Patents

Literature

953results about "Current responsive resistors" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

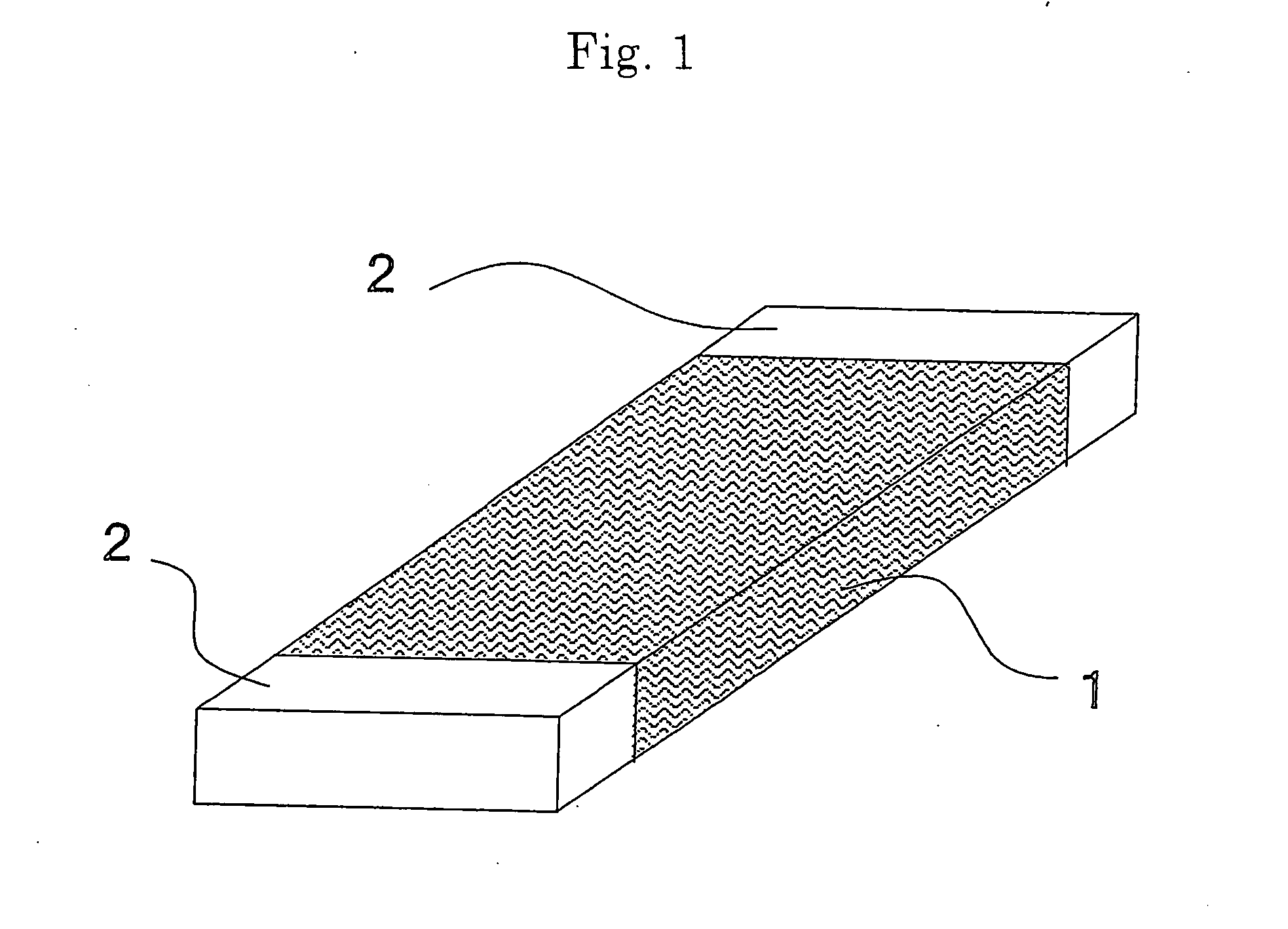

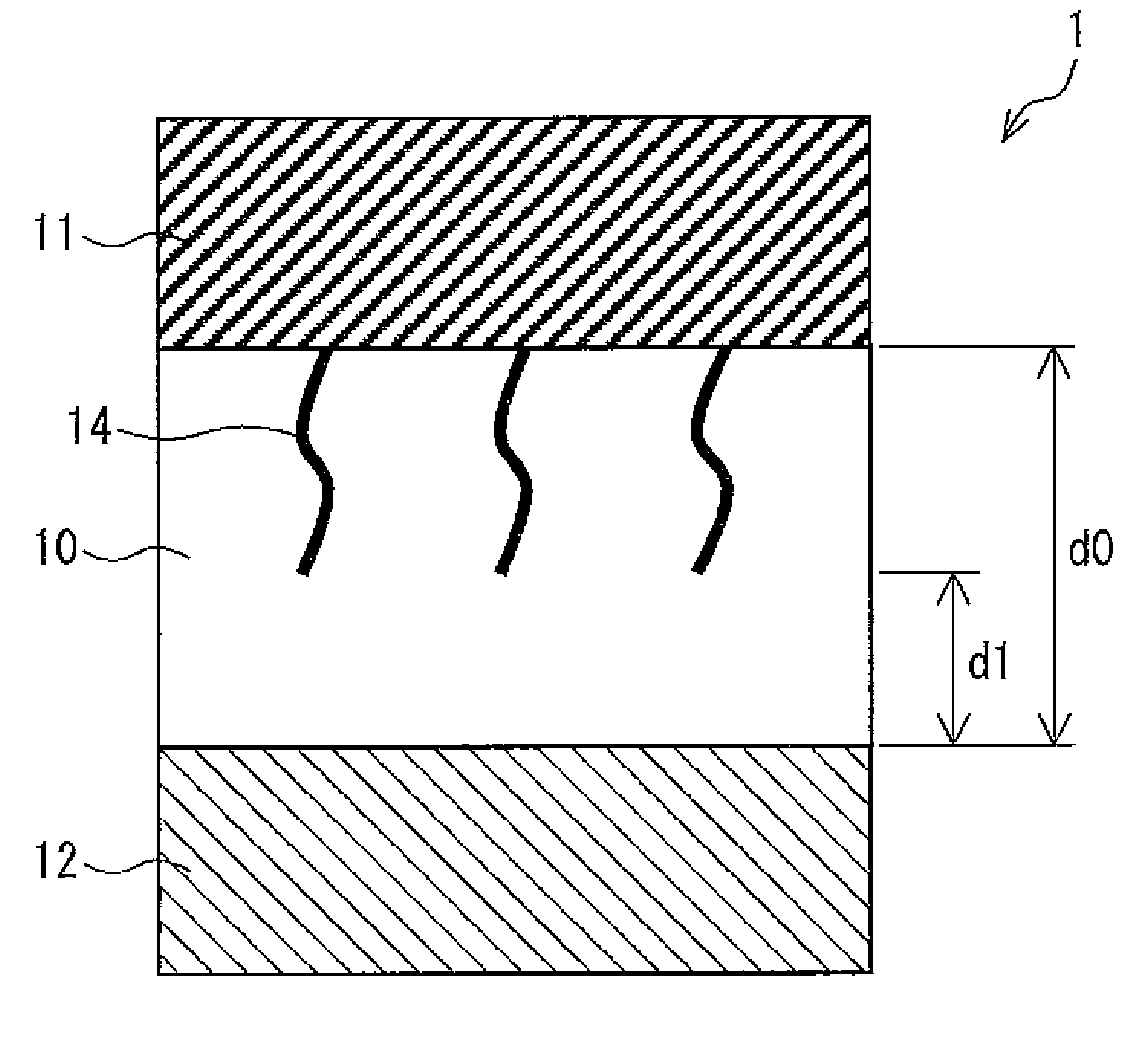

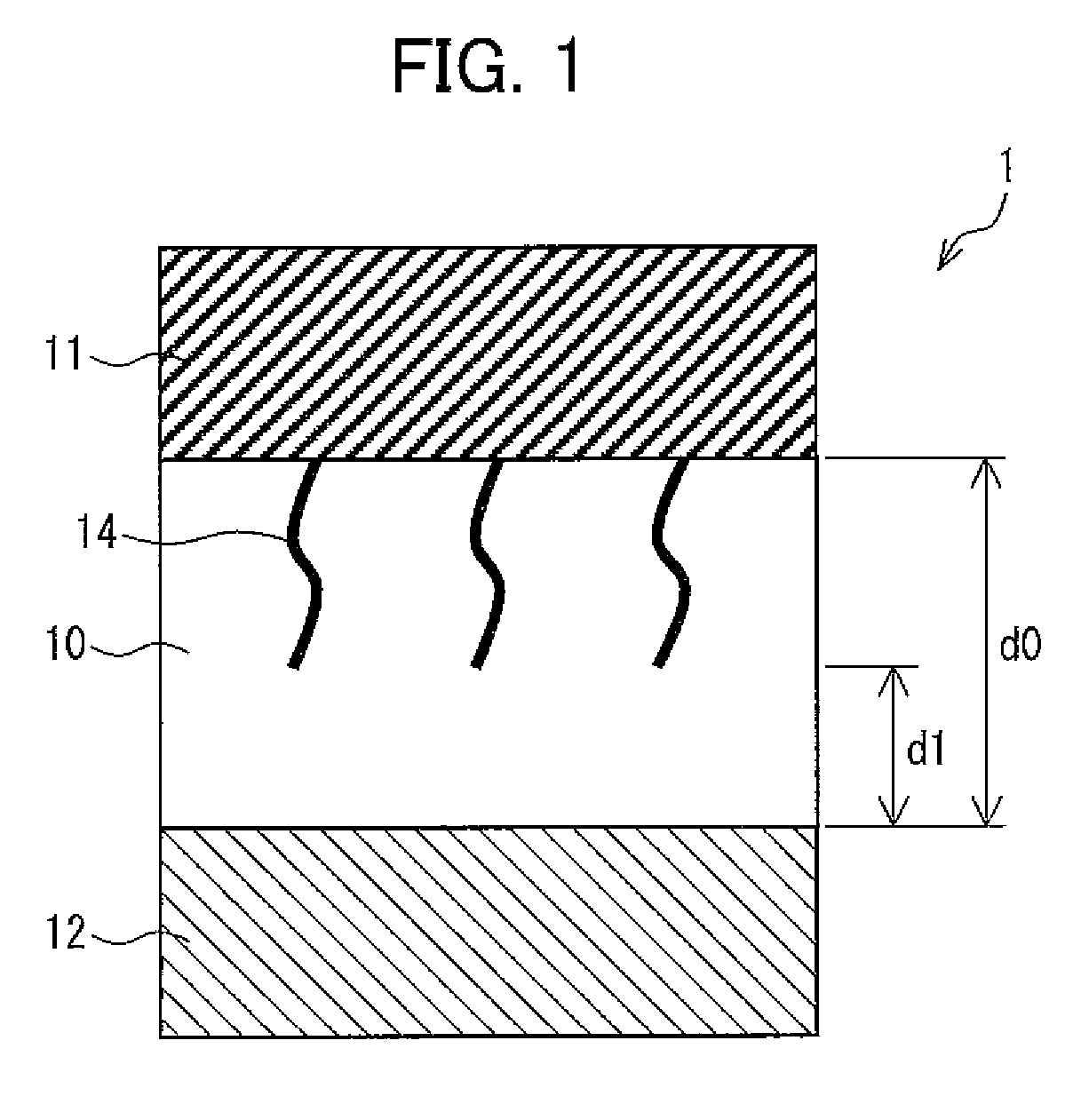

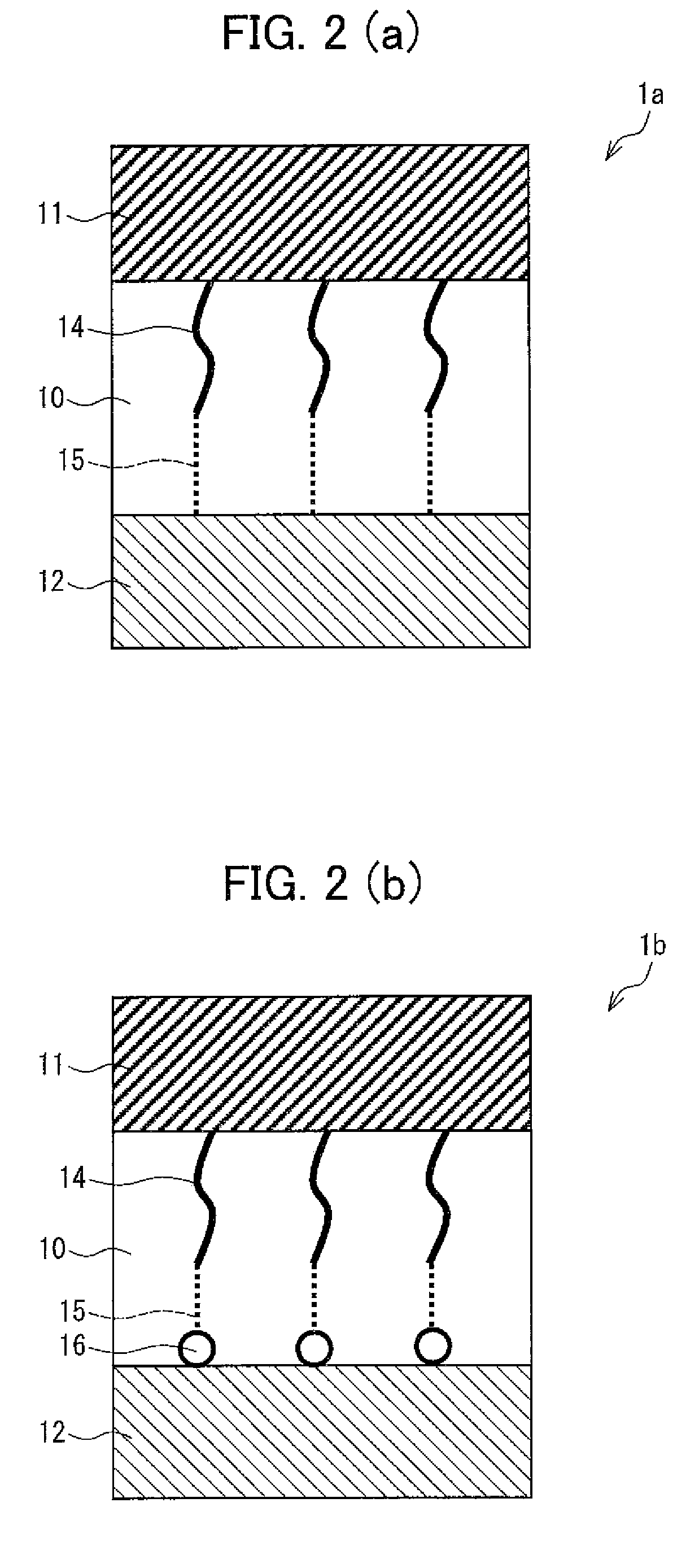

Resistance element, method of manufacturing the same, and thermistor

InactiveUS20050040371A1Easy and stable coatingLow resistivityMaterial nanotechnologyCurrent responsive resistorsResistive elementCarbon nanotube

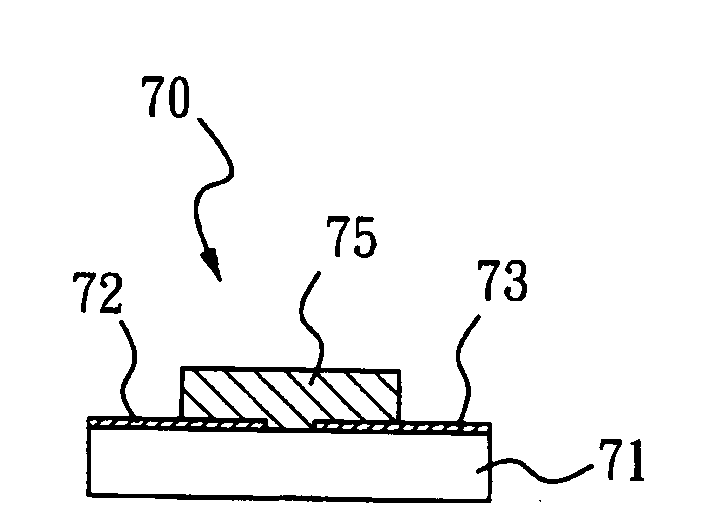

To provide a resistance element having an electric resistance body with excellent stability and a method of manufacturing the same. The resistance element includes an electric resistance body, on a base body surface, consisting of a carbon nanotube structure layer 14, which configures a mesh structure in which at least plural carbon nanotubes are cross-linked to one another. The method of manufacturing the resistance element includes: an applying step of applying the base body surface 12 with a liquid solution containing carbon nanotubes having functional groups; and a cross-linking step of forming the carbon nanotube structure layer 14, used as an electric resistance body, that configures a mesh structure in which the plural carbon nanotubes are cross-linked to one another through curing of the liquid solution after application.

Owner:FUJIFILM BUSINESS INNOVATION CORP

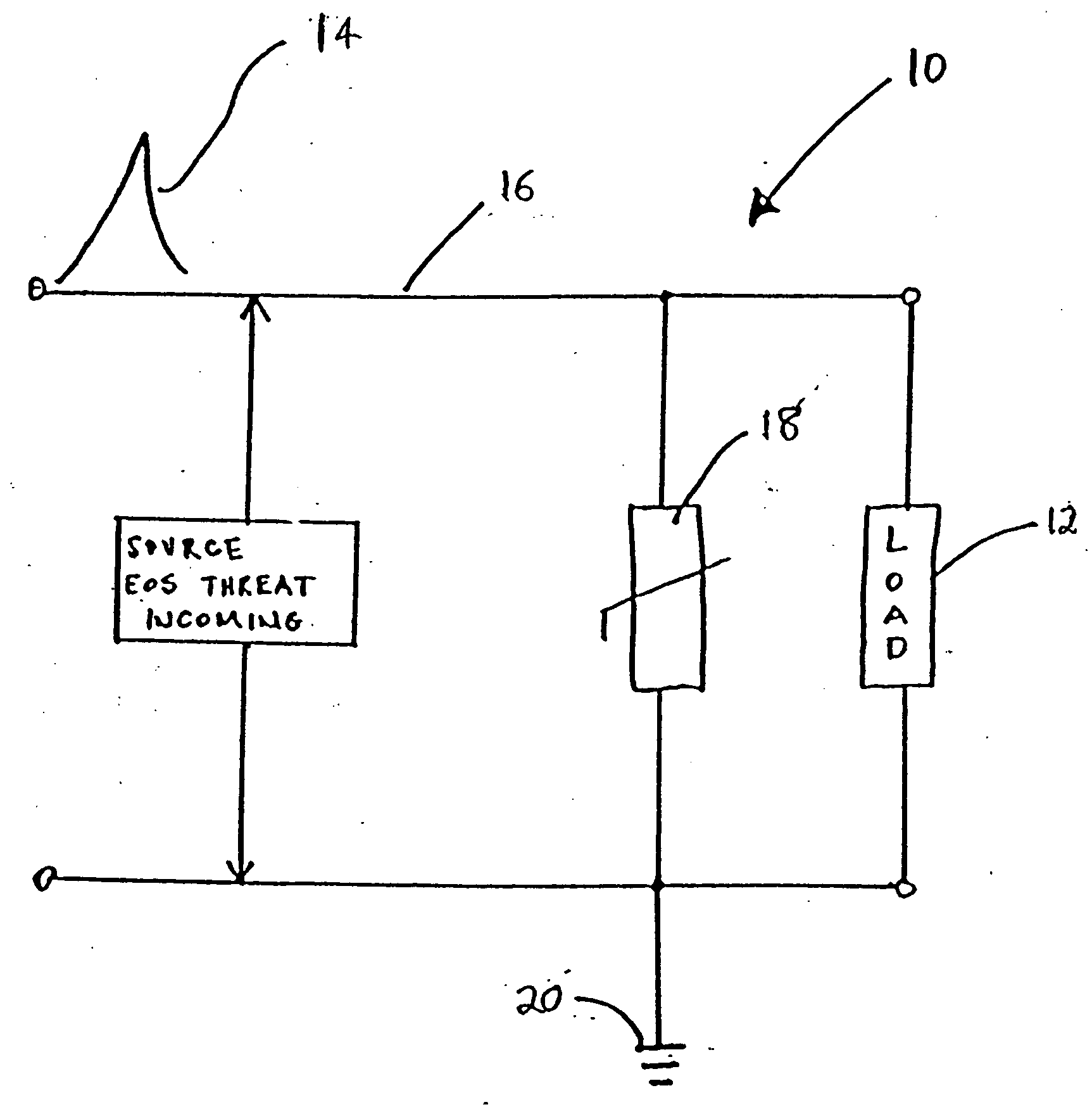

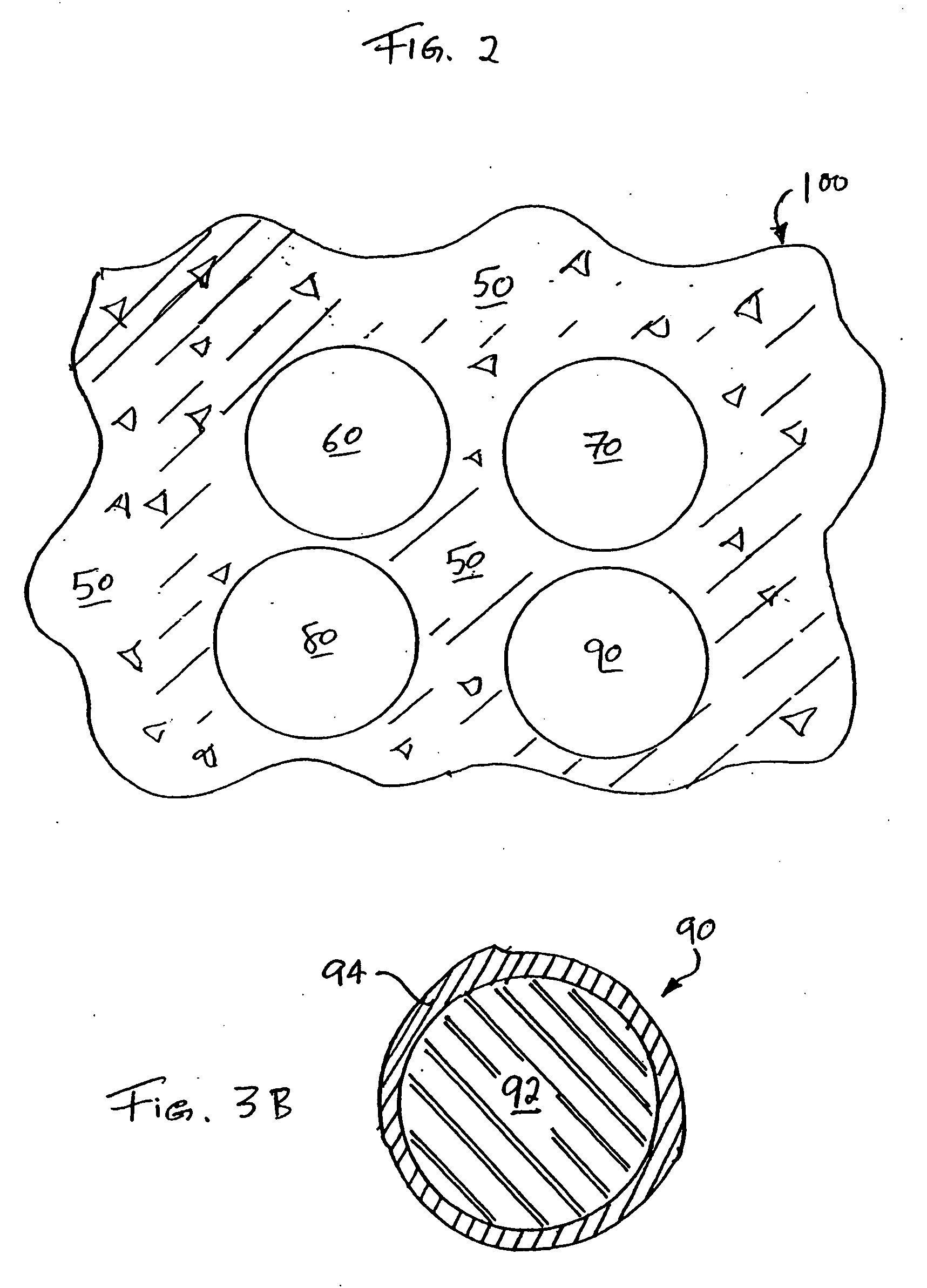

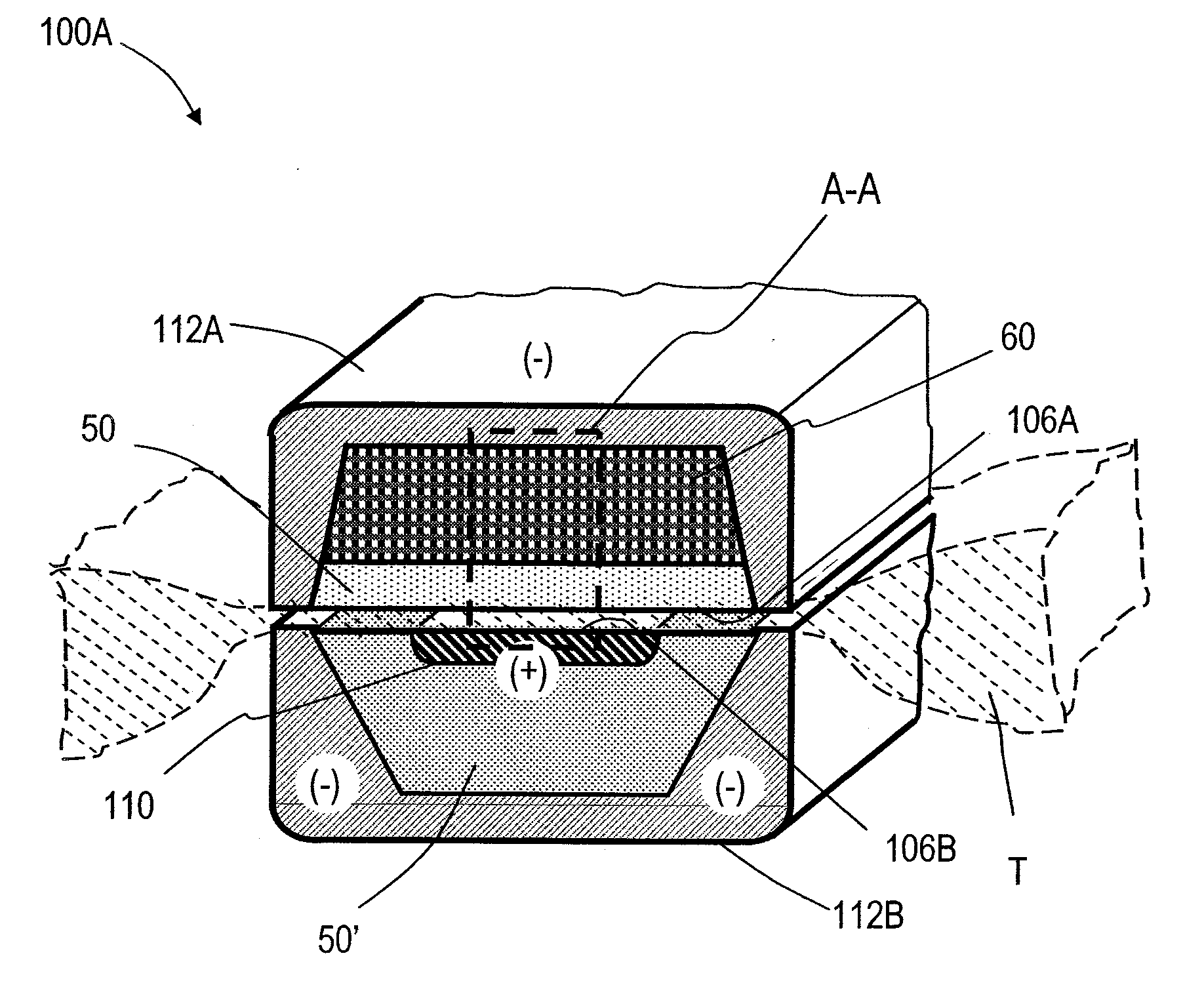

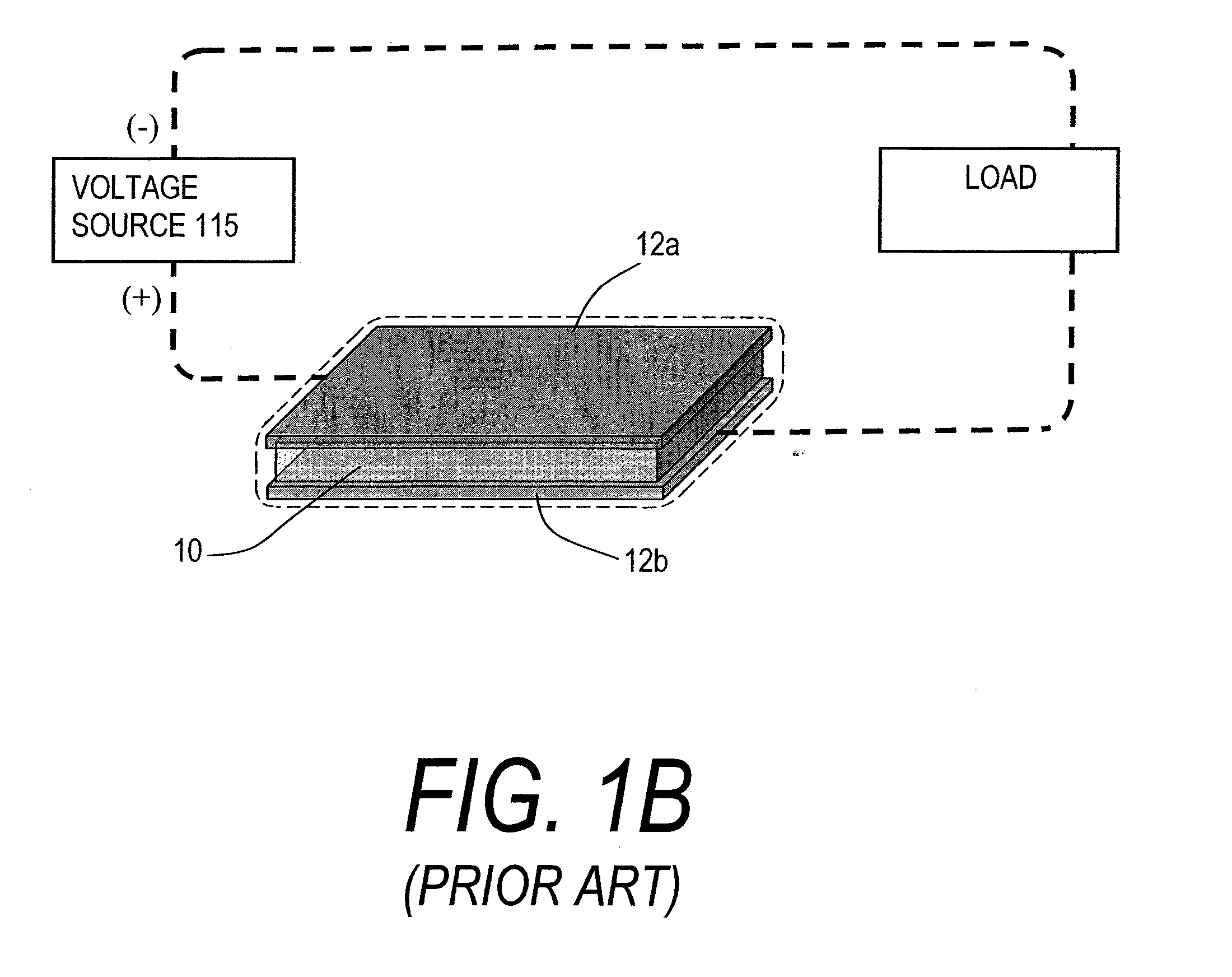

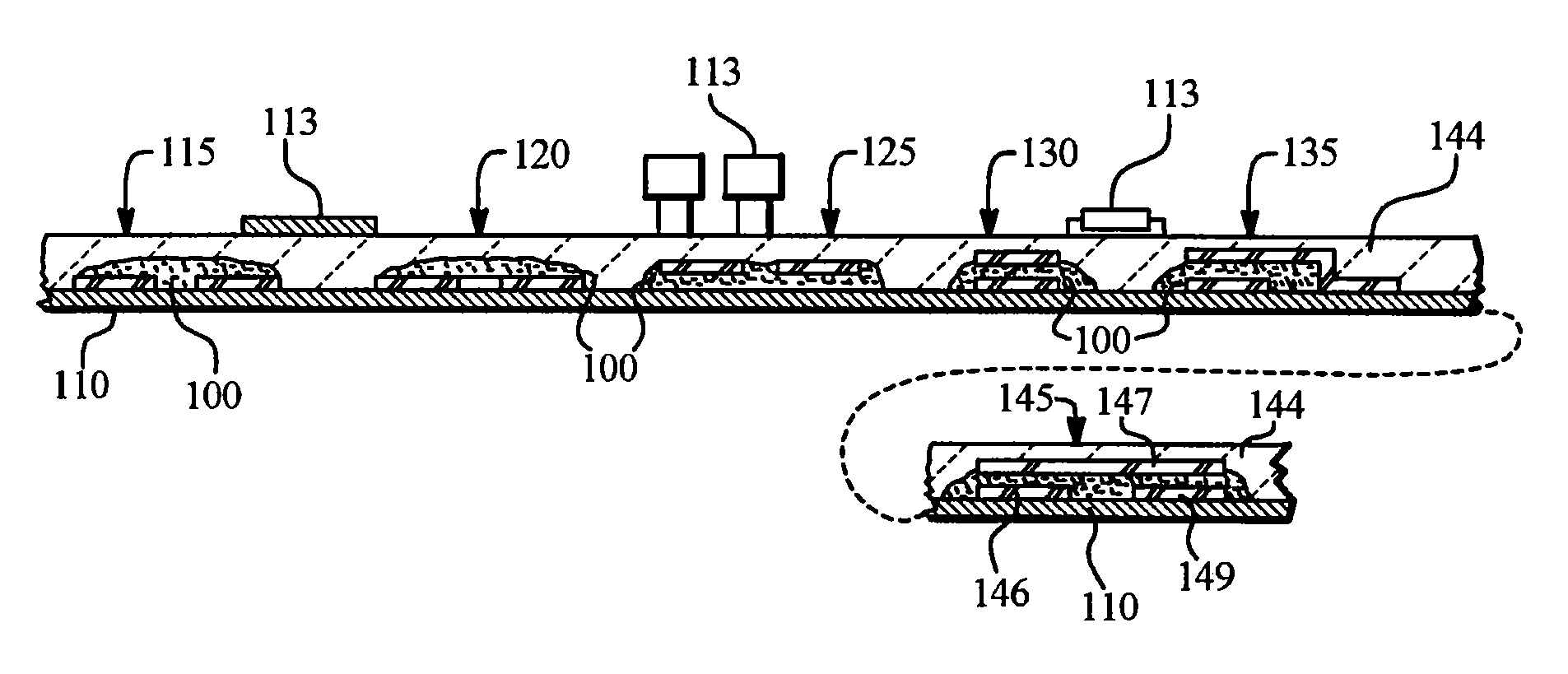

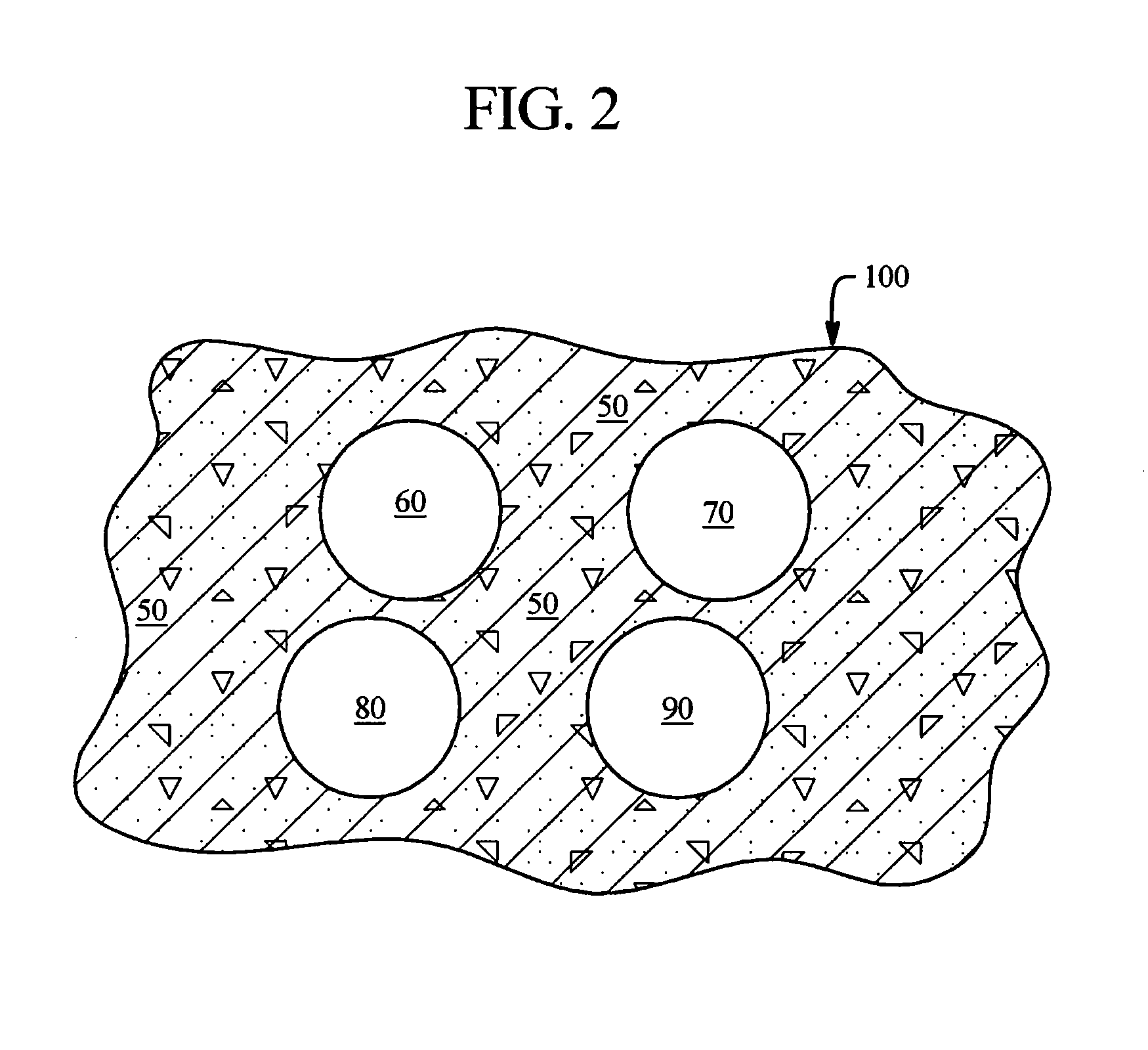

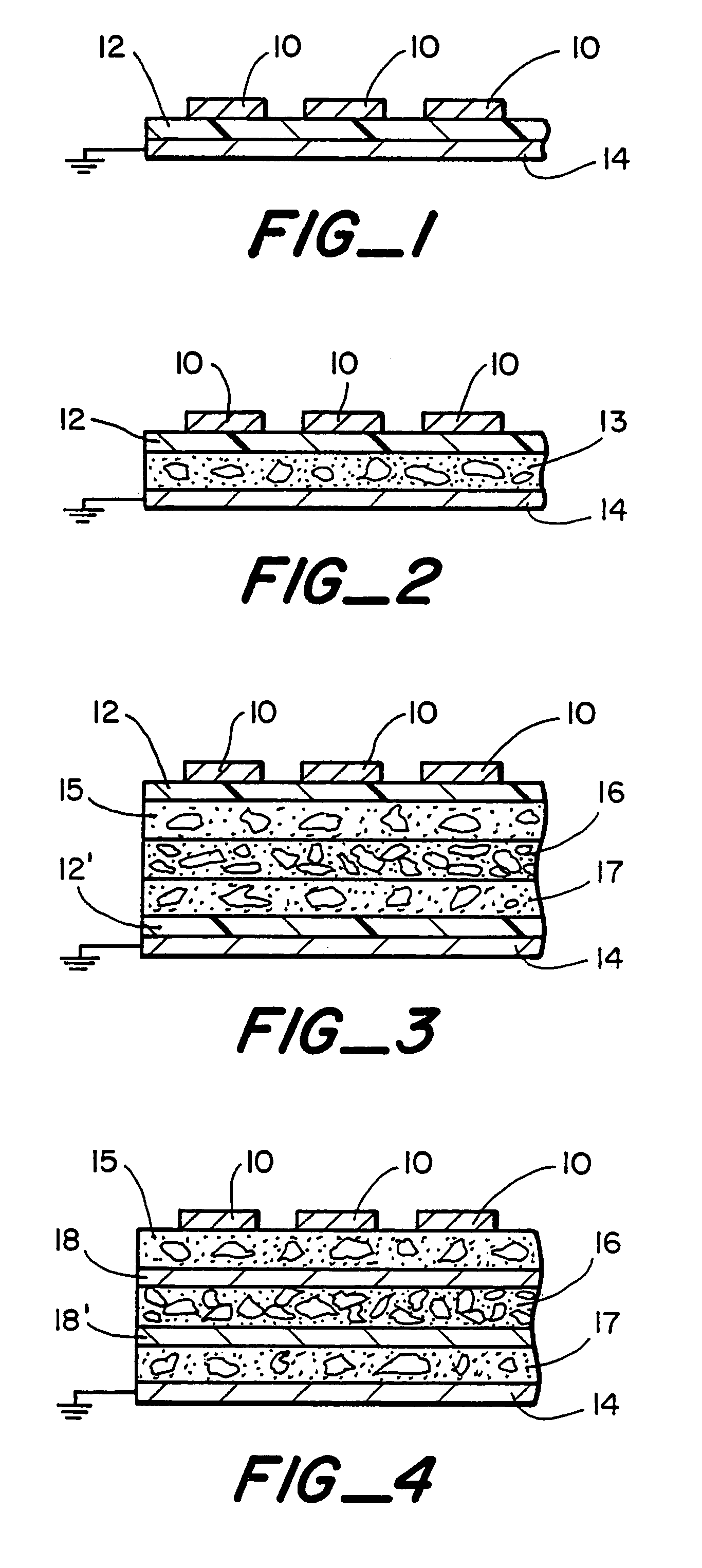

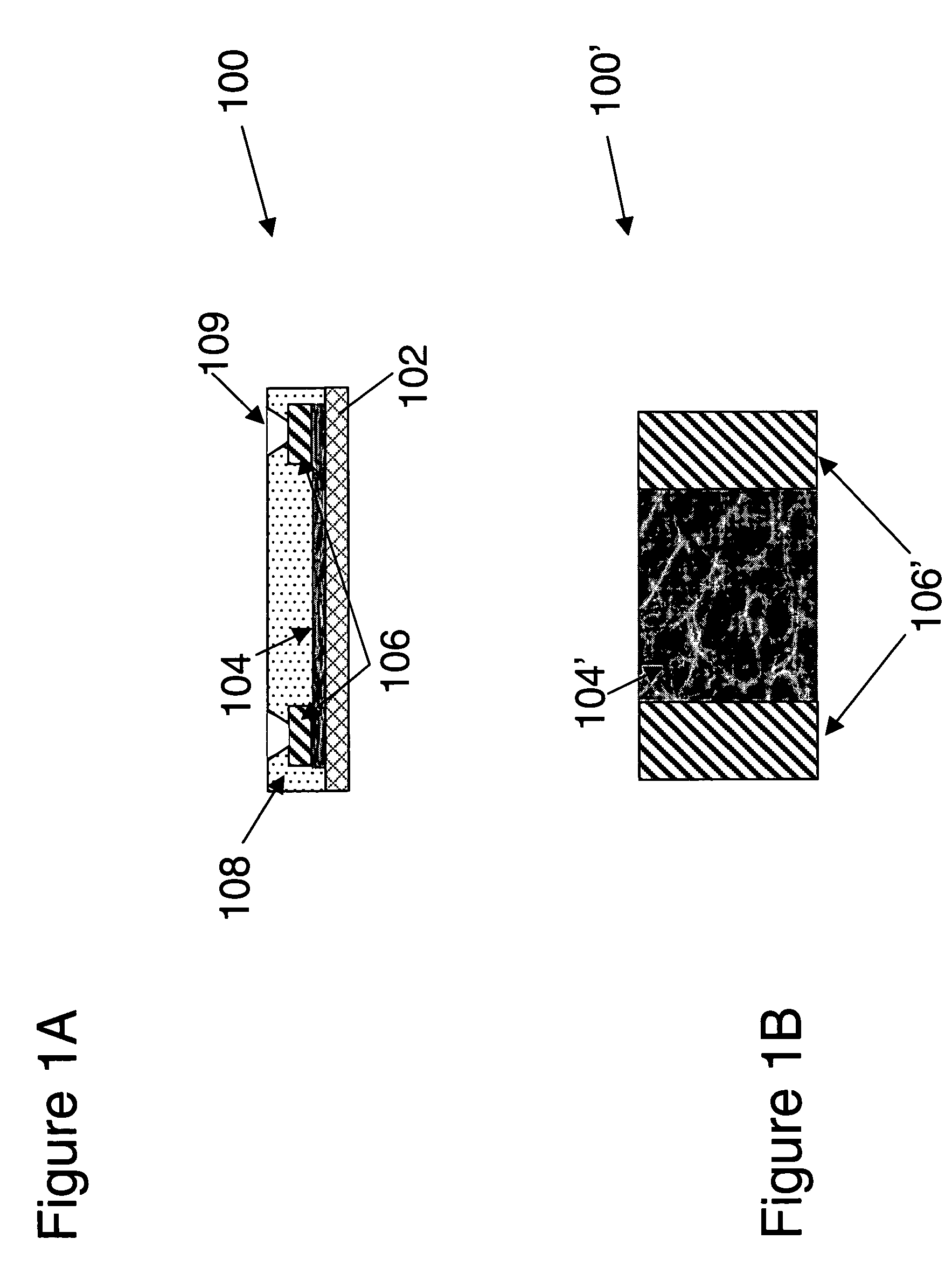

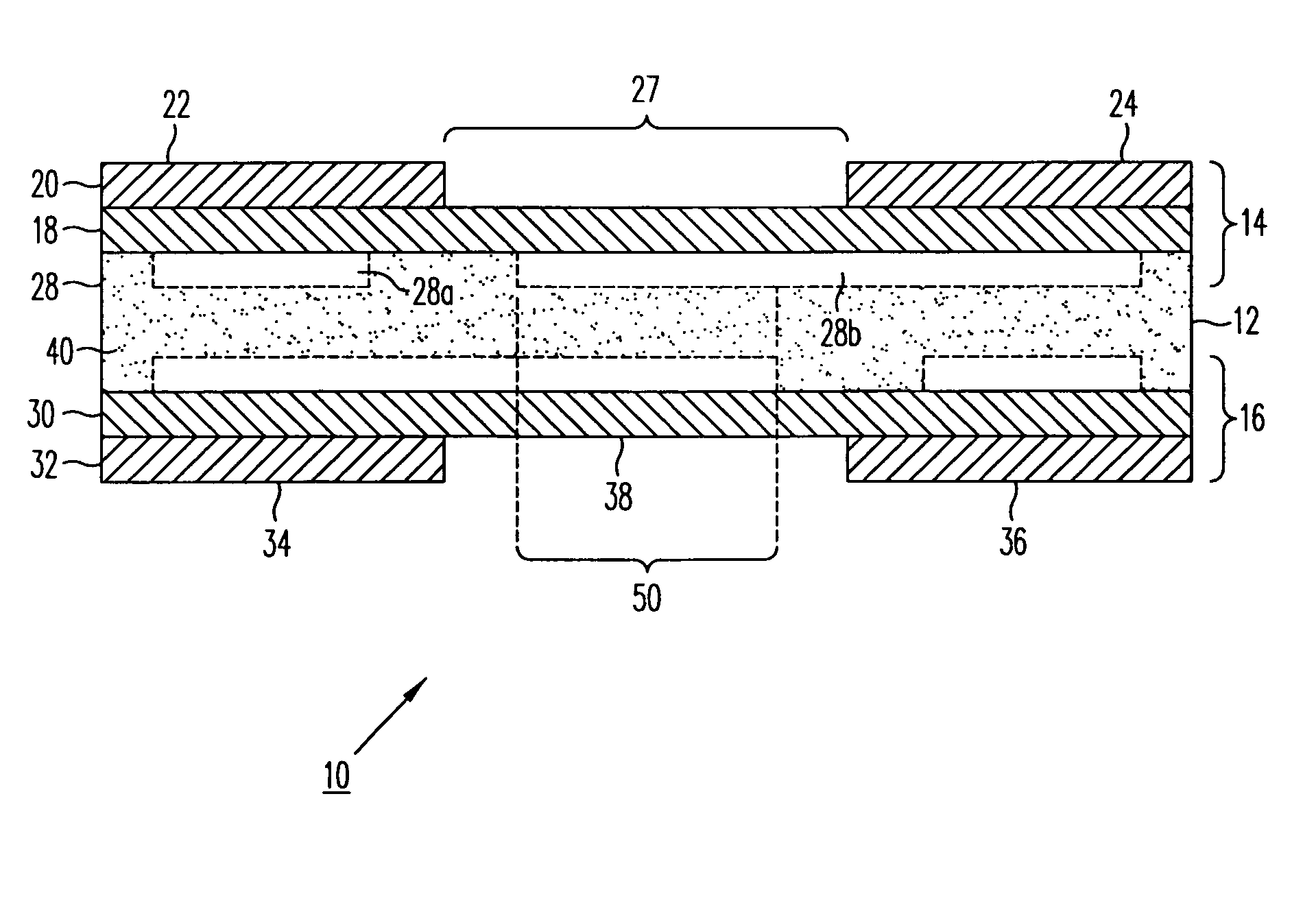

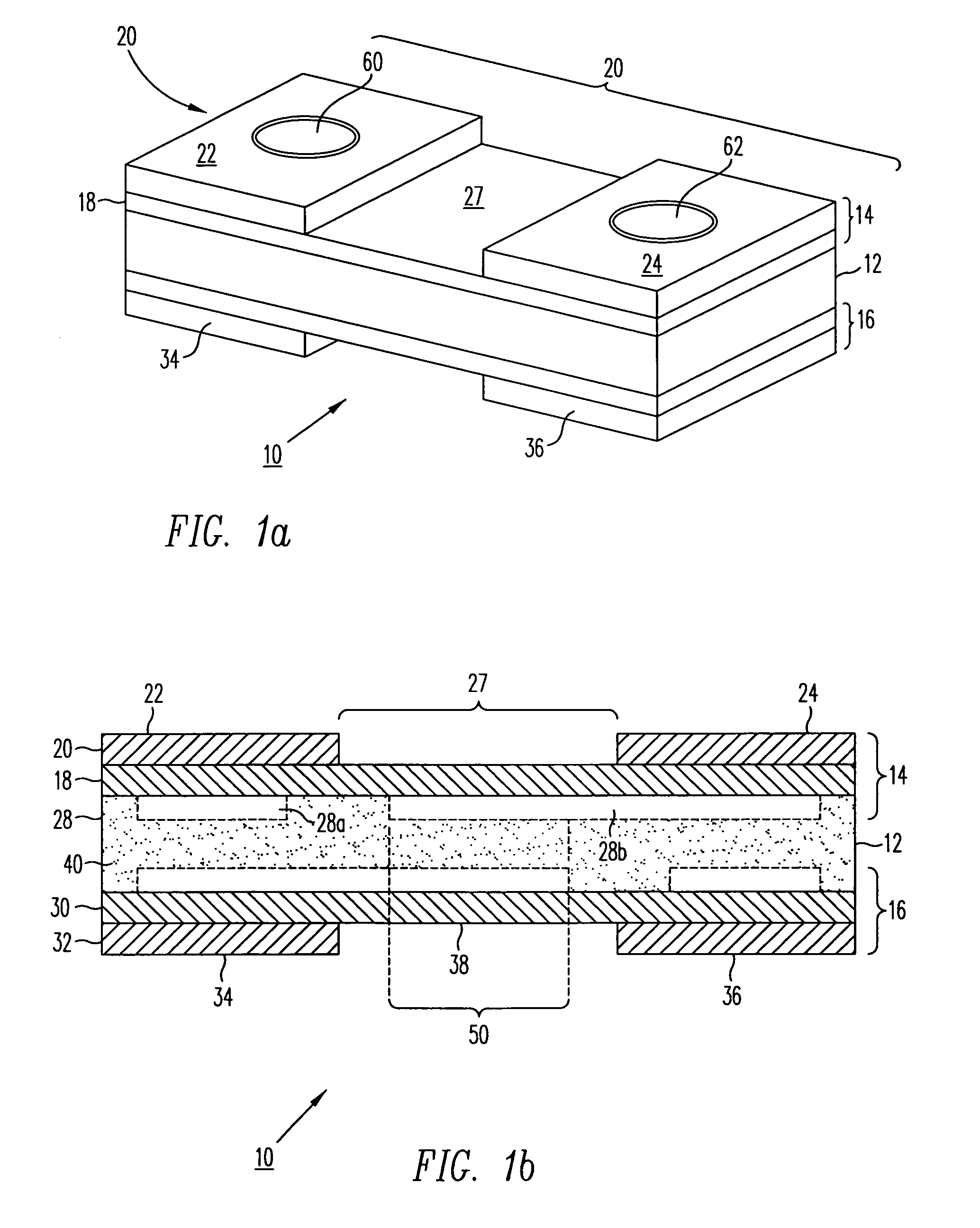

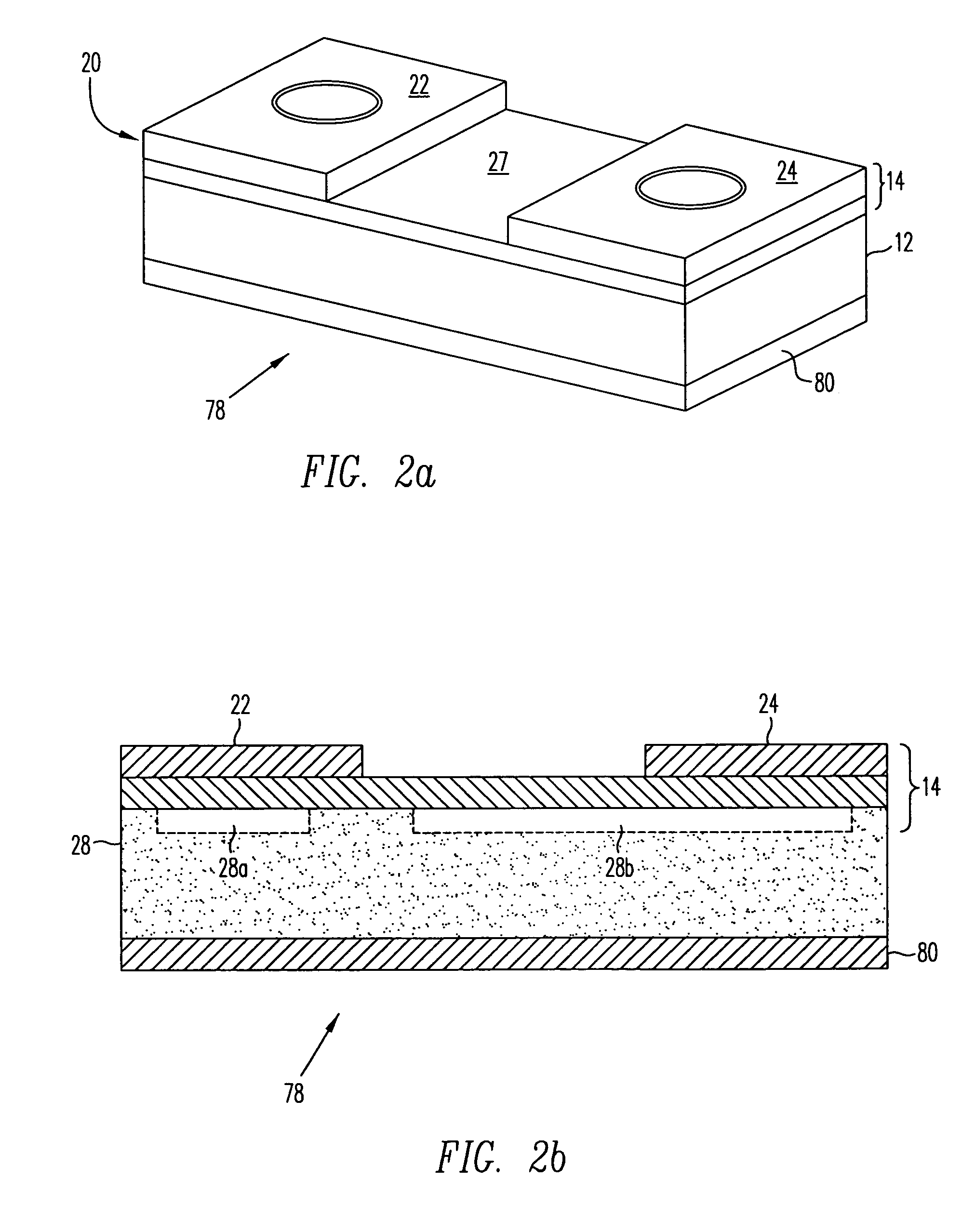

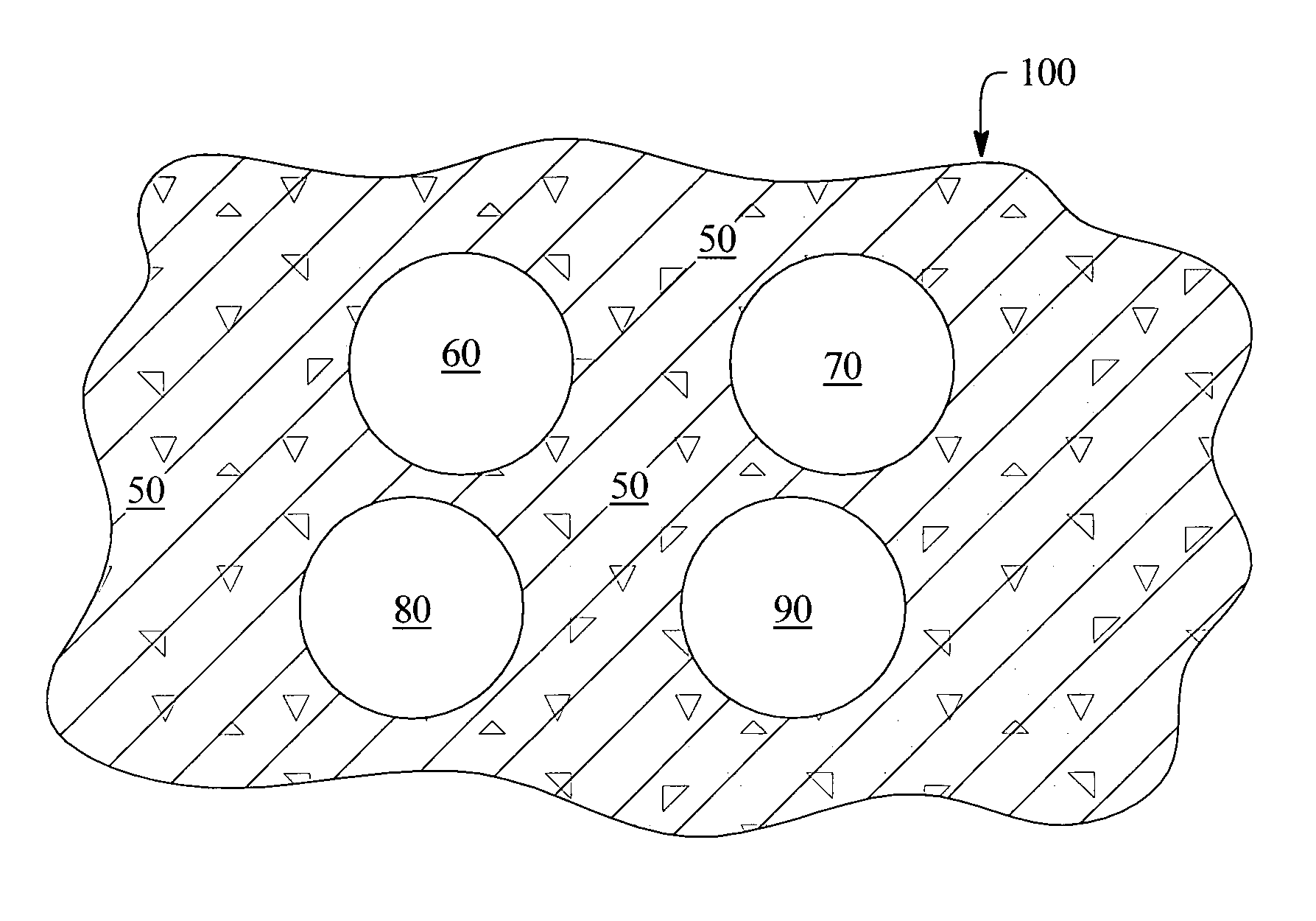

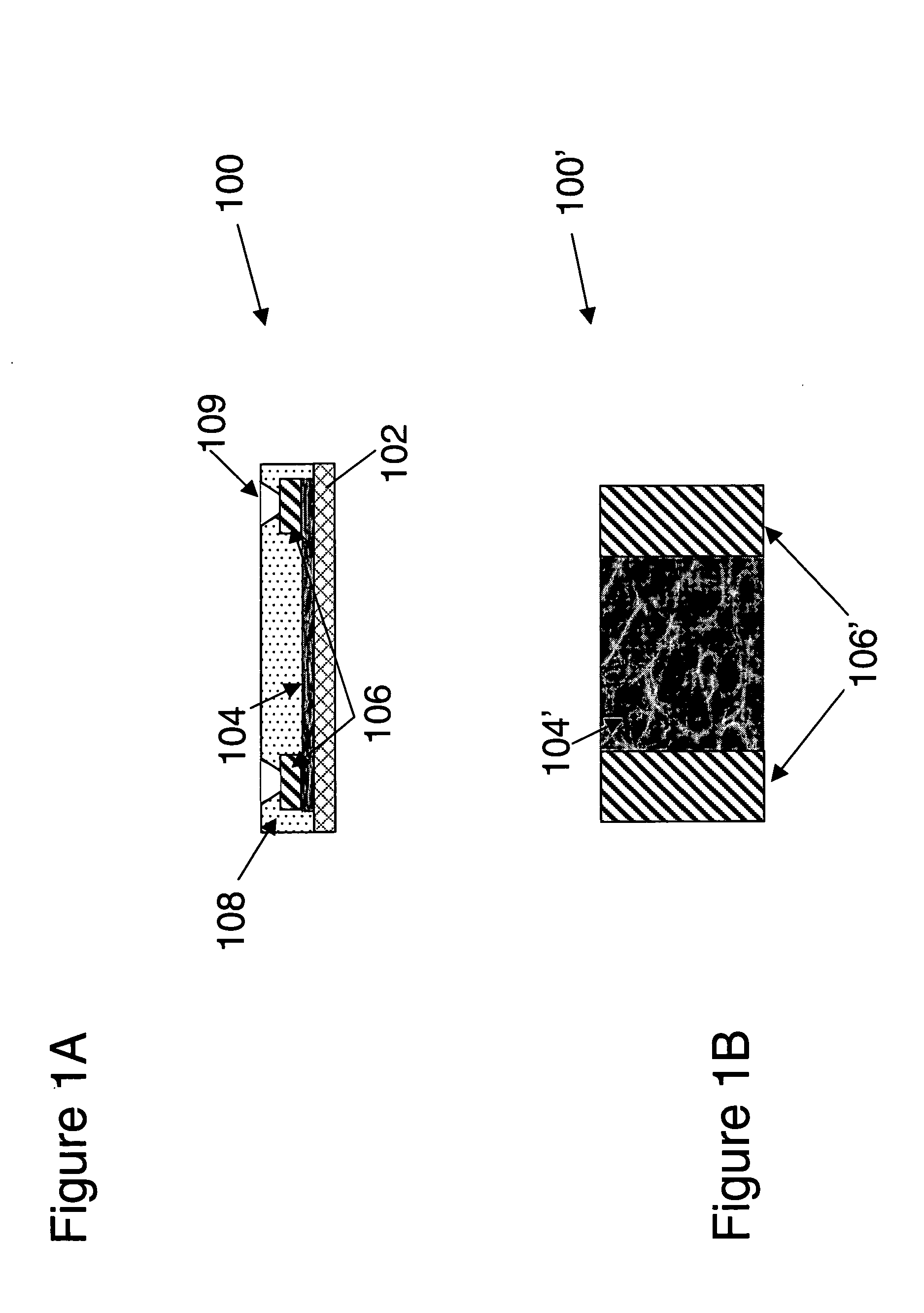

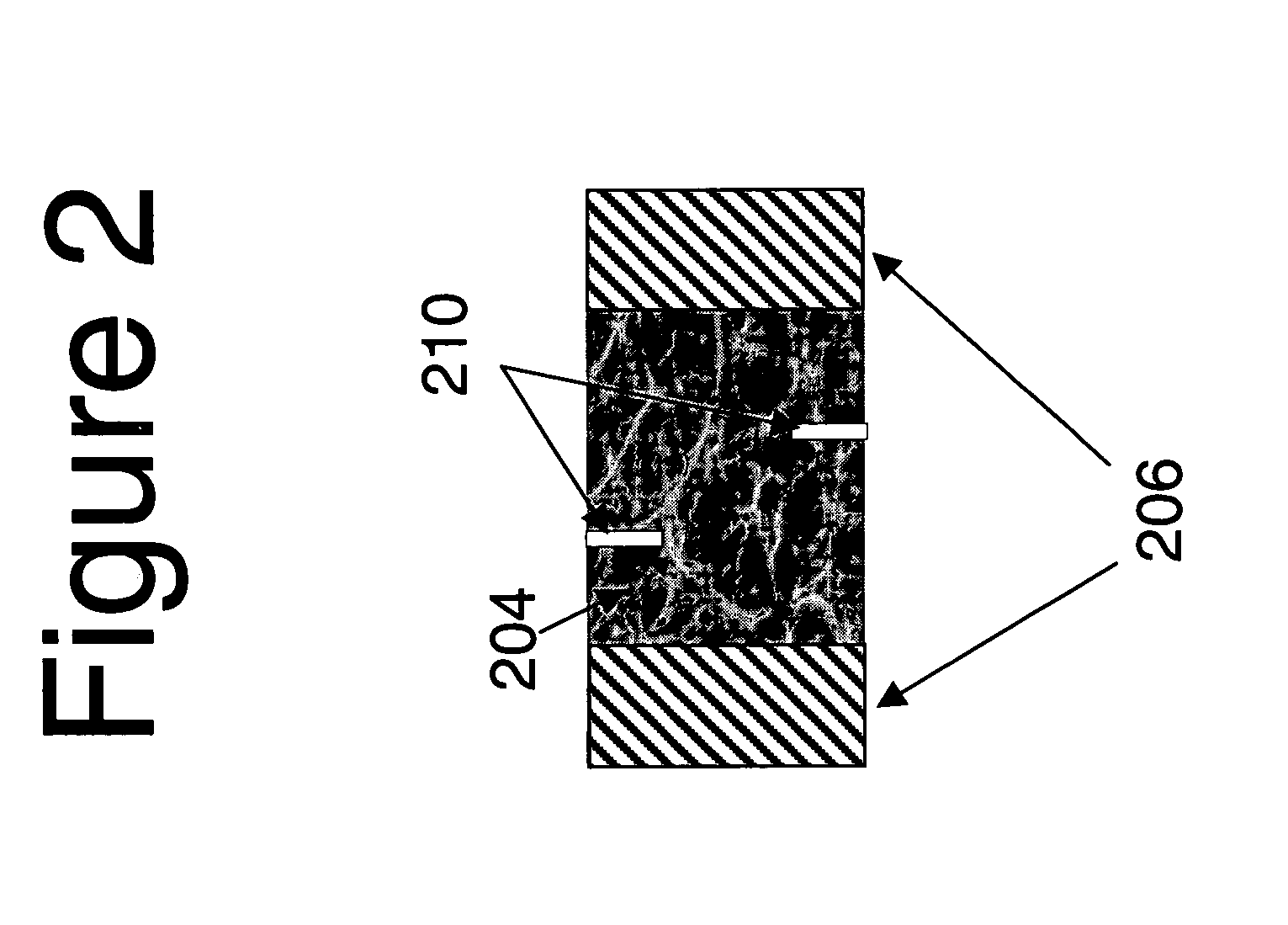

Direct application voltage variable material, devices employing same and methods of manufacturing such devices

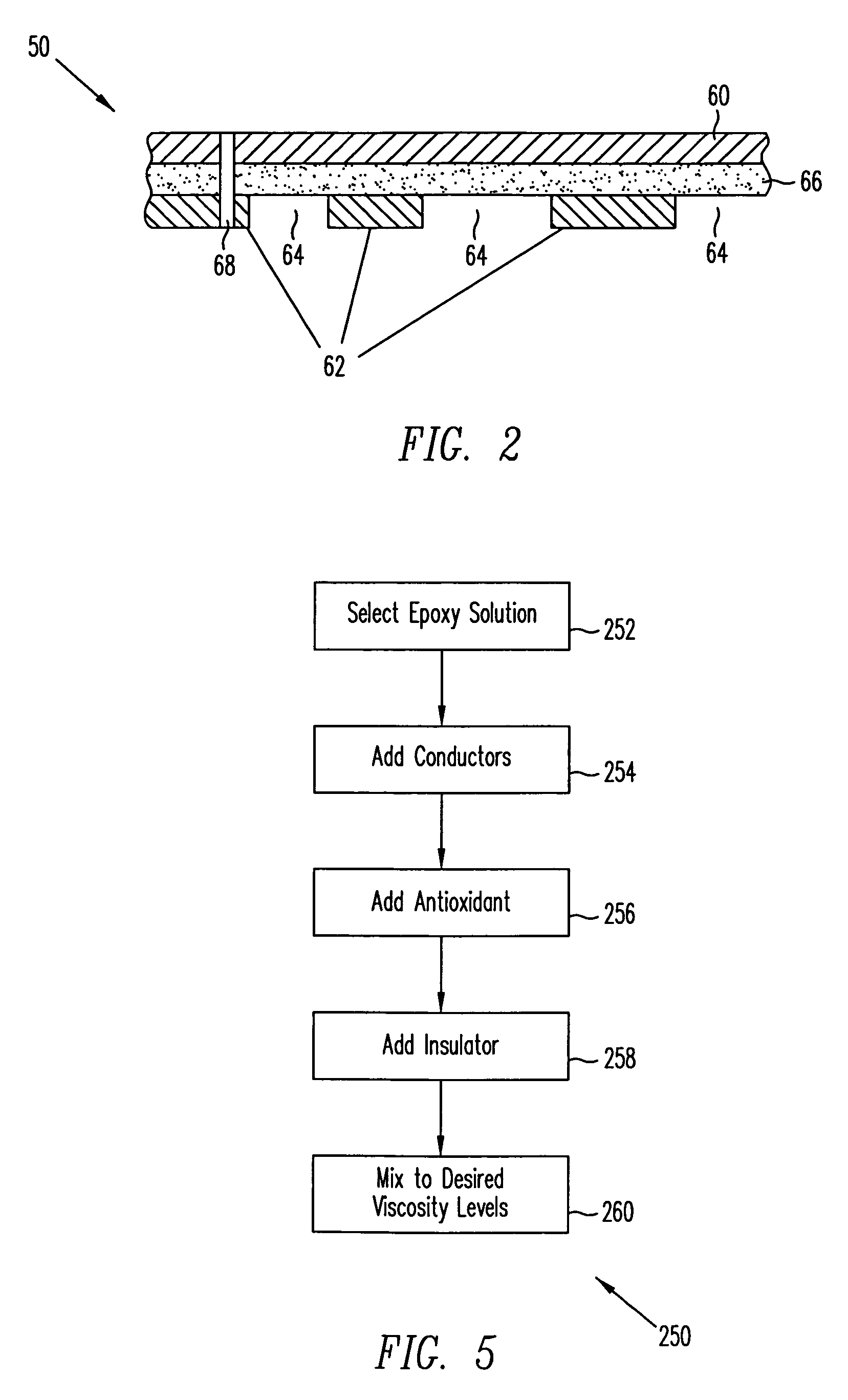

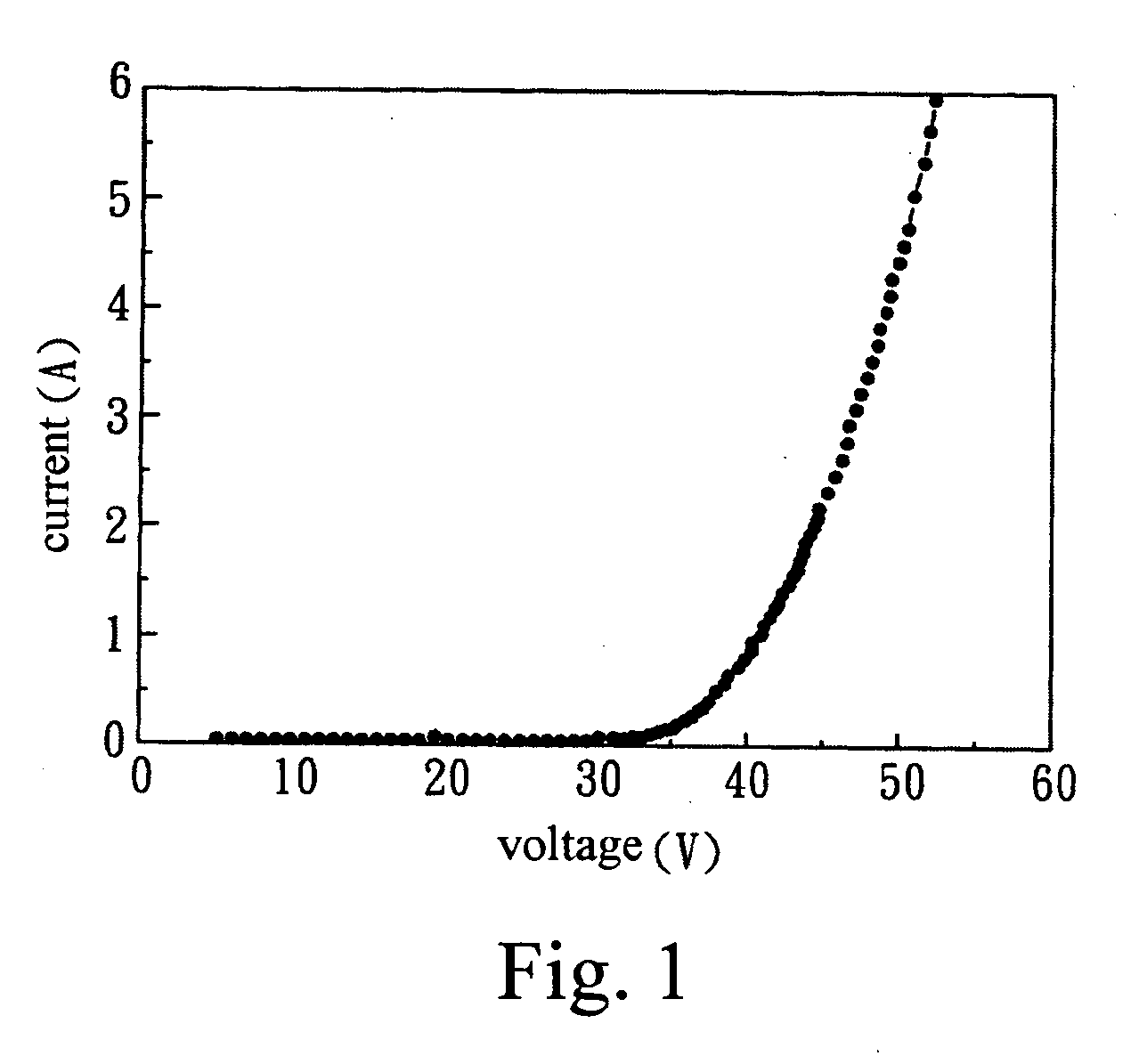

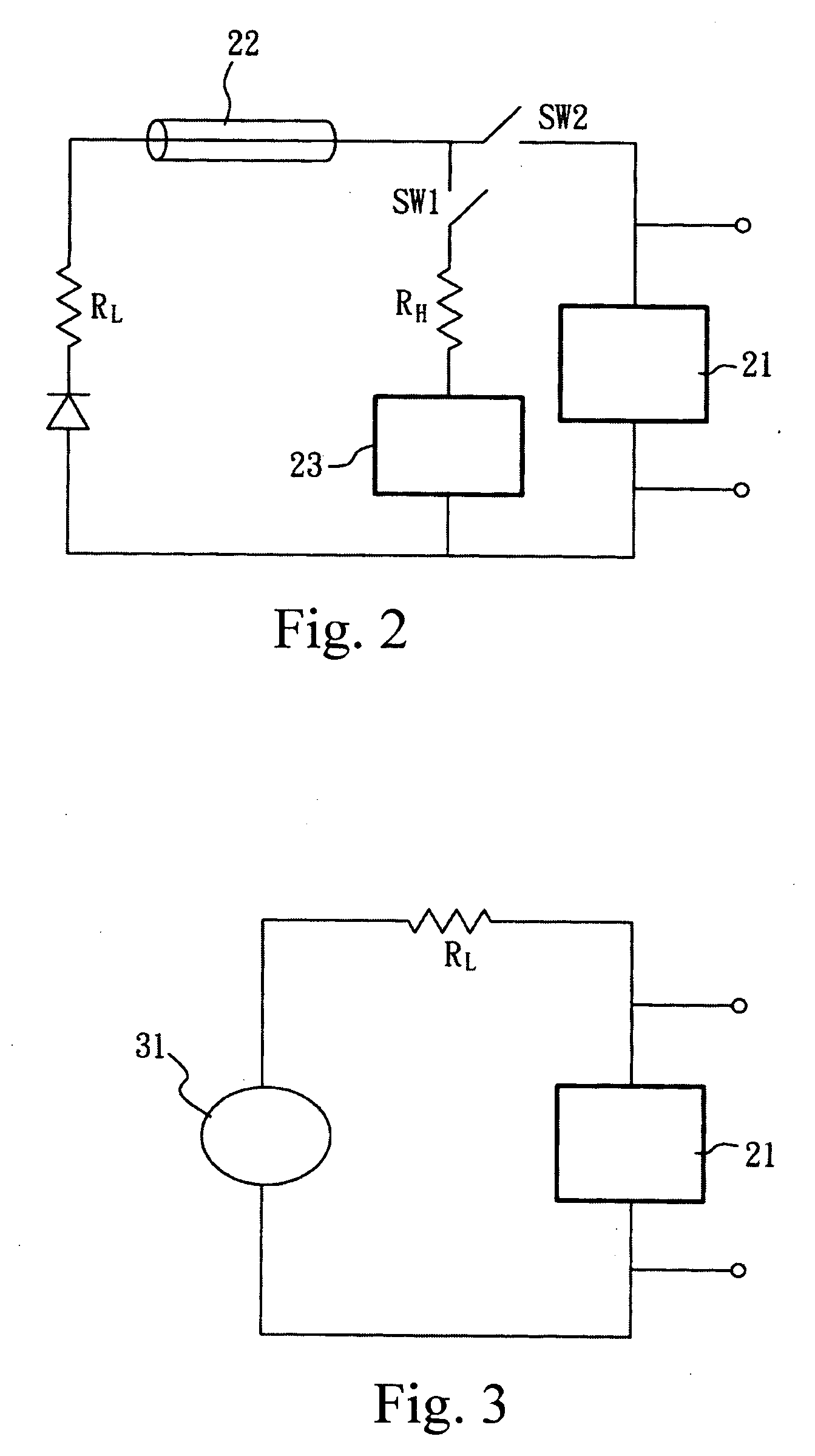

ActiveUS20050057867A1Directly appliedCurrent responsive resistorsPrinted circuit aspectsStencil printingMechanical engineering

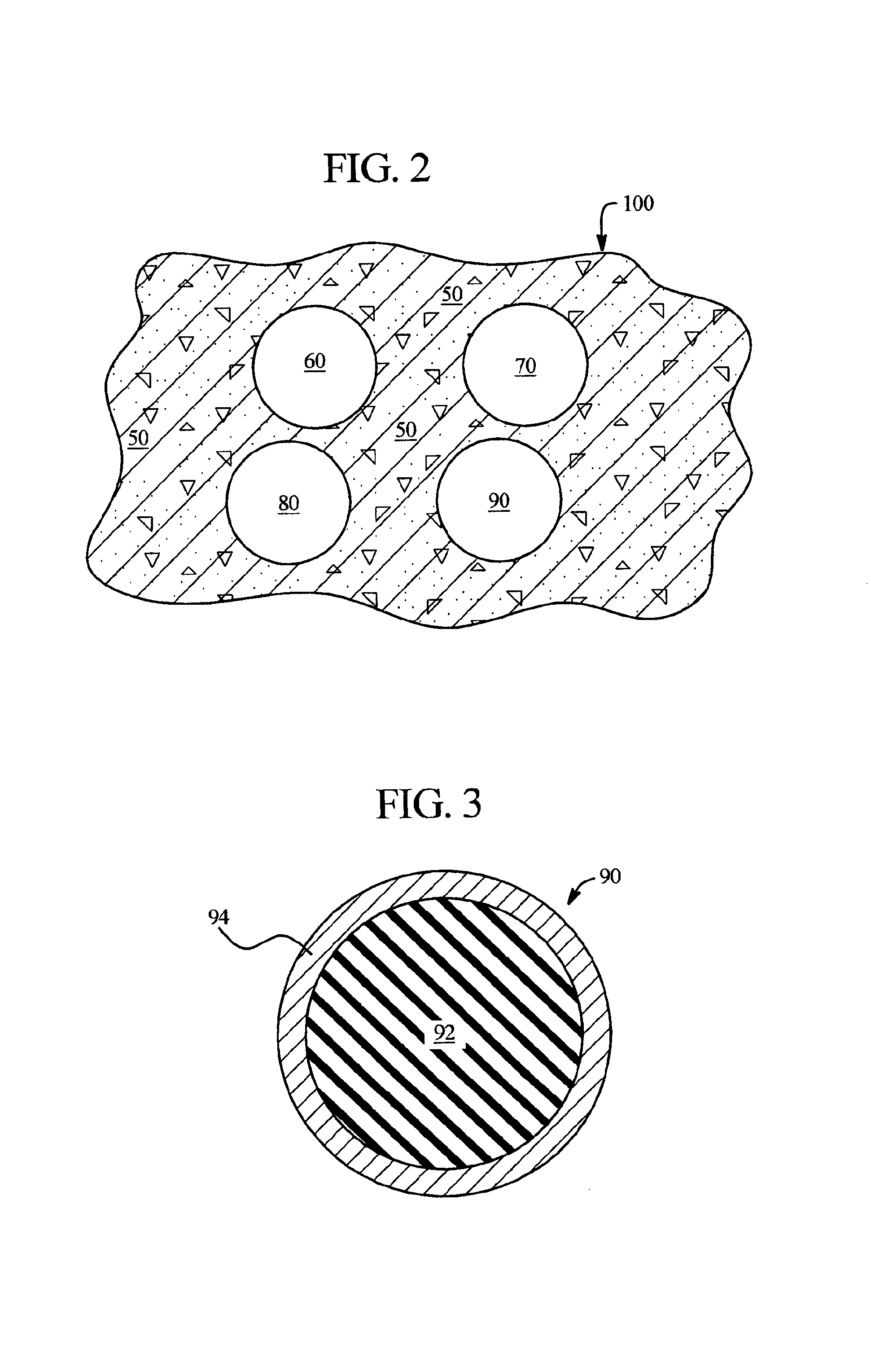

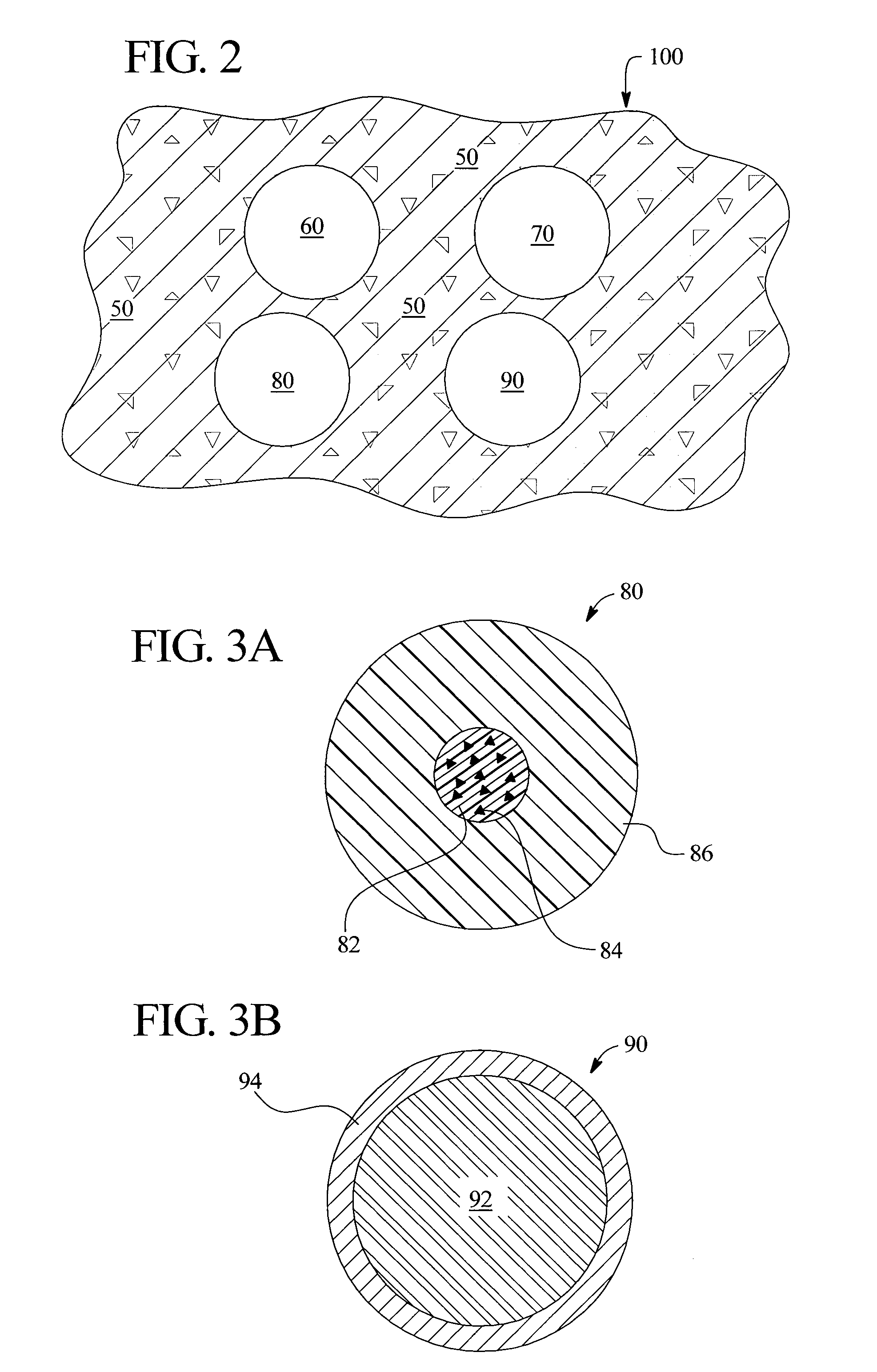

A voltage variable material (“VVM”) including an insulative binder that is formulated to intrinsically adhere to conductive and non-conductive surfaces is provided. The binder and thus the VVM is self-curable and applicable in a spreadable form that dries before use. The binder eliminates the need to place the VVM in a separate device or to provide separate printed circuit board pads on which to electrically connect the VVM. The binder and thus the VVM can be directly applied to many different types of substrates, such as a rigid FR-4 laminate, a polyimide, a polymer or a multilayer PCB via a process such as screen or stencil printing. In one embodiment, the VVM includes two types of conductive particles, one with a core and one without a core. The VVM can also have core-shell type semiconductive particles.

Owner:LITTELFUSE INC

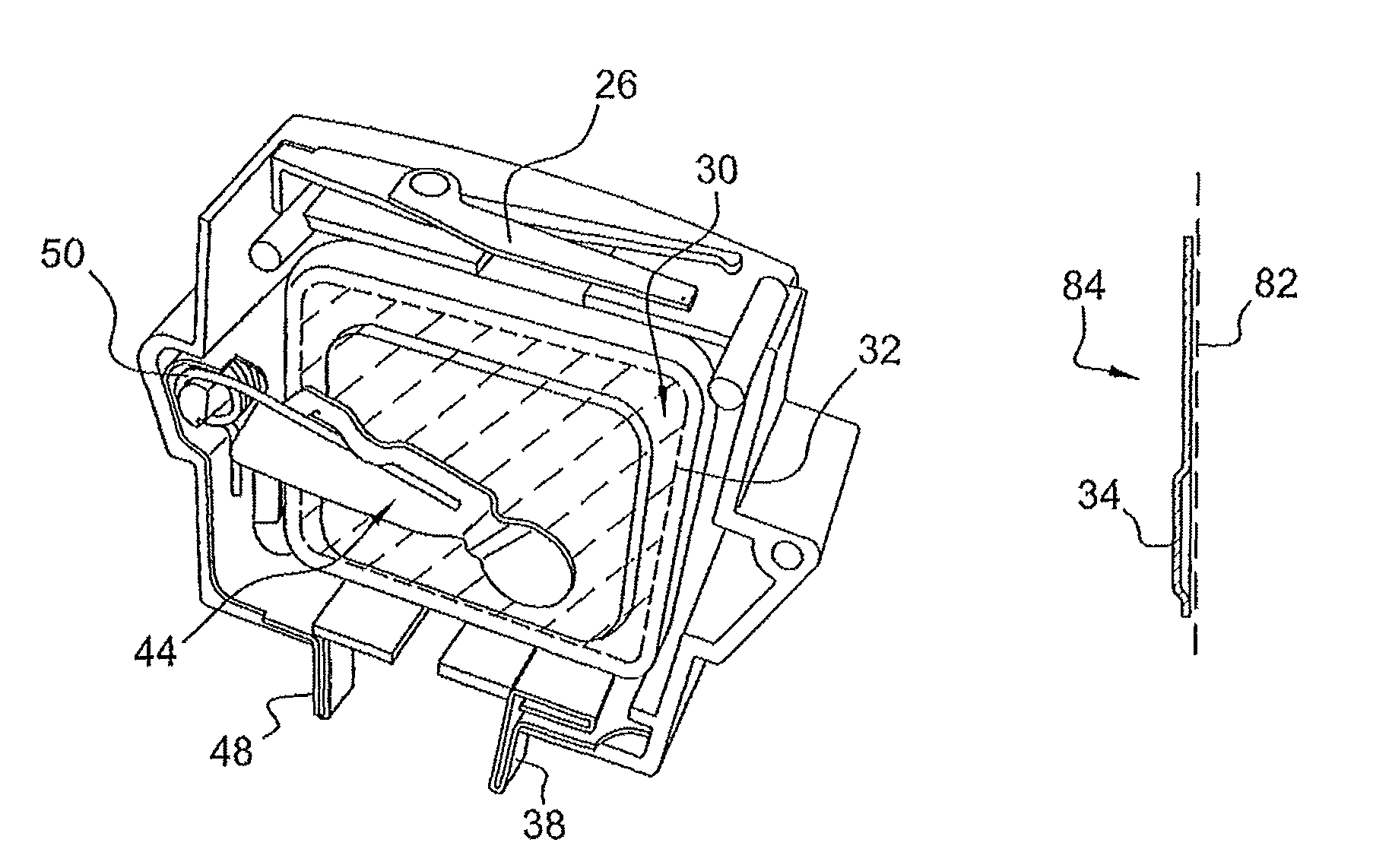

Surgical sealing surfaces and methods of use

ActiveUS20070146113A1Fast transferHighly stable current-limitingCurrent responsive resistorsHeating element shapesOmni directionalPositive temperature

Various embodiments provide compositions that exhibit positive temperature coefficient of resistance (PTCR) properties for use in thermal interactions with tissue—including thermal sensing and I2R current-limiting interactions. Embodiments also provide tissue-engaging surfaces having PTCR materials that provide very fast switching times between low resistance and high, current-limiting resistance. One embodiment provides a matrix for an electrosurgical energy delivery surface comprising a PTCR material and a heat exchange material disposed within an interior of the matrix. The PTCR material has a substantially conductive state and a substantially non-conductive state. The heat exchange material has a structure configured to have an omni-directional thermal diffusivity for exchanging heat with the PTCR material to cause rapid switching of the PTCR material between the conductive state and non-conductive state. Preferably, the structure comprises a graphite foam having an open cell configuration. The matrix can be carried by tissue contacting surfaces of various electrosurgical devices.

Owner:ETHICON ENDO SURGERY INC

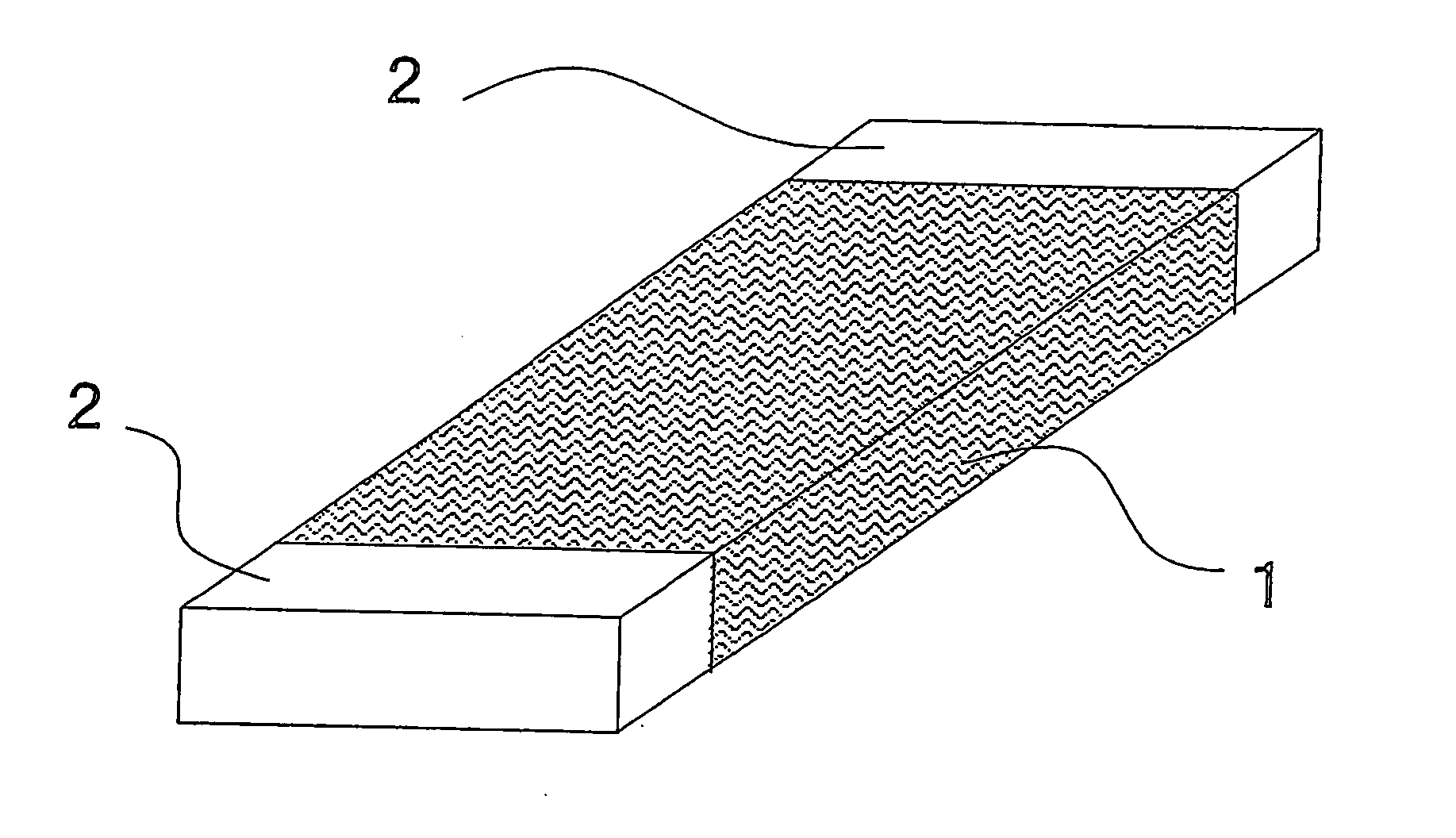

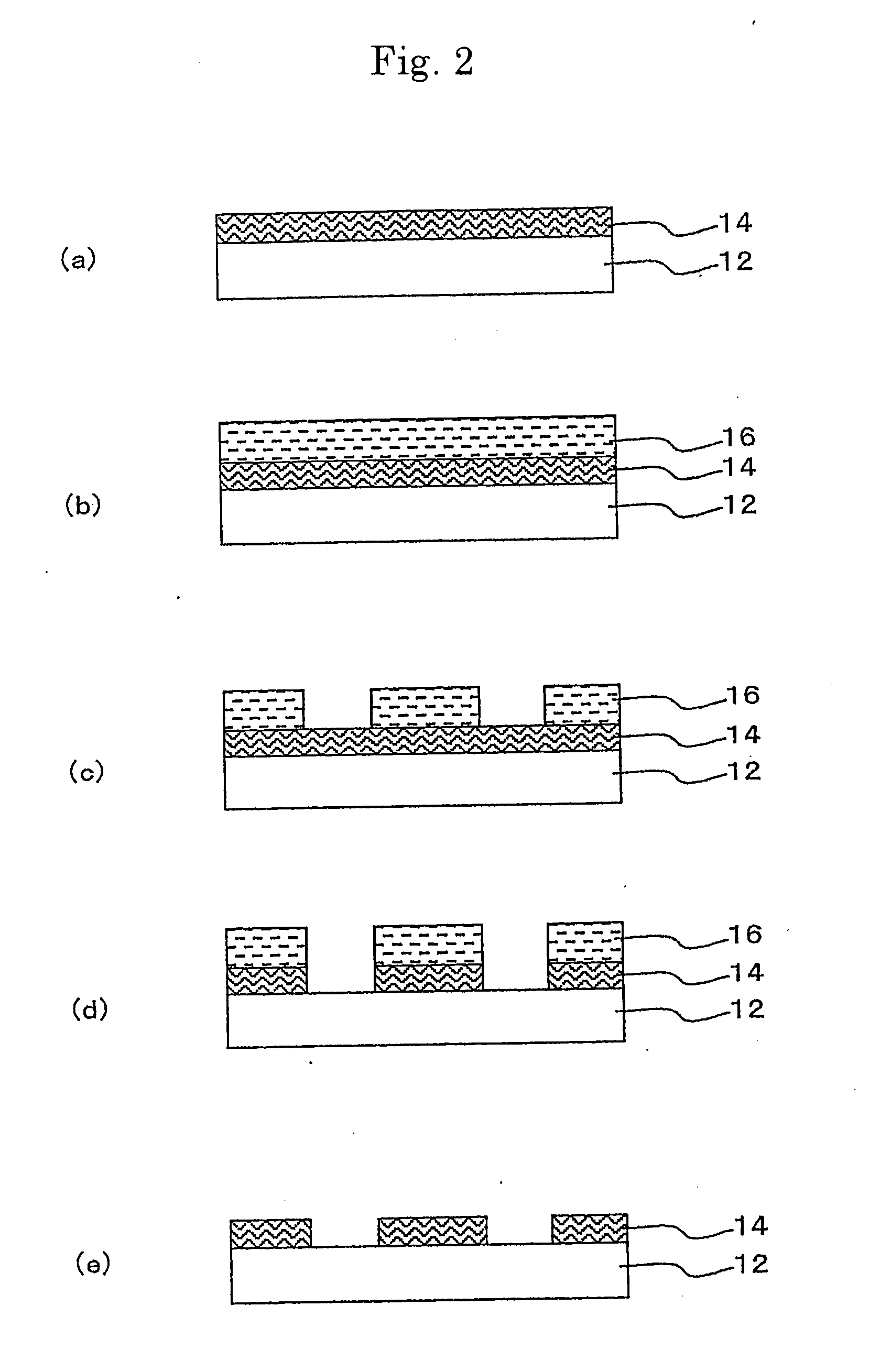

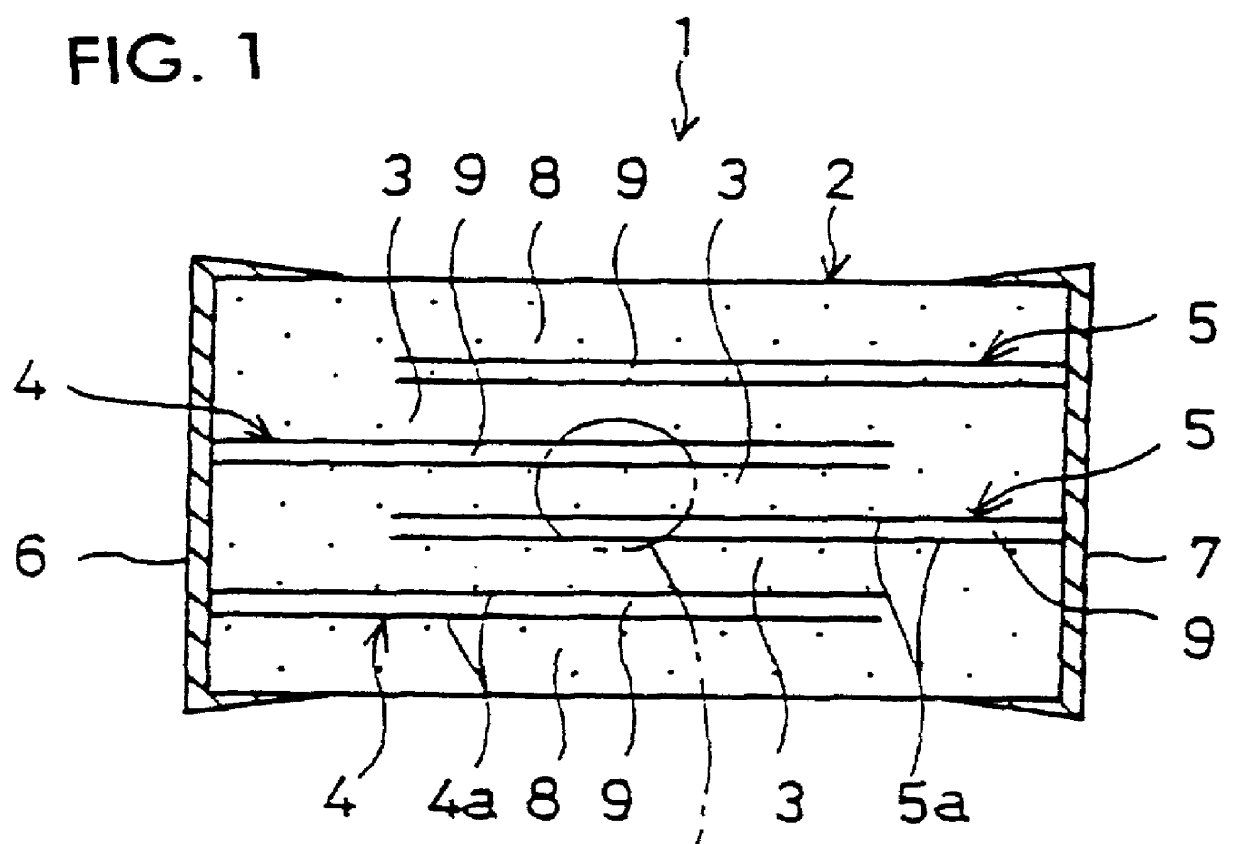

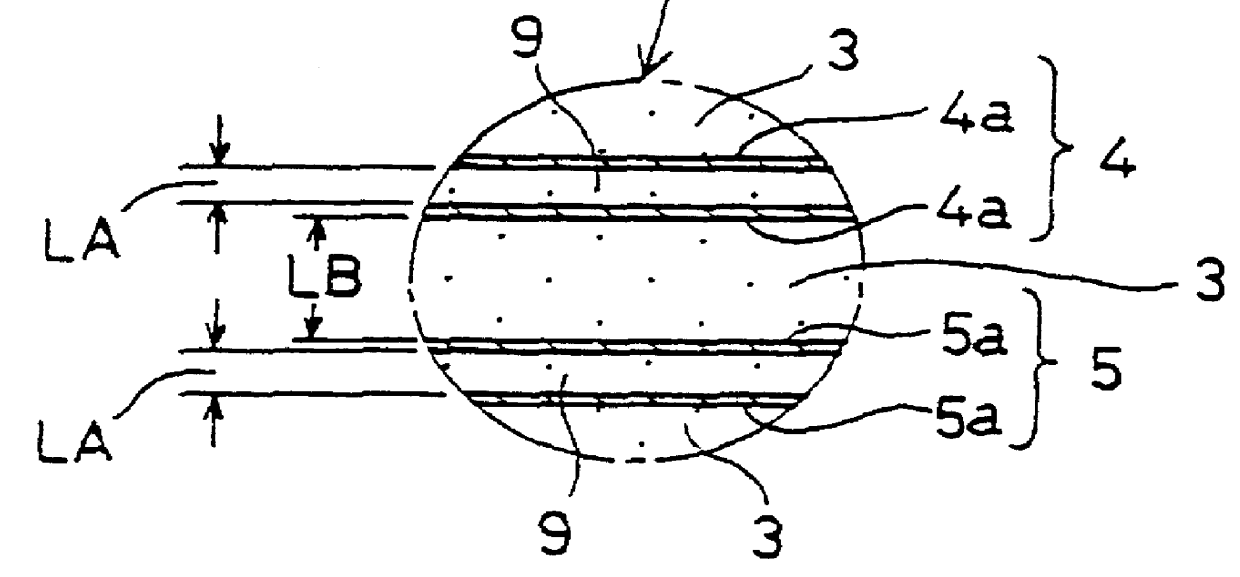

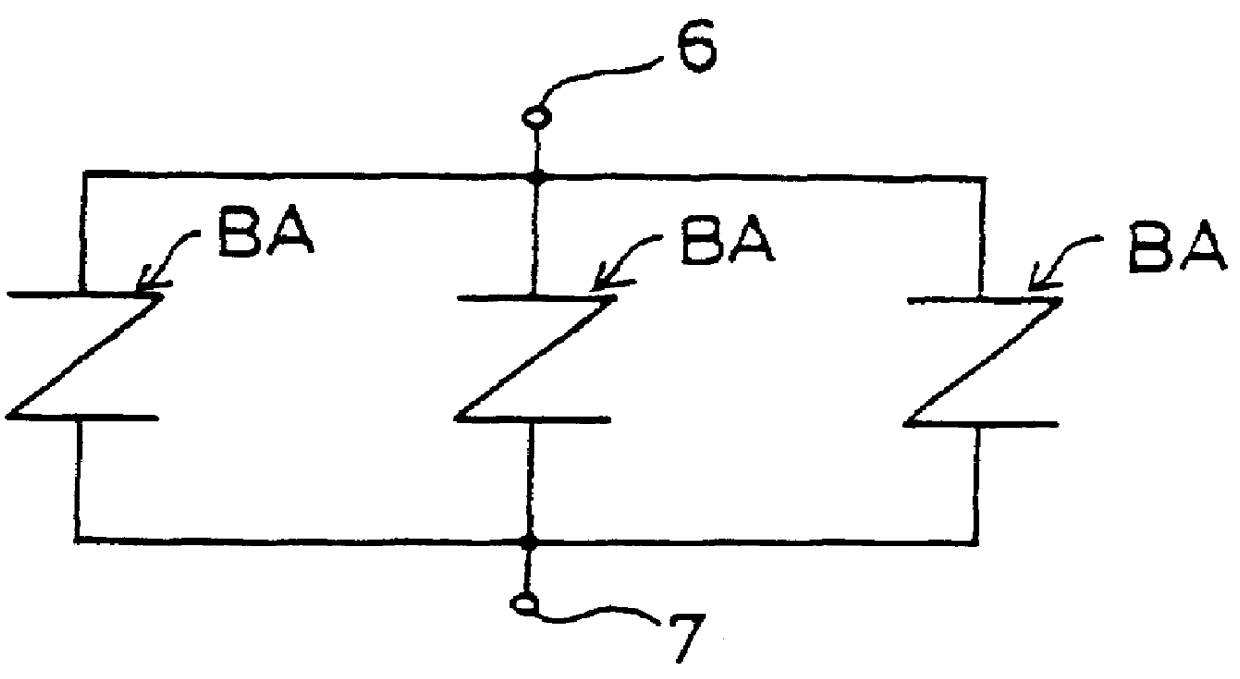

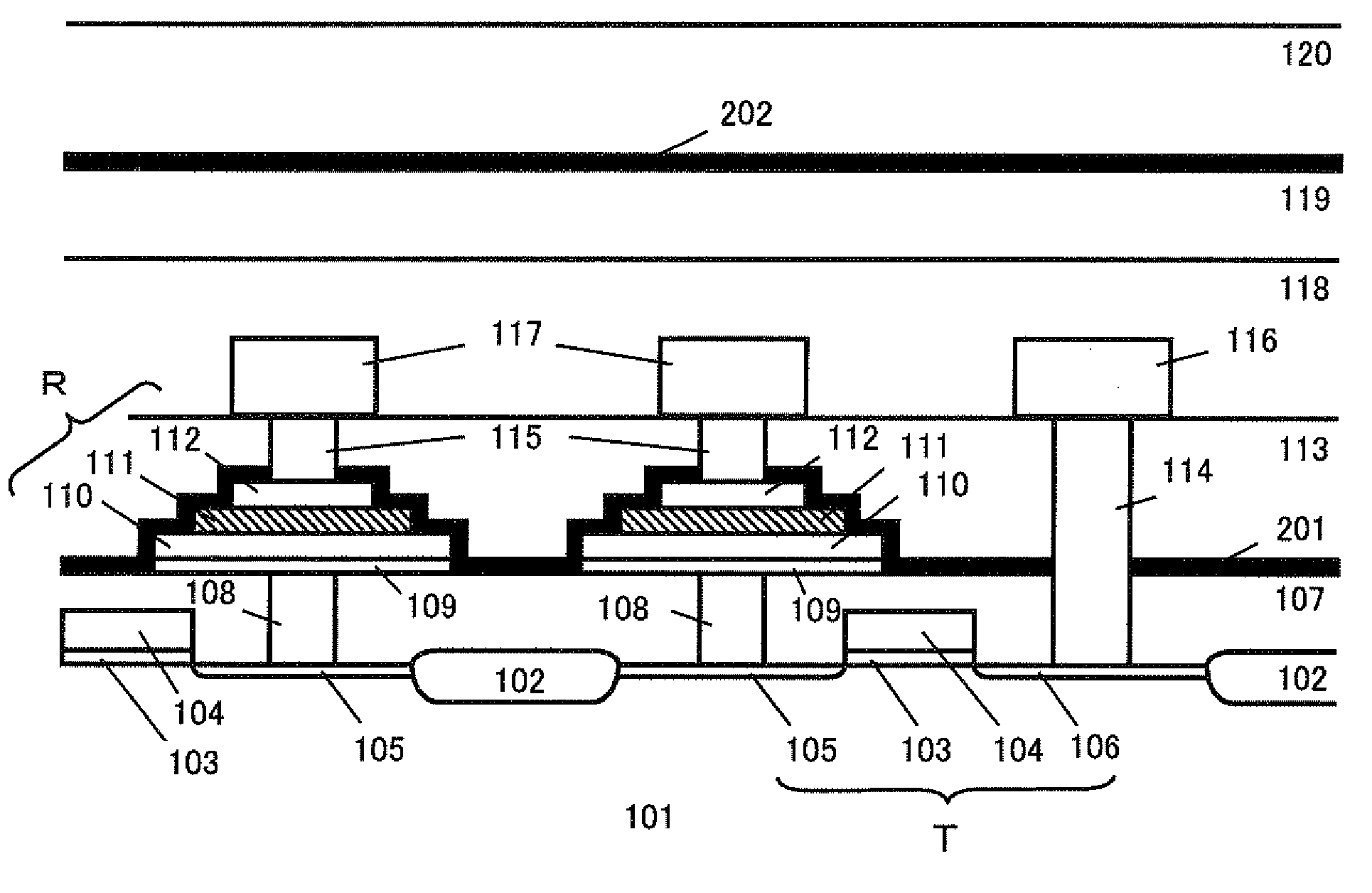

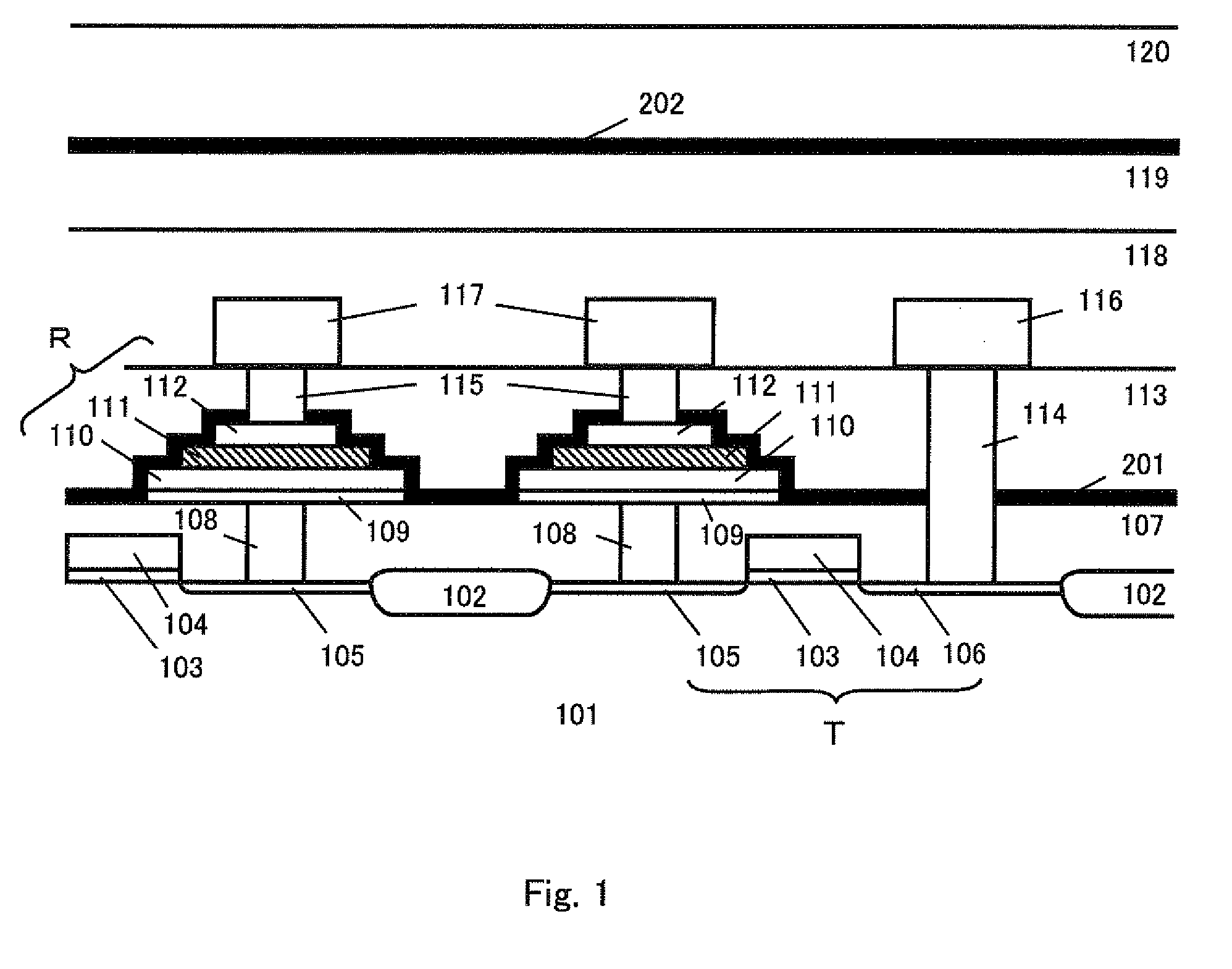

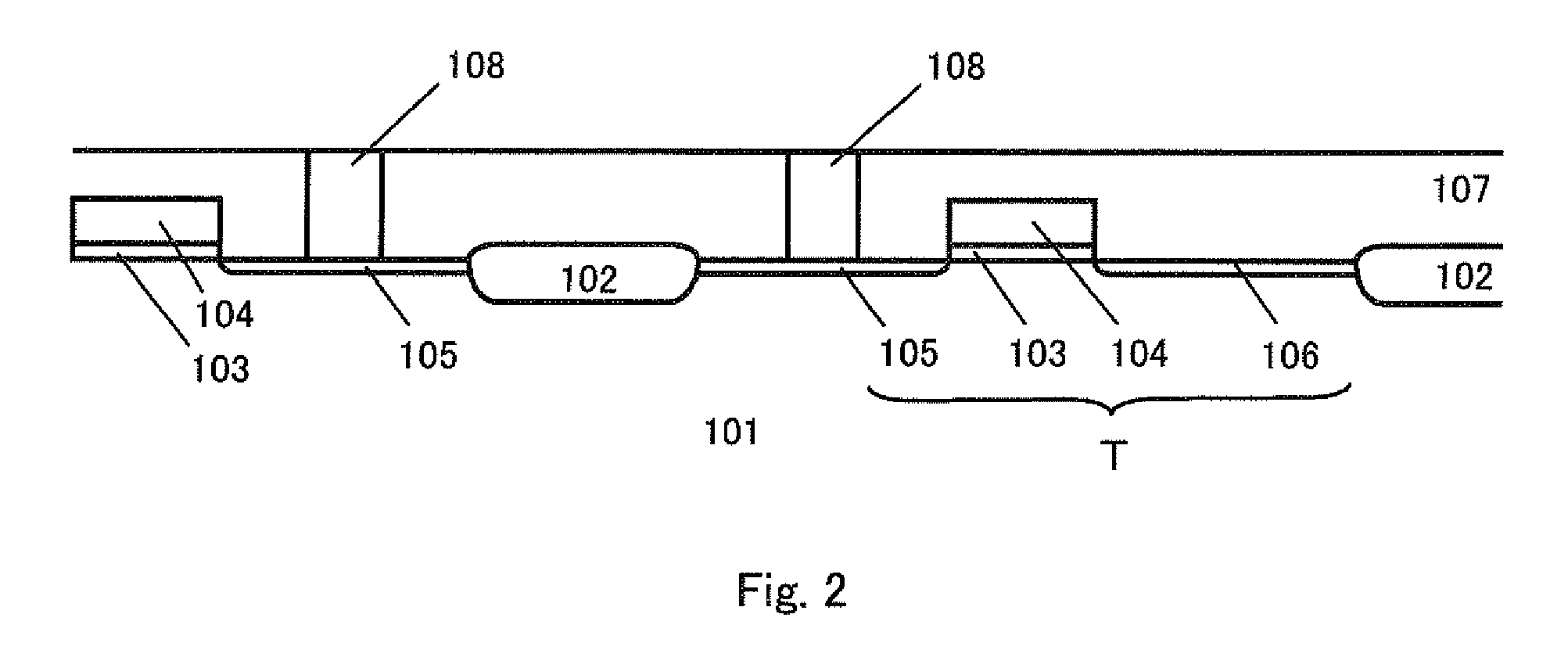

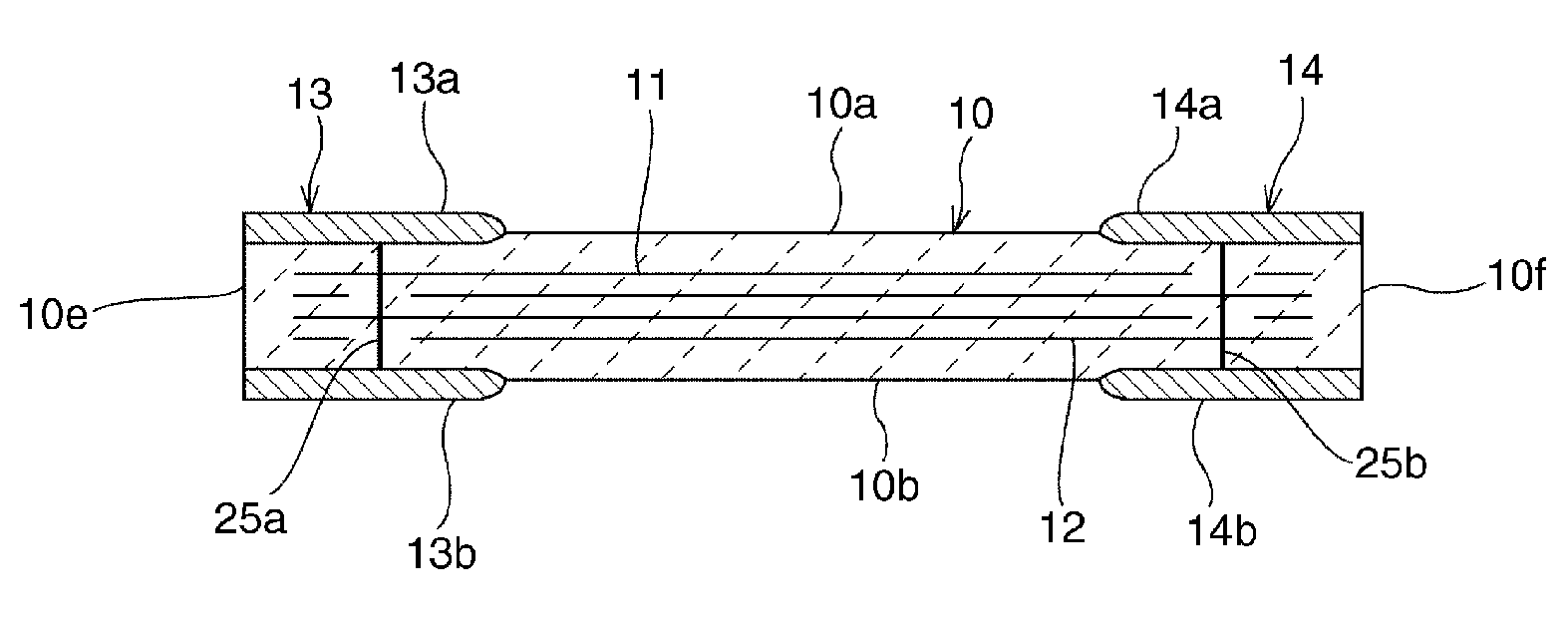

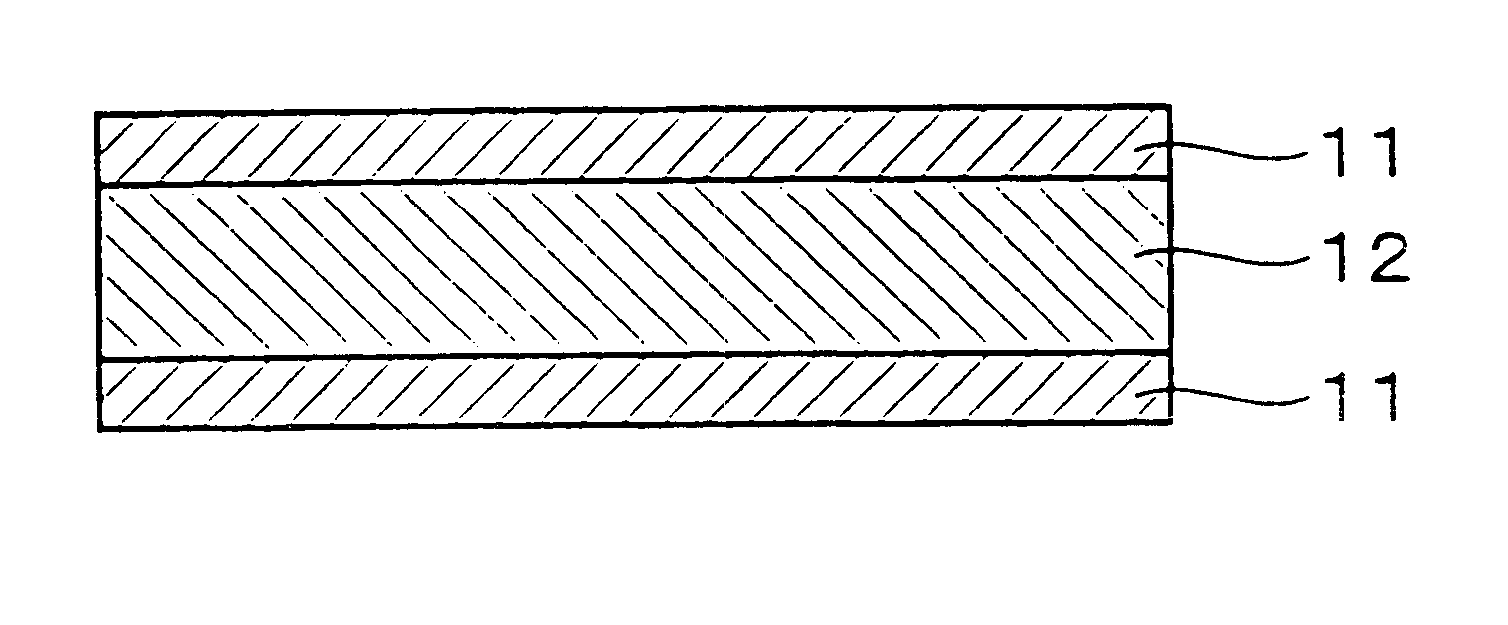

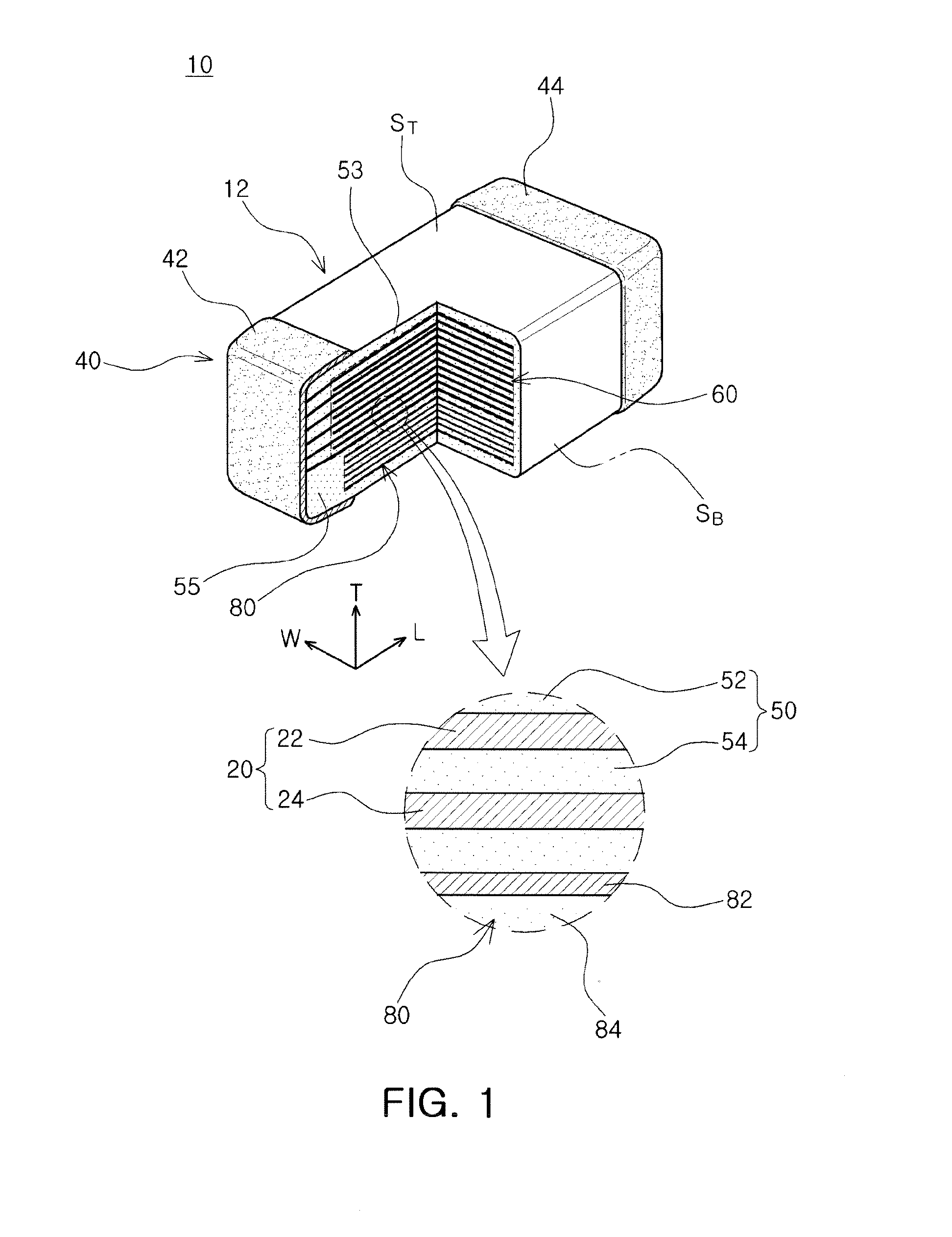

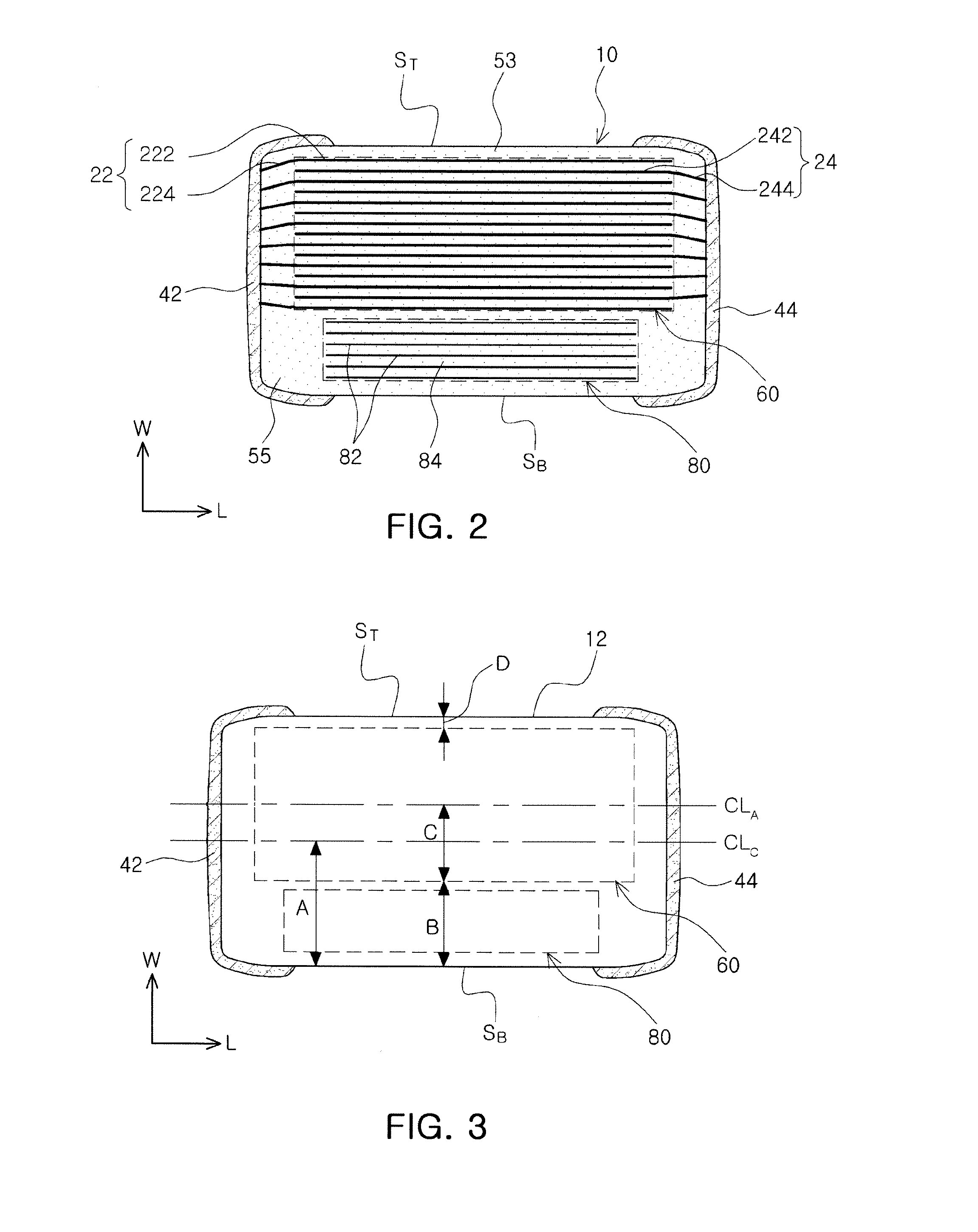

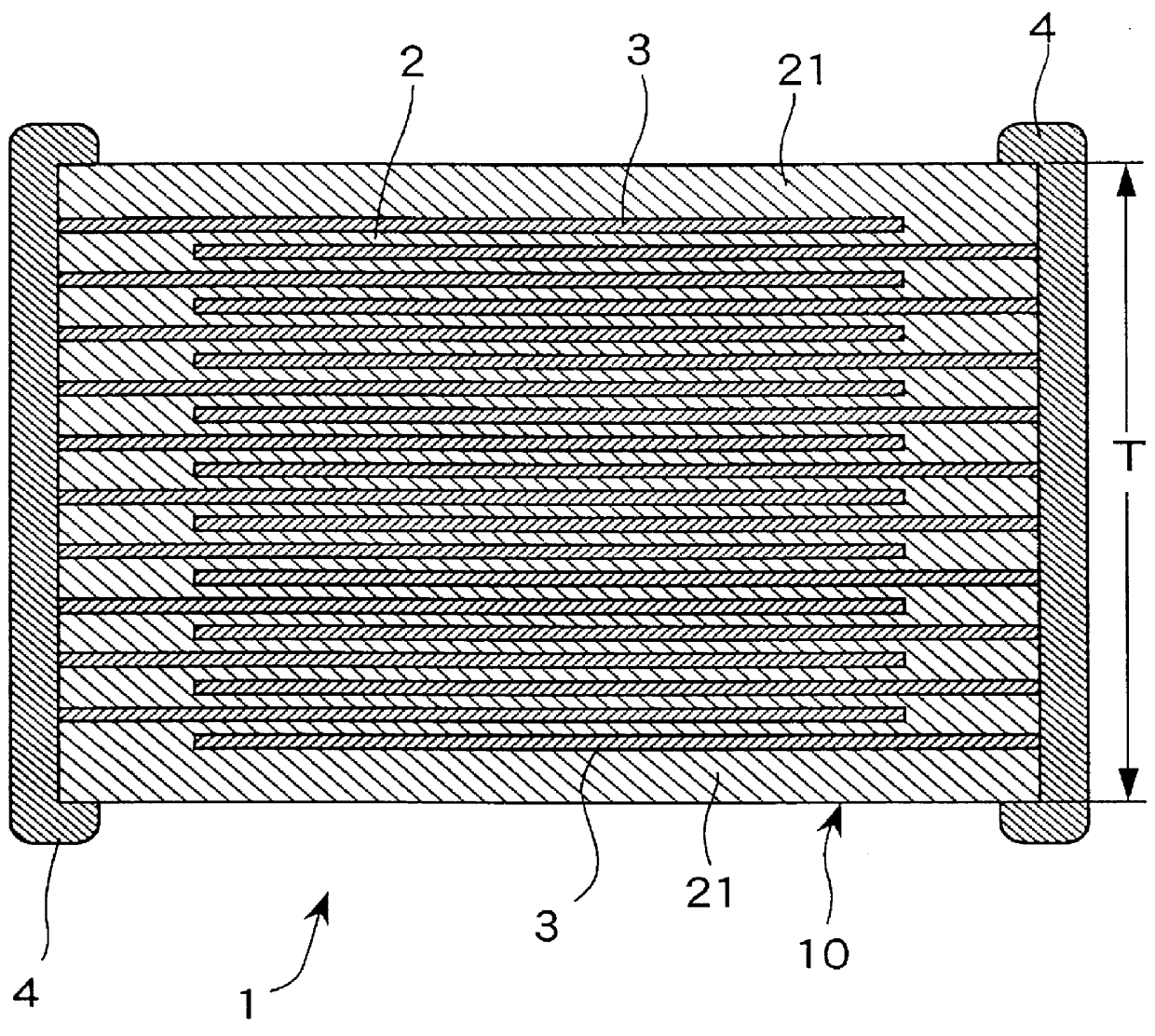

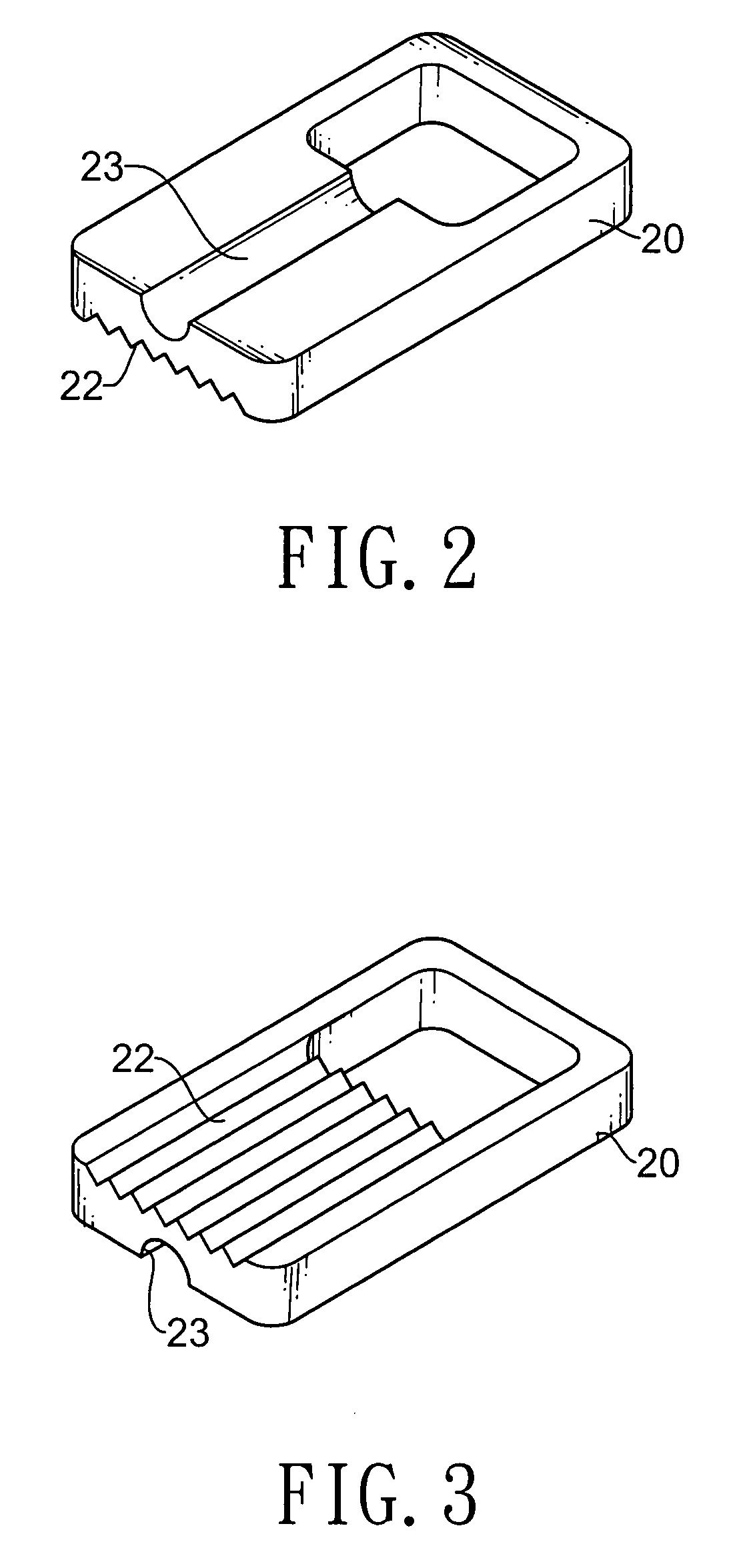

Laminated-type varistor

InactiveUS6147587ACurrent responsive resistorsResistor detailsElectrical resistance and conductancePeak current

A laminated-type varistor includes a laminated structure and a pair of external electrodes disposed on a surface of the laminated structure. The laminated structure includes effective sintered body layers and internal electrodes. The internal electrodes are connected to the external electrodes and are disposed apart from each other in the direction perpendicular to lamination surfaces. Each of the internal electrodes has a multilayer electrode structure in which a plurality of electrode layers are arranged in layers while an ineffective sintered body layer is disposed therebetween. The laminated-type varistor has increased maximum peak current and maximum energy and reduction in clamping voltage.

Owner:MURATA MFG CO LTD

Direct application voltage variable material, devices employing same and methods of manufacturing such devices

InactiveUS7183891B2Directly appliedCurrent responsive resistorsPrinted circuit aspectsScreen printingStencil printing

A voltage variable material (“VVM”) including an insulative binder that is formulated to intrinsically adhere to conductive and non-conductive surfaces is provided. The binder and thus the VVM is self-curable and applicable in a spreadable form that dries before use. The binder eliminates the need to place the VVM in a separate device or to provide separate printed circuit board pads on which to electrically connect the VVM. The binder and thus the VVM can be directly applied to many different types of substrates, such as a rigid FR-4 laminate, a polyimide, a polymer or a multilayer PCB via a process such as screen or stencil printing. In one embodiment, the VVM includes two types of conductive particles, one with a core and one without a core. The VVM can also have core-shell type semiconductive particles.

Owner:LITTELFUSE INC

Voltage variable material for direct application and devices employing same

InactiveUS7202770B2Directly appliedSemiconductor/solid-state device detailsSolid-state devicesOvervoltagePolymer

The present invention provides overvoltage circuit protection. Specifically, the present invention provides a voltage variable material (“VVM”) that includes an insulative binder that is formulated to intrinsically adhere to conductive and nonconductive surfaces. The binder and thus the VVM is self-curable and may be applied to an application in the form of an ink, which dries in a final form for use. The binder eliminates the need to place the VVM in a separate device or for separate printed circuit board pads on which to electrically connect the VVM. The binder and thus the VVM can be directly applied to many different types of substrates, such as a rigid (FR-4) laminate, a polyimide or a polymer. The VVM can also be directly applied to different types of substrates that are placed inside a device.

Owner:LITTELFUSE INC

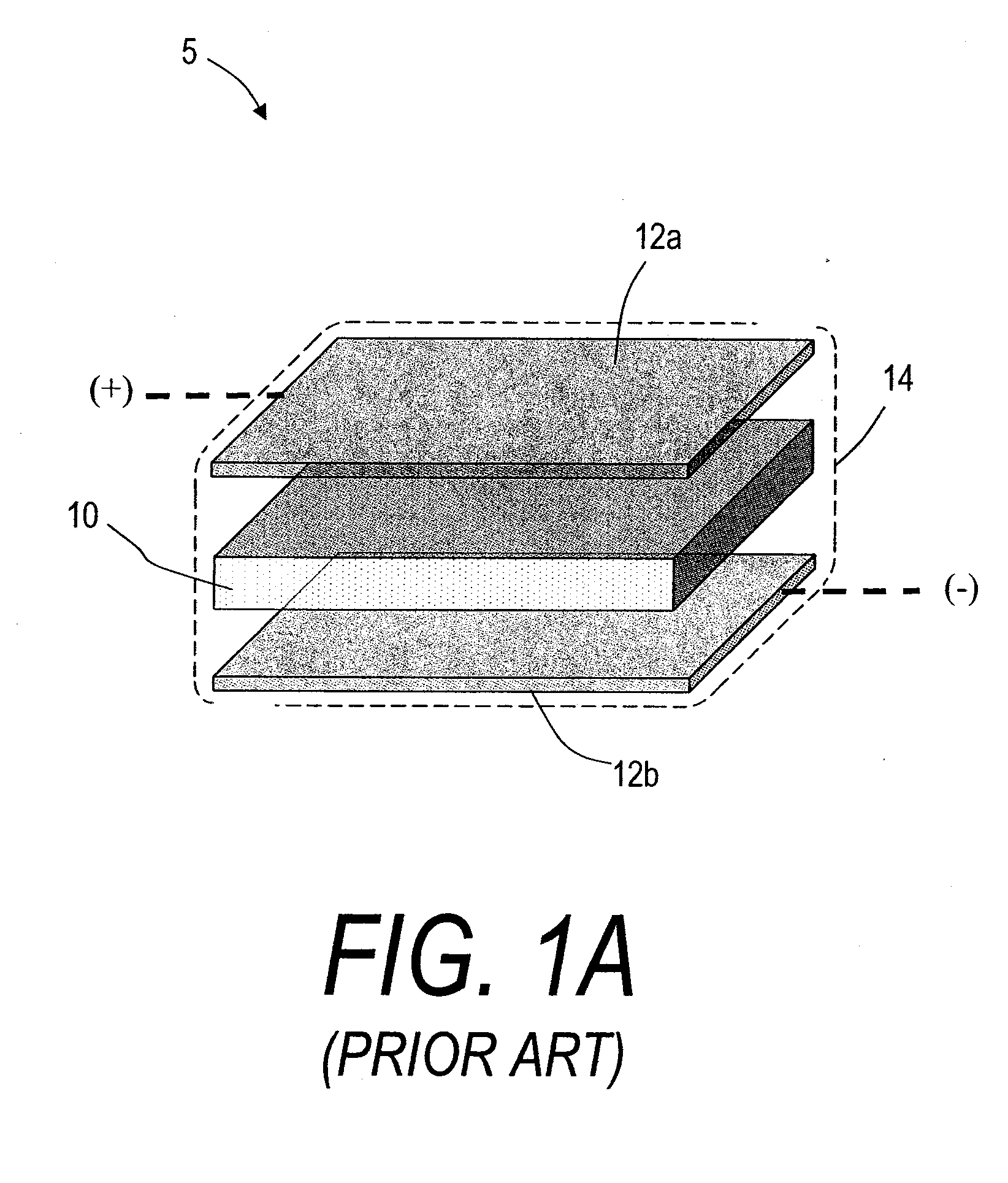

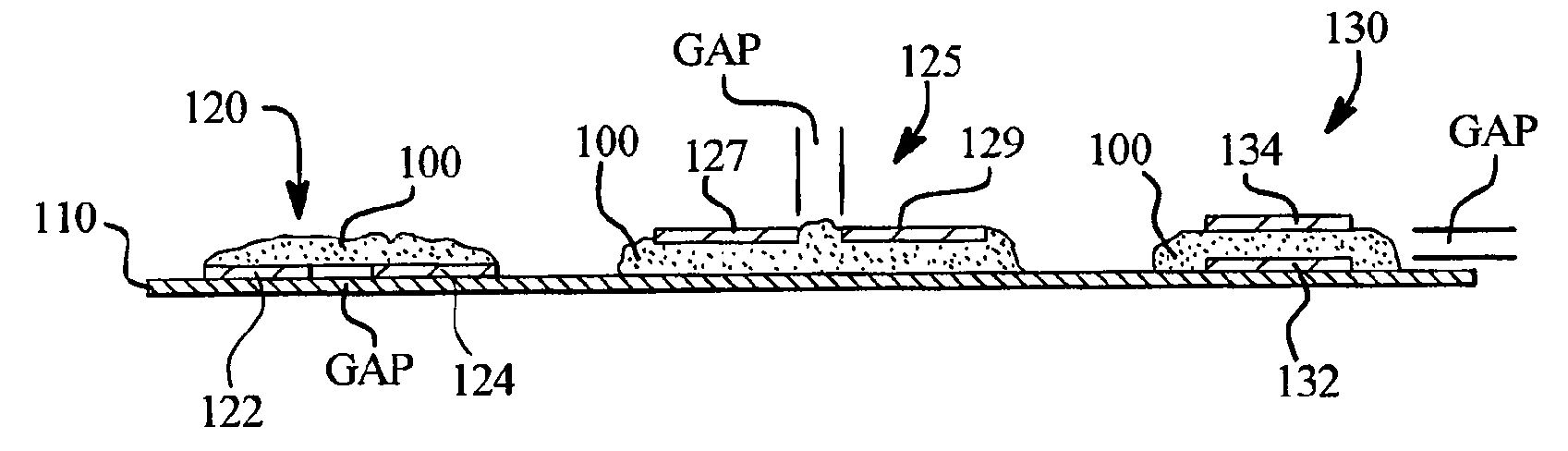

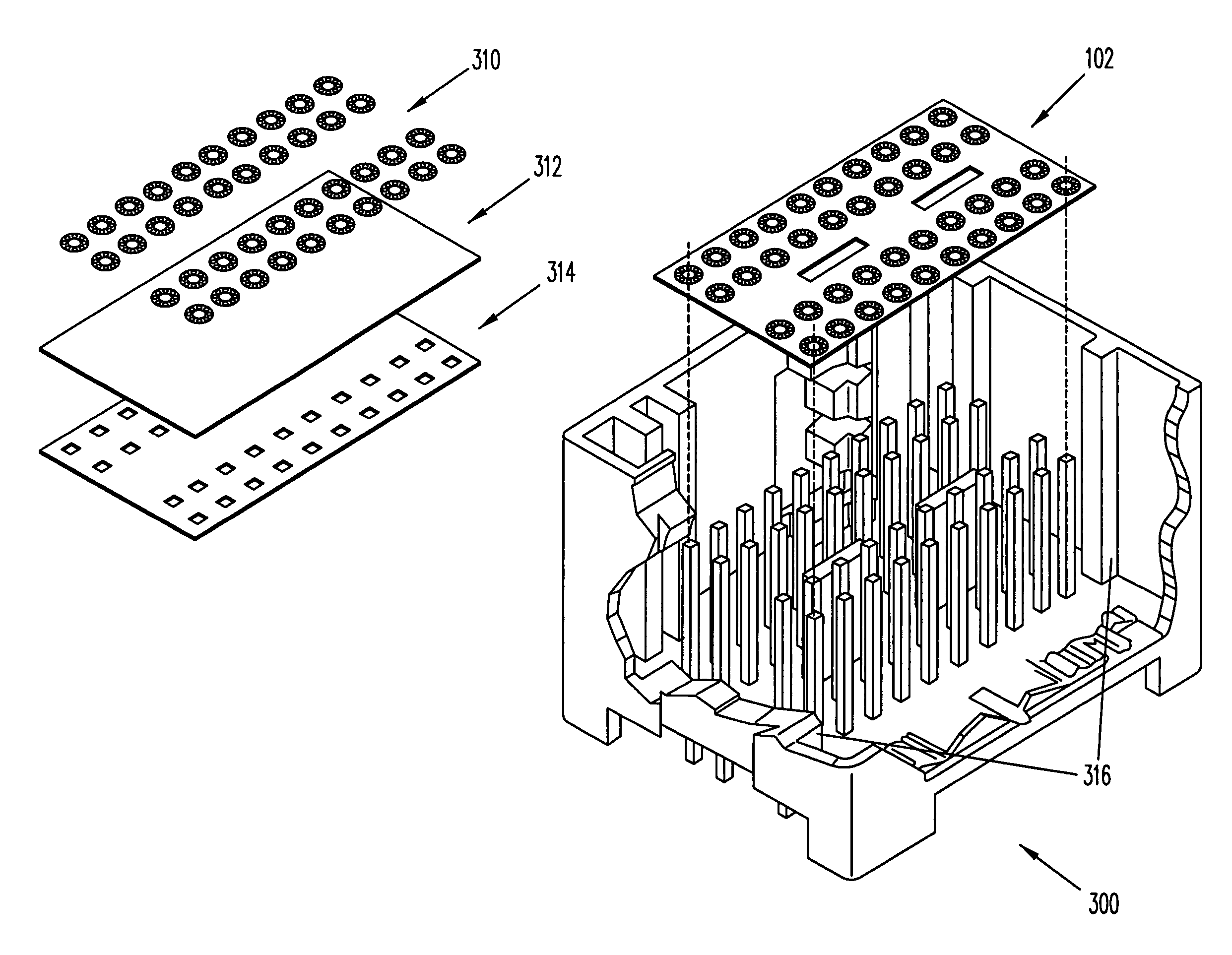

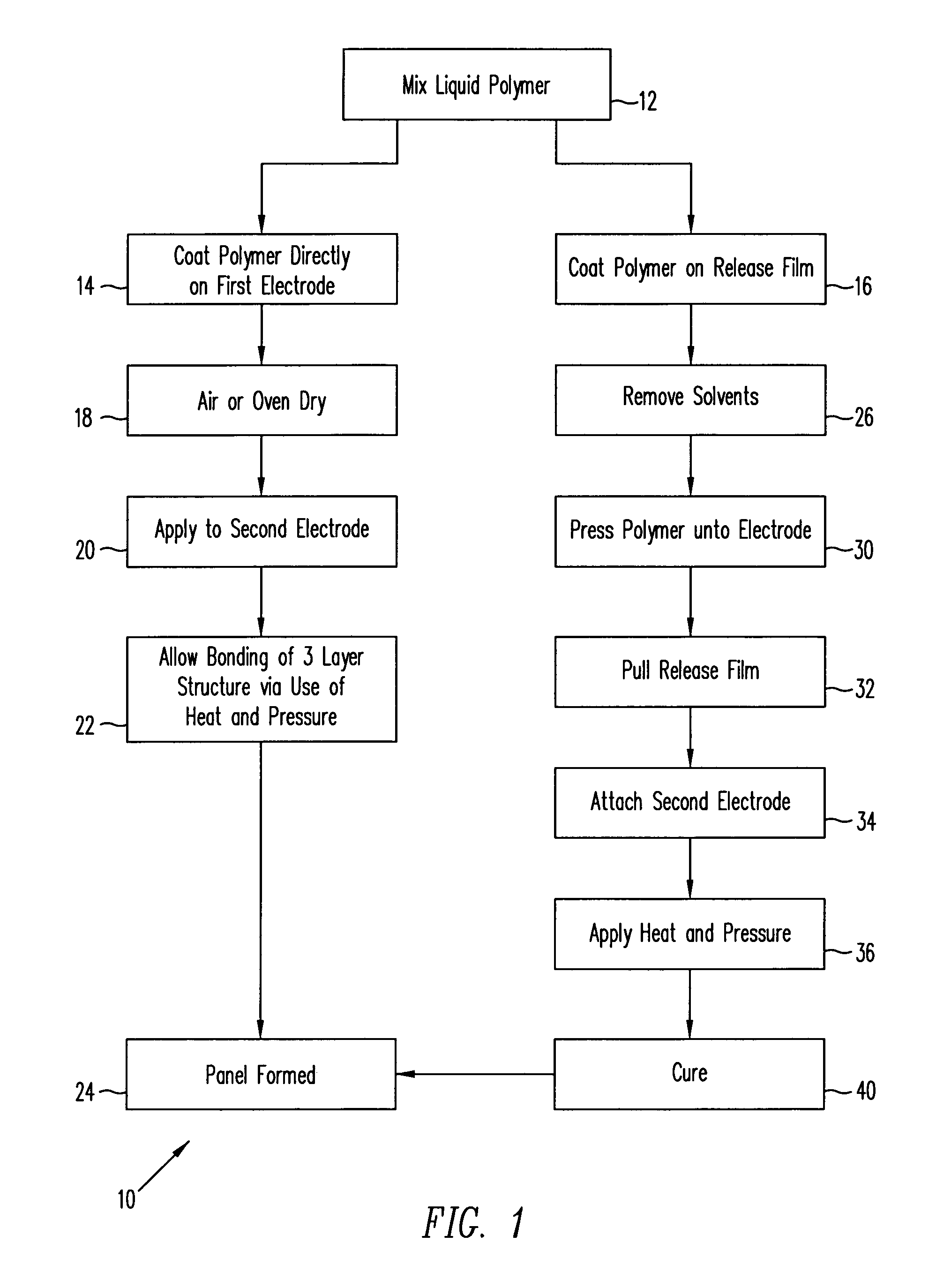

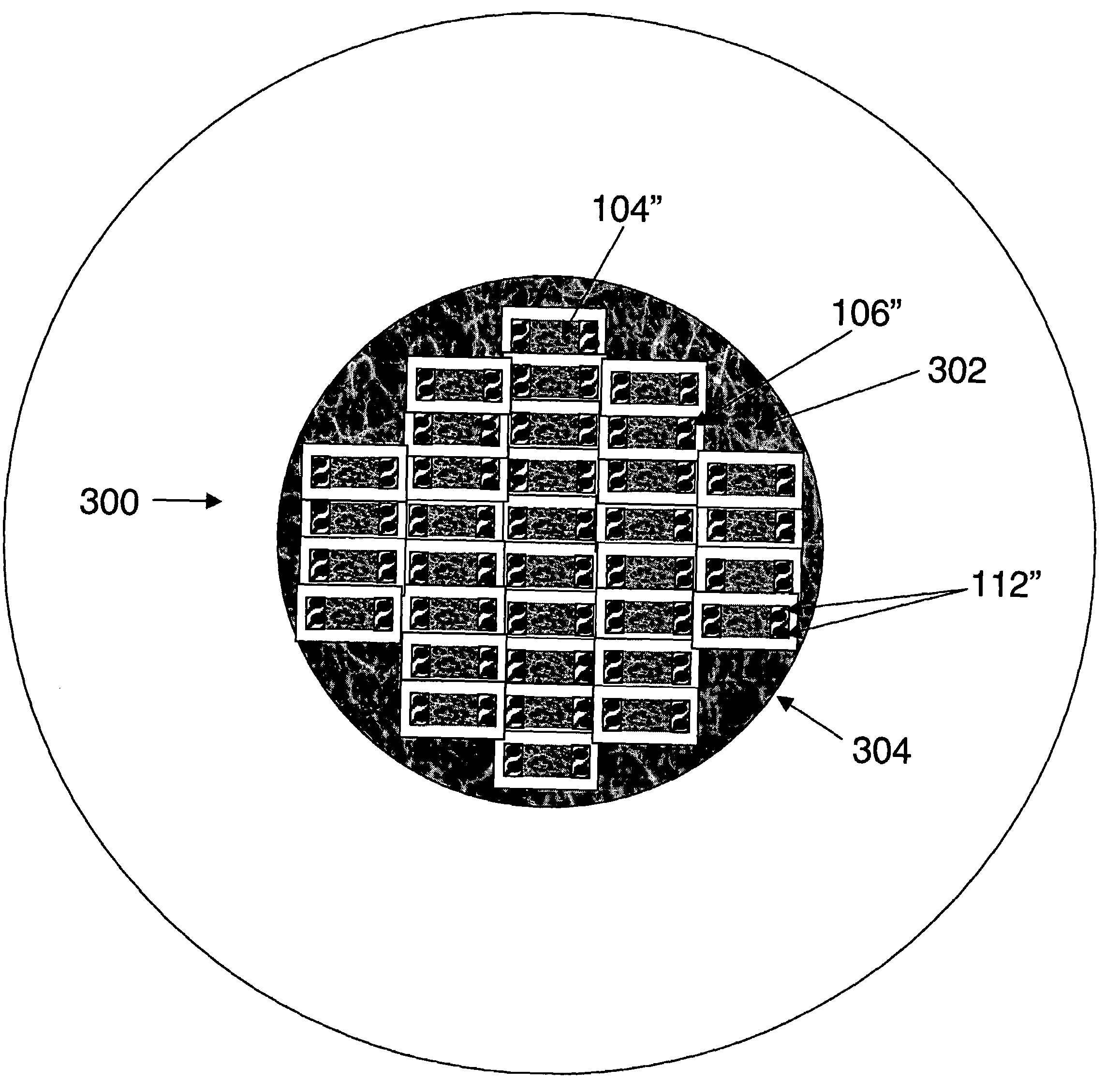

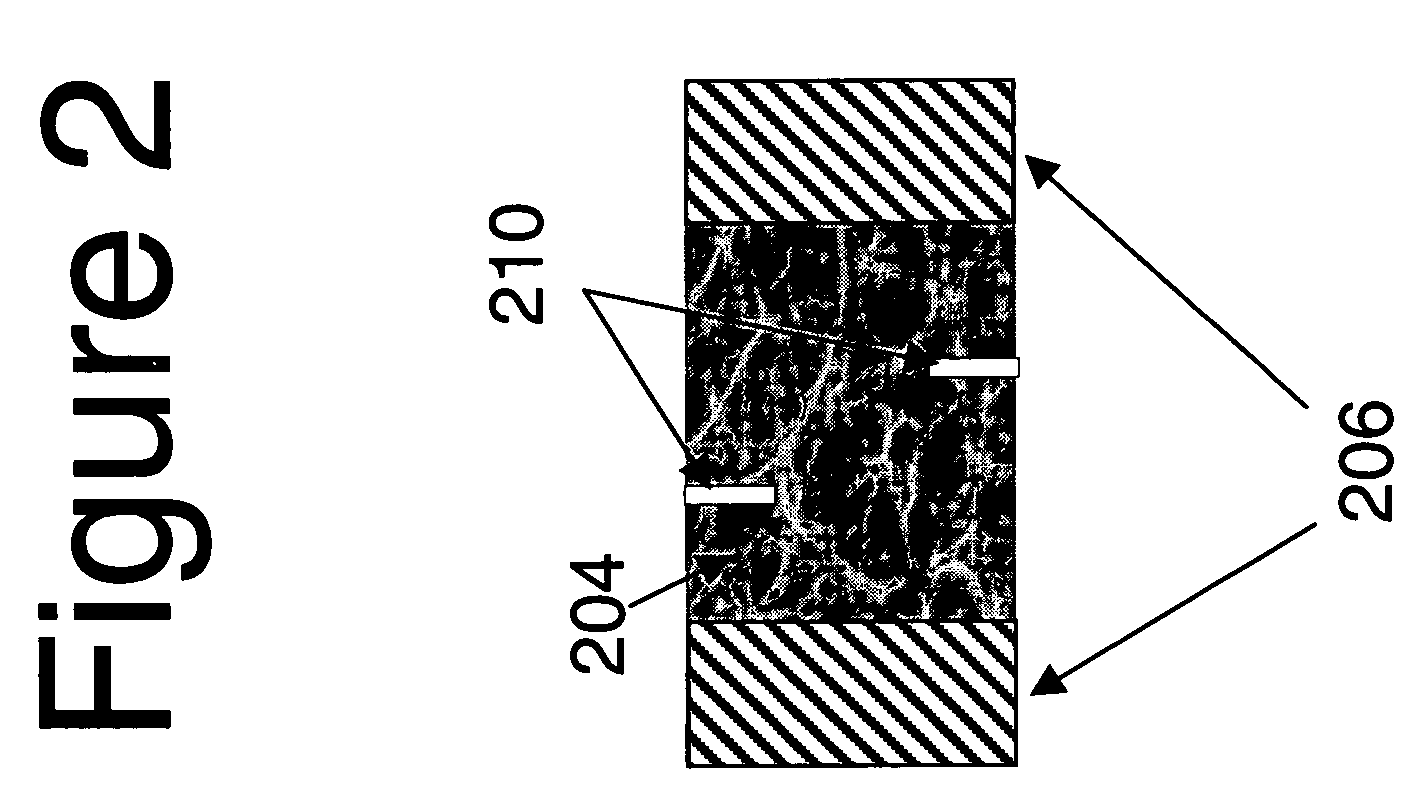

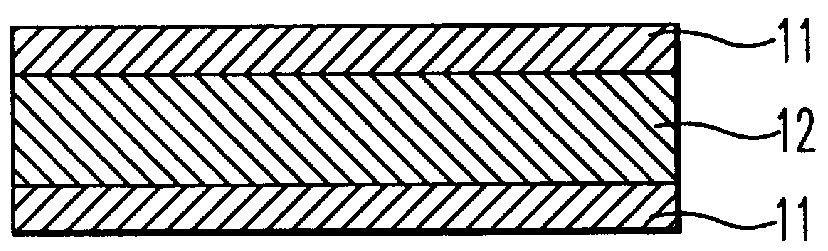

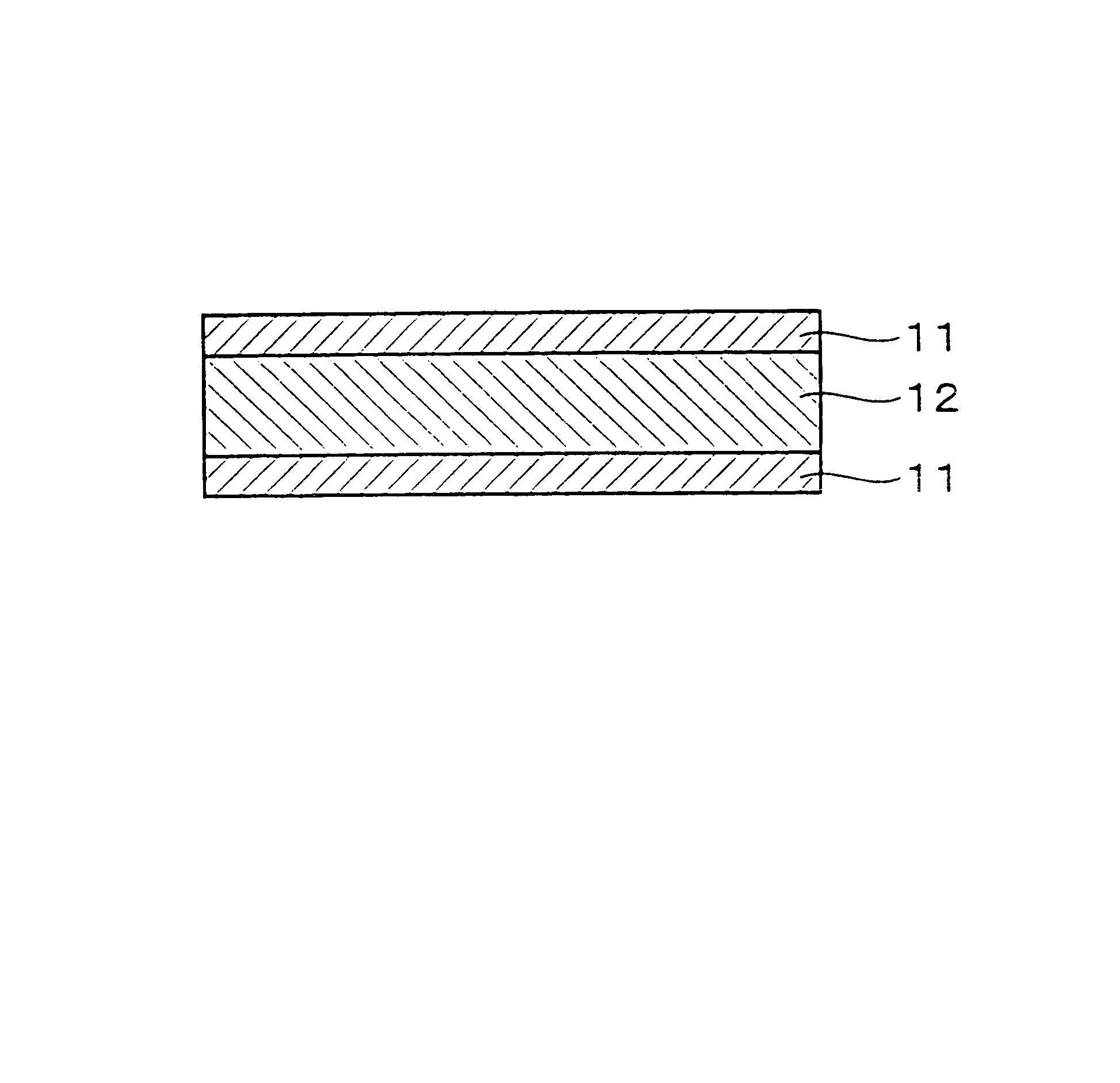

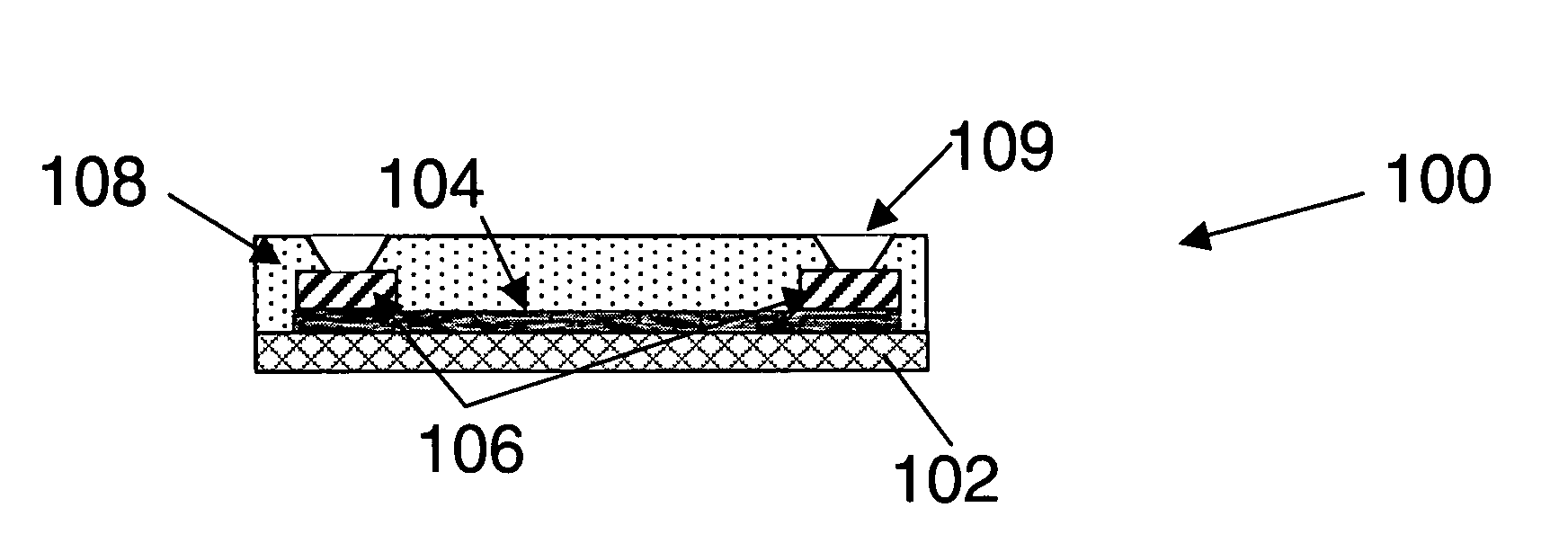

Method of manufacturing devices to protect election components

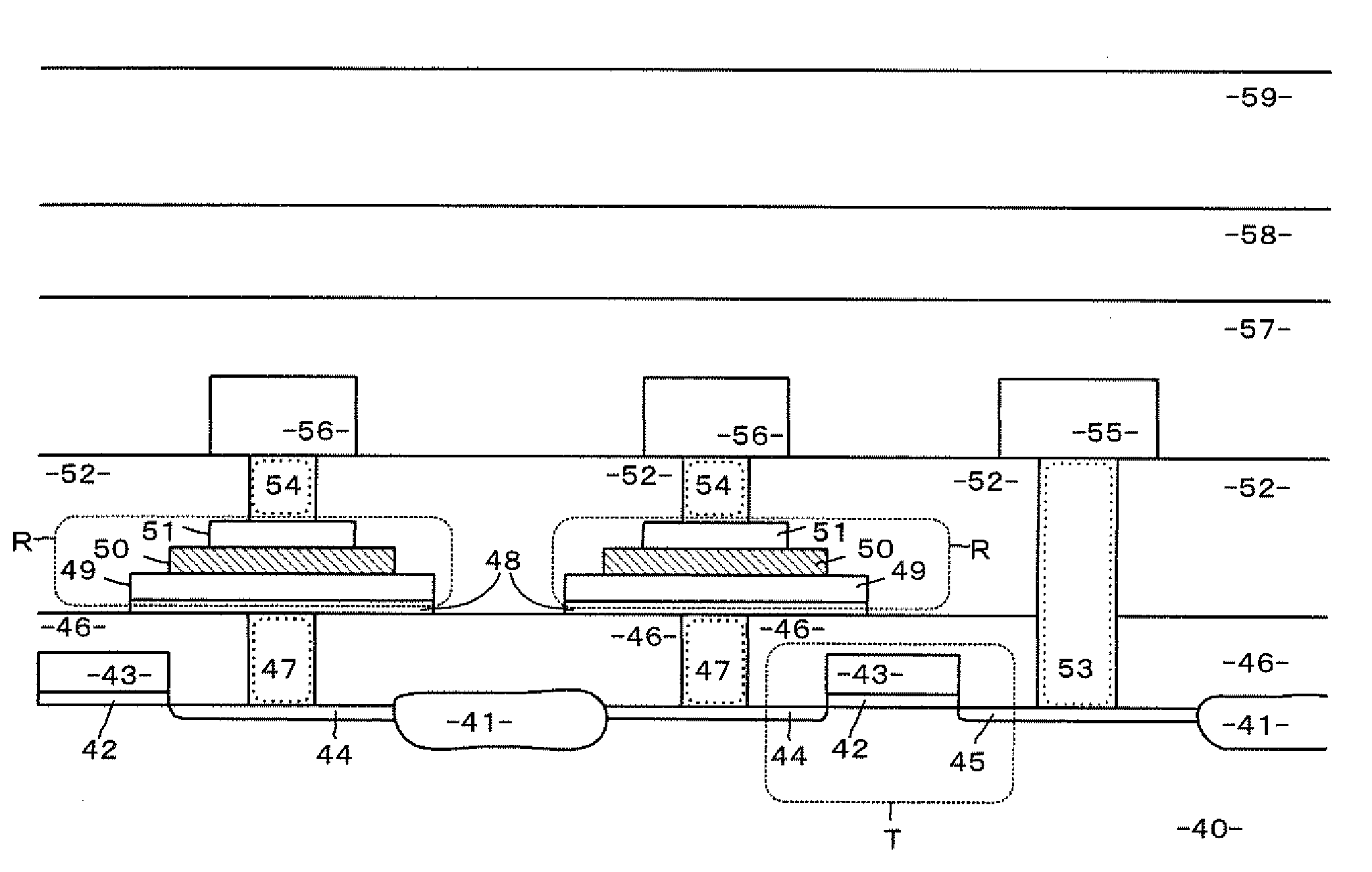

InactiveUS6981319B2Easy to customizeMake fastFuse device manufactureInsulating layers/substrates workingManufacturing technologyElectronic component

Devices capable of protecting electronic components during the occurrence of a disturbance event using printed circuit board manufacturing techniques. A three (3) layer structure is formed comprising a polymer-based formulation sandwiched between two electrode layers. The devices can be manufactured in panel form providing high quantities of devices which can be removed from the panel and applied directly to the component to be protected. Desired patterns can be formed on either one of the electrode layers by photo-etch techniques thereby providing a process that can be tailored to a large number of applications.

Owner:ELECTRONICS POLYMERS NEWCO

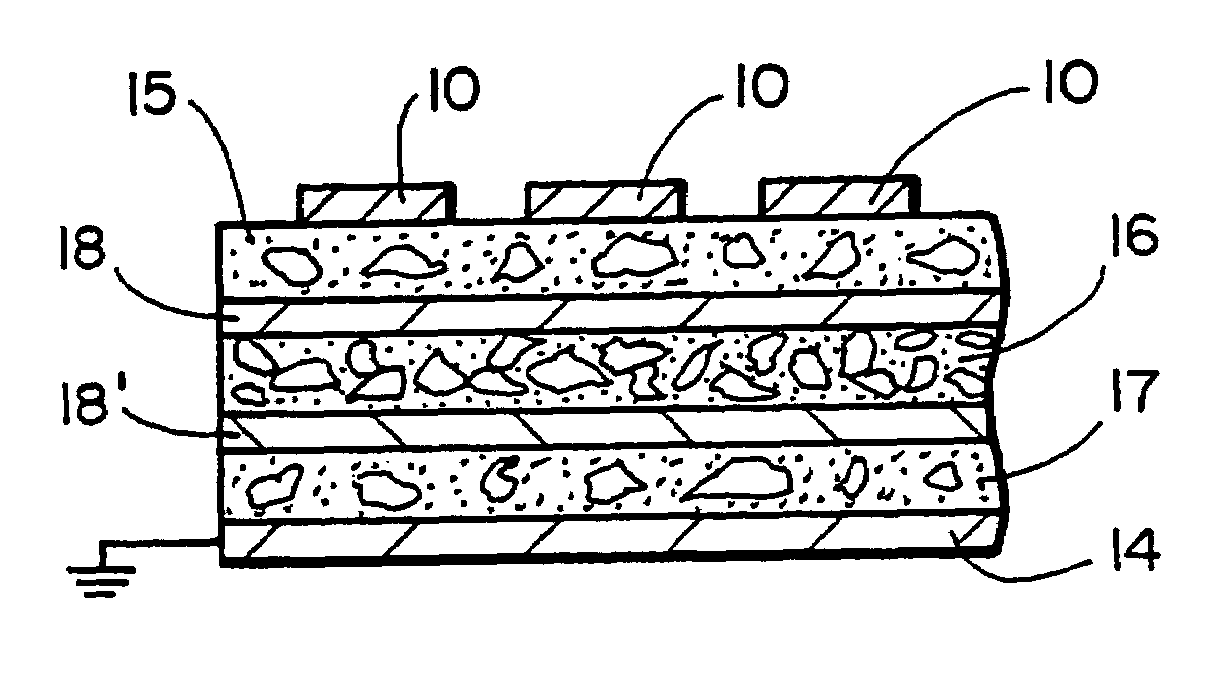

Single and multi layer variable voltage protection devices and method of making same

InactiveUS7049926B2Improve performanceDesirable propertyCurrent responsive resistorsAuxillary ticket-issuing devicesDielectricOvervoltage

Disclosed is a variable voltage protection device for electronic devices which in one aspect comprises a thin layer of neat dielectric polymer or glass positioned between a ground plane and an electrical conductor for overvoltage protection, wherein the neat polymer or glass layer does not include the presence of conductive or semiconductive particles. Also disclosed is the combination of the neat dielectric polymer or glass thin layer positioned on a conventional variable voltage protection material comprising a binder containing conductive or semiconductive particles. A multi-layer variable voltage protection component is disclosed comprising three layers of overvoltage protection material wherein the outer two layers contain a lower percentage of conductive or semiconductive particles and wherein the inner layer contains a higher percentage of conductive or semiconductive particles. The multi-layer component can optionally be used in combination with the neat dielectric polymer or glass layer and can optionally have interposed metal layers. A method is disclosed for dispersing insulative particles and conductive or semiconductive particles in a binder using a volatile solvent for dispersement of the insulative particles and the conductive or semiconductive particles before mixing with the binder.

Owner:SURGX CORP

Resistive elements using carbon nanotubes

ActiveUS7365632B2Function increaseEasy parameter controlCurrent responsive resistorsSolid-state devicesBulk resistanceCarbon nanotube

Resistive elements include a patterned region of nanofabric having a predetermined area, where the nanofabric has a selected sheet resistance; and first and second electrical contacts contacting the patterned region of nanofabric and in spaced relation to each other. The resistance of the element between the first and second electrical contacts is determined by the selected sheet resistance of the nanofabric, the area of nanofabric, and the spaced relation of the first and second electrical contacts. The bulk resistance is tunable.

Owner:NANTERO

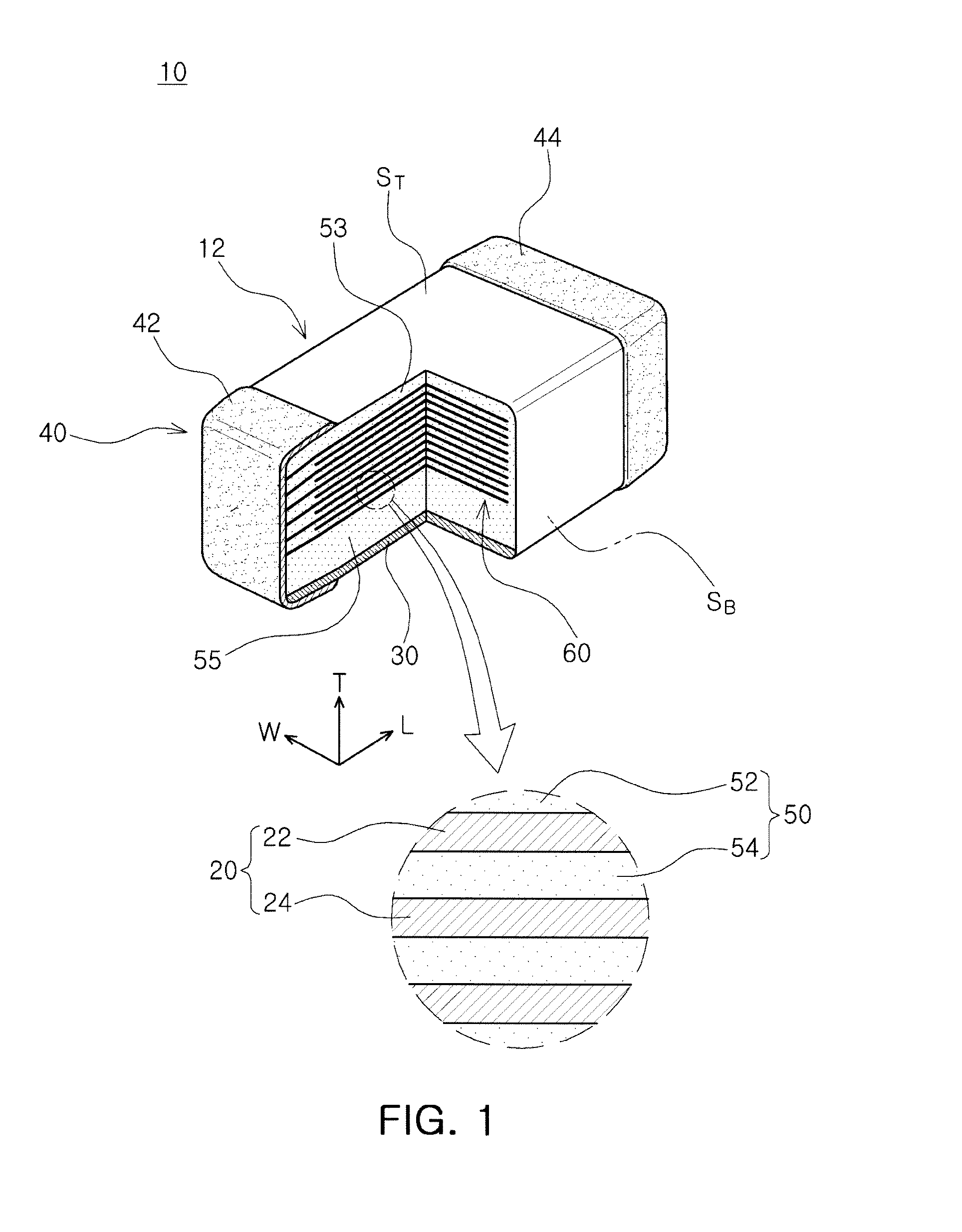

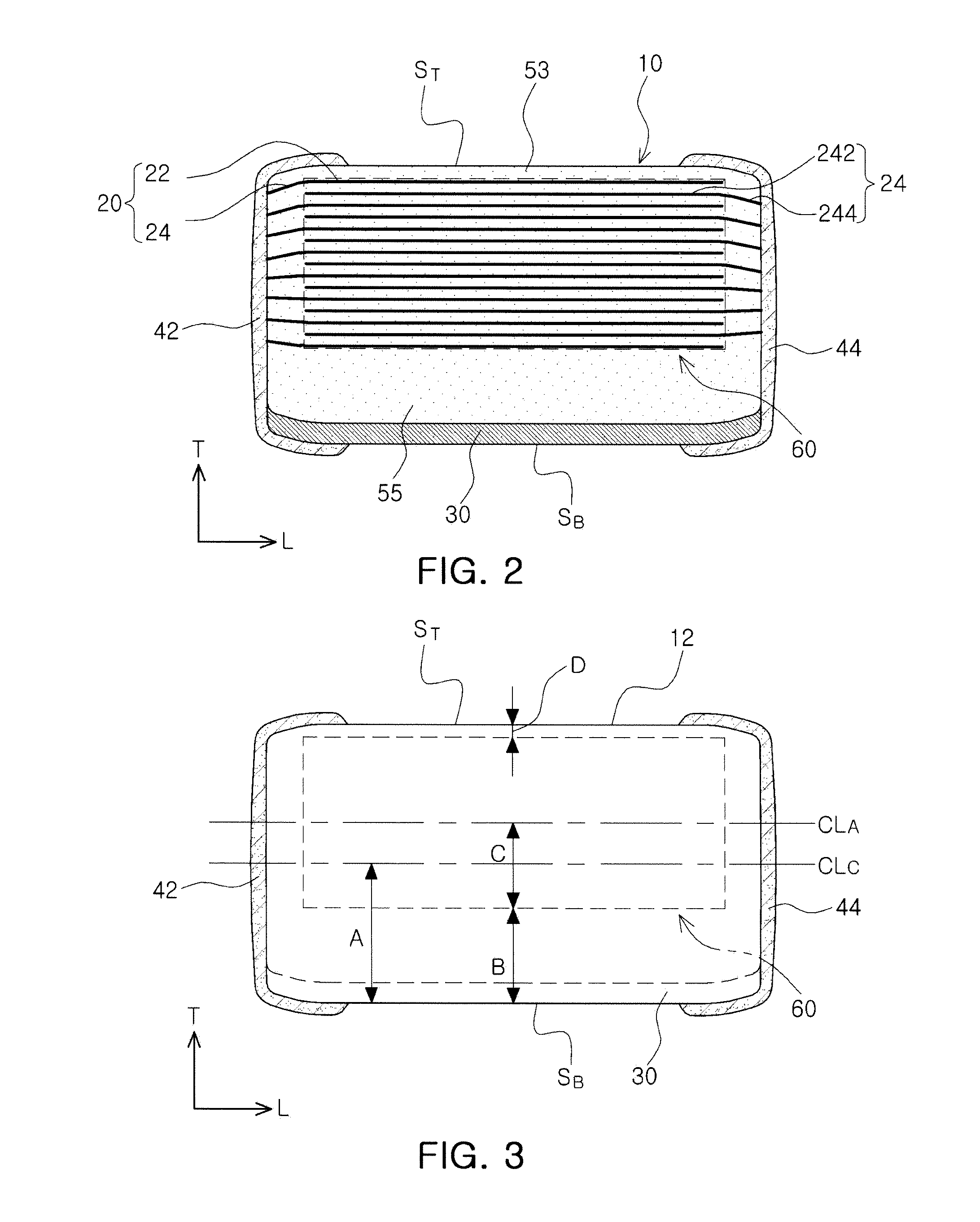

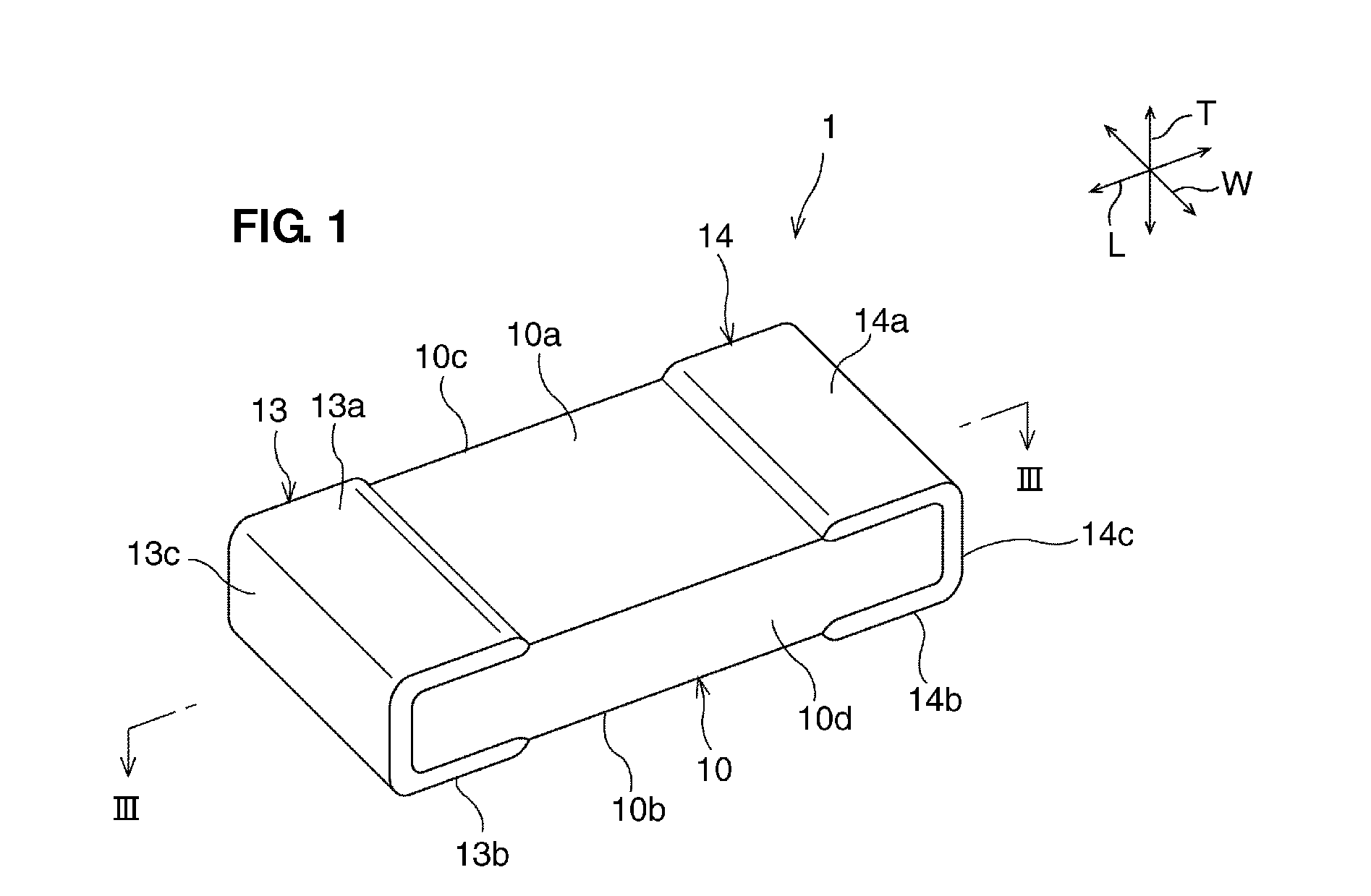

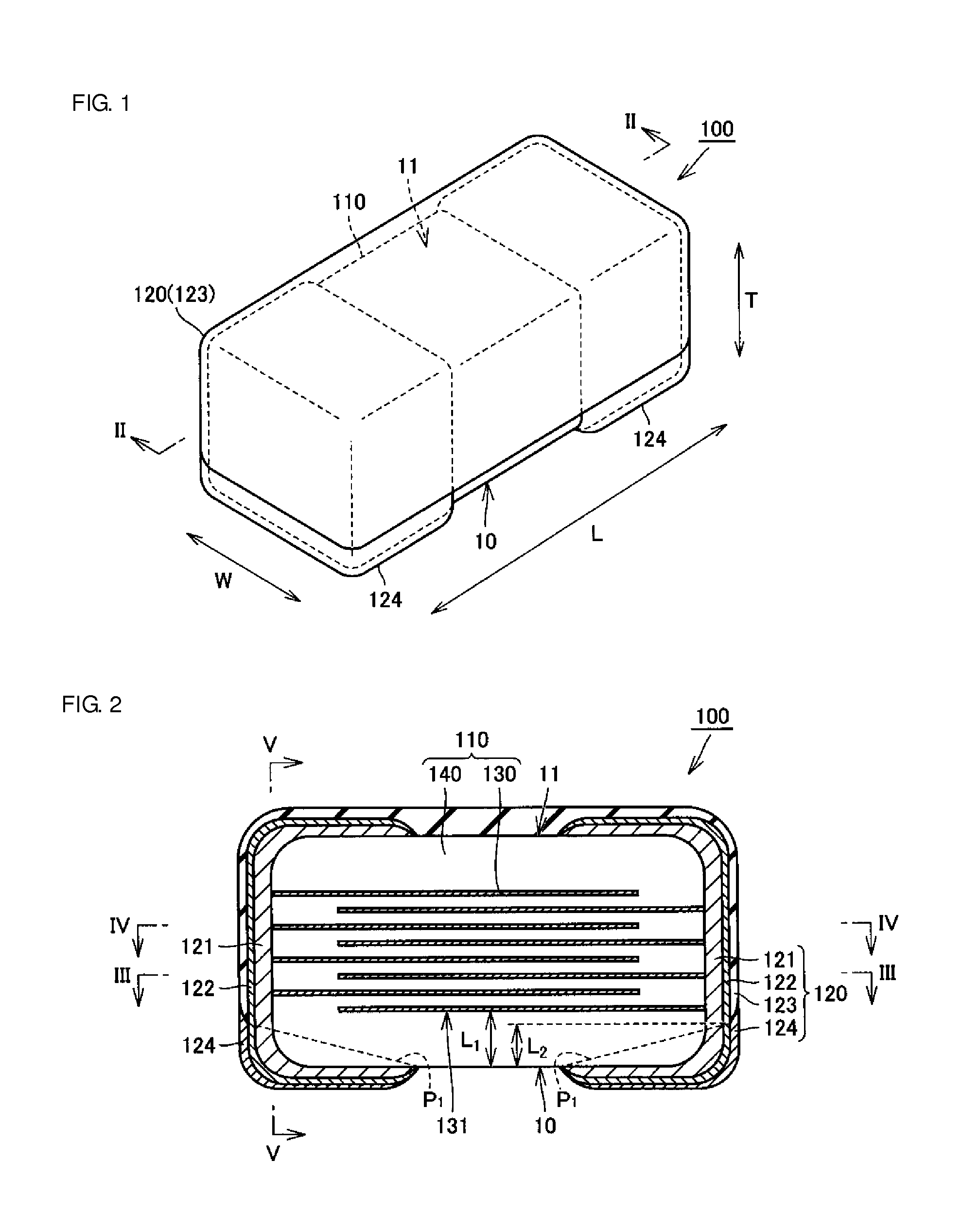

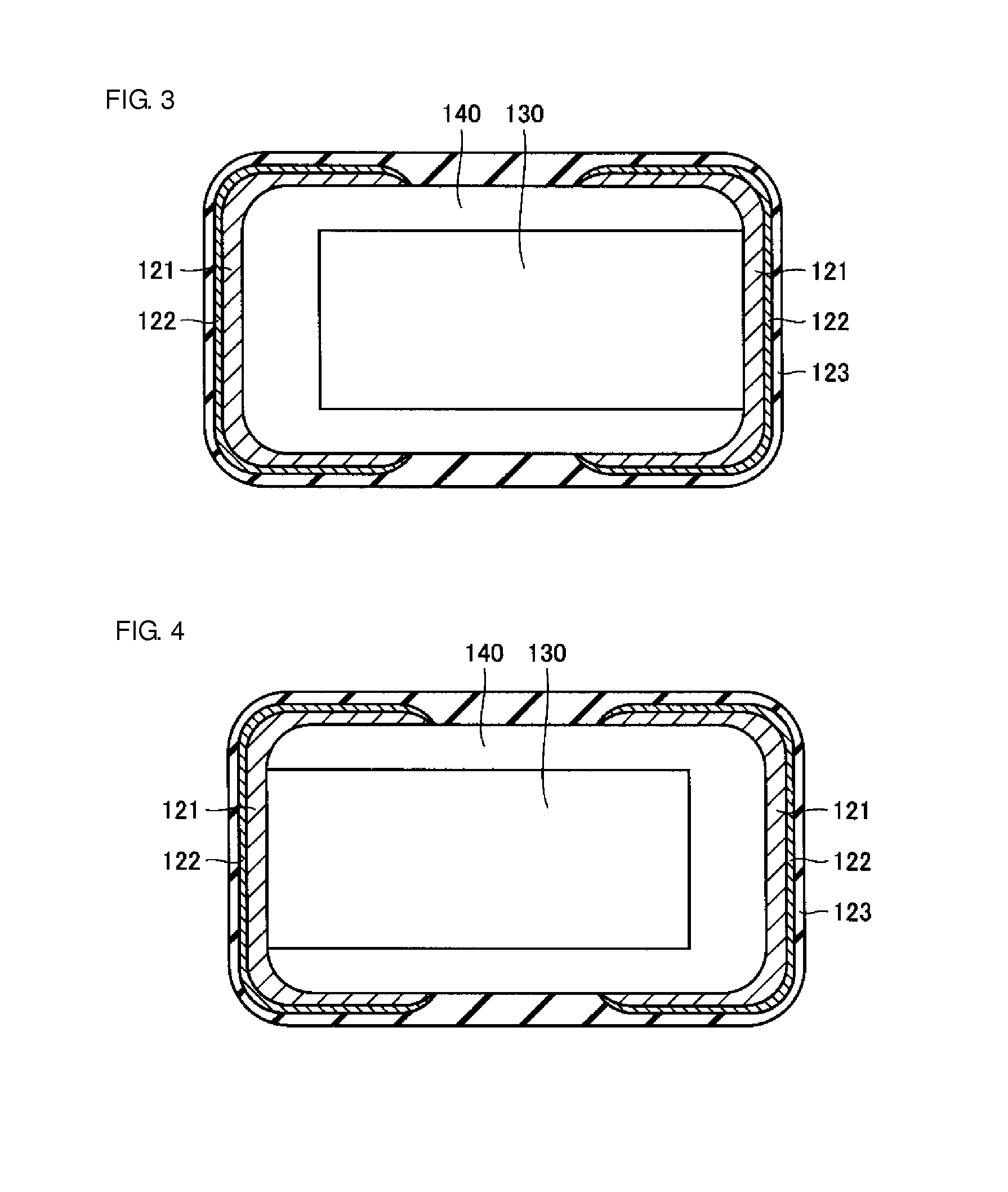

Laminated chip electronic component, board for mounting the same, and packing unit thereof

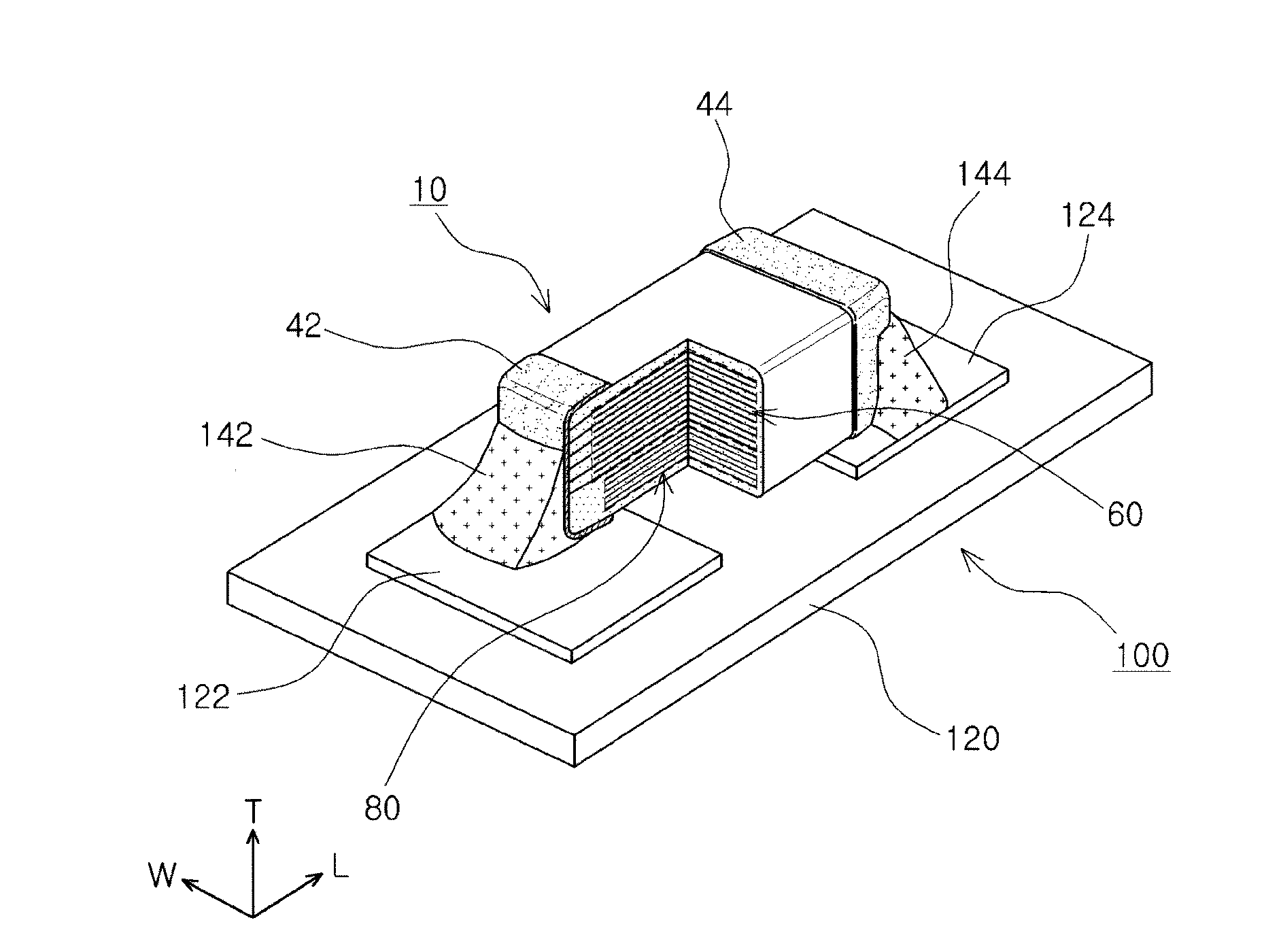

ActiveUS20140083755A1Reduce noisePiezoelectric/electrostriction/magnetostriction machinesFinal product manufactureCapacitanceElectronic component

A laminated chip electronic component includes: a ceramic body including internal electrodes and dielectric layers; external electrodes formed to cover both end portions of the ceramic body in a length direction; an active layer in which the internal electrodes are disposed in an opposing manner, while having the dielectric layers interposed therebetween, to form capacitance; and upper and lower cover layers formed on upper and lower portions of the active layer in a thickness direction, the lower cover layer having a thickness greater than that of the upper cover layer.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

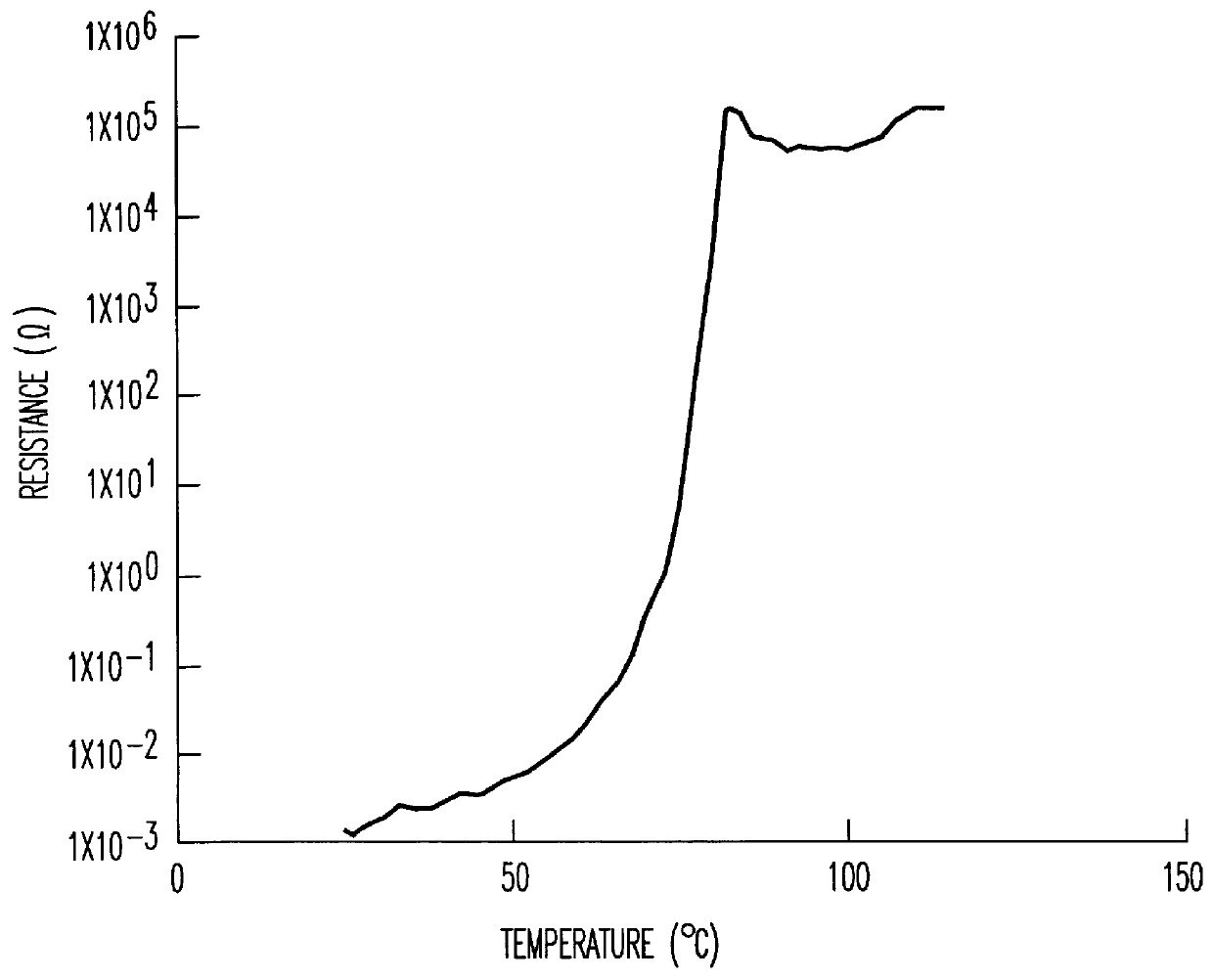

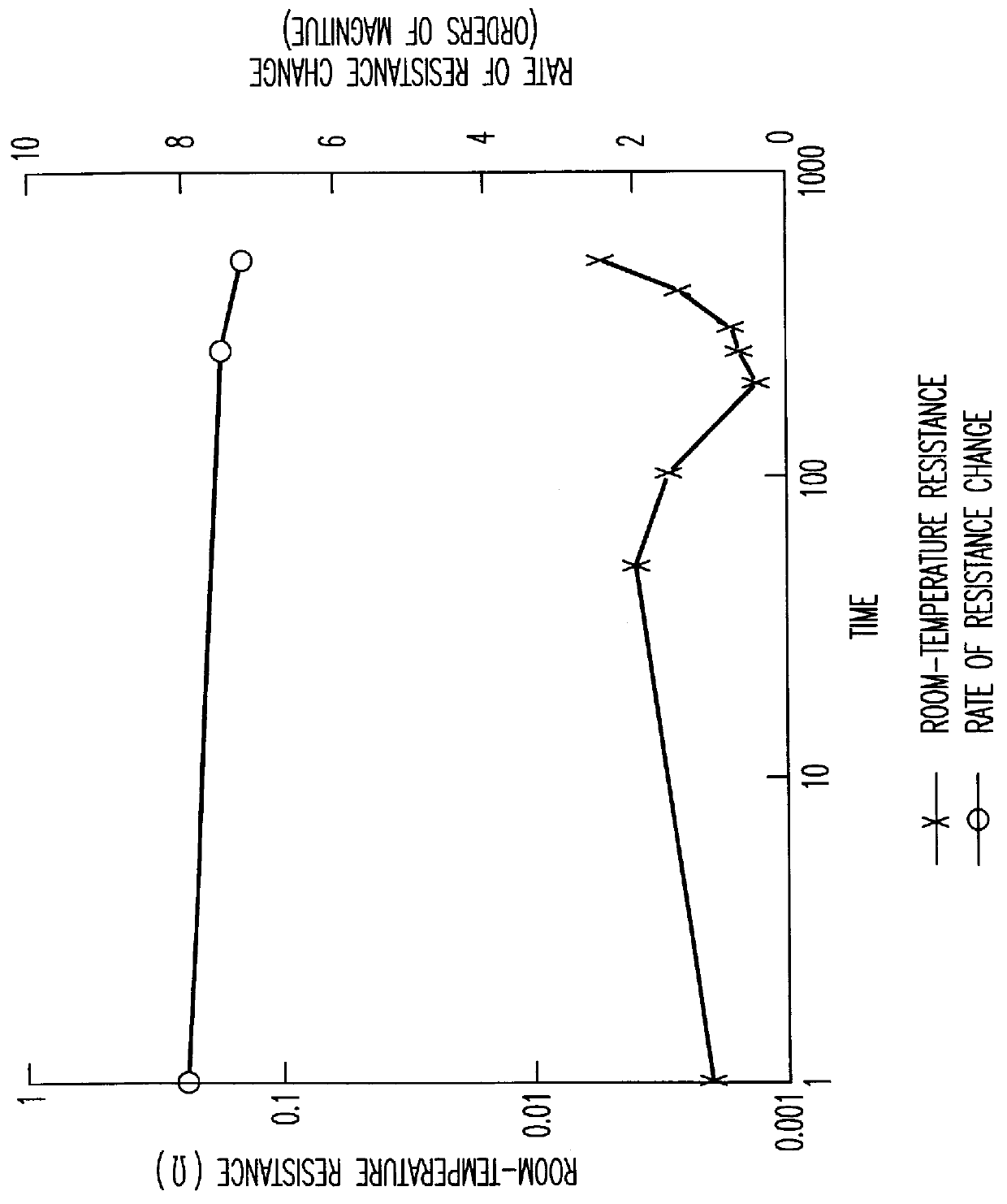

Organic positive temperature coefficient thermistor and manufacturing method therefor

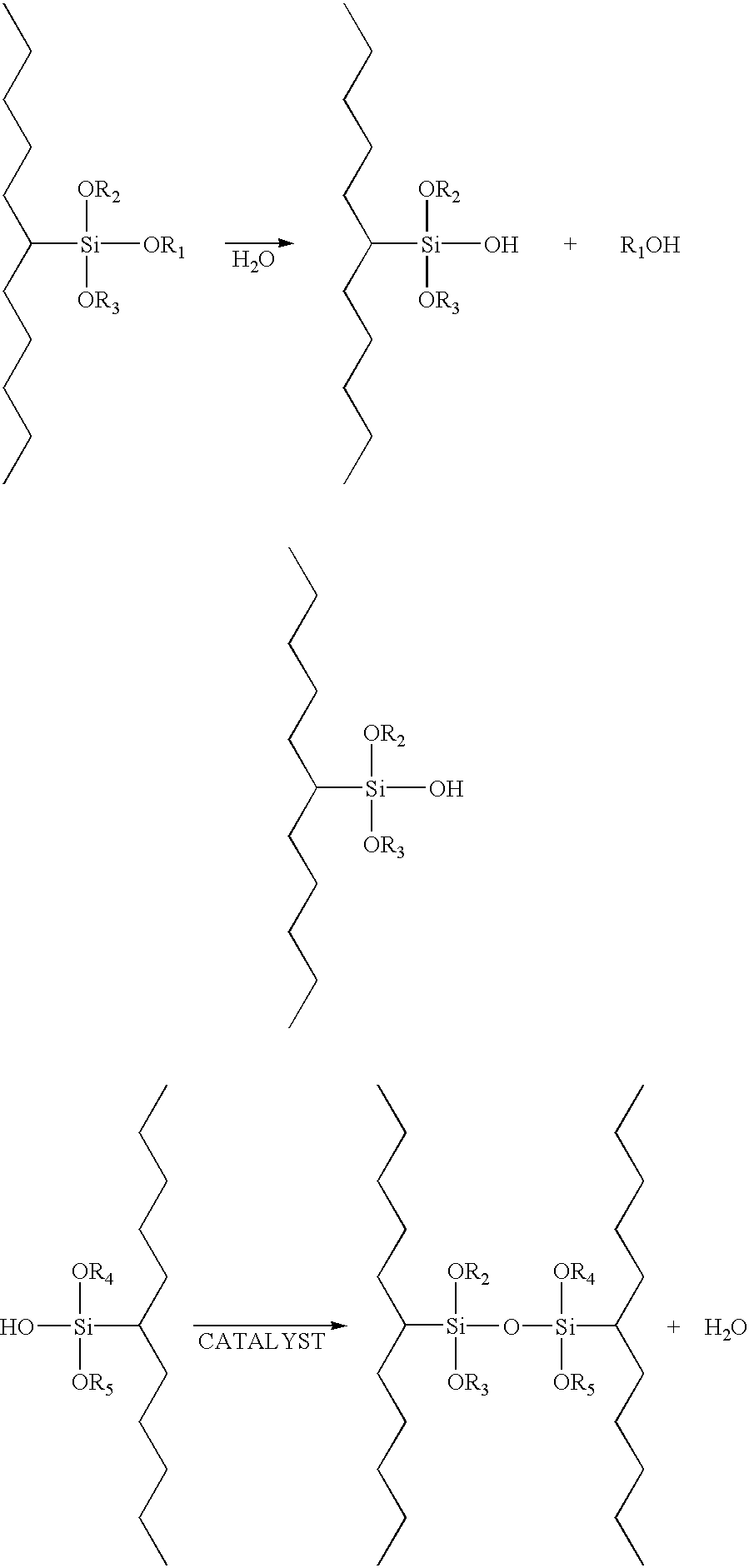

InactiveUS6143206ALower resistanceSignificant changeCurrent responsive resistorsConductive materialHysteresisMeth-

An organic positive temperature coefficient thermistor comprising a thermoplastic polymer matrix, a low-molecular organic compound having a melting point that is equal to or greater than 40 DEG C. and less than 100 DEG C. and conductive particles, each having spiky protuberances, is obtained by crosslinking a milled mixture of these components with a silane coupling agent comprising a vinyl group or a (meth)acryloyl group and an alkoxy group. This organic positive temperature coefficient thermistor has sufficiently low resistance at room temperature and a large rate of resistance change between an operating state and a non-operating state, and can be operated at less than 100 DEG C. with a reduced temperature vs. resistance curve hysteresis, ease of control of operating temperature, and high performance stability.

Owner:TDK CORPARATION

Semiconductor memory device with variable resistance element

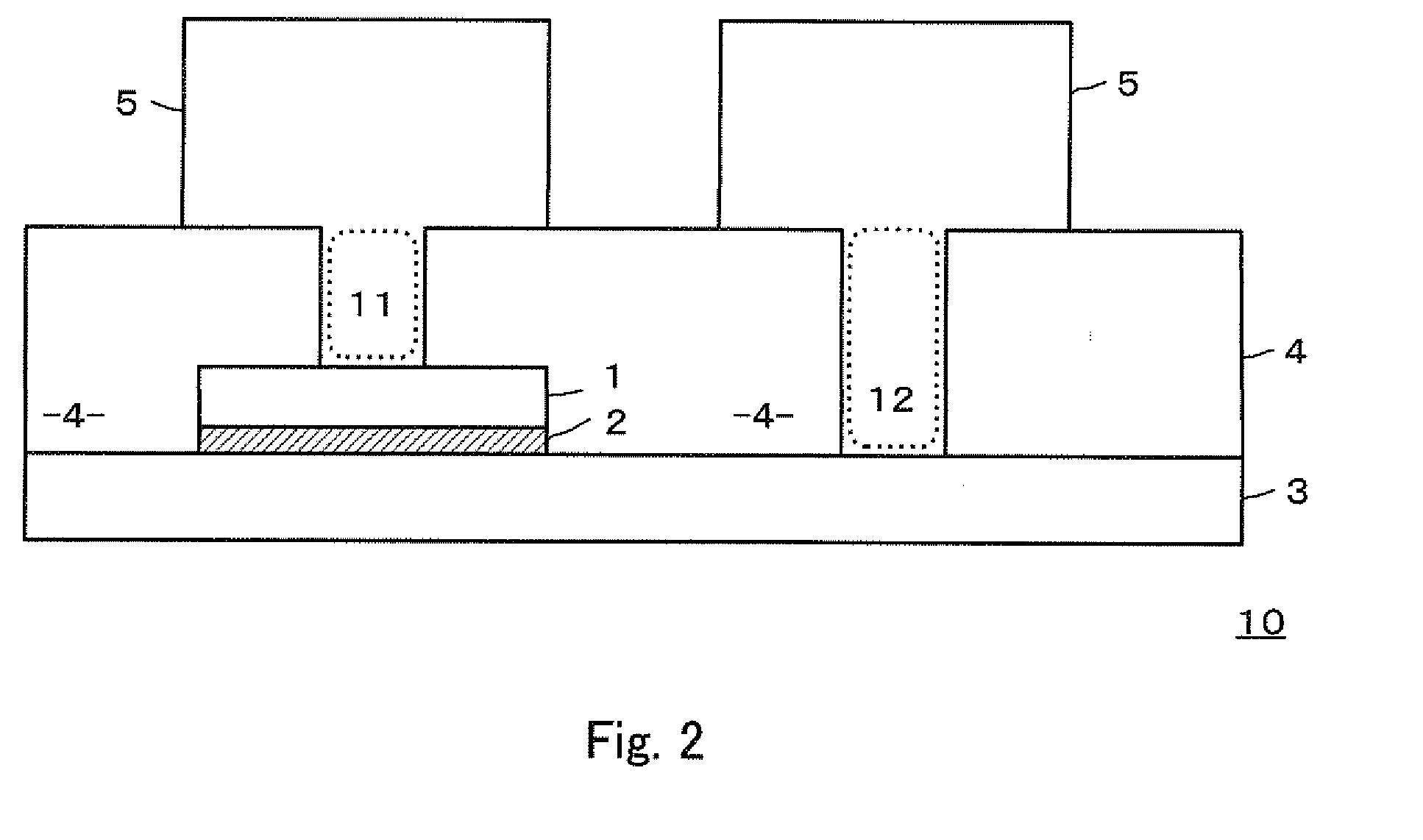

InactiveUS20090102598A1Avoid influenceIncrease the resistance valueCurrent responsive resistorsSolid-state devicesControllabilitySemiconductor memory

A semiconductor memory device comprising a variable resistance element having a variable resistor between a first electrode and a second electrode, in which electric resistance is changed by applying a voltage pulse between the electrodes comprises at least one reaction preventing film made of a material having an action of blocking the permeation of a reduction species promoting a reduction reaction of the variable resistor and an oxidation species promoting an oxidation reaction of the variable resistor. This prevents the resistance value of the variable resistance element from fluctuating due to a reduction reaction or an oxidation reaction of the variable resistor caused by hydrogen or oxygen existing in the manufacturing steps, so that a semiconductor memory device having a small variation of the resistance value and having a good controllability can be realized with good repeatability.

Owner:SHARP KK

Variable resistance element, method for producing the same, and nonvolatile semiconductor storage device

InactiveUS20090147558A1Forming voltage can be reducedReduce voltageCurrent responsive resistorsDigital storageElectrical resistance and conductanceSemiconductor storage devices

The variable resistance element of the present invention is a variable resistance element having an electrode, the other electrode, and a metal oxide material sandwiched between the electrodes and having an electrical resistance, between the electrodes, changing reversibly in response to a voltage applied between the electrodes. The variable resistance element further includes, inside the metal oxide material, a low resistance material having a lower electrical resistance than the metal oxide material and being out of contact with at least either one of the electrodes. This makes it possible to reduce a forming voltage for providing a conductive section inside the metal oxide material, without causing a leakage current to increase.

Owner:SHARP KK +1

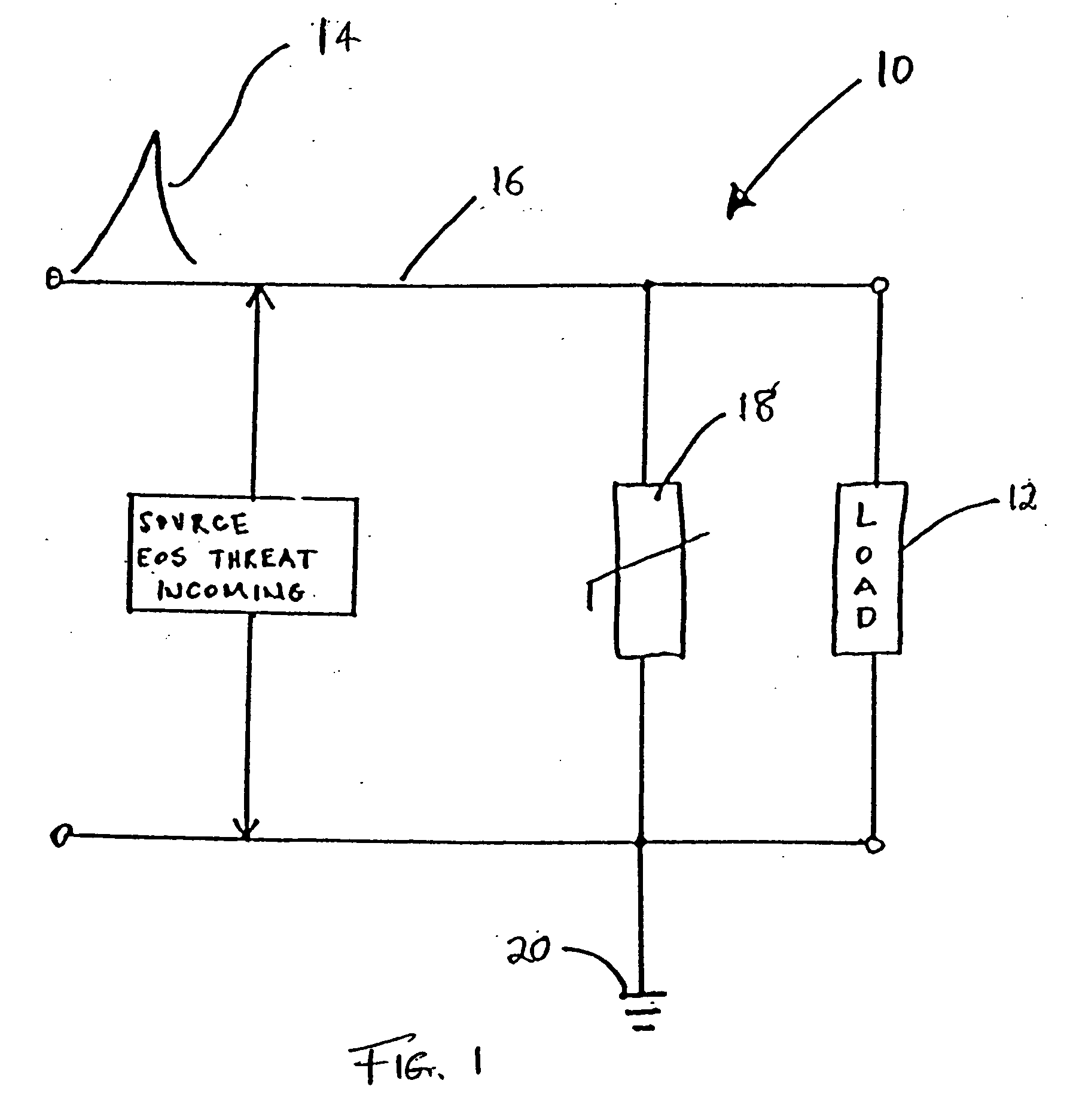

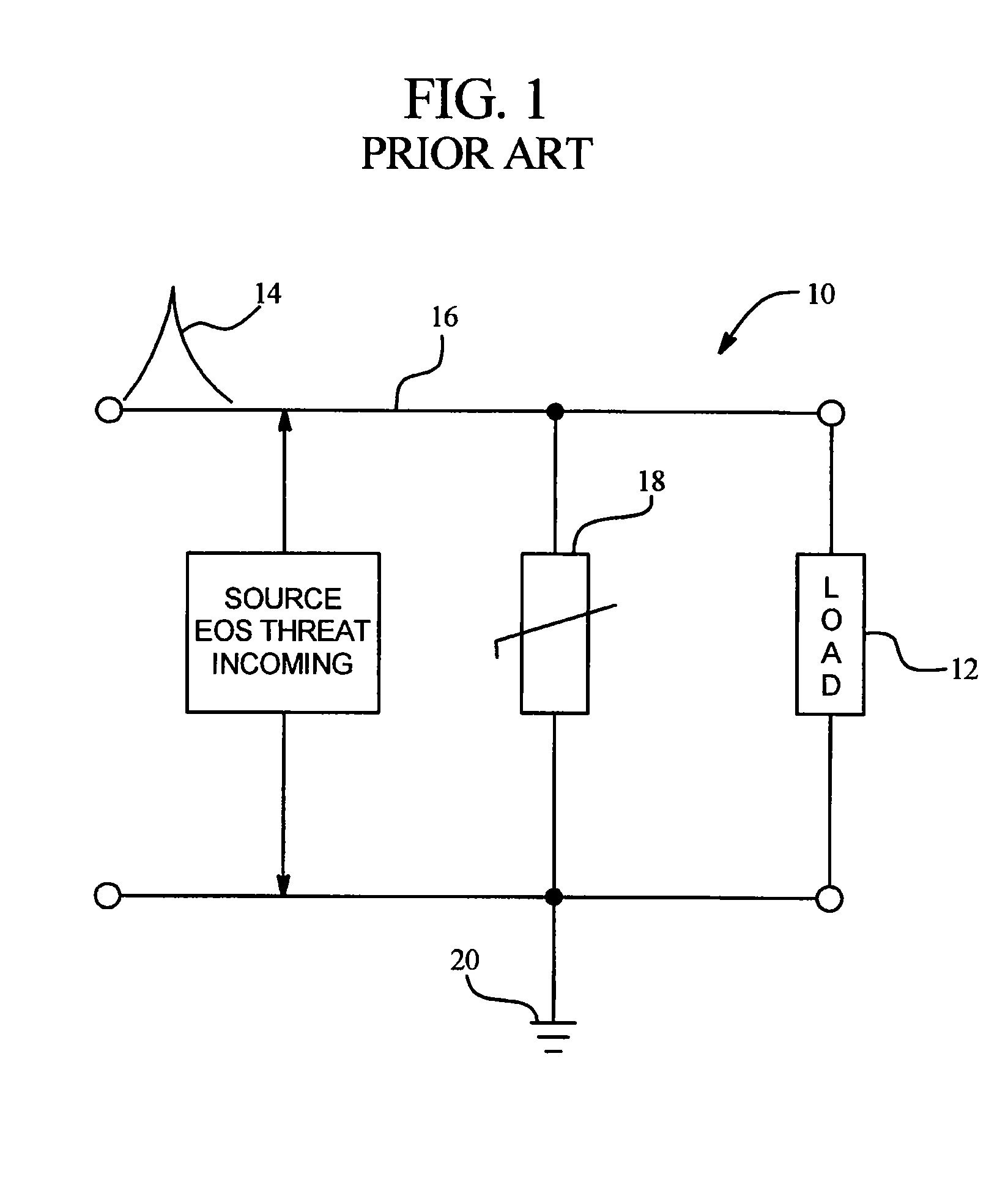

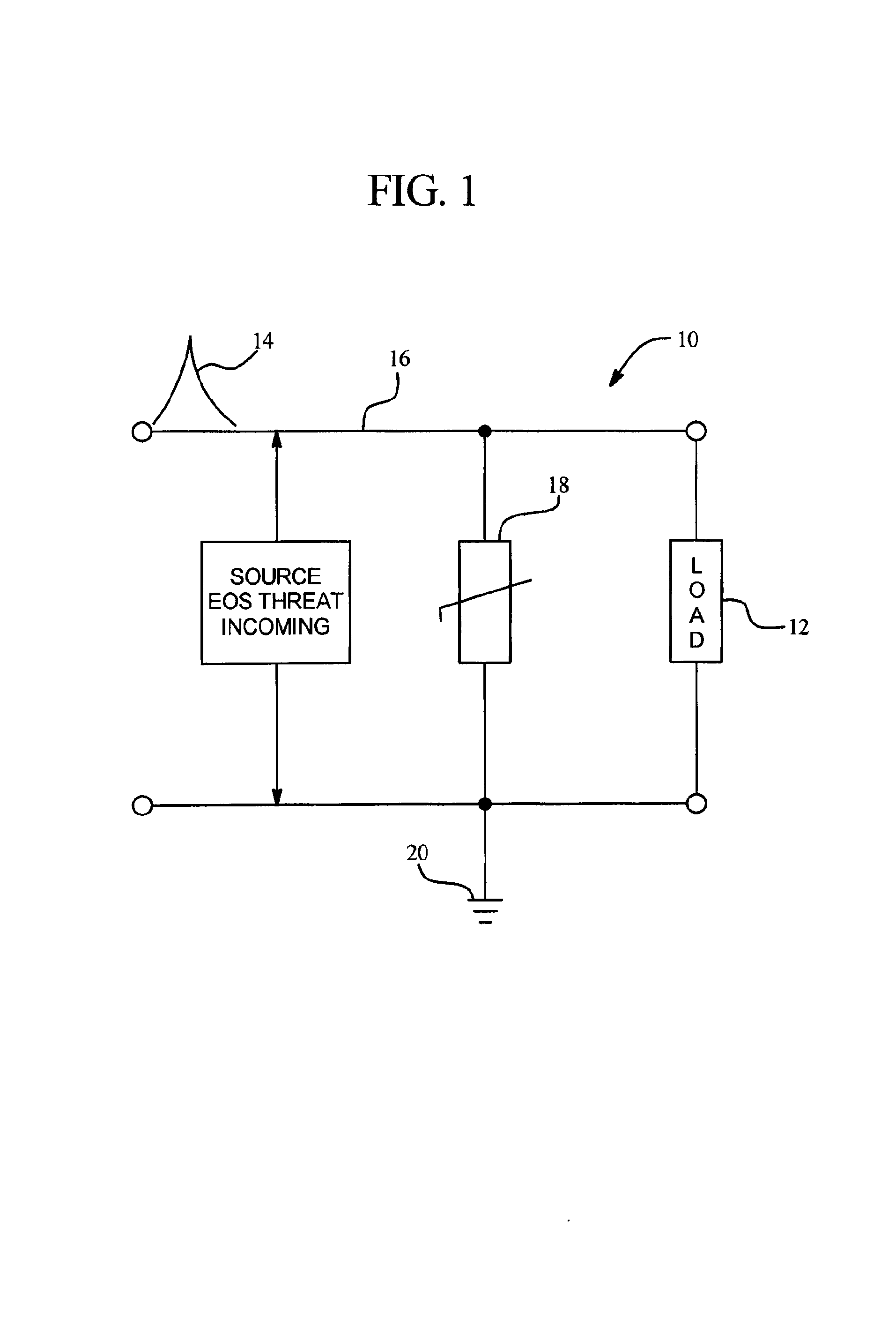

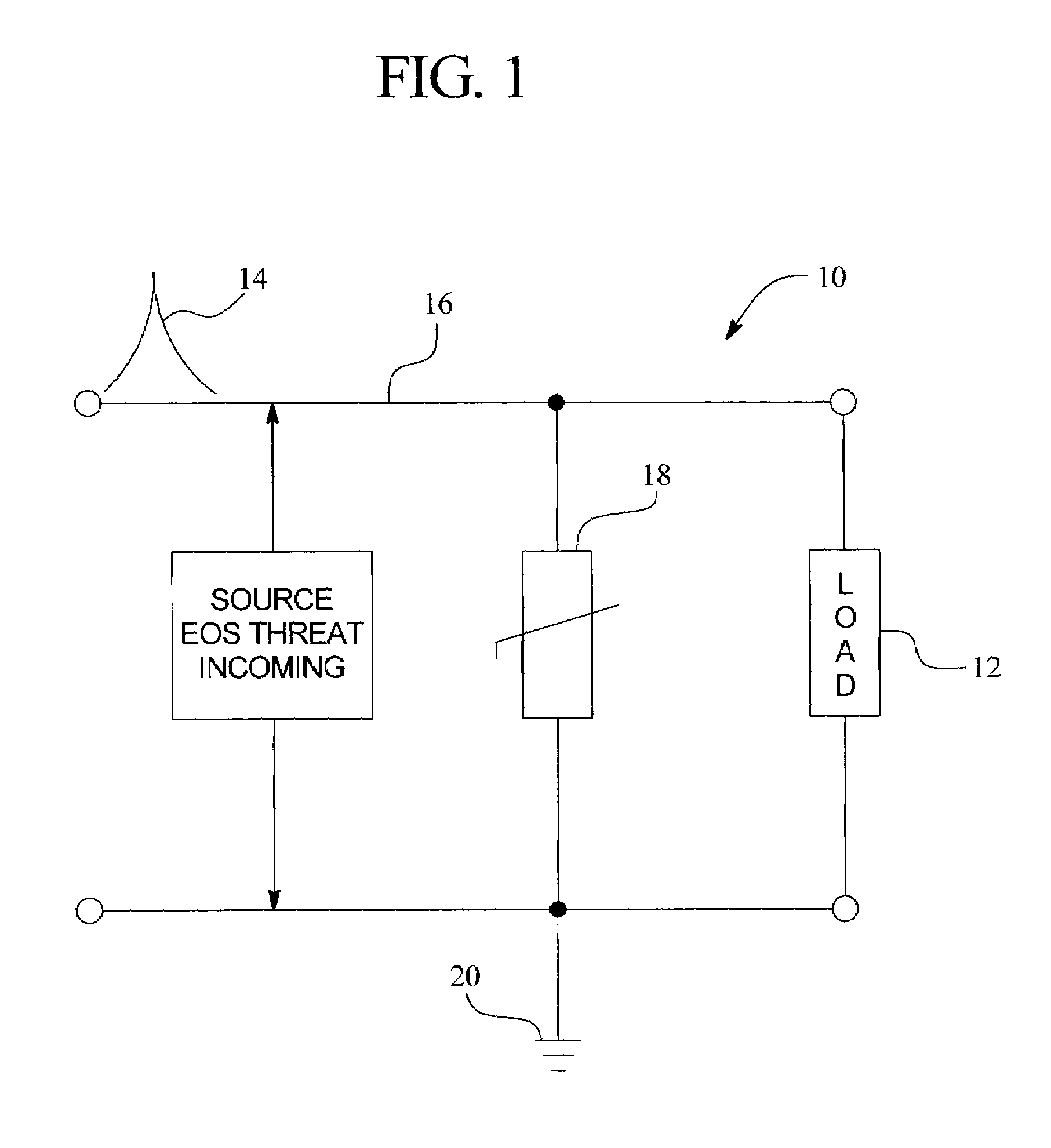

Devices and systems for electrostatic discharge suppression

Owner:ELECTRONICS POLYMERS NEWCO

Method of manufacturing ceramic electronic component, ceramic electronic component, and wiring board

ActiveUS20120018205A1Minimize changesCharacteristic is prevented and minimizedResistor terminals/electrodesFinal product manufactureConductive pasteMetallurgy

A method of manufacturing a ceramic electronic component prevents variations in characteristics even when the ceramic electronic component is embedded in a wiring board. Ceramic green sheets containing an organic binder having a degree of polymerization in a range from about 1000 to about 1500 are prepared. A first conductive paste layer is formed on a surface of each of the ceramic green sheets. The ceramic green sheets are laminated to form a raw ceramic laminated body. A second conductive paste layer is formed on a surface of the raw ceramic laminated body. The raw ceramic laminated body formed with the second conductive paste layer is fired.

Owner:MURATA MFG CO LTD

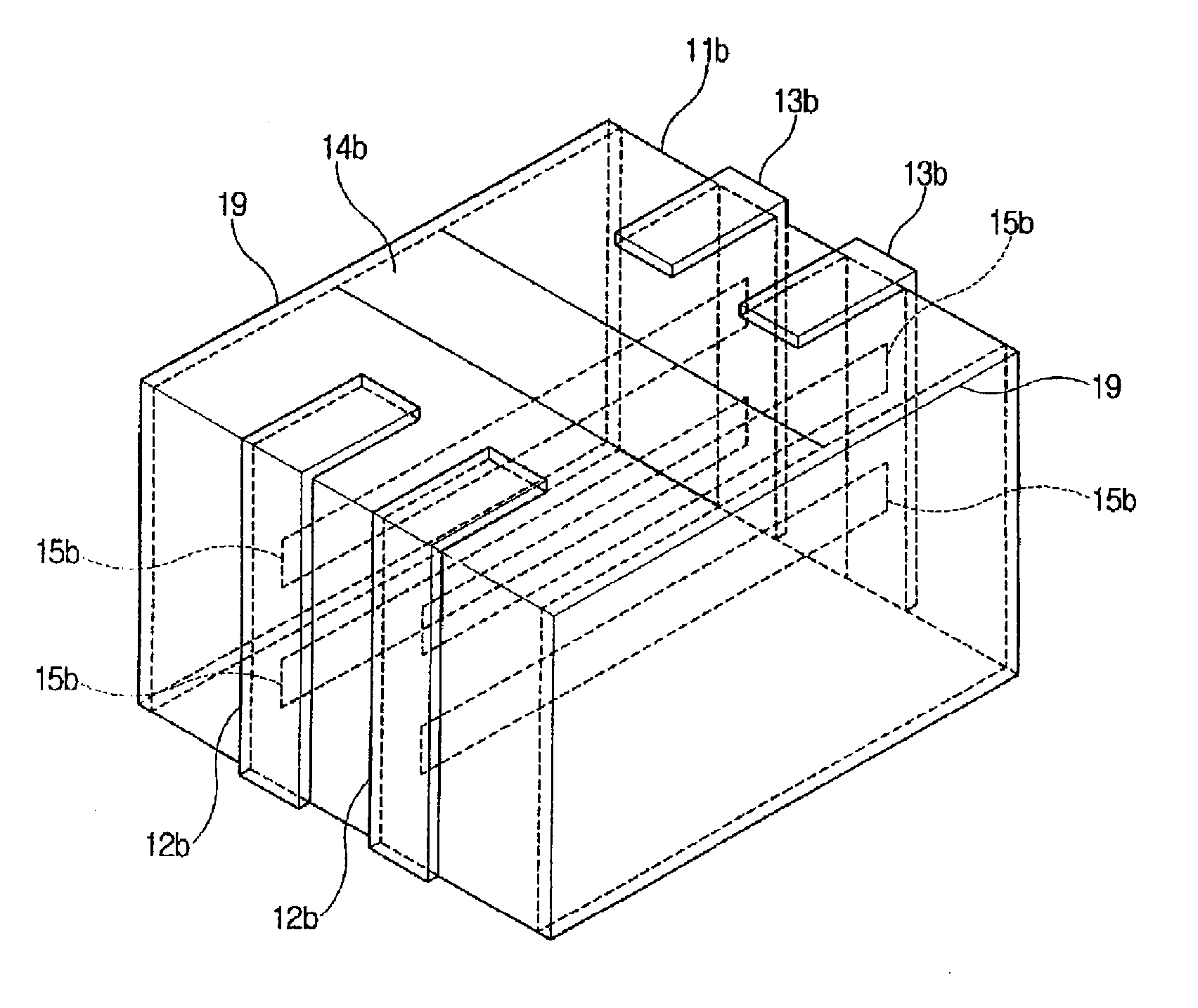

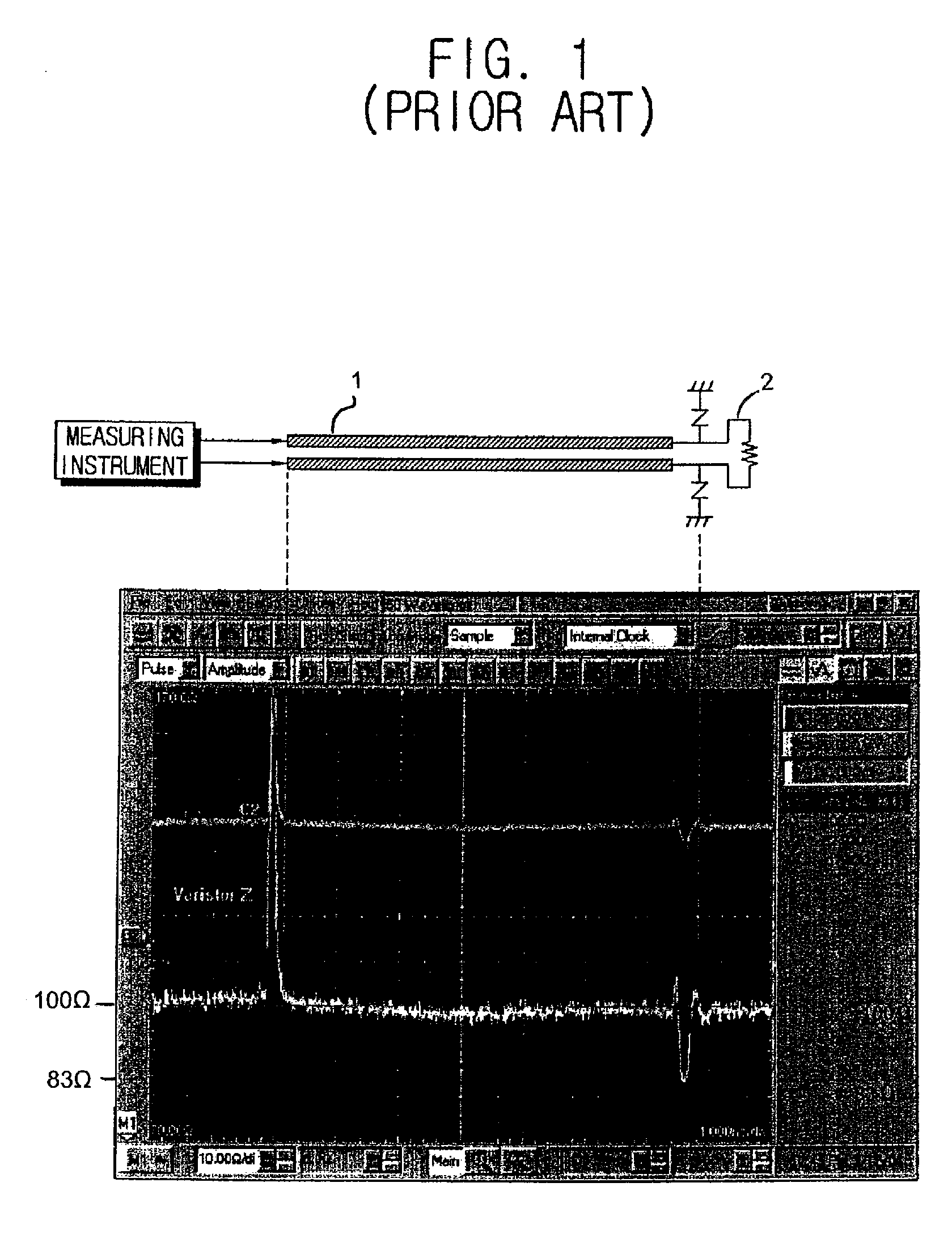

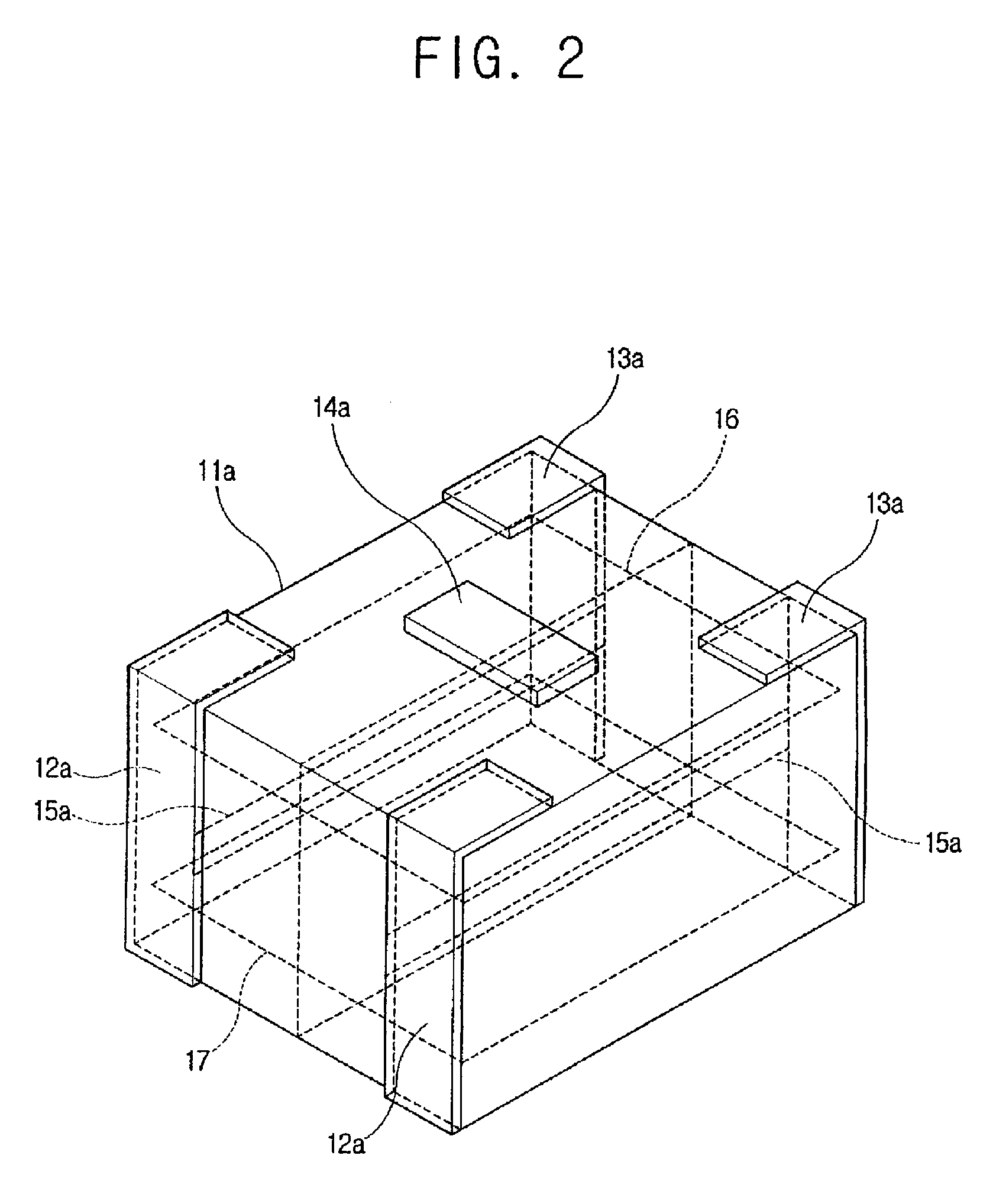

Device to protect against a surge voltage and an electronic apparatus including the same

InactiveUS20060291127A1Current responsive resistorsHigh voltage circuit adaptationsElectrical impedanceSurge voltage

A device to protect against a surge voltage includes a body having a hexahedron shape and filled with a varistor material, a pair of input signal electrodes attached to a first side surface of the body along upward and downward directions, a pair of output signal electrodes attached to a second side surface of the body that faces the first side surface of the body in the upward and downward directions, a ground electrode attached to an upper surface of the body, at least one pair of signal connection electrode plates to connect the input signal electrodes and the output signal electrodes, and a ground plate to be connected to the ground electrode. Thus, the device can protect an electronic circuit from a surge voltage and match an impedance of a transmission line.

Owner:SAMSUNG ELECTRONICS CO LTD

Organic PTC thermistor

InactiveUS6607679B2Improve reliabilityImprove stabilityPrimary cell maintainance/servicingConductive materialThermoplastic elastomerThermistor

In an organic PTC thermistor comprising a matrix of at least two high-molecular weight compounds, a low-molecular weight organic compound, and conductive particles having spiky protuberances, a thermoplastic elastomer is contained in the matrix whereby the thermistor is improved in reliability and performance stability.

Owner:TDK CORPARATION

High-temperature resistant PTC electroconductive composition, high-temperature resistant PTC device containing composition and manufacturing method thereof

ActiveCN101560325ALower resistanceImprove PTC StrengthCurrent responsive resistorsPositive temperature coefficient thermistorsMetallurgyOrganic polymer

The invention relates to a high-temperature resistant PTC electroconductive composition, which comprises 20 to 70 percent of organic polymers, 25 to 75 percent of electroconductive filler, 1 to 30 percent of inorganic filler and 0.1 to 10 percent of additive, wherein the preferred melting point of the organic polymers is more than 150 DEG C; the organic polymers are one or more crystalline or semi-crystalline polymers and made of one or more of nylon 11, nylon 12, polyvinylidene fluoride, soluble poly(tetrafluoroethylene), ethylene-tetrafluoroethylene copolymers, perfluoroethylene-propylene, ethylene-chlorotrifluoroethylene and copolymers thereof. The invention also provides a high-temperature resistant PTC device containing the composition and a manufacturing method thereof. The high-temperature resistant PTC device containing the composition has low resistance, high PTC strength and superior resistance stability, so that the high-temperature resistant PTC device can be used for overcurrent protection of circuits in high-temperature environments such as automobile motors and the like. Moreover, the high-temperature resistant PTC device is simple and convenient to manufacture and has high efficiency.

Owner:SHANGHAI KETER POLYMER MATERIAL

Direct application voltage variable material, components thereof and devices employing same

InactiveUS7132922B2Directly appliedSemiconductor/solid-state device detailsSolid-state devicesSiliconPolymer

A voltage variable material (“VVM”) including an insulative binder that is formulated to intrinsically adhere to conductive and non-conductive surfaces is provided. The binder and thus the VVM is self-curable and applicable in a spreadable form that dries before use. The binder eliminates the need to place the VVM in a separate device or to provide separate printed circuit board pads on which to electrically connect the VVM. The binder and thus the VVM can be directly applied to many different types of substrates, such as a rigid (FR-4) laminate, a polyimide or a polymer. The VVM can also be directly applied to different types of substrates that are placed inside a device. In one embodiment, the VVM includes doped semiconductive particles having a core, such which can be silicon, and an inert coating, which can be an oxide. The particles are mixed in the binder with conductive particles.

Owner:LITTELFUSE INC

Variable resistance element, its manufacturing method and semiconductor memory device comprising the same

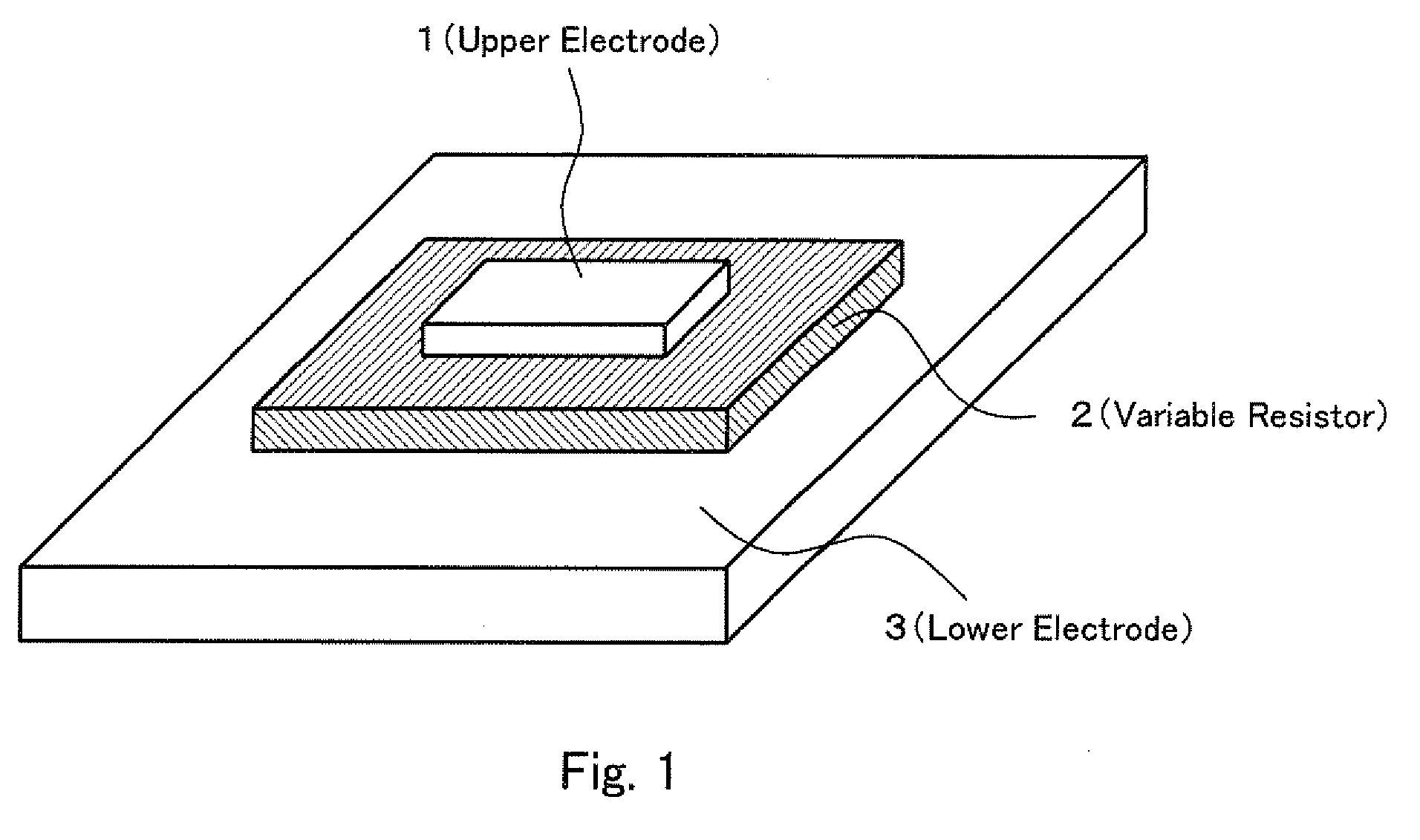

InactiveUS20090097300A1Stable switching operationFavorable data retention characteristicCurrent responsive resistorsSolid-state devicesElectrical resistance and conductanceVoltage pulse

Provided is a variable resistance element capable of performing a stable resistance switching operation and having a favorable resistance value retention characteristics, comprising a variable resistor 2 sandwiched between a upper electrode 1 and lower electrode 3 and formed of titanium oxide or titanium oxynitride having a crystal grain diameter of 30 nm or less. When the variable resistance 2 is formed under the substrate temperature of 150° C. to 500° C., an anatase-type crystal having a crystal grain diameter of 30 nm or less is formed. Since the crystalline state of the variable resistor changes by applying a voltage pulse and the resistance value changes, no forming process is required. Moreover, it is possible to perform a stable resistance switching operation and obtain an excellent effect that the resistance fluctuation is small even if the switching is repeated, or the variable resistance element is stored for a long time under a high temperature.

Owner:SHARP KK

Material of over voltage protection device, over voltage protection device and manufacturing method thereof

InactiveUS20080079533A1Lower the trigger voltageEasy to useCurrent responsive resistorsVaristor coresAdhesiveEngineering

The present invention relates to a material of an over voltage protection device and an over voltage protection device manufactured by the material. The material comprises a non-conductive powder, a metal conductive powder, and an adhesive. The over voltage protection device comprises a first electrode, a second electrode, and a porous structure connected between the first electrode and the second electrode. The present invention also relates to a method for manufacturing the over voltage protection device. The present invention also relates to a method of adjusting the breakdown voltage of an over voltage protection device.

Owner:INPAQ TECH

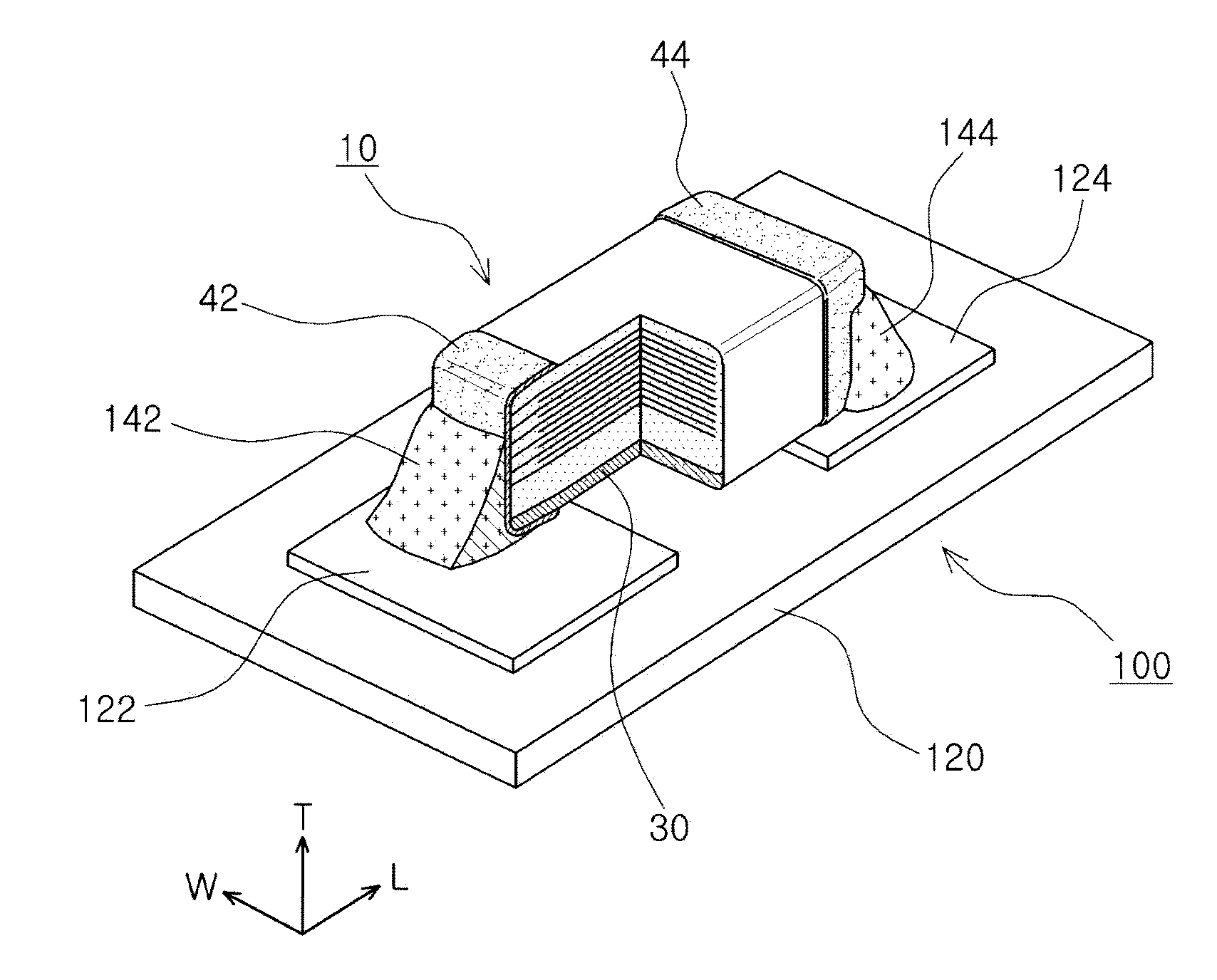

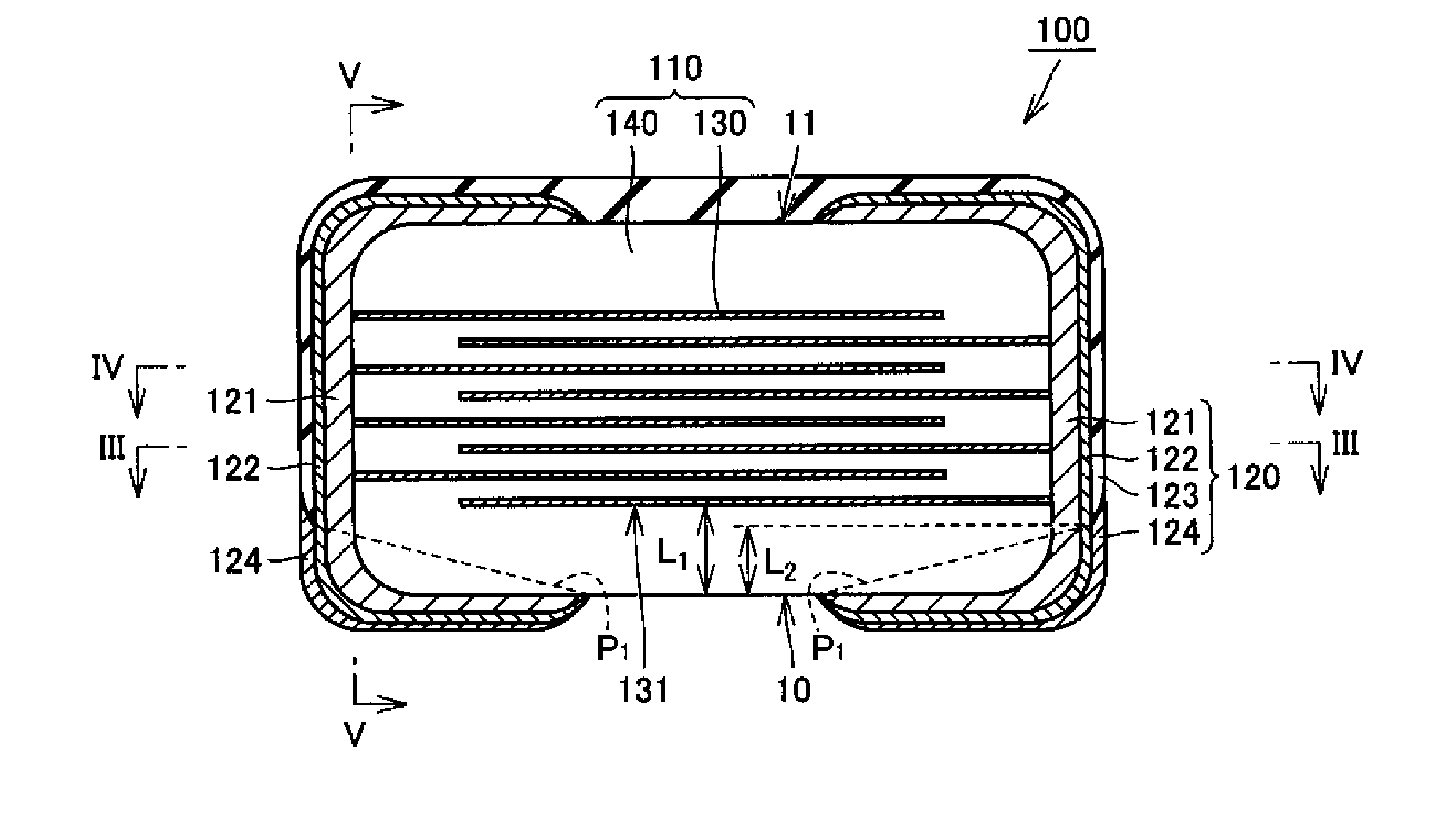

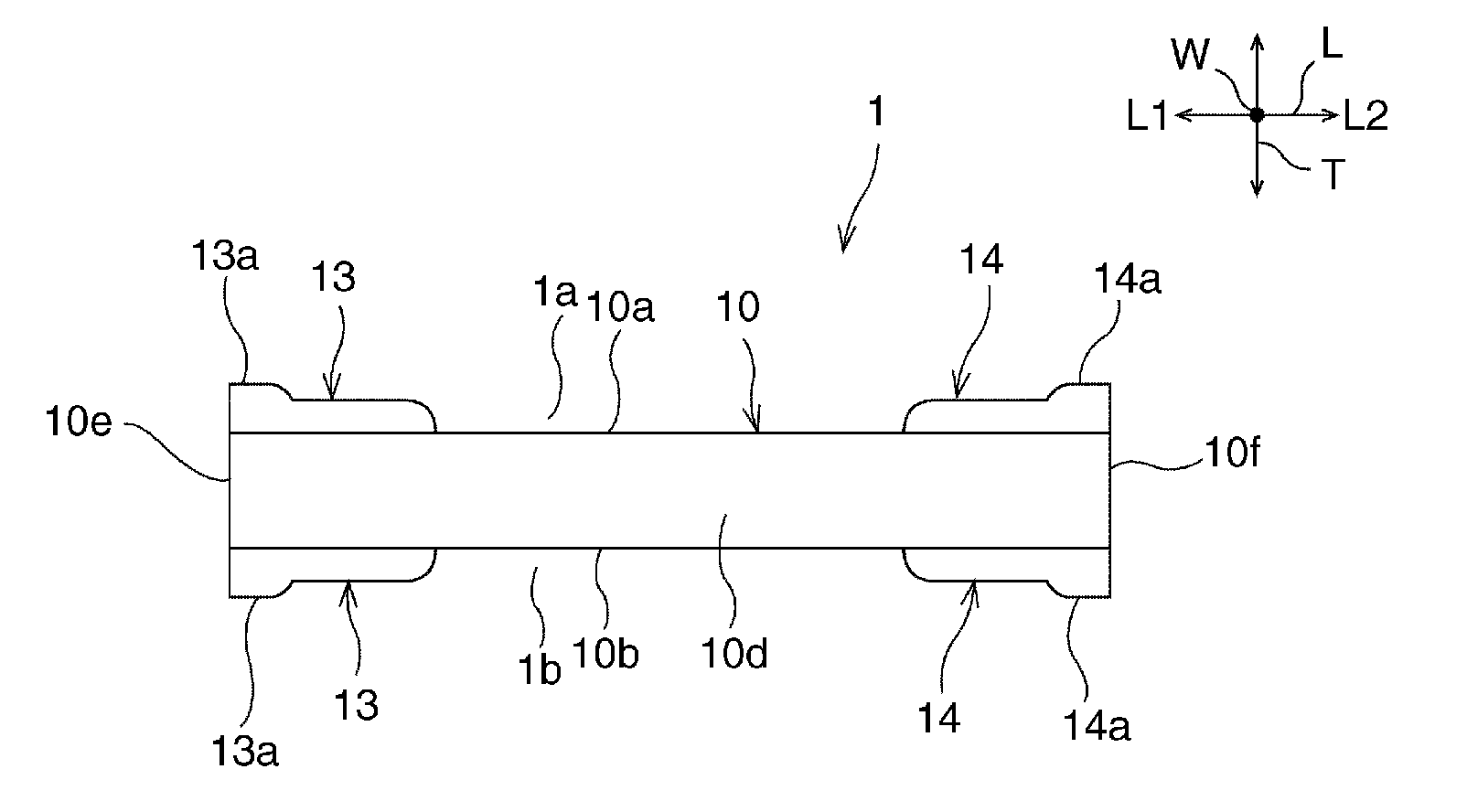

Laminated chip electronic component, board for mounting the same, and packing unit thereof

ActiveUS20130321981A1Reduce noiseFixed capacitor electrodesPiezoelectric/electrostriction/magnetostriction machinesCapacitanceElectronic component

A laminated chip electronic component includes: a ceramic body including internal electrodes and dielectric layers; first and second external electrodes formed to cover both end portions of the ceramic body in a length direction; an active layer in which the internal electrodes are disposed in an opposing manner, while having the dielectric layers interposed therebetween, to form capacitance; upper and lower cover layers formed on upper and lower portions of the active layer in a thickness direction, the lower cover layer having a thickness greater than that of the upper cover layer; and additional electrode layers disposed irrespective of a formation of capacitance within the lower cover layer.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

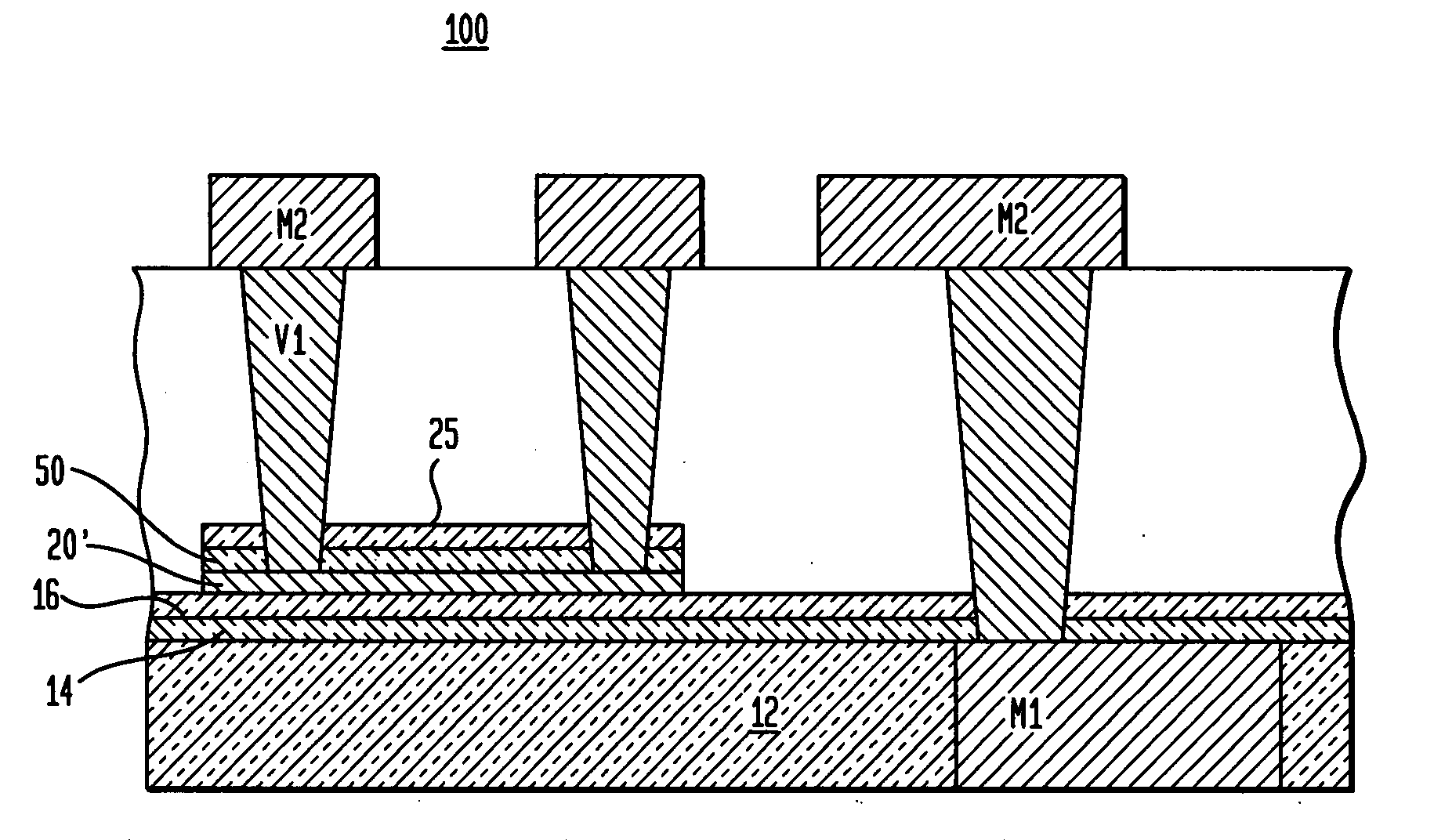

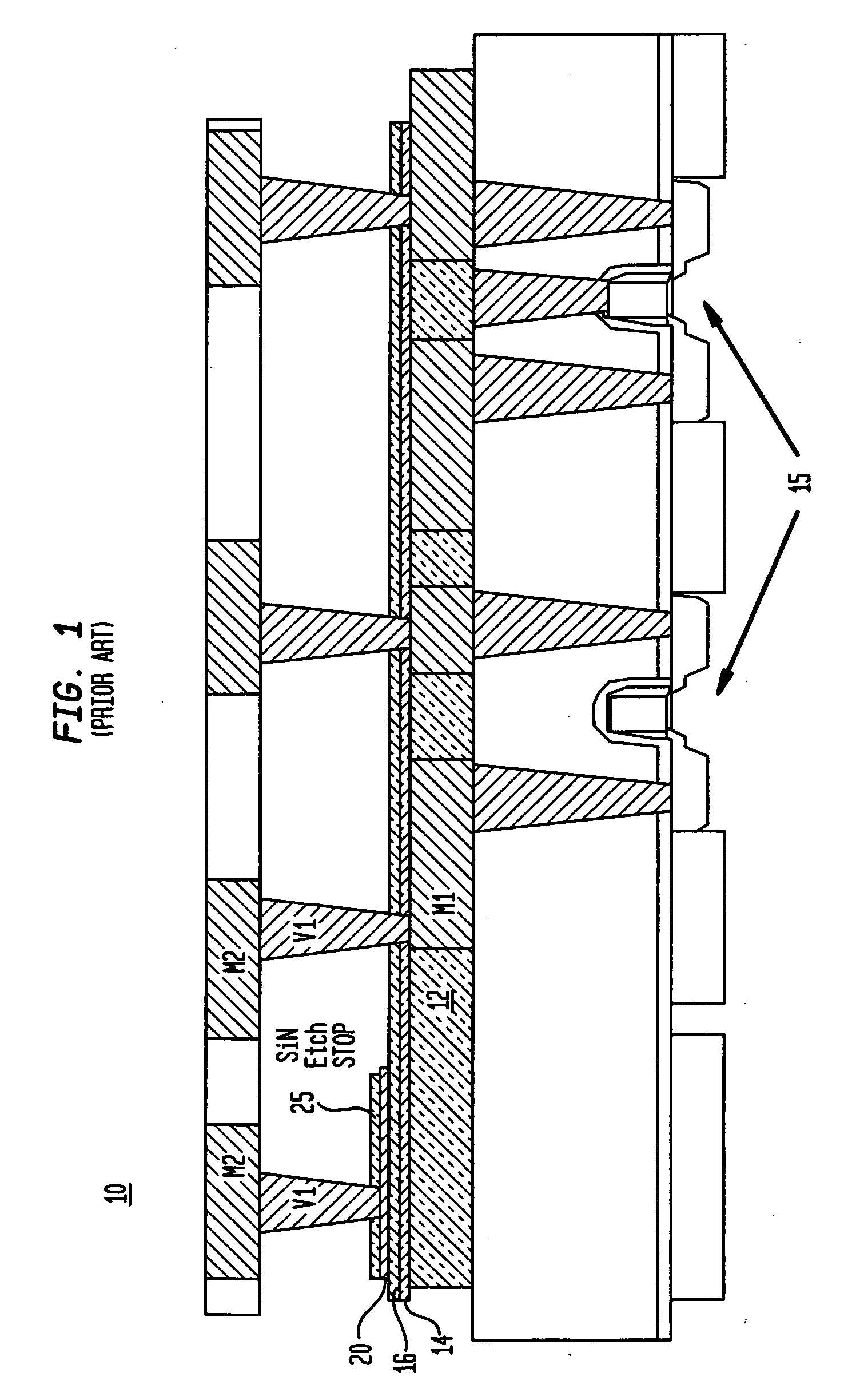

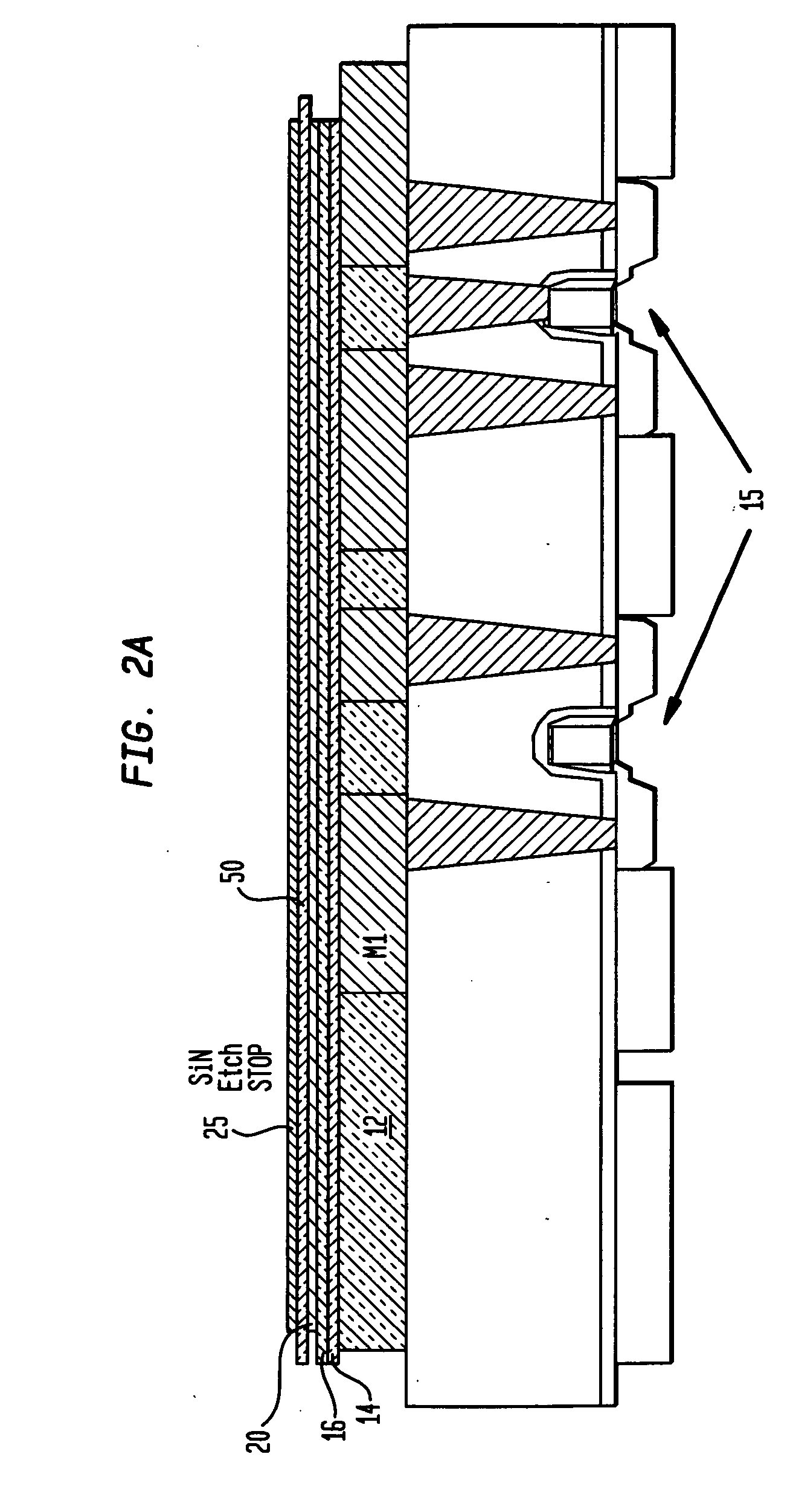

Thin film resistor with current density enhancing layer (CDEL)

ActiveUS20060181388A1Current-carrying capability can be increasedImprove adhesionTransistorElectrostatic/electro-adhesion relaysHigh current densityElectrical conductor

A thin film resistor device and method of manufacture includes a layer of a thin film conductor material and a current density enhancing layer (CDEL). The CDEL is an insulator material adapted to adhere to the thin film conductor material and enables the said thin film resistor to carry higher current densities with reduced shift in resistance. In one embodiment, the thin film resistor device includes a single CDEL layer formed on one side (atop or underneath) the thin film conductor material. In a second embodiment, two CDEL layers are formed on both sides (atop and underneath) of the thin film conductor material. The resistor device may be manufactured as part of both BEOL and FEOL processes.

Owner:GLOBALFOUNDRIES US INC

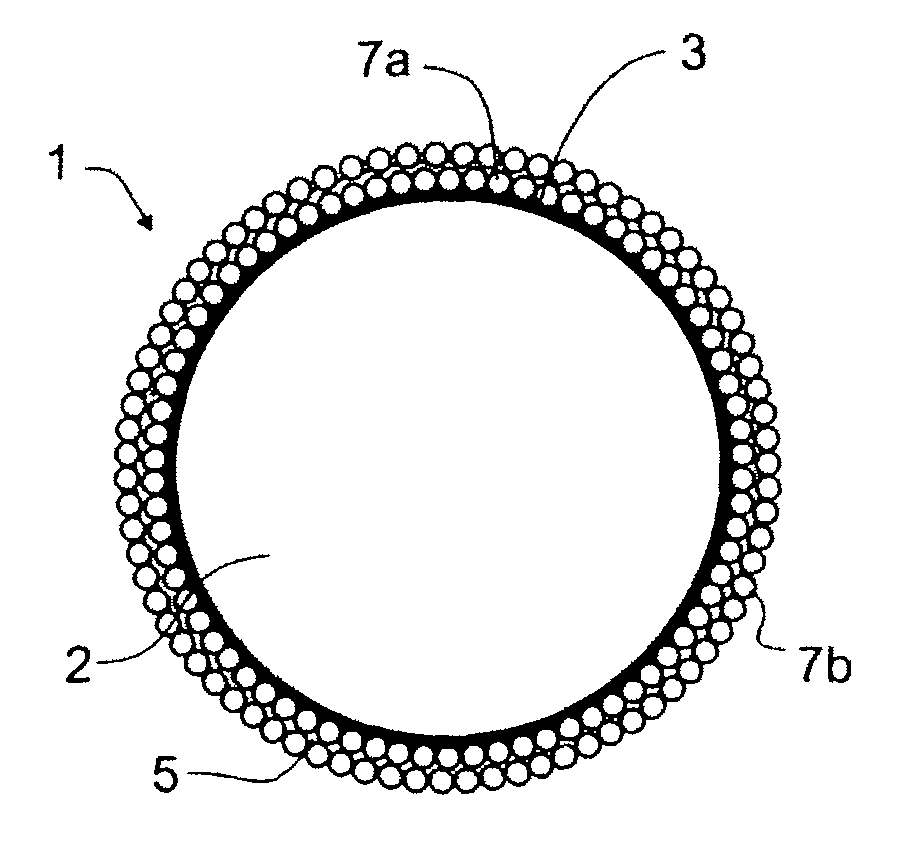

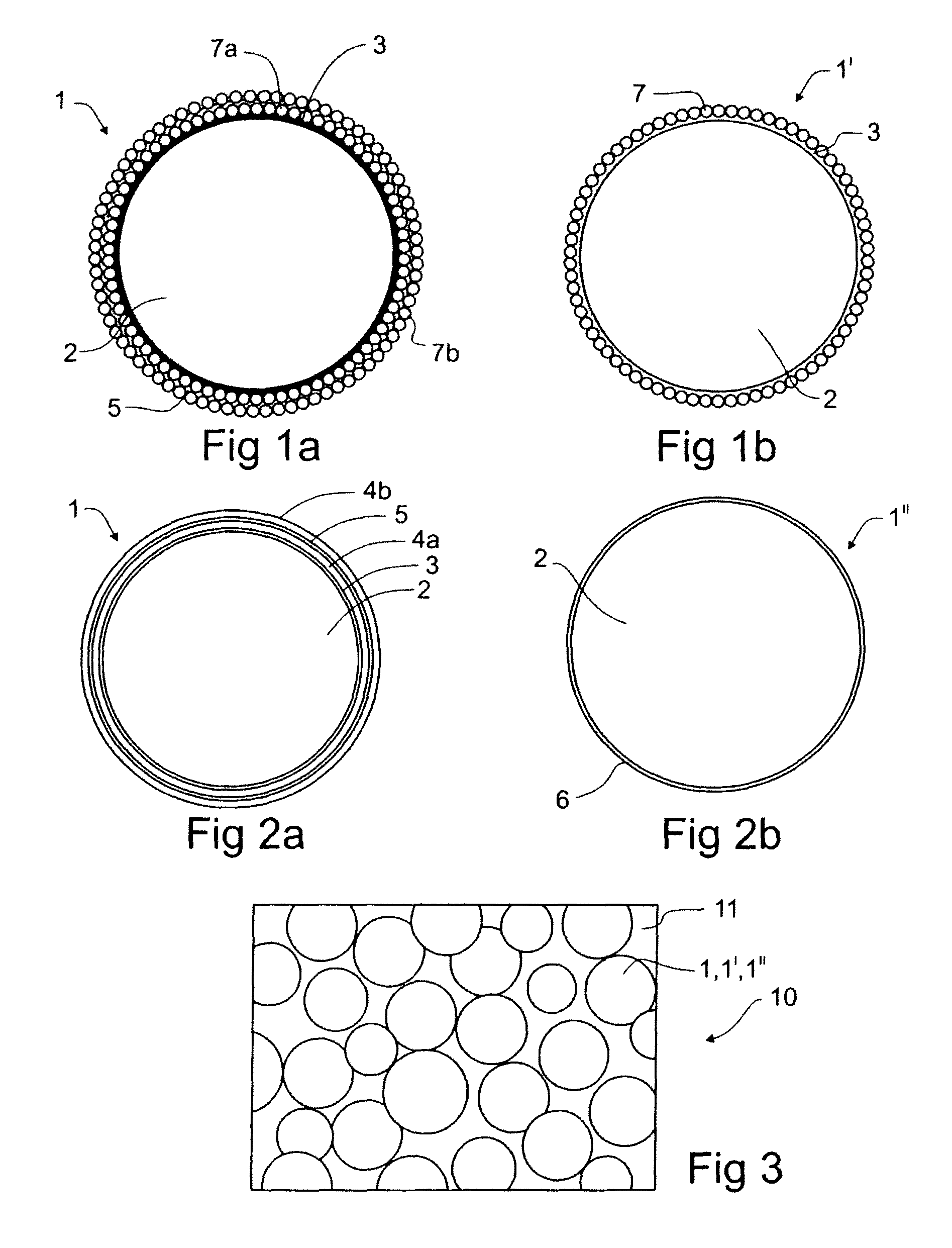

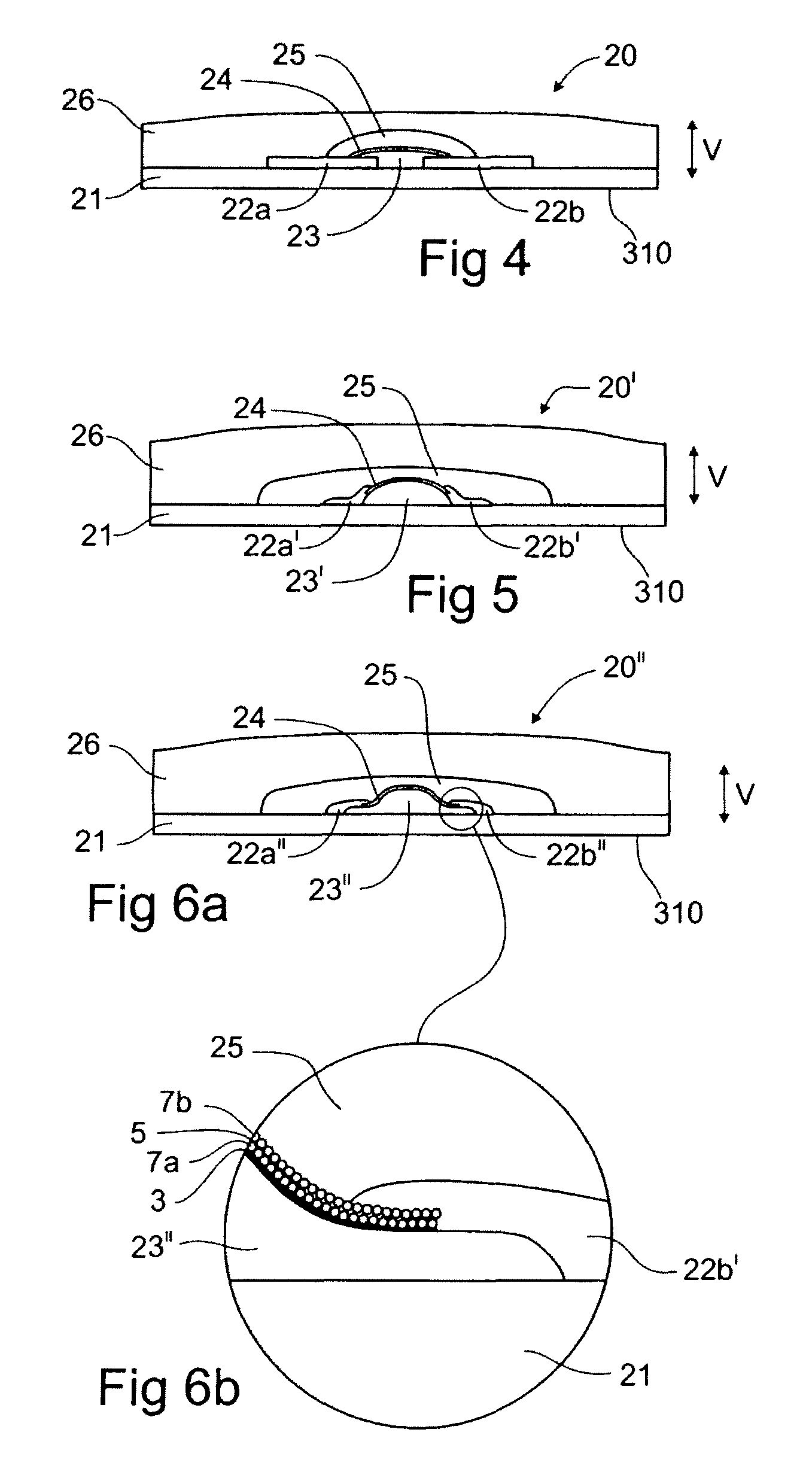

Elastomeric particle having an electrically conducting surface, a pressure sensor comprising said particles, a method for producing said sensor and a sensor system comprising said sensors

ActiveUS9027408B2Low costReduced creep, hysteresis and/or electrical agingPneumatic massageFluid pressure measurement using ohmic-resistance variationElastomerSensor cluster

An elastomeric particle (1, 1, 1″) comprises a non-conducting elastomeric body (2) having an electrically conducting surface (4a, 4b, 6). Pressure sensor elements (20, 20′, 20″; 30, 30′, 30″, 30′″) comprising such elastomeric particles are disclosed, as well as sensor clusters (50″, 50′″, 50IV, 50V, 50VI, 50VII, 70) comprising such sensor elements. There is also disclosed a pressure sensor element (40, 40′, 40″, 40′″, 40IV, 40V, 40VI, 40VII), comprising a resistive element (44, 44′, 44″) providing a conduction path, a first electrode (42a, 42a-1, 42a-2, 42a-3, 42a-4, 42a-5, 42a-6), connected to the resistive element, a second electrode (42b, 42b′), which in a quiescent state is spaced from said first electrode, wherein the second electrode, when the pressure sensor element is subjected to a pressure, is arranged to contact said first electrode or said resistive element. Systems comprising such sensor elements and sensor clusters are disclosed, as well as methods of their fabrication.

Owner:SWELLING SOLUTIONS

Electronic component and method for manufacturing the same

ActiveUS20150084487A1Contact member manufacturingPiezoelectric/electrostriction/magnetostriction machinesInsulation layerOptoelectronics

In an electronic component, an outer electrode includes a sintered layer including a sintered metal, a reinforcement layer not containing Sn but including Cu or Ni, an insulation layer, and a Sn-containing layer. The sintered layer extends from each end surface of an element assembly onto at least one main surface thereof to cover each end surface of the element assembly. The reinforcement layer extends on the sintered layer and covers the sintered layer entirely. The insulation layer is directly provided on the reinforcement layer at each end surface of the element assembly, extends in a direction perpendicular or substantially perpendicular to a side surface of the element assembly, and defines a portion of a surface of the outer electrode. The Sn-containing layer covers the reinforcement layer except for a portion of the reinforcement layer that is covered by the insulation layer, and defines another portion of the surface of the outer electrode.

Owner:MURATA MFG CO LTD

Resistive elements using carbon nanotubes

ActiveUS20070236325A1Easy parameter controlFunction increaseCurrent responsive resistorsSolid-state devicesBulk resistanceCarbon nanotube

Resistive elements include a patterned region of nanofabric having a predetermined area, where the nanofabric has a selected sheet resistance; and first and second electrical contacts contacting the patterned region of nanofabric and in spaced relation to each other. The resistance of the element between the first and second electrical contacts is determined by the selected sheet resistance of the nanofabric, the area of nanofabric, and the spaced relation of the first and second electrical contacts. The bulk resistance is tunable.

Owner:NANTERO

Multilayer varistor

A multilayer varistor comprising a varistor chip body having alternately stacked ceramic layers and internal electrode layers is provided. The ceramic layer is composed of a composite oxide containing Ti and / or Zr and Ba as a main component and Si and / or Al as a subordinate component, substantially free of Cr, and has a perovskite phase. The internal electrode layer is composed of a conductor containing a base metal such as Ni or Ni alloy as a main component. The varistor is used in an electric circuit for suppressing noise.

Owner:TDK CORPARATION

Varistor comprising an electrode having a protruding portion forming a pole and protection device comprising such a varistor

ActiveUS8378778B2Efficient conductionExtended reaction timeCurrent responsive resistorsEmergency protective arrangement detailsCopperVaristor

Owner:ABB FRANCE SAS

Metal oxide varistor with a heat protection

InactiveUS20080129440A1Go fastFacilitate speed of actionCurrent responsive resistorsResistor cooling/heating/ventillationElectrical resistance and conductanceEngineering

A metal oxide varistor integrally formed with a heat protection structure that will automatically go to open circuit in conditions of overheating due to sustained over-voltages. The metal oxide varistor integrally formed with a heat protection structure has a body, an insulation bracket, a number of terminals and a fuse. The insulation bracket is deposited on the body and has a number of slots. The fuse connects to the body and one of the terminals. The fuse is mounted one of the slots of the insulation bracket. The fuse reacts to the overheating timely and the melting fuse spreads quickly with the assistance of capillary action evolved by the slots of the insulation bracket to speed up the action to go to open circuit in against damage due to sustained over-voltages.

Owner:THINKING ELECTRONICS INDAL

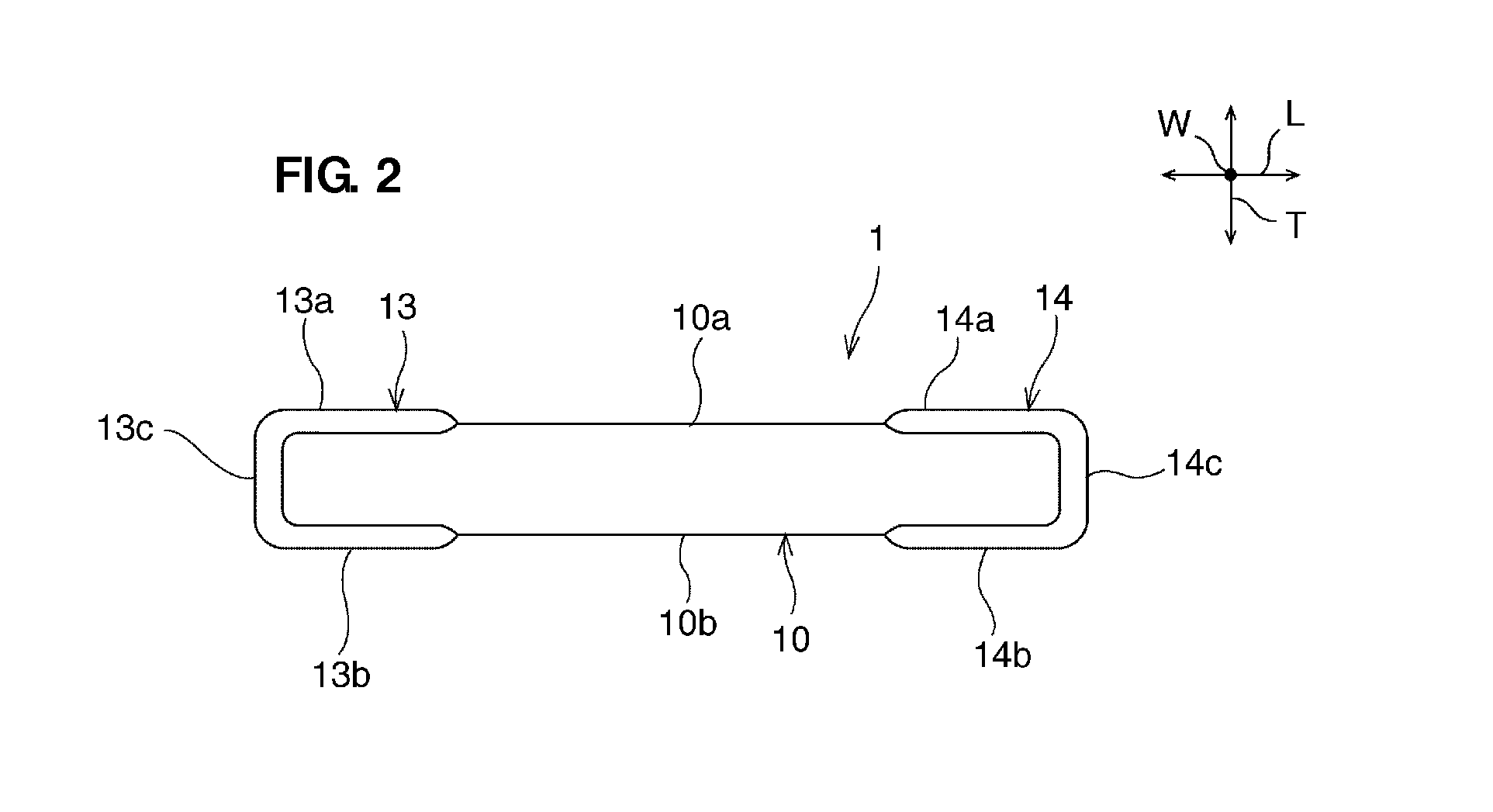

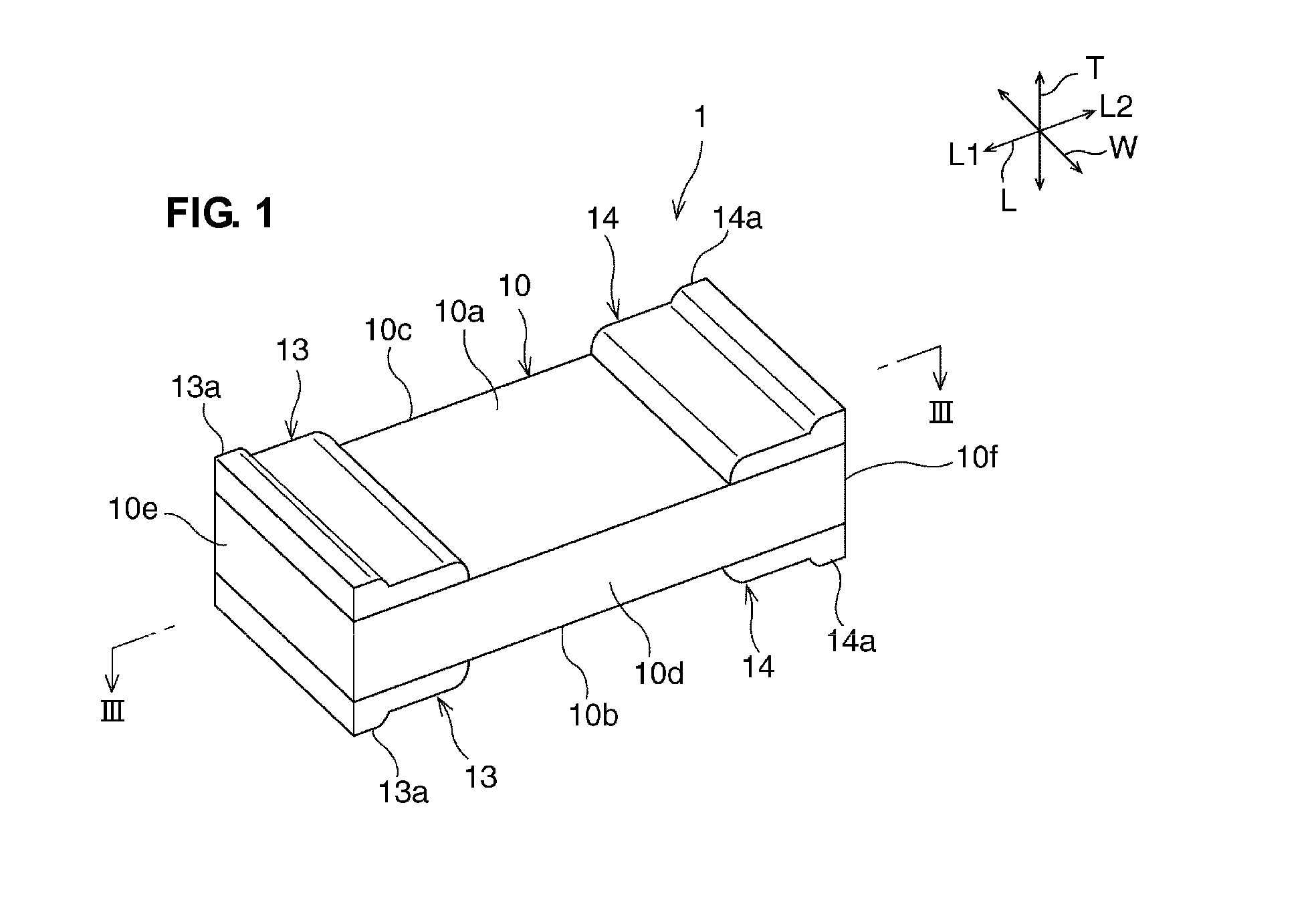

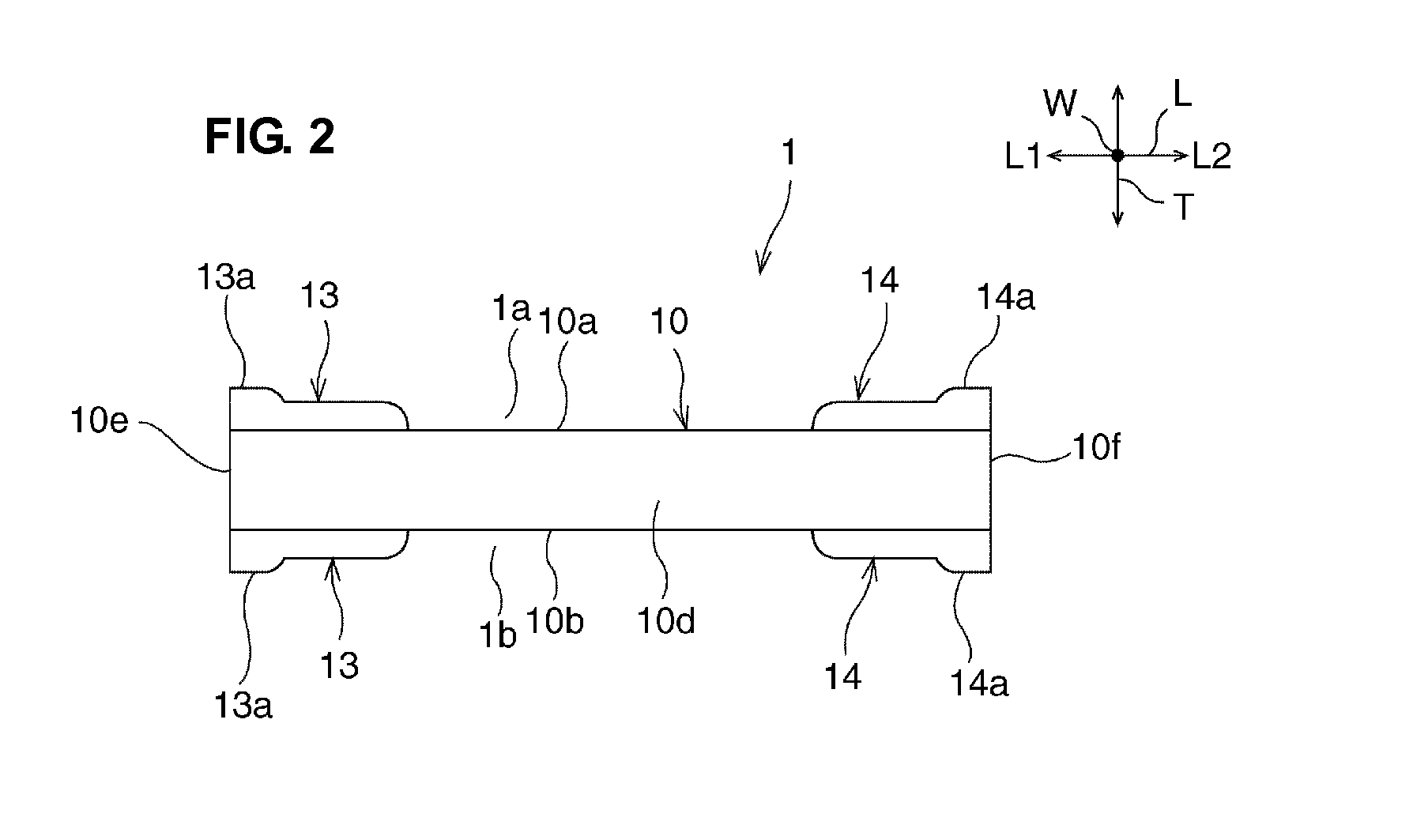

Ceramic electronic component and wiring board

ActiveUS20120018204A1Improve reliabilityBonded firmlyPiezoelectric/electrostriction/magnetostriction machinesSemiconductor/solid-state device detailsElectronic componentMaterials science

A ceramic electronic component includes a ceramic element body having a substantially rectangular parallelepiped shape, and first and second external electrodes. The first and second external electrodes are provided on a first principal surface. Portions of the first and second external electrodes project further than the other portions in a thickness direction. A projecting portion of the first external electrode is provided at one end of the first external electrode in a length direction and a second projecting portion of the second external electrode is provided at another end of the second external electrode in the length direction. Thus, a concave portion is provided between the projecting portions, and a portion of the first principal surface provided between the first and second external electrodes is exposed.

Owner:MURATA MFG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com