Preparation method of low-percolation graphene/macromolecule electromagnetism shielding material

An electromagnetic shielding material, graphene technology, applied in the direction of conductive materials dispersed in non-conductive inorganic materials, etc., can solve the problem of not checking graphene/polymer conductive composite materials, etc., to avoid the use of chemical reducing agents, The effect of low production cost and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The main raw materials are composed of the following weight percentages: UHMWPE99.7%; GONS0.3%.

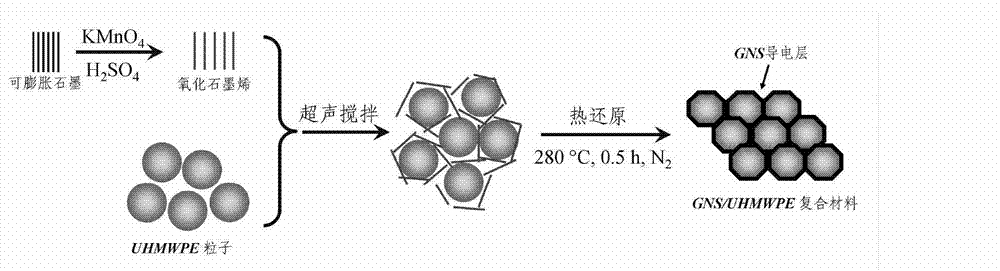

[0030] The process steps adopt:

[0031] (1) raw material drying: the prepared GONS is dried in a vacuum oven at a constant temperature of 60°C until the moisture weight content is lower than 0.01%;

[0032] (2) Preparation of GONS / UHMWPE conductive particles: the dried GONS and deionized water in step (1) were formulated into a GONS suspension at a mass ratio of 1:200, and then uniformly dispersed by ultrasonic and mechanical stirring for 60 minutes; the UHMWPE particles were poured Put into the dispersed GONS suspension, mix it uniformly by ultrasonic stirring for 30 minutes, then remove the solvent by distillation under reduced pressure at 60°C; finally dry in an oven below 60°C until the moisture content is low at 0.01%.

[0033] (3) High-temperature compression molding: the GONS / UHMWPE conductive composite particles prepared in step (2) were pre-pressed at room tempe...

Embodiment 2

[0035] Others are the same as in Example 1, and the ratio of raw materials is UHMWPE99.5%; GONS0.5%. In step (1), the GONS oven temperature is 59°C.

[0036] When preparing GONS / UHMWPE composite particles in step (2), the mass ratio of GONS and deionized water is 1:100.

Embodiment 3

[0038] Others are the same as in Example 1, and the ratio of raw materials is UHMWPE99%; GONS1%. In step (1), the GONS oven temperature is 58°C.

[0039] When (2) step prepares GONS / UHMWPE composite particle, the mass ratio of GONS and deionized water is 1: 80;

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com