Water-gas two-phase adsorption-desorption-seepage experimental system and method for loaded coal containing methane

An experimental system and gas coal technology, applied in the field of two-phase temperature swing adsorption-desorption-seepage experimental system of gas-containing coal-water two-phase adsorption-desorption-seepage, can solve problems such as consideration of influencing factors, not very comprehensive, etc., to ensure reliability, increase Effects of experimental features

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

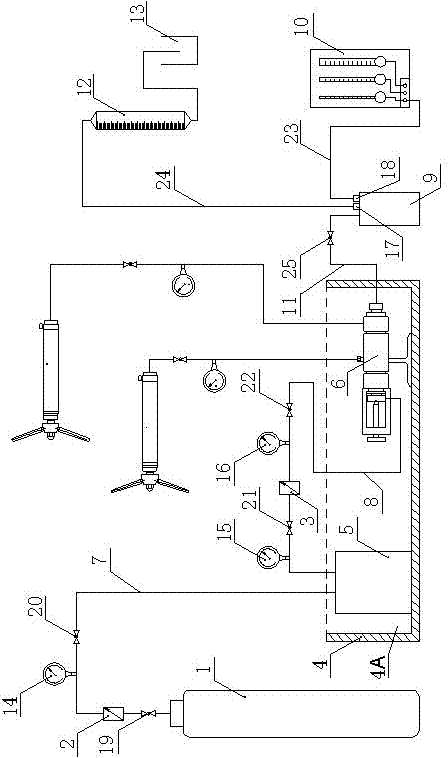

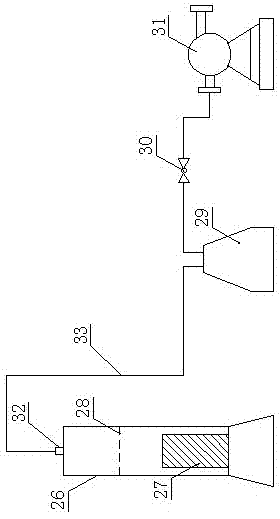

[0015] Depend on figure 1 and figure 2 The shown loaded gas-containing coal-water-gas two-phase temperature-swing adsorption-desorption-percolation experimental system includes a pressure loading part and a coal sample preparation device.

[0016] The pressure loading part includes a pool body 4 for holding a constant temperature water bath 4A. A reference tank 5 and a coal sample holder 6 are arranged inside the pool body 4. The reference tank 5 is airtight and is provided with an air inlet and an air outlet. The reference tank 5 The air inlet of the high-pressure gas delivery pipeline 7 is connected to the high-pressure gas delivery pipeline 7. The high-pressure gas tank 1, the first pressure reducing valve 2, the first pressure gauge 14 and the switch valve 20 are arranged in sequence on the high-pressure gas delivery pipeline 7. The gas can be input into the reference tank 5, and through the first decompression valve 2, the first pressure gauge 14 and the switch va...

Embodiment 2

[0026] Depend on figure 1 and figure 2 The shown load-bearing gas-containing coal-water-gas two-phase seepage test method includes the following steps:

[0027] (1) Prepare the loaded gas-containing coal-water-gas two-phase temperature-swing adsorption-desorption-percolation experimental system as described in Example 1, connect all pipelines and close all on-off valves.

[0028] (2) Take an initial coal sample, the size of the coal sample is about Φ50×100mm, place it on a precision electronic balance and weigh it, and calculate the initial weight of the initial coal sample as m 0, put the initial coal sample in the coal sample tank 26, put into the coal sample tank 26 at least distilled water 28 that has not passed the top surface of the initial coal sample, the water level of the distilled water 28 is lower than the air extraction port 32, and then connect the vacuum pipeline 33 to the coal sample The gas extraction port 32 of the tank 26, after checking the airtightness ...

Embodiment 3

[0040] Depend on figure 1 and figure 2 The shown adsorption-desorption experimental method of loaded gas-containing coal with different moisture content includes the following steps: (1) First prepare the loaded gas-containing coal water-gas two-phase temperature-swing adsorption-desorption-seepage experiment as described in Example 1 system, connect all pipelines and close all on-off valves.

[0041] (2) Put it on a precision electronic balance and weigh it, and calculate the initial weight of the initial coal sample as m 0 , put the initial coal sample into the coal sample tank 26, put into the coal sample tank 26 at least the distilled water 28 that has not passed the top surface of the initial coal sample, the water level of the distilled water 28 is lower than the air extraction port 32, and then connect the vacuum pipeline 33 to the coal sample The gas extraction port 32 of the tank 26, after checking the airtightness of the coal sample tank 26 and the vacuum pipeline...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com