Power supply device and vehicle including the same

A power supply device and battery technology, applied in electric vehicles, vehicle components, circuits, etc., to achieve high reliability, prevent condensation, and eliminate gaps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

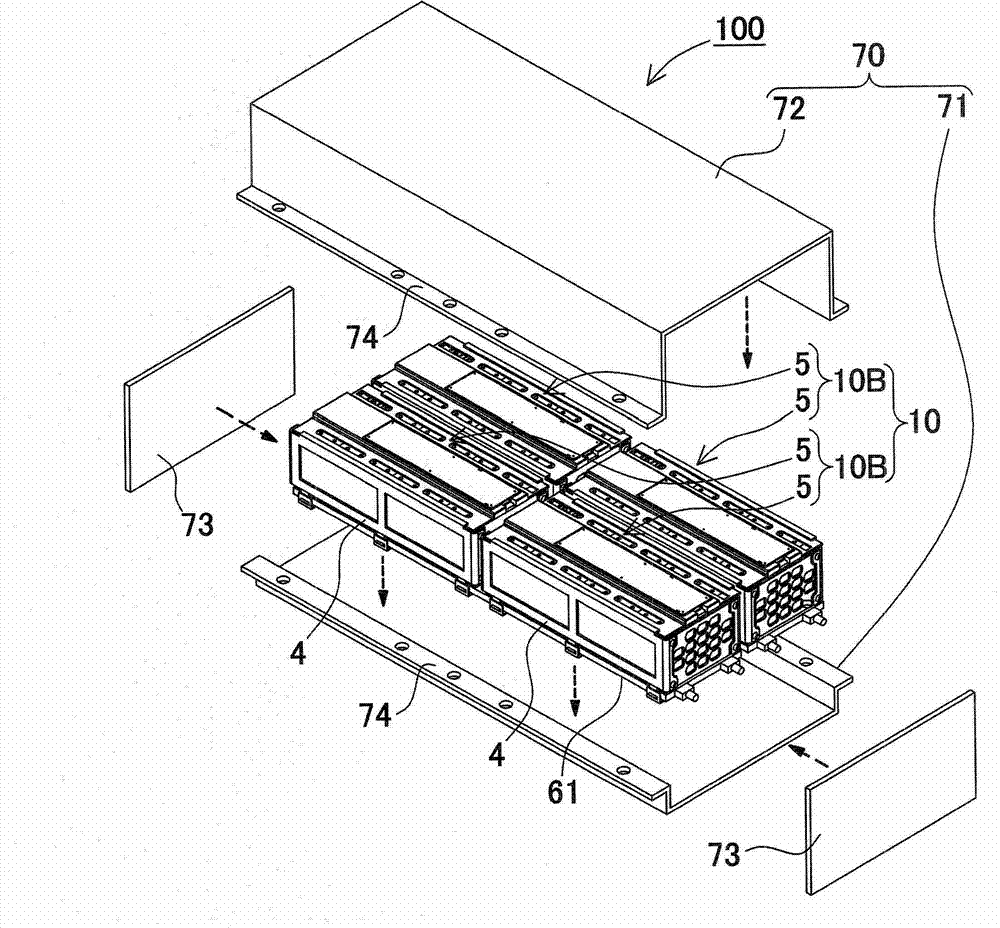

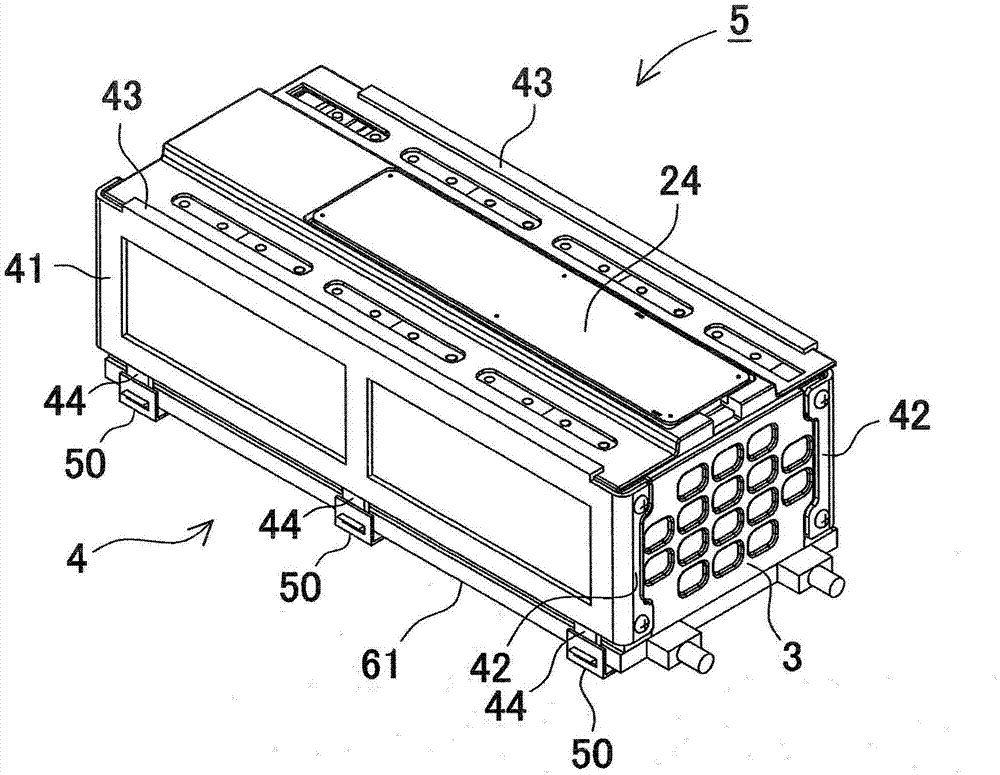

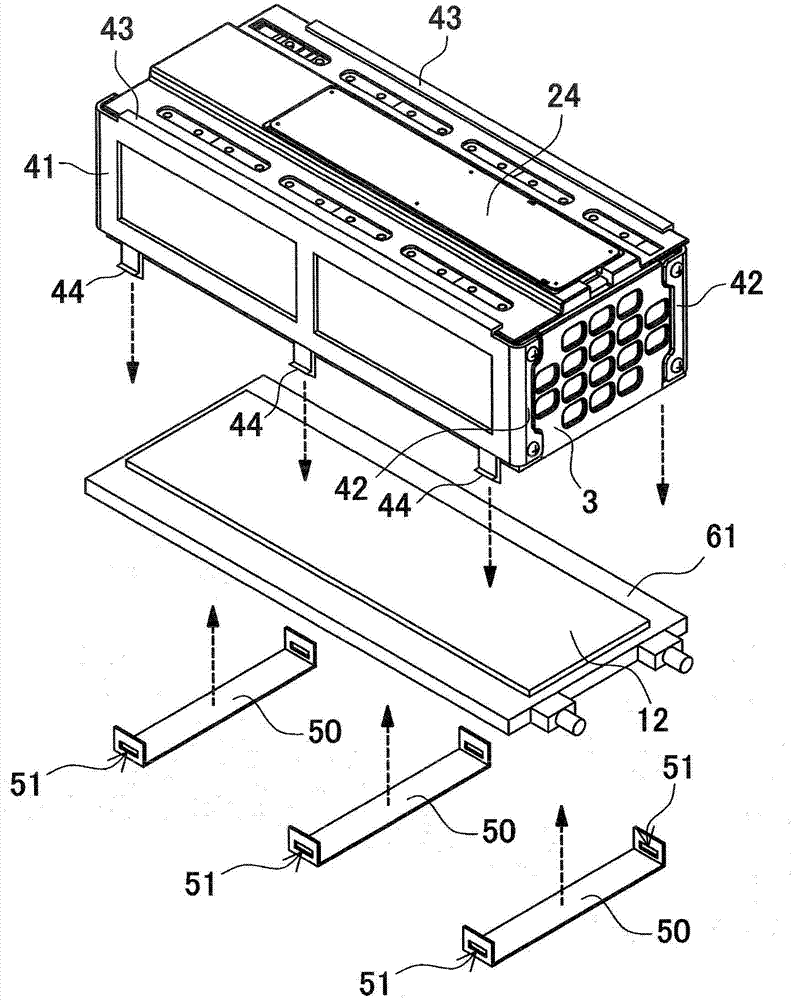

[0120] exist Figure 1 to Figure 13 Here, an example in which the power supply device 100 according to Embodiment 1 of the present invention is applied to a vehicle-mounted power supply device will be described. In the above figure, figure 1 is an exploded perspective view of the power supply device 100, figure 2 yes means figure 1 A perspective view of the battery stack 5, image 3 From figure 2 An exploded perspective view of the battery stack 5 with the cooling plate 61 removed, Figure 4 is viewed from obliquely below figure 2 The perspective view obtained from the battery stack 5, Figure 5 yes figure 2 An exploded perspective view of the battery stack 5 of Image 6 yes Figure 5 An exploded perspective view of the battery stack 5 of Figure 7 is a sectional view showing a power supply device according to a modified example, Figure 8 is a schematic cross-sectional view showing an example in which a water-absorbing sheet is disposed between the battery st...

Embodiment 2

[0163] As described above, by covering the case and the cooling plate and closing the battery stack 5 in an airtight state, circulation of air is blocked to avoid condensation of moisture in the air. In addition, not only the surface of the cover case can be formed into a waterproof structure, but also the surface of the battery stack can be covered with a filling layer to form a structure that fills the gap, thereby protecting the surface of the battery stack surrounded by the cover case from Affected by water droplets, etc. exist Figure 14 An example of a power supply device adopting such a structure is shown as Embodiment 2 in a cross-sectional view of . In the power supply device shown in the figure, a filling layer 18 is disposed between the battery stack 5 and the cover case 16 . That is, by filling the gap between the battery stack 5 and the cover case 16 with a filling material to form the filling layer 18 , it is possible to prevent moisture condensation in the air...

Embodiment 3

[0175] In addition, a part of the waterproof sheet 19 may be removed so that the thermally conductive sheet 12 is in direct contact with the battery stack 5 . exist Figure 15 Such an example is shown in Embodiment 3. The battery laminated body 5 shown in the figure is formed from Figure 17 In the state shown, the waterproof sheet 19 covering the bottom surface of the battery stack 5 is removed. The bottom surface of the battery stack 5 is exposed at the portion where the waterproof sheet 19 is removed, so the thermally conductive sheet 12 is pressed against this surface so that the battery stack 5 and the thermally conductive sheet 12 are directly in close contact with each other, thereby reducing thermal resistance and improving cooling performance through cooling. The plate 61 performs heat dissipation for heat dissipation. In addition, after curing of the filler, the surface of the battery stack 5 is already sealed except for the exposed portion, so the waterproof stru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com