Centrifugal casting annular array type automatic production line

An automated production line and centrifugal casting technology, applied in the field of production equipment, can solve the problems of workers running back and forth, high labor intensity, and low production efficiency, and achieve the effect of meeting the needs of automated production, reducing labor intensity, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

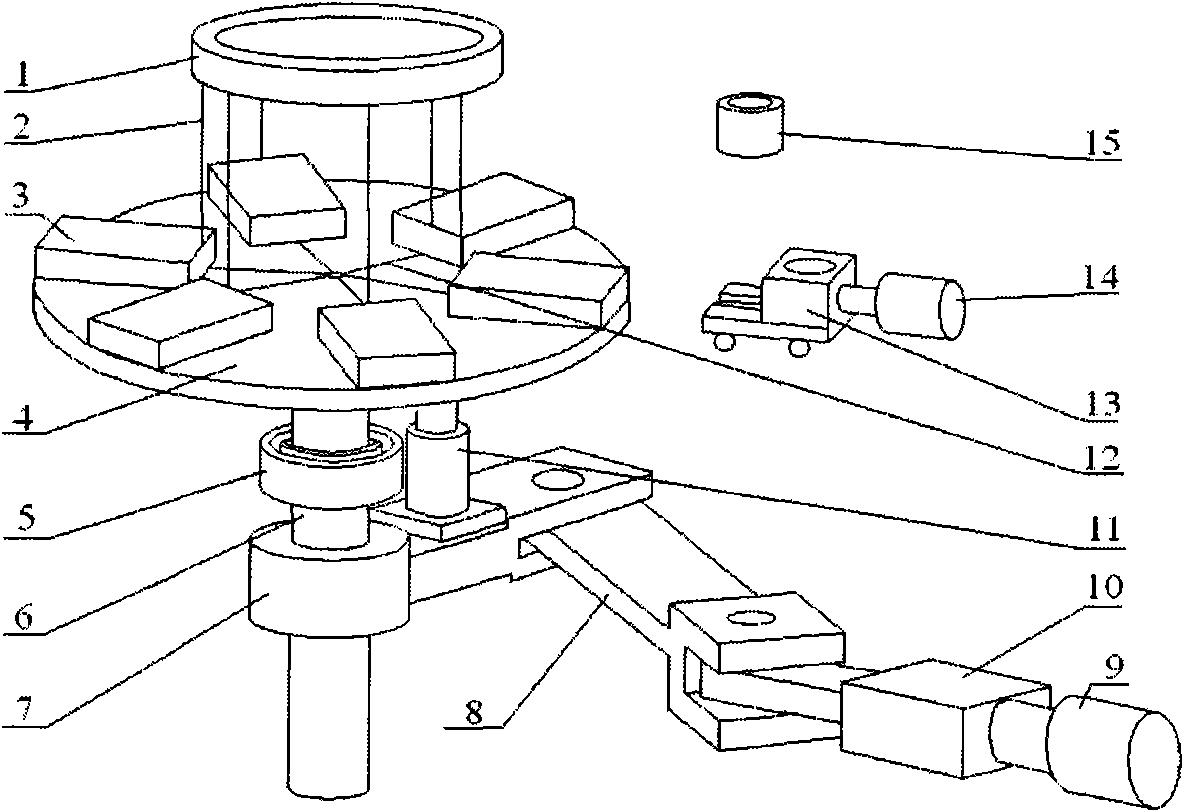

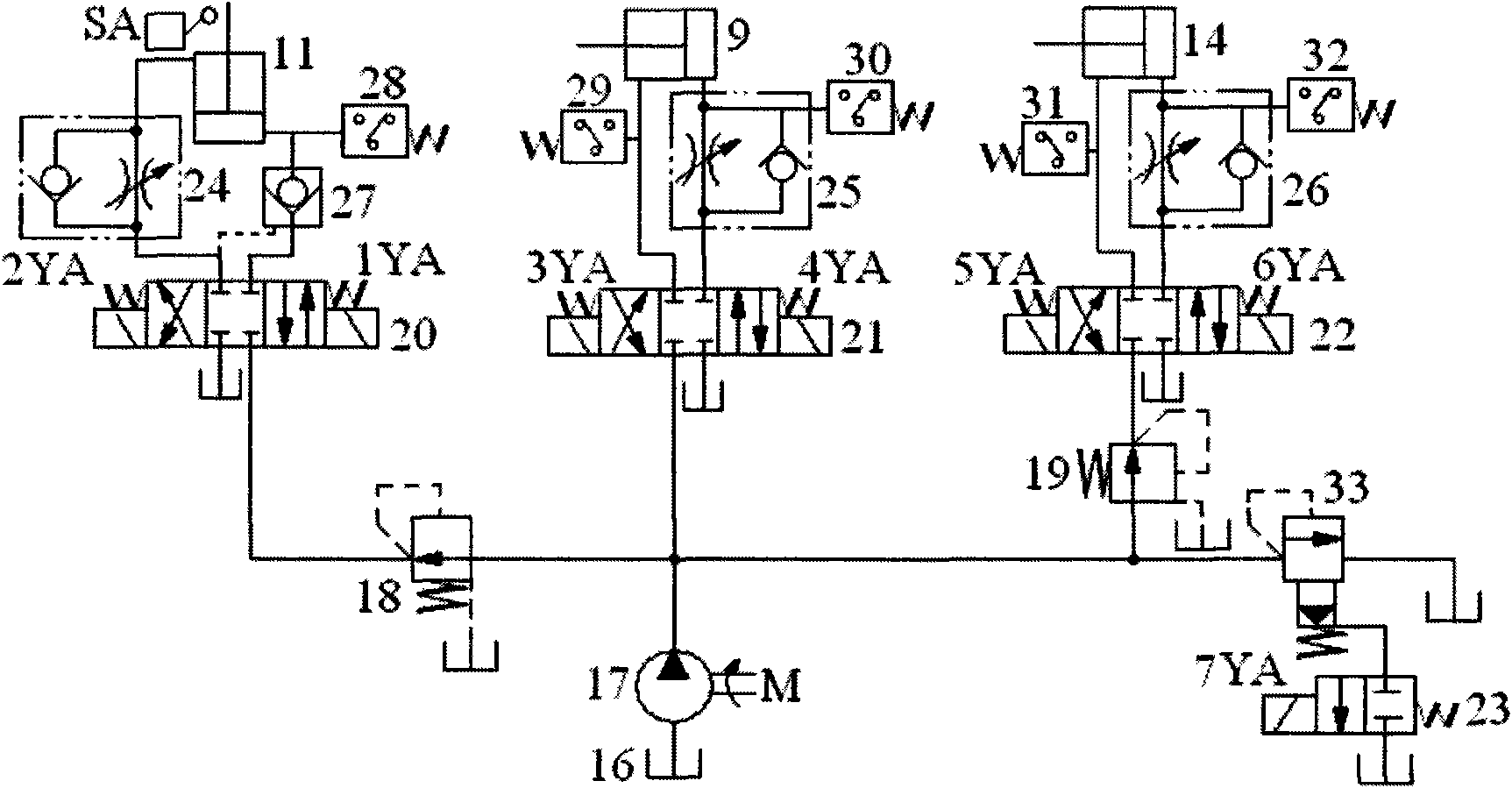

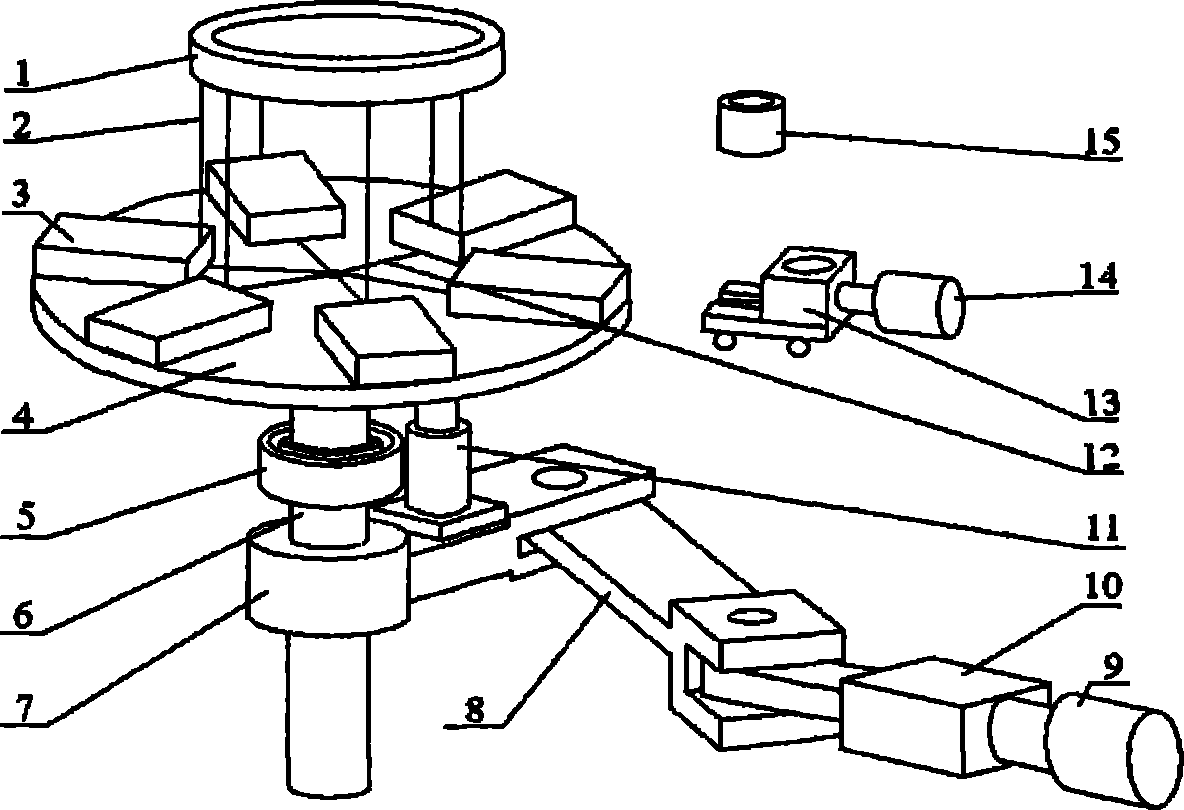

[0017] Such as figure 1 , 2 As shown, the automatic production equipment is composed of a mechanical movement device, a hydraulic transmission device and a centrifugal casting device. The mechanical movement device includes a rotating platform 4, a rotating column 6, a swing rod 7, a connecting rod 8, an active hydraulic cylinder 9, The slide block 10 and the bolt hydraulic cylinder 11 are processed on the rotating platform 4 according to the actual situation. Several taper pin holes arranged according to the specific rotation angle are processed, and the rotating platform 4 and the rotating column 6 are fastened and connected and installed on the frame. 4 and the rotating column 6 have relative movement with the frame, one end of the swing rod 7 is connected with the rotating column 6 to form a rotating pair, the latch hydraulic cylinder 11 is fixed on the swing rod 7, the other end of the swing rod 7 is hinged with the connecting rod 8, and the swing rod 7 forms a moving pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com