Self-repairing cyanate ester resin system and preparation method thereof

A cyanate ester resin and self-repairing technology, which is applied in the field of self-repairing cyanate ester resin system and its preparation, can solve the problems such as the difficulty in repairing crack damage of cyanate resin materials, and achieve the effect of improving service life and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

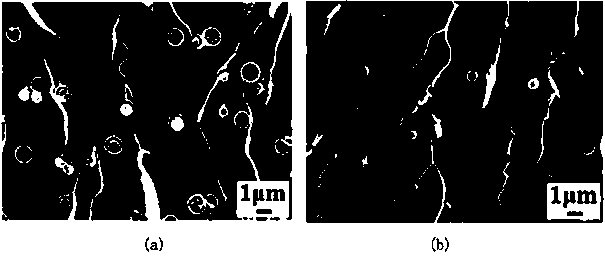

Embodiment 1

[0017] Weigh 100g of dicyclopentadiene bisphenol type CE into a 250ml beaker, heat it at 80°C to a transparent solution, add 0.125g of DDS and 5g of PPO (PPO* MX9000-111), and prepolymerize at 120°C for 60min under stirring conditions to obtain bicyclic Pentadiene bisphenol type CE / PPO prepolymerization system, inject the above system into a mold preheated at 120°C and coated with a mold release agent, vacuum degassing at 90-100°C, and according to the process 130°C / 2h+150°C / 2h+180°C / 2h+200°C / 2h for curing. The prepared material is cut to the required size on the cutting machine to test the performance. The fractured samples after the fracture toughness test were fixed with high-temperature adhesive tape and treated at 200°C for 1 hour, and then the fracture toughness value after healing was tested. See Table 1 for relevant performance data.

[0018] Table 1 Dicyclopentadiene bisphenol type CE / PPO resin system cured properties

[0019]

[0020] In this example, the pure...

Embodiment 2

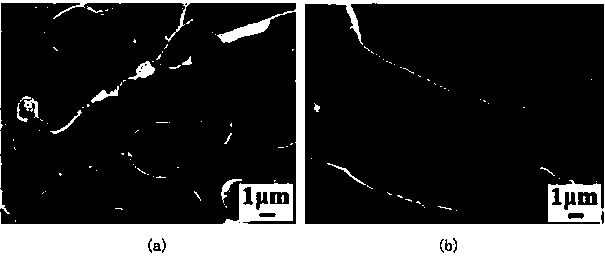

[0024] Weigh 100g of bisphenol A type CE into a 250ml beaker, heat it at 100°C to a transparent solution, add 1gDDS and 15g of PPO (PPO* MX9000-111), and prepolymerize at 130°C for 60min under stirring conditions to obtain bisphenol A type CE / PPO prepolymerization system, inject the above system into a mold preheated at 120°C and coated with a release agent, after vacuum defoaming at 90-100°C, according to the process 130°C / 2h+150°C / 2h+180°C / 2h+200°C / 2h for curing. The prepared material is cut to the required size on the cutting machine to test the performance. After the fracture toughness test, the fractured samples were fixed with high-temperature adhesive tape and treated at 220°C for 1 hour, and then the healing fracture toughness value was tested. See Table 2 for relevant performance data.

[0025] Table 2 Bisphenol A type CE / PPO resin system cured product properties

[0026]

[0027] In this embodiment, the pure resin curing process is: 130°C / 2h+150°C / 2h+180°C / 2h...

Embodiment 3

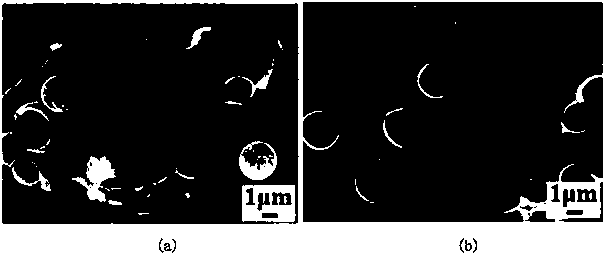

[0031] Weigh 100g bisphenol F type CE into a 250ml beaker, heat it to a transparent solution at 120°C, add 5gDDS and 15gPPO (PPO* MX9000-111), and pre-polymerize at 130°C for 30min under stirring conditions to obtain bisphenol F type CE / PPO prepolymerization system, inject the above system into a mold preheated at 130°C and coated with a release agent, after vacuum defoaming at 90-100°C, according to the process 130°C / 2h+150°C / 2h+180°C / 2h+200°C / 2h for curing. The prepared material is cut to the required size on the cutting machine to test the performance. After the fracture toughness test, the fractured samples were fixed with high-temperature adhesive tape and treated at 220°C for 1 hour, and then the healing fracture toughness value was tested. See Table 3 for relevant performance data.

[0032] Table 3 Properties of bisphenol F type CE / PPO resin cured product

[0033]

[0034] In this embodiment, the pure resin curing process is: 130°C / 2h+150°C / 2h+180°C / 2h+200°C / 2h;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com