Patents

Literature

37results about How to "Low percolation value" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

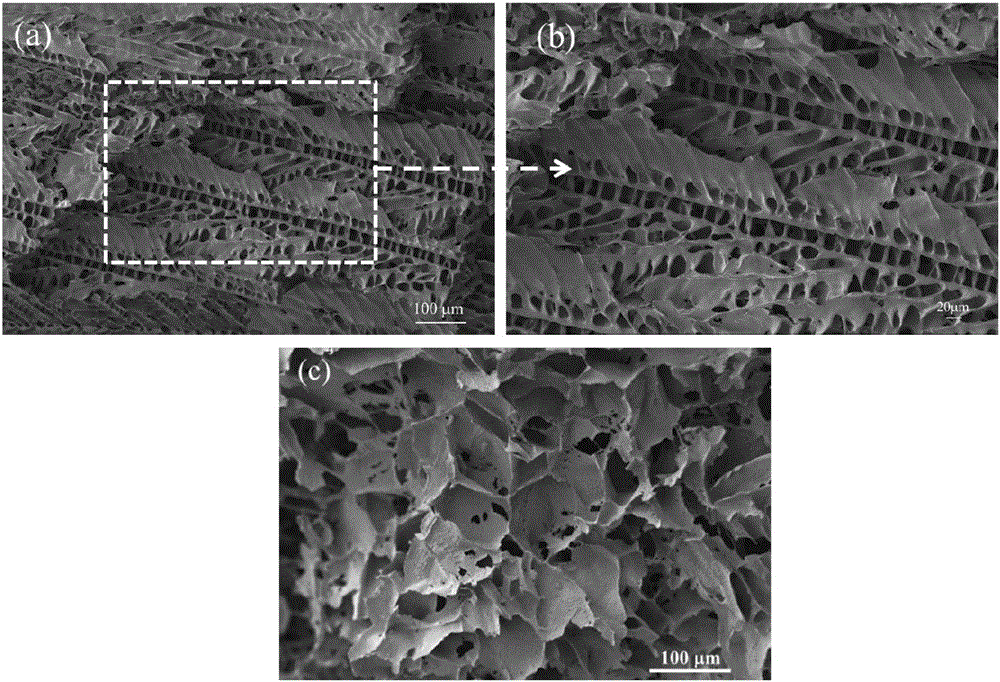

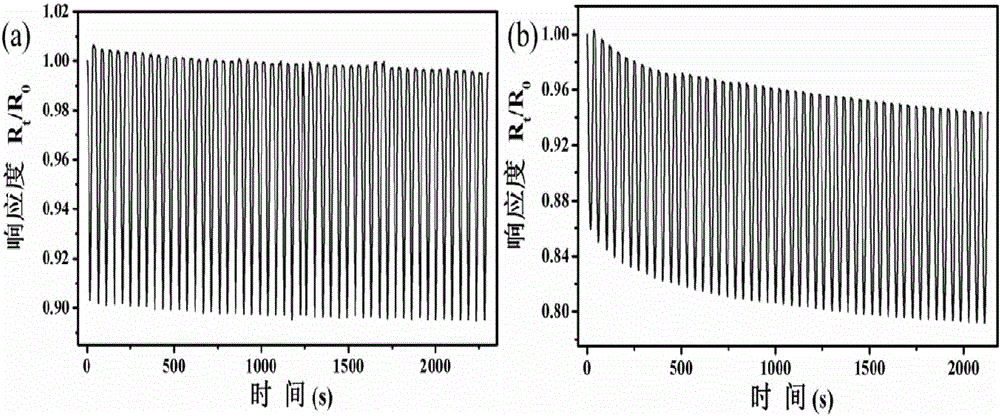

Preparation method of porous conductive polymer material with pressure-sensitive property and application thereof

ActiveCN106009029AImproved and stable electrical performanceLow percolation valueForce measurement using piezo-resistive materialsMaterial strength using repeated/pulsating forcesConductive polymer compositePolymer science

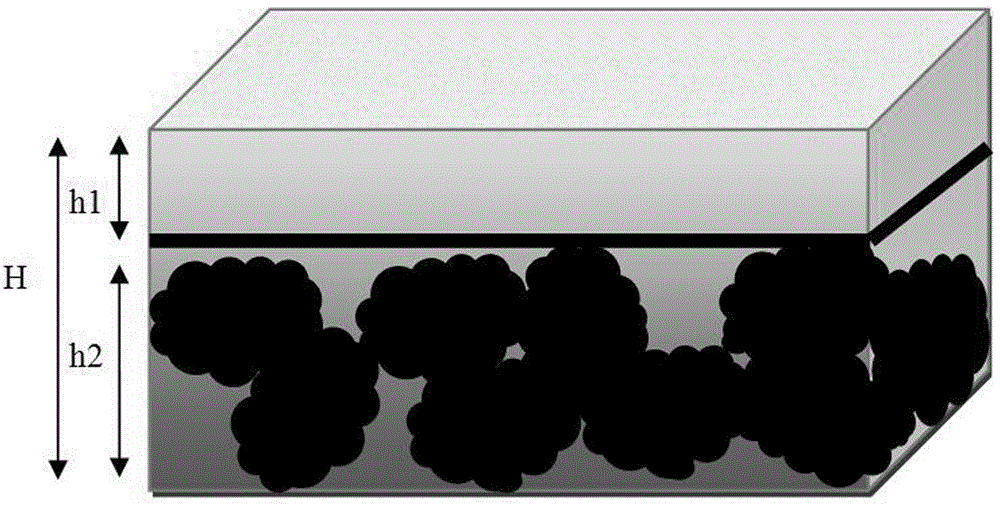

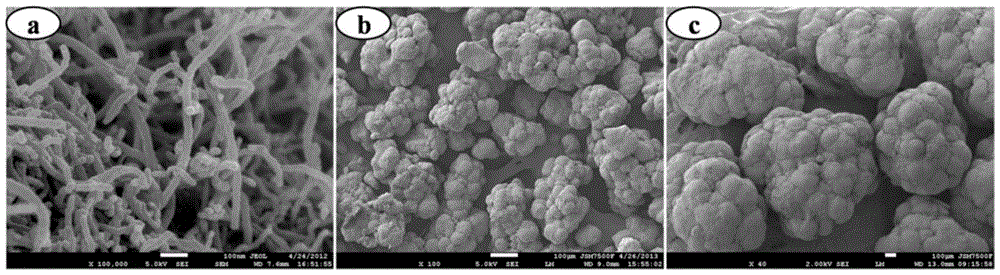

The invention belongs to the field of conductive polymer composites pressure-sensitive materials and particularly relates to a preparation method of a porous conductive polymer material with pressure-sensitive property and an application thereof. The preparation method of the porous conductive polymer material with pressure-sensitive property comprises the following steps: a) suspension preparation; b) unidirectional freezing; and c) low-temperature low-pressure drying. The porous conductive polymer composite with pressure-sensitive property prepared in the invention has excellent stability and resilience and can be used for preparing a light polymer-based strain sensor; and by combining the obtained conductive polymer composite with the circuit board and semiconductor technology, various pressure-sensitive sensors with good stability and long service life can be made.

Owner:ZHENGZHOU UNIV

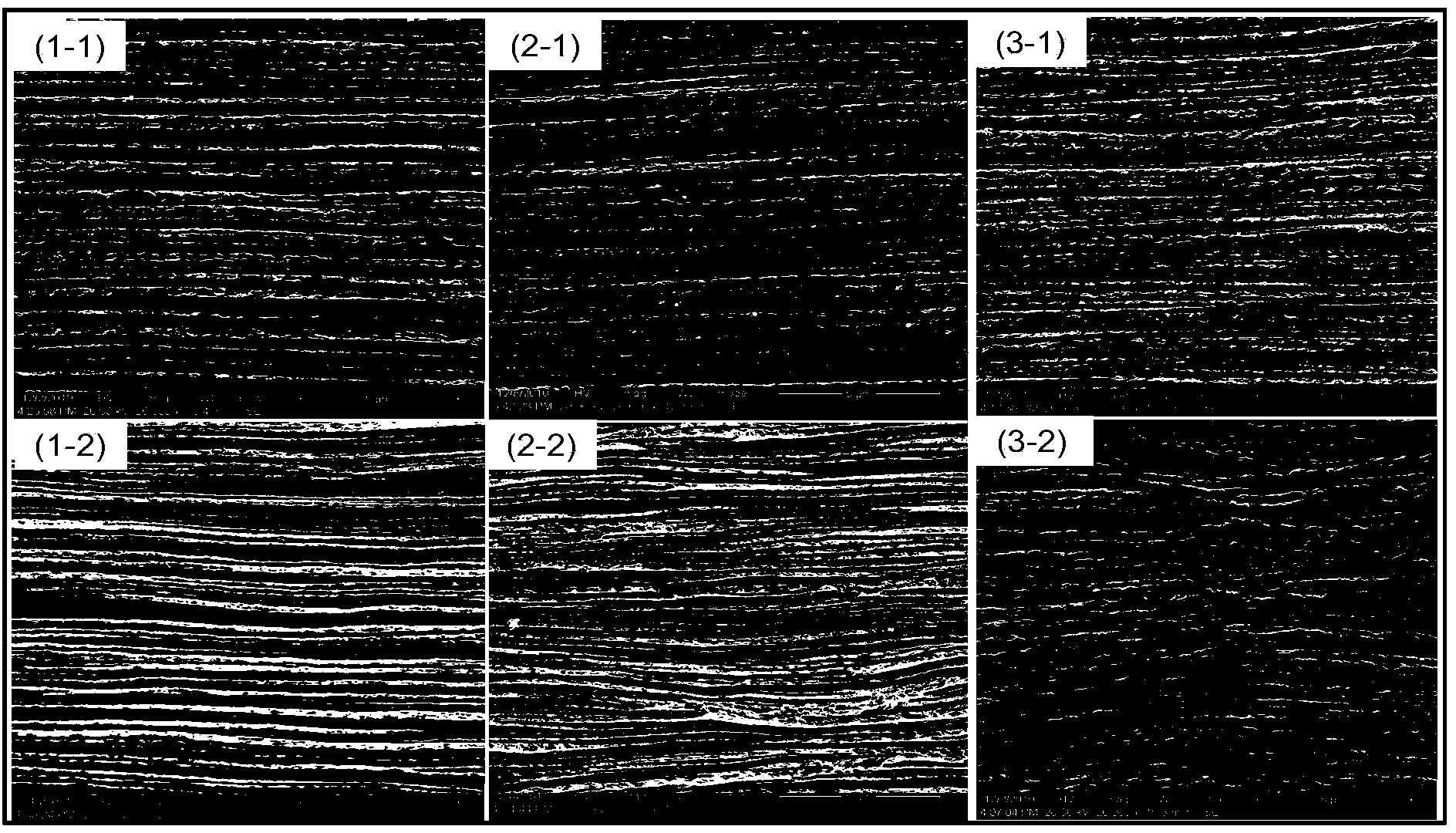

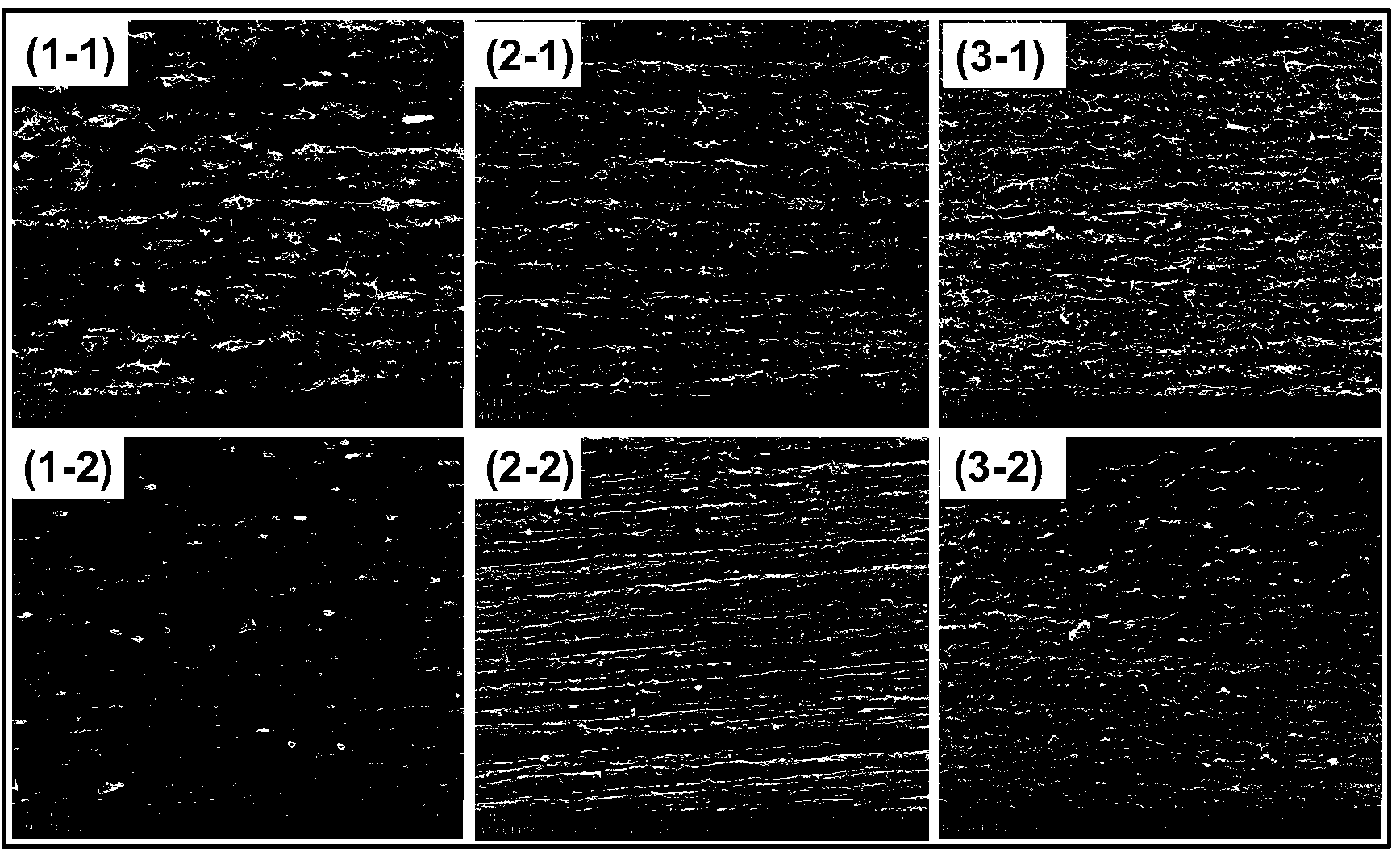

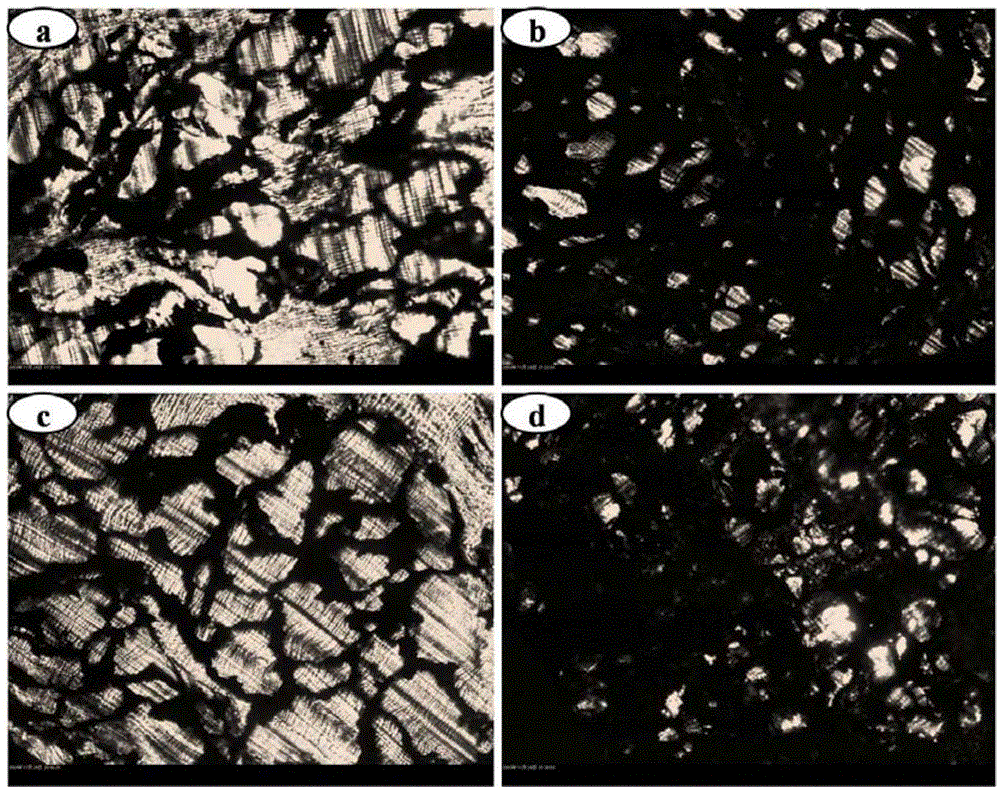

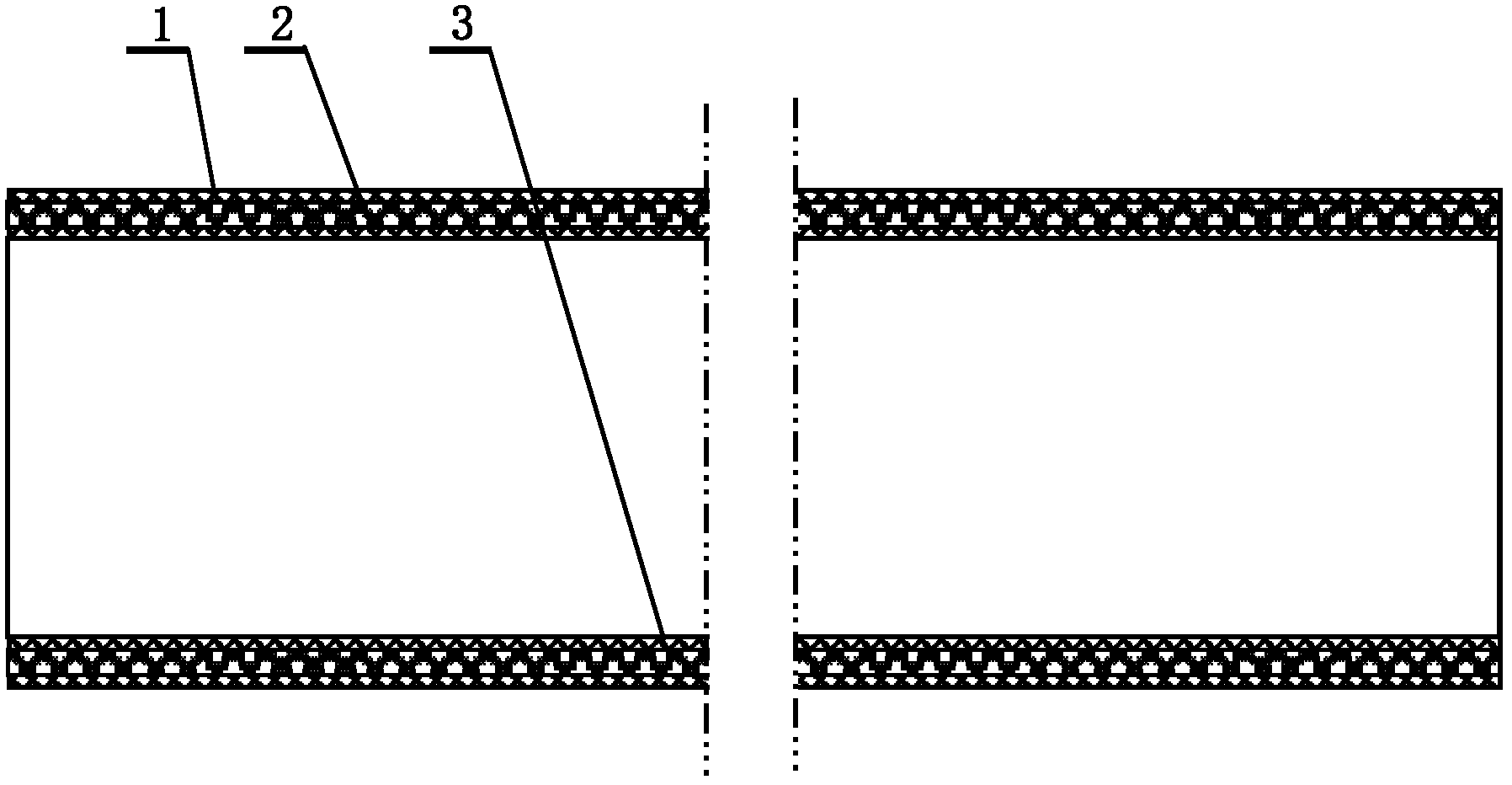

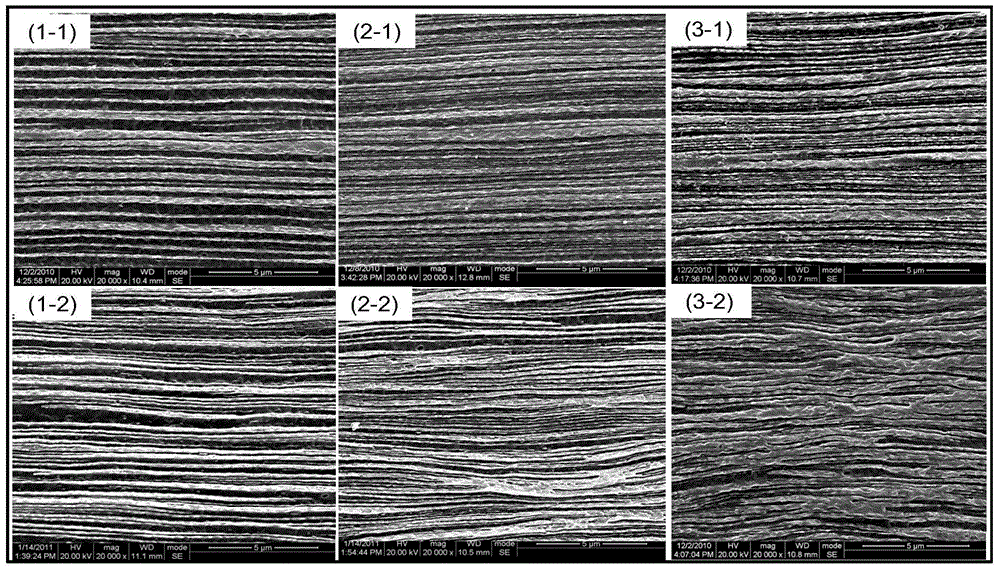

Polymer material with continuously-alternating layer structure and preparation method for same

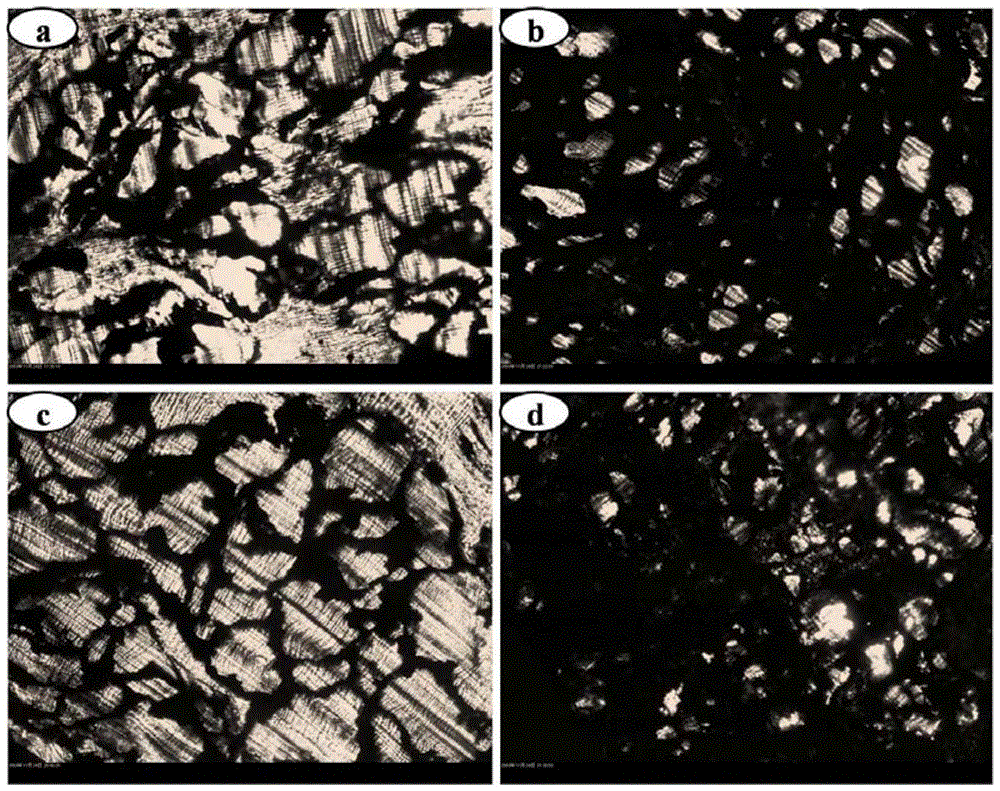

ActiveCN103481393ASimple operation processReduce manufacturing costPolymer scienceInjection moulding

The invention discloses a preparation method for a polymer material with a continuously-alternating layer structure. The preparation method comprises the following steps of step 1, premixing 30-70 parts of first resin or a first resin compound and 70-30 parts of second resin or a second resin compound, adding the premix in a double-screw extruder, performing melt blending and extrusion at a temperature of 100-300 DEG C, cooling, and slicing to obtain blend grains; and step 2, performing high-speed thin-wall injection forming on the obtained blend grains at an injection temperature of 100-300 DEG C and an injection speed of 50-1200 mm / s, so as to obtain the polymer material with a continuously-alternating layer structure. The preparation method disclosed by the invention is simple in the whole operation process, low in production cost, suitable for large-scale industrialized production, capable of regulating and controlling the thickness of the continuously-alternating layer structure by adjusting the component proportioning ratio of the blend, and suitable for various blend systems.

Owner:SICHUAN UNIV

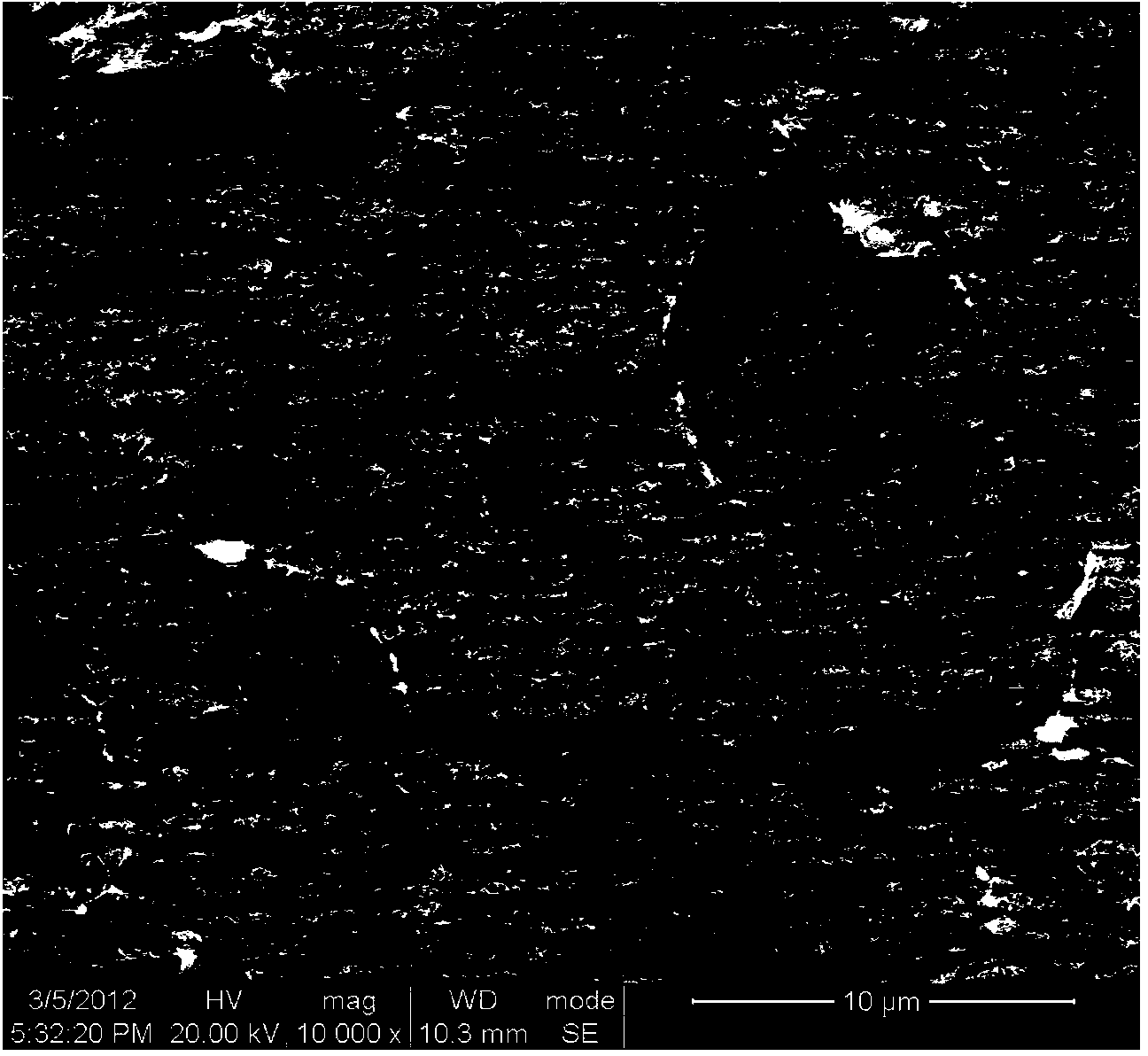

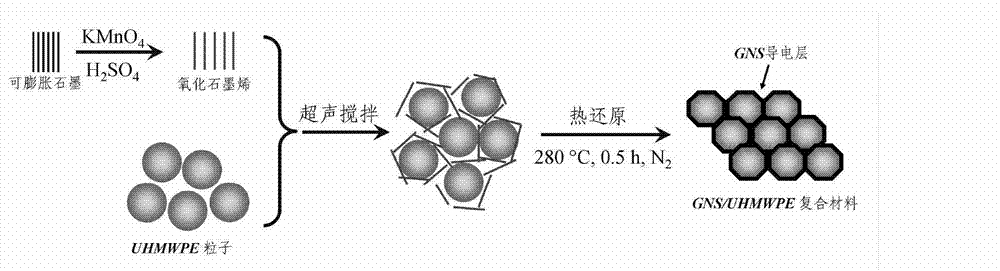

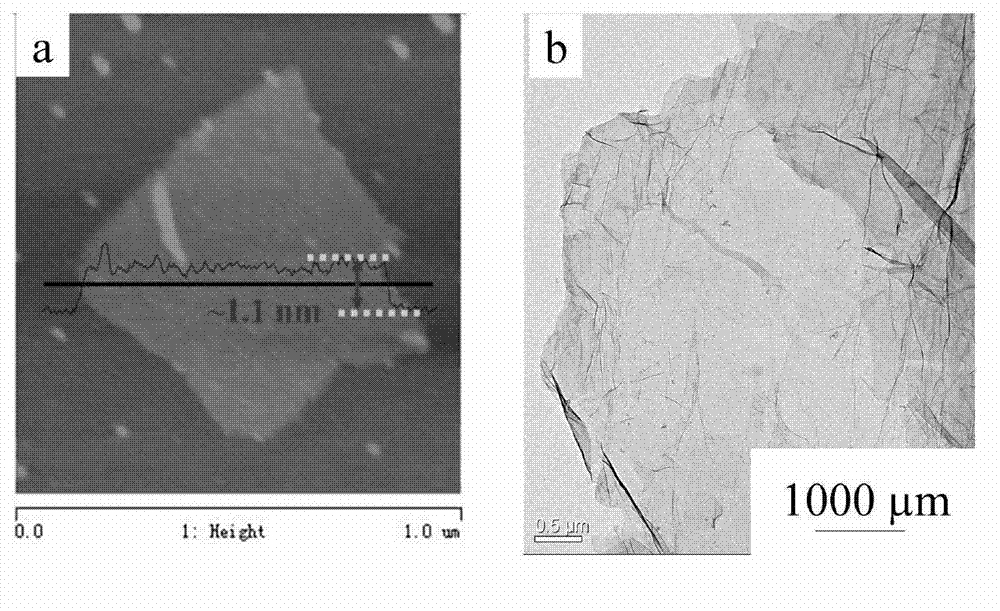

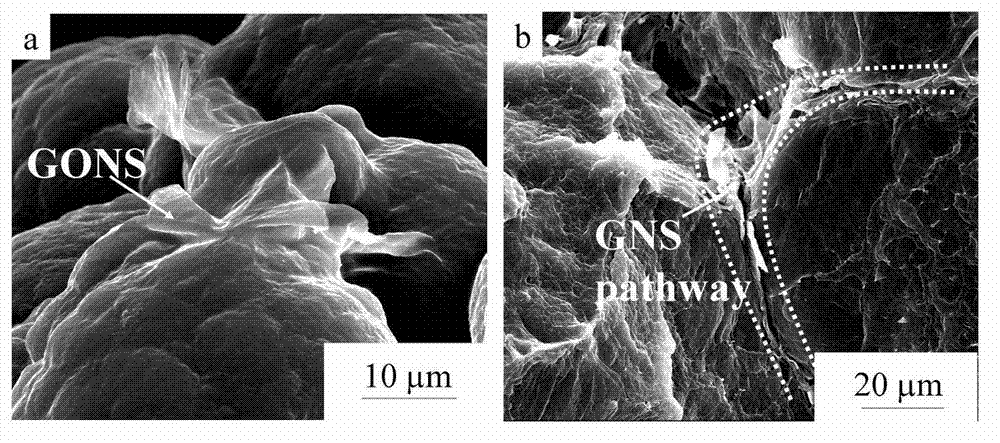

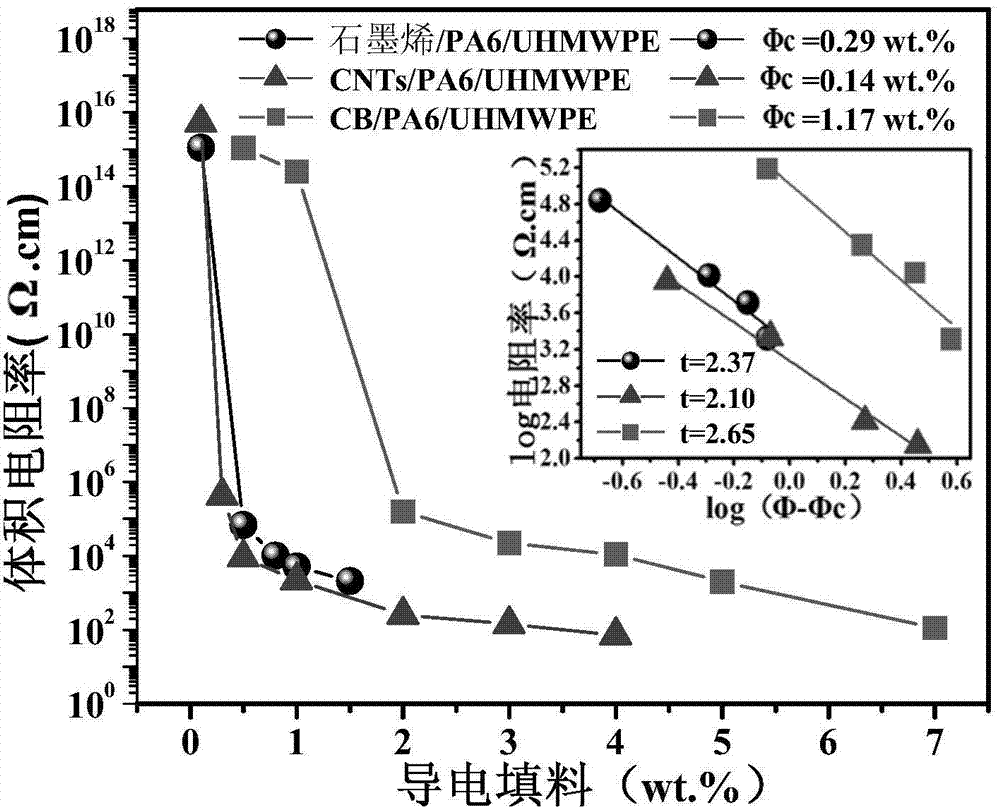

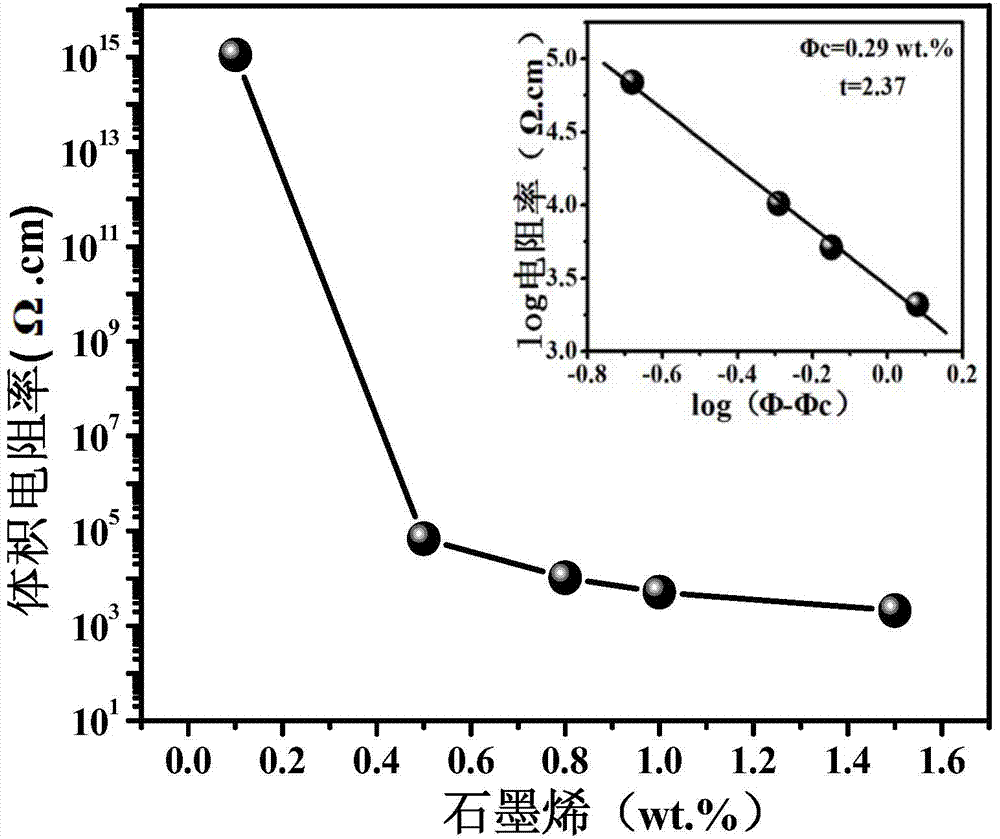

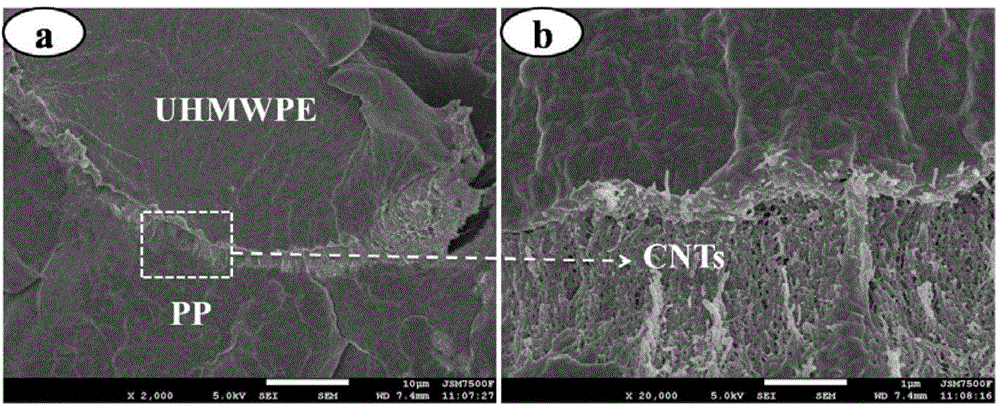

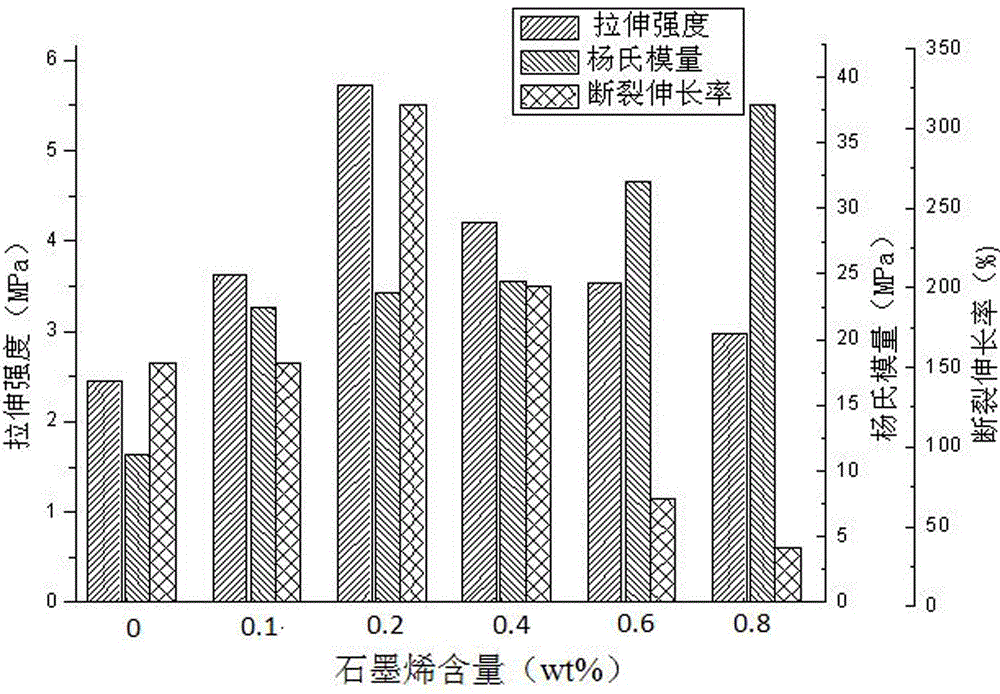

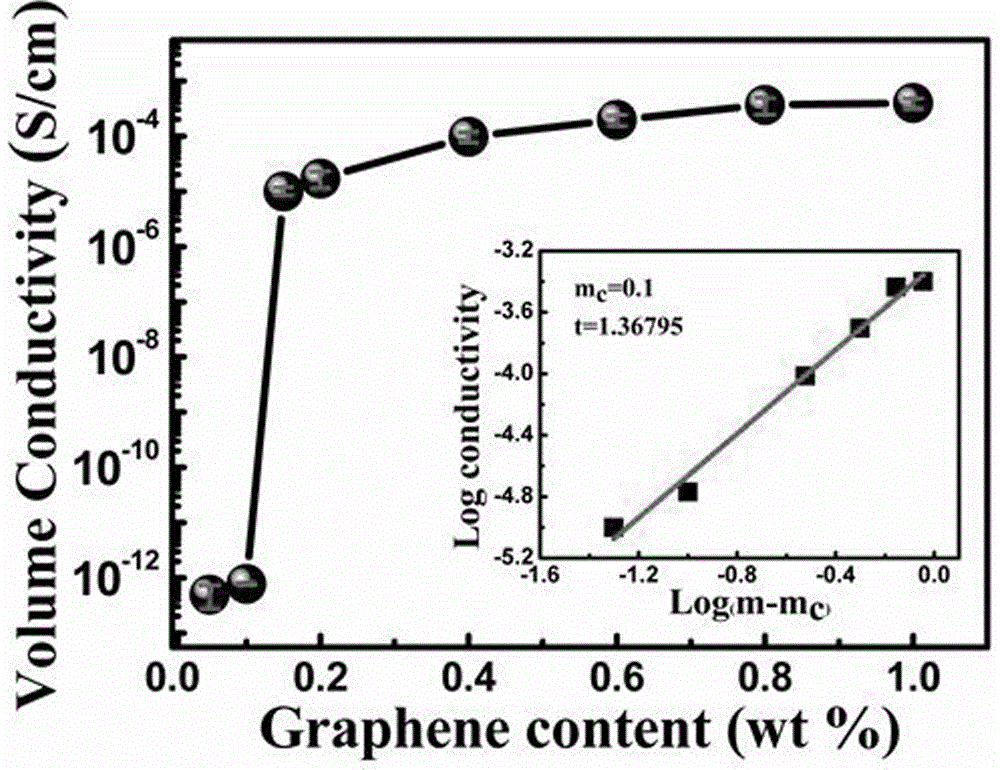

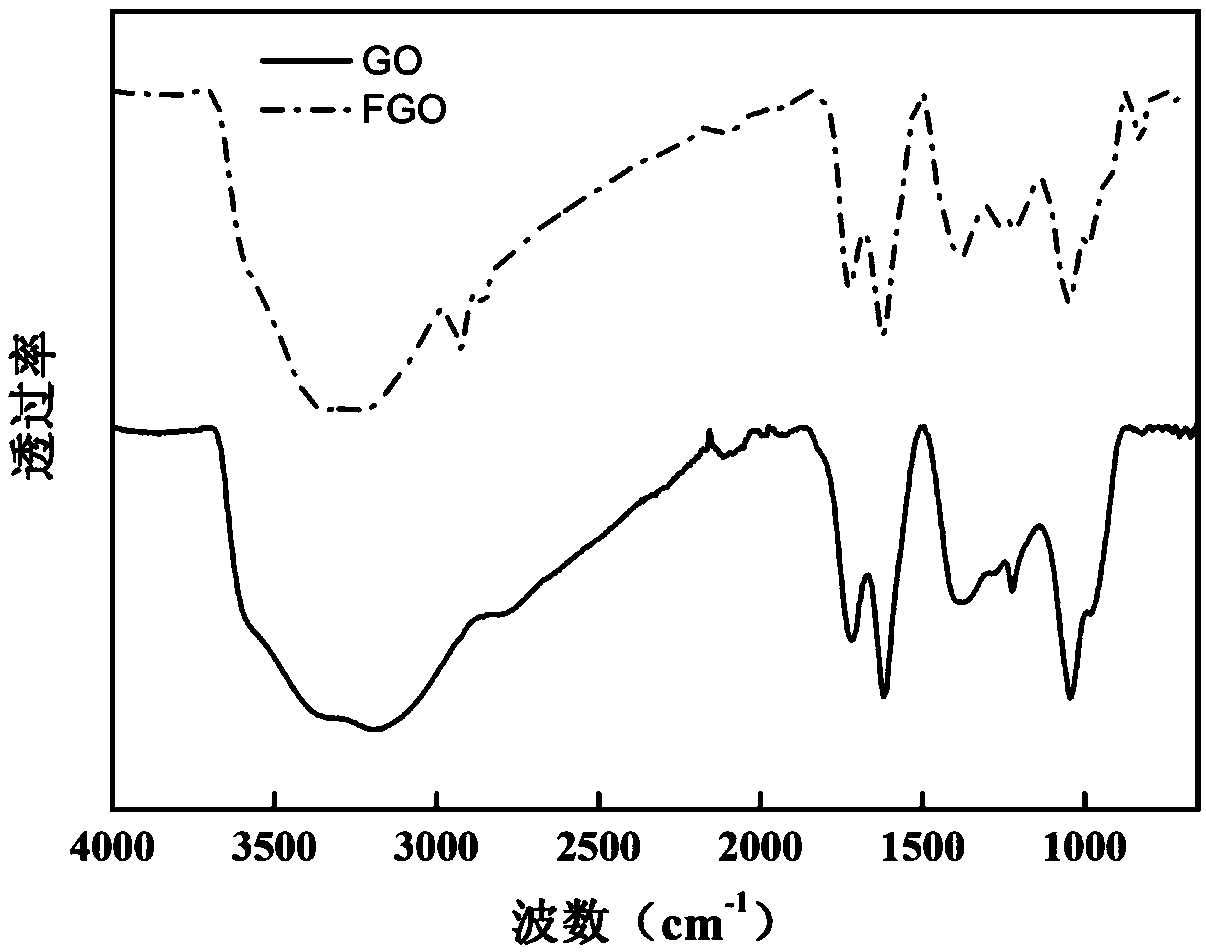

Preparation method of low-percolation graphene/macromolecule electromagnetism shielding material

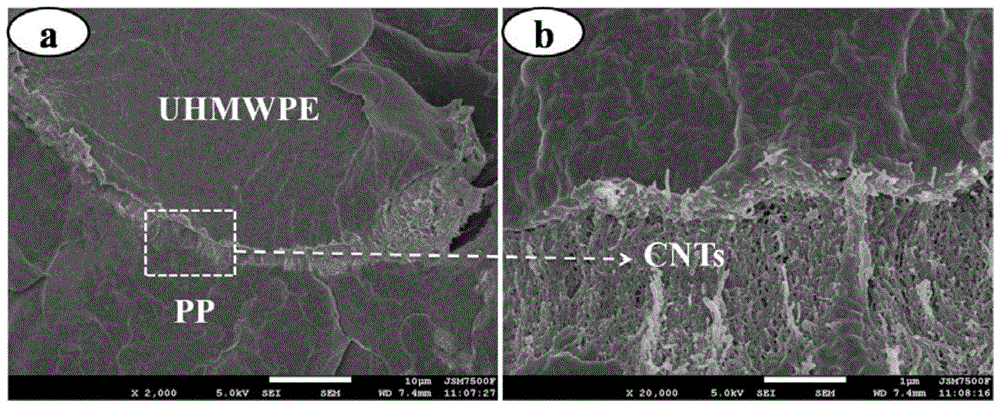

InactiveCN103087386ALow percolation valueReduce manufacturing costNon-conductive material with dispersed conductive materialPolymer scienceElectromagnetic shielding

The invention relates to a preparation method of a low-percolation graphene / macromolecule electromagnetism shielding material. The composite material comprises the following main raw materials by weight percent: 94-99.7wt% of ultra-high molecular weight polyethylene (UHMWPE) and 0.3-6wt% of graphene oxide GONS. The preparation process comprises the following steps: (1) drying the raw materials; (2) preparing GONS / UHMWPE conductive particles; and (3) pressing and forming at high temperatures. According to the invention, the graphene oxide is reduced in situ at high temperatures in a hot pressing preparation process, so that the agglomeration of the graphene oxide in a chemical reduction process is avoided, the composite material has lower conductive percolation value, higher conductivity and higher electromagnetism shielding performance; and the preparation process is simple and low in production cost, the process is easy to master and mass production is easy to achieve.

Owner:SICHUAN UNIV

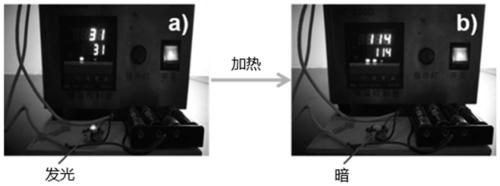

Polymer based temperature-sensitive resistance material with negative temperature coefficient (NTC) effect and preparation method thereof

ActiveCN104497394AImprove electrical performanceLow percolation valueElectrical resistance and conductanceManufacturing technology

The invention belongs to the technical field of manufacturing of conductive polymer composites, and in particular relates to a preparation method of a conductive polymer composite with negative temperature coefficient (NTC) characteristics. The invention discloses a polymer based temperature-sensitive resistance material with a NTC effect, and the polymer based temperature-sensitive resistance material comprises the following raw materials in parts by weight: 88.5-96.9 parts of a polymer 1 and a polymer 2, 0.1-1.5 parts of a conductive filler and 3-10 parts of a compatilizer; moreover, the conductive filler is selectively distributed in the polymer 2; the MFI of the polymer 1 is less than or equal to 7g / 10 minutes, and the MFI of the polymer 2 is more than or equal to 12g / 10 minutes; the thermal expansion coefficient of the polymer 2 is greater than that of the polymer 1, and the conductive filler is a two-dimensional conductive filler; and the mass ratio of the polymer 1 to the polymer 2 is (3:7)-(7:3). The resistance material prepared by the method disclosed by the invention is low in percolation threshold, the NTC characteristic repeatability of the obtained resistance material is good, and the resistance material is convenient to use for a long time.

Owner:ZHENGZHOU UNIV

High-dispersion silver powder and solar battery electrode conductive silver paste

InactiveCN102139368ALow percolation valueReduce fill rateSemiconductor devicesSilver pasteElectrical battery

The invention discloses high-dispersion silver powder and solar battery electrode conductive silver paste, wherein the conductive silver paste is prepared from the following components in mass percentage: 53-61.8% of high-dispersion silver powder in claim 1, 21.5-31% of glass cement and 15-17.6% of organic carrier. The high-dispersion silver powder provided by the invention has very good dispersity and by means of the conductive silver paste prepared by the high-dispersion silver powder, the usage amount of the silver powder is reduced and the conductive efficiency is improved in the mean time; in addition, the conductive silver paste provided by the invention is clean and environmental-friendly and is suitable for popularization and application. By means of the high-dispersion silver powder and the solar battery electrode conductive silver paste which are provided by the invention, the defects of poor dispersity of the conventional silver powder and large usage amount of the silver powder of the conventional conductive silver paste are overcome.

Owner:中科广化(重庆)新材料研究院有限公司 +3

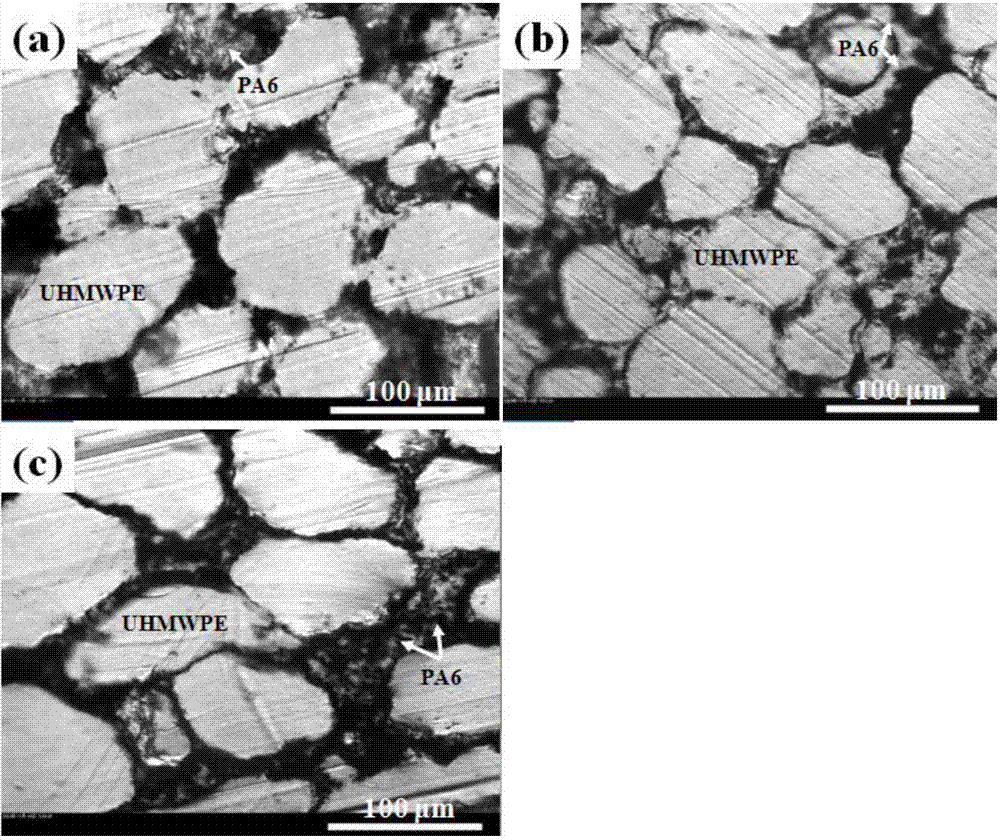

Method for preparing conductive macromolecular composite material with isolation structure

ActiveCN104530521ALow percolation valueSimple processGrain treatmentsConductive polymer compositeInjection moulding

The invention belongs to the technical field of conductive macromolecular materials and particularly relates to a method for preparing a conductive macromolecular composite material with an isolation structure. The invention provides the method for preparing the conductive macromolecular composite material with the isolation structure. The preparation method comprises the following steps: uniformly mixing two macromolecular materials and conductive particles by adopting a mechanical blending method to obtain a macromolecular material / conductive particle blending material, wherein the conductive particles are selectively distributed between interfaces of the two macromolecular materials to form a conductive network; and then, injection moulding the macromolecular material / conductive particle blending material by adopting a plunger injection moulding device to prepare the conductive macromolecular composite material with the isolation structure. According to the method provided by the invention, the conductive particles are selectively distributed between the two macromolecules to form the conductive network so as to form the so-called isolation structure, thus the percolation threshold of the material is reduced to a great extent. The invention provides a new concept for preparing the conductive macromolecular composite material which is low in percolation threshold, good in processing performance and extremely high in moulding efficiency.

Owner:ZHENGZHOU UNIV

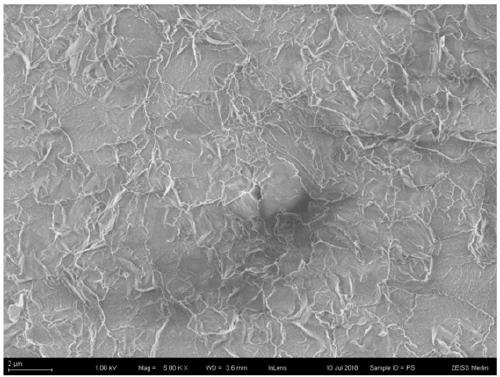

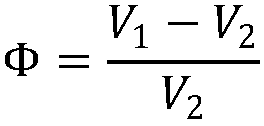

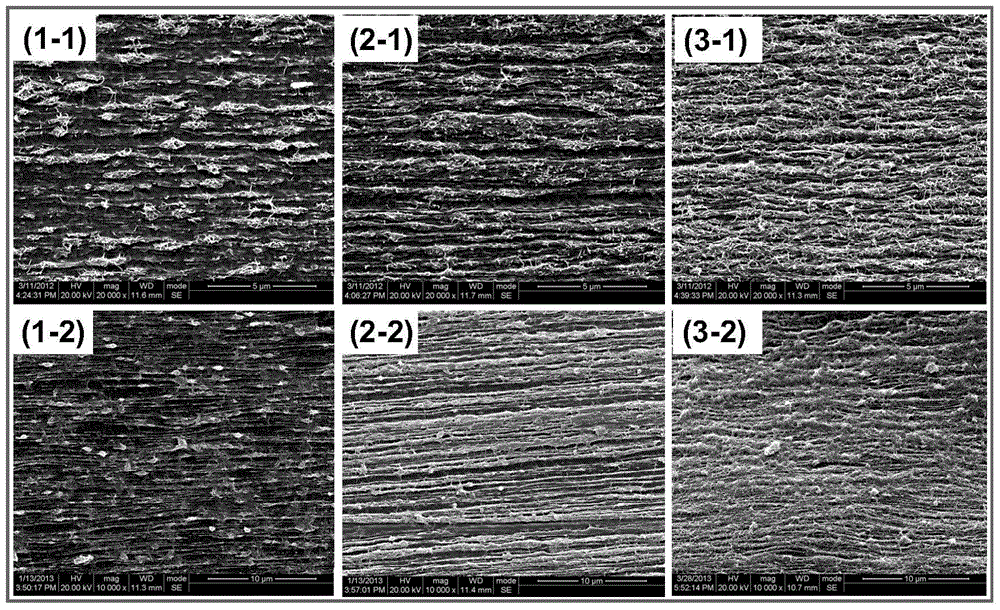

Preparation method of gradient graphene/polyurethane conductive composite material

ActiveCN105966038AAvoid reunionLow percolation valueFibre typesLaminationMaterials preparationNetwork structure

The invention discloses a preparation method of a gradient graphene / polyurethane conductive composite material. The preparation method comprises 1, graphene-containing polyurethane powder preparation, 2, graphene / polyurethane non-woven fabric film or nanometer clay tube / polyurethane non-woven fabric film preparation and 3, gradient graphene / polyurethane conductive composite material preparation. The preparation method prevents graphene agglomeration in blending. The surface of the polyurethane non-woven fabric is spray-coated with graphene with excellent electrical conductivity and a 3D conductive network structure gradient graphene / polyurethane conductive composite material layer is formed on the film surface so that high mechanical properties and a low permeability value are realized. Compared with the prior art, the preparation method realizes one-step molding and has simple processes. The preparation method can produce the gradient graphene / polyurethane conductive composite material with high mechanical properties and a low permeability value.

Owner:ZHENGZHOU UNIV

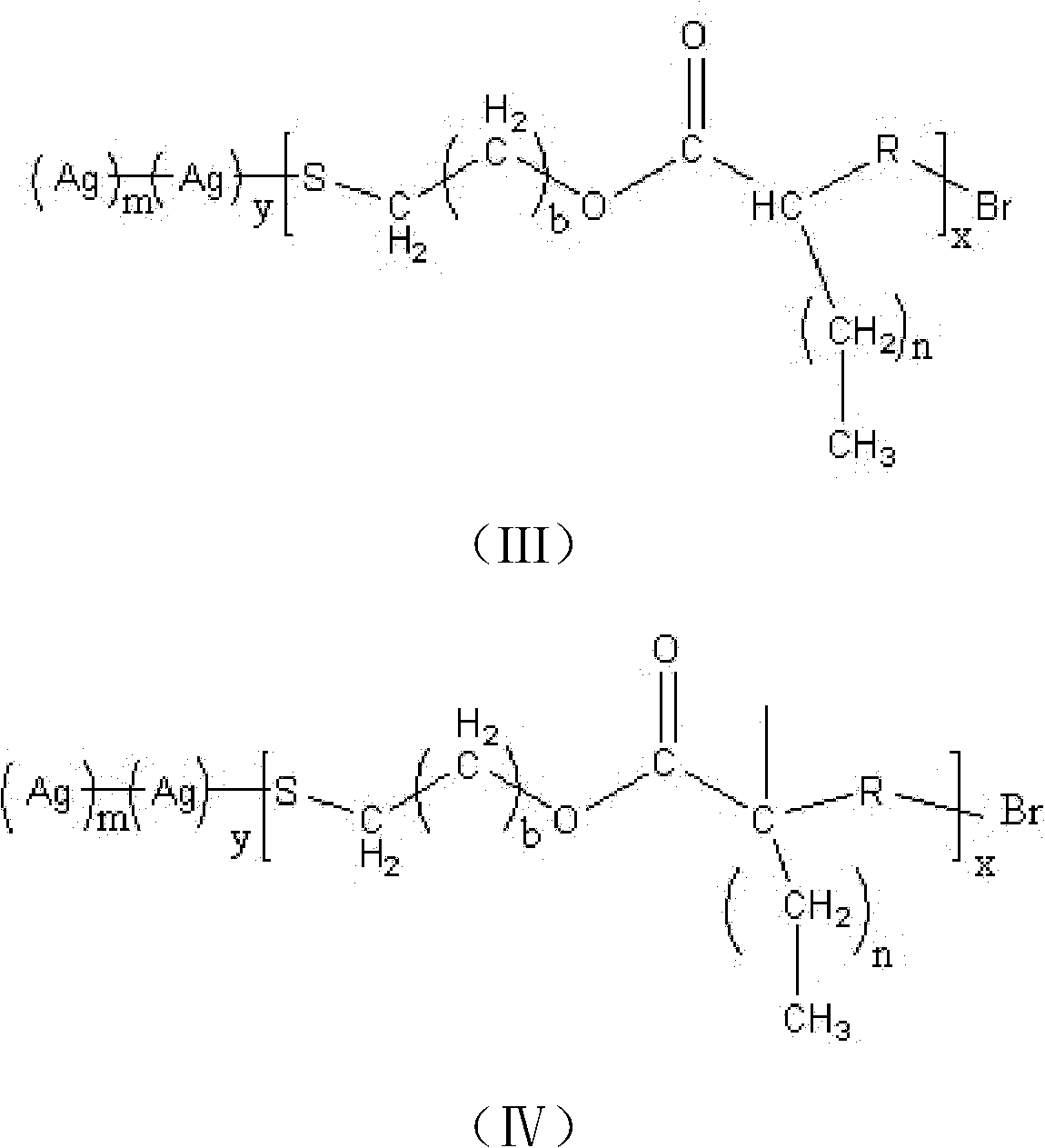

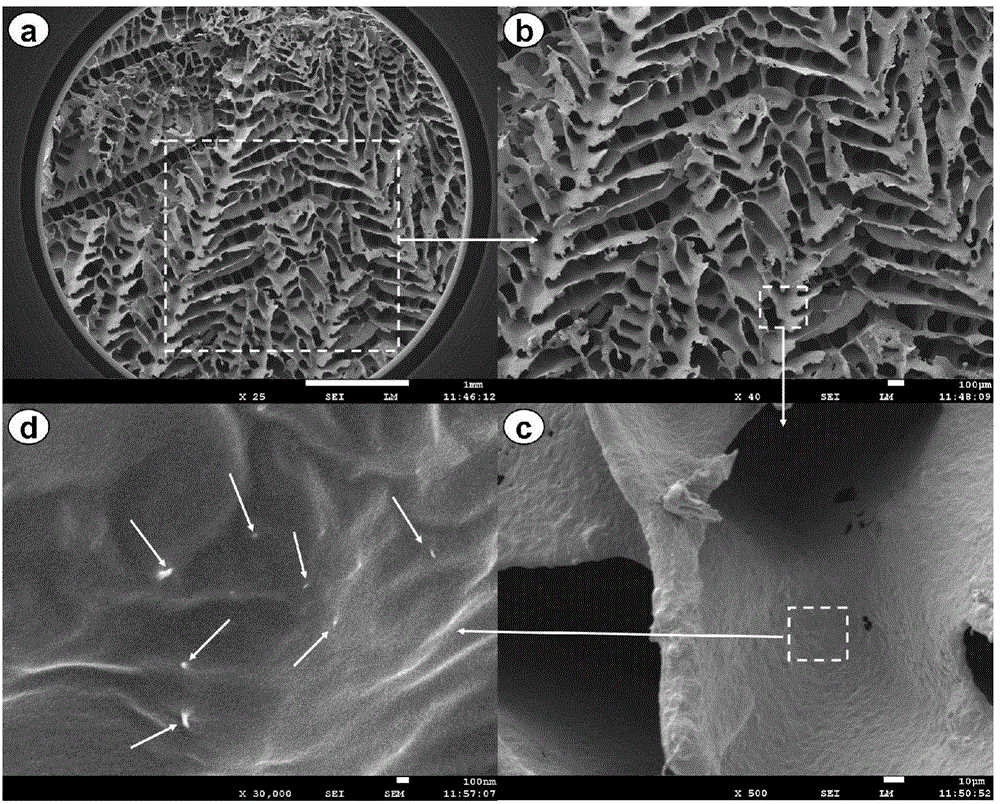

Conductive high-molecular composite material with dendritic cellular structure, and preparation method thereof

ActiveCN104861633AImproved and stable electrical performanceLow percolation valueConductive polymer compositeThermoplastic elastomer

The invention relates to the field of conductive high-molecular materials, and specifically relates to a conductive high-molecular composite material with a dendritic cellular structure. The conductive high-molecular composite material comprises the raw materials of, by weight, 1-5 parts of a thermoplastic elastomer material, 1-4 parts of thermosetting resin, 0.1-2 parts of a curing agent, and 0.01-1 part of conductive particles. The conductive high-molecular composite material has a dendritic cellular structure. The electrical performance of the high-molecular composite material is improved and stable, and the percolation threshold is low.

Owner:ZHENGZHOU UNIV

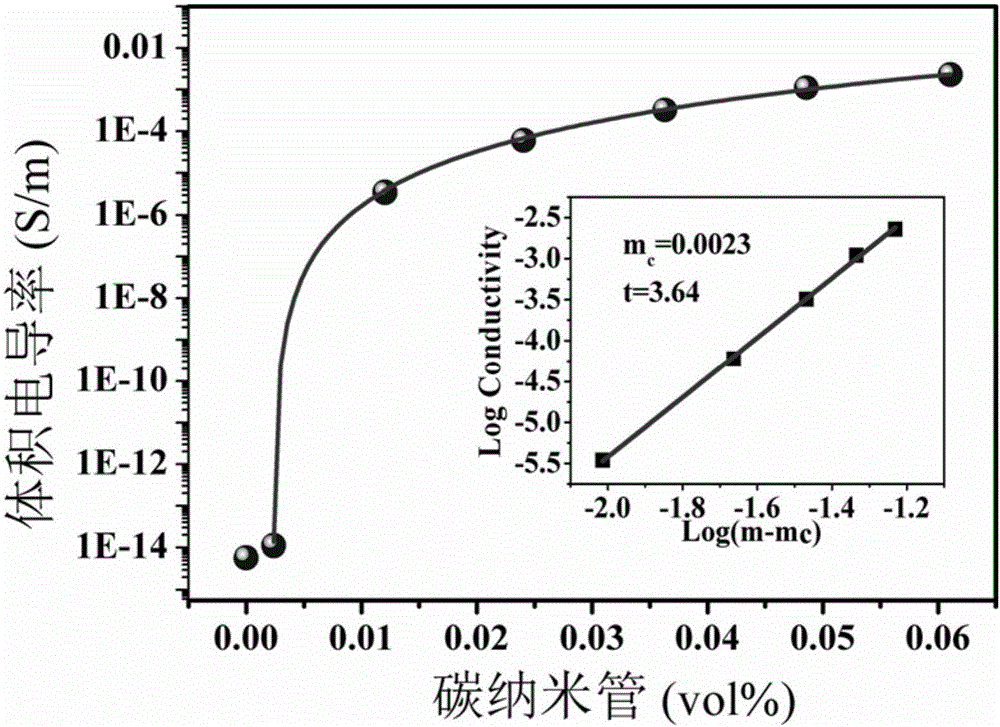

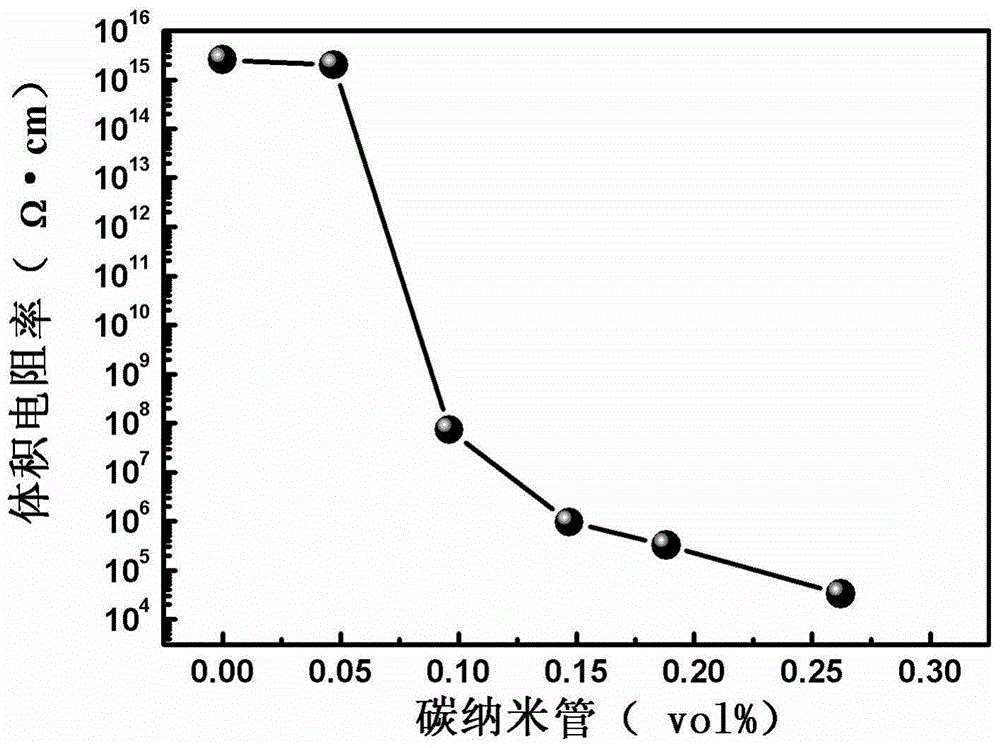

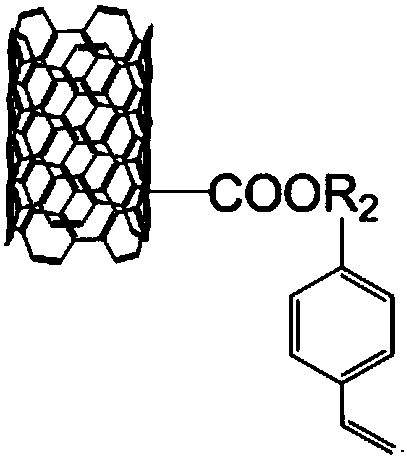

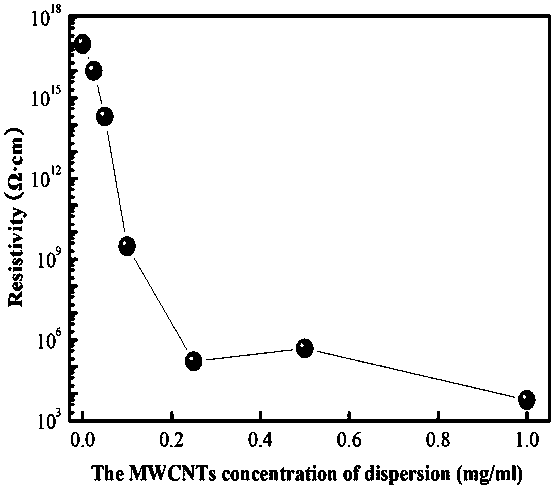

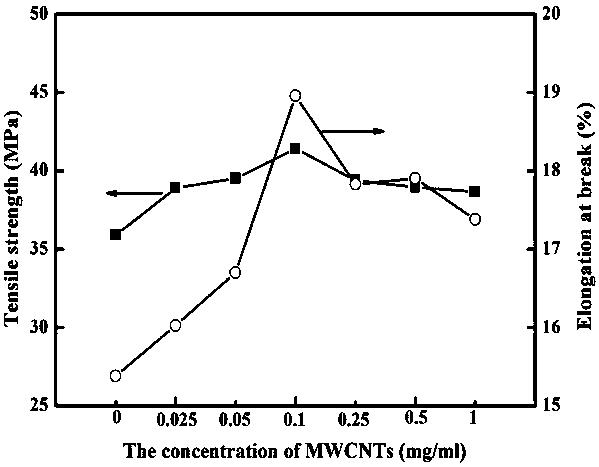

Low-percolation polyester/carbon nanotube conductive composite material and preparation method thereof

InactiveCN102532819AGood dispersionHighly uniform dispersionNon-conductive material with dispersed conductive materialPolyesterPtru catalyst

The invention belongs to the technical field of preparation of high molecular materials, and particularly relates to a low-percolation polyester / carbon nanotube conductive composite material and a preparation method thereof. The composite material comprises the following components in parts by weight: 0.05-5 parts of modified carbon nanotube, 78 parts of dimethyl terephthalate, 50-100 parts of aliphatic diol, 0.0078-0.78 part of ester exchange catalyst and 0.0078-0.78 part of polymerization catalyst. The invention also provides a preparation method of the low-percolation polyester / carbon nanotube conductive composite material. The method comprises the following two core steps: surface polymerization of carbon nanotubes and in-situ polymerization. Compared with the prior art, the specially modified carbon nanotubes in the polyester / carbon nanotube conductive composite material provided by the invention have high similarity with polyester, and thus, can be chemically combined with the polyester, and the system viscosity is very low in the in-situ polymerization process, so that the carbon nanotubes are highly dispersed in the substrate, thereby greatly lowing the conductive percolation value of the carbon nanotubes in the composite material.

Owner:GUANGXI LISHENG STONE CO LTD +1

Formula for producing conductive fiber through graphene

InactiveCN107119338AAddressing the Effects of ConductivityStretchableElectroconductive/antistatic filament manufactureMonocomponent synthetic polymer artificial filamentFiberOptoelectronics

The invention discloses a formula for producing conductive fiber through graphene. The formula for producing conductive fiber through graphene comprises the following components: (1) graphene with the addition amount of 0.1-5% vol; (2) a solvent; (3) polyphenylene sulfide with the addition amount of 5-20% in percent by mass. According to the formula for producing conductive fiber through graphene, through addition of the graphene, the influence on the conductivity of a nonconductive composite material is eliminated.

Owner:苏州介观智造新材料有限公司

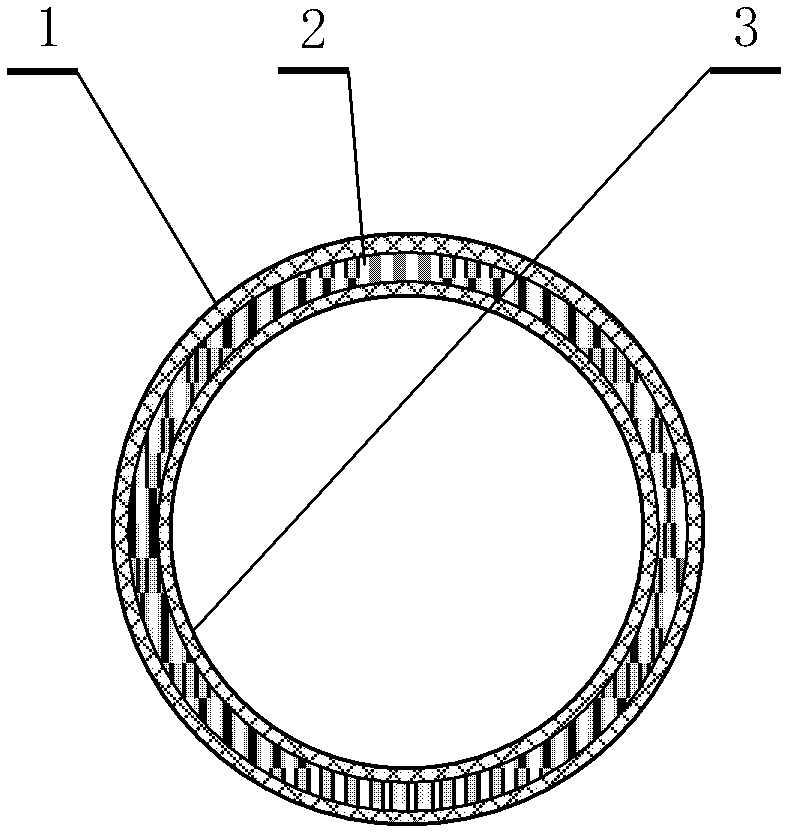

Polypropylene pipeline

InactiveCN102588683AImprove physical performanceEasy to processRigid pipesSocial benefitsGlass fiber

The invention relates to a pipeline, in particular to a polypropylene (PP) pipeline, which comprises a pipe. The technical scheme includes that a pipe wall has three layers, an inner layer and an outer layer are antistatic polypropylene layers, namely conductive carbon fiber materials with the weight ratio ranging from 1% to 5% and conducting carbon black with the weight ratio ranging from 2% to 8% are mixed in polypropylene materials to form each polypropylene layer, and an intermediate layer is a glass fiber reinforced polypropylene layer, namely glass fibers with the weight ratio ranging from 25% to 45% and amine beta nucleating agent with the weight ratio ranging from 0.1% to 0.5% are mixed in polypropylene materials to form the glass fiber reinforced polypropylene layer. The polypropylene pipeline has the advantages that the polypropylene pipeline is high in corrosion resistance and physical properties and excellent in antistatic performance, the quality of a product can be guaranteed, maintenance cost of equipment is low, resources can be greatly saved, production cost of the product is greatly lowered, and the polypropylene pipeline is a product with excellent economic and social benefits.

Owner:张扩潮

Low-percolation-threshold polypropylene-based composite electroconductive high polymer material and preparation method thereof

The invention discloses a low-percolation-threshold polypropylene-based composite electroconductive high polymer material which is composed of, by weight, 40-50 parts of polypropylene, 1-2 parts of carbon nano tube, 20-30 parts of electroconductive carbon black, 5-12 parts of glass fiber, 5-10 parts of titanium-magnesium alloy, 5-8 parts of calcium powder, 5-10 parts of decabromodiphenyl ether and 1-2 parts of silicone oil.The invention further discloses a preparation method of the material.The silicone oil is adopted as a phase solvent, so that dispersity of the electroconductive carbon black in polypropylene is improved, percolation value of the composite material is lowered, and electroconductivity of the material is improved greatly; various fillers are compounded and added, overall mechanical performance of the material is improved, and the material has better properties.

Owner:北京北交富沃机电工程科技有限公司

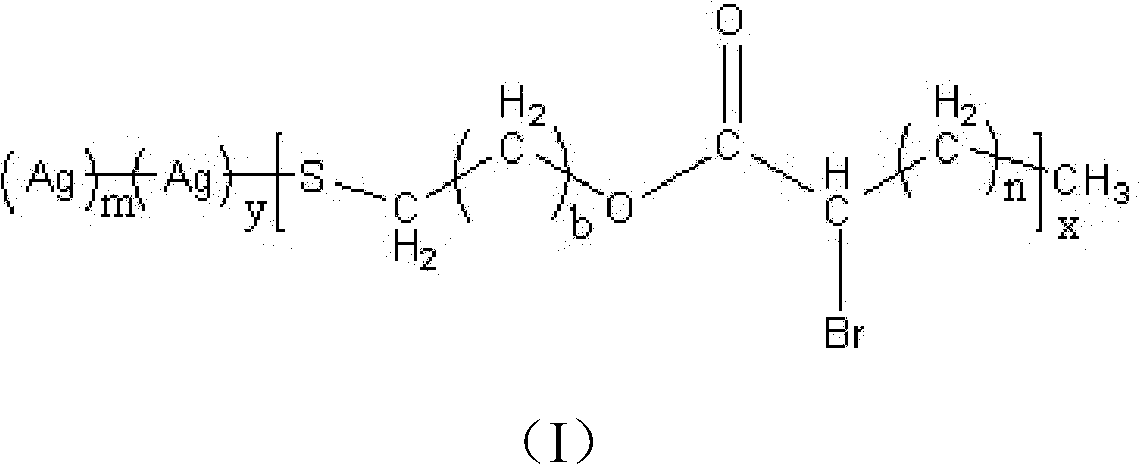

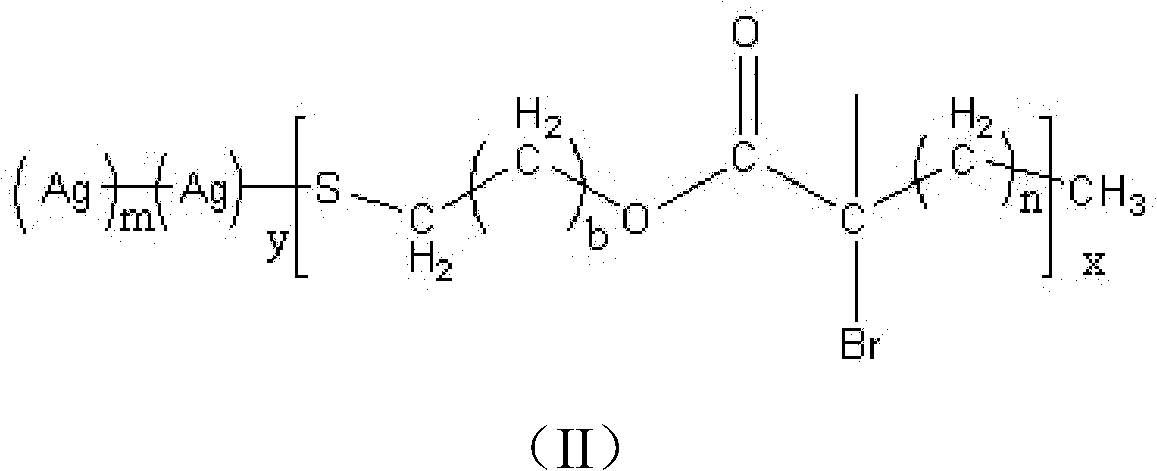

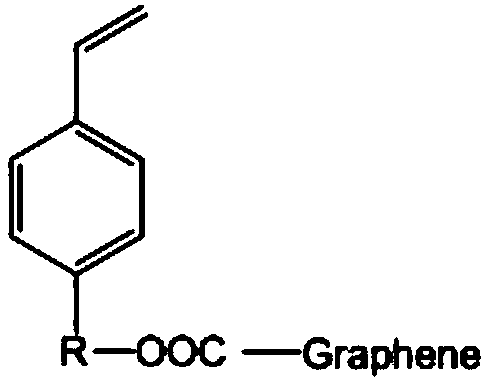

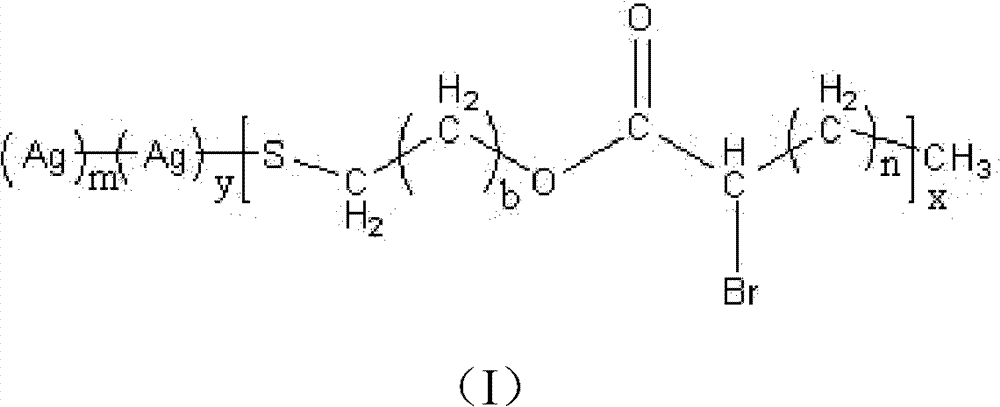

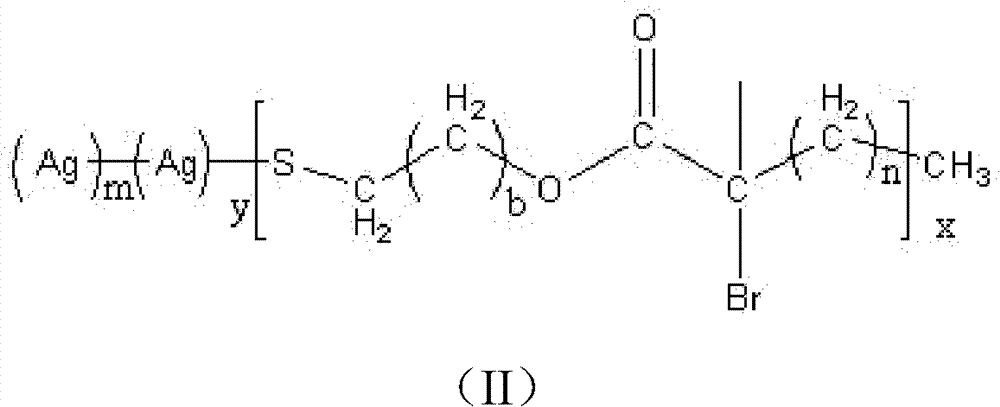

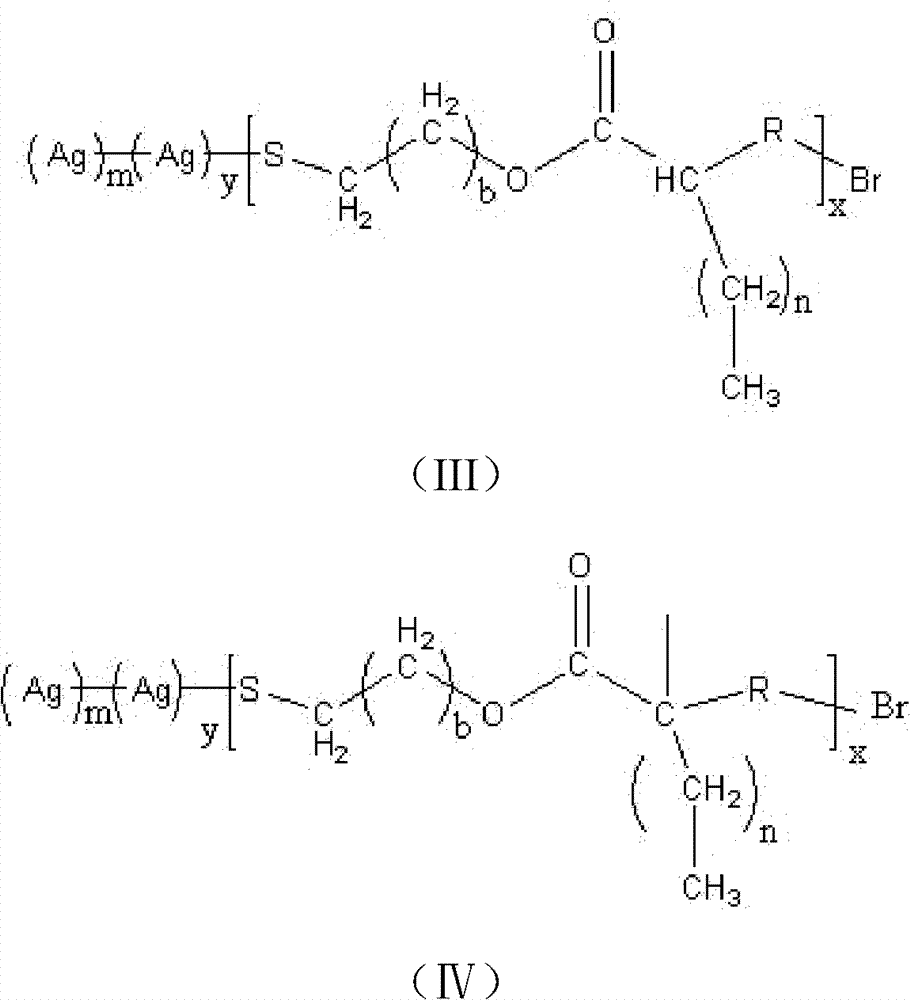

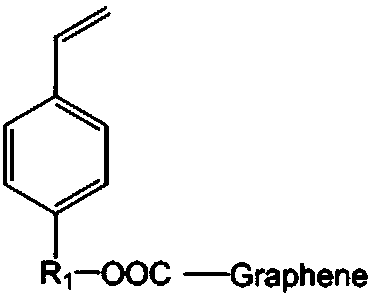

Strong-basicity graphene composite ion exchange resin material and preparation method thereof

The invention relates to a strong-basicity graphene composite ion exchange resin material and a preparation method thereof. A matrix and graphene in the strong-basicity graphene composite ion exchangeresin material are combined in a covalent bond form. The technical scheme adopted by the invention is as follows: the strong-basicity graphene composite ion exchange resin material comprises the following components in parts by weight: (a) 75-90 parts of a polymeric monomer; (b) 5-15 parts of a comonomer; and (c) 0.1 to 10 parts of a graphene-styrene derivative compound. According to the technical scheme, the thermal decomposition temperature and the swelling resistance of the composite ion exchange resin are well improved, and the method can be applied to industrial production and application of strong-basicity composite ion exchange resin materials in the future.

Owner:CHINA PETROLEUM & CHEM CORP +1

High-dispersion silver powder and solar battery electrode conductive silver paste

InactiveCN102139368BLow percolation valueReduce fill rateSemiconductor devicesSilver pasteElectrical battery

The invention discloses high-dispersion silver powder and solar battery electrode conductive silver paste, wherein the conductive silver paste is prepared from the following components in mass percentage: 53-61.8% of high-dispersion silver powder in claim 1, 21.5-31% of glass cement and 15-17.6% of organic carrier. The high-dispersion silver powder provided by the invention has very good dispersity and by means of the conductive silver paste prepared by the high-dispersion silver powder, the usage amount of the silver powder is reduced and the conductive efficiency is improved in the mean time; in addition, the conductive silver paste provided by the invention is clean and environmental-friendly and is suitable for popularization and application. By means of the high-dispersion silver powder and the solar battery electrode conductive silver paste which are provided by the invention, the defects of poor dispersity of the conventional silver powder and large usage amount of the silver powder of the conventional conductive silver paste are overcome.

Owner:中科广化(重庆)新材料研究院有限公司 +3

A method for preparing conductive polymer composite material with isolation structure

ActiveCN104530521BLow percolation valueSimple processGrain treatmentsConductive polymer compositeInjection moulding

The invention belongs to the technical field of conductive macromolecular materials and particularly relates to a method for preparing a conductive macromolecular composite material with an isolation structure. The invention provides the method for preparing the conductive macromolecular composite material with the isolation structure. The preparation method comprises the following steps: uniformly mixing two macromolecular materials and conductive particles by adopting a mechanical blending method to obtain a macromolecular material / conductive particle blending material, wherein the conductive particles are selectively distributed between interfaces of the two macromolecular materials to form a conductive network; and then, injection moulding the macromolecular material / conductive particle blending material by adopting a plunger injection moulding device to prepare the conductive macromolecular composite material with the isolation structure. According to the method provided by the invention, the conductive particles are selectively distributed between the two macromolecules to form the conductive network so as to form the so-called isolation structure, thus the percolation threshold of the material is reduced to a great extent. The invention provides a new concept for preparing the conductive macromolecular composite material which is low in percolation threshold, good in processing performance and extremely high in moulding efficiency.

Owner:ZHENGZHOU UNIV

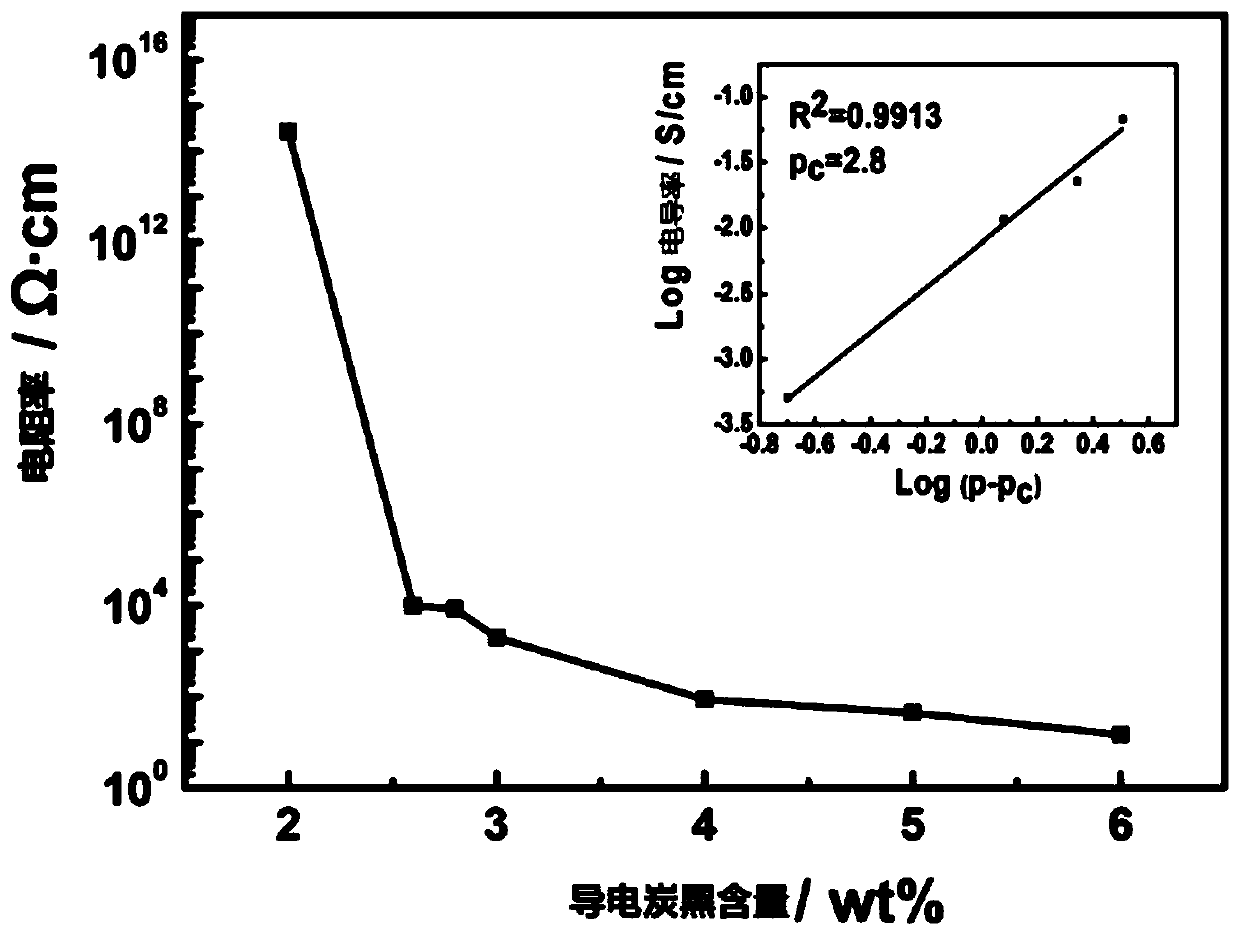

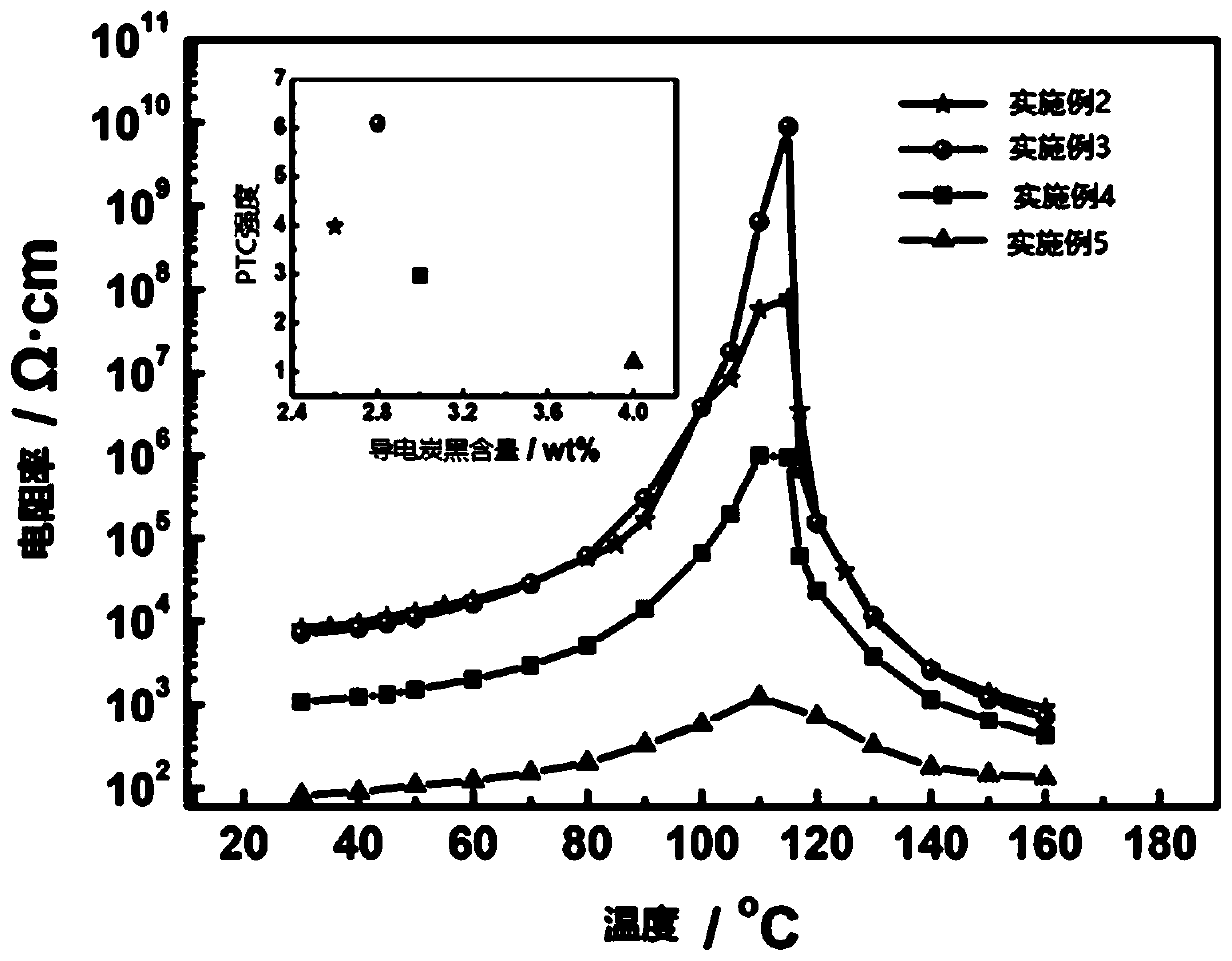

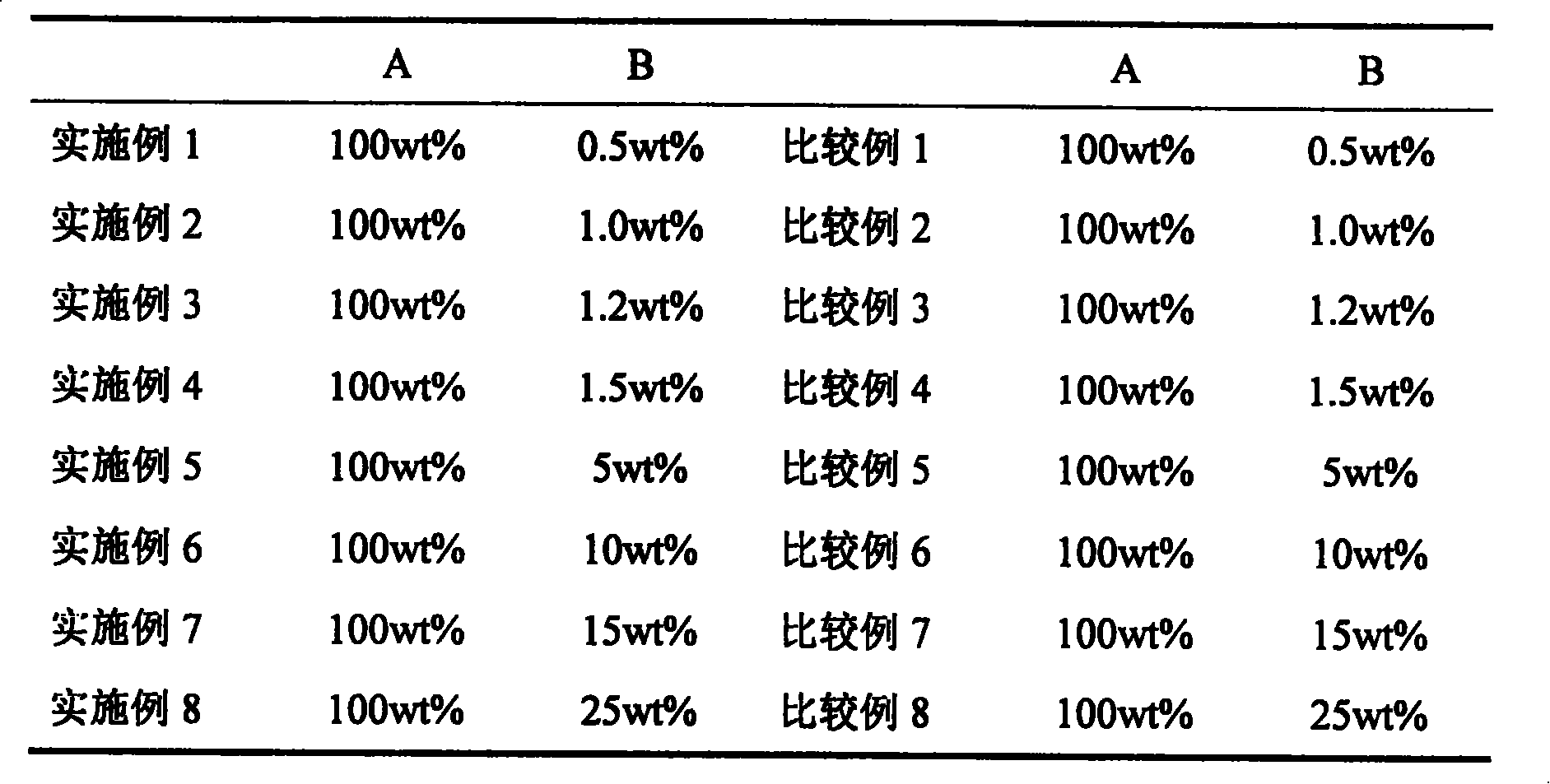

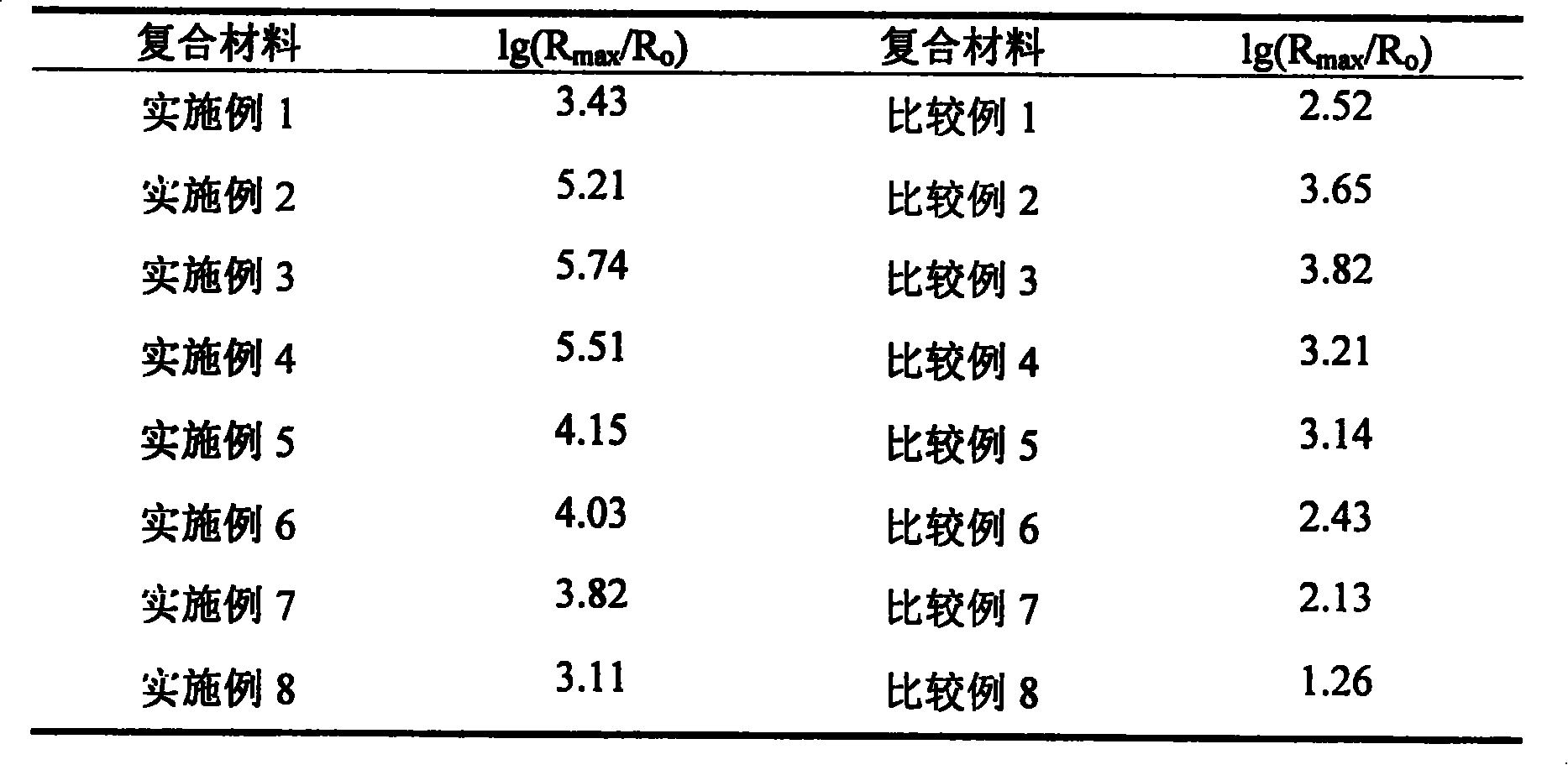

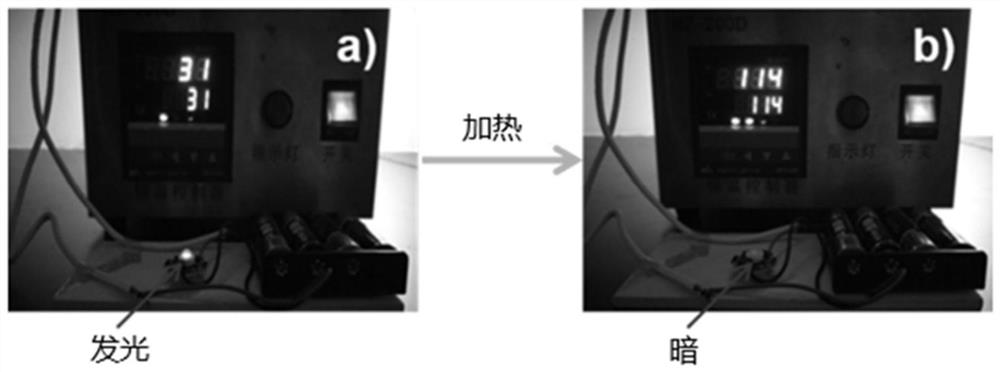

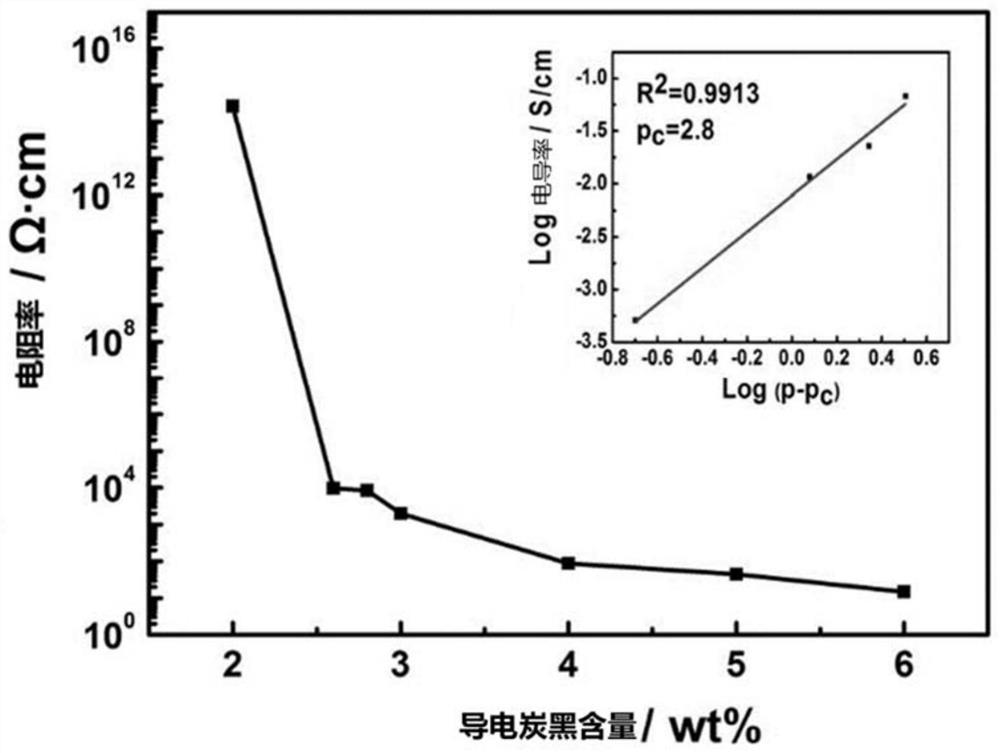

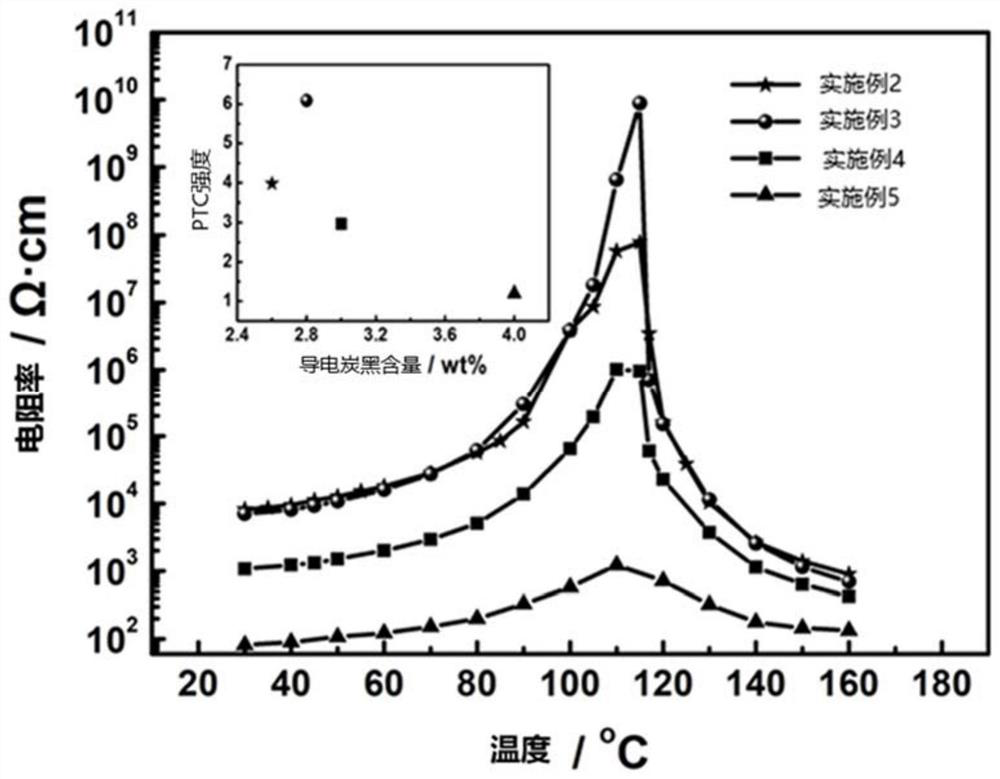

Conductive composite material with isolation and double-percolation structure and high PTC strength, and preparation method and application of conductive composite material

ActiveCN109762277AImprove PTC StrengthImprove conductivityLinear low-density polyethyleneAntioxidant

The embodiment of the invention relates to a conductive composite material with an isolation and double-percolation structure and high PTC strength, and a preparation method and application of the conductive composite material. The conductive composite material is prepared from raw materials comprising following components: linear low-density polyethylene, polyvinylidene fluoride, a conductive filler and an antioxidant. The preparation method of the conductive composite material comprises the following steps that the linear low-density polyethylene, the conductive filler and the antioxidant are fused and blended in an internal mixer, the temperature of the internal mixer is set to be 130-160 DEG C, and a clad master batch is prepared; then the polyvinylidene fluoride is added into the internal mixer, the temperature of the internal mixer is set to be 130-150 DEG C, and the clad master batch and the polyvinylidene fluoride are fused, blended and then taken out; and hot pressing is conduced to obtain the conductive composite material. The prepared CB / LLDPE / PVDF conductive composite material has the isolation and double-percolation structure, is low in conductive content, high in PTCstrength and high in stability, and can be used as a temperature-sensitive material.

Owner:QINGDAO UNIV OF SCI & TECH

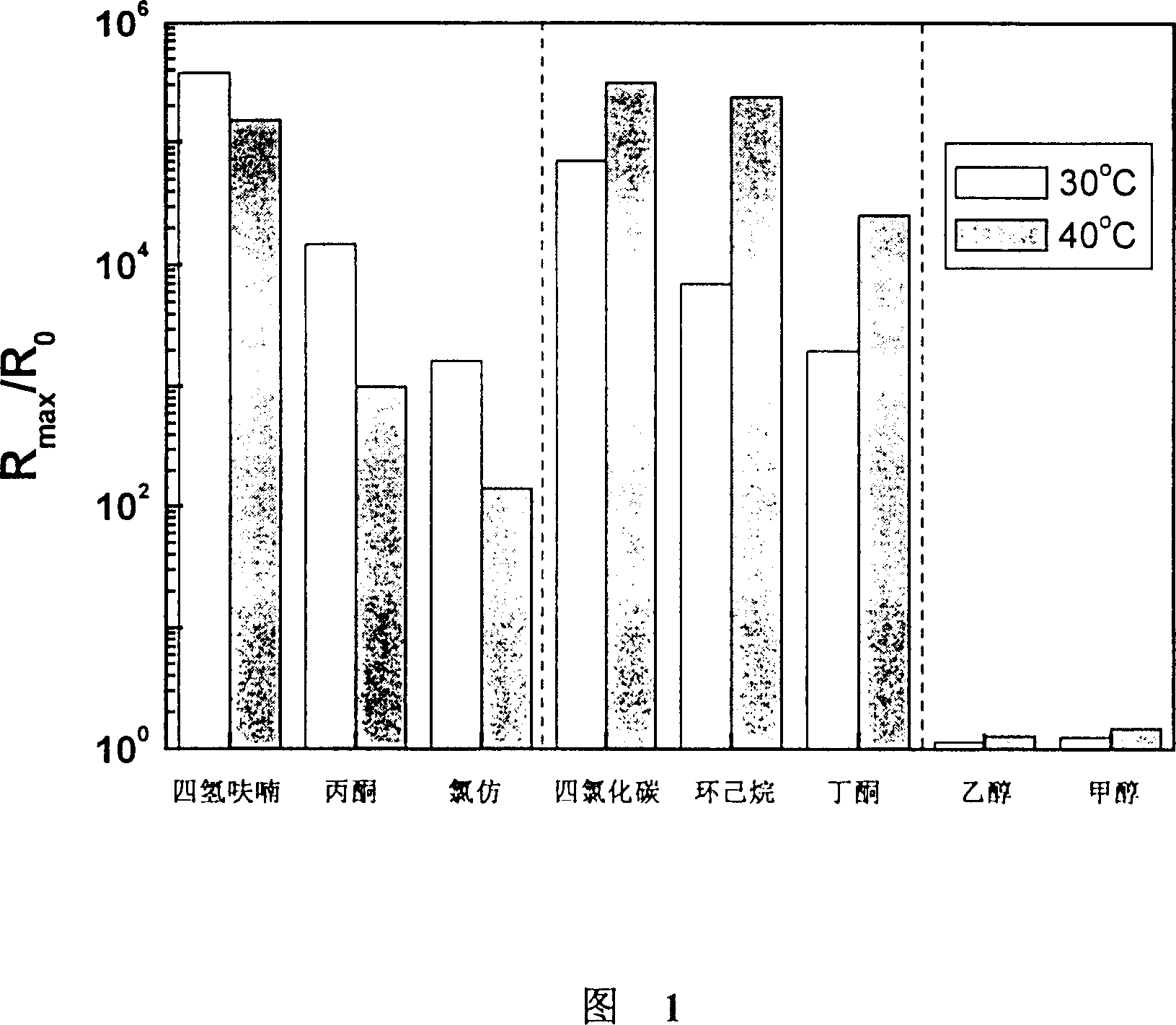

Gas-sensitive conducting composite material of aqueous polyurethane group and preparation method

InactiveCN100402607CLow percolation valueImprove conductivityConductive polymer compositeOrganic solvent

A composition formula and preparation method for high polymer composite of air-sensitive conduction are disclosed by the present invention. The composite can be prepared by using water polyurethane containing polar hard section and nonpolar soft section as base body to compound with conductive packing.

Owner:SUN YAT SEN UNIV

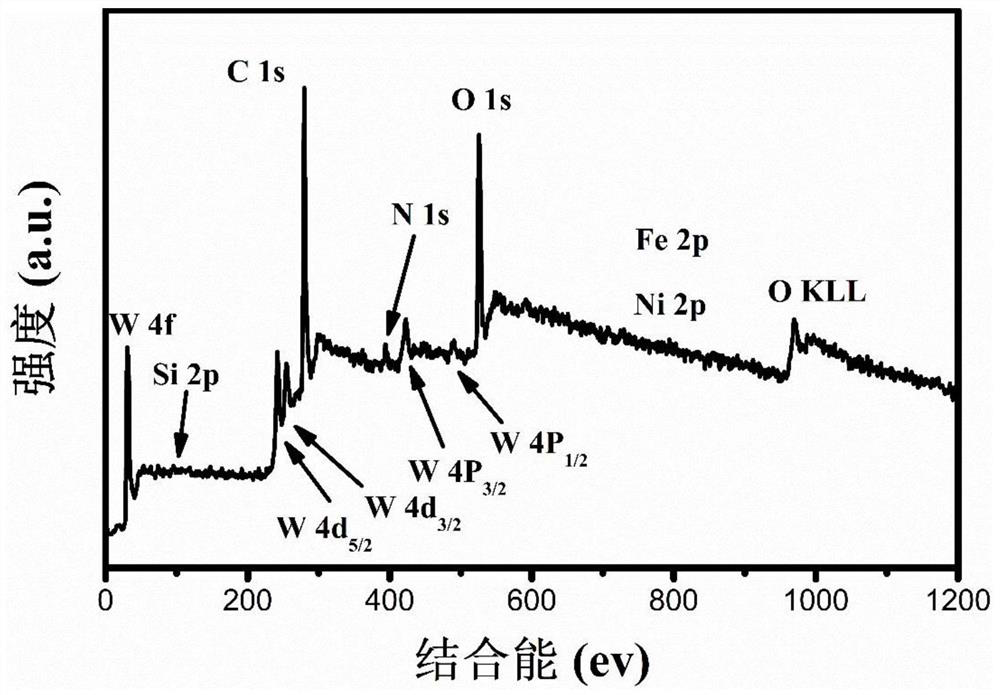

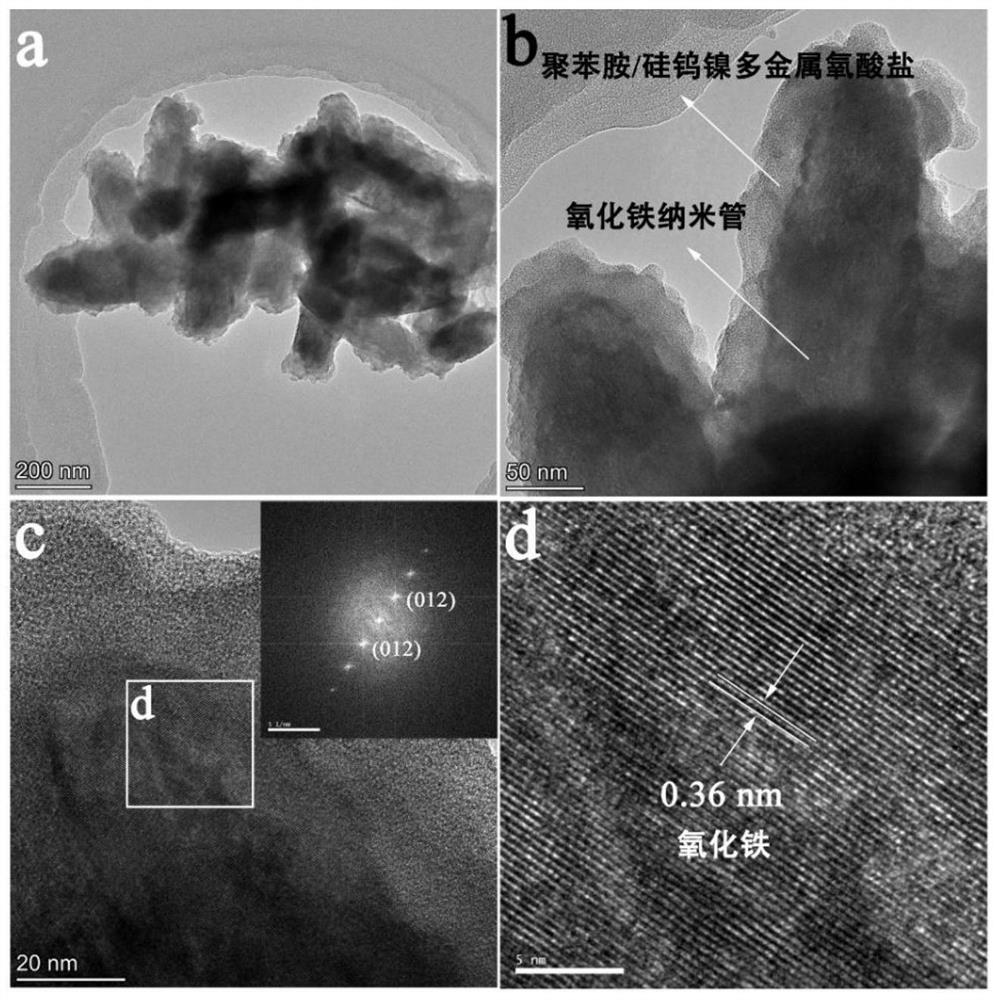

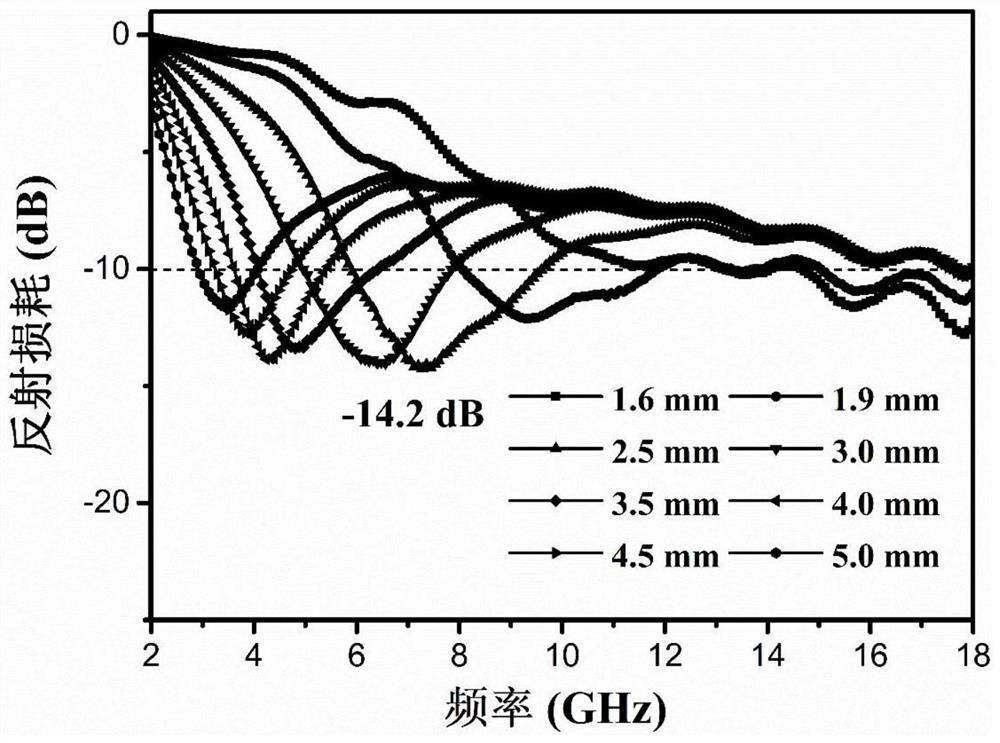

Composite wave-absorbing material and preparation method thereof

PendingCN113922102ASolve the lack of spaceMany gapsMagnetic/electric field screeningAntennasImpedance matchingIron oxide

The invention relates to a composite wave-absorbing material and a preparation method thereof, in particular to an iron oxide nanotube@polyaniline / silicon tungsten nickel polyoxometallate composite wave-absorbing material prepared by adopting a hydrothermal-supramolecular self-assembly method. According to the prepared composite wave-absorbing material, on the basis of magnetic loss, conductive and dielectric materials are introduced, the impedance matching characteristic of the material is improved, the wave-absorbing performance of the material is enhanced, and the defects that an existing composite wave-absorbing material is large in density, poor in impedance matching characteristic, narrow in absorption bandwidth, poor in absorption performance and the like are overcome.

Owner:XIAN TECHNOLOGICAL UNIV

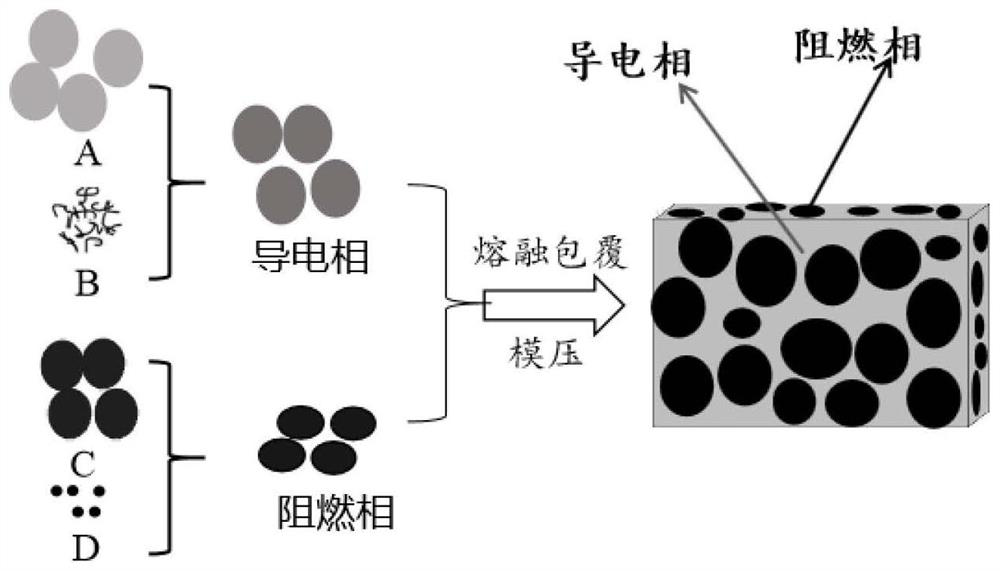

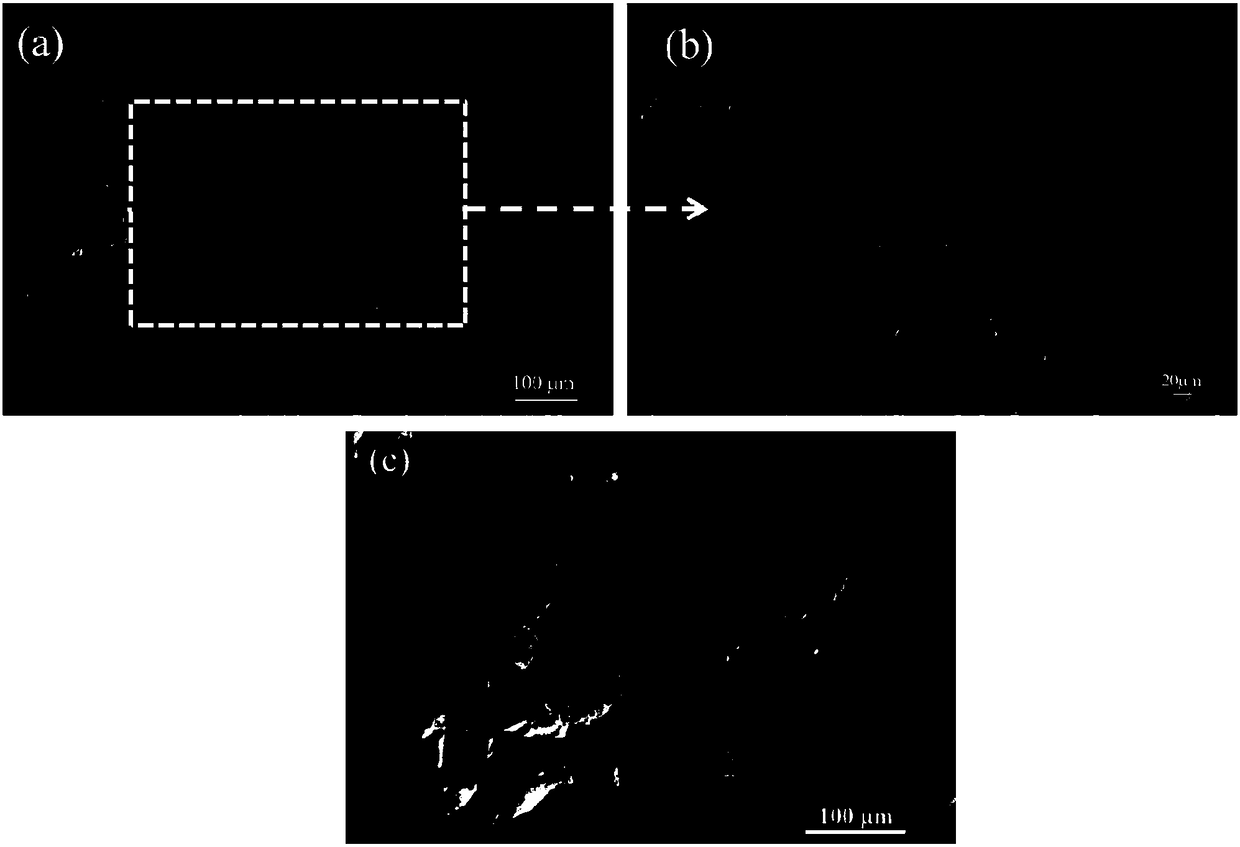

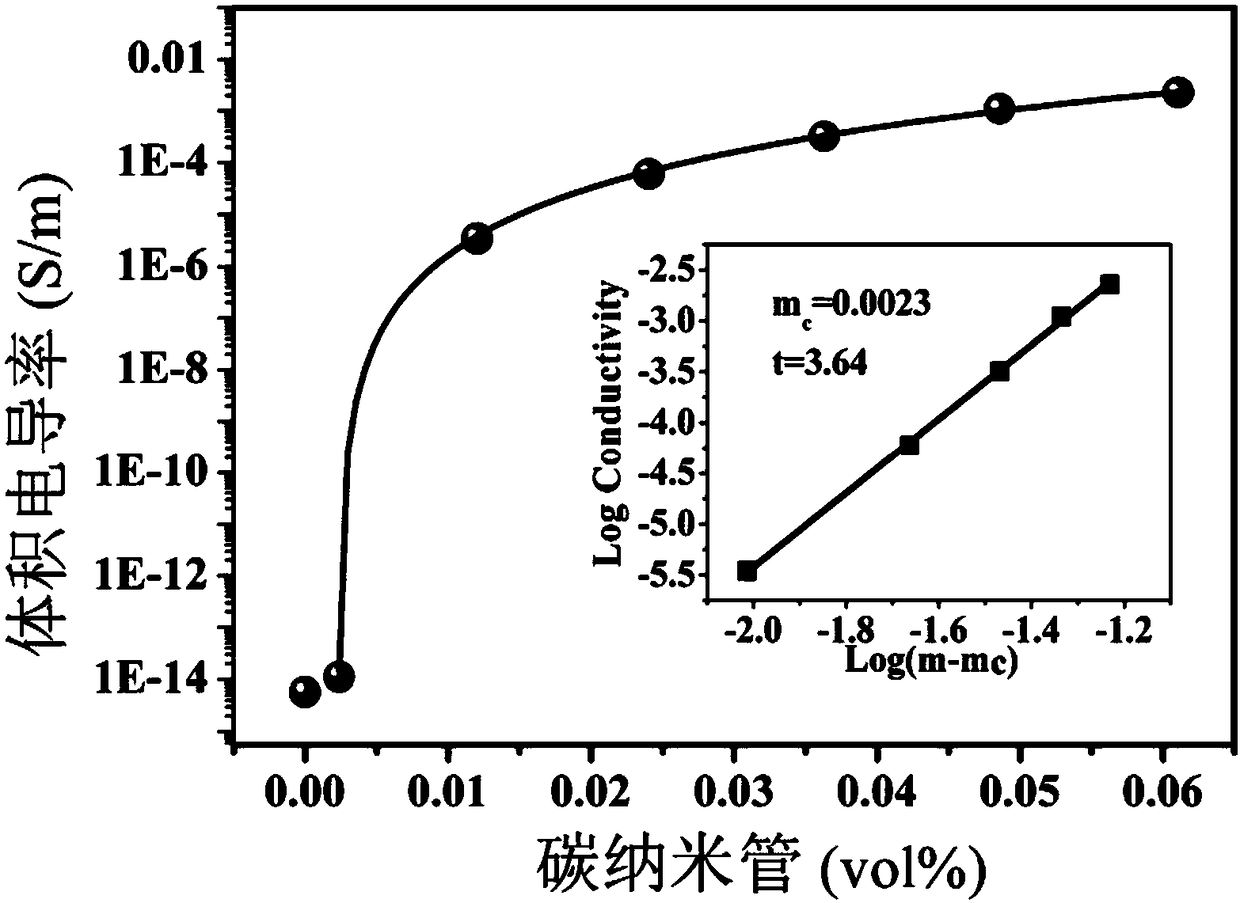

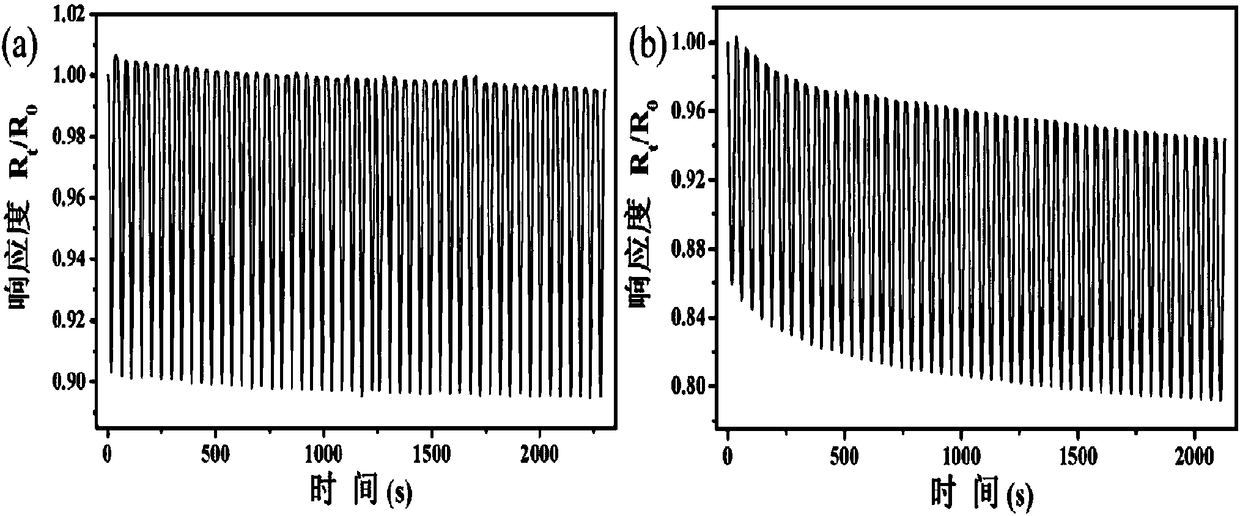

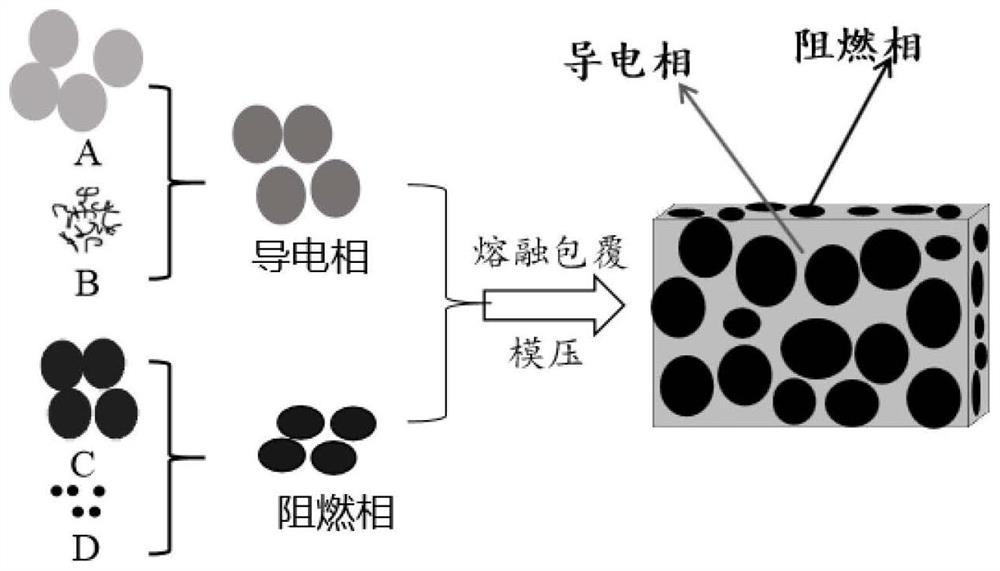

Flexible polyurethane-based composite material with excellent flame retardance and electromagnetic shielding performance and preparation method thereof

ActiveCN112094492AImprove flame retardant performanceImprove shielding effectOrganic solventMacromolecule

The invention discloses a flexible polyurethane-based composite material with excellent flame retardance and electromagnetic shielding performance and a preparation method thereof, the material prepared by the method is composed of a conductive composite material and a flame-retardant composite material, and a sample with an isolation structure is obtained by melt blending and hot press molding. Wherein the conductive composite material is a polymer-based composite material filled with conductive filler, and the flame-retardant composite material is a polymer-based composite material filled with flame retardant particles. The mass ratio of the conductive phase to the flame-retardant phase, the sample thickness and the performance of the composite material with the isolation structure prepared by the preparation method provided by the invention are controllable, and the raw material formula is adjustable; the electromagnetic shielding performance and the flame retardant performance areexcellent; the used raw materials are commercially available, wide in source and low in cost, no chemical reaction or organic solvent is involved in the preparation process, and the preparation process is simple, safe, environmentally friendly and suitable for industrial production.

Owner:SICHUAN UNIV

Preparation method and application of porous conductive polymer material with pressure sensitive properties

ActiveCN106009029BImproved and stable electrical performanceLow percolation valueForce measurement using piezo-resistive materialsMaterial strength using repeated/pulsating forcesConductive polymer compositePolymer science

The invention belongs to the field of conductive polymer composites pressure-sensitive materials and particularly relates to a preparation method of a porous conductive polymer material with pressure-sensitive property and an application thereof. The preparation method of the porous conductive polymer material with pressure-sensitive property comprises the following steps: a) suspension preparation; b) unidirectional freezing; and c) low-temperature low-pressure drying. The porous conductive polymer composite with pressure-sensitive property prepared in the invention has excellent stability and resilience and can be used for preparing a light polymer-based strain sensor; and by combining the obtained conductive polymer composite with the circuit board and semiconductor technology, various pressure-sensitive sensors with good stability and long service life can be made.

Owner:ZHENGZHOU UNIV

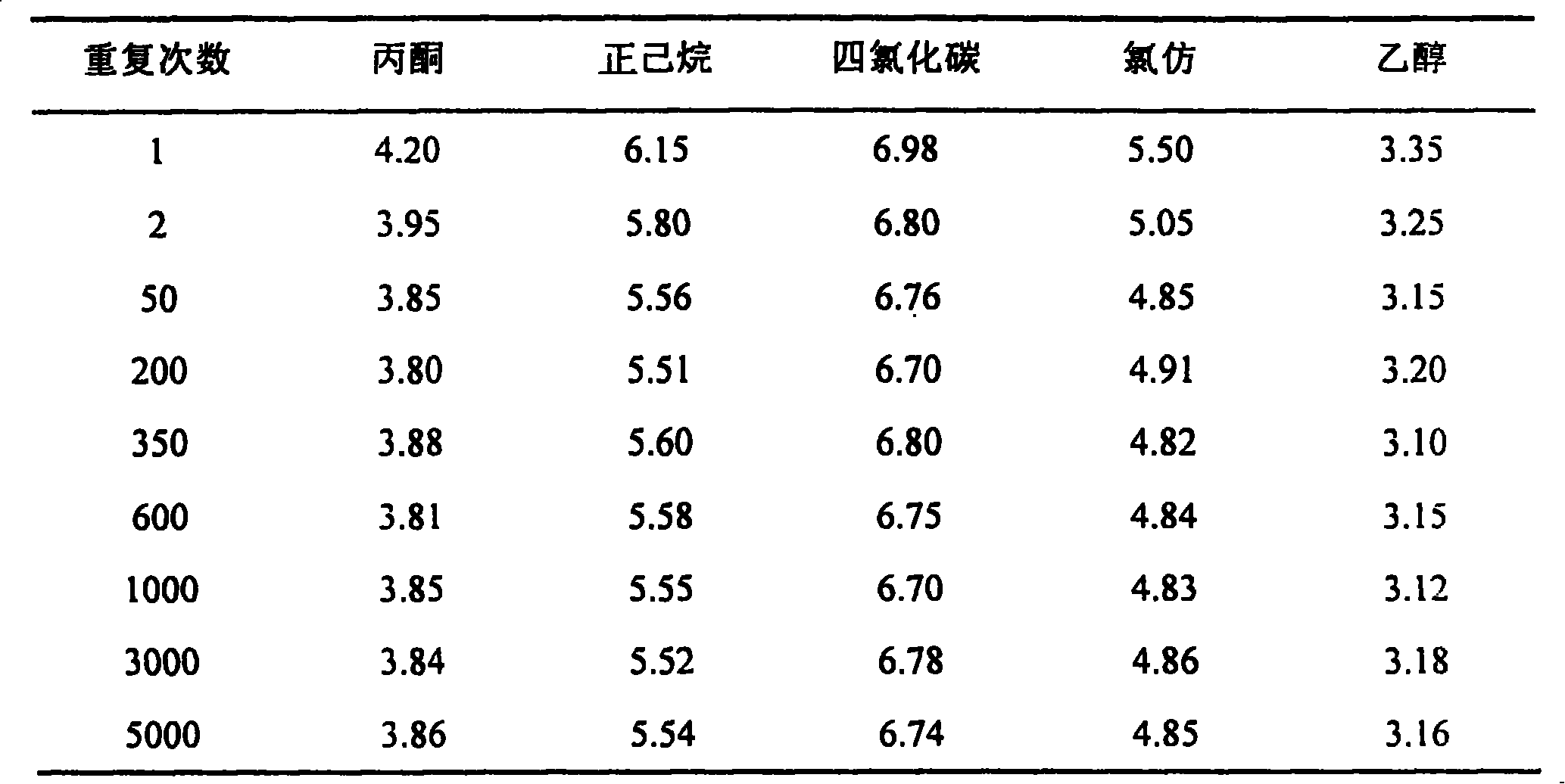

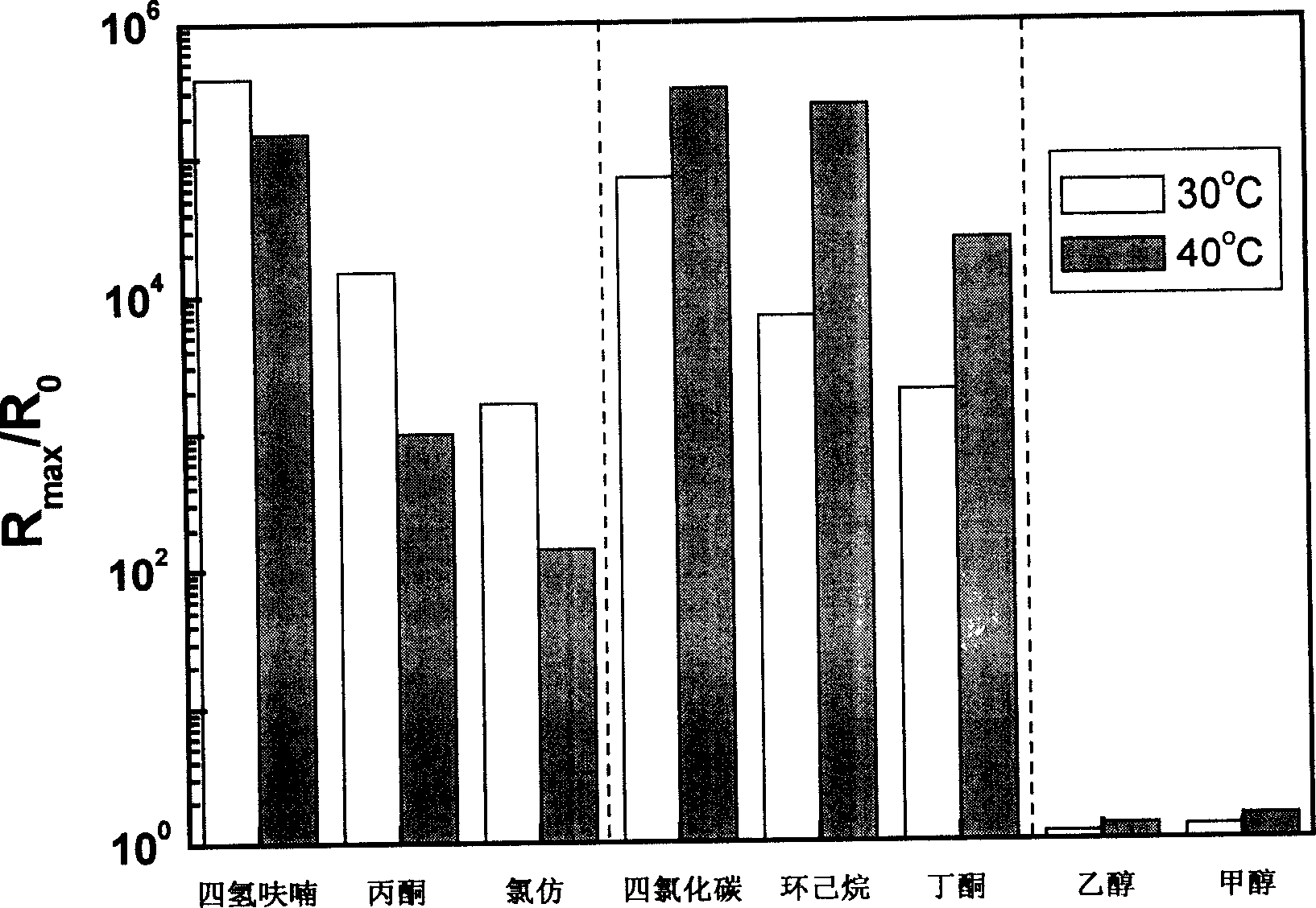

Amorphous polystyrene base gas sensitive conductive composite material and preparation method thereof

InactiveCN1321147CEvenly dispersedLow percolation valueChemical recyclingElectrical resistance and conductanceConductive polymer composite

The present invention relates to an electroconductive high-molecular composite material composition which has gas-sensing response characteristics and its made by using amorphous polystyrene matrix filled up with electroconductive filler and its preparation method. Said material is made up by using amorphous polystyrene as matrix and combining it with electroconductive filler, and has higher gas-sensing response characteristics for organic solvent steam having a certain compatibility with said matrix, so that when it is met with several organic solvent gases, the electric resistance of said composite material can be quickly changed.

Owner:SUN YAT SEN UNIV

Strong-basicity carbon nano tube-graphene composite ion exchange resin material and preparation method thereof

ActiveCN111097554ALow percolation valueReduce technical effectOrganic anion exchangersPolymer scienceGraphene

The invention relates to a strong-basicity carbon nano tube-graphene composite ion exchange resin material and a preparation method thereof. In the strong-basicity carbon nano tube-graphene compositeion exchange resin material, a matrix and carbon nanotubes / graphene are combined in a covalent bond form, and the strong-basicity carbon nano tube-graphene composite ion exchange resin material comprises the following components in parts by weight: (a) 75-90 parts of a polymeric monomer; (b) 5-15 parts of a comonomer; (c) 0.1 to 10 parts of carbon nanotubes; and (d) 0.1 to 10 parts of graphene. According to the technical scheme, the thermal decomposition temperature and the swelling resistance of the composite ion exchange resin are well improved, and the method can be applied to industrial production and application of strong-basicity composite ion exchange resin materials in the future.

Owner:CHINA PETROLEUM & CHEM CORP +1

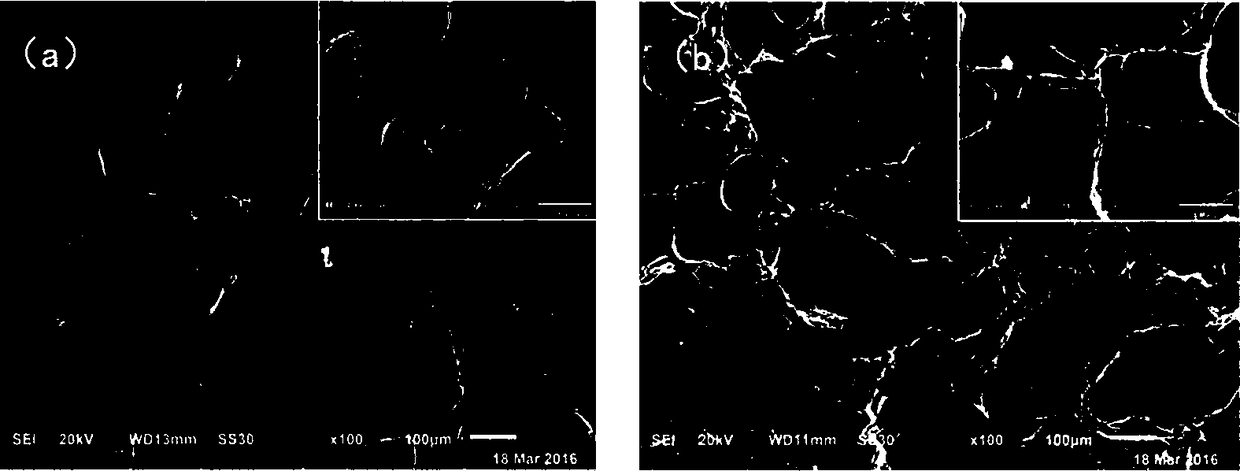

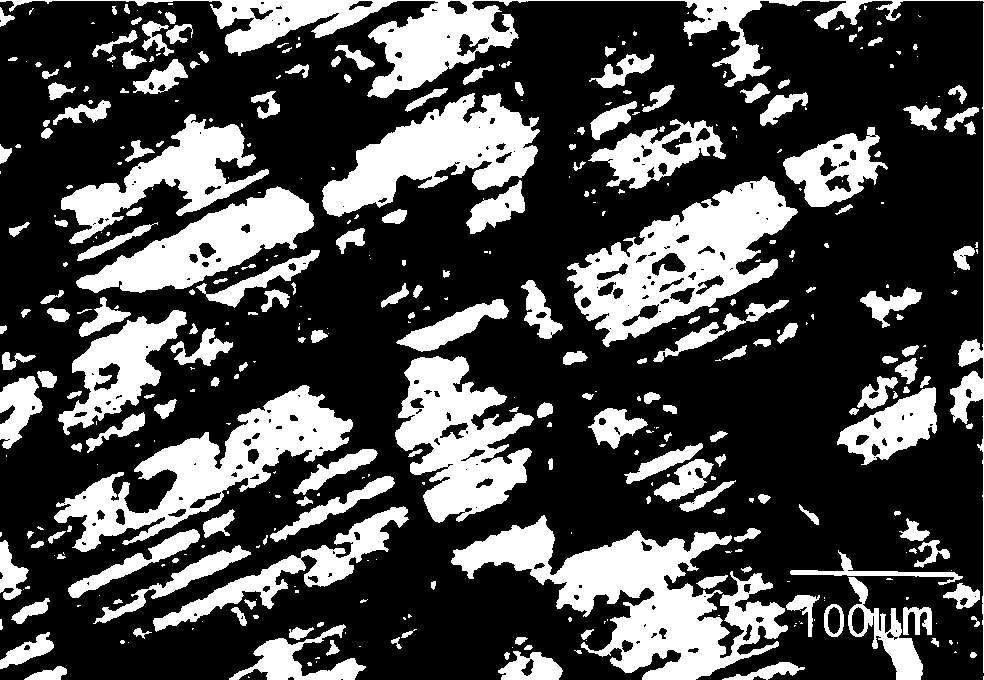

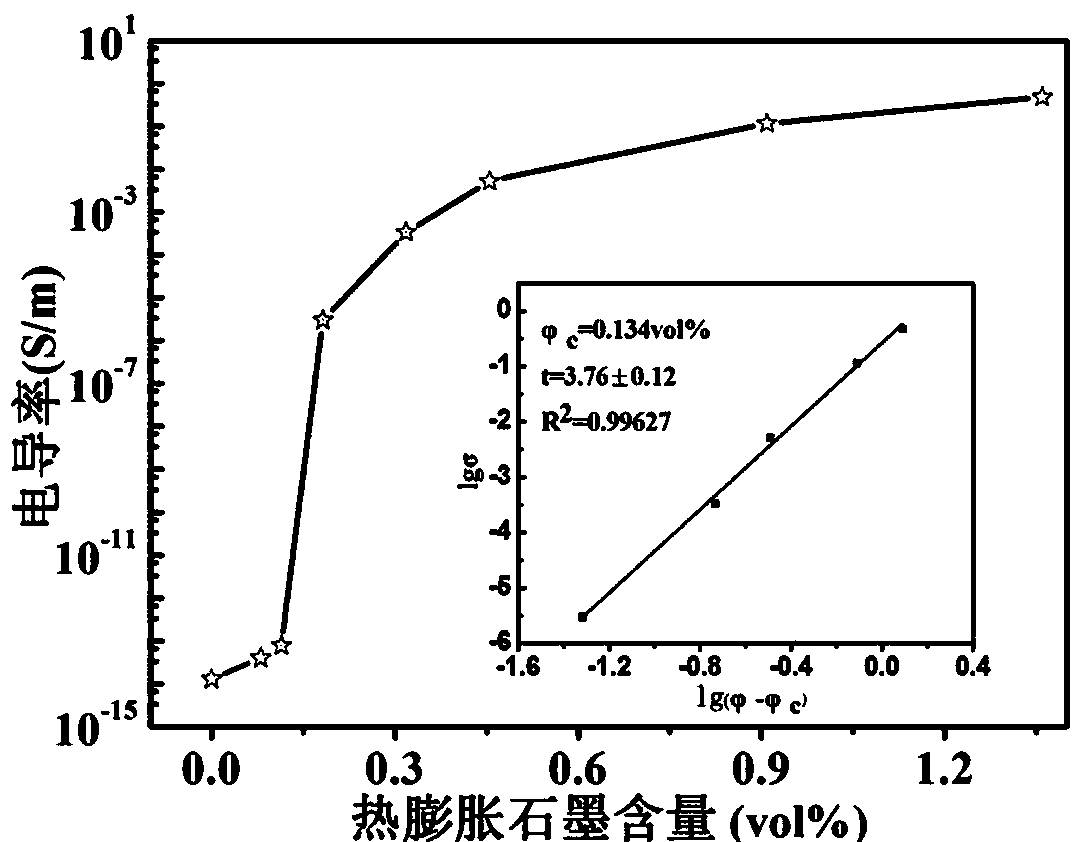

A kind of nylon 6/thermally expanded graphite conductive composite material and preparation method thereof

The invention relates to the field of polymer composite materials, in particular to a nylon6 / thermal expansion graphite conductive composite material and a preparation method thereof. The composite material is prepared from 98.636099.818vol% of nylon 6(PA6) and o.182-1.364 vol% of thermal expansion graphite (EG). The preparation method comprises the steps that the surface of the nylon 6 is evenly wrapped by the thermal expansion graphite through mechanical mixing, nylon6 / thermal expansion graphite conductive composite particles are obtained, and the composite particles are subjected to compression molding to obtain the conductive composite material. In the composite material, EG forms a continuous conductive network with an isolation structure in a PA6 base body, and the composite material has good conductivity and extremely low percolation value.

Owner:ZHONGBEI UNIV

Non-metal conductor used for button switches and preparation method of non-metal conductor

InactiveCN110760122AGood elasticityImprove electrical conductivityNon-conductive material with dispersed conductive materialActive agentElectrically conductive

The invention relates to the technical field of button switches, in particular to a non-metal conductor used for button switches. The non-metal conductor comprises the following raw materials in partsby weight: 75-85 parts of polymer elastic particles, 23-31 parts of polydodecalactam, 2-8 parts of an alkali metal salt, 85-105 parts of a conductive material, 15-20 parts of carbon black and 2-4 parts of an active agent. The polymer elastic particles enable the conductor to have good elasticity, and the surfaces of the polymer elastic particles are coated with a vulcanizing agent, so that the conductive elastomer has a low percolation value. An organic polymer polyelectrolyte is prepared by complexing and coordinating alkali metal ions with a polydodecactam polyether block, and the polyetherblock (C-O-C) generally have flexibility and can form an associated matter with an electron acceptor or certain inorganic electrolytes. Through addition of an auxiliary conductive agent, surface activity of the polymer elastic particles can be improved and conductivity is improved. The non-metal conductor has outstanding substantive characteristics and remarkable progress.

Owner:浙江天华电器有限公司

Amorphous polystyrene base gas sensitive conductive composite material and preparation method thereof

InactiveCN1687220ALow percolation valueGood electrical conductivityChemical recyclingPolystyreneOrganic solvent

The present invention relates to an electroconductive high-molecular composite material composition which has gas-sensing response characteristics and its made by using amorphous polystyrene matrix filled up with electroconductive filler and its preparation method. Said material is made up by using amorphous polystyrene as matrix and combining it with electroconductive filler, and has higher gas-sensing response characteristics for organic solvent steam having a certain compatibility with said matrix, so that when it is met with several organic solvent gases, the electric resistance of said composite material can be quickly changed.

Owner:SUN YAT SEN UNIV

A high ptc-strength conductive composite material with isolation-double percolation structure, and preparation method and application thereof

ActiveCN109762277BImprove PTC StrengthImprove conductivityLinear low-density polyethyleneMasterbatch

The embodiment of the invention relates to a conductive composite material with an isolation and double-percolation structure and high PTC strength, and a preparation method and application of the conductive composite material. The conductive composite material is prepared from raw materials comprising following components: linear low-density polyethylene, polyvinylidene fluoride, a conductive filler and an antioxidant. The preparation method of the conductive composite material comprises the following steps that the linear low-density polyethylene, the conductive filler and the antioxidant are fused and blended in an internal mixer, the temperature of the internal mixer is set to be 130-160 DEG C, and a clad master batch is prepared; then the polyvinylidene fluoride is added into the internal mixer, the temperature of the internal mixer is set to be 130-150 DEG C, and the clad master batch and the polyvinylidene fluoride are fused, blended and then taken out; and hot pressing is conduced to obtain the conductive composite material. The prepared CB / LLDPE / PVDF conductive composite material has the isolation and double-percolation structure, is low in conductive content, high in PTCstrength and high in stability, and can be used as a temperature-sensitive material.

Owner:QINGDAO UNIV OF SCI & TECH

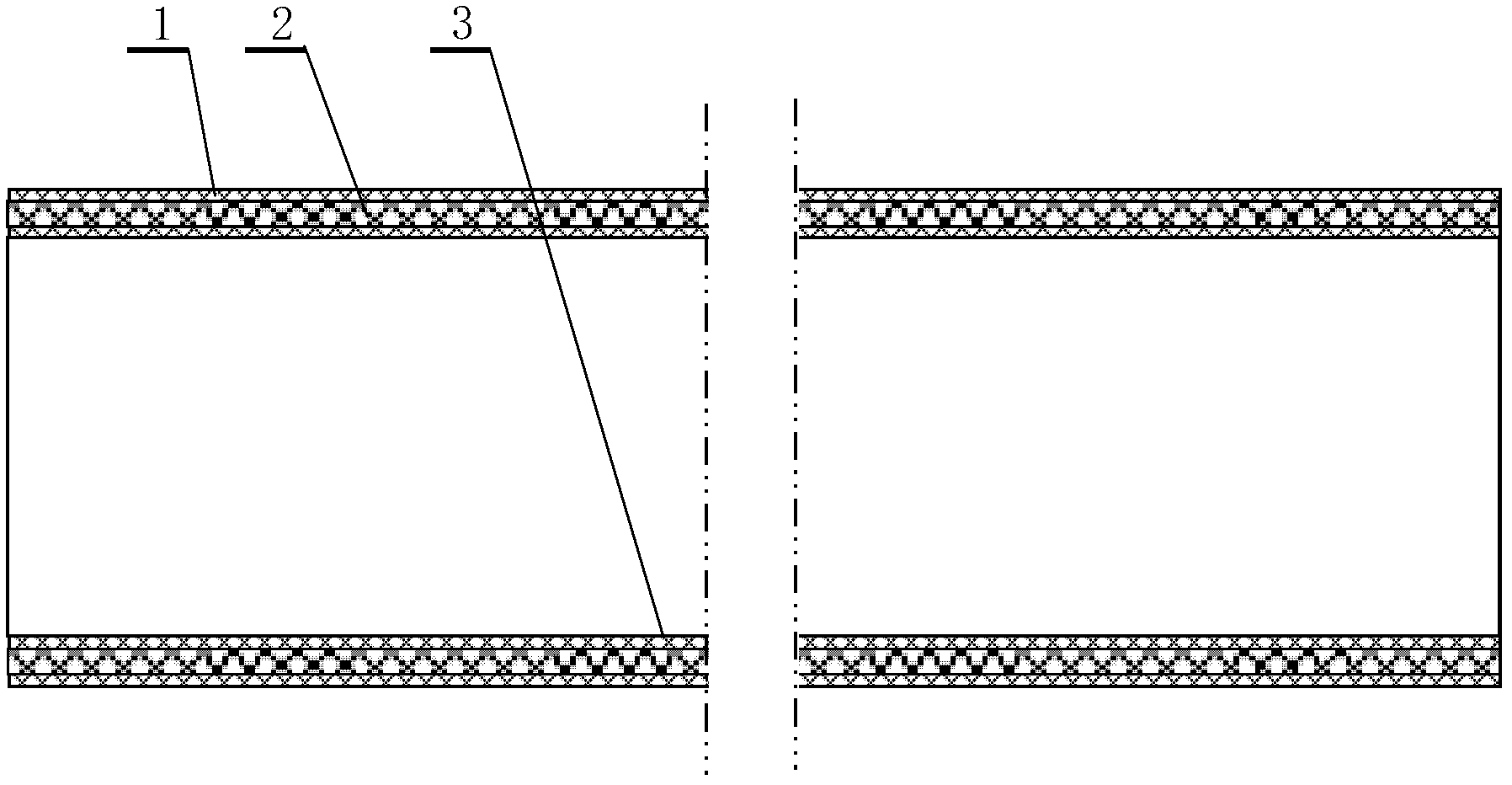

A kind of preparation method of low percolation value high mechanical property polypropylene conductive film

The invention discloses a preparation method of a conductive PP (polypropylene) thin film with a low percolation threshold and high mechanical properties. The preparation method comprises steps as follows: PP aggregates are put in a melt-blowing machine for preparation of PP fiber webs through melt-blowing; conductive particles are dispersed in a xylene solvent and subjected to ultrasonic oscillation, and a solution A is prepared; the PP fiber webs are placed in the solution A and subjected to the ultrasonic oscillation for 2-5 min, then the PP fiber webs are taken out, washed and naturally dried, and conductive fibers are obtained; the conductive fiber webs are divided into an upper layer and a lower layer and are laid on templates of a press device, a few PP aggregates are placed between the fiber webs and subjected to hot pressing in a vacuum press for 10-15 min, and the conductive PP thin film with higher comprehensive mechanical properties and the lower percolation threshold is obtained. The ultrafine PP fiber webs prepared with a melt-blowing technology have large specific surface area, surfaces of the fiber webs are uniformly modified with conductive filler with an ultrasonic dispersion method, a uniform conductive network structure is formed in the film after hot pressing, the technology is simple, and the prepared conductive thin film has both the higher mechanical properties and the lower percolation threshold.

Owner:山东中塑新材料有限公司

A flexible polyurethane-based composite material with excellent flame retardant and electromagnetic shielding properties and its preparation method

ActiveCN112094492BImprove flame retardant performanceImprove shielding effectChemical reactionOrganic solvent

The invention discloses a flexible polyurethane-based composite material with excellent flame-retardant and electromagnetic shielding properties and a preparation method thereof. The material prepared by the method is composed of a conductive composite material and a flame-retardant composite material, and is melt-blended and hot-pressed A sample with an isolated structure is obtained by molding. Among them, the conductive composite material is a polymer-based composite material filled with conductive fillers, and the flame-retardant composite material is a polymer-based composite material filled with flame retardant particles. The mass ratio of the conductive phase and the flame-retardant phase of the composite material with an isolation structure prepared by the preparation method provided by the invention, the thickness and performance of the sample can be controlled, and the raw material formula can be adjusted; the electromagnetic shielding performance and flame-retardant performance are excellent; the present invention The raw materials used are all commercially available, with wide sources and low cost, and the preparation process does not involve any chemical reaction and organic solvent, the production process is simple, safe and environmentally friendly, and suitable for industrial production.

Owner:SICHUAN UNIV

Polymer material with continuous alternating layered structure and preparation method thereof

ActiveCN103481393BSimple operation processReduce manufacturing costPolymer scienceInjection moulding

The invention discloses a method for preparing a polymer material with a continuous alternating layered structure, which comprises the following steps: step 1, mixing 30-70 parts of the first resin or the first resin composite, 70-30 parts of The second resin or the second resin compound is pre-mixed and added to a twin-screw extruder, melted, blended and extruded at a temperature of 100-300 ° C, cooled, and pelletized to obtain blended pellets; step 2, the obtained The blended pellets are subjected to high-speed thin-wall injection molding at an injection temperature of 100-300° C. and an injection speed of 50-1200 mm / s to prepare a polymer material with a continuous alternating layered structure. The whole operation process of the invention is simple, the production cost is low, it is suitable for large-scale industrial production, the thickness of the continuous alternating layered structure can be regulated by adjusting the component distribution ratio of the blend, and it is suitable for various blend systems.

Owner:SICHUAN UNIV

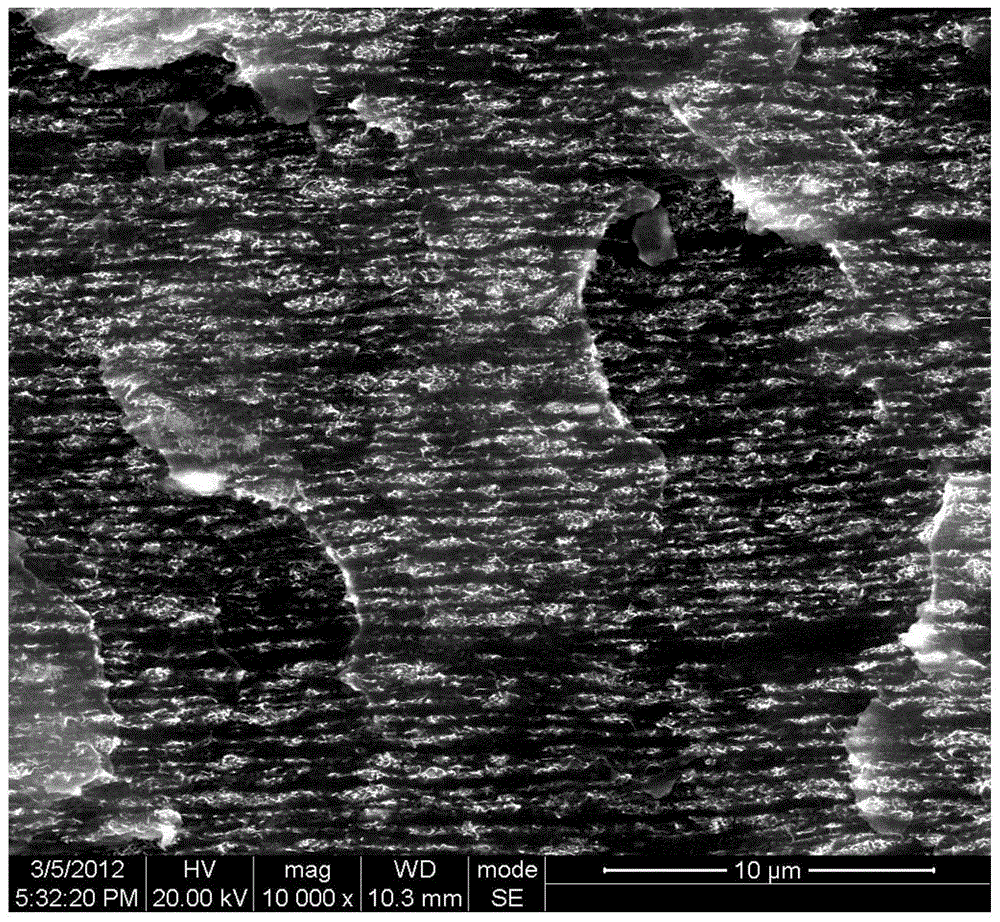

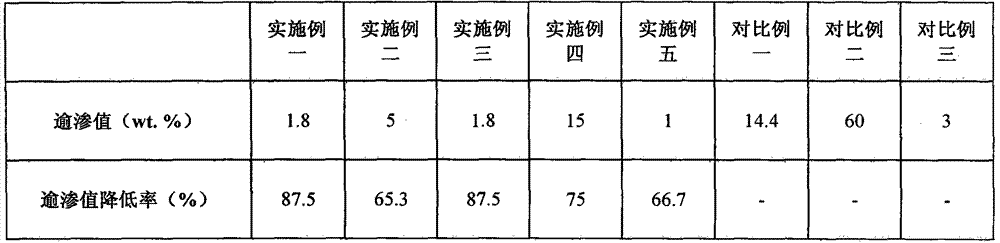

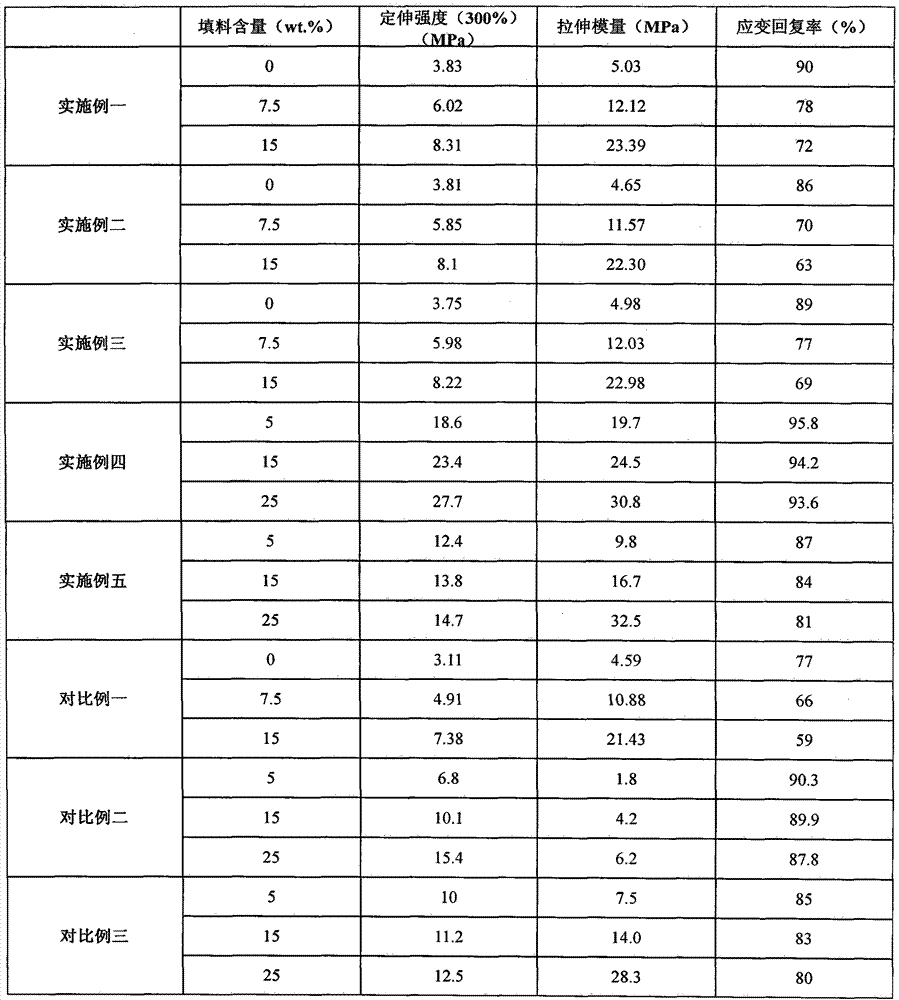

A kind of polymer-based conductive elastomer and preparation method thereof

The invention discloses a polymer-based conductive elastomer and its preparation method. According to the preparation method, a certain percentage of a cross-linking agent is used to crosslink a polymer matrix and the cross-linked polymer matrix is crushed to obtain cross-linked particles; and the cross-linked particles are added in proportion into the matrix to prepare a cross-linked particles / elastic matrix / conductive carbon material composite elastomer. By the above method, conductive percolation threshold of the polymer-based conductive elastomer can effectively be reduced; stretching strength of the polymer-based conductive elastomer under the stretching action can be enhanced; and elasticity of the polymer-based conductive elastomer can effectively be raised, and strain recovery rate of the polymer-based conductive elastomer under strain retraction action can be raised. The polymer-based conductive elastomer prepared by the above method has advantages of good electrical property, enhanced stretching strength and good and stable elasticity and rebound resilience. The method provided by the invention has advantages of simple preparation technology, low cost, short production period and the like during the construction process.

Owner:SICHUAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com