Patents

Literature

44results about How to "Improve PTC Strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polymer-carbon nanotube-carbon black composite temperature self-regulating positive temperature coefficient (PTC) electric heating material

InactiveCN102344598ALow resistivityImprove PTC StrengthPositive temperature coefficient thermistorsPigment treatment with macromolecular organic compoundsPolyvinylidene fluorideTemperature coefficient

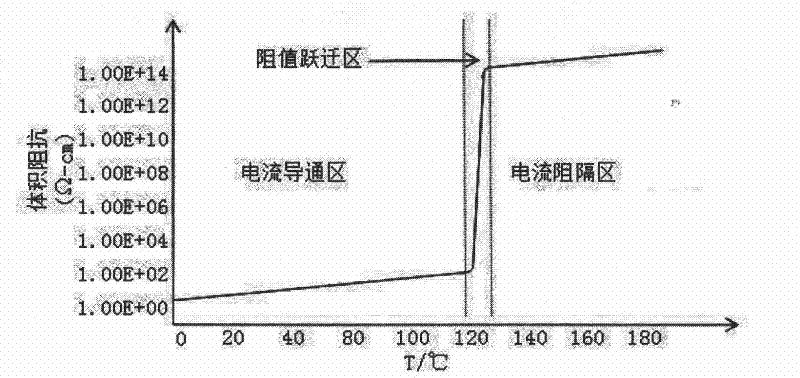

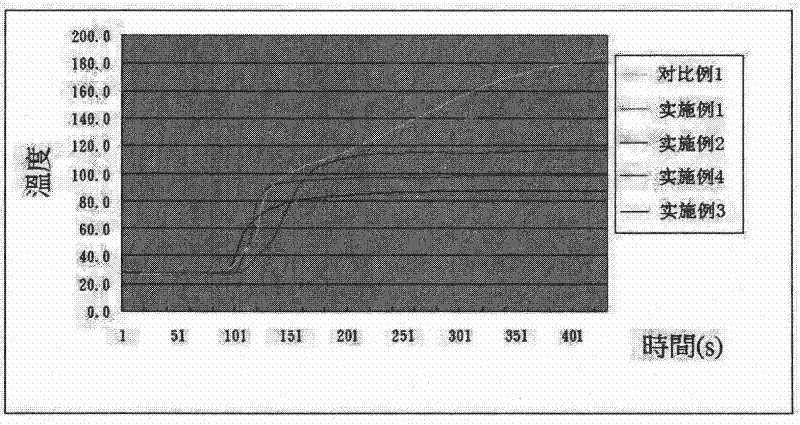

The invention discloses a polymer-carbon nanotube-carbon black composite temperature self-regulating positive temperature coefficient (PTC) electric heating material. The polymer-carbon nanotube-carbon black composite temperature self-regulating PTC electric heating material has positive temperature coefficients and high PTC intensity. The polymer-carbon nanotube-carbon black composite temperature self-regulating PTC electric heating material comprises: by weight, 35 to 75% of one or more of high-density polyethylene, low-density polyethylene, ethylene-vinyl acetate copolymer, ethylene-ethyl acrylate copolymer, nitrile rubber buna, epoxy resins and polyvinylidene fluoride, 15 to 55% of carbon black and carbon nanotubes, 3 to 12% of an inorganic filling material, and 0.02 to 0.1% of an antioxidant. The above raw materials are mixed, then are subjected to processing molding by a banbury or a double-screw extruder, and are subjected to radiation crosslinking to form the polymer-carbon nanotube-carbon black composite temperature self-regulating PTC electric heating material with high PTC intensity. The polymer-carbon nanotube-carbon black composite temperature self-regulating PTC electric heating material has high PTC intensity and thus a leakage current is low and security and heat stability are good. In an electric warming respect, the polymer-carbon nanotube-carbon black composite temperature self-regulating PTC electric heating material is widely utilized in the fields of temperature self-regulating heaters, over-current protection and temperature sensors.

Owner:谢志军

PTC thermistor and substrate applied therein and manufacturing method thereof

InactiveCN102176360AUniform cross-linked structurePromote absorptionPositive temperature coefficient thermistorsHigh resistanceCross-link

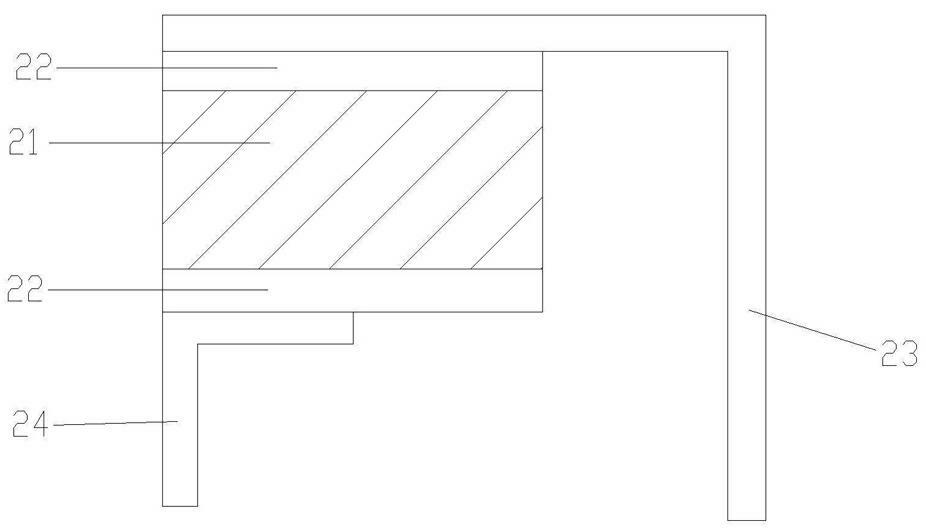

A PCT thermistor comprises a substrate and two tinsel-shaped electrodes which are combined with two surfaces of the substrate. The substrate is made of the following components in weight percentage: 28-55% of high-polymer material; 22-32% of conductive filling material; 13-46% of auxiliary filling material; and 1-5% of auxiliary agent in processing. The high-polymer material is obtained through mixing one or multiple materials selected from: polyethylene, polypropylene, maleic anhydride grafted polyethylene, ethane-vinyl acetate copolymer, ethane-acrylic acid copolymer, polyvinylidene fluoride, polycaprolactam, polyhexamethylene adipamide, polydecamethylene sebacamide and polyundecylamide. The auxiliary agent in processing is one component or a mixture of multiple components selected from: an anti-oxidant, a coupling agent, a cross-linking agent and a sensitized cross-linking agent. The sensitized cross-linking agent is one component or multiple components selected from the unsaturated compounds of multiple functional groups with higher decomposition temperature. The PTC thermistor of the invention has the following advantages: high strength, and high resistance for multiple times of large current impact.

Owner:深圳市长园维安电子有限公司

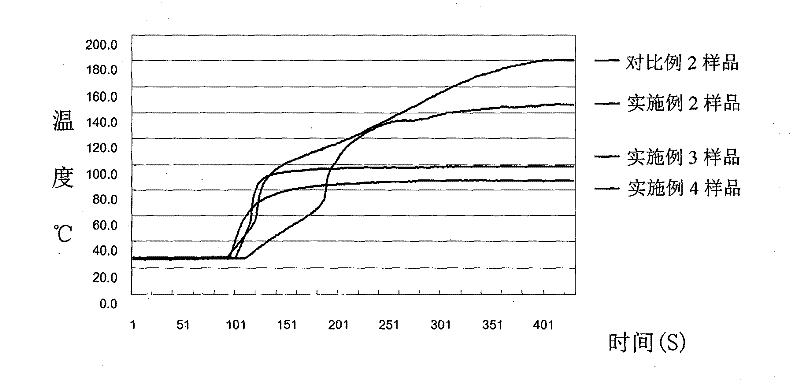

Positive temperature coefficient (PTC) self-temperature-control hand warmer and manufacturing method thereof

InactiveCN102342869ASimple structureEasy to manufactureTherapeutic coolingTherapeutic heatingElectricityState of art

The invention discloses a hand warmer using composite conducting macromolecules as heating chips and a manufacturing method for the hand warmer. Compared with the prior art, the hand warmer has a simple structure and is easy and convenient to manufacture, wherein the composite conducting macromolecule heating chips have high PTC intensity, little current leakage and high safety; and the hand warmer has a self-temperature-control function, so a temperature-control circuit system is not required. The chip composite material adopts different polymers as matrixes to realize limited temperature self-control of different temperature, and adopts different polymer-based heating elements, which are connected in parallel, to realize different self-control temperature of the same hand warmer. The hand warmer can heat by plugging into a socket and through a self-contained battery, has continuous heating and intermittent heating functions, and can be used outdoors for a long time.

Owner:谢志军

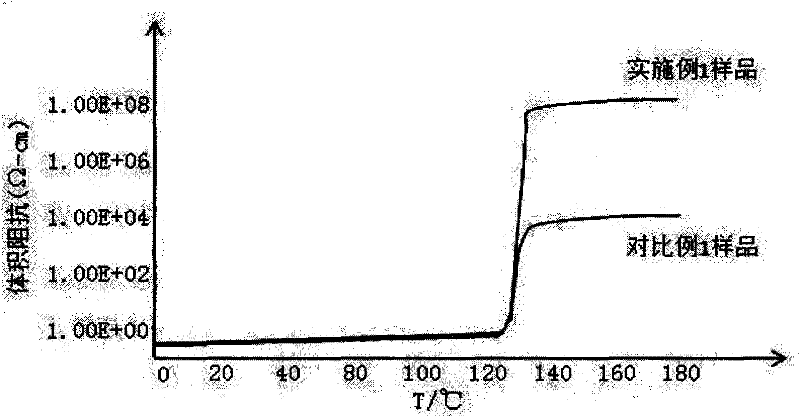

Polymer matrix composite material with high PTC strength and stability and preparation method thereof

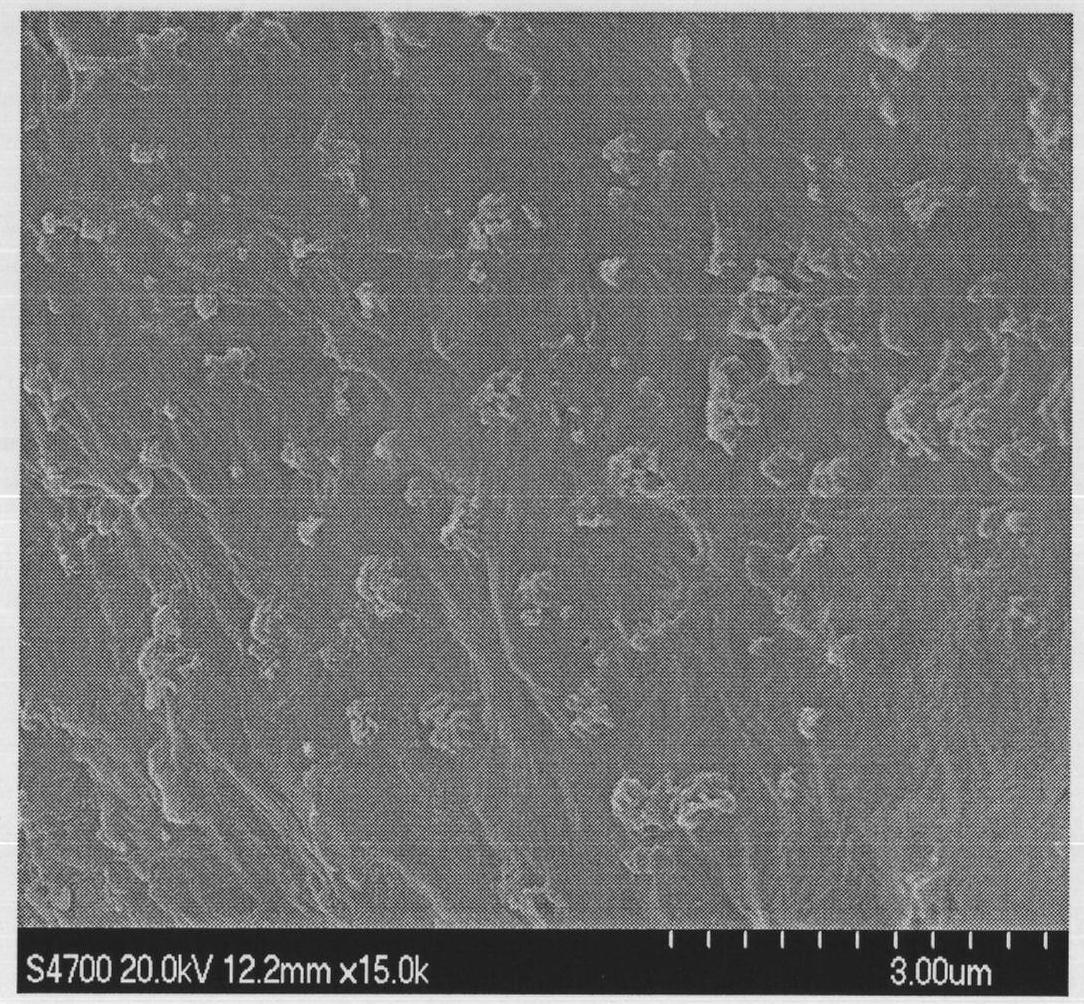

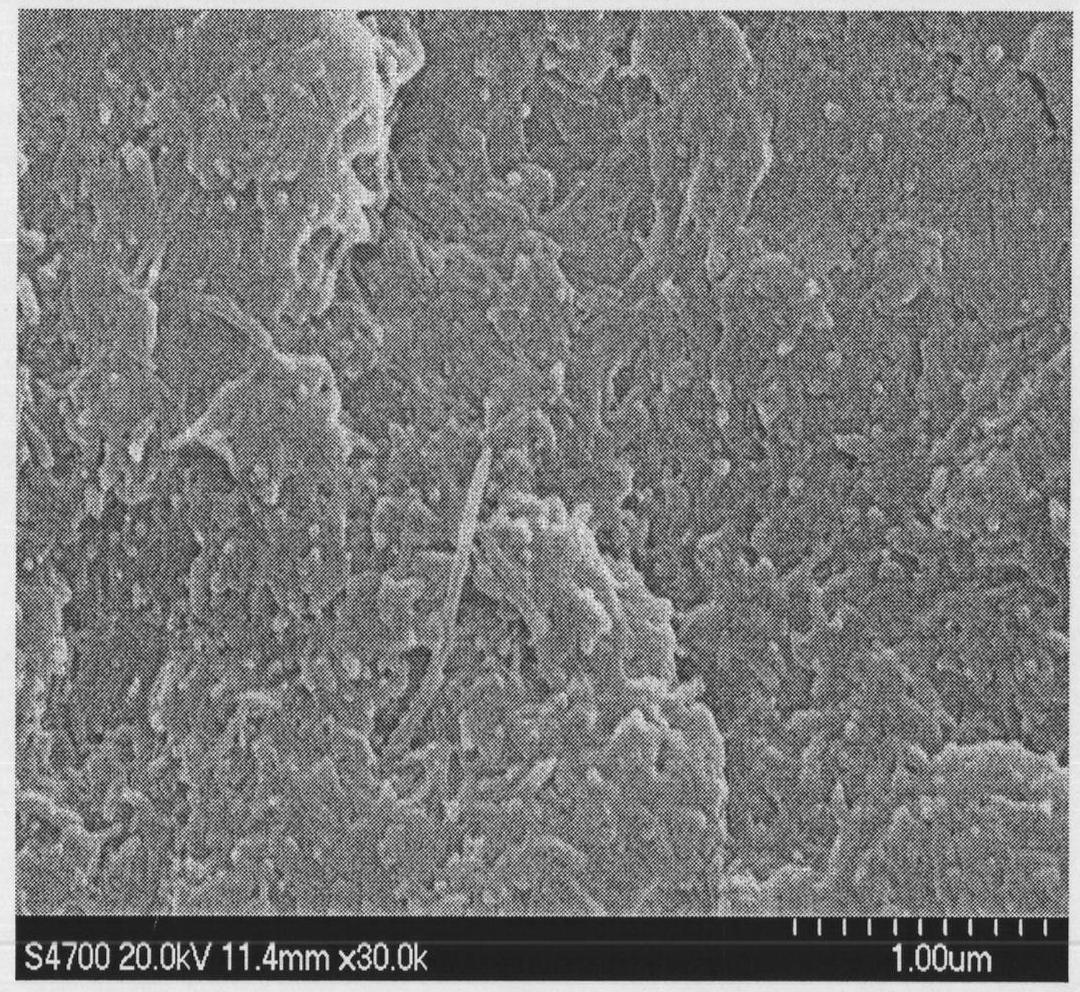

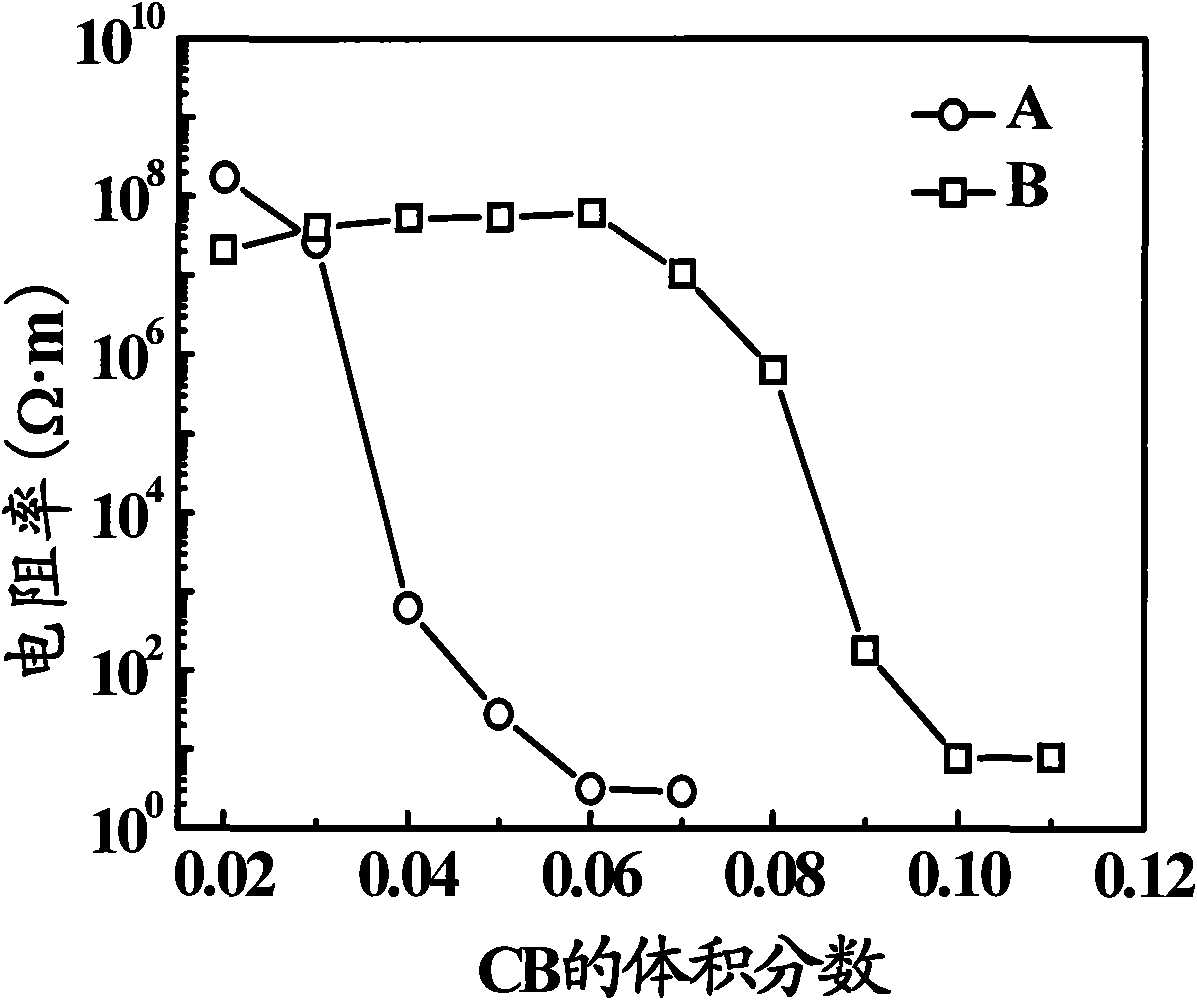

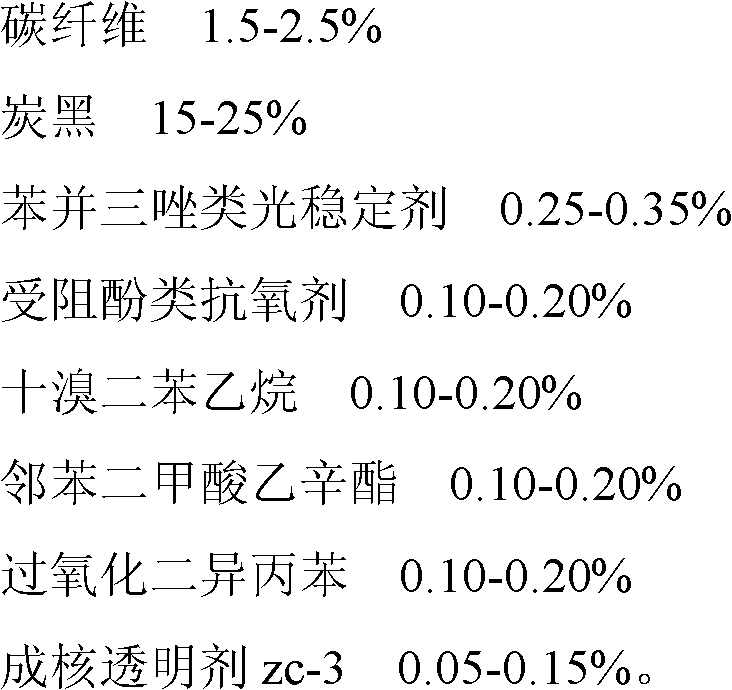

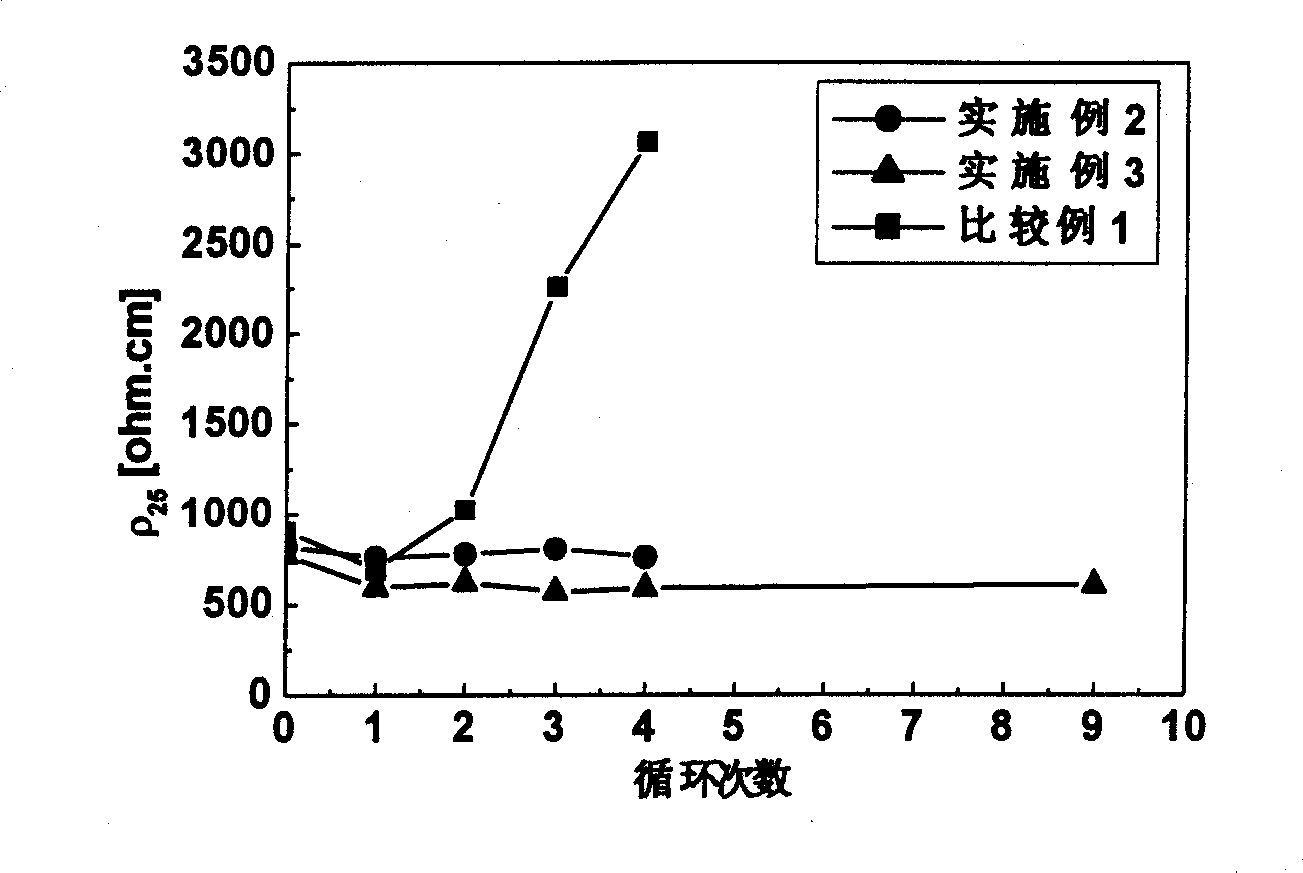

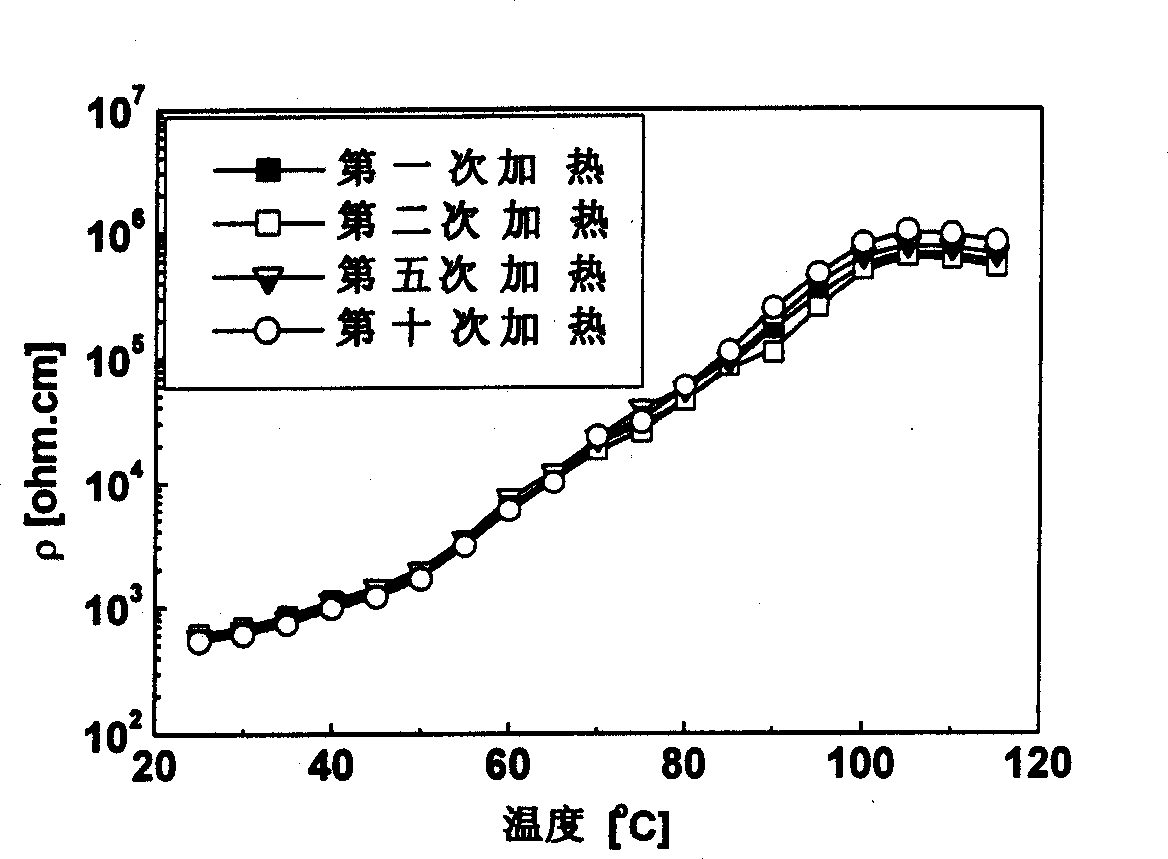

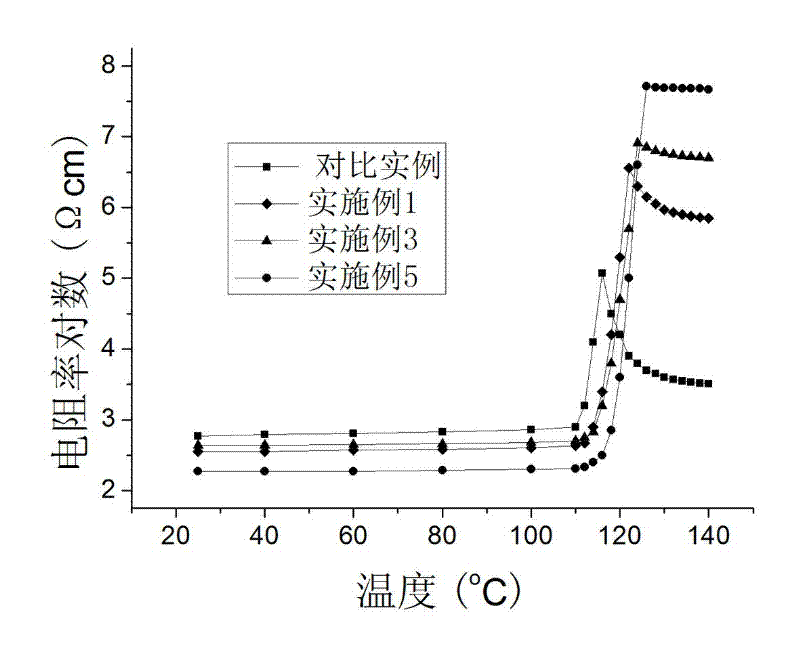

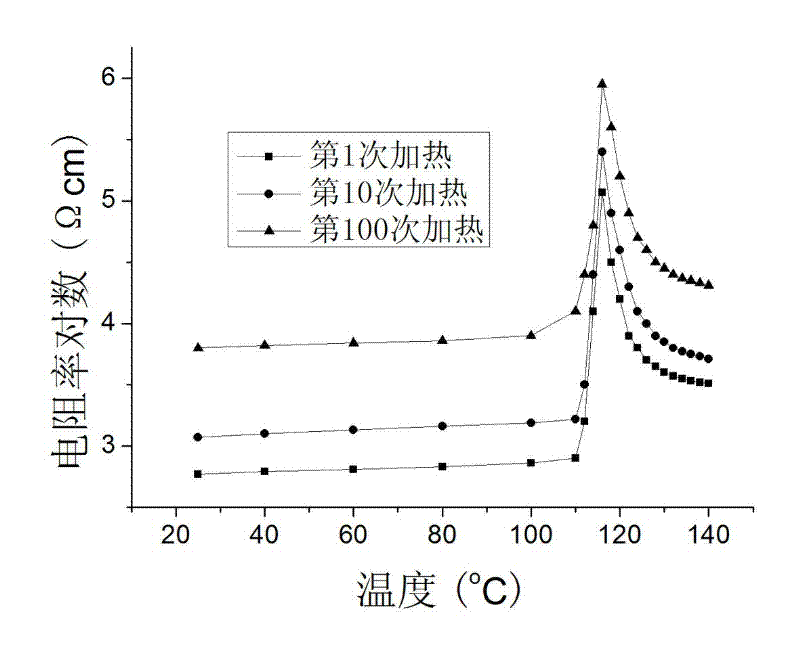

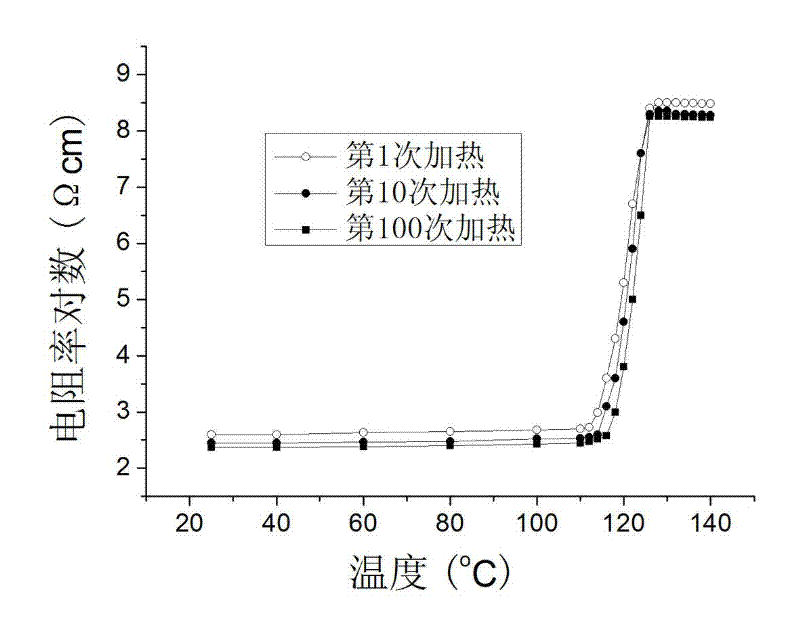

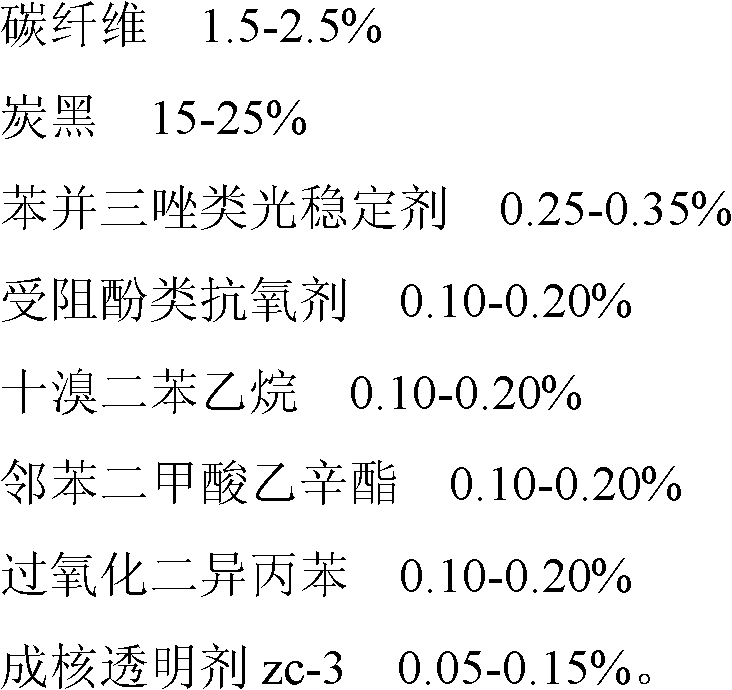

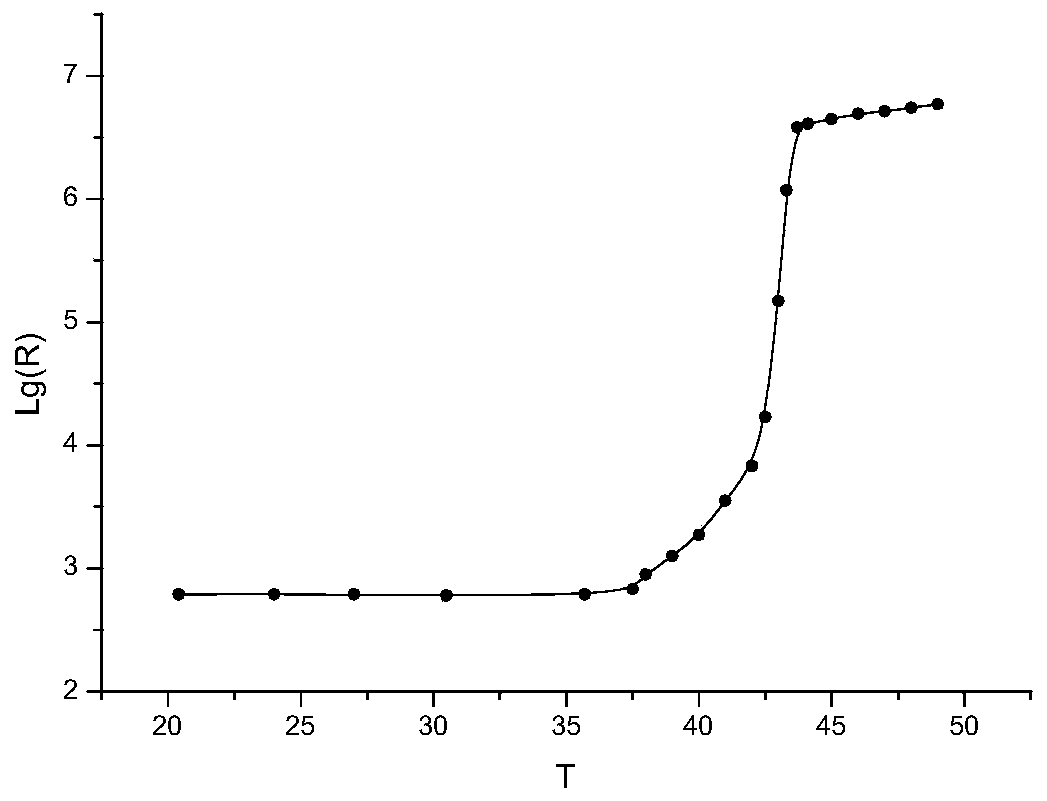

The invention discloses a polymer matrix composite material with high PTC strength and stability and a preparation method thereof, and the composite material comprises UHMWPE and PVDF, CB and MWNT conductive filling materials which are treated by surface treatment by a titanate coupling agent, and an antioxidant 1010; the preparation method comprises the following steps: performing surface treatment of the CB and MWNT conductive filling materials by the titanate coupling agent, performing vacuum drying of PVDF and UHMWPE with a volume ratio of 1:1, adding PVDF into a torque rheometer, heating and melting for 2 min, adding another matrix of UHMWPE and the antioxidant 1010, wherein the amount of the antioxidant 1010 is 1% of the total mass of the matrix; mixing the mixture of the two matrixes for 10 min, adding the filling materials, mixing at 250 DEG C for 15 min; after melt blending, performing hot pressing with a constant temperature of 250 DEG C and a constant pressure of 18 MPa for 10 min to obtain the sample. The composite material of the invention has good conductivity and low room-temperature conductivity, and has a conductivity of up to 10-1 near a percolation threshold; the conductivity of the composite material can be changed by adjusting the contents of the filling materials in the composite material; the composite material has high PTC strength, good repetition stability, and reduced NTC effect.

Owner:BEIJING UNIV OF CHEM TECH

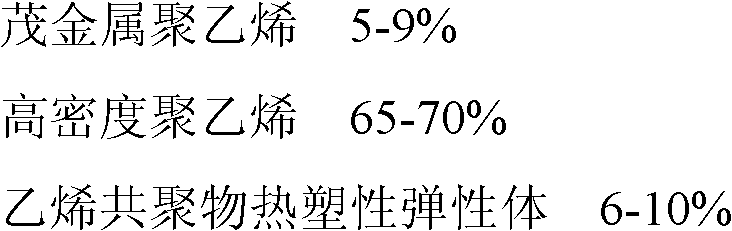

PTC (Positive Temperature Coefficient) high polymer heating material for self-limiting temperature electric tracing band

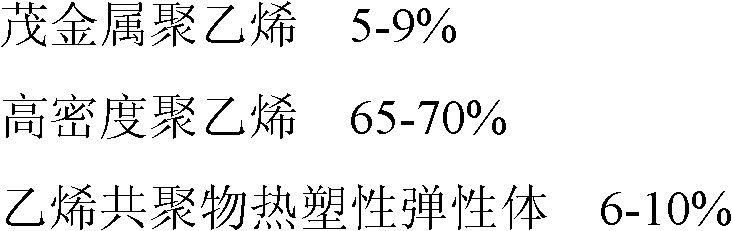

InactiveCN102604189AImprove PTC StrengthImprove tensile propertiesHeating element shapesPositive temperature coefficient thermistorsFiberCarbon fibers

The invention discloses a PTC (Positive Temperature Coefficient) high polymer heating material for a self-limiting temperature electric tracing band, which is prepared from the following raw materials in percentage by weight: 5 to 9 percent of metallocene polyethylene, 65 to 70 percent of high-density polyethylene, 6 to 10 percent of vinyl copolymer thermoplastic elastomer, 1.5 to 2.5 percent of carbon fibers, 15 to 25 percent of carbon black, 0.25 to 0.35 percent of benzotriazole light stabilizer, 0.10 to 0.20 percent of hindered phenol antioxygen, 0.10 to 0.20 percent of decabromodiphenylethane, 0.10 to 0.20 percent of diisooctyl ortho-phthalate, 0.10 to 0.20 percent of dicumyl peroxide and 0.05 to 0.15 percent of nucleating transparent agent zc-3. According to the invention, the elasticity modulus of the PTC material is improved, the maximum stress and the stress of a breaking point of the PTC material are increased, so that the PTC strength and the stretch resistance performance of the PTC heating material are improved.

Owner:WUHU XUHUI ELECTRIC NEW MATERIAL

Process for preparing electrically conductive high-molecular composite material by in-situ graft to modify electrically conductive filler

InactiveCN1363629AInhibition of NTC effectImproved repetitive stabilityPre treatmentElectrically conductive

An electrically conductive composite high-molecular material with positive temp coefficient (PTC) for heater with self limitation of temp and over-current protection element is prepared through pre-treating the electrically conductive filler by reactive treating agent and chemically graft reaction between said filler, treating agent and high-molecular base body. Its advantages include high adhesive to metallic electrode, high PTC and high stability.

Owner:SUN YAT SEN UNIV

Low-temperature PTC conducting composition, PTC over-current protection device and manufacturing method of PTC over-current protection device

ActiveCN103762012ALower operating temperatureImprove PTC StrengthNon-conductive material with dispersed conductive materialPositive temperature coefficient thermistorsElectrical resistance and conductanceEngineering

The invention relates to a low-temperature PTC conducting composition, a PTC over-current protection device and a manufacturing method of the PTC over-current protection device. The low-temperature PTC conducting composition comprises, by weight, 40%-55% of organic polymer, 40%-55% of conducting carbon black and 1%-10% of voltage-resistant reinforcing filler. The PTC over-current protection device comprises the low-temperature PTC conducting composition. The PTC over-current protection device has an operating temperature lower than 80 DEG C, high PTC strength and good resistance stability, thereby being capable of achieving good over-current and over-temperature protection for circuits in a low-temperature environment.

Owner:SHENZHEN HUIRUI ELECTRONICS MATERIALS

Positive plate and lithium ion battery containing positive plate

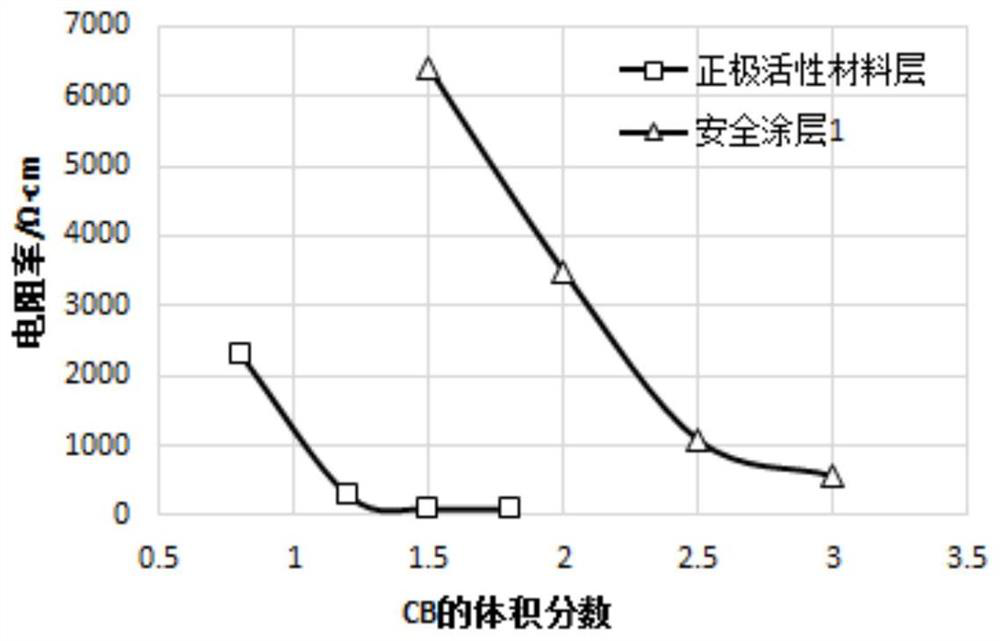

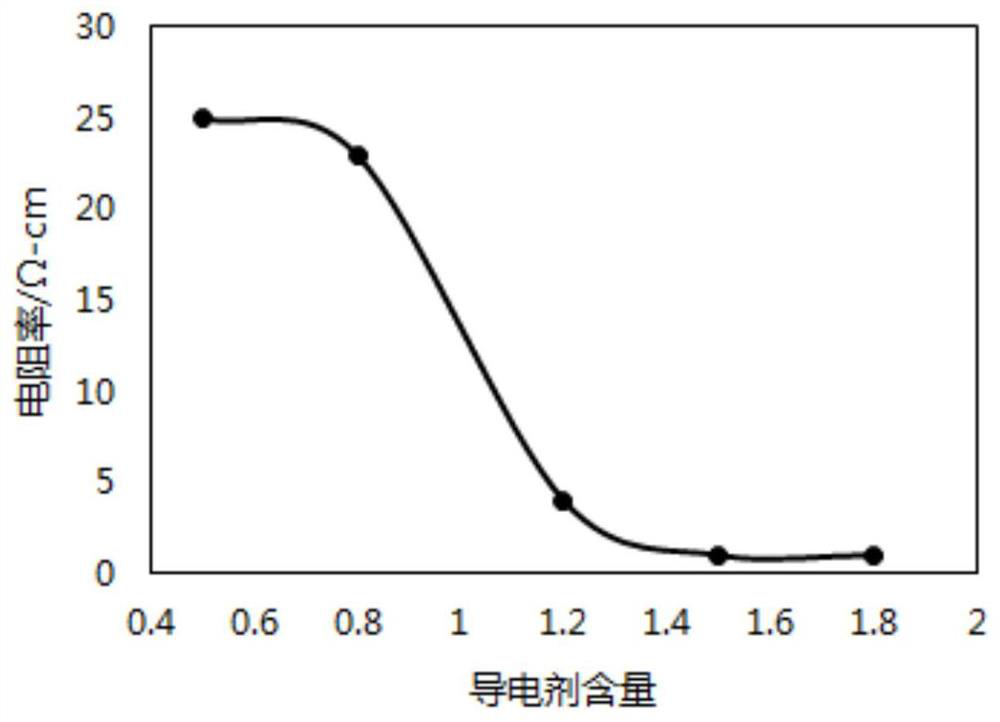

ActiveCN111900392AIncrease energy densityIncreased seepage thresholdPositive electrodesSecondary cells servicing/maintenanceHigh energyPhysical chemistry

The invention provides a positive plate and a lithium ion battery containing the positive plate. The safety of the battery cell is improved by controlling the seepage thresholds of the safety coatingcoating the surface of the positive current collector and the positive active material layer, and meanwhile, relatively high energy density and excellent electrical properties are ensured. Particularly, the seepage threshold value of the positive active material layer is small, and the addition amount of the conductive agent is small, so that a good electron path can be ensured, and the energy density of the positive plate can be increased.

Owner:ZHUHAI COSMX BATTERY CO LTD

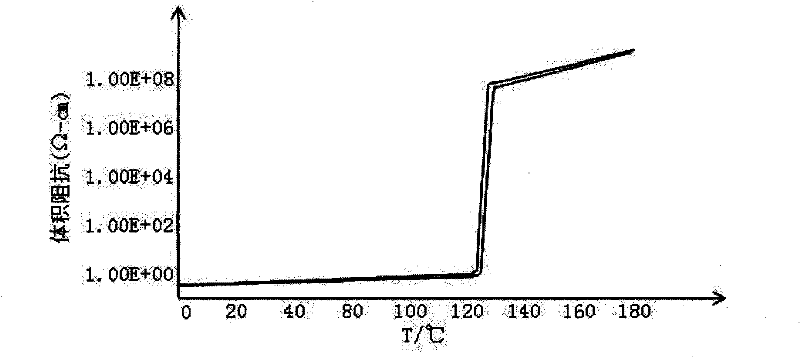

Positive temperature coefficient material and thermistor containing the material

ActiveCN102260385ALower internal resistanceImprove PTC StrengthPositive temperature coefficient thermistorsHigh concentrationElectrical conductor

The invention provides a positive temperature coefficient material, the material comprises resin, a conductive filler, a non-conductive filler and an auxiliary agent, the resin is a mixture composed of one of high-concentration polyethylene, medium-concentration polyethylene, low-concentration polyethylene and polyvinylidene fluoride and 1, 3: 2,4-dibenzylidene sorbitol, the conductive filler is a mixture composed of one of nickel coated copper powder, nickel coated iron powder and nickel coated molybdenum powder and nickel coated silver powder, the non-conductive filler is a mixture composedof one of magnesium hydroxide and magnesium oxide and one of aluminum hydroxide and alumina, simultaneously a positive temperature coefficient thermistor is provided in the invention, the thermistor comprises a first conductor, and the positive temperature coefficient material as well as a second conductive conductor which are successively attached on the first conductor, wherein the positive temperature coefficient material is the positive temperature coefficient material provided in the invention, the positive temperature coefficient thermistor has characteristics of low resistor, high positive temperature coefficient (PCT) strength and good stability.

Owner:BYD CO LTD

Low-resistance PTC (positive temperature coefficient) composite material

The invention discloses a low-resistance PTC (positive temperature coefficient) composite material. The composite material comprises thermoplastic polymers, conductive materials subjected to surface treatment by a coupling agent, inert fillers, compatilizers, antioxidants and a titanate coupling agent. The conductive fillers are carbon black or carbon nano tubes which are subjected to surface treatment by the coupling agent and serve as conductive substances, thus improving the dispersibility of the conductive fillers in a matrix and combinability of the conductive fillers and the matrix, improving the conductivity, reducing the room temperature resistivity of the composite material and improving the property stability of the composite material; therefore the composite material has low resistivity, high PTC strength, good resistance stability and extremely low leakage current and meets the requirements of large current and high voltage.

Owner:ANBANG ELECTRICAL GRP

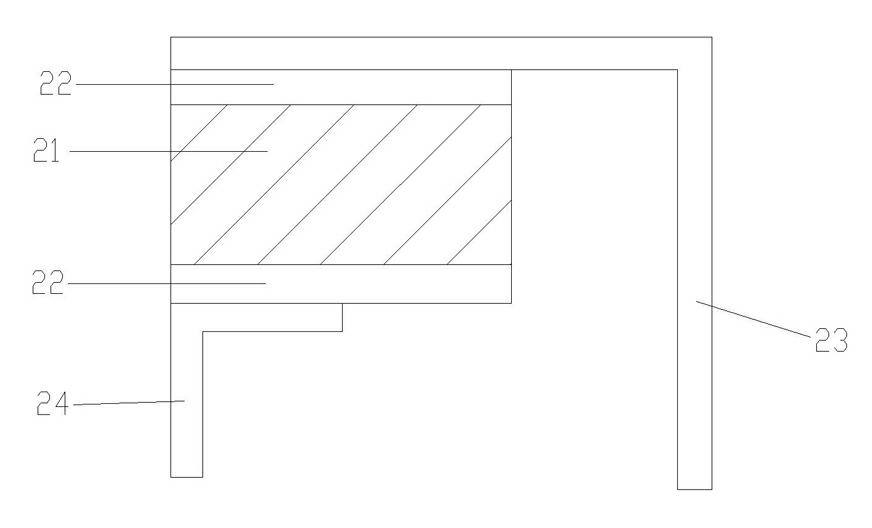

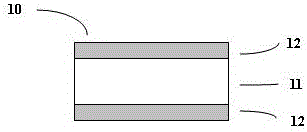

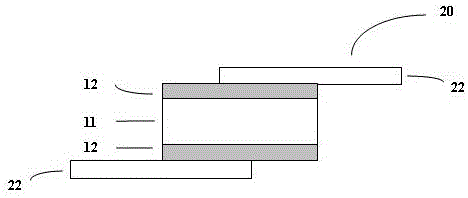

Polymer complex substance with resistance nonlinear positive temperature coefficient effect

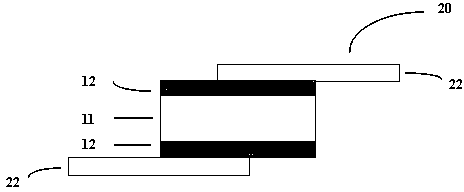

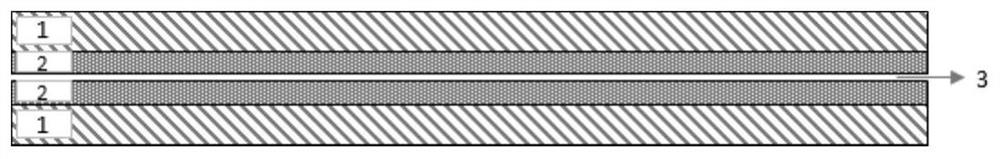

This invention refers to a kind of polymer complex of non-linear positive temperature coefficient effect of resistance and the overflow protection organ of electrocircuit made from this polymer complex and is featured by the following components: polyethylene whose fusion index changes between 0.2g / 10min and 10.0g / 10min and whose density varies from 0.90g / cm3 to 0.99g / cm3, charcoal black, inorganic filler, crosslinking auxiliary agent and antioxidant. The inorganic filler is polar compound with oxygen, and the crosslinking agent is polyfunctional group compound with double bond. This invention makes use of the polymer complex to produce the overflow protection organ of electrocircuit and includes double-decked tinsel and electrode and its feature lies in there is sheet material of polymer complex between the two tinsels and that the tinsels connect with sheet material of polymer complex through hot pressing. The invention has positive temperature coefficient effect of resistance, restrains the NTC effect and has relatively low resistivity at room temperature and high PTC intensity.

Owner:沈守兵

Material with positive temperature coefficients

ActiveCN101638521AImprove PTC StrengthLow room temperature resistivityNon-conductive material with dispersed conductive materialTemperature coefficientPositive temperature

The invention provides a material with positive temperature coefficients, which is a product obtained by mixing a mixture containing conductive particles and polymers, wherein the conductive particlesare metal conductive particles with partially oxidized surfaces, and the oxygen content in the conductive particles is between 0.001 and 0.05 percent by weight. According to the material with positive temperature coefficients, the conductive particles are the metal conductive particles with partially oxidized surfaces so that the compatibility between the conductive particles and the polymers andthe dispersity of the conductive particles in the polymers can be improved; moreover, the material with positive temperature coefficients has high PTC intensity reaching as high as 10.4, and can still maintain low room-temperature resistivity at the same time.

Owner:BYD CO LTD

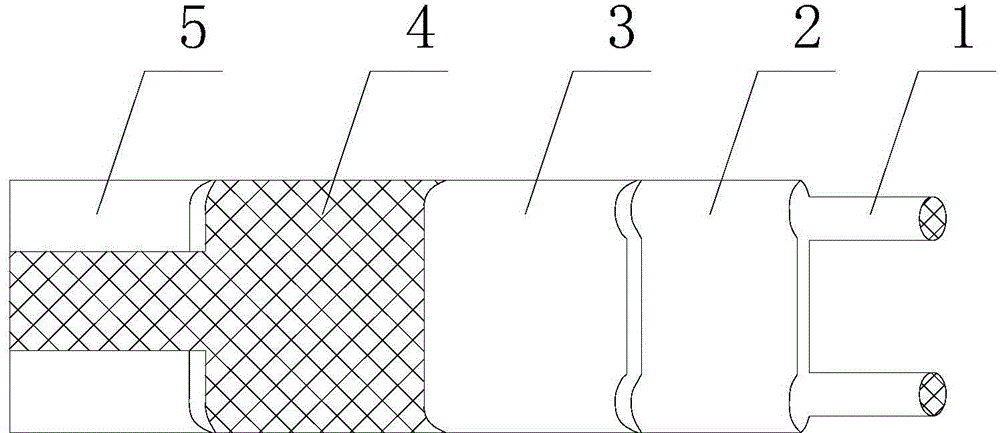

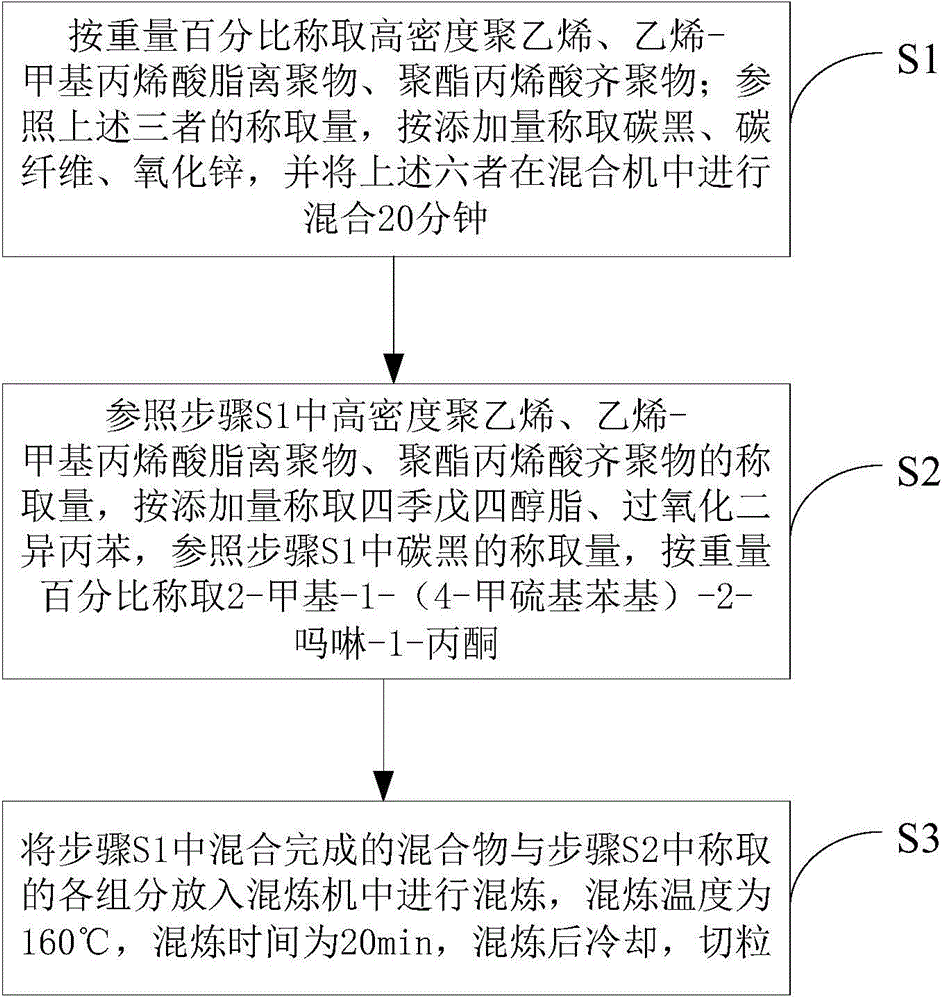

Low-resistance type automatic-temperature-limited polymer heat tracing cable

InactiveCN104582031AIncrease Add ThresholdAdd Threshold BoostHeating element shapesHeating element materialsMethacrylateFiber

The invention discloses a low-resistance type automatic-temperature-limited polymer heat tracing cable. A PTC (positive temperature coefficient) material adopts a polymer based PTC composite material, wherein high density polyethylene, ethylene- methacrylate ionomer and polyester acrylate oligomer at the weight ratio of (5:2:1)-(4:2:1) jointly form a polymer material matrix; the weight percentages of carbon black, carbon fiber, zinc oxide, tetra-pentaerythritol ester and dicumyl peroxide added to the polymer material matrix is 14%-17%, 6%-12%, 0.3%-0.6%, 0.06%-0.08% and 0.005%-0.01%, and the weight ratio of 2-methyl-1-(4-(methylthio)phenyl)-2-morpholine-1-propanon and carbon black is 0.05-0.2. According to the low-resistance type automatic-temperature-limited polymer heat tracing cable, performance of the heat tracing cable is optimized, the structure is simple, the low-temperature resistivity is low, and the PTC strength is high.

Owner:ANBANG ELECTRICAL GRP

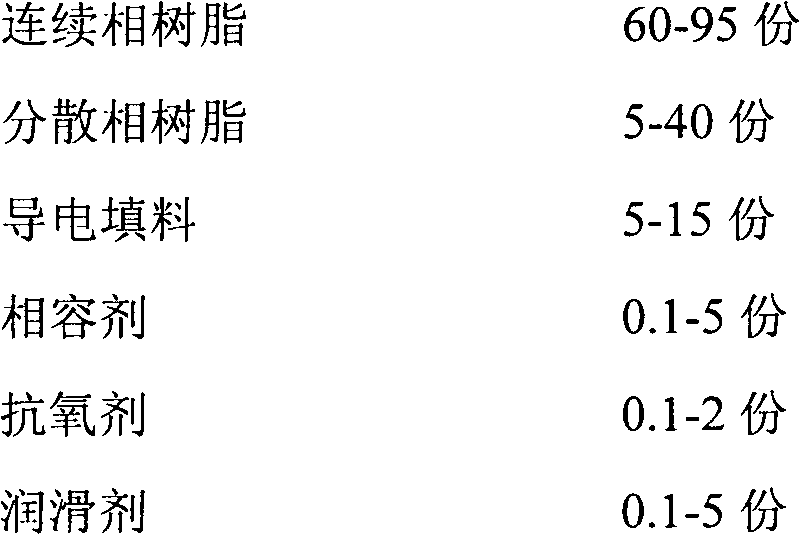

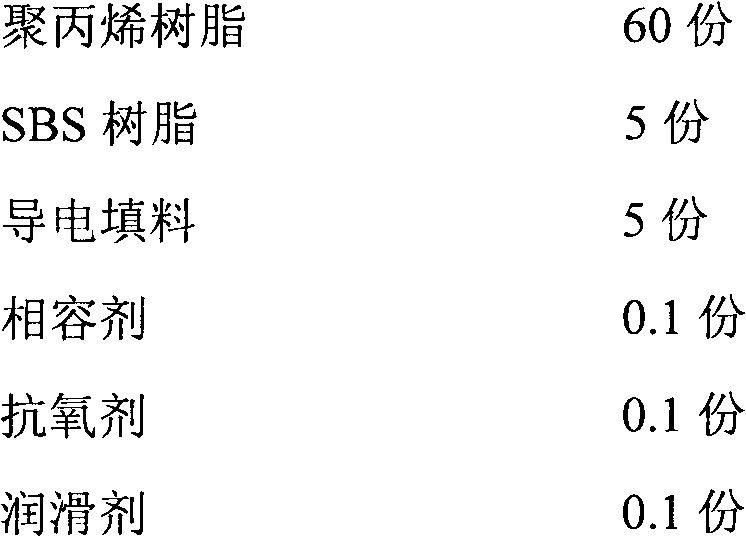

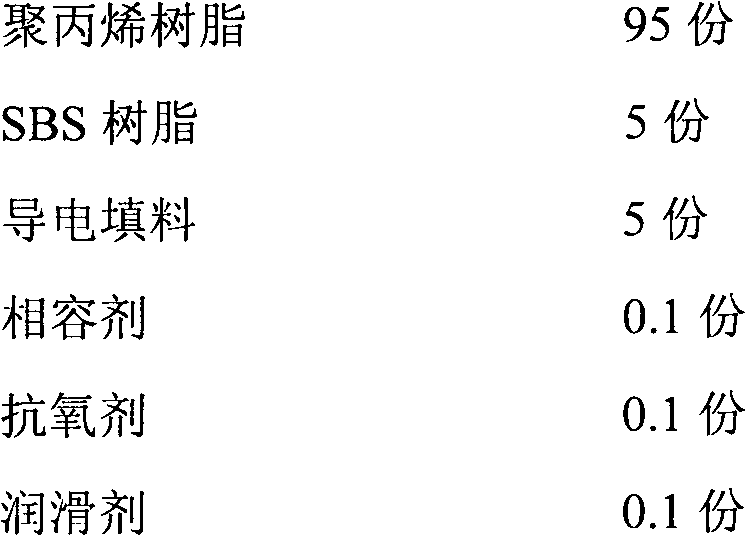

Phase separation conductive high molecular composite material

The invention discloses a phase separation conductive high molecular composite material, which has the composition comprising the following components in parts by weight: 60-95 parts of continuous phase resin, 5-40 parts of dispersed phase resin, 5-15 parts of conductive filler, 0.1-5 parts of compatilizer, 0.1-2 parts of antioxidant and 0.1-5 parts of lubricant. According to component proportioning in the scheme provided by the invention, polypropylene resin forms a continuous phase, SBS (Styrene-Butadiene-Styrene) resin forms a dispersed phase, and meanwhile, the SBS resin forms a conductive path of a continuous network structure in the continuous phase resin of the polypropylene matrix. During preparation, radiation cross-linking is adopted for an extrusion formed product, and further, the repeatability, the stability and the PTC (Positive Temperature Coefficient) strength of the material are improved. According to the phase separation conductive high molecular composite material, the conductive capacity and the PTC strength of the material are kept while the using amount of the conductive filler is reduced; and the material can be used as a superior PTC material.

Owner:上海聚威新材料股份有限公司

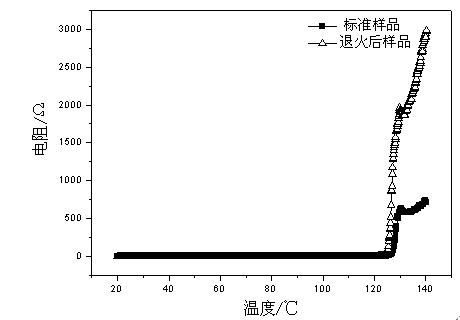

Heat treatment method for improving strength of PTC (Positive Temperature Coefficient) thermistor core materials

InactiveCN102543329AImprove PTC StrengthPositive temperature coefficient thermistorsPolyolefinThermistor

The invention relates to a heat treatment method for improving the strength of PTC (Positive Temperature Coefficient) thermistor core materials. The thermistor core materials comprise the following components in percentage by weight: 45-50 parts of high-density polyolefin and 50-55 parts of carbon black, wherein the polyolefin is the high-density polyolefin with high crystallinity of greater than or equal to 70 percent and the density of greater than or equal to 0.94g / cm<3>; and the carbon black is the stove method carbon black with good electrical conductivity, the grain size of 20-100nm and the DBP oil absorption value of greater than or equal to 70ml / 100g. The heat treatment method for composite materials comprises the step of annealing under the condition above a melting point of polymer at a temperature of 10-30 DEG C for 4-6 hours. Under the condition that the performances of the raw materials are unchanged, through optimization of an annealing temperature and the annealing manner, the PTC strength of the composite materials is greatly improved, and a foundation is laid for development of PTC thermistor components with high withstand voltage level.

Owner:SHANGHAI CHANGYUAN WAYON CIRCUIT PROTECTION CO LTD

Low temperature ptc conductive composition, ptc overcurrent protection device and manufacturing method thereof

ActiveCN103762012BLower operating temperatureImprove PTC StrengthNon-conductive material with dispersed conductive materialPositive temperature coefficient thermistorsEngineeringUltimate tensile strength

The invention relates to a low-temperature PTC conducting composition, a PTC over-current protection device and a manufacturing method of the PTC over-current protection device. The low-temperature PTC conducting composition comprises, by weight, 40%-55% of organic polymer, 40%-55% of conducting carbon black and 1%-10% of voltage-resistant reinforcing filler. The PTC over-current protection device comprises the low-temperature PTC conducting composition. The PTC over-current protection device has an operating temperature lower than 80 DEG C, high PTC strength and good resistance stability, thereby being capable of achieving good over-current and over-temperature protection for circuits in a low-temperature environment.

Owner:SHENZHEN HUIRUI ELECTRONICS MATERIALS

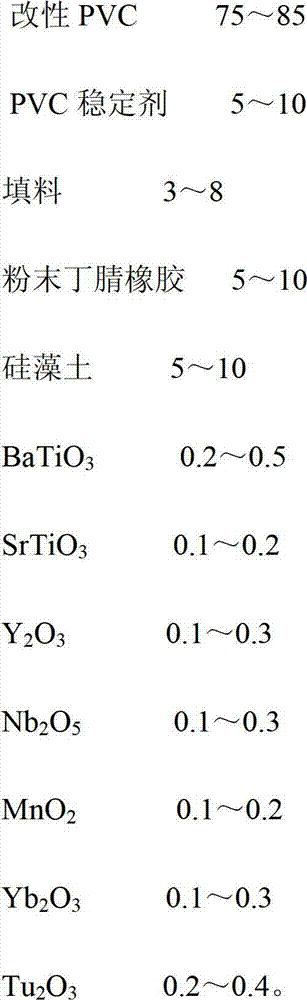

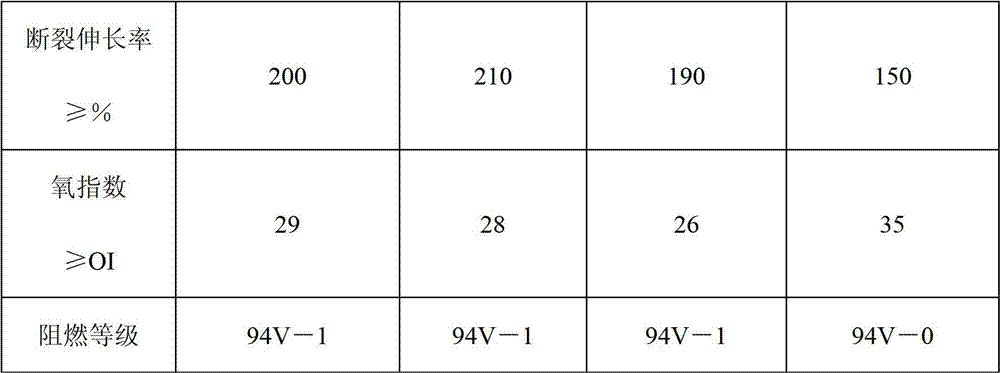

Cable filler composition

The invention provides a cable filler composition, particularly a cable filler composition which has the advantages of high PTC (positive temperature coefficient) strength, favorable temperature control property, small self-limit temperature fluctuation, high strength, high tension rate and favorable flame retardancy. The cable filler composition is prepared from modified PVC (polyvinyl chloride), a PVC stabilizer, a filler, powder nitrile-butadiene rubber, kieselguhr, BaTiO3, SrTiO3, Y2O3, Nb2O5, MnO2, Y2O3 and Tu2O3.

Owner:JIANGSUSNGSHANG CABLE GROUP

High-temperature resistant PTC electroconductive composition, high-temperature resistant PTC device containing composition and manufacturing method thereof

ActiveCN101560325BLower resistanceImprove PTC StrengthCurrent responsive resistorsPositive temperature coefficient thermistorsNylon 12Metallurgy

The invention relates to a high-temperature resistant PTC electroconductive composition, which comprises 20 to 70 percent of organic polymers, 25 to 75 percent of electroconductive filler, 1 to 30 percent of inorganic filler and 0.1 to 10 percent of additive, wherein the preferred melting point of the organic polymers is more than 150 DEG C; the organic polymers are one or more crystalline or semi-crystalline polymers and made of one or more of nylon 11, nylon 12, polyvinylidene fluoride, soluble poly(tetrafluoroethylene), ethylene-tetrafluoroethylene copolymers, perfluoroethylene-propylene, ethylene-chlorotrifluoroethylene and copolymers thereof. The invention also provides a high-temperature resistant PTC device containing the composition and a manufacturing method thereof. The high-temperature resistant PTC device containing the composition has low resistance, high PTC strength and superior resistance stability, so that the high-temperature resistant PTC device can be used for overcurrent protection of circuits in high-temperature environments such as automobile motors and the like. Moreover, the high-temperature resistant PTC device is simple and convenient to manufacture and has high efficiency.

Owner:SHANGHAI KETER POLYMER MATERIAL

Conductive composite material with isolation and double-percolation structure and high PTC strength, and preparation method and application of conductive composite material

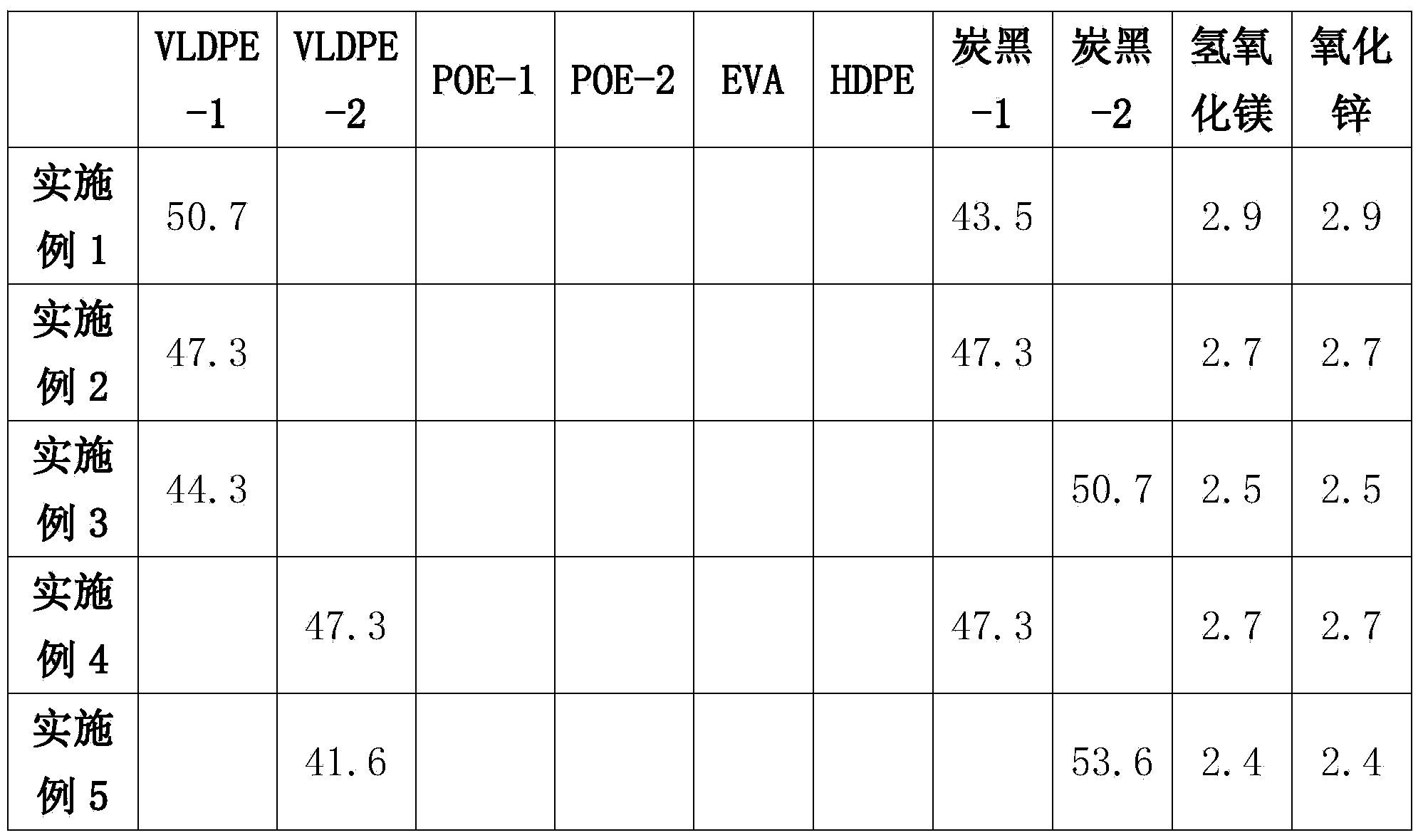

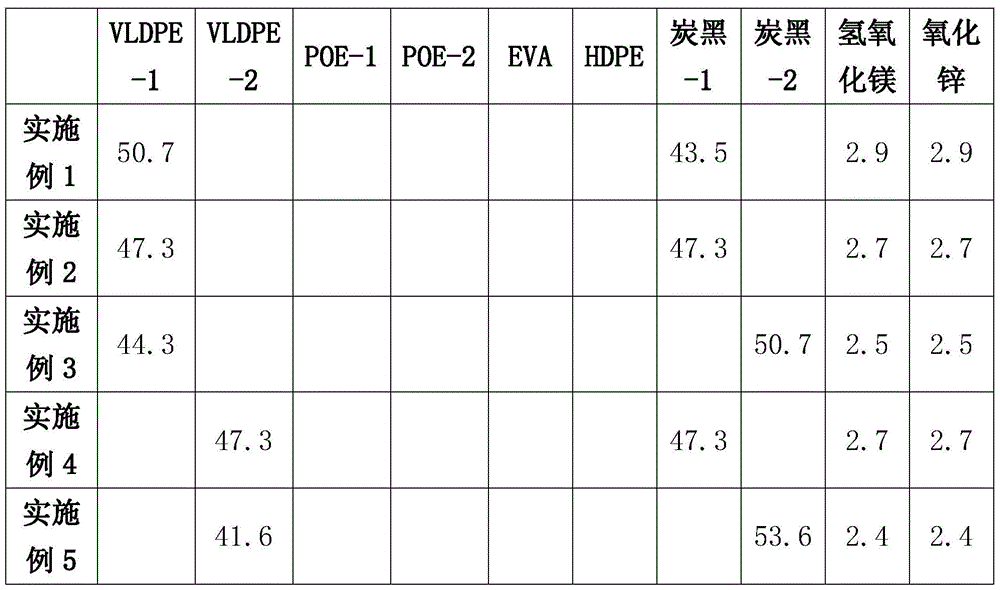

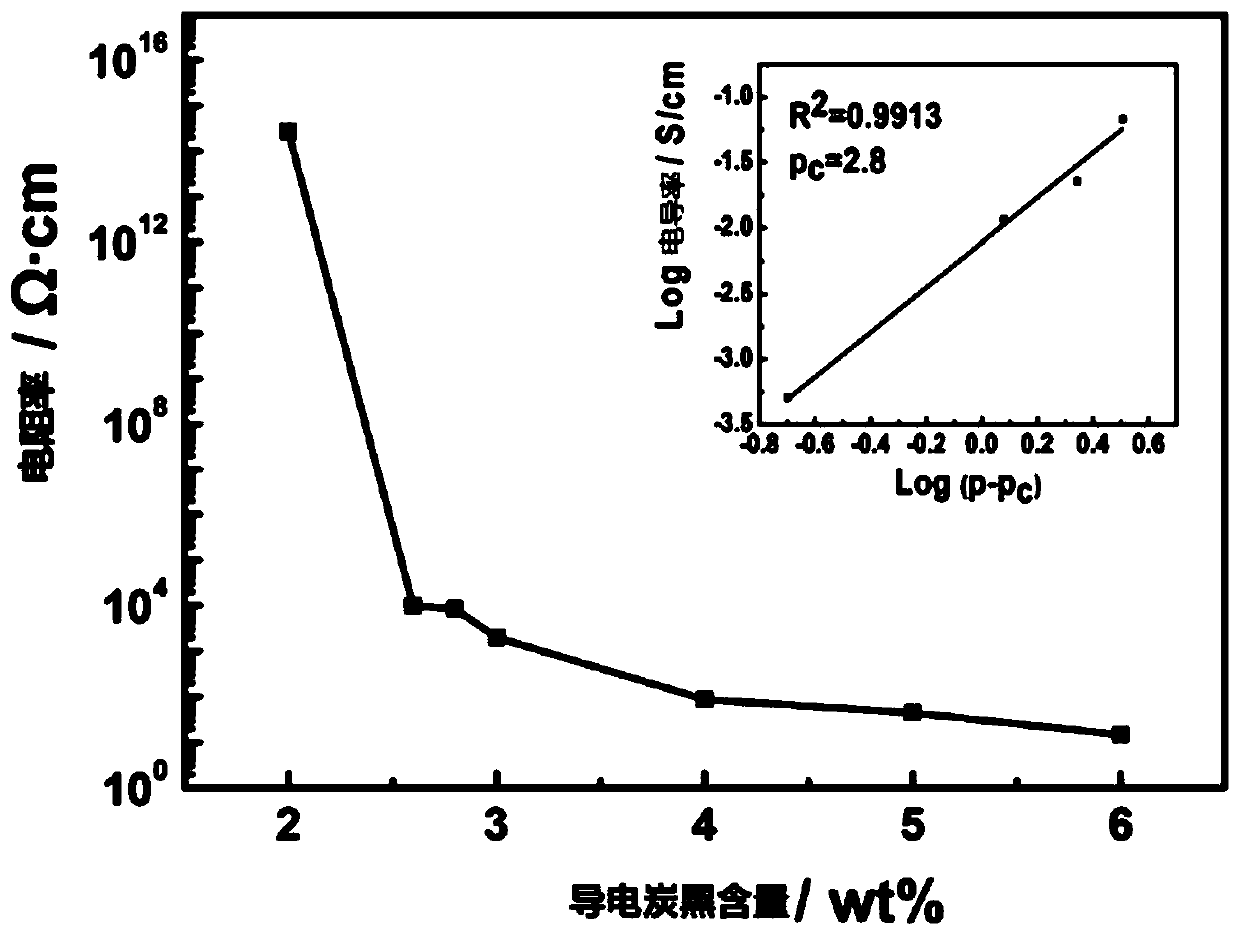

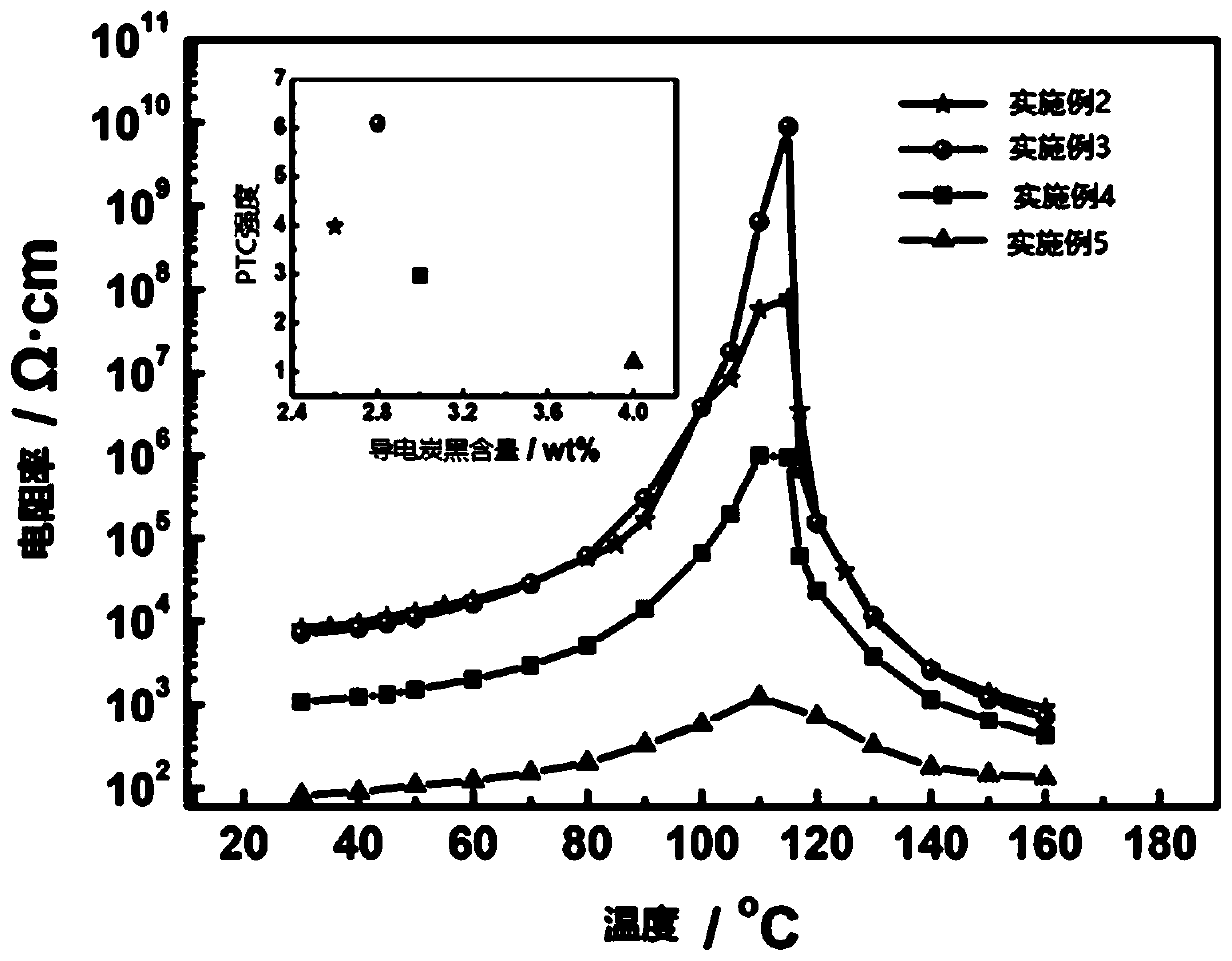

ActiveCN109762277AImprove PTC StrengthImprove conductivityLinear low-density polyethyleneAntioxidant

The embodiment of the invention relates to a conductive composite material with an isolation and double-percolation structure and high PTC strength, and a preparation method and application of the conductive composite material. The conductive composite material is prepared from raw materials comprising following components: linear low-density polyethylene, polyvinylidene fluoride, a conductive filler and an antioxidant. The preparation method of the conductive composite material comprises the following steps that the linear low-density polyethylene, the conductive filler and the antioxidant are fused and blended in an internal mixer, the temperature of the internal mixer is set to be 130-160 DEG C, and a clad master batch is prepared; then the polyvinylidene fluoride is added into the internal mixer, the temperature of the internal mixer is set to be 130-150 DEG C, and the clad master batch and the polyvinylidene fluoride are fused, blended and then taken out; and hot pressing is conduced to obtain the conductive composite material. The prepared CB / LLDPE / PVDF conductive composite material has the isolation and double-percolation structure, is low in conductive content, high in PTCstrength and high in stability, and can be used as a temperature-sensitive material.

Owner:QINGDAO UNIV OF SCI & TECH

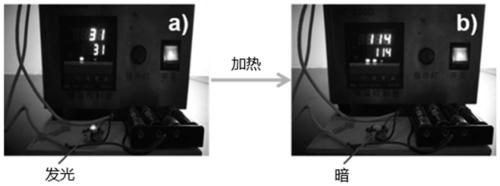

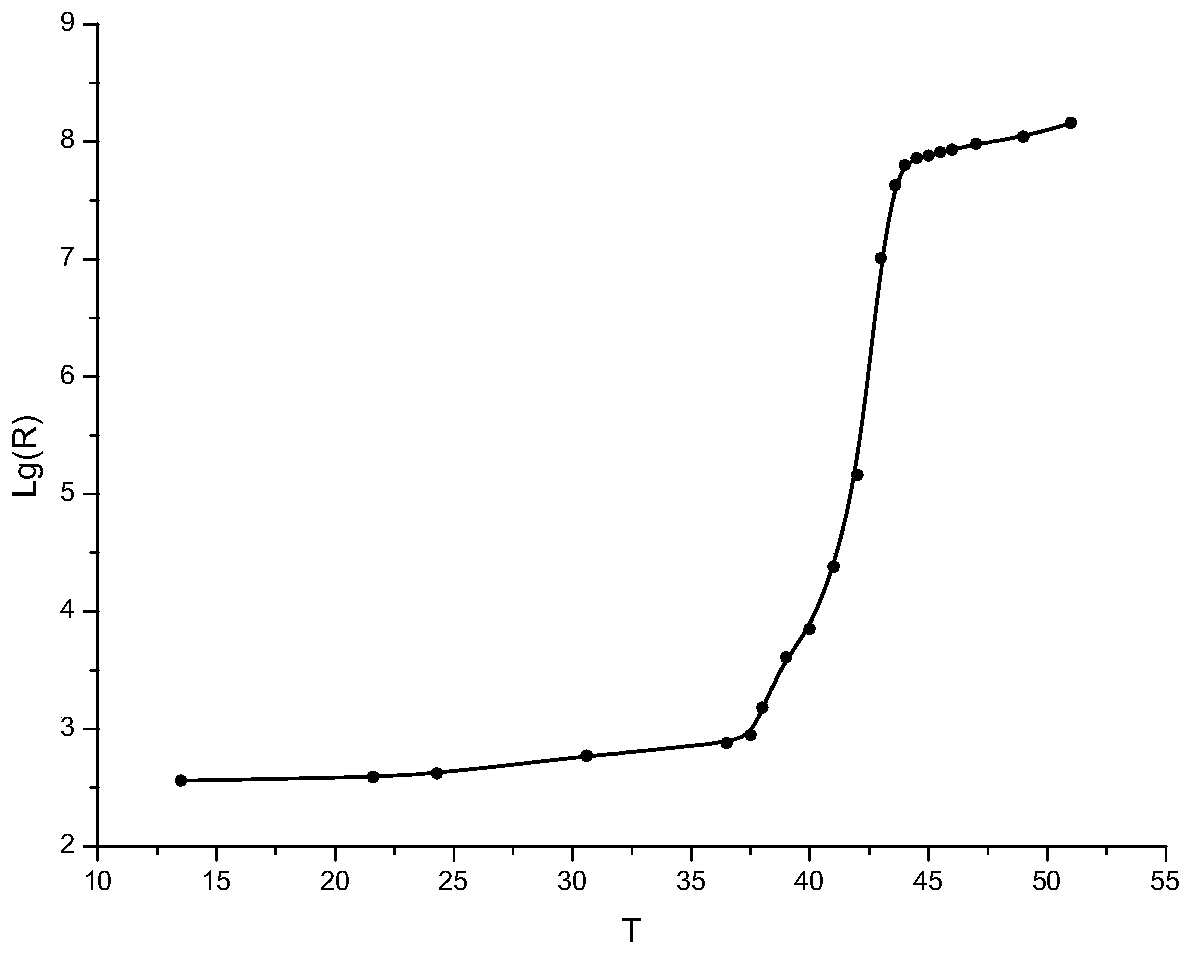

Composite ptc material for thermal control at room temperature

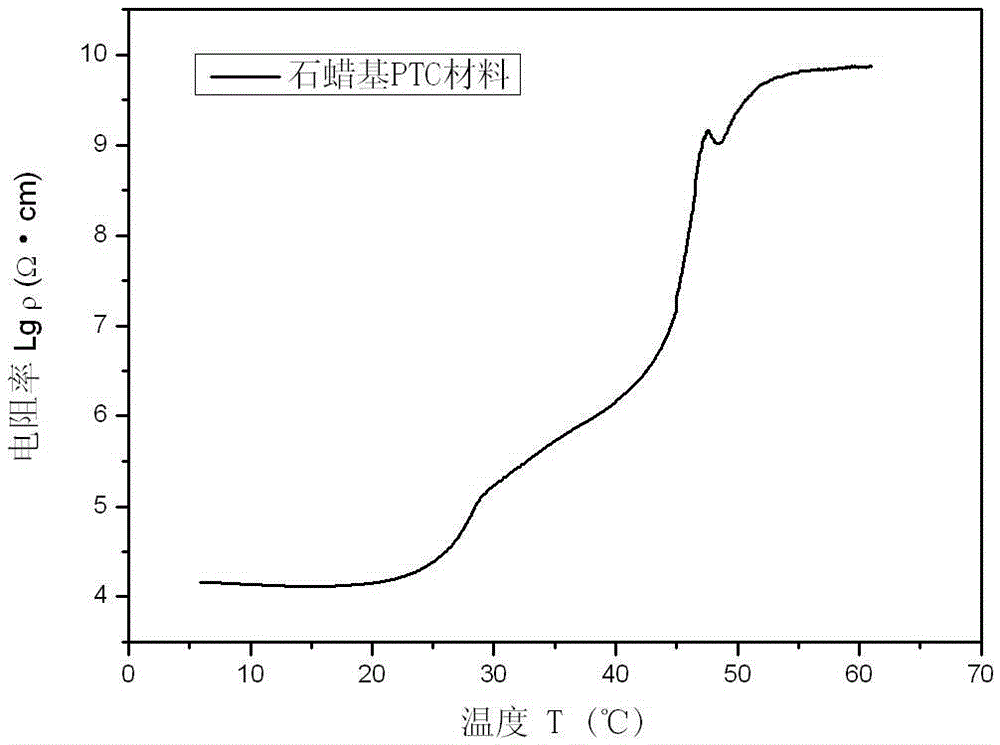

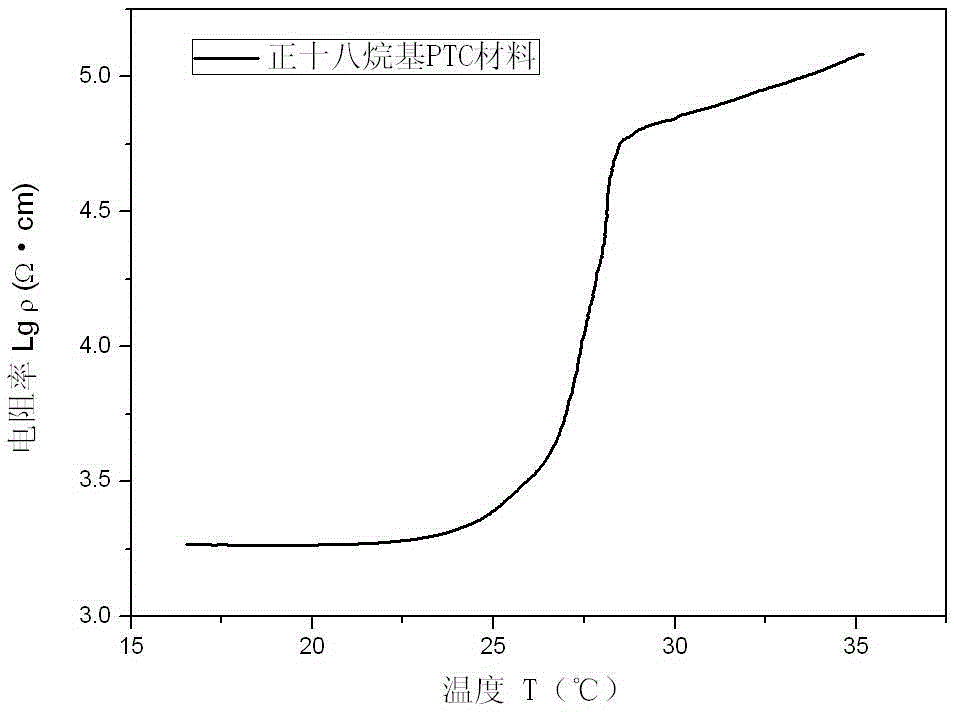

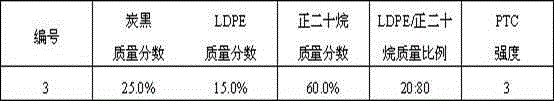

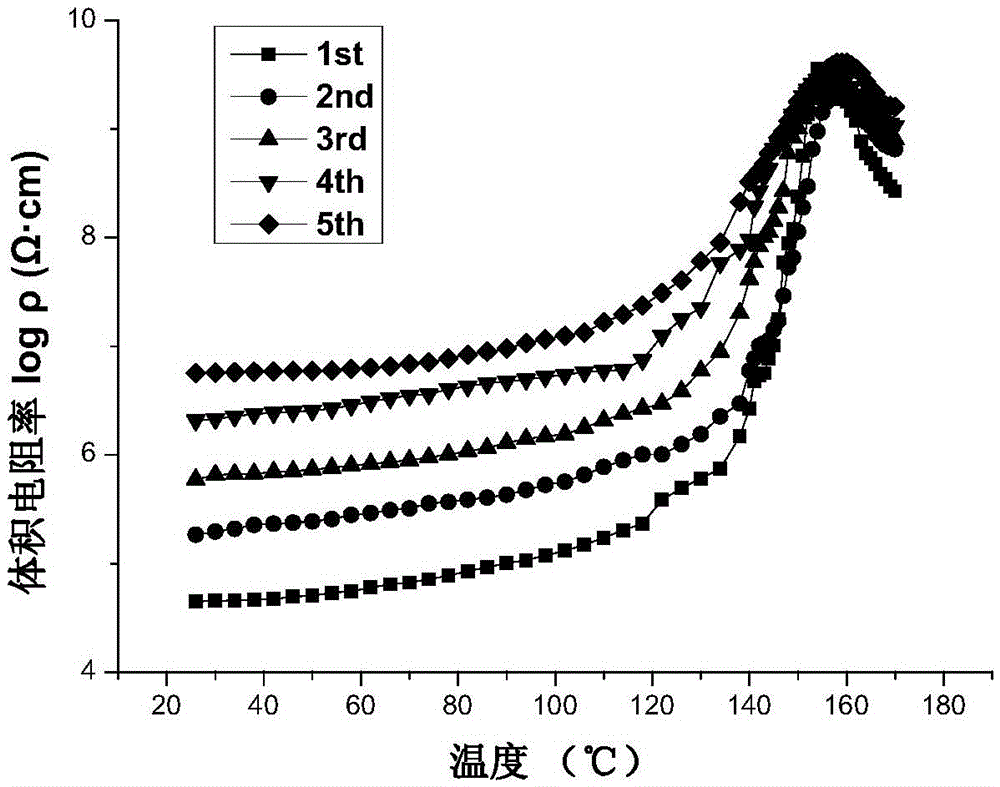

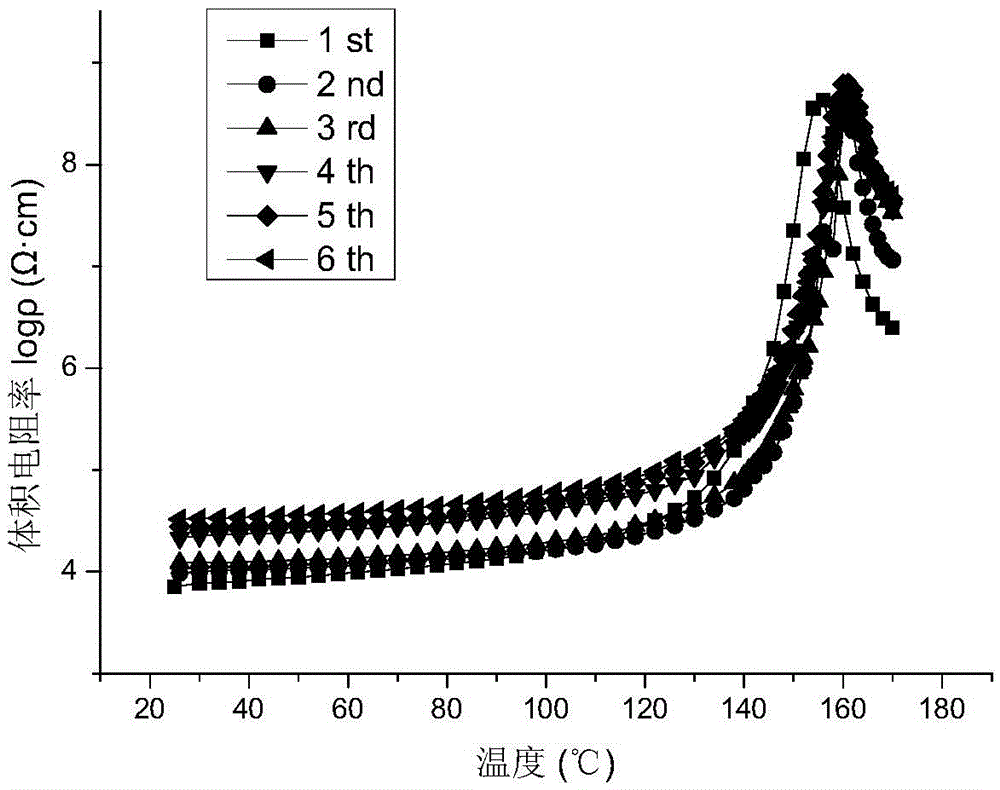

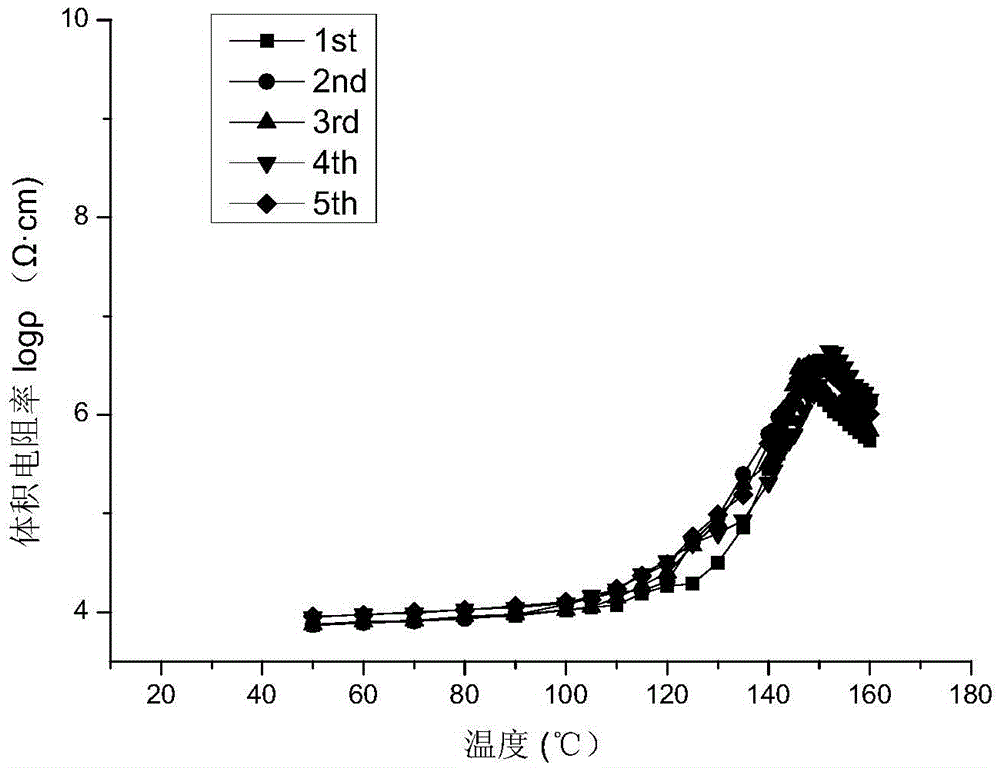

ActiveCN103594214BImprove PTC StrengthPTC effect eliminationPositive temperature coefficient thermistorsLow-density polyethyleneAlkane

The invention relates to a composite PTC (positive temperature coefficient) material for normal temperature heat control. The material comprises the following substances of graphite powder / carbon black, paraffin / alkane substance, and low-density polyethylene. A method for preparing the composite PTC material comprises the following steps: melting and mixing the paraffin or the alkane substance and the low-density polyethylene under the temperature of 130-170 DEG C and a vacuum condition, and uniformly stirring the paraffin or the alkane substance and the low-density polyethylene; then adding the graphite powder or the carbon black, and uniformly stirring and mixing the graphite powder or the carbon black under the temperature of 130-170 DEG C and the vacuum condition to obtain a mixture; putting the mixture into a mold for compression molding, and cooling the mixture to room temperature to obtain the rod-type composite PTC material for the normal temperature heat control. The Curie temperature, at which a PTC effect can be achieved, of the material disclosed by the invention is -10 to 40 DEG C and slightly lower than the melting point of a blended substrate; the material is higher in PTC strength, better eliminates an NTC (negative temperature coefficient) effect and can be applied to active temperature control of electronic appliances and other fields of normal temperature heat control; the main defect that the Curie temperature of the conventional PTC material is not in a normal temperature section is overcome.

Owner:UNIV OF SCI & TECH OF CHINA

Method for preparing conductive polymer composite material from metal granule modified carbon black

InactiveCN1850898AImprove conductivityImprove PTC StrengthConductive polymer compositeModified carbon

The invention discloses a method to make metal particle modification carbon black making conductive macromolecule compounding material that includes the following steps; adding the carbon black into H(AuCl) solution that the thickness aurum iron is 150ppm-250ppm, whisking, filtering the carbon black and washing, drying to gain the carbon black that the surface is adsorbed aurum iron; putting the carbon black into NaBH solution, whisking and filtering, washing, drying to gain the carbon black that has aurum particle adsorbed on the surface; mixing the carbon black with high density polyethylene, devoting into Banbury mixer, milling for 12-18 minutes in 160-180 degree centigrade. The invention improves the PTC intension of the conductive macromolecule compound material.

Owner:ZHEJIANG UNIV

Polymer-based conductive composite material and method for preparing heat tracing tape cable from same

InactiveCN110483876ASimple preparation processImprove PTC StrengthHeating element shapesLinear low-density polyethyleneAntioxidant

The invention discloses a polymer-based conductive composite material and a method for preparing a heat tracing tape cable from the polymer-based conductive composite material and belongs to the fieldof cable preparation. The material comprises the following raw materials by weight: 50-70 parts of linear low density polyethylene, 30-40 parts of an ethylene-vinyl acetate copolymer, 15-25 parts ofoil furnace carbon black, 10-20 parts of dicumyl peroxide, 8-12 parts of a conductive filler, and 5-10 parts of an auxiliary agent. The heat tracing cable is simple in preparation process and worthy of popularization; the ternary composite material is constructed by adopting linear low-density polyethylene, an ethylene-vinyl acetate copolymer and oil furnace carbon black as basic components; the ternary composite material is endowed with electrical conductivity and high PTC strength through the oil furnace carbon black, dicumyl peroxide can be prevented from thermal decomposition through the antioxidant in the auxiliary agent, and the comprehensive performance of the heat tracing cable can be further improved through the flame retardant, the stabilizer and the dispersing agent in the auxiliary agent.

Owner:安徽省天盛仪表线缆有限公司

Thermistor core material and production technology thereof

InactiveCN105206361AImprove PTC StrengthHas a positive temperature coefficientPositive temperature coefficient thermistorsEngineeringThermistor

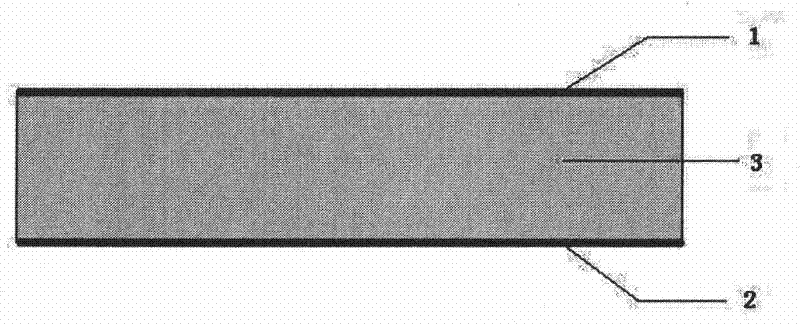

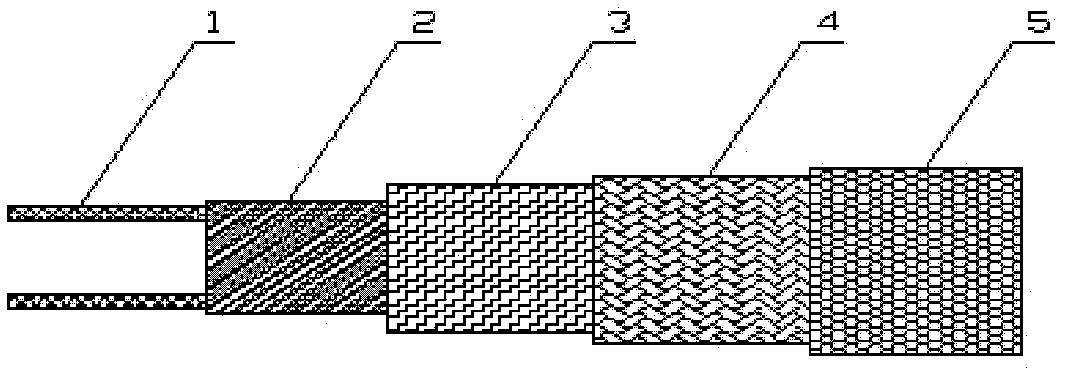

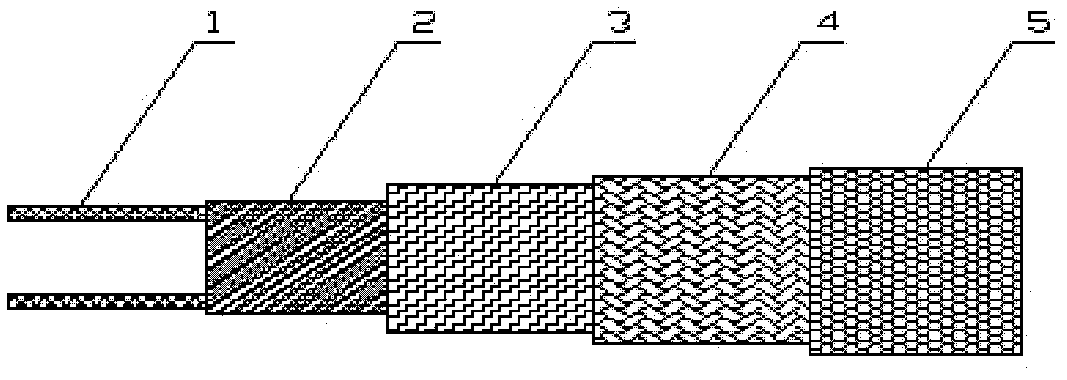

The invention relates to the field of manufacturing materials of electron components, in particular to a kernel material of a novel voltage-withstanding overcurrent self-recovery protector, namely a core material manufacturing material, and the voltage-withstanding capacity can reach 600 V. The voltage-withstanding overcurrent self-recovery protector is composed of a core material arranged between two metal membranes, the metal membranes are provided with leading-out electrodes, and the outer layers of the metal membranes are enveloped with insulating and sealing materials. The core material is prepared from, by weight, high-density polyethylene, a conducting material, antioxidant 1010 and fire retardant prepared from magnesium hydrate. A novel thermistor kernel manufacturing material with good adhesive performance and the more remarkable jump performance can be provided, a thermistor has a positive temperature coefficient effect, the room temperature specific resistance is 10-2 Omega.cm, the PTC strength is larger than 107 orders of magnitude, and meanwhile a material manufacturing method is provided.

Owner:深圳市万瑞和电子有限公司

Graphene/HDPE thermistor composite material and preparation method

The invention relates to a polymer-based PTC (positive temperature coefficient) thermistor composite material, in particular to a graphene / high-density polyethylene PTC thermistor composite material and a preparation method thereof, and belongs to the field of high molecular composite materials. The composite material comprises a graphene conductive filler and a high-density polyethylene base body, wherein the weight percentage of the graphene in the components of the PTC thermistor composite material is 1%-10%. The preparation method comprises the following steps: grinding high-density polyethylene particles into powder by a high-speed universal grinder, mixing the powder with the graphene, performing melt blending through a torque rheometer, and finally performing hot-pressing by a press vulcanizer to prepare the graphene / high-density polyethylene PTC thermistor composite material. The polymer-based composite material taking the graphene as the conductive filler has the advantages of low initial resistance, high response speed, high PTC intensity, good circularity and the like, and can lay a foundation for an application of the graphene to a thermistor and indicate a direction for the application of the graphene.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI +1

PTC thermistor and substrate applied therein and manufacturing method thereof

InactiveCN102176360BUniform cross-linked structurePromote absorptionPositive temperature coefficient thermistorsHigh resistanceCross-link

A PCT thermistor comprises a substrate and two tinsel-shaped electrodes which are combined with two surfaces of the substrate. The substrate is made of the following components in weight percentage: 28-55% of high-polymer material; 22-32% of conductive filling material; 13-46% of auxiliary filling material; and 1-5% of auxiliary agent in processing. The high-polymer material is obtained through mixing one or multiple materials selected from: polyethylene, polypropylene, maleic anhydride grafted polyethylene, ethane-vinyl acetate copolymer, ethane-acrylic acid copolymer, polyvinylidene fluoride, polycaprolactam, polyhexamethylene adipamide, polydecamethylene sebacamide and polyundecylamide. The auxiliary agent in processing is one component or a mixture of multiple components selected from: an anti-oxidant, a coupling agent, a cross-linking agent and a sensitized cross-linking agent. The sensitized cross-linking agent is one component or multiple components selected from the unsaturated compounds of multiple functional groups with higher decomposition temperature. The PTC thermistor of the invention has the following advantages: high strength, and high resistance for multiple timesof large current impact.

Owner:深圳市长园维安电子有限公司

Method for preparing conductive polymer composite material from metal granule modified carbon black

InactiveCN100381493CImprove conductivityImprove PTC StrengthConductive polymer compositeModified carbon

Owner:ZHEJIANG UNIV

Self-temperature-limiting electric tracing band with positive temperature coefficient and preparation method of self-temperature-limiting electric tracing band

ActiveCN114786282AHigh tensile strengthImprove PTC StrengthHeating element shapesHeating element materialsThermodynamicsEngineering

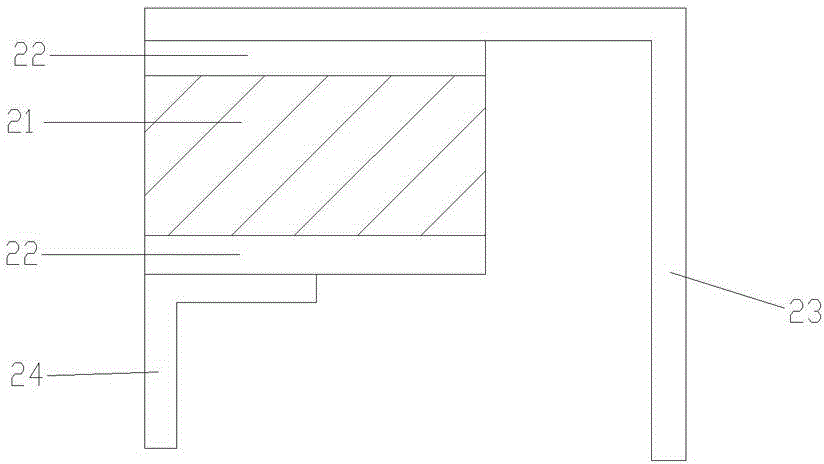

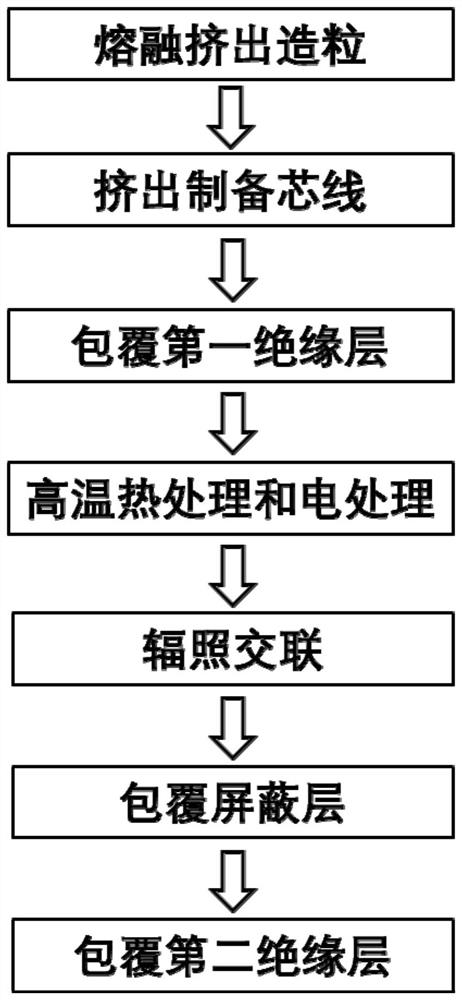

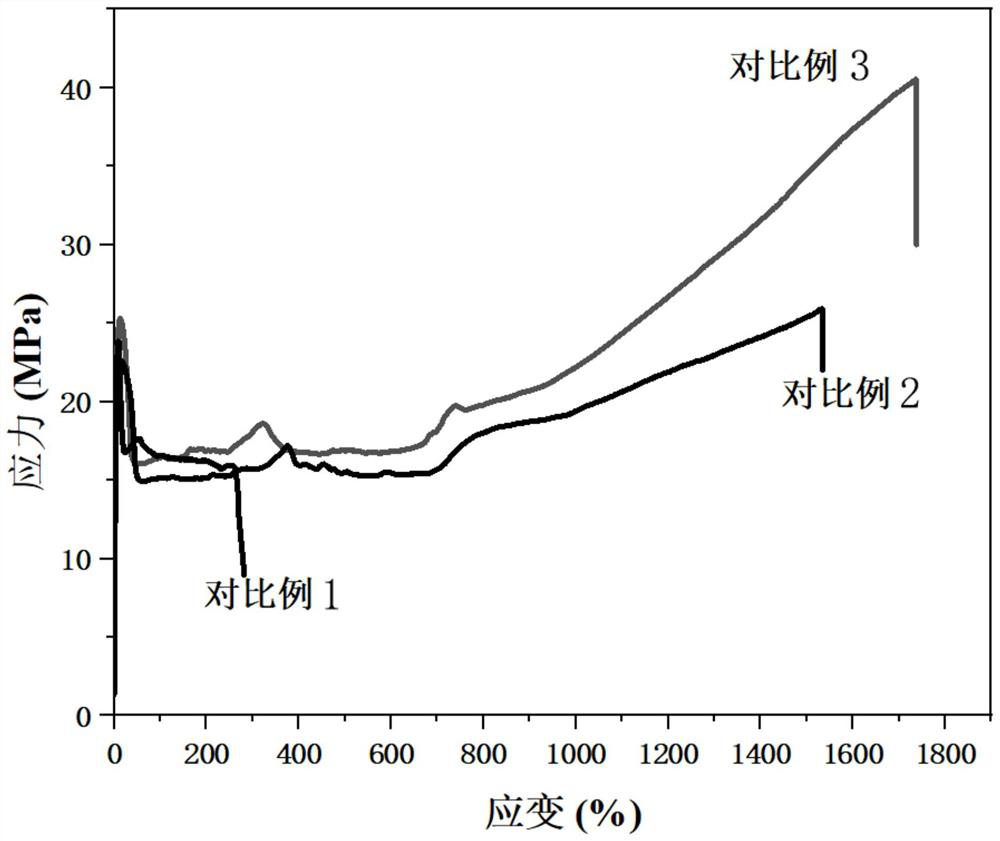

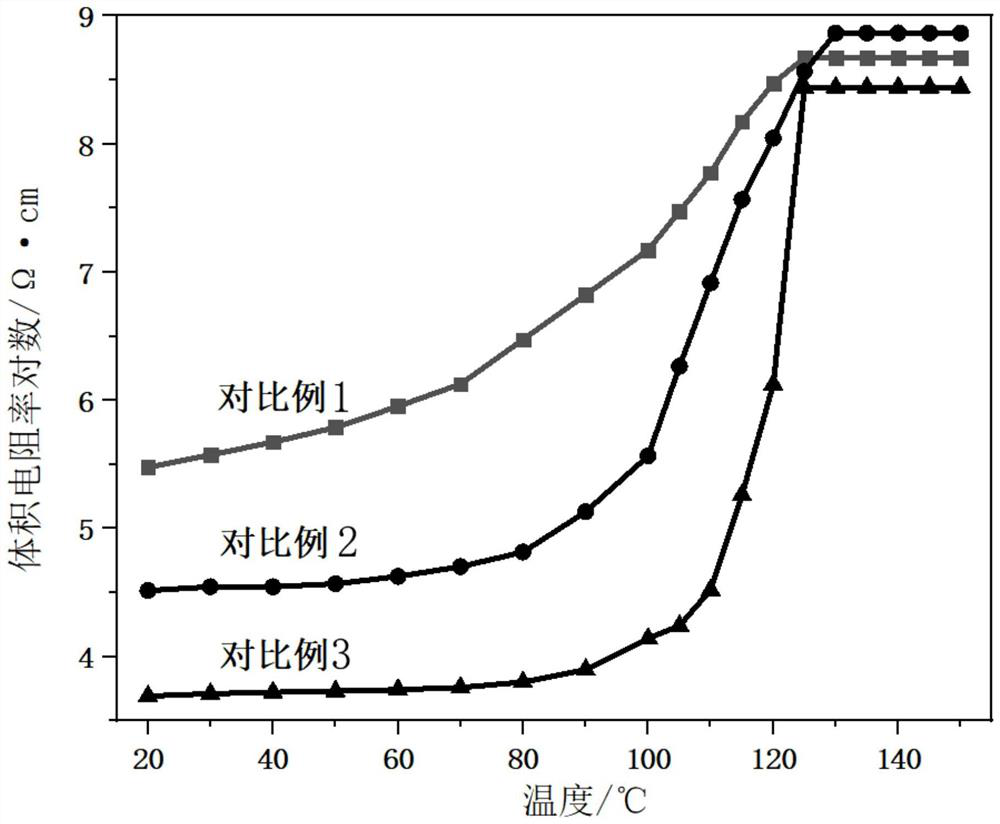

The invention discloses a self-temperature-limiting electric tracing band with a positive temperature coefficient and a preparation method thereof, and relates to the technical field of tracing band preparation, the self-temperature-limiting electric tracing band comprises a wire, the wire is coated with a heat conduction material, and the heat conduction material is sequentially provided with a first insulating layer, a shielding layer and a second insulating layer; the heat conduction material is composed of, by mass, 5-15% of a conductive filler, 1-5% of a sensitizer and a heat tracing band base material. According to the invention, a single high polymer material is adopted as a heat tracing band base material, and the content of conductive filler is low, so that the heat tracing band has excellent bending resistance, high tensile strength and high PTC strength; in the preparation process, after the electric tracing band is extruded into a line, static high-temperature heat treatment and electric treatment are utilized to promote directional movement and agglomeration of the conductive filler, the distribution state of the filler is accurately regulated and controlled, a locally concentrated conductive network is constructed, and the electric tracing band has excellent processing fluidity, mechanical property and heating performance; the method can be widely applied to the fields of various tank bodies, pipeline heat preservation, electric blankets and the like.

Owner:SICHUAN UNIV

Method for preparing composite conductive polyethylene carbon black material with improved positive temperature coefficient performance

InactiveCN102093617BGood compatibilityImprove PTC StrengthNon-conductive material with dispersed conductive materialPigment treatment with macromolecular organic compoundsLow-density polyethylenePhosphate

The invention relates to a method for preparing a composite conductive polyethylene carbon black material with improved positive temperature coefficient performance. The method comprises the following steps of: (1) preparing a hyper dispersant from 12-oxystearic acid, an antioxidant, a catalyst, dimethylbenzene and the like; (2) preparing modified carbon black from carbon black and a titanate hyper dispersant or a phosphate hyper dispersant or a mixture of the titanate hyper dispersant and the phosphate hyper dispersant; and (3) preparing the composite conductive polyethylene carbon black material from high-density polyethylene, low-density polyethylene, the modified carbon black, the antioxidant and the like. The composite conductive polyethylene carbon black material provided by the invention improves the interaction between a conductive filler and a high molecular matrix, effectively inhibits the agglomeration and the position offset of carbon black in the matrix, increases the PTC(Positive Temperature Coefficient) strength, retards the NTC (Negative Temperature Coefficient) effect, and increases the stability of PTC effect in repeated heating cycle. The method has simple process and low cost, basically causes no pollution to the environment and is convenient to popularize and apply widely.

Owner:HEFEI UNIV OF TECH

PTC (Positive Temperature Coefficient) high polymer heating material for self-limiting temperature electric tracing band

InactiveCN102604189BImprove PTC StrengthImprove tensile propertiesHeating element shapesPositive temperature coefficient thermistorsFiberCarbon fibers

Owner:WUHU XUHUI ELECTRIC NEW MATERIAL

A kind of low Curie temperature point PTC organic composite material and preparation method thereof

The invention discloses a low-Curie-temperature-point positive temperature coefficient (PTC) organic composite material and a preparation method thereof. The low-Curie-temperature-point PTC organic composite material is prepared from the following raw materials by mass percent: 18-22% of ethylene-vinyl acetate copolymer (EVA), 54-66% of lauric acid, 5-10% of acetylene black and 10-15% of auxiliarymaterial. The preparation method adopts a solution method, and comprises the steps of mixing the dried EVA powder and lauric acid granules according to the proportion, adding an aromatic hydrocarbonsolvent, and dissolving; adding the treated acetylene black, evenly mixing, and adding the auxiliary material; carrying out ultrasonic treatment; removing the aromatic hydrocarbon solvent, and carrying out heat treatment. The composite material prepared by the method has a Curie temperature of lower than 50 DEG C, and the adding amount of conducting particles is less than 10%; furthermore, the composite material has flexibility, is low in cost, thin, safe and reliable, has low resistivity at the room temperature, and is suitable for large-area heating.

Owner:SOUTH CHINA UNIV OF TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com