Automatic centering welding deice for bolts of shell liner of mixing machine

An automatic centering and lining technology, which is applied in the direction of auxiliary equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of low precision, difficult installation of linings, and poor control of strength, so as to ensure accuracy and quality, meet The effect of overhauling quality and construction period requirements and improving the speed of assembly and welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

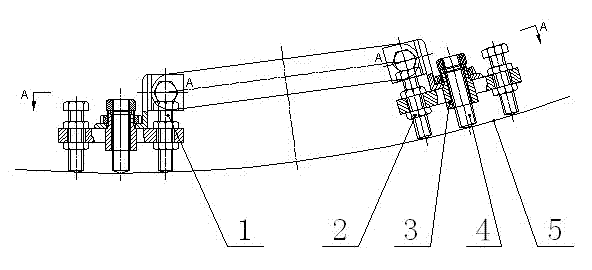

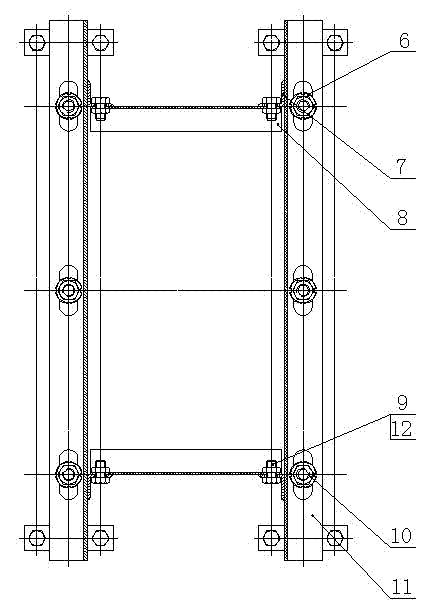

[0011] The automatic centering and welding device for the barrel liner bolts of the mixing machine of the present invention includes left and right centering brackets 11, a height adjustment mechanism and a hole pitch adjustment mechanism arranged on the left and right centering brackets 11; the height adjustment mechanism includes adjustment bolts 1 , nut 2, adjusting bolt 1 is eight, symmetrically arranged on the front and rear four corners of the left and right centering support 11 respectively, the upper and lower sides of the adjusting bolt 1 and the left and right centering support 11 are equipped with nuts 2.

[0012] The hole distance adjustment mechanism includes a longitudinal hole distance adjustment mechanism and a transverse hole distance adjustment mechanism.

[0013] The longitudinal hole distance adjustment mechanism includes a centering mold 3 and a centering mold nut 10. The centering mold 3 is arranged in the waist-shaped hole on the longitudinal centerline o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com