Method for comprehensively extracting polyunsaturated fatty acid and polysaccharide from seaweed

A technology for comprehensive extraction of unsaturated fatty acids, which is applied in the field of comprehensive extraction of polyunsaturated fatty acids and polysaccharides, can solve problems such as environmental pollution, waste of seaweed and organic solvents, and achieve cost reduction, resource utilization efficiency, reduced usage and The effect of waste generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

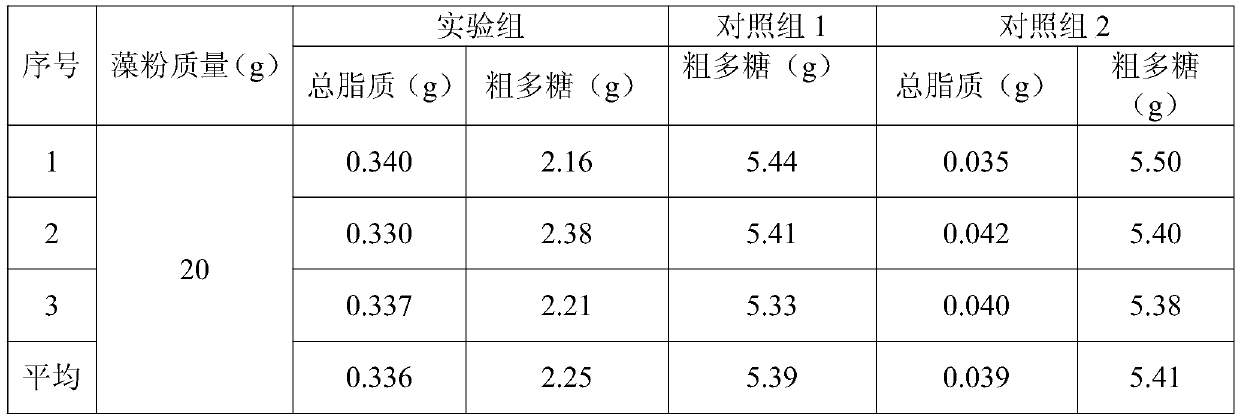

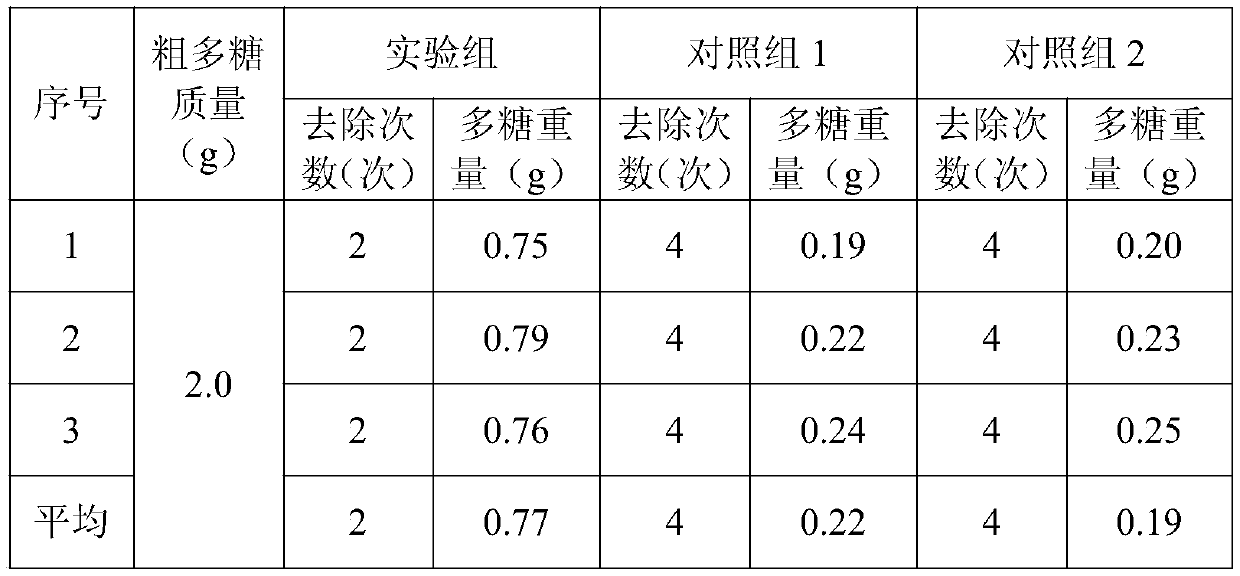

Embodiment 1

[0038] The method for comprehensively extracting polyunsaturated fatty acids and polysaccharides from seaweeds of the present invention comprises the following steps:

[0039] Polyunsaturated fatty acid extraction:

[0040] A. Soak Sargasso algae in tap water equivalent to 20 times its weight for 5 minutes, then wash once with tap water and deionized water, and then bake at 80°C for 10 hours; after drying, crush it into 10-mesh Sargassum powder, Disperse Sargassum powder in petroleum ether according to the ratio of material to liquid at 1:5, and perform ultrasonic crushing. The ultrasonic power is 60W, the crushing time is 5min, and the temperature is maintained at 80°C during crushing;

[0041] B. The suspension after ultrasonic crushing is subjected to solid-liquid separation, and petroleum ether is added to the separated liquid as an extraction solvent, so that the solid-liquid ratio of seaweed powder and extraction solvent is 1:5, and the extraction solvent and solid resid...

Embodiment 2

[0050] The method for comprehensively extracting polyunsaturated fatty acids and polysaccharides from seaweeds of the present invention comprises the following steps:

[0051] Polyunsaturated fatty acid extraction:

[0052] A. Soak Sargassum in tap water equivalent to 30 times its weight for 10 minutes, then wash twice with tap water and deionized water, and then bake at 78°C for 12 hours; after drying, crush it into 20-mesh Sargassum powder, Disperse Sargassum powder in petroleum ether according to the ratio of material to liquid of 1:8, and perform ultrasonic crushing. The ultrasonic power is 65W, the crushing time is 10min, and the temperature is kept at 79°C during crushing;

[0053] B. The suspension after ultrasonic crushing is subjected to solid-liquid separation, and petroleum ether is added to the separated liquid as an extraction solvent, so that the solid-liquid ratio of seaweed powder and extraction solvent is 1:8, and the extraction solvent and solid residue Put ...

Embodiment 3

[0062] The method for comprehensively extracting polyunsaturated fatty acids and polysaccharides from seaweeds of the present invention comprises the following steps:

[0063] Polyunsaturated fatty acid extraction:

[0064] A. Soak Sargasso algae in tap water equivalent to 40 times its weight for 15 minutes, then wash with tap water and deionized water three times each, and then bake at 76°C for 14 hours; after drying, crush it into 30-mesh Sargassum powder, Disperse Sargassum powder in petroleum ether according to the material-to-liquid ratio of 1:10, and perform ultrasonic crushing. The ultrasonic power is 70W, the crushing time is 15 minutes, and the temperature is kept at 78°C during crushing;

[0065] B. The suspension after ultrasonic crushing is subjected to solid-liquid separation, and petroleum ether is added to the separated liquid as an extraction solvent, so that the solid-liquid ratio of seaweed powder and extraction solvent is 1:10, and the extraction solvent and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com