Patents

Literature

149results about How to "Fast welding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

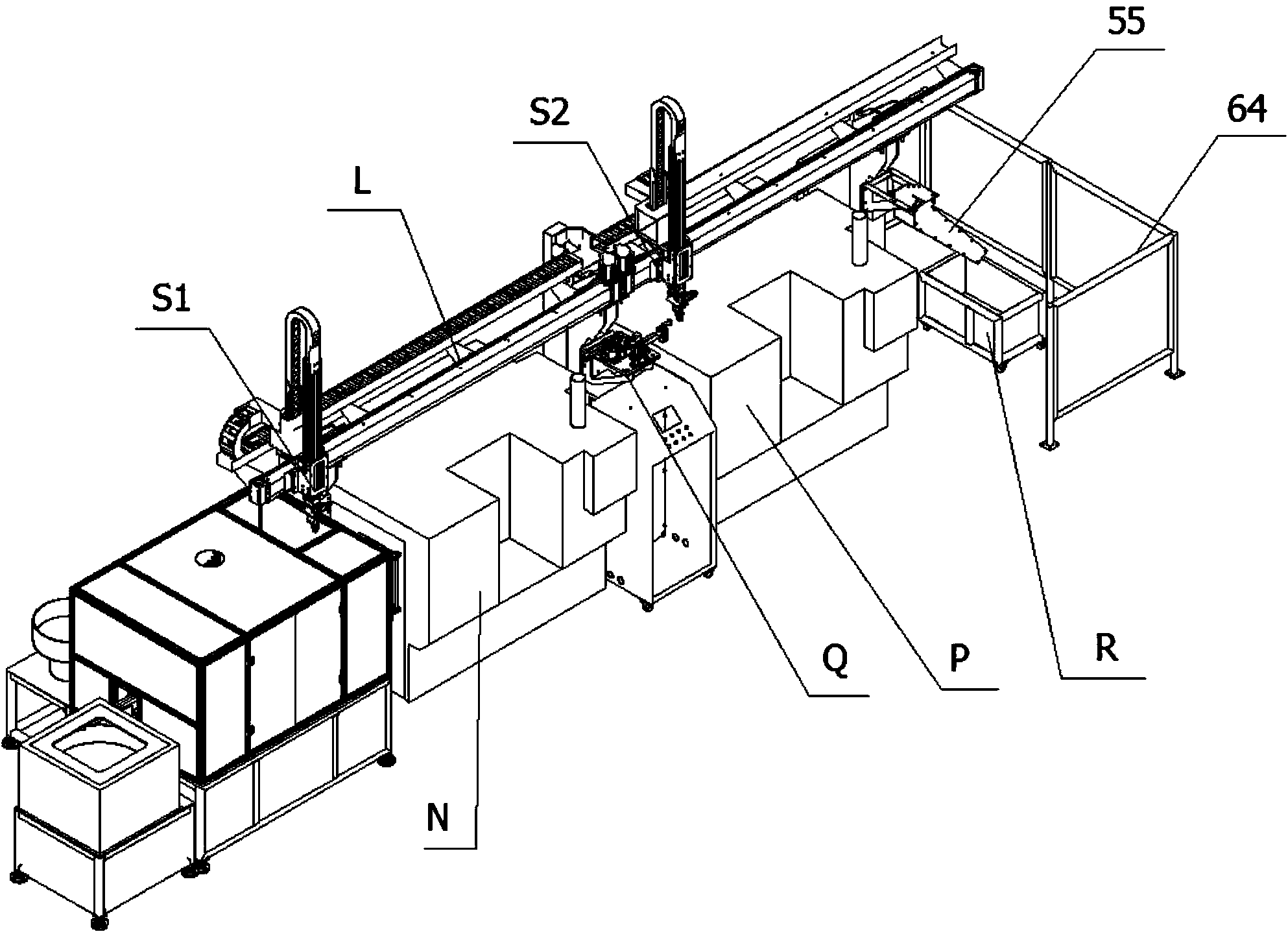

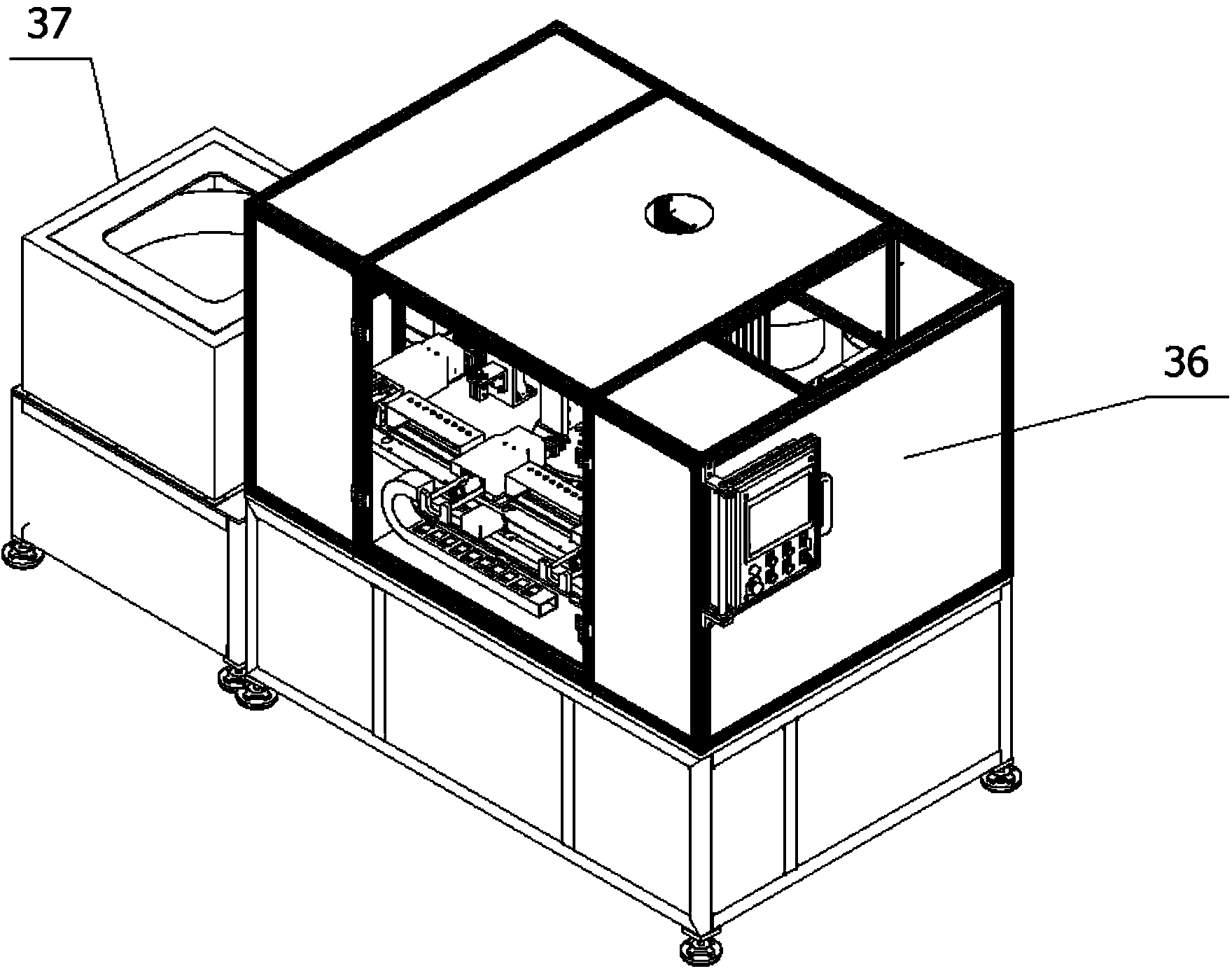

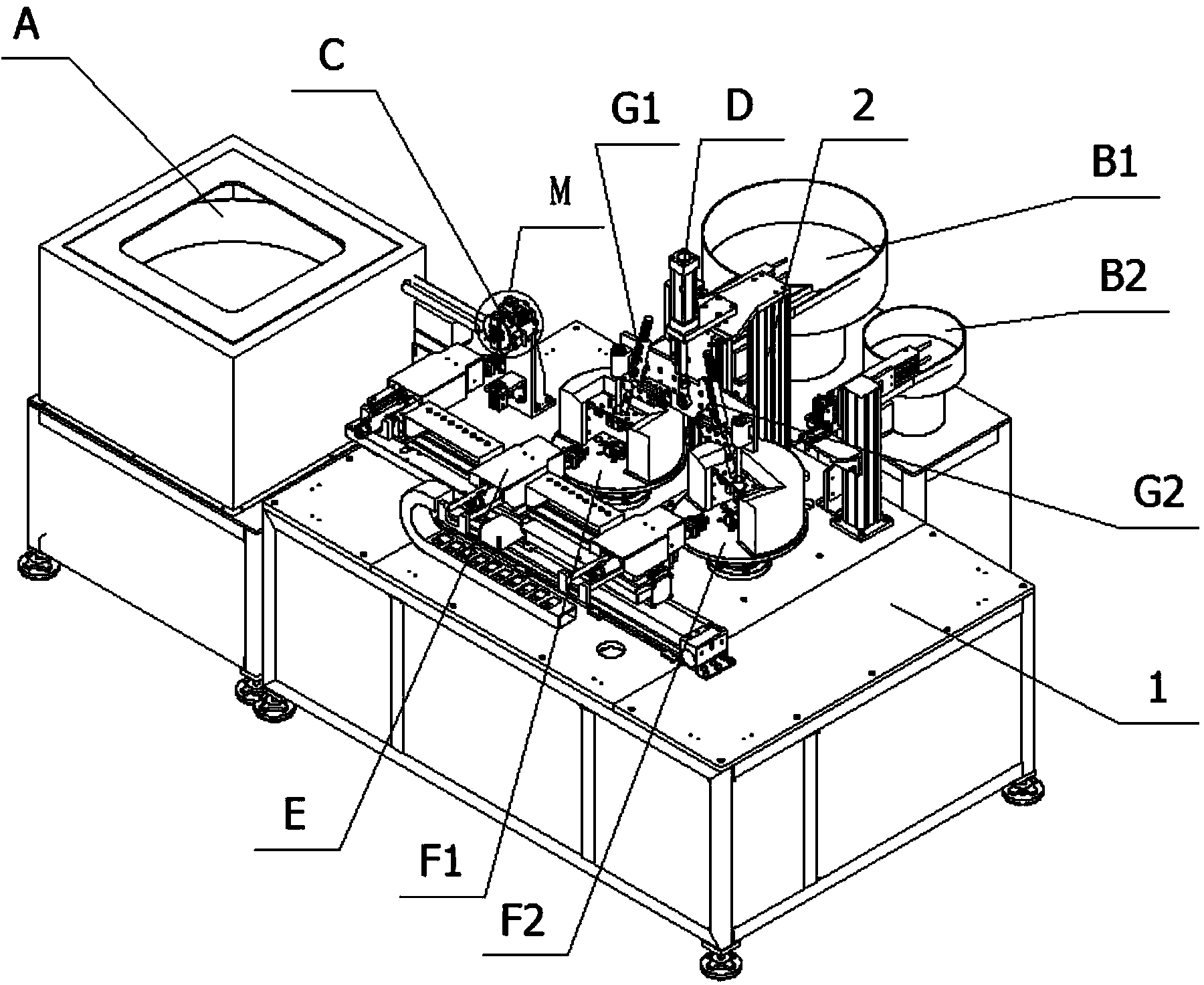

Car instrument panel IP tube welding and machining all-in-one machine

InactiveCN104368933AIncrease productivityFast weldingWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMachine tool

The invention discloses a car instrument panel IP tube welding and machining all-in-one machine. The car instrument panel IP tube welding and machining all-in-one machine comprises a welding station and a machining station; the welding station comprises a sleeve vibration feeding machine, a first gasket vibration feeding machine, a second gasket vibration feeding machine, an overturning feeding mechanism, a welding gun supporting assembly, a workpiece clamping mechanical arm mechanism, a first workpiece welding rotation assembly and a second workpiece welding rotation assembly; the machining station comprises a truss robot, a first lathe, a second lathe, a transposition device and a receiving device. By means of the car instrument panel IP tube welding and machining all-in-one machine, full-automatic welding and full-automatic machining of a car instrument panel IP tube are achieved, and the production efficiency is improved.

Owner:CHONGQING LINGYUN AUTO PARTS

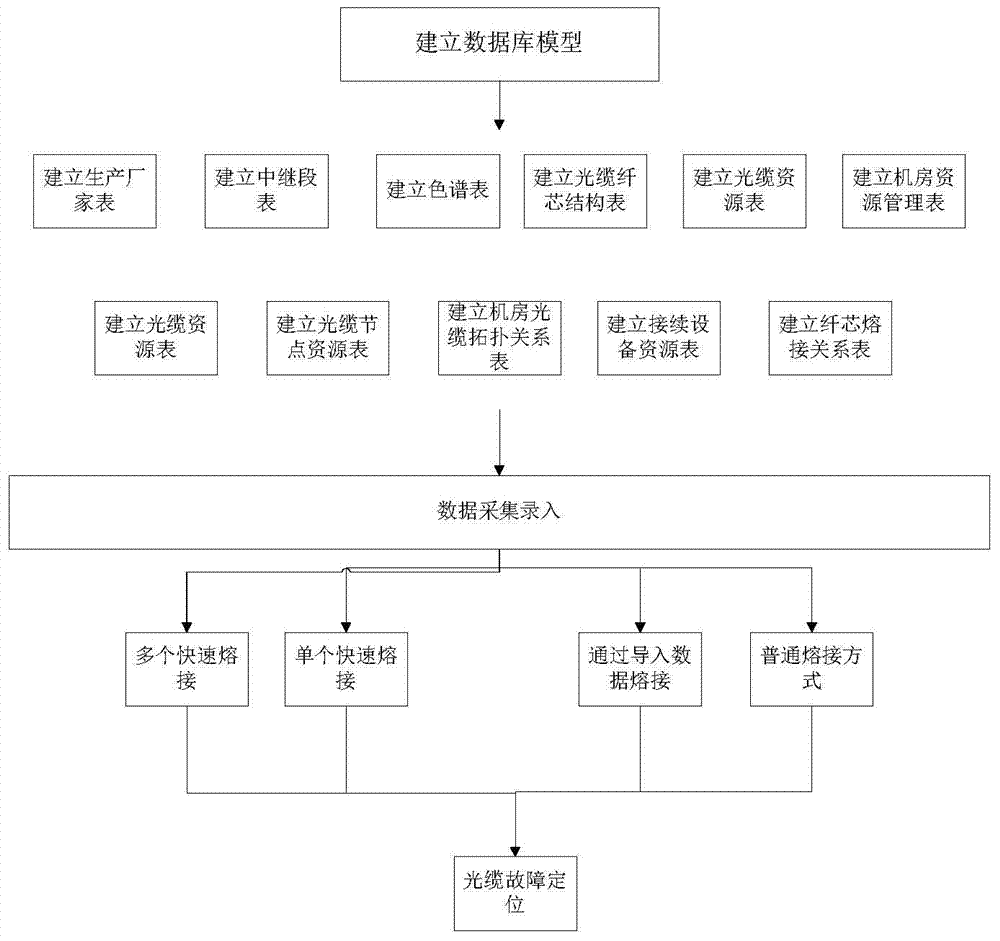

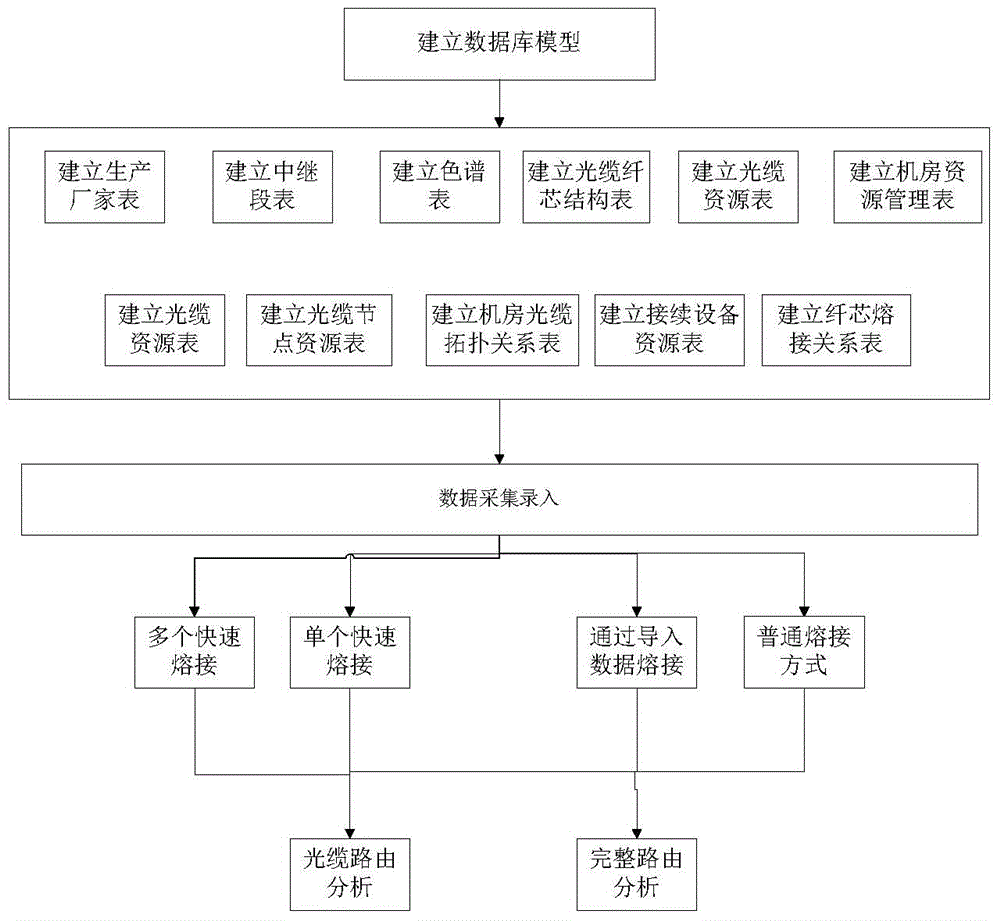

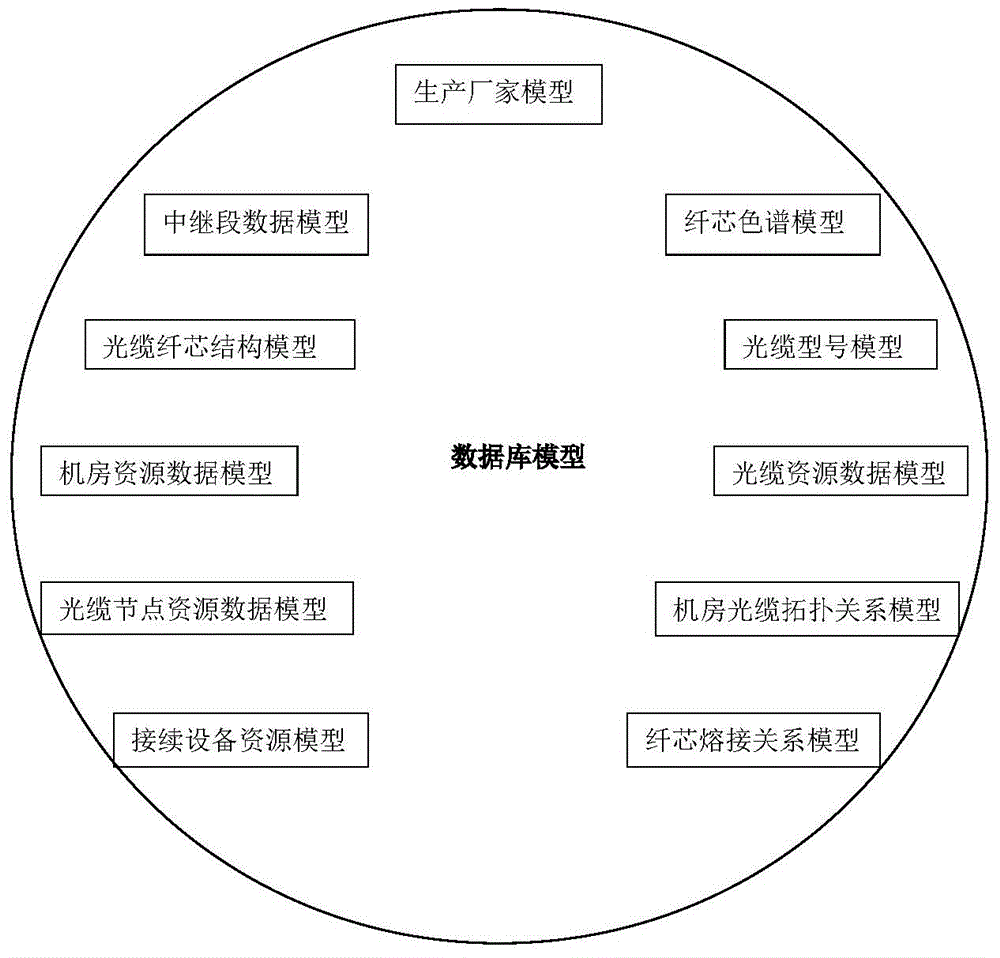

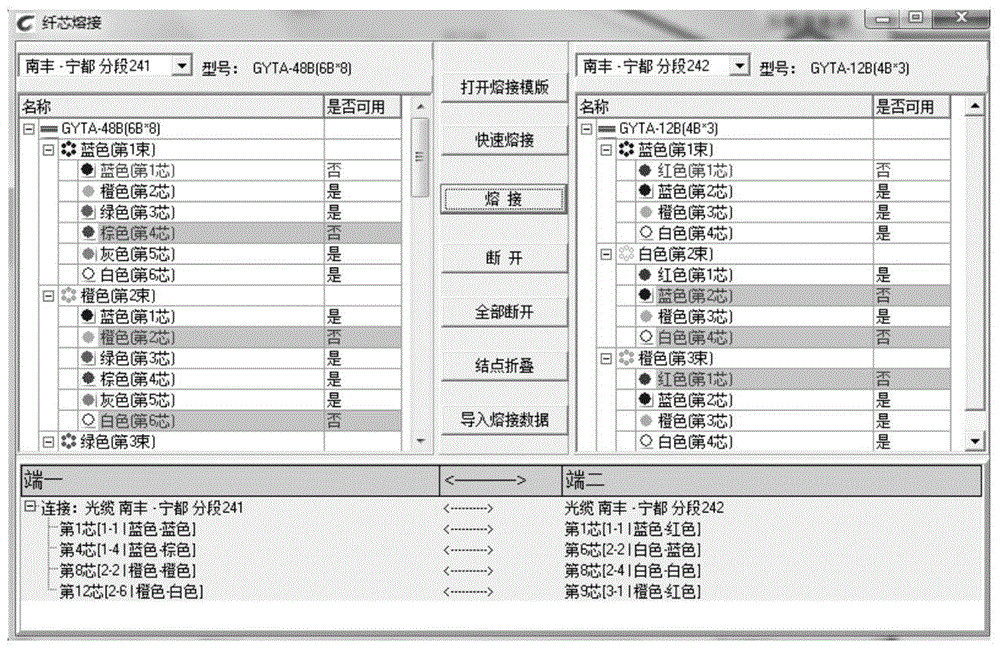

Method for quick positioning of fiber core fault

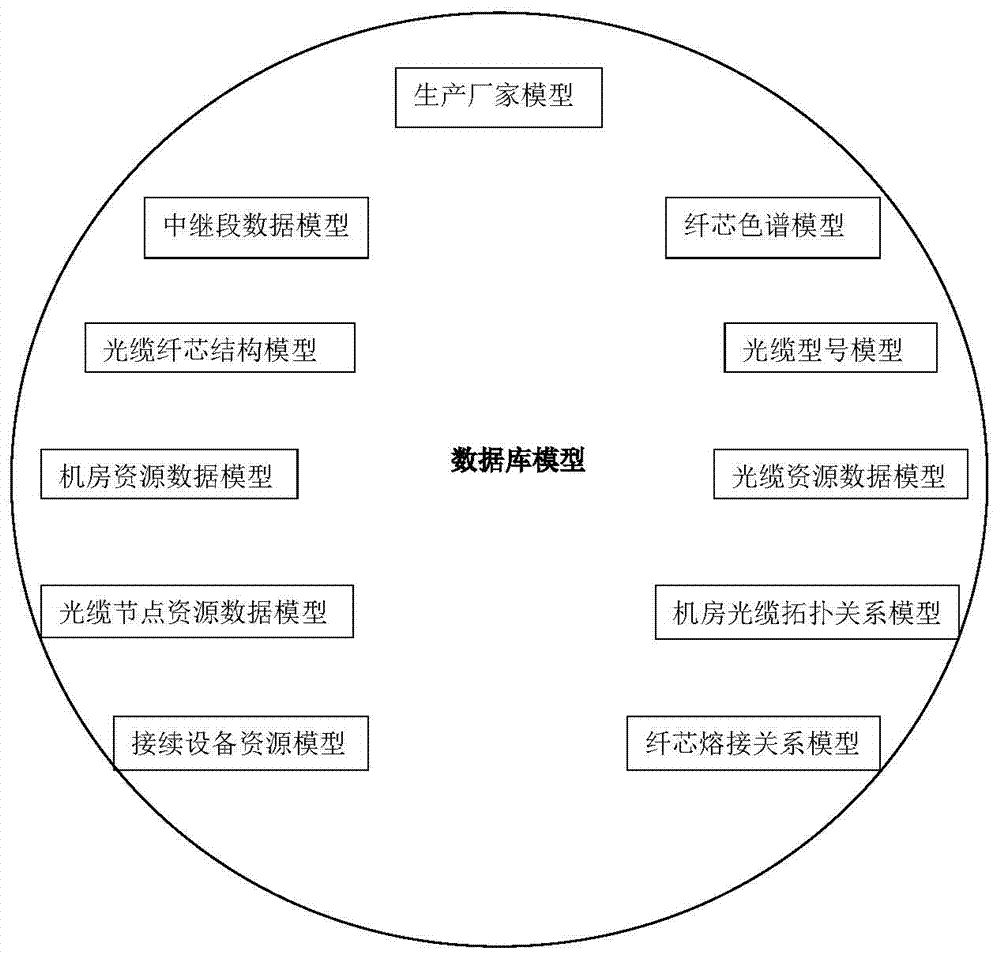

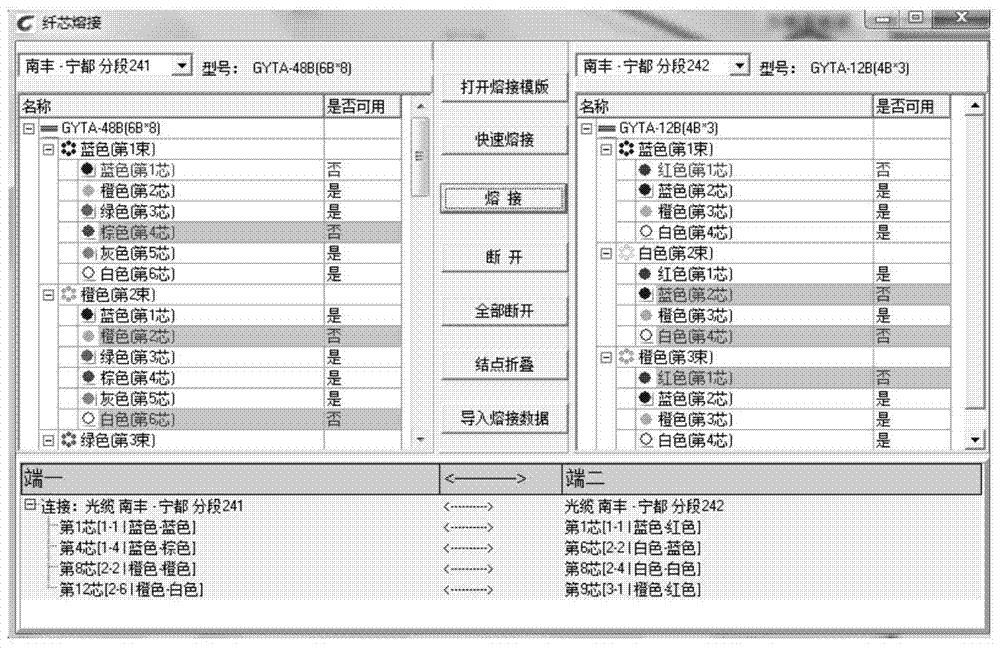

The invention discloses a method for quick positioning of a fiber core fault. A system is used for performing fiber core fault quick-positioning on an optical cable network system comprising a machine room, connection equipment and optical cables. The method comprises the steps that firstly, for 11 data models of an optical cable fiber core connection relation, uniform, normal and standard management to optical cable network resource data is realized; for a practical optical cable network, actual measurement is performed, so as to obtain attribute data in network resources and topological relation data among the resources; the data is stored into a database model established in the first step, and geographic data in the network resources is obtained at the same time; then a connection relation forming link of an optical cable fiber core is established; after a fault distance and a fiber core in failure are measured through an optical time domain reflectometer, a route relation among the optical cables of the whole link can be established by taking the tendency of the fiber core as a basis, and a fault point can be quickly and accurately positioned.

Owner:北京千禧维讯科技有限公司

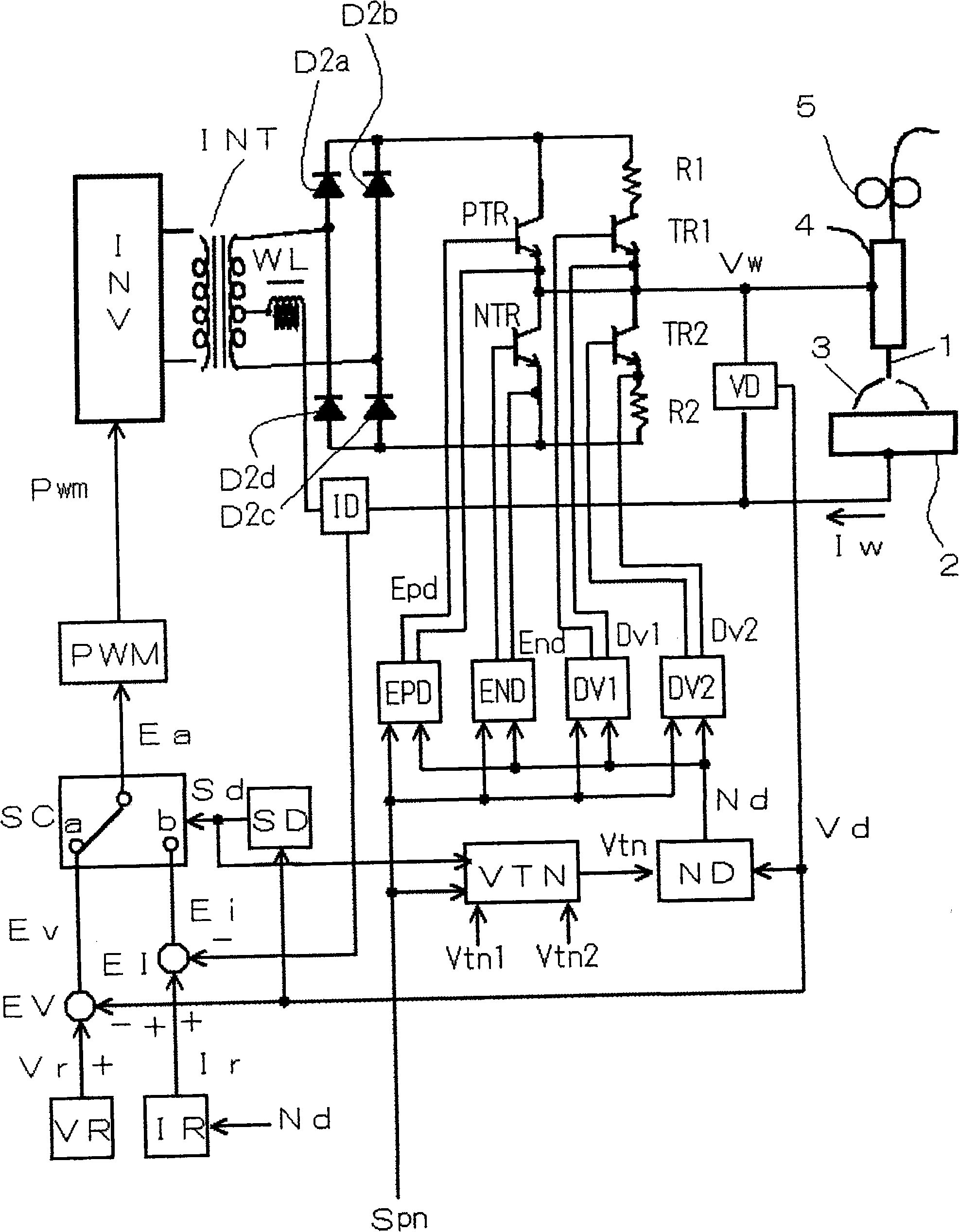

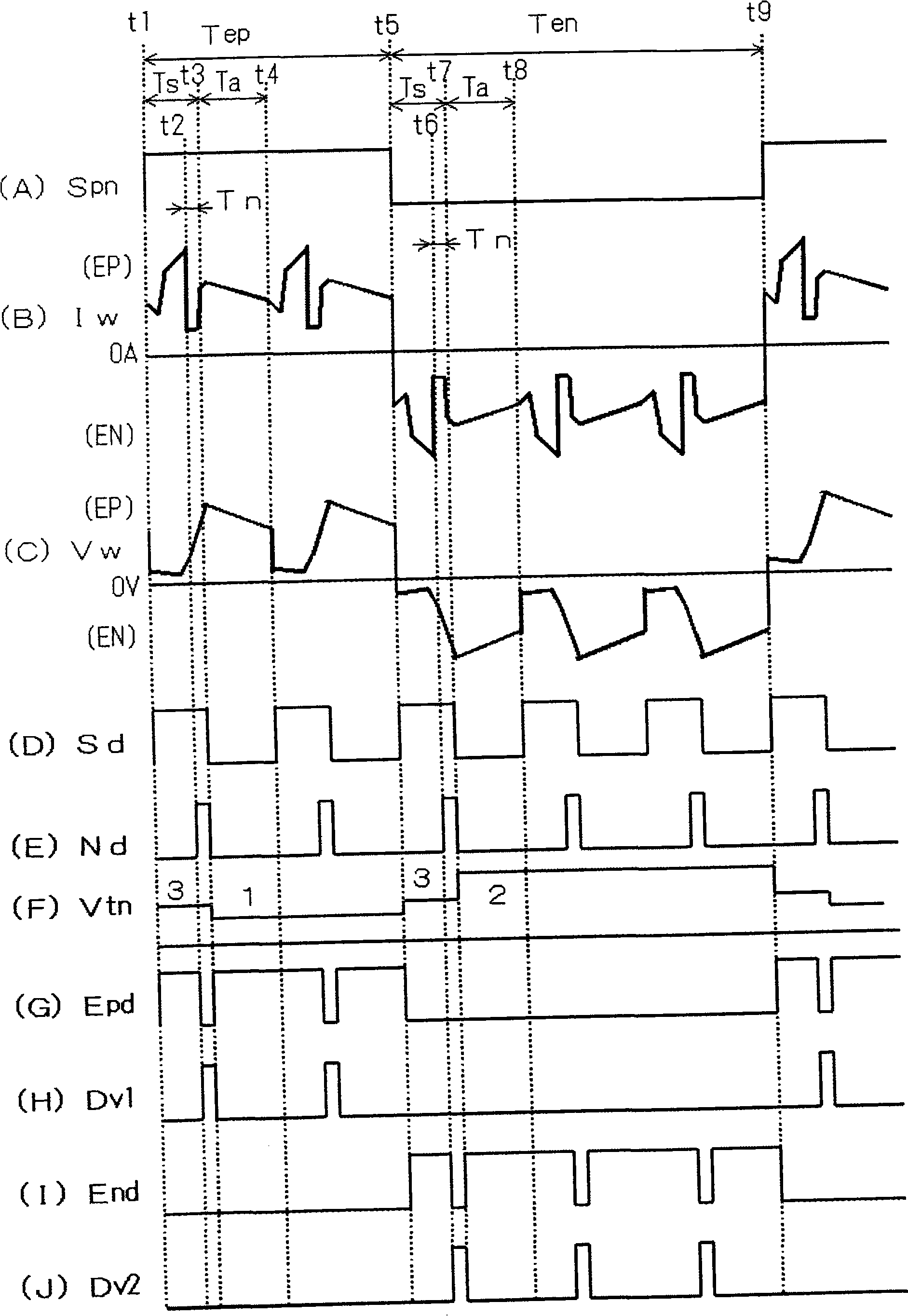

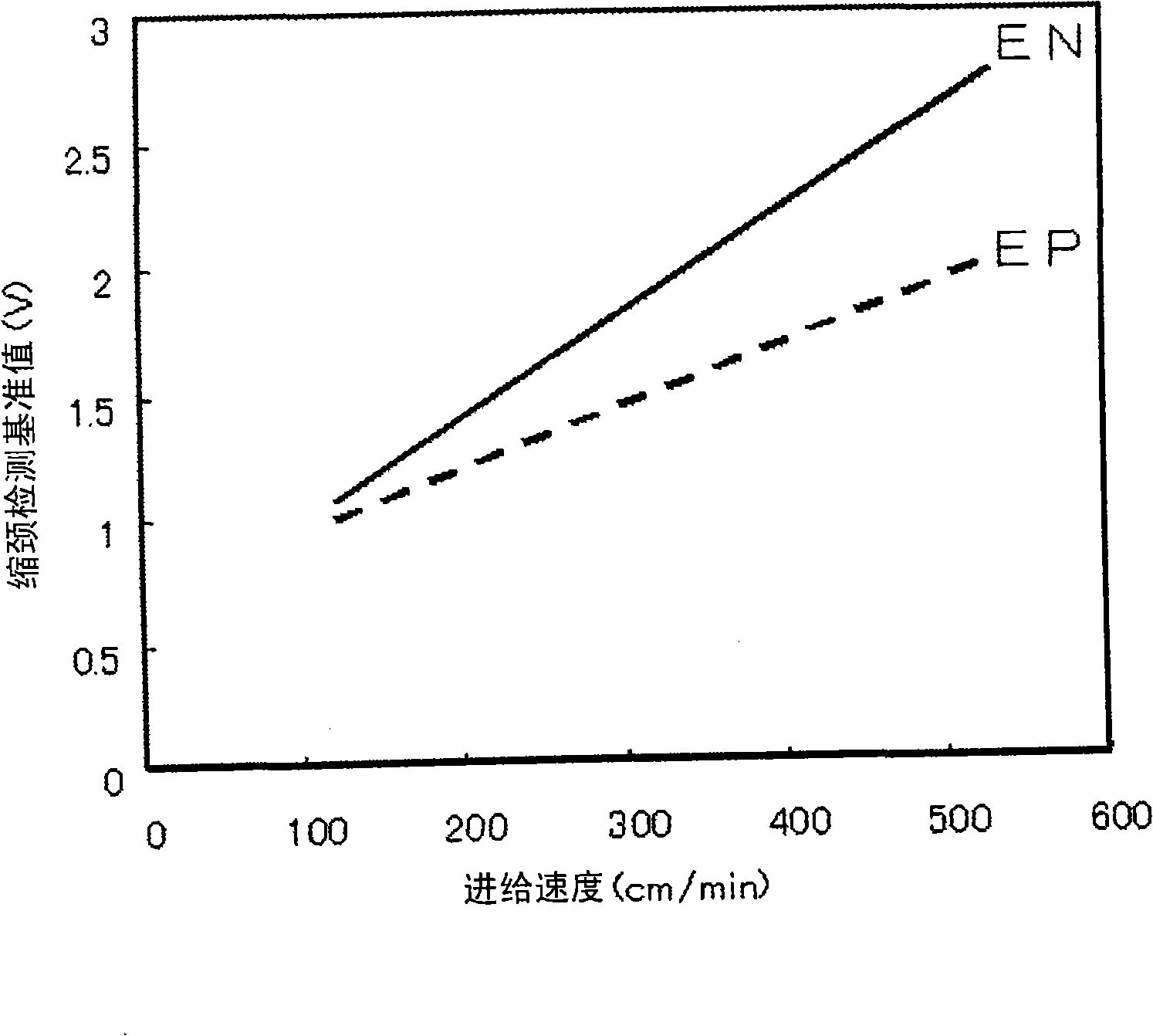

Squeezing detection control method for consumable electrode arc welding

ActiveCN101264543AReduce sputtering generationFast weldingArc welding apparatusElectrical resistance and conductanceElectrical current

The invention provides a squeezing detection control method for consumable electrode arc welding along with short circuit which can increase squeezing detection precision. The method includes a step of detecting a droplet squeezing phenomenon by checking that a change in a voltage or resistance between the consumable electrode and base material reaches a squeezing detection reference value (Vtn), and a step of executing output control for rapidly decreasing a welding current (Iw) passing through a short-circuited load when the squeezing phenomenon is detected, so that arc re-striking occurs in a state of low current (Ia). The squeezing detection reference value (Vtn) is set to a first value (Vtn1) during the electrode positive polarity (EP), and set to a second value (Vtn2) during the electrode negative polarity (EN). The second value (Vtn2) is different from the absolute value of the first value.

Owner:DAIHEN CORP

Method for quick querying and locating of optical cable link relation

ActiveCN104796193ARapid positioningRealize managementMultiplex system selection arrangementsElectromagnetic transmissionCable networkRoute analytics

The invention discloses a method for quick querying and locating of an optical cable link relation. The method is used for conducting quick querying of the optical cable link relation for an optical cable network system which comprises a machine room, a connection device and optical cables. The method comprises the steps that eleven data models aiming at the connection relation between optical cable fiber cores are established; actual testing is conducted on an actual optical cable network, attribute data of resources in the network and data of the topological relation between the resources are acquired and stored in database models established in the first step, and geographic data of the resources in the network are acquired; a link for formation of the connection relation between the optical cable fiber cores is established, and route analysis is conducted on the link. The established eleven data models can establish the route relation between the optical cables in the whole link on the basis of the direction of the fiber cores, and therefore the purpose that complete route analysis and resource locating are conducted on the fiber cores is achieved, fault removal personnel can be helped to conduct quick locating on faulted fiber cores, and the maintenance working efficiency is improved.

Owner:北京千禧维讯科技有限公司

Automatic submerged arc welding agent and preparation method thereof

ActiveCN102198573ANo secondary pollutionStart fastWelding/cutting media/materialsSoldering mediaSlag (welding)Chemical composition

The invention discloses a preparation method of an automatic submerged arc welding agent. The method comprises the following steps of: taking industrial waste residues as raw materials and setting chemical composition content of smelting high-temperature granulated slag and manganese ore; mixing the two materials to form a raw material containing 15-21 percent of MnO and calculating the using amounts of the two raw materials; detecting the chemical compositions of the two raw materials; adding each chemical raw material to meet the requirement of each chemical composition content; fully stirring and uniformly mixing; pouring into an electric furnace for smelting; performing water quenching and granulating; drying; and screening to obtain products, wherein the chemical composition comprises 26-32 percent of SiO2, 17-29 percent of CaO, 15-22 percent of MnO, 9-16 percent of Al2O3, 8-19 percent of CaF2, 1-5 percent of TiO2, less than or equal to 2 percent of FeO, less than or equal to 0.04 percent of S, less than or equal to 0.05 percent of P and less than 1 percent of H2O. By adopting the preparation method, the problems of high cost, high energy consumption, serious pollution and instable performance existing in the conventional product are solved.

Owner:蒋才银

Preformed solder containing soldering flux and preparation method thereof

ActiveCN107433400AWon't hurtWon't scatterWelding/cutting media/materialsSoldering mediaThermal bridgeIngot

The invention relates to the technical field of materials for electronic device welding and specifically discloses a kind of performed solder containing soldering flux and a preparation method thereof. The performed solder containing the soldering flux comprises a soldering material and the soldering flux wrapped in the soldering material; the mass percent of the soldering material is 95%-99.9%, and the mass percent of the soldering flux is 0.1%-5%. The preparation method of the performed solder containing the soldering flux comprises the steps of preparing the soldering flux; smelting and casting an ingot of the soldering material; conducting charging and extruding the ingot of the soldering material into a preform body; rolling the perform body into a material strap; and cutting the material strap. By adopting the performed solder provided by the invention, the deficiencies of dipping the liquid soldering flux and externally applying the solid soldering flux are made up; the soldering flux can reduce the surface tension of the molten soldering material, facilitates wetting and spreading of the performed solder, promotes welding, prevents secondary oxidation of the performed solder and has an auxiliary heat conduction effect as a thermal bridge. By means of the performed solder containing the soldering flux, the welding quality is effectively improved, the good welding effect is achieved, the stability of the welding process can be guaranteed, and the production efficiency can be improved.

Owner:SOLDERWELL MICROELECTRONIC PACKAGING MATERIALS CO LTD

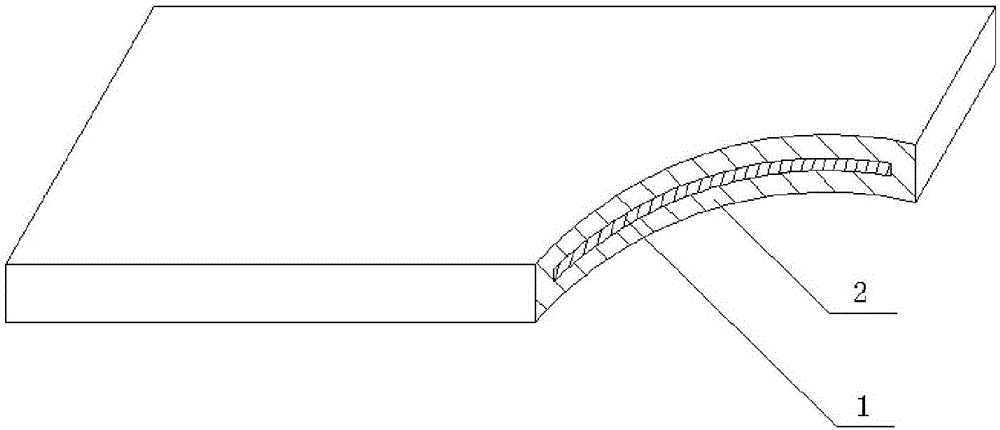

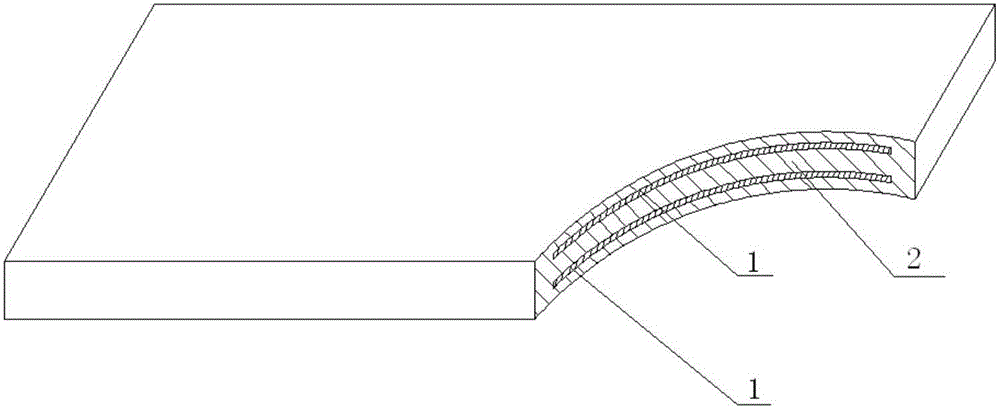

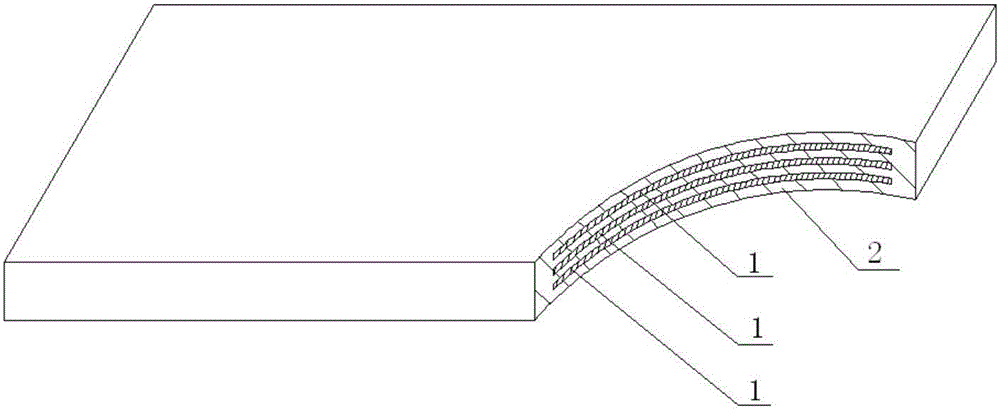

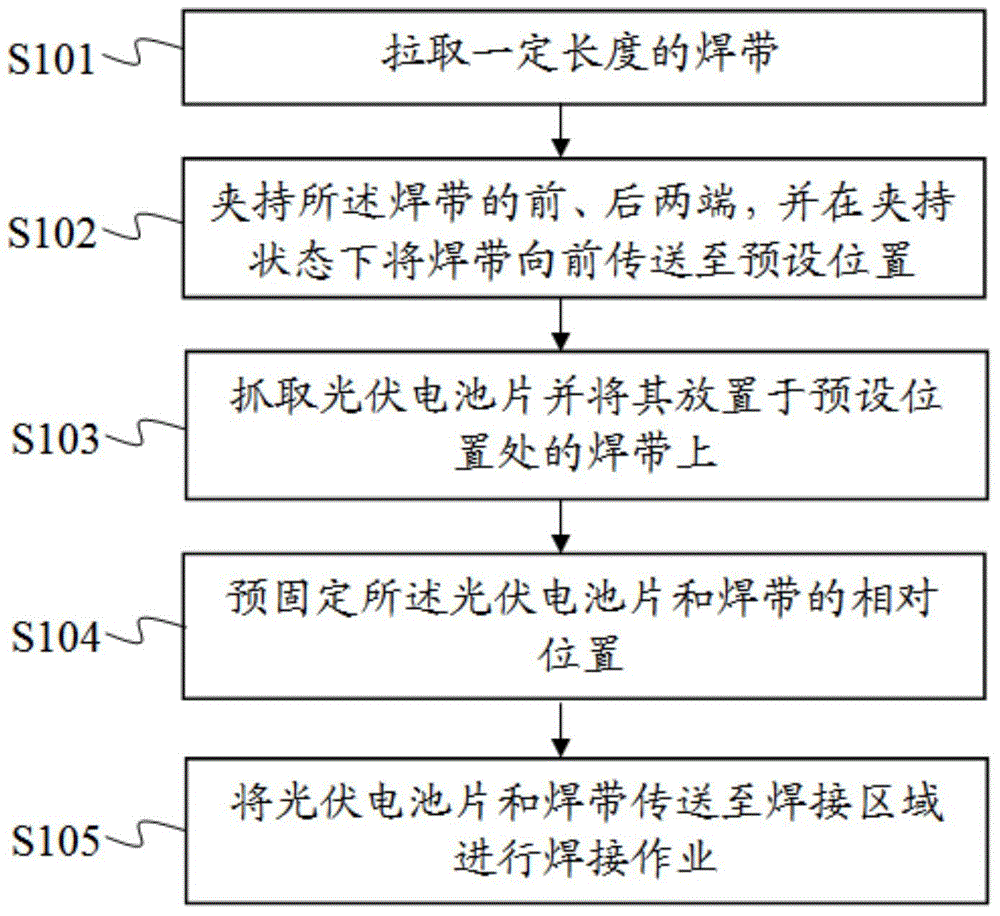

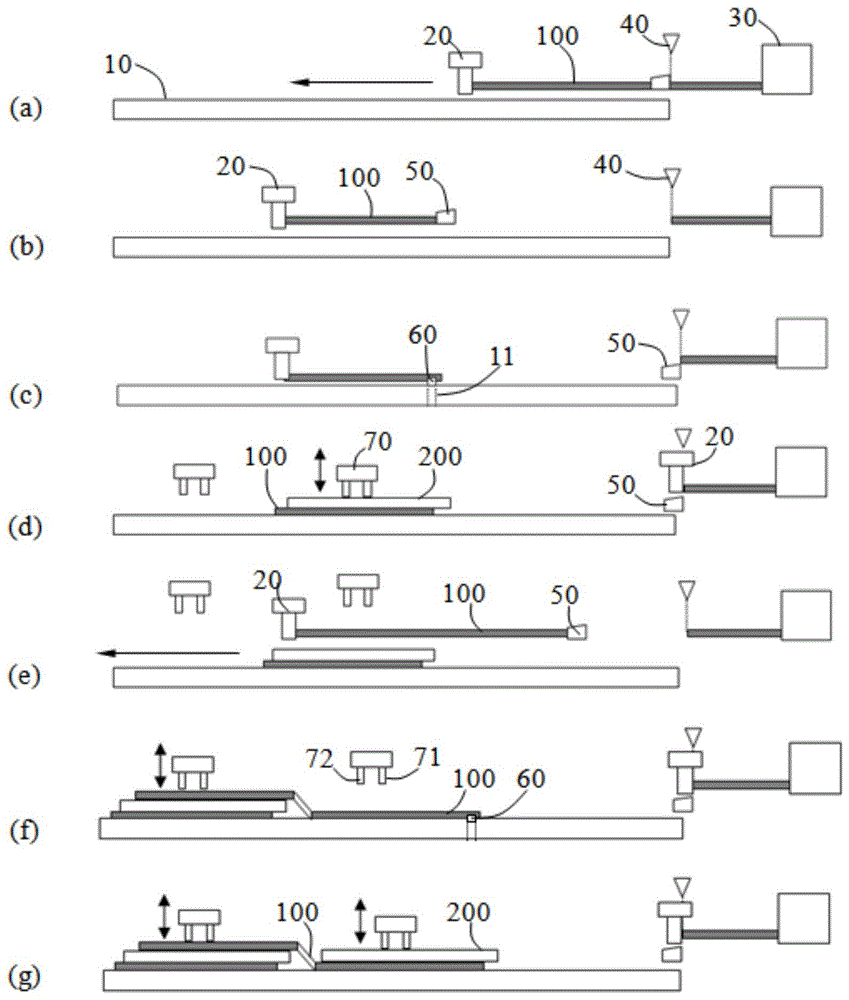

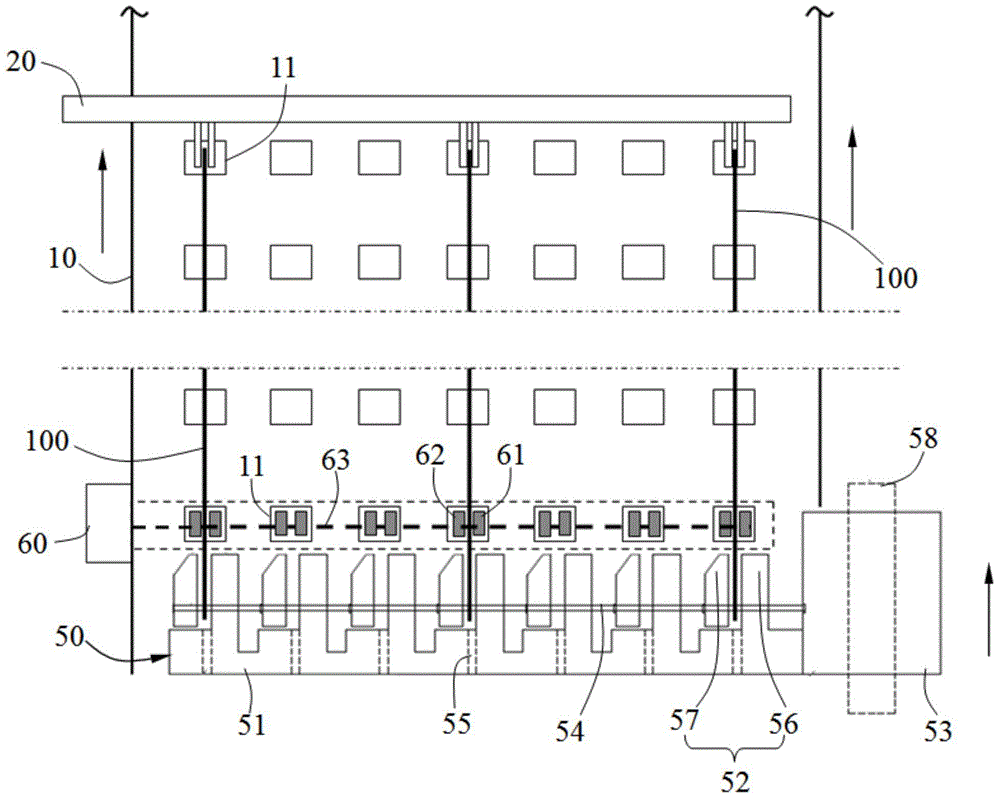

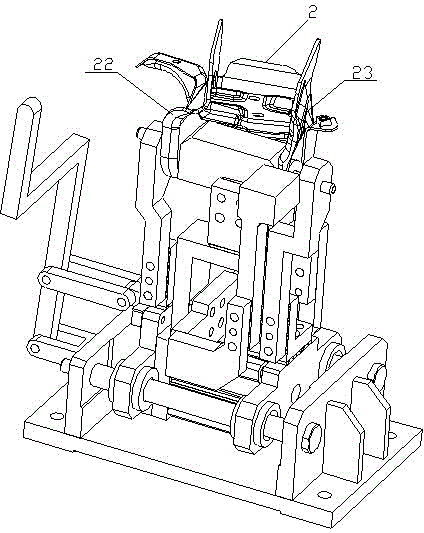

Photovoltaic cell piece series welding device and method

ActiveCN104785972AAvoid curlAvoid bendingWelding/cutting auxillary devicesAuxillary welding devicesEngineeringWelding process

The invention provides a photovoltaic cell piece series welding device and method. The method comprises the steps that a solder strip of a certain length is pulled out; the front end and the rear end of the solder strip are clamped, and the solder strip is delivered forwards to a preset position in the clamped mode; photovoltaic cell pieces are grabbed and placed on the solder strip located at the preset position; the relative positions of the photovoltaic cell pieces and the solder strip are prefixed; the photovoltaic cell pieces and the solder strip are delivered to a welding area to be welded. In the solder strip delivery process, the front end and the rear end of the solder strip are well located, the phenomenon that the rear end of the solder strip is curled or bent after the solder strip is cut off can be effectively avoided, the welding efficiency and the welding quality are improved, and the welding process can be more efficient and quicker.

Owner:CSI CELLS CO LTD +1

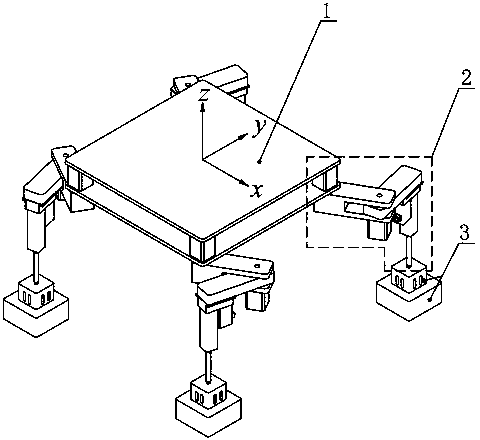

A foot-type magnetic adsorption wall climbing robot

The invention belongs to the field of wall-climbing robots, in particular to a foot-type magnetic adsorption wall-climbing robot, which is composed of a carrying platform, a walking leg and an adsorption foot. Various actuators can be mounted on the carrier platform to perform various operations on the iron-based wall surface. Each walking leg comprises a two-degree-of-freedom series mechanism, aservo-electric cylinder and a ball hinge, wherein the end of each walking leg is connected and absorbed sufficiently. The suction foot adopts a screw nut mechanism to adjust the height of the permanent magnet and the wall surface so that the suction force can be adjusted. Robots can be thought of as combinations of 4-RRR Planar mechanisms and elevating mehcanisms. the movement of the two mechanisms is controlled to realize the omni-directional movement of the platform in the space. Robot can move straight, turn and adjust posture flexibly on the different curvature of the wall. The invention solves the shortcomings of unreliable adsorption and inflexible steering of the conventional magnetic adsorption wall climbing robot, and has the advantages of simple structure, strong load capacity, good obstacle-crossing ability, flexible movement and reliable adsorption.

Owner:SOUTHWEST PETROLEUM UNIV

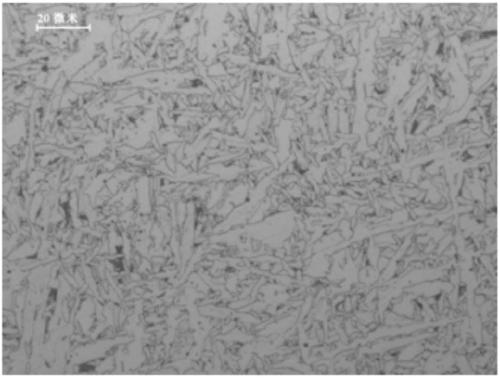

Large heat input energy welding high-strength EH36 steel plate and making method thereof

The invention relates to a large heat input energy welding high-strength EH36 steel plate which is made of the following components in percentage by weight through smelting: 0.06-0.18% of C, 0.15-0.50% of Si, 1.10-1.60% of Mn, less than or equal to 0.012% of P, less than or equal to 0.003% of S, 0.10-0.40% of Ni, 0.010-0.030% of Nb, less than or equal to 0.010% of Al, 0.010-0.030% of Ti, 0.001-0.010% of Ca and the balance of Fe and inevitable impurities. The maximum thickness of the steel plate is 100mm, the yield strength of the steel plate is greater than or equal to 355MPa, the tension strength of the steel plate is greater than or equal to 510MPa, and the low-temperature impact absorption energy KV2 of the steel plate at minus 40 DEG C is greater than or equal to 150KJ. A production method of the steel plate comprises the following steps: carrying out smelting, LF / RH (Ladle Furnace / Ruhrstahl Heraeus) refining, continuous casting, heating, rolling, and rapid cooling, thereby obtaining a finished product of the steel plate. The steel plate produced by using the method provided by the invention has the characteristics of high purity, high strength, good low-temperature impact resistance, good toughness when the maximum input line energy is 300KJ / CM, and the like, can be widely applied to fields such as shipbuilding, bridges and building structures, and has wide application prospects.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

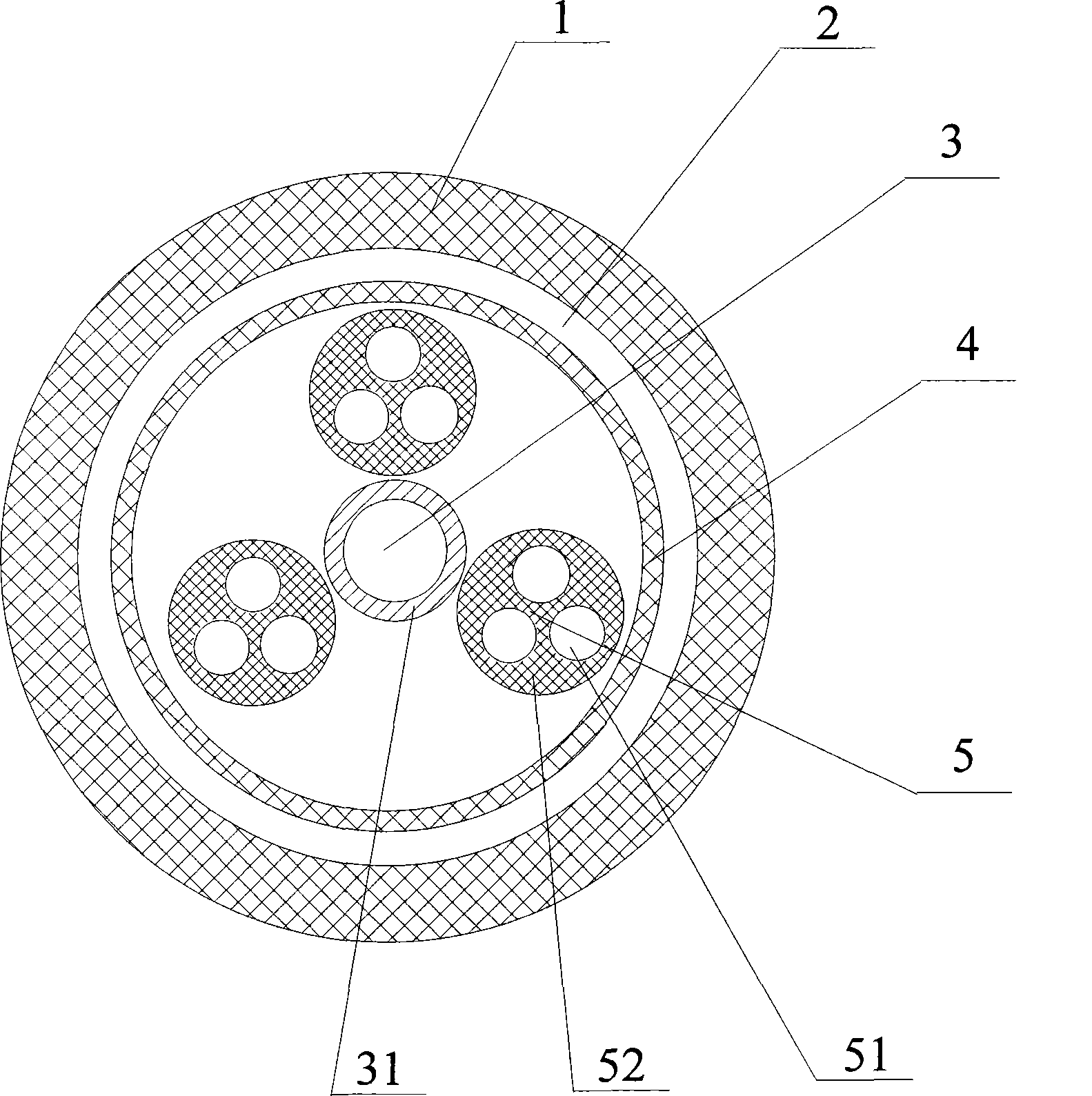

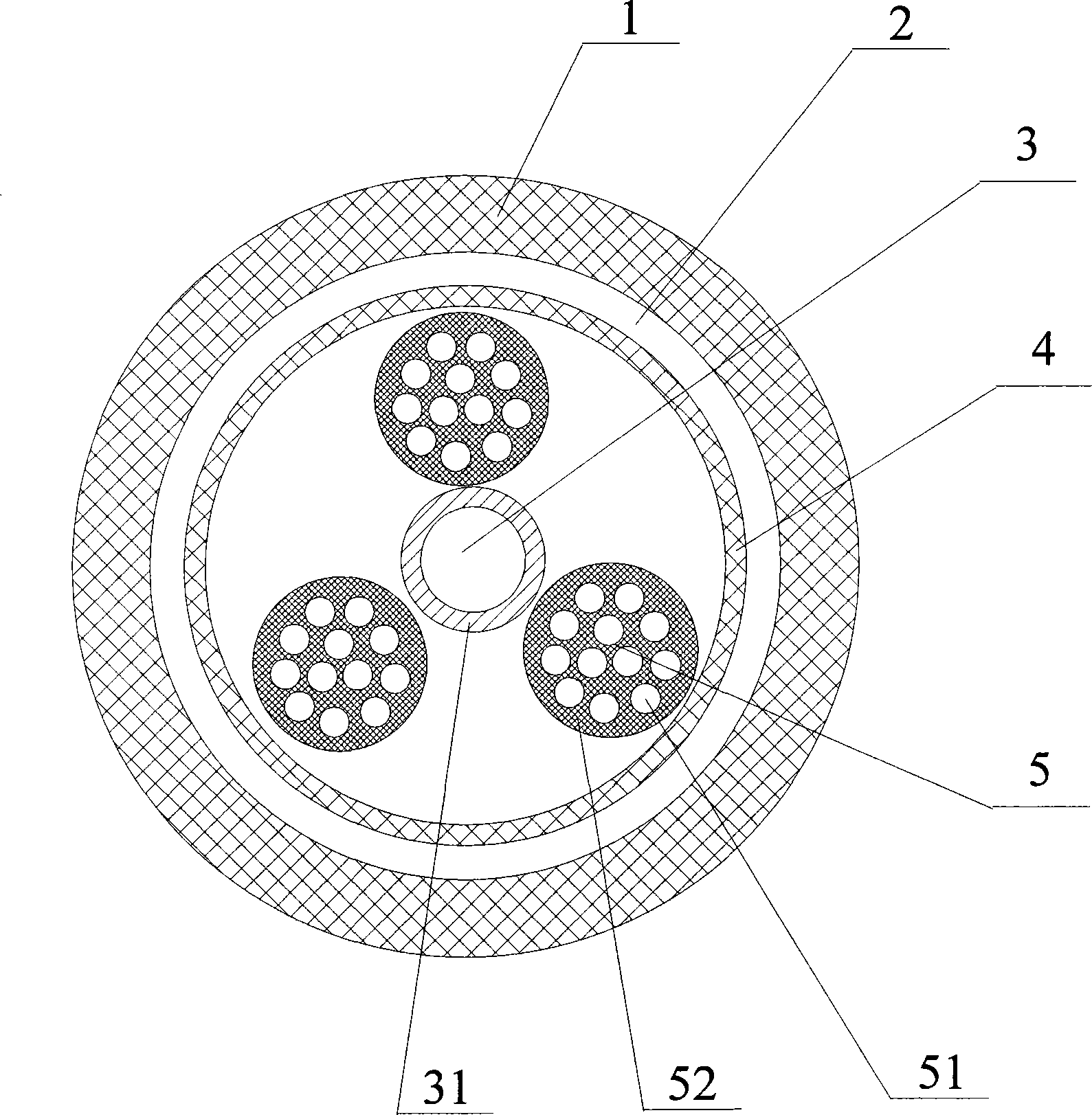

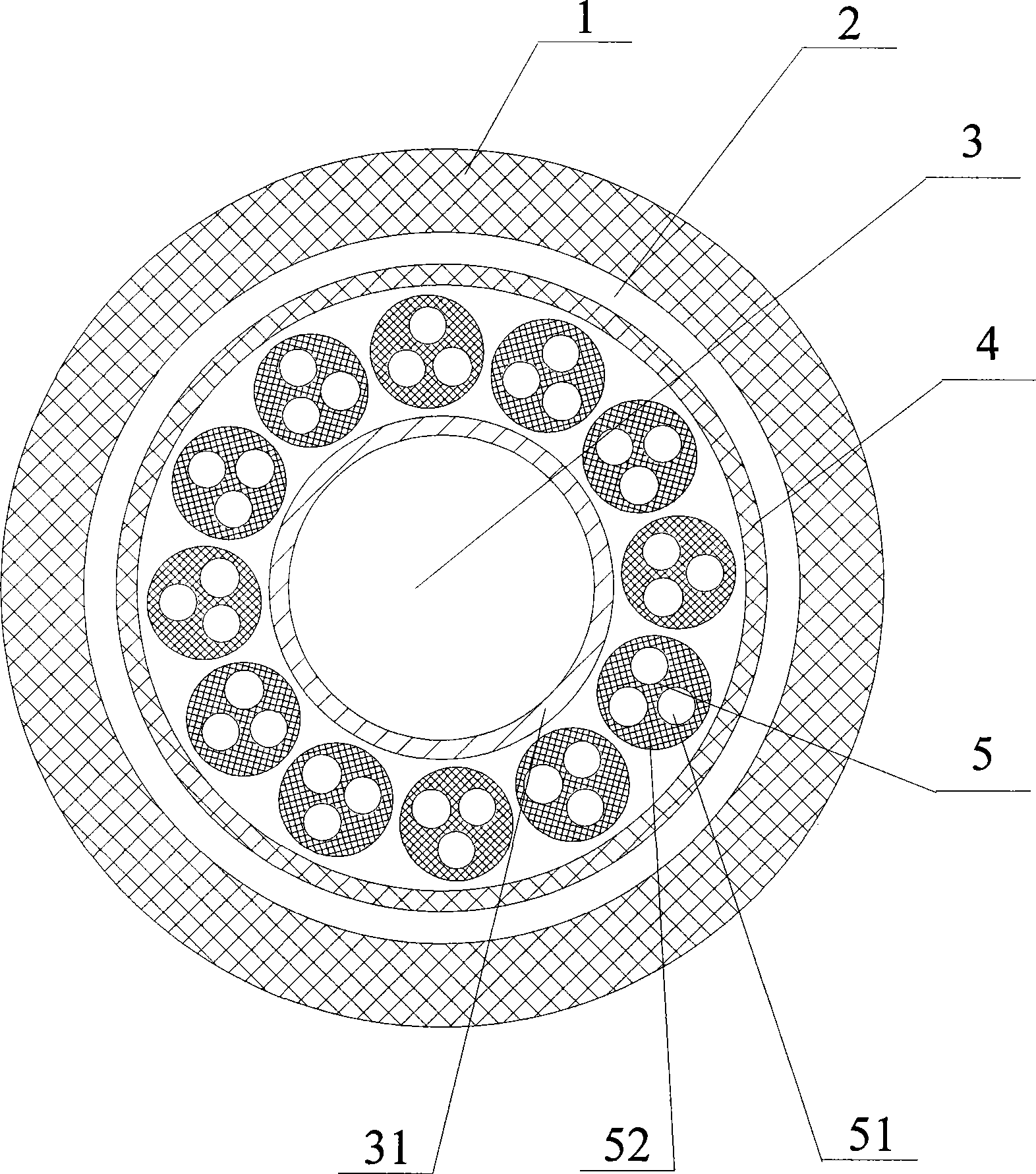

UV optical cable

The present invention relates to an optical cable for communication network, and specifically to a UV optical cable which comprises a central reinforcement, a plurality of optical fiber bundles twisted around the central reinforcement, and the sleeves coated on the peripheral surface of the plurality of optical fiber bundles. Each optical fiber bundle is formed by a plurality of optical fibers which are alternately fixed in the UV curing resin with a beam shape. The invention uses the UV optical fiber bundle as an optical fiber unit. The clearance between the optical fibers in the UV optical fiber bundle is filled by UV cured resin. The diameter of optical cable is greatly reduced. The density of optical cable is increased. The optical cable for communication network has the advantages of small diameter, light weight, high production rate, convenient and quick welding, etc. The pipe wiring of optical cable in the building greatly saves the resource of pipe and furthermore facilitates the optical fiber branching without cutting off the optical fiber. The optical cable of the invention is a novel optical cable for aiming at the FTTH communication network construction.

Owner:FENGHUO COMM SCI & TECH CO LTD

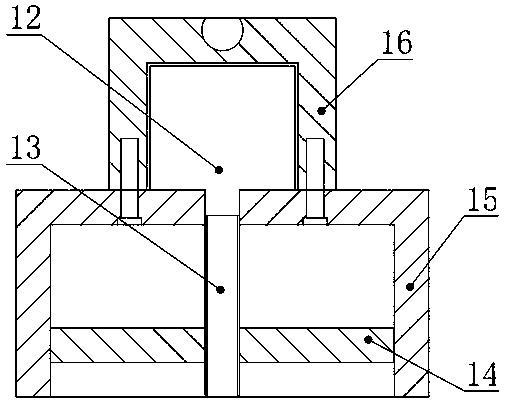

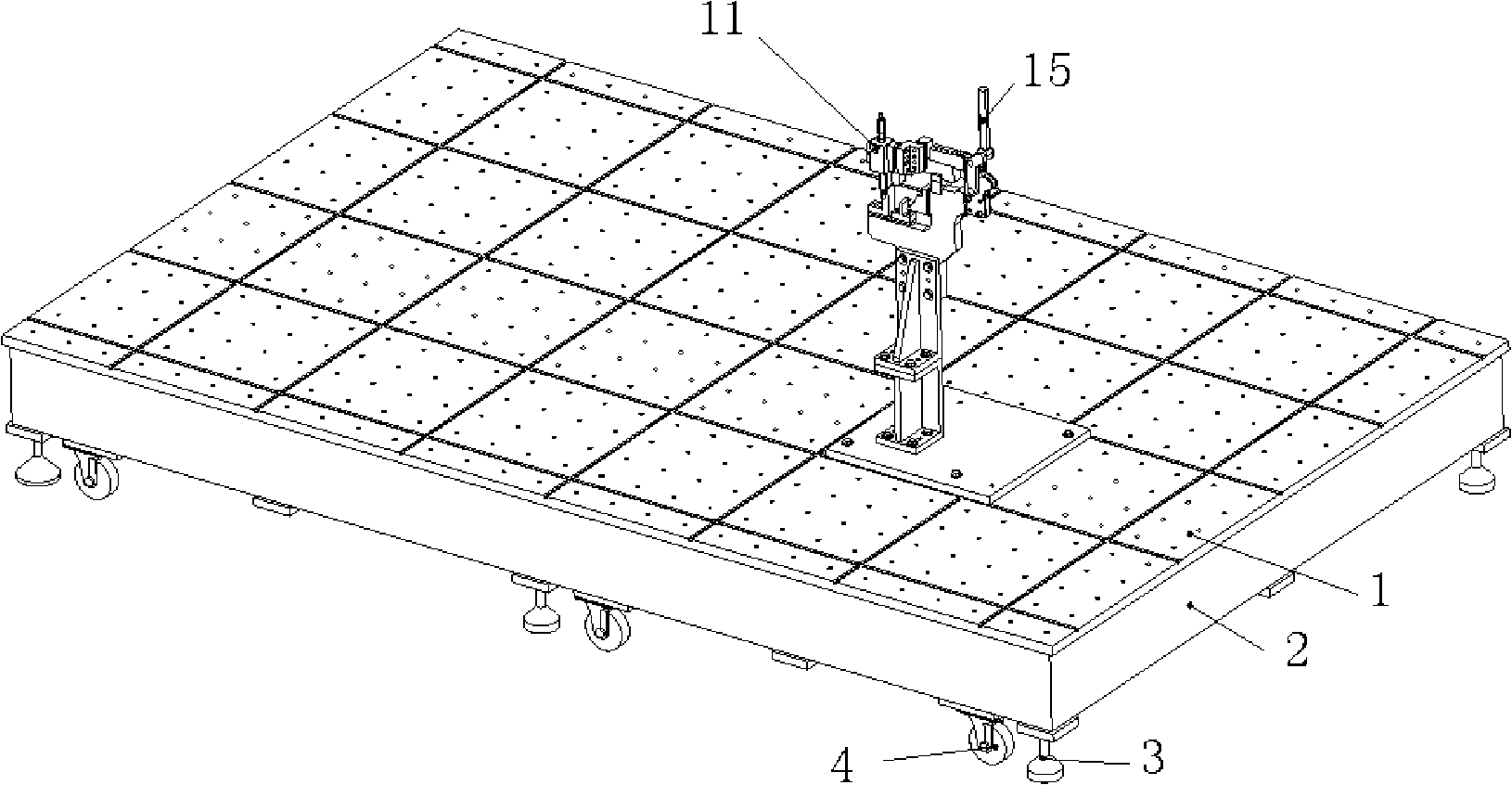

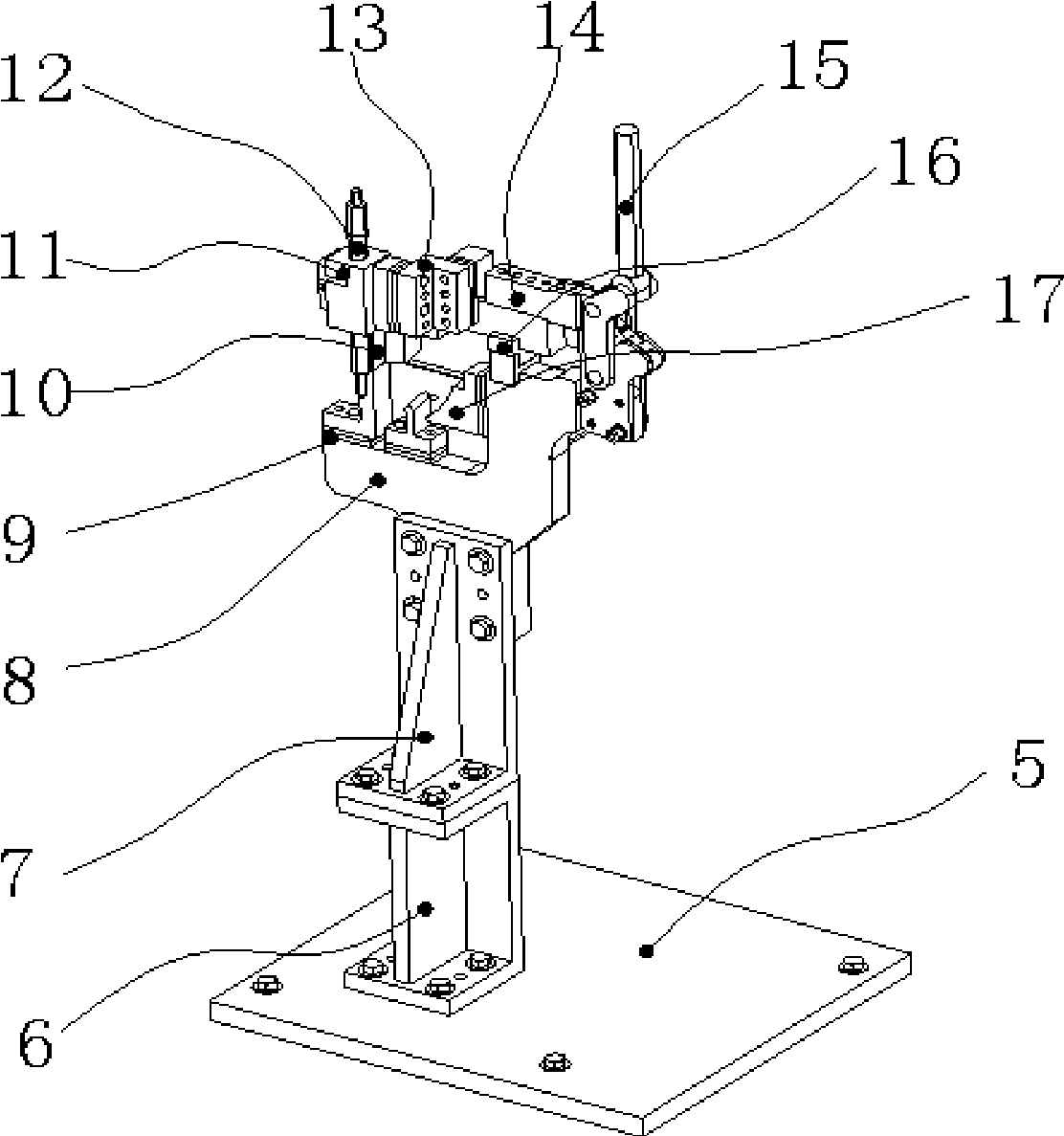

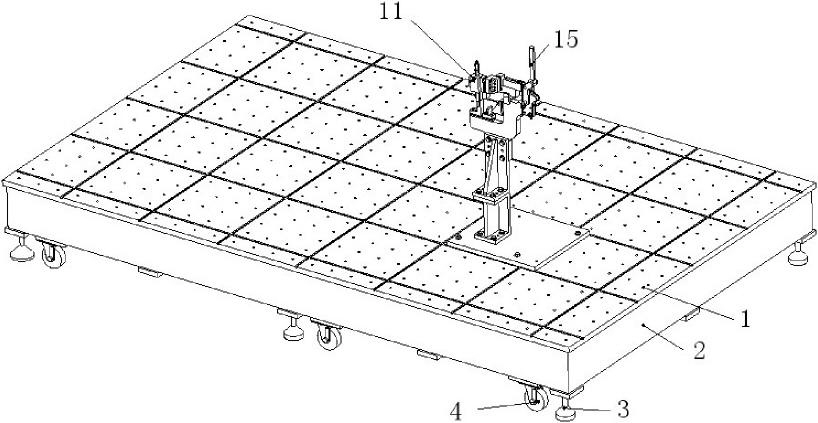

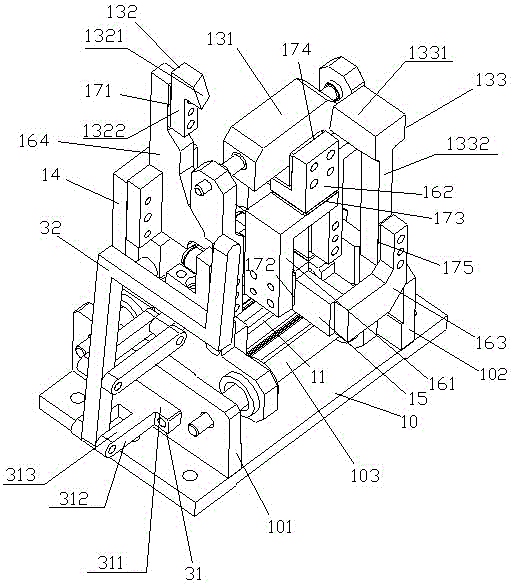

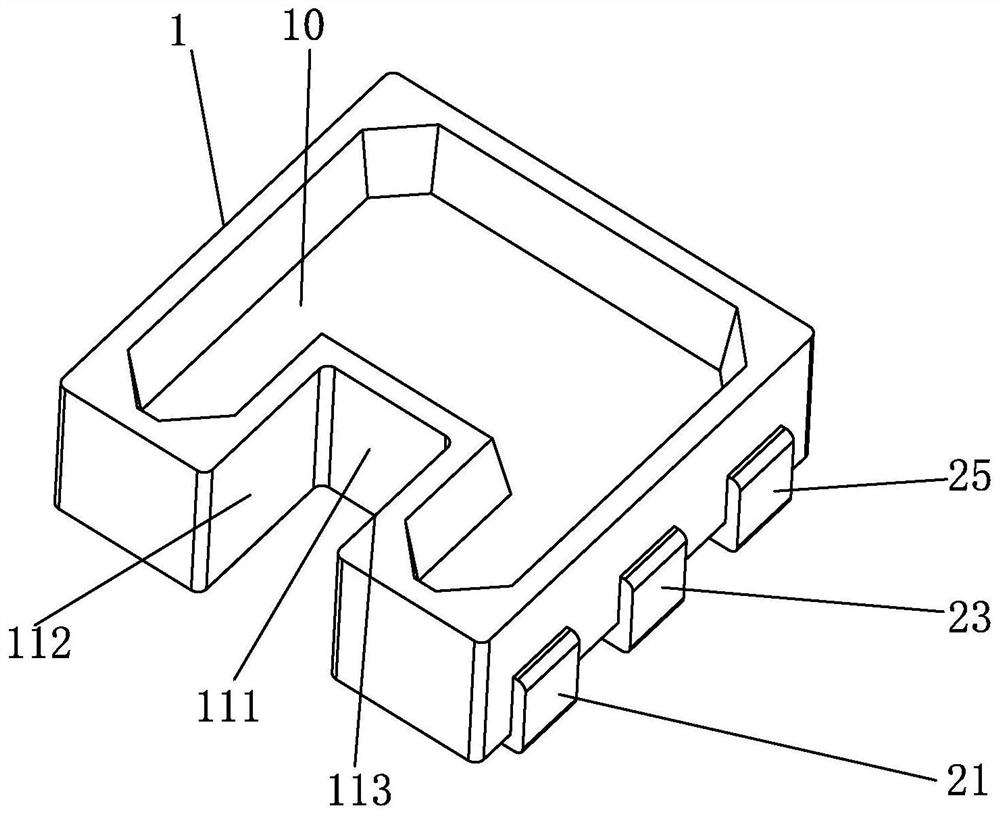

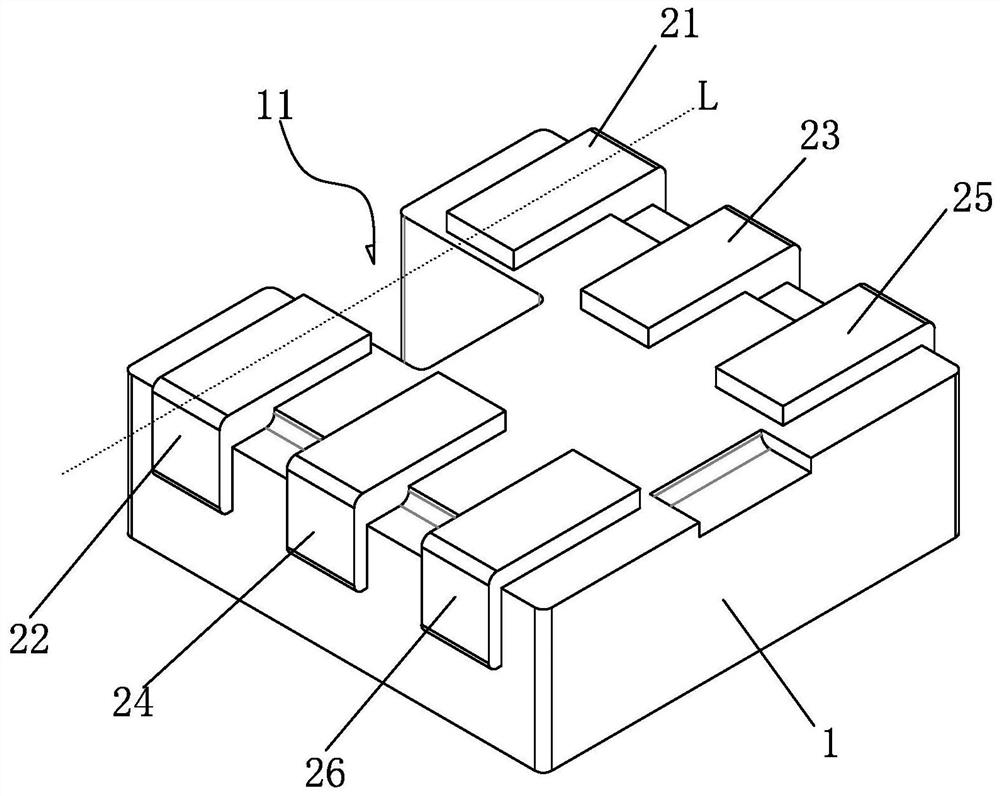

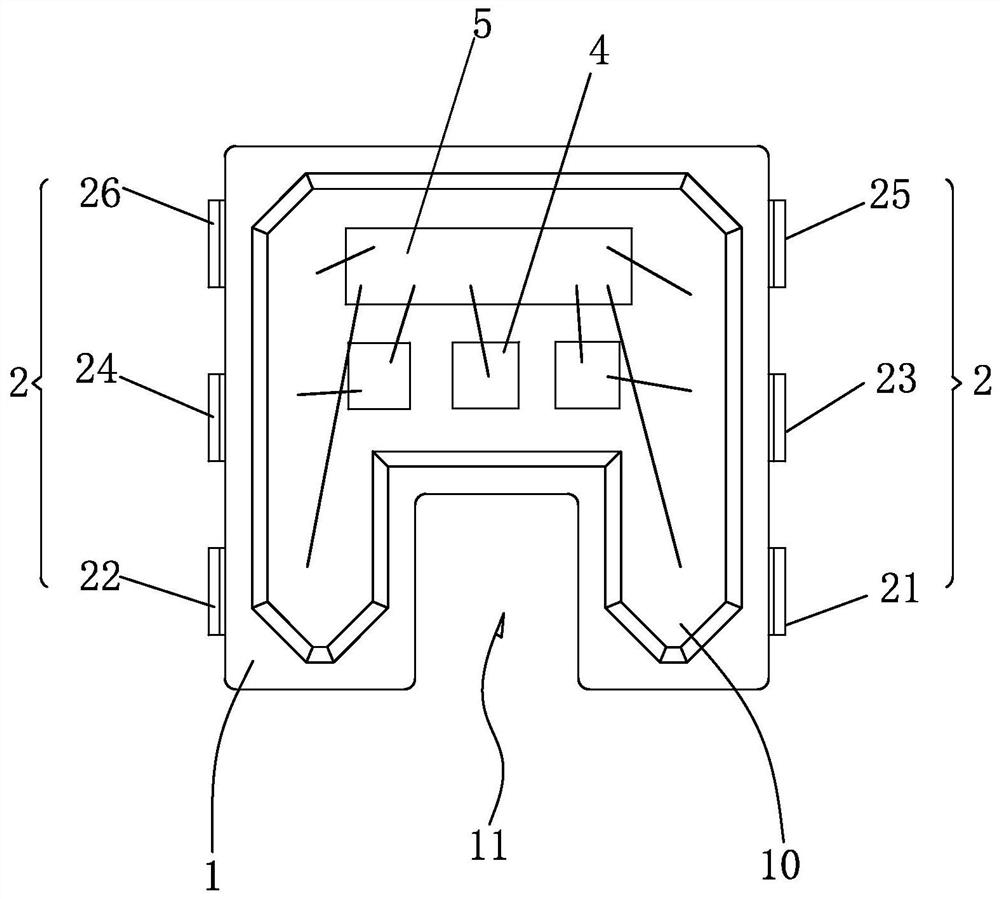

Modular design method and structure of welding fixture for trial-manufacture sample vehicles

ActiveCN101905403ASimple design methodShorten the design and production cycleWelding/cutting auxillary devicesAuxillary welding devicesModular designModularity

The invention relates to the technical field of automobile manufacturing equipment, in particular to a modular design method and a modular design structure of a welding fixture for trial-manufacture sample vehicles, which solve the problems of incapability of recycling, long design and manufacturing period and high manufacturing cost of sample vehicle trial-manufacture fixture parts of automobiles in the prior art. The welding fixture comprises a base and a fixture unit arranged on the base; structural members with the same functions in the welding fixture for the trial-manufacture sample vehicles are formulated into standard or standard series parts in the process of design and development to form a fixture module series, so that the standard or standard series parts are recycled in the development of the welding fixture for new type trial-manufacture sample vehicles and the welding fixture for small-lot vehicles, and non-standard parts in the fixture are subjected to structural design; and the standard parts and the non-standard parts in the welding fixture for the trial-manufacture sample vehicles are matched to form novel and complete welding fixture equipment for the trial-manufacture sample vehicles. Through the modular design method and the modular design structure, the aims of shortening the design and manufacturing period, recycling general and standard parts and reducing manufacturing cost are fulfilled.

Owner:ZHEJIANG GEELY AUTOMOBILE RES INST CO LTD +1

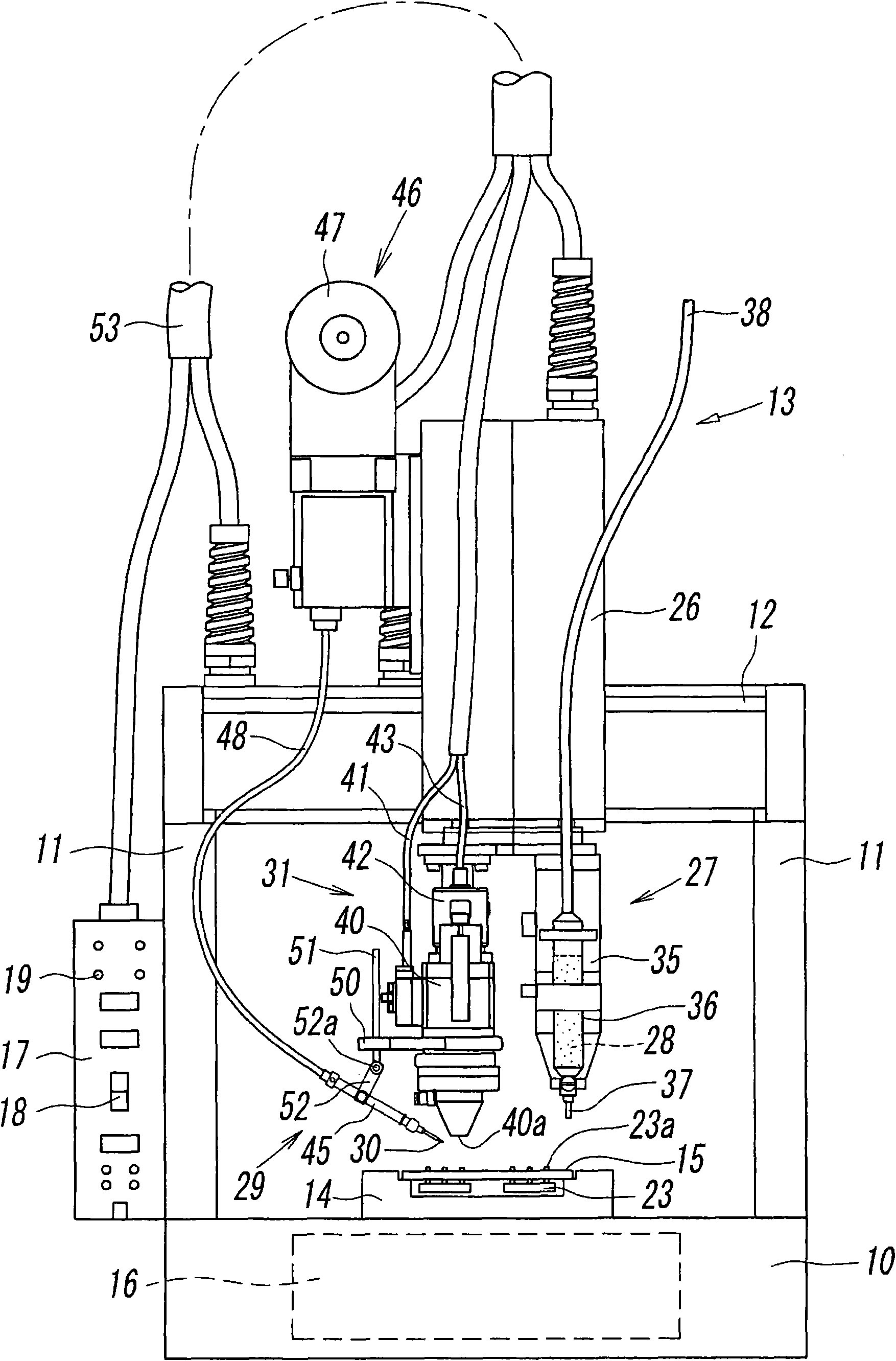

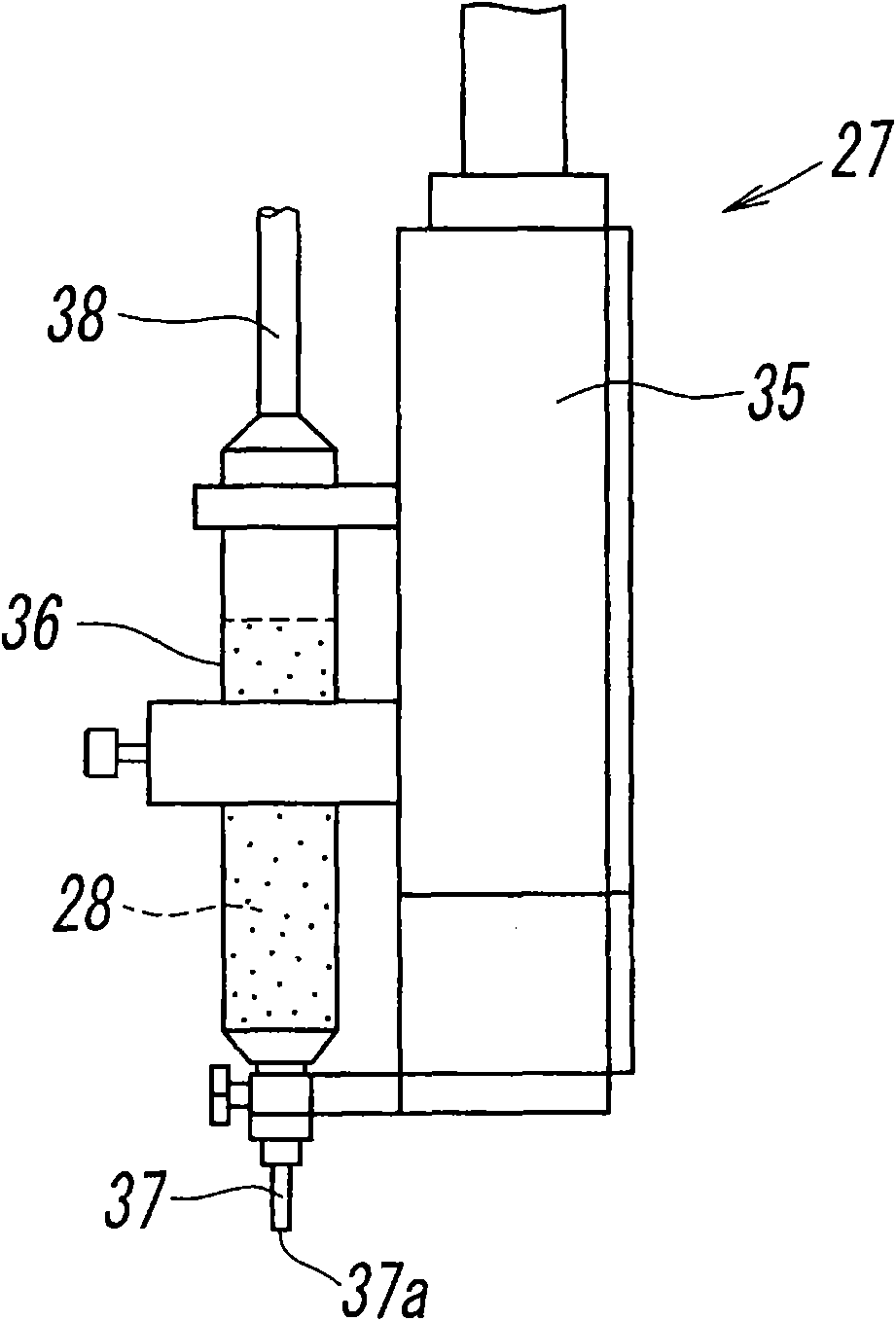

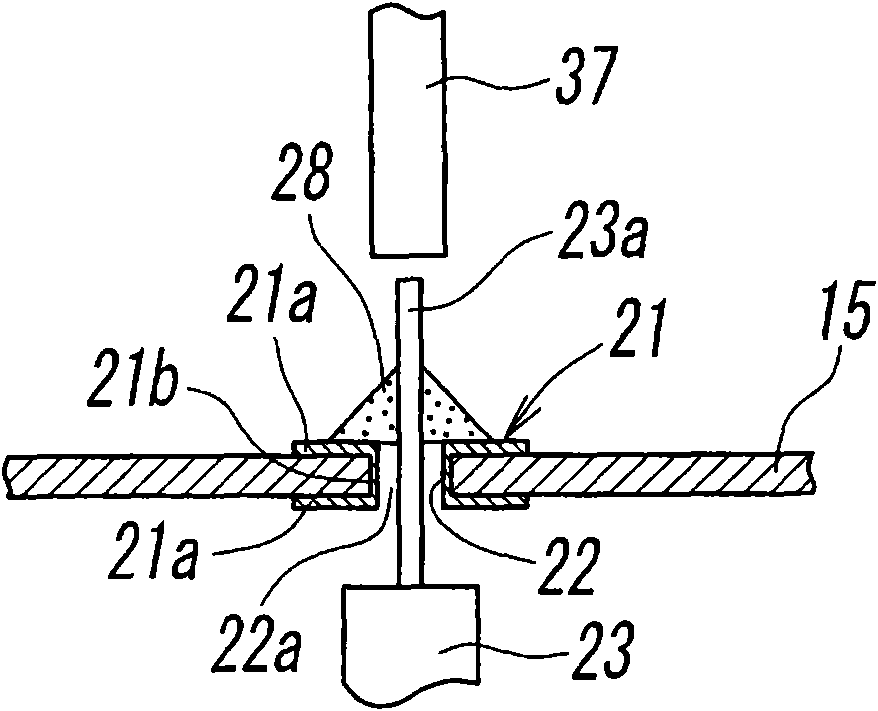

Method and apparatus for laser soldering

ActiveCN101618481AEliminate burning problemsFast weldingPrinted circuit assemblingWelding/soldering/cutting articlesMetallurgySolder paste

In accordance with an aspect of the invention, a solder paste feeding device feeds solder paste to a ring-like terminal surrounding a through-hole and a rod terminal fitted in the through-hole so as to fill in the through-hole, the laser beam irradiation device irradiates the solder past with a laser beam, and wire solder is further fed from above the solder past at the same time as melting of the solder paste is started, thereby fusing the wire solder and the solder paste to solder the ring-like terminal and the rod terminal.

Owner:JAPAN UNIX

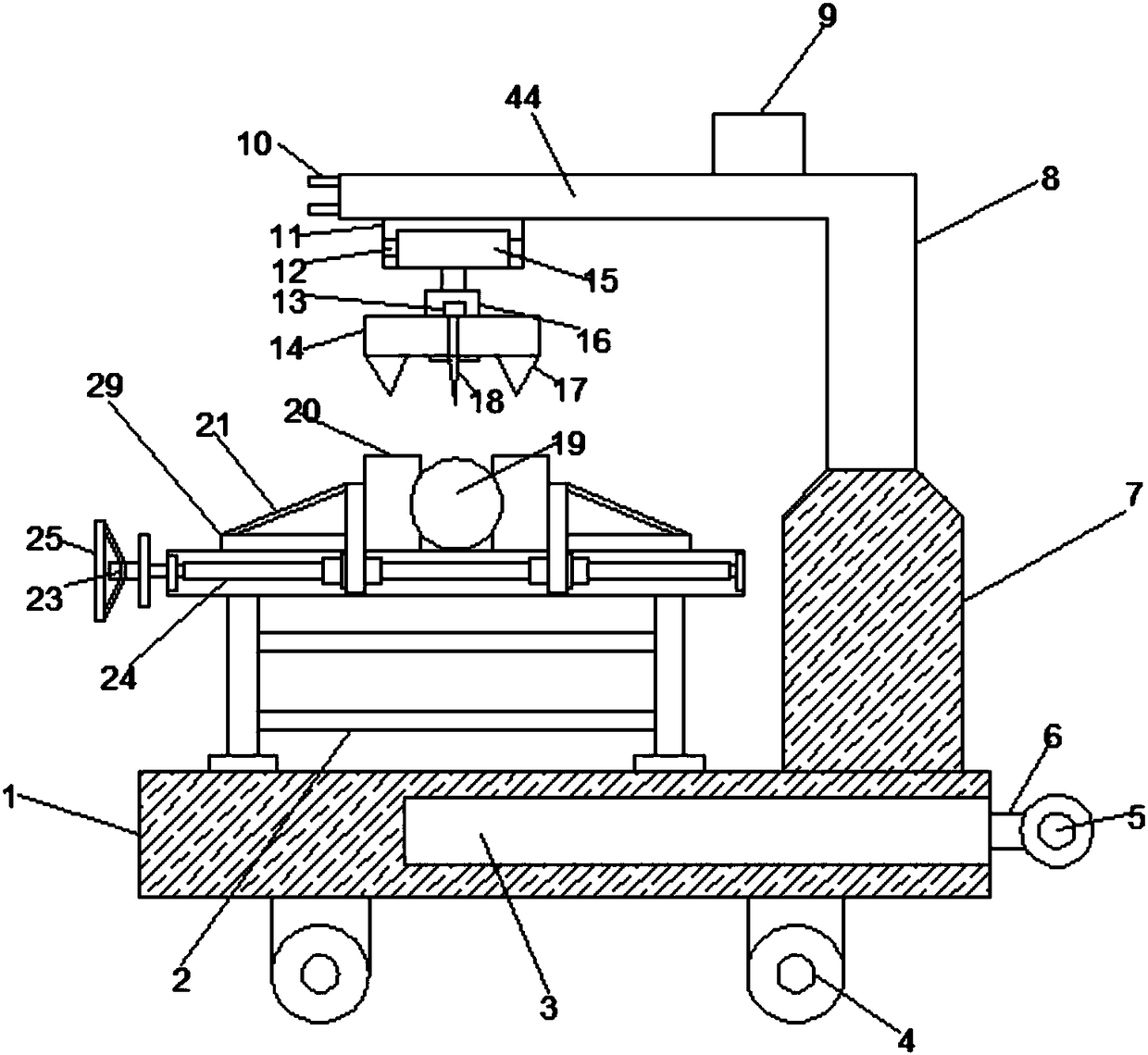

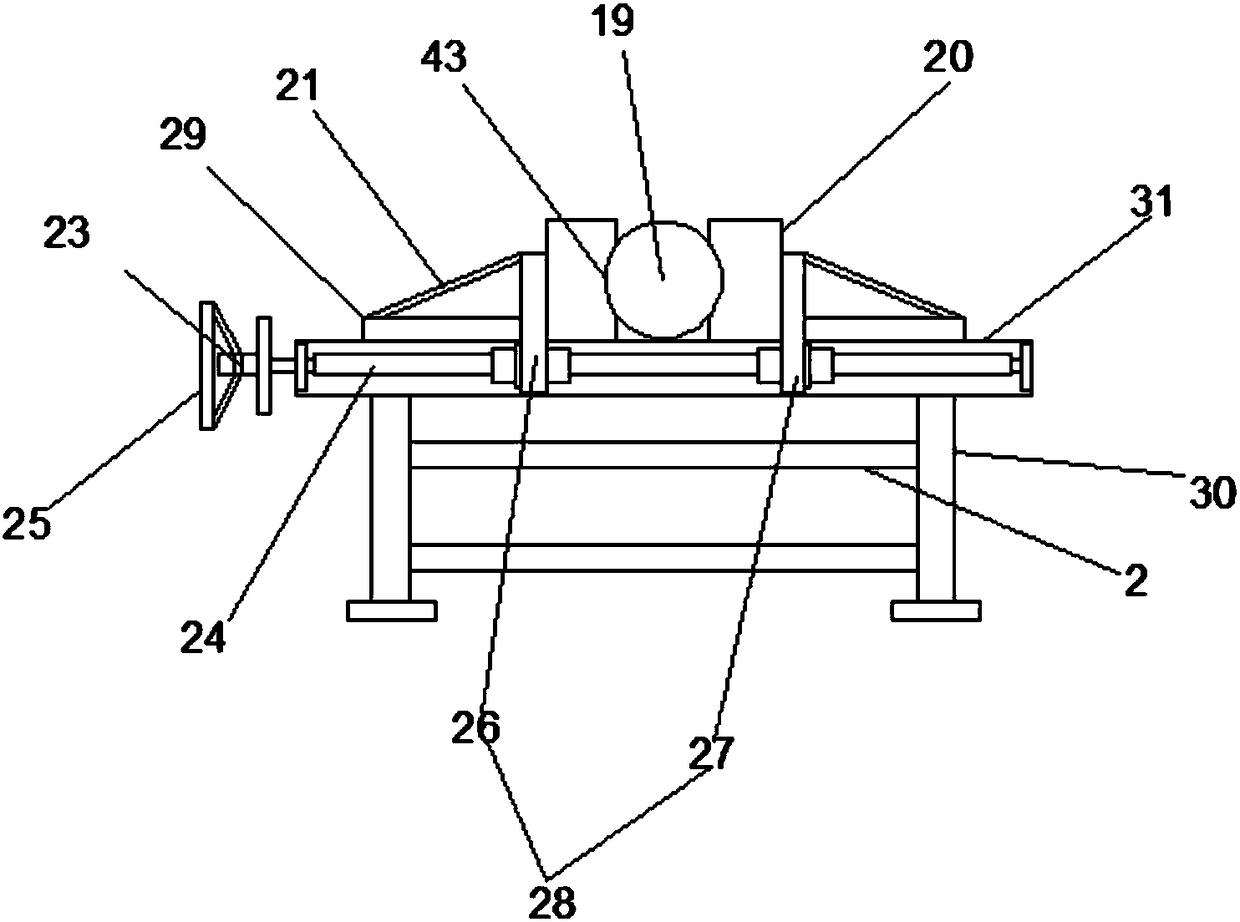

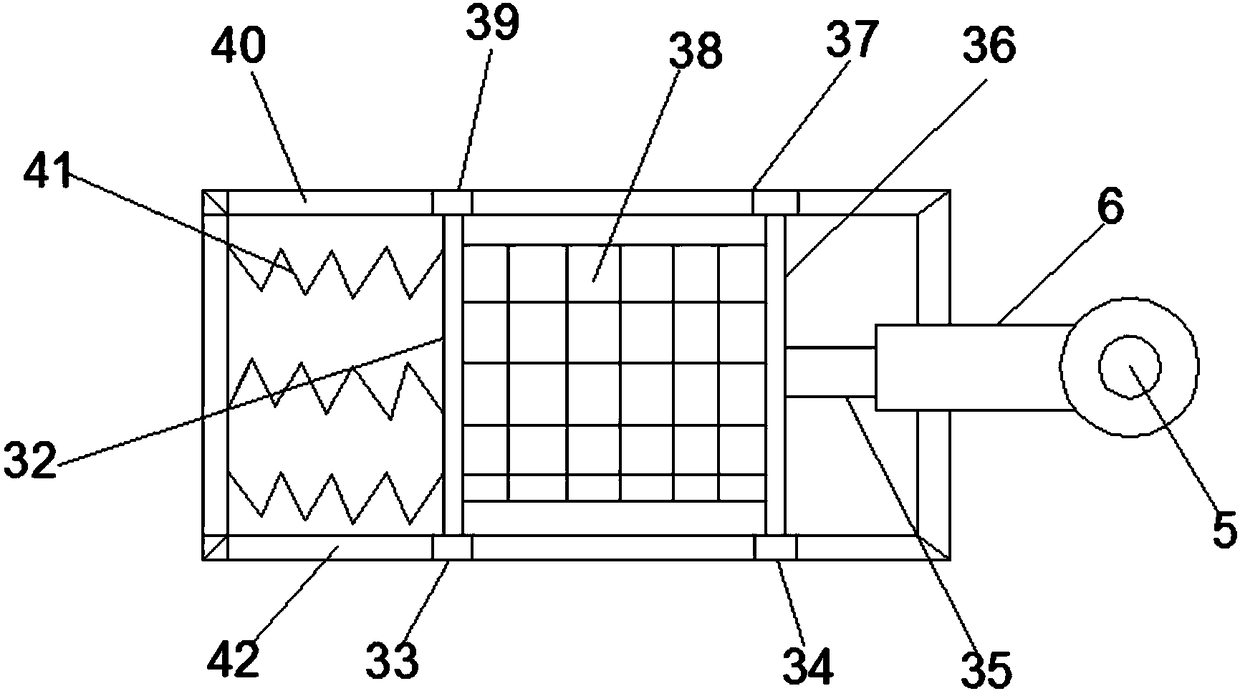

Full-automatic electric welding mechanical equipment

InactiveCN108340050APrevent movementEasy to replaceWelding/cutting auxillary devicesAuxillary welding devicesFixed frameMechanical equipment

The invention discloses full-automatic electric welding mechanical equipment. The full-automatic electric welding mechanical equipment comprises a supporting base. Wheels are arranged at the bottom end of the supporting base. A welding part fixing supporting device is arranged at the upper end of the supporting base and comprises a fixing frame, a screw, a hand wheel and a pair of clamping blocks.A supporting column is arranged on the right side of the welding part fixing supporting device. The full-automatic electric welding mechanical equipment has the beneficial effects that the arranged welding part fixing supporting device can well fix a component needing to be welded, and the distance between arc grooves can be adjusted according to the first clamping block and the second clamping block; in addition, through an arranged telescopic air cylinder and an arranged stepping motor, a welding gun device can move up and down, welding rod replacement is convenient, the welding gun devicecan conduct local welding through the stepping motor, welding limitation is reduced, and welding of the special welding position is improved.

Owner:马鞍山力众机械科技有限公司

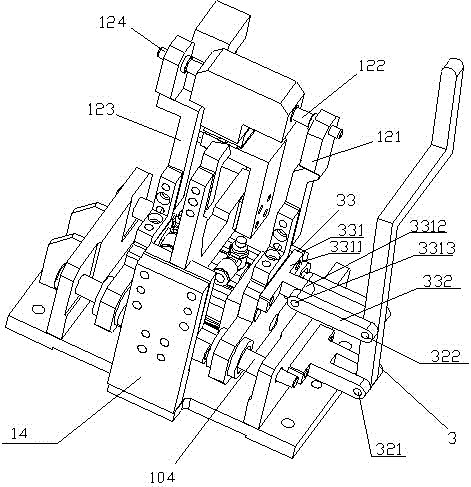

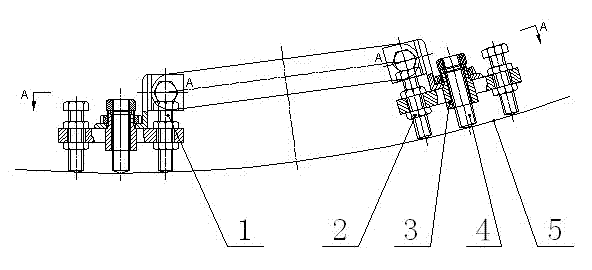

Welding tool applied to suspension installation assembly

InactiveCN104607845APrecise positioningPrecision weldingWelding/cutting auxillary devicesAuxillary welding devicesWork periodEngineering

The invention discloses a welding tool applied to a suspension installation assembly. The welding tool applied to the suspension installation assembly comprises a substrate, a first fixing plate, a second fixing plate, two shafts, an air cylinder, a first positioning block, a second positioning block, a first positioning pin, a second positioning pin, a first limiting block, a second limiting block and a third limiting block, wherein the first fixing plate and the second fixing plate are arranged on two sides of the substrate oppositely, the two shafts are arranged between the first fixing plate and the second fixing plate, the air cylinder is arranged in the middle of a rectangular frame, the first positioning block and the second positioning block are arranged at two ends of the air cylinder and connected with the two shafts in a sliding mode, the first positioning pin and the second positioning pin are arranged at the upper ends of the first positioning block and the second positioning block respectively, the first limiting block is located between the first positioning pin and the second positioning pin, the second limiting block is arranged at the back of the first limiting block, and the third limiting block is arranged in front of the first limiting block and near the second positioning pin. The welding tool applied to the suspension installation assembly enables a worker to conveniently and rapidly position a suspension, shortens the welding time and improves welding efficiency.

Owner:力帆科技(集团)股份有限公司

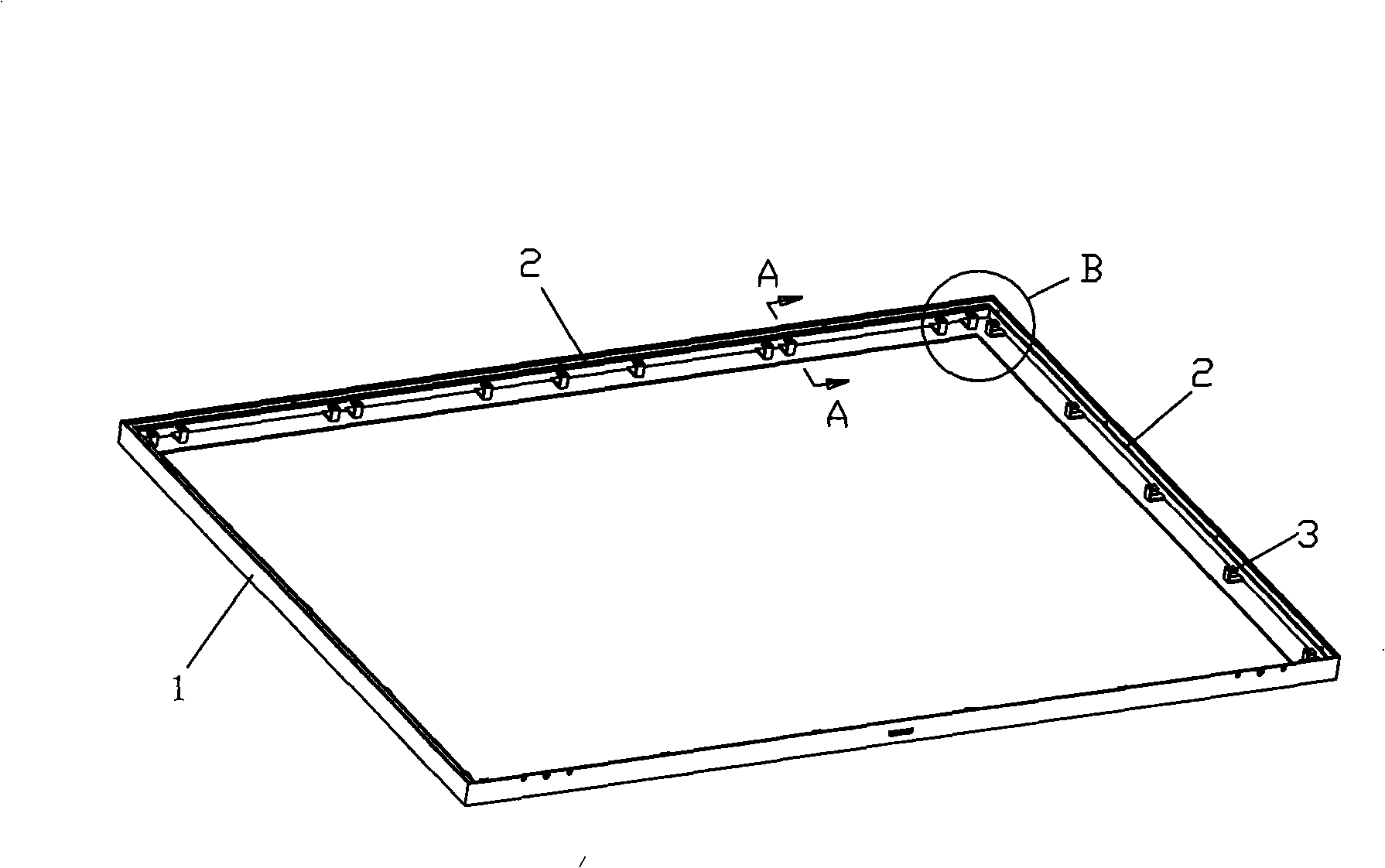

Sheet-metal screen panel of back projected television and manufacture method thereof

InactiveCN101309381ASave mold costSave non-ferrous metal materialsTelevision system detailsColor television detailsEngineeringRear-projection television

The invention discloses a sheet metal screen surface frame of a rear projection television, including that the sheet metal is bent and butt jointed to form a surface frame strip of the rectangle screen surface frame; a folded rear cover fixing strip is arranged on the surface frame strip and is vertical to the inner side of the fold edge of the plane of the screen surface frame; a plurality of rear cover locking screw holes are in staggered arrangement on the rear cover fixing strip; a plurality of double folding screen layering strip fixing bases are in staggered arrangement on the surface frame strip and is in parallel with the inner side of the fold edge of the plane of the screen surface frame; a plurality of screw hole for locking the screen layering strips are in staggered arrangement on the screen layering strip fixing bases. The invention also discloses a manufacturing method of the sheet metal screen surface frame of the rear projection television. The sheet metal screen surface frame and the manufacturing method adopt the common sheet metal, use the sheet metal process to manufacture screen surface frame of the large-size rear projection television, saves the mould cost and the non-ferrous materials in the traditional process greatly and reduces the production cost; thereby, the market competitive power of the large-size rear projection television is improved.

Owner:SHENZHEN SKYWORTH RGB ELECTRONICS CO LTD

Alignment device for pipeline welding

ActiveCN105965199AQuick alignmentFast weldingWelding/cutting auxillary devicesAuxillary welding devicesMetallic materialsEngineering

The invention provides an alignment device for pipeline welding. The alignment device for pipeline welding comprises two aligner racks, an angular pipeline support and two spiral ejector rods. Each aligner rack is in a handle shape and is provided with a transverse flat upper end, a vertical middle portion and a lower end, wherein the included angle between the lower end and the vertical middle portion is 135 degrees. The angular pipeline support is made of a V-shaped metal material, wherein the included angle between the two planes of the V-shaped metal material is 90 degrees. The angular pipeline support is fixed to the oblique surfaces of the inner sides of the lower ends of the two aligner racks. The two aligner racks are located at the two ends of the angular pipeline support correspondingly. Threaded through holes are formed in the transverse flat upper ends of the aligner racks. The central axes of the threaded through holes are perpendicular to the regression line of the angular pipeline support, and the central axes of the threaded through holes and the regression line of the angular pipeline support are located in the same plane. The spiral ejector rods are rods provided with threads, and the lower ends of the spiral ejector rods penetrate through the threaded through holes in the aligner racks and can be screwed or unscrewed through the threaded through holes. By the adoption of the alignment device for pipeline welding, the end openings of two pipelines can be aligned rapidly, and welding requirements are met.

Owner:国网冀北电力有限公司管理培训中心 +1

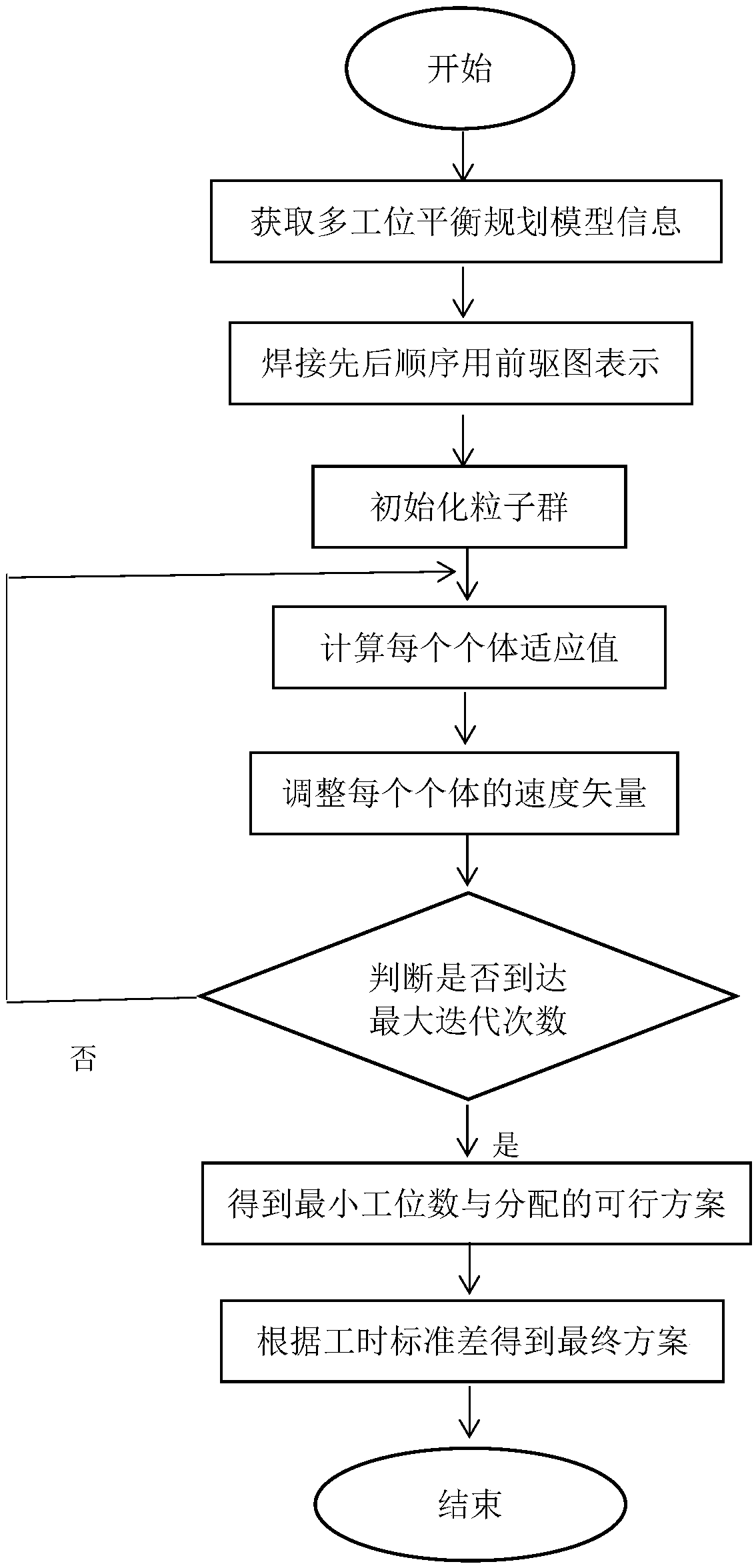

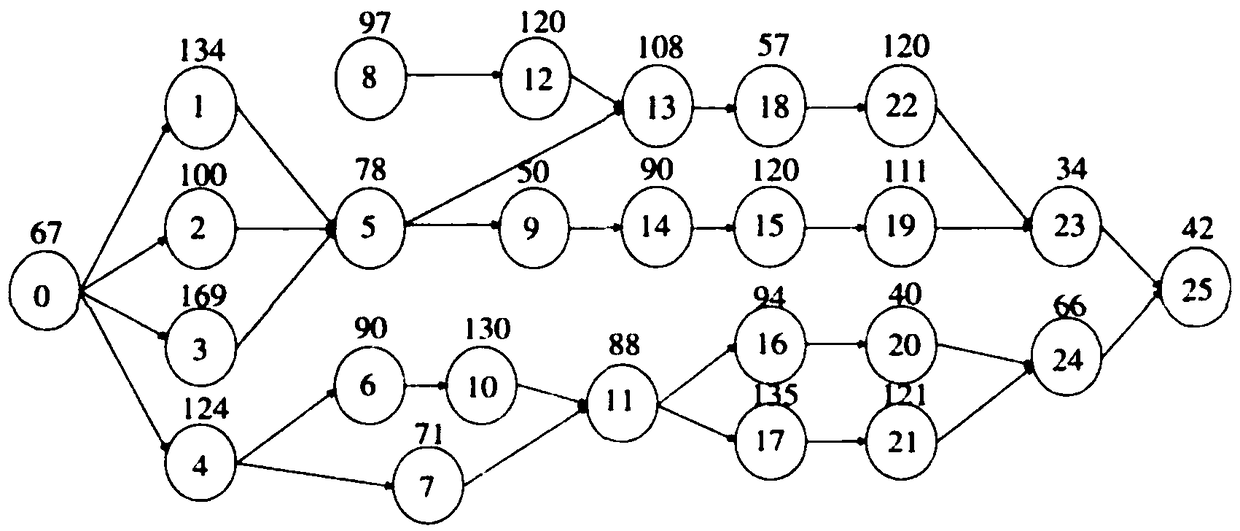

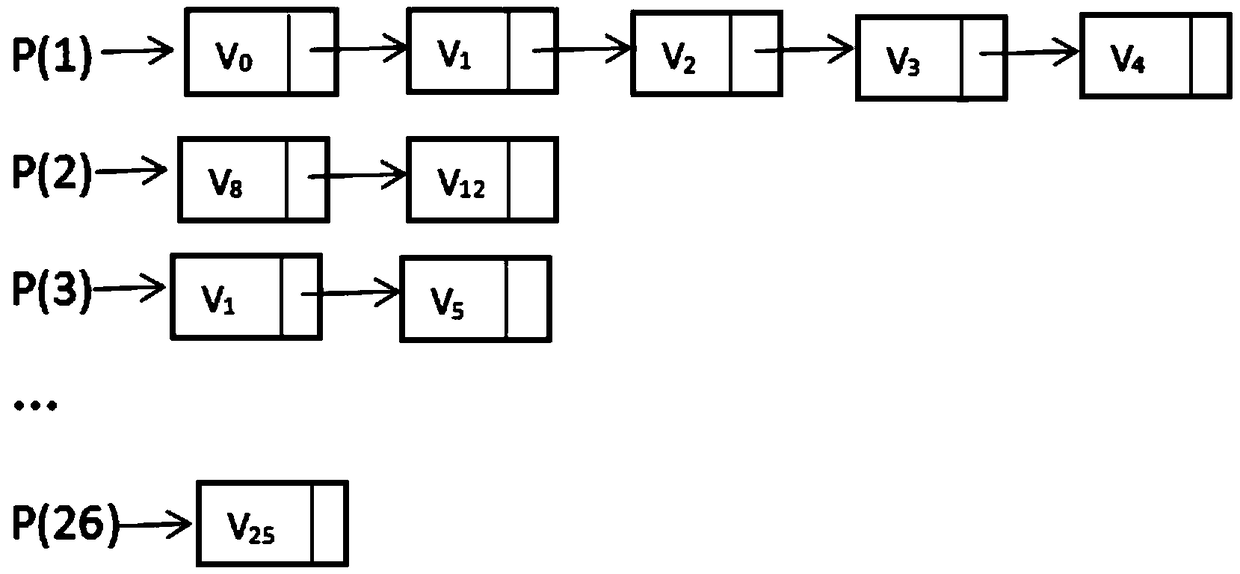

A welding production line work class assignment system and method based on particle swarm optimization algorithm

InactiveCN109255465AIncrease profitPrecise welding workForecastingArtificial lifeProduction lineMan-hour

The invention relates to a welding production line work class assignment system and method based on a particle swarm optimization algorithm, which relates to a particle swarm algorithm and a balance programming solving algorithm. The invention solves a multi-station balance programming problem by using the particle swarm optimization algorithm and completes the reasonable arrangement of the multi-station, and belongs to the technical field of artificial intelligence and control. The invention mainly comprises the following contents: step 1: acquiring multi-station balance planning model information; 2, representing the welding sequence by a precursor diagram and storing in an adjacency table; 3, solving that multi-station balance programming problem by using the particle swarm optimizationalgorithm to obtain the minimum work number under a given beat; 4: According to the optimization process and result of step 3, obtaining the feasible scheme, and then obtaining the final scheme according to the man-hour standard deviation. From the results, it can be seen that the welding task assignment of each station is relatively balanced, which maximizes the utilization rate of each weldingrobot, shortens the man-hour of the station and meets the requirements of the production rhythm.

Owner:CHINA UNIV OF MINING & TECH

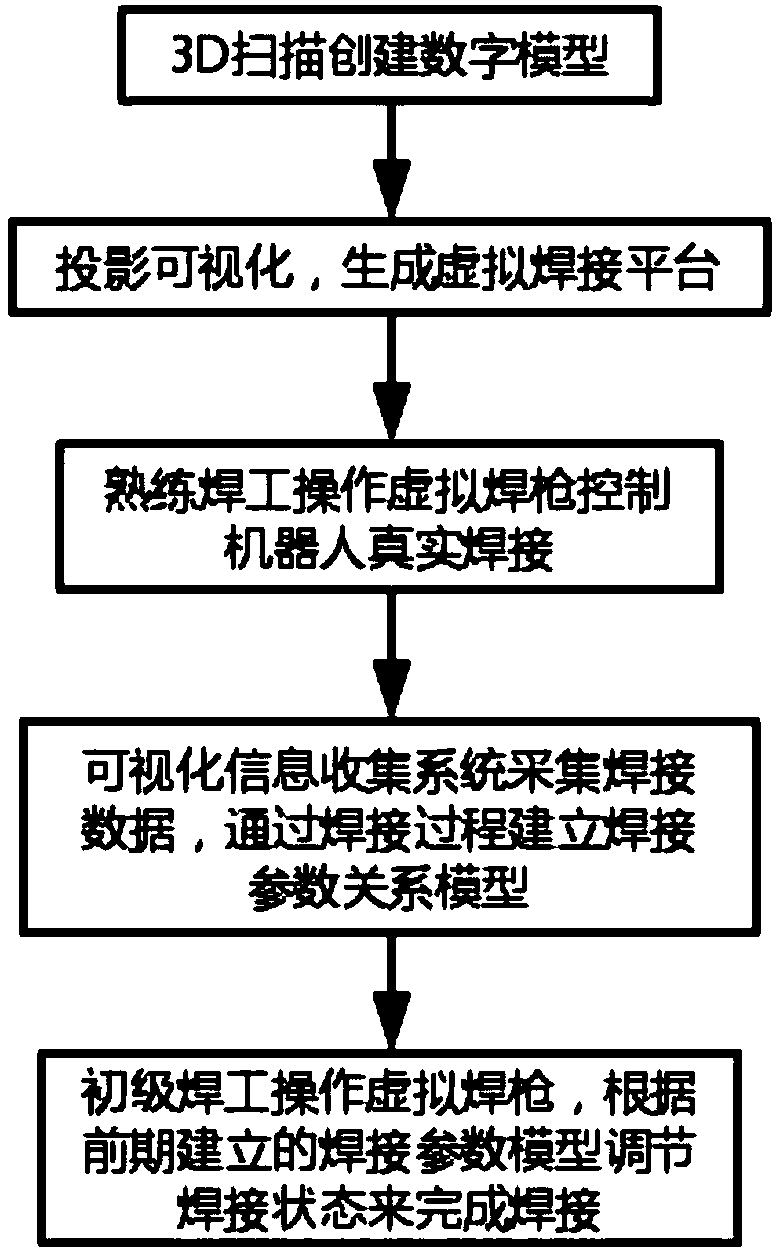

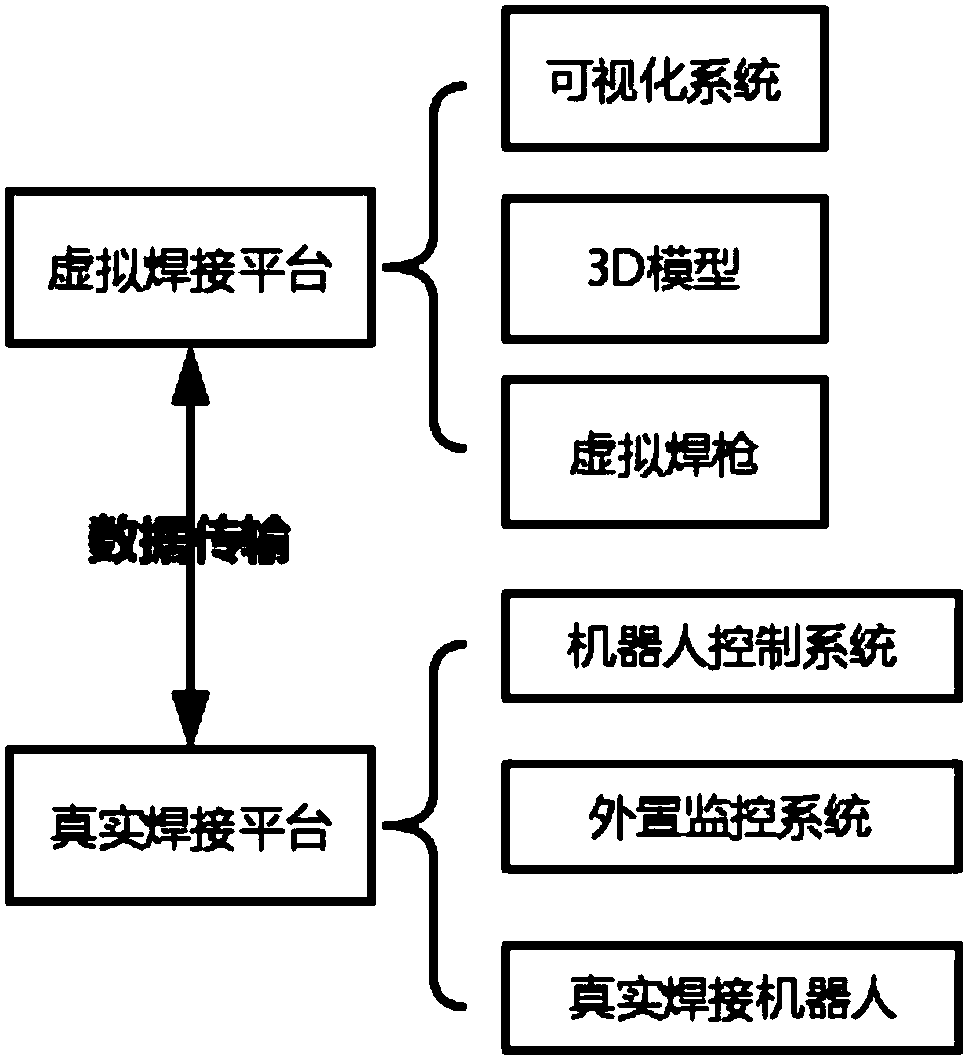

Ocean engineering module structure welding method based on VR technology

ActiveCN109514141AEnsure safetyGuaranteed welding efficiencyWelding/cutting auxillary devicesAuxillary welding devicesRelational modelMolten bath

The invention discloses an ocean engineering module structure welding method based on a VR technology. The method comprises the following steps: digital models of real workpieces are built through 3Dscanning, and corresponding 3D solid models are generated; a real welding process is caught by using a camera, and a projector is used for visual displaying on the 3D solid models; skilled welding workers finish the welding process through observing molten bath images and operating a virtual welding gun; a welding robot finishes real welding through welding parameters of the virtual welding gun; an external monitoring system transfers welding information in the robot welding process to a computer; the computer forms speed-current relation models through welding data; and primary welding workers finish welding through operating a virtual welding device according to the speed-current. The method performs virtual-real welding on ocean engineering module structures, so that profile steel and pipelines in the ocean engineering modules are welded more quickly and accurately, and the personal safety and the welding efficiency are guaranteed in the welding process.

Owner:BOMESC OFFSHORE ENG CO LTD

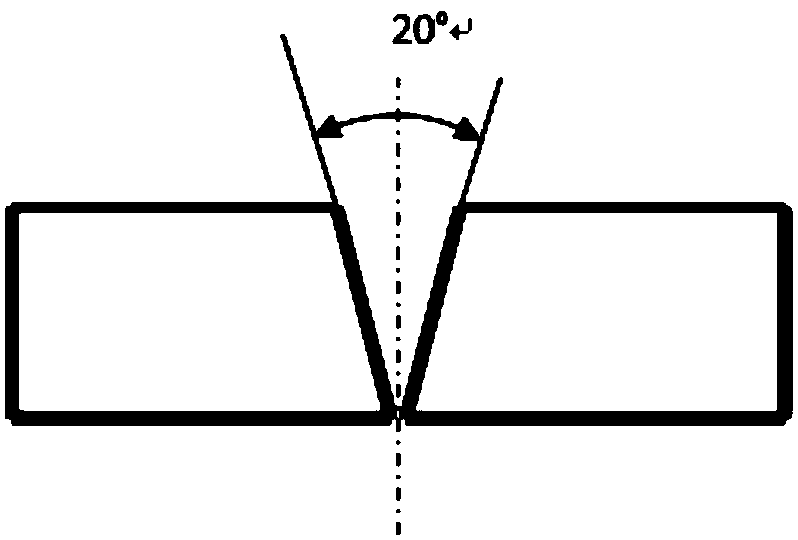

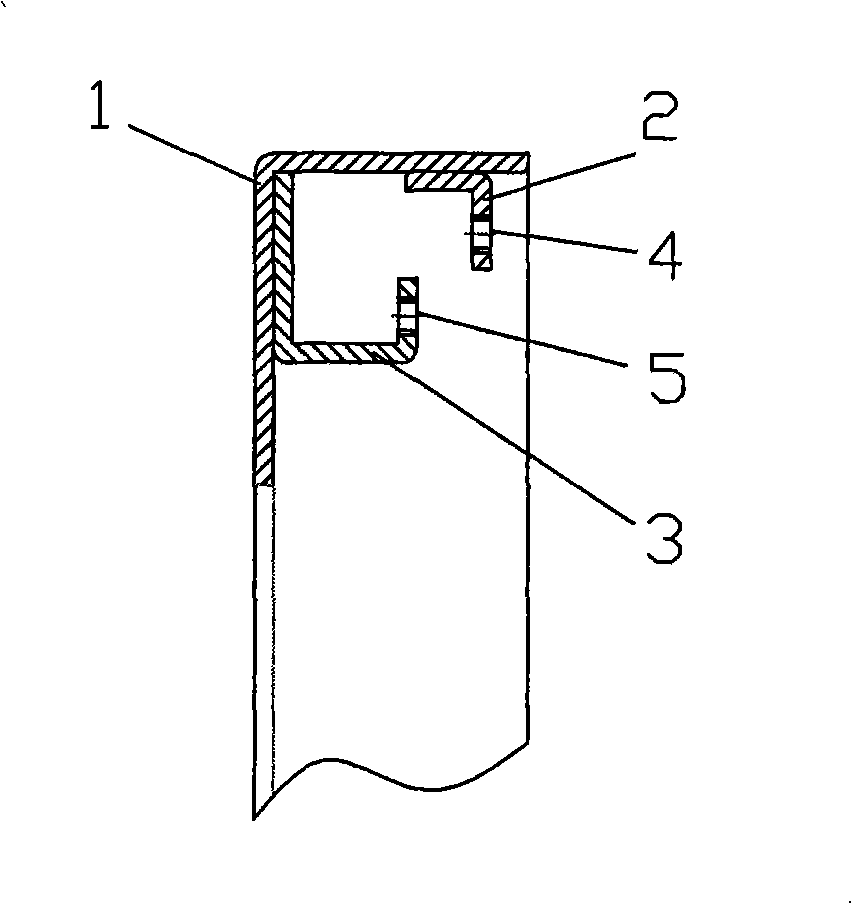

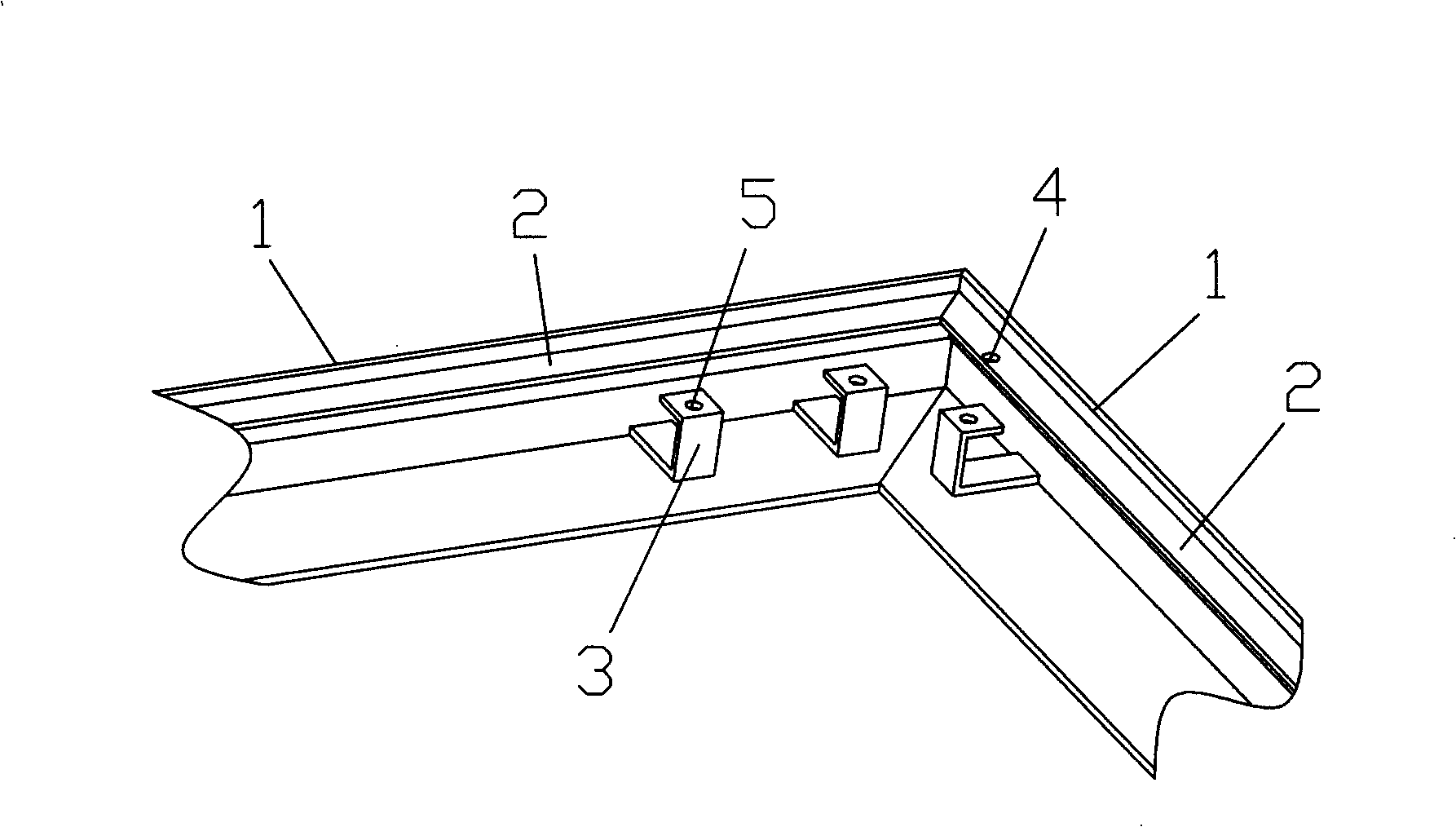

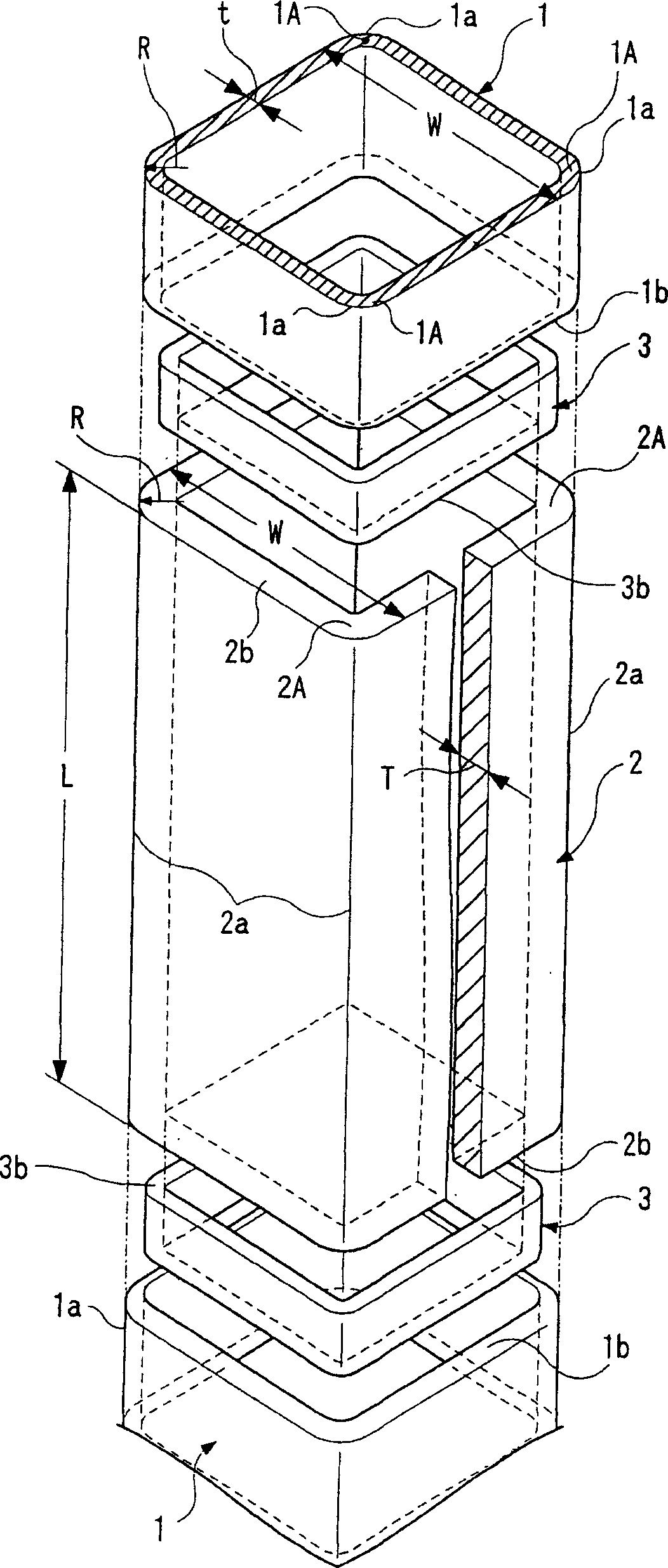

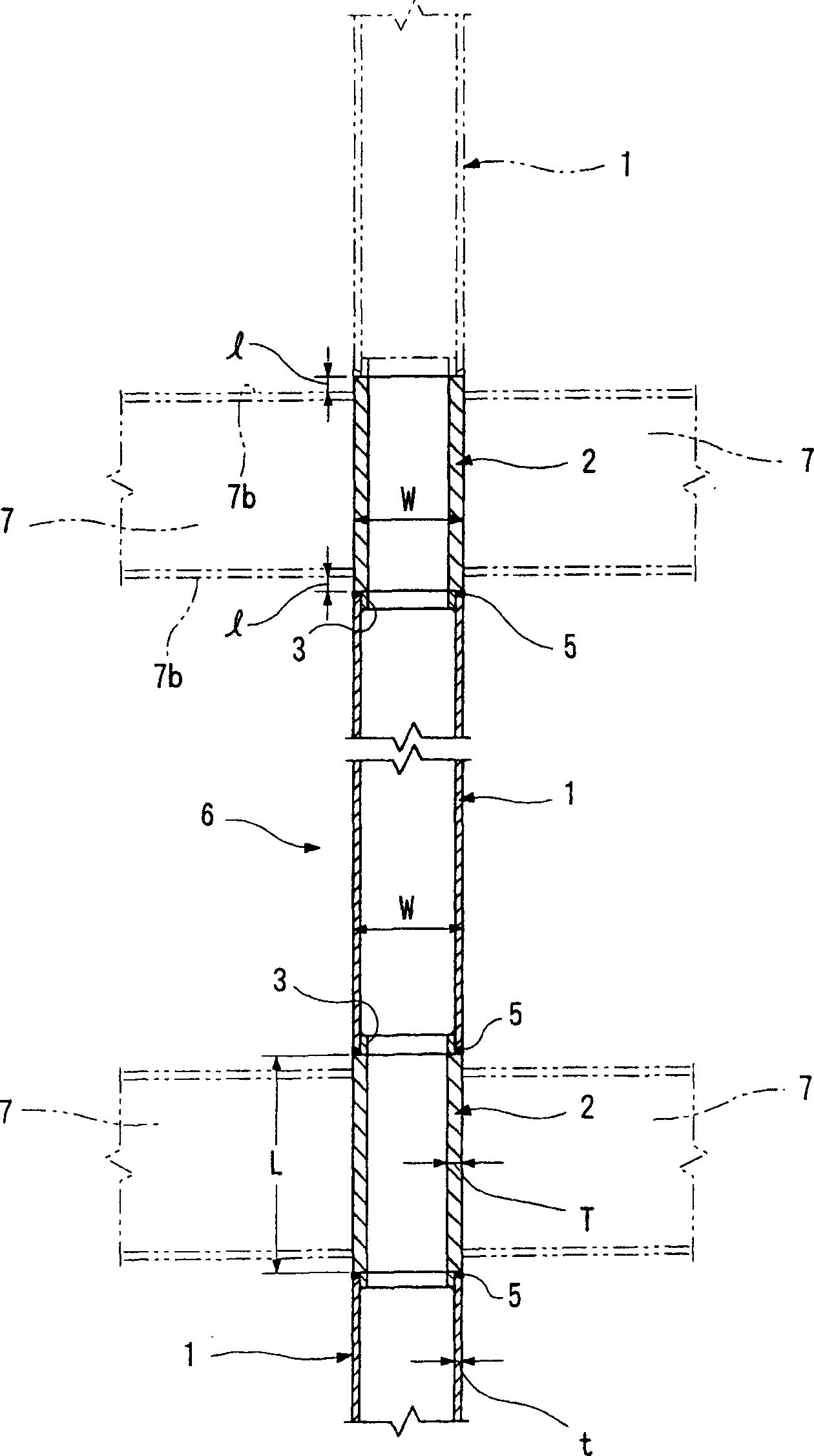

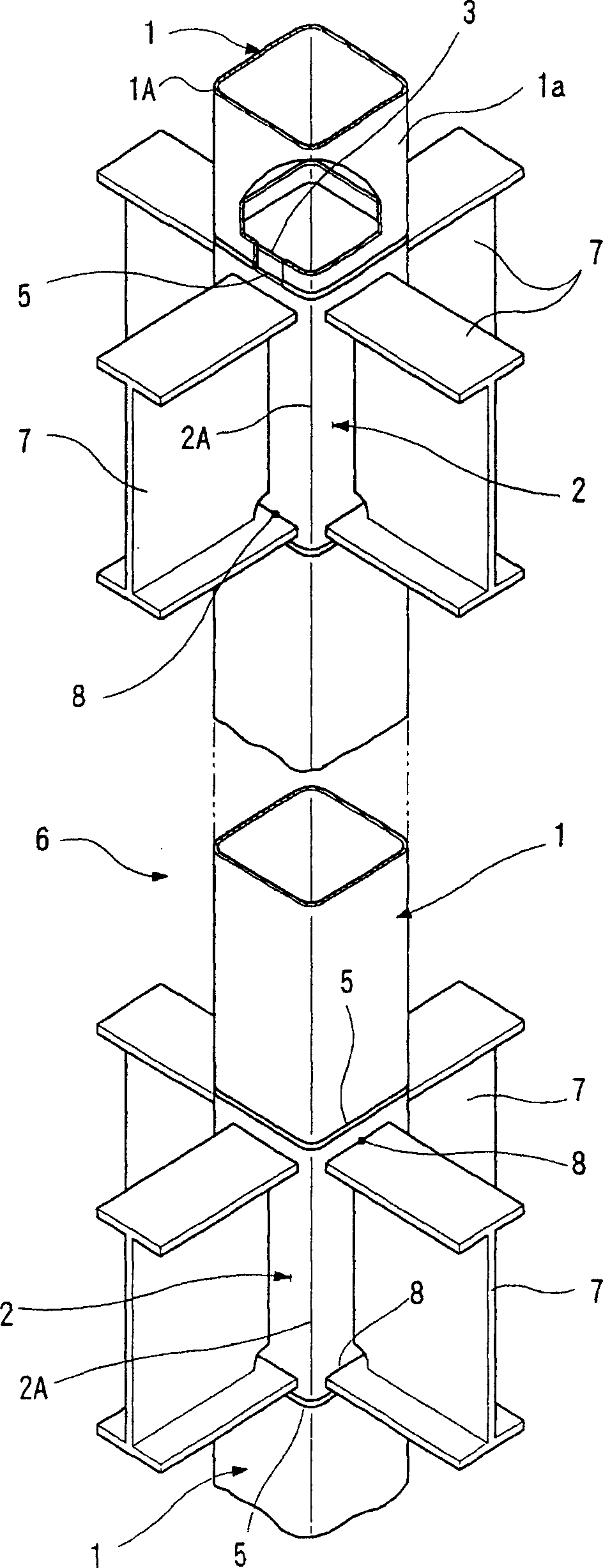

A welded joint construction for a steel pipe column

InactiveCN1467349AImprove stress transferShorten production timeStrutsArc welding apparatusSteel tubeEngineering

A joint construction for a column of steel pipes comprises a long steel pipe 1 of a first thickness t and a second steel pipe 2 of a second thickness T which is greater than that of the first. The steel pipes 1,2 are formed by either cold or hot forming to have the same outer shape and diameter, and they are welded together from the outside in an arrangement in which an end surface of the long pipe 1 is opposed to an end surface of the short pipe 2 which has no bevelled portion. An inner collar 3 can be included in the joint construction and may be positioned inside the long pipe 1 so that it can be abutted against the end surface of the short pipe 2. The pipes 1,2 may either be quadrangular or cylindrical.

Owner:NAKAJIMA STEEL PIPE CO LTD

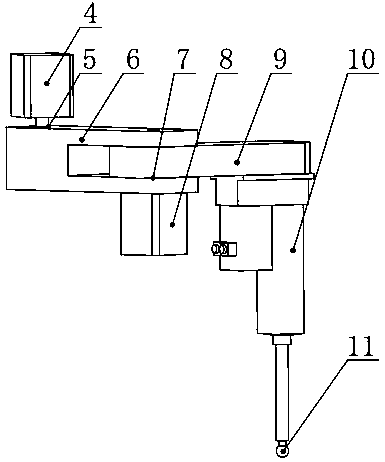

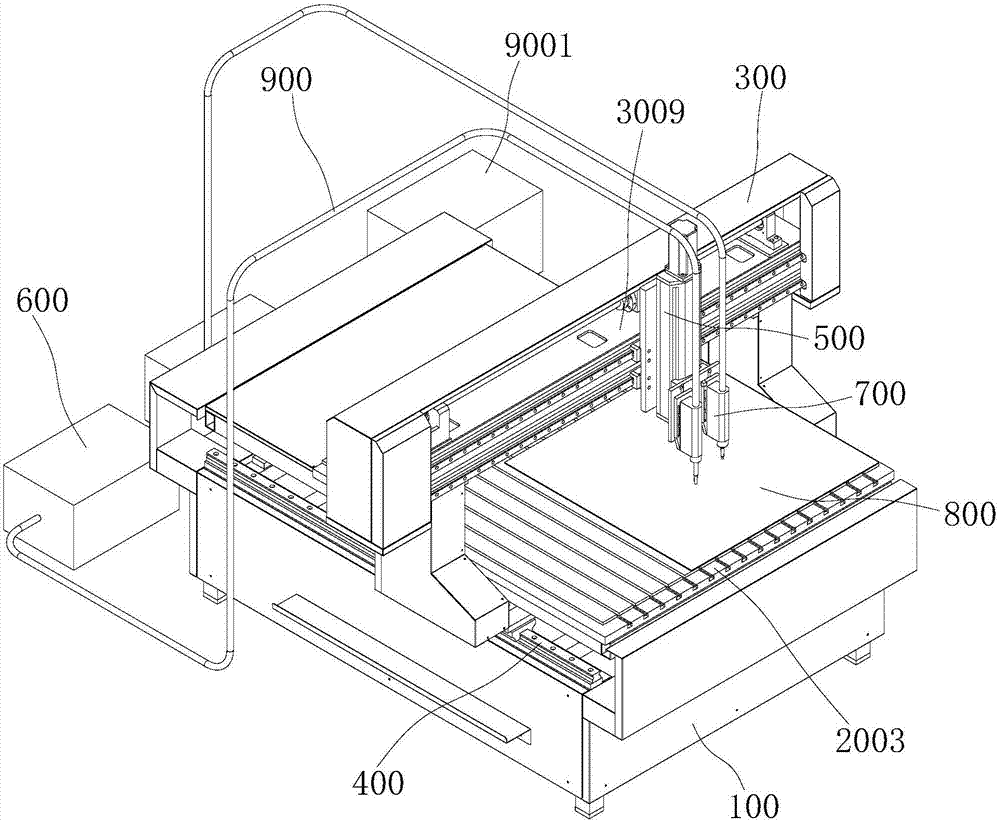

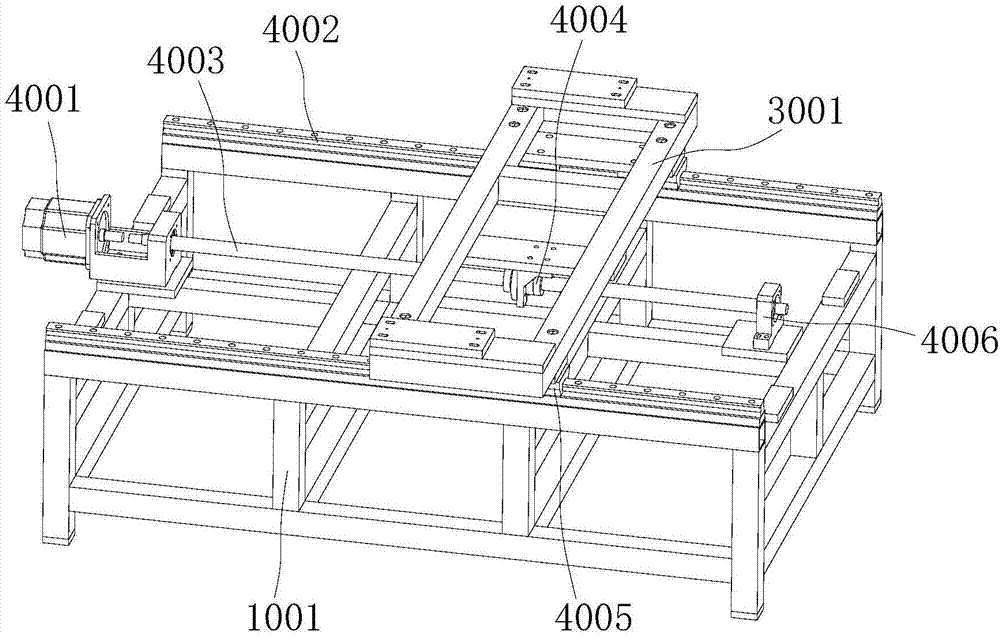

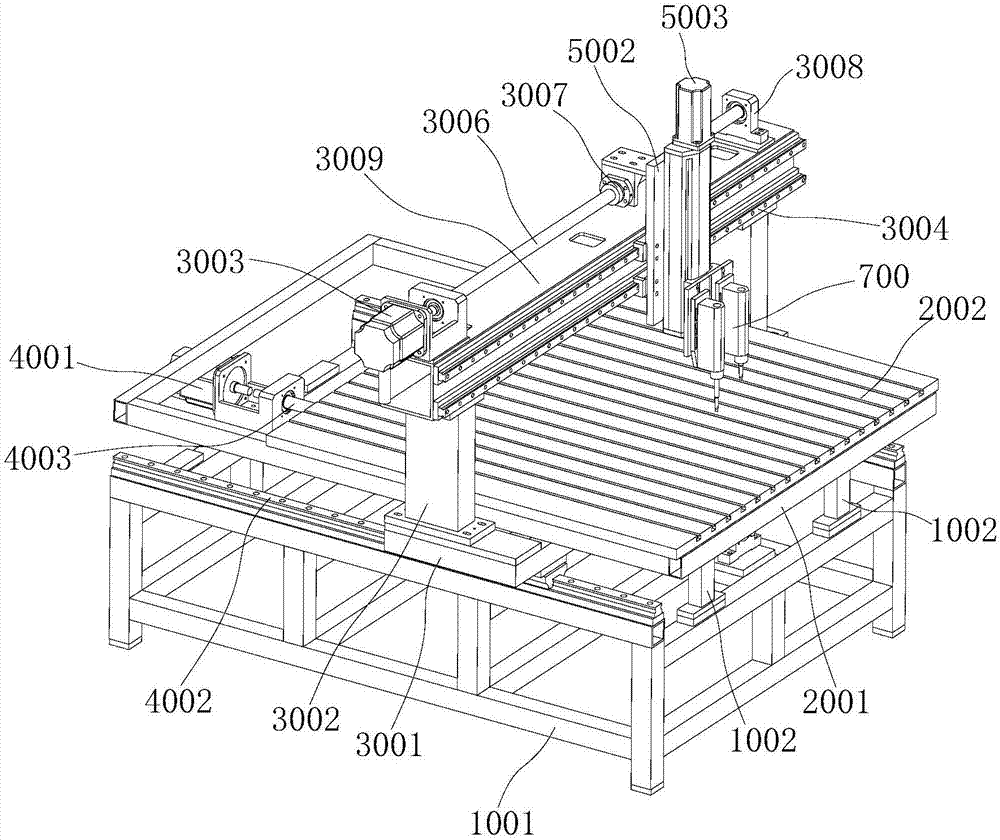

CNC stud welding dedicated machine

ActiveCN107322144ASmall welding heat affected zoneNo deformationWelding accessoriesManufacturing cost reductionHeat-affected zone

The invention discloses a CNC stud welding dedicated machine and relates to the technical field of welding machines. The CNC stud welding dedicated machine comprises a base, a working platform, an X-axis moving mechanism, a Y-axis moving mechanism, a plurality of Z-axis moving mechanisms, a nail feeding mechanism and a plurality of welding gun mechanisms, wherein the working platform is arranged on the base; sheet metal parts are arranged on the working platform; the Y-axis moving mechanism is arranged on the base; the X-axis moving mechanism comprises a cross beam; the cross beam is arranged on the Y-axis moving mechanism; the Z-axis moving mechanisms are arranged on the X-axis moving mechanism side by side; a plurality of welding gun mechanisms are mounted on each of the Z-axis moving mechanisms; each of the welding gun mechanisms comprises a gun cylinder and a welding gun chuck; and the nail feeding mechanism is positioned at the rear of the base and is connected with the gun cylinder of the welding gun mechanism through a nail feeding tube. The CNC stud welding dedicated machine has the following beneficial effects: welding heat affected zones on the welded sheet metal parts are small, and the sheet metal parts are free of deformation and color change, so that the welding quality is improved, the yield is greatly increased, the production efficiency of welding is improved and the manufacturing cost is reduced.

Owner:深圳市迈思克科技有限公司

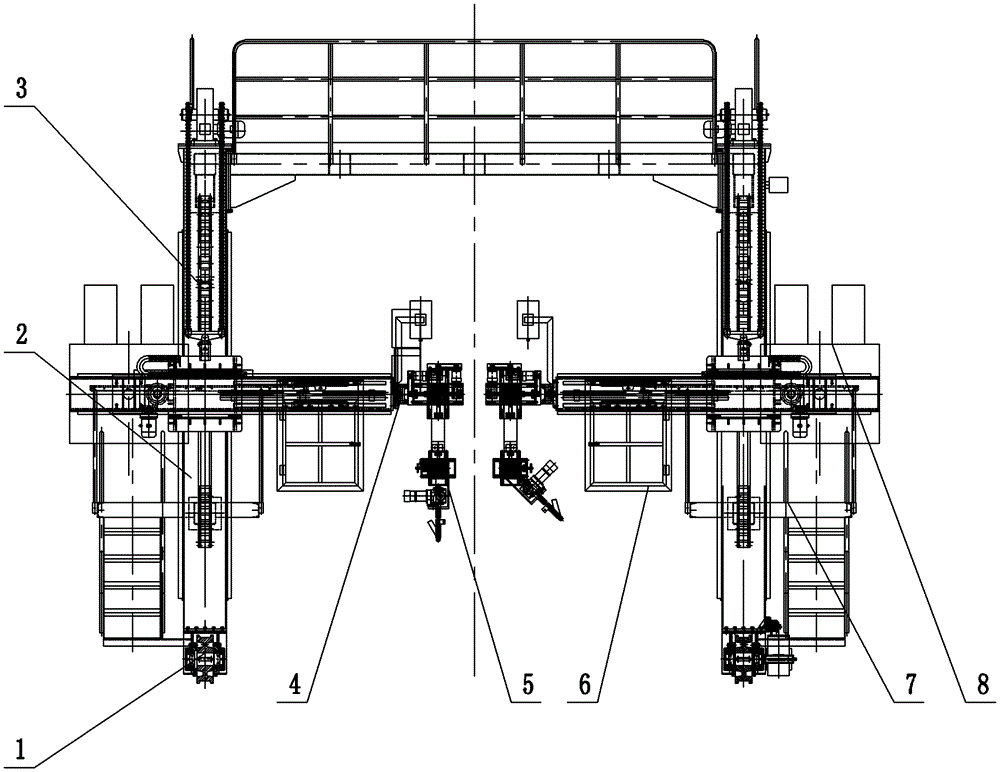

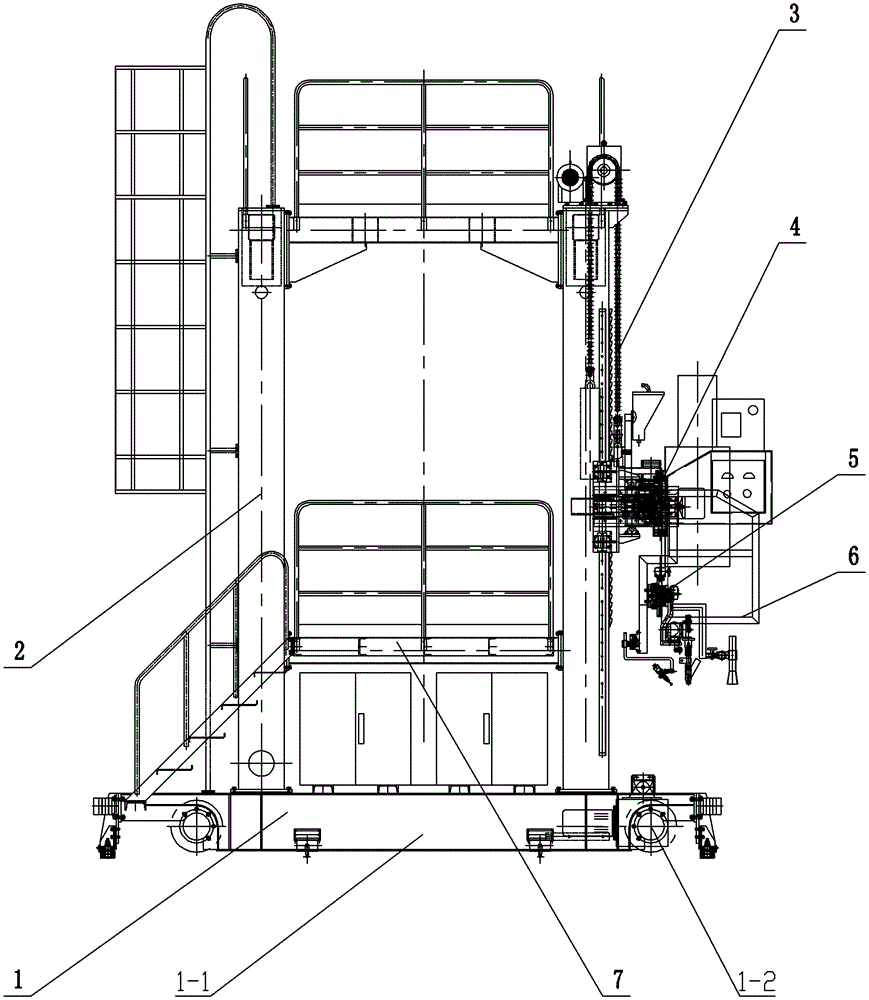

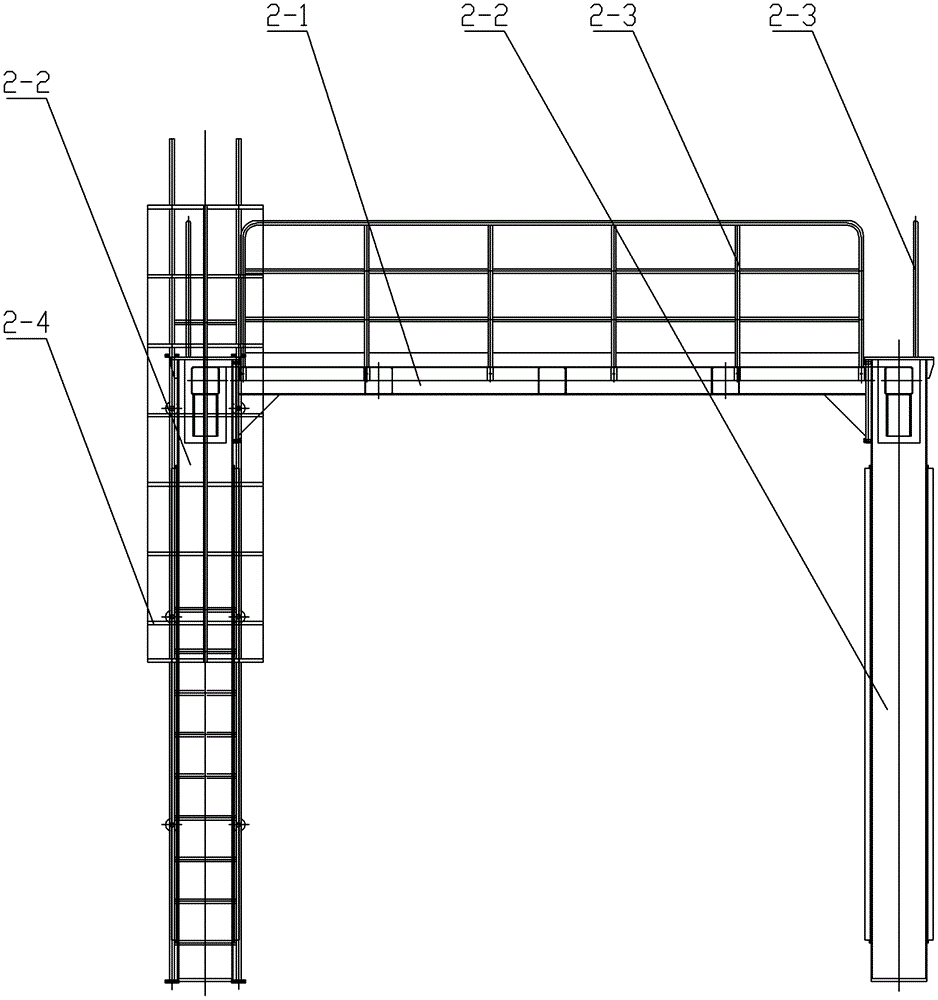

Rod piece welding machine

ActiveCN103978329ASimple structureCompact structureWelding/cutting auxillary devicesElectrode holder supportersControl engineeringWeld seam

The invention relates to a rod piece welding machine, particularly relates to an automatic welding device for a large rod piece box beam, and belongs to the technical field of mechanical devices. The machine comprises a walking mechanism, a door frame, a welding arm lifting mechanism, a welding seam servo tracking mechanism, a welding gun three-dimensional adjusting mechanism, an operation platform, a carrier platform, a welding flux conveying recycling system and the like. The door frame is installed on the walking mechanism, the welding arm lifting mechanism is installed on the door frame, the welding seam servo tracking mechanism is installed on the welding arm lifting mechanism, the welding gun three-dimensional adjusting mechanism is arranged on the welding seam tracking mechanism, the operation platform is installed on the welding arm lifting mechanism, the carrier platform is installed on the door frame, and the welding flux conveying recycling system is installed on the welding arm lifting mechanism. The rod piece welding machine is simple, compact and reasonable in structure and capable of accurately and quickly achieving welding of different rod pieces and different box beams, greatly reduces labor intensity of workers, and is high in automation degree, high in welding accuracy, low in cost and convenient and flexible to use.

Owner:WUXI HUALIAN SCI & TECH GROUP +1

Canned spray type welding anti-splashing agent and preparation method thereof

ActiveCN106984917ALow toxicityFast evaporationWelding/cutting media/materialsSoldering mediaGas phasePolyamide

The invention discloses a canned spray type welding anti-splashing agent and a preparation method thereof and belongs to the technical field of fine chemical engineering. According to the technical scheme, the agent is characterized by being prepared from raw materials in parts by weight as follows: 40-60 parts of petroleum ether, 10-20 parts of ethyl acetate, 20-40 parts of isopropanol or / and ethanol with the volume fraction being 95%, 1-3 parts of alcohol-soluble polyamide, 2-4 parts of rosin glycerin ester or / and terpene phenolic resin, 1-2 parts of C5 petroleum resin, 1-2 parts of fumed silica of 4,000-5,000 meshes, 2-4 parts of nano-aluminium oxide or / and zinc chloride of 100-200 nm and 2-3 parts of rutile powder of 2,000-3,000 meshes. The invention further discloses the preparation method of the agent. The agent is convenient to carry, sanitary and rapid to spray and capable of effectively reducing the labor amount of welding workers and improving the welding efficiency.

Owner:ZHEJIANG NORMAL UNIVERSITY

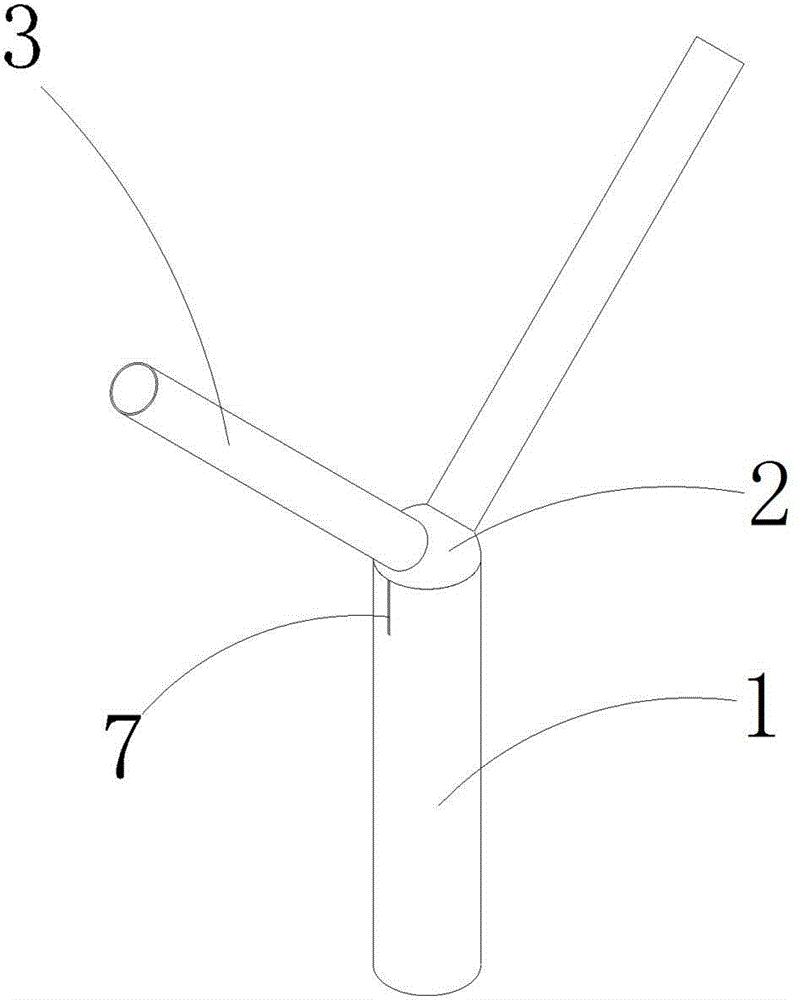

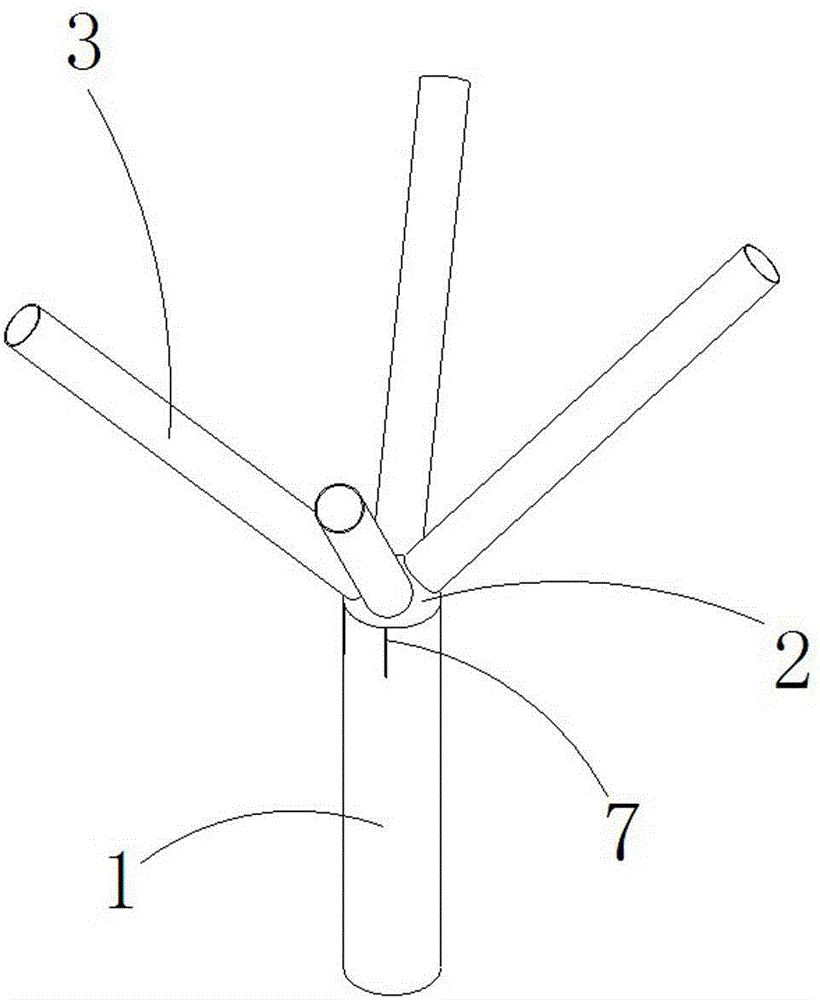

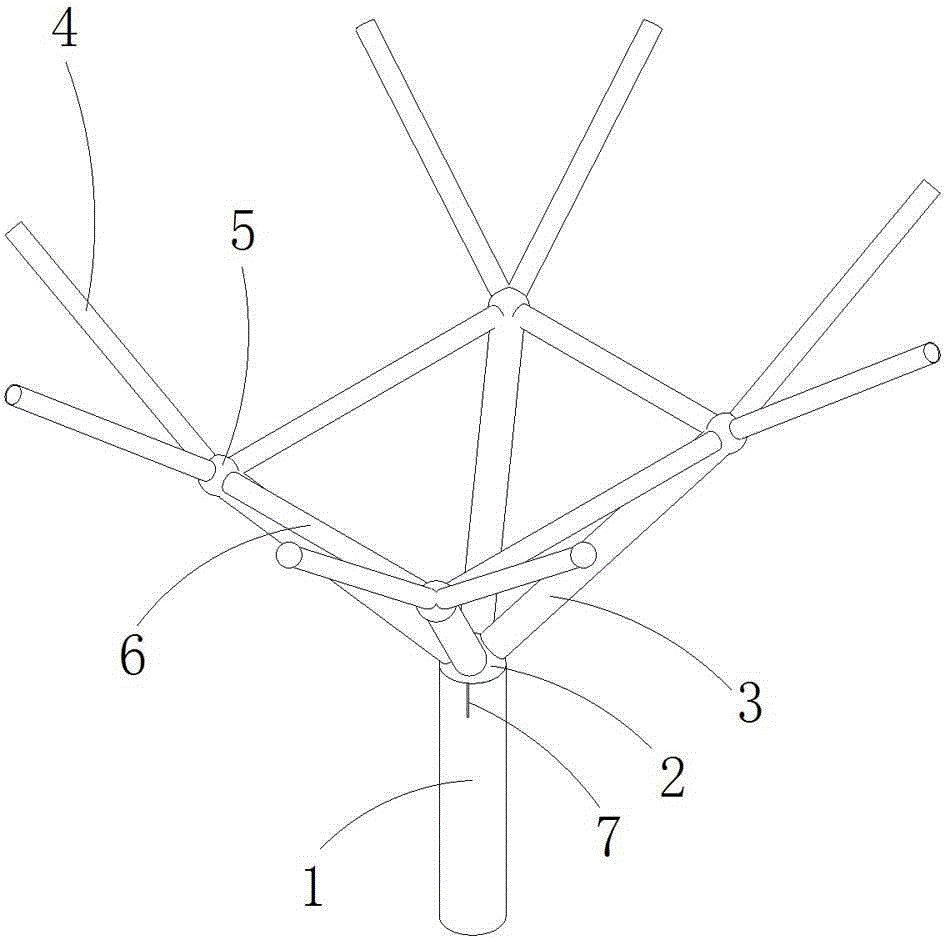

Crotch-shaped element and processing method thereof

ActiveCN104060690AIncrease the use of spaceIncrease spanBuilding material handlingEngineeringUltimate tensile strength

The invention relates to a crotch-shaped element, in particular to the crotch-shaped element and a processing method thereof which are applied to a steel structure. The Y-shaped element comprises a supporting main pipe and top nodes, wherein the top nodes fixed with the supporting main pipe are arranged at the top of the supporting main pipe; at least two bottom branch pipes extending outwards are arranged on each top node; extending mechanisms, which are continuously distributed, are arranged at the upper part of the bottom branch pipes, and comprise branch pipes, upper layer nodes and horizontal pipes; the upper layer nodes are arranged at the upper parts of the bottom branch pipes; the horizontal pipes are arranged between adjacent upper layer nodes; one or more branch pipes are arranged on each upper layer node. The processing method comprises the following steps: cutting, blanking, assembling, welding and detecting strength. The crotch-shaped element and the processing method thereof have the advantages that the structure is compact and reasonable; the modeling is novel; the stress is reliable; resources are saved; the processing is fast and accurate.

Owner:浙江东南网架股份有限公司

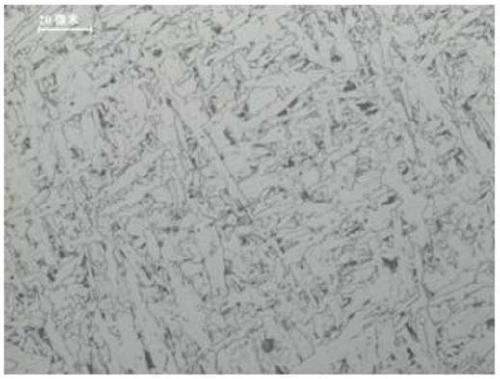

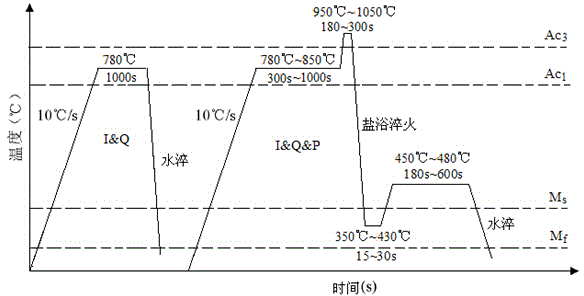

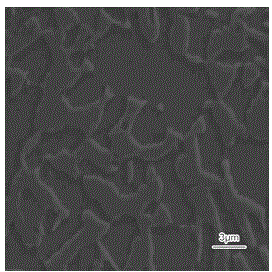

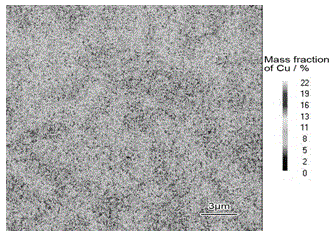

Low-carbon silicon-manganese high-strength steel containing Cu and production method of steel

The invention relates to low-carbon silicon-manganese high-strength steel containing Cu and a production method of the steel. The low-carbon silicon-manganese high-strength steel containing Cu comprises the following chemical components by weight percent: 0.18-0.22% of C, 1.3-1.5% of Si, 1.3-1.8% of Mn, 0.4-0.55% of Cu, 0.32-0.4% of Ni, less than or equal to 0.05% of P, less than or equal to 0.03% of S and the balance of Fe and unavoidable impurities. The production method comprises the following steps: smelting according to the chemical components, and forging a casting blank into a slab; performing hot rolling on the slab to obtain a final rolling plate; and performing heat treatment process to obtain the high-strength steel. By adopting the method, the retained austenite volume fraction in the steel is increased, the mechanical property is improved, and the bad influence on the smelting and casting process by adding plenty of Mn is avoided. The production method is simple and practicable and the cost is low.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

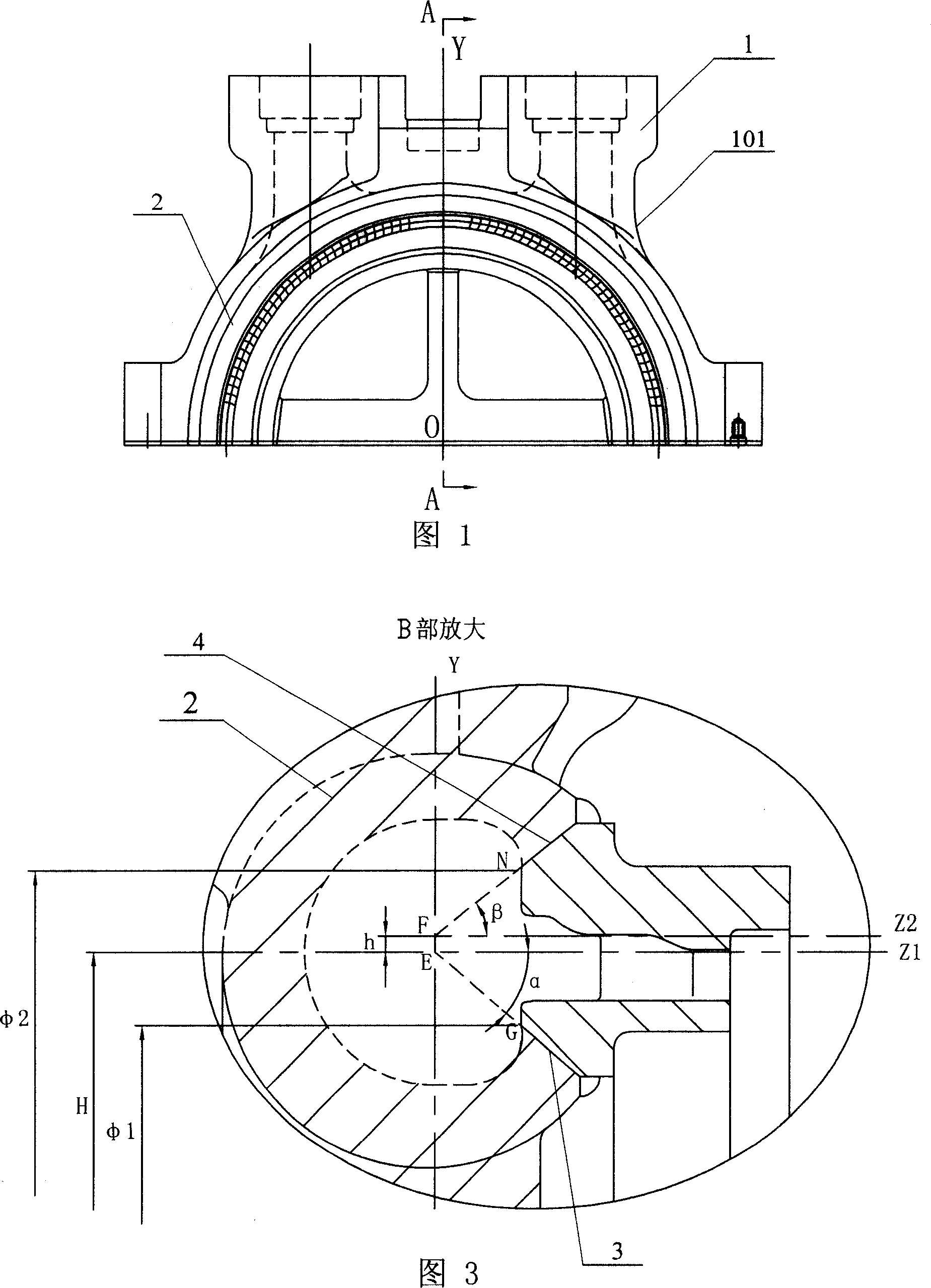

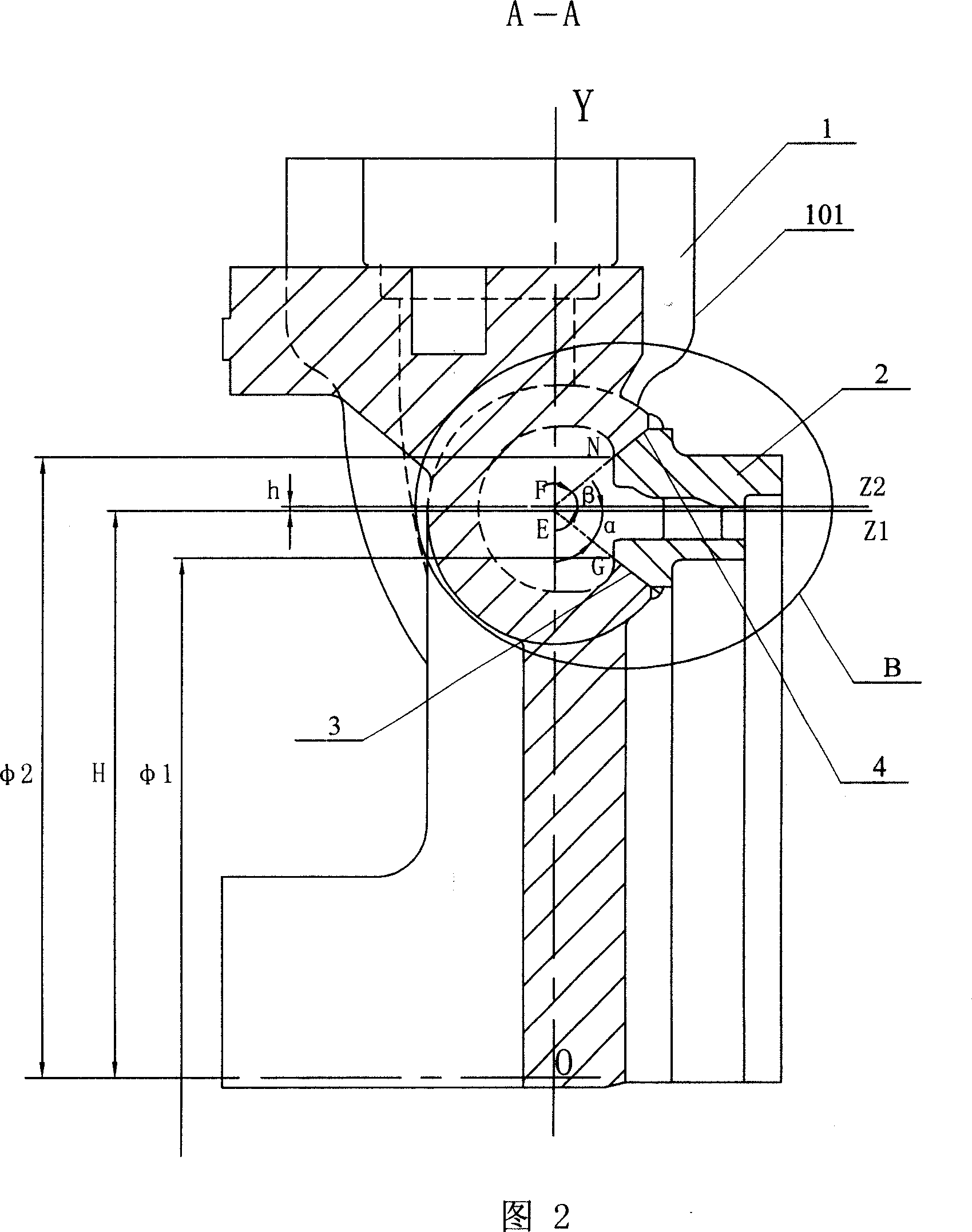

Nozzle of steam turbine with structure of groove face by using electron beam bonding

This invention relates to a seal structure of turbine nozzles, in which the prolonged lines of lower welding groove faces between a nozzle chamber and a nozzle set meet at point E of Y central axes of a nozzle and the distance H between point E to the central point O of the nozzle is 1100mm, and the included angle between the lower groove face and Z1 direction line over point E is 40deg., prolonged lines of the upper groove faces between the chamber and the set meet at point F of the Y-oriented central axes of the nozzle and F is above E, the distance between them is 5mm and the included angle between the upper groove face and the Z2 line over point F is 40deg., which finishes two seams of a nozzle at one run with electronic beams.

Owner:HARBIN TURBINE

Brazing and welding method of aluminum target and copper-containing back plate

The invention relates to a brazing method for an aluminum target and a copper-containing back plate. The brazing method includes using different solders to perform an infiltration treatment on the aluminum target and the copper-containing back plate, and then combining the two. After the welding process is completed, the welding strength of the aluminum target material and the copper-containing backing plate obtained by the method of the present invention is significantly improved, and the welding strength is 70 to 100 MPa, and the welding bonding rate is also significantly improved. Recycle.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

LED lamp string, and manufacturing method thereof and LED device used in LED lamp string

PendingCN112838153AFast weldingIncrease productivityElongate light sourcesElectric circuit arrangementsLED lampSurface-mount technology

The invention discloses an LED lamp string and LED devices used in the LED lamp string, the LED lamp string comprises a plurality of LED devices and a wire group, each LED device comprises an insulating body, a conductive terminal fixed on the insulating body and connected with the wire group, and a light-emitting LED chip and a control unit arranged on the insulating body, the insulating body is provided with an inward concave gap, the wire group at least comprises a first wire penetrating through the notch, and the first wire forms a cut-off part at the position of the notch. When the LED lamp string connected in series is produced, an LED device and a corresponding uninterrupted wire can be directly welded through a surface mount technology, and then the wire penetrating through the gap position is cut off through a cutter by utilizing the reserved gap position. Therefore, the patch welding operation of the lamp string can be rapidly completed, the shearing operation can also be rapidly completed through manual or automatic operation, the production efficiency is greatly improved, and the yield of products is improved.

Owner:DONGGUAN WORLDSEMI TECHNOLOGY CO LTD

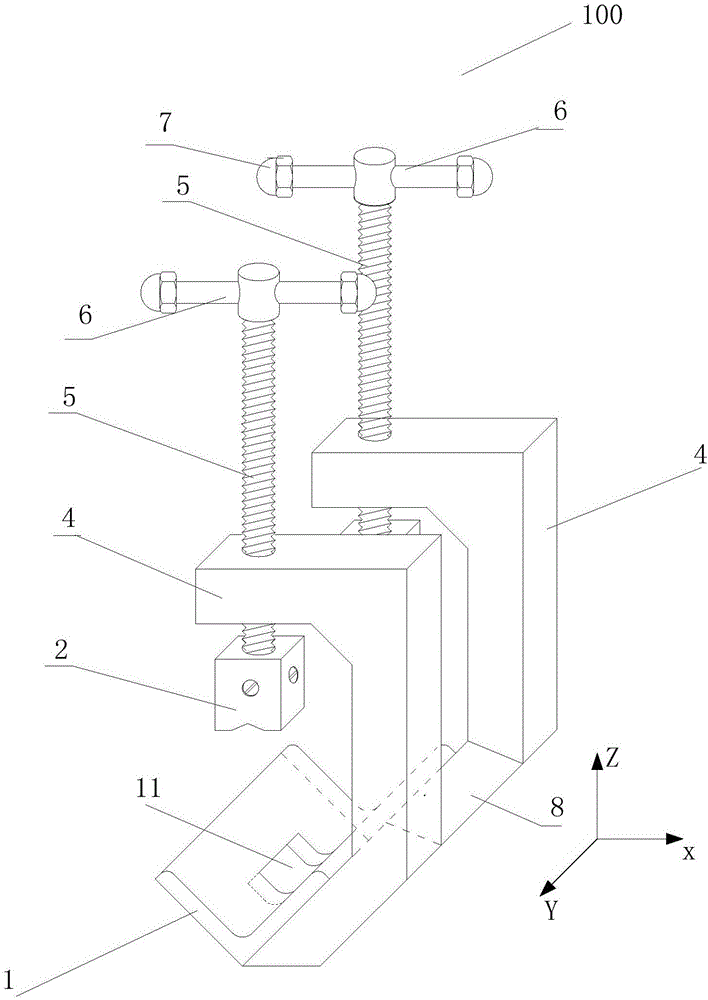

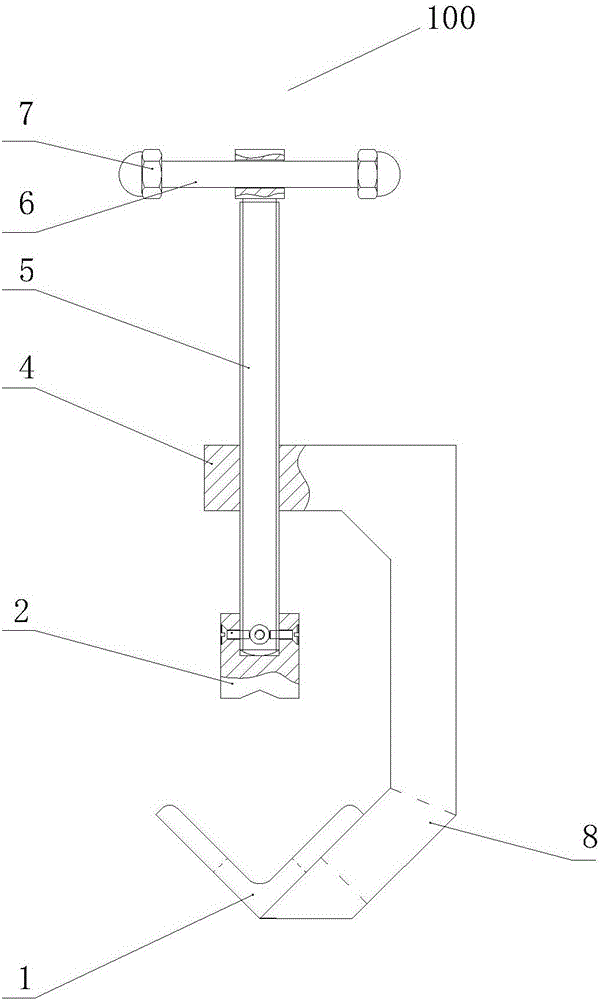

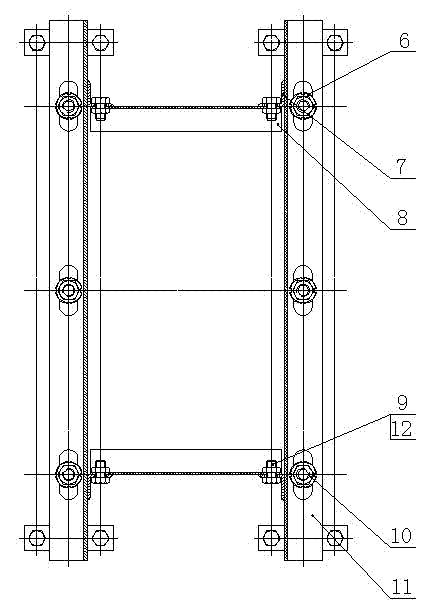

Automatic centering welding deice for bolts of shell liner of mixing machine

ActiveCN102962621AGuaranteed parallelFast weldingWelding/cutting auxillary devicesAuxillary welding devicesAgricultural engineering

The invention discloses an automatic centering welding deice for bolts of a shell liner of a mixing machine. The device comprises a left centering bracket, a right centering bracket, a height adjusting mechanism and a pitch adjusting mechanism, wherein the height adjusting mechanism and the pitch adjusting mechanism are arranged on the left centering bracket and the right centering bracket; the height adjusting mechanism comprises adjusting bolts and nuts; eight adjusting bolts are symmetrically arranged on four front and rear corners of the left centering bracket and the right centering bracket respectively; and the nuts are mounted on the adjusting bolts and upper and lower surfaces of the left centering bracket and the right centering bracket. The height of the adjusting bolts on the four corners of the left centering bracket and the right centering bracket in the device are determined by the length of the liner bolts and are adjusted by upper and lower double nuts; the space between front, middle and rear centering dies on the left centering bracket and the right centering bracket are adjusted according to the space between the same row of liner bolts on the shell liner; and the space between the left centering bracket and the right centering bracket is adjusted by waist-shaped holes of a connecting rod according to the pitch of two rows of holes of the shell liner. The device can guarantee welding precision and quality and also can greatly increase the welding speed so as to meet the maintenance quality and the project duration requirement.

Owner:MAGANG (GROUP) HOLDING CO LTD +1

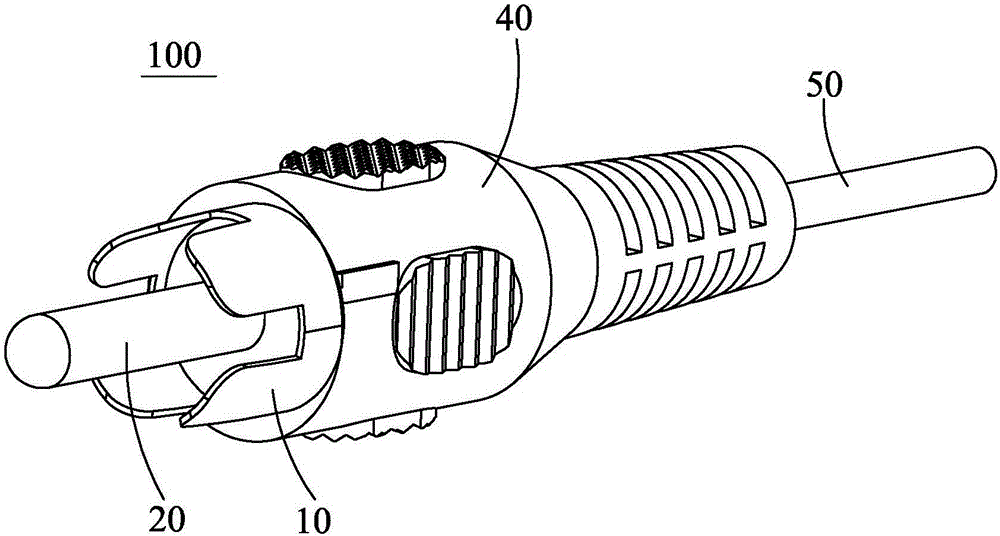

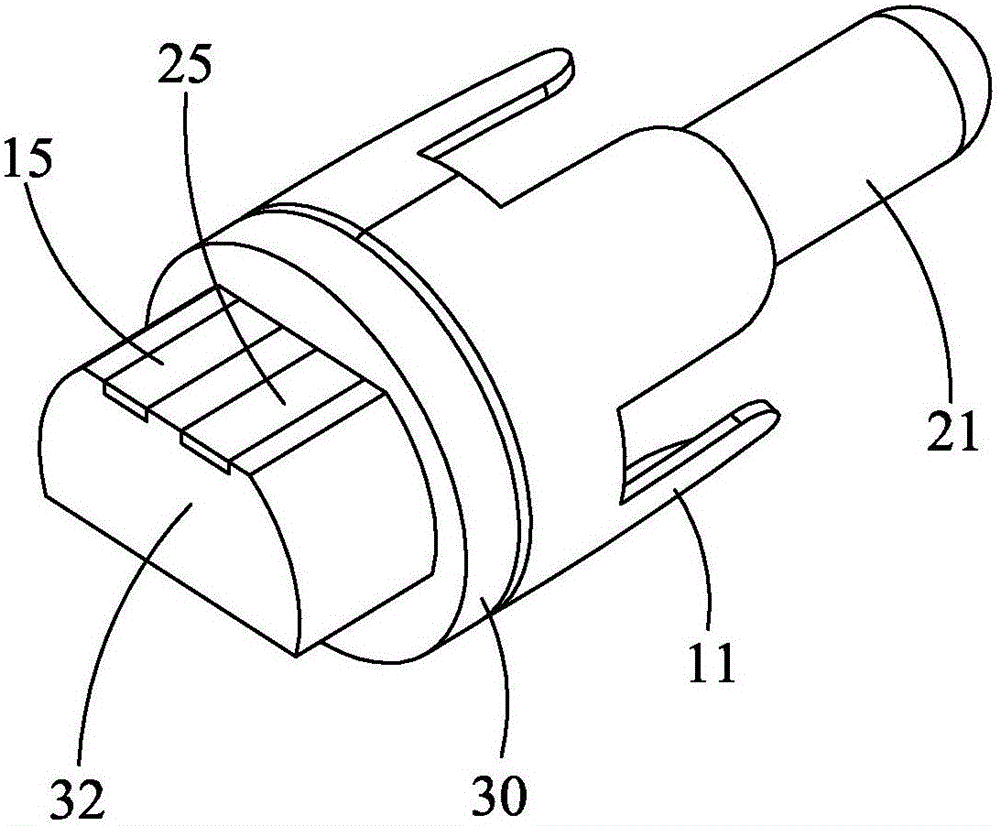

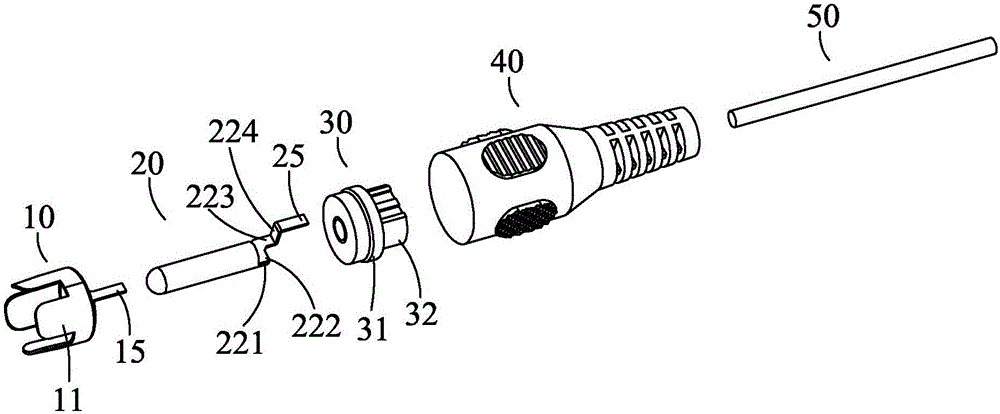

RCA plug

PendingCN105932431ASimplify the welding processIncrease productivityCoupling device detailsSoldered/welded conductive connectionsEngineeringTransmission quality

The invention relates to an RCA plug, which comprises a lotus terminal, a center terminal, an insulating body and a cable, wherein the insulating body is used for fixing the lotus terminal and the center terminal; the lotus terminal comprises an external contact part and a first bonding pad; the external contact part is in a lotus form; the first bonding pad extends backwards; the center terminal comprises an internal contact part and a second bonding pad; the internal contact part is located at the inner side of the external contact part; the second bonding pad extends backwards; the first bonding pad and the second bonding pad are welded with the cable respectively; and the first bonding pad and the second bonding pad are partitioned on the left and right and are located on the same horizontal plane. The welding procedure of the cable is simple; the production efficiency is improved; the capacity is improved; the cost is reduced; welding is fast and convenient; the signal transmission quality is ensured; meanwhile, the binding force is improved; and the cable is prevented from falling off.

Owner:BOZHOU LIAN TAO ELECTRONICS

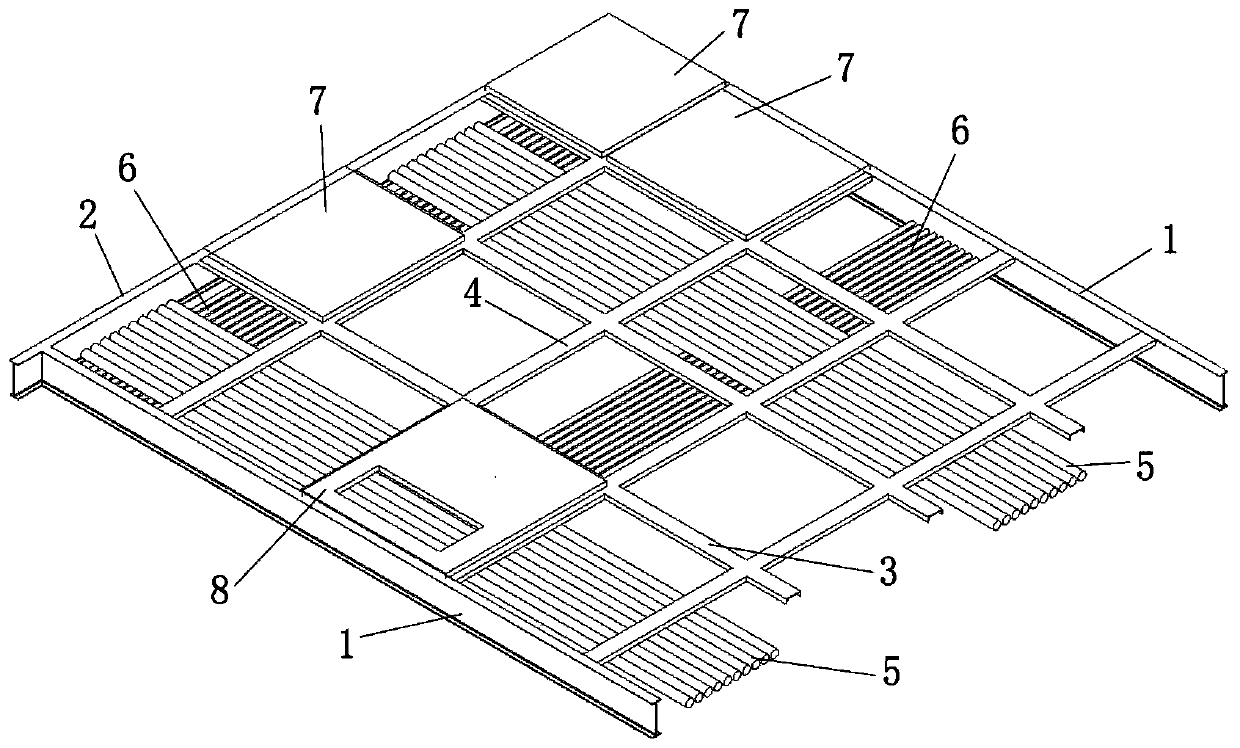

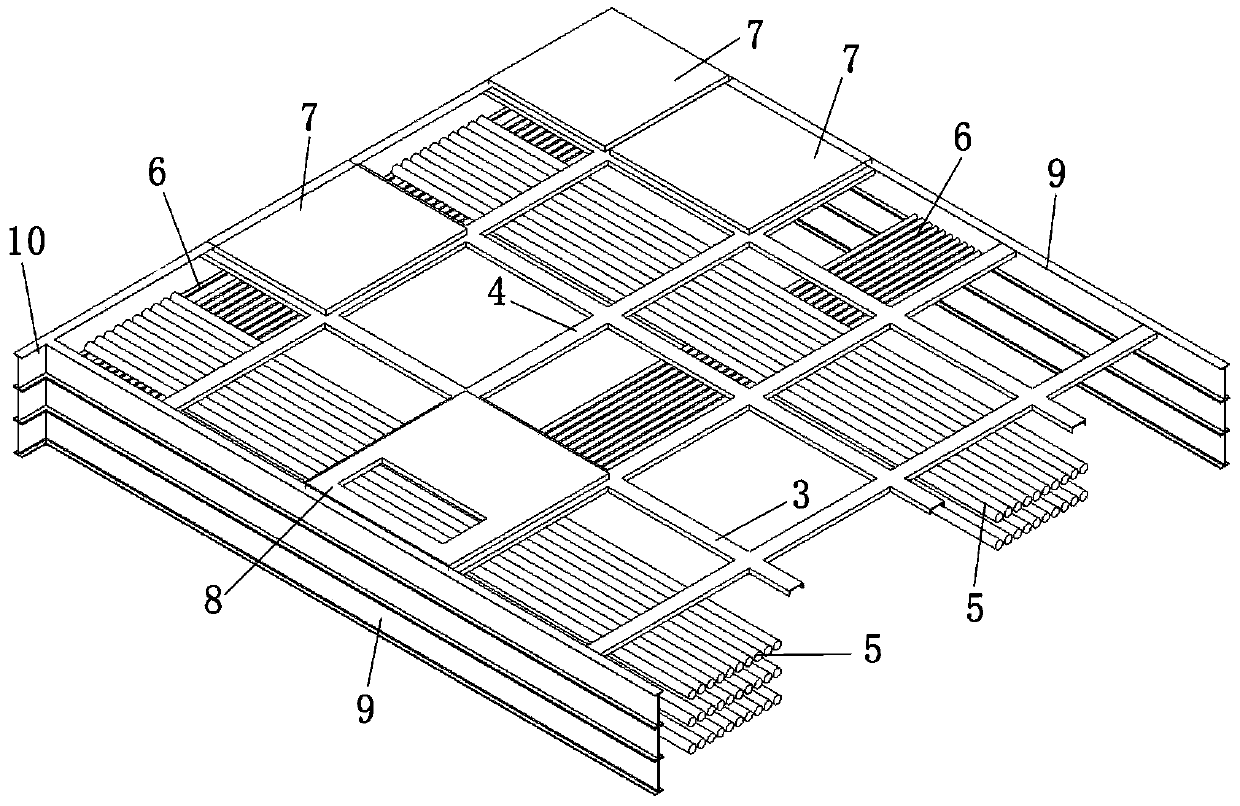

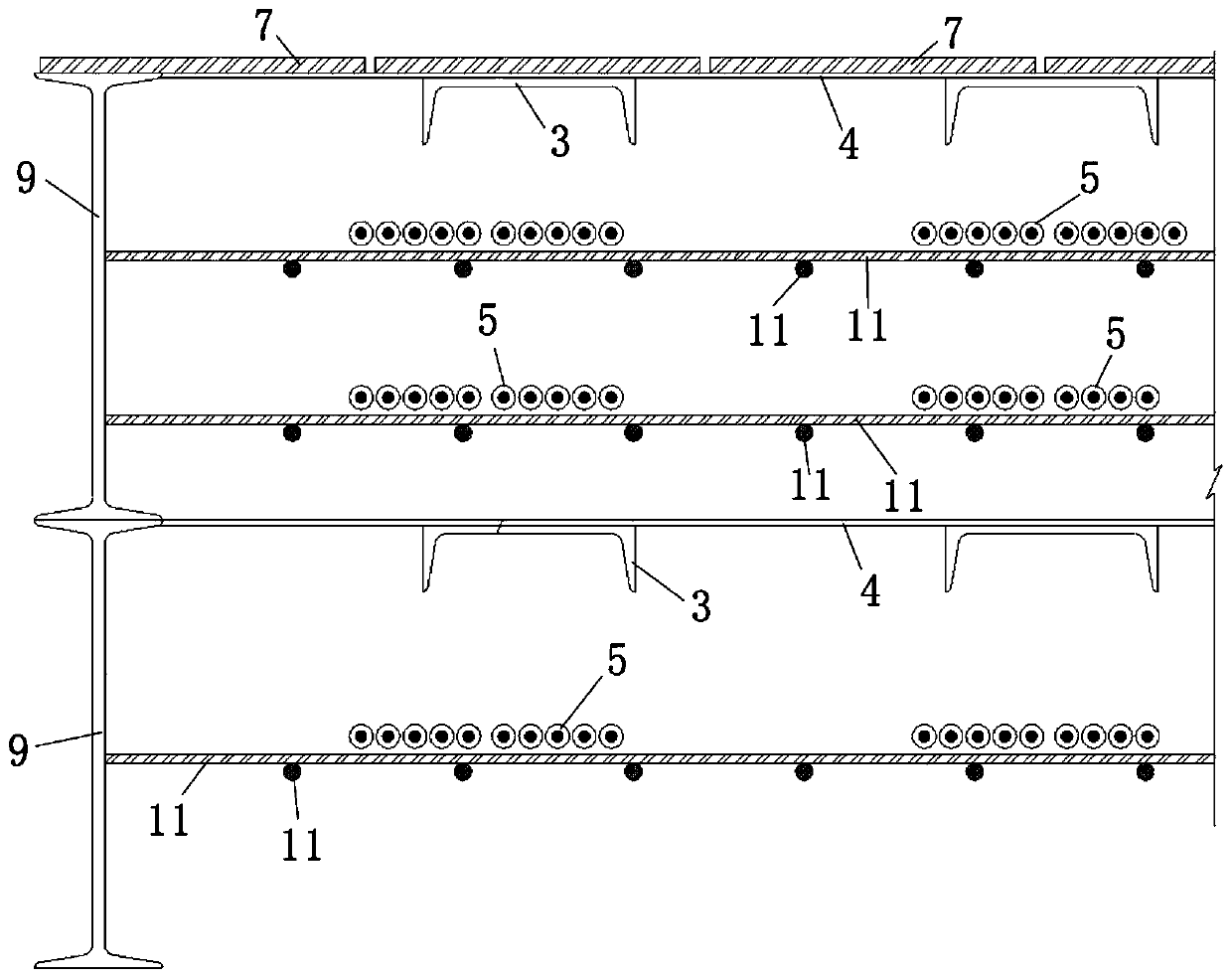

Novel plant cable interlayer structure and implementation method thereof

PendingCN111139935ACompact layoutImprove efficiencyElectrical apparatusBuilding constructionsAgricultural engineeringElectric equipment

The invention discloses a novel plant cable interlayer structure and an implementation method thereof. The novel plant cable interlayer structure comprises a cable interlayer outer overall stress frame formed by first I-shaped steel and second I-shaped steel, and an inner stress net frame system formed by a first steel channel and a second steel channel is arranged in the outer overall stress frame. An overall space net frame structure is formed by the outer overall stress frame and the inner stress net frame system, and a first cable and a second cable are vertically and horizontally placed in the overall space net frame structure according to the trend of the cables. According to the steel structure interlayer, it is only needed to reserve certain floor height during plant frame structure construction, construction can be carried out after all electrical equipment is purchased in place, the plane view size type and space floor height of the steel structure frame can be adjusted according to the number and trend of actually laid cables, the use efficiency of the reserved space is effectively improved, and the cables are arranged more compactly.

Owner:CHINA POWER CONSRTUCTION GRP GUIYANG SURVEY & DESIGN INST CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com