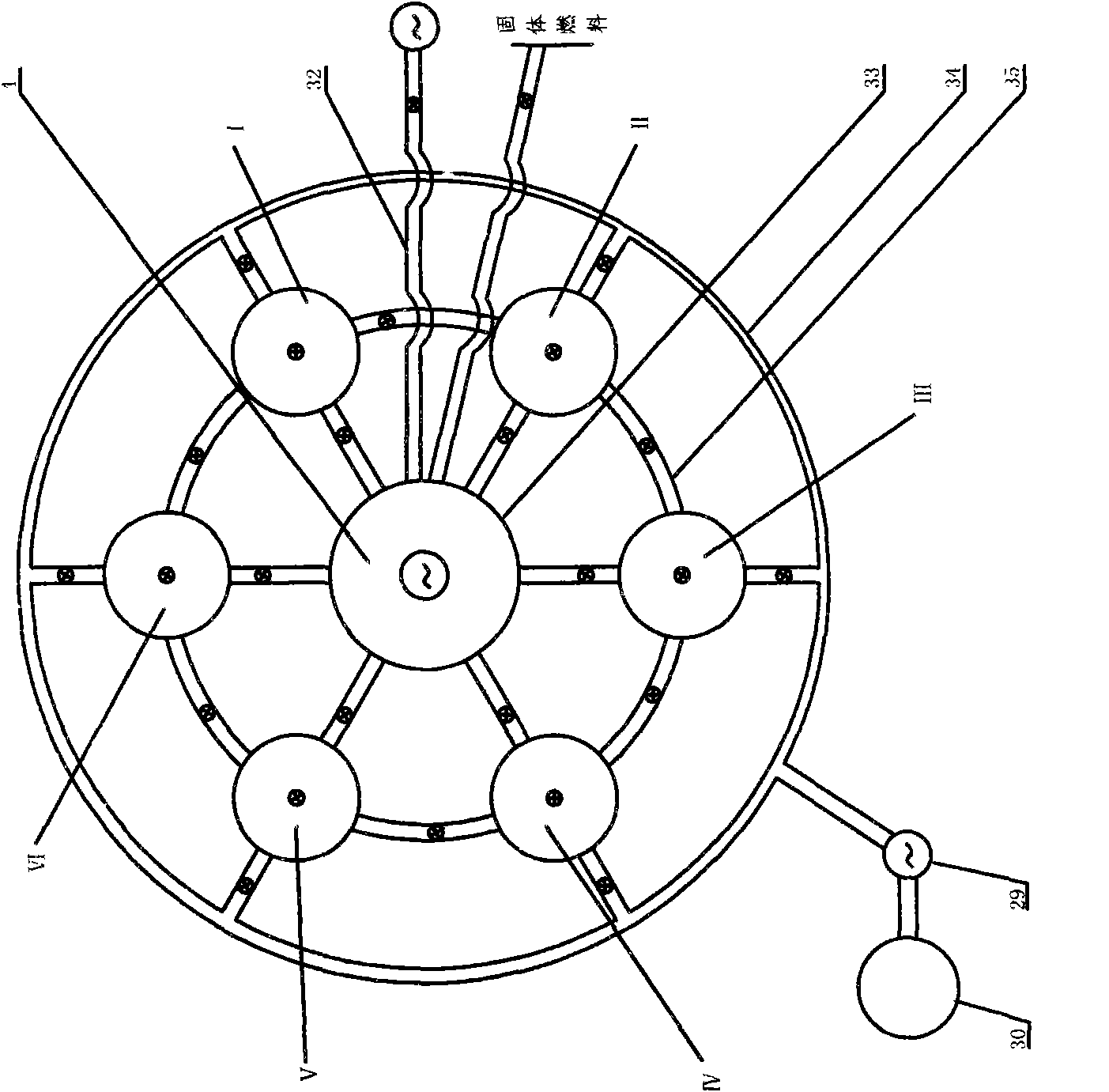

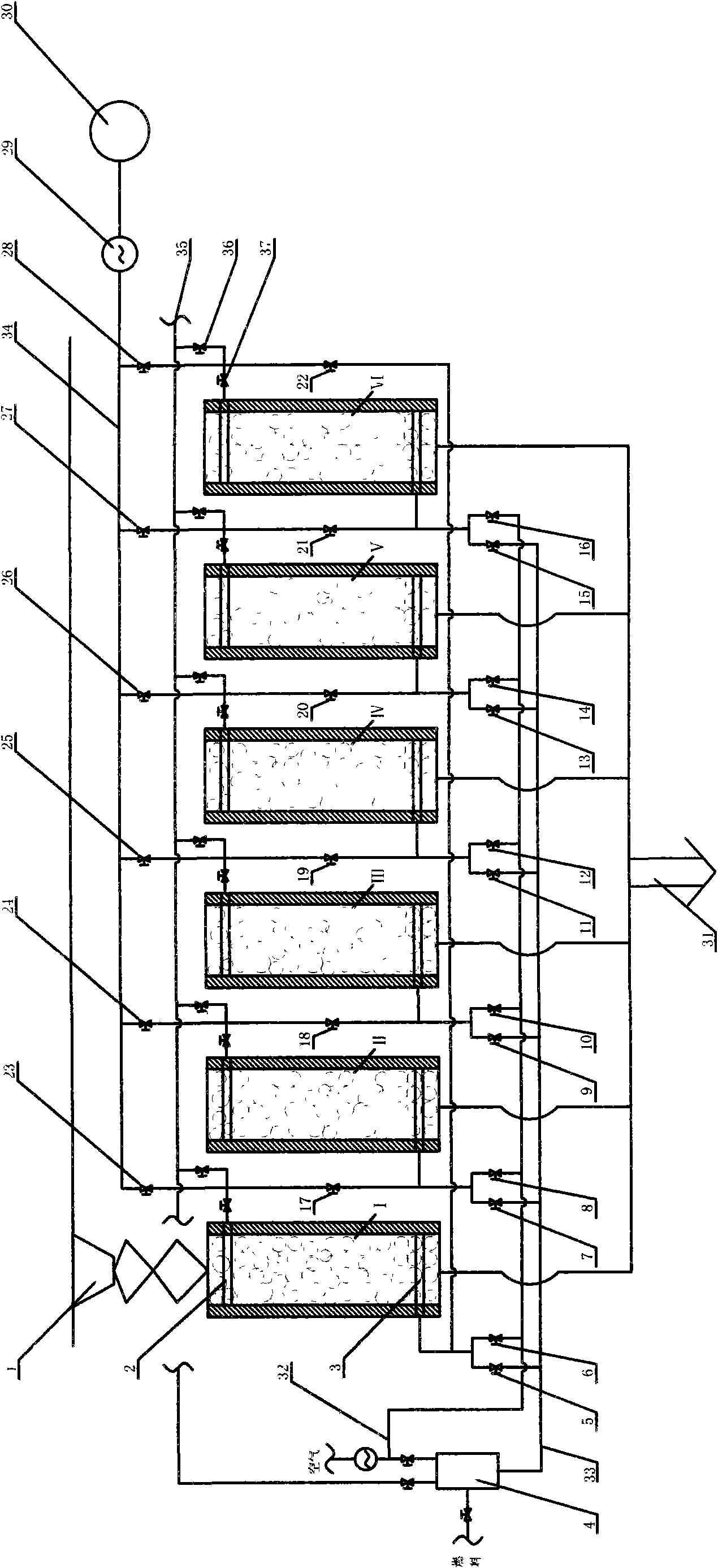

Water-gas two-phase adsorption-desorption-seepage experimental system and method for loaded coal containing methane

ActiveCN102901803AAccurate detectionAccurate measurementFuel testingPermeability/surface area analysisWater bathsHigh pressure

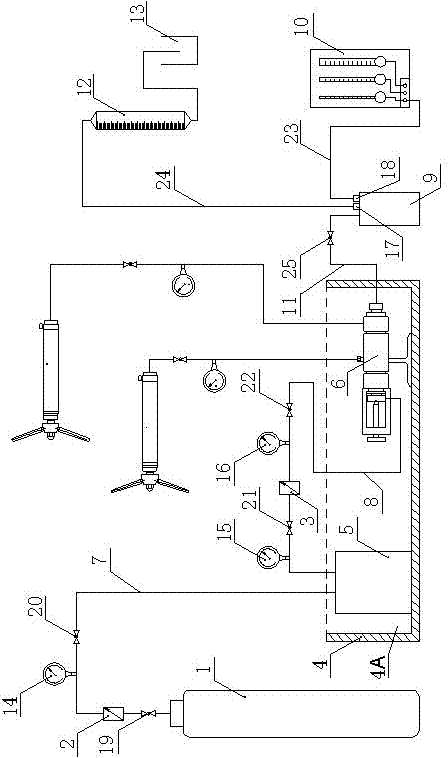

The invention discloses a water-gas two-phase adsorption-desorption-seepage experimental system and method for loaded coal containing methane. The water-gas two-phase adsorption-desorption-seepage experimental system for loaded coal containing methane comprises a pressure loading part, wherein the pressure loading part comprises a tank body for containing a constant-temperature water bath, a reference pot and a coal sample holder are arranged in the tank body, the gas inlet of the reference pot is connected with a high-pressure methane delivery pipeline, the gas outlet of the reference pot is connected with the gas inlet of the coal sample holder through a connecting pipeline, and the gas outlet of the coal sample holder is connected with a water-gas separation device. The water-gas two-phase seepage experimental method for loaded coal containing methane is carried out on the basis of the experimental system. By changing different loading conditions, loading paths and experimental temperatures, adsorption-desorption experiments and methane seepage experiments for the loaded coal containing methane under the conditions of different solid-gas thermal coupling can be realized, and water-gas two-phase seepage experiments and methane adsorption-desorption experiments under the condition of different moisture contents also can be realized.

Owner:HENAN POLYTECHNIC UNIV

Fire extinguishing agent

ActiveCN103007479AImprove fire extinguishing efficiencyReduce dispersion speedFire extinguisherMass ratioSolid particle

The invention provides a fire extinguishing agent. The fire extinguishing agent is prepared by mixing and dispersing hydrophobic solid particles, water-soluble surfactant and water solution according to mass ratio of (5-100):(0.001-2):100. The fire extinguishing agent can simultaneously play stifling, cooling and chemical inhibition roles, and the fire extinguishing efficiency is high. Compared with the existing fire extinguishing agent, according to the fire extinguishing agent, due to addition of the surfactant in the water phase, the dispersion of rotating speed in preparation process can be lowered, the dispersion time can be shortened, and the preparation efficiency can be improved; and with the fire extinguishing agent, the adhesion property of solid gas interface and liquid gas interface can be greatly improved, the usage amount for extinguishing fire can be greatly reduced, and the fire extinguishing property can be obviously improved.

Owner:XIAN UNIV OF SCI & TECH

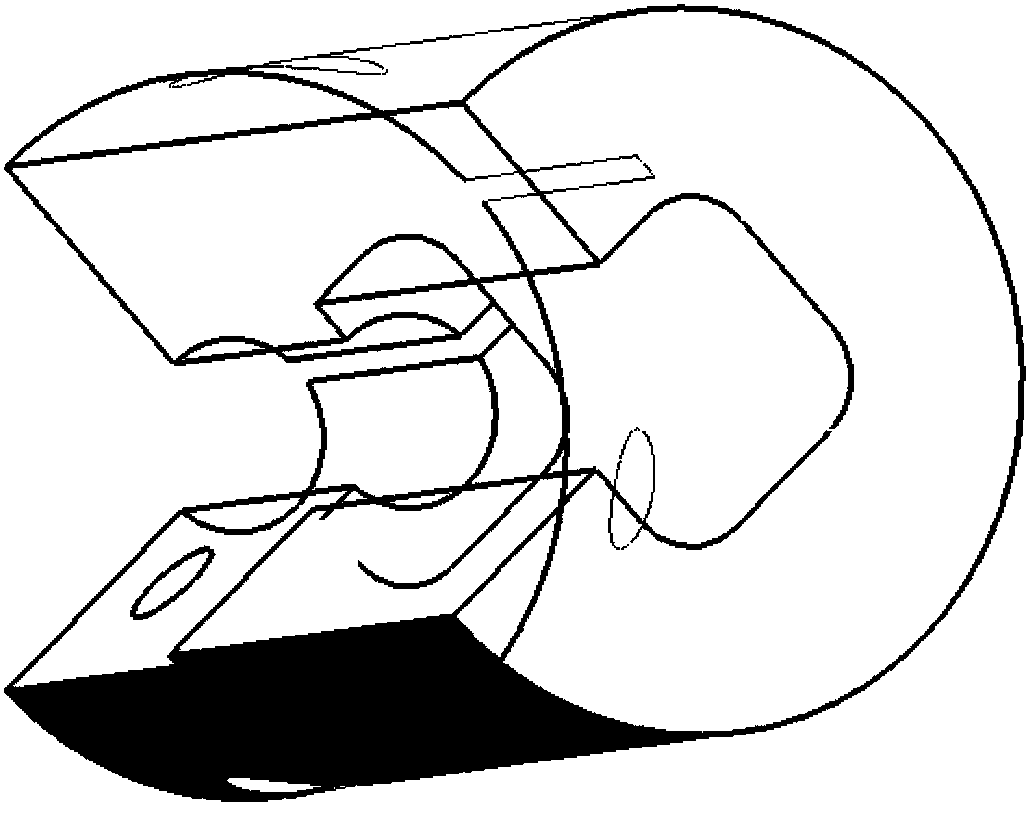

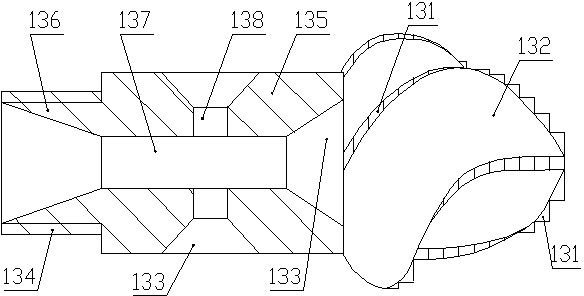

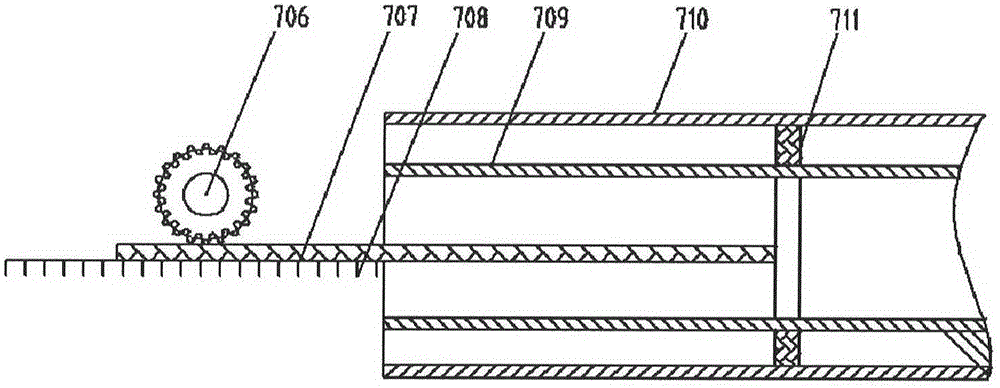

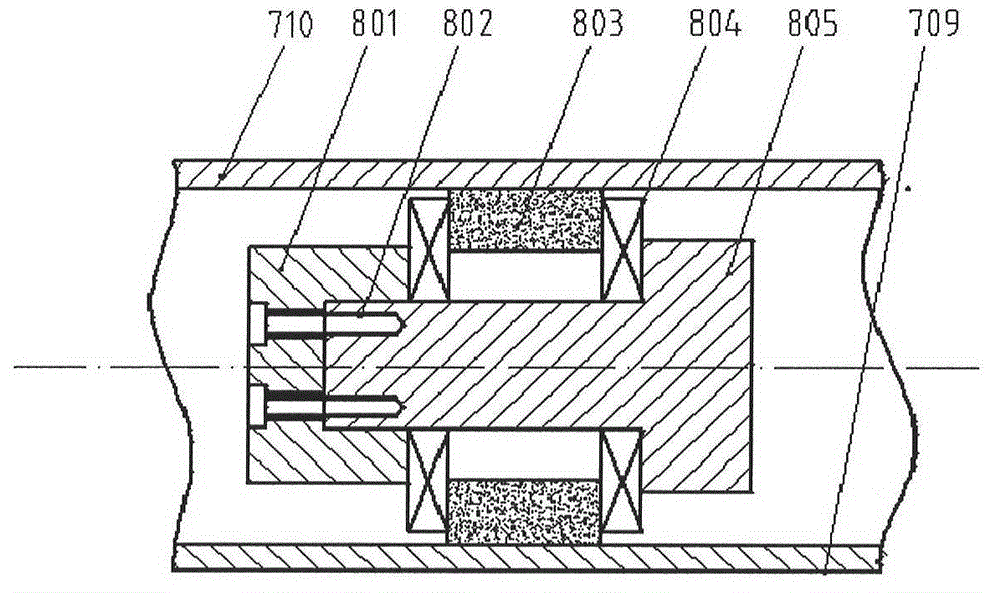

Electric conical valve type gas flow regulator for solid rocket ramjets

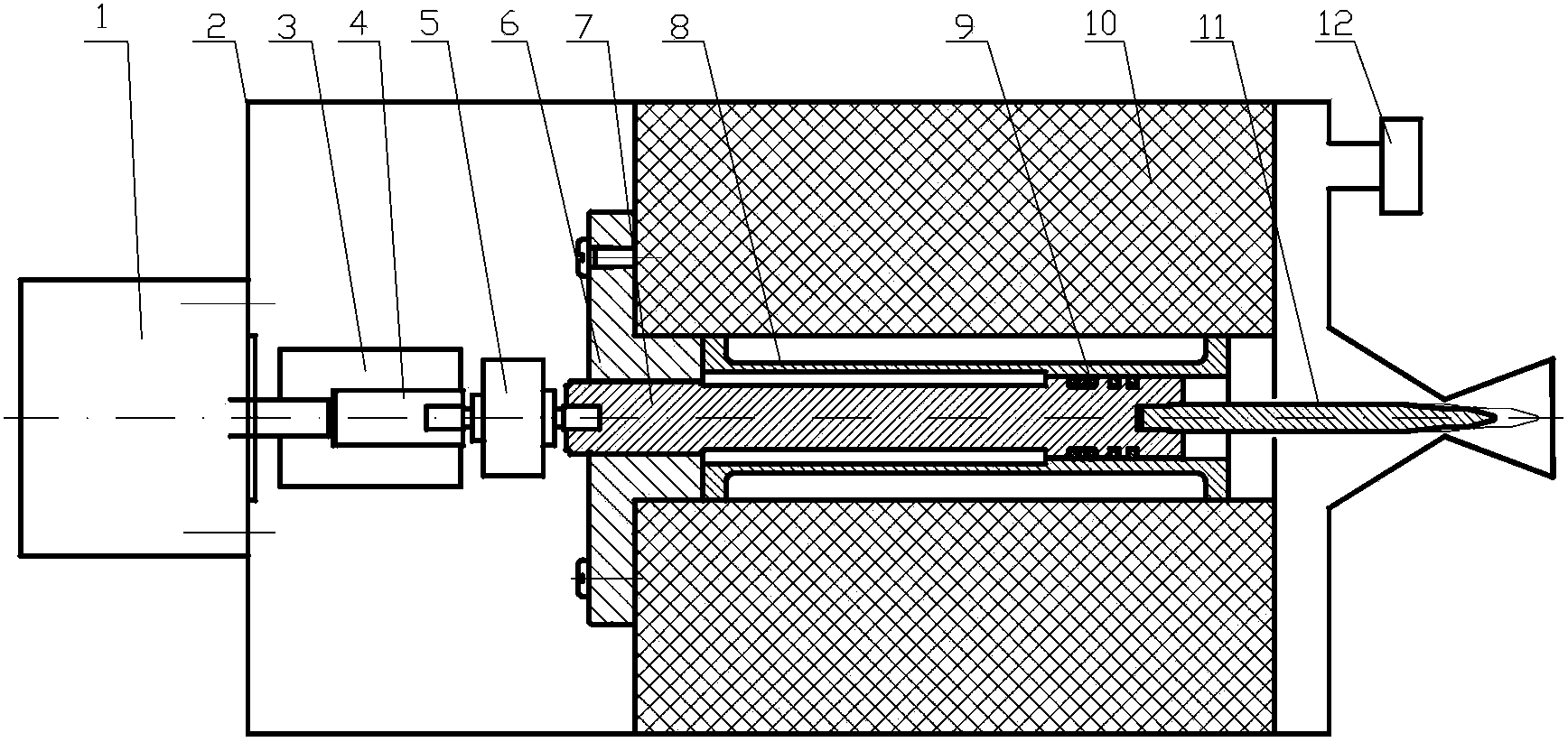

The invention discloses an electric conical valve type gas flow regulator for solid rocket ramjets. A drive motor is fixed to a connecting box. One end of a coupling is fixedly connected with a shaft of a motor, and a slider is disposed in a slide hole in the other end of the coupling. The slider is fixedly connected with a valve stem through a tension and pressure sensor. A drive nut is fixedly connected to a solid gas generator. The valve stem passes the drive nut and in threaded fit with the drive nut. A conical valve head is fixedly connected with the valve stem in a threaded manner and extends into a spray pipe of the gas generator. The gas generator is in an inner shell structure which is hollow. The valve stem is fitted in the inner shell, and a bushing is fitted between the valve stem and the gas generator. One end of the valve stem, close to the conical valve head, is provided with a peripheral circular groove, and a moving seal is disposed in the circular groove. A pressure sensor is mounted on the rear head of the gas generator. The electric conical valve type gas flow regulator for solid rocket ramjets is simple in structure, small in size, reliable in operation, low in ablation effect, low in cost, and accurately controllable.

Owner:NANJING UNIV OF SCI & TECH

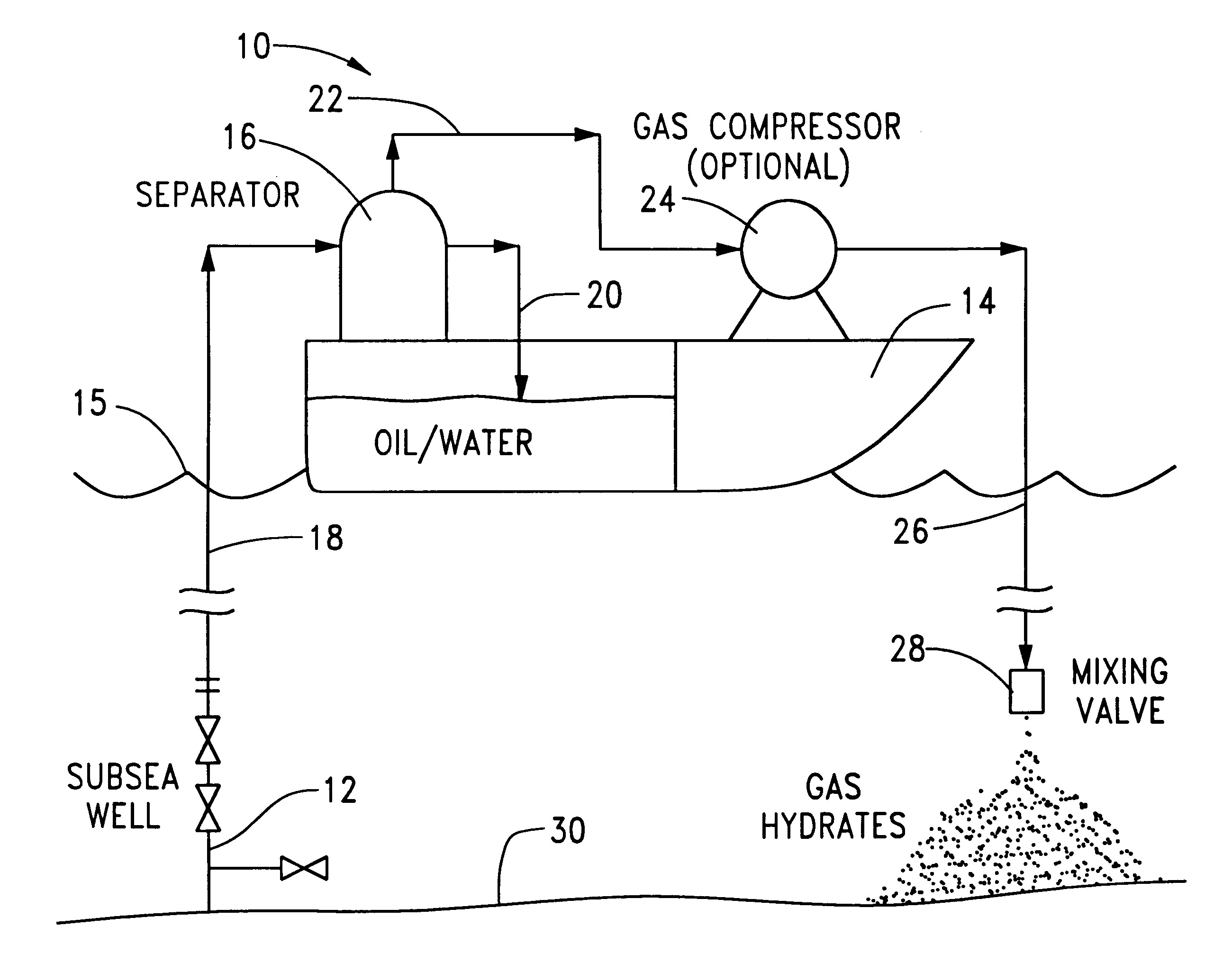

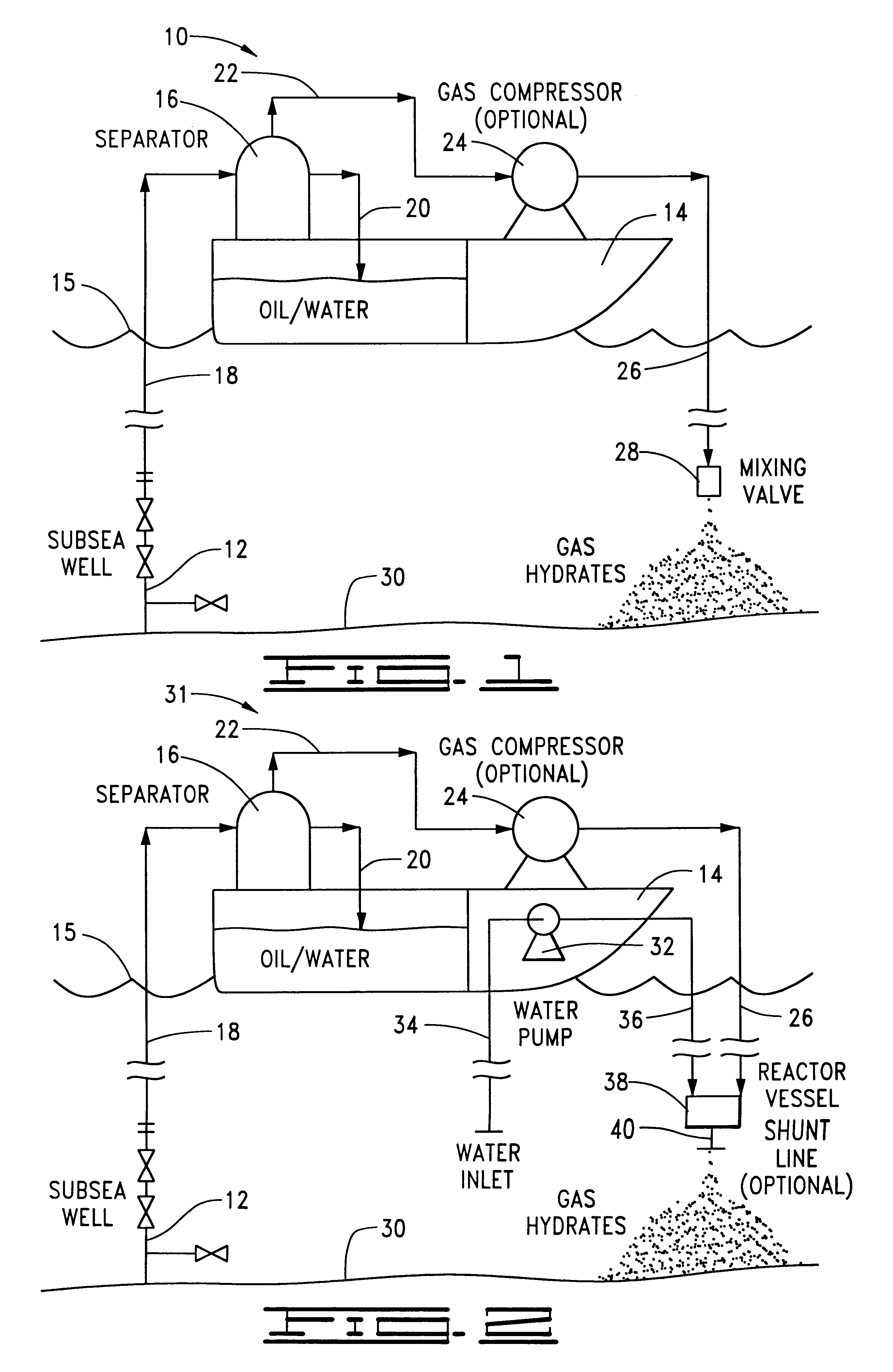

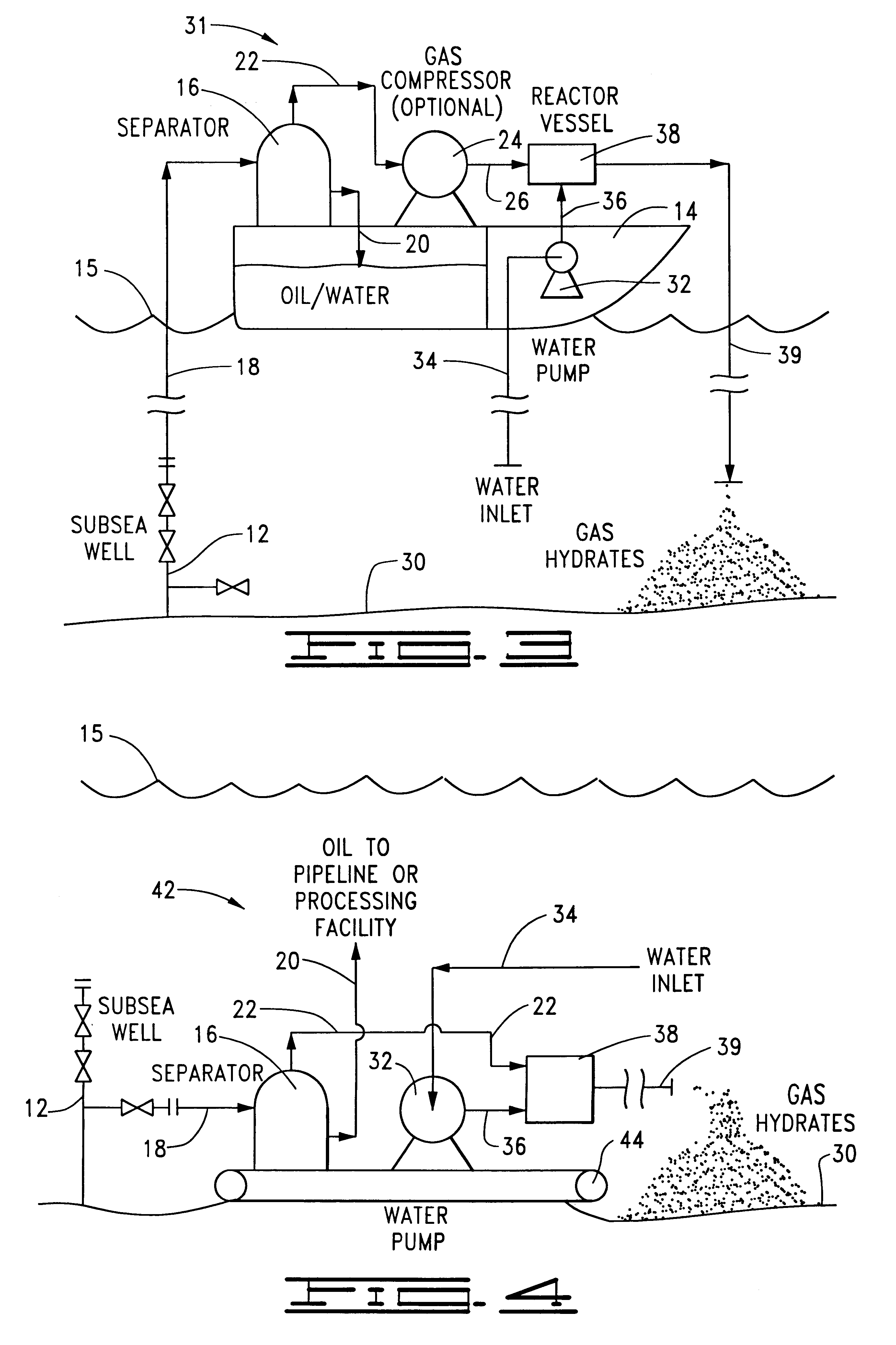

Methods and systems for producing off-shore deep-water wells

Methods of placing off-shore wells on production comprising the steps of separating a gas from oil or oil and water produced by the well, introducing the gas into the seawater surrounding the well at a depth where the temperature and pressure of the seawater are such that solid gas hydrates are formed when the gas is mixed with the seawater, mixing the gas with the seawater whereby the gas is converted to solid gas hydrates and depositing the solid gas hydrates on the sea floor.

Owner:KERR-MCGEE

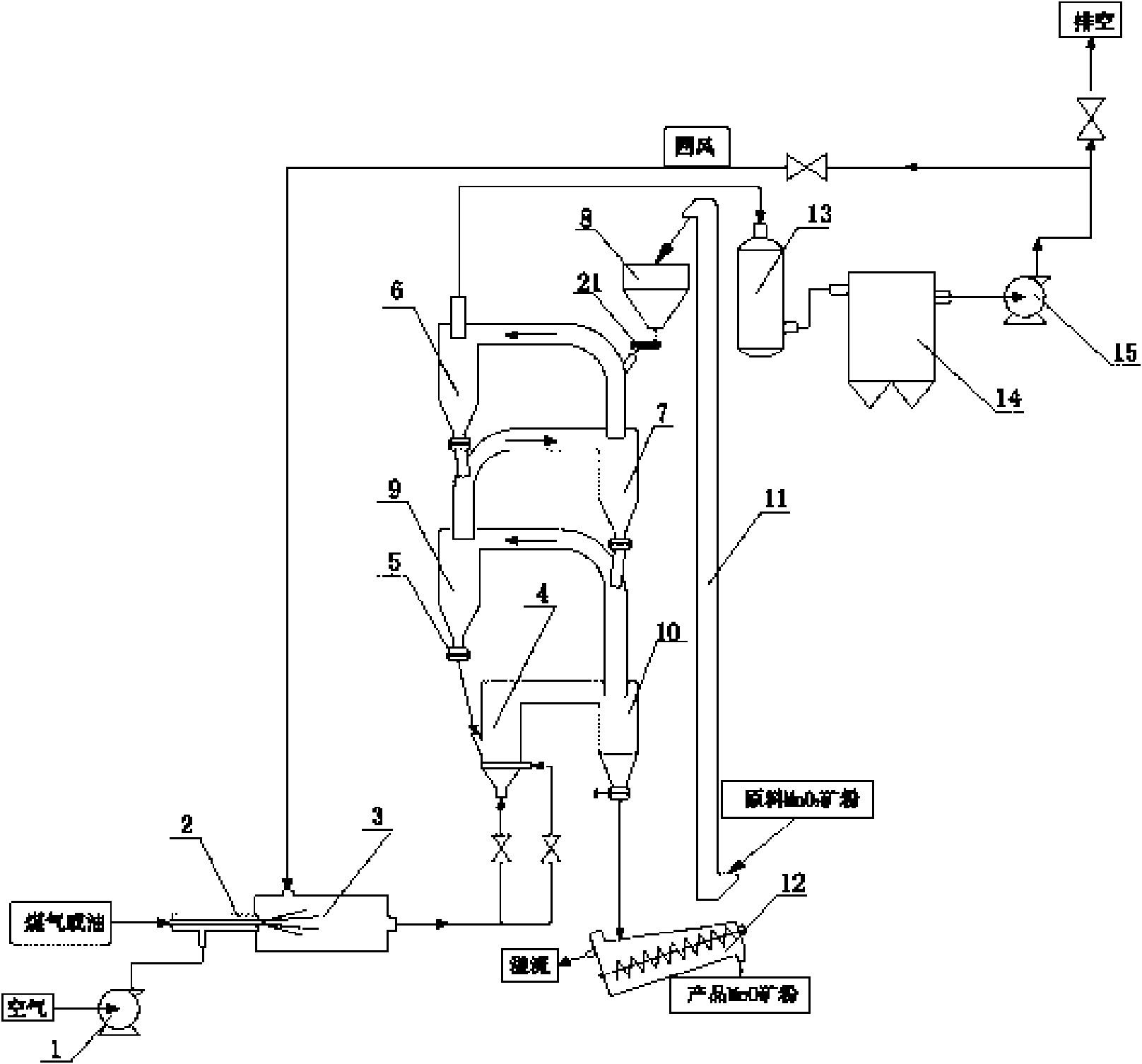

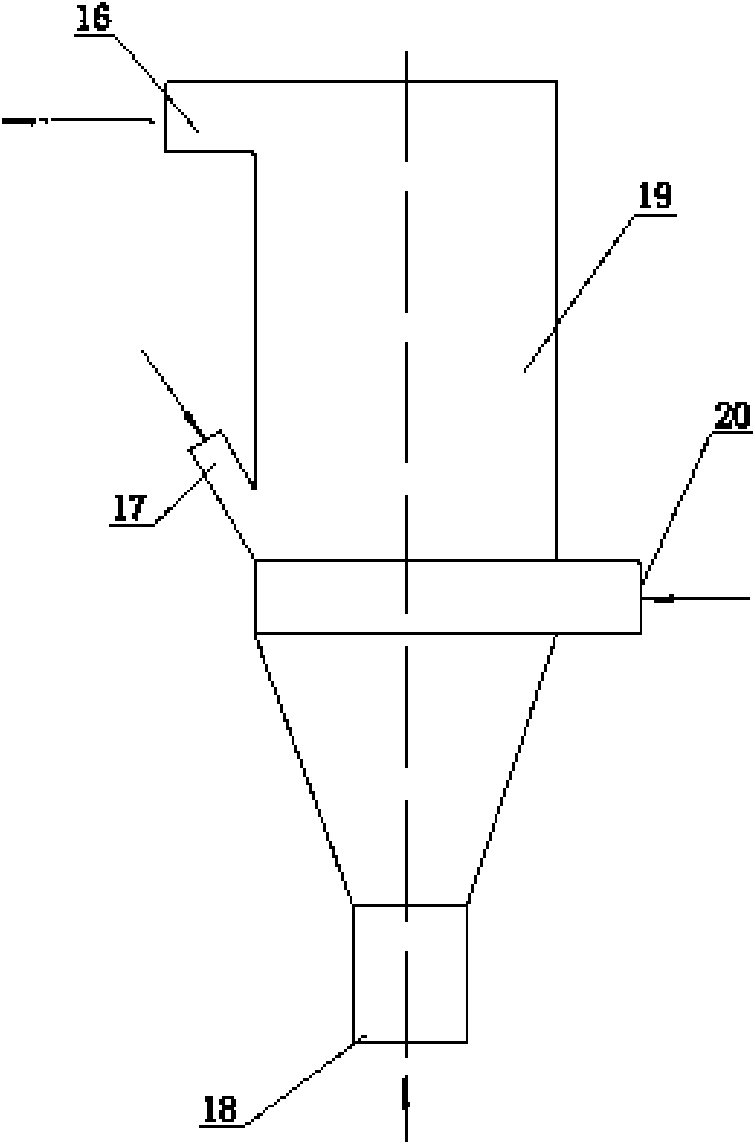

Method and device for reducing and baking for high-valent manganese minerals

The invention provides a method and a device for reducing and baking for high-valent manganese minerals. The method comprises the following steps: (1) combusting combustible gas and air in a hot blast furnace through a nozzle, controlling coefficient of excess air to ensure that the gas of the hot blast furnace is required reduction atmosphere and temperature, and introducing a fluidized roaster; (2) finely grinding manganese minerals, feeding the manganese minerals into a suspension preheat assembly for sufficient heat exchange in several times, separating gas and mineral powder granules, and feeding the granules into the fluidized roaster for a reduction reaction; and (3) controlling the CO content and solid-gas ratio in the fluidized roaster; reducing manganese mineral powder in the fluidized roaster into acidsoluble manganous oxide, and discharging the manganous oxide from a solid material outlet of a cyclone preheater in the last stage. The device comprises a feed assembly, the suspension preheat assembly, the fluidized roaster, a dust-removal exhaust assembly, a gas feed assembly and a combustion assembly. The method and the device have the advantages of simple and compact structure, low cost, simple and convenient operation, good reduction effect, low energy consumption and the like.

Owner:CHANGSHA RES INST OF MINING & METALLURGY

Method for preparing dietary fiber through solid-gas explosion

The invention belongs to the technical field of preparation of dietary fibers, and particularly relates to a method for preparing the dietary fibers by using grain seed husks, such as corn husks and the like as raw materials and utilizing a solid-gas explosion technology, which comprises the following steps of: regulating the water content of the grain seed husks to 50-300 percent, and then placing into a sealed gas explosion device; raising the pressure of the gas explosion device to 0.4-1.2Mpa within 5-25 minutes, and retaining the pressure for 10-120 seconds and then instantaneously depressurizing; and adding water into the processed grain seed husks for extraction, removing the starch and the protein therein, modifying, separating and removing impurities to obtain the dietary fibers. The method has the advantages of simple operation, convenient and rapid extraction, abundant raw material sources and low production cost and can simultaneously obtain two types of high-quality corn-husk dietary fiber products with high purity and large yield, and both the yield and the physiological activity of the products are markedly improved.

Owner:河南省农科院农副产品加工研究所

Gasified Food Products and Methods of Preparation Thereof

InactiveUS20080069924A1Good water solubilityImprove production efficiencyDough treatmentFrozen sweetsHot cerealFood products

The present invention provides a gasified food product comprising a solid-gas clathrate and methods for making the same. The solid-gas clathrates used in the present invention are selected from the group consisting of an α-cyclodextrin-gas clathrate and a derivative thereof. Furthermore, the present invention provides food products such as a powdered coffee mix, dough, sauce, soup, hot cereal and the like comprising the solid-gas clathrate.

Owner:INTERCONTINENTAL GREAT BRANDS LLC

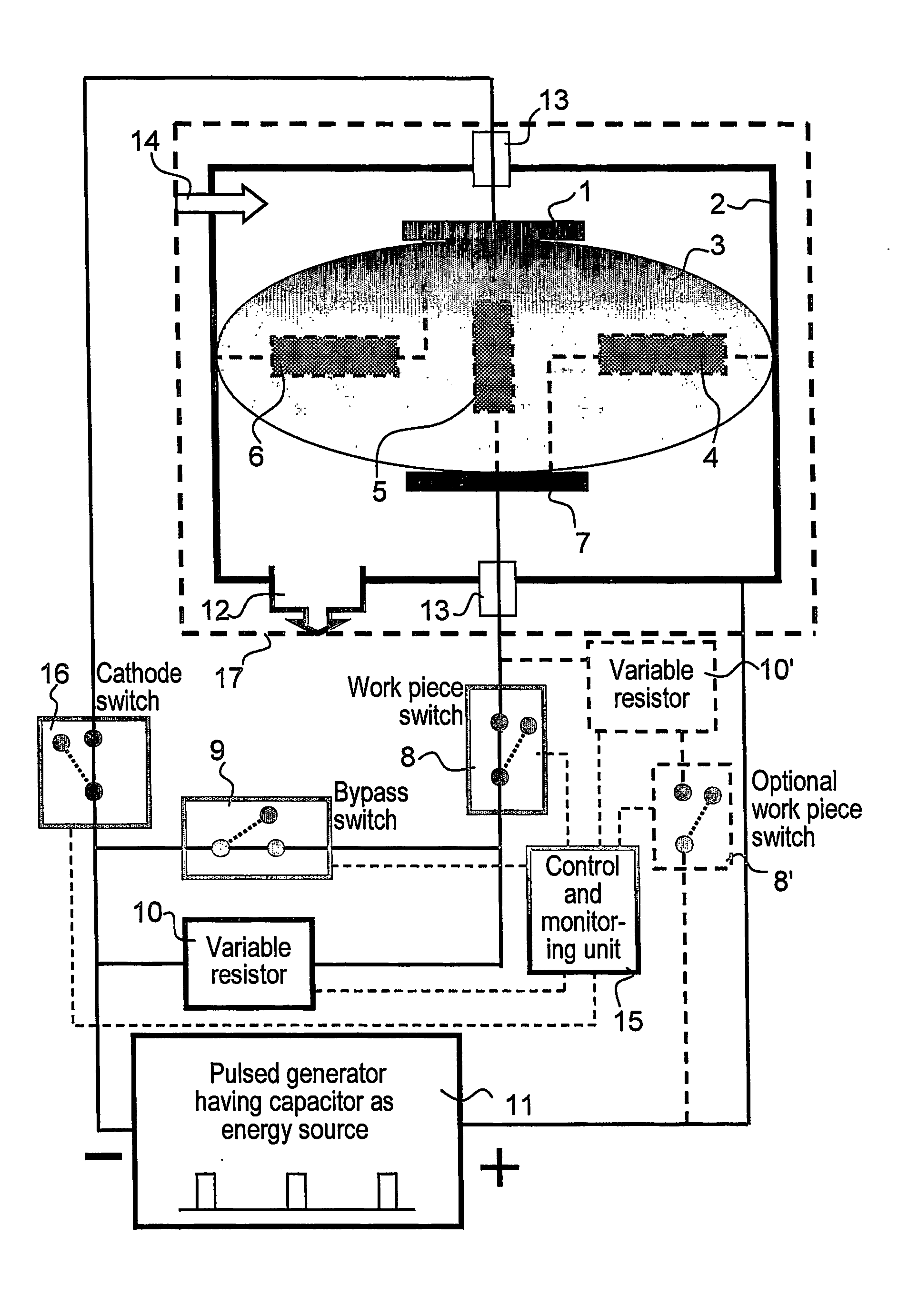

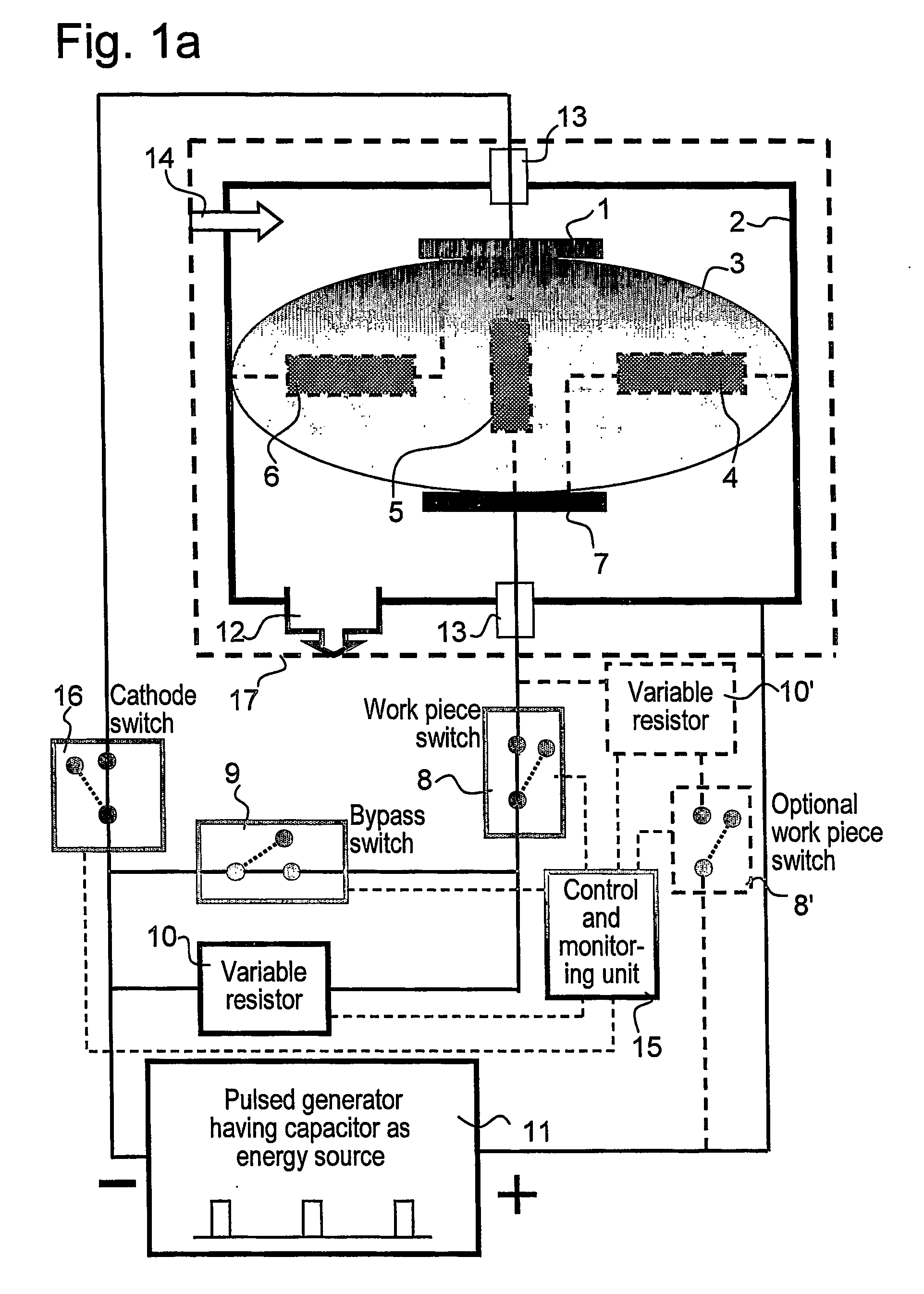

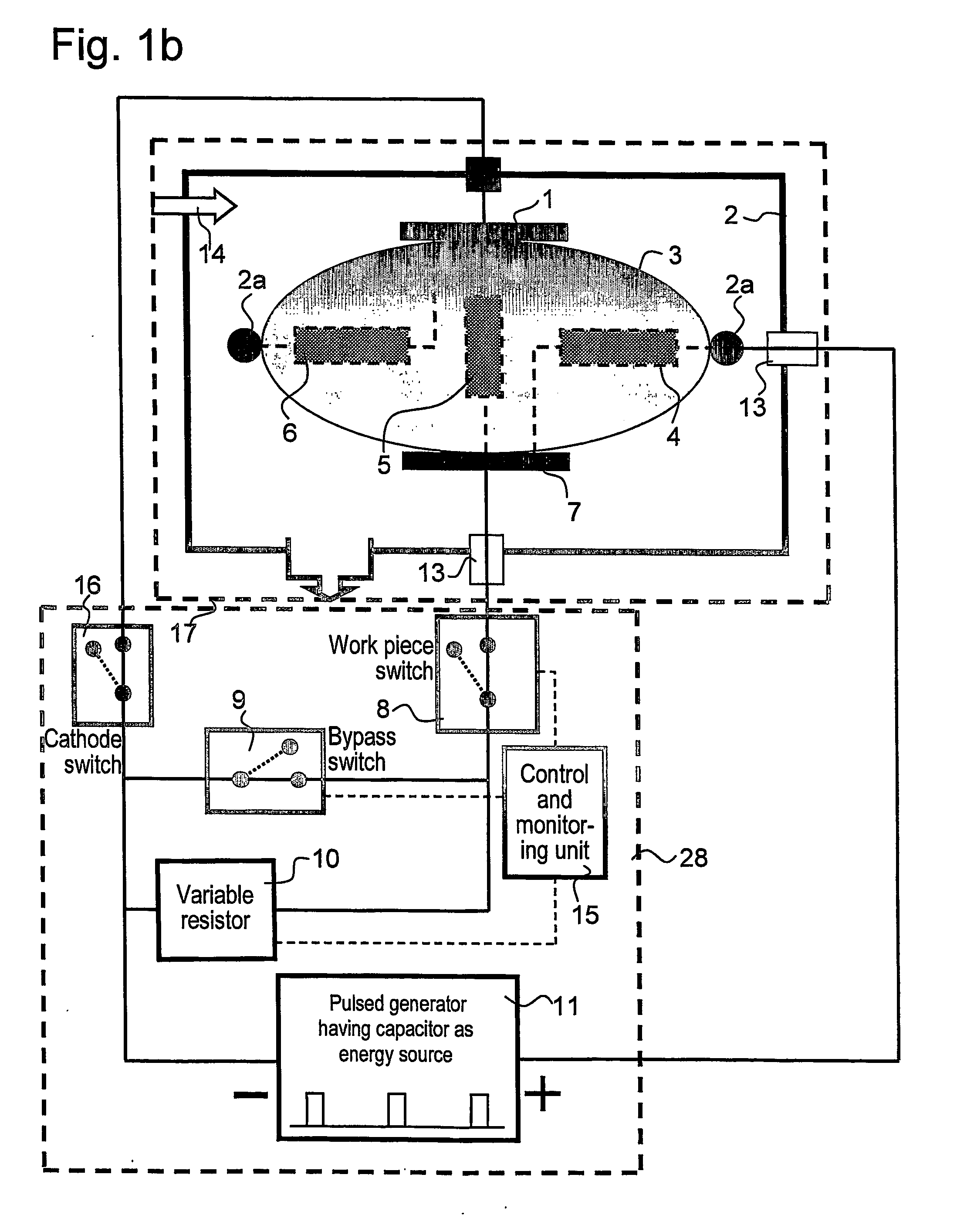

Work piece processing by pulsed electric discharges in solid-gas plasma

ActiveUS20060278518A1Easy to handleEfficient processing and modifyingCellsElectric discharge tubesEtchingElectric discharge

Work piece processing is performed by pulsed discharges between an anode (2) and a magnetron sputtering cathode (1) in solid-gas plasmas using a chamber (2) containing the work piece (7). A system (12) maintains a vacuum in the chamber and another system (14) provides sputtering and reactive gases. The pulses are produced in a plasma pulser circuit including the anode and the cathode, the discharges creating gas and partially ionized solid plasma blobs (3) moving or spreading from a region at a surface of the cathode towards the work piece and the anode. A potential is applied to the work piece so that a pulsed current comprising biasing pulses arises between the second electrodes. In particular biasing discharges are produced between the anode and the work piece when said plasma blobs have spread to regions at the anode and at the work piece so that the pulsed current is the current of these biasing discharges. The method is efficient for processing or modifying surface regions of work pieces of various kinds and configurations and can be employed for achieving efficient work piece etching, interface mixing, surface and balk diffusion, gas absorption and desorption, initial and further stages of thin film condensation, and for performing ion plating.

Owner:BRANNSTOM RUNE +1

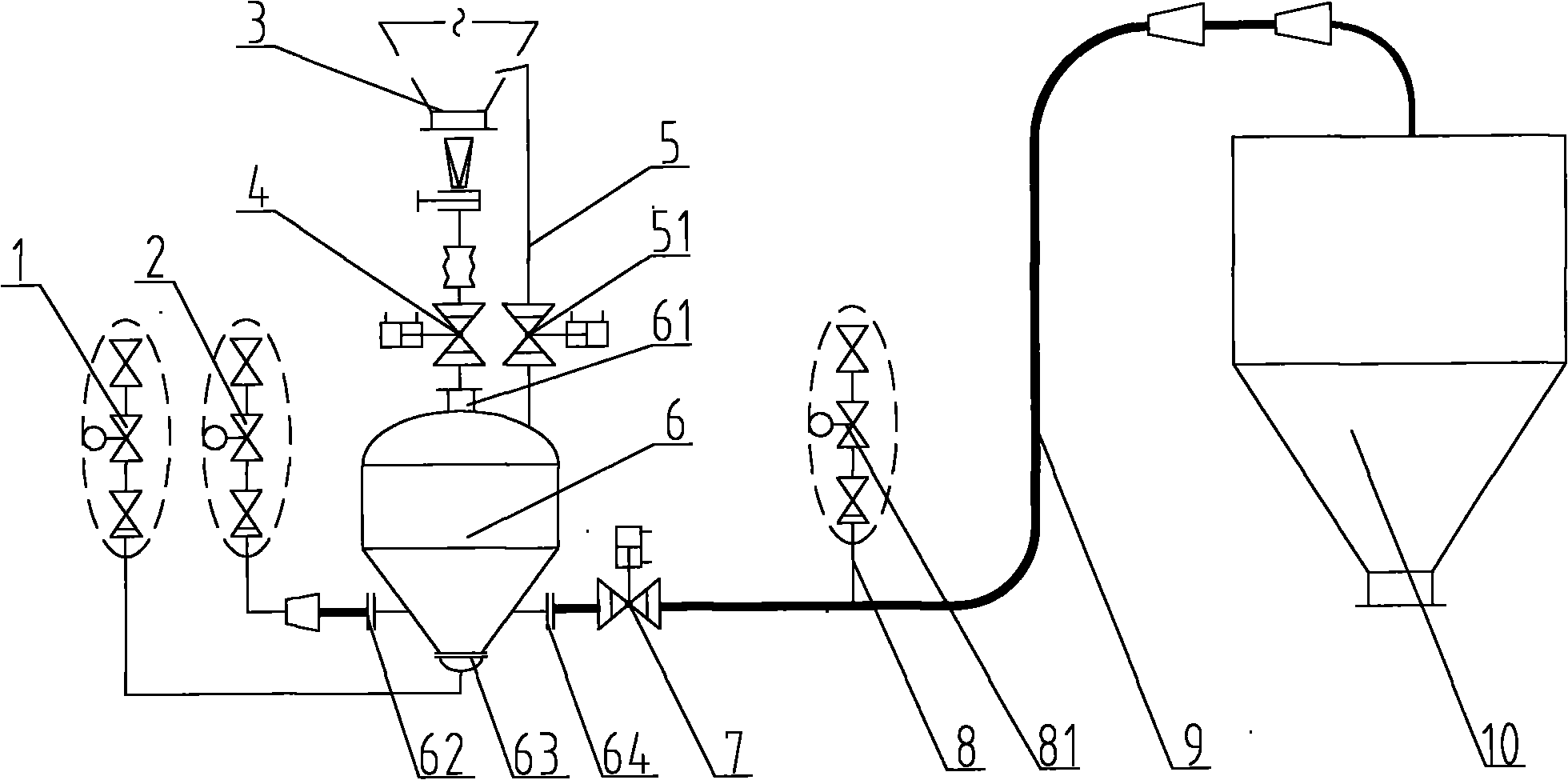

Pneumatic conveyer

The invention discloses a pneumatic conveying device, which comprises a bin pump and a delivery duct. The driving air inlet of the bin pump is connected with a bin pump cone and is in the same central line with the discharging hole of the bin pump. The diameter of the delivery duct is increased gradually. The device also comprises at least one air make-up duct. The air make-up duct is provided with a plurality of openings circumferentially distributed along the inner wall of the delivery duct. The opening direction is consistent with the flowing direction of a solid-gas mixture. The working process comprises three steps, namely feeding, fluidifying and adjusting the flow rate of the solid-gas mixture. Air is introduced into the delivery duct by the air make-up duct to adjust pressure in the delivery duct and adjust the flow velocity of solid-gas mixture so as to ensure that the solid-gas mixture has proper flow velocity, thus lowering the wear rate of the delivery duct, reducing the possibility of delivery duct blockage, and ensuring the working reliability of the pneumatic conveyer.

Owner:FUJIAN LONGKING

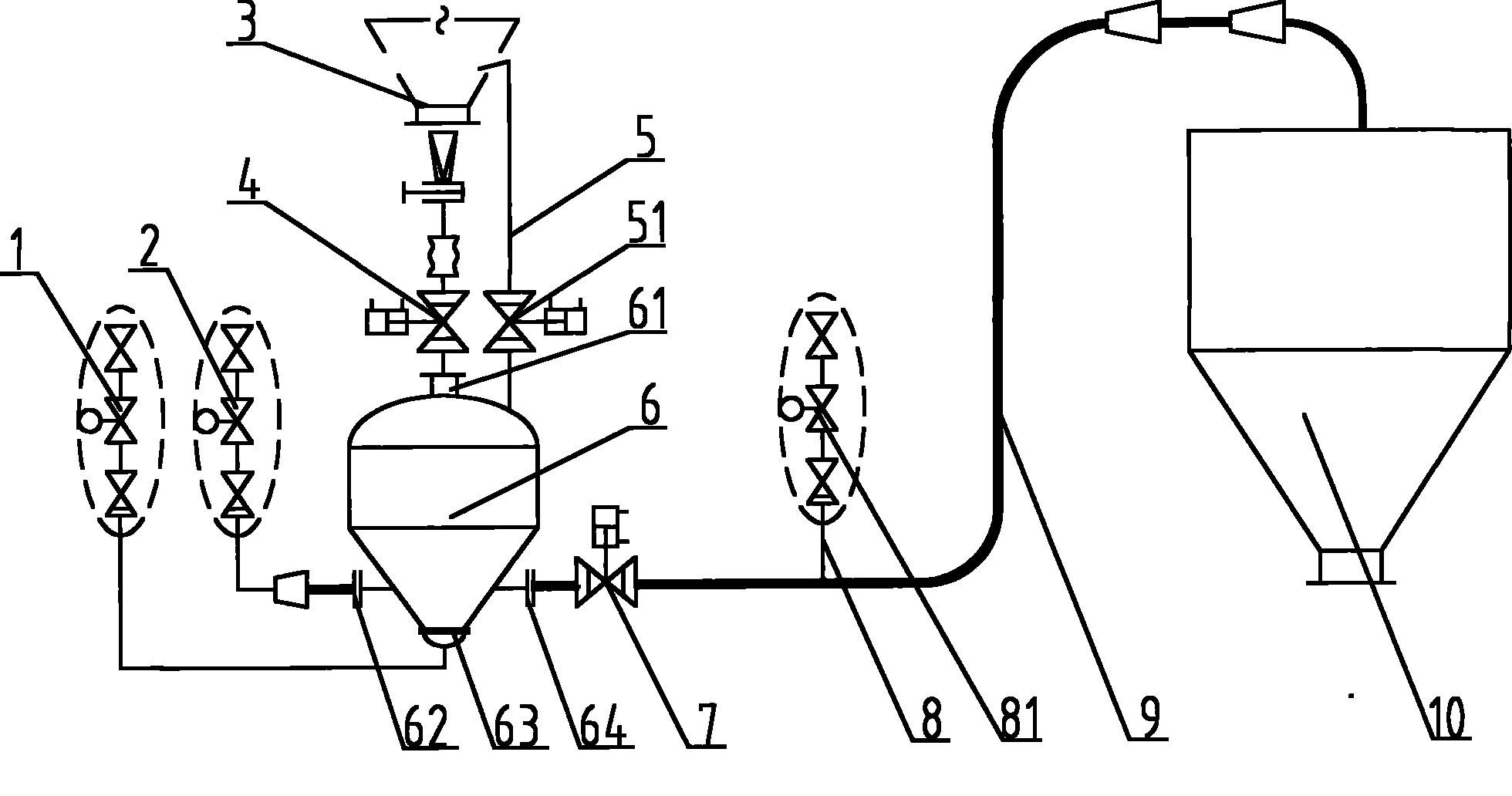

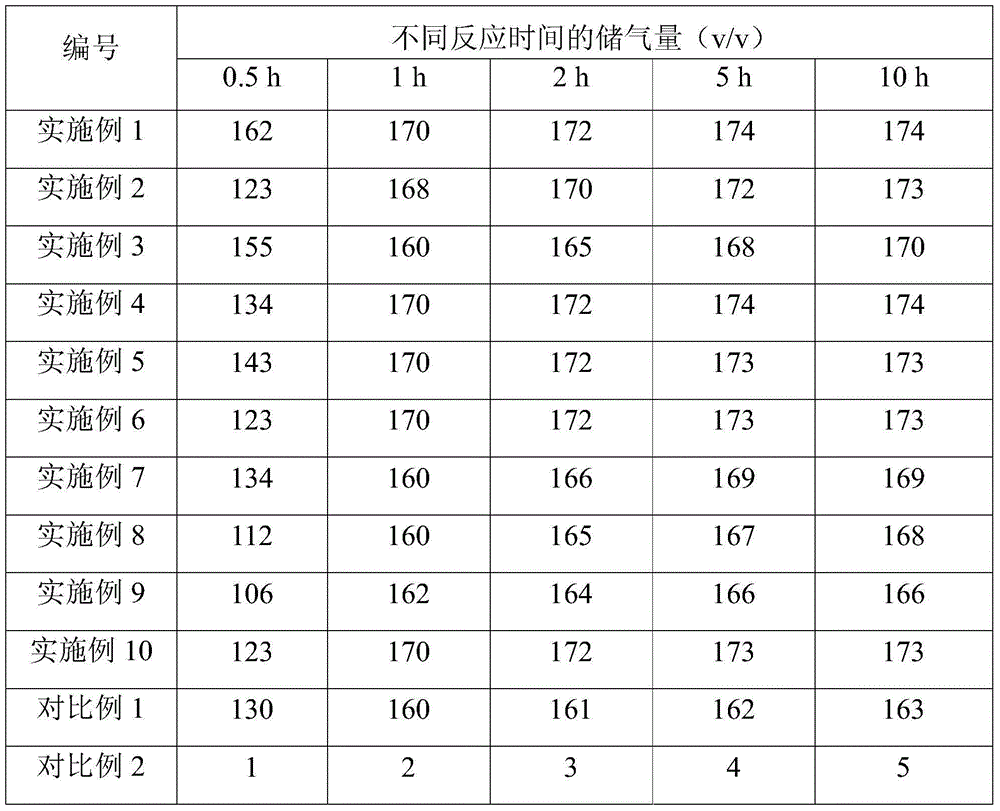

Hydrate accelerant and application thereof in preparing high-gas-storage-density gas hydrate

ActiveCN104974713ANon-toxicNo pollution in the processOther chemical processesGaseous fuelsVolumetric Mass DensityHigh pressure

The invention relates to the technical field of energy materials, and discloses a hydrate accelerator and an application thereof in preparing a high-gas-storage-density gas hydrate. The accelerant comprises amino acid and water, and is prepared by well mixing 100 parts by mass of water and 0.05-5 parts by mass of amino acid. The application comprises the specific steps that 100 parts by mass of water and 0.05-5 parts by mass of amino acid are well mixed, such that an accelerant water solution is obtained; the accelerant water solution is placed in an autoclave; high-pressure gas is delivered in under a low temperature; and a reaction is allowed for a period of time, such that the high-gas-storage-density solid gas hydrate is obtained. The accelerant provided by the invention is green and environment-friendly. With the accelerant, hydration induction time can be reduced, gas storage capacity can be increased, and gas storage density can be improved. The accelerant provided by the invention also has the advantages of low price, low dosage, and wide source. The accelerant is recyclable, and has no special requirement on temperature and pressure conditions. The method for preparing the high-gas-storage-density gas hydrate is fast, highly efficient, simple, and easy to realize.

Owner:SOUTH CHINA UNIV OF TECH

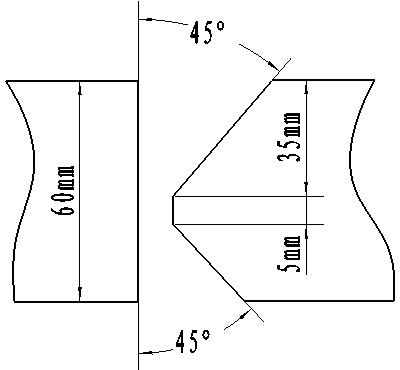

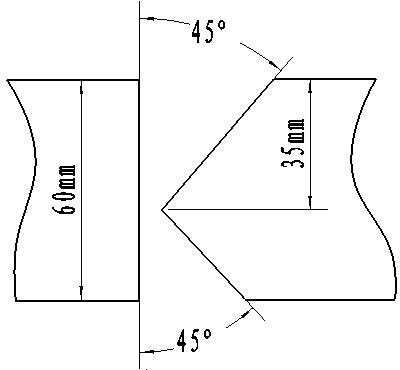

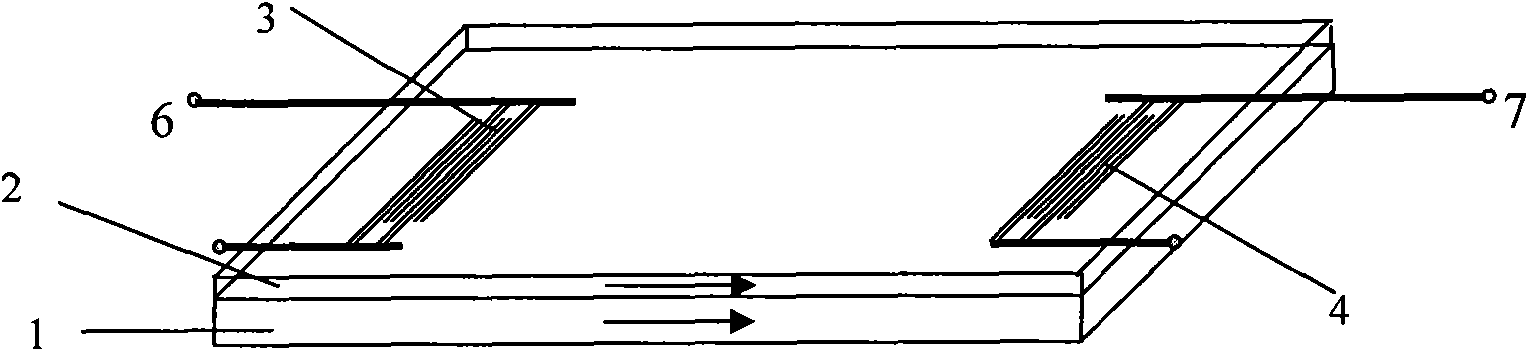

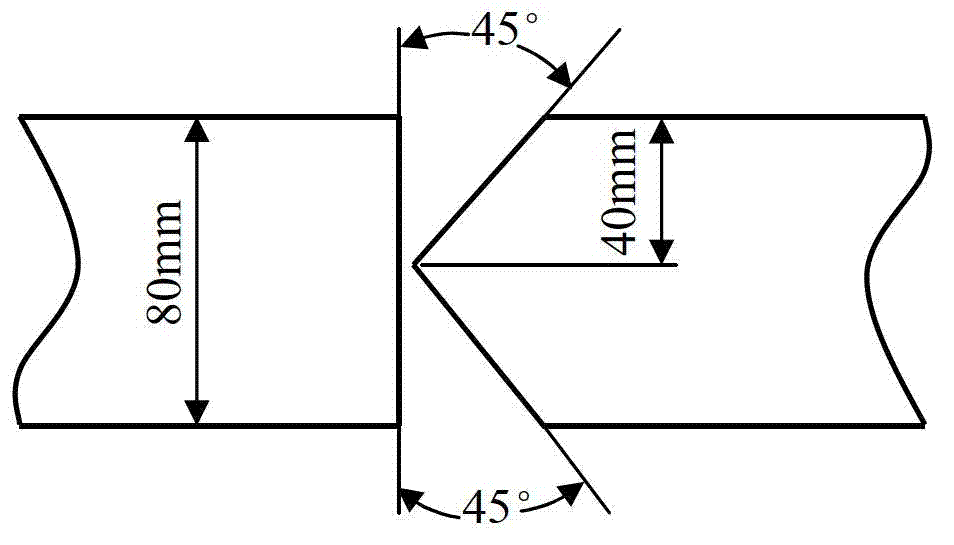

Submerged-arc welding root welding and back chipping process of thick plate with K-type groove

InactiveCN102554416AShorten welding auxiliary timeShorten welding timeArc welding apparatusThick plateSlag

The invention discloses a submerged-arc welding root welding and back chipping process of a thick plate with a K-type groove. The K-type groove is an asymmetric K-type groove, an upper open angle and a lower open angle of the groove are both 45 degrees to 50 degrees, and truncated edges are not reserved at the root. During assembly, groove clearance of 2mm to 3mm is reserved. During welding, solid gas protection welding wires under pulse current are adopted for backing welding of a root pass of the front side of a K-type groove test piece, and after the root pass is thoroughly fused, a part of weld metal penetrates through the reverse side of the groove to achieve backing welding. After welding, back chipping of the reverse side is performed. Finally, gas shielded welding under large current is adopted for fusion welding of the roof of the reverse side groove, and gas rich in argon is used as protective gas. The submerged-arc welding root welding and back chipping process reduces time for slag removal of root pass of submerged-arc welding and polishing and finishing of the reverse side groove of the welding test piece, improves welding efficiency by more than 30%, removes a carbon arc gouging process, decreases welding noises and dust emission, lowers labor intensity of welders and reduces time for damaging workers under high-decibel noises.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

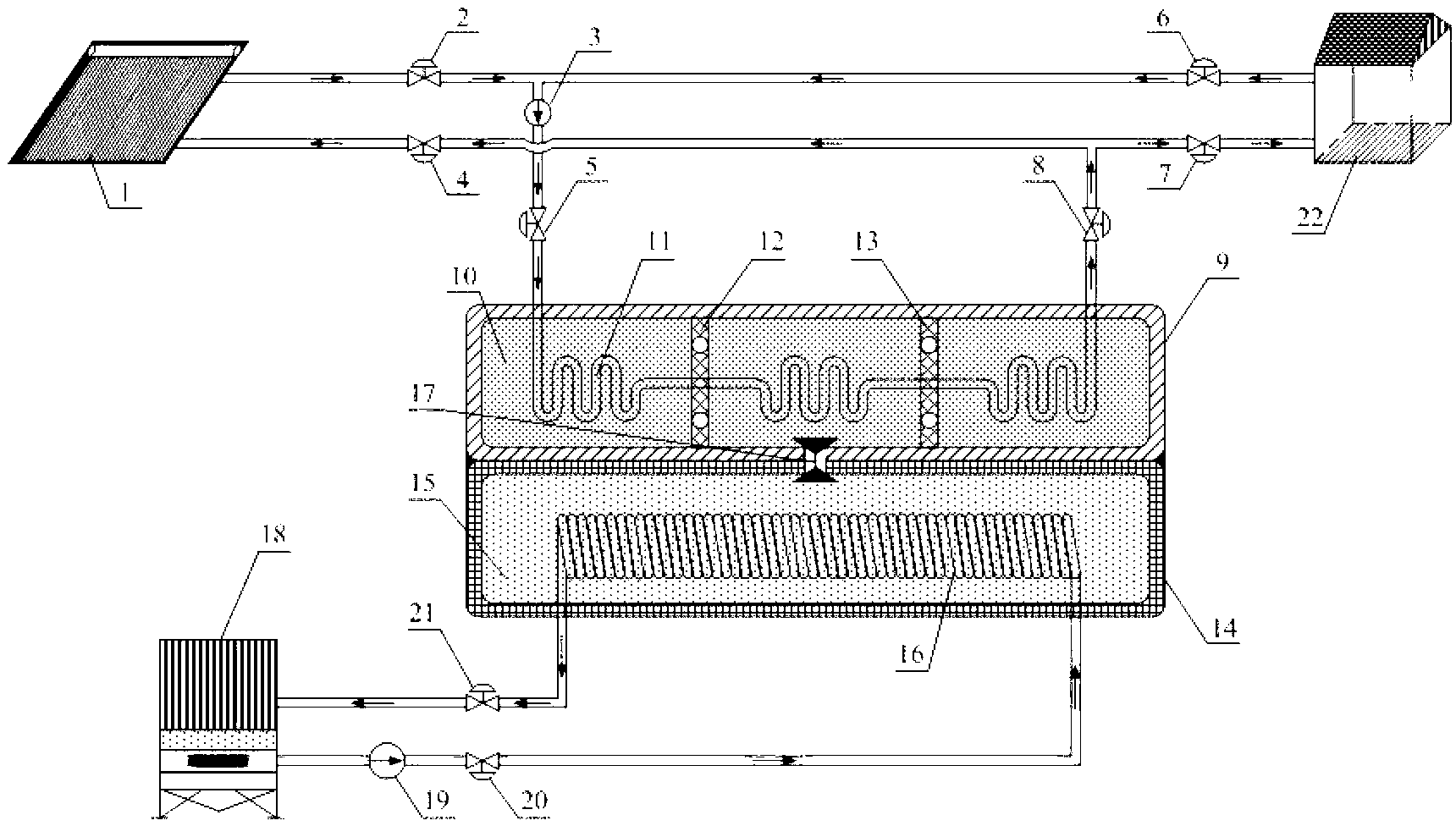

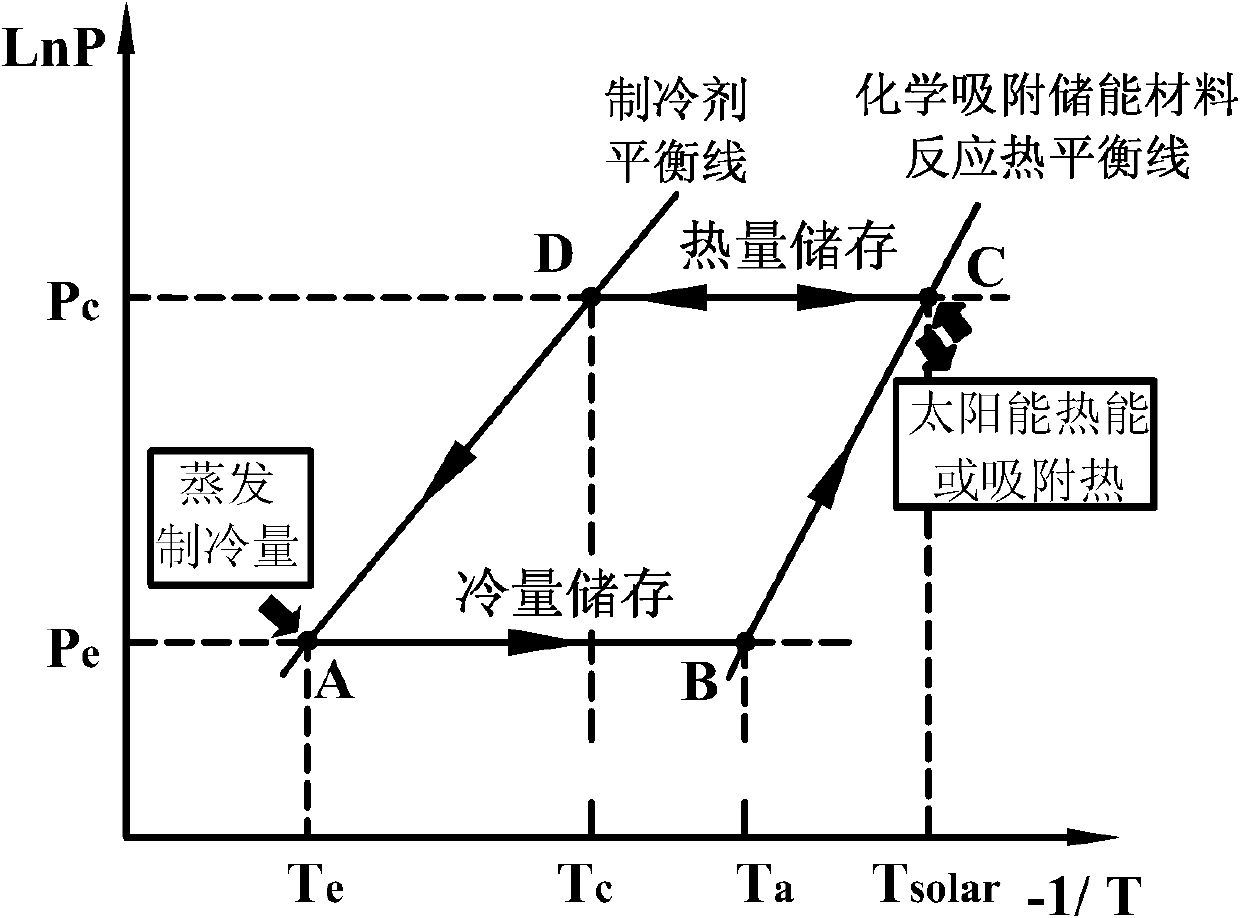

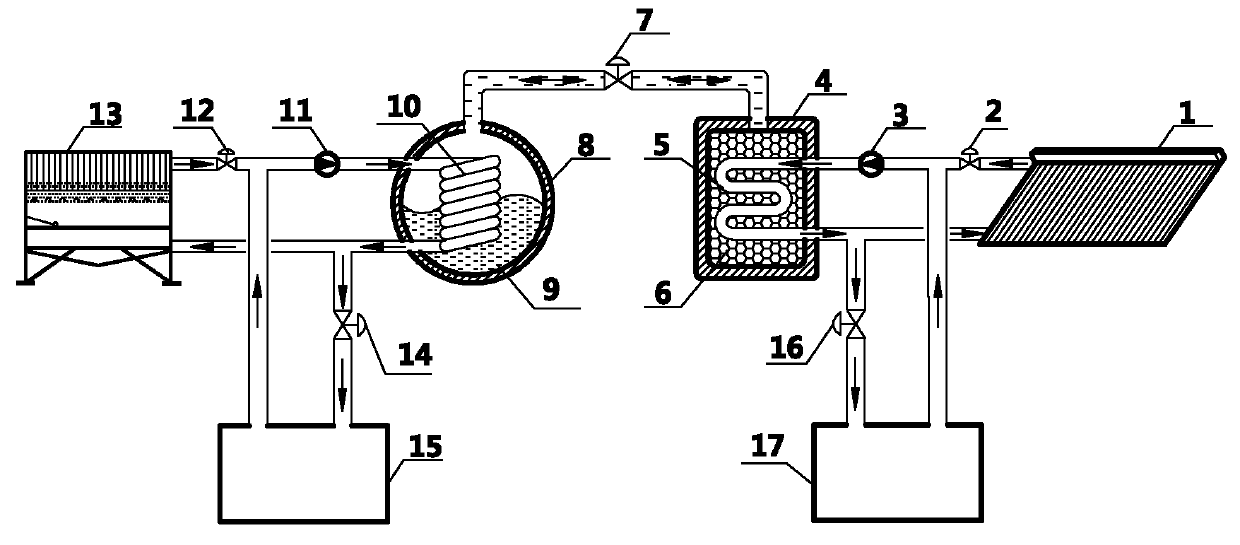

High-capacity combination type solar energy thermochemistry cascaded heat storage device and solar energy application

ActiveCN103256729AImprove storage densityReduce lossesSolar heat devicesSolar thermal energy generationThermal energyCooling tower

The invention relates to a high-capacity combination type solar thermochemistry cascaded heat storage device and solar energy application. The high-capacity combination type solar thermochemistry cascaded heat storage device comprises a solar heat collector, a solid-gas chemical reactor, a refrigerant liquid storage device and a cooling towel. Three heat storage slat absorbing agents are filled inside the solid-gas chemical reactor. Under the same working pressure, desorption equilibrium temperatures of the three heat storage salt absorbing agents decrease gradually in the flowing direction of heat exchanging fluid and the three heat storage salt absorbing agents are distributed in a cascaded mode. Thermochemistry absorption heat storage is utilized, and multiple reaction salts of different temperature zones are adopted so that the defect that in an existing solar energy thermochemistry heat storage device, reactants cannot conduct thermal decomposition reaction at a certain moment due to the fact that the temperature of collected solar heat energy is low is overcome. Therefore, a novel solar energy thermochemistry cascaded heat storage technology can reduce the influences of solar energy time volatility and can be better matched with solar heat energy, and high-efficiency heat storage of the solar heat energy can be realized through the cascaded combination of the heat storage reaction slats of different temperature zones.

Owner:SHANGHAI JIAO TONG UNIV

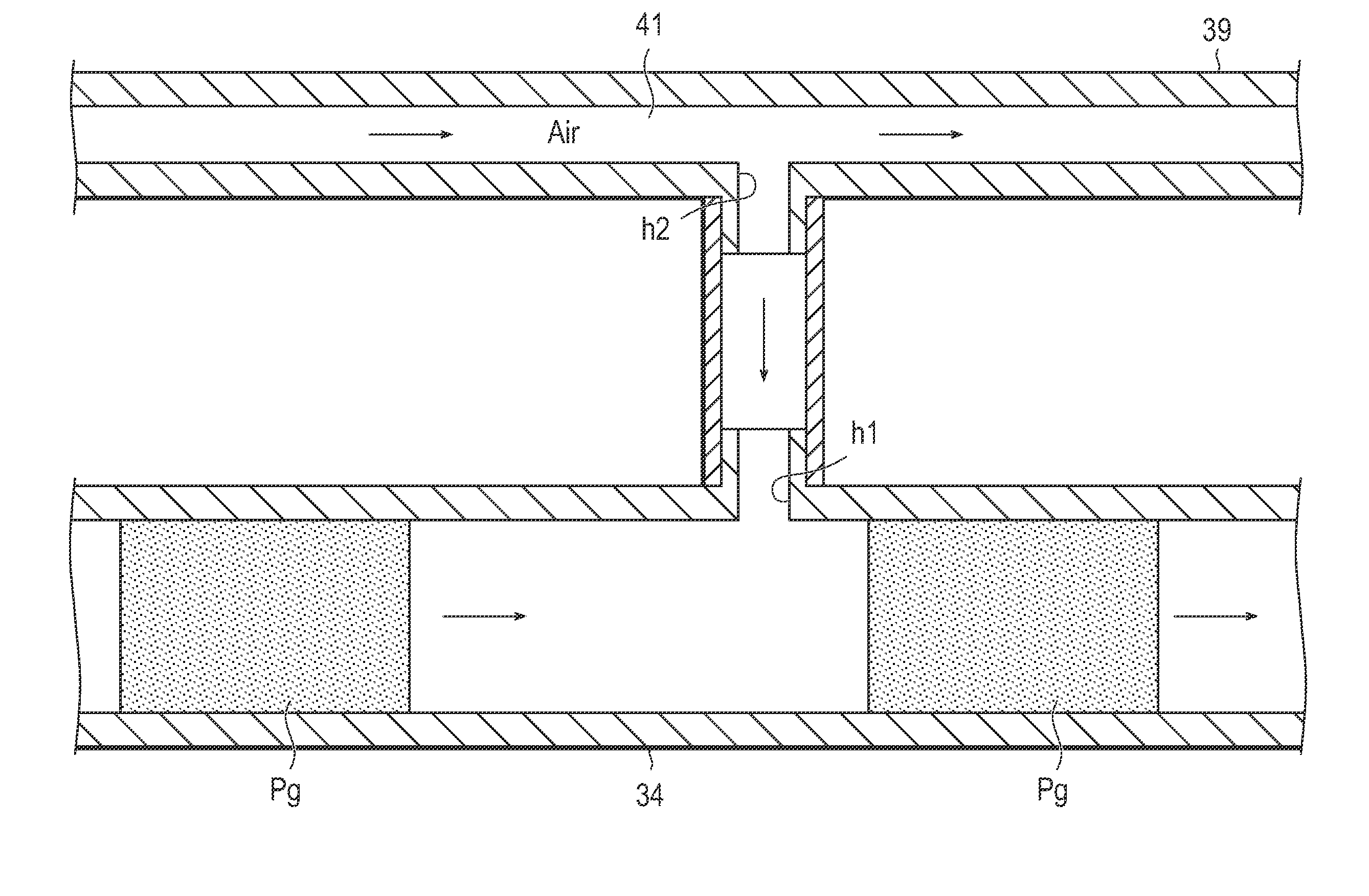

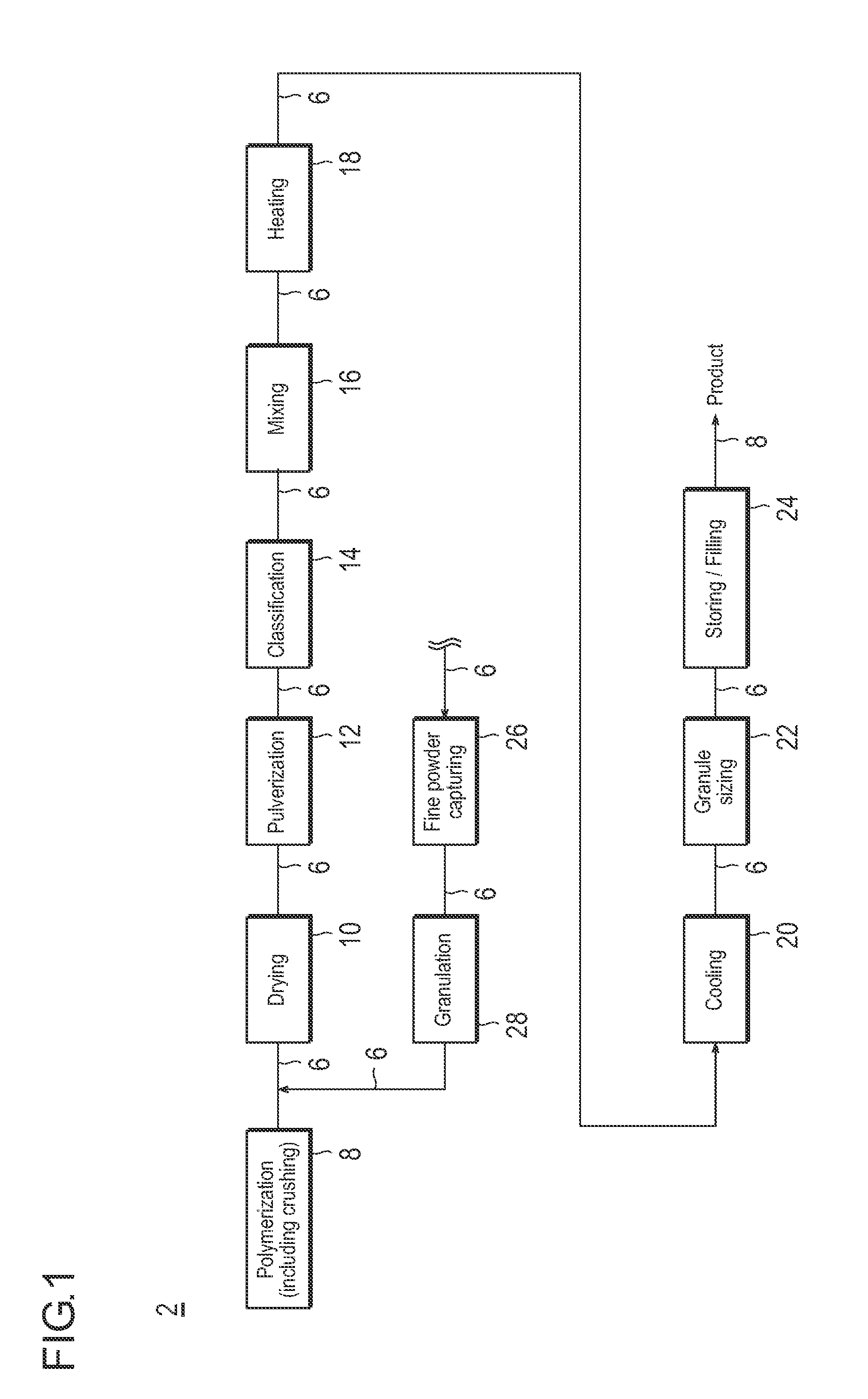

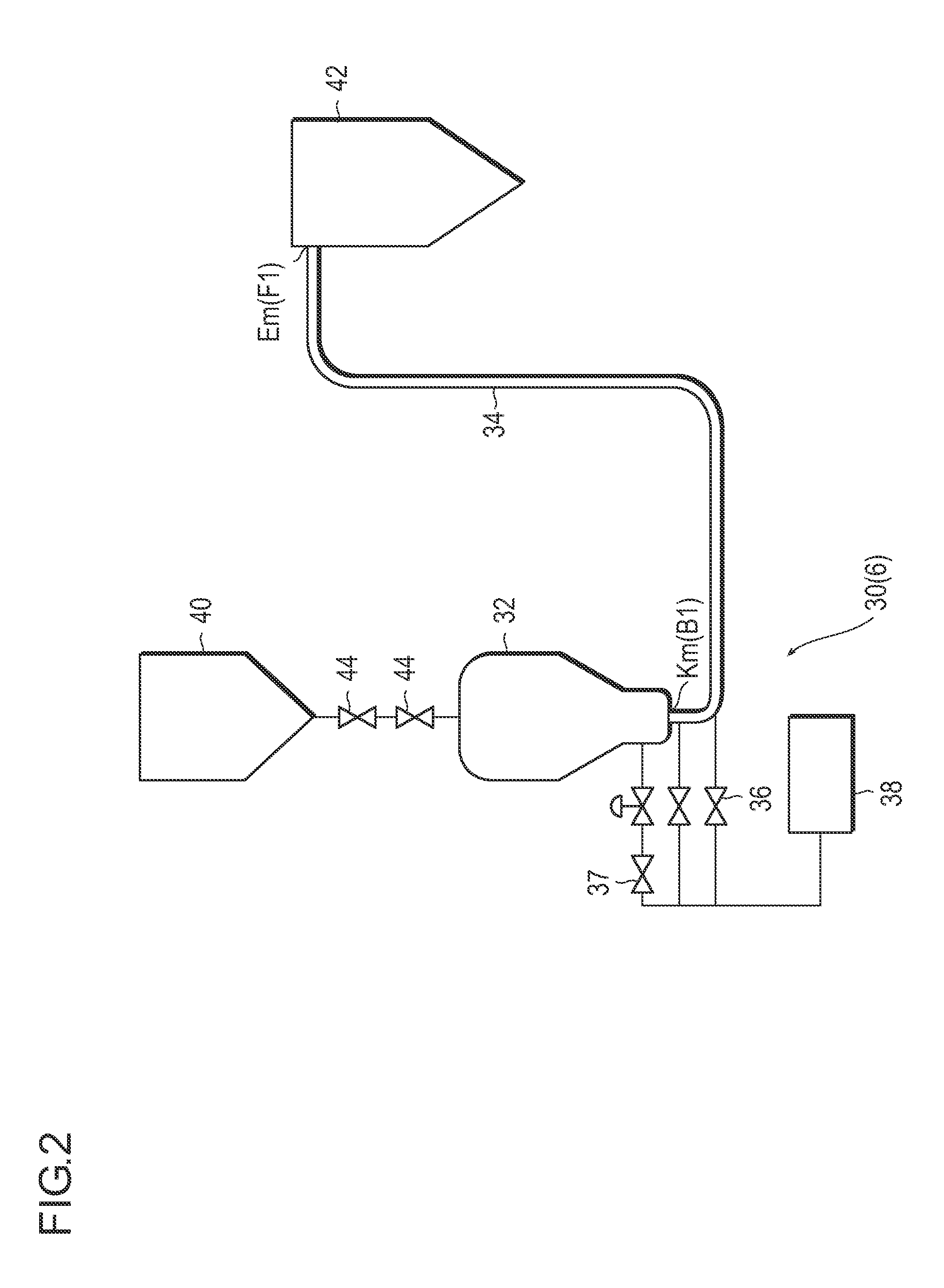

Transport method for absorbend resin powder

ActiveUS20110110730A1Linear velocity can be suppressedProperty decrease of the water-absorbing resin powder substance can be suppressedBulk conveyorsSolid gasChemistry

[Problem] To provide a pneumatic conveyance method for a water-absorbing resin powder substance, which is capable of suppressing property decrease of the water-absorbing resin powder substance, while suppressing obstruction phenomenon.[Solution] A conveyance method for a water-absorbing resin powder substance by pneumatic conveyance of the water-absorbing resin powder substance during a production step via a transportation pipeline, wherein a variation of a solid-gas ratio (R1 / R2) exceeds 1 and is equal to or smaller than 7, provided that R1 (kg-resin / kg-air) stands for an initial solid-gas ratio at a start point of the transportation pipeline, and R2 (kg-resin / kg-air) stands for a terminal solid-gas ratio at a terminal point of the transportation pipeline is provided.

Owner:NIPPON SHOKUBAI CO LTD

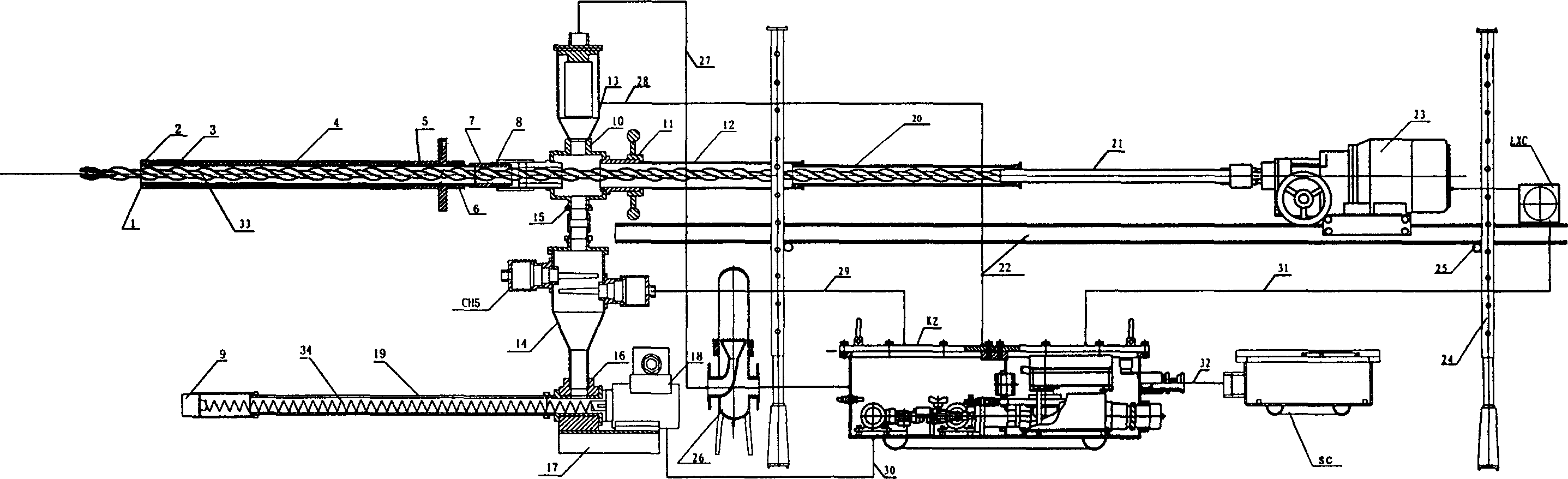

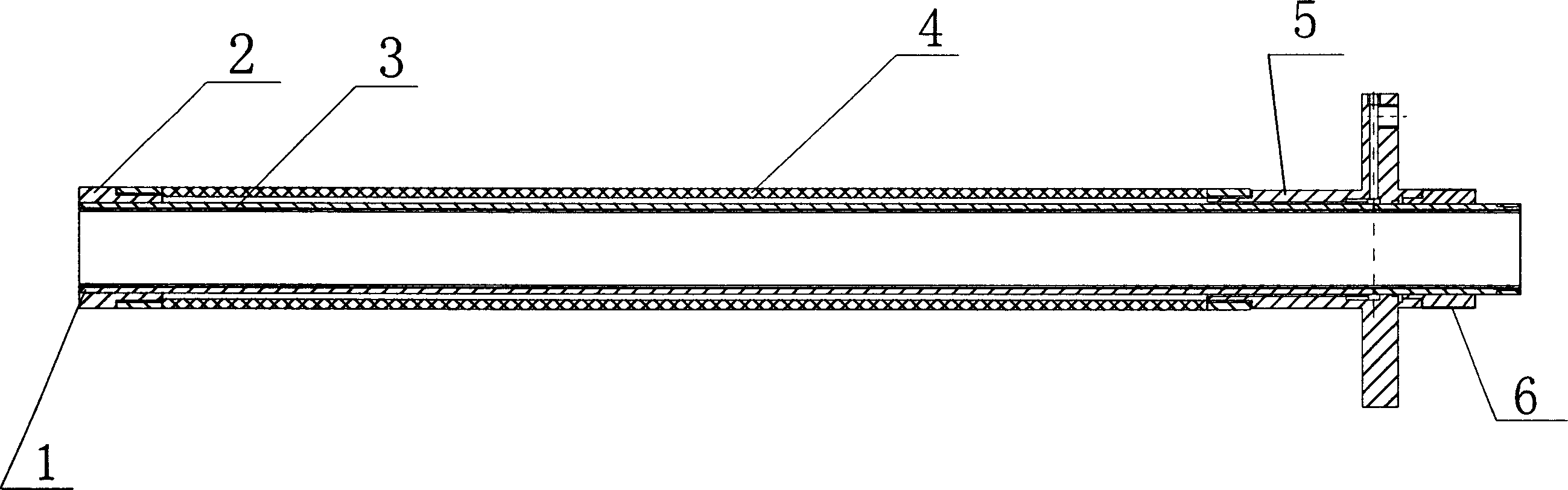

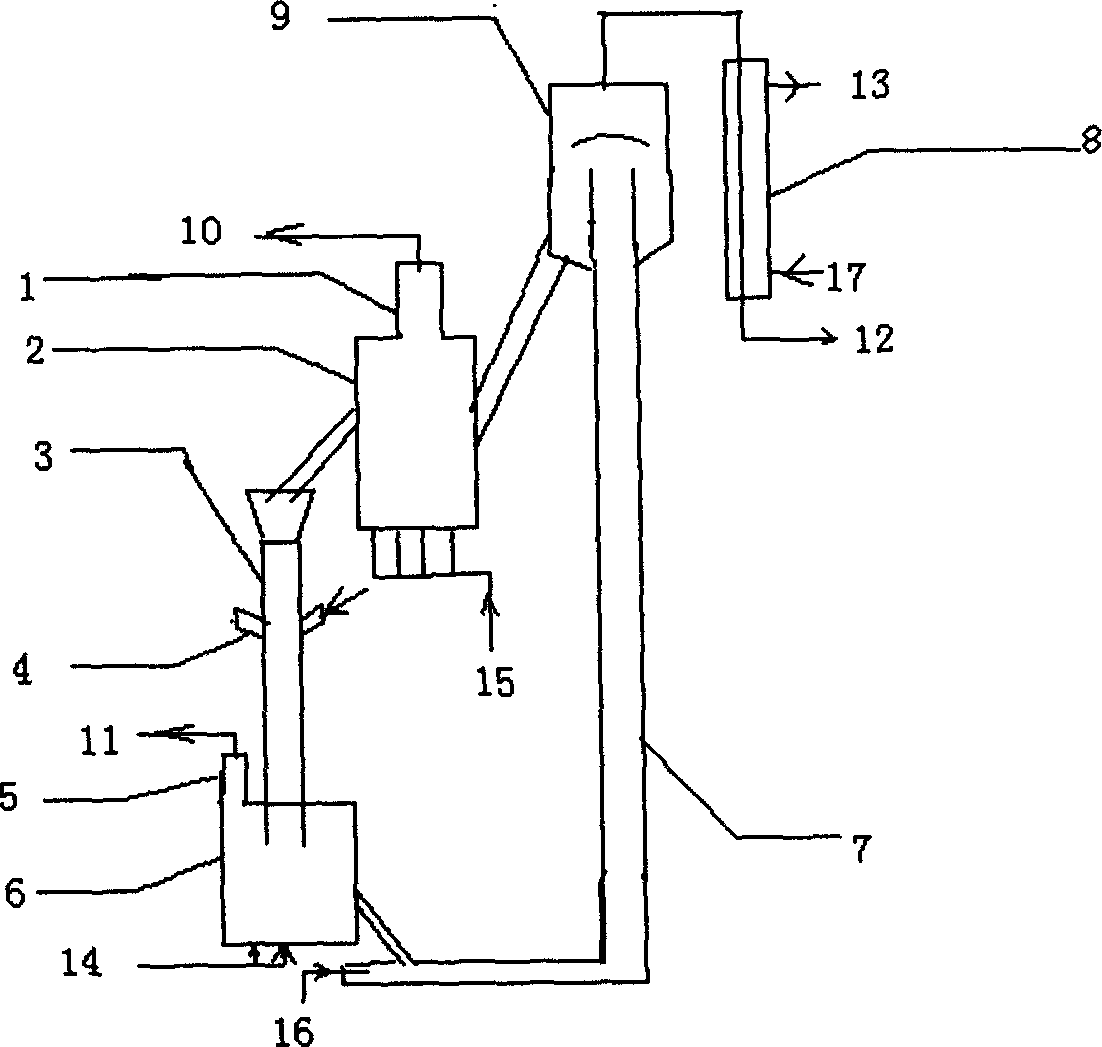

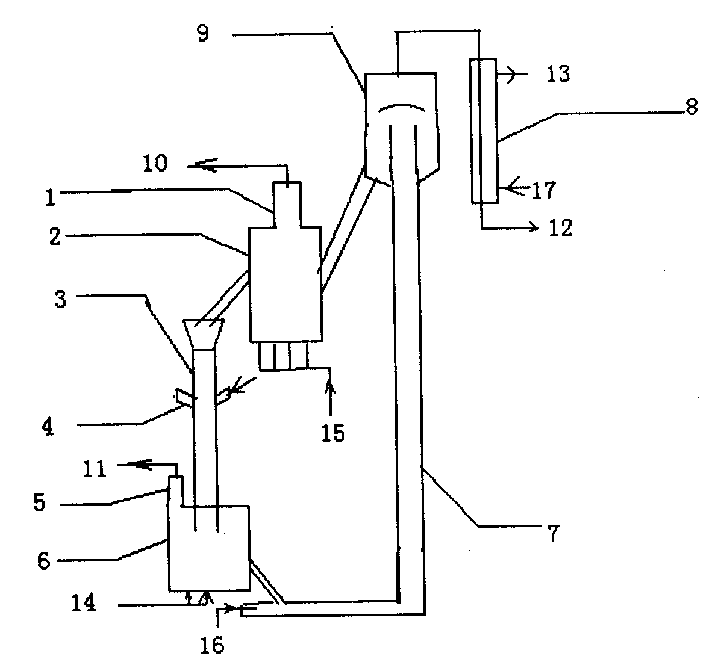

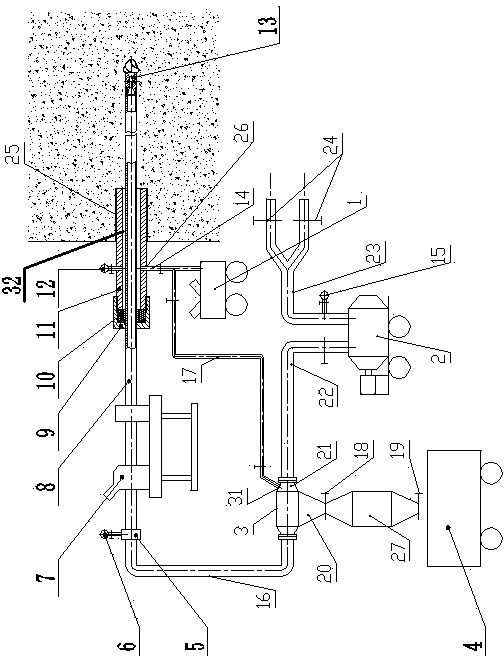

Continuous drilling flowrate process capable of predicting coal draft outburst and its apparatus

InactiveCN1847620APerceived heightControl startMining devicesDust removalData acquisitionEngineering

The present invention is continuous drilling flow rate capable of predicting coal draft outburst and its apparatus. By means of the method of drilling holes in the coal bed drilling direction for data acquisition and the apparatus comprising hole sealing capsule unit, solid-gas separator, filter, coal bit controller, electric rock drill with connected displacement sensor LXC, controller unit KZ with explosion resistant enclosure and connected computer data acquisitor SC, the present invention can determine the gas distribution in the drilling direction, obtain the gas flow rate distribution curve along the drilling depth during coal bed drilling process, so as to determine the distance of soft coal containing high pressure gas to the ground, judge the distance to the place with maybe outburst. The present invention has compact reasonable structure, high accuracy and stable and reliable measurement result, and may be used widely.

Owner:CHINA UNIV OF MINING & TECH

Technique of solid phase heat carrier for recycle cracking heavy oil and gasification technique

Raw material heavy oil at temp. of 150-340 deg.C is fed, by high efficiency atomizing nozzle, into the middle down-flow lift-pipe, said atomized oil being then heated by solid phase heat-carrier, at temp. of 750-950 deg.C, falling down-from the top of gasifying fluidized bed, and then being gasified and cracked, both oil and carrier falling down to the bottom and proceeding gas / solid separation; and oil gas fed into fractional column for separation, the carrier being then fed into up flow life-pipe for air burning-off of coke, after the the temp. being rised to 800-1200 deg.C, proceeding gas / solid separation; high temp. fume being fed into waste heat boiler to produce over-heat steam at temp. of 200-1000 deg.C, then fed into fluidized bed, then solid-gas separation; said gas being as product being pumped off, said solid carrier being recircled to down-flow life-pipe.

Owner:田原宇

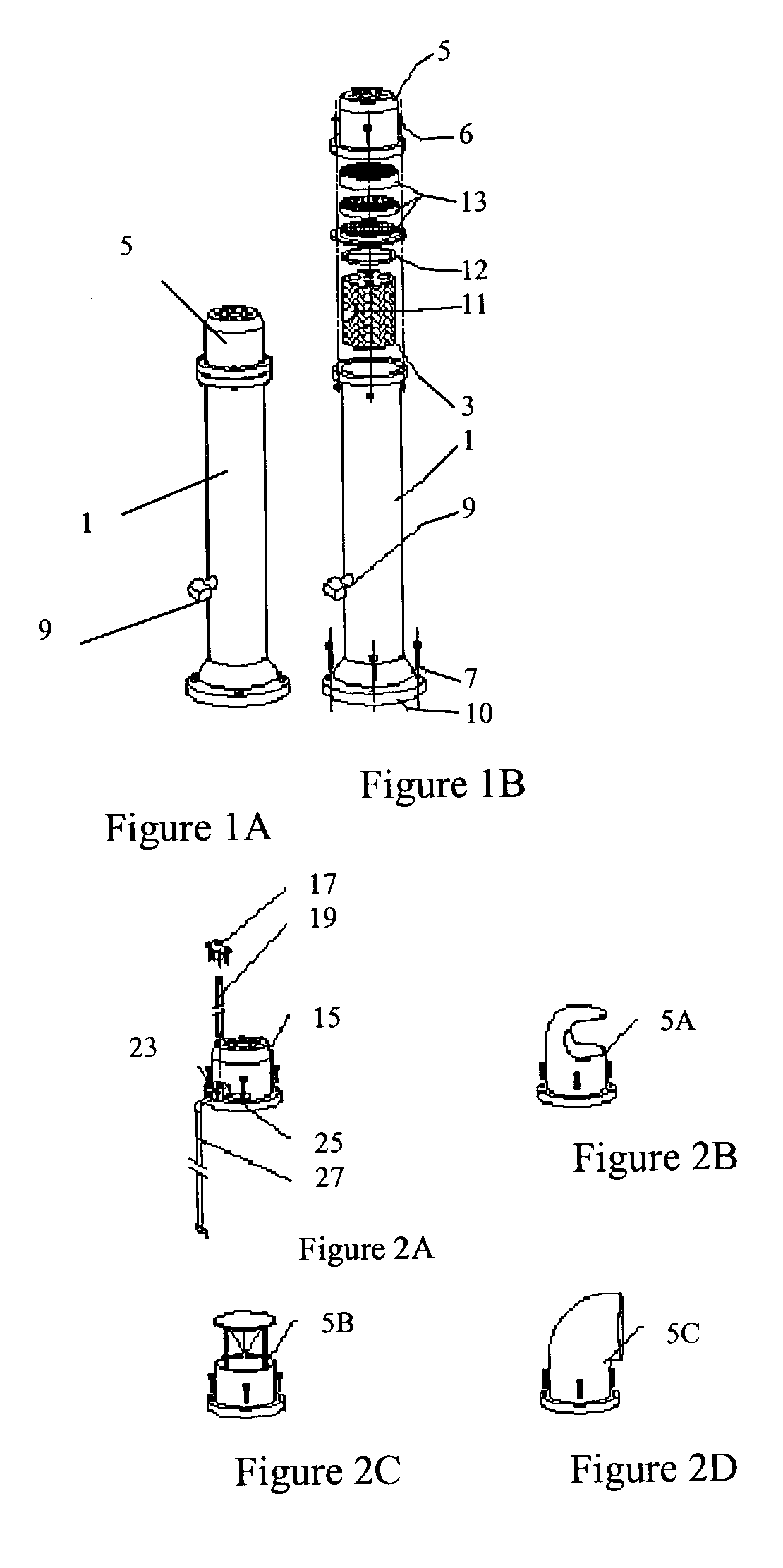

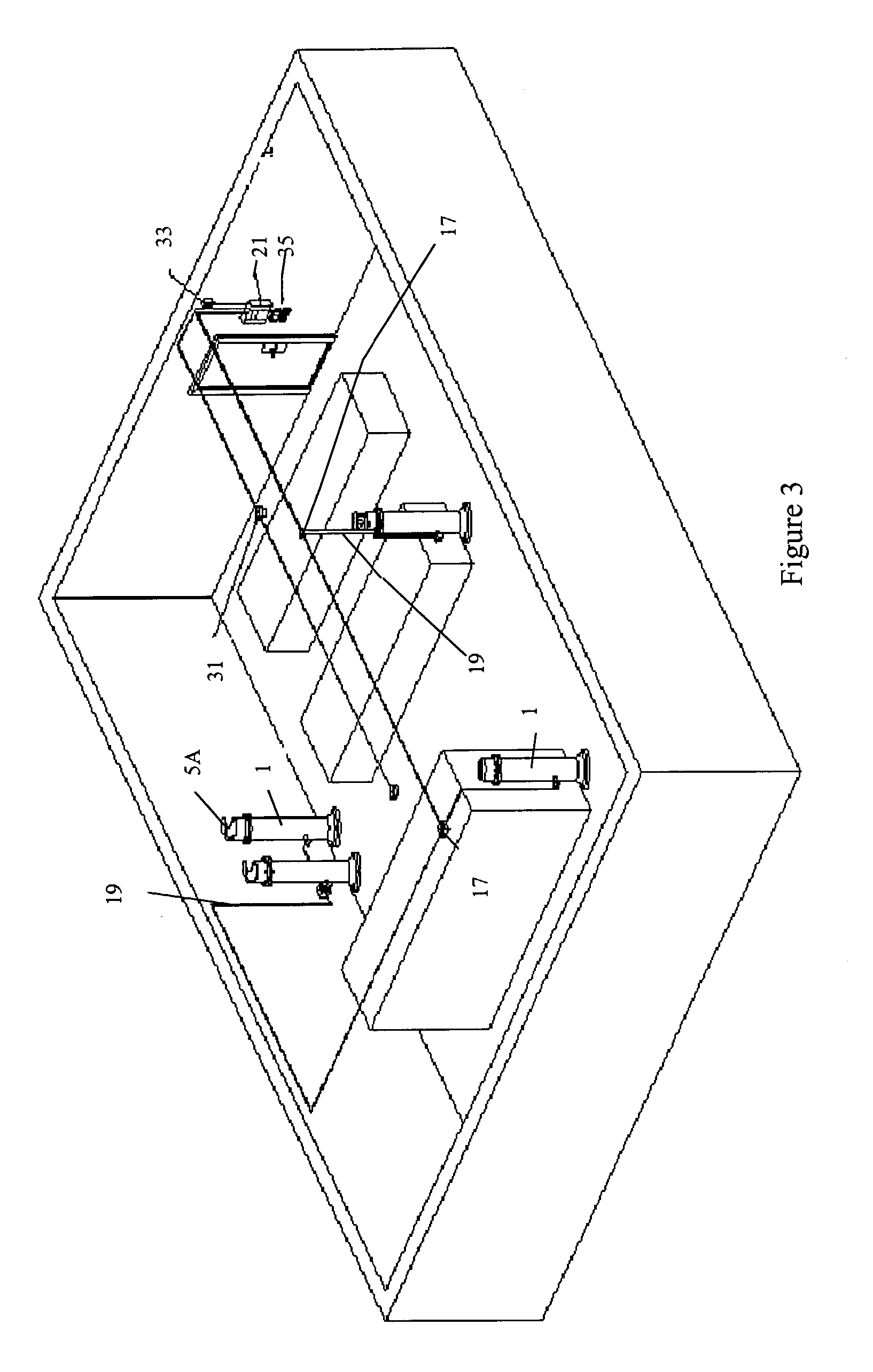

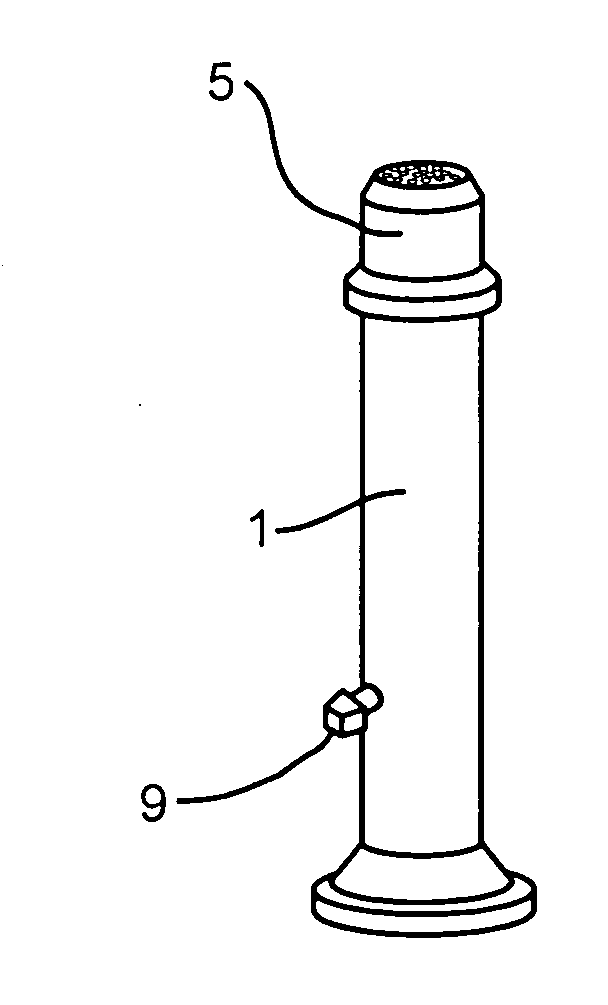

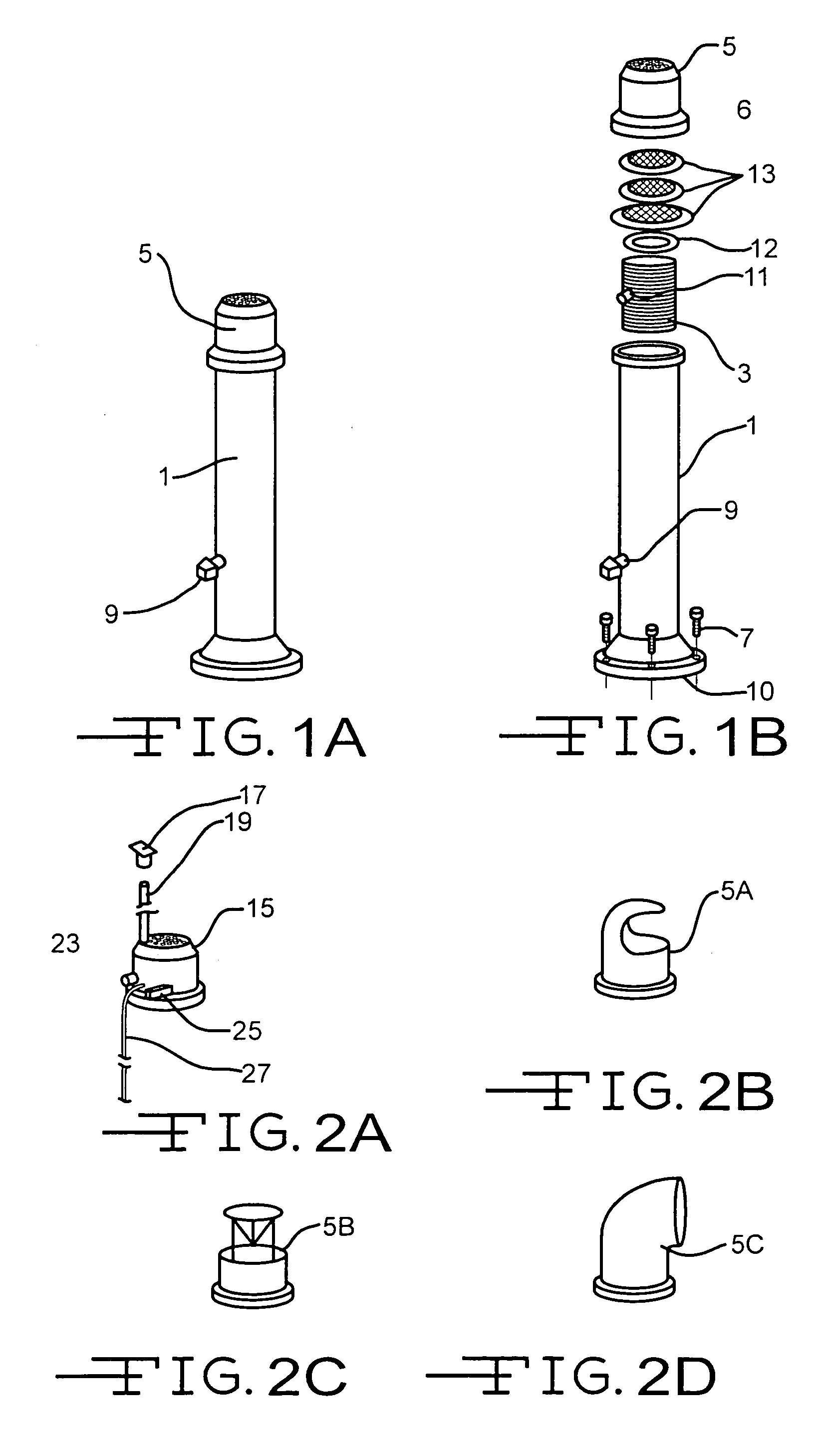

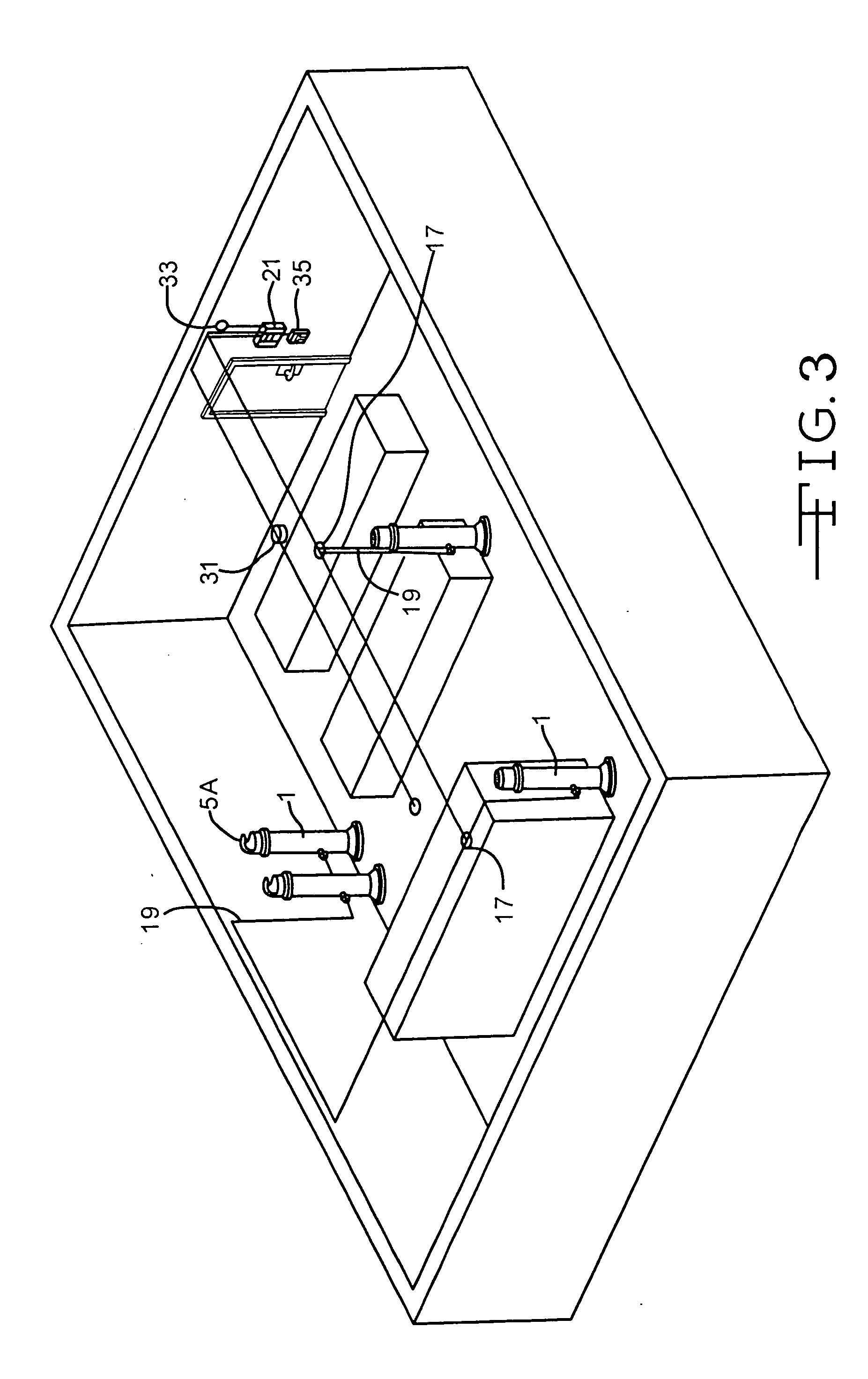

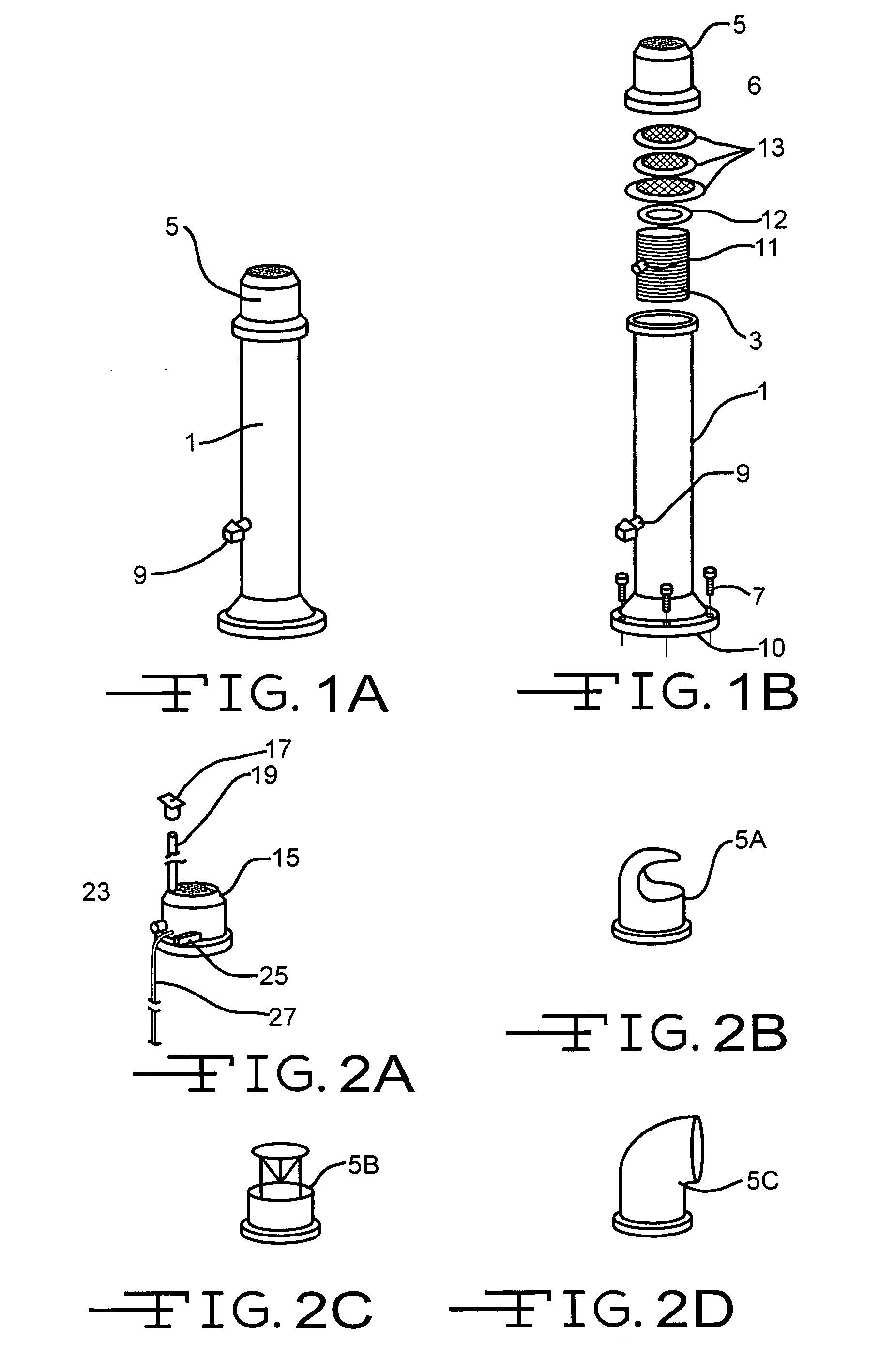

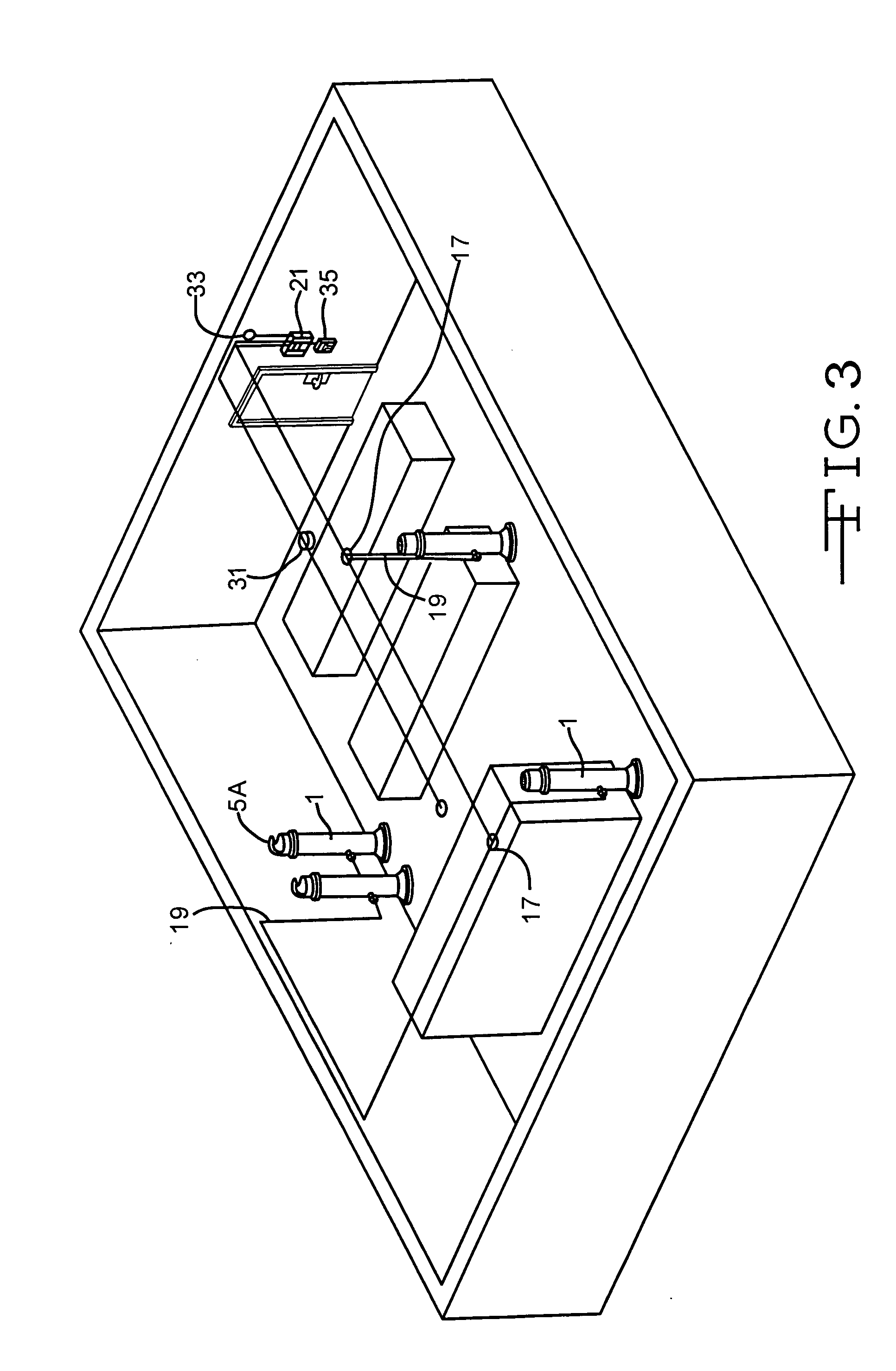

System and method for suppressing fires

InactiveUS7028782B2Minimal “ down time ”Save a lot of costFire rescueBoring toolsProduct gasNitrogen gas

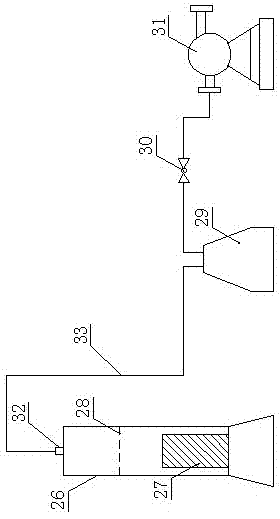

A method and apparatus for suppressing a fire utilizing non-azide solid gas propellant generation to produce and transport a suitable gas for suppressing a fire in a normally occupied area. The nitrogen gas produced by the solid propellant gas generation is optionally treated to remove undesirable elements such as water and / or carbon dioxide from the product gas prior to the delivery of the product gas to the protected hazard area.

Owner:N2 GLOBAL SIA

System and method for suppressing fires

InactiveUS20050139365A1Minimal “ down time ”Save a lot of costFire rescueBoring toolsProcess engineeringProduct gas

A method and apparatus for suppressing a fire utilizing non-azide solid gas propellant generation to produce and transport a suitable gas for suppressing a fire in a normally occupied area. The nitrogen gas produced by the solid propellant gas generation is optionally treated to remove undesirable elements such as water and / or carbon dioxide from the product gas prior to the delivery of the product gas to the protected hazard area.

Owner:N2 TOWERS INC

Fully-sealed wind power slagging gas-drainage deep well drilling system and method

The invention discloses a fully-sealed wind power slagging gas-drainage deep well drilling system and method. The fully-sealed wind power slagging gas-drainage deep well drilling system comprises a drilling rod with inner holes, an inverted-spinning smashing dust-collection drill is arranged at the front end of the drilling rod, and the rear portion of the drilling rod is connected to a drilling machine. An orifice-sealed pipe, sealing fillers and a sealed pressing cover are arranged on the drilling rod. An air inlet portion with annular section is formed between the orifice-sealed pipe and the outer wall of the drilling rod, and the air inlet portion is connected with a movable type air compressor through a first connecting pipe. The rear end of the drilling rod is connected with a second connecting pipe through a pneumatic rotary connector, the second connecting pipe is connected with a drainage conveying pipeline slagging device, and the slagging port of the slagging device is connected with a slagging cylinder. The air outlet of the slagging cylinder is connected with a gas drainage pump through a third connecting pipe, and the gas drainage pump is connected with a gas drainage pipe. According to the fully-sealed wind power slagging gas-drainage deep well drilling system and method, pressing feeding type wind force in the outer annular space of the drilling rod and the drainage type wind force of the inner holes of the drilling rod can be utilized to discharge the coal scraps smoothly to carry out solid-gas separation, fully-sealed type wind power scrap discharge is achieved, the fact that hole-drilling operation is conducted continuously and safely is ensured, and working efficiency is improved.

Owner:HENAN POLYTECHNIC UNIV

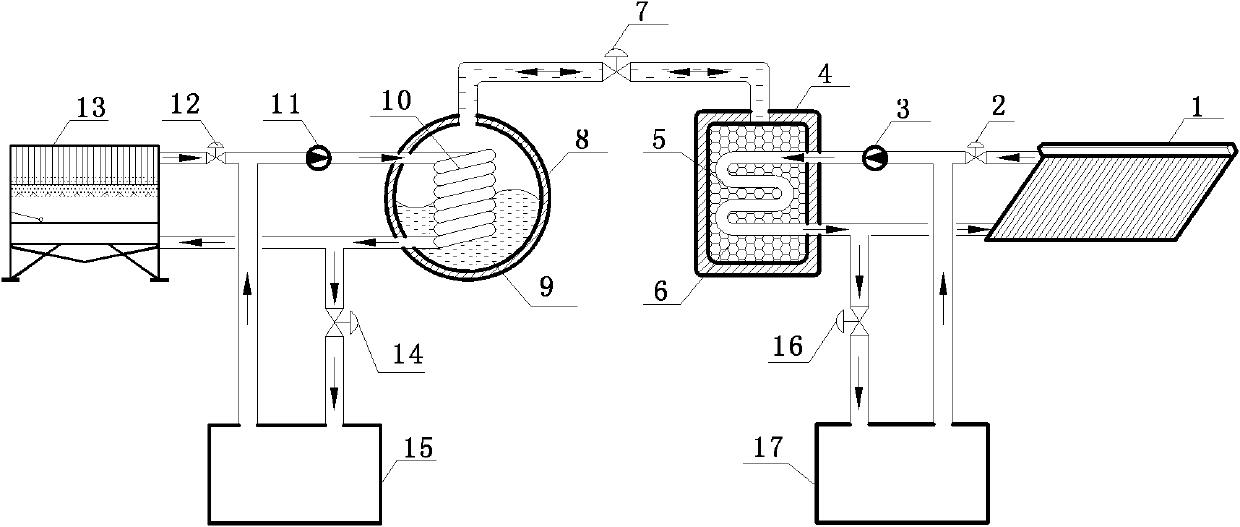

Cold-heat combined supply solar thermochemical adsorption composite energy storing device

InactiveCN101793447AImprove storage densityReduce volumeEnergy efficient heating/coolingClimate change adaptationCooling towerHigh energy

The invention discloses a cold-heat combined supply solar thermochemical adsorption composite energy storing device in the technical field of solar photo-thermal conversion utilization. A solar heat collector, a heat collector heat-transfer fluid adjusting valve, a high-temperature heat-transfer fluid circulating pump and a reactor heat exchange coil are circularly connected; a cooling tower, a cooling tower heat-transfer fluid adjusting valve, a low-temperature heat-transfer fluid circulating pump and a liquid accumulator heat exchange coil are circularly connected; a solid-gas chemical reactor, a refrigerant adjusting valve and a refrigerant accumulator are connected; the reactor heat exchange coil, a heat user side adjusting valve, a heat user side and the high-temperature heat-transfer fluid circulating pump are connected; the liquid accumulator heat exchange coil, a color user side adjusting valve, a color user side and the low-temperature heat-transfer fluid circulating pump are connected; the liquid accumulator heat exchange coil, the cooling tower, the cooling tower heat-transfer fluid adjusting valve and the low-temperature heat-transfer fluid circulating pump are circularly connected; and the refrigerant accumulator, the refrigerant adjusting valve and the solid-gas chemical reactor are connected. The device has high energy storage density and can realize cold-heat combined supply and simultaneous storage of heat and cold.

Owner:SHANGHAI JIAO TONG UNIV

System and method for suppressing fires

InactiveUS20050189123A1Minimal down timeLow costFire rescueBoring toolsProcess engineeringProduct gas

Owner:N2 GLOBAL SIA

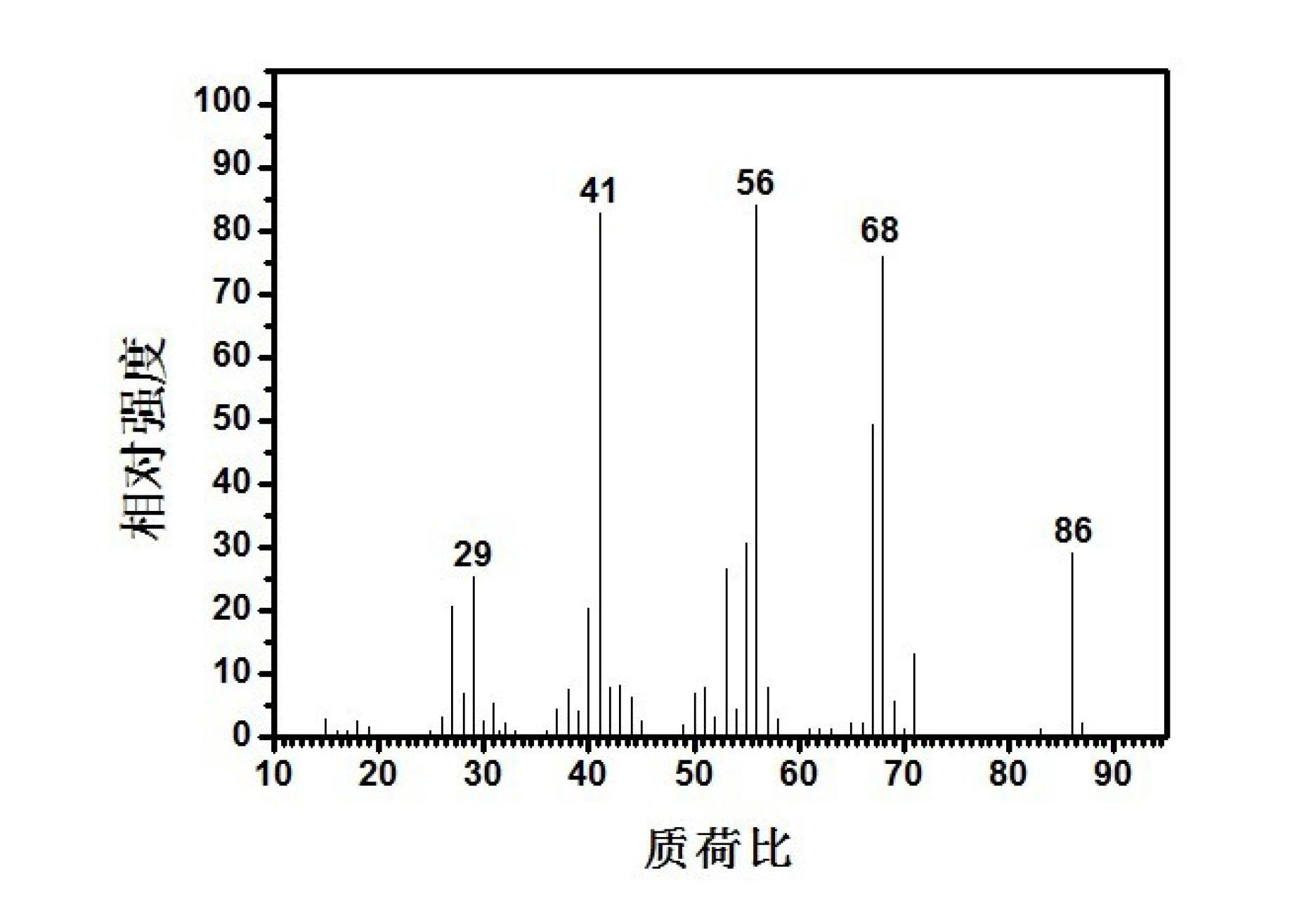

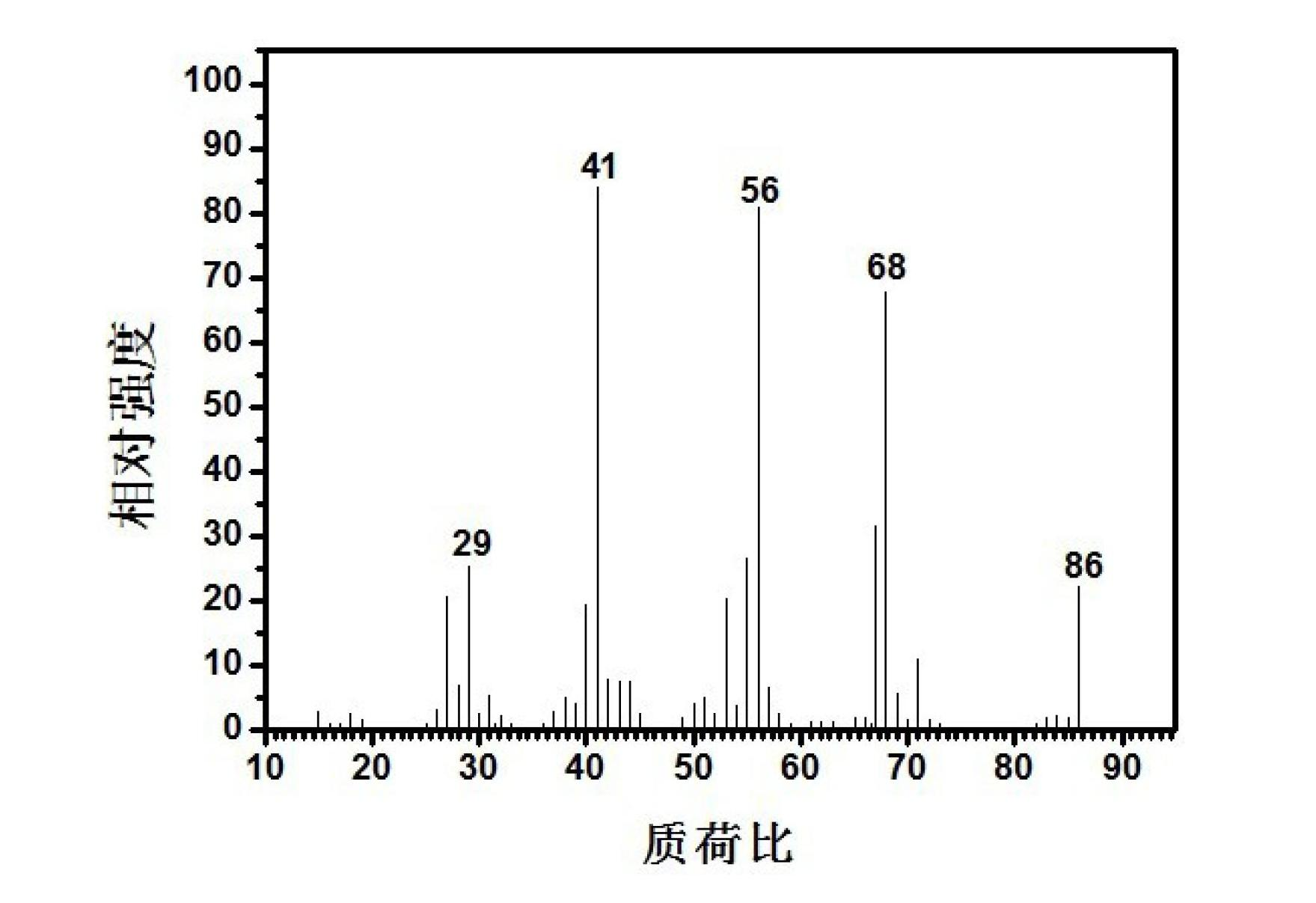

Solid gas generator and preparation method thereof

The invention provides a solid gas generator and a preparation method thereof. The solid gas generator comprises 12 to 23% of a polyether adhesive, 1.2 to 3.6% of a curing agent, 50 to 80% of an oxidizing agent, 0 to 5% of a plasticizer, 0 to 30% of a cooling agent, 0 to 5% of a combustion conditioning agent and 0 to 2% of other additives, wherein the polyether adhesive is one or a composition of more than one selected from the group consisting of ethylene oxide tetrahydrofuran copolyether and propylene oxide tetrahydrofuran copolyether, the curing agent is one or a composition of more than one selected from the group consisting of toluene diisocyanate, isophorone diisocyanate and multifunctional aliphatic diisocyanate, and the plasticizer is one or a composition of more than one selected from the group consisting of dioctyl sebacate, acetyl triethyl citrate and triethyl glycerin tricarbonate. The solid gas generator provided by the invention has a negative pressure exponent of 0 to - 0.30 and provides a power source for attitude control and orbit control power systems of light-weight kinetic kill vehicles (KKV).

Owner:HUBEI INST OF AEROSPACE CHEMOTECHNOLOGY

Method and device for sintering lime

The invention relates to a method and a device for sintering lime. The device comprises a plurality of kilns which are distributed in a ring or matrix or other shapes. Solid fuel such as coal powder, and the like, or gas fuel or liquid fuel, or mixed fuels of solid, gas and liquid combusts in the kilns or a separately arranged combustion chamber, and generated high-temperature smoke sinters limestone in the kilns and preheats the limestone in other kilns. Each kiln is internally provided with an air inlet girder and an up-sucking girder. The top of each kiln is provided with a movable feeding device capable of feeding for each kiln in a system. The bottom of each kiln is provided with a movable discharging device connected with a discharging channel and gathering dust generated by each kiln. By using the method and the device for sintering lime, the limestone can be sintered more sufficiently and evenly and has good quality and high activity degree; and meanwhile, the invention can sufficiently utilize afterheat, save the energy source, improve the thermal efficiency of the system, lower the production cost and realize large-scale continuous production.

Owner:SHIJIAZHUANG XINHUA IND FURNACE CO LTD

Method for preparing 3-methyl-3-butylene-1-alcohol

InactiveCN102659518ASolve equipment corrosionSolve the pollution of the environmentPhysical/chemical process catalystsOrganic compound preparationSolid acidReaction temperature

The invention relates to a method for synthesizing 3-methyl-3-butylene-1-alcohol on a solid acid catalyst and belongs to the field of catalytic synthesis. According to the method, by the solid acid catalyst, SnCl2 is immobilized on Al2O3, SiO2 and Al2O3-SiO2 compound oxides, which have a porous channel structure and hydroxyl groups on the surface, or silicon-aluminum molecular sieves, and isobutene and formaldehyde serving as raw materials are reacted to synthesize 3-methyl-3-butylene-1-alcohol. The catalytic synthesis is conducted in a solid-gas reactor, the catalyst is the SnCl2 immobilized catalyst, the reaction temperature is between 120 and 300 DEG C, and the reaction pressure is the normal pressure. The method solves the problem that acid catalysts erode equipment and contaminate environment in the conventional production process; and the method also solves the problem of requirement on high reaction temperature and high reaction pressure during use of the conventional alkali catalysts.

Owner:DALIAN UNIV OF TECH

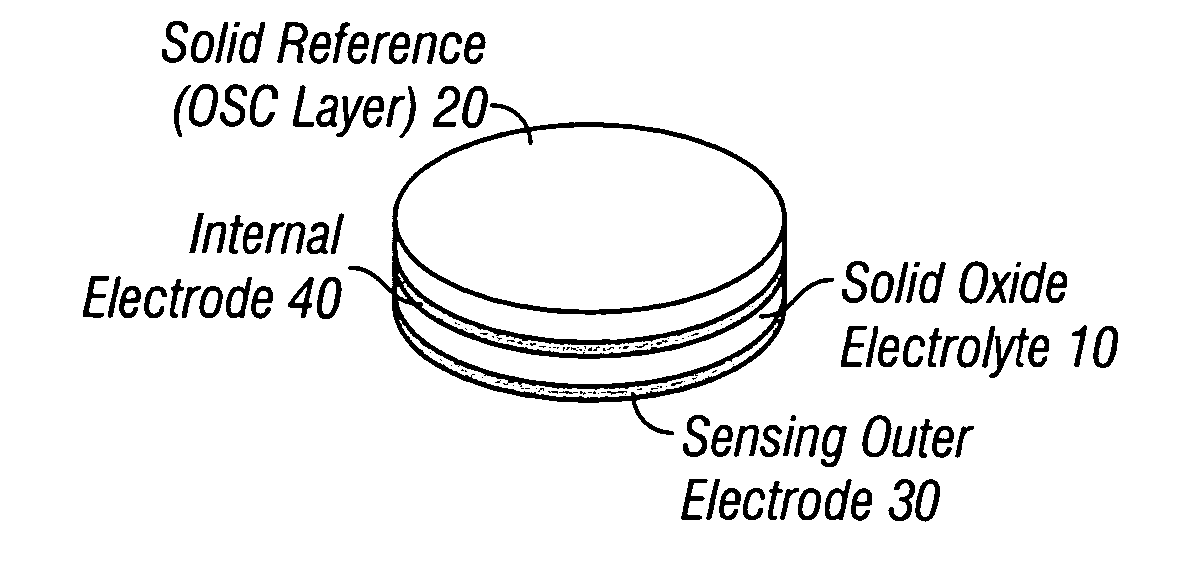

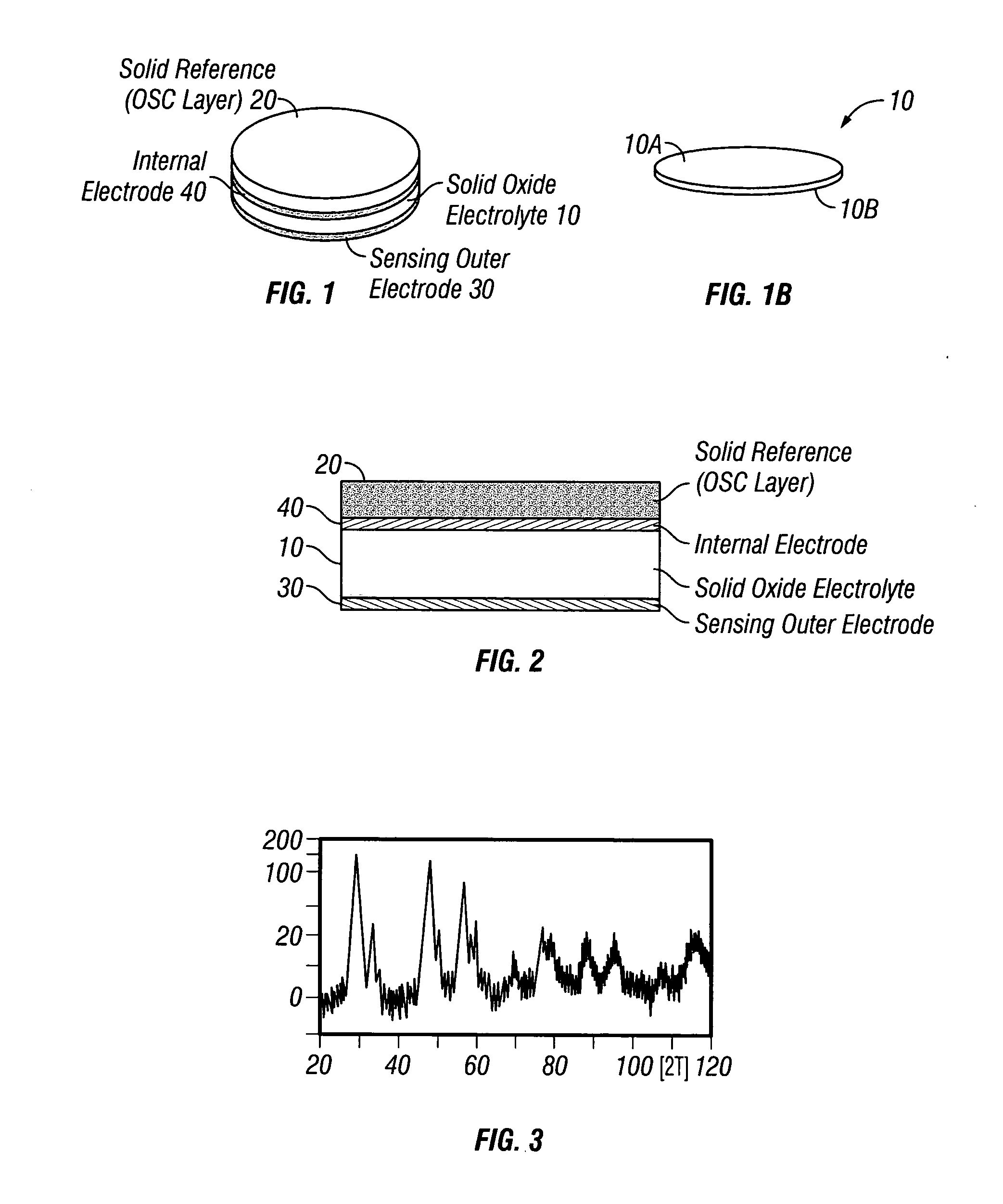

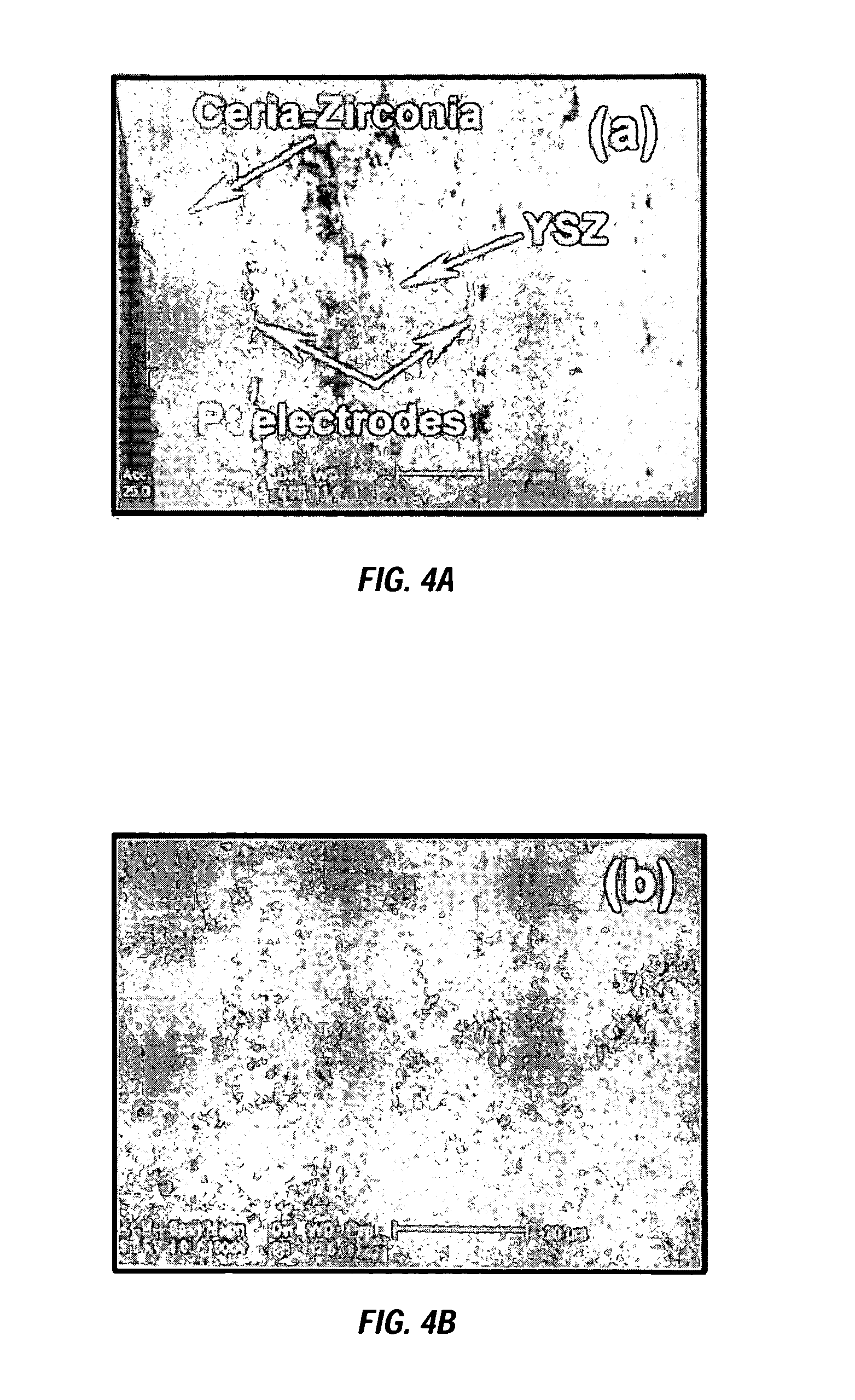

Oxygen sensor with a solid-state reference and manufacturing thereof

A self-contained, integrated-structure, miniature, electrochemical-type gas sensor is provided. An internal electrode is present on a surface of a solid electrolyte and is sandwiched between the solid electrolyte and a solid gas reference component. Also provided is an oxygen sensor as well as methods of making an oxygen sensor and gas sensor.

Owner:UNIV OF SOUTHERN CALIFORNIA

Love wave gas sensor

InactiveCN101644696AExcellent sensitivityExcellent stabilityAnalysing solids using sonic/ultrasonic/infrasonic wavesLower limitElectricity

The invention provides a love wave gas sensor which comprises a piezoelectric substrate, an input interdigital transducer, an output interdigital transducer and sensitive films, wherein the input interdigital transducer and the output interdigital transducer are deposited on the surface of the piezoelectric substrate, the sensitive films are covered on the piezoelectric substrate, the input interdigital transducer and the output interdigital transducer, the sensitive films are semiconductor-type gas sensitive material layers, the input interdigital transducer excites and spreads sound waves inthe piezoelectric substrate, the output interdigital transducer is used for receiving the sound waves, the characteristics of the sound waves can be changed after a loaded measured object reacts withthe sensitive films, and the characteristic conclusion about the measured object is acquired through detecting the changes. The love wave gas sensor can overcome the defect of lower detection lower limit of an existing semiconductor-type sensor, improves the performance of the sensor from the aspect of detection means, and realizes a gas detection function with high sensitivity and stability by combining the structure of a love wave sensor with an existing semiconductor-type solid gas sensitive film technology.

Owner:INST OF ACOUSTICS CHINESE ACAD OF SCI

Submerged arc welding method for K-shaped groove of 80mm extra-thick steel plate with excellent plate shape after welding

InactiveCN102922103AReduce peak residual stressOffset deformationArc welding apparatusWorkpiece edge portionsResidual deformationMixed gas

Owner:NANJING IRON & STEEL CO LTD

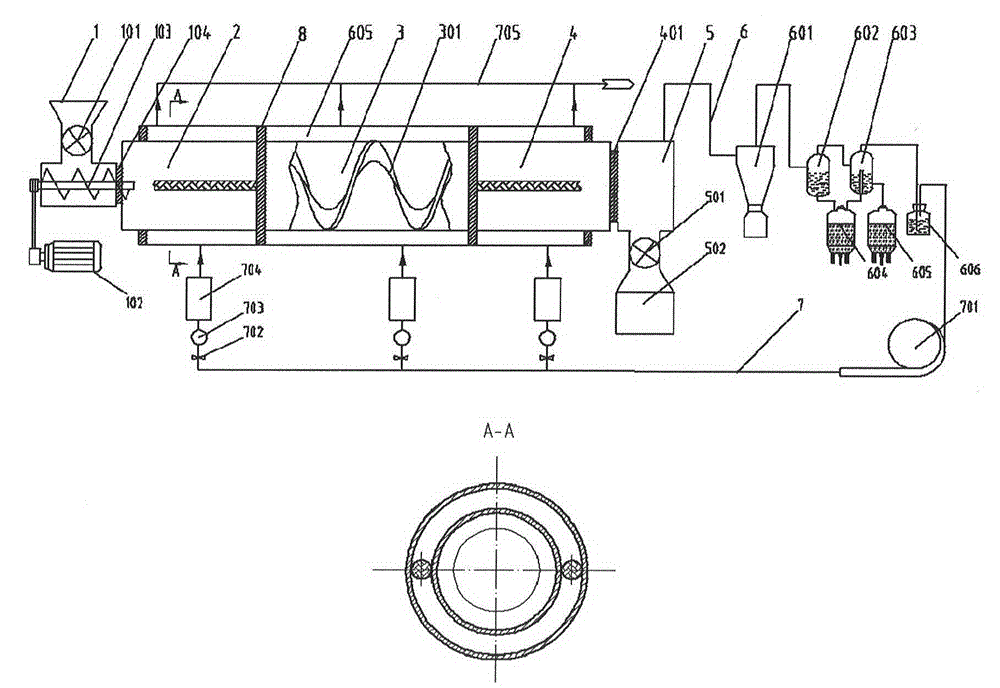

Rotary sectional heating biomass continuous pyrolysis equipment

InactiveCN104946279AEasy to adjust the interval lengthTemperature controlChemical industryBiofuelsFlue gasProcess engineering

The invention discloses rotary sectional heating biomass continuous pyrolysis equipment, which mainly is composed of a feeding system, a drying chamber, a pre-pyrolysis chamber, a heat preservation pyrolysis chamber, a solid-gas separation system, a pyrolysis gas purification separation system, a gas regenerative system and a sealing system. By means of continuous closed feeding and discharge, continuous pyrolysis reaction is ensured. A rotary furnace adopts high temperature flue gas regeneration principle to provide heat source for biomass material pyrolysis. The pyrolysis temperature is adjusted by adjusting the air input. At the same time, two moveable heat insulation rings are employed in the rotary furnace jacket to divide pyrolysis into three parts: drying, pre-pyrolysis and heat preservation pyrolysis, and the length ratio and temperature of the three sections can be adjusted according to technological requirements.

Owner:ACADEMY OF PLANNING & DESIGNING OF THE MINIST OF AGRI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com