Production technique of andrographolide and neoandrographolide, dehydroanddrographolide, oxyandrographolide

A technology of neoandrographolide and total andrographolide can be applied to cardiovascular system diseases, medical raw materials derived from angiosperm subphylum, digestive system, etc. To meet the screening and clinical application of pharmacological activity, it is not conducive to the labor protection and environmental protection of operators, to achieve the effect of simple production equipment, conducive to labor protection and environmental protection, and to achieve large-scale industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

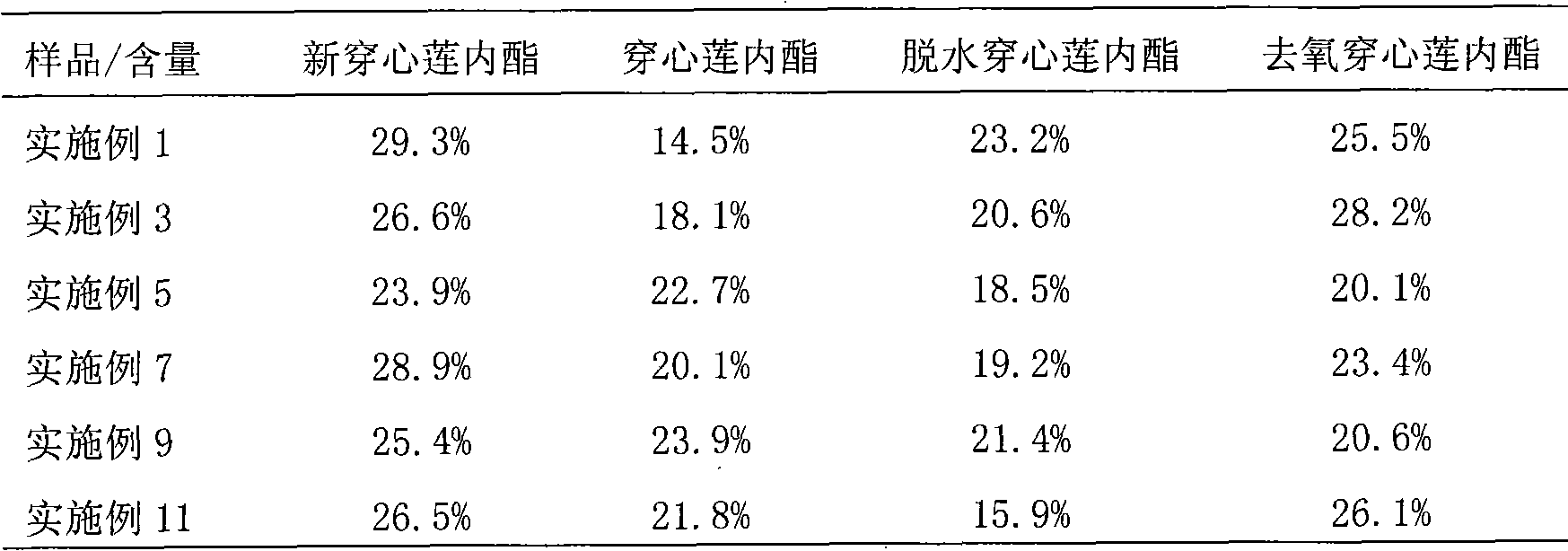

Examples

Embodiment 1

[0025] The preparation of embodiment 1 andrographolide

[0026] Take 2 kg of Andrographis paniculata stem and leaf powder, heat-dip and extract twice with 18 times the amount of 95% ethanol, recover the ethanol extract, dilute it to about 4000ml with water, and wash away fat-soluble impurities such as chlorophyll with 6000ml of petroleum ether for three times, and the aqueous solution Concentrate, dissolve the concentrated extract in 1500ml of 95% ethanol, reflux with 50g of activated carbon for decolorization, filter while it is hot, recover the ethanol to 800ml, slowly add 200ml of water, when the water is added, there should be no solid precipitation, place it, and most of the andrographolide will precipitate Crystallize, filter, concentrate the mother liquor to 400ml, place, and then separate out a small part of andrographolide crystals, filter, recycle the solvent from the filtrate to dryness, and obtain an extractum, which is heated and dissolved in 1000ml95% ethanol, and...

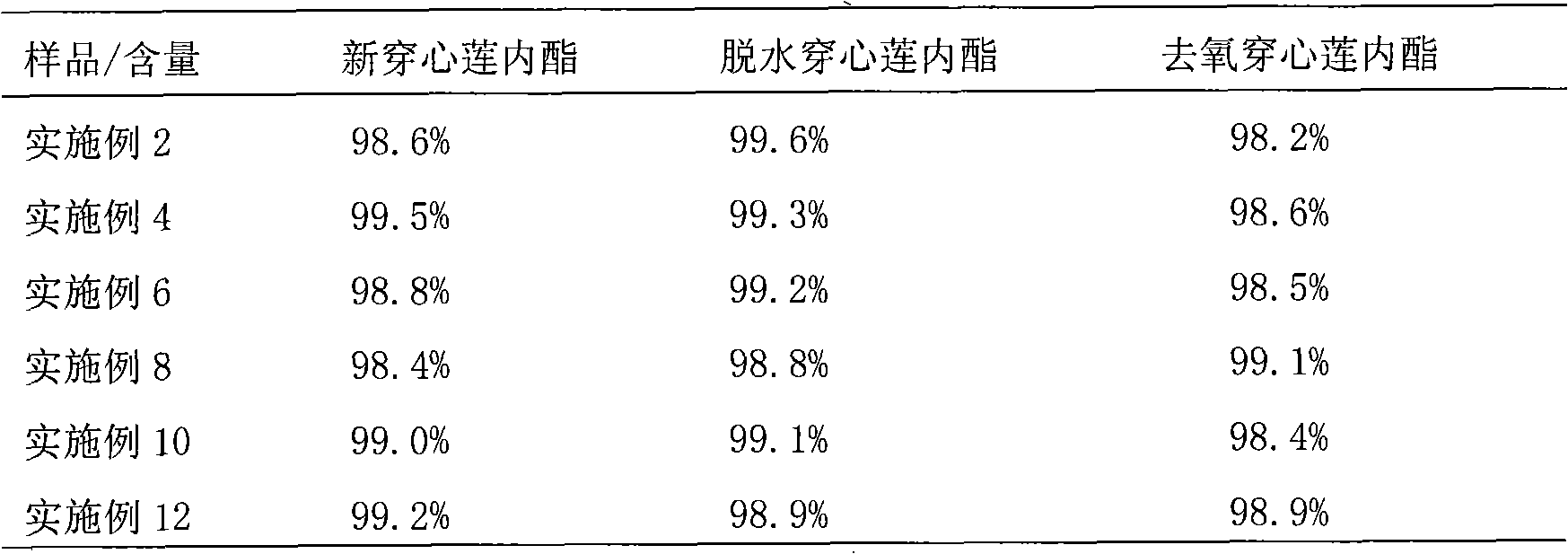

Embodiment 2 3

[0027] The separation of three kinds of andrographis paniculata diterpene lactone monomers of embodiment 2

[0028] Get 20g of total andrographolide in Example 1, grind finely, dissolve with chloroform 200ml, filter, and insoluble matter is cold-dissolve 2 times with chloroform 200ml, 100ml respectively again, filter, merge the chloroform liquid, obtain Two parts of chloroform liquid and insoluble matter. Recover the chloroform solution to dryness, dissolve it in 100ml of 95% ethanol, place it, and precipitate deoxyandrographolide flaky crystals, concentrate the mother liquor to 60ml, place it, and precipitate dehydroandrographolide needle crystals, and continue to concentrate the remaining mother liquor alternately Crystallization, merging deoxyandrographolide crystals, and recrystallization with ethanol and acetone respectively to obtain pure product 3.6g (deoxyandrographolide can still be recovered in the filtrate). The combined dehydroandrographolide crystals were recrystal...

Embodiment 3

[0029] The preparation of embodiment 3 total andrographolides

[0030] Take 1kg of Andrographis paniculata stem and leaf coarse powder, use 15 times the amount of 95% ethanol to extract by cold soaking twice, each time for 24 hours, recover the ethanol extract, dilute it to about 2000ml with water, and use 3000ml of petroleum ether to wash off the chlorophyll etc. Fat-soluble impurities, concentrated aqueous solution, heat-dissolve the concentrated extract in 1000ml of methanol, reflux with 30g of activated carbon for decolorization, filter while it is hot, recover methanol to about 500ml, slowly add 100ml of water, no solids should be precipitated after adding water, first place it at room temperature , and then transferred to the refrigerator overnight, until the andrographolide crystals are completely separated out, vacuum filtered, the filtrate is concentrated to about 350ml, placed in the same way as above, a small amount of andrographolide crystals continue to separate ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com