Patents

Literature

128results about How to "Improve stress transfer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

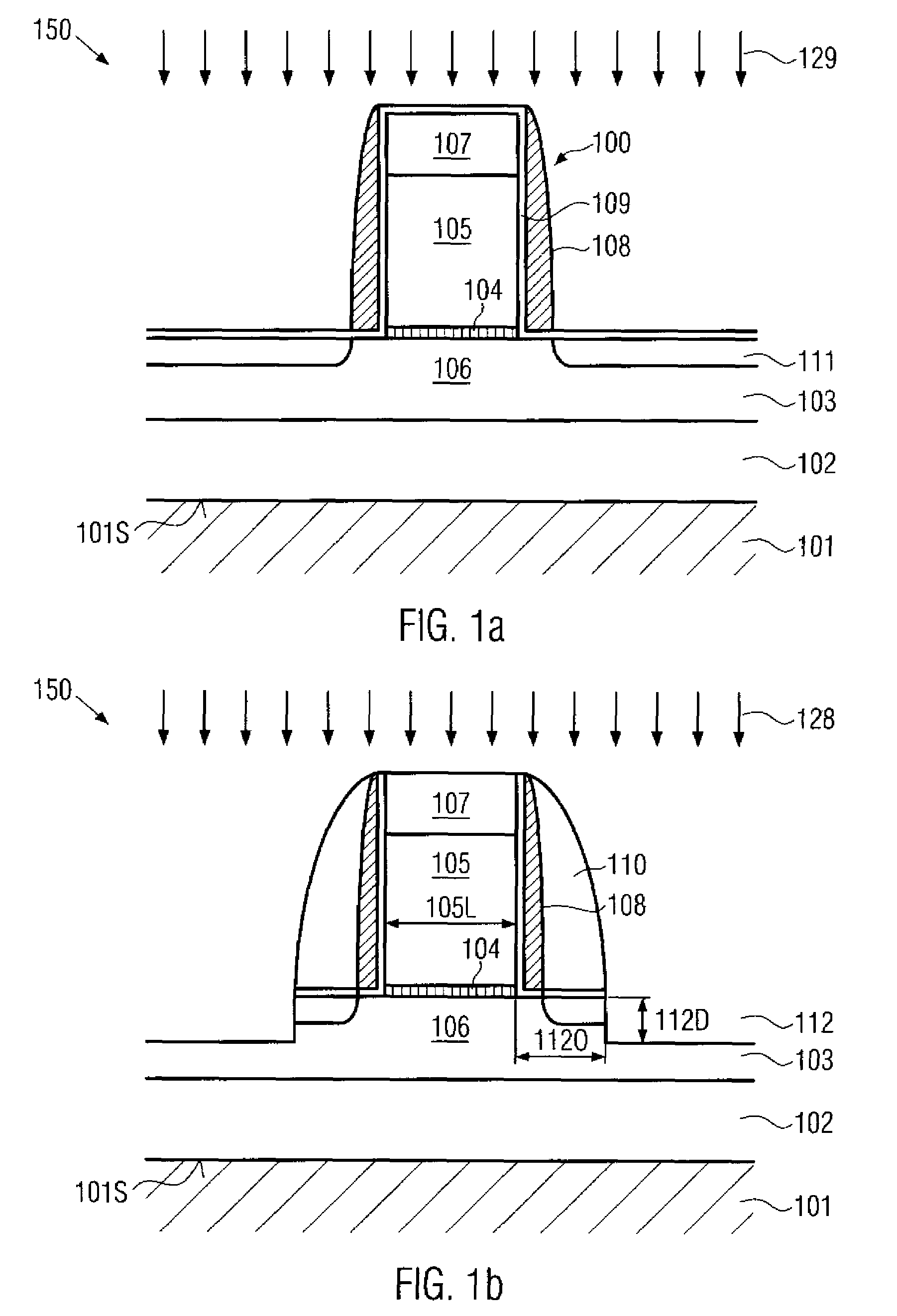

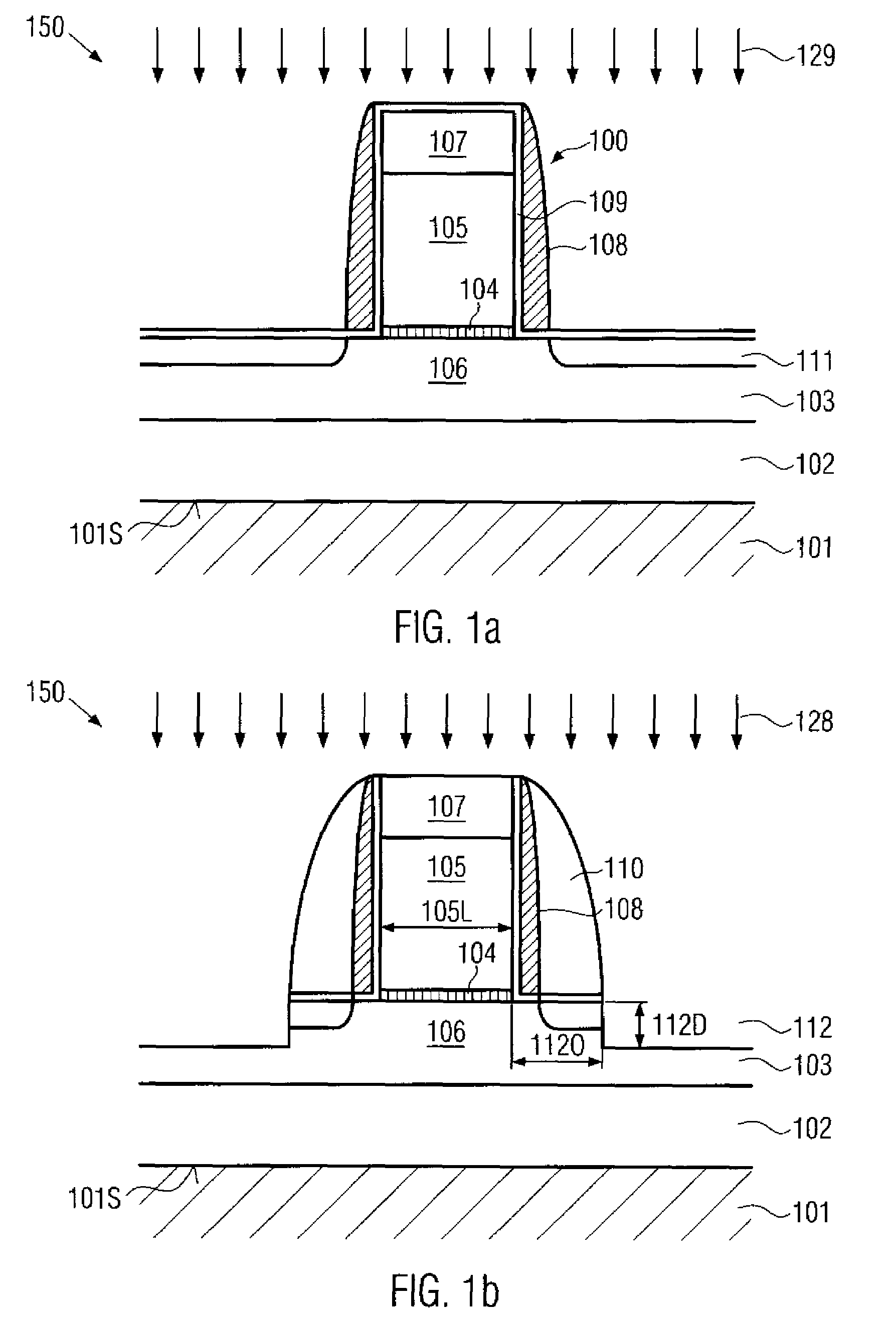

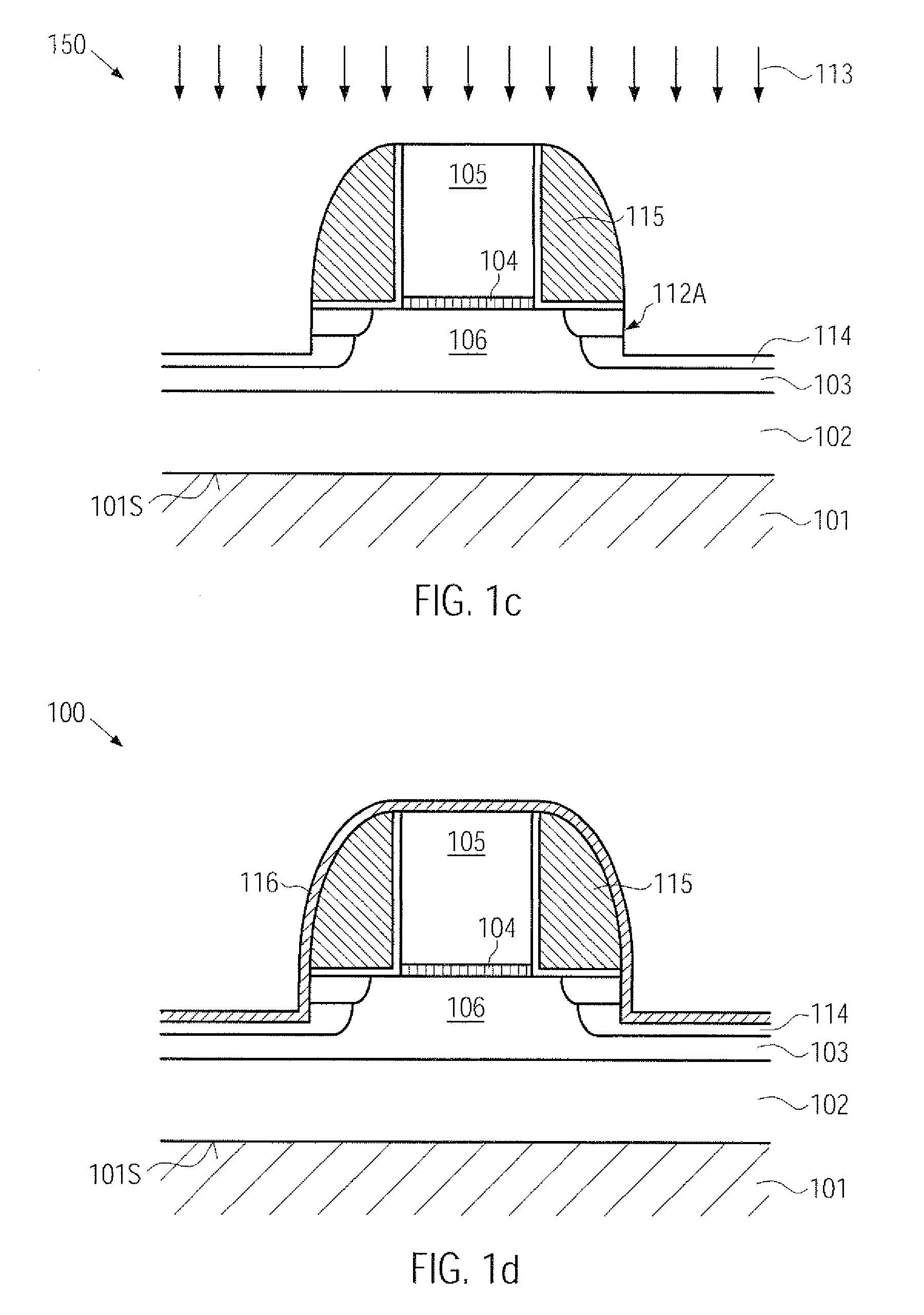

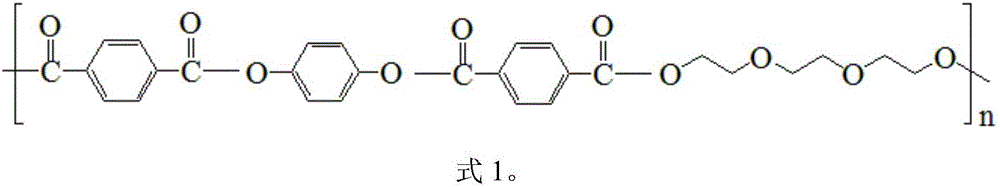

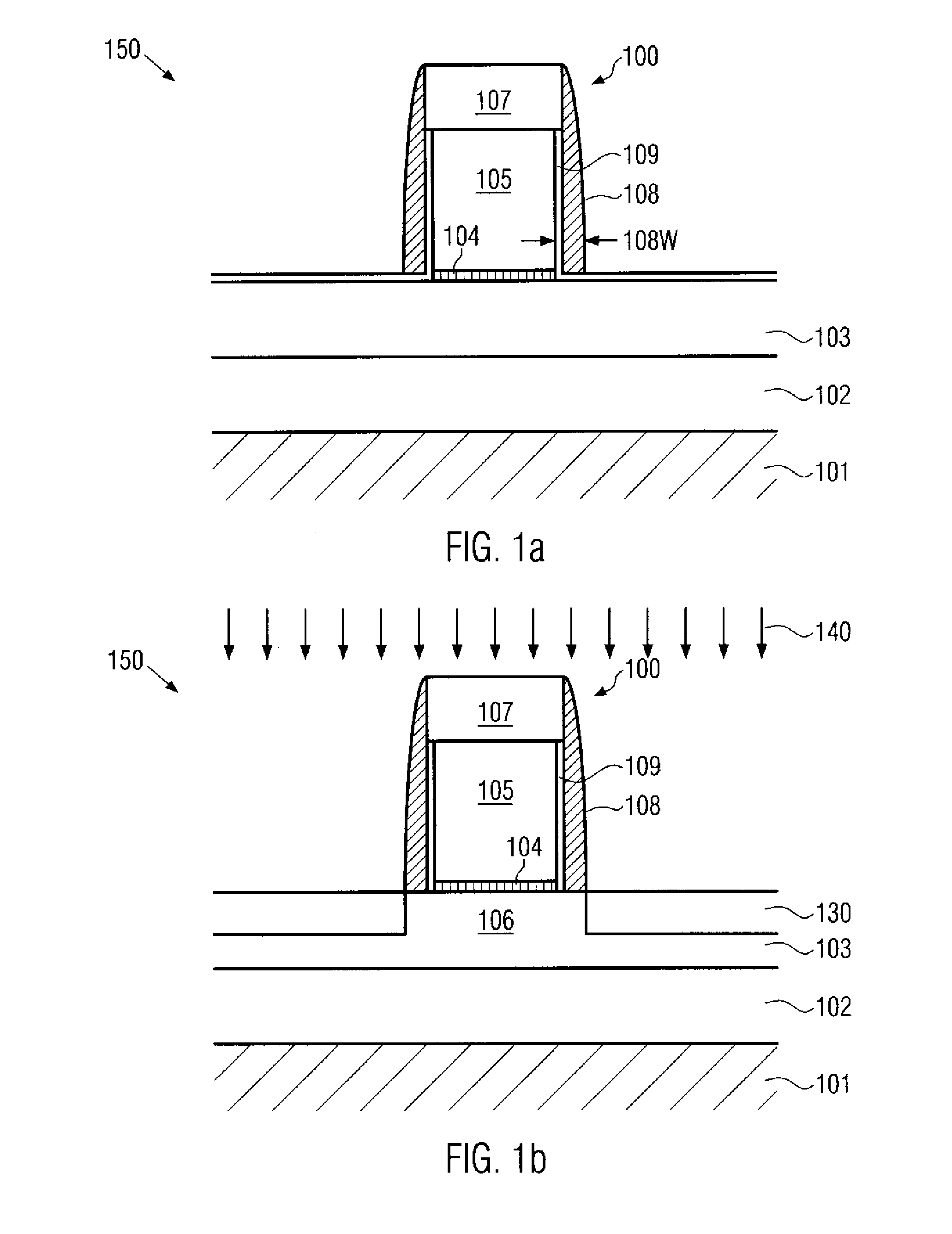

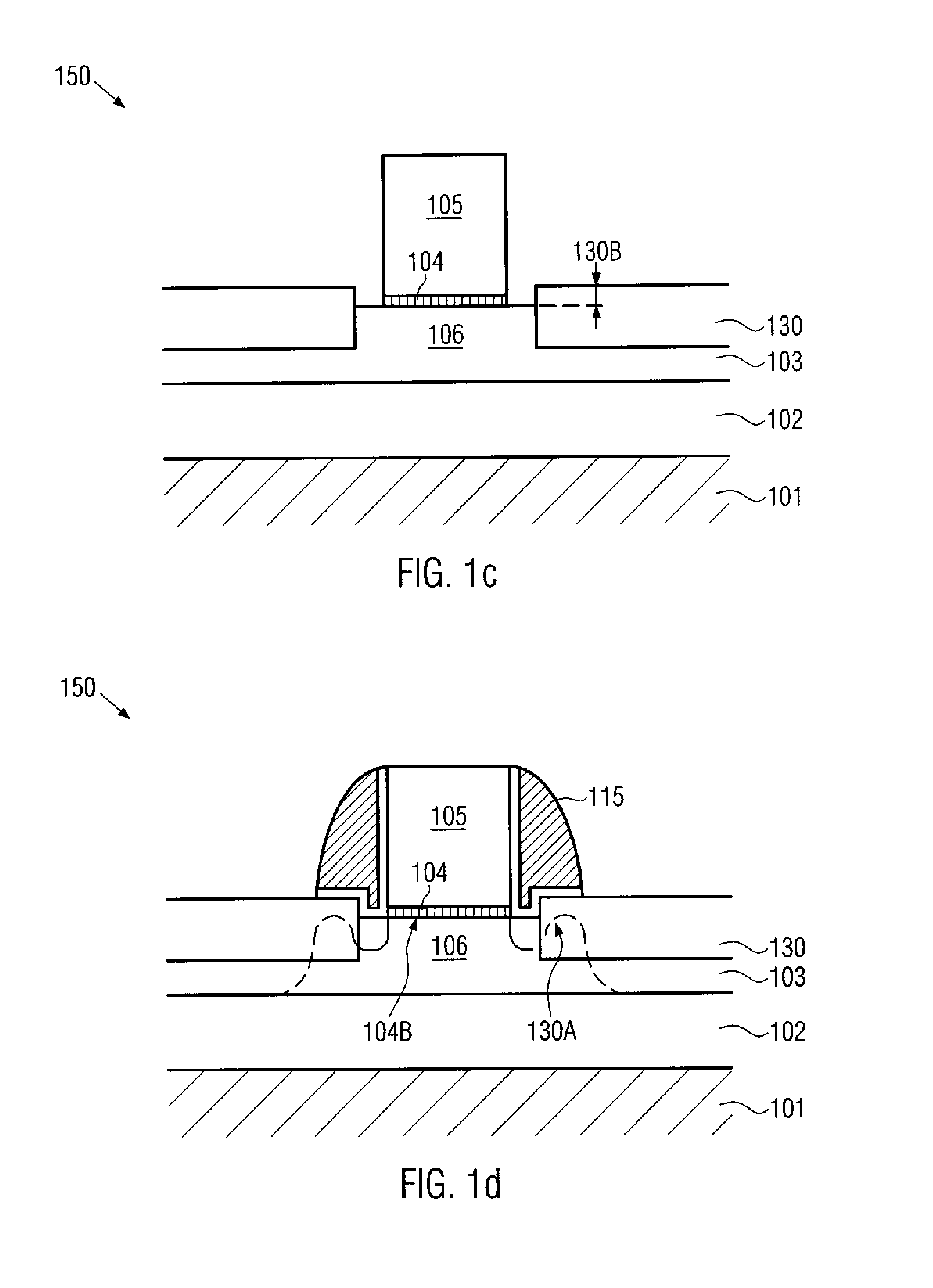

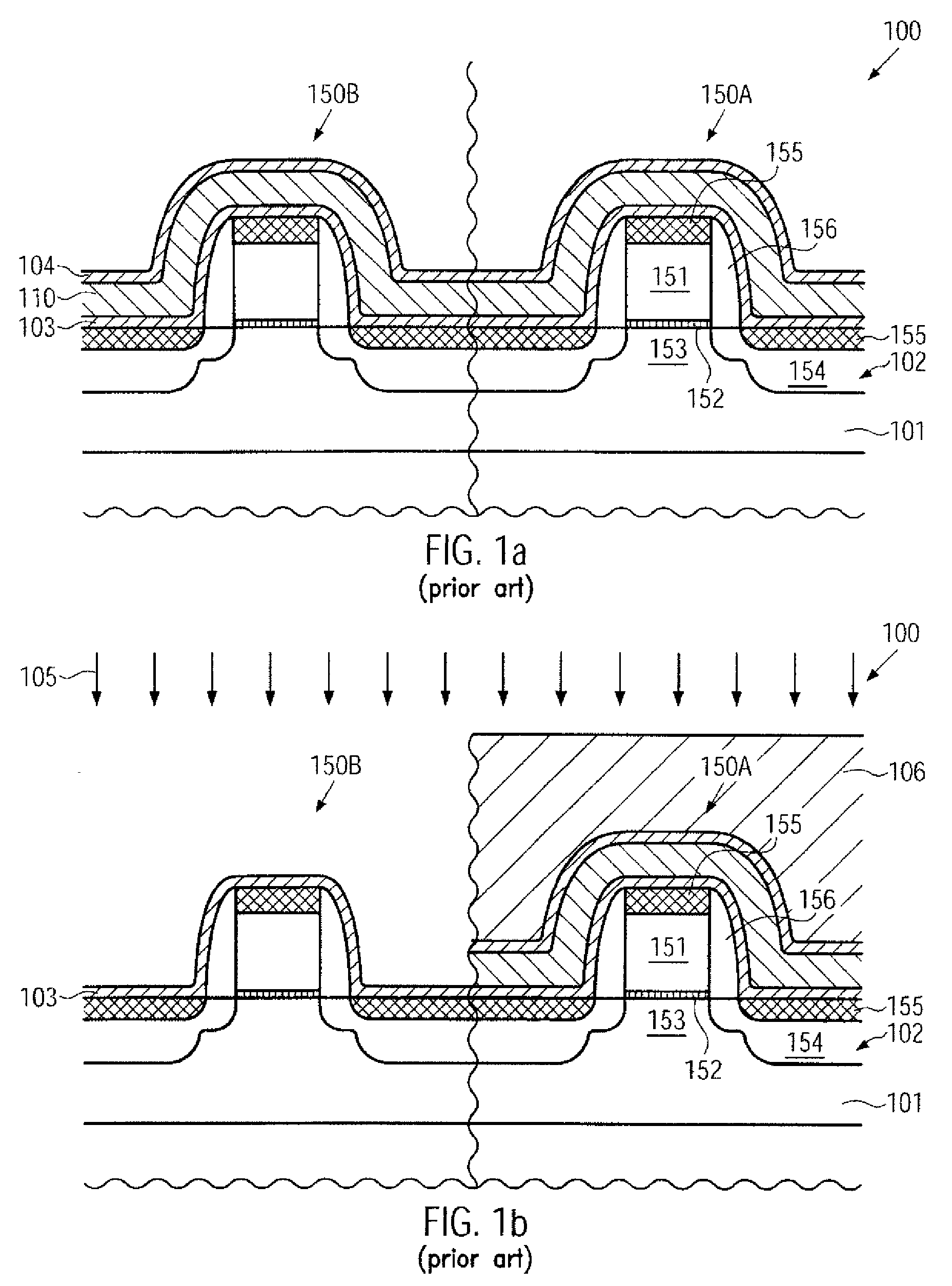

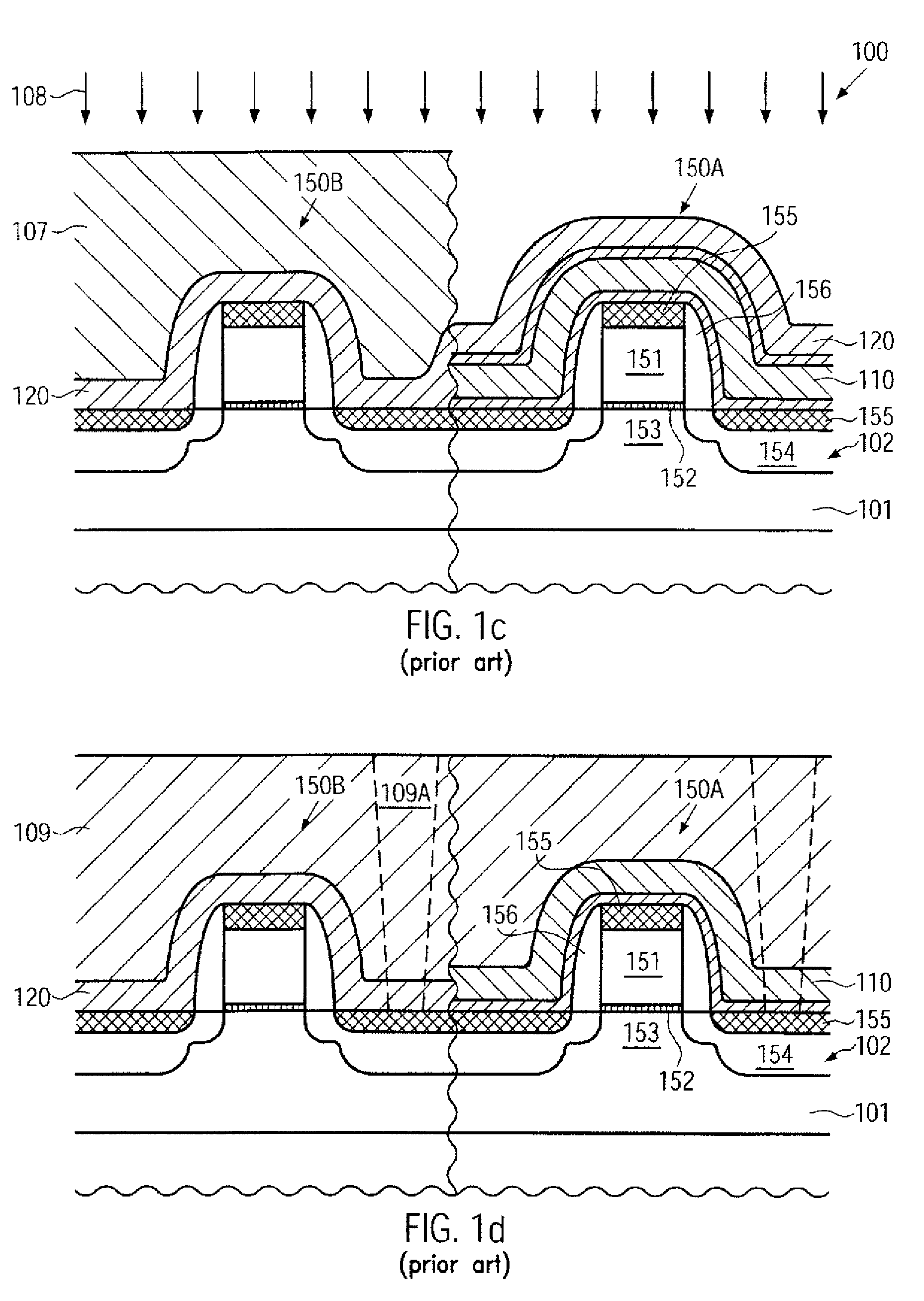

Technique for providing stress sources in transistors in close proximity to a channel region by recessing drain and source regions

ActiveUS20070228482A1Increase strainEfficient transferSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringField-effect transistor

By recessing drain and source regions, a highly stressed layer, such as a contact etch stop layer, may be formed in the recess in order to enhance the strain generation in the adjacent channel region of a field effect transistor. Moreover, a strained semiconductor material may be positioned in close proximity to the channel region by reducing or avoiding undue relaxation effects of metal silicides, thereby also providing enhanced efficiency for the strain generation. In some aspects, both effects may be combined to obtain an even more efficient strain-inducing mechanism.

Owner:CONVERSANT INTPROP MANAGEMENT INC +1

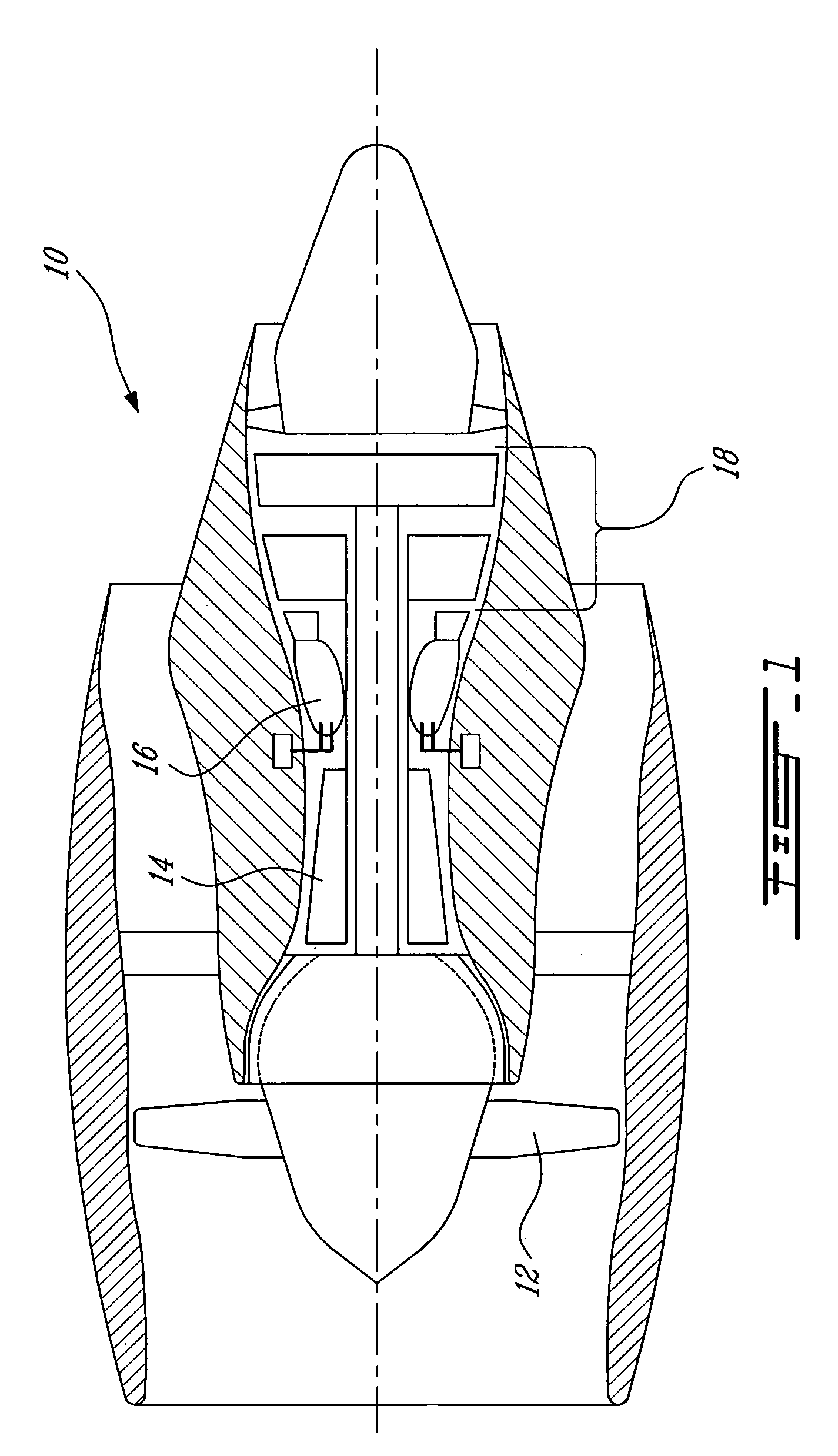

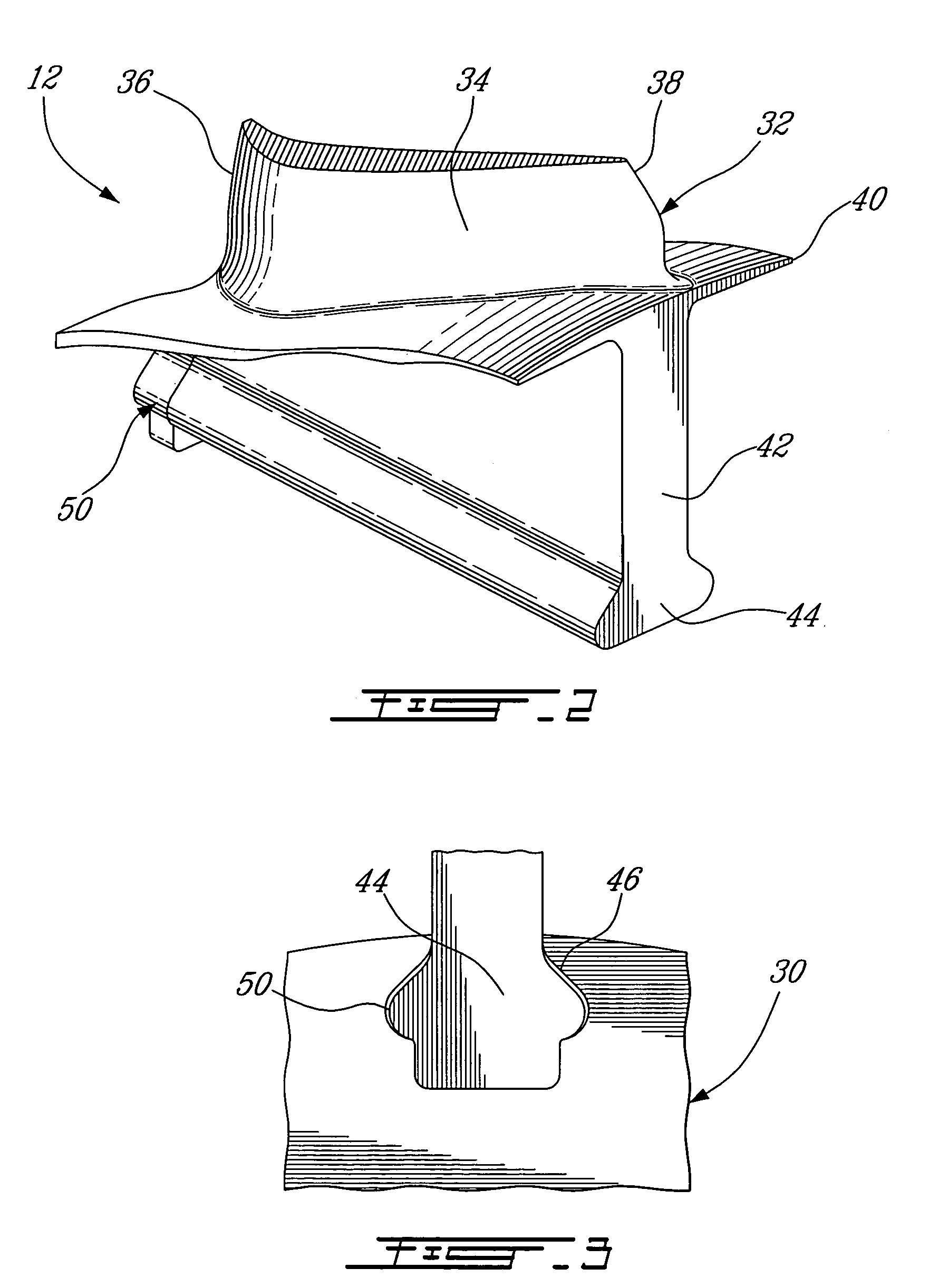

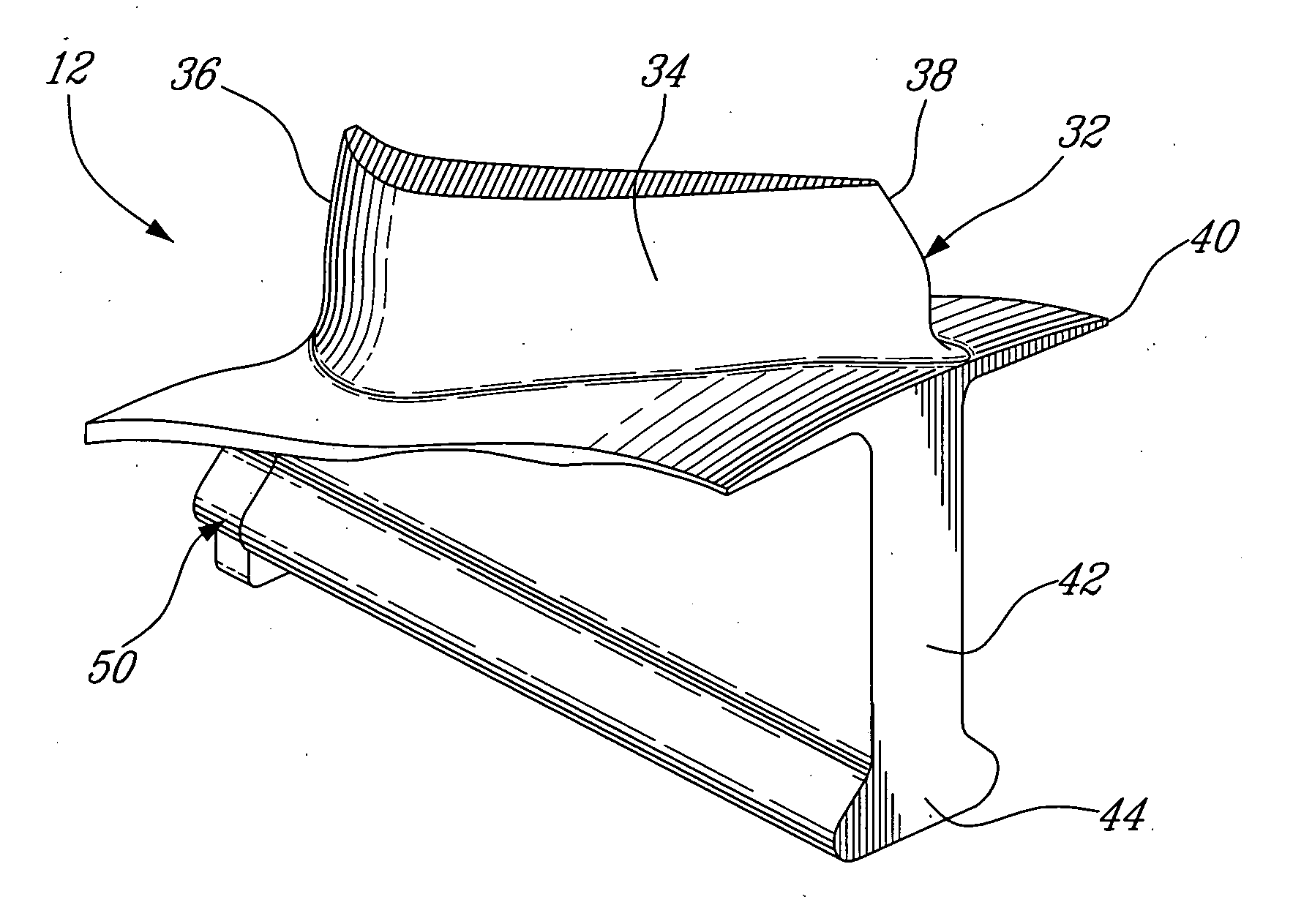

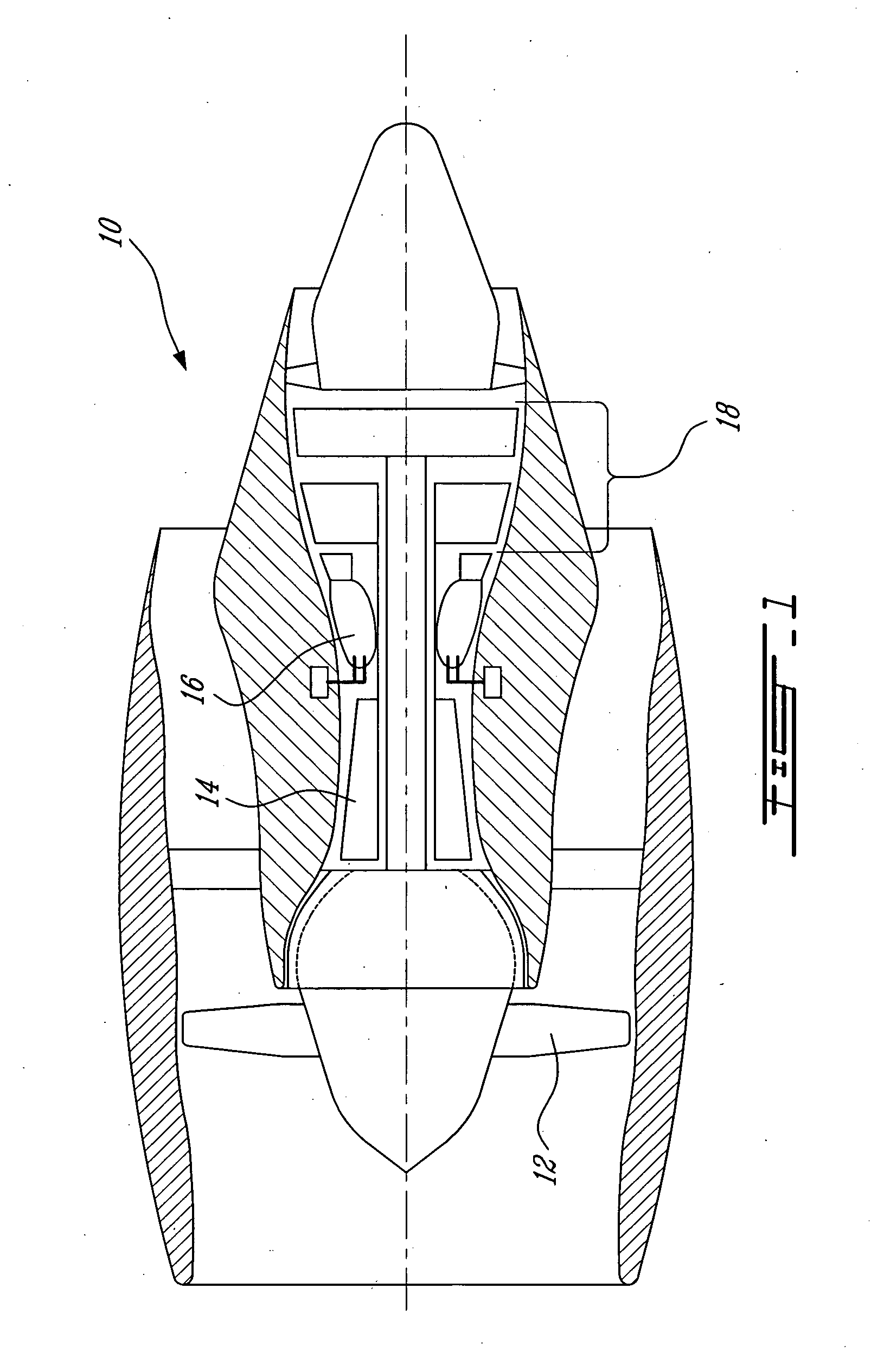

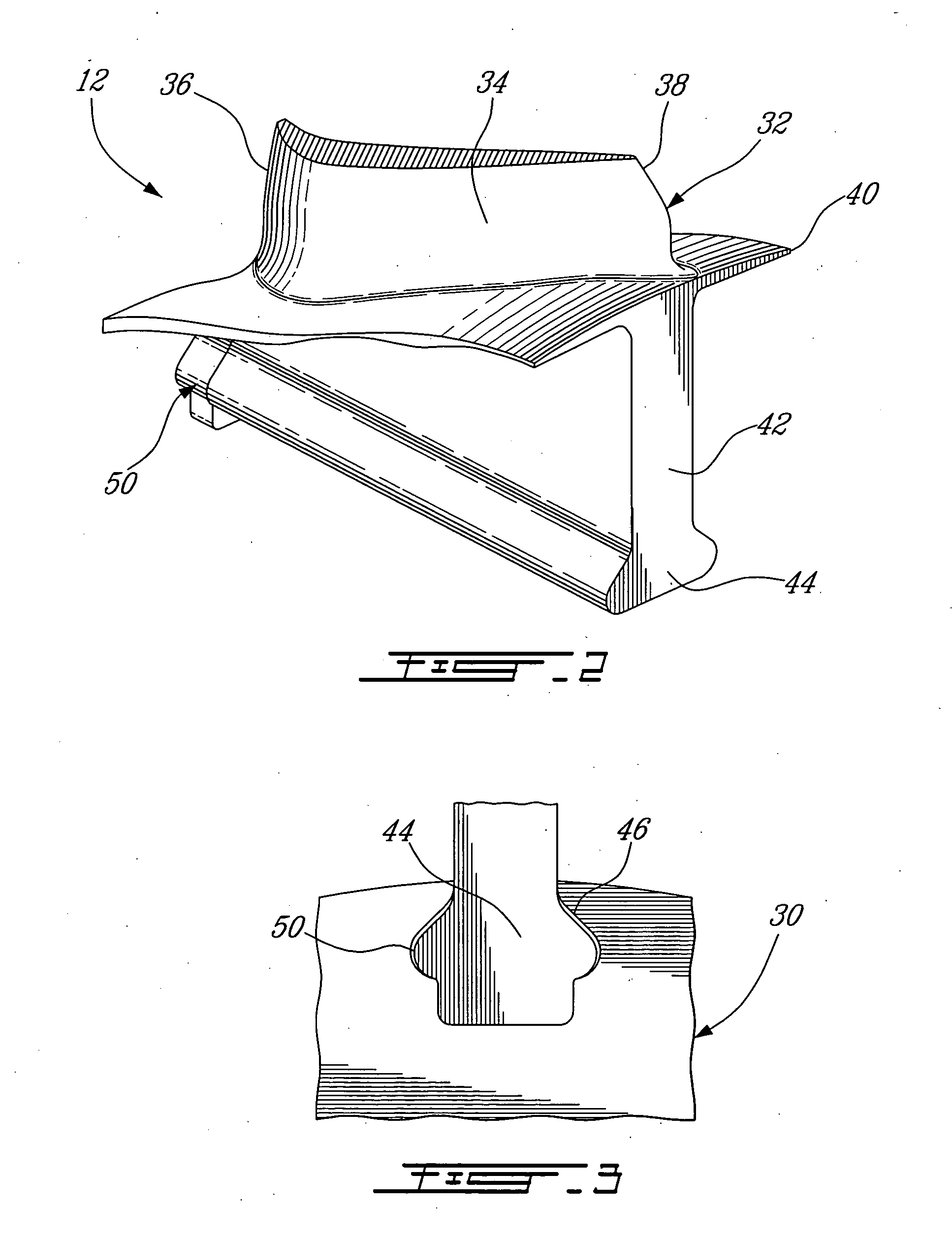

Blade fixing relief mismatch

ActiveUS7156621B2Improved blade and disk interfaceReduce local contact stressPropellersRotary propellersEngineeringGas turbines

A blade fixing and blade mounting slot arrangement for a gas turbine engine has a mismatch fit along a portion of the length of the blade fixing and slot where contact stress would otherwise be maximal.

Owner:PRATT & WHITNEY CANADA CORP

Whole coxa thighbone prosthesis and method for making same

InactiveCN1593356AImprove stress transferImprove bindingJoint implantsFemoral headsFiberRight femoral head

The invention discloses a full coax femoral head prosthetic appliance and its making process, wherein the prosthetic appliance comprises an inner layer and an outer layer, the inner layer being an uninterrupted carbon fiber reinforced polyetheretherketone composite material layer, the outer layer being a short cut carbon fiber reinforced polyetheretherketone composite material layer, and a core rod die arrangement and a prosthesis die arrangement are utilized to realize thermal compression bonding of the two composite material layers. The invention also discloses the process for making the prosthetic appliance.

Owner:SHANGHAI JIAO TONG UNIV

Artificial crystalline lens

InactiveCN101011300AConform to the physiological structureReduce loosenessBone implantSpinal implantsLamina terminalisProsthesis

The invention relates to an artificial sacrum prosthese, formed by an iliac bone connecting structure and a low lumbar vertebral arch nail rod. The invention is characterized in that the main body of the iliac bone connecting structure is in arc shape, whose middle is arranged with a lumbar bottom support table engaged with the cut lower plate of lumbar; the lower ends of two sides of arc are engaged with the cut sacrum joint and arranged with the iliac bone nail; two upper sides of the arc are arranged with both one sacrum rod whose end is arranged with the connecting part engaged with the upper part of iliac bone. The invention sets the iliac bone connecting structure in arc shape to meet the sacrum physiological structure, to stabilize the basin ring, improve the stress transmission and reduce the nail loosen. When in use, the two side sacrum joint cut are less, to avoid damaging the ear face, to be used to rebuild the basin.

Owner:杨惠林 +2

Epoxy resin coating in marine steel pipe 3PE anticorrosive coating and preparation method thereof

InactiveCN104449249AReduce dosageAvoid crackingAnti-corrosive paintsEpoxy resin coatingsEpoxyShrinkage rate

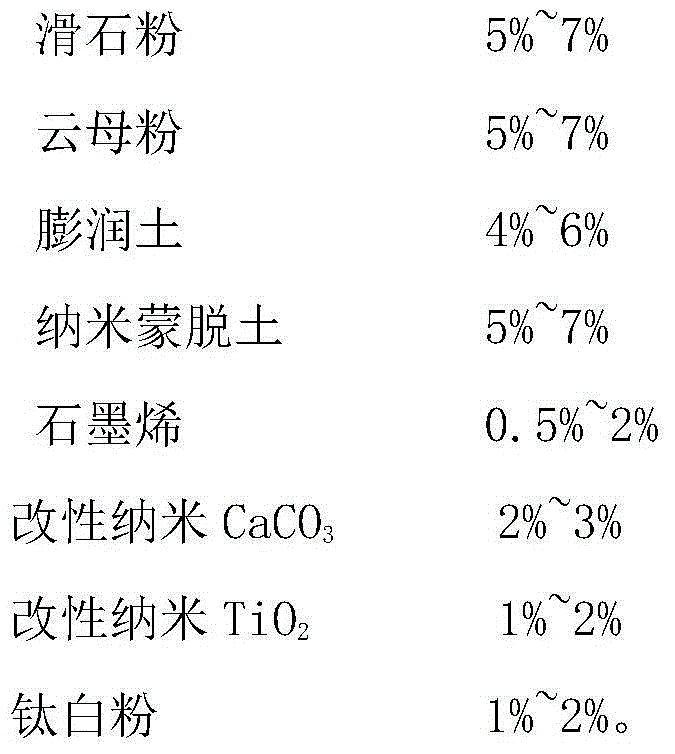

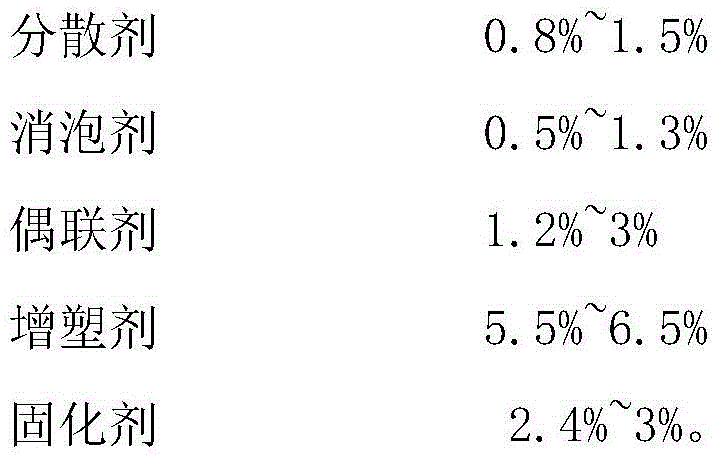

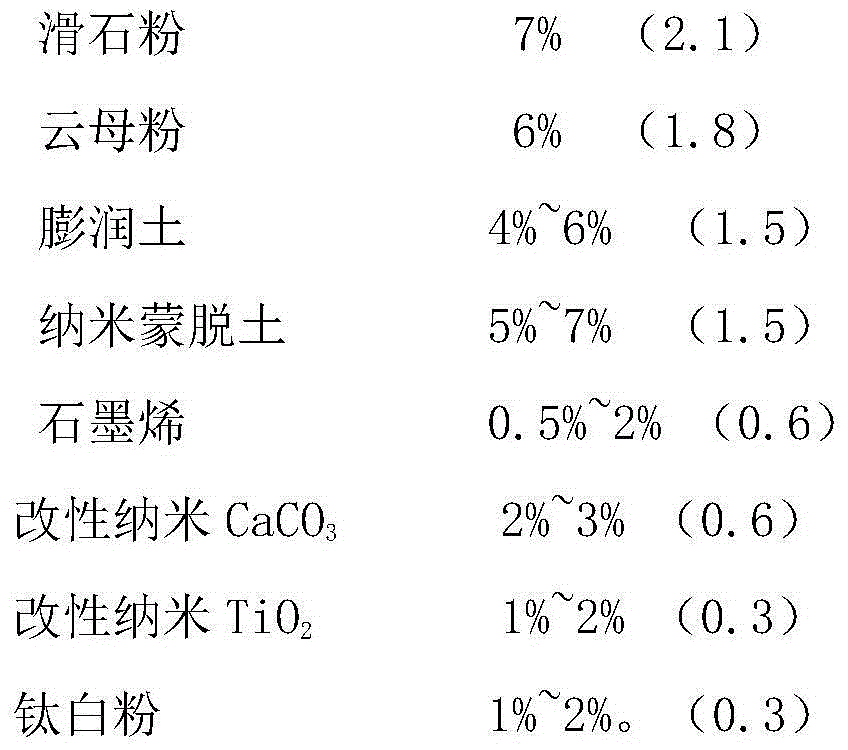

The invention discloses an epoxy resin coating in a marine steel pipe 3PE anticorrosive coating and a preparation method thereof. The epoxy resin anticorrosive coating comprises the following components in percentage by weight: 55-65 percent of epoxy resin, 23.5-36 percent of filler and pigments and 10.4-15.3 percent of aids, wherein the epoxy resin comprises the following components in percentage by weight: 39-47 percent of E-12 epoxy resin and 16-23 percent of novolac epoxy resin. Talcum powder, mica powder, bentonite and titanium dioxide are properly added into the epoxy resin to serve as partial fillers. The use amount of the resin can be relatively reduced, the cost is reduced, the physical and mechanical properties can be improved; particularly, the elasticity modulus is increased, the cure shrinkage rate is reduced, the seawater impact resistance is increased, and the seawater resistance is improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

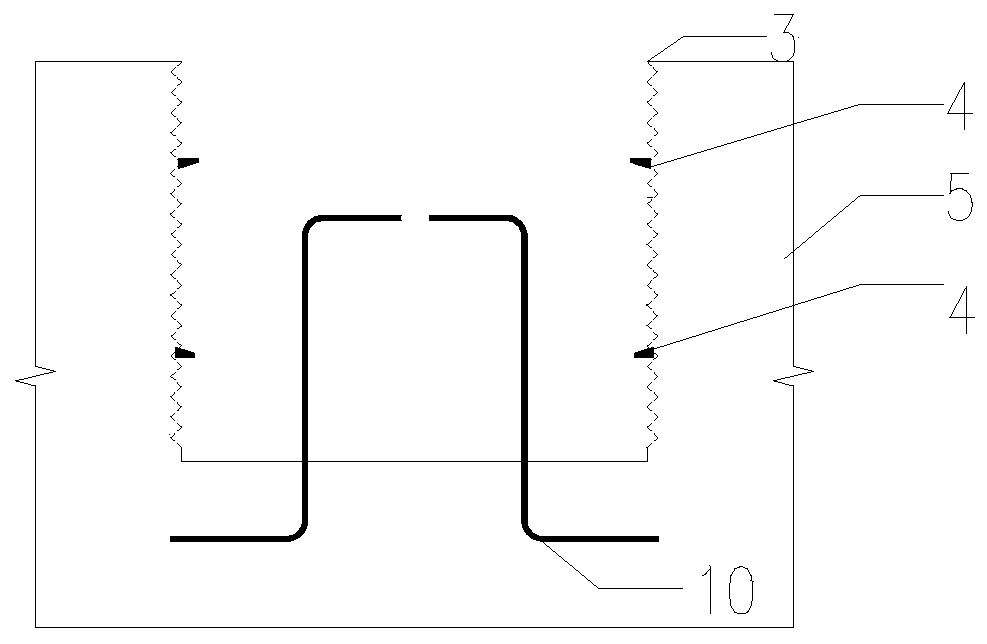

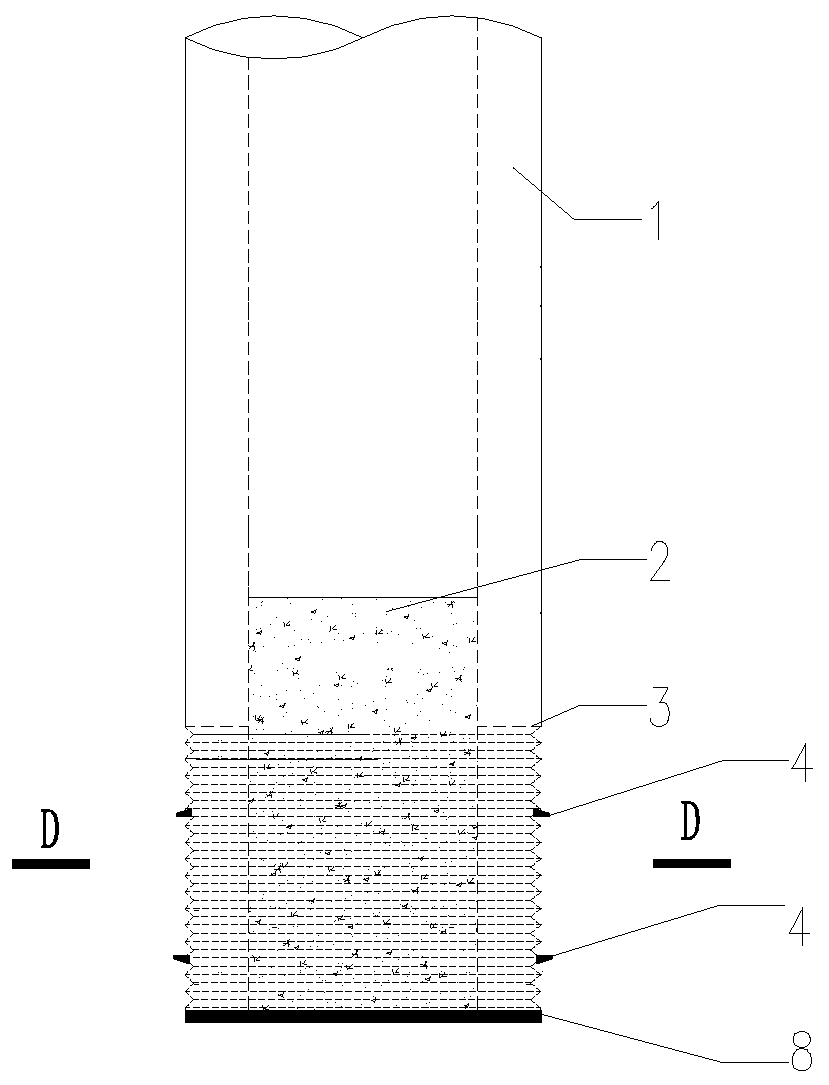

Prefabricated reinforced concrete hollow pier socket and spigot joint connecting structure and manufacturing method

InactiveCN110886202AHigh construction precision requirementsImprove construction fault toleranceBridge structural detailsFoundation engineeringReinforced concreteArchitectural engineering

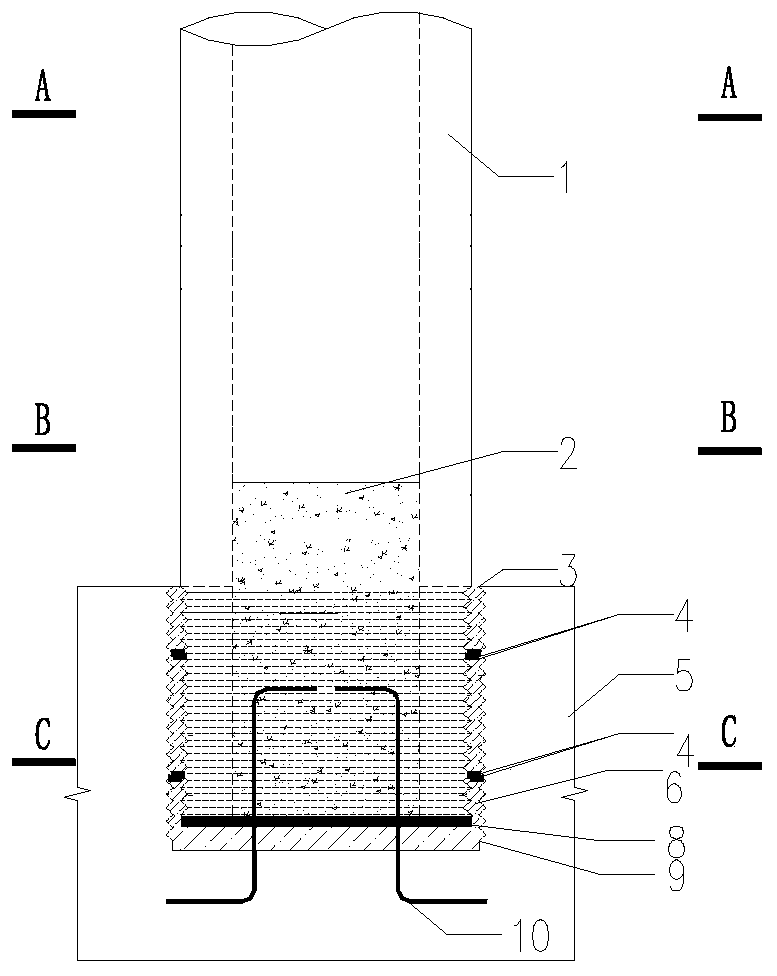

The invention discloses a prefabricated reinforced concrete hollow pier socket and spigot joint connection structure and a manufacturing method. A component I of the structure is a prefabricated bearing platform; a corresponding pier column groove hole is reserved when the bearing platform is poured and is convenient for connection with a pier column, and meanwhile steel bar anchoring in the bearing platform and penetrating a hole is provided at the socket and spigot position, a component II is a prefabricated hollow pier column; the bottoms of the pier columns are welded through steel plates,holes are reserved in the corresponding positions of the steel plates, bearing platform anchoring steel bars can stretch into the holes conveniently, the overall connecting performance of the pier columns and the bearing platform can be obviously improved, meanwhile, inclined steel wedges are arranged at the corresponding positions of the pier columns and the bearing platform, after the pier columns are inserted, a self-locking function is achieved through rotation, temporary supports are not needed for reinforcement, and construction is facilitated. Meanwhile, interface ripples are arrangedon the surfaces of the pier column and the bearing platform, the connecting and shearing resistance performance is improved, a gap between the pier column and the bearing platform is subjected to crack pouring through UHPC, the socket and spigot joint quality is met to a great extent, and meanwhile the performance of high early strength and rapid construction is achieved. The operation is simple and convenient, the construction is easy and the quality is controllable.

Owner:BEIJING UNIV OF TECH

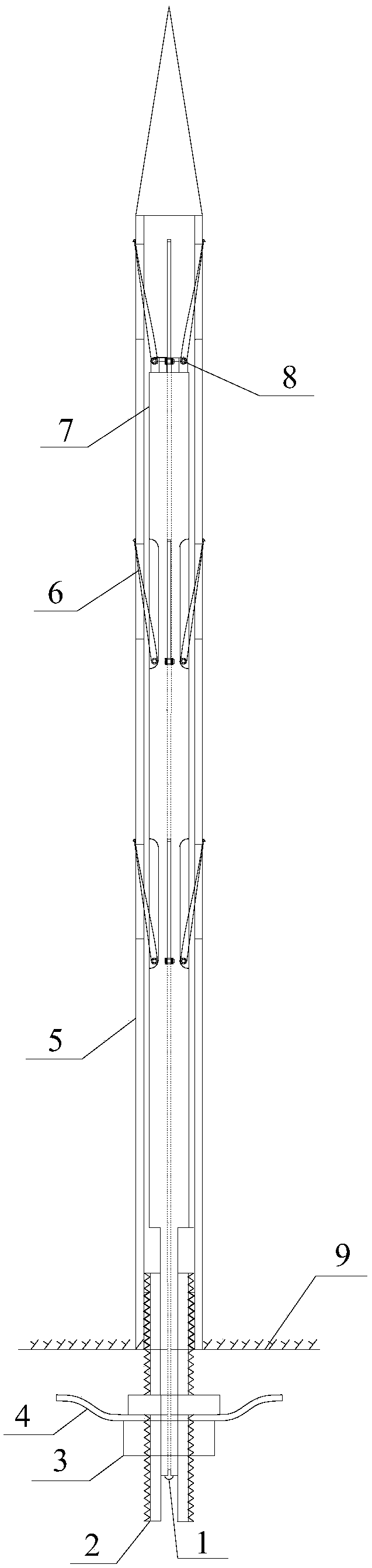

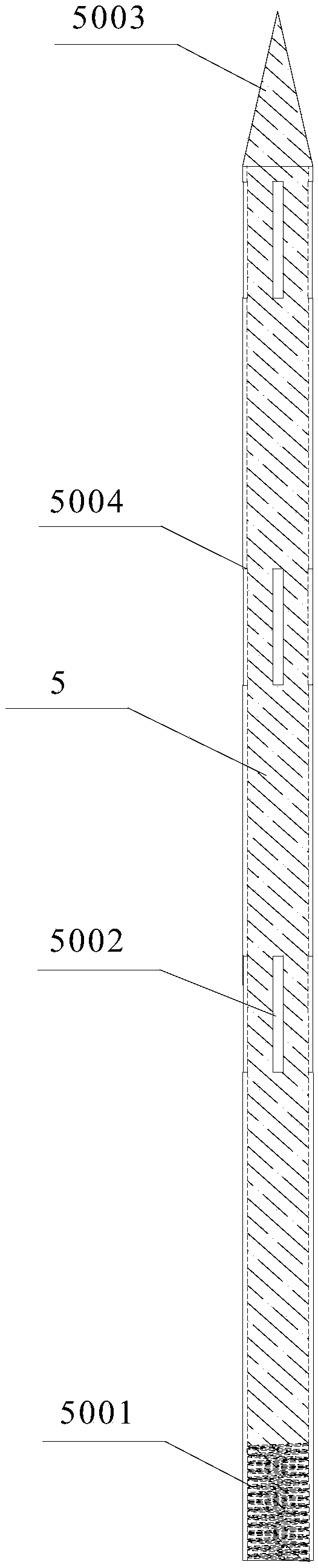

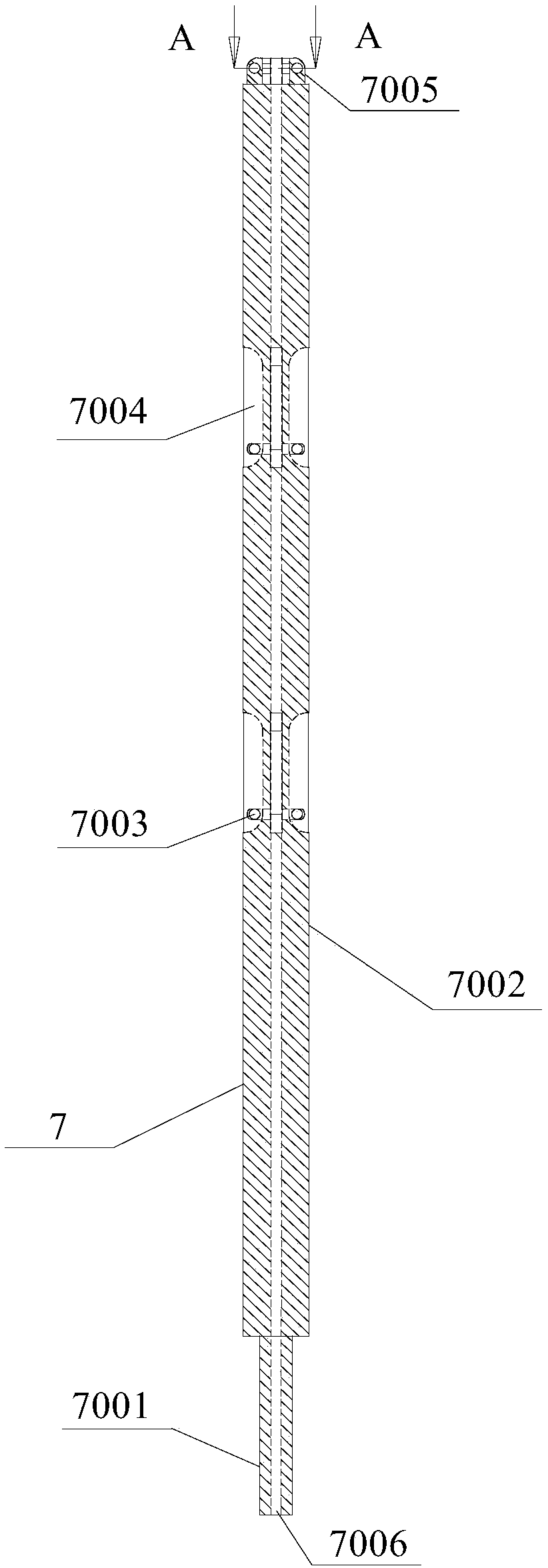

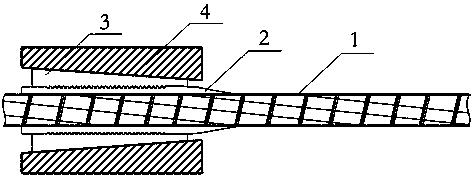

Arrow anchor rod of multi-section clamping grouting anchoring and using method thereof

The invention relates to the field of slope reinforcement and surrounding rock support control of underground engineering, disclosing an arrow anchor rod of multi-section clamping grouting anchoring,which comprises a sleeve (5), a grouting rod body device and a sealing device, wherein the grouting rod body device is arranged in the sleeve (5); the grouting rod body device comprises a grouting rodbody (7) and a plurality of groups of anchor heads (6); each group of anchor heads (6) forms a clamping anchoring structure and are connected to the outer wall of the grouting rod body (7) in hinge mode; the sleeve (5) is provided with a slotted hole (5002) which is in one-to-one correspondence with the anchor head (6) and suitable for the anchor head (6) to pass; the anchor head (6) is guided into the rock mass along the slotted hole (5002) by the external force of propelling grouting rod body device; a sealing structure is formed between the sleeve (5) and the grouting rod body device by utilizing a sealing device and is fixed on the rock wall (9). By adopting the technical innovation of the arrow anchor rod of multi-section clamping grouting anchoring, continuous high-resistance and high-strength working resistance can be provided timely and efficiently, so that the long-term stability of the engineering geotechnical mass maintenance under the environment of high stress or strong power disturbance can be truly achieved.

Owner:CENT SOUTH UNIV

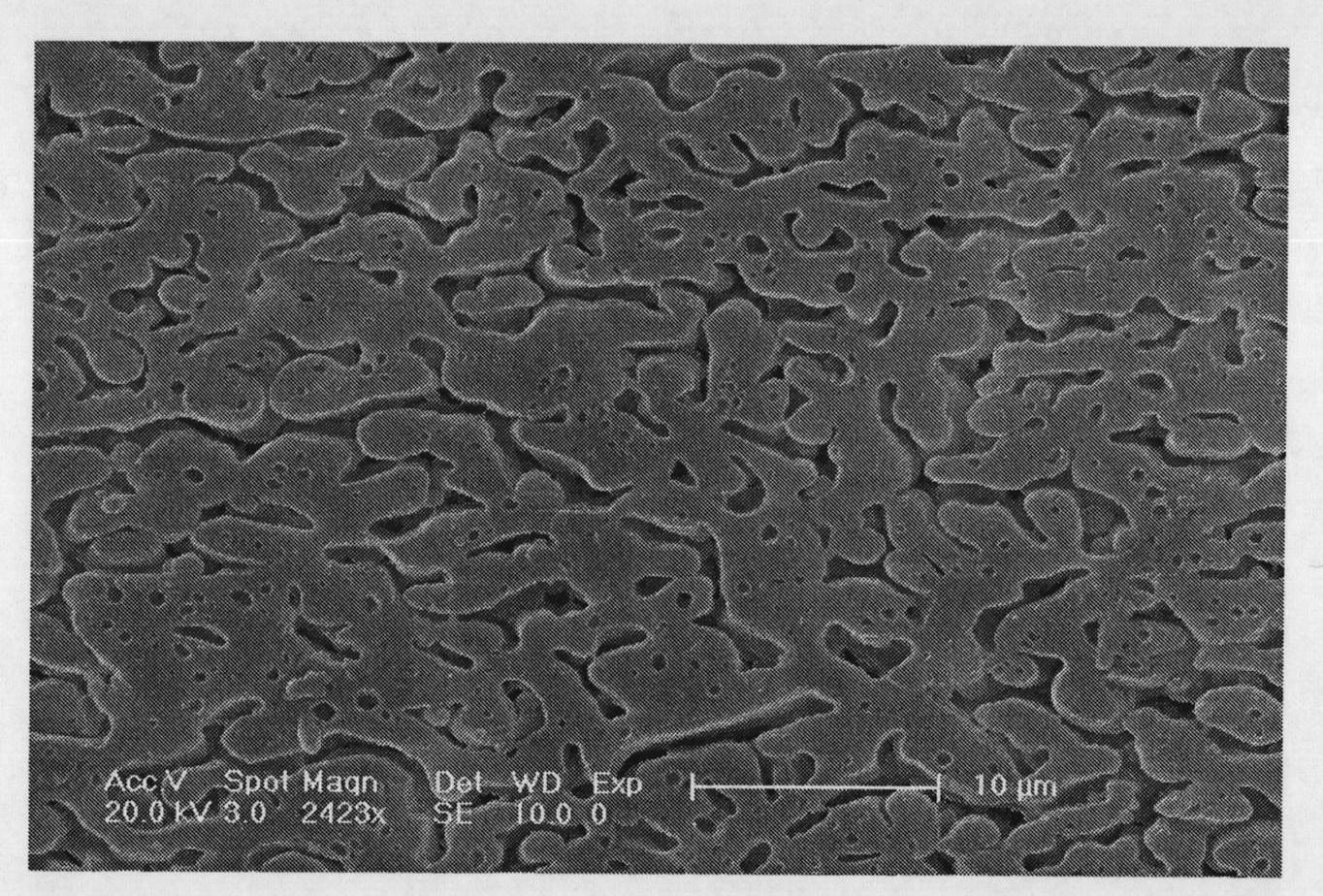

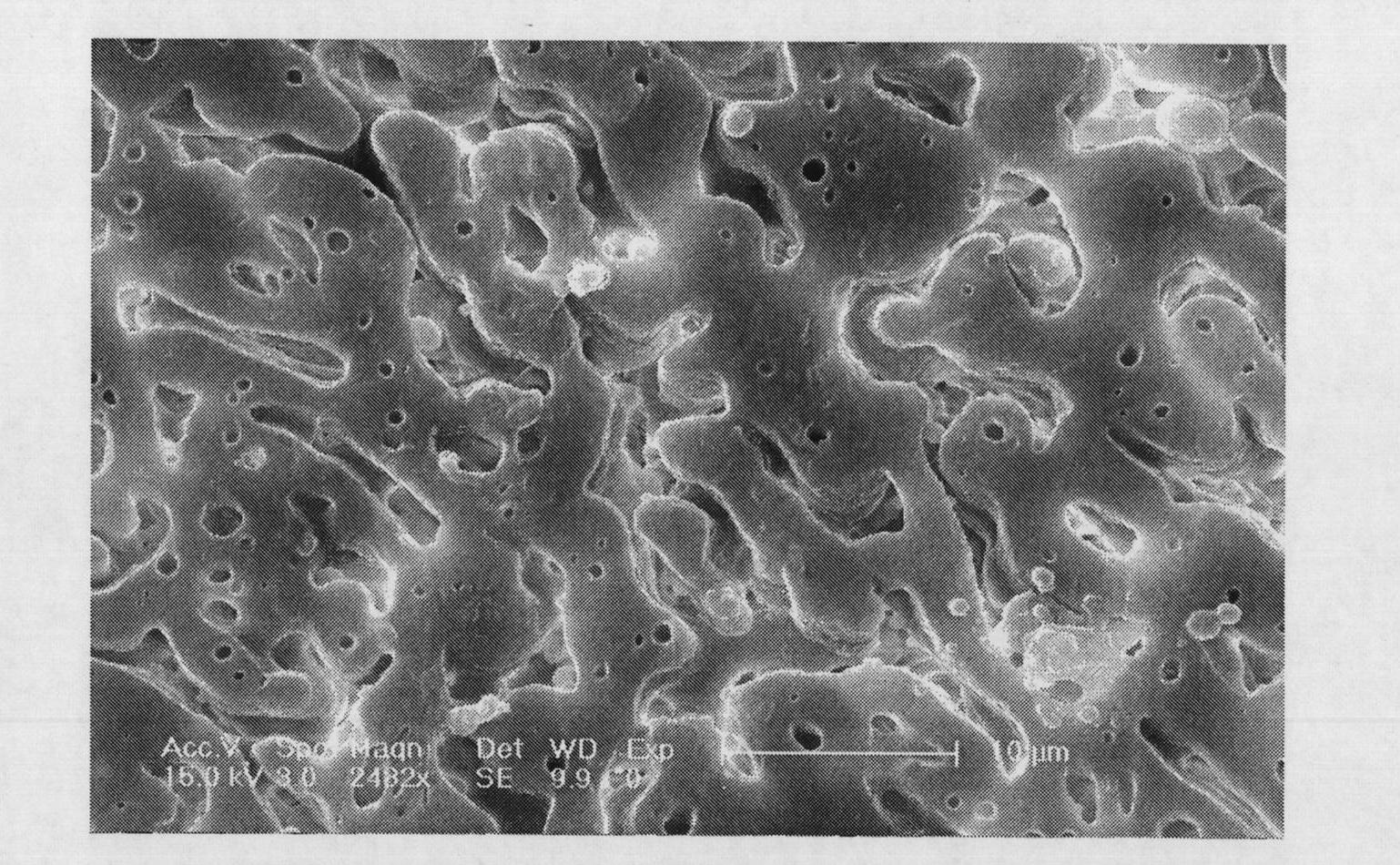

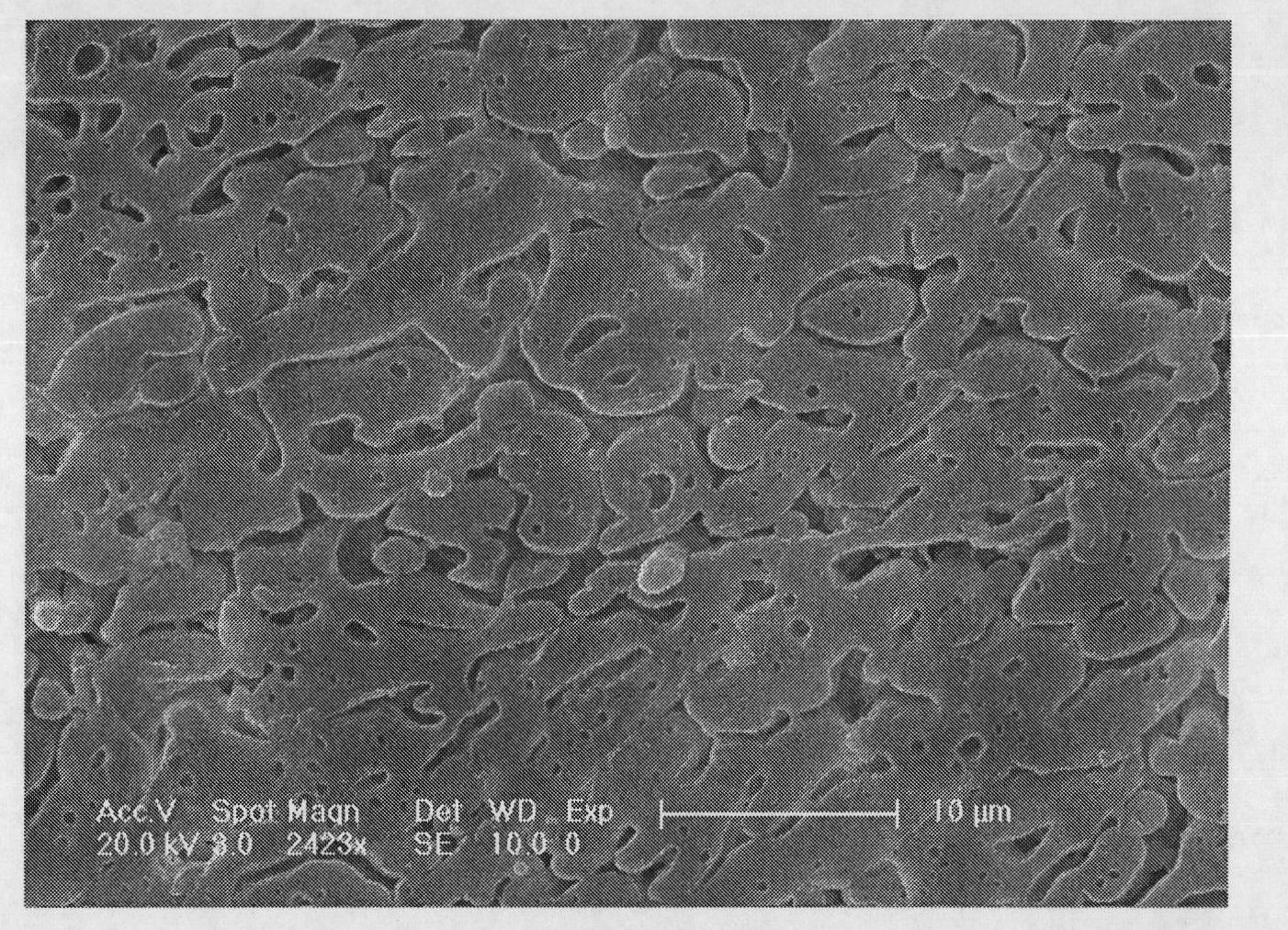

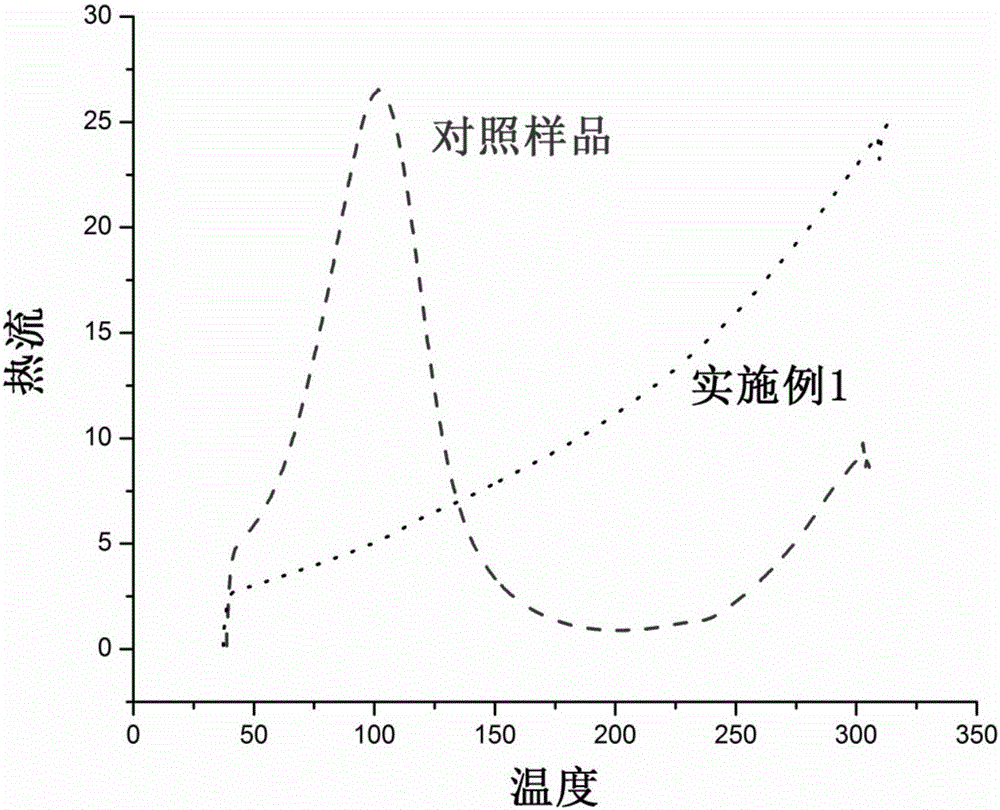

Preparation method of polyolefine/polyamide alloy material with bicontinuous structure

The invention provides a preparation method of a polyolefine / polyamide alloy material with a bicontinuous structure, which comprises the following steps: mixing fictionalized polybutadiene and polyolefine which is irradiated or added with peroxide initiator, wherein the weight ratio of the polybutadiene to the polyolefine is 3-20:80-97, and putting the mixture into an extruder for granulating by melt extrusion at 160-210 DEG C to obtain a first reaction product; and mixing the first reaction product and polyamide in weight ratio of 70-85:15-30, and putting the mixture into an extruder for granulating by blend extrusion at 230-300 DEG C to obtain the polyolefine / polyamide alloy material with the bicontinuous structure. By the method provided by the invention, the polyolefine / polyamide alloy material with the bicontinuous structure can be prepared under the condition of a small phase of polyamide, and the method has the advantages of simple process, low preparation cost and the like and is suitable for industrialized production.

Owner:横店集团得邦工程塑料有限公司

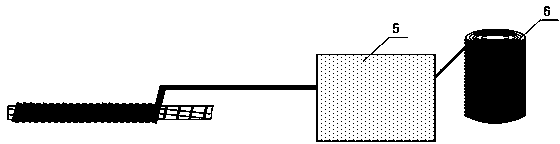

Anchoring method applicable to large-tonnage FRP inhaul cable

ActiveCN103669208AGood bonding performanceIncrease stress transferBridge structural detailsBuilding reinforcementsShearing deformationEngineering

The invention discloses an anchoring method applicable to a large-tonnage (larger than 50 tones) FRP inhaul cable. The FRP inhaul cable is anchored with a clamping piece type anchorage device, a protection transition layer with the length no smaller than the length of an anchoring area of the clamping piece type anchorage device is formed at the anchoring end of the FRP inhaul cable, the protection transition layer and the FRP inhaul cable are integrated, and the clamping piece type anchorage device is anchored to the protection transition layer. After the FRP inhaul cable and the protecting layer are pressed into a whole, while the shearing strength of the FRP inhaul cable and a protecting layer interface is increased, the phenomenon that the FRP inhaul cable weak in transverse strength makes direct contact with load transmitting mediums large in rigidity in the anchoring area can be avoided, a stressed buffering layer is formed, and the FRP inhaul cable can be indirectly protected. The anchoring method used for anchoring the FRP inhaul cable has the advantages of facilitating construction and being high in anchoring efficiency and the like, long-term performance of an anchoring system can be guaranteed, the method can also be used for tensile tests on the FRP inhaul cable, samples can be prepared easily and conveniently, and compared with an adhesive type anchoring method, test errors caused by overlarge shearing deformation of resin can be avoided.

Owner:SOUTHEAST UNIV +1

Dopamine modified hexagonal boron nitride/para-aramid nanofiber composite material and preparation method thereof

InactiveCN110229518AImprove insulation performanceImprove thermal conductivityHeat-exchange elementsVacuum assistedFiltration

The invention relates to a dopamine modified hexagonal boron nitride / para-aramid nanofiber composite material and a preparation method thereof. The method includes: step 1, mixing a dopamine modifiedhexagonal boron nitride dispersion solution and a para-aramid nanofiber dispersion solution, and then performing ultrasonic treatment to obtain a mixed system A, wherein the mass of the dopamine modified hexagonal boron nitride accounts for 10%-40% of the total mass of the para-aramid nanofiber; and step 2, conducting vacuum-assisted filtration and hot press drying on the mixed system A to obtainthe dopamine modified hexagonal boron nitride / para-aramid nanofiber composite material. The method ensures the formation of certain microstructure in the composite material, and then enhances the insulation properties of the composite material, and improves the interfacial binding capacity of the dopamine modified hexagonal boron nitride and para-aramid nanofiber, strengthens the stress transfer between the two materials while guaranteeing good heat conduction, strengthens the mechanical strength of the composite material, and acquires the composite material with excellent insulating performance and heat-conducting properties.

Owner:SHAANXI UNIV OF SCI & TECH

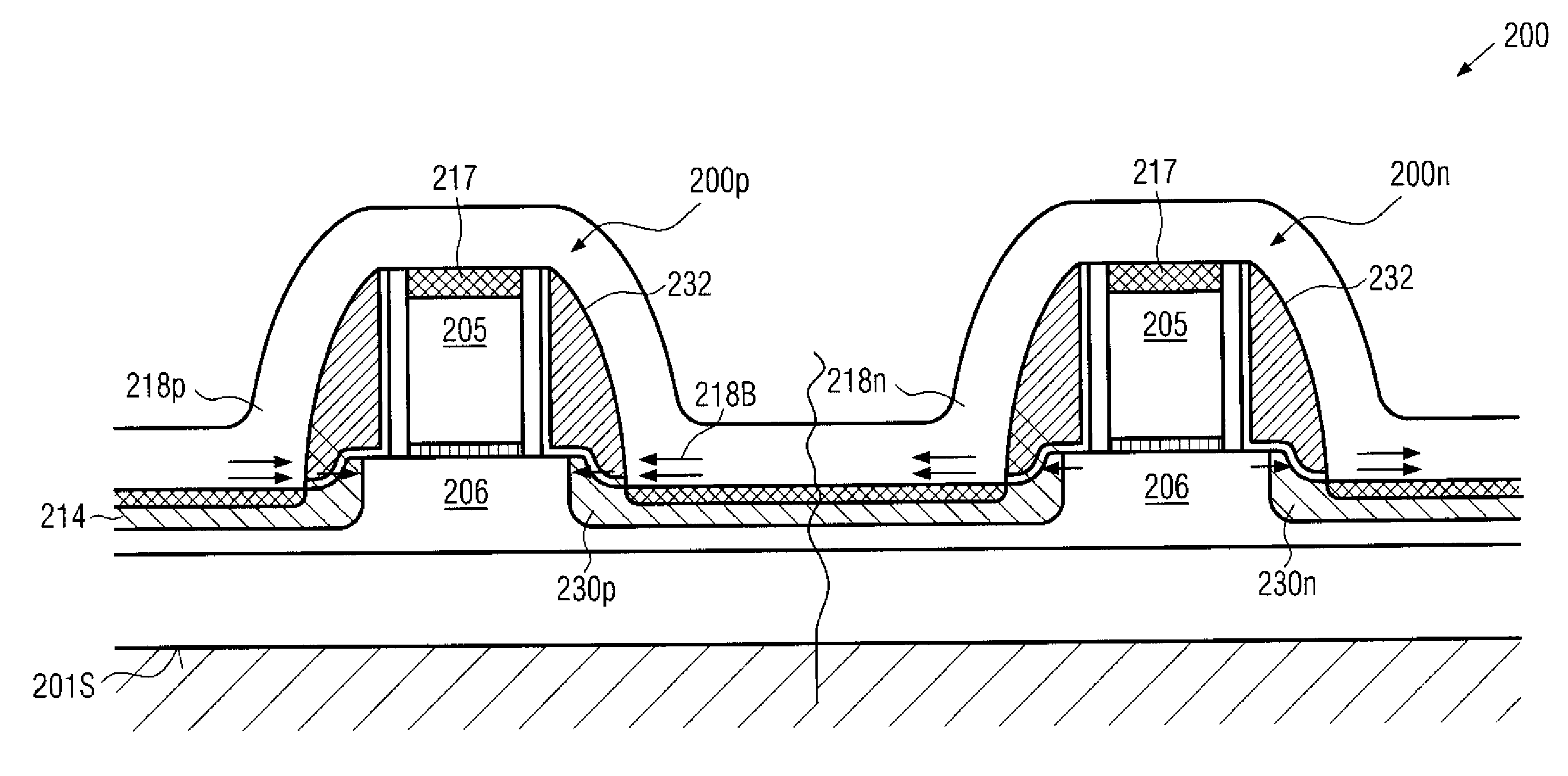

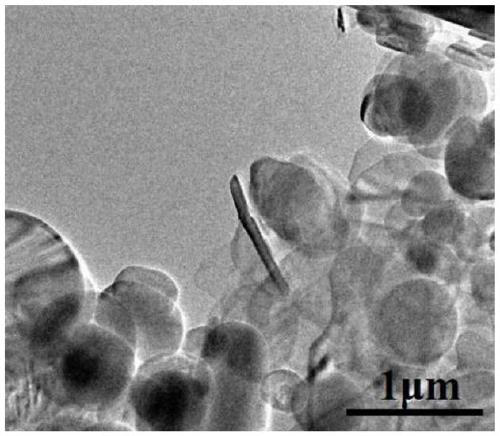

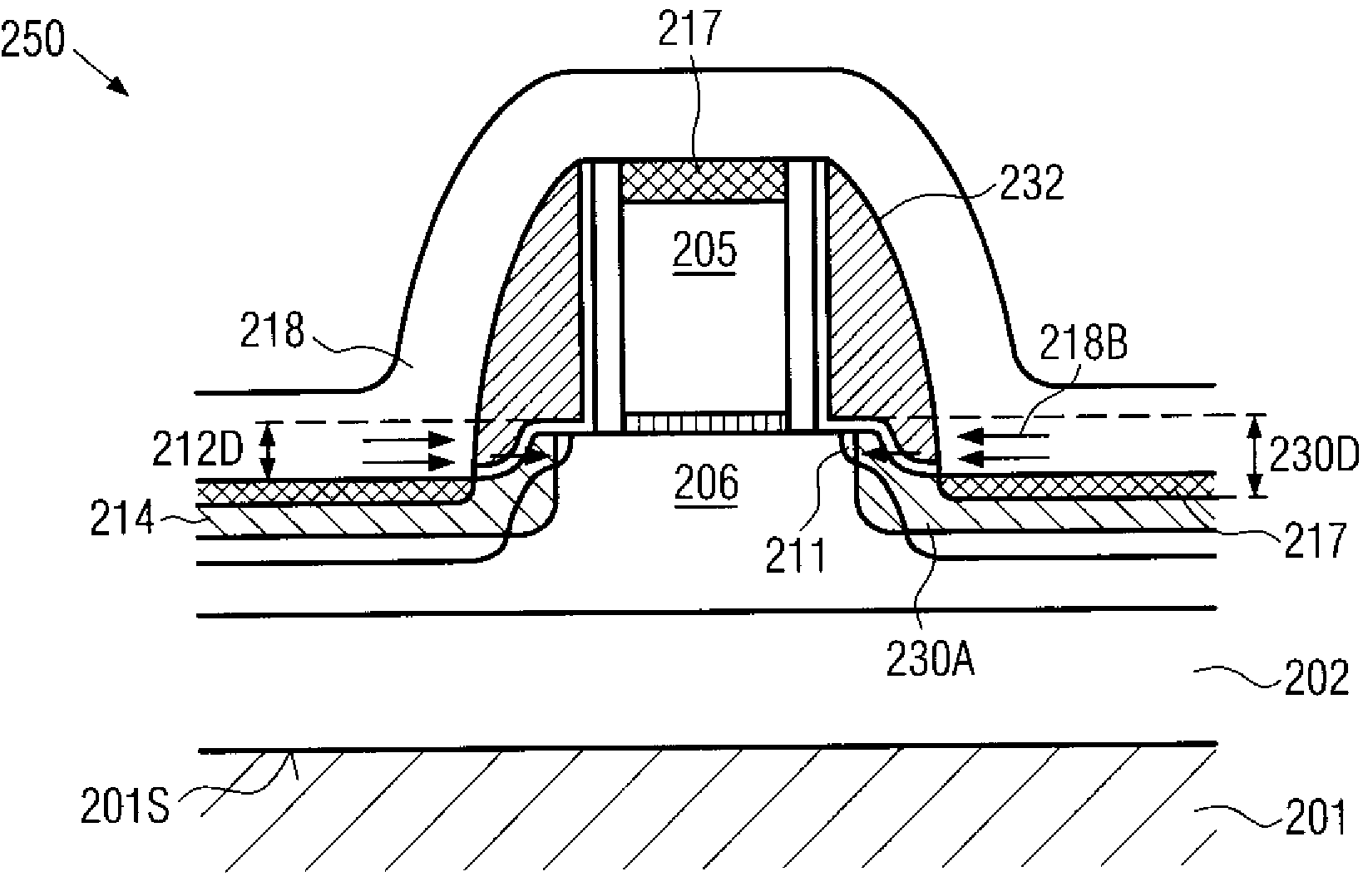

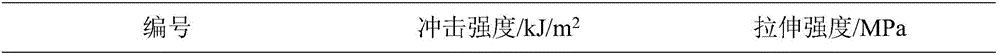

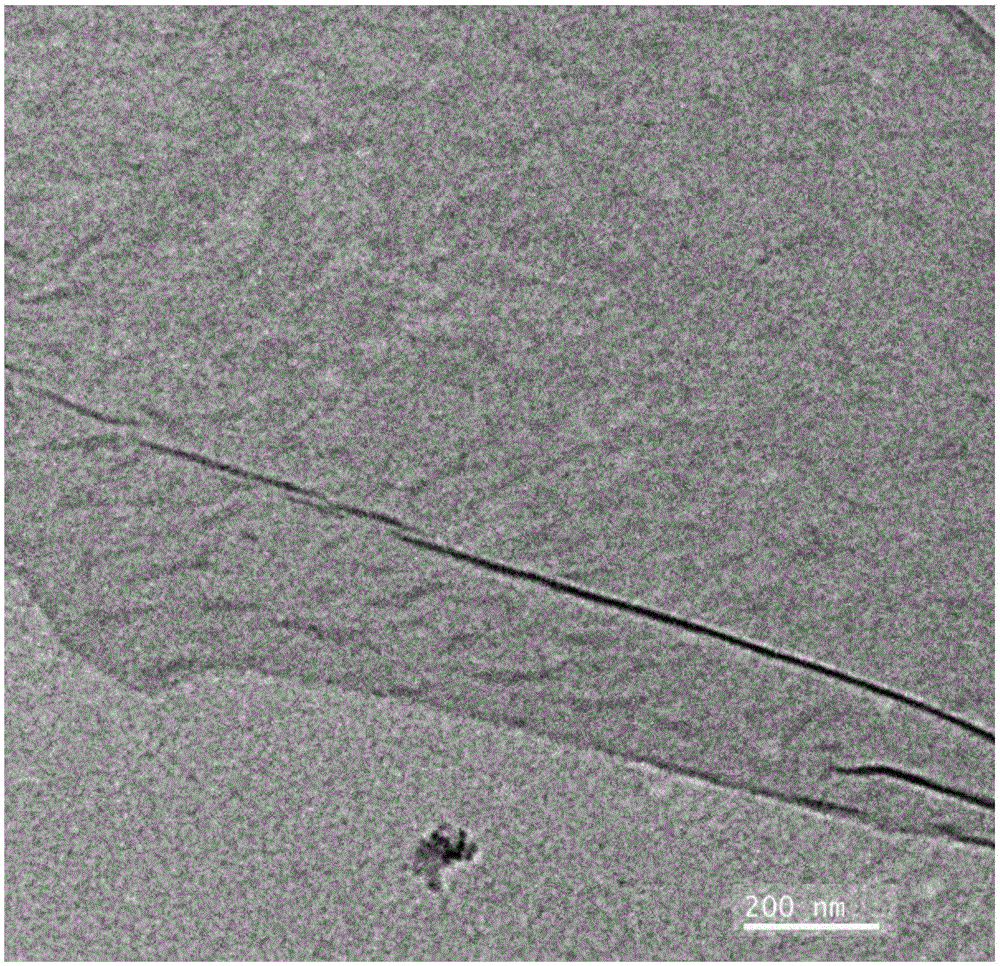

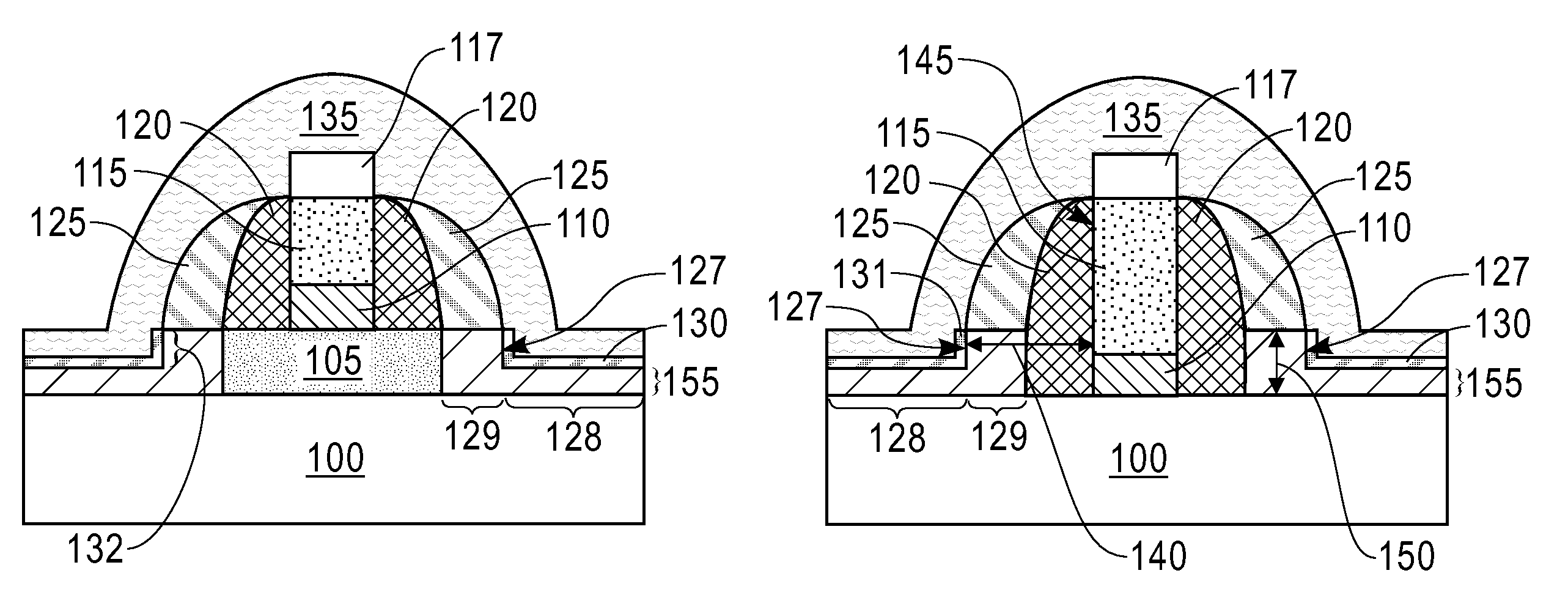

Technique for providing stress sources in transistors in close proximity to a channel region by recessing drain and source regions

ActiveUS7696052B2Increase strainEfficient transferSolid-state devicesSemiconductor/solid-state device manufacturingRelaxation effectSemiconductor materials

By recessing drain and source regions, a highly stressed layer, such as a contact etch stop layer, may be formed in the recess in order to enhance the strain generation in the adjacent channel region of a field effect transistor. Moreover, a strained semiconductor material may be positioned in close proximity to the channel region by reducing or avoiding undue relaxation effects of metal silicides, thereby also providing enhanced efficiency for the strain generation. In some aspects, both effects may be combined to obtain an even more efficient strain-inducing mechanism.

Owner:CONVERSANT INTPROP MANAGEMENT INC +1

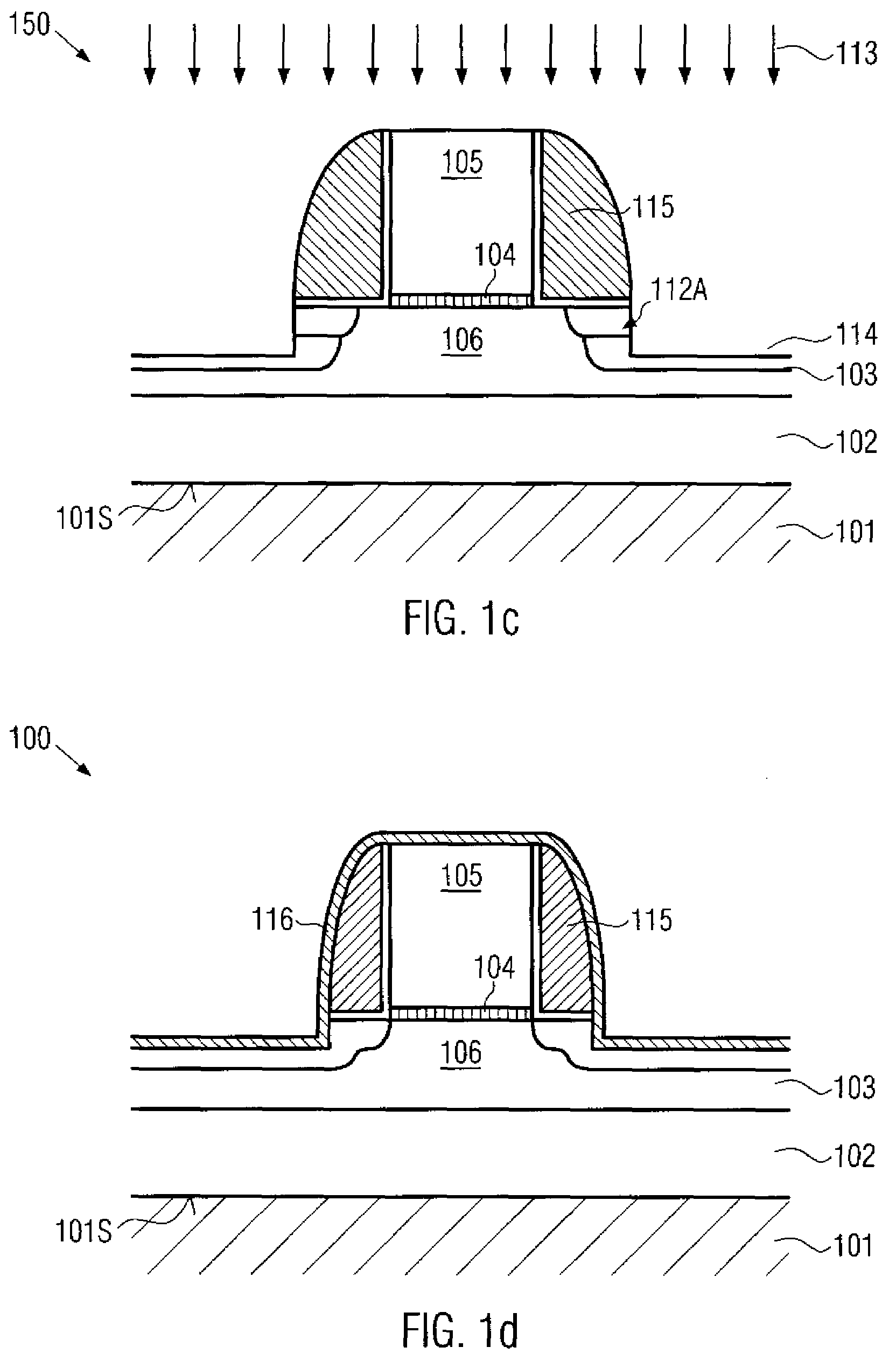

Blade fixing relief mismatch

ActiveUS20050254953A1Improved blade and disk interfaceReduce local contact stressPropellersPump componentsEngineeringStructural engineering

A blade fixing and blade mounting slot arrangement for a gas turbine engine has a mismatch fit along a portion of the length of the blade fixing and slot where contact stress would otherwise be maximal.

Owner:PRATT & WHITNEY CANADA CORP

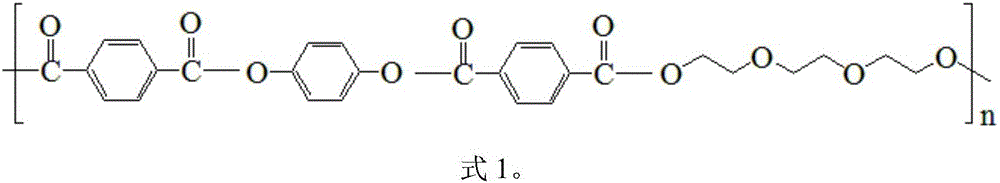

Glass fiber reinforced polystyrene micro-foam double-layer co-extrusion section and its making method

ActiveCN103213366AWon't breakEvenly dispersedSynthetic resin layered productsGlass fiberSurface layer

The invention aims to provide a glass fiber reinforced polystyrene micro-foam double-layer co-extrusion section. The core layer of the section contains 3-8% of a uniform-distribution glass fiber (by polystyrene) having a length-diameter ratio of 10-20. The surface of the core layer is coated with a layer of high-impact-resistance polystyrene, and the mass fraction ratio of the material of the core layer to the material of the surface layer is 100:5-25. The density of the section reaches 0.40g / cm<3>, so the tensile strength and the charpy impact strength of the section can reach 12MPa and 4.5kJ / m<2> respectively, and are 31% and 23% higher than that of a same micro-foam material not added with the glass fiber respectively. In the invention, a polystyrene raw material is substantially saved, and the production cost is reduced.

Owner:SHANGHAI INTCO INDUSTRIES CO LTD +1

Toughened epoxy-resin-based glass fiber composite material and preparation method thereof

ActiveCN106476365AGood dispersionEvenly dispersedLamination ancillary operationsSynthetic resin layered productsGlass fiberEpoxy

The invention provides a toughened epoxy-resin-based glass fiber composite material and a preparation method thereof, wherein the composite material comprises at least one composite material unit, each composite material unit comprises an epoxy resin substrate layer and a glass fiber cloth laying layer, the glass fiber cloth laying layer is laid on the epoxy resin substrate layer, the epoxy resin substrate layer comprises the following components by mass: 40 to 90 parts of epoxy resin, 20 to 80 parts of a curing agent and 1 to 25 parts of a toughening agent; and the toughening agent is one or more substance of a liquid crystal material, nano silica and TPU. According to the number of the composite material units containing in the composite material to be prepared by the method, the epoxy resin substrate layer and glass fiber are alternately coated or laid to prepare the toughened epoxy-resin-based glass fiber composite material. Compared with the prior pure epoxy resin based glass fiber composite material, the impact strength of the toughened epoxy-resin-based glass fiber composite material is increased by 17% to 35%, and the tensile strength is not reduced.

Owner:广东丙辛新材料有限公司

Technique for providing stress sources in mos transistors in close proximity to a channel region

ActiveUS20070228357A1Enhanced transistor performanceIncrease strainSemiconductor/solid-state device manufacturingSemiconductor devicesSalicideRelaxation effect

A strained semiconductor material may be positioned in close proximity to the channel region of a transistor, such as an SOI transistor, while reducing or avoiding undue relaxation effects of metal silicides and extension implantations, thereby providing enhanced efficiency for the strain generation.

Owner:ADVANCED MICRO DEVICES INC

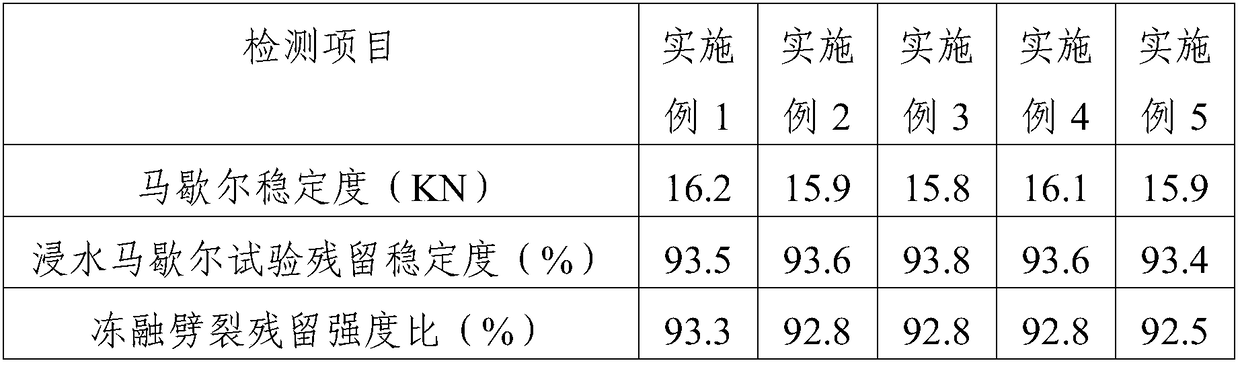

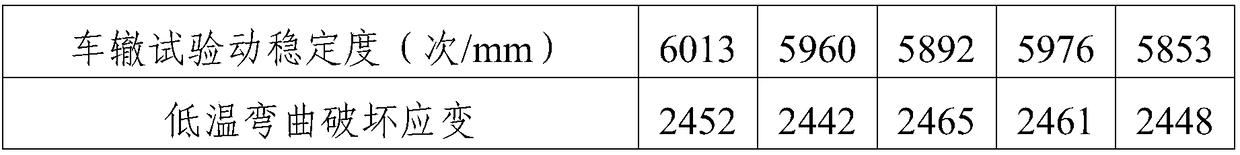

Modifier applied to high-strength asphalt concrete as well as preparation and application thereof

The invention provides a modifier applied to high-strength asphalt concrete as well as preparation and application thereof. The modifier applied to the high-strength asphalt concrete comprises a component A and a component B, wherein the mass ratio of the component A to the component B is 1 to (0.1-0.3). The component A is prepared from the following raw materials in percentage by weight: 90-96% of a waterborne epoxy resin emulsion, 2-6% of nano aluminum oxide, 1.5-5% of hollow mesoporous silicon dioxide microspheres and 0.1-0.3% of a silane coupling agent. The component B is prepared from thefollowing raw materials in percentage by weight: 70-85% of a waterborne epoxy curing agent and 15-30% of deionized water. The prepared modifier can be used for forming a stable cross-linked space mesh structure in the asphalt concrete; the structure stress state of the asphalt concrete is improved; the strength, the stability, the rut resistance and the cracking resistance of the asphalt concretecan be effectively improved.

Owner:和县祥龙沥青混凝土有限公司

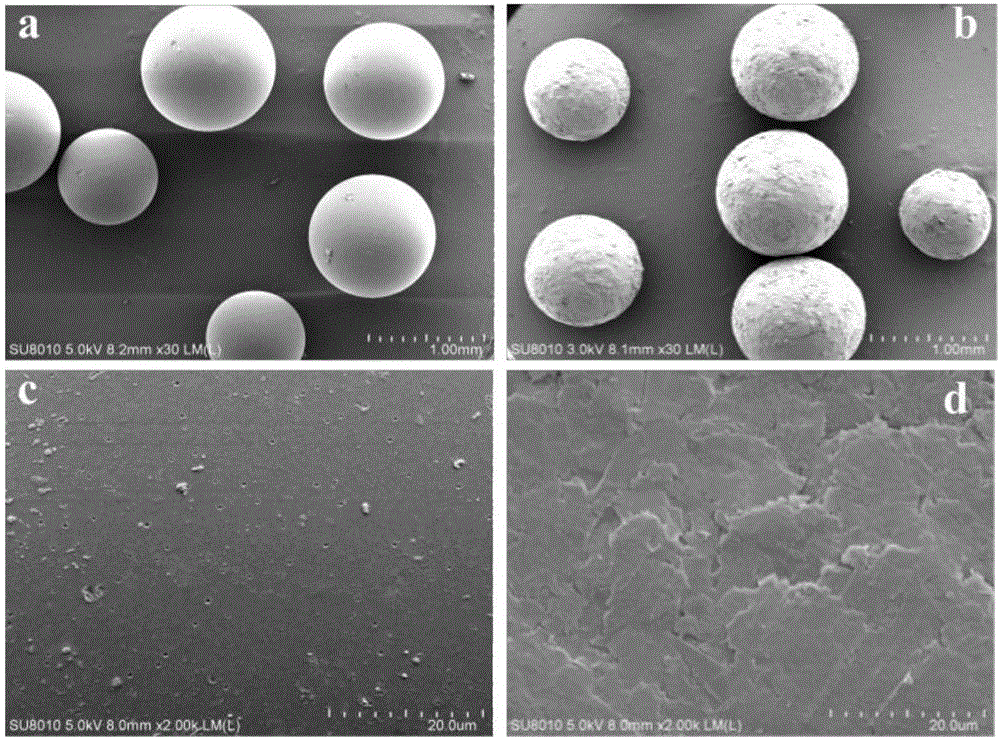

Graphene modified ultralow-density propping agent and preparation method thereof

InactiveCN106833601AHigh strengthLow thermal conductivityFluid removalDrilling compositionCross-linkMicrosphere

The invention belongs to the field of petroleum and gas fracturing extraction and in particular relates to a graphene modified ultralow-density propping agent and a preparation method thereof. The preparation method comprises the following steps: uniformly mixing graphene, an olefin monomer, a cross-linking agent (divinyl benzene) and an initiator under ultrasonic or stirring conditions so as to obtain a monomer mixture in which a Pi-Pi assembly effect is achieved between graphene and aromatic ring components; adding the monomer mixture into an aqueous solution of dispersing agents, performing the processes of balling, cross-linking and curing under the heating condition so as to obtain a microsphere precipitate; and filtering, washing and drying, thereby obtaining the graphene modified ultralow-density propping agent. According to the method disclosed by the invention, the organic polymer microsphere has low density, while the graphene has the performances of ultrahigh strength, high thermal conductivity and high temperature resistance, and then the composite material has ultralow density as well as the characteristics of high strength and high temperature resistance, so that the deep-well hydraulic fracturing requirement is met.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Method and a semiconductor device comprising a protection layer for reducing stress relaxation in a dual stress liner approach

InactiveUS20090140348A1Reducing undesired incorporationStress can be transferredTransistorSemiconductor/solid-state device manufacturingDevice materialEngineering

By providing a protection layer for suppressing stress relaxation in a tensile-stressed dielectric material during a dual stress liner approach, performance of N-channel transistors may be increased, while nevertheless maintaining a high degree of compatibility with conventional dual stress liner approaches.

Owner:TAIWAN SEMICON MFG CO LTD

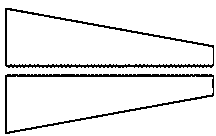

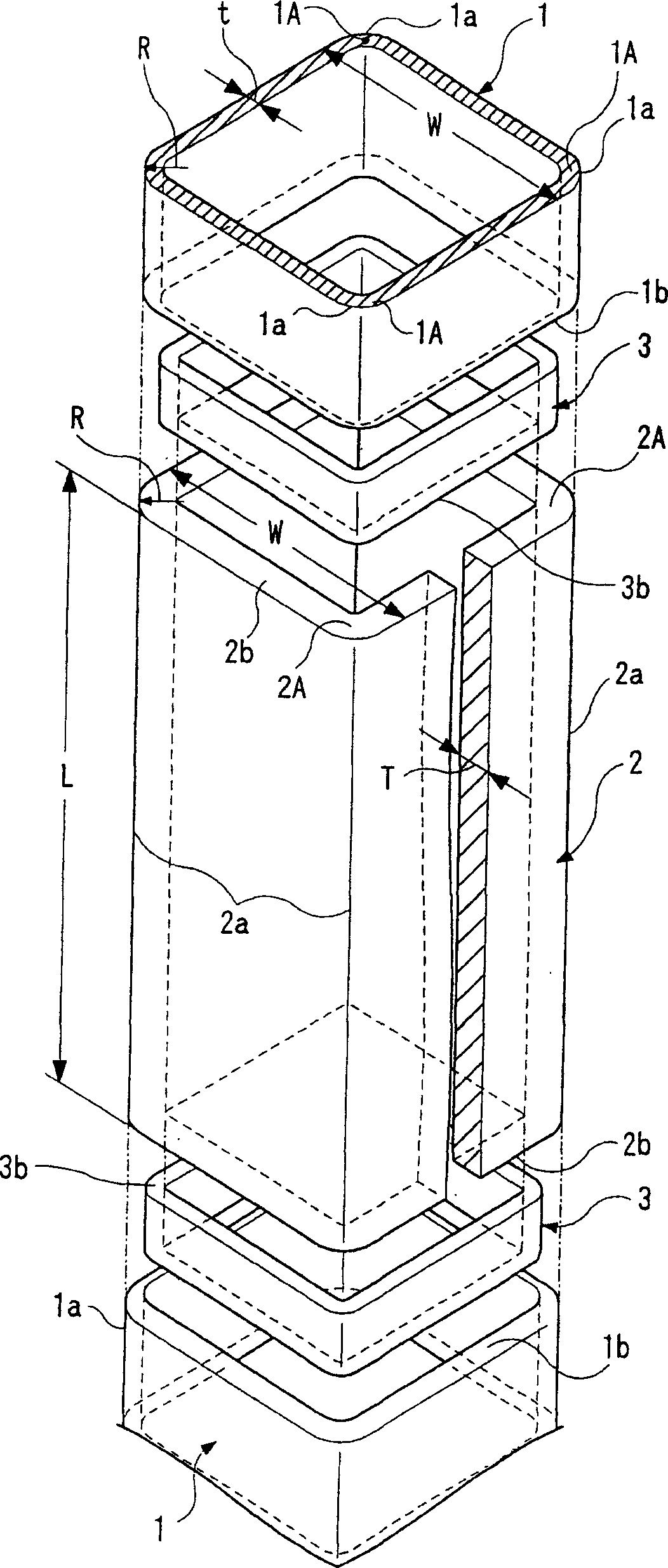

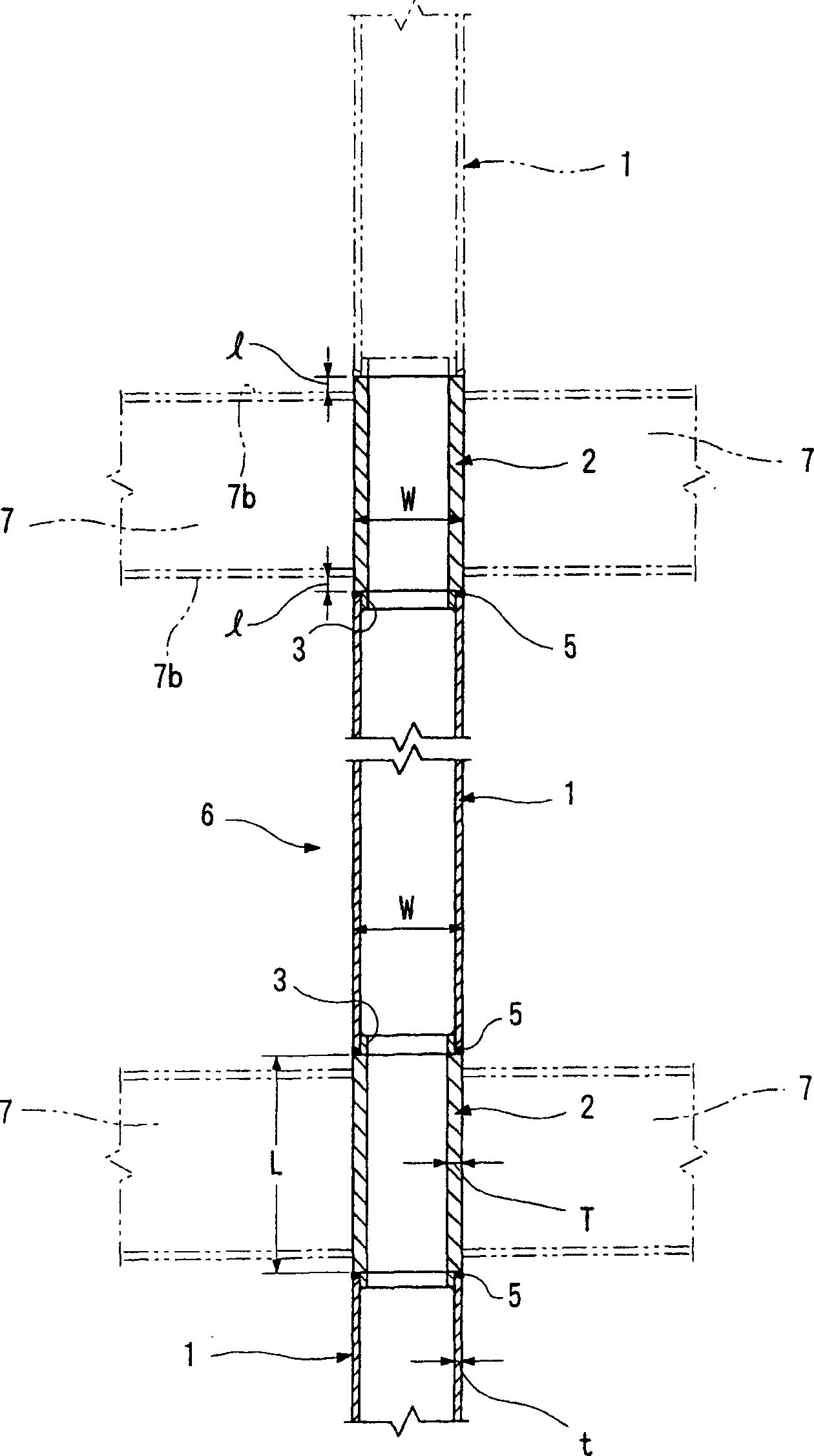

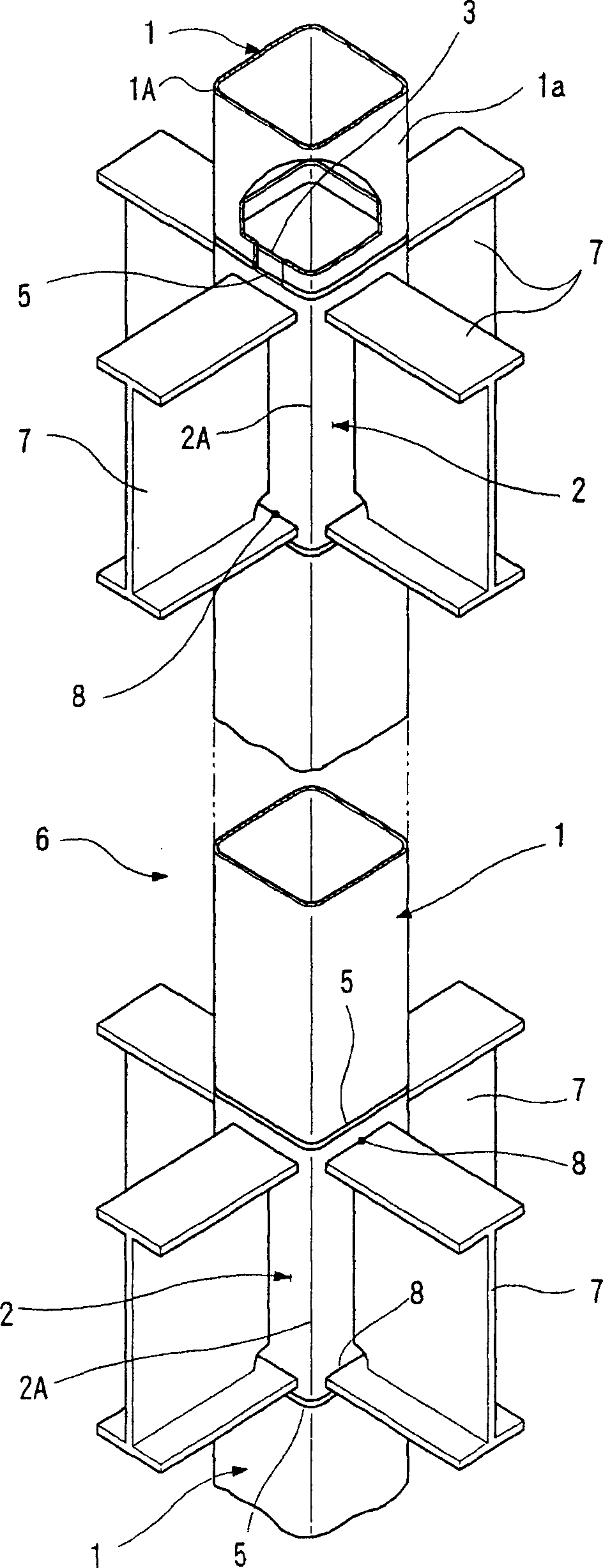

A welded joint construction for a steel pipe column

InactiveCN1467349AImprove stress transferShorten production timeStrutsArc welding apparatusSteel tubeEngineering

A joint construction for a column of steel pipes comprises a long steel pipe 1 of a first thickness t and a second steel pipe 2 of a second thickness T which is greater than that of the first. The steel pipes 1,2 are formed by either cold or hot forming to have the same outer shape and diameter, and they are welded together from the outside in an arrangement in which an end surface of the long pipe 1 is opposed to an end surface of the short pipe 2 which has no bevelled portion. An inner collar 3 can be included in the joint construction and may be positioned inside the long pipe 1 so that it can be abutted against the end surface of the short pipe 2. The pipes 1,2 may either be quadrangular or cylindrical.

Owner:NAKAJIMA STEEL PIPE CO LTD

Carbon nanotube reinforced copper-based composite material and preparation method thereof

InactiveCN105861872AGood dispersionAvoid the phenomenon of abnormal grain growthDispersityRare-earth element

The invention discloses a carbon nanotube reinforced copper-based composite material. The carbon nanotube reinforced copper-based composite material is prepared from, by weight, 0.5%-5% of surface-modified carbon nanotubes, 2%-5% of graphite, 6%-15% of Ti3SiC2, 2%-5% of boron nitride (BN), 0.01%-0.5% of rare earth element La and the balance copper. The surface-modified carbon nanotubes are carbon nanotubes of which the surfaces are grafted with gallic acid. According to the copper-based composite material, the surface-modified carbon nanotubes are used, the carbon nanotubes are good in dispersity, the bonding area with a copper matrix is large, the reinforcement effect is good, a better stress transfer effect can be achieved, stress concentration is reduced, and defects are reduced. In addition, the carbon nanotubes, graphite powder, Ti3SiC2 powder and BN powder exert the synergistic reinforcement effect in the copper matrix, the mechanical property and friction-resistant and wear-resistant properties of the copper-based composite material are significantly improved, and meanwhile the copper-based composite material has excellent strength and impact resistance. The invention further discloses a preparation method of the copper-based composite material. The method is simple in process, production is easy, and the method has a wide application prospect.

Owner:CHENGDU TECH UNIV

Gel LED (light-emitting diode) heat-dissipation paint and preparation method thereof

InactiveCN105111851AHigh impact strengthImprove adhesionPowdery paintsEpoxy resin coatingsPhosphateSilicon dioxide

The invention discloses a gel LED (light-emitting diode) heat-dissipation paint which is prepared from the following raw materials in parts by weight: 4-6 parts of fine silicon dioxide aerogel, 2-3 parts of trichloroiminocyanuric acid, 360-400 parts of high-density polyethylene, 100-130 parts of sodium hydroxide, 400-420 parts of bisphenol A, 160-180 parts of epoxy chloropropane, 10-12 parts of silicon nitride, 2-3 parts of acrylamide, 1-1.6 parts of ammonium chloride, 0.05-0.1 part of N,N-methylene-bis acrylamide, 3-4 parts of ammonium persulfate, 0.01-0.02 part of TritonX114, 1.8-2 parts of ammonia water, 10-20 parts of diethylenetriamine, 30-42 parts of nano carbon tube, 1-2 parts of N-hydroxymethyl acrylamide, 3-5 parts of aluminum dihydrogen phosphate, 1-2 parts of isopropyl myristate, 4-7 parts of dioctyl azelate and 7-10 parts of ceramic powder. The added fine silicon dioxide aerogel can improve the compatibility among the materials and enhance the surface strength and shock strength of the paint film.

Owner:ANHUI MINGWEI ILLUMINATION EQUIP

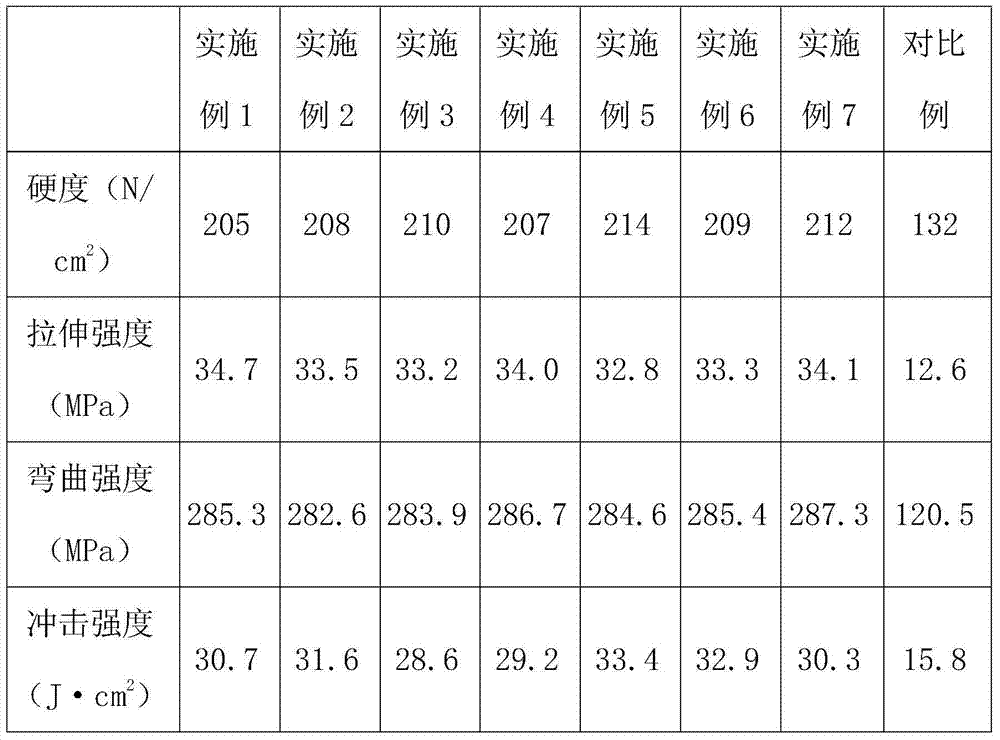

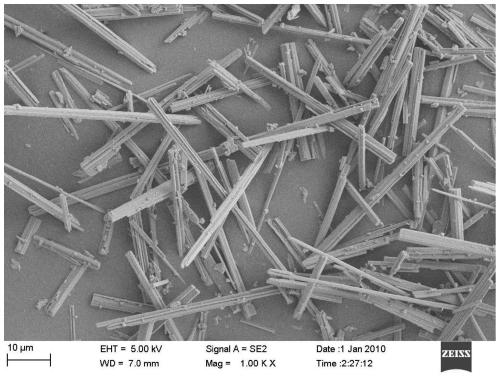

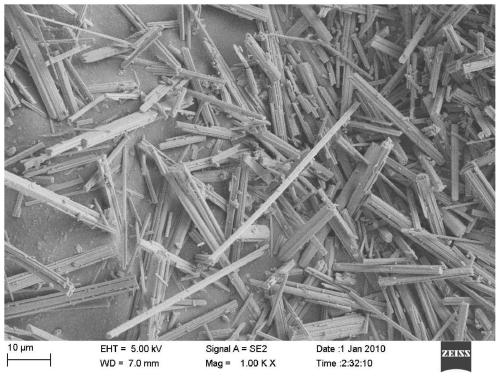

Method for preparing novel phenolic resin base composite material

The invention discloses a method for preparing a novel phenolic resin base composite material. The method comprises the following steps: (1) washing and drying a shell, cooling to obtain the dried shell, immersing the dried shell in a sodium hydroxide solution, taking out, washing, drying and grinding to obtain the shell powder; (2) adding the shell powder into a silane coupling agent solution, stirring and performing ultrasonic treatment to obtain the modified shell powder; (3) compounding a calcium sulfate crystal whisker into a suspension slurry, stirring and adding sodium stearate, continuously stirring, taking out, washing, filtering and drying the filter cake to obtain the modified calcium sulfate crystal whisker; (4) adding the phenolic resin, the modified shell powder and the modified calcium sulfate crystal whisker into a stirring kettle, stirring, drying to constant weight, and cooling to obtain a mixed material; and (5) putting the mixed material into a mould, putting the mould in a thermocompressor, performing decompression and degassing after prepressing, performing hot-pressing, baking and cooling to obtain the composite material. The composite material prepared by the invention is good in hardness and mechanical property.

Owner:NANTONG DEMING PLASTIC NEW MATERIALS

Bonding structure of wind turbine foundation steel ring and concrete and construction method

ActiveCN105350564AGood toughness and impact resistanceGood stress transferFoundation engineeringImpact resistanceTurbine

The invention provides a bonding structure of a wind turbine foundation steel ring and concrete and a construction method and belongs to the technical field of wind turbine foundation construction. The bonding structure comprises the wind turbine foundation steel ring and concrete foundations. The lower end of the wind turbine foundation steel ring is arranged in the concrete foundations. The spaces between the inner wall of the wind turbine foundation steel ring and the concrete foundations, between the outer wall of the wind turbine foundation steel ring and the concrete foundations and between an end plate and the concrete foundations are filled with modified epoxy layers respectively. The construction method comprises the step of pouring of modified epoxy. According to the bonding structure of the wind turbine foundation steel ring and the concrete and the construction method, the spaces between the inner wall of the wind turbine foundation steel ring and the concrete foundations, between the outer wall of the wind turbine foundation steel ring and the concrete foundations and between the end plate and the concrete foundations are filled with the modified epoxy layers respectively, so that the wind turbine foundation steel ring and the concrete foundations are bonded into a whole through the modified epoxy, and good toughness and impact resistance are achieved. Therefore, the good effect of stress transfer of the wind turbine foundation steel ring is achieved, and safe operation of a wind turbine generator system is ensured.

Owner:HUNAN HAONUO ENG CO LTD

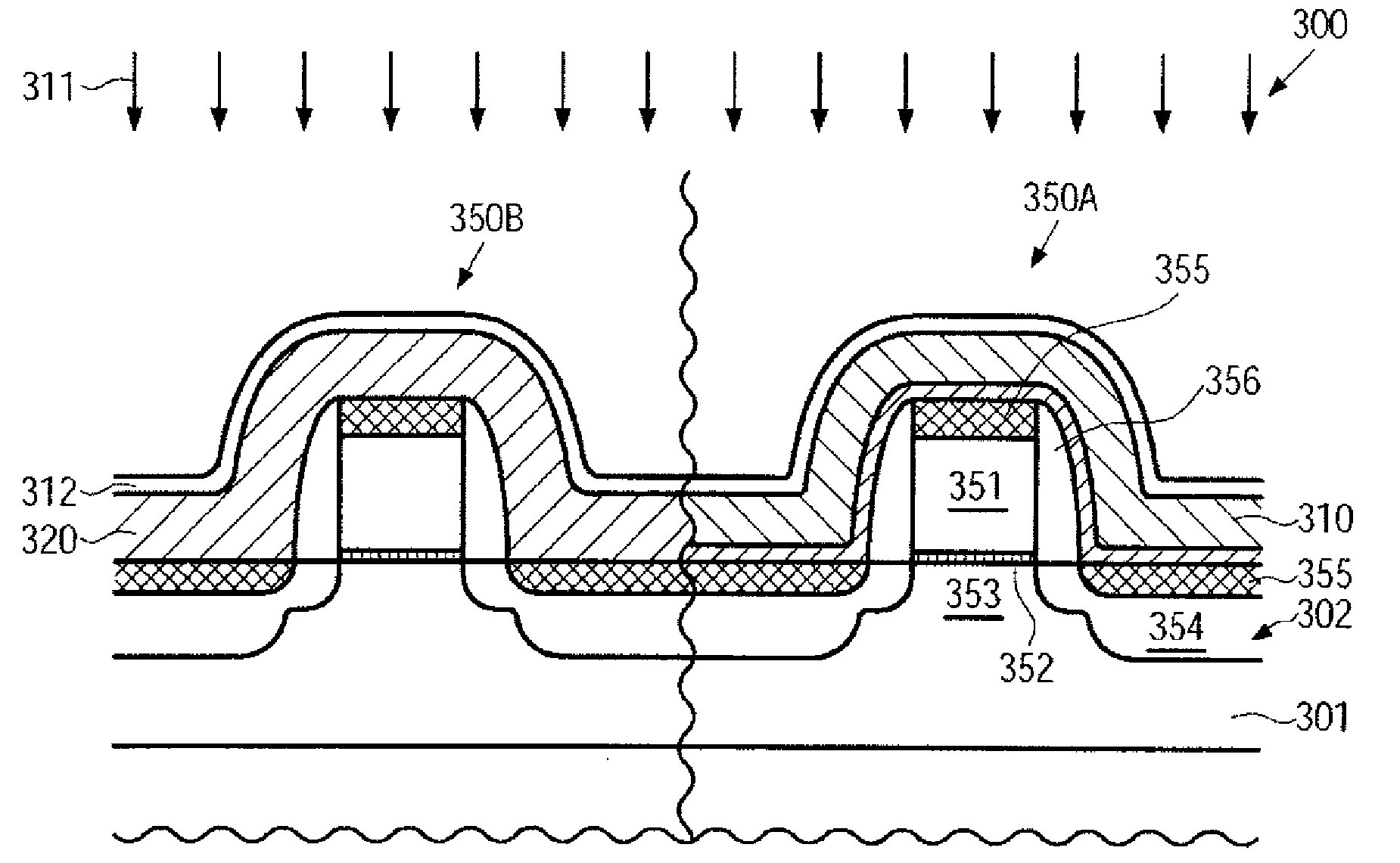

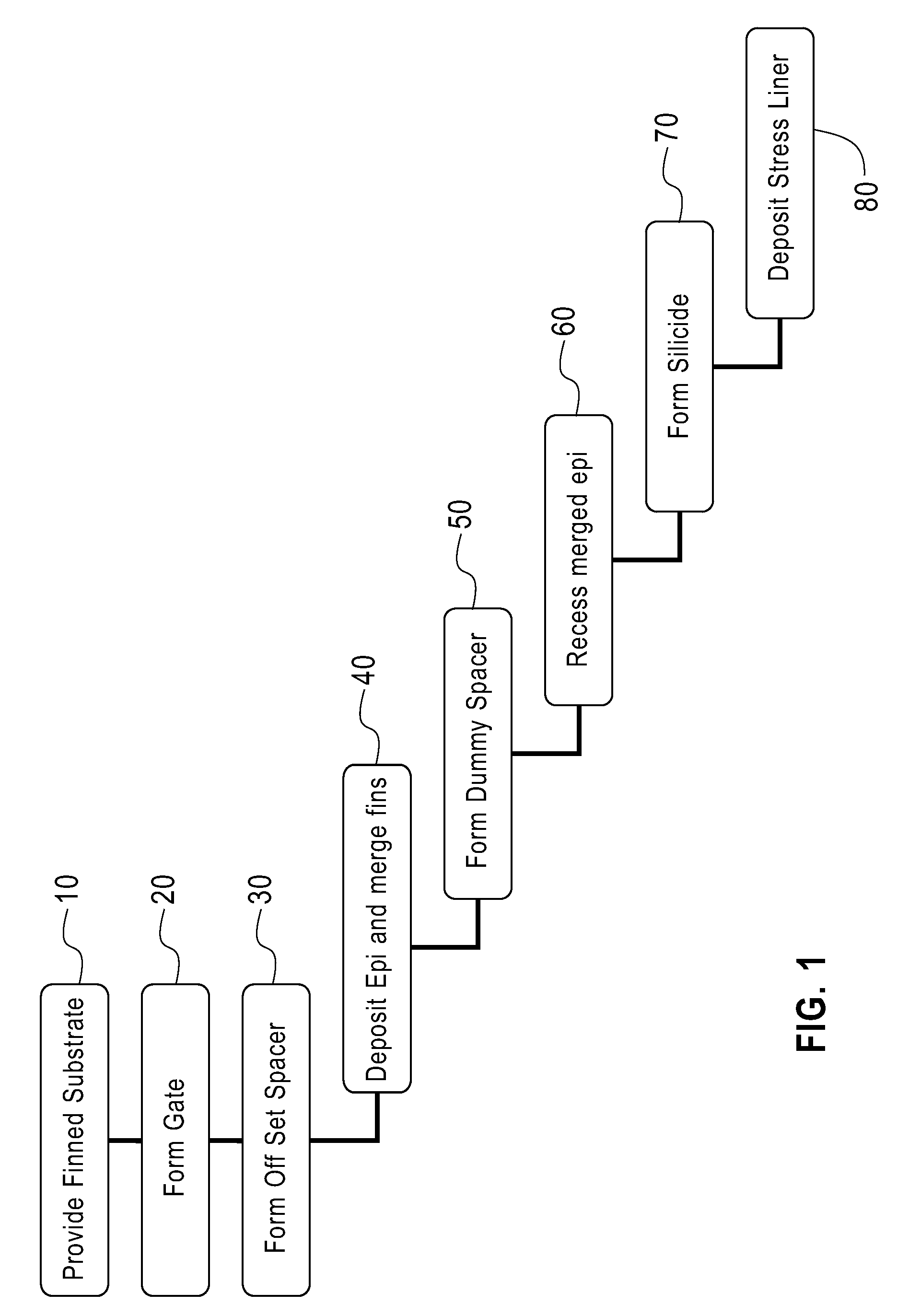

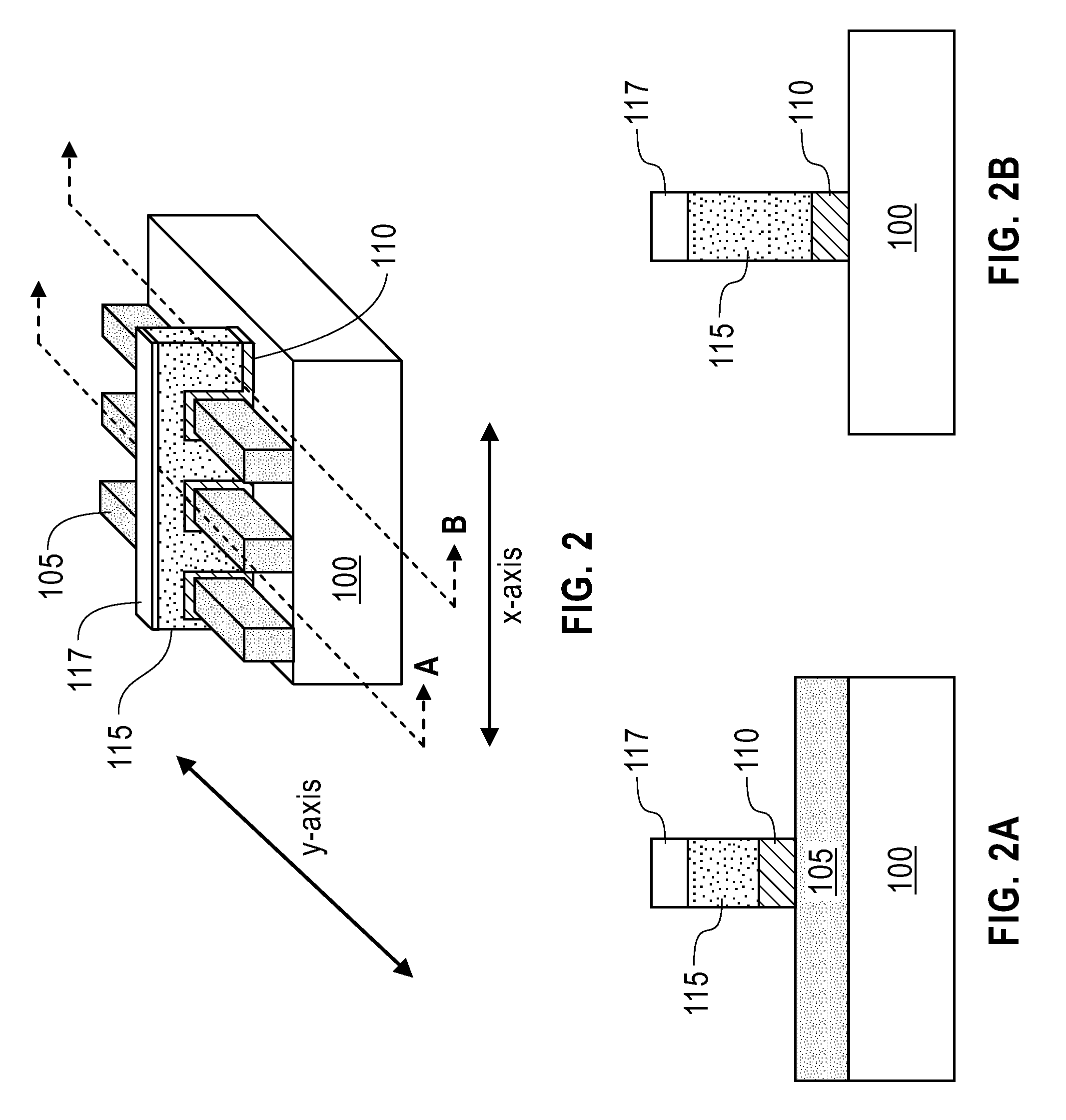

SOI FinFET with recessed merged fins and liner for enhanced stress coupling

ActiveUS8723262B2Minimize possibility of shortingImprove stress transferTransistorSolid-state devicesSoi substrateEngineering

FinFETS and methods for making FinFETs with a recessed stress liner. A method includes providing an SOI substrate with fins, forming a gate over the fins, forming an off-set spacer on the gate, epitaxially growing a film to merge the fins, depositing a dummy spacer around the gate, and recessing the merged epi film. Silicide is then formed on the recessed merged epi film followed by deposition of a stress liner film over the FinFET. By using a recessed merged epi process, a MOSFET with a vertical silicide (i.e. perpendicular to the substrate) can be formed. The perpendicular silicide improves spreading resistance.

Owner:GLOBALFOUNDRIES US INC

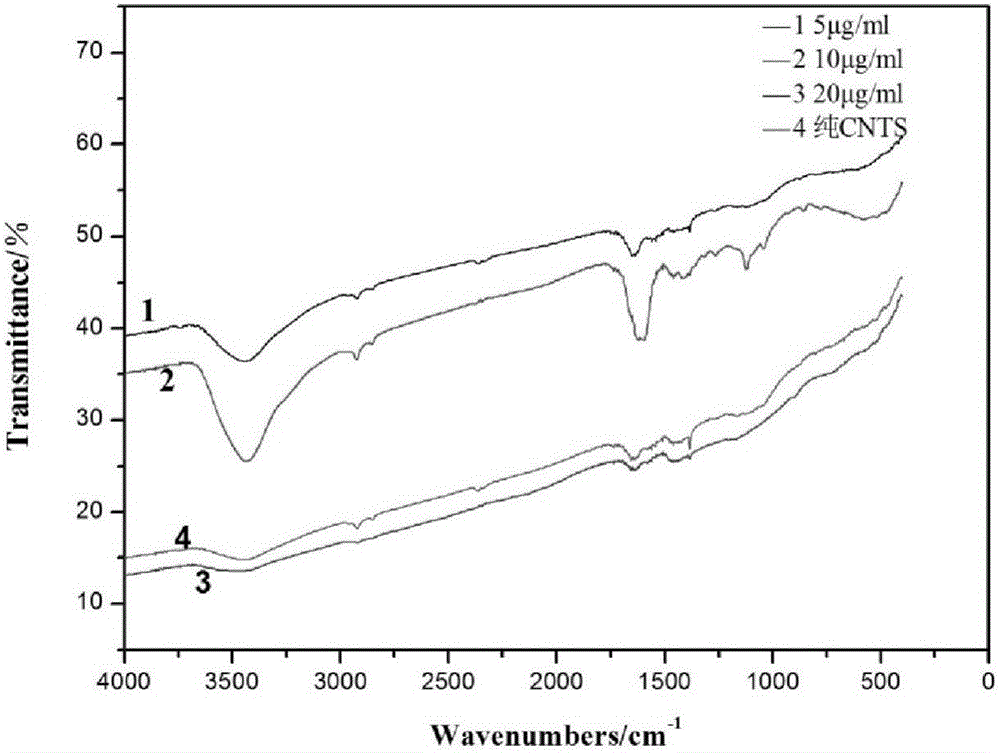

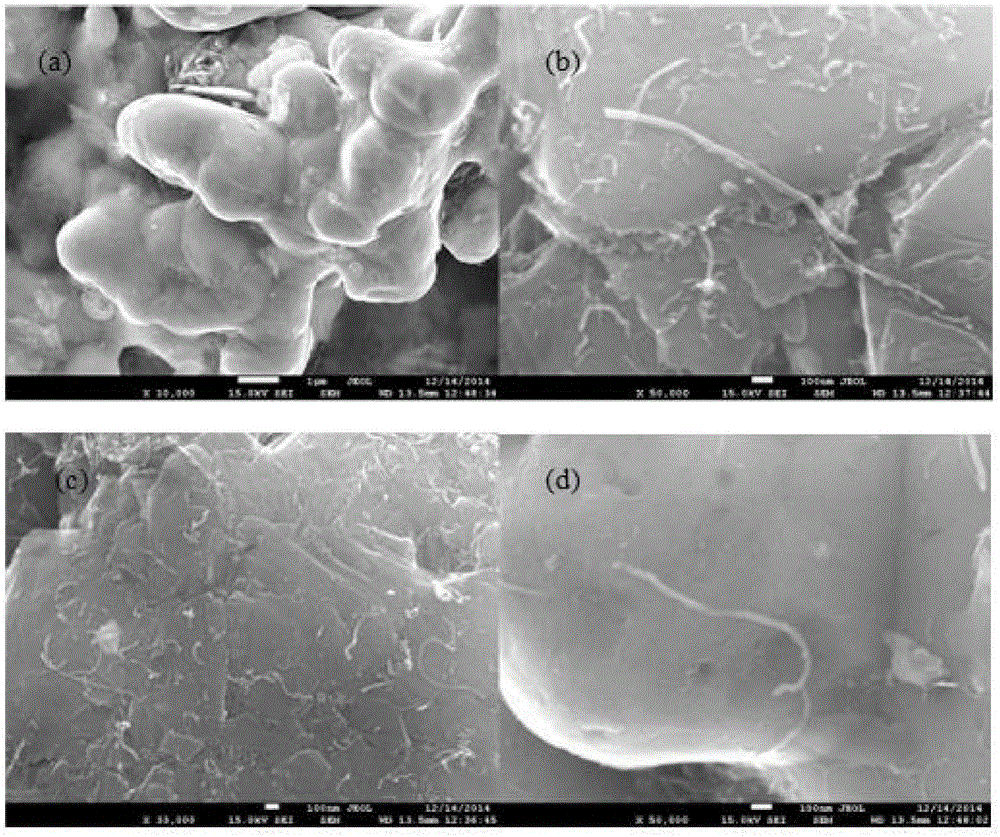

Epoxy resin based cooling powder coating with high adhesion and manufacturing method thereof

InactiveCN106147520AImprove distributionGood storage stabilityPowdery paintsEpoxy resin coatingsIn situ polymerizationCarbon nanotube

The invention discloses an epoxy resin based cooling powder coating with high adhesion. Bisphenol A and epichlorohydrin are used as raw materials, and carbon nanotubes are used as thermal conducting fillers, so that modified epoxy resin is obtained through in-situ polymerization, the carbon nanotubes and epoxy groups form acting force which is much larger than Van der Waals force, stress transfer between the carbon nanotubes and the epoxy groups is facilitated, the interface bonding force and compatibility between the carbon nanotubes and the epoxy groups are increased, and the storage stability of the coating is improved; additionally, chitosan, modified assistant and the like are added as reinforcing fillers, so that the stretching vibration intensity of carbon chlorine keys in composite materials is reduced, the binding force of C and Cl atoms and surrounding atoms is increased, the dispersibility of all components in the coating is improved, thus, the carbon nanotubes make full contact with the coating, and the effect of an additional physical crossing point is achieved, so that a cooling channel is formed, and heat dissipation is facilitated. The cooling coating has the advantages of high cohesion of molecules, ageing resistance and high adhesion.

Owner:合肥燕美新材料科技有限公司

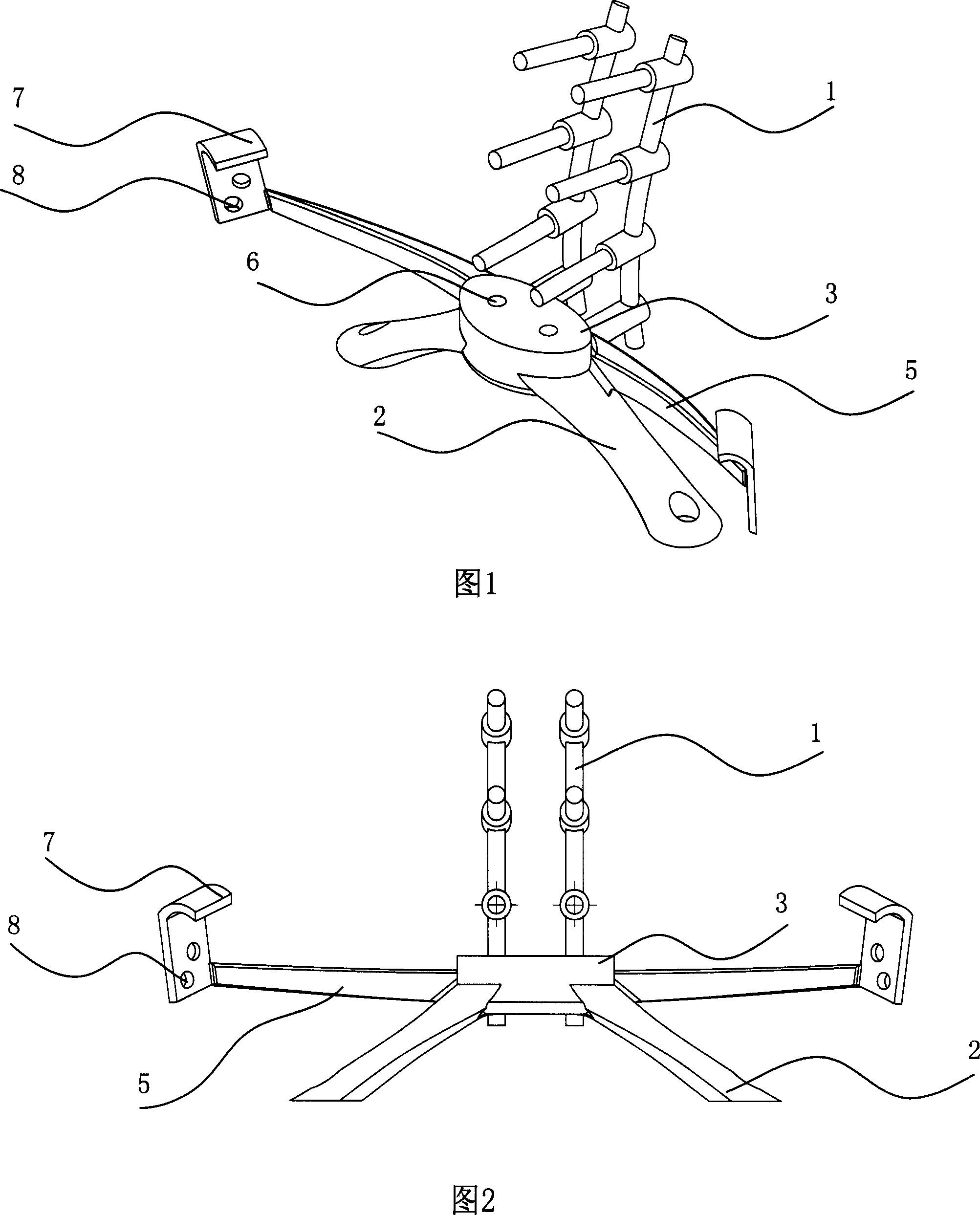

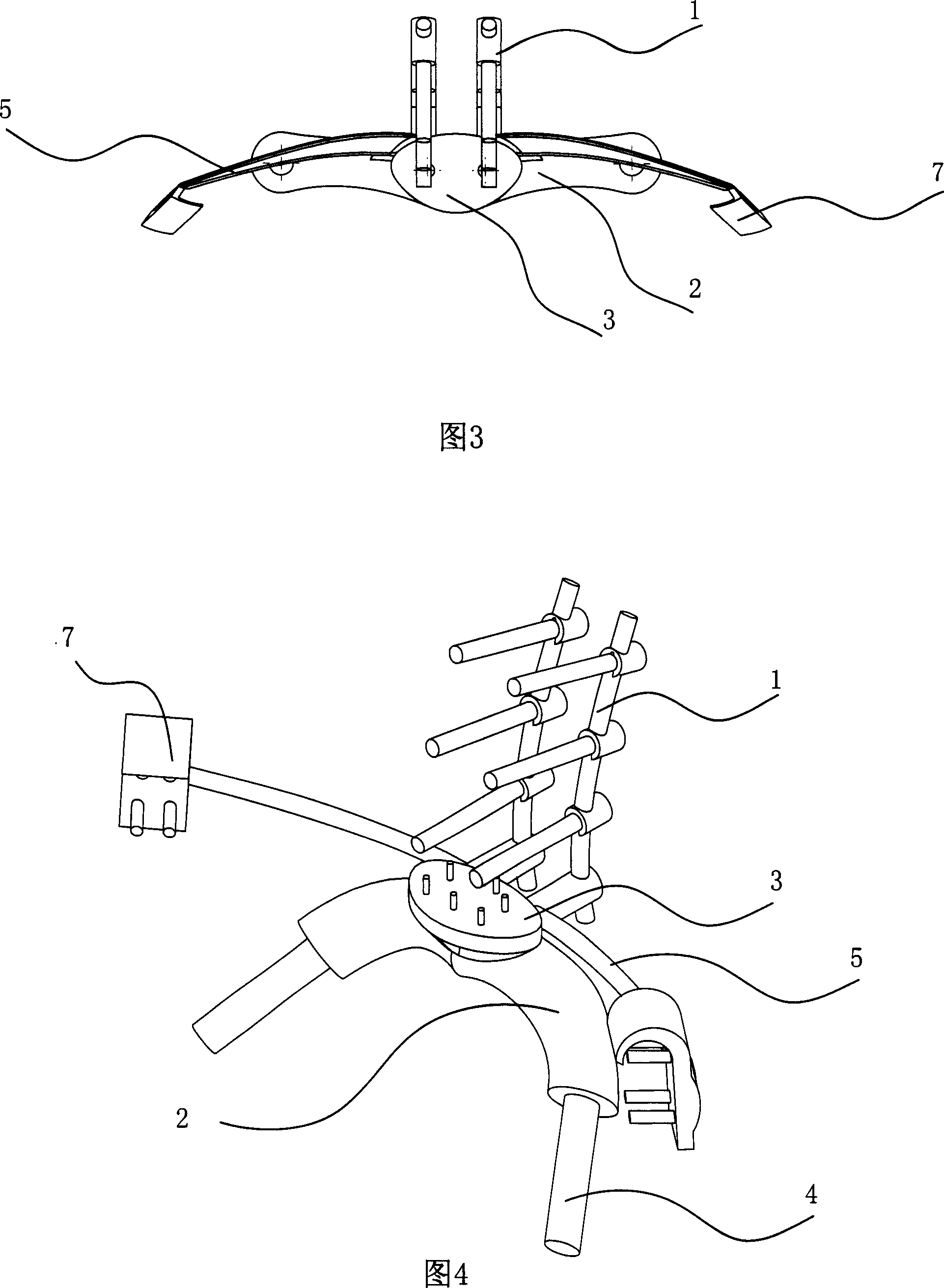

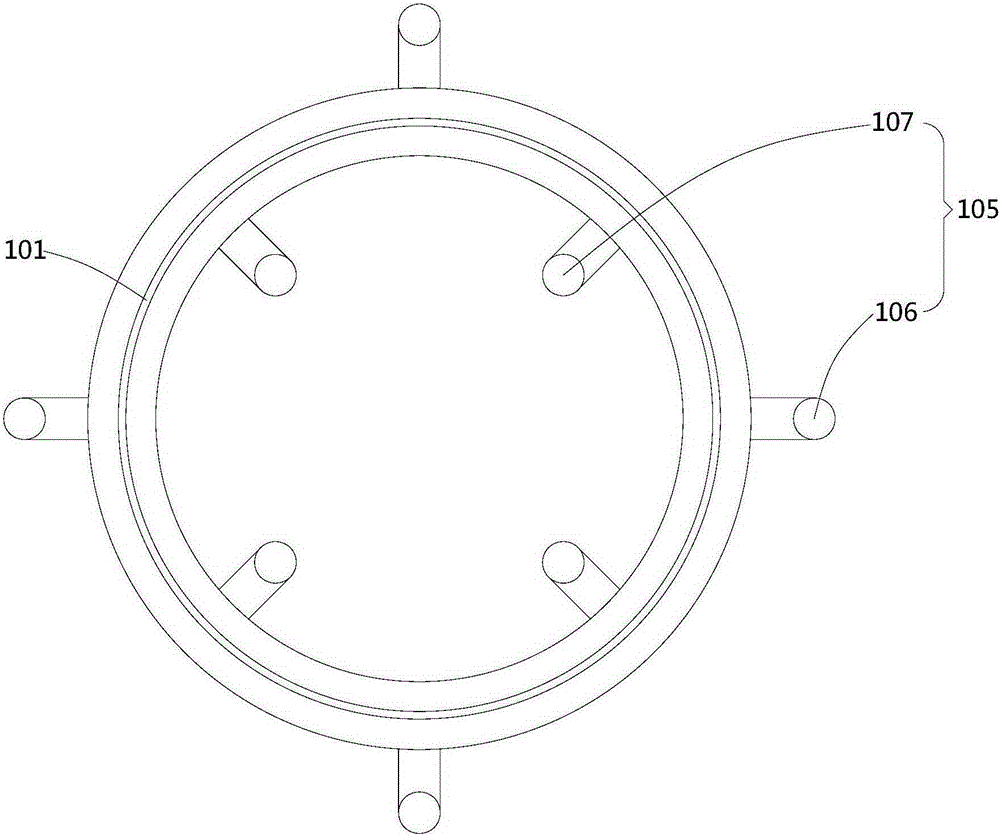

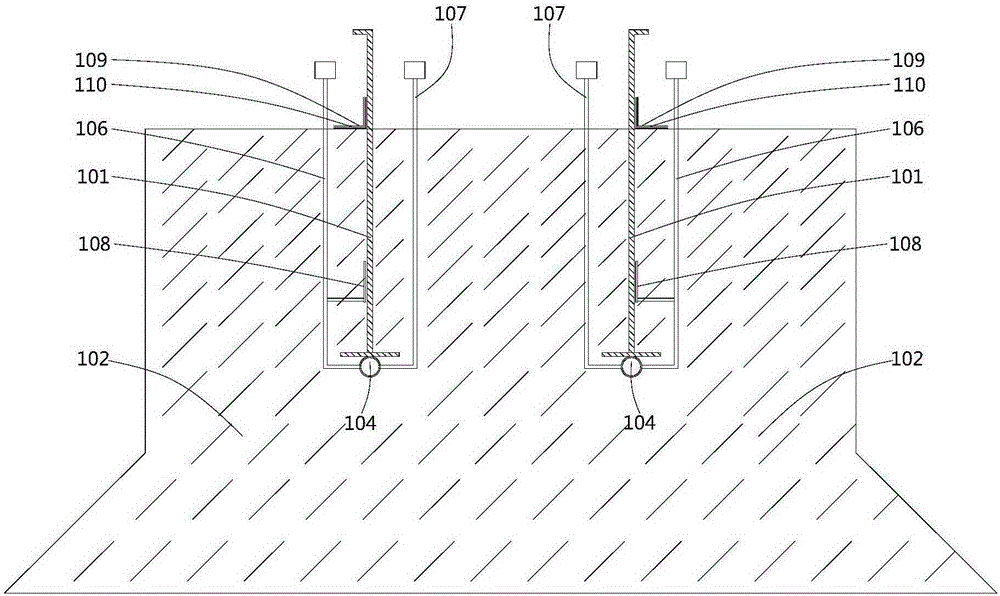

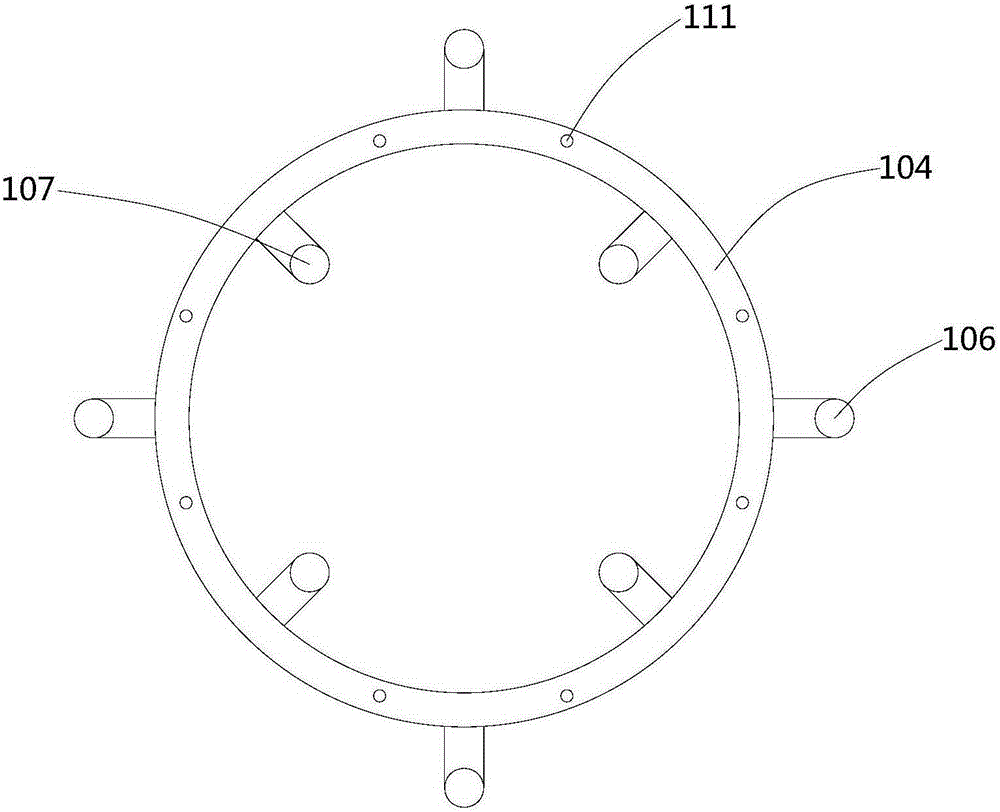

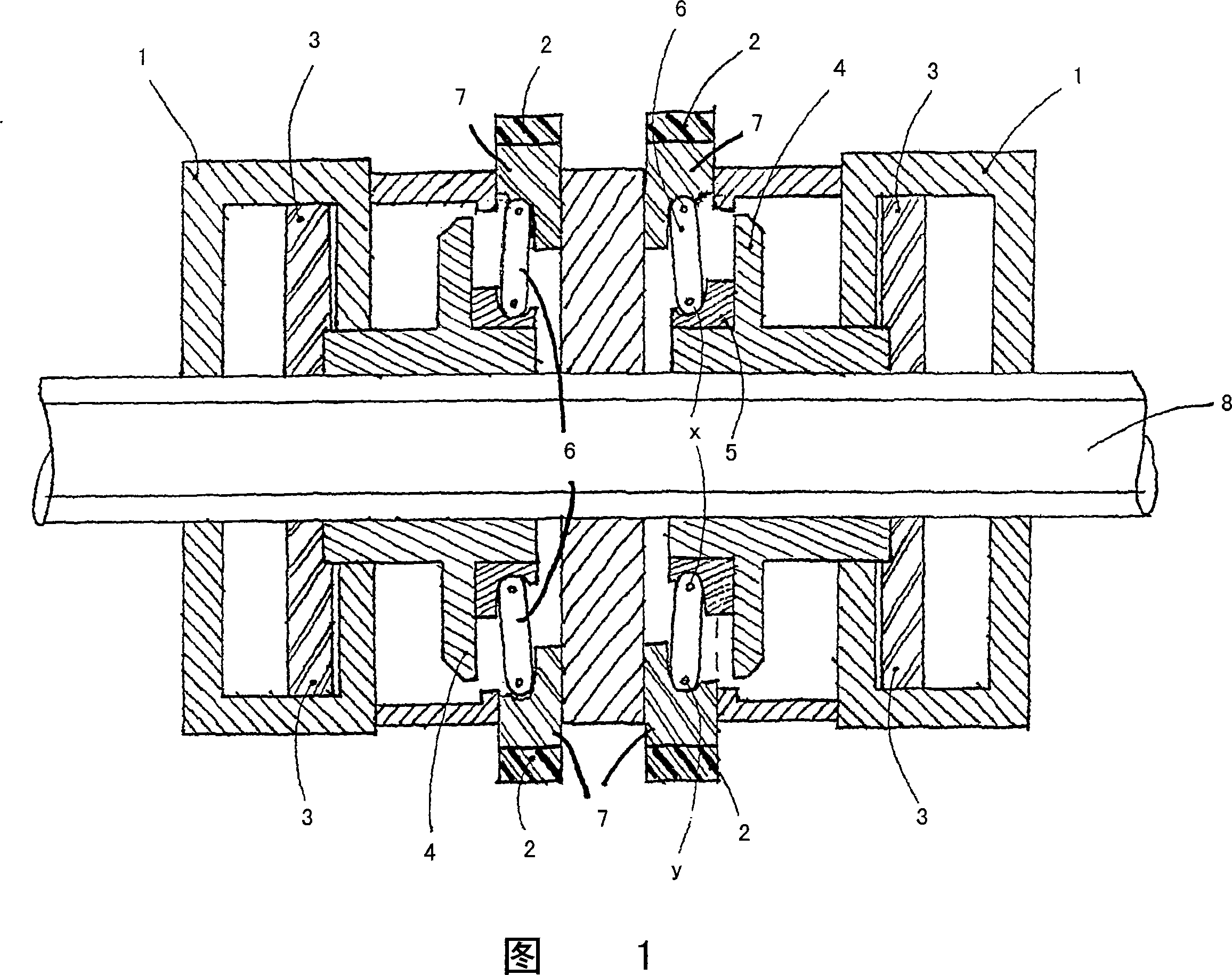

Device for centering and clamping tubular parts

InactiveCN101242928ASimple designLimit wearJoints with sealing surfacesWelding/cutting auxillary devicesEngineeringRadial displacement

The invention concerns a device for centering and clamping tubular parts such as conduits designed to form pipeline pipes of the type consisting of an elongated cylinder (1) comprising in particular clamping means, such as at least clamping shoes (2) arranged over its entire periphery and adapted to be radially mobile projecting from said cylinder (1) to be urged to press against the walls of the conduits to be clamped as well as means for moving each of the series of clamping shoes (2) between a position projecting from the cylinder (1) and a position wherein they are retracted into the cylinder (1). The invention is characterized in that said driving means consist of a driving member (3) removably connected to a plate (4) which bears a plurality of support components (5) on each of which is mounted pivoting about an axis of the first end of a link rod (6) in the manner of a swivel joint, the second end of the link rod (6) being likewise mounted pivoting about an axis, in the manner of a swivel joint in a second support component bearing a centering shoe (2), the sliding driving movement of the driving member (3) in a longitudinal direction of the cylinder (1) causing the first end of the link rods (6) to pivot while the resulting pivoting movement of the second end of the link rods (6) causes the radial displacement of the associated clamping shoes (2). The invention is applicable to the construction of piping systems.

Owner:塞丽麦克斯公司

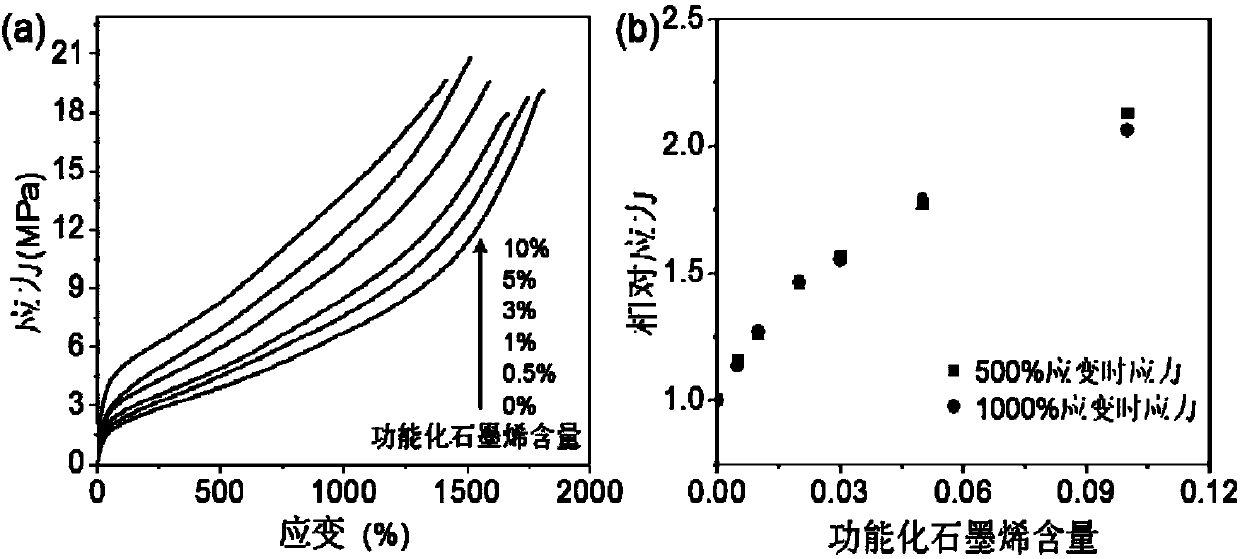

Graphene modified polyolefin elastomer composite material and preparation method thereof

The invention discloses a graphene modified polyolefin elastomer composite material and a preparation method thereof. The preparation method comprises the following steps: grafting and reducing graphene oxide by octadecylamine under an acid catalysis condition, so as to prepare octadecylamine functional graphene; blending and compounding the octadecylamine functional graphene and a polyolefin elastomer to prepare the graphene modified polyolefin elastomer composite material. The composite material is prepared from the following raw materials in parts by weight: 100 parts of a polyolefin elastomer and 0.1 to 20 parts of the octadecylamine functional graphene. The interfacial compatibility between a graphene sheet layer and a polymer matrix can be effectively improved in the presence of a grafting long alkyl chain and through removing an oxygen-containing group on the surface of the graphene. The graphene in the graphene modified polyolefin elastomer composite material is uniformly dispersed in the polyolefin elastomer; compared with a pure polyolefin elastomer material, the mechanical property of the graphene modified polyolefin elastomer composite material is remarkably improved; when the adding amount of the graphene is 2 percent, the tensile strength of the composite material is improved by 50 percent.

Owner:ZHEJIANG SHANYU TECH CO LTD

Manufacturing method of shock-resistant lead-acid storage battery plastic case

InactiveCN107337894AExtended service lifeThe formula is scientific and reasonableDomestic articlesMold fillingEngineering

The invention discloses a manufacturing method of a shock-resistant lead-acid storage battery plastic case. The manufacturing method is characterized by comprising the following steps of 1, material weighing; 2, material mixing and pelletizing; 3, injection molding and mold filling; 4, pressure maintaining; 5, sizing demolding. According to the manufacturing method of the shock-resistant lead-acid storage battery plastic case, the manufacturing method of the shock-resistant lead-acid storage battery plastic case is optimized and improved, through reasonable selection of and control over technological conditions, the technological steps are simple, the operability is high, the forming quality is good, the generation of plastic case defects can be greatly reduced, the shock resistance of the obtained plastic case is good, and the service life is prolonged.

Owner:长兴吉兴塑业有限公司

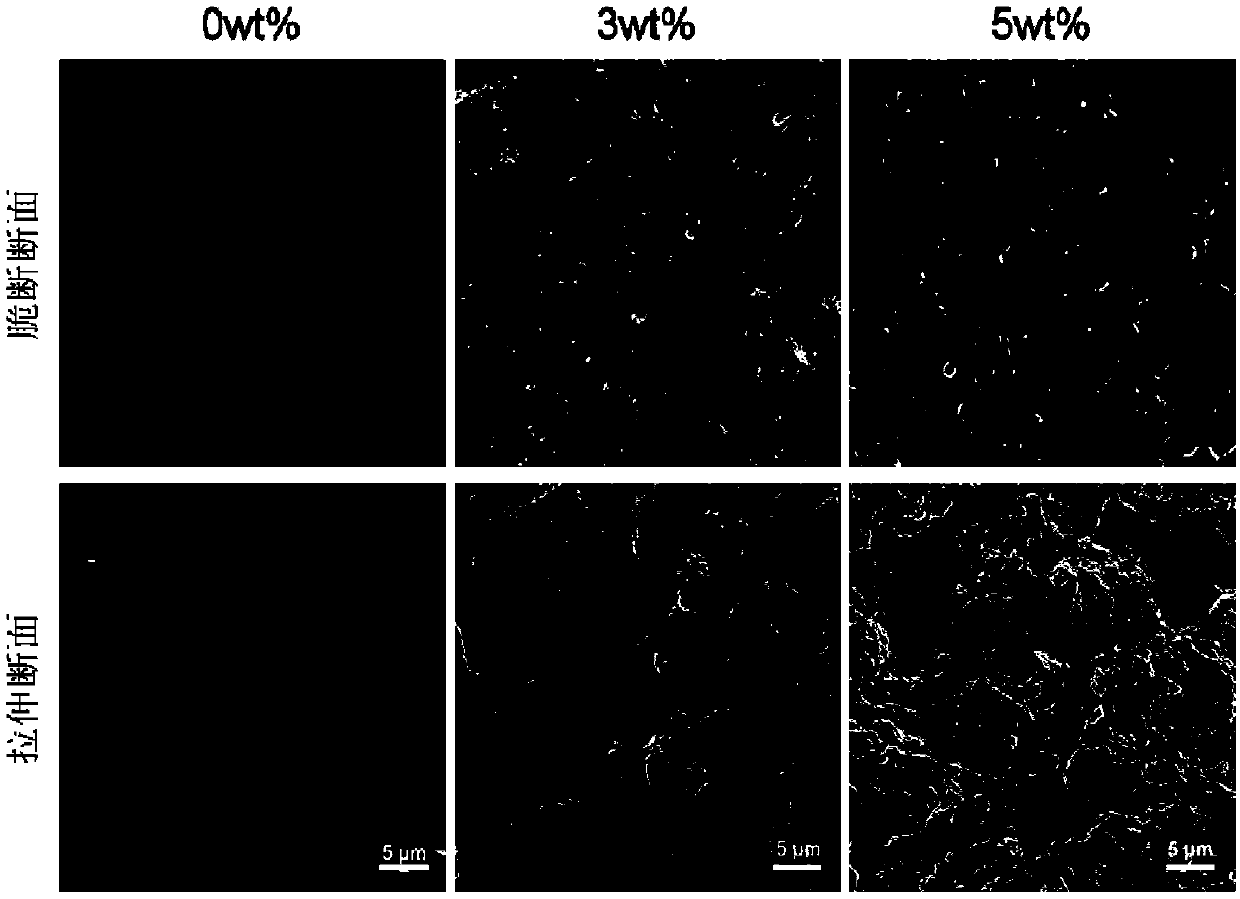

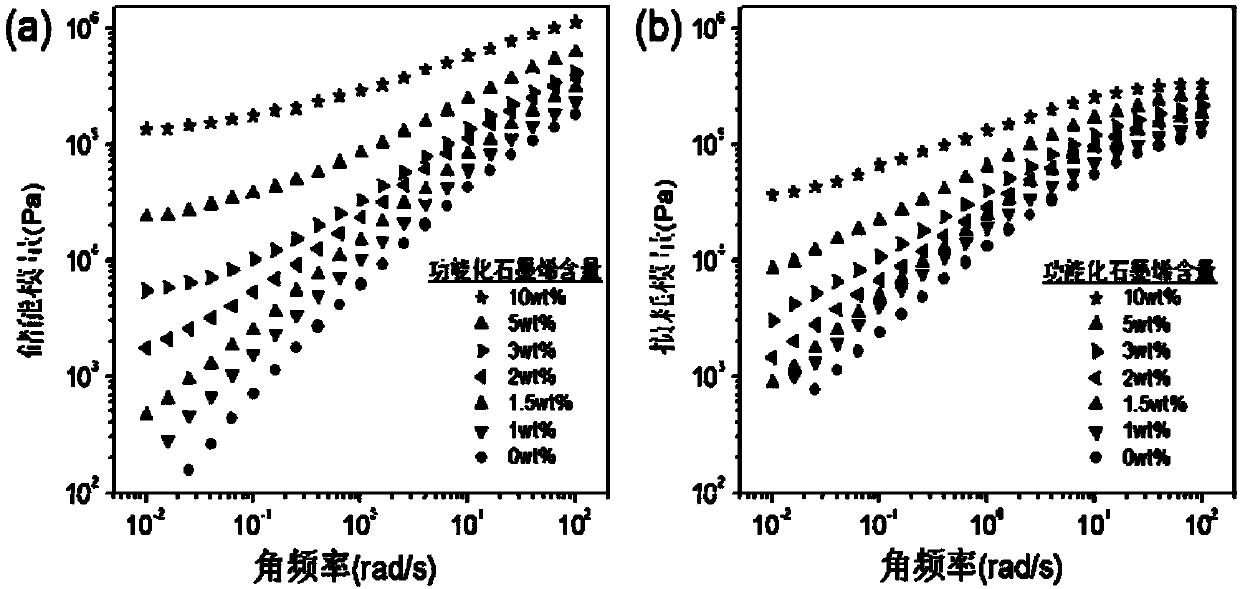

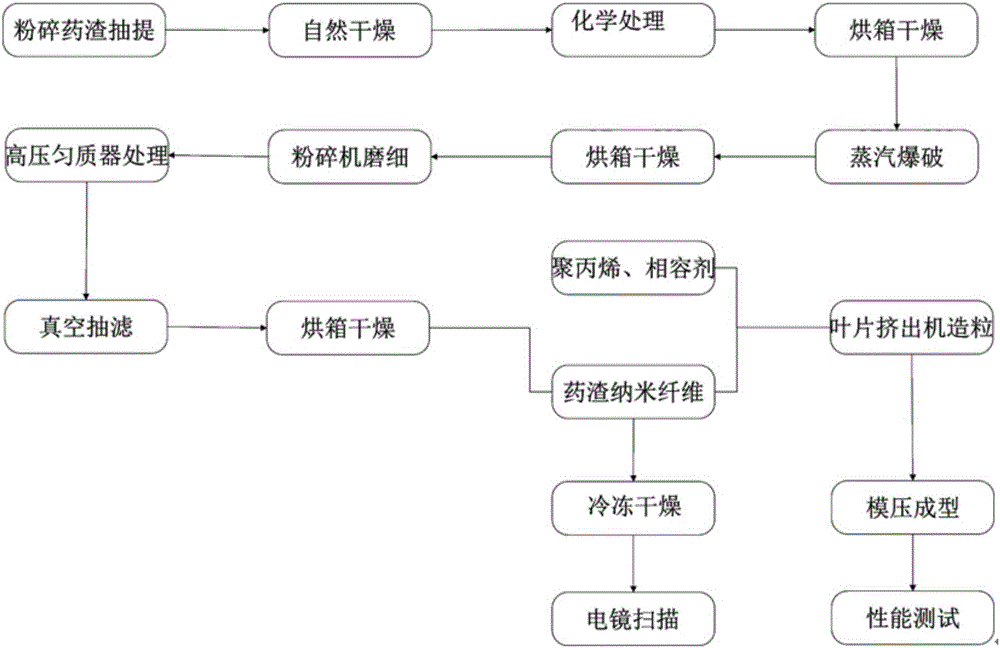

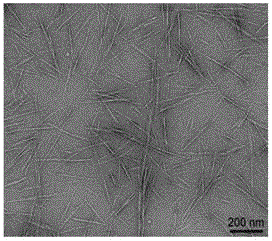

Method for manufacturing high-toughness traditional Chinese medicine residue / plastic composite material

The invention discloses a method for manufacturing a high-toughness traditional Chinese medicine residue / plastic composite material. According to the method, the high-toughness traditional Chinese medicine residue / plastic composite material is manufactured through a step of extraction processing through a traditional Chinese medicine residue chemical method and steam explosion pretreatment and a step of mixing of nano-fibers prepared from the traditional Chinese medicine residue and thermoplastic plastics. Through the composite material, material performances such as plasticization and stretch enhancement effects are improved. The physical modification of medicine residue cellulose does not lead to environmental pollution, and the resource utilization rate is improved.

Owner:ZHEJIANG FORESTRY UNIVERSITY

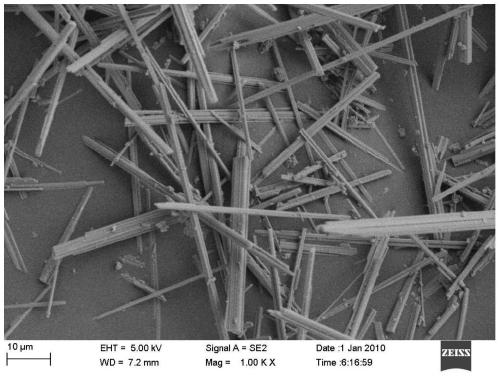

Polymer graft-coated modified calcium sulfate whisker, and preparation method and application thereof

ActiveCN111423621AImprove mechanical propertiesImprove compatibilityPolymer scienceAnhydrous Calcium Sulfate

The invention is suitable for the technical field of material modification, and provides a polymer graft-coated modified calcium sulfate whisker, and a preparation method and application thereof. Thepreparation method comprises the following steps: in a water phase, carrying out surface modification on anhydrous calcium sulfate whisker with sodium oleate to obtain sodium oleate modified calcium sulfate whisker; mixing the sodium oleate modified calcium sulfate whisker with an acrylic monomer and an initiator, and carrying out polymer graft modification on the sodium oleate modified calcium sulfate whisker to obtain the polymer graft-coated modified calcium sulfate whisker. The anhydrous calcium sulfate whisker is modified by utilizing sodium oleate containing carbon-carbon double bonds, and acrylate monomers and introduced double bonds are subjected to copolymerization reaction under the action of an initiator, so that long-chain high-molecular polymers can be grafted and coated on the surface of the calcium sulfate whisker. The polymer grafted and coated modified calcium sulfate whisker can achieve a good stress transmission effect so as to improve the mechanical properties of ahigh polymer material.

Owner:GUIZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com