A kind of preparation method of low percolation value high mechanical property polypropylene conductive film

A technology of conductive film and percolation value, applied in the field of polymer material processing, can solve the problems that restrict the preparation and application of high-performance conductive composite materials, conductive particles are prone to agglomeration, and the amount of conductive fillers is large. Effects requiring low, low percolation values

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The preparation method of the low percolation value and high mechanical properties polypropylene (PP) conductive film of this embodiment, the steps are as follows:

[0022] (1) Put the PP pellets in the melt-blown machine at 180°C to prepare a PP fiber web with a thickness of about 60 μm and a fiber diameter of 3-7 μm;

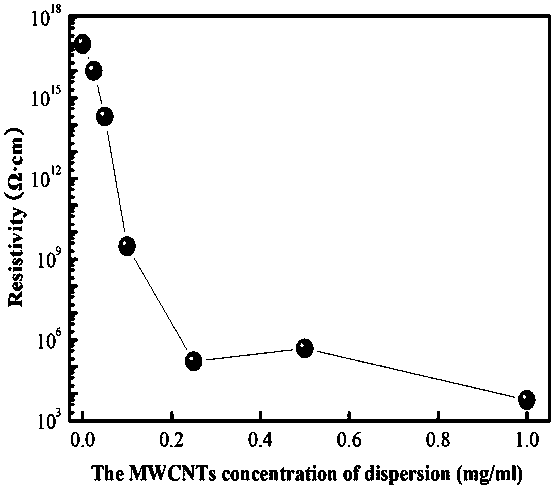

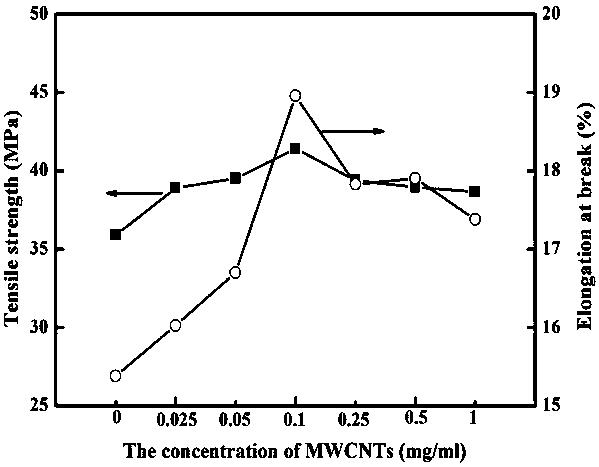

[0023] (2) Weigh a certain mass of MWCNTs and disperse them in 40 mL of xylene solvent for 10 minutes of ultrasonic oscillation, and prepare solutions with MWCNTs concentrations of 1, 0.5, 0.25, 0.1, 0.05, 0.025, and 0.01 mg / mL;

[0024] (3) Place the PP fiber web prepared in step (1) in the xylene solution of carbon nanotubes prepared in step (2) and ultrasonically vibrate for 2 min, take out the PP fiber web, wash with absolute ethanol, and dry naturally , to obtain a conductive fiber mesh;

[0025] (4) Lay two layers of the dried conductive fiber mesh on the press template, and place a certain quality of PP pellets in the middle of the upper and low...

Embodiment 2

[0029] The preparation method of the low percolation value and high mechanical properties polypropylene (PP) conductive film of this embodiment, the steps are as follows:

[0030] (1) Put the PP pellets in the melt-blown machine at 185°C to prepare a PP fiber web with a thickness of about 60 µm and a fiber diameter of 3-7 µm;

[0031] (2) Weigh a certain mass of MWCNTs and disperse them in 40 mL of xylene solvent for 10 minutes of ultrasonic oscillation, and prepare solutions with MWCNTs concentrations of 1, 0.5, 0.25, 0.1, 0.05, 0.025, and 0.01 mg / mL;

[0032] (3) Place the PP fiber web prepared in step (1) in the xylene solution of carbon nanotubes prepared in step (2) and ultrasonically vibrate for 2 min, take out the PP fiber web, wash with absolute ethanol, and dry naturally , to obtain a conductive fiber mesh;

[0033] (4) Lay two layers of the dried conductive fiber mesh on the press template, and place a certain quality of PP pellets in the middle of the upper and low...

Embodiment 3

[0035] The preparation method of the low percolation value and high mechanical properties polypropylene (PP) conductive film of this embodiment, the steps are as follows:

[0036] (1) Put the PP pellets in the melt-blown machine at 185°C to prepare a PP fiber web with a thickness of about 60 µm and a fiber diameter of 3-7 µm;

[0037] (2) Weigh a certain mass of MWCNTs and disperse them in 40 mL of xylene solvent for 10 minutes of ultrasonic oscillation, and prepare solutions with MWCNTs concentrations of 1, 0.5, 0.25, 0.1, 0.05, 0.025, and 0.01 mg / mL;

[0038] (3) Place the PP fiber web prepared in step (1) in the xylene solution of carbon nanotubes prepared in step (2) and ultrasonically vibrate for 5 minutes, take out the PP fiber web, wash with absolute ethanol, and dry naturally. Obtain conductive fiber net;

[0039] (4) Lay two layers of the dried conductive fiber mesh on the press template, and place a certain quality of PP pellets in the middle of the upper and lower ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com