Patents

Literature

6136 results about "Petroleum ether" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Petroleum ether is the petroleum fraction consisting of aliphatic hydrocarbons and boiling in the range 35‒60 °C; commonly used as a laboratory solvent. Despite the name, petroleum ether is not classified as an ether; the term is used only figuratively, signifying extreme lightness and volatility.

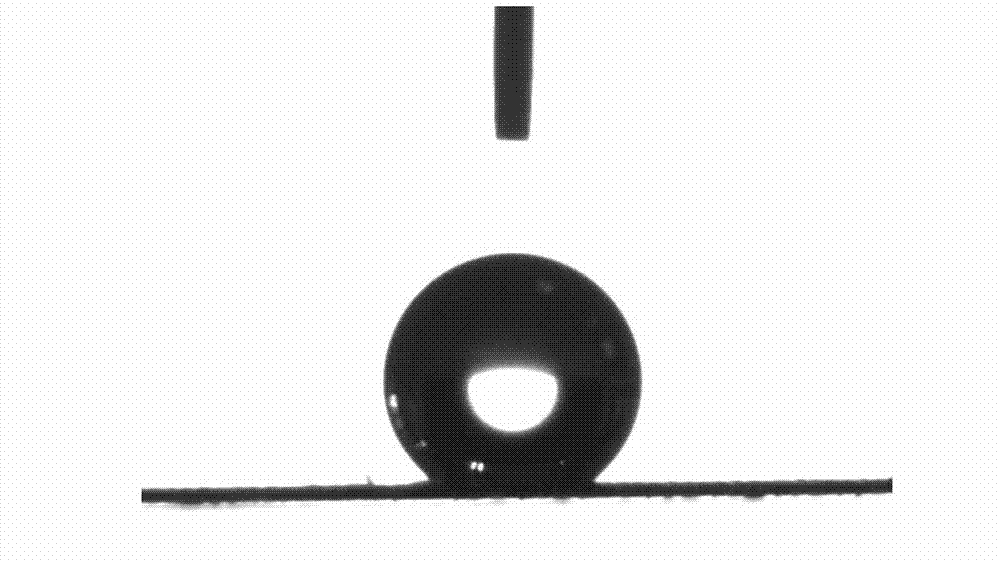

Super-hydrophobic and super-oleophylic oil-water separating mesh membrane and preparation method thereof

The invention discloses a super-hydrophobic and super-oleophylic oil-water separating mesh membrane and a preparation method thereof. The method comprises the following steps of: (1), cleaning a fabric mesh and drying the cleaned fabric mesh; (2), dissolving dopamine hydrochloride and trihytdroxy methyl-aminomethane to water to acquire a mixed solution, wherein the pH value of the mixed solution is 8.0-12.0; (3), soaking the dried fabric mesh in the mixed solution, and then getting out the soaked fabric mesh for drying; (4), dissolving mercaptan compound and sodium hydroxide in water to acquire mixed turbid liquid; (5), soaking the fabric mesh acquired in the step (3) in the mixed turbid liquid, reacting the mixture to acquire the oil-water separating mesh membrane. The oil-water separating mesh membrane disclosed by the invention has high bearing pressure to water so that oil can quickly pass, a separating effect is good, the speed is high, and the separating effect on normal hexane, petroleum ether, benzene, gasoline, diesel oil, animal and vegetable oil, crude oil and the like is good. The oil-water separating mesh membrane is non-toxic and harmless, environment-friendly, easy to clean and keep, can be reusable, and has good stability.

Owner:TSINGHUA UNIV

Method for purifying sesamin and sesamolin

InactiveCN101602768AHigh purityEasy to operateOrganic chemistryMetabolism disorderFiltrationSesamolin

The invention relates to a method for purifying sesamin and sesamolin in sesame oil, which comprises the steps of: separating lignanoid compounds without fat constituents from the sesame oil first; adding ether into the lignanoid compounds to precipitate the sesamin; performing the filtration; dissolving an obtained filtrate by chloroform after concentration under reduced pressure, adding petroleum ether into the mixture until white opacity appears; heating and dissolving the obtained solution; and standing the obtained solution to precipitate the sesamolin. The method for purifying the sesamin and the sesamolin has the advantages of simple operation, safety, economization, strong process stability and the like, and is particularly suitable for industrialized application; and the method can synchronously obtain high-purity sesamin and sesamolin, and achieve the aim of comprehensive utilization.

Owner:河南省农科院农副产品加工研究所

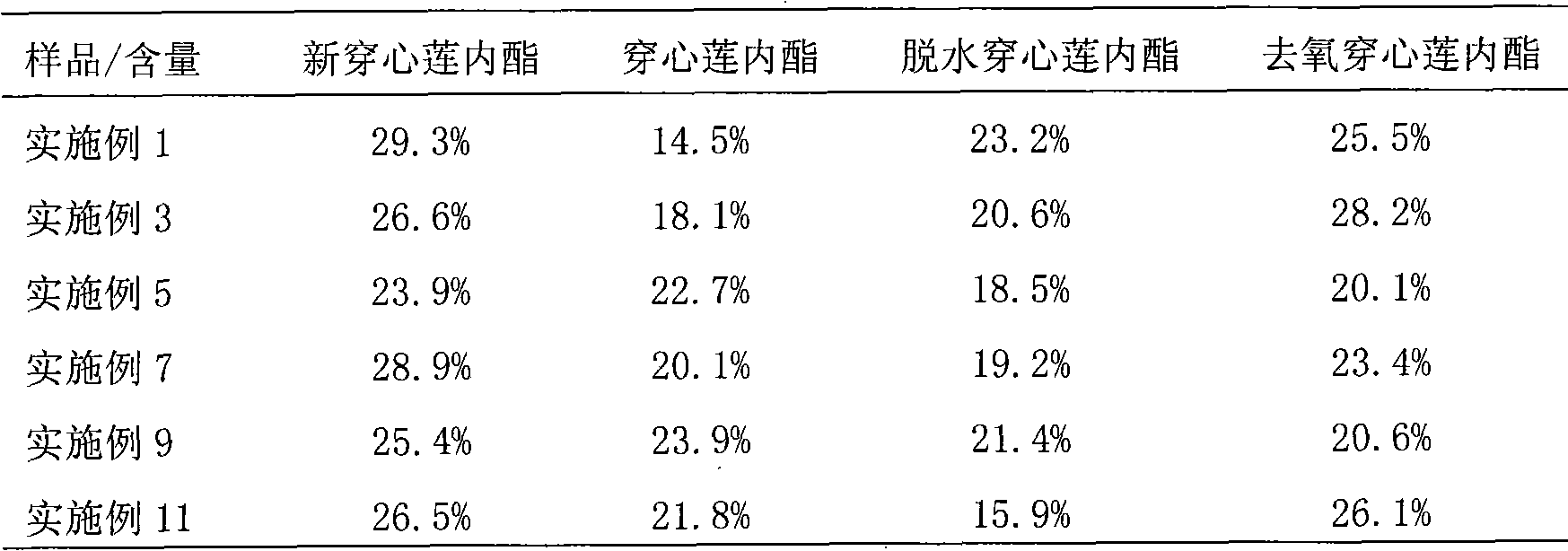

Fuel additive composition and method for treatment of middle distillate fuels and gasoline

InactiveUS6923838B2Increase and improvement of performanceIncrease and improvement of and lubricityLiquid carbonaceous fuelsFuel additivesVegetable oilAntioxidant

A fuel additive for middle distillate fuels is a mixture of at least one methyl, ethyl, propyl or butyl ester of a vegetable oil or a C16-C18 fatty acid, at least one alkyl ether of propylene glycol, a surfactant, and an antioxidant. A fuel additive for gasoline is a mixture of ligroin or toluene / xylene, at least one alkyl ether of propylene glycol, a surfactant, and tertiary amyl methyl ether.

Owner:ADVANCED COMBUSTION TECH

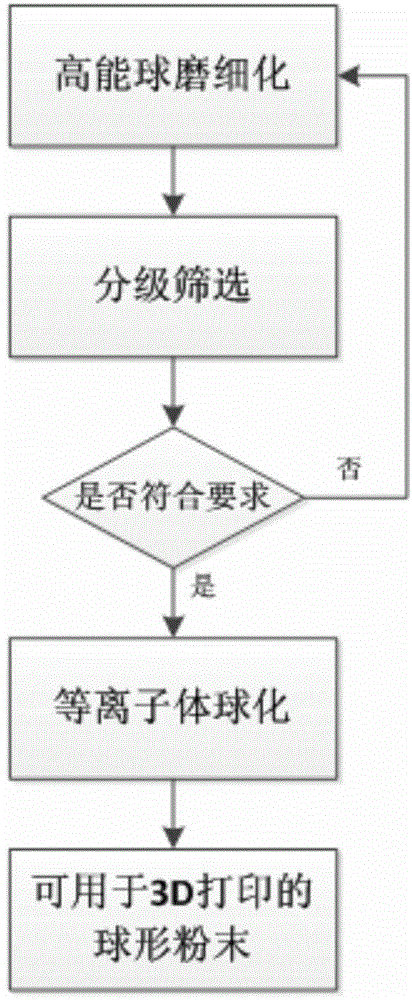

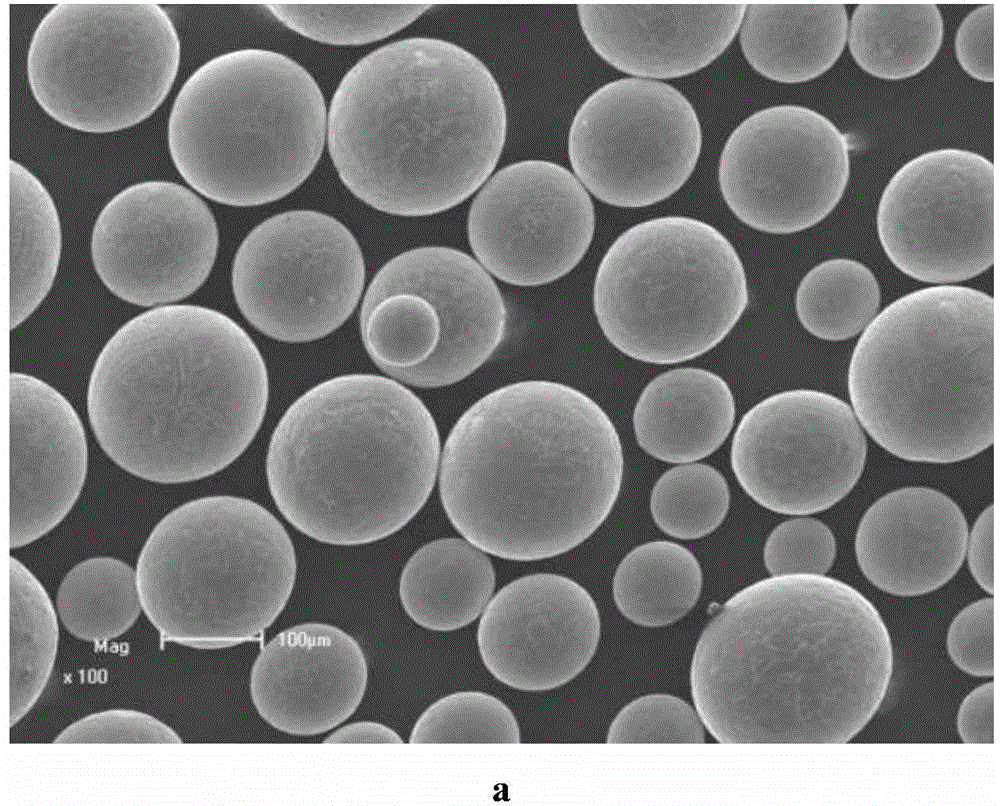

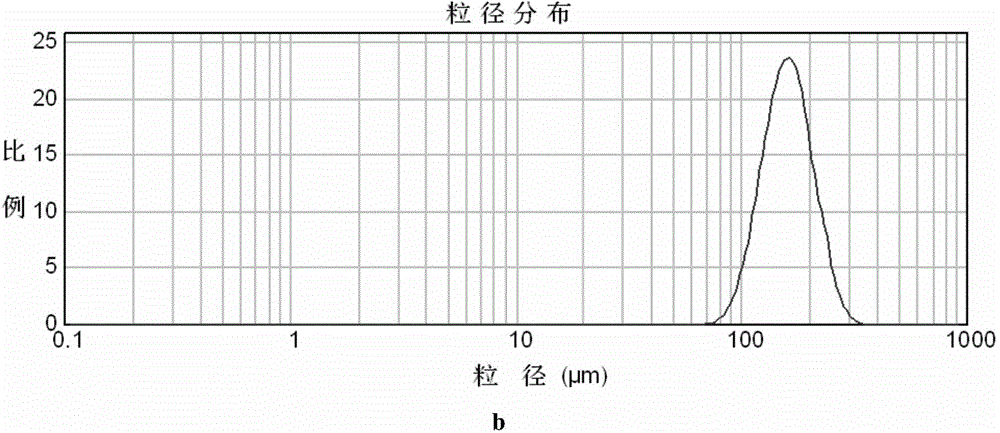

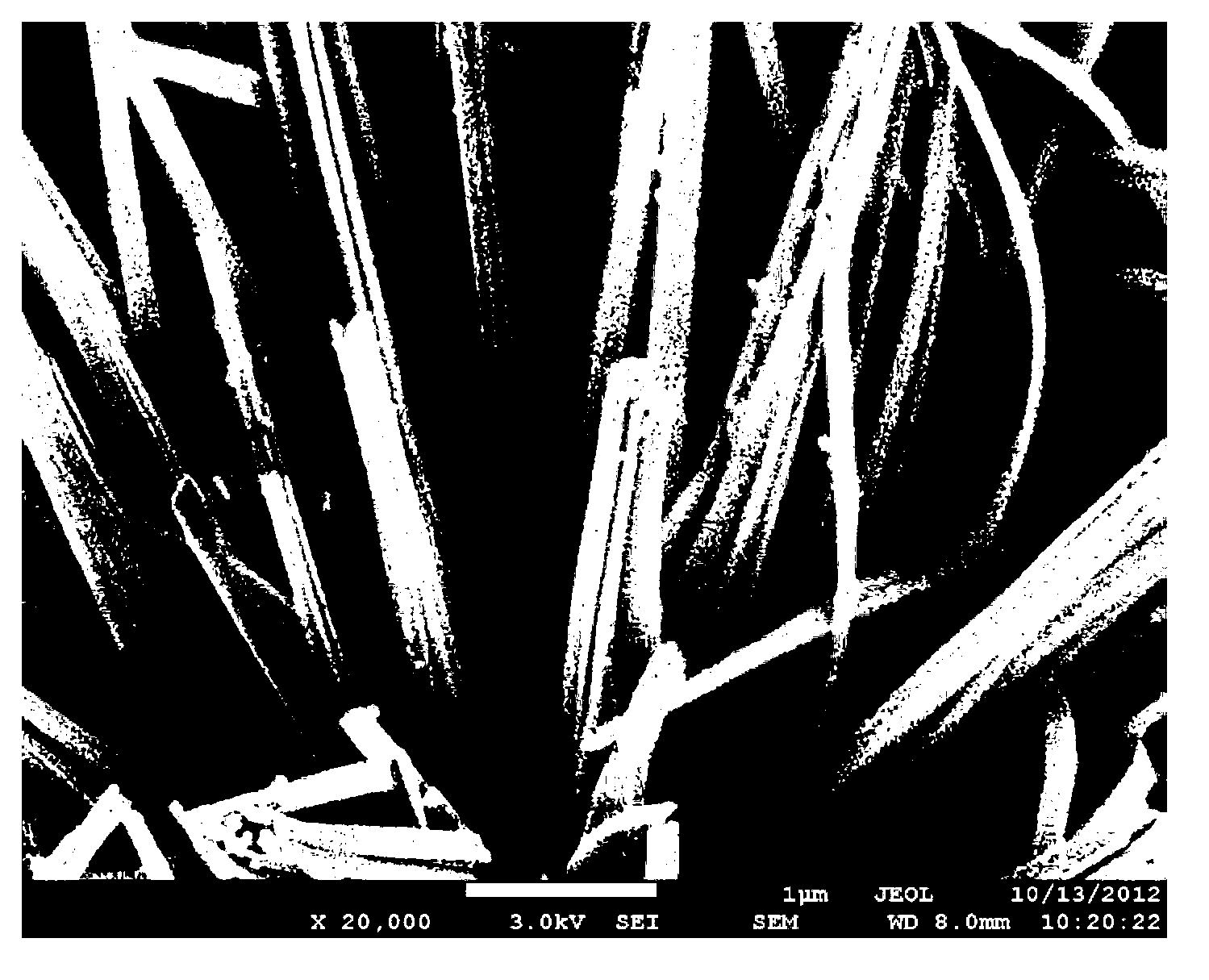

Method for preparing spherical powder material used for three-dimensional printing

The invention discloses a method for preparing a spherical powder material used for three-dimensional printing. The method includes the steps of raw material selecting, high-energy ball milling and radio-frequency plasma spherizing. Selected raw materials are metal or alloy powder in the step of raw material selecting; the step of high-energy ball milling is carried out under the argon shielding condition, petroleum ether serves as the ball milling medium, and the metal or alloy powder is aluminum alloy powder, or titanium alloy powder, or nickel-base alloy powder, or stainless steel powder or tungsten alloy powder; according to the step of radio-frequency plasma spherizing, the total gas flow is 100 L / min-200 L / min, the input power of plasma is 50 kW-100 kW, the negative pressure of a gas outlet of a system is minus 1000 Pa-minus 2000 Pa, and the powder conveying amount is 50 g / min-150 g / min. The manufactured spherical powder is high in sphericity degree, even in granularity, low in oxygen content and good in liquidity, has few defects and is suitable for three-dimensional printing. The method for preparing the spherical powder material used for three-dimensional printing has the advantage that the process is accurate and controllable.

Owner:CHONGQING INST OF GREEN & INTELLIGENT TECH CHINESE ACADEMY OF SCI

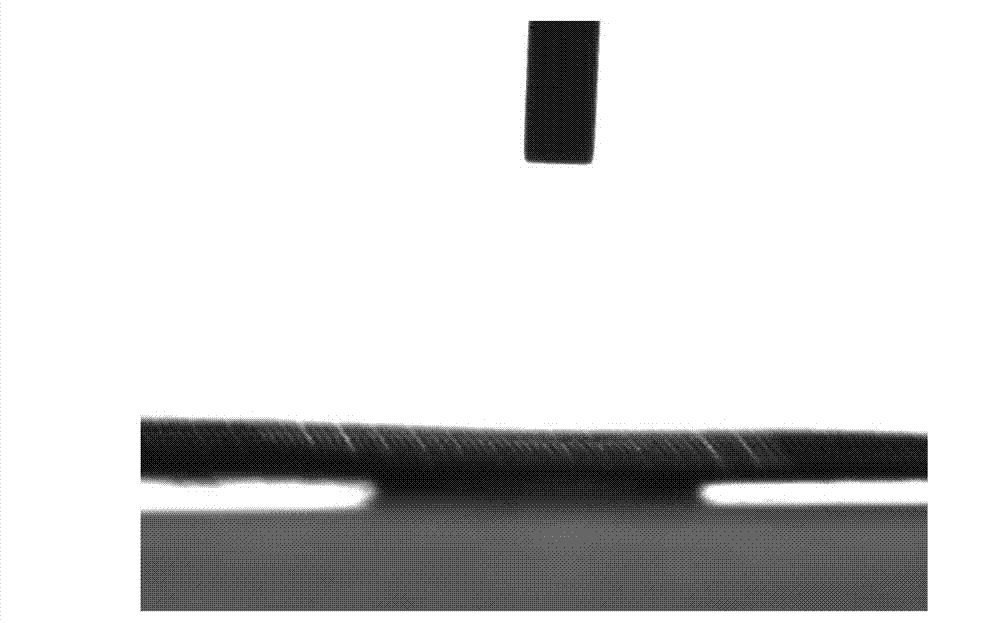

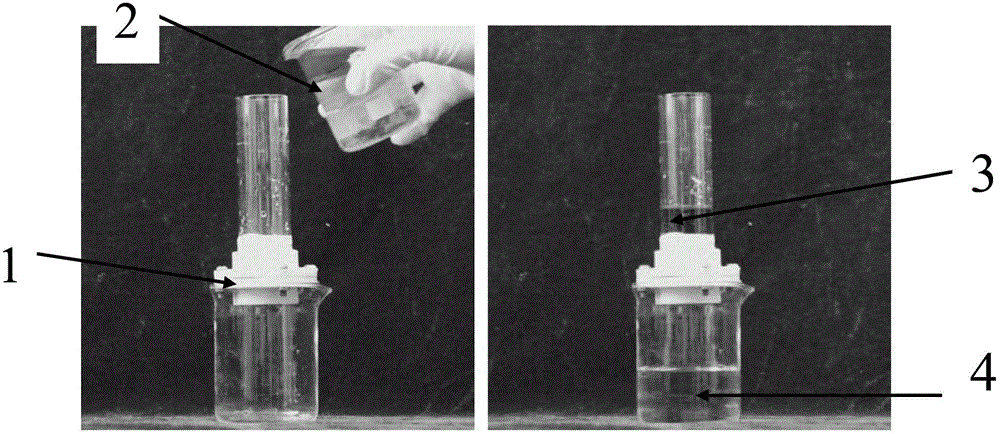

Super-hydrophilic and underwater super-oleophobic oil-water separation mesh membrane having, and its preparation method

The invention discloses a super-hydrophilic and underwater super-oleophobic oil-water separation mesh membrane, and its preparation method. The method comprises the following steps: 1, cleaning a copper mesh, and airing; 2, dissolving an alkaline medium and an oxidant in water, and uniformly stirring to obtain a mixed solution; and 3, dipping the aired copper mesh in the mixed solution, and carrying out an oxidation reaction to obtain the oil-water separation mesh membrane. The oil-water separation mesh membrane has the advantages of easily available raw material, low cost, simple equipment and making technology, realization of large-scale preparation, large water flux, fast water-water separation speed, good oil-water separation effect, suitableness for the treatment of sewage containing a large amount of water, very good separation effect on n-hexane, petroleum ether, dichloroethane, benzene, gasoline, diesel oil, kerosene, machine oil, crude oil, animal and plant oil, and the like, easy cleaning, repeatable use, and good stability.

Owner:TSINGHUA UNIV

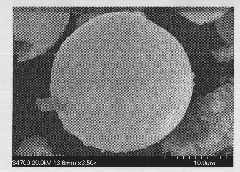

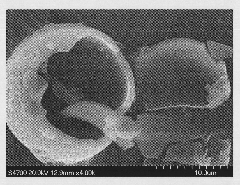

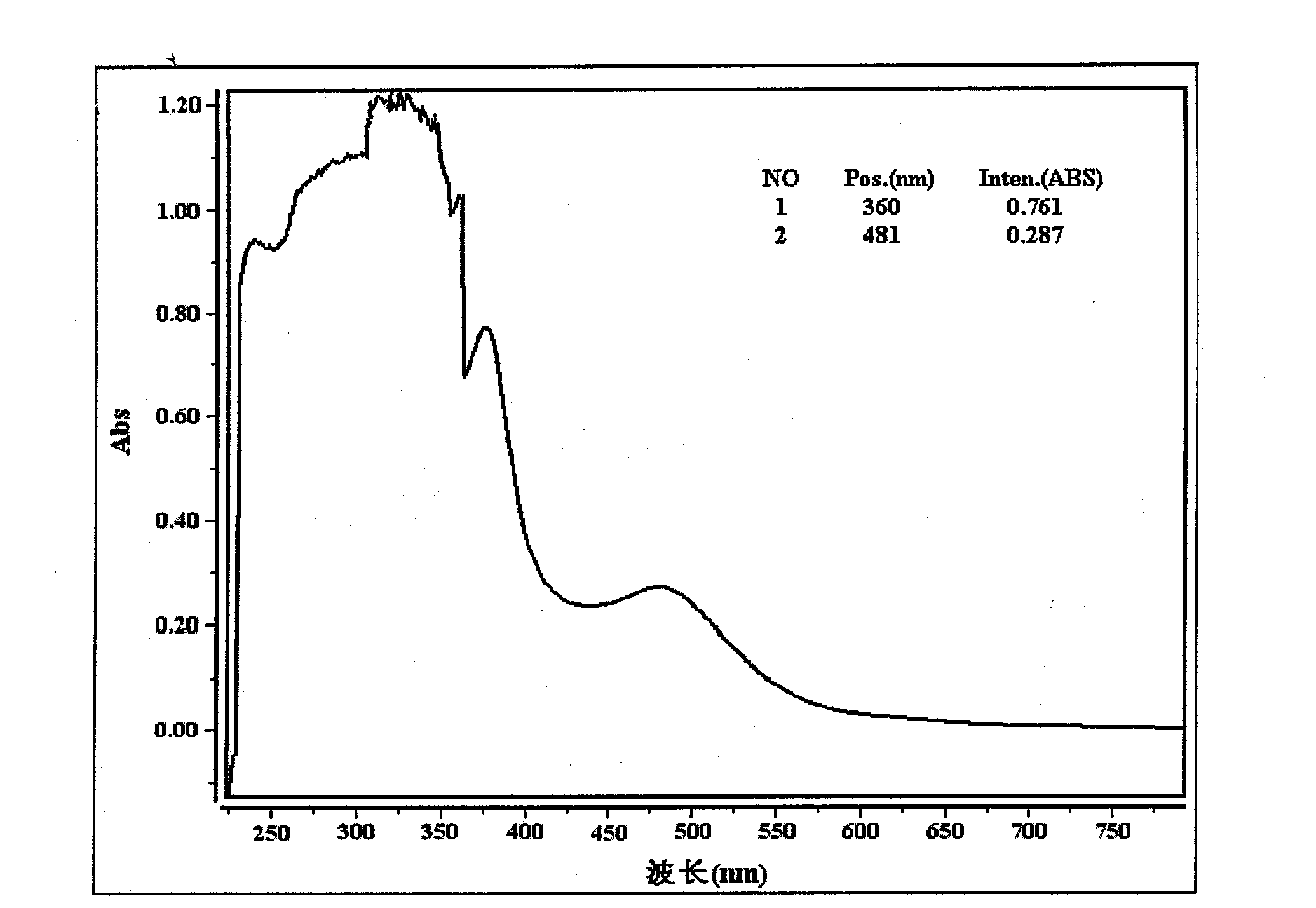

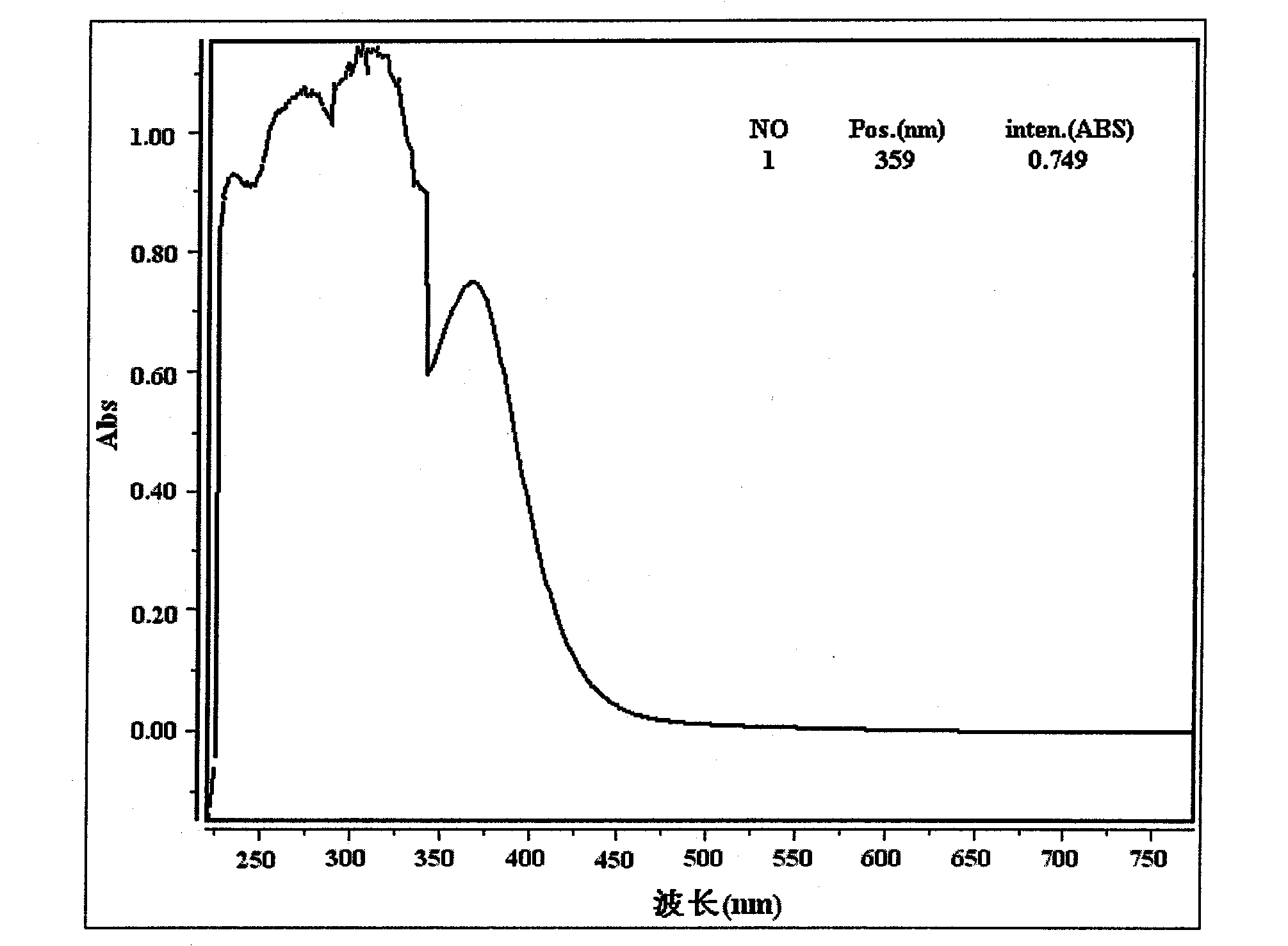

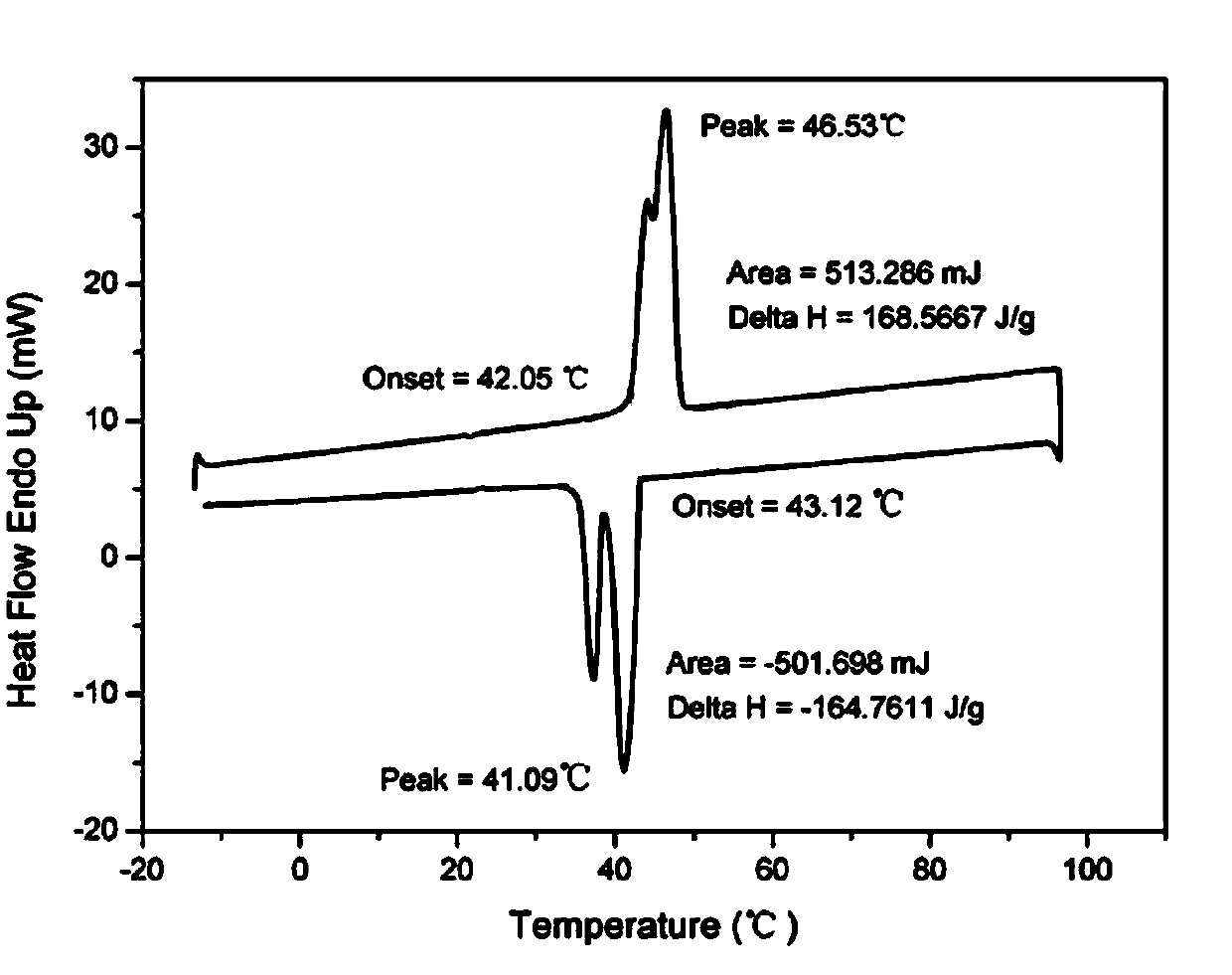

Composite phase-change energy storage material for microcapsule and preparation method thereof

InactiveCN101824307ANo leaksPlay the role of self-control temperature controlHeat-exchange elementsMicroballoon preparationCrack resistanceSolvent

The invention discloses a composite phase-change energy storage material for microcapsules and a preparation method thereof. The coating of the microcapsule is made of silicon dioxide, and the core of the microcapsule is made of a phase-change energy storage material, wherein the phase-change energy storage material is a paraffin organic solid-liquid phase-change energy storage material. 0.2 to 0.5 wt.% of dispersed emulsifier, 52.5 to 62.5 wt.% of solvent water, 18.75 to 31.5 wt.% of phase-change energy storage material and 15.5 to 18.75 wt.% of inorganic silica source are matched and put into a reactor for stirring for 5 to 8 hours; the mixture is uniformly dispersed and emulsified at the temperature 3 to 8 DEG C higher than that for solid-liquid phase change; hydrochloric acid aqueous solution catalyst with the pH value of 0.93 to 4.07 or sodium hydroxide aqueous solution catalyst with the pH value of 8.0 to 12.0 is added into the emulsion; the reacting solution is naturally cooled to room temperature and precipitation solution is obtained; the precipitate is washed with the combination of water and petroleum ether, wherein the mass percent of the petroleum ether is 30 wt.%; then the precipitate is washed with deionized water and is filtered, and the product is naturally aired. The invention improves the technology of phase-change energy storage and conservation, and has the function of automatic temperature regulation, favorable physical and chemical stability, crack resistance, flame retardancy, wear resistance and high thermal conductivity.

Owner:BEIJING UNIV OF CHEM TECH

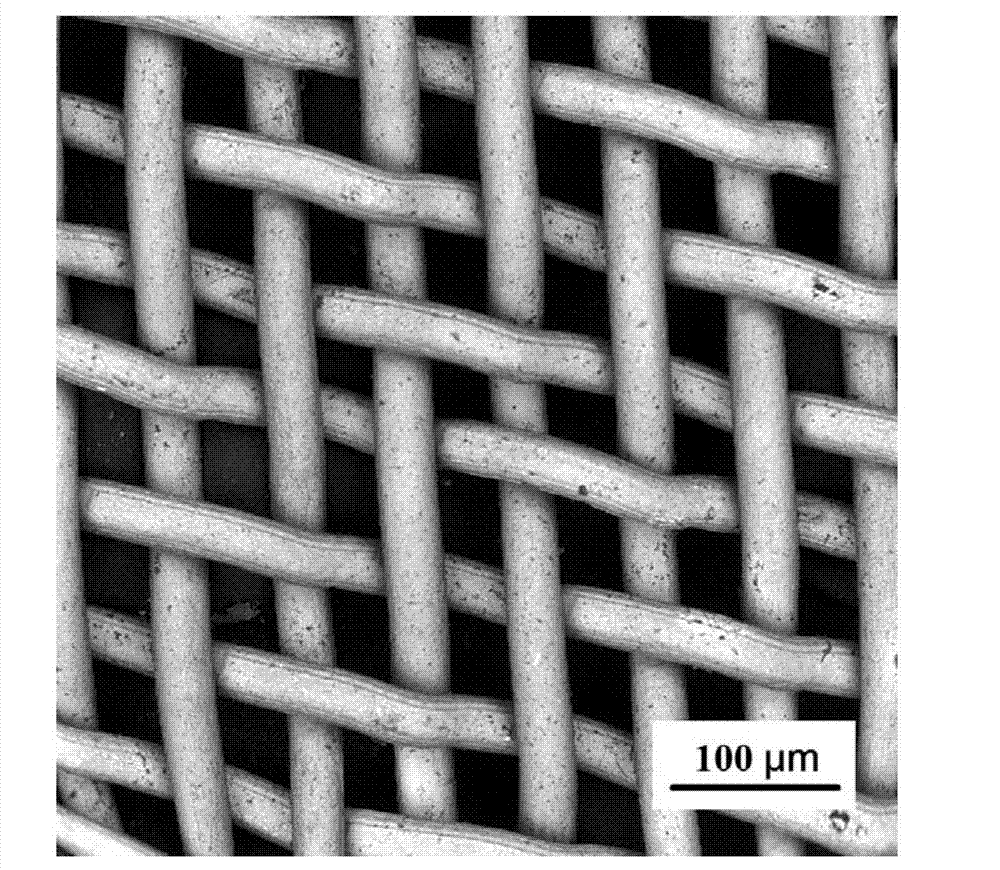

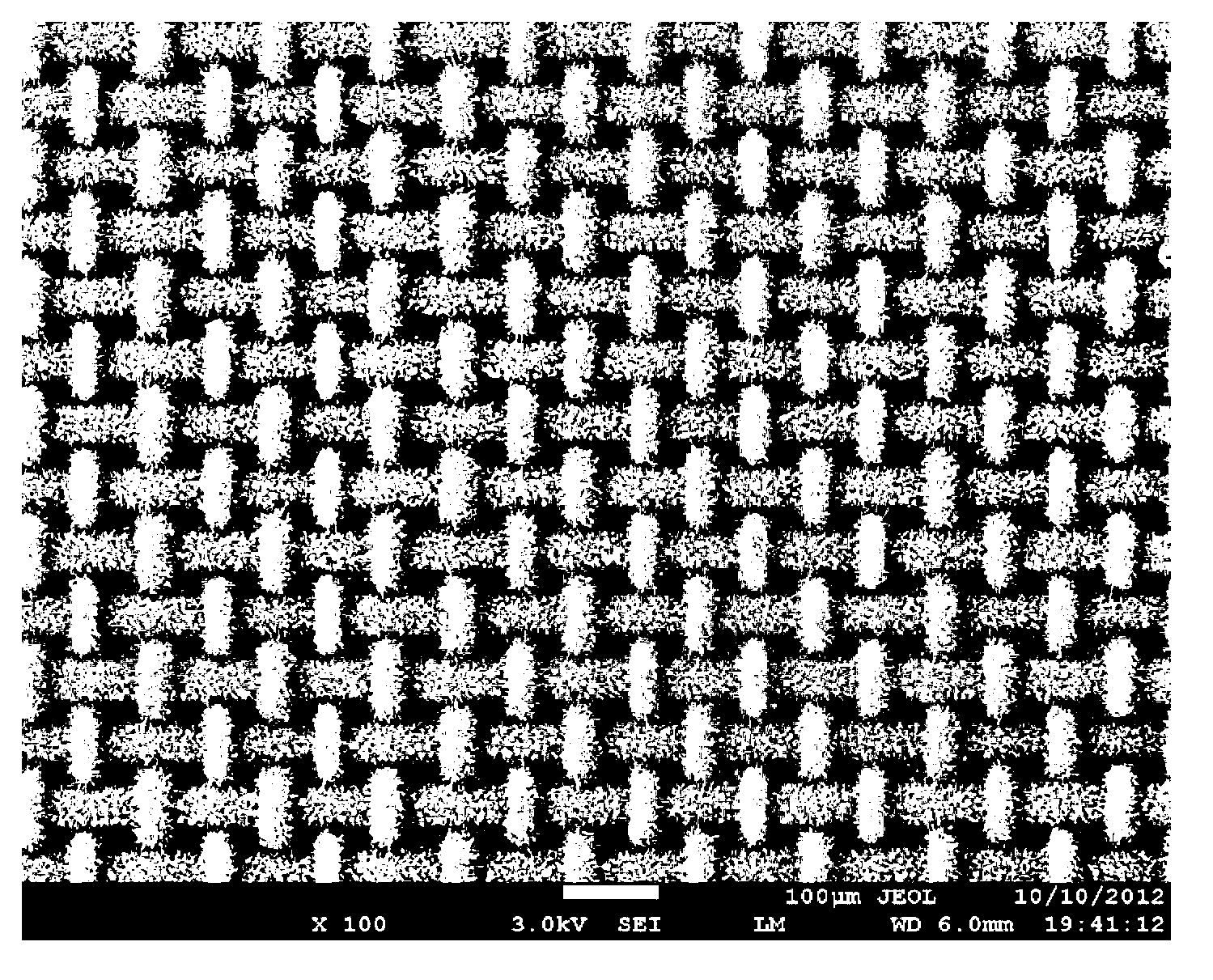

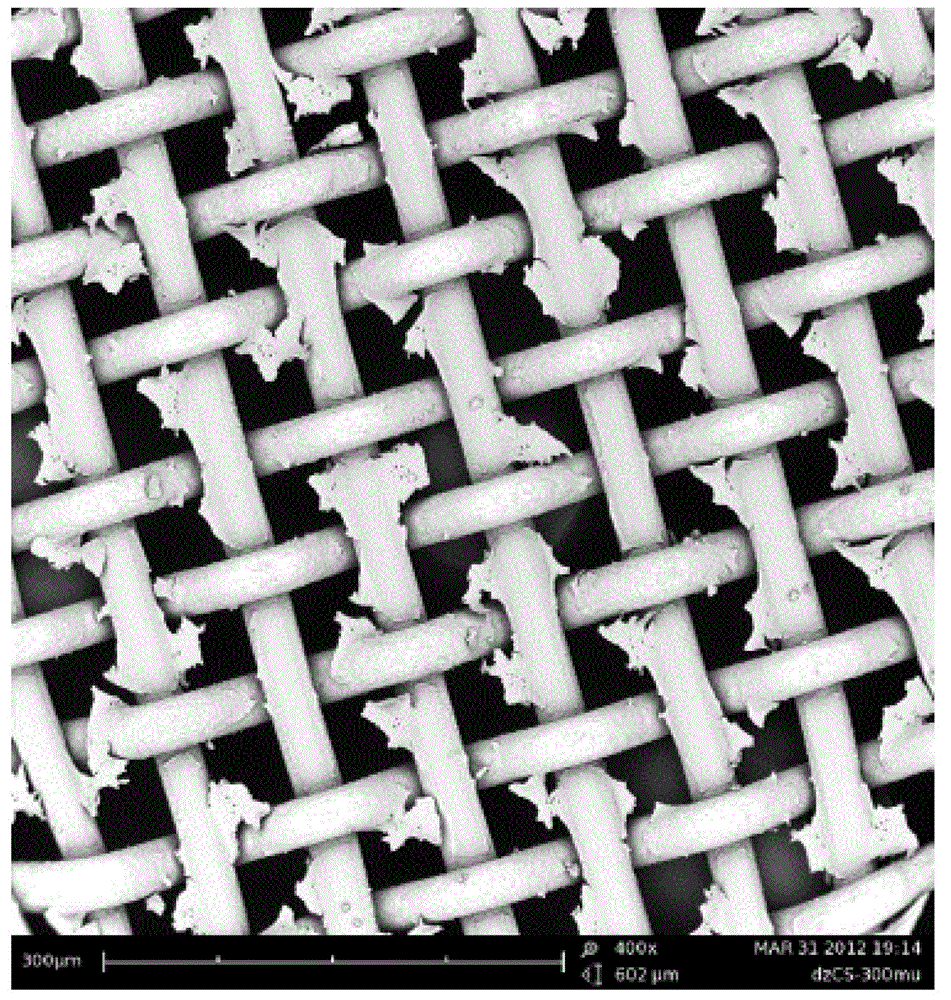

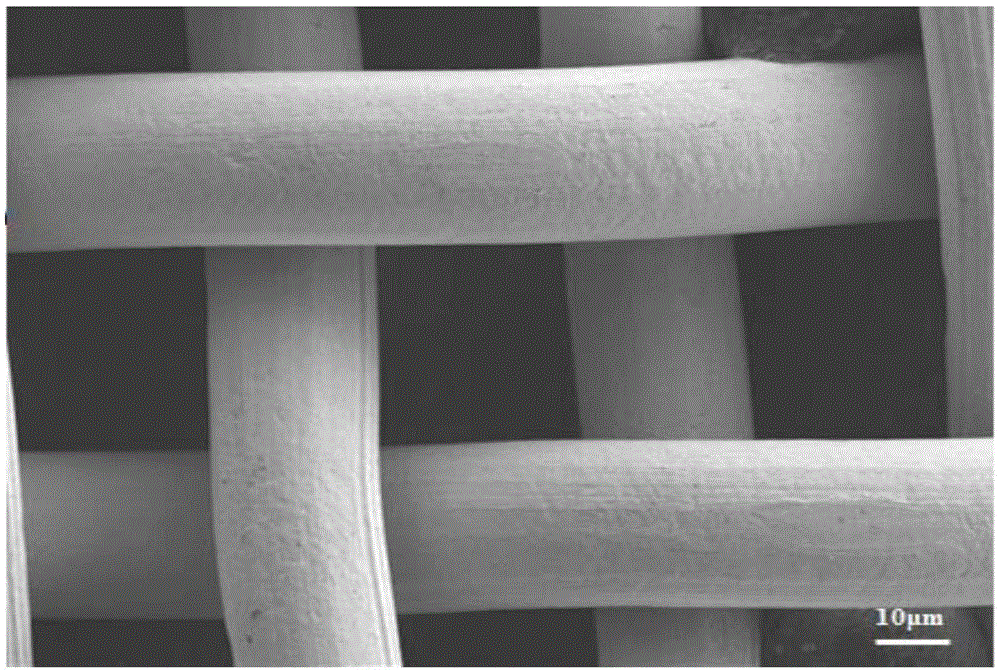

Underwater super-oleophobic oil-water separation mesh membrane and preparation method thereof

InactiveCN102716676AFast separationEasy to separateSemi-permeable membranesPolymer scienceVegetable oil

The invention discloses an underwater super-oleophobic oil-water separation mesh membrane and a preparation method thereof. The oil-water separation mesh membrane is prepared by coating a micron-thickness chitosan-based polymer coating layer on the mesh wire of a fabric mesh with 100-400 meshes. The oil-water separation mesh membrane is provided with micrometer-scale meshes and the chitosan-based polymer coating layer is provided with protruding structures with a nanoscale width. The preparation method of the oil-water separation mesh membrane comprises the following steps of: (1) cleaning and drying the fabric mesh; (2) dissolving a chitosan-based polymer in acid solution and stirring evenly to obtain mixed solution; (3) immersing the cleaned and dried fabric mesh in the mixed solution, taking out and drying the fabric mesh; and (4) immersing the fabric mesh obtained by the step (3) in alkaline solution, taking out and drying the fabric mesh to obtain the oil-water separation mesh membrane. The oil-water separation mesh membrane provided by the invention has the advantages of large water flux, high oil-water separation speed and good oil-water separation effect, is applicable to treatment of sewage with high oil content, and has good separation effect on normal hexane, petroleum ether, dichloroethane, benzene, animal and vegetable oils and the like.

Owner:TSINGHUA UNIV

Method for extracting suaeda salsa flavone and measuring content of flavones in suaeda salsa

InactiveCN103027962AImprove production rateIncrease profitAntipyreticComponent separationConcentration gradientSolvent

Owner:YANCHENG INST OF IND TECH

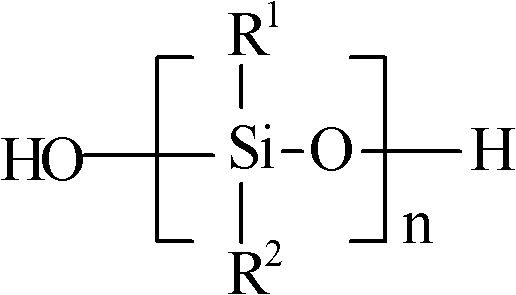

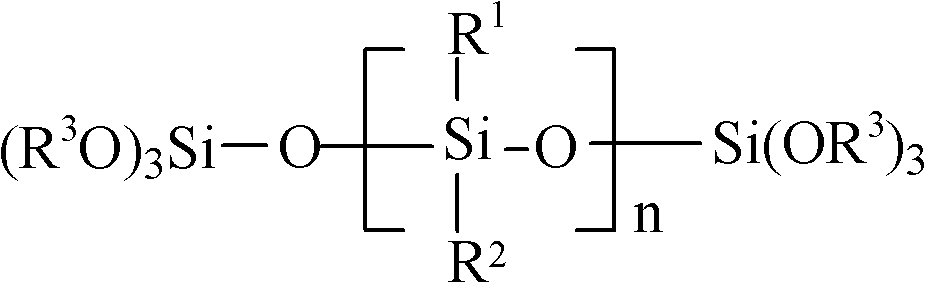

Room-temperature cured phenyl silicon resin conformal coating

The invention discloses a room-temperature cured phenyl silicon resin conformal coating which comprises components A) a segmented copolymer of phenyl silicon resin and linear polyorganosiloxane or methyl phenyl silicon resin and linear polyorganosiloxane, B) alkoxy silane, C) a silane coupling agent containing amino or epoxy group, D) an organic titanium compound, E) organic phosphate flame retardant synergist, and (F) an organic hydrocarbon solvent or low molecular weight siloxane, wherein the organic hydrocarbon solvent is one or multiple of methylbenzene, dimethylbenzene, petroleum ether, cyclohexane and normal heptane; and the low molecular weight siloxane is a mixture of octamethyl-trisiloxan, octamethyl cyclotetrasiloxane or methyl cyclosiloxane. A product produced by the cured resin conformal coating of the invention has the advantages of very high transparency, good elasticity, tough and wearable surfaces as well as excellent high / low temperature performance, waterproofing, heat resistance, cold resistance, weathering resistance, ultraviolet ray resistance, medium resistance, irradiation resistance, flame retarding and the like.

Owner:MIANYANG WELLS ELECTRONICS MATERIAIS

American falx extract, medicinal composition containing it and its making method

An extract of American periplaneta and its medicinal composition with high content of general amino acids are disclosed. Its preparing process includes such steps as immersing American periplaneta in petroether for removing fat, extracting in water or alcohol, and mixing with pharmacologically acceptable additives.

Owner:SICHUAN GOODDOCTOR PANXI PHARMA

High content environmental protection alcohol ether fuel for vehicle

InactiveCN101100618AHigh calorific valueImprove thermal efficiencyLiquid carbonaceous fuelsIsobutanolNitromethane

A high-content environmental-protecting alcohol ether fuel for vehicle consists of additives and methanol or alcohol 75-87 proportion. The additives contain methanol, alcohol, isopropyl alcohol, isobutanol, dimethylcuprate, n-amyl alkyl, dipropyl, cyclopentane, nitro-methane, dimethyl benzene, pinecone oil, cyclopentadienyl, poly-isobutylene, propane diamine, carbomethoxy formate, dimethoxyester carbonate, natural gasoline, hydrocarbon solvent oil, diisopropyl ester, dimethoxy-methane, petroleum ether, methyl tert-amyl ether, tert-amyl tert-butyl ether, lauryl phenol poly-ethenoxy ether, anti-static agent, metal-corrosive inhibitor, rubber plastic swelling inhibitor and anti-oxidant. It's clean and universal; it has excellent burning stability, shock resistance and dynamic character and less oil consumption.

Owner:鲁家政

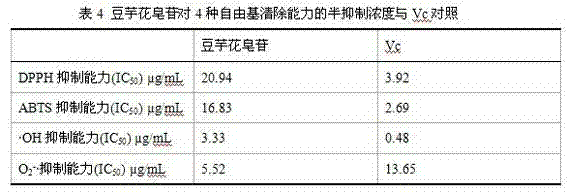

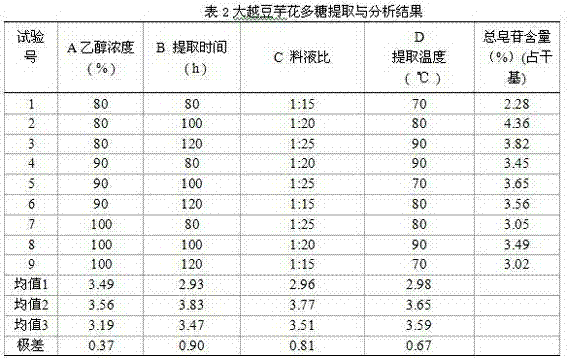

Method for preparing total saponins and polysaccharides from Apios americana flowers simultaneously, and application of total saponins and polysaccharides

InactiveCN103040917AGood curative effectIncrease profitOrganic active ingredientsMetabolism disorderPotato-beanPolysaccharide

The invention discloses a method for preparing total saponins and polysaccharides from Apios americana flowers simultaneously and relates to the technical field of plant extraction. The method comprises the following steps: (1) harvesting raw materials, cleaning and drying; (2) reflux-extracting with ethanol, and filtering to obtain a supernatant and filter residues; (3) defatting the supernatant with petroleum ether, extracting with n-butanol, performing adsorption and elution, concentrating, and drying to obtain powdery Apios americana flower saponins; (4) removing the solvent from the filter residues, reflux-extracting with water, filtering, collecting and mixing the filtrates; and (5) decolorizing the filtrate, performing deproteinization, concentrating, precipitating with alcohols, dialyzing and concentrating, and drying to obtain Apios americana flower polysaccharides. The method has the advantages of simple process, high yield and low cost. Besides, the total saponins and polysaccharides of Apios americana flowers are prepared simultaneously, have high purity and strong activity, and can be widely used in pharmaceuticals or functional foods with antioxidant and blood sugar regulating effects.

Owner:ZHEJIANG FORESTRY UNIVERSITY

Lutein crystal preparing process from marigold flower

The present invention is the lutein crystal preparing process from marigold flower. Lutein ester is first extracted from marigold flower with non-polar solvent under heating condition and then saponified with alkali solution in stirring and heating condition; and the saponified product is diluted with deionized water and separated, washed and vacuum dried. After that, the obtained lutein crystal is re-crystallized in three-component solvent of tetrahydrofuran, deionized water and normal hexane or petroleum ether; and the lutein crystal is suction filtered, washed and vacuum dried. The present invention has low-toxicity solvent in small amount used, simple technological process, high extraction, rate, and high product purity. The product of the present invention may be used widely as feed coloring additive and food coloring agent and in medicine and health care article.

Owner:海宁凤鸣叶绿素有限公司

Super-hydrophobic/super-oleophilicity copper wire mesh for oil and water separation and preparation method and application thereof

ActiveCN105536296AImprove separation efficiencyEfficient separationNon-miscible liquid separationKeroseneCopper sulfate

The invention discloses a super-hydrophobic / super-oleophilicity copper wire mesh for oil and water separation and a preparation method and application thereof. The preparation method comprises the steps that firstly, the copper wire mesh is ultrasonically cleaned through diluted hydrochloric acid, absolute ethyl alcohol and deionized water respectively and dried through nitrogen; chemical deposition liquid of copper sulfate and a sodium thiosulfate solution is prepared; the cleaned copper wire mesh is placed into the chemical deposition liquid for a deposition reaction; the copper wire mesh is taken out and cleaned through the deionized water and dried in the air; the dried copper wire mesh is placed in a solution of a curing agent and polydimethylsiloxane with hydroxyl sealed end, and the copper wire mesh is taken out and heated. No expensive fluorine-containing substance is needed, the copper wire mesh has the advantages that the preparation technology is simple, reaction conditions are mild, no strong acidity or strong basicity or corrosivity reagents are needed, and no harm is caused to the environment, separation of oily wastewater can be achieved rapidly and efficiently, the good separation effect on chloroform, normal hexane, petroleum ether, plant oil, diesel oil, aviation kerosene and the like is achieved, and separation of strong acidity, strong basicity and high salinity oily wastewater can be achieved.

Owner:SOUTH CHINA UNIV OF TECH

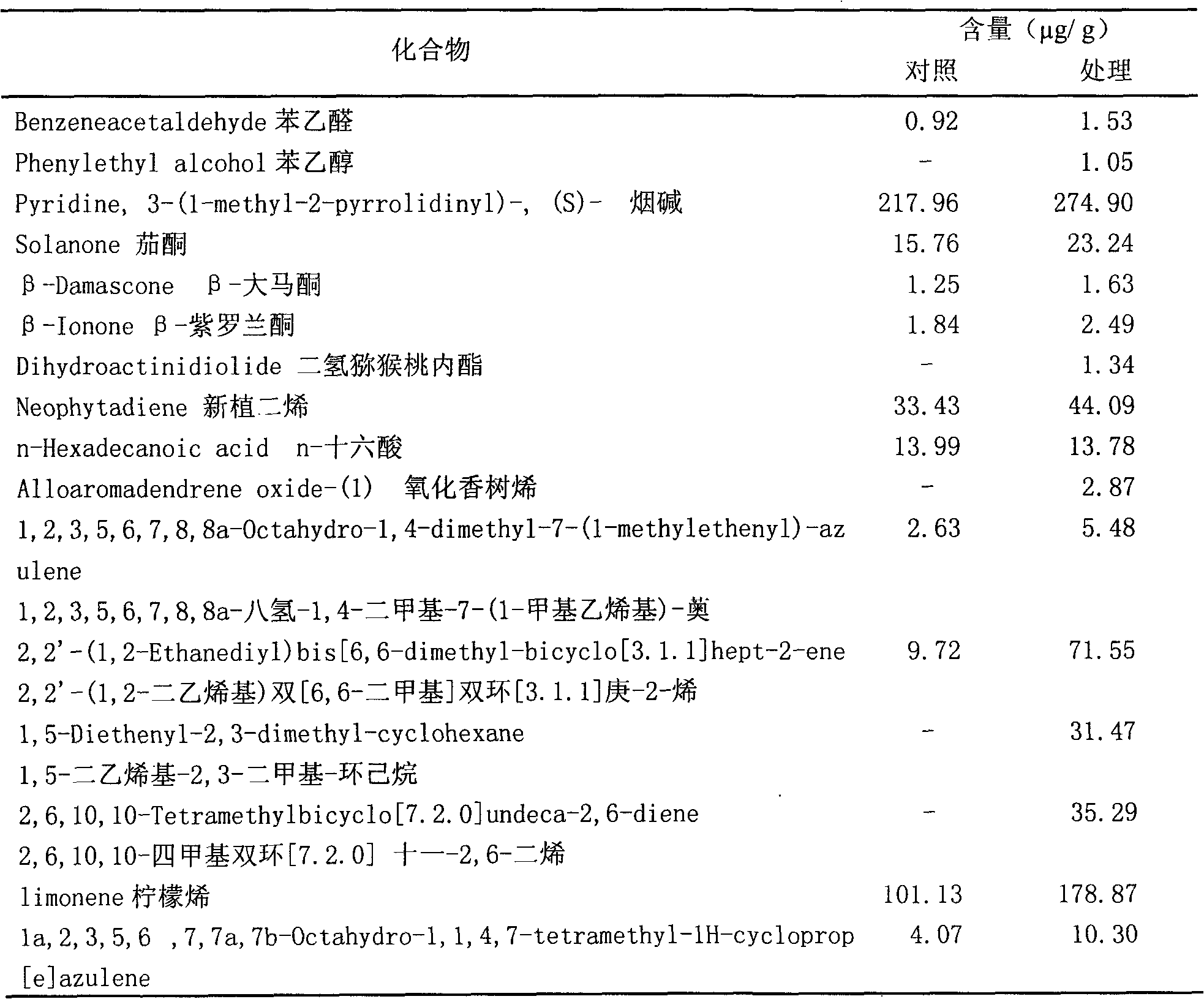

Method for improving content and aromas of tobacco secondary metabolite products

InactiveCN102986391AImprove qualityIncrease contentBiocidePlant growth regulatorsMetaboliteSecondary metabolite

The invention provides a method for improving the content and aromas of tobacco secondary metabolite products. During any tobacco plant growth period or after tobacco harvesting, a leaf surface spraying method, a stem top spraying method or a root-irrigation method is adopted to implement one or more of salicylic acid elicitors and / or jasmonic elicitors on the tobacco plants or the tobaccos so as to induce synthesis of the tobacco secondary metabolite products. The method can not only remarkably increase the content of tobacco essential oil, petroleum ether extract and glandular hair secreta and the like and improve tobacco aroma quality, but also improve yield of some important natural products in the tobacco such as solenesol and provide high-content raw materials for extraction of the natural products. Meanwhile, the method can activate tobacco plant immune system and improve insect resistance, disease resistance and stress resistance of the tobacco plants.

Owner:ZHENGZHOU UNIV

Extraction method of microalga grease

InactiveCN103045352AImprove dissolution efficiencyHigh yieldFatty-oils/fats productionAlcoholOrganic solvent

The invention discloses an extraction method of microalga grease. The extraction method comprises the following steps of: (1) microalga cell collection: adjusting the pH value of a microalga culture solution to 11-12 at the later period of microalga cultivation, and collecting microalga cells in a centrifugal way; (2) microalga cell crushing: adding a C1-C6 short-chain alcohol solvent into microalga ooze obtained in the step (1), shaking and mixing the microalgae to be uniform, and then, carrying out cell breaking treatment on the microalgae; (3) grease extraction: adding one or more of organic solvents such as n-hexane and petroleum ether into a microalga cell breaking solution obtained in the step (2), and extracting the grease component in the cell breaking solution by using the organic solvents; and (4) solvent recovery: after the extraction reaction is ended, cooling the solvent to room temperature, standing for 10-30min, respectively extracting an organic solvent layer (oil phase) and a water layer (water phase), and recovering the organic solvents in the oil phase in a distillation way, and meanwhile, obtaining the microalga grease. The method has the advantages of simple operation process, short extraction time, low energy consumption, high microalga grease yield and the like and is suitable for directly extracting grease from alga ooze.

Owner:CHINA PETROLEUM & CHEM CORP +1

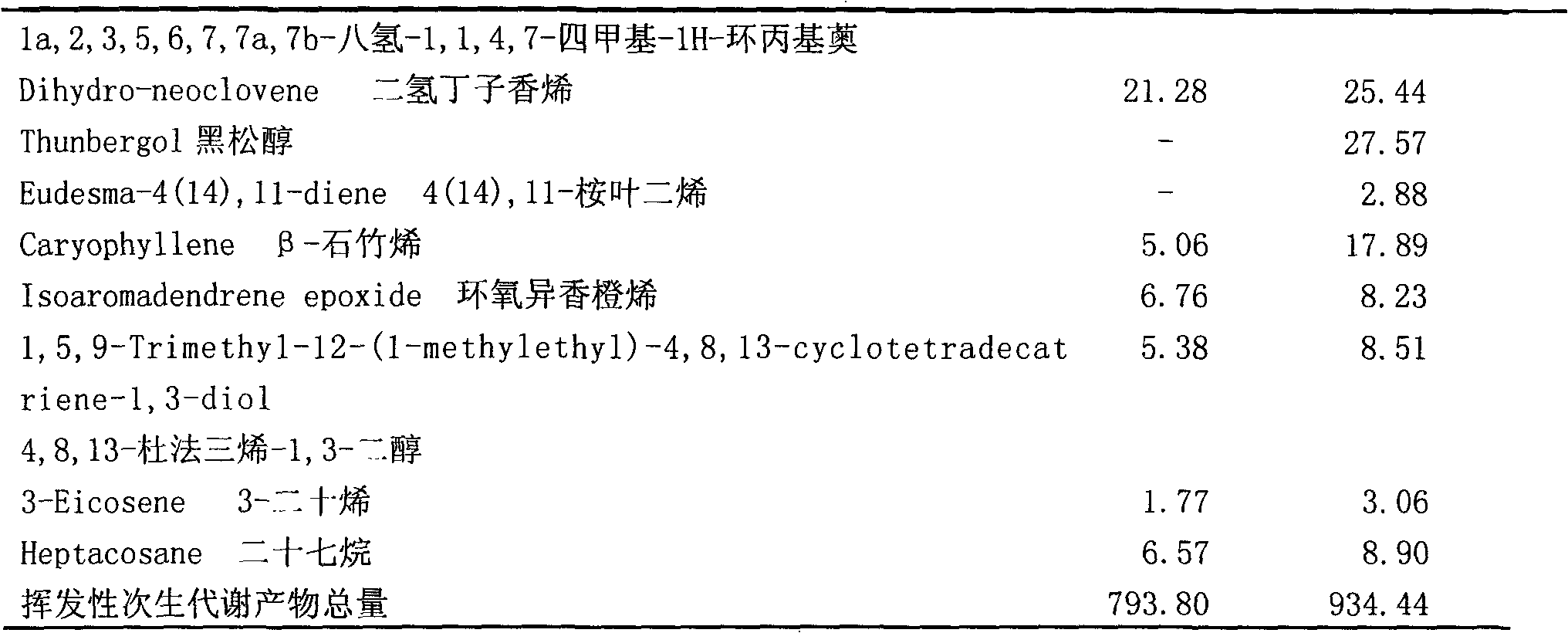

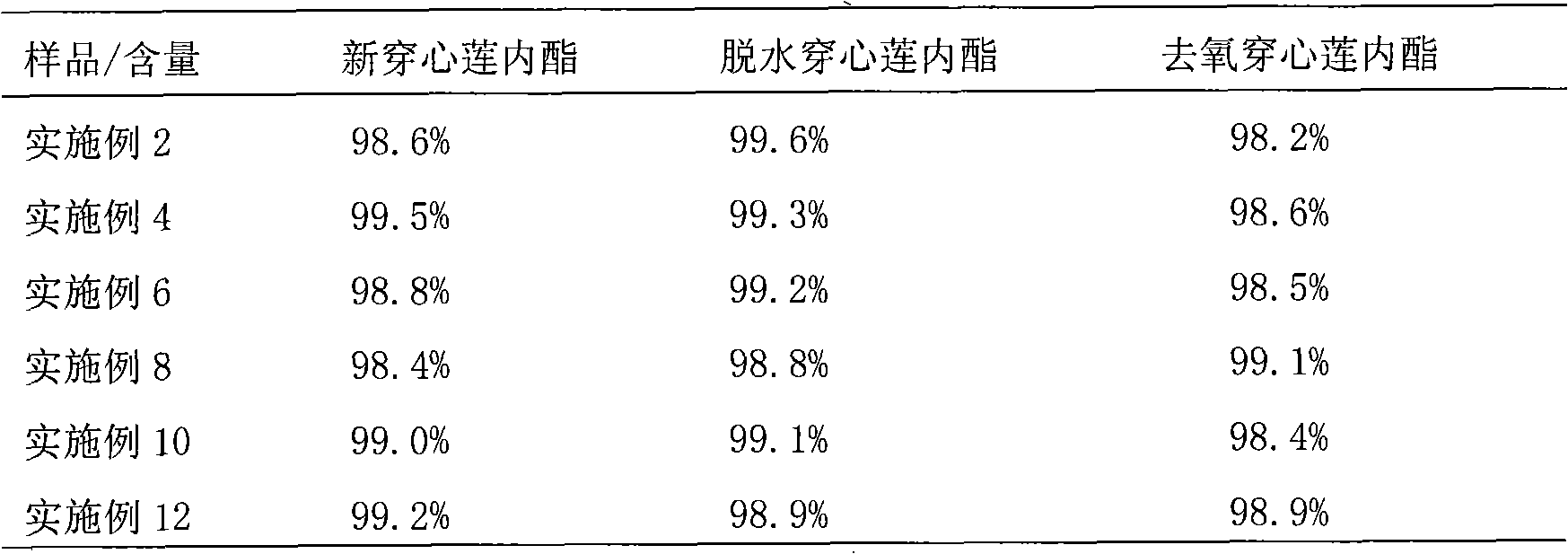

Production technique of andrographolide and neoandrographolide, dehydroanddrographolide, oxyandrographolide

ActiveCN101559088ARaise the ratioReduce usageAntibacterial agentsOrganic chemistryChemical industryImpurity

The invention discloses a production technique of andrographolide and neoandrographolide, dehydroanddrographolide and oxyandrographolide; the technique comprises the following steps of: firstly preparing stem and leaf extract of andrographis paniculata, removing fat-soluble impurities such as chlorophyll and the like with petroleum ether, and then hot-melting the extract in lower alcohol or aqueous lower alcohol, conducting reflux and decolorization with active carbon, separating out a majority of andrographolide crystals, then removing flavonoid through an alumina column or alkali cleaning, obtaining the andrographolide, cold-melting the andrographolide with trichloromethane or dichloromethane for 2 to 4 times, filtering and obtaining two parts of filtrate and insoluble substances, concentrating the filtrate, then conducting solvent crystallization and recrystallization or column chromatography for separation, and finally, respectively obtaining dehydroanddrographolide and pure product of andrographolide; the insoluble substances go through solvent crystallization and recrystallization or column chromatography for separation to obtain the neoandrographolide and pure product of andrographolide. The technique has simple production equipment, simplified routes and easy operation, can realize industrialized batch production; and the proportion of neoandrographolide, dehydroanddrographolide and oxyandrographolide in the obtained andrographolide is high, while the content of impurities is low. The obtained neoandrographolide, dehydroanddrographolide and oxyandrographolide all have monomer purity of higher than 98 percent, thus being capable of being used as chemical reference substance of the traditional Chinese medicine, or being applied as raw materials of medicine and chemical industry.

Owner:雷允上药业集团有限公司

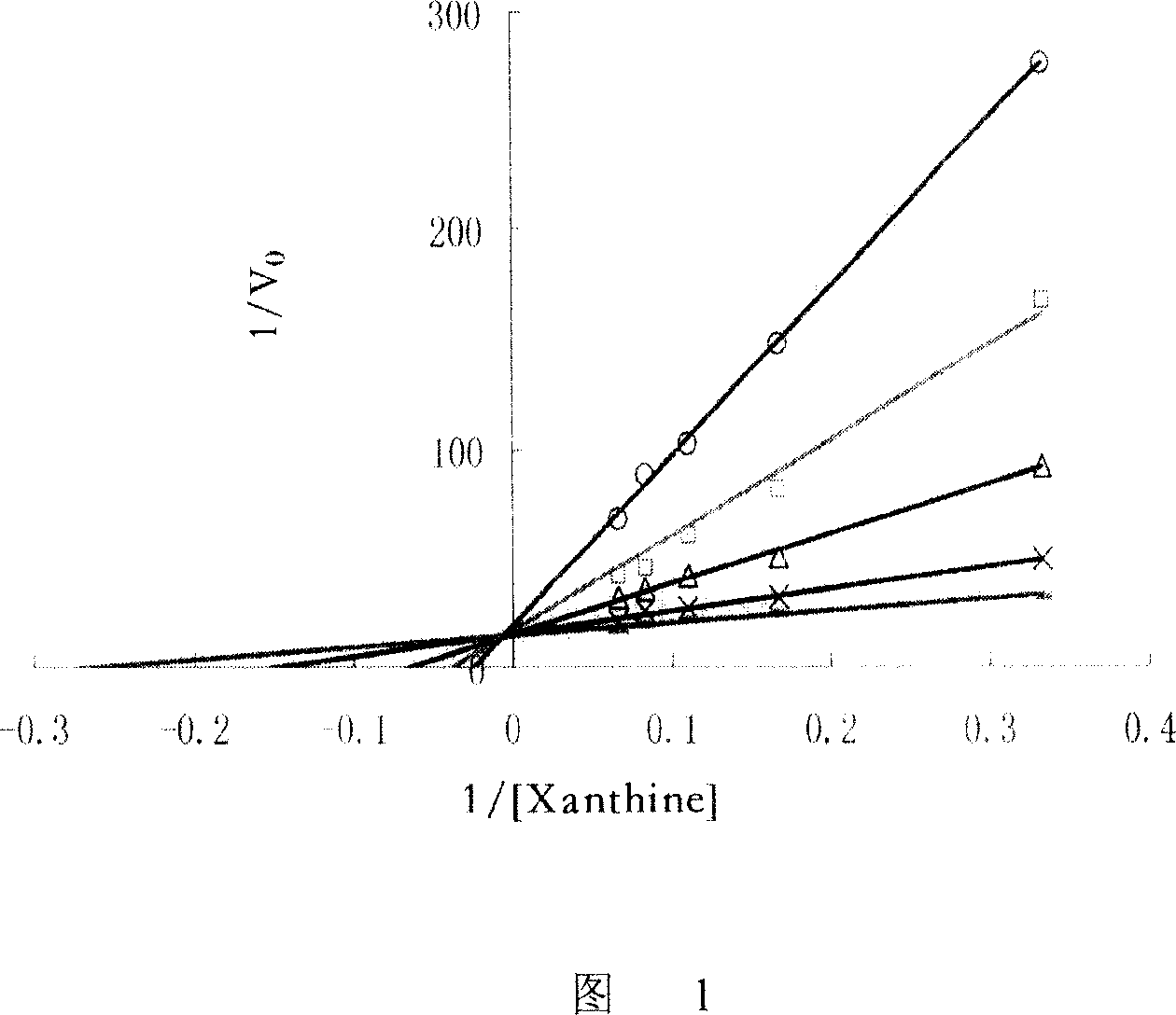

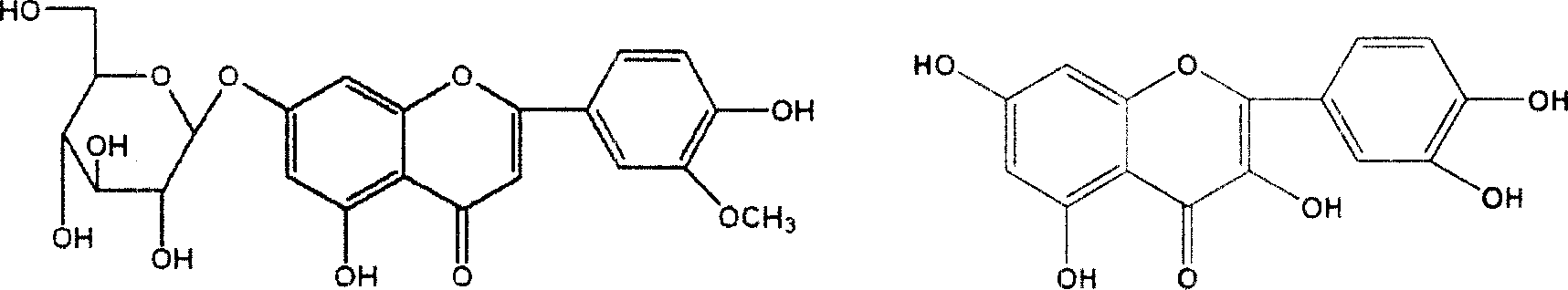

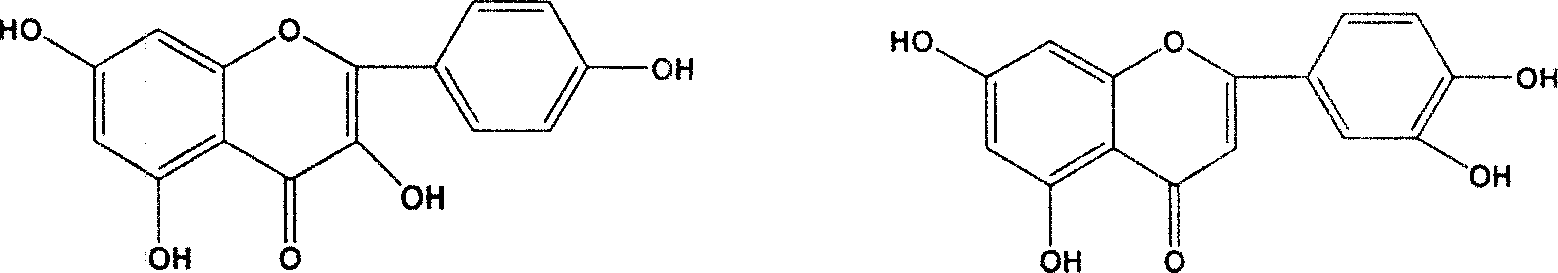

Application of flavonoids of celery seed and coumarins in preparation of drug for preventing and treating gout

ActiveCN101007015ASuppress generationLower serum uric acid levelsAntipyreticAnalgesicsSerum uric acidEthyl acetate

The invention disclosed the application of celery seed coumarins and flavanoid in preparing arthrifuge, anti-inflammatory agent or health food, which belongs to the natural occurring drugs and medical technology domain. The coumarins and flavanoid is the extract from acetic ether. The preparing method includes the following steps: selecting 10kg celery dry seed, adding 15-20 times of 75-95%(V / V) as the seed or extracting with 4-5 times of 75-95%(V / V) alcohol at higher temperature, heating for 1-1.5h every time; vacuum condensing the extracts until nearly all the alcohol is away; adding 1-2 times of water, extracting with 1 / 3 volume of the diluted solution sherwood oil (60-90DEG C) for 2-3 times; reclaiming the sherwood oil; extracting the water layer with 1 / 3 volume of acetic ether for 4 times; reclaiming the acetic ether to get the extracts. The invention has very simple preparing technologies; the product in the invention has obvious anti-inflammatory function; it can also decrease the amount of serum uric acid of rats.

Owner:BEIJING HUMANWELL JUNWEI PHARM TECH CO LTD

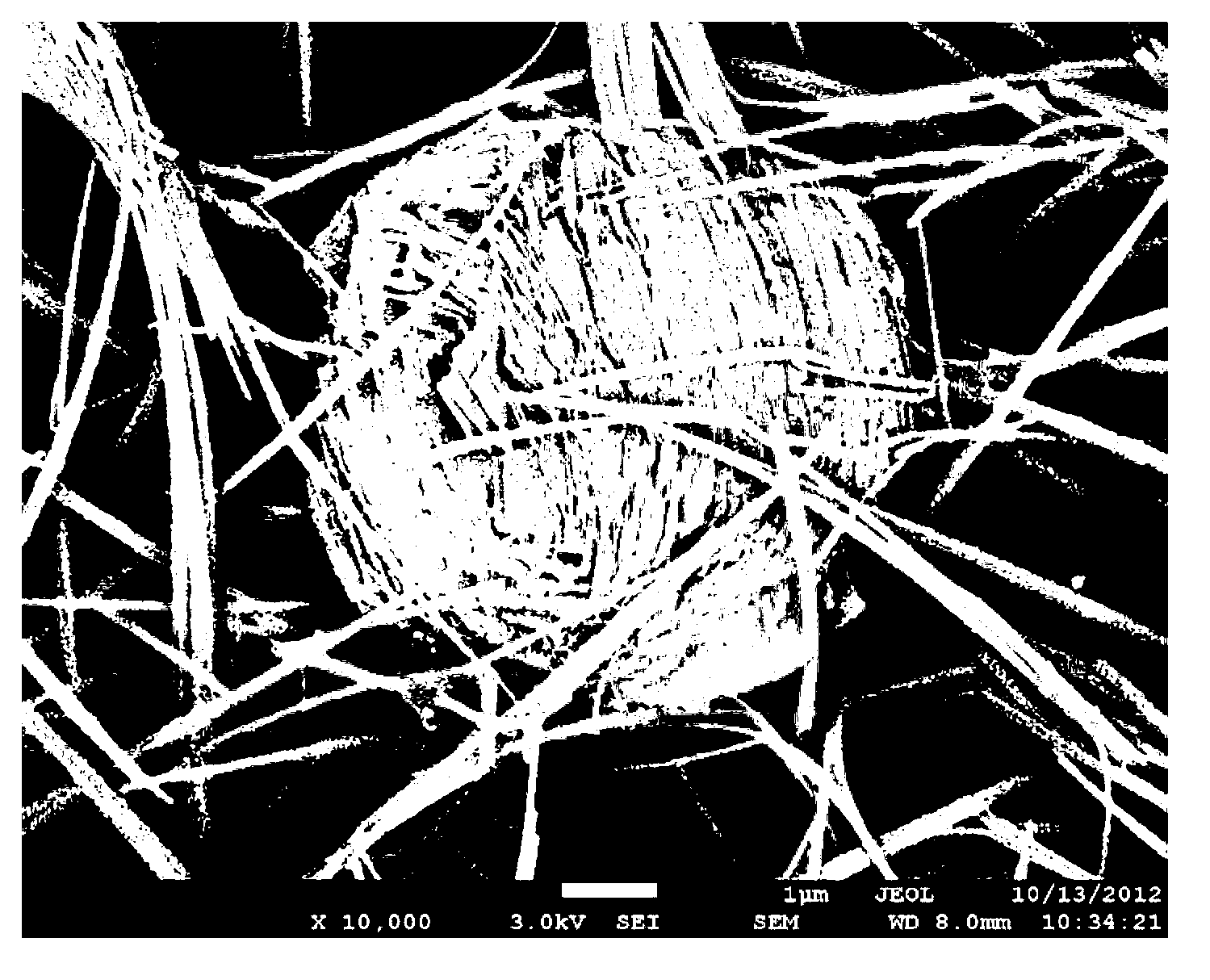

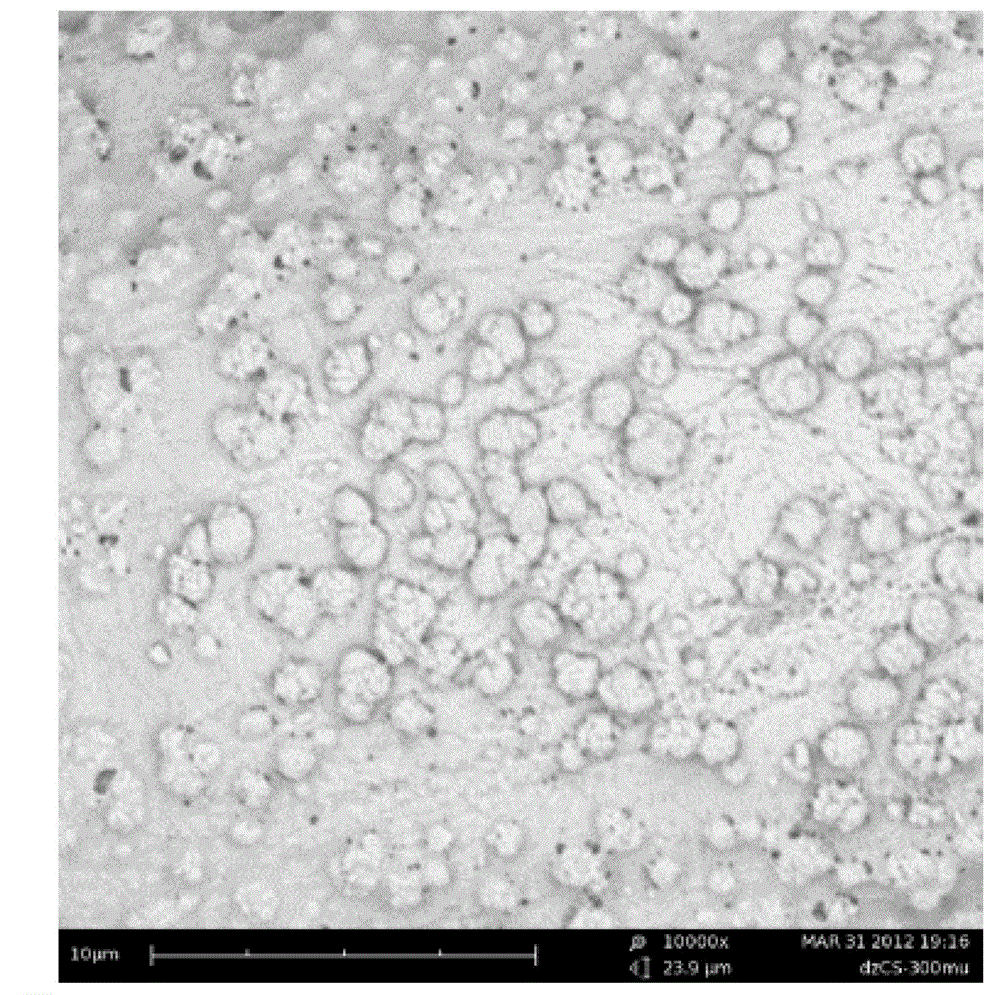

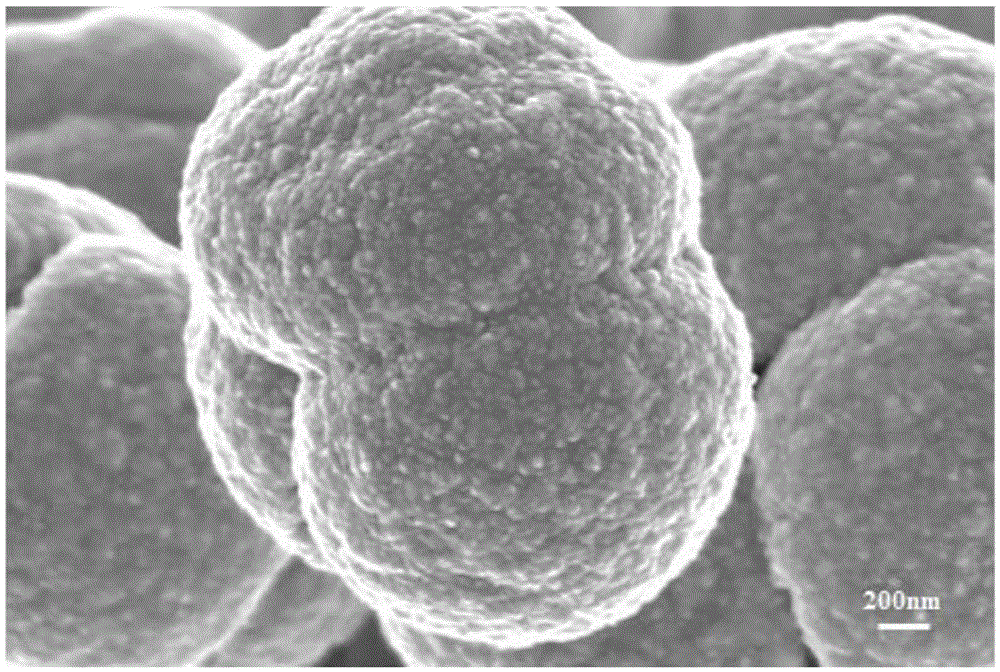

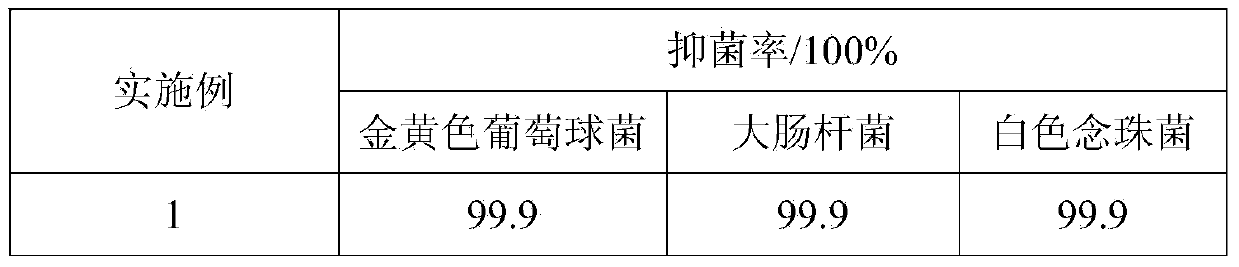

Nano-TiO2 loaded chitosan compound and preparation method thereof

ActiveCN103726319AImprove antibacterial propertiesHigh antibacterial activityFibre treatmentOil phaseMicro spheres

The invention discloses a nano-TiO2 loaded chitosan compound and a preparation method thereof. The preparation method comprises the following steps: mixing chitosan and a nano-TiO2 solution into water to obtain an aqueous phase mixture; taking petroleum ether / liquid petrolatum as an oil phase mixture; preparing nano-TiO2 loaded chitosan anti-bacterial micro-spheres according to the suspension-cross-linking technology. As the natural antibacterial agent chitosan is taken as a wall material, a metal ion-type antibacterial agent TiO2 is taken as a core material, and the compound antibacterial agent is prepared according to the suspension-cross-linking technology, the performance and the application range of the antibacterial agent can be greatly improved through the synergistic effect and advantage complementation of chitosan and TiO2. Furthermore, after being compounded, the novel antibacterial agent is high in performance, relatively wide in anti-bacterial range, and high in stability.

Owner:科凯精细化工(上海)有限公司

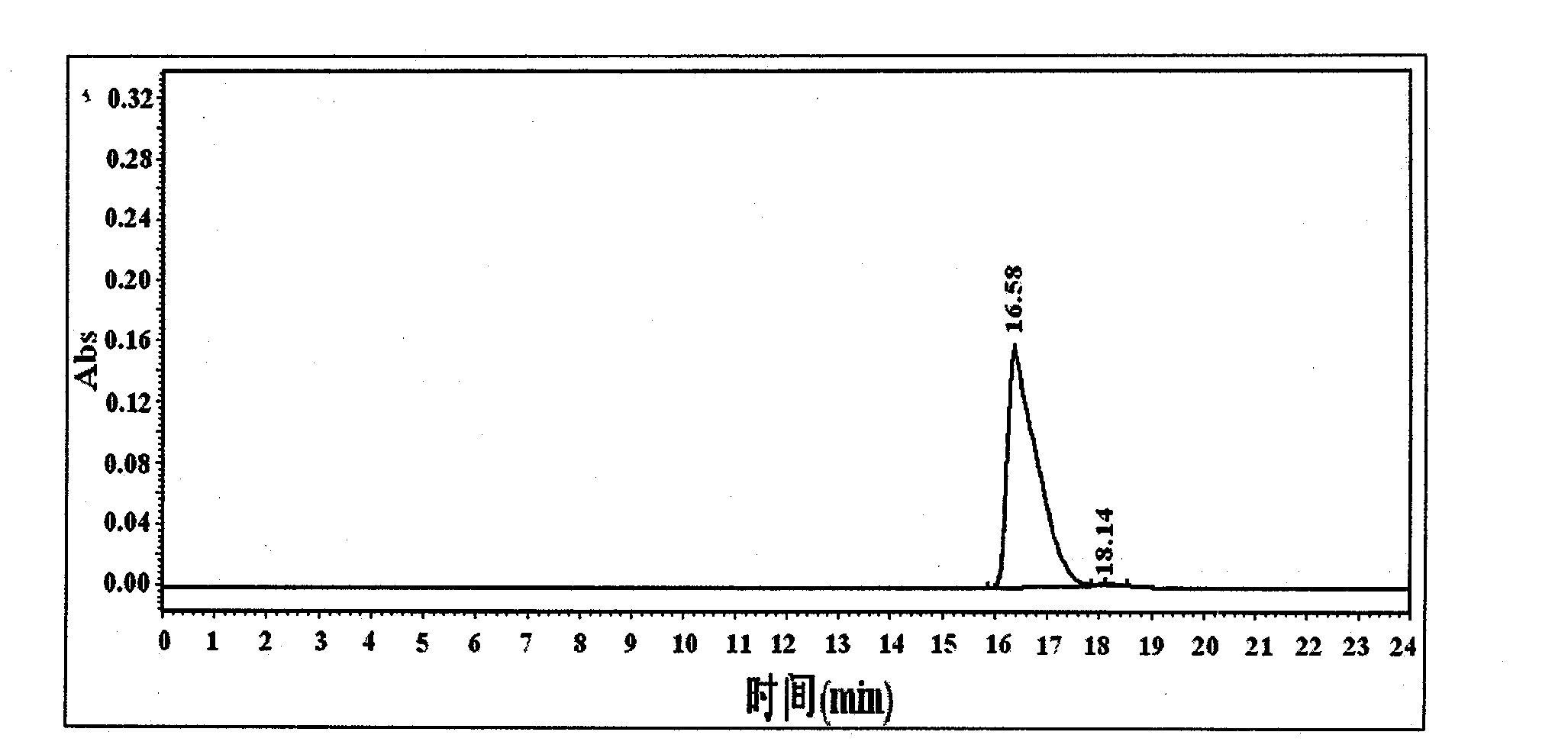

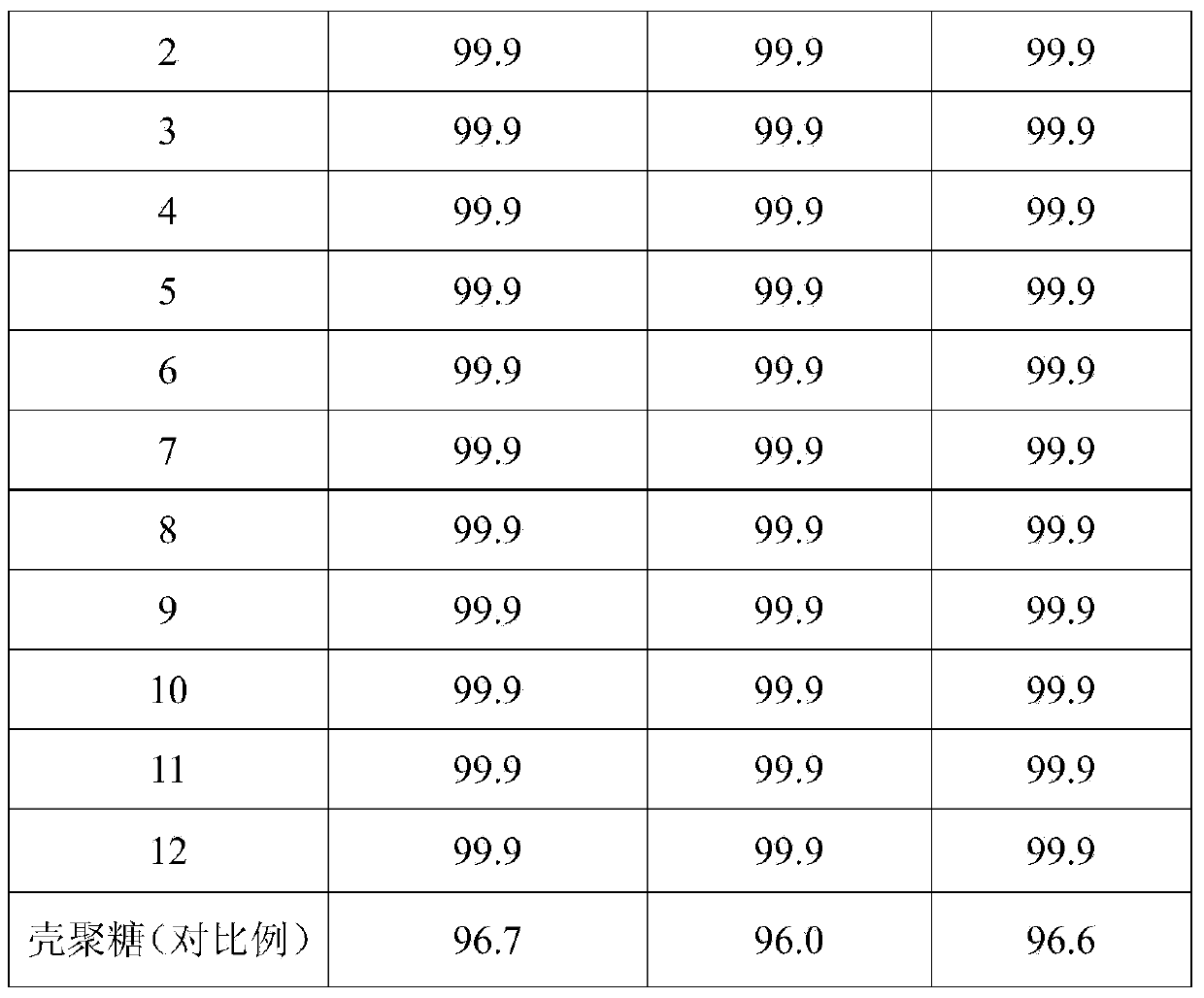

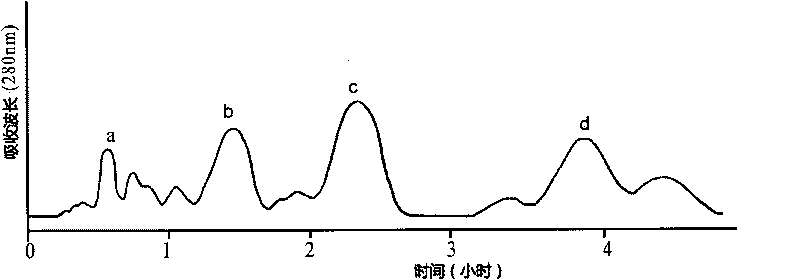

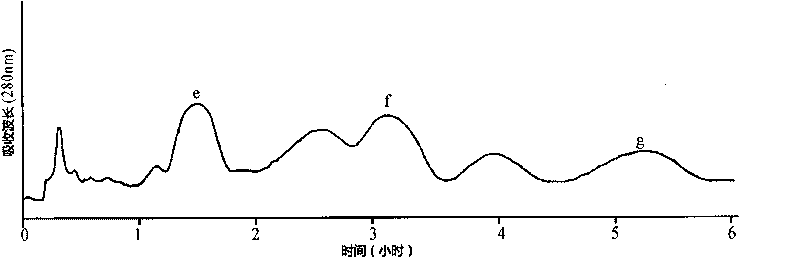

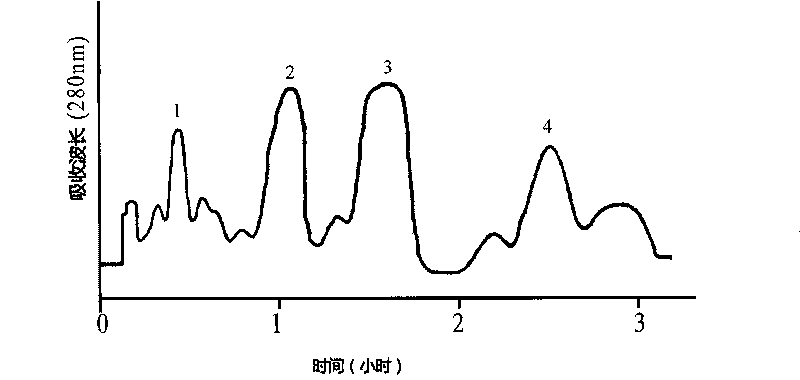

Method for separating high-purity anthocyanin monomers from black rice

ActiveCN101723996AGood choiceGood degreasing effectSugar derivativesSugar derivatives preparationFreeze-dryingEvaporation

The invention provides a method for separating high-purity anthocyanin monomers from black rice. The method comprises the following steps of: grinding 5 to 8 percent of episperm on the outer layer of black rice and brown rice to obtain black rice pericarp, leaching anthocyanin in the black rice pericarp by acidized ethanol, and extracting and defatting petroleum ether; performing primary purification of ethanol extracts of the black rice pericarp by using macroporous resin; separating the anthocyanin in coarse extracts of the anthocyanin of the black rice pericarp by the medium pressure preparation liquid phase chromatographic technique, collecting two leading anthocyanin components, which are cyanidin-3-glucoside and paeonidin-3-glucoside, in the black rice pericarp respectively according to the obtained chromatogram, and performing rotary evaporation of eluent at a temperature of below 45 DEG C until all methanol is gone, and performing freeze-drying to obtain powder of the anthocyanin monomers.

Owner:GUANGZHOU TRACE ELEMENTS BIOLOGICAL TECH CO LTD

Extract of mulberry twig and its extracting process and novel usage

An extract of mulberry twigs is dislcosed, which can be used to prepare the food or the medicine to cure hyperuricemia and gout diseases. The said extract is prepared from mulberry twigs through extracting in solvent (aqueous solution of alcohol, chloroform, acetone, etc) at 10-100 deg.C more than one time, mergint the liquid extracts, recovering solvent, regulating pH value to 7.5-9.5, centrifugal separation to obtain supernatant, regulating pH value to 4-6, deposition, water washing wand drying. Several other approaches for purifying it are also disclosed.

Owner:NANJING UNIV +1

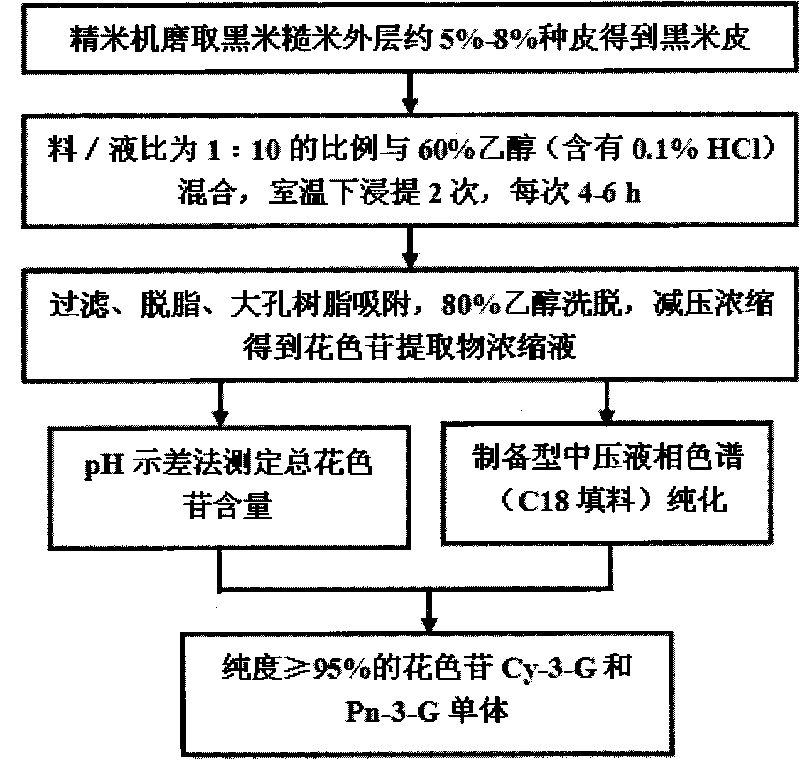

Method for extracting chlorogenic acid

InactiveCN101602668AEnables step-by-step gradient purificationHigh purityOrganic compound preparationCarboxylic acid esters separation/purificationChlorogenic acidSolvent

The invention relates to a method for extracting chlorogenic acid, which belongs to the technical field of pharmaceutical chemicals. The method combines macroporous resin enrichment, ethyl acetate extraction and a mixed solvent split-phase method to achieve multi-step gradient purification of the chlorogenic acid so as to obtain a chlorogenic acid product with high purity. The method comprises the processes of water extraction, column passing, extraction, phase splitting and recrystallization. The macroporous resin adopted by the column passing process is 306 type or XAD series resin; and the split-phase agent adopted by the split-phase method is petroleum ether, chloroform or the mixture of the petroleum ether and the chloroform. The method is applicable to the process of extracting and preparing the chlorogenic acid from honeysuckles, cortex eucommiae leaves and cortex eucommiae barks.

Owner:INST OF APPLIED CHEM JIANGXI ACAD OF SCI

Method for preparing functionalized polyethylene wax

The invention discloses a method for functionalizing polyethylene wax. Petroleum ether is used as a solvent, and functionalized monomers are grafted in a solution. The polyethylene wax can be dissolved and dispersed in the petroleum ether at the temperature of between 90 DEG C and 120 DEG C and is completely separated out when cooled to room temperature; products can be conveniently separated by using difference in solubility; and the solvent can be recycled. Polyethylene wax-grafted-acrylic acid (PEW-g-AA), polyethylene wax-grafted-methacrylic acid (PEW-g-MAA), polyethylene wax-grafted-glycidyl methacrylate (PEW-g-GMA), polyethylene wax-grafted-maleic anhydride (PEW-g-MAH), polyethylene wax-grafted-acrylamide (PEW-g-AM), polyethylene wax-grafted-N-methylol acrylamide (PEW-g-NMAM) and products obtained by neutralization, namely polyethylene wax-grafted-acrylic acid sodium (PEW-g-AAS) and polyethylene wax-grafted-methacrylic acid sodium (PEW-g-AAS), are obtained. The grafting products can be applied to the aspects of polyolefin modification, polyethylene wax emulsion, ink coating and the like. The method has a simple process and can be applied to industrial production.

Owner:张燕妮 +1

Process for extracting dendrobium polysaccharide and dendrobine from dendrobium officinale

The invention provides a process for extracting dendrobium polysaccharide and dendrobine from dendrobium officinale. The raw material used in the process comprises dendrobium officinale, cellulase (a biochemical reagent), glucose, phenol, acetone, petroleum ether and absolute ethyl alcohol. According to the process provided by the invention, the polysaccharide and dendrobine in the dendrobium officinale are extracted by using cellulase-catalyzed extraction in a combination manner; the dendrobine is obtained when the dendrobium polysaccharide is obtained; high efficiency for single extraction of the polysaccharide by an enzymic method is kept; the effects of effectively breaking cell walls are improved; dissolution of polysaccharide and the like are promoted; the process and condition are mild; the extraction rate is improved to a certain extent; and the economic benefits are relatively high.

Owner:HUOSHAN COUNTY TIANXIA ZEYU BIOLOGICAL TECHDEV

Preparation method for paraffin microcapsule phase-change material modified by graphene oxide

ActiveCN104212416AEnthalpy increaseGood dispersionHeat-exchange elementsMicroballoon preparationIce waterFiltration

The invention discloses a preparation method for a paraffin microcapsule phase-change material modified by graphene oxide. A technical scheme is that the preparation method comprises the following steps: adding concentrated acid and a strong oxidant in low-temperature ice-water bath to oxidize graphite; successively adding deionized water, hydrogen peroxide and hydrochloric acid, carrying out vacuum filtration, drying and grinding to obtain graphene oxide, adding the graphene oxide into the deionized water to prepare the graphene oxide liquor; adding paraffin, a non-ionic emulsifier and an ionic emulsifier into a stirring kettle, heating and adding graphite to stir to obtain paraffin emulsion; and adding an initiator into the paraffin emulsion to dissolve and dropwise adding monomers, carrying out vacuum filtration after the dropwise adding, carrying out petroleum ether washing and water washing, drying in vacuum and crushing to obtain paraffin microcapsule powder. The preparation method has the beneficial effect that the thermal stability, and the thermal conductivity of the paraffin microcapsule phase-change material are improved by virtue of reaction of multiple oxygen-containing groups on the graphite oxide and the polymer; and moreover, the paraffin microcapsule phase-change material is simple to prepare, environmentally friendly, and has market prospect in the fields such as building energy conservation, thermal insulation products and floor heating.

Owner:江苏节霸新能源材料有限公司

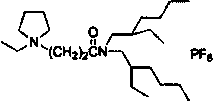

Lithium extraction system

ActiveCN106498184AReduce usageEasy material selectionProcess efficiency improvementSolvent extractionLithium chlorideKerosene

The invention provides a system from extracting lithium from salt lake brine, comprising ionic liquid, a co-extracting agent and a diluent; the ionic liquid is pyrrole hexafluorophosphate ionic liquid comprising lithium extraction functional groups, and the diluent is from solvent gasoline, sulfonated kerosene and petroleum ether. The use of the co-extracting agent iron trichloride is avoided in the lithium extraction system, adjusting pH of brine is not required, at least 5 tons of industrial hydrochloric acid and 2 tons of sodium hydroxide may be saved per ton of lithium chloride produced, and the production cost is greatly reduced; saponifying step, pickling step and deironing step are omitted from the technique, and therefore, the system is easier to use in industrial large-scale production.

Owner:青海柴达木兴华锂盐有限公司

Chinese magnoliavine fruit monomer composition separation preparation method

InactiveCN101709059ANo lossHigh recovery rateOrganic chemistryOrganic compound preparationMonomer compositionEthyl acetate

The invention relates to a Chinese magnoliavine fruit monomer composition separation preparation method; ethanol extracts from Chinese magnoliavine fruit are extracted by petroleum ether, chromatography is carried out to the petroleum ether extracts by a silicagel column, and then the petroleum ether is eluted by petroleum ether-ethylacetate, and HPLC is used for monitoring, and then crude extract A and crude extract B are fraction-collected, and eluted; the volume ratio of eluant petroleum ether and ethylacetate is 3-5:1, the crude extract A and crude extract B are respectively applied to a high-speed counter-current chromatography for separation, so as to obtain SCHisanhenol, deoxyschizandrin, schizandrin B, schisandrin C, schizandrol A, schizandrol B and schisantherrin B monomers, and the purity is higher than 98 percent.

Owner:华美恒盛(北京)科技有限公司

Method for extracting filament gutta-percha from eucommia leaf and skin

InactiveCN101157827AHigh yieldImprove qualityNatural resin processFermentationGutta-perchaPolymer science

The invention discloses an extraction method of filament eucommia rubber from eucommia leaves and peel; the method uses petrol ether as solvent to extract the eucommia rubber and has the steps: first, the eucommia leaves or the peel is made into small pieces and added with NaOH solution to dissolve cuticle; then cellulase is added to hydrolyze cell wall; the petroleum ether solvent at 60 DEG C to 90 DEG C of boiling range is added; then the obtained solution is extracted through recirculation at the temperature of 85 DEG C and filtrated when being hot, then cooled and frozen; the filament eucommia rubber is produced after filtration. Concentration of the NaOH solution is 0.5 percent to 1.5 percent and the dissolution time is 6 hours; pH value of the cellulase used for hydrolyzing the cell wall is 4 at temperature of 50 DEG C; enzymatic hydrolysis time is 1 hour to 2 hours and the time for reflux extraction is 2 hours; the frozen time is 30 minutes to 60 minutes at temperature of minus 20 DEG C to 0 DEG C. The method can effectively and completely extract the eucommia rubber to make original eucommia rubber and keep the original biological characteristics and physical properties and status and the original molecular structure and polymerization of the eucommia rubber; the method uses the cellulose to extract pretreated eucommia leaves raw materials, and gets the eucommia rubber of high quality when getting high yield.

Owner:GUIZHOU UNIV

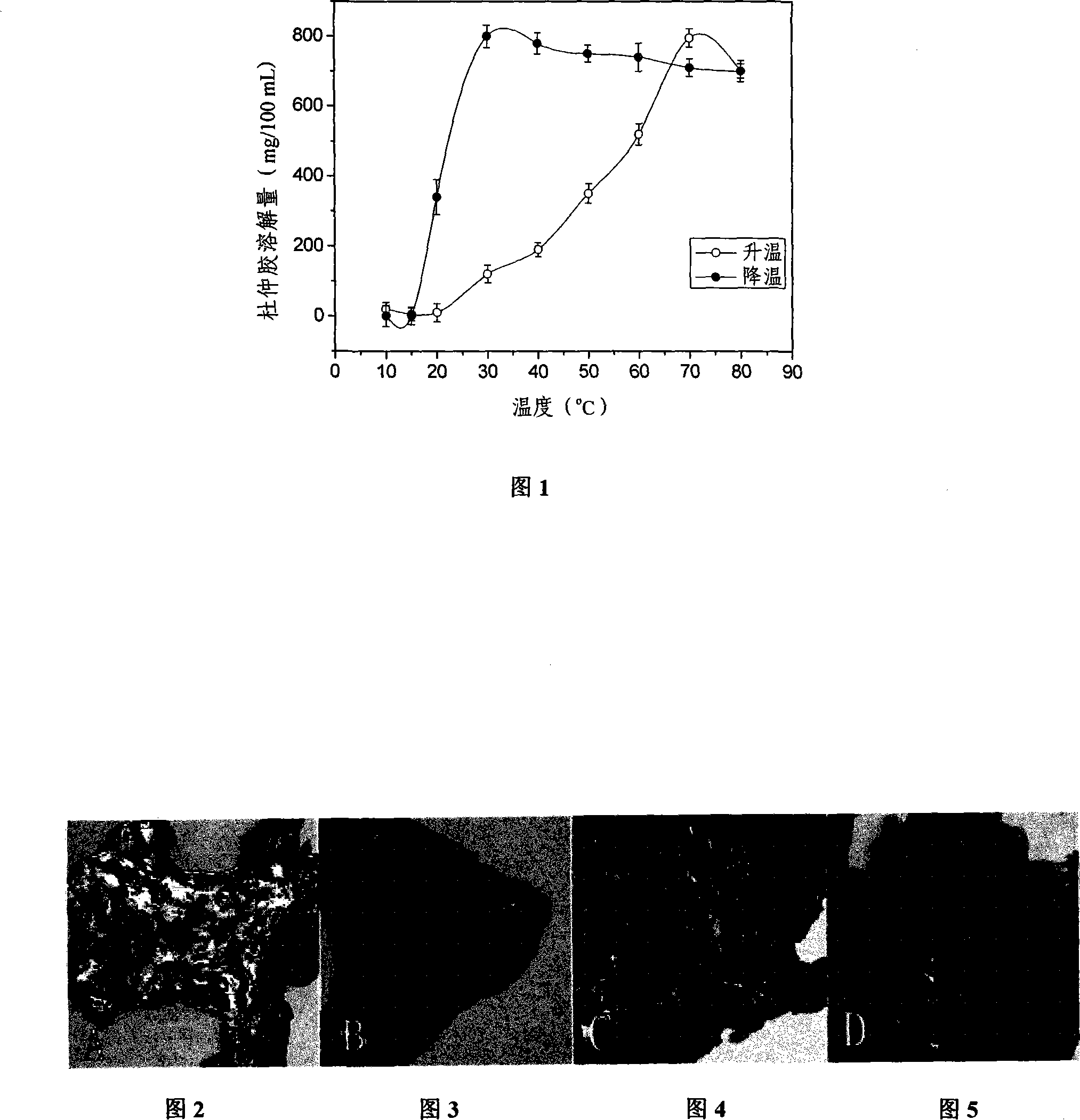

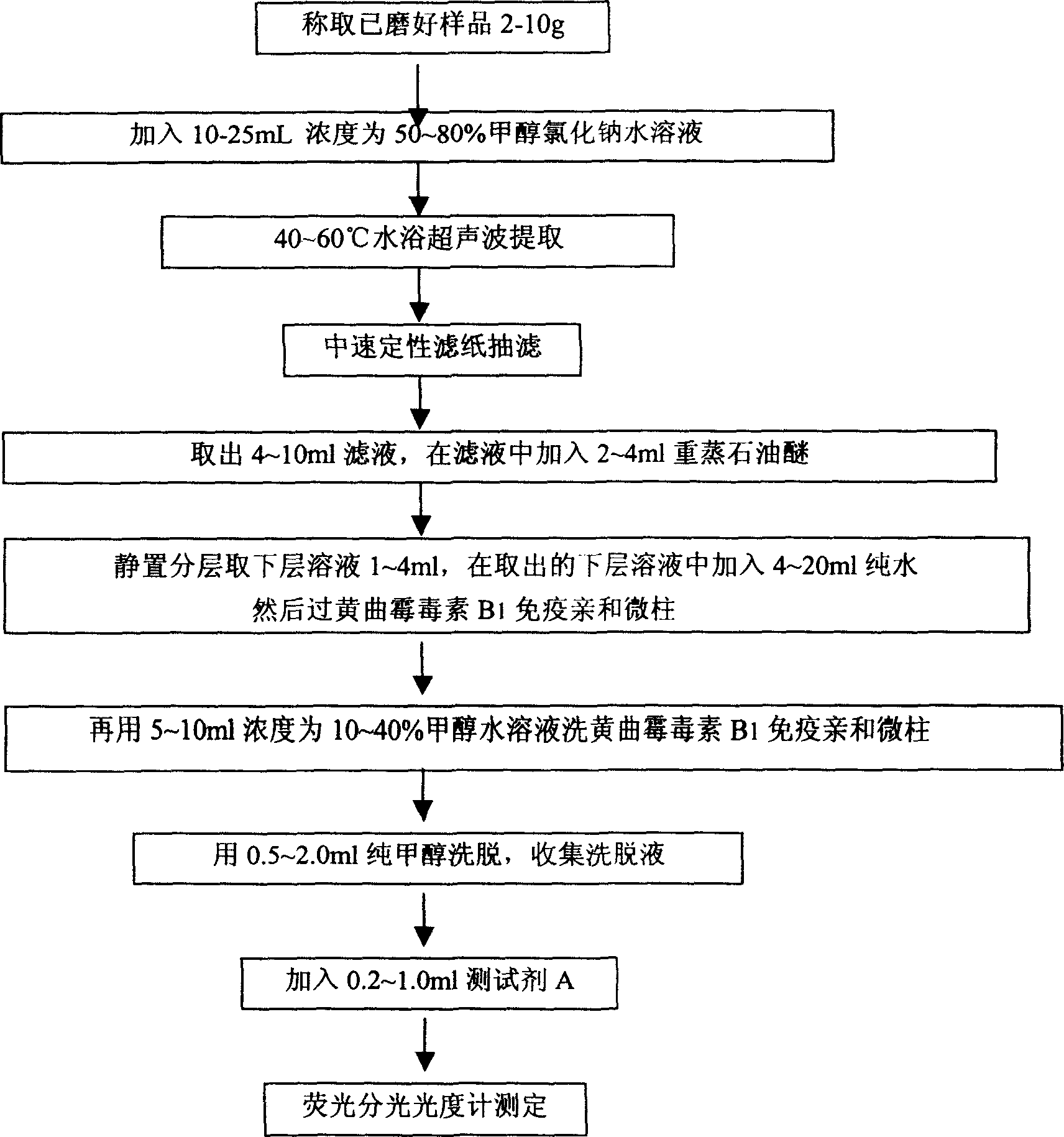

Fast detecting method for aftatoxin B1

The present invention is fast detection method of aflatoxin B1 in food and feed. The fast detection method includes the following steps: adding ground sample to be tested in 2-10 g in test tube, adding methanol-sodium chloride aqua of 50-80 % concentration in 10-25 ml, ultrasonic extraction in water bath at 40-60 deg.c, and suction filtering to obtain filtrate in 4-10 ml; adding re-distilled petroleum ether in 2-4 ml into the filtrate, shaking, letting stand to laminate, taking the lower layer of solution in 1-4 ml and adding pure water in 4-20 ml; adding to micro immunoaffinity column of aflatoxin B1, washing with methanol aqua of 10-40 % concentration in 5-10 ml, eluting with methanol in 0.5-2.0 ml, collecting the eluted liquid, adding test agent A in 0.2-1.0 ml; and detecting in fluorescent spectrophotometry or similar instrument. The present invention has the features of simple process, high detection precision and stability, fast detection speed and high safety.

Owner:BEIJING CHINAINVENT INSTR TECH +1

Purification process for preparing high-purity coenzyme Q10

ActiveCN101987815AImprove adsorption capacitySimple and fast operationQuinone separation/purificationDesorptionSolvent

The invention relates to a purification process for preparing high-purity coenzyme Q10 from crude coenzyme Q10 extracts obtained from thallus fermentation, which belongs to the technical field of compound separation purification. The purification process is characterized by sequentially comprising the following steps of: carrying out adsorbent resin adsorption, elution, concentration, crystallization and recrystallization on the crude coenzyme Q10 extracts; then, carrying out chromatography on a silicagel column; and purifying and refining by using a petroleum ether -aether or normal hexane-ethyl acetate mixed solvents as eluant. The invention has the following advantages that by adopting an adsorbent resin, good adsorption performance can be exerted on the coenzyme Q10, the desorption operation is simple, the stability is good, and the adsorbent resin can be reused many times; and by combining the adsorbent resin with the silica gel chromatography method, the silica gel utilization rate is high, the required silica gel is low quantity and can maintain good purification effect after being reused more than 10 times, the waste quantity of the silica gel is small, and the solvents can be recycled so that the purpose of environment protection is achieved. The production operation is simple and convenient, and the purity of the obtained coenzyme Q10 is higher than or equal to 98 percent.

Owner:EAST CHINA UNIV OF SCI & TECH +1

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com