Patents

Literature

123 results about "Environmental standard" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Environmental standards are administrative regulations or civil law rules implemented for the treatment and maintenance of the environment. Environmental standards are set by a government and can include prohibition of specific activities, mandating the frequency and methods of monitoring, and requiring permits for the use of land or water. Standards differ depending on the type of environmental activity.

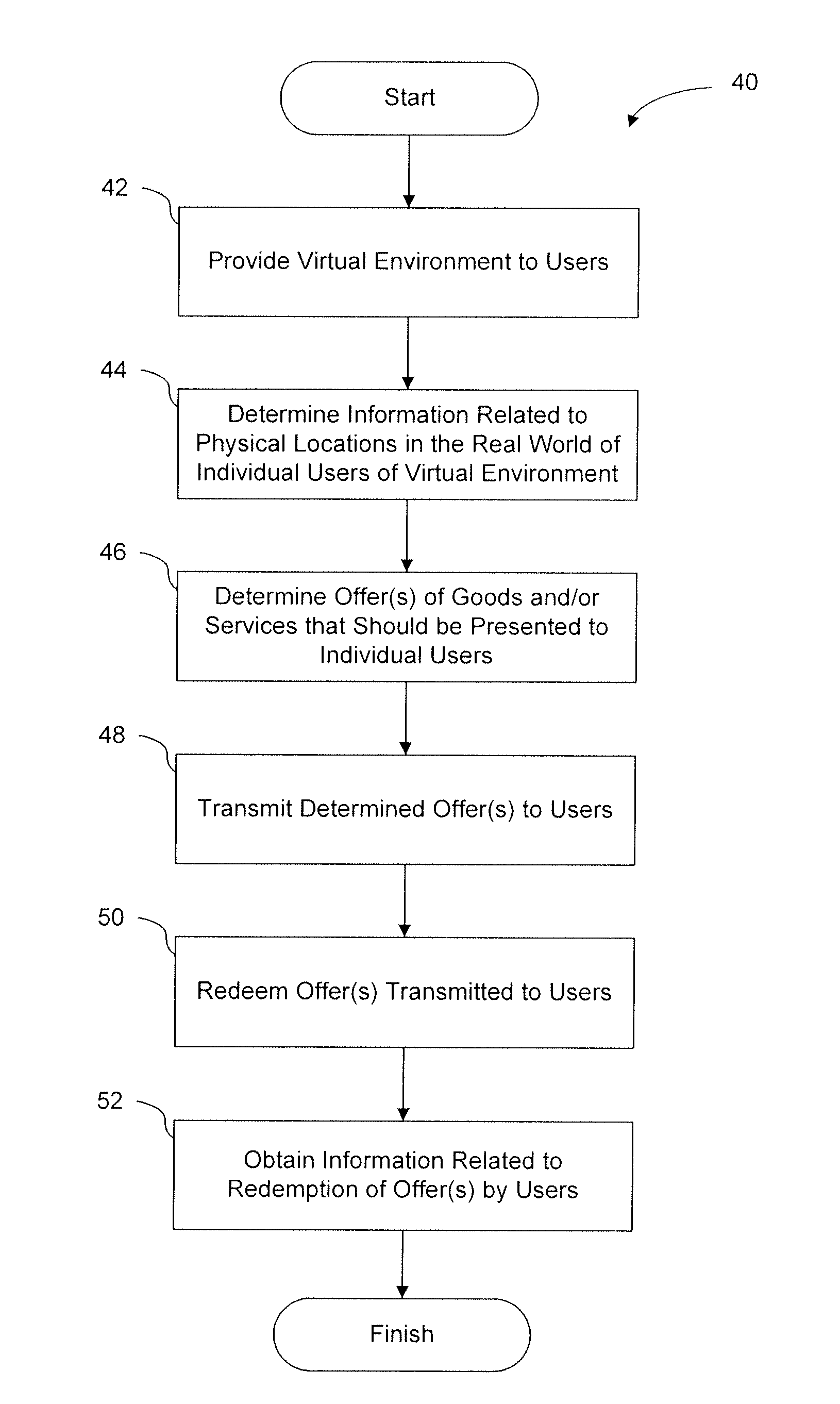

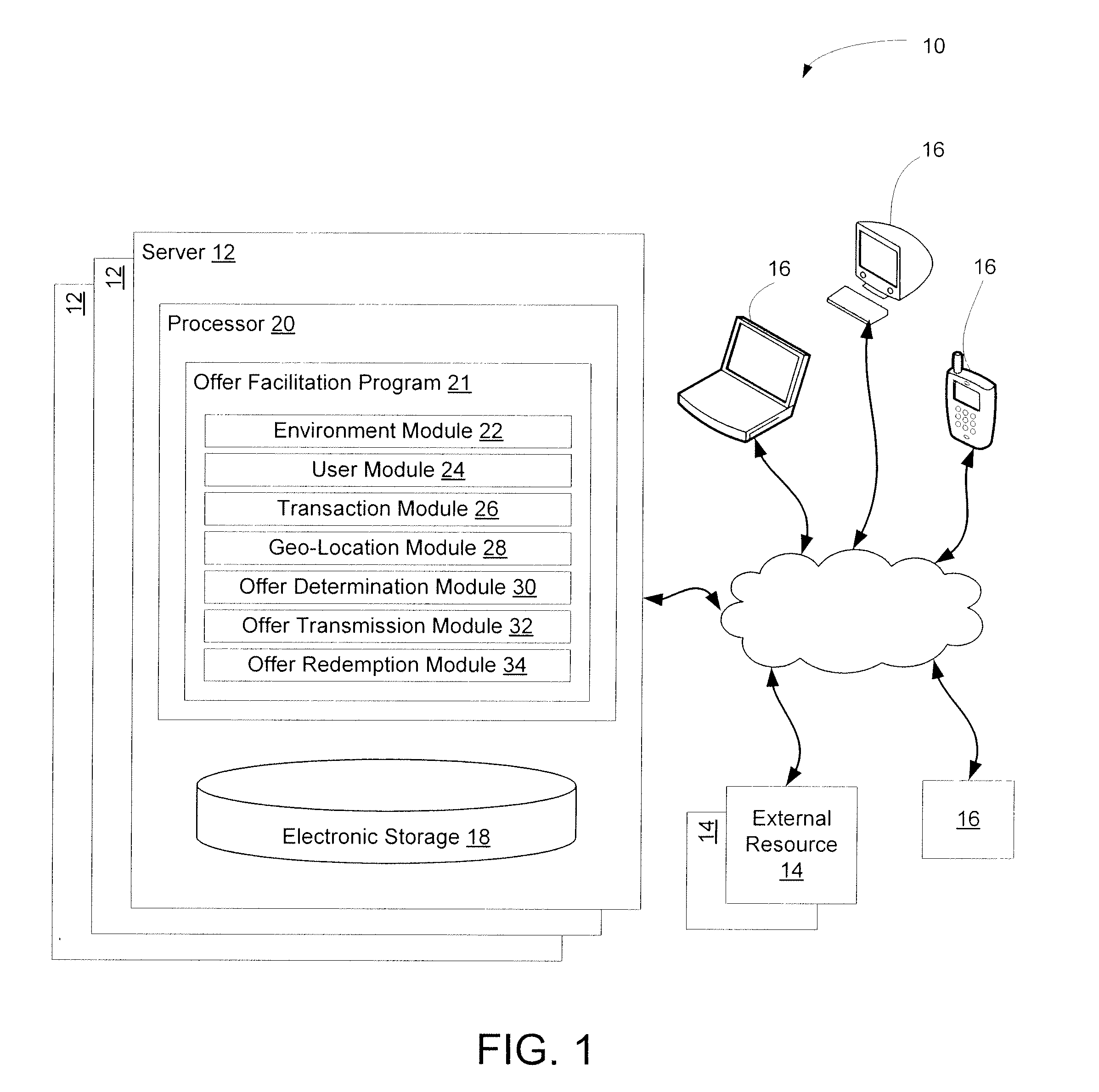

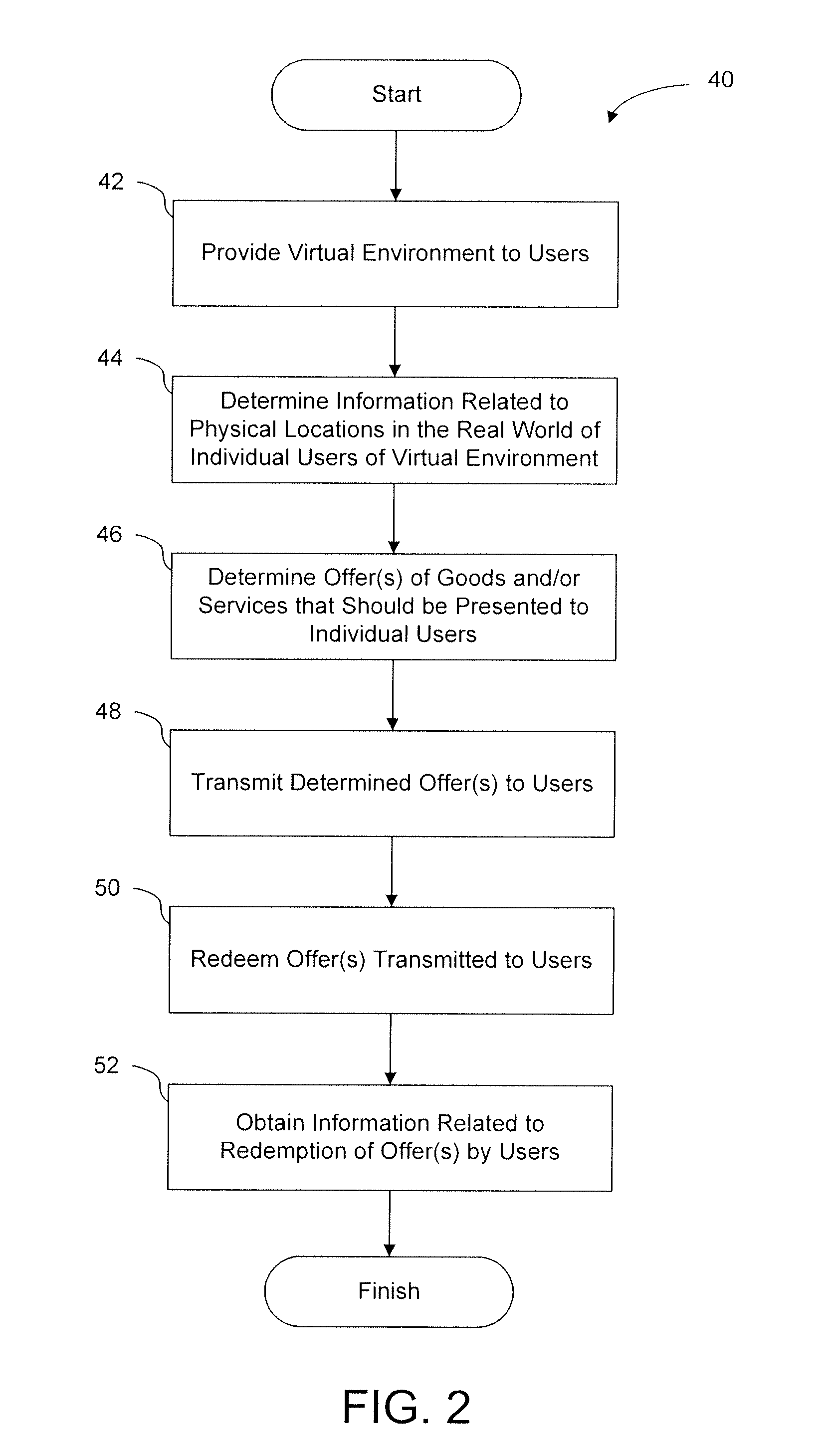

Providing offers based on locations within virtual environments and/or the real world

InactiveUS20120047002A1Improve immersionEnhance user retention and user enjoyment and other featureDiscounts/incentivesEnvironmental standardHuman–computer interaction

Owner:ENVIE INTERACTIVE

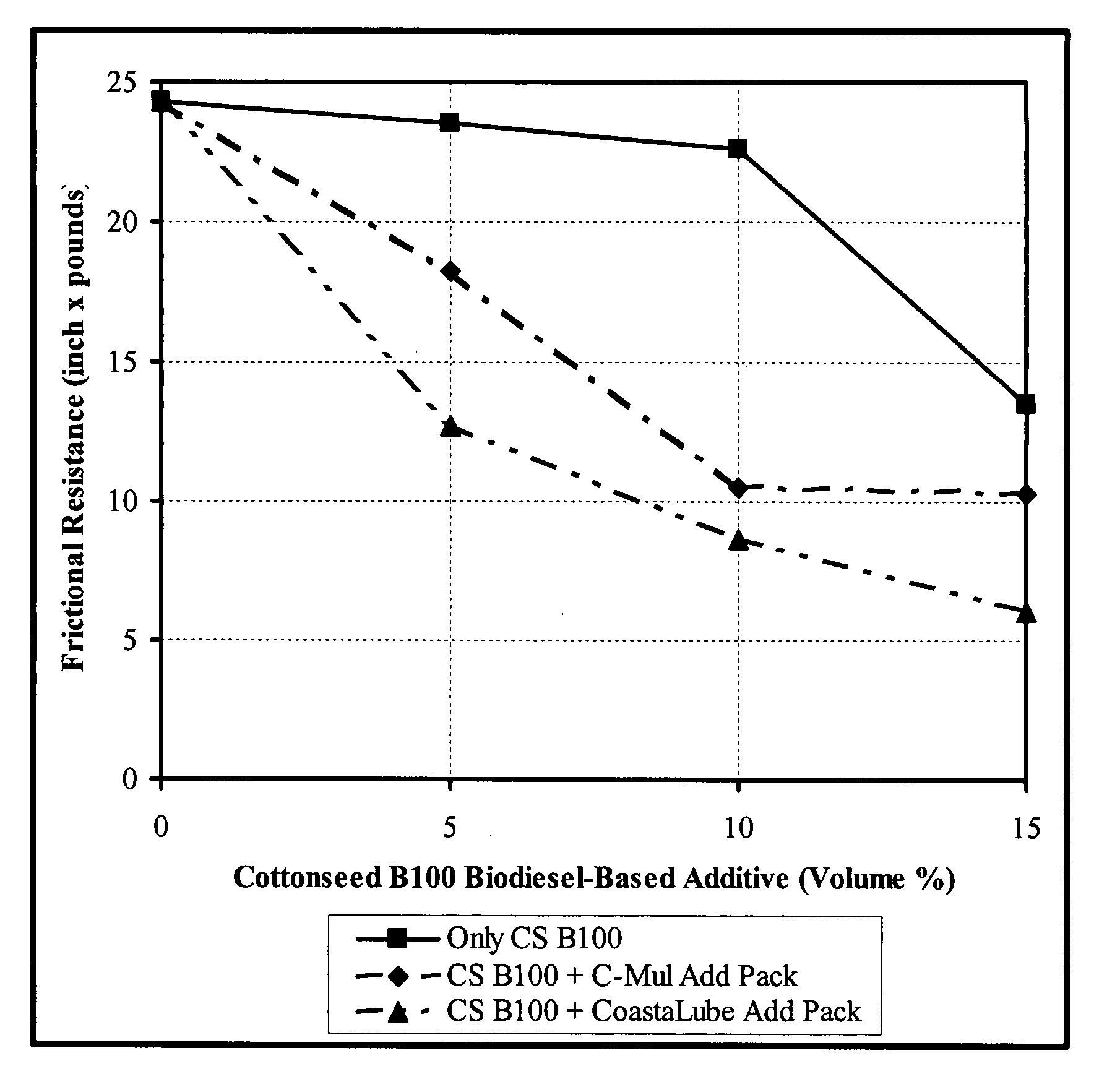

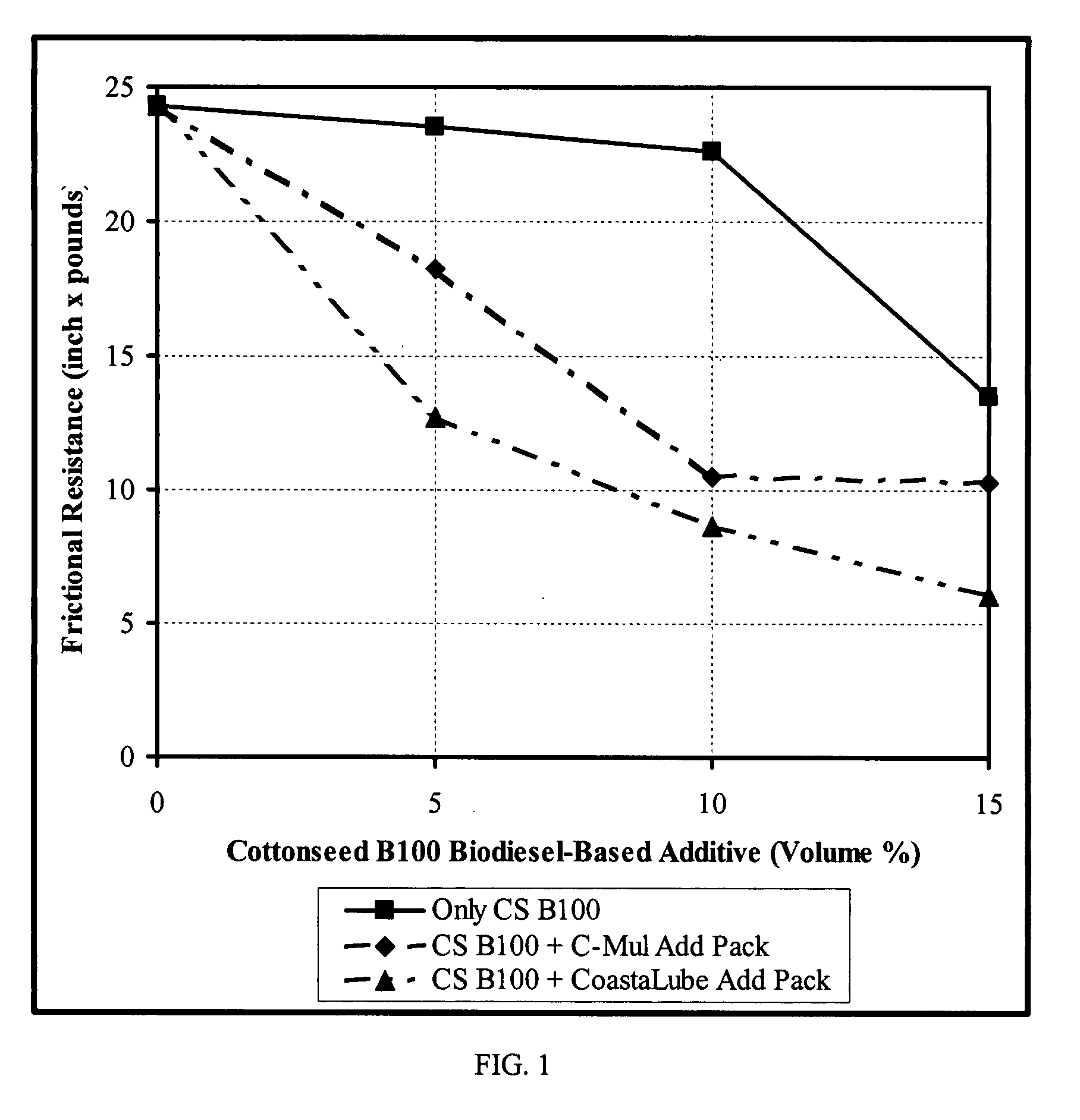

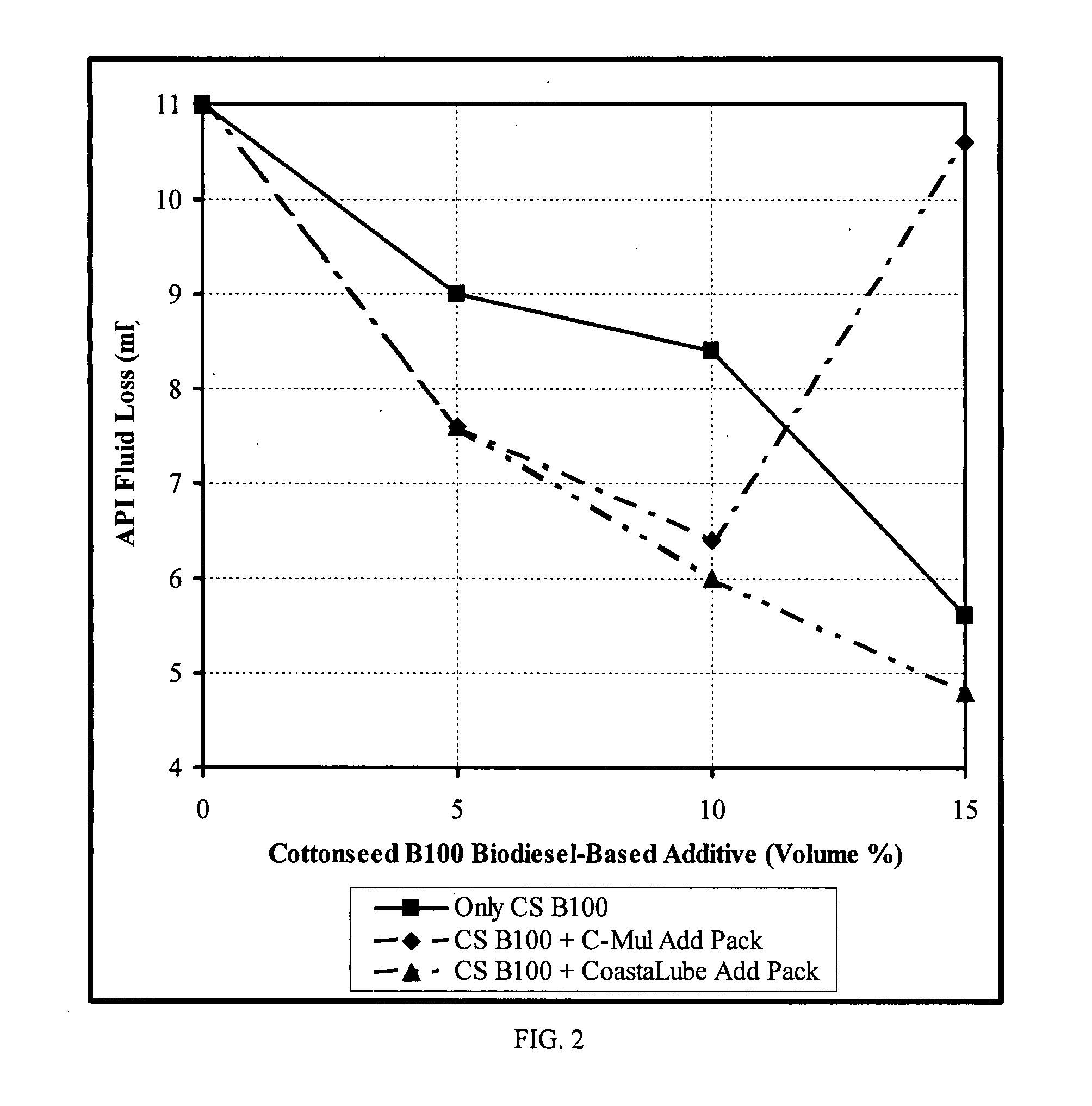

Drilling fluid additive and base fluid compositions of matter containing B100 biodiesels; and applications of such compositions of matter in well drilling, completion, and workover operations

InactiveUS20070287636A1Reducing differential pressure bondReduce fluid lossFluid removalFlushingWater basedBiodiesel

A drilling fluid compound, for use as an additive in a water-based drilling mud system, comprises a neat (B100) biodiesel liquid at a concentration of at least 5% by volume, and is useful in downhole applications such as lubrication, spotting, shale inhibition, fluid loss control, and rate of penetration enhancement. A base fluid for a synthetic-based drilling mud system comprises a B100 biodiesel liquid at a concentration of at least 5% by volume. A polyalphaolefin, another isomerized olefin, a petrodiesel, a mineral oil, a mineral oil derivative, or combinations thereof, may also be included in the drilling fluid compound or in the base fluid, within suitable ranges. The compositions of matter satisfy the current environmental standards defined by the U.S. Environmental Protection Agency for drilling fluids.

Owner:SUN DRILLING PRODS

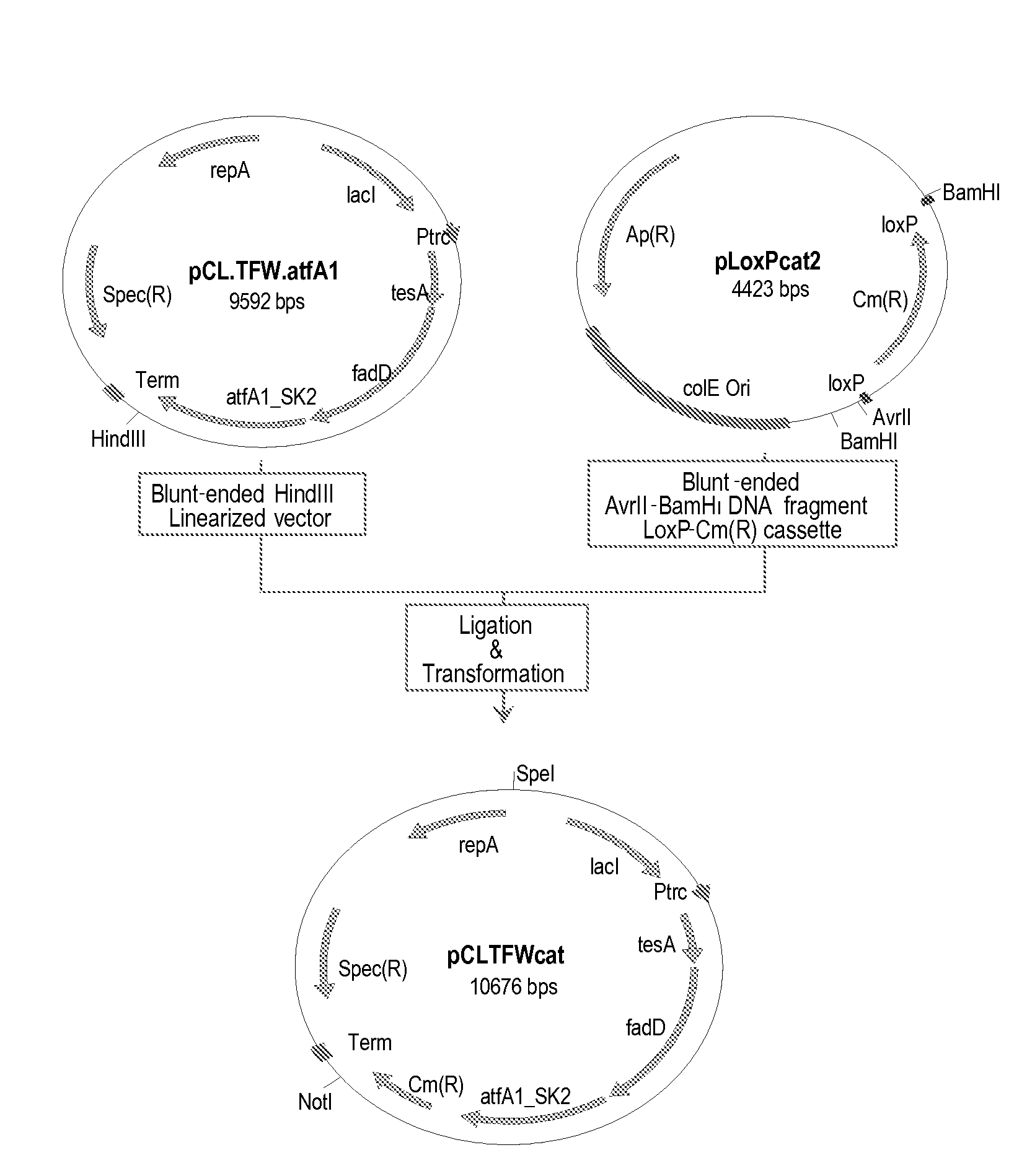

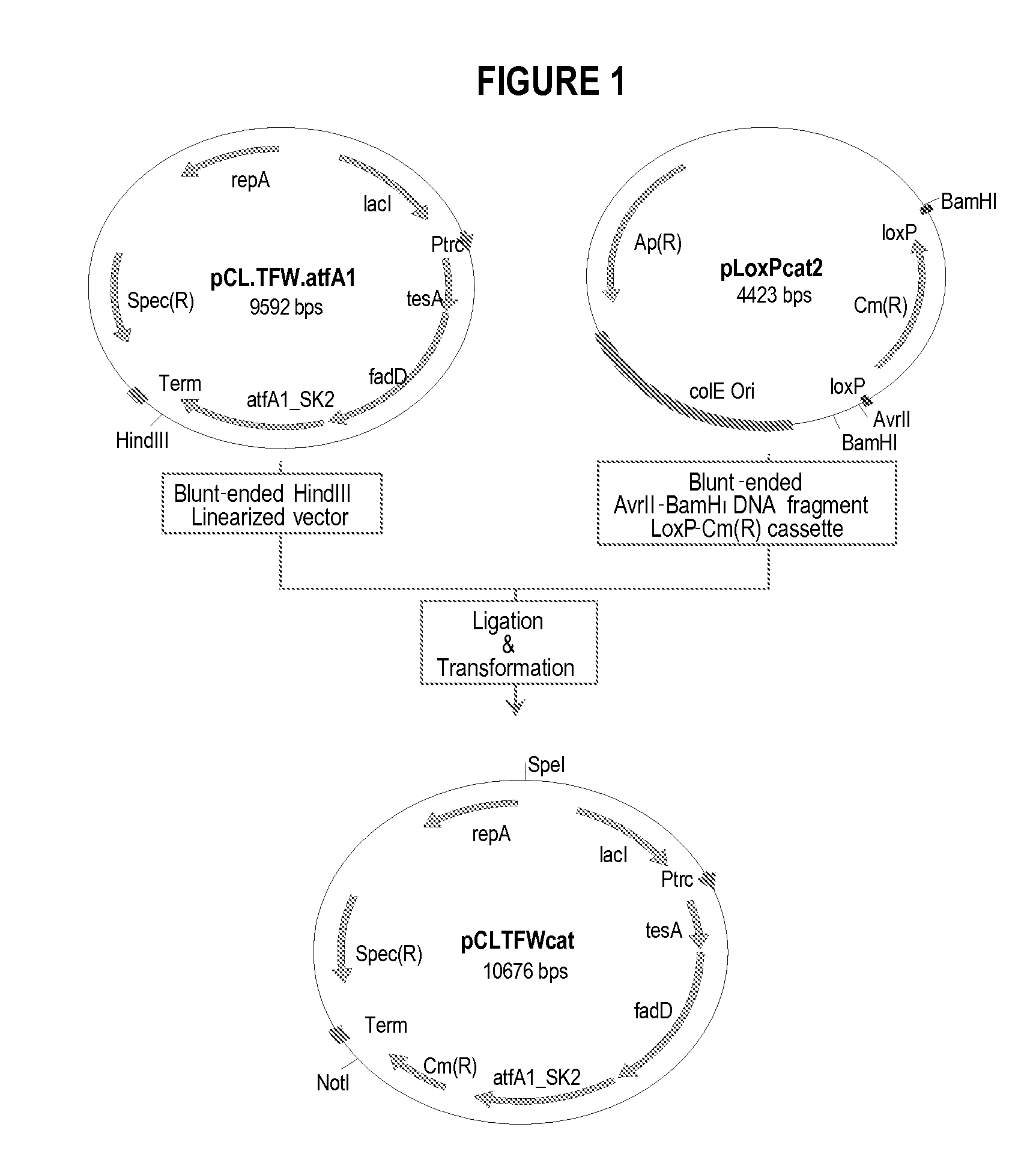

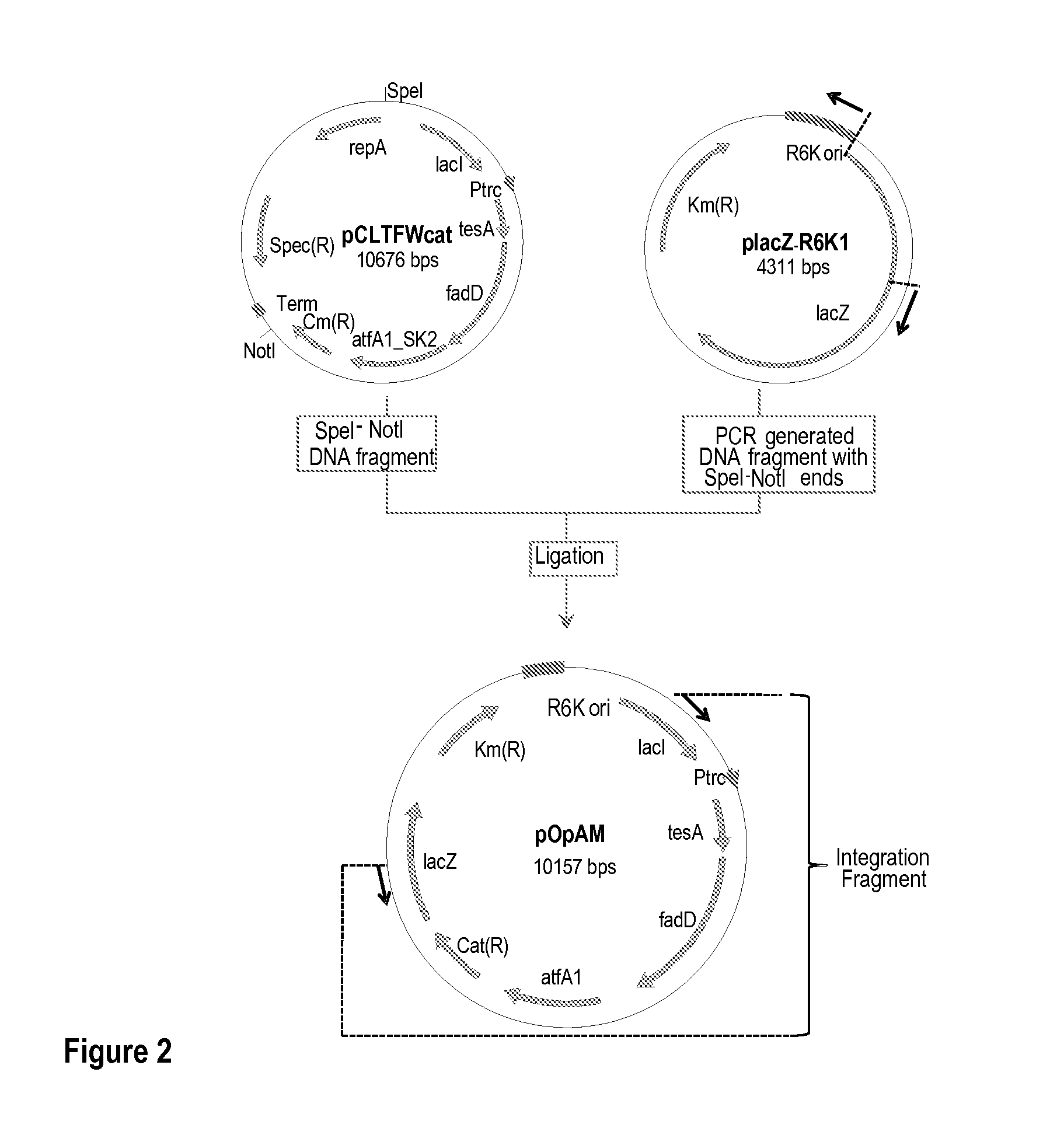

Production of commercial biodiesel from genetically modified microorganisms

InactiveUS20100257777A1Clean emission profileReduce the amount requiredBiofuelsLiquid carbonaceous fuelsBiodieselGlycerol

The invention provides a fermentation and recovery process for the production of biodiesel of commercial grade quality according to commercial and environmental standards (e.g., ASTM ANP, or EPA trace elements and emissions standards), by fermentation of carbohydrates using a genetically modified microorganism. The process provides a direct route for the production of fatty esters, without the need for producing oils which are later chemically transesterified with the concomitant production of large quantities of glycerin and other undesirable side-products.

Owner:GENOMATICA INC +1

Chromium-contaminated soil remediation method

InactiveCN103100561ALow toxicityGuaranteed dissolution efficiencyContaminated soil reclamationTreatment effectSludge

The invention discloses a chromium-contaminated soil remediation method, belonging to the technical field of environment engineering. The method comprises the following steps of: dissolving out hexavalent chromium in the chromium-contaminated soil, separating the soil from water, treating trivalent chromium-contaminated soil, treating hexavalent chromium sewage and treating filter residue; the dissolution efficiency of the hexavalent chromium in the chromium-contaminated soil can be improved by the KH2PO4 solution; the trivalent chromium-contaminated soil is treated by biochar made of municipal sludge, so that waste reclamation and secondary utilization of the contaminated soil can be realized; Na2S2O5 can be added into the hexavalent chromium sewage and is used for adjusting the reaction environment, so that the efficiency of converting hexavalent chromium into trivalent chromium can be improved; a flocculating agent is used for accelerating the precipitation and concentration of the trivalent chromium; the filtered water can be used as flushing water for recycling, so that the method is economical and environment-friendly; and a curing stabilization method is used for treating the filter residue, so that the chromium in the filter residue is passivated, and the national environmental standard requirements can be reached. According to the method, the hexavalent chromium and the trivalent chromium are respectively treated, and the solid and the solution are respectively treated, so that the treatment efficiency is improved, the treatment effect is guaranteed, and the method has the characteristics of being free from secondary pollution, low in cost, high in resource utilization rate, etc.

Owner:INST OF ROCK AND SOIL MECHANICS - CHINESE ACAD OF SCI

Production method for high-purity copper and low-oxygen bright copper rod

The invention relates to a high pure copper and a production method of low-oxidizing bright copper rod, comprising the steps of: performing melting and slag-skimming, poling and crystallisation by cooling to the waste copper crap to obtain the high pure copper; heating the copper to 1080-1120 DEG C to obtain the copper liquid, wherein the infusible high melting point impurities are eliminated by slag-skimming, after that, adding arenaceous quartz and silicon dioxide into the copper liquid and blowing excessive oxygen to convert the metals which are livelier than the copper into the scruff to remove, then pressurizing and blowing the oxygen to the copper liquid so that lead sub-oxide deposited at the bottom of furnace to sufficiently react with the arenaceous quartz to generate the scruff for removing the lead, guaranteeing the purity of the copper is larger than 99.5% and the lead content is less than 2ppm; the production method of low-oxidizing bright copper rod mainly comprises the steps of: taking purple copper crap as the raw material, directly placing the high pure copper liquid through the melting and slag-skimming, poling and crystallisation by cooling orderly into the continuous-casting and continuous-rolling apparatus to cast, the yield of low-oxidizing bright copper rod is larger than 98%, reaching the green environmental standard required by Europe Union ROHS, the production method has low production cost.

Owner:江苏万宝铜业集团有限公司

Non-phosphorus electrolytic polishing liquid and technology for polishing workpiece surfaces with same

The invention discloses non-phosphorus electrolytic polishing liquid and a technology for polishing workpiece surfaces with the same. The non-phosphorus electrolytic polishing liquid comprises 30%-60% of sulfuric acid, 15%-35% of organic acid, 1%-5% of brightener, 2%-10% of viscosity modifier, 1%-5% of corrosion inhibitor and 20%-30% of water. The non-phosphorus electrolytic polishing liquid does not contain components not allowed by environmental standards, waste water is convenient to process in the cleaning process, and toxic effects on human body and livestock are avoided. The invention further provides the best polishing process condition for polishing stainless steel workpieces with the non-phosphorus electrolytic polishing liquid. The electrolytic polishing effect is completely identical with the polishing effect of original phosphoric acid electrolytic polishing liquid. The polishing time is short, and machining cost is low.

Owner:SHANGHAI MIRROR METAL SURFACE TREATMENT

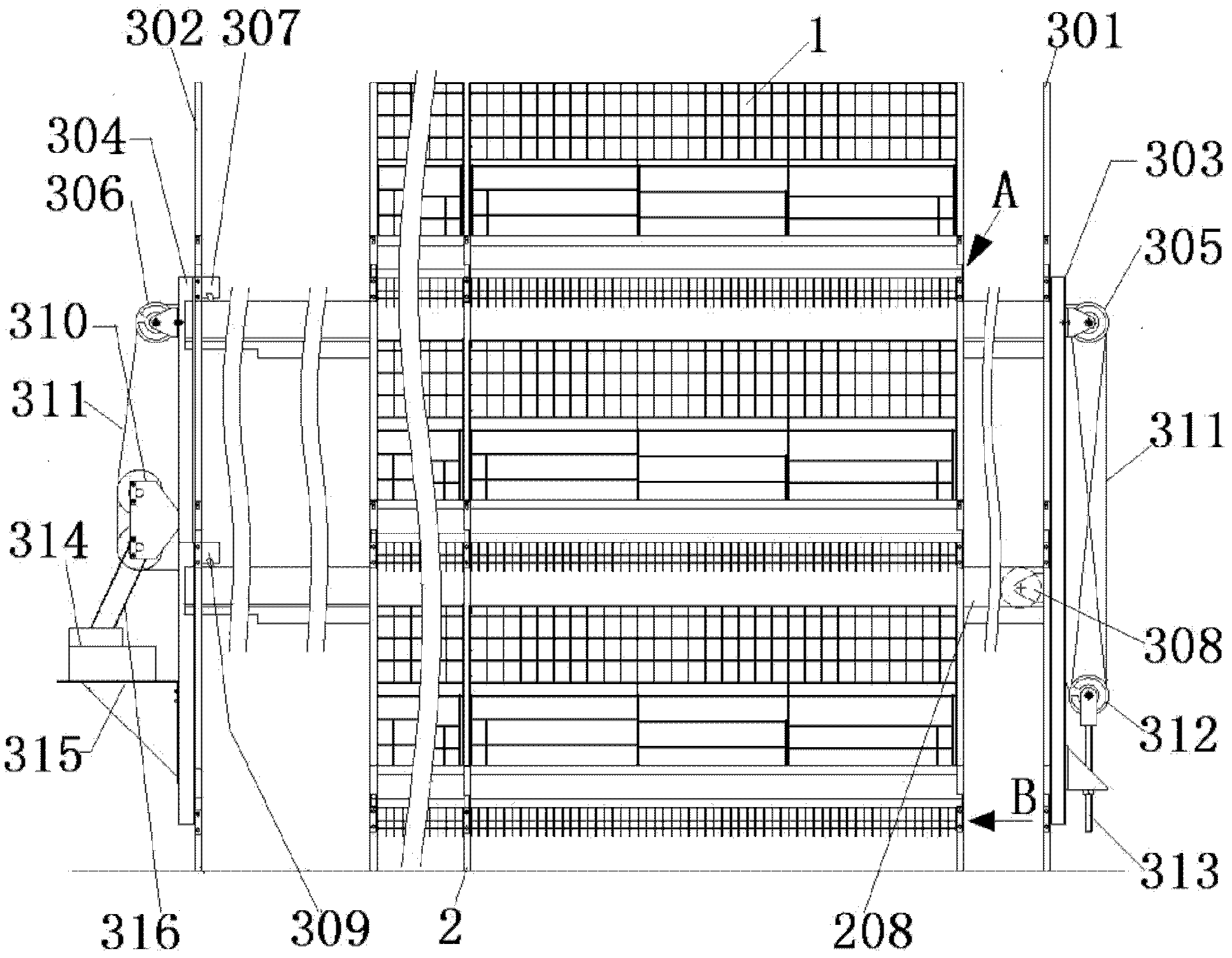

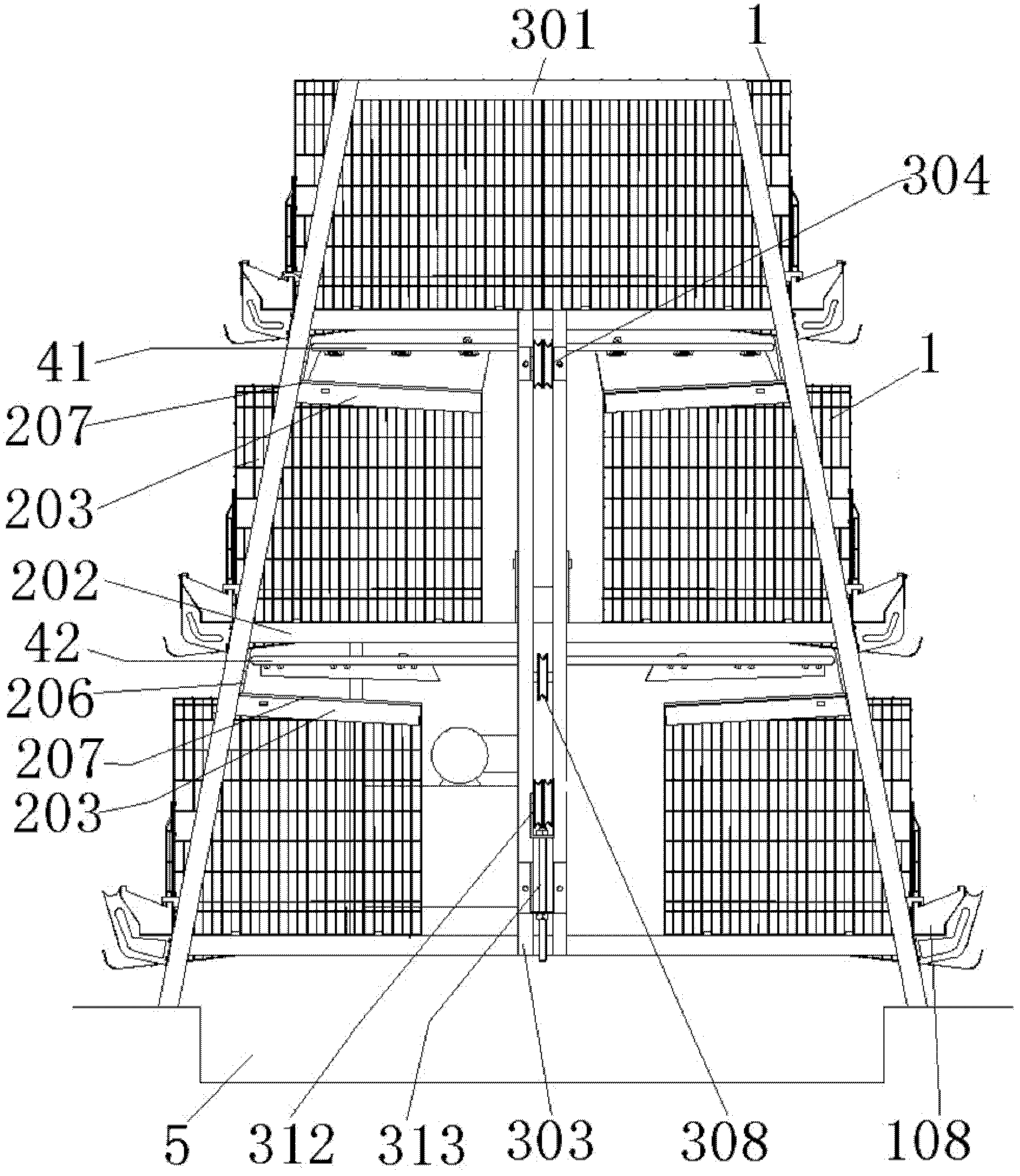

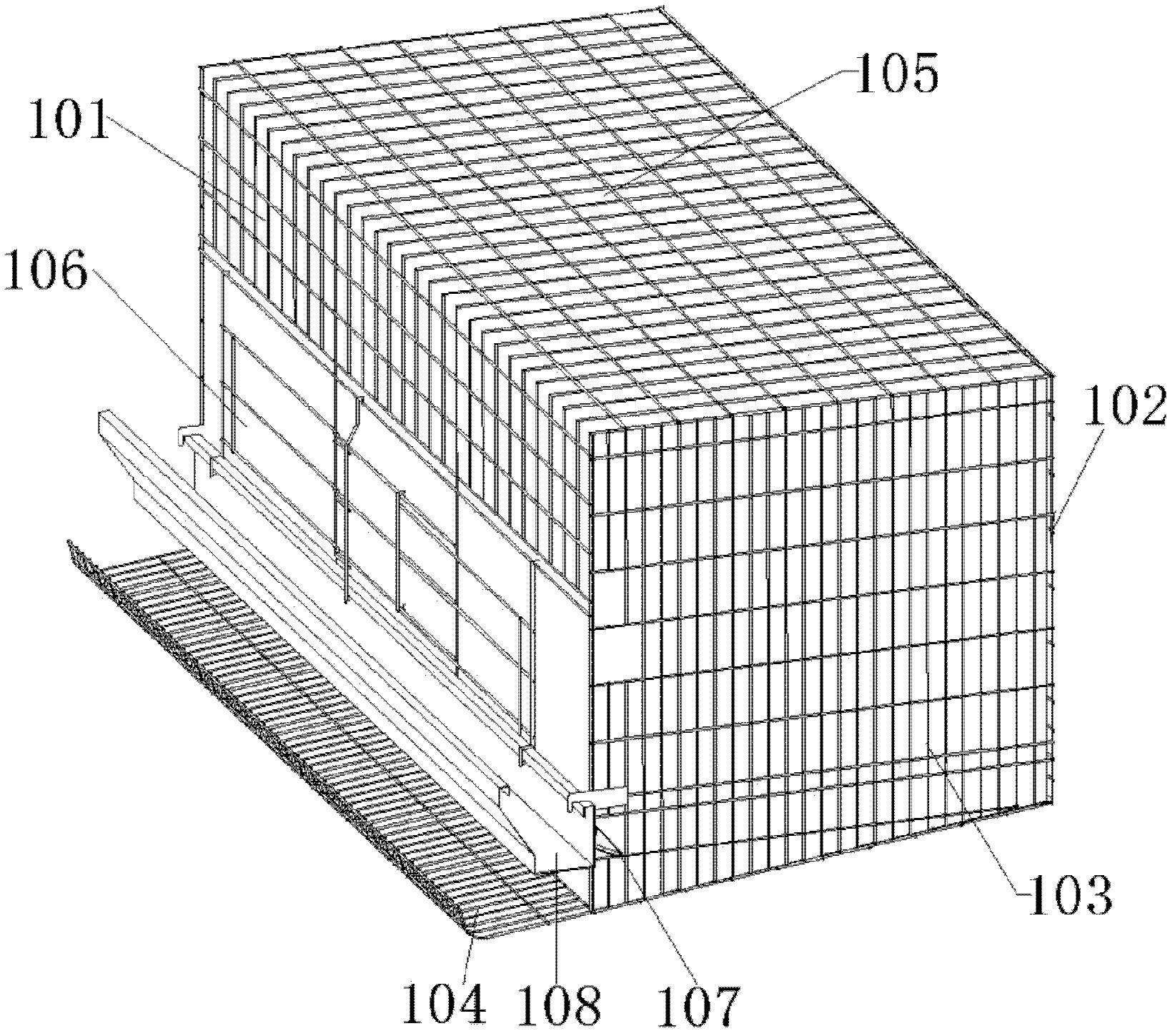

Small stepped type natural mating breeding equipment for breeding poultry

ActiveCN102422819AGuaranteed ventilation effectGuaranteed lighting effectsBird housingsMatingEnvironmental standard

The invention belongs to the technical field of stockbreeding machines, relating to small stepped type natural mating breeding equipment for breeding poultry. The small stepped type natural mating breeding equipment comprises a small stepped type natural mating cage and a manure removing device, wherein the small stepped type natural mating cage is formed by combining small stepped type natural mating cage units comprising six chicken cages and two three-layer trapezoid cage frames; every two adjacent stepped type natural mating cage units form a feeding unit; a top-layer chicken cage rear net is opened up and side nets of each layer of two adjacent chicken cages are opened up; and all cage tools of the whole cage groups respectively form a two-in-one large cage. The manure removing device comprises a manure removing machine driving mechanism and two manure removing machines which are respectively arranged below a bottom net of the top-layer chicken cage and bottom nets of two layers of chicken cages; and the manure removing machine driving mechanism can be used for simultaneously driving the two manure removing machines to alternatively carry out manure removing progress and manure removing return, so that the manure removing operation at the top of the cage is implemented. According to the small stepped type natural mating breeding equipment disclosed by the invention, the requirements of welfare breeding of the poultry and natural mating of the breeding poultry can be met; and the small stepped type natural mating breeding equipment is matched with feeding, drinking, trench manure removing and egg collecting systems and is suitable for large-scale intensive breeding poultry farms having high requirement on environmental standard.

Owner:CHINA AGRI UNIV

EPT rubber waterproofing paint and process for preparing the same

InactiveCN101113262AImprove waterproof performanceImprove anti-agingReclaimed rubber coatingsAntifouling/underwater paintsVertical planePolymer science

The invention relates to an epdm rubber waterproof coating and a preparation method thereof. The total weight portions of dry raw material component of the waterproof coating are: epdm rubber 5-7, chlorinated polyethylene 10-15, reclaimed rubber 20-25, coumarone resin 2-3, naphthenic oil 5-10, carbon black 5-8, zinc oxide 0.5-0.7, stearic acid 0.1-0.3, sulfur 0.4-0.6, accelerator 0.5-0.9 and antioxidant 1-3. The waterproof coating adopts epdm rubber, reclaimed rubber and chlorinated polyethylene as film forming main bodies and also various modified promoter and fillings, which results in that the waterproof coating not only has excellent waterproof, ageing and cold resistance, but also has the advantages of convenient construction and low cost, and the components and construction thereof meet the requirements of national environmental standards. The invention has simple preparation process steps, is convenient to be widely industrially produced, and the store property and life service of the waterproof coating obtained is greatly prolonged. The waterproof coating can be widely applied to the waterproof construction in building, engineering, vertical plane and various waterproof datum planes.

Owner:北京立高科技股份有限公司

Artificial turf

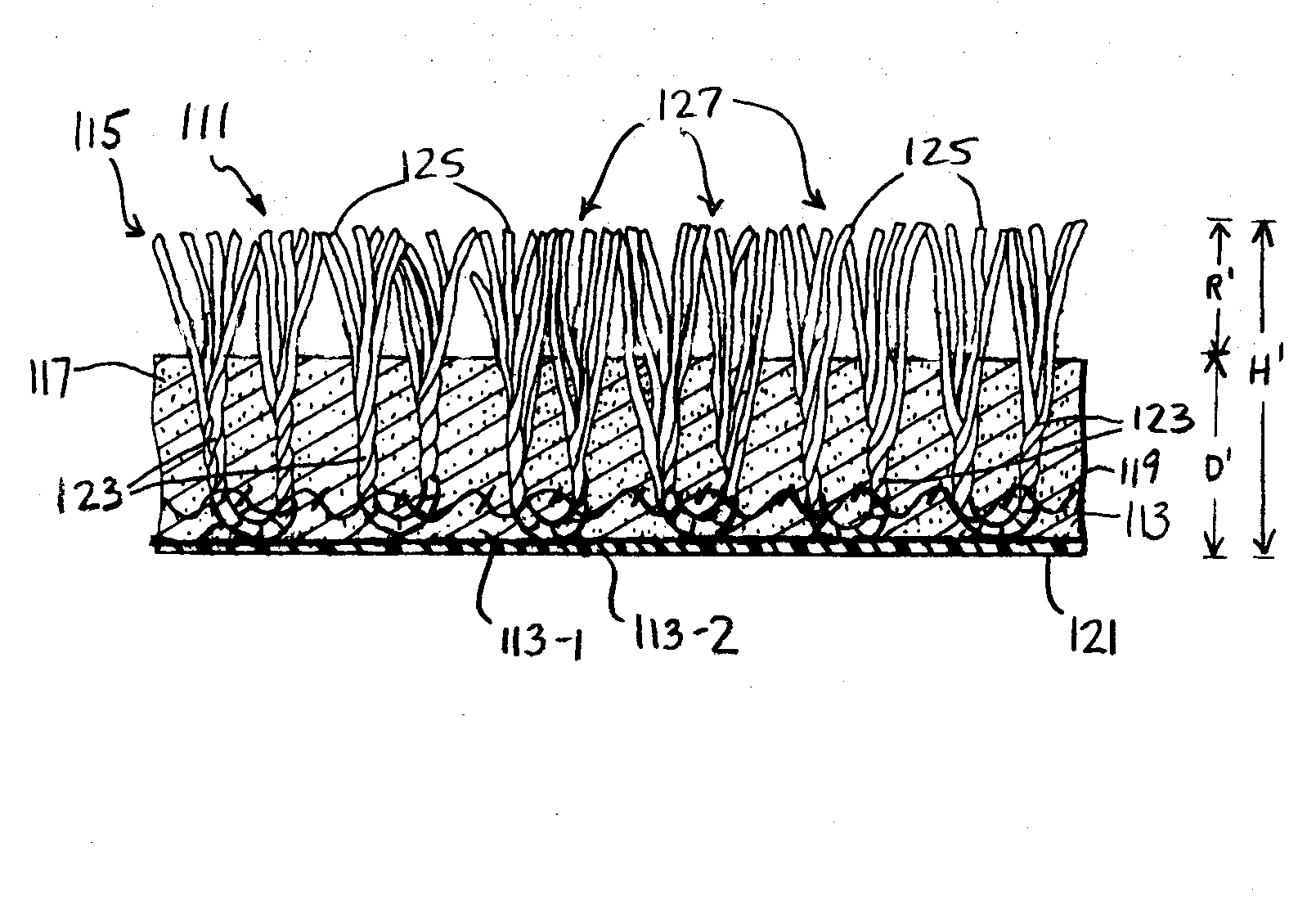

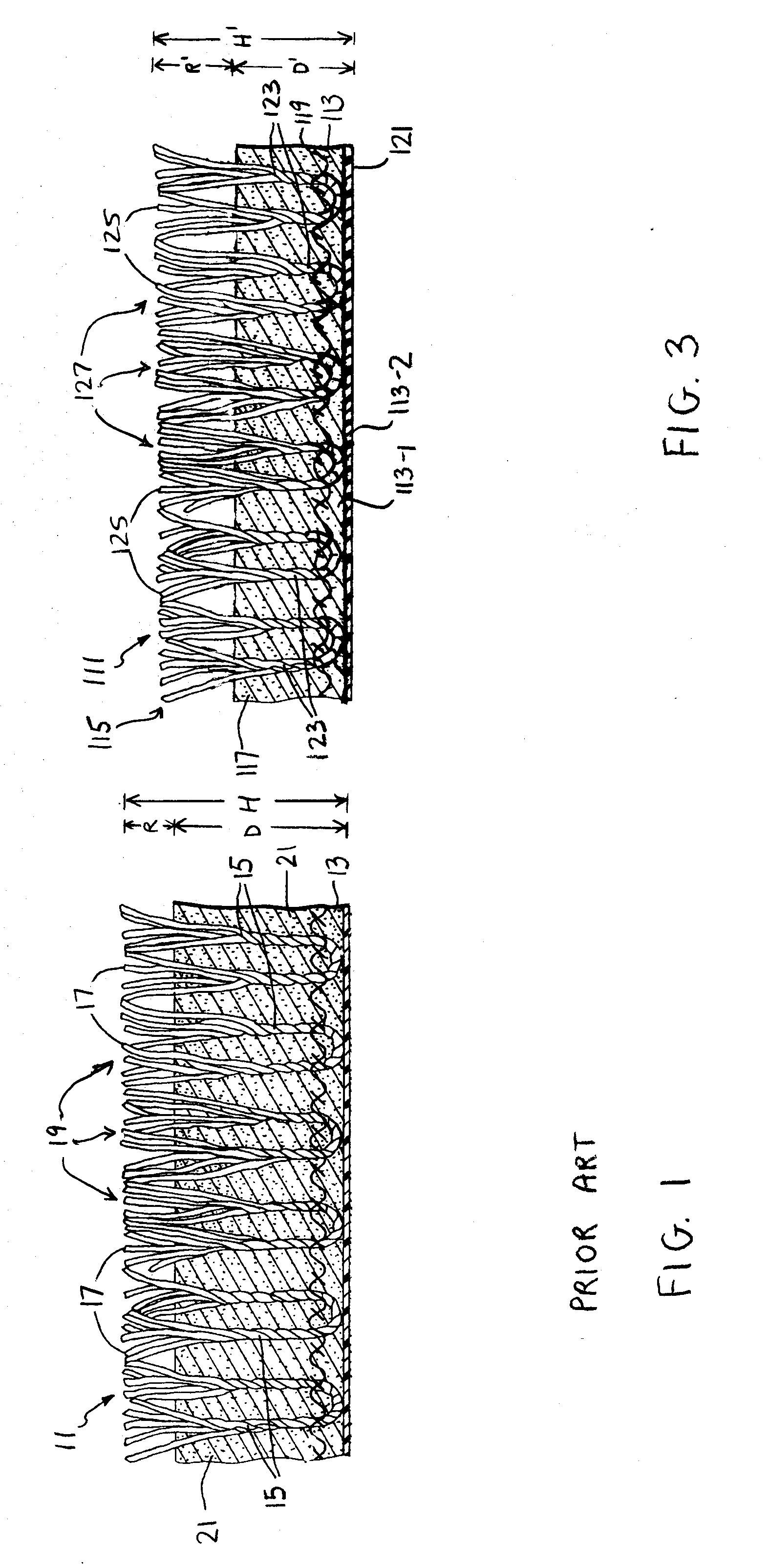

InactiveUS20140193593A1Optimal performance characteristicMinimize retention of heatDead plant preservationArtificial flowers and garlandsInfillEnvironmental standard

An artificial turf for a synthetic field system includes a flexible, water-permeable backing, a pile fabric woven into the backing, and a limited layer of water-absorbent, eco-friendly and light reflective infill deposited within voids formed in the pile fabric. The pile fabric is constructed with a plurality of separate, upwardly standing, reduced height tufts, each tuft including a plurality of synthetic filaments that resemble individual blades of natural grass. The tufts are arranged into parallel rows, with the spacing between rows being fixed and equal to the spacing between successive tufts in each row so as to yield an artificial field surface with an increased density of filaments. The dimensional aspects and high filament density of the artificial turf introduces a number of notable advantages over conventional artificial turfs including better performance, less surface heat retention, improved aesthetics, reduced infill maintenance requirements, and greater compliance with environmental standards.

Owner:SPORTS FIELD HLDG

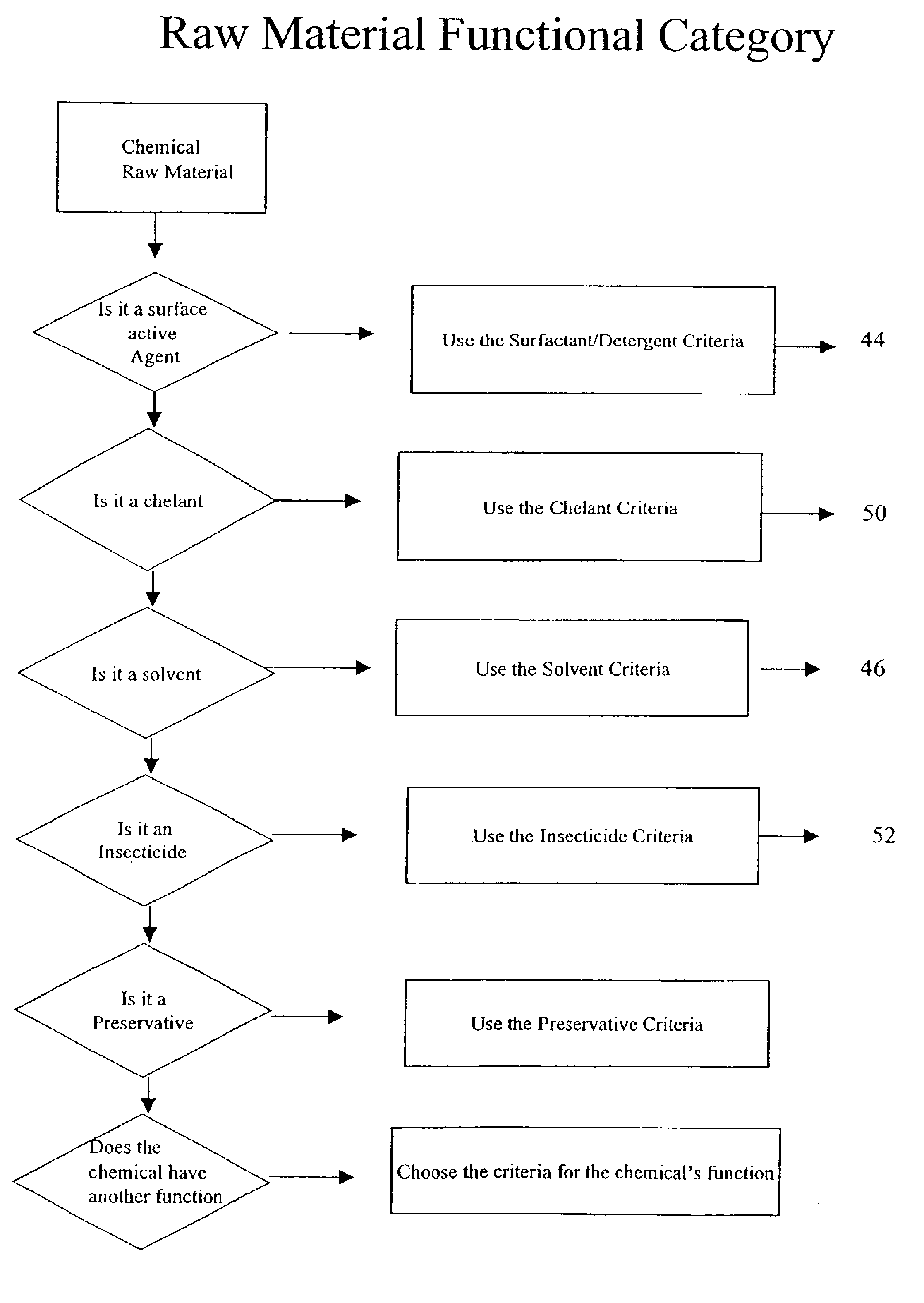

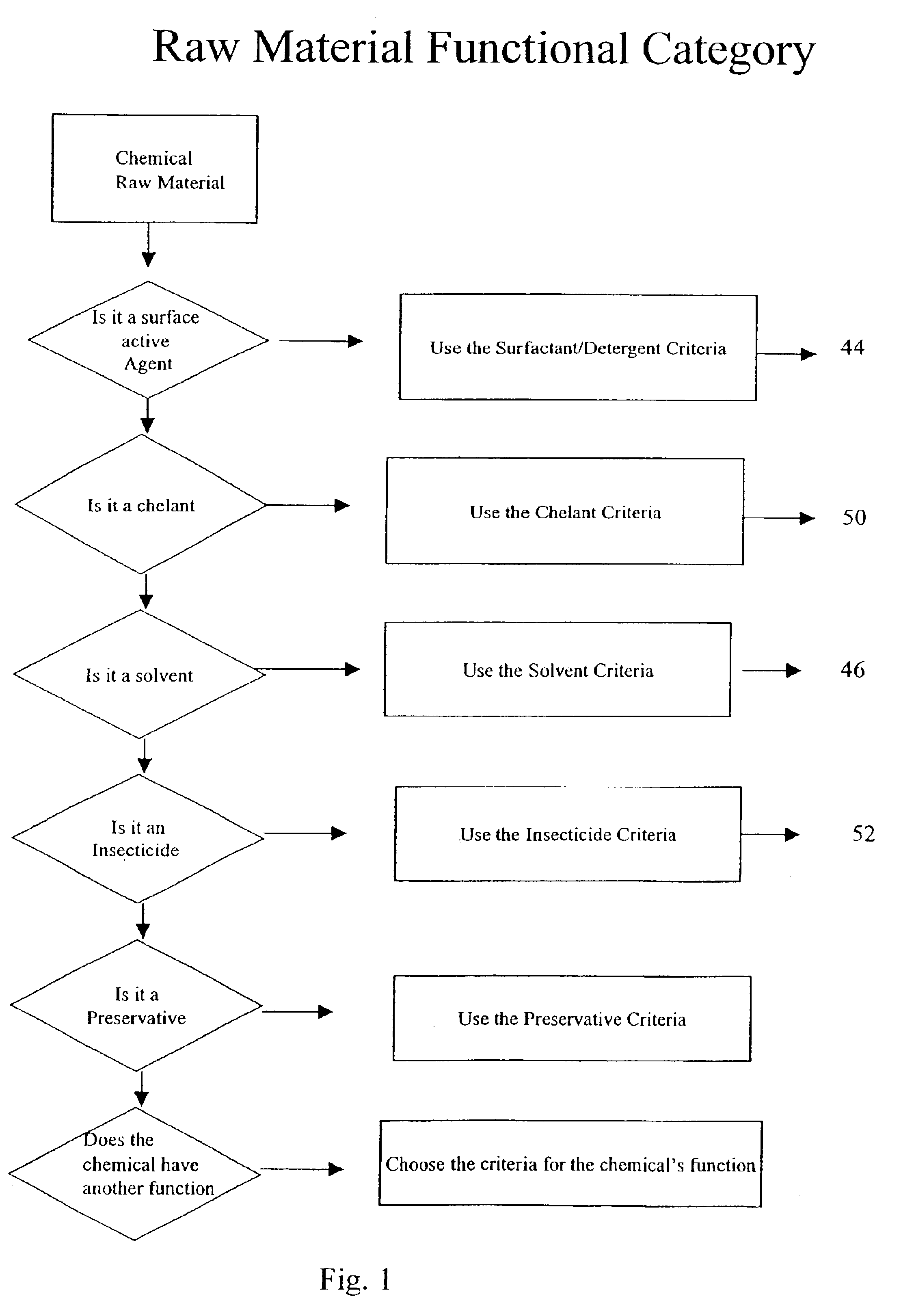

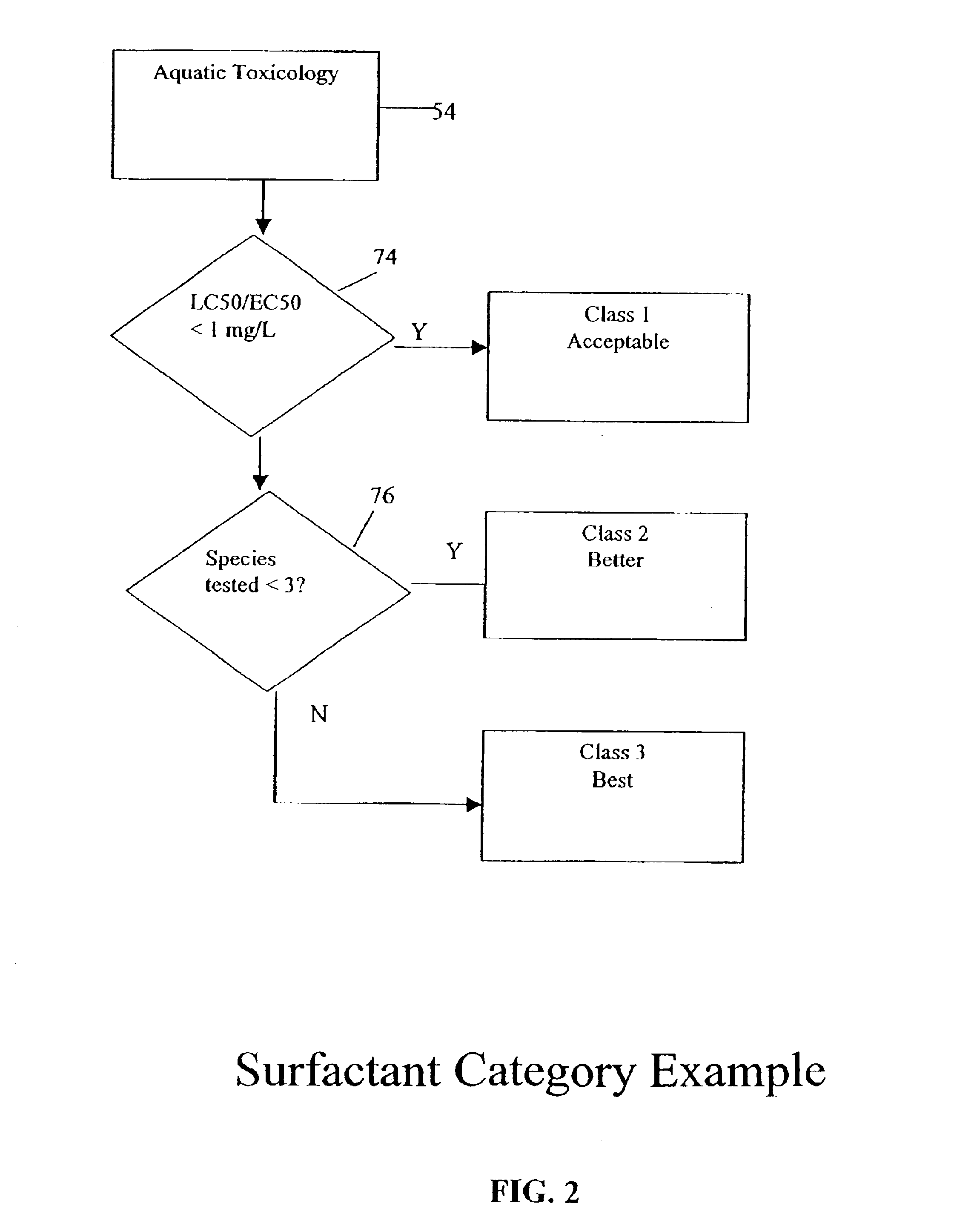

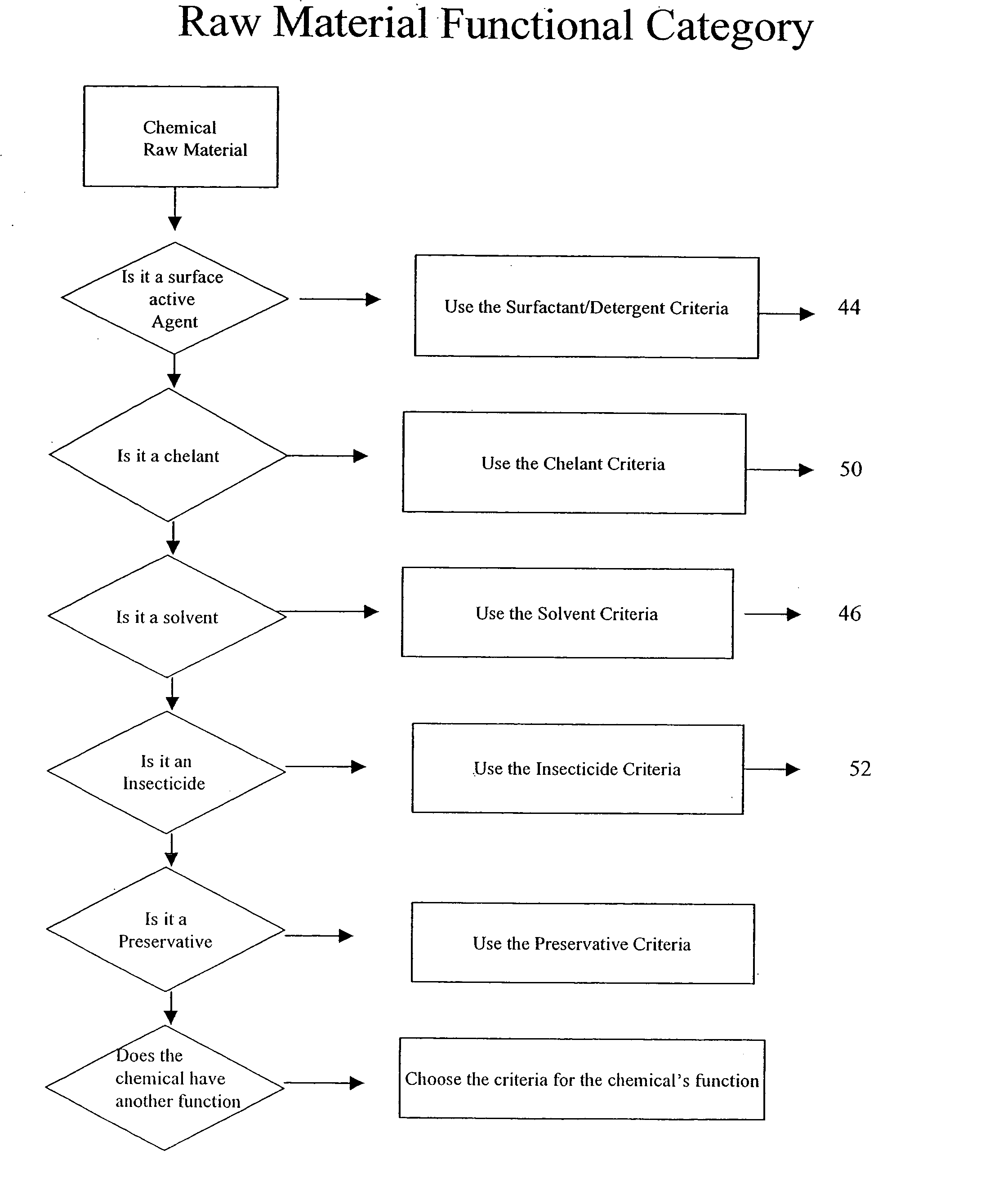

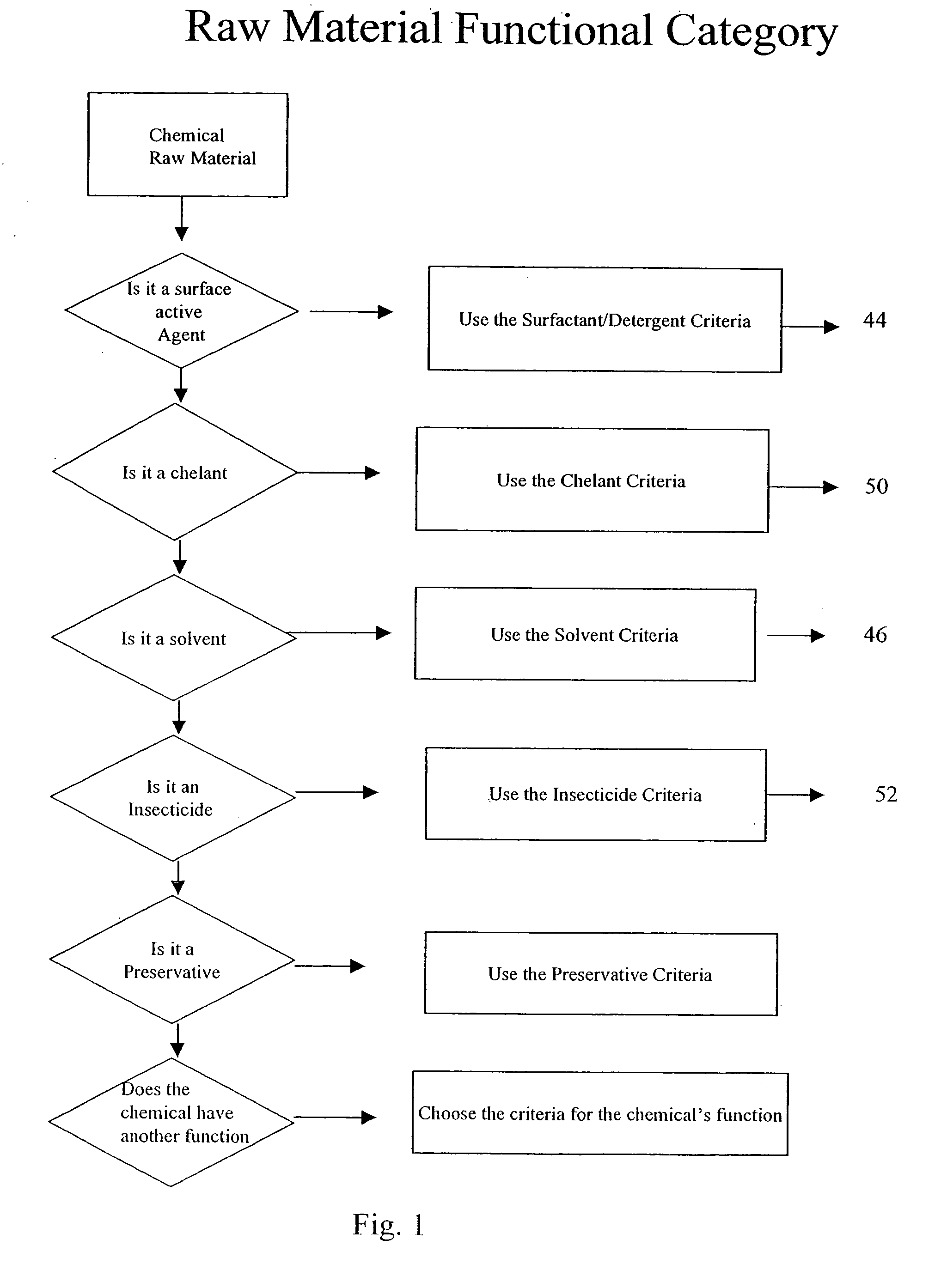

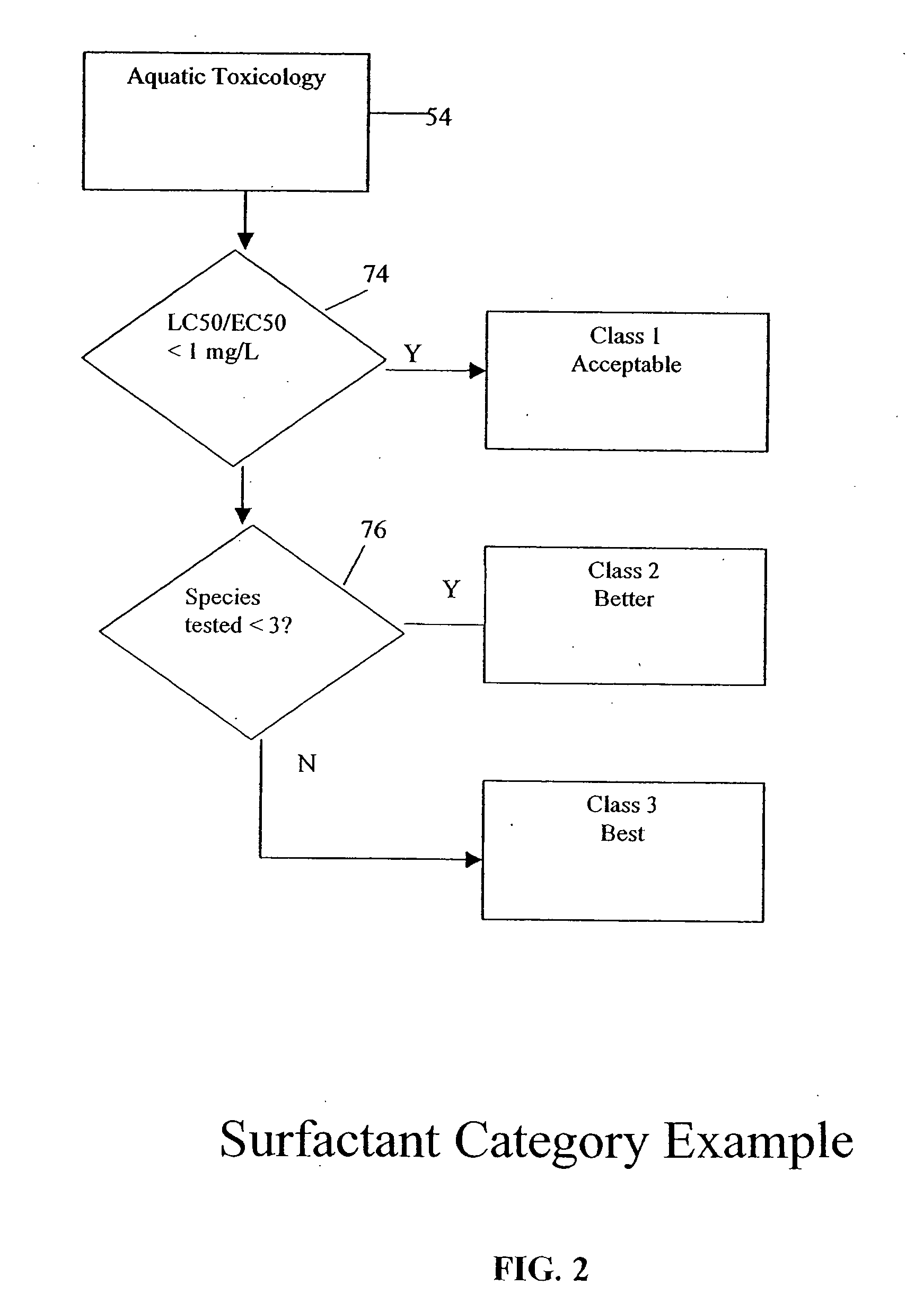

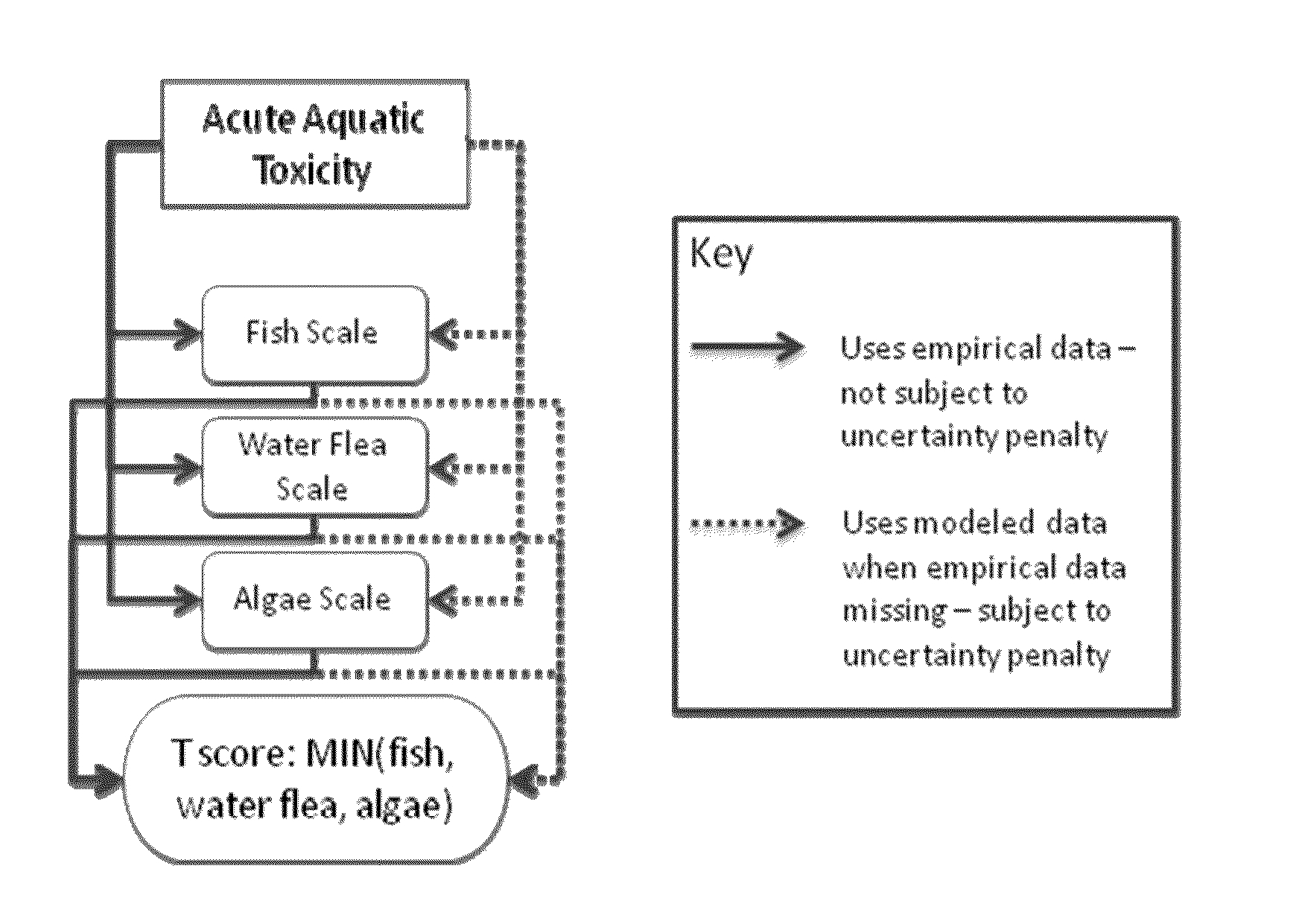

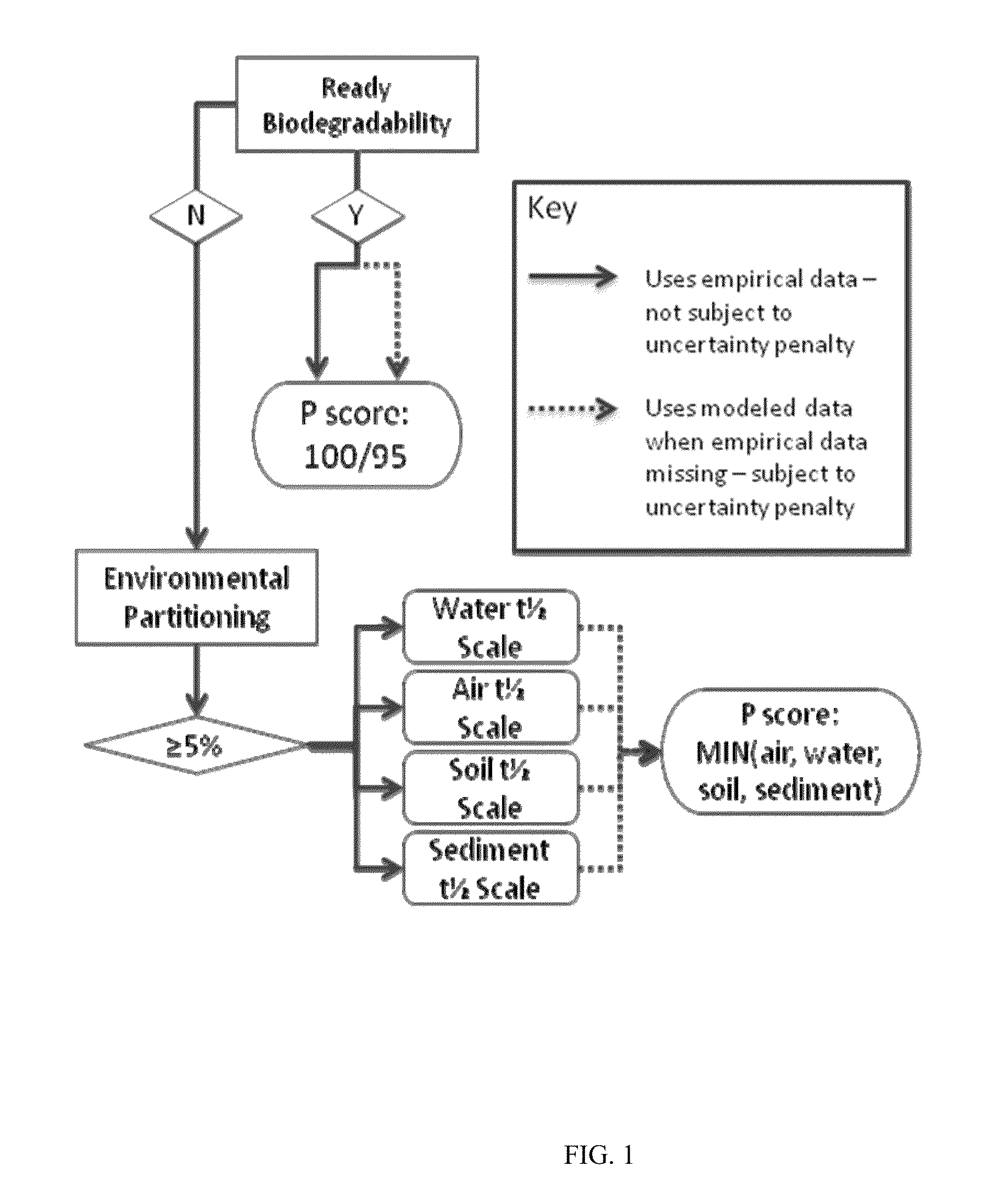

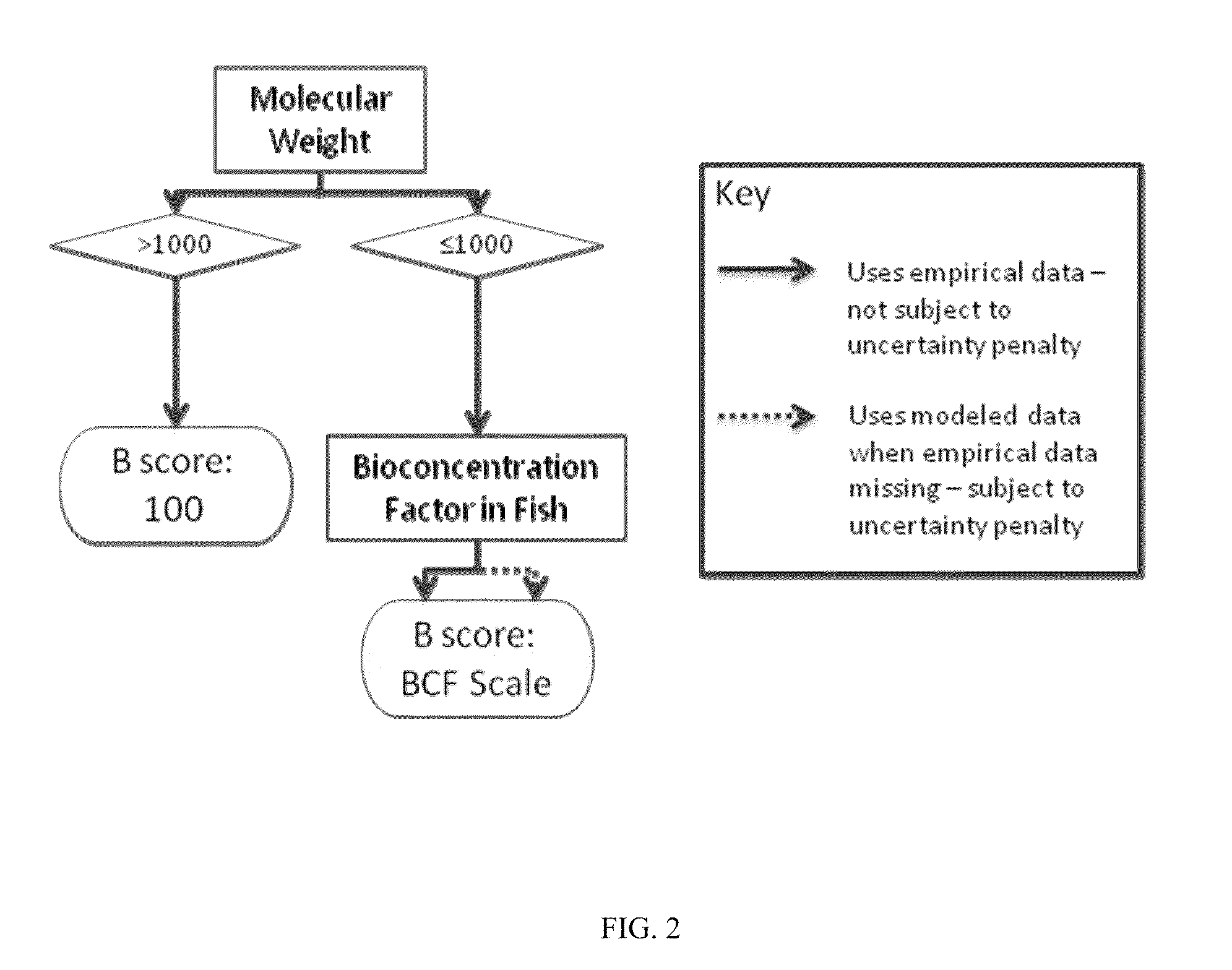

Methods for evaluating chemical components based on their proposed function in the product they are to be used in

ActiveUS6973362B2Quick modificationEasy to useResourcesSpecial data processing applicationsChemical compositionEnvironment effect

Disclosed are methods for evaluating the environmental impact of various chemical components as a function of their proposed functional use in a chemical product, methods for formulating products based on those evaluations, and databases for assisting in those methods. Consumer products can be environmentally improved using these methods. Environmental criteria are in part developed based on the nature of the ultimate use of the product, and usually vary for a given chemical between types of proposed uses. The environmental classes for components are adjusted by their weight representation in the final product.

Owner:SC JOHNSON & SON INC

Method for processing arsenic-containing wastewater by pteris vittata artificial wet land

InactiveCN101254974ASustainable biological treatmentBiological water/sewage treatmentConstructed wetlandArsenic pollution

The invention discloses a method for processing wastewater containing arsenic by using the ciliate desert grass artificial wetland. Super concentration plant ciliate desert grass which is planted in a drowned flow wetland system is utilized to process wastewater containing arsenic, cobblestones are used as the loading material of the drowned flow wetland system, soil with a certain thickness is covered on the groundmass of the drowned flow wetland system, and the arsenic in water body is continuously extracted till the content of arsenic in the water body reach the corresponding state environmental standard. With the advantages of high efficiency, low investment, low running, low maintenance technology, easy popularization and application, etc., the method has no secondary pollution, and meanwhile the ecologic system can not be damaged during recondition process, the method also can facilitate the soil or the water degradation and the falling of the productivity caused by the arsenic pollution of the soil and the water, and recover and improve the diversity of the soil or the water life-forms.

Owner:NANCHANG UNIV

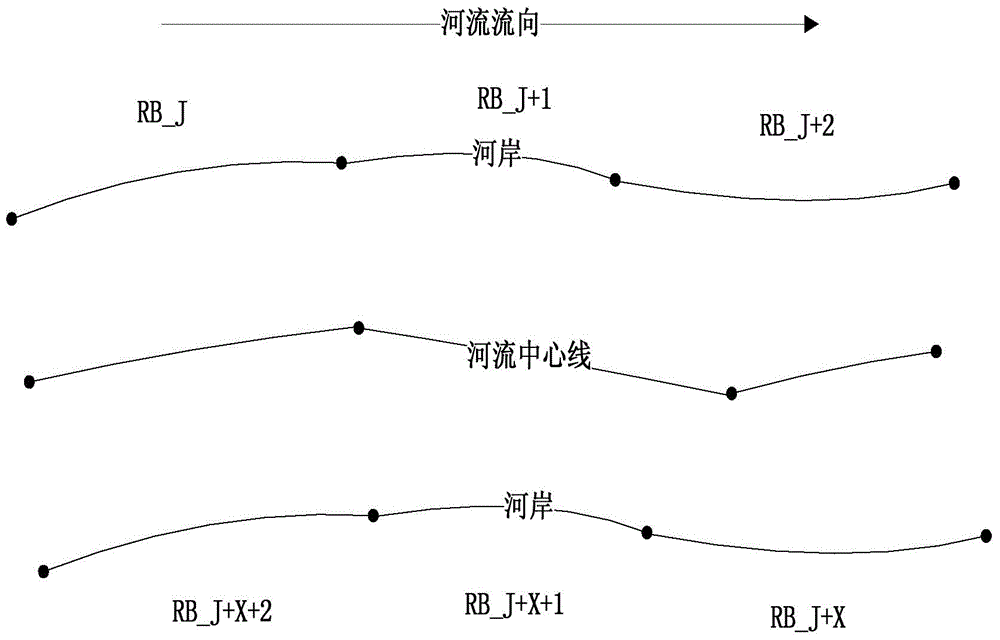

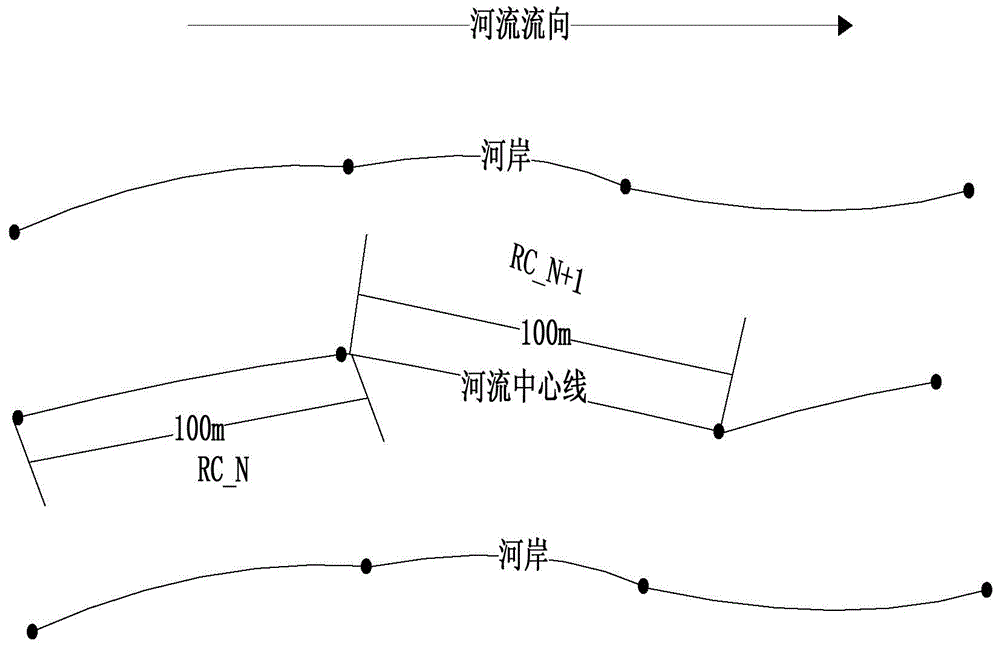

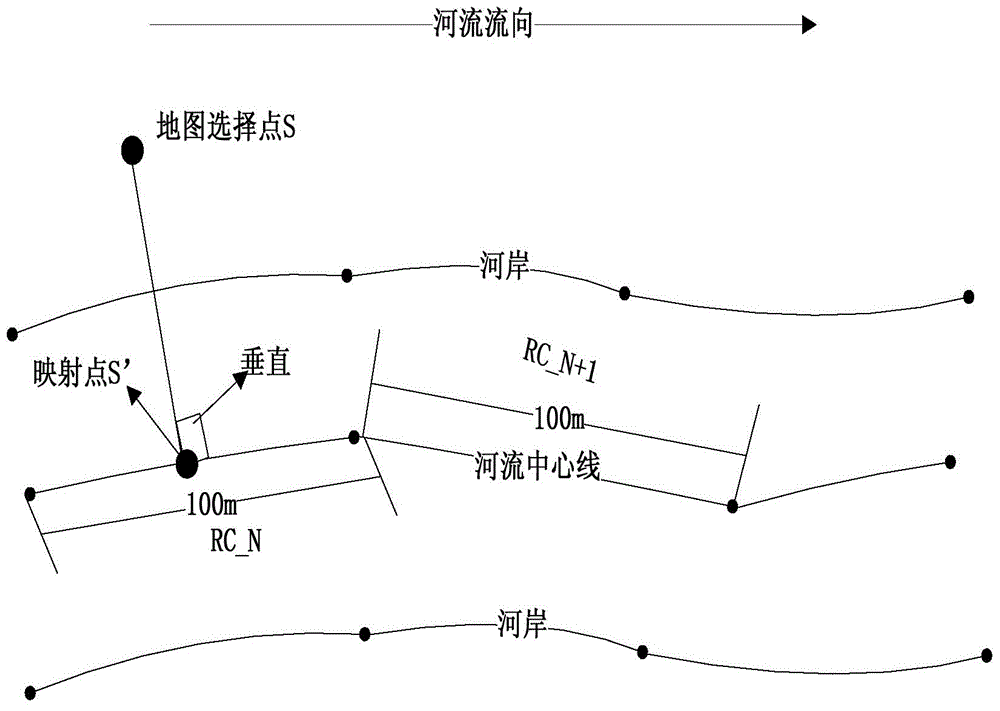

Pollutant diffusion dynamic simulation method for water environment quality monitoring

ActiveCN105675448AShow the degree of influenceNot really pollutingGeneral water supply conservationSurface/boundary effectWater qualityLocation planning

The present invention relates to a pollutant diffusion dynamic simulation method for water environment quality monitoring, and the pollutant diffusion dynamic simulation method comprises the following steps: establishing a river model; then calculating current concentration of pollutants in a measuring point in a zone according to a continuous stable emission model or an instantaneous emission model; and comparing the current concentration of the pollutants with environmental standards to determine a water quality grade, and applying a color to the zone in the river model. The pollutant diffusion dynamic simulation method is not limited by time and regions, more importantly, does not really cause water pollution, and pollutant diffusion conditions can be simulated at any time, so that strong reference information is provided for a best solution for plant location planning and urban development, according to different requirements, a number of parameters are set for the simulation of the pollutant diffusion conditions under different conditions so as to meet different needs.

Owner:中国科学院沈阳计算技术研究所有限公司

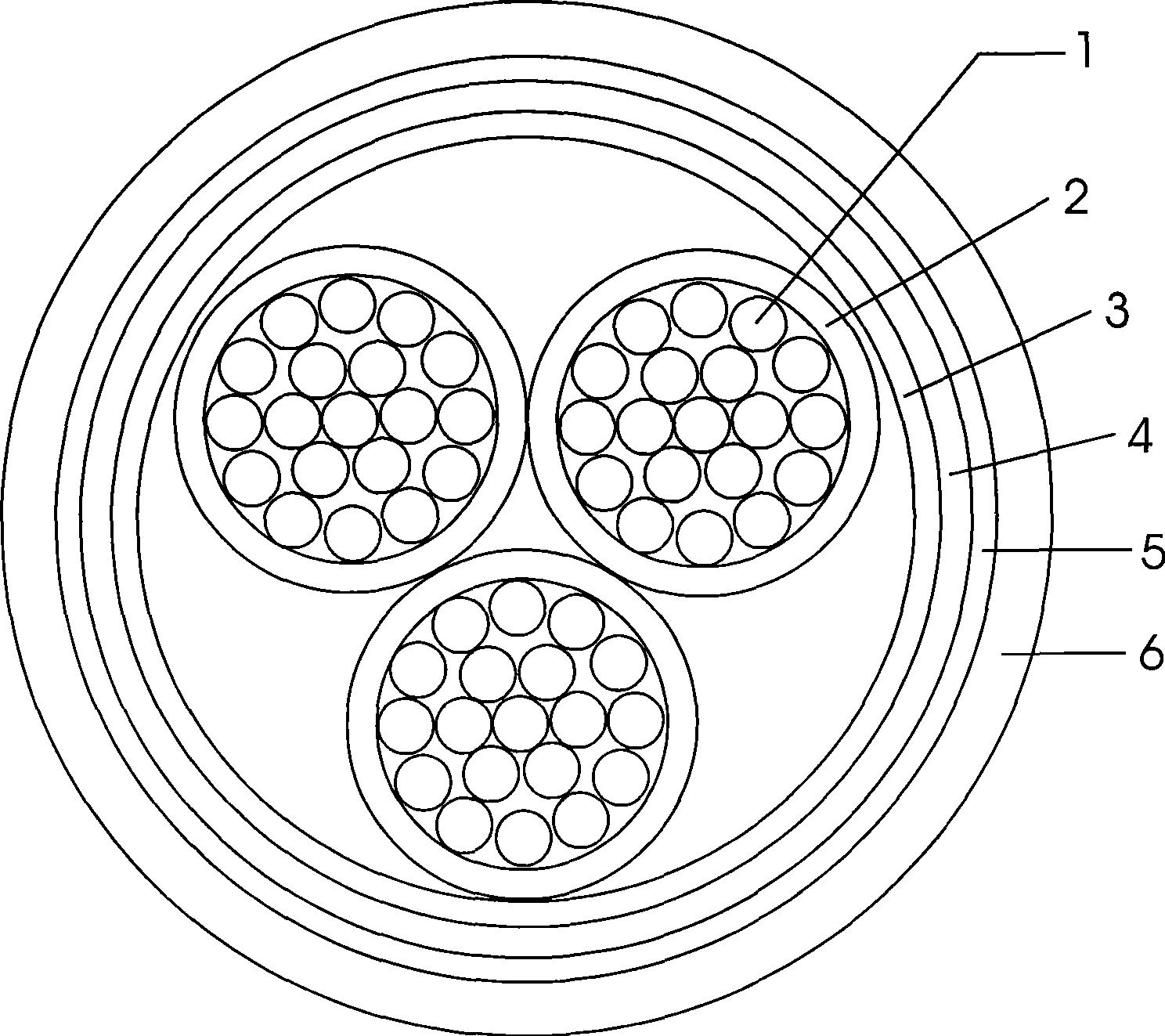

Photovoltaic electric cable for switching between the wind power and solar power

ActiveCN101483086AExtended service lifeComply with RoHS environmental protection standardPlastic/resin/waxes insulatorsInsulated cablesCopper conductorCross-link

The invention discloses a wind and solar energy conversion photovoltaic cable and manufacturing method thereof, which is object to allow the photovoltaic cable to have characteristics of easy laying, environmental protection, anti-ozone and ultraviolet light, moisture-proof, grease-proof, flame resistance, corrosion resistance, wide temperature range width, as well as anti-electromagnetic interference. To solve the above technical problems, the invention adopts the following technical projects: a wind and solar energy conversion photovoltaic cable includes including the insulated wire core, wherein, the insulated wire core is a copper conductor coated with an irradiated cross-linked low smoke zero halogen insulation layer, and the outer layer of the insulated wire core is in sequence concentrically wrapped with a glass fiber tape, a metal shield layer, a water blocking tape and an irradiated cross-linked low smoke zero halogen jacket. Compared with the prior art, the temperature range of the inventive cable can reach the temperature range from +150 DEG C to -45 DEG C, the laying temperature of the cable is not lower than -30 DEG C, and the cable has a long service life, and all indexes of the cable are in line with the RoHS environmental standards.

Owner:新疆中超新能源电力科技有限公司

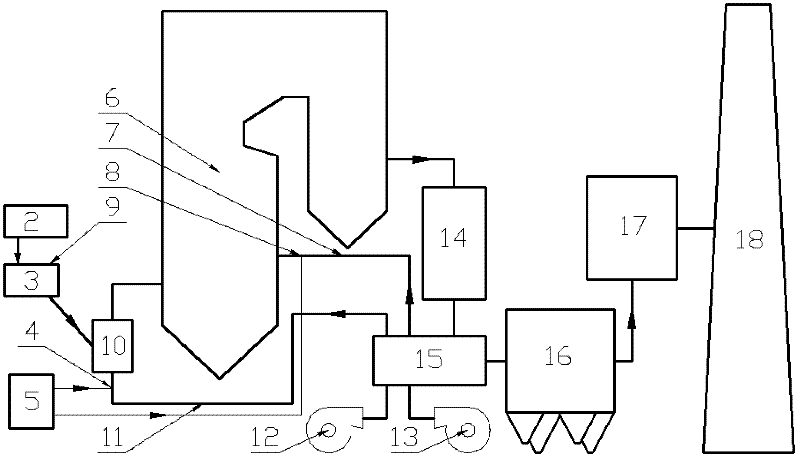

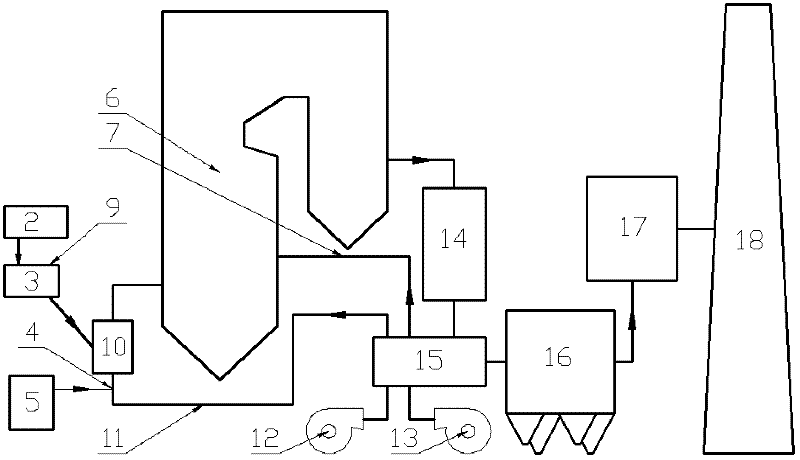

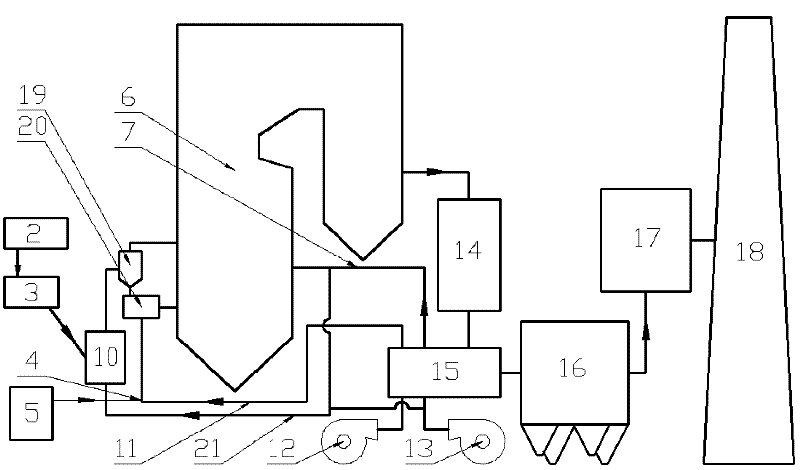

Method and system for efficiently controlling mercury pollution of coal-fired power plant at low cost

InactiveCN102343200ARaise the ratioImprove mercury removal efficiencyDispersed particle separationAir preheaterControl system

The invention discloses a method and system for efficiently controlling mercury pollution of a coal-fired power plant at low cost. The system comprises a primary hot air duct, a secondary hot air duct and a liquid storing tank, wherein the primary hot air duct and the secondary hot air duct are communicated with an air preheater and a hearth; a coal conveying system is communicated with a coal grinding system through a coal feeder; the liquid storing tank is filled with a halide additive solution; and the liquid storing tank is communicated with at least one of the coal conveying system, the coal feeder, the primary hot air duct and the secondary hot air duct. According to the system, the halide additive solution enters a boiler body and participates in a combustion reaction, the oxidation of the mercury in flue gas is promoted and the ratio of mercury oxide in the flue gas is increased, so that the synergetic demercuration effect of flue gas purifying equipment such as denitration equipment, desulfurization equipment, dedusting equipment and the like in a tail flue of a boiler is improved, and the mercury content of flue gas in a chimney is greatly lowered. A mercury pollutant control system has the advantages of small investment and low running cost while the mercury pollutant emission level of the coal-fired power plant can meet stricter environmental standard requirements.

Owner:HUANENG CLEAN ENERGY RES INST

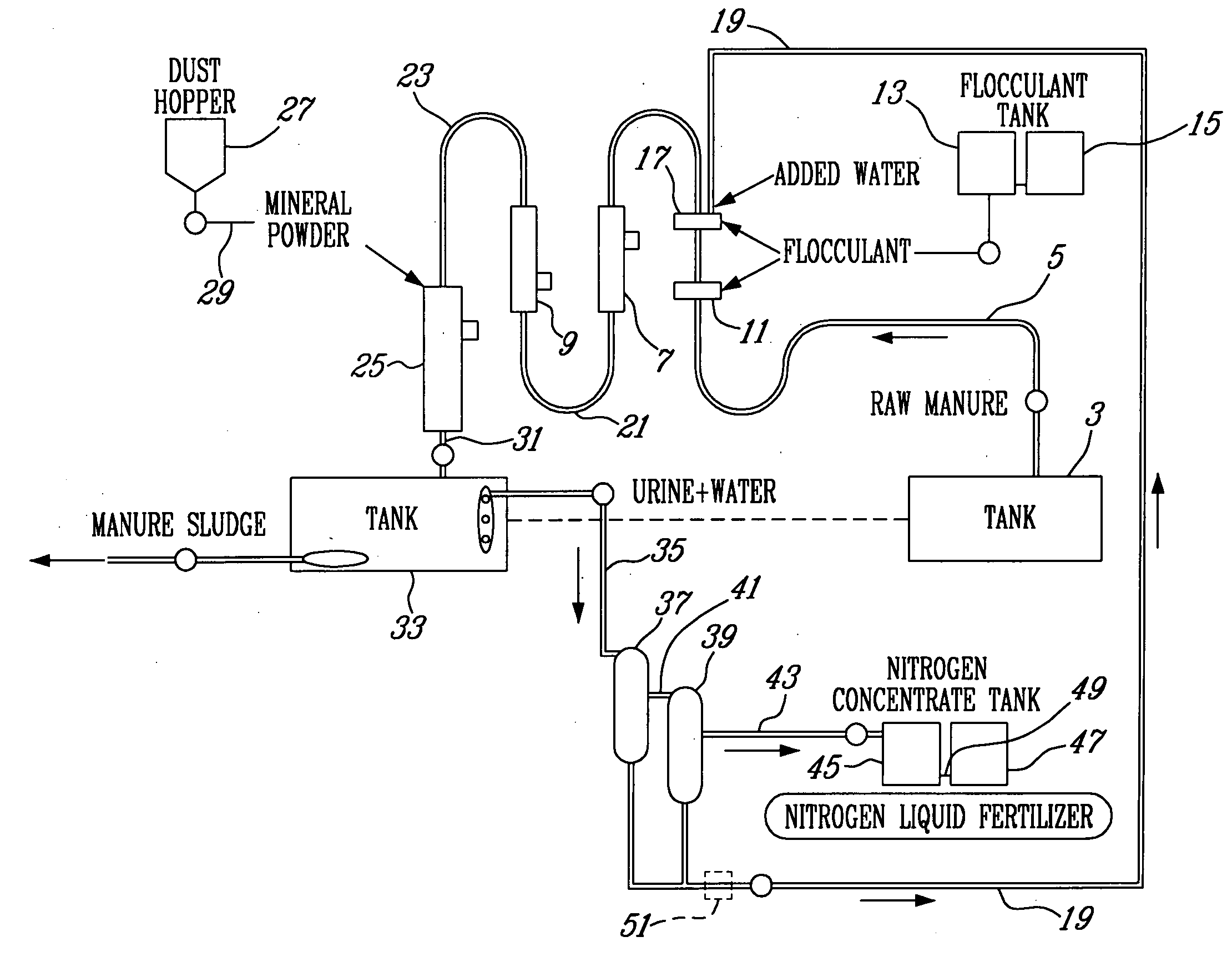

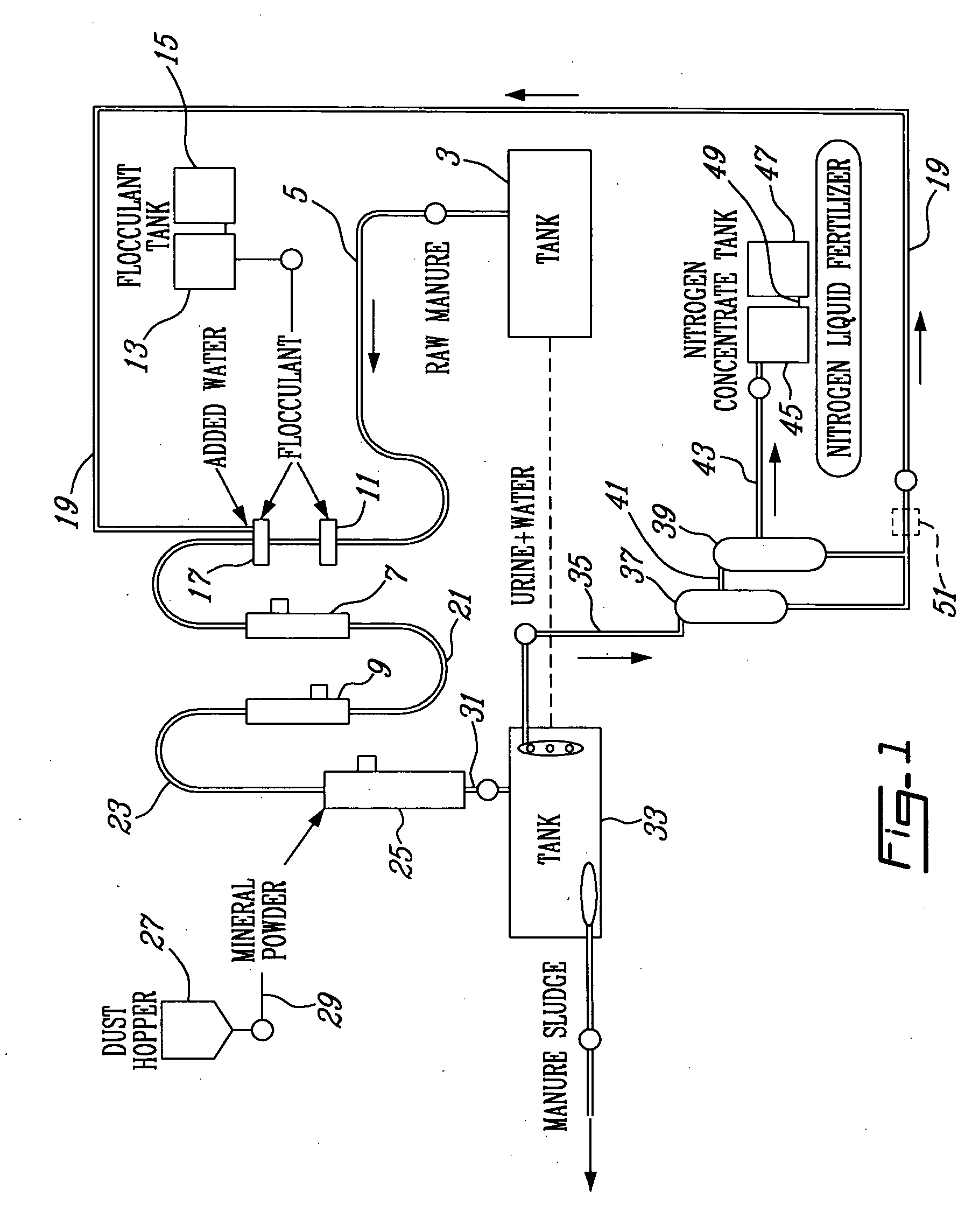

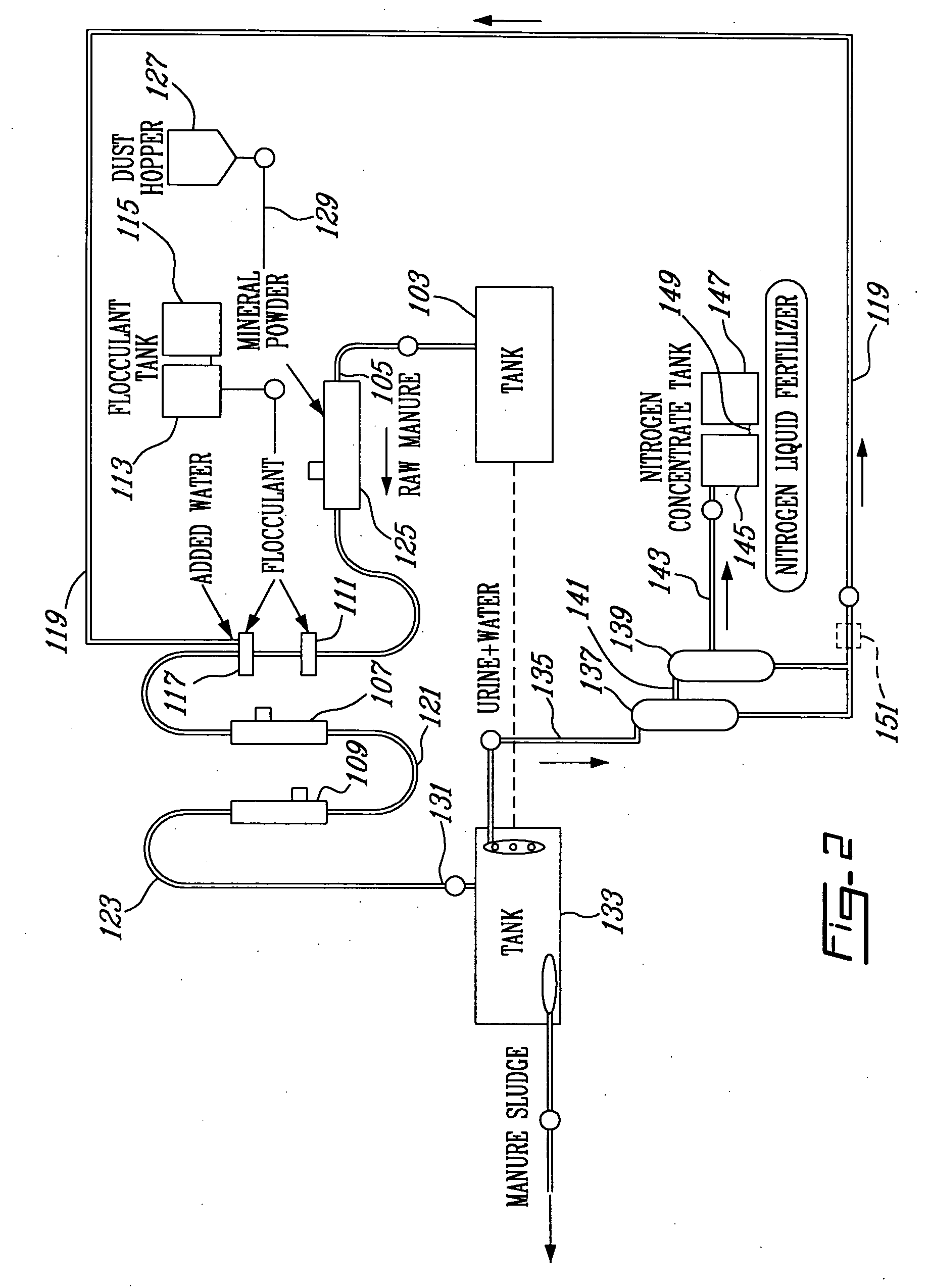

Process and device for treating raw manure

ActiveUS20060021407A1BiocideLiquid separation auxillary apparatusSolid componentEnvironmental standard

A process and a device for treating and upgrading raw manure. The method and the device comprise steps which consist in promoting agglomeration of solid constituents of the manure and precipitating the agglomerated particles by using a sedimentation agent. More particularly, the sedimentation agent used is based on natural stone and / or industrial derivative dusts. Sedimentation of the agglomerated particles enables the solid phase and the liquid phase to be separately treated, leading eventually to the production of a solid fertilizer, a liquid fertilizer and water corresponding to environmental standards and capable of being released into the environment or simply recycled.

Owner:9401 5104 QUEBEC INC

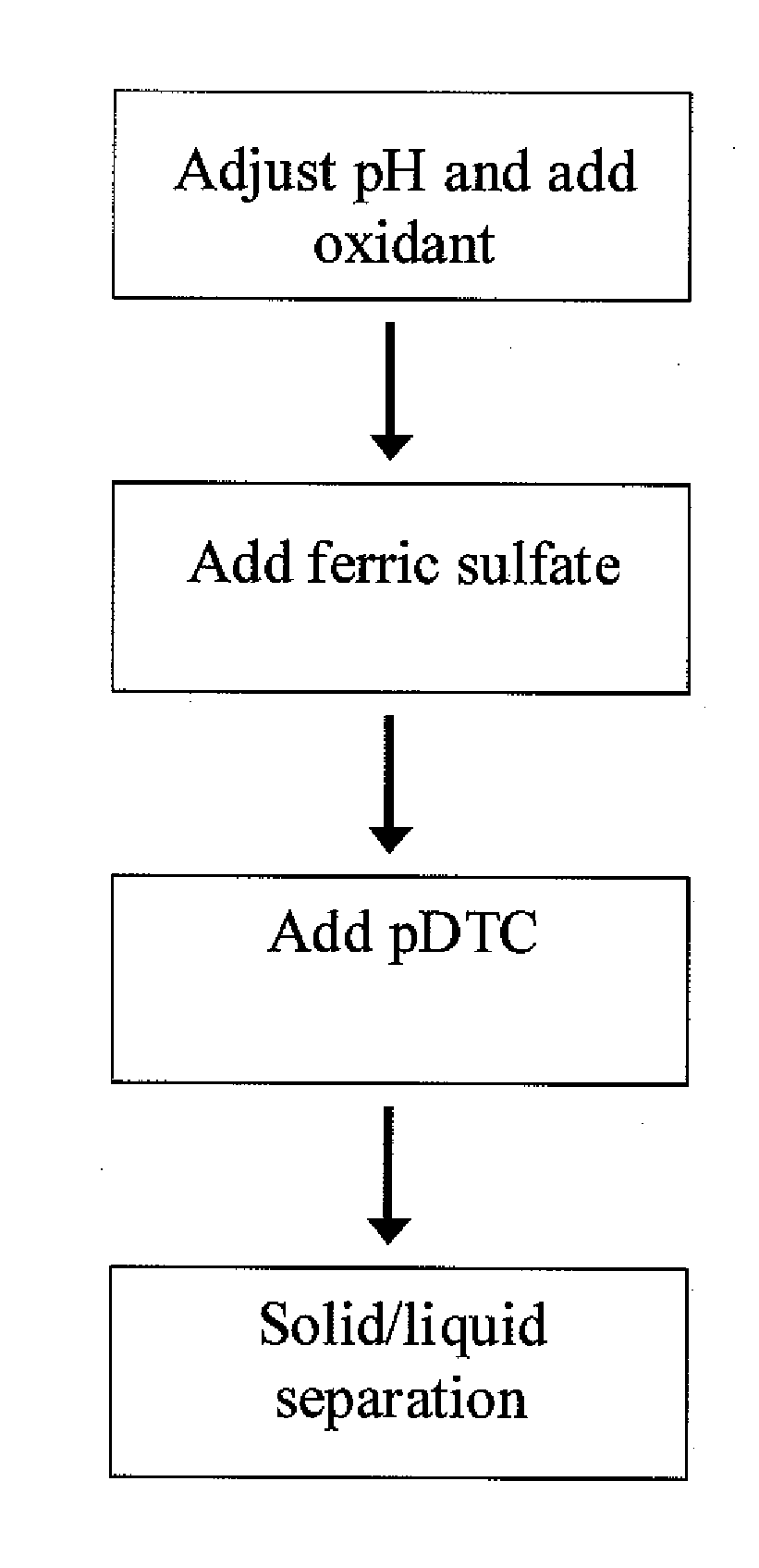

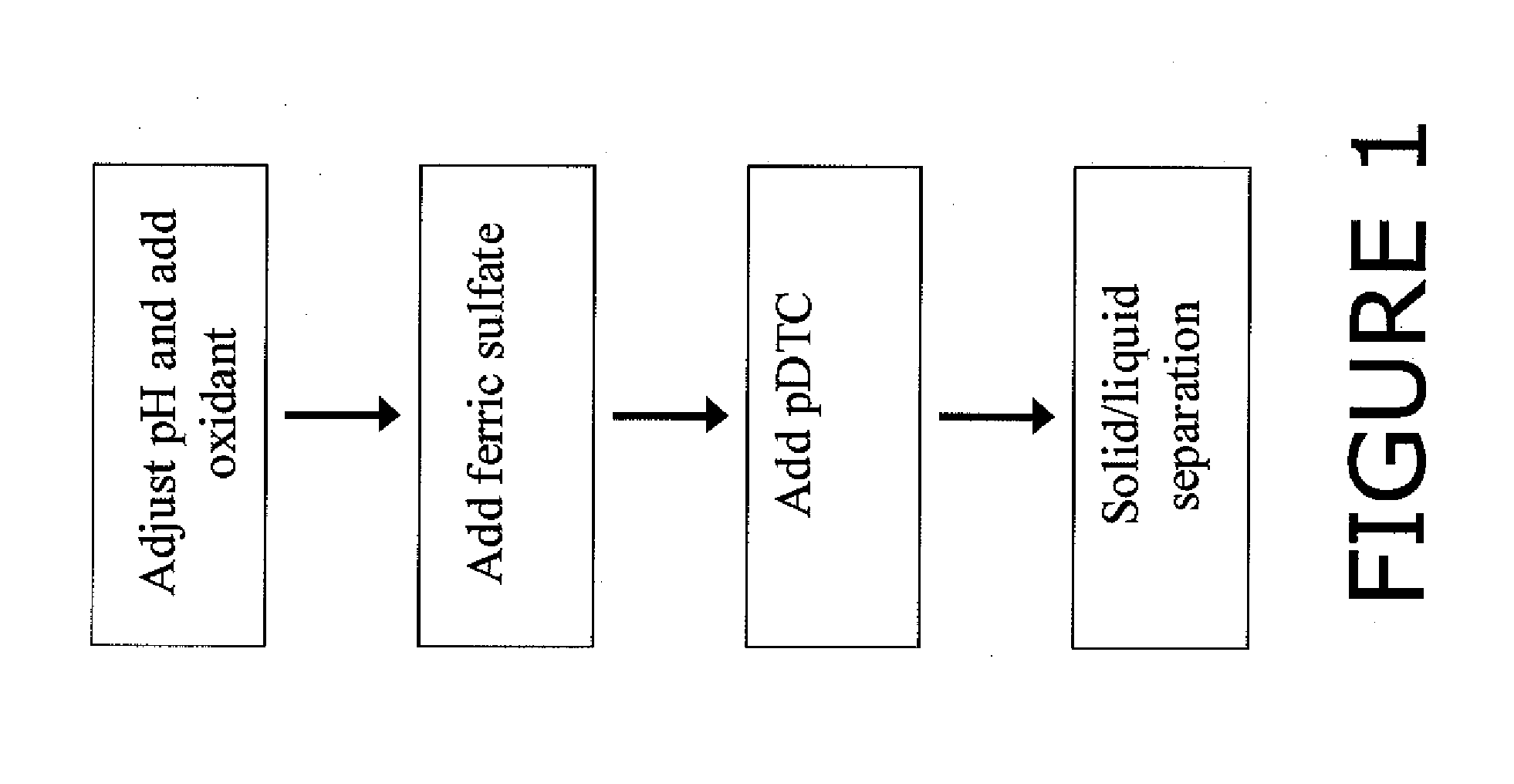

Removal of selenium from refinery wastewater

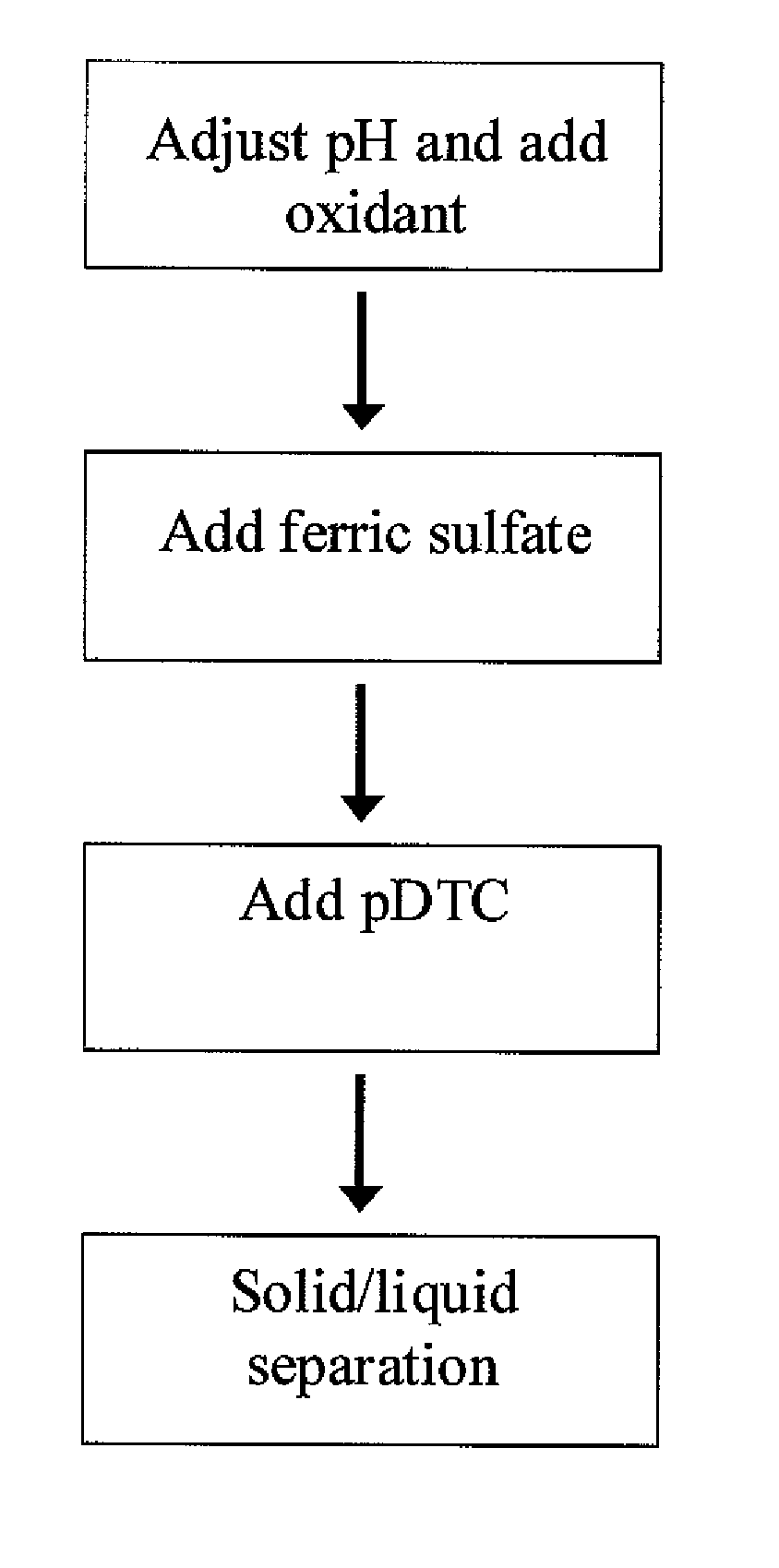

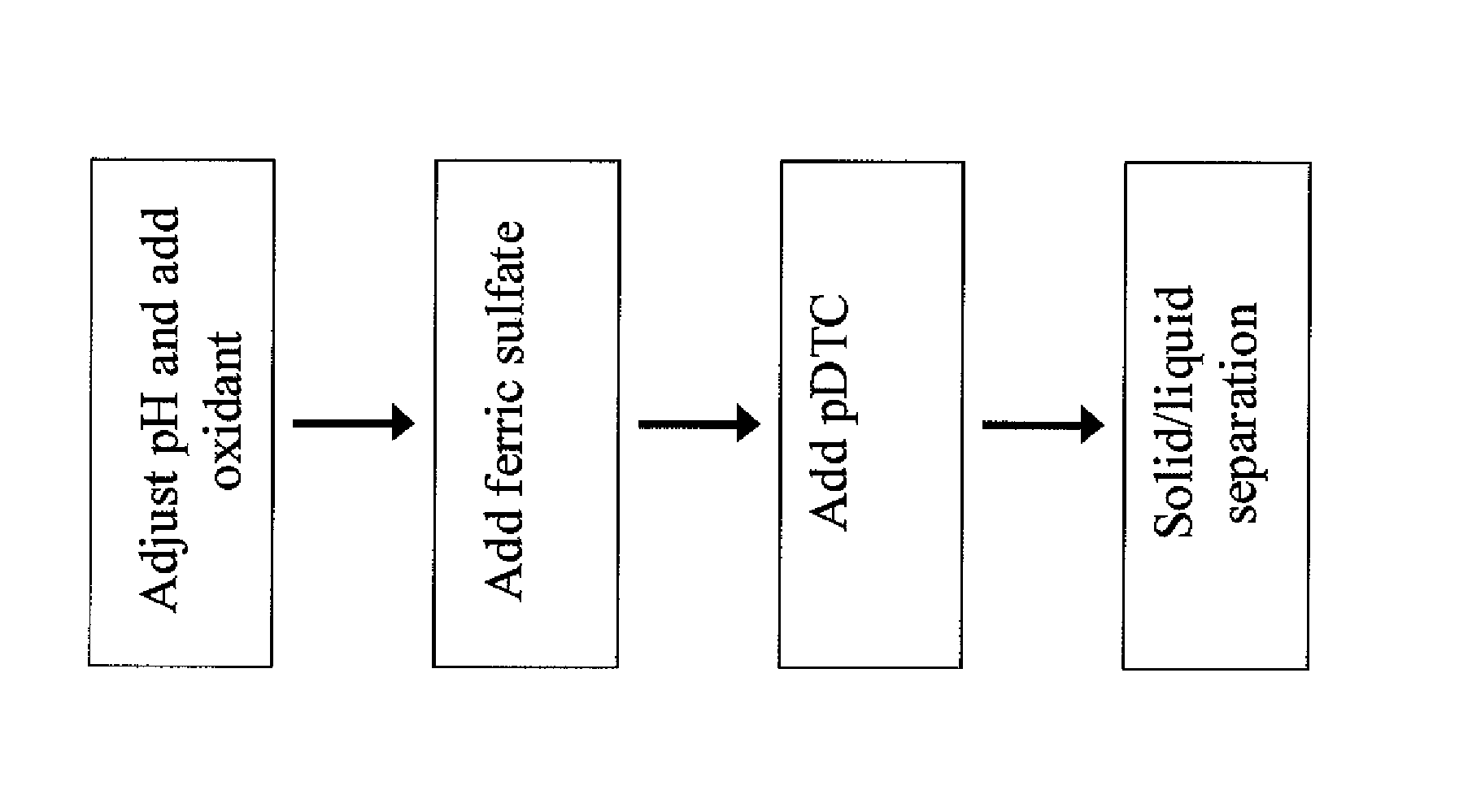

ActiveUS8282835B2Reduce the amount requiredWater contaminantsSedimentation separationEnvironmental standardSe element

The invention provides a method of efficiently removing selenium from water. The method involves: adding an oxidant to the liquid, adjusting the liquid's pH to below 7.5, adding ferric salt in an amount such that less than a quarter of selenium in the liquid precipitates and adding a poly dithiocarbamate material to the liquid in an amount such that the amount of poly dithiocarbamate material (in ppm) is greater than the amount of ferric salt (in ppm). This method removes far more selenium than previous methods, and does it using a smaller amount of expensive chemicals. Moreover this method makes it far more likely to achieve cost effective compliance with the ever-increasing environmental standards for selenium in water.

Owner:NALCO CO

Methods for evaluating chemical components based on their proposed function in the product they are to be used in

InactiveUS20060004474A1Quick modificationEasy to implementResourcesSpecial data processing applicationsChemical compositionEnvironment effect

Disclosed are methods for evaluating the environmental impact of various chemical components as a function of their proposed functional use in a chemical product, methods for formulating products based on those evaluations, and databases for assisting in those methods. Consumer products can be environmentally improved using these methods. Environmental criteria are in part developed based on the nature of the ultimate use of the product, and usually vary for a given chemical between types of proposed uses. The environmental classes for components are adjusted by their weight representation in the final product.

Owner:SC JOHNSON & SON INC

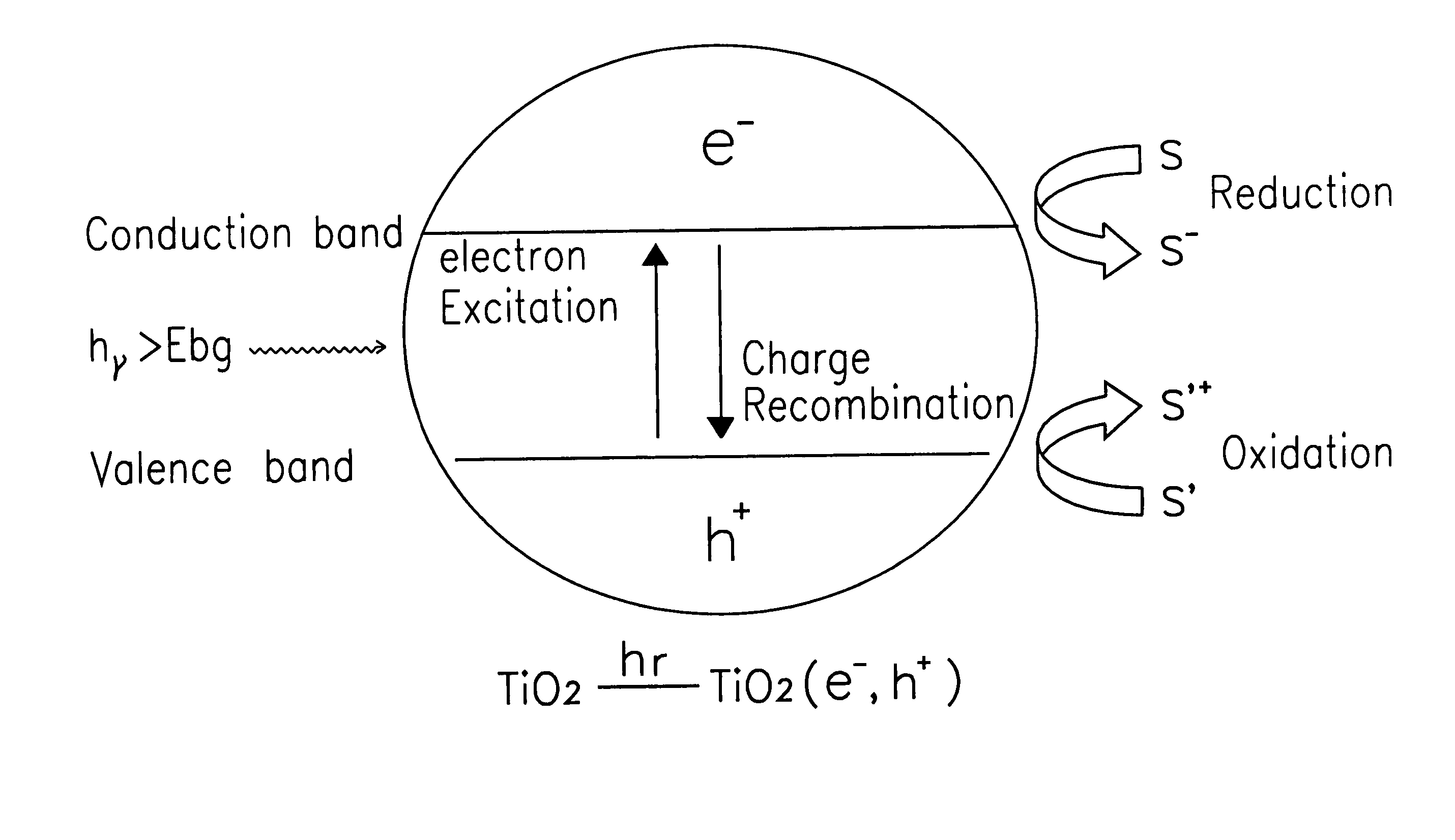

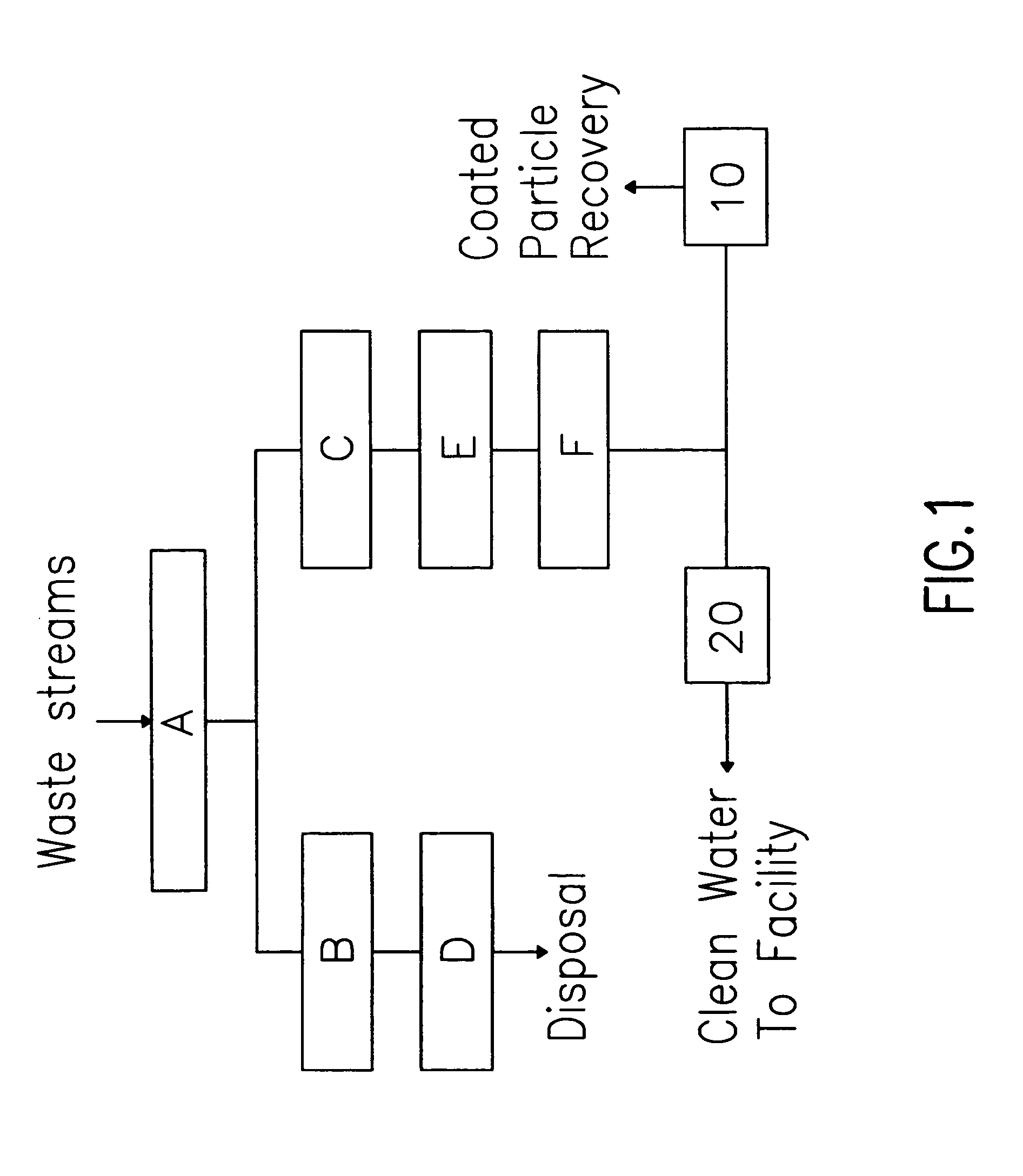

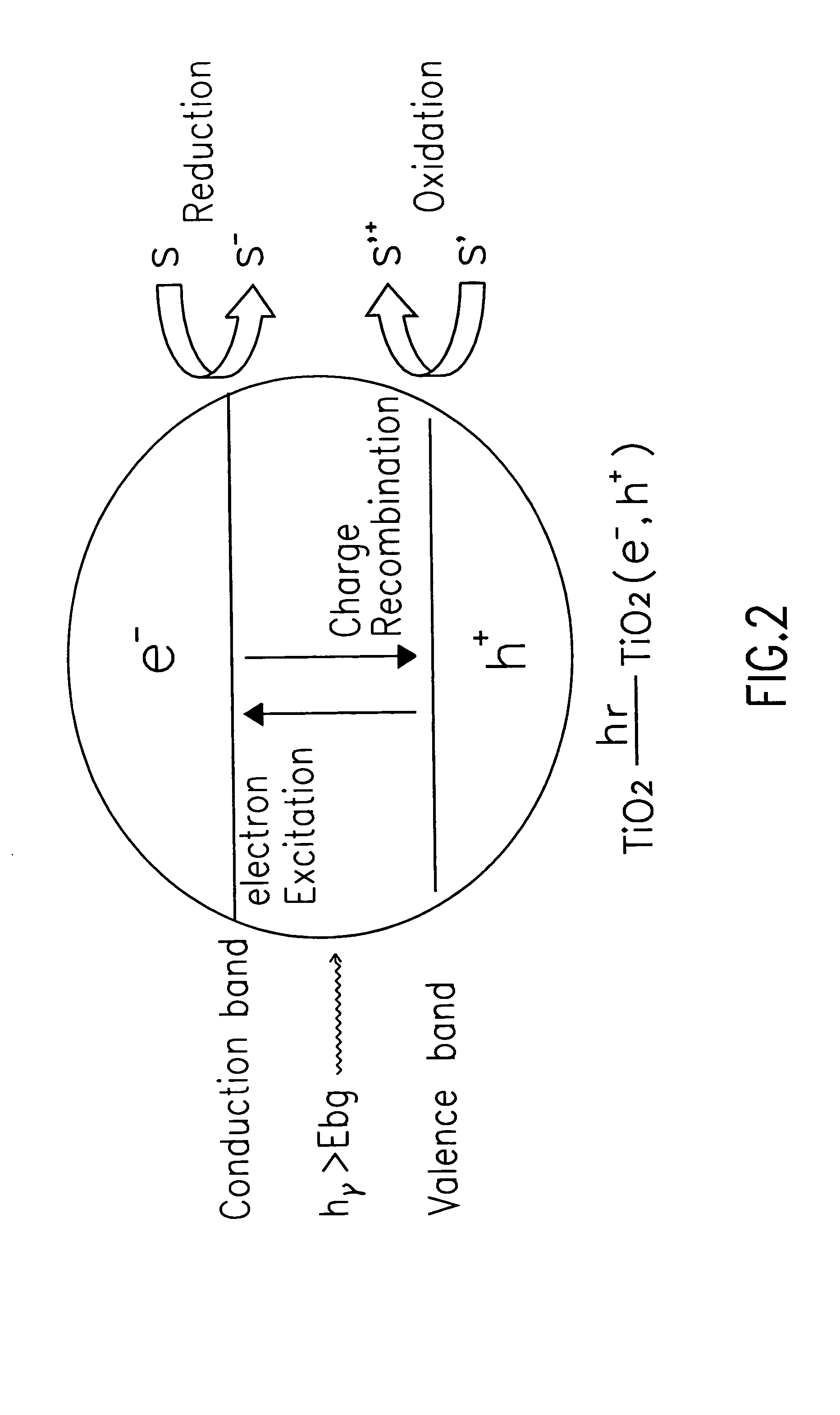

Photo-chemical remediation of Cu-CMP waste

InactiveUS20050072742A1Counteract operational costWater/sewage treatment by irradiationWater treatment compoundsEnvironmental standardWaste stream

A photo-chemical remediation of Cu-CMP waste streams basically includes the following acts: adding photo-catalyst particles into waste streams containing copper ions and organic pollutants and exposing the waste streams to UV light or sunlight to make copper ions become deposited on surfaces of the photo-catalyst particles. Whereby, the copper ions are removed from the waste streams. Meanwhile, organic and inorganic pollutants are decomposed by the photolysis capability of the photo-catalyst to make the waste streams dischargable within environmental standards to the environment.

Owner:PERSEE CHEM +1

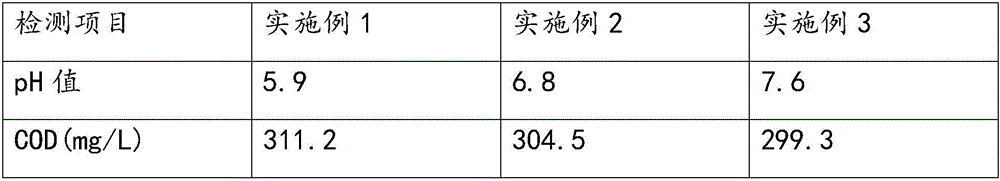

Method for treating waste water from food industry

InactiveCN106348523AEconomic treatmentEasy to handleWater/sewage treatment by irradiationSpecific water treatment objectivesActivated carbon filtrationUltrafiltration

The invention relates to a method for treating waste water from the food industry, which includes the steps of: A. Waste water flows through aplurality of grilles and is flocculated and added with air via blowing, and then is settled; B. First waste water is sterilized with ultraviolet, whose pH is adjusted to 5.5-7.5 with base; C. Waste water flows into an anaerobic aeration tank and an aerobic tank, and next is treated by the oxygen film bioreactor, and then is filtered by an activated carbon filter and by a ultrafiltration membrane filter, finally is settled; D. Waste water is filtered firstly by a cartridge filter, and then by a microfiltration membrane filtration process, filtering by a ultrafiltration membrane filter, and finally by a reverse osmosis membrane filter, to obtain the discharge water in accordance with the environmental standard. Compared with the prior art, the method for treating waste water from the food industry is a simple, convenient and fast method for neutralizing waste water from the food industry, as well as a method for removing suspended solids, metal oxides, colloids, organic matters, nitrogen source materials and bacteria, etc., which not only can be used for economically, efficiently treating a large amount of waste water, with simple operation procedures, low operating costs, and smaller covering area, but also have remarkable treatment effects.

Owner:潘纪鸿

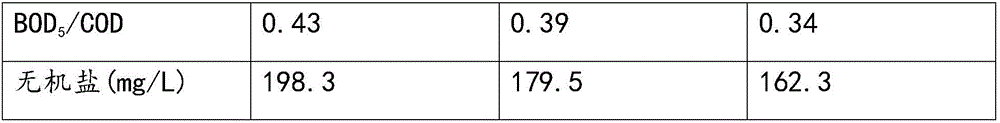

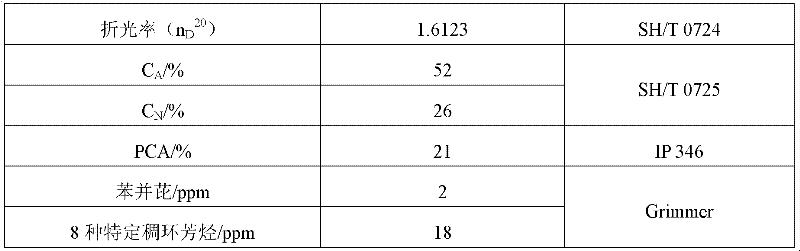

Production method of environmentally-friendly rubber filling oil

InactiveCN102517074AReduce PCA contentReduce the number of extractionsTreatment with hydrotreatment processesSolubilityCyclone

The invention discloses a technology for producing environmentally-friendly rubber filling oil by using RFCC (residue fluid catalytic cracking) slurry. The technology comprises the following specific steps: performing liquid-solid separation on catalyst particles in the slurry by utilizing a rotary liquid separation method, and carrying out hydrogenation reaction on the overflows of a cyclone by virtue of a slurry-bed hydrogenation reactor; after the reaction, introducing the hydrogenation product in a first extraction tower so as to be subjected to two-solvent extraction, wherein the slurry enters the middle of the extraction tower, a solvent I enters from the lower part of the extraction tower, a solvent II enters from the upper part of the extraction tower, the three materials perform counter-current contact in the tower, a primary refining solution is obtained from the top of the tower; directly feeding the primary refining solution into the lower part of a second extraction tower so as to perform counter-current contact with a solvent III coming from the upper part, thus a secondary refining solution is obtained from the top of the tower; and carrying out steam stripping on the secondary refining solution to recycle the solvent, thus obtaining secondary refined oil, namely the environmentally-friendly rubber filling oil. The rubber filling oil produced in the technology meets the environmental standards of the European Union, and has the advantages of good solubility to rubber, high yield and very good market application prospect.

Owner:JIANGSHAN UNITED CHEM GRP CO LTD +1

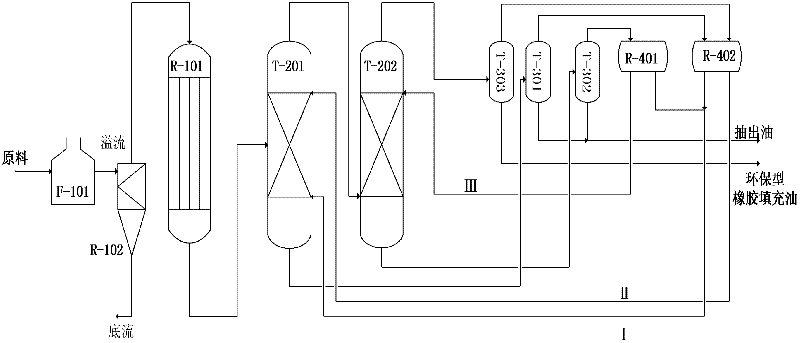

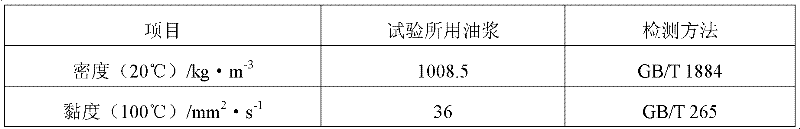

Flocculating agent

InactiveCN101497468AReduce usageWaste water treatment from food industryWater/sewage treatment by flocculation/precipitationSodium sulfateAmmonium aluminium sulfate

The invention relates to a flocculating agent; the usage amount of the flocculating agent is less than that of the marketing products; and the flocculated deposits can be chemical substances for executing refuse treatment; the treated drain satisfies the environmental standard (BOD and COD). The flocculating agent is characterized by comprising 1 to 3 weight % of natural organic acids, 40 to 55 weight % of ammonium aluminum sulfate, 7 to 10 weight % of aluminum sodium sulfate, 8 to 15 weight % of acrylamide polymer with average molecular weight being 9 million to 10 million, 20 to 25 weight % of sodium carbonate (treated pH being set between 6.71 to 7.70); wherein, the natural organic acids are selected from natural organic acids of citric acid, lactic acid and ferrous lactate.

Owner:TECH CORPORATION CO LTD

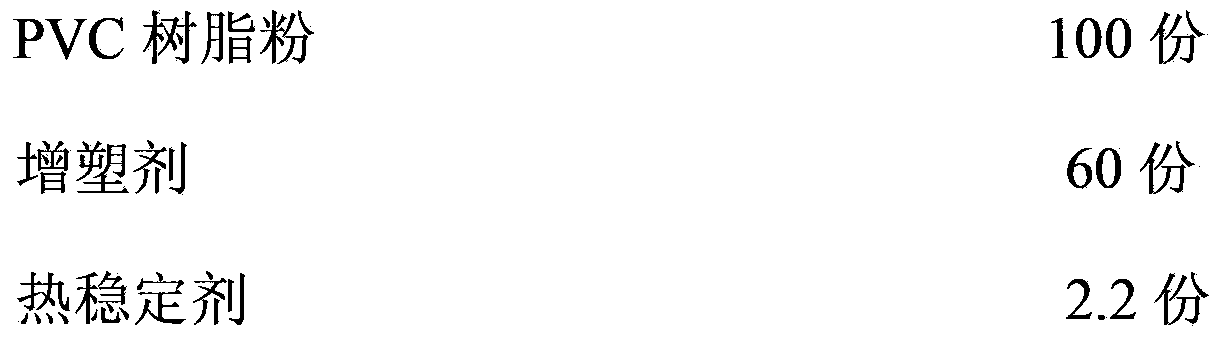

Formula of transparent polyvinyl chloride section bar applied in LED rainbow strip light

The invention discloses a formula of a transparent polyvinyl chloride section bar applied in an LED rainbow strip light. A core line material comprises the components of, by weight: 100 parts of PVC resin powder, 60 parts of a plasticizer, 1.5 parts of a heat stabilizer, 0.4 parts of an external lubricant, and 0.2 parts of an internal lubricant. A coating material comprises the components of, by weight: 100 parts of PVC resin powder, 60 parts of a plasticizer, 2.2 parts of a heat stabilizer, 0.4 parts of an external lubricant, 0.2 parts of an internal lubricant, and 0.25 parts of an ultraviolet light absorber. According to the invention, the two-step formed LED rainbow strip light plastic material does not contain heavy metal or phthalate ester, and satisfies current international environmental standards. The material has excellent weathering resistance. The material is not whitened on contacting water, and is resistant to vulcanization contamination.

Owner:NEW NAVIGATOR PLASTICS

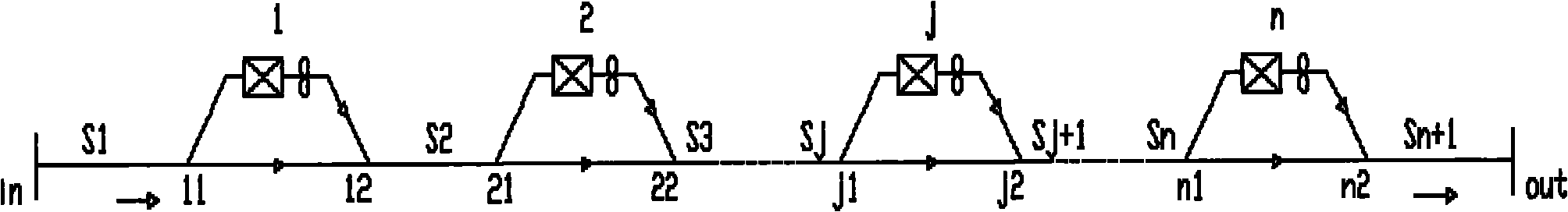

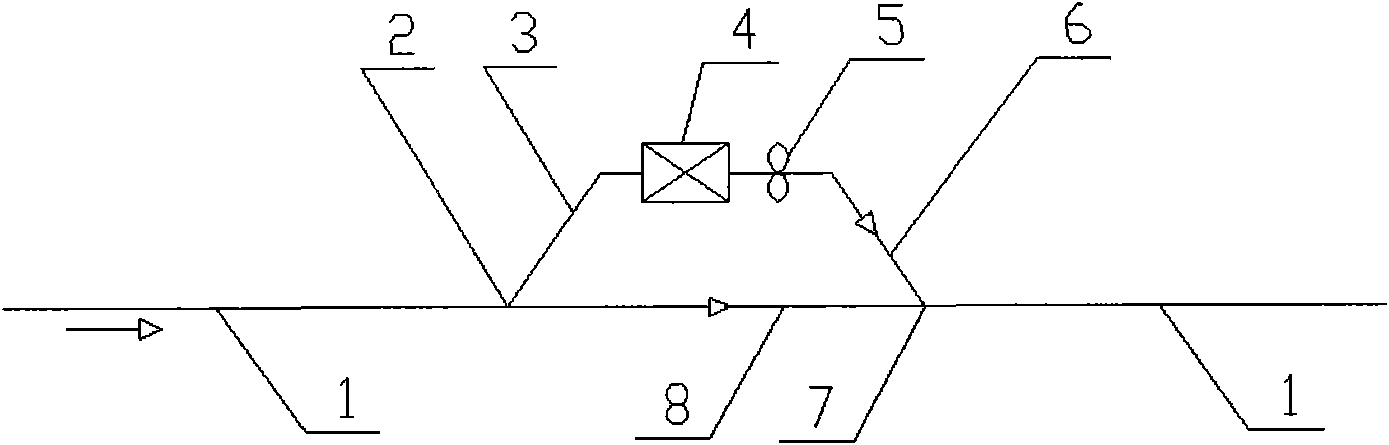

Group count determining and stationing universal method of pollutant purification ventilation system for road tunnel

The invention discloses a group count determining and stationing method of a pollutant purification ventilation system for a road tunnel. In the group count determining and stationing method, a group count N and an interval Sj of the pollutant purification ventilation system set as required are obtained by calculating through a formula so that tunnel air pollutant concentration can meet a control standard of the tunnel air pollutant concentration or air externally exhausted from the tunnel achieves an environmental standard of an air pollutant.

Owner:SHANGHAI URBAN CONSTR DESIGN RES INST GRP CO LTD +1

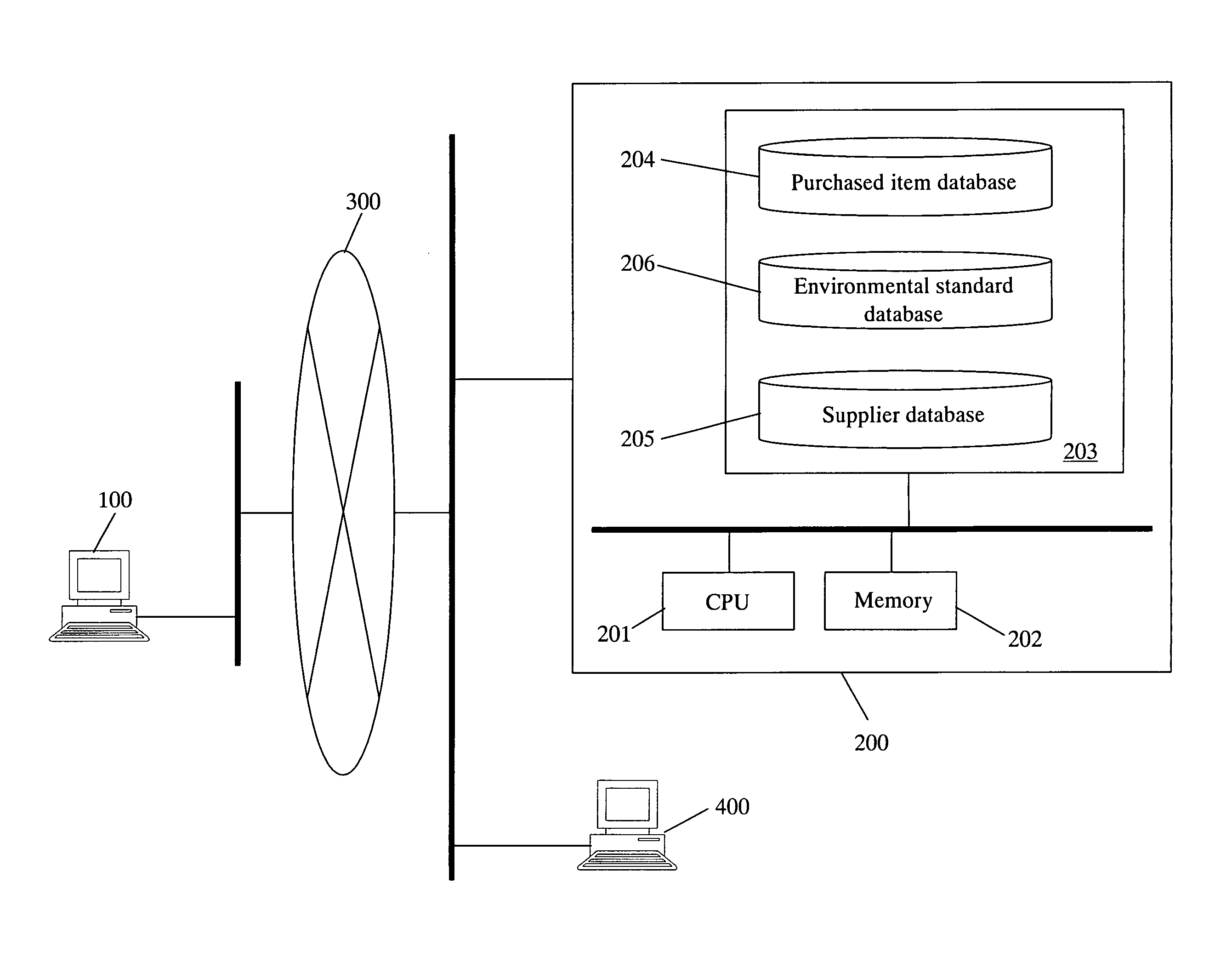

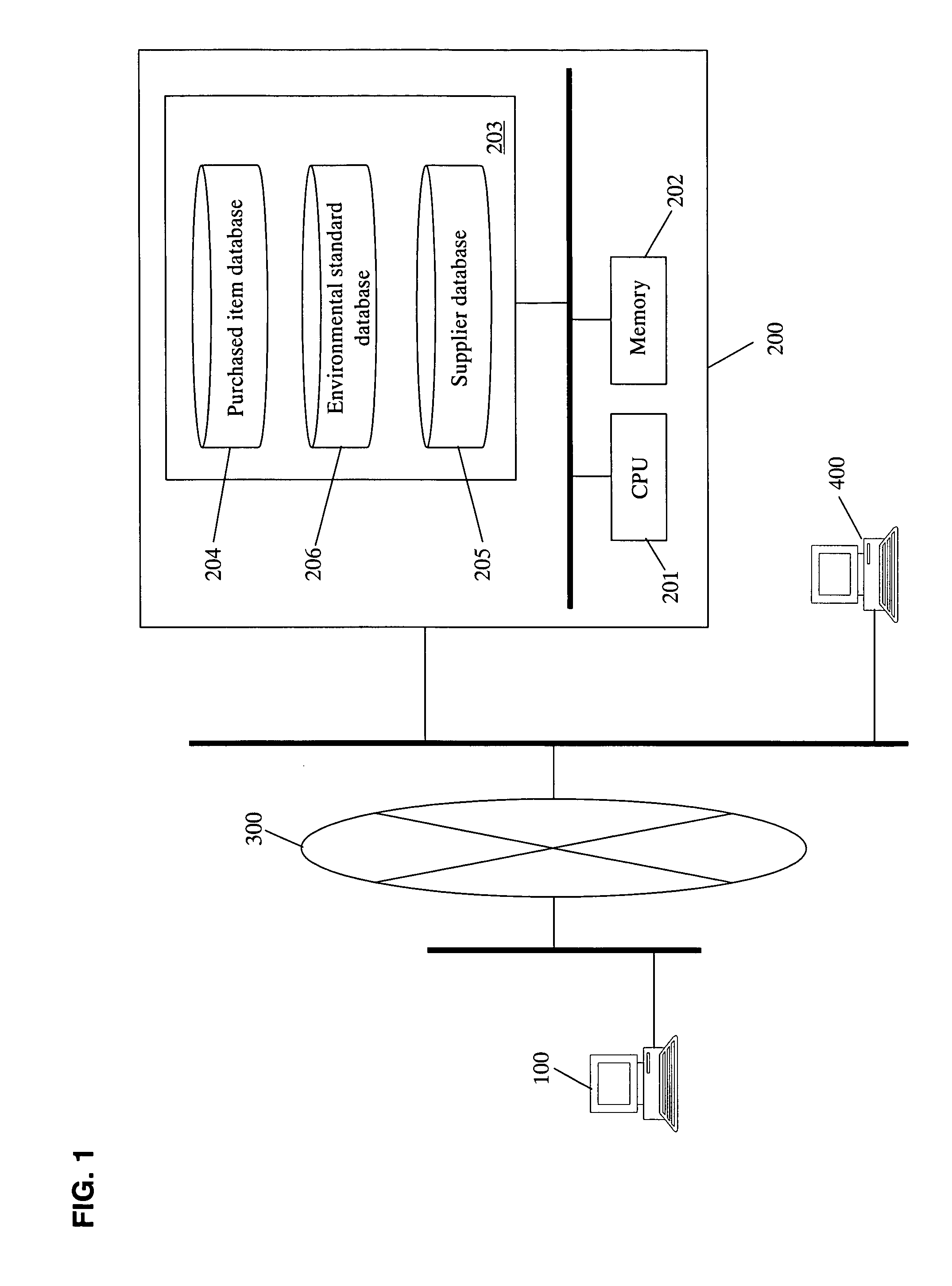

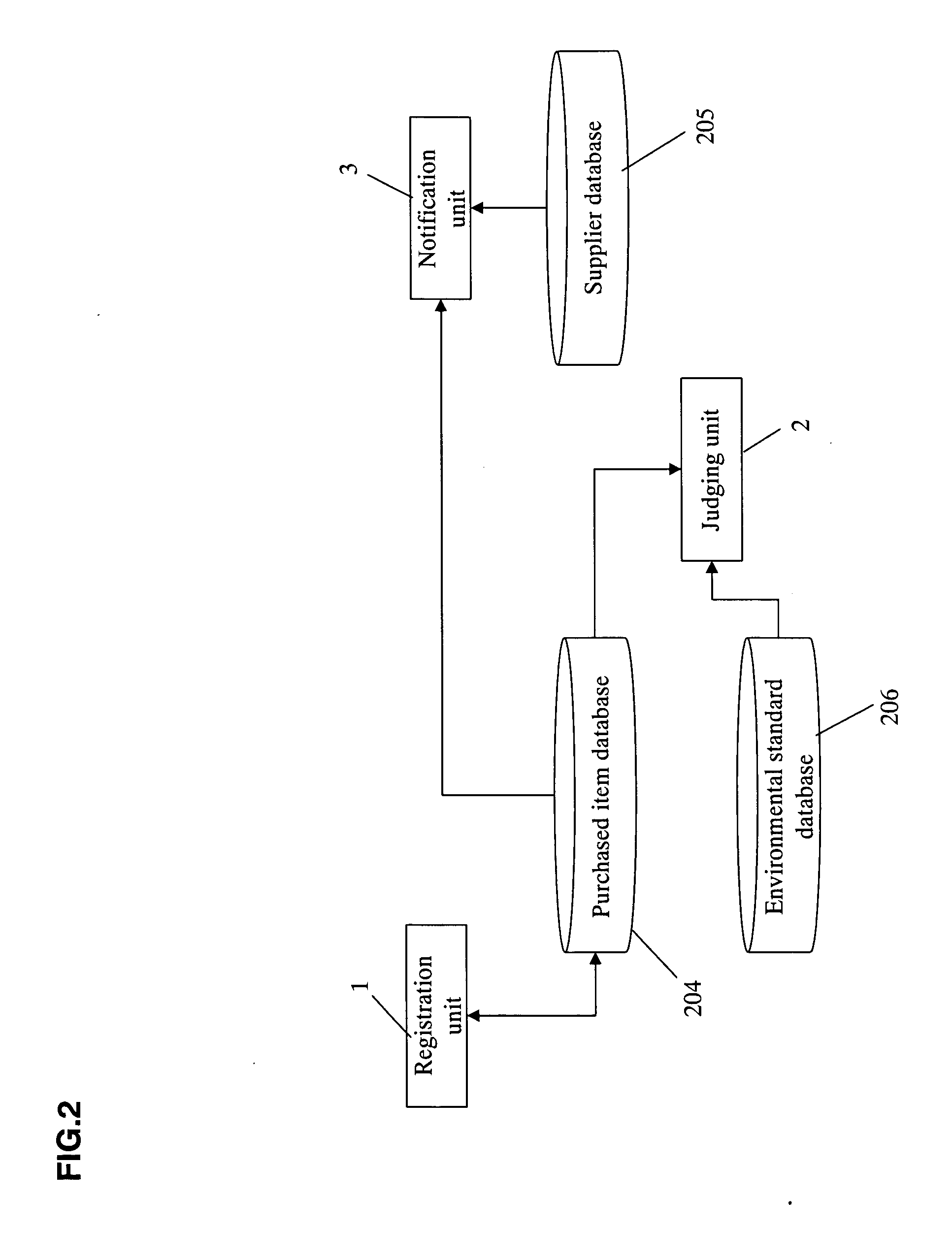

Procurance data management system

InactiveUS20070090179A1Visual presentationSpecial data processing applicationsEnvironmental standardData management

A procurement data management system to judge environmental suitability of portions in design stages and product recycling. In this system, data of purchased items used in products, parts, and materials or chemical substances of purchased items are registered. A purchased item database manages registered data in a hierarchical relationship of purchased items, component parts of each purchased item, component materials of each part, and contained chemical substances of each material. An environmental standard database manages environmental standard data for chemical substances. The system utilizes the hierarchical relationship among purchased items between chemical substances to extract parts unsuitable for environmental standards among the parts in each product.

Owner:PANASONIC CORP

Removal of selenium from refinery wastewater

ActiveUS20110220583A1Reduce the amount requiredWater contaminantsSedimentation separationEnvironmental standardOxidizing agent

The invention provides a method of efficiently removing selenium from water. The method involves: adding an oxidant to the liquid, adjusting the liquid's pH to below 7.5, adding ferric salt in an amount such that less than a quarter of selenium in the liquid precipitates and adding a poly dithiocarbamate material to the liquid in an amount such that the amount of poly dithiocarbamate material (in ppm) is greater than the amount of ferric salt (in ppm). This method removes far more selenium than previous methods, and does it using a smaller amount of expensive chemicals. Moreover this method makes it far more likely to achieve cost effective compliance with the ever-increasing environmental standards for selenium in water.

Owner:NALCO CO

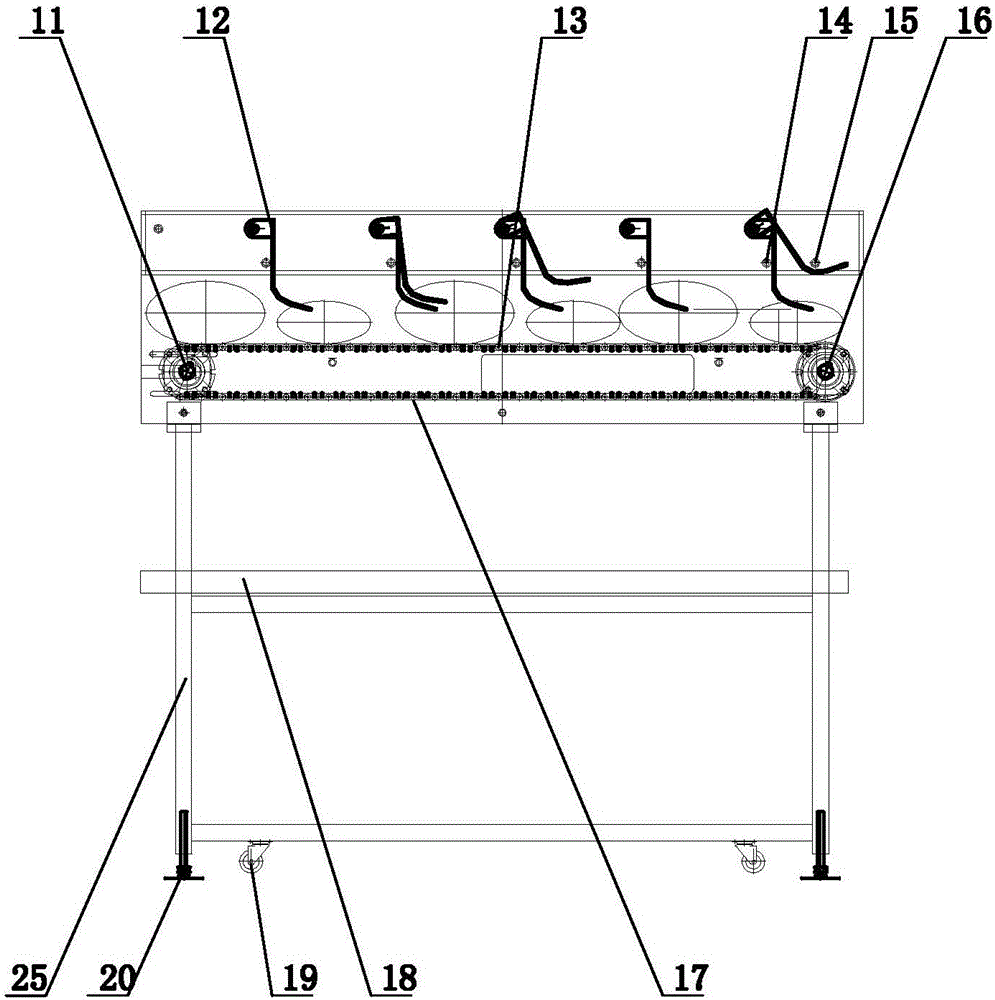

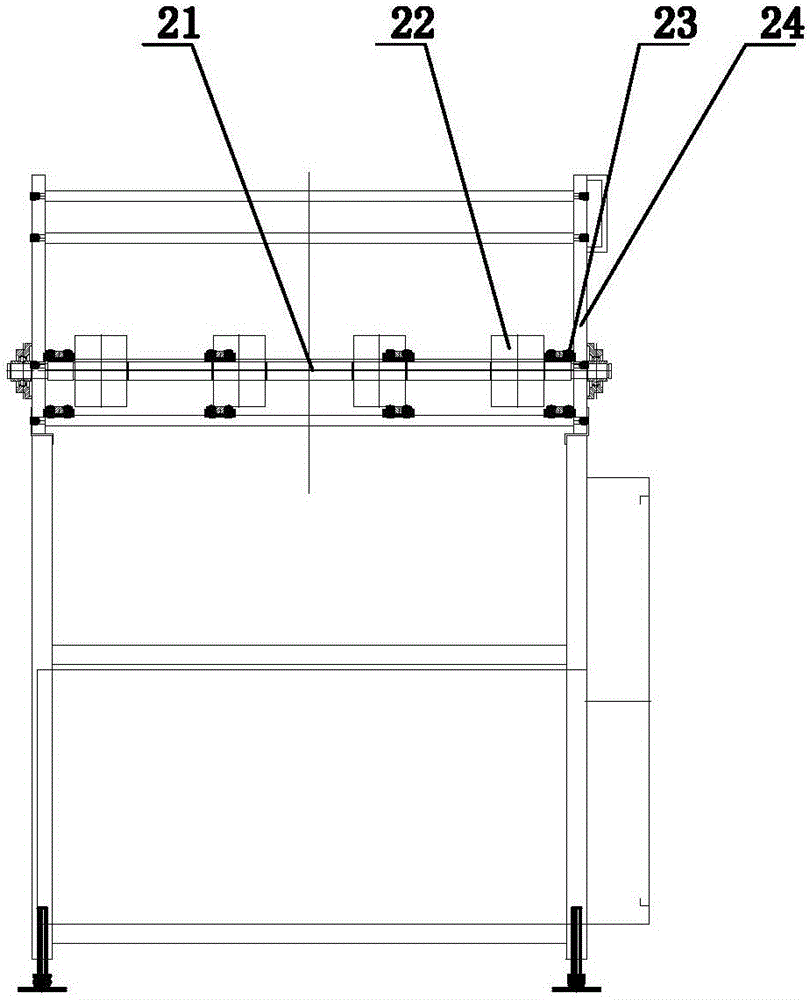

Salmon automatic processing line and automatic processing method

ActiveCN106035601AAvoid manual transport transfer processIncrease productivityFish work-tablesWater treatment systemEnvironmental standard

The invention relates to a salmon automatic processing line and automatic processing method and belongs to the field of fish processing lines; fish processing steps are subdivided, workers at each position only perform one fixing operation, platforms are connected through a conveyer belt, a manual conveying process is avoided, time differences for handling each step are created for the workers at each position, each station is enabled for continuous production so that production efficiency is greatly improved, the workers at each station repeat only the single work so that working speed is effectively increased, each of a gill-binding conveyer belt, a bloodletting apparatus, a dirt suction platform, a flushing platform, a ripping platform and a hemal gland scraping platform is provided with a dirt collection system so that dirt is collected centrally at its place of origin and is finally gathered to a fully-closed sewage treatment system for central treatment, and therefore, operations at each station are green and environmental standards for production are greatly increased.

Owner:新疆额河生态养殖科技有限公司 +1

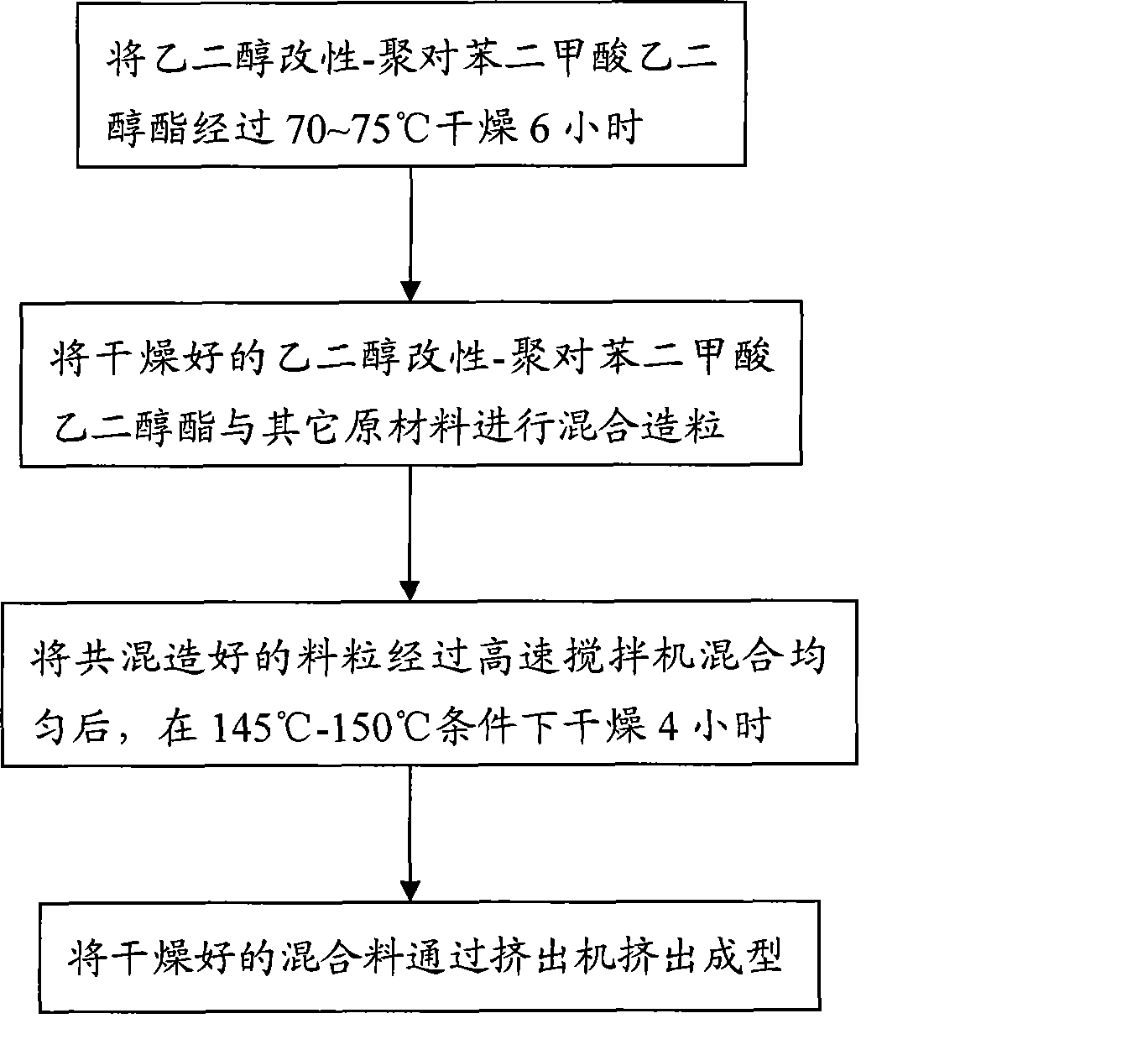

Flame-retardant environment friendly PET thermal shrinkage material and preparation thereof

ActiveCN101475733AImprove fire and flame retardant performanceImprove securityPhosphateEnvironmental standard

The invention relates to a flame retardant and environment-friendly PET heat-shrinkable material and a method for preparing the same. The flame retardant and environment-friendly PET heat-shrinkable material comprises 40 to 60 percent of PETP, 15 to 30 percent of PETG, 5 to 8 percent of poly terephthalic acid succinimide ester, 1 to 2 percent of thermoplastic elastomers, 10 to 20 percent of phosphate flame retardant and 0.01 to 0.05 percent of lubricant. The method comprises the following steps: 1, pre-drying raw materials; 2, blending the materials and pelletizing; 3, blending material and drying; and 4, extruding to mold. The method is simple in technology, the flame retardant and environment-friendly PET heat-shrinkable material has better fireproof flame retardant property than the prior PET heat-shrinkable material, and all the environmental standards are higher than the prior PET heat-shrinkable material.

Owner:CYG CHANGTONG NEW MATERIAL

Method for improving the environmental impact of formulated products

ActiveUS20110246397A1ResourcesSpecial data processing applicationsEnvironment effectChemical composition

Disclosed are methods for developing a product having a relatively benign environmental impact. The methods evaluate the environmental hazard of various chemical components in formulated products and identify improvements in environmental safety based on those evaluations. Environmental criteria are in part developed based on three factors including; persistence, bioaccumulation and toxicity. One method includes obtaining a preliminary formula for a product, wherein the preliminary formula includes a plurality of chemical components, identifying at least one different chemical component that is capable of being substituted for the chemical component in the preliminary formulation and determining an environmental performance score for the chemical component and the different chemical component and determining an environmental performance score of the preliminary formula and a second formula, wherein the second formula utilizes the different chemical component. The formula having the highest environmental performance score is selected as the product. A second method includes tracking the use of chemical components in an existing product portfolio offered or sold by a business unit or a company, in which existing products having the lowest environmental performance scores would be targeted for replacement by reformulated products having higher environmental scores in order to improve the environmental performance of the business unit or company.

Owner:JOHNSON & JOHNSON CONSUMER COPANIES

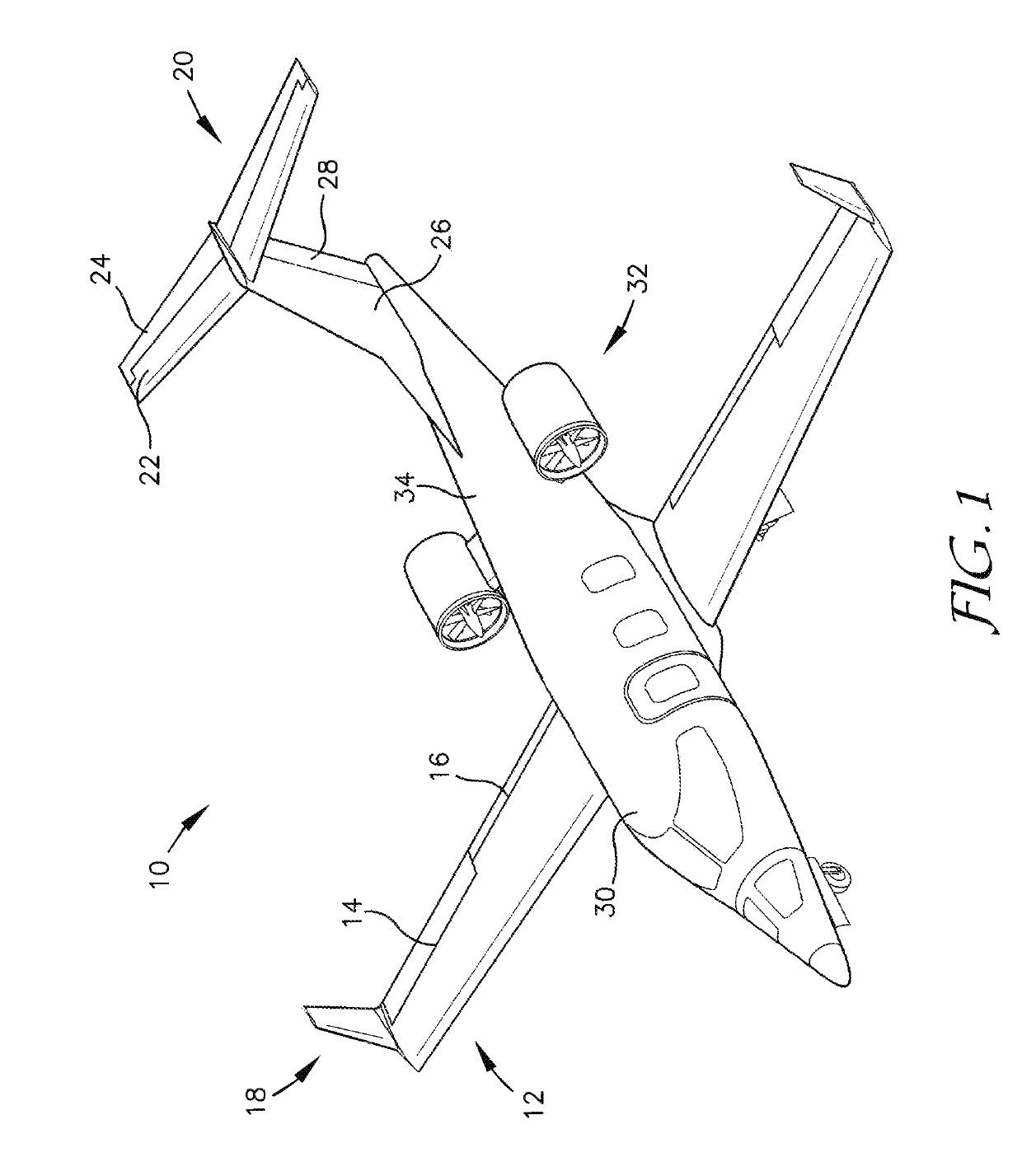

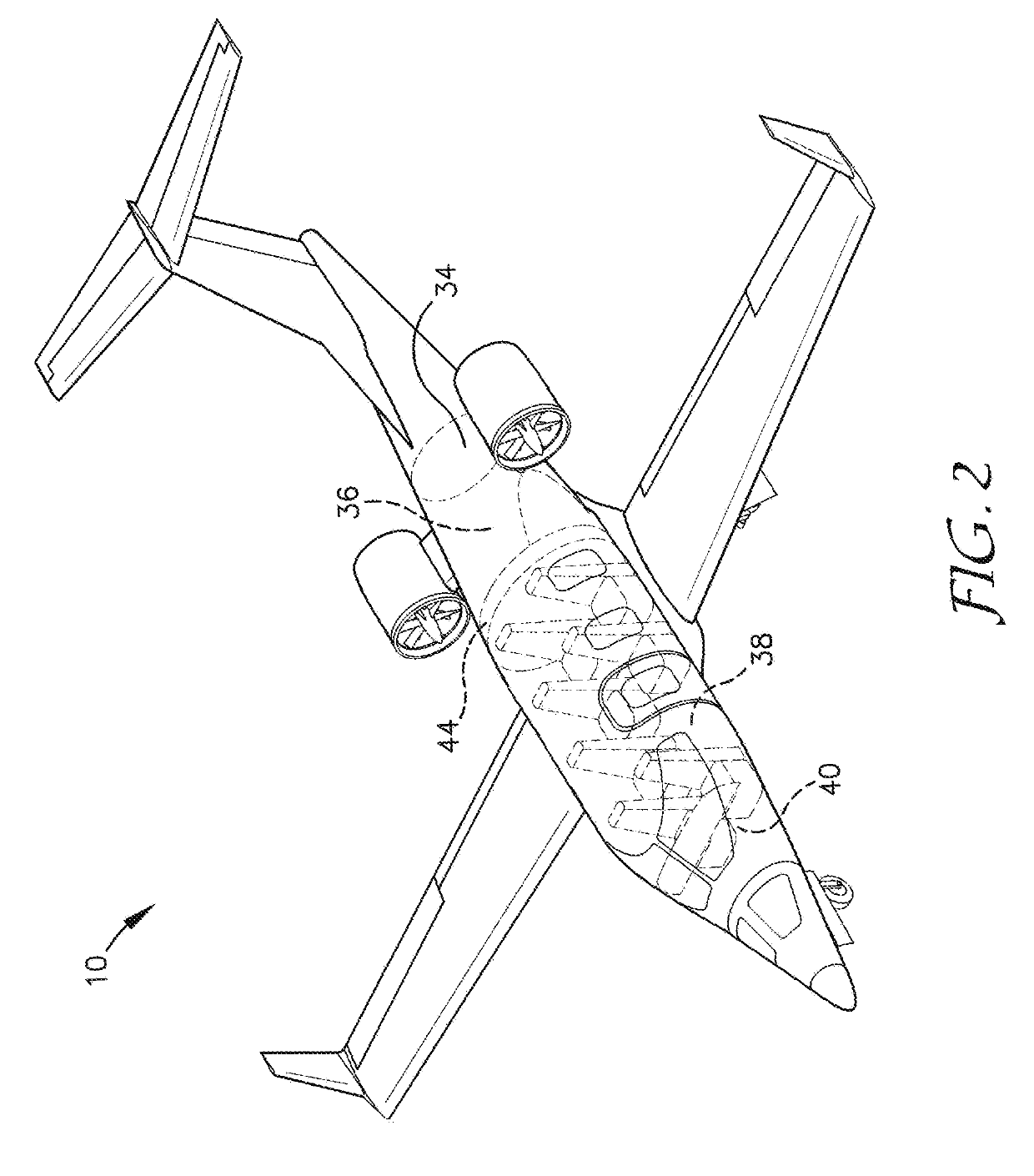

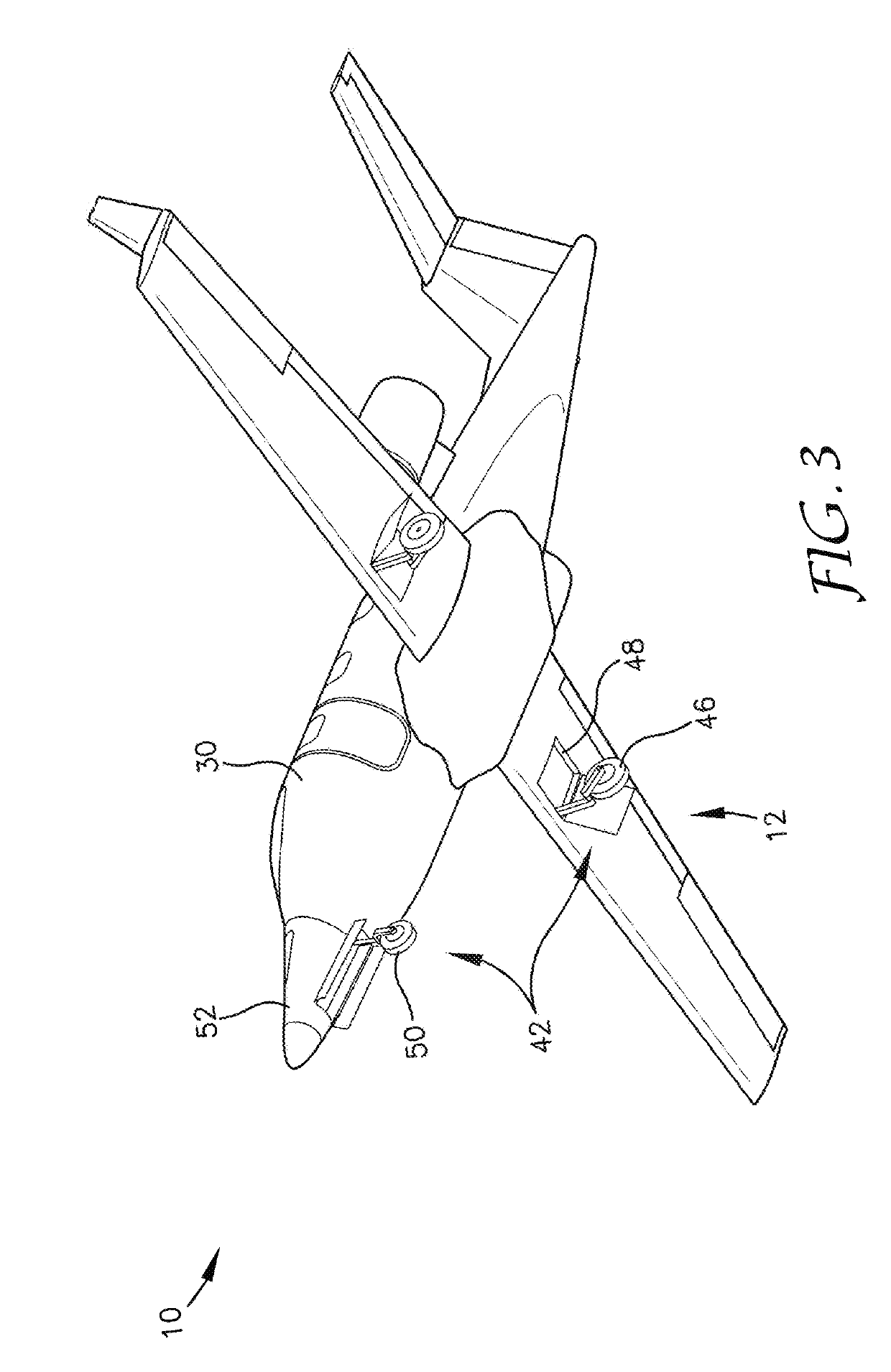

Efficient low-noise aircraft propulsion system

An aircraft propulsion system comprising a reciprocating liquid cooled engine housed within the fuselage driving twin fuselage mounted ducted-fans is disclosed. The propulsion system may be liquid cooled with a liquid cooled exhaust and at least one turbocharger. The ducted-fans may run fan blade tip speeds of up to 97% Mach driven by a near constant RPM engine through a continuously variable transmission. The propulsion system may be low noise and may meet environmental standards typical in the automotive industry.

Owner:U S AERONAUTICS INC

Method of solidifying and detoxifying soil (including soil contaminated with dioxins and/or heavy metals), incinerated ash (including incinerated ash contaminated with dioxins, heavy metals and the like) and coal ash (including coal ash contaminated with heavy metals and the like) and method of detoxifying polluted water containing dioxins and polluted water containing PCB

ActiveUS20090272163A1Easy to useQuality improvementCalcareous fertilisersMagnesium fertilisersPolychlorinated biphenylEnvironmental standard

A method of solidifying and detoxifying a soil, incinerated ash and coal ash to yield a solidified substance detoxified to a level complying with the environmental standards and a method of detoxifying polluted water containing dioxins and polluted water containing PCB are provided. First solidifying and detoxifying agent contains light burnt magnesite as component (1) and chrysolite powder as component (2), in which a ratio by weight of the component (1) and the component (2) is 1:5 to 5:1, preferably 1:3 to 3:1, more preferably 1:2 to 2:1 and is the solidifying and detoxifying agent applied to one kind selected from soil, incinerated ash and coal ash as well as polluted water containing dioxins and polluted water containing PCB. Other solidifying and detoxifying agent further contains as an additional component a fused phosphate fertilizer and titanium dioxide powder as well as anhydrous gypsum powder, light burnt dolomite and / or calcined lime powder.

Owner:OKADA KIKUO +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com