Production method of environmentally-friendly rubber filling oil

A technology for rubber filler oil and production method, which is applied in the treatment of hydrocarbon oil, petroleum industry, hydrotreating process, etc., can solve the problems of complicated process, increased equipment investment, and decreased product yield, etc., and achieves high solvent recovery rate and reduced The number of extractions and the effect of improving product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

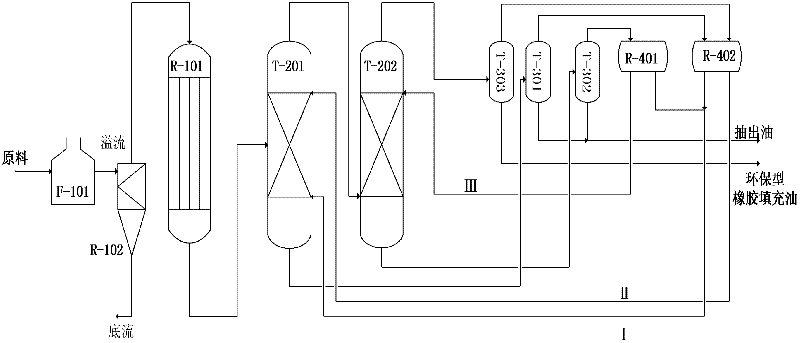

Method used

Image

Examples

Embodiment 1

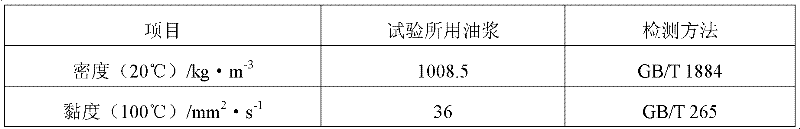

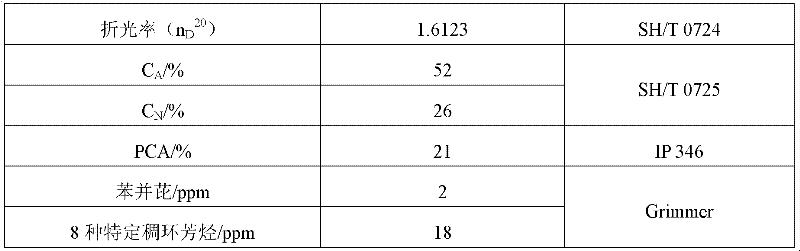

[0031] The raw material used in the experiment is oil slurry from the catalytic unit of a refinery in Dongying. The main properties are shown in Table 1. The experiment was carried out on a pilot plant. After the oil slurry was preheated to 150°C, it entered the cyclone. After hydrocyclone separation, the overflow of the cyclone was introduced into the slurry bed hydrogenation reactor for hydrogenation reaction. The catalyst was Oil-soluble Mo-Ni hydrogenation catalyst, catalyst addition is 200 μ g / g, after 12 hours of circulation reaction, the product after hydrogenation is cooled to room temperature and enters the first extraction column, according to product: furfural: 140 # Solvent oil = 1:1:0.3 ratio for dual-solvent extraction, wherein the temperature at the top of the tower is 90°C, and the temperature at the bottom of the tower is 60°C; the primary refined liquid flowing out of the top of the tower enters the second extraction tower from the bottom for secondary extract...

Embodiment 2

[0037] With the stock oil in embodiment 1, experiment according to the method and the condition in embodiment 1, difference is that N-methylpyrrolidone (NMP) is the main solvent of the first extraction tower, oil: NMP: 140 #Solvent oil=1:2:0.3, the temperature at the top of the tower is 100°C, and the temperature at the bottom of the tower is 60°C. Other conditions and operations remain unchanged, and the properties of the obtained secondary refined oil are shown in Table 3.

Embodiment 3

[0039] With the stock oil in embodiment 1, experiment according to the method and condition of embodiment 1, difference is that heptane is the second solvent of the first extraction tower, oil: furfural: heptane=1: 1: 0.2, The temperature at the top of the tower is 90°C, and the temperature at the bottom of the tower is 65°C. Other conditions and operations remain unchanged, and the properties of the obtained secondary refined oil are shown in Table 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com