Patents

Literature

38results about How to "Short polishing time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

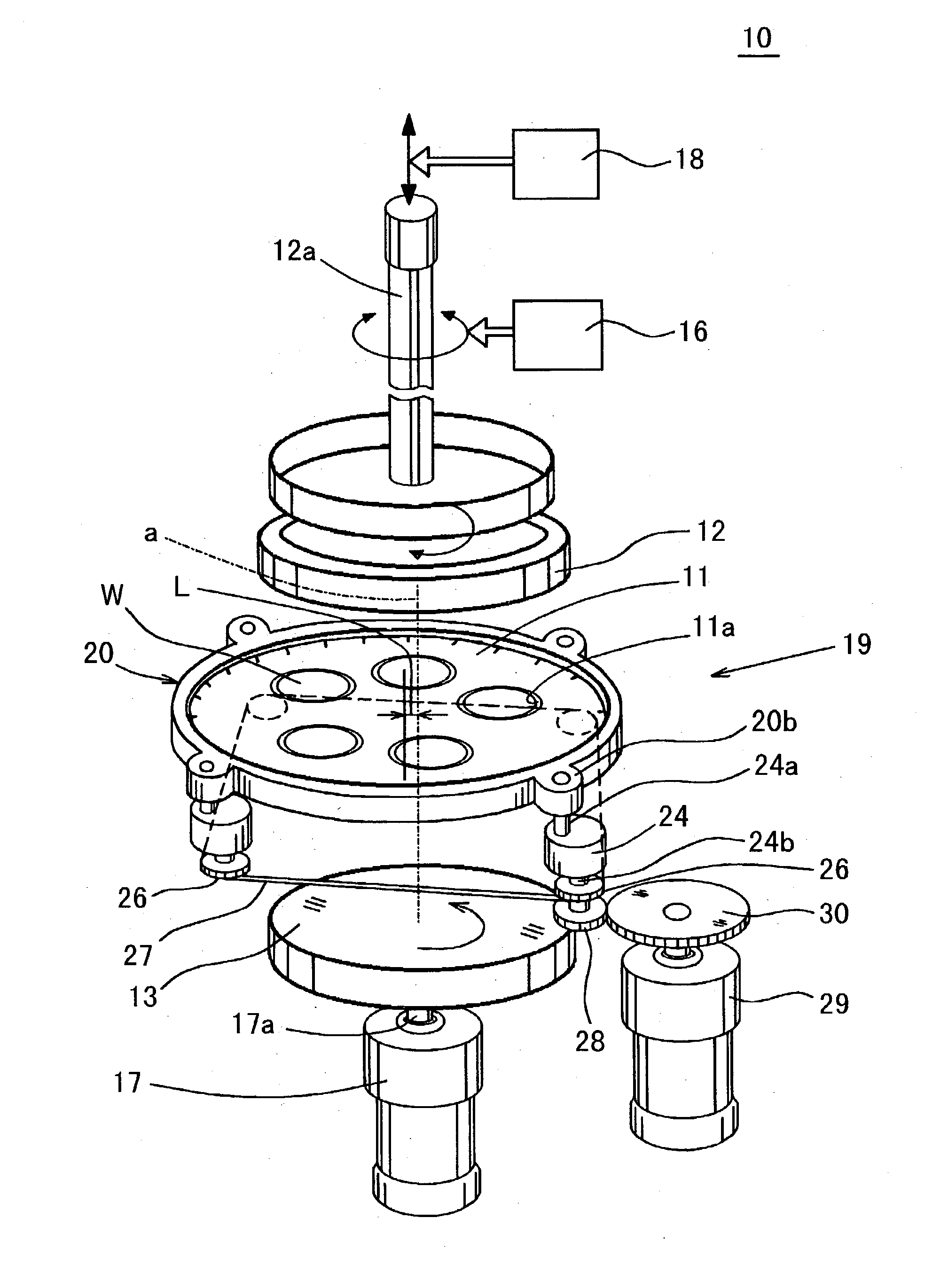

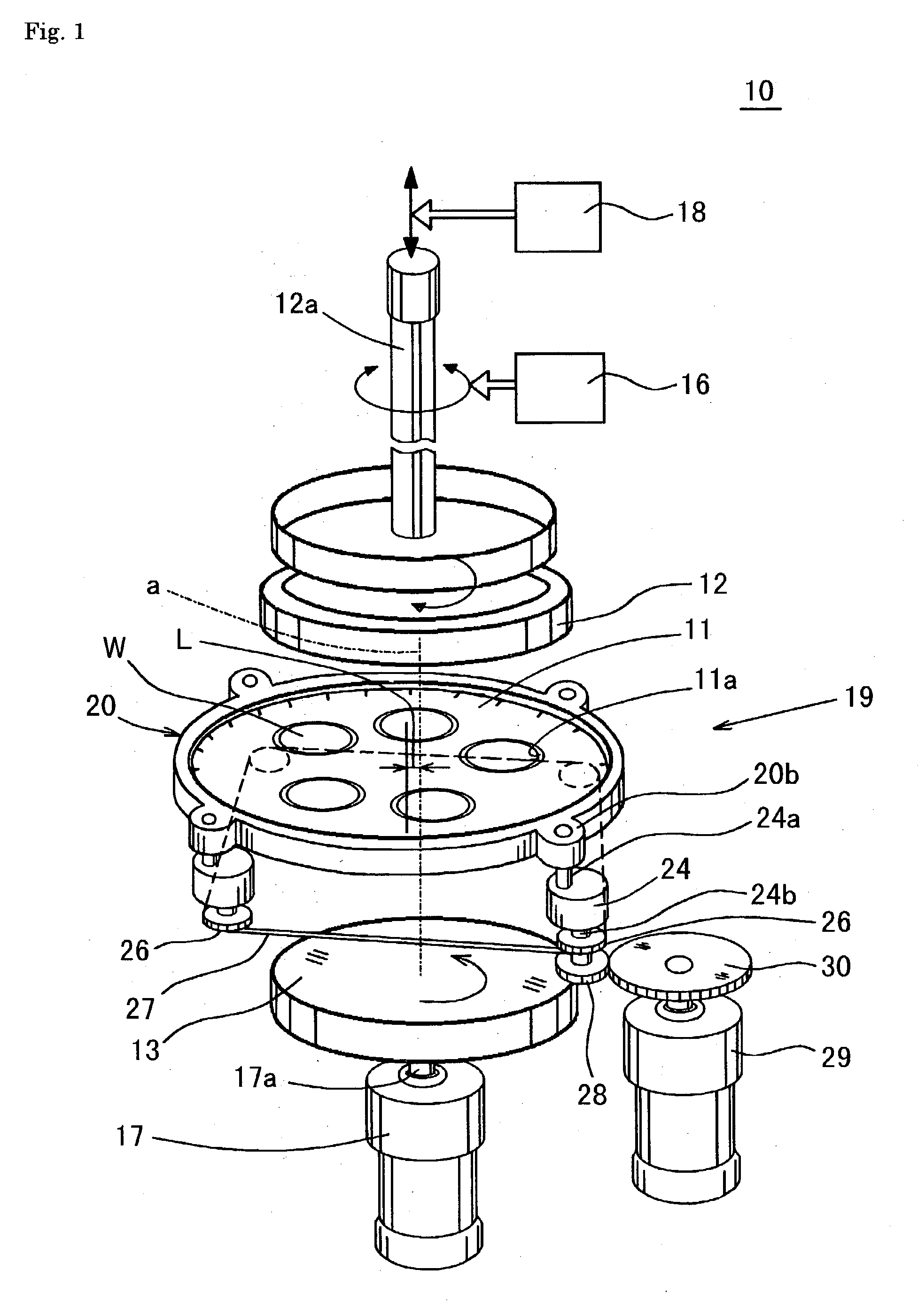

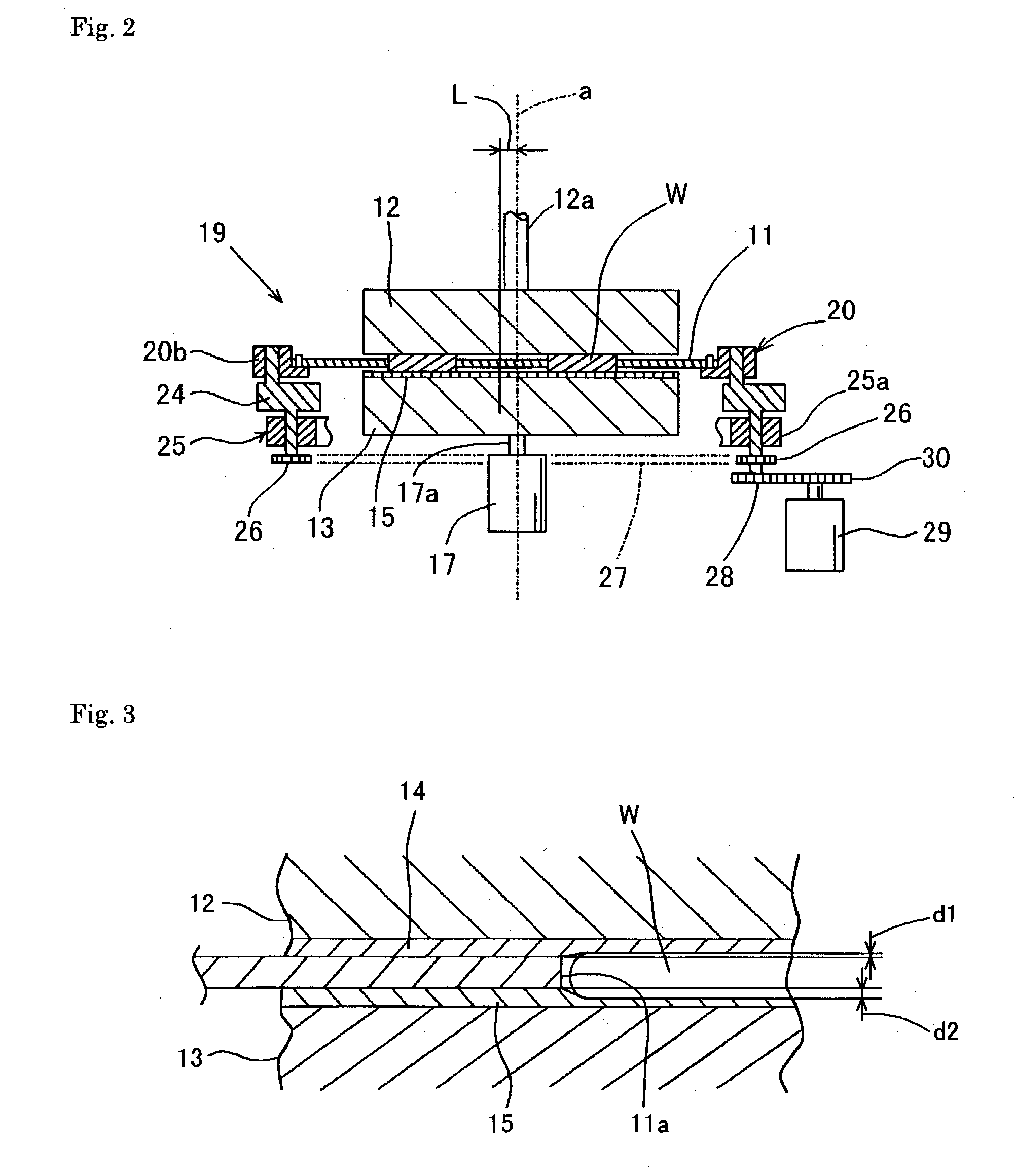

Method of manufacturing semiconductor wafer

ActiveUS20030104698A1Small polishing volumeShort polishing timePolishing machinesRevolution surface grinding machinesSlurryEngineering

An object of the present invention is to provide a semiconductor wafer having a front and a back surfaces polished so as to have different glossiness from each other, yet with a lower cost. The glossiness of the front surface and the back surface can be selected arbitrarily. In a double-sided polisher with no sun gear, silicon wafers W are inserted in respective holding holes 11a of a carrier plate 11. The wafers W are placed with their back surfaces facing up. An expanded urethane foam pad 14 is pressed against the back surfaces of the wafers W and a non-woven fabric pad 15 is pressed against the front surfaces of the wafers W. A carrier holder 20 and thus the carrier plate 11 are then driven to make a circular motion associated with no rotation on their own axes within a horizontal plane while supplying a slurry to the wafers W from an upper surface plate 12 side. As a result, each of the front and the back surfaces of respective silicon wafers W can be polished uniformly over entire area thereof respectively. At that time, the urethane pad 14 has a sink rate of the wafer lower than that of the non-woven fabric pad 15. Therefore, such a polished wafer having the back surface formed into a satin-finished surface and the front surface formed into a mirror-finished surface can be obtained. Alternatively, those polishing cloths having different sink rates from each other may be employed for the upper and the lower surface plates, respectively. Further, the upper surface plate and the lower surface plate may be rotated at different speeds from each other. Those methods are also advantageously used to manufacture the semiconductor wafer having different glossiness between the front surface and the back surface thereof.

Owner:SUMITOMO MITSUBISHI SILICON CORP

Electrolytic polishing process

The invention relates to an electrolytic polishing process. The electrolytic polishing process of the invention comprises the following steps of: removing oil from a workpiece; washing with water; soaking in acid; performing electrolytic polishing; performing countercurrent rinsing for three times; soaking in alkali; washing with water; passivating; wiping or drying; and packaging.

Owner:BEIJING SANLIAN HOPE TEXTILE & CHEM TECH

Non-phosphorus electrolytic polishing liquid and technology for polishing workpiece surfaces with same

The invention discloses non-phosphorus electrolytic polishing liquid and a technology for polishing workpiece surfaces with the same. The non-phosphorus electrolytic polishing liquid comprises 30%-60% of sulfuric acid, 15%-35% of organic acid, 1%-5% of brightener, 2%-10% of viscosity modifier, 1%-5% of corrosion inhibitor and 20%-30% of water. The non-phosphorus electrolytic polishing liquid does not contain components not allowed by environmental standards, waste water is convenient to process in the cleaning process, and toxic effects on human body and livestock are avoided. The invention further provides the best polishing process condition for polishing stainless steel workpieces with the non-phosphorus electrolytic polishing liquid. The electrolytic polishing effect is completely identical with the polishing effect of original phosphoric acid electrolytic polishing liquid. The polishing time is short, and machining cost is low.

Owner:SHANGHAI MIRROR METAL SURFACE TREATMENT

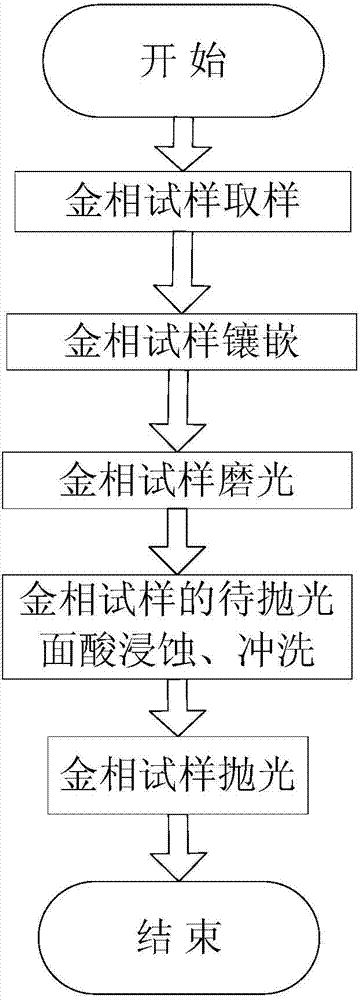

Metallographic specimen preparation method

ActiveCN103759993AThe preparation method is simple and quickDoes not leave wear marksPreparing sample for investigationAcid etchingSpecimen preparation

The invention discloses a metallographic specimen preparation method. The metallographic specimen preparation method particularly comprises the following steps: firstly, sampling a metallographic specimen; secondly, inserting the metallographic specimen; thirdly, polishing the metallographic specimen; fourthly, carrying out acid etching and washing on a to-be-polished surface of the metallographic specimen, namely putting the to-be-polished surface into nital for etching and washing with water; and finally, polishing the metallographic specimen. The metallographic specimen preparation method is simple and rapid; abrasive material particles and metal abrasive dust particles on the polished surface are dissolved by adding the nital etching procedure before polishing; obvious polishing marks cannot be left on the polished specimen, and thus the polishing effect of the metallographic specimen is improved; the polishing time of the metallographic specimen is shorter than before, and the polishing efficiency is improved.

Owner:GUANGXI YUCHAI MASCH CO LTD

Polishing fluid for polishing metal surfaces and preparation method thereof

A disclosed polishing fluid for polishing metal surfaces is characterized by being prepared from the following raw materials in parts by weight: 1-2 parts of diethanolamine, 2-3 parts of ethanolamine, 2-4 parts of lauryl diethanolamide, 3-4 parts of hydroxy propyl cellulose, 3-5 parts of 2-(2-methoxyethoxy)ethanol, 2-4 parts of polyoxypropylene polyoxyethylene propylene glycol ether, 10-15 parts of nanometer aluminium oxide, 1-2 parts of gelatin, 1-2 parts of methionine, 5-7 parts of an auxiliary agent, and 300 parts of deionized water. The prepared polishing fluid is safe, non-toxic, good in polishing performance, uniform, high in luster and short in polishing time. By adding methionine, the polishing fluid has good corrosion inhibition effect. By adding the auxiliary agent, the polishing fluid has good wear resistance, dispersity, lubricity and film-forming property, and is capable of avoiding air corrosion under the synergic effect of a corrosion inhibitor. The polishing speed is stable, and the polishing fluid is capable of reducing environmental pollution, and is suitable for polishing of metal surfaces, and especially suitable for steel surfaces.

Owner:苏州威力士精细化工有限公司

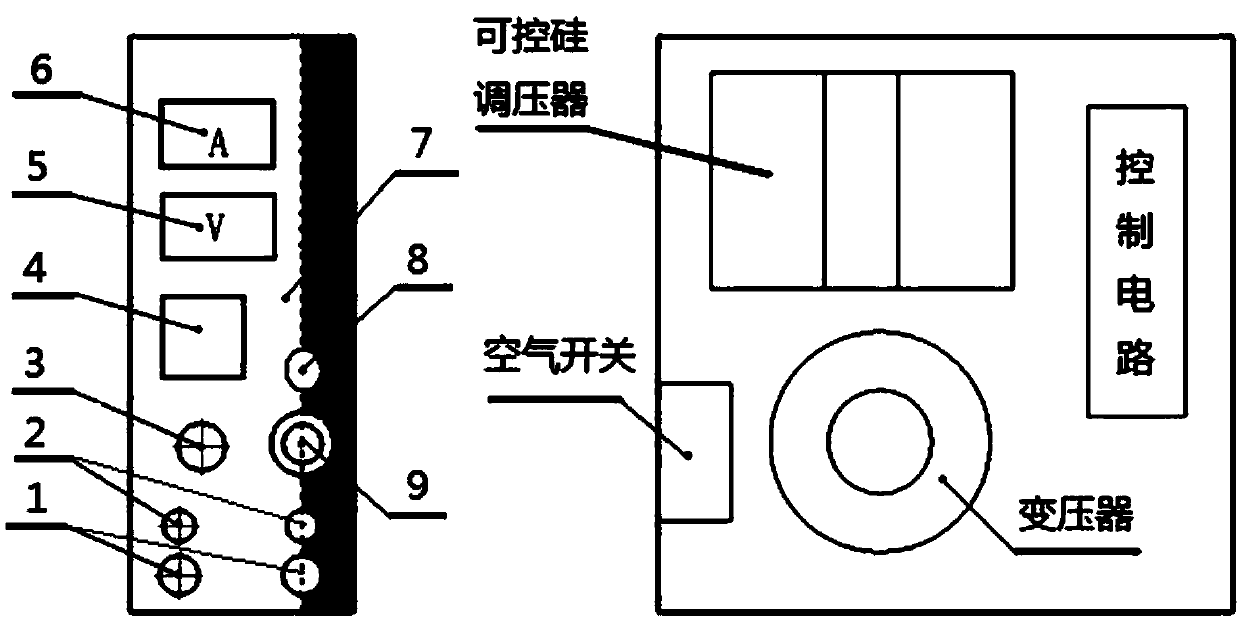

Liquid-phase plasma polishing liquid and polishing process of aluminum product

InactiveCN102310357ANon-volatileAvoid harmPolishing machinesPolishing compositionsFluid phaseMetallurgy

The invention discloses a liquid-phase plasma polishing liquid and a polishing process of an aluminum product. The polishing liquid comprises the following components calculated by weight percentage: 3-4 percent of ferric trichloride, 1-2 percent of ammonium chloride and the balance of purified water. The polishing process comprises the following steps of: mounting the aluminum product to be polished on a hanger and then soaking and showering in the purified water; pouring the liquid-phase plasma polishing liquid into a polishing groove; heating the liquid-phase plasma polishing liquid to be 70-90DEG C; soaking the aluminum product to be polished on the hanger into the liquid-phase plasma polishing liquid; connecting an anode of a liquid-phase plasma polishing machine with the aluminum product to be polished; connecting a cathode of the liquid-phase plasma polishing machine with a plurality of cathode plates in parallel; controlling an output polishing power supply to be 270-330V; taking the aluminum product out after polishing and soaking and showering; and drying the aluminum product. The liquid-phase plasma polishing liquid disclosed by the invention does no harm to an operator; and the polishing process disclosed by the invention has the advantages of short polishing time, high efficiency, greatly-improved glossiness of the aluminum product and the like.

Owner:无锡清源数字信息技术研究院有限公司

Polishing agent for liquid crystal touch screen of mobile phone and preparation method of polishing agent

InactiveCN107011806AImprove performanceProcess stabilityPolishing compositions with abrasivesO-Phosphoric AcidActive agent

The invention discloses a polishing agent for a liquid crystal touch screen of a mobile phone and a preparation method of the polishing agent and relates to the technical field of production of touch screens of the mobile phone. The polishing agent is prepared from the following raw materials: phosphoric acid, concentrated sulfuric acid, chromic acid, glycerin, gelatin, a tanning extract, glucose, ethylenediamine tetraacetic acid disodium, antimonous oxide, titanium dioxide, cerium oxide, rare earth carbonate, water, a surfactant, a fluxing agent and an antifoaming agent. The method comprises the steps of stirring and blending phosphoric acid, concentrated sulfuric acid, chromic acid, glycerin, gelatin, tanning extract, glucose, ethylenediamine tetraacetic acid disodium and water; fully mixing antimonous oxide, titanium dioxide, cerium oxide and rare earth carbonate, grinding, sieving, and carrying out high-temperature calcinations on a mixture formed after grinding antimonous oxide, titanium dioxide, cerium oxide and rare earth carbonate; and adding the calcined powder, the surfactant, the fluxing agent and the antifoaming agent to a mixed solution and fully stirring. The polishing agent is high in quality, good in polishing effect, high in polishing efficiency, reasonable in preparation technology, good in heat dissipation effect and low in production cost.

Owner:安徽智诚光学科技有限公司

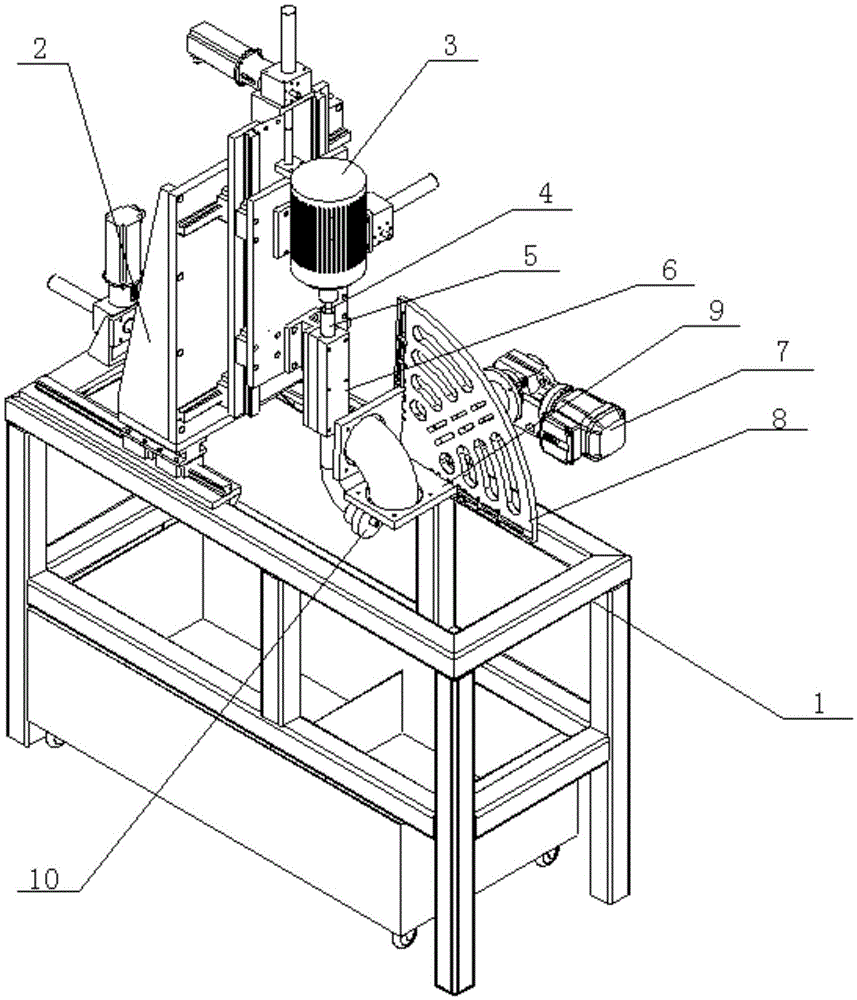

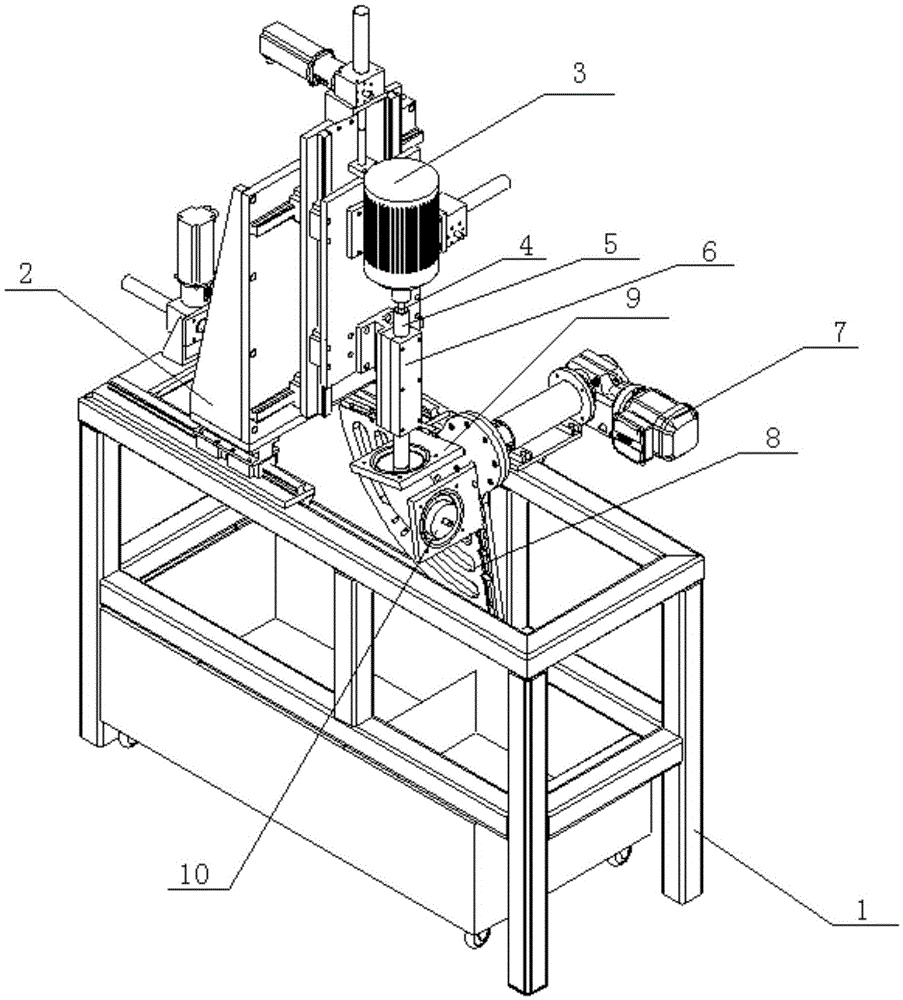

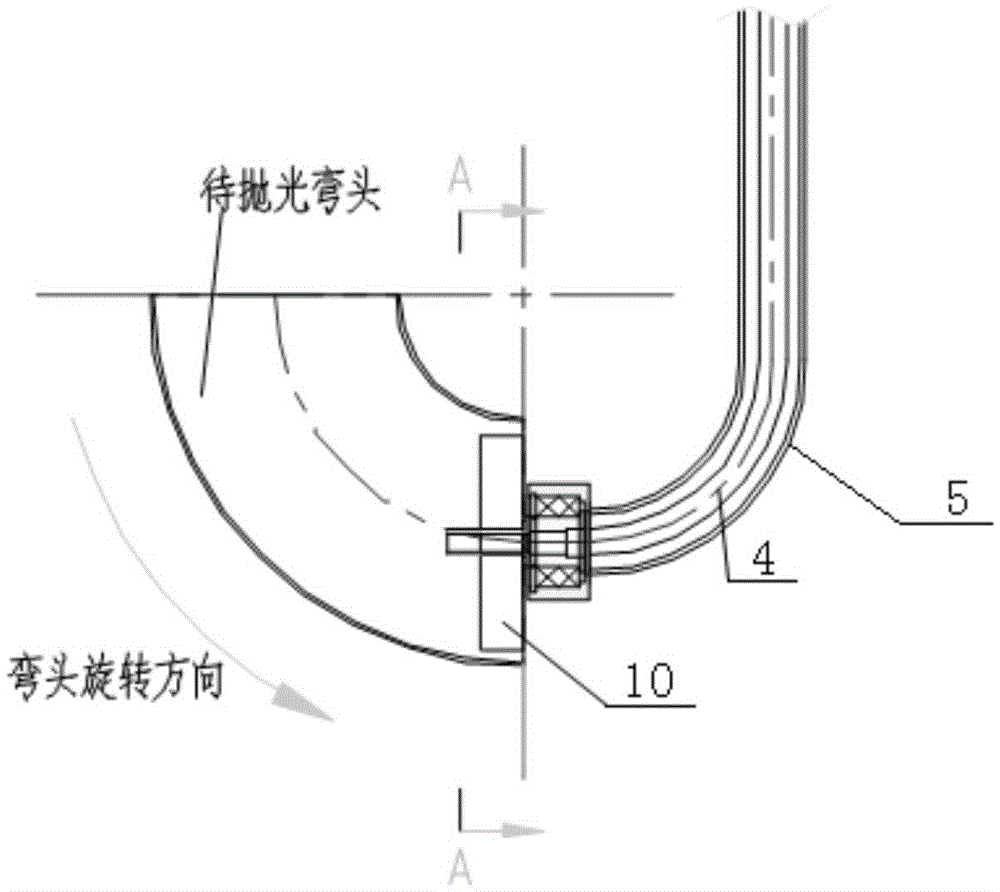

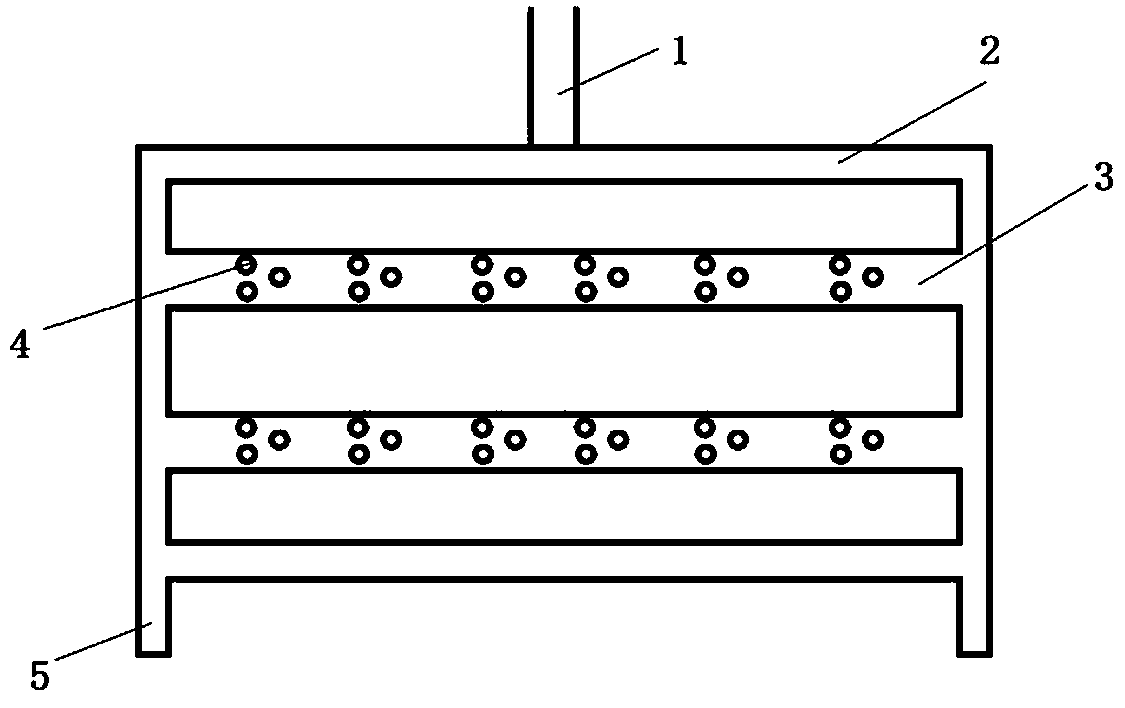

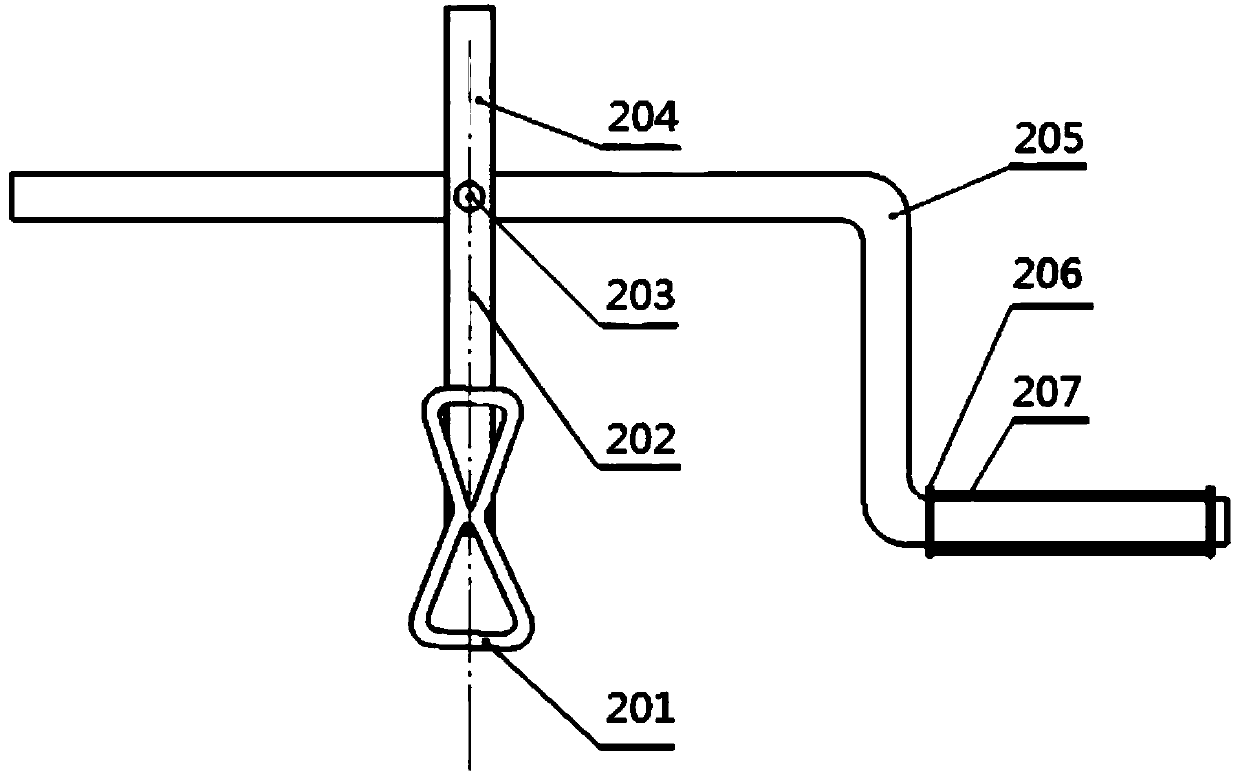

Polishing machine for polishing inner surface of elbow

InactiveCN105598811AEasy to useShort polishing timeGrinding carriagesPolishing machinesNumerical controlFixed frame

The invention discloses a polishing machine for polishing an inner surface of an elbow. The polishing machine comprises a rack, a numerical control slide platform, a motor, a flexible shaft, a bent sleeve, a bent sleeve fixed frame, a speed reducer, a rotary platform, a clamp and a polishing disc, wherein the numerical control slide platform and the speed reducer are fixed on the rack; the speed reducer is arranged on one side of the numerical control slide platform; the motor is arranged on the numerical control slide platform; the bent sleeve fixed frame is fixed on the numerical control slide platform; the bent sleeve is arranged on the bent sleeve fixed frame; one end of the flexible shaft is connected with the motor and the other end of the flexible shaft penetrates through the bent sleeve and is fixedly provided with the polishing disc; and the rotary platform is fixed on the speed reducer and the clamp is mounted on the rotary platform. With the adoption of the polishing machine disclosed by the invention, the inner surface of the elbow can be automatically polished and the polishing machine is relatively convenient and safe to use; when being used for polishing, the polishing machine only needs to enter from one end of the elbow, and the polishing time is short, so that the polishing efficiency is effectively improved; and meanwhile, directions of wiredrawing traces on the inner surface of the polished elbow are consistent and thus the elbow is relatively beautiful.

Owner:LIYANG SIFANG STAINLESS STEEL PRODS

Polishing method for mirror effect of amorphous alloy

The invention provides a polishing method for a mirror effect of amorphous alloy. The polishing method comprises the following steps that S1, grinding liquid containing single crystal diamond particles with a particle diameter of 10-20um is adopted, and first grinding is carried on a first grinding machine; S2, grinding liquid containing single crystal diamond particles with a particle diameter of2-6um is adopted, and second grinding is carried on a second grinding machine; S3, polishing liquid containing silicon dioxide particles with a particle diameter of 70-100um is adopted, and an amorphous alloy product is polished on a polishing machine; and S4, after the amorphous alloy product is ultrasonically cleaned with alkaline cleaning solution, the product is dried. According to the polishing method for the mirror effect of the amorphous alloy, grinding and polishing of the surface of the amorphous alloy product can be carried out through three processes of coarse grinding, fine grinding and polishing, and a better machining surface can be obtained under the mechanical friction action of abrasive with particles with uniformity and good dispersibility; and the machining process is simple and stable, the grinding and polishing time is short, the removal rate is high, the cost is low, and the qualification rate is high.

Owner:上海驰声新材料有限公司

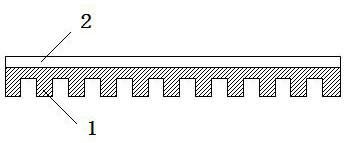

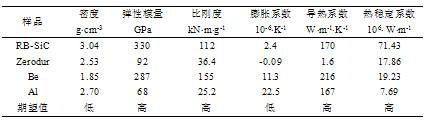

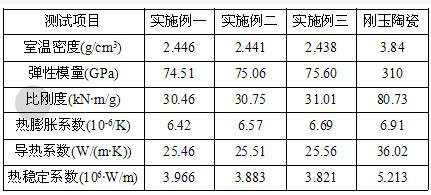

Composite mirror blank material for ceramic-based space mirror

ActiveCN107935567BOvercome the disadvantages of coating conditionsSimple preparation processOxide ceramicManufacturing technology

Owner:海南海控特玻科技有限公司

Processing method and solution for chemical polishing of zinc alloy

The invention provides a processing method and solution for the chemical polishing of a zinc alloy. The method comprises the following steps: a, pretreatment, namely degreasing and cleaning a zinc alloy workpiece; b, chemical polishing, namely dipping the degreased and cleaned zinc alloy workpiece into chemical polishing solution; and c, posttreatment, namely performing cleaning and drying treatment after the polishing is finished, wherein the chemical polishing solution takes water as solvent, and mainly comprises nitric acid, phosphonic acid, sulphuric acid and thiourea; the chemical polishing solution is prepared by mixing ordinary acids and organic substances, thus the components are simple and convenient to control, and the polishing effect is good; and the chemical polishing solution can be matched with other chemical treatment links.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Semiconductor substrate material polishing method

InactiveCN110314896AReduce processing stepsGood removal effectCleaning using liquidsLaser beam welding apparatusSemiconductor materialsMegasonic cleaning

The invention relates to a semiconductor substrate material polishing method and belongs to the technical field of semiconductor material polishing. The semiconductor substrate material polishing method comprises the following steps: carrying out laser polishing on a semiconductor substrate material subjected to linear cutting; carrying out ultrasonic cleaning on the semiconductor substrate material subjected to laser polishing, so that the laser polishing treatment can be completed; and treating the semiconductor substrate material obtained in the previous step by the adoption of chemical mechanical polishing. The semiconductor substrate material polishing method provided by the invention has the beneficial effects that through the laser polishing process, the surface damage can be efficiently removed as well as a structure and a component which are beneficial to chemical mechanical polishing and removal can be formed; meanwhile, the laser polishing process is contactless and no new mechanical damage is generated, so that the ultra-precision polished surface can be obtained within only 0.1-5 hours in the next step of chemical mechanical polishing; all the processing steps in the semiconductor substrate material polishing method can be completed through commercial equipment; the implementation is easy; and the application prospects are good.

Owner:TSINGHUA UNIV +1

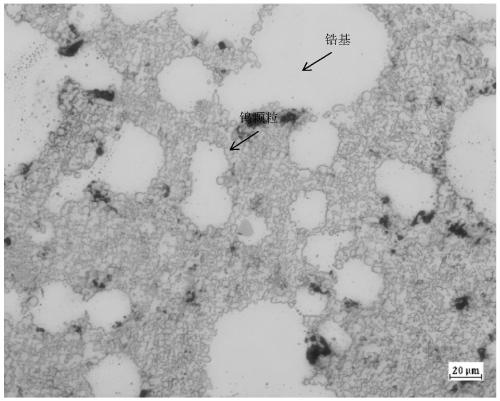

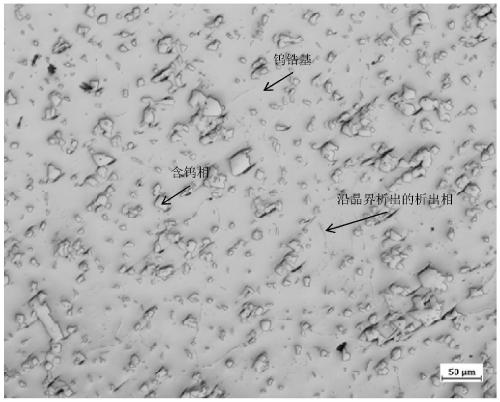

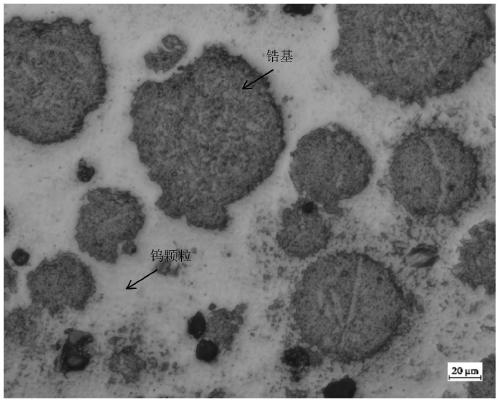

Metallographic preparation method of tungsten-zirconium alloy

PendingCN111289328AIncrease labor costShort polishing timePreparing sample for investigationChromium sesquioxideZirconium alloy

The invention discloses a metallographic preparation method of a tungsten-zirconium alloy. The metallographic preparation method is characterized by comprising the following steps of: 1) sampling, intercepting a small block sample, and enabling a cutting surface to be an inspection surface, 2) grinding, grinding the inspection surface with abrasive paper to remove surface scratches, and after grinding is finished, putting the sample into alcohol for ultrasonic cleaning, and then taking out and blow-drying the sample, (3) rough polishing, specifically, conducting rough polishing through a diamond spray polishing agent, and enabling the rotating speed to range from 300 r / min to 500 r / min, and after rough polishing is finished, putting the sample into alcohol, ultrasonically cleaning, takingout and blow-drying, (4) conducting fine polishin, specifically, conducting fine polishing through a chromium sesquioxide polishing agent, and enabling the rotating speed to range from 100 r / min to 150 r / min, and after the fine polishing is finished, putting the sample into alcohol, ultrasonically cleaning, taking out and blow-drying, and (5) final polishing, specifically, conducting final polishing through silicon latex suspension liquid, enabling the rotating speed to be 100-150 r / min, after final polishing is completed, putting the sample into alcohol to be subjected to ultrasonic cleaningand then taken out to be blow-dried to be observed. The metallographic preparation method has the advantages that the sample preparation time is shortened, and the microscopic structure is clear and visible.

Owner:CHINA WEAPON SCI ACADEMY NINGBO BRANCH

Reusable aluminum profile polishing solution and preparation method thereof

The invention relates to a reusable aluminum profile polishing solution and a method for polishing an aluminum alloy workpiece by using the reusable aluminum profile polishing solution. The polishing solution consists of the following raw materials in percentage by mass: 30-45% of concentrated sulfuric acid, 35-45% of concentrated phosphoric acid, 0.5-1.5% of a corrosion inhibitor, 1-3% of tartaric acid and the balance of water. The corrosion inhibitor is composed of carboxymethyl cellulose and sulfosalicylic acid. The adopted polishing method comprises the steps that the aluminum alloy workpiece is subjected to oil removal, washed with water and then placed in the polishing solution to be polished, the aluminum alloy workpiece is washed with water, washed with absolute ethyl alcohol and then blow-dried, and the polished aluminum alloy workpiece is obtained. The polishing treatment temperature ranges from 70 DEG C to 85 DEG C, and the polishing time ranges from 120 s to 160 s. After the polishing solution is used for polishing the aluminum alloy workpiece, the surface roughness and glossiness of the aluminum alloy workpiece are good. The weight loss rate of the aluminum alloy workpiece is low, and the size of the aluminum alloy workpiece is hardly affected. The used polishing solution is subjected to chemical precipitation to remove aluminum ions, and the polishing solution without aluminum ions can be reused.

Owner:柏安美创新科技 (广州) 有限公司

Liquid-phase plasma polishing liquid and polishing process of aluminum product

InactiveCN102310357BNon-volatileAvoid harmPolishing machinesPolishing compositionsMetallurgyPurified water

The invention discloses a liquid-phase plasma polishing liquid and a polishing process of an aluminum product. The polishing liquid comprises the following components calculated by weight percentage: 3-4 percent of ferric trichloride, 1-2 percent of ammonium chloride and the balance of purified water. The polishing process comprises the following steps of: mounting the aluminum product to be polished on a hanger and then soaking and showering in the purified water; pouring the liquid-phase plasma polishing liquid into a polishing groove; heating the liquid-phase plasma polishing liquid to be 70-90DEG C; soaking the aluminum product to be polished on the hanger into the liquid-phase plasma polishing liquid; connecting an anode of a liquid-phase plasma polishing machine with the aluminum product to be polished; connecting a cathode of the liquid-phase plasma polishing machine with a plurality of cathode plates in parallel; controlling an output polishing power supply to be 270-330V; taking the aluminum product out after polishing and soaking and showering; and drying the aluminum product. The liquid-phase plasma polishing liquid disclosed by the invention does no harm to an operator; and the polishing process disclosed by the invention has the advantages of short polishing time, high efficiency, greatly-improved glossiness of the aluminum product and the like.

Owner:无锡清源数字信息技术研究院有限公司

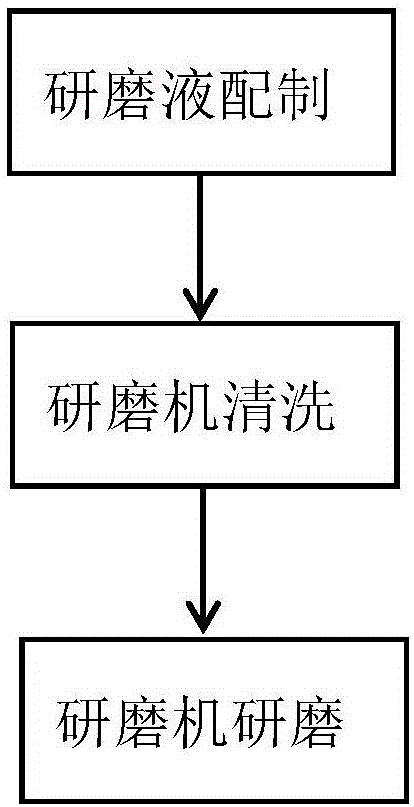

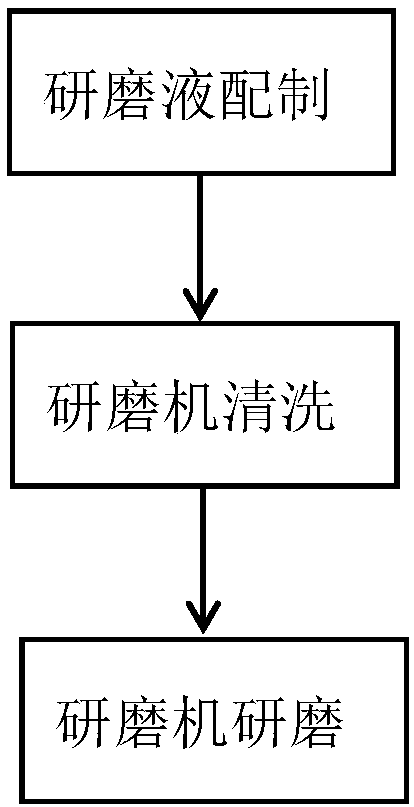

Grinding treatment method for thinned liquid crystal glass substrate

ActiveCN106272085AStrong cutting forceShort polishing timeOther chemical processesLapping machinesMetallurgyLiquid crystal

The invention belongs to the technical field of grinding for the thinning process of liquid crystal glass substrates, and discloses a grinding treatment method for a thinned liquid crystal glass substrate. By the adoption of the grinding treatment method for the thinned liquid crystal glass substrate, the defects of existing grinding techniques for thinning are overcome. The grinding treatment method for the thinned liquid crystal glass substrate comprises the following steps of preparation of grinding fluid, cleaning of a grinding machine, and grinding through the grinding machine. The grinding treatment method for the thinned liquid crystal glass substrate has the beneficial effects that mechanical scratches on the surface of the liquid crystal glass substrate can be obviously reduced effectively and conveniently, the surface grain yield of the ground liquid crystal glass substrate is increased, the probability of regrinding after grinding is lowered, and the production efficiency is improved.

Owner:赣州帝晶光电科技有限公司

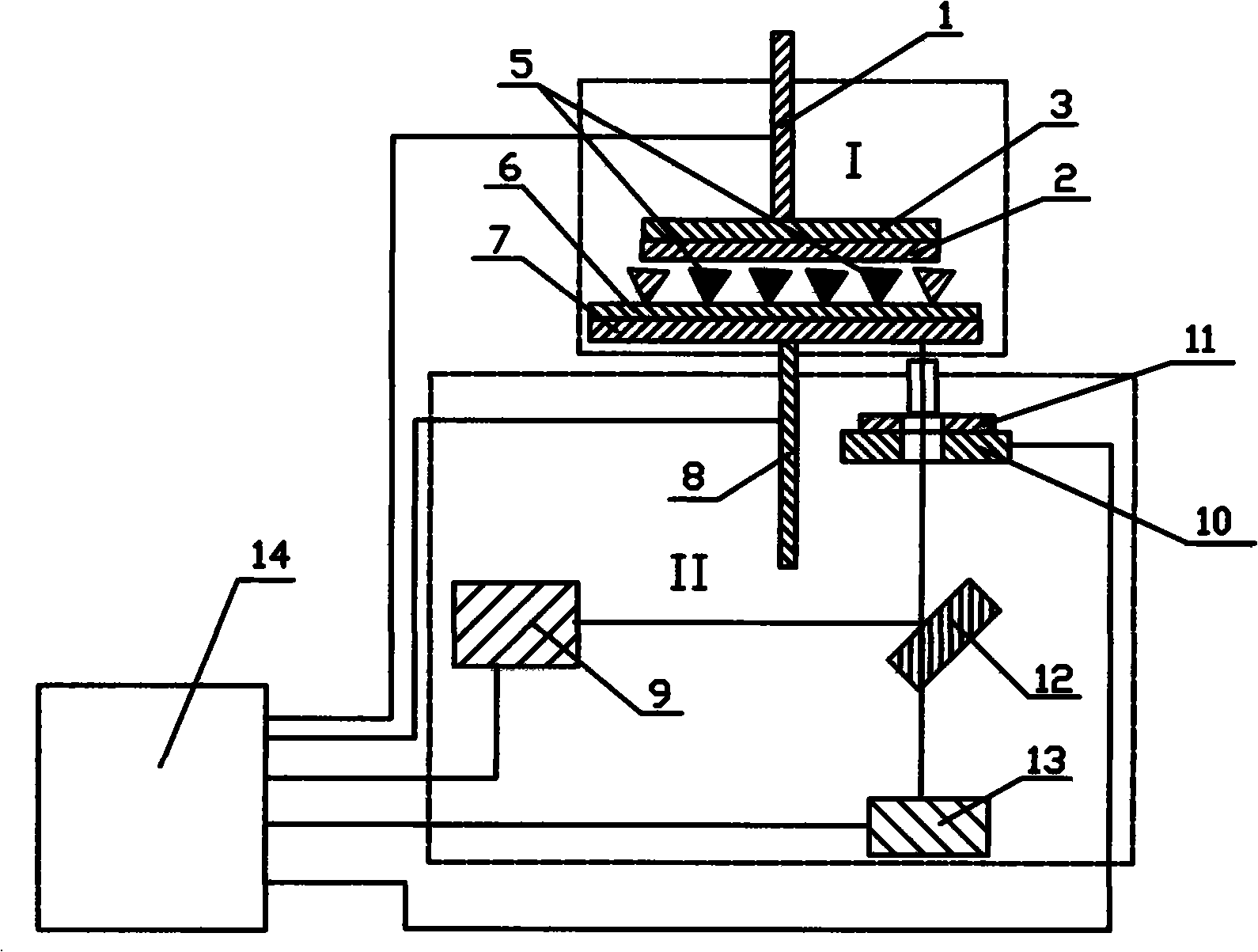

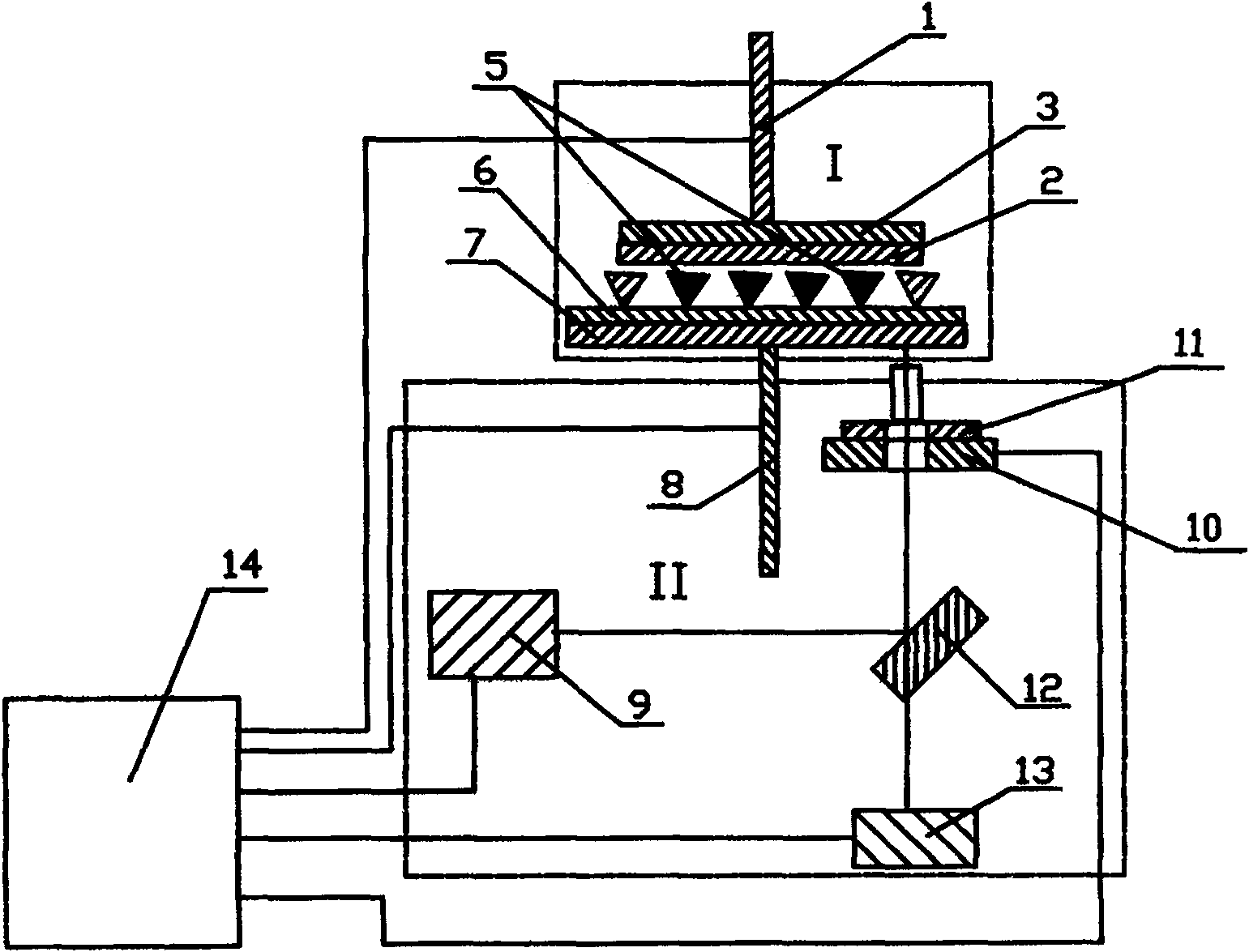

Ultra-precision processing apparatus based on photon crystal material and imaging monitoring method

InactiveCN101314212AReduce wasteImprove polishing effectPolishing machinesOptical surface grinding machinesEngineeringMonitoring methods

The invention discloses a superprecision machining device based on a photon crystal material and a method for monitoring imaging and relates to the mechanical manufacturing industry technical field, in particular to the technical field of the superprecision machining device based on the photon crystal material. The lower end of a polishing sheet supporting frame power system is connected with a supporting clamp; the lower end of the supporting clamp is connected with the polishing sheet; the lower end of the polishing sheet is correspondingly provided with a substrate; a polished and fallen grinding medium is filled between the polishing sheet and the substrate; detecting light emitted by a detecting light source is reflected on a spectrum scanning platform by a phase dichroscope and transported to a scanning lens arranged on the upper end of the spectrum scanning platform; and the detecting light runs through the scanning lens and reaches a substrate supporting frame. The superprecision machining device and the method realize the aims of having good polishing effect, monitoring the spectral characteristic of the polishing sheet in a polishing region at any moment and acquiring the local deformation and the stress parameters of the polishing sheet in time.

Owner:SOUTHEAST UNIV

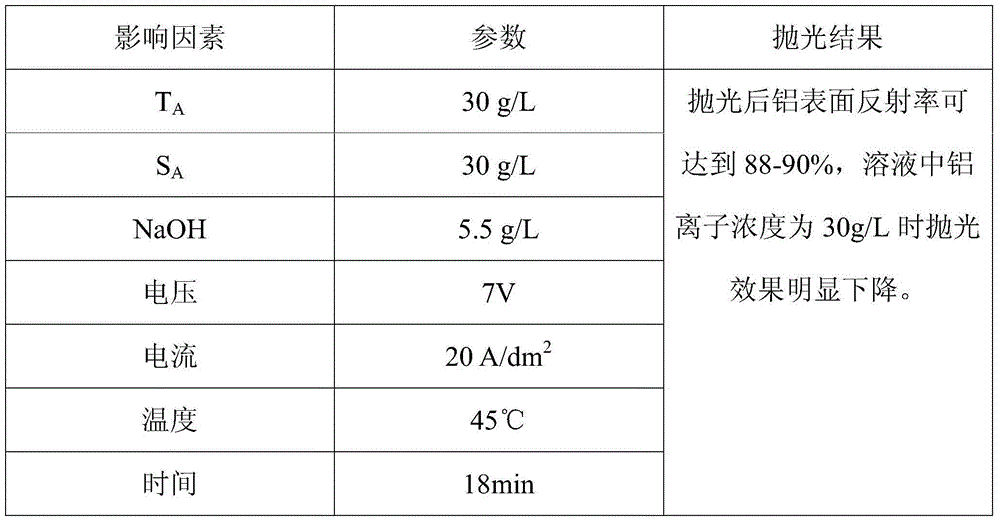

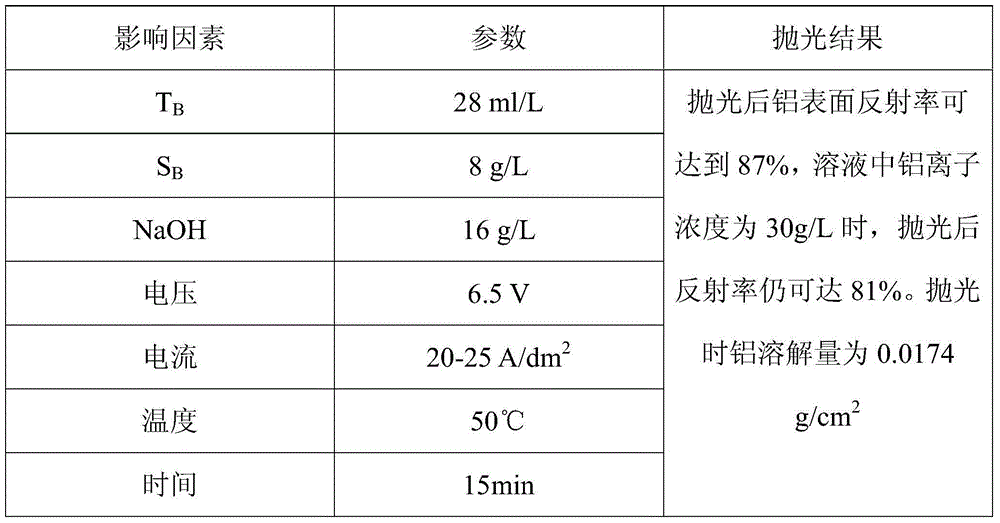

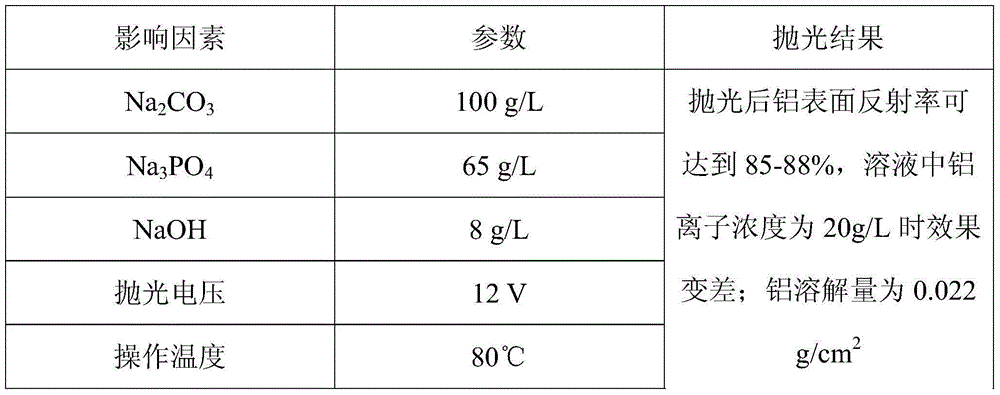

Alkaline non-polluting aluminum alloy electrochemical polishing solution

The invention discloses an alkaline non-polluting aluminum alloy electrochemical polishing solution, including an alkaline substance, a brightener and a stabilizer. The brightener is preferably TA or TB; and the stabilizer is preferably SA or SB. The surface subjected to electrochemical by the polishing solution has high flatness, and the polishing solution has the advantages of low energy consumption, short polishing time, less aluminum consumption and long life cycle. The polishing method can significantly reduce production costs, improve the working environment, improve the quality of the polished surface, and has broad application prospect.

Owner:无锡市万士达羽绒制品有限公司

Processing method of brass product before electroplating nickel

ActiveCN103981551AViolent oxidation reactionViolent reactionChemical combinationElectroplated nickel

The invention relates to a processing method of a brass product before electroplating nickel. The processing method comprises the steps: taking 15-20 kg of the brass product, adding into a grinding machine, adding 4-6 L of a grinding fluid and 15-25 L of water into the grinding machine, under a condition of room temperature, grinding for 30-60 min at the speed of 50-60 rpm, washing with water, pickling, activating, and completing. The novel machinery and chemical combination method is adopted to preprocess the brass product, and the appearance and the quality of electroplated nickel of the brass product are improved.

Owner:YANGZHOU HY TECH DEV

Coin-making copper alloy blank cake electrolyte plasma polishing solution and polishing process

The invention relates to a coin-making copper alloy blank cake electrolyte plasma polishing solution. The polishing solution is prepared from, by weight percent, 1%-3% of ammonium phosphate, 1%-5% ofaluminum potassium sulfate, 0.2%-1.5% of citric acid, 0.4%-1% of sodium citrate, 0.1%-1.5% of brightening agents, and the balance water, wherein the pH range of the polishing solution is 6-8, the polishing solution component is neutral salt, the polishing solution is environment-friendly and pollution-free, and can be recycled. The polishing process comprises the following steps of, 1) adding thepolishing solution into a polishing tank in a polishing machine, and heating to 65-105 DEG C; 2) clamping a copper alloy blank cake device to be polished on a polishing special hanging tool; (3) hanging the hanging tool on a bracket in the polishing machine, lowering the bracket to enable the blank cake on the hanging tool to be immersed in the polishing solution, and keeping the blank cake at theposition 50 mm below the liquid level; 4) turning on the power supply of the machine, wherein the voltage is 250-400 V, the current density is 55-95 A / dm<2>, and the polishing time is 60-110 s; and 5) taking out the hanging tool after polishing treatment, putting the blank cake into a cleaning tank, performing washing with deionized water for 5-15s, then performing washing with alcohol, and thenperforming drying. The polishing process is simple to operate, short in polishing time, and high in efficiency.

Owner:SHENYANG MINT CO LTD

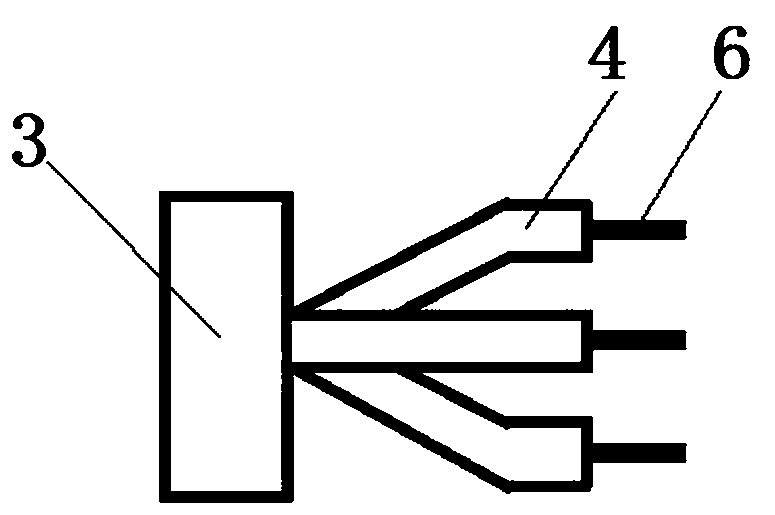

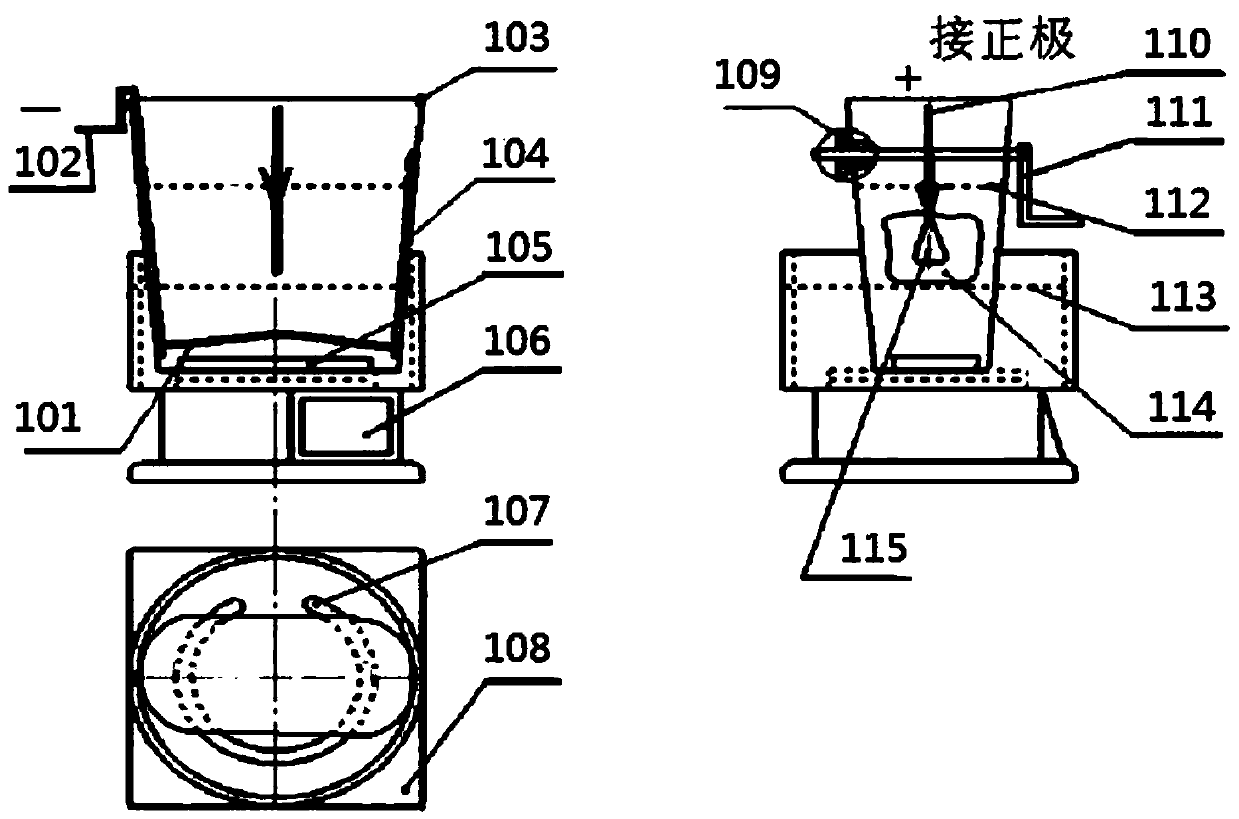

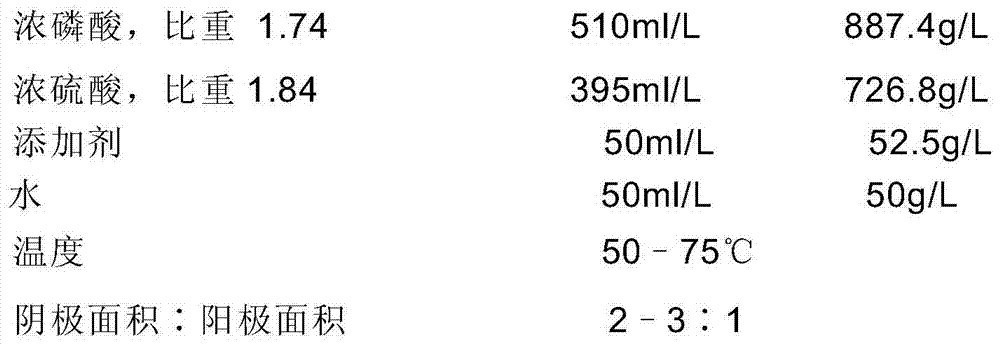

Electrochemical polishing device for teaching

InactiveCN109594121ASimple structureImprove polishing effectElectrolysis componentsTeaching apparatusWater bathsSurface roughness

The invention belongs to the technical field of metal surface treatment, and relates to an electrochemical polishing device for teaching. At present, various electrochemical polishing devices are mostly complex in structure and high in safety protection requirement and need to be operated by professionals. The electrochemical polishing device for teaching overcomes the defects, and comprises a direct-current chemical polishing power supply, a constant-temperature water bath kettle, an electrolyte polishing groove and a polishing part hanging frame. The electrochemical direct-current power supply can be used for converting 220V single-phase alternating current into electrochemical polishing direct current to be output. The output voltage is adjusted according to the area of a polished material. The electrolyte polishing groove is placed in the constant-temperature water bath kettle. The polishing part hanging frame is installed in the short axis direction of the cross section of the polishing groove. The electrochemical polishing device for teaching is used for a thin-sheet-shaped single part with the area smaller than 45 mm * 45 mm, simple in structure, convenient to use, low in manufacturing cost, high in safety and short in polishing time. The surface roughness of a polished part is low.

Owner:杨皓然

An electrolytic polishing process

The invention relates to an electrolytic polishing process. The electrolytic polishing process of the invention comprises the following steps of: removing oil from a workpiece; washing with water; soaking in acid; performing electrolytic polishing; performing countercurrent rinsing for three times; soaking in alkali; washing with water; passivating; wiping or drying; and packaging.

Owner:BEIJING SANLIAN HOPE TEXTILE & CHEM TECH

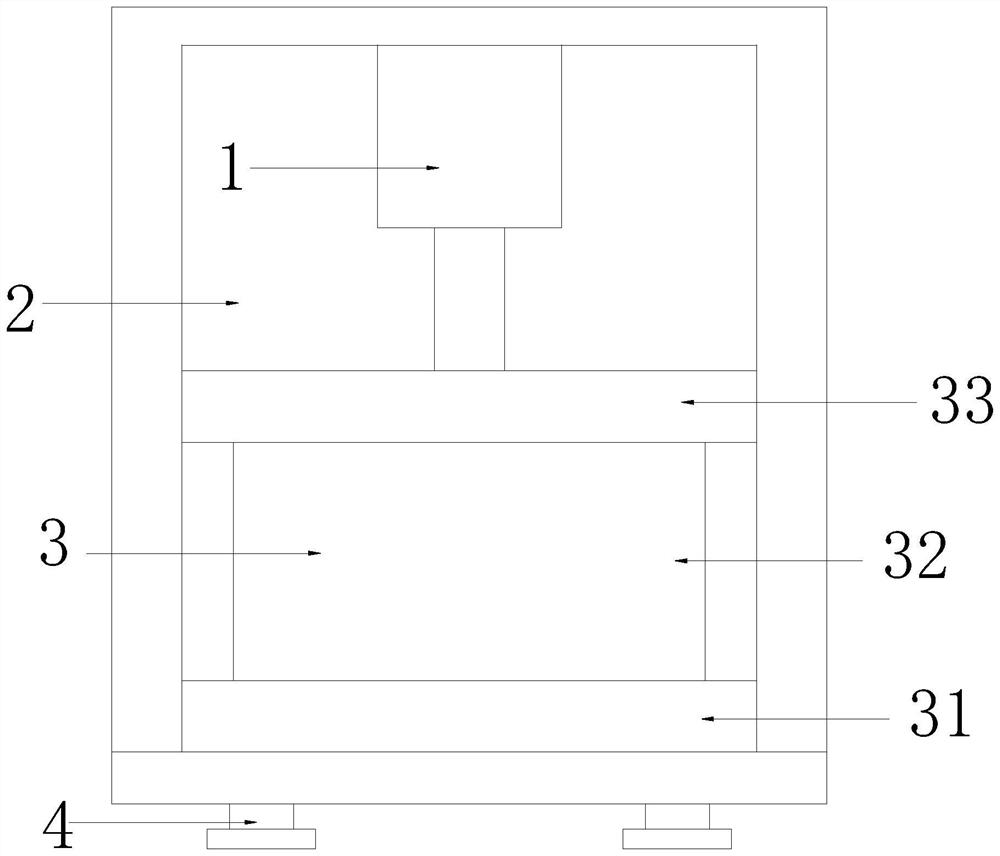

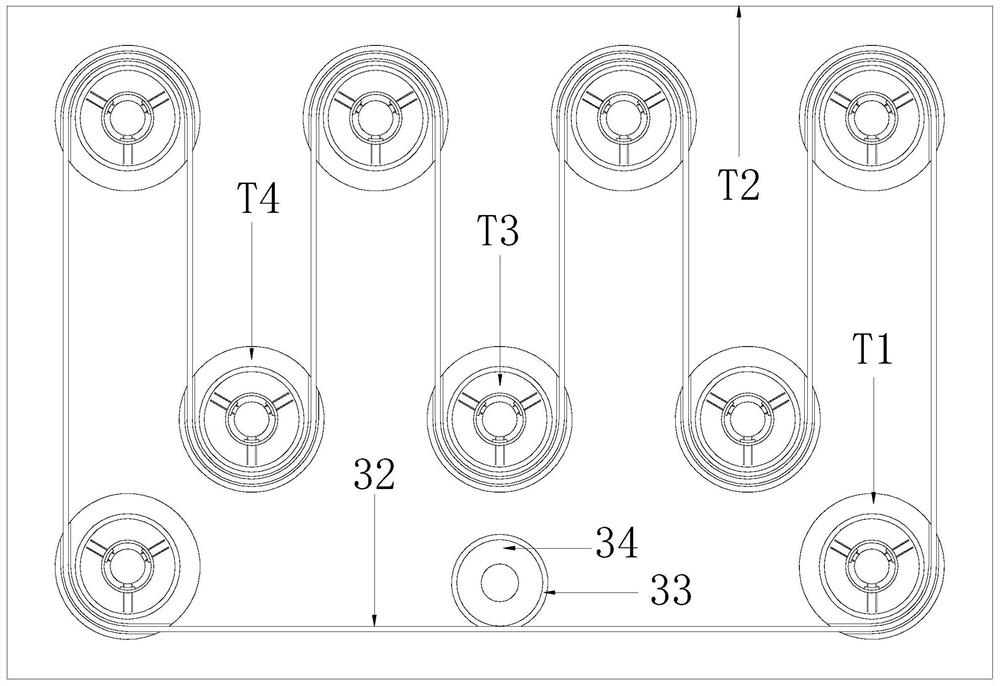

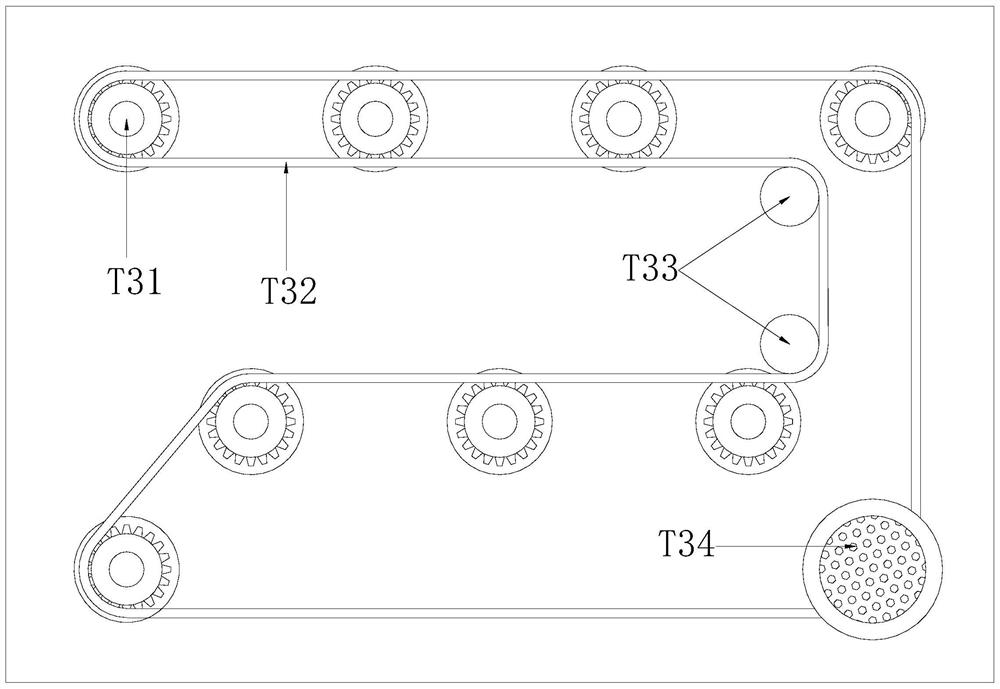

A kind of equipment for polishing the outer surface of aluminum alloy tube

ActiveCN110814967BIncrease contact areaImprove work efficiencyGrinding carriagesPolishing machinesHydraulic cylinderPolishing

The invention discloses a polishing device for outer surfaces of aluminum alloy pipes. The polishing device structurally comprises a hydraulic cylinder, a machine body, a polishing device and a base,wherein the bottom of the machine body is vertically connected with the base; the hydraulic cylinder is mounted at the inner top of the machine body and connected to the center of the top of the polishing device; and the polishing device is arranged in the machine body. Compared with the prior art, the polishing device has the beneficial effects that through combined arrangement of a lower fixingclamping mechanism, a polishing belt, an upper fixing clamping mechanism, a micro motor, a transmission wheel and other components, the multiple aluminum alloy pipes can be clamped at the same time, the outer surfaces of the multiple aluminum alloy pipes can be polished at the same time after clamping, and the polishing time is short; and through arrangement of a first polishing belt guide disc and a second polishing belt guide disc, the polishing belt can make contact with the outer surfaces of the aluminum alloy pipes in a large area, the contact area of the polishing belt and the aluminum alloy pipes is increased, accordingly, the operation efficiency of the polishing technology is improved, and the polishing cost is reduced.

Owner:孙秋梅

Method for removing oxide at bottom of miniature electric device shell

InactiveCN104589196AEliminate the effects ofSpeed up corrosionEdge grinding machinesPolishing machinesAlcoholSURFACTANT BLEND

The invention discloses a method for removing oxide at the bottom of a miniature electric device shell. The temperature of deionized water is raised to 20-60 DEG C, sodium hydroxide and sodium carbonate are added in and are stirred to be totally dissolved, then, surfactant and emulgator are added in, a mixture is evenly stirred, heat preservation is performed for 5 min, cooling is performed, and polishing agents are made for standby use; the polishing agents comprise 8-12 g / L sodium hydroxide, 50-60 g / L sodium carbonate, 6-8 g / L surfactant and 10-15 ml / L emulgator; the deionized water with the temperature being 20-60 DEG C and the polishing agents are added in a polisher machine according to the volume ratio of 10-15:1; after the polisher machine is started for polishing, the miniature electric device shell and abrasive materials are separated, and the shell is dewatered through ethyl alcohol, aired and packaged in a bag. Through the method, the oxide at the bottom of the miniature electric device shell can be thoroughly removed, efficiency is high, cost of the polishing agents is low, and time and labor are saved.

Owner:贵州振华群英电器有限公司(国营第八九一厂)

Ultra-precision processing apparatus based on photon crystal material and imaging monitoring method

InactiveCN100589933CReduce wasteImprove polishing effectPolishing machinesOptical surface grinding machinesEngineeringMonitoring methods

The invention discloses a superprecision machining device based on a photon crystal material and a method for monitoring imaging and relates to the mechanical manufacturing industry technical field, in particular to the technical field of the superprecision machining device based on the photon crystal material. The lower end of a polishing sheet supporting frame power system is connected with a supporting clamp; the lower end of the supporting clamp is connected with the polishing sheet; the lower end of the polishing sheet is correspondingly provided with a substrate; a polished and fallen grinding medium is filled between the polishing sheet and the substrate; detecting light emitted by a detecting light source is reflected on a spectrum scanning platform by a phase dichroscope and transported to a scanning lens arranged on the upper end of the spectrum scanning platform; and the detecting light runs through the scanning lens and reaches a substrate supporting frame. The superprecision machining device and the method realize the aims of having good polishing effect, monitoring the spectral characteristic of the polishing sheet in a polishing region at any moment and acquiring thelocal deformation and the stress parameters of the polishing sheet in time.

Owner:SOUTHEAST UNIV

A kind of polishing liquid for metal surface polishing and preparation method thereof

A disclosed polishing fluid for polishing metal surfaces is characterized by being prepared from the following raw materials in parts by weight: 1-2 parts of diethanolamine, 2-3 parts of ethanolamine, 2-4 parts of lauryl diethanolamide, 3-4 parts of hydroxy propyl cellulose, 3-5 parts of 2-(2-methoxyethoxy)ethanol, 2-4 parts of polyoxypropylene polyoxyethylene propylene glycol ether, 10-15 parts of nanometer aluminium oxide, 1-2 parts of gelatin, 1-2 parts of methionine, 5-7 parts of an auxiliary agent, and 300 parts of deionized water. The prepared polishing fluid is safe, non-toxic, good in polishing performance, uniform, high in luster and short in polishing time. By adding methionine, the polishing fluid has good corrosion inhibition effect. By adding the auxiliary agent, the polishing fluid has good wear resistance, dispersity, lubricity and film-forming property, and is capable of avoiding air corrosion under the synergic effect of a corrosion inhibitor. The polishing speed is stable, and the polishing fluid is capable of reducing environmental pollution, and is suitable for polishing of metal surfaces, and especially suitable for steel surfaces.

Owner:苏州威力士精细化工有限公司

Processing method and solution for chemical polishing of zinc alloy

The invention provides a processing method and solution for the chemical polishing of a zinc alloy. The method comprises the following steps: a, pretreatment, namely degreasing and cleaning a zinc alloy workpiece; b, chemical polishing, namely dipping the degreased and cleaned zinc alloy workpiece into chemical polishing solution; and c, posttreatment, namely performing cleaning and drying treatment after the polishing is finished, wherein the chemical polishing solution takes water as solvent, and mainly comprises nitric acid, phosphonic acid, sulphuric acid and thiourea; the chemical polishing solution is prepared by mixing ordinary acids and organic substances, thus the components are simple and convenient to control, and the polishing effect is good; and the chemical polishing solution can be matched with other chemical treatment links.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Artificial tooth polishing method

InactiveCN105729252AShort polishing timeImprove polishing effectArtificial teethPolishing compositionsTooth polishingEngineering

The invention discloses an artificial tooth polishing method. The artificial tooth polishing method includes the steps of S1, grinding, namely grinding tongue tip metal smoothly by a grinding stone, and polishing the smooth tongue tip metal to enable tongue tip edge to be free of burrs or edge notches by a rubber wheel and a rubber strip; S2, polishing, namely subjecting a ground artificial tooth to soaking polishing in a solution. Due to the fact that the artificial tooth is subjected to primary grinding and chemical soaking polishing, the artificial tooth polishing method is short in polishing time but good in polishing effect. The artificial tooth polishing method combining a mechanical method with a chemical method has the advantages of simplicity in operation, convenience in treatment and low cost, thereby being applicable to industrialized mass production.

Owner:CHENGDU BESMILE BIOTECH

Chemical Polishing Fluid for Aluminum Alloy Frosted Exterior Parts and Its Application

Owner:SOUTHWEST PETROLEUM UNIV

A kind of grinding treatment method after thinning liquid crystal glass substrate

ActiveCN106272085BStrong cutting forceShort polishing timeOther chemical processesLapping machinesMetallurgyLiquid crystal

The invention belongs to the technical field of grinding for the thinning process of liquid crystal glass substrates, and discloses a grinding treatment method for a thinned liquid crystal glass substrate. By the adoption of the grinding treatment method for the thinned liquid crystal glass substrate, the defects of existing grinding techniques for thinning are overcome. The grinding treatment method for the thinned liquid crystal glass substrate comprises the following steps of preparation of grinding fluid, cleaning of a grinding machine, and grinding through the grinding machine. The grinding treatment method for the thinned liquid crystal glass substrate has the beneficial effects that mechanical scratches on the surface of the liquid crystal glass substrate can be obviously reduced effectively and conveniently, the surface grain yield of the ground liquid crystal glass substrate is increased, the probability of regrinding after grinding is lowered, and the production efficiency is improved.

Owner:赣州帝晶光电科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com