Conductive composite material with isolation and double-percolation structure and high PTC strength, and preparation method and application of conductive composite material

A conductive composite material, double percolation technology, applied in the field of high PTC strength conductive composite materials, can solve the problems of poor stability, low PTC strength, high conductive filler filling, etc., achieve high stability, reduce percolation value, improve The effect of conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

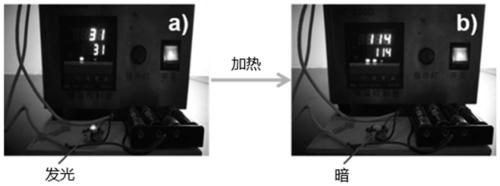

Examples

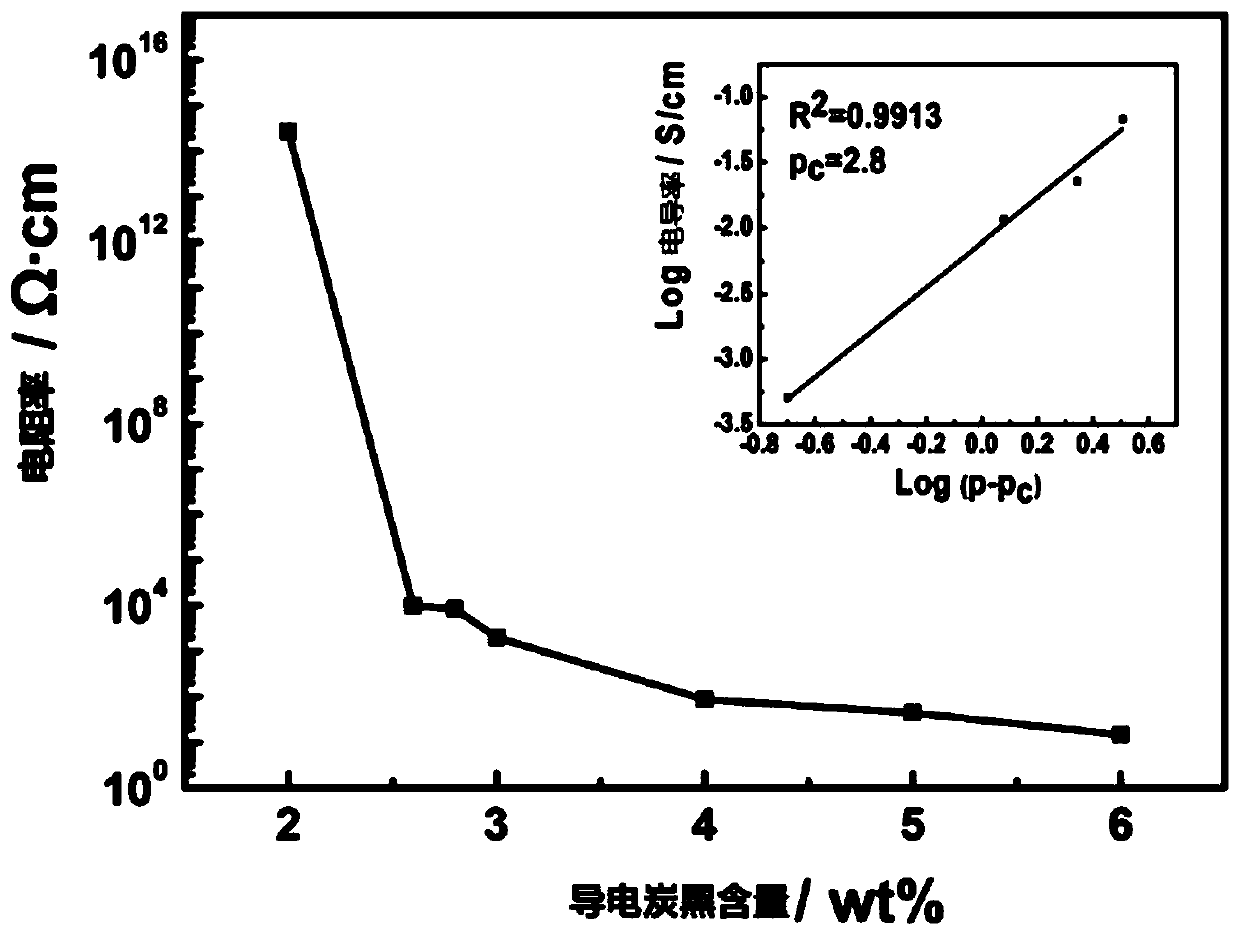

Embodiment 1

[0048] A high PTC strength conductive composite material with isolation-double percolation structure, the conductive composite material is prepared from raw materials comprising the following components: linear low density polyethylene 5g, polyvinylidene fluoride 45g, conductive carbon black 1g and antioxidant 10100.05g;

[0049] That is, the mass ratio of linear low density polyethylene and polyvinylidene fluoride is 1:9; the mass of conductive carbon black is 2% of the total mass of linear low density polyethylene and polyvinylidene fluoride; the mass of antioxidant 1010 is linear low 1% of the mass of density polyethylene.

[0050] Its preparation method comprises the following steps:

[0051] The linear low-density polyethylene and polyvinylidene fluoride are vacuum-dried; at 150 ° C, the linear low-density polyethylene is added to the internal mixer, and melted for 2 minutes; then conductive carbon black and antioxidant 1010 are added according to the above ratio, and me...

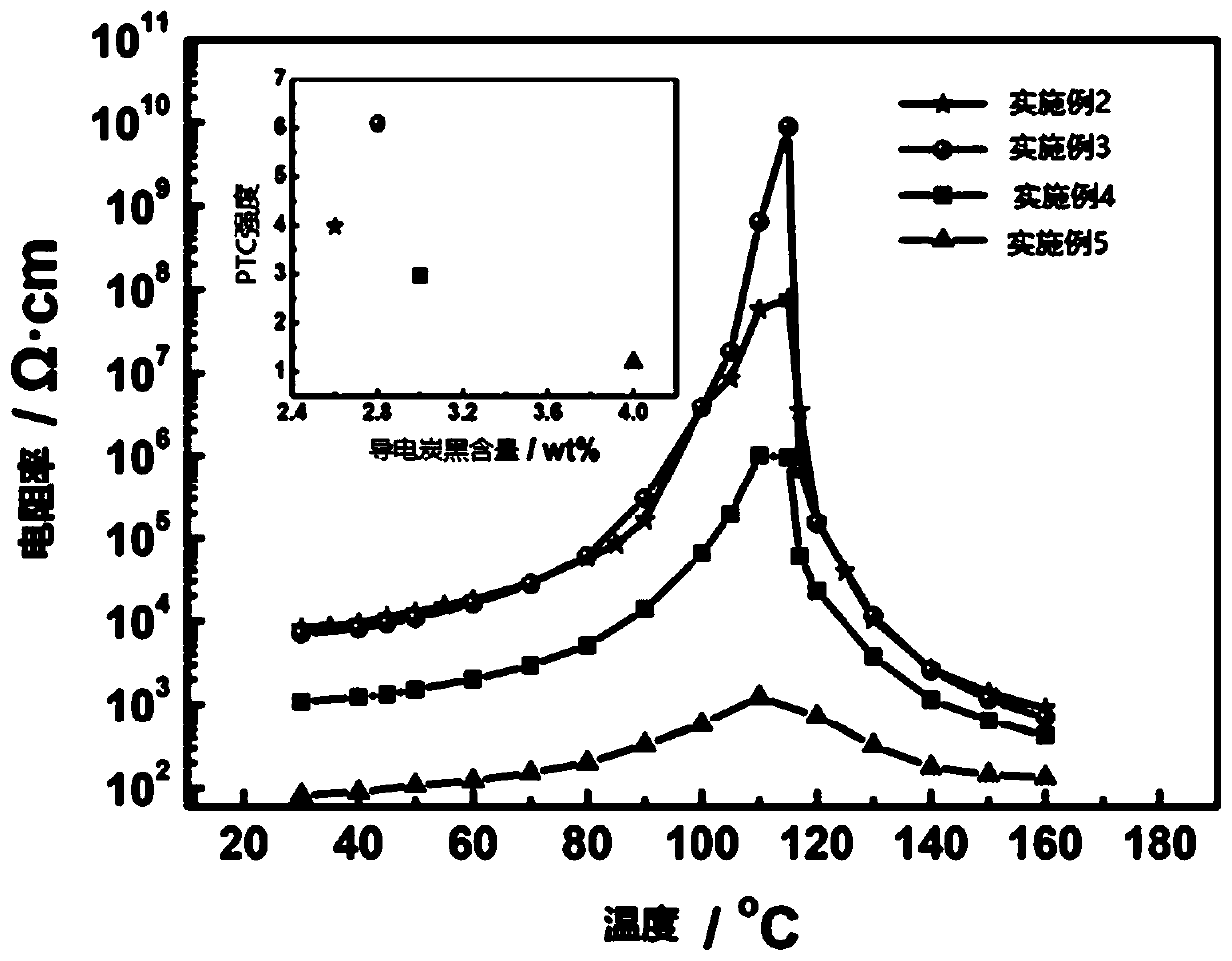

Embodiment 2

[0054] A high PTC strength conductive composite material with isolation-double percolation structure, the conductive composite material is prepared from raw materials comprising the following components: linear low density polyethylene 5g, polyvinylidene fluoride 45g, conductive carbon black 1.3g g and antioxidant 10100.05g;

[0055] That is, the mass ratio of linear low density polyethylene and polyvinylidene fluoride is 1:9; the mass of conductive carbon black is 2.6% of the total mass of linear low density polyethylene and polyvinylidene fluoride; the mass of antioxidant 1010 is linear low 1% of the mass of density polyethylene.

[0056] The preparation method is the same as in Example 1.

Embodiment 3

[0058] A high PTC strength conductive composite material with isolation-double percolation structure, the conductive composite material is prepared from raw materials comprising the following components: linear low density polyethylene 5g, polyvinylidene fluoride 45g, conductive carbon black 1.4 g and antioxidant 10100.05g;

[0059] That is, the mass ratio of linear low density polyethylene and polyvinylidene fluoride is 1:9; the mass of conductive carbon black is 2.8% of the total mass of linear low density polyethylene and polyvinylidene fluoride; the mass of antioxidant 1010 is linear low 1% of the mass of density polyethylene.

[0060] The preparation method is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com