Nitrogen-doped carbon-supported monoatomic oxygen reduction catalyst and preparation method thereof

A technology of nitrogen-doped carbon and monatomic oxygen, which is applied in electrical components, battery electrodes, circuits, etc., can solve the problems of easy reunion channels, single coordination structure, low conductivity, etc., and achieve abundant lattice defect sites , simple operation process, high load effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 01-12

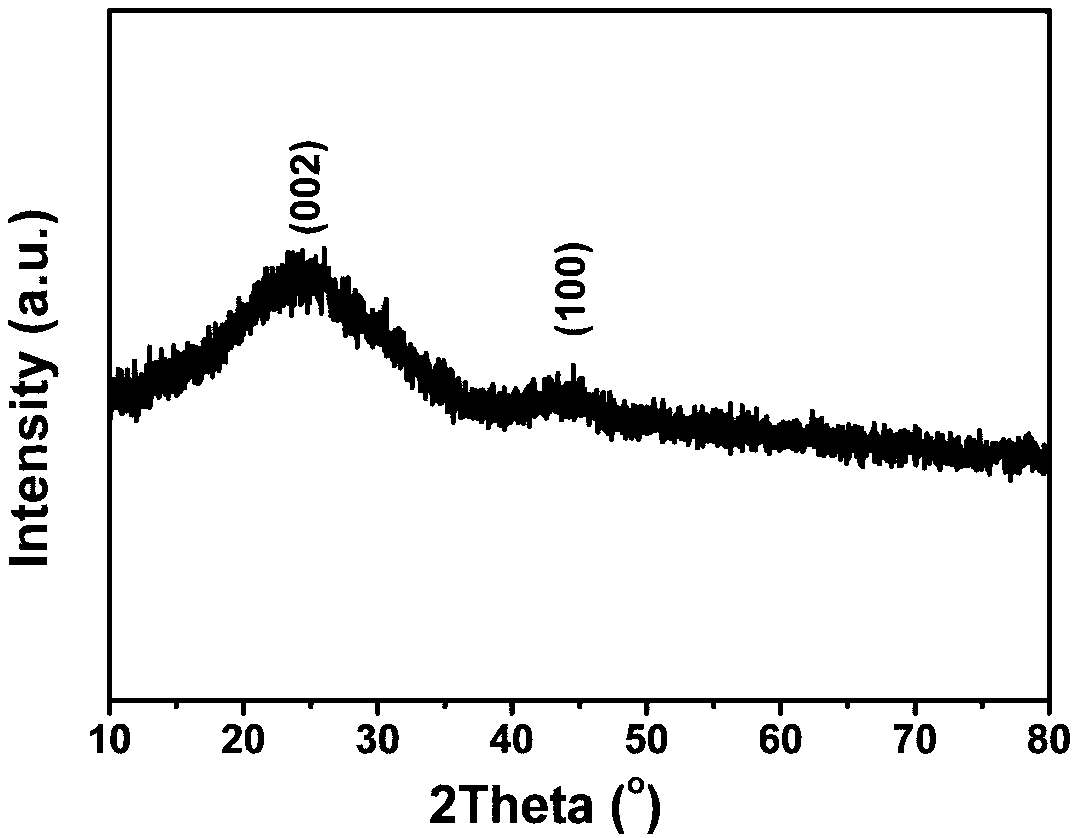

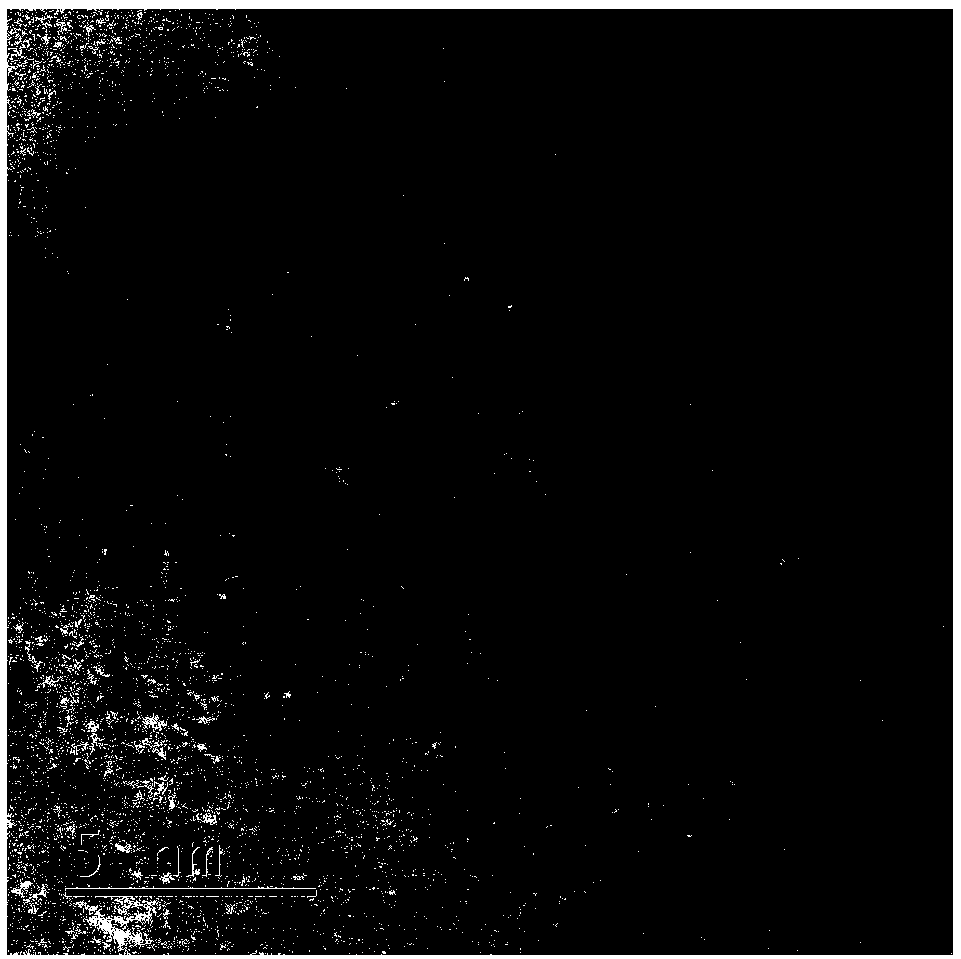

[0028] Example 01-12 Preparation method of nitrogen-doped carbon-supported single-atom catalyst using Zn / Ni-ZIF as MOF precursor

[0029] 1) Grinding a certain amount of Zn / Ni-ZIF and glucose evenly in a mortar, in the Zn / Ni-ZIF, the molar ratio of Zn to Ni is 0.25:1.

[0030] 2) Heat the mixture obtained in 1) in a tube furnace at 5°C min -1 The heating rate is increased to the pyrolysis temperature, calcined under nitrogen atmosphere, and the temperature is naturally lowered;

[0031] 3) Post-treat the catalyst obtained in 2) in a tube furnace at 5°C min -1 The heating rate was increased to the pyrolysis temperature, calcined in an ammonia atmosphere, and the temperature was naturally lowered to obtain a nitrogen-doped carbon-supported Ni single-atom catalyst.

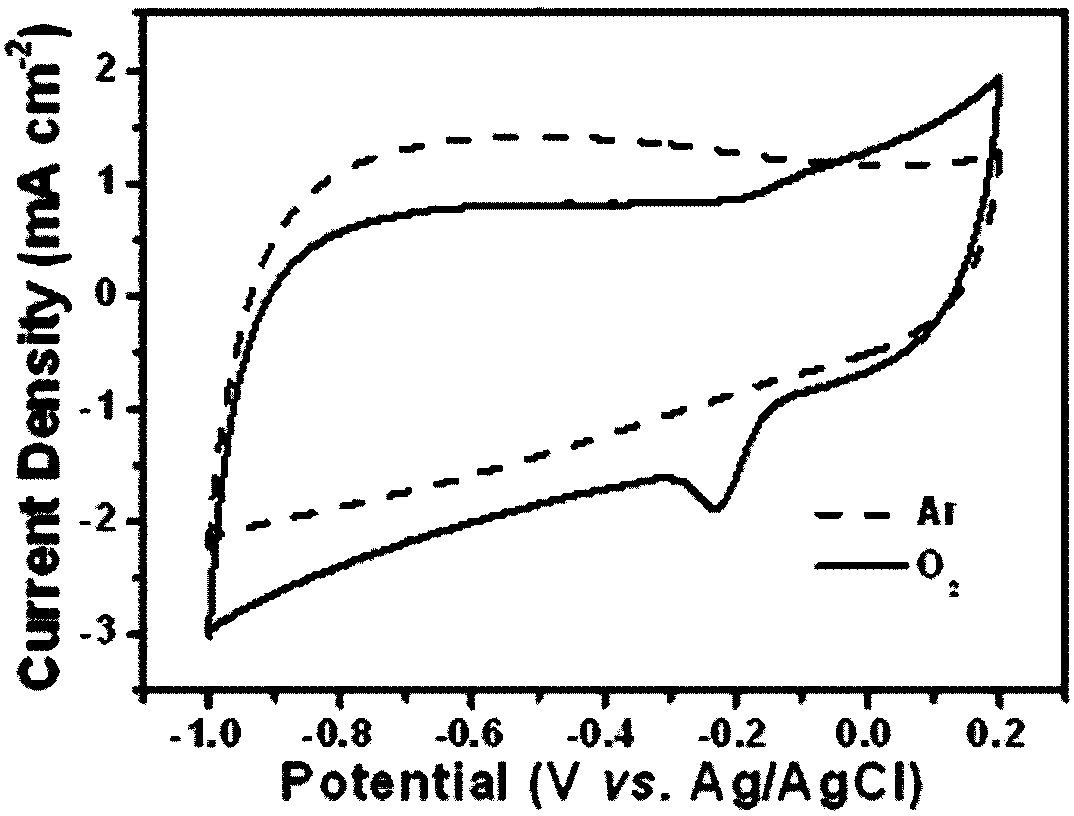

[0032]4) Electrochemical test: Take 4 mg of the catalyst prepared in step 3) and add it to 485 μl of alcohol, 500 μl of water and 15 μl of 0.05% Nafion mixed solution, ultrasonically disperse evenly, remove 10 μl a...

Embodiment 13-24

[0037] Example 13-24 Preparation method of nitrogen-doped carbon-supported single-atom catalyst using Zn / Ni-ZIF as MOF precursor

[0038] 1) Stir a certain amount of Zn / Ni-ZIF and glucose in an aqueous solution for 24 hours, filter and dry; in the Zn / Ni-ZIF, the molar ratio of Zn to Ni is 0.25:1.

[0039] 2) Heat the mixture obtained in 1) in a tube furnace at 5°C min -1 The heating rate is increased to the pyrolysis temperature, calcined for a certain period of time under nitrogen atmosphere, and the temperature is naturally lowered;

[0040] 3) Post-treat the catalyst obtained in 2) in a tube furnace at 5°C min -1 The heating rate was raised to the pyrolysis temperature, calcined for a certain period of time in an ammonia atmosphere, and the temperature was naturally lowered to obtain a nitrogen-doped carbon-supported Ni single-atom oxygen reduction catalyst.

[0041] 4) The electrochemical test method is the same as that of Example 01-12. The results show that the Ni-N-C...

Embodiment 25-36

[0046] Example 25-36 Preparation method of nitrogen-doped carbon-supported single-atom oxygen reduction catalyst using Zn / Co-ZIF as MOF precursor

[0047] 1) Stir a certain amount of Zn / Co-ZIF and glucose in an aqueous solution for 24 hours, filter and dry; in the Zn / Co-ZIF, the molar ratio of Zn to Co is 1:1.

[0048] 2) Heat the mixture obtained in 1) in a tube furnace at 5°C min -1 The heating rate is increased to the pyrolysis temperature, calcined for a certain period of time under nitrogen atmosphere, and the temperature is naturally lowered;

[0049] 3) Post-treat the catalyst obtained in 2) in a tube furnace at 5°C min -1 The heating rate was raised to the pyrolysis temperature, calcined for a certain period of time in an ammonia atmosphere, and the temperature was naturally lowered to obtain a nitrogen-doped carbon-supported Ni single-atom oxygen reduction catalyst.

[0050] 4) The electrochemical test method is the same as that of Example 1-12. The results show th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com