Patents

Literature

207results about How to "Meet the needs of automated production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

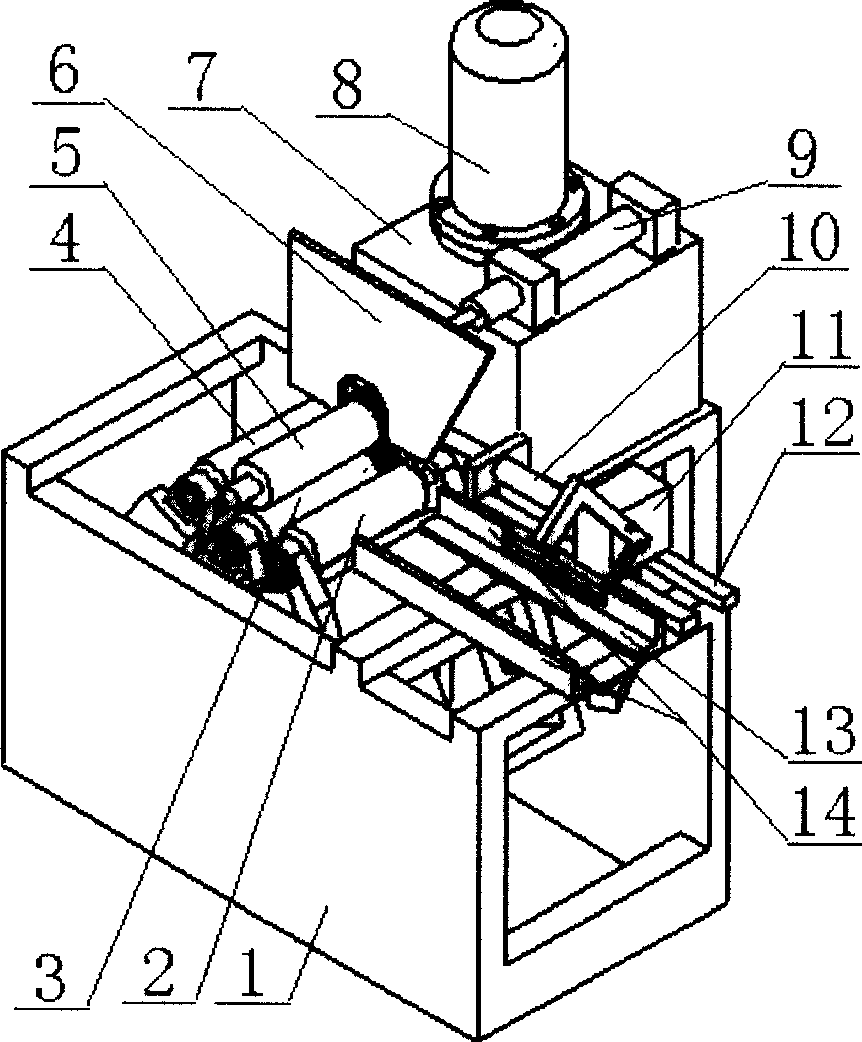

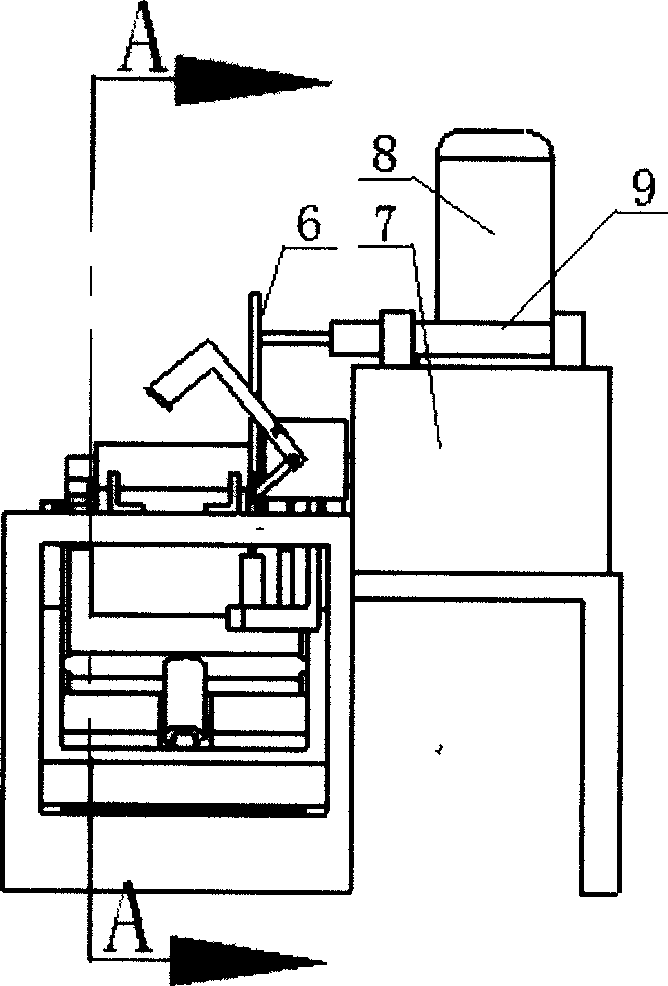

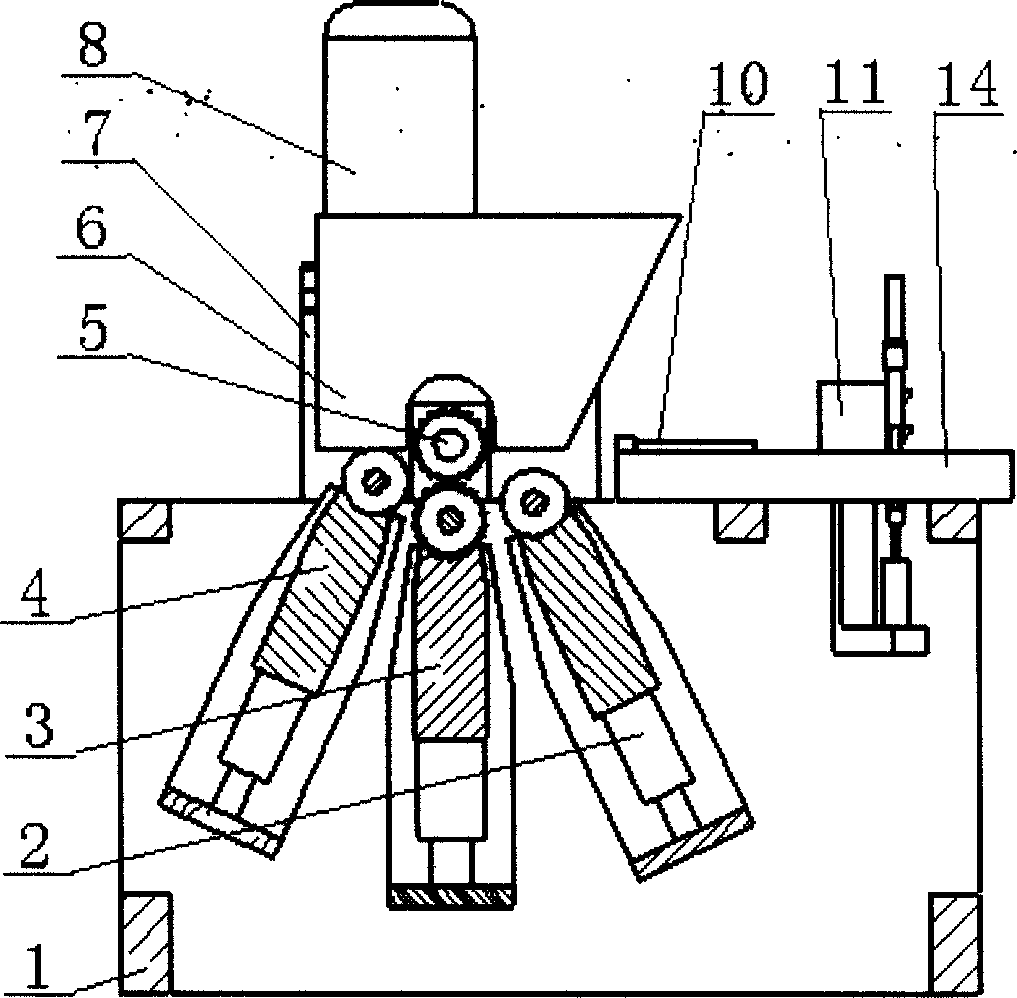

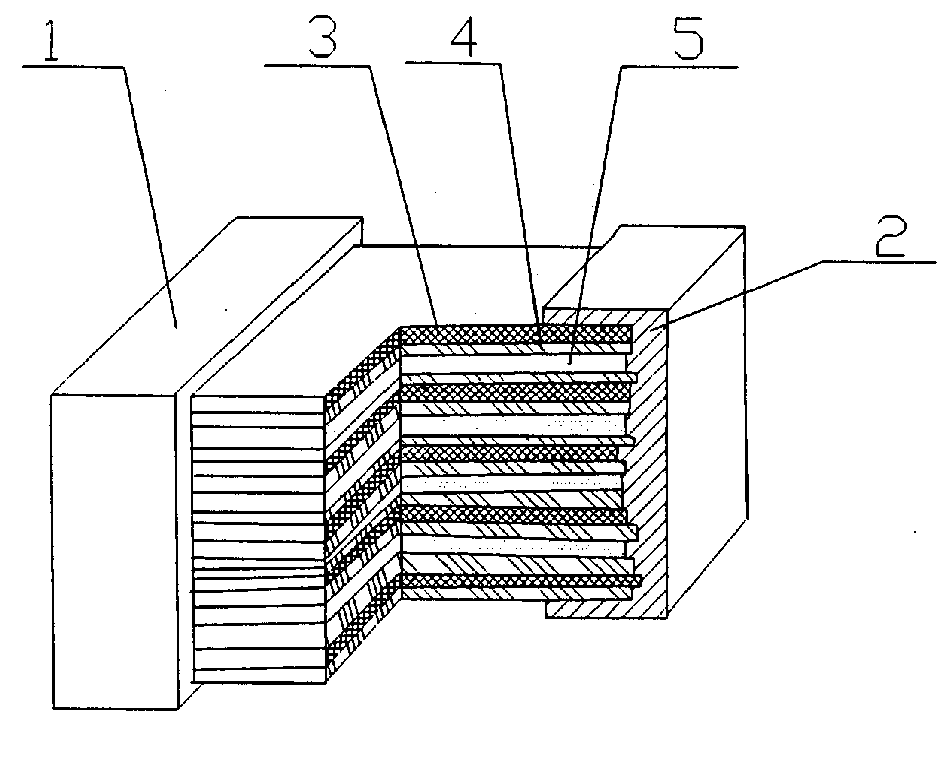

Four rollers automatic reeling mechanism in product line of manufacturing ternary cleaner for tail gas of cars

InactiveCN1759949AMeet the needs of automated productionAdjustable radiusMetal-working feeding devicesPositioning devicesProduction lineBarrel Shaped

An automatic 4-roller barrel shaping unit for the production line of three-element cleaner used to treat the tail gas of car is composed of machine frame, feeding track with both side barrier plates, feeding manipulator with its guide track and cylinder, blanking cylinder with push plate, the upper, lower, front and back rollers, AC motor and speed reducer. Its advantages are high automation level and productivity, and simple structure.

Owner:SHANGHAI JIAO TONG UNIV

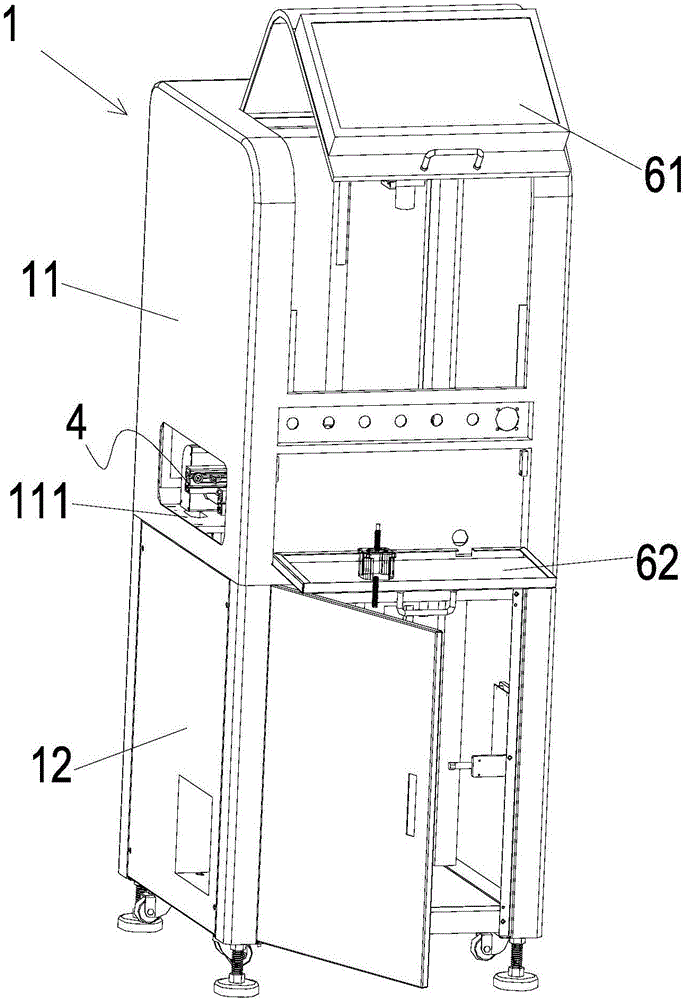

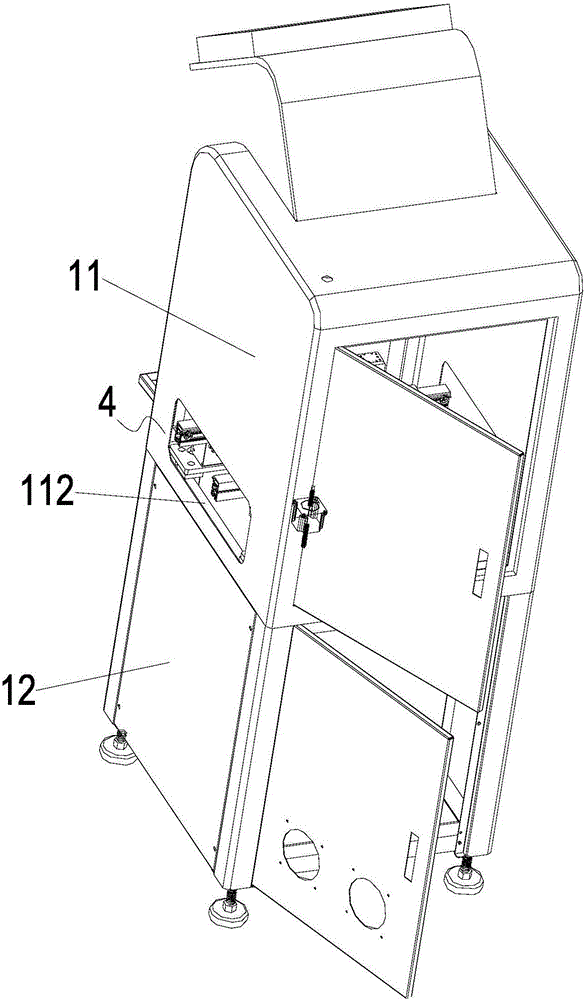

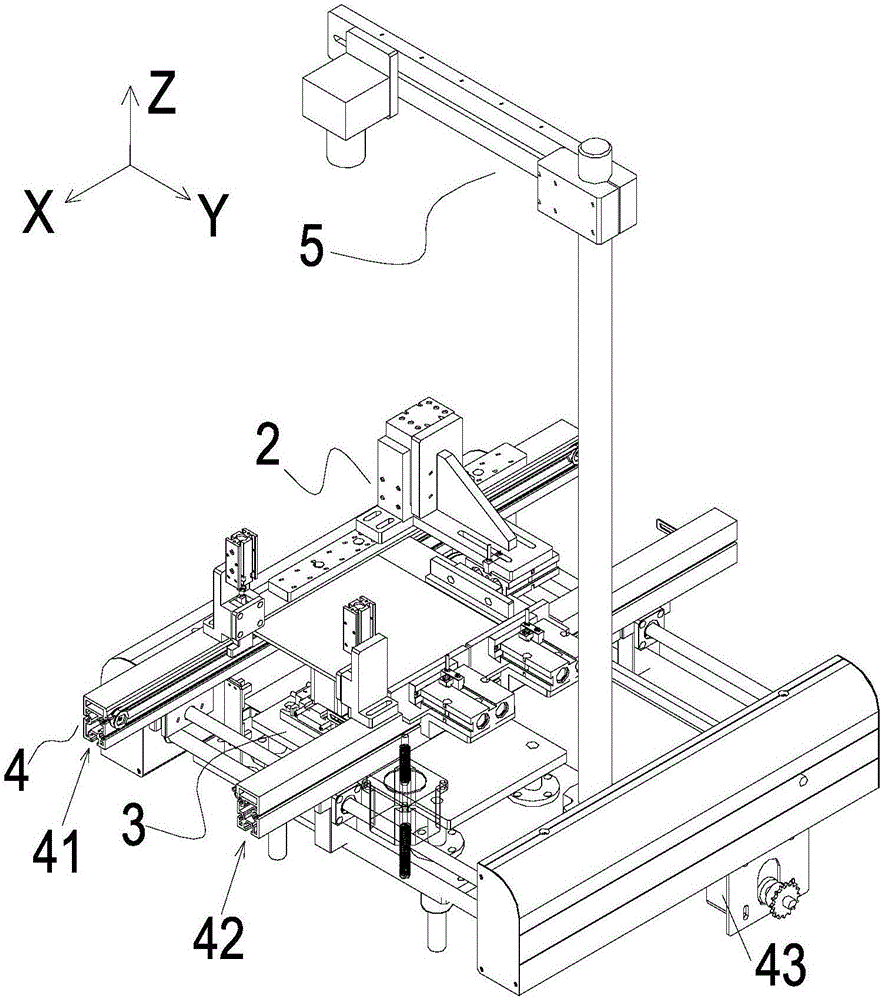

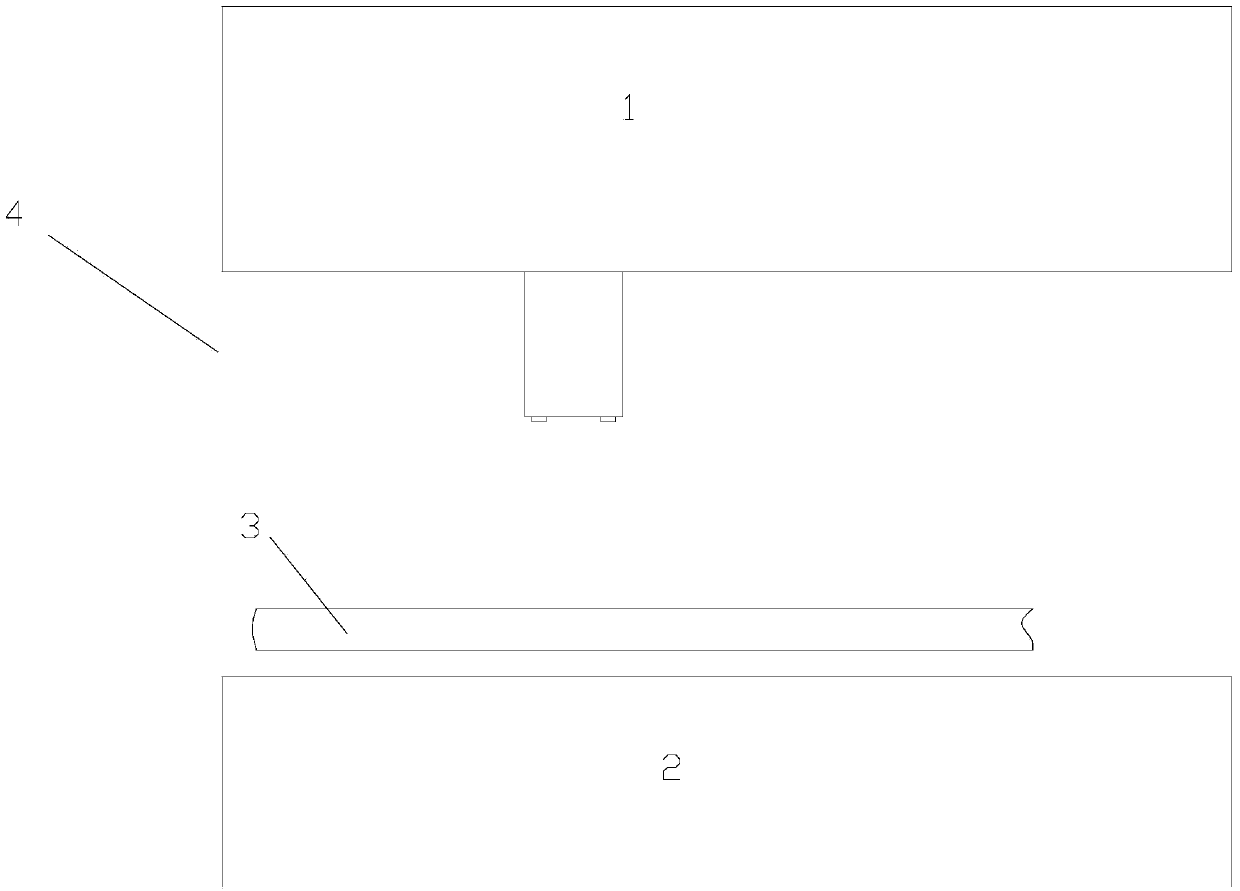

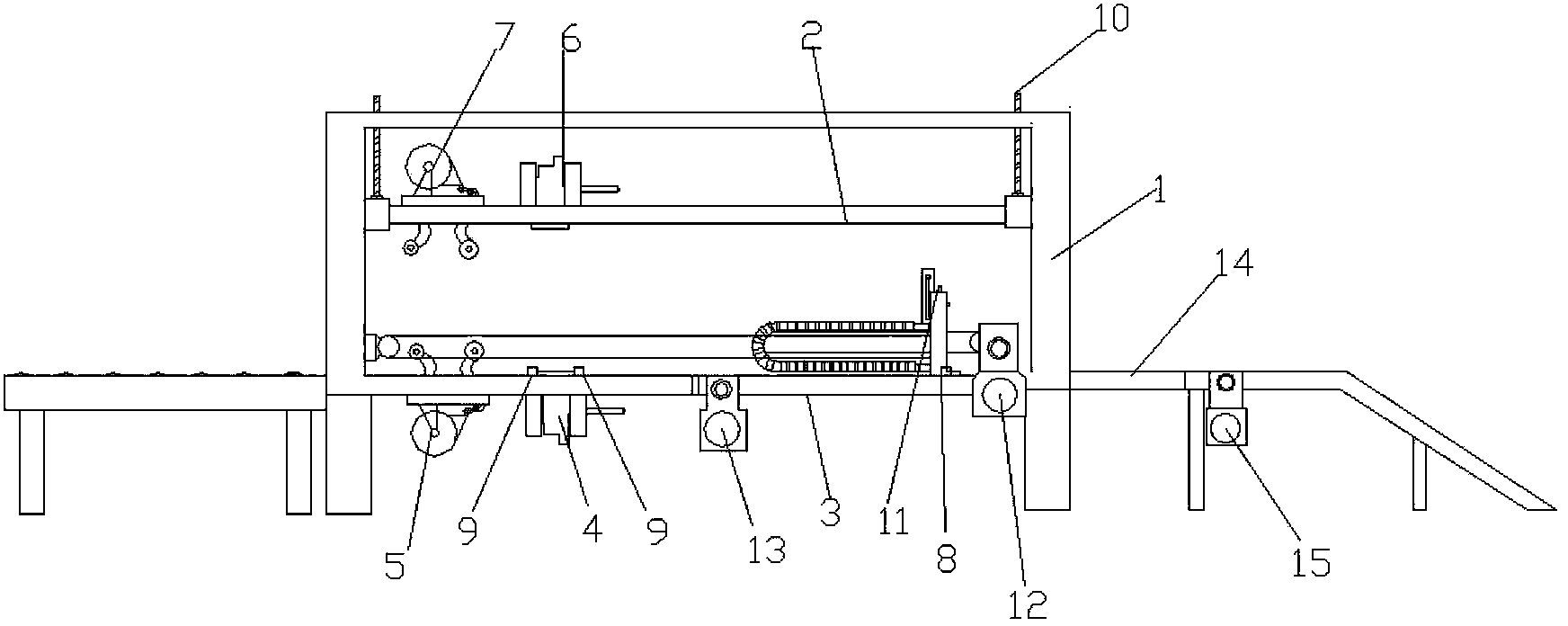

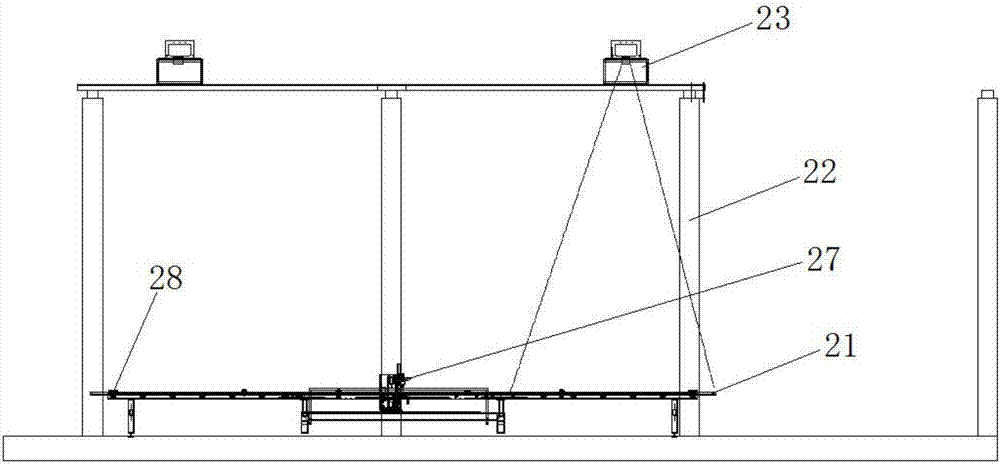

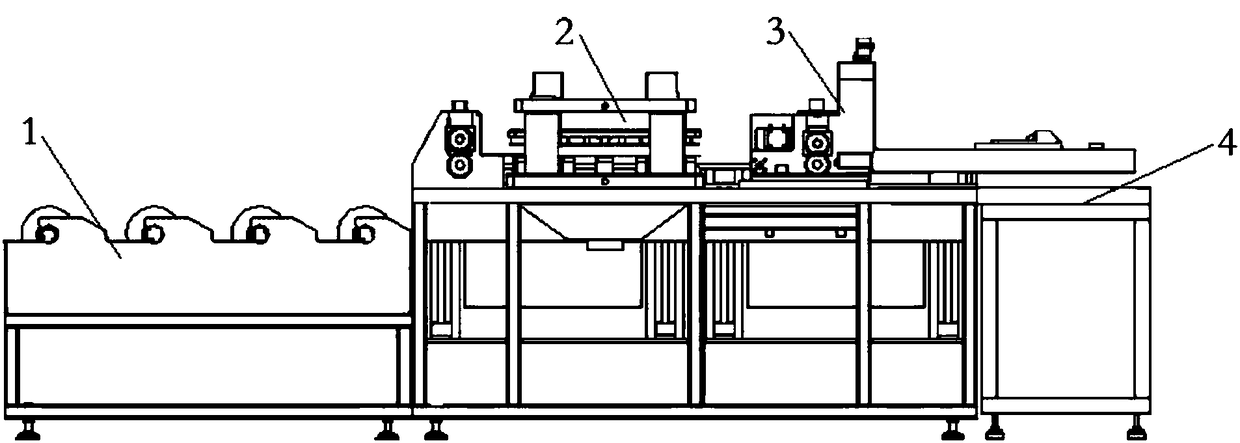

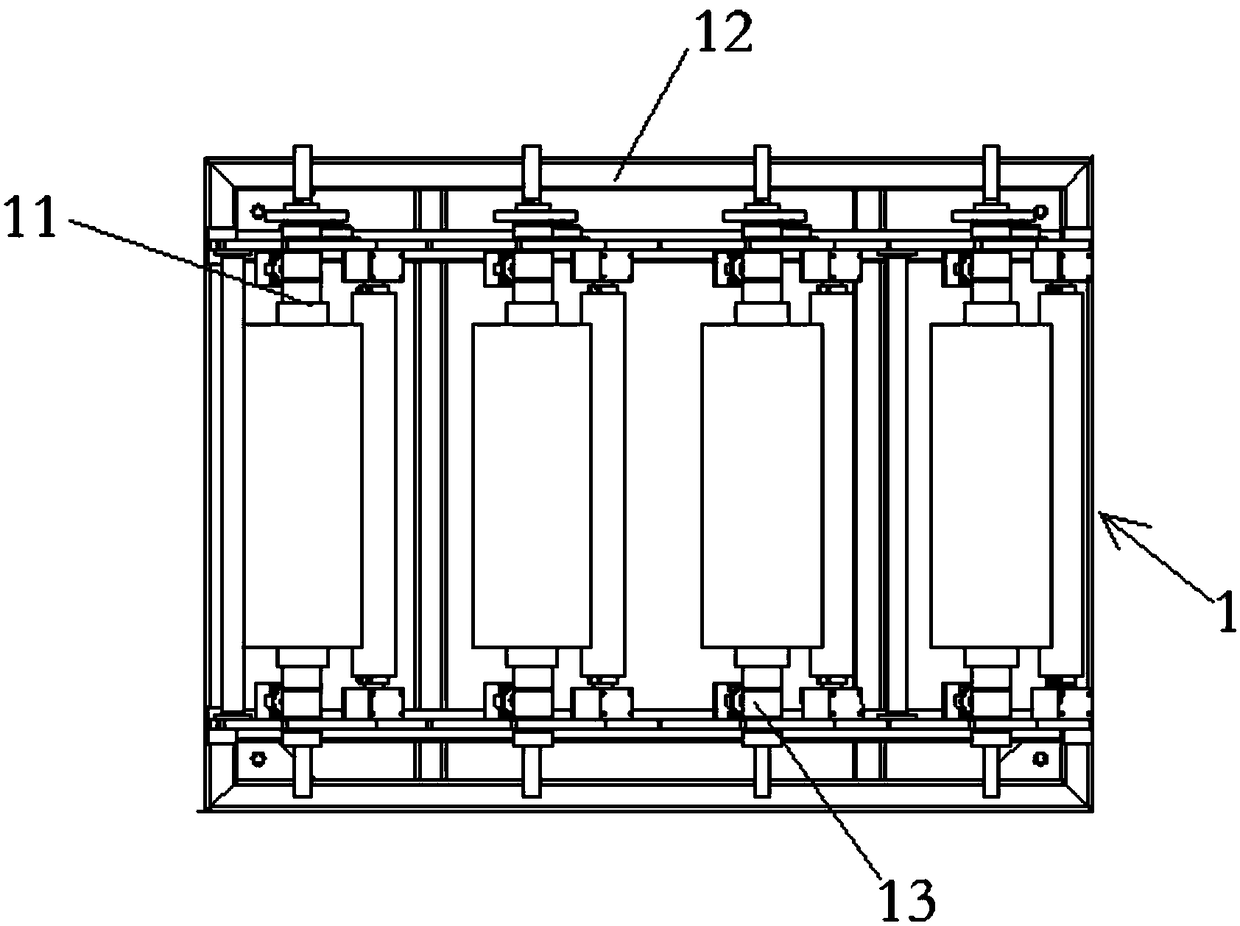

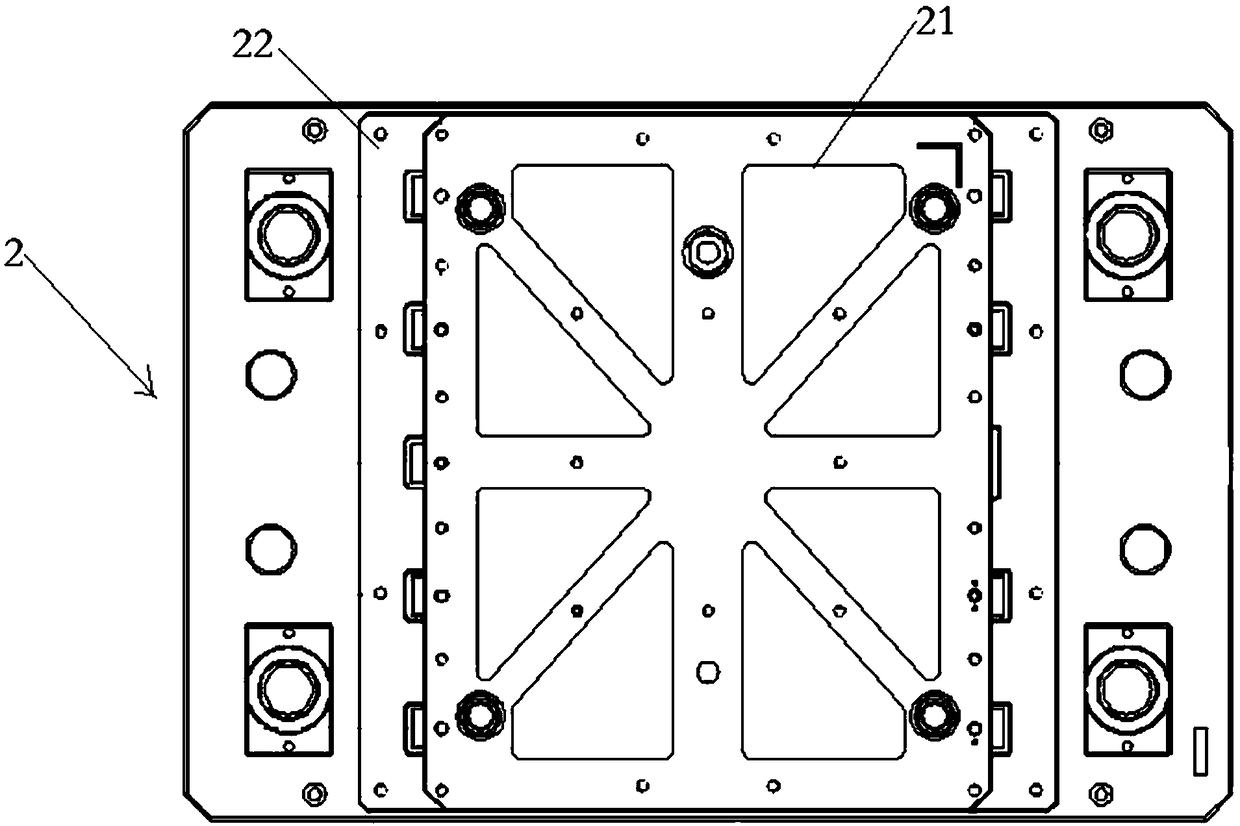

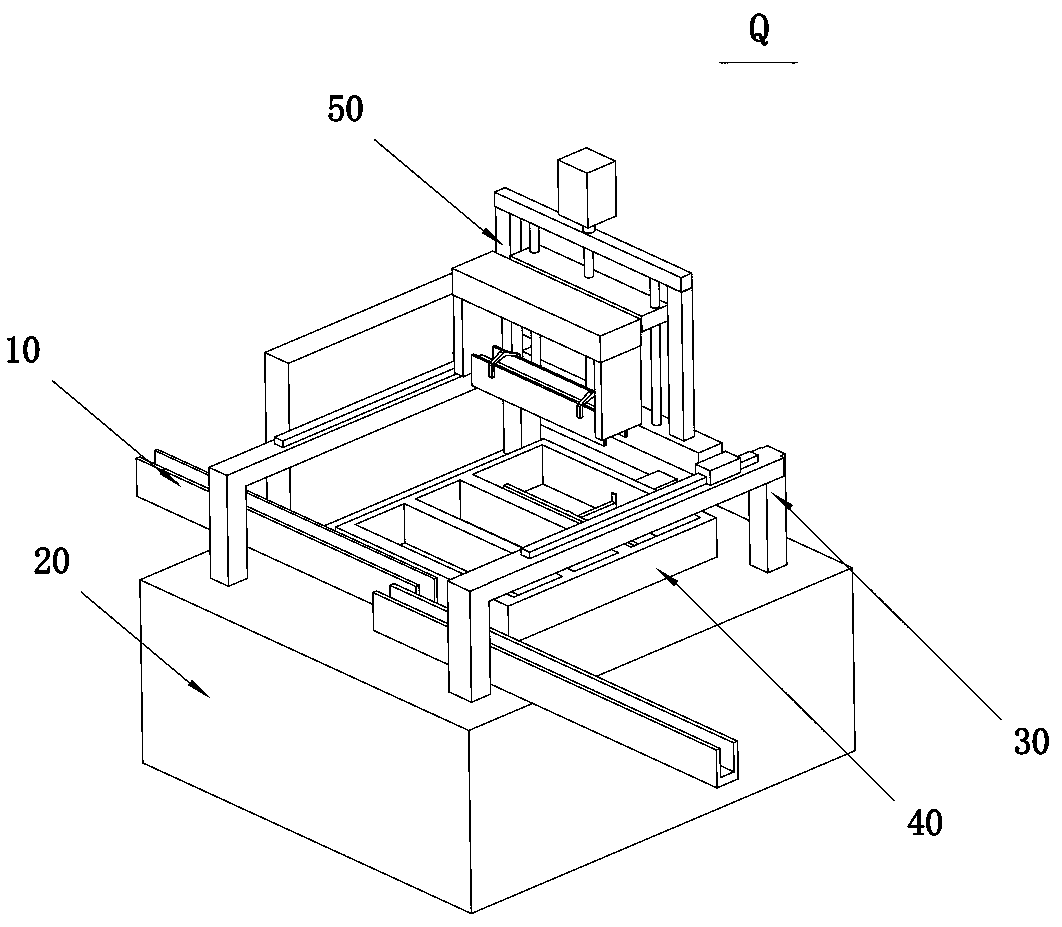

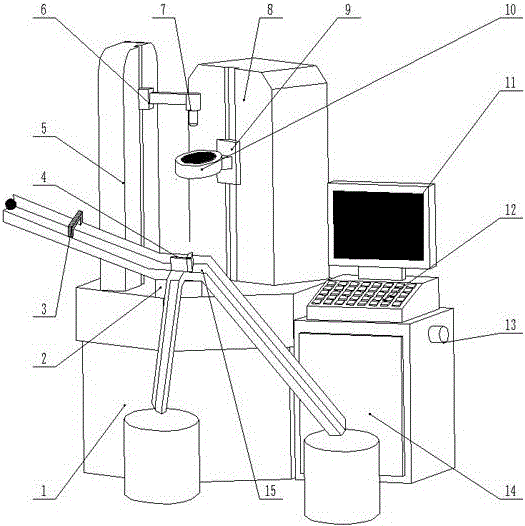

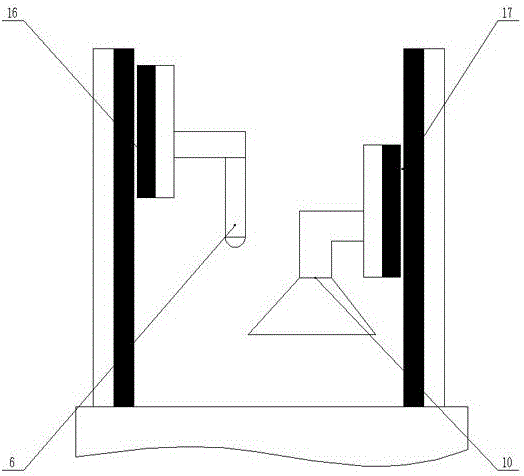

Display screen full-automatic detector

ActiveCN106353334AImprove detection efficiencyHigh degree of automationOptically investigating flaws/contaminationDisplay deviceComputer science

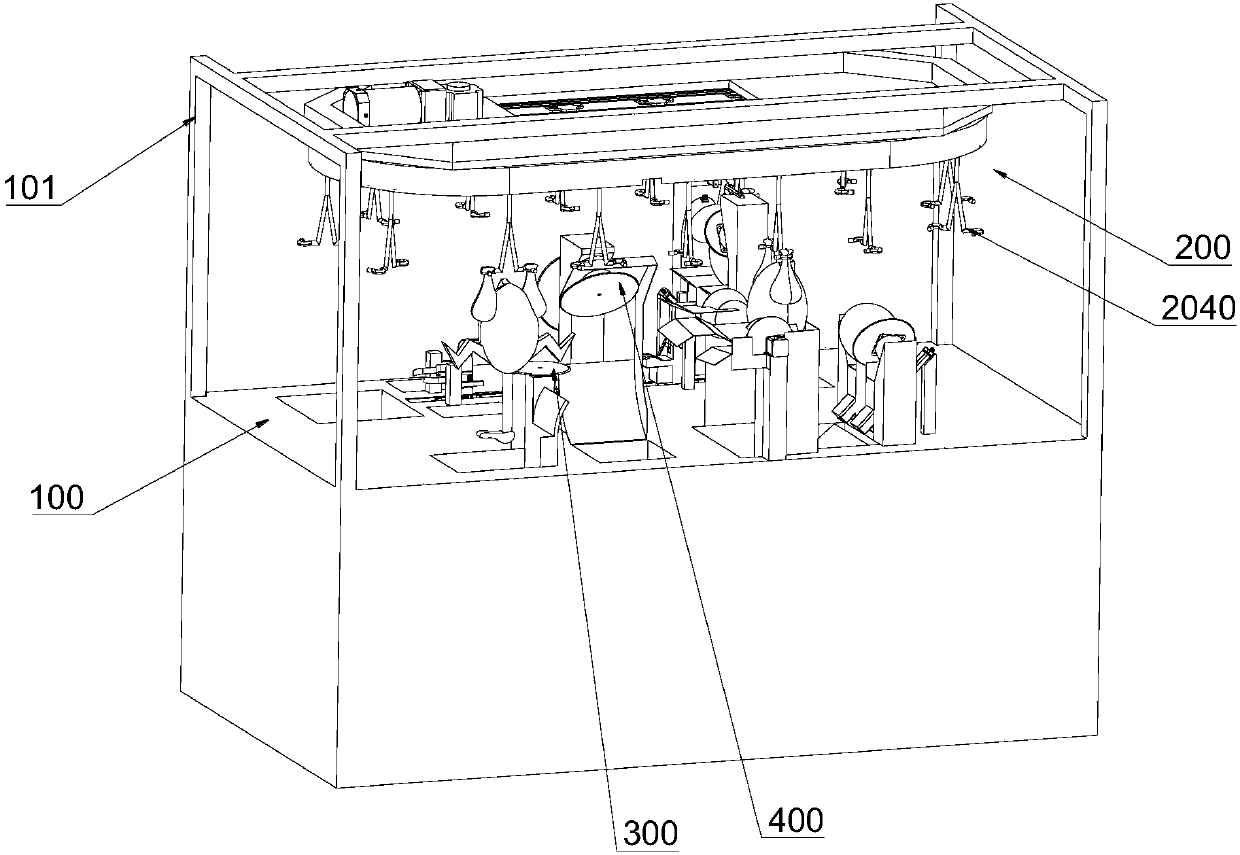

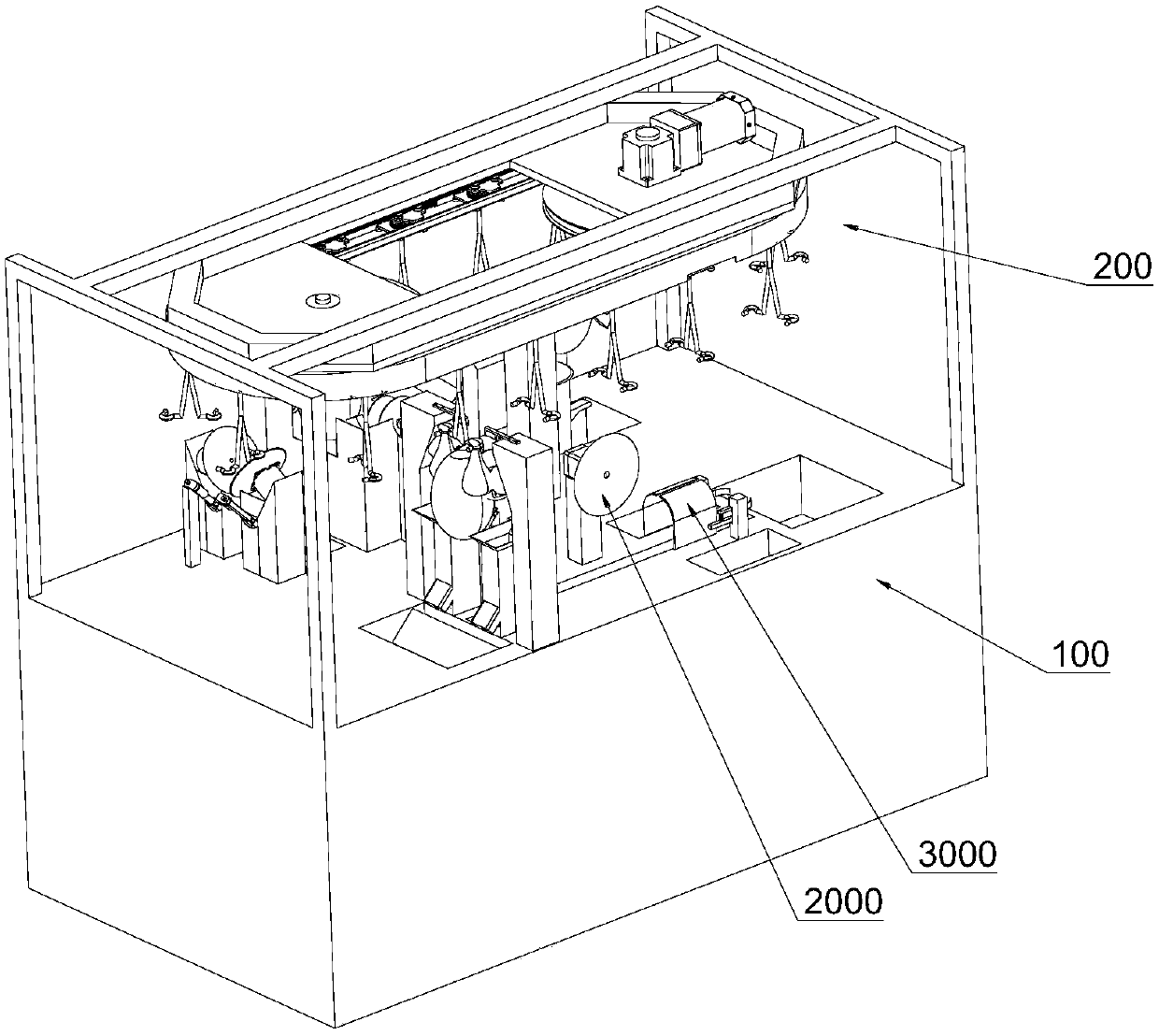

The invention discloses a display screen full-automatic detector which comprises a cabinet, a translation device arranged in the cabinet and used for conveying a display screen, a positioning device for positioning the display screen, an electrifying device for electrifying the display device after being positioned and a detection device for performing photographing detection on the display screen. The detection device is positioned above the translation device. The display screen full-automatic detector can realize automatic conveying of a product through the translation device, automatic positioning and fixing of the product through the positioning device, automatic electrifying and signal transmission of the product fixed by the positioning device and automatic detection recording of the product after being electrified and displaying an image. The display screen full-automatic detector can detect whether the display screen is damaged, insufficient in brightness and unclear in displaying or not, is high in detection efficiency, high in automation level, time-saving and labor-saving and capable of fully meeting needs of automated production.

Owner:深圳市尚宏自动化设备有限公司

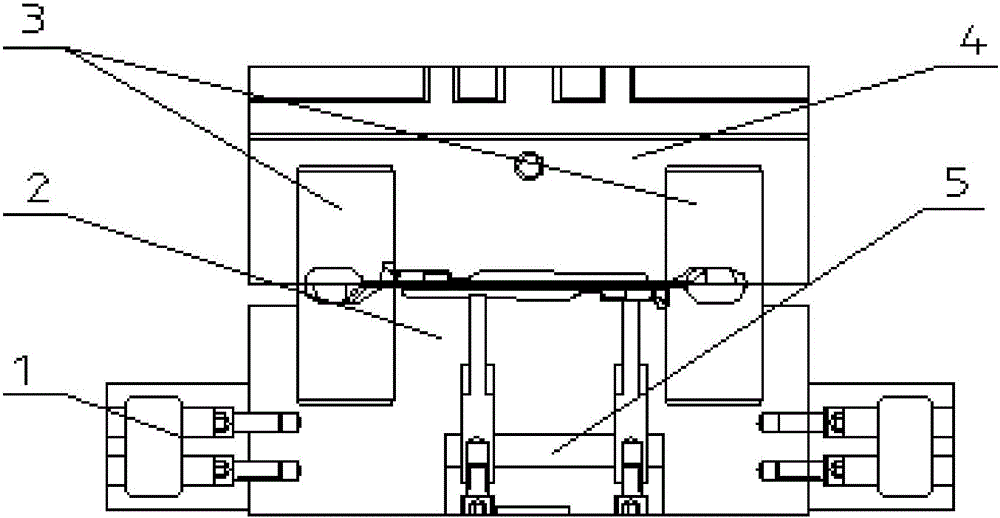

Valve automatic detection equipment

ActiveCN105043690AMeet the needs of automated productionImprove work efficiencyDetection of fluid at leakage pointMachine part testingAutomatic test equipmentEngineering

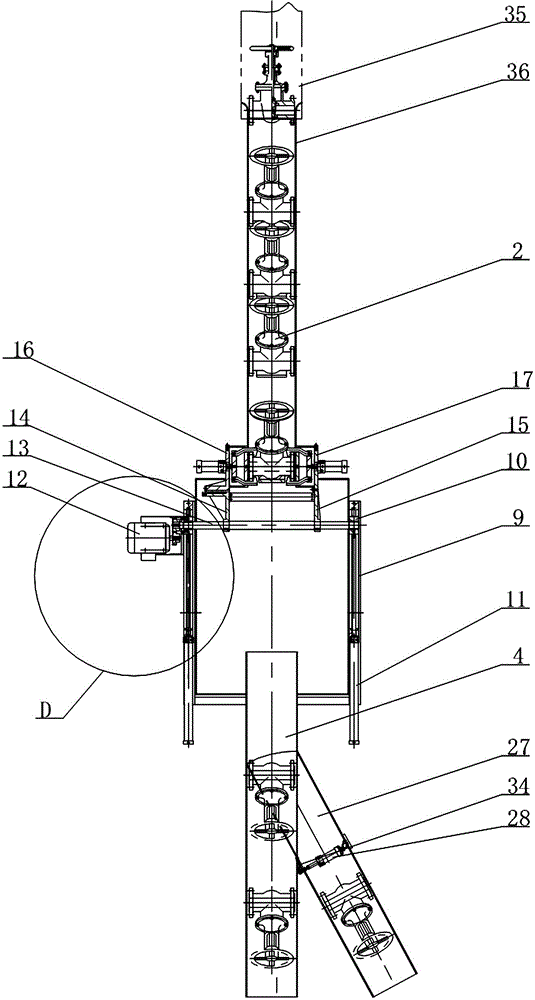

The invention relates to valve automatic detection equipment, and mainly solves problems that existing valve detection devices are low in work efficiency and cannot detect valves one by one and cannot realize automatic detection. The valve automatic detection equipment is characterized in that a rotating shaft (13) is installed between two slide blocks (10) and driven by two synchronous operating horizontal cylinders (11). A left swing arm (14) and a right swing arm (15) are respectively provided with a left clamp (16) and a right clamp (17) which are corresponding. A clamping cylinder (19) drives a claw (20) to open and close. The lower end of a material discharge carriage (4) is provided with a separating slideway (27). With combination of forward and backward rotation of a motor and reciprocating movement of the horizontal cylinders, automatic detection is realized under the control of a PLC so that work efficiency is effectively enhanced, the valves can be detected one by one, the defective valves can be automatically separated and thus the requirement for automatic production of the valves can be met.

Owner:江苏捷迈斯阀门有限公司

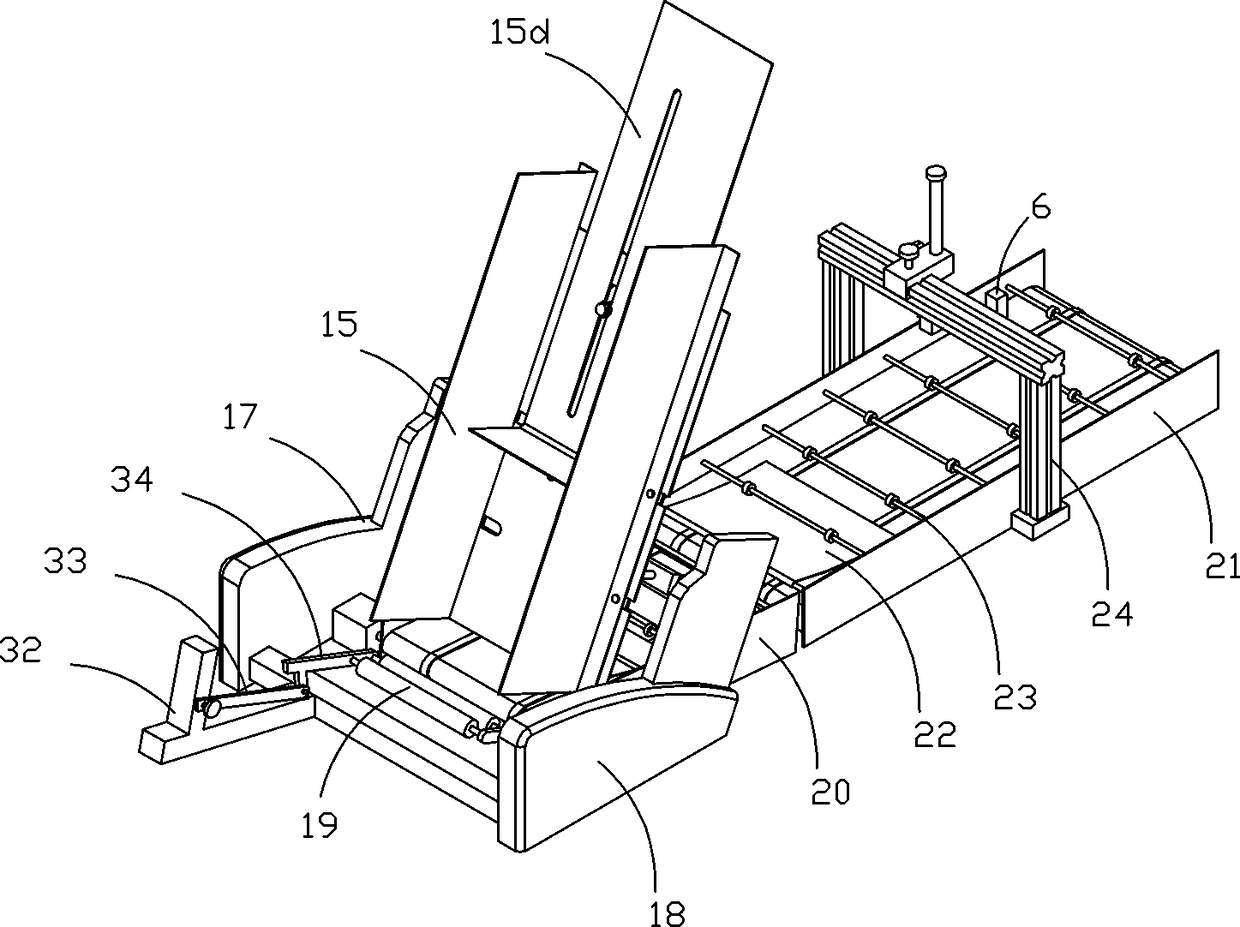

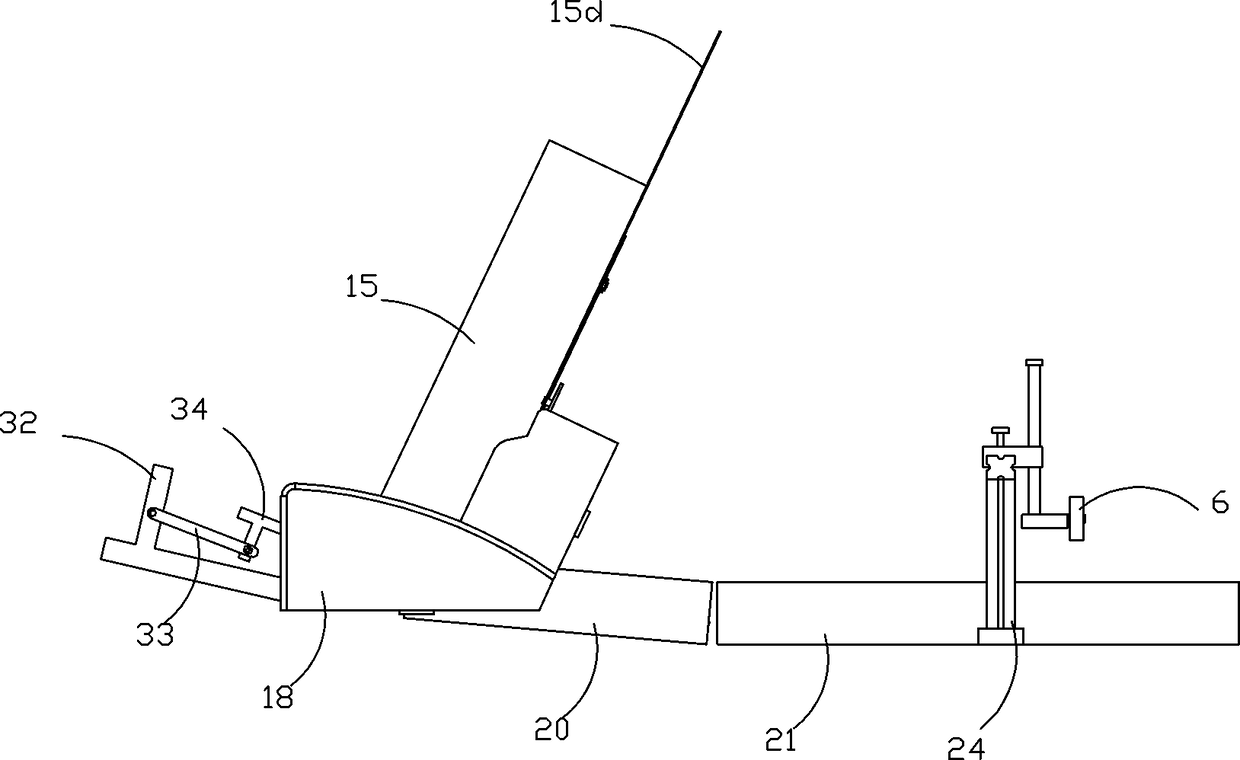

Domestic fowl processing equipment

PendingCN109673710AImprove bone removal efficiencyMeet the needs of automated productionPoultry deboningPoultry transferring/conveying devicesAerospace engineeringFowl

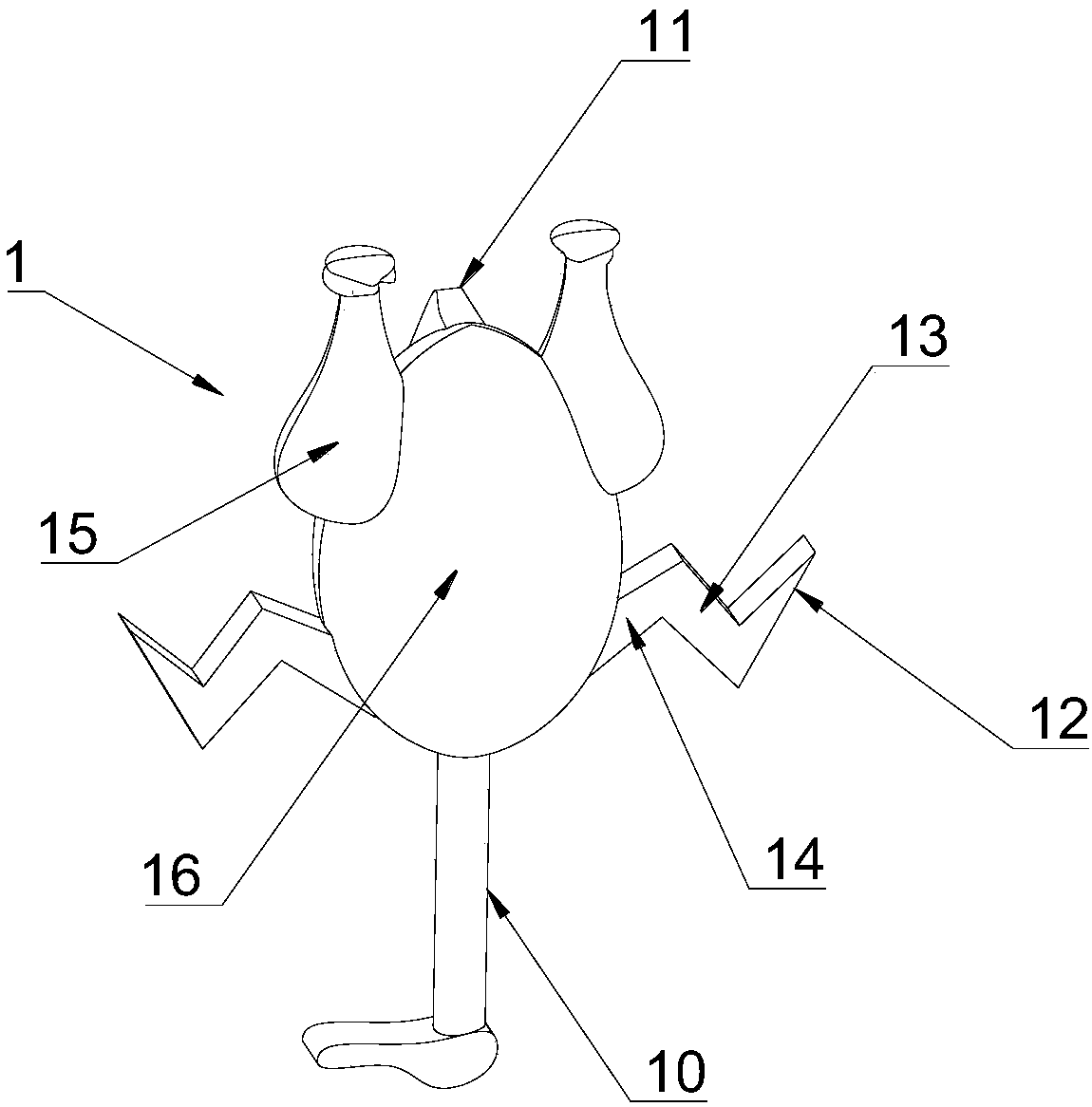

The invention discloses domestic fowl processing equipment. The domestic fowl processing equipment comprises a processing platform and a conveying device, wherein the conveying device comprises a conveying guide rail, suspension devices and a conveying driving mechanism which is used for driving the suspension devices to move along a conveying path of the conveying guide rail; a neck processing station is provided with a neck cutter knife; a tail processing station is provided with a tail cutter knife; a first wing processing station is provided with a wing tip cutter knife and a middle wing cutter knife; a second wing processing station is provided with a wing root cutter knife and a wing root bone removing push rod; a leg processing station is provided with a leg cutter knife and a leg bone removing push rod; the leg processing station is provided with a leg removing mechanism; the neck cutter knife, the tail cutter knife, the wing tip cutter knife, the middle wing cutter knife, thewing root cutter knife and the leg cutter knife are rotatably mounted on the processing platform; the processing platform is provided with a clamping movement device for clamping a chest of a domesticfowl; a chest processing station is provided with a separation assembly. The domestic fowl processing equipment is used for replacing manual operation, the labor intensity can be reduced and the automatic operation is realized.

Owner:GUANGZHOU FUGANG WANJIA INTELLIGENT TECH CO LTD

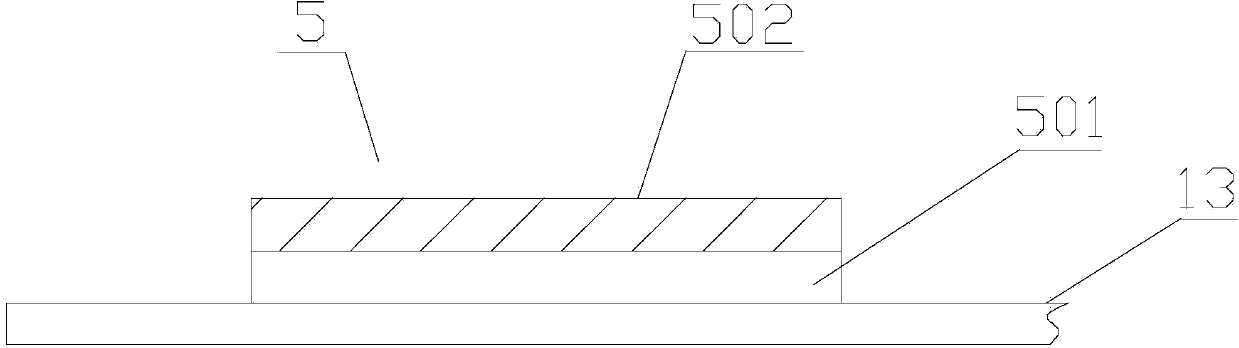

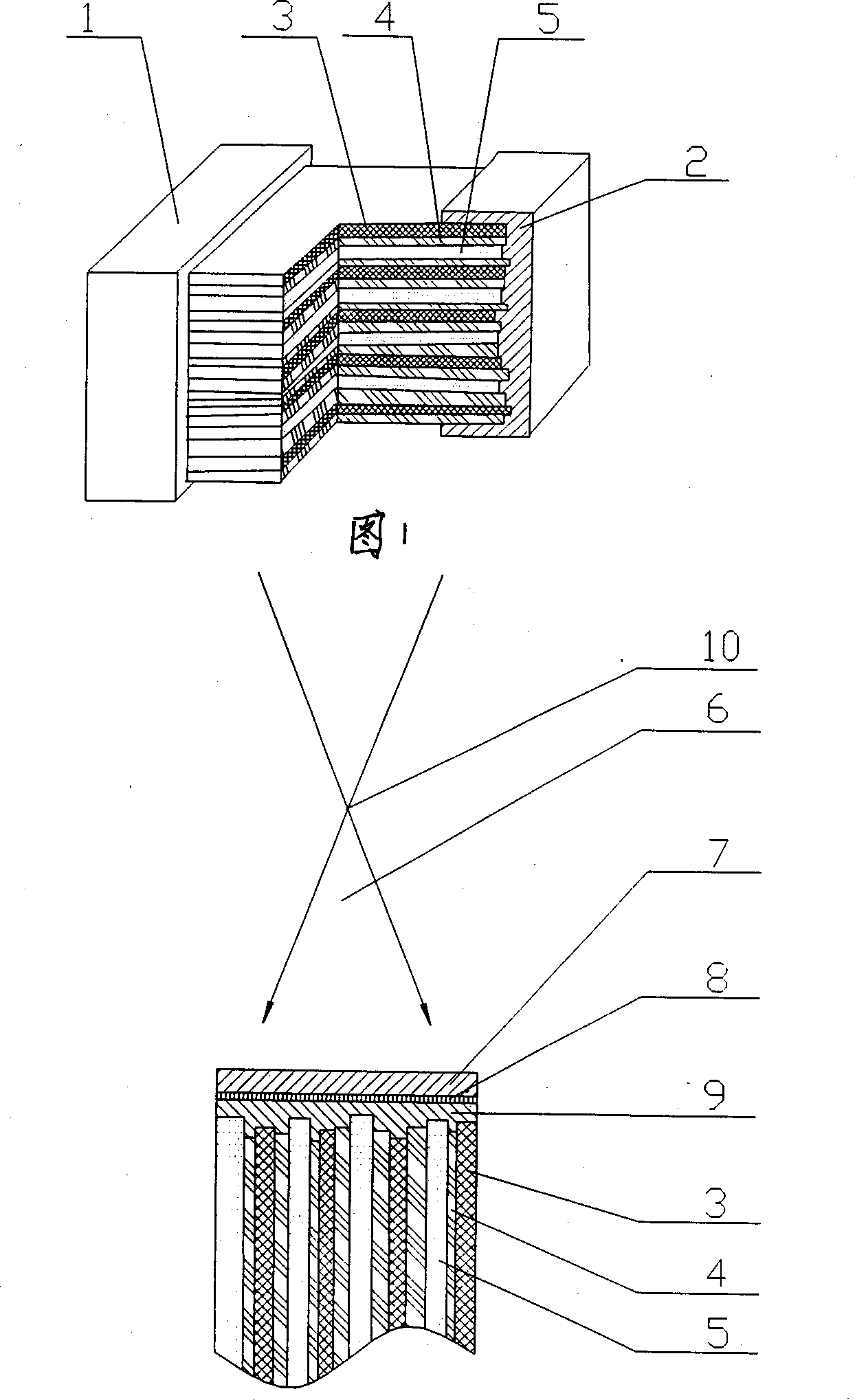

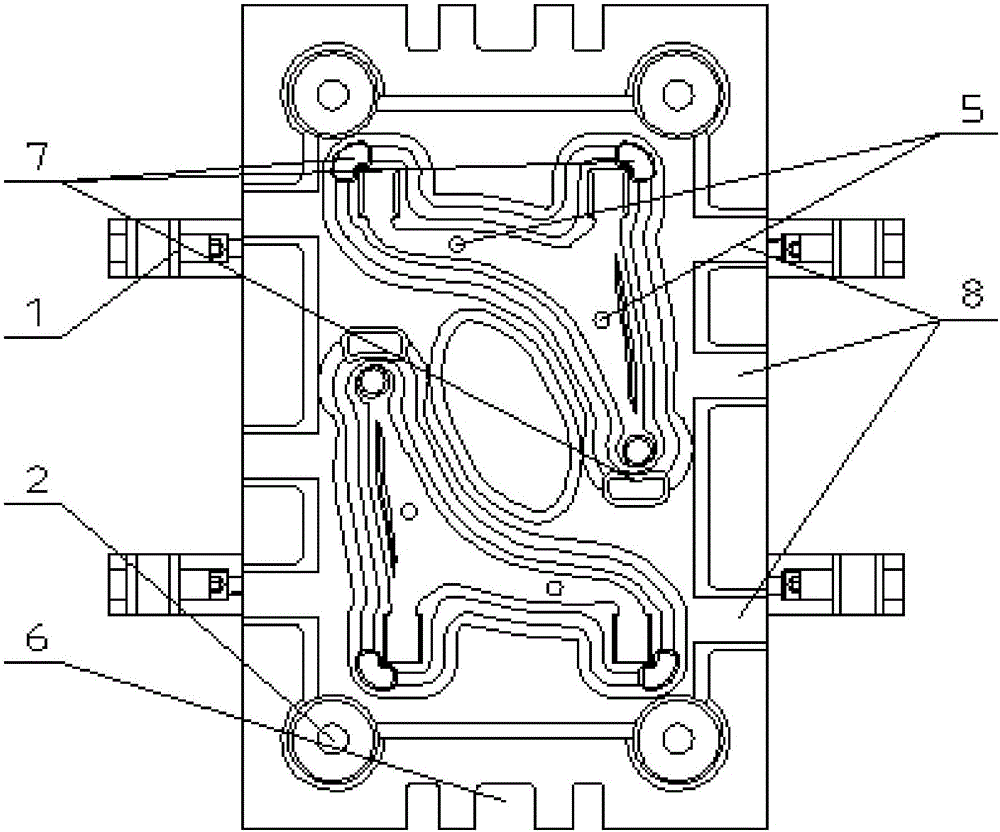

Method for manufacturing regularly-arranged rectangular indentation reinforcing pieces

The invention discloses a method for manufacturing regularly-arranged rectangular indentation reinforcing pieces, and relates to the technical field of machining of flexible printed circuit boards. The method comprises the steps that a steel plate (3) is stamped through an upper die (1) and a lower die (3) of a forming mechanism (4), and the steel reinforcing pieces (501) are obtained; the steel reinforcing pieces (501) are arranged through a jig (10), and the steel reinforcing pieces (501) are placed in containing grooves (9) of the jig one by one. According to the method for manufacturing the reinforcing pieces, the steel reinforcing pieces are obtained through stamping forming; compared with an etching method, cost is lower, and accuracy is higher; the jig is used for positioning, the regularly-arranged reinforcing pieces can be obtained as well, and the requirement for automatic production can be met.

Owner:NANTONG MEELAIN ELECTRIC APPLIANCE CO LTD

Integrated device with automatic box sealing and nailing functions

InactiveCN103395516AMeet the needs of automated productionIncrease productivityWrapper twisting/gatheringCartonIntegrated devices

The invention discloses an integrated device with automatic box sealing and automatic nailing functions. The integrated device comprises a transmission rack, and an upper working support and a lower working support are fixedly arranged on the transmission rack, wherein the upper working support and the lower working support are opposite to each other in an up-and-down mode and the distance between the upper working support and the lower working support can be adjusted. A working table, a lower automatic nailing machine, a lower automatic sealing tape adhering machine and a pushing mechanism are installed on the lower working support. An upper automatic nailing machine and an upper automatic sealing tape adhering machine are fixedly arranged on the upper working support. In addition, the integrated device is provided with a main controller, a first photo-electric sensor and a plurality of second photo-electric sensors. The main controller can control the pushing mechanism to push paper boxes to be packaged through the first photo-electric sensor and the second photo-electric sensors, and can control the upper automatic nailing machine and the lower automatic nailing machine to nail upper seal openings of the paper boxes to be packaged and lower seal openings of the paper boxes to be packaged and the upper automatic sealing tape adhering machine and the lower automatic sealing tape adhering machine to adhere sealing tapes to the upper seal openings of the paper boxes to be packaged and the lower seal openings of the paper boxes to be packaged. The integrated device has the advantages of being automatic in conveying, accurate in locating and capable of automatically nailing the upper seal openings of the paper boxes and the lower seal openings of the paper boxes and adhering the sealing tapes to the upper seal openings of the paper boxes and the lower seal openings of the paper boxes.

Owner:ANHUI KONKA ELECTRONICS

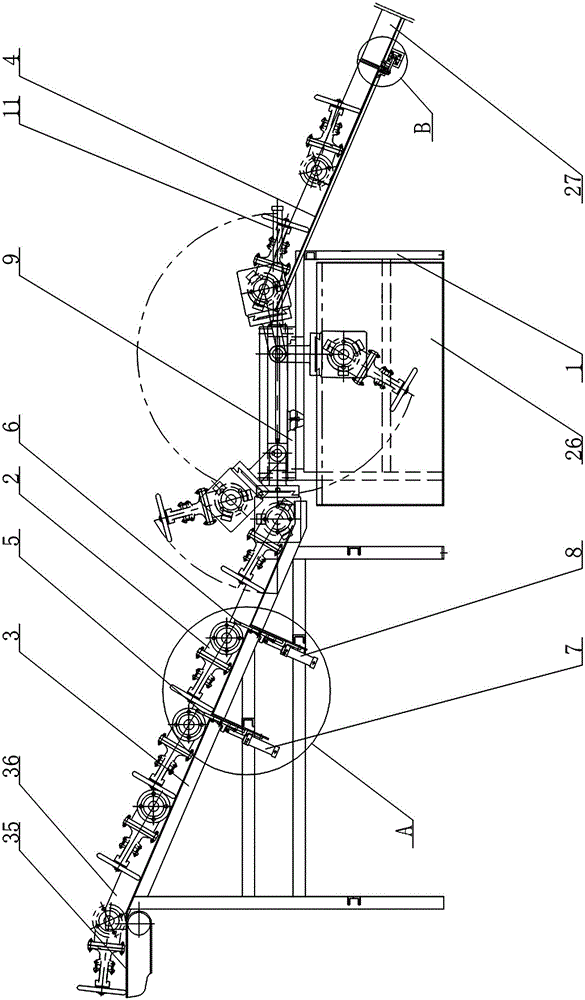

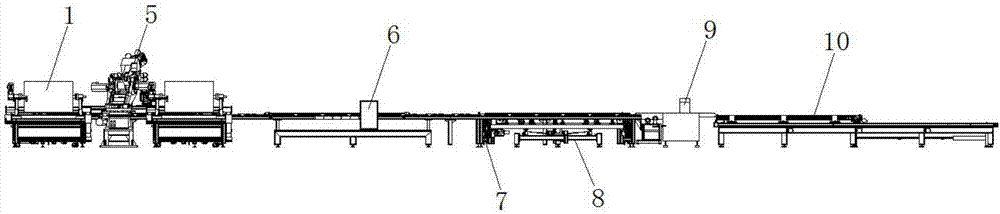

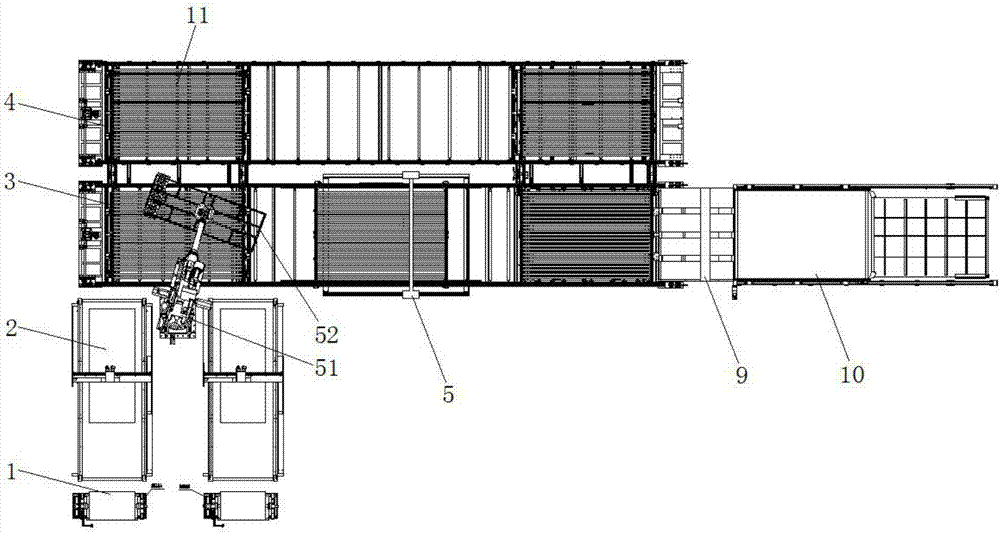

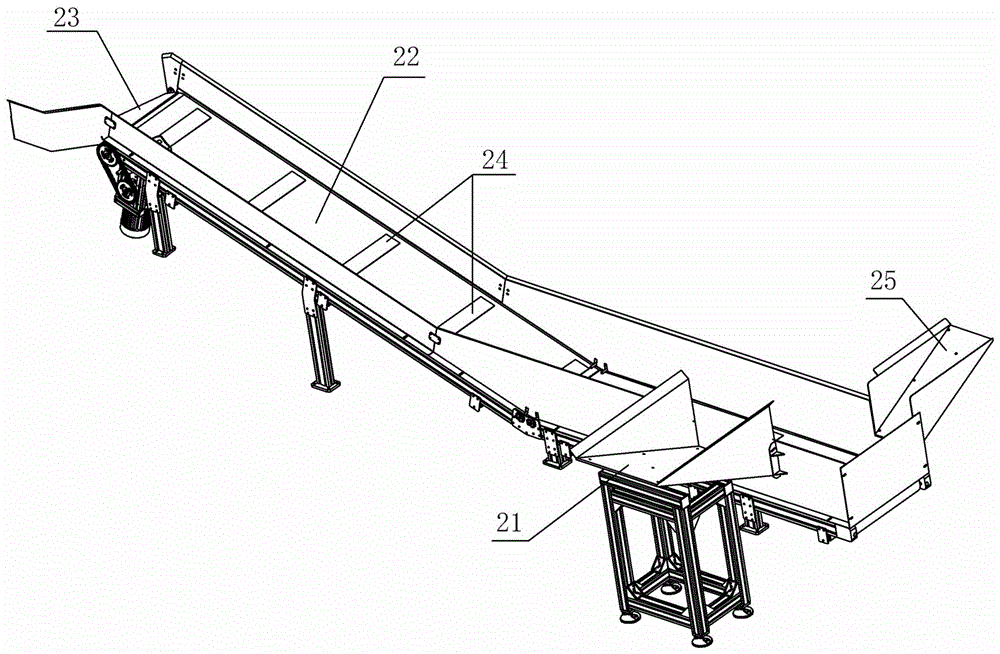

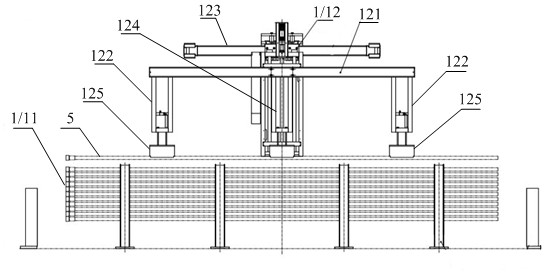

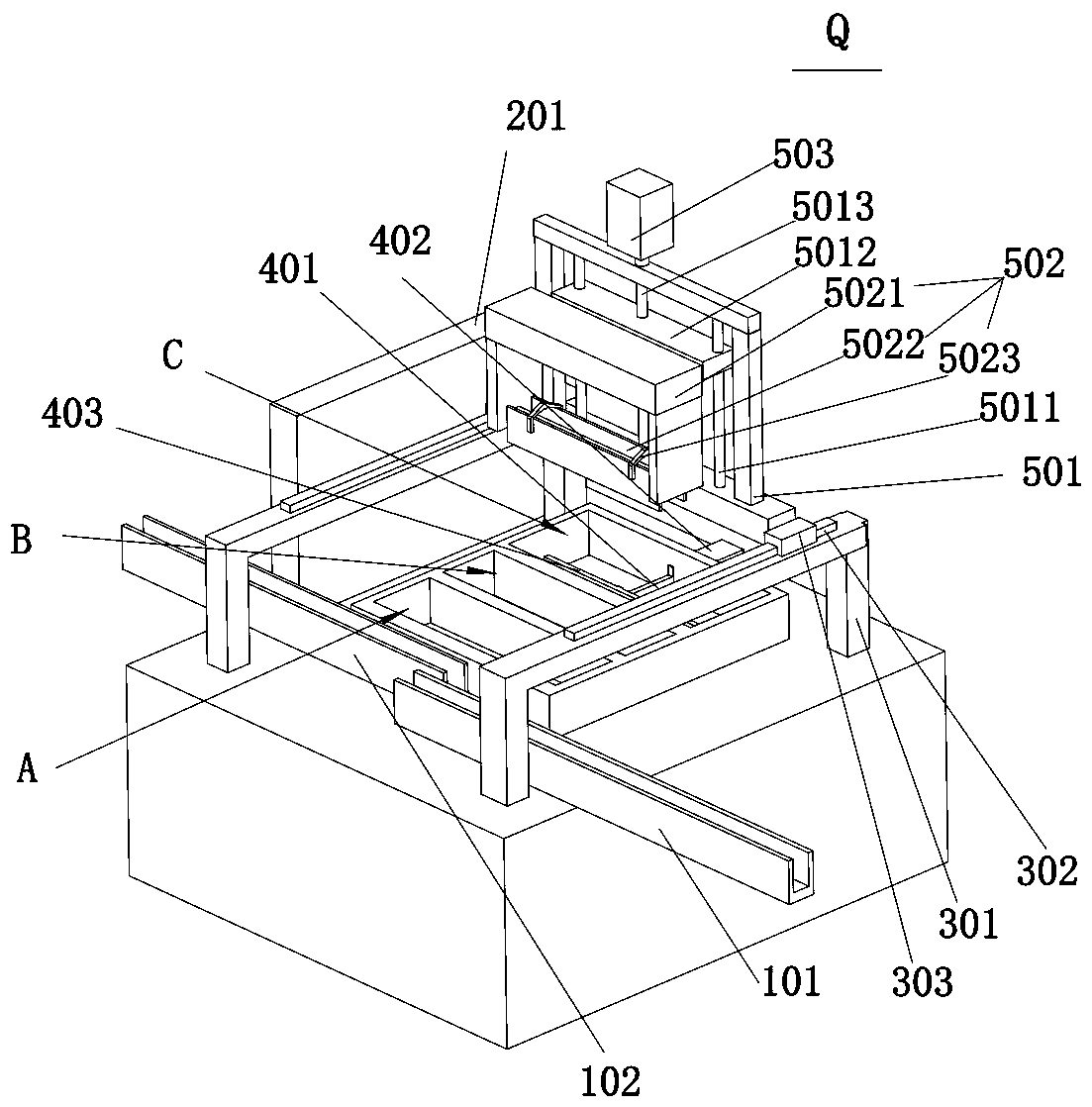

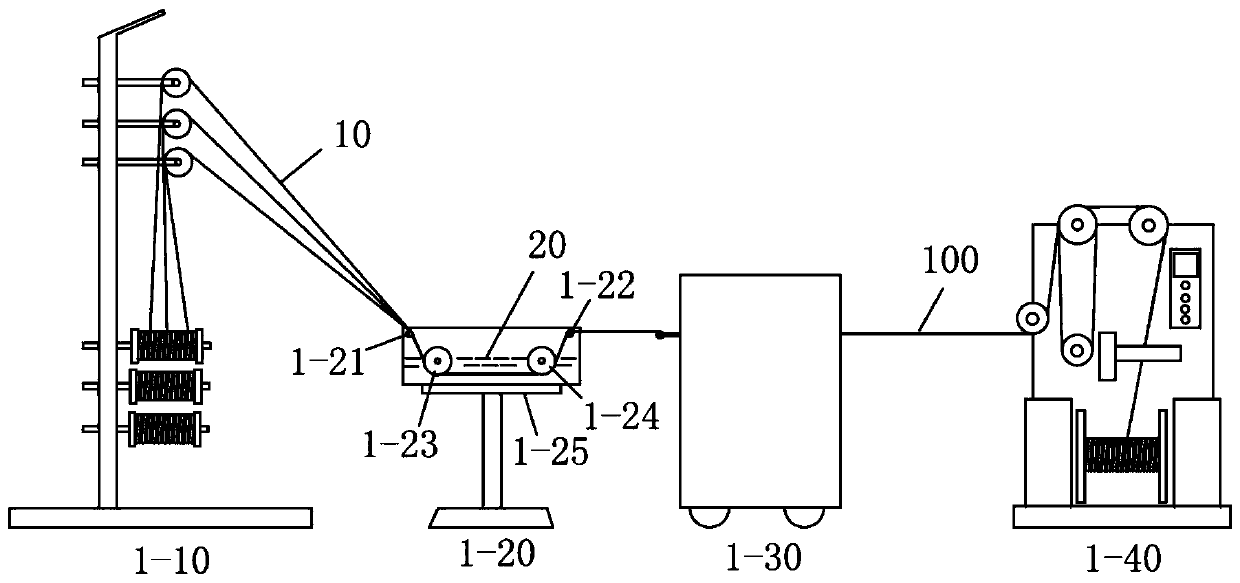

Wind power blade preforming production line

PendingCN107327376AIncrease productivityImprove cutting accuracyEngine manufactureWork-feeding meansElectricityTextile

The invention discloses a wind power blade preforming production line. An unreeling mechanism is arranged near the input end of a cutting mechanism; the output end of the cutting mechanism is arranged near the input end of a first conveying line; a second conveying line and the first conveying line are arranged adjacent and in parallel; the conveying directions of the second conveying line and the first conveying line are opposite; a grabbing and stacking mechanism is arranged near the output end of the cutting mechanism and the input end of the first conveying line; a sewing mechanism is arranged on the middle part of the first conveying line; the first conveying line, a metal detection mechanism and a stacking and discharging mechanism are arranged sequentially along the conveying direction of the first conveying line; a turnover box is conveyed on the first conveying line and the second conveying line; jacking and translation mechanisms are arranged at the bottoms of the input end and the output end of the first conveying line as well as at the bottoms of the input end and the output end of the second conveying line; and a jacking and cloth taking mechanism is arranged at the bottom of the output end of the first conveying line. According to the wind power blade preforming production line, automatic production of a wind power blade preforming piece is realized and the production efficiency is effectively improved.

Owner:NEWTRY COMPOSITE

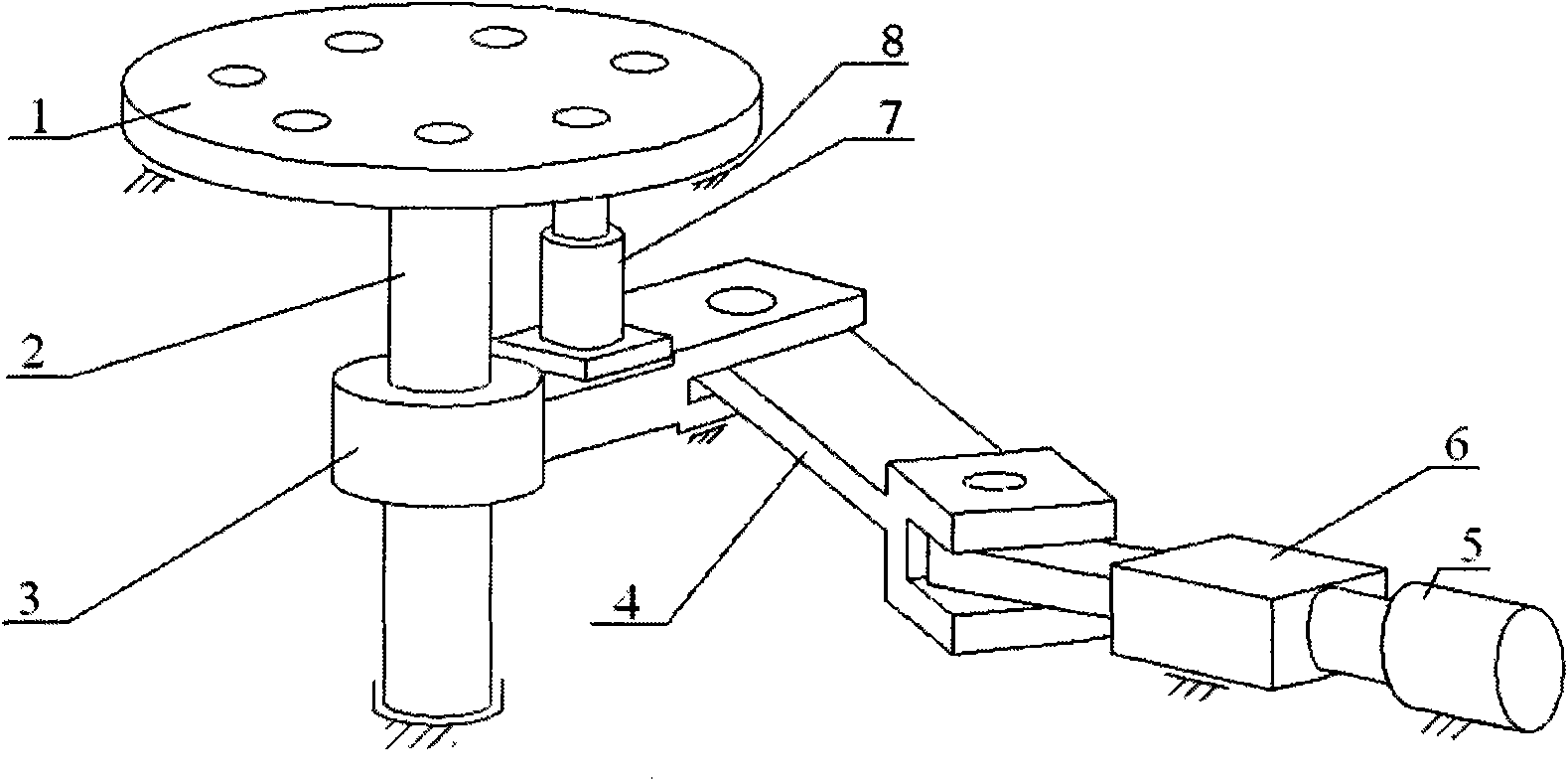

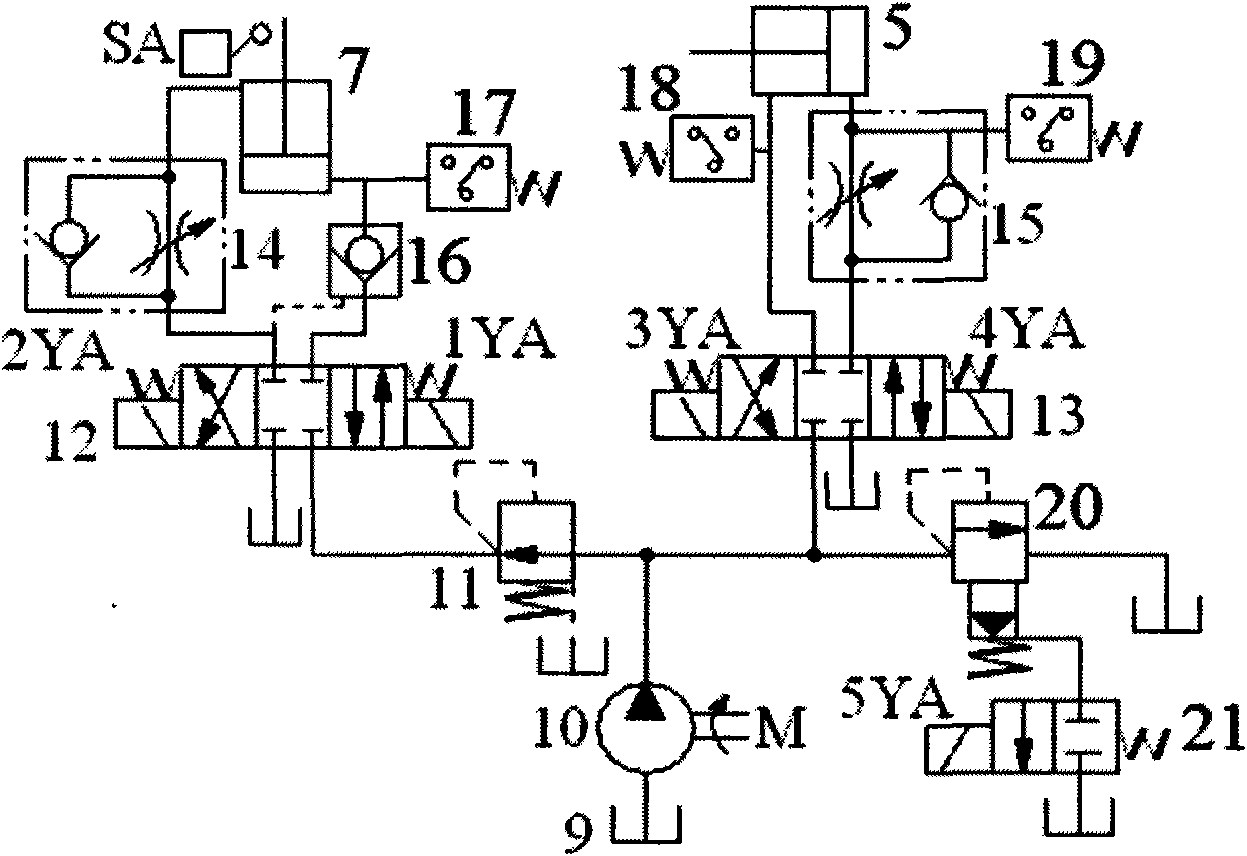

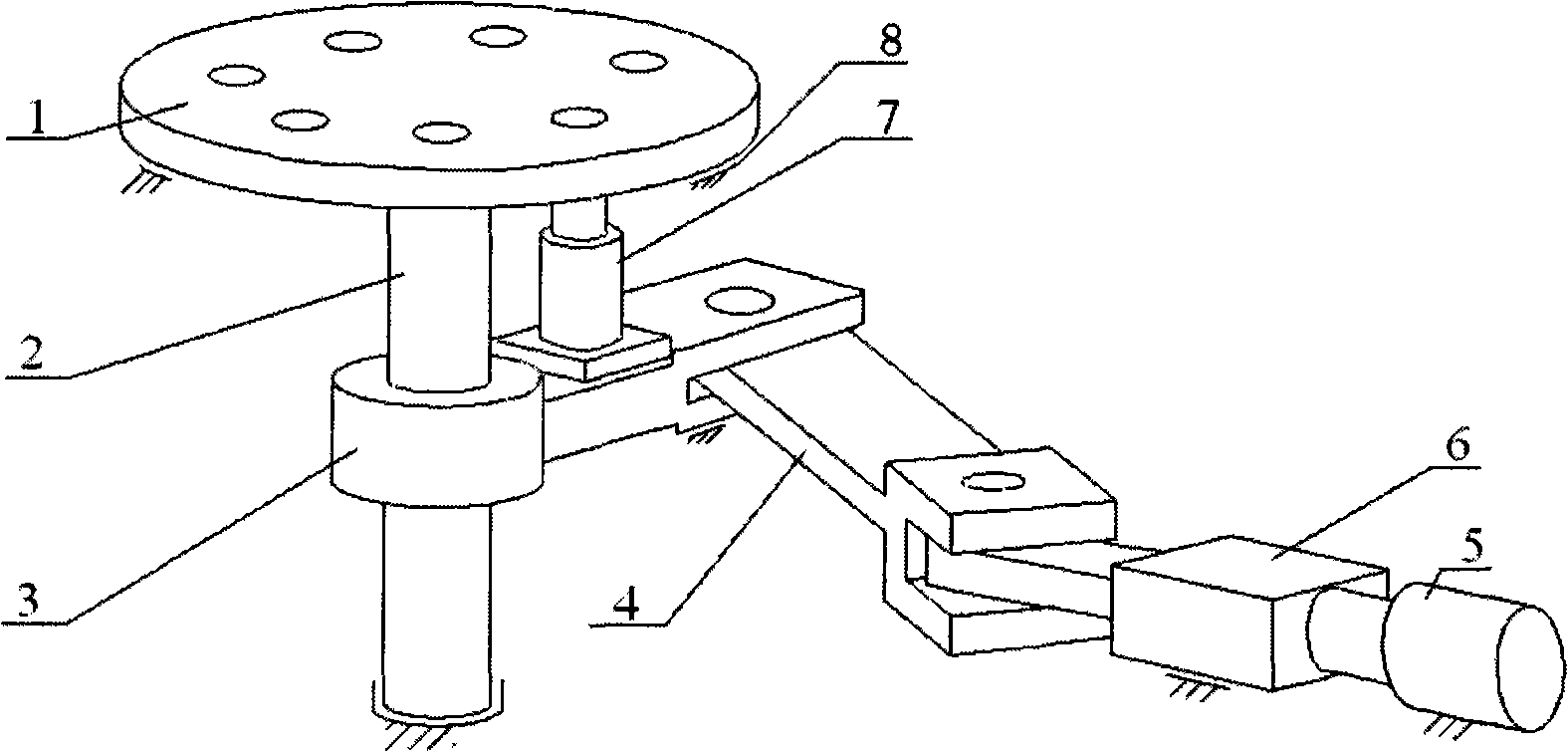

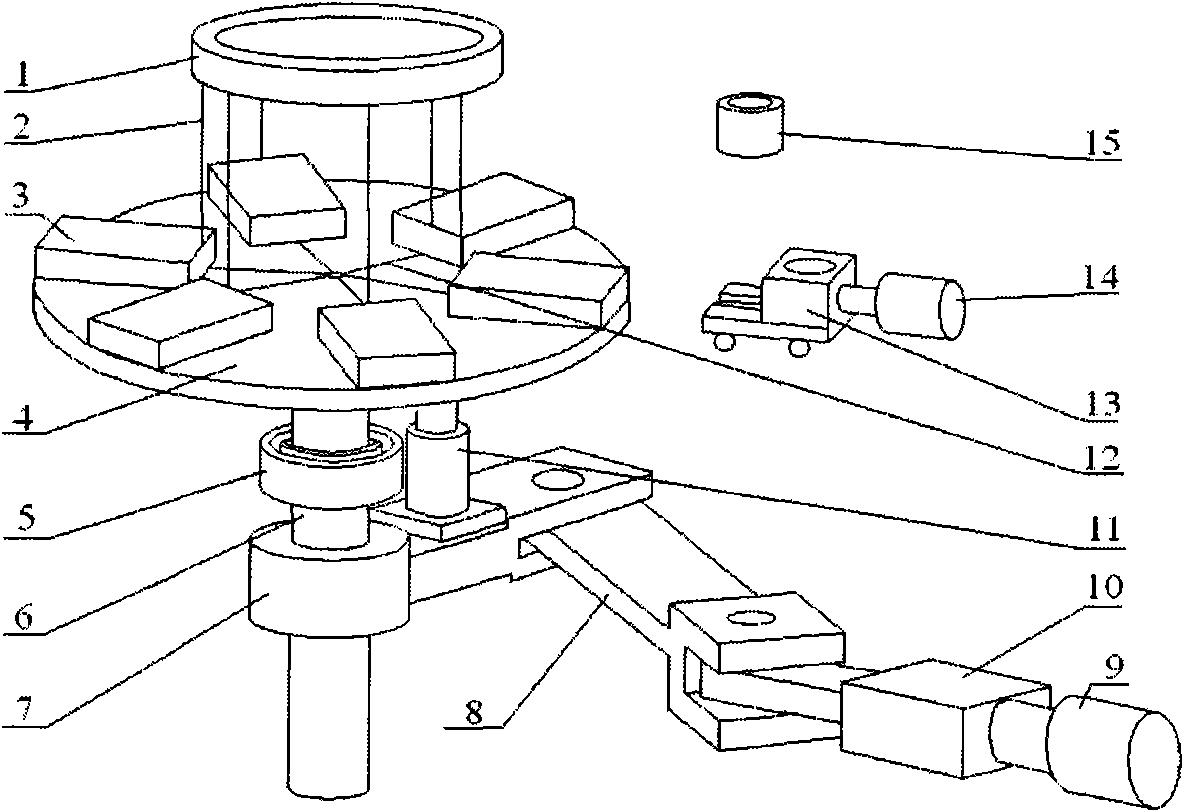

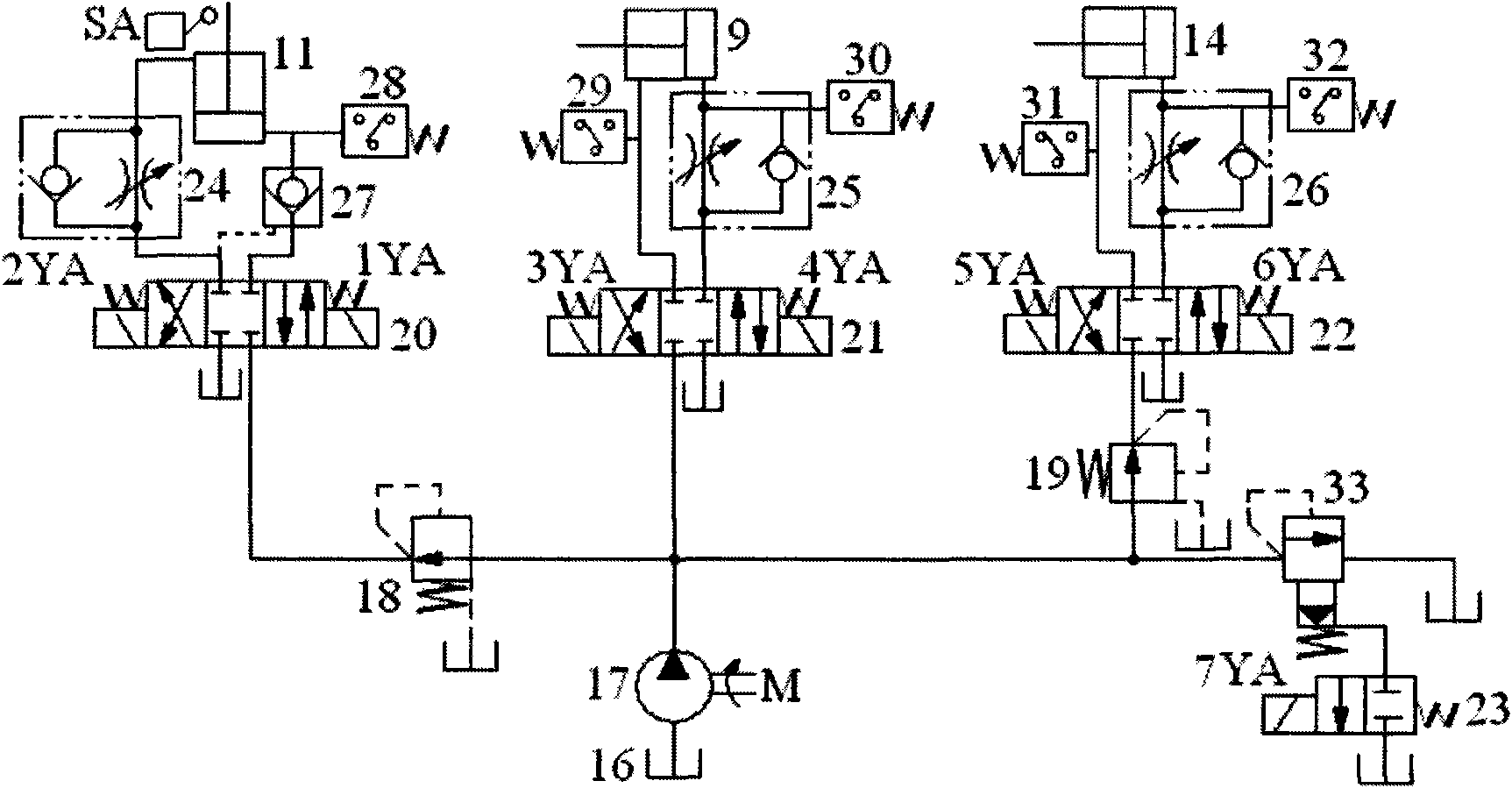

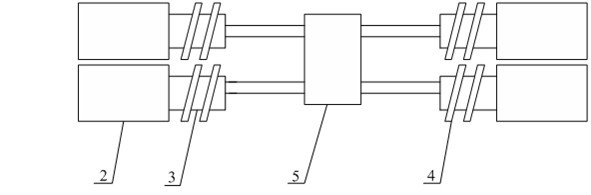

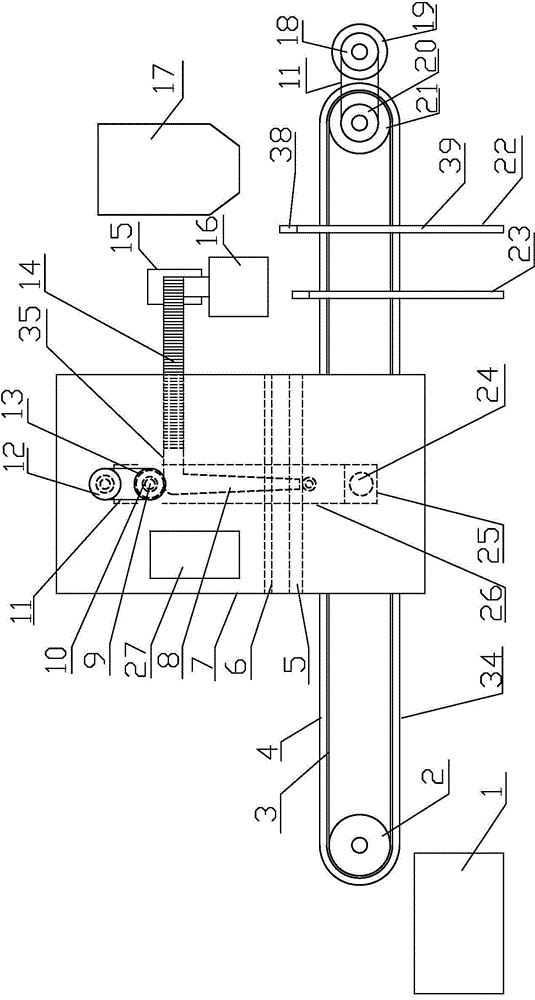

Hydraulic intermittent motion mechanism

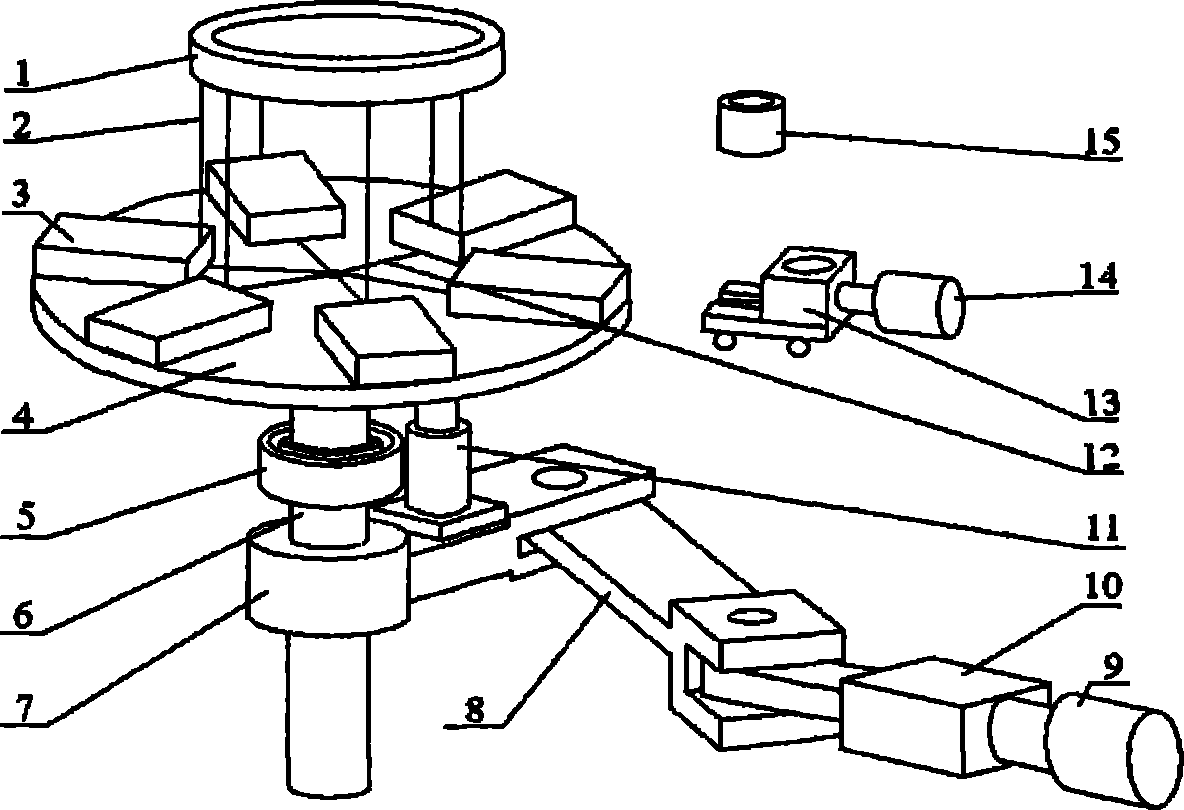

InactiveCN101984273ASimple geometryRelieve pressureFluid gearingsHydraulic cylinderIntermittent motion

The invention discloses a hydraulic intermittent motion mechanism, wherein, a rotating platform (1) is provided with a plurality of taper pin holes; the rotating platform (1) is tightly connected with a rotating column (2) and then arranged on a frame (8); the rotating platform (1) and the rotating column (2) moves relative to the frame (8); a pin hydraulic cylinder (7) is fixed on a swinging rod (3); the other end of the swinging rod (3) is hinged with a connecting rod (4); the swinging rod (3) and the frame (8) form a prismatic pair to ensure the rigidity of the swinging rod under the action of the pin hydraulic cylinder; the other end of the connecting rod (4) is hinged with a sliding block (6); the sliding block (6) is arranged on the frame (8) and slides on the frame, and the sliding block (6) is fixedly connected with a piston rod of an active hydraulic cylinder (5); and the active hydraulic cylinder (5) is fixedly connected with the frame (8). In the invention, the sliding block and the swinging rod are organically combined with hydraulic transmission so as to realize connection and disconnection between the swinging rod and the rotating platform, thus achieving intermittent circular motion of the rotating platform, solving the problem of heavy load that the common intermittent mechanism can not adapt to, and meeting the demand of automatic production.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

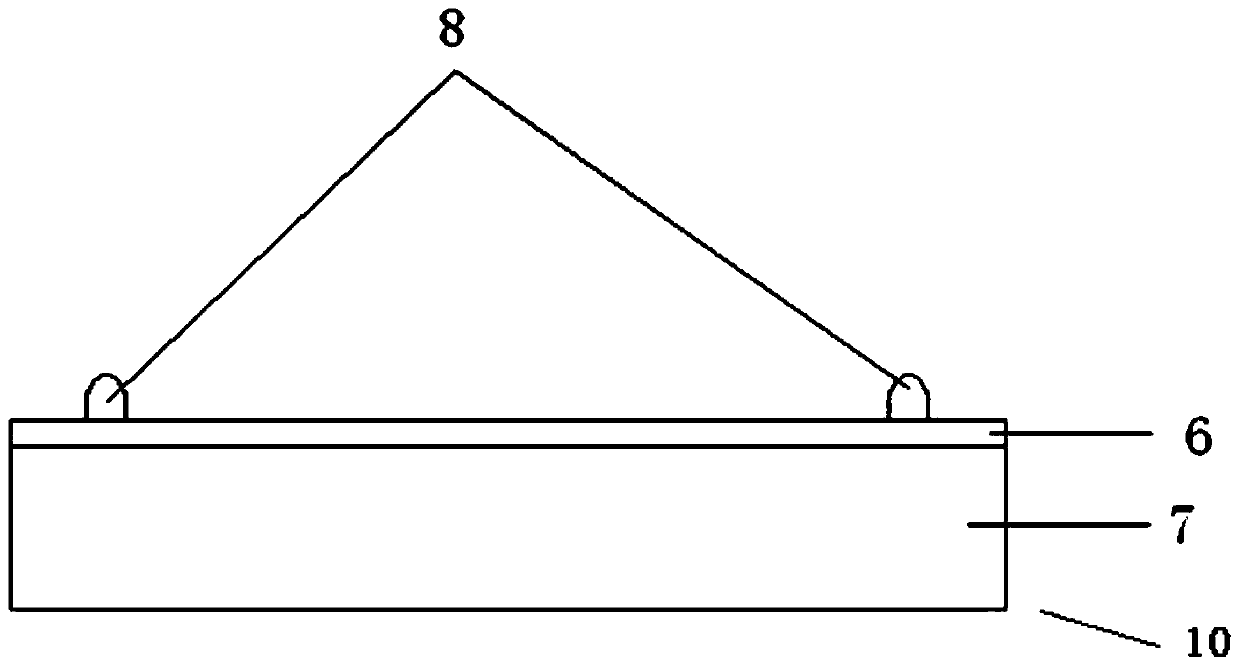

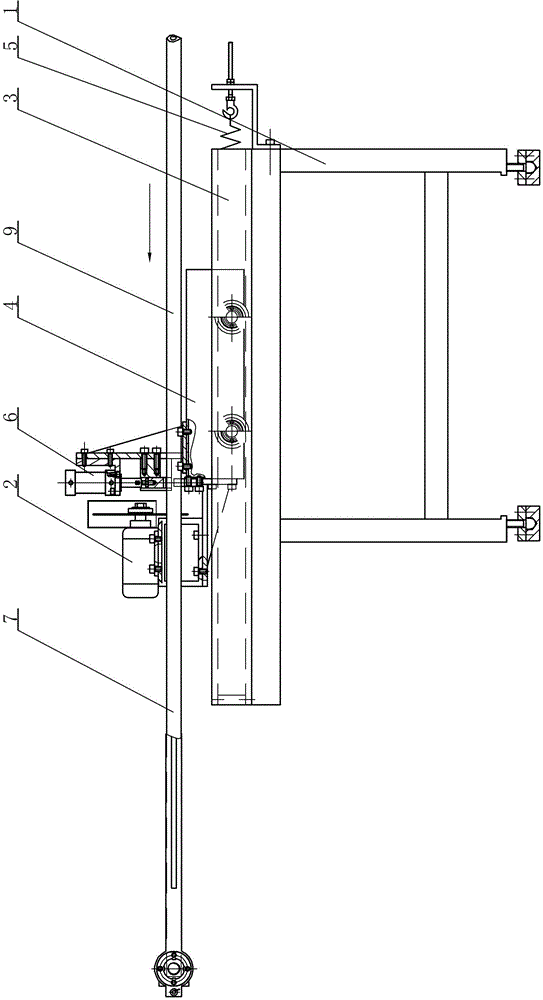

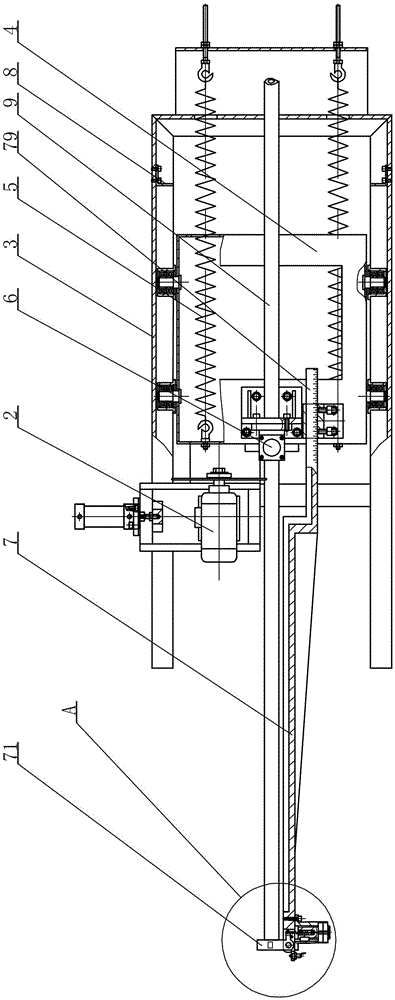

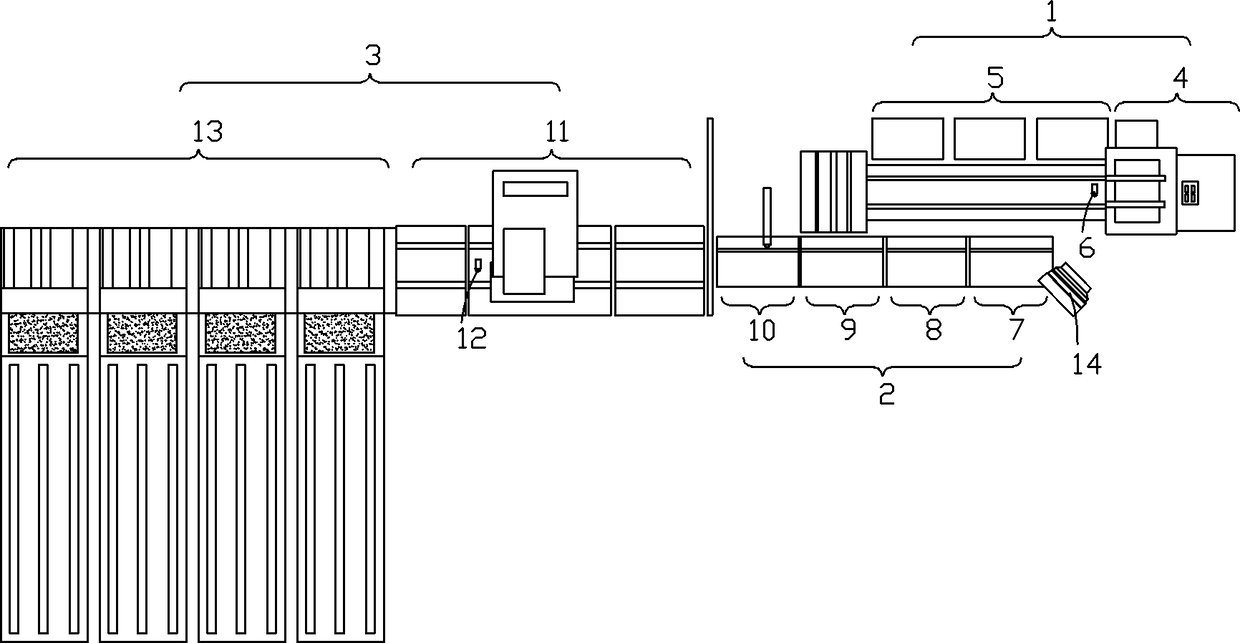

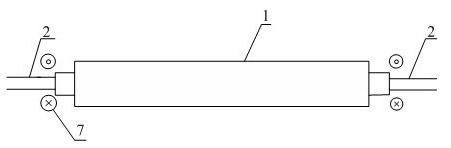

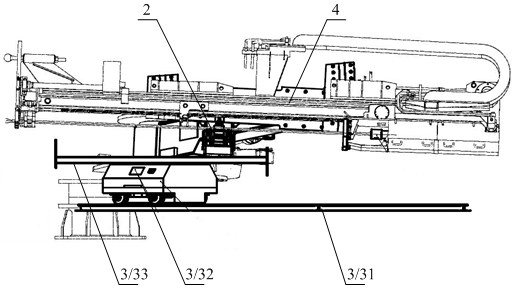

Full-automatic pipe cutting machine for production line

ActiveCN105478879AGuaranteed length and dimension accuracyMeet the needs of automated productionStock shearing machinesTube shearing machinesProduction lineReciprocating motion

The invention relates to a full-automatic pipe cutting machine for a production line and mainly solves the problems that manual pipe cutting wastes time and energy, the pipe length deviation is larger and automatic production is difficult to meet. The full-automatic pipe cutting machine is characterized in that guide tracks (3) and a walking trolley (4) linearly reciprocating along the guide tracks are arranged on a support (1), the walking trolley (4) is connected with one end of the support (1) through a tension spring (5), and a clamping device (6) and a sizing mechanism (7) are fixed on the walking trolley (4). According to the full-automatic pipe cutting machine for the production line, a pipe can be full-automatically cut off at a certain length, the clamping device and a cutoff device are controlled to perform operation orderly by means of a PLC (programmable logic controller) program, manual operation is replaced, cut-off pipes have consistent lengths, and demands of automatic production of the pipes can be met.

Owner:佛山市三水精诚五金有限公司

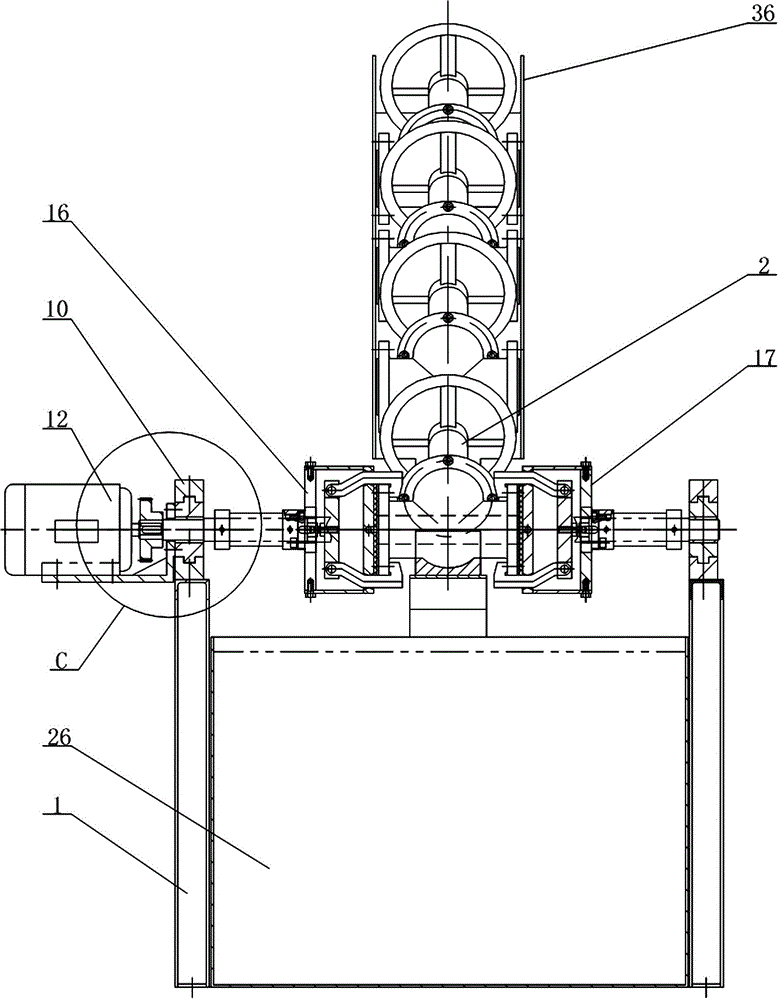

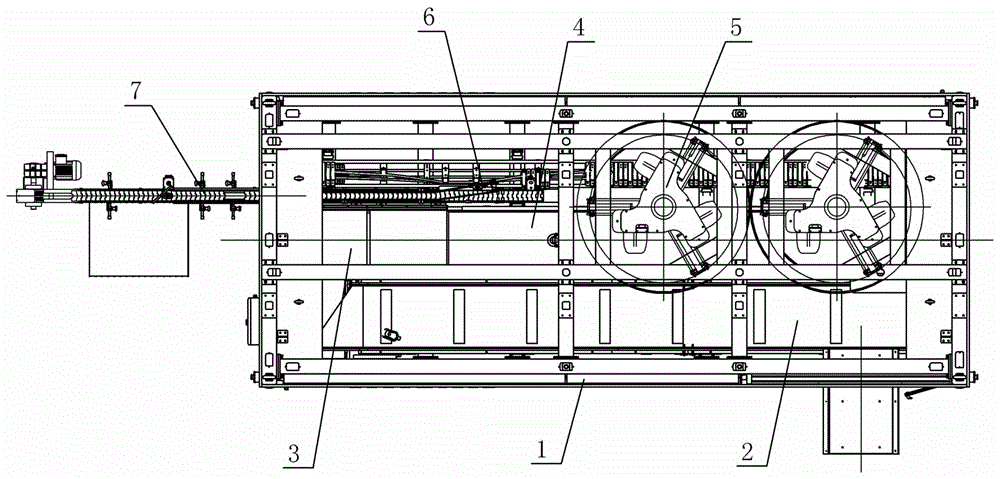

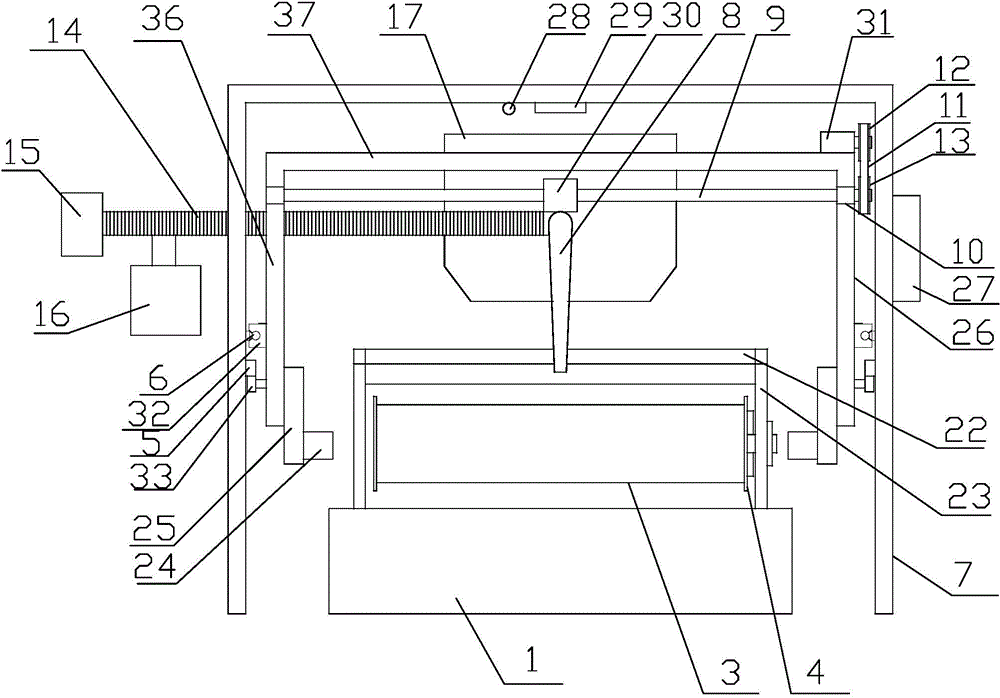

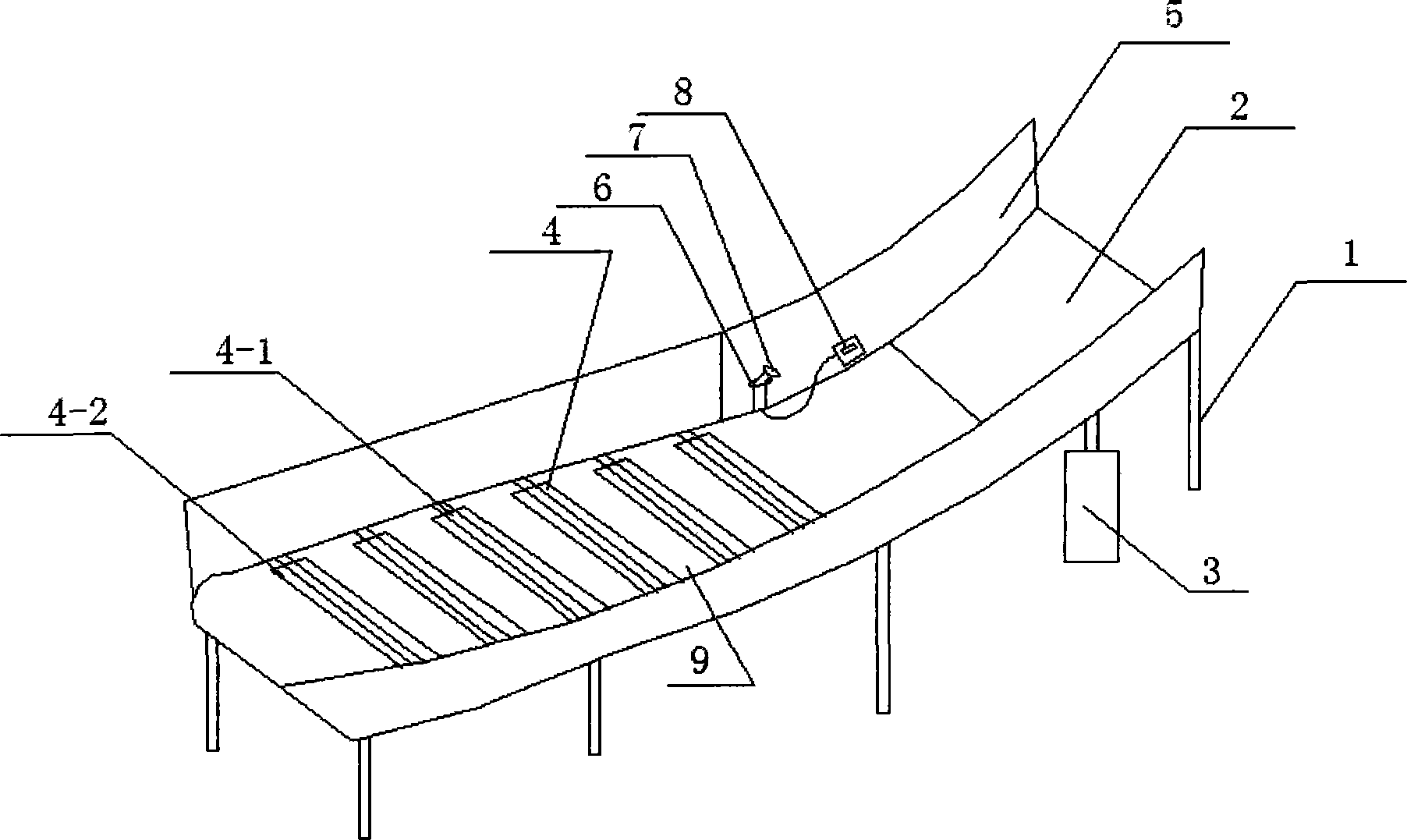

Centrifugal casting annular array type automatic production line

InactiveCN101983801AAchieve intermittent circular motionReduce labor intensityProduction lineIntermittent motion

The invention discloses a centrifugal casting annular array type automatic production line which comprises a mechanical movement device, a hydraulic transmission device and a centrifugal casting device. A slider swinging rod and a hydraulic transmission and control system are comprehensively utilized to form intermittent movement. The production line has the advantages of high degree of automation, small labor intensity of workers, high production efficiency, low workshop management difficulty and good application prospects.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

Automatic mail packaging and sorting production line

PendingCN108906640AImprove packaging efficiencyImprove sorting efficiencySortingIndividual articlesProduction linePersonal computer

The invention discloses an automatic mail packaging and sorting production line. The automatic mail packaging and sorting production line comprises a conveying line A, a conveying line B and a conveying line C. A letter conveying device and an insert feeding device are sequentially arranged on the conveying line A, and a bar code scanner A is arranged. An envelope feeding device, an envelope sealing cover unsealing device, a letter bagging device and an envelope sealing device are sequentially arranged on the conveying line B. A mail address tag pasting device is arranged on the conveying lineC, and a bar code scanner B is arranged. A mail sorting device is arranged at the tail end of the conveying line C. The bar code scanner A and the bar code scanner B are in communication connection with an industrial personal computer, and the industrial personal computer controls the mail address tag pasting device and the mail sorting device in real time. According to the automatic mail packaging and sorting production line, the links of letter and envelope feeding, mail bagging operation and subsequent mail sorting on a mail packaging production line are updated and optimized, the efficiency of mail packaging and sorting is greatly improved, the workload of workers is greatly reduced, and the work intensity of the workers is reduced.

Owner:中国邮政速递物流股份有限公司黄石市分公司

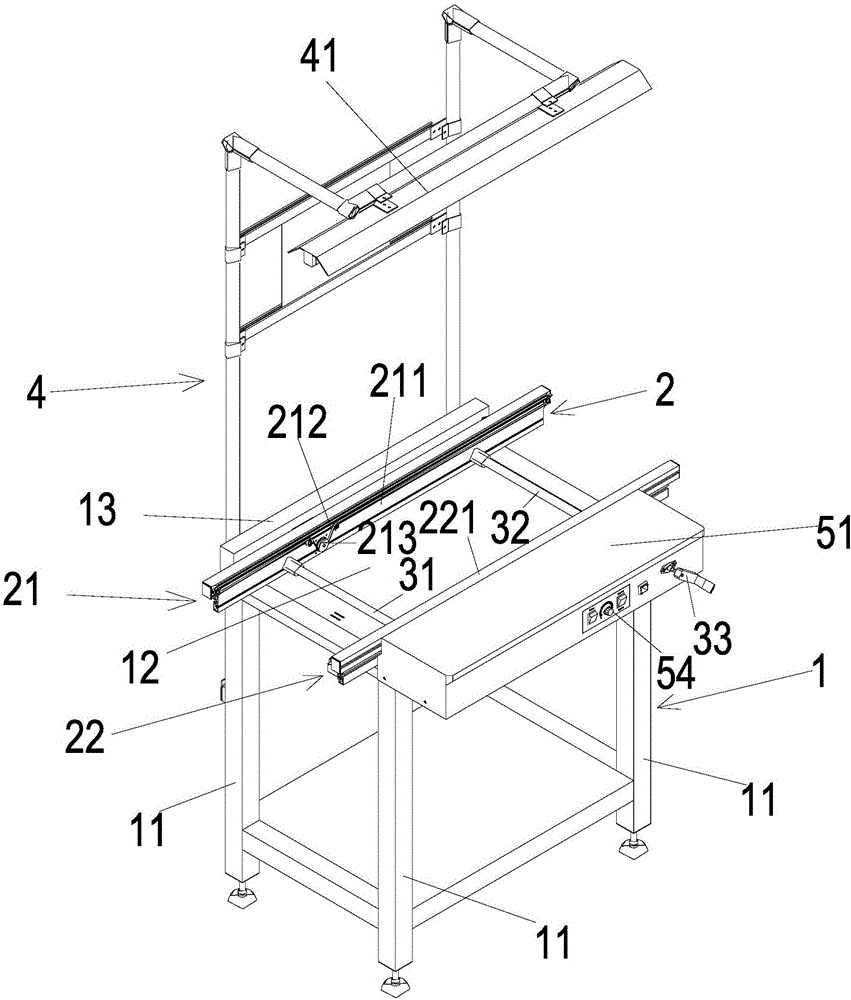

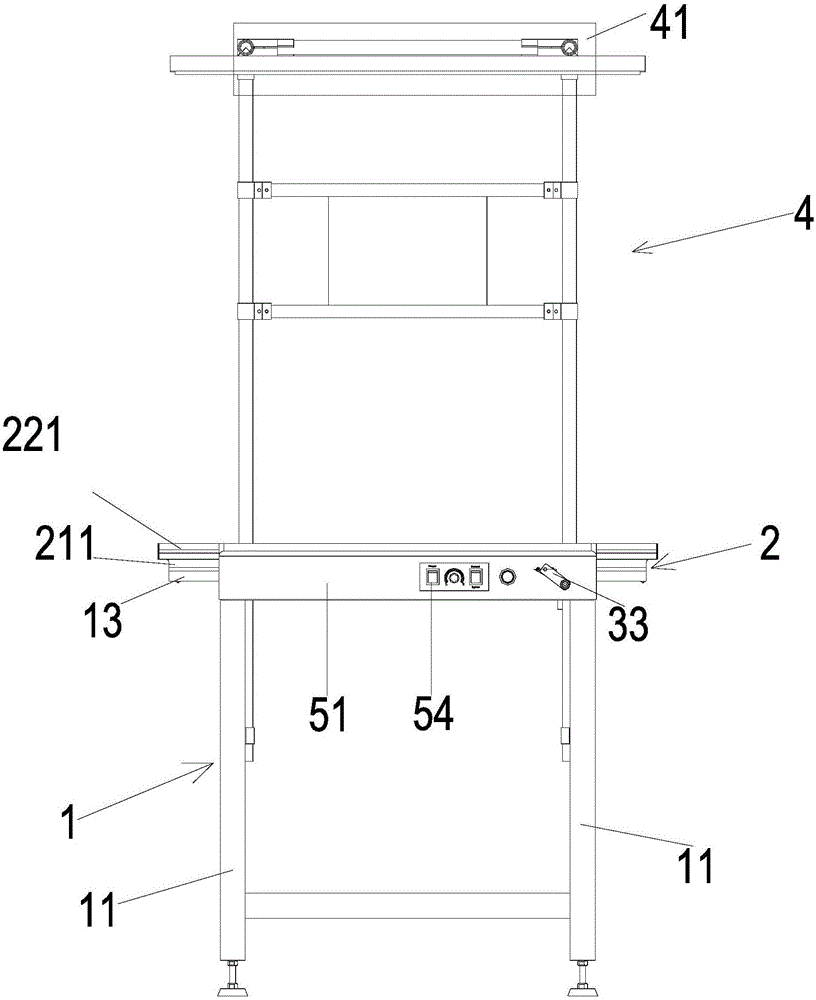

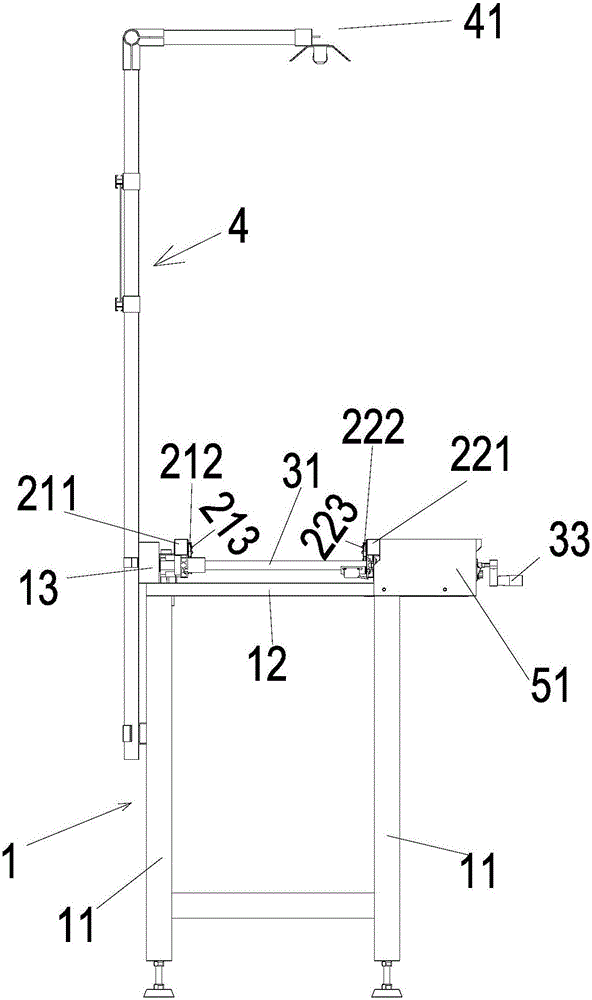

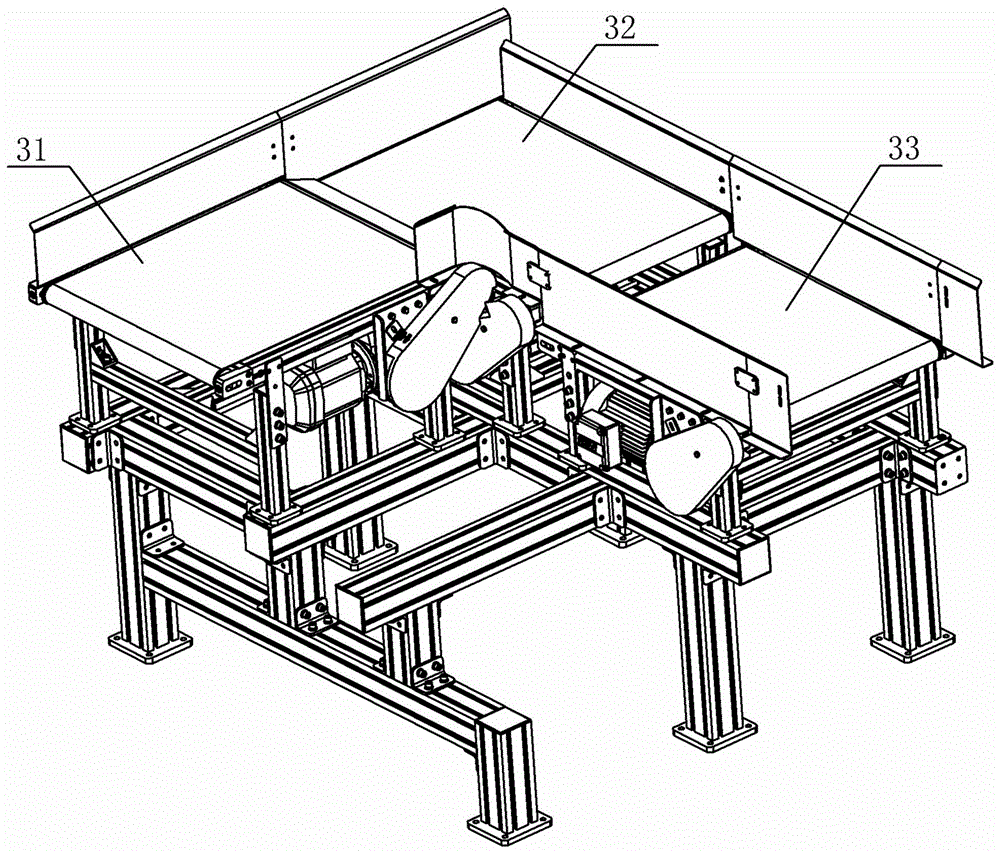

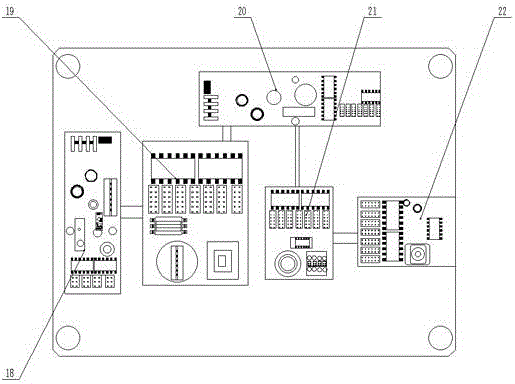

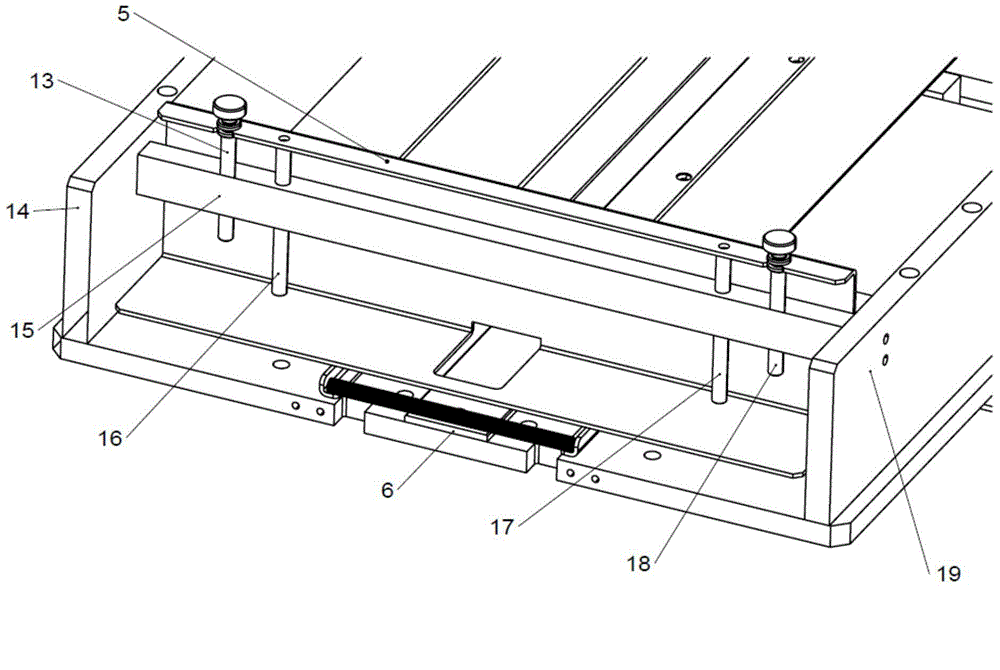

Automatic width adjustment connection table

InactiveCN106335738AHigh precision of width adjustmentRealize automatic adjustmentConveyorsConnection tableEngineering

The invention discloses an automatic width adjustment connection table. The automatic width adjustment connection table comprises a supporting frame, a conveying rail assembly used for conveying products and an automatic width adjustment assembly used for automatically adjusting the width of the conveying rail assembly. The conveying rail assembly and the automatic width adjustment assembly are mounted on the supporting frame. The automatic width adjustment assembly is connected with the conveying rail assembly. In the automatic width adjustment connection table, the width of the position between a fixed rail assembly and a moving rail assembly of the conveying rail assembly can be adjusted through the automatic width adjustment assembly, so that the product width need is met; the width adjustment precision of the automatic width adjustment assembly is high, and the needed width can be obtained through real-time adjustment according to the width of a PCB; and the automation degree is high, time and manpower are saved, and the need for automatic production is fully met.

Owner:深圳市尚宏自动化设备有限公司

Bottle management device

ActiveCN105923385AReduce usage requirementsMeet the needs of automated productionConveyorsLiquid bottlingEngineeringBottle

The invention discloses a bottle management device comprising a feeding conveying assembly, an accelerated conveying assembly, a grabbing conveying assembly, a grabbing robot, an overturning assembly and a discharging conveying assembly, wherein bottles enter from the feeding conveying assembly and are conveyed to the accelerated conveying assembly by the feeding conveying assembly; then, the bottles are conveyed into the grabbing conveying assembly by the accelerated conveying assembly and are to be grabbed by the grabbing robot; next, the bottles are conveyed in a lying state into the overturning assembly according to a set way by the grabbing robot; the bottle in the lying state is changed to be in an upright state under the action of the overturning assembly; and finally, the bottles are conveyed to the next process by the discharging conveying assembly so as to be subjected to filling operation. By using the bottle management device, disordered bottles can be conveyed for filling operation after being automatically managed, so that the production demand of automation is met, and the work efficiency is greatly increased; in addition, the use demand of personnel is effectively reduced, and furthermore the labor cost is reduced.

Owner:GUANGZHOU TECH LONG PACKAGING MACHINERY CO LTD

Brazing method for cable shielding layer and shell

InactiveCN102350552ARealize one-time moldingUniform and stable shapeSoldering apparatusEngineeringConductor Coil

The invention discloses a brazing method for a cable shielding layer and a shell, wherein wire branching holes are formed in two ends of the shell; a cable passes through the wire branching holes; and the brazing method comprises the following steps of: winding, namely winding brazing wires on parts, opposite to the wire branching holes, of the cable shielding layer; fixing, namely fixing the cable, the shell and the brazing wires by a clamp; heating, namely, putting a brazing part into an induction coil and heating the brazing part by induction heating equipment; and cooling, namely stopping heating until the brazing part is cooled. By the brazing method, one-time molding of joints at two ends of the shell can be realized, the shape of the shell is uniform and stable, the brazing quality is easy to guarantee, and efficient and automatic production requirements can be met.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL

Workpiece tray rack

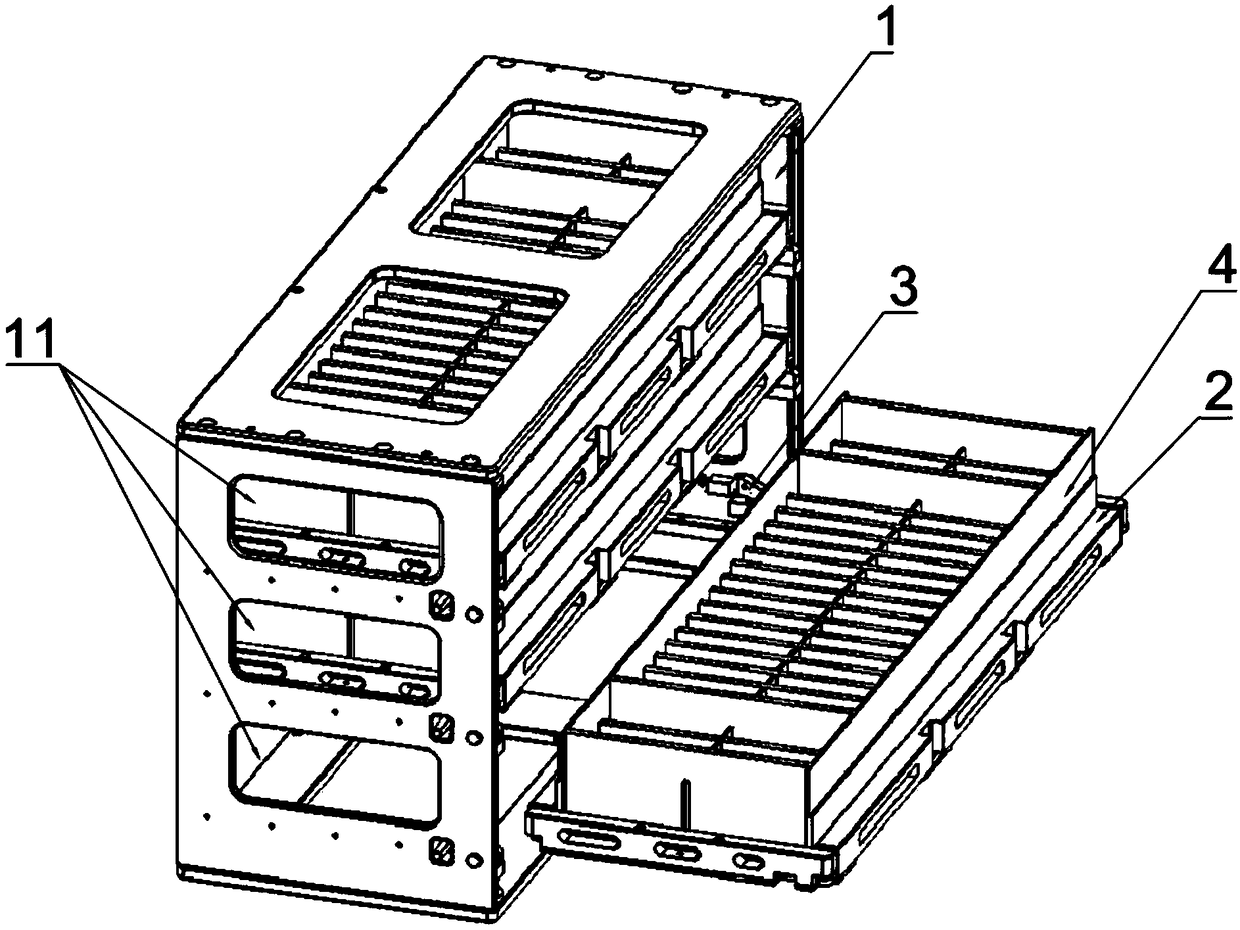

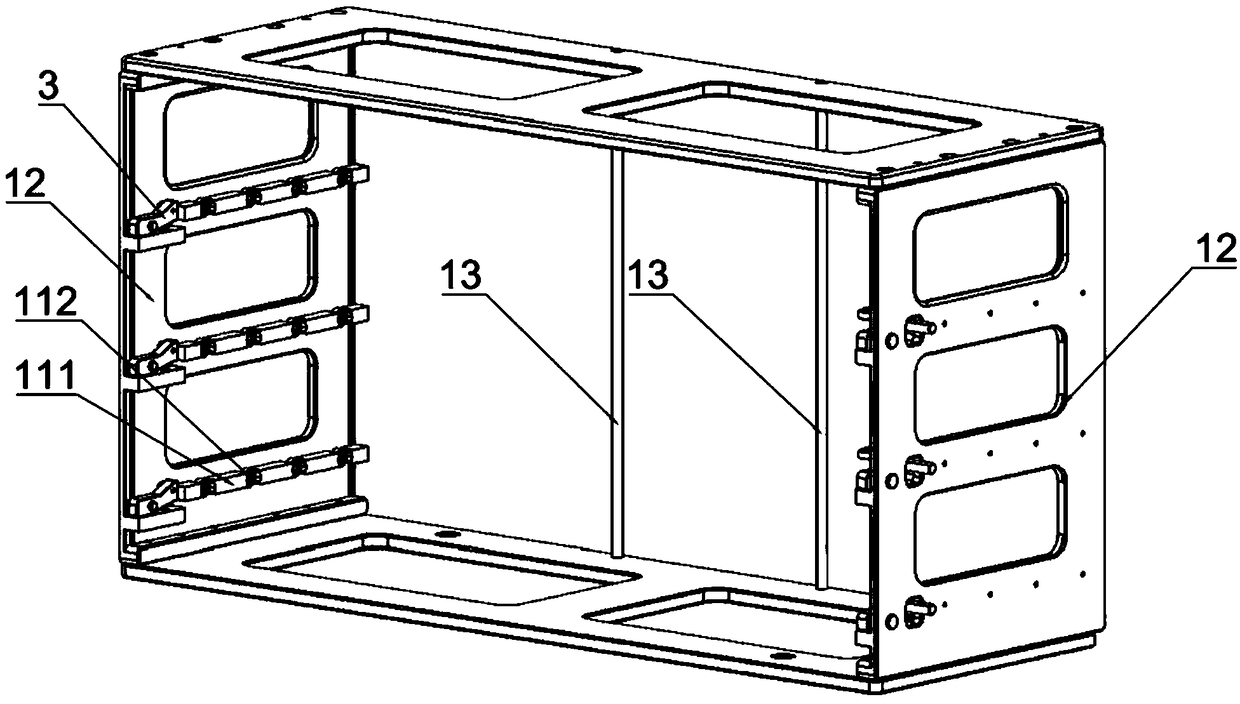

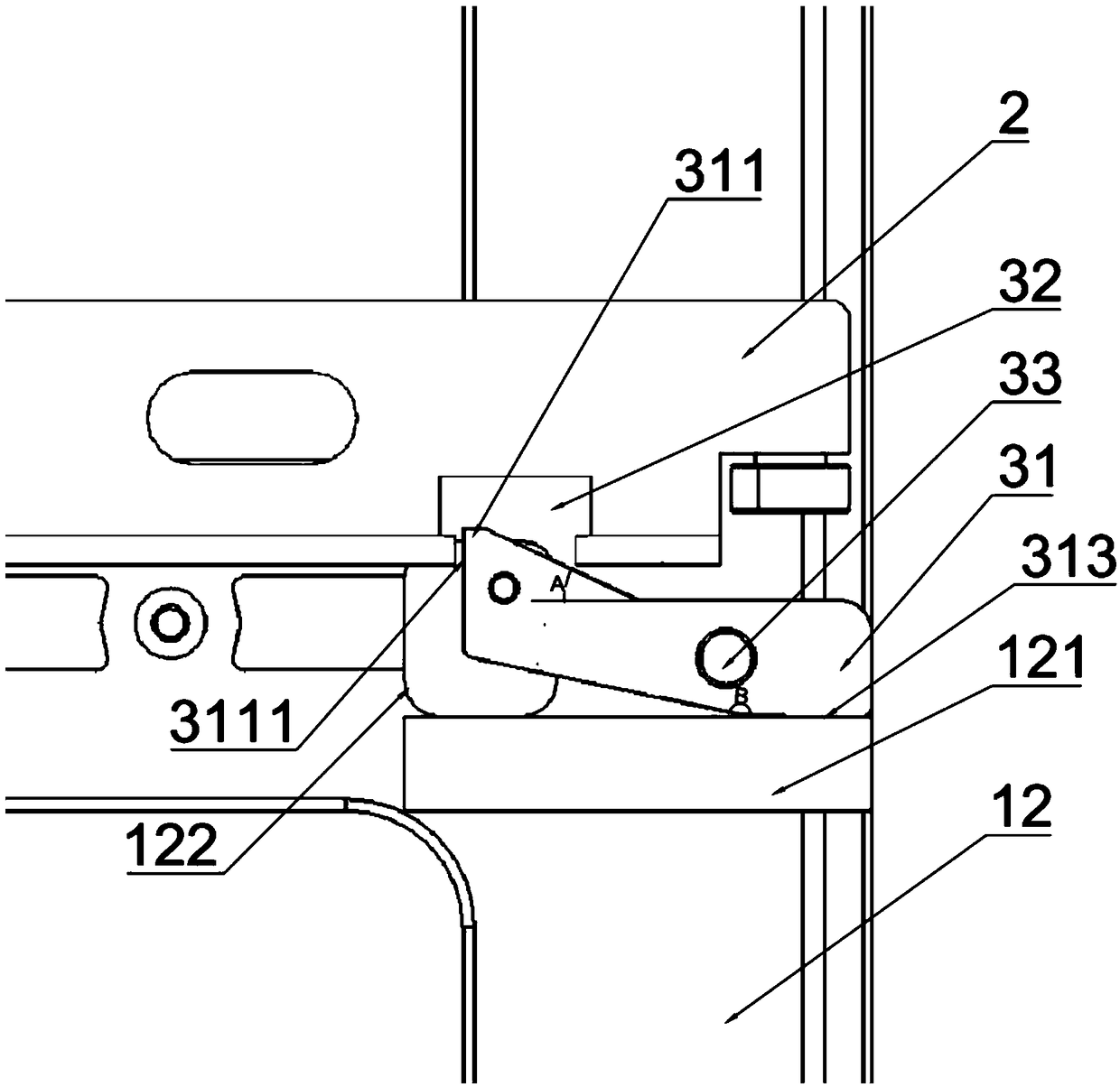

PendingCN109128755AEasy to moveImprove work efficiencyWork tools storageMetal working apparatusEngineeringLocking mechanism

The invention provides a workpiece tray rack. The workpiece tray rack comprises a main rack body which is provided with a plurality of storing layers, and a supporting frame which is arranged in eachstoring layer and is used for bearing a workpiece tray, wherein the supporting frames are used for moving out the storing layer from one side of the main rack body in the horizontal direction; a storing position which is positioned in each storing layer and a workpiece supplying position where each storing layer can be completely moved are provided; a locking mechanism arranged in each storing layer is capable of locking the bottom part of each supporting frame through locking parts on locking blocks; the locking parts are provided with locking states that the locking parts enter locking holesand unlocking states that the locking parts are at the outer parts of the locking holes; when the supporting frames are at the storing positions, the locking parts are in the locking states; when thesupporting frames are outwards pulled again, the locking holes in the bottom parts of the supporting frames are limited by the locking parts, so that the supporting frames cannot continuously outwards slide. Therefore, each supporting frame in the workpiece tray rack is at the storing position in the whole workpiece tray rack carrying process, and as a result, workpieces in trays cannot fall off;the carrying work is conveniently carried out; and the working efficiency is improved.

Owner:SUZHOU RS TECH

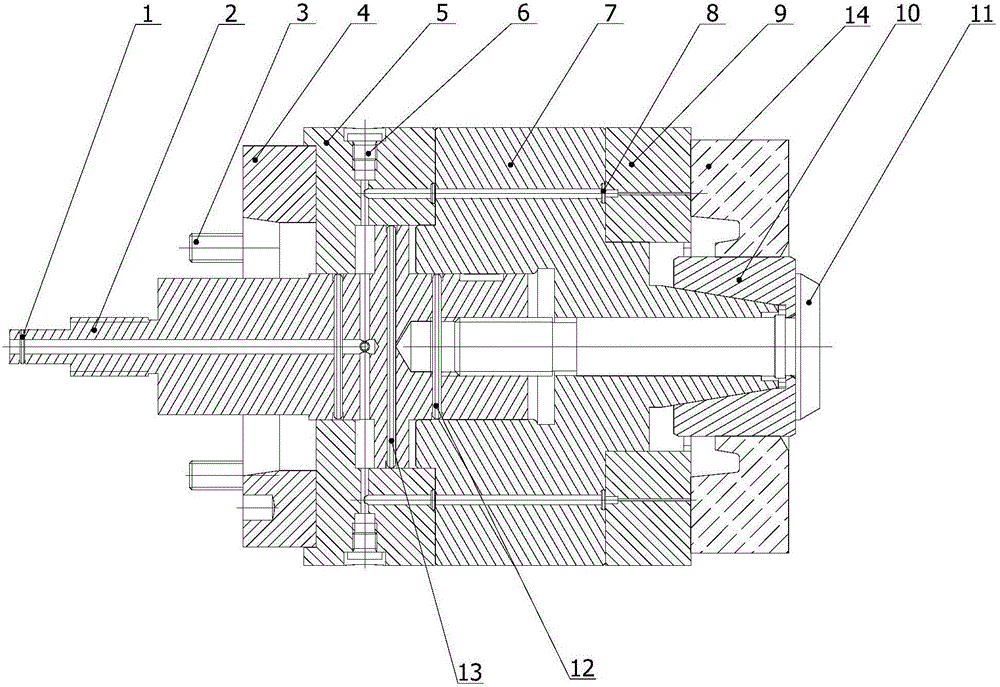

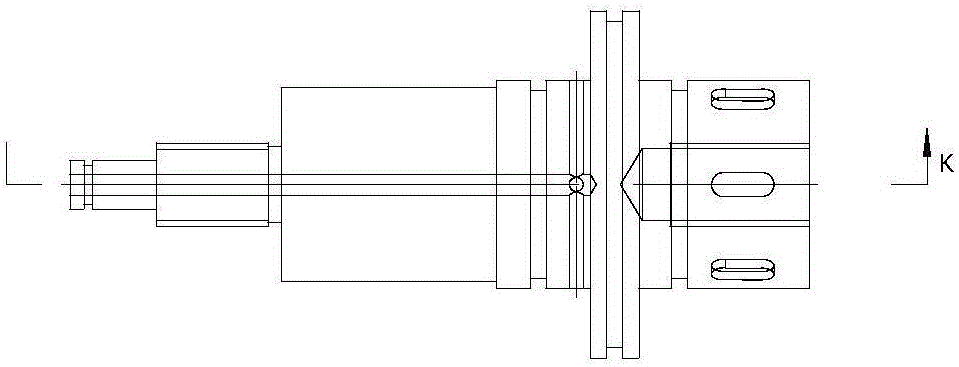

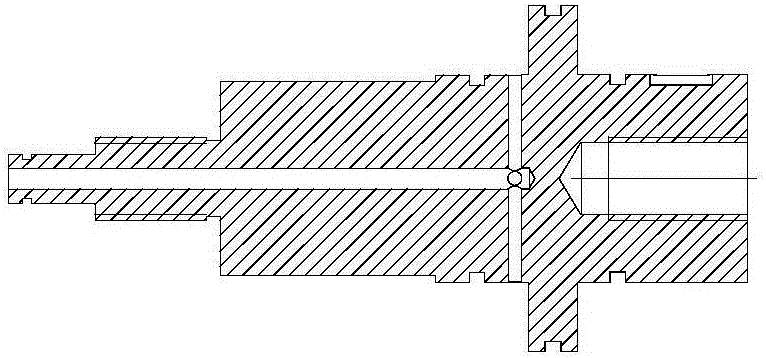

Finish turning clamp with detecting function

InactiveCN105904240ARealize unmanned processingMeet the needs of automated productionMeasurement/indication equipmentsPositioning apparatusNumerical controlProduction line

The invention provides a finish turning clamp with a detecting function. The finish turning clamp comprises a body, a gas detecting piston rod, a gas detecting sealing cylinder, an integrated expanding sleeve and an integrated drawbar, wherein the gas detecting piston rod and the integrated expanding sleeve are separately arranged at the two ends of the body; the integrated drawbar passes through the body for connecting the gas detecting piston and the integrated expanding sleeve together; the gas detecting sealing cylinder is sleeved on the gas detecting piston rod and is mounted at one end of the body; a gas detecting gasket is sleeved on the integrated expanding sleeve and is mounted at the other end of the body; gas pores are formed in the gas detecting piston rod, the gas detecting sealing cylinder, the body and the gas detecting gasket to form a gas flow passage; a to-be-detected workpiece is clamped by the integrated expanding sleeve, and is positioned by a gas outlet of the gas detecting gasket; gas flow enters the finish turning clamp from the gas detecting piston rod, and flows out from the gas detecting gasket; gas pressure changes at the gas inlet of the gas detecting position rod are monitored to detect whether the positioning surface of the to-be-detected workpiece is fitted or not; and a numerical-control lathe is matched with a joint robot for use, so that an automatic processing production line is formed, and therefore, unmanned processing is realized, and automatic production needs are met.

Owner:BAOJI FAST GEAR

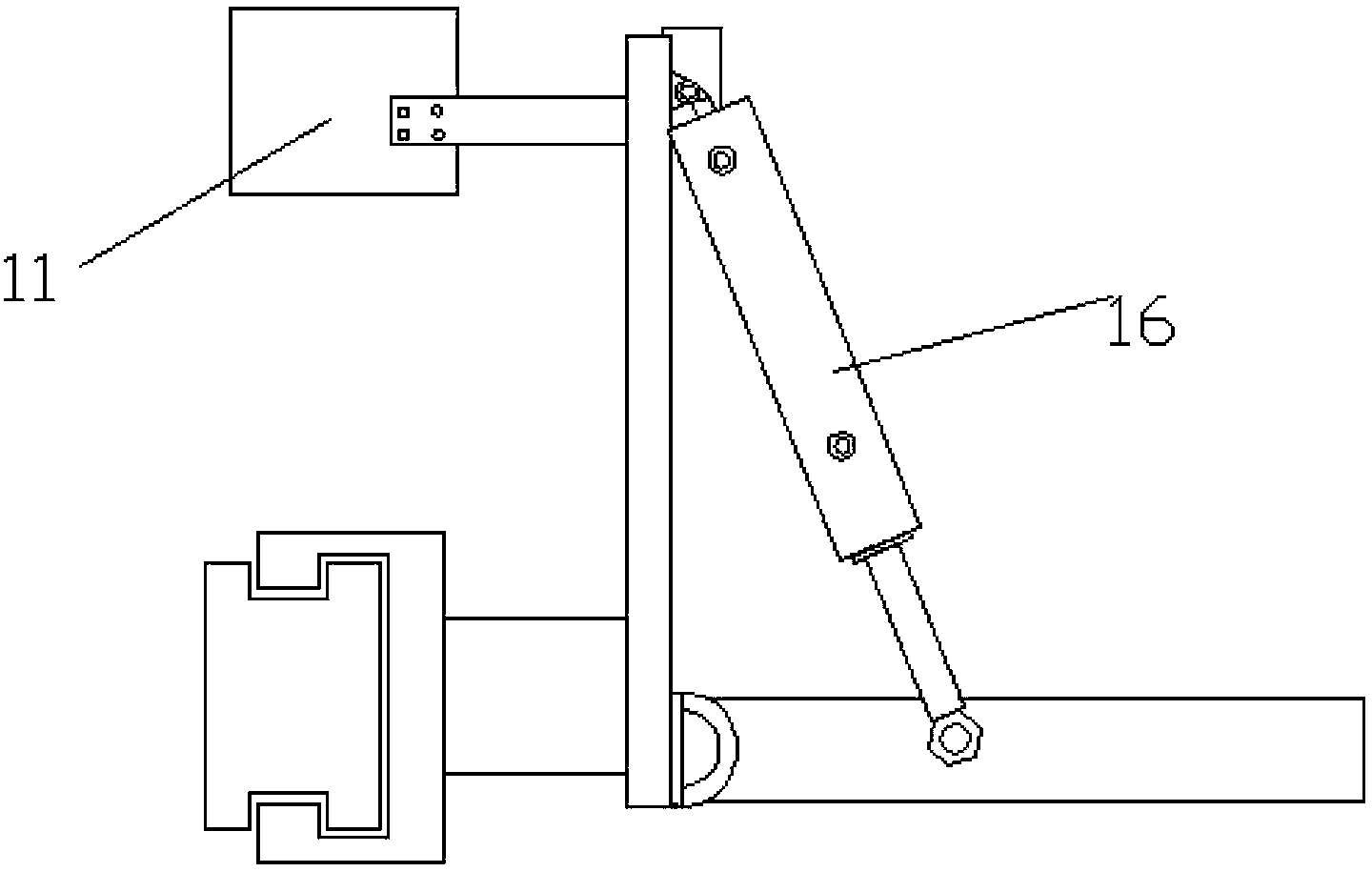

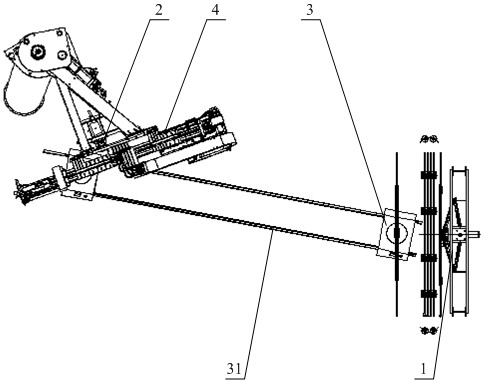

Automatic replacing device for drill rod of tapping machine and operation method of automatic replacing device

InactiveCN111996321AIncrease success rateHigh degree of automationBlast furnace componentsBlast furnace detailsEconomic benefitsStructural engineering

The invention discloses an automatic replacing device for a drill rod of a tapping machine and an operation method of the automatic replacing device. The automatic replacing device for the drill rod of the tapping machine comprises a drill rod taking assembly, a drill rod replacing assembly, a drill rod preparing assembly and a controller, wherein the drill rod taking assembly comprises a drill rod warehouse and an automatic drill rod frame arranged above the drill rod warehouse; the drill rod replacing assembly is arranged on a trolley of the tapping machine and comprises a clamping drill rod, a hydraulic push rod driving the clamping drill rod to stretch out and draw back and a hydraulic drive device driving the clamping drill rod to be opened and closed; and the drill rod preparing assembly comprises a guide rail, an RGV trolley and a drill rod bracket arranged on the RGV trolley. In the technical scheme, through seamless connection and cooperation of the drill rod taking assembly,the drill rod replacing assembly and the drill rod preparing assembly, manual work can be replaced to the maximum degree, automatic drill rod dismounting and replacing are achieved, the drill rod replacing automation degree is high, the drill rod replacing operation success rate is high, the automatic production requirement at the present stage is met, economic benefits and use convenience are better, and the automatic replacing device is suitable for application and popularization.

Owner:WUHAN IRON & STEEL GRP ECHENG IRON & STEEL CO LTD +1

Screening method of mildewed seeds

ActiveCN104475356ARealize factoryAvoid damageProgramme-controlled manipulatorGripping headsElectricityOrganic solvent

The invention discloses a screening method of mildewed seeds, and belongs to the field of seed selection. A device comprises an ultraviolet fluorescent tube, a visible light single-color CCD (charge coupled device) sensor, a two-dimension grabbing mechanism, a single-layer seed conveying device and a control system, wherein the ultraviolet fluorescent tube, the visible light single-color CCD sensor, the two-dimension grabbing mechanism and the single-layer seed conveying device are electrically connected with the control system respectively. The autofluorescence characteristic of fungi is used, that is, to-be-processed seeds are irradiated by 356 nm ultraviolet rays, and the mildewed seeds are identified by detecting fluorescence excitation of the mildewed seeds under radiation of 356 nm ultraviolet rays. The method has the characteristics that the cost is low, industrialized screening of the mildewed seed is realized, and the demand of seed engineering for automatic production is met; the screening efficiency and the accuracy are higher, seed processing by an organic solvent and the like is reduced, and damage to healthy seeds is reduced, growth of the seeds cannot be influenced, environmental pollution is reduced, the cost is reduced and the like.

Owner:SHANDONG CROP GERMPLASM CENT

Method for preparing particle-shaped bag tea

InactiveCN101273742AGood net weight controllabilityNot susceptible to moisturePre-extraction tea treatmentCooking & bakingAdditive ingredient

The invention provides a preparation method of particle shape teabag, which is characterized in that the raw materials of fresh tea leaves are bagged to become finished products after being treated in sequence by spreading, deactivation of enzymes, matching ingredients, crushing, pelleting, sieving, basic baking and full drying, moreover, the sweet atmosphere abstraction can also be proceeded after full drying. The preparation method of particle shape tea bag of the invention has good controllability, high automation degree, and is suitable for convenient and quick tea bag form packaging; the produced particle shape tea bag is not added with any additives and has good tea quality, even extraction, and no deterioration.

Owner:CHONGQING YUNLING TEA IND TECH

Prepreg cutting and drilling integrated device and machining process

InactiveCN108274529AImprove punching accuracyNot easy to deviateInsulating layers/substrates workingMetal working apparatusPunchingLocking mechanism

The invention discloses a prepreg cutting and drilling integrated device. The prepreg cutting and drilling integrated device comprises a prepreg coiling and locking mechanism, a punching mechanism, acutting mechanism and a collection mechanism. The punching mechanism and the cutting mechanism are progressive die mechanisms. The cutting mechanism and the collection mechanism are connected througha conveying mechanism. According to the prepreg cutting and drilling integrated device, the punching mechanism is additionally arranged in front of a cutting position and can complete the punching procedure before cutting. The prepreg cutting and drilling integrated device is high in punching precision, not prone to deviation and low in product rejection rate. The punching procedure is conducted before the cutting procedure. Time consumed for manually collecting and stacking plates is saved. The number of equipment purchasing types is reduced. The connection time between a slicing machine anda punching machine and the preparation time are saved. The production efficiency is improved. The production cost is lowered. The requirements for automatic production are met. The invention further discloses a machining process. The machining process is high in machining precision, efficiency and automation degree and low in production cost.

Owner:江西景旺精密电路有限公司

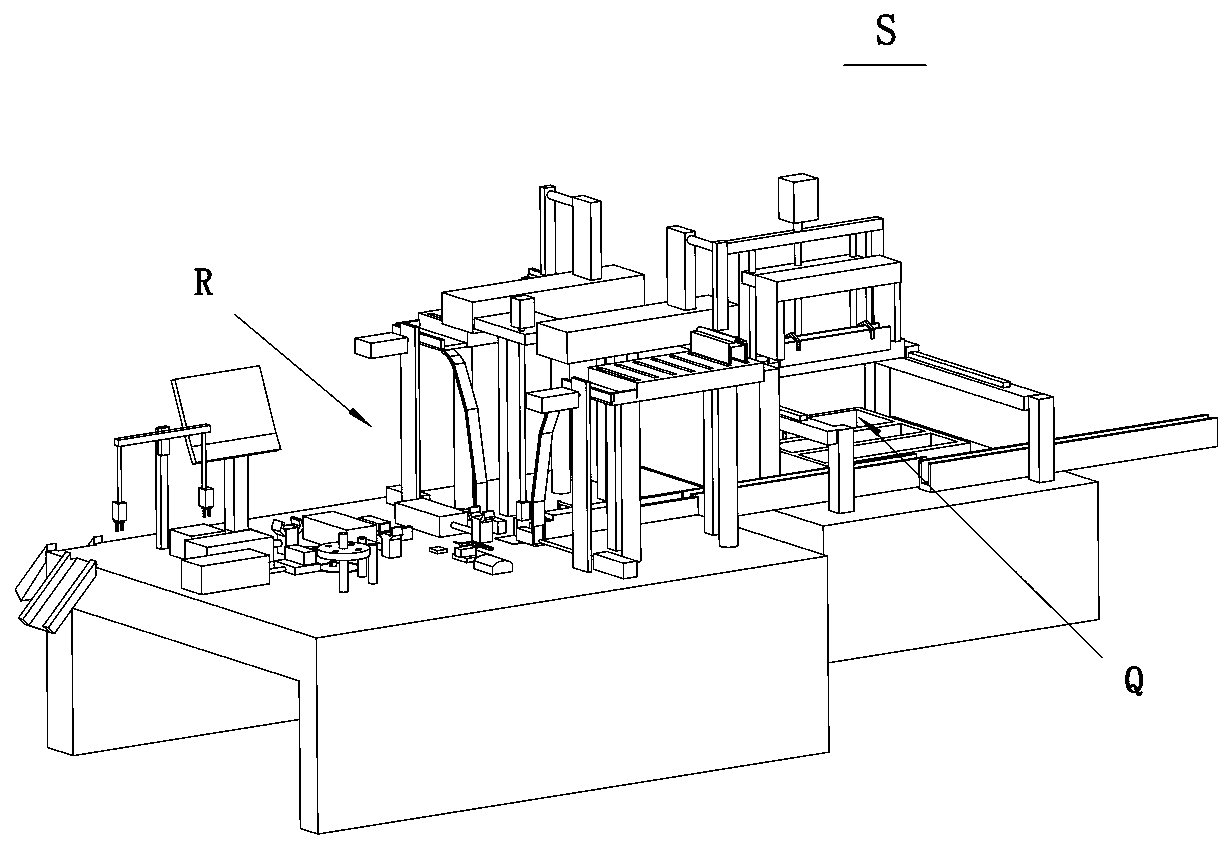

Transformer welding and assembling integrated production line

PendingCN111531238AMeet the needs of automated productionIncrease productivityTransformers/inductances magnetic coresCoils manufactureProduction lineSoldering

The invention provides a transformer welding and assembling integrated production line. The production line comprises a first conveying belt, a second conveying belt, a welding device and an assembling device, wherein the welding device comprises a welding pool arranged on a first machine table and a welding grabbing mechanism installed above the welding pool and used for grabbing and releasing atransformer, and the first conveying belt and the second conveying belt are arranged in front of the welding pool; the welding grabbing mechanism comprises a welding grabbing mechanism frame, the welding grabbing mechanism frame is in sliding connection with the first machine table through a sliding rail assembly, a welding gripper assembly is arranged in the frame of the welding grabbing mechanism frame, and the welding gripper assembly is provided with a rotatable welding gripper and can move up and down relative to the welding grabbing mechanism frame so as to clamp the transformer from thefirst conveying belt, place the transformer into the welding pool for tin soldering and then place the transformer to the second conveying belt; and the assembling device is used for flattening the grounding wire of the welded transformer, conveying the iron core, pasting the iron core and encapsulating. By means of the production line, welding and assembling of the transformer can be automatically completed, labor is saved, and efficiency is improved.

Owner:科一诺(厦门)电子有限公司

Bamboo chip conveying device

InactiveCN103287783AReasonable structural designReduce volumeJigging conveyorsElectric machineryMachining process

The invention discloses a bamboo chip conveying device, and relates to the technical field of bamboo ware devices. A vibration conveying belt is arranged above a support, the vibration conveying belt is connected with a conveying belt in an abutting mode, a vibration motor is arranged on the bottom of the vibration conveying belt, a plurality of driving rolls are arranged on the conveying belt, baffles are arranged on the two sides of the vibration conveying belt and the conveying belt, a fixing base is fixedly arranged on the baffles, an infrared sensing head is arranged on the fixing base, and the infrared sensing head is connected with a counter. The bamboo chip conveying device solves the problems that potential safety hazards exist due to the fact that the bamboo slices are conveyed manually, labor intensity is high, time and energy are wasted, and working efficiency is low. Operation is safer in the machining process, the working efficiency is high, the requirement of automatic production is met, automatic counting is achieved in the conveying process, no manual counting is required, counting is accurate and rapid, and the bamboo chip conveying device is convenient to use.

Owner:CIXI KUANGYAN YINGYING BAMBOO PROD FACTORY GENERAL PARTNERSHIP

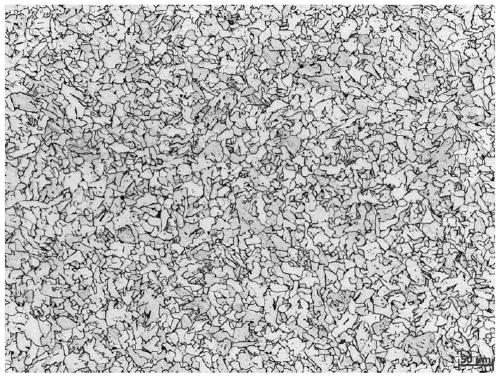

Production method for hot rolling acid pickling automobile plate

The invention discloses a production method for a hot rolling acid pickling automobile plate. The hot rolling acid pickling automobile plate comprises chemical elements including, by weight, 0.02-0.04% of C, smaller than or equal to 0.05% of Si, 0.20%-0.30% of Mn, smaller than or equal to 0.020% of P, smaller than or equal to 0.020% of S, 0.010%-0.020% of Nb, 0.030-0.050% of Als, smaller than or equal to 0.008% of N and the balance Fe and inevitable impurities. The preparing method for the hot rolling acid pickling automobile plate sequentially includes the following steps of molten iron pre-desulfuration treatment, converter steelmaking, steel ladle LF refining, continuous casting, casting blank heating, rough rolling, finish rolling, laminar cooling, high-temperature coiling, flattening,acid pickling, rinsing, oil smearing and coiling. By means of the production method for the low-carbon, low-manganese and low-silicon component design is adopted, the carton equivalent is reduced onone hand, and the steel plate welding performance is improved; on the other hand, ferrous silicate which is hardly subjected to acid pickling is prevented from being formed on the surface of a steel plate in the hot rolling process, and the surface quality of the steel plate is improved; a proper amount of Nb alloys are added, so that the strengthening effect of the Nb alloys is sufficiently achieved, and low-cost component design is achieved; and high-temperature coiling is adopted, the laminar cooling control difficulty is lowered, the steel roll through roll technology is stability, and thesteel roll plate shape quality and the through roll performance stability are improved.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE +2

Automatic checkout device for quality of plastic gear

ActiveCN105855188AImprove detection accuracyHigh precisionOptically investigating flaws/contaminationSortingMobile cameraVisual technology

The invention relates to an automatic checkout device for the quality of a plastic gear. The automatic checkout device comprises an electromechanical control case, a guide groove support base, a photoelectric trigger, a gear positioning unit, an image acquiring unit, a mobile camera support, a high-definition industrial camera and a gear guide groove, wherein the upper surface of the electromechanical control case is provided with the guide groove support base, the upper surface of the guide groove support base is provided with the gear guide groove, the gear guide groove is composed of an inlet skewed slot, a defective product guide groove and a qualified product guide groove, the central part of the inlet skewed slot is equipped with the photoelectric trigger, and the outlets of the defective product guide groove and the qualified product guide groove are provided with a defective product recovery case and a qualified product packaging case, respectively. The automatic checkout device has the beneficial effects that detection of typical defects is realized in virtue of the characteristics of no contact, high detection precision and the like of computer vision technology; product quality and production efficiency can be greatly improved; detection speed is fast; detection precision is high; needs of automatic production are met; and the automatic checkout device can replace artificial detection in practical production.

Owner:ZHEJIANG TEXTILE & FASHION COLLEGE

Silk screen aided laser soldering method for heterogeneous multi-layer structure

InactiveCN1343543AHigh electrode strengthImprove processing efficiencySoldering apparatusLaser beam welding apparatusLaser solderingSoldering

A wire screen aided laser soldering technology for making multi-layer heterogeneous composite side electrode of element includes coating soldering material on the side of element, putting metallic wire screen in the soldering material, heating by laser beams to fuse them, and cooling to form the side electrode of element. Its advantages include good connection between layers, local heating, no damage to element, high electrode strength, and high machining efficiency.

Owner:TSINGHUA UNIV

Die for forging production of aluminum alloy control arms

InactiveCN105710268ARapid positioningQuick installationForging/hammering/pressing machinesControl armAluminium alloy

The invention provides a mold for forging and producing an aluminum alloy control arm, and the mold is composed of an upper mold (4), a guide column (3) and a lower mold (2). The beneficial effect of the present invention is that, by designing the connection, guide and positioning structures of the mold design, the requirements of the automatic production of the control arm can be met, and the production of multiple pieces in one mold can be realized.

Owner:CITIC DICASTAL

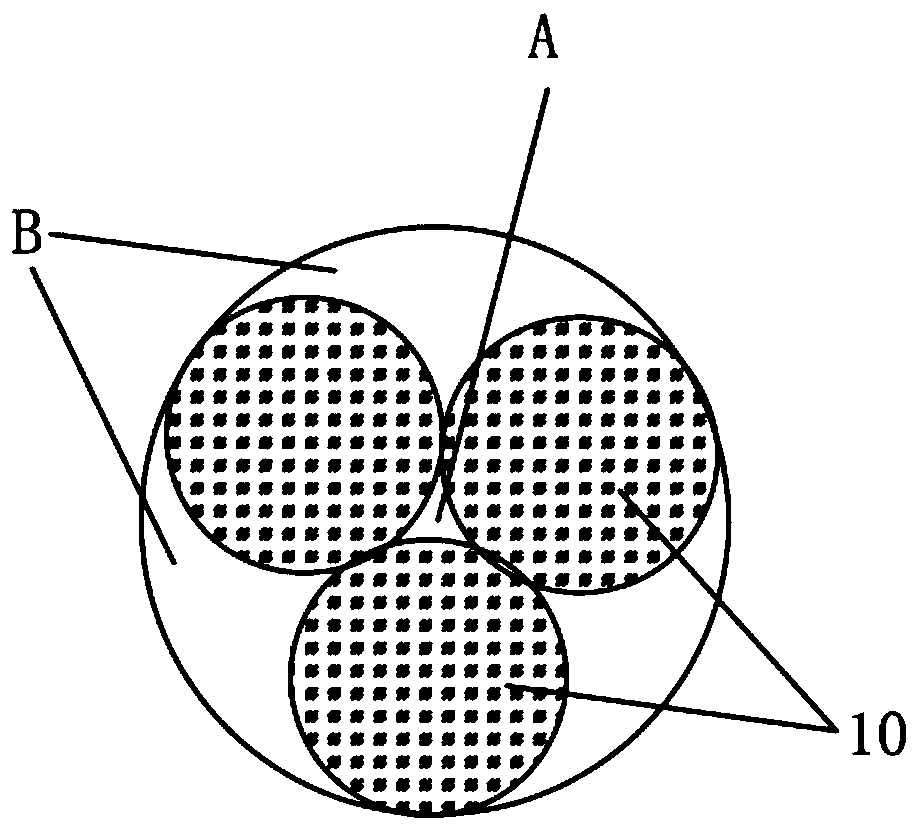

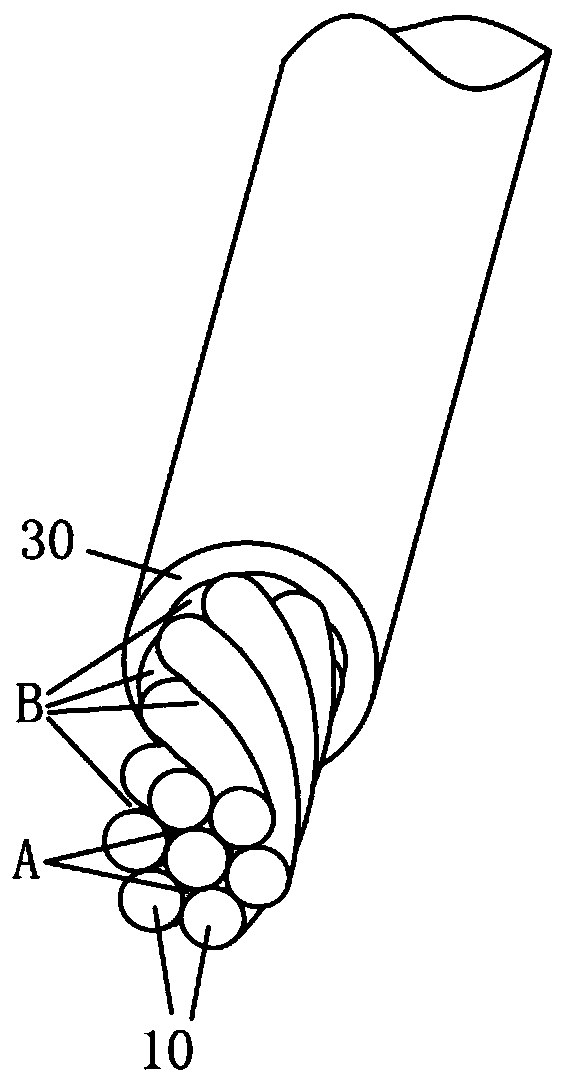

Waterproof core wire and manufacturing method thereof

ActiveCN110556206AMeet the needs of automated productionIncrease production capacityInsulated cablesCable/conductor manufactureElectrical conductorCoating

The invention relates to the technical field of wires and cables and particularly provides a waterproof core wire and a manufacturing method thereof. The waterproof core wire comprises an outer wrapping leather coated glued stranded wire, the glued stranded wire comprises multiple strands of conductors, each conductor comprises a circular outer surface, the circular outer surface is covered with glue, the glue is cured to form a first coating layer coating the circular outer surface, the first coating layer forms an overlapping part and a concave surface along with mutual stranding of the conductors, and the overlapping parts are located in gaps formed by mutual stranding of the conductors. The waterproof core wire is advantaged in that technical problems of automatic operation and integrated molding are solved, and effects of improving the productivity and improving the product yield are achieved.

Owner:HENAN CARVE ELECTRONICS TECH INC +1

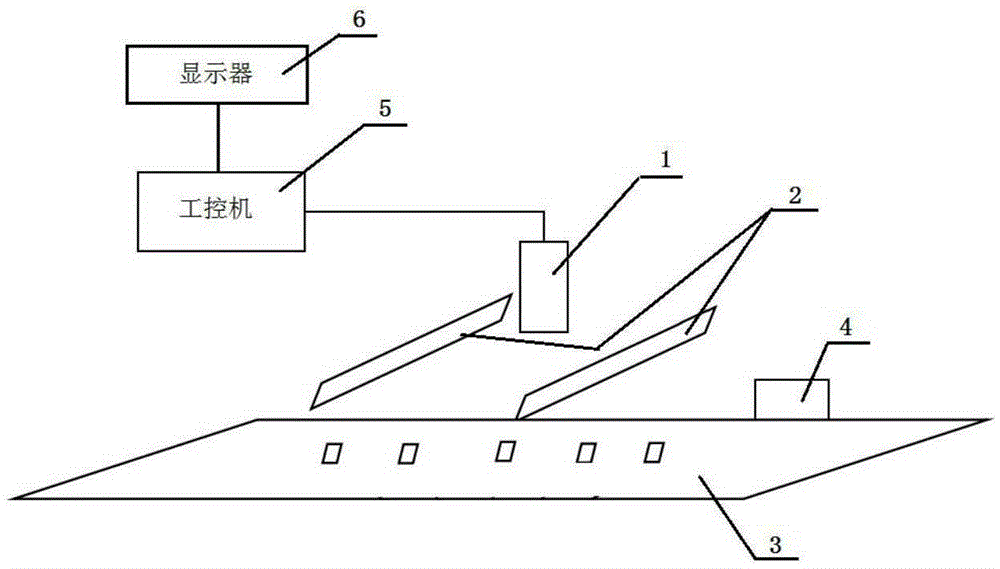

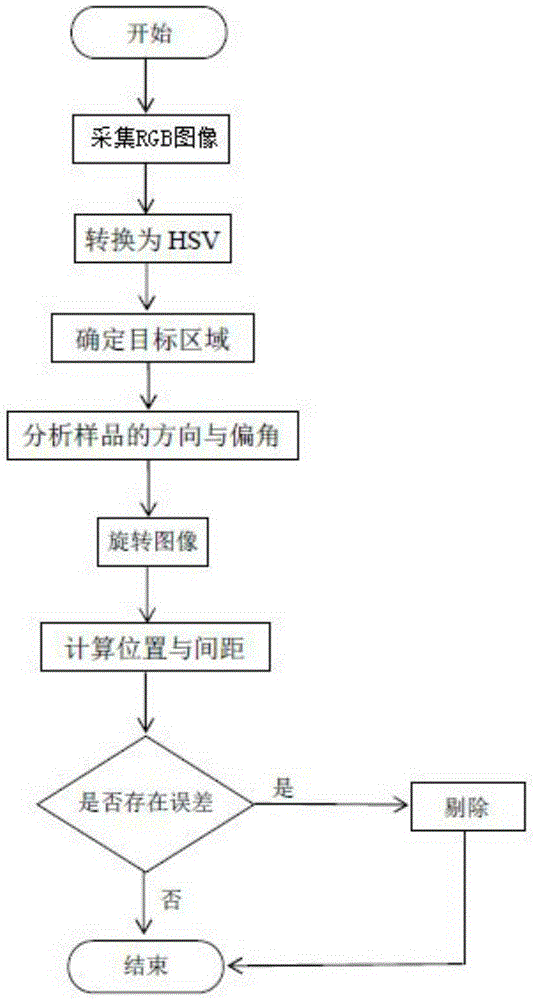

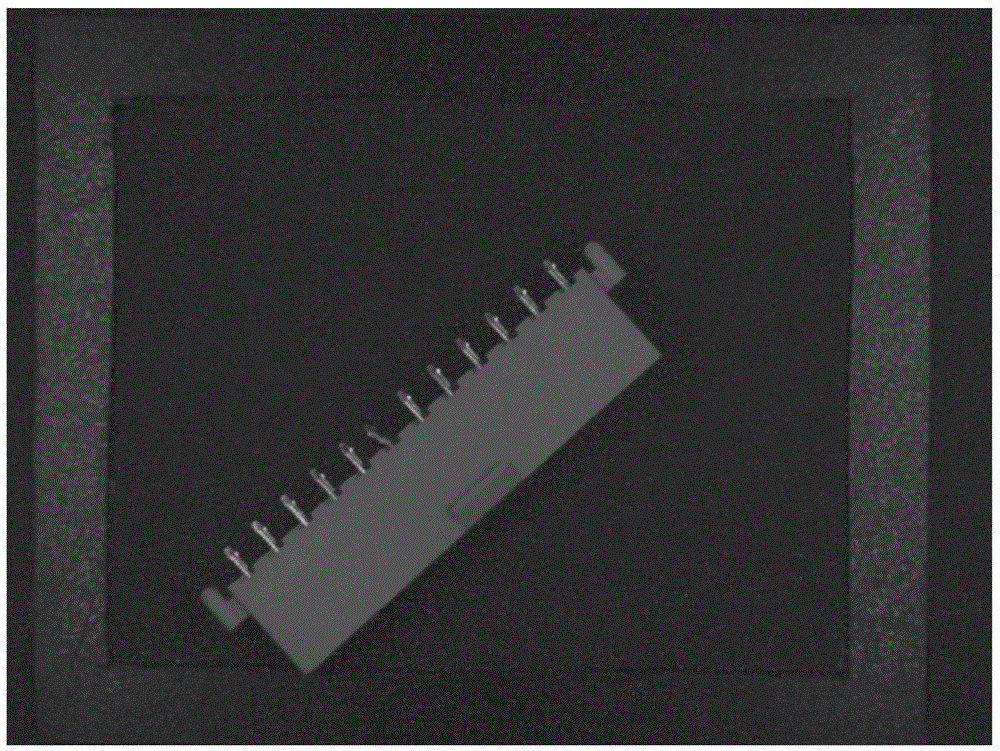

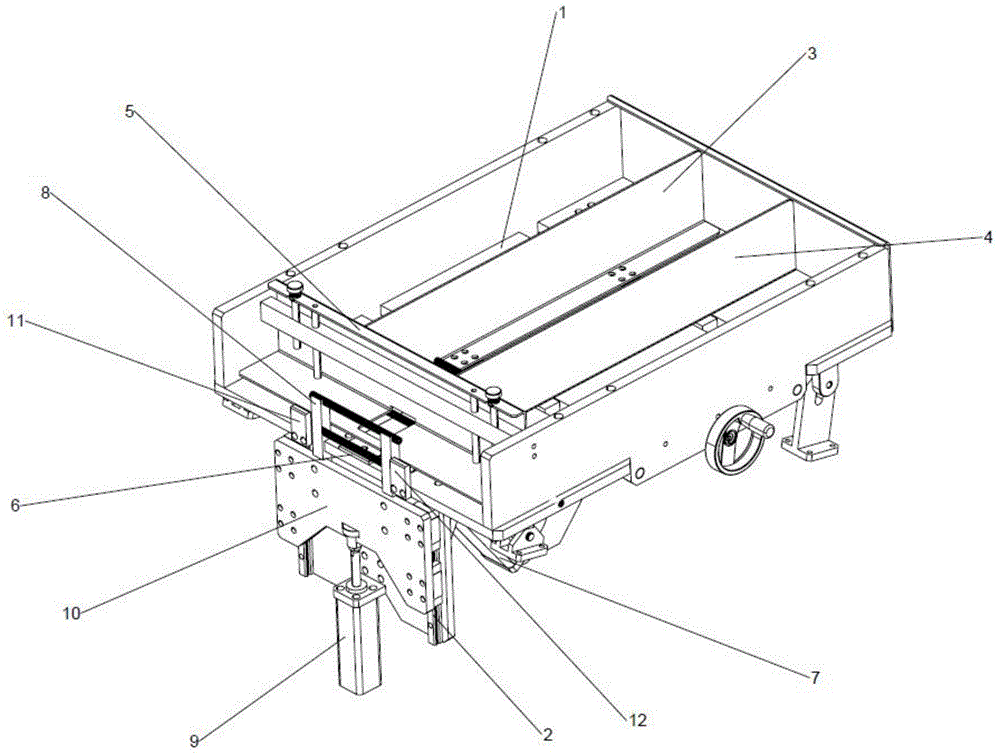

Multi-pin-based defect detection device and detection method thereof

ActiveCN105424714AQuick checkAccurate detectionOptically investigating flaws/contaminationImaging processingDisplay device

The invention discloses a multi-pin-based defect detection device and a detection method thereof. The defect detection device comprises a camera for collecting a sample image, wherein two LED light sources adopting a high-angle lighting method are symmetrically arranged below the camera, a transmitting platform for placing and transporting a sample is arranged below the LED light sources, and the side edge of the transmitting platform is provided with a removing mechanism for removing an unqualified sample; the camera is connected with an industrial personal computer which is for receiving and processing the collected sample image, and the industrial personal computer is also connected with a displayer for displaying an image processing result made by the industrial personal computer. The multi-pin-based defect detection device and the detection method thereof realize automatic online detection on a multi-pin defect, the production cost is lowered, the detection efficiency is improved, the away-detection precision is greatly increased, and a detection missing phenomenon and a detection error phenomenon in conventional manual direction are well avoided.

Owner:南京河豚智能科技有限公司

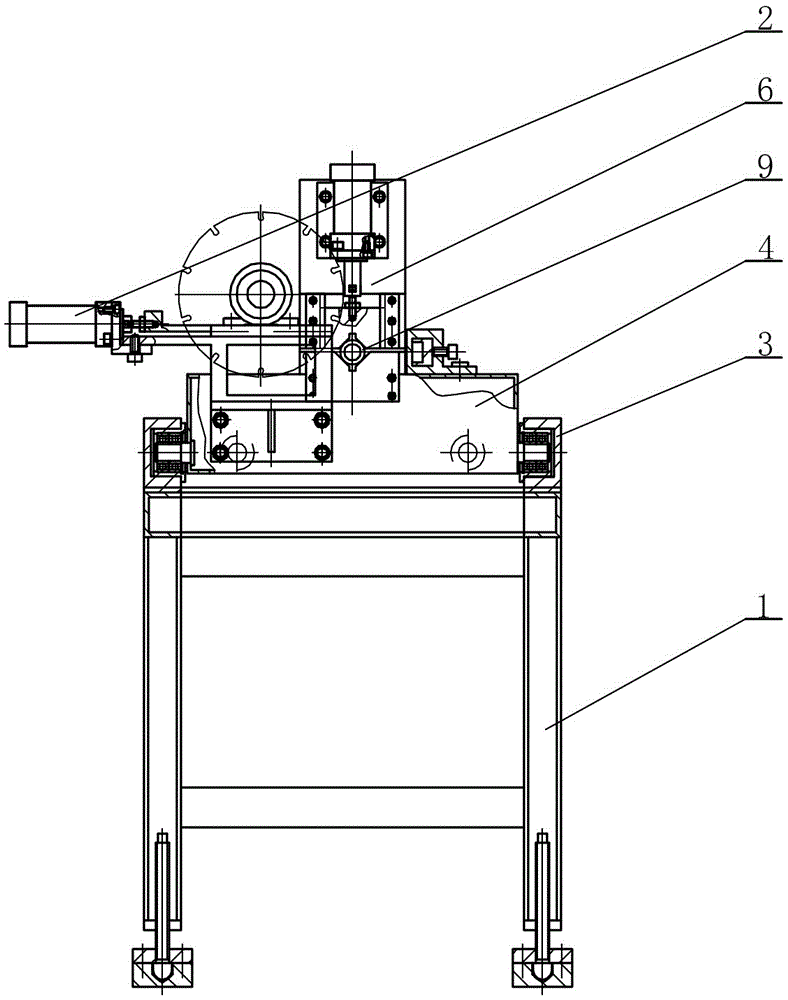

Automatic managing machine for managing straight rubber pipes

ActiveCN104477610AIncrease productivitySatisfy automated productionControl devices for conveyorsMechanical engineering

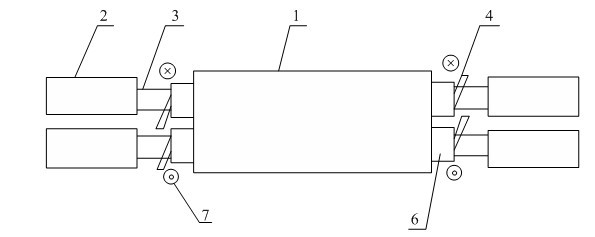

Disclosed is an automatic managing machine for managing straight rubber pipes. The automatic managing machine comprises a managing plate (1), a jacking device (2), a left managing baffle (3), a right managing baffle (4), a front adjustment baffle (5), a feed slider (6) and a feed air cylinder (7). The left managing baffle (3) and the right managing baffle (4) are arranged on the managing plate (1), the front adjustment baffle (5) is arranged at the front end of the managing plate (1), the feed slider (6) is arranged between the front adjustment baffle (5) and the managing plate (1) and is connected with the feed air cylinder (7), the jacking device (2) comprises a jacking rod (8), a jacking air cylinder (9), a slider (10), a first sensor (11) and a second sensor (12), and the jacking rod (8) and the jacking air cylinder (9) are connectively fixed on the slider (10). The automatic managing machine can manage different specifications of straight rubber pipes and substitute for manual management, automatic production of rubber pipe assembly can be well realized, and production efficiency is greatly improved.

Owner:NANJING ORIENTLEADER TECH CO LTD

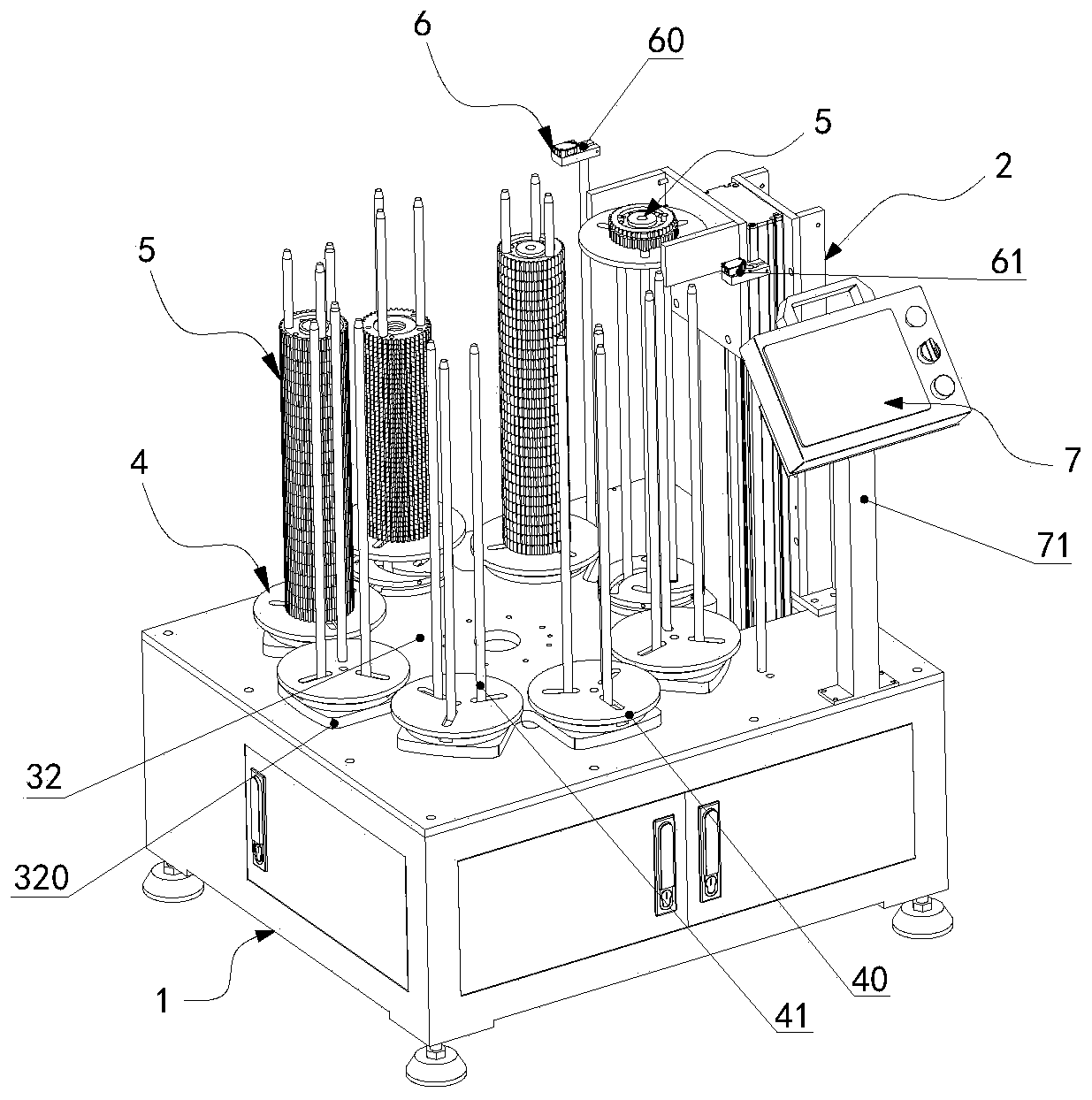

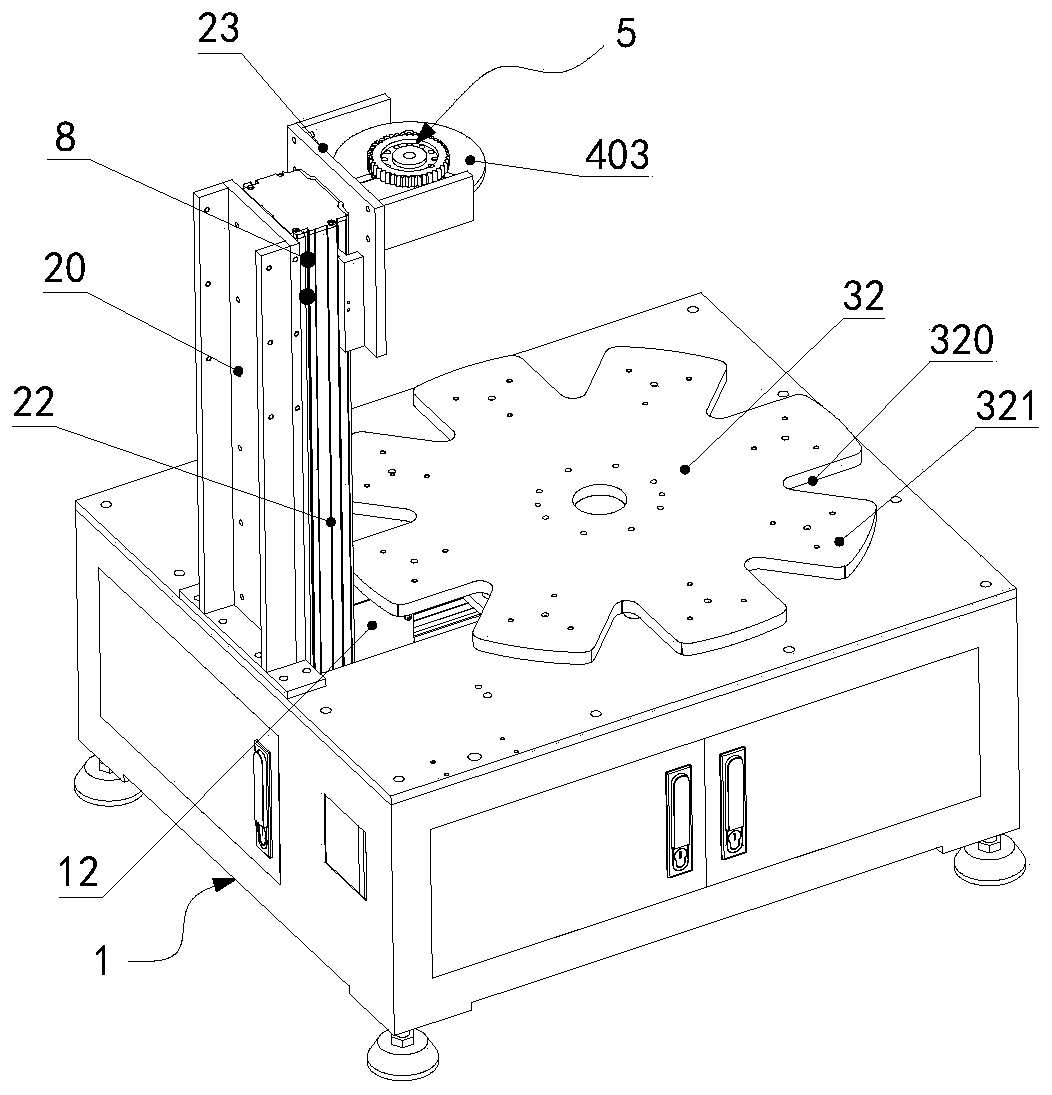

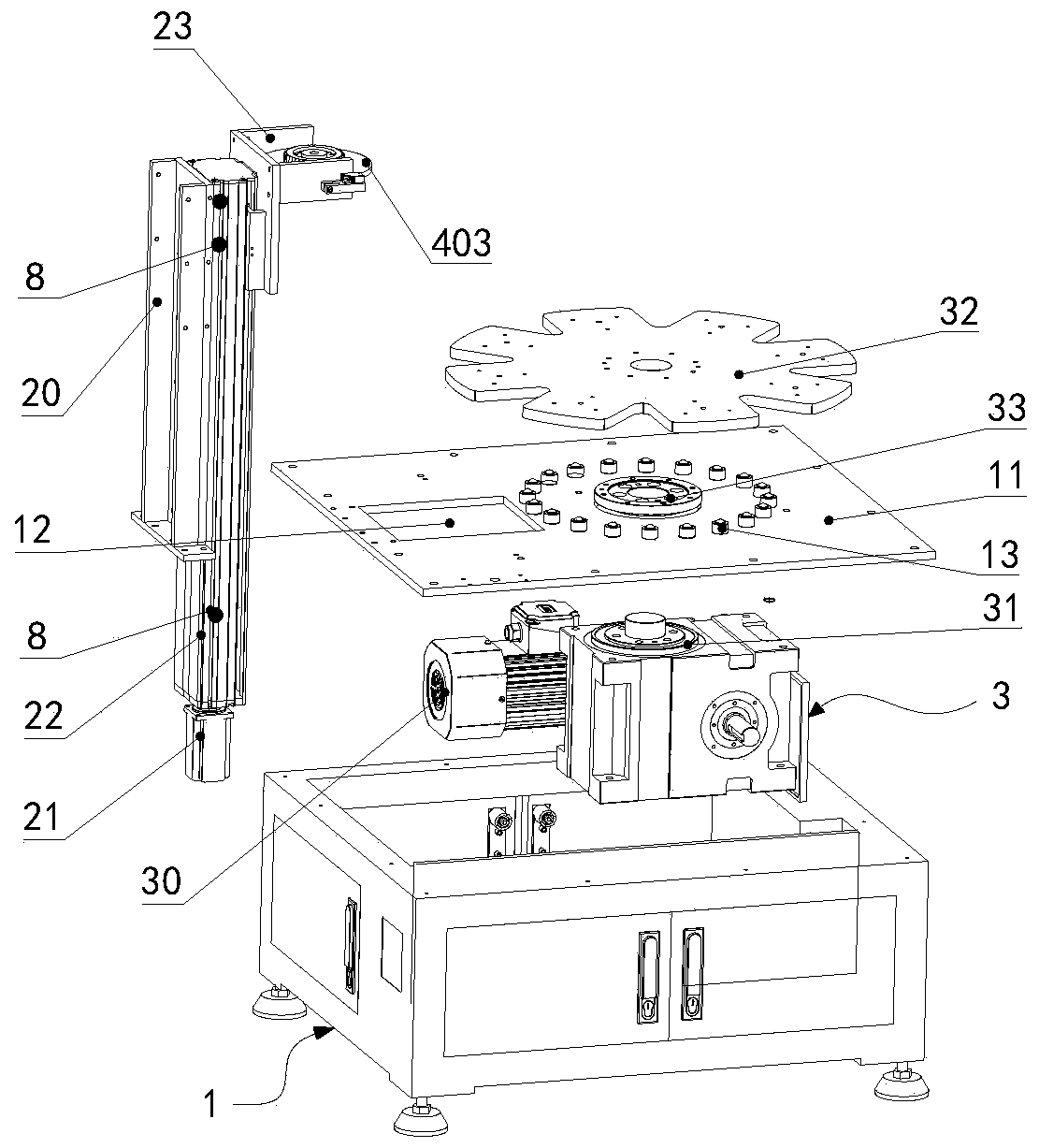

Automatic turntable stock bin for disc parts of low-bed equipment and control system thereof

The invention relates to the field of automatic production equipment, in particular to an automatic turntable stock bin for disc parts of low-bed equipment and a control system thereof. The automaticturntable stock bin for disc parts of low-bed equipment comprises a low bed base, a lifting feeding mechanism, an intermittent motion mechanism and a rotary stock bin mechanism. The intermittent motion mechanism comprises an alternating current motor, a cam divider and an intermittent rotating disc; the rotary stock bin mechanism comprises a plurality of fixed base plate sets and guide rods, the fixed base plate sets are installed on the intermittent rotary disc with the center hole as the axis; and the lifting feeding mechanism comprises a lifting supporting frame, a servo motor, a linear lifting module and a pushing plate. The design is front-end equipment for automatic feeding and discharging of a machine tool, cooperates with automatic equipment such as an industrial robot for use; fordisc part development, the versatility is high, machining and feeding of the disc parts such as gears and chain wheels are facilitated, and during the using process, the automatic turntable stock binfor the disc parts can effectively reduce the feeding height, reduce the size, reduce the design difficulty of an automatic feeding and discharging workstation of a machine tool and reduce the cost.

Owner:CHONGQING ELECTROMECHANICAL VOCATIONAL INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com