Patents

Literature

430results about "Thermally actuated switches" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

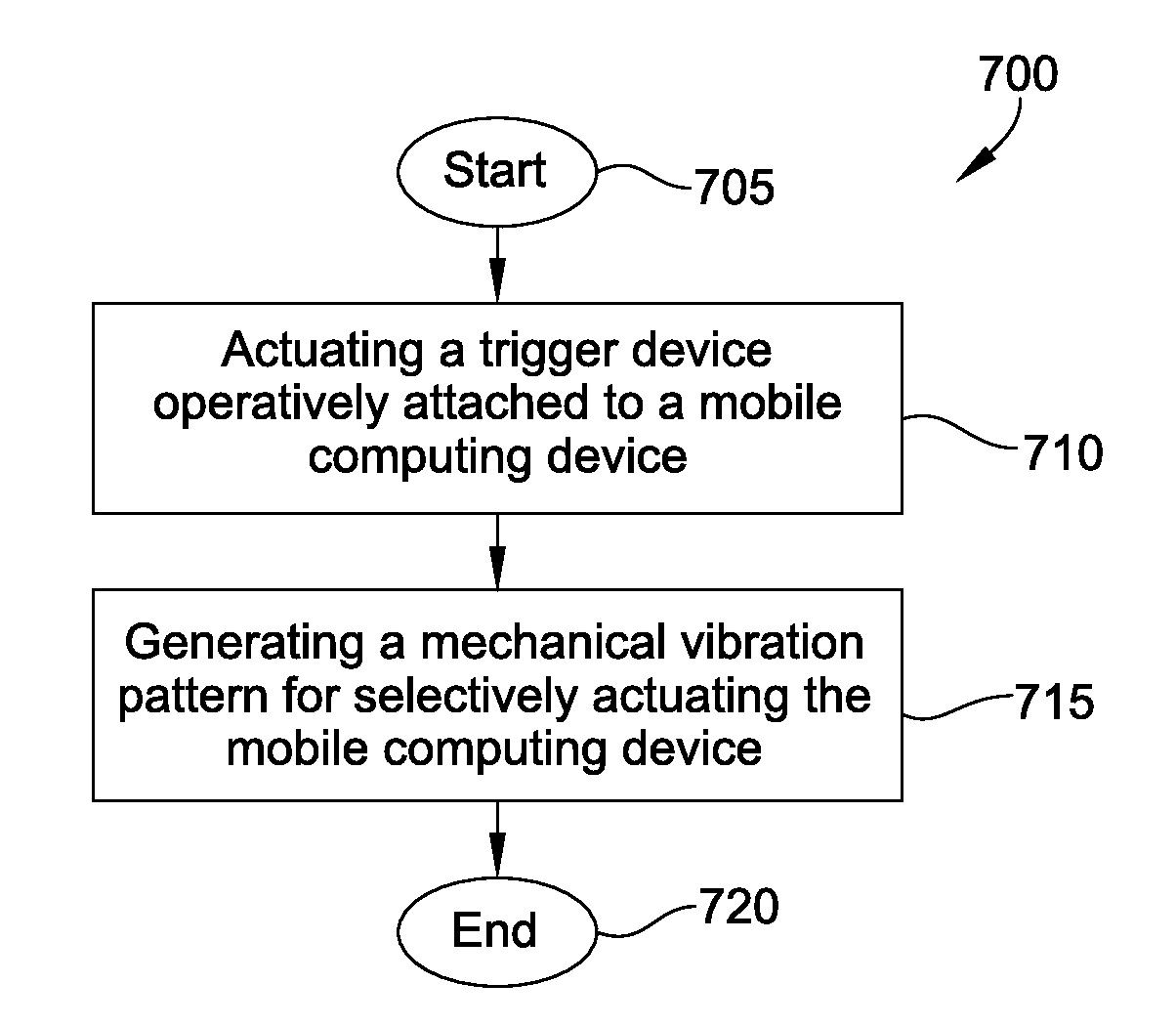

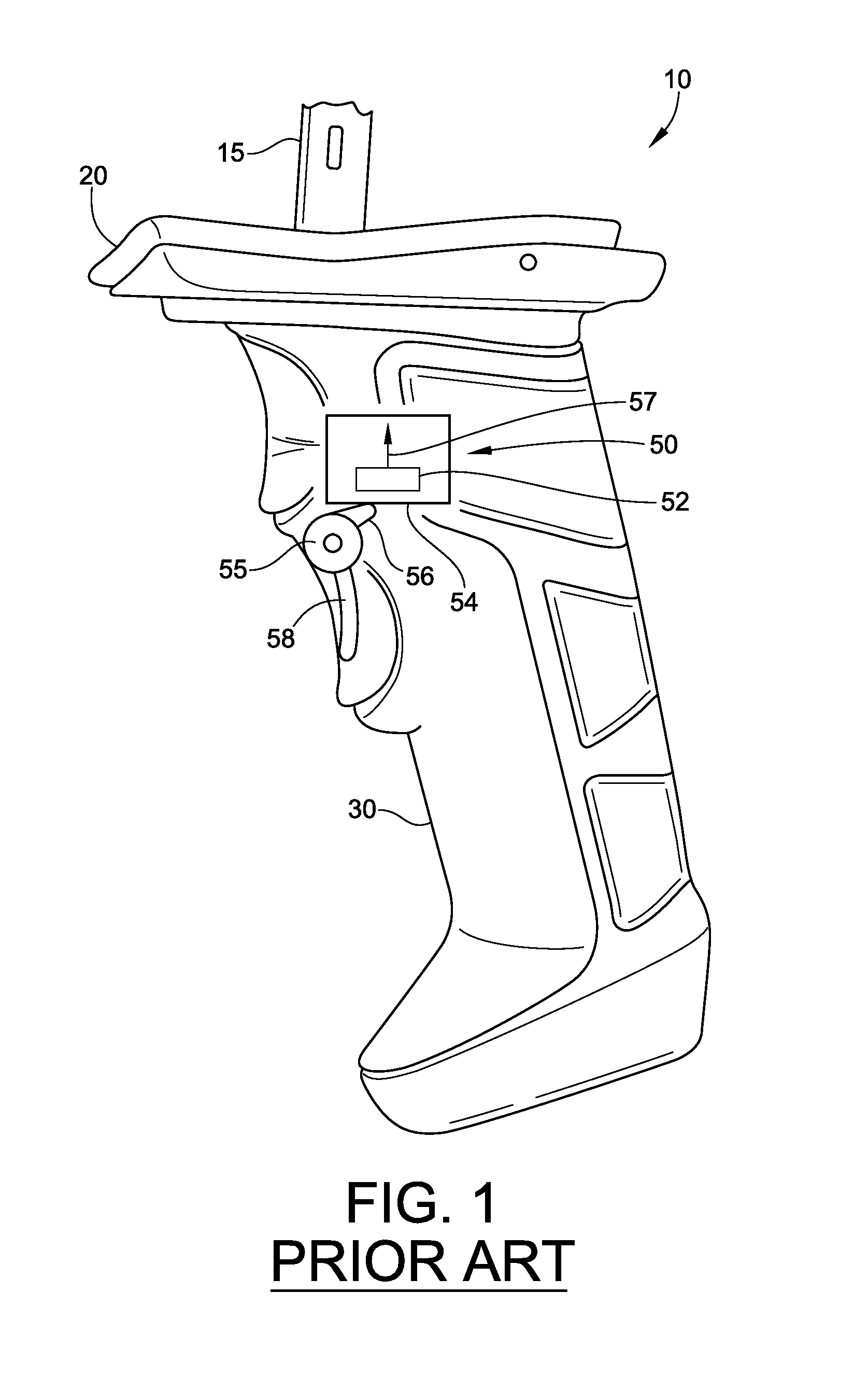

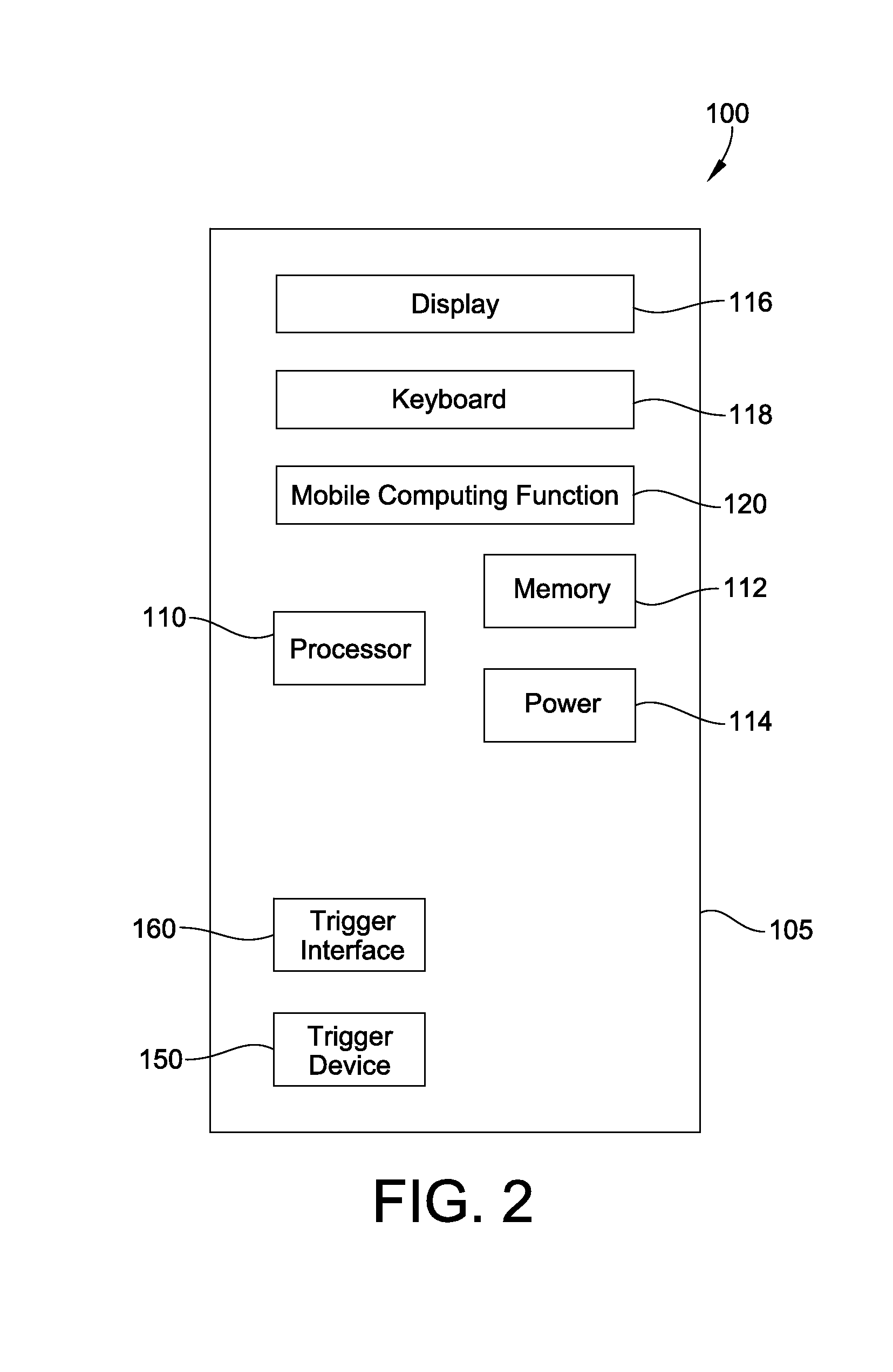

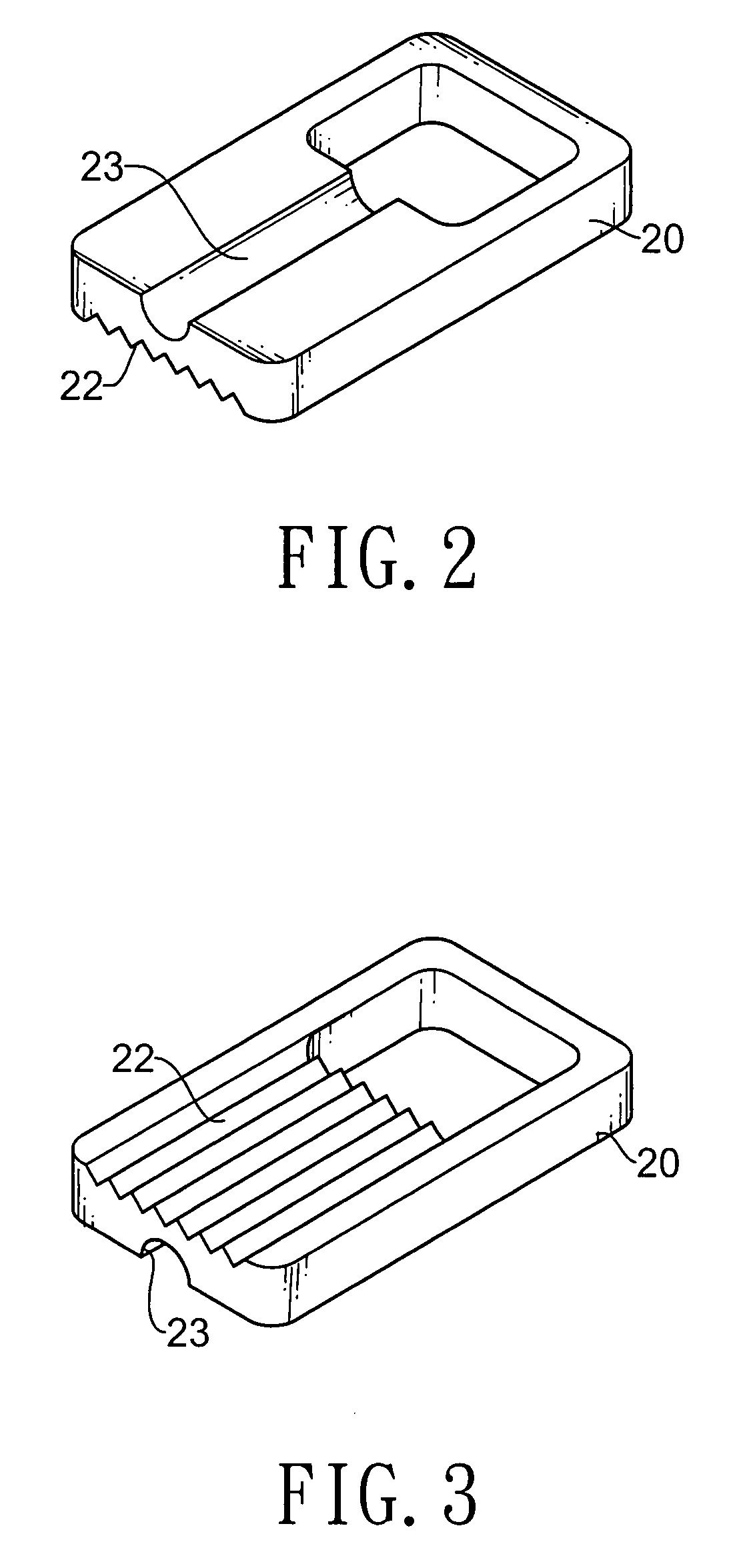

Trigger device for mobile computing device

InactiveUS20140049120A1Controlling membersManual control with multiple controlled membersAccelerometerComputer science

A mobile computing device includes a processor and a trigger device operatively attached to the mobile computing device and configured to generate a mechanical vibration pattern for selectively actuating the mobile computing device. A trigger interface, illustratively an accelerometer, is configured to convert the mechanical vibration pattern into an electrical signal pattern. The processor is configured to actuate a mobile computing function depending on the mechanical vibration pattern generated by the trigger device. A table of properties stored in memory correlates the mechanical vibration generated by the trigger device with a specific mobile computing function. The trigger device may include a plurality of trigger parts; and the mechanical vibration pattern generated by the trigger device may include multiple bits of data generated by the plurality of trigger parts. The mobile computing device may be in a candy bar, clam shell, or other form factor and may include a removable handle.

Owner:INTERMEC IP

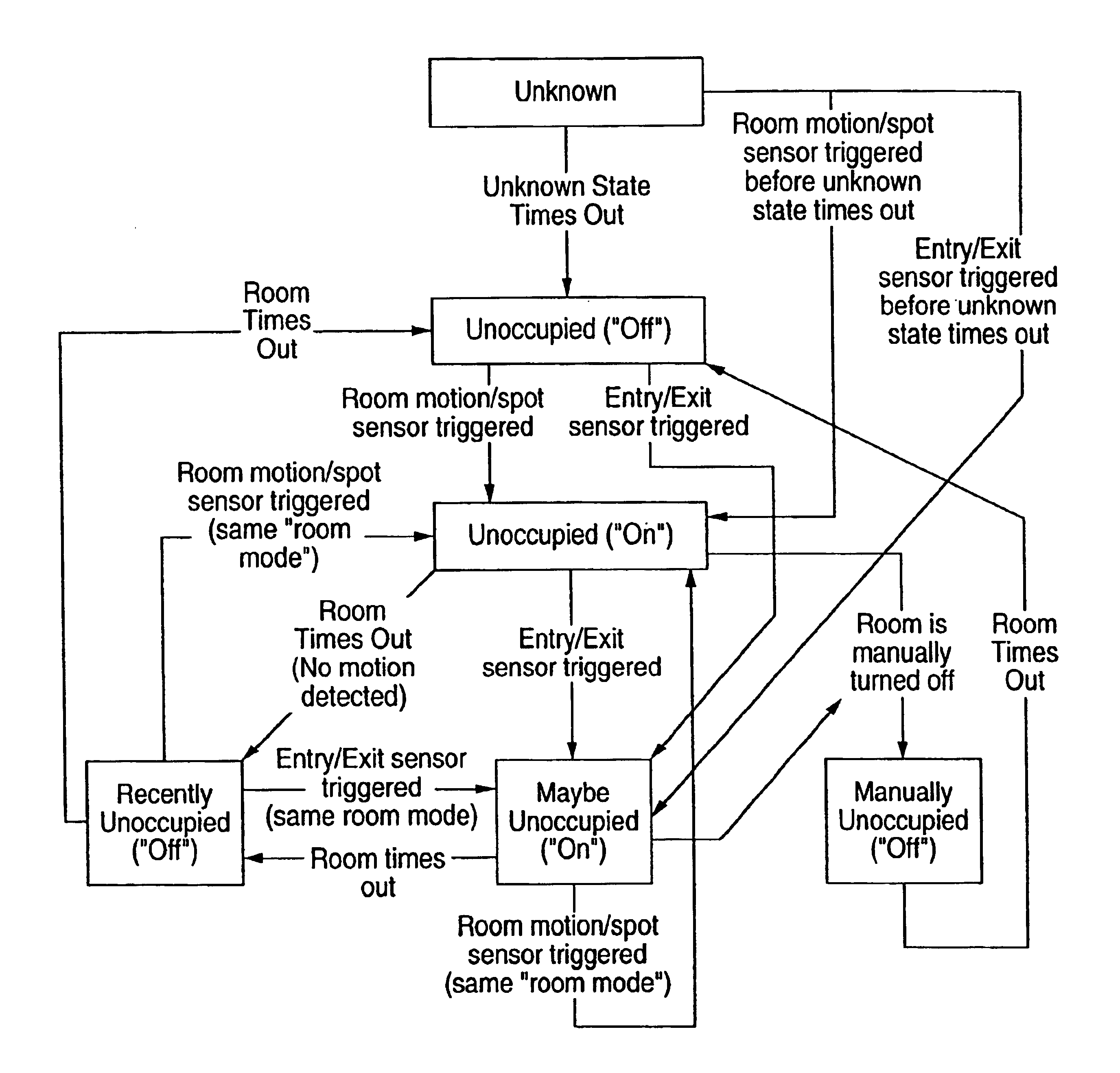

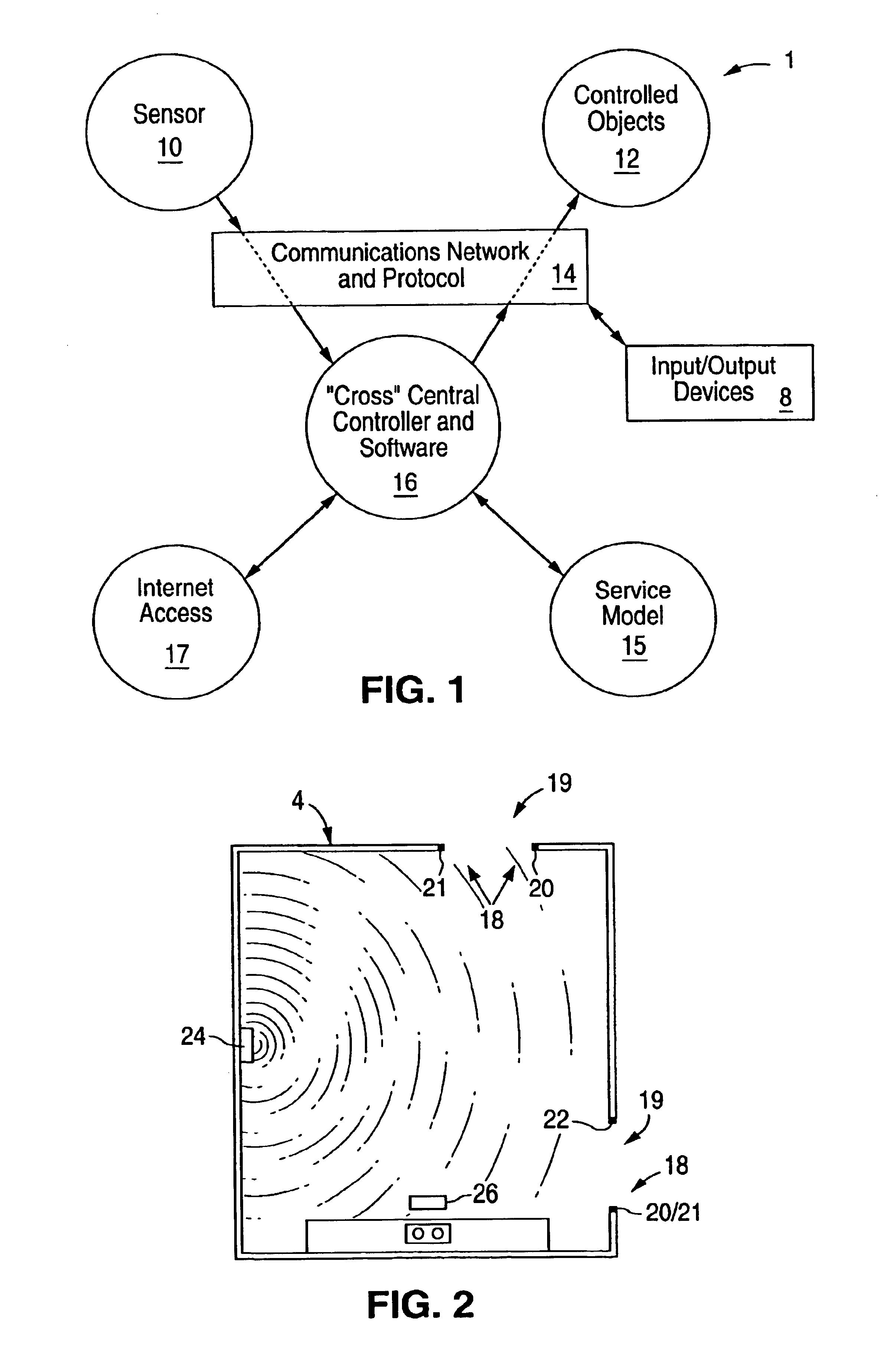

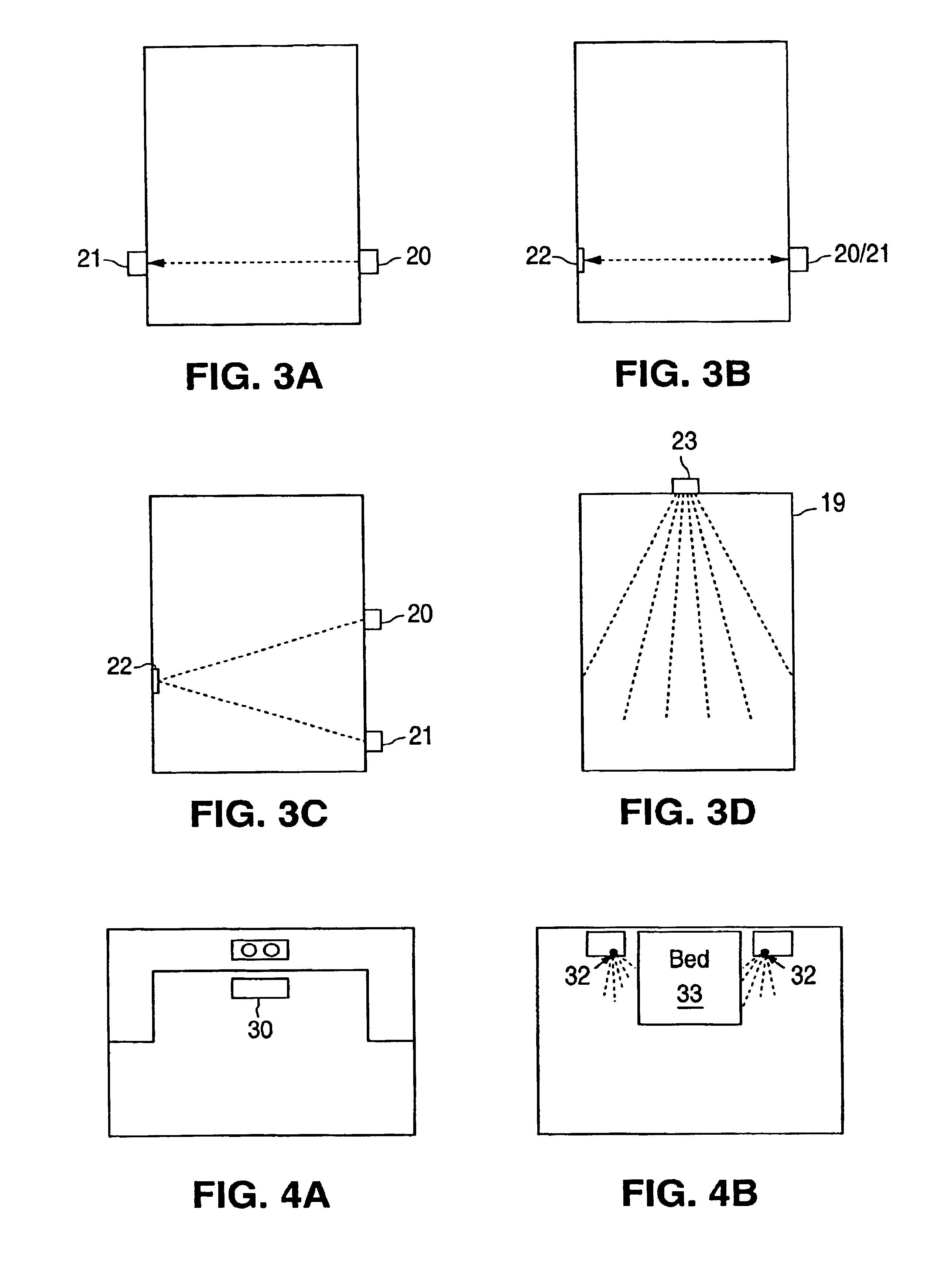

Home automation system and method

InactiveUS6912429B1Matches need and abilityImprove automationSpace heating and ventilationTemperatue controlAutomatic controlEngineering

A home automation system and method for automatic control of controlled devices throughout a home. A unique architecture of occupancy sensors includes entry / exit sensors for detecting movement through doorways that separate rooms in the home, room motion sensors for detecting room occupancy, spot sensors to detect occupancy of specific locations within the rooms, and house status sensors to detect the status of certain parameters of the home. A central controller communicates with the sensors and controlled objects over a communications network, where the sensors and controlled objects can be added to the system in a ‘plug and play’ manner. The central controller controls the controlled objects in response to the entry / exit sensors, room motion sensors, spot sensors and the house status sensors. This control is accomplished by assigning each room to one of a plurality of room occupancy states, and to one of a plurality of room modes for creating desired room atmospheres using the controlled objects, which both dictate how the controlled objects are controlled by the central controller. The room modes travel from room to room as the occupant moves throughout the home, and multiple occupants can be using different room modes as they move about the home. The controlled objects also have controlled object states, which are used by the central controller to control the controlled objects.

Owner:HOME DIRECTOR

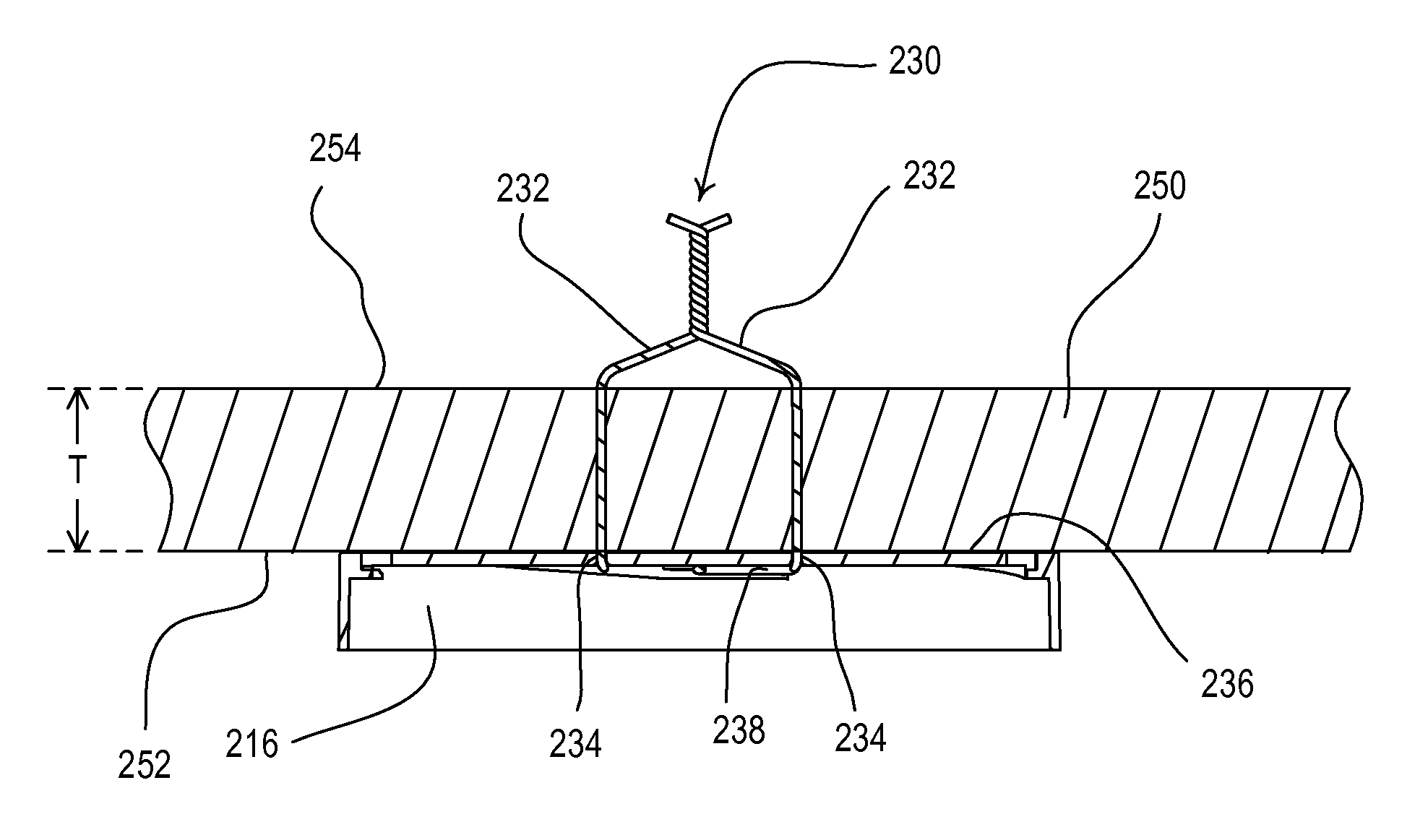

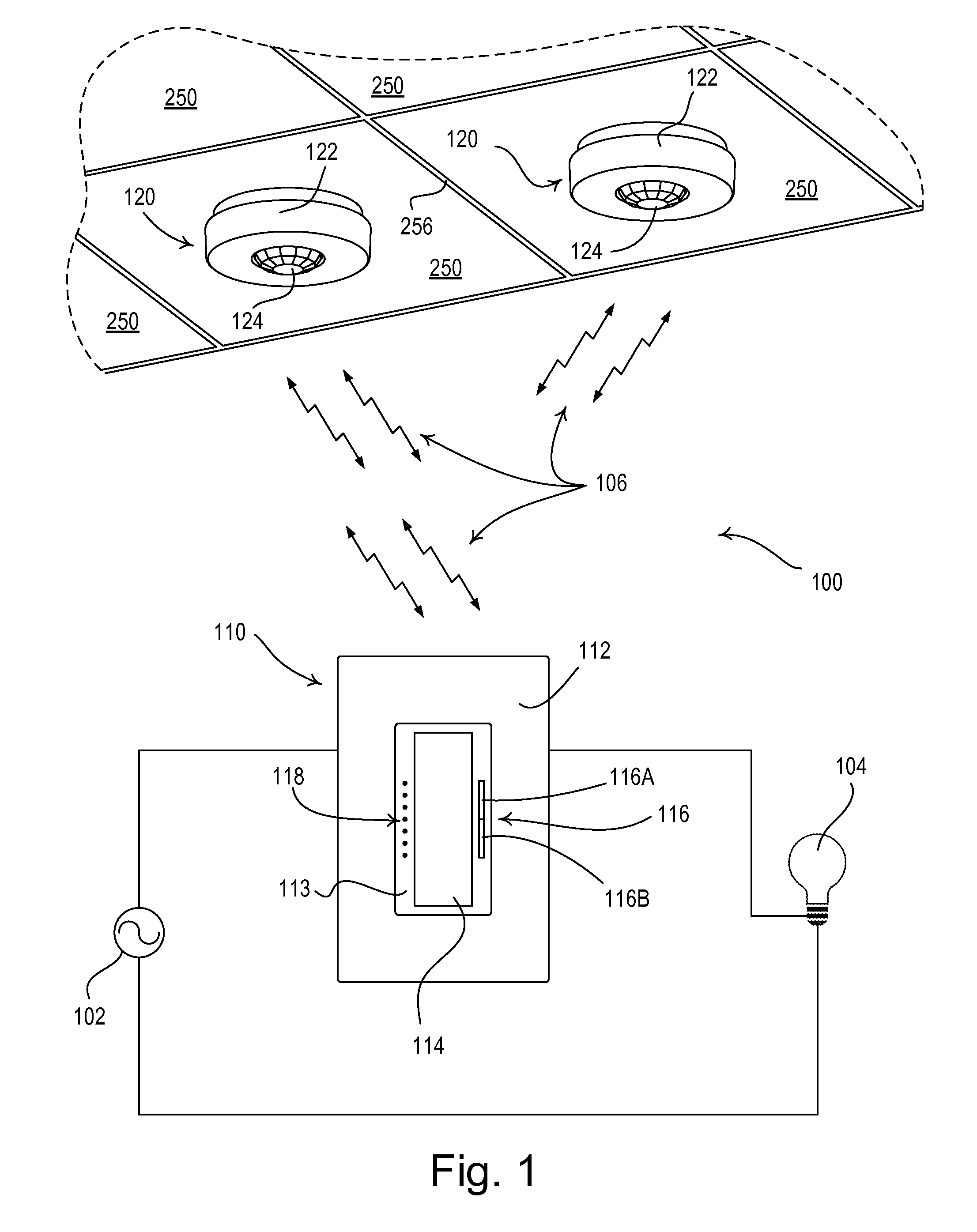

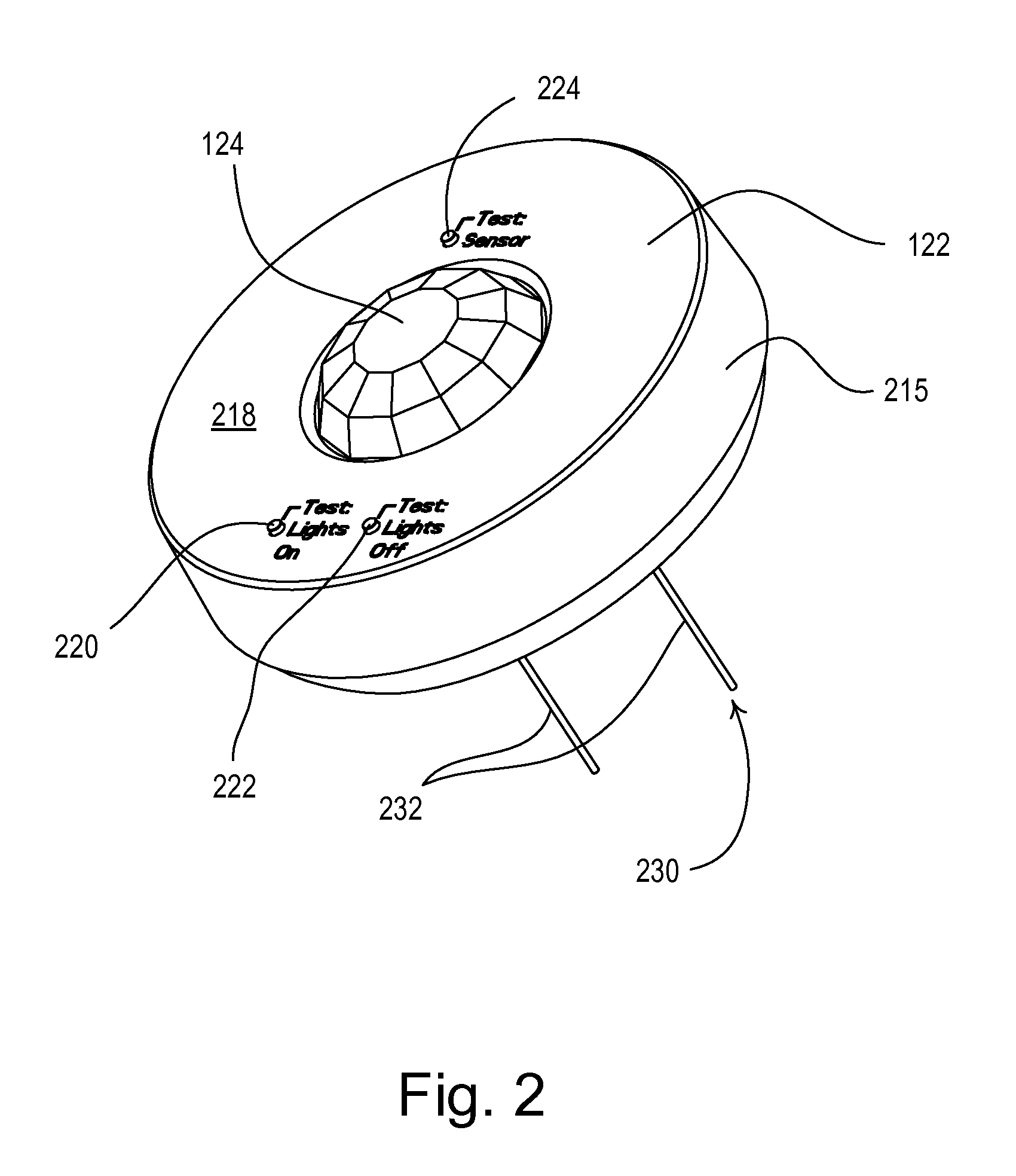

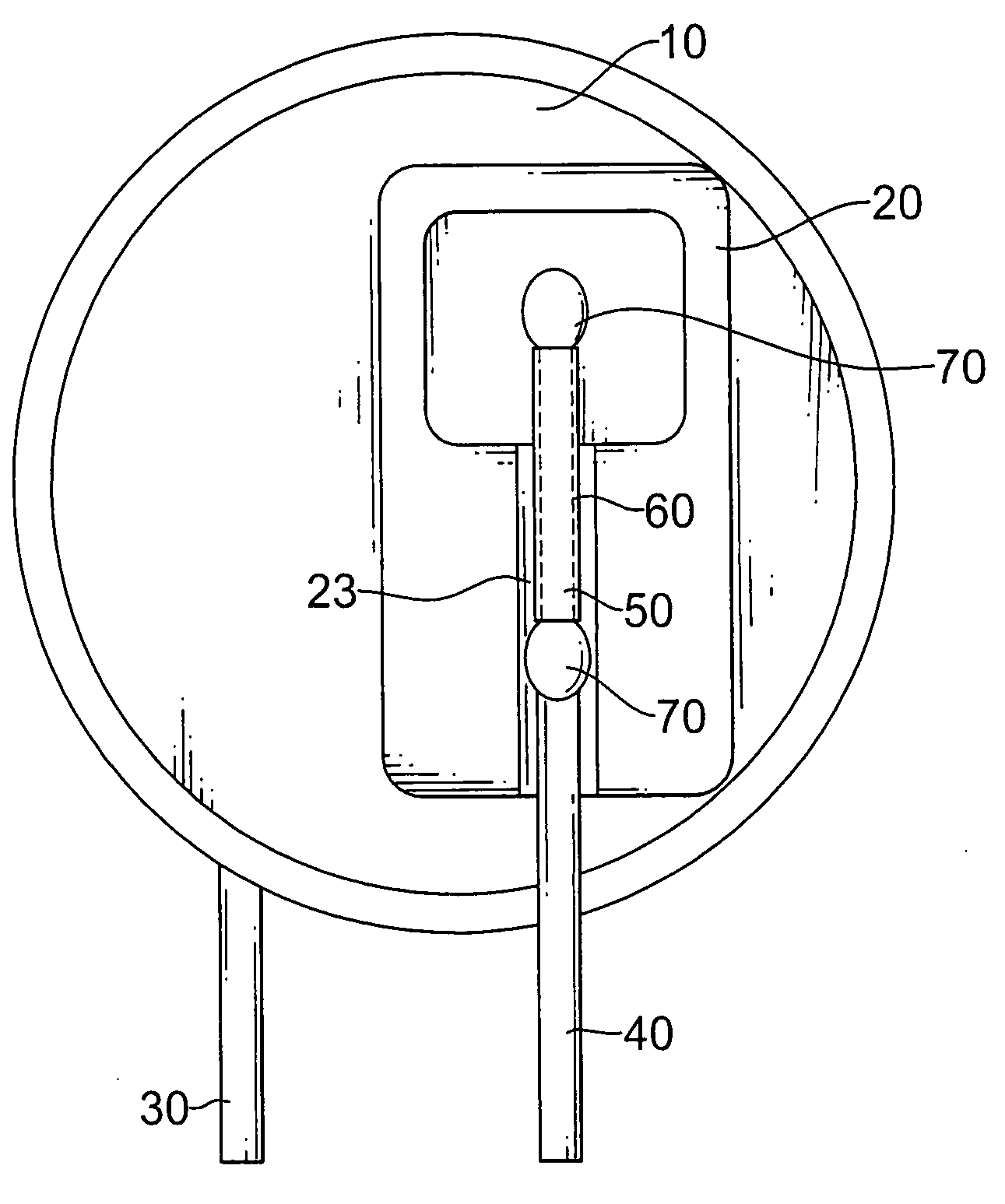

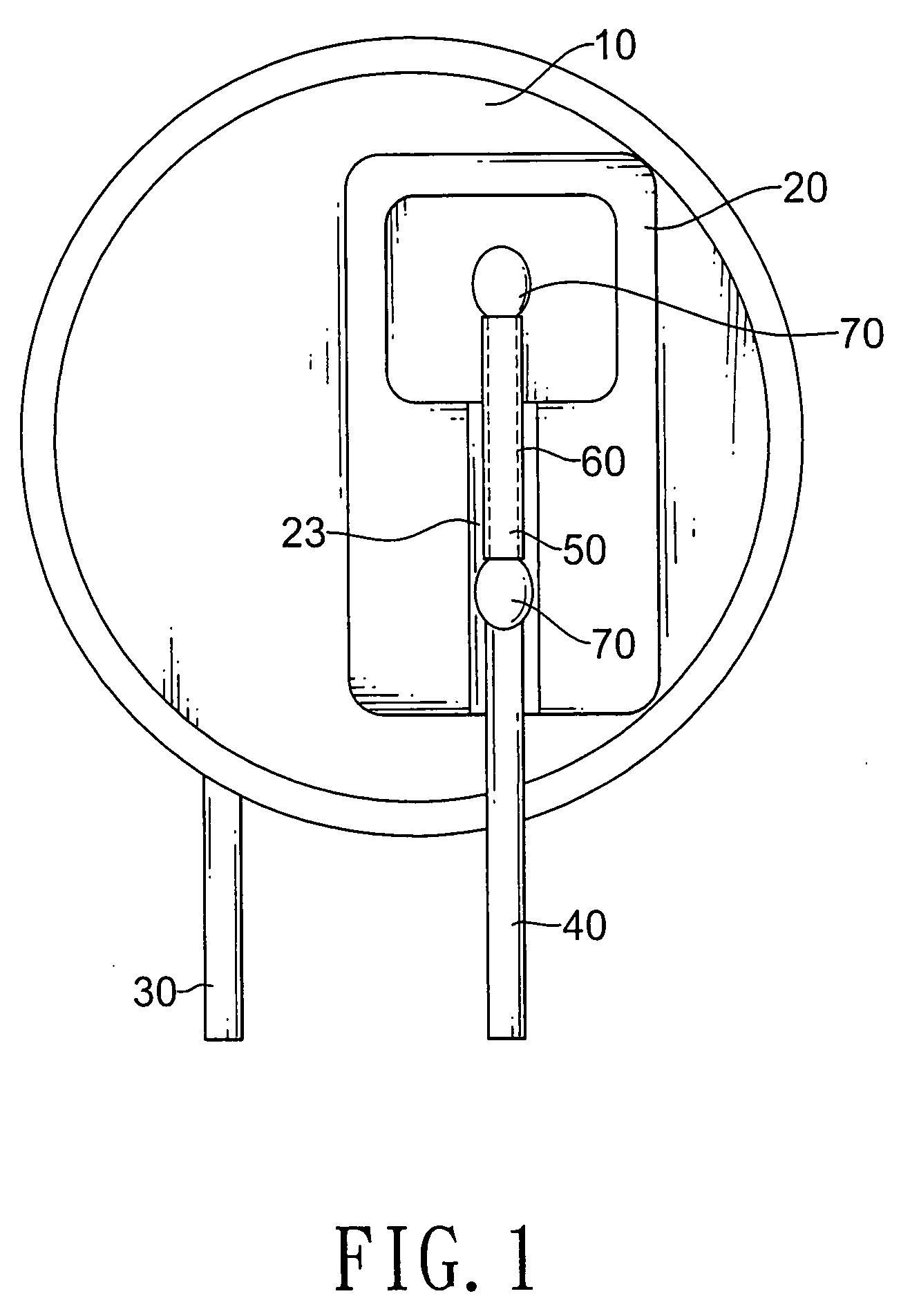

Method and apparatus for configuring a wireless sensor

ActiveUS8199010B2Electric signal transmission systemsBoards/switchyards circuit arrangementsLine sensorControl system

A wireless sensor for a load control system is adapted to be releasably mounted to a surface, such as a drop ceiling panel, to allow the optimum location of the sensor to be determined. A releasable mounting means of the sensor comprises two posts extending perpendicularly from a rear surface of the sensor. Each post has a small diameter and is rigid enough to pierce the panel without creating a large aesthetically-displeasing hole. The sensor may be permanently affixed to the panel by bending the posts at a rear surface of the panel without the use of a tool, such that the panel is captured between the mounting plate and the deformed posts. The sensor further comprises multiple test buttons provided on an outwardly-facing surface of the sensor for separately testing the communications of the load control system and the operation of the sensor. Alternatively, the releasable mounting means may comprise one or more magnets for magnetically coupling the sensor to a grid structure of the ceiling.

Owner:LUTRON TECH CO LLC

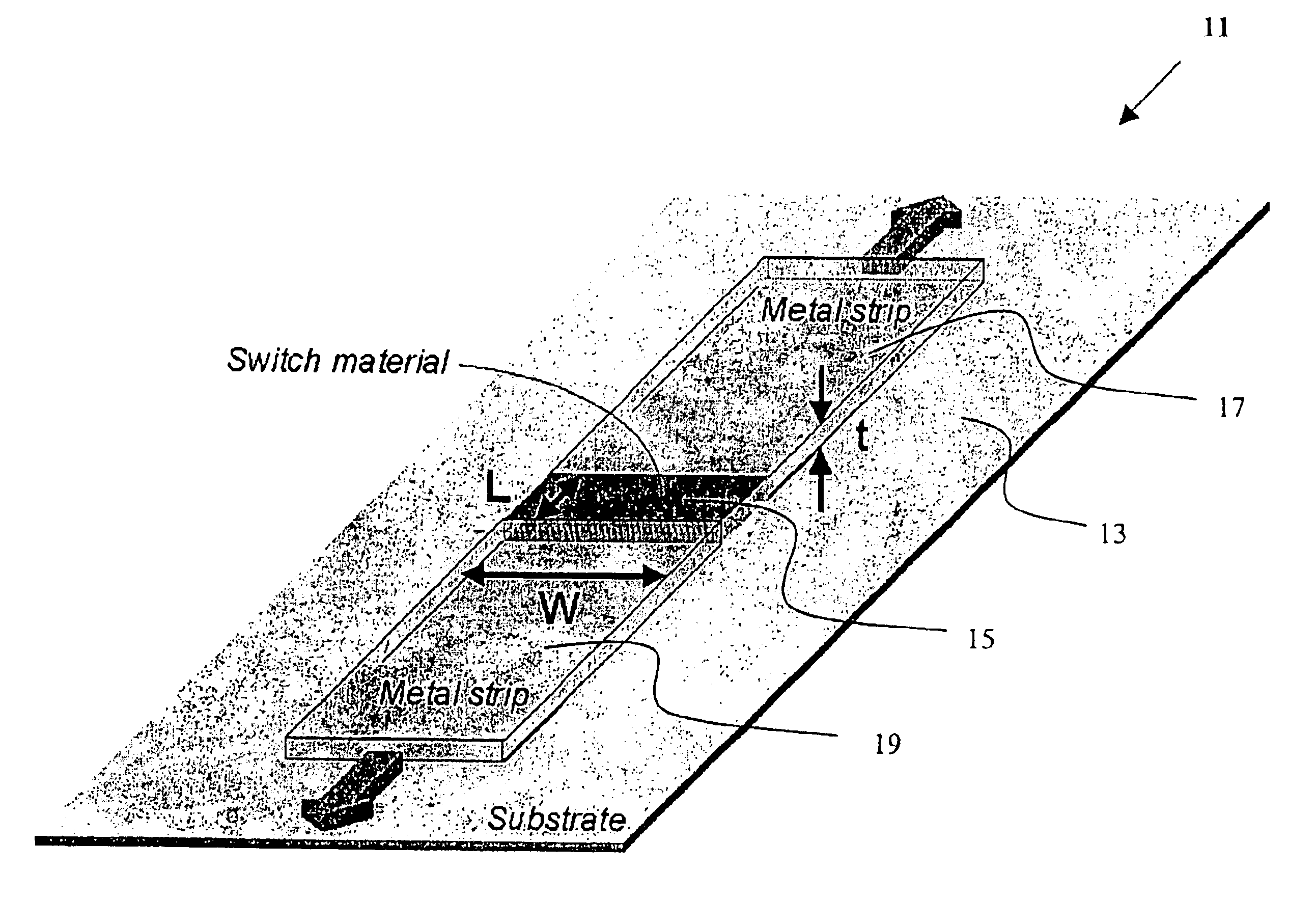

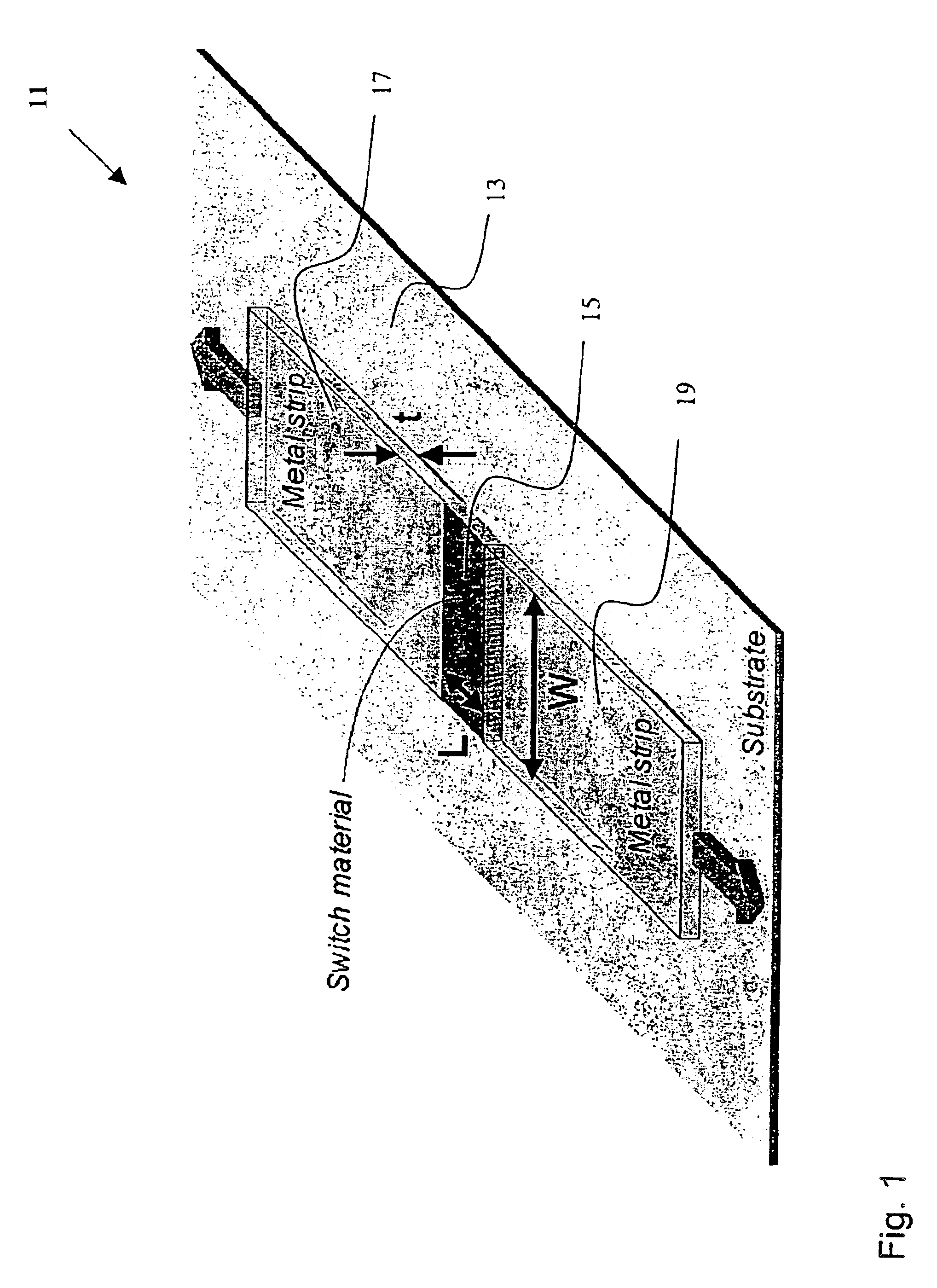

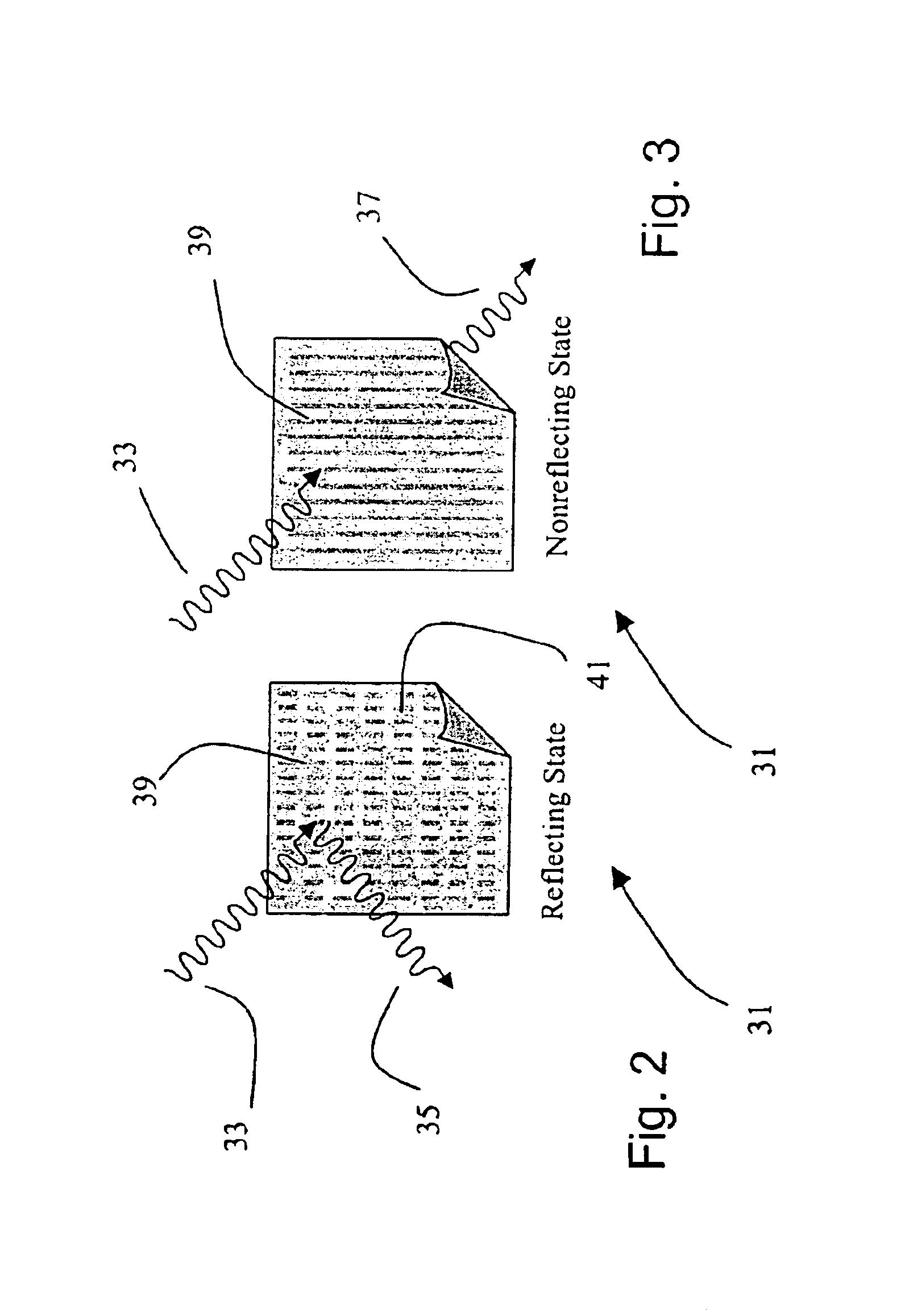

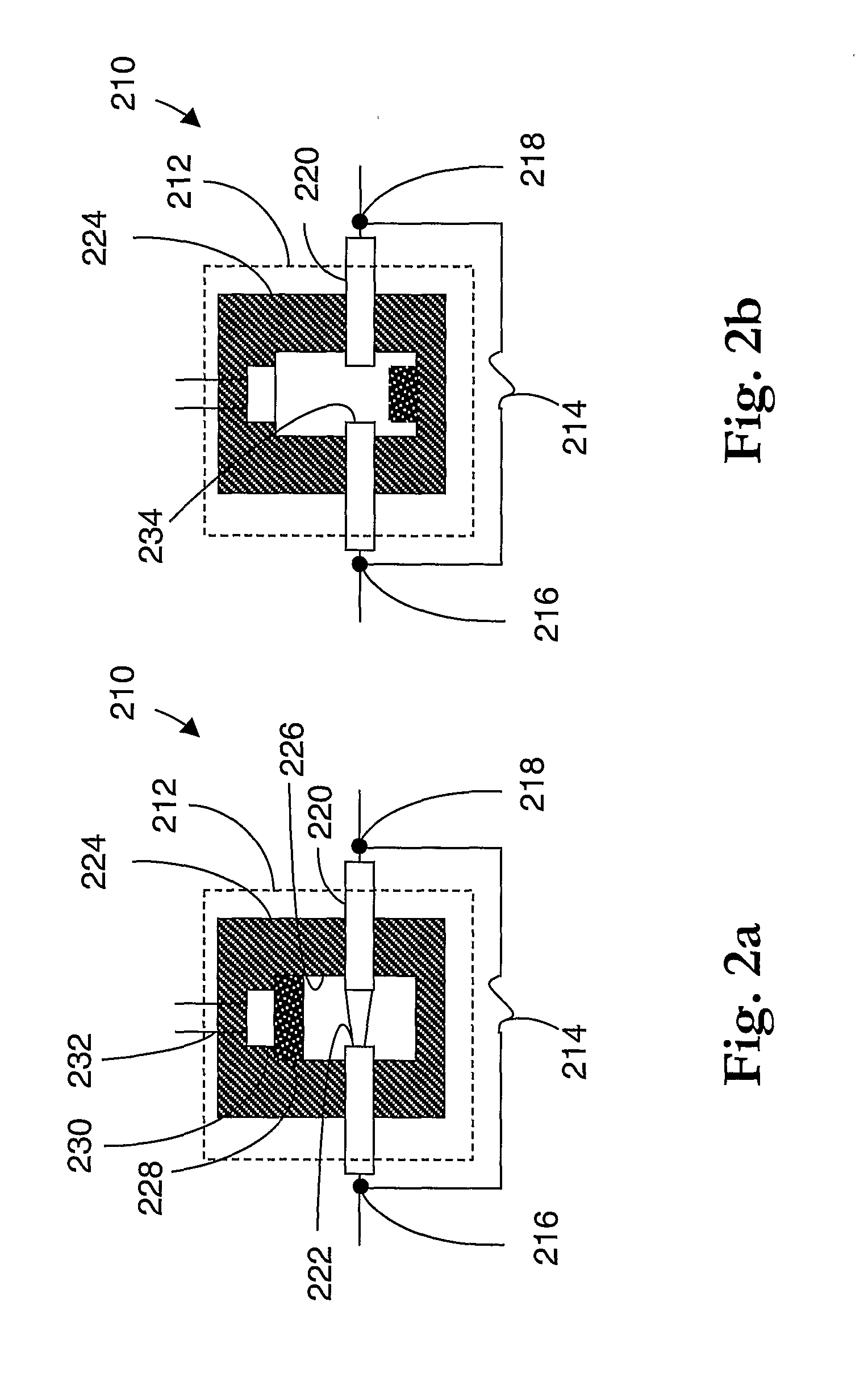

Phase change switches and circuits coupling to electromagnetic waves containing phase change switches

InactiveUS6903362B2Boards/switchyards circuit arrangementsSemiconductor/solid-state device manufacturingElectromagnetic radiationPhase change

A switch is used in circuits which interact with electromagnetic radiation. The switch includes a substrate for supporting components of the switch. A first conductive element on the substrate is provided for connecting to a first component of the circuit, and a second conductive element on the substrate serves to connect to a second component of the circuit. A switch element is made up of a switching material on the substrate and connects the first conductive element to the second conductive element. The switching material is a compound which exhibits a bi-stable phase behavior and is switchable between a first impedance state value and a second impedance state value upon the application of energy thereto. A circuit consisting of a plurality of conductive elements includes the switch for varying current flow which has been induced by the application of electromagnetic radiation.

Owner:LEIDOS

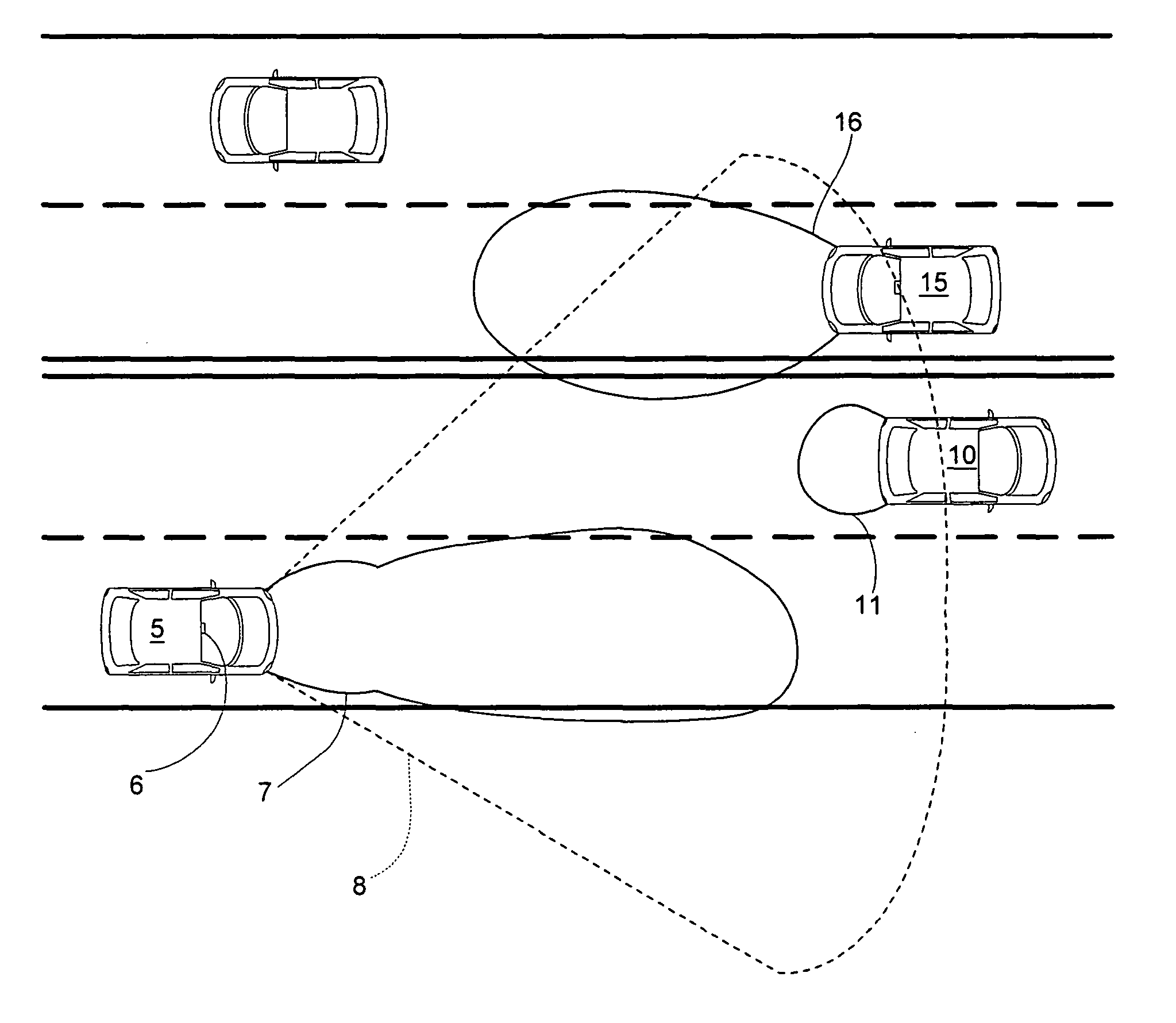

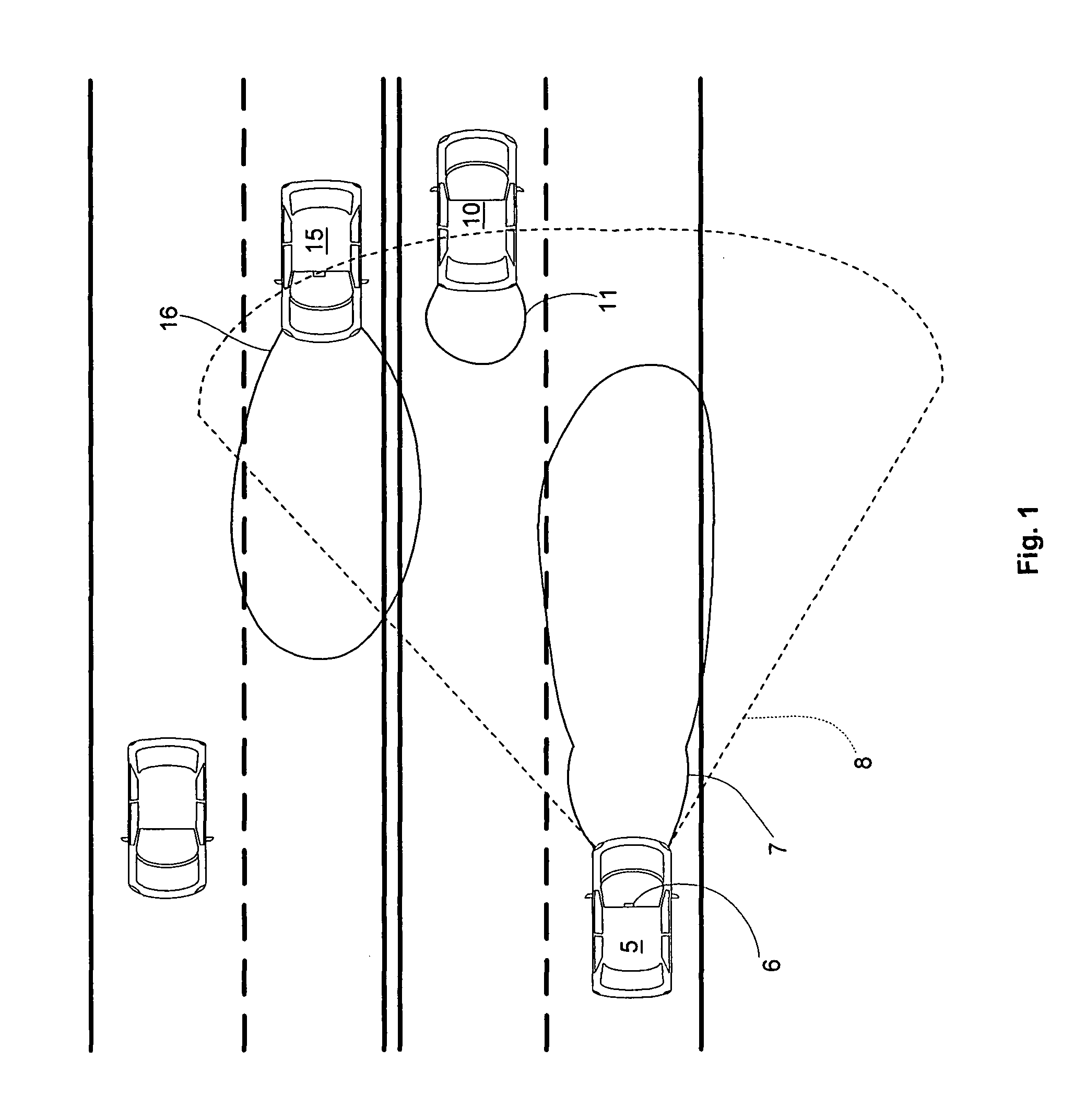

Automatic vehicle exterior light control systems

ActiveUS8045760B2Easy to operateLow costElectric signal transmission systemsLighting support devicesEngineeringLight control

Owner:GENTEX CORP

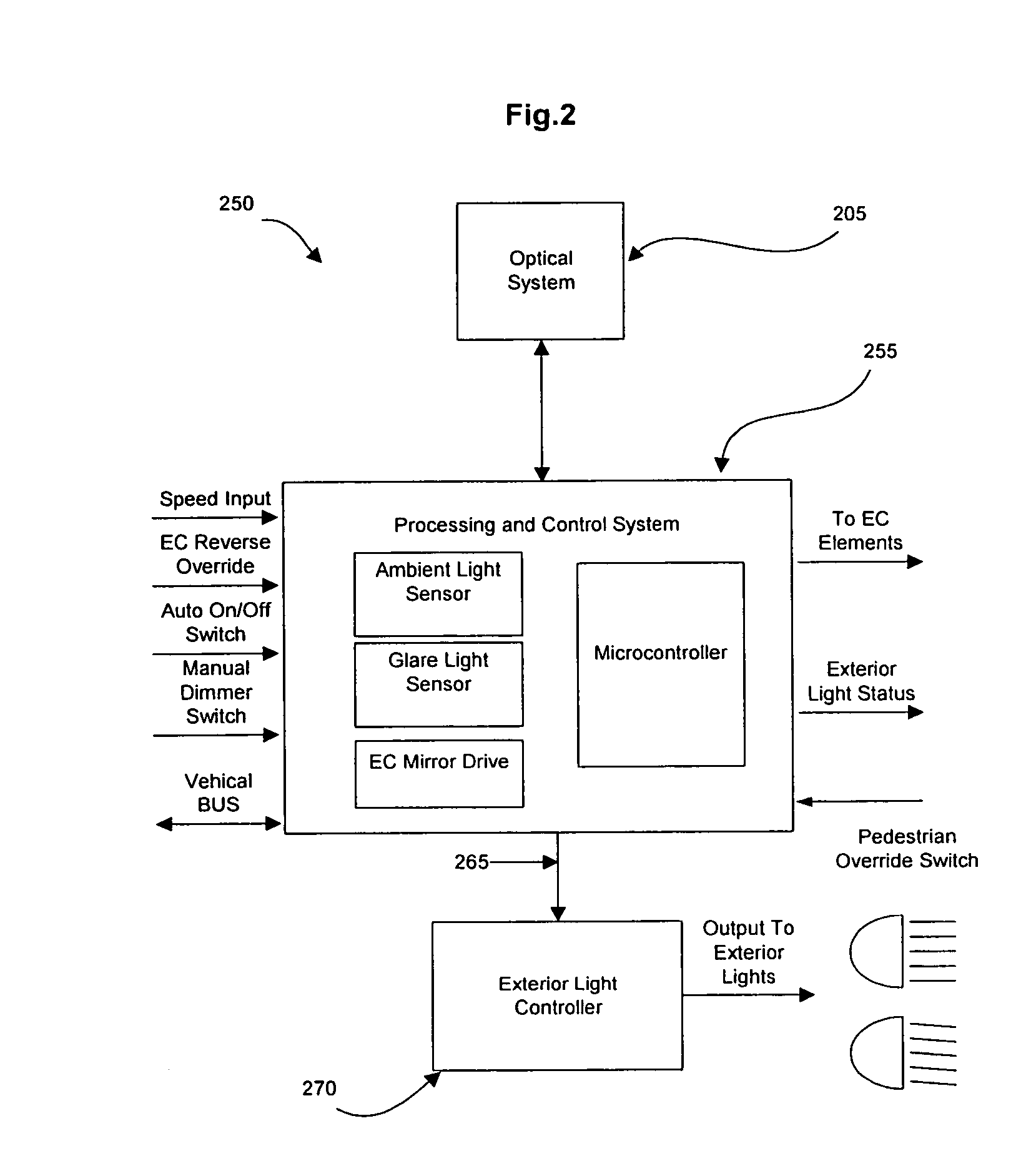

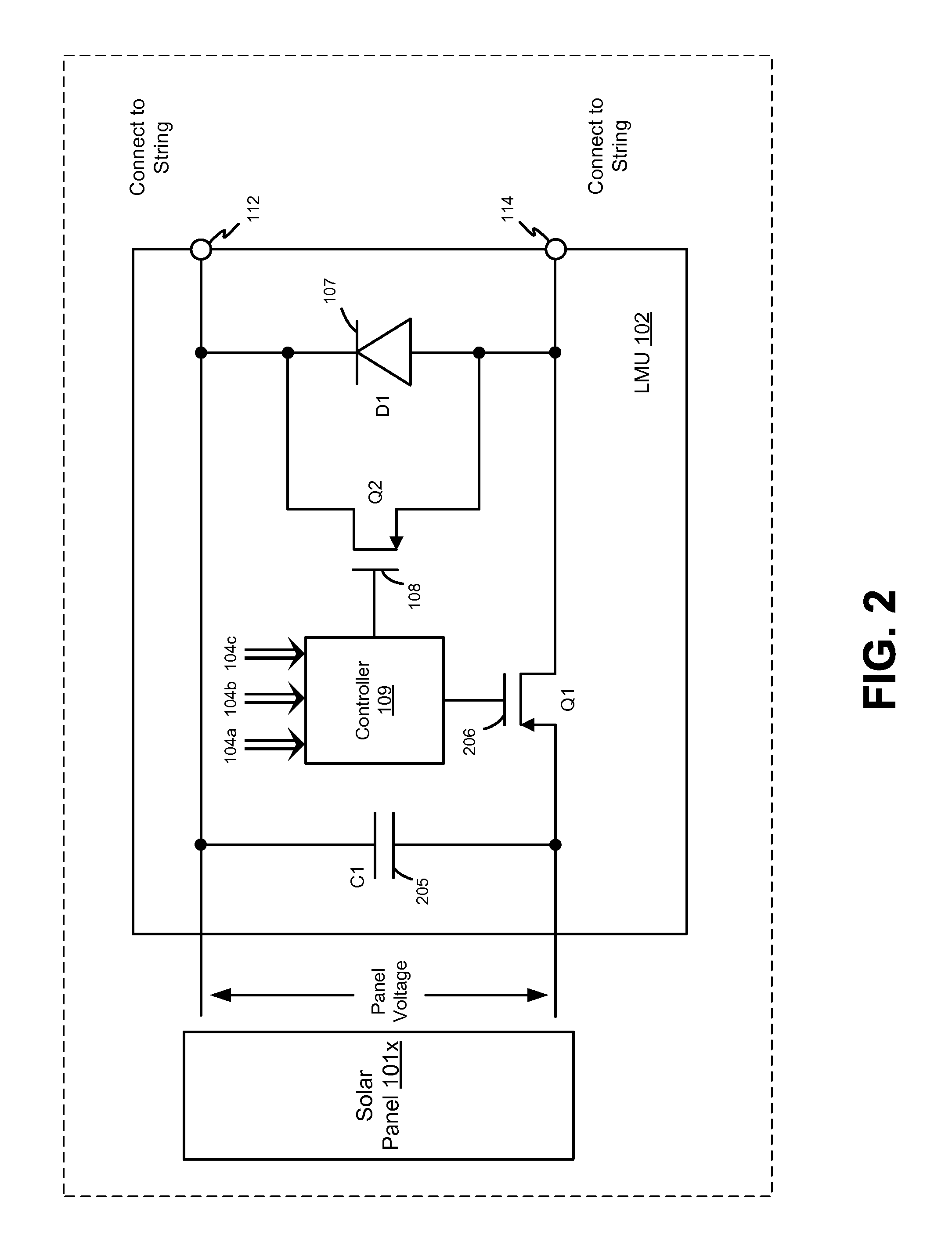

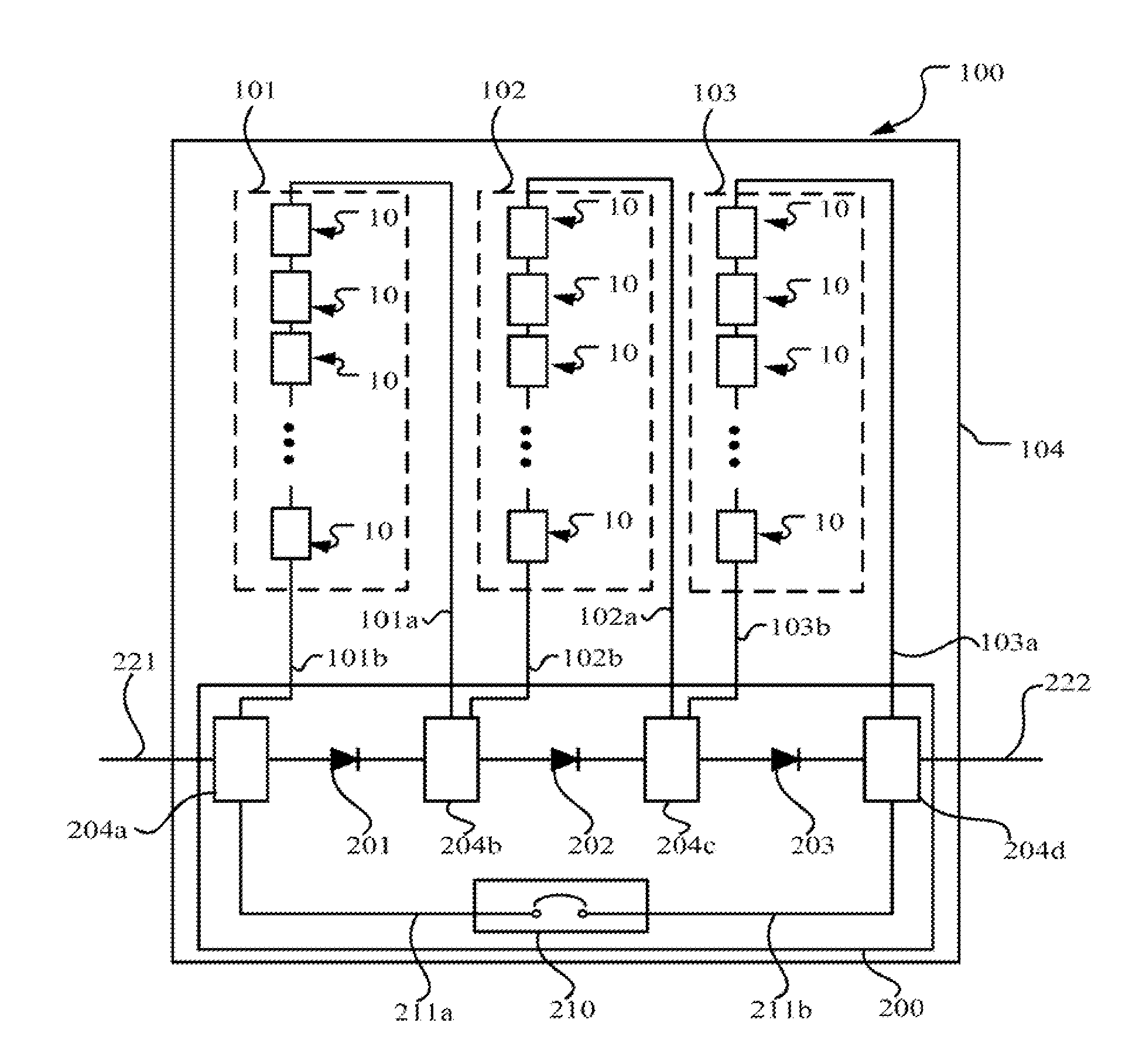

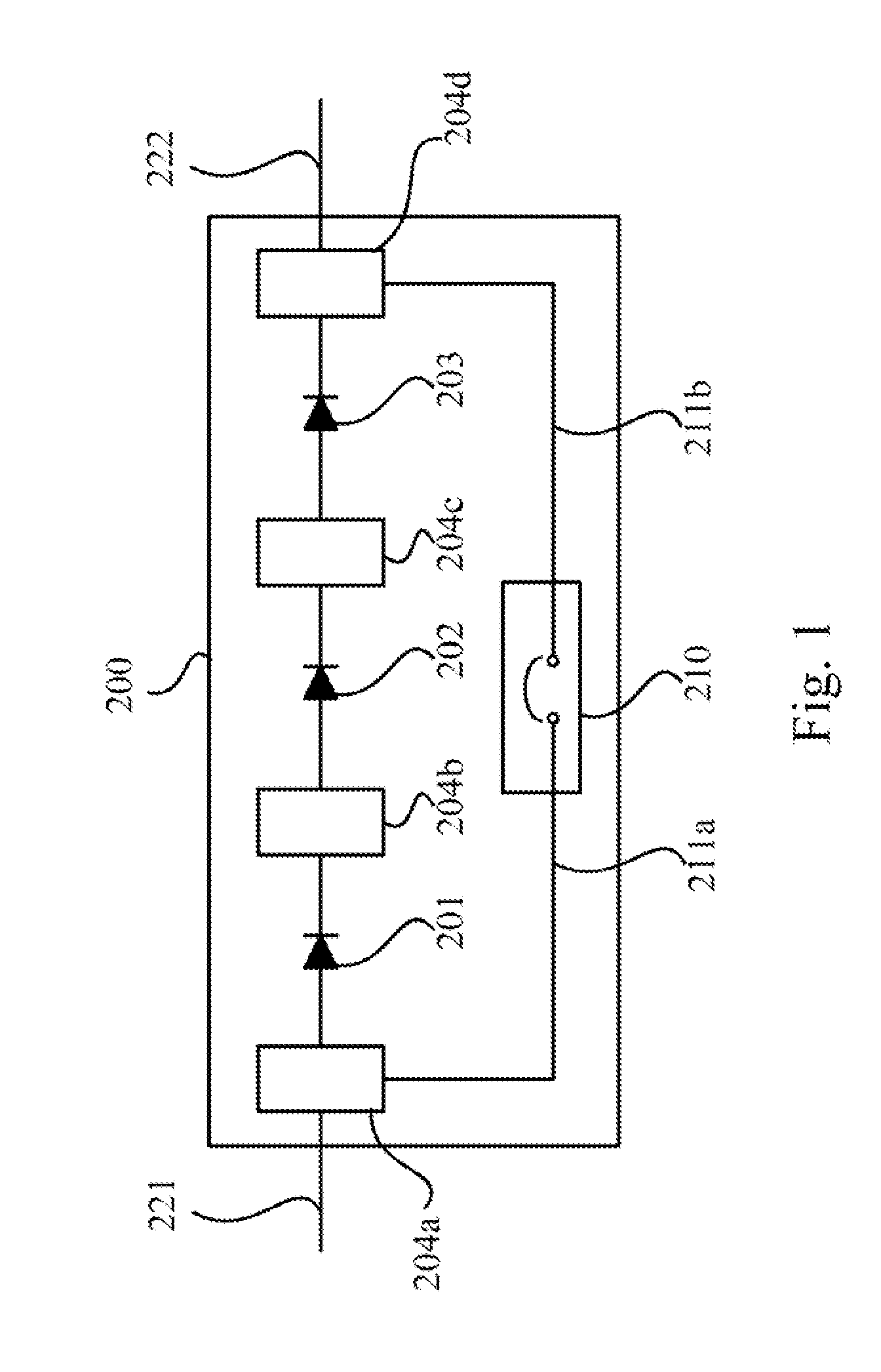

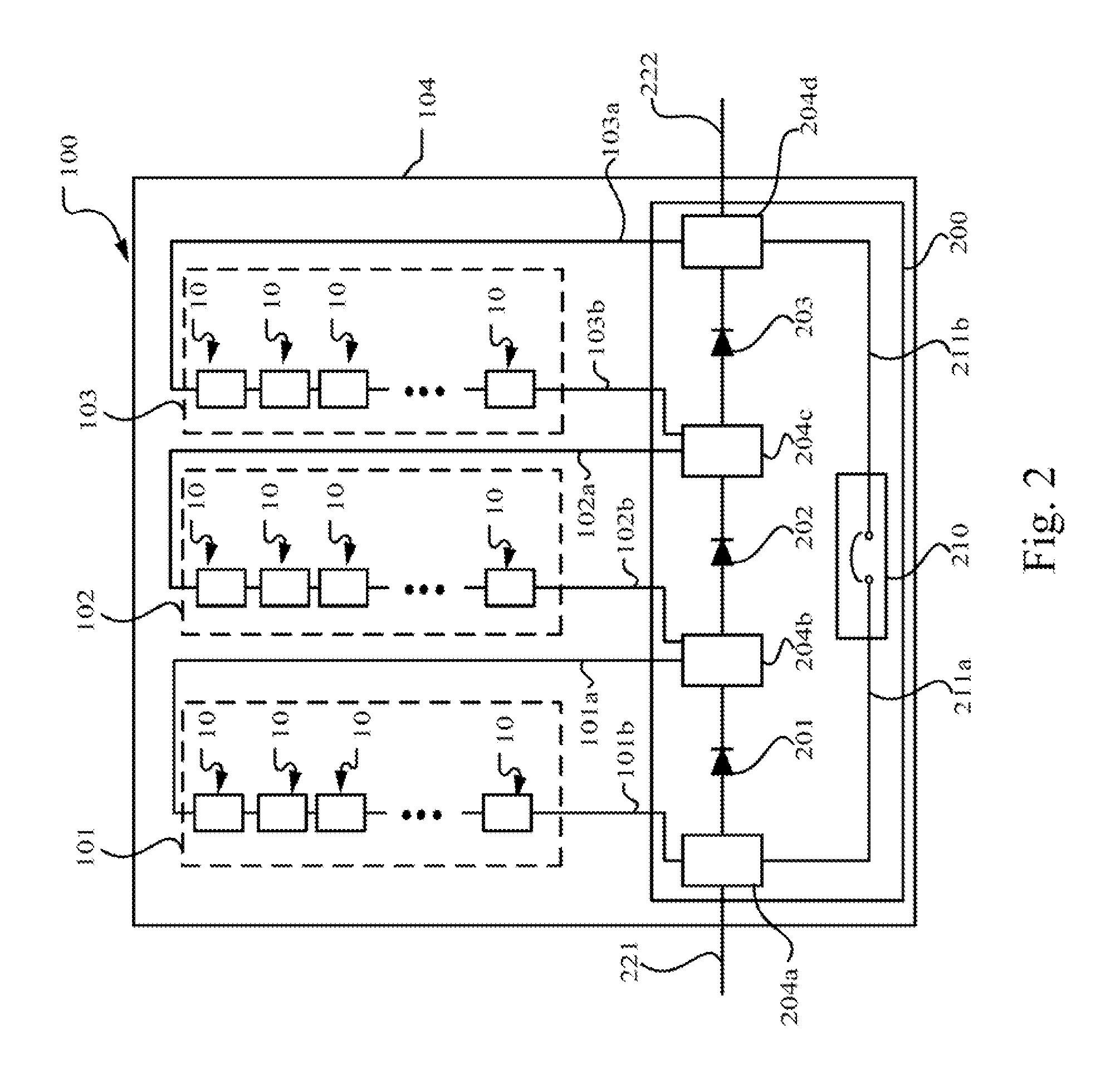

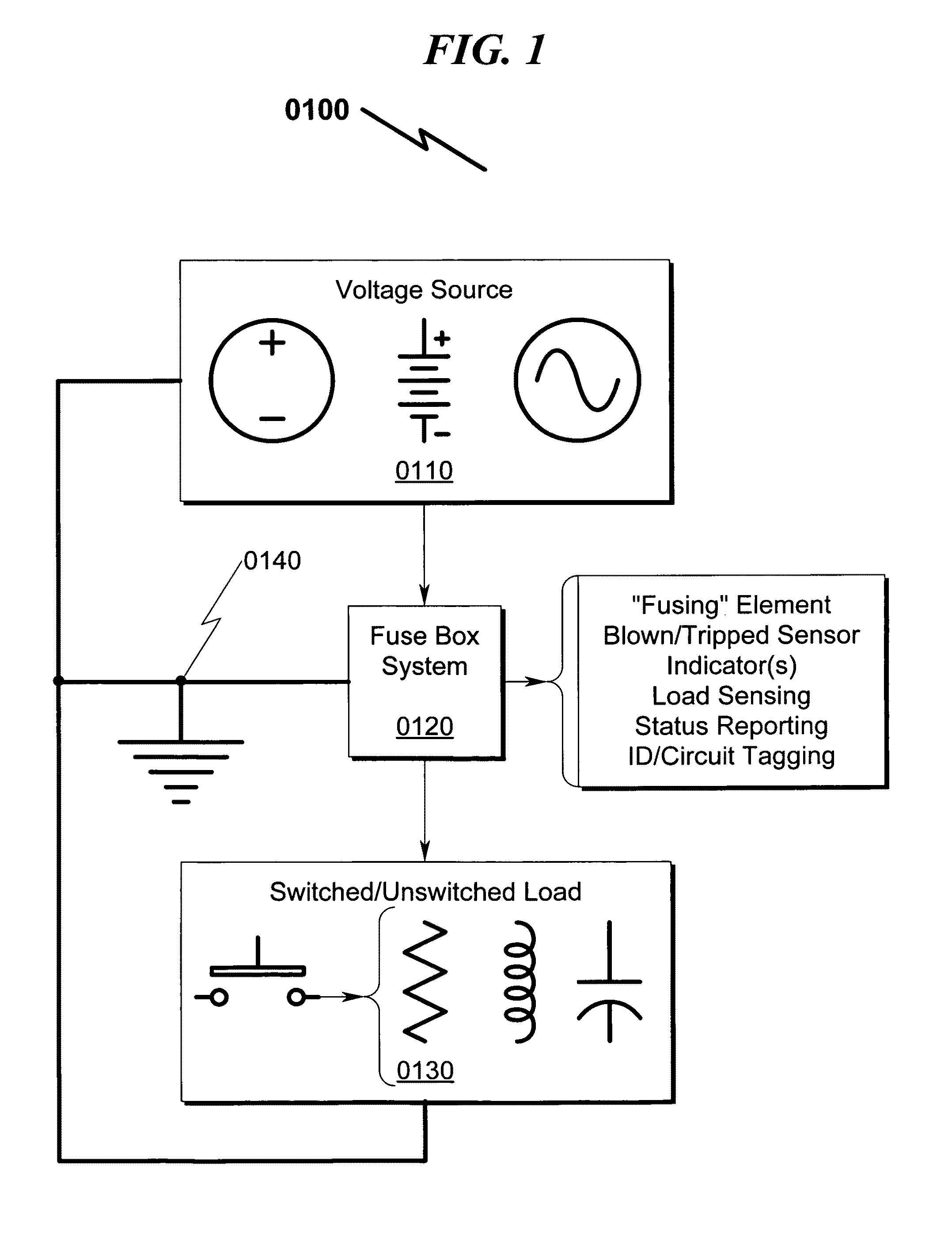

System and Method for Flash Bypass

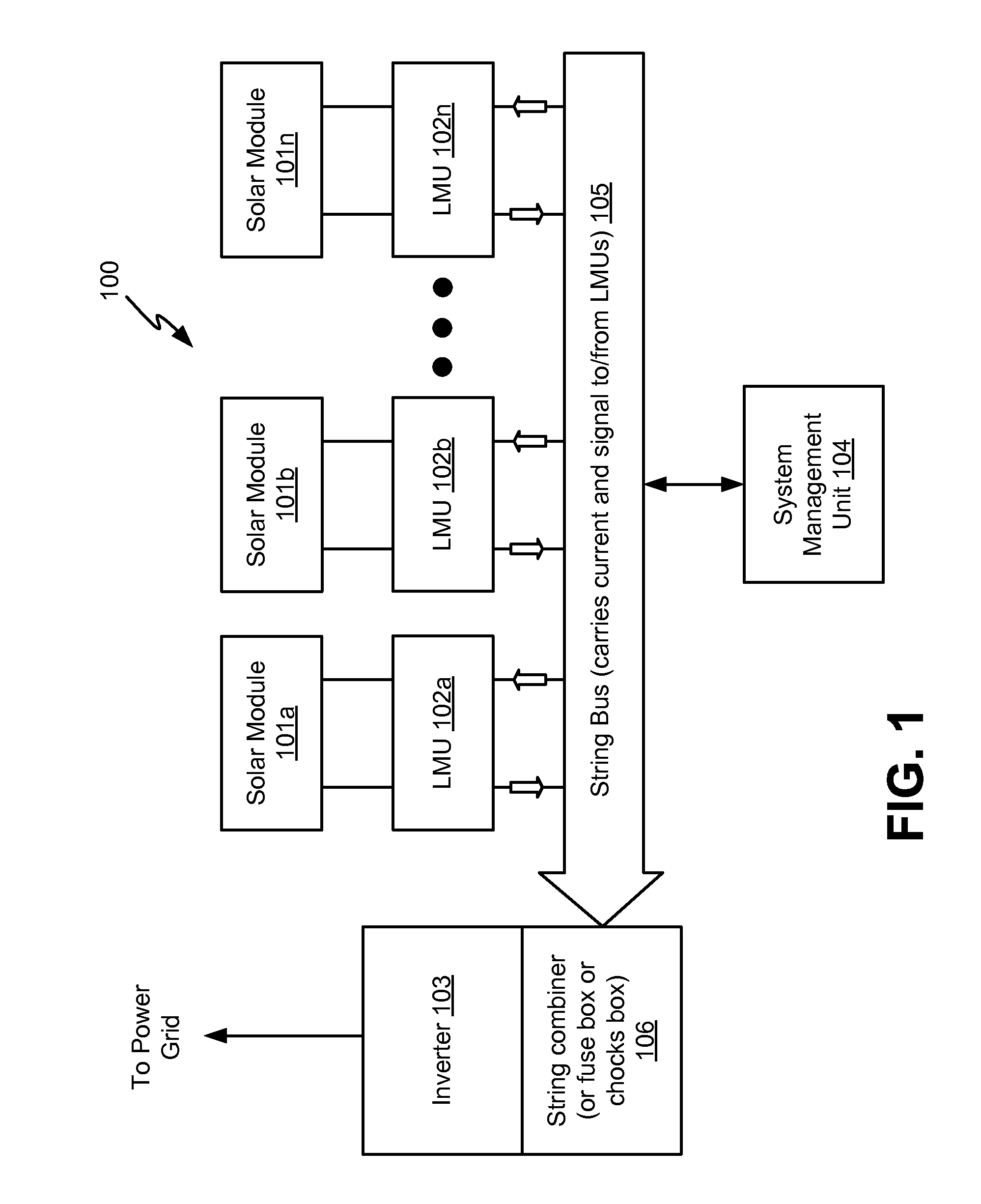

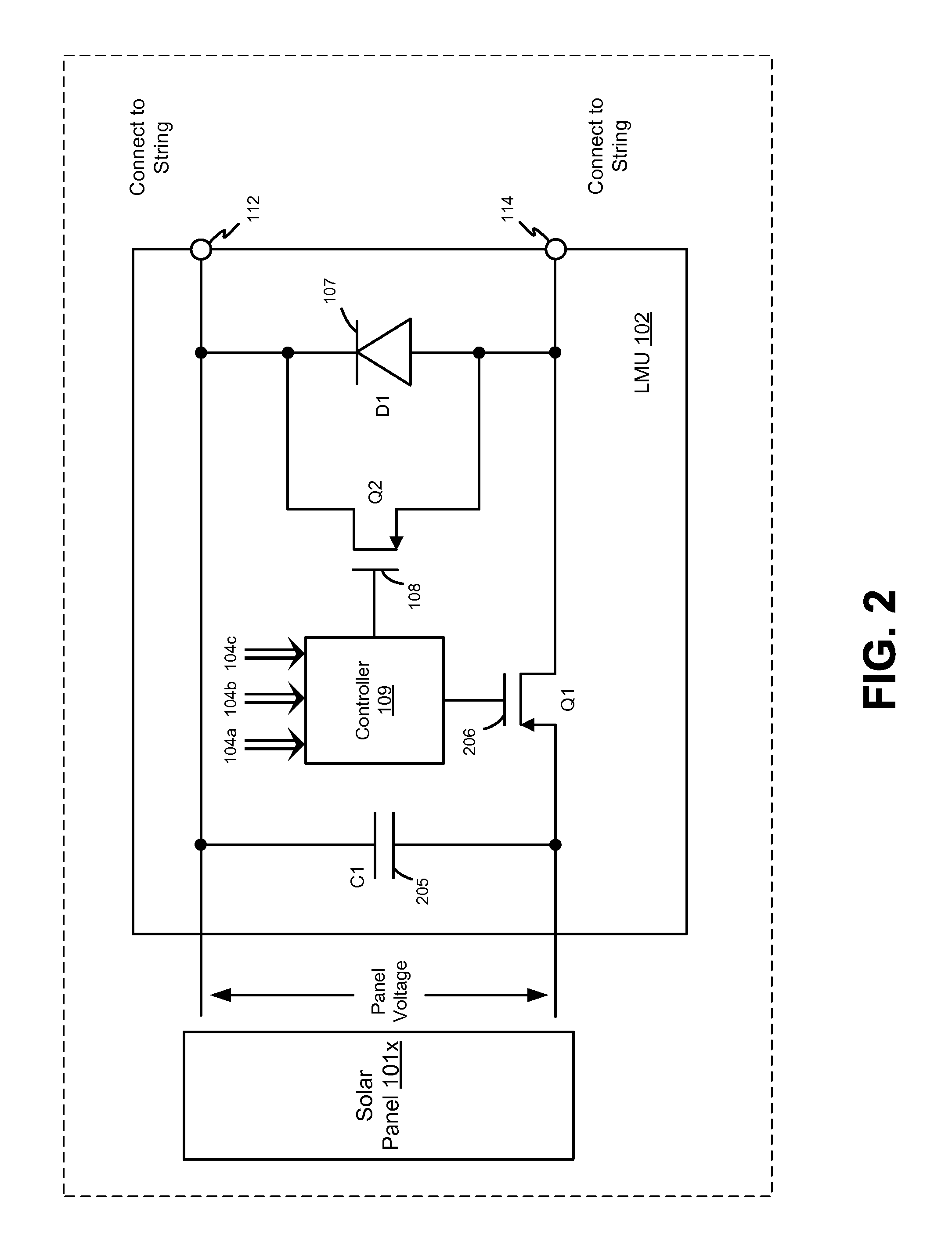

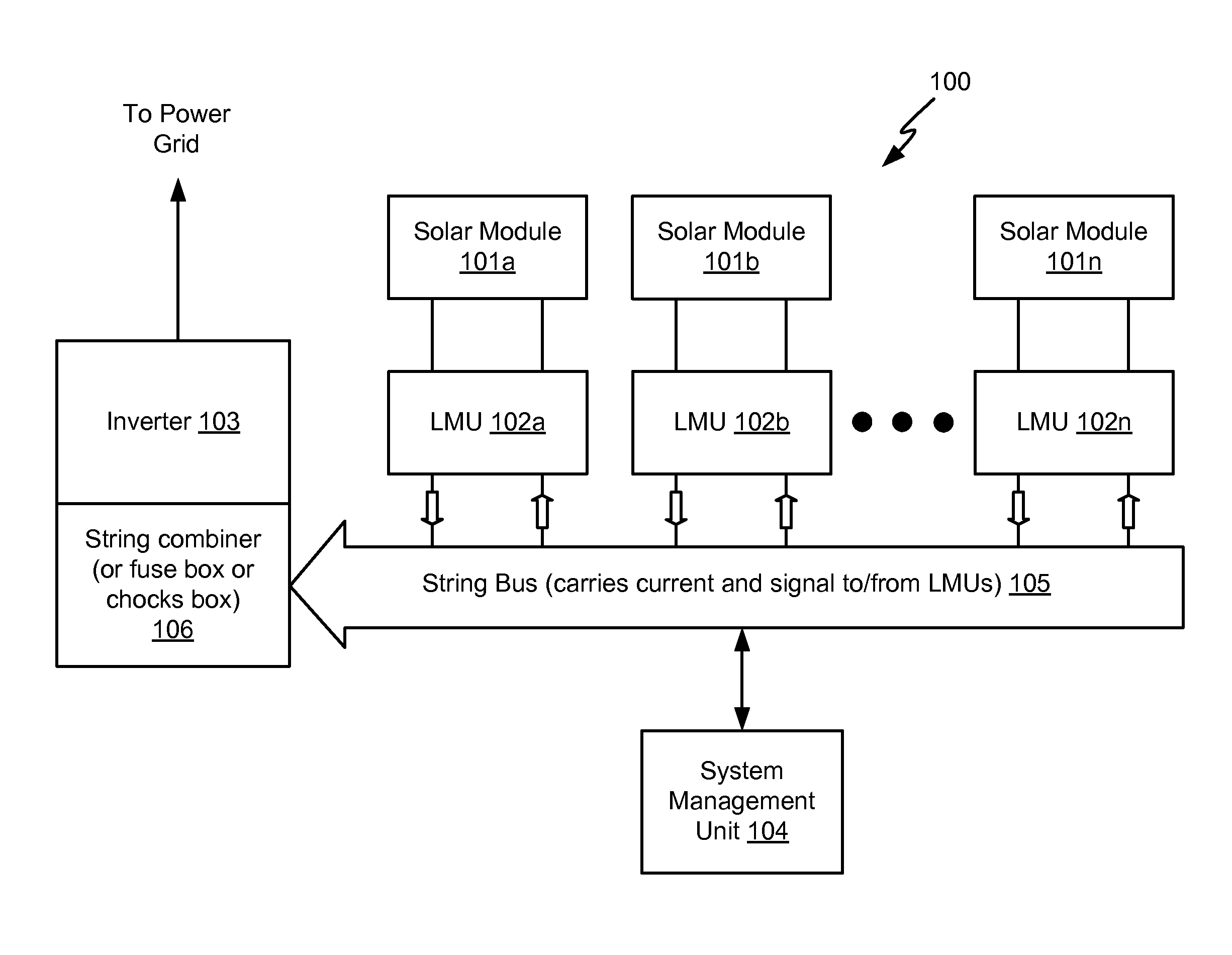

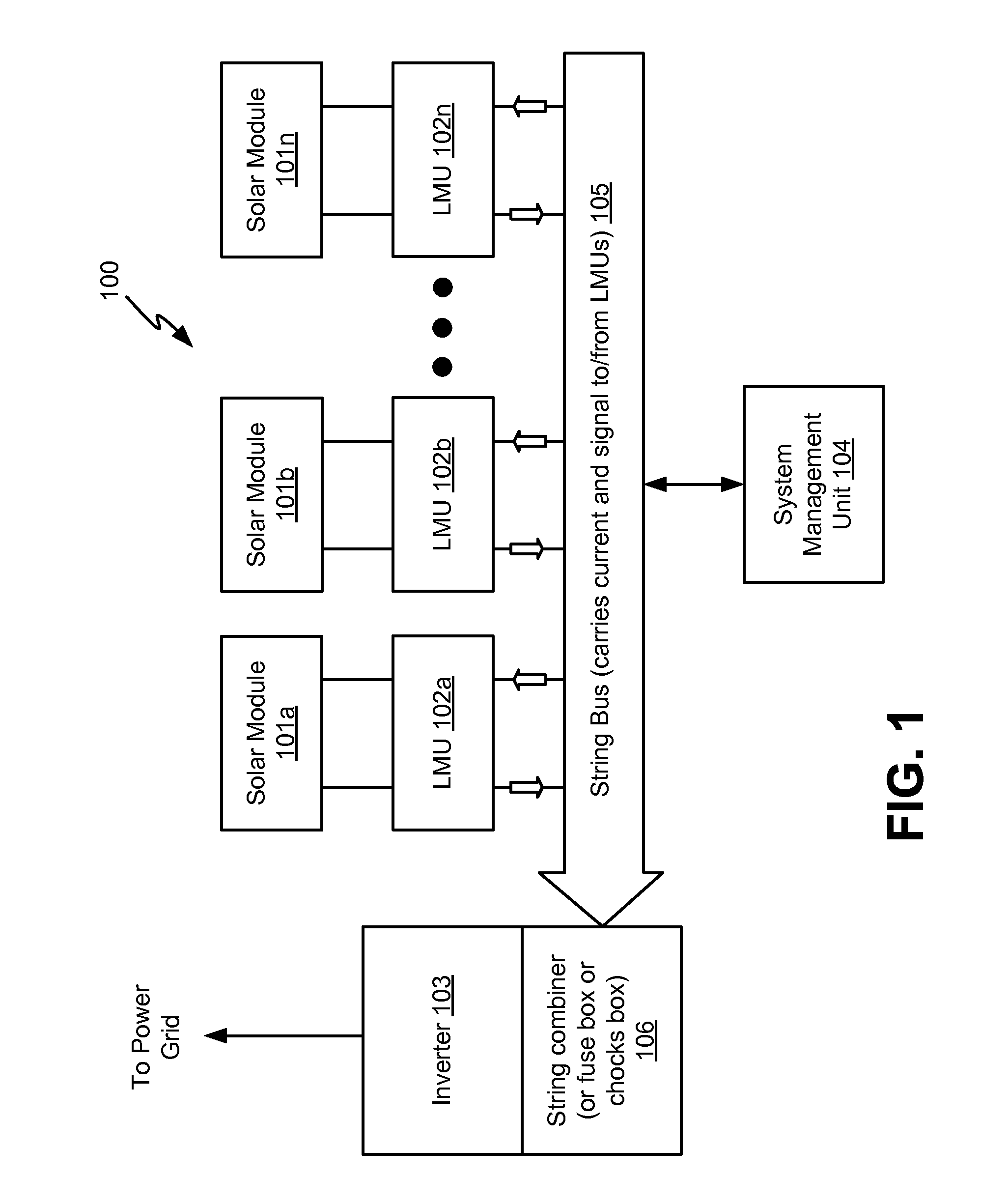

ActiveUS20120217973A1Photovoltaic monitoringBoards/switchyards circuit arrangementsManagement unitEngineering

A solar photovoltaic panel is disclosed that includes a photovoltaic cell, a local management unit connected between the cell and a string bus, and a bypass device connected to the cell that is operable to bypass the local management unit when conducting a flash test. The panel preferably further includes a transient detector connected to the cell that is operable to sense an output from the cell having a predetermined transient rise time. The transient detector and the bypass device may be contained within a junction box integrated into the panel and may include the local management unit within the junction box. The transient detector may include a switch connected to a circuit that electrically bypasses the local management unit when the switch is turned on as a result of an output transient rise time less than the predetermined time, thus facilitating a flash test of the photovoltaic panel.

Owner:NEWLIGHT CAPITAL LLC

System and method for flash bypass

ActiveUS8841916B2Electric signal transmission systemsBatteries circuit arrangementsManagement unitJunction box

A solar photovoltaic panel is disclosed that includes a photovoltaic cell, a local management unit connected between the cell and a string bus, and a bypass device connected to the cell that is operable to bypass the local management unit when conducting a flash test. The panel preferably further includes a transient detector connected to the cell that is operable to sense an output from the cell having a predetermined transient rise time. The transient detector and the bypass device may be contained within a junction box integrated into the panel and may include the local management unit within the junction box. The transient detector may include a switch connected to a circuit that electrically bypasses the local management unit when the switch is turned on as a result of an output transient rise time less than the predetermined time, thus facilitating a flash test of the photovoltaic panel.

Owner:NEWLIGHT CAPITAL LLC

Thermostatically controlled terminal box and photovoltaic power generation system utilizing the same

InactiveUS20110240100A1Reduce voltagePrevent from erroneous short-circuitBoards/switchyards circuit arrangementsPV power plantsEngineeringThreshold temperature

A system comprising a photovoltaic module and a terminal box. Two terminals of the box output voltage generated by the photovoltaic module. A thermal switch shorts the two terminals in response to temperature rise to a threshold temperature and is structured to prevent short-circuit due to the temperature rise of the normally operating photovoltaic module and bypass diodes in the terminal box.

Owner:HON HAI PRECISION IND CO LTD

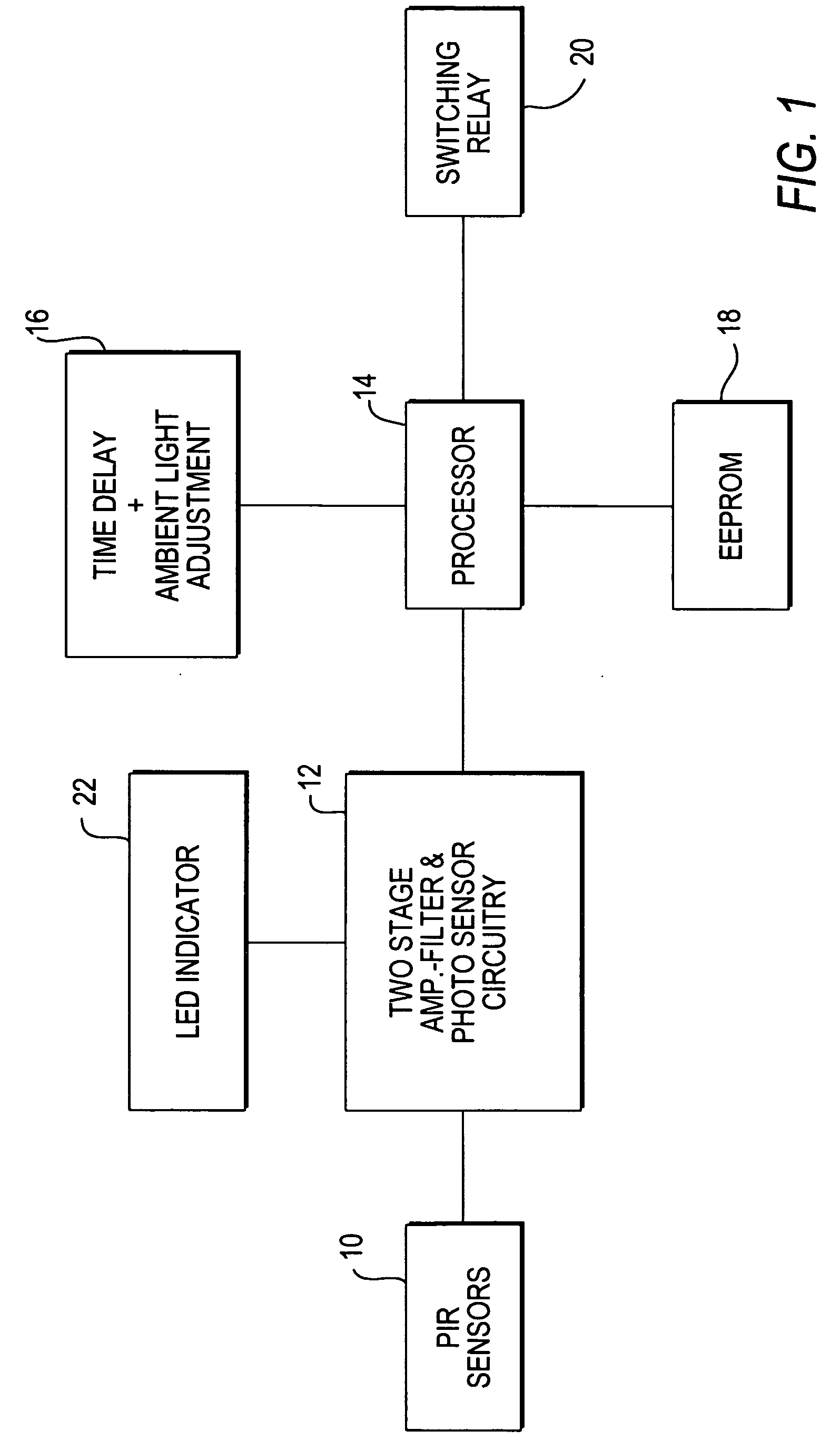

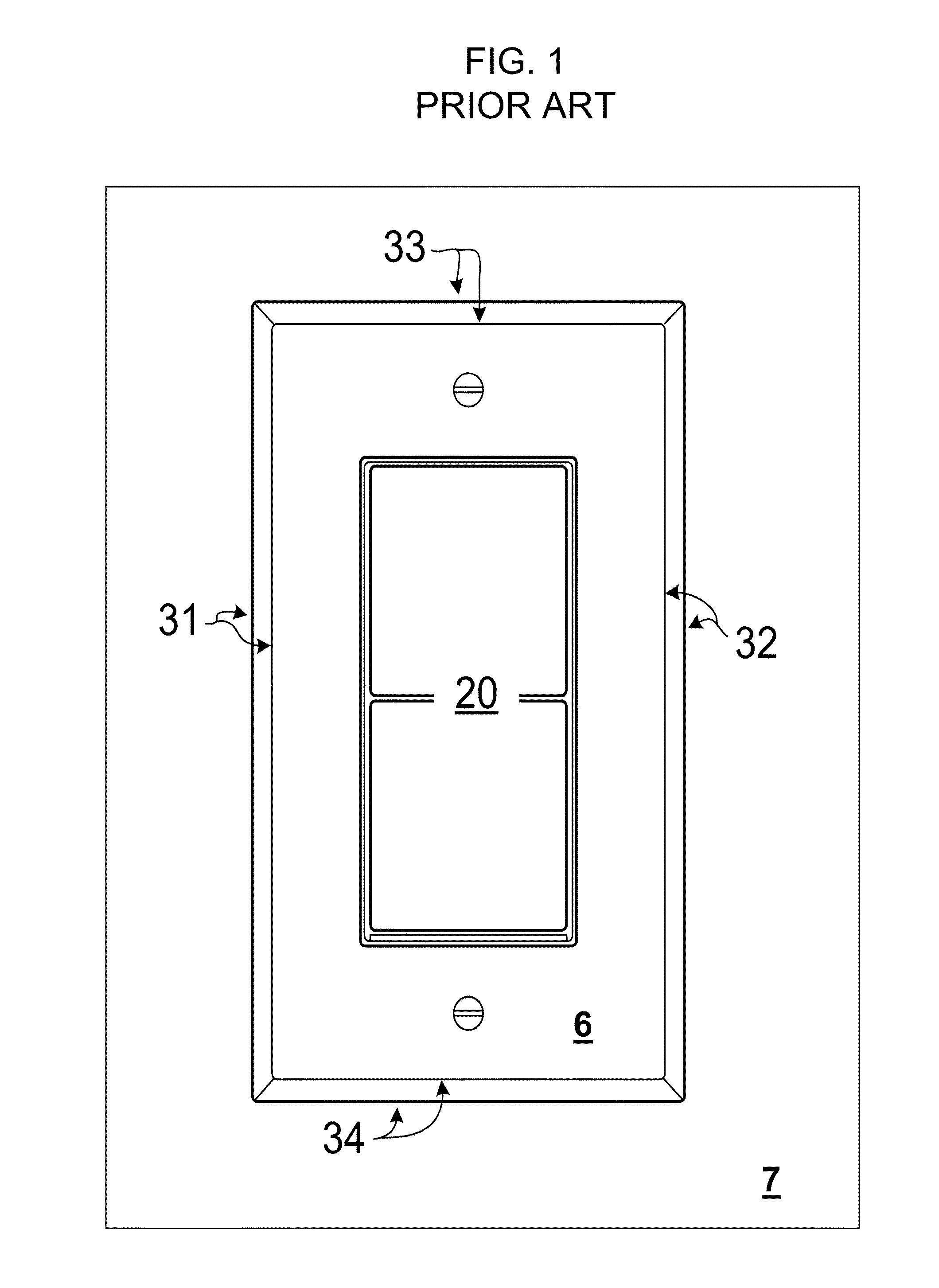

Occupant Counter Control Switch for automatic turning on and off electrical appliances in a room

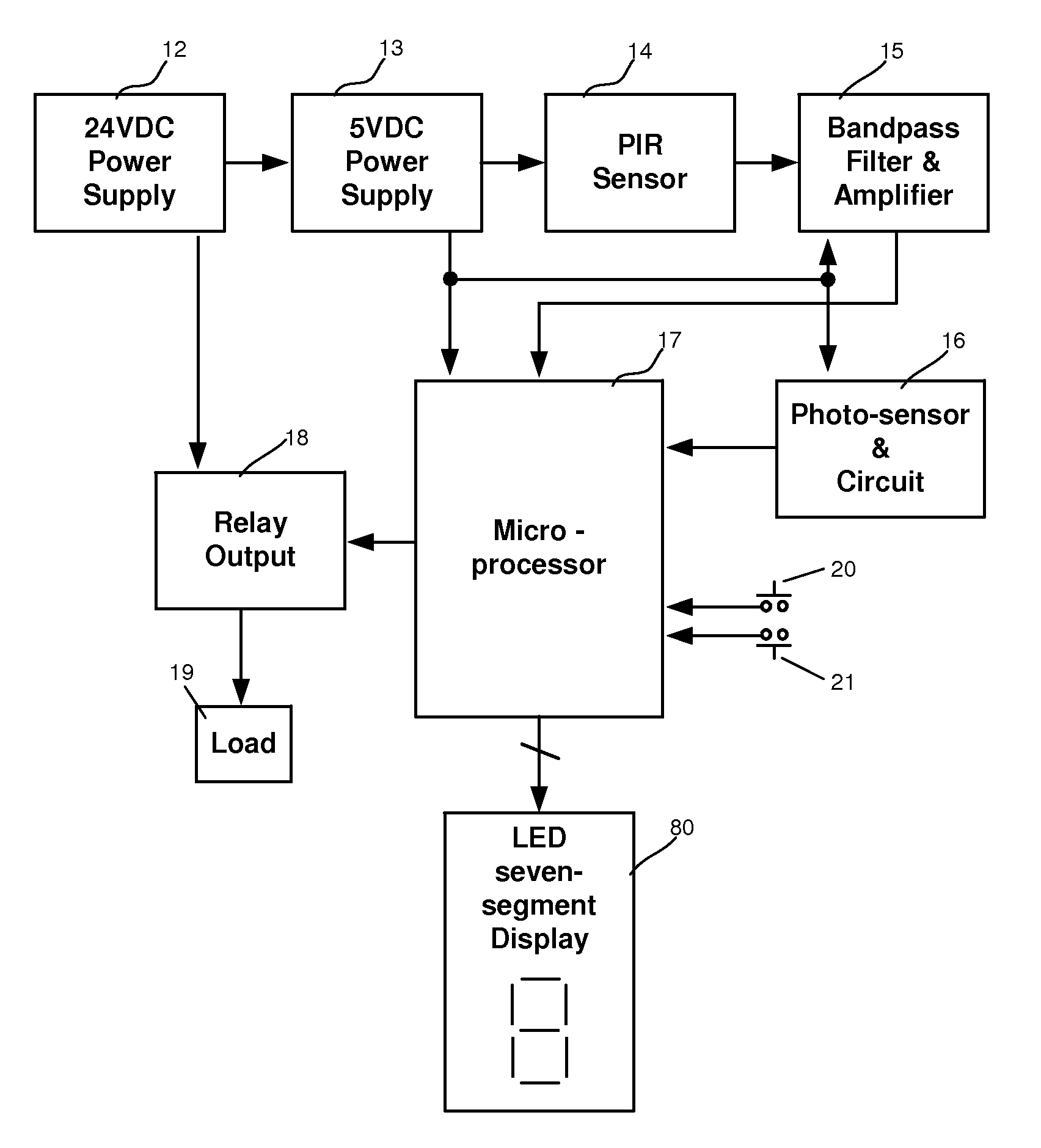

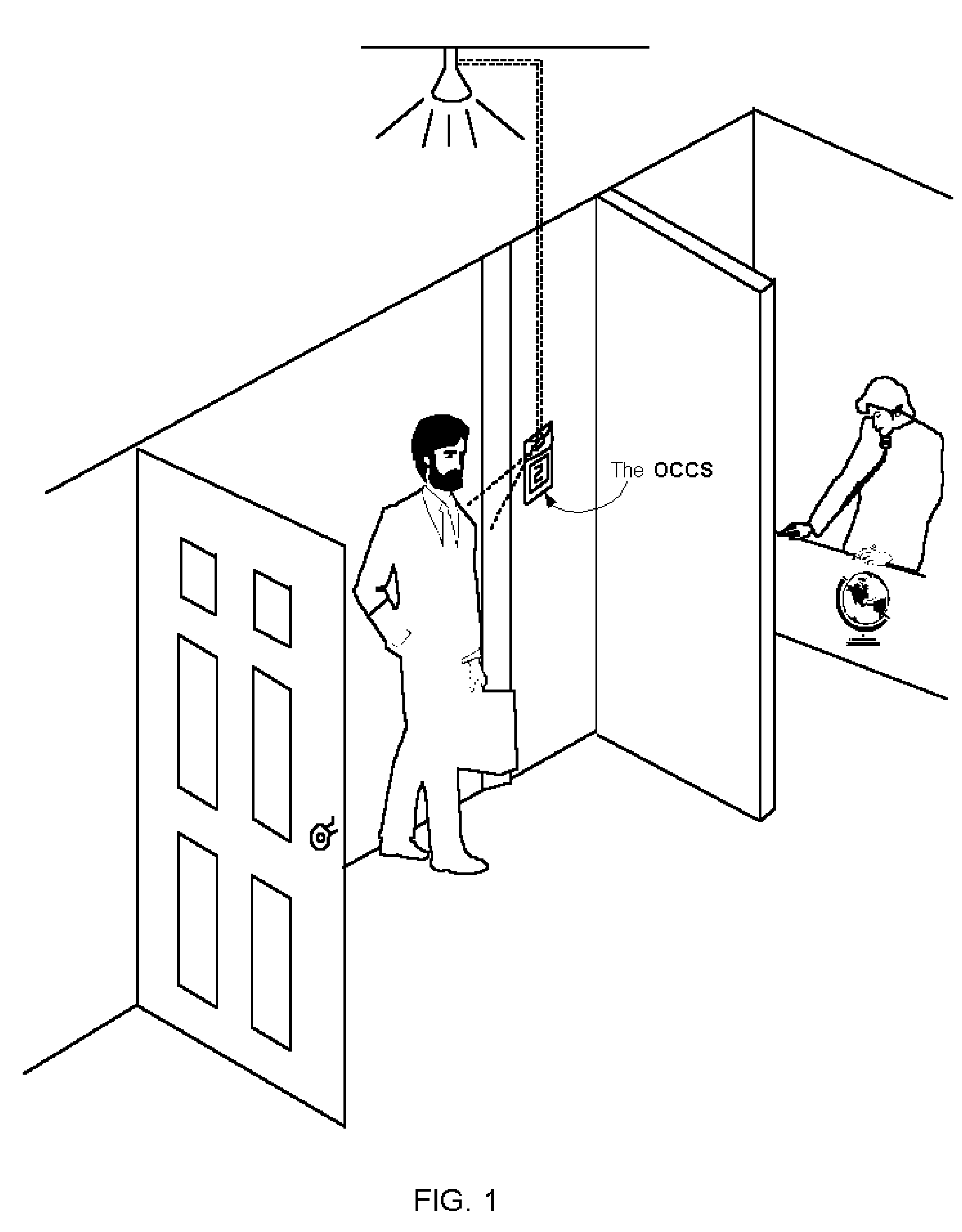

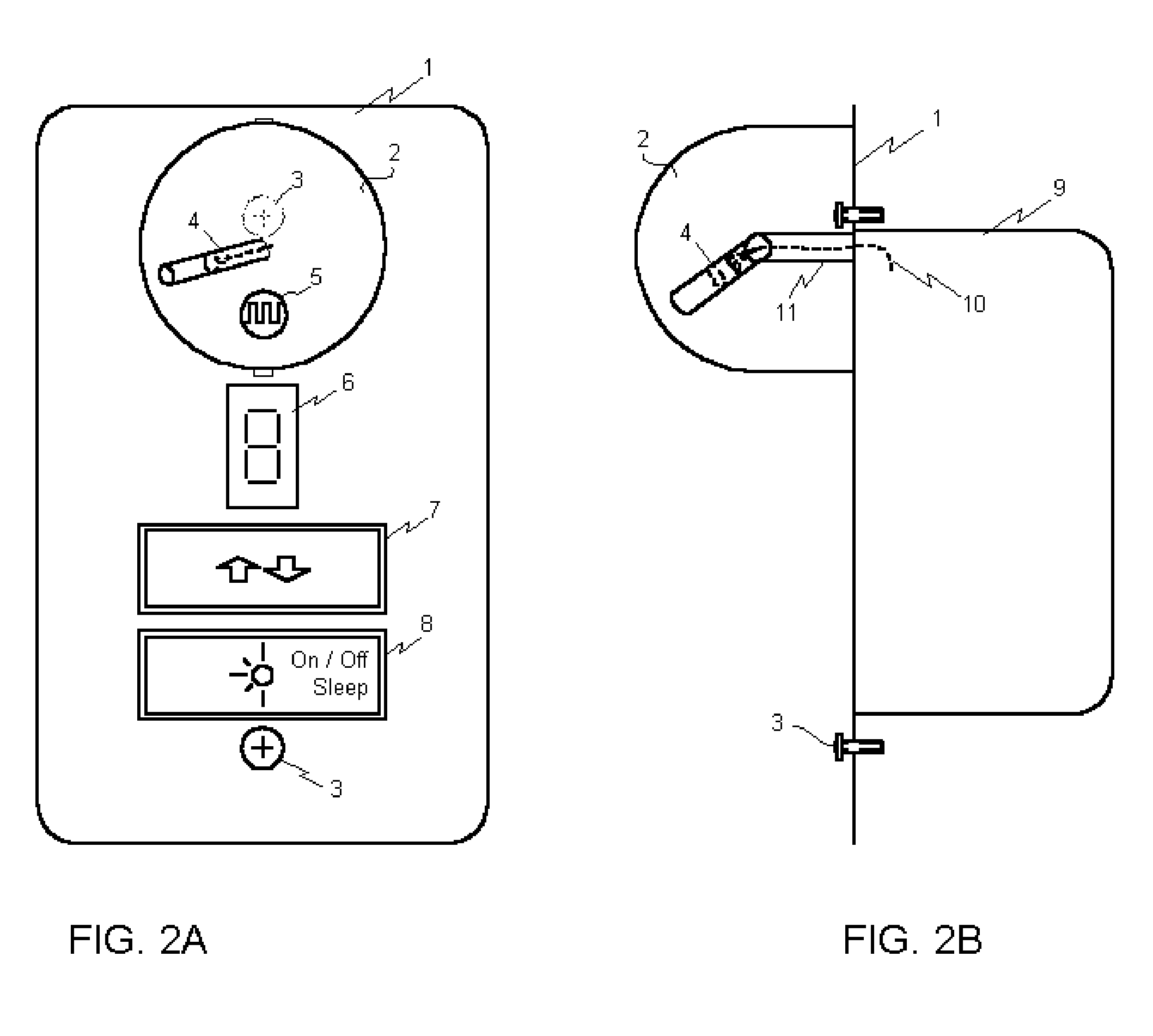

InactiveUS7155317B1Save energyEasy to changeProgramme controlBoards/switchyards circuit arrangementsAlone leftAudio power amplifier

A provided smart switch called Occupant Counter Control Switch, or OCCS, basically comprises of a motion sensor PIR, a photo sensor, an amplifier with band-pass filter, a microprocessor, a digital display, and a relay or triac to drive electrical appliances such as lights. The PIR sensor detects heat from a human body moving across it and generates a distinctive signal that is, unique to each of the two directions, further processed by the microprocessor for counting and thereby controlling the relay. Installed at the entrance of a room replacing the regular switch (see FIG. 1), the OCCS counts up, displaying a digit great than zero, upon detecting a person entering the room and turns on the lights if sensing insufficient ambient light. OCCS constantly energizes the lights during the room is occupied and immediately switches them off upon counting down to zero when detecting the last person exiting the room.

Owner:TRAN NHAN

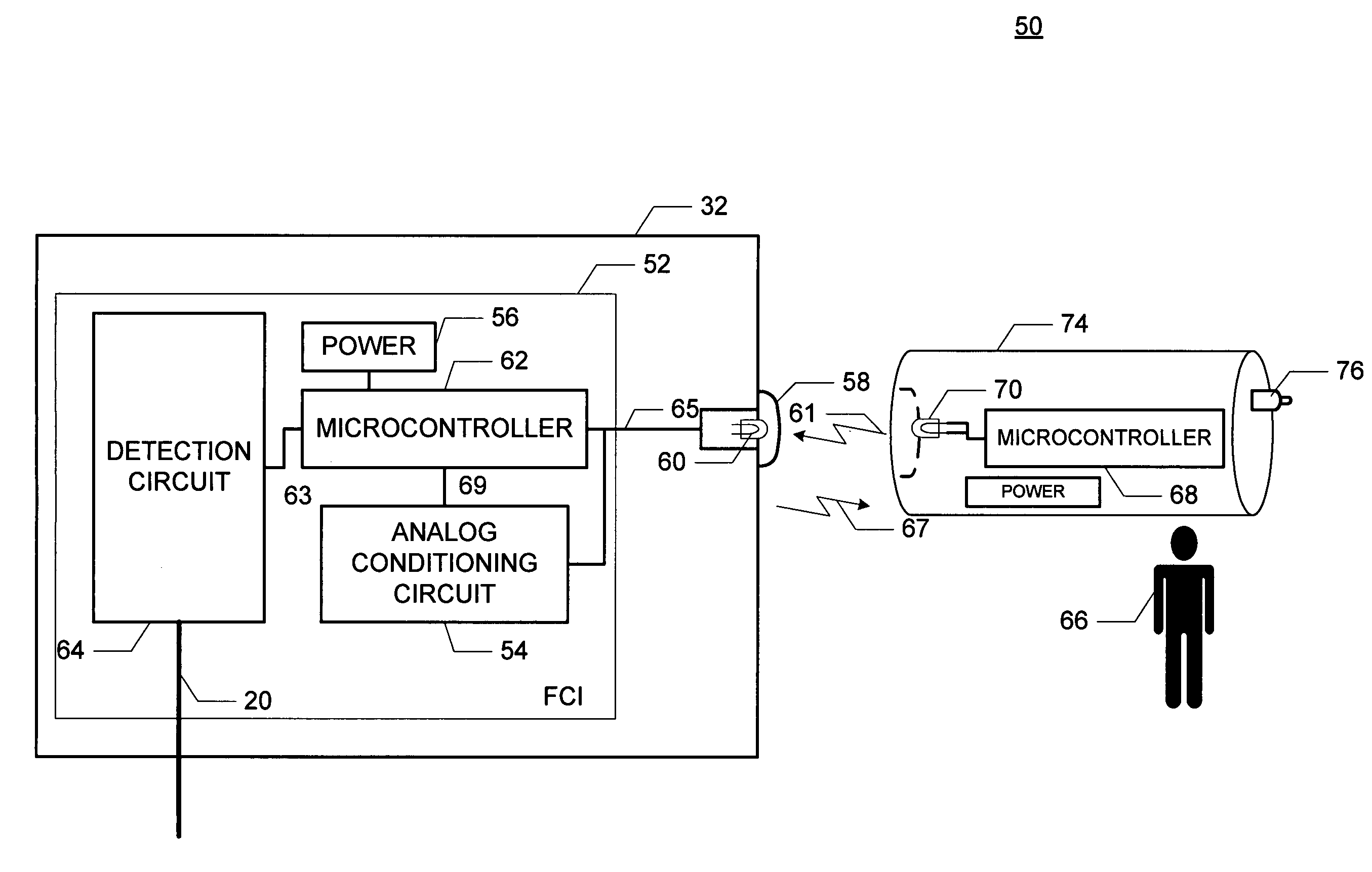

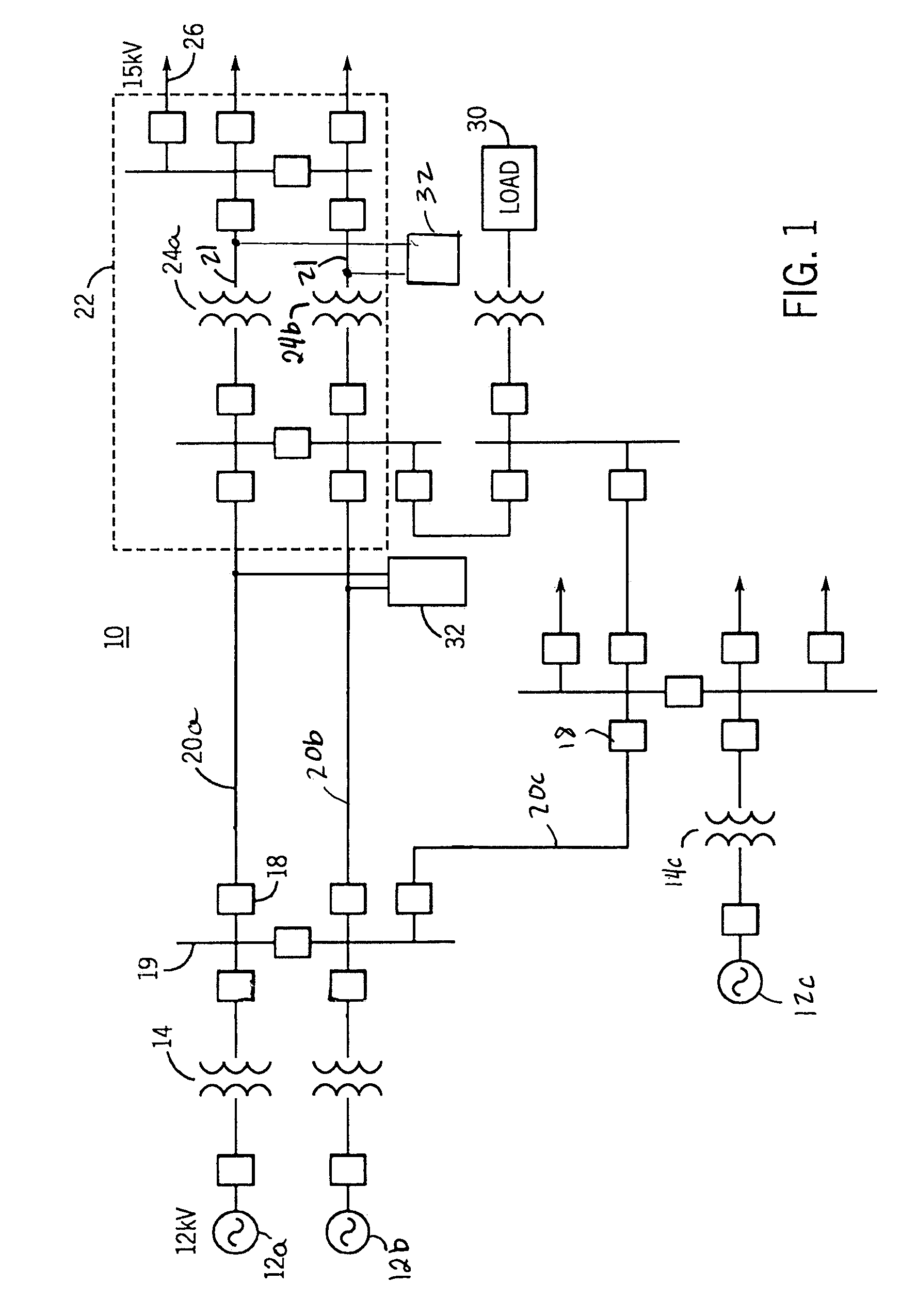

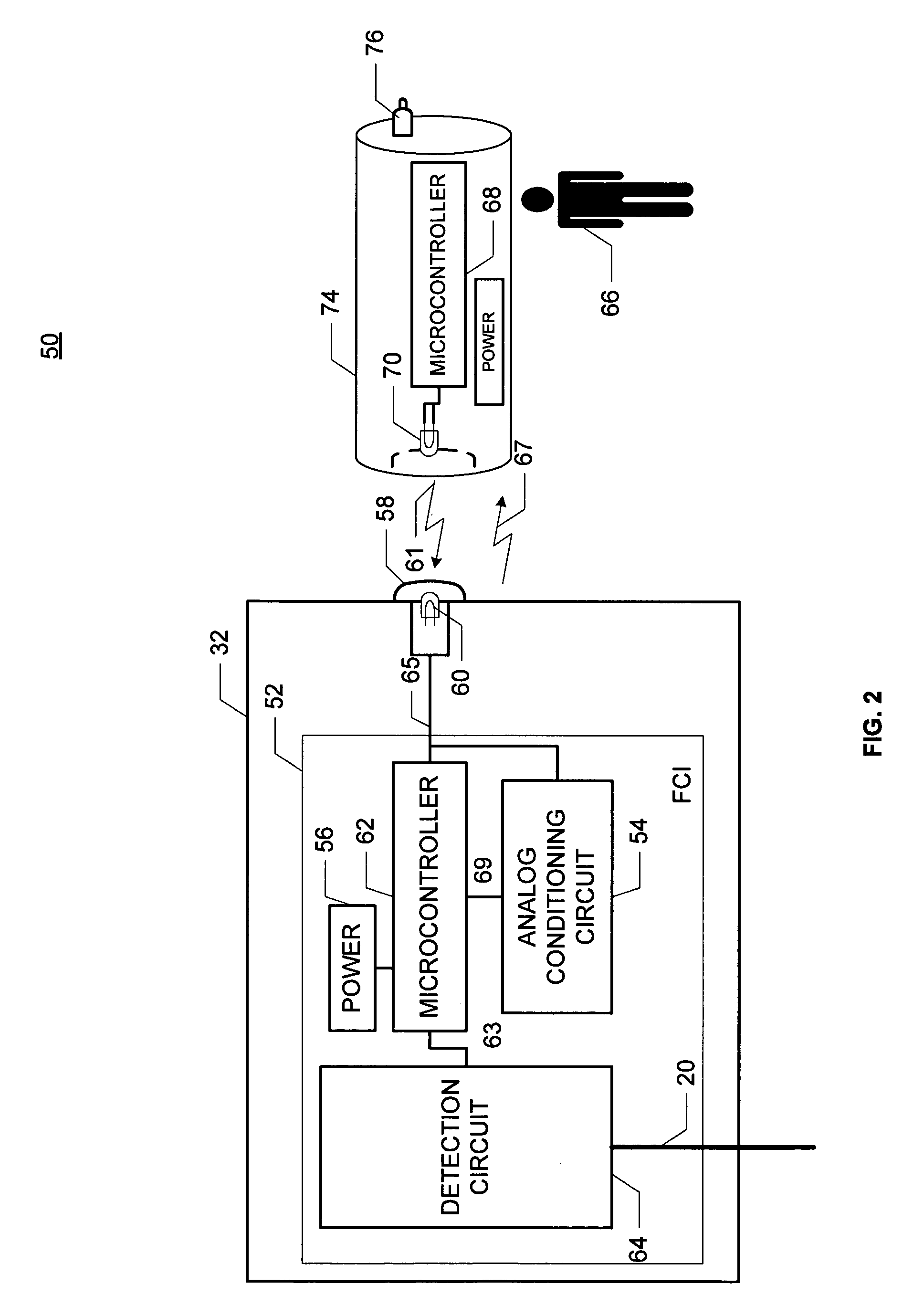

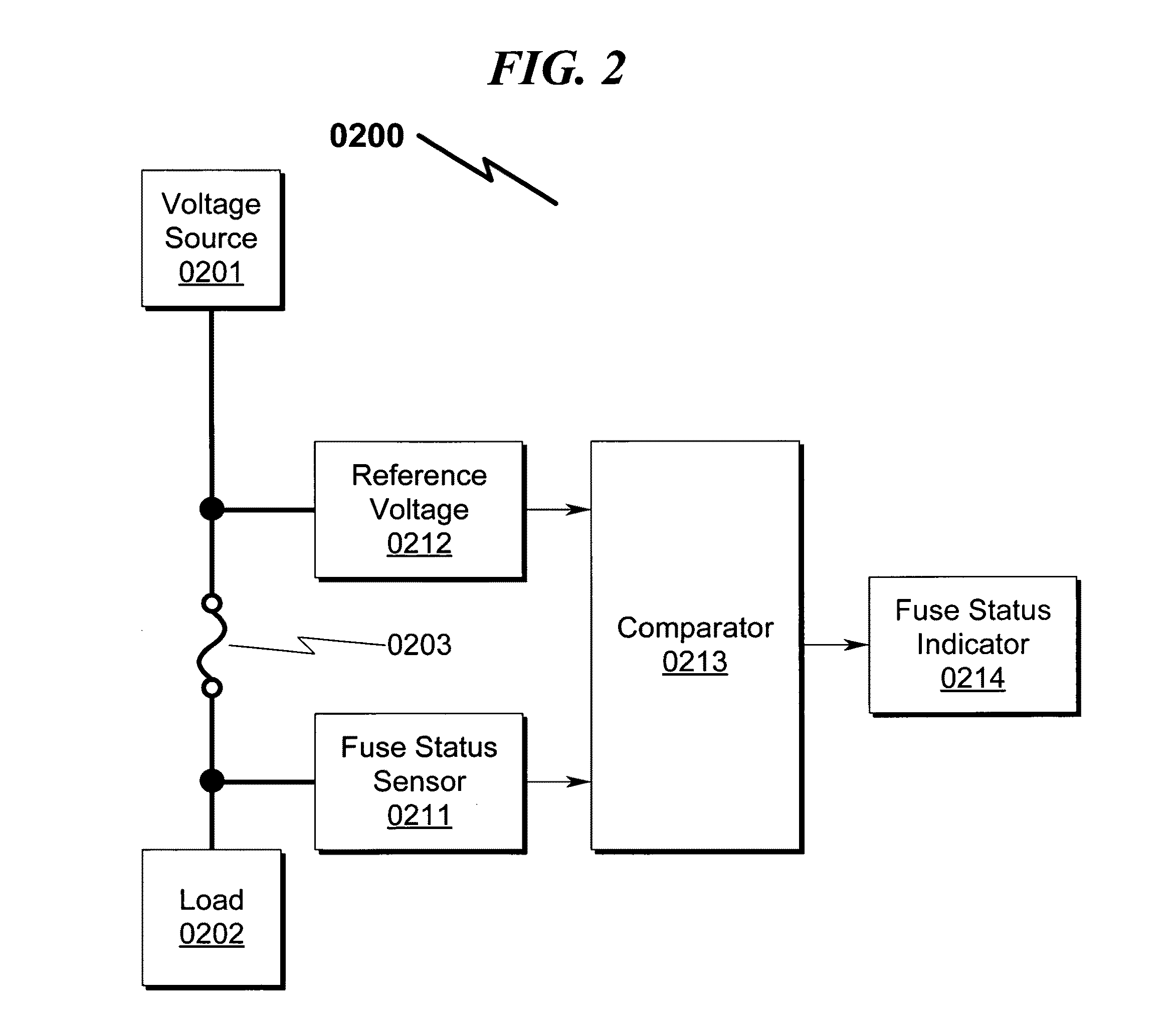

System, a tool and method for communicating with a faulted circuit indicator using a remote display

ActiveUS7382272B2Frequency-division multiplex detailsElectric testing/monitoringMicrocontrollerElectrical conductor

Owner:SCHWEITZER ENGINEERING LABORATORIES

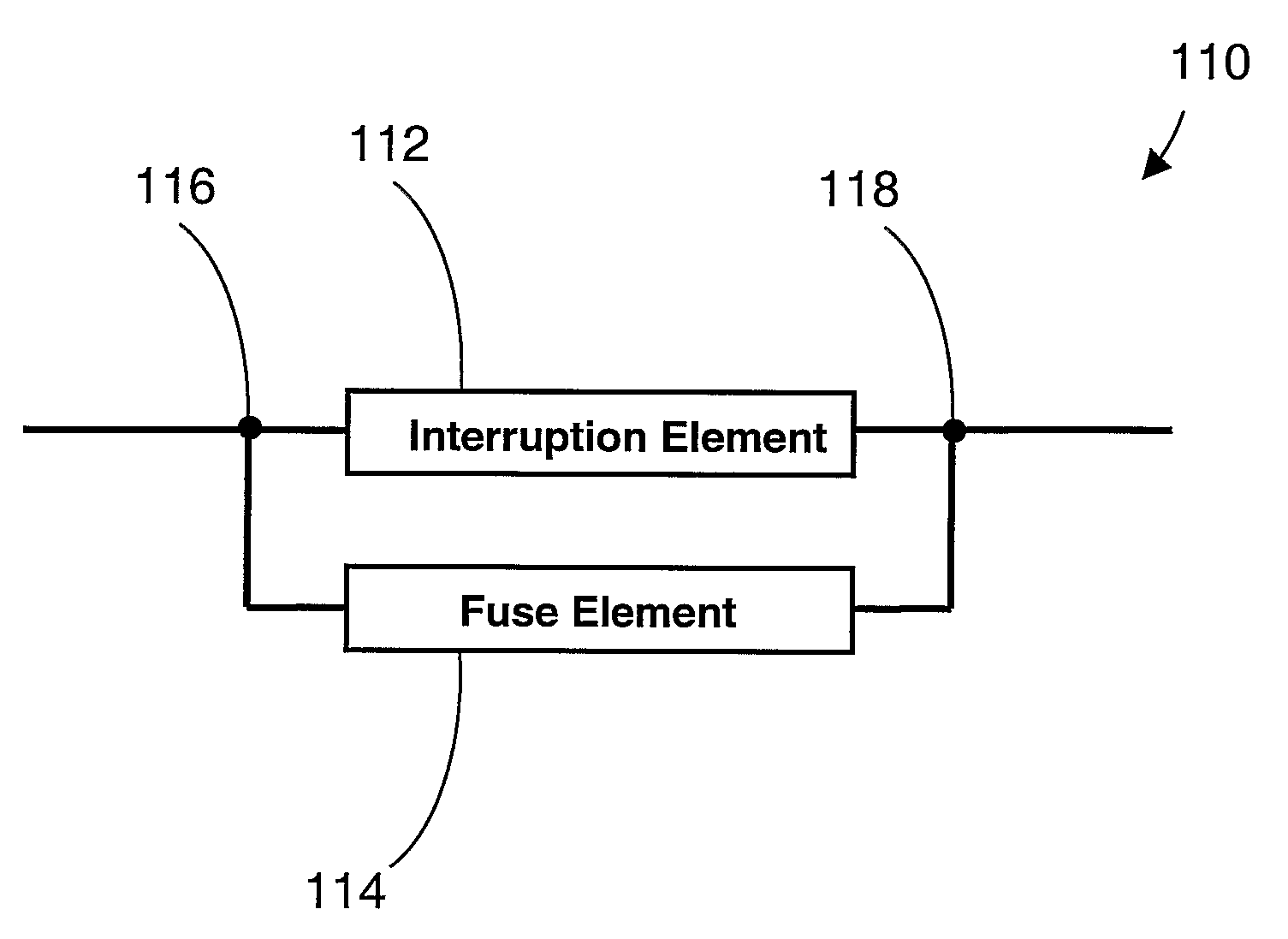

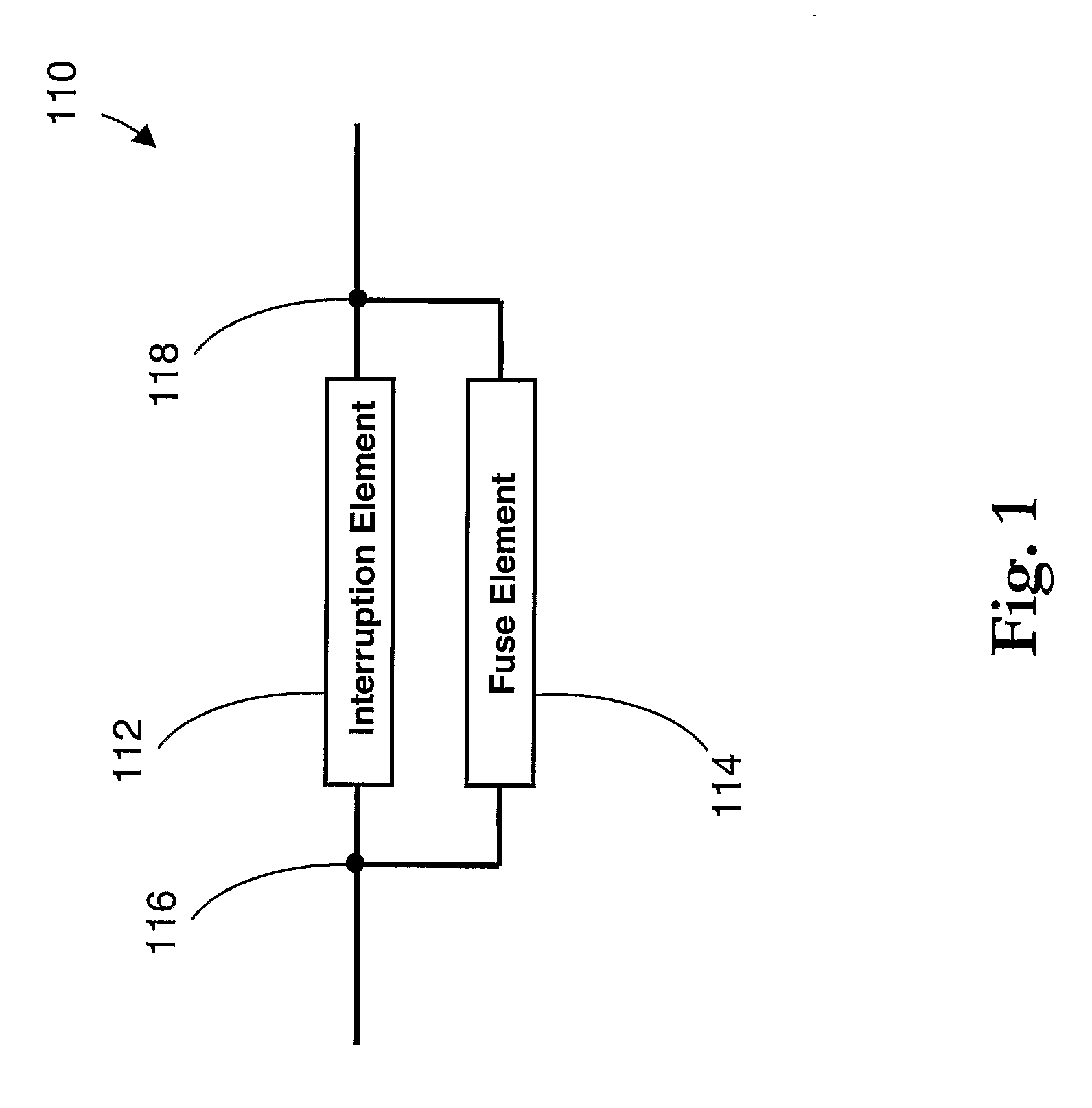

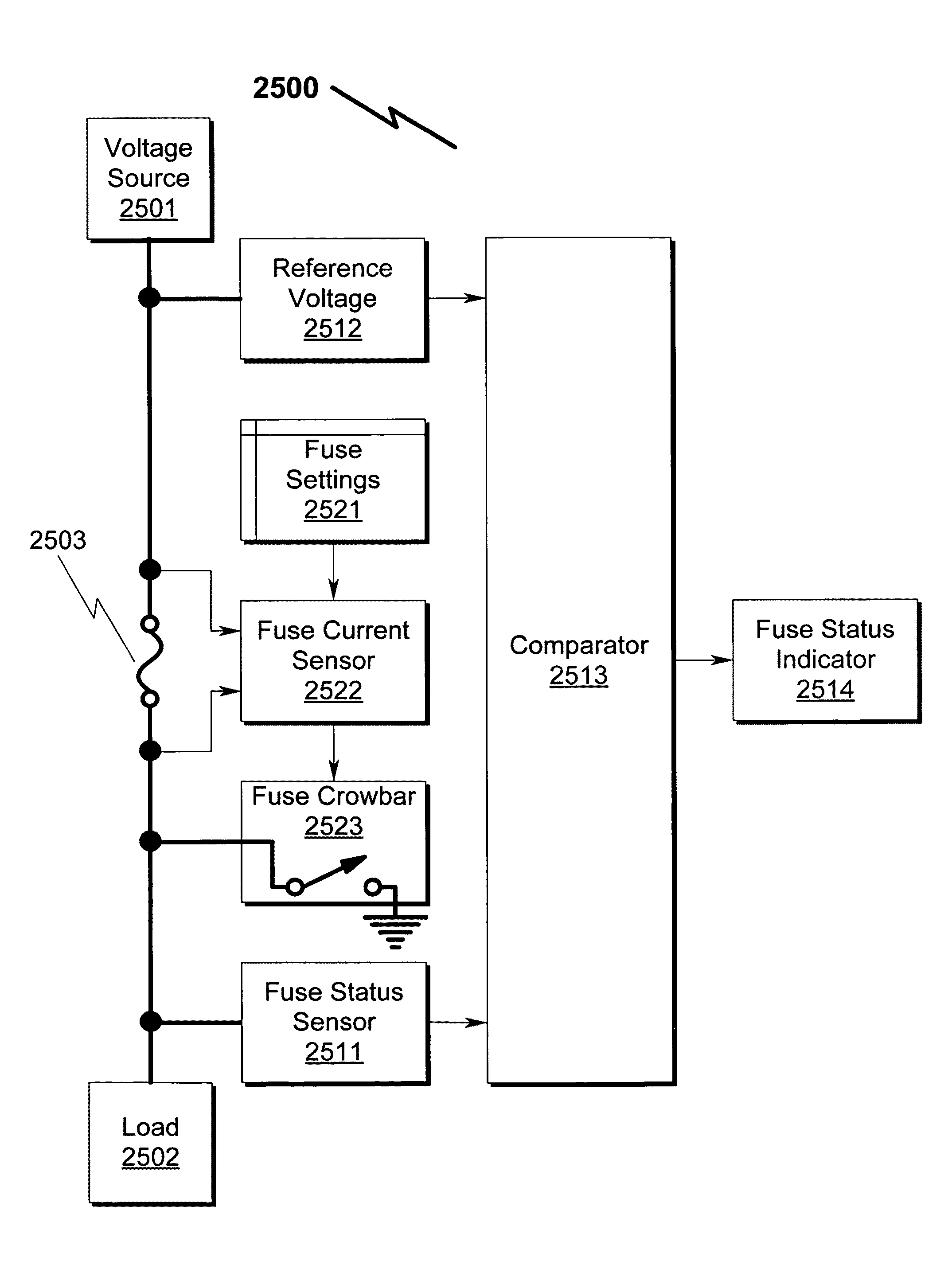

Circuit Interruption Device

ActiveUS20080137253A1Reduce capacityBoards/switchyards circuit arrangementsConductor severing switchesElectrical conductorControl signal

A circuit interruption device (110) is provided in which an interruption element (112) and a fuse element (114) are configured electrically in parallel. The interruption element includes an electrical conductor and a current interrupter capable of severing the electrical conductor to eliminate its capacity to carry current. An exemplary embodiment of a circuit interruption device is capable of detecting an interrupt control signal and actuating in response to the signal.

Owner:APTIV TECH LTD

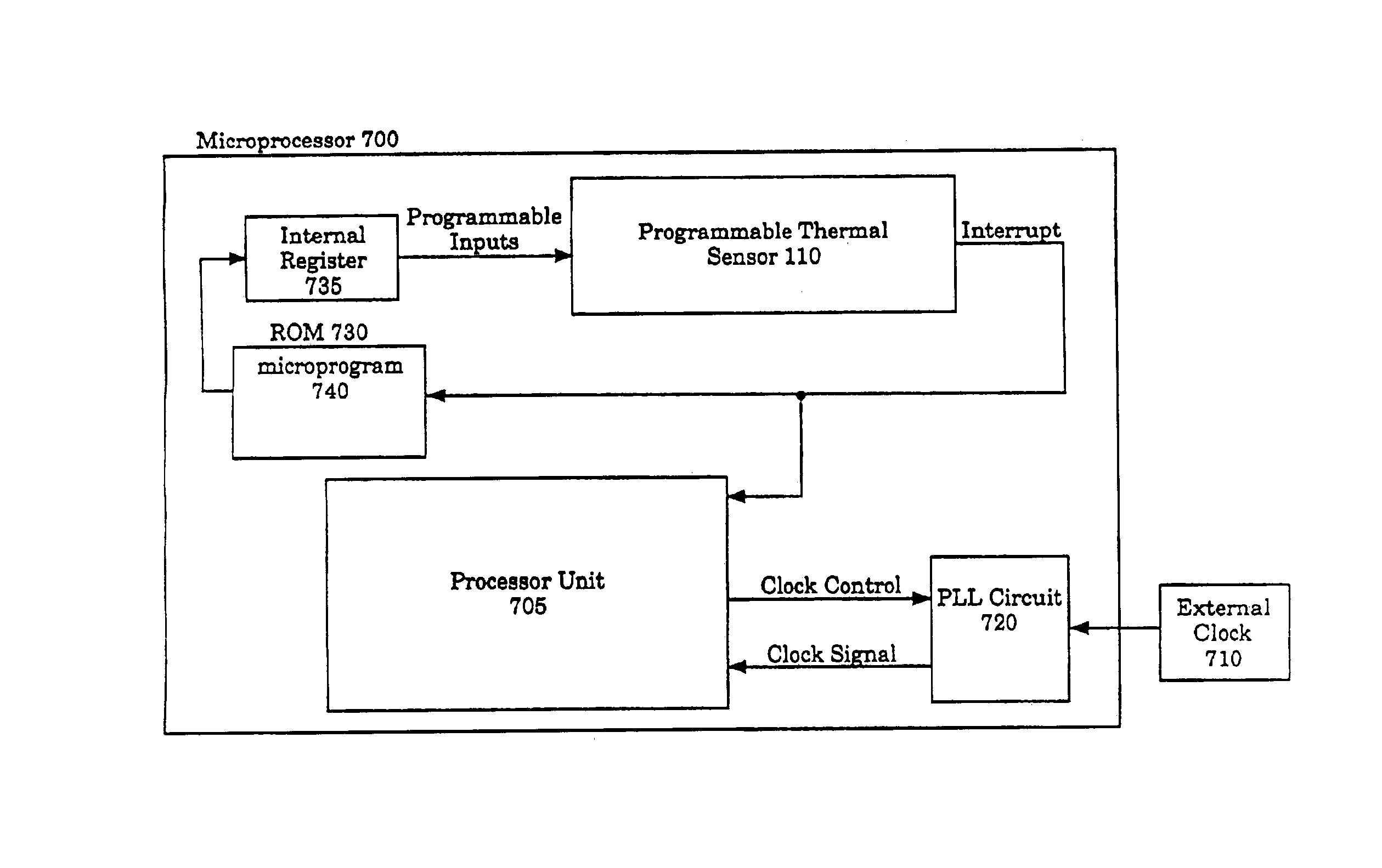

Temperature-based cooling device controller apparatus and method

InactiveUS6975047B2Reduce clock frequencySystem clock frequency is increasedEnergy efficient ICTDigital data processing detailsProcessor registerThreshold temperature

A temperature-based cooling device controller is implemented in an integrated circuit such as a microprocessor. The temperature-based cooling device controller includes a register to store a threshold temperature value, a thermal sensor, and clock adjustment logic to activate a cooling device in response to the thermal sensor indicating that the threshold temperature value has been exceeded. In a microprocessor implementation, the microprocessor contains a plurality of thermal sensors each placed in one of a plurality of different locations across the integrated circuit and an averaging mechanism to calculate an average temperature from the plurality of thermal sensors. Threshold adjustment logic increases the threshold temperature value to a new threshold temperature value in response to the thermal sensor indicating that the threshold temperature value has been exceeded. Threshold adjustment logic further lowers the new threshold temperature to detect decreases in temperature.

Owner:INTEL CORP

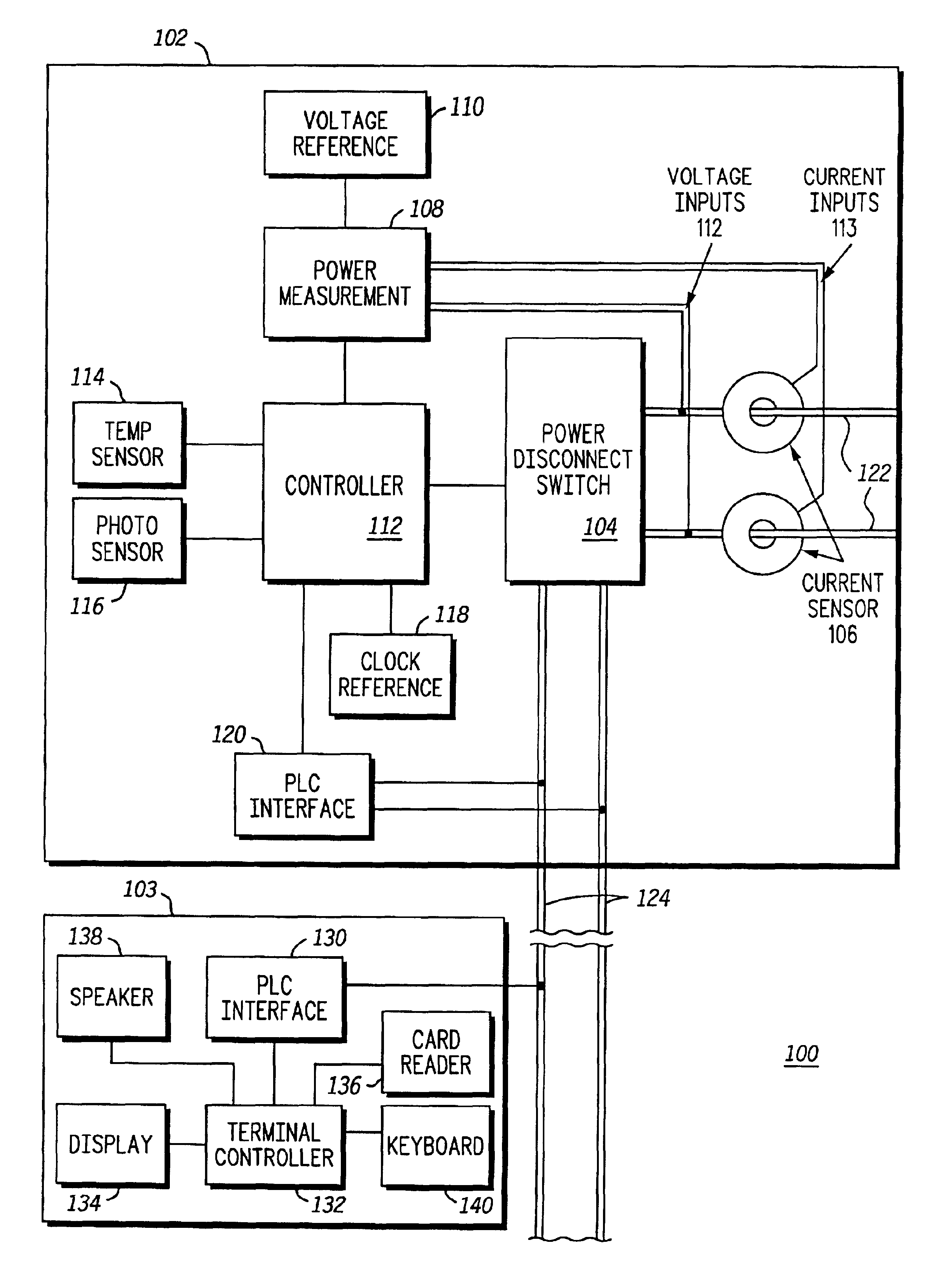

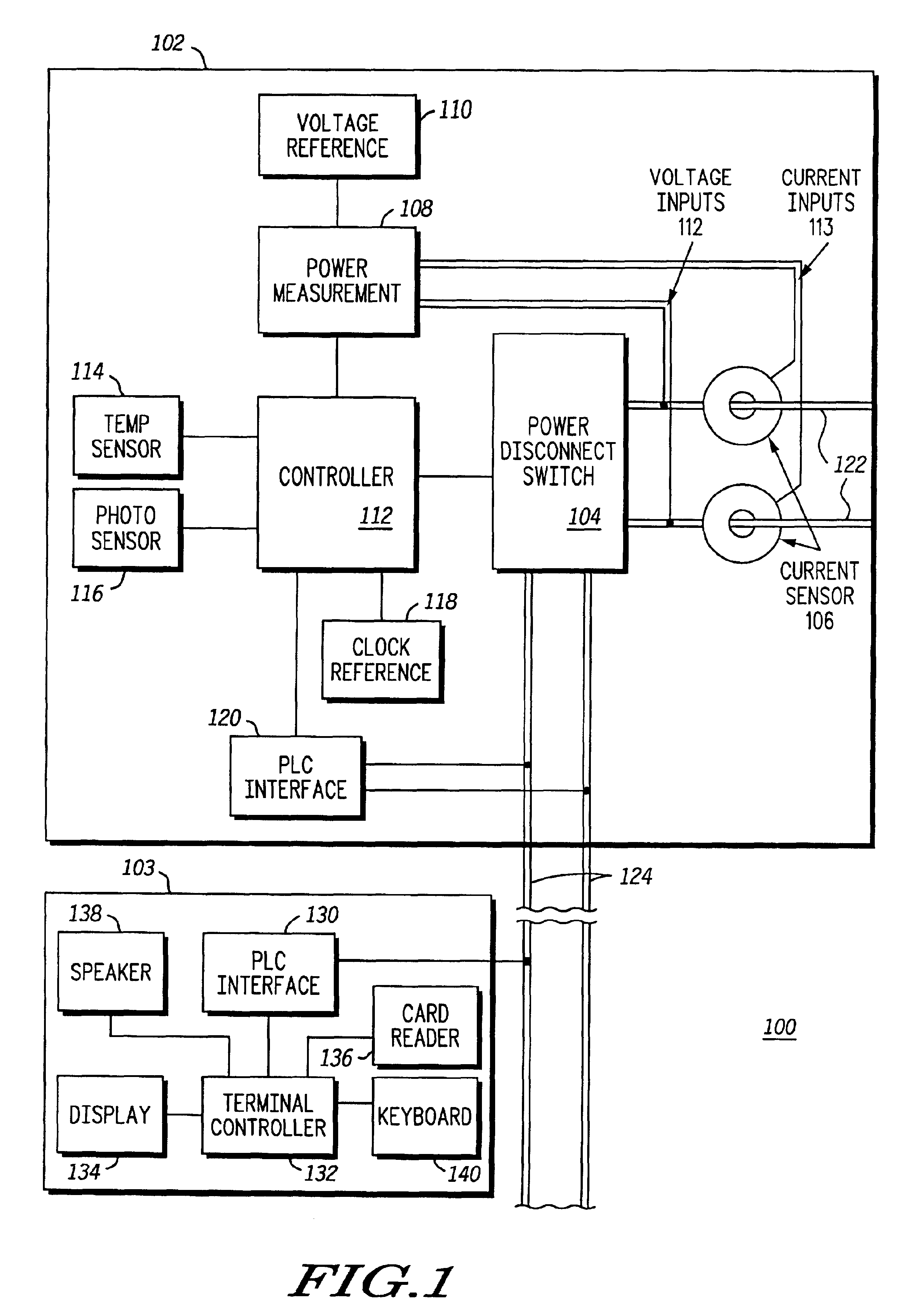

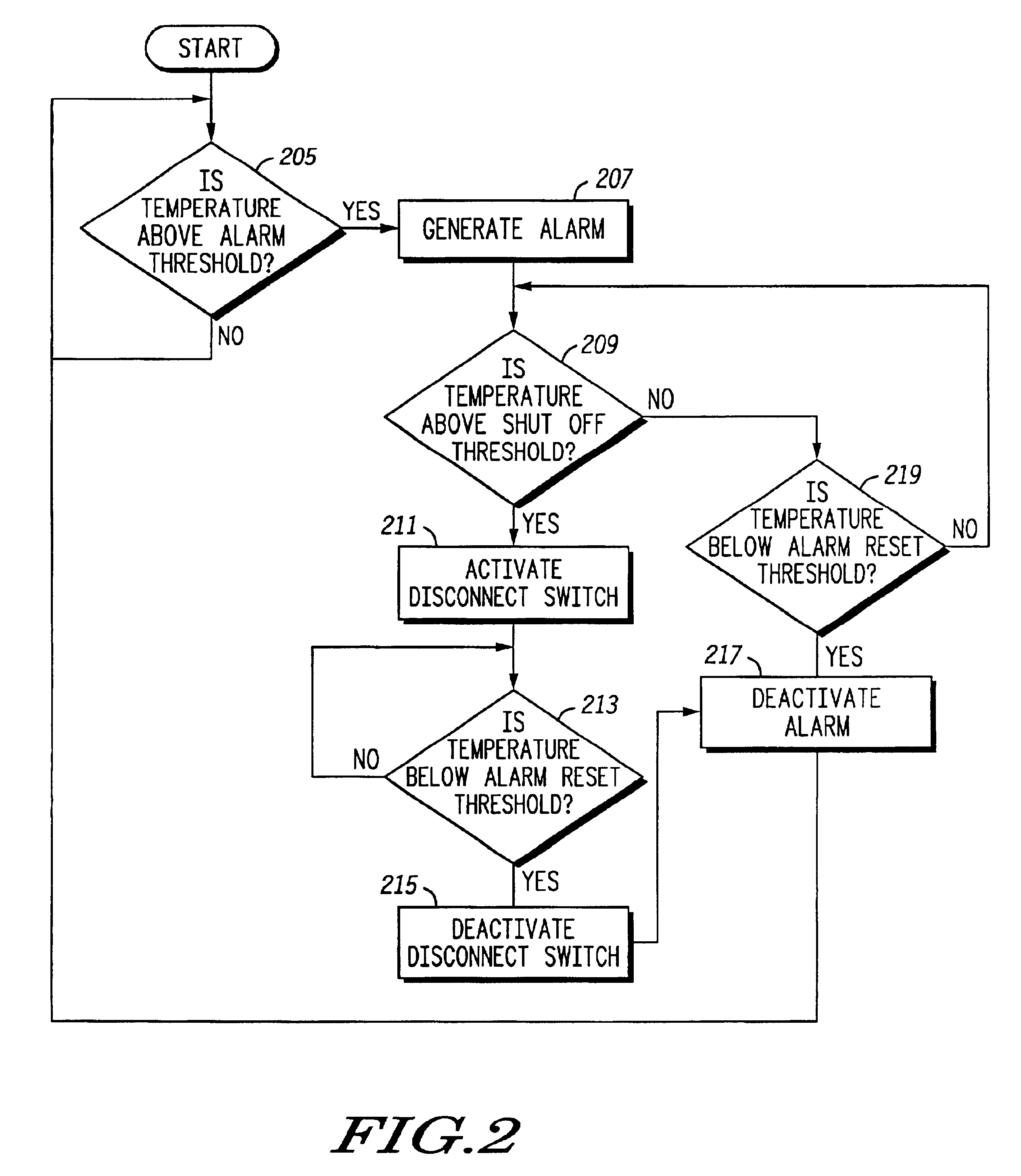

Electric power meter including a temperature sensor and controller

InactiveUS6847300B2Electric signal transmission systemsBoards/switchyards circuit arrangementsElectric power systemEngineering

An electric power meter (102) includes a temperature sensor (114) and a controller (112). The controller (112) is operable, based on the temperature reported from the temperature sensor (114), to generate alarm(s) when the temperature exceeds certain alarm threshold(s) (307, 507, 508) and to activate a power disconnect switch (104), thereby shutting off power to a customer premises, when the temperature exceeds a shut off threshold (309, 509). The controller (112) is operable to activate the power disconnect switch (104) for non-payment of electricity cost, subject to secondary criteria based on regulatory requirements. A customer terminal (103) may be used to notify a customer of an alarm condition, to provide information regarding electrical power usage or to provide information regarding disconnection of electrical power.

Owner:MOTOROLA SOLUTIONS INC

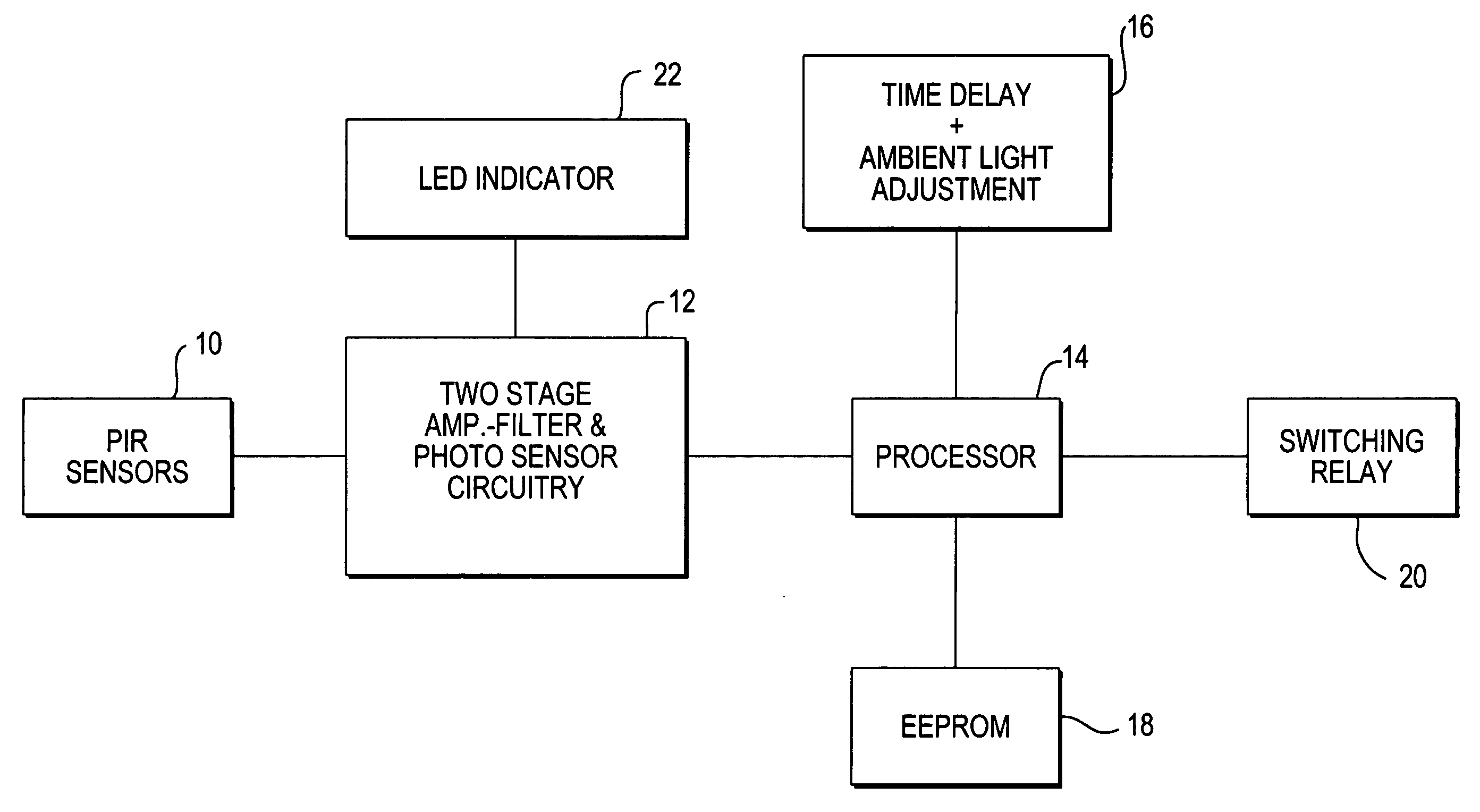

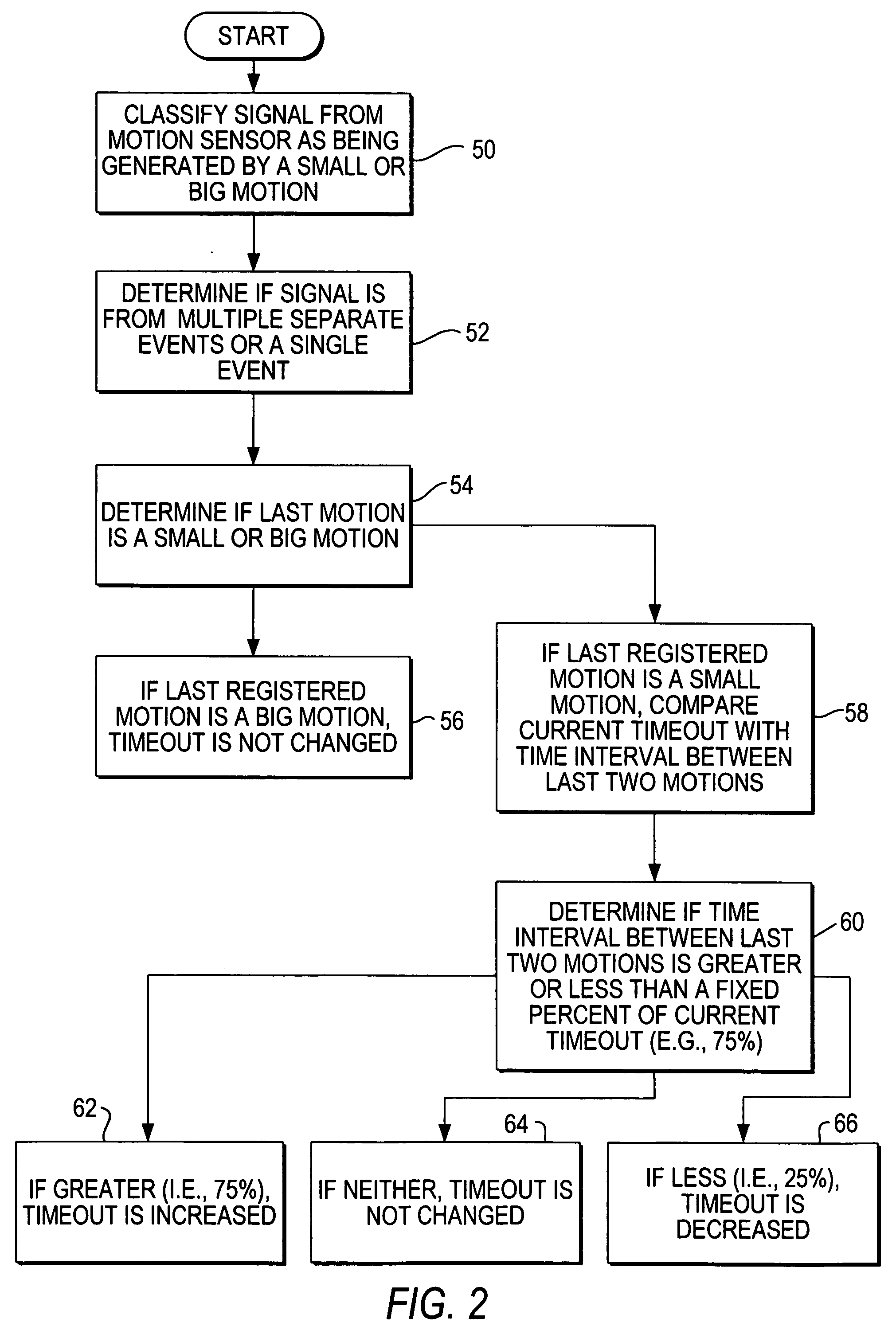

Passive infrared motion sensor

InactiveUS20060125624A1Reduce usageShorter timeoutBoards/switchyards circuit arrangementsThermally actuated switchesEngineeringMotion sensors

An intelligent occupancy sensor, such as a Passive InfraRed (PIR) sensor, with variable adaptive timeout. When a person first walks into the room and, after a very short time, walks out of the room, the occupancy sensor operates with a short timeout. When, however, a person lingers in the room, the occupancy sensor switches to another mode of operation where the timeout increases or decreases based on the frequency that the sensor detects motion in the room and the amplitude and / or duration of the signal of the detected motion.

Owner:LEVITON MFG

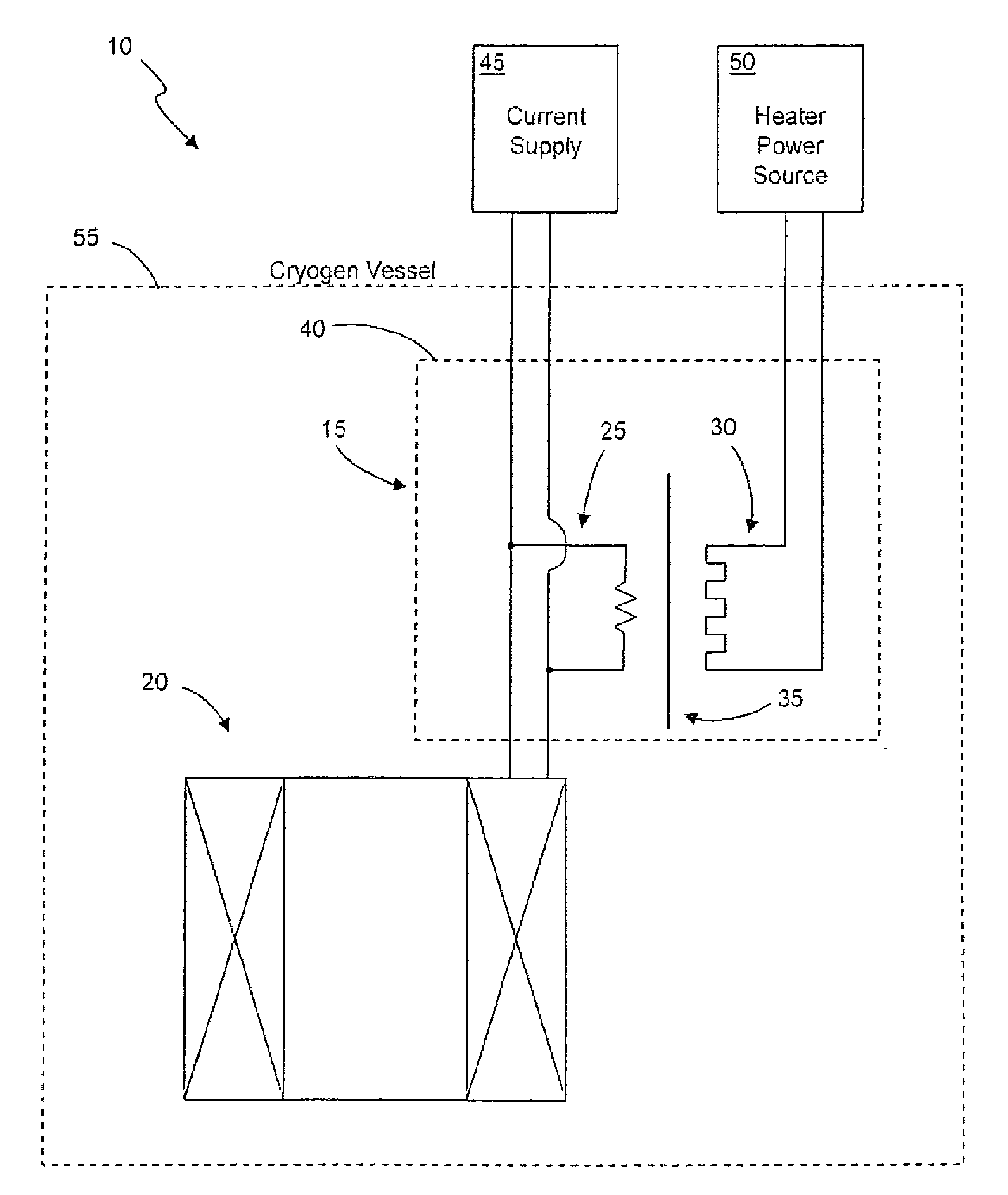

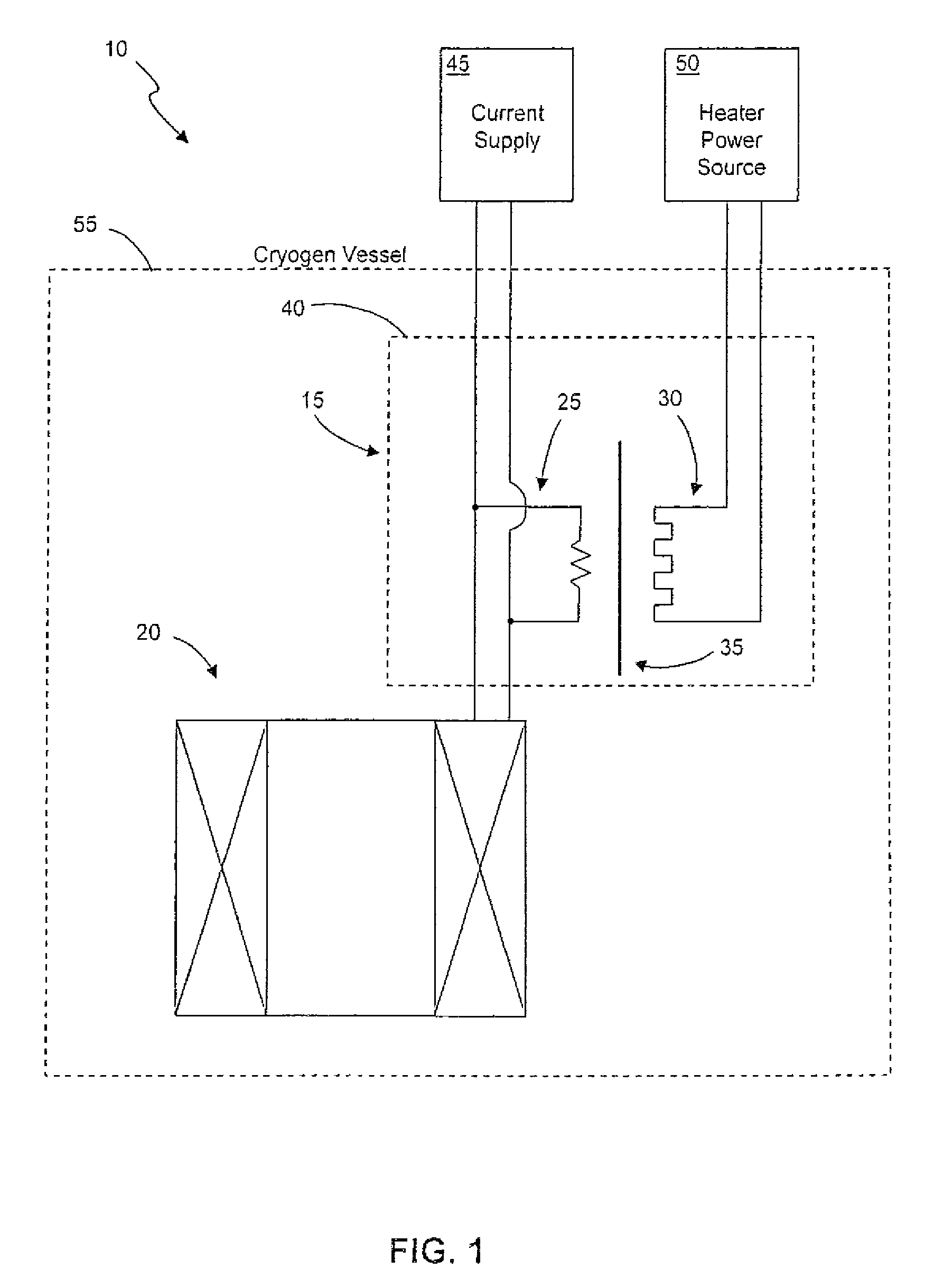

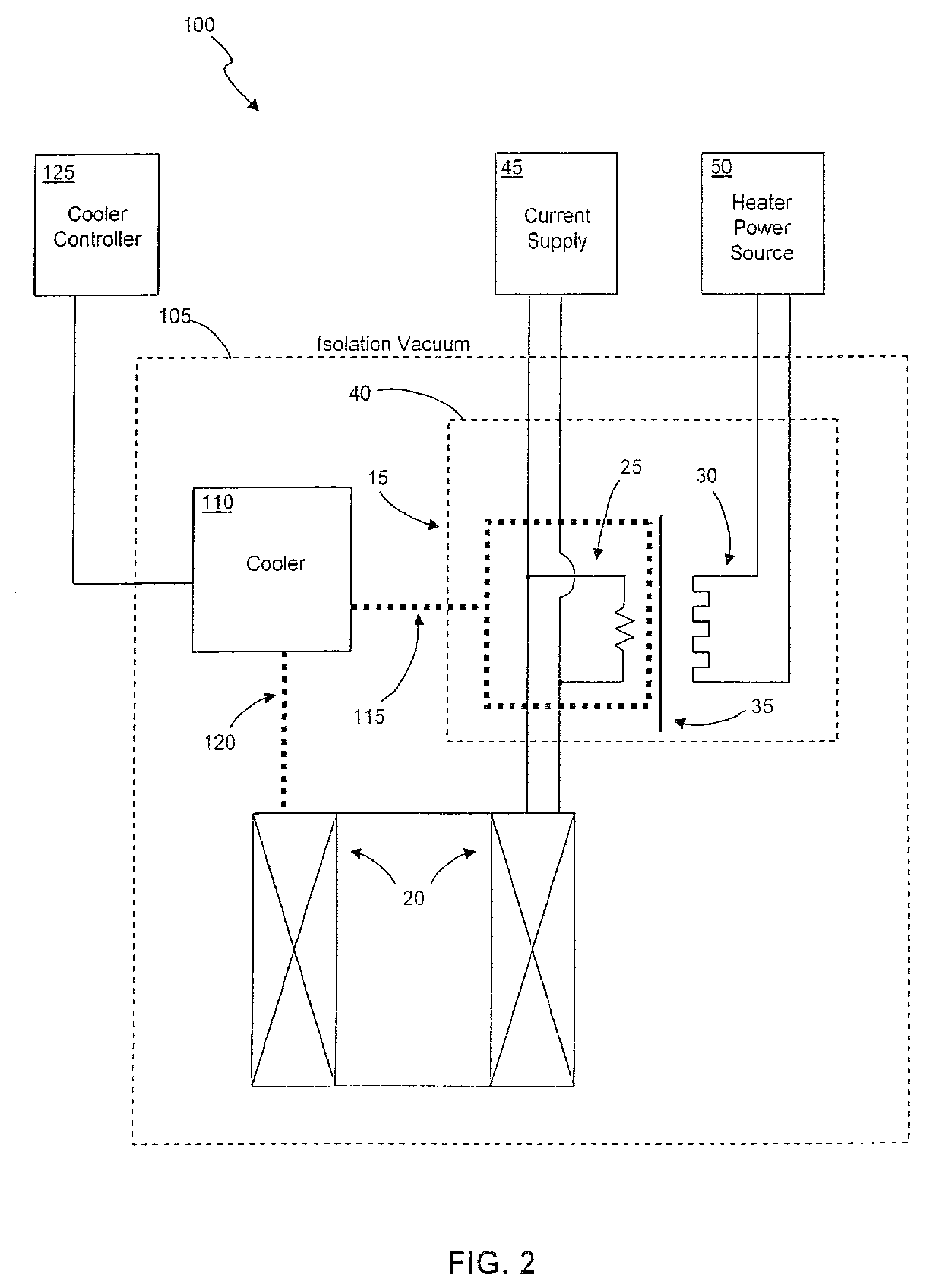

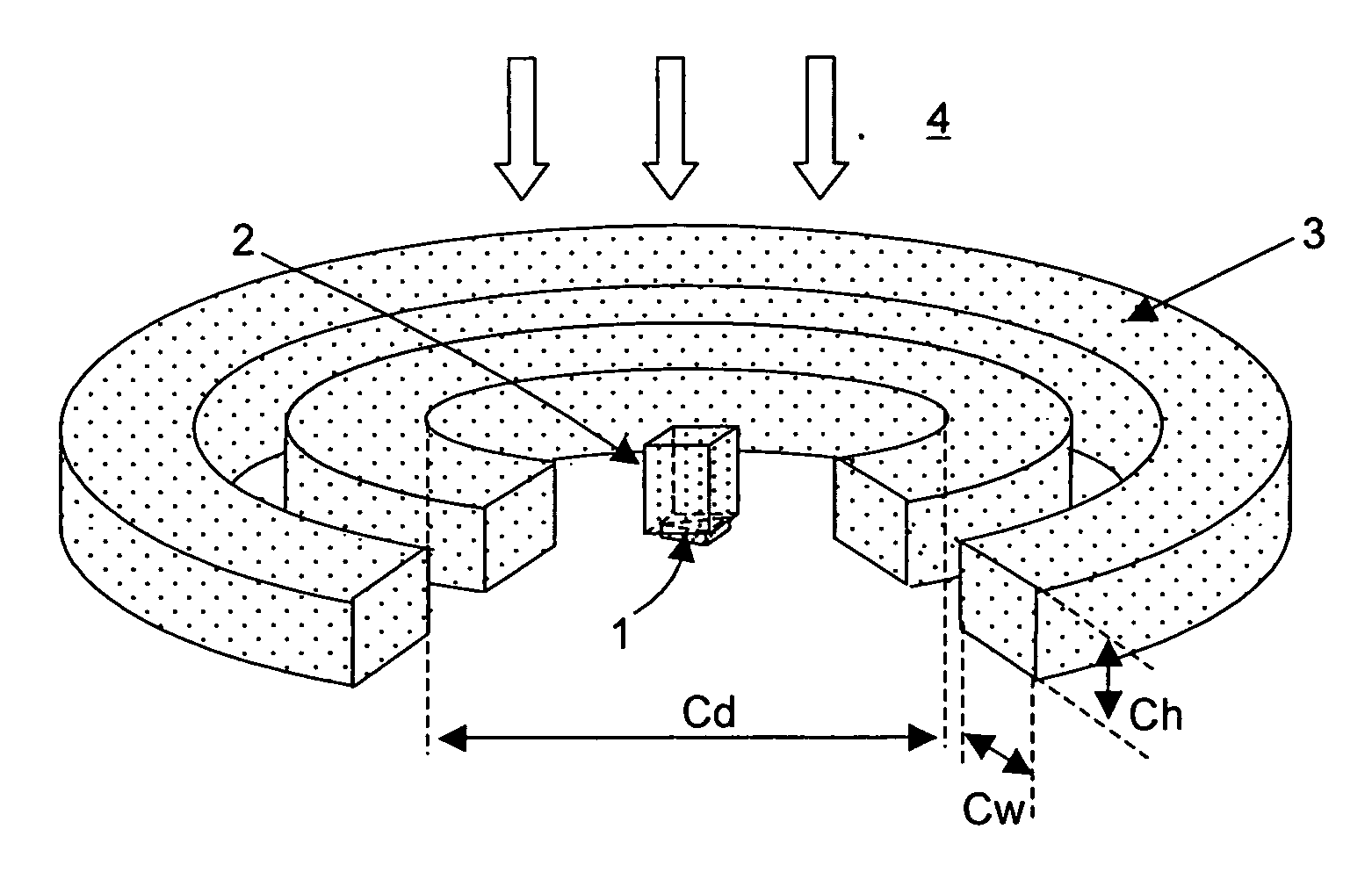

Superconducting quick switch

A magnet system for generating a magnetic field may include a superconducting magnet, a switch, and a heater element thermally coupled to the switch. The superconducting magnet is structured to generate magnetic fields, and the switch includes a non-inductive superconducting current carrying path connected in parallel to the superconducting magnet. In general, the switch is structured to only carry a level of current that is a portion of the current required to obtain a full field by the superconducting magnet.

Owner:QUANTUM DESIGN

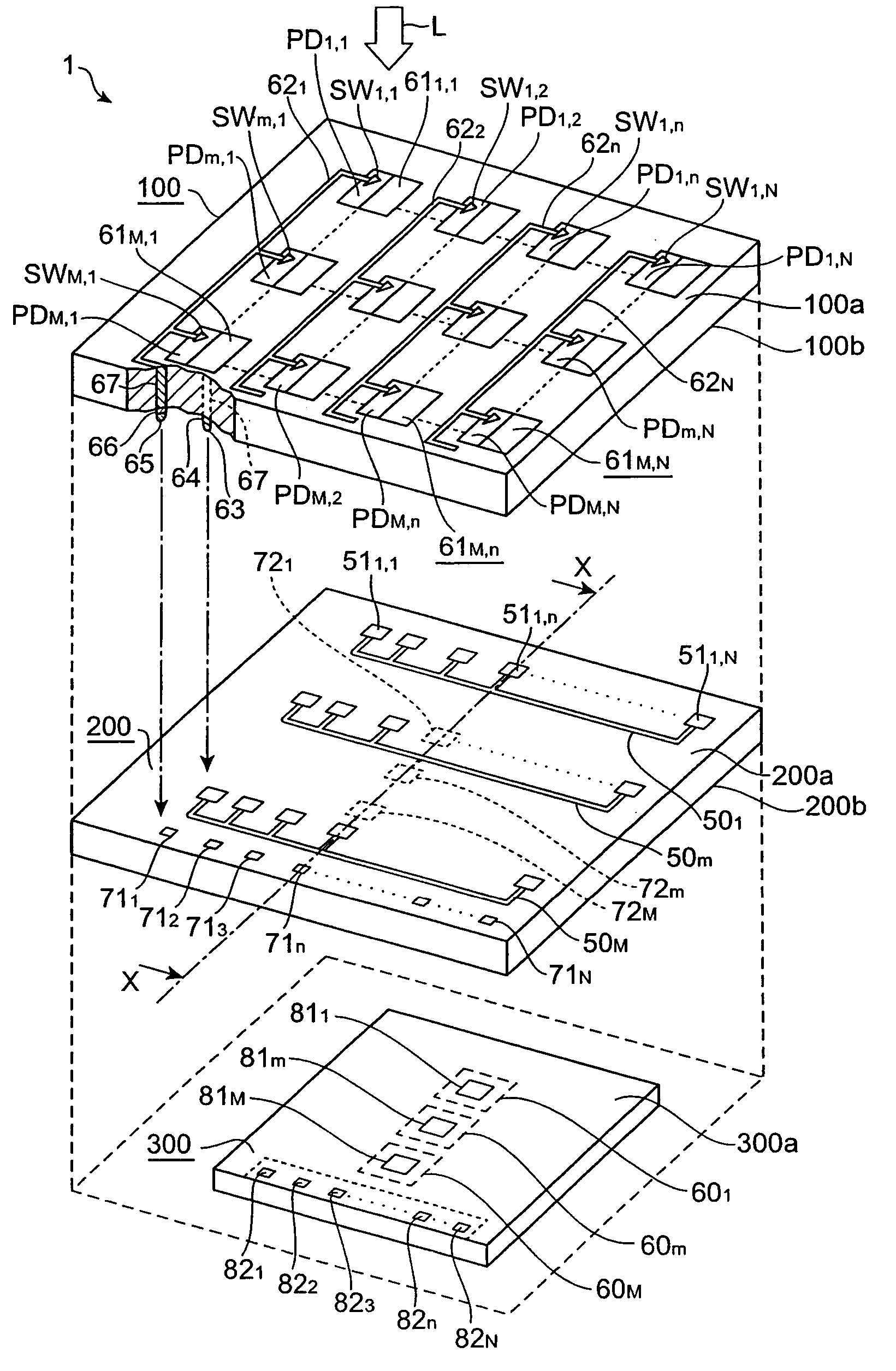

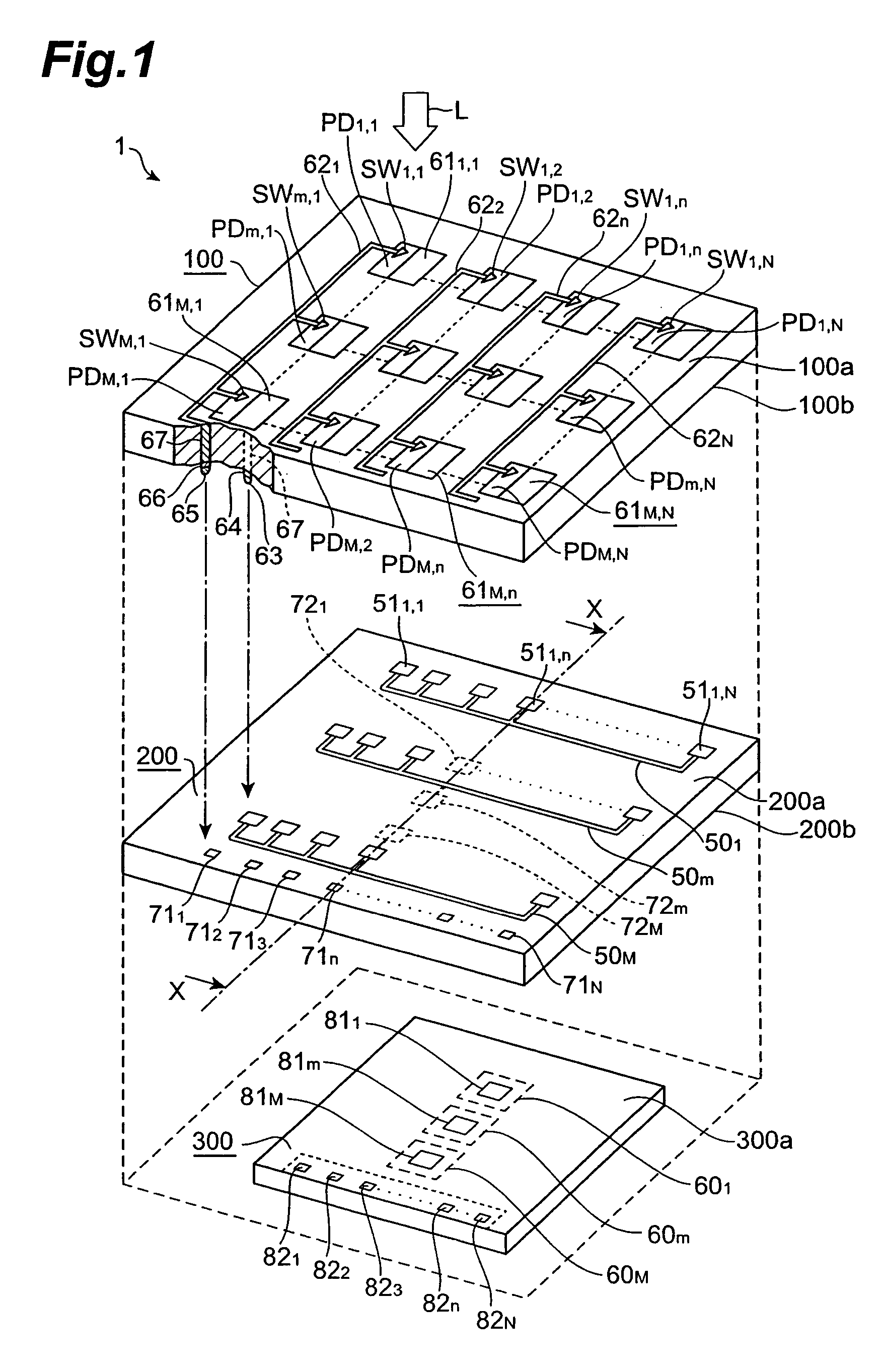

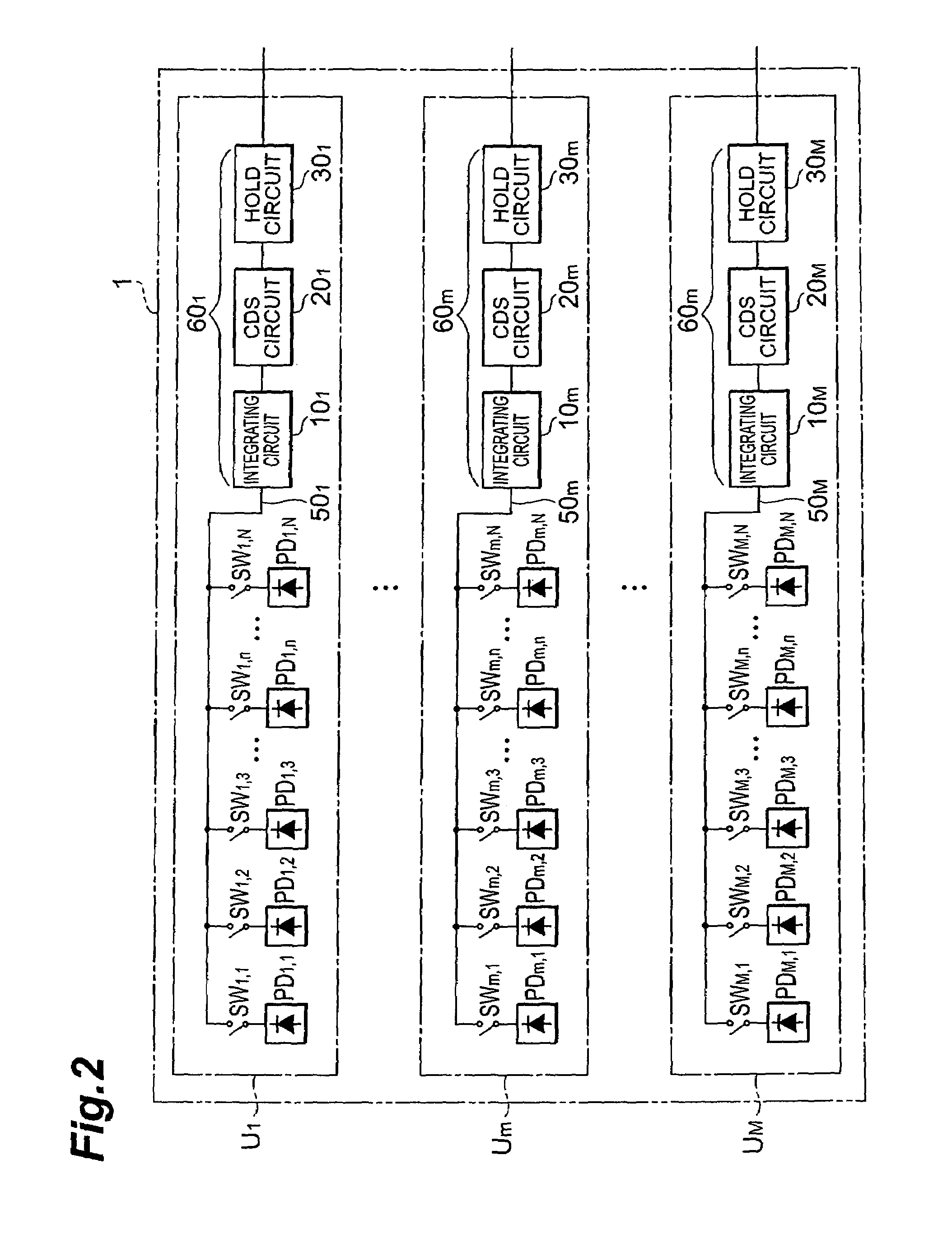

Photo-detection device

InactiveUS7470893B2Accurate detectionShorten the lengthTelevision system detailsSemiconductor/solid-state device detailsPhotodiodeSignal processing

The present invention relates to a photo-detecting apparatus having a structure which can accurately detect light by restraining noises from occurring. The photo-detecting apparatus comprises a first substrate having a surface provided with M×N photodiodes and switches; a second substrate having a surface provided with signal processing parts for processing output signals of the photodiodes; and a third substrate arranged between the first and second substrates. The third substrate has a first surface opposing the first substrate and a second surface opposing the second substrate. In the third substrate, M common wires for connecting the photodiodes to the signal processing parts are arranged on the first surface, whereas bonding pads connected to the respective common wires are arranged on the second surface. The photodiodes on the first substrate are electrically connected to their corresponding common wires in the third substrate by way of first bumps, whereas the signal processing parts on the second substrate are electrically connected to their corresponding bonding pads in the third substrate by way of second bumps.

Owner:HAMAMATSU PHOTONICS KK

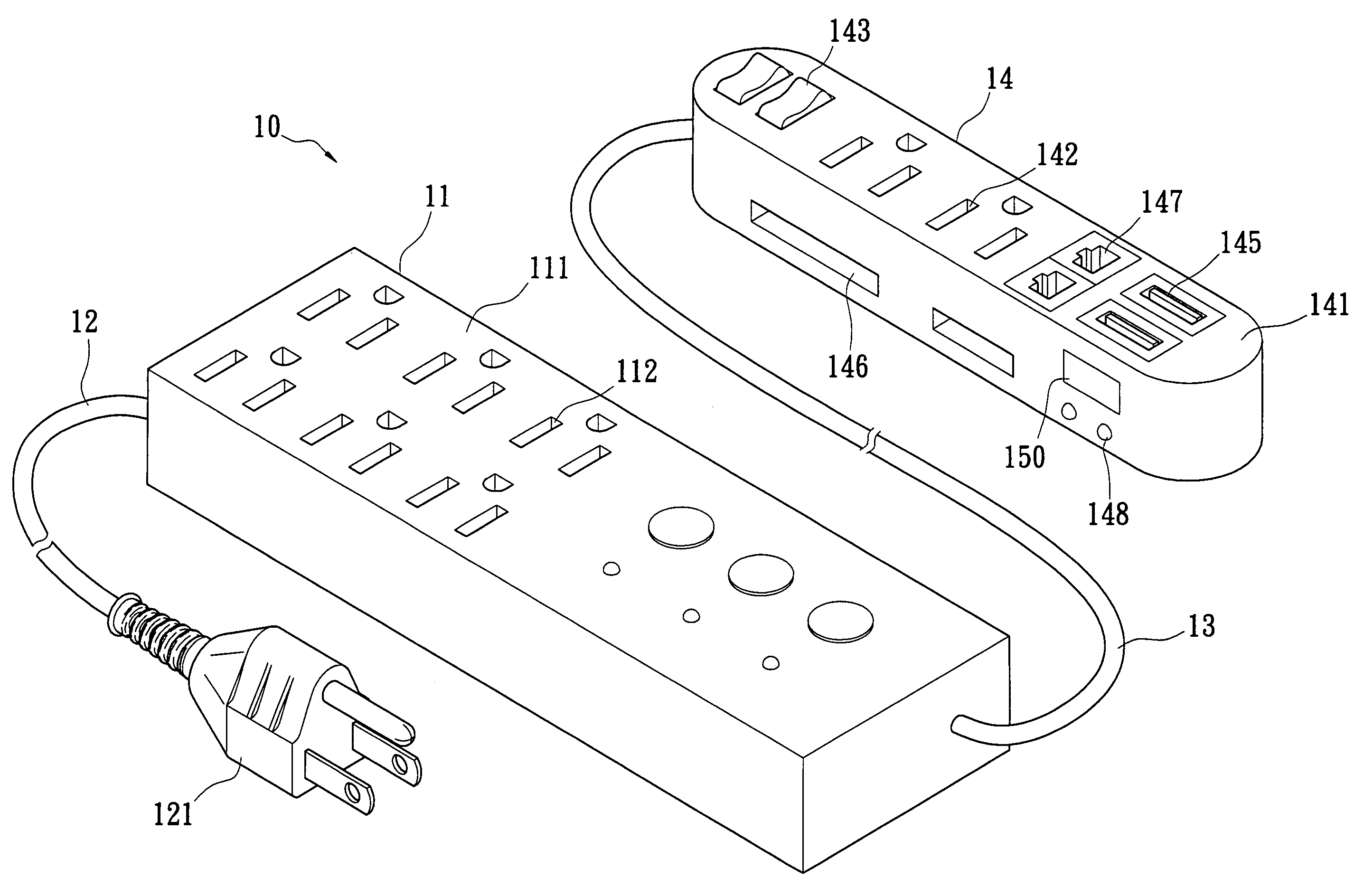

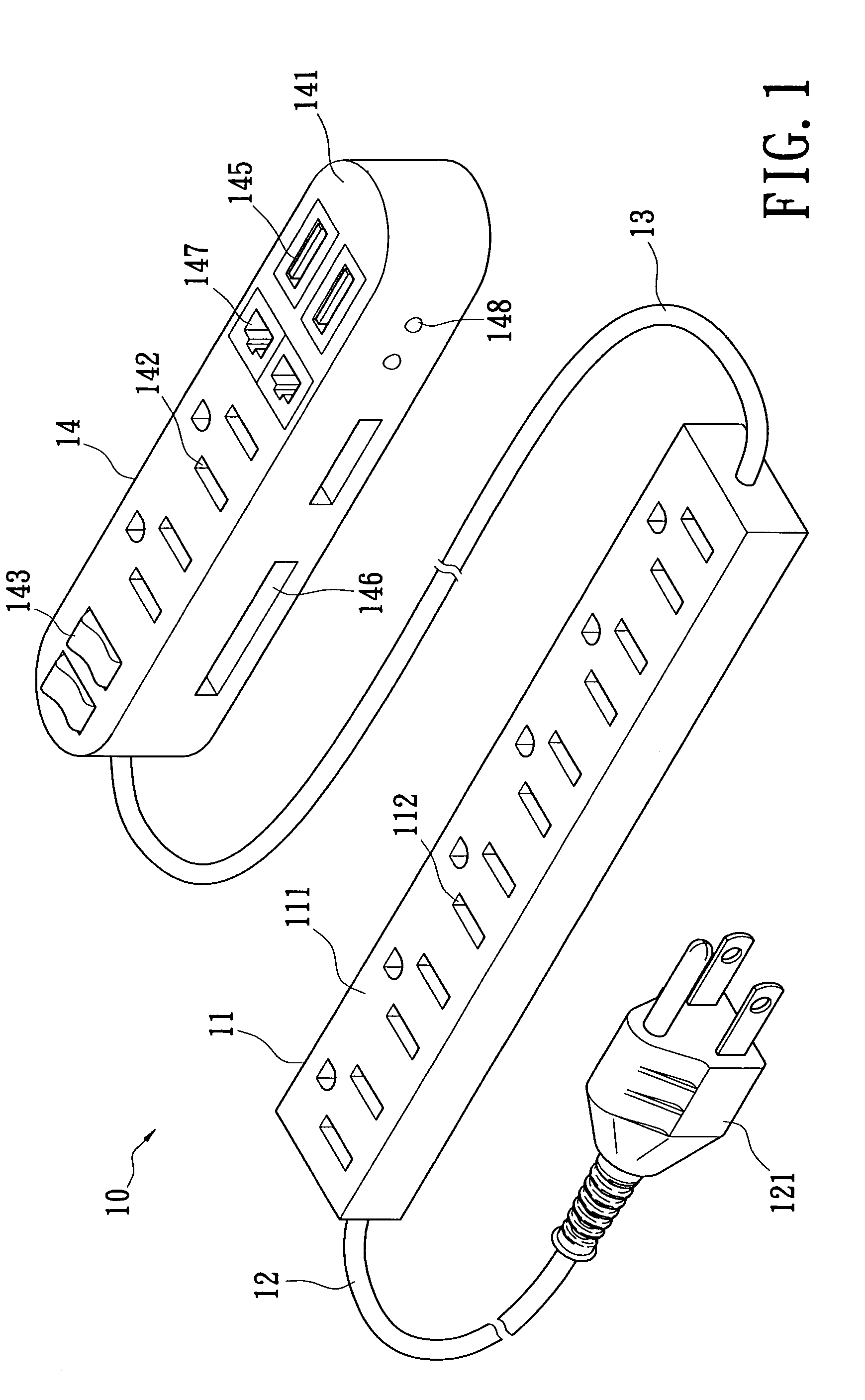

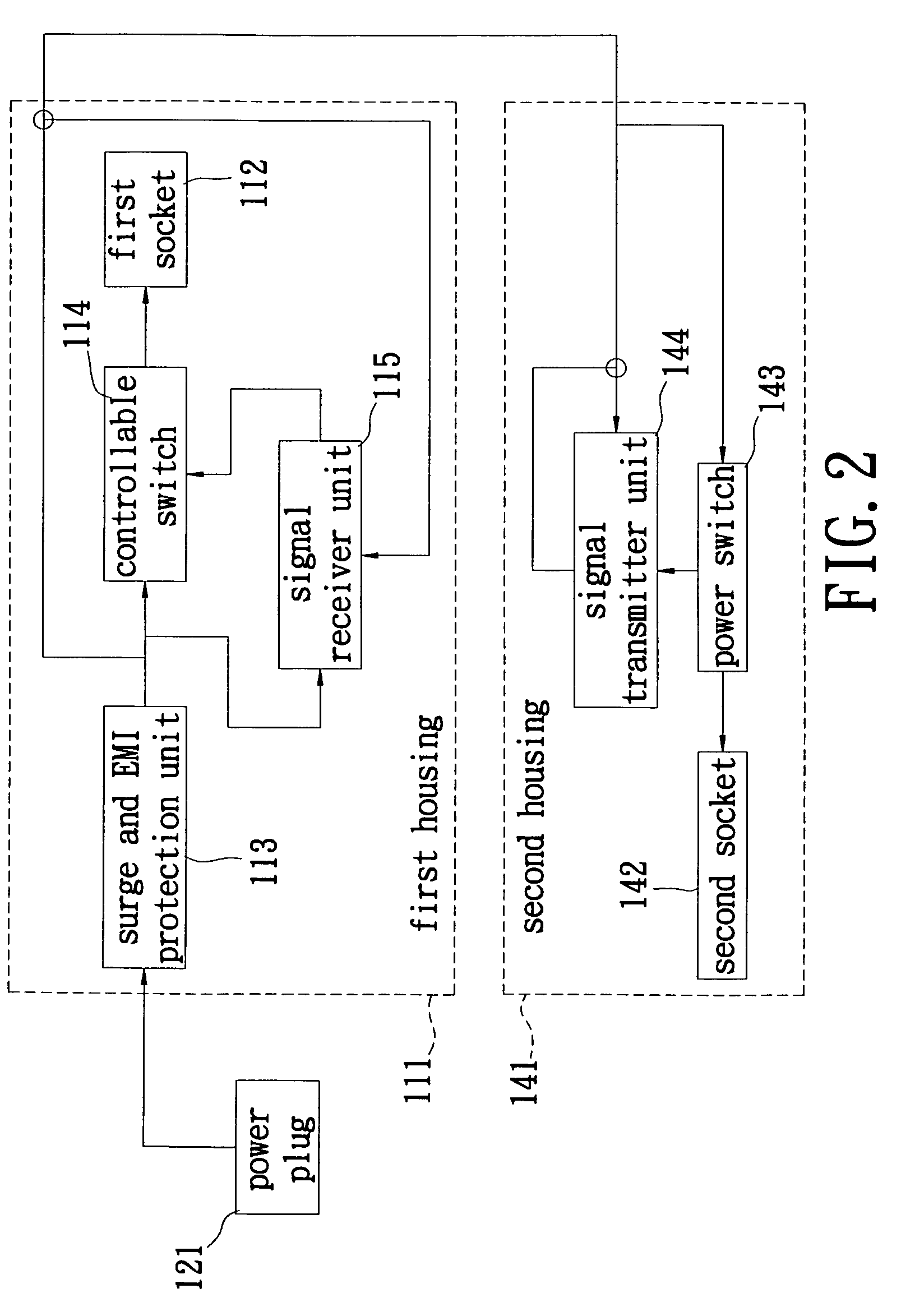

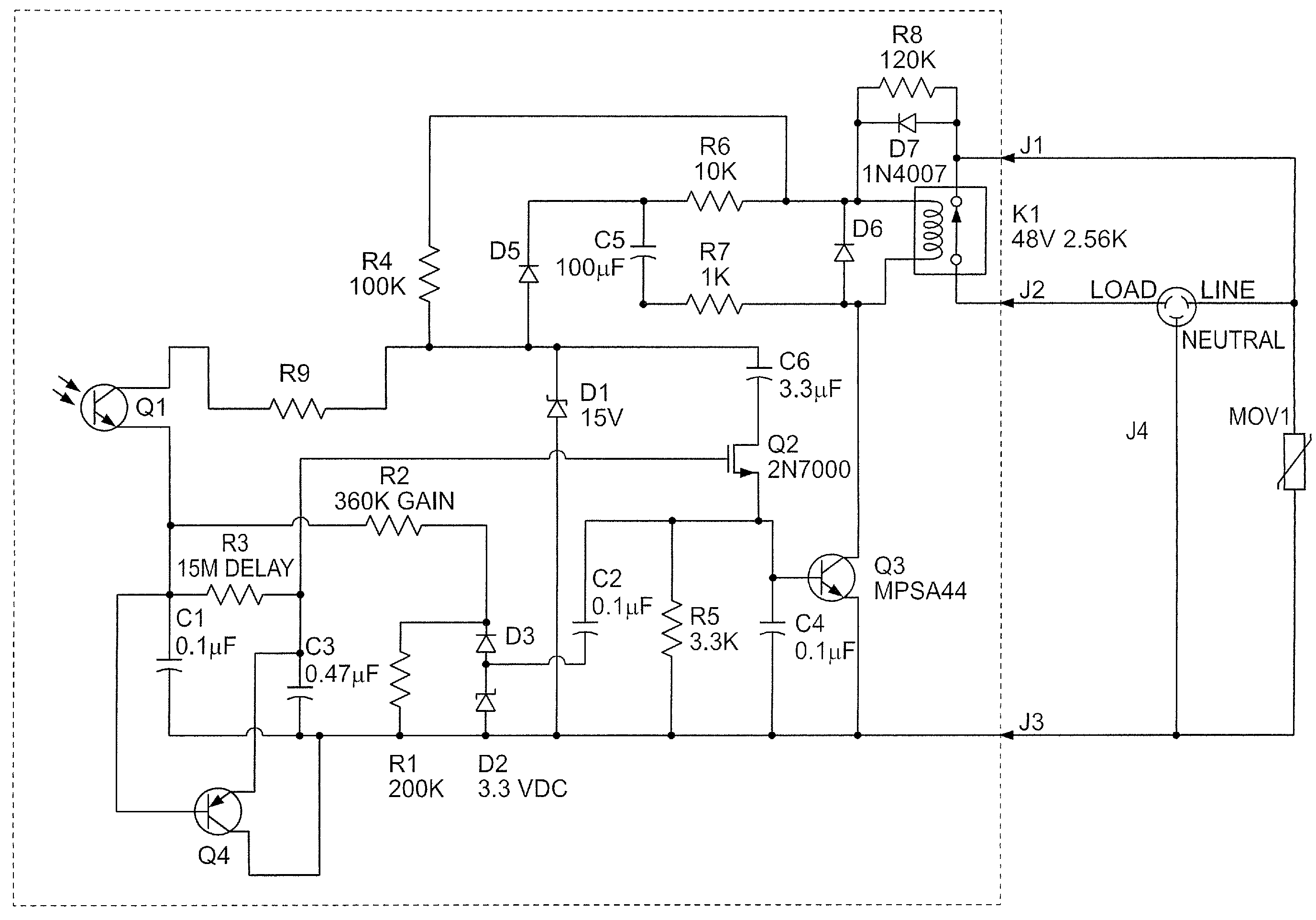

Remote control duo power set

InactiveUS7663866B2Easily supply power to electronic deviceControl the supply of powerDc network circuit arrangementsBoards/switchyards circuit arrangementsPower switchingRemote control

A remote control duo power set comprises one first power outlet which has one first housing, a plurality of first sockets being set on one surface of said first housing, a power cord extending from one side of said first housing; one connecting cord of which one end is connected to the other side of said first housing; and one second power outlet, which is connected to the other side of said connecting cord and has one second housing, a plurality of second sockets and at least one power switch being provided at a side of the second housing. User can easily supply power to the electronic devices by said second power outlet. Furthermore, users can also easily control the supply of power by said power switch.

Owner:POWERTECH INDAL

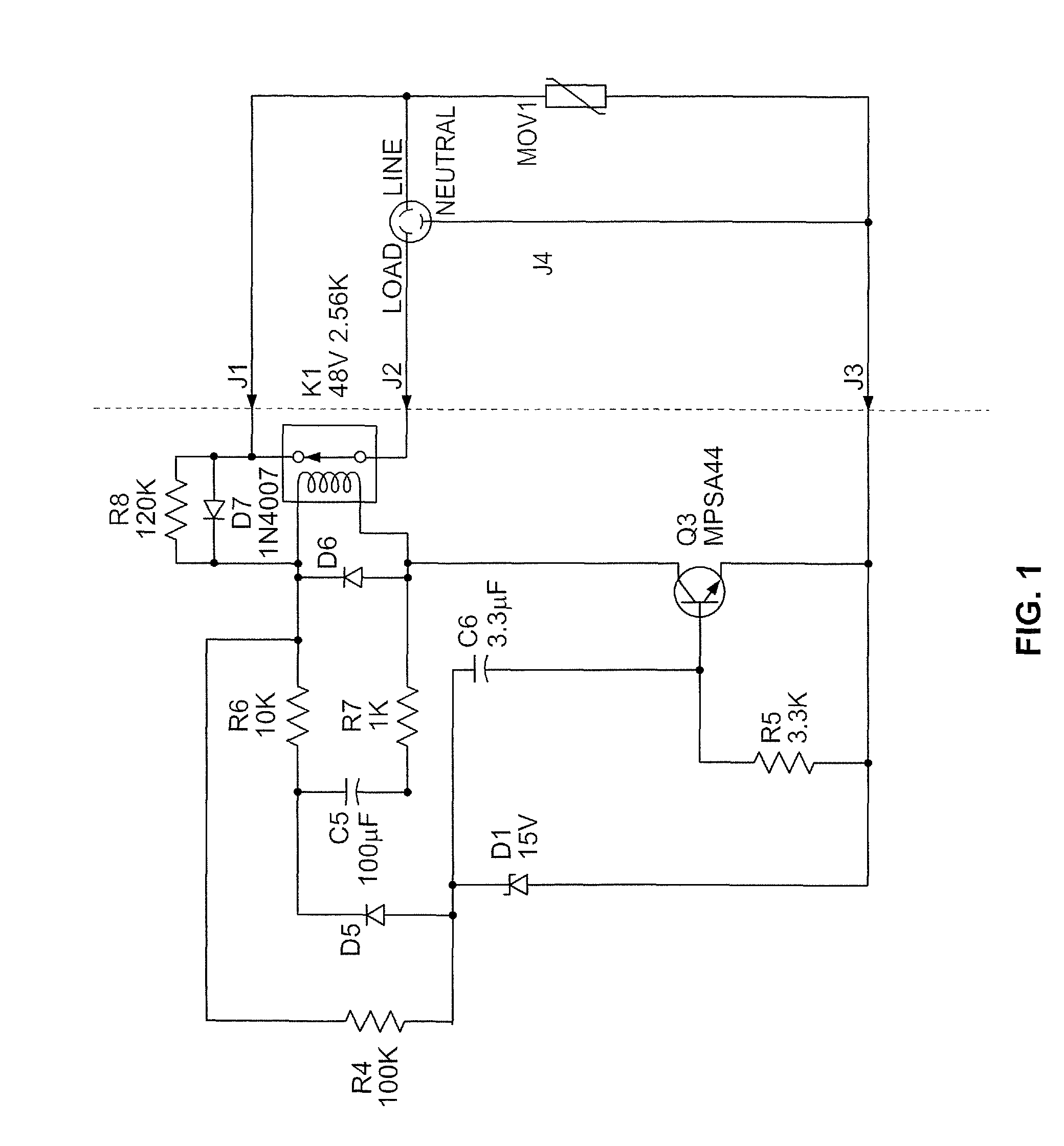

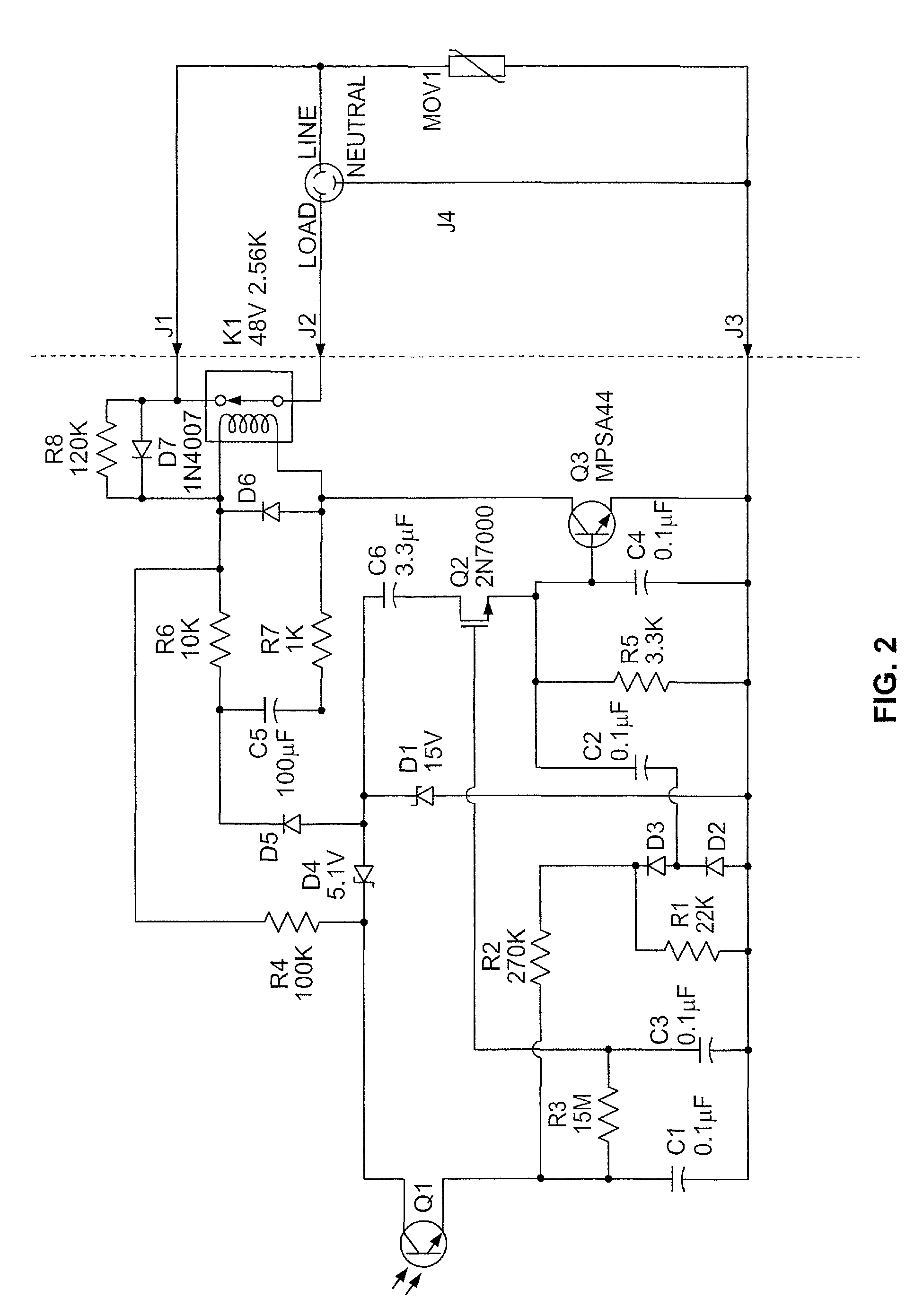

Photosensor circuits including a switch mode power converter

ActiveUS7804200B2Boards/switchyards circuit arrangementsElectronic switchingHysteresisLow-pass filter

Photosensor circuits include a relay coil configured to control application of an alternating current (AC) power source to a load. A pulse width modulator circuit is configured to generate a pulse width modulated signal having a pulse width that varies responsive to an average voltage across the relay coil. A drive transistor controls the average voltage across the relay coil responsive to the pulse width modulated signal. A photo control circuit controls application of the pulse width modulated signal to the drive transistor responsive to a detected light level. A half-wave rectifier provide a power signal to the pulse width modulator circuit and the photo control circuit during one of the halves of the line cycle of the AC power source. The photo control circuit includes a phototransistor. A low pass filter circuit filters the output current of the phototransistor to provide a light level signal voltage. A select transistor couples the pulse width modulated signal to the drive transistor during one of the halves of the line cycle of the AC power source responsive to the light level signal voltage having a selected level. A capacitor coupled between the second terminal of the phototransistor and the neutral bus modulates an amount of positive feedback through the first terminal of the phototransistor proportional to a current flowing through the relay coil to provide hysteresis to control of the relay coil by the photosensor circuit.

Owner:TYCO ELECTRONICS LOGISTICS AG (CH)

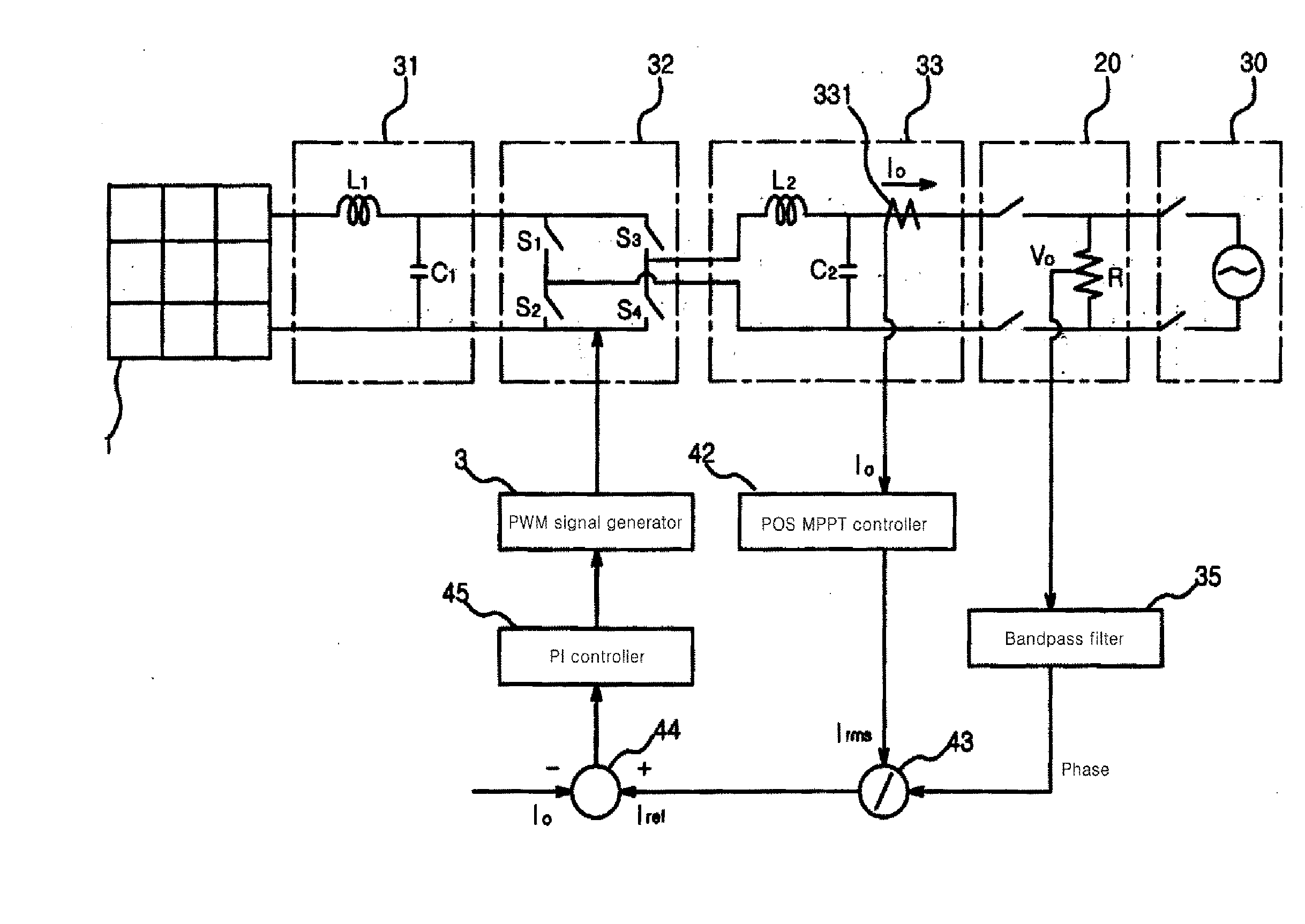

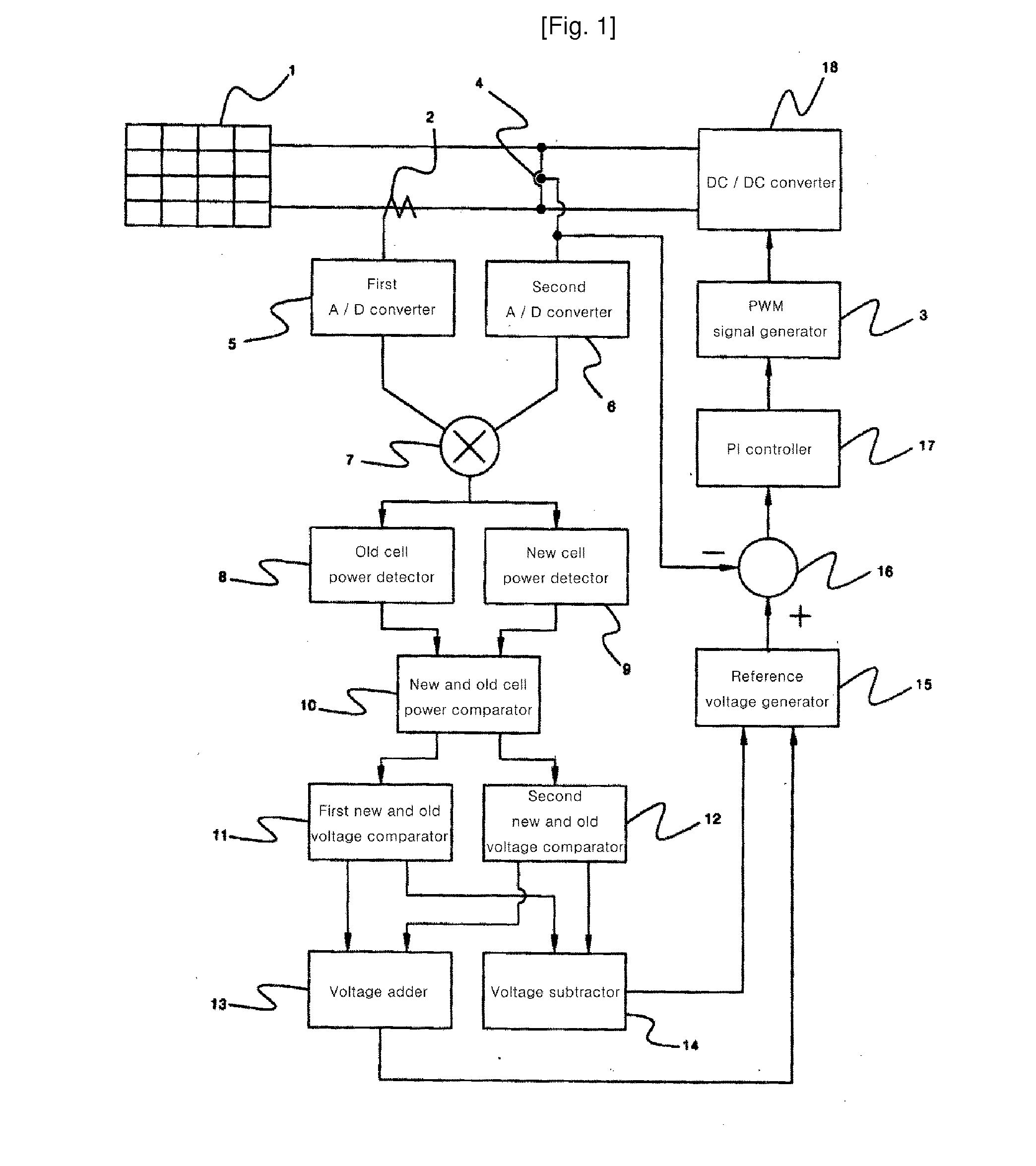

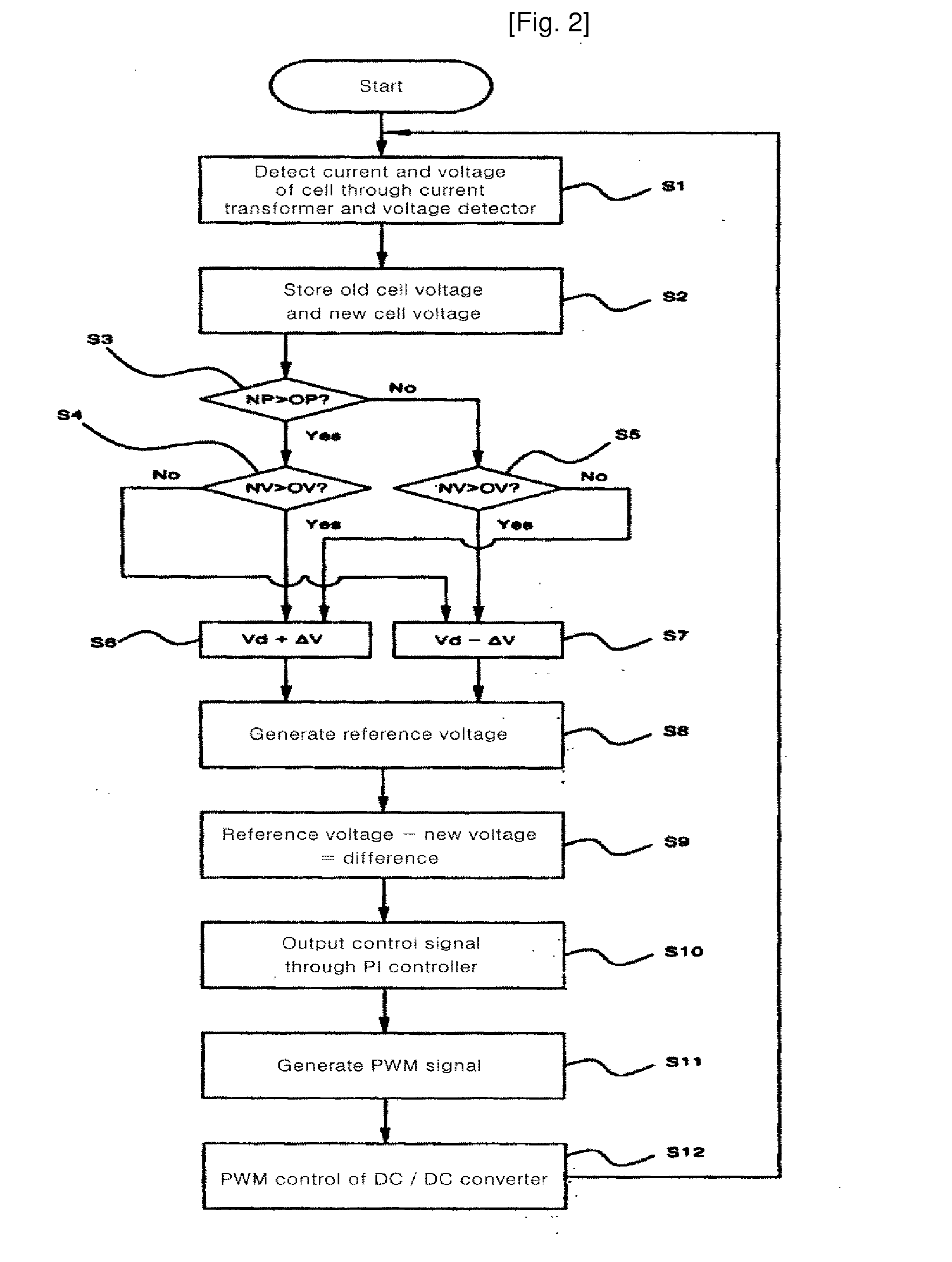

Controlling Apparatus of a Power Converter of Single-Phase Current For Photovoltaic Generation System

InactiveUS20080278983A1Insufficient ratioReduce installation costsBatteries circuit arrangementsBoards/switchyards circuit arrangementsBandpass filteringReference current

A control apparatus of a single-phase power converter for a photovoltaic power generation system is disclosed, including a POS MPPT controller for calculating a rating current by applying a POS MPPT control method to an output current detected through a current transformer of a single-phase AC filter, a bandpass filter for filtering only signals of a low-frequency band from a load, a single-phase reference current generator for producing a reference current by matching a phase of the current from the POS MPPT controller to a phase from the bandpass filter, a single-phase current subtractor for subtracting an output current of a current transformer from the reference current calculated by the single-phase reference current generator to thereby calculate a difference current between the output current of the current transformer and the reference current, a PI controller for outputting a control signal, corresponding to the difference current from the single-phase current subtractor, to a PWM signal generator, and the PWM signal generator for generating a PWM phase control signal corresponding to the control signal from the PI controller.

Owner:CHANG WON NAT UNIV BUSINESS ADMINISTRATION

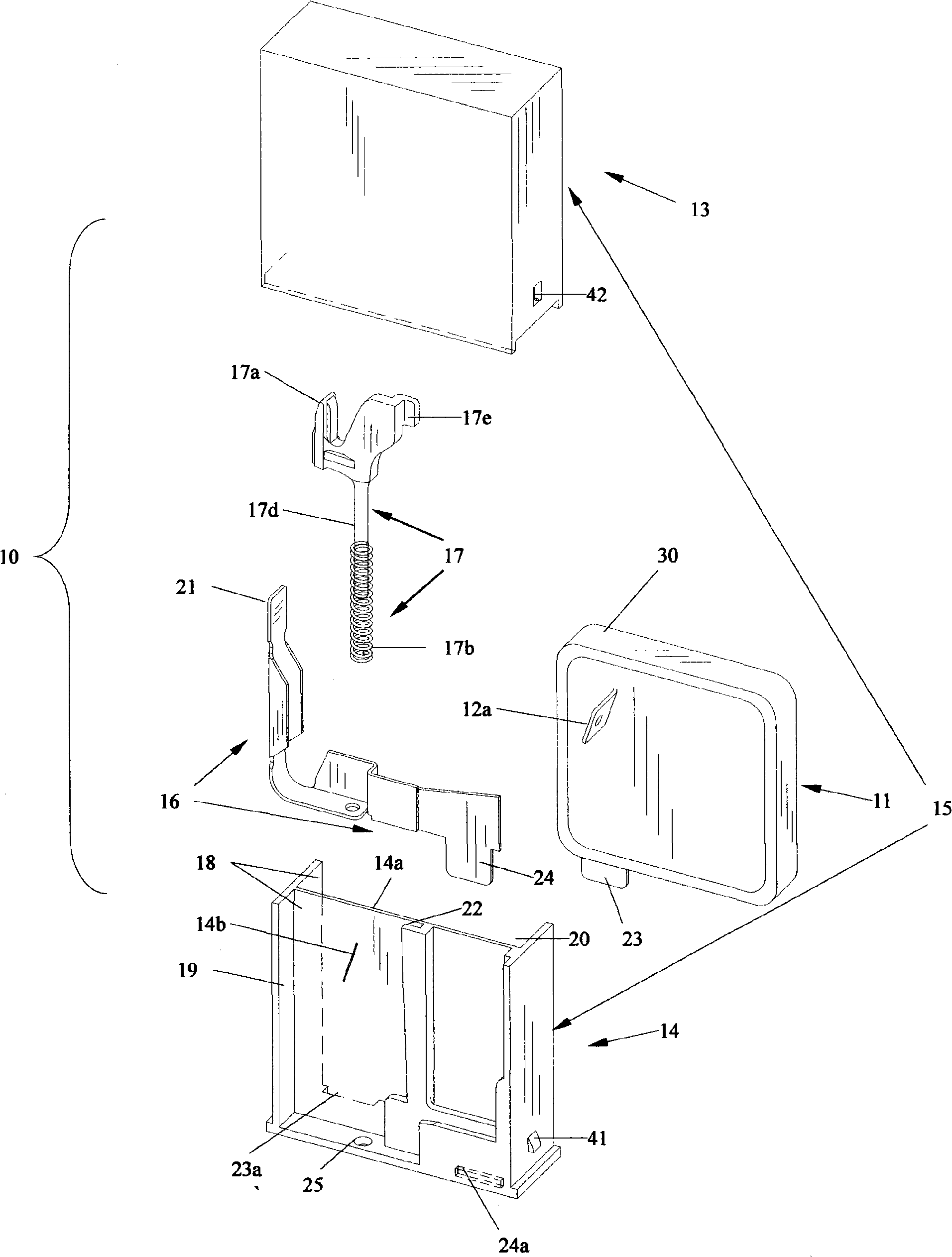

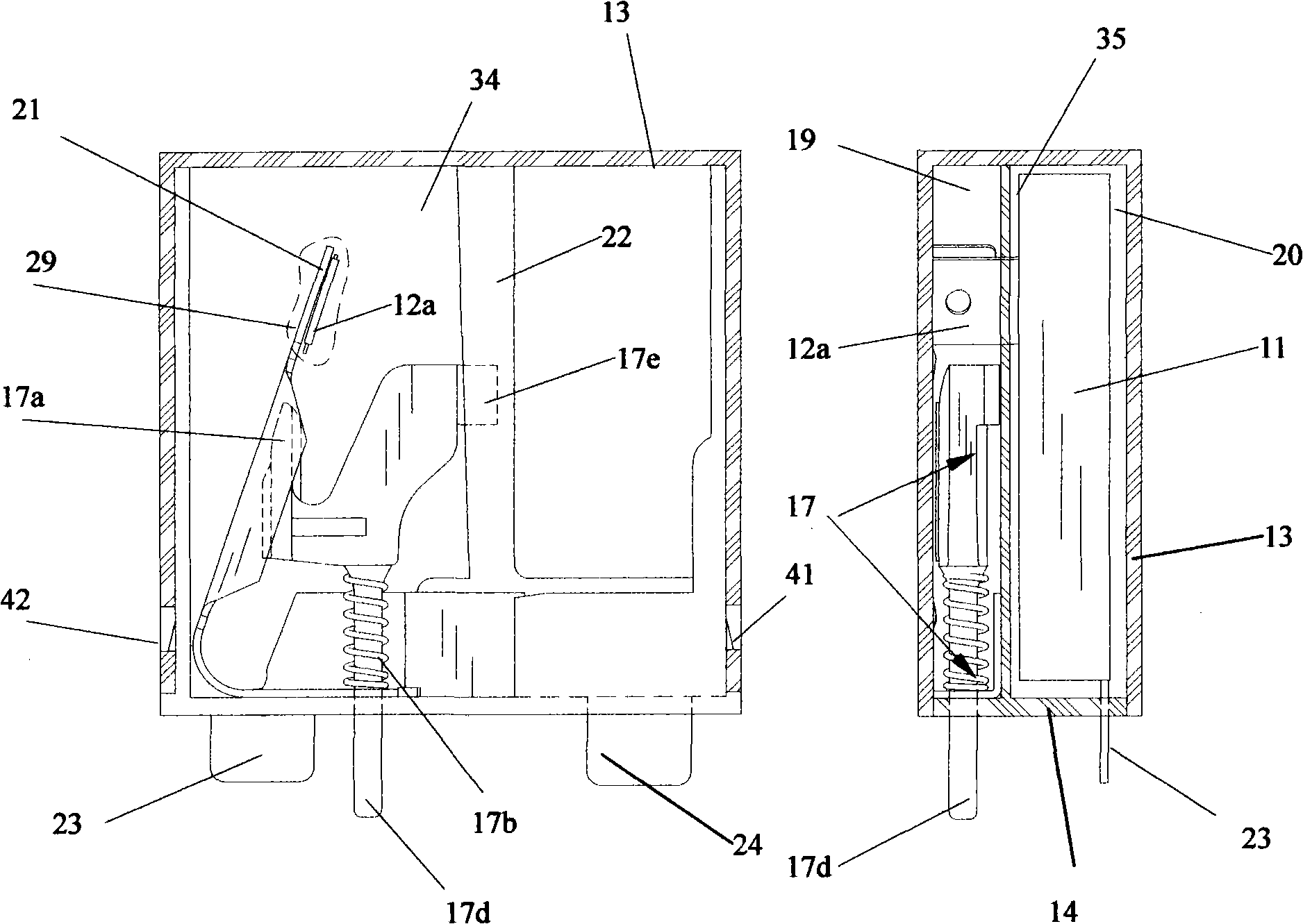

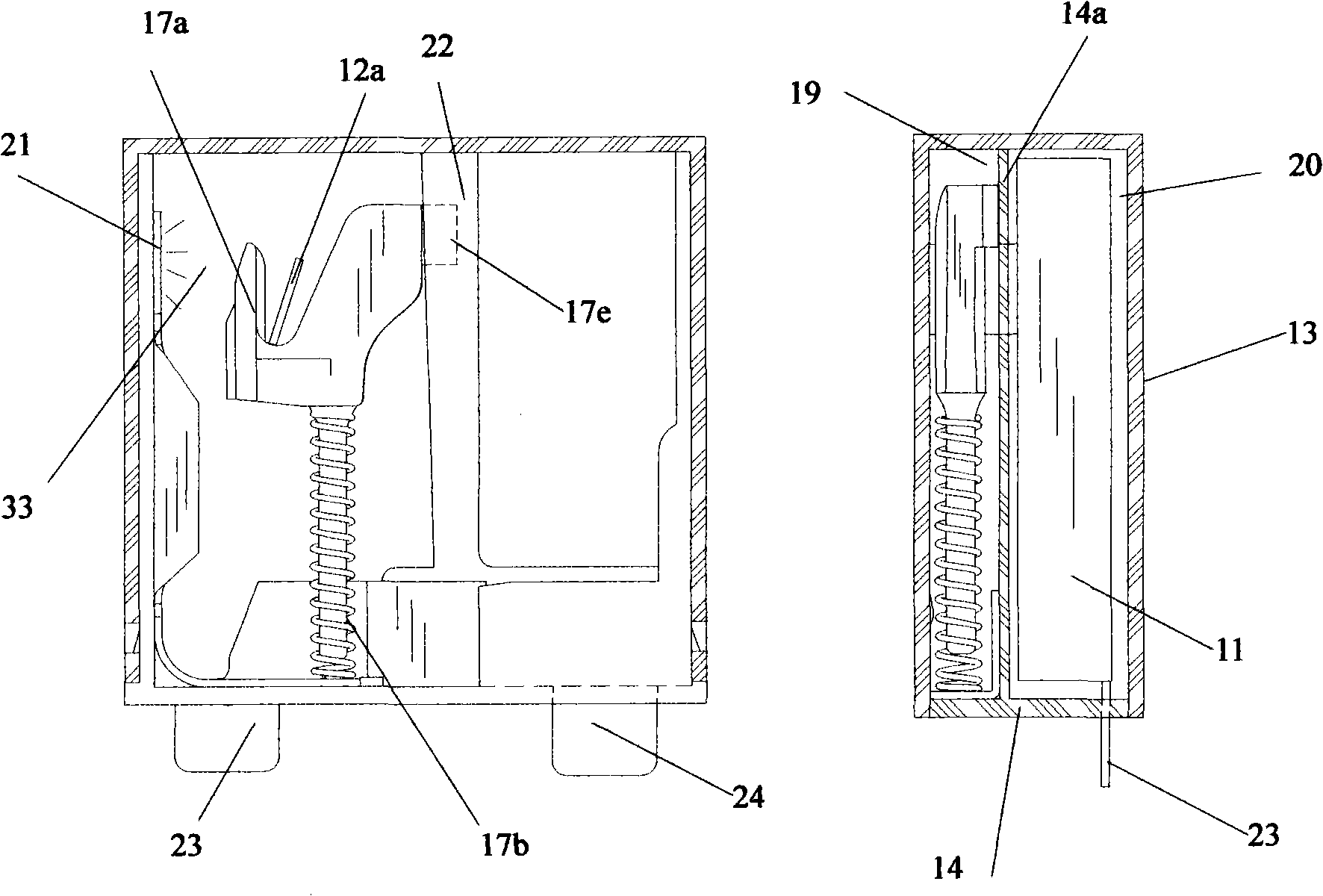

Heat protection pressure sensitive resistor module

ActiveCN101261893APlay the role of arc extinguishingSwitch operated by excess voltageThermally actuated switchesQuenchingMetal

The invention provides a thermal protection voltage-sensitive resistor module used for surge protection, which consists essentially of a metal oxide voltage-sensitive resistor, a thermal response switch, a set of thruster with a compression spring and a wedge-shaped quencher and a case. Thermal coupling exists between the thermal response switch and the metal oxide voltage-sensitive resistor. When the metal oxide voltage-sensitive resistor is overstressed, the resistor emits heat, the thermal response switch can immediately sense the heat and soften the welding point of solder with low melting point, then the welding point is forced to be quickly disconnected and part of the wedge-shaped quencher is inserted into the clearance at the breakage place of the welding point under the joint effect of the thruster with the spring and the wedge-shaped quencher and the resilient conductive connection arm, thus the quenching effect is enhanced.

Owner:毛小毛

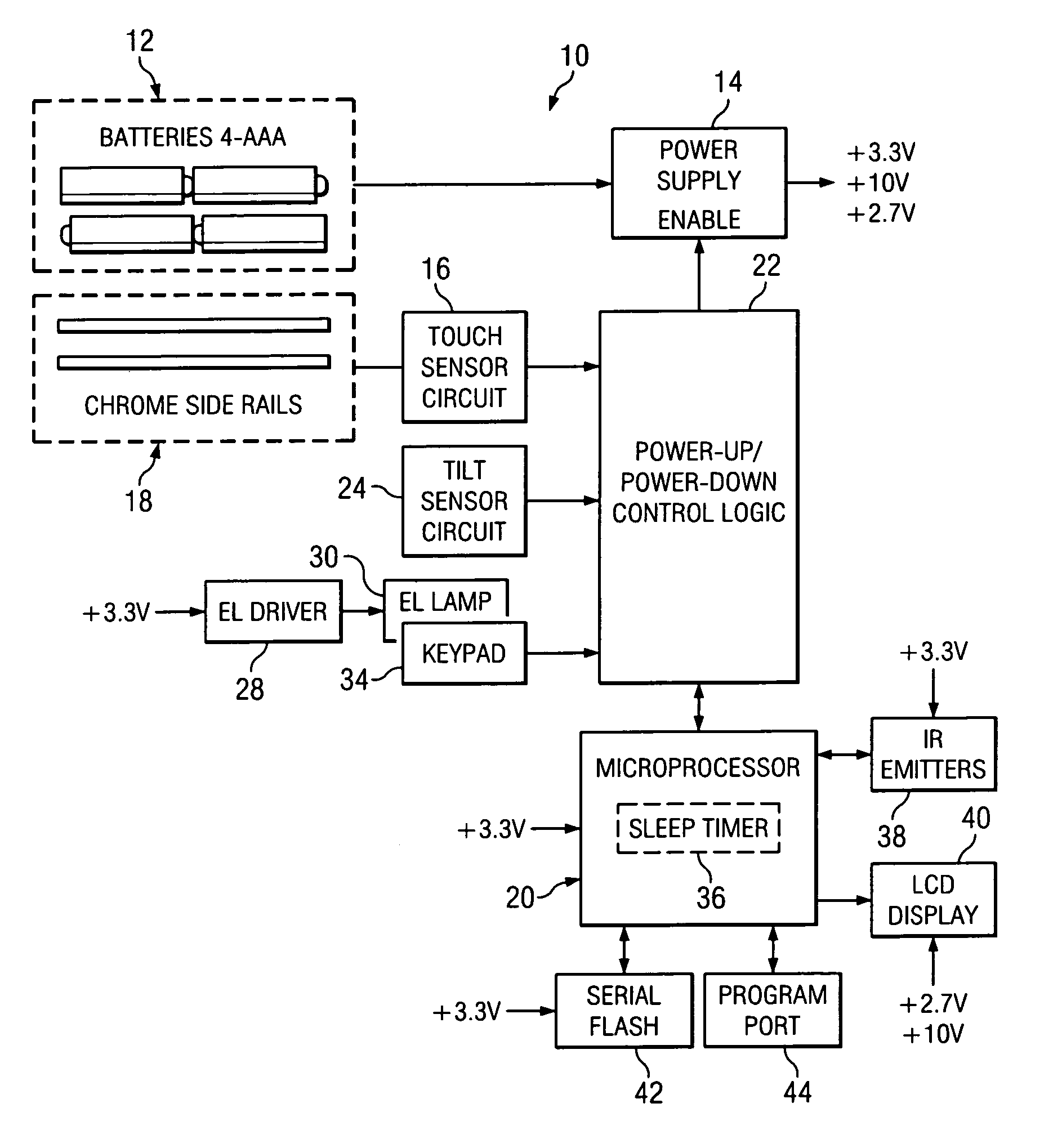

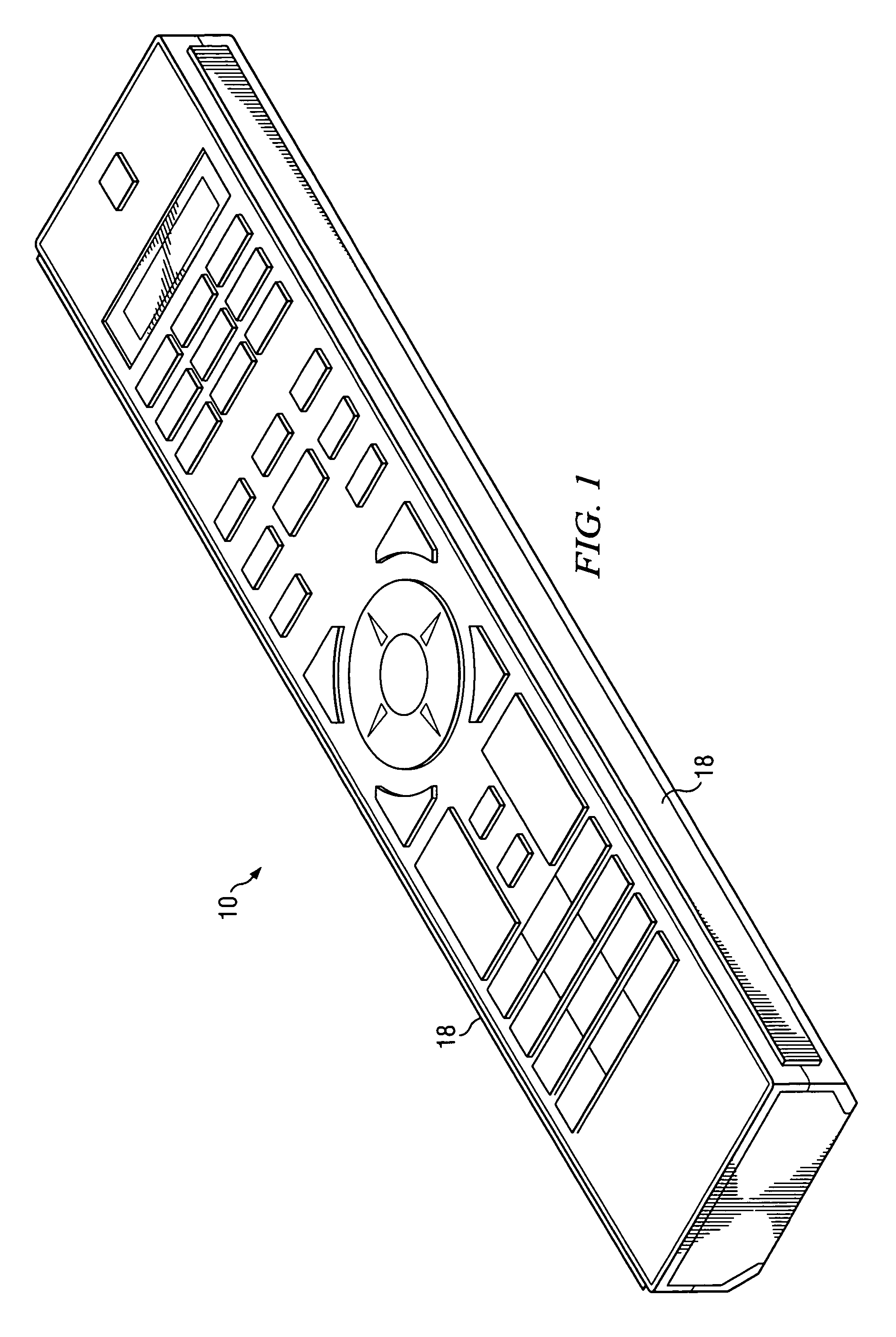

Power management for electronic devices

A cordless electronic device with power management system and method is provided that includes an outer surface, a power consumption circuit operable to consume power and for use in a cordless electronic device, a power supply circuit operable to regulate the power from a power source used to power the power consumption circuit of the cordless electronic device, a power control circuit operable to receive an input signal and to place the power consumption circuit in a lower or higher power state upon receipt of the input signal, a presence sensor operable to detect the presence of a user and to provide a presence sensor input signal to the power control circuit to place the power consumption circuit in the higher power state.

Owner:HARMAN PROFESSIONAL INC

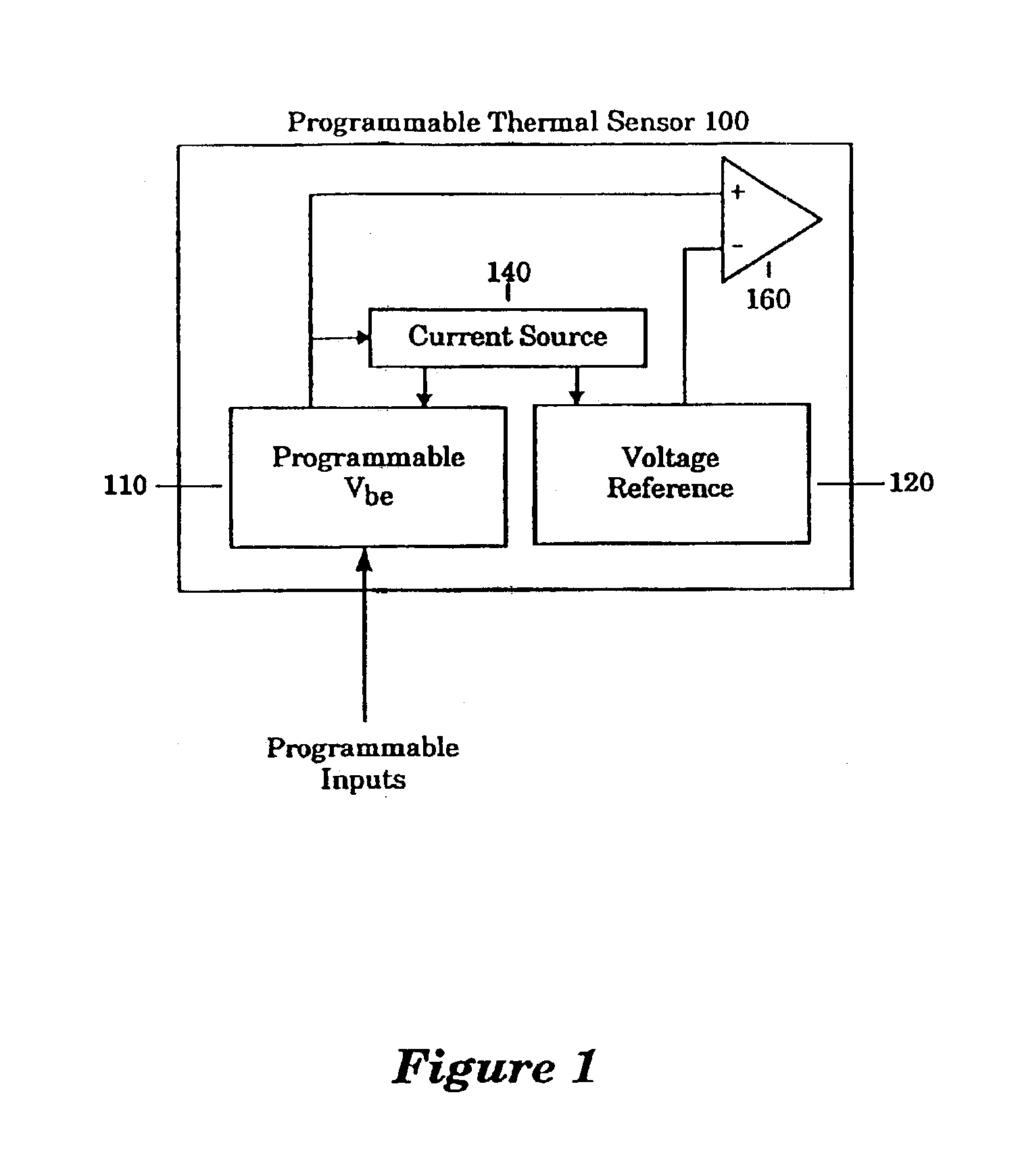

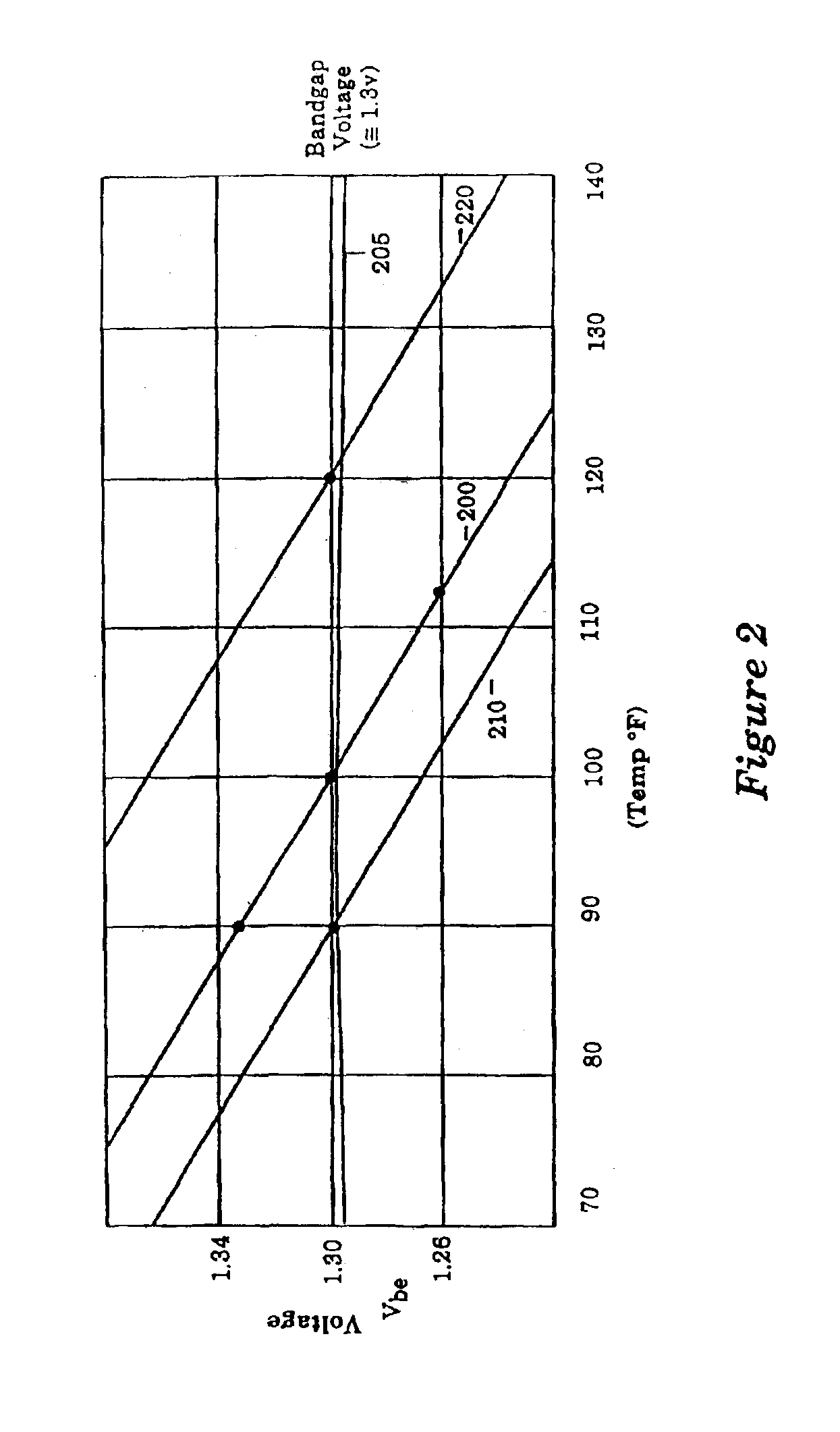

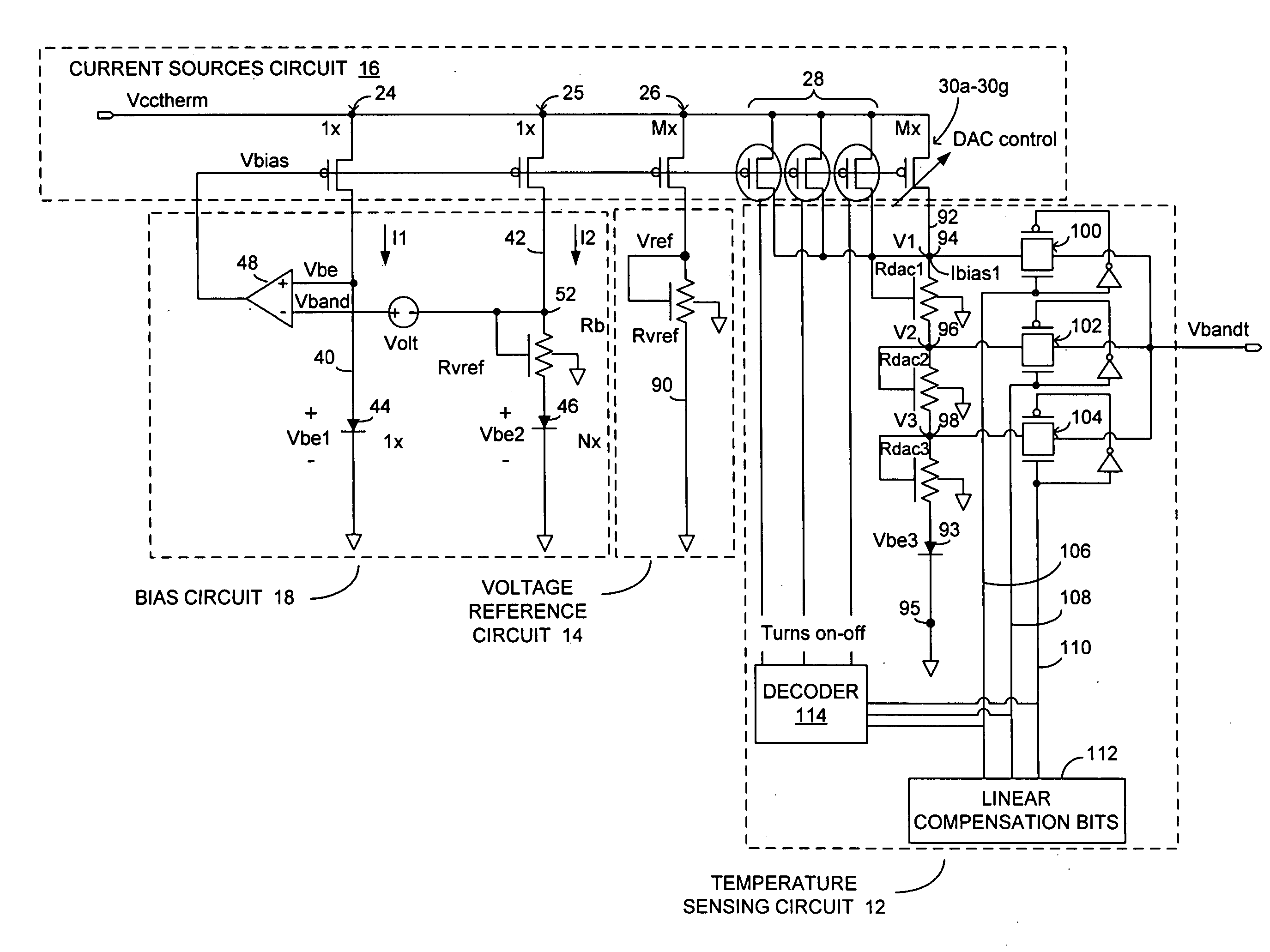

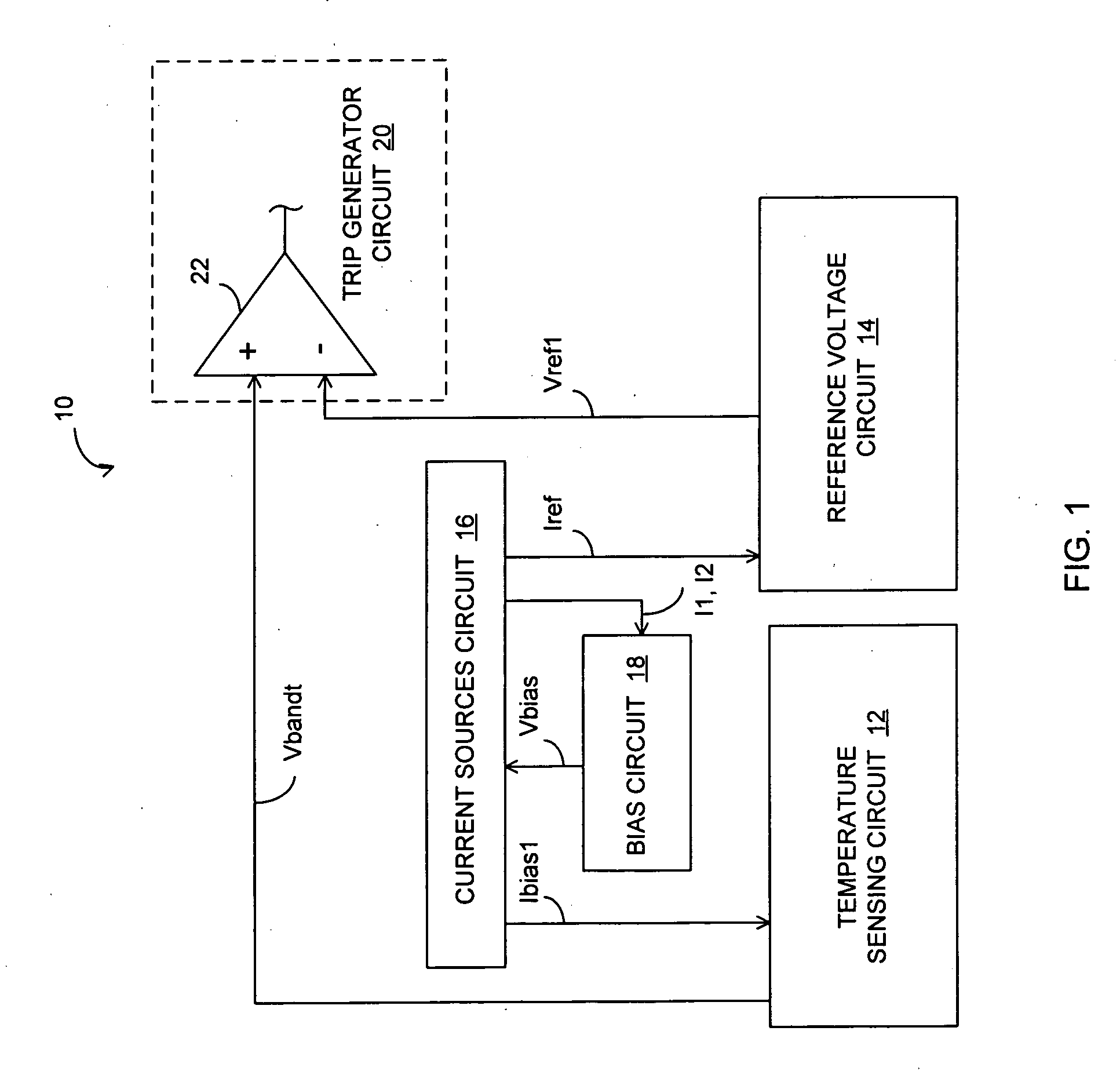

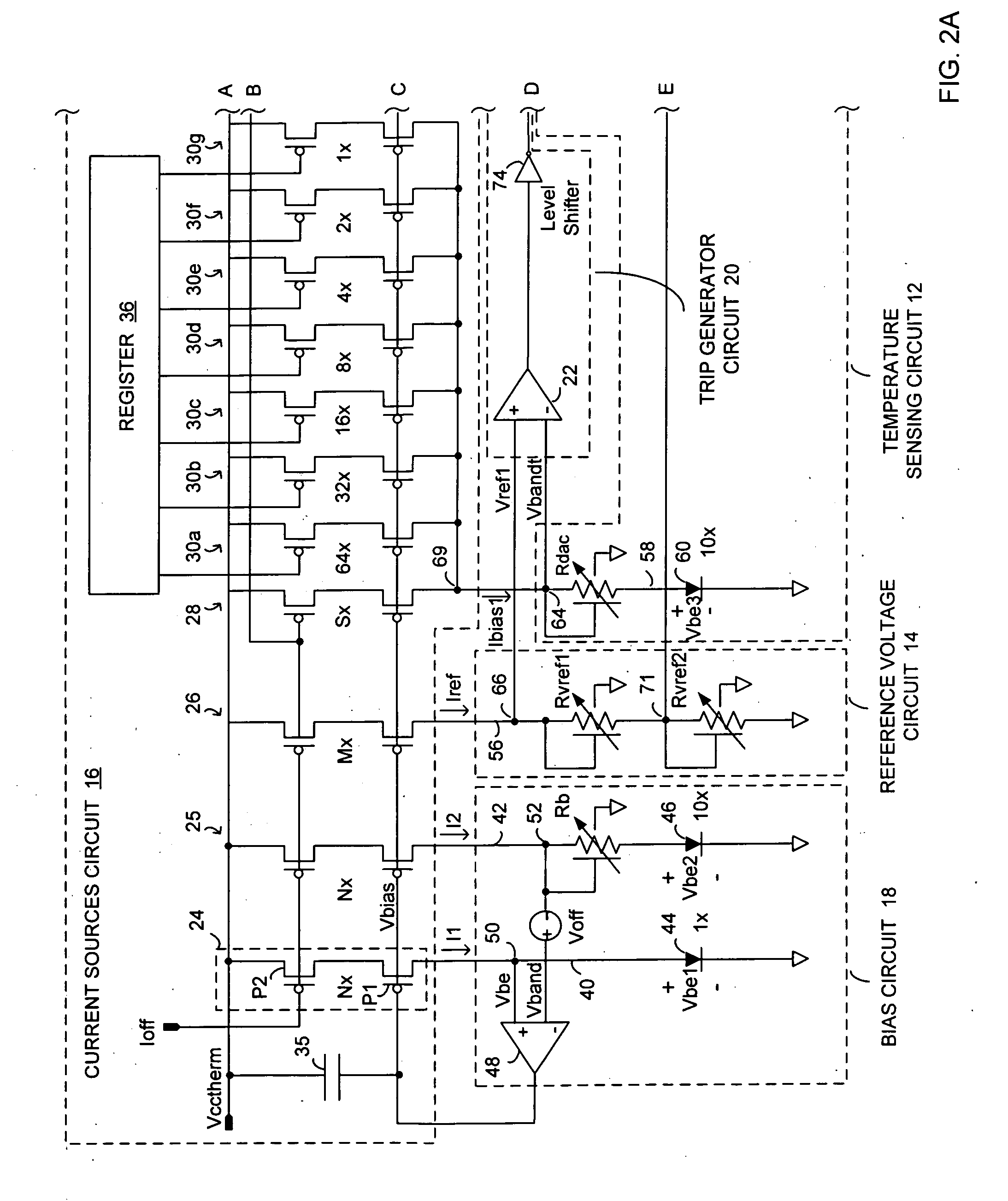

Thermal sensor and method

InactiveUS20070216468A1Thermometer detailsBoards/switchyards circuit arrangementsReference currentVoltage reference

In one embodiment, an apparatus is constituted with a temperature sensing circuit adapted to be coupled to a current sources circuit, and configured to measure a circuit temperature and to generate a temperature-indicating signal in response to the circuit temperature and an adjustable current output by the current sources circuit; a reference voltage circuit to be coupled the current sources circuit and configured to provide a reference signal in response to a reference current output by the current sources circuit; and a trip generator circuit coupled to the temperature sensing circuit and the reference voltage circuit and configured to generate a trip point signal if a difference between the reference and the temperature-indicating signals indicates that a threshold circuit temperature has been reached or exceeded.

Owner:INTEL CORP

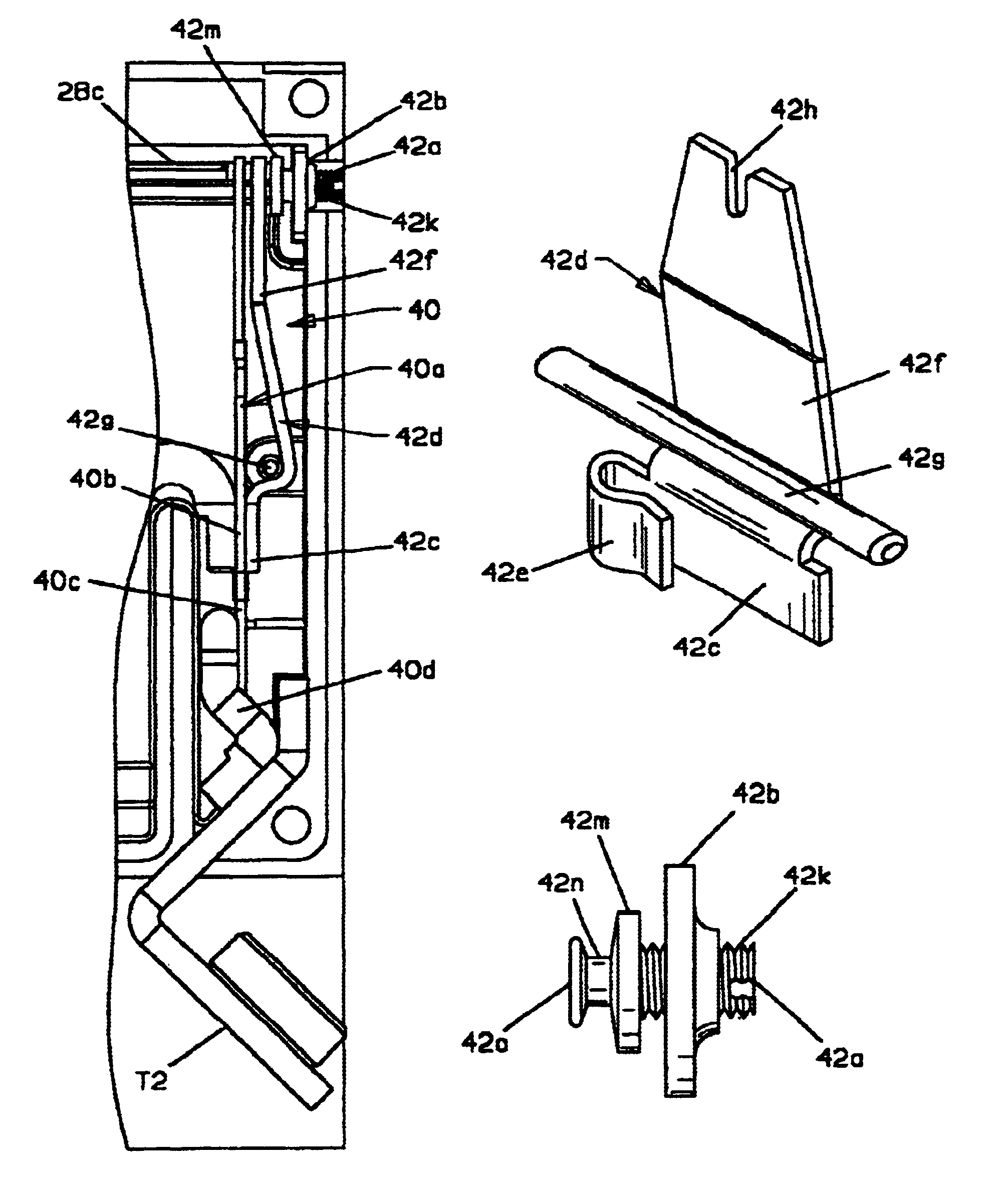

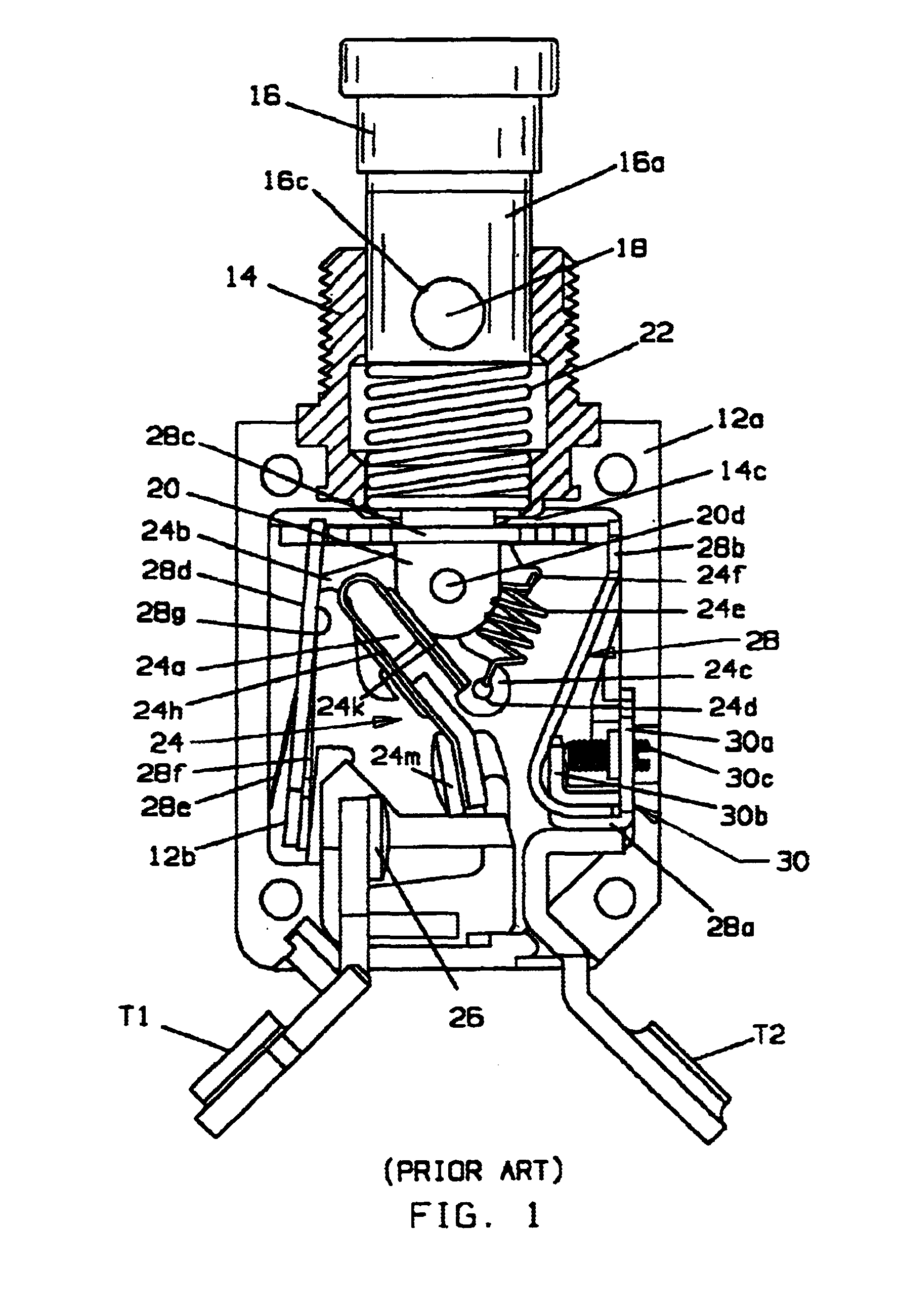

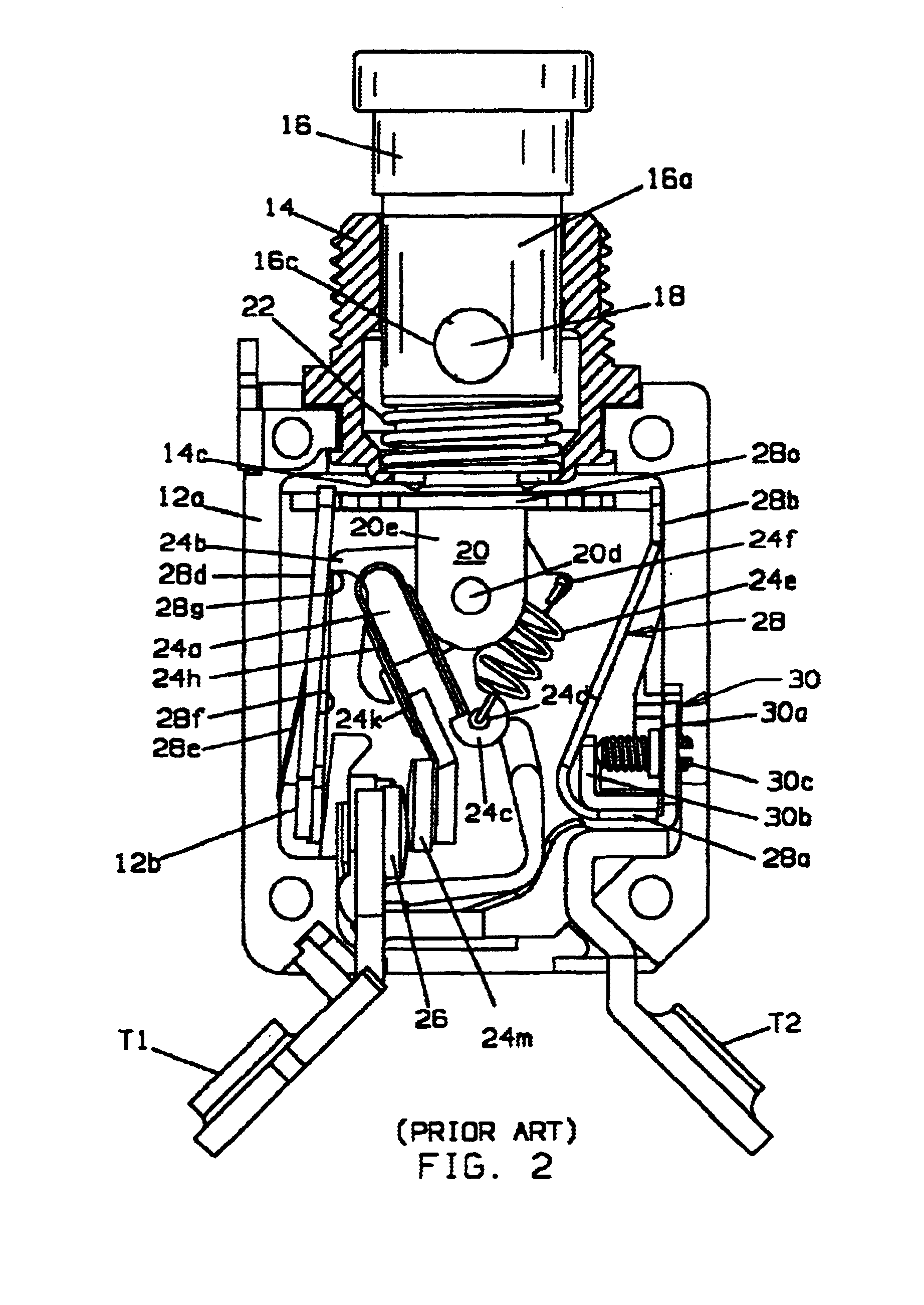

Calibration structure for circuit breakers having bimetallic trip member

InactiveUS6720856B1Less sensitivityIncreased durabilityElectrothermal relaysThermally actuated switchesContact forceActuator

A thermally compensated circuit breaker has a movable contact assembly (24) which mounts a movable electrical contact (24m) for movement between open and closed contacts positions with a stationary electrical contact (26). The contacts are maintained in the closed circuits position by a latching mechanism (24b, 28g) which prevents opening of the contacts through an opening contacts force provided by a spring (24e). A current carrying trip arm (40a, 44a) deflects upon sufficient I.sup.2 R heating to transfer motion to the latch to separate the latch (24b) from the latch receiving catch (28g) to trip the circuit breaker. The trip arm (40a, 44a) is part of a pivotably mounted actuator assembly (40, 44) having a movable end portion spaced from the pivot disposed adjacent a motion transfer member (28c). A calibration screw (42a) is located so that the longitudinal axis is in line with a movable end portion of the actuator assembly and the motion transfer member. In one embodiment the head of the calibration screw is captured in a slot in the free end of a calibration base (42d) attached to the trip arm so that deflection of the trip arm directly transfers motion to the motion transfer member and in another embodiment the calibration screw head is captured in a slot in the free end of the trip arm so that a bowing deflection of the trip arm causes a calibration base (46) to which it is attached at an end thereof to rotate with the calibration base directly transferring motion to the motion transfer member.

Owner:SENSATA TECH MASSACHUSETTS INC

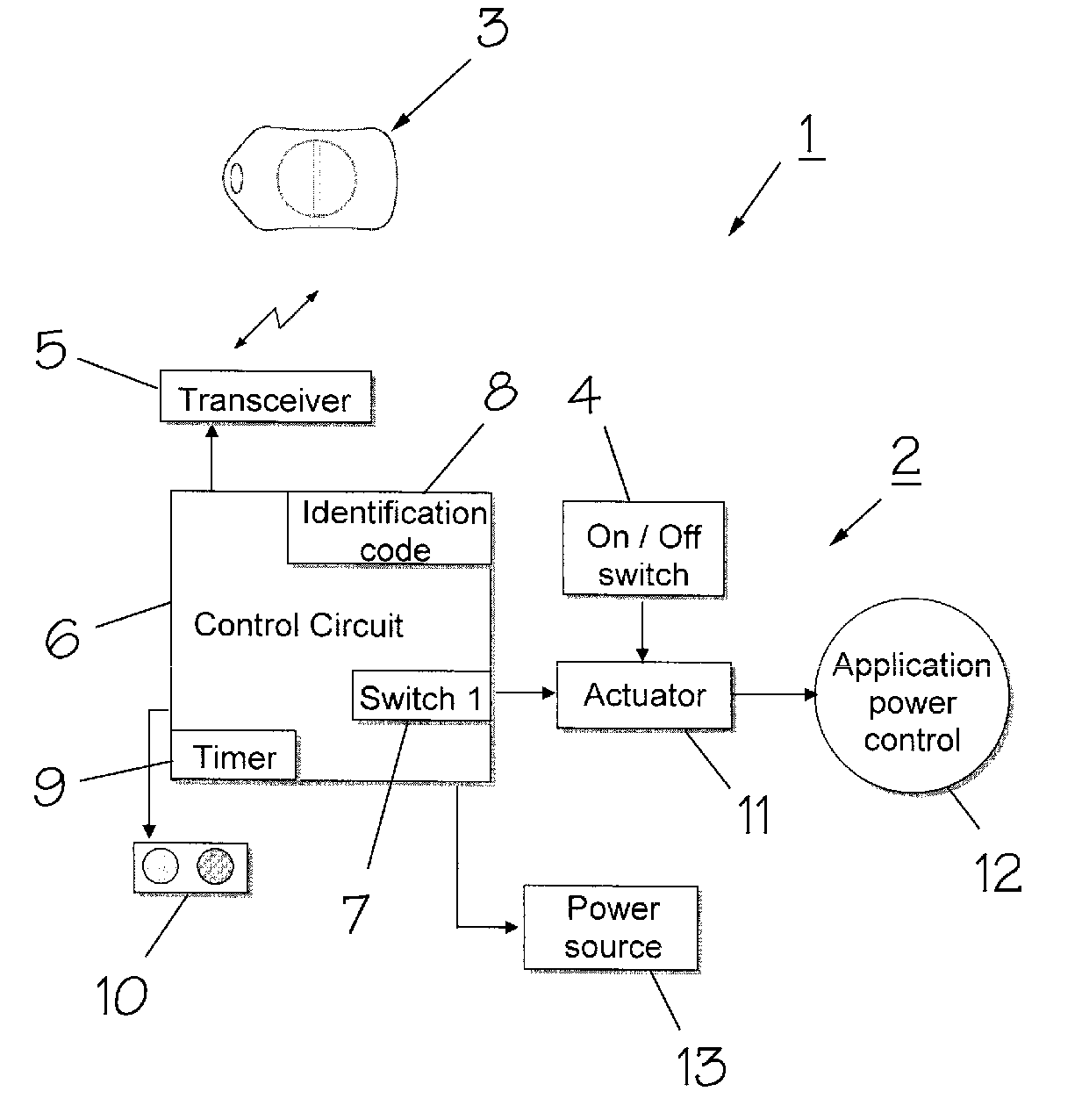

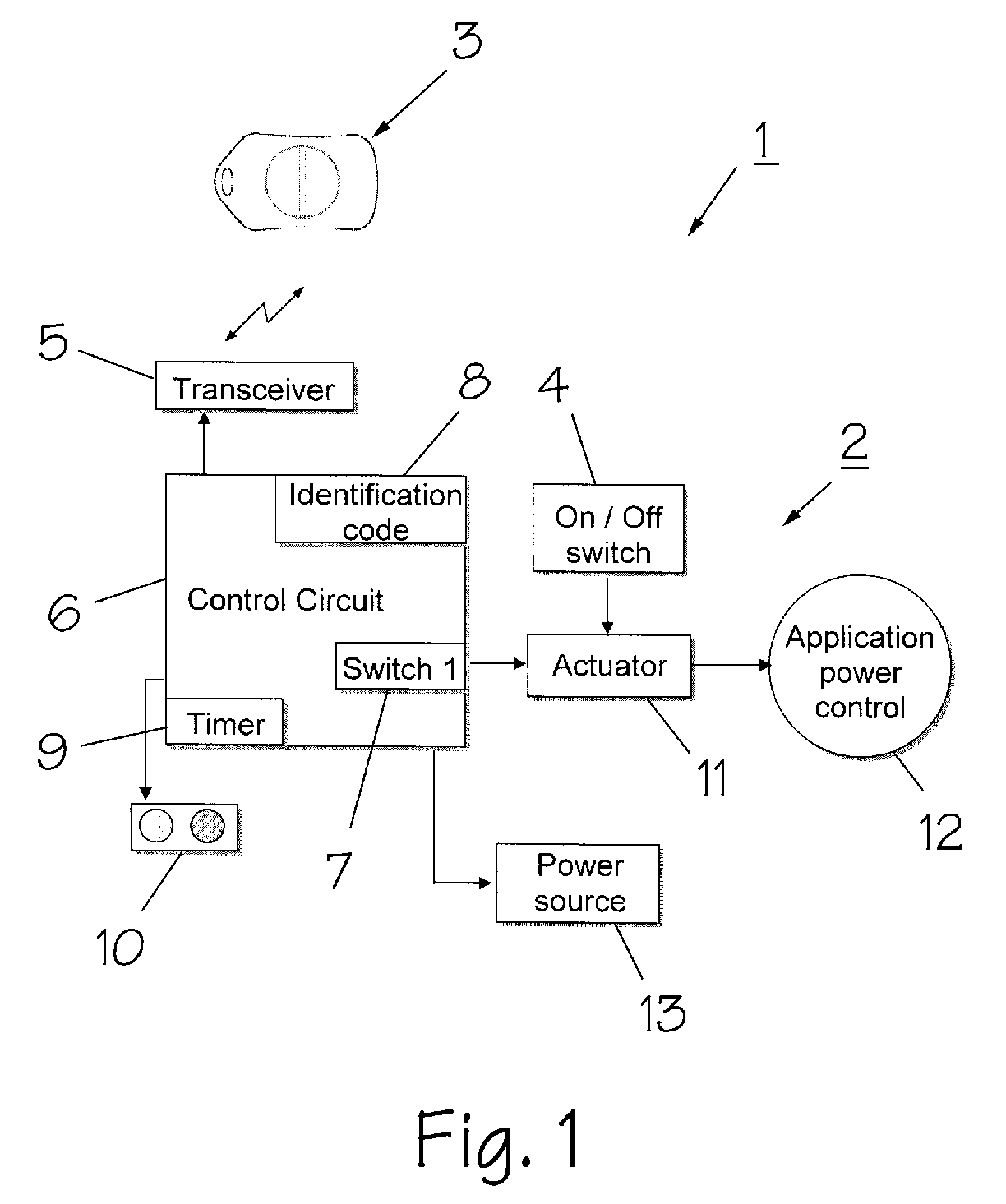

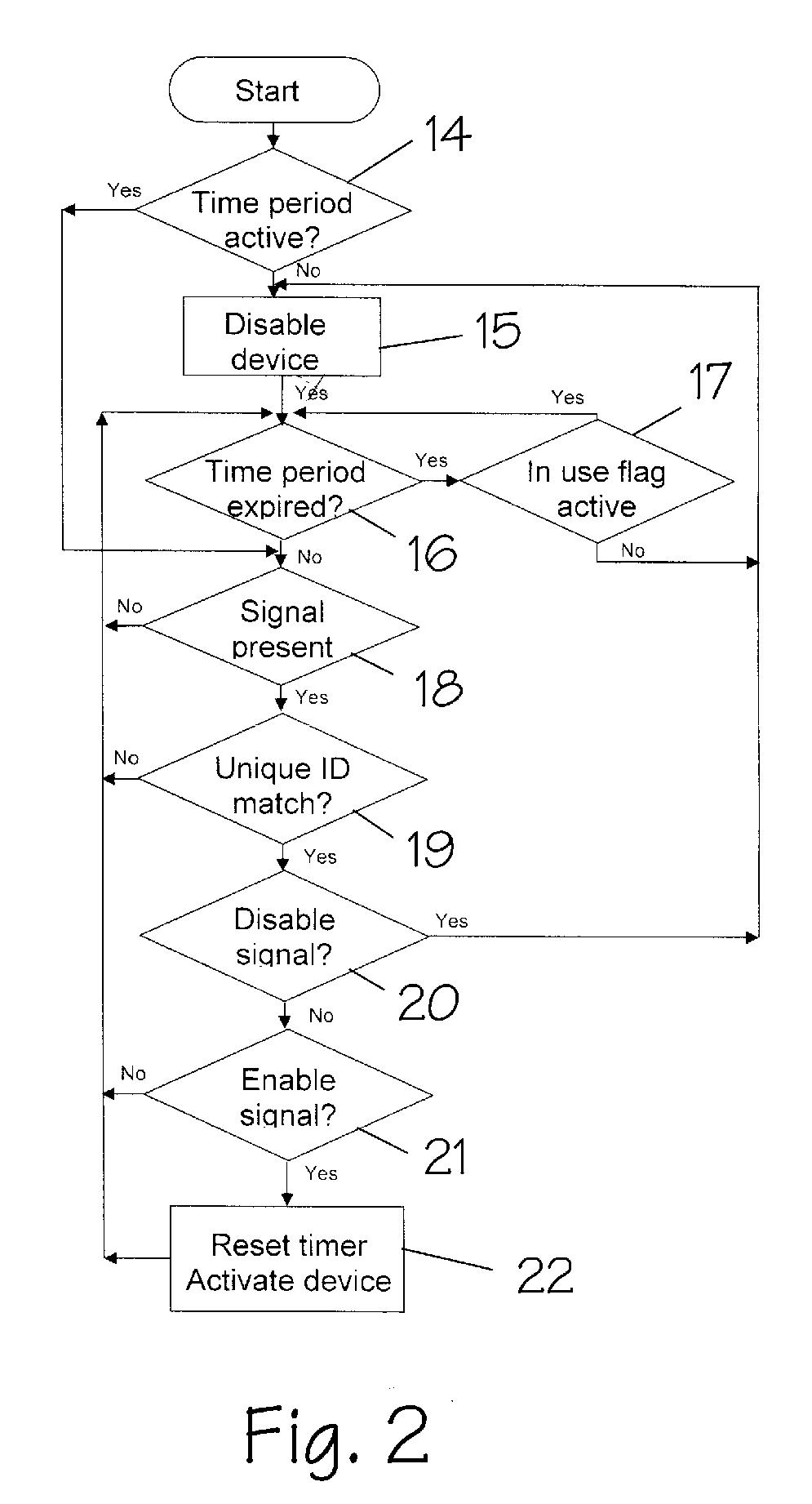

Electronically enabling devices remotely

InactiveUS20060071753A1Stable positionDisabling can be delayedDigital data processing detailsBurglar alarm mechanical actuationComputer hardwareEmbedded system

A device has (1) an electronic key that transmits a wireless coded signal and (2) at least one tool that can receive that signal. The coded signal is compared to a coded signal stored in said tool. If the coded signal matches the stored signal, a switch is closed for a predetermined amount of time. An on / off switch then enables the user of the tool to turn the tool on and off during the predetermined amount of time. After the predetermined amount of time, the switch is opened so that the tool can no longer be used. Opening the switch may be delayed if the tool is in use. The tool may also contain a unique identification code that can be read by various electronic means to identify the tool.

Owner:LAMAR DAVID

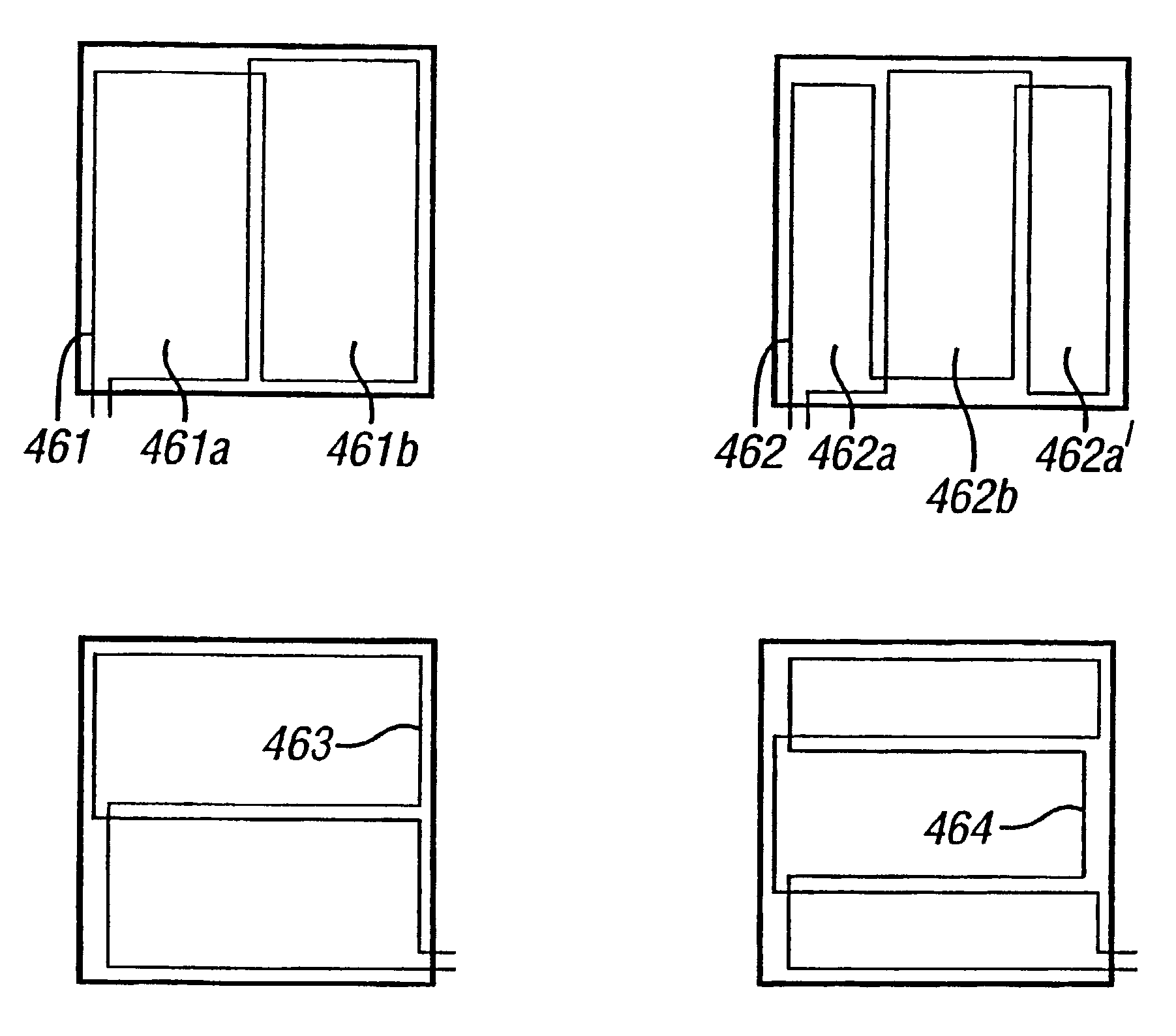

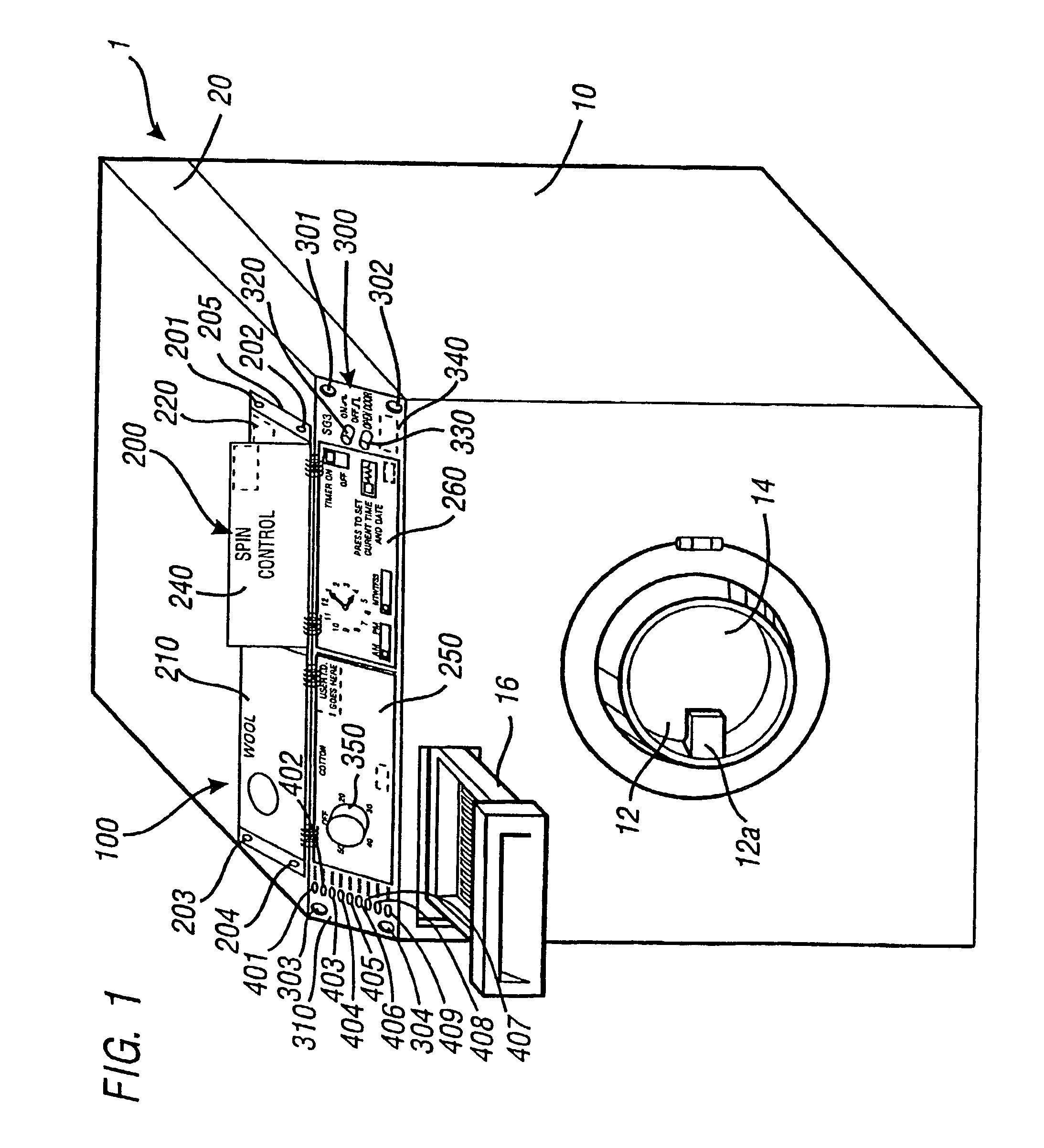

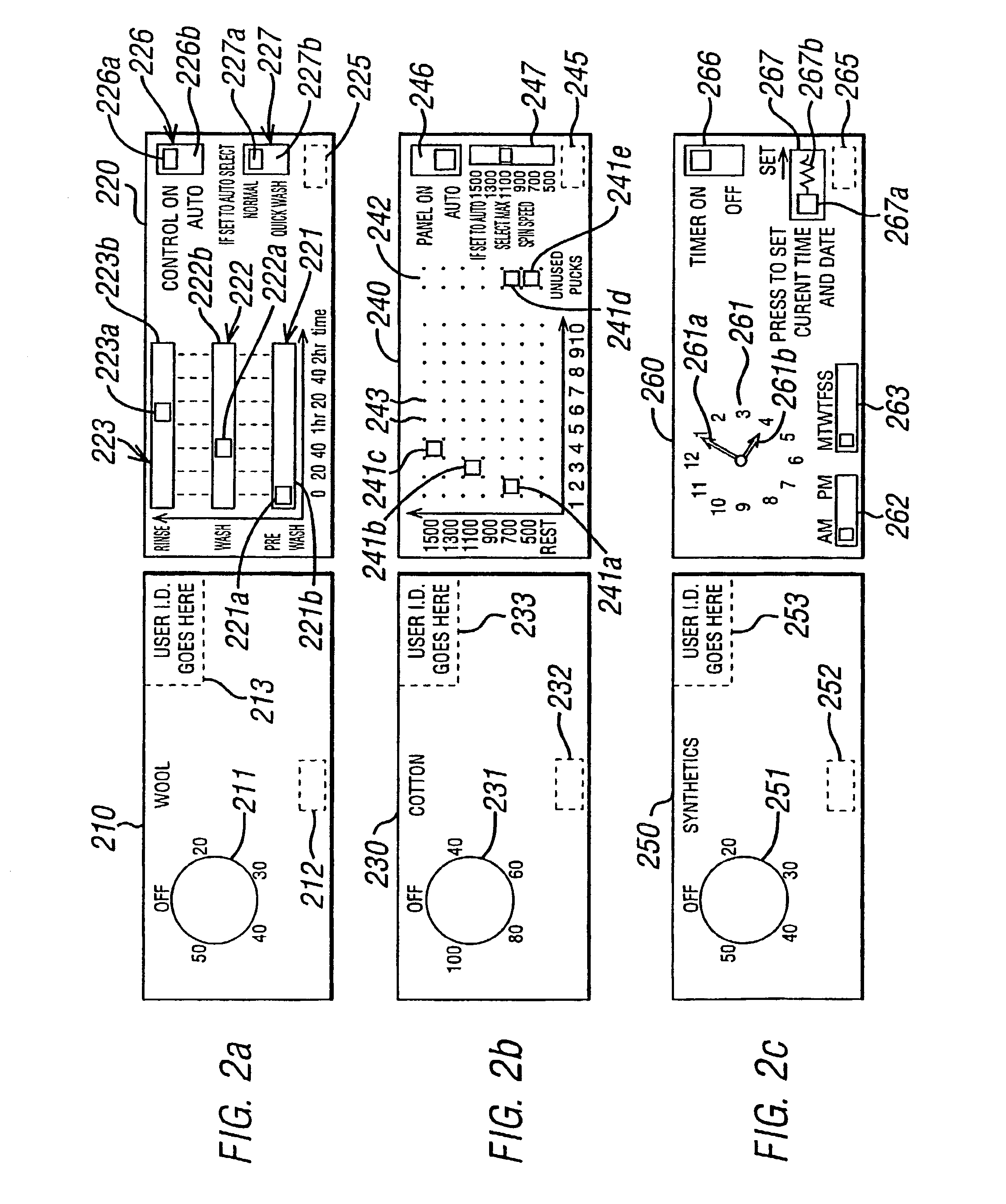

Man-machine interface

InactiveUS7016744B2Low costEasy to installProgramme control in sequence/logic controllersSpecial data processing applicationsHuman–machine interfaceMan machine

A man-machine interface is provided for a domestic appliance in which remotely sensed buttons, slider bars, marker pucks and a knob are used. The sensing coils for remotely sensing the positions of the buttons, slider bars, marker pucks and the knob are formed on a printed circuit board which is located behind a sealed surface such that there is no risk of contaminants accessing the printed circuit board.

Owner:SCI GENERICS LTD

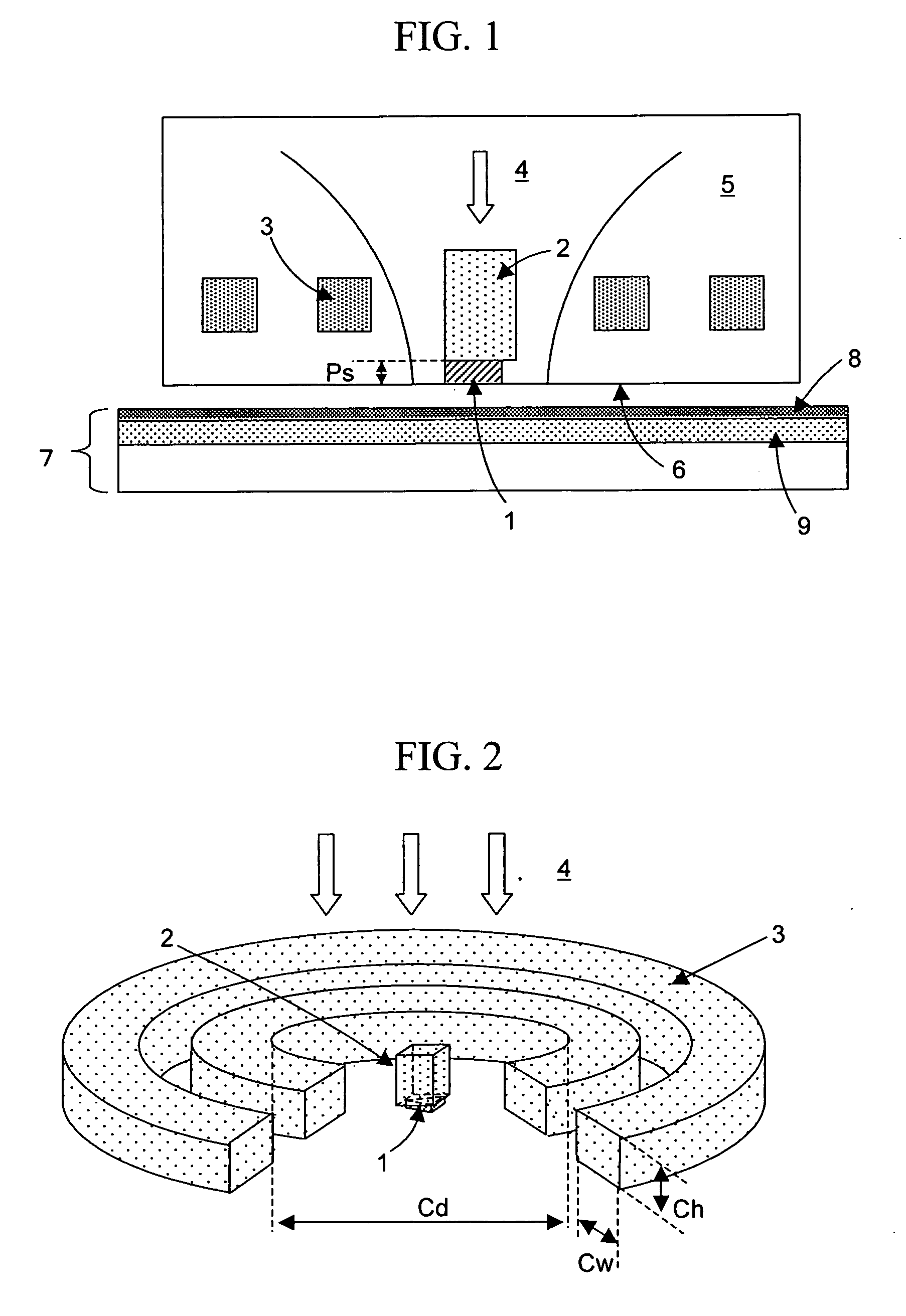

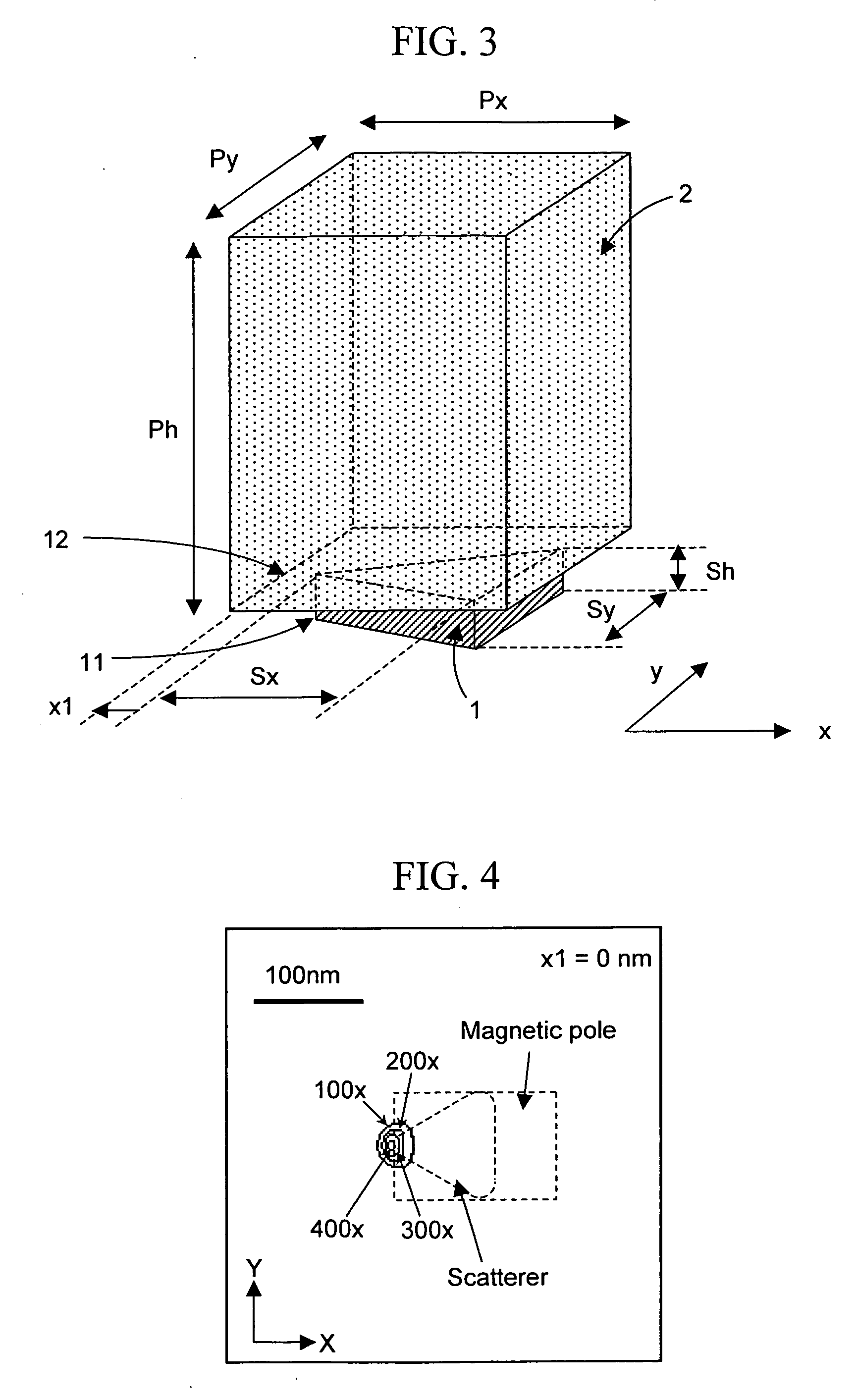

Head for thermal assisted magnetic recording device, and thermal assisted magnetic recording device

InactiveUS20070096854A1Reduce decreaseReduce lightCombination recordingRecord information storageHeat-assisted magnetic recordingMagnetic poles

The aim of the present invention is to apply an intense magnetic field to a portion where an optical near-field is generated by a thermal assisted magnetic recording head with a scatterer having conductivity as an optical near-field generating element. To this end, a scatterer for generating an optical near-field is formed in a bottom portion of a slider, and a magnetic field is applied thereto using a coil. In order to increase the intensity of the magnetic field, a magnetic pole made of a soft magnetic material is formed over the scatterer.

Owner:HITACHI LTD

Metal oxide varistor with a heat protection

InactiveUS20080129440A1Go fastFacilitate speed of actionCurrent responsive resistorsResistor cooling/heating/ventillationElectrical resistance and conductanceEngineering

A metal oxide varistor integrally formed with a heat protection structure that will automatically go to open circuit in conditions of overheating due to sustained over-voltages. The metal oxide varistor integrally formed with a heat protection structure has a body, an insulation bracket, a number of terminals and a fuse. The insulation bracket is deposited on the body and has a number of slots. The fuse connects to the body and one of the terminals. The fuse is mounted one of the slots of the insulation bracket. The fuse reacts to the overheating timely and the melting fuse spreads quickly with the assistance of capillary action evolved by the slots of the insulation bracket to speed up the action to go to open circuit in against damage due to sustained over-voltages.

Owner:THINKING ELECTRONICS INDAL

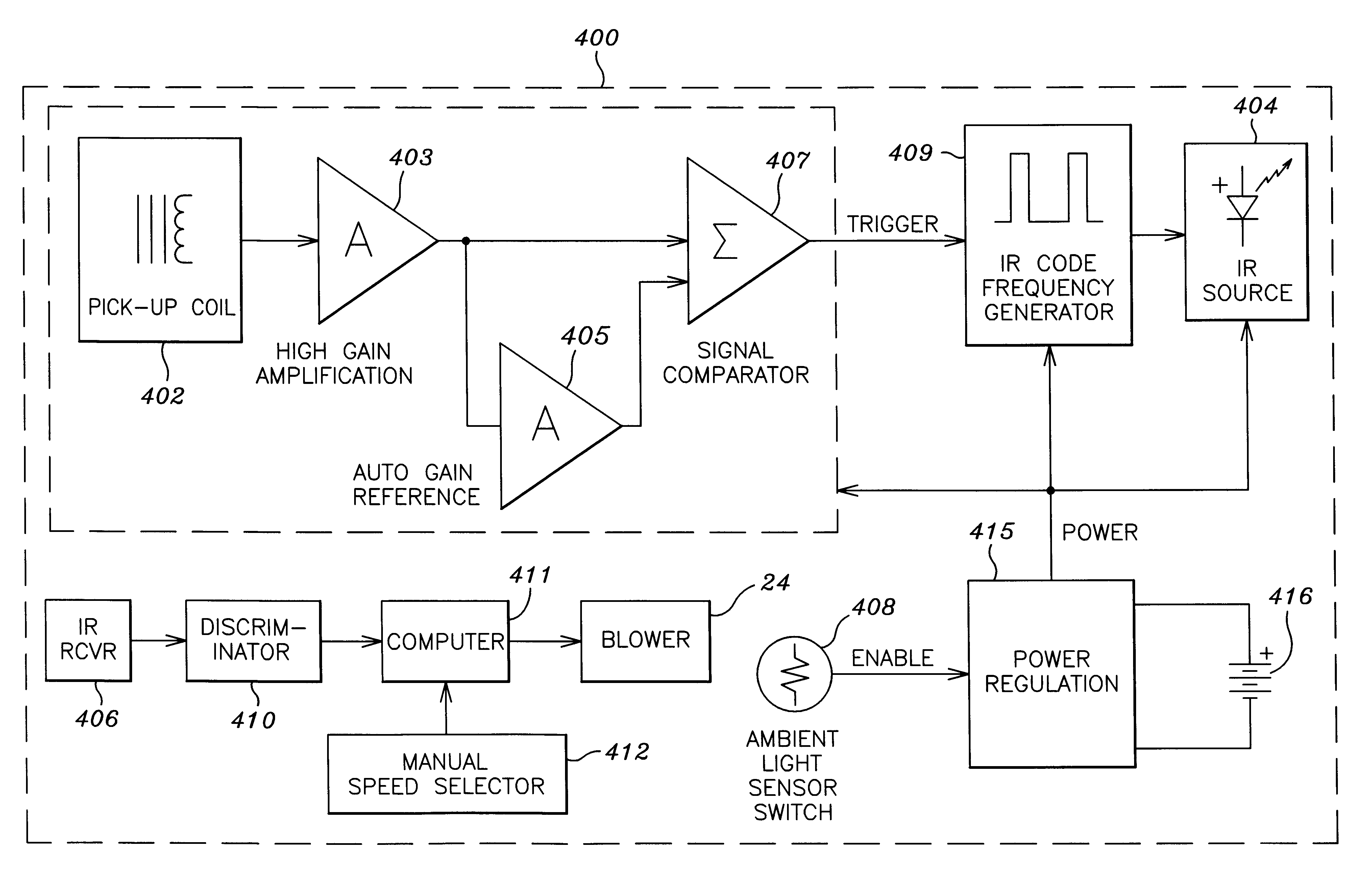

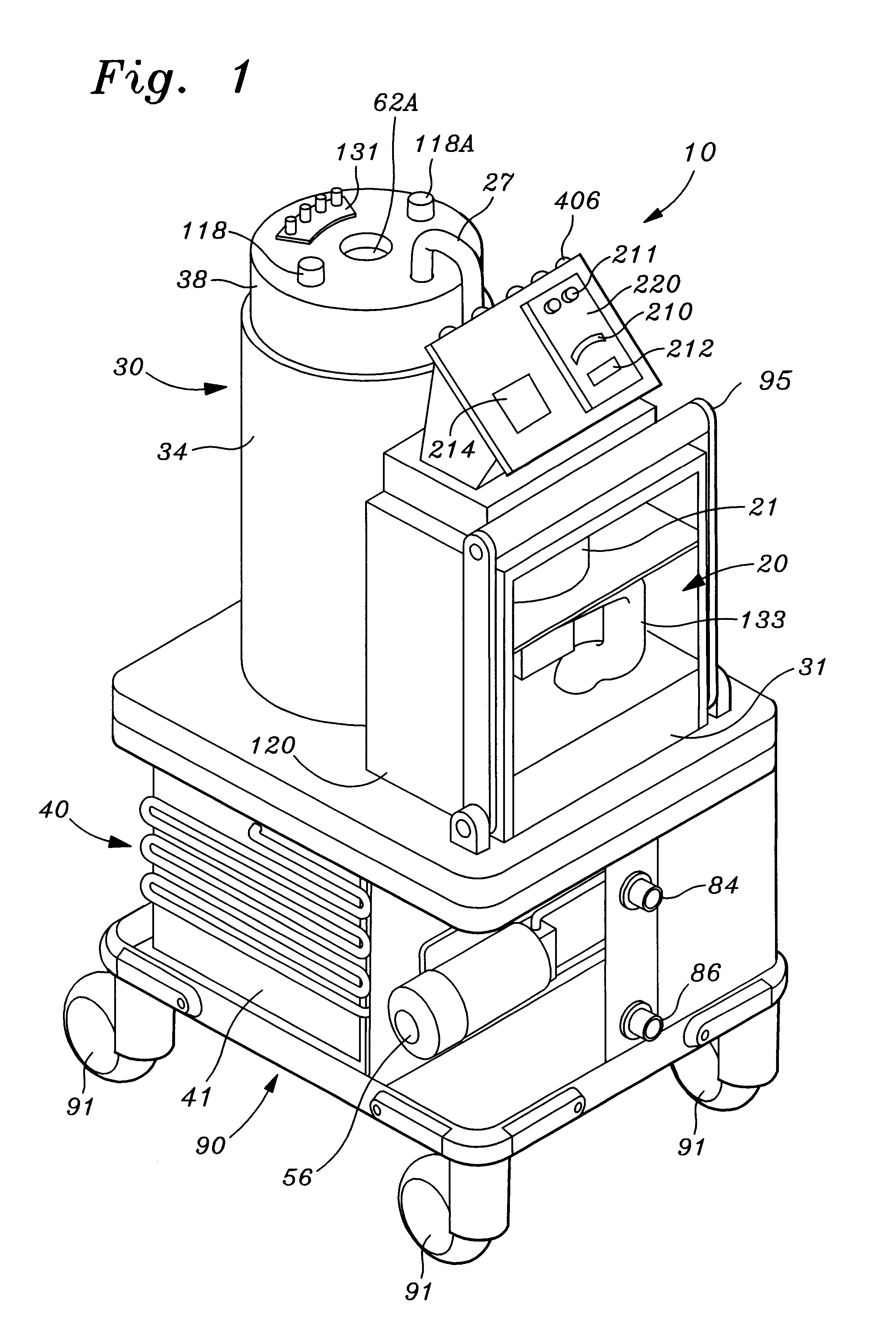

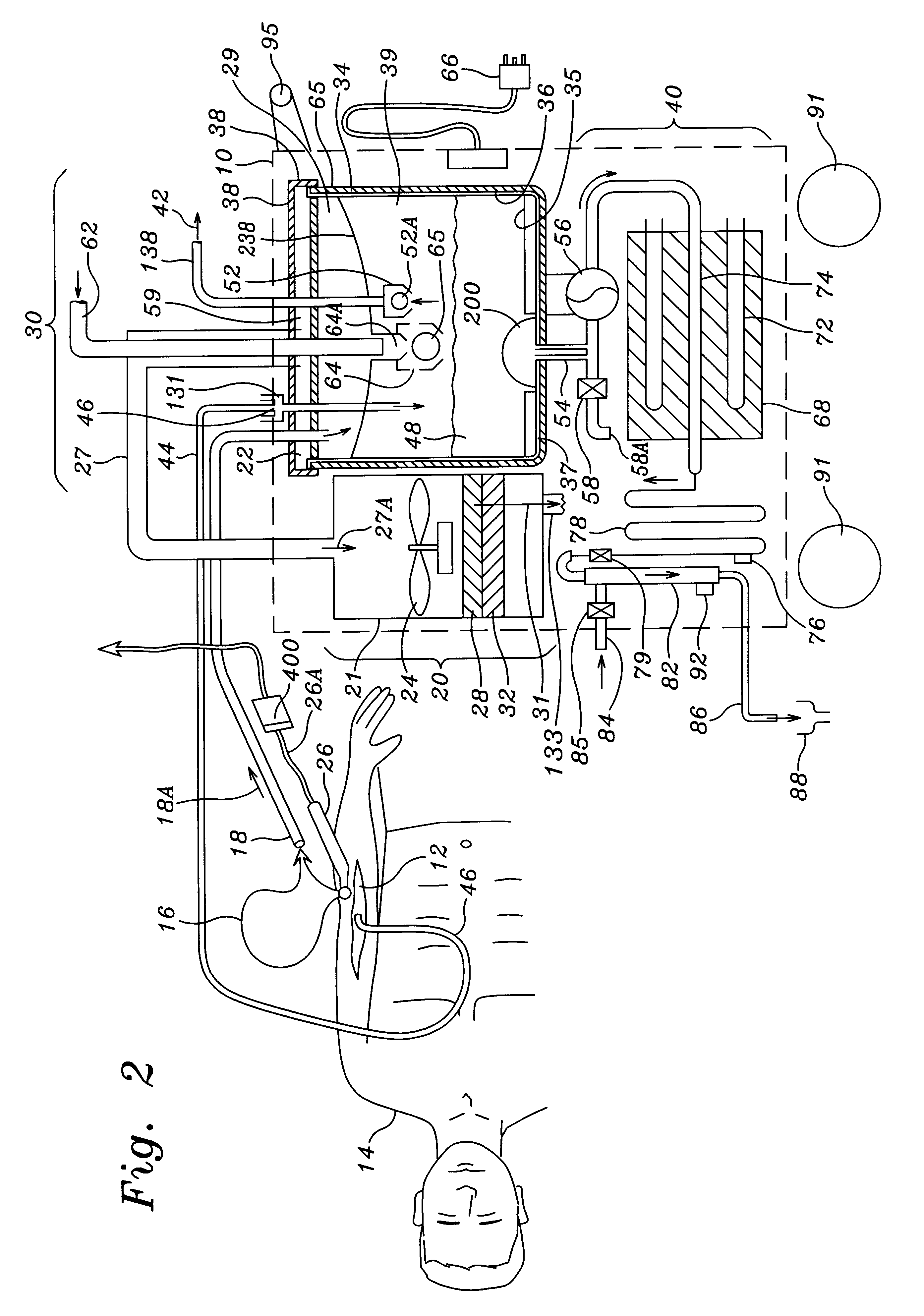

Current sensor switch

InactiveUS6222283B1Quickly and easily and efficiently maintain integrity of surgical siteLow efficiencyDc network circuit arrangementsBatteries circuit arrangementsElectrical conductorCurrent sensor

An IR current sensor circuit which is operative to detect an existing current level in a conductor and to produce output signals representative of the existing current level wherein changes of the current level in the conductor can produce changes in the output signals and effect a control function in response thereto.

Owner:STRYKER CORP

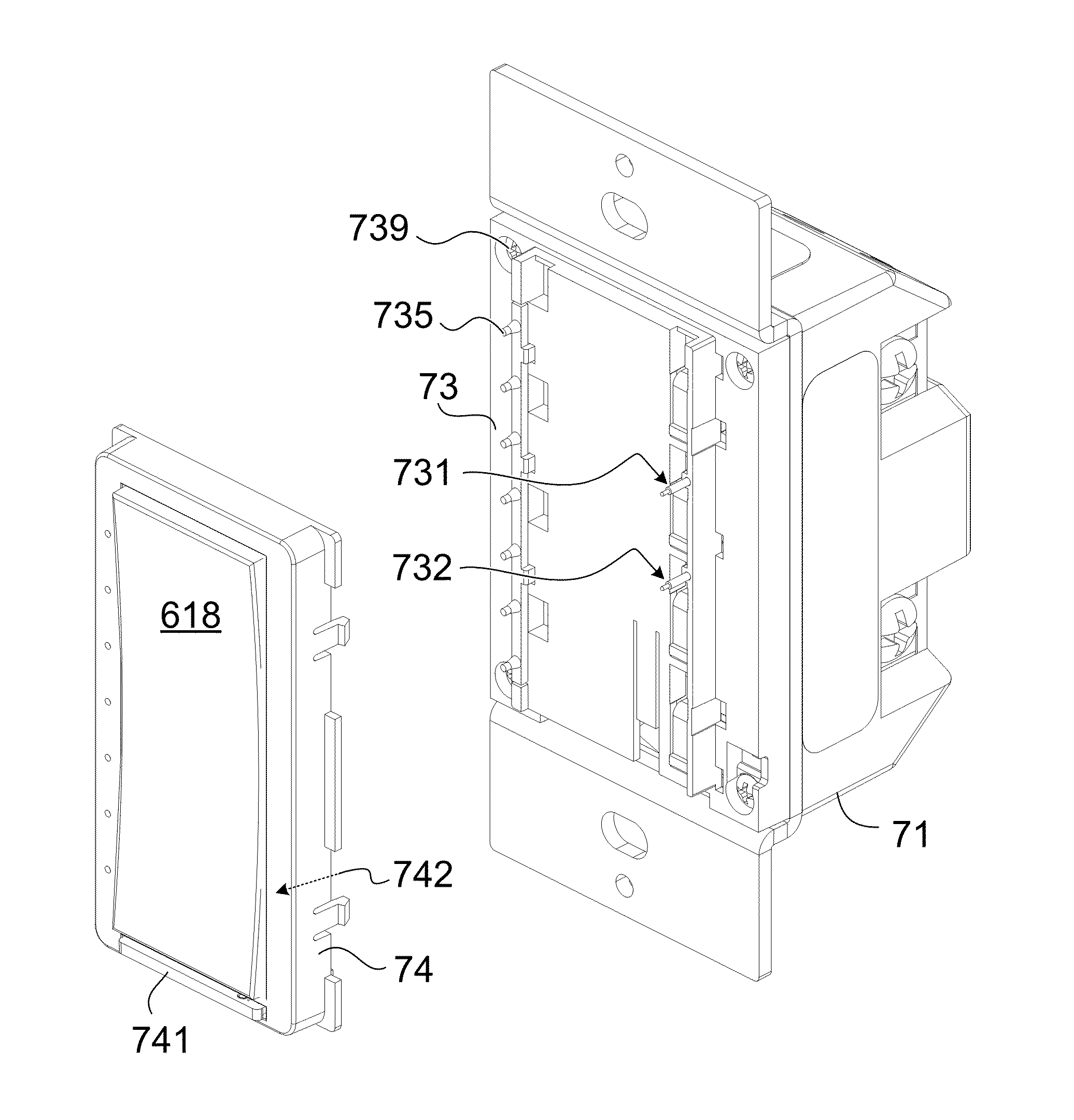

Wall-mounted electrical device with modular antenna bezel frame

ActiveUS20110095622A1Boards/switchyards circuit arrangementsAntenna supports/mountingsElectricityControl signal

An electrical device configured to install within a wall mounted electrical box includes an antenna bezel frame, an antenna element, and a radio frequency circuitry component. At least a portion of the antenna bezel frame is configured to protrude through an opening in a faceplate. The antenna element is mounted to the antenna bezel frame such that the antenna element is located a distance forward of a plane that contains a front surface of the faceplate when the field configurable electrical device is installed. The radio frequency circuitry component is in electrical communication with the antenna element and is configured to receive a control signal from the antenna element.

Owner:CRESTRON ELECTRONICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com