Polymer material with continuous alternating layered structure and preparation method thereof

A technology of polymer materials and alternating layers, applied in the field of polymer materials with continuous alternating layered structure and its preparation, can solve the problems of long time-consuming, complicated process, and difficulty in industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

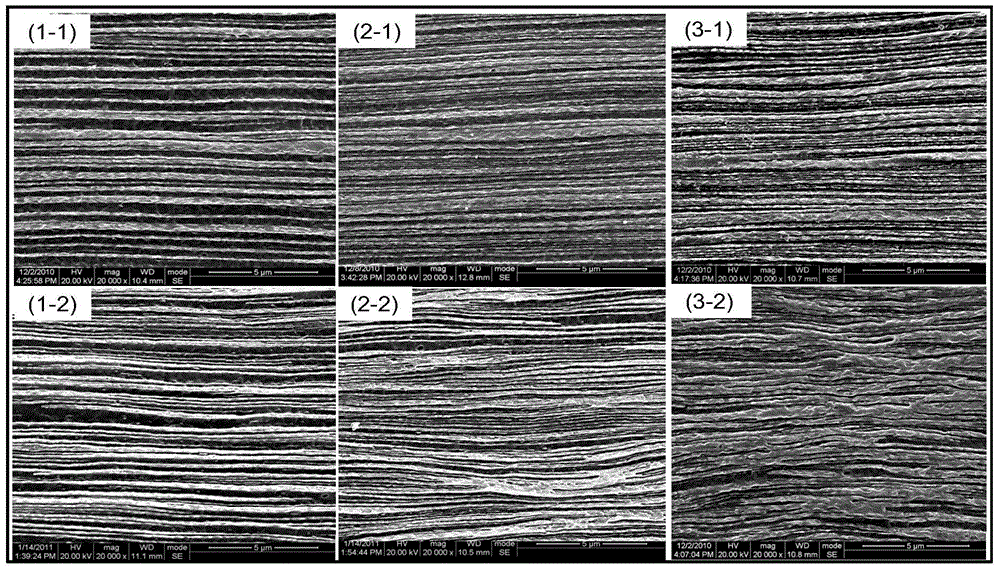

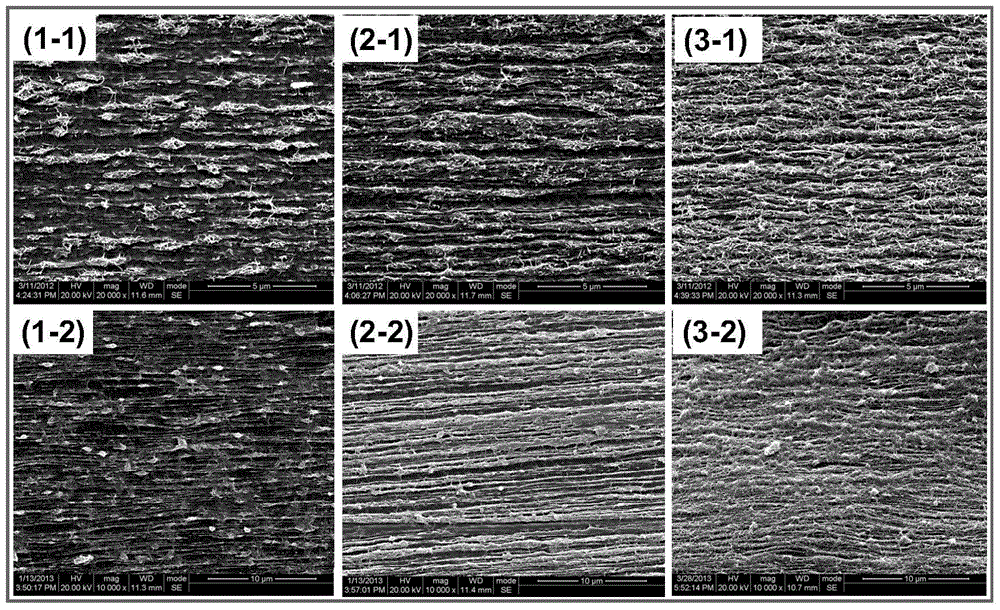

[0087] Firstly, 70 parts of polypropylene and 30 parts of polyethylene are premixed and then added to a twin-screw extruder, melted, blended and extruded at a temperature of 200 ° C, cooled, and pelletized to obtain blended pellets; the obtained blended pellets The material is subjected to high-speed thin-wall injection molding, the injection temperature is 200°C, and the injection speed is 300mm / s, and the material with continuous alternating layered structure can be prepared (see figure 1 Medium 1-1, 1-2).

Embodiment 2

[0089] 50 parts of polypropylene and 50 parts of polyethylene are pre-mixed and then added to a twin-screw extruder, melted, blended and extruded at a temperature of 200 ° C, cooled, and pelletized to obtain blended pellets; the resulting blended pellets The material is subjected to high-speed thin-wall injection molding, the injection temperature is 200°C, and the injection speed is 300mm / s, and the material with continuous alternating layered structure can be prepared (see figure 1 Medium 2-1, 2-2).

Embodiment 3

[0091] 30 parts of polypropylene and 70 parts of polyethylene are pre-mixed and then added to the twin-screw extruder, melt blended and extruded at a temperature of 200 ° C, cooled, and pelletized to obtain blended pellets; the obtained blended pellets The material is subjected to high-speed thin-wall injection molding, the injection temperature is 200°C, and the injection speed is 300mm / s, and the material with continuous alternating layered structure can be prepared (see figure 1 Medium 3-1, 3-2).

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com