Patents

Literature

1421 results about "Thermal coupling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

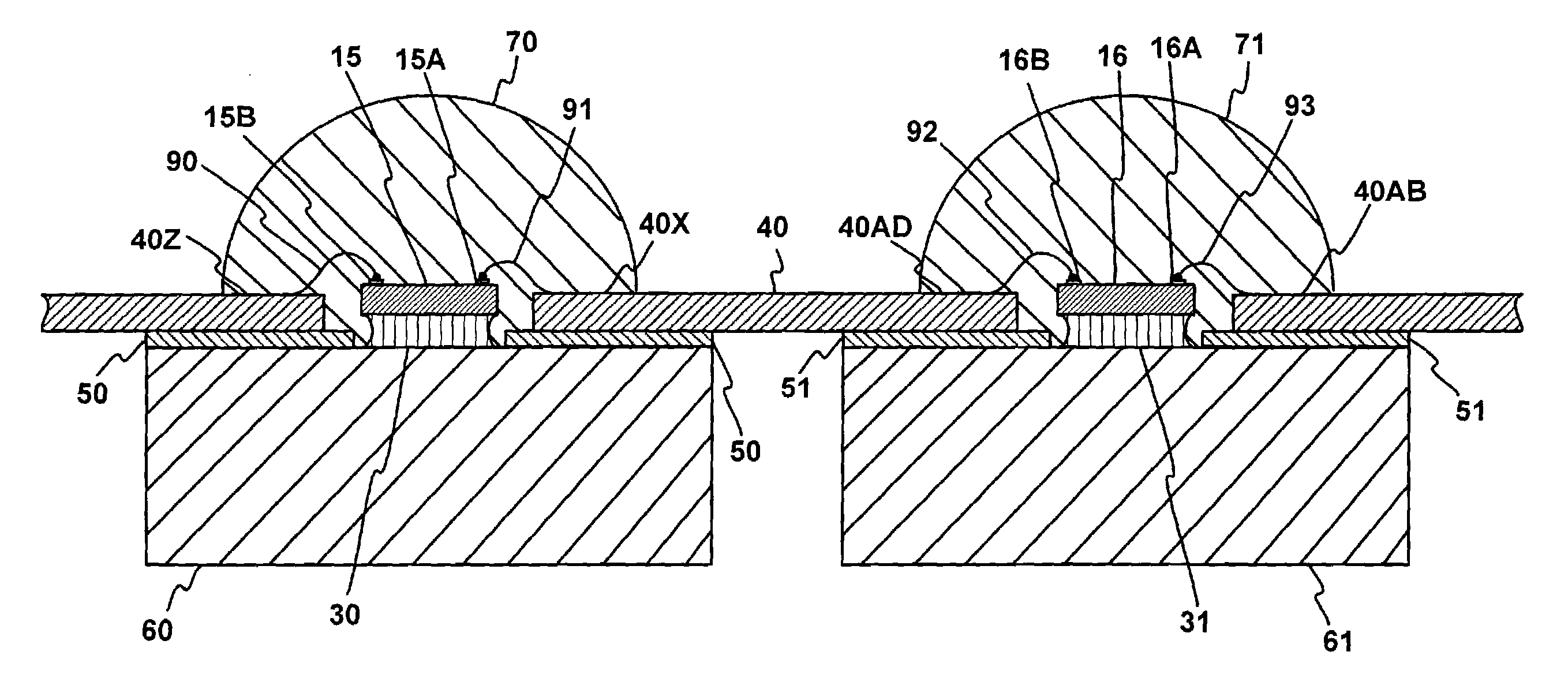

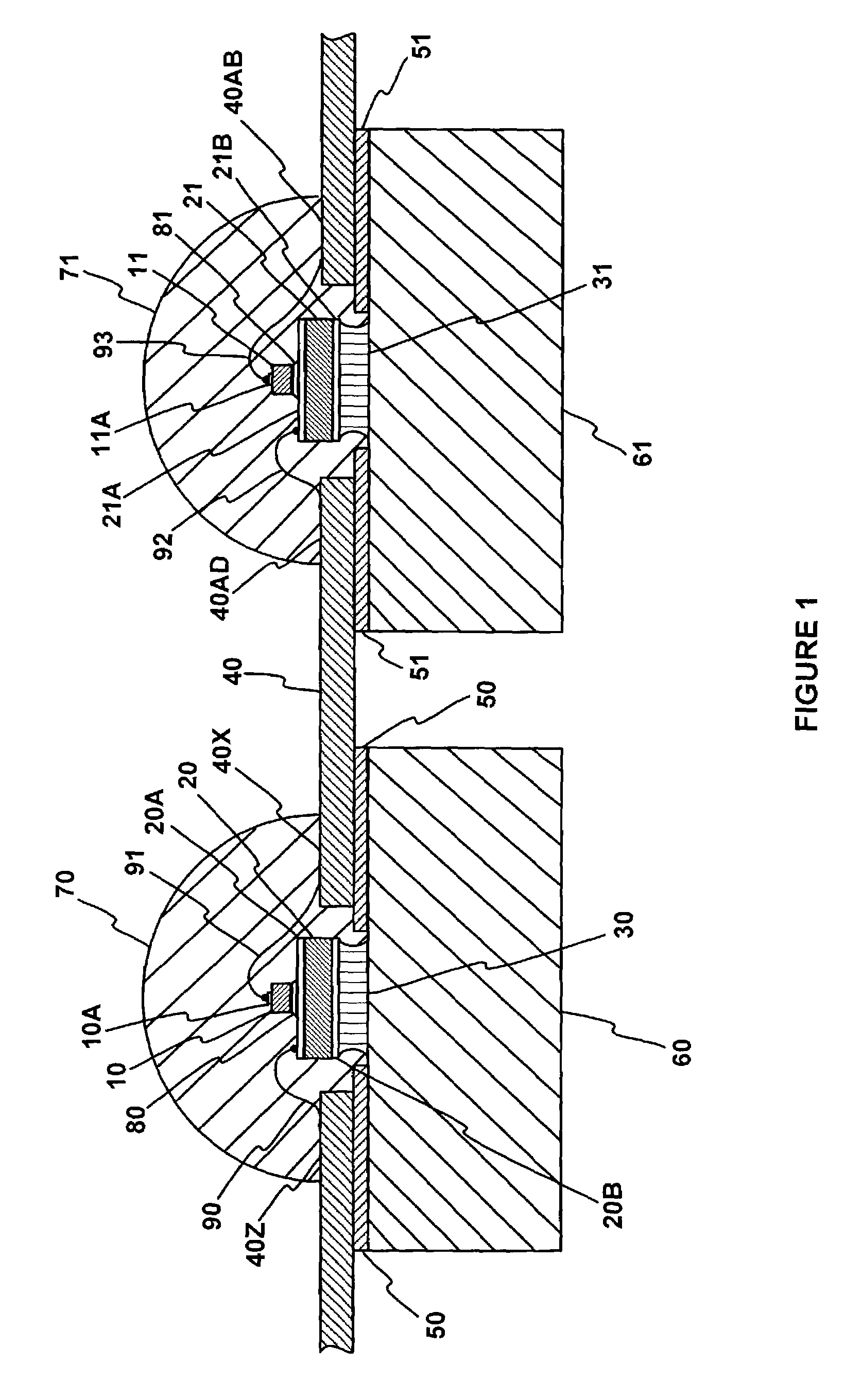

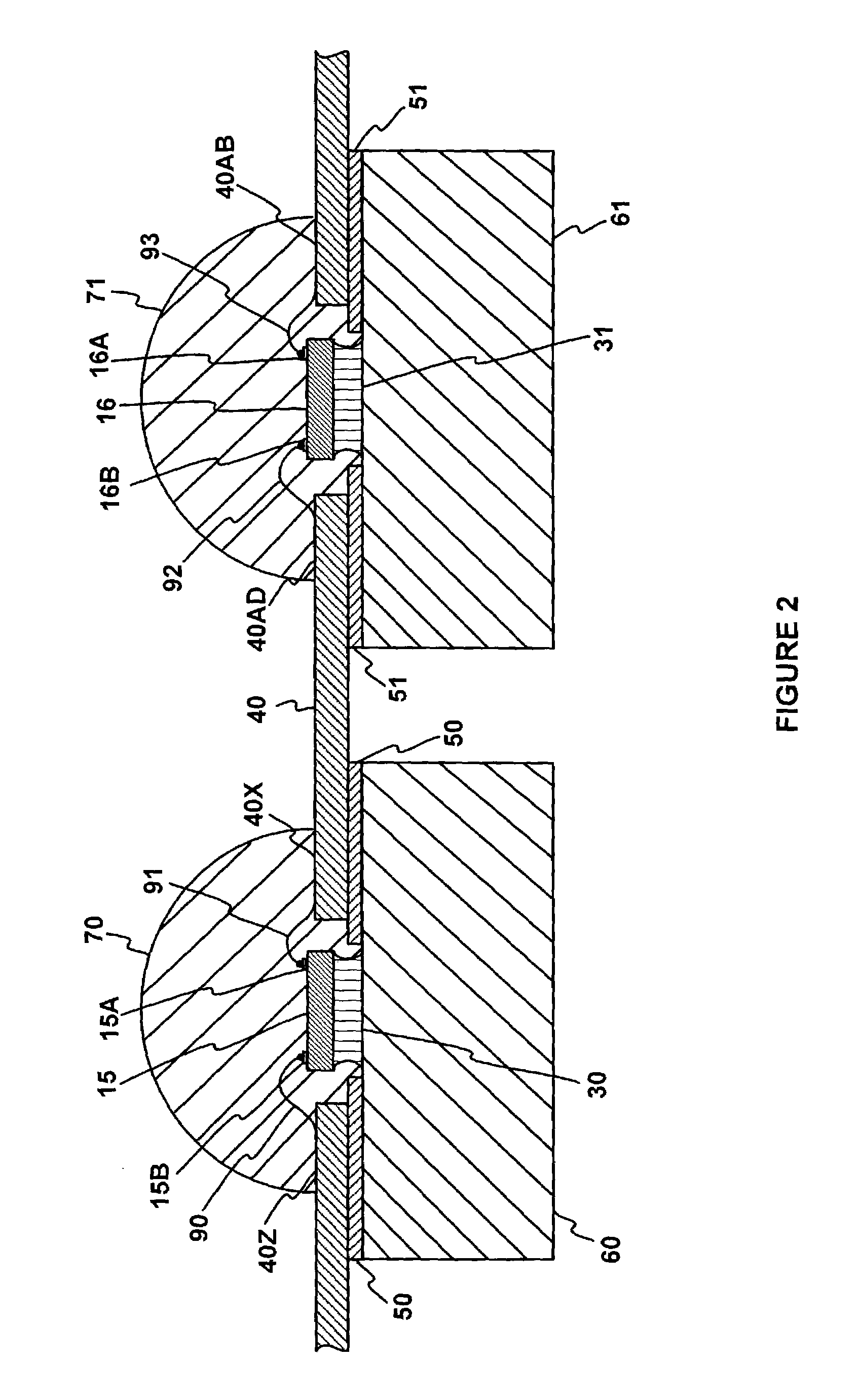

Bendable high flux LED array

ActiveUS6936855B1Easily variableWell formedSolid-state devicesSemiconductor devices for light sourcesLed arrayHigh flux

A bendable light emitting diode (LED) array in accordance with the present invention includes heat spreaders, dielectric material disposed above each heat spreader, and a bendable electrical interconnection layer disposed above these heat spreaders and electrically insulated from these heat spreaders by the dielectric material. At least one via passes through the dielectric material above each heat spreader, and at least one LED die is disposed above each via. The bendable electrical interconnection layer may be a lead frame comprising metal pathways that electrically interconnect some or all LED dice in series, in parallel, in anti-parallel, or in some combination of these configurations. Each via contains a thermally conductive material in thermal contact with the corresponding heat spreader below it and in thermal contact with the corresponding LED die above it. The LED dice may be thermally and electrically coupled to submounts disposed above corresponding heat spreaders in some embodiments.

Owner:EPISTAR CORP

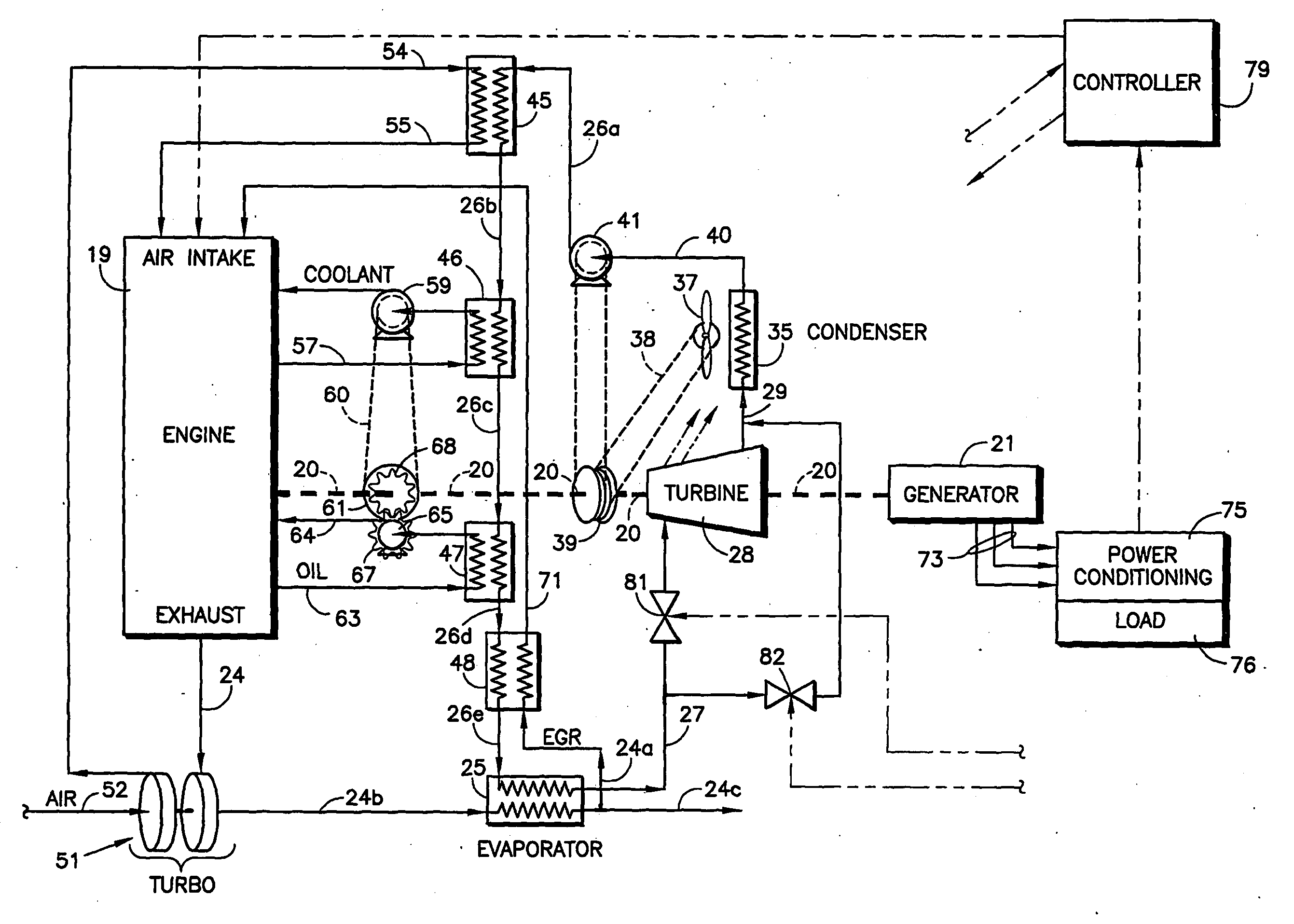

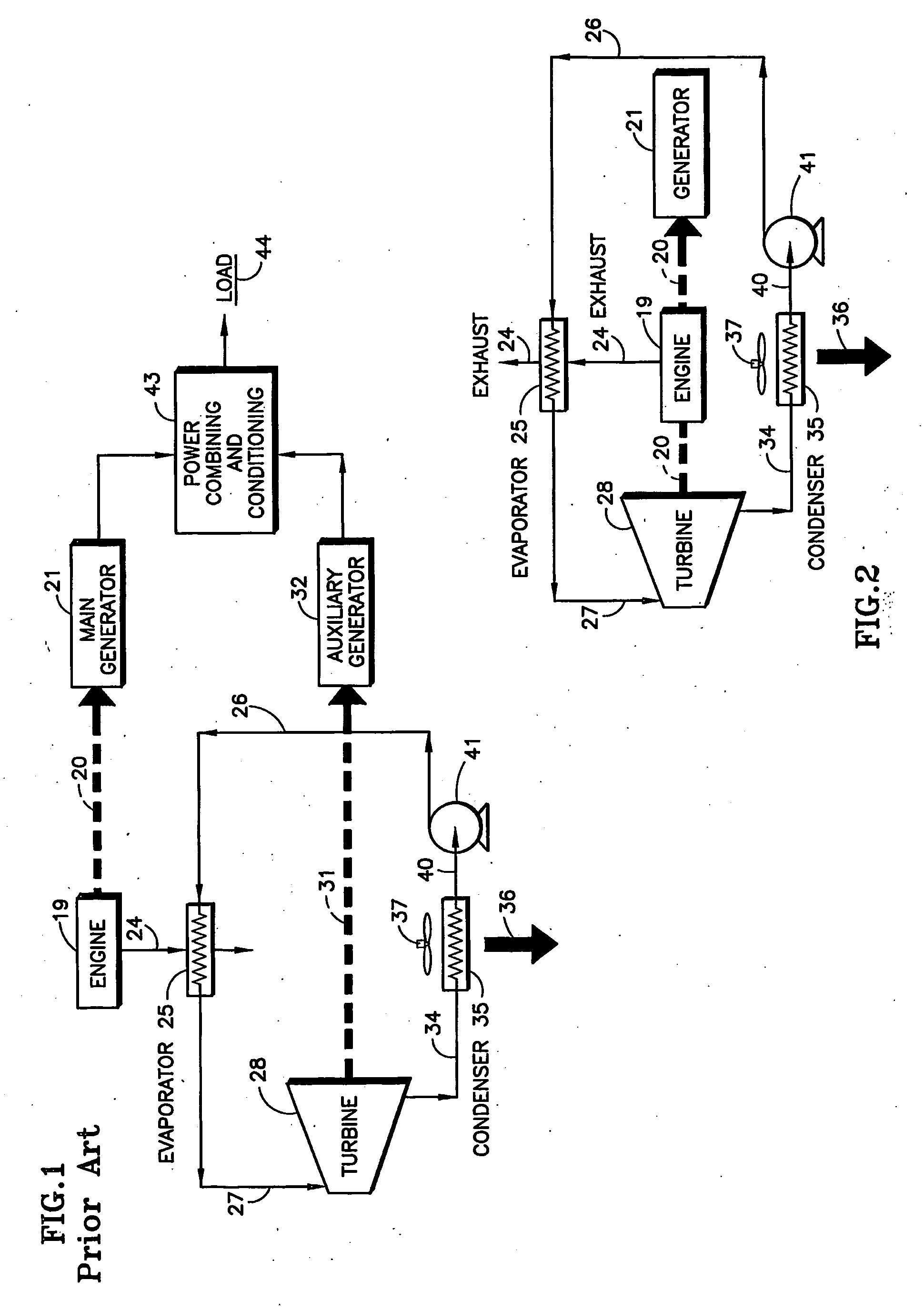

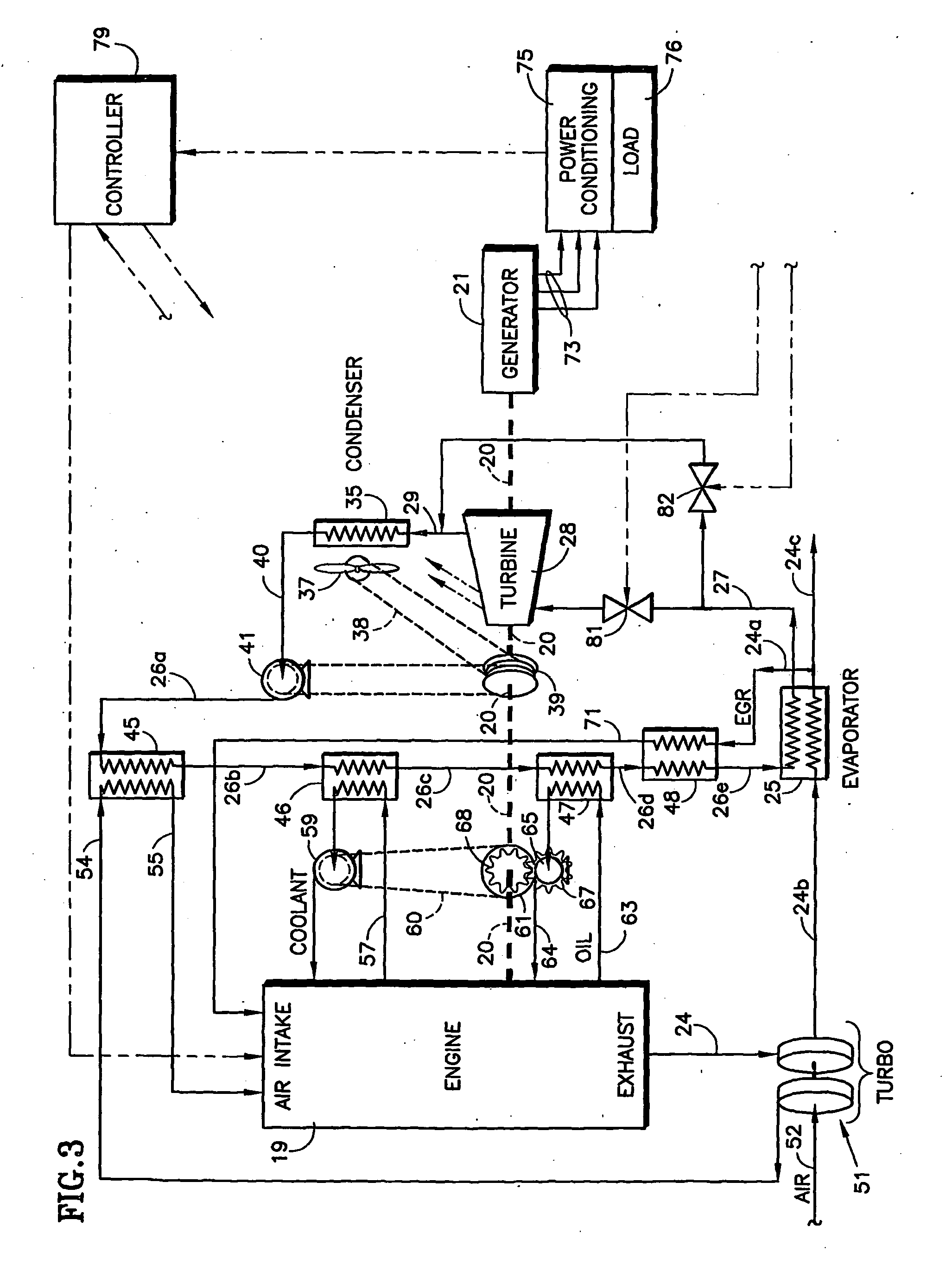

Organic Rankine Cycle Mechanically and Thermally Coupled to an Engine Driving a Common Load

InactiveUS20090211253A1Maximize efficiencyEngine componentsSteam engine plantsPtru catalystOrganic Rankine cycle

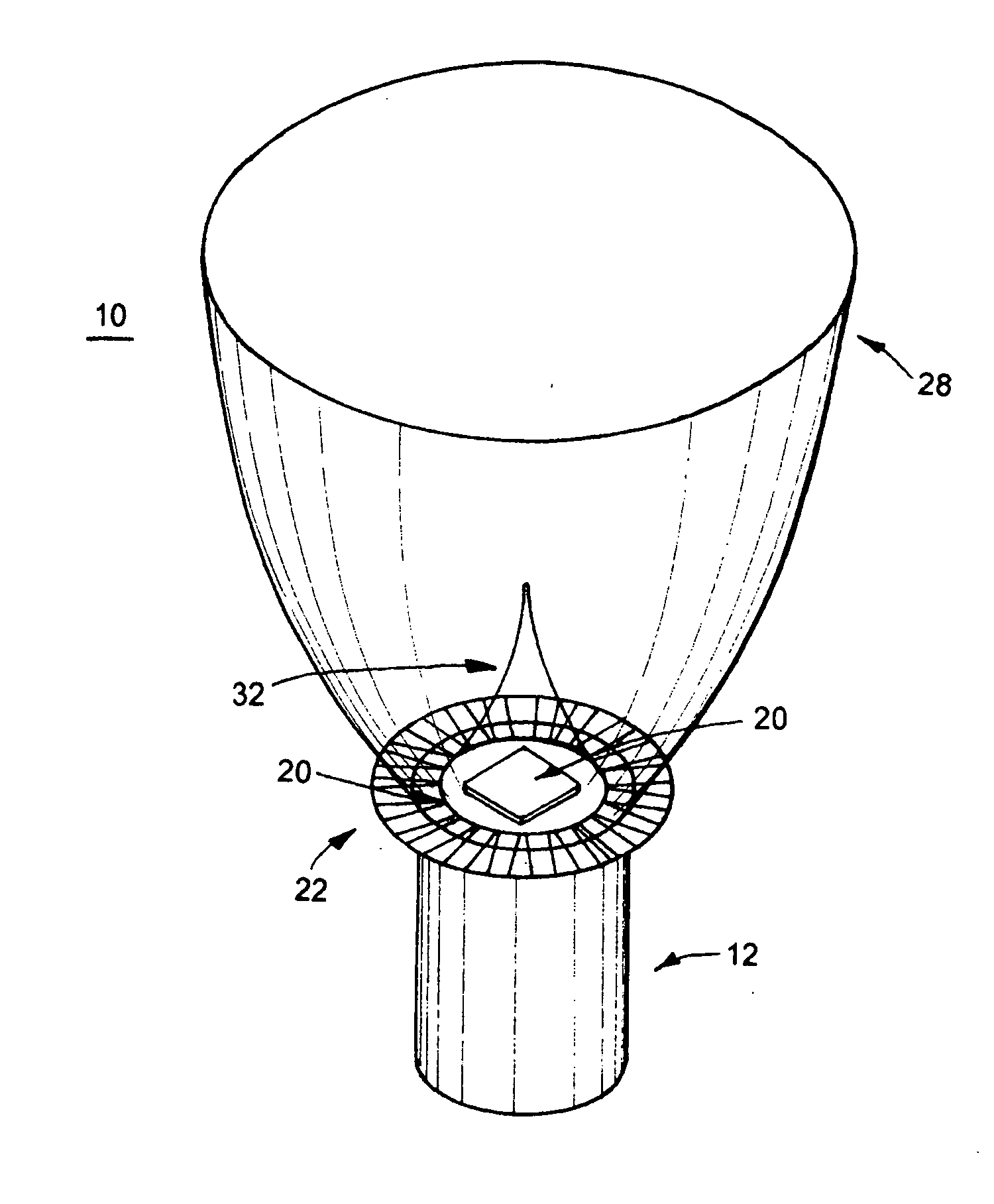

The shaft (20) of an engine (19) is coupled to a turbine (28) of an organic Rankine cycle subsystem which extracts heat (45-48, 25) from engine intake air, coolant, oil, EGR and exhaust. Bypass valves (92,94, 96, 99) control engine temperatures. Turbine pressure drop is controlled via a bypass valve (82) or a mass flow control valve (113). A refrigeration subsystem having a compressor (107) coupled to the engine shaft uses its evaporator (45a) to cool engine intake air. The ORC evaporator (25a) may comprise a muffler including pressure pulse reducing fins (121, 122), some of which have NOx and / or particulate reducing catalysts thereon.

Owner:UNITED TECH CORP

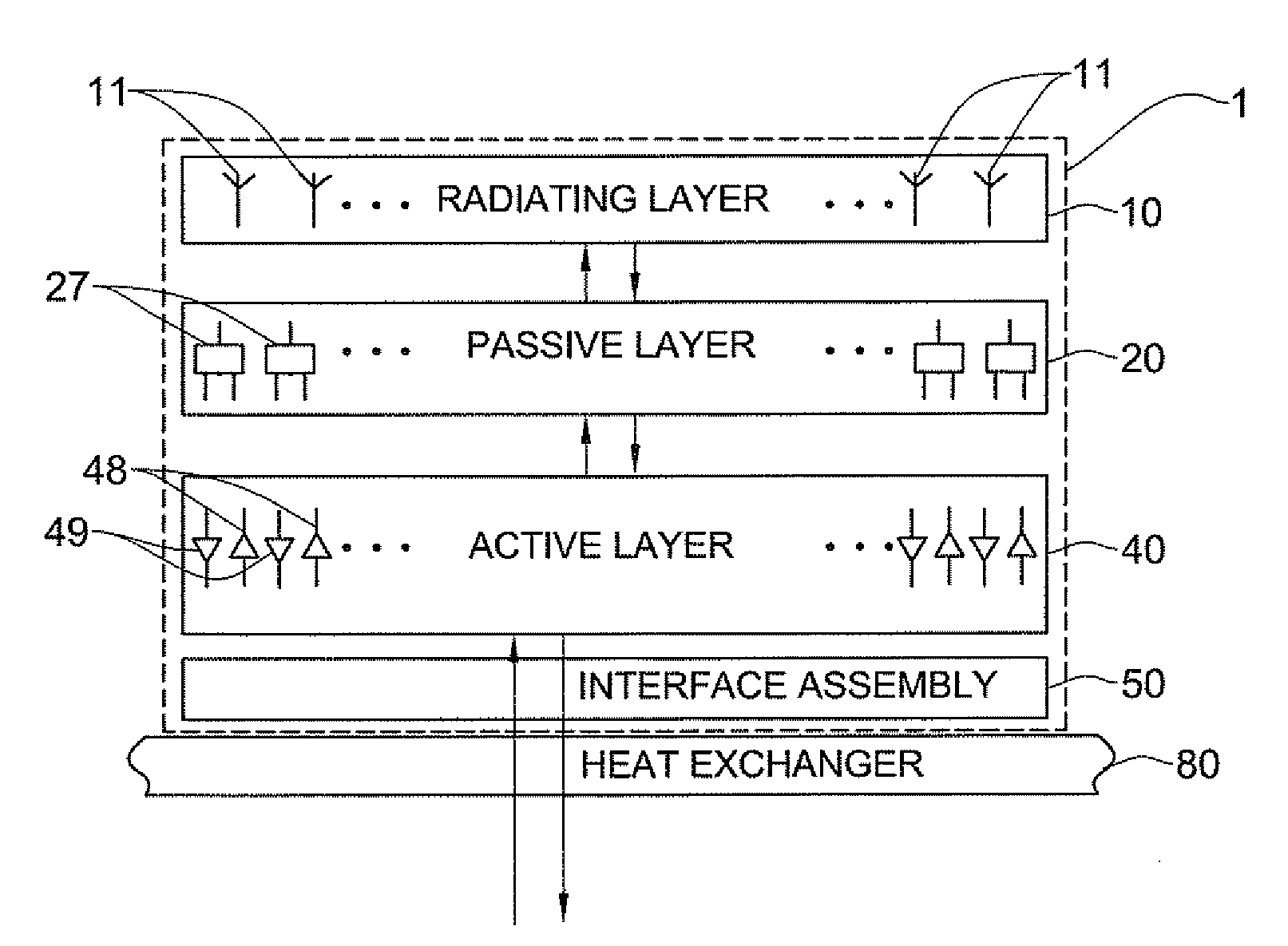

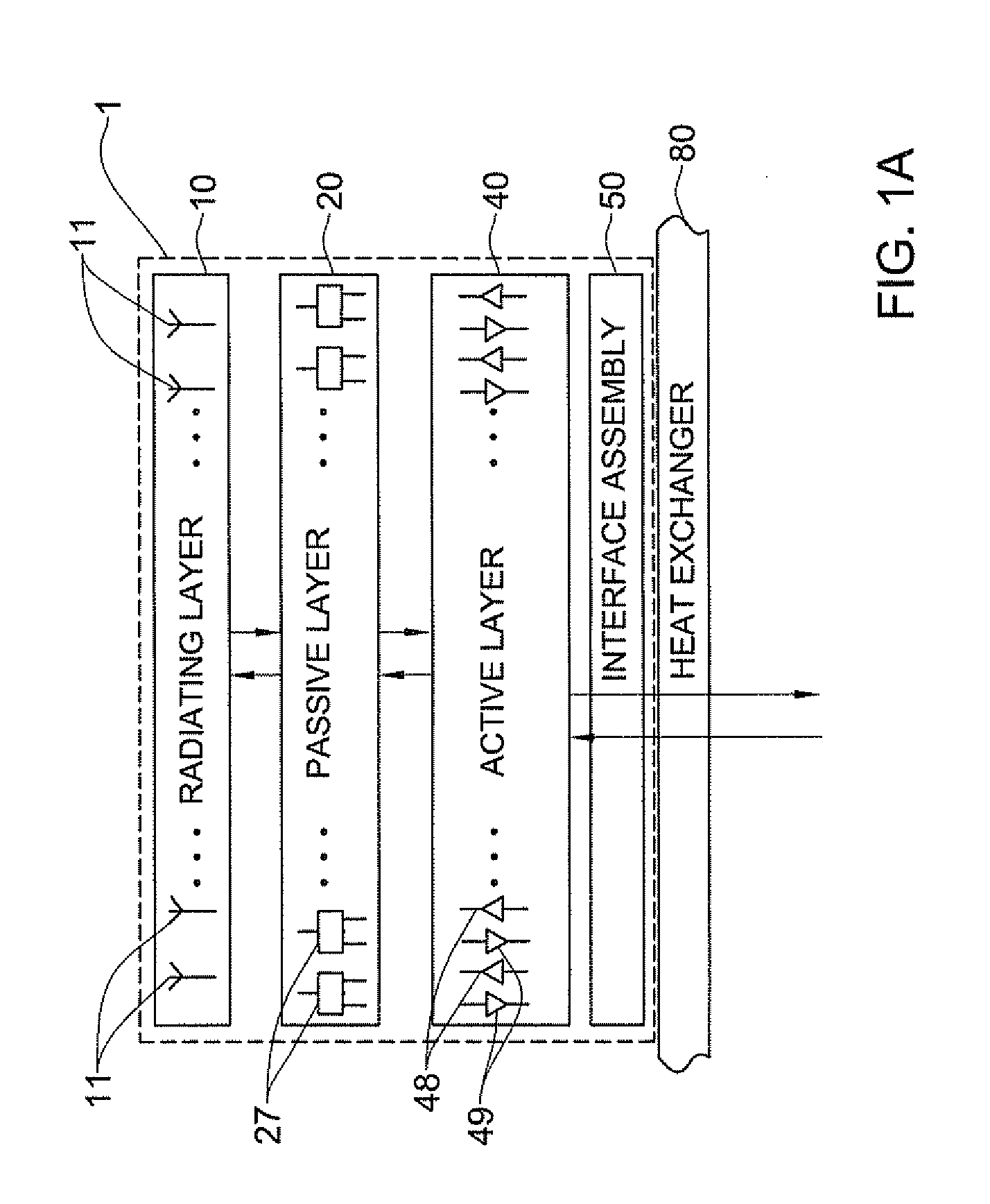

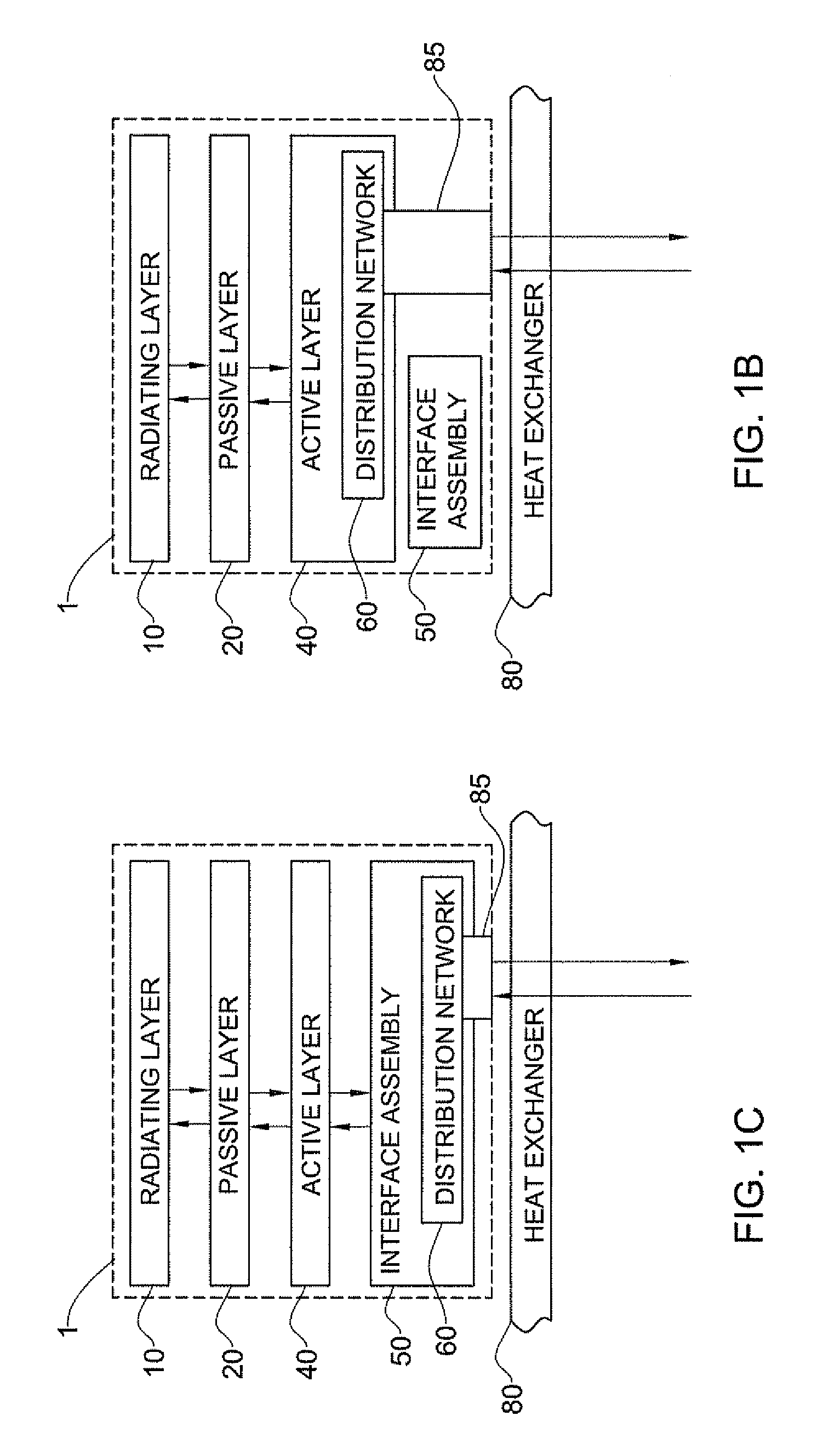

Phased array antenna and method for producing thereof

A vertically stacked array antenna structure is described. The structure comprises a radiating layer, a passive layer disposed under said radiating layer, an active layer disposed under said passive layer, and an interface assembly. The radiating layer comprises an array of radiating elements. The passive layer has only passive components. At least a part of the passive components includes an array of RF duplexers corresponding to the array of radiating elements. The active layer comprises RF amplifiers. The interface assembly comprises at least one metallic frame which is in direct thermal coupling with the RF amplifiers. The interface assembly is configured for providing thermal communication of the active layer with a heat exchanger.

Owner:ELTA SYST LTD

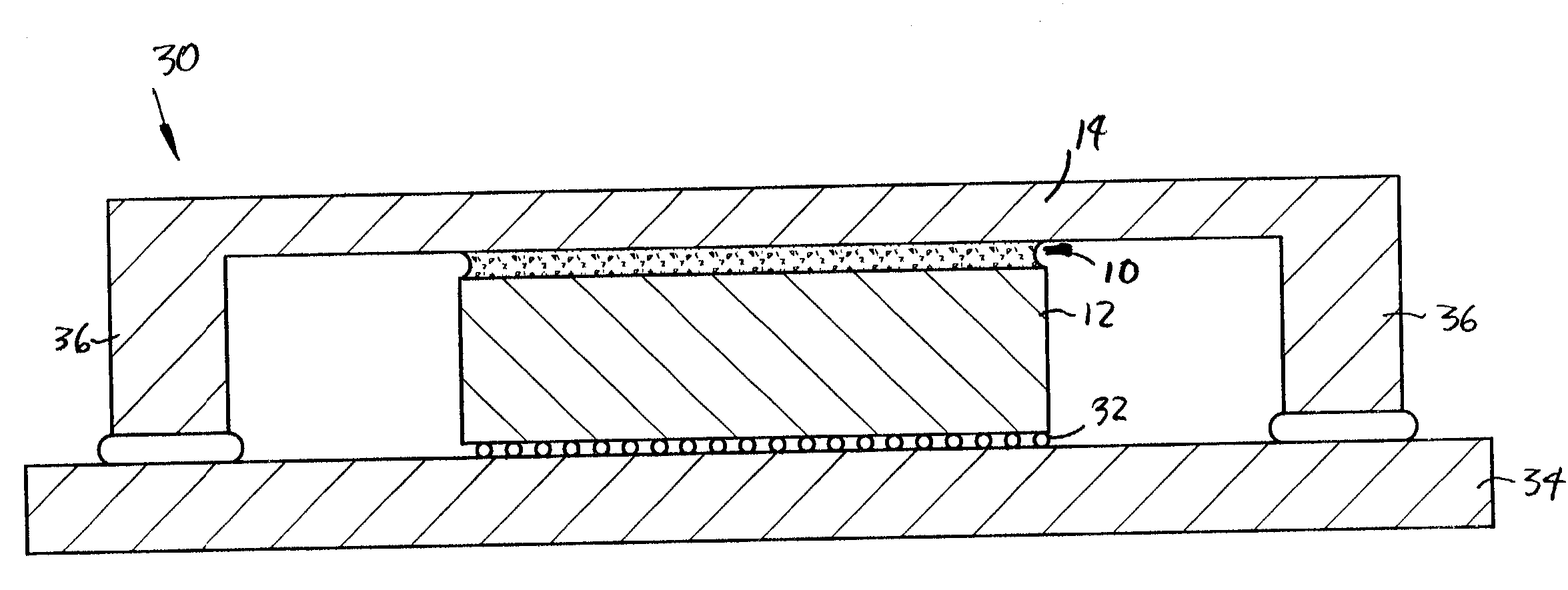

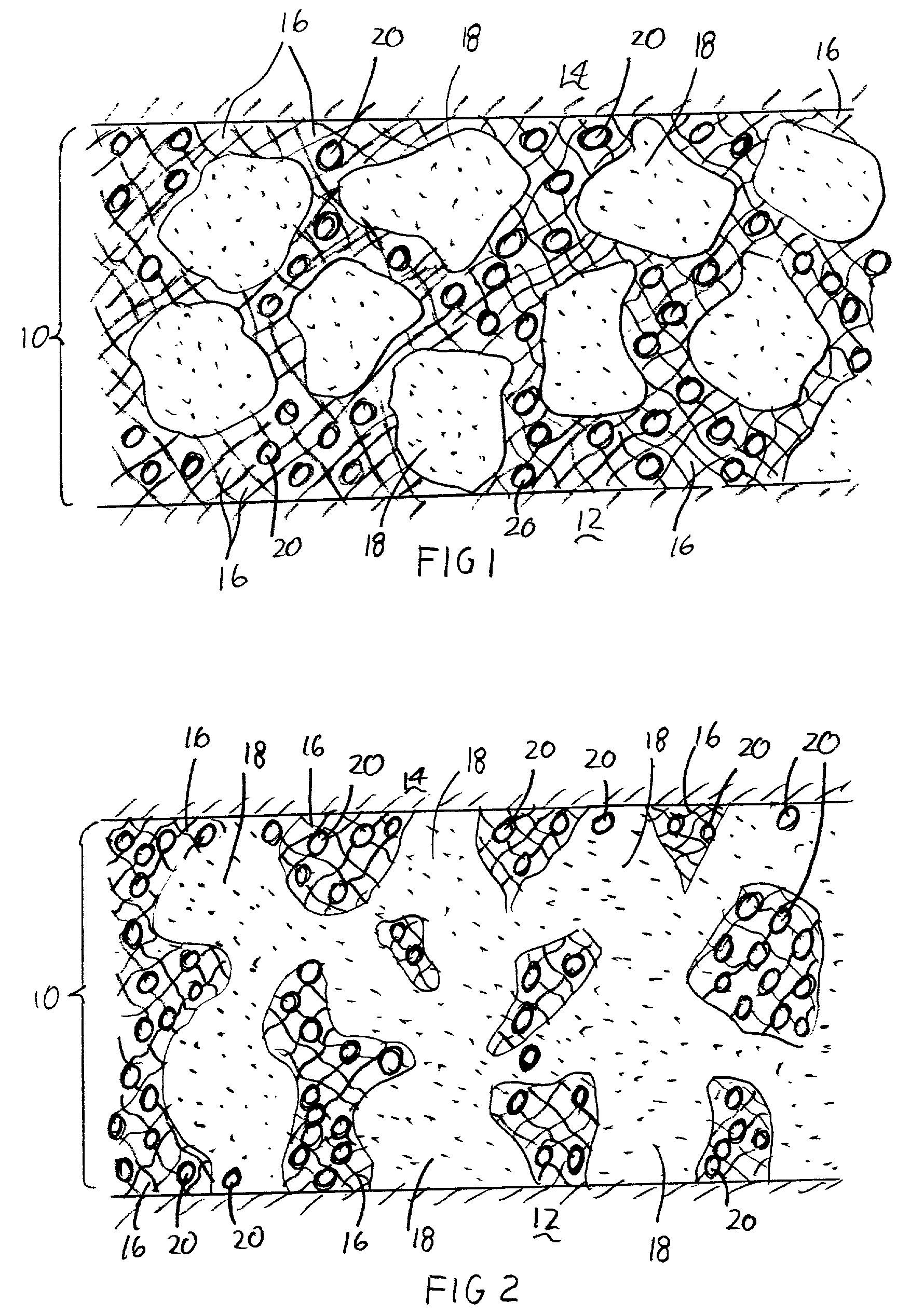

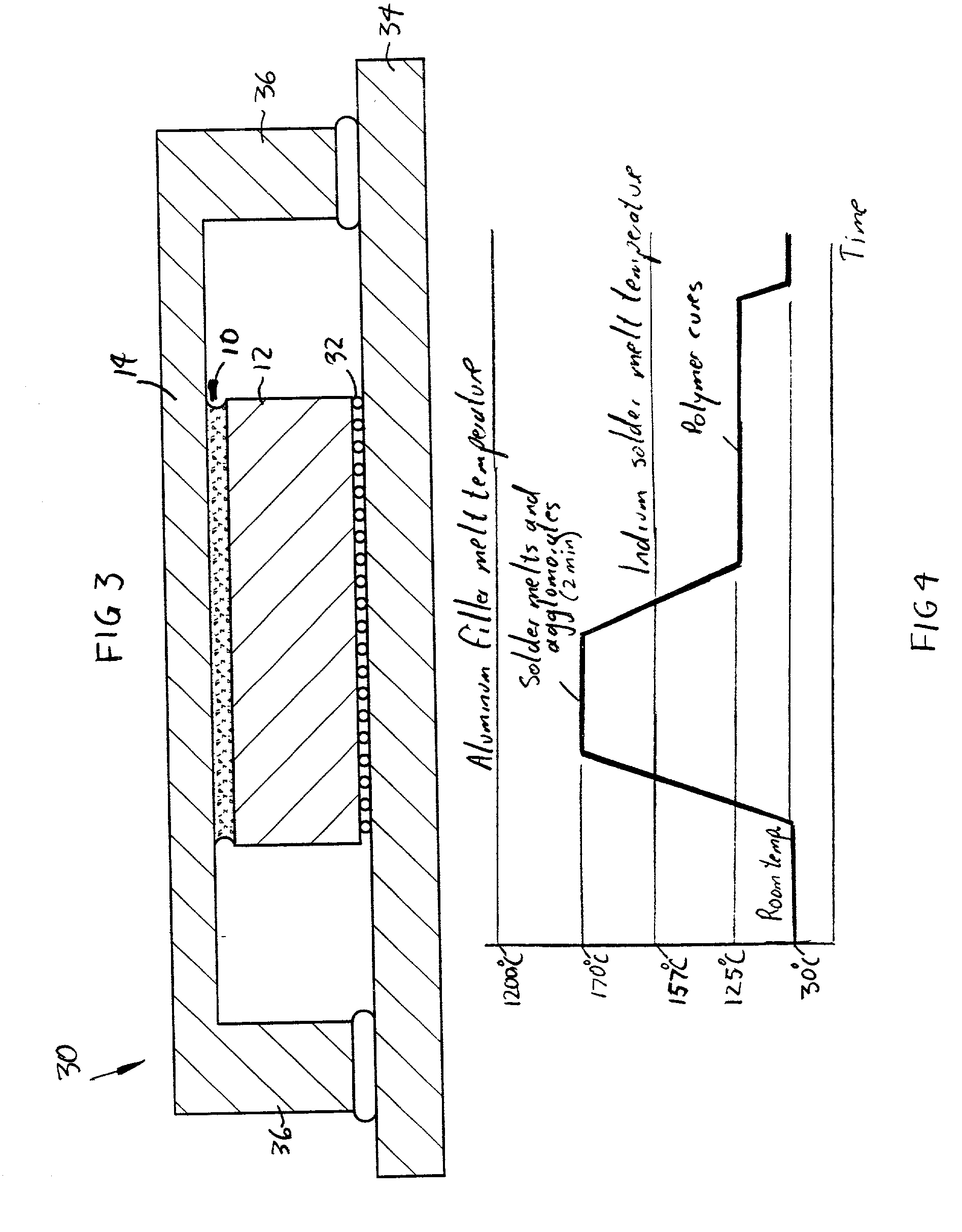

Thermal interface material and electronic assembly having such a thermal interface material

InactiveUS20030077478A1Artificial flowers and garlandsSemiconductor/solid-state device detailsStress conditionsIndium

A thermal interface material is described for thermal coupling of an electronic component to a thermally conductive member. The thermal interface material includes a viscoelastic polymer matrix material, fusible solder particles in the matrix material, and filler particles in the matrix material. The solder particles have a melting temperature below a selected temperature (e.g. 157° C. for indium) and the filler particles have a melting temperature substantially above the selected temperature (e.g. 961° C. for silver). The filler particles keep the thermal interface material intact under adverse thermal and stress conditions.

Owner:INTEL CORP

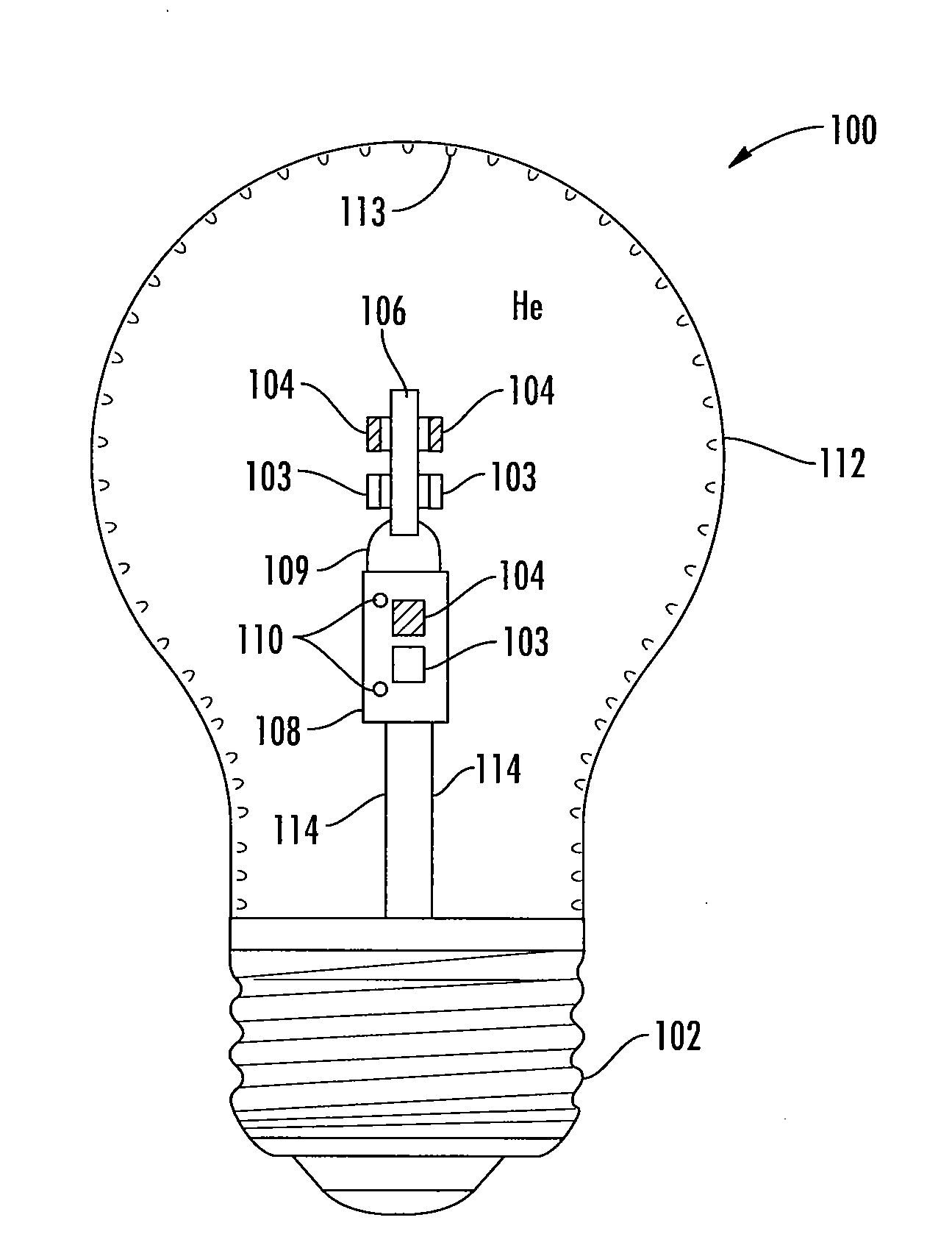

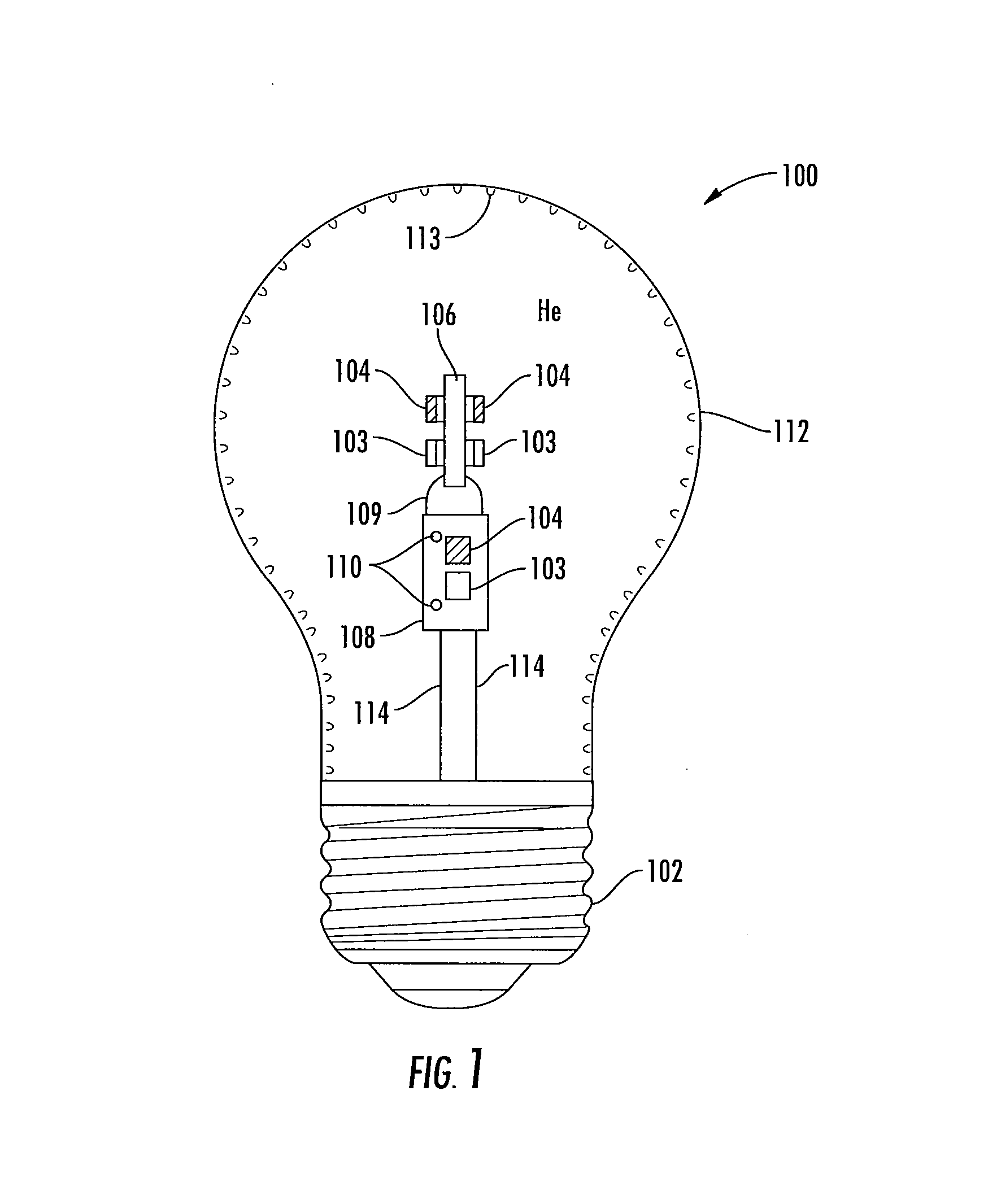

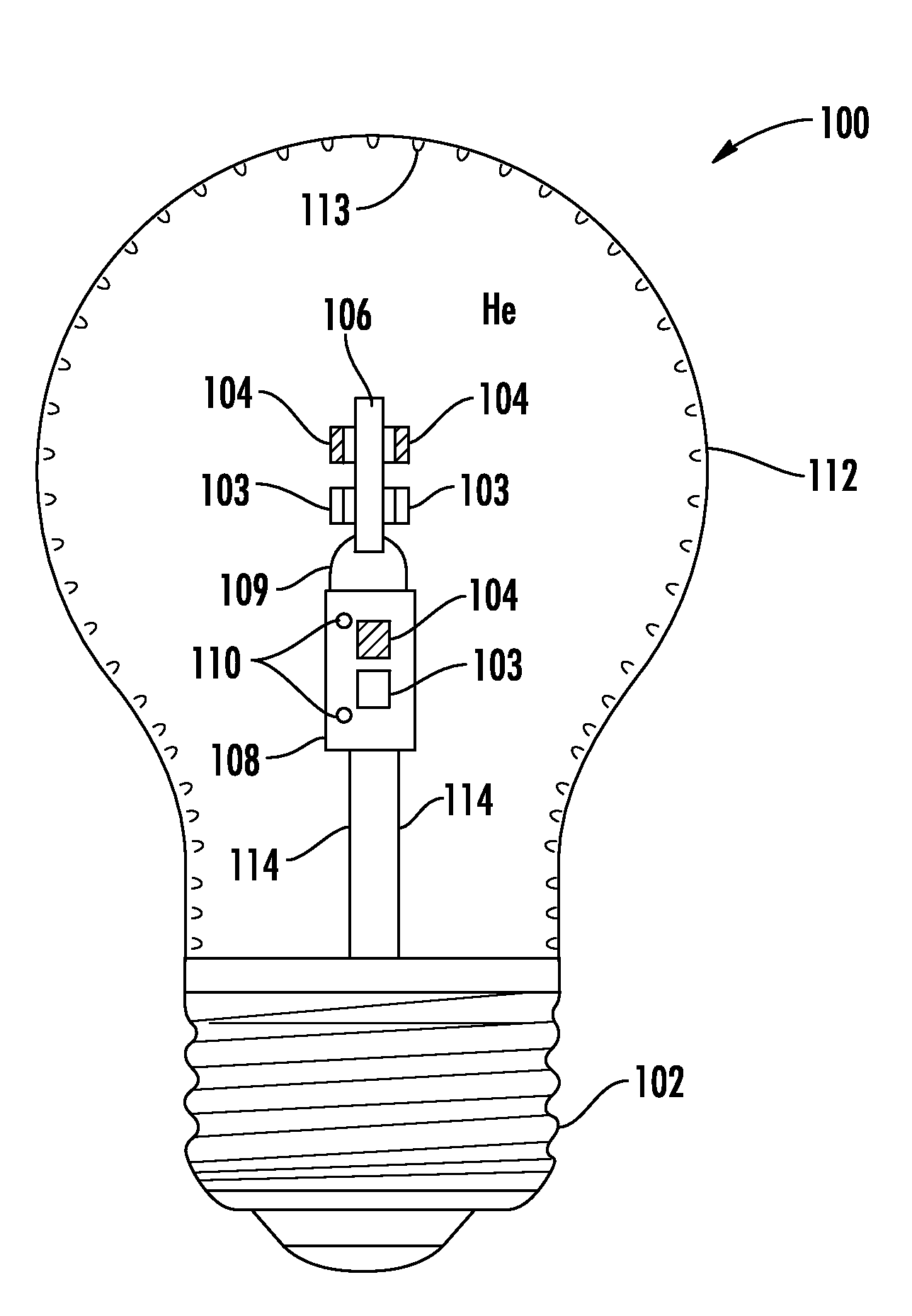

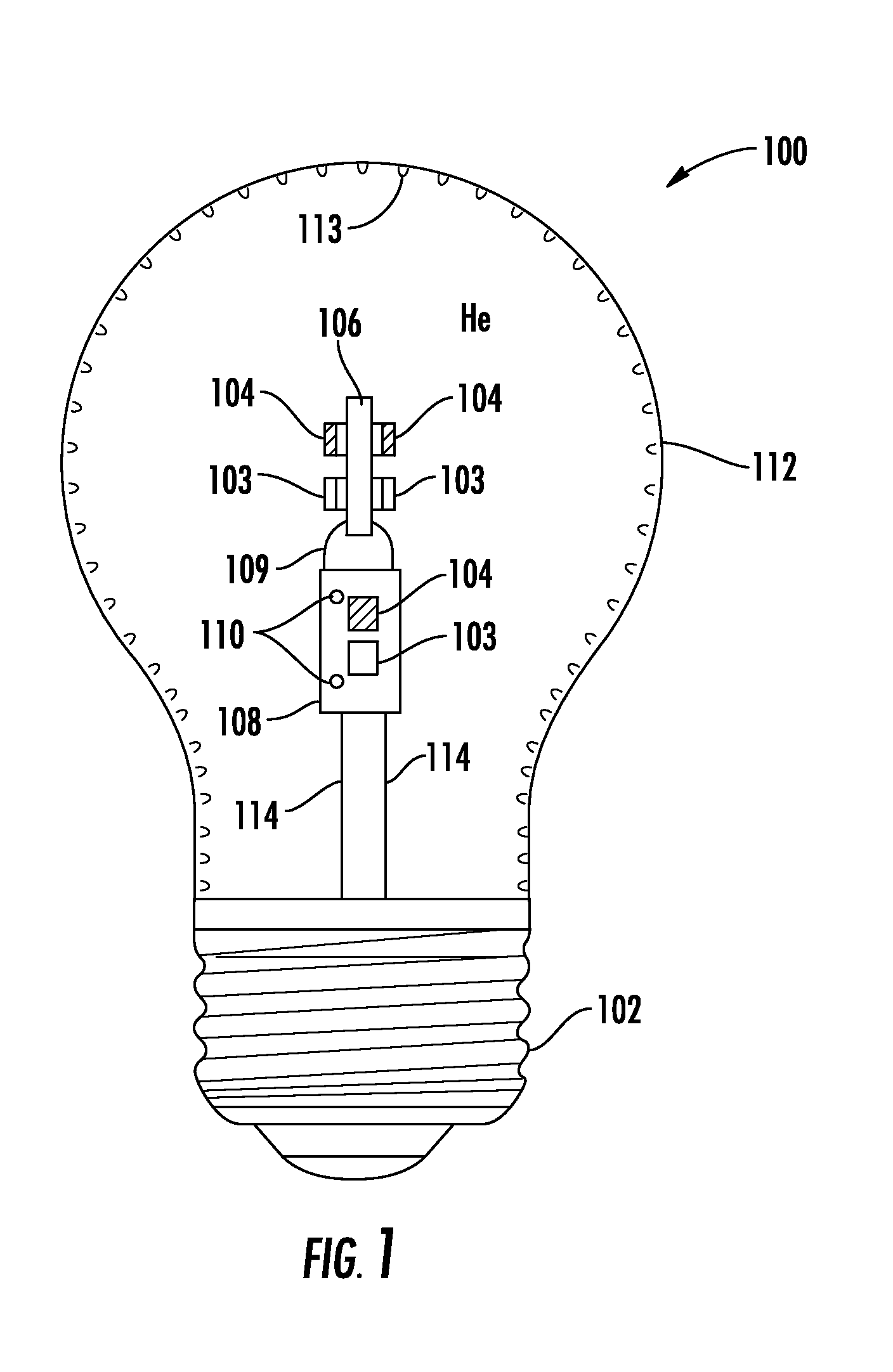

Gas cooled LED lamp

ActiveUS20130271989A1Prevent degradationImprove thermal conductivityLighting support devicesLighting heating/cooling arrangementsElectricityLed array

In one embodiment, a lamp comprises an optically transmissive enclosure. An LED array is disposed in the optically transmissive enclosure operable to emit light when energized through an electrical connection. A gas is contained in the enclosure to provide thermal coupling to the LED array. The gas may include oxygen.

Owner:IDEAL IND LIGHTING LLC

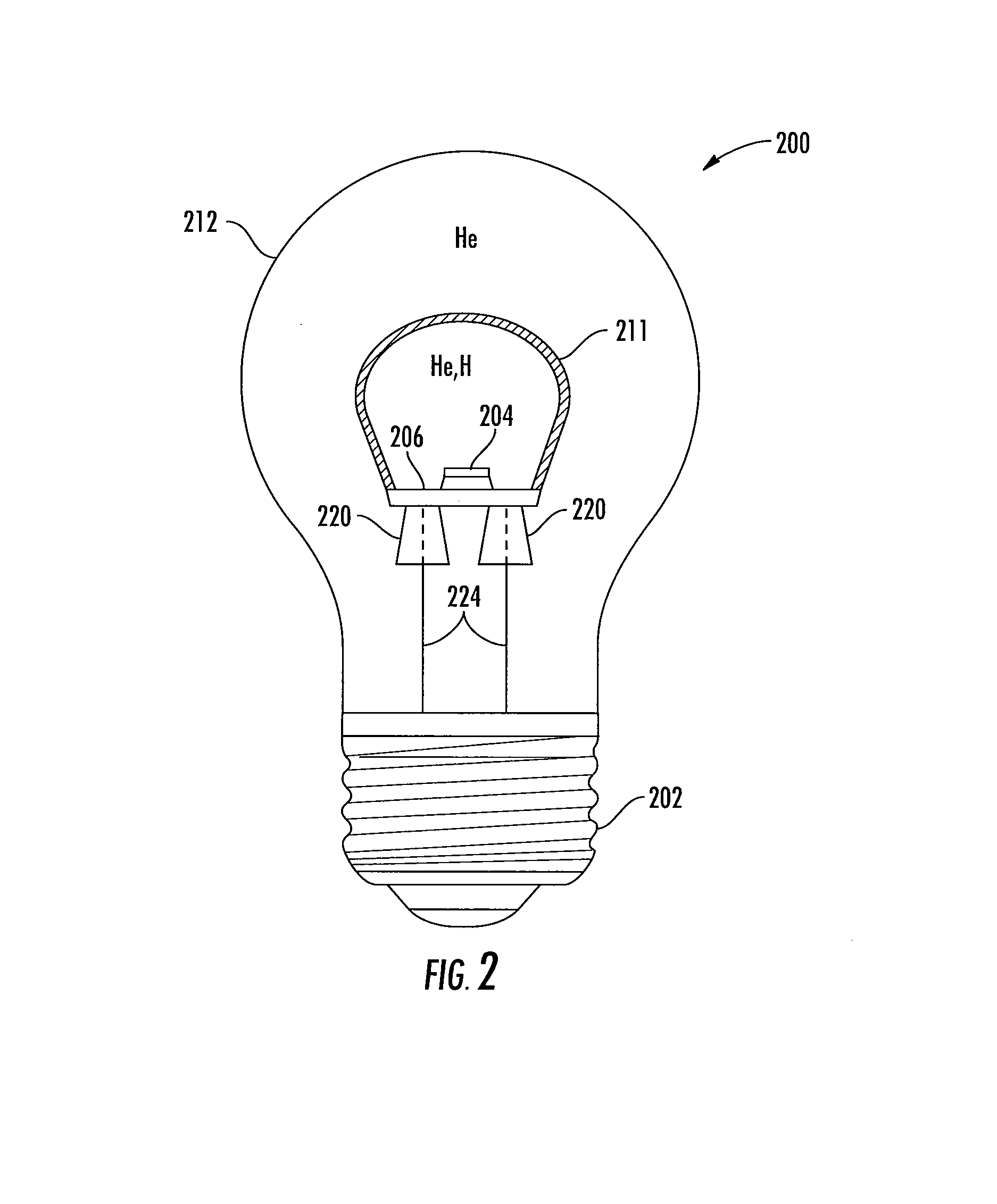

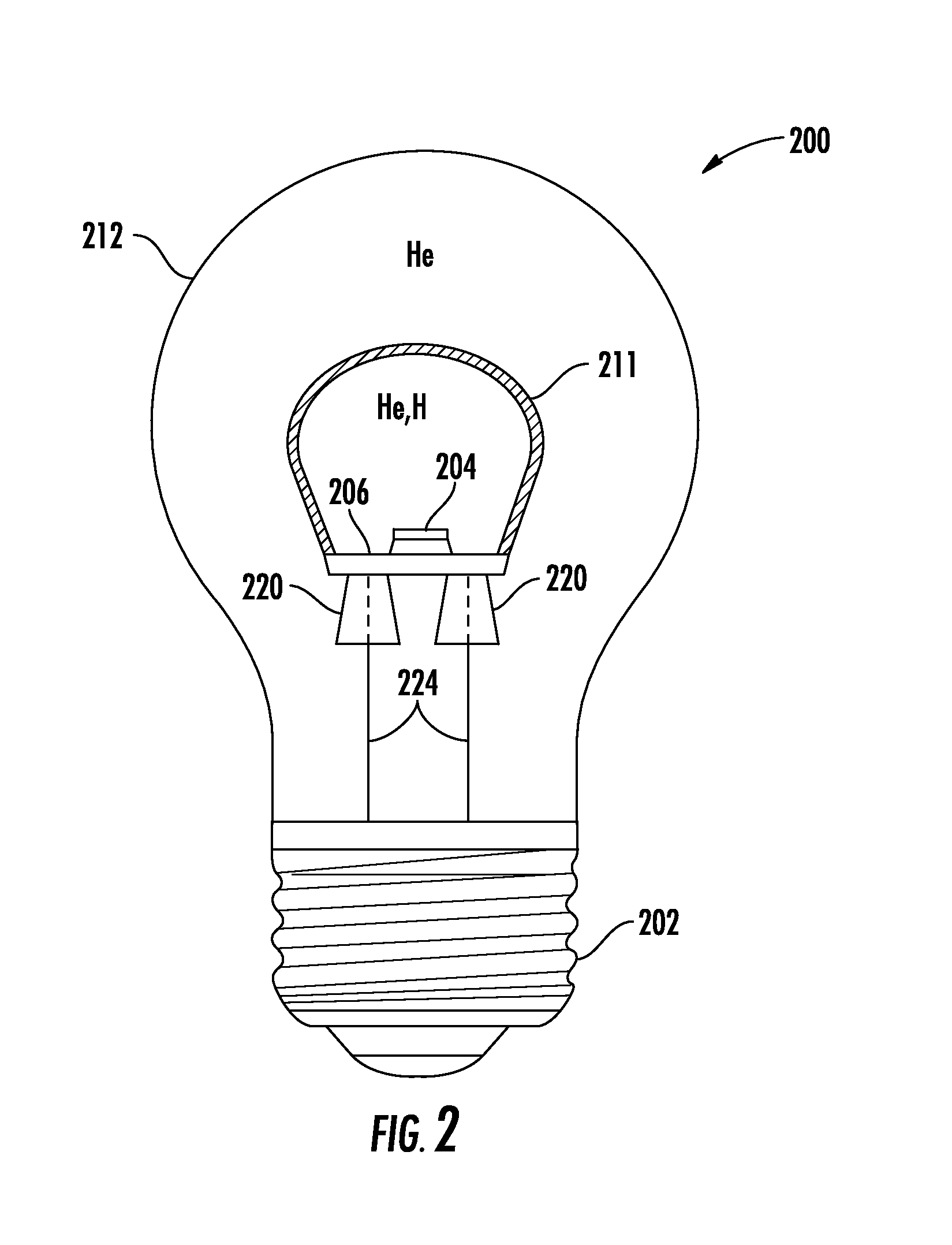

Gas cooled LED lamp

ActiveUS20130301252A1Improve heat transfer performanceHeat dissipationLighting heating/cooling arrangementsLighting elementsLed arrayElectrical connection

In one embodiment, a lamp comprises an optically transmissive enclosure. An LED array is disposed in the optically transmissive enclosure operable to emit light when energized through an electrical connection. A gas is contained in the enclosure to provide thermal coupling to the LED array. A board supports lamp electronics for the lamp and is located in the enclosure. The LED array is mounted to the board and LEDs are mounted on a submount formed to have a three dimensional shape. The board is electrically coupled to the LED array and the submount may be thermally coupled to the gas for dissipating heat from the plurality of LEDs.

Owner:IDEAL IND LIGHTING LLC

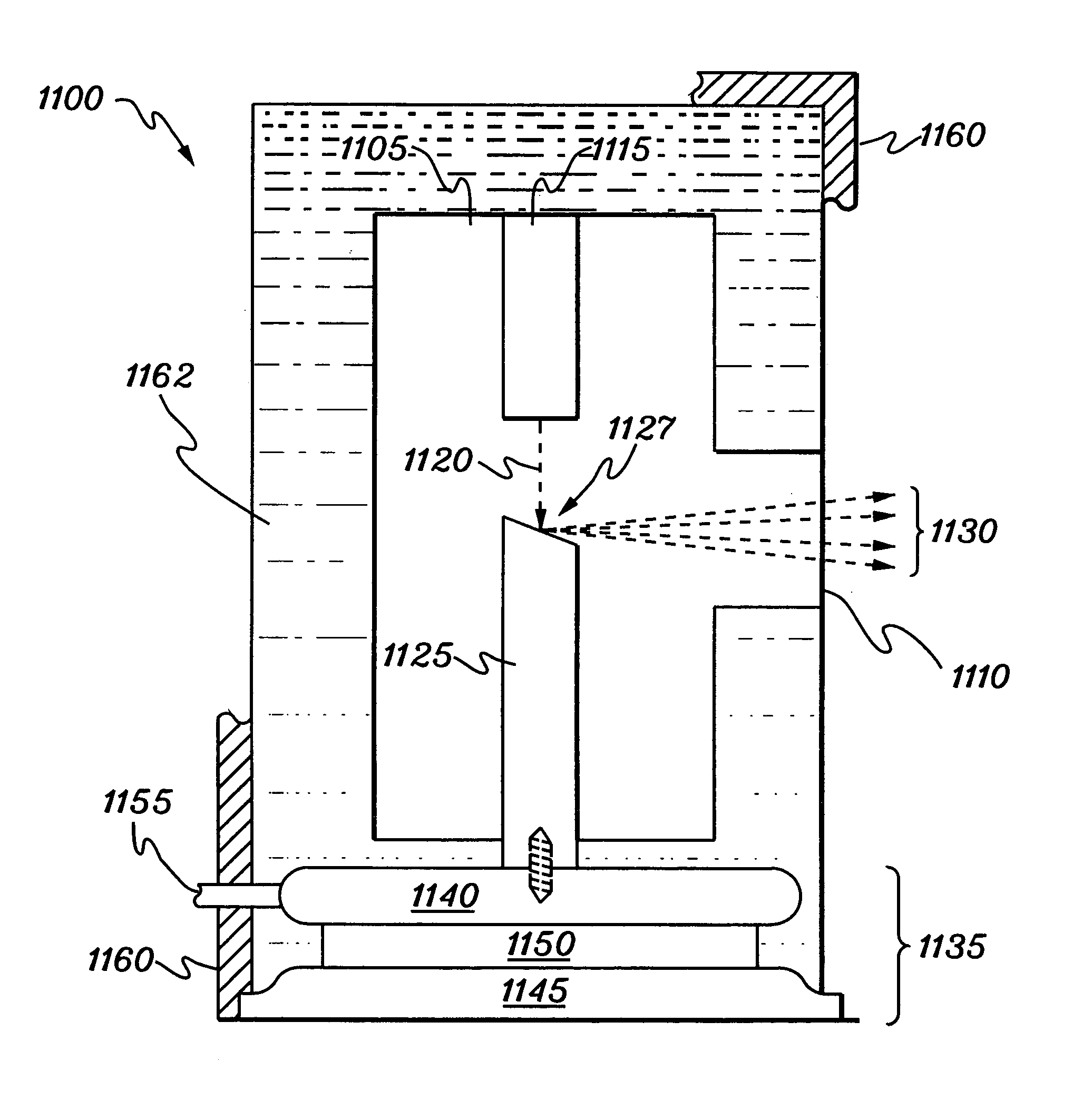

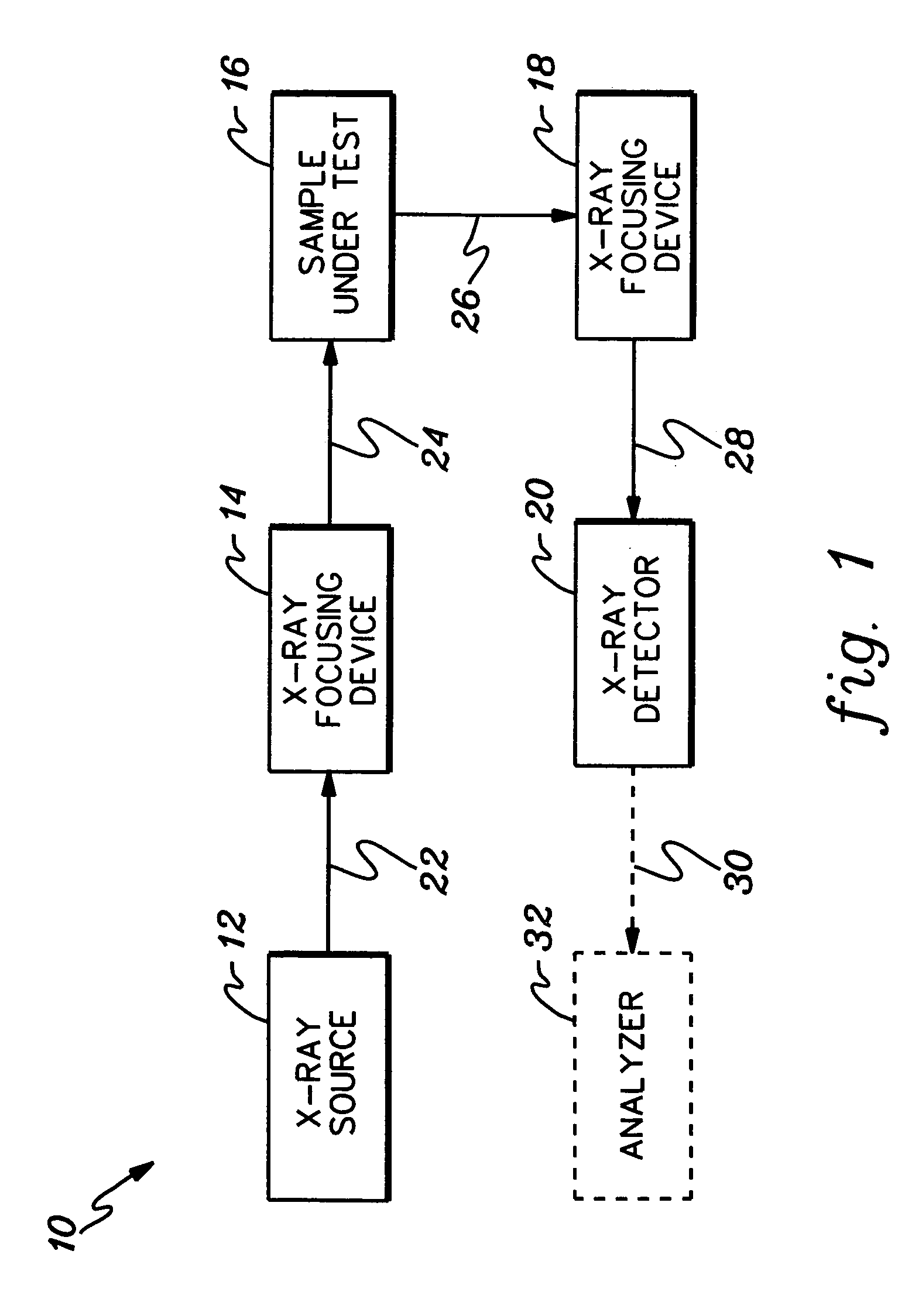

Method and device for cooling and electrically insulating a high-voltage, heat-generating component such as an x-ray tube for analyzing fluid streams

InactiveUS7110506B2Minimise currentCurrent lossElectrically conductive connectionsX-ray tube electrodesX-rayHigh pressure

Owner:S RAY OPTICAL SYST

Thermal management system and method for electronics system

InactiveUS6972365B2Lighting and heating apparatusSemiconductor/solid-state device detailsThermal energySemiconductor chip

A thermal energy management system is provided having a heat spreading device that is operatively engaged with at least one semiconductor chip and a thermal bus operatively engaged with the heat spreading device so as to transport thermal energy from the heat spreading device to a heat sink. The heat spreading device includes a heat pipe and the thermal bus includes a loop thermosyphon. A second thermal bus may be operatively engaged with the first thermal bus so as to transport thermal energy from the first thermal bus to a heat sink. The second thermal bus may also include a loop thermosyphon. A method of managing thermal energy in an electronic system is also provided that includes spreading thermal energy generated by one or more devices over a surface that is relatively larger than the devices, thermally coupling an evaporator portion of a loop thermosyphon to the surface, and thermally coupling a condensing portion of the loop thermosyphon to a thermal energy sink, e.g., a second loop thermosyphon, convection fin, or cold plate.

Owner:THERMAL

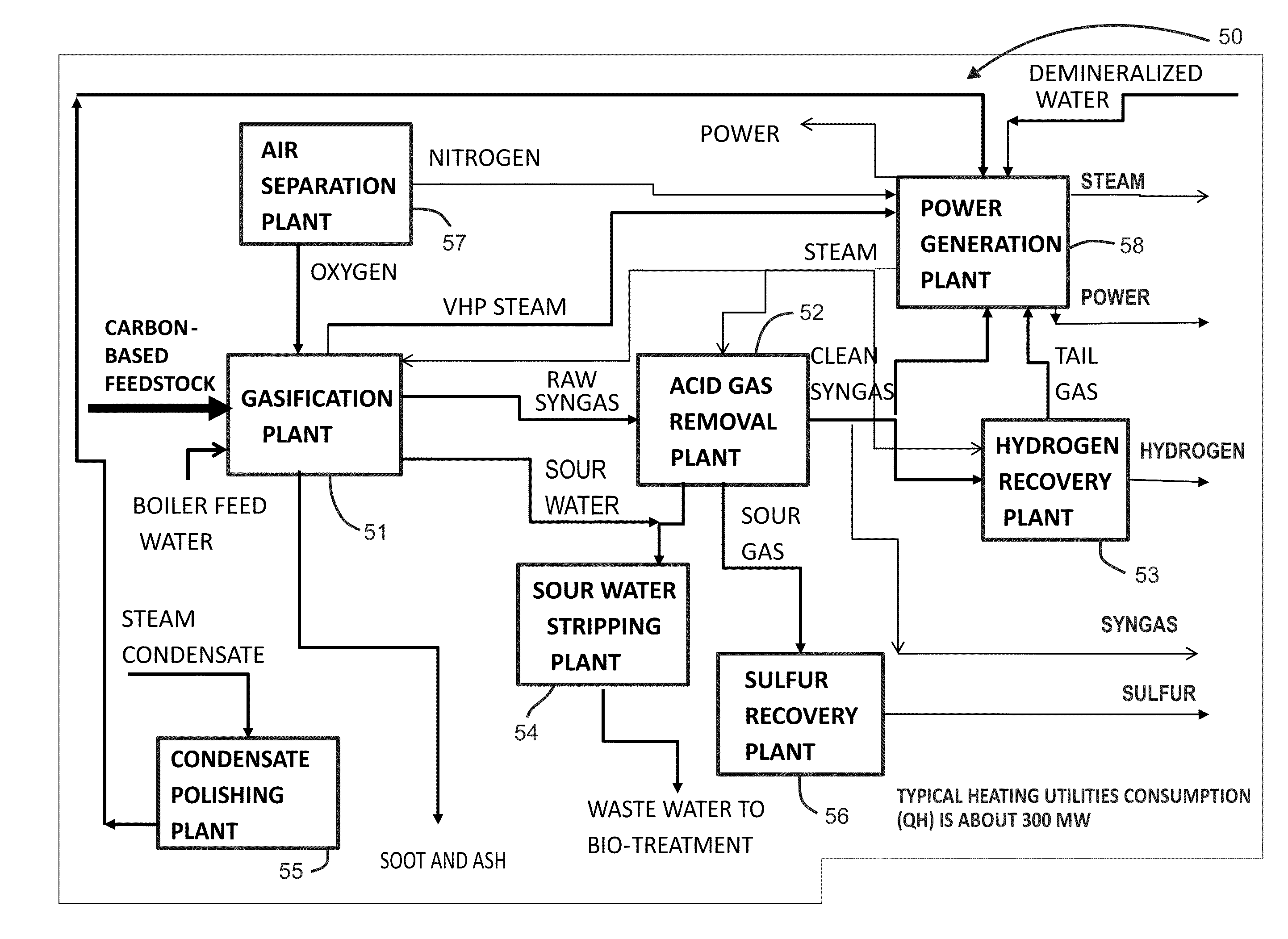

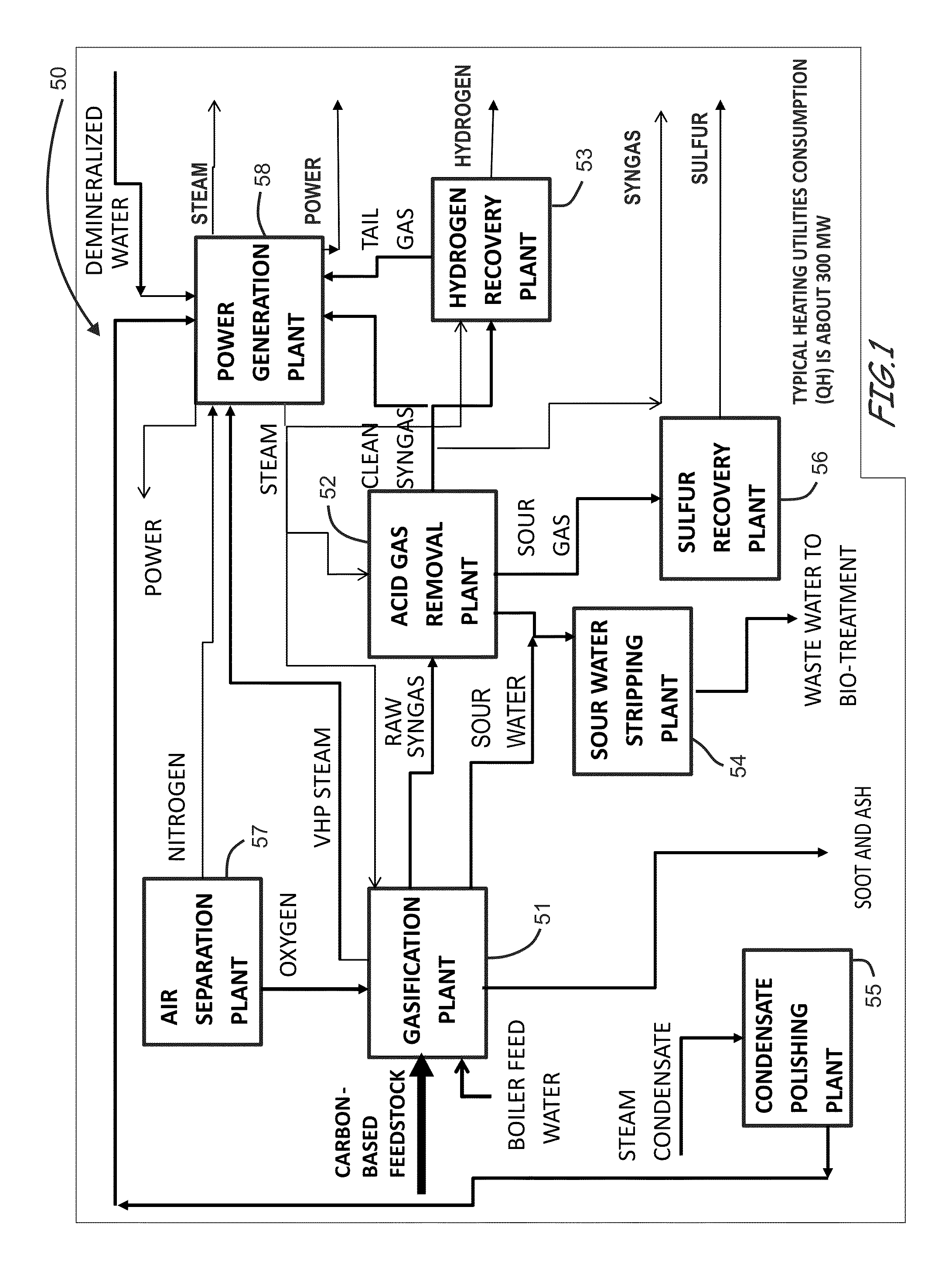

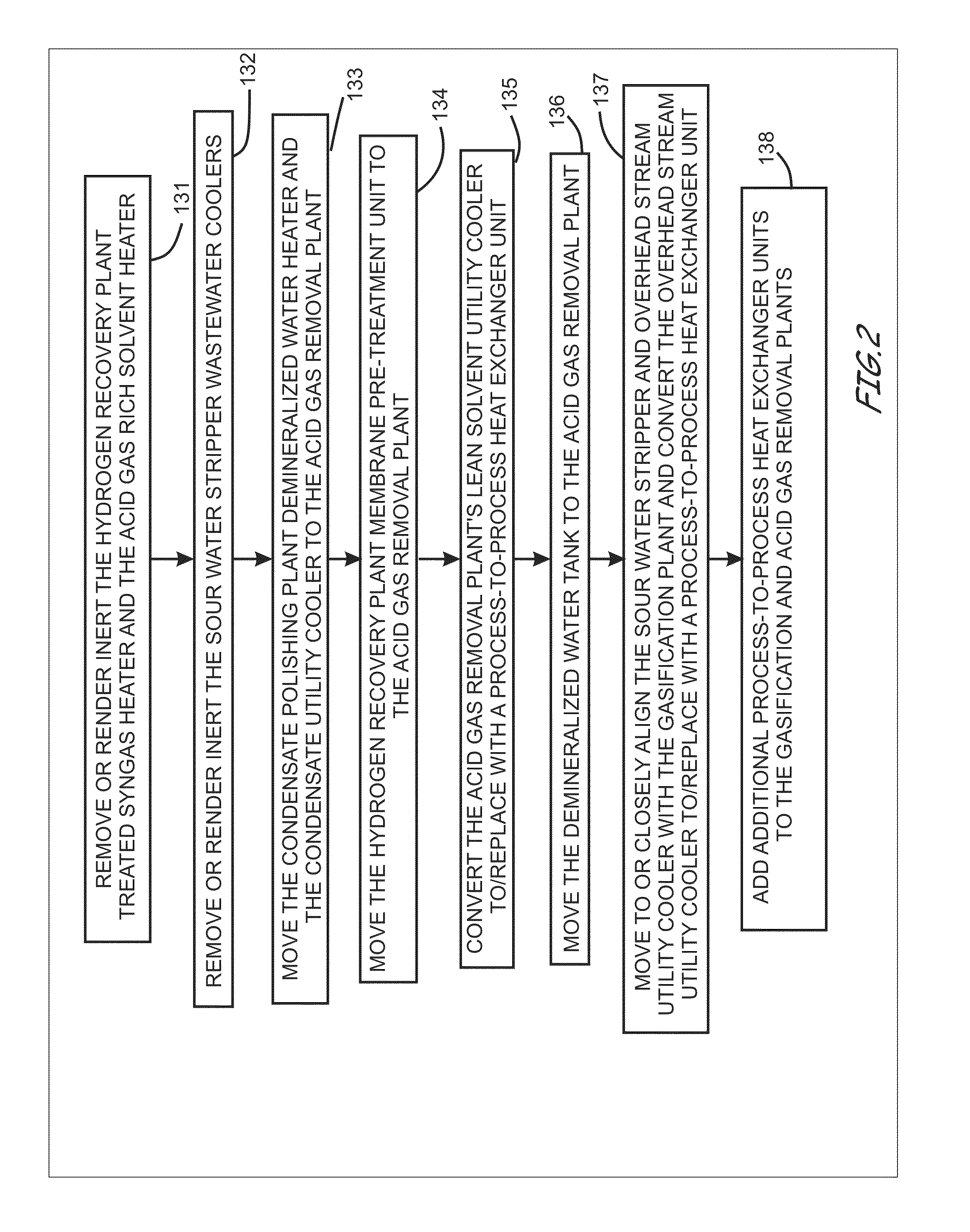

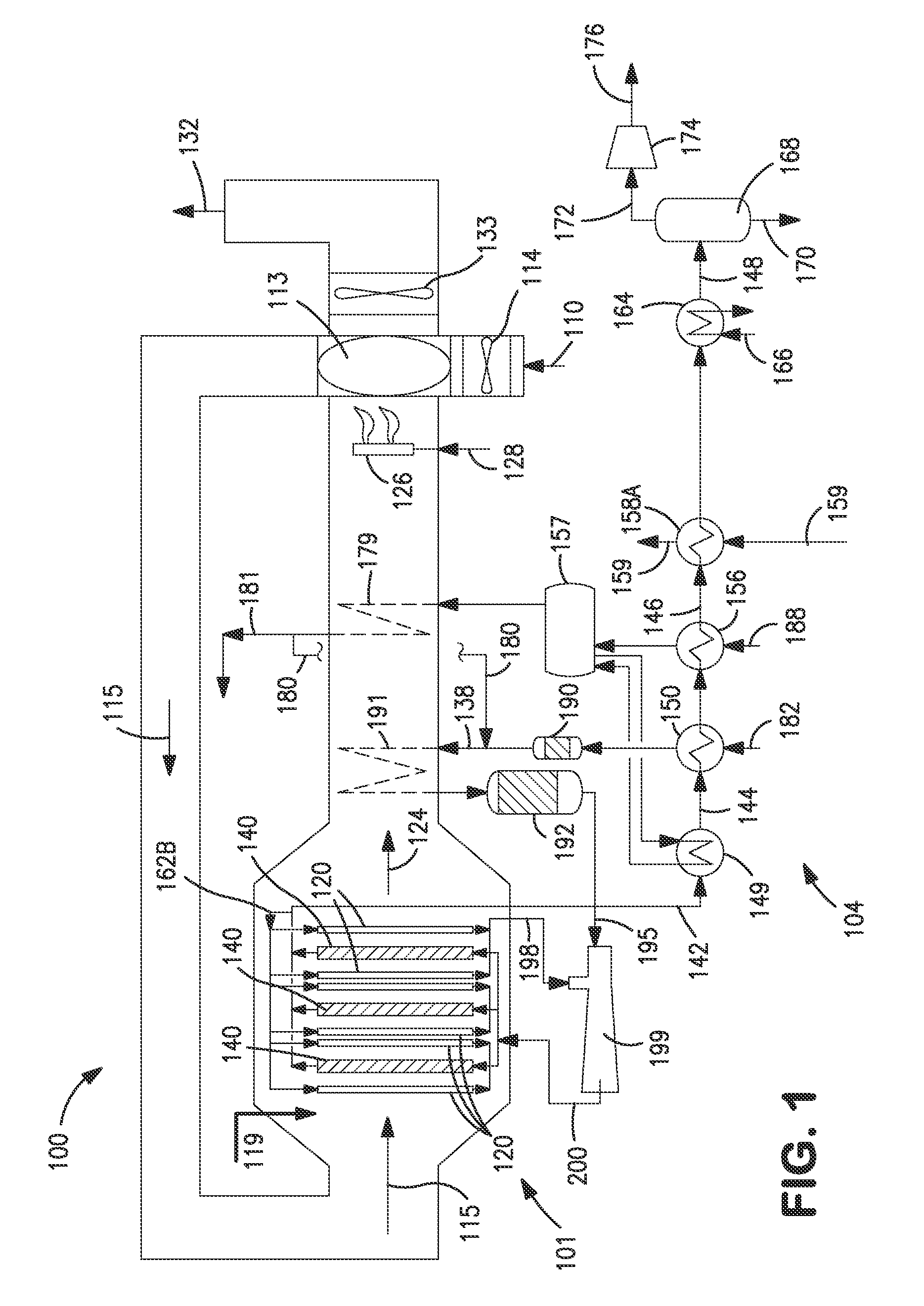

Energy efficient apparatus employing energy efficient process schemes providing enhanced integration of gasification-based multi-generation and hydrocarbon refining facilities and related methods

ActiveUS20150377079A1Less pollutionEasy to modifyProcess control/regulationGasifier mechanical detailsSolventMulti generation

Energy-efficient gasification-based multi-generation apparatus, facilities, or systems, and methods of modifying existing gasification-based multi-generation apparatus and the various conventional thermal coupling arrangements, are provided. Apparatus for managing waste heat recovery through integration of a gasification-based multi-generation facility or other multi-generation system with a hydrocarbon refining facility or other hydrocarbon refining system and methods of providing the respective integration are also provided. An exemplary apparatus includes an integrated site energy management system configured according to one or more process-based thermal coupling schemes comprising one or more thermal coupling arrangements between a gasification-based multi-generation system or facility and a hydrocarbon refining system or facility. The gasification-based multi-generation system or facility can include an acid gas removal system or plant configured to remove acidic contaminants from a raw syngas feed to thereby provide a treated syngas feed, the acid gas removal system or plant containing a separation section including a solvent regenerator, and a gasification system configured to generate the raw syngas feed from a carbon-based feedstock. The hydrocarbon refining system or facility can include an aromatics system or plant containing a xylene products separation section including one or more of the following: an Extract column and a Raffinate column. The integrated site energy management system can include a hot-water system extending between the separation section of the acid gas removal system or plant and the xylene products separation section of the aromatics system or plant, and a plurality of added heat exchanger units providing various advanced thermal coupling arrangements.

Owner:SAUDI ARABIAN OIL CO

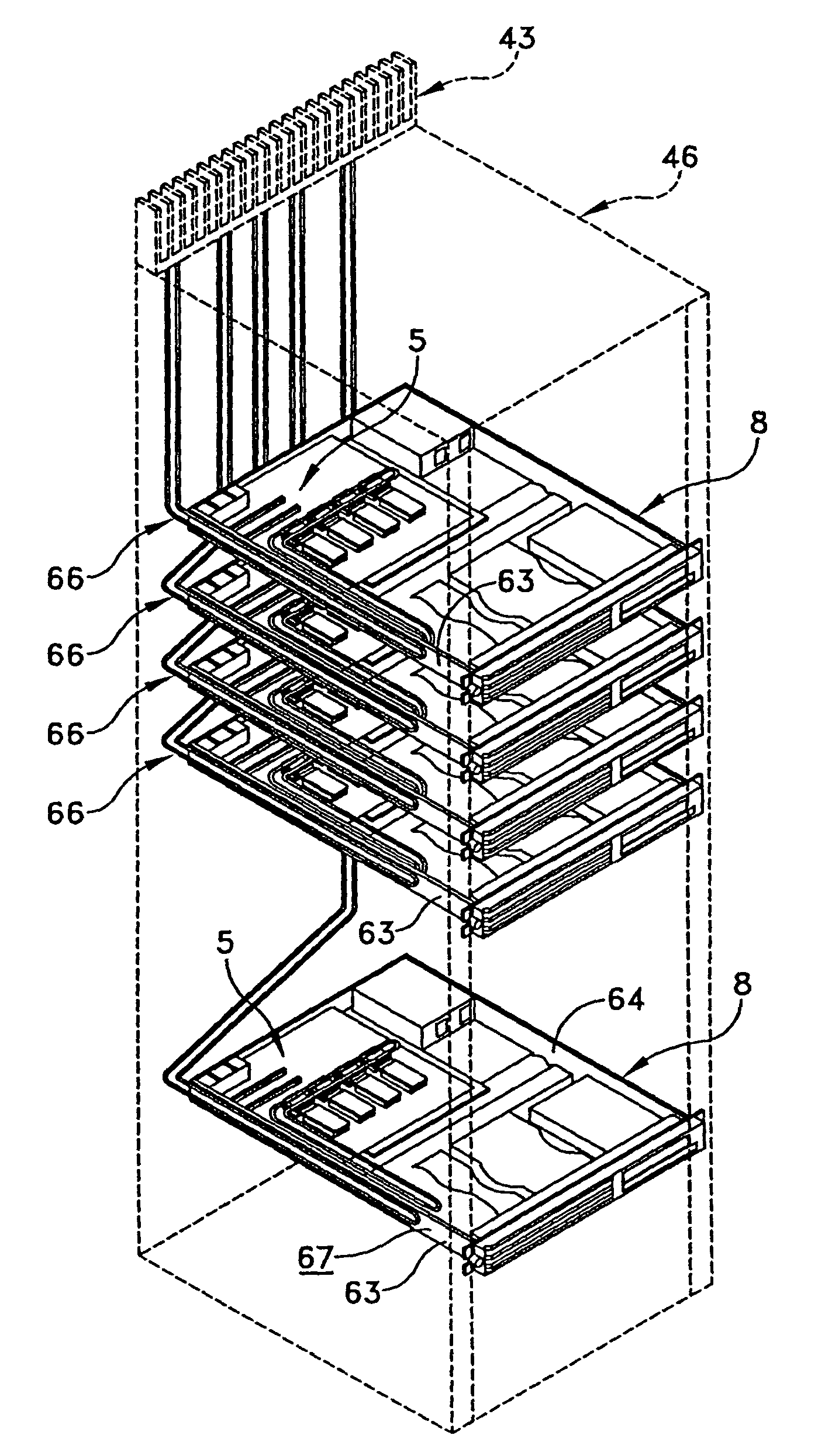

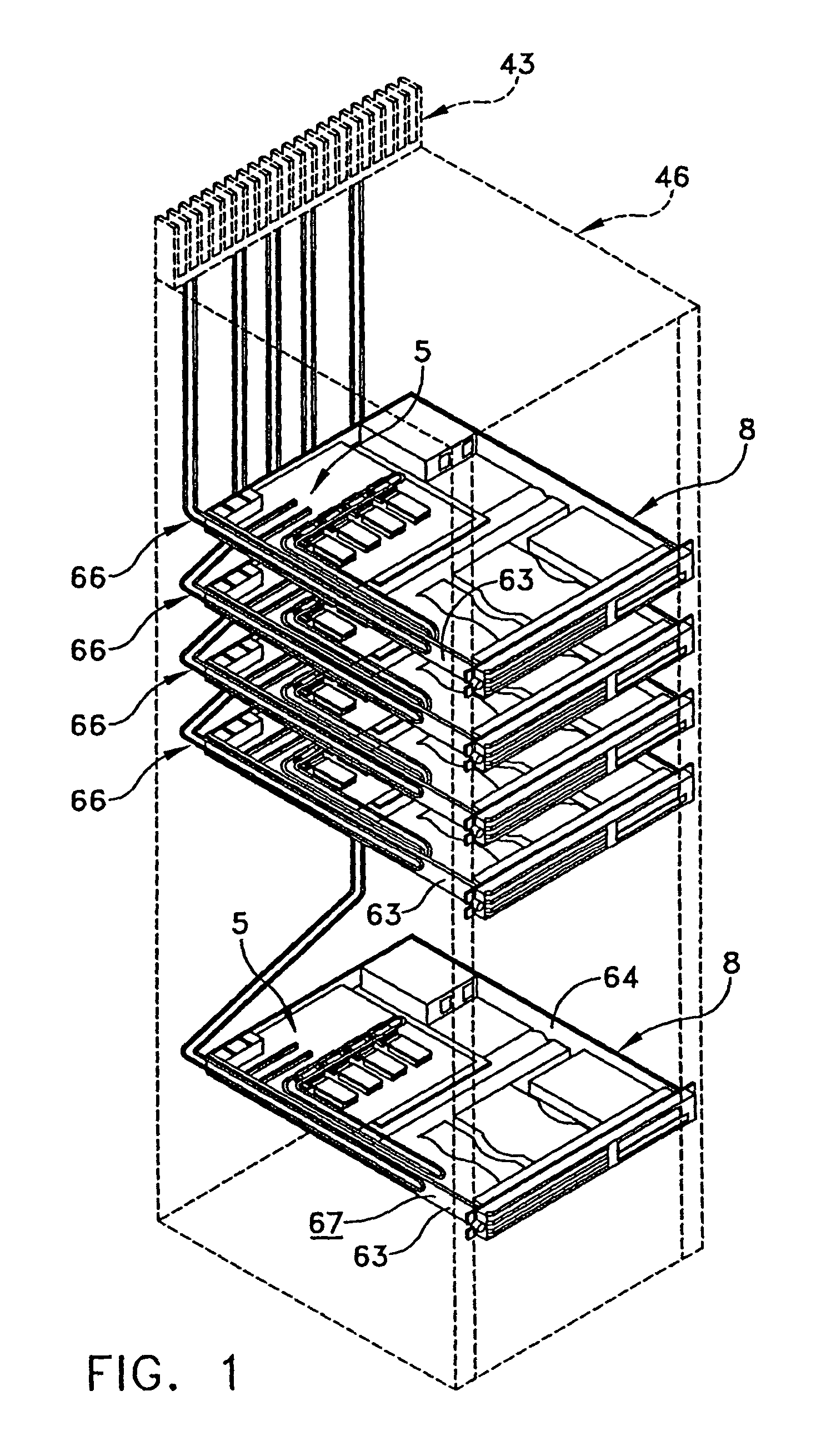

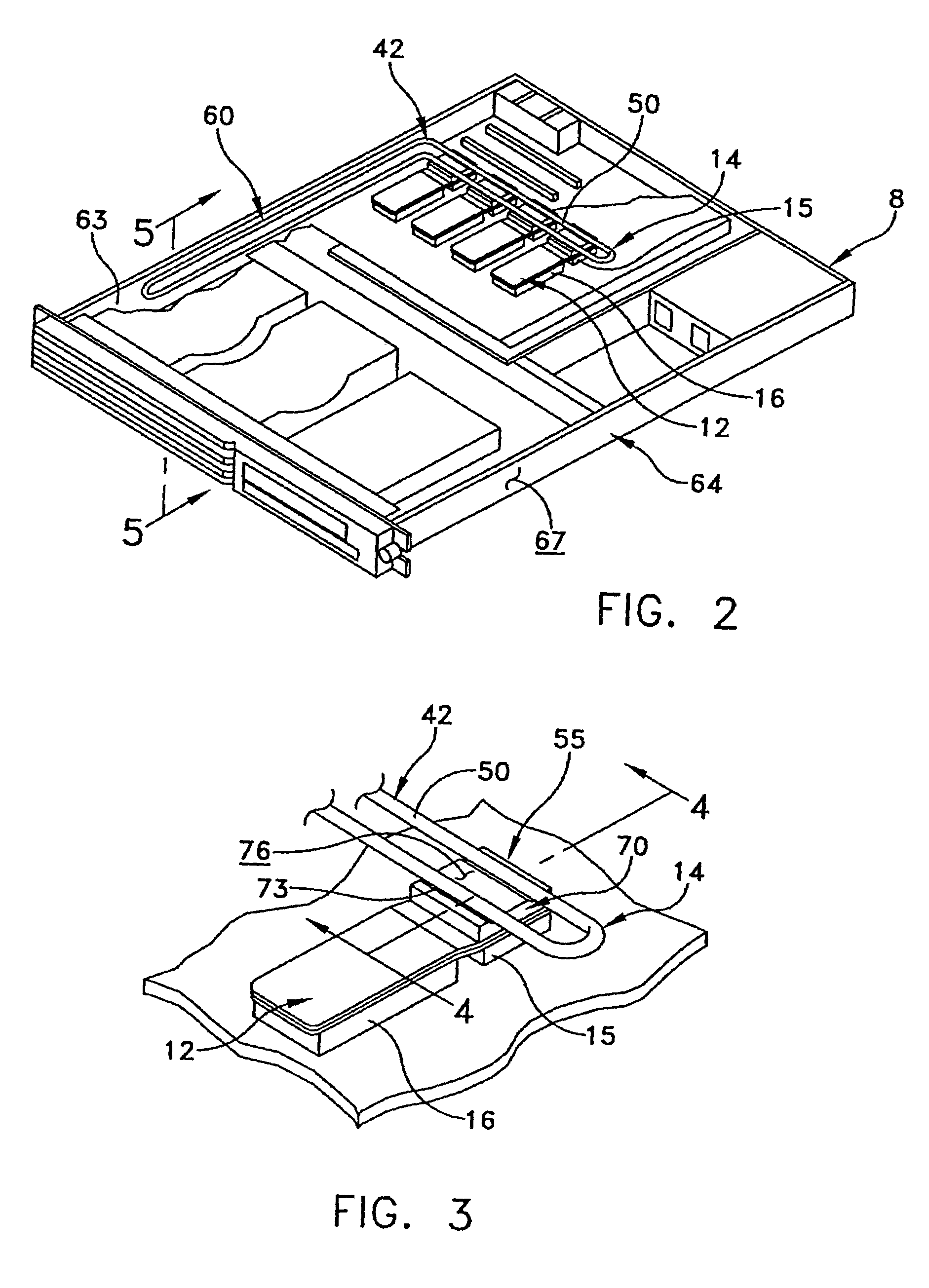

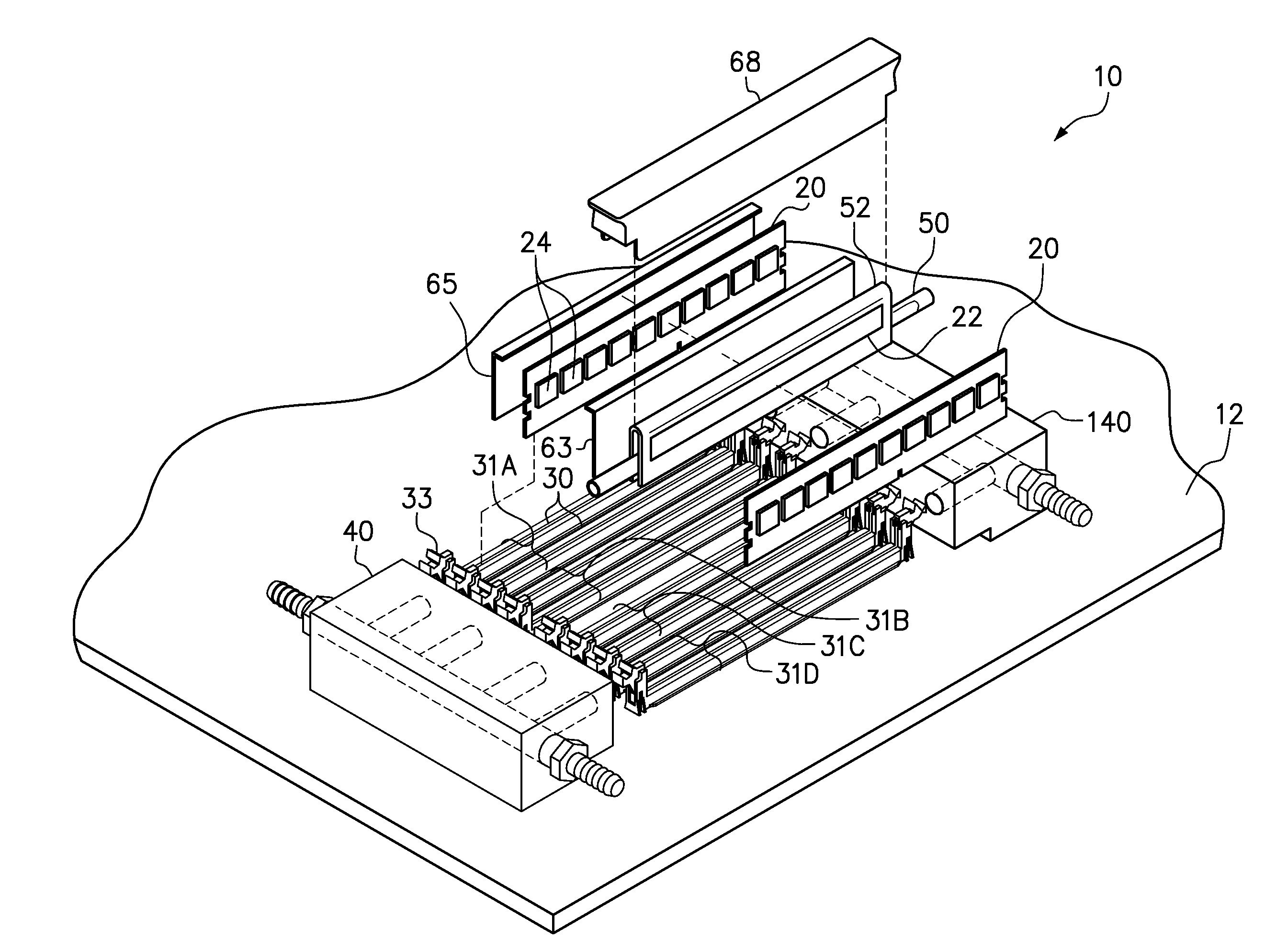

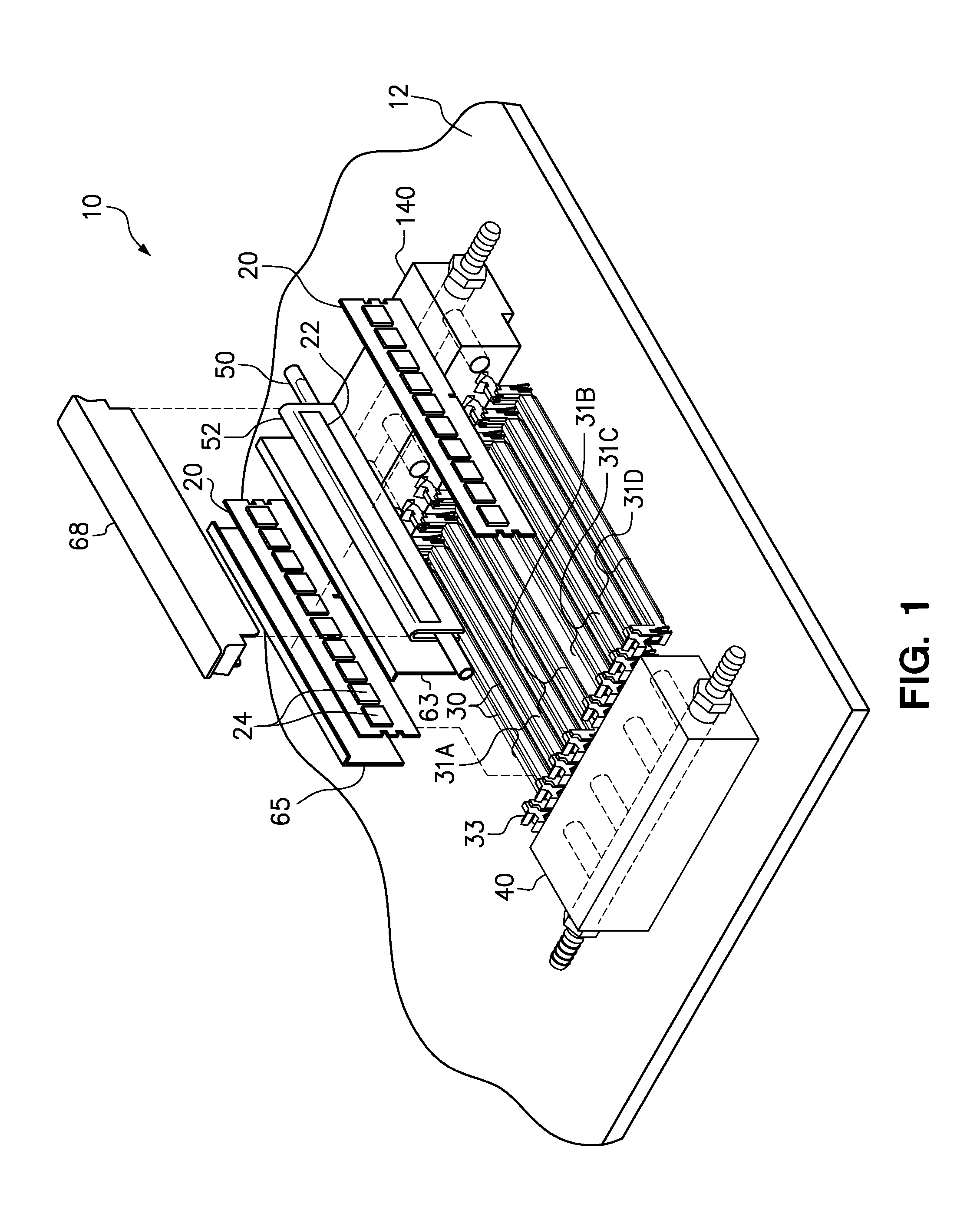

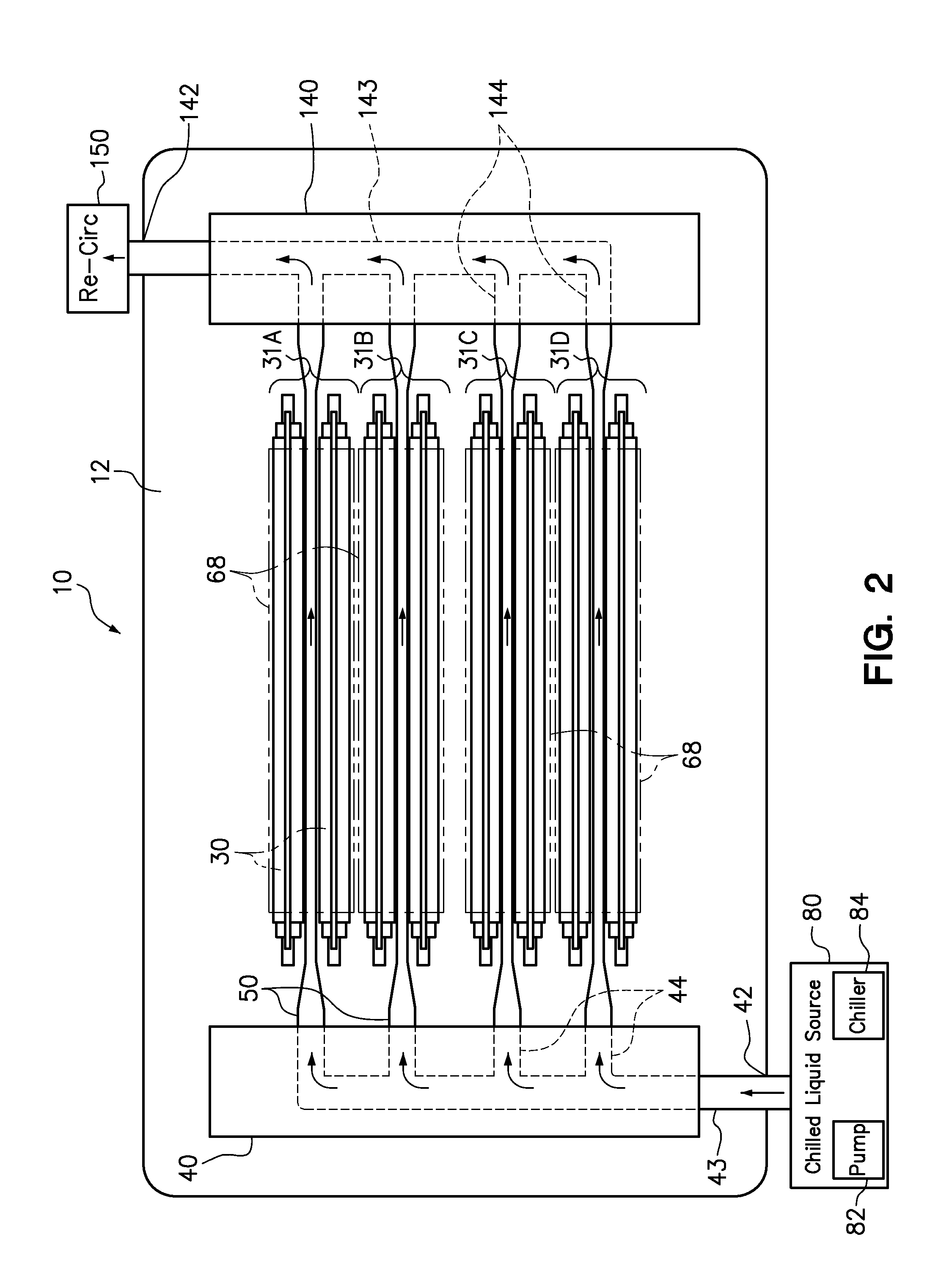

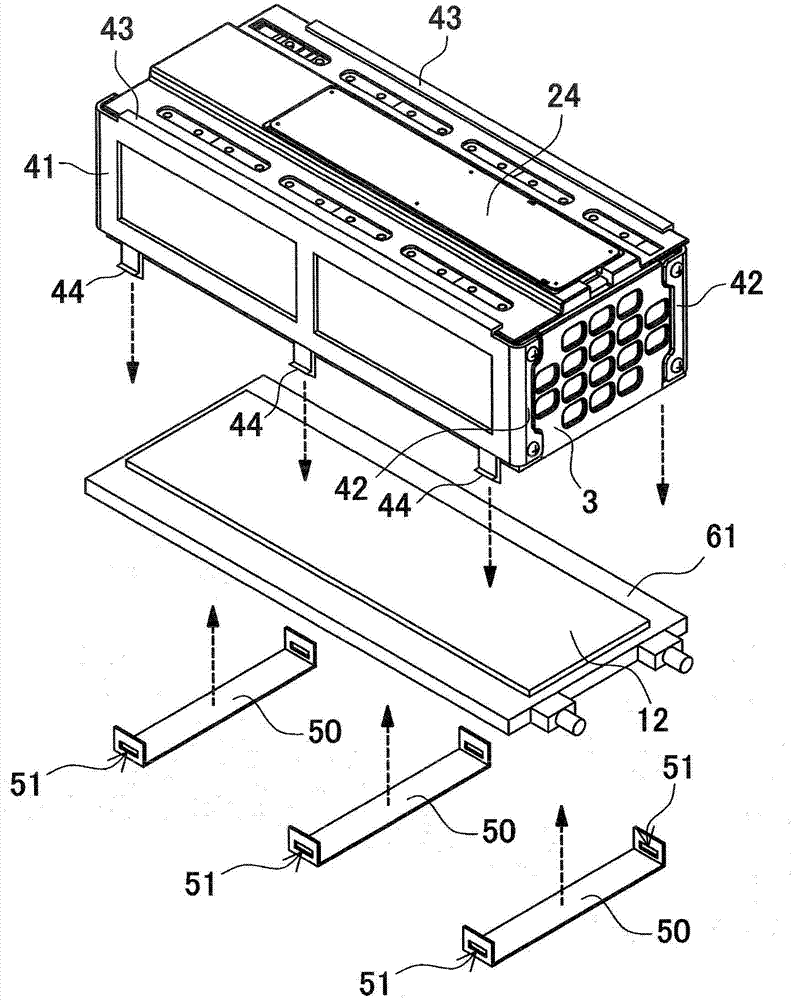

Liquid-cooled memory system having one cooling pipe per pair of dimms

ActiveUS20130194745A1Digital data processing detailsCooling/ventilation/heating modificationsComputer moduleEngineering

Each pair of memory modules in a memory system are cooled using a shared cooling pipe, such as a heat pipe or liquid flow pipe. An example embodiment includes one pair of memory module sockets on opposite sides of the respective cooling pipe. An inner heat spreader plate is thermally coupled to the cooling pipe and in thermal engagement with a first face of the memory module adjacent to the included cooling pipe. Heat is conducted from the second face of the memory module to the cooling pipe, such as from an outer plate in thermal engagement with an opposing second face of the memory modules and with the inner plate.

Owner:LENOVO GLOBAL TECH INT LTD

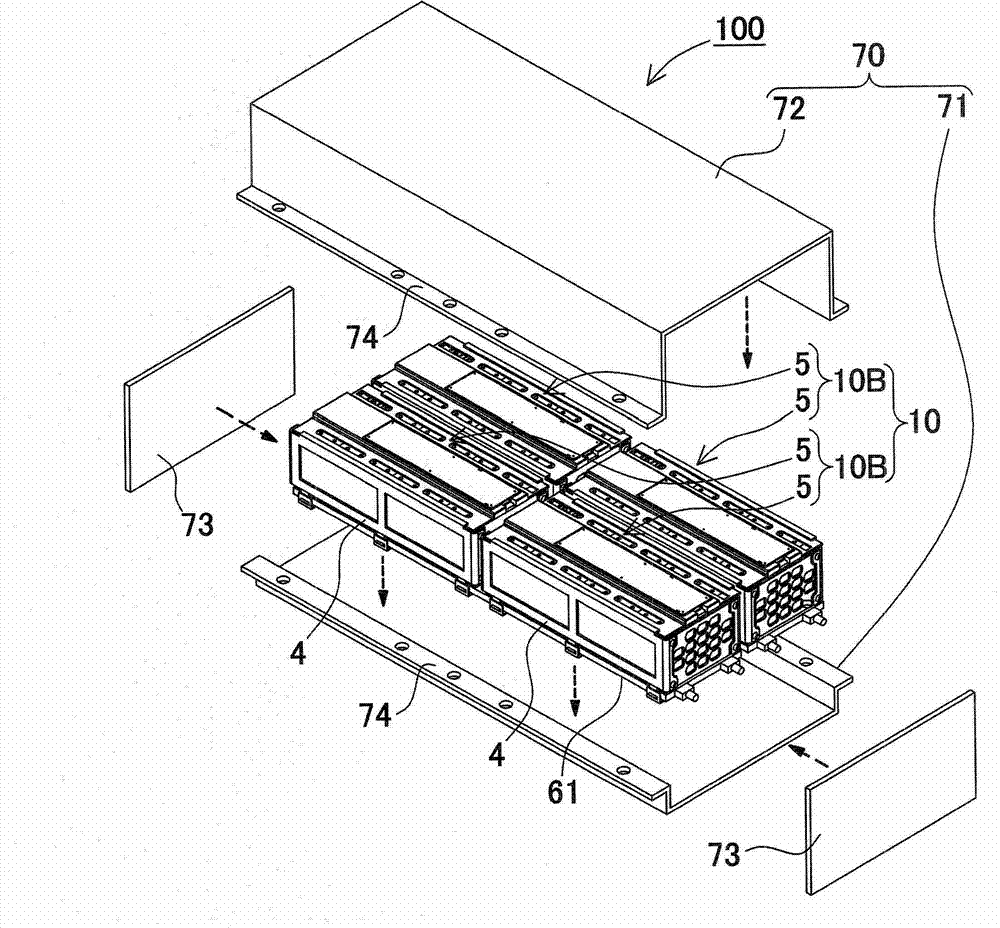

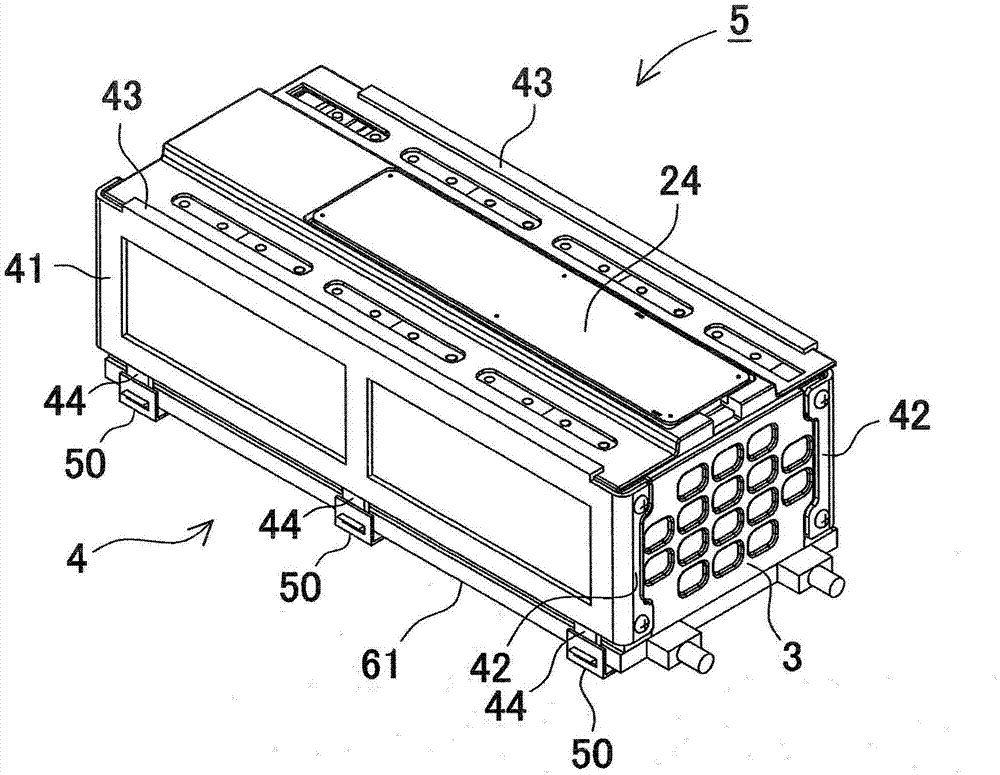

Power supply device and vehicle including the same

InactiveCN102856516AReduce gapReliable formationCell temperature controlBattery isolationMoisture condensationEngineering

The invention provides a power supply device and a vehicle including the same, the condition of moisture condensation at the surface of a battery unit can be prevented, and thermal coupling of the battery unit and a cooling plate (61) can also be maintained. The power supply device includes a battery assembly (5), a box-shaped cover case (16), a cooling plate (61), and a waterproof sheet (19). The battery assembly (5) includes rectangular battery cells (1) arranged side by side. Exterior surfaces of the battery assembly (5) are covered with surfaces of the cover case (16) other than the local of one surface. The cooling plate (61) is thermally coupled to one surface of the battery assembly (5). Coolant flows through the cooling plate (61) whereby transferring heat from the battery assembly (5) to the coolant. The waterproof sheet (19) covers the one surface of the battery assembly (5). Gaps between the battery assembly (5) and the cover case (16) are filled with a sealing material so that a sealing layer (18) is interposed between them. The waterproof sheet (19) is fastened by the sealing layer (18).

Owner:SANYO ELECTRIC CO LTD

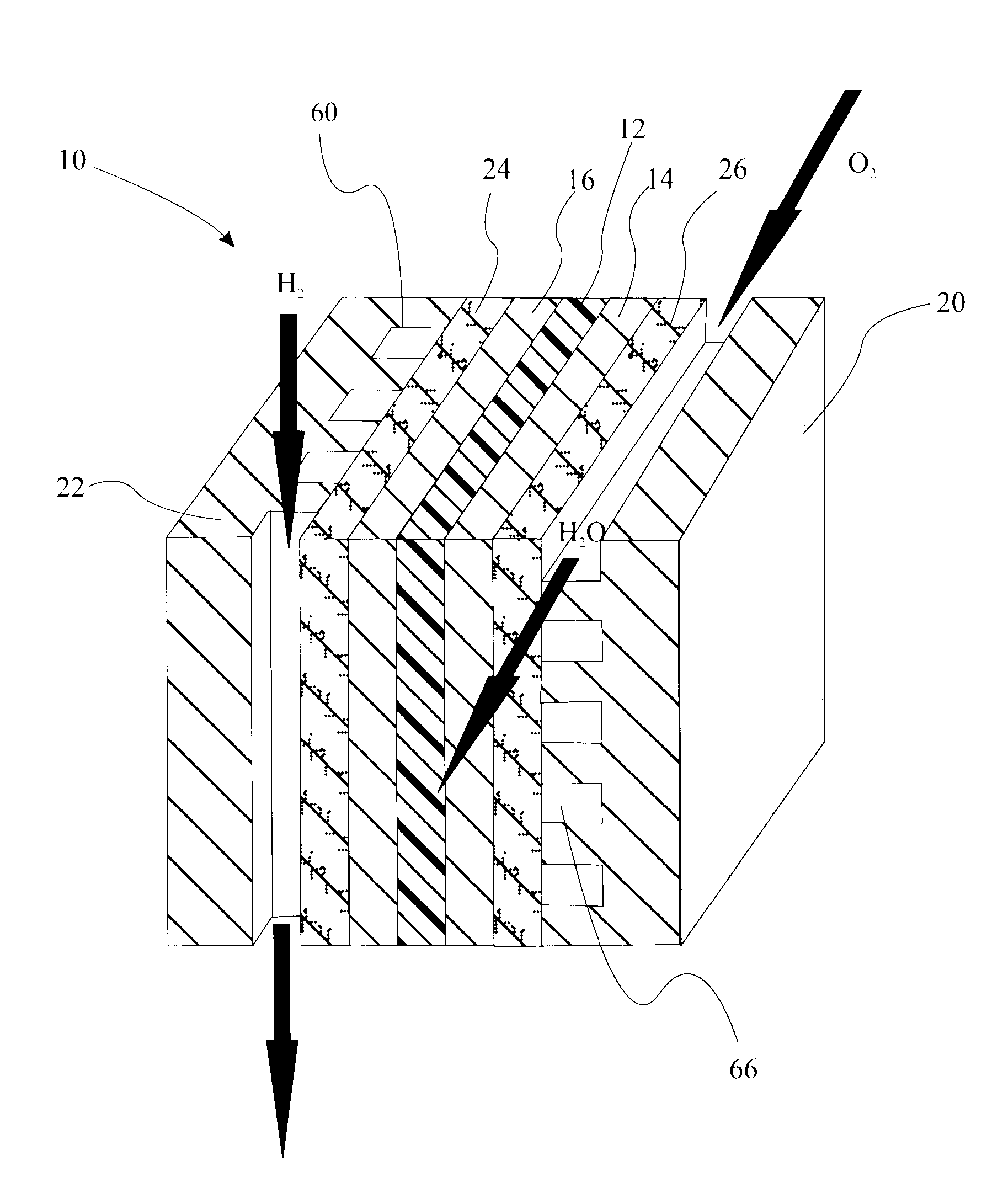

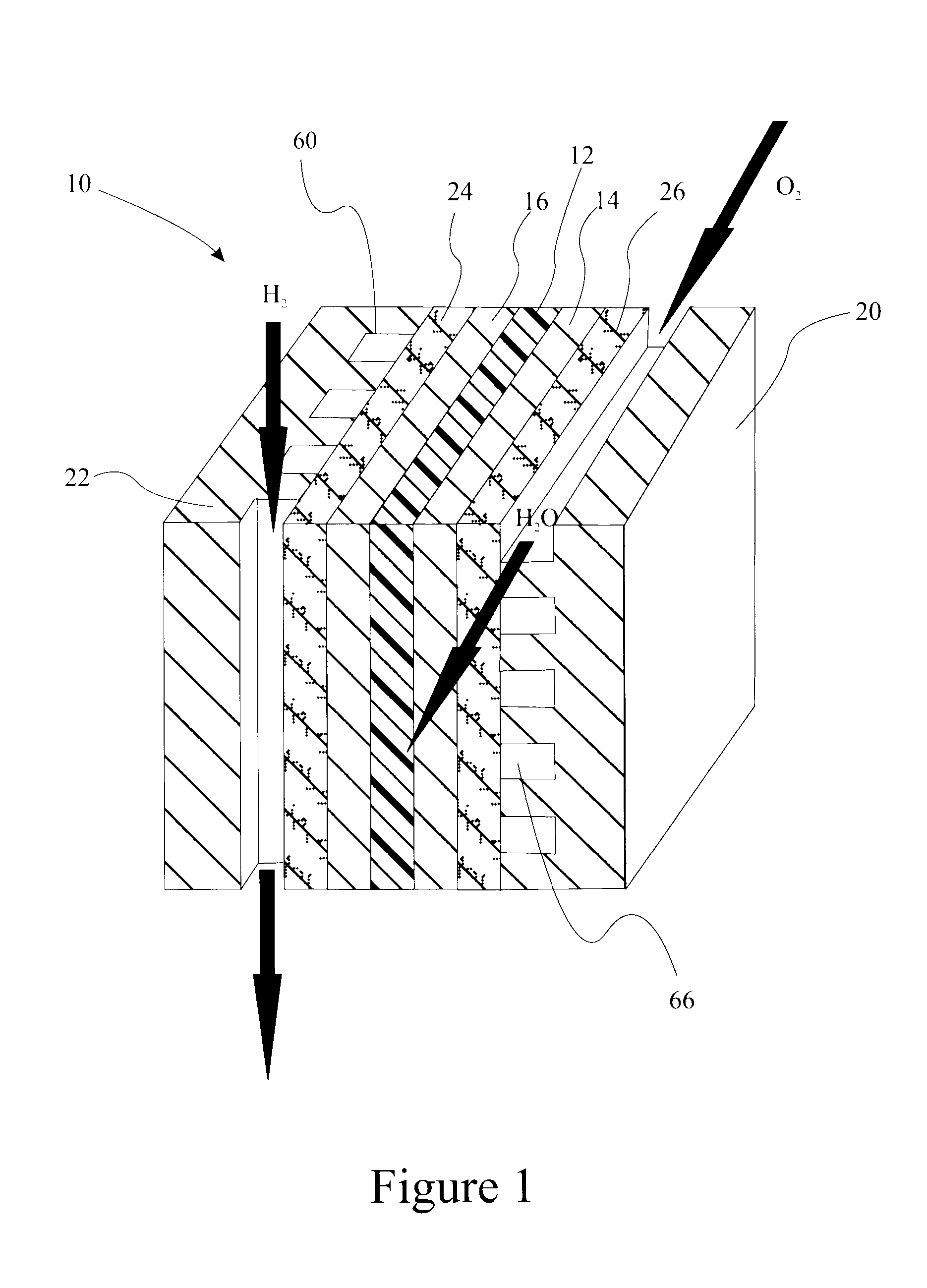

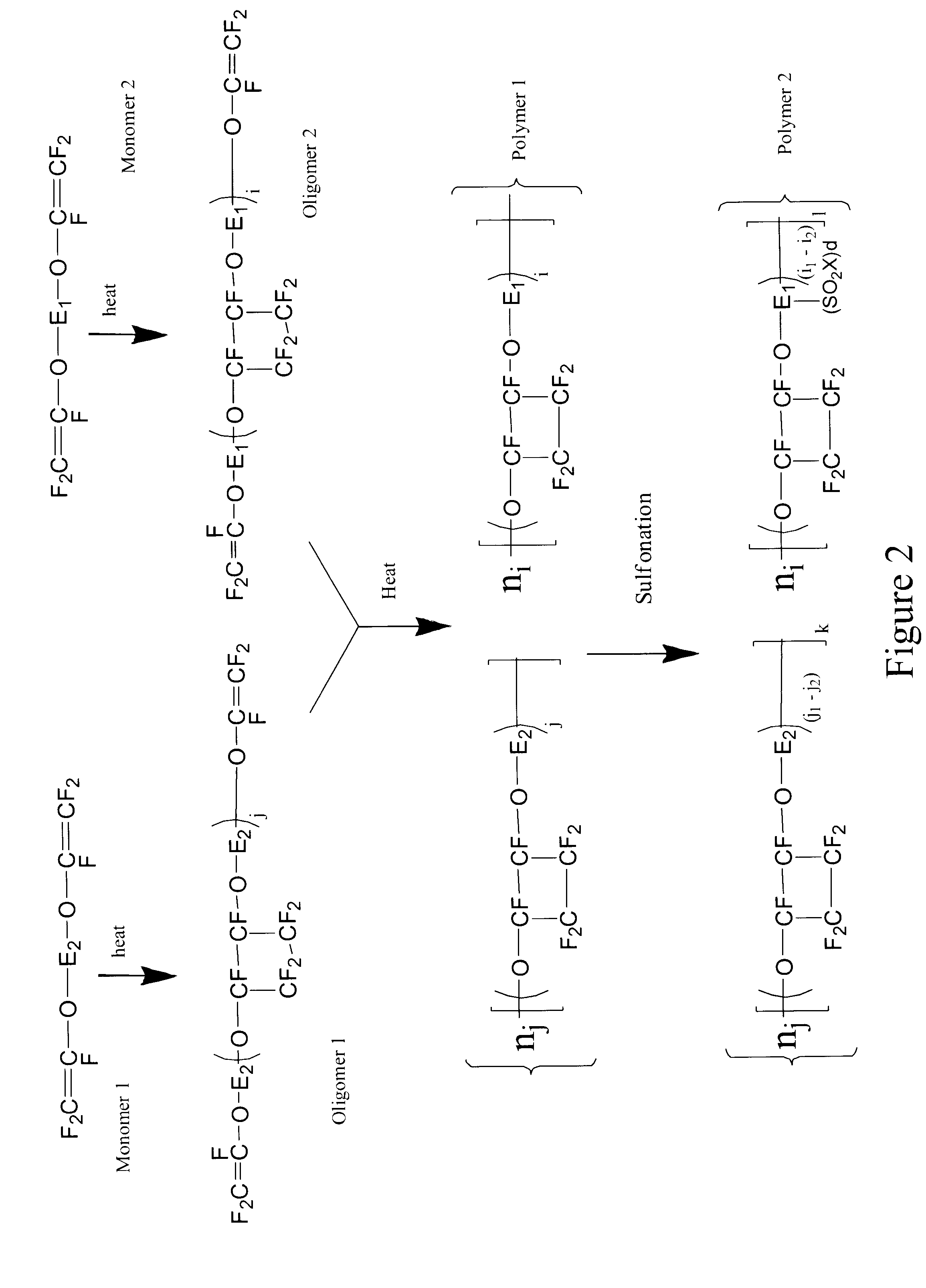

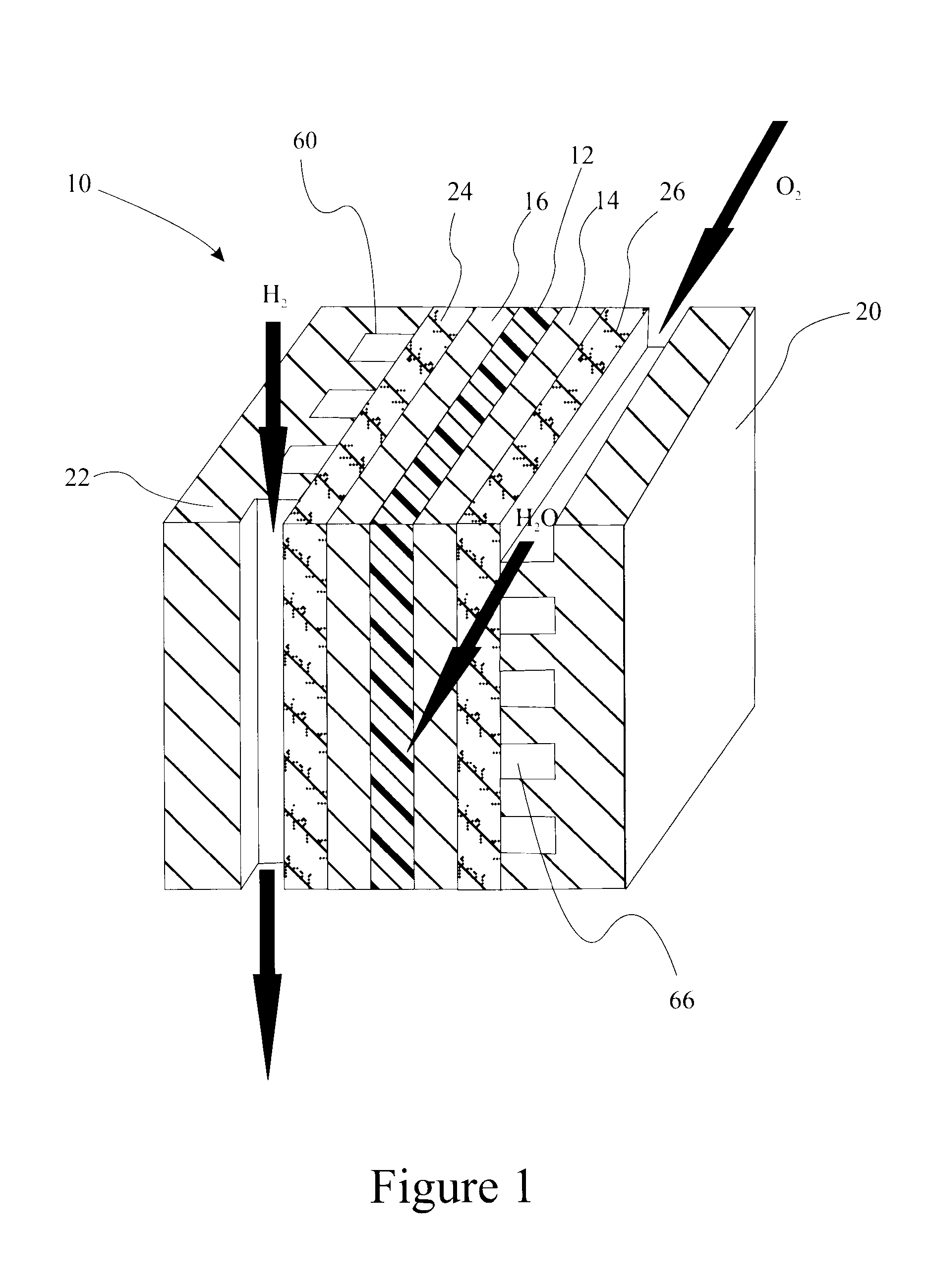

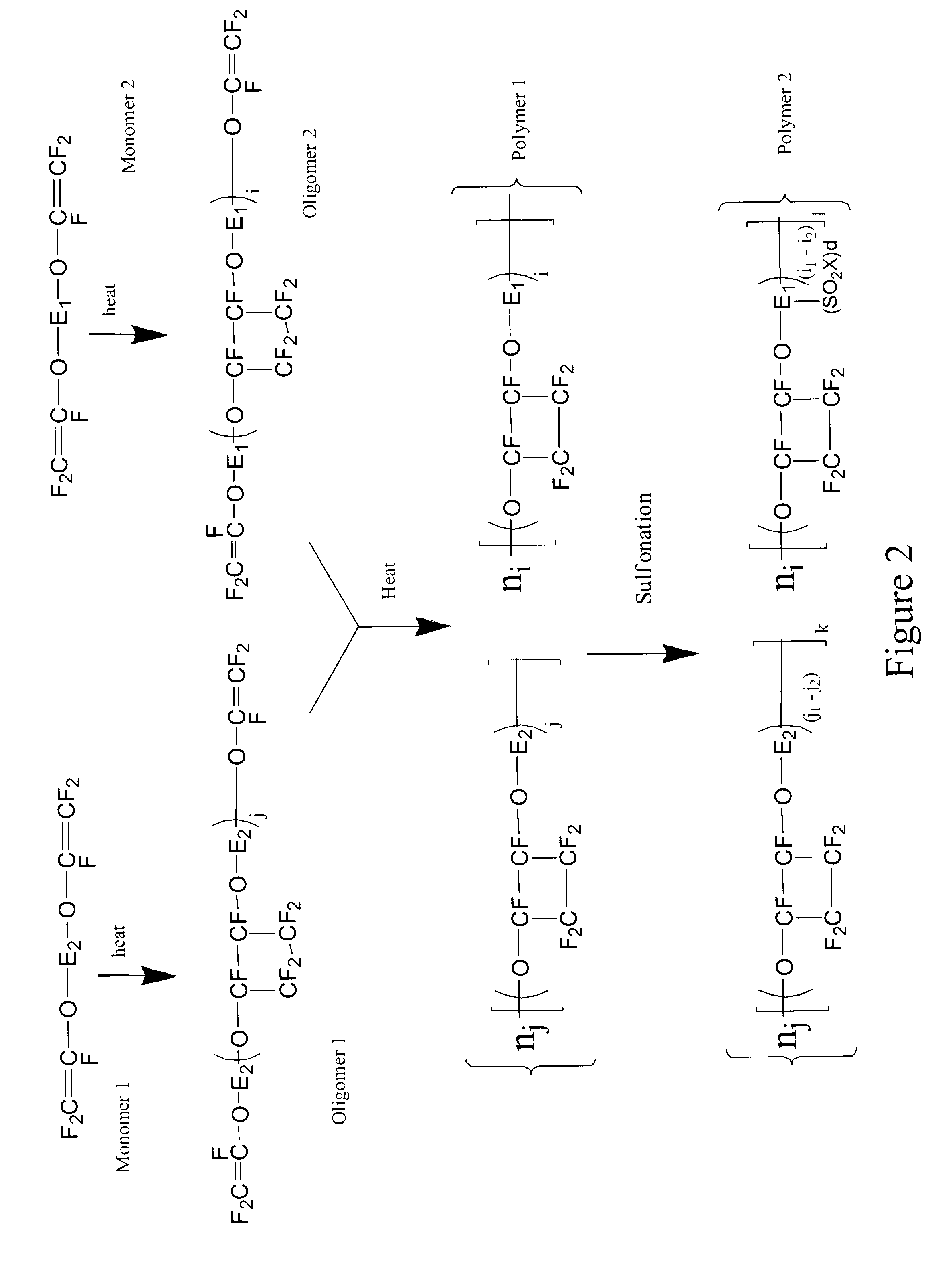

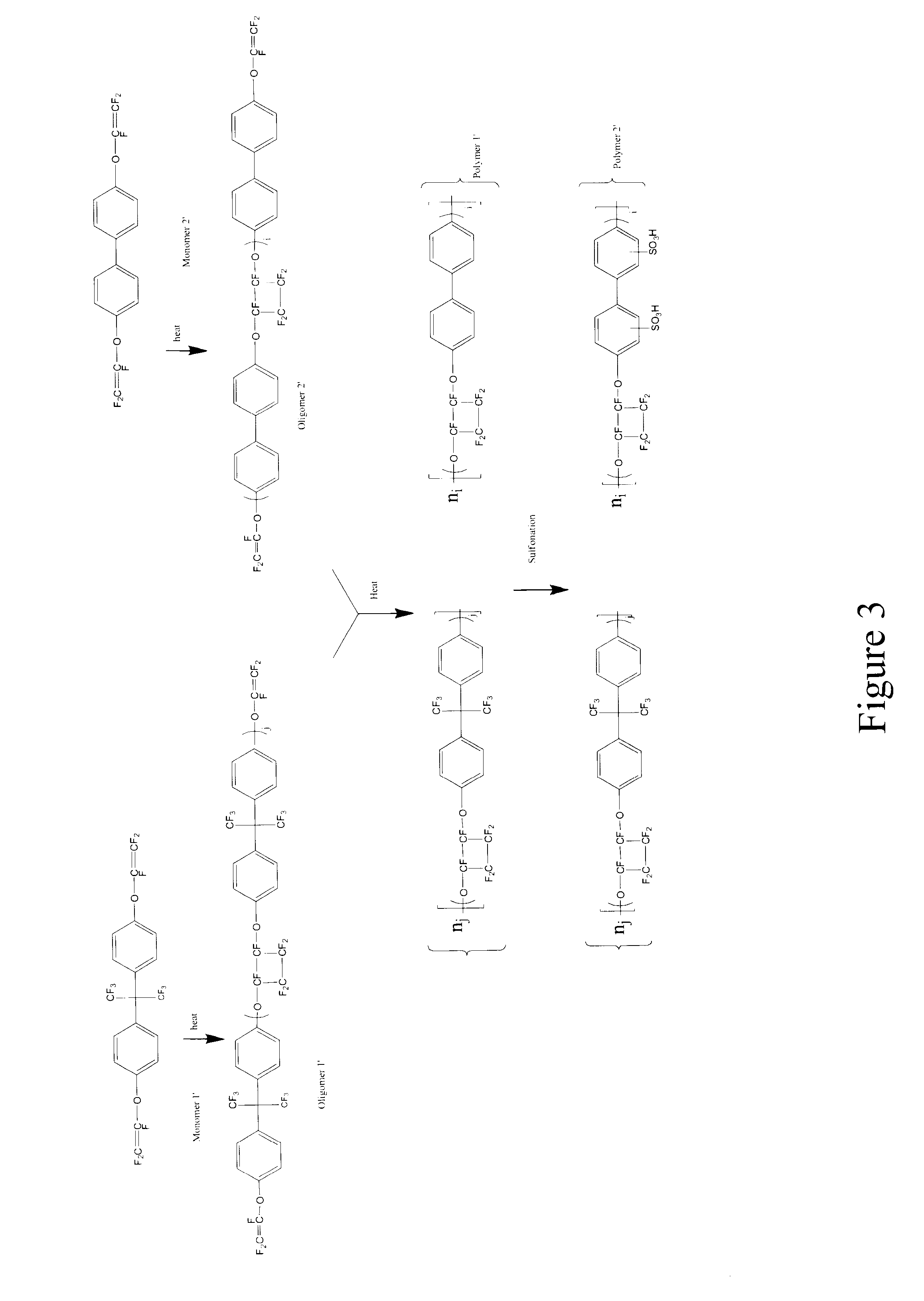

Sulfonated perfluorocyclobutane block copolymers and proton conductive polymer membranes

A sulfonated aromatic perfluorocyclobutane block copolymer comprises a hydrophobic perfluorocyclobutane ether chain segment and a hydrophilic sulfonated perfluorocyclobutane ether chain segment. The sulfonated perfluorocyclobutane copolymer may be used to make proton conductive membranes and membrane electrode assemblies in fuel cells. Processes of making the block copolymer through thermal coupling reactions are also disclosed.

Owner:GM GLOBAL TECH OPERATIONS LLC

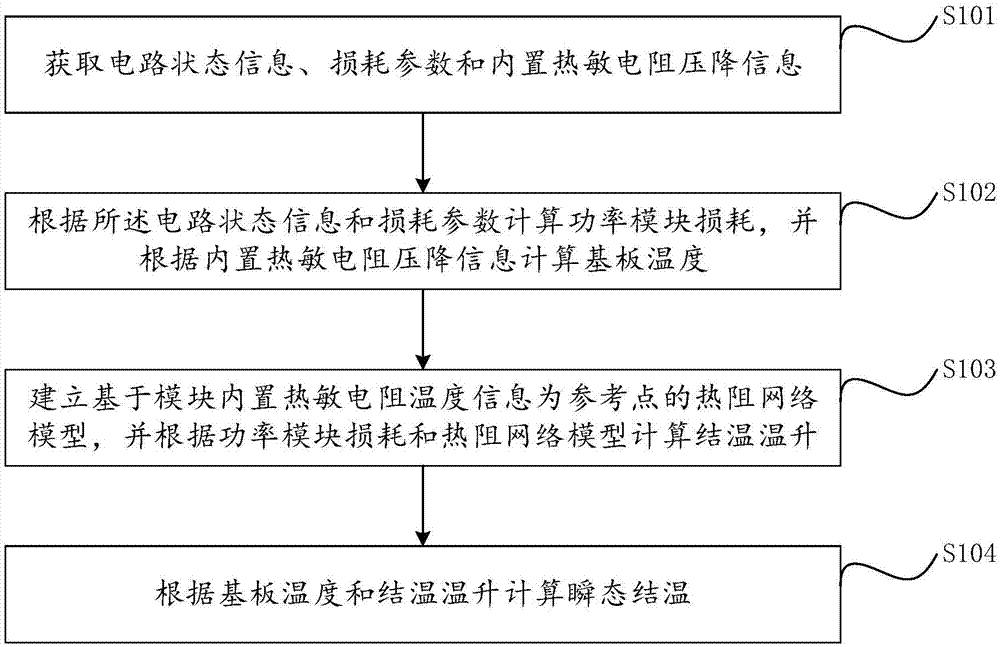

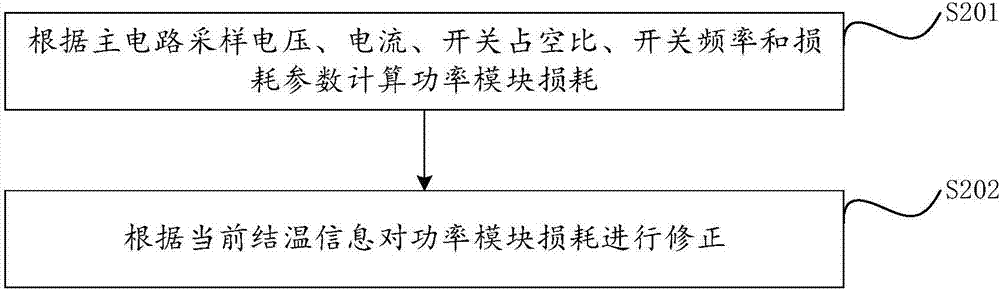

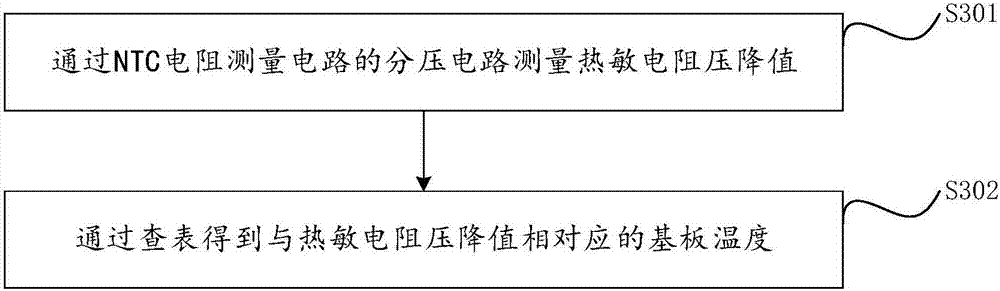

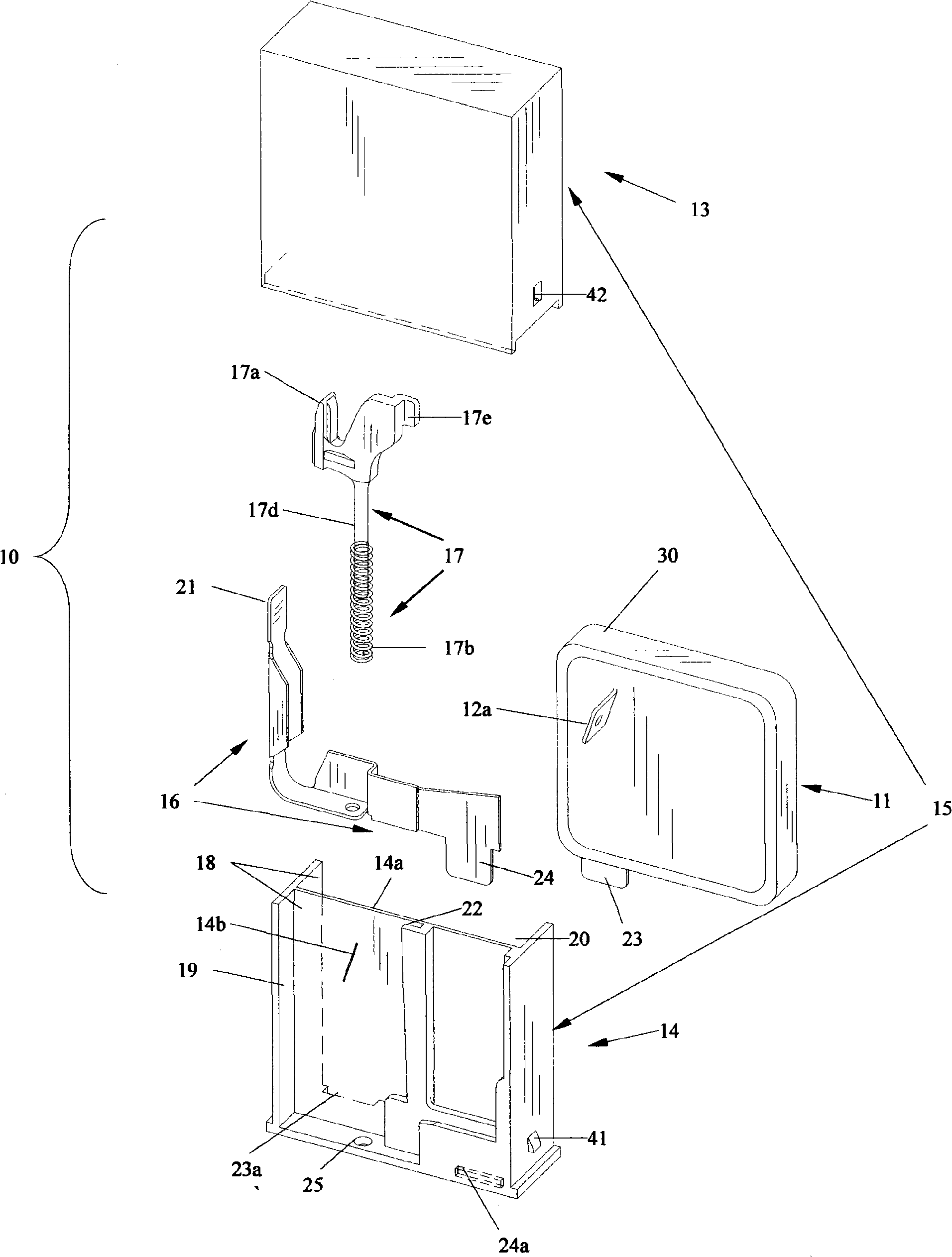

Method and system for calculating transient junction temperature of IGBT (Insulated Gate Bipolar Translator) module

ActiveCN107219016AAccurate Junction Temperature InformationAchieve online accessThermometers using electric/magnetic elementsUsing electrical meansElectrical resistance and conductanceJunction temperature

The invention provides a method and a system for calculating the transient junction temperature of an IGBT (Insulated Gate Bipolar Translator) module. The method comprises the steps of: acquiring circuit state information, loss parameter and internal thermistor voltage drop information; calculating power module loss according to the circuit state information and the loss parameter, and calculating substrate temperature according to the internal thermistor voltage drop information of the module; according to the temperature information provided by internal chips and the internal thermistor of the module as reference temperature, in consideration with thermal coupling between the internal chips of the power module at the same time, establishing a simpler IGBT module thermistor network model, and calculating a junction temperature rise according to the power module loss and the thermistor network model; and calculating the transient junction temperature according to the substrate temperature and the junction temperature rise, thus realizing on-line acquisition of the transient working junction temperature of the IGBT. By sufficiently utilizing the existing thermistor resource inside the power module, a junction temperature measurement system based on a power module electro-thermal coupling model is established, so that accurate power device junction temperature information is provided for security operation and health management of a converter system.

Owner:HUNAN UNIV

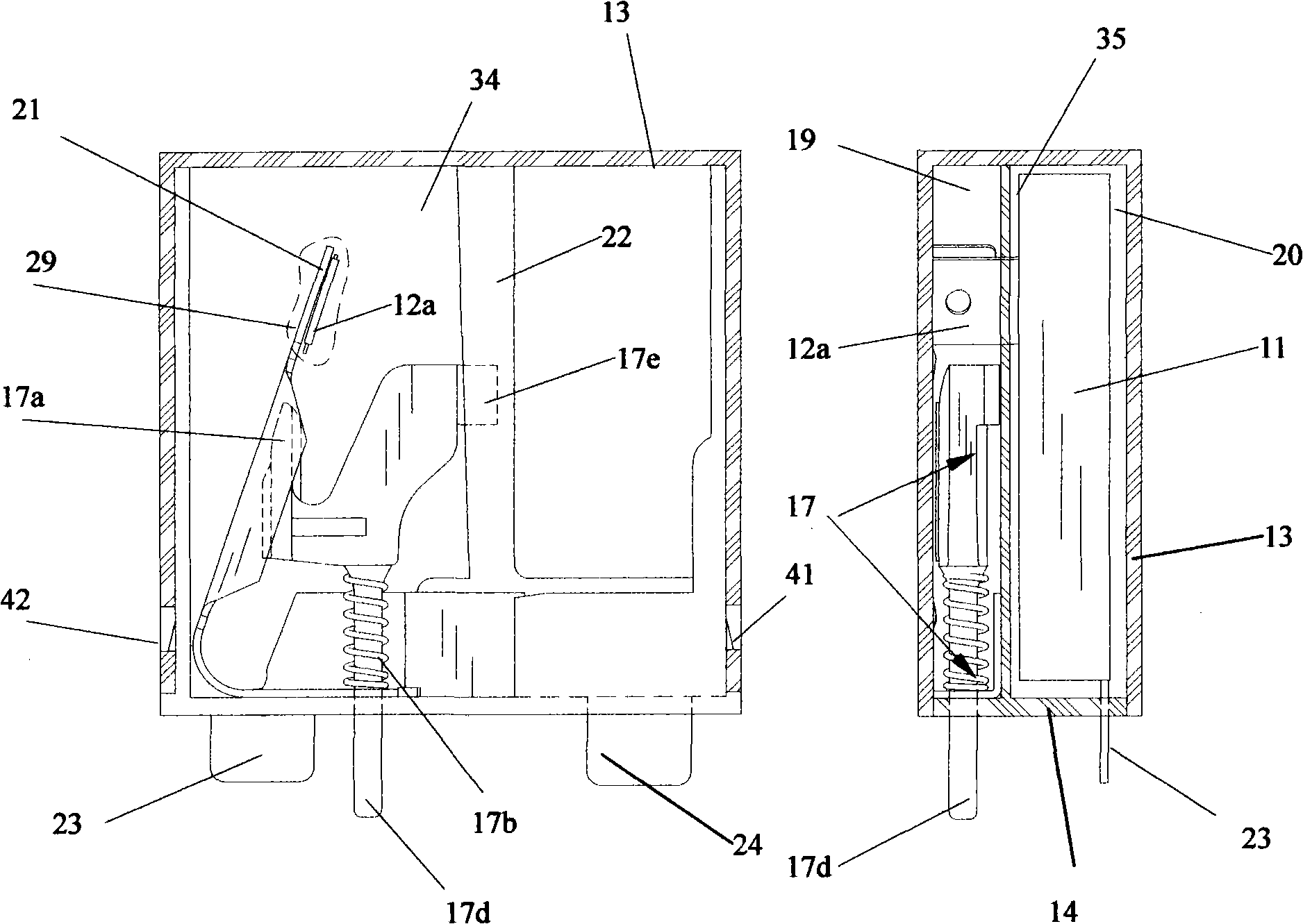

Heat protection pressure sensitive resistor module

ActiveCN101261893APlay the role of arc extinguishingSwitch operated by excess voltageThermally actuated switchesQuenchingMetal

The invention provides a thermal protection voltage-sensitive resistor module used for surge protection, which consists essentially of a metal oxide voltage-sensitive resistor, a thermal response switch, a set of thruster with a compression spring and a wedge-shaped quencher and a case. Thermal coupling exists between the thermal response switch and the metal oxide voltage-sensitive resistor. When the metal oxide voltage-sensitive resistor is overstressed, the resistor emits heat, the thermal response switch can immediately sense the heat and soften the welding point of solder with low melting point, then the welding point is forced to be quickly disconnected and part of the wedge-shaped quencher is inserted into the clearance at the breakage place of the welding point under the joint effect of the thruster with the spring and the wedge-shaped quencher and the resilient conductive connection arm, thus the quenching effect is enhanced.

Owner:毛小毛

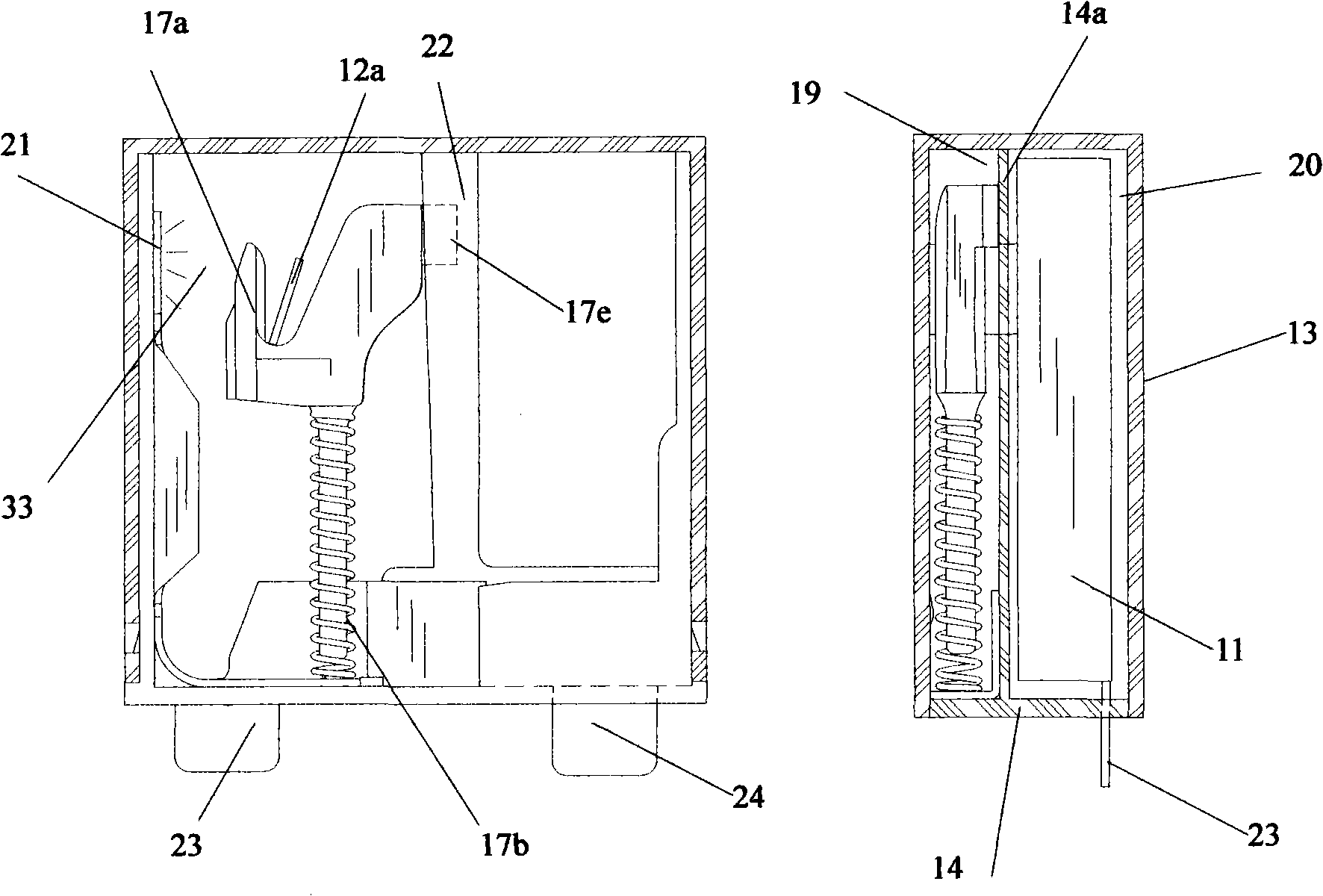

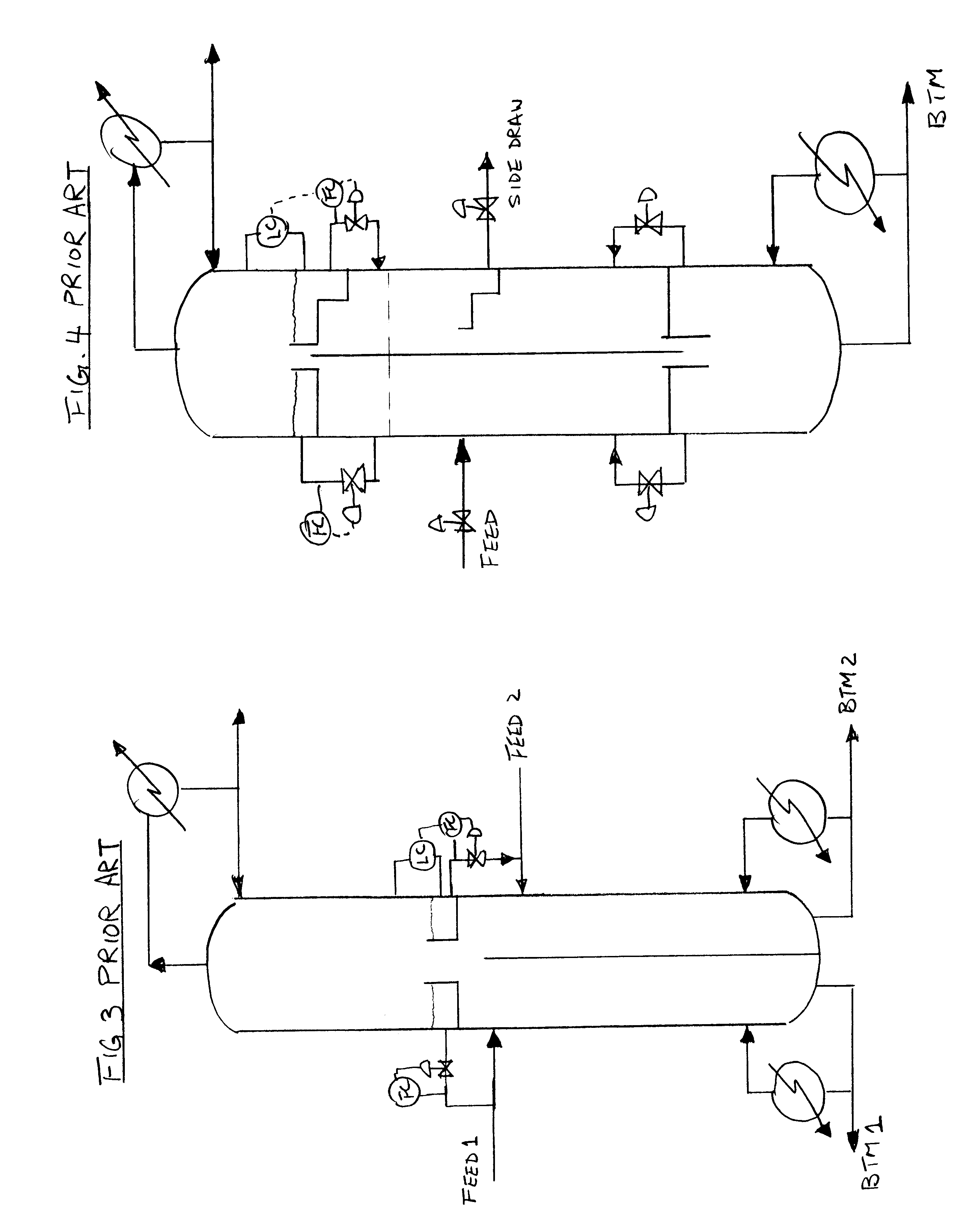

Hydraulically balanced fully thermally coupled system

A fully thermally coupled distillation structure designed to overcome hydraulic limitations in the past has been revealed for separating a multi-component feed stream into three product streams. The fractionation apparatus is equipped with at least one condenser and one reboiler to provide fractionation efficiency surpassing the PETLYUK system. Further, the fractionation apparatus includes innovative designs to enable hydraulically balanced and energy efficient operation at various feed rates, compositions and product specifications.

Owner:TUNG PETER

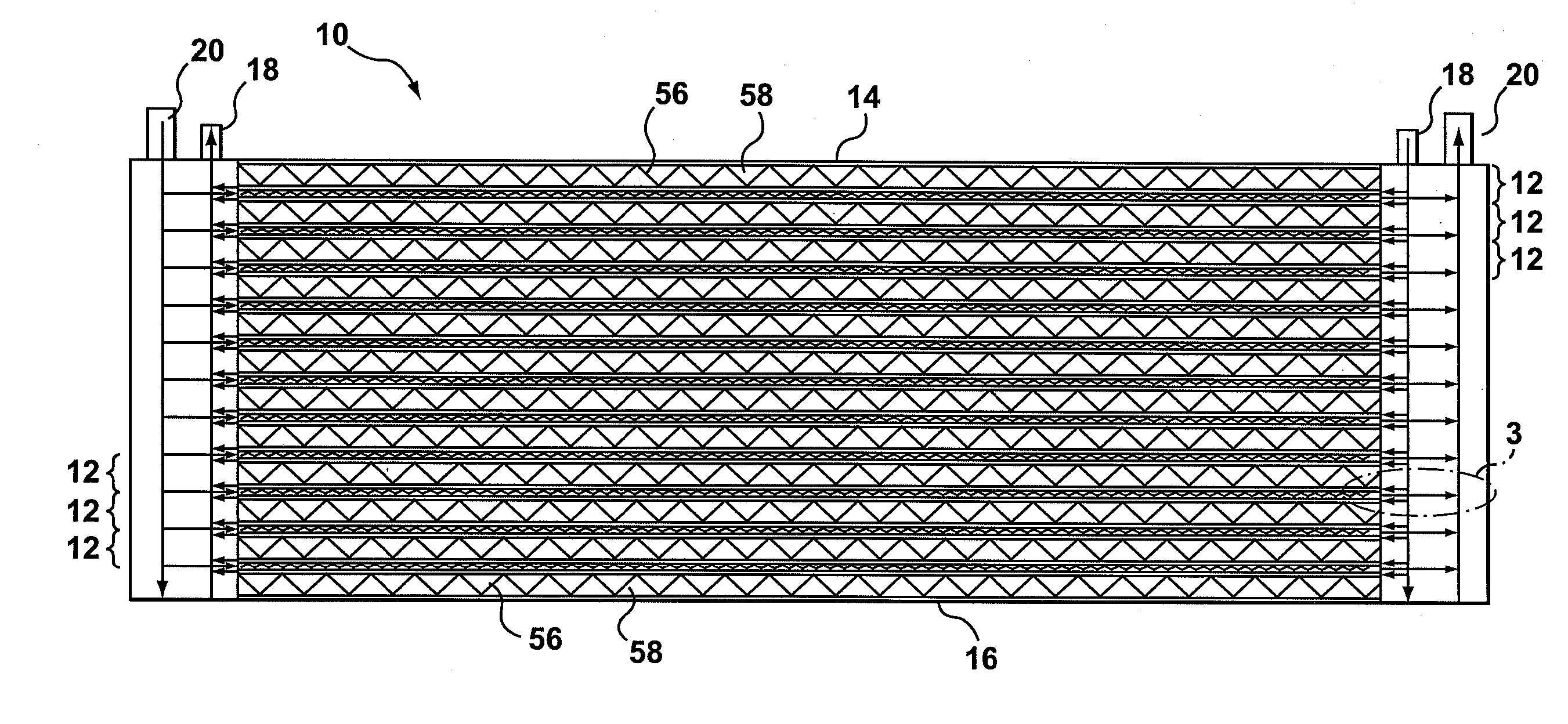

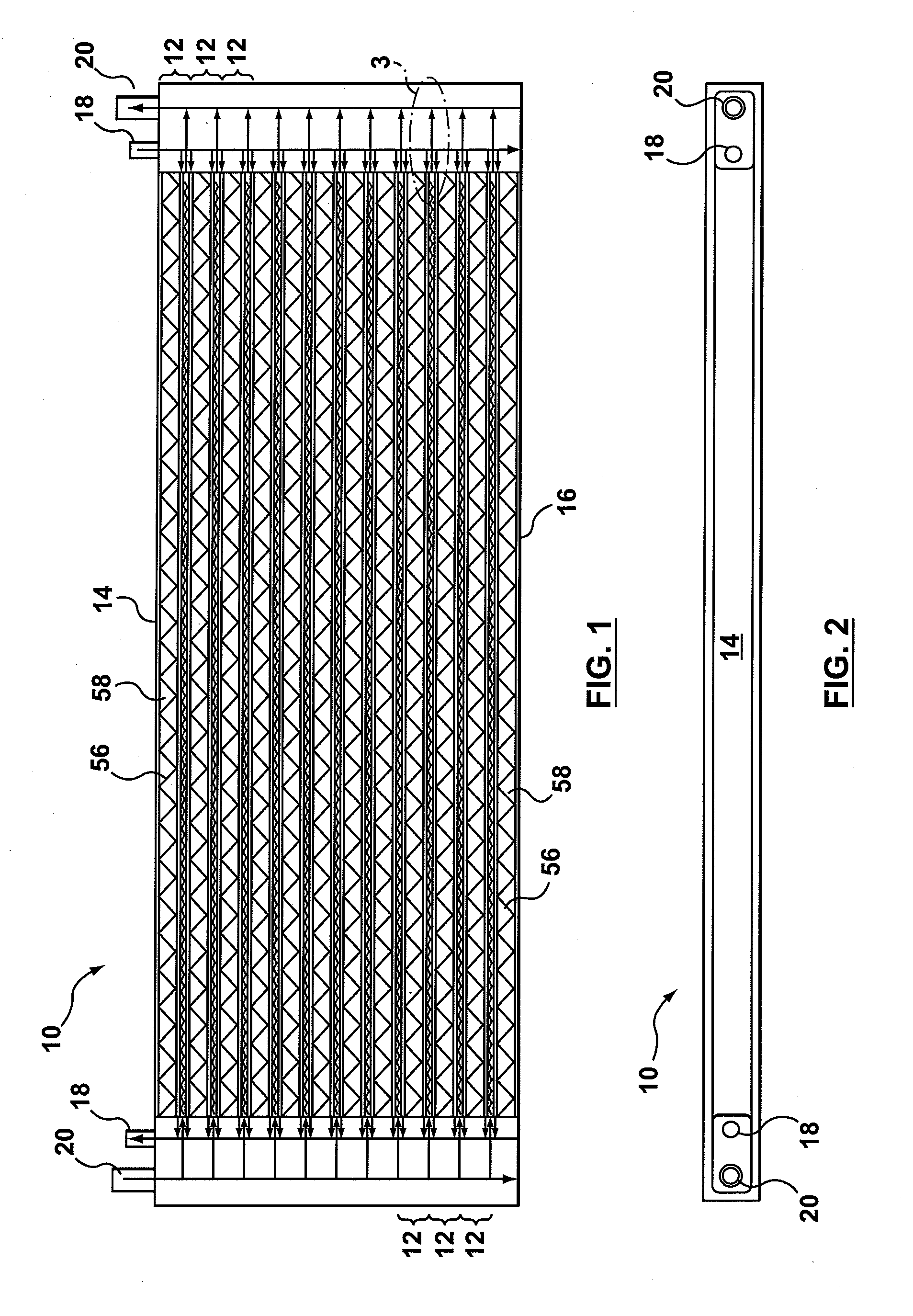

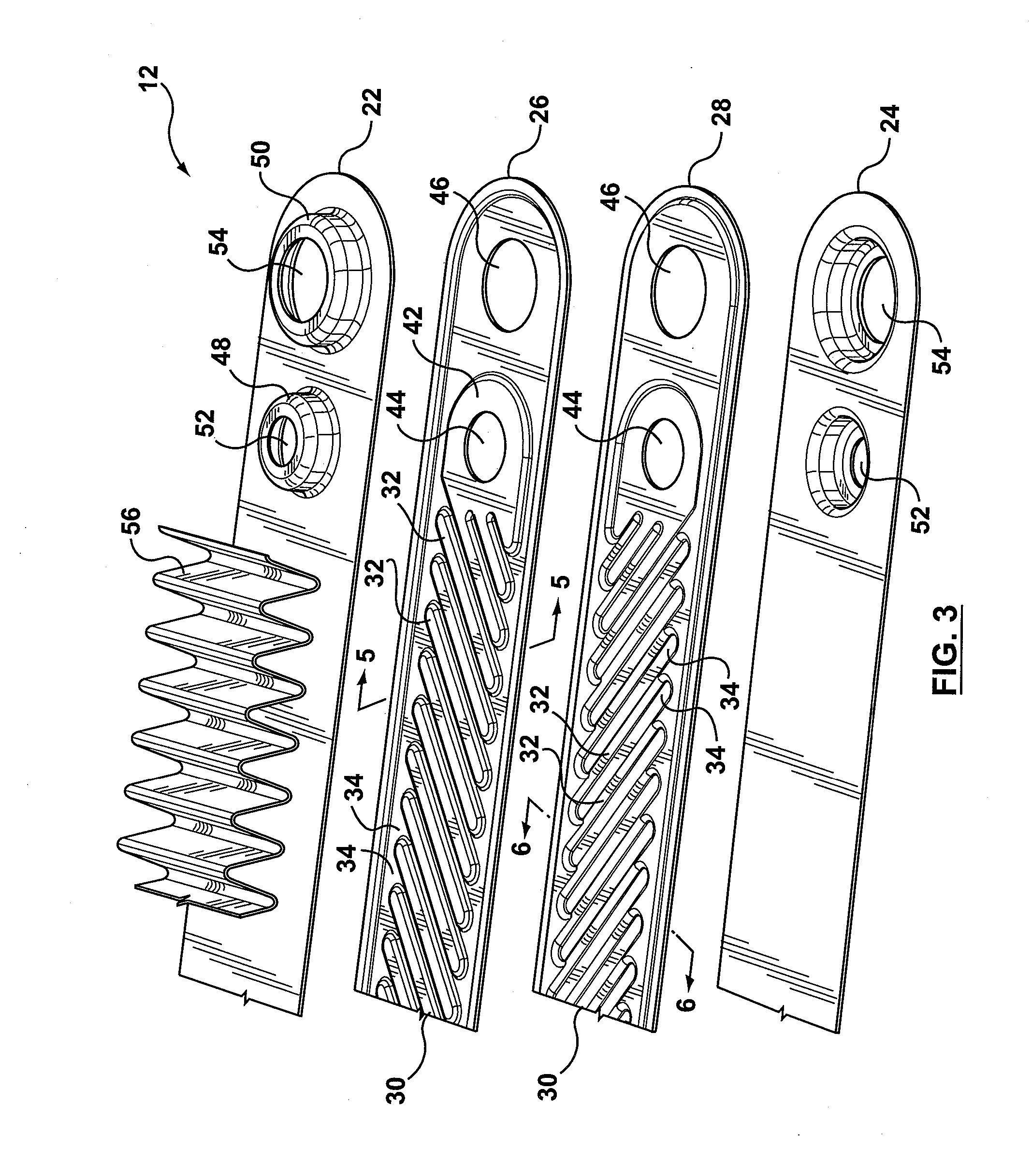

Multifluid heat exchanger

ActiveUS20060266501A1Efficiently transferEfficient transferHeat exhanger conduitsStationary conduit assembliesEngineeringHeating energy

A heat exchanger has a pair of heat exchange conduits having adjacent primary heat exchange surfaces thermally coupled together for the transfer of heat energy between the conduits. A third fluid conduit has a primary heat transfer surface thermally coupled to the primary heat transfer surfaces of the pair of fluid conduits, so that heat can be transferred between any one of the fluid conduits and each of the other fluid conduits.

Owner:DANA CANADA CORP

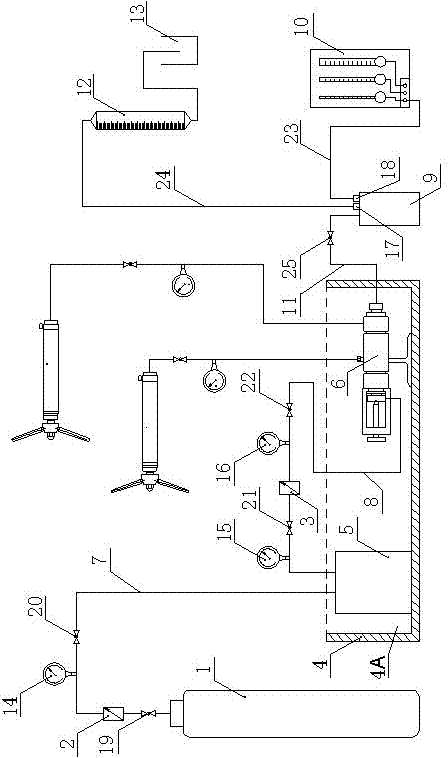

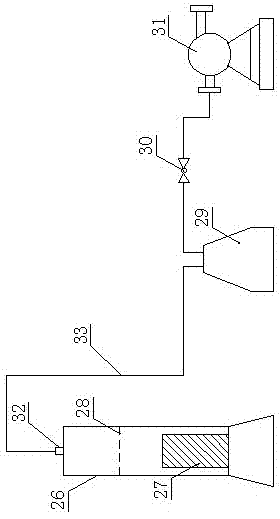

Water-gas two-phase adsorption-desorption-seepage experimental system and method for loaded coal containing methane

ActiveCN102901803AAccurate detectionAccurate measurementFuel testingPermeability/surface area analysisWater bathsHigh pressure

The invention discloses a water-gas two-phase adsorption-desorption-seepage experimental system and method for loaded coal containing methane. The water-gas two-phase adsorption-desorption-seepage experimental system for loaded coal containing methane comprises a pressure loading part, wherein the pressure loading part comprises a tank body for containing a constant-temperature water bath, a reference pot and a coal sample holder are arranged in the tank body, the gas inlet of the reference pot is connected with a high-pressure methane delivery pipeline, the gas outlet of the reference pot is connected with the gas inlet of the coal sample holder through a connecting pipeline, and the gas outlet of the coal sample holder is connected with a water-gas separation device. The water-gas two-phase seepage experimental method for loaded coal containing methane is carried out on the basis of the experimental system. By changing different loading conditions, loading paths and experimental temperatures, adsorption-desorption experiments and methane seepage experiments for the loaded coal containing methane under the conditions of different solid-gas thermal coupling can be realized, and water-gas two-phase seepage experiments and methane adsorption-desorption experiments under the condition of different moisture contents also can be realized.

Owner:HENAN POLYTECHNIC UNIV

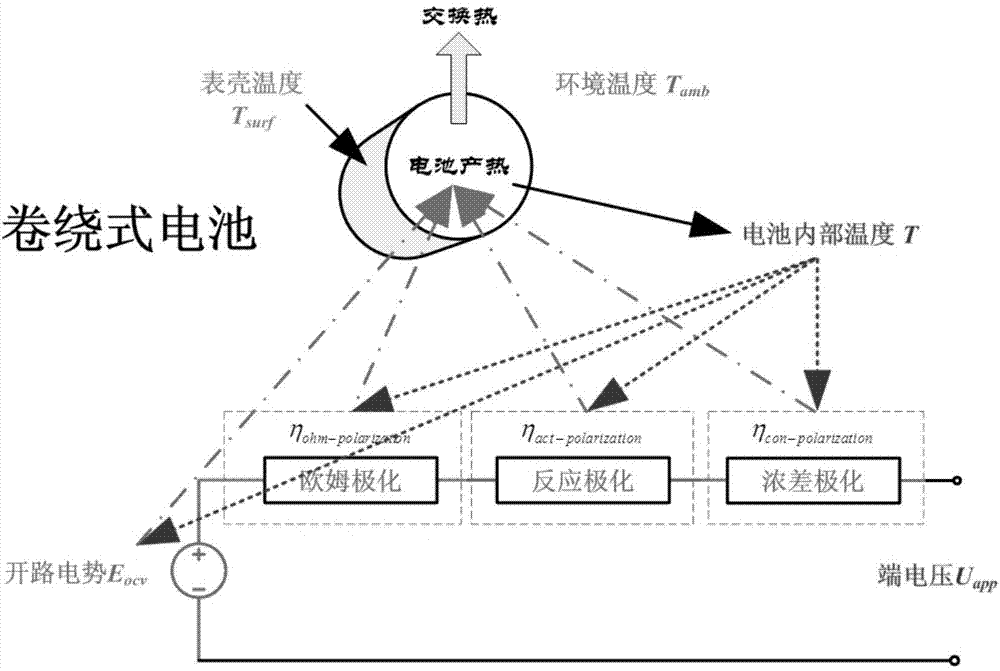

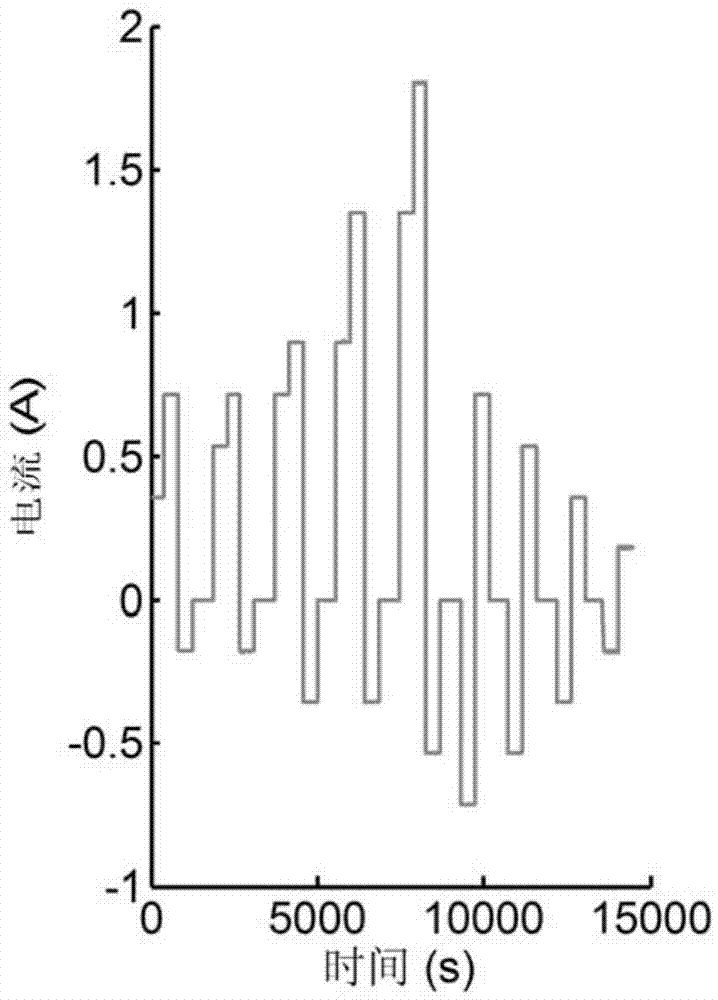

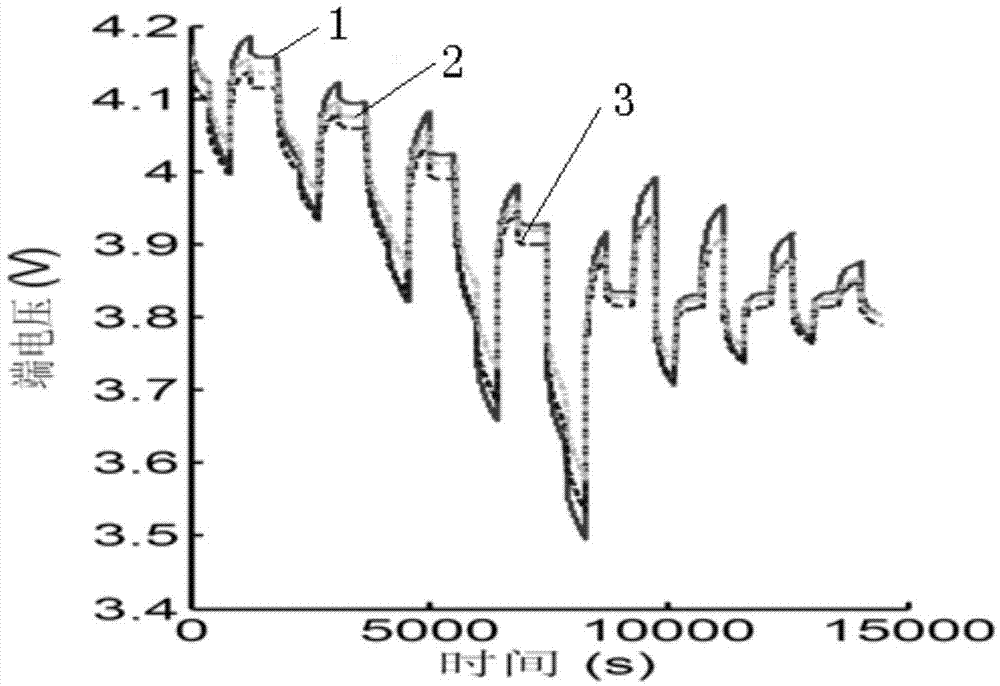

Method for obtaining electrochemical and thermal coupling models of lithium ion battery

InactiveCN104849675AComprehensive descriptionAccurate estimateElectrical testingSpecial data processing applicationsElectrical batteryPower grid

The invention relates to a method for obtaining electrochemical and thermal coupling models of a lithium ion battery, and relates to the field of large-capacity energy storage of an intelligent power grid. The invention aims at solving a problem that there is short of electrochemical and thermal coupling models for the simulation of the change of a battery end voltage and housing temperature with time. According to the invention, the lithium ion battery is placed under different temperatures, and current is inputted into the lithium ion battery. The parameters of the electrochemical and thermal coupling models of the lithium ion battery are obtained according to the response curves of the battery end voltage and the housing temperature of the lithium ion battery. The coupling models can be used for the simulation of the end voltage and the housing temperature of the lithium ion battery.

Owner:HARBIN INST OF TECH

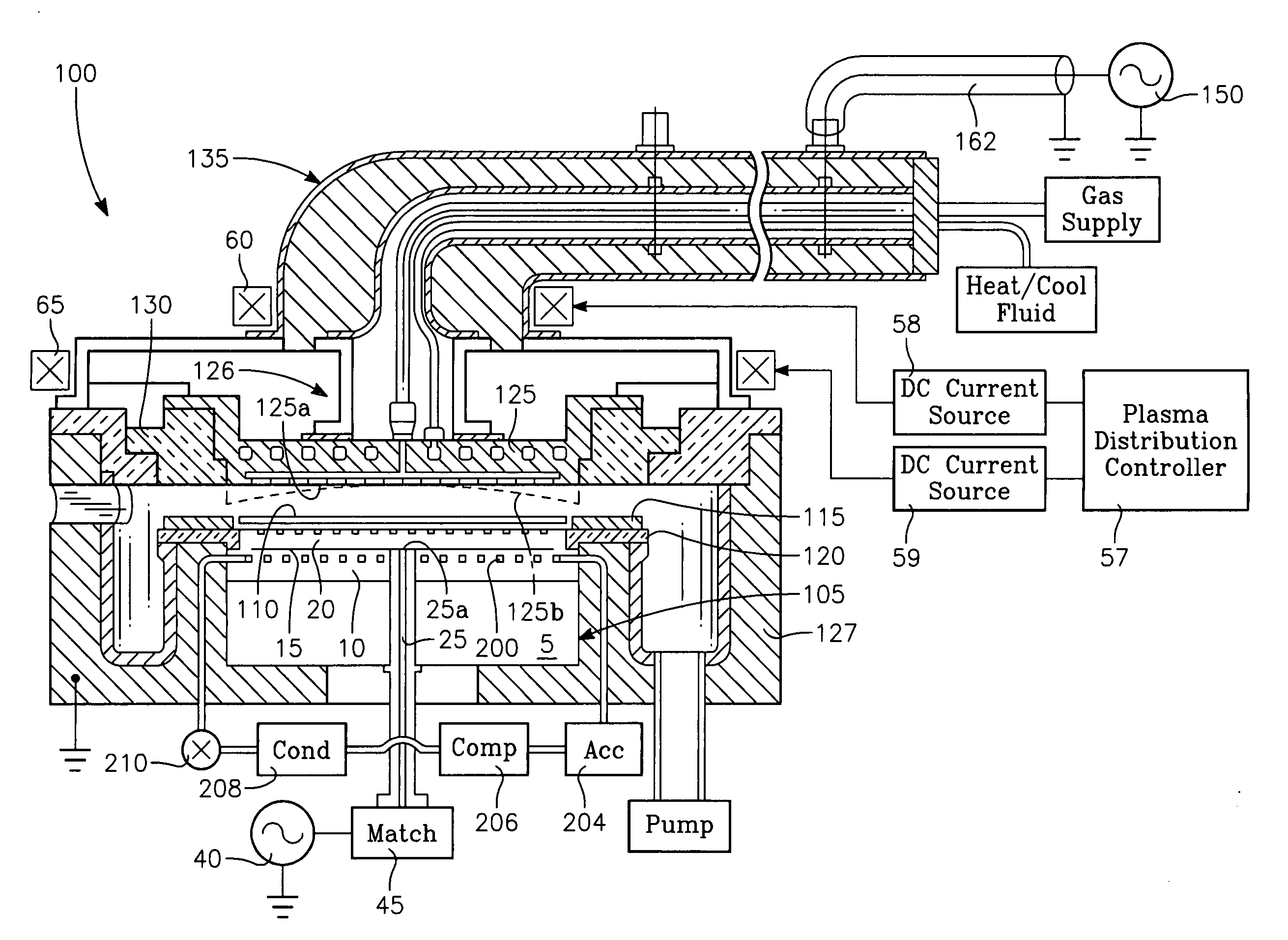

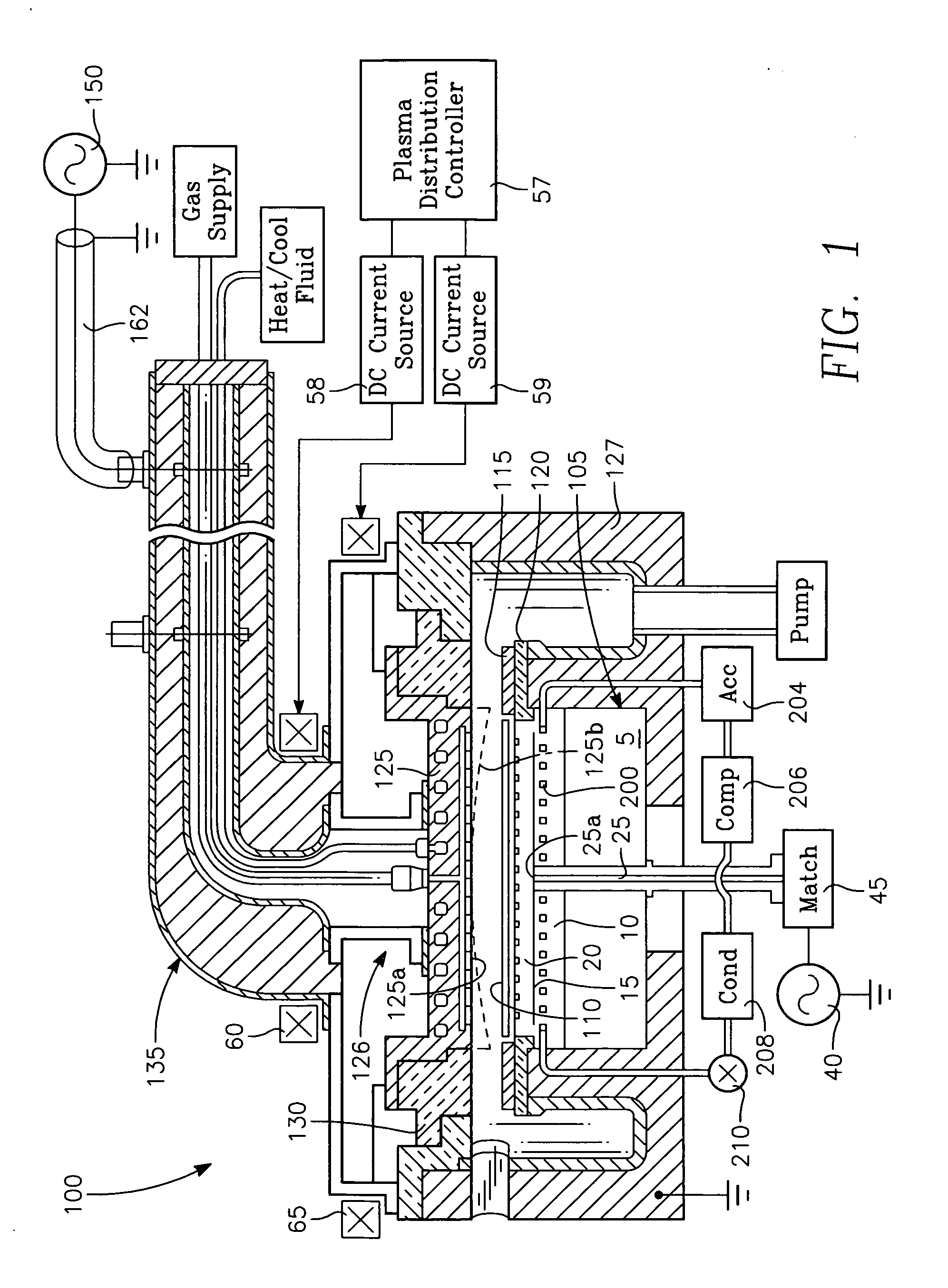

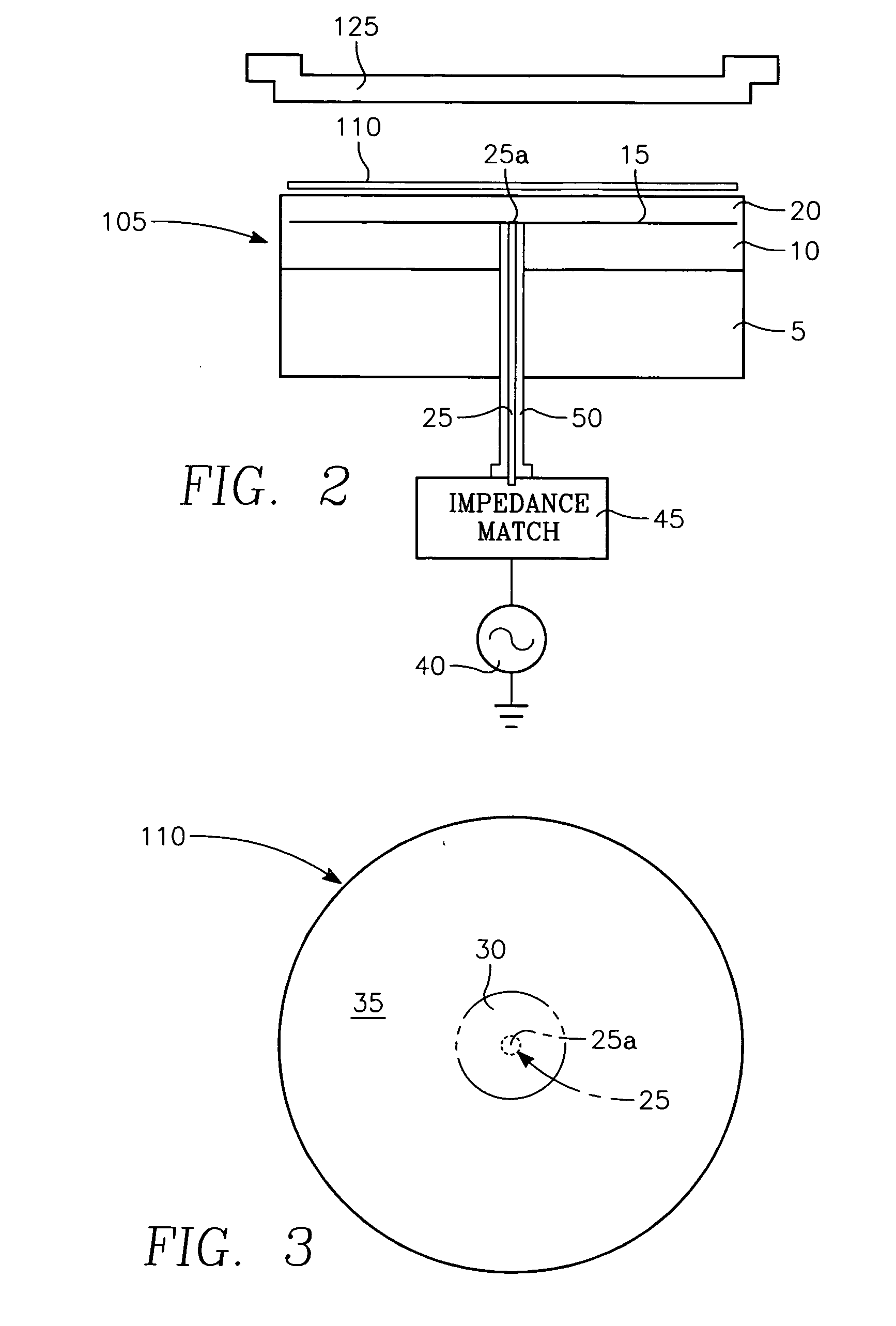

Capacitively coupled plasma reactor having very agile wafer temperature control

ActiveUS20070081294A1Promote fillingLiquid surface applicatorsSemiconductor/solid-state device manufacturingCapacitanceProcess engineering

A plasma reactor for processing a workpiece includes a reactor chamber, an electrostatic chuck within the chamber having a top surface for supporting a workpiece and having indentations in the top surface that form enclosed gas flow channels whenever covered by a workpiece resting on the top surface. The reactor further includes thermal control apparatus thermally coupled to the electrostatic chuck, an RF plasma bias power generator coupled to apply RF power to the electrostatic chuck, a pressurized gas supply of a thermally conductive gas, a controllable gas valve coupling the pressurized gas supply to the indentations to facilitate filling the channels with the thermally conductive gas for heat transfer between a backside of a workpiece and the electrostatic chuck at a heat transfer rate that is a function of the pressure against the backside of the workpiece of the thermally conductive gas. The reactor further includes an agile workpiece temperature control loop including (a) a temperature probe in the electrostatic chuck, and (b) a backside gas pressure controller coupled to an output of the temperature probe and responsive to a specified desired temperature, the controller governing the gas valve in response to a difference between the output of the temperature probe and the desired temperature.

Owner:BE AEROSPACE INCORPORATED

Thermal monitoring system for semiconductor devices

A method for monitoring the operating temperature of a semiconductor device. The method comprising the steps of: placing a thermal coupling material between the bottom of the semiconductor device and the top of a printed circuit board for inserting the device thereinto; inserting a sensor so to be at least partially covered by the thermal coupling material; and measuring the temperature from the sensor within a predetermined time interval. In accordance with another aspect of the invention, an apparatus is described to carry out the above process.

Owner:IBM CORP

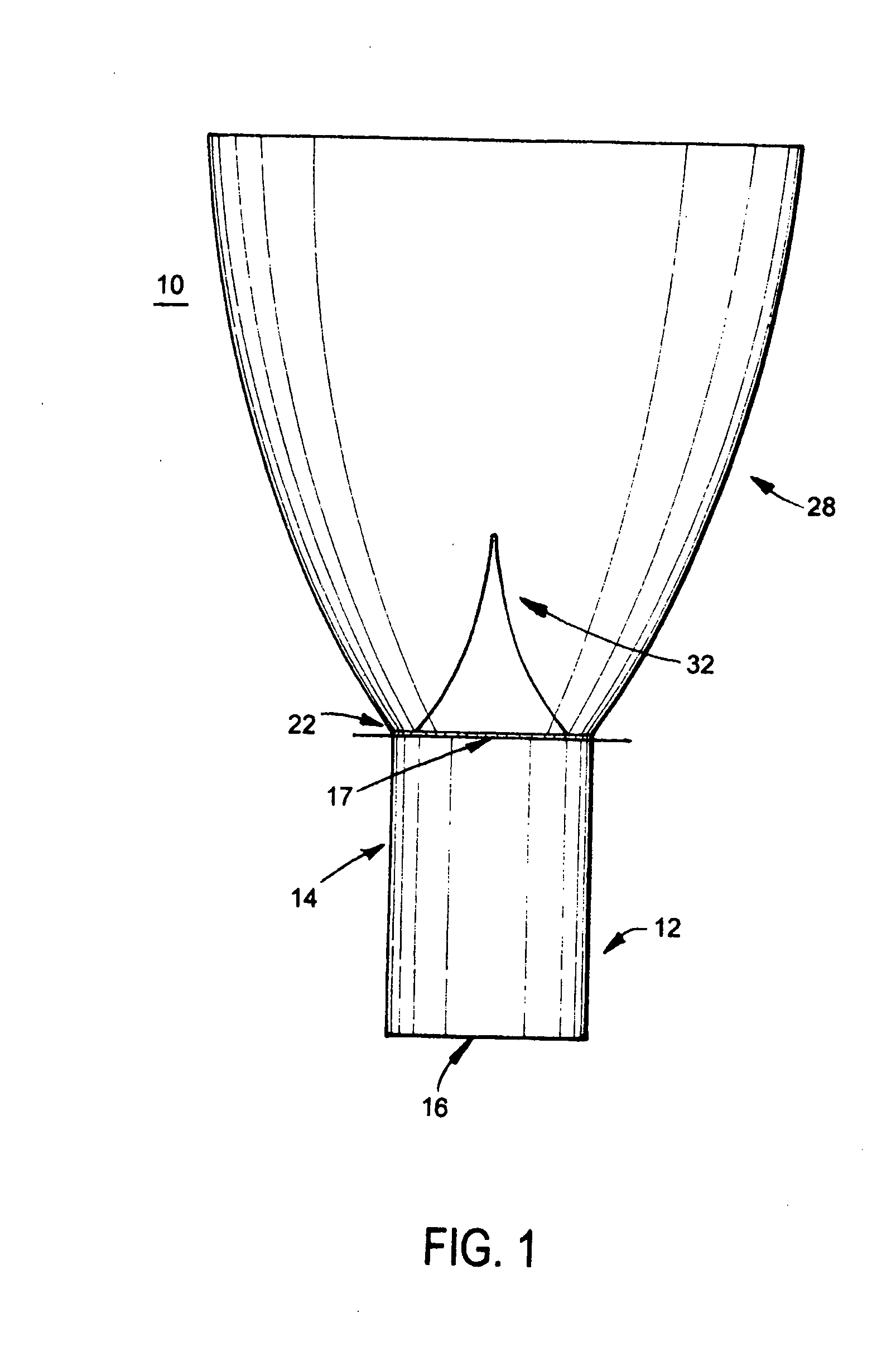

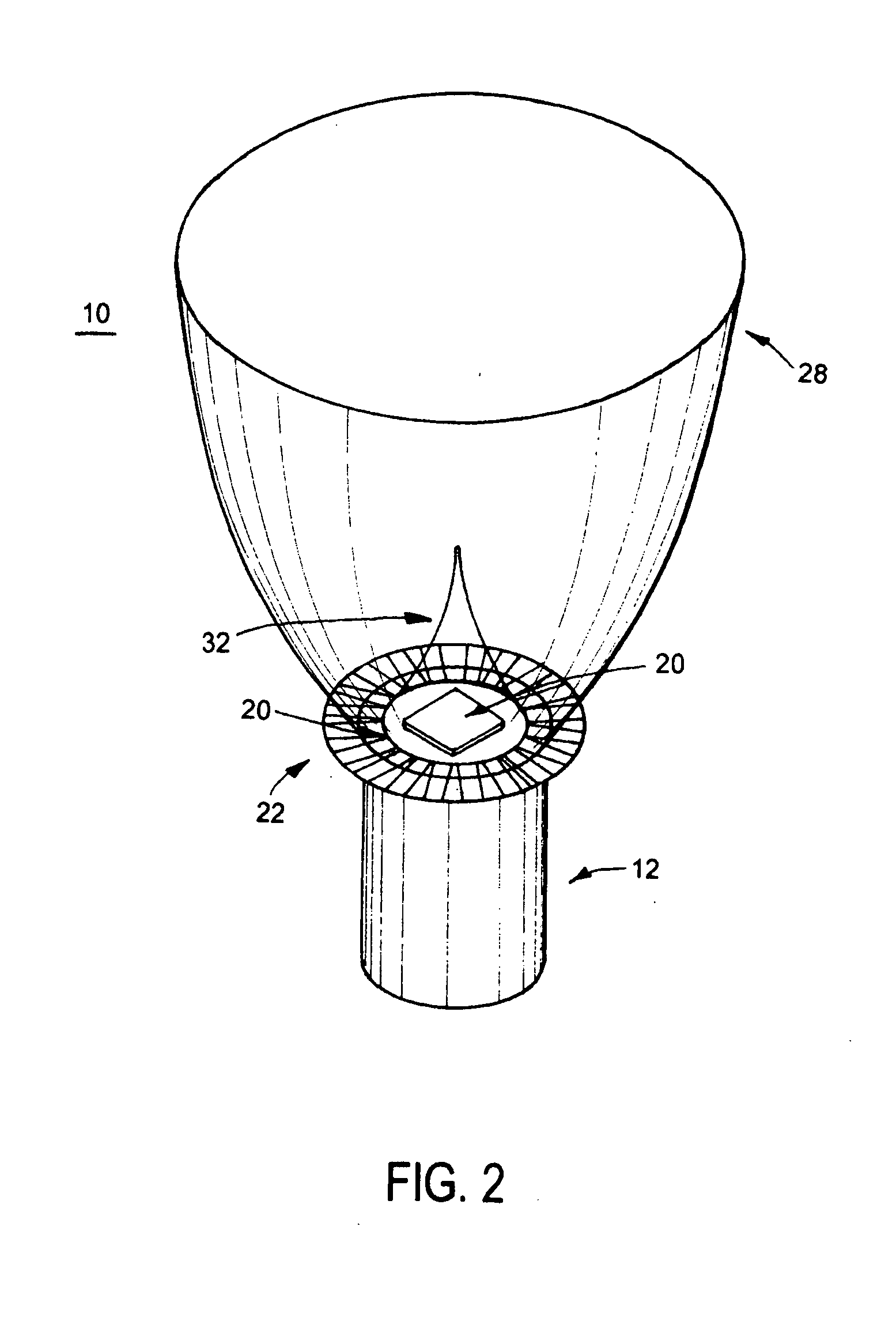

Multiple light-emitting element heat pipe assembly

InactiveUS20080205062A1Semiconductor/solid-state device detailsLighting heating/cooling arrangementsHeat pipeElectrical and Electronics engineering

The present invention provides an optical device comprising one or more heat pipes with a desired level of thermal coupling with the light-emitting elements which are positioned along a periphery of the evaporator surface portion of the heat pipe in such a way that they are thermally coupled to the heat pipe. In one embodiment, the heat pipe of the present invention can be readily integrated with optical elements such as reflectors or collimators.

Owner:TIR TECH LP

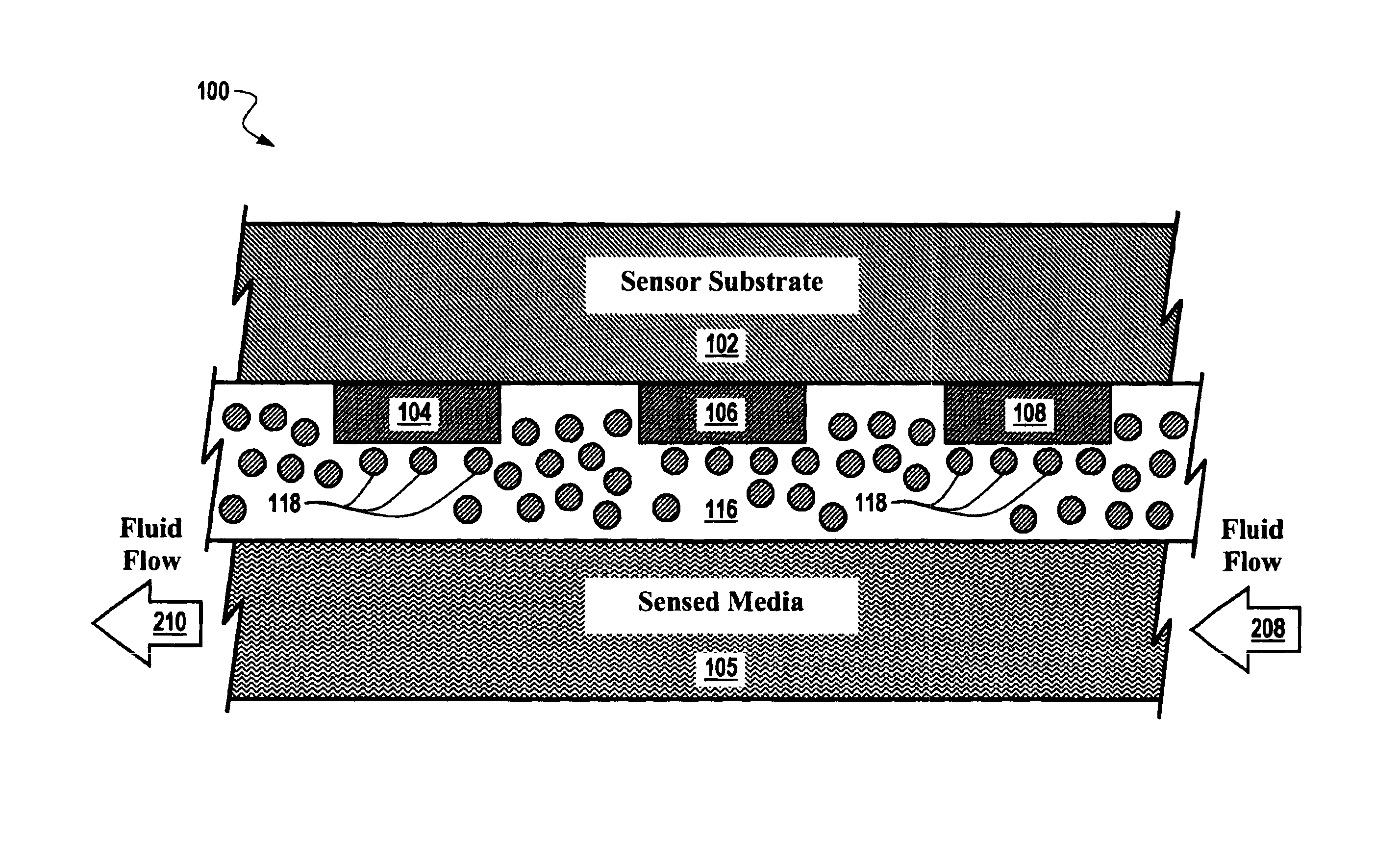

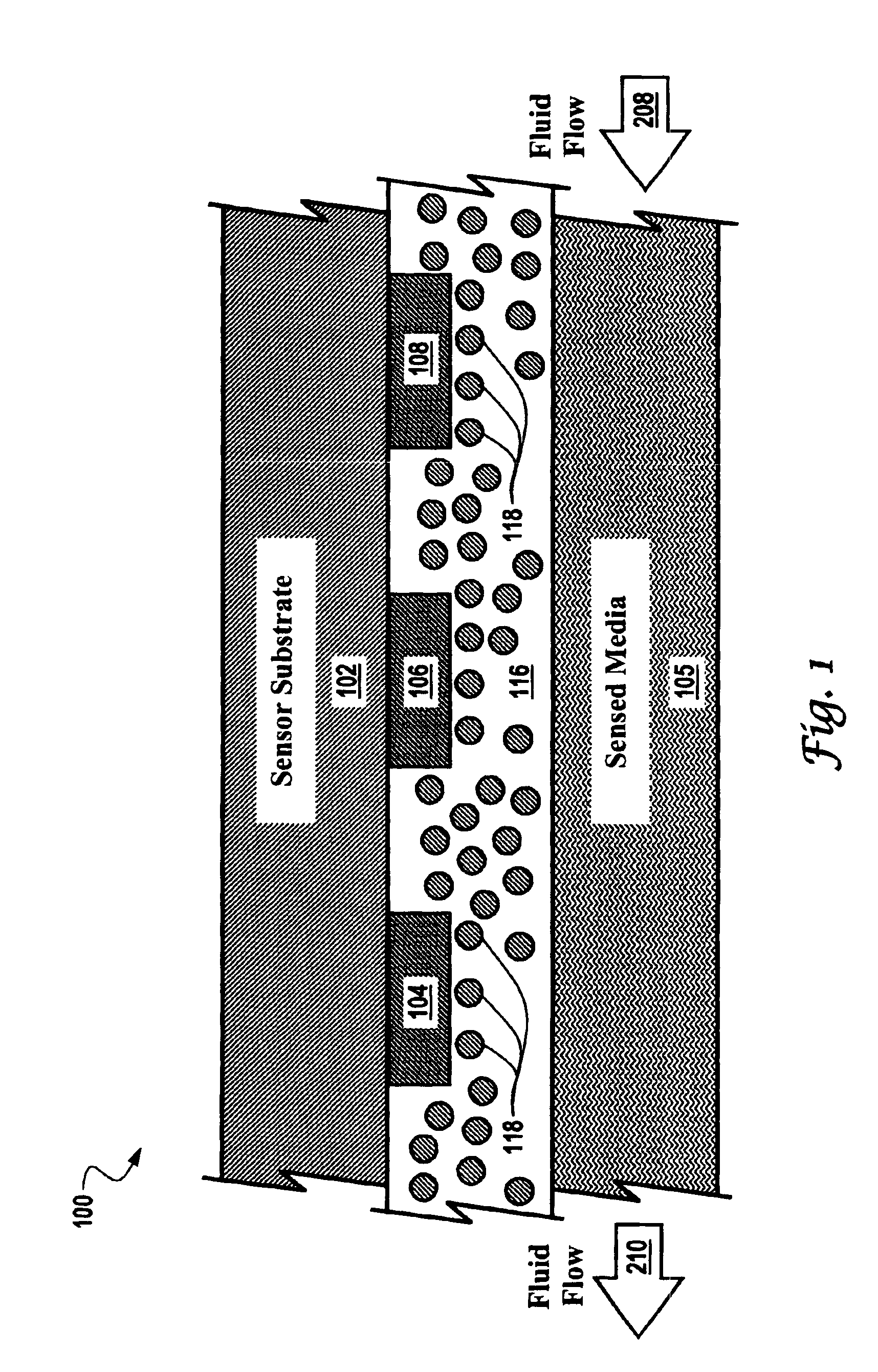

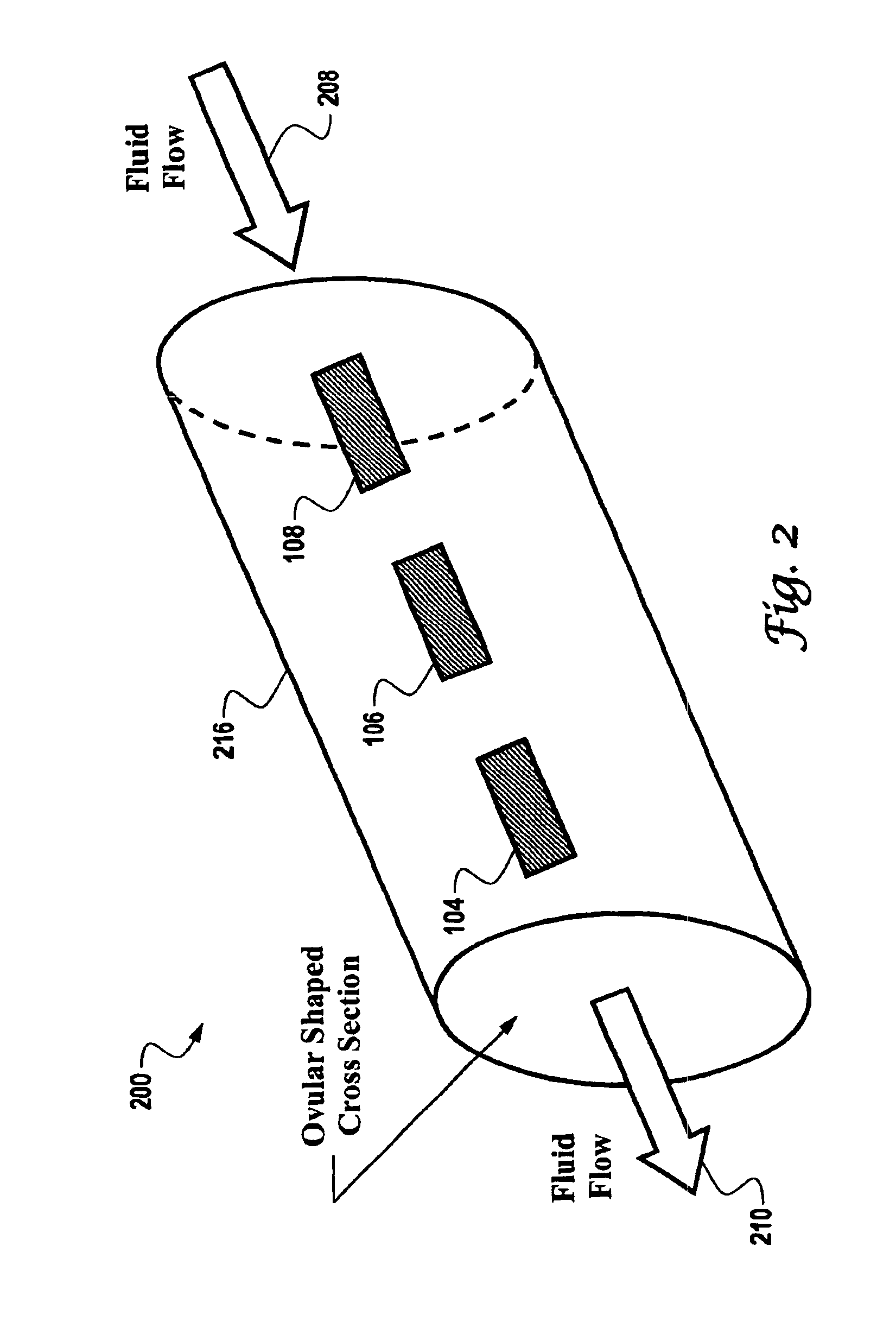

Liquid flow sensor thermal interface methods and systems

ActiveUS6871537B1Easy to measureMaterial thermal conductivityVolume/mass flow by thermal effectsEngineeringThermal conductivity

A sensor method and system are disclosed. A fluid flow sensor can be provided, which measures the thermal conductivity of a fluid. The sensor itself can be configured to comprise one or more sensing element associated with a sensor substrate. A heater can be associated with said sensor wherein said heater provides heat to said fluid. A film component can also be provided that that isolates said fluid from said heater and said sensor, such that said film component conducts heat in a direction from said heater to said sensor, thereby forming a thermal coupling between said sensor, said heater and said fluid, which permits said sensor to determine a composition of said fluid by measuring thermal conductivity thereof without undesired losses of heat in other directions. The film component can be configured on or in the shape of a tubing or a flow channel.

Owner:HONEYWELL INT INC

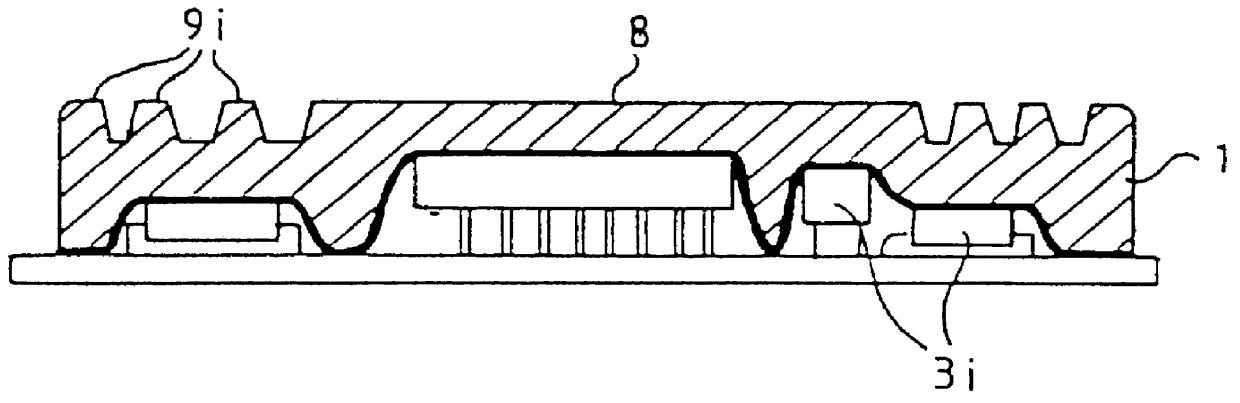

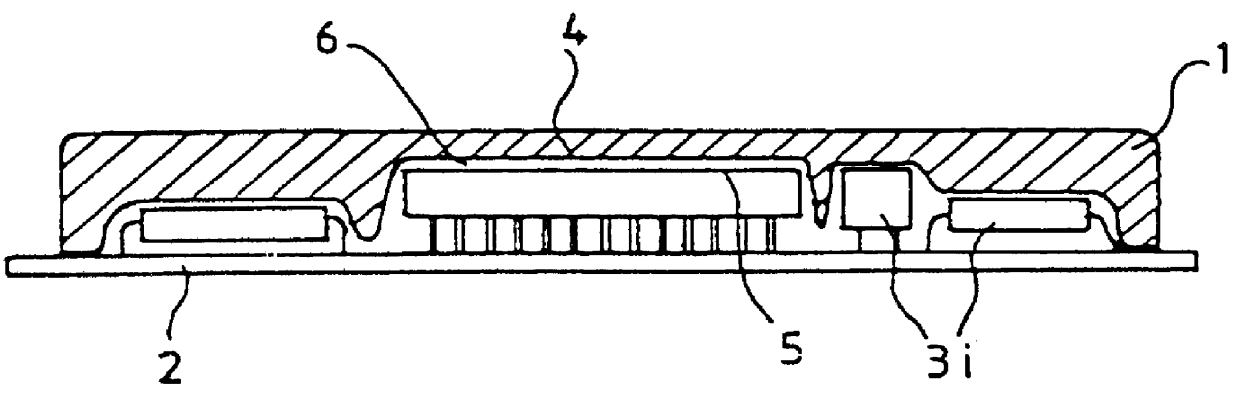

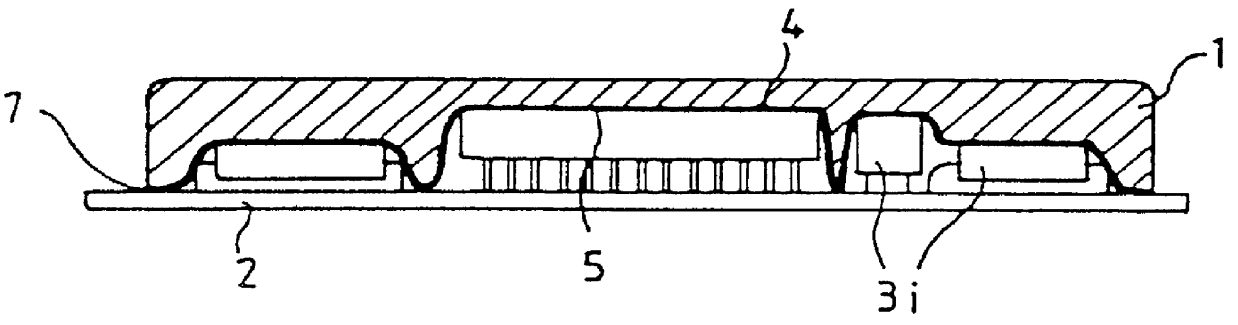

Method for fabricating an electronics board with thermal-conduction cooling

InactiveUS6035524APrinted circuit assemblingSemiconductor/solid-state device detailsEngineeringElectronic board

PCT No. PCT / FR96 / 00150 Sec. 371 Date Aug. 21, 1997 Sec. 102(e) Date Aug. 21, 1997 PCT Filed Jan. 30, 1996 PCT Pub. No. WO96 / 26631 PCT Pub. Date Aug. 29, 1996Method for fabricating thermally cooled electronic cards. A card of any kind is covered with a rigid heat sink shaped to fit the card and is attached thereto. The heat sink is formed in such a way that it fits as closely as possible the shape of the printed circuit. The printed circuit has components on one or both faces so that it is possible to increase the surface thermal coupling between the sink and the board. An optical sensor using a laser beam may be used.

Owner:THOMSON CSF SA

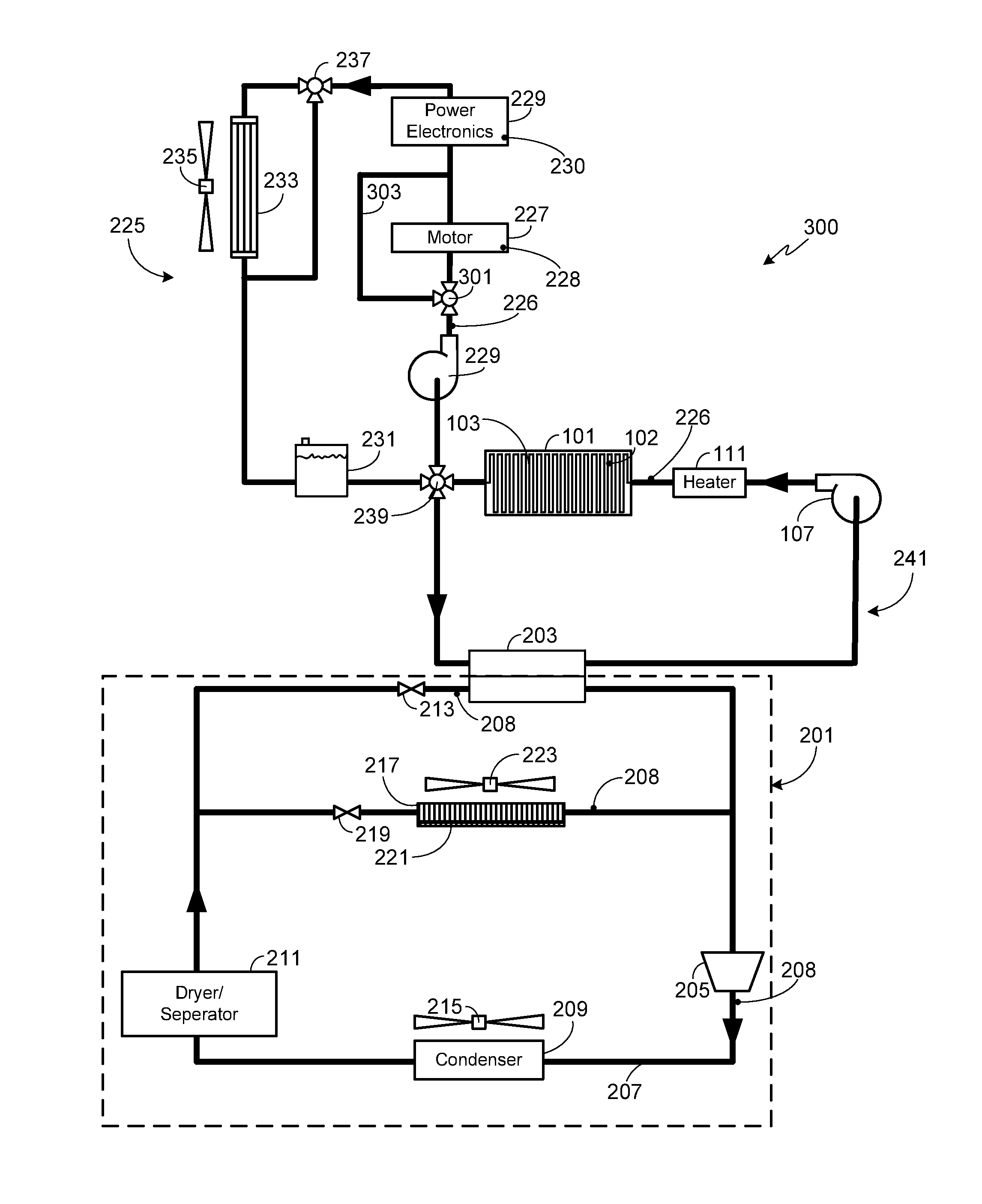

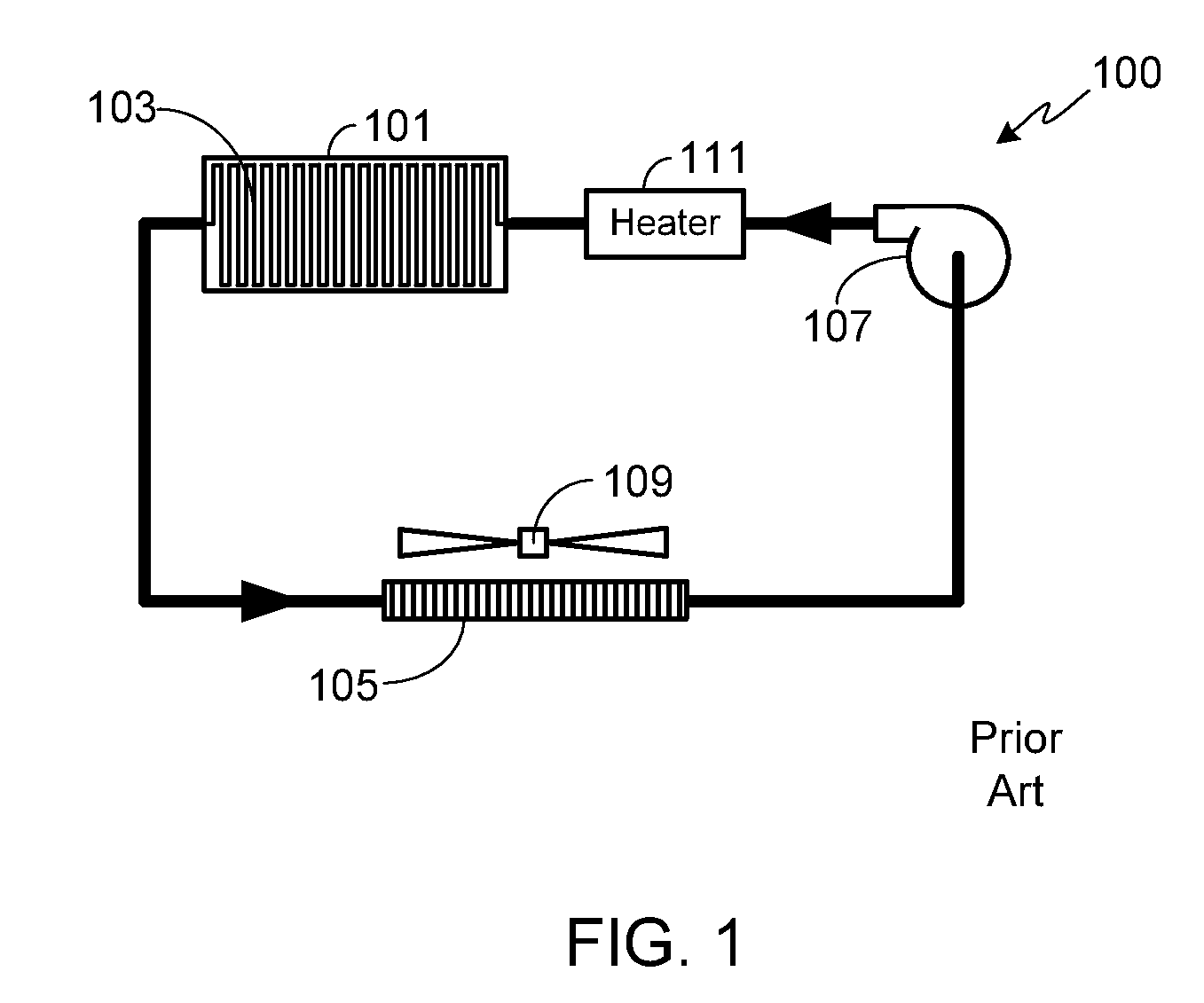

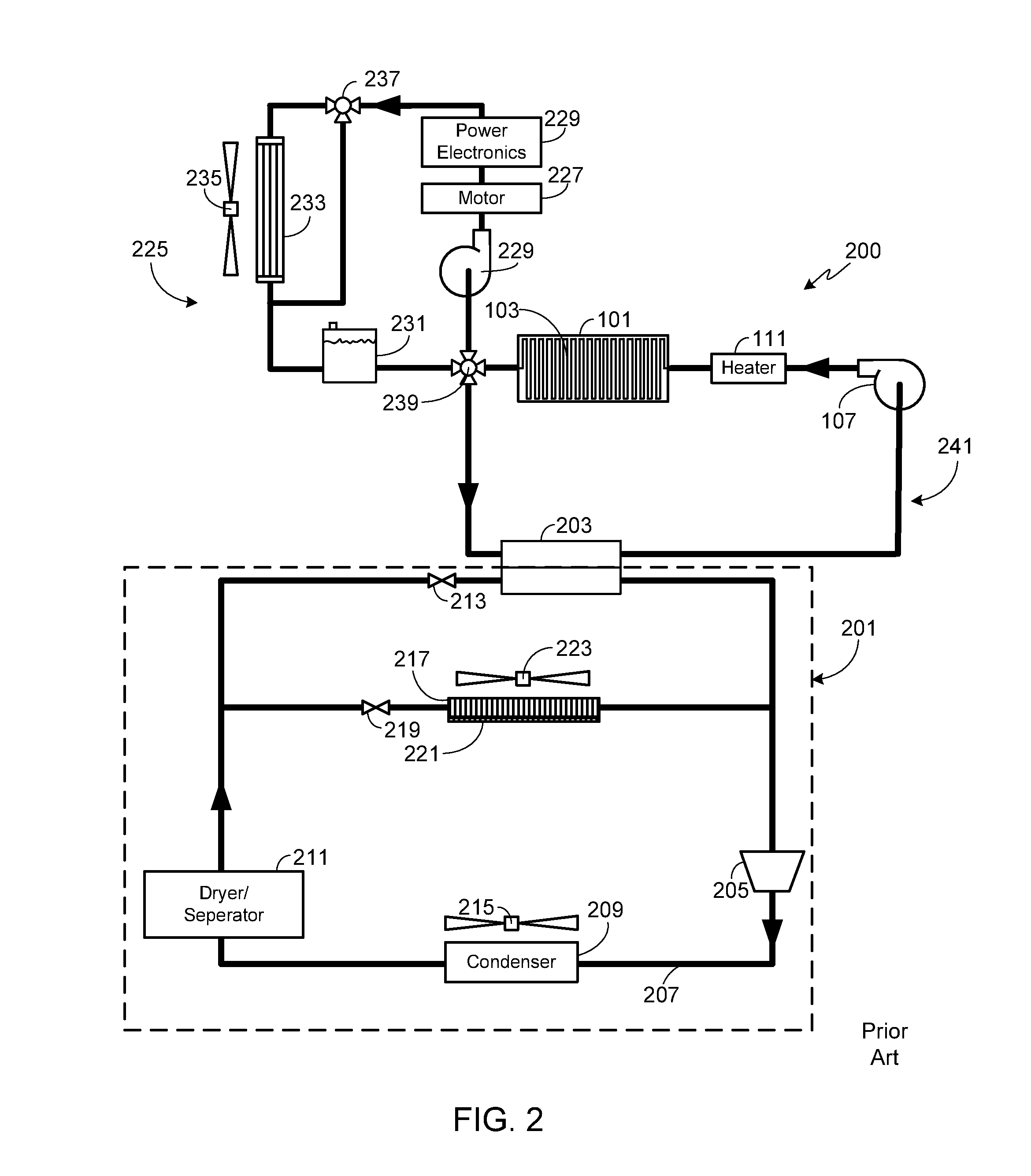

EV Muti-Mode Thermal Control System

ActiveUS20160318370A1Efficient thermal controlAir-treating devicesElectric devicesControl systemThermal management system

A thermal management system that utilizes a multi-mode valve assembly within the drive train control loop to provide efficient thermal control of the drive train components is provided. The multi-mode valve assembly allows the mode of thermal coupling between the thermal control loop and the various drive train components (e.g., vehicle propulsion motor, gearbox assembly, power electronics subsystem, etc.) to be varied in accordance with present conditions.

Owner:ATIEVA USA INC

Sulfonated perfluorocyclobutane block copolymers and proton conductive polymer membranes

A sulfonated aromatic perfluorocyclobutane block copolymer comprises a hydrophobic perfluorocyclobutane ether chain segment and a hydrophilic sulfonated perfluorocyclobutane ether chain segment. The sulfonated perfluorocyclobutane copolymer may be used to make proton conductive membranes and membrane electrode assemblies in fuel cells. Processes of making the block copolymer through thermal coupling reactions are also disclosed.

Owner:GM GLOBAL TECH OPERATIONS LLC

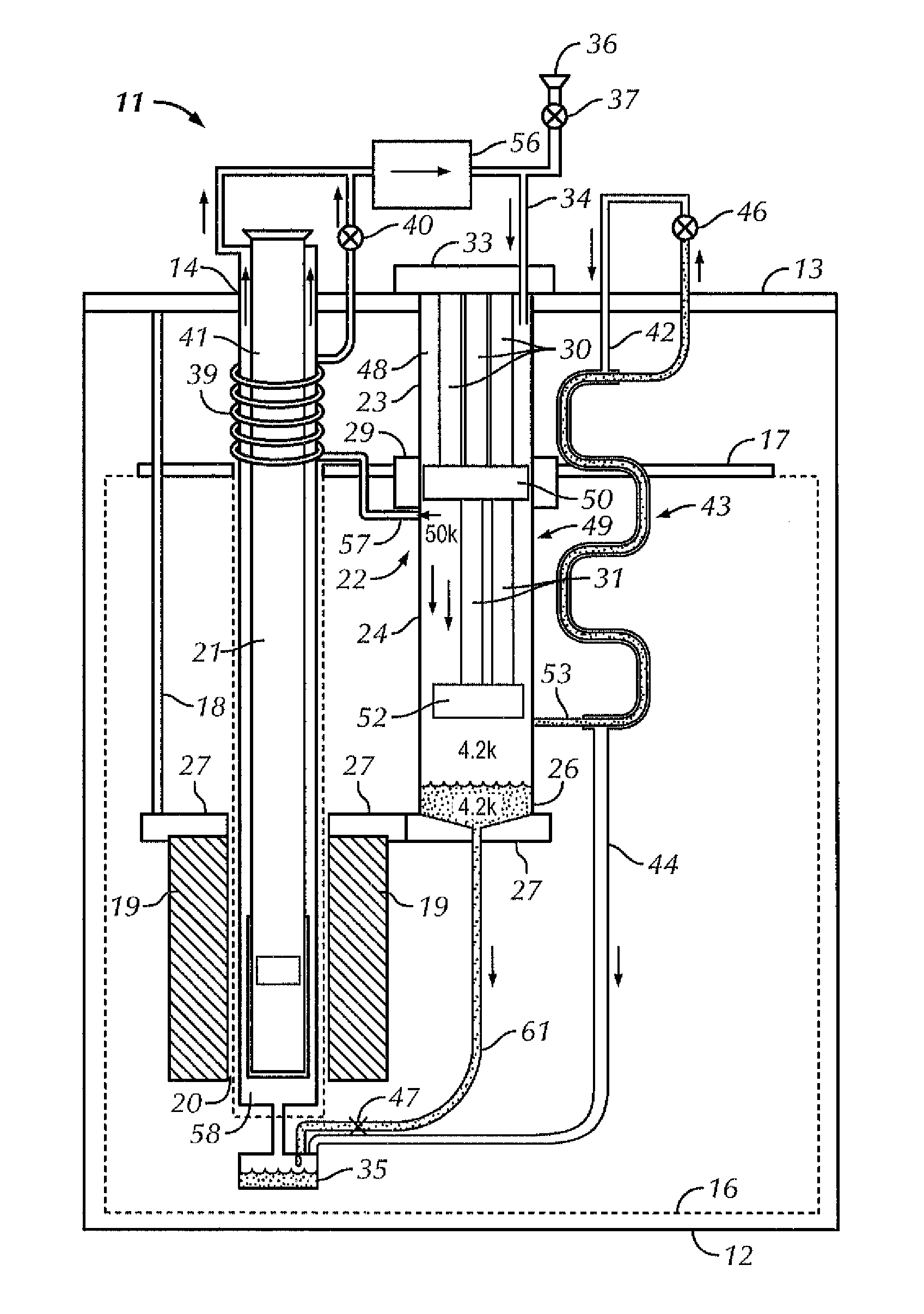

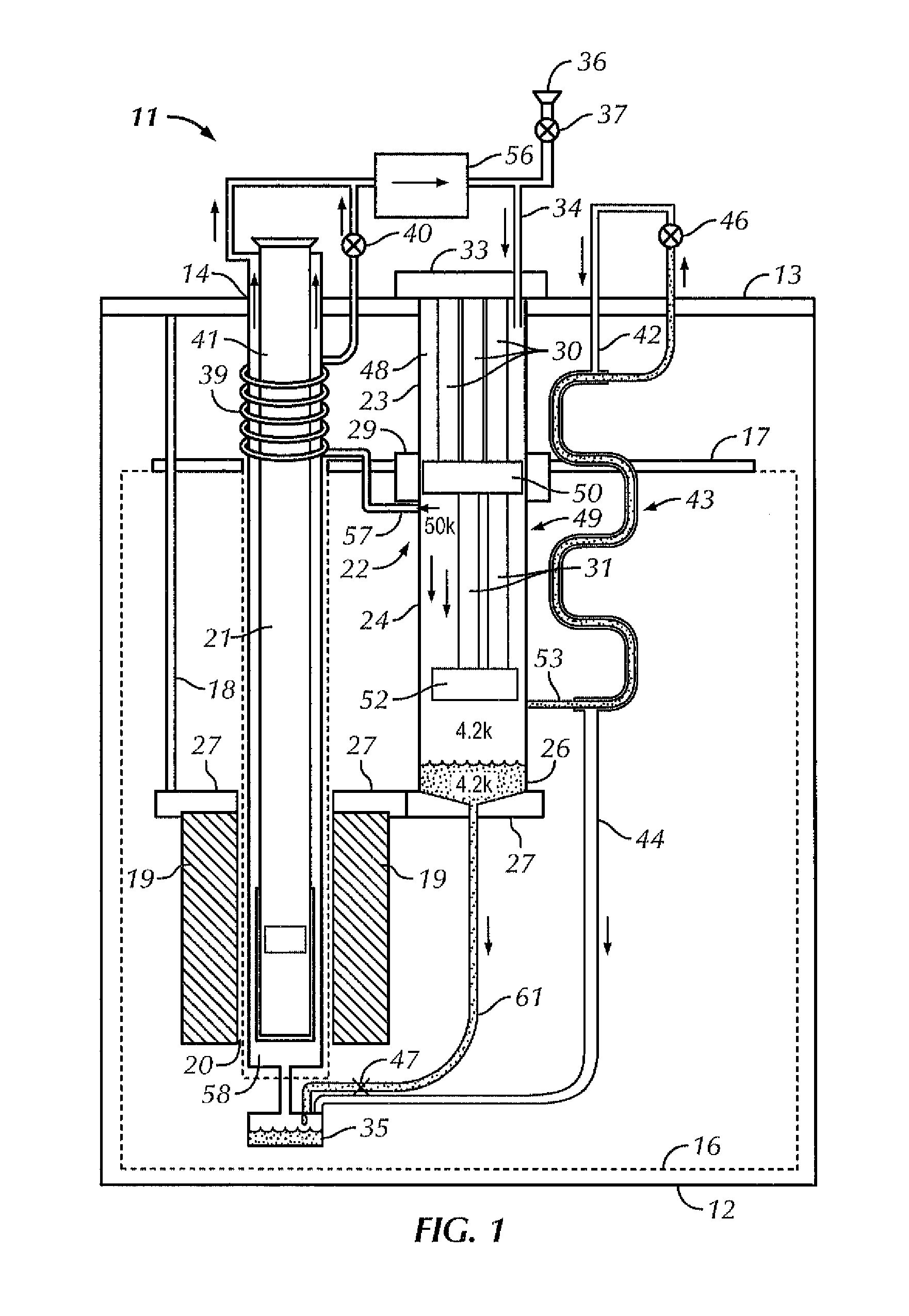

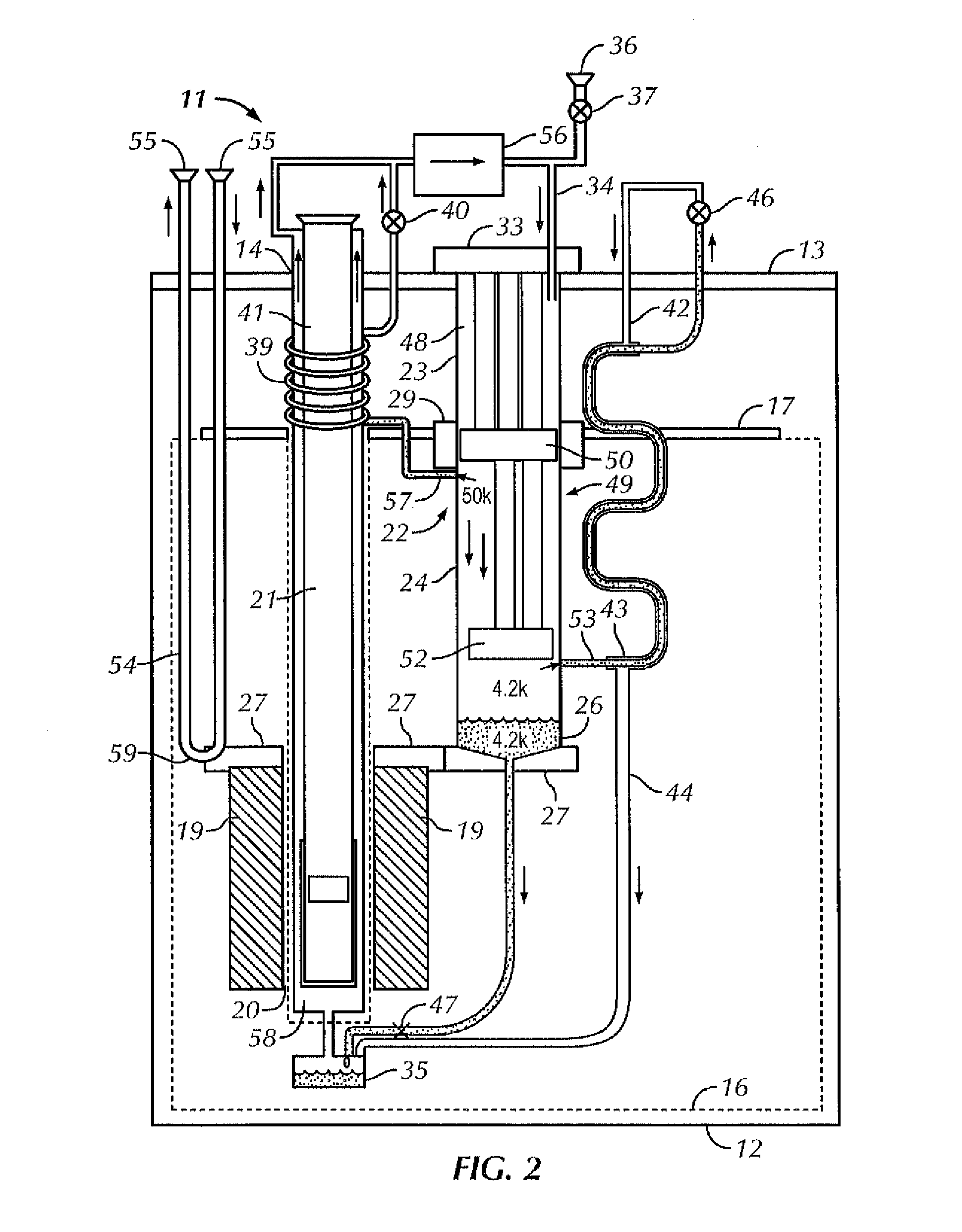

Method and apparatus for controlling temperature in a cryocooled cryostat using static and moving gas

ActiveUS20110219785A1Rapid initial cool-downMinimal, if any, helium replenishmentSolidificationLiquefactionCounter flowTemperature conditioning

A cryostat for providing temperature regulation, one purpose being measuring physical properties of materials, the cryostat employing a superconducting magnet assembly for generating variable magnetic field in the sample space and a cryogenic cooler for cooling the sample space. The cryogenic cooler chamber configuration provides for efficient heat exchange between different stages of the cryogenic cooler without the need for physical heat links. This construction enables selective delivery of cooling power from the cryogenic cooler to the desired areas within the cryostat without using flexible physical thermal links. A counter flow exchanger and ambient temperature valves facilitate efficient use of the cryogenic cooler stages. The removal of large heat load generated by the superconducting magnet while operating in the sweeping mode is achieved, in part, by employing a solid plate thermal coupling element between the cryogenic cooler chamber and the magnet assembly.

Owner:QUANTUM DESIGN

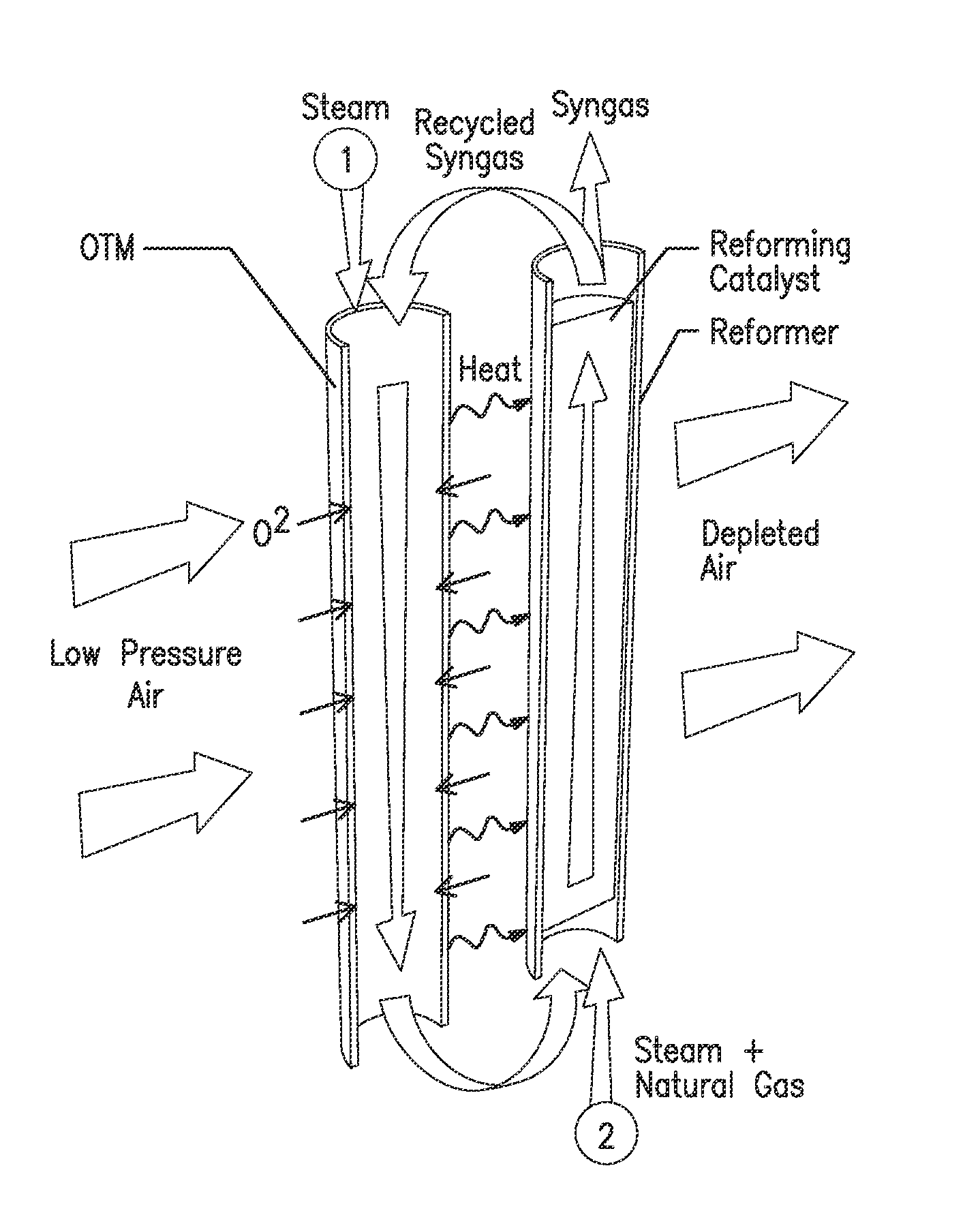

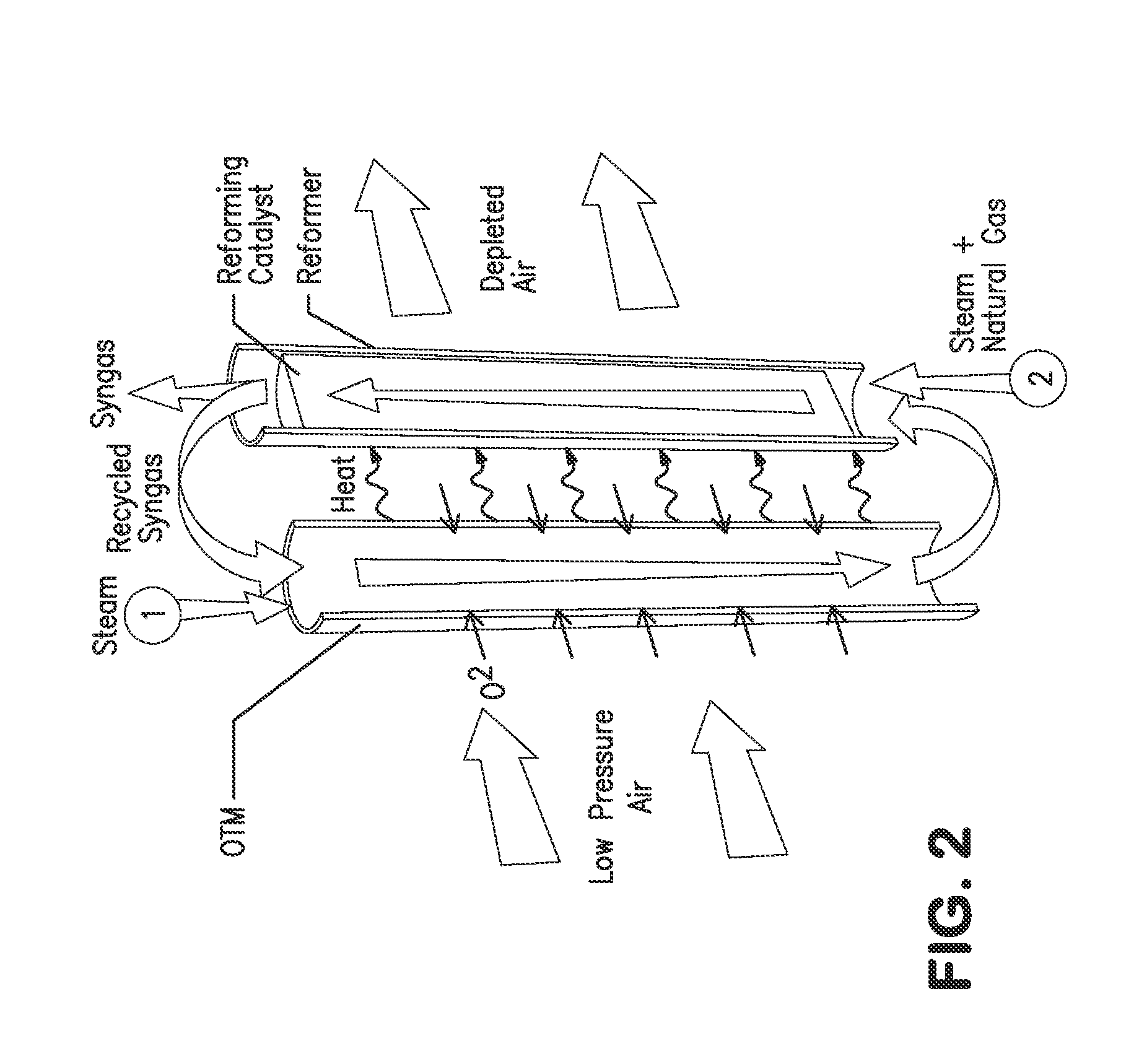

Ceramic oxygen transport membrane array reactor and reforming method

A commercially viable modular ceramic oxygen transport membrane reforming reactor for producing a synthesis gas that improves the thermal coupling of reactively-driven oxygen transport membrane tubes and catalyst reforming tubes required to efficiently and effectively produce synthesis gas.

Owner:PRAXAIR TECH INC

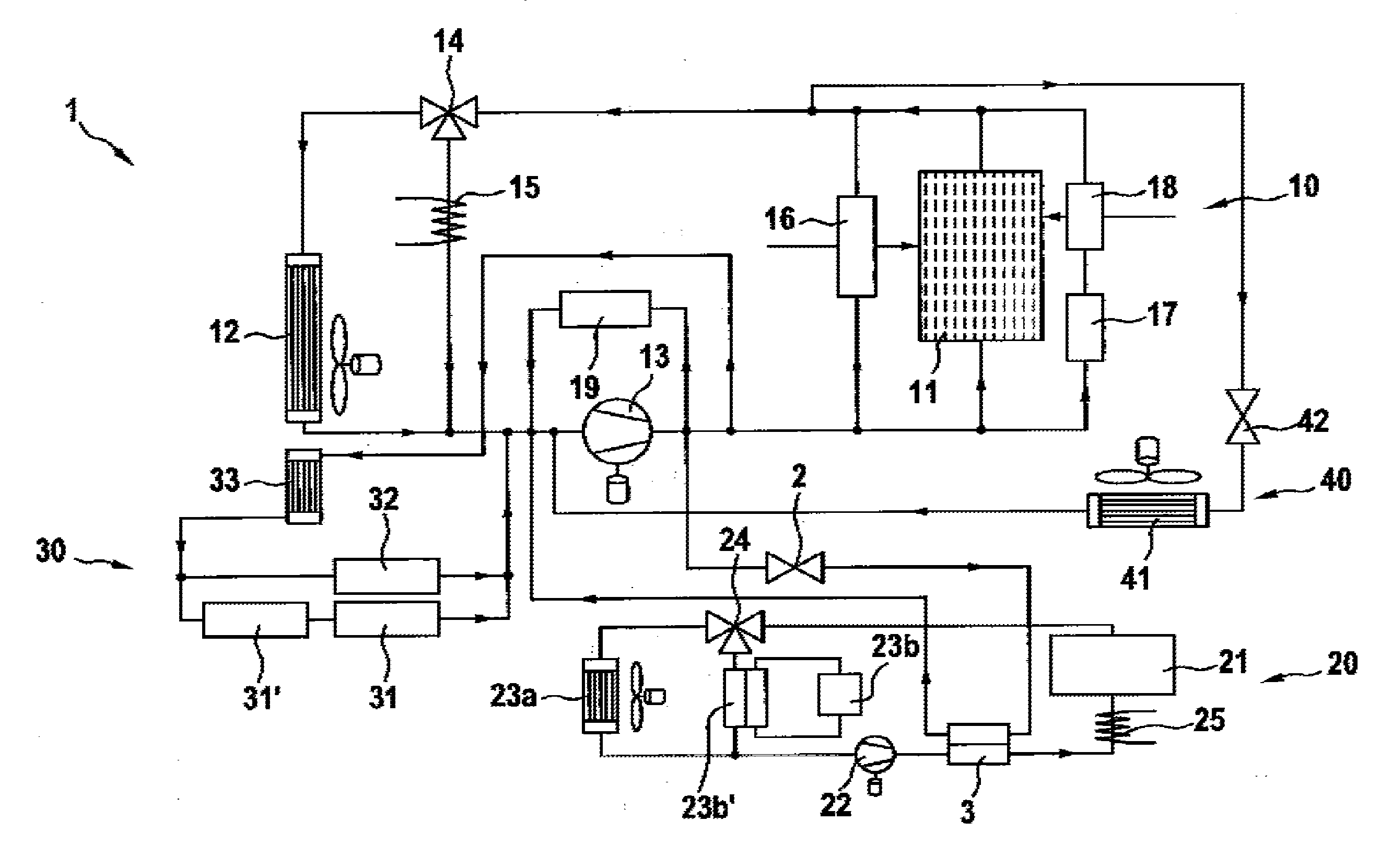

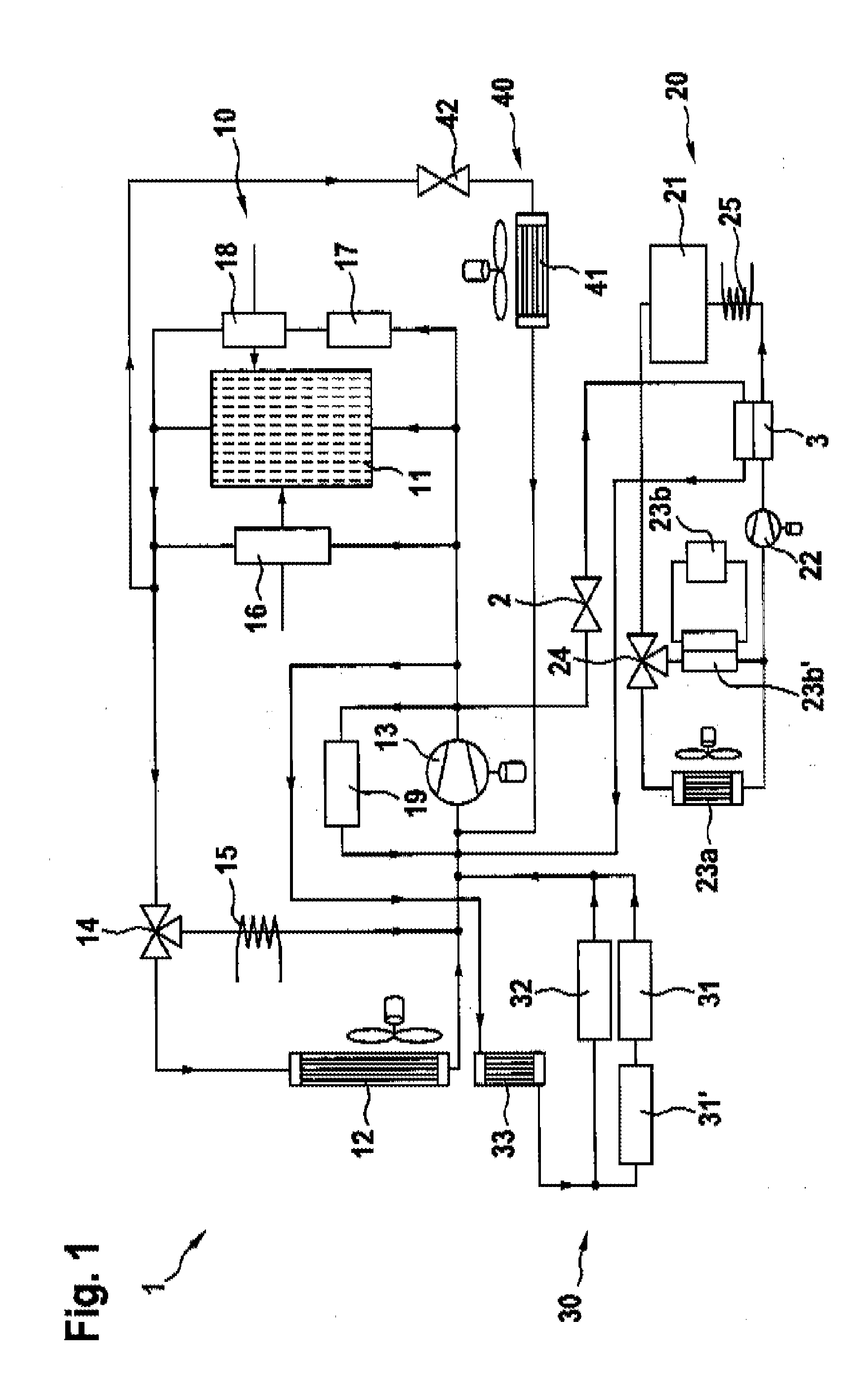

Fuel cell cooling system with coupling out of heat

ActiveUS20130022888A1Reduce loadIncrease capacityFuel cell heat exchangeCell temperature controlThermal energyFuel cells

A cooling system (1) for a fuel cell system (11), in particular for a vehicle, which comprises a fuel cell cooling circuit (10) for cooling the fuel cell system (11), and a battery cooling circuit (20) for cooling a battery (21), with an exchange of thermal energy between the fuel cell cooling circuit (10) and the battery cooling circuit (20).

Owner:ROBERT BOSCH GMBH

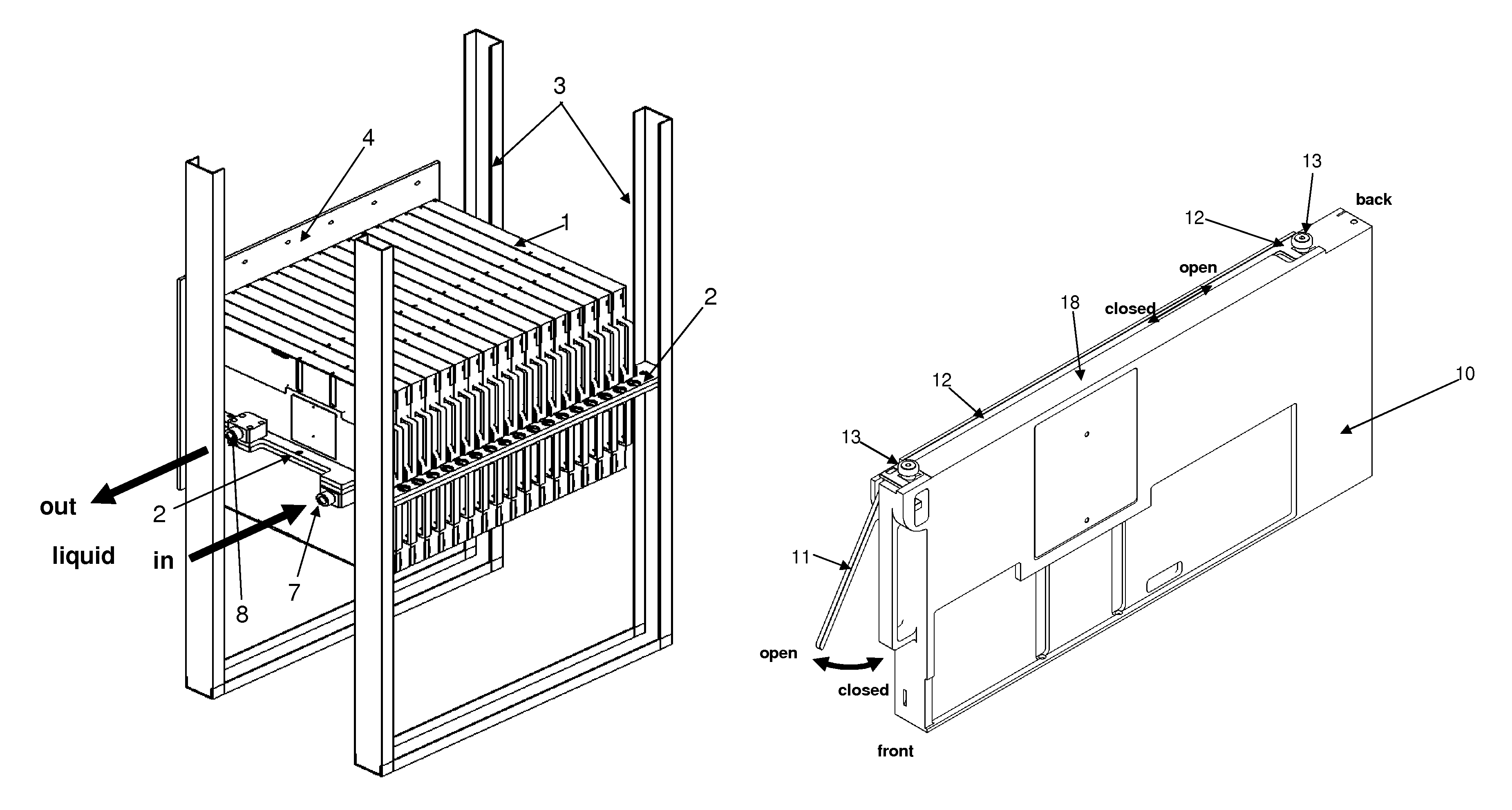

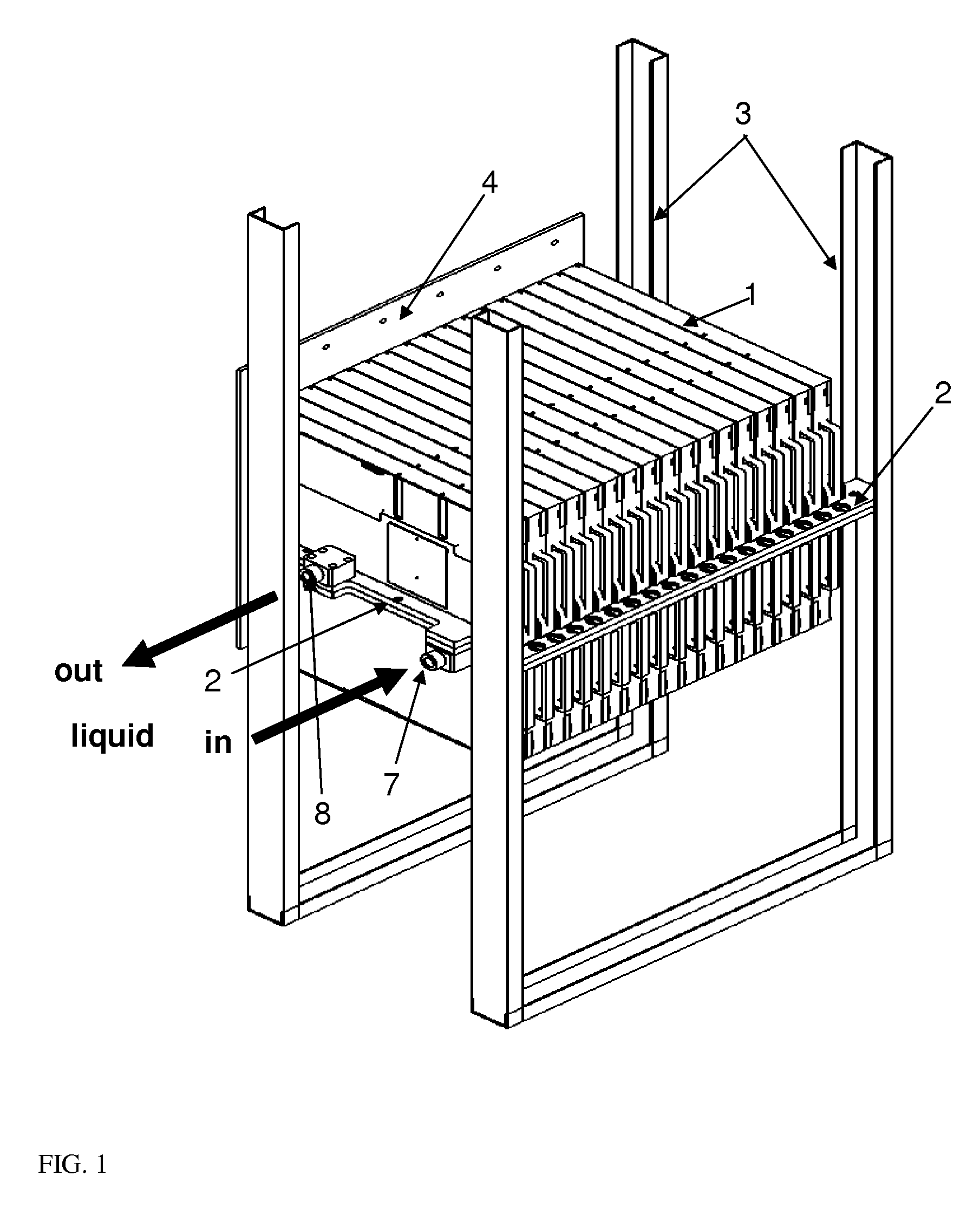

Low cost liquid cooling

InactiveUS7961465B2Good thermal couplingAchieve couplingDigital data processing detailsSemiconductor/solid-state device detailsEngineeringElectronic component

A system for cooling processor assembly is disclosed which comprises printed circuit boards (PCB) with a plurality of heat emitting electronic components, and a housing for each PCB with a heat sink covering at least partly the heat emitting electronic components. The housing comprises a base portion to which are transferred heat emitted by the electronic components. Furthermore, the system for cooling processor comprises a cooling plate on which are fixed in series the different PCBs by directly positioning the base portion of the housings onto the cooling plate. The housings for each PCB system include at their base portions clamps to be inserted into corresponding guiding holes of the cooling plate when a PCB together with its housing is positioned onto the cooling plate at a specific therefor dedicated place defined by the guiding holes. Advantageously, the PCB together with its housing is pressed against the cooling plate alongside the base portion when fixed onto the cooling plate allowing thermal coupling between the housing and the cooling plate and a hot plugging of the PCB onto the cooling plate without requiring interrupting the cooling process applied to the cooling plate.

Owner:IBM CORP

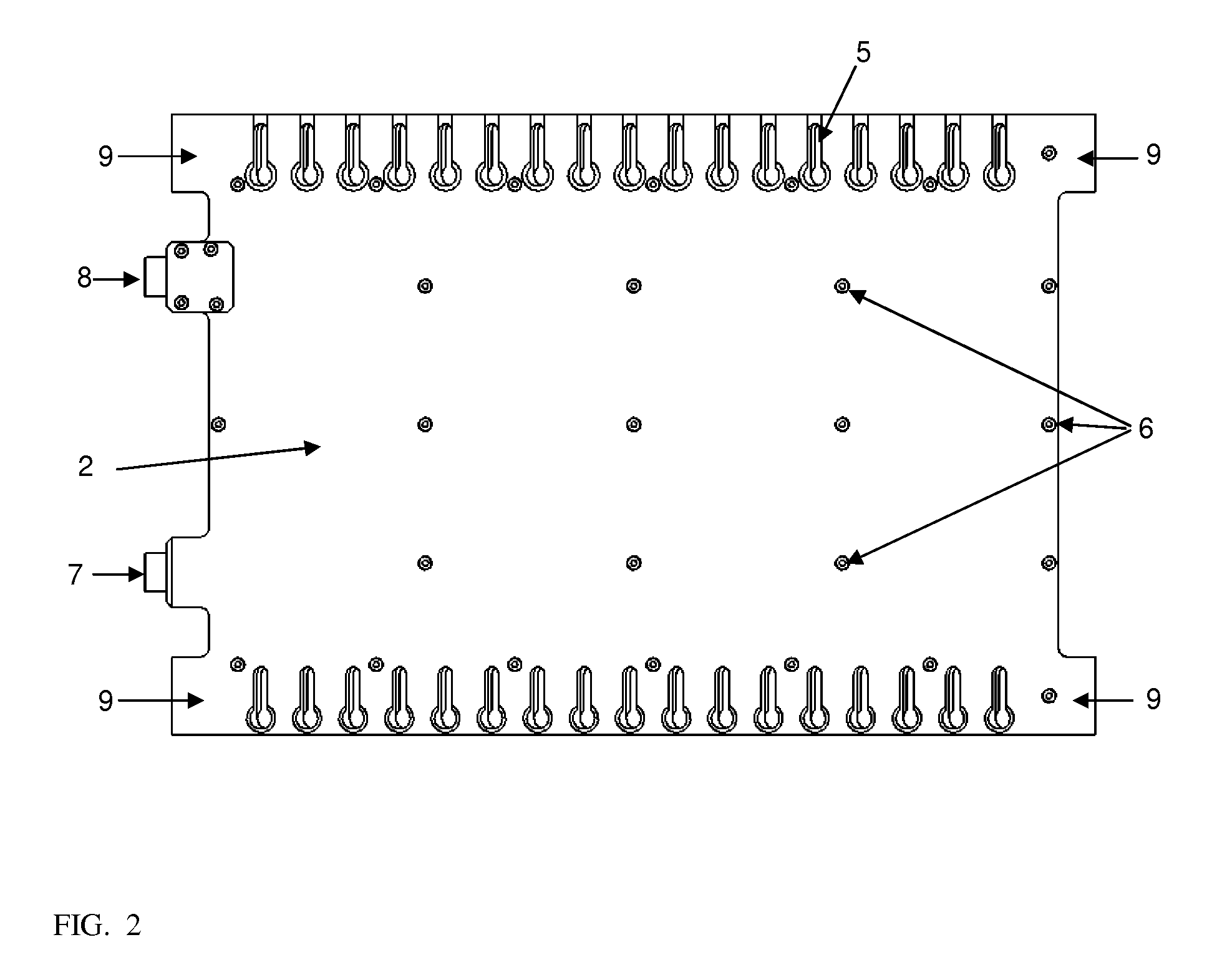

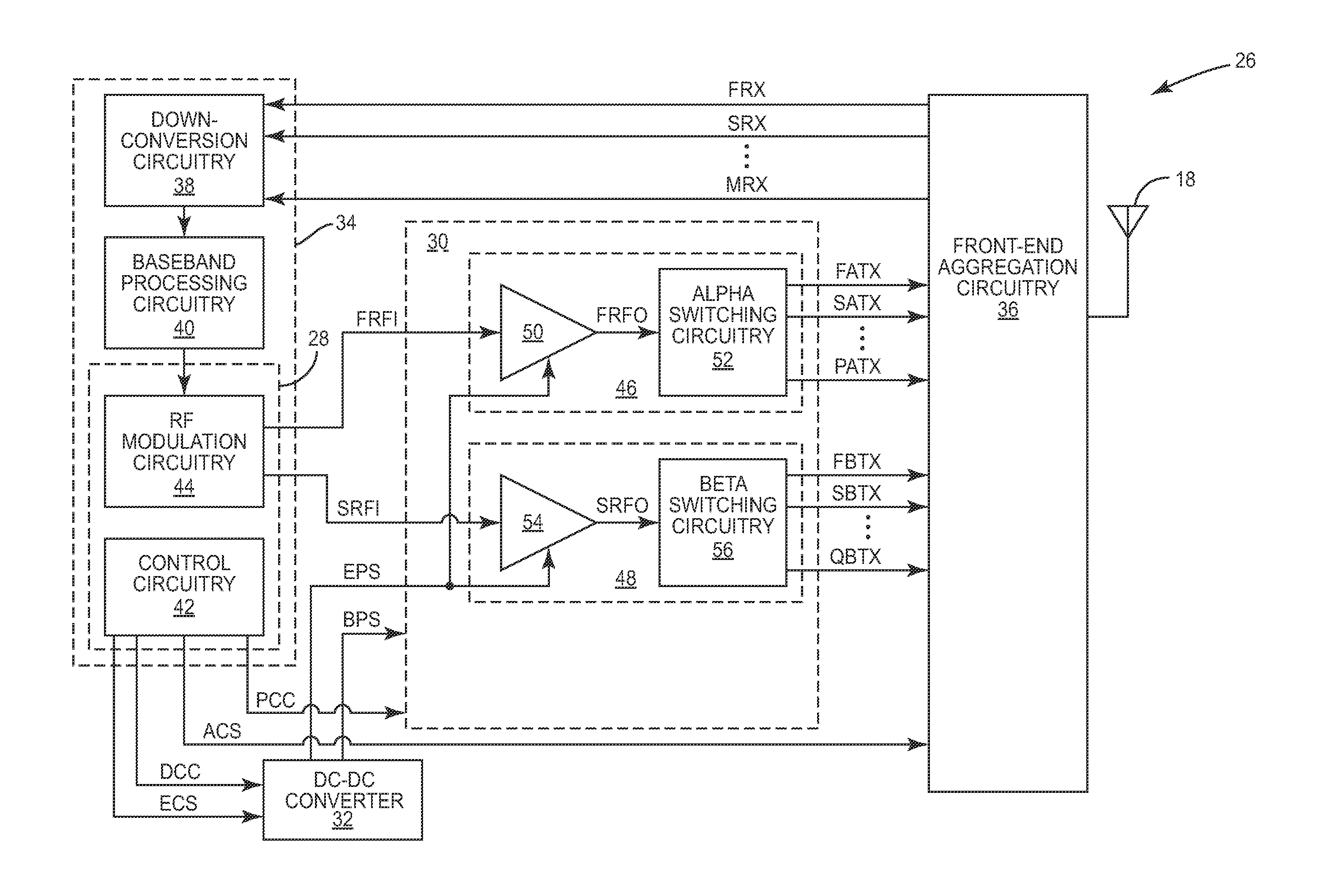

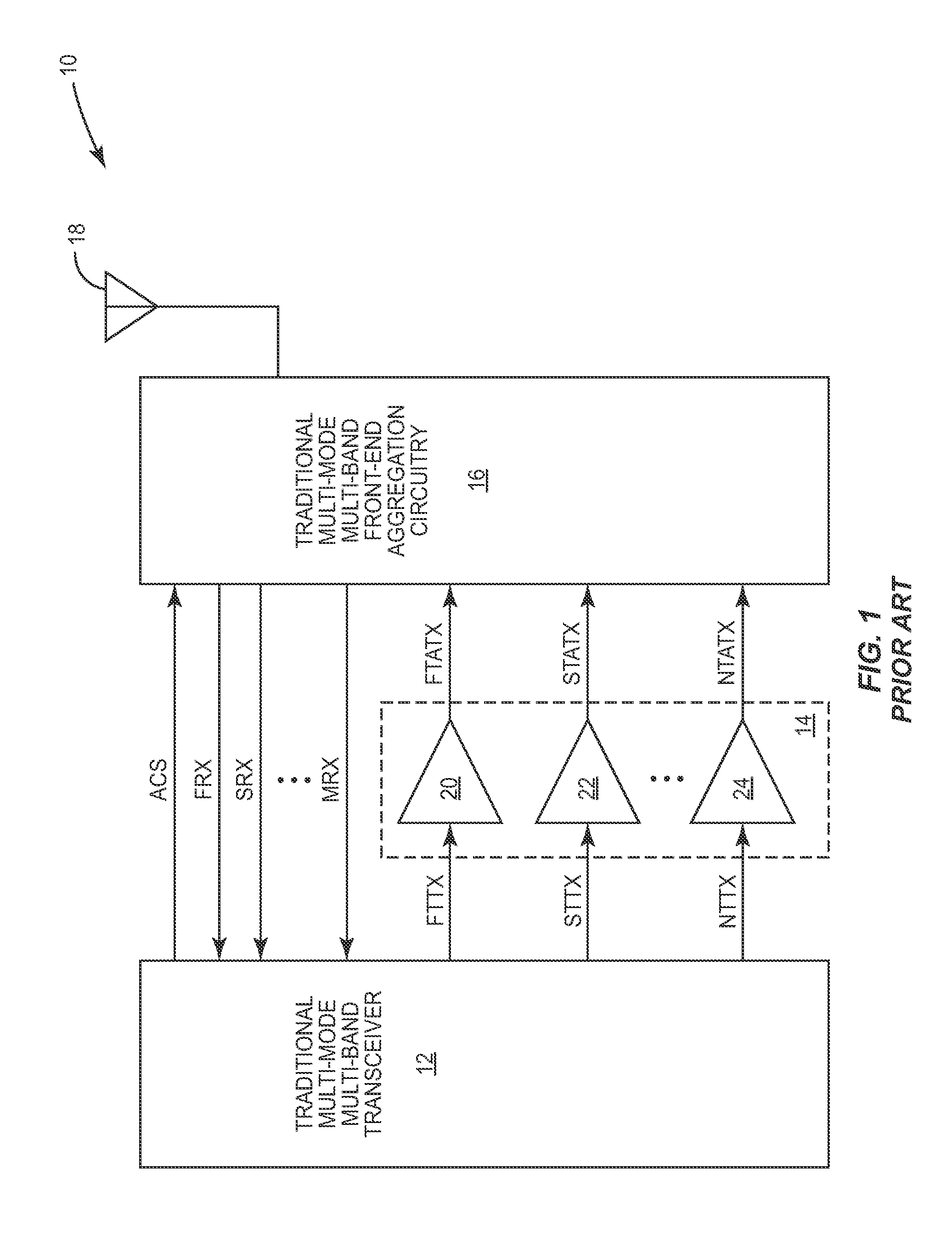

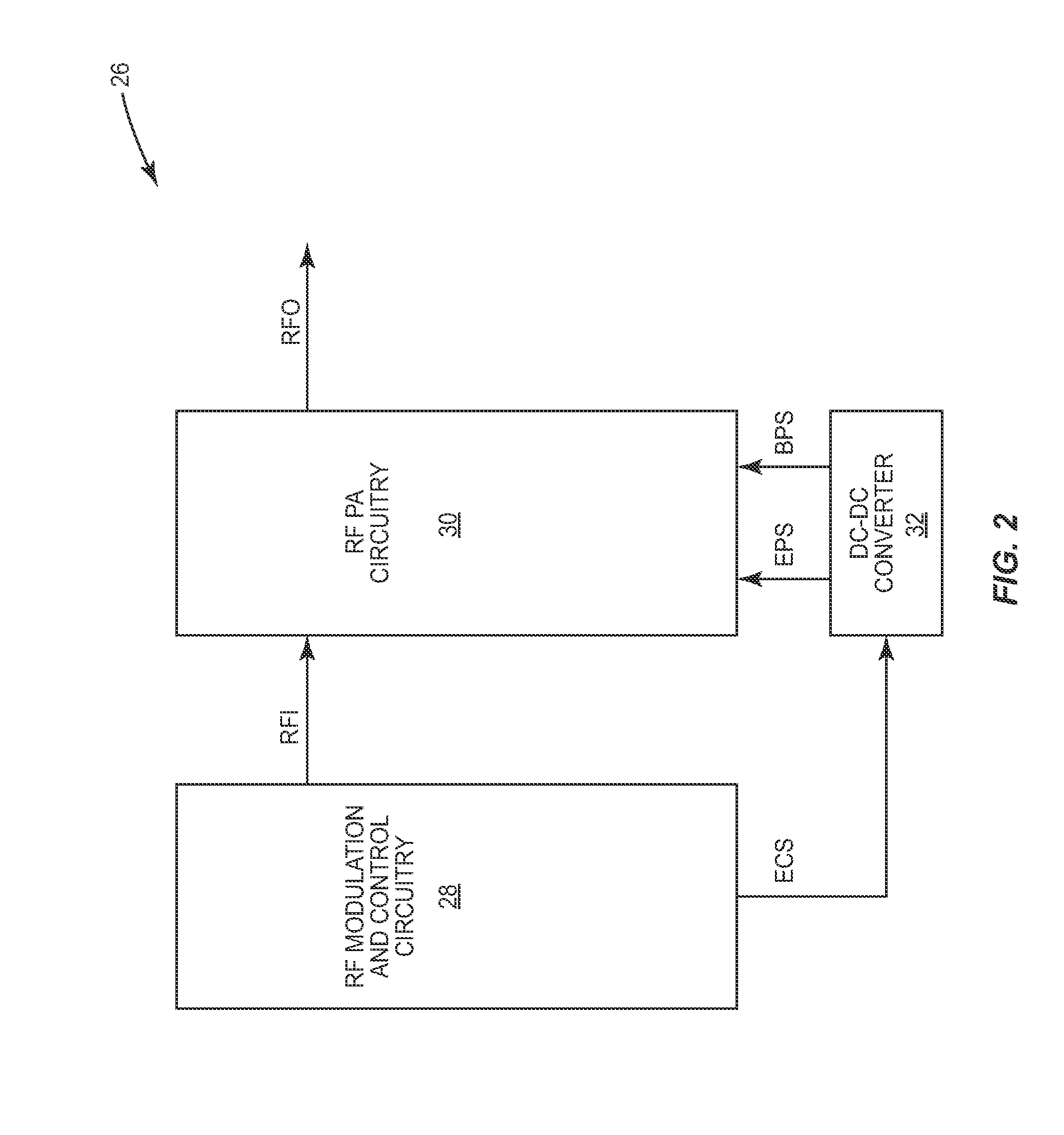

Temperature correcting an envelope power supply signal for RF pa circuitry

A direct current (DC)-DC converter and radio frequency (RF) power amplifier (PA) circuitry are disclosed. The DC-DC converter provides an envelope power supply signal to the RF PA circuitry based on a first power supply output control signal. As a temperature of the RF PA circuitry changes, the envelope power supply signal may need to be adjusted to meet temperature compensation requirements of the RF PA circuitry. With adequate thermal coupling between the DC-DC converter and the RF PA circuitry, adjustments to the envelope power supply signal may be based on temperature measurements of the DC-DC converter. A desired correction of the first power supply output control signal is determined based on a measured temperature of the DC-DC converter and the temperature compensation requirements of the RF PA circuitry. The first power supply output control signal is adjusted based on the desired correction.

Owner:QORVO US INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com