Patents

Literature

109 results about "Material repair" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Dry type manufacturing method of animal specimen

InactiveCN1971663AImprove qualityAdequate perfusionDead animal preservationEducational modelsHigh concentrationGlycerol

The invention relates to a dry type making method for animal specimen that includes six steps: collecting material, reshaping antisepsis fix and tube cavity cast, alcohol dewatering fix, glycerol process, turpentine impregnation and air drying, material repairing tinction preservation or seal up for keeping. Thereinto, in step 1, the animal material is bleed and killed via health quarantine, in step 2, potting it with the formalin with colorless glycerin and phenol or alcohol solution, in step 3, controlling the concentration of every step and fixed time, in step 4, marinating it with glycerol moisture absorption soften liquid, and transfer it from low concentration to high concentration of glycerin, and the time is prolonged gradually, in step 5, treating it with turpentine continually, in step 6, printing it. The invention improves the present technique, the quality of specimen is improved greatly, and that can keep the original state of material, the color and the luster. The dried specimen is sanitation without peculiar smell, and good at handle and quality.

Owner:王荣林

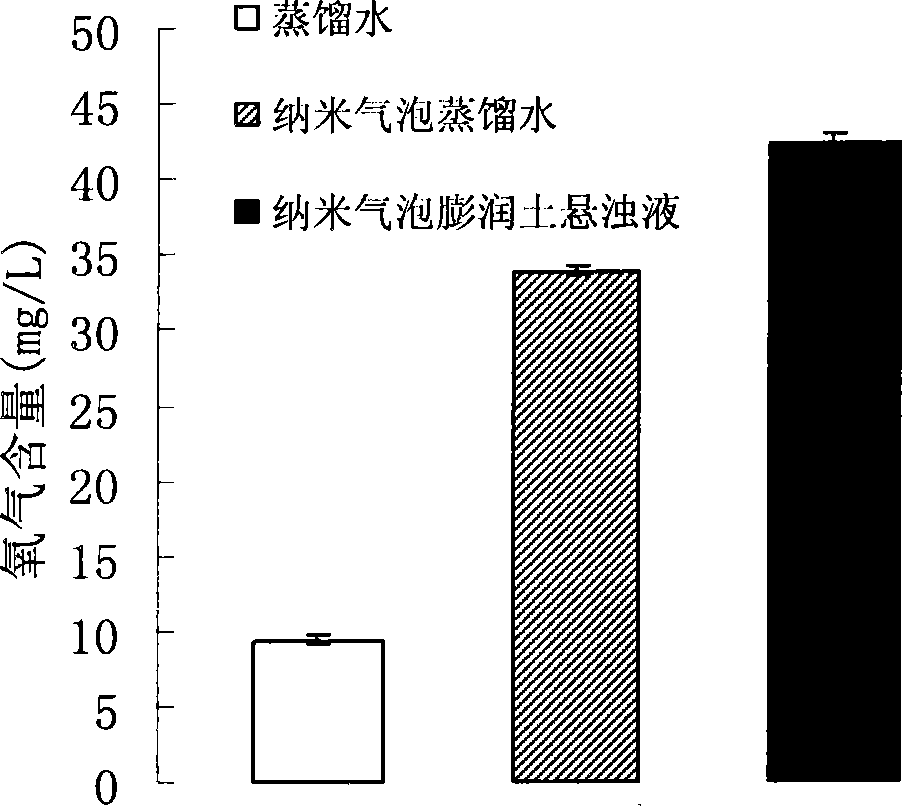

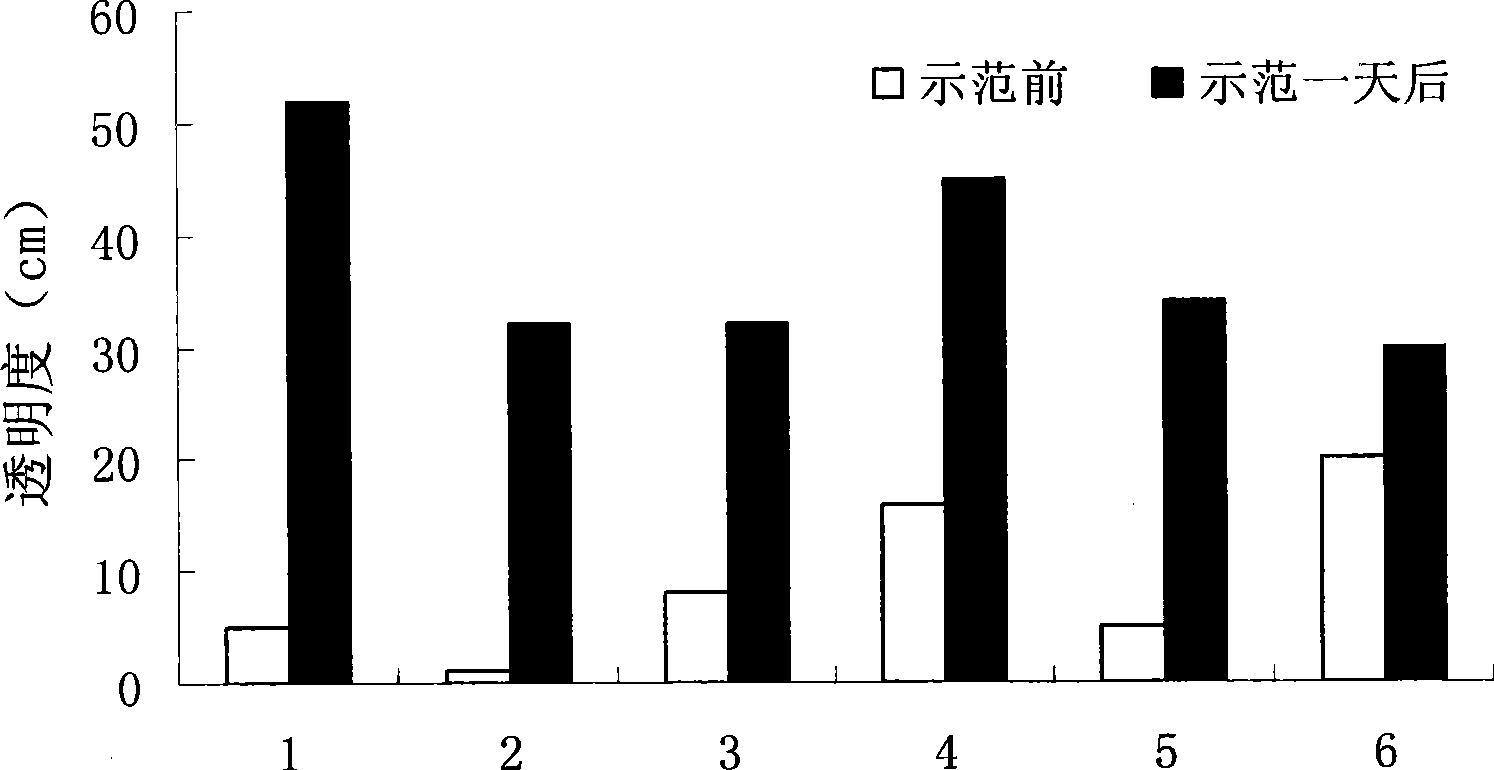

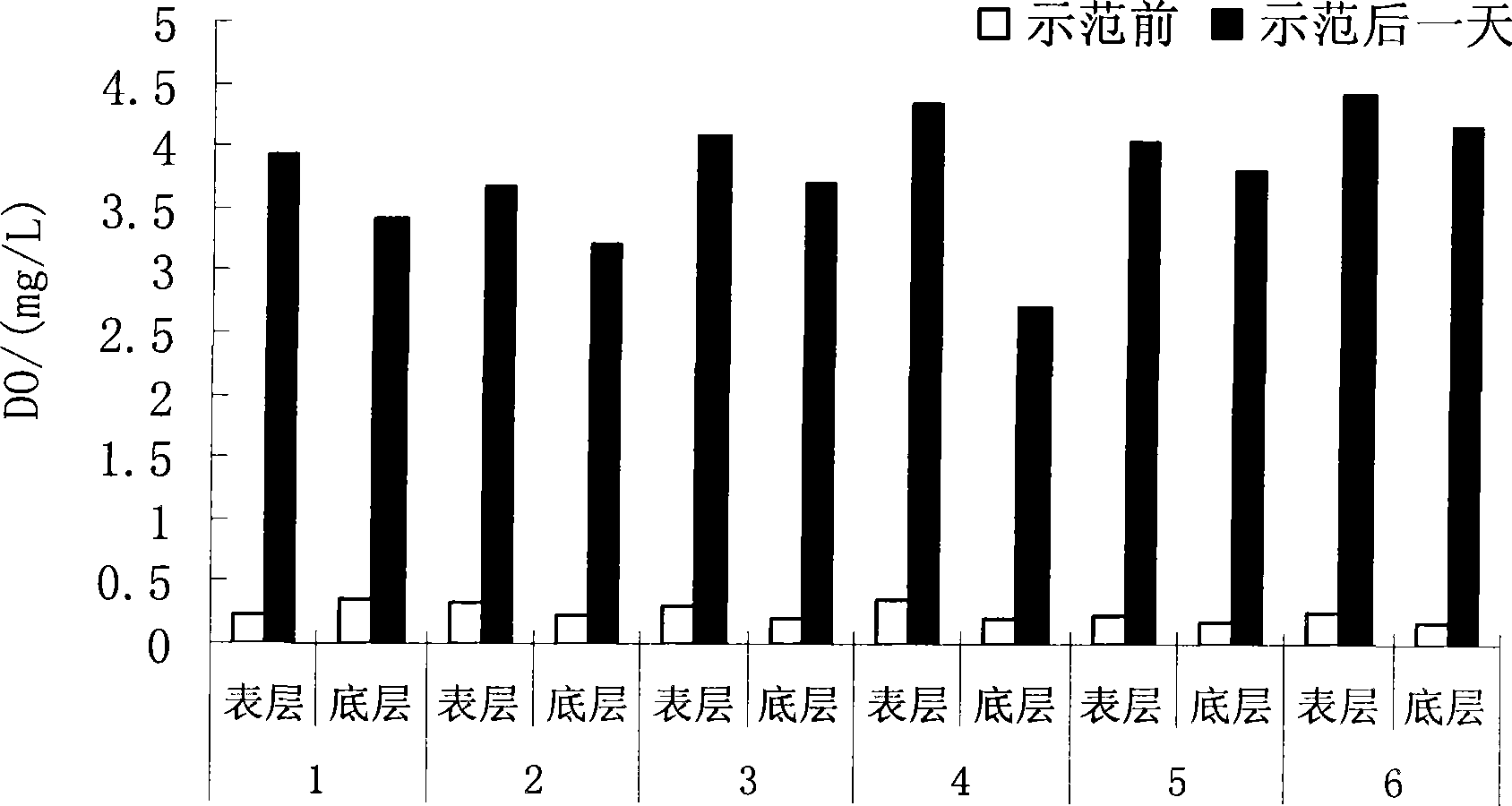

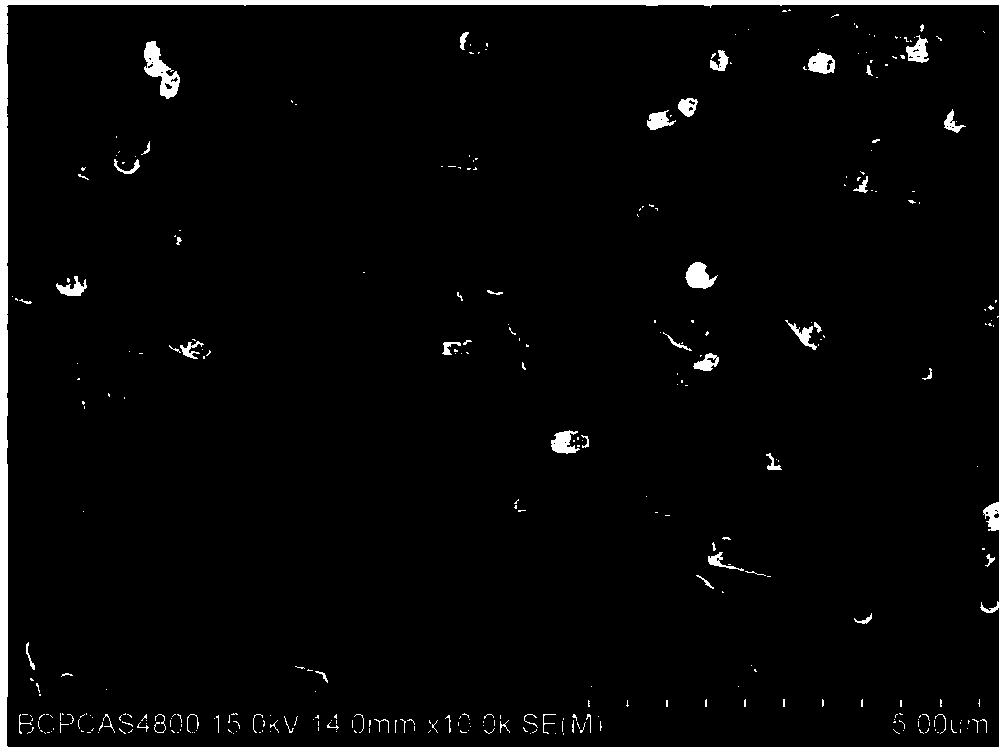

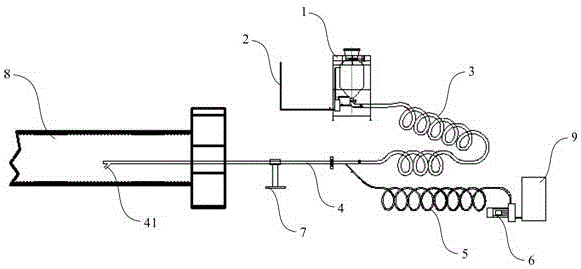

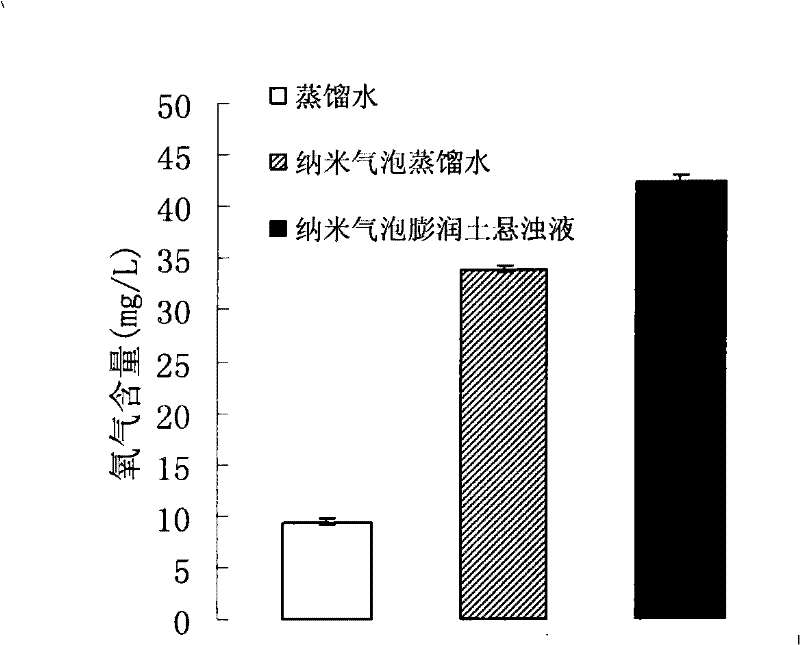

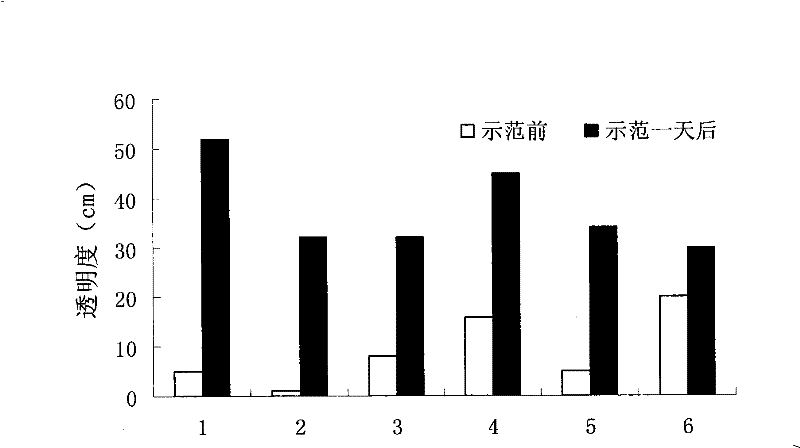

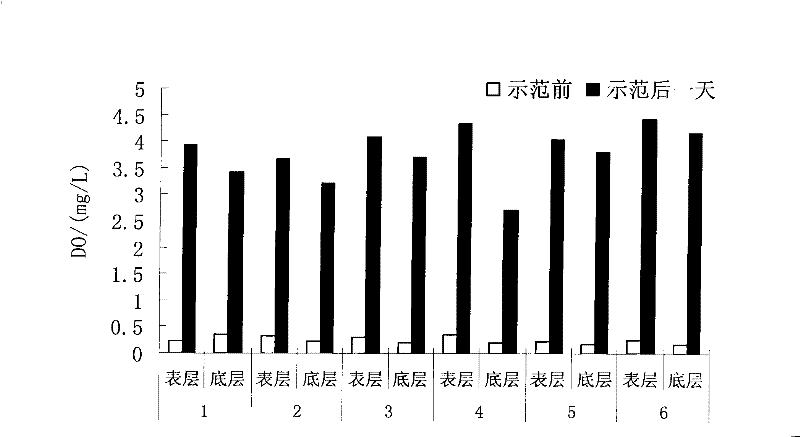

Method for repairing lake and anaerobic bottom mud by nano bubble

ActiveCN101503238AHigh transparencyIncrease dissolved oxygen levelsWater aerationSustainable biological treatmentVegetationEutrophication

The invention provides a composite material which uses nanometer bubbles to rapidly eliminate lake algae bloom and repair anaerobic substrate sludge. The composite material repairs anaerobic substrate sludge, increases the oxidation-reduction potential of the substrate sludge and the dissolved oxygen level of the water body while rapidly eliminating algae blood in a large area and increasing the transparency of the water body. The nanometer bubbles are oxygen nanometer bubbles, ozone nanometer bubbles or air nanometer bubbles. Natures of nanometer bubbles such as quantity, size, density and the like can be adjusted and controlled with a particular method. The invention also provides a method for using the composite material to repair the lake and anaerobic substrate sludge, which comprises that a mechanical method is used for spreading or spraying the composite material onto the lake surface, thus simultaneously finishing the algae bloom removal in the large area, increasing the transparency of the water body, repairing the anaerobic substrate sludge, increasing the dissolved oxygen level of the water body, and providing a good environment for the rapid growth of submerge vegetation and ecological restoration of the eutrophication water body; and the method has ecological security and long effect of the lake treatment.

Owner:BEIJING GREEN ECO ENVIRONMENTAL TECH

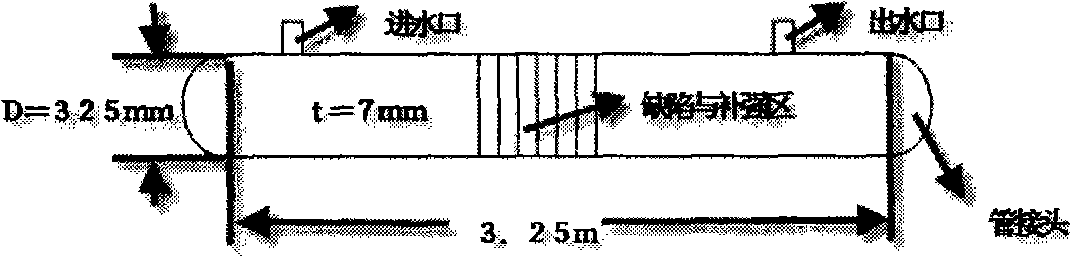

Pipe renovation method and its special renovation material system

InactiveCN101344208AExcellent resistance to cathodic disbondmentHigh strengthPipe elementsDesign standardRepair material

The invention discloses a method for repairing pipelines and a repair material system thereof. The combined material system used for the repair and reinforcement of the pipelines provided by the invention consists of a healant for filling and leveling up the flaws, an anti-negative pole peeling coating, carbon cloth and impregnant rubber. The pressurization test proves that the pipelines repaired by adopting the method and the combined material system of the invention can restore or improve the loading capacity of the pipelines, thereby achieving the loading design standard of the pipelines. The combined material system not only plays the role of repairing and reinforcing the flaws, but also effectively avoids the occurrence of various electrochemical corrosion problems of the flaws. The combined material repair system has easy and practicable repair method and high operability in the process of the repair and reinforcement of the pipelines. The repair material system and the repair technology have very high use value.

Owner:BEIJING FIRMBASE ENG

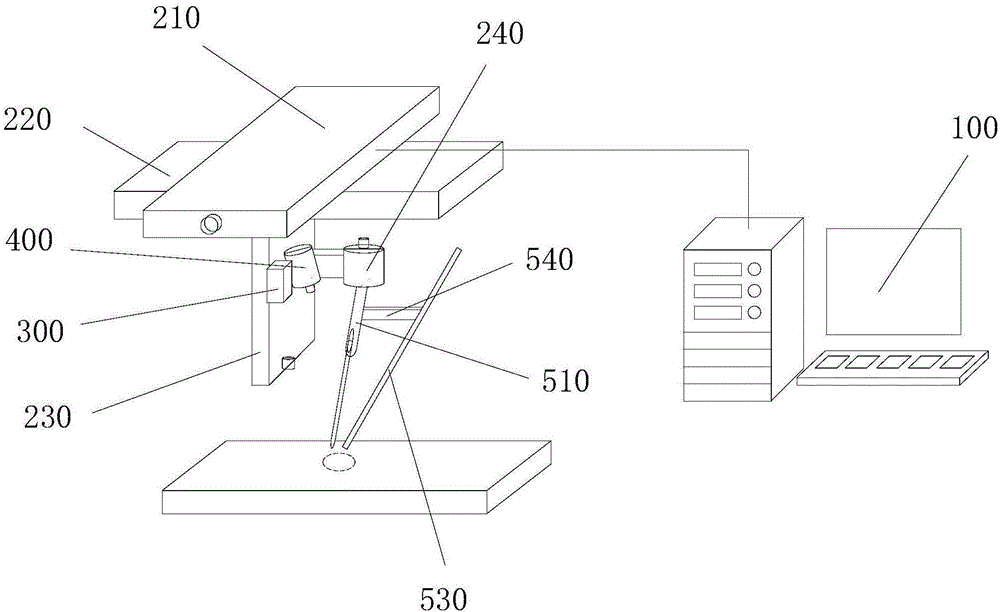

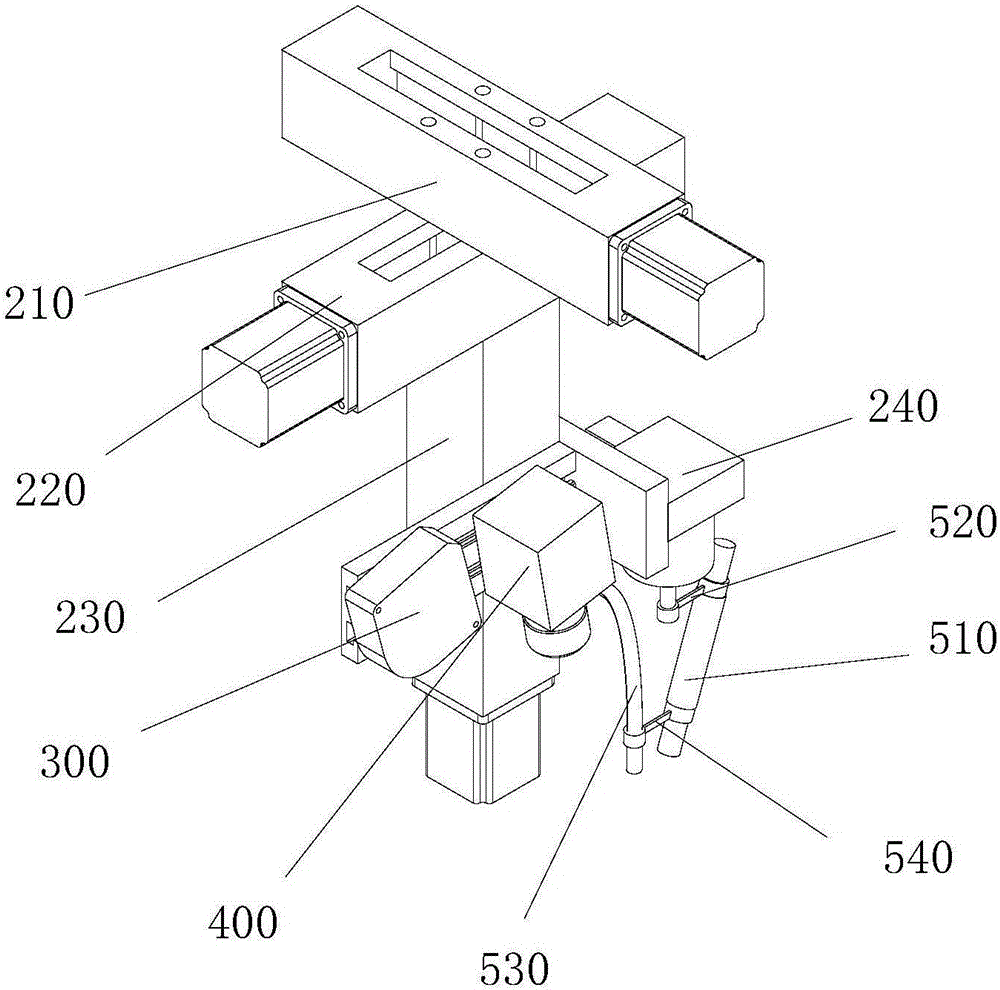

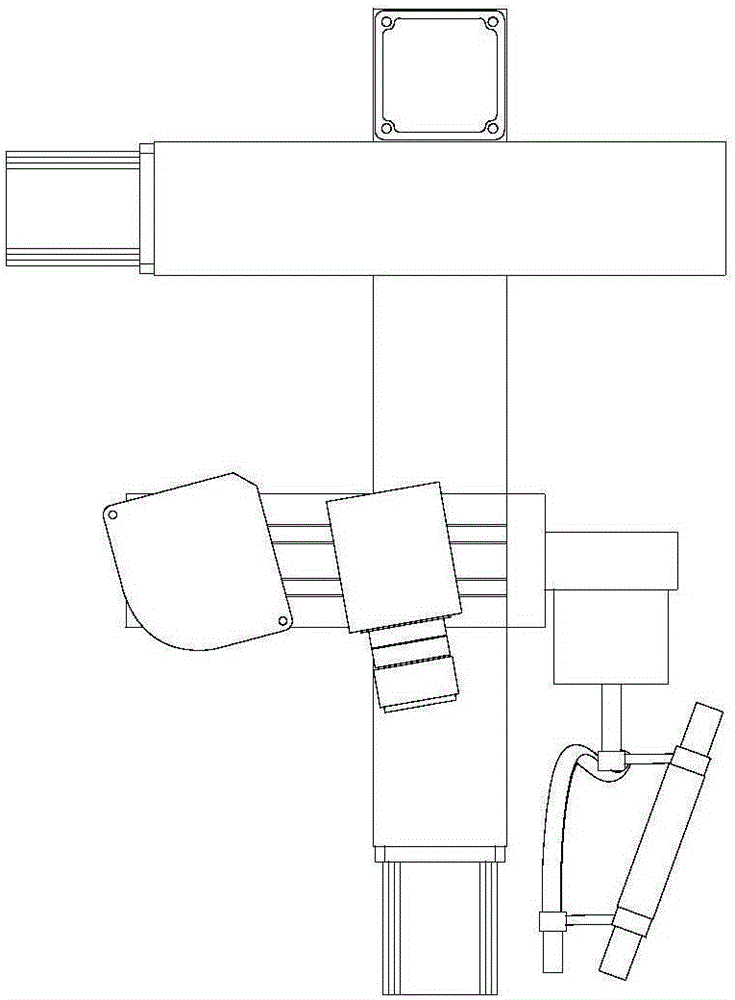

Non-gas metal arc welding 3 D adding material repair device and repair method

InactiveCN106141374AReduce missing solderReduce the situationArc welding apparatusMelting tankDefect repair

The invention discloses a non-gas metal arc welding 3 D adding material repair device and repair method. The repair device comprises a controller, a four-axis linkage platform, a laser vision sensor, an infrared vision sensor, a clamp, a non-metal arc welding torch, a wire feeding unit and a welding wire disc. The repair method comprises the steps that a defective workpiece is installed on a repair workbench; the laser vision sensor is driven to scan a defective three-dimensional outline; the controller rebuilds the defective three-dimensional outline; specific welding parameters are determined; the controller drives the infrared vision sensor to scan a molten pool, time-frequency parameters of a molten pool image are obtained, a compensation control code is generated according to the time-frequency parameters of the molten pool image, and the set welding parameters are corrected in real time; and after repair, the laser vision sensor is driven again to scan the defective three-dimensional outline, whether the repaired workpiece reaches the standard is determined, and if not, defects are repaired again till defect repair reaches the standard. The repair device is simple in structure, convenient to operate and high in reliability and adaptability.

Owner:GUANGDONG UNIV OF TECH

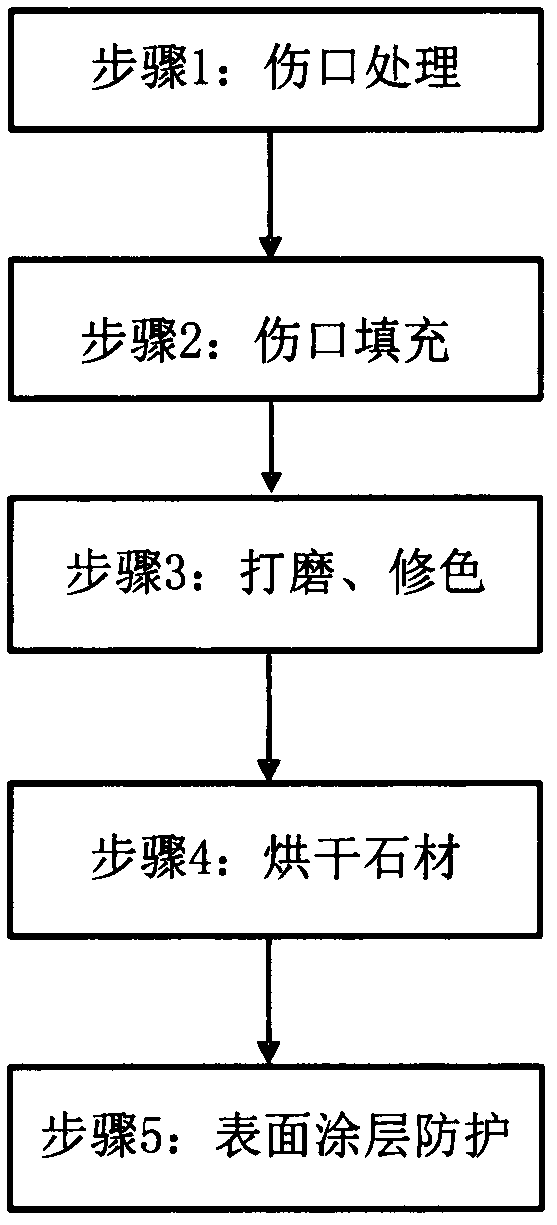

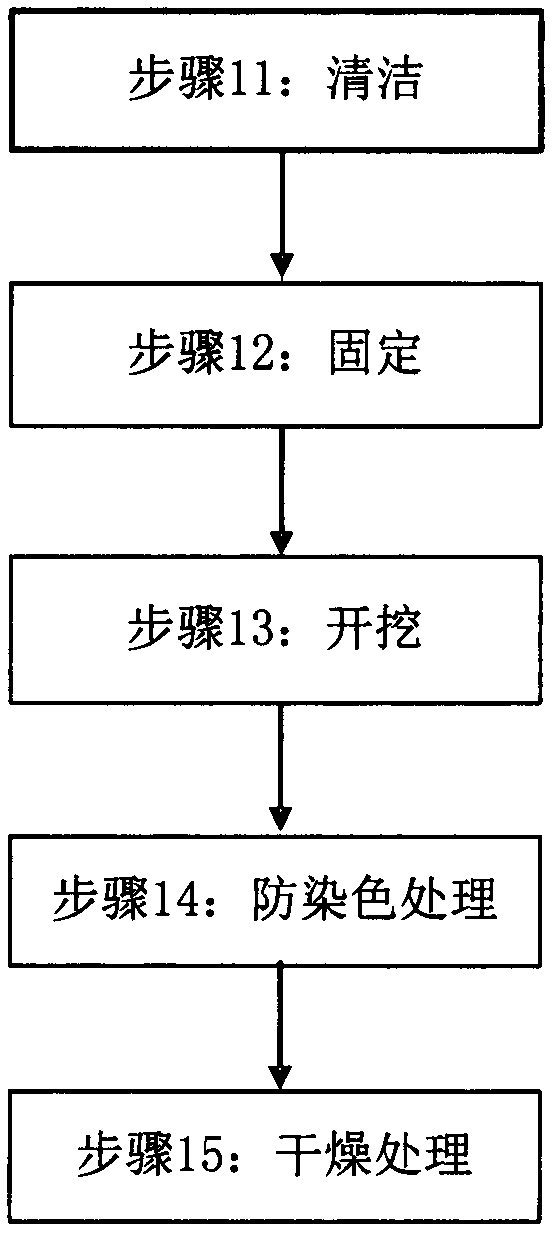

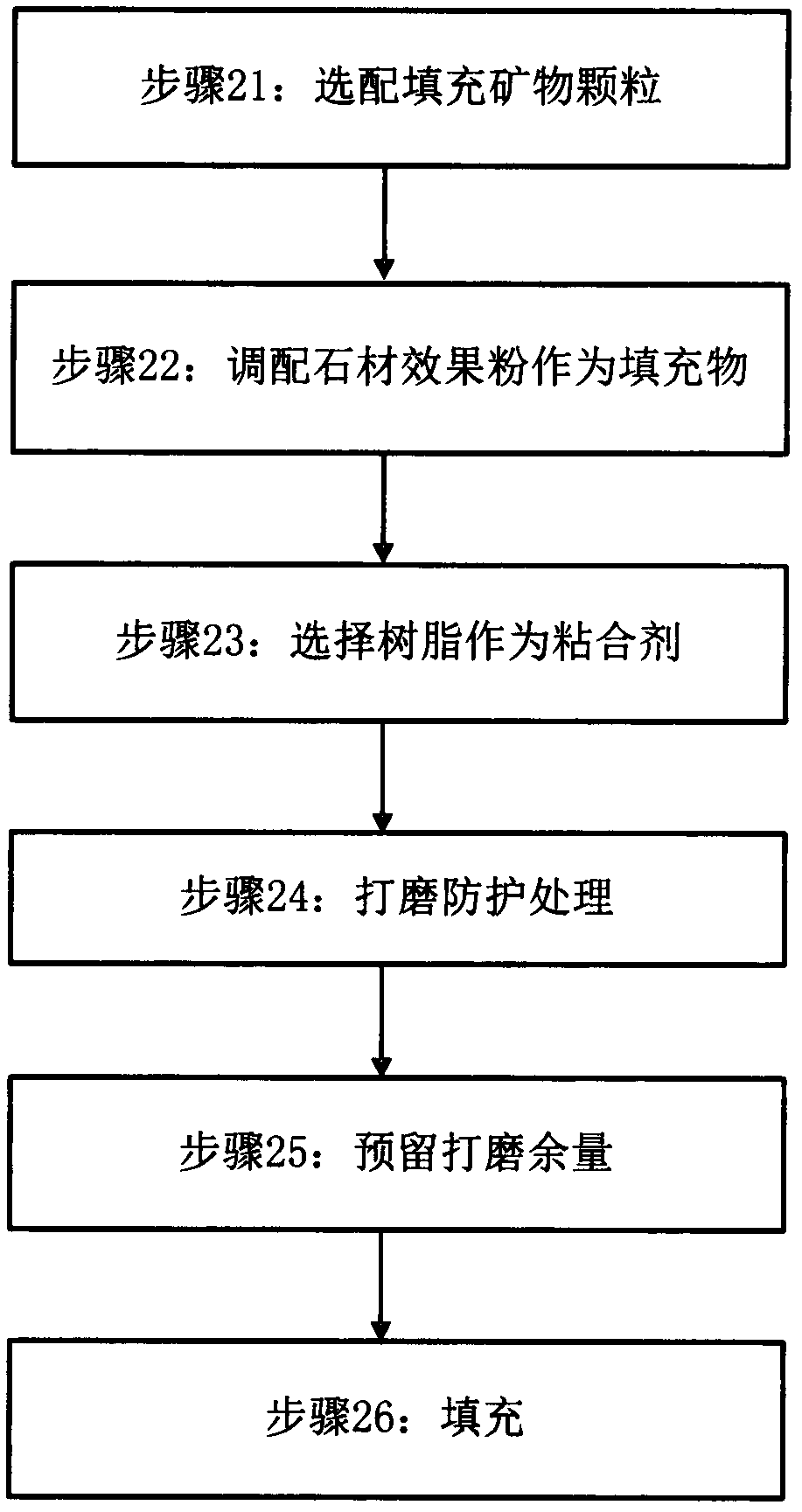

On-site rapid stone material repairing method

The invention belongs to the field of utensil repairing technology and provides a stone material repairing method, which is characterized by comprising the following steps of: wound processing; wound filling; polishing and color correction; stone material drying; and surface-coating protection by using a nanometer protective agent. The method, which is used to repair stone materials in the invention, is suitable for stone material repairing in various complex situations, and has a good and lasting repairing effect. The invention can be widely applied in repairing various stone materials of various defects and various grades and has a good market prospect.

Owner:SHANGHAI KUNLUN TECH DEV

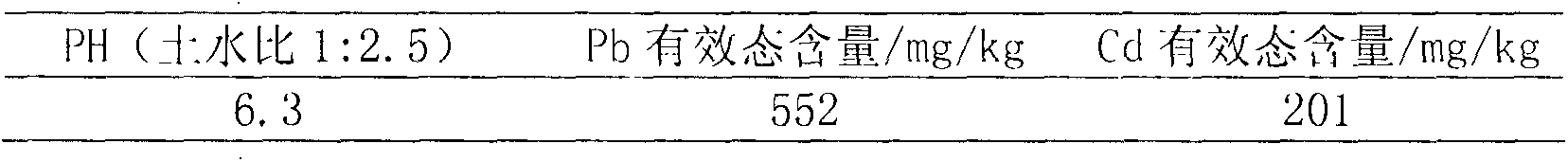

Nano-material repairing agent restoring heavy-metal polluted soil and restoring method using same

InactiveCN104117532AImprove coordinationChemically activeContaminated soil reclamationMass ratioOleic Acid Triglyceride

The invention discloses a nano-material repairing agent restoring heavy-metal polluted soil and a restoring method using the same, and belongs to the technical field of soil pollution processing. The nano-material repairing agent restoring heavy-metal polluted soil is prepared by mixing the following substances: 60-70% by volume of nano hydroxyapatite (nHA) with the particle size of 27 nm and the purity of 98%, 10-20% by volume of nanoscale zero-valent iron (nZVI) with the particle size of 10 nm and in the shape of a ball, and 10-30% by volume of pure oleic acid. The invention also comprises the restoring method for heavy-metal polluted soil by using the above repairing agent. The method comprises the following step: applying the repairing agent to soil according to the mass ratio of 1:10000-15000. The nano-material repairing agent used to restore heavy-metal polluted soil comprises the characteristics of obvious restoring effect and no secondary pollution.

Owner:苏州中科慧盛生物科技有限公司

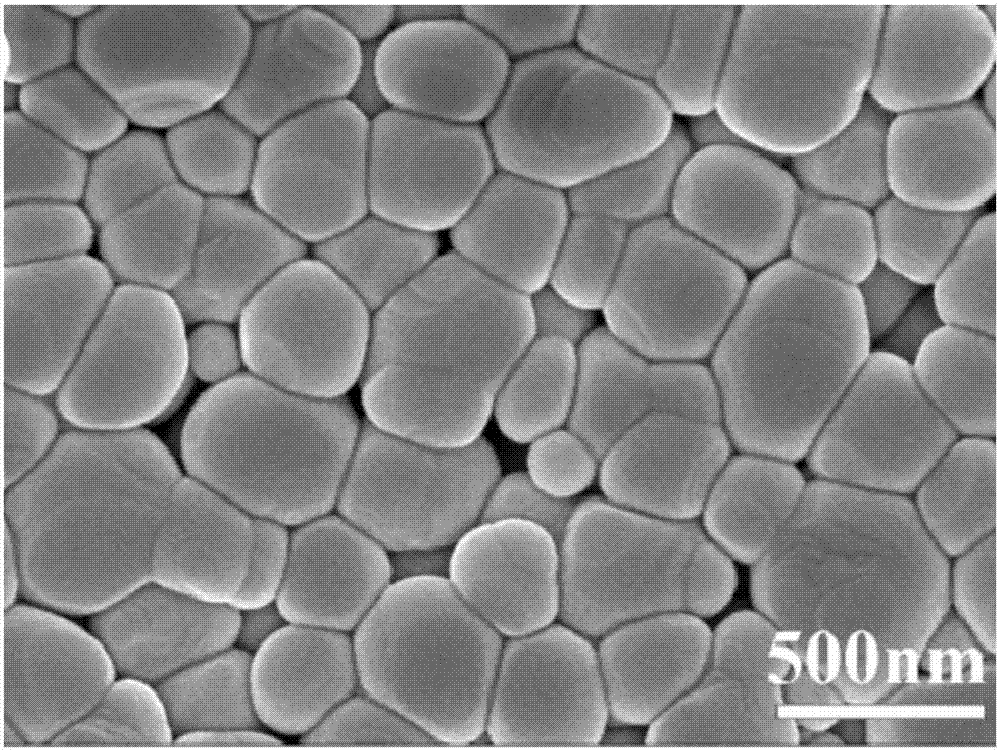

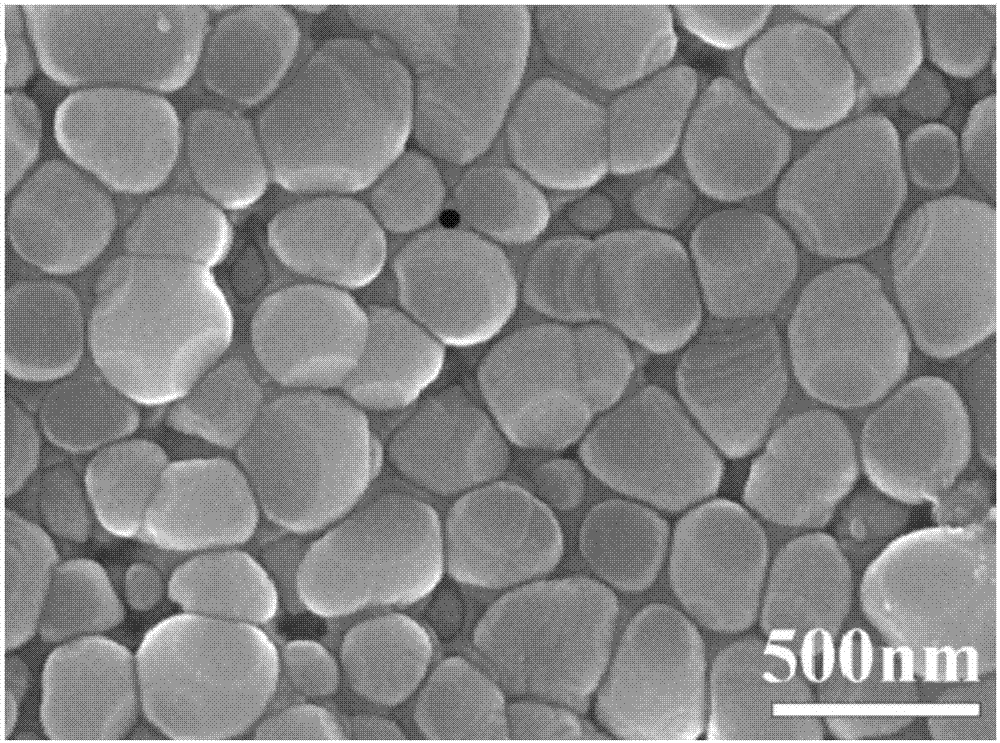

Preparation method of dental bioactive zirconia ceramic material

ActiveCN106904962AImprove biological activityLittle impact on mechanical propertiesImpression capsDentistry preparationsTriethylamine phosphateMechanical property

The invention discloses a preparation method of a dental bioactive zirconia ceramic material. The preparation method comprises steps as follows: with adoption of a method for preparing bioactive glass from sol-gel, a hydrolysable silicone-containing compound, triethyl phosphate, calcium nitrate, other nitrates and the like are added to deionized water, pH is regulated, a mixed solution is subjected to hydrolytic condensation, and bioactive glass sol is obtained; after being soaked in the prepared bioactive glass sol in a vacuum negative-pressure environment for a period of time, a zirconia pre-sintered body is taken out, dried and sintered at the high temperature, and the dental bioactive zirconia ceramic material is obtained. The bioactive zirconia ceramic material has good biological activity and excellent mechanical properties and has great social and economic value in improvement of the dental material repairing effect and promotion of wider clinical application of the material.

Owner:SOUTH CHINA UNIV OF TECH

Quick bonding repair method of ultraviolet-curing composite material

InactiveCN104371488AImprove curing efficiencyHigh tensile strengthNon-macromolecular adhesive additivesEpoxy resin adhesivesUltraviolet lightsTransmittance

The invention provides a quick bonding repair method of an ultraviolet-curing composite material. An ultraviolet-curing resin composition with quick self-propagating curing characteristic, which is used as a base material, is mixed with a fiber reinforcing material to obtain a composite material repair patch. The method comprises the following steps: 1) carrying out surface treatment on a damage region in need of bonding repair; 2) laying a composite material layer on the treated damaged region surface, wherein the thickness and direction of the composite material layer are determined according to the actual demands for repair; and 3) irradiating the composite material layer by an ultraviolet light source to form the composite material repair patch, thereby completing the bonding repair on the damage structure. The composite material repair patch has high designability, can be cured only by single irradiation in the preparation process, and has the advantages of high curing efficiency, favorable tensile strength, high repair efficiency and the like; the curing is not influenced by the number of the fiber layers and the light transmittance of the enhanced phase of the resin-base composite material; and thus, the method is especially suitable for emergency repair operation.

Owner:青岛煊龙机电科技有限公司

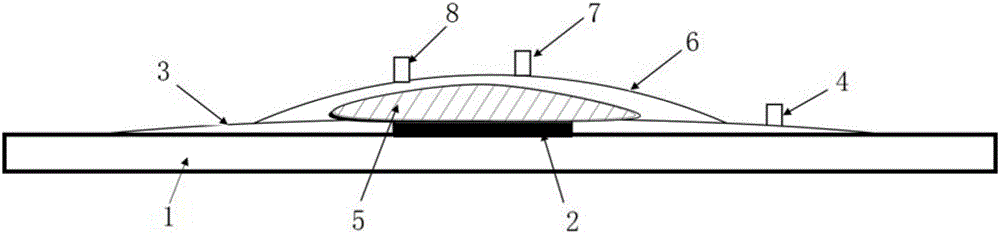

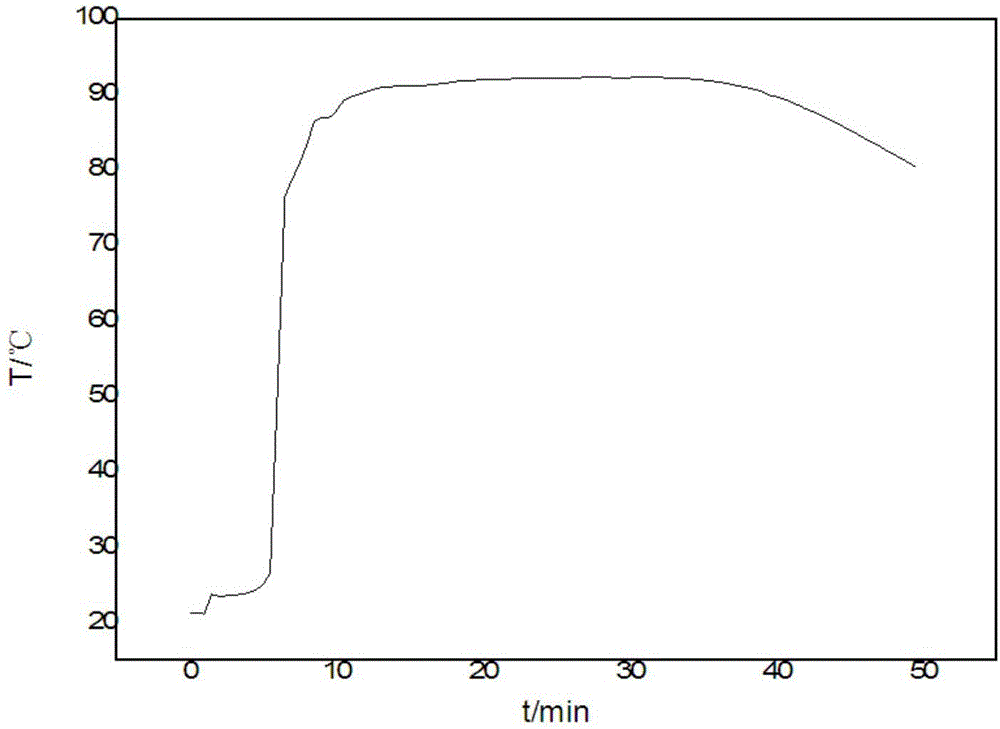

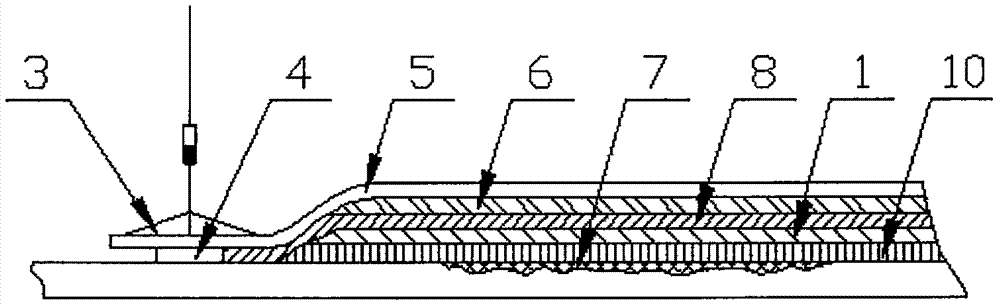

Self-heating molding repair device of medium-temperature curing composite material

ActiveCN106195515AExcessive heat releaseExothermic reaction violentThermal insulationPipe elementsInsulation layerSilica gel

The invention provides a self-heating molding repair device of a medium-temperature curing composite material. The repair device comprises a vacuum pressing layer for pressing a composite material repair piece on the surface of a repaired composite material structure, and a heating layer module. The repair device is characterized in that the vacuum pressing layer includes a high-temperature resisting film, and an air sucking port mounted in the high-temperature resisting film; the air sucking port is a one-way valve; the heating layer module includes a self-heating material layer formed by a self-heating material solid part, an insulation layer for bonding the self-heating material layer on the outer surface of the vacuum pressing layer and coating the self-heating material layer, a water injecting port and an exhaust port; and the insulation layer includes a high-temperature resisting film on the outermost layer, a ventilation felt on the middle layer, and a silica gel film on the inner layer. The repair device use self heat release performance of a self-heating material for quickly and conveniently curing and repairing composite material patches, satisfies the curing requirements of the composite material patches through heating temperature and time, and can enable repaired pieces to obtain excellent mechanical performances.

Owner:ACADEMY OF ARMORED FORCES ENG PLA

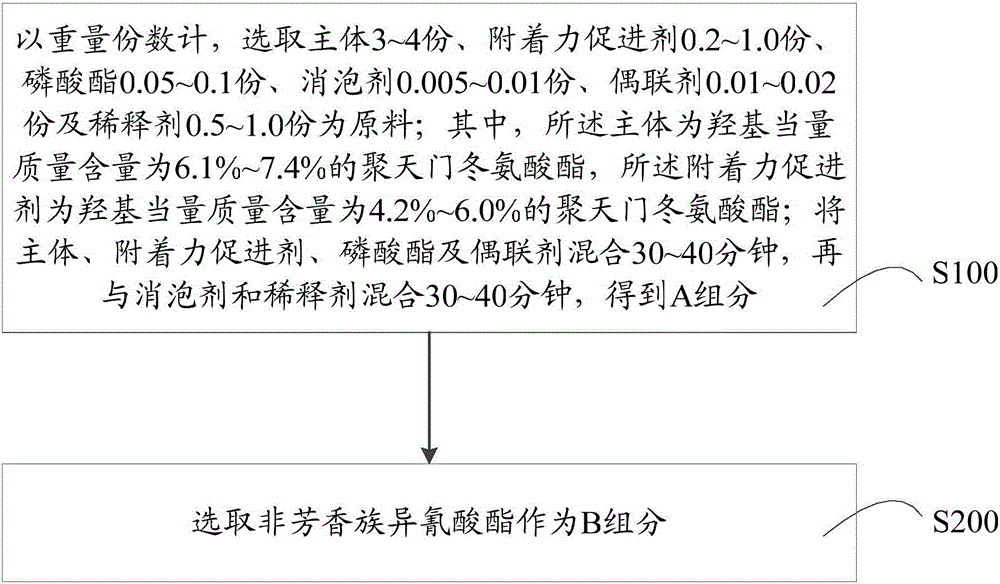

Yellow-resistance and rapid-curing stone material repair surface glue, preparation method and use method thereof

ActiveCN106560497AHigh bonding strengthGuaranteed aestheticsNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPhosphateDiluent

The present invention relates to a yellow-resistance and rapid-curing stone material repair surface glue, a preparation method and a use method thereof. The yellow-resistance and rapid-curing stone material repair surface glue comprises a component A and a component B, wherein the component A comprises, by weight, 3-4 parts of a main body, 0.5-1.0 part of an adhesion promoter, 0.05-0.1 part of phosphate, 0.005-0.01 part of an antifoaming agent, 0.01-0.02 part of a coupling agent and 0.5-1.0 part of a diluent, the main body is polyaspartate having a hydroxyl equivalent mass content of 6.1-7.4%, the adhesion promoter is polyaspartate having a hydroxyl equivalent mass content of 4.2-6.0%, and the component B comprises a nonaromatic isocyanate. According to the present invention, the main body and the adhesion promoter are subjected to combined use, such that the problems that the resin using the high hydroxyl equivalent mass content polyaspartate as the main body provides poor adhesion and poor permeability to the substrate and has short application period are effectively solved, and the obtained yellow-resistance and rapid-curing stone material repair surface glue has characteristics of rapid curing, good yellowing resistance, good adhesion, good permeability, and high bond strength.

Owner:HUNAN MAGPOW ADHESIVE INDS

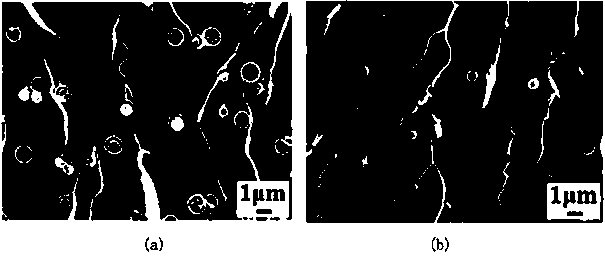

Self-repairing cyanate ester resin system and preparation method thereof

The invention relates to a self-repairing cyanate ester resin system and a preparation method of the self-repairing cyanate ester resin system. The preparation method comprises the steps of adding vinyl terminated poly-p-phenylene oxide (PPO) resin with low molecular weight into a cyanate ester (CE) resin system, and using 4,4 phi-diamino diphenyl sulfone (DDS) as a catalyst to treat the CE / PPO resin system through low-temperature process to obtain the self-repairing cyanate ester resin system with high performance. According to the technical scheme, the vinyl terminated PPO is utilized for maintaining thermoplasticity of the CE during forming; after the cured CE resin system is damaged, the PPO ingredients can be melted and flow to fill a crack to realize material repairing through a heating system, therefore, the vinyl terminated PPO has positive effects on prolonging the service life of the material and improving the safety of the material; the resin system can be used for preparing high-performance composite materials, electronic devices and the like for aerospace construction.

Owner:丹阳市俊琪塑业有限公司

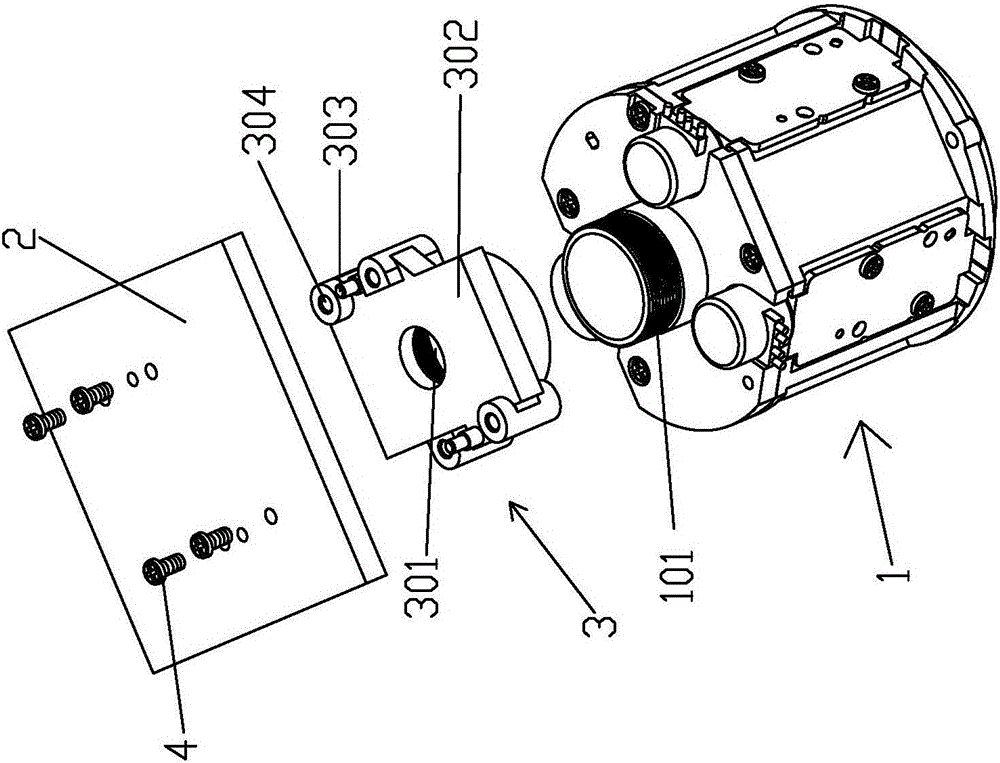

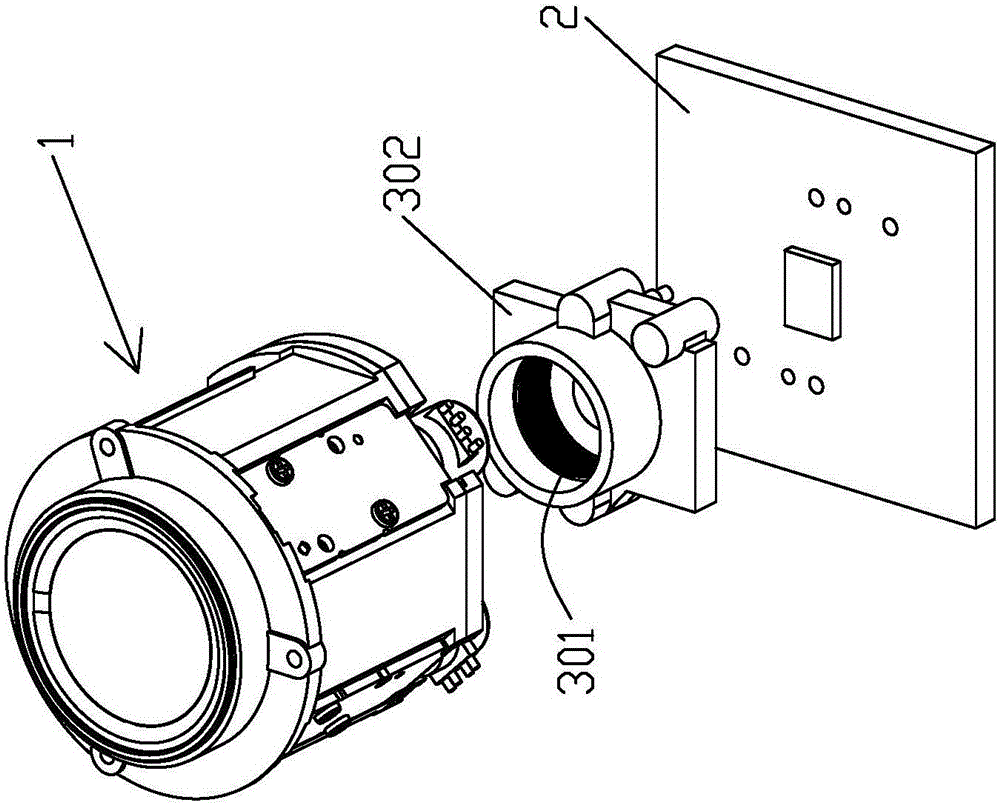

Novel lens connecting mechanism

The invention discloses a novel lens connecting mechanism. The technical scheme is characterized in that the novel lens connecting mechanism comprises a lens, a chip module and a connecting assembly for detachably connecting the lens and the chip module, wherein a first port is formed in the lens, and a second port detachably connected with the first port is formed in the connecting assembly. The original direct connection of the lens and the chip module is replaced with the novel lens connecting mechanism, a detachable transitional connecting assembly is adopted between the lens and the chip module, the lens is mounted on the chip module through the transitional connecting assembly, when a product needs to update or other styles are needed to add, any lens matched with the second port can be mounted on the chip module or any chip module matched with the first port can be mounted on the lens, so that the problem that failure of one of the lens and the chip module due to replacement of the other one is solved, and the material maintenance and change costs are reduced greatly.

Owner:UNION OPTECH

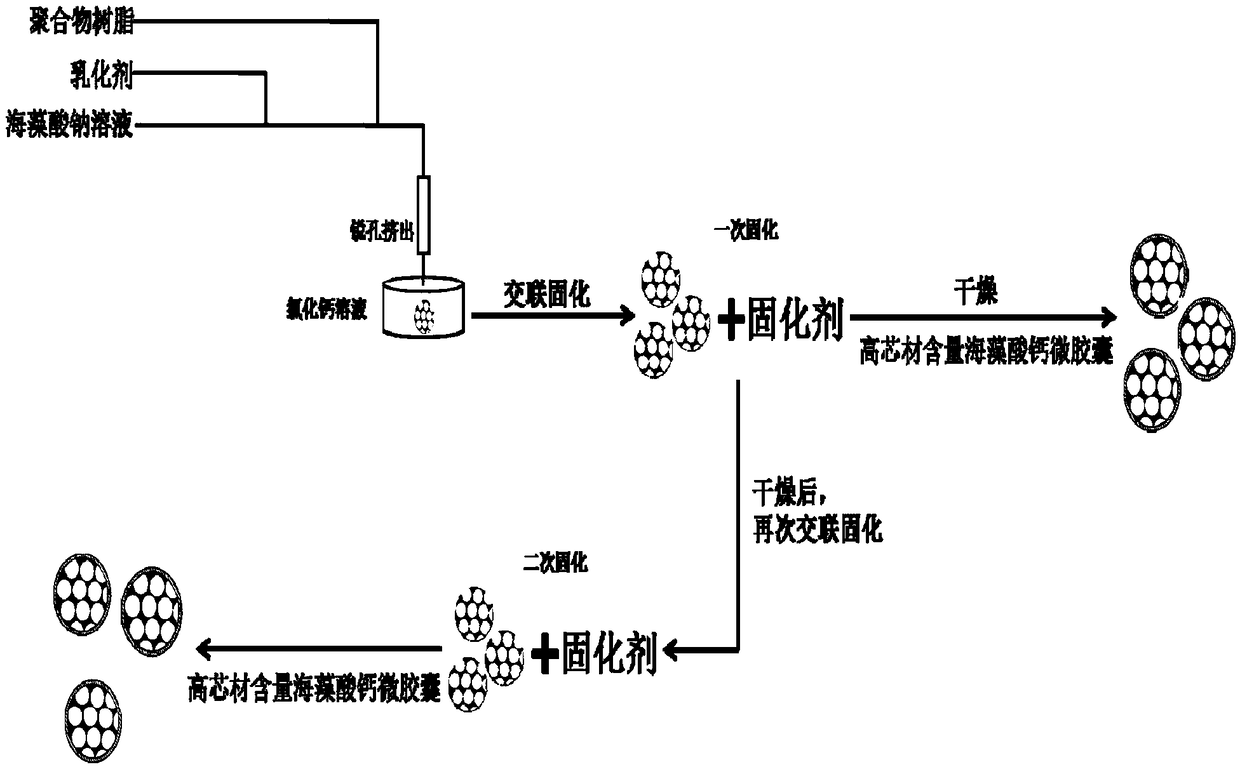

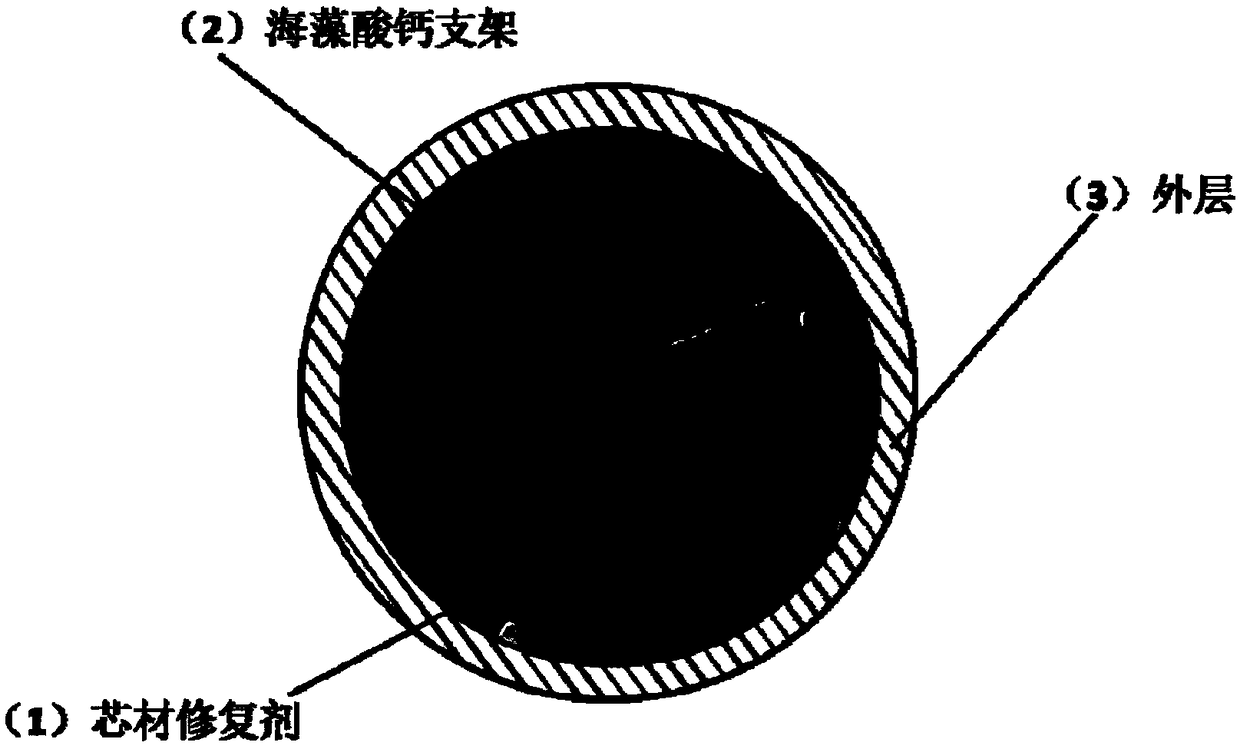

Calcium alginate microcapsule with high core material content

ActiveCN109250940ASolve the problem of fragmentationReduce interfacial voidsPolymer sciencePolymer resin

The invention relates to a calcium alginate microcapsule with high core material content. The calcium alginate microcapsule with high core material content comprises a polymer outer layer, a calcium alginate bracket and a core material repairing agent. Curable polymer resin is the core material repairing agent and fills interconnected channels of the calcium alginate bracket; an outermost layer isa cured polymer resin layer. The preparation method comprises the steps: firstly, primarily prepared calcium alginate microcapsules with high core material content are prepared by a sharp hole-coagulation bath method; secondly, the outer-layer polymer resin is cured to obtain the calcium alginate microcapsule with high core material content and with the structure. The microcapsule has water absorption and controllable volume swelling rate, has the content of the polymer core material of 65%-95%, and can be used for self-repairing of cracks in a cement matrix.

Owner:BEIJING UNIV OF TECH

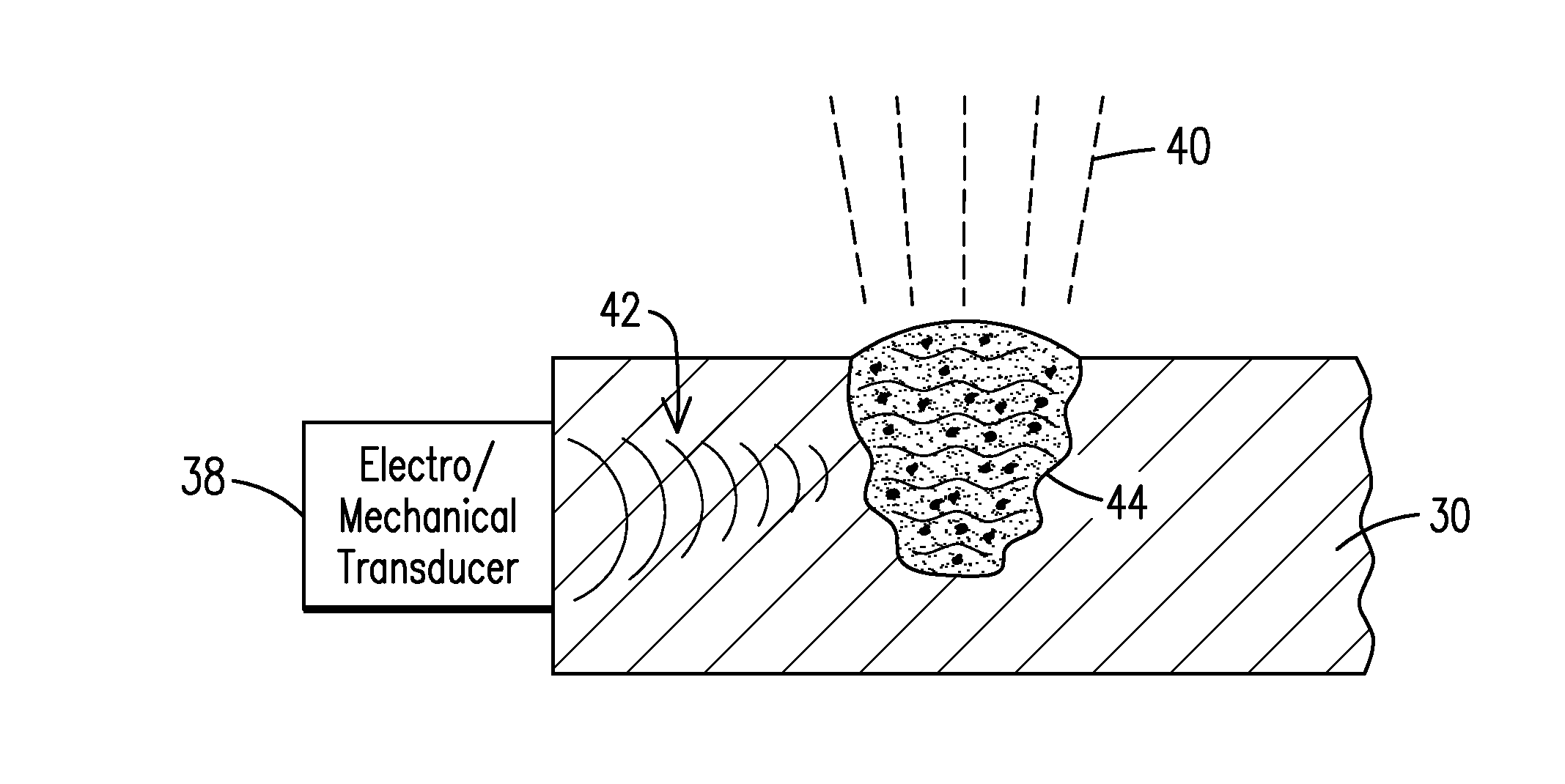

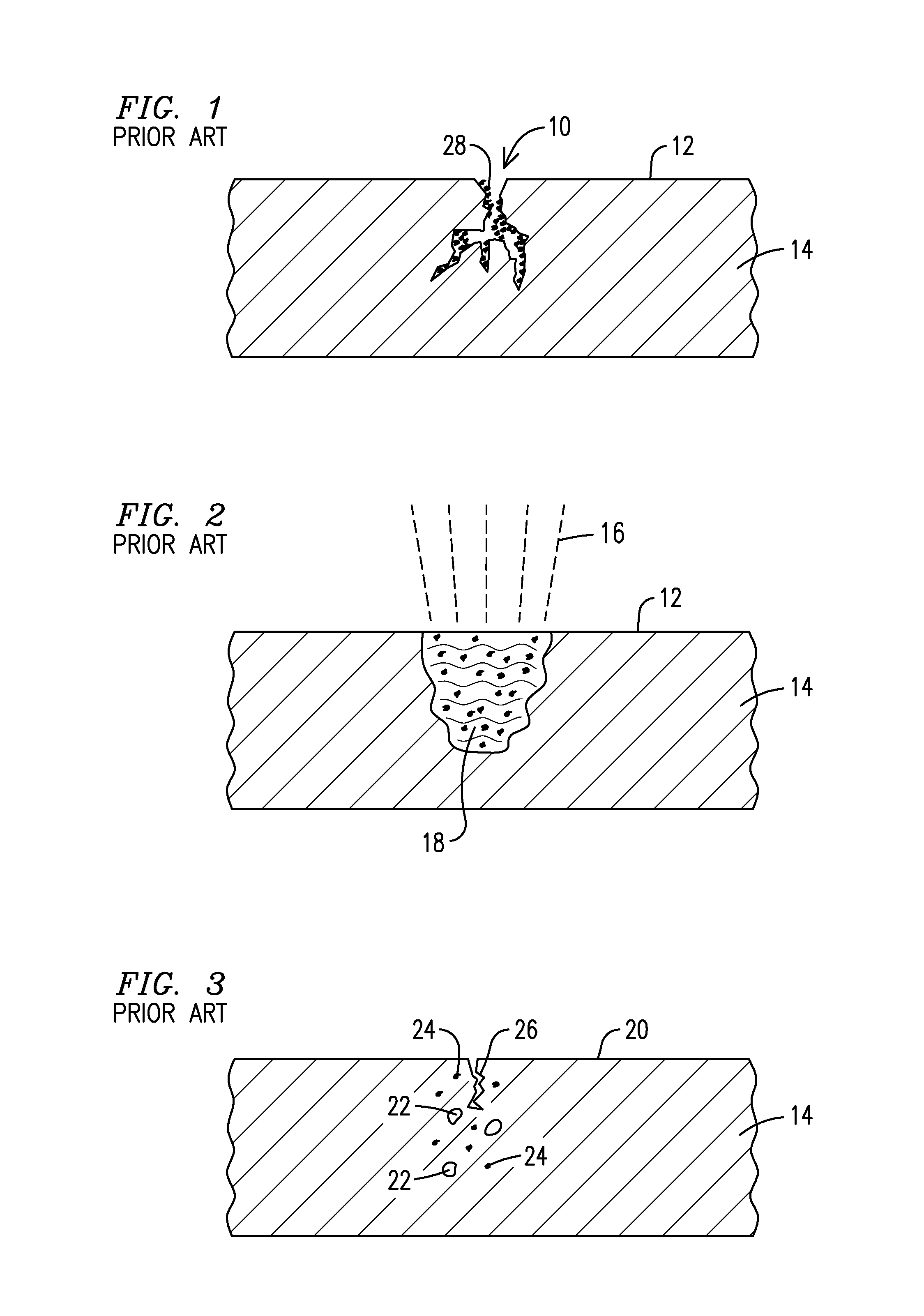

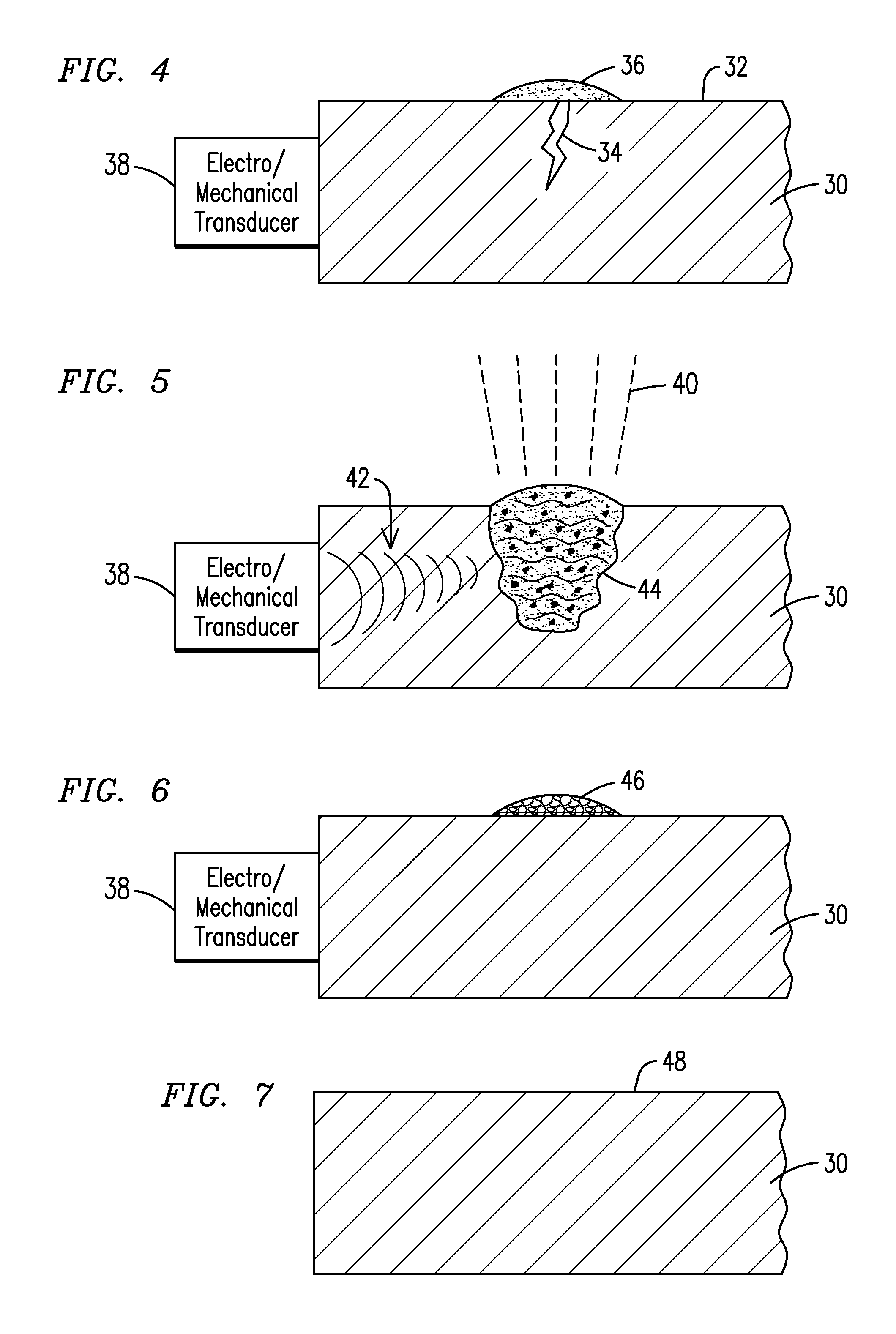

Material repair process using laser and ultrasound

A process for repair of a surface (32) of a substrate (30) including the application of an energy beam (40) and vibratory mechanical energy (42) to the surface in a region of a discontinuity (34) in order to form a renewed surface (48) on the substrate. A powdered flux material (36) may be disposed over the discontinuity and melted in order to trap and remove contaminants (28) into a layer of slag (46). The vibratory mechanical energy may be applied to dislodge contaminants within the discontinuity, to add friction heat to the discontinuity, to assist in the flotation of the slag, to remove solidified slag, and / or to provide stress relief of the renewed surface.

Owner:SIEMENS ENERGY INC

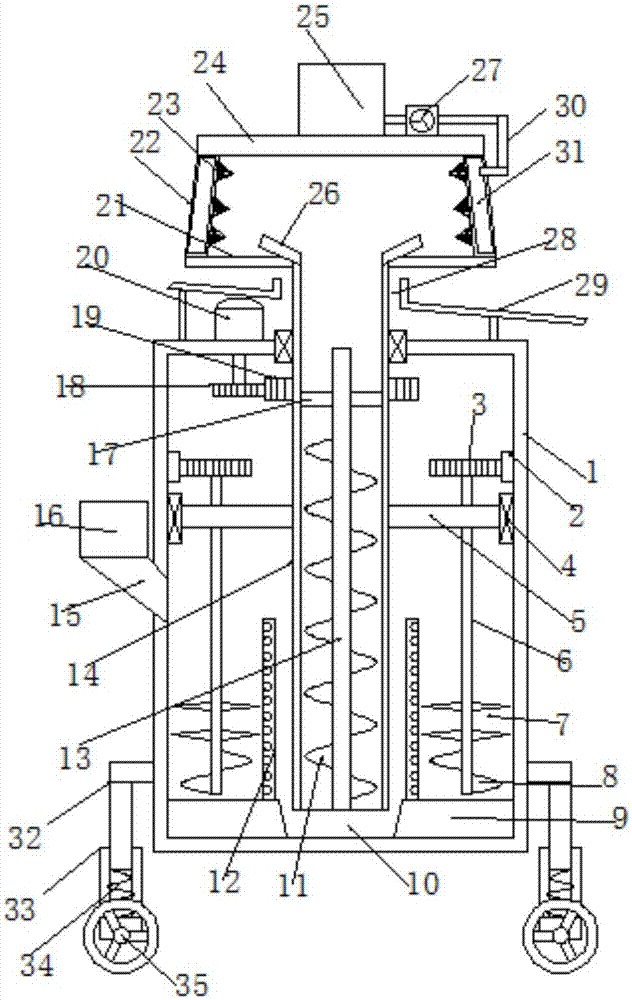

Efficient soil crushing treatment equipment

InactiveCN107999532AVolume qualifiedGuaranteed repair effectContaminated soil reclamationPulp and paper industryCentrifugal force

The invention discloses efficient soil crushing treatment equipment. The equipment comprises a machining box, supporting legs are symmetrically arranged on the left side and the right side of the processing machining box, and supporting sleeves are arranged at the lower ends of the supporting legs in a sliding mode; and rolling wheels are arranged at the lower ends of the supporting sleeves, wherein the rolling wheels facilitate carrying of the equipment, buffering springs are arranged in the supporting sleeves, and the buffering springs are used for connecting and fixing the supporting sleeves and the supporting legs. According to the efficient soil crushing treatment equipment, carrying is convenient, and the anti-seismic property is good; materials are subjected to circumferential crushing, and then are screened through filter cylinders, so that the size of the material is qualified when the materials are repaired, and the materials is fully contacted with repairing liquid in the later period; then the screened materials upwell along a lifting cylinder through a lifting blade, are scattered along dispersing buckets under the action of centrifugal force and are struck to the inner walls of fences; and conical blocks at water spraying ports also help to further scatter the materials, so that the materials are in full contact with the repairing liquid, the material repairing effect is guaranteed, and practicability is high.

Owner:ZHENGZHOU AIMOFU INFORMATION TECH CO LTD

Heavy rare earth metal target material repairing method

ActiveCN110373642ALower diffusion temperatureHigh densityVacuum evaporation coatingSputtering coatingRare earthHigh pressure

The invention provides a heavy rare earth metal target material repairing method and belongs to the technical field of magnetron sputtering surface treatment. The heavy rare earth metal target material repairing method comprises the following steps: filling the loss area of a to-be-repaired target material with alloy powder, and performing the repairing operation by adopting a vacuum sintering method or a high-pressure cold spraying method, wherein the alloy powder comprises a dysprosium-terbium alloy or one or two of dysprosium and terbium and one or two of metalloids. The heavy rare earth metal target material repairing method provided by the invention has the beneficial effects that the alloy powder is adopted as a repairing material; the repairing operation is performed by adopting thevacuum sintering method or the high-pressure cold spraying method; the alloy powder plays a role in brazing, and thus the sintering temperature during the follow-up target material repairing operation is reduced; furthermore, the diffusion temperature after the film coating operation on a magnetic sheet is reduced, and the repairing difficulty and cost are reduced; according to the structure of the target material repaired through the heavy rare earth metal target material repairing method, the problem that the existing target surface cannot be reused after being defective is effectively solved; and the process is simple, the cycle is short, the use effect is close to a new target material, and the application value is good.

Owner:BAOTOU JINSHAN MAGNETIC MATERIAL

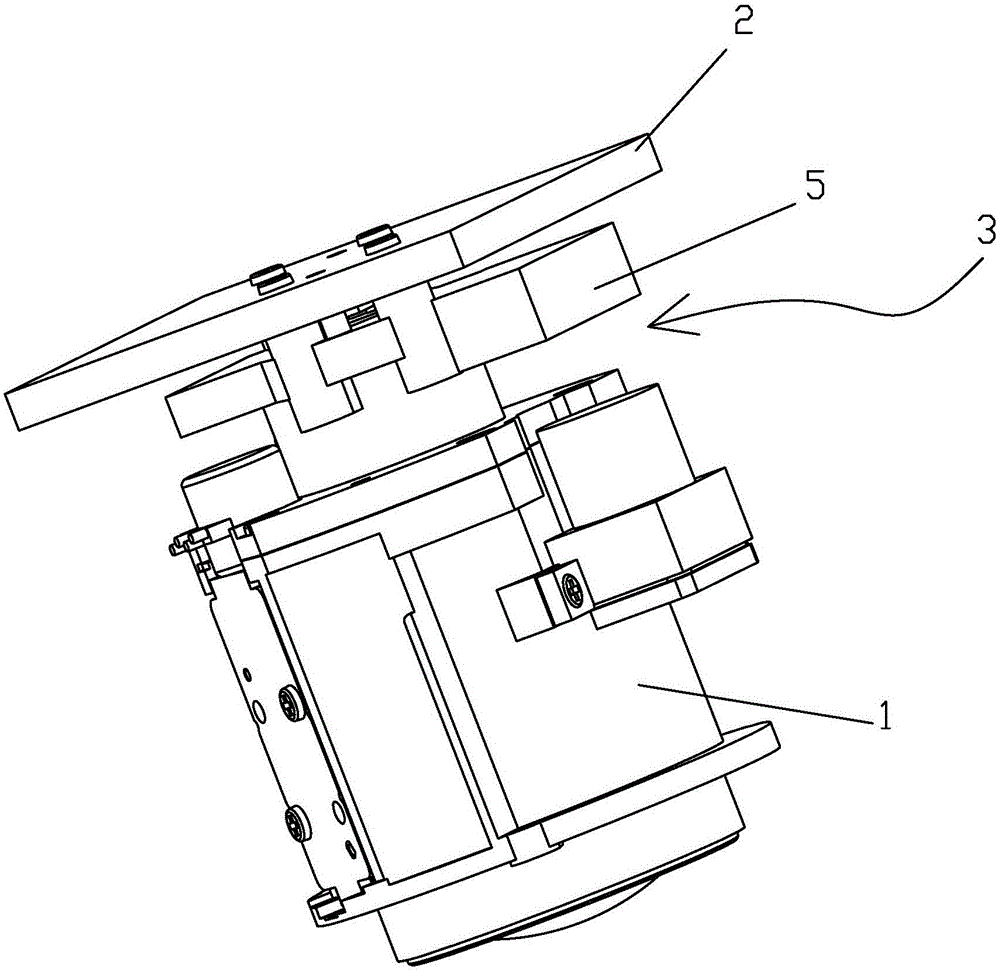

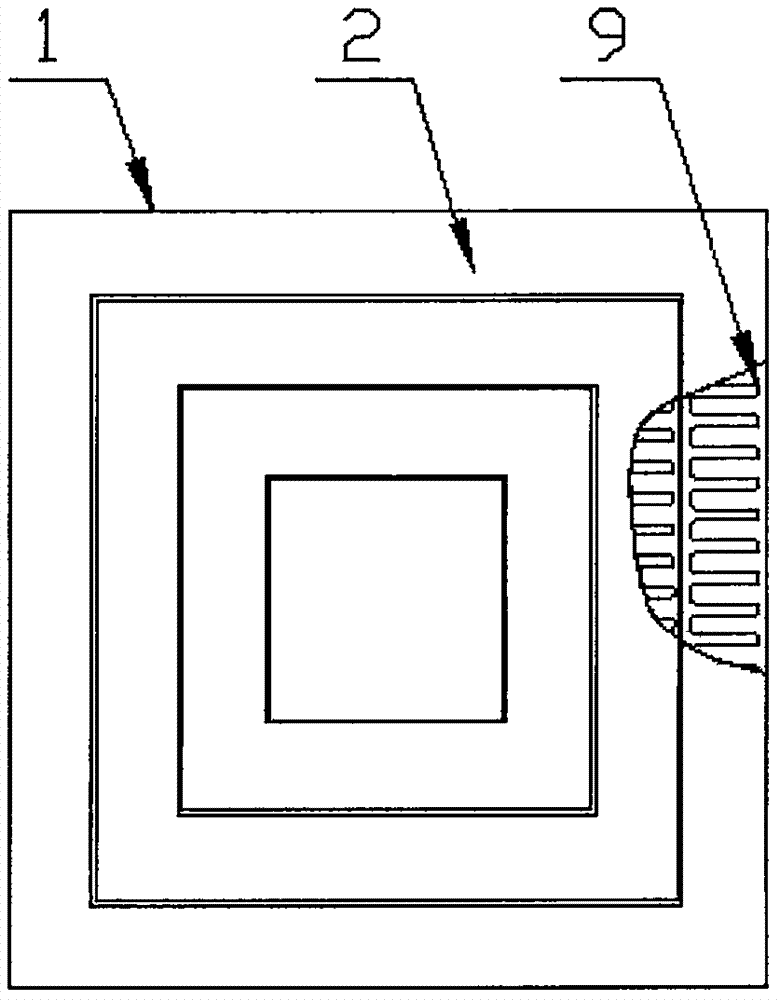

Monitoring and repairing method for curing and cementing of composite material

PendingCN107538771AUniform temperature fieldAvoid excessive temperature differenceDomestic articlesField conditionsDamage zone

The invention provides a method for monitoring and repairing composite material curing adhesive bonding, which belongs to the field of composite material adhesive bonding repair equipment. The method is based on a composite material curing adhesive repair instrument, which includes a body, and a curing source module is provided at the adhesive repair working surface of the body, and the curing source module provides energy for the composite material prepreg to cure, and the curing The source module is surrounded by multiple temperature zones from the inside to the outside. Each temperature zone is equipped with an independent curing source for providing energy to the temperature zone. The multiple temperature zones are used alone or in conjunction with each other, and according to The shape of the damaged area of the structure is determined, and the temperatures of multiple temperature zones are the same or different. The present invention is based on multi-area curing source control, establishes a uniform and stable temperature field under external field conditions, and solves the problem of avoiding excessive temperature differences. Based on the principle of heat conduction, the multi-area temperature field control technology is used to achieve uniform and stable bonding repair areas. temperature field while avoiding excessive temperature differences.

Owner:青岛东正浩机电科技有限公司

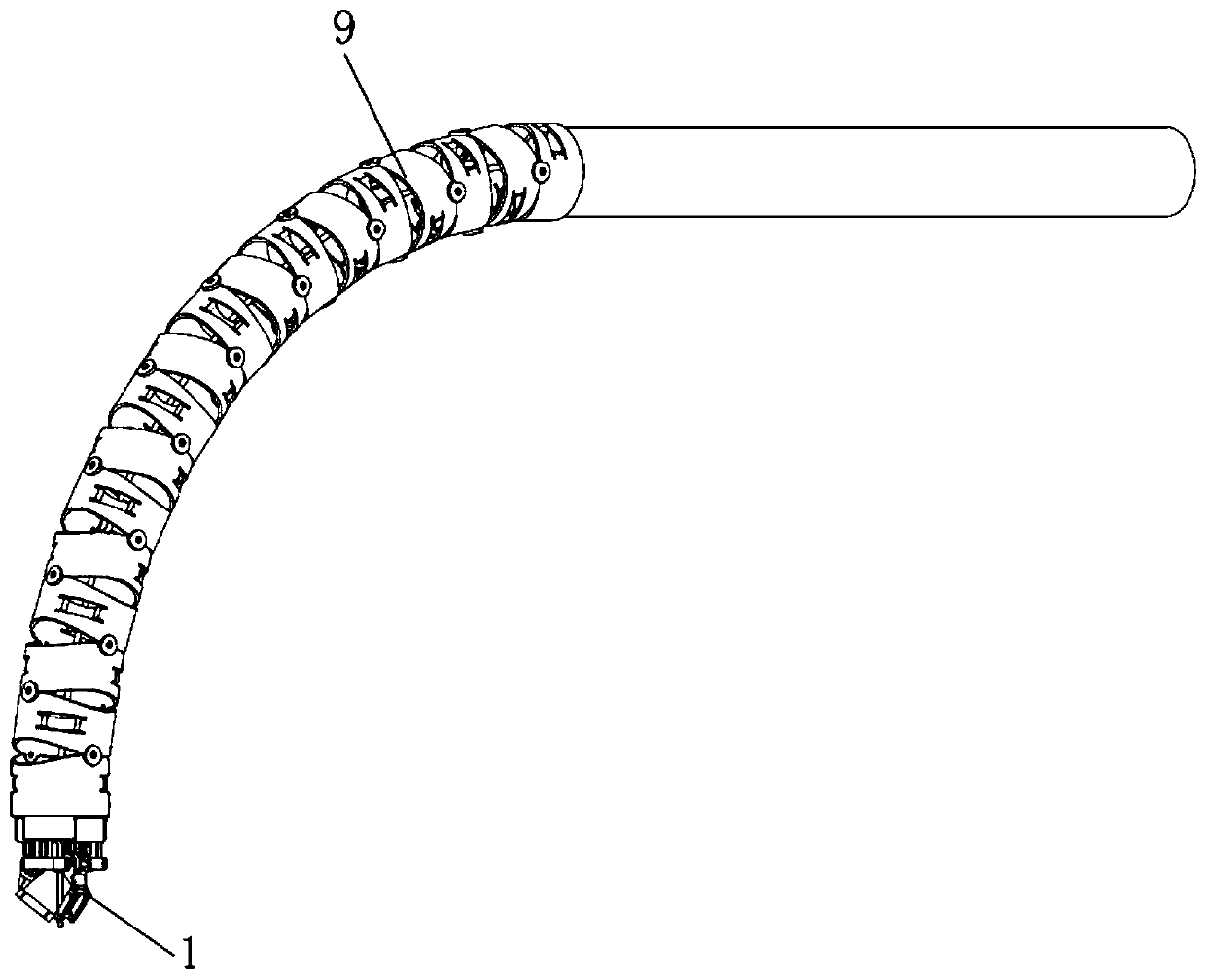

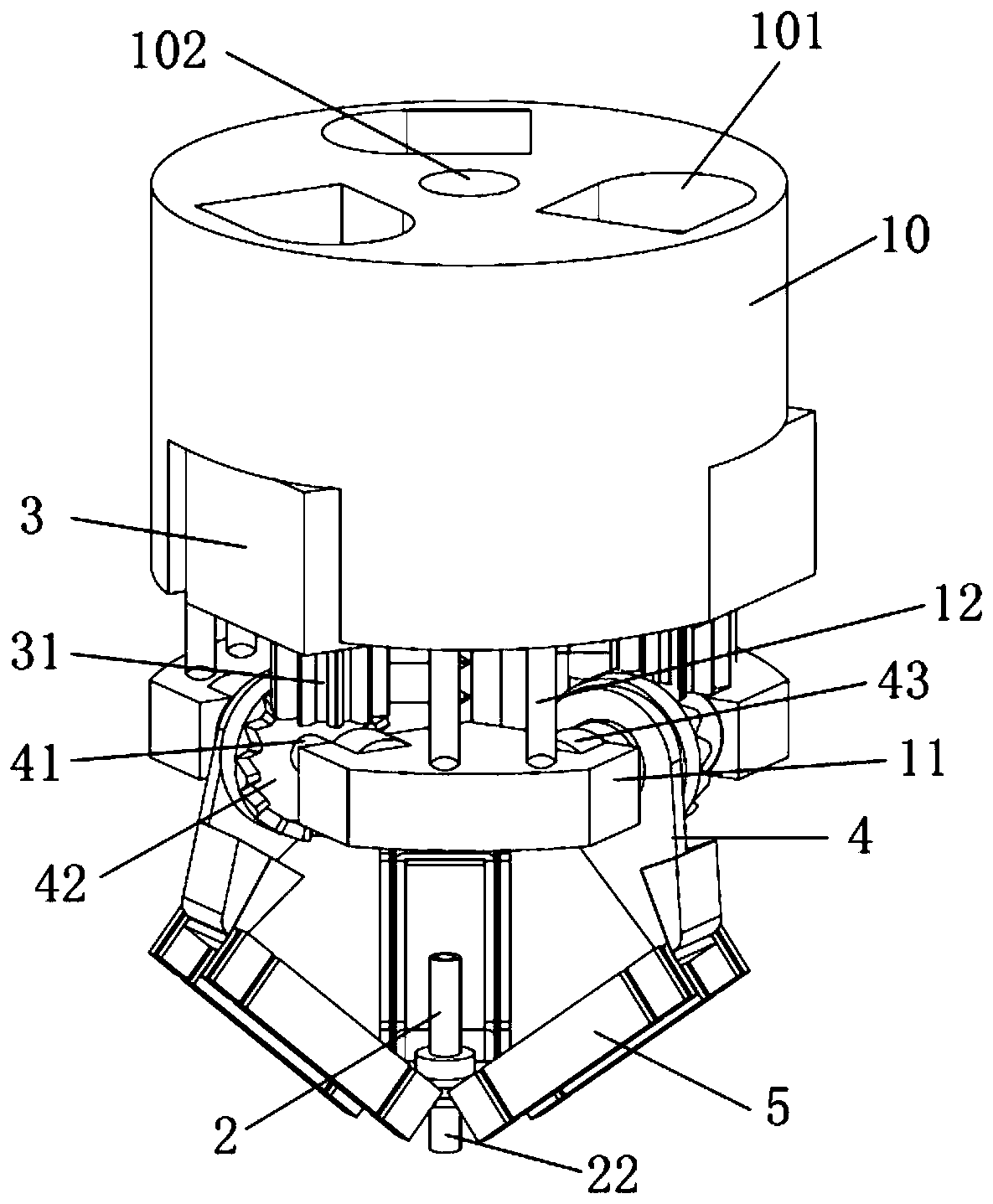

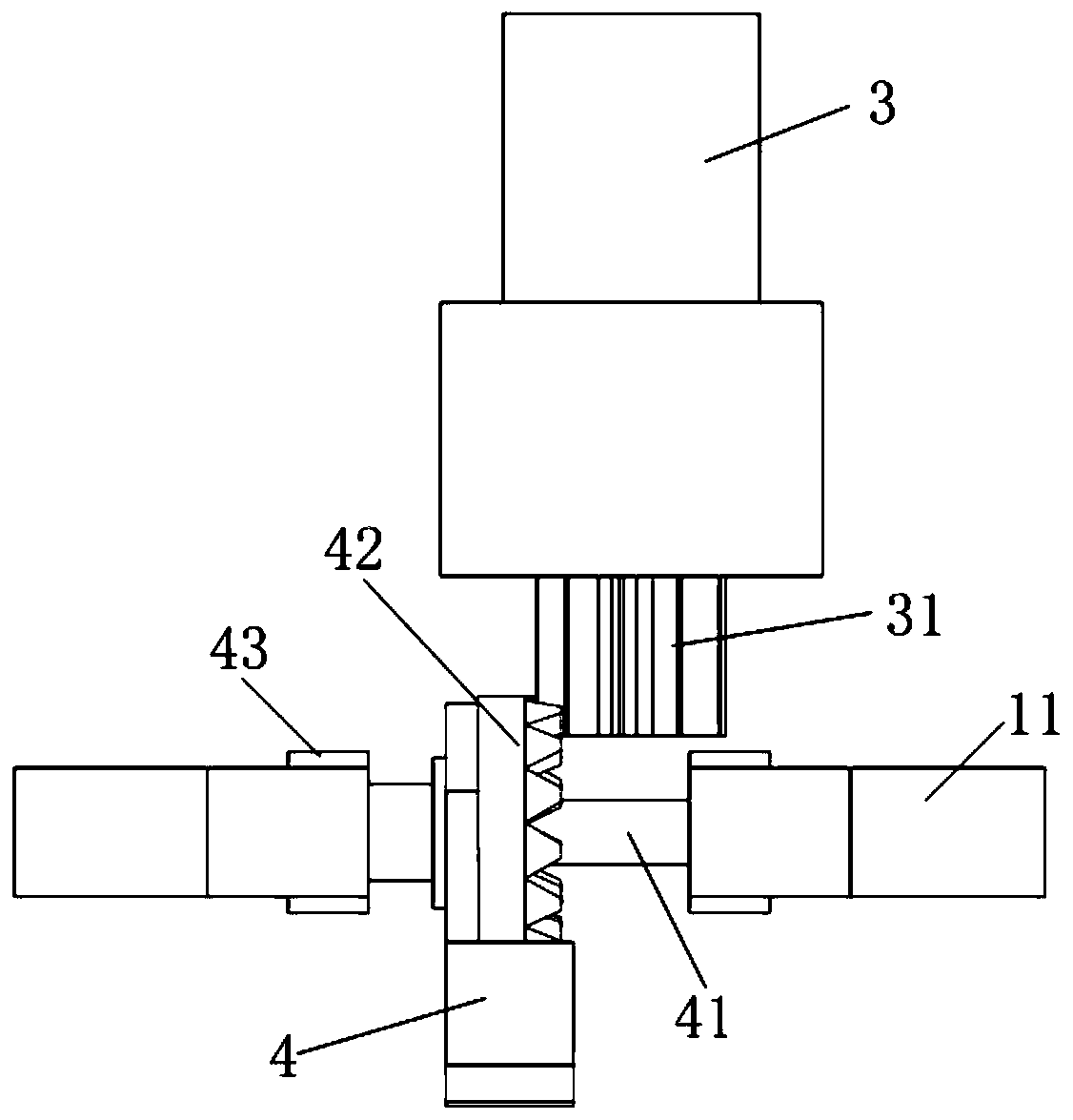

In-vivo additional material repair system and in-vivo repair device

The invention provides an in-vivo additional material repair system and an in-vivo repair device. The in-vivo repair device comprises a driving mechanism, a transmission mechanism and a printing device. The printing device prints a biological material; the driving mechanism drives the transmission mechanism to rotate; the transmission mechanism comprises a revolute pair assembly, and the revolutepair assembly comprises at least two revolute pairs; the printing device is connected to the transmission mechanism through the revolute pair assembly, and the revolute pair assembly is provided withat least two revolute axes perpendicular to each other. Each of the at least two revolute pairs has the following structures: two rigid bodies and a flexible film clamped between the two rigid bodies;the two rigid bodies are missing at corresponding positions so that each rigid body can form two discrete segments, the two discrete segments are connected together through the flexible film, and therevolute axes of the revolute pairs are formed at the missing positions of the rigid bodies. At least two revolute pairs with orthogonal revolute axes are adopted to replace spherical hinge revolutepairs, so that the processing difficulty of the in-vivo repair device is reduced, and the space required by operation is reduced.

Owner:TSINGHUA UNIV

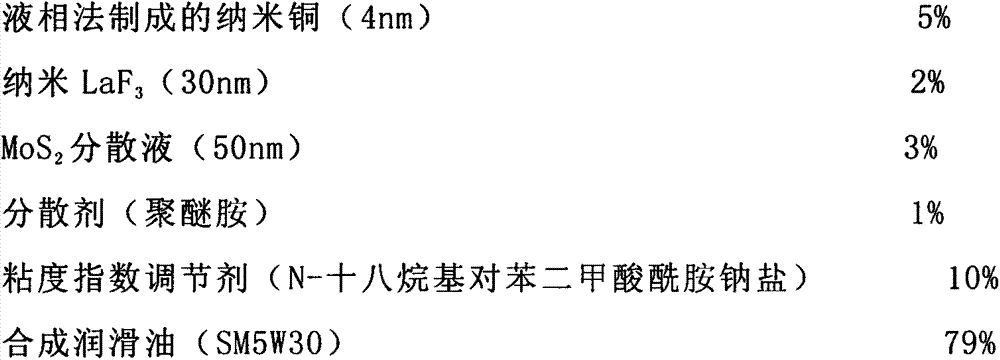

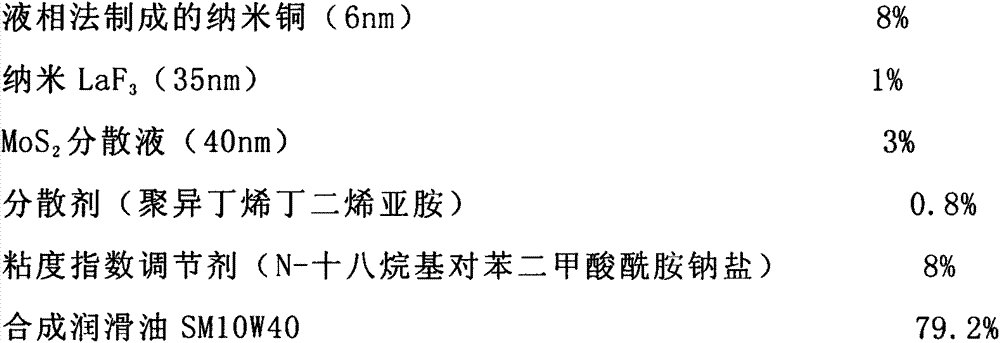

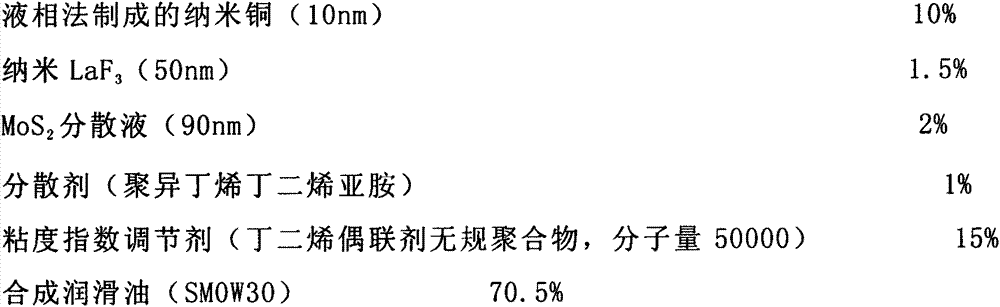

Nanometer material repairing agent capable of repairing engine cylinder block

The invention discloses a nanometer material repairing agent capable of repairing an engine cylinder block. The nanometer material repairing agent comprises the components in percentage by weight as follows: 2-15% of nano-copper, 1-5% of nano-LaF, 2-5% of MoS2 dispersion liquid, 0.5-1% of dispersant, 2-15% of viscosity index adjustor, and 66-92% of synthetic lubricating oil. The nano-copper used is prepared by a liquid phase method. The nanometer material repairing agent disclosed by the invention can automatically repair the surface of the worn engine cylinder block, so that the pressure of the cylinder is improved, the resisted oxygen capability of engine oil is improved, and the power of the engine is enhanced.

Owner:吕林利 +1

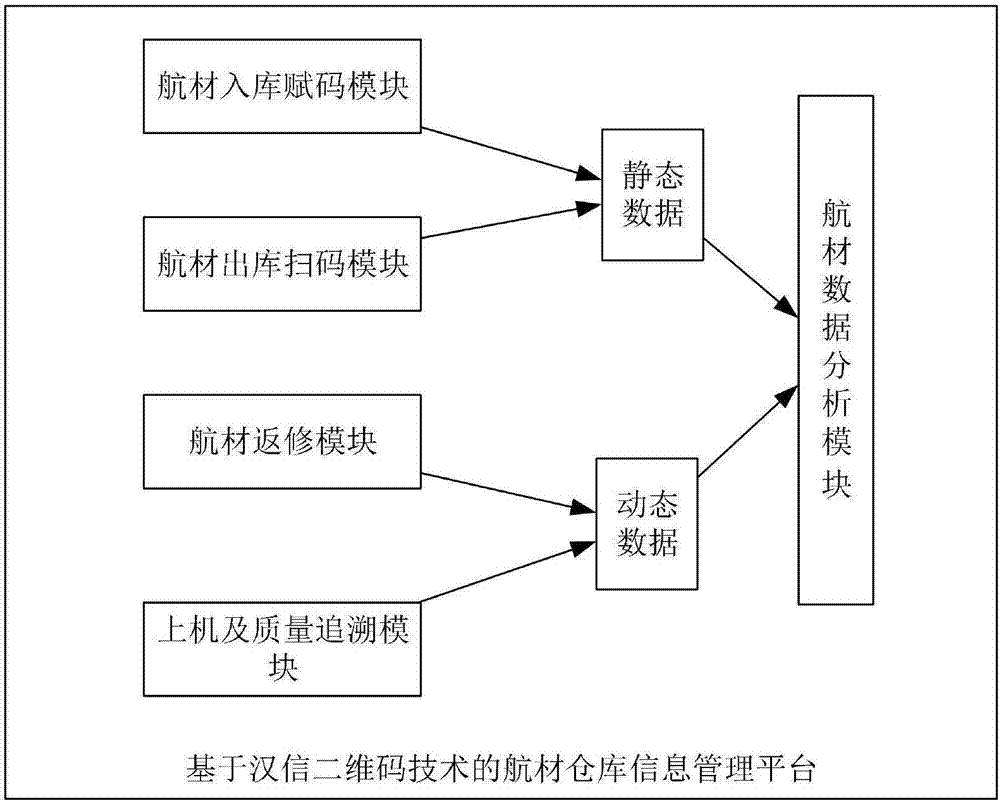

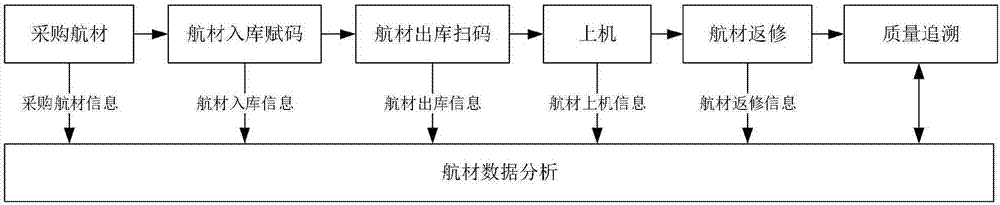

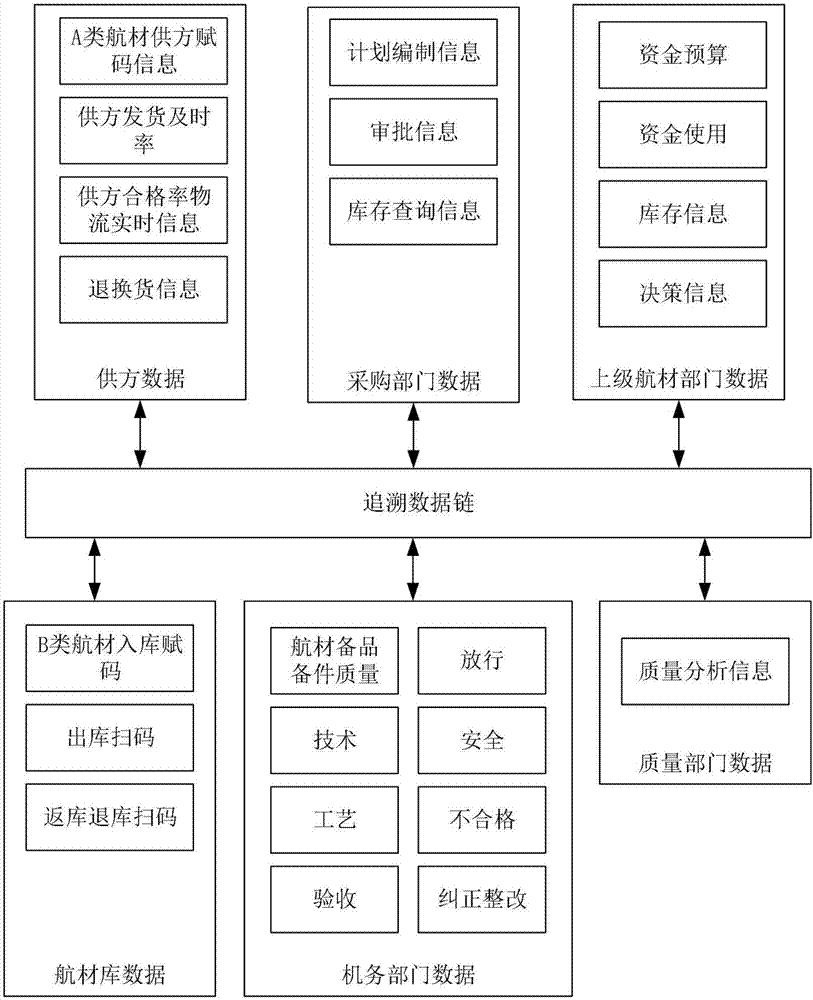

Aviation material warehouse information management platform based on Chinese sensible code technology

InactiveCN107451783ALarge information capacityImprove compression efficiencyLogisticsCommerceAviationChinese characters

The invention relates to an aviation material warehouse information management platform based on Chinese sensible code technology and belongs to the field of informationization. The platform herein includes an information purchase module, an aviation material warehouse-in tagging module, an aviation material repair module, a warehouse-out module, an aviation warehouse-out code scanning module, an upper computer and quality tracking module, and an aviation material data analyzing module. According to the invention, the platform has large information capacity, high level Chinese character representation capability and Chinese character compression efficiency, and wide encoding range. The platform supports encryption technology. The platform has strong anti-contamination, anti-deformation and mistake correction capability. The platform allows users to select mistake correction capability. The platform is easy to make, has low cost, and has variable shapes of bar code symbols.

Owner:中国人民解放军95605部队

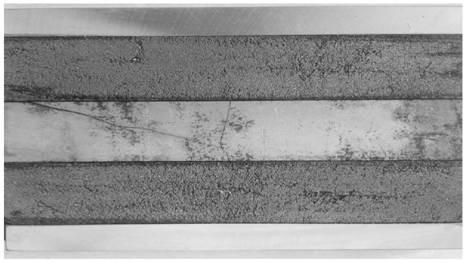

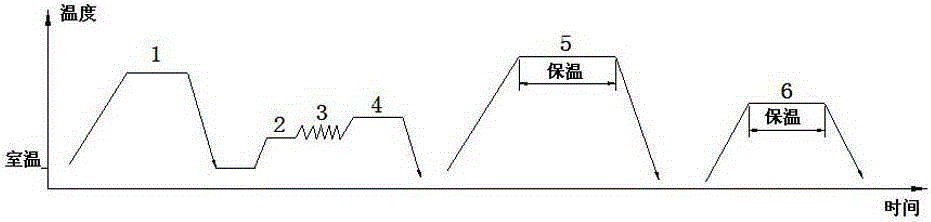

Material repair welding method of CB2 casting of ultra-supercritical turbine unit

InactiveCN105234598AConsistent performanceWelding/cutting auxillary devicesFurnace typesRoom temperatureBody area

The invention discloses a material repair welding method of a CB2 casting of an ultra-supercritical turbine unit. The method comprises the following steps that firstly, high-temperature softening tempering preheating is carried out; secondly, nondestructive inspection is carried out; thirdly, flaws are eliminated; fourthly, the portions where the flaws are eliminated are preheated; fifthly, a welding material which is the same as and cooperates with a base material is used for performing repair welding; sixthly, post-heating is carried out on the repair welding area; seventhly, nondestructive inspection is carried out on the repair welding area; eighthly, the austenitizing temperature is achieved through heating and then preserved, the cooling speed of the CB2 casting is controlled after heat preservation is finished, after the room temperature is achieved through cooling, high-temperature tempering is performed when the temperature of the casting is raised to about 100 DEG C below a point AC1 of a CB2 material, and the cooling speed is controlled for achieving the room temperature after heat preservation is finished; and ninthly, the nondestructive inspection is carried out. The procedures that the repair welding is carried out firstly, and then the performance thermal treatment is carried out are adopted, it can be ensured that the same performance thermal treatment process is adopted in the repair welding area and a body area, and it is guaranteed that the performance of a welding line joint and the performance of a body are basically consistent.

Owner:DONGFANG TURBINE CO LTD

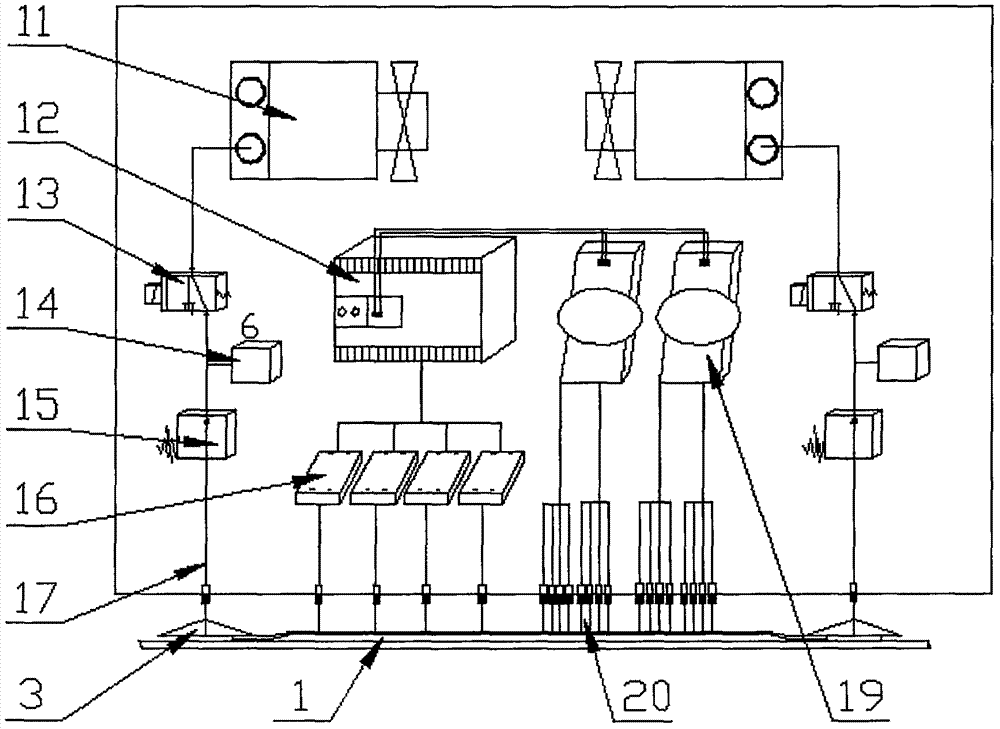

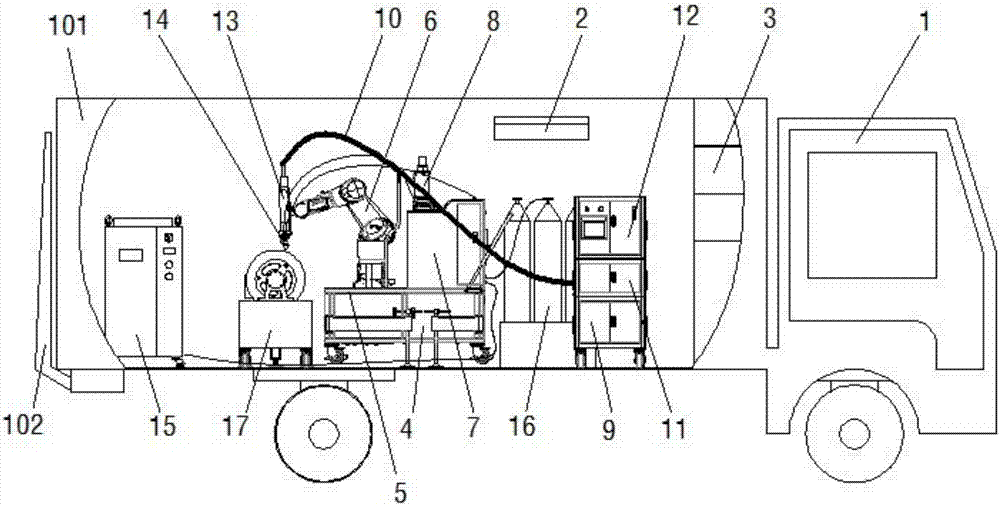

Site moving type laser augmented material repair equipment based on vehicle transport

InactiveCN107972557APromote recoveryEnabling Mobile Restoration JobsMetallic material coating processesItem transportation vehiclesRestoration deviceDemand response

The invention provides site moving type laser augmented material repair equipment based on vehicle transport. The site moving type laser augmented material repair equipment includes multiple equipmentunits, and further includes a transport vehicle with a carriage. Each equipment unit is detachably mounted in the carriage. The laser augmented material repair equipment can improve the response speed and the operation efficiency required by site augmented material repair.

Owner:NANJING HUIRUI PHOTOELECTRIC TECH CO LTD

Adhesive for repairing stone surface and in the use of stone material repair method

InactiveCN102464967ALow costNo side effectsNon-macromolecular adhesive additivesWax adhesivesWaxAdhesive

The invention discloses an adhesive for repairing a stone surface and in the use of stone material repair method. The adhesive is prepared from the following raw materials in parts by weight: 30-50 parts of bees wax, 20-40 parts of rosin and 20-40 parts of aggregate. The method for repairing the stone surface by using the adhesive comprises the following steps of: (1) cleaning positions required to be repaired on the stone, drying and heating to 20-40 DEG C; (2) selecting a stone surface repairing adhesive of the same color and repairing the color of the stone to be repaired, and melting; (3) filling the stone required to be repaired with the molten adhesive; and (4) ironing and repairing. Due to the adoption of the technical scheme, the invention has the advantage that: stone surface repairing adhesives of different colors can be prepared by using stone powder of different colors to adapt to stone of different colors. The adhesive is made of natural components, and is free from toxic and side effects. Moreover, the adhesive is made of readily-available materials, and is low in cost. Places repaired with the adhesive are as hard as stone and are free from repairing marks.

Owner:林州市腾龙工艺建材厂

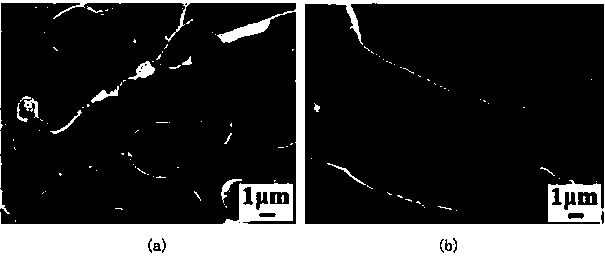

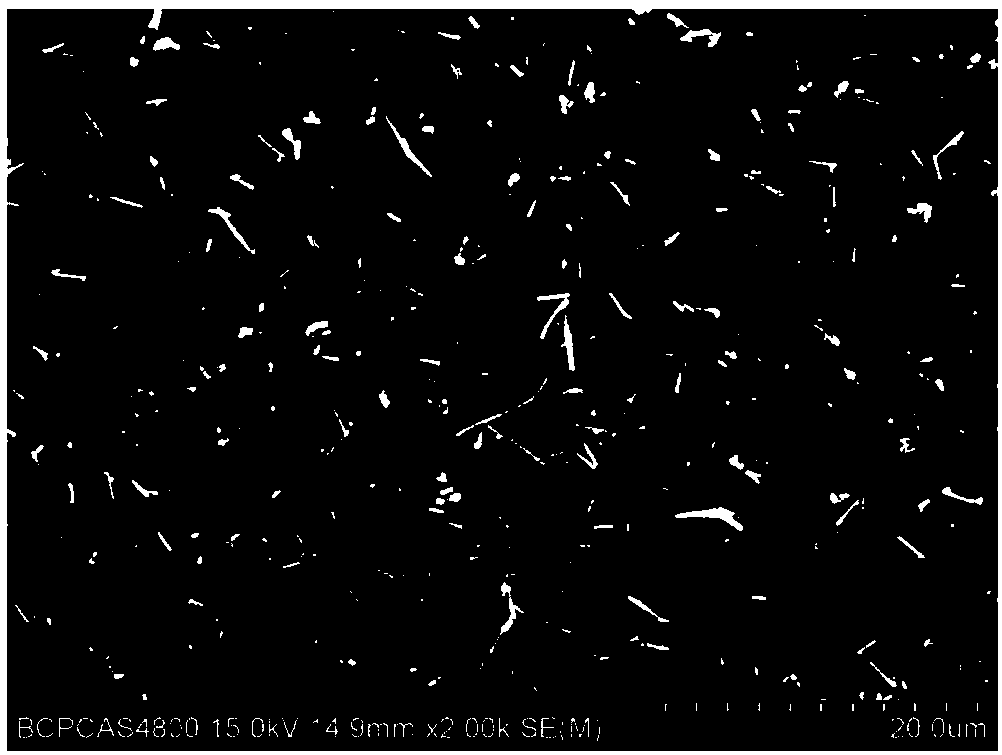

Electrified composite membrane with extracellular matrix electrical topology characteristics, and preparation method thereof

ActiveCN108498868AUniform structureImprove performanceSurgeryTissue regenerationFiberFerroelectric polymers

The invention relates to an electrified composite membrane with extracellular matrix electrical topology characteristics, and a preparation method thereof, and solves the technical problems that the electrical characteristics of a traditional material has poor matching performance with natural extracellular matrix characteristics and a material repairing effect is restricted. The electrified composite membrane with extracellular matrix electrical topology characteristics mainly consists of a ferroelectric polymer matrix and piezoelectric active fiber filler. According to the electrified composite membrane, the draw ratio and the content of the piezoelectric active fiber and the thickness of the composite membrane are regulated, the flexibility of a membrane material and biomimetic extracellular matrix electrical topology characteristics can be realized, and the electrified composite membrane has the advantages of good tissue attachment performance, good electrical adaptability and highclinic operability.

Owner:PEKING UNIV SCHOOL OF STOMATOLOGY

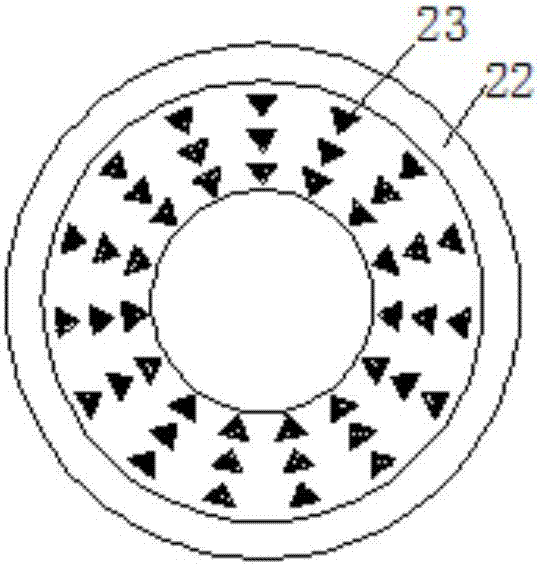

Semidry method hot gunning repair device and method of rotary kiln lining refractory material

ActiveCN106766926AExtended service lifeAvoid production stoppage situationsLinings repairRefractoryMullite

The invention discloses a semidry method hot gunning repair device and method of a rotary kiln lining refractory material, and belongs to a rotary kiln lining refractory material repair technology. The repair device comprises a gunning machine, the gunning machine is communicated with a high pressure air source through a compressed air pipe, the gunning machine is further communicated with a spray gun through a first high pressure pipeline, the spray gun is further communicated with a water tank through a second high pressure pipeline, a self-priming pump is installed between the water tank and the second high pressure pipeline, and is used for outputting a gunning refractory from the gunning machine through the first high pressure pipeline by utilizing high pressure air, then outputting a silica sol solution from the water tank through the second high pressure pipeline by utilizing the self-priming pump, mixing the gunning refractory and the silica sol solution in the spray gun and spraying the gunning refractory and the silica sol solution. By spraying the mixture of a mixed solution of spray gun silica sol solution and water and high alumina mullite to the inner wall of the rotary kiln through the spray gun, filling a perfoliate fracture, thickening the thickness of the refractory material, repairing a castable which sheds locally, and adopting a hot repair technology, the time for slow-down kiln cooling during cold repair is avoided, the repair time is short, and the production of the subsequent process is not influenced.

Owner:GUANGDONG GUANGQING METAL TECH

Method for repairing lake and anaerobic bottom mud by nano bubble

ActiveCN101503238BHigh transparencyIncrease dissolved oxygen levelsWater aerationSustainable biological treatmentVegetationEutrophication

The invention provides a composite material which uses nanometer bubbles to rapidly eliminate lake algae bloom and repair anaerobic substrate sludge. The composite material repairs anaerobic substrate sludge, increases the oxidation-reduction potential of the substrate sludge and the dissolved oxygen level of the water body while rapidly eliminating algae blood in a large area and increasing the transparency of the water body. The nanometer bubbles are oxygen nanometer bubbles, ozone nanometer bubbles or air nanometer bubbles. Natures of nanometer bubbles such as quantity, size, density and the like can be adjusted and controlled with a particular method. The invention also provides a method for using the composite material to repair the lake and anaerobic substrate sludge, which comprises that a mechanical method is used for spreading or spraying the composite material onto the lake surface, thus simultaneously finishing the algae bloom removal in the large area, increasing the transparency of the water body, repairing the anaerobic substrate sludge, increasing the dissolved oxygen level of the water body, and providing a good environment for the rapid growth of submerge vegetation and ecological restoration of the eutrophication water body; and the method has ecological security and long effect of the lake treatment.

Owner:BEIJING GREEN ECO ENVIRONMENTAL TECH

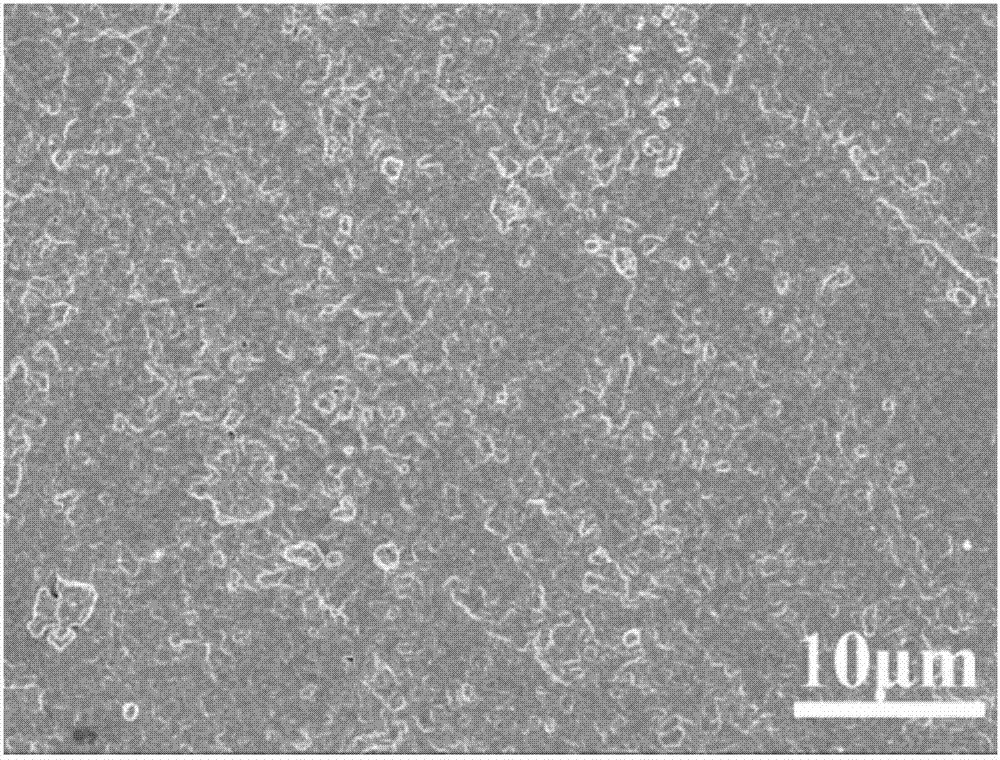

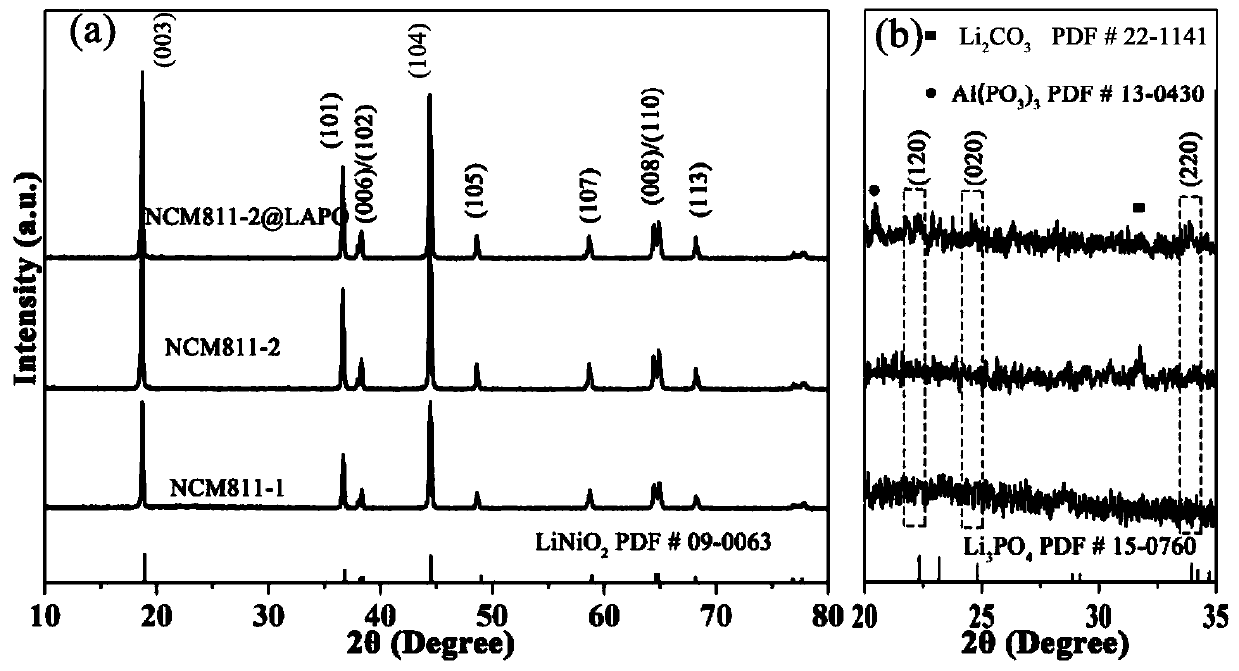

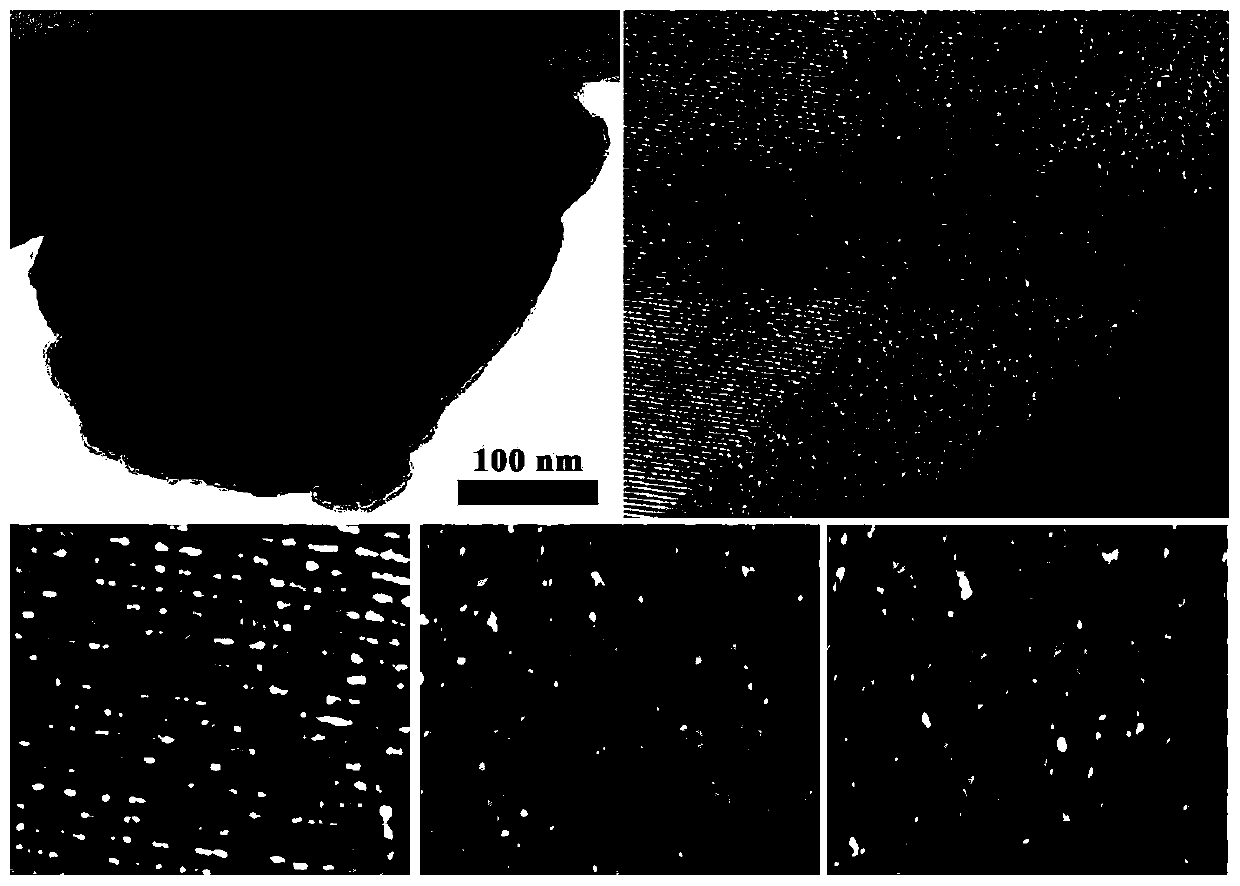

Method for repairing ternary positive electrode material with deteriorated performance and acquired ternary positive electrode material

ActiveCN110534721ASolve dropSimple processSecondary cellsPositive electrodesOrganic solventUltrasonic dispersion

Owner:CENT SOUTH UNIV

Electrified repair film material controllable in surface potential and preparation method thereof

ActiveCN109453431AUniform structureImprove flexibilityPharmaceutical delivery mechanismTissue regenerationOrganic solventRepair material

The invention relates to an electrified repair film material controllable in surface potential and solves the technical problem that existing materials are not adjustable in surface potential, cannotbe adapted to electrophysiological microenvironment of each tissue defective position and limited in material repair effect. The electrified repair film material is a thin-film-shaped material prepared from ferroelectric high-molecular polymer and an organic solvent. The invention further provides a preparation method of the electrified repair film material. The electrified repair film material can be widely applied in the technical field of surgical implanting of bionic electrified microenvironment repair materials.

Owner:PEKING UNIV SCHOOL OF STOMATOLOGY

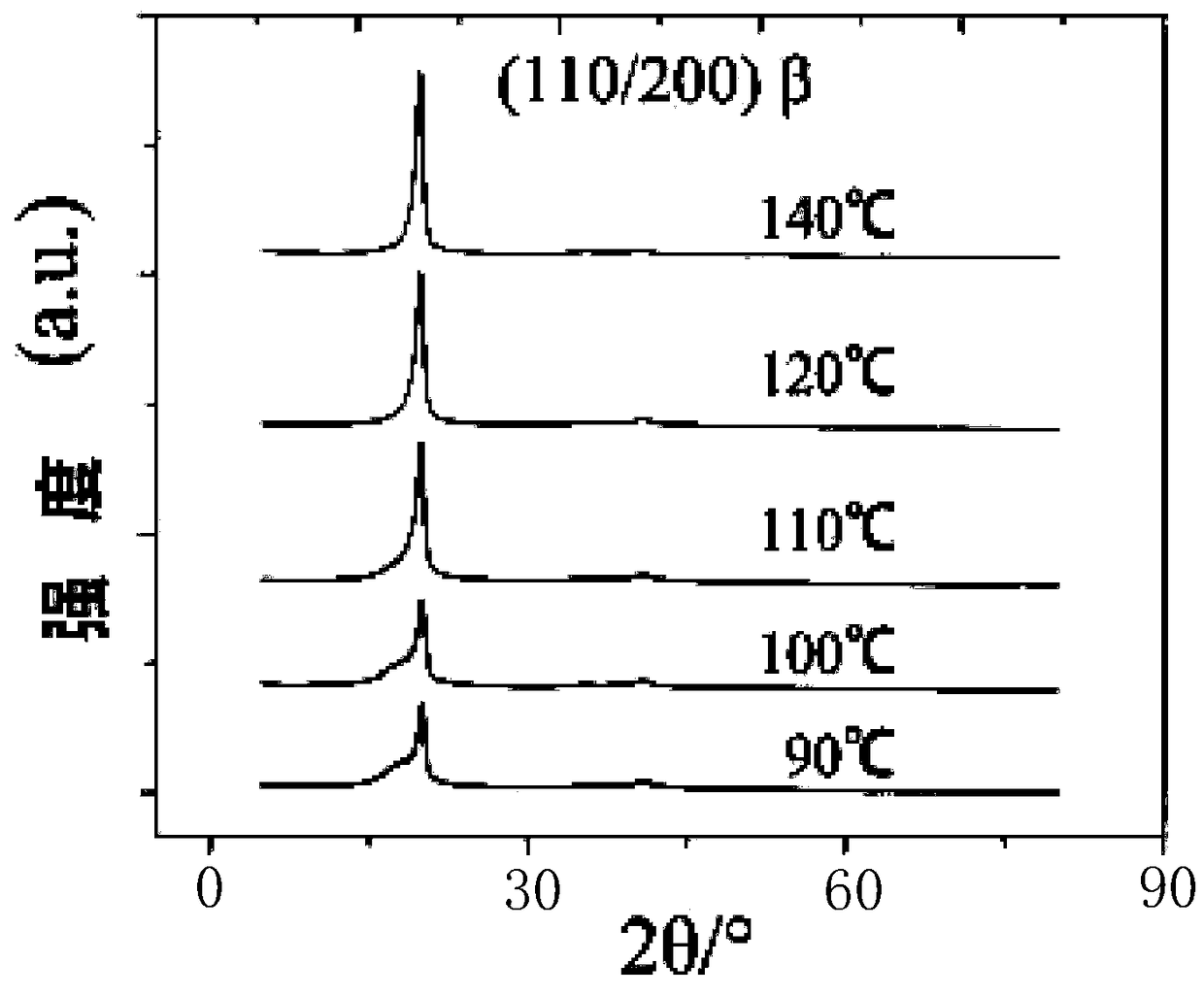

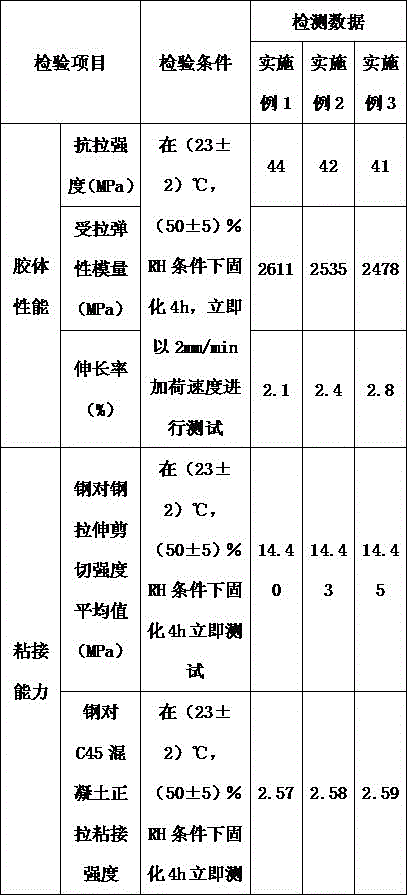

Fast-cured epoxy impregnating adhesive and preparation method thereof

ActiveCN106189973ASolve the technical problems of slow curing speed and long early strengthHigh reactivityNon-macromolecular adhesive additivesEpoxy resin adhesivesFiberHeat resistance

The invention discloses a fast-cured epoxy impregnating adhesive. The fast-cured epoxy impregnating adhesive is composed of a component A and a component B at a weight ratio of 1: (0.5-0.7), wherein the component A comprises the following components in parts by weight: 100 parts of bisphenol A-type epoxy resin, 0.5-2 parts of a silane coupling agent and 1-5 parts of a thixotropic agent; the component B comprises the following component in parts by weight: 100 parts of a modified amine curing agent. The fast-cured epoxy impregnating adhesive overcomes the technical difficulties that in a fiber composite material repairing and reinforcing project, the conventional epoxy impregnating adhesive is low in curing speed and takes a long time for obtaining early strength. By matching with fiber cloth for use, the fast-cured epoxy impregnating adhesive provided by the invention can quickly repair and reinforce a base material. The fast-cured epoxy impregnating adhesive is high in reaction activity; after the fast-cured epoxy impregnating adhesive is cured for 4 h, a test shows that the tensile strength reaches 40 Mpa and the positive pulling bond strength reaches 2.56 Mpa, so that relevant requirements of GB50728 are met; the fast-cured epoxy impregnating adhesive is good in dampness resistance, heat resistance and aging resistance, and thus can be used for a long time.

Owner:CARBON TECH CO LTD

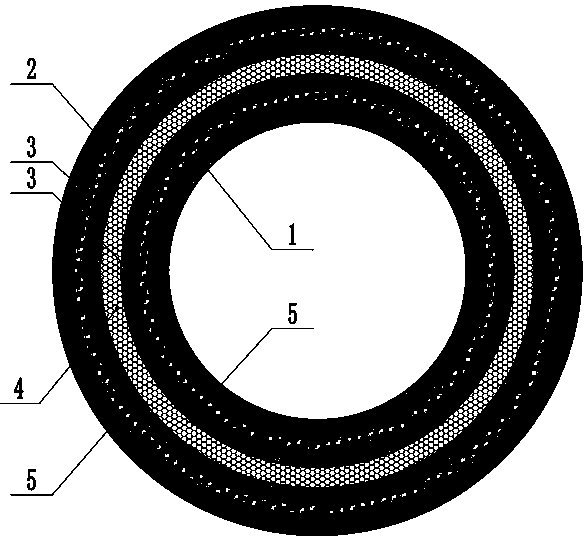

Anti-twisting high-pressure rubber hose

InactiveCN107816583AExtended service lifeAvoid harmPipe elementsFlexible pipesHigh pressureDistortion

The invention relates to the technical field of high-pressure rubber hoses, and discloses a twist-resistant high-pressure rubber hose, which includes an inner rubber layer and an outer rubber layer, and several middle rubber layers are arranged between the inner rubber layer and the outer rubber layer. There are at least two middle glue layers, and a repair layer is arranged between the middle glue layers, and the repair layer is composed of composite materials, repair agents and catalysts. The invention adds a repair layer between the inner rubber layers. When the rubber hose is damaged by twisting or extrusion, the repair layer can identify the occurrence of damage within a certain limit and repair the cracks by itself; greatly prolonging the life of the rubber hose Long service life, to avoid the hazard caused by hose rupture.

Owner:济宁市友领机械设备制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com