Method for producing ultra-small water soluble near-infrared Ag2S quantum dots

A water-soluble, near-infrared technology, applied in chemical instruments and methods, silver compounds, silver compounds, etc., can solve the problems of inappropriate biological analysis and biological imaging, and achieve easy large-scale application, high luminous efficiency, and small size Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

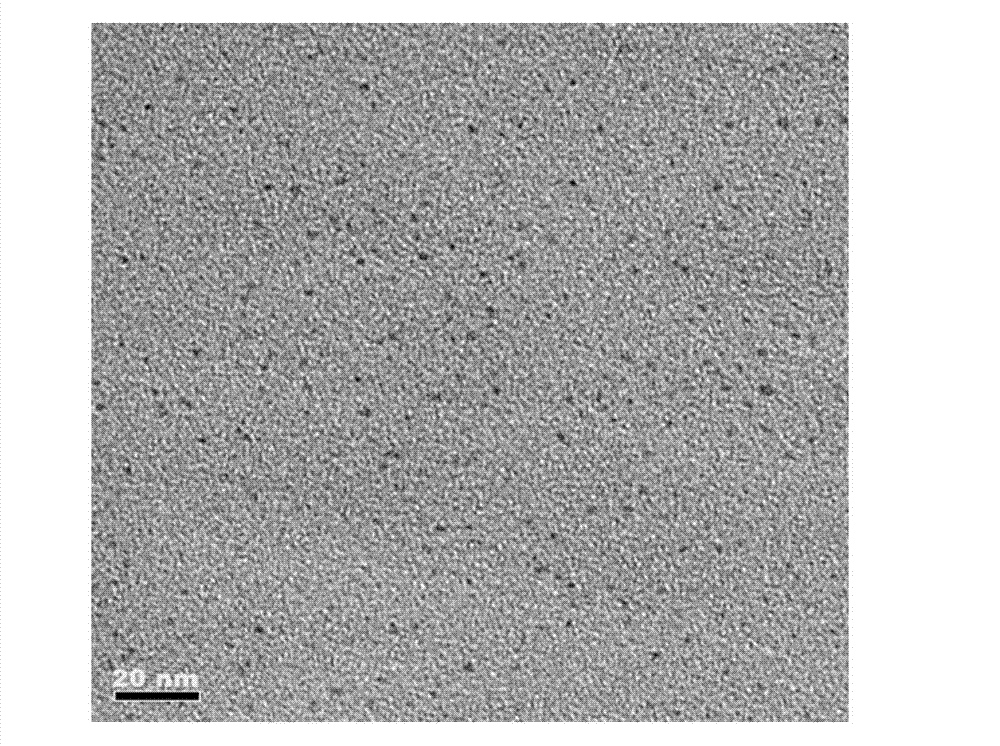

[0020] An ultra-small water-soluble near-infrared Ag 2 The preparation method of S quantum dots is prepared by a one-pot method, and the steps are as follows:

[0021] 1) In a 50 ml round bottom flask, mix 5 ml of bovine serum albumin solution with a concentration of 50 mg / ml and 5 ml of an aqueous solution with a concentration of 10 mmol / l AgNO 3 Mix the aqueous solution evenly, and react at room temperature for 5 minutes under magnetic stirring to obtain a colorless transparent liquid;

[0022] 2) Use 0.5 ml of NaOH aqueous solution with a concentration of 1 mol / L to adjust the pH of the above liquid to 12.0;

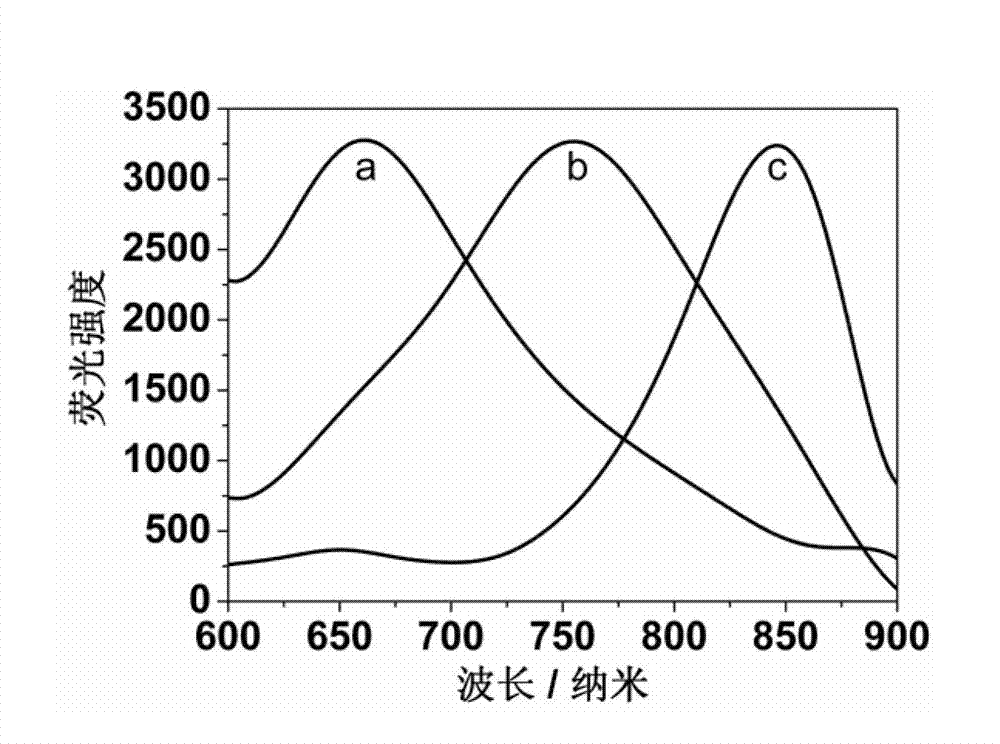

[0023] 3) According to the steps 1) and 2) above, prepare three volumes of liquids of 10.5 ml and add them to three containers respectively. 100 mmol / L sodium sulfide aqueous solution to adjust the molar ratio of Ag element to S element to be 6:1, 4:1, 2:1. After stirring and reacting at 37°C for 12 hours, the ultra-small size water-soluble near-infrared Ag can be ...

Embodiment 2

[0026] An ultra-small water-soluble near-infrared Ag 2 The preparation method of S quantum dots adopts a one-pot method, and the steps and methods are basically the same as those in Example 1, except that the chalcogen compound is thioacetamide.

[0027] Get the Ag that 2 milliliters of this embodiment prepares 2 The S quantum dot solution was used as a sample for observing fluorescence and characterizing, and the test results were similar to those in Example 1.

Embodiment 3

[0029] An ultra-small water-soluble near-infrared Ag 2 The preparation method of S quantum dots adopts a one-pot method, and the steps and methods are basically the same as those in Example 1, except that the chalcogen compound is glutathione.

[0030] Get the Ag that 2 milliliters of this embodiment prepares 2 The S quantum dot solution was used as a sample for observing fluorescence and characterizing, and the test results were similar to those in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com