Patents

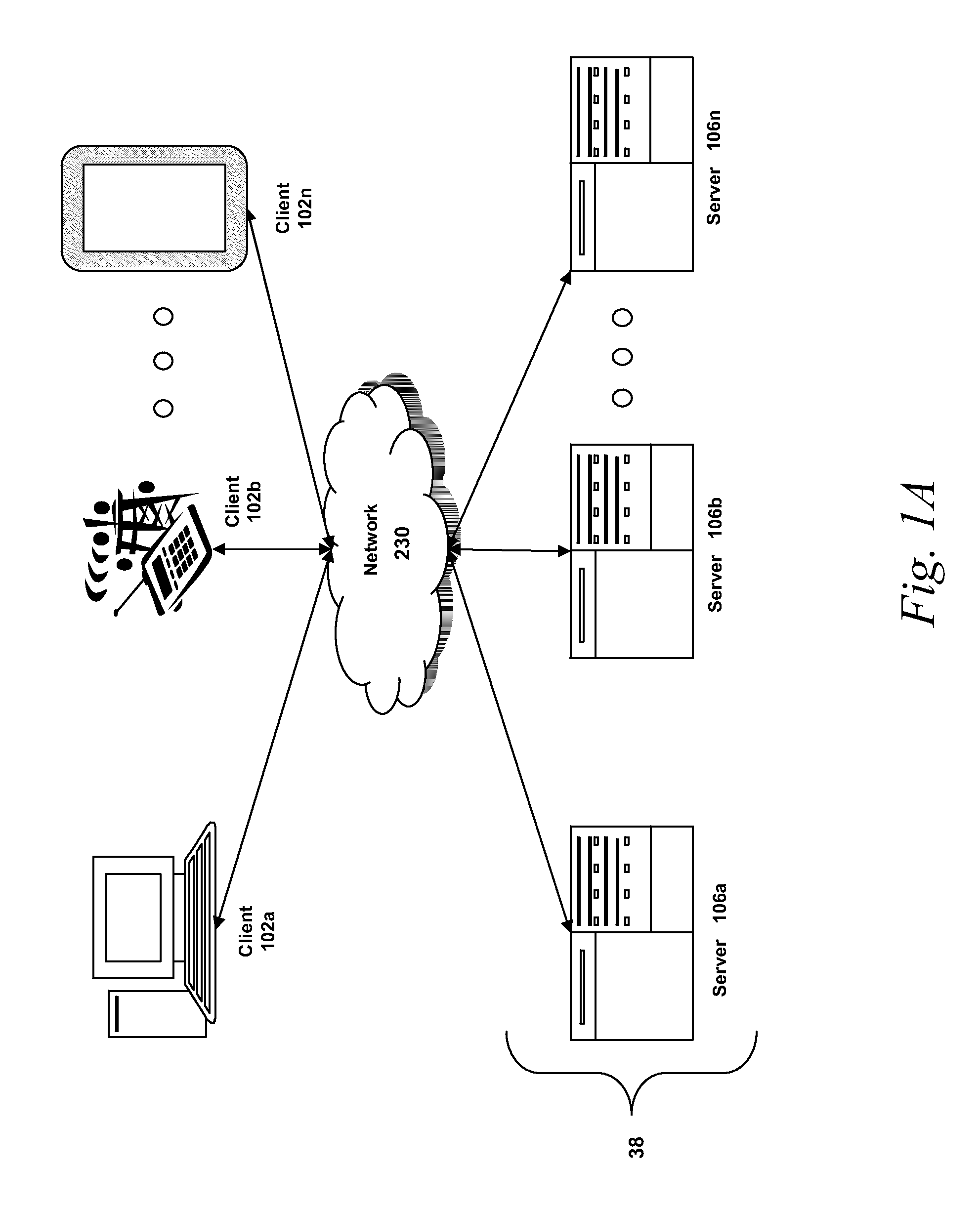

Literature

3534 results about "Circular motion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In physics, circular motion is a movement of an object along the circumference of a circle or rotation along a circular path. It can be uniform, with constant angular rate of rotation and constant speed, or non-uniform with a changing rate of rotation. The rotation around a fixed axis of a three-dimensional body involves circular motion of its parts. The equations of motion describe the movement of the center of mass of a body.

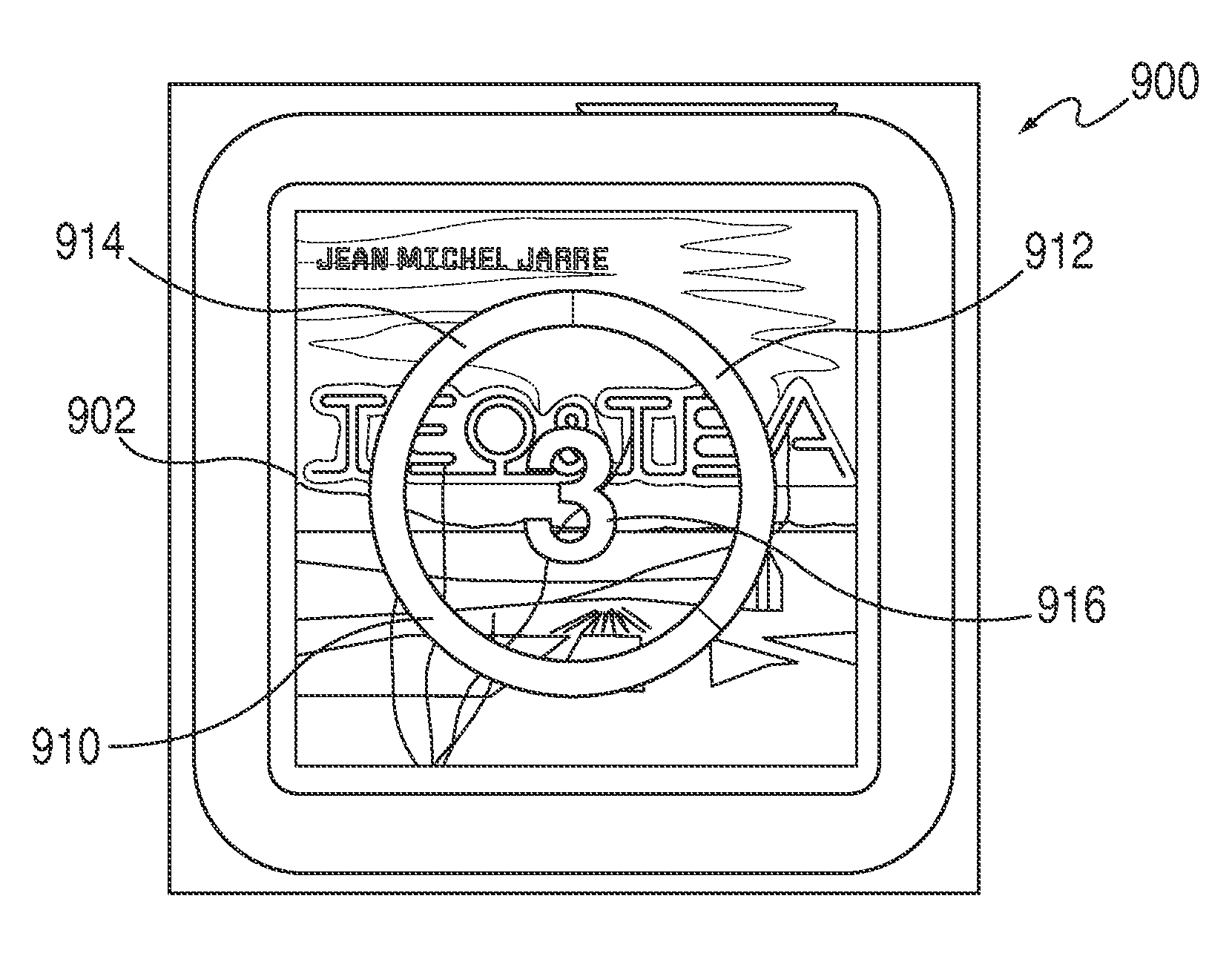

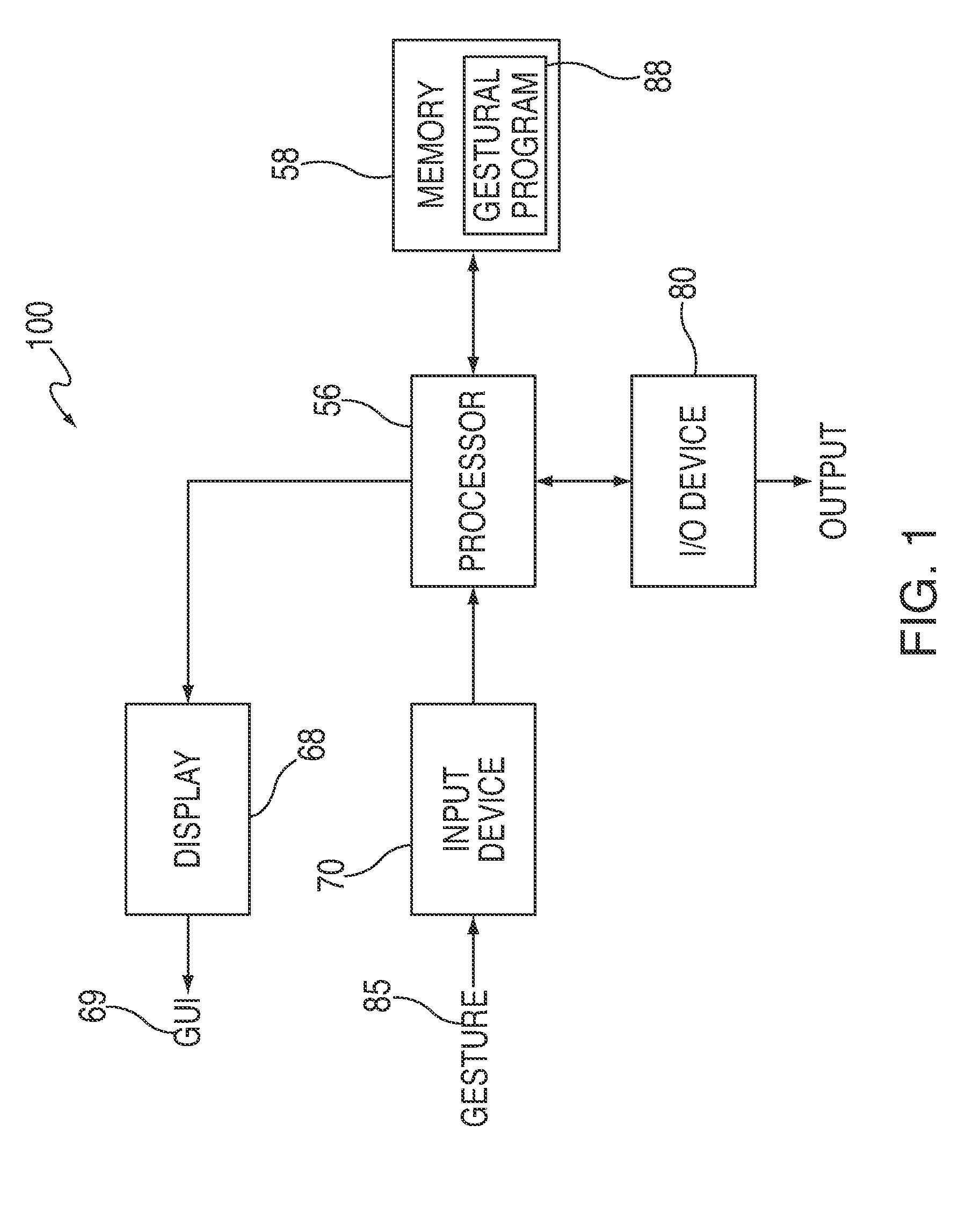

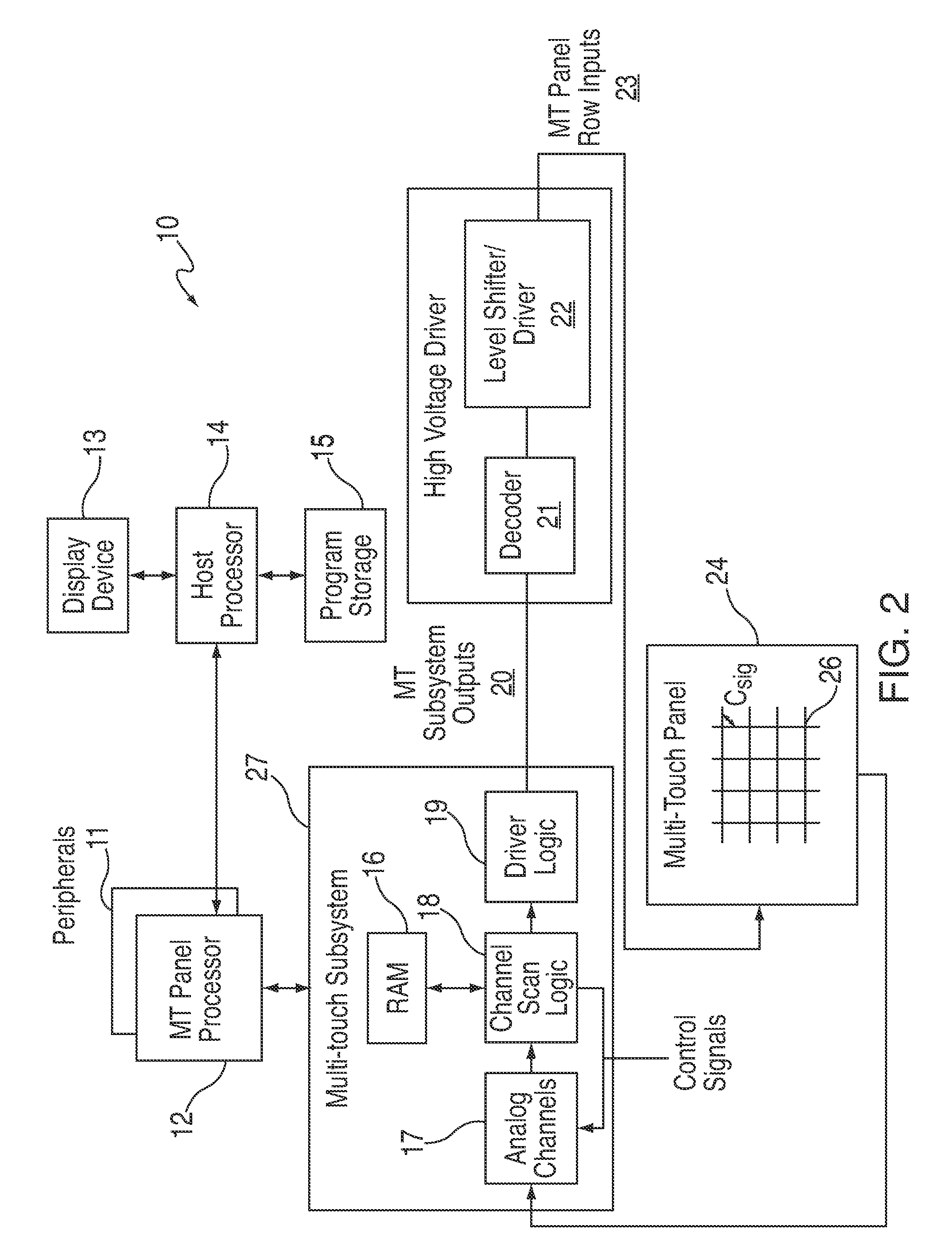

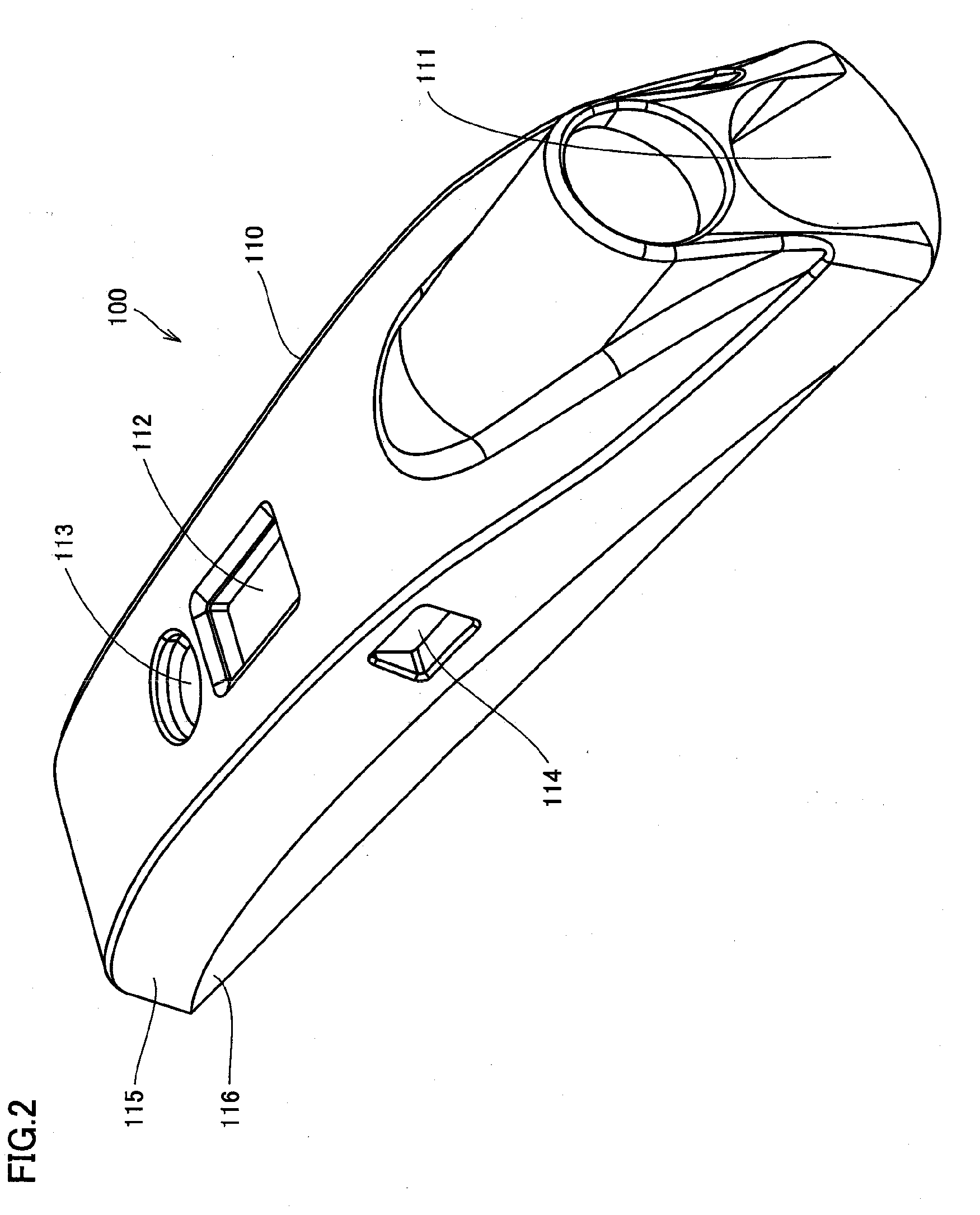

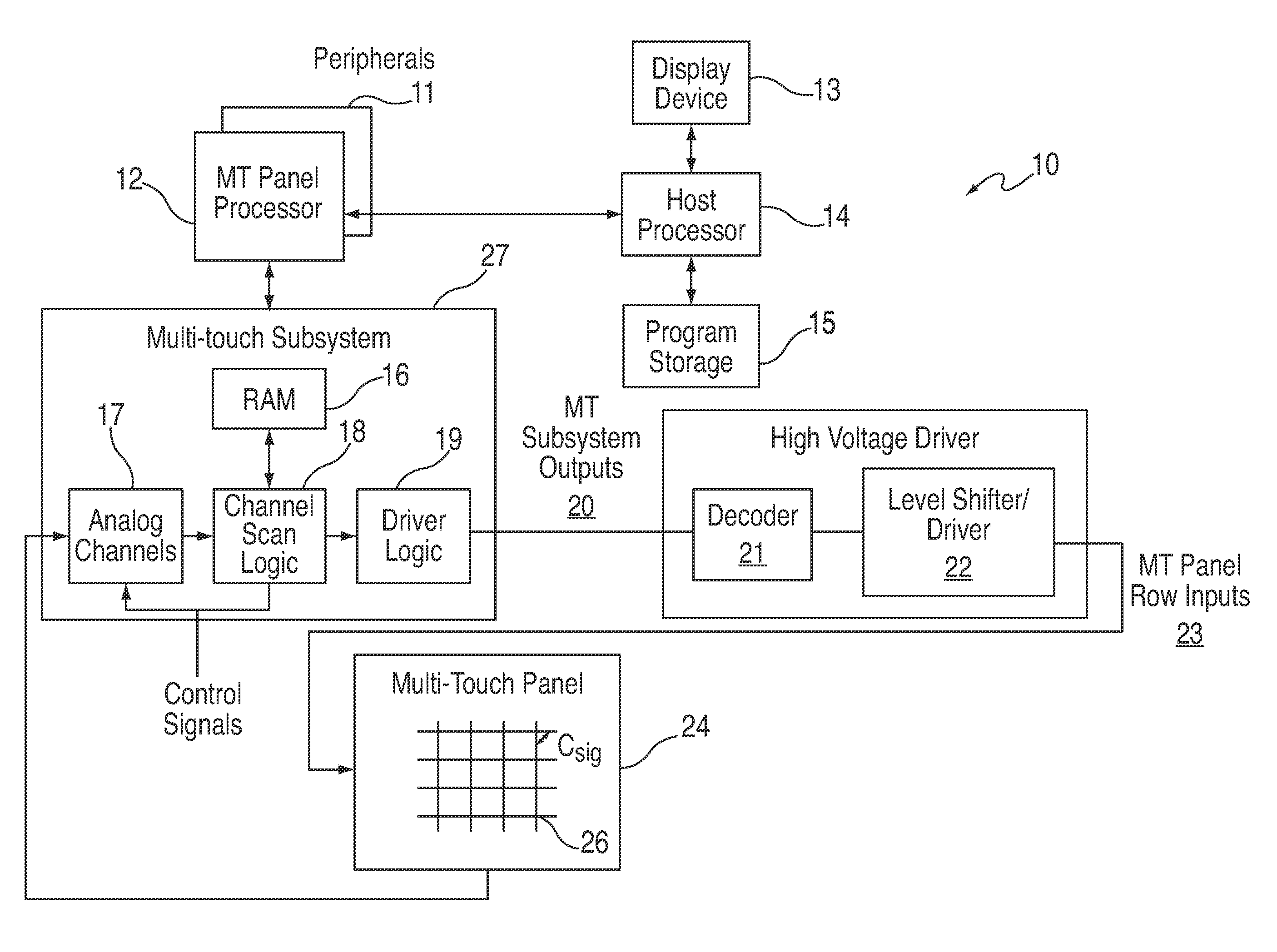

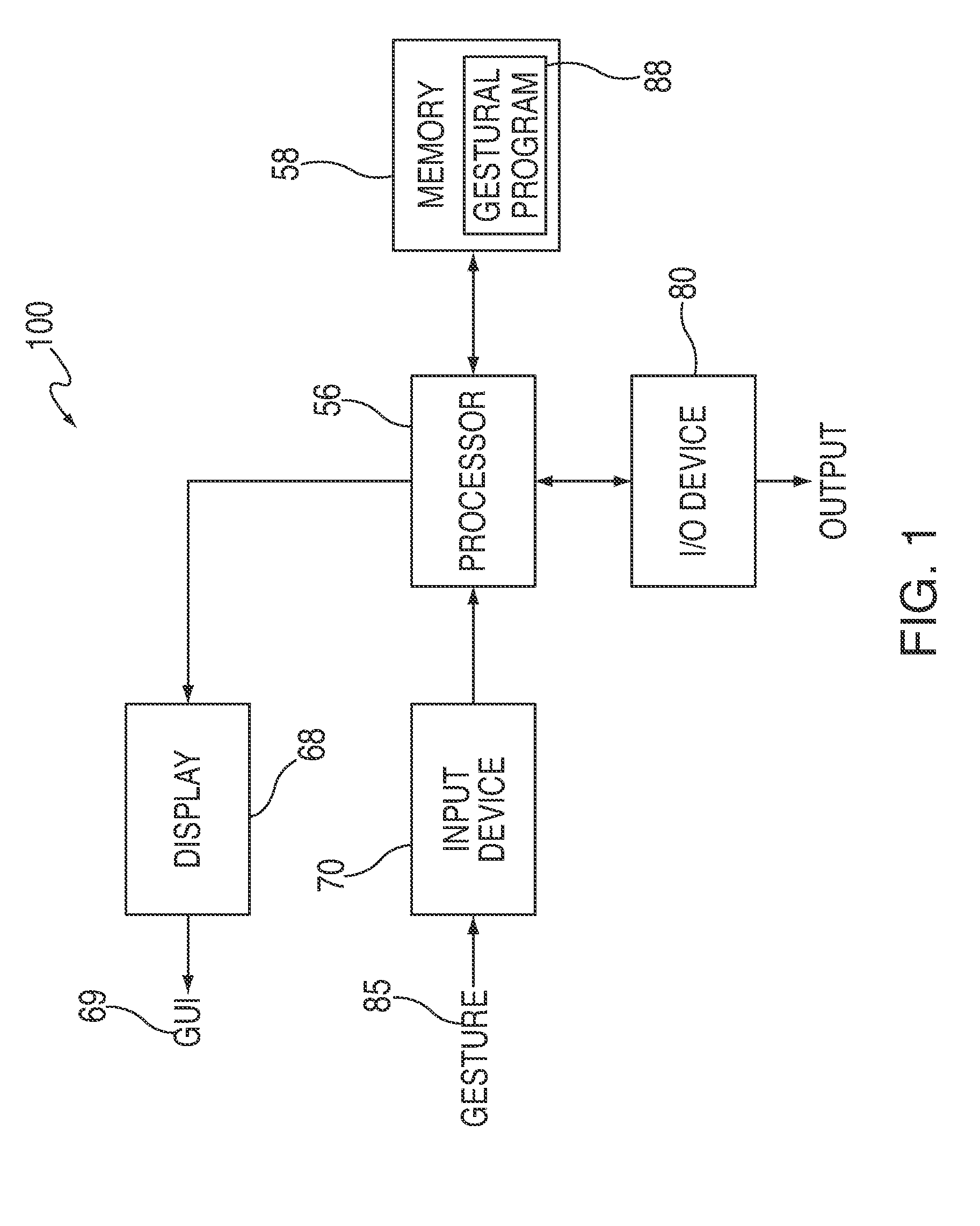

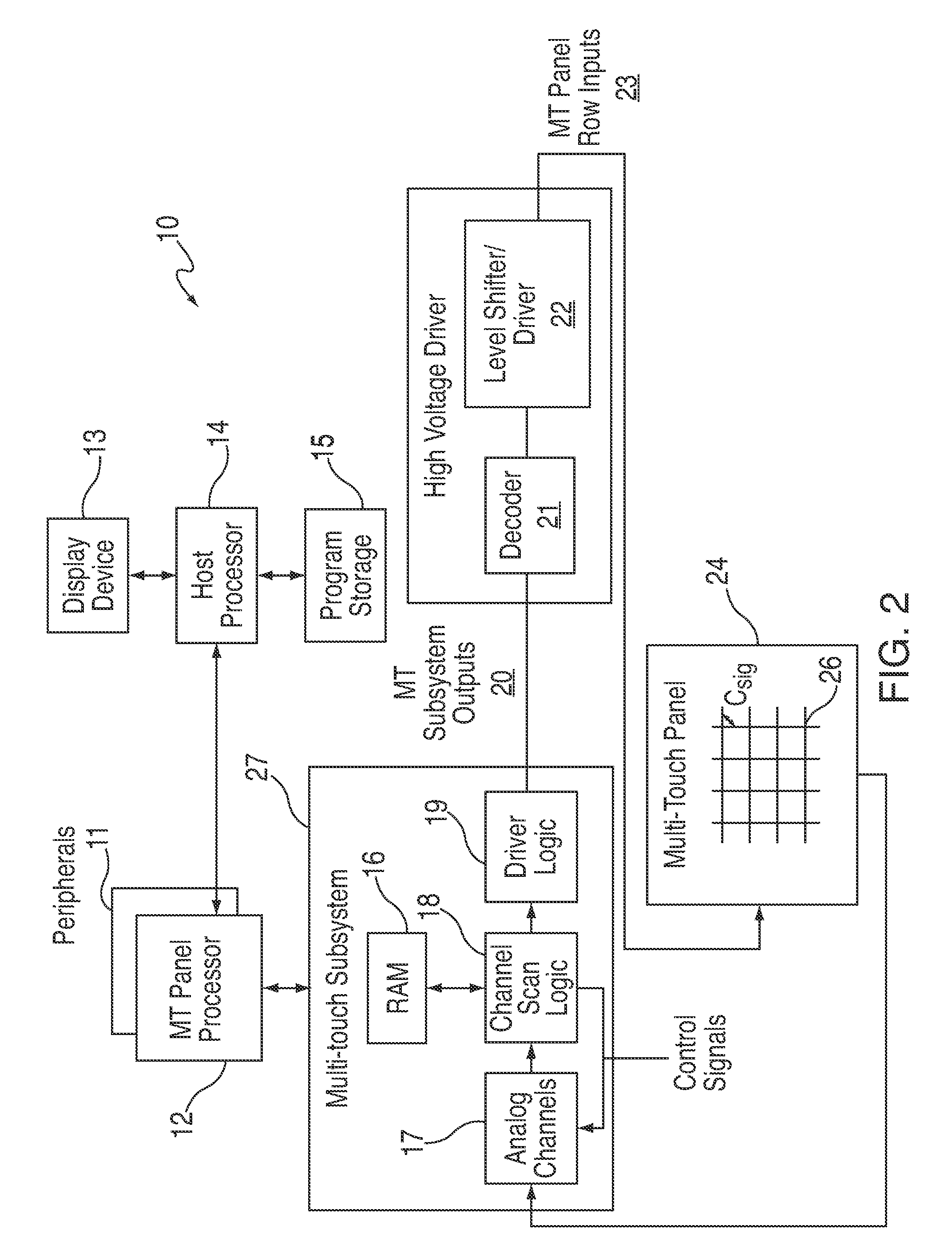

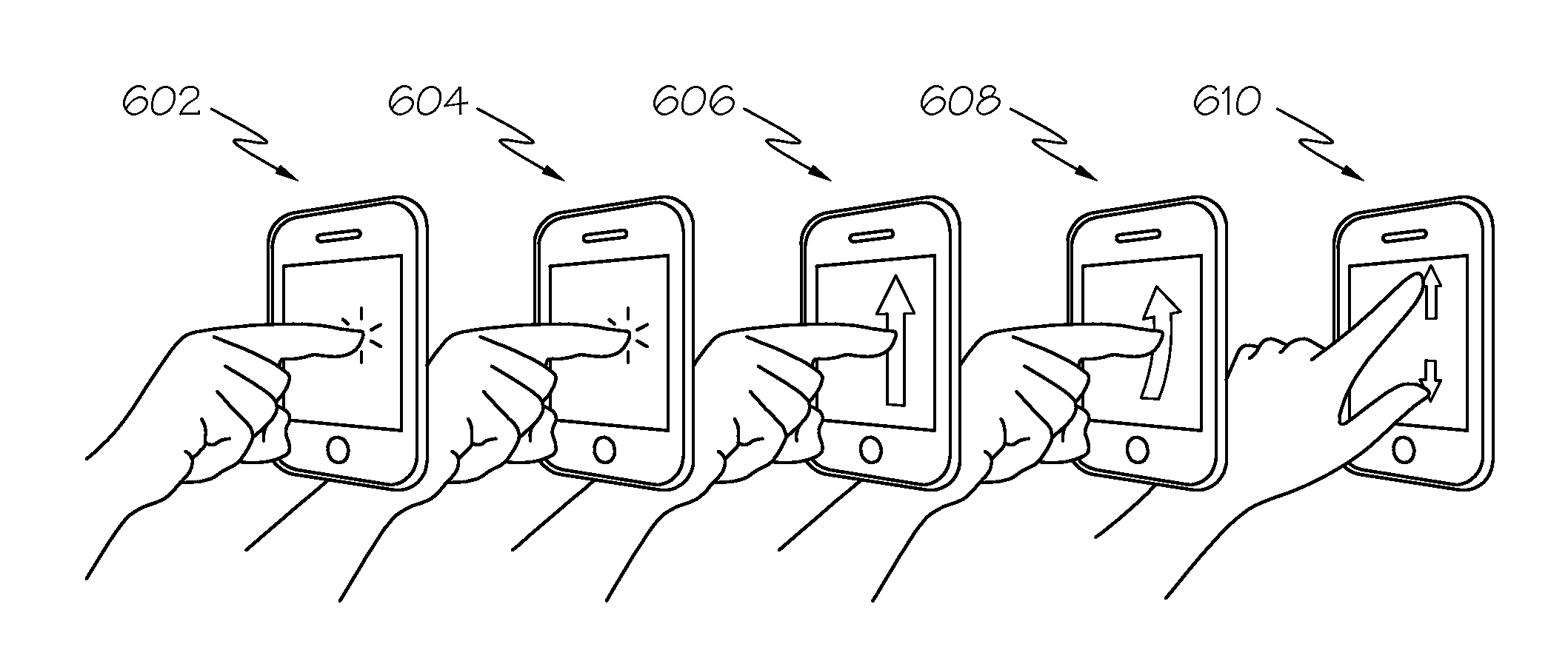

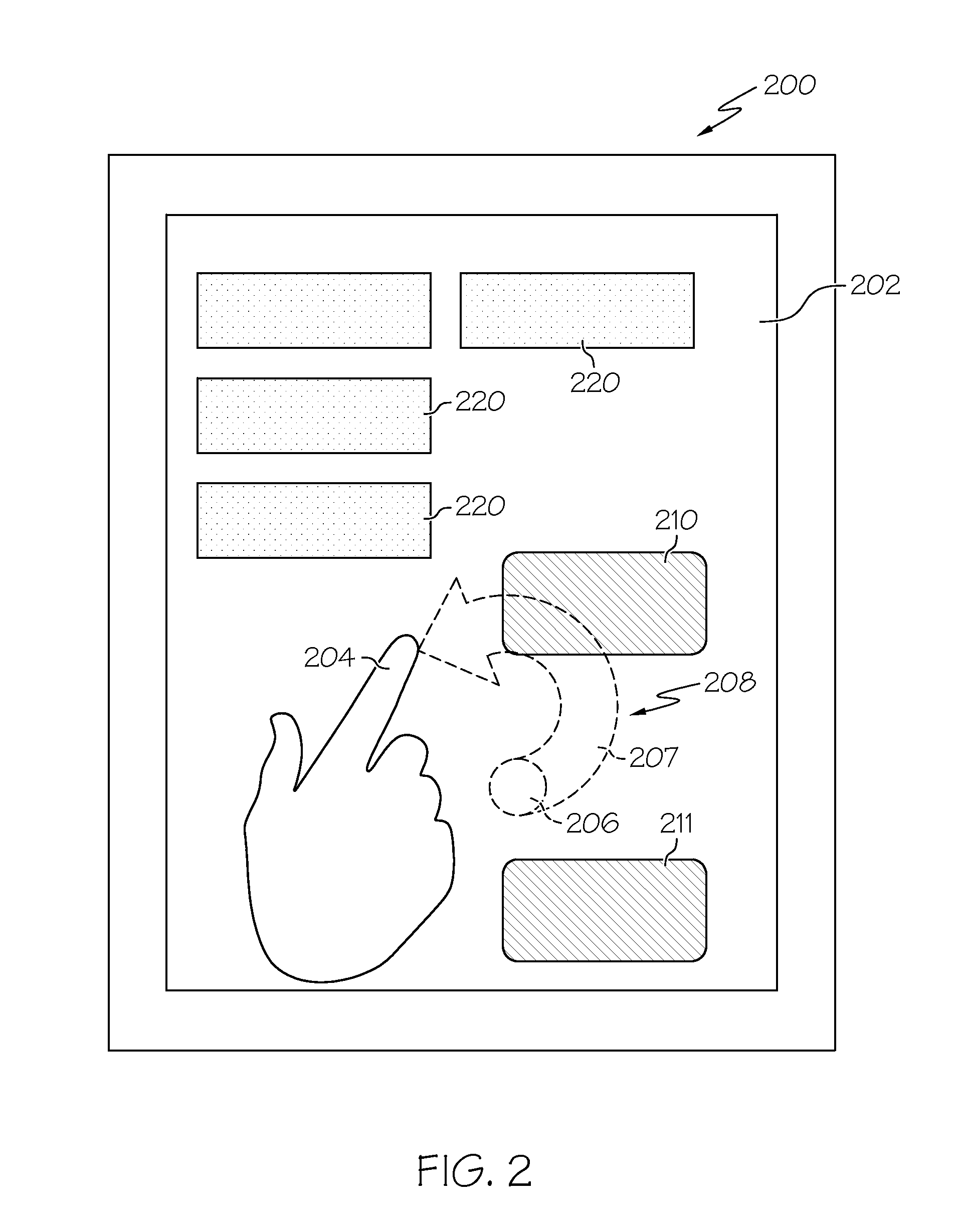

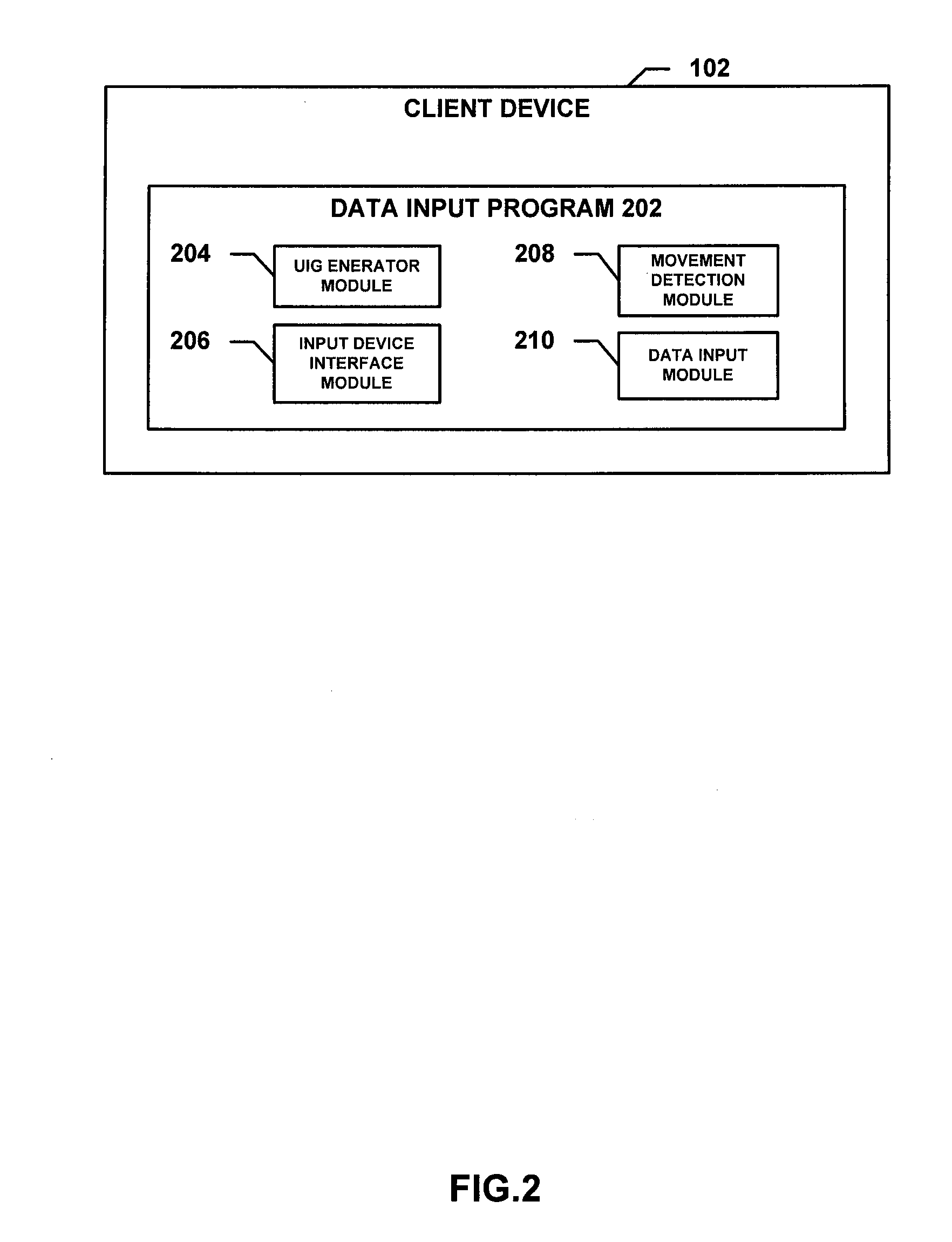

Playback control using a touch interface

ActiveUS8407623B2Digital computer detailsInput/output processes for data processingTouch SensesHuman–computer interaction

This is directed to controlling media playback based on particular touch gestures detected by a touch-sensing interface. The electronic device can identify particular touch inputs, such as combinations of tapping and holding a touch sensitive surface, or circular motions. In response to detecting a particular touch gesture, the electronic device can perform a playback operation specifically associated with the detected touch gesture. To provide a consistent user interface with the device, some of the particular touch gestures can match other inputs provided using a button, for example a button integrated on a wired headset. In such an embodiment, the same combination of tapping and holding a touch input and pressing and holding a button can control the same electronic device operations.

Owner:APPLE INC

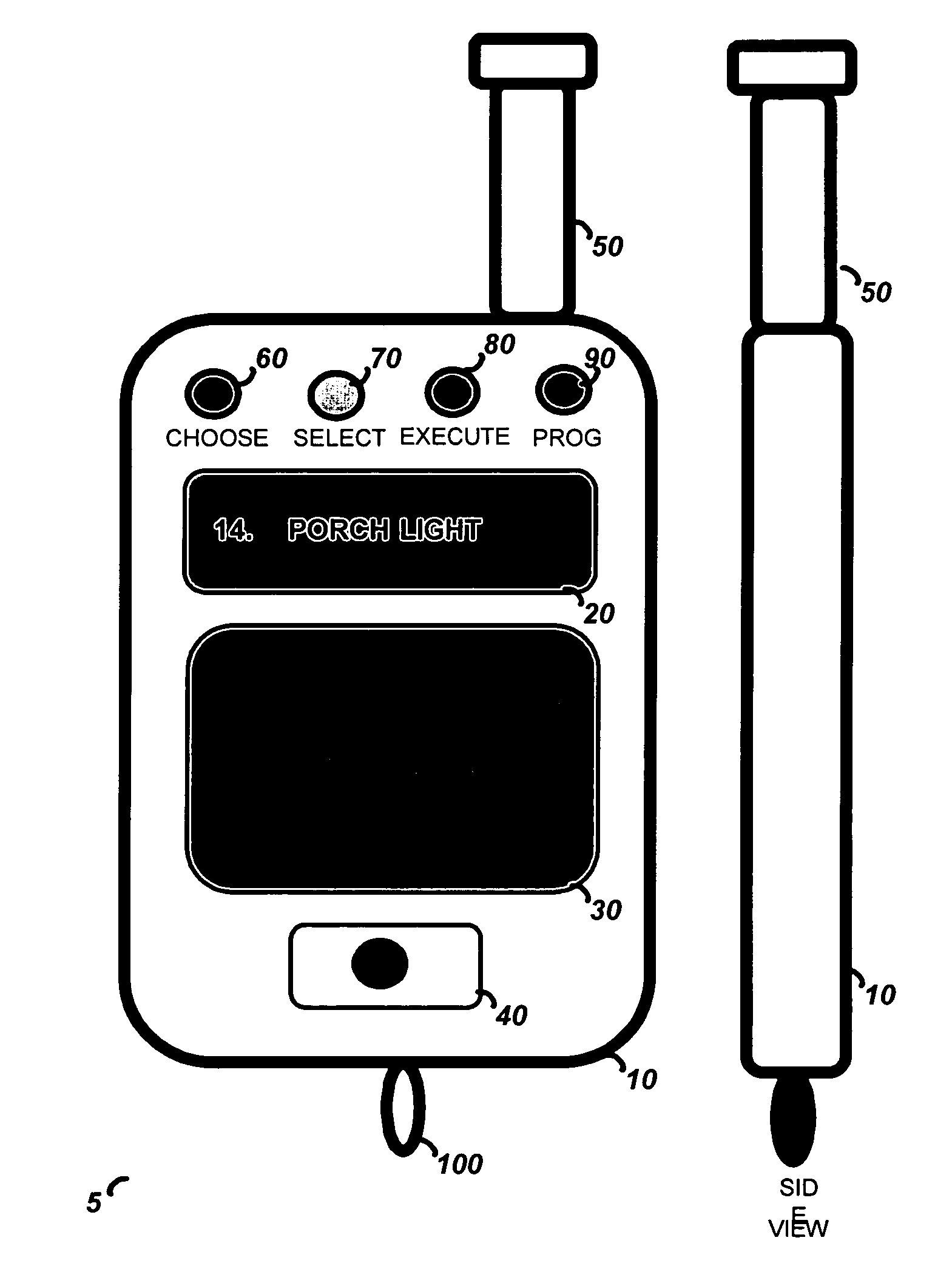

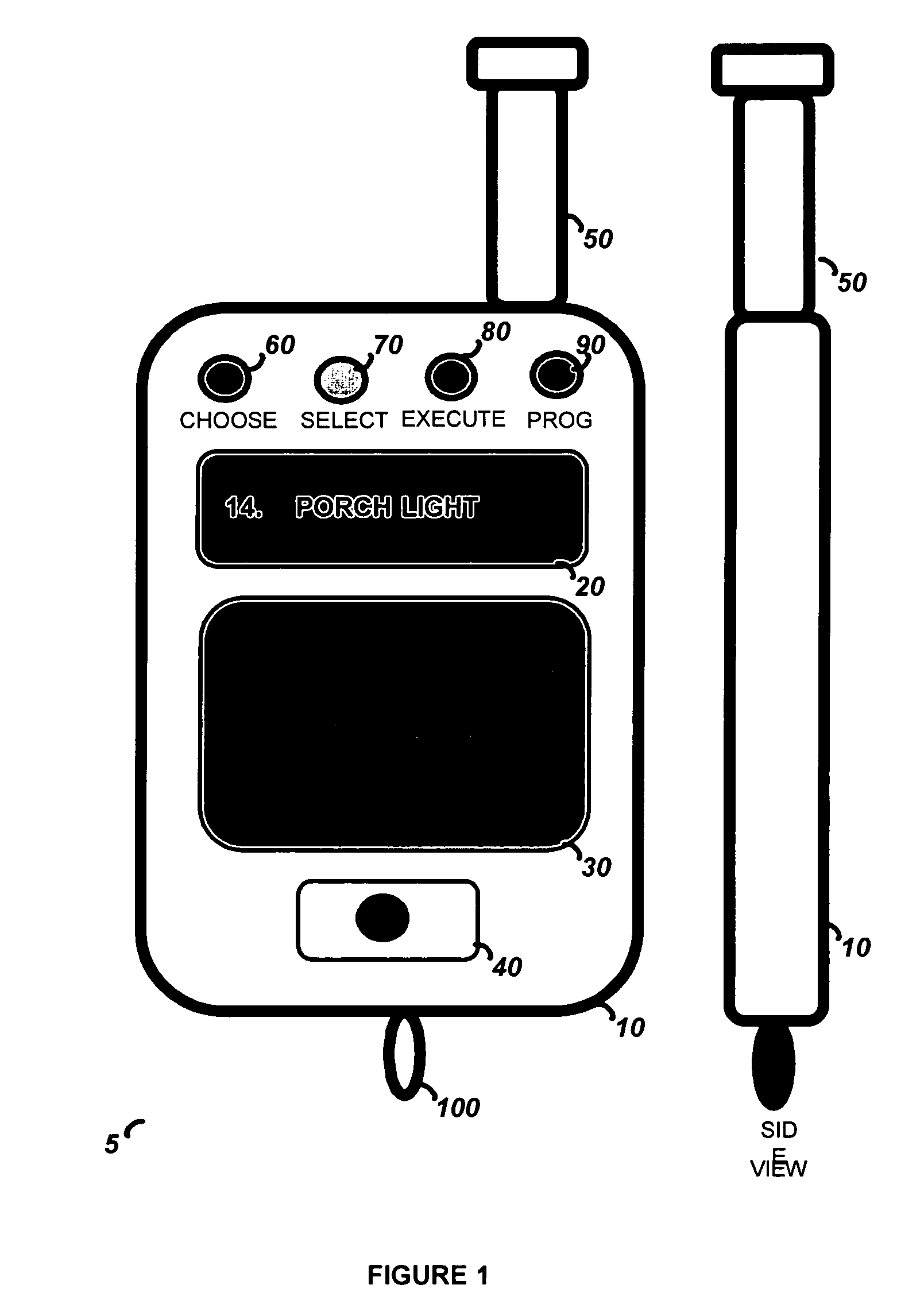

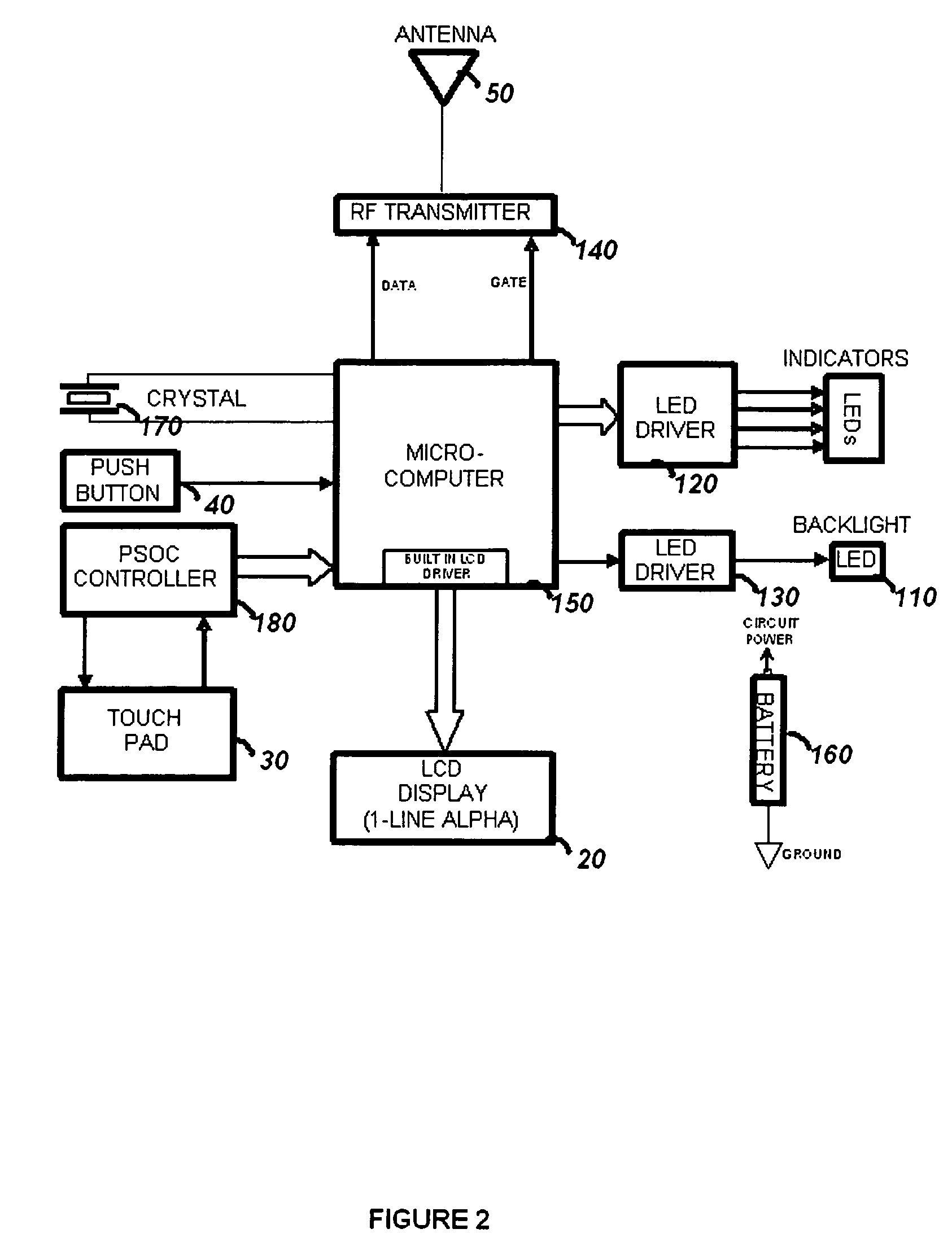

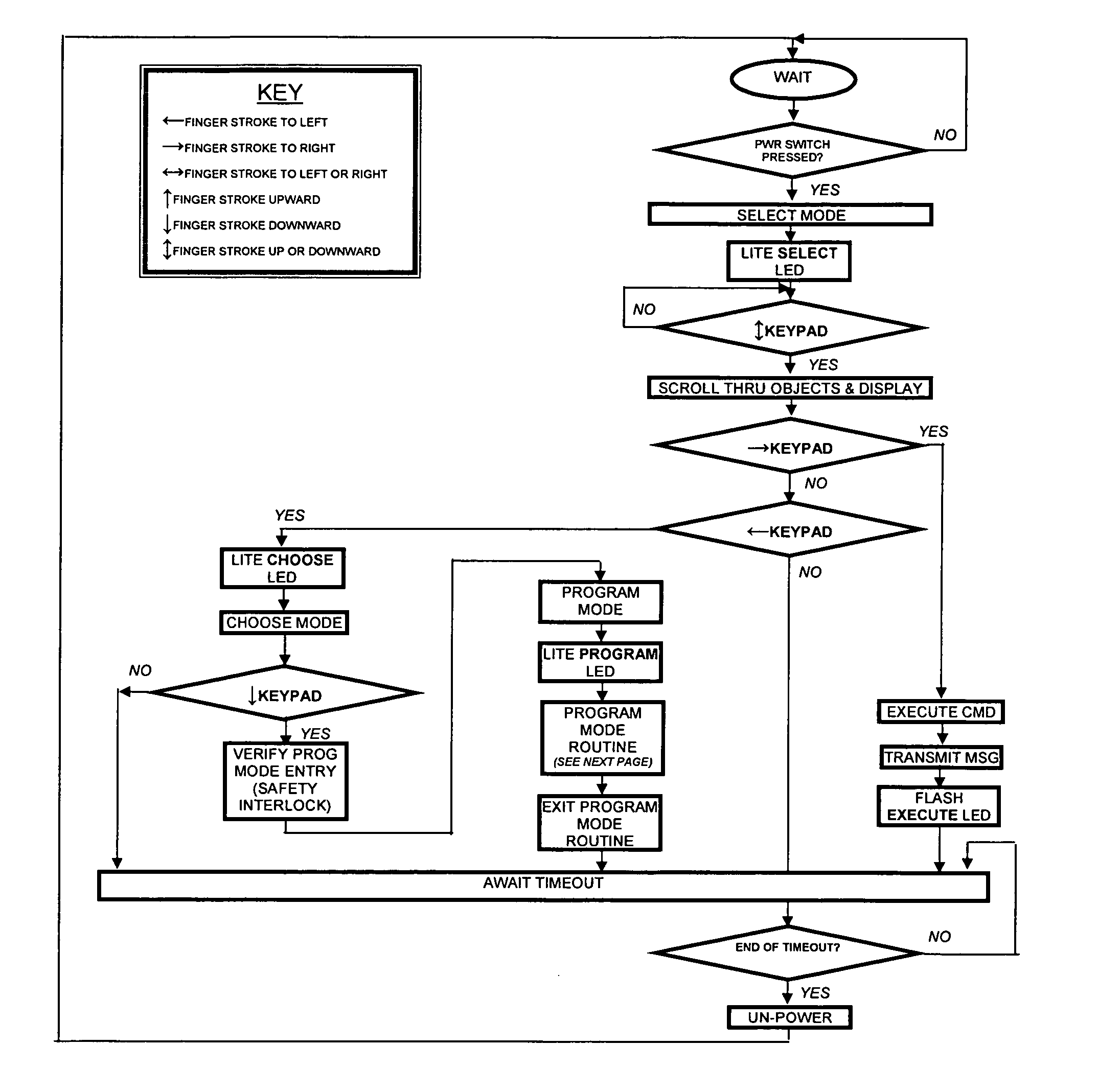

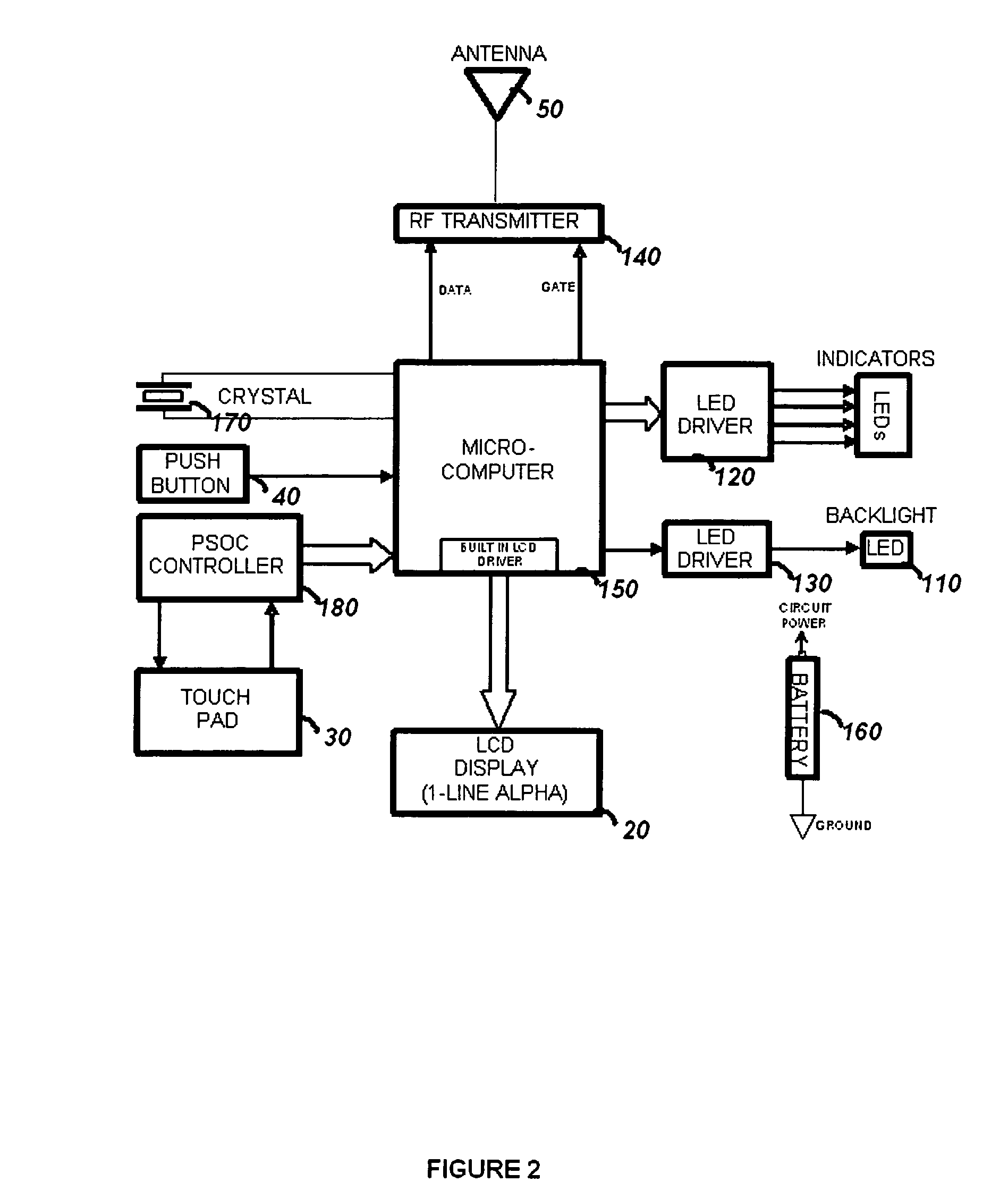

Touchscreen device for controlling a security system

The present invention is a hand held portable remote such as a key fob that allows a user to interact with the security system using a flat panel touch-pad. The touch-pad input allows a user to rapidly select and control a large number of security functions, such as Arm, Disarm, Panic, garage door open, lamp on / off, and lamp dimming control, etc. The security device comprises a housing, a wireless communication port for interface with the security system, a touch-pad input device, and processing circuitry. In order to operate the security device, the user generates a user input by creating a contact motion on the touch-pad input device with a fingertip. The contact motion may consist of a swiping motion, a tapping, or a circular motion. In order to distinguish the contact motion clearly, when the fingertip contact comprises a wider than normal contact, it causes the processing circuitry to not generate an output signal. The security device also comprises an LCD display for displaying alpha numeric control options to a user and LED indicators for indicating the modes of the processing circuitry.

Owner:ADEMCO INC

Touchscreen device for controlling a security system

The present invention is a hand held portable remote such as a key fob that allows a user to interact with the security system using a flat panel touch-pad. The touch-pad input allows a user to rapidly select and control a large number of security functions, such as Arm, Disarm, Panic, garage door open, lamp on / off, and lamp dimming control, etc. The security device comprises a housing, a wireless communication port for interface with the security system, a touch-pad input device, and processing circuitry. In order to operate the security device, the user generates a user input by creating a contact motion on the touch-pad input device with a fingertip. The contact motion may consist of a swiping motion, a tapping, or a circular motion. In order to distinguish the contact motion clearly, when the fingertip contact comprises a wider than normal contact, it causes the processing circuitry to not generate an output signal. The security device also comprises an LCD display for displaying alpha numeric control options to a user and LED indicators for indicating the modes of the processing circuitry.

Owner:ADEMCO INC

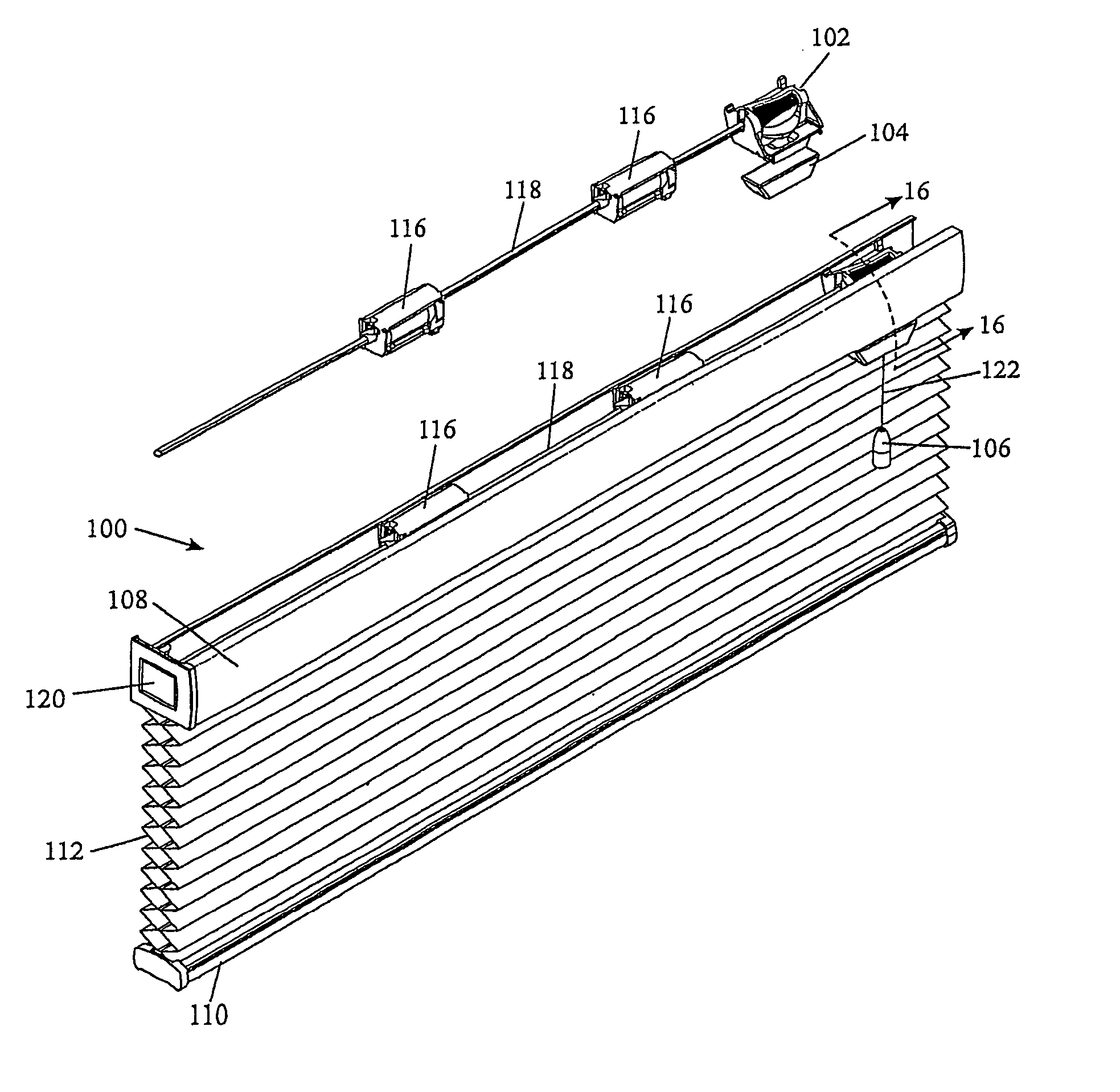

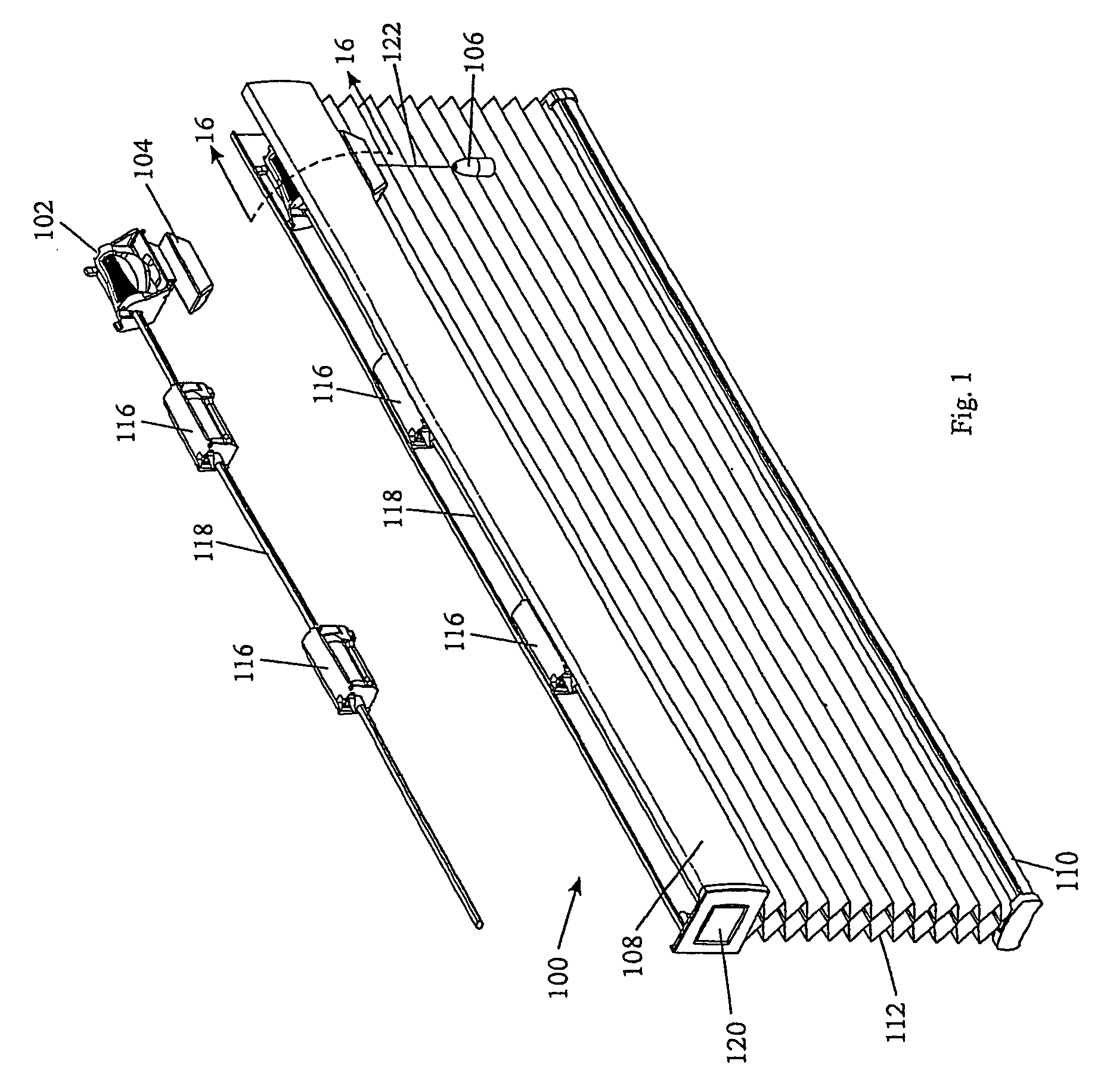

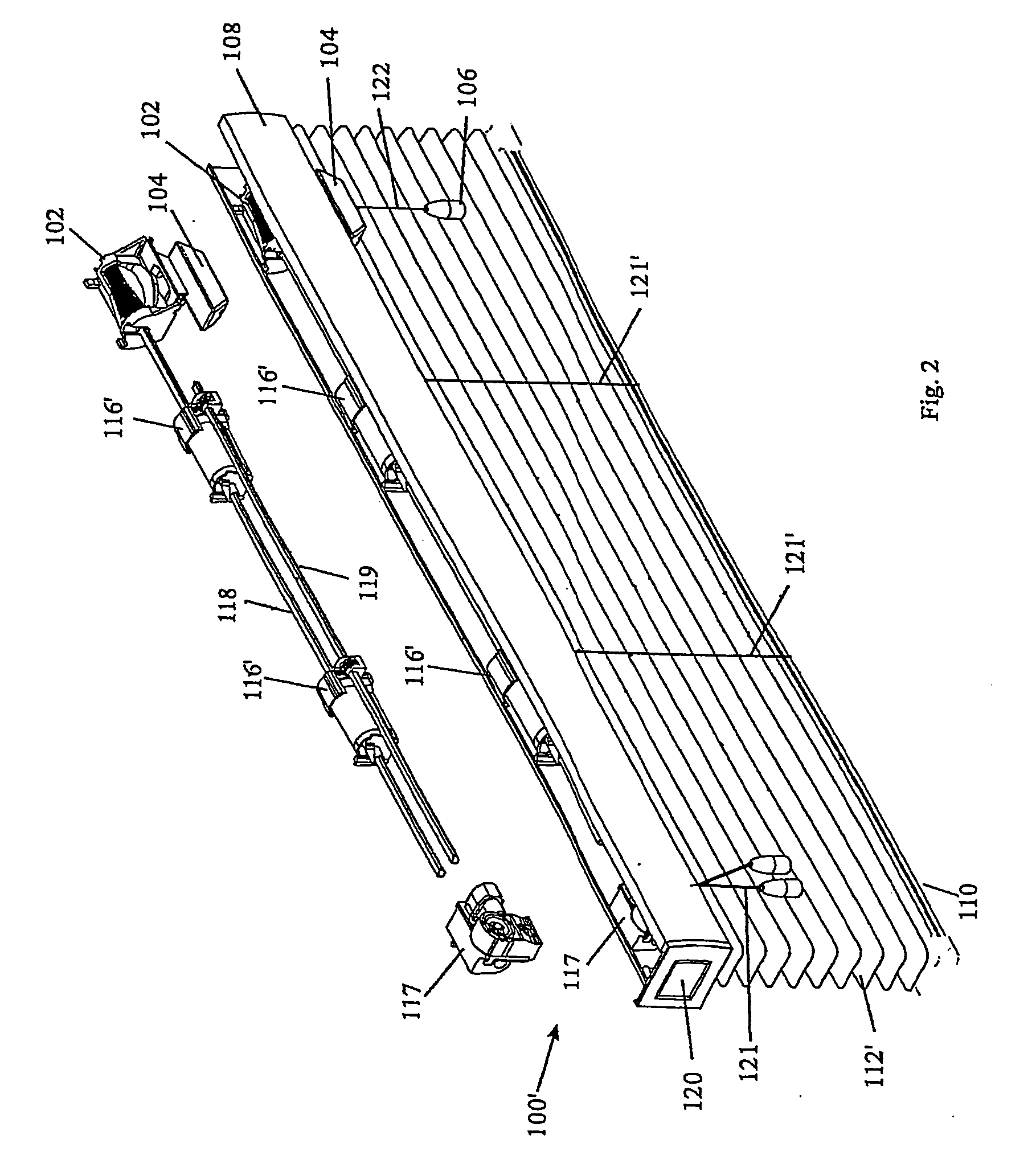

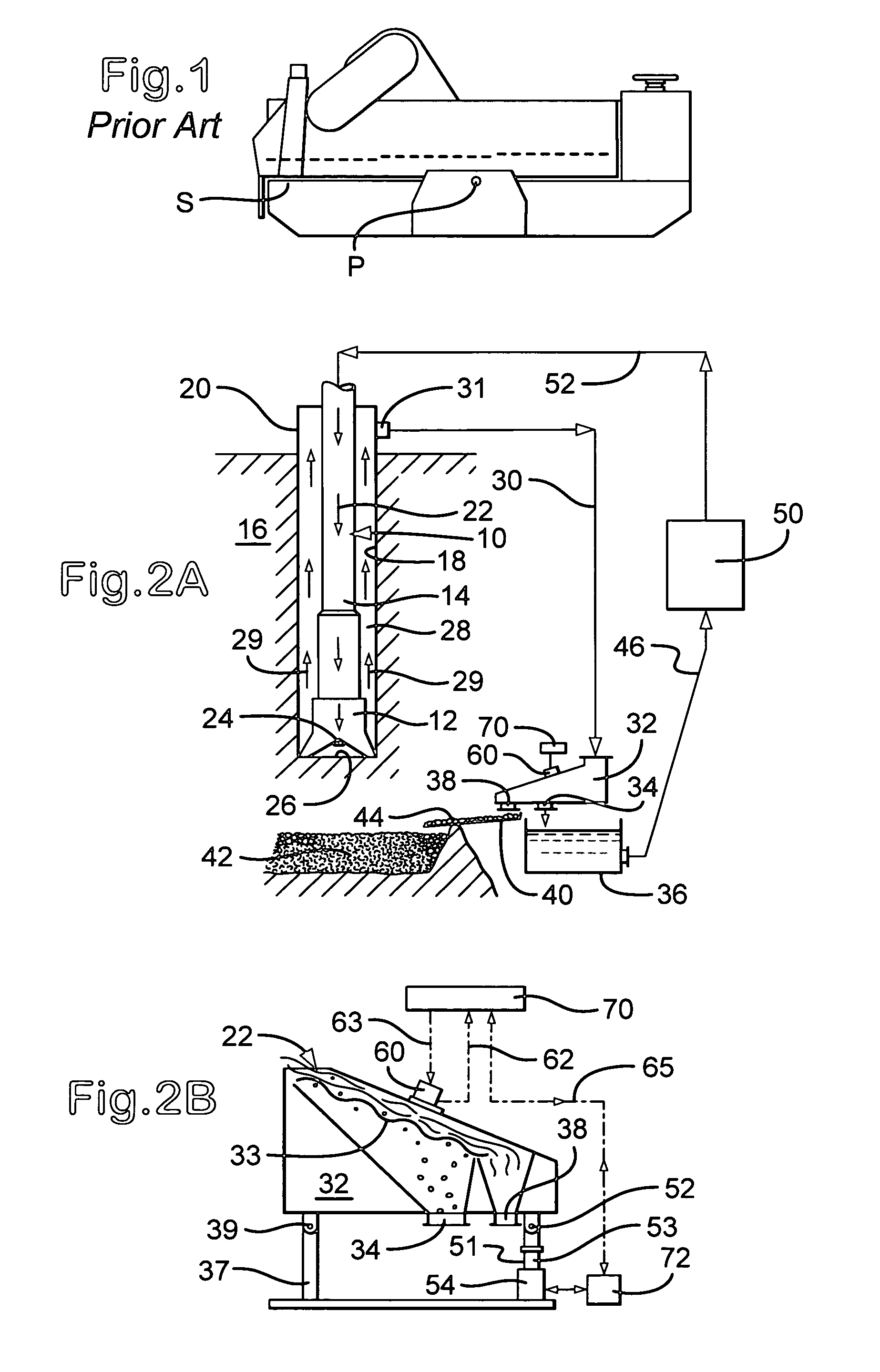

Drive for coverings for architectural openings

ActiveUS20060118248A1Many problemEliminate needExtensible doors/windowsCurtain accessoriesLinear motionEngineering

A cord drive mechanism to convert linear motion to circular motion for use in coverings for architectural openings. Various controls are used to provide a braking force on the cord. Some of the embodiments incorporate a capstan.

Owner:HUNTER DOUGLAS INC

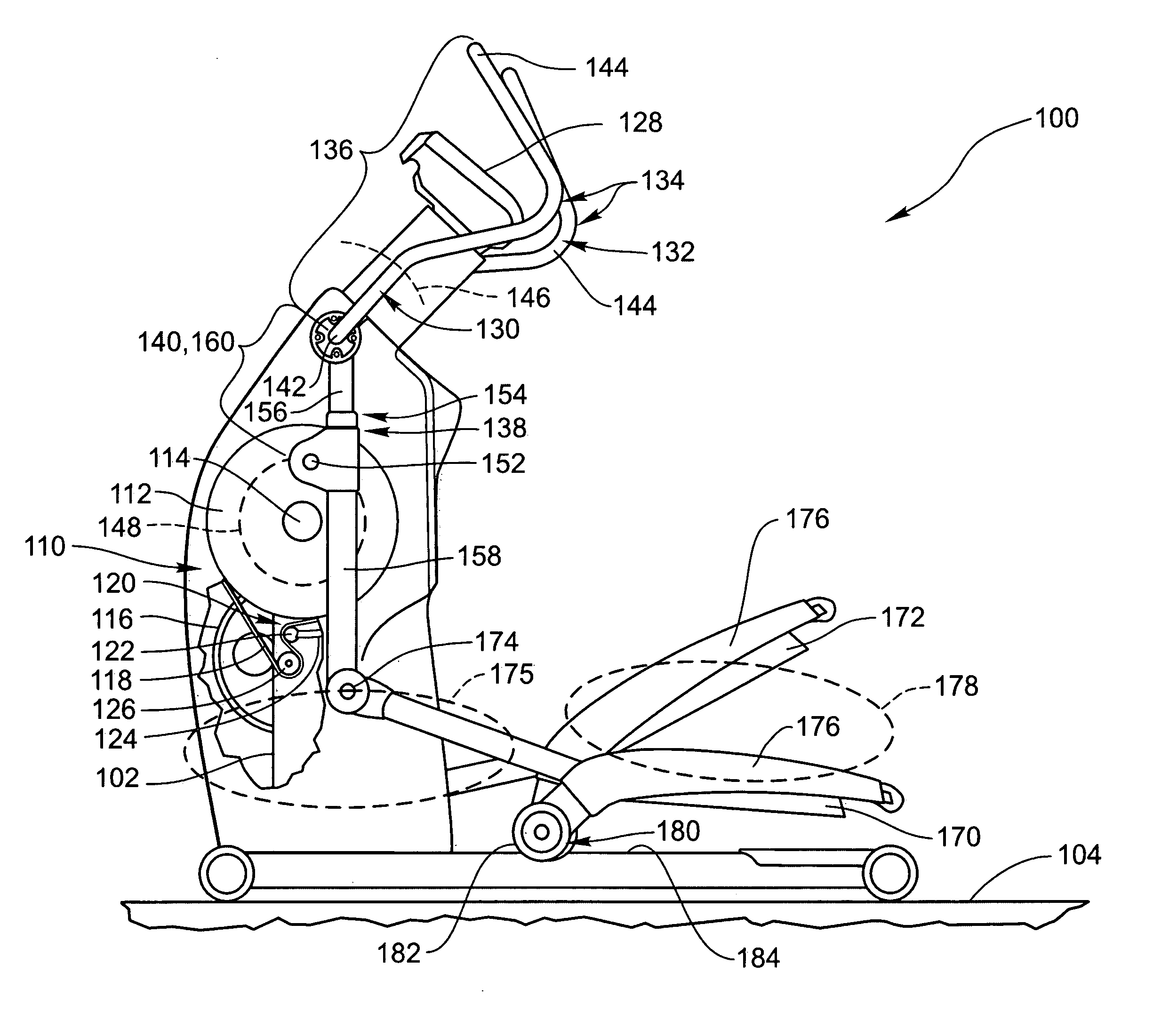

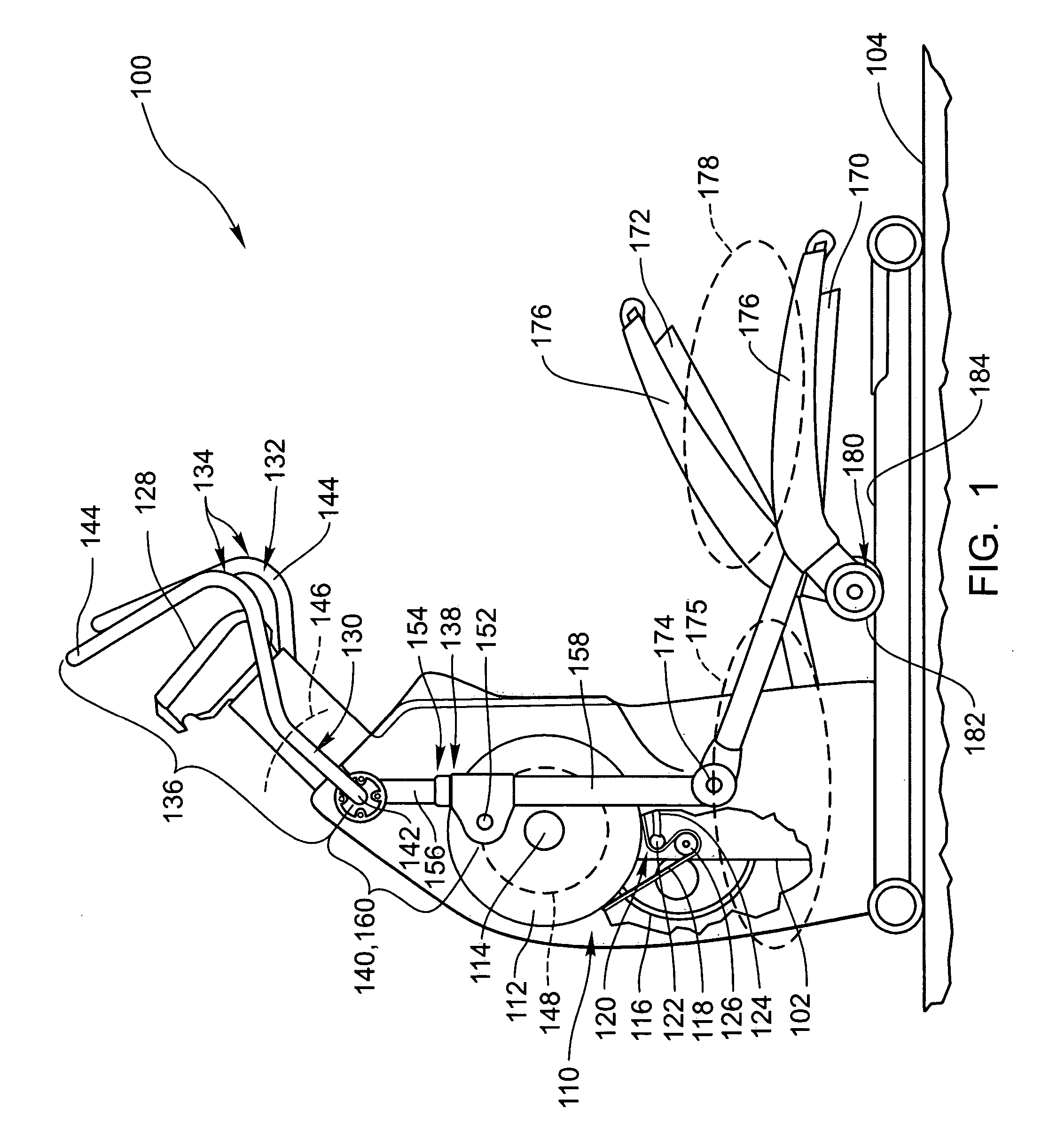

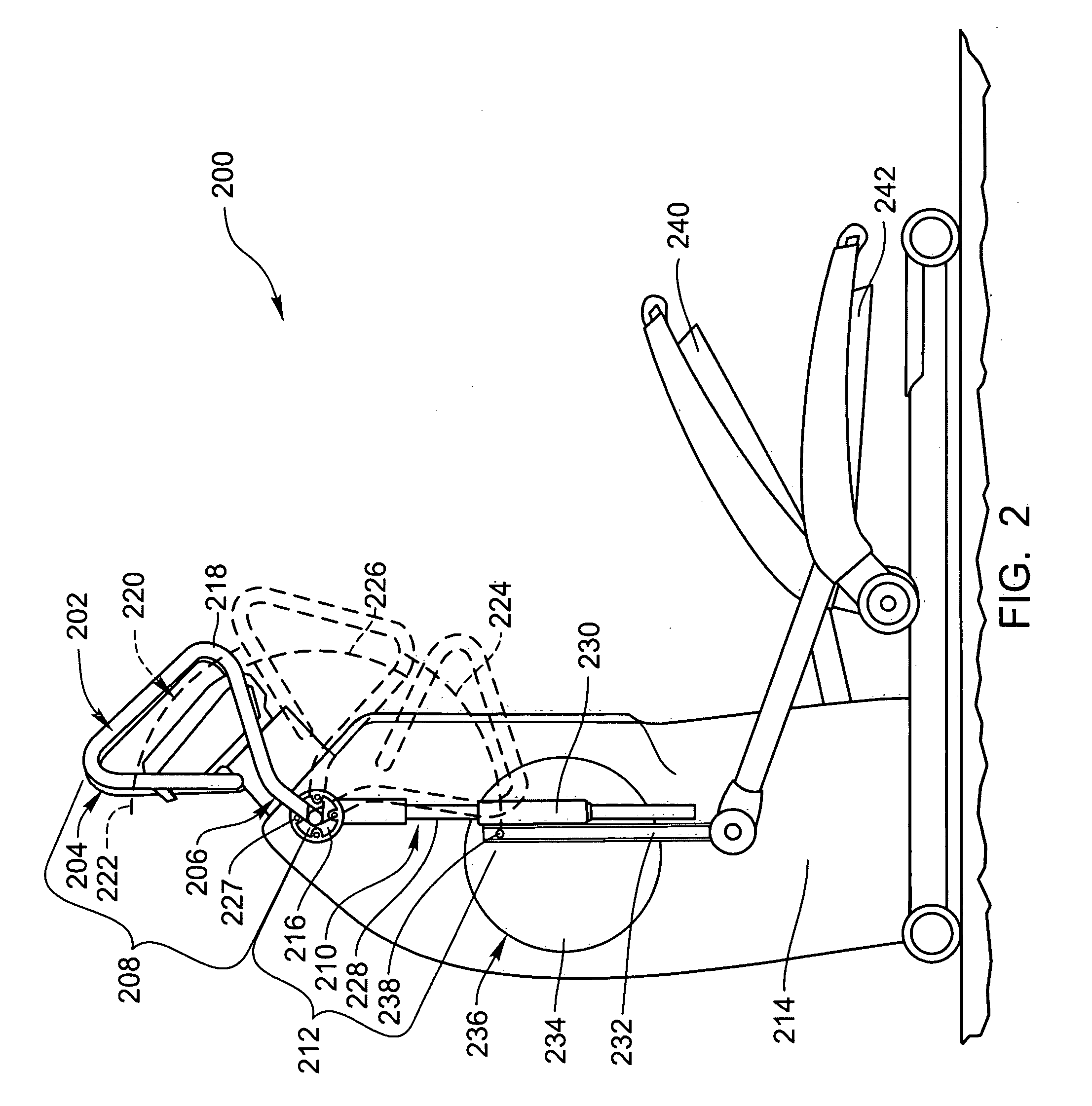

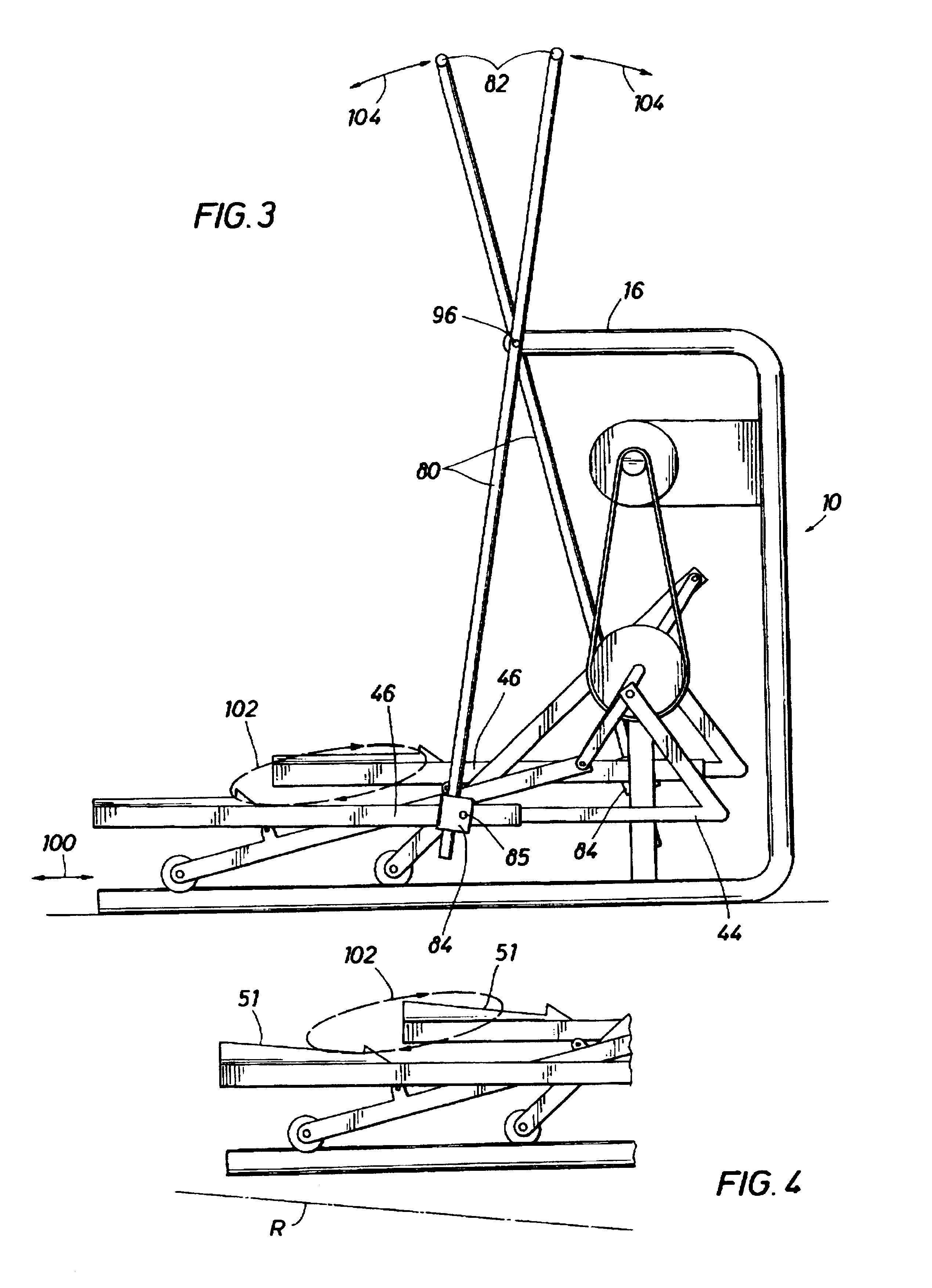

Exercising apparatus with varying length arms

InactiveUS20070117683A1Conserves the momentum generated by the movement of the userEasy to monitorSpace saving gamesFrictional force resistorsReciprocating motionEngineering

An exercise apparatus, such as a front end or an upright elliptical trainer, includes a drive mechanism connected to a first reciprocating member and a second reciprocating member. Each reciprocating member includes a footpad that travels in an elliptical path. The exercise apparatus also includes a first arm member and a second arm member connected to the drive mechanism. Each arm member includes a first portion having a handle that travels in a back and forth path and a second portion having at least a part of which that travels in a circular or elliptical path. To convert the circular motion of the second portion to the back and forth motion of the handle, the second portion has an effective variable length that permits the distance between a first connection point and a second connection point of the arm members to change as the drive mechanism is actuated.

Owner:ICON IP

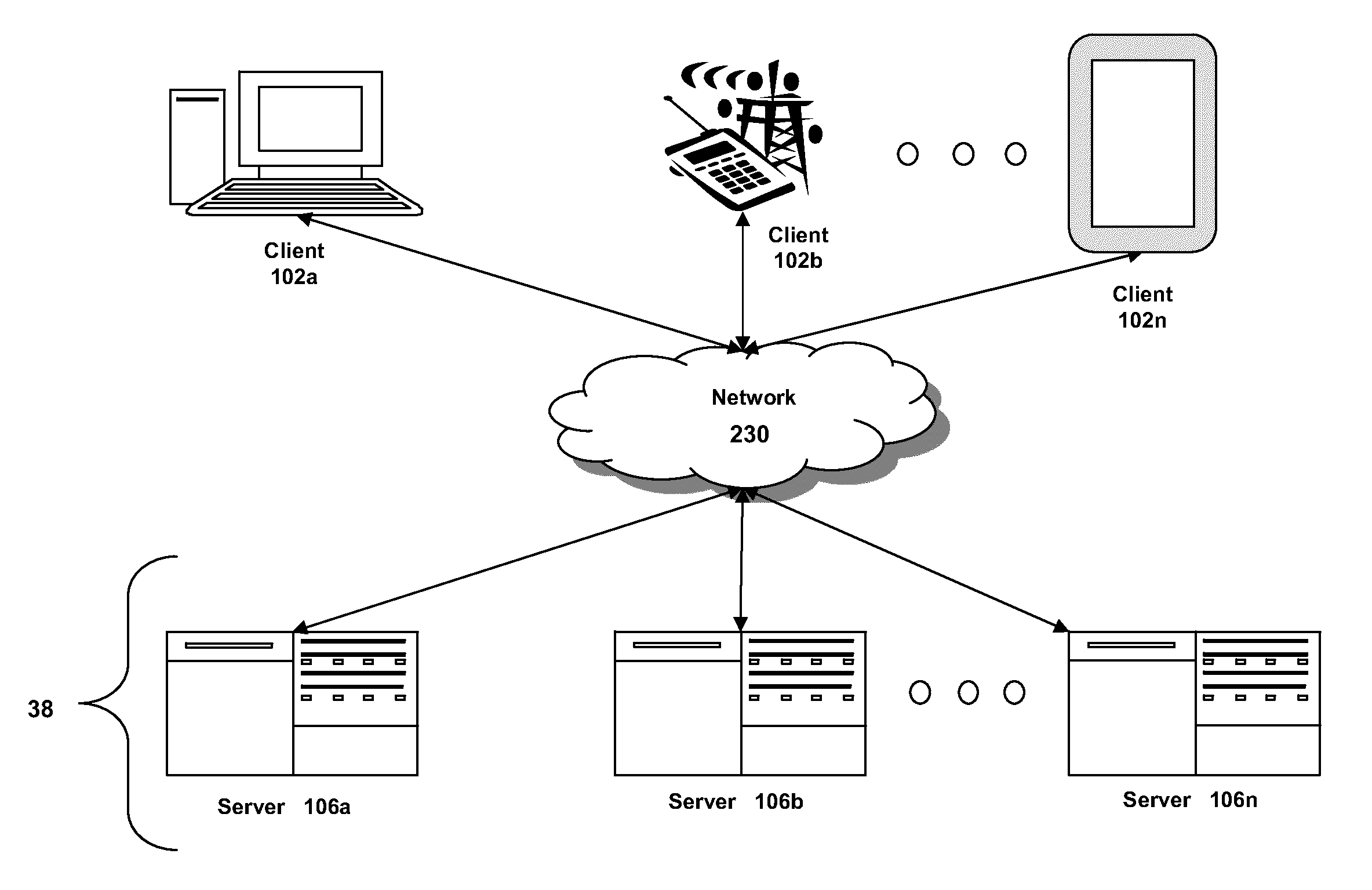

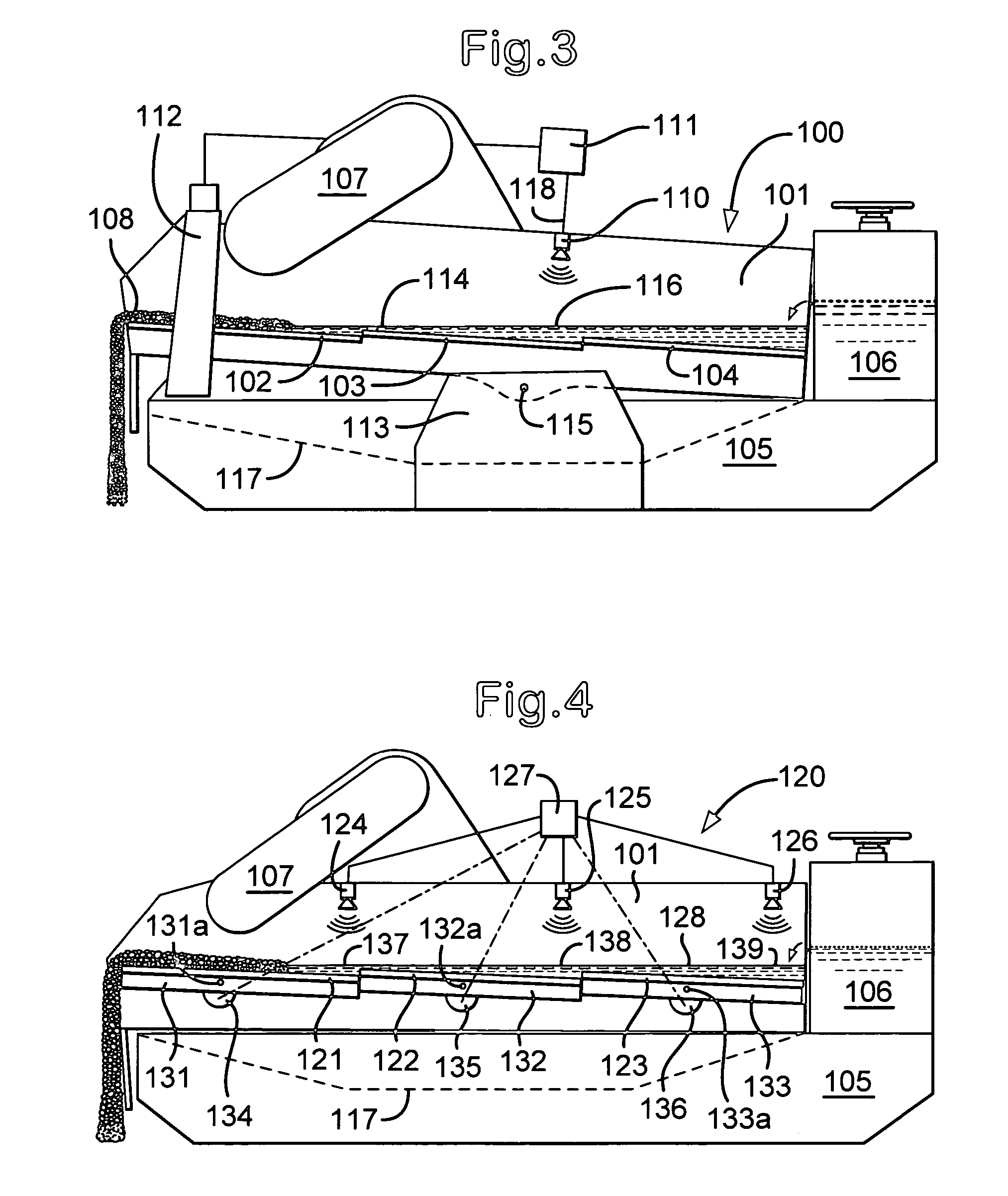

Wireless sensor network for determining cardiovascular machine usage

InactiveUS20130127636A1Electric signal transmission systemsWireless architecture usageWireless sensor networkingEngineering

To provide users the ability to track their cardiovascular exercise and determine cardiovascular exercise machine usage, the present system and methods describe an activity tracking platform. The platform includes a wireless sensor configured to monitor a piece of cardiovascular exercise equipment. The sensor can be configured and positioned to monitor a moving part of the exercise equipment, such as the spinning tread of a treadmill or the circular movement of a bike peddle. Responsive to detecting activity, the sensor can associate the data with a specific user and, using a wireless sensor network, transmit the data to a central server. The platform provides the user an associated website, where the user may view historical workout information, current exercise equipment usage at a local gym, or current workout goals.

Owner:CARDIBO

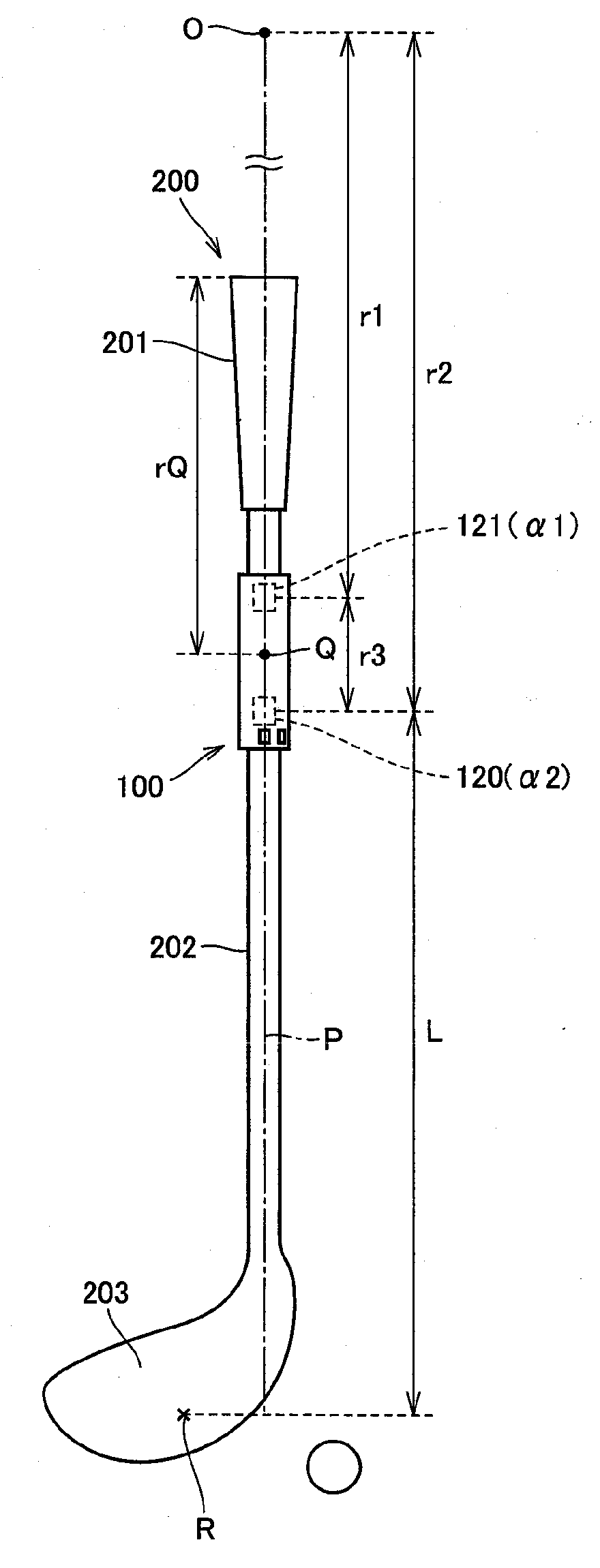

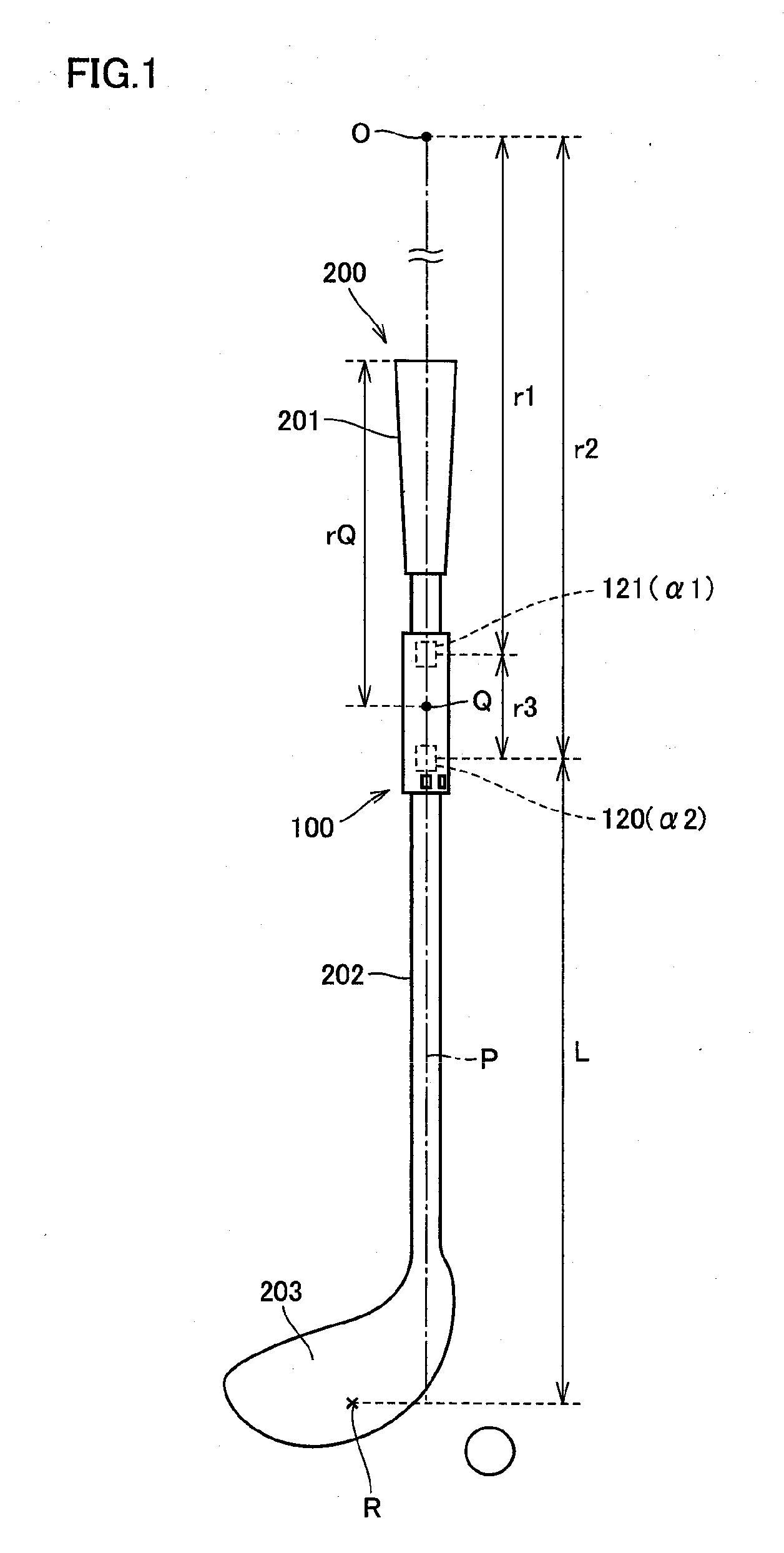

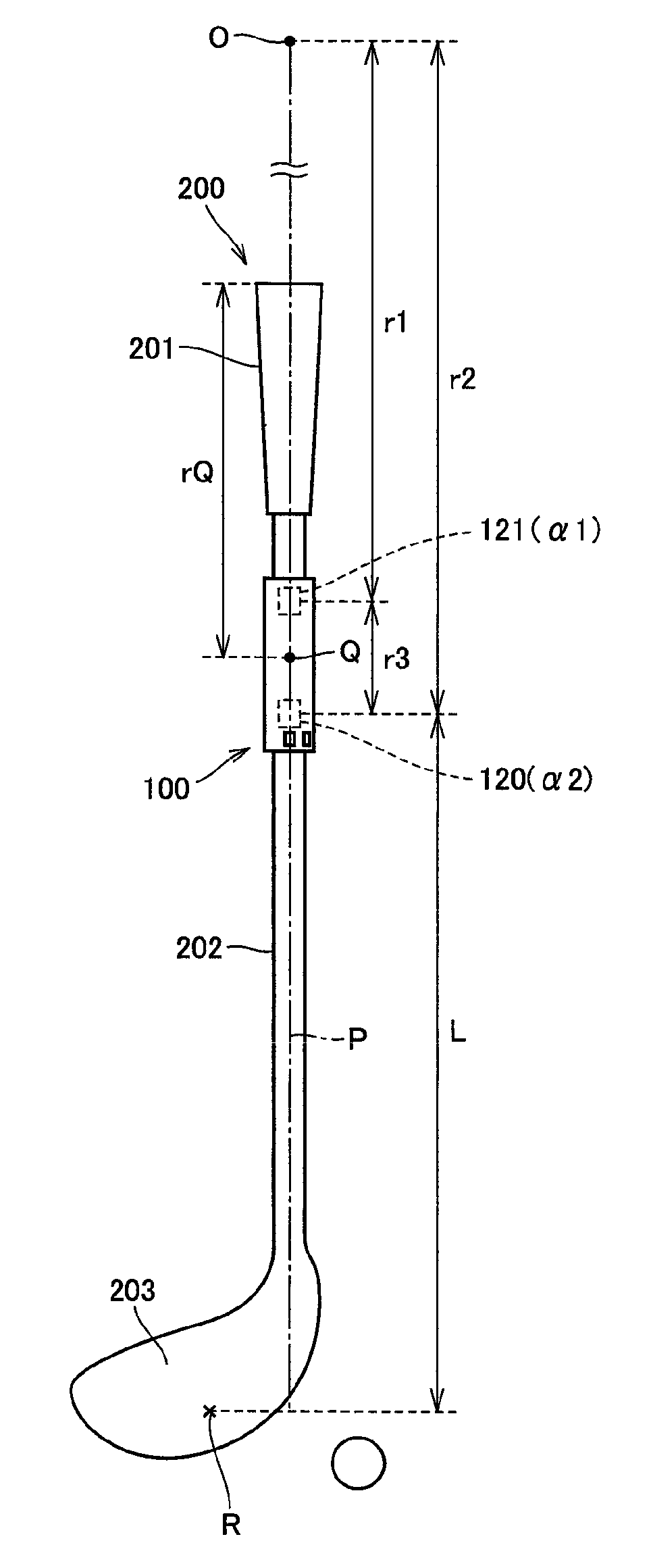

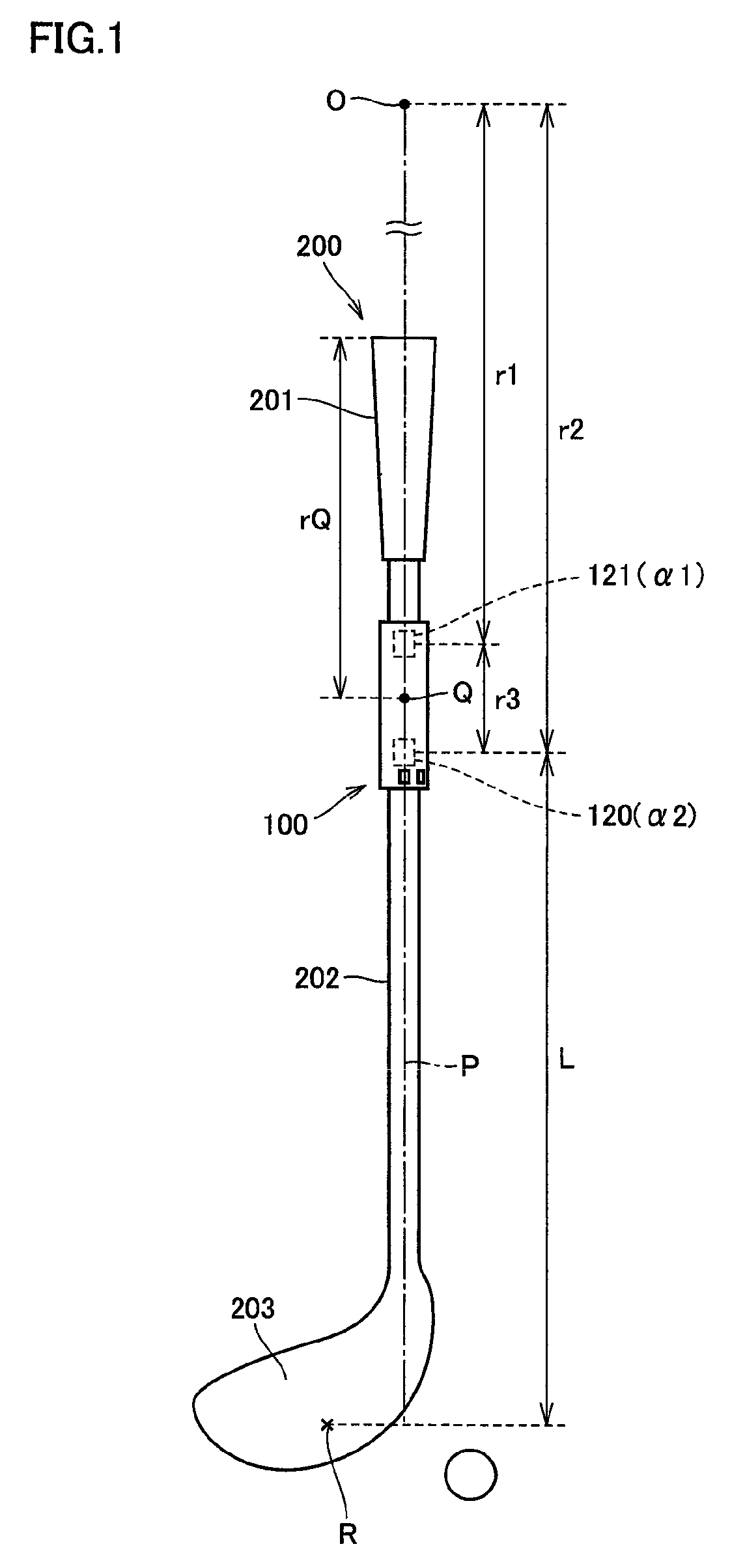

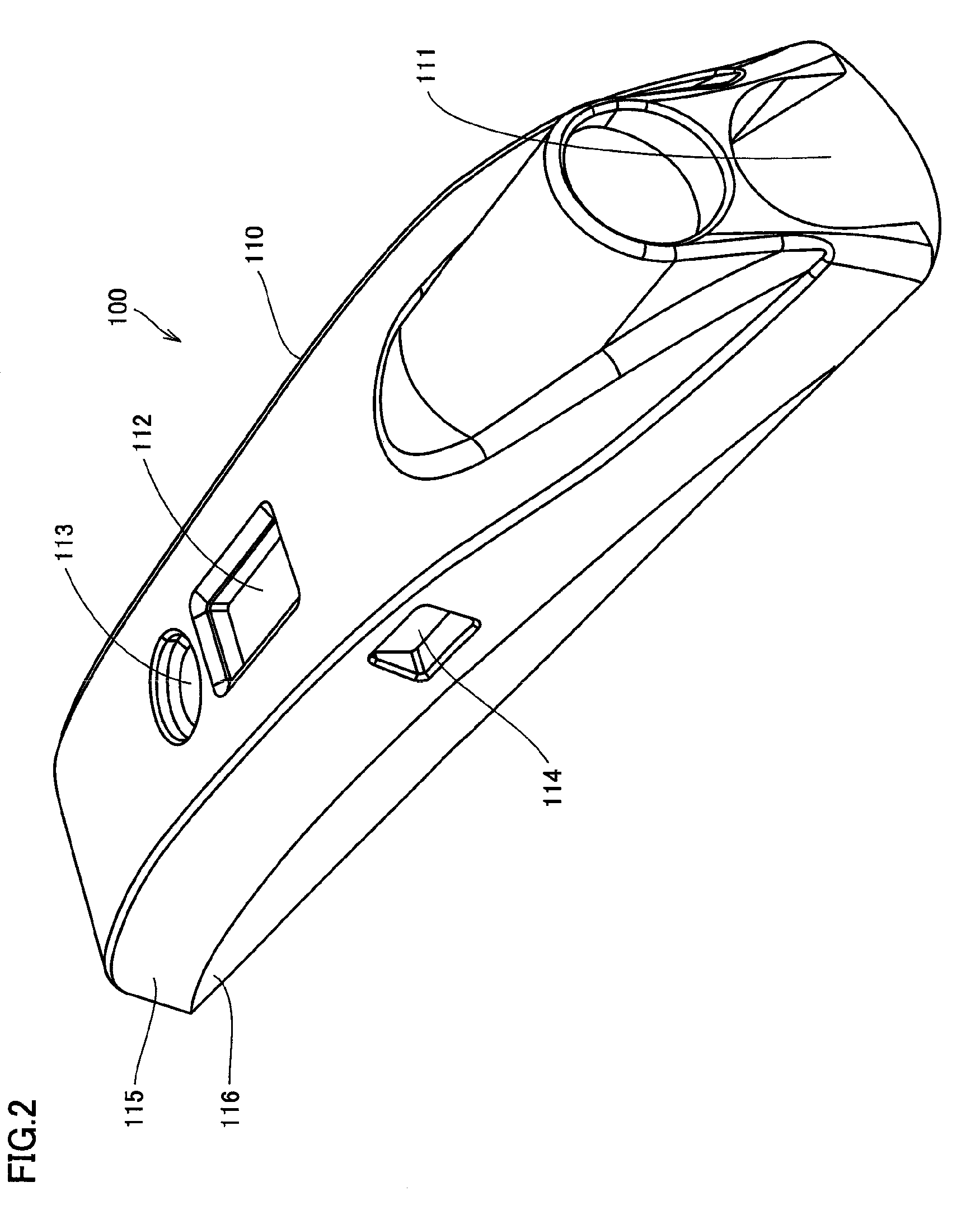

Swing analyzer

InactiveUS20090247312A1Accurate calculationReduce manufacturing costGolfing accessoriesGolf clubsEngineeringGolf Ball

A calculating unit of a swing analyzer calculates, assuming that a golf club is in a uniform circular motion about a virtual center of rotation 0 during a swing, a virtual speed Vh at a central point R of a golf club head, based on a distance between first and second acceleration sensors, a distance between the first acceleration sensor and the central point R of a golf club head and outputs from the first and second acceleration sensors, and calculates the speed of central point R of a golf club head utilizing the virtual speed Vh.

Owner:MIZUNO CORPORATION

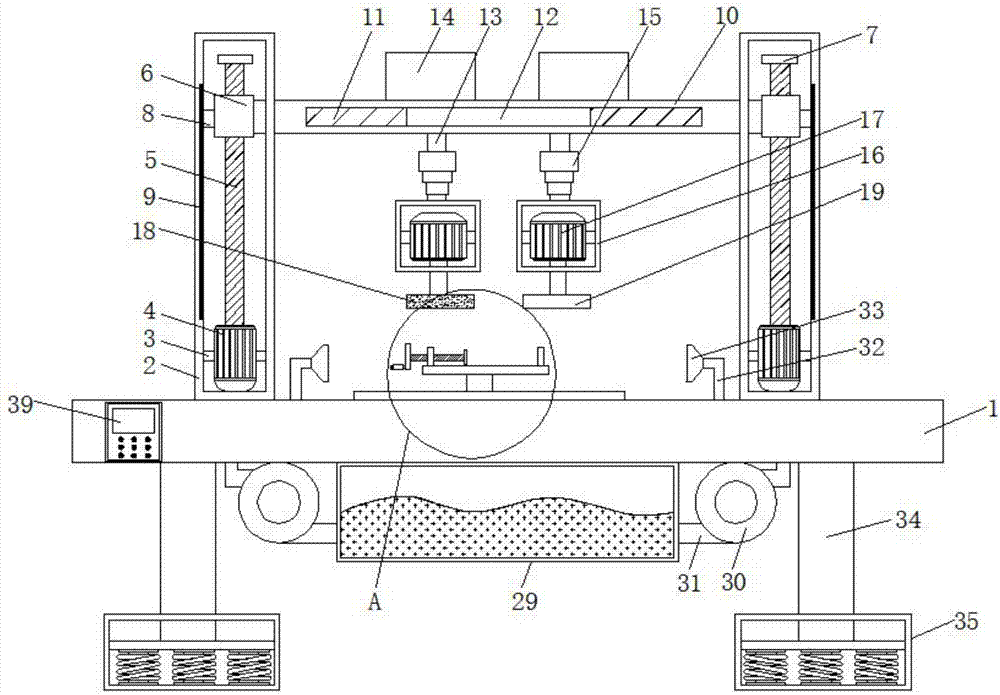

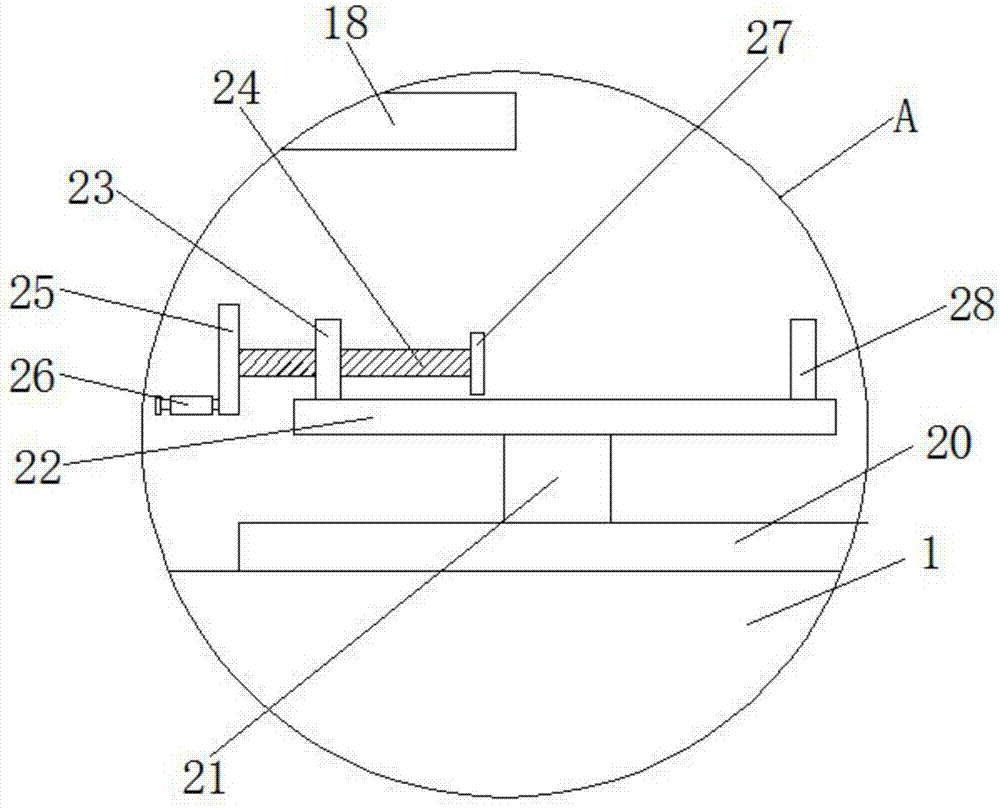

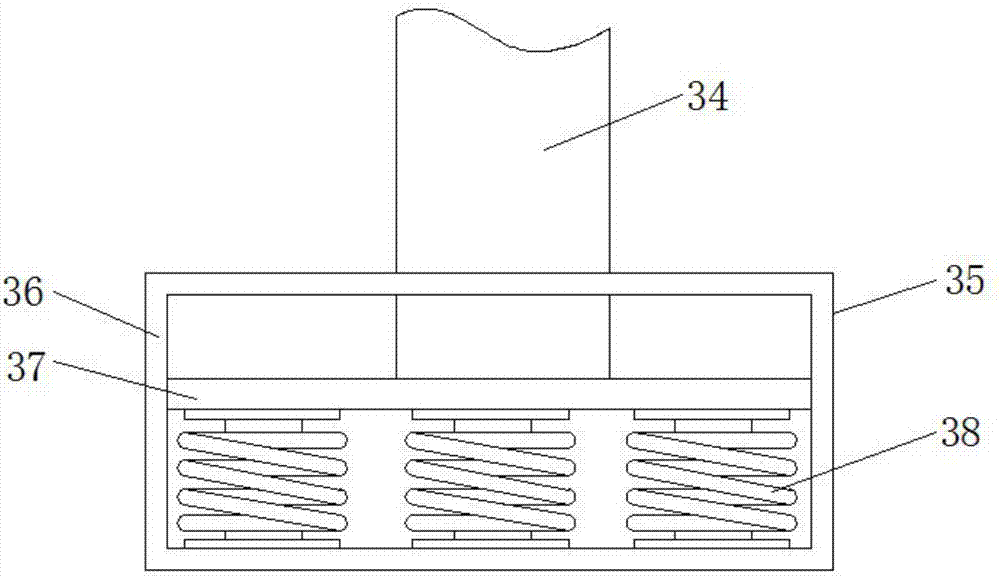

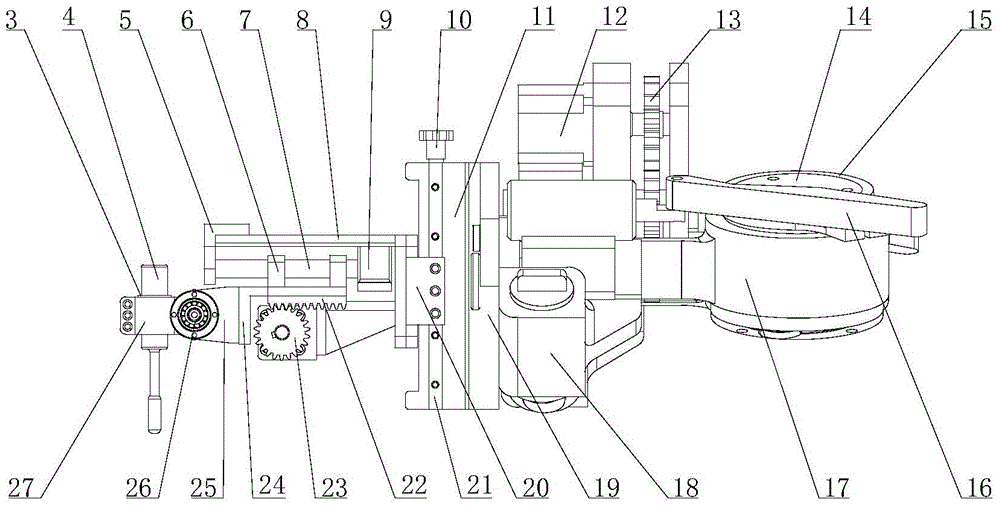

Automobile gear end surface polishing device

InactiveCN107336096AQuality improvementEasy to polishGrinding carriagesGrinding work supportsGear wheelEngineering

The invention provides an automobile gear end surface polishing device, and relates to the technical field of automobile gear polishing. The automobile gear end surface polishing device comprises a working table, standing columns are fixedly installed on both sides of the top of the working table, and motor mounting blocks are fixedly installed on both sides of the inner wall of each standing column. According to the automobile gear end surface polishing device, through arrangement of telescopic motors, threaded rods, telescopic blocks, sliding rods, a strip-shaped sliding groove and a cross plate, a polishing device body on the bottom of the cross plate can vertically move between the two standing columns under driving of the telescopic motors; through arrangement of the cross plate, the sliding groove and supports, the polishing device body on the bottom of the cross plate can transversely move on the bottom of the cross plate; through arrangement of a polishing table, a rotating rod and a clamping base, a gear to be polished which is fixed to the top of the clamping base in a clamped mode can conduct circular motion on the bottom of a polishing motor under driving of the rotating rod. In sum, by means of the automobile gear end surface polishing device, the effect that adjustment is convenient is achieved, it is convenient for people to polish the end surface of the gear from different angles, and the quality of the gear after polished is better.

Owner:姚飞

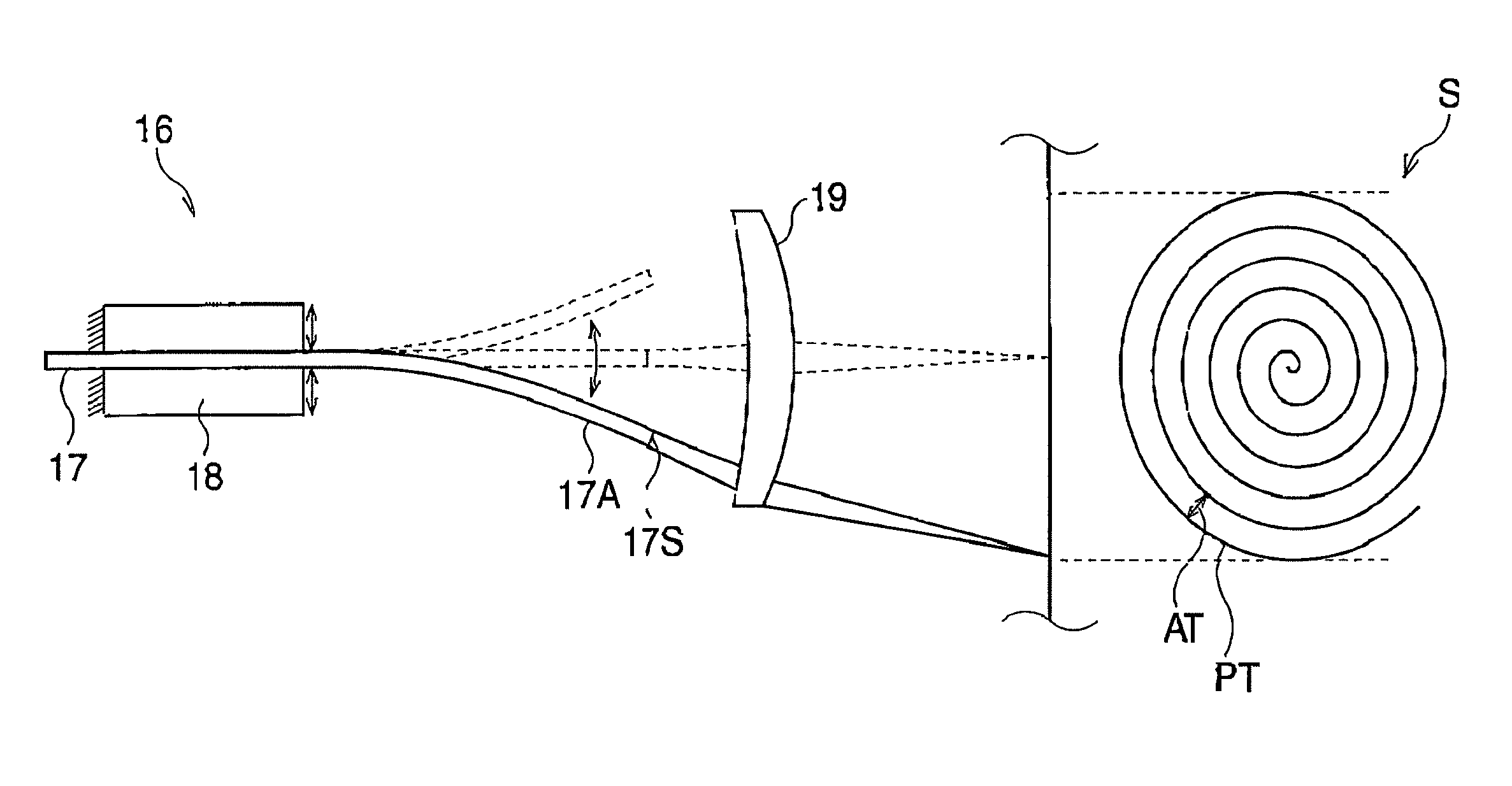

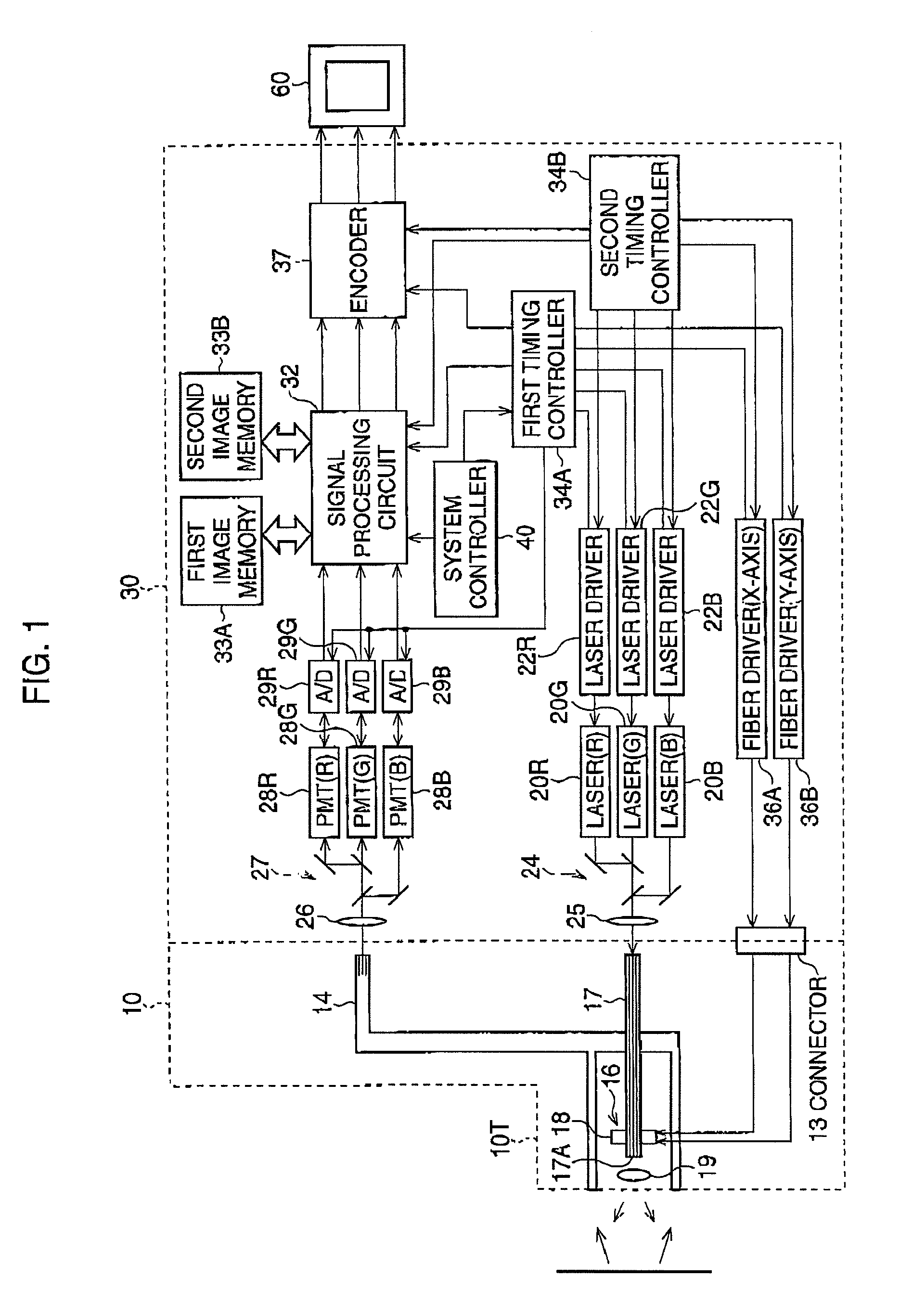

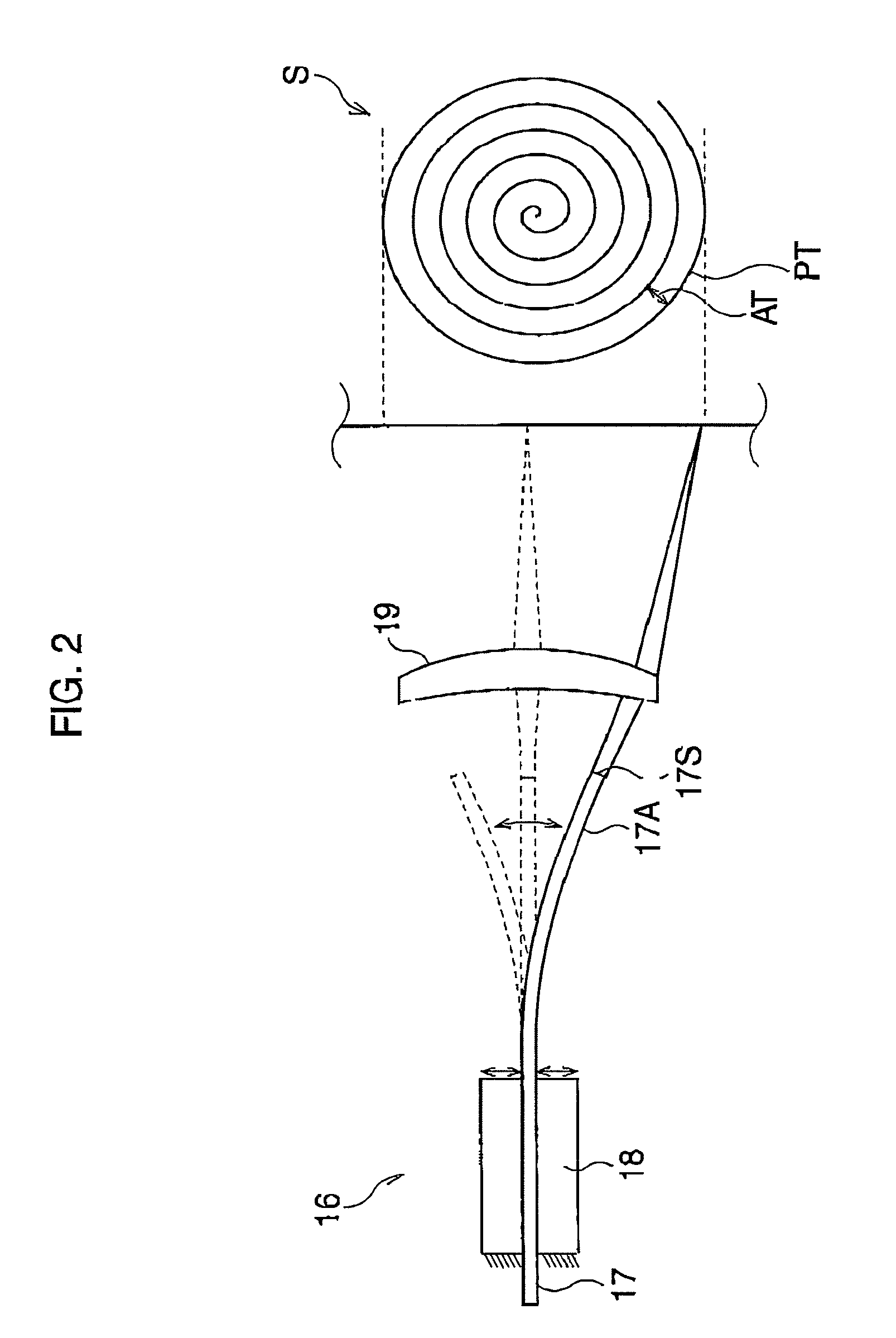

Endoscope system with scanning function

An endoscope system has an optical fiber configured to transmit illumination light emitted from a light source to the tip portion of a scope; a scanner configured to spirally scan a target area with illumination light by vibrating the tip portion of said optical fiber; and an image generator configured to generate image data from image-pixel signals obtained from the light reflected from the target area. Then, the scanner scans the illumination light in a circular motion midway through a spiral scanning procedure.

Owner:HOYA CORP

Playback control using a touch interface

This is directed to controlling media playback based on particular touch gestures detected by a touch-sensing interface. The electronic device can identify particular touch inputs, such as combinations of tapping and holding a touch sensitive surface, or circular motions. In response to detecting a particular touch gesture, the electronic device can perform a playback operation specifically associated with the detected touch gesture. To provide a consistent user interface with the device, some of the particular touch gestures can match other inputs provided using a button, for example a button integrated on a wired headset. In such an embodiment, the same combination of tapping and holding a touch input and pressing and holding a button can control the same electronic device operations.

Owner:APPLE INC

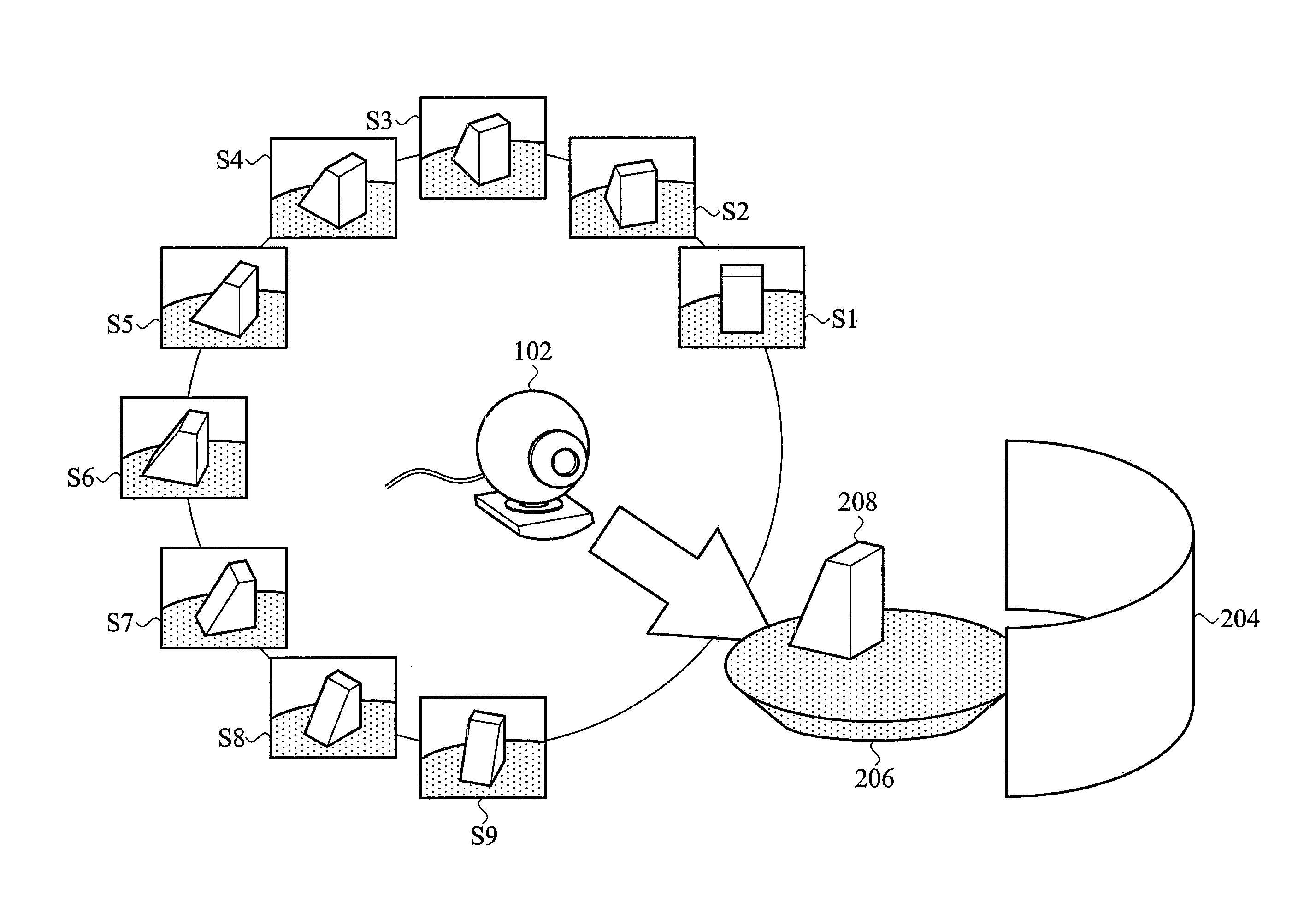

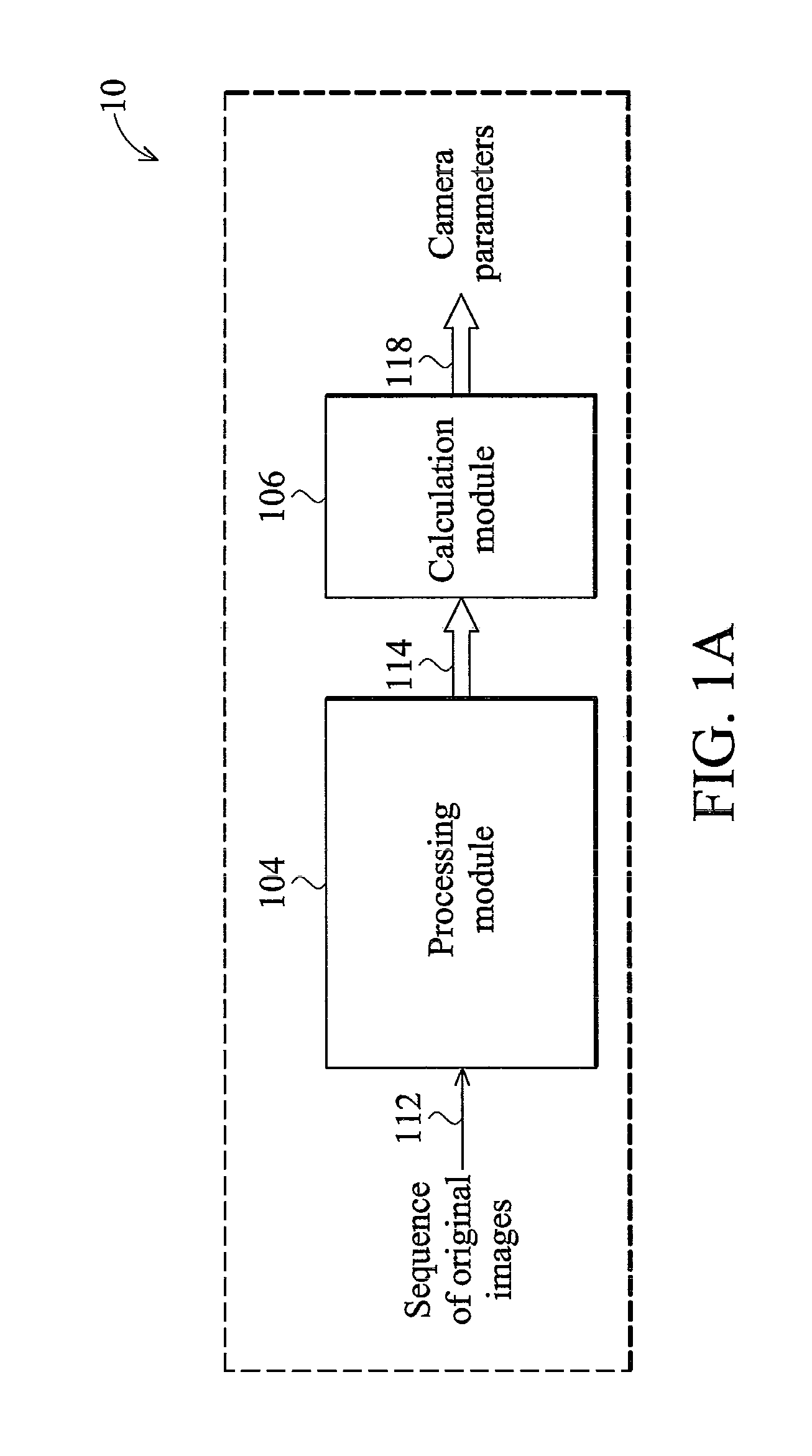

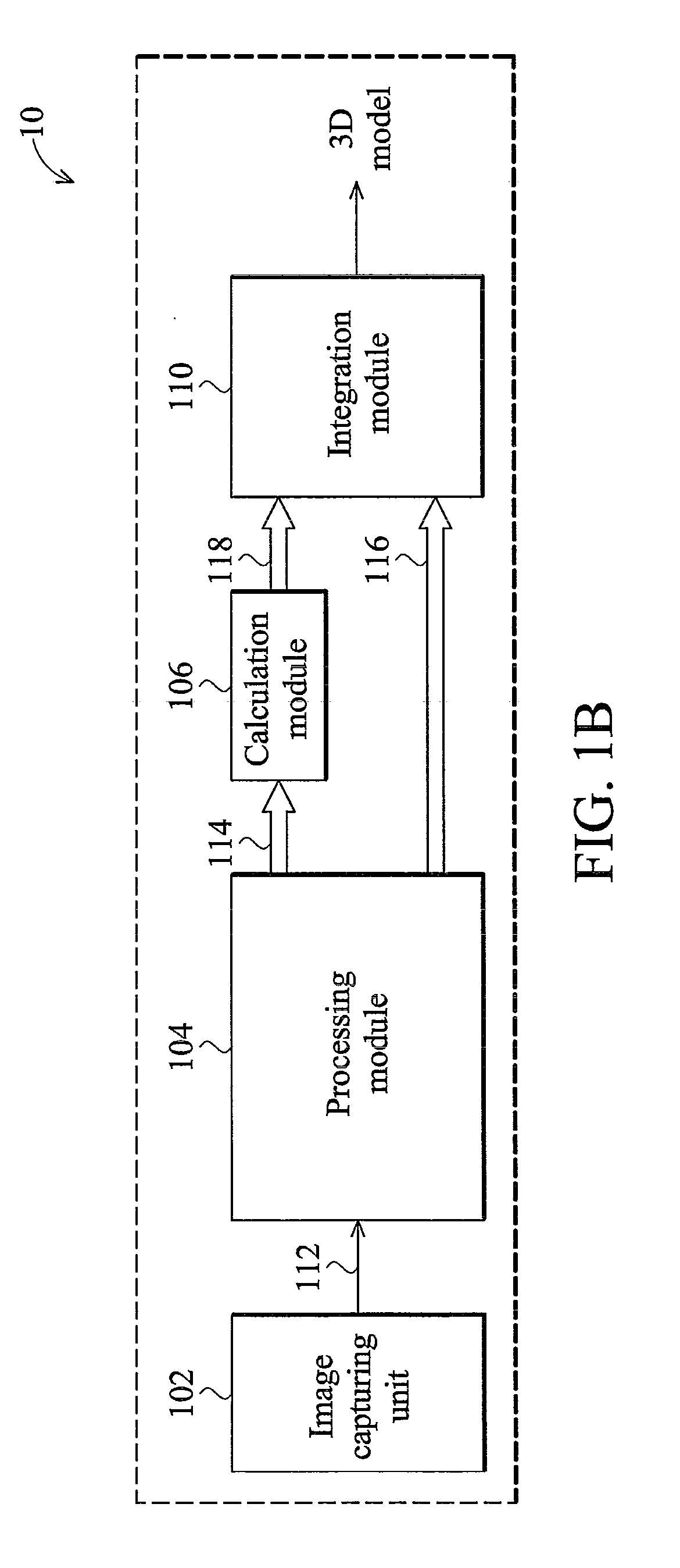

System and method for obtaining camera parameters from multiple images and computer program products thereof

Systems and methods for obtaining camera parameters from images are provided. First, a sequence of original images associated with a target object under circular motion is obtained. Then, a background image and a foreground image corresponding to the target object within each original image are segmented. Next, shadow detection is performed for the target object within each original image. A first threshold and a second threshold are respectively determined according to the corresponding background and foreground images. Each original image, the corresponding background image, the first and second threshold are used for obtaining silhouette data and feature information associated with the target object within each original image. At least one camera parameter is obtained based on the entire feature information and the geometry of circular motion.

Owner:INSTITUTE FOR INFORMATION INDUSTRY

Apparatus for mixing fluids

InactiveUS6669843B2Eliminate needLiquid separation auxillary apparatusSpace heating and ventilationGas passingSolid particle

Owner:HYDROTREAT

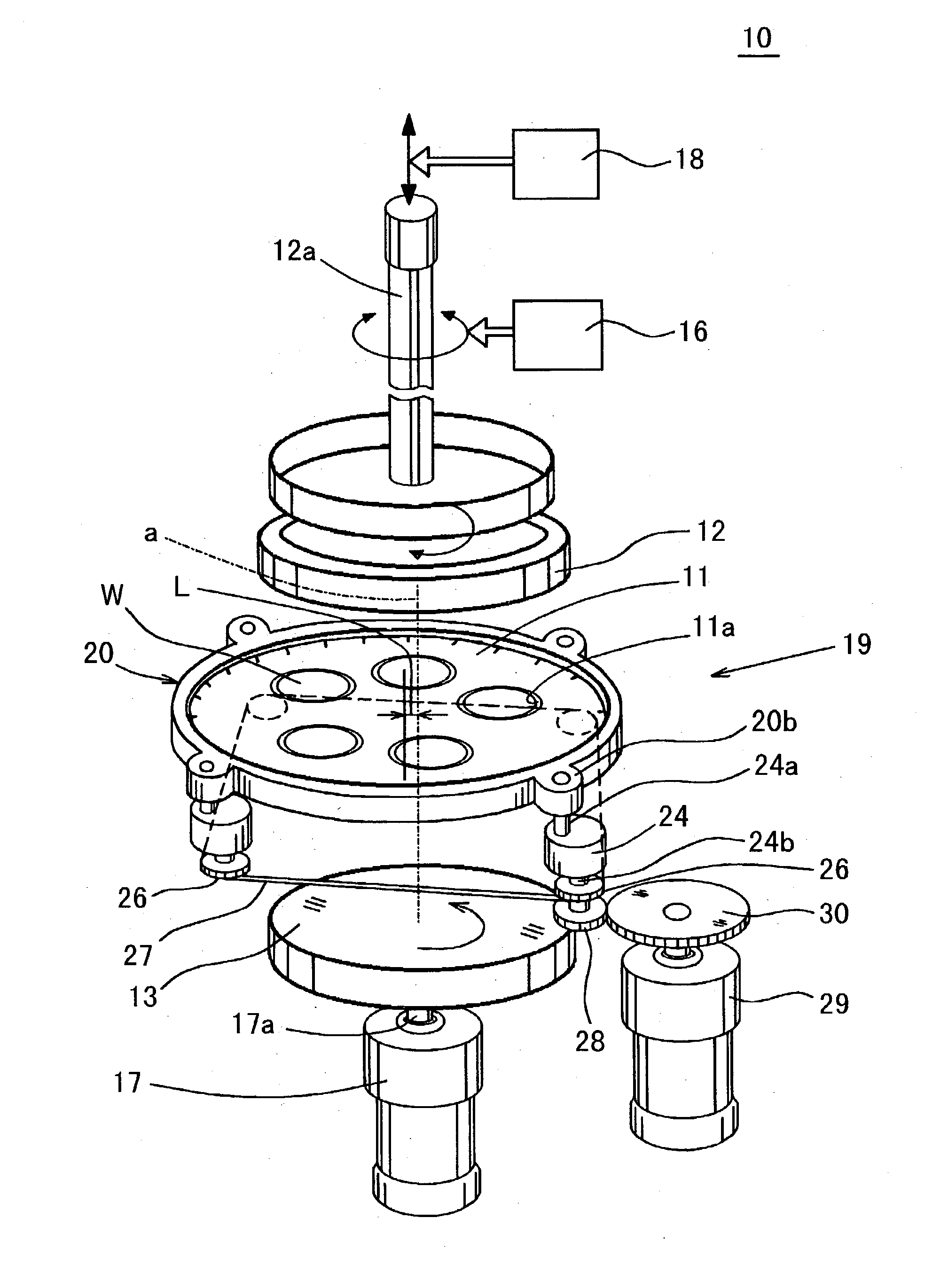

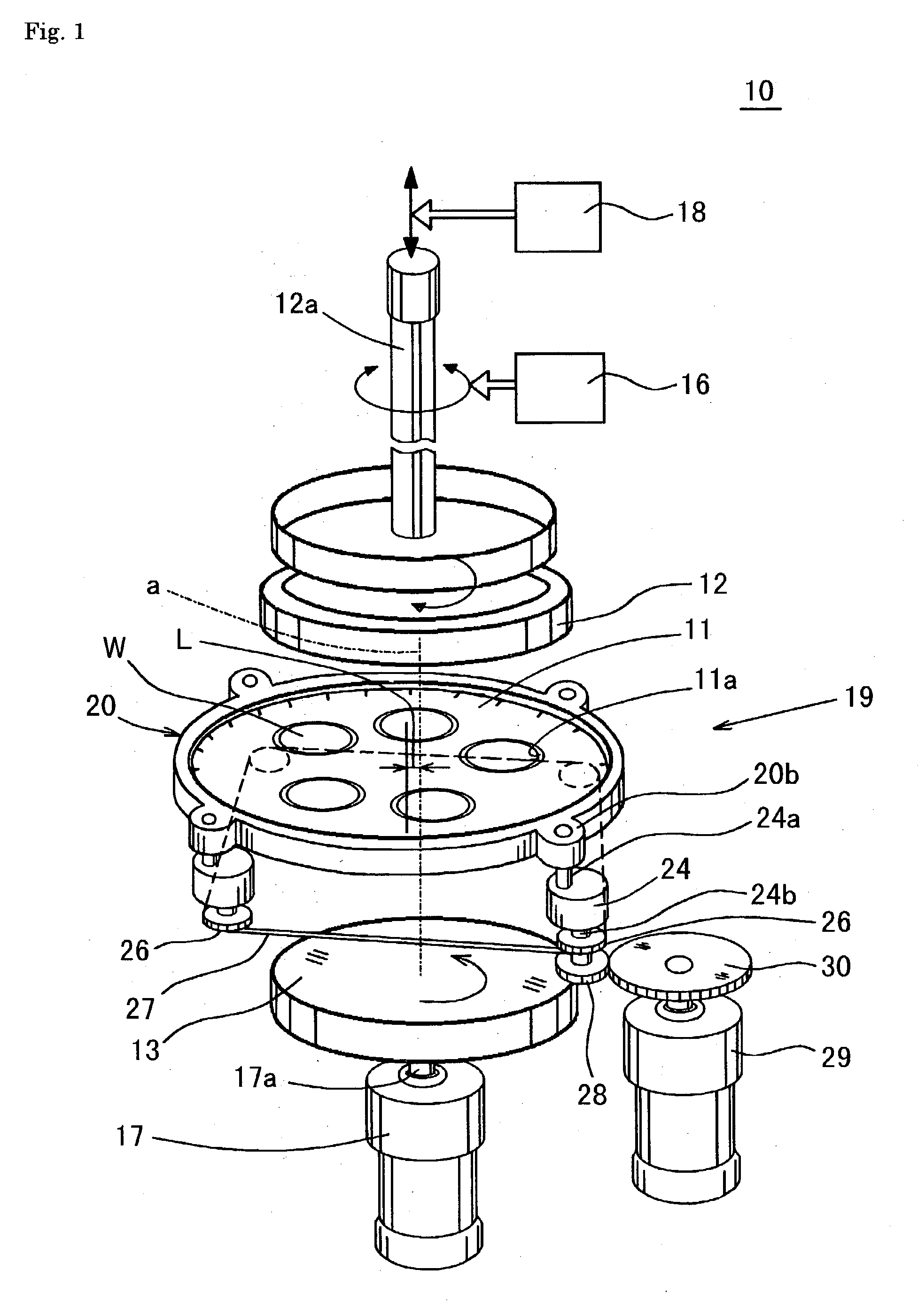

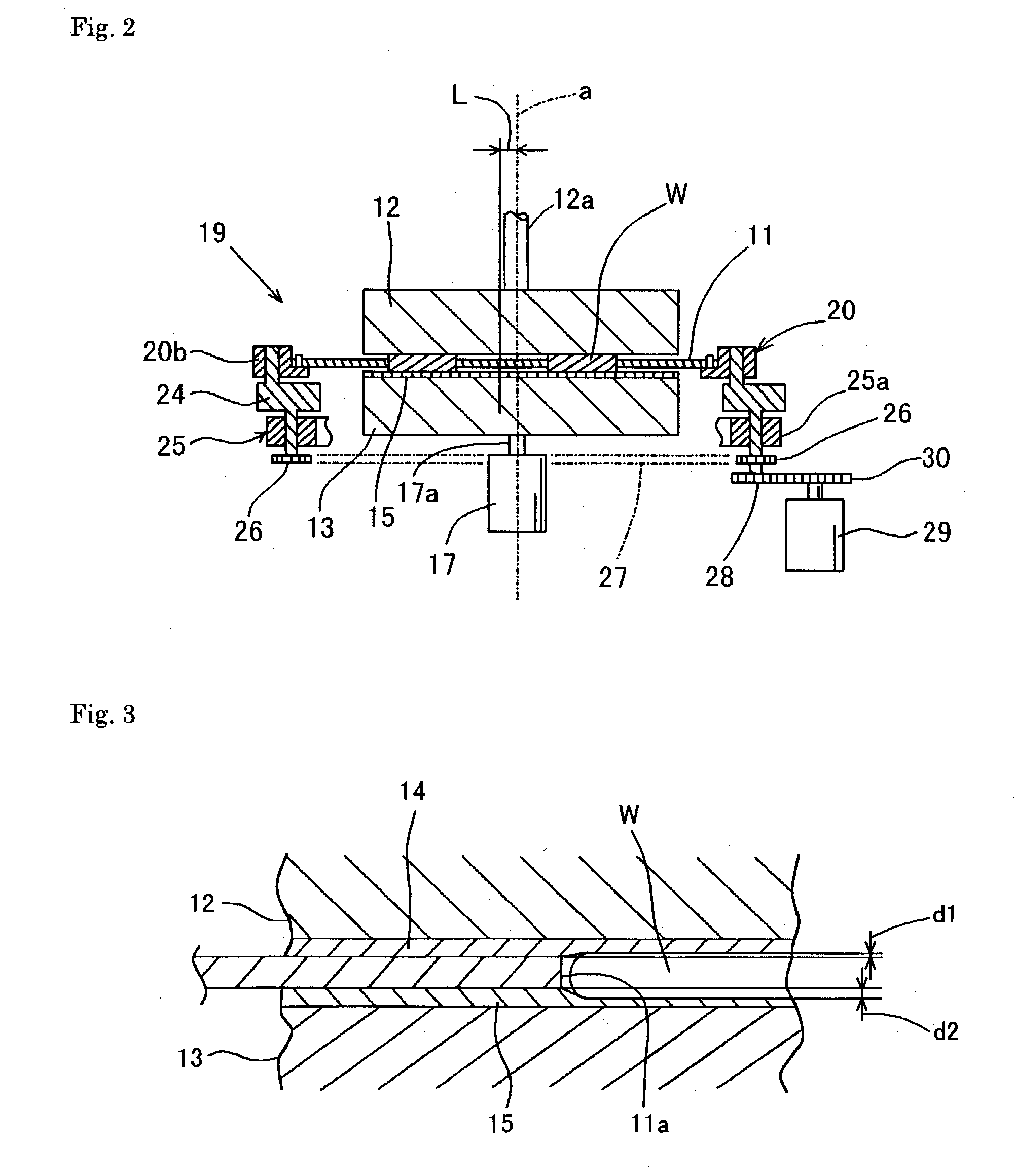

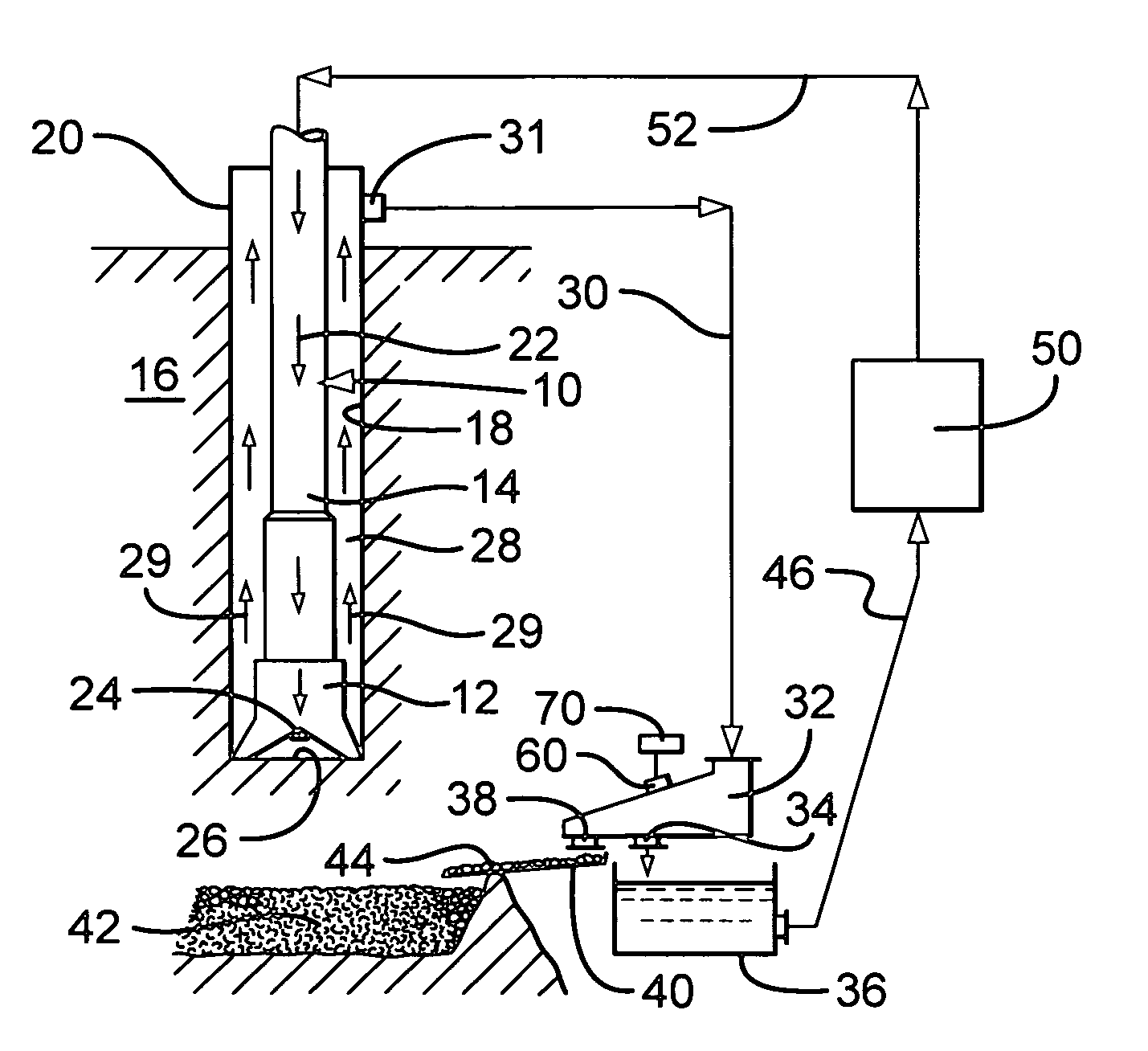

Method of manufacturing semiconductor wafer

ActiveUS20030104698A1Small polishing volumeShort polishing timePolishing machinesRevolution surface grinding machinesSlurryEngineering

An object of the present invention is to provide a semiconductor wafer having a front and a back surfaces polished so as to have different glossiness from each other, yet with a lower cost. The glossiness of the front surface and the back surface can be selected arbitrarily. In a double-sided polisher with no sun gear, silicon wafers W are inserted in respective holding holes 11a of a carrier plate 11. The wafers W are placed with their back surfaces facing up. An expanded urethane foam pad 14 is pressed against the back surfaces of the wafers W and a non-woven fabric pad 15 is pressed against the front surfaces of the wafers W. A carrier holder 20 and thus the carrier plate 11 are then driven to make a circular motion associated with no rotation on their own axes within a horizontal plane while supplying a slurry to the wafers W from an upper surface plate 12 side. As a result, each of the front and the back surfaces of respective silicon wafers W can be polished uniformly over entire area thereof respectively. At that time, the urethane pad 14 has a sink rate of the wafer lower than that of the non-woven fabric pad 15. Therefore, such a polished wafer having the back surface formed into a satin-finished surface and the front surface formed into a mirror-finished surface can be obtained. Alternatively, those polishing cloths having different sink rates from each other may be employed for the upper and the lower surface plates, respectively. Further, the upper surface plate and the lower surface plate may be rotated at different speeds from each other. Those methods are also advantageously used to manufacture the semiconductor wafer having different glossiness between the front surface and the back surface thereof.

Owner:SUMITOMO MITSUBISHI SILICON CORP

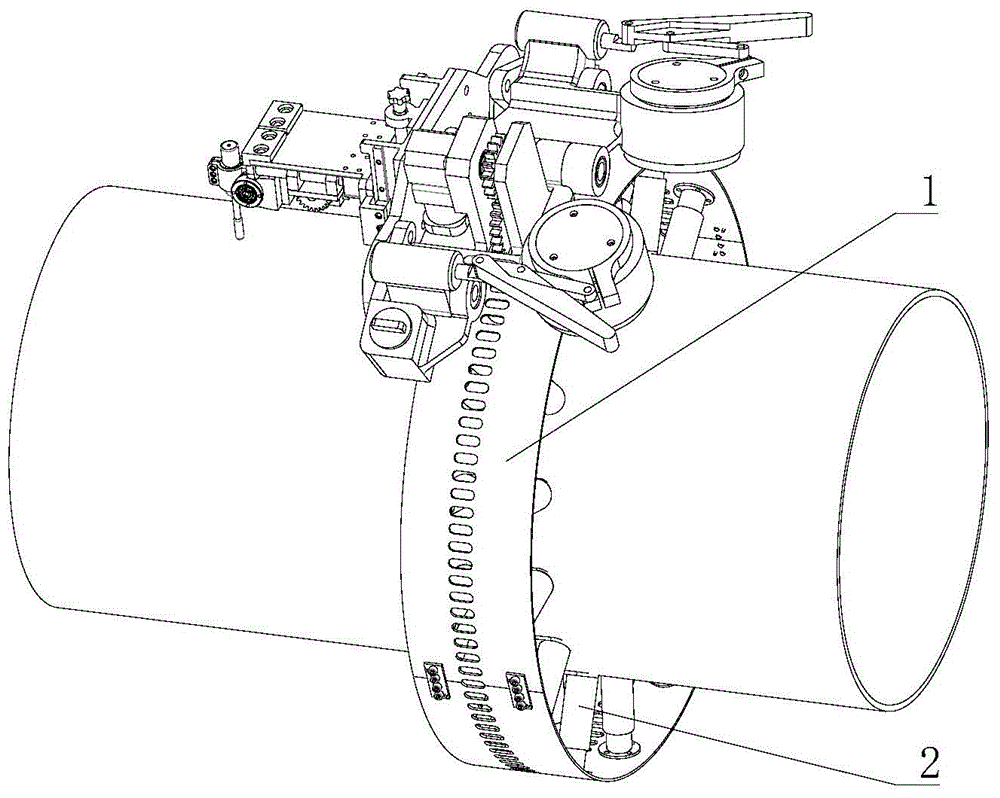

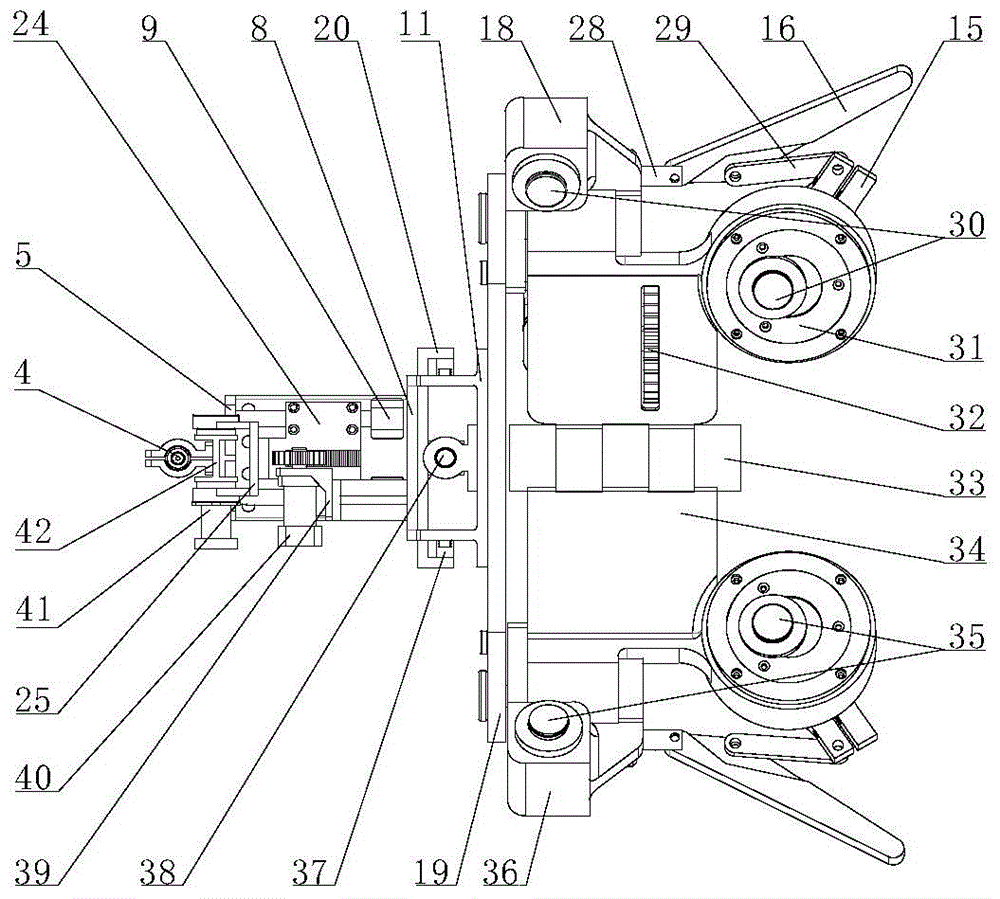

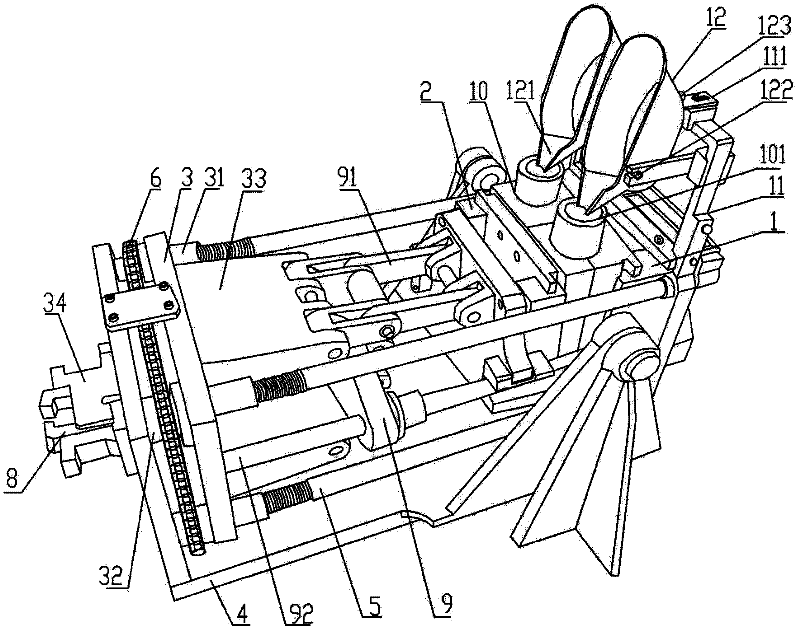

Elastic rail type automatic pipeline outer wall welding mechanism

InactiveCN104139265ASimple and fast operationCompact designWelding/cutting auxillary devicesAuxillary welding devicesLocking mechanismMiniaturization

The invention provides an elastic rail type automatic pipeline outer wall welding mechanism. Two cam bases are connected through a pin shaft, the two cam bases are adjustable in angle and suitable for different pipe diameters, and the two cam bases are fixed to a rail through cam locking mechanisms. An angle adjusting plate, wheel bases and cam bases can jointly form a basic framework of a welding trolley. The welding trolley are driven by gears and can do uniform circular motion around the elastic rail. A welding gun radial moving mechanism is arranged on the angle adjusting plate and is manually adjusted, a welding gun axial moving mechanism is connected to the radial moving mechanism, an axial moving driving motor can drive a rack to move to achieve axial welding gun movement, a welding gun swinging mechanism is arranged at the front end of a rack supporting seat, and a welding gun is directly driven by a stepping motor to swing around the welding joint center in a cycling and reciprocating mode. The elastic rail type automatic pipeline outer wall welding mechanism has the advantages of achieving miniaturization and modularization and being light in weight, even in weight distribution, economical and practical, simple to control, stable in operation and conveniently matched with various walking mechanisms of pipeline outer wall welding machines.

Owner:HARBIN ENG UNIV

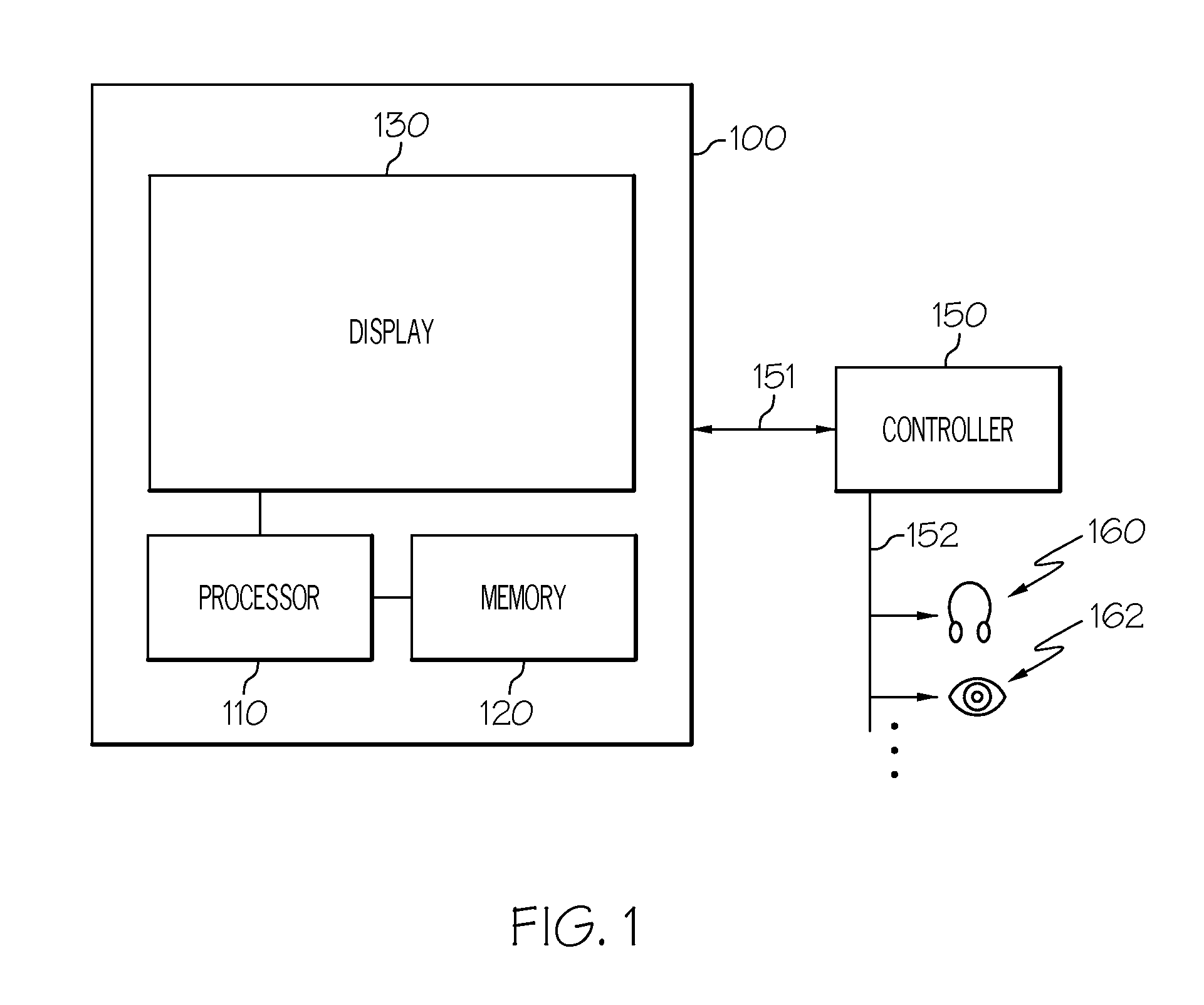

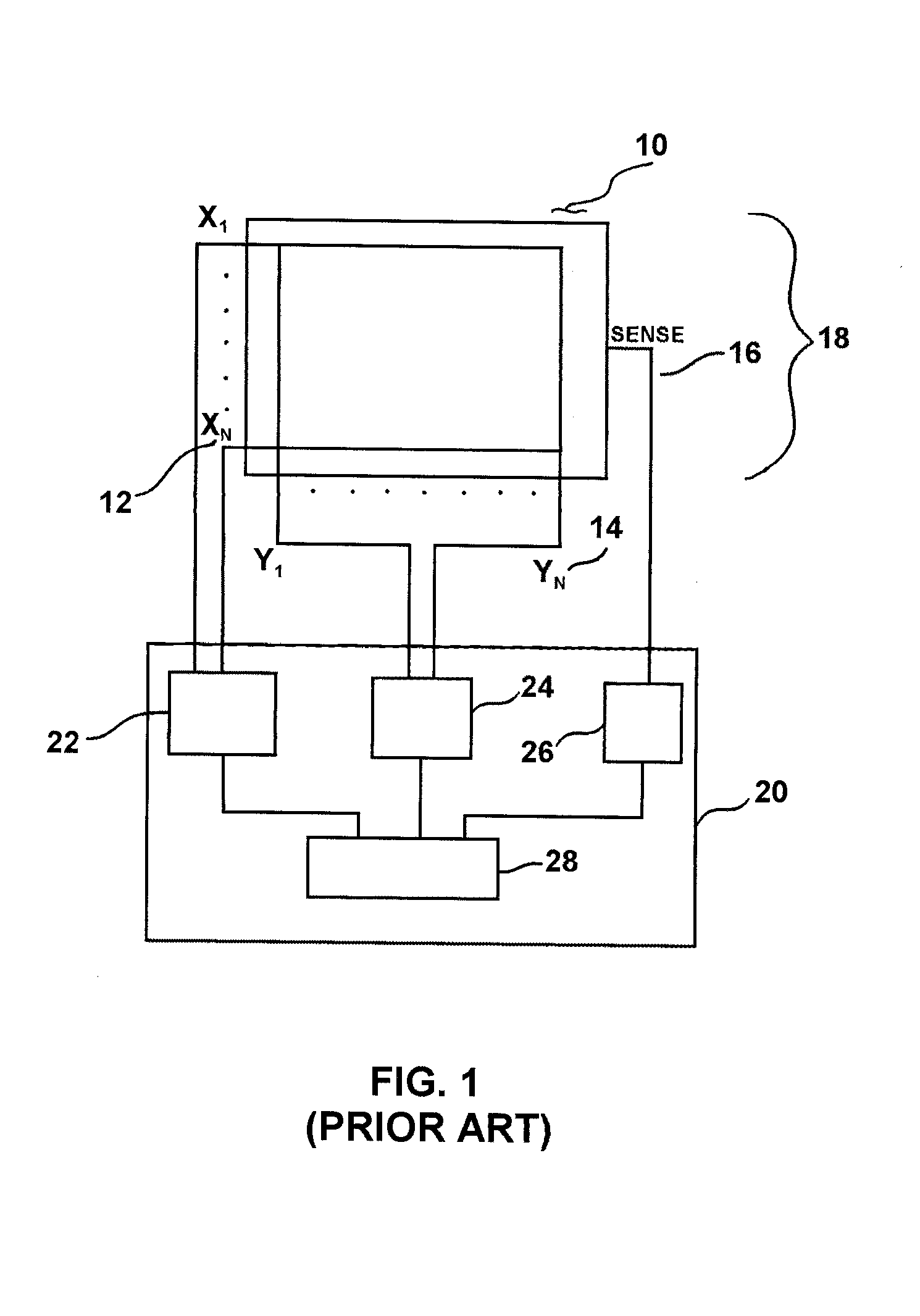

Method and apparatus for gesture recognition

InactiveUS20120110517A1Input/output for user-computer interactionGraph readingTouchscreenManipulator

A touchscreen device is configured to display a number of user interface elements in accordance with a menu hierarchy. Upon receipt of a predetermined touchscreen gesture (e.g., the circular motion of a manipulator) the menu hierarchy is bypassed and the user is given immediate control over a selected function, for example, a tuning function such as audio volume, screen contrast, and the like.

Owner:HONEYWELL INT INC

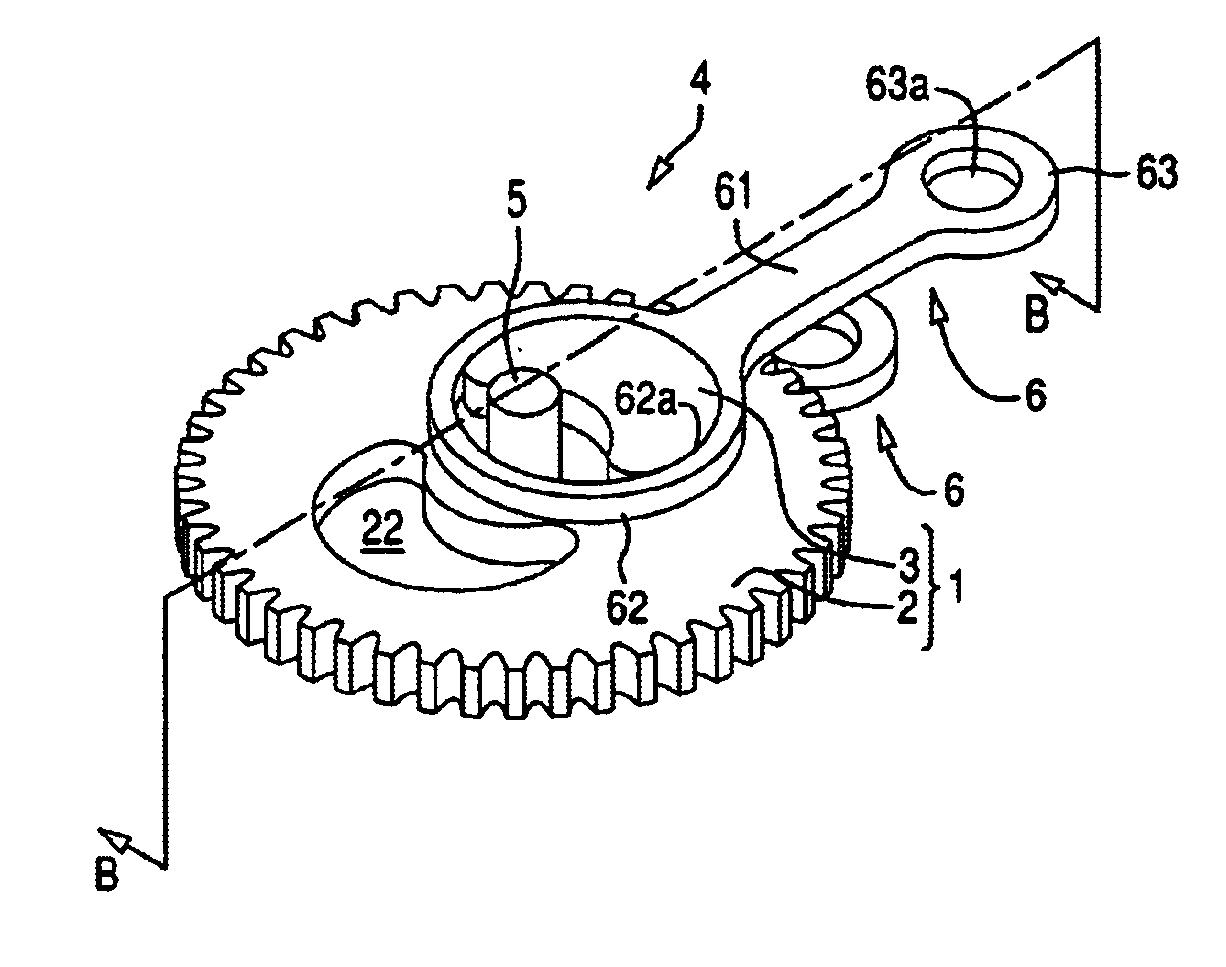

Antenna phase-shift system

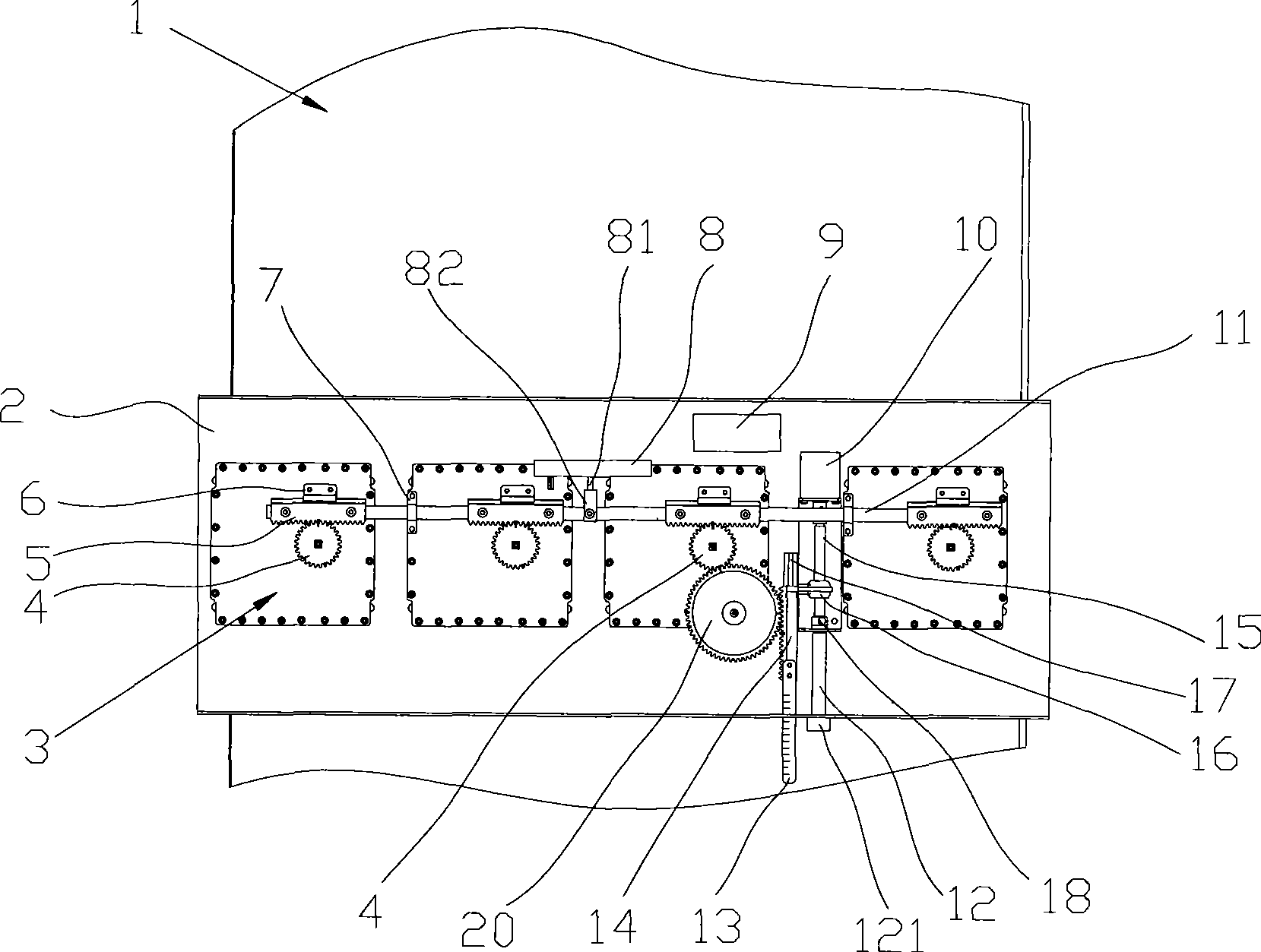

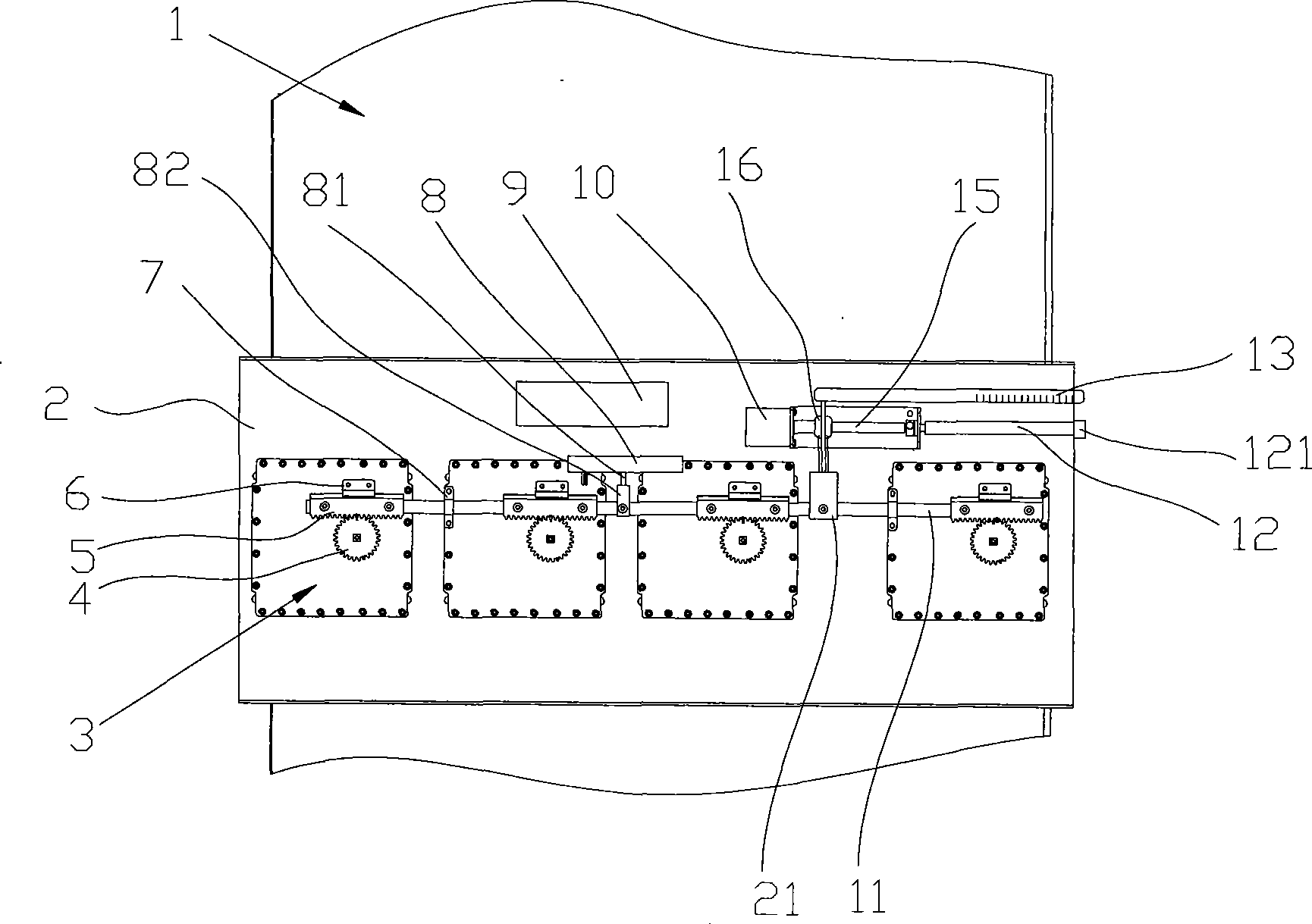

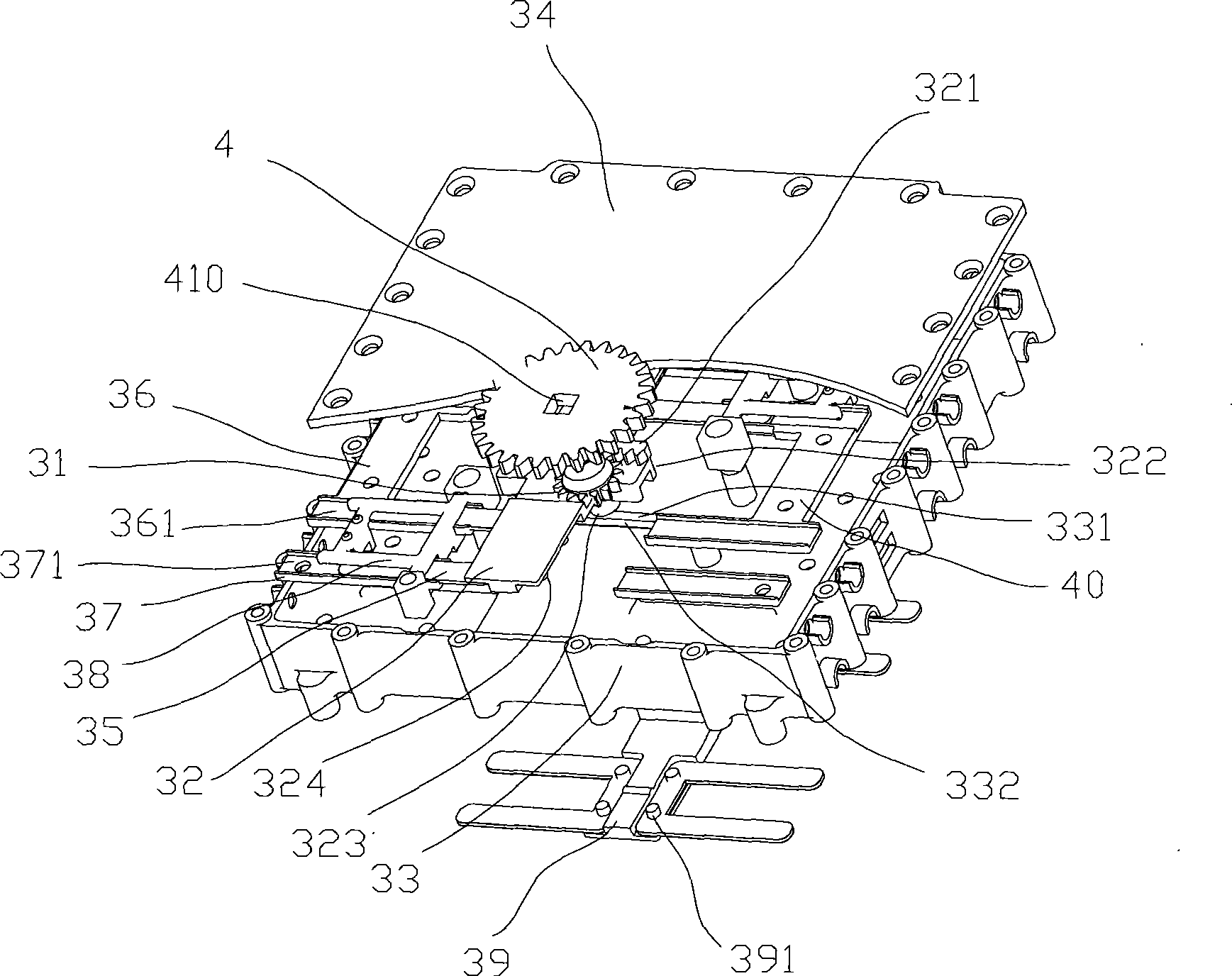

ActiveCN101521312ACompact structureSynchronized movement is preciseWaveguide type devicesAntennasLinear motionPhase shifted

The invention relates to an antenna phase-shift system, in particular to a simultaneous transmission device which accurately adjusts a plurality of groups of beam-forming networks in a multi-array antenna, a beam-forming network which is suitable for the antenna phase-shift system, and a precise phase-adjusting measurement and control device. The simultaneous transmitting device is used in an antenna which is provided with at least two radiating element arrays, implements control and realizes simultaneous phase shift to a phase-shift part which is owned by the beam-forming network of each radiating element array, comprising a driving device, a connecting rod and a transmission device, wherein the driving device is under the control of a control system which is independent of the antenna and provides a circular motion arm, the connecting rod is flexibly connected with the phase-shift part of each beam-forming network and causes each beam-forming network to shift the phase in a linking way under the linear motion of the connecting rod, and the transmission device converts the circular motion arm of the driving device into the linear motion of the connecting rod. The whole antenna phase-shift system has compact structure and can realize simultaneous precise phase adjustment to the antenna, in particular to TD-SCDMA antenna.

Owner:COMBA TELECOM TECH (GUANGZHOU) CO LTD +1

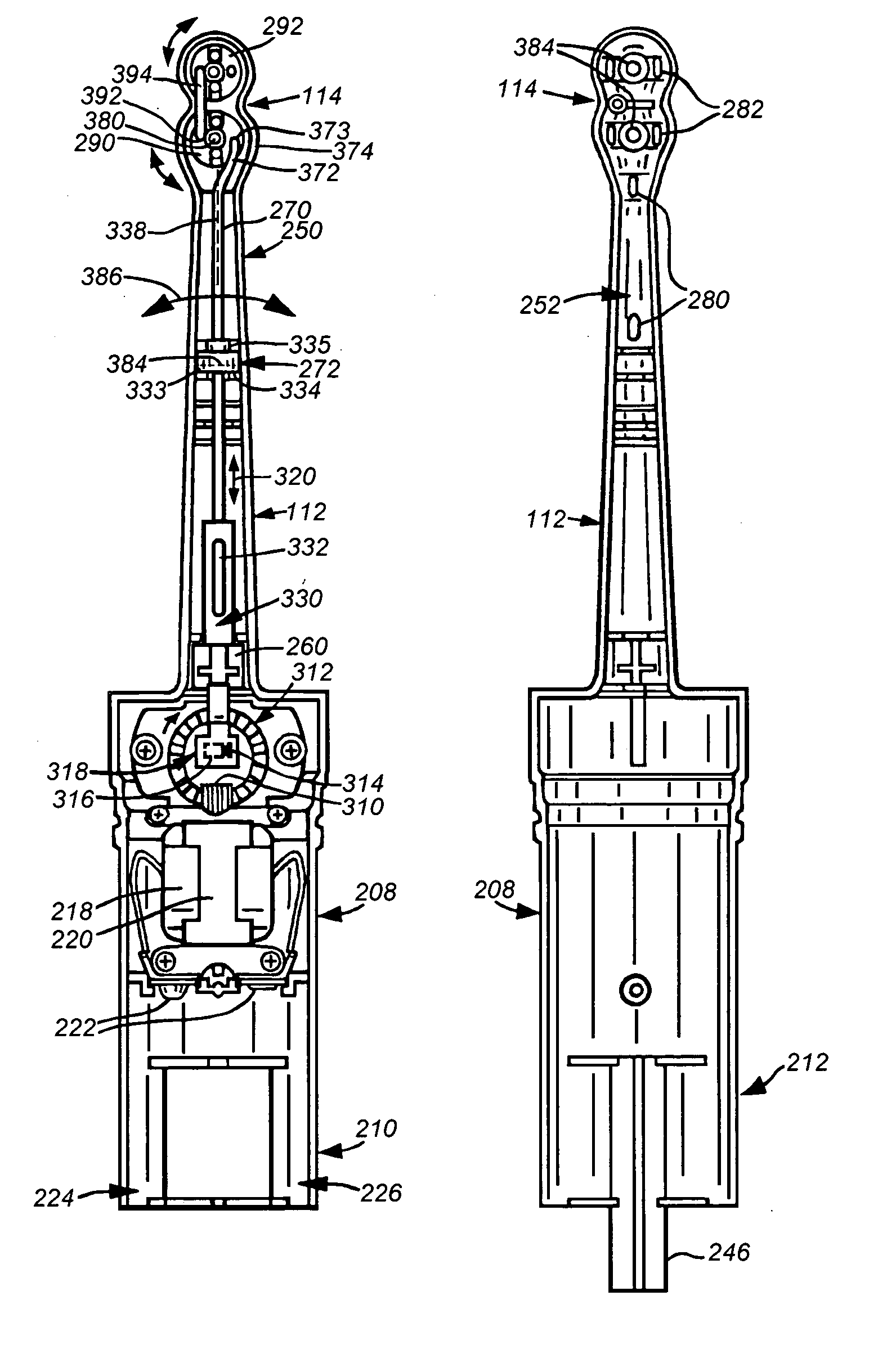

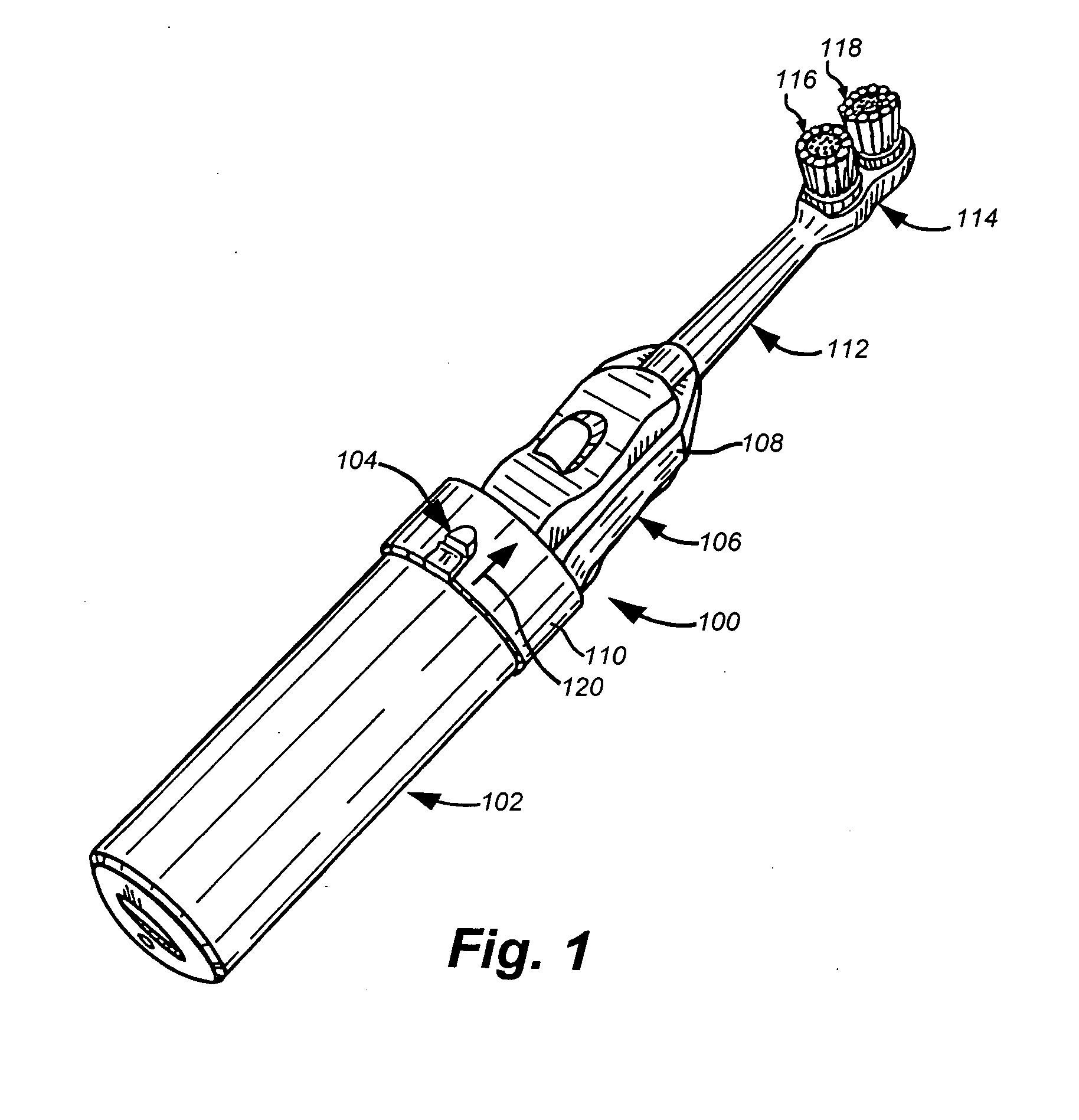

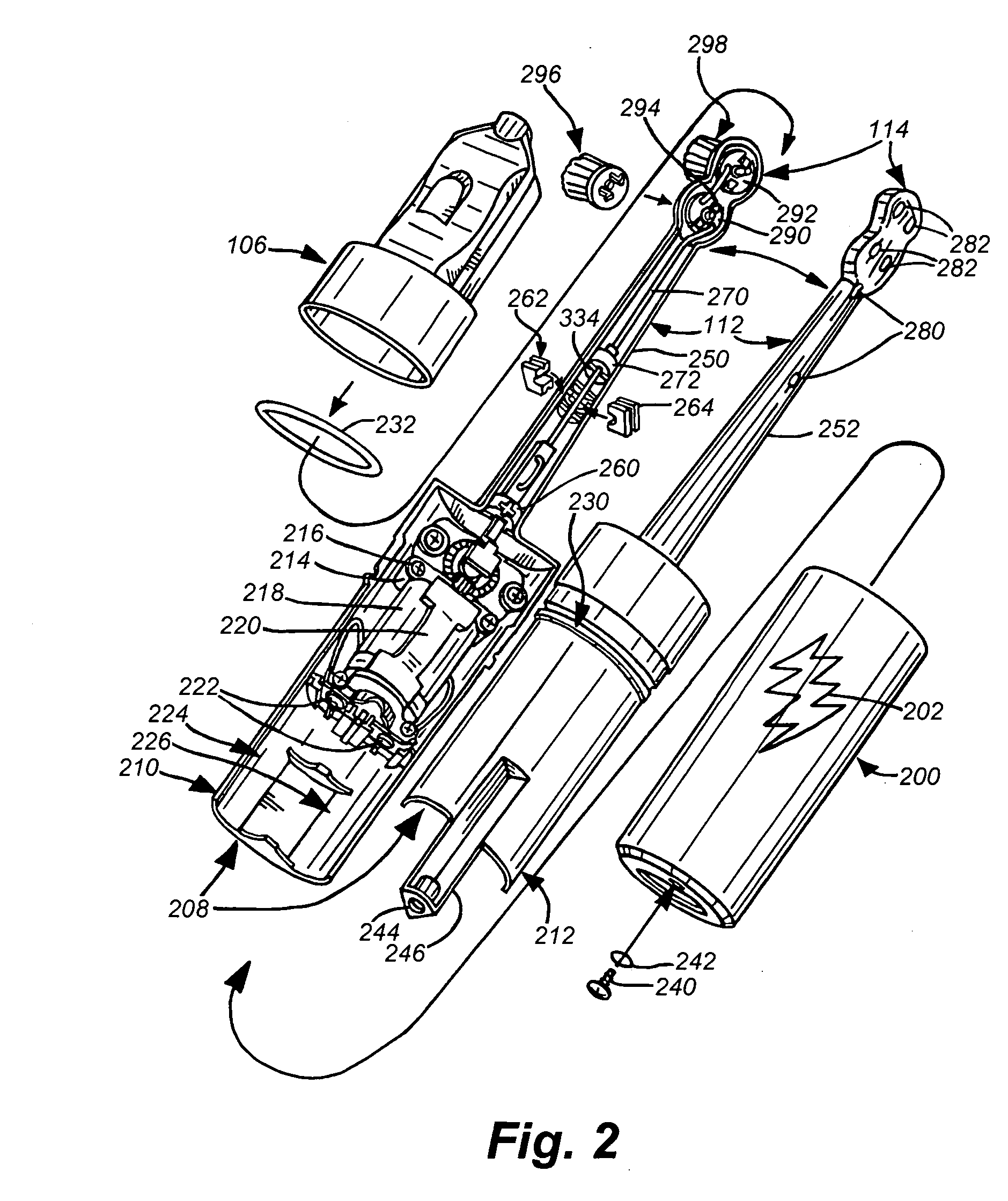

Power toothbrush

InactiveUS20060254007A1Easy to manufactureReliable serviceCarpet cleanersKitchenware cleanersCircular discReciprocating motion

A power toothbrush with a drive train that is easy to manufacture, reliable in service and that enables multiple heads or other complex design or functional elements is provided. In an illustrative embodiment, the power toothbrush includes a sealed case that encloses a motor with a pinion gear joined to an eccentric link. This eccentric link can be a circular rack having an eccentric pin that rides in a slot on a drive plate. The drive plate is joined to a push rod, typically constructed of metal that passes up a hollow toothbrush shaft through an elastomeric seal to a head assembly. The head assembly includes one or more moving disks that are each connected to generally circular brush heads, which project outwardly from the head assembly. One disk receives a bent end of the drive shaft in a hole located eccentrically to the axis of rotation. When the circular rack rotates in a single direction, it drives the shaft in a reciprocating motion that, thereby, rotates the disk in a corresponding reciprocating circular motion about its axis. Additional disks can be linked by a short connecting shaft or link to the first disk via eccentric holes—other linkages, such as mating gears between disks can be used to simultaneously drive further disks, thereby providing a multiple moving-head power toothbrush.

Owner:THE GILLETTE CO

Swing analyzer

A calculating unit of a swing analyzer calculates, assuming that a golf club is in a uniform circular motion about a virtual center of rotation O during a swing, a virtual speed Vh at a central point R of a golf club head, based on a distance between first and second acceleration sensors, a distance between the first acceleration sensor and the central point R of a golf club head and outputs from the first and second acceleration sensors, and calculates the speed of central point R of a golf club head utilizing the virtual speed Vh.

Owner:MIZUNO CORPORATION

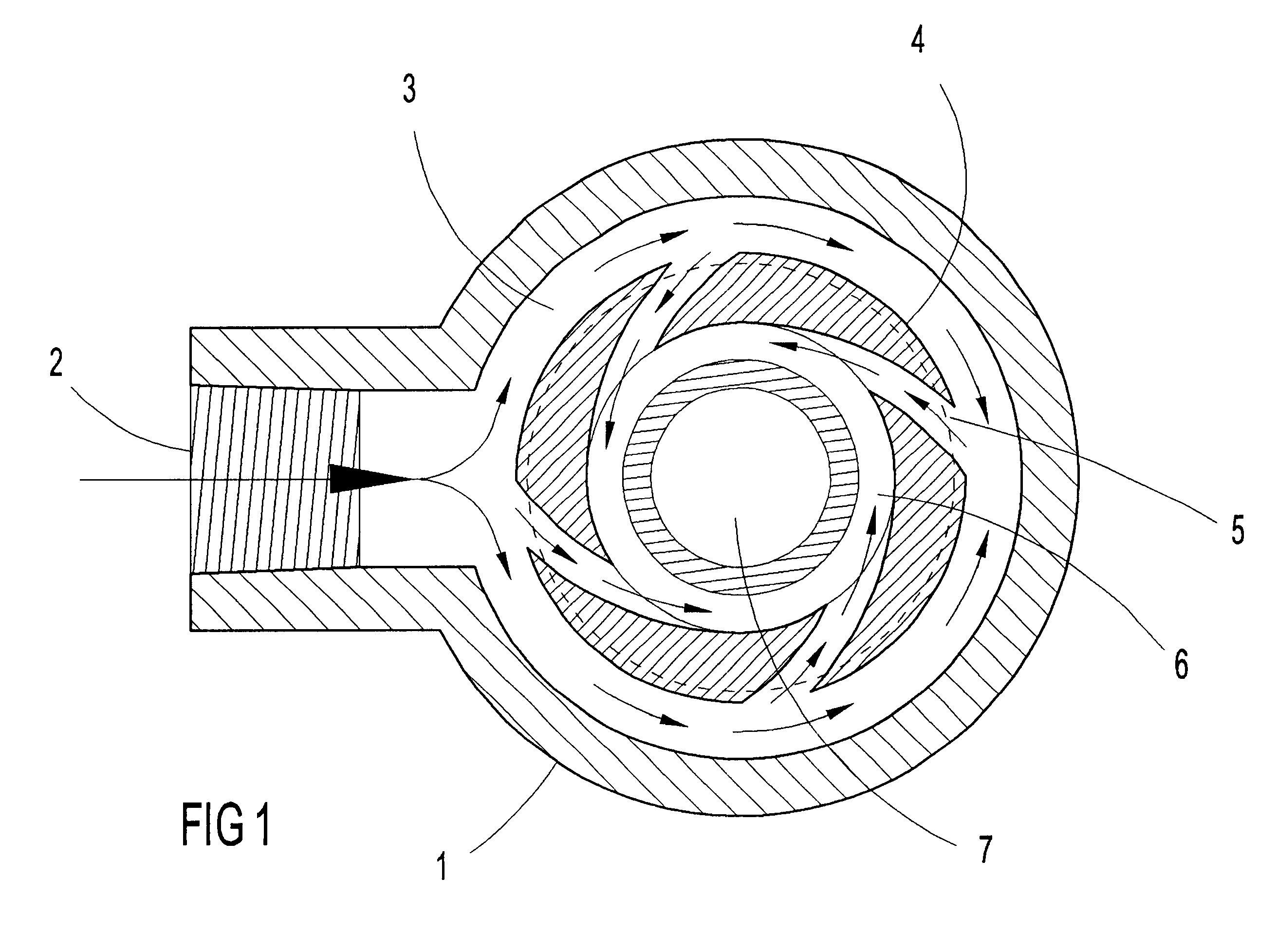

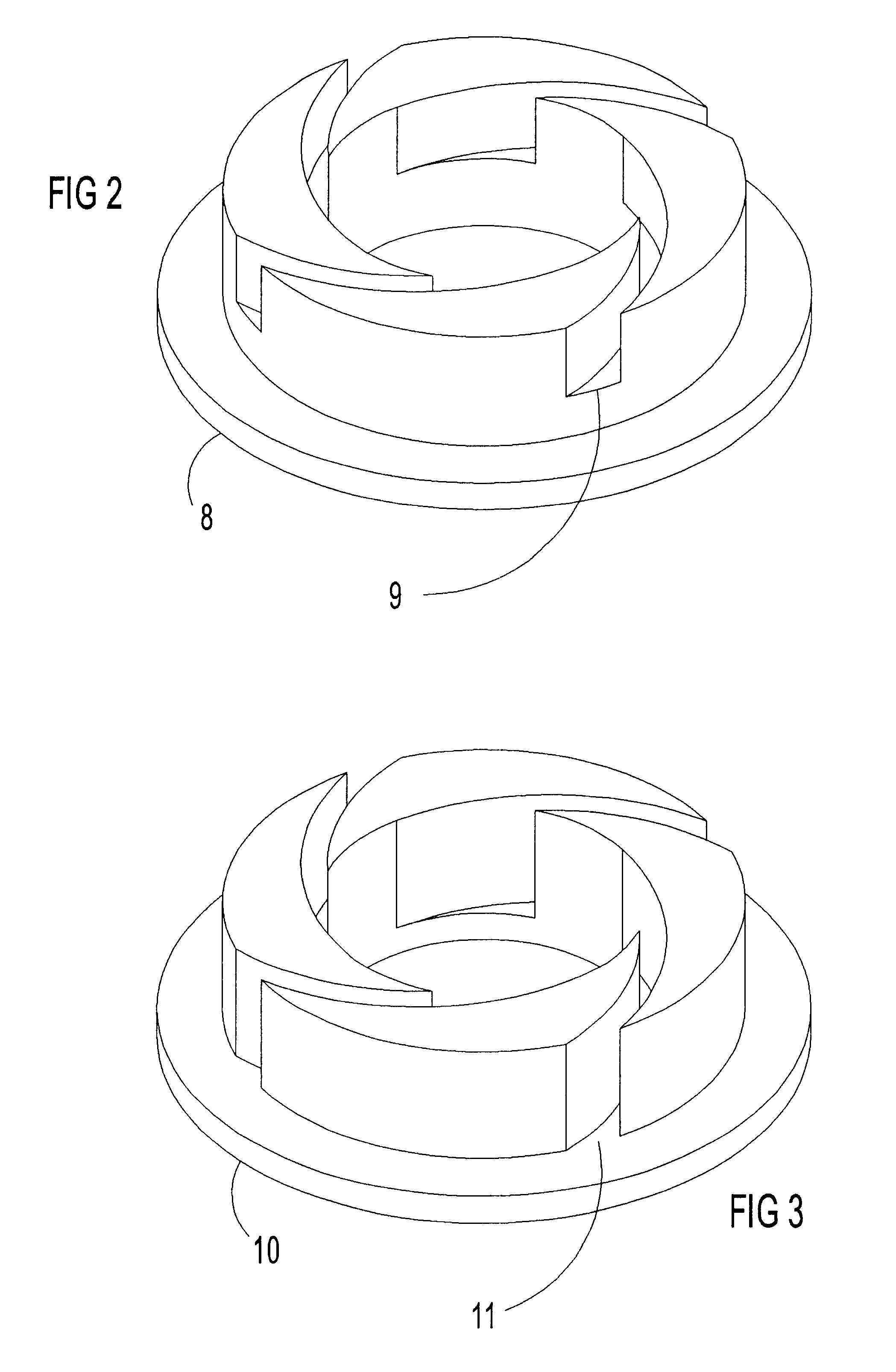

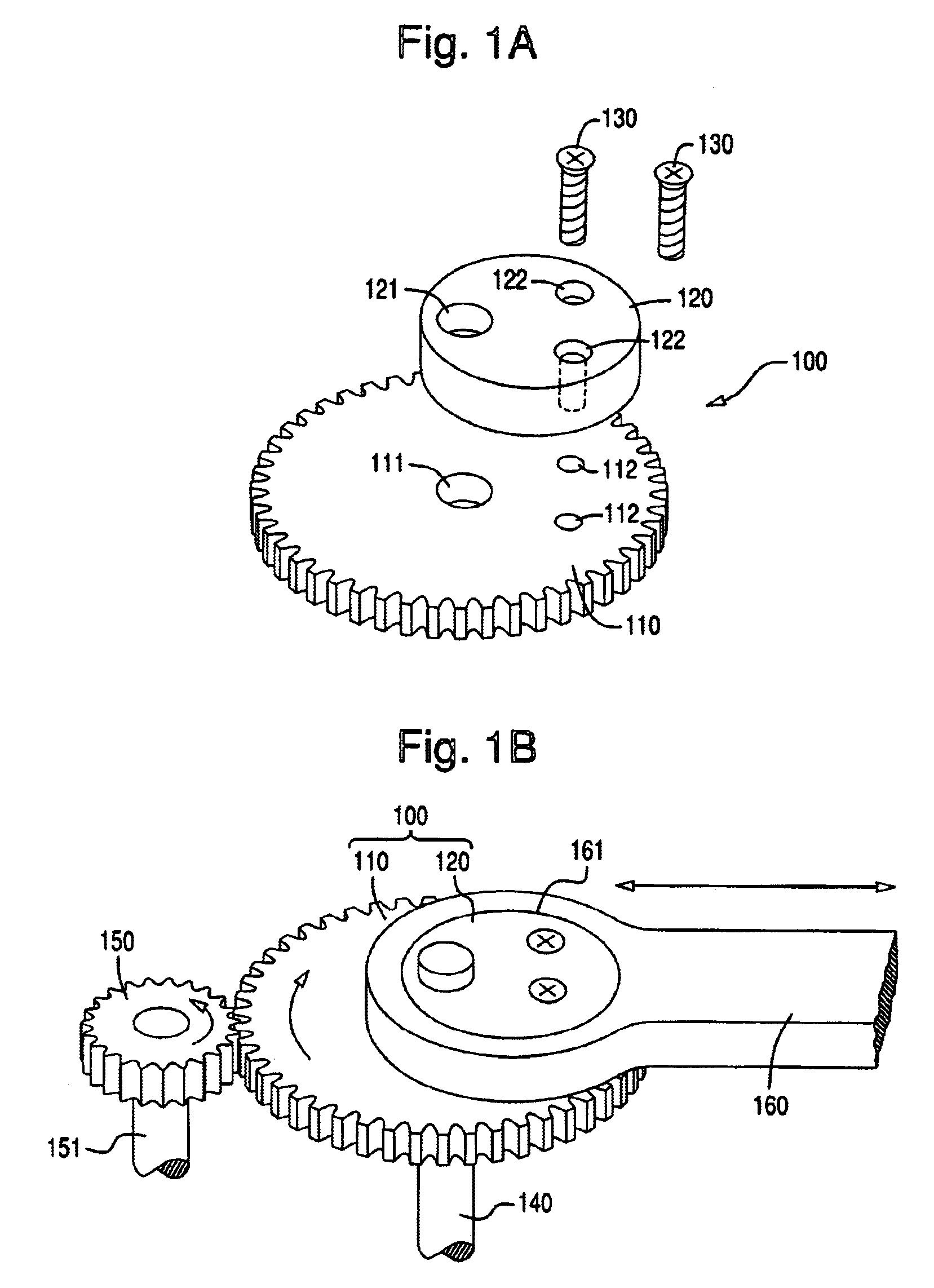

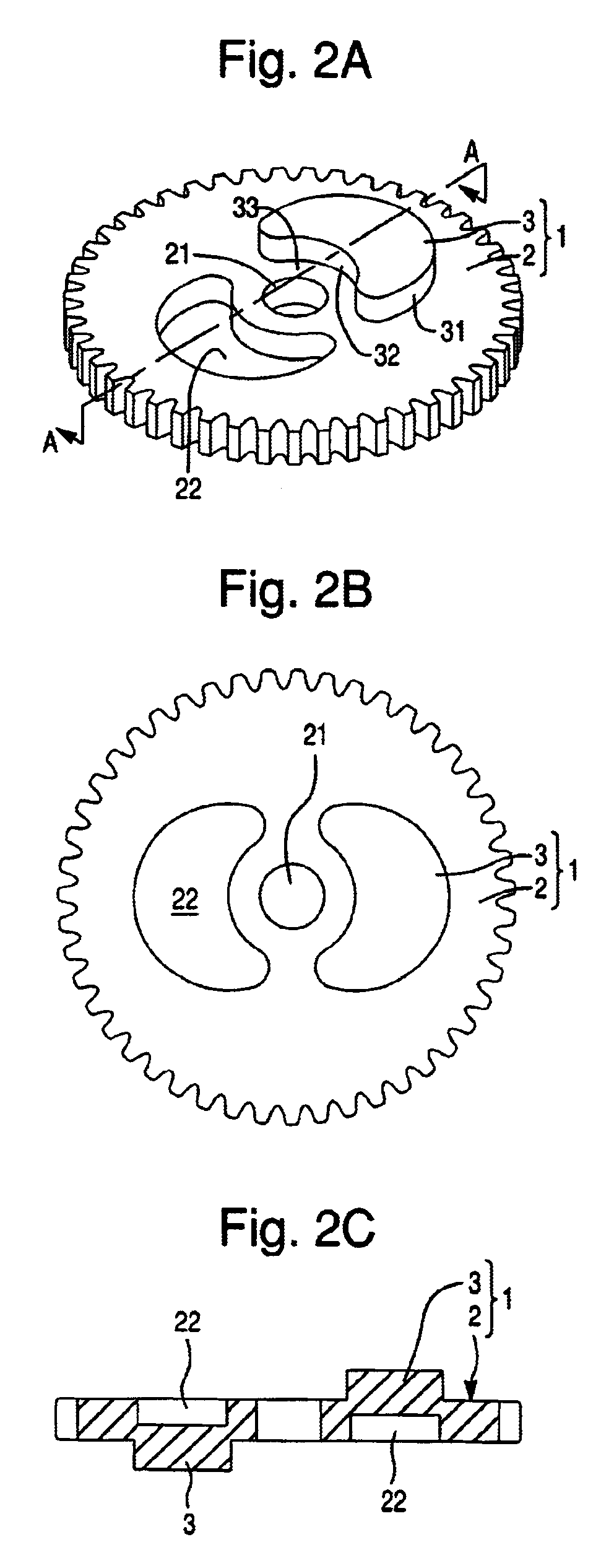

Cam mechanism for translation of circular motion into reciprocal motion

A cam mechanism for use in a mowing machine. The cam mechanism is comprised of a spur gear and protruding eccentric cams from the top and bottom surfaces of the spur gear. The cam mechanism is formed from a half blanking press process. The eccentric cams are symmetrically formed around a shaft hole located in the center of the spur gear. Members with a hole equaling that of the eccentric cam and shaft hole point symmetry are then fitted onto the eccentric cam. The members are then capable of reciprocation with a phase differential of 180 degrees of each other. The concave portion of the eccentric cam permits lubricants to be filled in the space facilitating the smooth operation of the cam mechanism.

Owner:DELTA KOGYO CO LTD +1

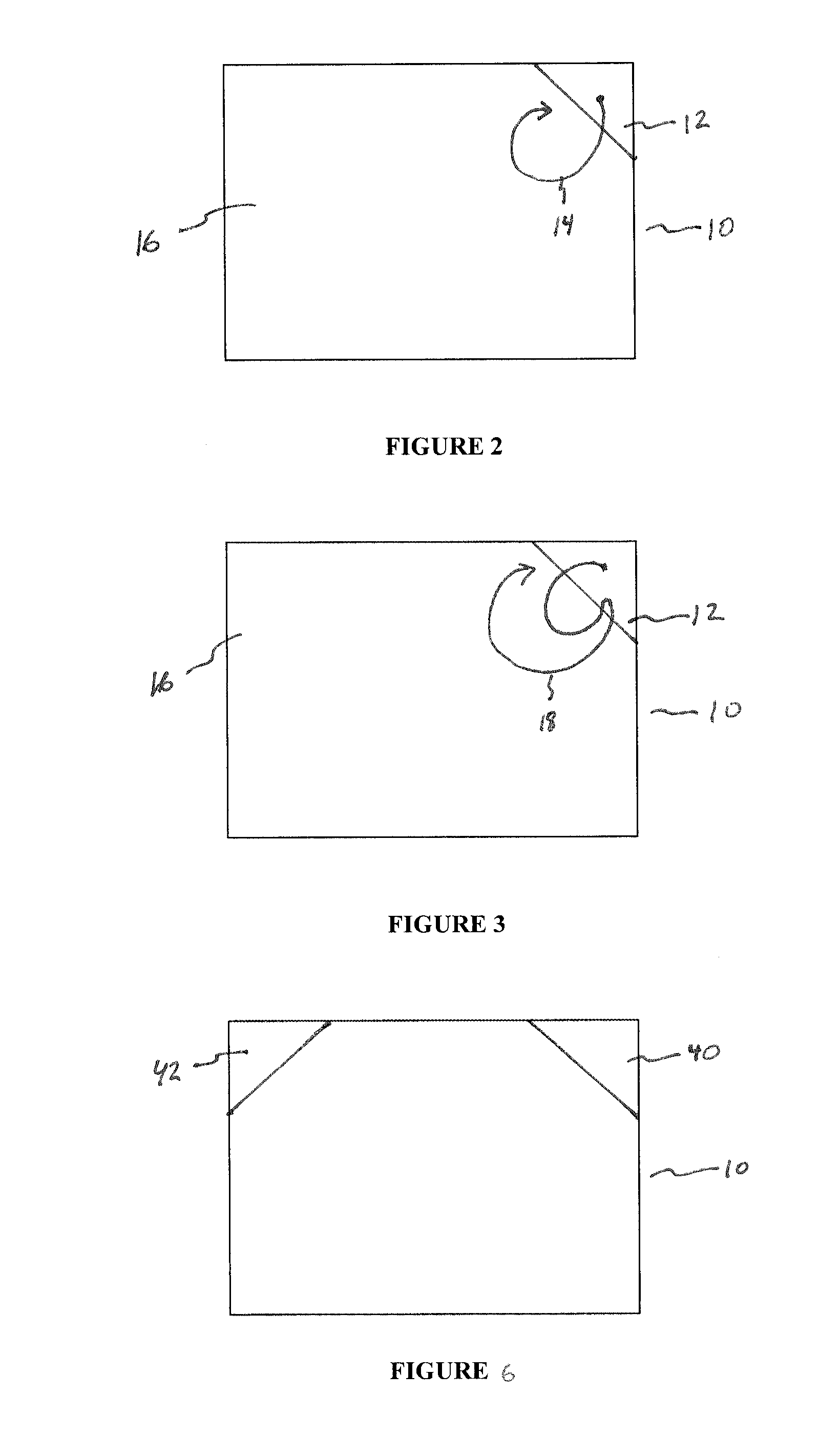

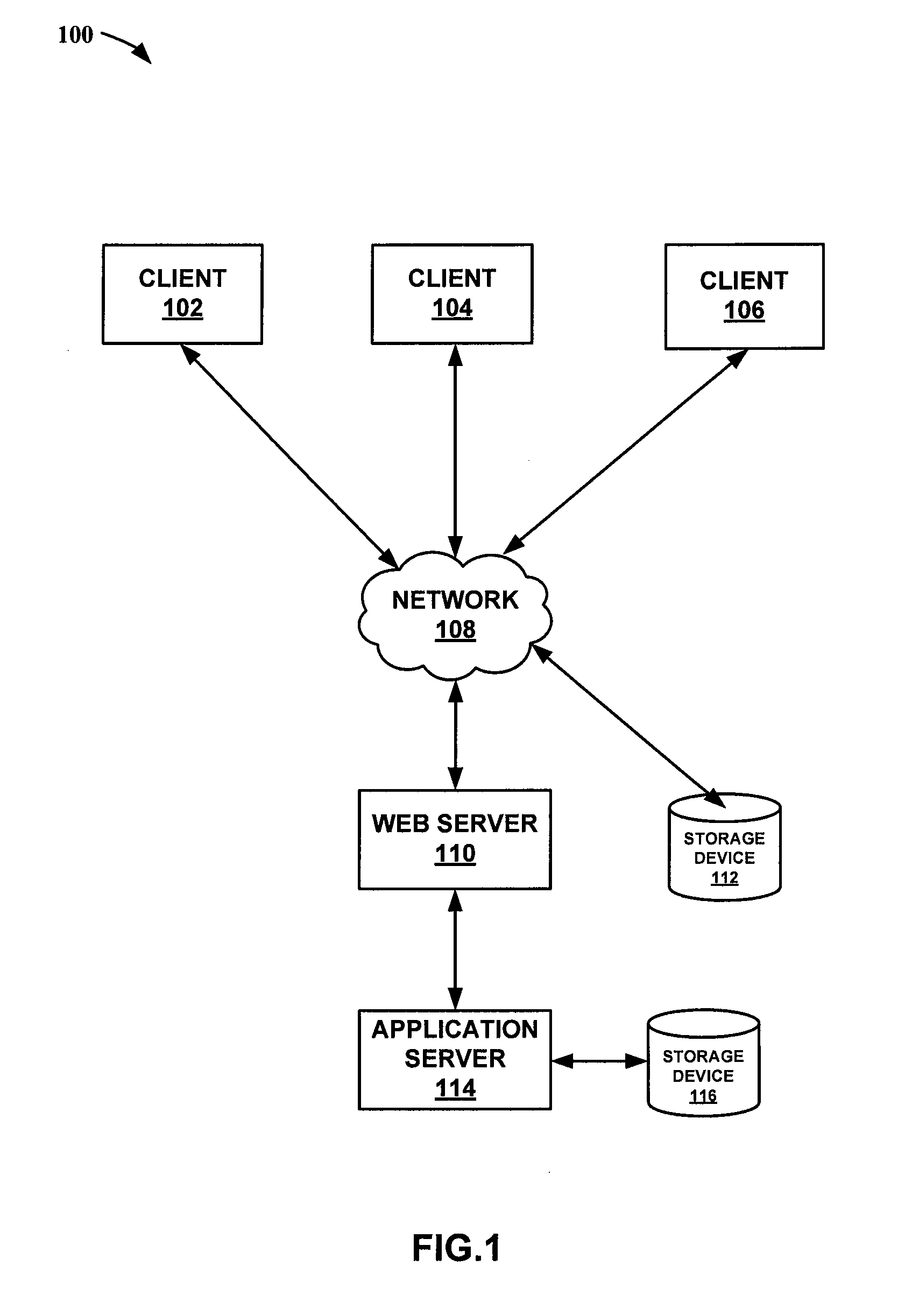

Method of scrolling that is activated by touchdown in a predefined location on a touchpad that recognizes gestures for controlling scrolling functions

ActiveUS20070291014A1Cathode-ray tube indicatorsInput/output processes for data processingCapacitancePoint object

A method of using a capacitance-sensitive touchpad, wherein the touchpad includes a zone on a surface thereof, wherein touchdown of a pointing object within the zone enables activation of a scrolling function, wherein direction of scrolling is then controlled by a gesture by the pointing object, such as moving in a circular motion in a clockwise direction to move down in a list, and in a counter clockwise direction to move up in a list, and wherein fast and slow scrolling speeds are controlled by tapping functions within the scroll zone.

Owner:CIRQUE CORPORATION

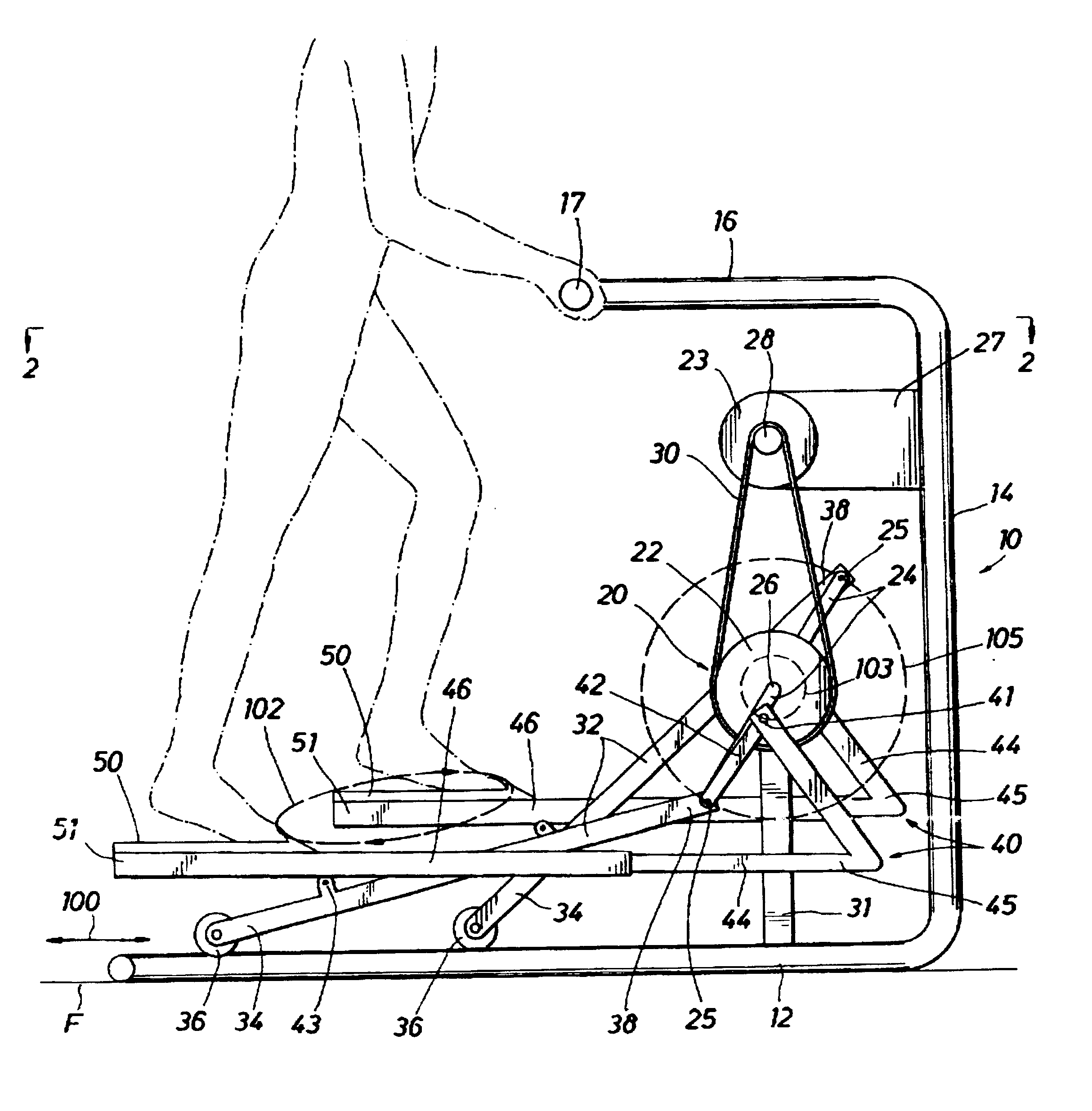

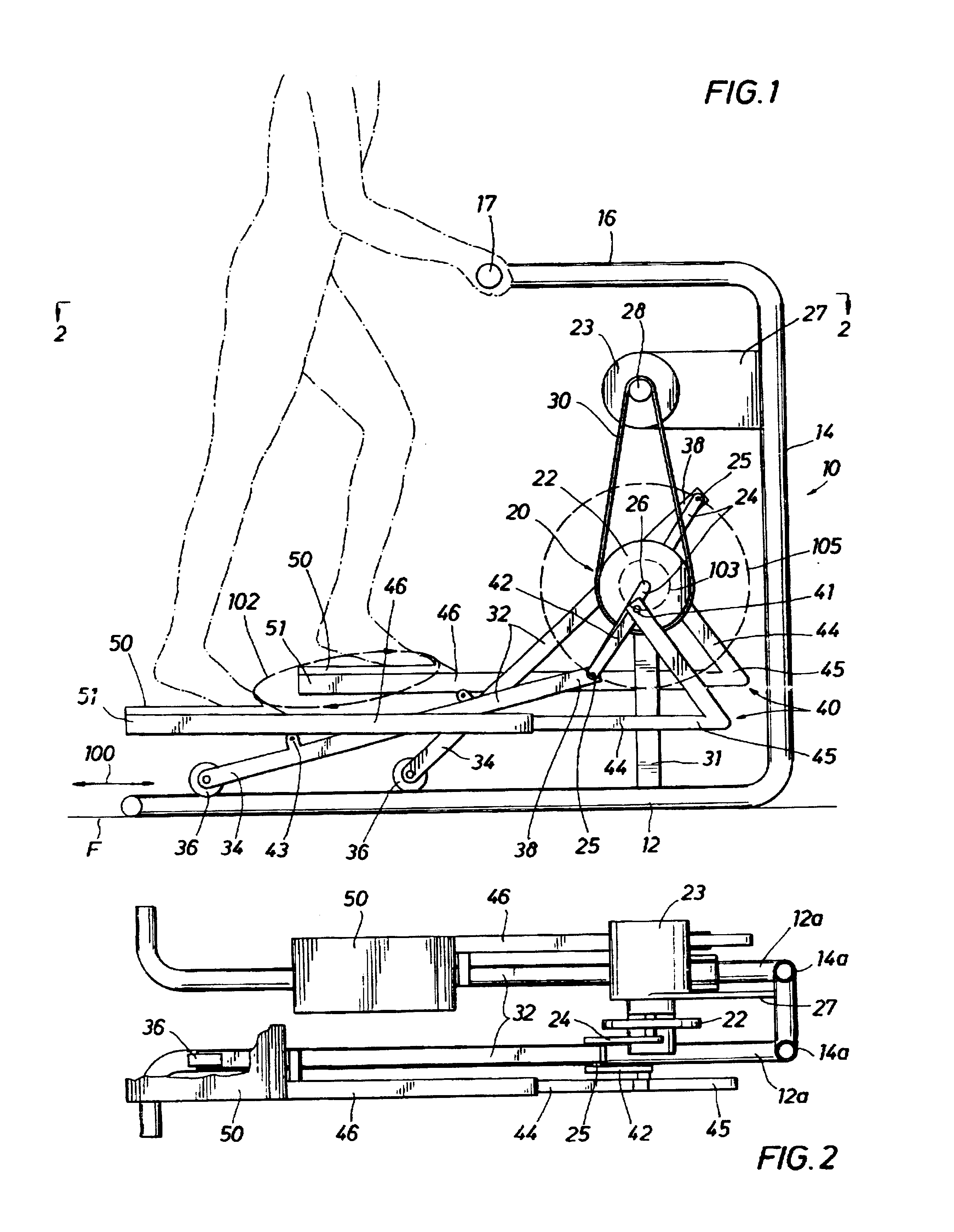

Stationary exercise apparatus having a preferred foot platform path

InactiveUSRE38803E1Promote sportsRider propulsionBicyclesPhysical medicine and rehabilitationReciprocating motion

A stationary exercising apparatus which promotes cardiovascular exercise yet minimizes impact on critical joints through the generation of a predetermined elliptical path movement while maintaining foot platforms substantially parallel with the floor. A base structure supports a pair of reciprocating members which are displaced in a horizontal direction parallel with the floor at one end yet reciprocate in circular motion at the other end through a coupling system attached to the frame. A linkage assembly is included which operates in conjunction with the reciprocation of one end of the reciprocating members to maintain the foot platforms substantially parallel with a reference plane while revolving the foot platforms in a substantially elliptical path. The apparatus may include additional linkage to facilitate a corresponding upper body exercise involving movement of the arms along a predetermined arc.

Owner:NAUTILUS INC

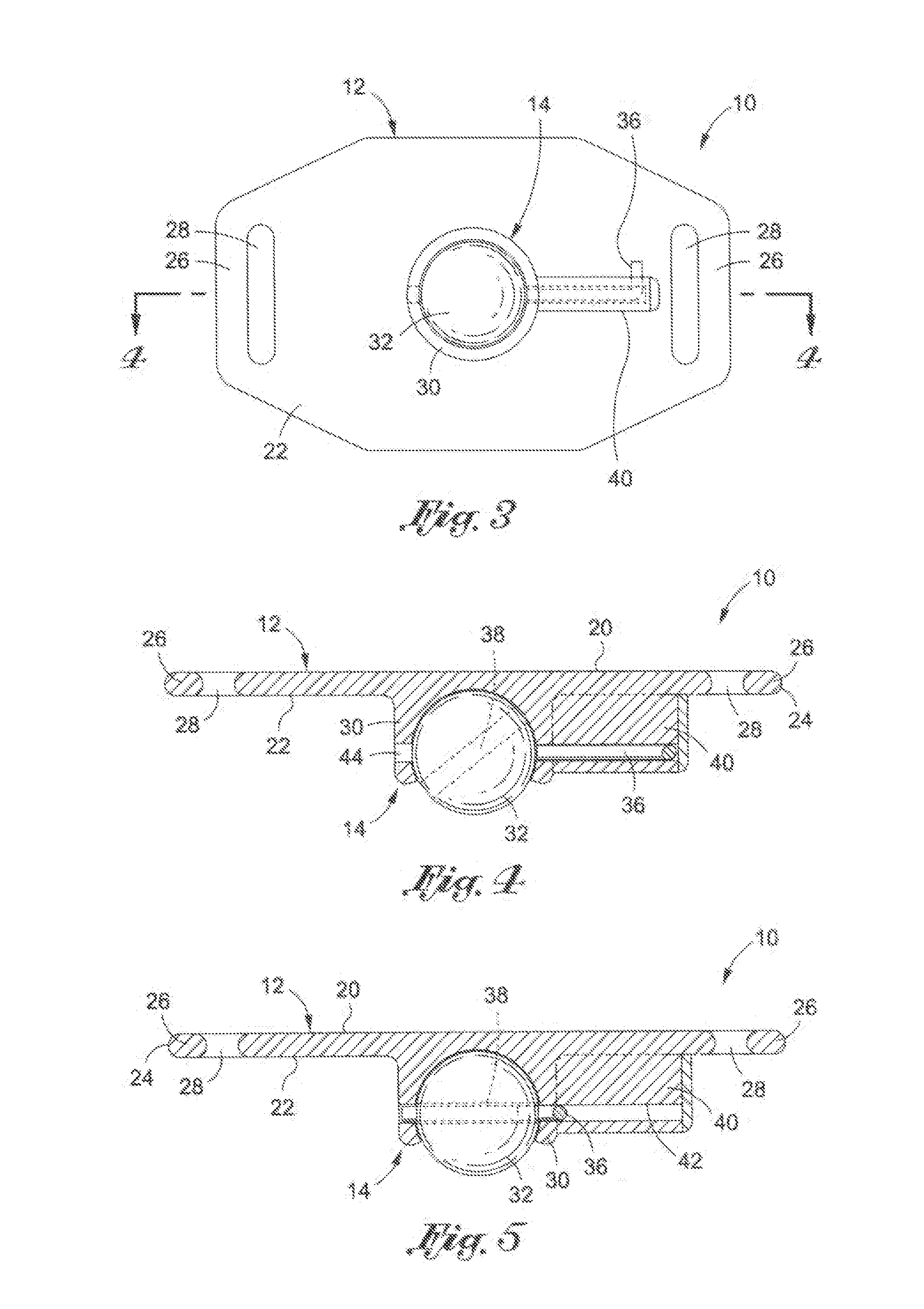

Automatic vibratory separator

InactiveUS20050242003A1Affect effectivenessAffect efficiencySievingGas current separationElectric machineryEngineering

A vibratory separator and methods for using it, the separator in certain aspects having a base, a basket on the base, motor apparatus for vibrating the basket and screen apparatus thereon, variable frequency drive apparatus for selectively driving the vibratory motor apparatus, and, in certain aspects, angle adjustment apparatus for adjusting angle of the basket; and, in certain aspects, for sensing a parameter indicative of operation of the vibratory separator, and control apparatus for receiving signals from the sensor apparatus, for controlling the separator based on said signals; and, in certain aspects, for automatically signalling a drive apparatus to change the speed of the motor apparatus; and, in certain aspects, the vibratory motor apparatus connectible to the basket at a plurality of locations so that a motion profile of the basket is selectively variable between linear, elliptical, and circular motion.

Owner:VARCO I P INC

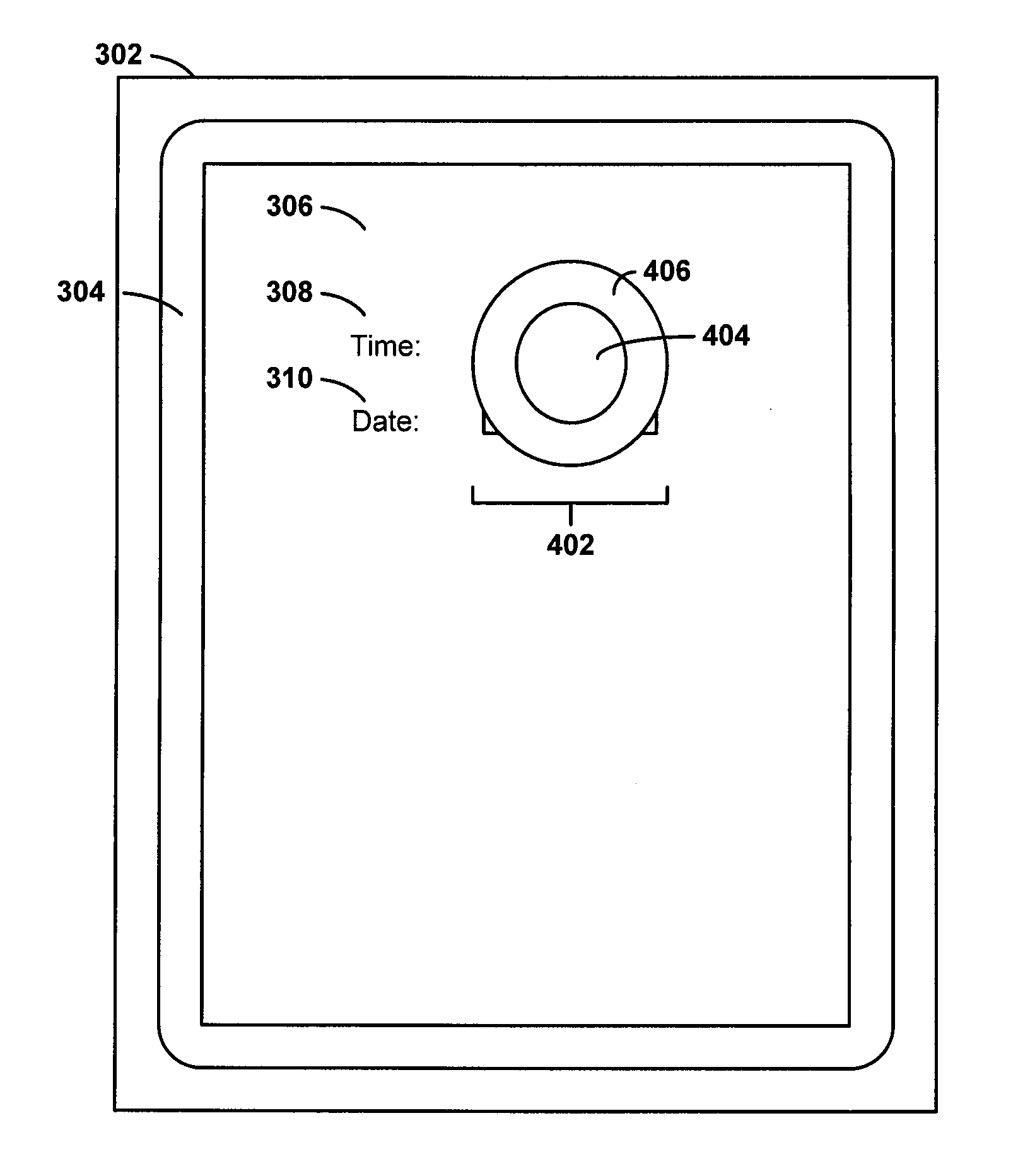

Touch-enabled circle control for time and date entry

In a system and a method, a selection of an input data field is detected. In response to the selection of the input data field, a user interface having an inner concentric circle and an outer concentric circle is generated. A contact point corresponding to a location of a touch gesture submitted via a touch-enabled input device within one of the inner concentric circle and the outer concentric circle is detected. An angular velocity of circular movement from the contact point around one of the concentric circles is measured. An input data value is adjusted at a granularity based on the contact point and at a rate based on the measured angular velocity of circular movement.

Owner:SAP AG

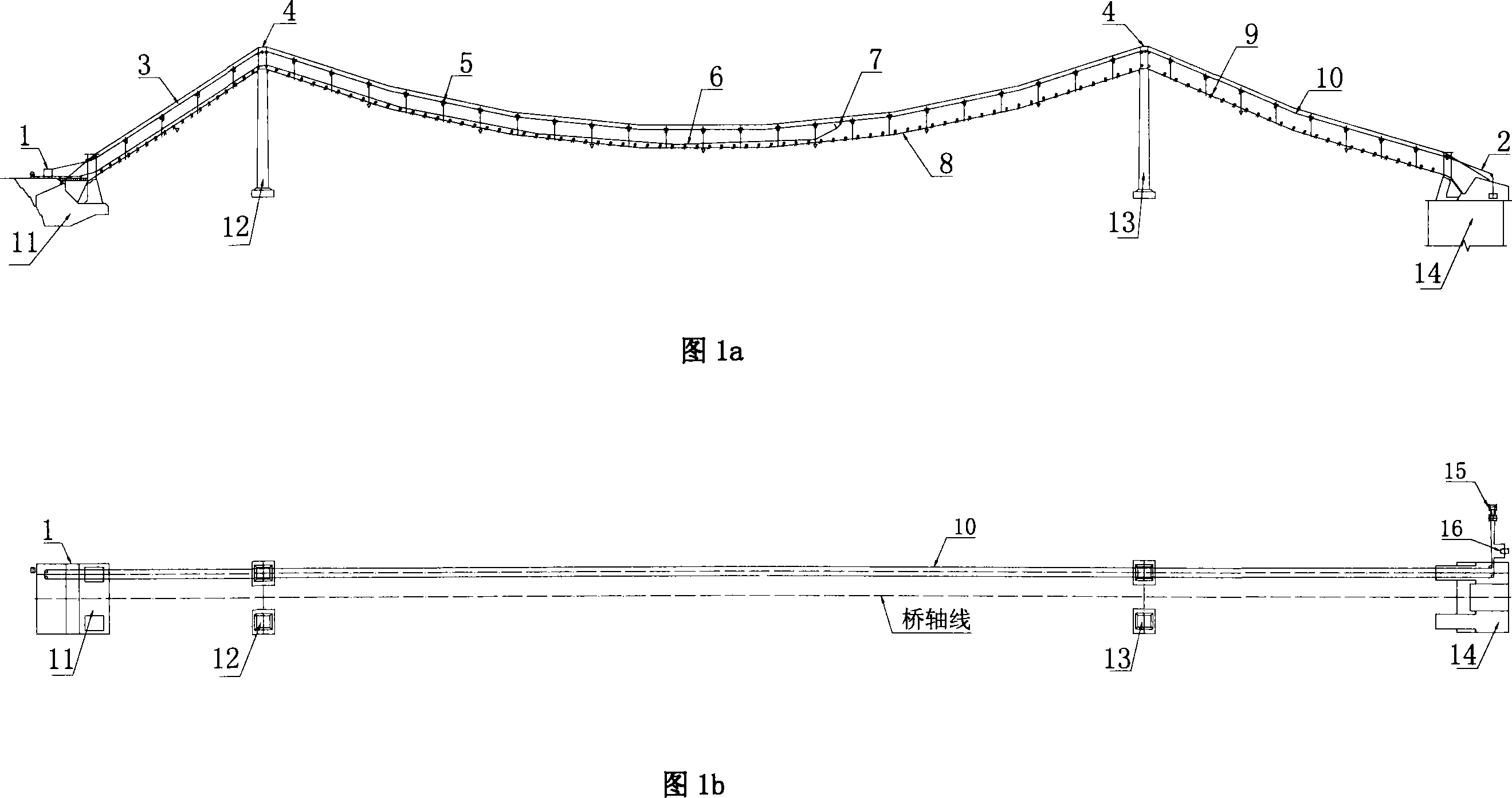

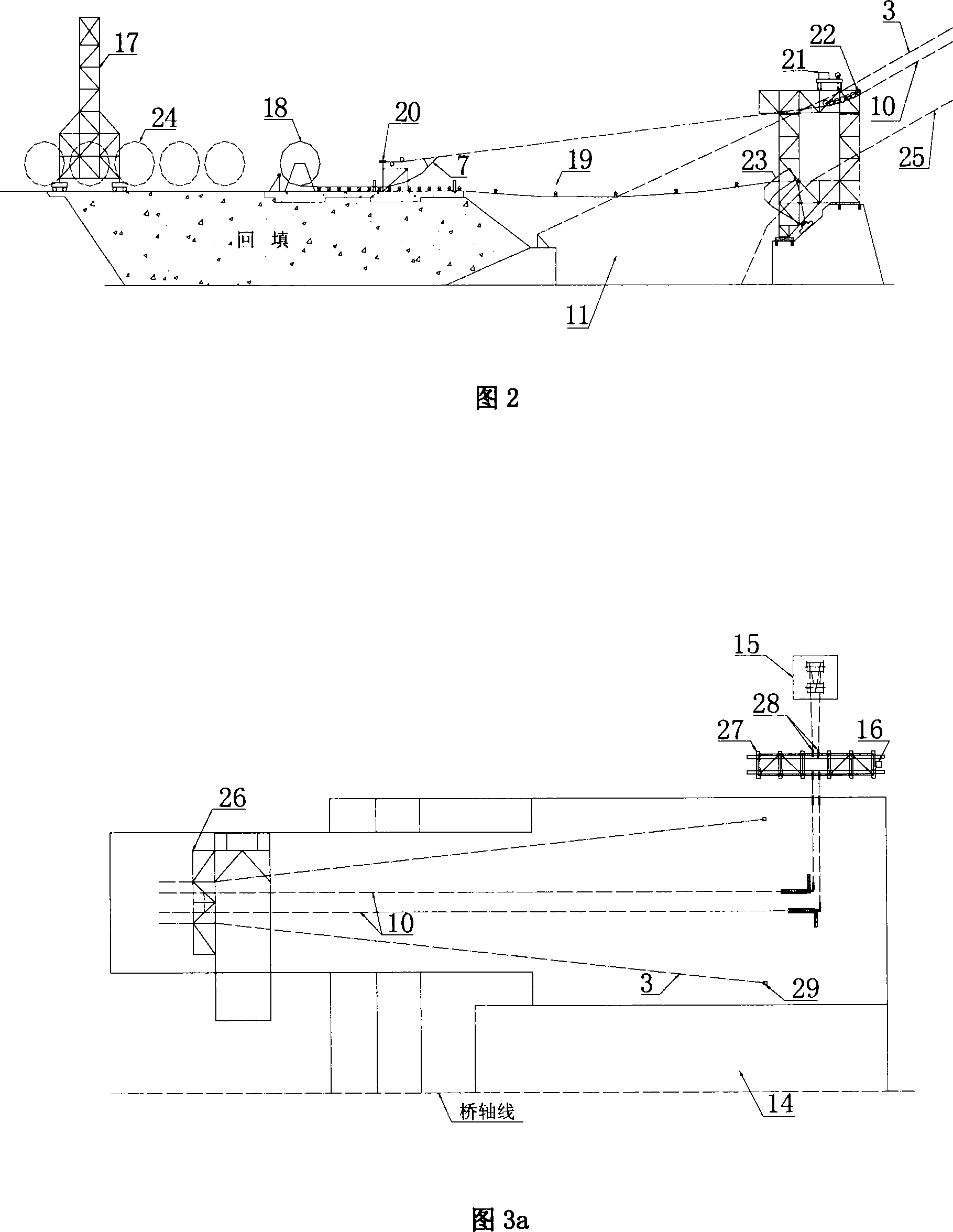

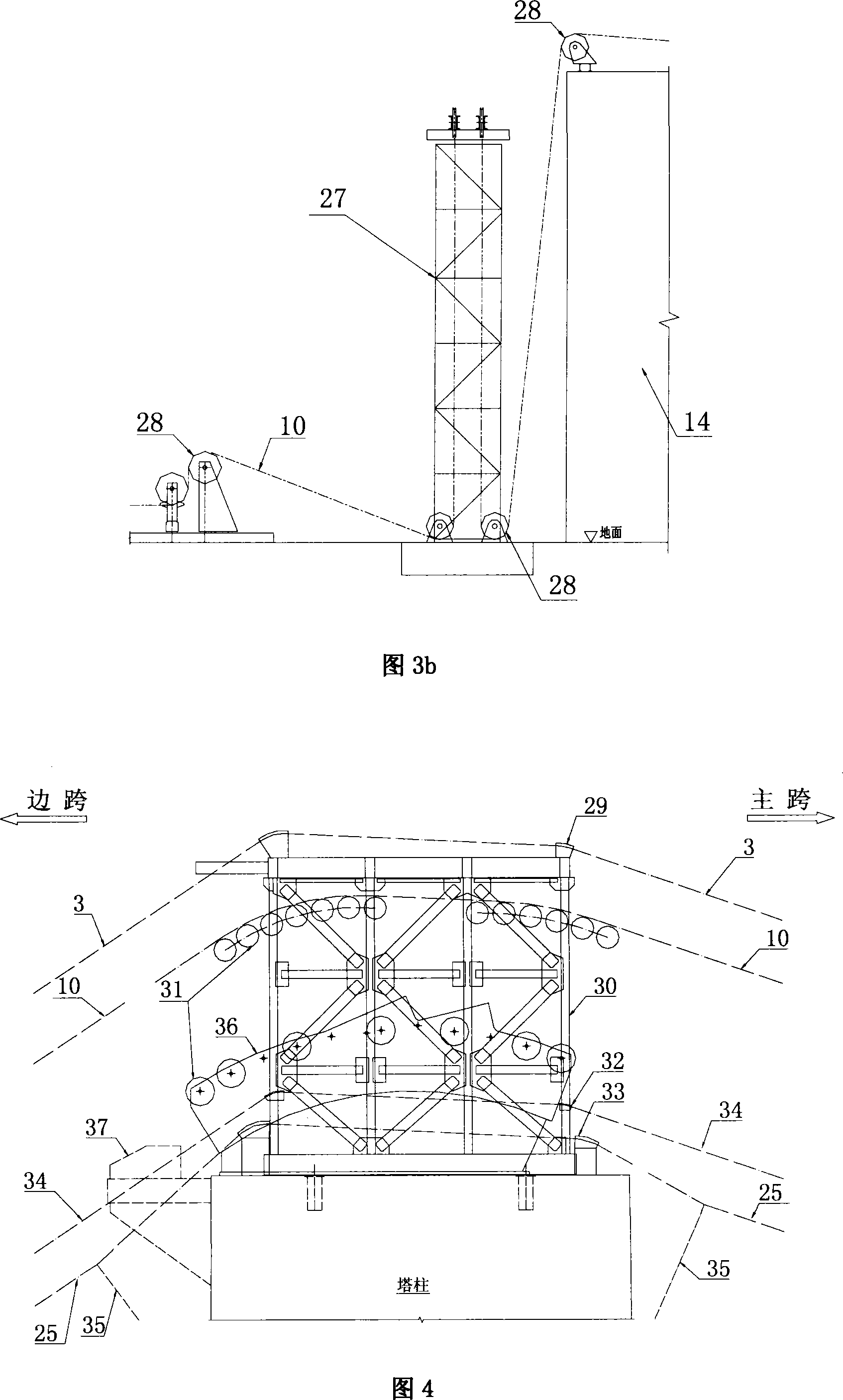

Erection of gantry type small-cycle traction system on large-span suspension bridge main cable

ActiveCN101177931AStable tractionImprove erection qualityBridge erection/assemblyTraction systemTraveling block

The utility model relates to a gantry type small circulation traction system for a main cable erection of a large-span suspension bridge, which belongs to the technical field of bridge superstructure construction. Set up a cable storage area behind the A anchorage, and install a 60-ton gantry crane and a cable-laying bracket; set up a traction cable revolving wheel behind this anchorage; set up a 25-ton main traction hoist and a balance weight bracket on the side of the B anchorage. The traction cable is connected by a puller at Anchor Anchor, bypasses the hoist drum at B Anchor Anchor, and is inserted through the balance weight bracket and each steering block to form a ring-shaped endless cable. Make a horizontal circular motion to form an independent small circular traction system. The small circulation system has the advantages of high power, large traction force, high construction efficiency and low cost.

Owner:CHINA RAILWAY MAJOR BRIDGE ENG GRP CO LTD

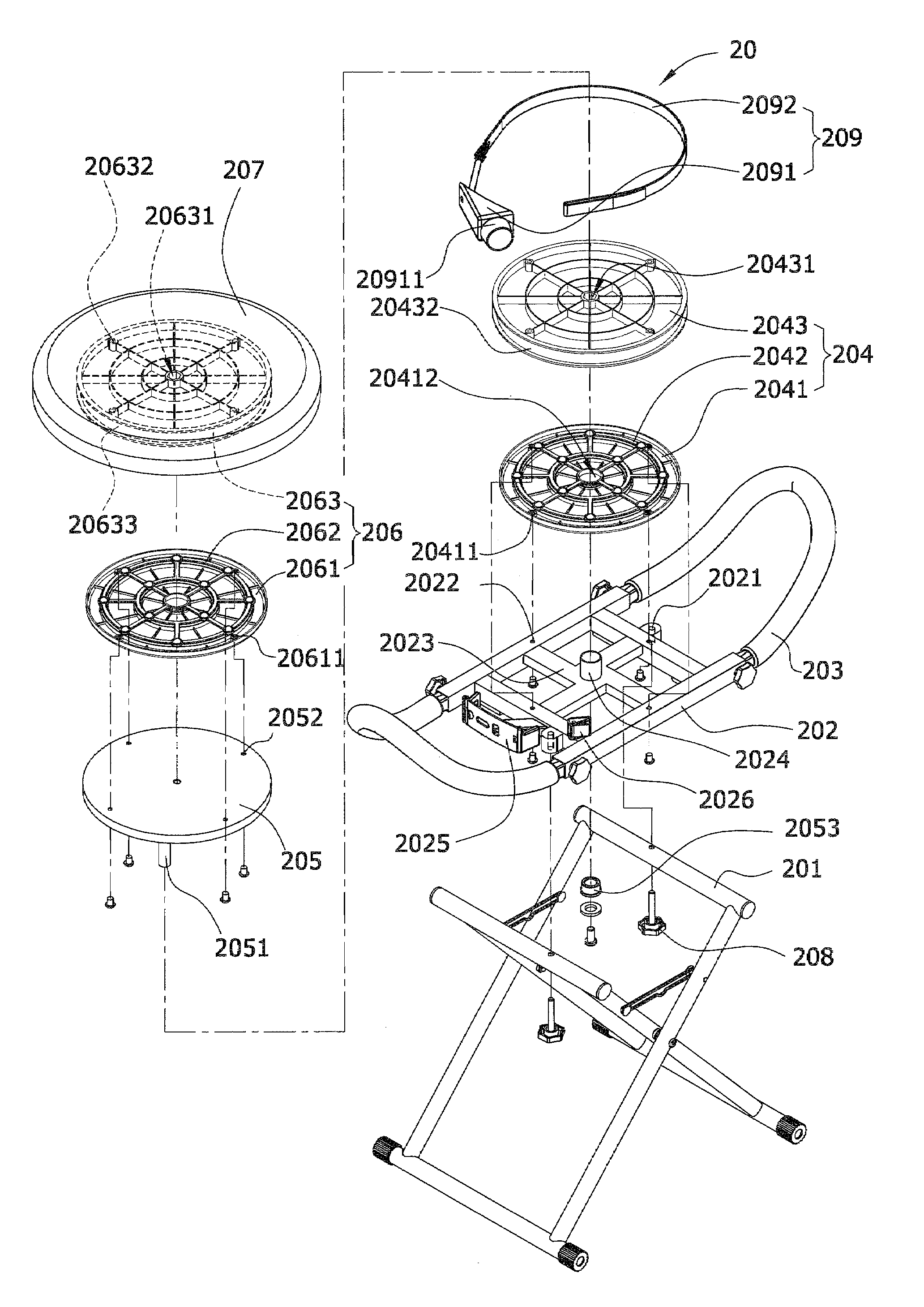

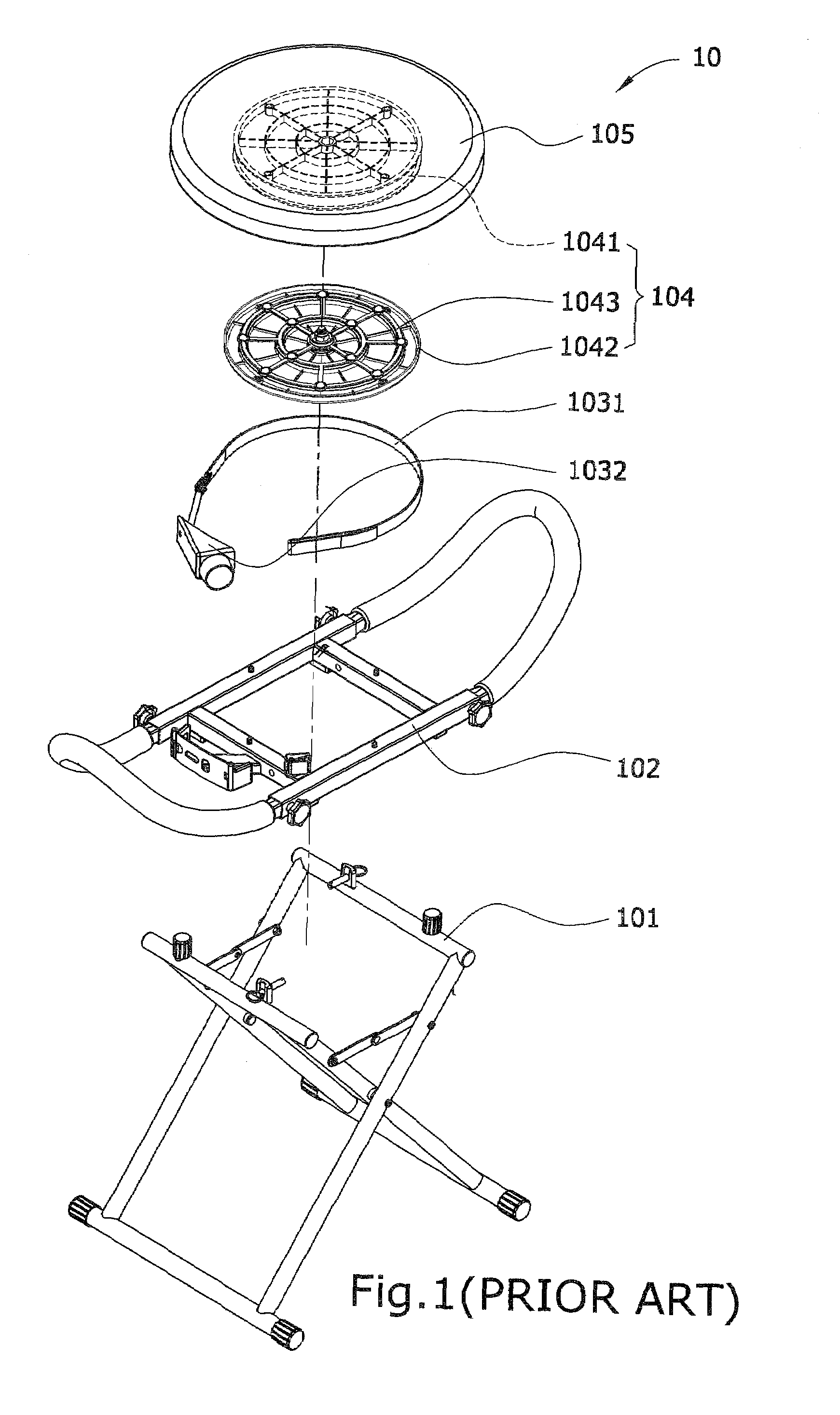

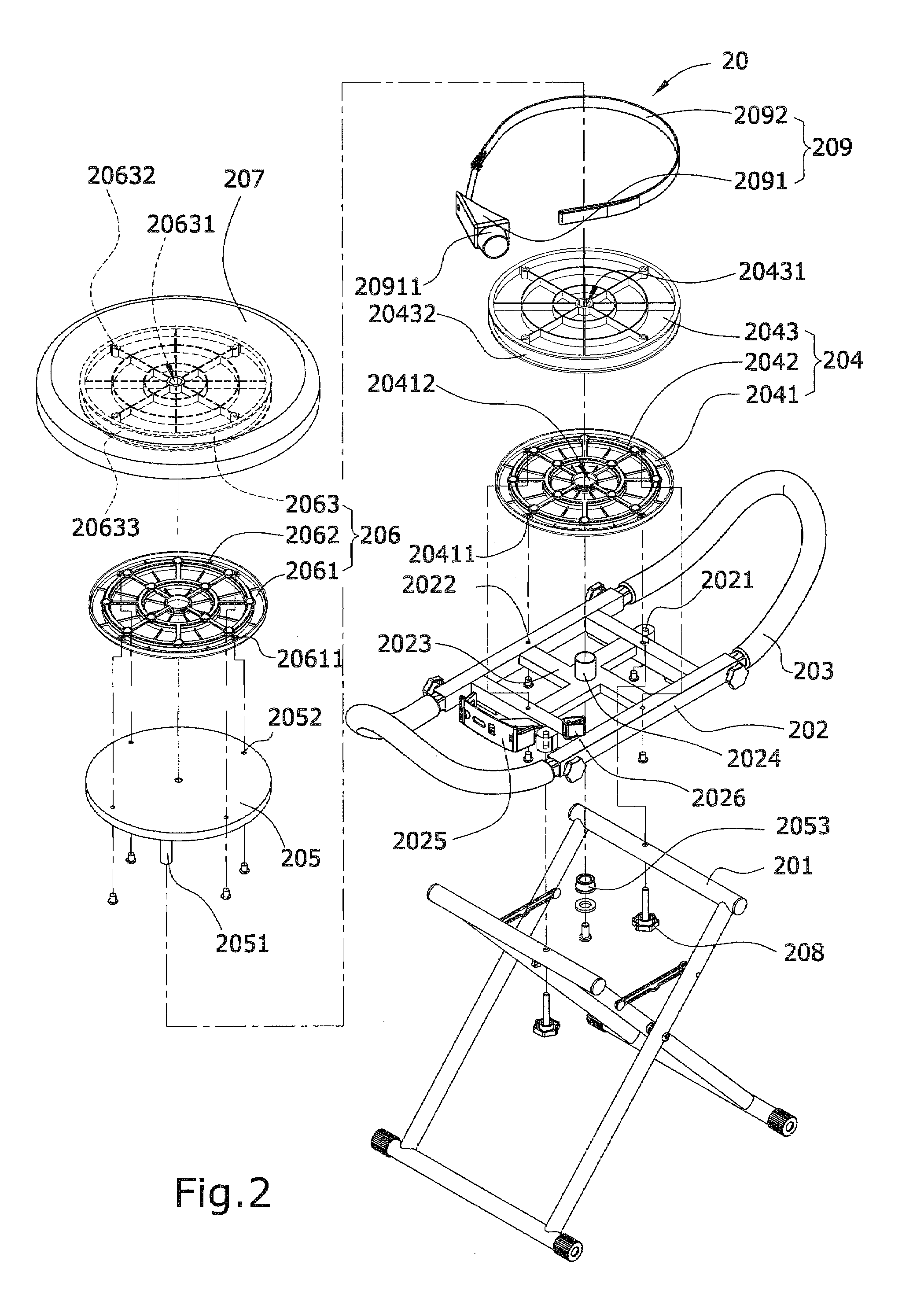

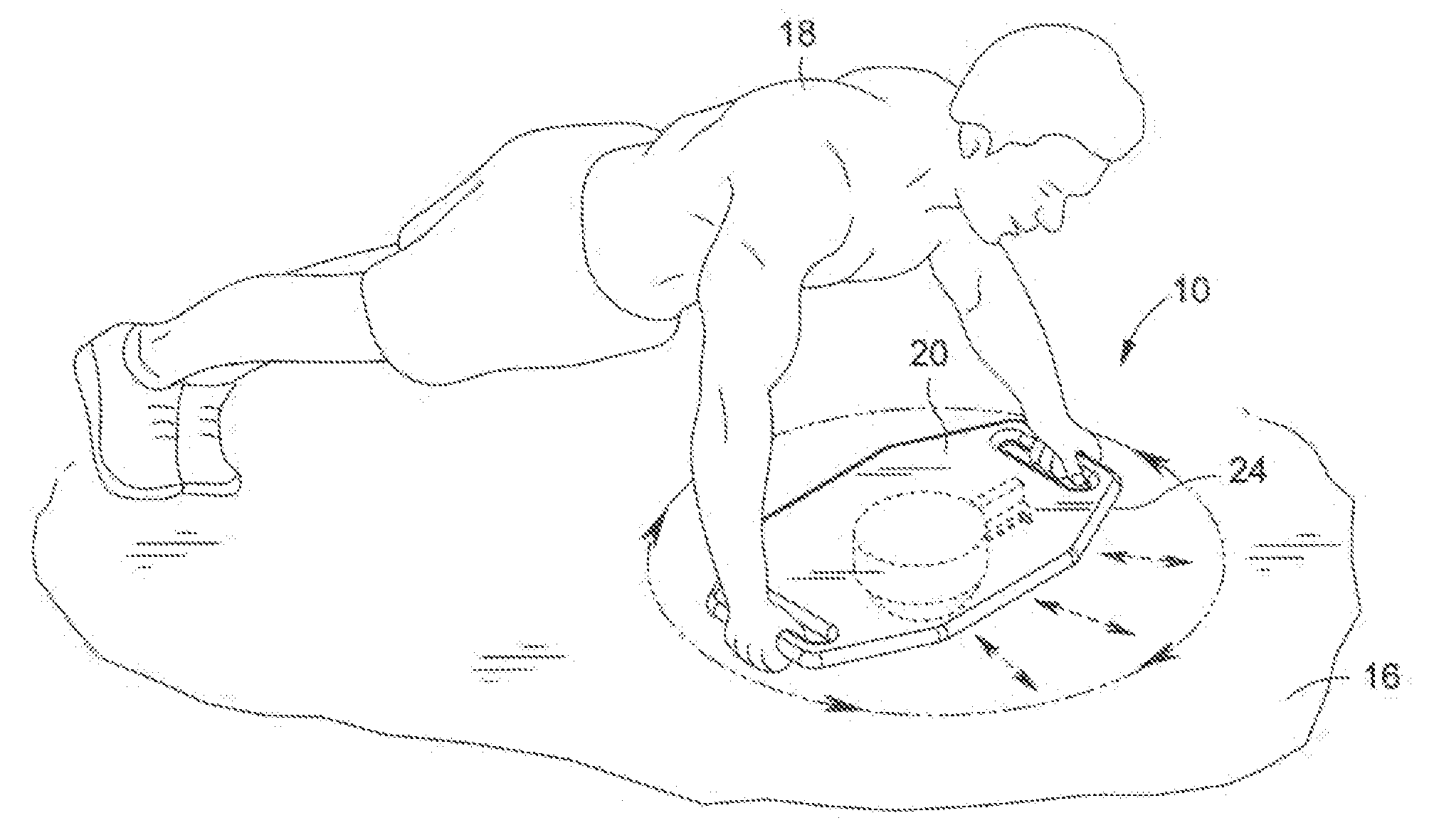

Rotatory abdominal crunch machine

Owner:XIAMEN KANG SOU FITNESS

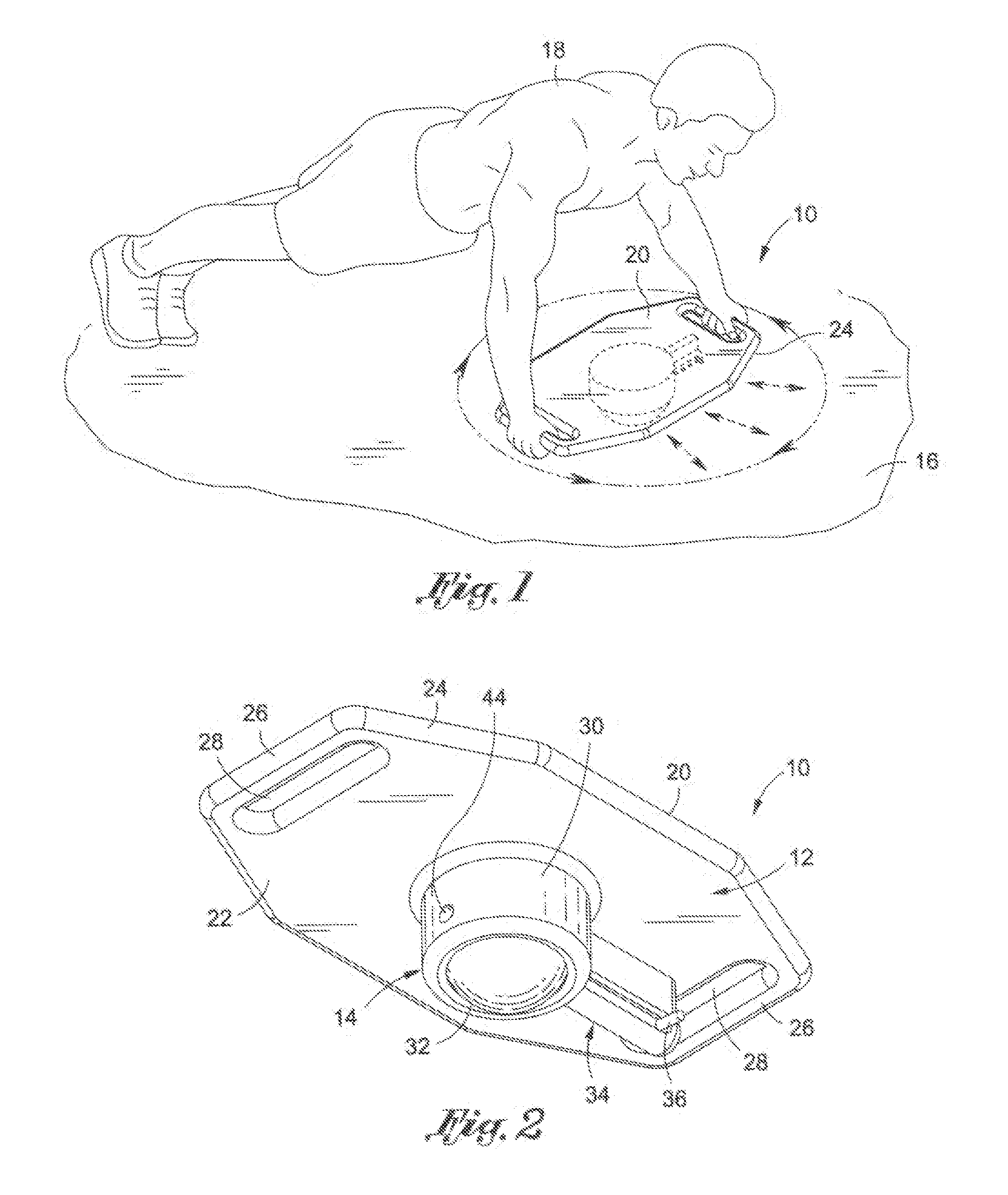

Exercise device

ActiveUS20120252645A1Easy to catchFacilitates motion of exerciseStiltsMuscle exercising devicesRange of motionEngineering

Provided is an exercise device including a planar support surface and a rolling joint which is configured to enable a 360° range of motion for the exercise device. In this regard, the user may roll the exercise device along a planar surface in a forward-and-backward motion, a side-to-side motion, or in an arcuate or circular motion.

Owner:AGOSTINI SCOTT C

Virtual wall gas sampling for an ion mobility spectrometer

InactiveUS6888128B2Time-of-flight spectrometersSamples introduction/extractionChemical physicsProduct gas

The presence of trace molecules in air may be determined using an ion mobility spectrometer. Such devices may be used in the fields of explosives detection, identification of narcotics, and in applications characterized by the presence of very low airborne concentrations of organic molecules of special interest. The sensitivity of such instruments may depend upon on the method of gas sampling utilized. A virtual wall gas sampling system can greatly improve the sampling efficiency, particularly when the sampling needs to be performed at a distance from the air intake and large volumes need to be sampled. The virtual wall gas sampling system consists of an intake gas flow and a separate group of one or more sheet-like gas flows, which may be either mutually deflected to move with a circular motion or may be formed into a cylindrical bounding surface.

Owner:LEIDOS SECURITY DETECTION & AUTOMATION INC

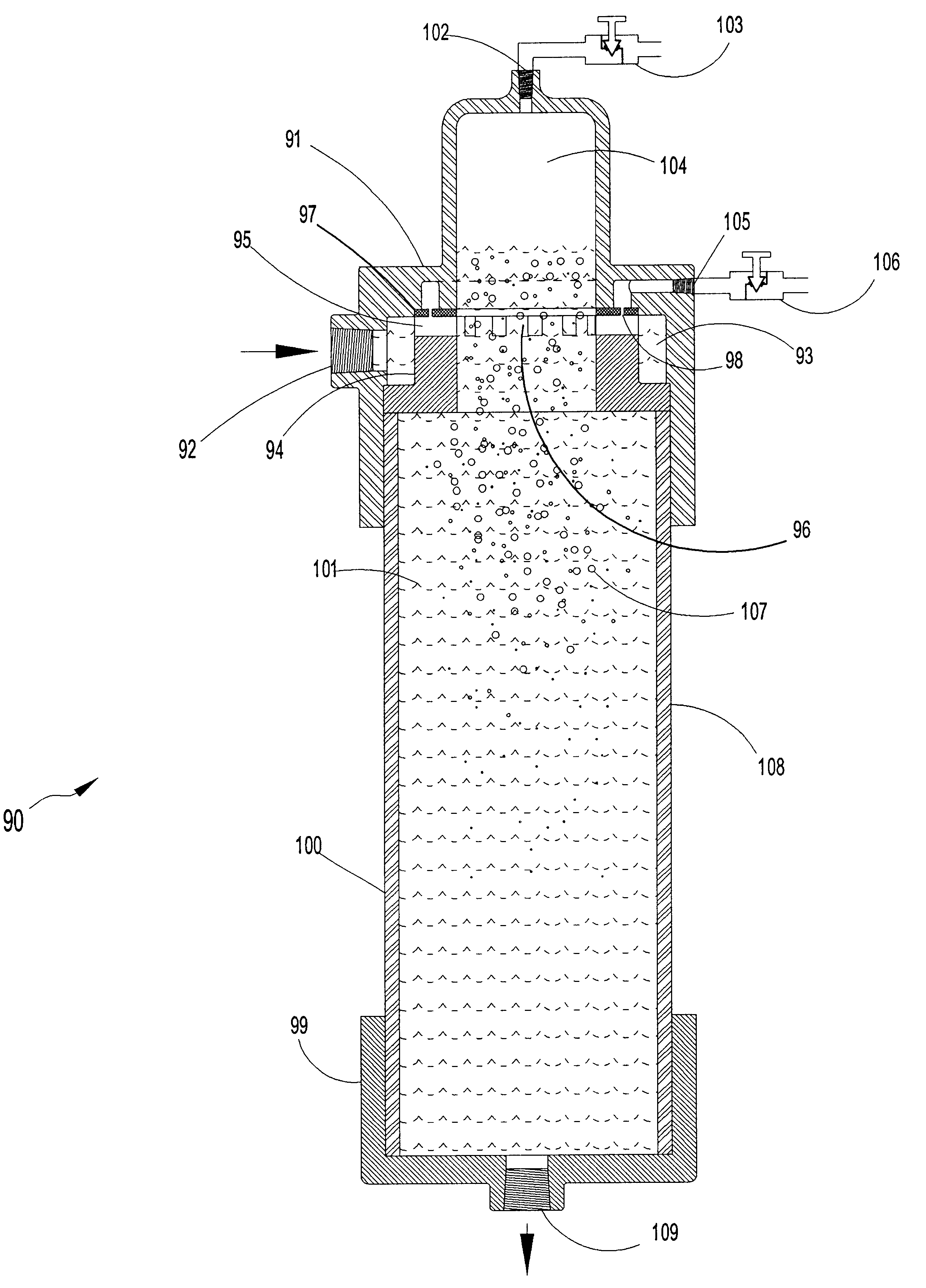

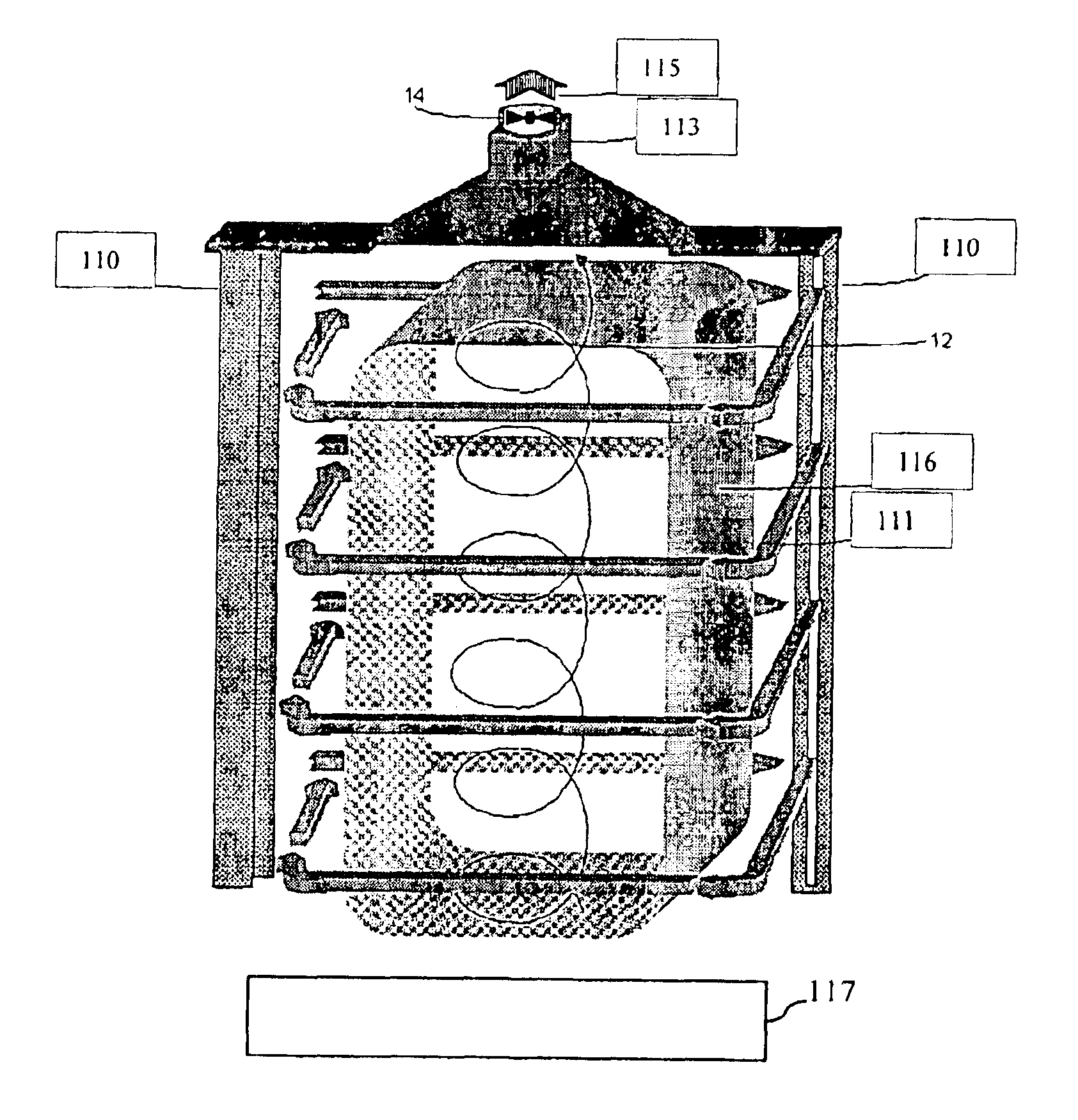

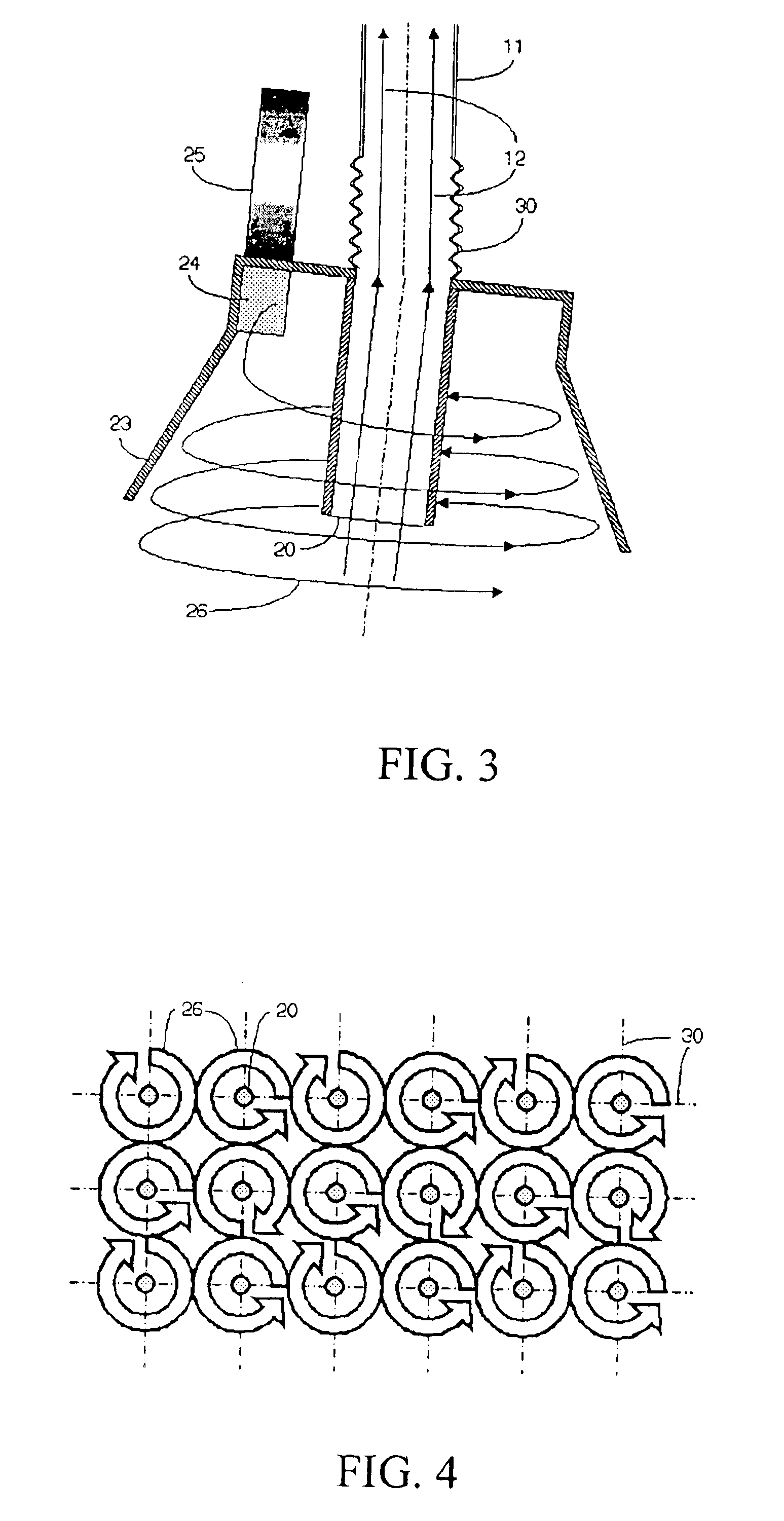

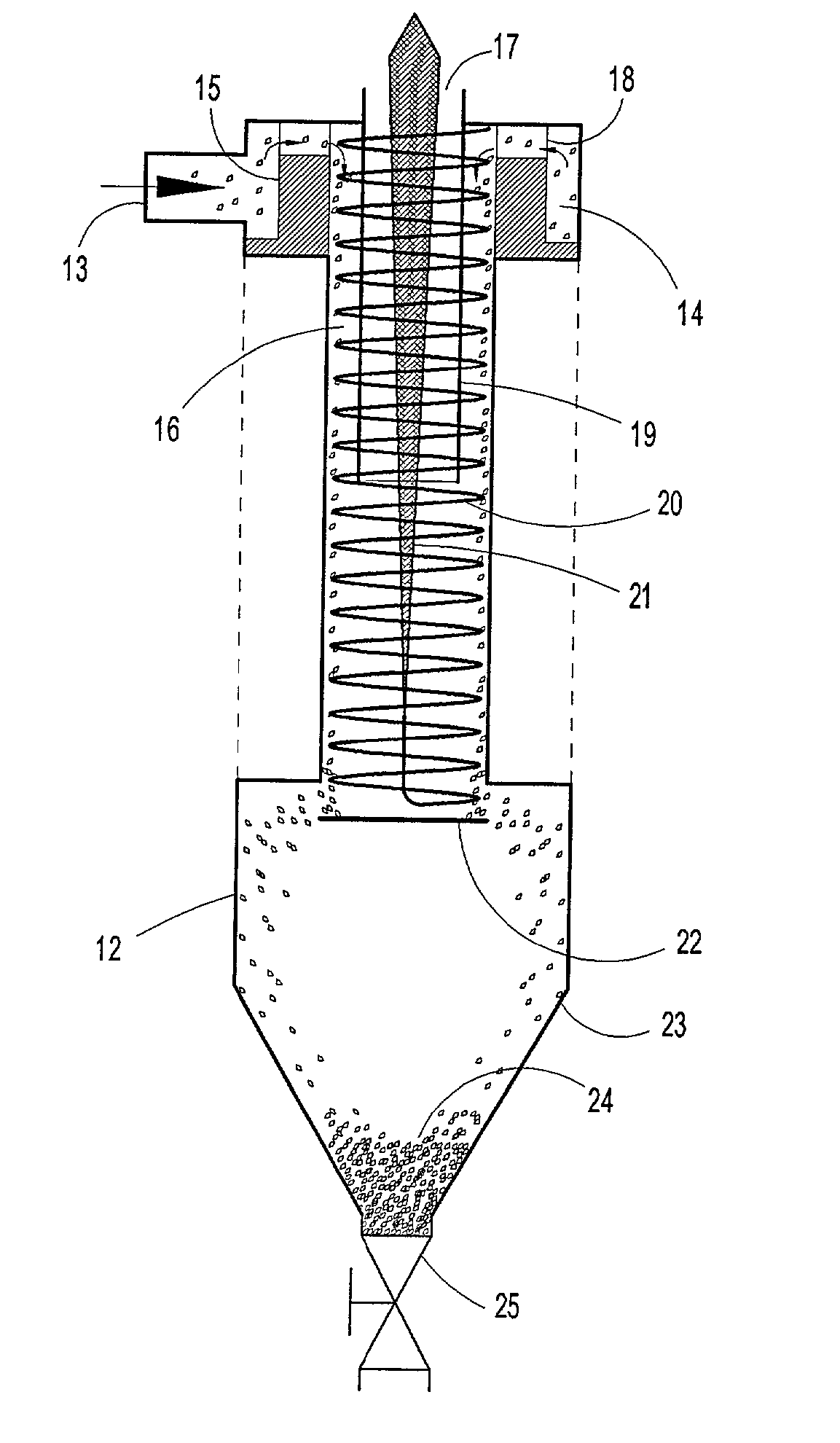

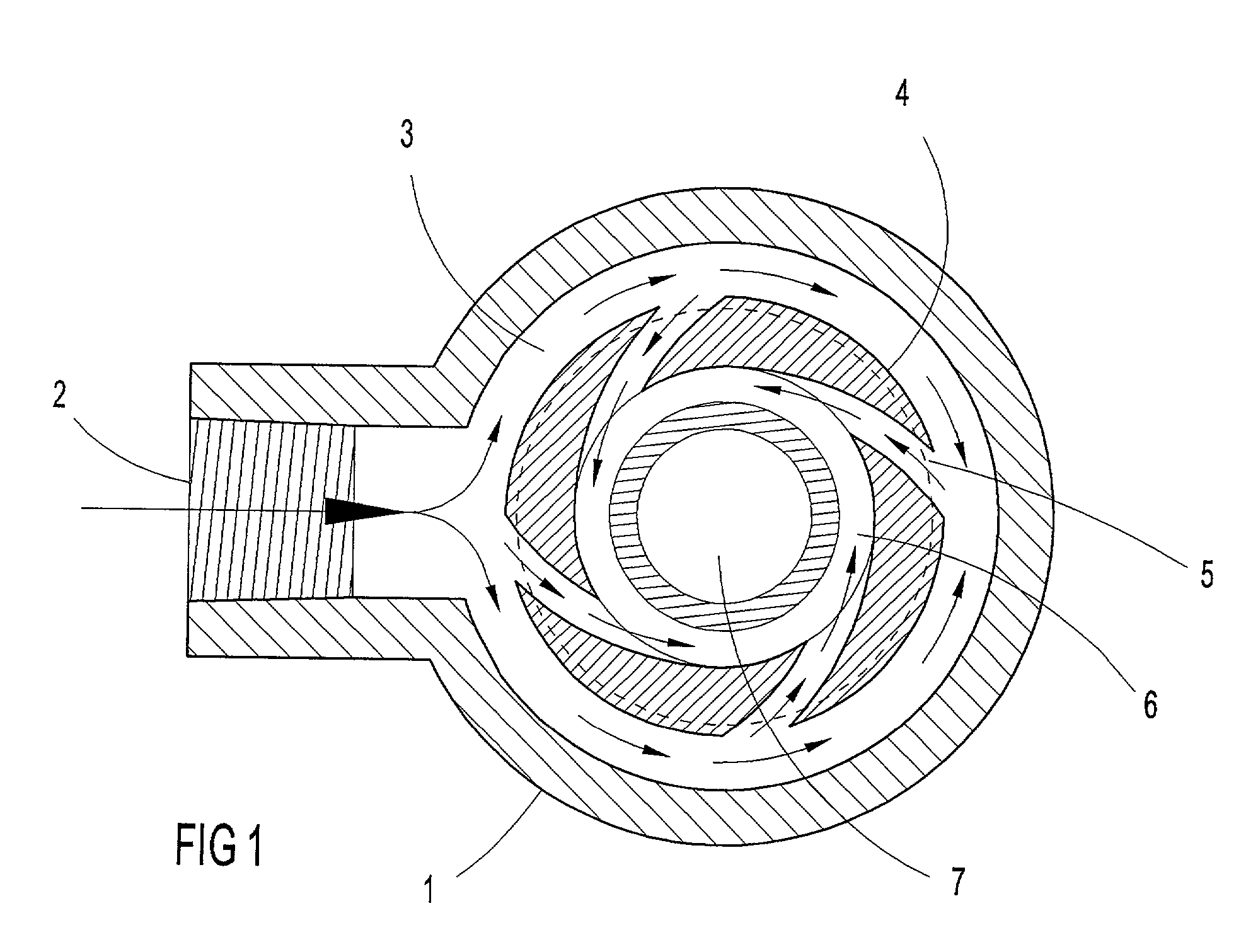

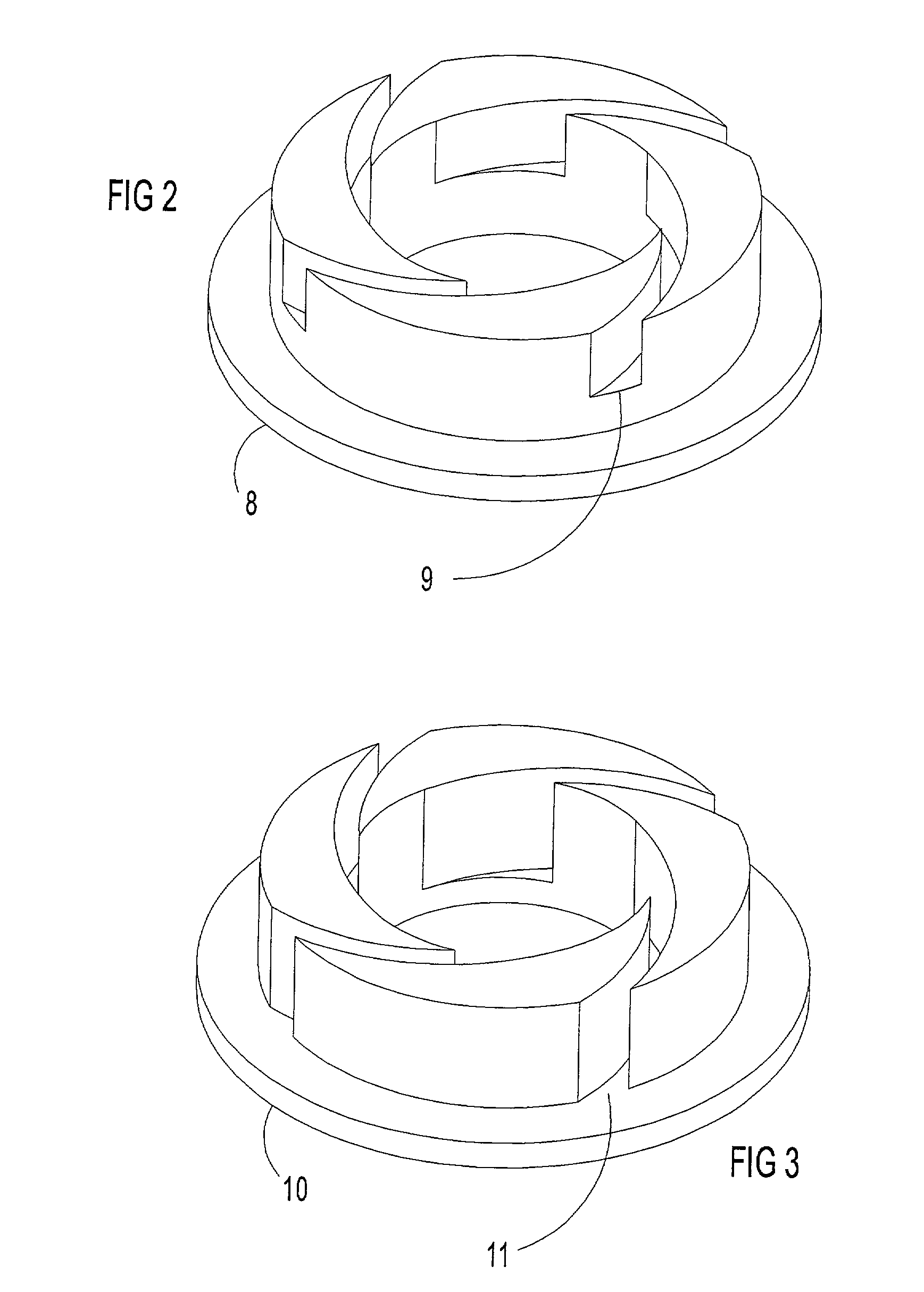

Apparatus for mixing fluids

InactiveUS20030164328A1Eliminate needLiquid separation auxillary apparatusSpace heating and ventilationGas passingSolid particle

An apparatus is provided for separation of suspended solid particles from fluids, for separation and mixing of fluids, and for dissolving gases in aqueous fluids. The apparatus employs a grooved ring to divide the fluid stream and impart a high velocity on each of the divided or sub-streams. A grooved ring with any number of grooves that may be spiral in shape is used to create a high velocity circular motion on a divided stream for separation of suspended solid particles by centrifugal force in a cyclone filter and for saturation of liquid with gases in a fluid mixer where gases are introduced through a diffuser. A grooved ring with any number of grooves that may be radial is used in a fluid mixer to divide a stream of fluid, produce a high velocity flow through each groove, introduce a second fluid through an orifice into the first fluid flowing through each groove, and direct the fluid mixture to a center impact zone where the various streams collide to complete the mixing.

Owner:HYDROTREAT

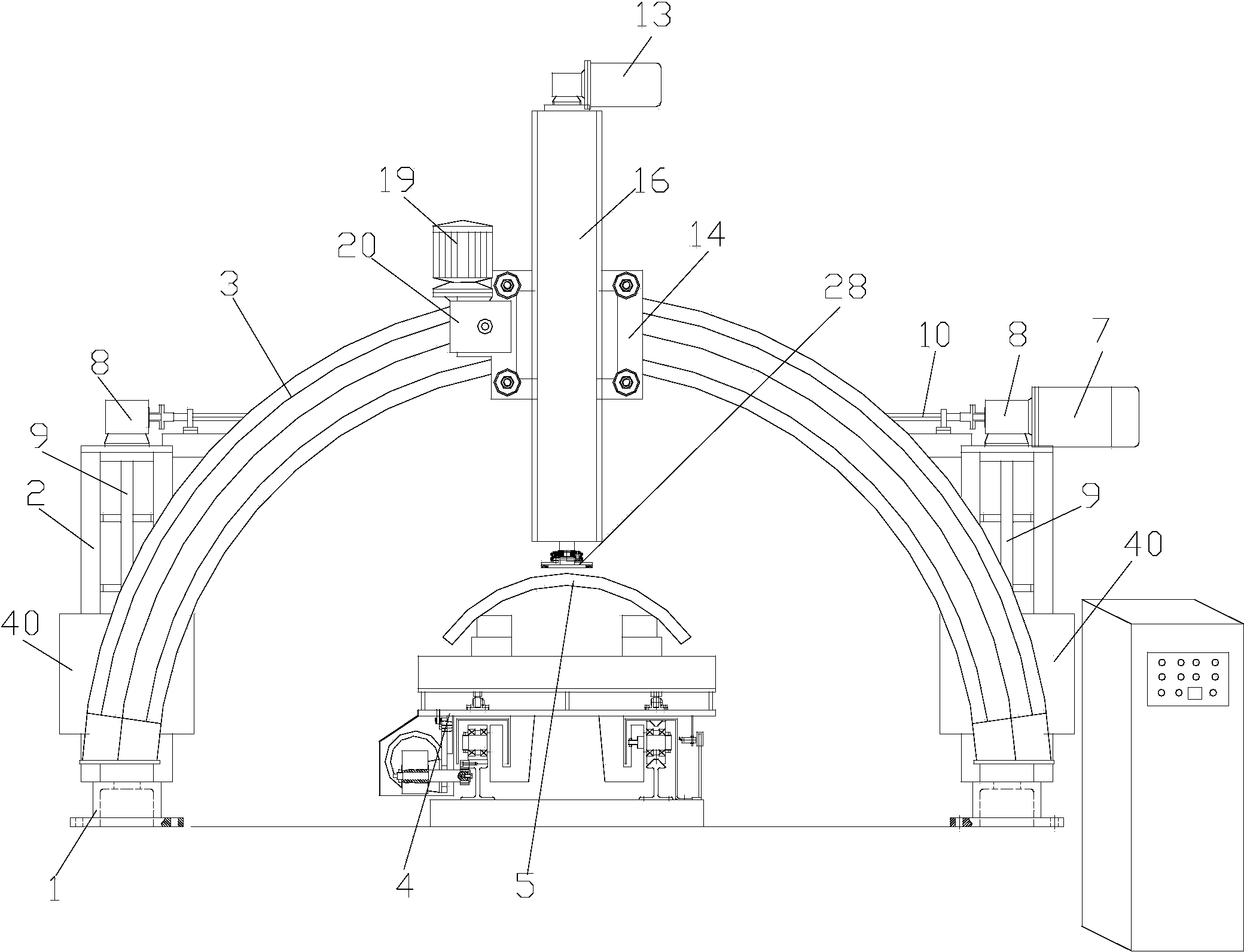

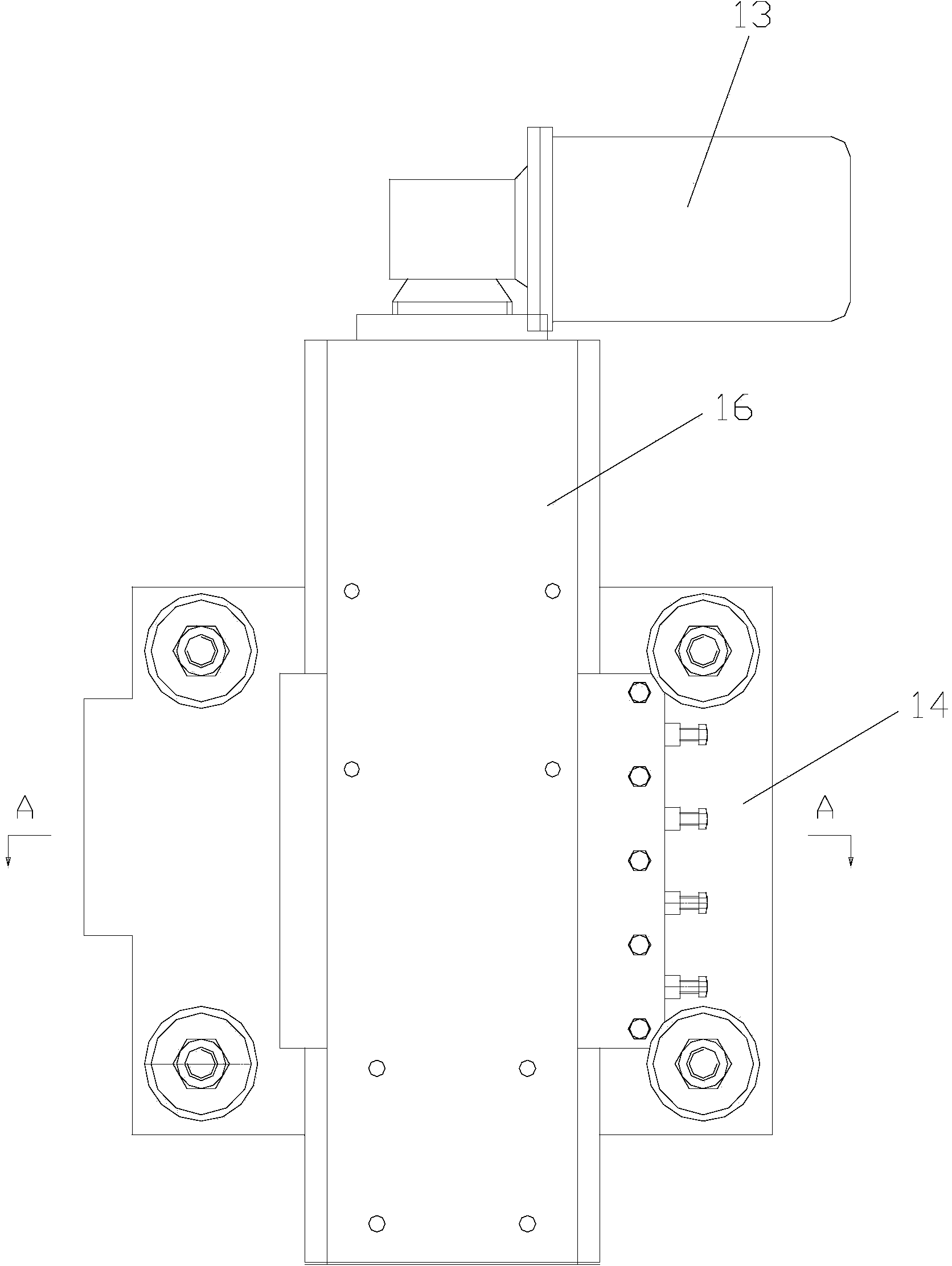

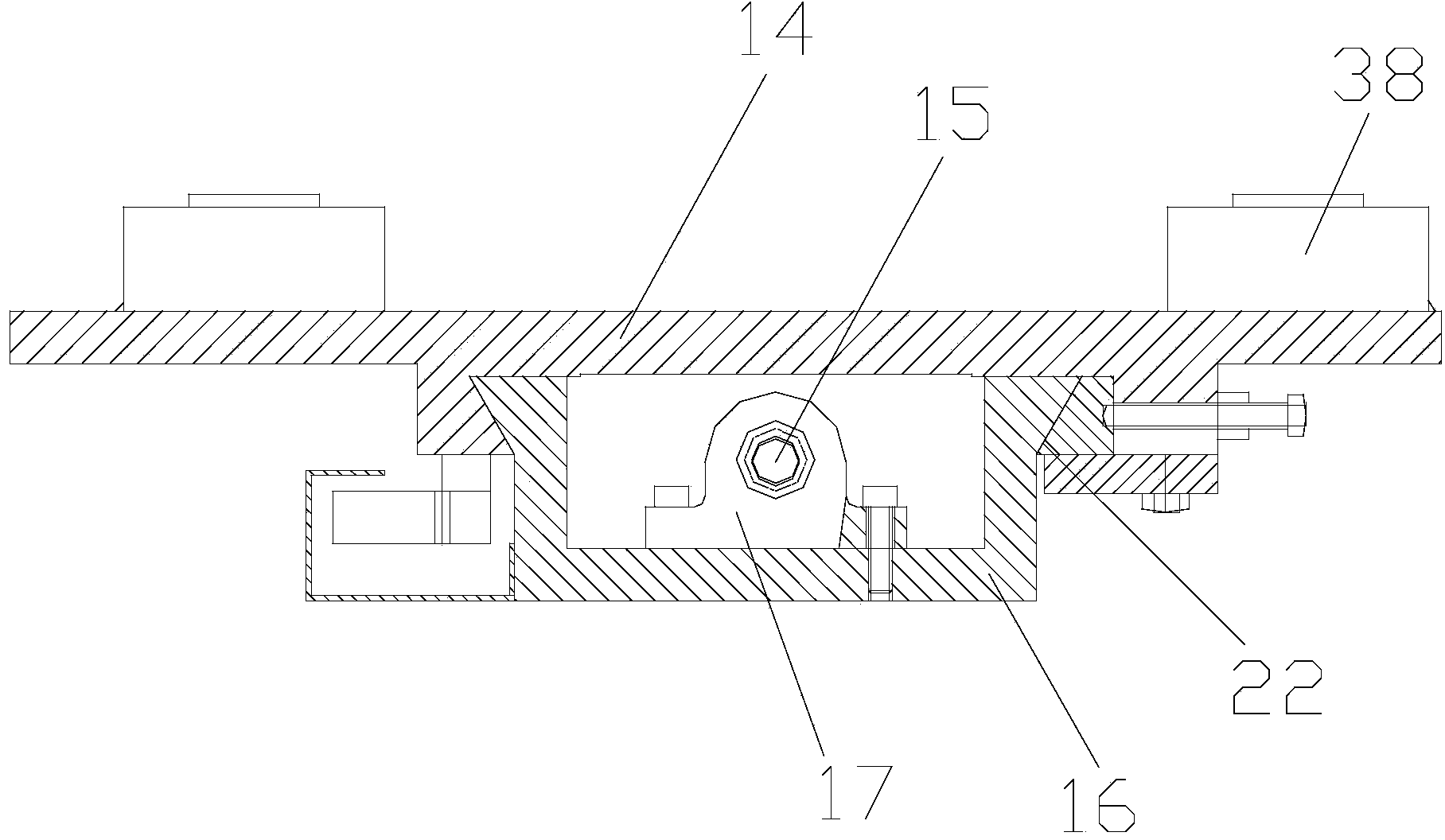

Automatic arc slab rough grinding machine

InactiveCN103978414AReduced strength requirementsLow technical requirementsGrinding machinesGrinding/polishing safety devicesWorking environmentWet grinding

The invention provides an automatic arc slab rough grinding machine which comprises a base, stand columns, an arched girder and an adjustable working platform in the middle of the base. The two ends of the arched girder are fixedly connected with arched girder lifting devices arranged on the stand columns, and the arched girder lifting devices drive the arched girder to slide along the stand columns synchronously in the vertical direction. A grinding head lifting device and a circular motion mechanism are arranged on the arched girder, and the grinding head lifting device is fixed to the circular motion mechanism and drives a grinding head device fixed in the grinding head lifting device to make contact with or be separated from the surface of a workpiece fixed to the adjustable working table. Water is sprayed on the grinding head device so that wet grinding can be conducted between the grinding head device and the workpiece during work. The circular motion mechanism is matched with a long chain fixed to the arched girder, and drives the grinding head lifting device to do the circular motion in a rail direction of an arc-shaped guide rail on the arched girder and to grind the workpiece on the adjustable working table. By means of the automatic arc slab rough grinding machine, accuracy and efficiency of grinding the workpiece are improved, the working environment for workers is improved, and grinding powder is prevented.

Owner:BAOJI YINKANG MACHINERY EQUIP

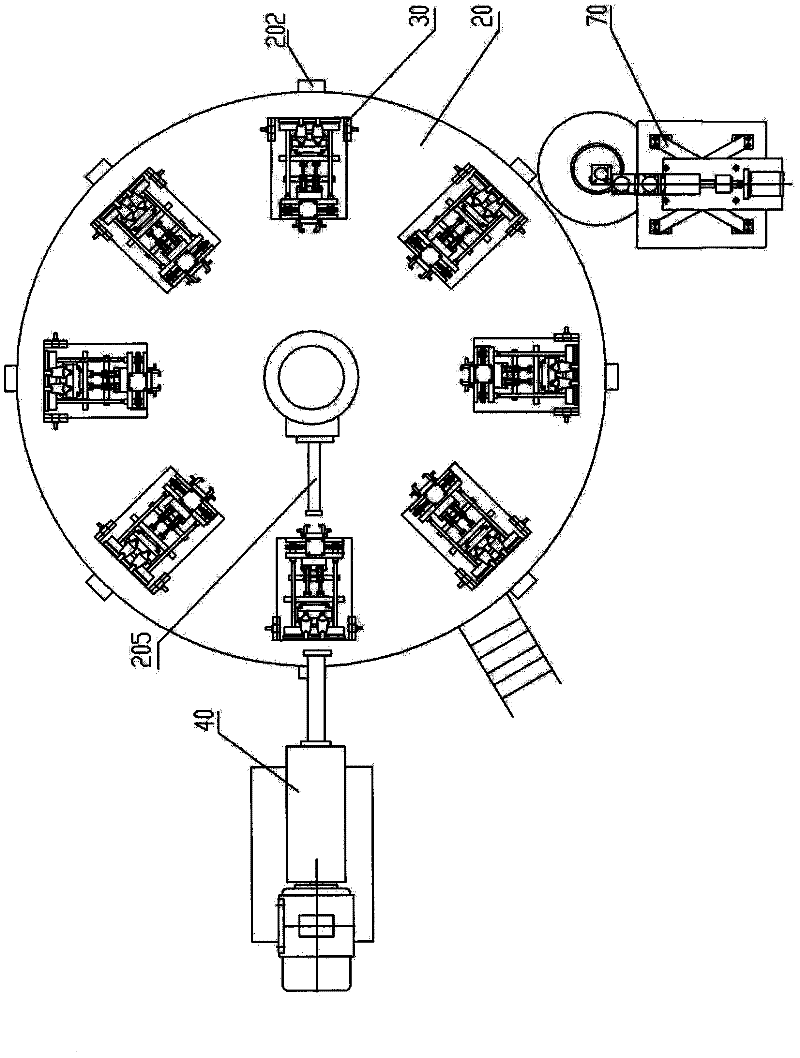

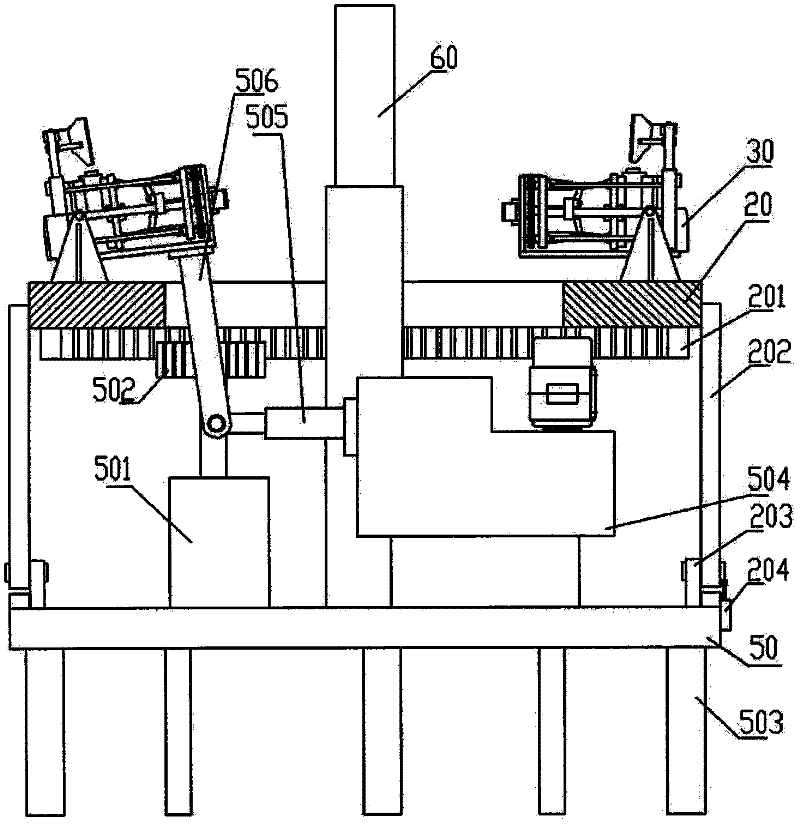

A multi-station automatic pouring machine

ActiveCN102259183AEasy to adjustAccurate adjustmentPig casting plantsMolten metal conveying equipmentsMotor driveGear wheel

The invention discloses a multi-station full-automobile casting machine comprising a casting robot. The casting robot is fixed on one side of a workbench on a mainframe, at least three casting units are annularly distributed on the workbench, and a hydraulic pushrod mechanism is arranged face to face at one casting unit on one side of the workbench; the hydraulic pushrod mechanism supports the casting unit, a bull gear is arranged at the bottom of the workbench, pulley supports are fixed on the edge of the workbench corresponding to the casting units, each pulley support is provided with a pulley, a guide rail table is arranged on the mainframe and is provided with a motor, the motor drives a small pinion to rotate, the small pinion is meshed with the bull gear, and the pulleys acts circular movement along the guide rail table. With the multi-station full-automobile casting machine, a whole lower mould fixture moves to be regulated through the regulation of a guide rod so as to meet the requirement of an upper casting mould and a lower casting mould on compact matching; simultaneously, the casting units rotate through a hydraulic system, thus the manufactured castings have higher degree of crystallization and higher strength.

Owner:浙江文源智能科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com