Patents

Literature

639results about How to "Precision welding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Laser welding control system

ActiveUS7107118B2Improve reliabilityReduce the amount requiredProgramme controlElectrical apparatusClosed loopVision based

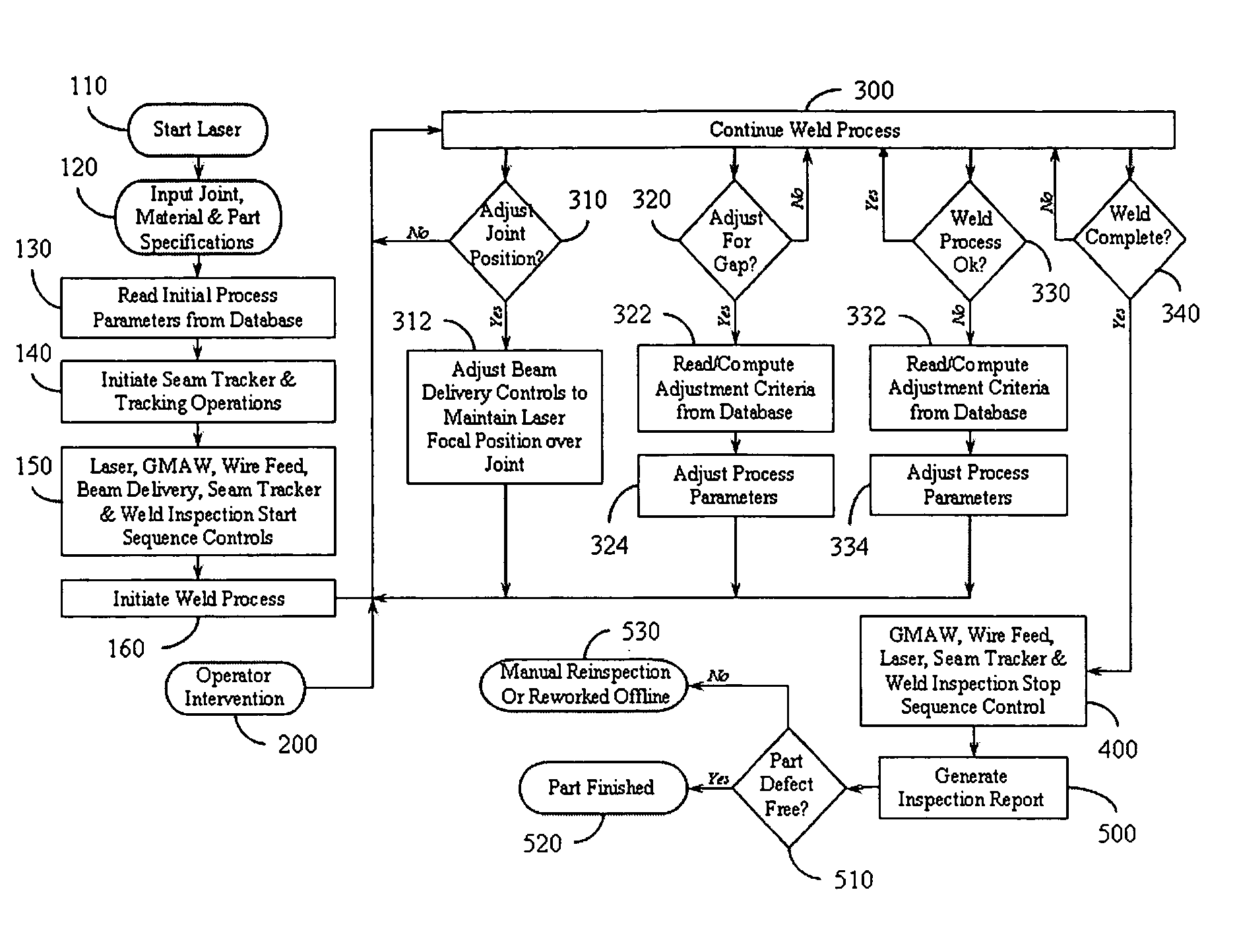

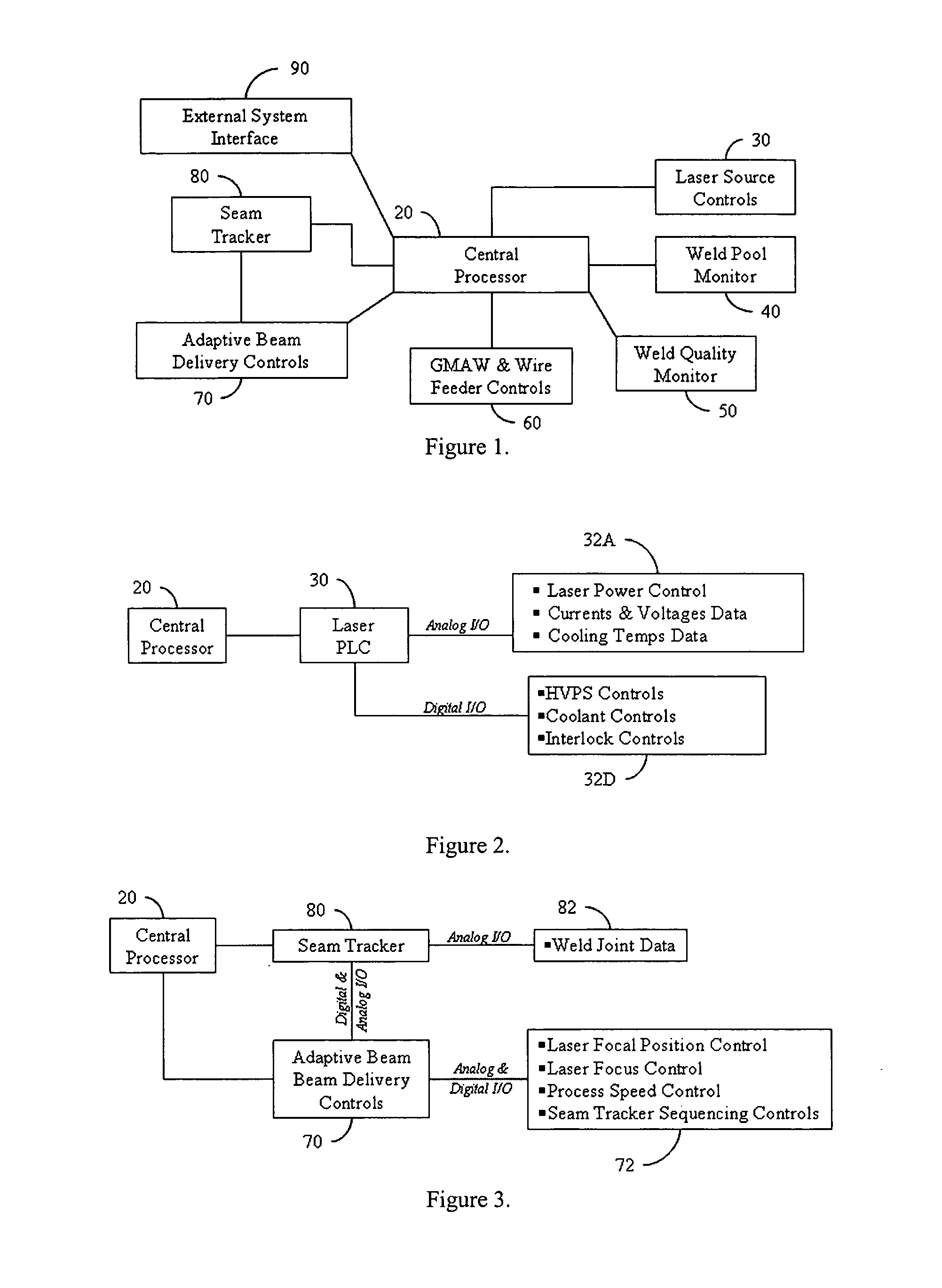

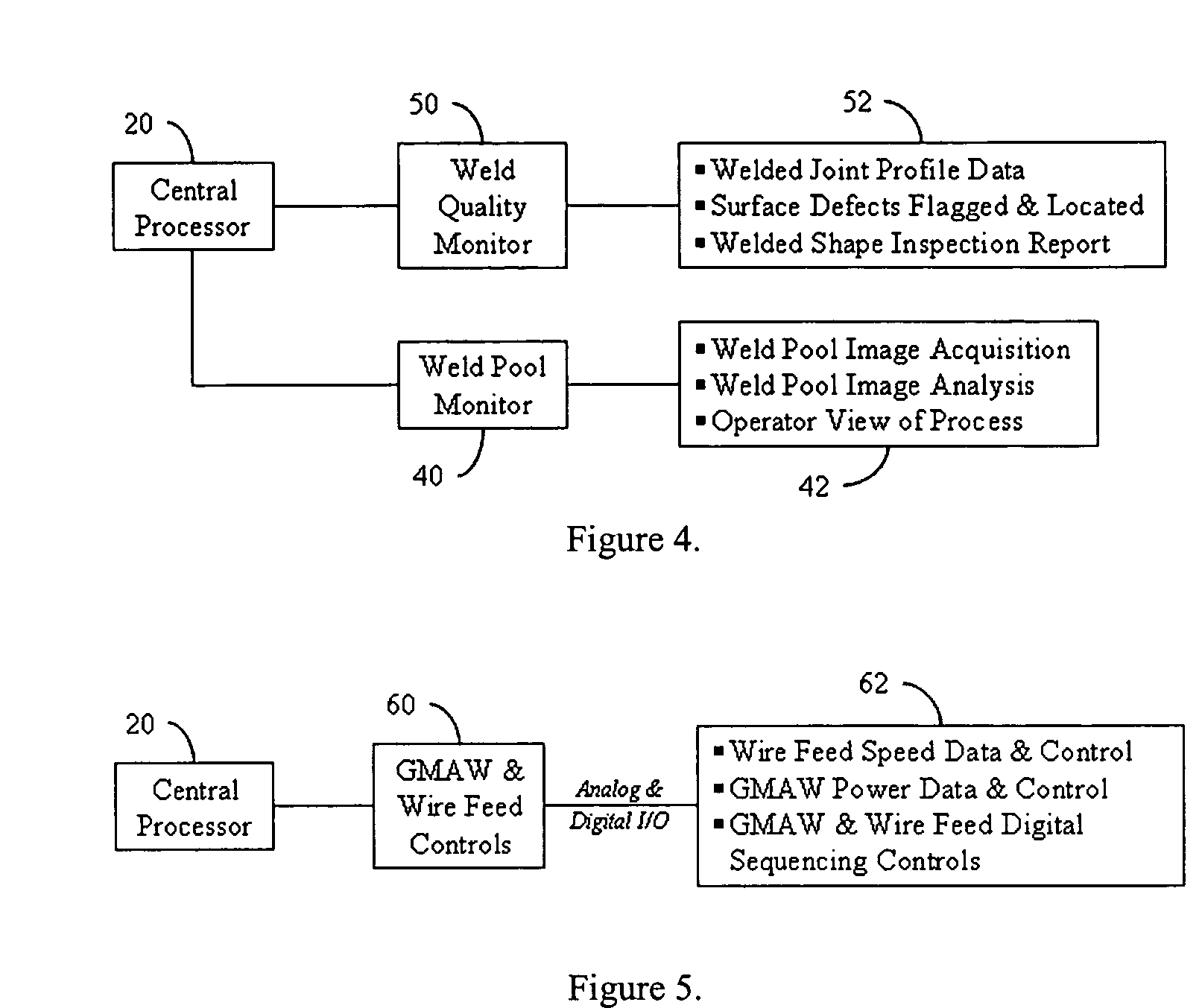

A fully integrated automated laser weld process control system (LWPCS) and method of controlling the fabrication of structural parts, particularly for shipbuilding and other industries. The LWPCS defines joint and weld quality attributes as process control variables and integrates these weld quality variables, along with the more traditional process parameters such as laser power, wire feed, GMAW voltage and active seam tracking, into a closed-loop monitoring and control system. The LWPCS includes a central processor and a plurality of subsystems that control laser beam positioning, vision-based monitoring and image processing, active weld-quality monitoring and inspection, adaptive beam delivery, and seam tracking. Cross-communication between subsystems is managed by the central processor. In addition to process control, the system extracts weld quality attributes during the weld process and provides immediate documentation of the weld quality.

Owner:ESAB AB

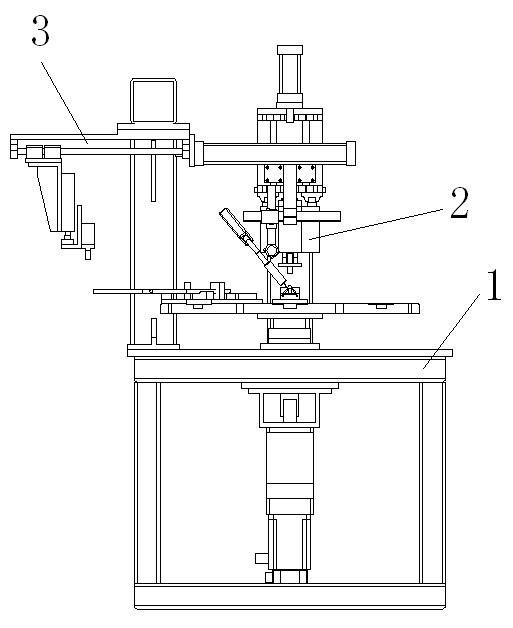

Welding machine

ActiveCN101934447AEasy to moveRealize all-round weldingWelding/cutting auxillary devicesAuxillary welding devicesEngineeringReducer

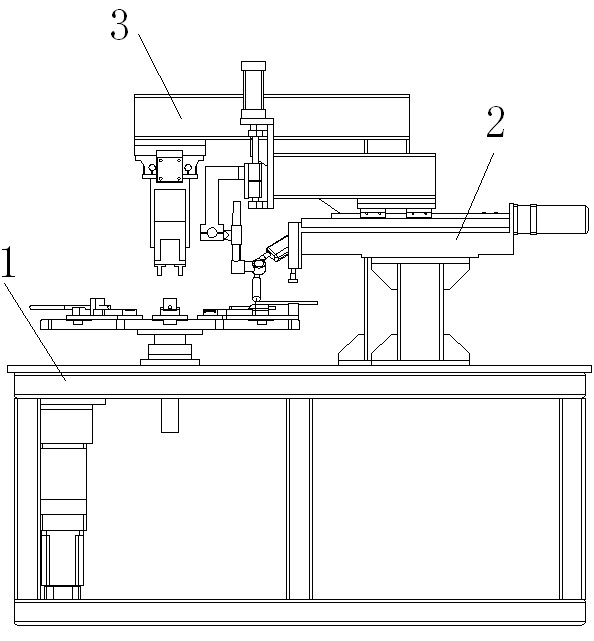

The invention relates to a welding machine, belonging to welding equipment. At present, no welding machine with simple structure, convenient use and high working efficiency exists. The welding machine is characterized by comprising a rotary table device, a welding gun device and a mechanical arm device, wherein the rotary table device comprises a workbench, a rotary table servo motor, a servo speed reducer, a limiting air cylinder, a rotary table and a plurality of fixtures; the welding gun device comprises a welding gun, a welding gun pushing air cylinder, a translation frame, a slider block, a guide rail, a welding gun servo motor, a screw rod and a main support, the welding gun servo motor is fixed on the main support, the screw rod is installed on the welding gun servo motor, the guide rail is fixed on the main support, the slider block is installed on the guide rail, the translation frame is fixed on the slider block and is matched with the screw rod, the welding gun pushing air cylinder is installed on the translation frame, and the welding gun is installed on the welding gun pushing air cylinder; and the main support and a mechanical arm device are both installed on the workbench. The welding machine has reasonable structural design, convenient use and high welding efficiency, and welded products have high quality.

Owner:QIFENG PRECISION IND SCI TECH

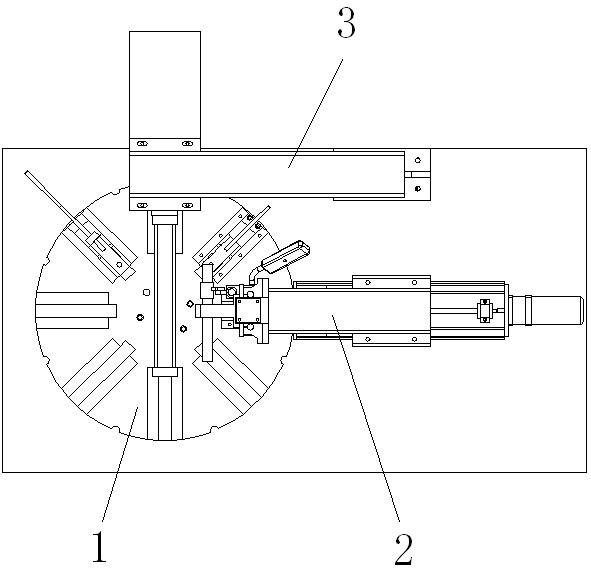

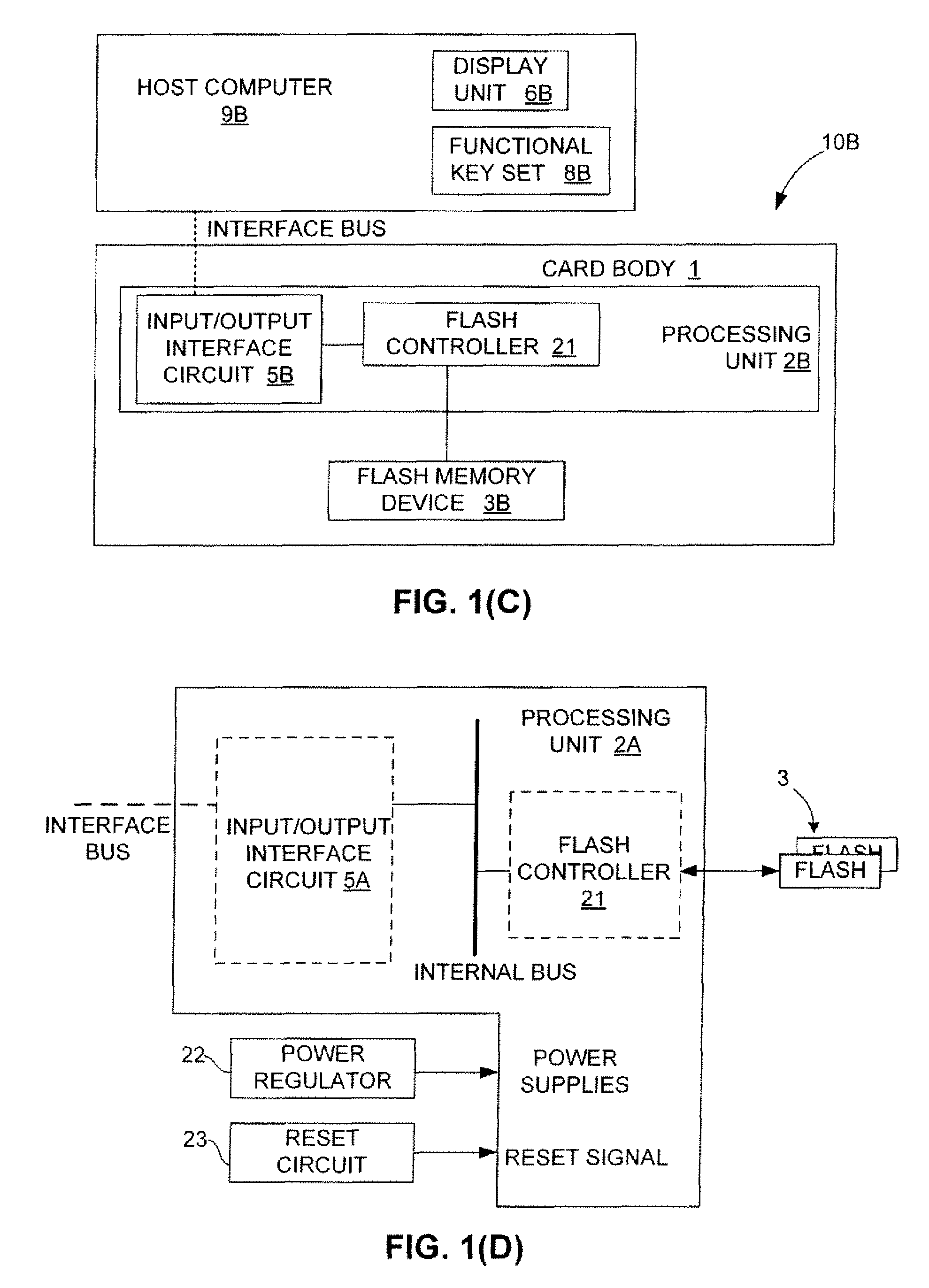

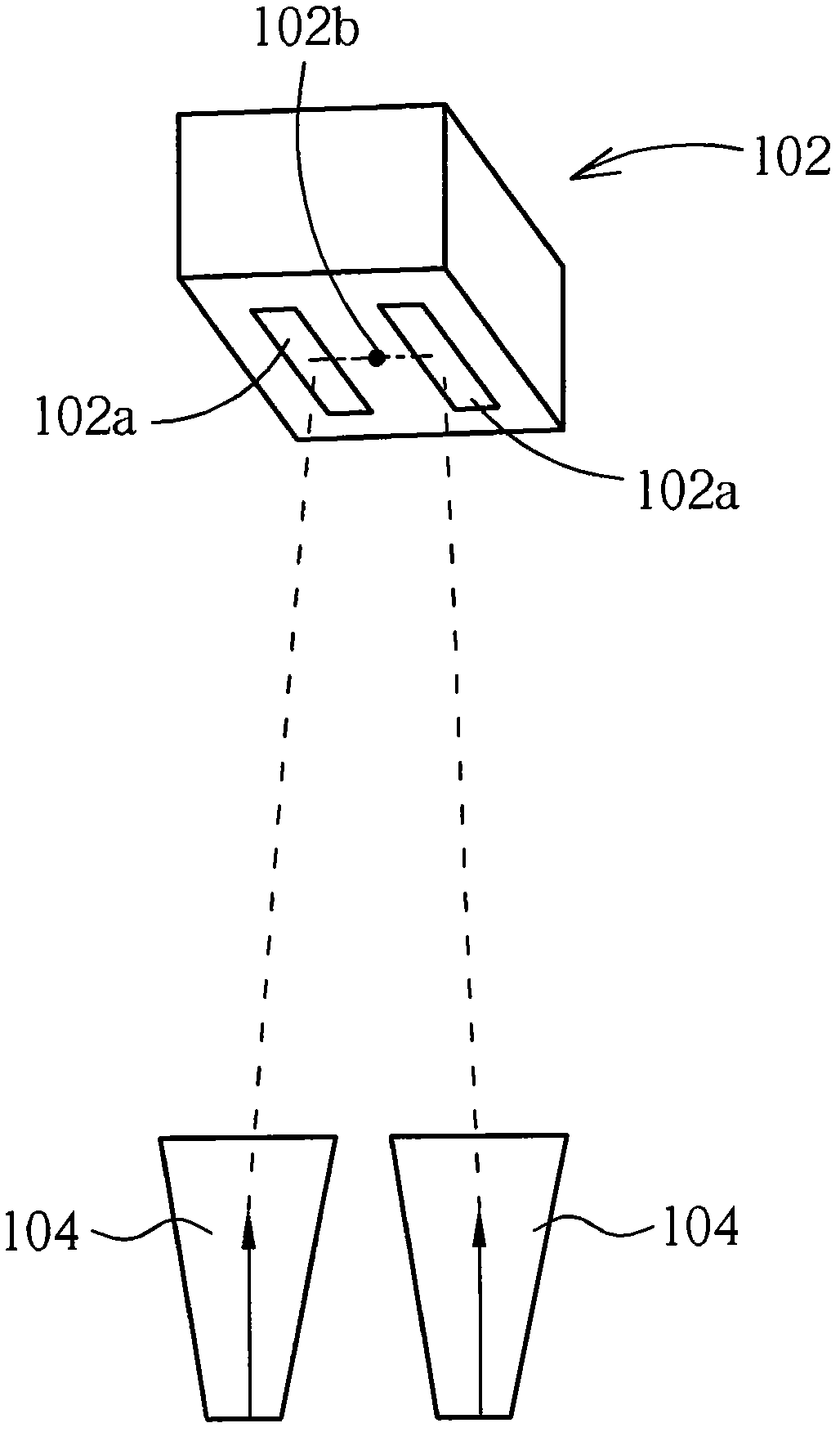

Mass production testing of USB flash cards with various flash memory cells

InactiveUS7788553B2Facilitates efficient and high volume testing/formattingFacilitates high volume formatting/testingElectronic circuit testingError detection/correctionCard readerUSB

A high volume testing / formatting process is provided for Universal Serial Bus-based (USB-based) electronic data flash cards (USB devices) that meets the increasing demand for USB electronic data flash cards (USB devices). A test host is simultaneously coupled to the multiple USB devices (e.g., using a multi-port card reader or a probe fixture), a controller endpoint value is read from each of the USB devices and verified with a known good value, and then testing / formatting is performed on each of the USB devices by writing predetermined data into each USB device in a pipelined manner, then reading out and testing the predetermined data. In one embodiment, the test host implements a special USB driver that blocks standard USB registration procedures upon detecting the plurality of USB devices. Control and / or boot code data are written onto the flash memory device (i.e., instead of being provided on a controller ROM).

Owner:SUPER TALENT TECH CORP

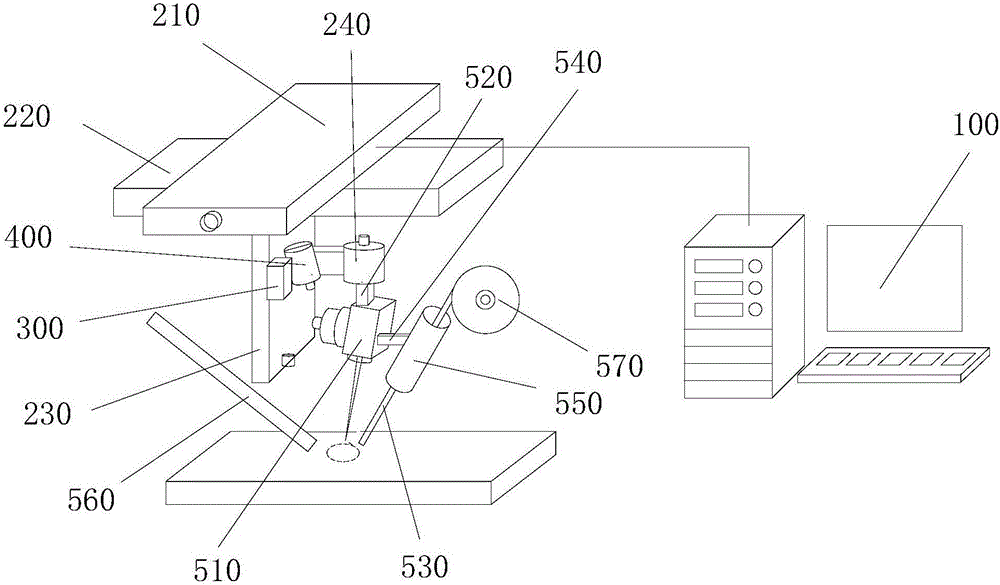

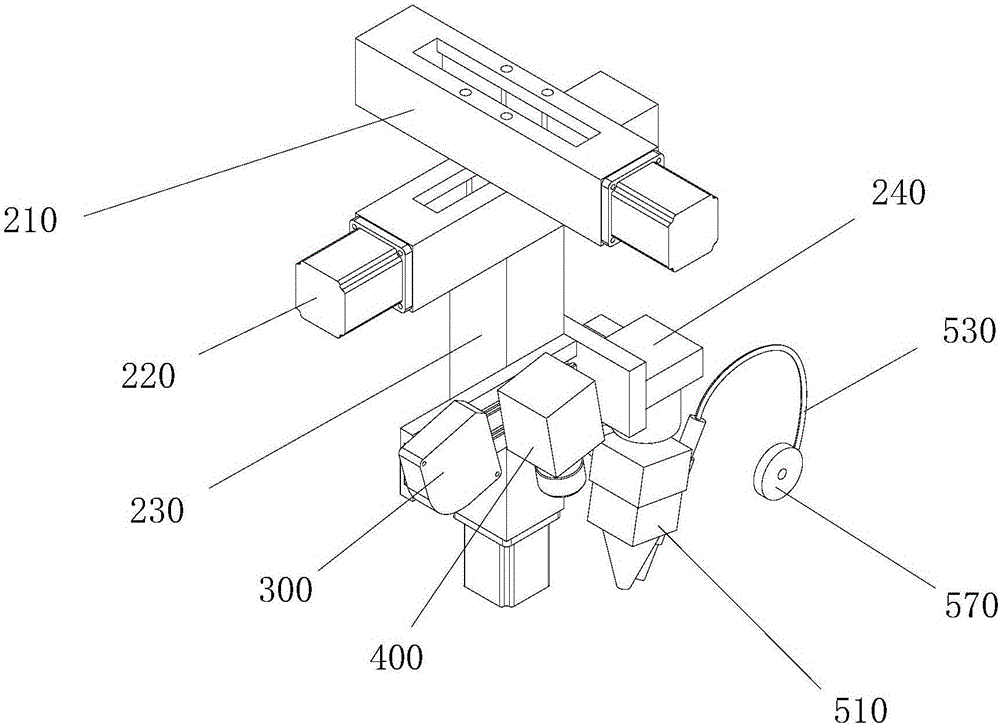

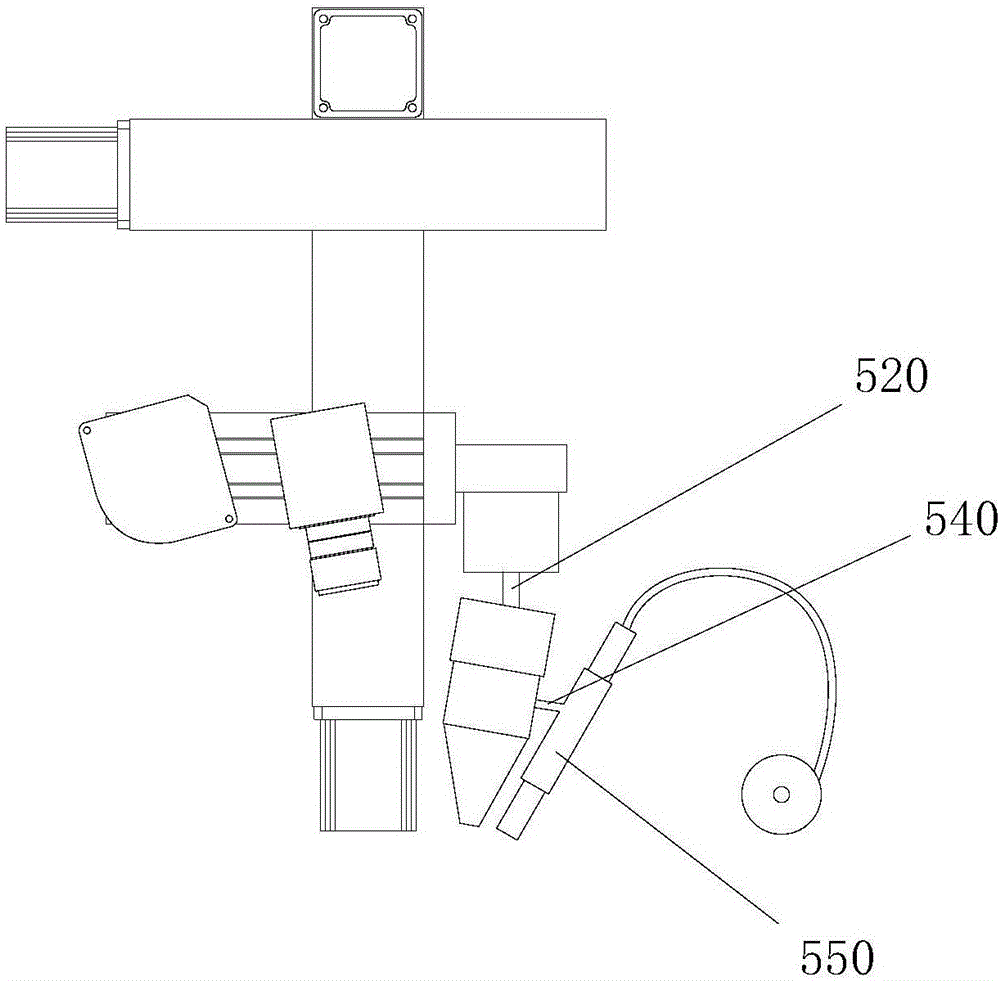

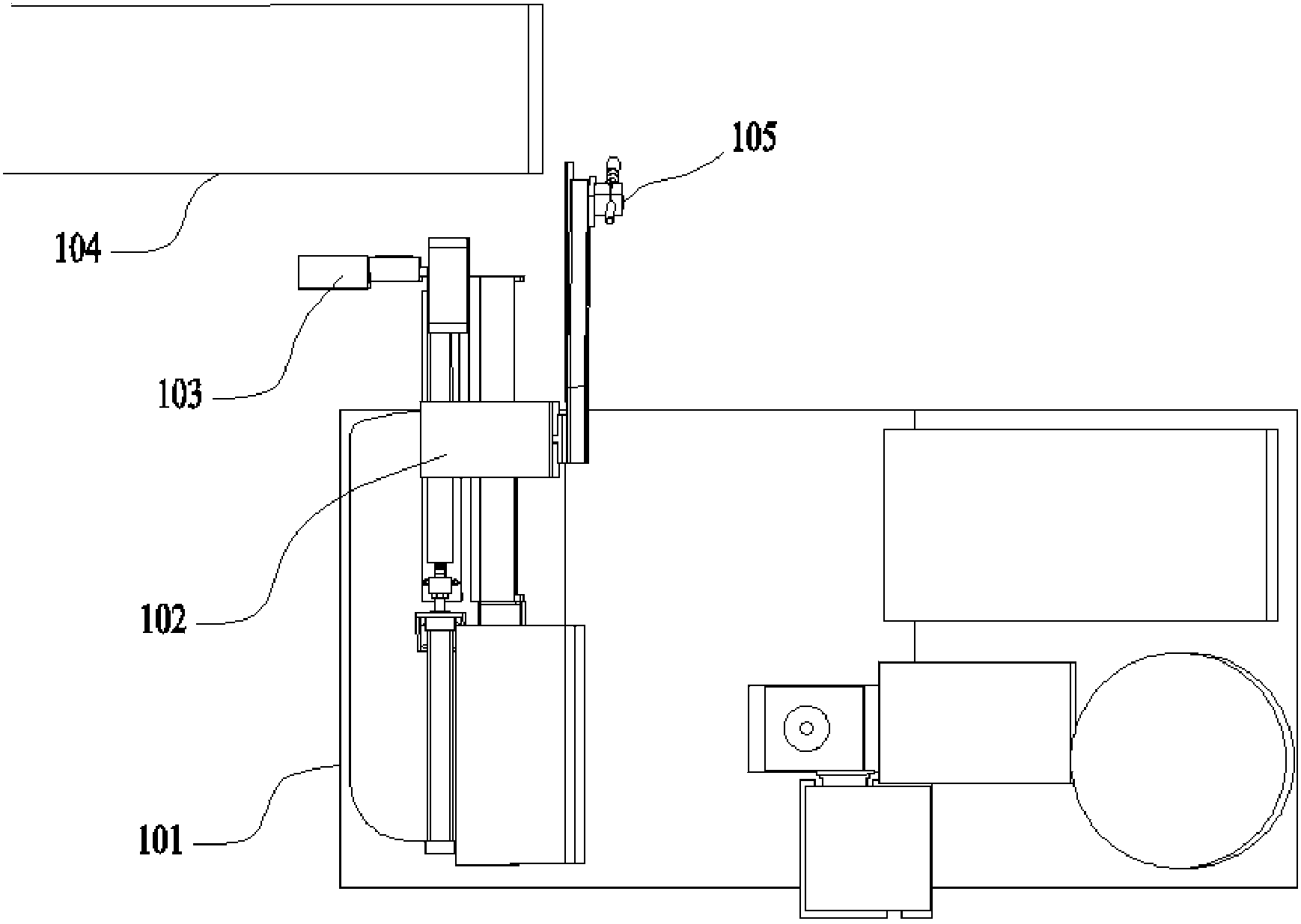

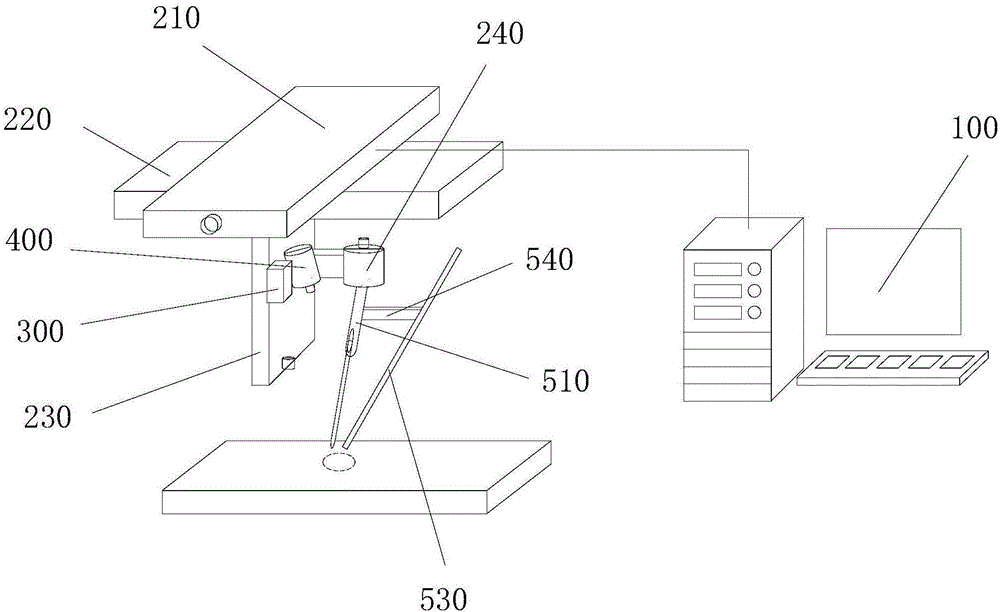

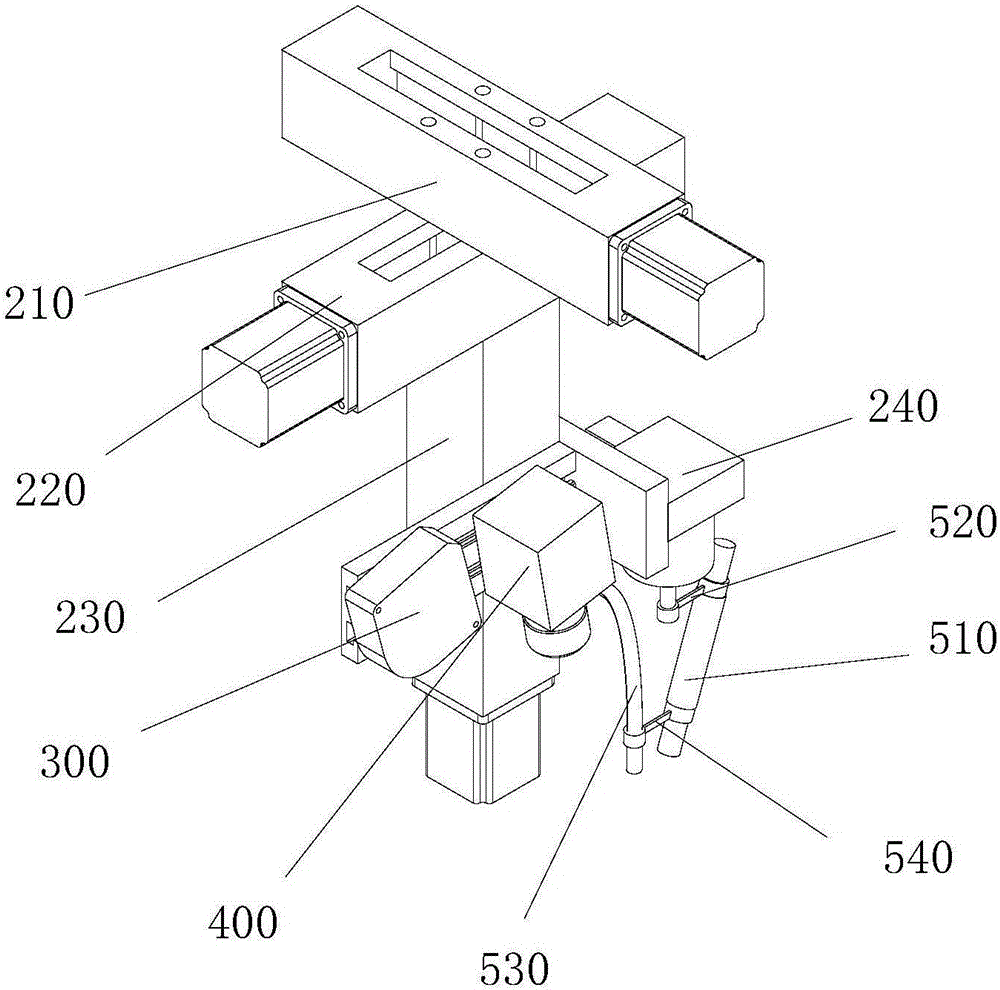

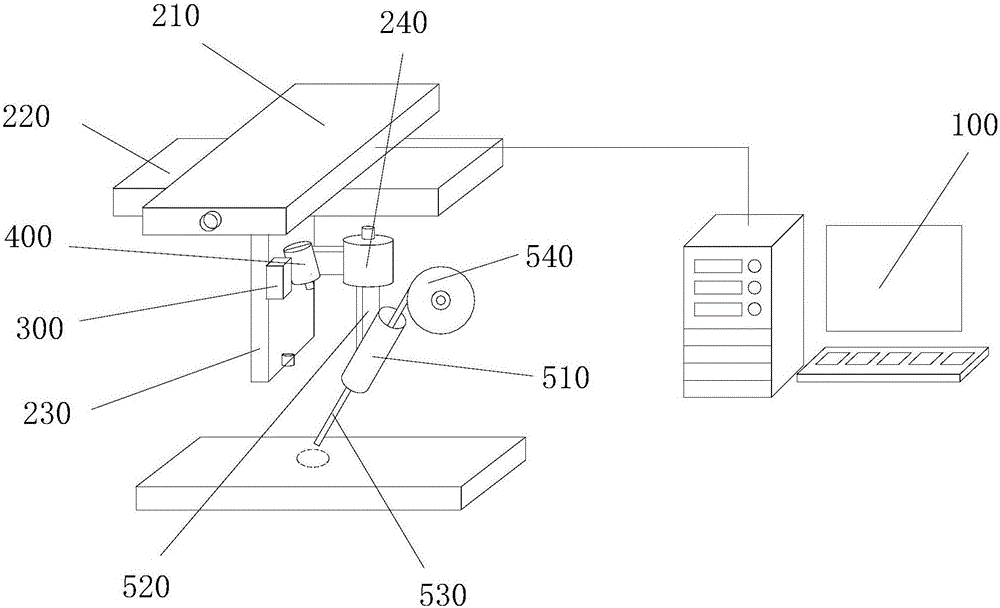

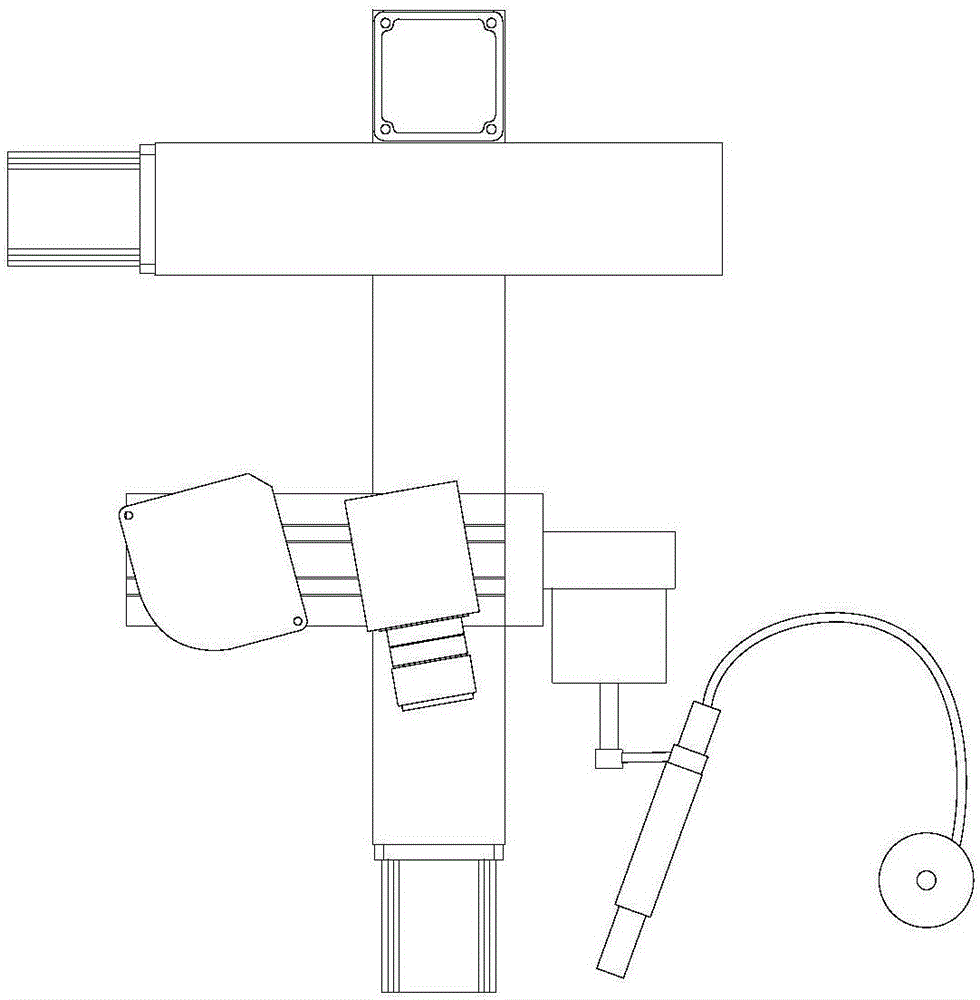

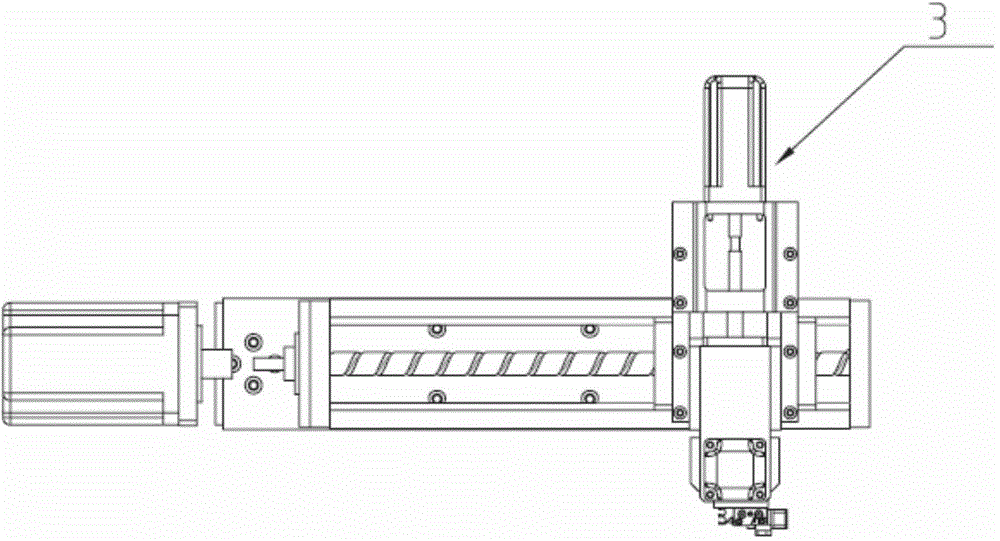

3D additive repair device for laser-arc hybrid welding and repair method

ActiveCN106141435AImprove welding efficiencyImprove welding effectLaser beam welding apparatusEngineeringInfrared vision

The invention discloses a 3D additive repair device for laser-arc hybrid welding and a repair method. The 3D additive repair device comprises a controller, a four-axis linkage platform, a laser vision sensor, an infrared vision sensor, a fixture, a laser welding torch, an arc welding torch, a filling welding wire, a wire reel and a gas guide pipe. The method includes the steps that a defective workpiece is mounted on a repair workbench; the laser vision sensor is driven to scan the three-dimensional profile of a defect; the three-dimensional profile of the defect is rebuilt through the controller; welding parameters are confirmed; the controller drives the near-infrared vision sensor to scan a molten pool, the time-frequency parameter of an image of the molten pool is obtained, a compensation control code is generated according to the time-frequency parameter of the image of the molten pool, and the set welding parameters are corrected in real time; and after repair is completed, the laser vision sensor is driven again to scan the three-dimensional profile of the defect, whether the repaired workpiece meets the standard or not is confirmed, and if not, the defect is repaired again till the repaired defect meets the standard. The 3D additive repair device for laser-arc hybrid welding and the repair method have the beneficial effects that the structure is simple, operation is convenient, and reliability and adaptability are high.

Owner:GUANGDONG UNIV OF TECH

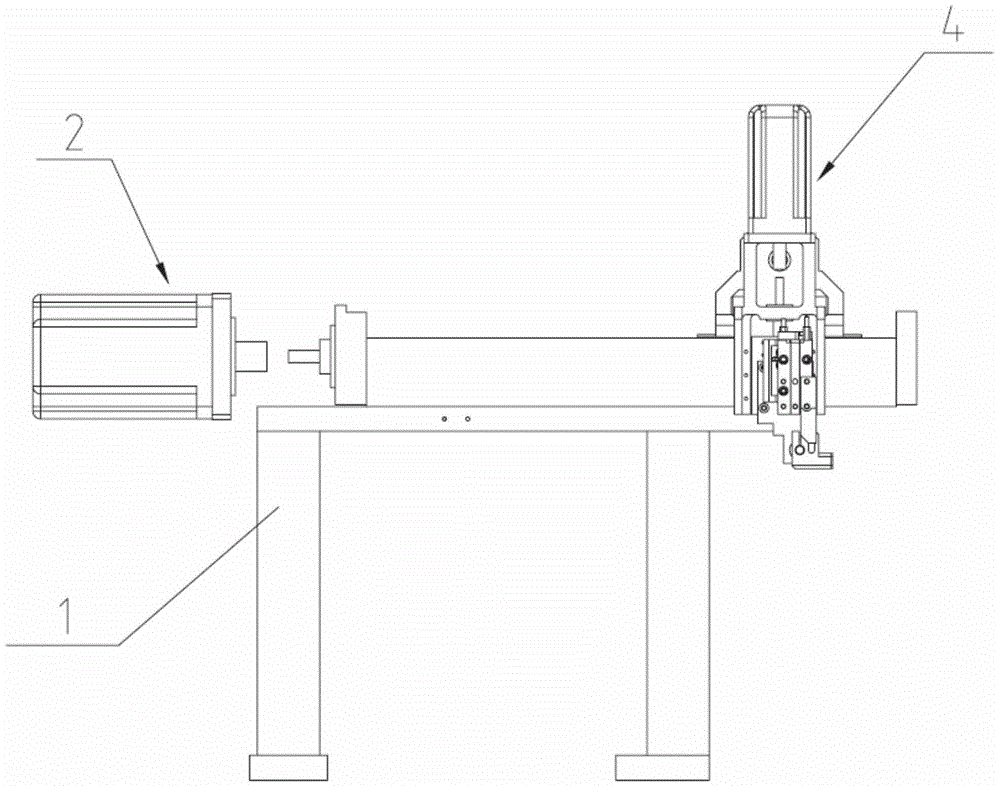

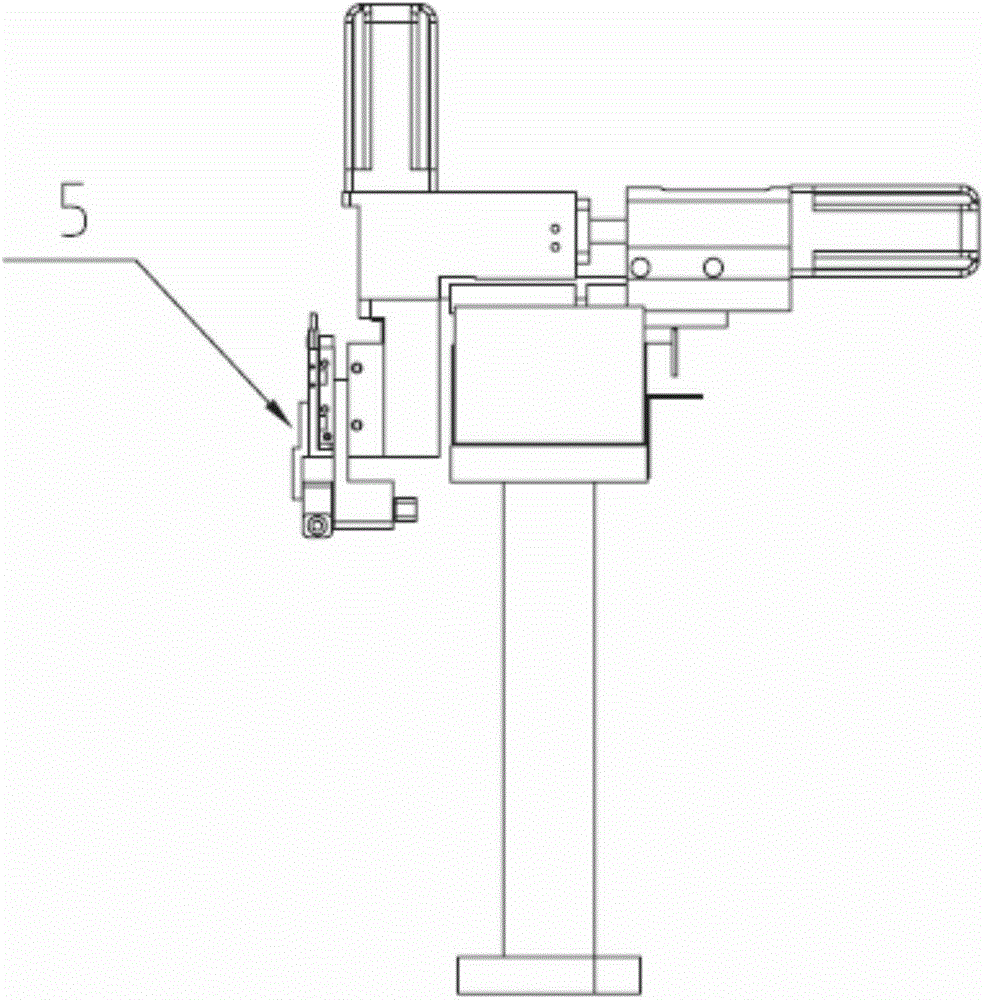

Welding device capable of being overturned automatically

InactiveCN102218632ASave human effortSave operating timeWelding/cutting auxillary devicesAuxillary welding devicesPositioning systemWelding

The invention relates to a mechanical welding apparatus, in particular to a welding device that is used for double face welding and can be overturned automatically. The welding device comprises a welding component, an automatic overturning component and a bracket; the welding component and the automatic overturning component are arranged on the bracket; the welding component comprises an automatic welding gun; the automatic overturning component comprises an overturning platform and a driving platform; a positioning system used for fixing an article to be welded is arranged on the overturning platform; rotating shafts are arranged at two ends of the overturning platform; a driving system connected with the rotating shafts is arranged on the driving platform; and the welding device also comprises a locking system used for fixing the overturning platform. The welding device has the advantages of greatly saving manpower, improving production efficiency, making products more uniform and attractive, and being produced and operated more safely.

Owner:浙江爱婴博士科技有限公司

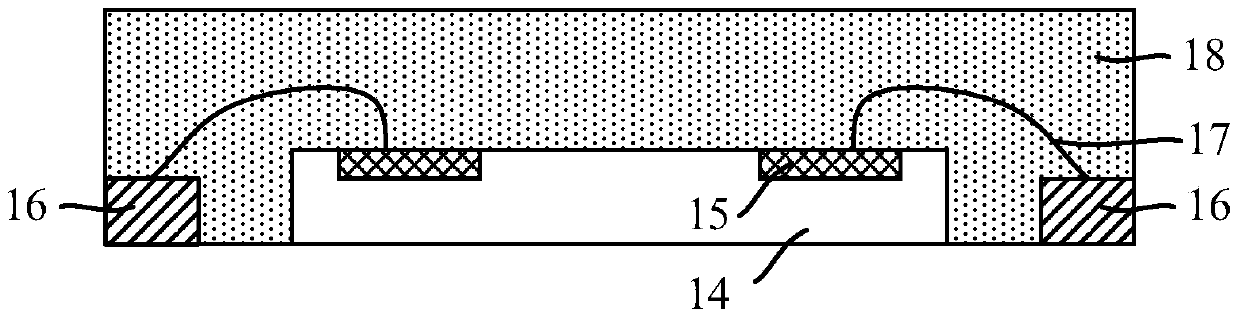

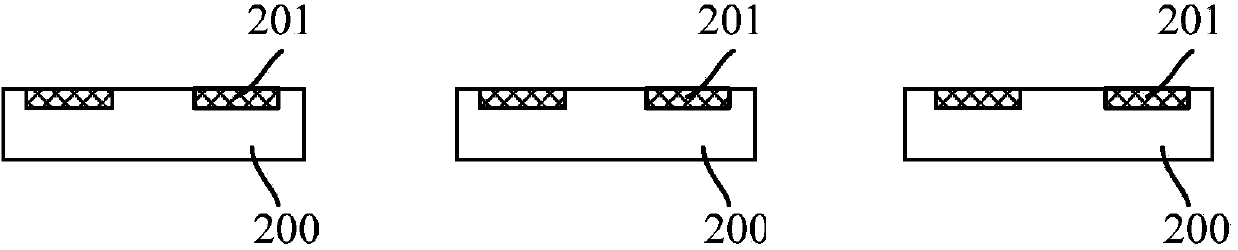

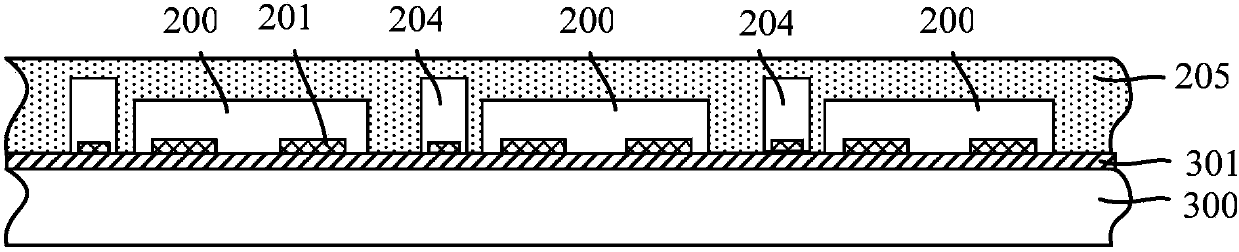

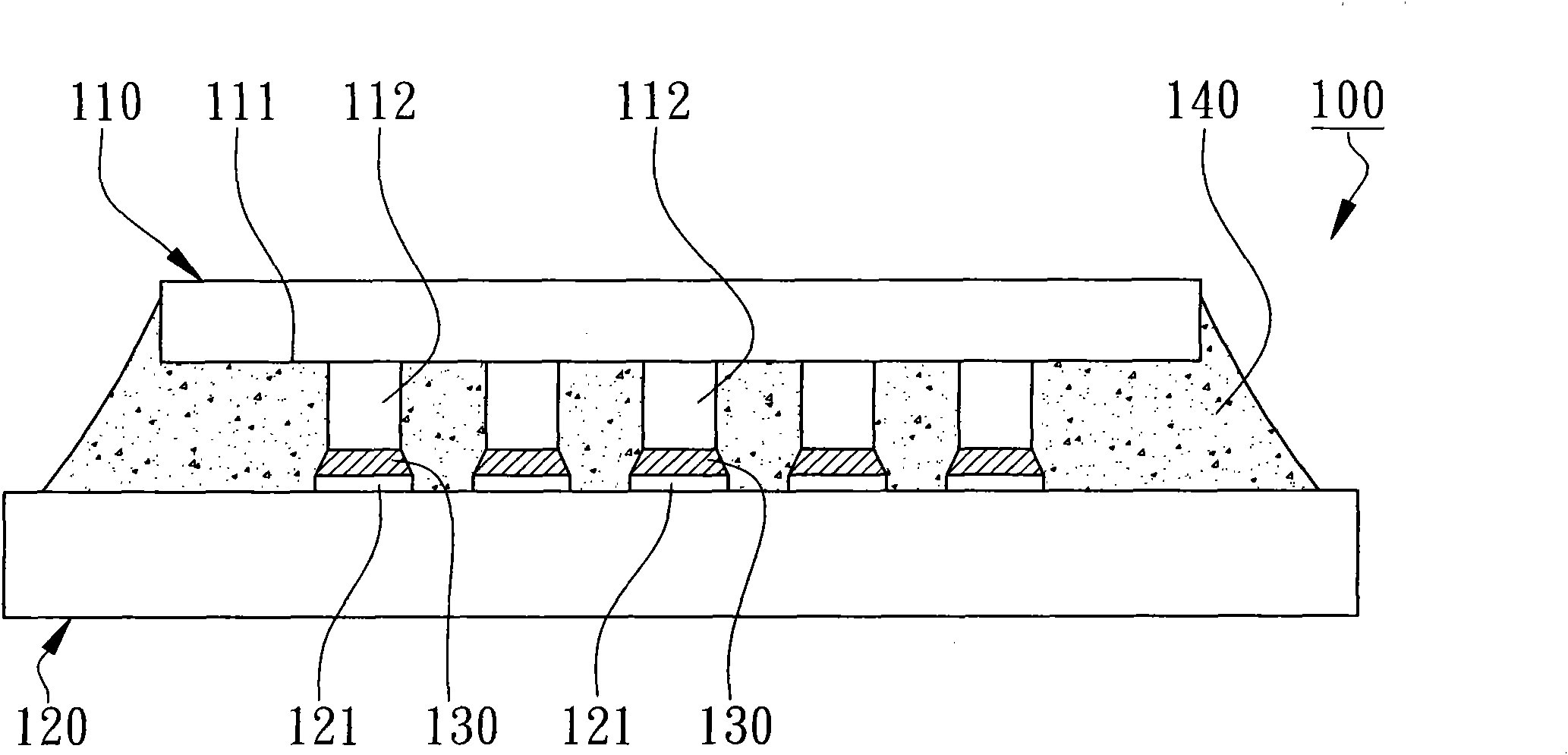

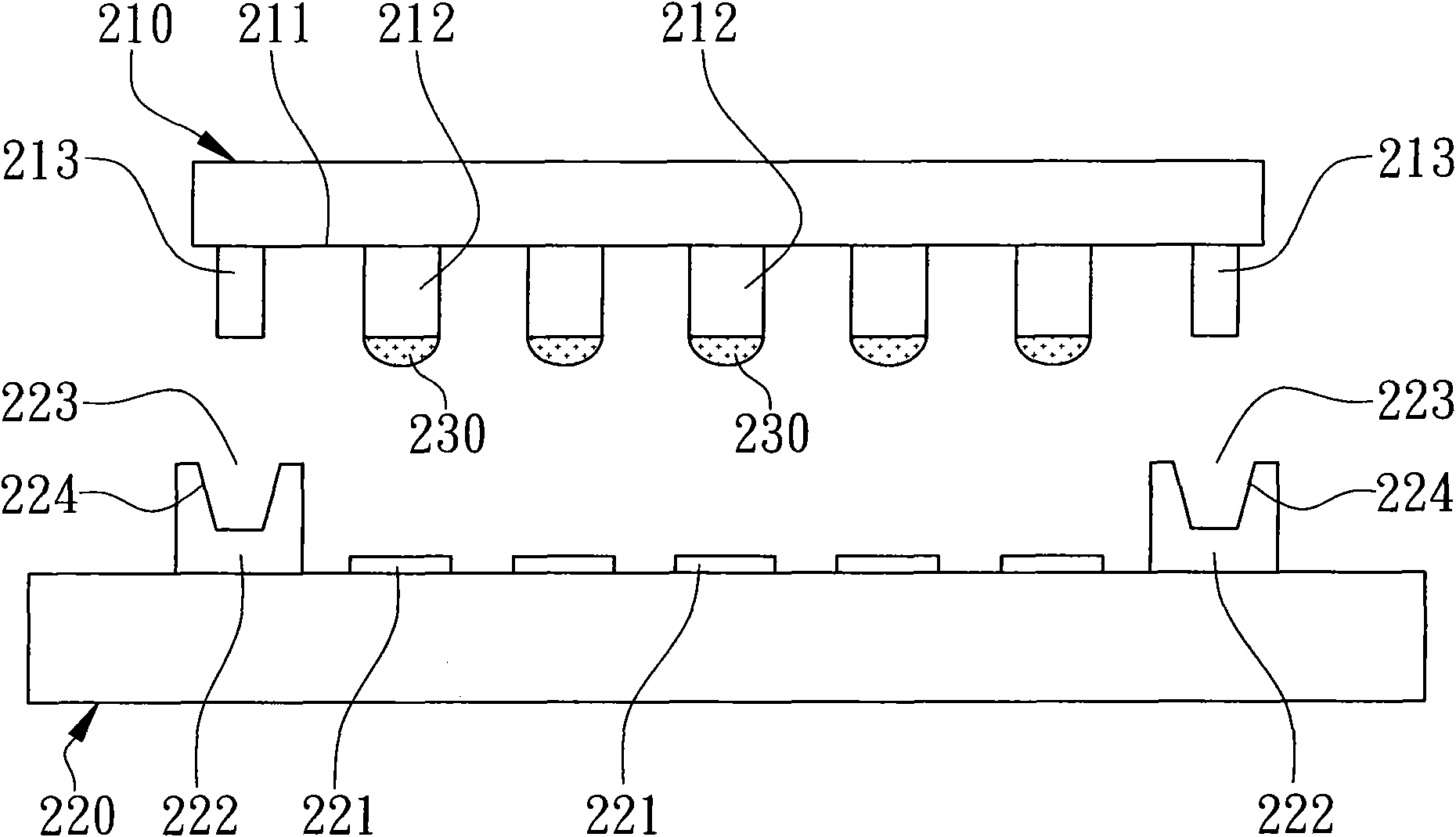

Packaging structure

ActiveCN103730429AHighly integratedImprove packaging efficiencySemiconductor/solid-state device detailsSolid-state devicesSemiconductor chipEngineering

A packaging structure comprises a lead frame, a pre-packaging face plate. The lead frame is provided with a plurality of bearing units distributed in a matrix mode and middle ribs used for fixing the bearing units, each bearing unit comprises a plurality of independent pins, and openings are formed between adjacent pins. The pre-packaging face plate comprises a first plastic-packaging layer, openings, and a second plastic-packaging layer, wherein a plurality of integration units distributed in a matrix mode are arranged in the first plastic-packaging layer, at least one semiconductor chip is arranged in each integration unit, a plurality of welding discs are arranged on the surface of the semiconductor chip, the welding discs are provided with metal protruding blocks, the pre-packaging face plate is inversely arranged on the first surface of the lead frame, the integration units correspond to the bearing units, the metal protruding blocks on the semiconductor pins are connected with the first surfaces of the pins in a welding mode. The openings are filled into the openings between the pins, the second plastic-packaging layer is filled into the space between the pre-packaging face plate and the first surface of the lead frame, and the second plastic-packaging layer is exposed of the second surfaces of the pins. The packaging structure is small in occupied space, and the integration level is improved.

Owner:NANTONG FUJITSU MICROELECTRONICS

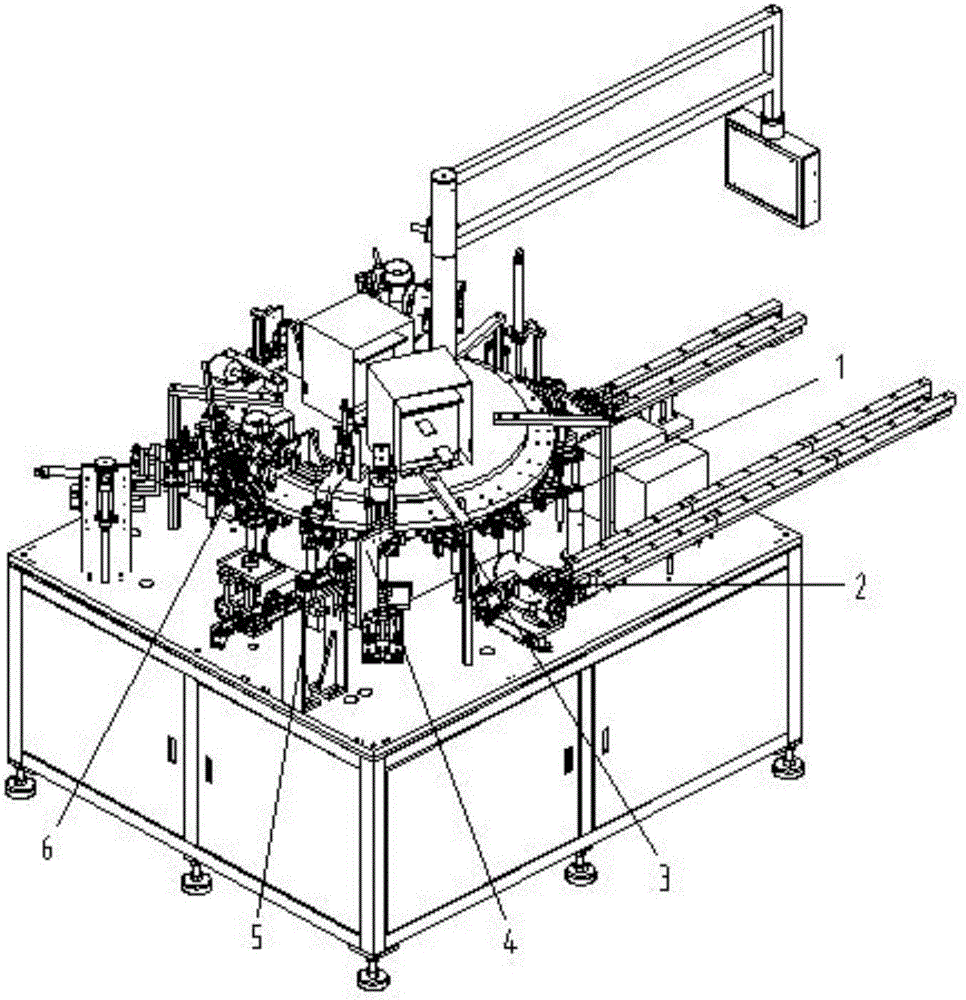

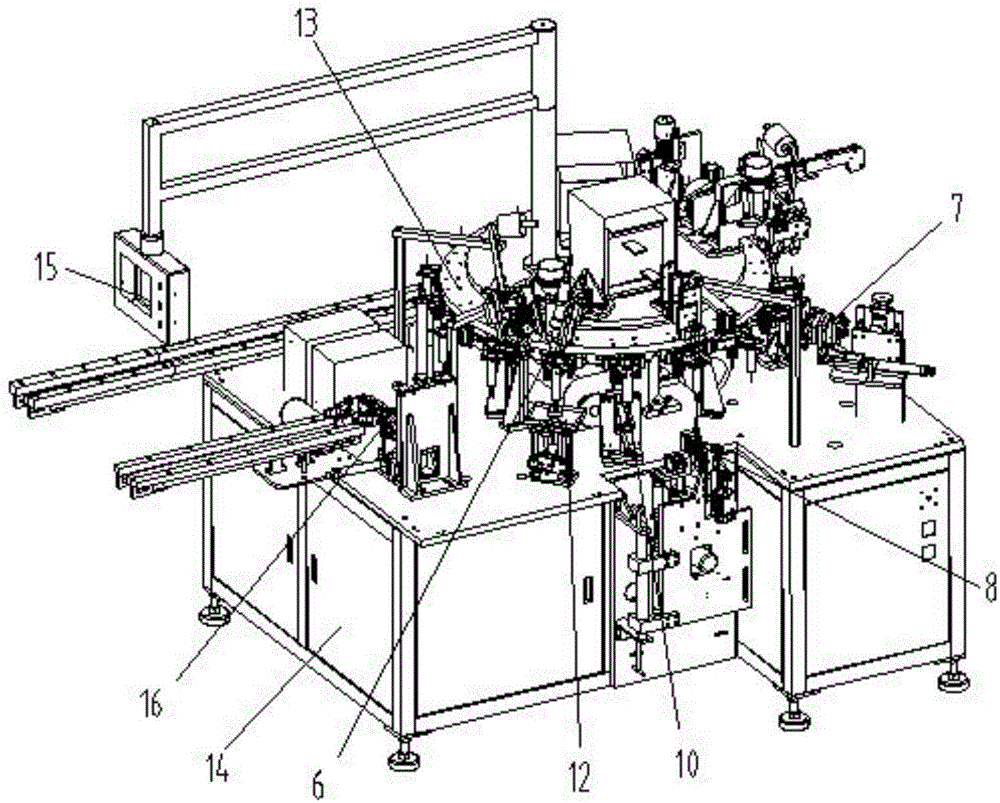

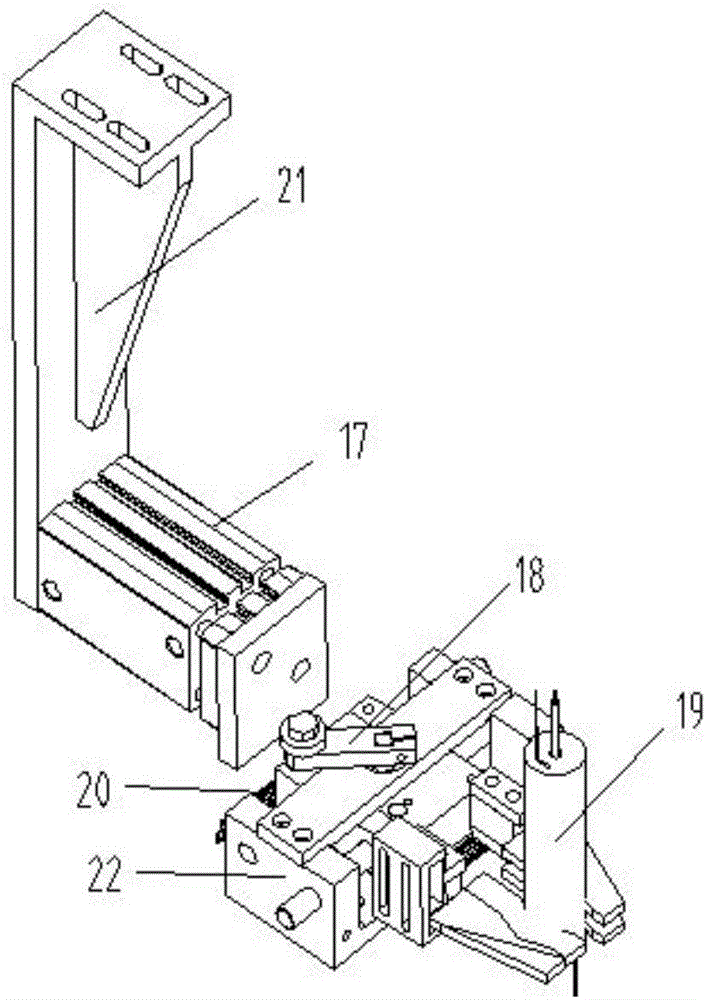

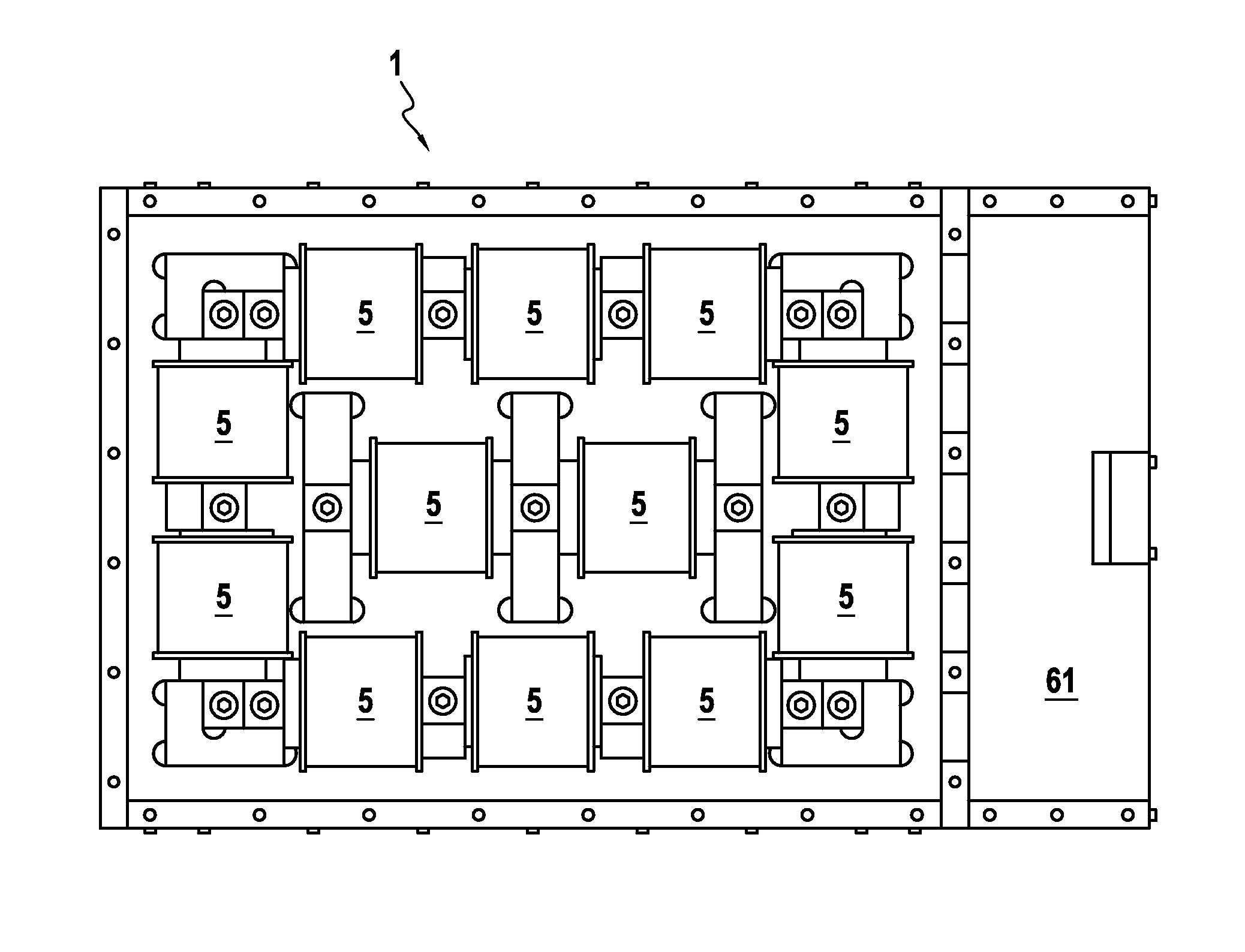

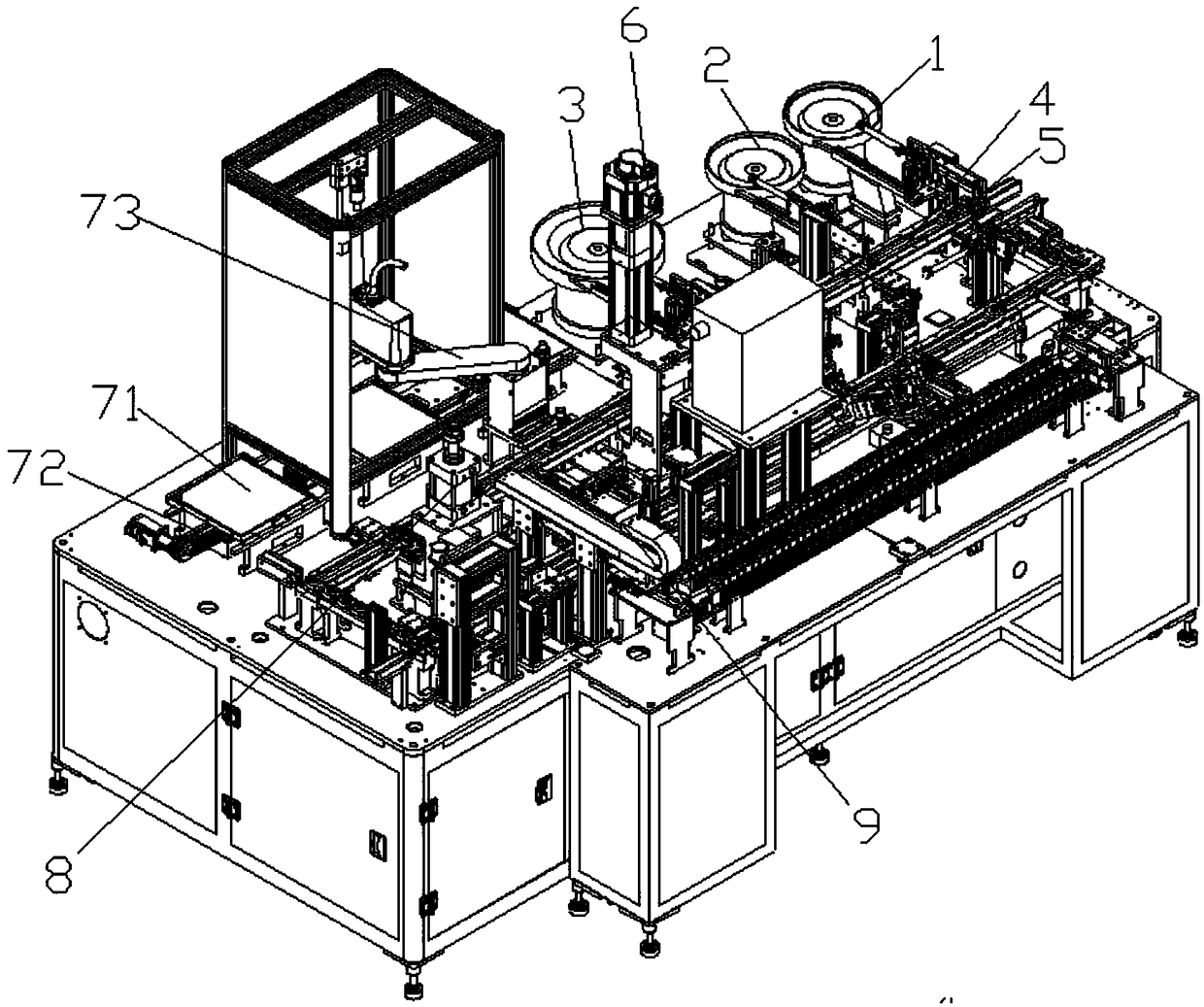

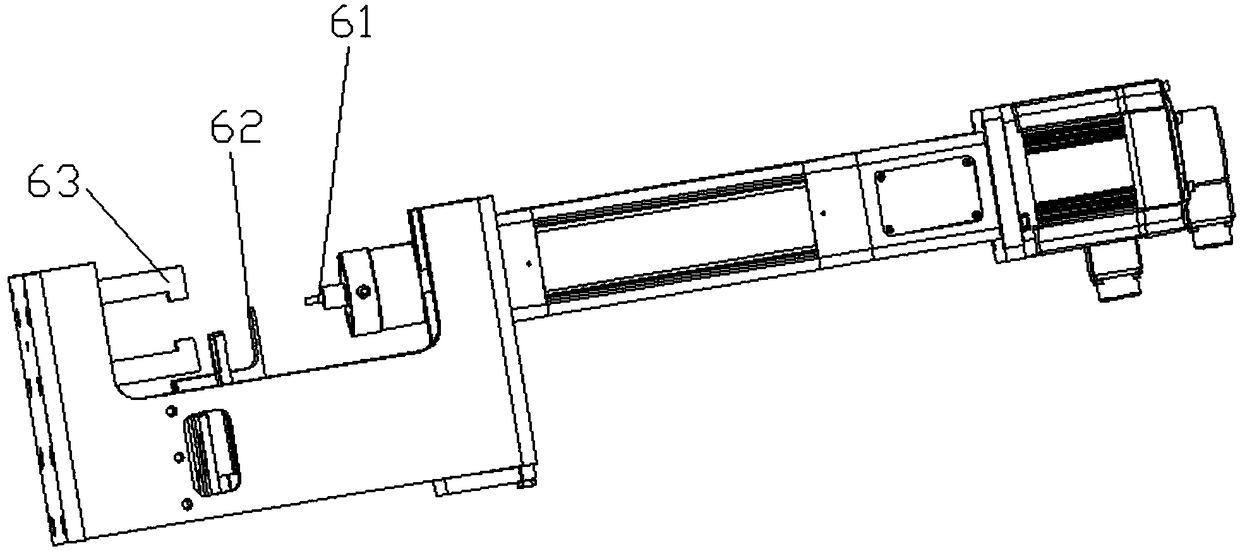

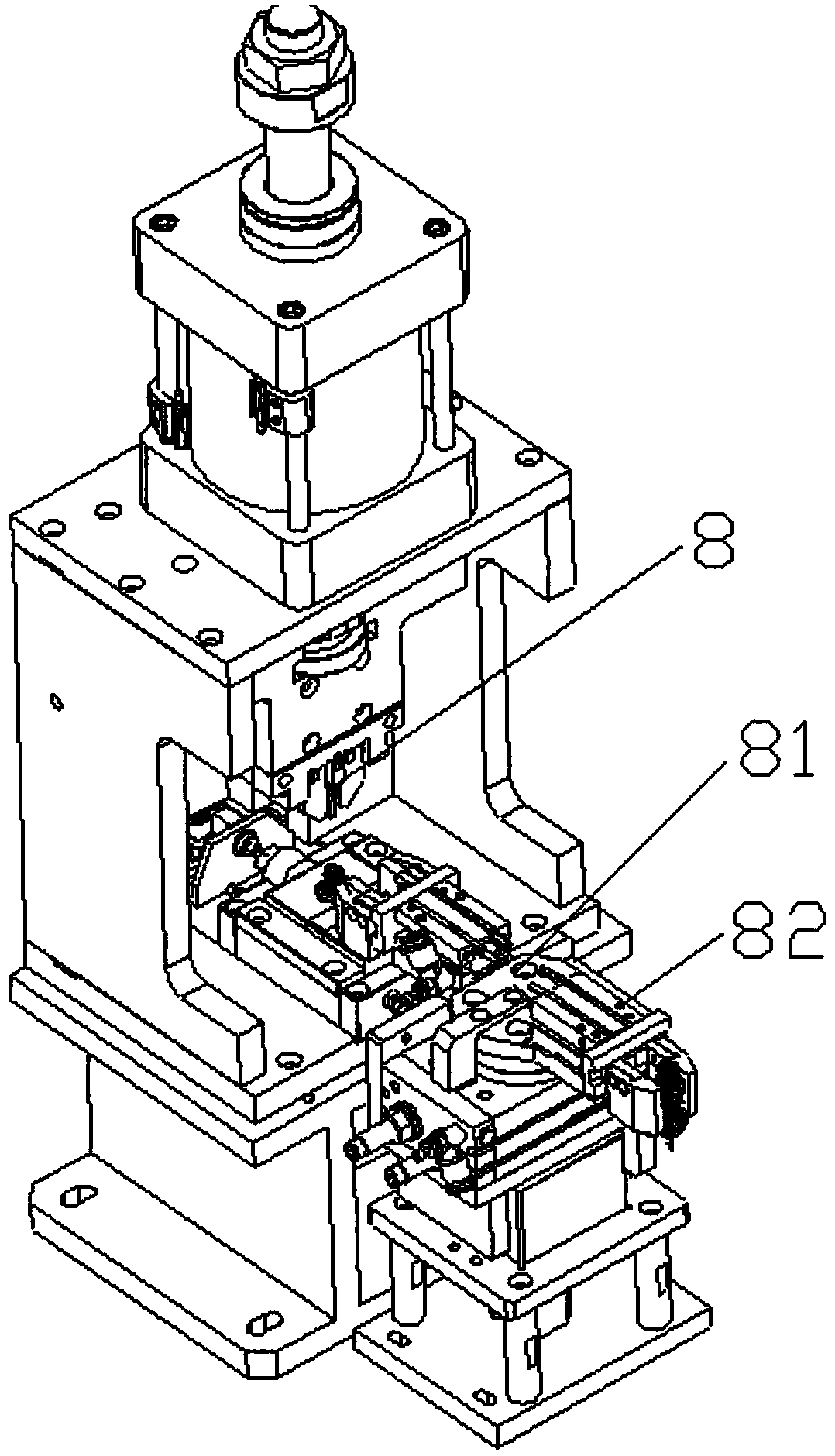

Automatic assembly machine of round capacitor

ActiveCN106847558ARealize automatic flipImprove welding efficiencyTerminal applying apparatusCapacitanceDistribution control

The invention relates to the field of capacitor processing equipment, in particular to an automatic assembly machine of a round capacitor. The machine includes a power distribution control box, a rotary plate and an operation screen, wherein the rotary plate and the operation screen are arranged above the power distribution control box through a bracket and communicated with the power distribution control box; clamps are uniformly arranged along a circle under the rotary plate; a feeding device, a positioning detection device, an upper tin-wire feeding device, a polarity detection device, a first tin-wire welding device, a capacitor turnover device, a lower tin-wire feeding device, a second tin-wire welding device and a discharging device are arranged in sequence on the outer side of the rotary plate in the clockwise direction and connected with the power distribution control box. The automatic assembly machine of the round capacitor has the advantages that automatic operation is adopted from feeding to discharging, the processing accuracy and processing efficiency of the round capacitor are greatly improved, and a large amount of working time is saved.

Owner:天长市中发电子有限公司

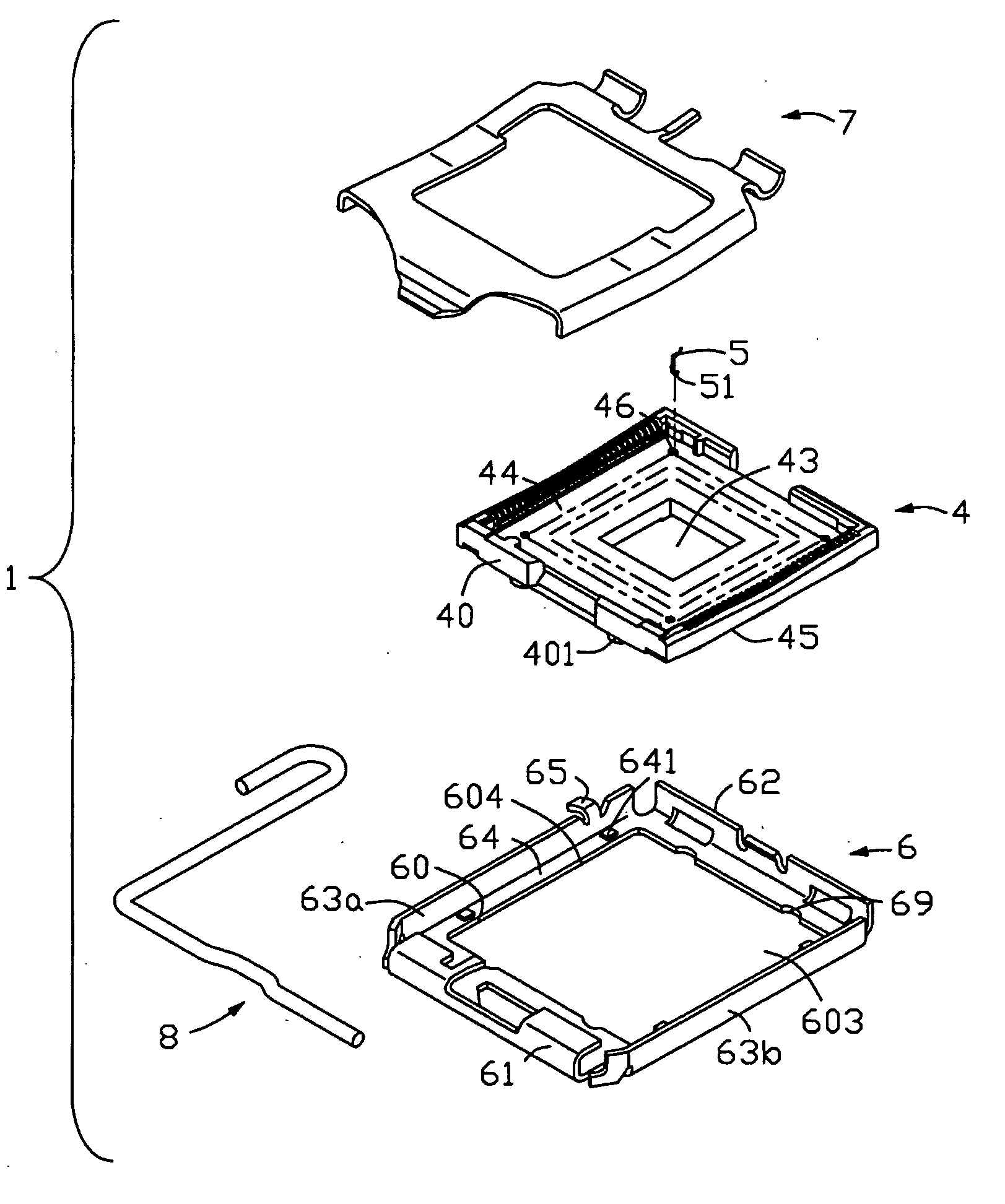

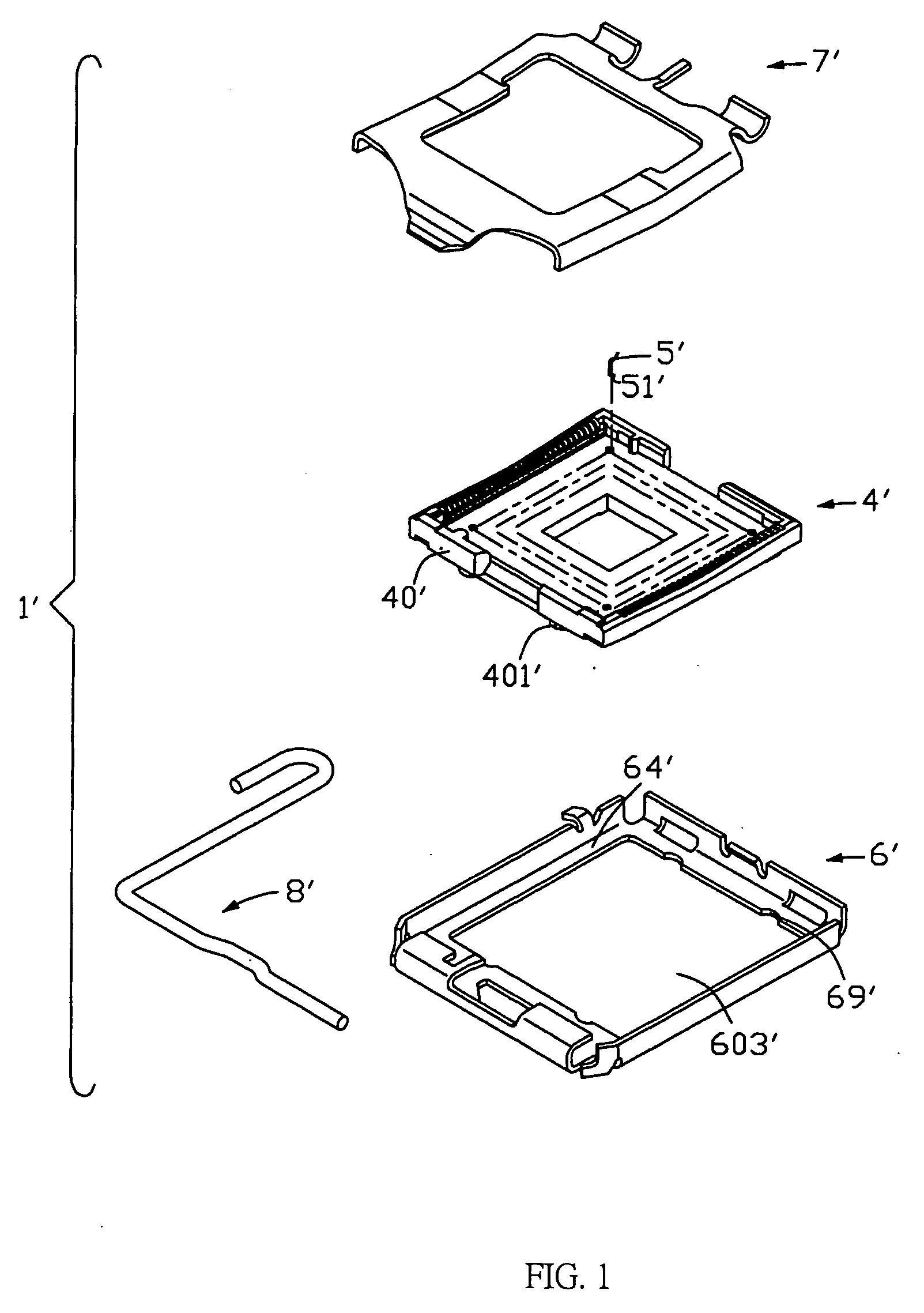

Socket assembly

InactiveUS20070173081A1Ensure reliability connect performancePrevent undesired engagementEngagement/disengagement of coupling partsElectrical apparatus contructional detailsEngineeringElectrical connector

An electrical connector (1) comprises an insulative housing (4), a stiffener (6) defined around the housing (4), a clip (7) pivotably engaged on one end of the stiffener (6), and a lever (8) engaged on an opposite end of the stiffener (6) for fastening the clip (7) onto the housing (4). The housing (4) comprises an upper surface (44) and a lower surface (45) opposite to the upper surface (44) and a platform surface (47) projected between the upper surface (44) and the lower surface (45) and a planar sidewall (40) surrounded thereof. The sidewall (1) comprises an upper section (42) and a lower section (48) that is the circumference of the upper sidewall (42) is longer than that of the lower sidewall (48). The lower sidewall (48) is enveloped by the first sidewall (481) and the second sidewall (482) opposite to the first sidewall (481) and configured as a shape similar to that of the opening (603) of the stiffener (6), hence the housing (4) can be interferentially mounted into the opening (603) of the stiffener (6). The housing (4) defines a number of positioning poles (401) on the platform surface (47) adjacent to the outside of the first sidewall (481) of the housing (4). The stiffener (6) defines a number of recesses (69) for receiving the poles (401). In addition, the stiffener (6) defines a number of projections (641) projected toward the platform surface (47) of the housing (4) for engaging with the platform surface (1).

Owner:HON HAI PRECISION IND CO LTD

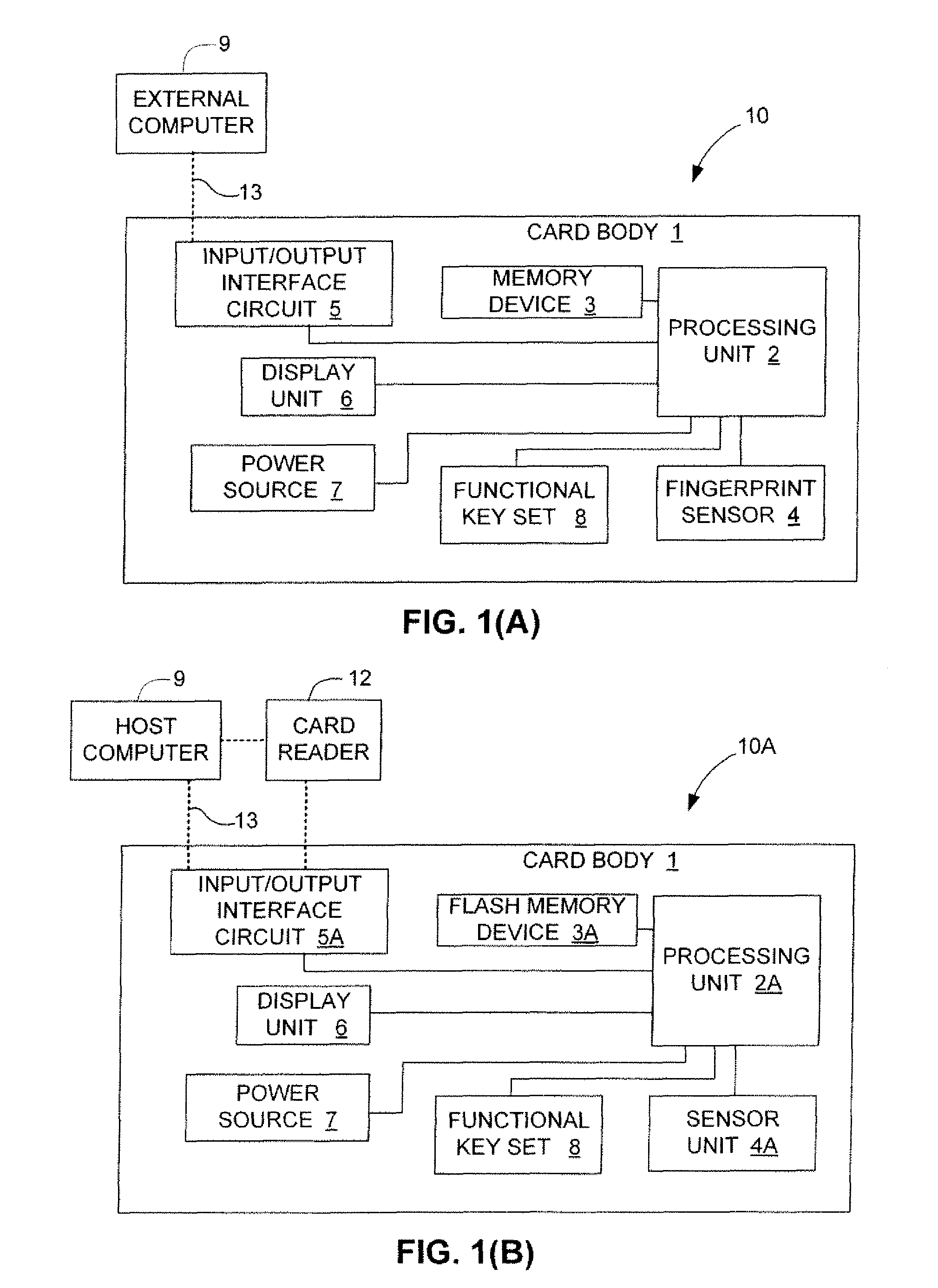

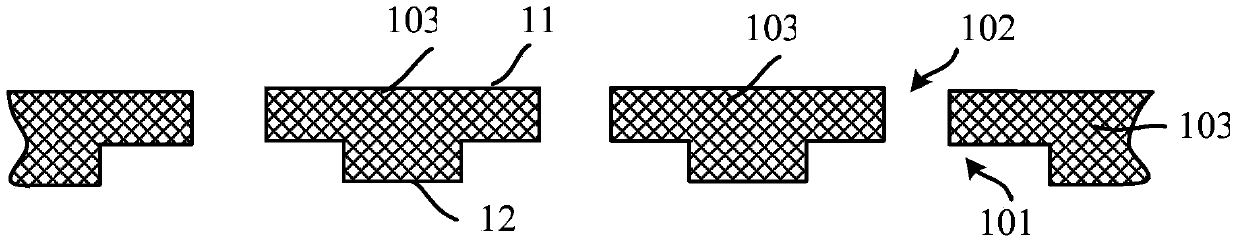

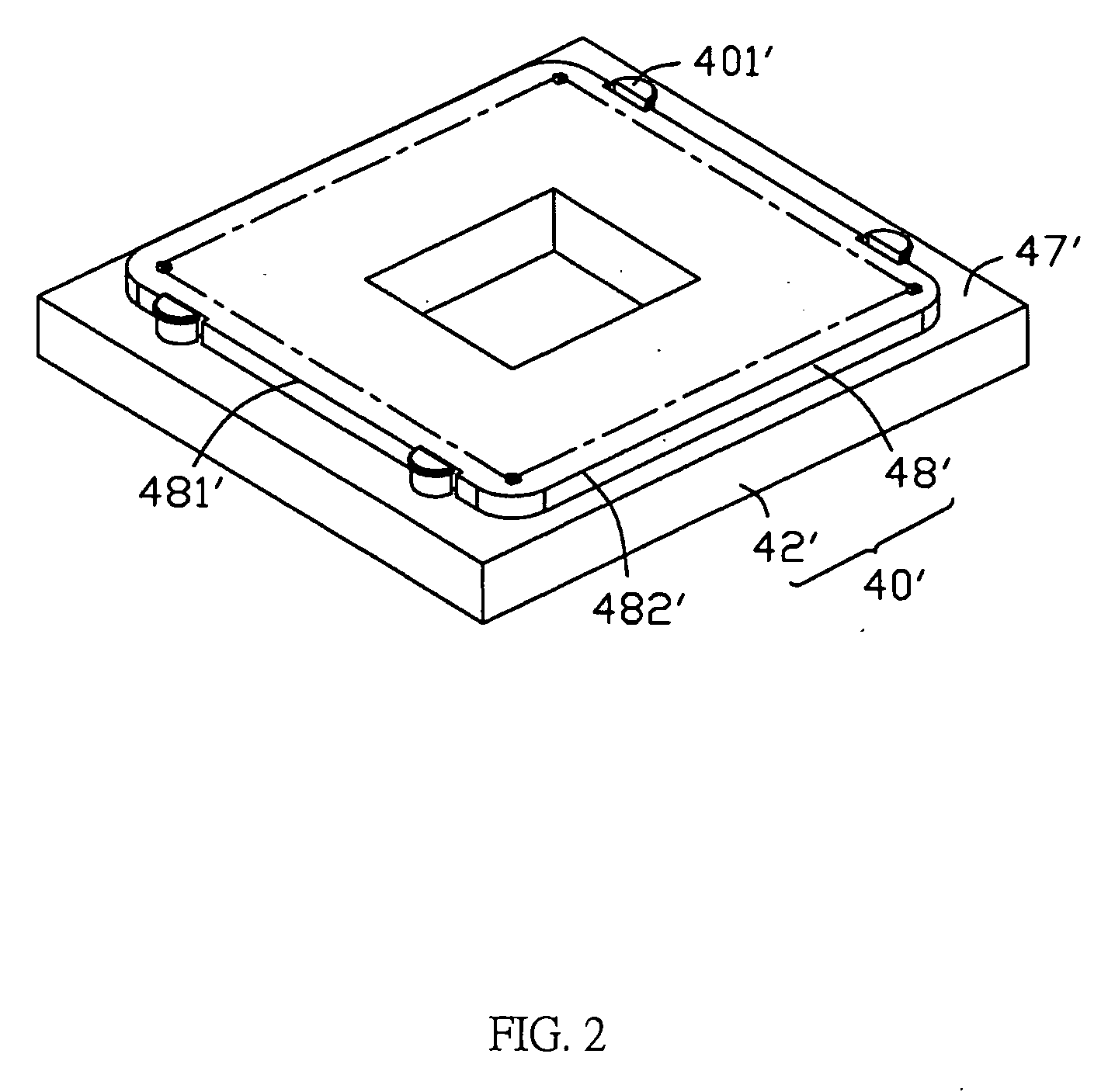

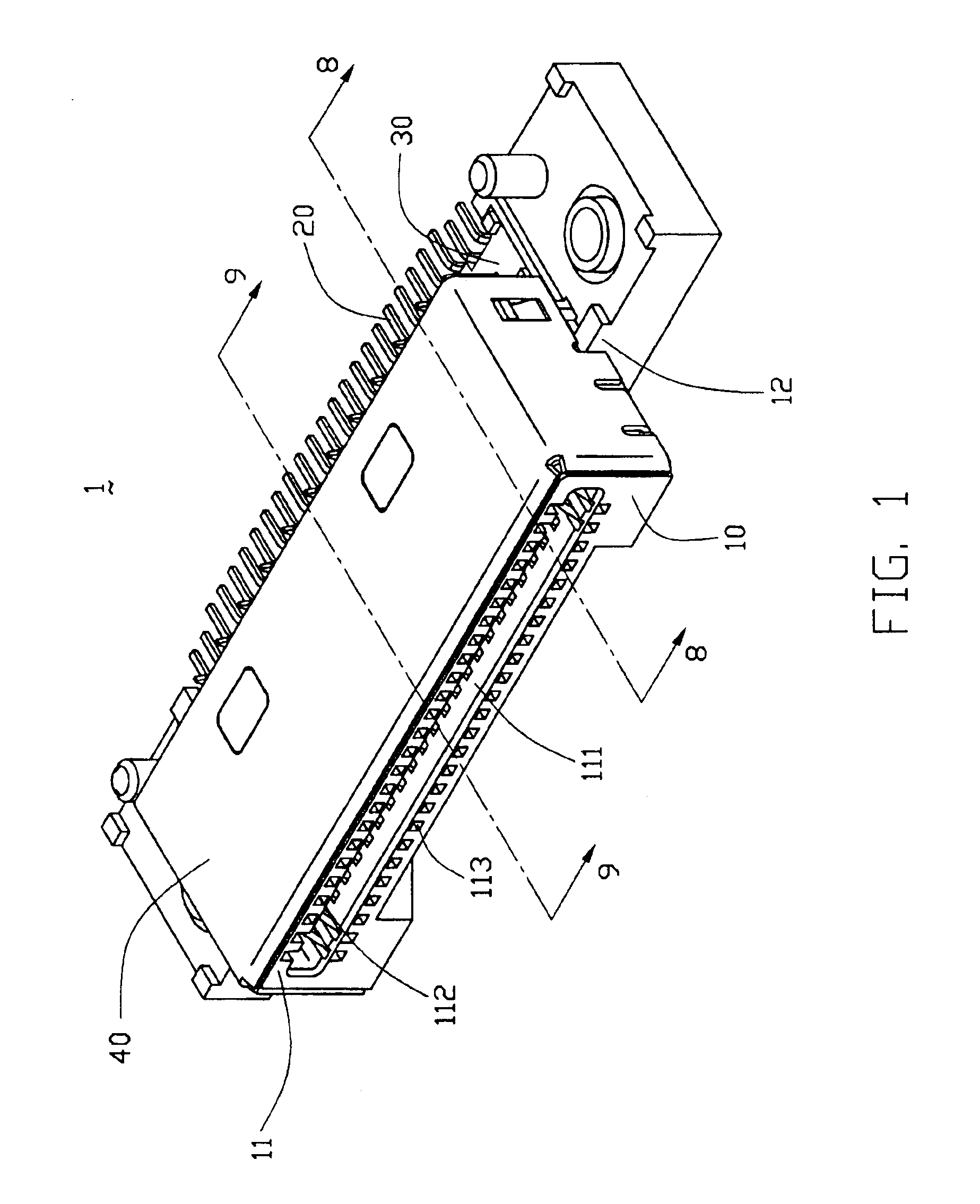

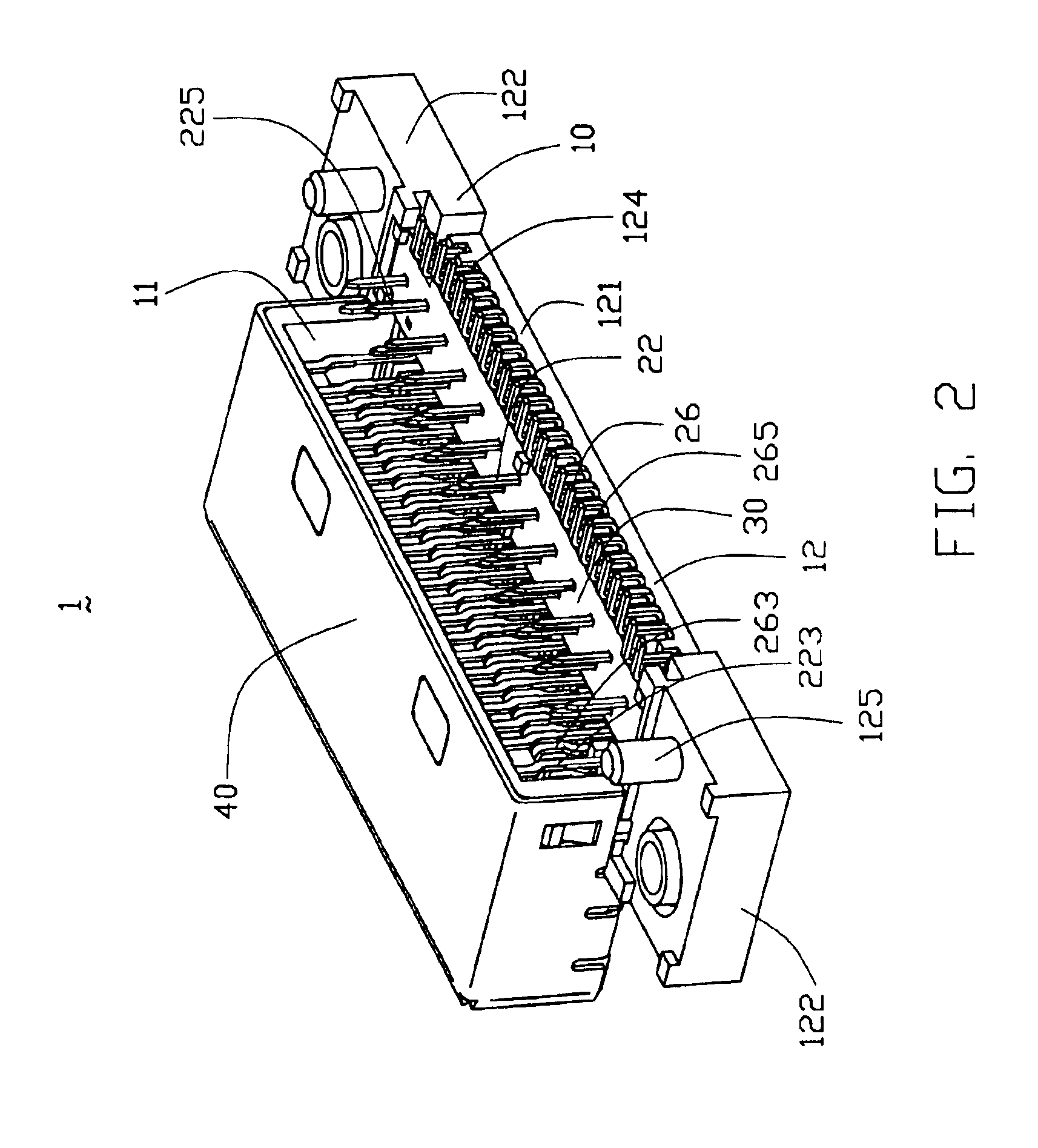

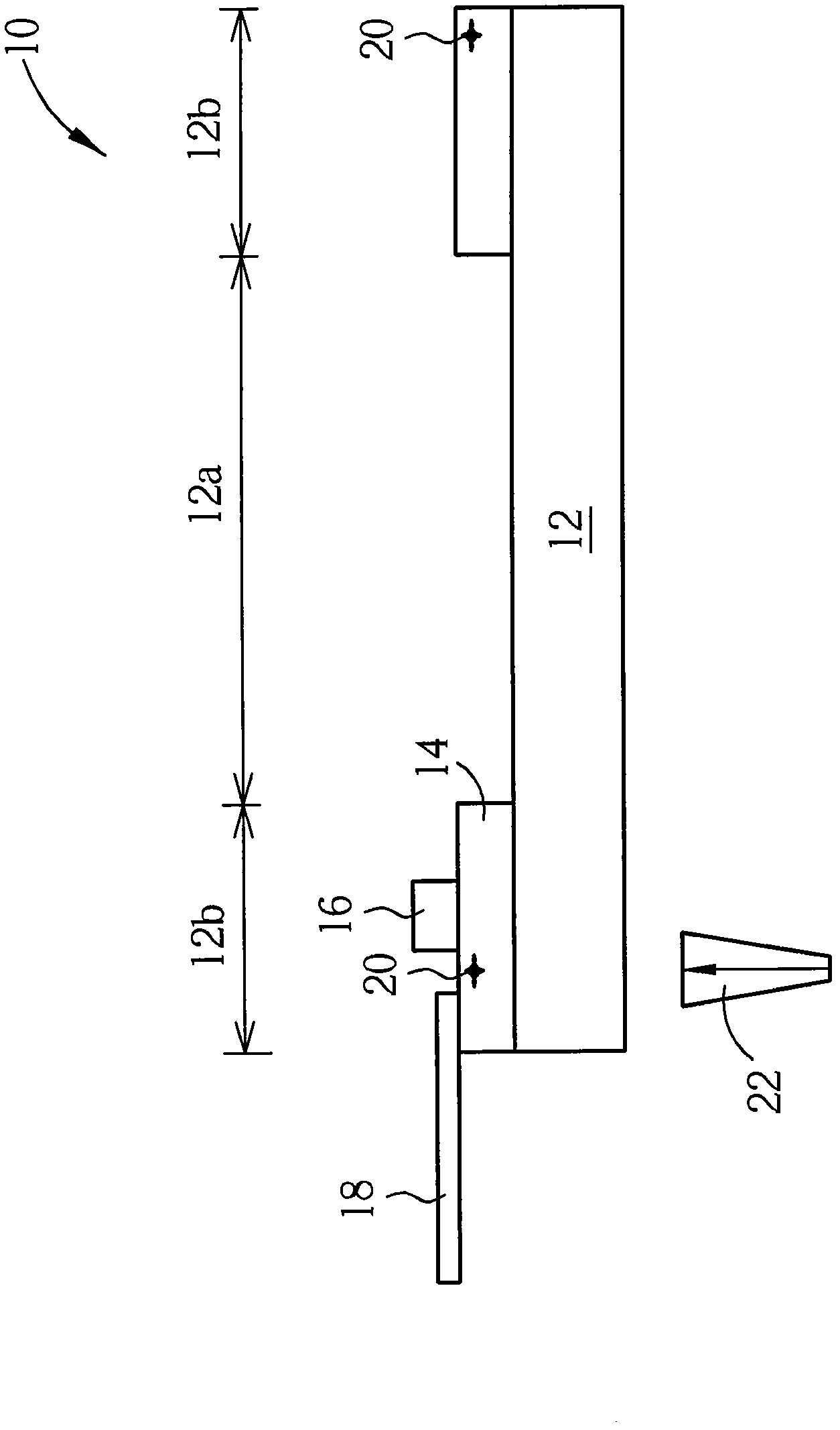

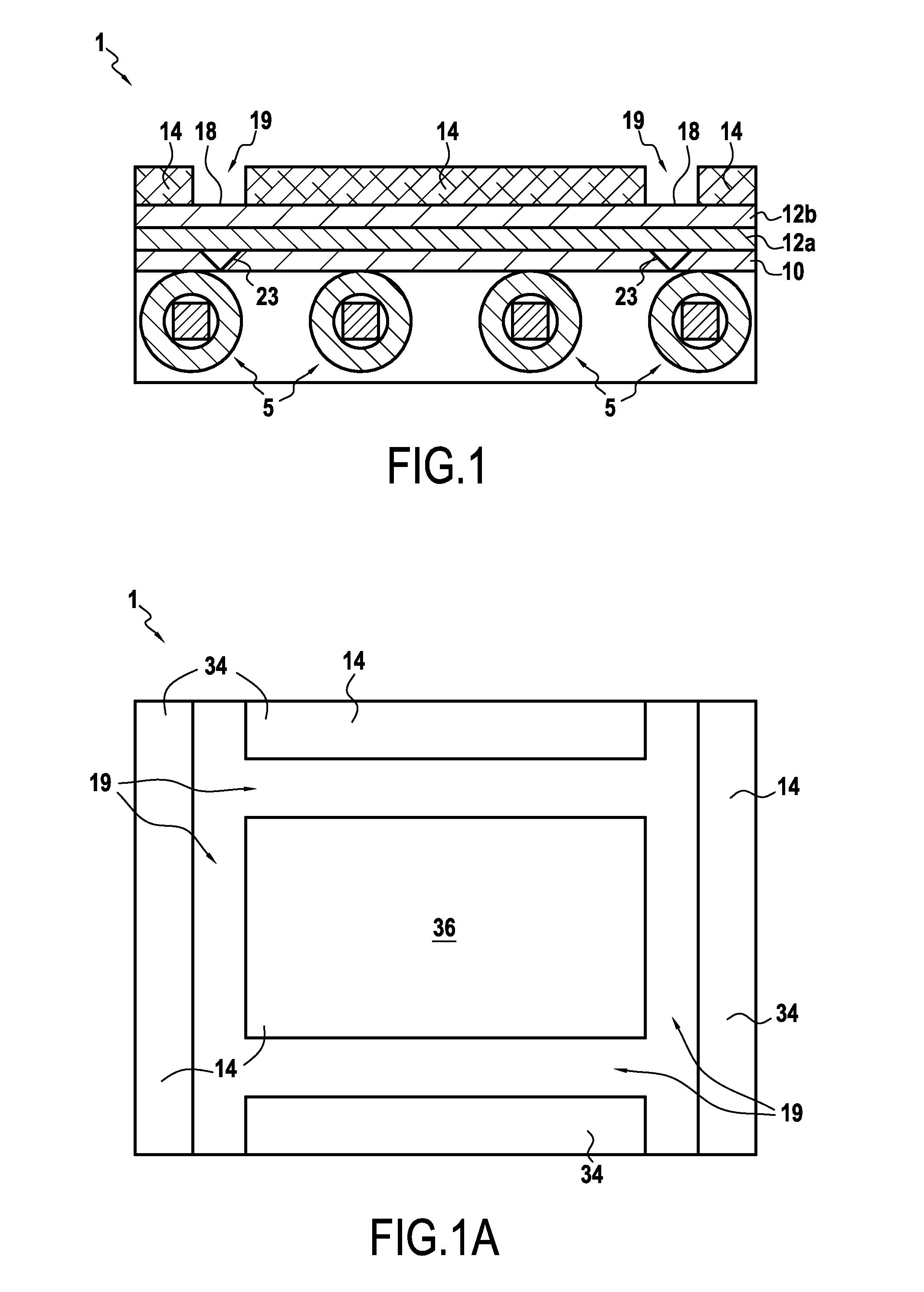

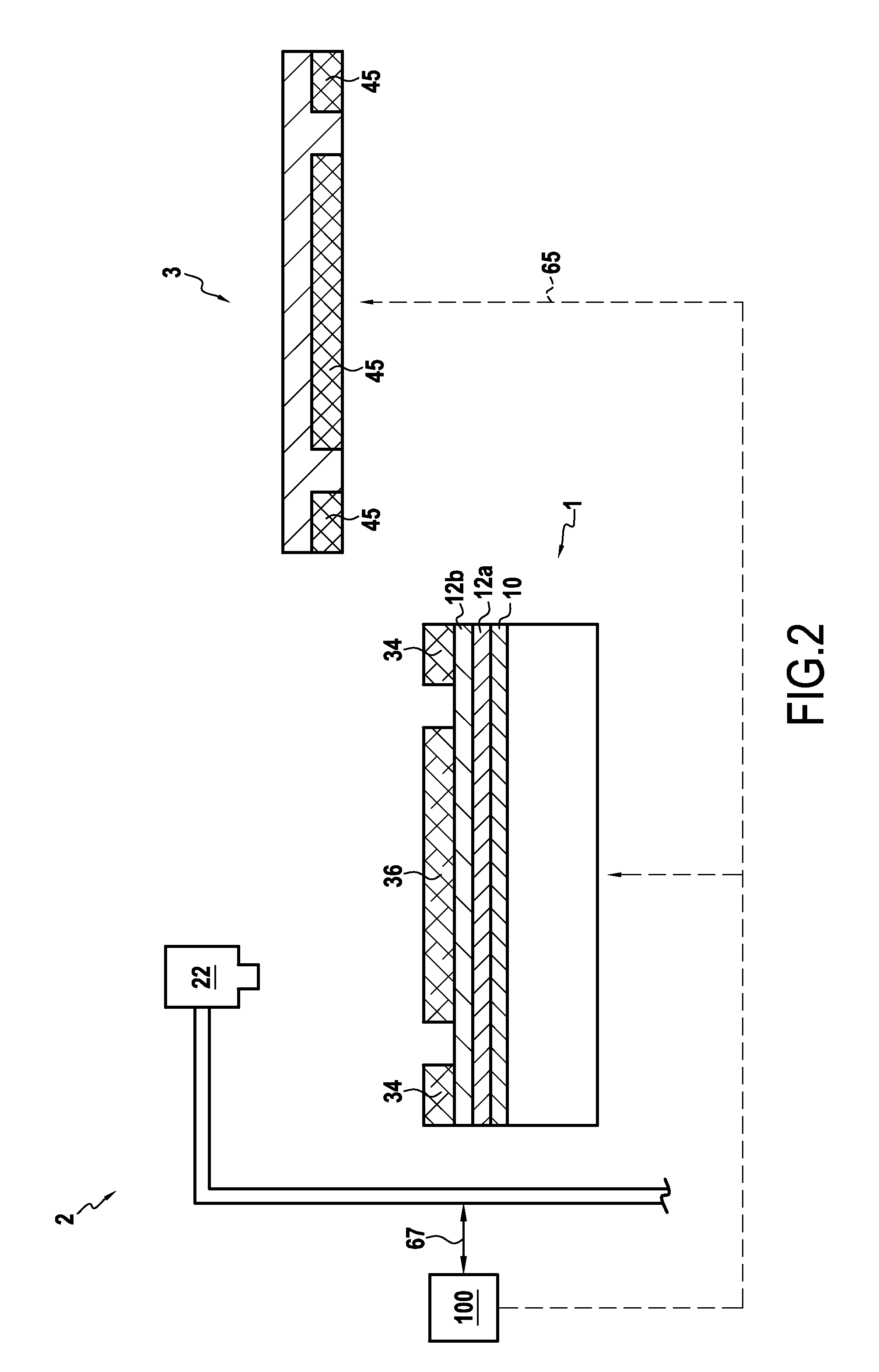

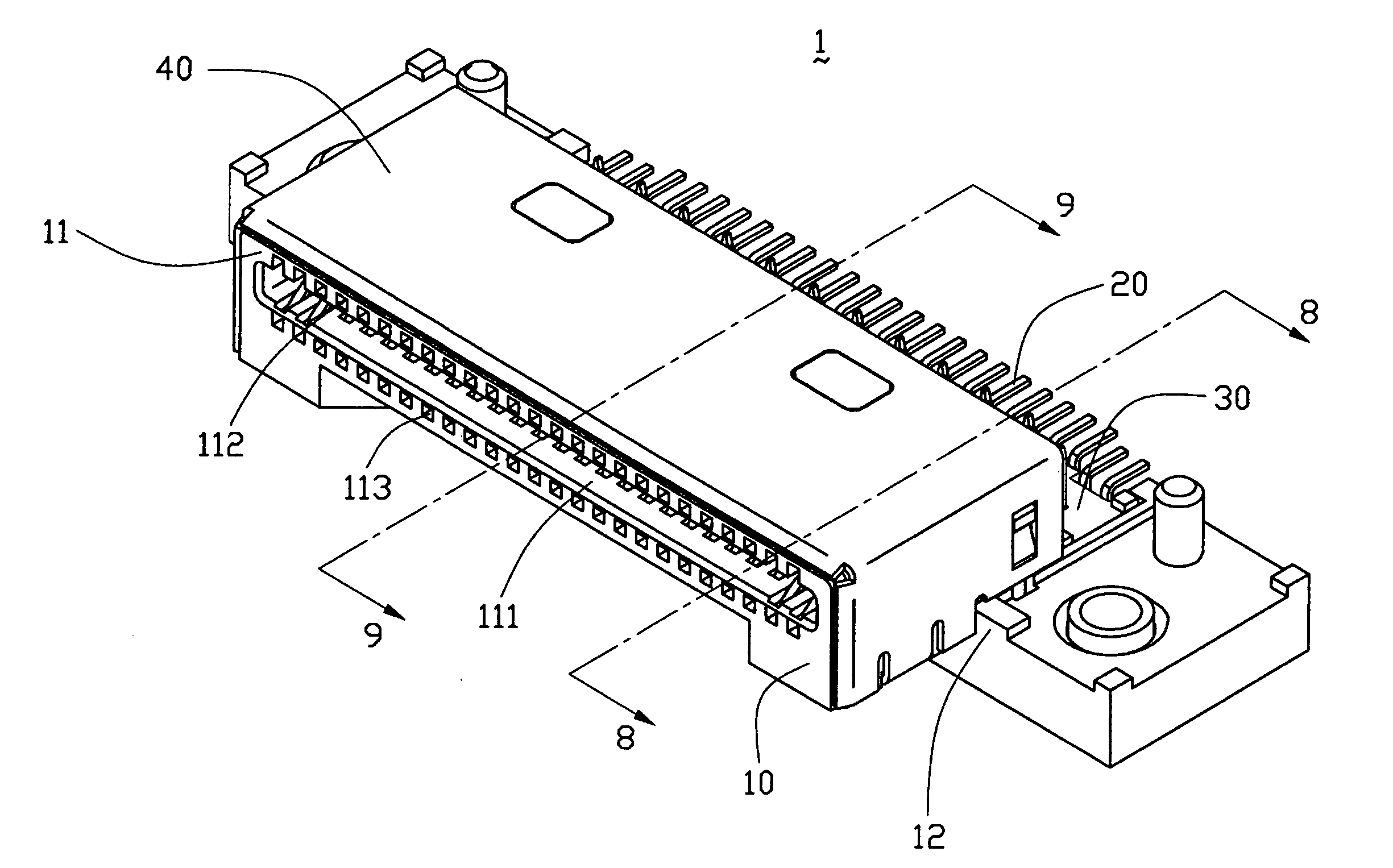

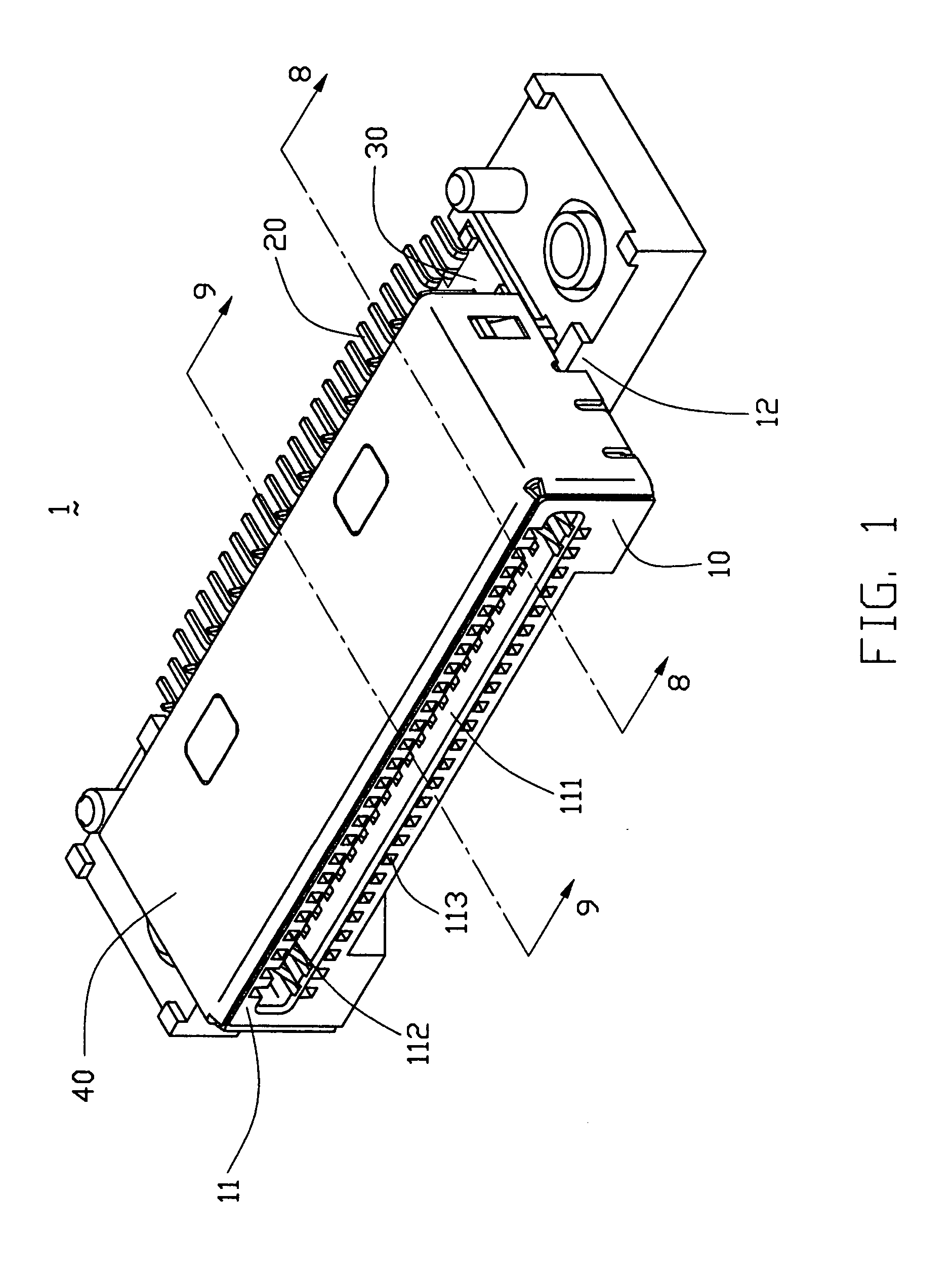

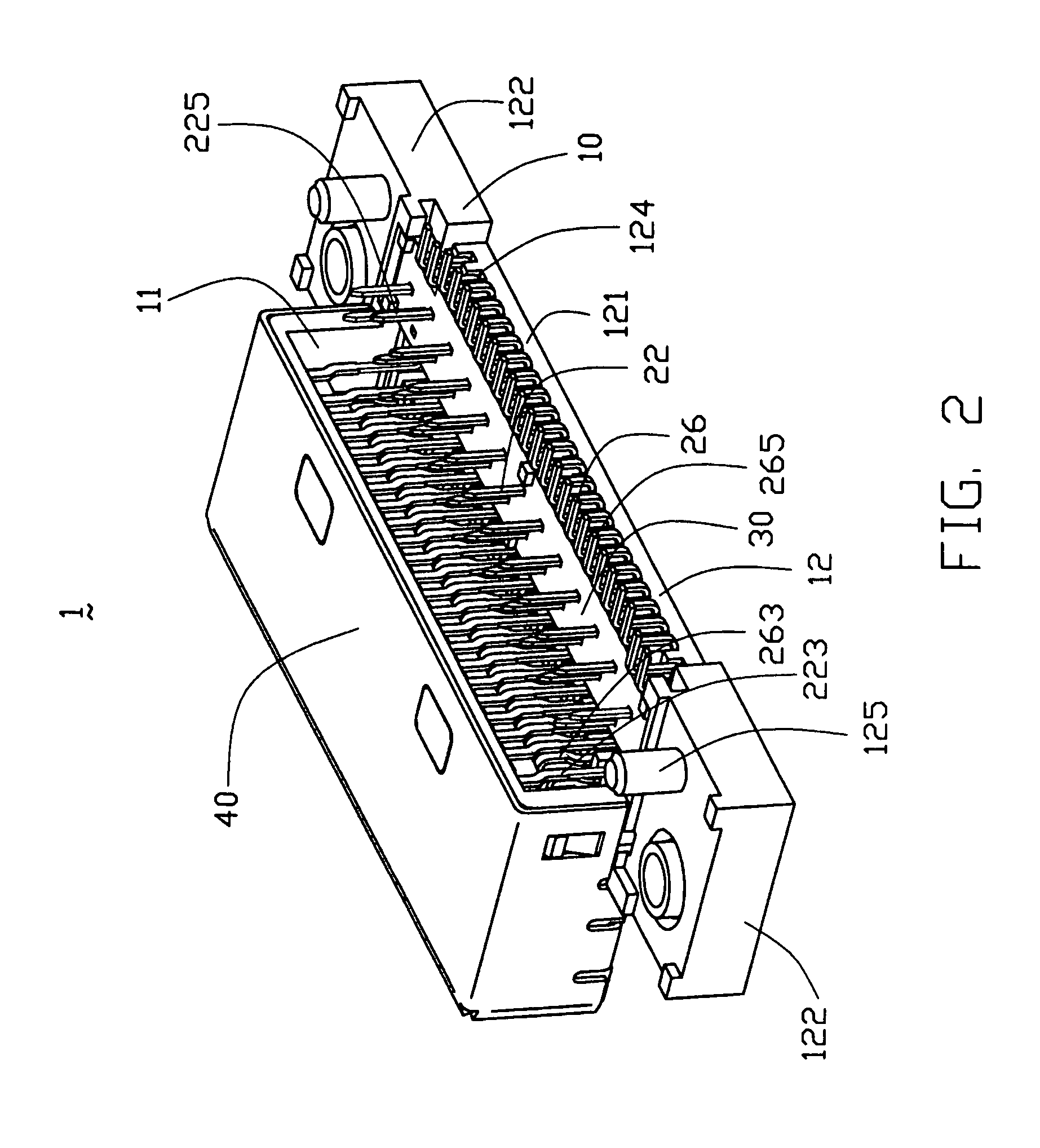

Electrical connector having improved terminals

InactiveUS6926542B2Precision weldingCoupling device connectionsFixed connectionsEngineeringSoldering

A board-mounted electrical connector (1) includes an insulative housing (10), a number of first terminals (22) and a number of second terminals (26) received in the housing, and a spacer (30) assembled on the housing. The insulative housing includes a base portion (12) defining a number of recesses (124) thereon. Each first terminal includes a contacting portion (222) and a soldering portion (225) extending perpendicularly to a printed circuit board (50). Each second terminal includes a contacting portion (262), a soldering portion (265) extending parallel to the PCB and a connecting portion (264) connecting the contacting portion and the soldering portion. The spacer defines a number of holes (33) for receiving and organizing the soldering portions of the first terminals and forms a number of protrusions (34) cooperating with the recesses of the base portion for organizing corresponding connecting portions of the second terminals to thereby precisely position the soldering portions of the second terminals.

Owner:HON HAI PRECISION IND CO LTD

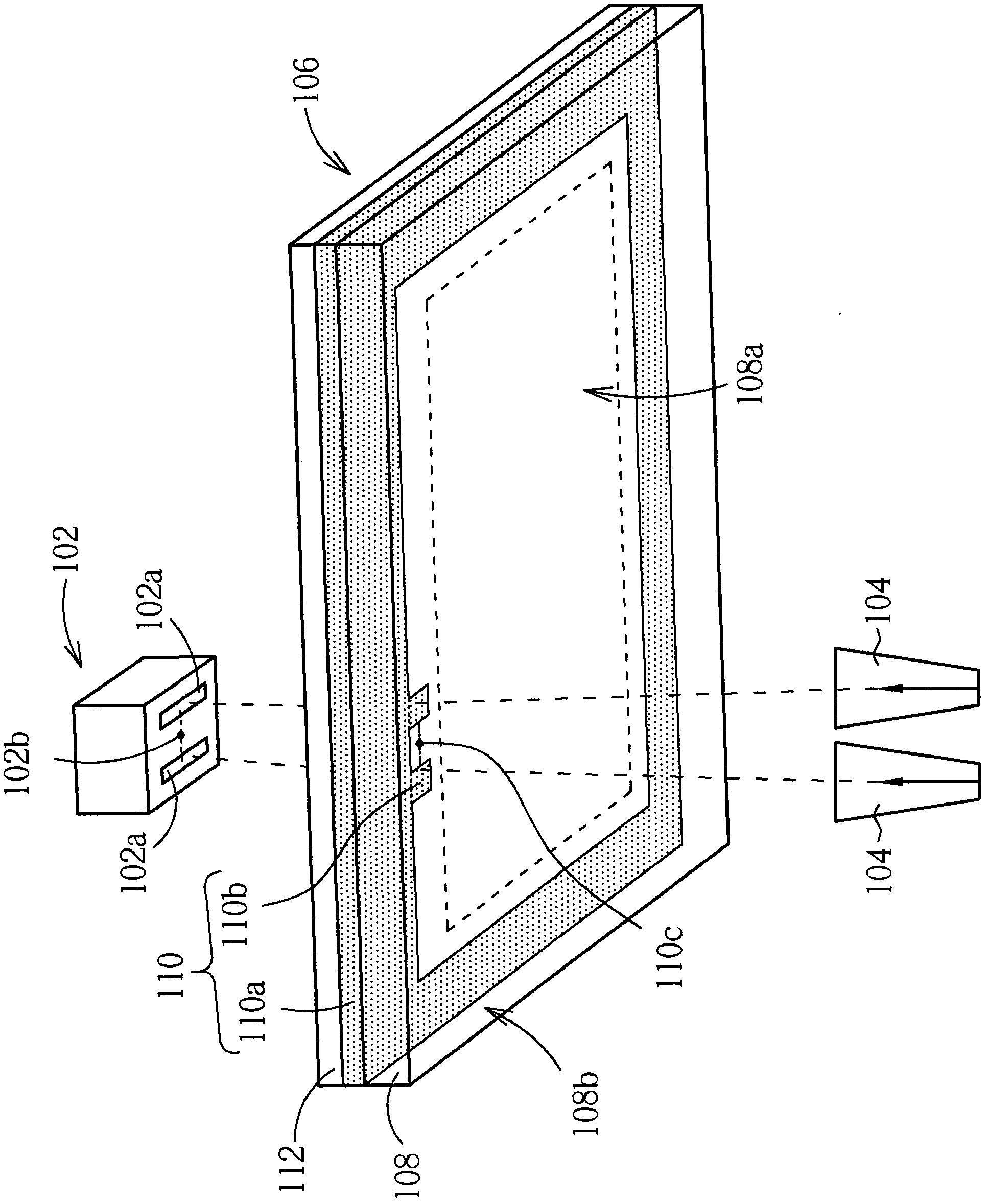

Touch control display device, touch control panel and manufacturing method thereof

InactiveCN102221928APrecision weldingStatic indicating devicesInput/output processes for data processingDisplay deviceComputer science

The invention discloses a touch control display device, a touch control panel and a manufacturing method thereof. The touch control panel comprises a transparent base plate, a light-shielding layer and a circuit module. The transparent base plate comprises a display region and a peripheral region surrounding the display region. The light-shielding layer which is located on the peripheral region comprises a light-shielding part and at least two contraposition parts. Each contraposition part is connected with the light-shielding part and projects towards the display region. The circuit module is equipped on one side of the light-shielding layer.

Owner:AU OPTRONICS CORP

Welding equipment and welding method thereof

InactiveCN103464942AImprove accuracyImprove welding qualityWelding/cutting auxillary devicesAuxillary welding devicesH shaped

The invention relates to the field of welding, in particular to welding equipment and a welding method thereof. The welding equipment comprises a welding seam location detector, a controller, a driving device and a welding gun. The welding seam location detector is used for detecting the welding seam location of corrugated web H-shaped steel in real time, and sending obtained welding seam location information to the controller; the controller is use for controlling the driving device to run according to the welding seam location information; the welding tip of the welding gun is moved to the welding seam location of the corrugated web H-shaped steel by the driving device according to the control of the controller. According to the welding equipment and the welding method thereof provided by the invention, a welding location can be adjusted in real time according to changes of the welding location, the welding location is high in accuracy, and the welding quality is high.

Owner:GUANGZHOU XINBO NUMERICAL CONTROL WELDING EQUIP

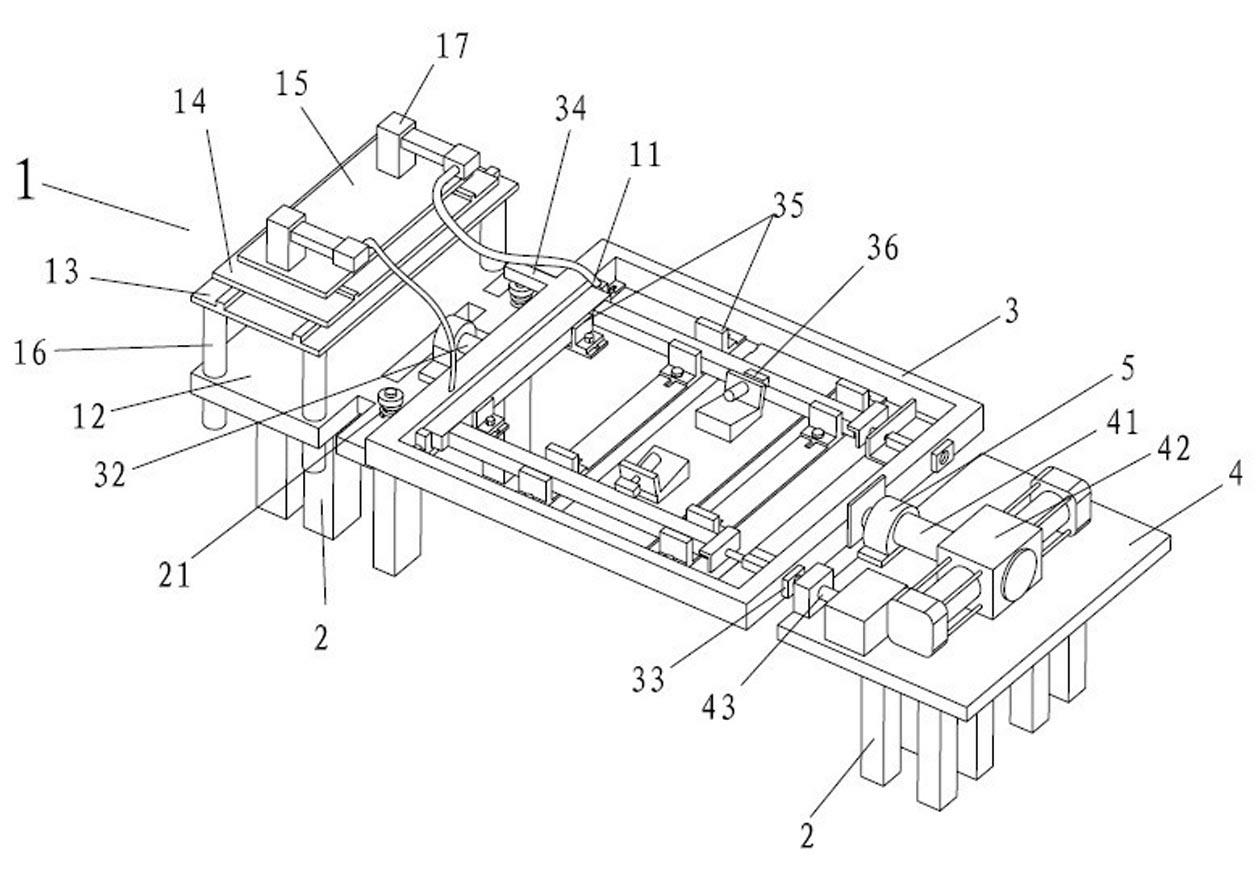

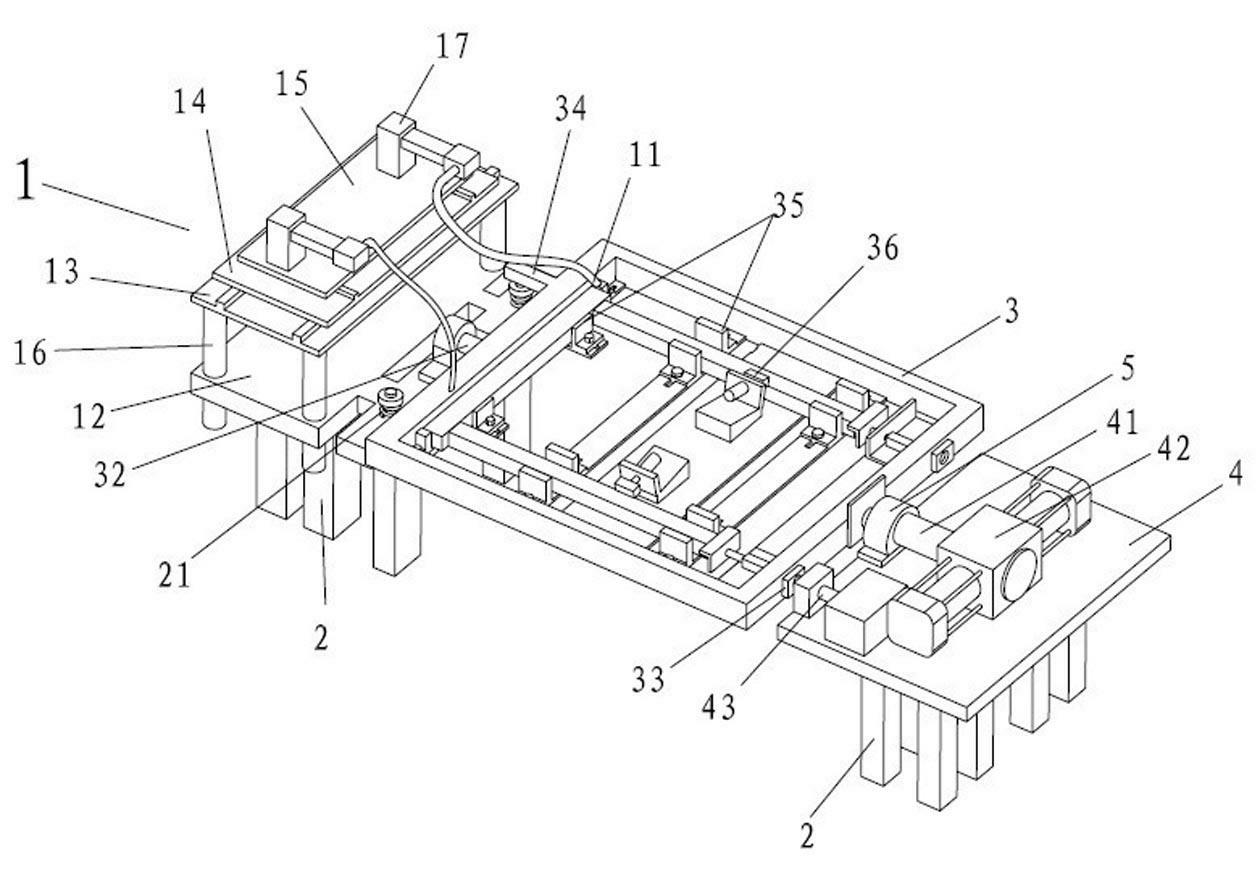

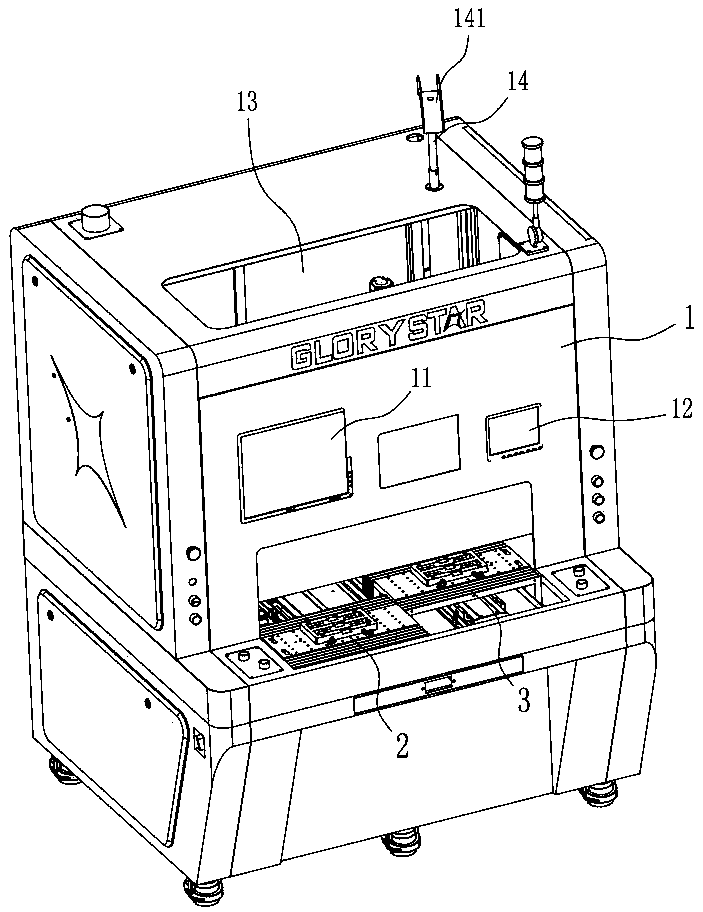

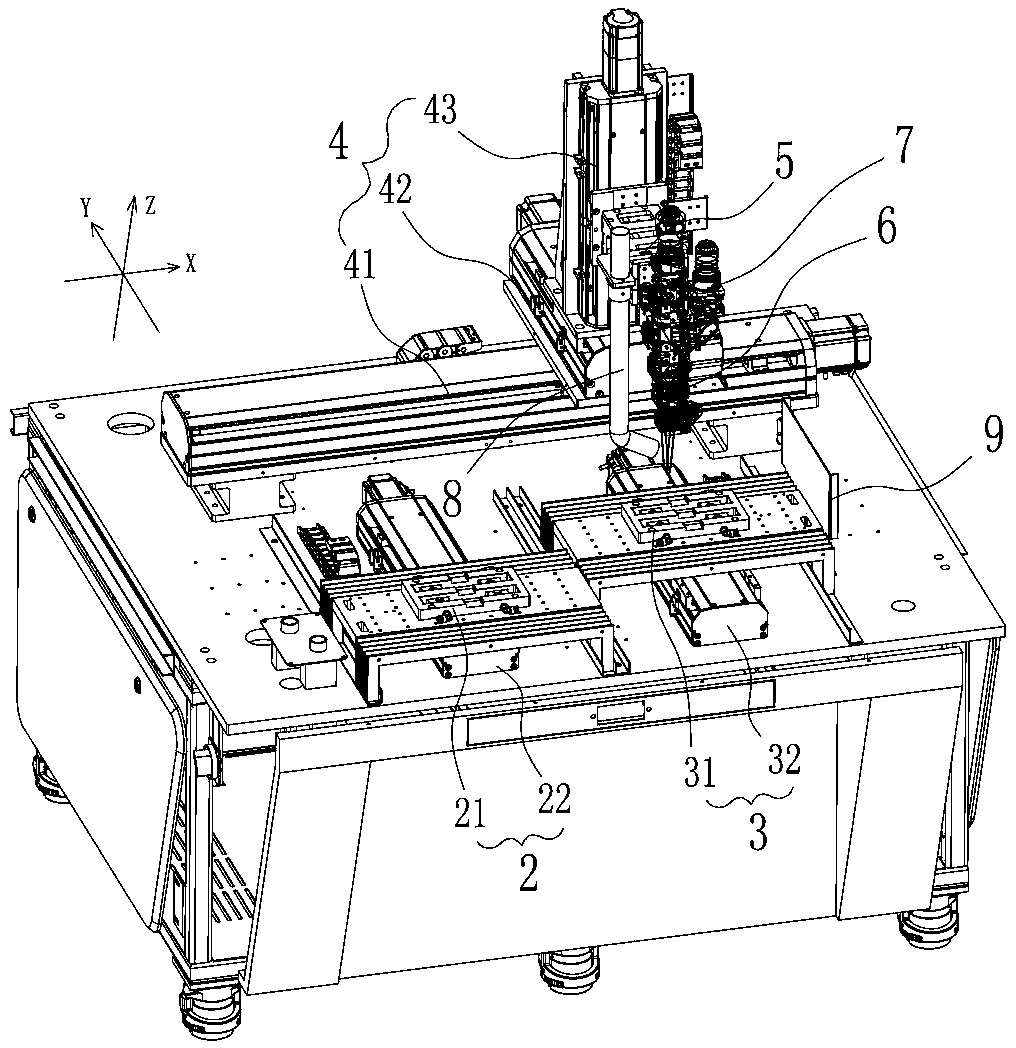

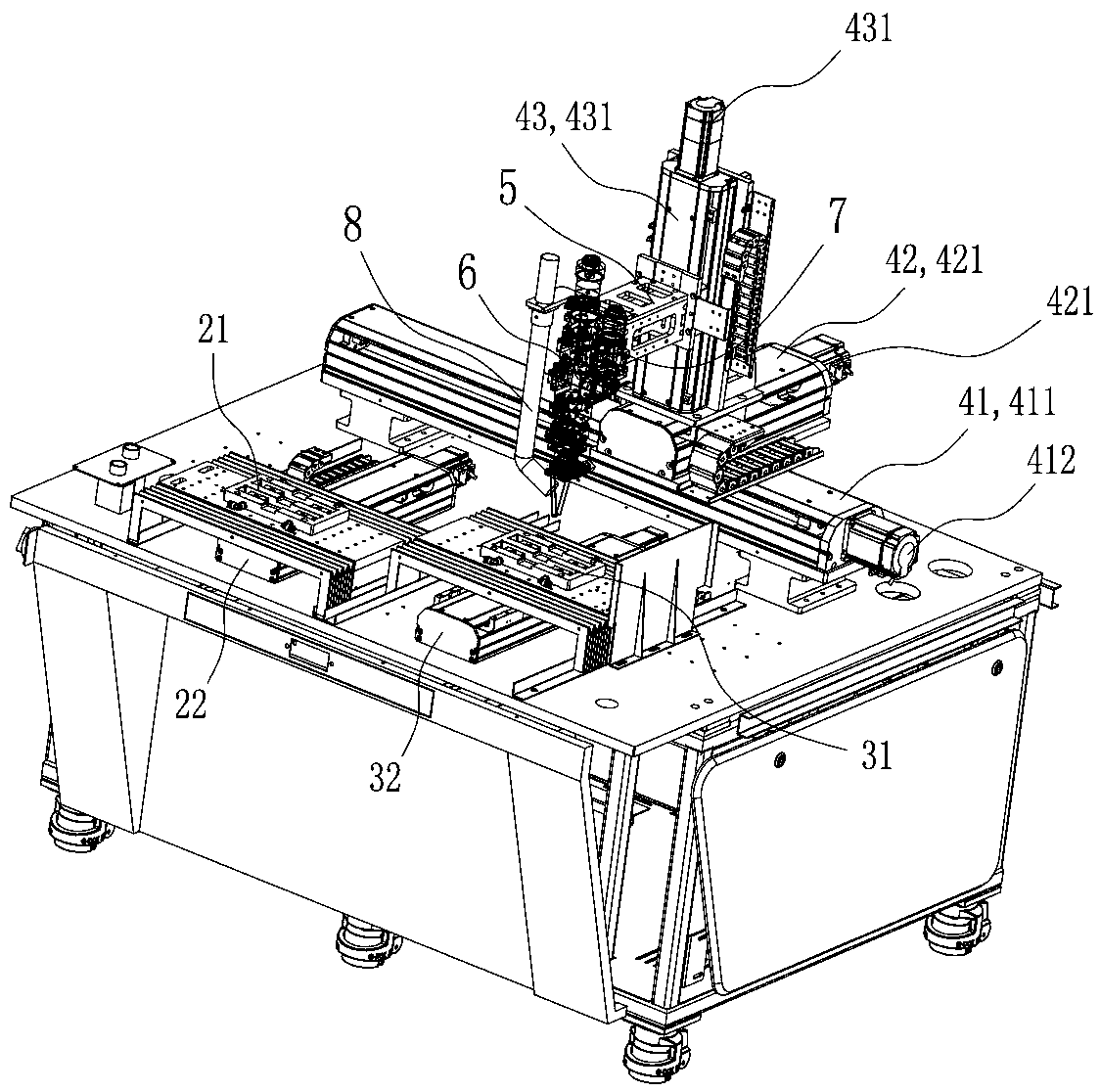

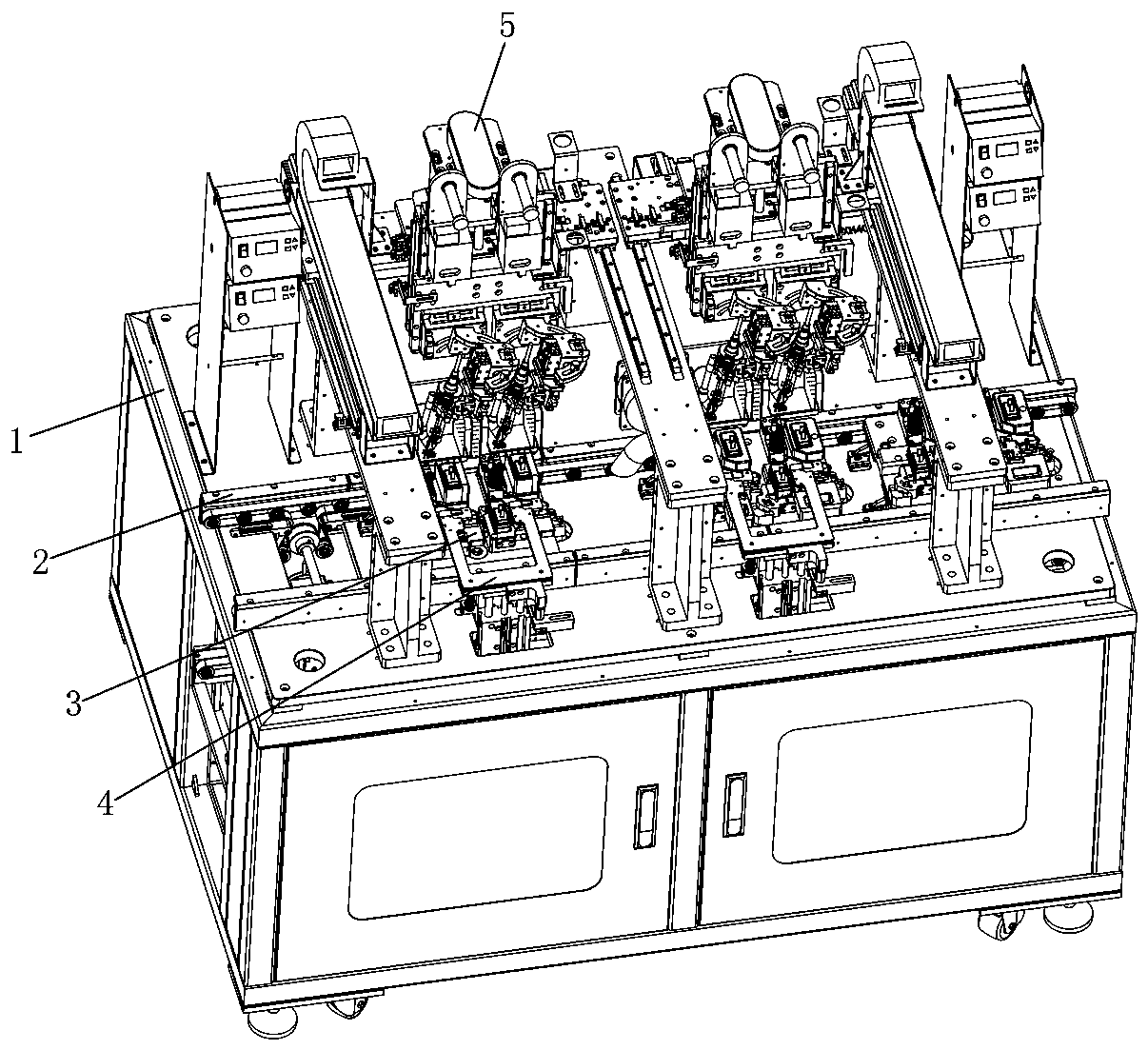

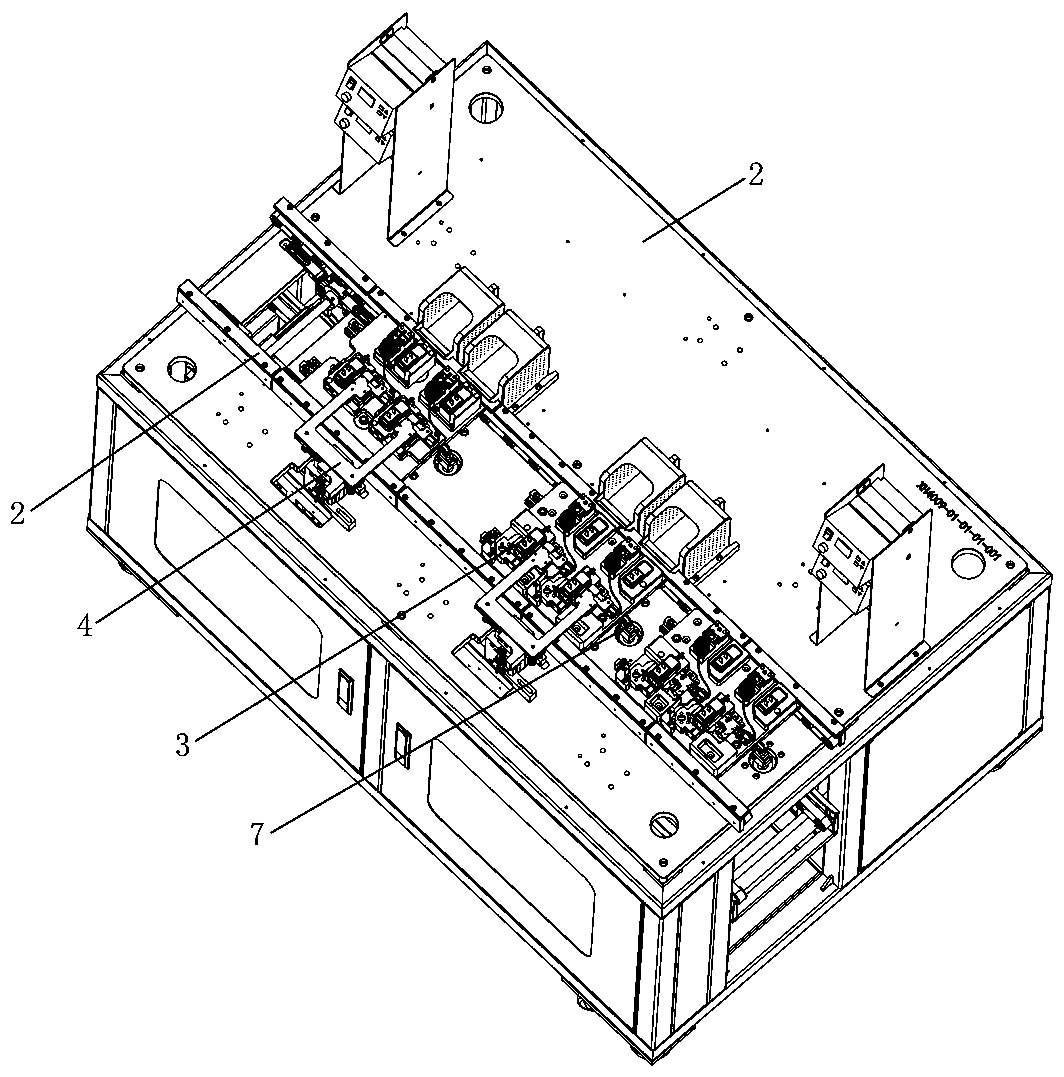

Double-station power battery cover plate laser welding machine and welding method

PendingCN107790879AWeld firmlyPrecision weldingLaser beam welding apparatusPower batteryElectrical battery

The invention discloses a double-station power battery cover plate laser welding machine and a welding method. The power battery cover plate laser welding machine comprises a control system, and a first power battery cover plate feeding system, a second power battery cover plate feeding system, an XYZ-axle transmission system, a welding machine head, a laser welding system and a CCD positioning system electrically connected with the control system; and the first power battery cover plate feeding system and the second power battery cover plate feeding system are mounted in the X-axle directionside by side. The power battery cover plate laser welding machine is convenient to feed and high in welding efficiency, realizes movement in X, Y and Z directions, can adjust distances from the laserwelding device to products, can fix the products through vacuum absorption, can determine positioning errors through CCD positioning, and can compensate error values from the X, Y and Z directions.

Owner:DONGGUAN GLORYSTAR LASER TECH

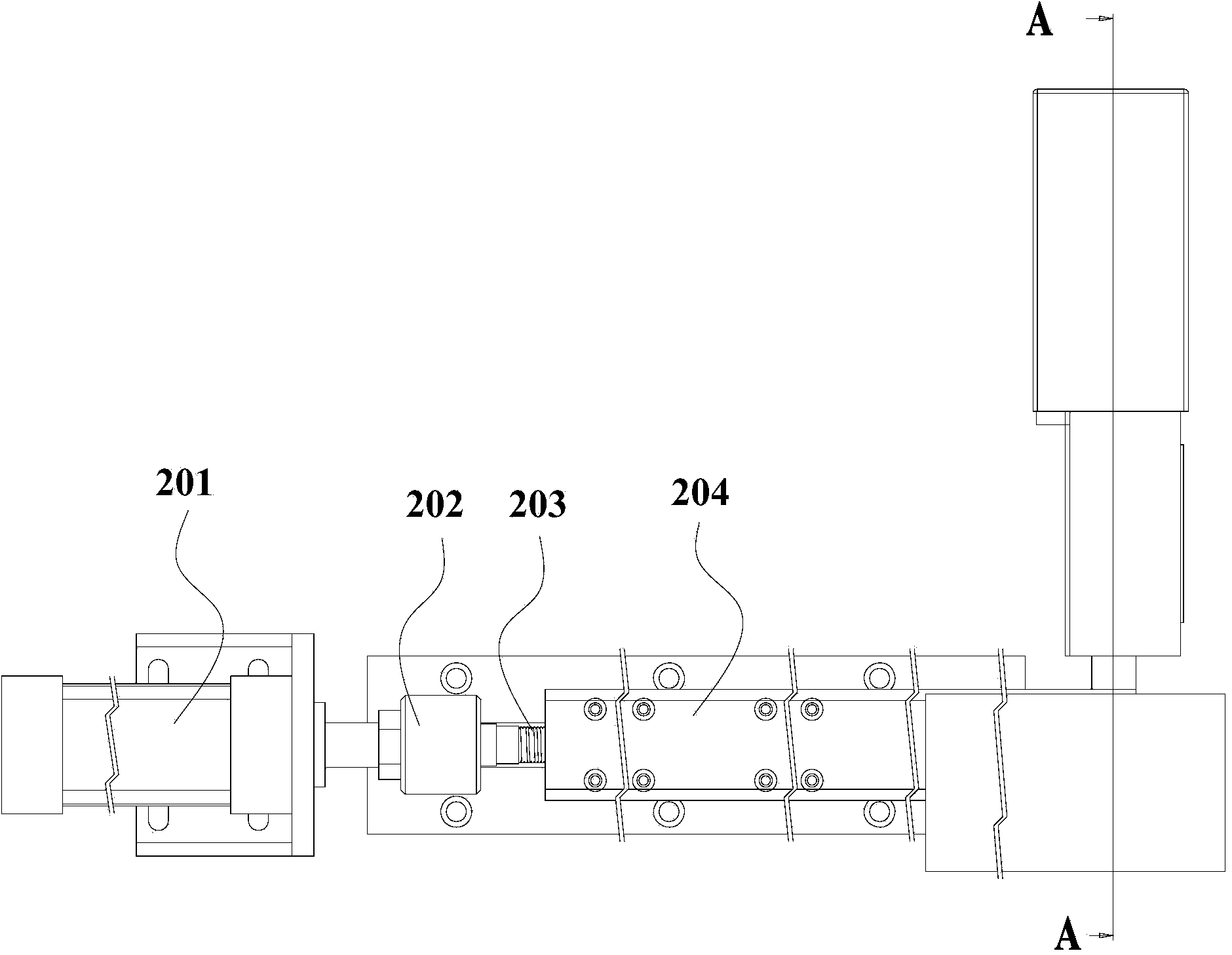

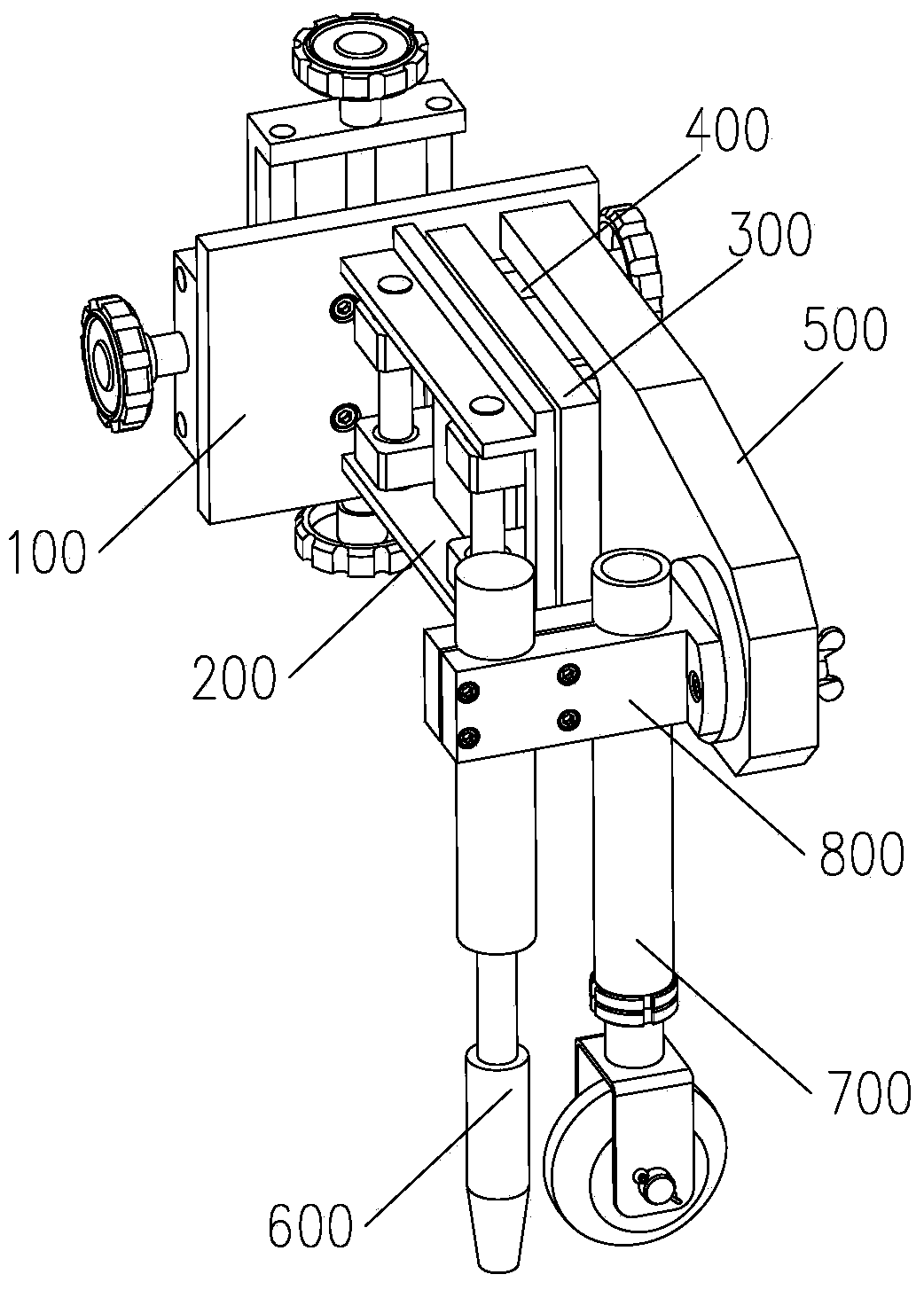

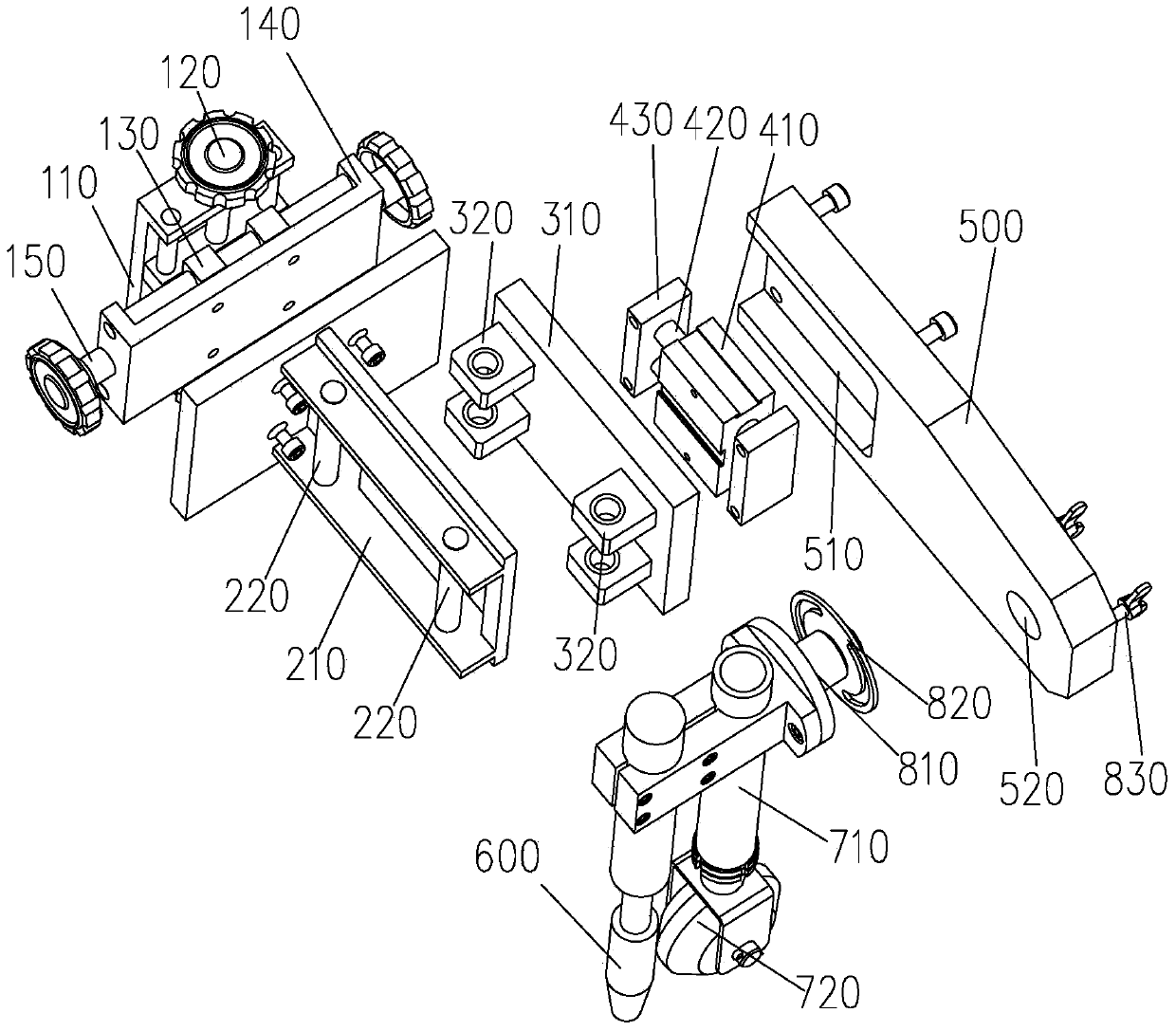

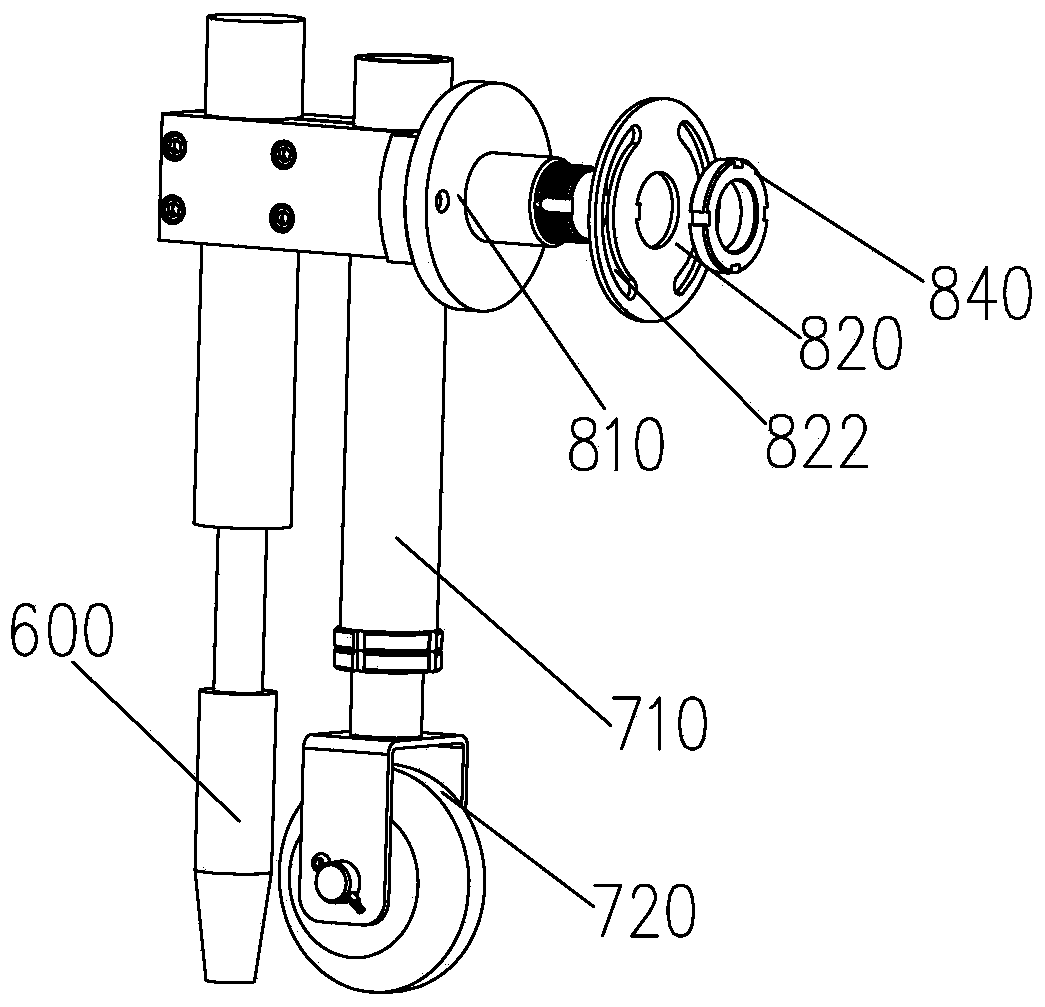

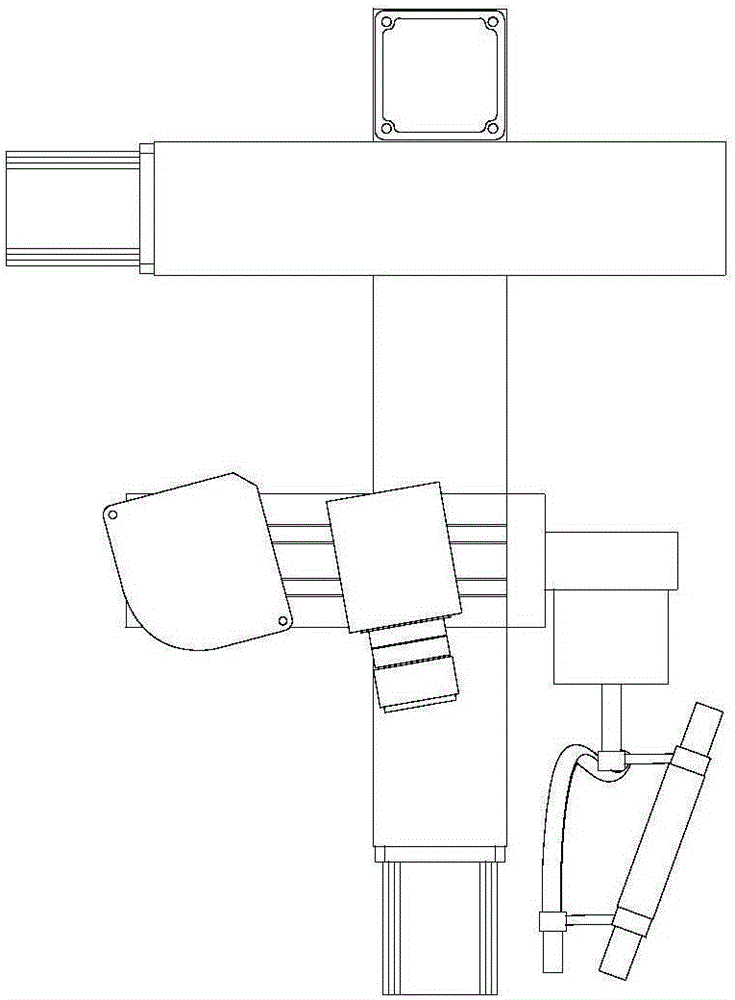

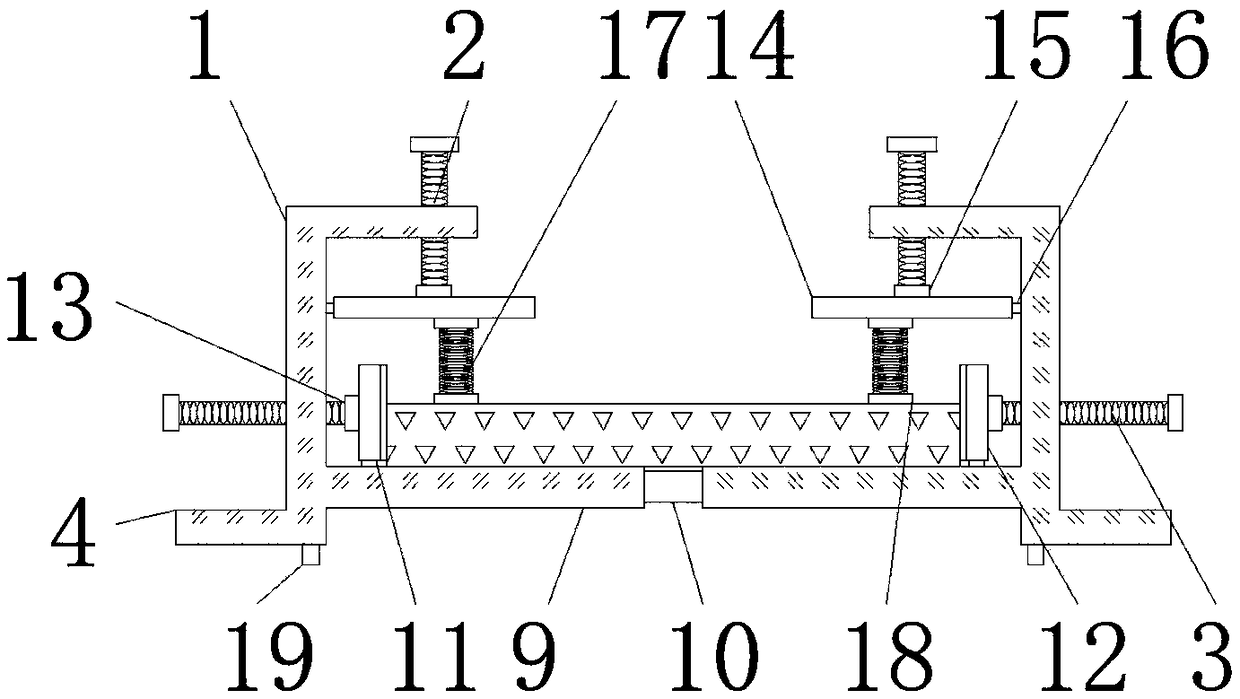

Mechanical welding seam tracking device

The invention discloses a mechanical welding seam tracking device. The mechanical welding seam tracking device comprises a fine adjustment mechanism, a guide rod mechanism, a guide plate mechanism, a horizontal driving mechanism, a connecting plate, a welding gun, a tracking assembly and a steering gear, wherein the fine adjustment mechanism and the guide plate mechanism are respectively connected with the guide rod mechanism, the guide plate mechanism can move up and down relative to the guide rod mechanism, the horizontal driving mechanism is respectively connected with the connecting plate and the guide plate mechanism, the welding gun and the tracking assembly are respectively installed on the steering gear, and the steering gear is installed on the connecting plate. The mechanical welding seam tracking device is simple in structure, no electric sensors need to be arranged, and the cost is effectively reduced; due to the horizontal driving mechanism and the gravity of the mechanical welding seam tracking device, the tracking assembly can make contact with the surface of a workpiece to be welded all the time; due to the guide plate mechanism and the guide rod mechanism which move relative to each other, the mechanical welding seam tracking device is better in flexibility, and the initial position of the welding gun and the initial position of the tracking assembly can be aligned conveniently through the fine adjustment mechanism; due to the steering gear, the angle of the welding gun and the angle of the tracking assembly can be adjusted conveniently.

Owner:上海气焊机厂有限公司

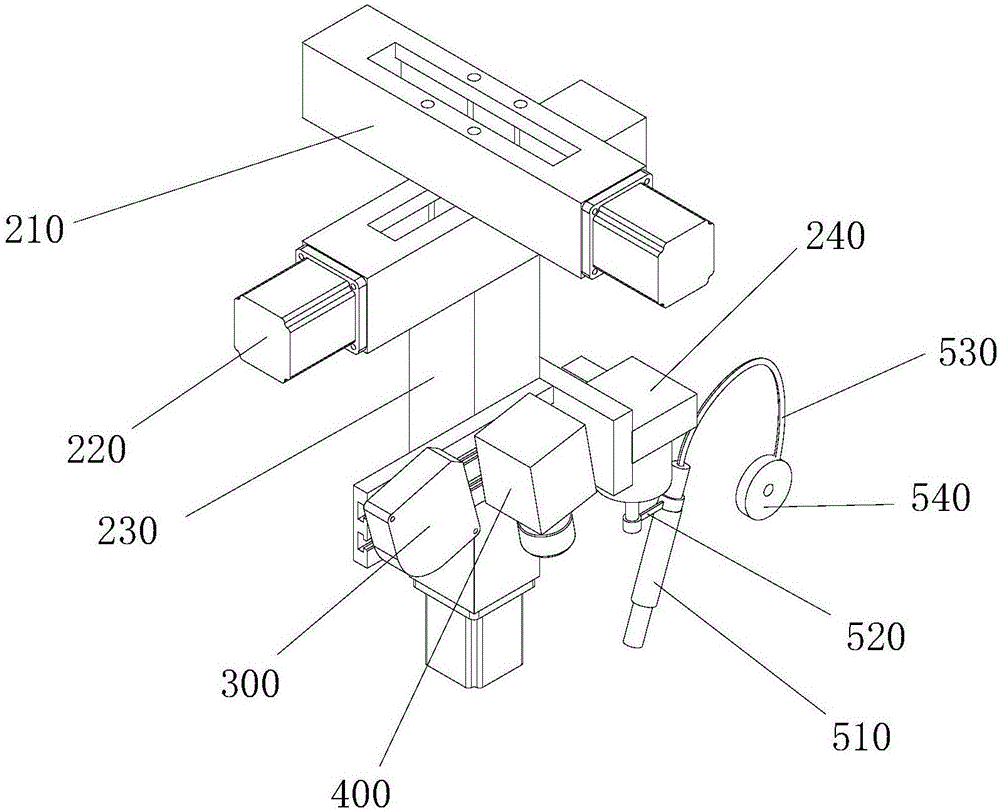

Non-gas metal arc welding 3 D adding material repair device and repair method

InactiveCN106141374AReduce missing solderReduce the situationArc welding apparatusMelting tankDefect repair

The invention discloses a non-gas metal arc welding 3 D adding material repair device and repair method. The repair device comprises a controller, a four-axis linkage platform, a laser vision sensor, an infrared vision sensor, a clamp, a non-metal arc welding torch, a wire feeding unit and a welding wire disc. The repair method comprises the steps that a defective workpiece is installed on a repair workbench; the laser vision sensor is driven to scan a defective three-dimensional outline; the controller rebuilds the defective three-dimensional outline; specific welding parameters are determined; the controller drives the infrared vision sensor to scan a molten pool, time-frequency parameters of a molten pool image are obtained, a compensation control code is generated according to the time-frequency parameters of the molten pool image, and the set welding parameters are corrected in real time; and after repair, the laser vision sensor is driven again to scan the defective three-dimensional outline, whether the repaired workpiece reaches the standard is determined, and if not, defects are repaired again till defect repair reaches the standard. The repair device is simple in structure, convenient to operate and high in reliability and adaptability.

Owner:GUANGDONG UNIV OF TECH

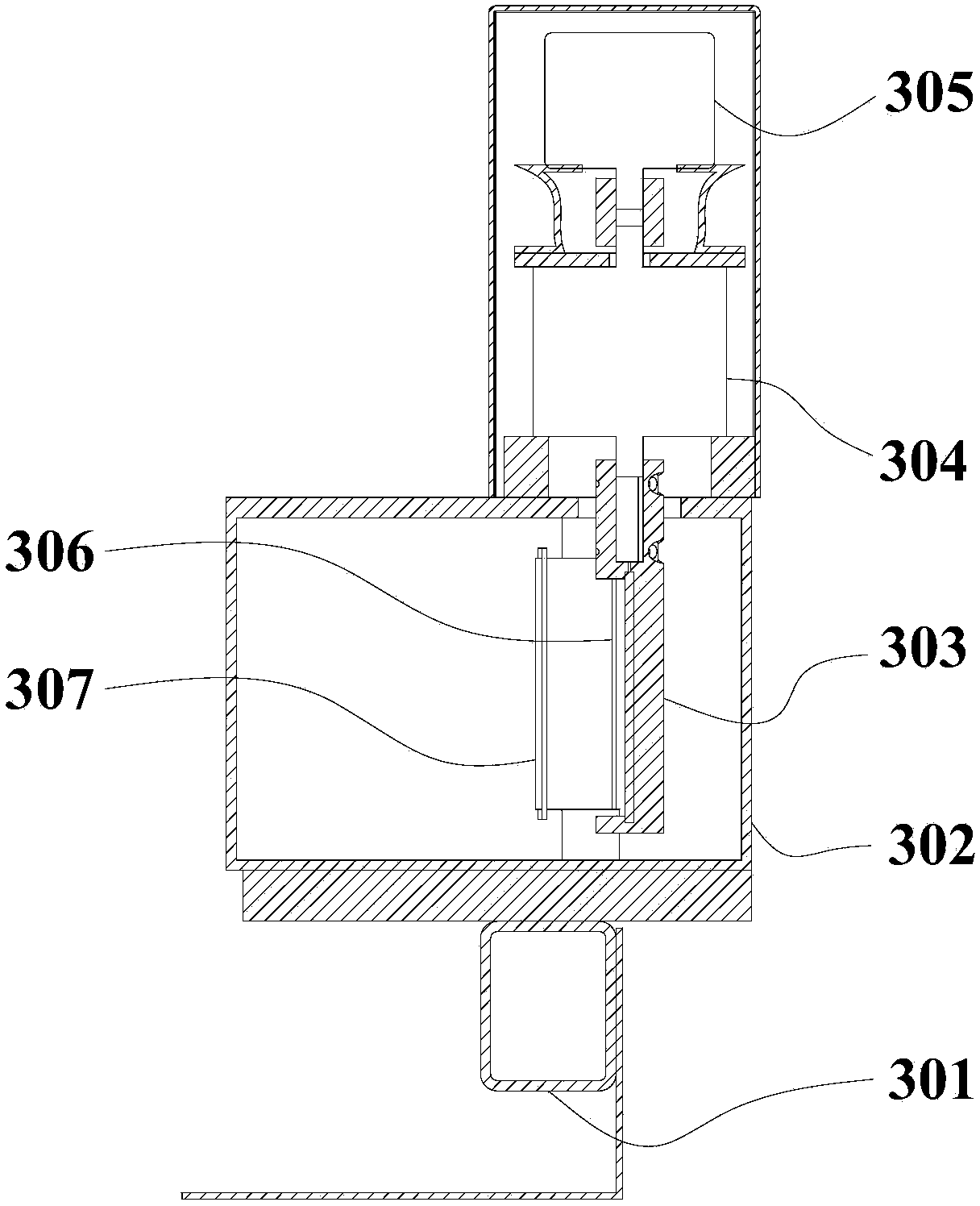

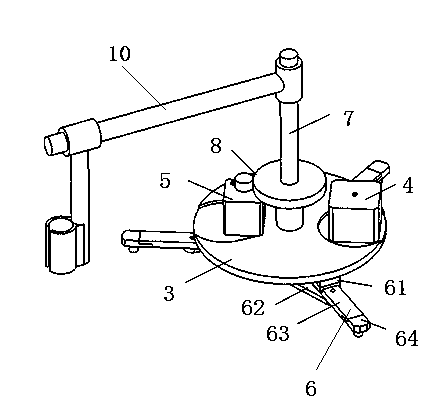

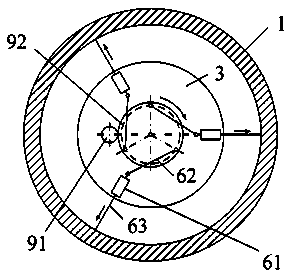

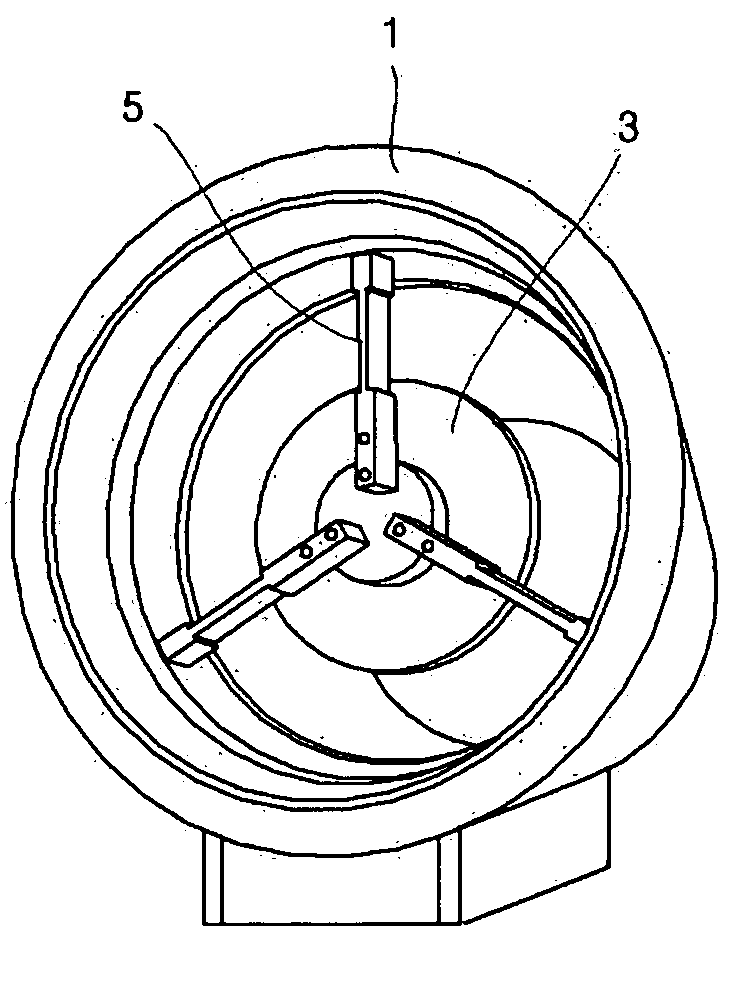

Automatic circular-seam welding device

ActiveCN103586620ARapid positioningPrecision weldingWelding/cutting auxillary devicesElectrode supporting devicesMotor driveEngineering

The invention discloses an automatic circular-seam welding device. The automatic circular-seam welding device is characterized by comprising a positioning mechanism and a welding mechanism, wherein the positioning mechanism comprises a machine base, a positioning motor and a slider-crank mechanism set, the positioning motor and the slider-crank mechanism set are arranged on the machine base, the slider-crank mechanism set comprises three slider-crank mechanisms, a 120-degree angle is formed between every two adjacent slider-crank mechanisms, and the positioning motor drives all the slider-crank mechanisms to move synchronously in the radial direction of the machine base; the welding mechanism comprises a welding-gun support located in the center of the slider-crank mechanism set, a transverse rod is arranged on the welding-gun support, and a welding gun for circular-seam welding is arranged at the other end of the transverse rod. The automatic circular-seam welding device is suitable for circular-seam welding satisfying the conditions that the variation range of diameters of pipes is large and the pipes cannot be rotated, achieves rapid positioning and accurate welding, has the advantages of being automatic, efficient and good in welding effect, and can be adapted to various different pipes by adjusting the lengths of the slider-crank mechanisms.

Owner:HOHAI UNIV CHANGZHOU

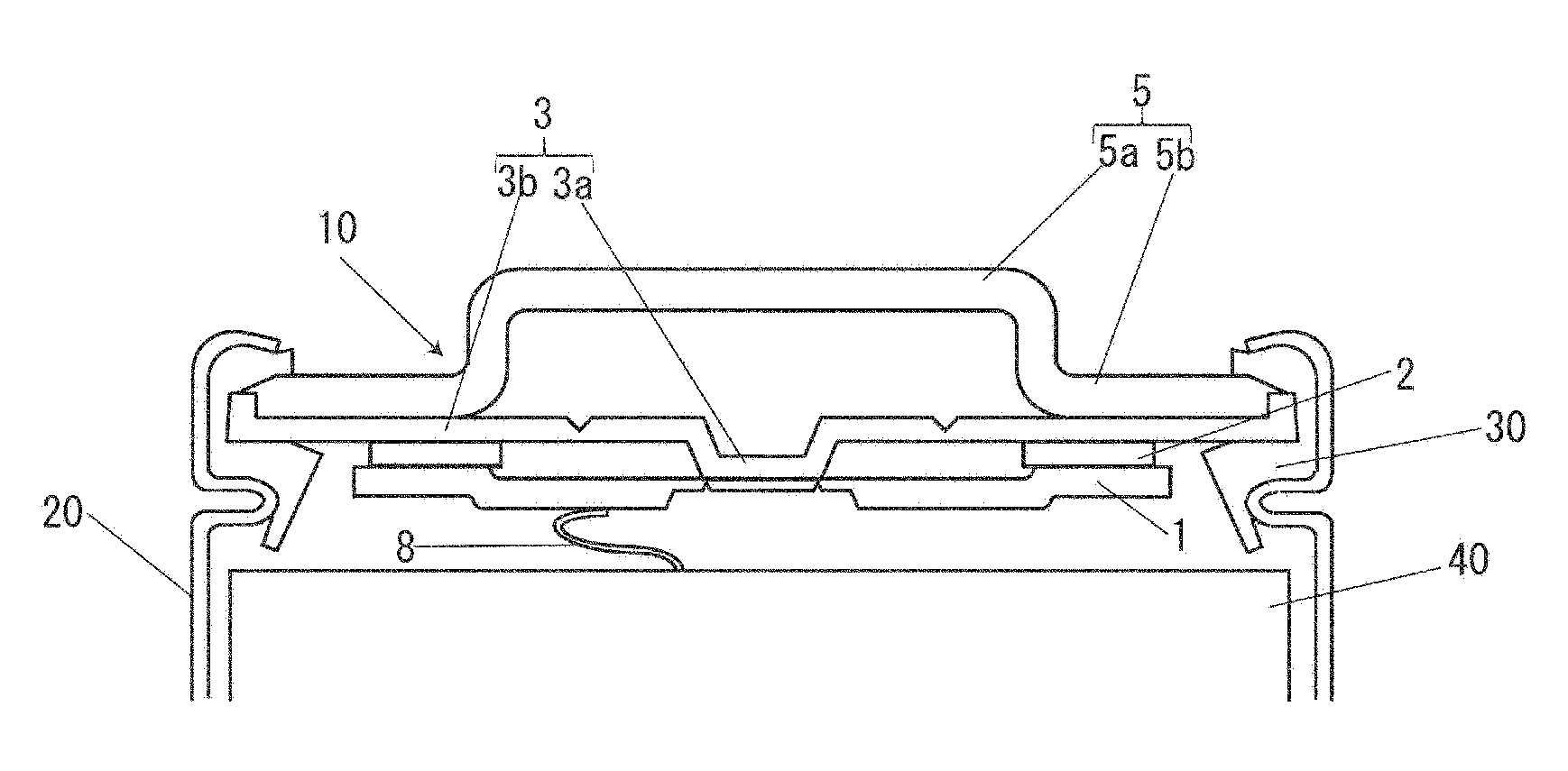

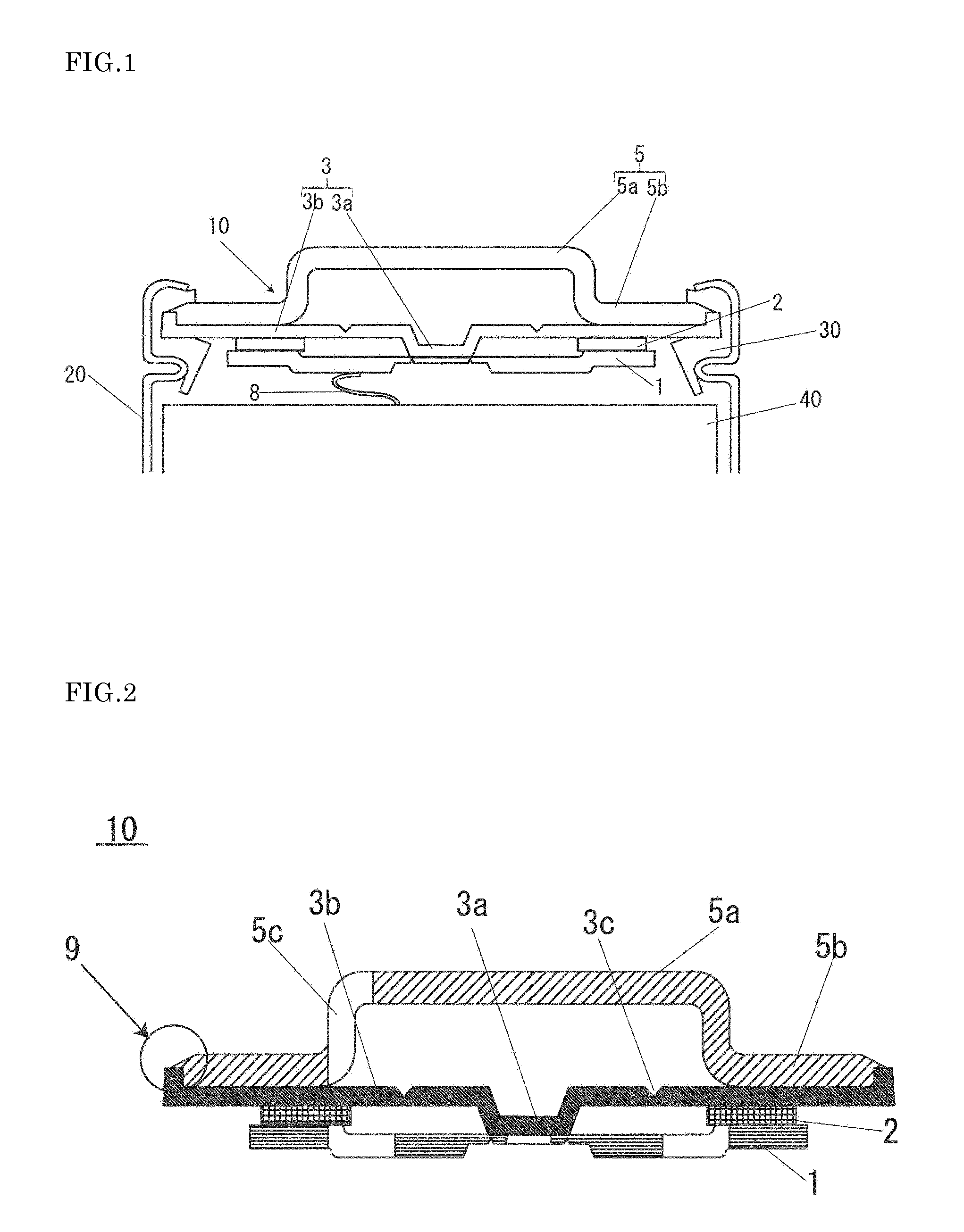

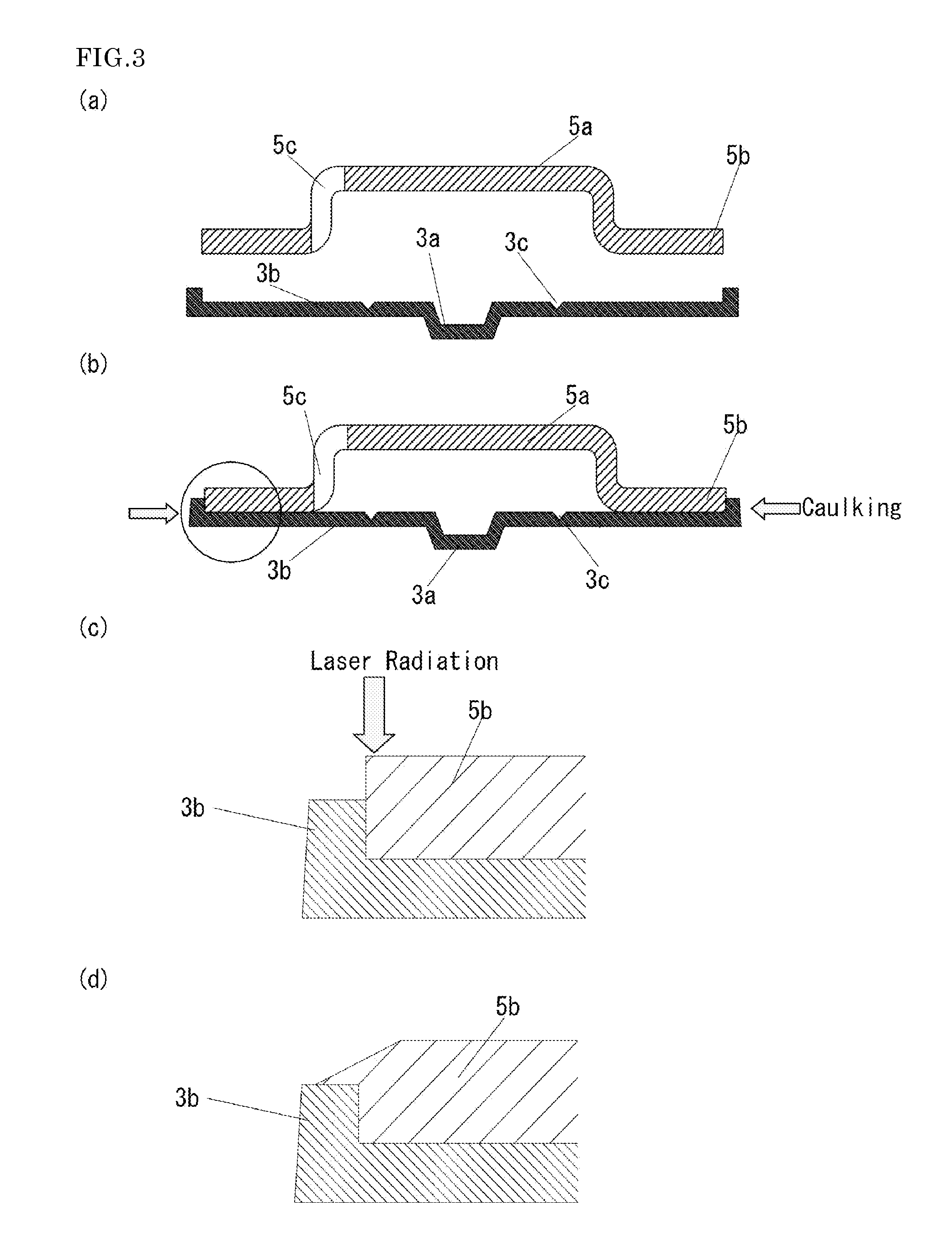

Sealed cell and method for manufacturing same

InactiveUS20140038005A1Improve conductivityImprove productivityPrimary cellsElectrode carriers/collectorsProduction rateEngineering

An object of the present invention is to manufacture a sealed cell having a highly conductive sealing body with a safety valve at high productivity. In order to accomplish above object, the present invention espouses a method of manufacturing a sealed cell including: preparing a terminal cap and a safety valve, the terminal cap including an external terminal projecting toward the outside of the cell, and a flange, and the safety valve including a conductive contact portion projecting toward the inside of the cell, and a peripheral portion and having an outer periphery bent toward the outside of the cell so as to form a bent portion; temporarily fixing the safety valve and the terminal cap together at the bent portion after coupling the safety valve and the terminal cap to each other; and conductively adhering the flange and the peripheral portion to each other near the bent portion.

Owner:SANYO ELECTRIC CO LTD

Systems and methods for welding

ActiveUS9555522B2Precision weldingEffective and efficient systemElectromagnets without armaturesWelding/cutting auxillary devicesMagnetic tension forceOptical Obstruction

A welding fixture including an electromagnet, a non-magnetic support configured to receive at least two sheets of material to be welded, and one or more clamping shoes configured to cooperate with the electromagnet to apply a clamping pressure to the at least two sheets of material and the non-magnetic support as a result of a magnetic force produced by the electromagnet is provided. A first of the at least two sheets of material is in contact with at least one of the one or more clamping shoes, and a second of the at least two sheets of material is in contact with at least the non-magnetic support. The one or more clamping shoes being shaped such that a perimeter defined by the one or more clamping shoes is located in the vicinity of a defined weld line to be welded on the at least two sheets of material, the weld line remaining substantially free from optical obstruction during production of the magnetic force.

Owner:TOYOTA JIDOSHA KK

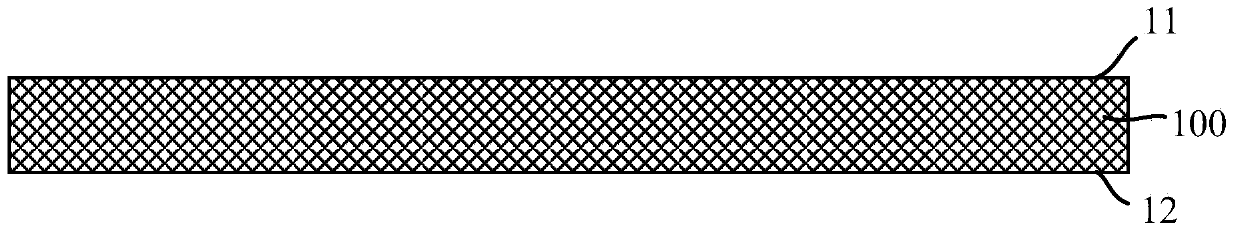

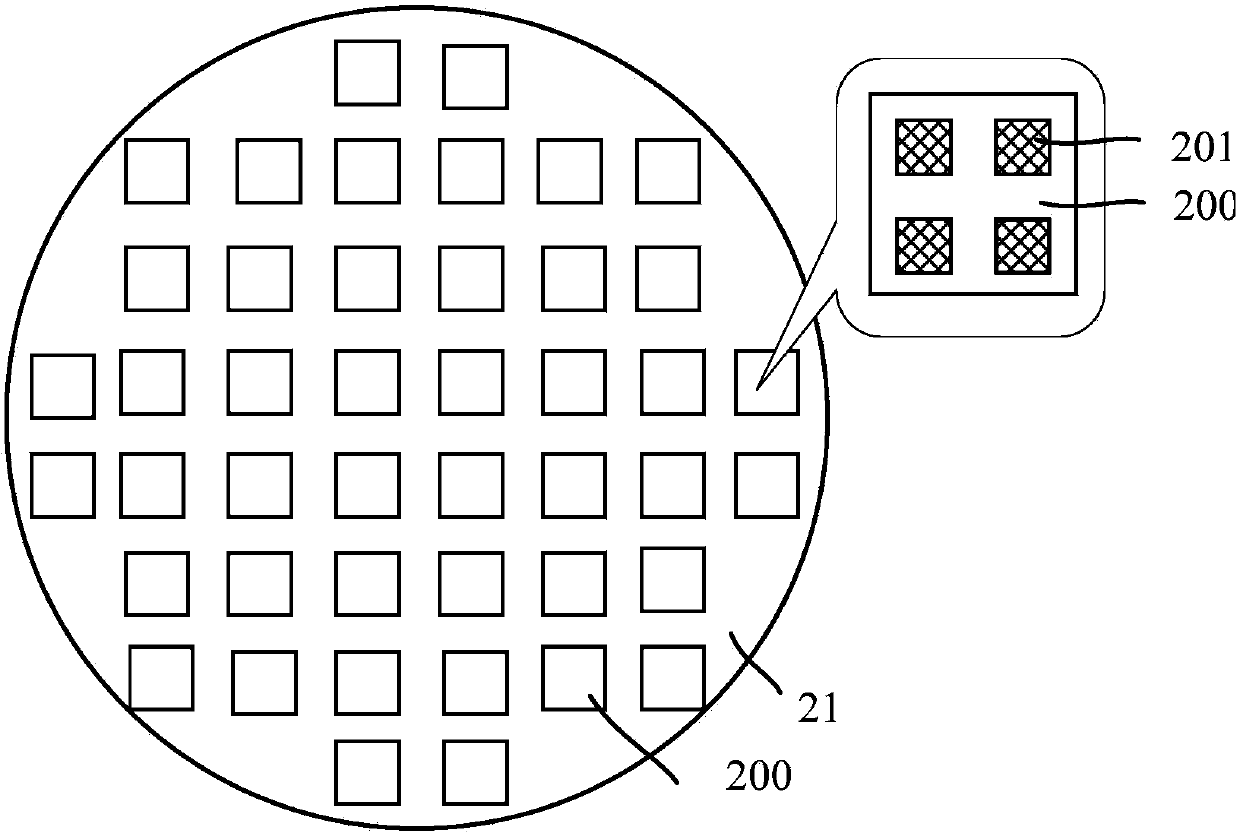

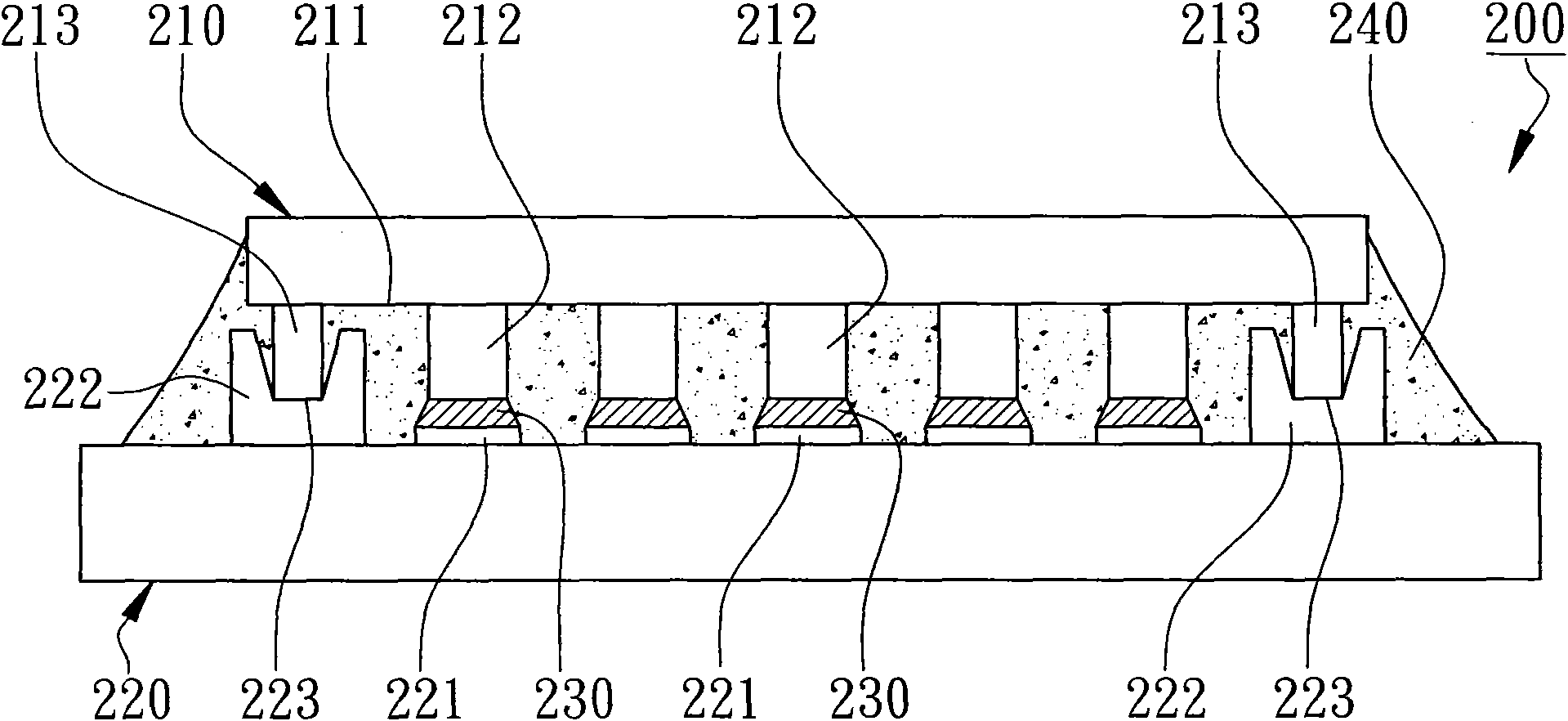

Packaging structure

ActiveCN103745958AImprove efficiencyRealize one packageSemiconductor/solid-state device detailsPrinted circuit aspectsSemiconductor chipInterconnection

The invention discloses a packaging structure. The packaging structure comprises: a circuit carrier board, wherein the circuit carrier board comprises a first surface and a second surface which is opposite to the first surface, the circuit carrier board is provided with a plurality of bearing units which are arranged in a matrix manner, first surfaces of the bearing units are provided with a plurality of input bonding pads, second surfaces of the bearing units are provided with a plurality of output bonding pads, and the input bonding pads and the output bonding pads are connected through an interconnection structure; a pre-packaged panel, wherein the pre-packaged panel comprises a first plastic packaged layer, a plurality of integrated unit which are arranged in a matrix manner are arranged in the first plastic packaged layer, at least one semiconductor chip is arranged in each integrated unit, surfaces of the semiconductor chips are provided with a plurality of bonding pads, the bonding pads are provided with first metal bumps, the pre-packaged panel is arranged on the first surface of the circuit carrier board in a flipping manner, and the first metal bumps and the input bonding pad are soldered together; a filling layer for filling the space between the first surfaces of the bearing units and the pre-packaged panel; and second metal bumps located on the output bonding pads of the second surfaces of the bearing units. According to the packaging structure of the invention, the integration level is improved.

Owner:NANTONG FUJITSU MICROELECTRONICS

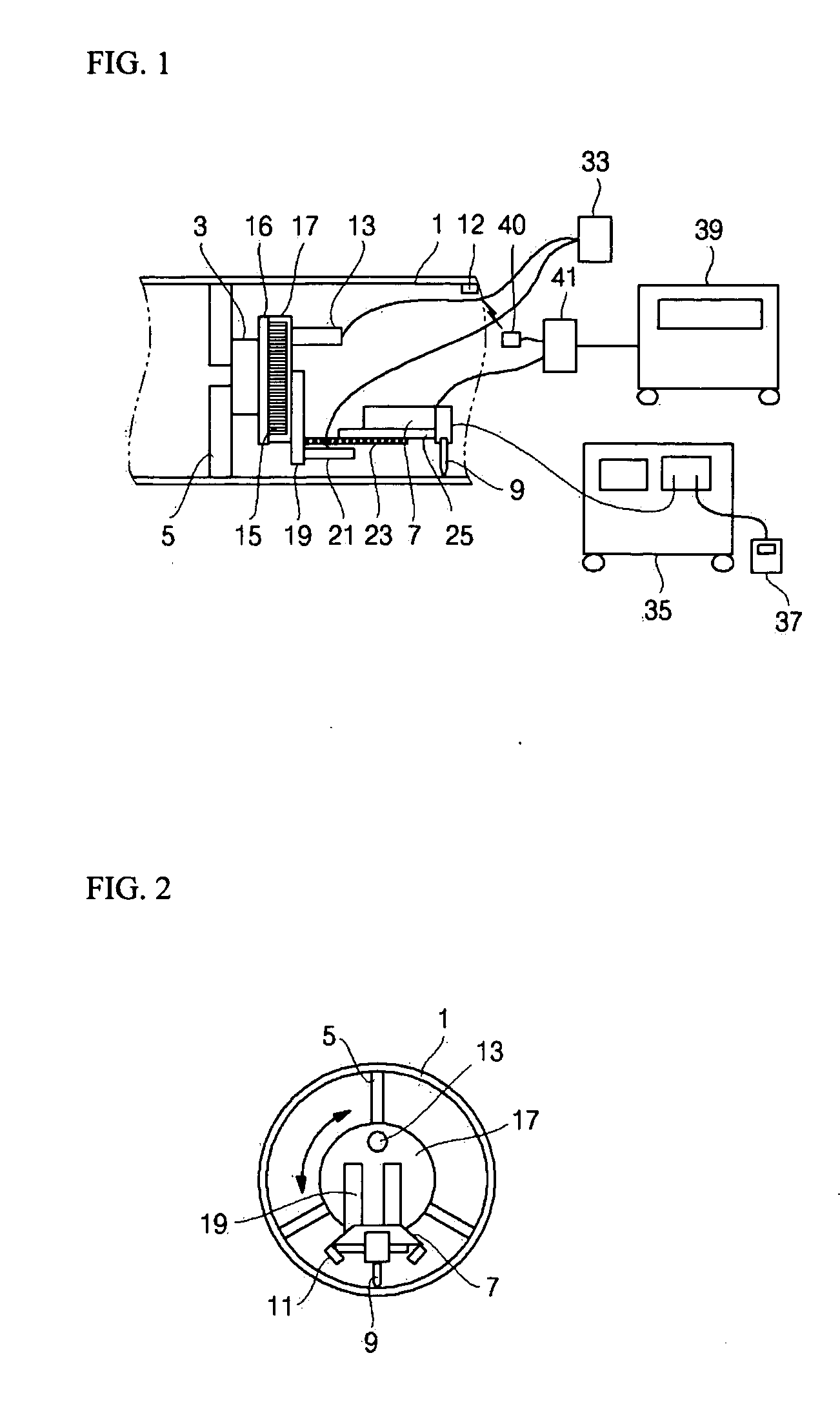

Welding head carrier for use in welding inner surface of tube

InactiveUS20090230120A1Easy to installExpand the scope of useWelding/cutting auxillary devicesAuxillary welding devicesDisplay deviceEngineering

A welding head carrier for use in welding the inner surface of a tube includes inter alia a welding head provided with a welding torch and a camera, a wireless camera mounted at the inner side of the tube to monitor whether cables are entangled, a wireless receiver for receiving wirelessly an image from the wireless camera, including a camera controller for controlling the camera and the wireless receiver, display for displaying the welding operation and the inside of the tube. Fixing units can be adjusted in length depending on the size of the tube, thus eliminating the need for the rebuilding or replacement of the welding head carrier, leading to cost savings. The welding head can be easily mounted, regardless of size and configuration of the welding head, and the range of use of the welding head carrier can be extended.

Owner:KOREA HYDRO & NUCLEAR POWER CO LTD

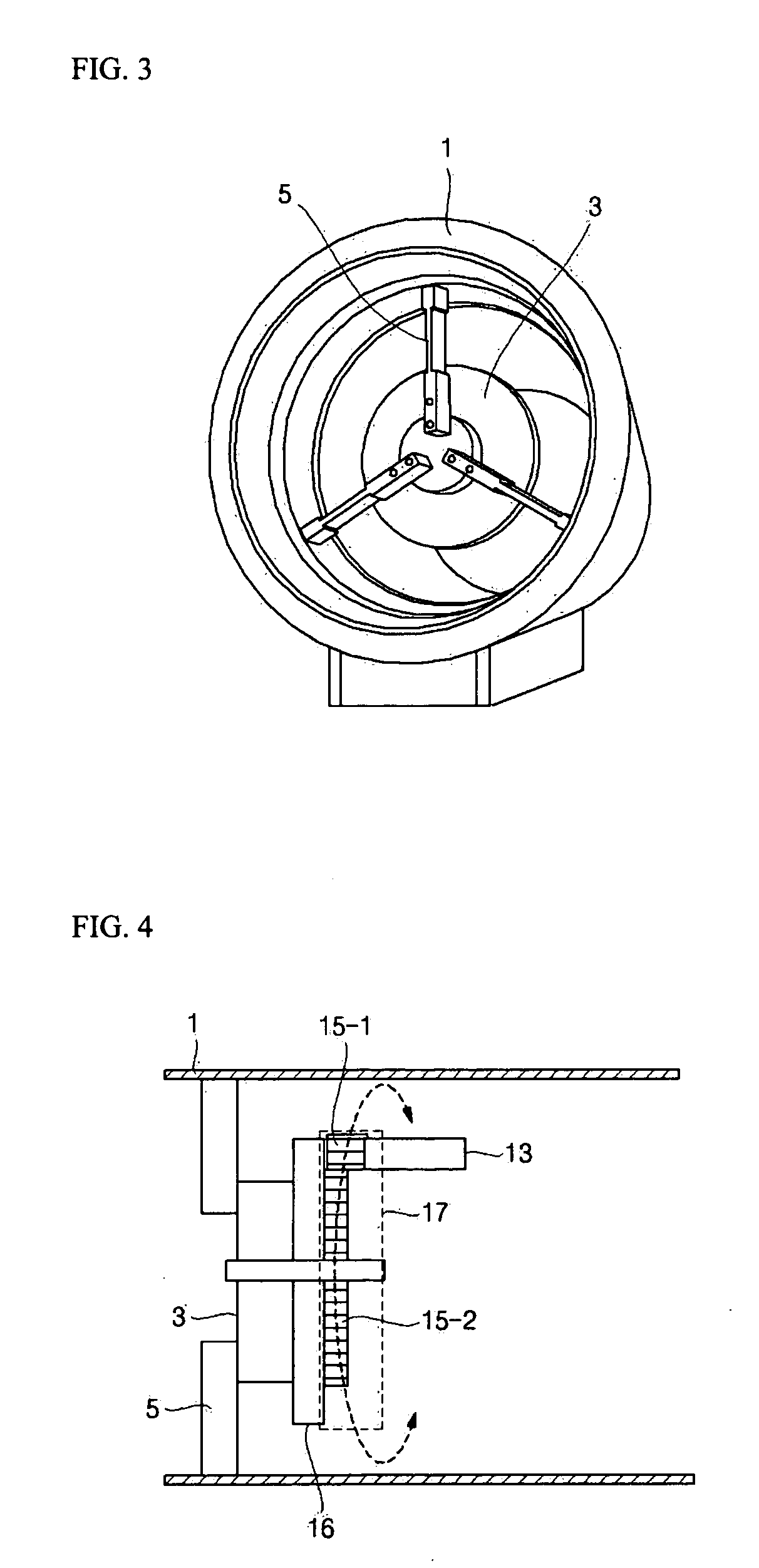

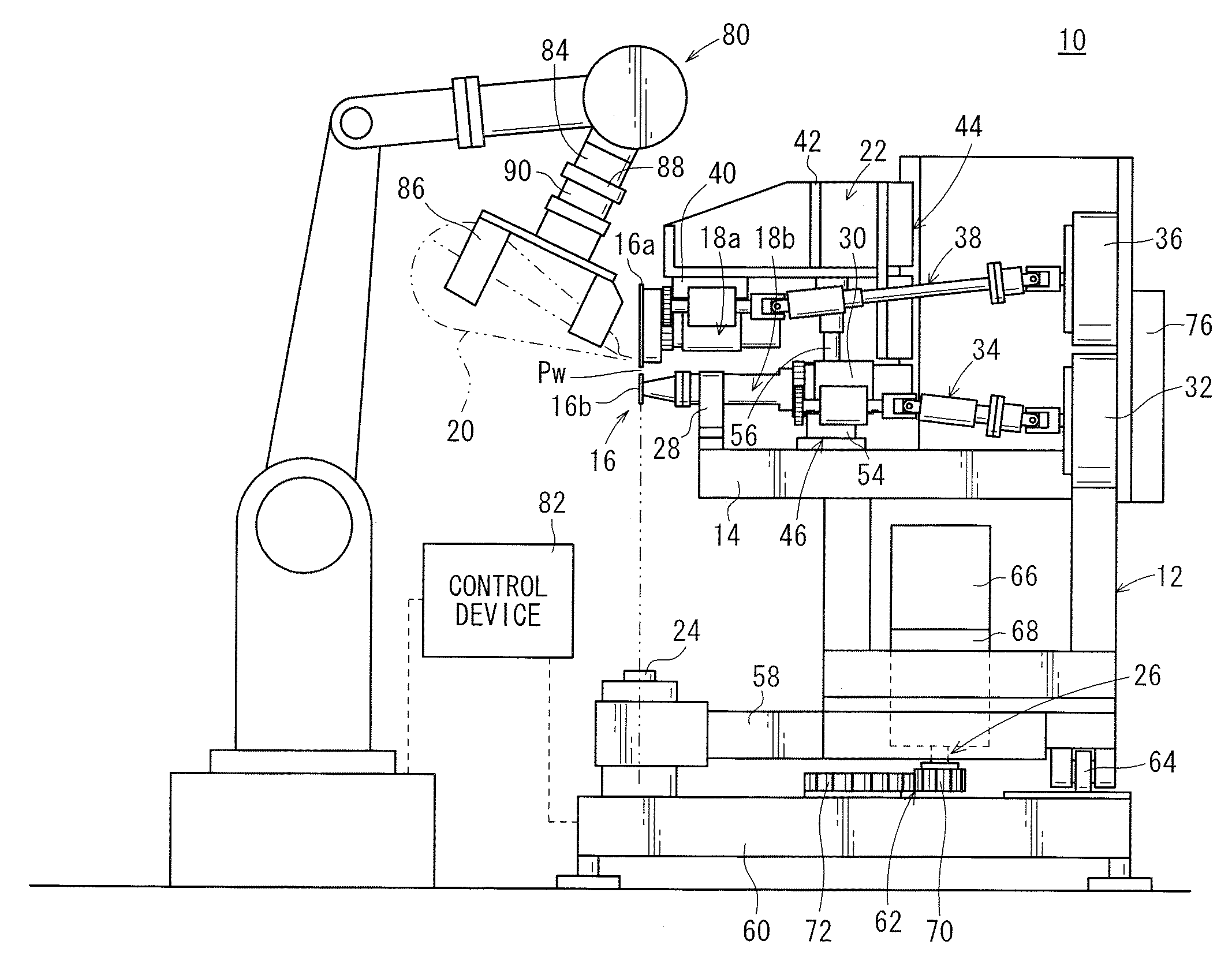

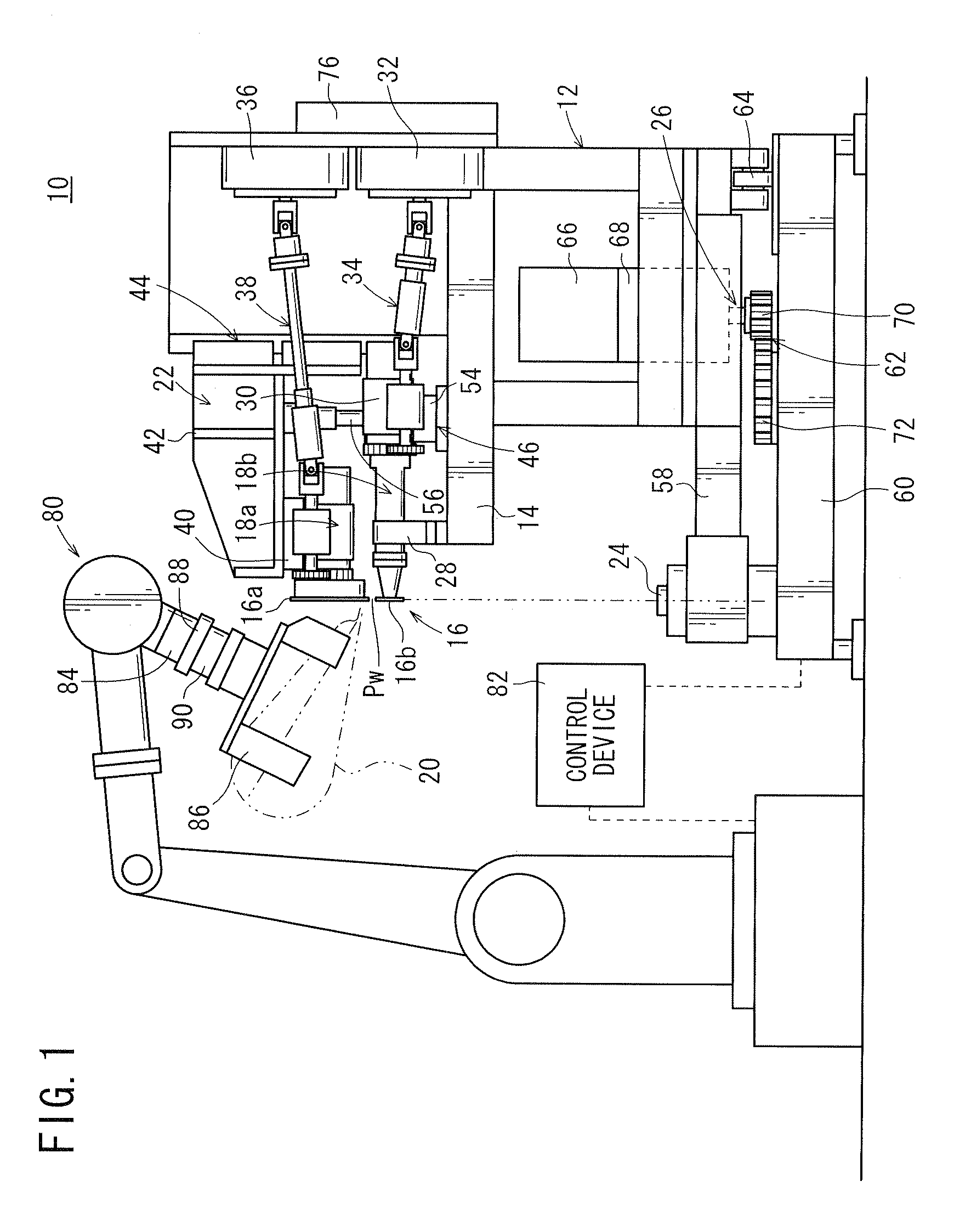

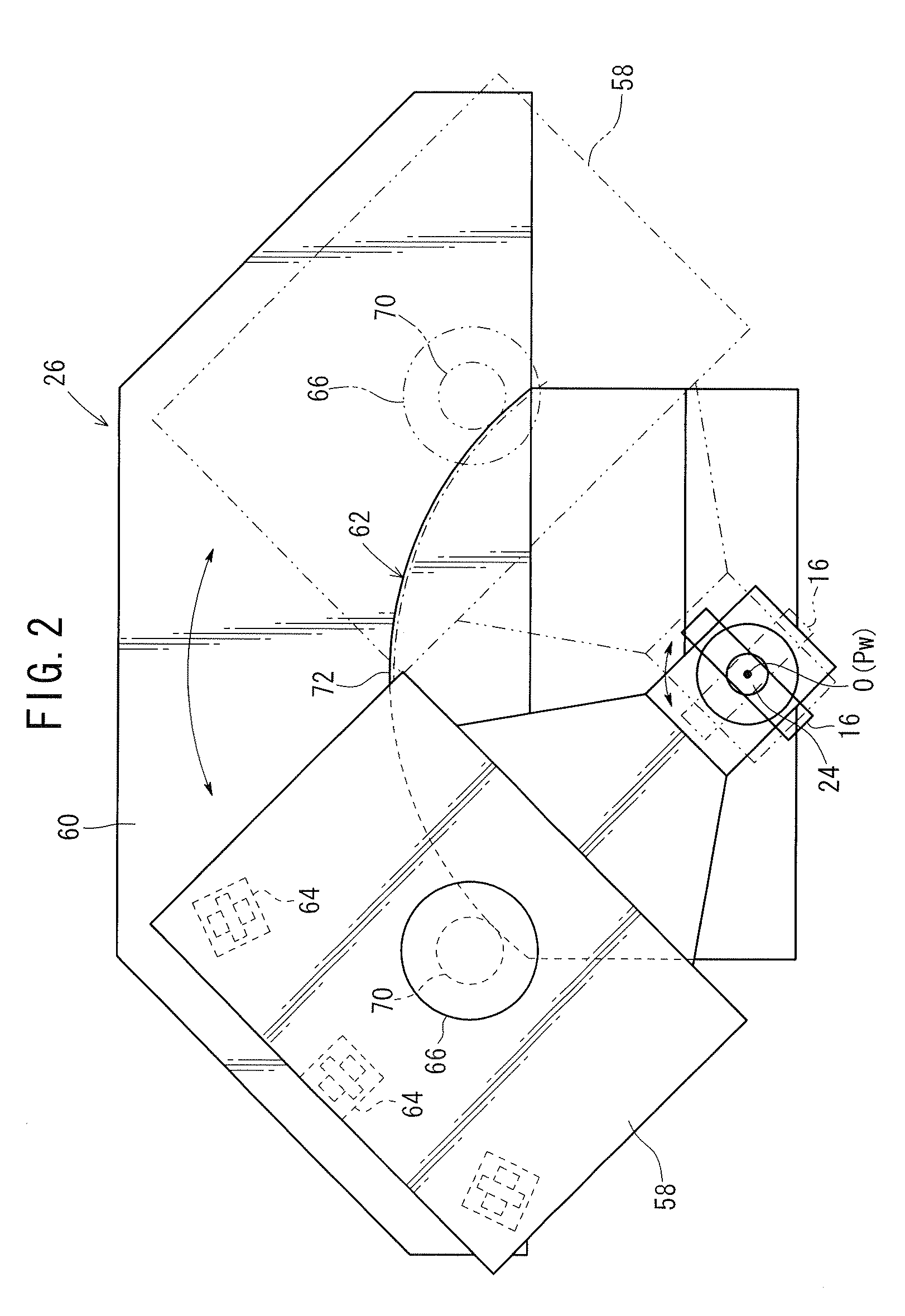

Seam welding method and seam welding apparatus

ActiveUS20100170879A1Quality improvementCorrecting a welding track more simply and accuratelyWelding electric supplyArc welding apparatusEngineeringSeam welding

The seam welding apparatus welds a workpiece held by a robot while delivering the workpiece between a pair of electrode rolls. The seam welding apparatus includes a load cell mounted on the robot, for detecting a load imposed along a Y direction which is perpendicular to a pressing direction Z along which the electrode rolls press the workpiece at a weld point and a delivering direction X along which the robot delivers the workpiece at the weld point, a robot controller and an arithmetic unit, a turning mechanism for turning the electrode rolls about the pressing direction Z, and a control device for controlling the turning mechanism to operate depending on the magnitude of the load in the Y direction detected by the load cell.

Owner:HONDA MOTOR CO LTD

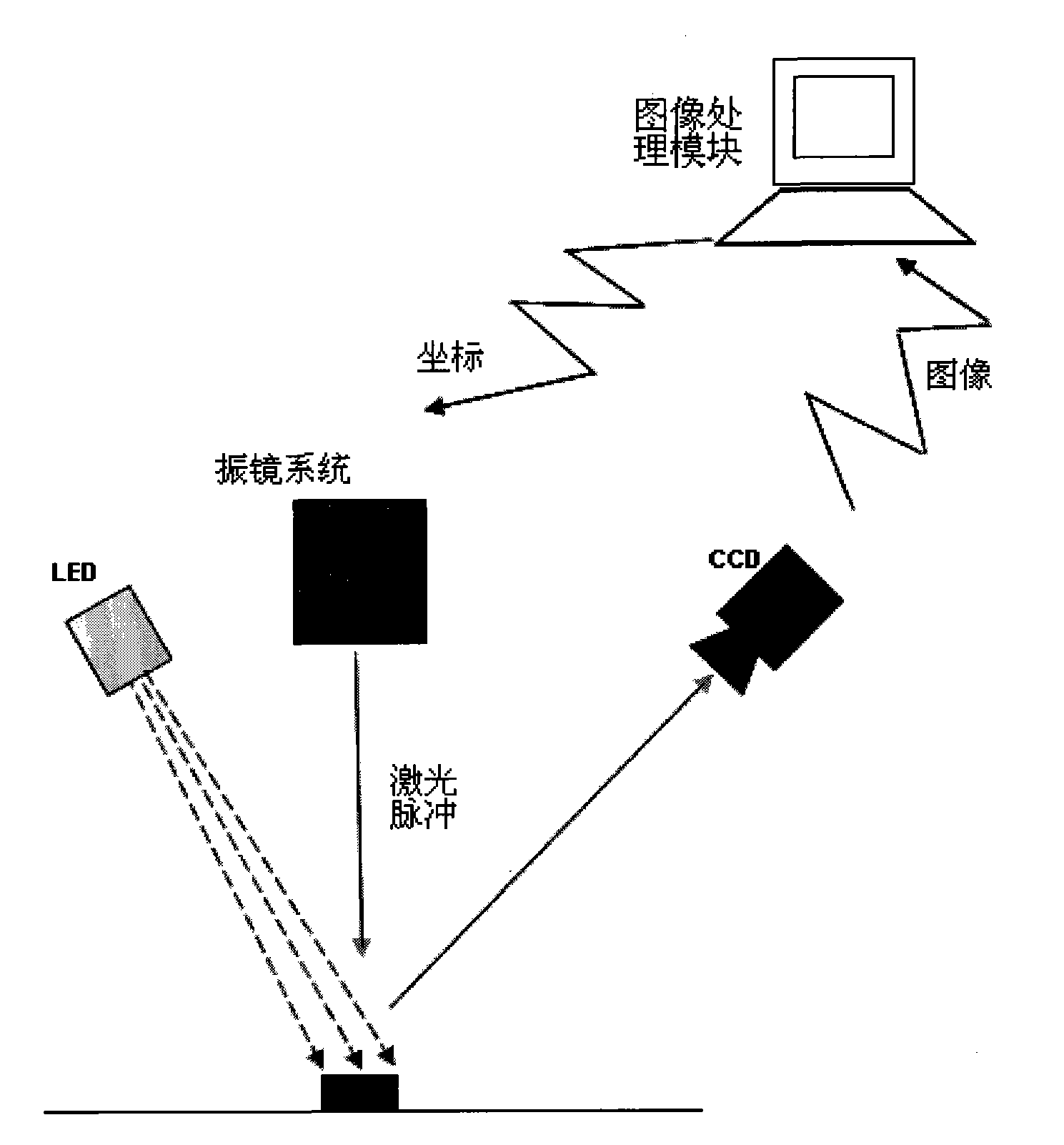

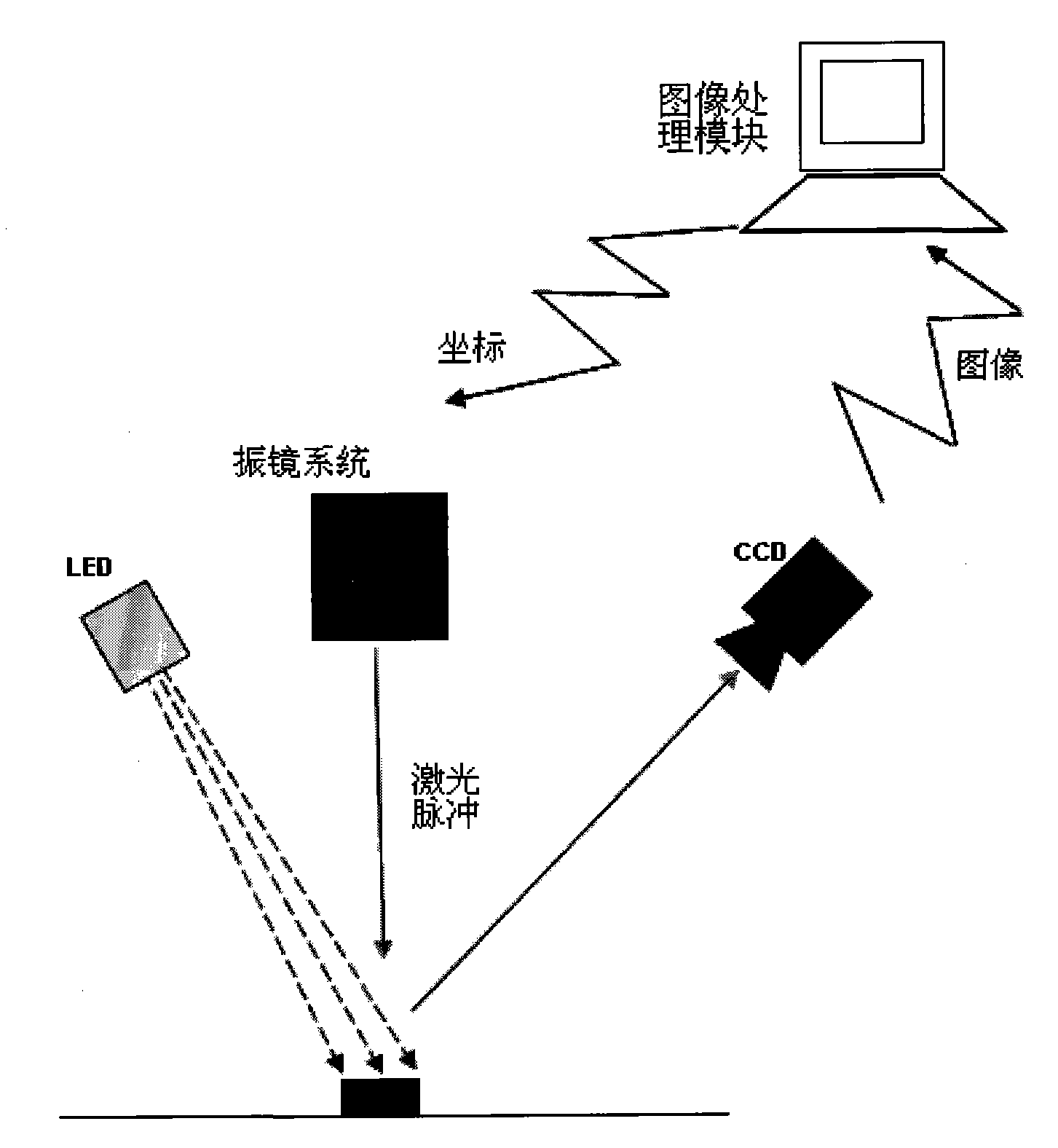

CCD (Charge Coupled Device) galvanometer type laser welding device and method

ActiveCN101835348APrecision weldingEasy to controlPrinted circuit assemblingMetal working apparatusImaging processingGalvanometer

The invention discloses a CCD (Charge Coupled Device) galvanometer type laser welding device which comprises an LED lamp, a CCD image acquisition device, an image processing module and a galvanometer system, wherein the LED lamp is used for obliquely irradiating an electronic component pin from the side face of the electronic component pin to project the shadow of the electronic component pin onto a printed circuit board; the CCD image acquisition device is used for acquiring the image data of the electronic component pin through the light and shade contrast on the printed circuit board; the image processing module is used for calculating according to the image data to obtain a welding position coordinate of the electronic component pin and conveying the welding position coordinates to the galvanometer system; and the galvanometer system is used for emitting laser pulses according to the information of the welding position coordinate to smelt the electronic component pin material and form a welding spot on the printed circuit board. The invention also discloses a CCD galvanometer type laser welding method. The invention can dynamically and precisely control the welding position and is not easy to cause pollution.

Owner:UNITED AUTOMOTIVE ELECTRONICS SYST

Electrical connector having improved terminals

InactiveUS20050026474A1Precision weldingCoupling device connectionsFixed connectionsElectrical connectorSoldering

A board-mounted electrical connector (1) includes an insulative housing (10), a number of first terminals (22) and a number of second terminals (26) received in the housing, and a spacer (30) assembled on the housing. The insulative housing includes a base portion (12) defining a number of recesses (124) thereon. Each first terminal includes a contacting portion (222) and a soldering portion (225) extending perpendicularly to a printed circuit board (50). Each second terminal includes a contacting portion (262), a soldering portion (265) extending parallel to the PCB and a connecting portion (264) connecting the contacting portion and the soldering portion. The spacer defines a number of holes (33) for receiving and organizing the soldering portions of the first terminals and forms a number of protrusions (34) cooperating with the recesses of the base portion for organizing corresponding connecting portions of the second terminals to thereby precisely position the soldering portions of the second terminals.

Owner:HON HAI PRECISION IND CO LTD

Gas metal arc welding 3D material increase repair device and repair method

InactiveCN106112207AReduce missing solderReduce the situationArc welding apparatusGas metal arc weldingEngineering

The invention discloses a gas metal arc welding 3D material increase repair device and a repair method. The device comprises a controller, a four-axis linkage platform, a laser vision sensor, an infrared vision sensor, a clamp and a melting electrode welding torch. The repair method comprises the following steps: mounting a defective workpiece on a repair working table; driving the laser vision sensor to scan a three-dimensional outline of a defect; reestablishing the three-dimensional outline of the defect by using the controller; determining specific welding parameters; driving the near infrared vision sensor to scan a molten pool by using the controller to obtain a time-frequency parameter of an image of the molten pool, generating a compensation control code according to the time-frequency parameter of the image of the molten pool, and correcting the set welding parameters in real time; and after repair is finished, driving the laser vision sensor again to scan the three-dimensional outline of the defect, judging whether the repaired workpiece reaches the standard or not, and if the repaired workpiece does not reach the standard, repairing the defect again until repair of the defect reaches the standard. The gas metal arc welding 3D material increase repair device is simple in structure, convenient to operate, high in reliability and high in adaptability.

Owner:GUANGDONG UNIV OF TECH

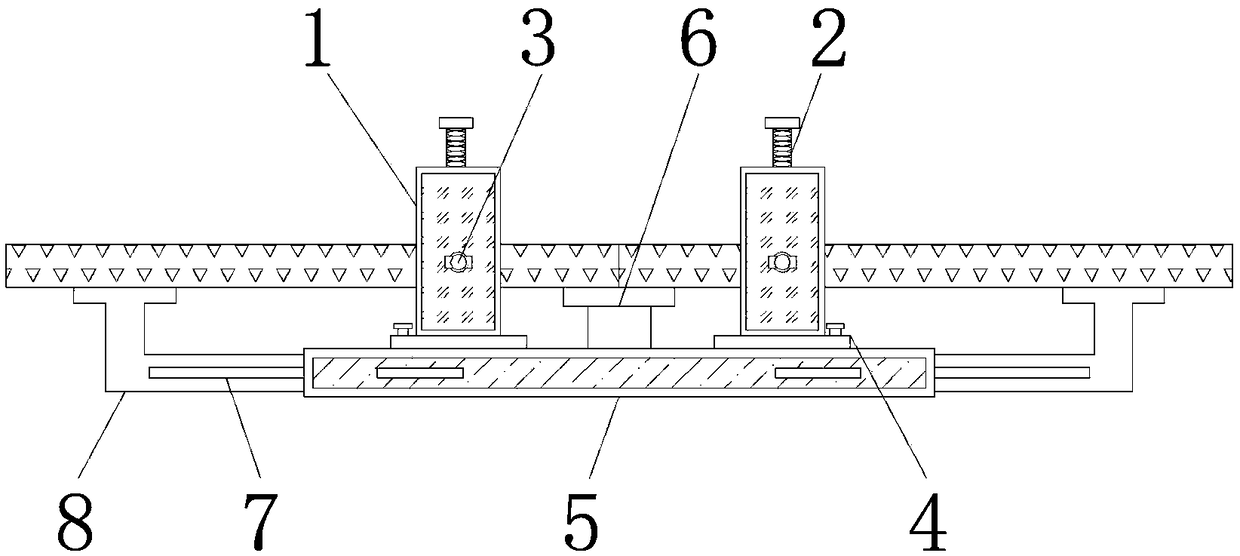

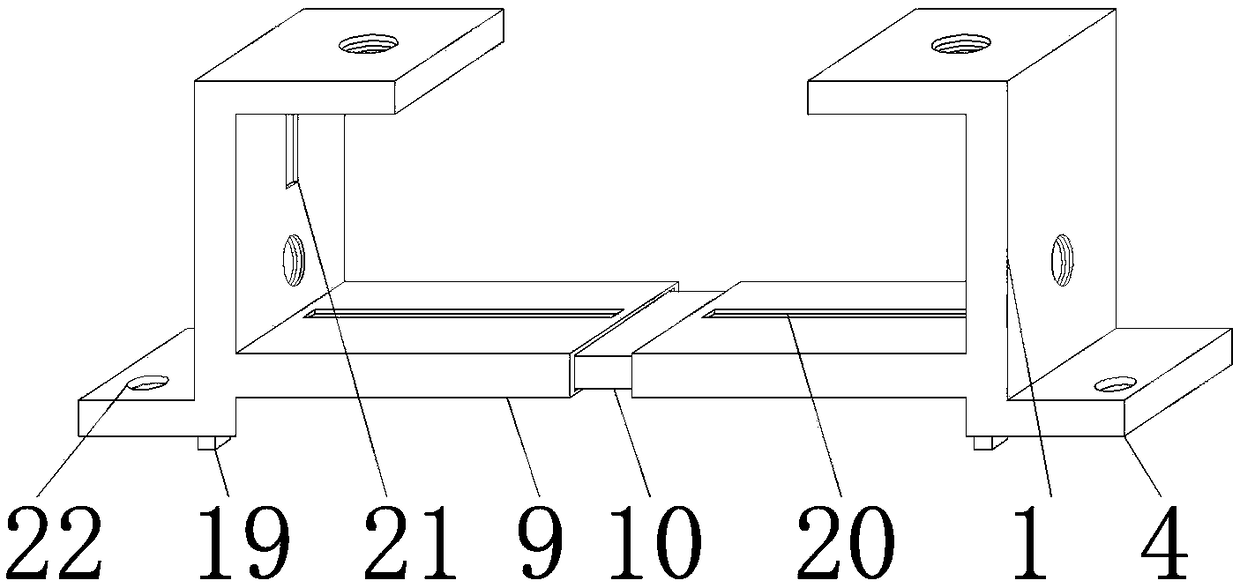

Panel welding clamping device convenient to adjust

InactiveCN108637565APrecision weldingEasy to adjustWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMechanical engineering

The invention discloses a panel welding clamping device convenient to adjust. The panel welding clamping device convenient to adjust comprises fixing bases, containing plates, pressing plates, side edge sliding grooves and connecting sliding grooves. The upper portions of the fixing bases are in penetrating connection with first threaded rods. A bearing table is fixed to the upper portion of a base. The containing plates are fixed to the lower portions of the inner side walls of the fixing bases. The upper portions of the containing plates are connected with bottom sliding blocks fixed to thebottoms of side clamping plates. The pressing plates are arranged above the side clamping plates. Connecting springs are arranged below the pressing plates. Surface sliding grooves are reserved in theupper surfaces of the containing plates, and the side edge sliding grooves are formed in the inner side walls of the fixing bases. The connecting sliding grooves are formed in the upper surface of the base, and limiting holes are reserved in the base. According to the panel welding clamping device convenient to adjust, the upper end faces of the bearing table, a supporting table and the containing plates are located at the same horizontal line position, and therefore panels can be well supported when placed on the device; and the situation of unevenness is avoided, and welding between the panels becomes more accurate.

Owner:ANHUI ORIGINAL POWER PRODUCTIVITY PROMOTION CENT CO LTD

Flip-chip construction maintaining solder positioning

InactiveCN102142402APrecision weldingGood yieldSemiconductor/solid-state device detailsSolid-state devicesSolder pasteMetal

The invention discloses a flip-chip construction which maintains solder positioning. The flip-chip construction mainly comprises a chip and a substrate, wherein a plurality of bumps and at least one convex basic mark are formed on an active surface of the chip; the substrate is provided with a plurality of soldering pads and at least one basic mark seat; the basic mark seat is provided with a concave basic mark pattern which corresponds to the convex basic mark; and when the chip is arranged on the substrate in an alignment mode, the convex basic mark is embedded into the concave basic mark pattern to make the bumps aligned with the soldering pads. Therefore, even if a mechanical alignment error exists, the bumps of the chip can be soldered to the soldering pads of the substrate accurately, and particularly, products which are applied to metal post solder-chip connection (MPS-C2) have a better yield.

Owner:POWERTECH TECHNOLOGY

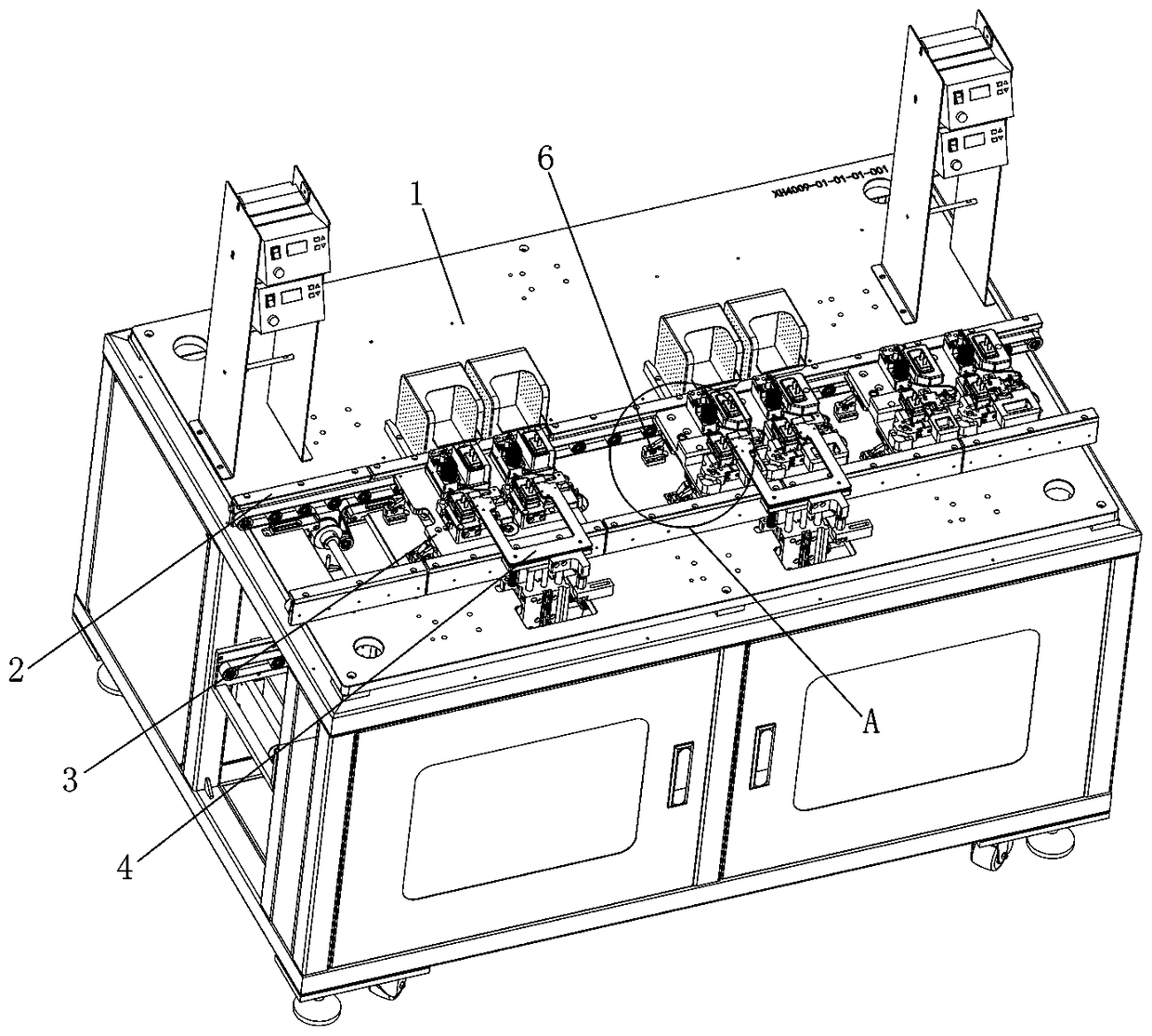

Automatic welder for DC wire of power supply

PendingCN108213645AImprove welding efficiencyPrecision weldingOther manufacturing equipments/toolsSoldering auxillary devicesFine-tuningWelding

The invention discloses an automatic welder for DC wires of a power supply. The automatic welder comprises a conveying pulling body, jigs, a jig positioning mechanism, a pressing mechanism and a welding mechanism, wherein the conveying pulling body is arranged on a rack along a left-right direction; the at least two jigs are arranged on the conveying pulling body; at least two PCBs of the power supply and DC wires of the power supply are placed on the jigs; a welding station is arranged on the side part of the conveying pulling body; the jig positioning mechanism is arranged at the welding station; the pressing mechanism is arranged on the front side of the jig positioning mechanism; the welding mechanism bestrides the upper side of the conveying pulling body and is arranged correspondingto the jig positioning mechanism, and the welding mechanism solders and fixes the connecting parts of the DC wires of the power supply and the PCBs of the power supply; and the jig positioning mechanism loosens the jigs after being soldered. The PCBs and the DC wires which are automatically conveyed and welded are effectively jointed, the PCBs and the DC wires are clamped stably; and the welding mechanism with a flexible fine tuning function achieves precise welding and automatic smoke exhaust and is high in welding efficiency.

Owner:SHENZHEN XING GRAIN AUTOMATION CO LTD

Electromagnetic valve assembling machine

PendingCN108311883AReduce loading spacePrecision weldingAssembly machinesOther manufacturing equipments/toolsEngineeringElectromagnetic valve

The invention discloses an electromagnetic valve assembling machine. The electromagnetic valve assembling machine comprises a needle vibrating loading mechanism, a gasket vibrating loading mechanism and a valve seat vibrating loading mechanism which are successively arranged, wherein a pin pressing mechanism, a valve element loading mechanism for putting a valve element in a valve seat, a valve seat riveting pressure mechanism for fixing the valve element and the valve seat, a coil assembling mechanism for assembling a coil to an electromagnetic valve body, a coil welding mechanism and a coiltailoring mechanism are successively arranged on two sides of an electric runner; the moving directions of a first coil electric track and a second coil electric track are opposite; a first pushing air cylinder for pushing a coil to the input end of the second coil electric track is arranged at the output end of the first coil electric track; and a second pushing air cylinder for pushing the coilout of the output end of the second coil electric track and a chuck mechanism for conveying the coil to the coil assembling mechanism are arranged at the output end of the second coil electric track.The coil loading space is reduced, and the track is lengthened, so that the coil is manually loaded conveniently.

Owner:KUNSHAN HUAYU AUTOMATION TECH

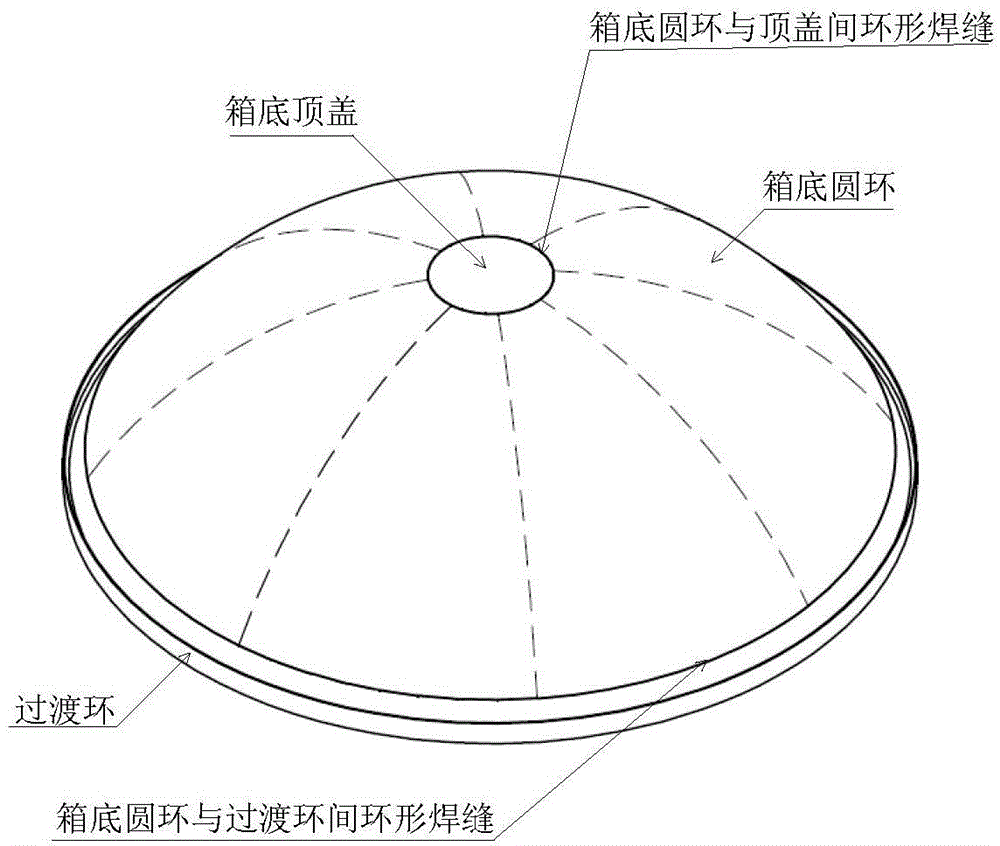

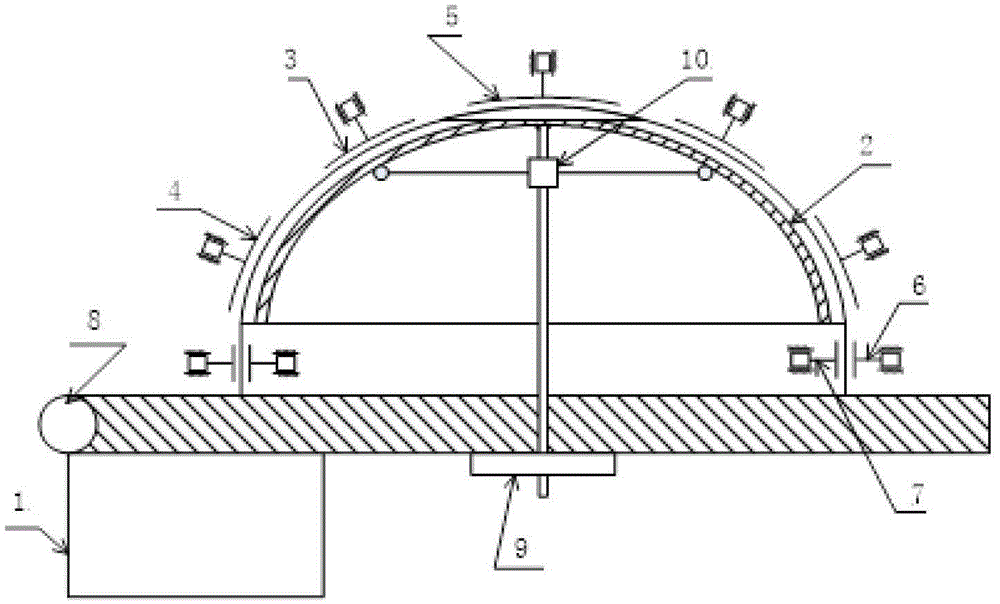

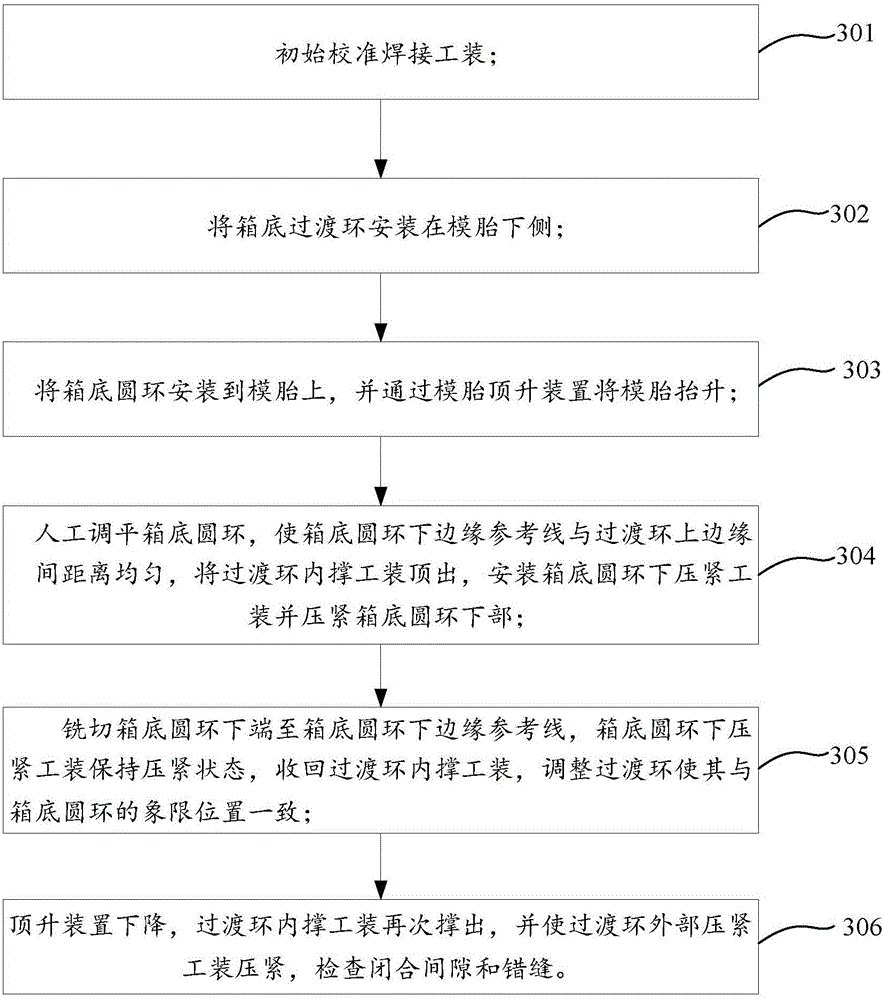

Method for controlling annular gap small clearance of spherical box bottom of 5M-level thin-wall storage box

ActiveCN104690471APrecision weldingNo gapWelding/cutting auxillary devicesArc welding apparatusEngineeringReference line

The invention discloses a method for controlling an annular gap small clearance of a spherical box bottom of a 5M-level thin-wall storage box, and aims to realize the control on the annular gap small clearance before an annular gap of the spherical box bottom of the 5M-level thin-wall storage box is welded. The method comprises the following steps: initially calibrating a welding tool; mounting a box bottom circular ring on a welding tool mould; mounting a box bottom circular ring lower compressing tool, and compressing the lower end of the box bottom circular ring; milling the lower end of the box bottom circular ring, wherein the box bottom circular ring is milled to be level with a reference line of the lower edge of the box bottom circular ring; supporting an internal supporting tool of a transition ring outwards, enabling a transition ring external compressing tool to compress a box bottom transition ring, and ensuring that the end faces of welded joints between the box bottom transition ring and the box bottom circular ring lower end are closely fitted.

Owner:CHINA ACAD OF LAUNCH VEHICLE TECH +2

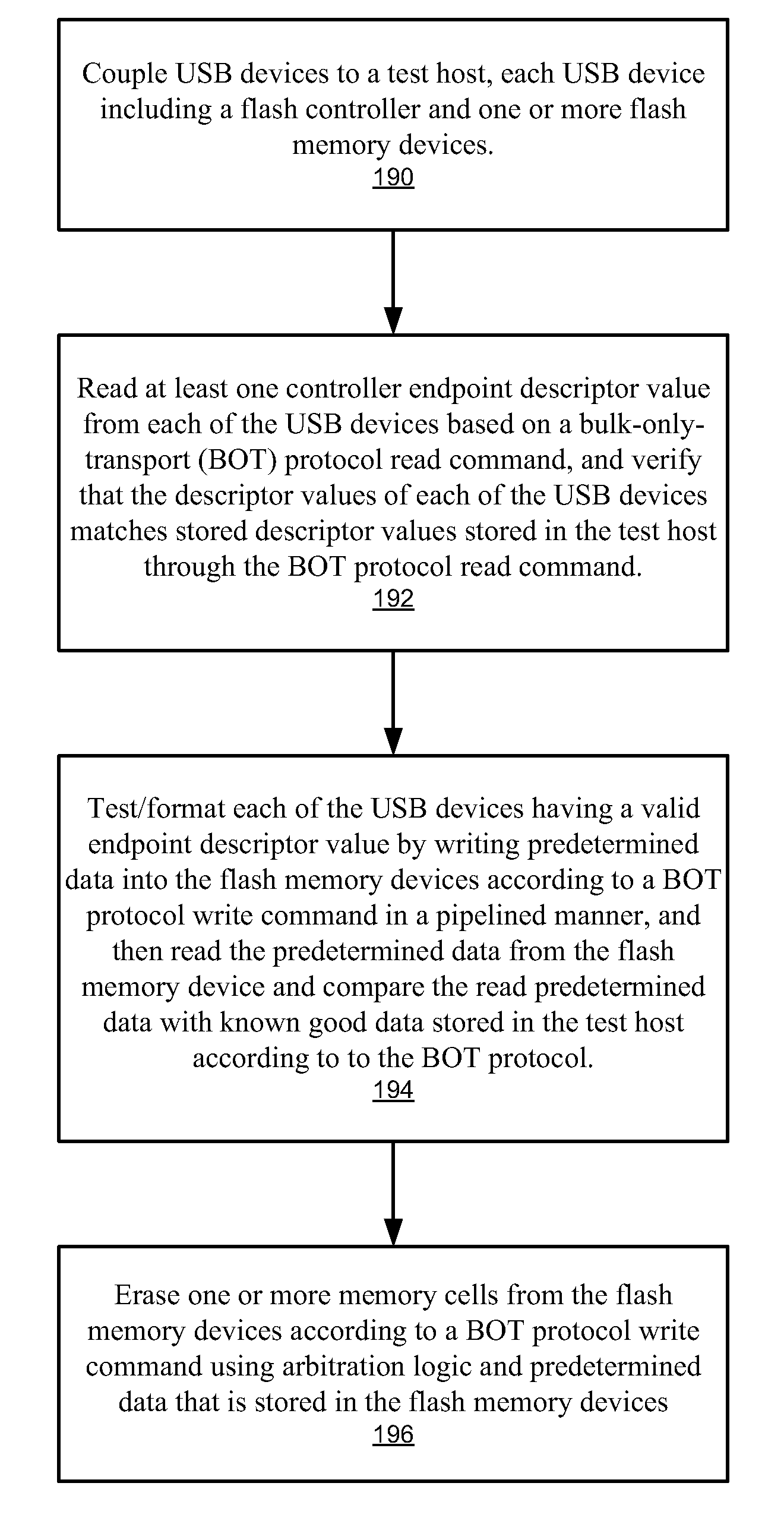

Intelligent card chip handling device

ActiveCN104835768AImprove versatilityLow costSemiconductor/solid-state device manufacturingConveyor partsSmart cardRisk stroke

The present invention discloses an intelligent card chip handling device which comprises a frame, a chip adsorbing mechanism and a moving mechanism. The chip adsorbing mechanism comprises an adsorbing head, a vacuum device which is connected to the adsorbing head, and a mounting frame which is connected to the moving mechanism. The adsorbing head is connected to a turning mechanism which comprises a power mechanism, a hinge structure arranged between the adsorbing head and the mounting frame, a driving connection structure which is arranged between the power mechanism and the adsorbing head, and a spring which is connected between the adsorbing head and the mounting frame. The driving connection structure comprises a sliding groove arranged on the adsorbing head and a driving rod arranged on the power mechanism. The driving rod extends into the sliding groove. When the driving rod moves to two end points of a vertical stroke, the driving rod is at two ends of the sliding groove, and the working end faces of the adsorbing head are in horizontal and vertical states respectively. The intelligent card chip handling device has the advantages of simple structure, small size, high efficiency, and good positioning accuracy.

Owner:GUANGZHOU MINGSEN TECH CO LTD

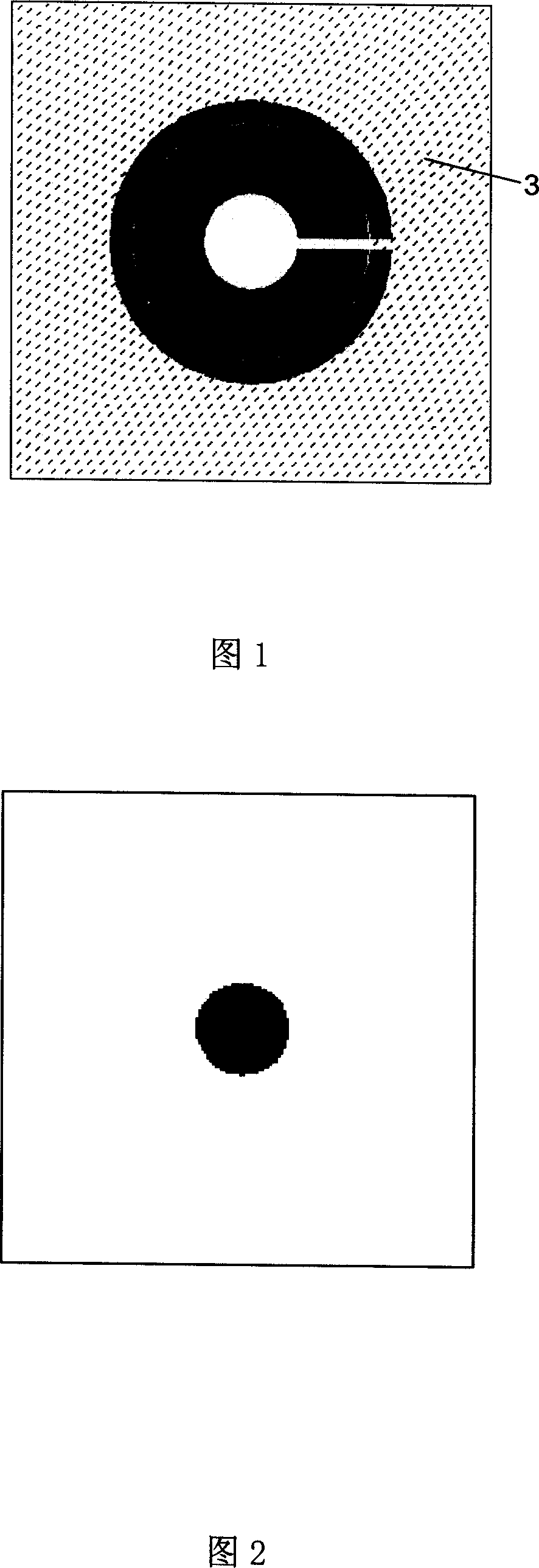

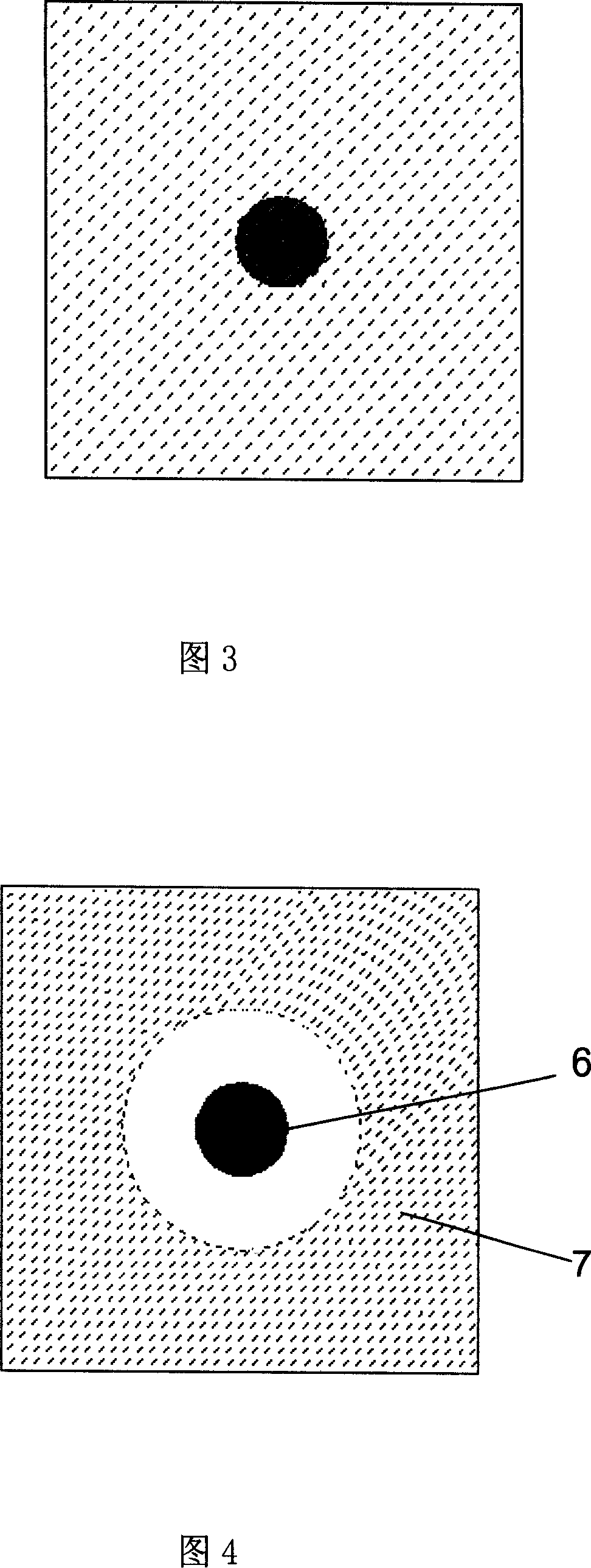

Optical identifying welding plate for printed circuit board and mfg. method

ActiveCN1980522AIncrease contrastPrecision weldingPrinted circuit assemblingPrinted circuit detailsEngineeringSoldering

This system includes: (1) the soldering plates (SP) residing on the printed circuit board (PCB), (2) the photo recognition points (PRP), which contrast differs from ambient, (3) the etch points (EP) remained from removing PRP on SP, (4) the soldering resistance (RS) area with openings around PRP, and (5) the plating layer on this RS opening area. This invention also offers a manufacture method for the PRP on a flexible PCB. It includes steps of 1) etching a PRP on SP, 2) making RS on SP, making openings around PRP on RS area, and then plating the opening area. On the flexible PCB made by this way, the color contrast between PRP and the ambient is rather high. The shape of PRP is round. Due to the good photo recognition effect, the surface stick installation machine can accurately orientate with the aid of photo recognition.

Owner:靖江德方科技服务有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com