A welded joint construction for a steel pipe column

A technology of steel pipe joints and steel pipes, which is applied in the direction of building structures, columns, pier columns, etc., can solve the problems of inability to quickly perform welding operations, backing plate deformation, and increased welding volume, and achieve shortened production time, good stress transmission, and reduced cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

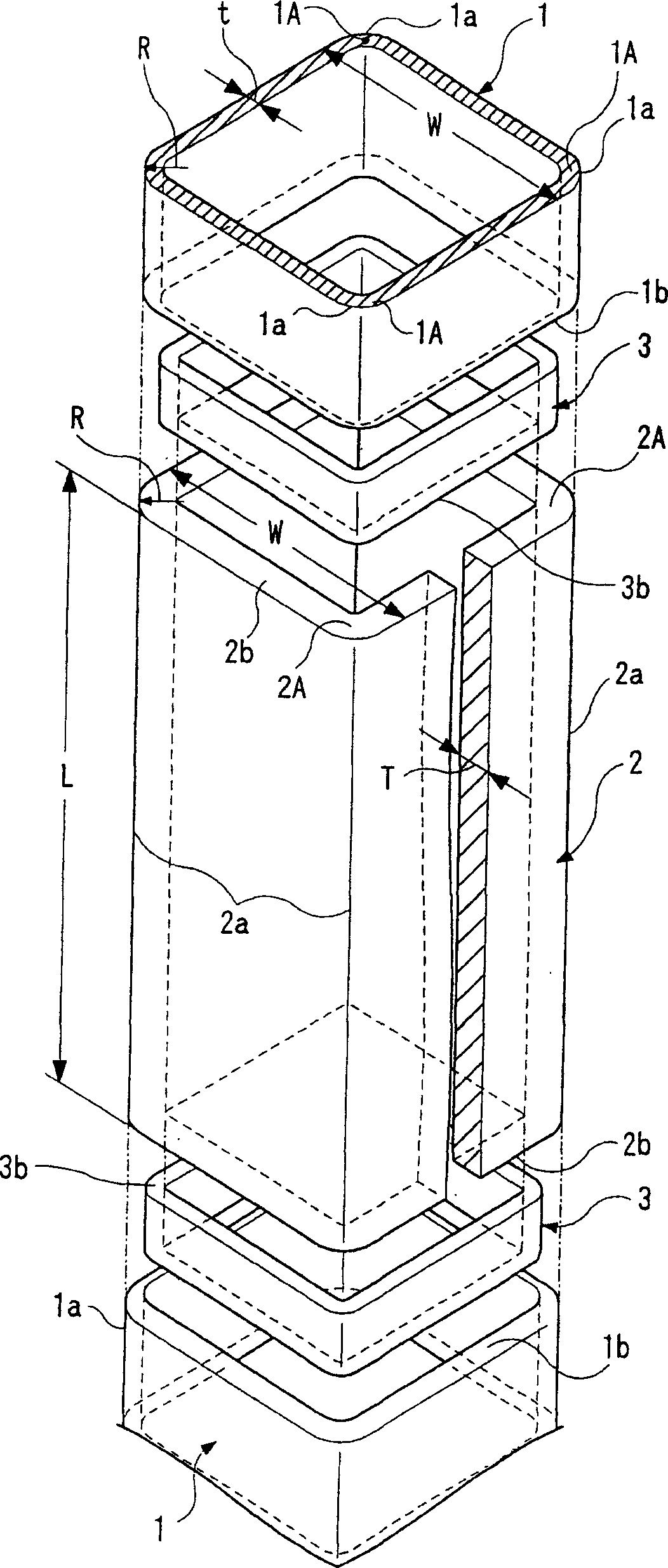

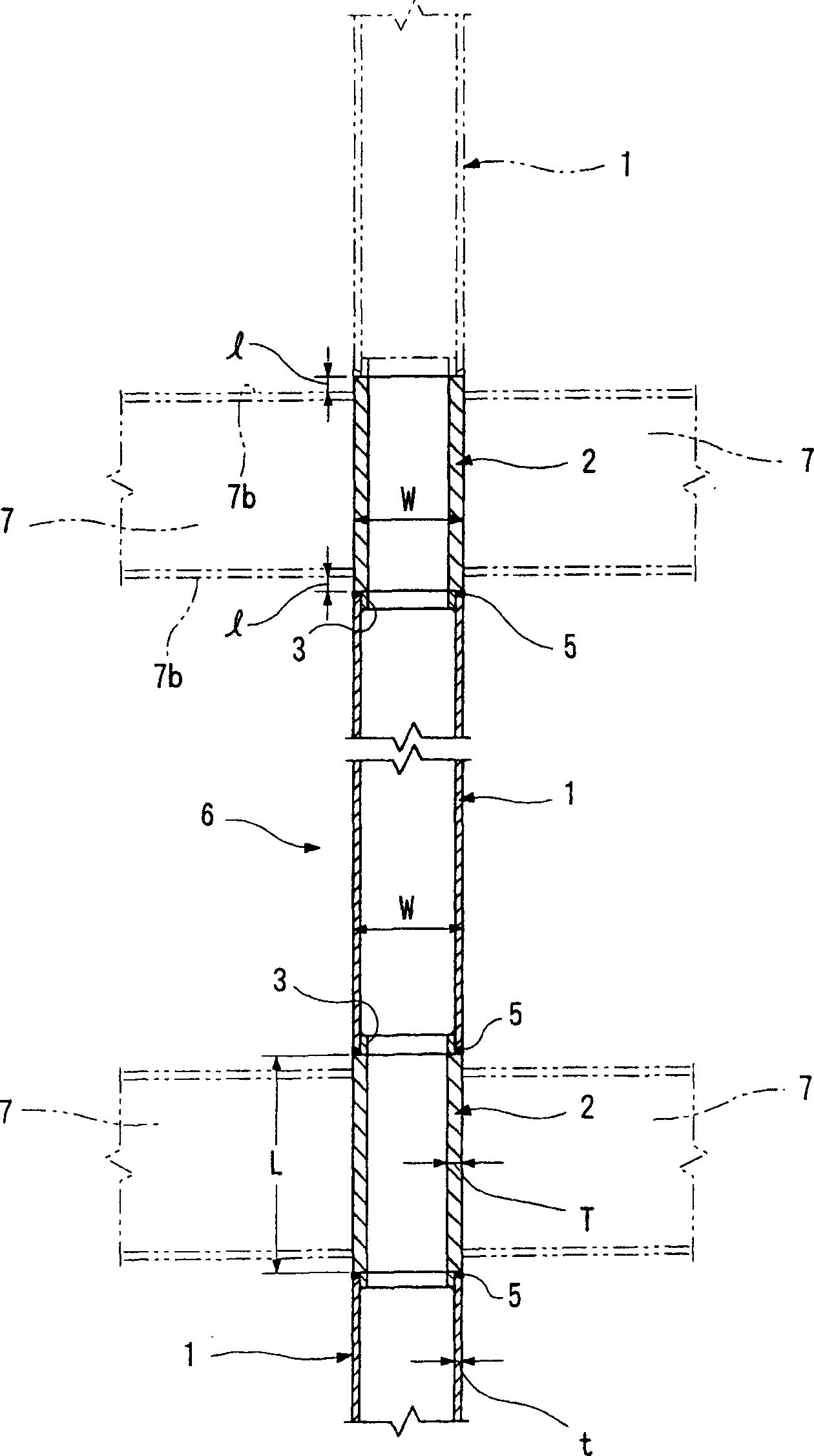

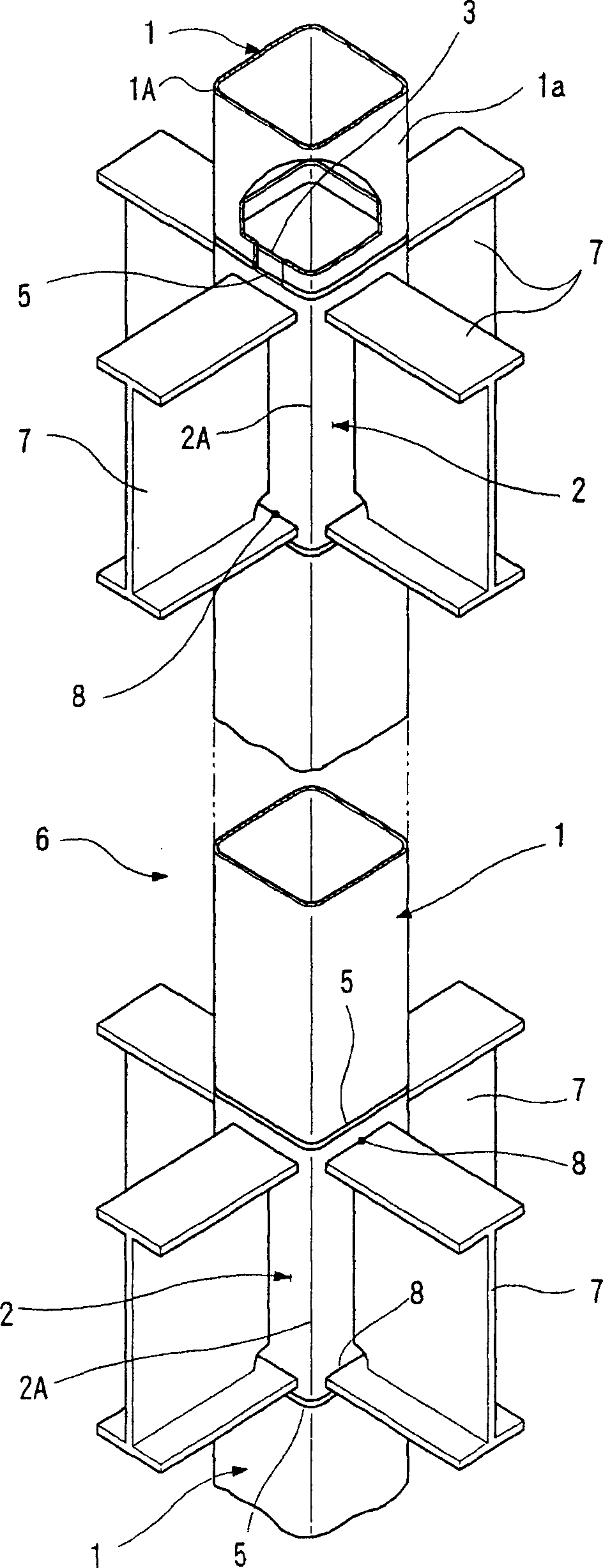

[0058] Borrow below Figure 1~Figure 8 The first embodiment of the present invention will be explained as the state of a square steel tube.

[0059] Such as figure 1 As shown, a long rectangular steel pipe (an example of a long steel pipe) 1 having a predetermined plate thickness t, and a plate thickness T thicker than the plate thickness t of the long rectangular steel pipe 1 form a plate seat area (バネルゾ一ン), a short square steel pipe (an example of a short steel pipe) 2 having a length (height) of L. Here, the predetermined plate thickness t is determined by the outer dimension W of the square steel pipe column used in accordance with the scale of the steel frame structure. For example, when the outer dimension W is 500 mm, the plate thickness t is 25 mm. In addition, the plate thickness t of the long square steel pipe 1 and the plate thickness T of the short square steel pipe 2 are, for example, 2tT.

[0060] The long square steel pipe 1 and the short square steel pipe 2 are f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com