Graphene modified polyolefin elastomer composite material and preparation method thereof

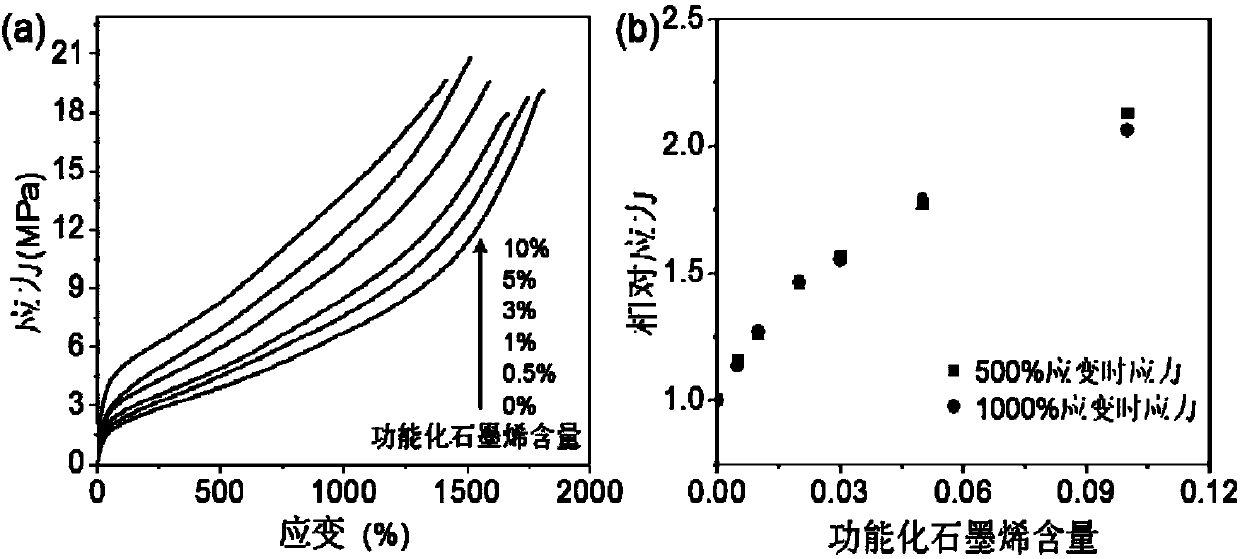

A polyolefin elastomer and graphene modification technology, which is applied in the field of graphene modified polyolefin elastomer composite materials and the preparation thereof, can solve the problems of poor compatibility between graphene sheets and polymers, and is convenient for industrial production. , The effect of simple reaction conditions and improved mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

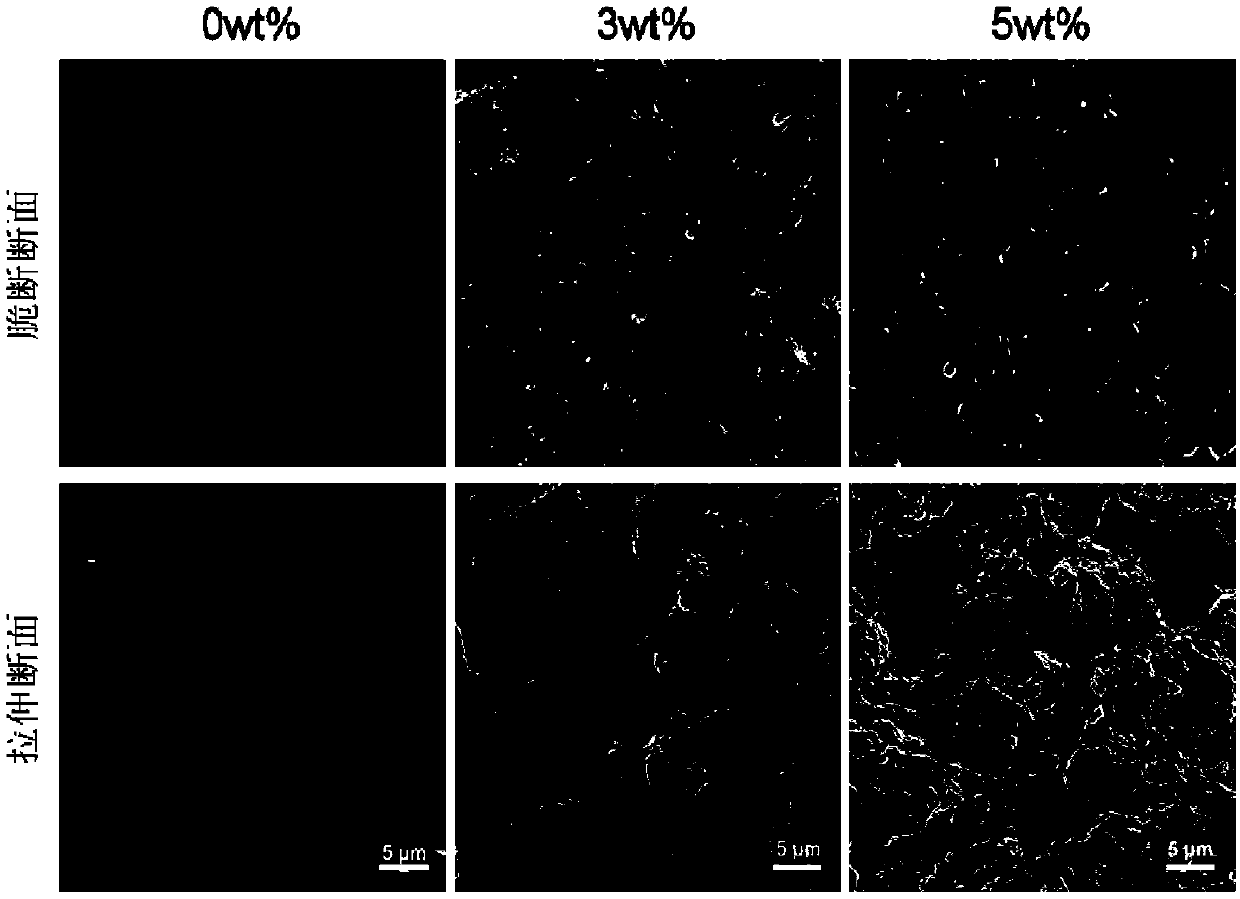

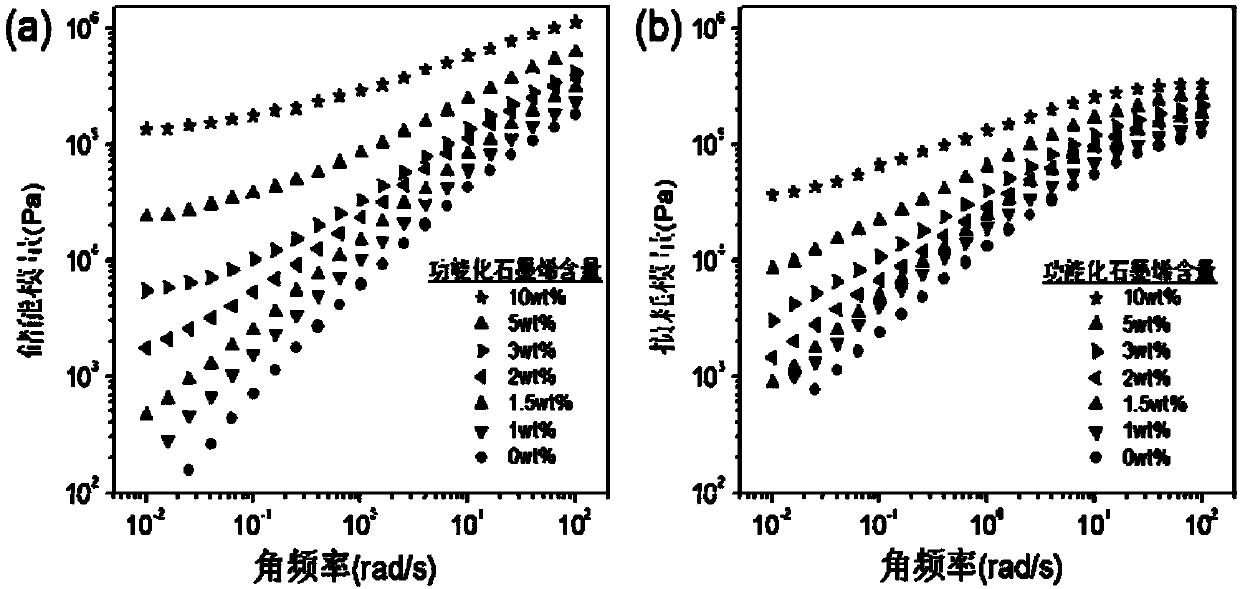

[0035] Embodiment 1: A kind of graphene modified polyolefin elastomer composite material and preparation method thereof

[0036] (1) Preparation of octadecylamine functionalized graphene: add 1 g graphene oxide into 250 mL water, stir, and sonicate to obtain an aqueous solution of graphene oxide, add concentrated hydrochloric acid to the above aqueous solution to adjust the pH value to 1, and dissolve 1 g Octadecylamine was dissolved in 250 mL of ethanol to obtain an ethanol solution of octadecylamine, and the above-mentioned aqueous solution of graphene oxide and ethanol solution of octadecylamine were mixed and stirred evenly, and then the above mixed solution was reacted at 85°C for 12 hours to obtain a black suspension. Unreacted octadecylamine was removed by repeated filtration and ethanol washing to obtain ethanol-containing wet octadecylamine-functionalized graphene filter cake, which was vacuum-dried at 50° C. for 24 hours to obtain octadecylamine-functionalized graphen...

Embodiment 2

[0039] Embodiment 2: A kind of graphene modified polyolefin elastomer composite material and preparation method thereof

[0040] (1) Preparation of octadecylamine-functionalized graphene: Add 1 g graphene oxide into 250 mL water, stir, and sonicate to obtain an aqueous solution of graphene oxide, add concentrated hydrochloric acid to the above aqueous solution to adjust the pH value to 2, and dissolve 1 g Octadecylamine was dissolved in 250 mL of ethanol to obtain an ethanol solution of octadecylamine, and the above-mentioned aqueous solution of graphene oxide and ethanol solution of octadecylamine were mixed and stirred evenly, and then the above mixed solution was reacted at 85°C for 12 hours to obtain a black suspension. Unreacted octadecylamine was removed by repeated filtration and ethanol washing to obtain ethanol-containing wet octadecylamine-functionalized graphene filter cake, which was vacuum-dried at 50° C. for 24 hours to obtain octadecylamine-functionalized graphen...

Embodiment 3

[0043] Embodiment 3: A kind of graphene modified polyolefin elastomer composite material and preparation method thereof

[0044] (1) Preparation of octadecylamine functionalized graphene: add 1 g graphene oxide into 250 mL water, stir, and sonicate to obtain an aqueous solution of graphene oxide, add concentrated hydrochloric acid to the above aqueous solution to adjust the pH value to 0, and dissolve 1 g Octadecylamine was dissolved in 250 mL of ethanol to obtain an ethanol solution of octadecylamine, and the above-mentioned aqueous solution of graphene oxide and ethanol solution of octadecylamine were mixed and stirred evenly, and then the above mixed solution was reacted at 85°C for 12 hours to obtain a black suspension. Unreacted octadecylamine was removed by repeated filtration and ethanol washing to obtain ethanol-containing wet octadecylamine-functionalized graphene filter cake, which was vacuum-dried at 50° C. for 24 hours to obtain octadecylamine-functionalized graphen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com