Patents

Literature

155results about How to "Simplified separation steps" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

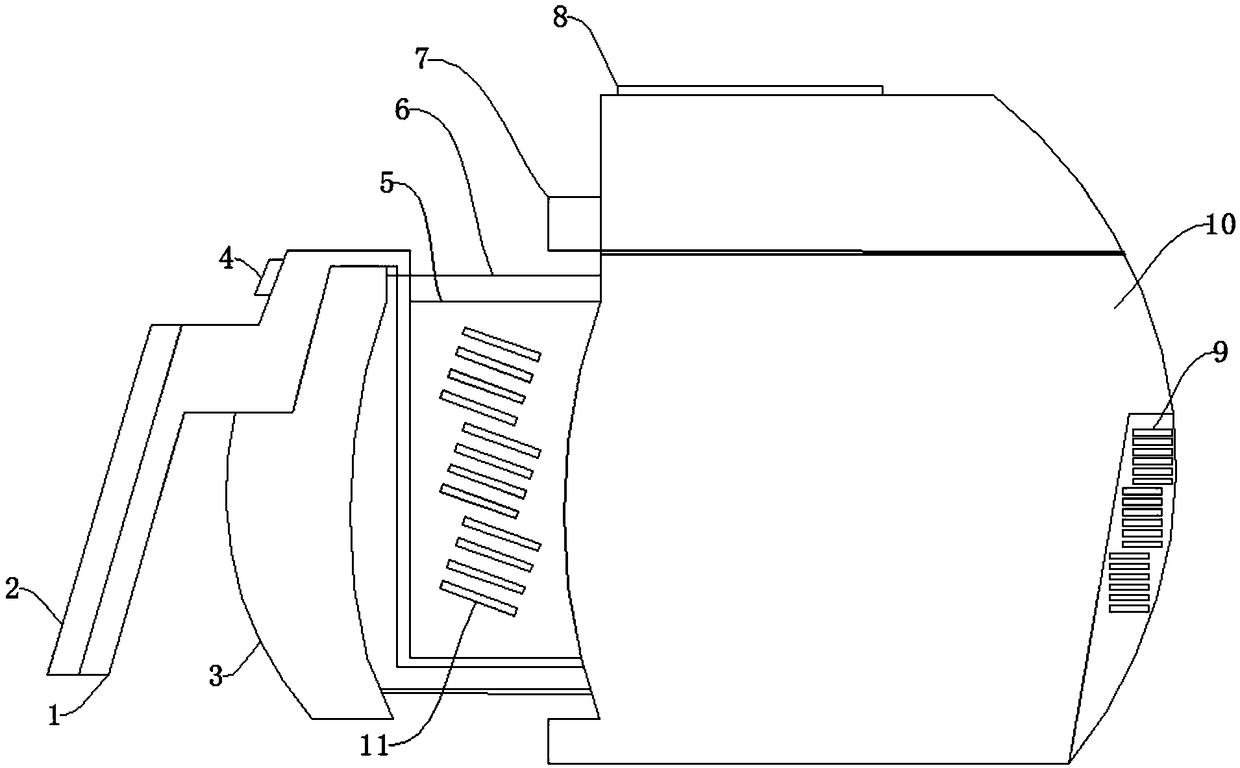

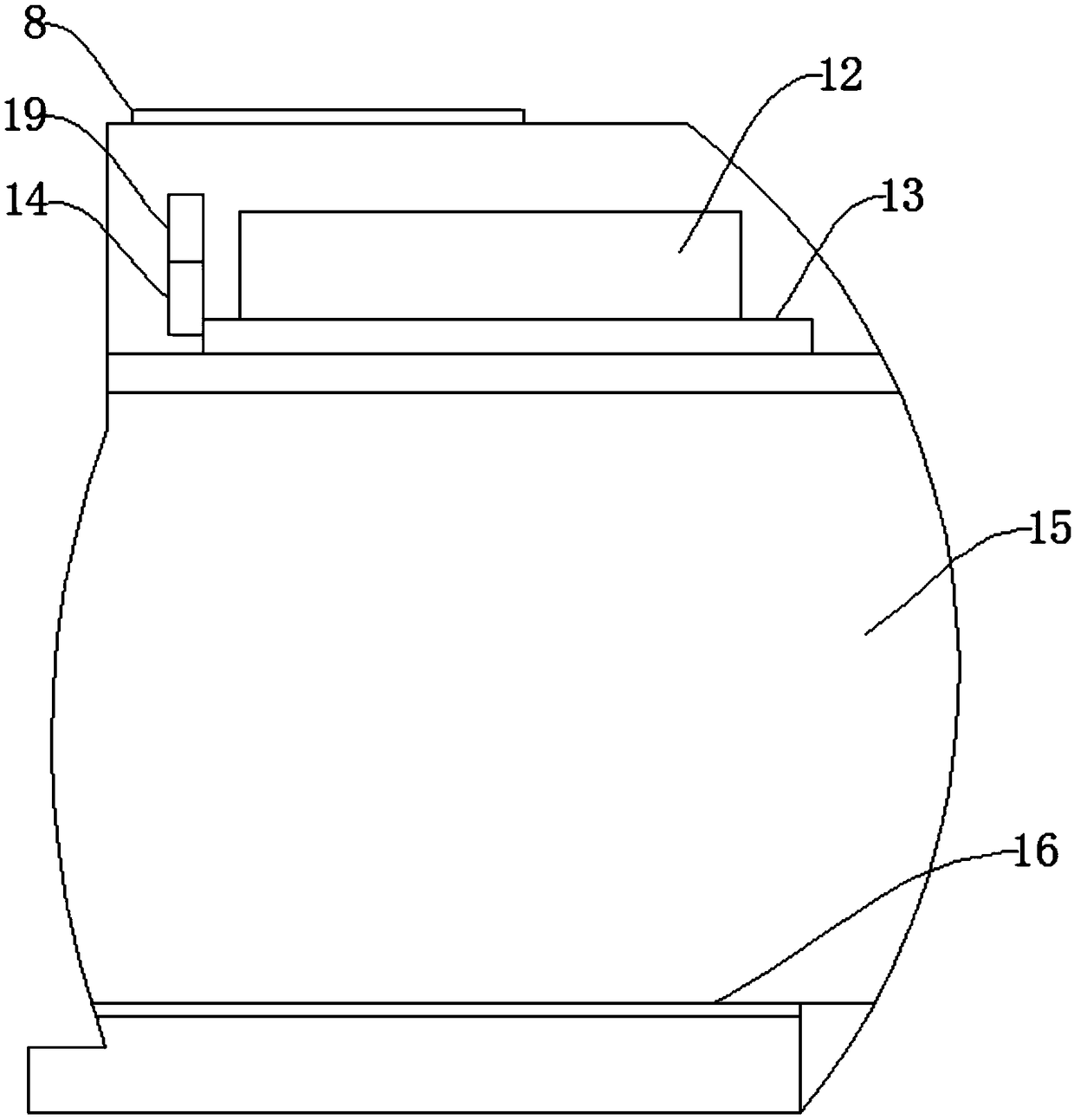

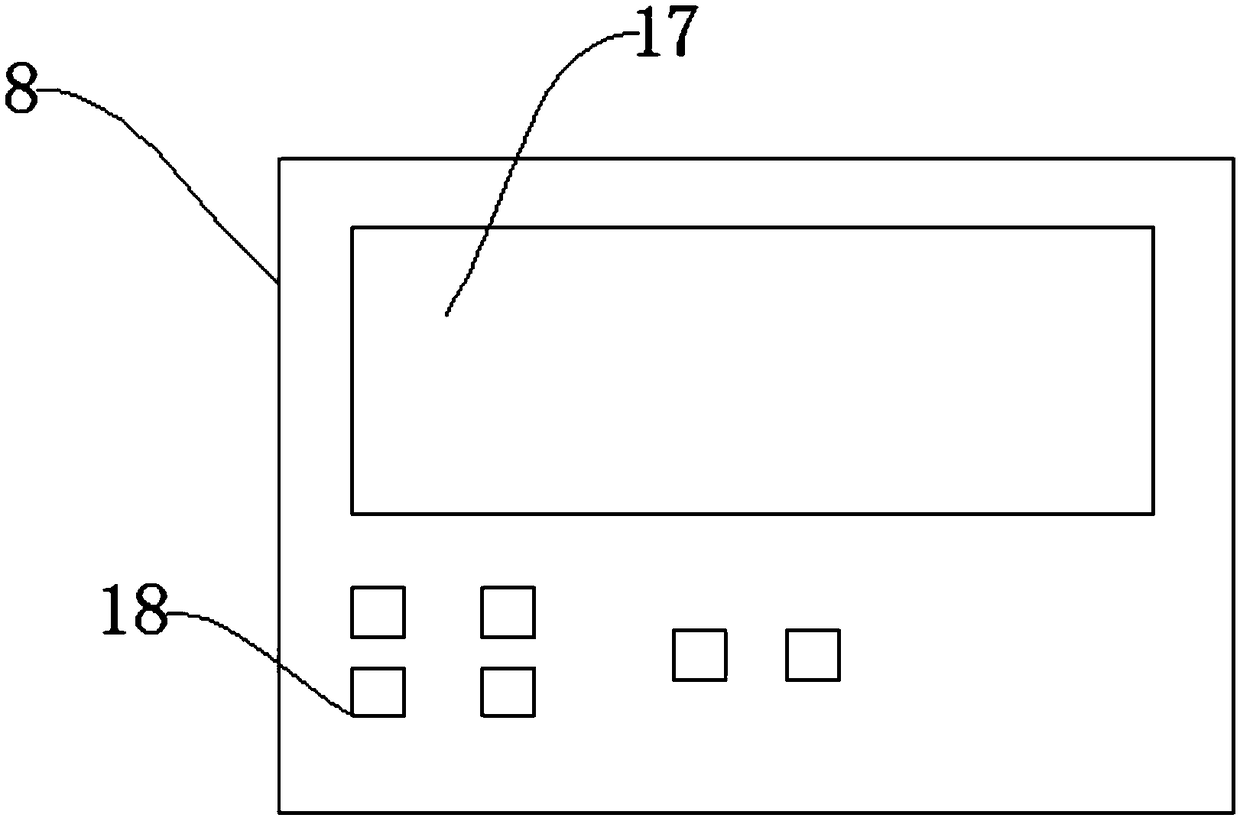

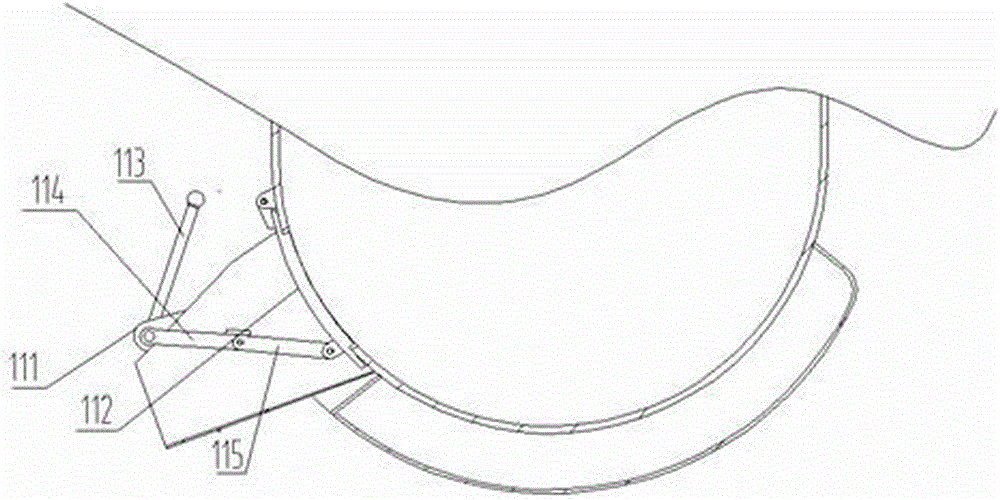

Air fryer with transparent visual window

InactiveCN108618651AObserve the frying situationGuaranteed frying qualityRoasters/grillsRemote controlEngineering

The invention discloses an air fryer with a transparent visual window. The air fryer comprises a fryer body, a handle and a transparent fryer shell, wherein the side, away from the transparent fryer shell, of the handle is provided with an anti-skid pad; a release key is arranged on the upper side of the handle. The air dryer has the advantages that through the arrangement of a transparent fryer body and the transparent fryer shell, the frying condition of food in a frying basket can be visually observed by an operator, and the frying quality of the food is guaranteed; due to the arrangement of a wireless connector, the operator can control the air fryer by being connected to a wireless network and a remote control terminal when away from the fryer body, and application is greatly facilitated; due to the arrangement of the release key, the separation step of the frying basket and the fryer is simplified, the operation is easy and convenient, and the cleaning efficiency of the frying basket is greatly improved.

Owner:郭鑫

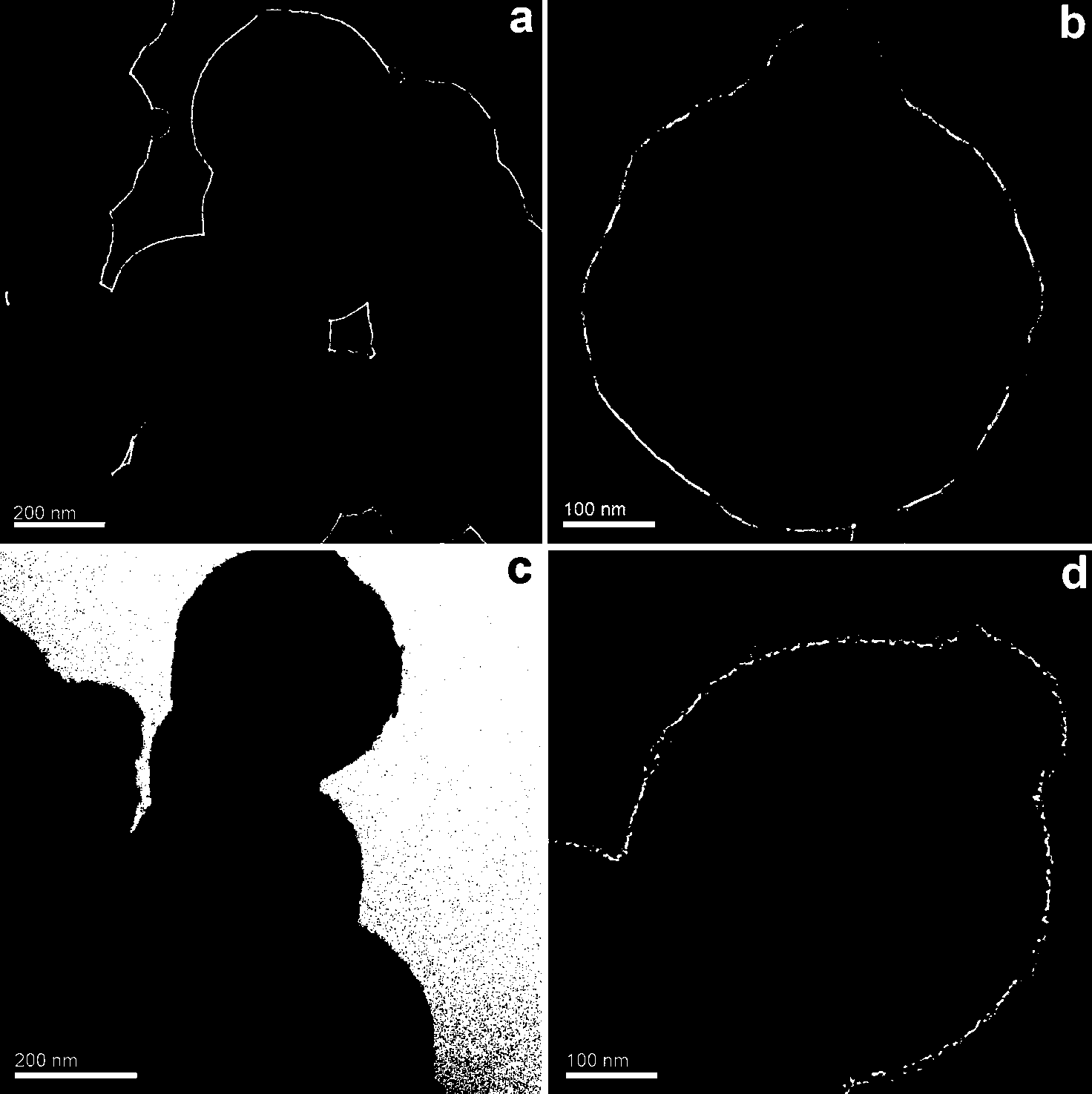

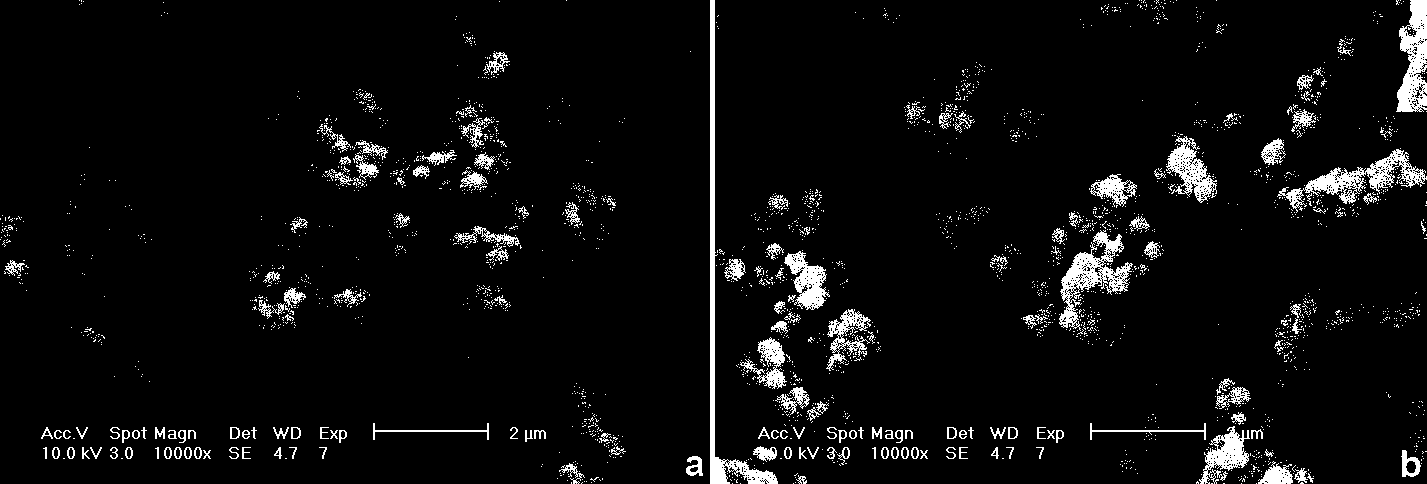

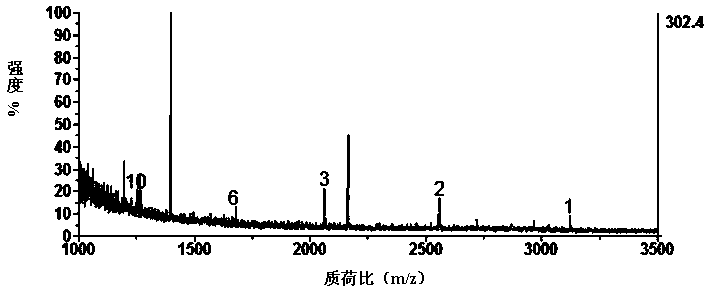

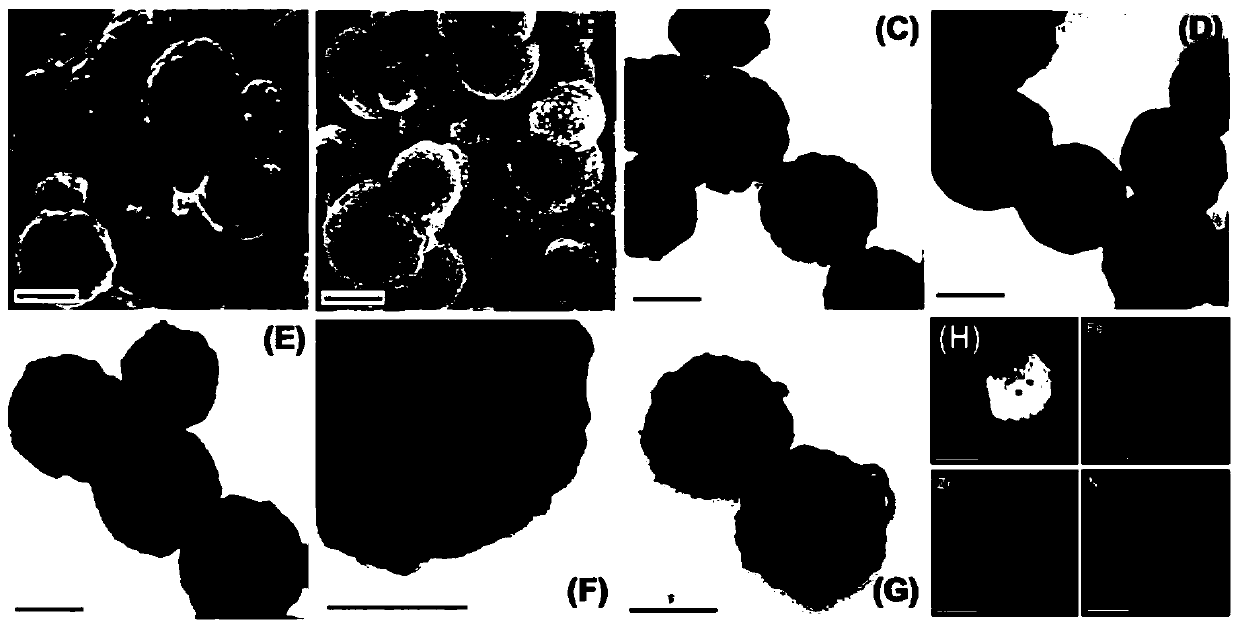

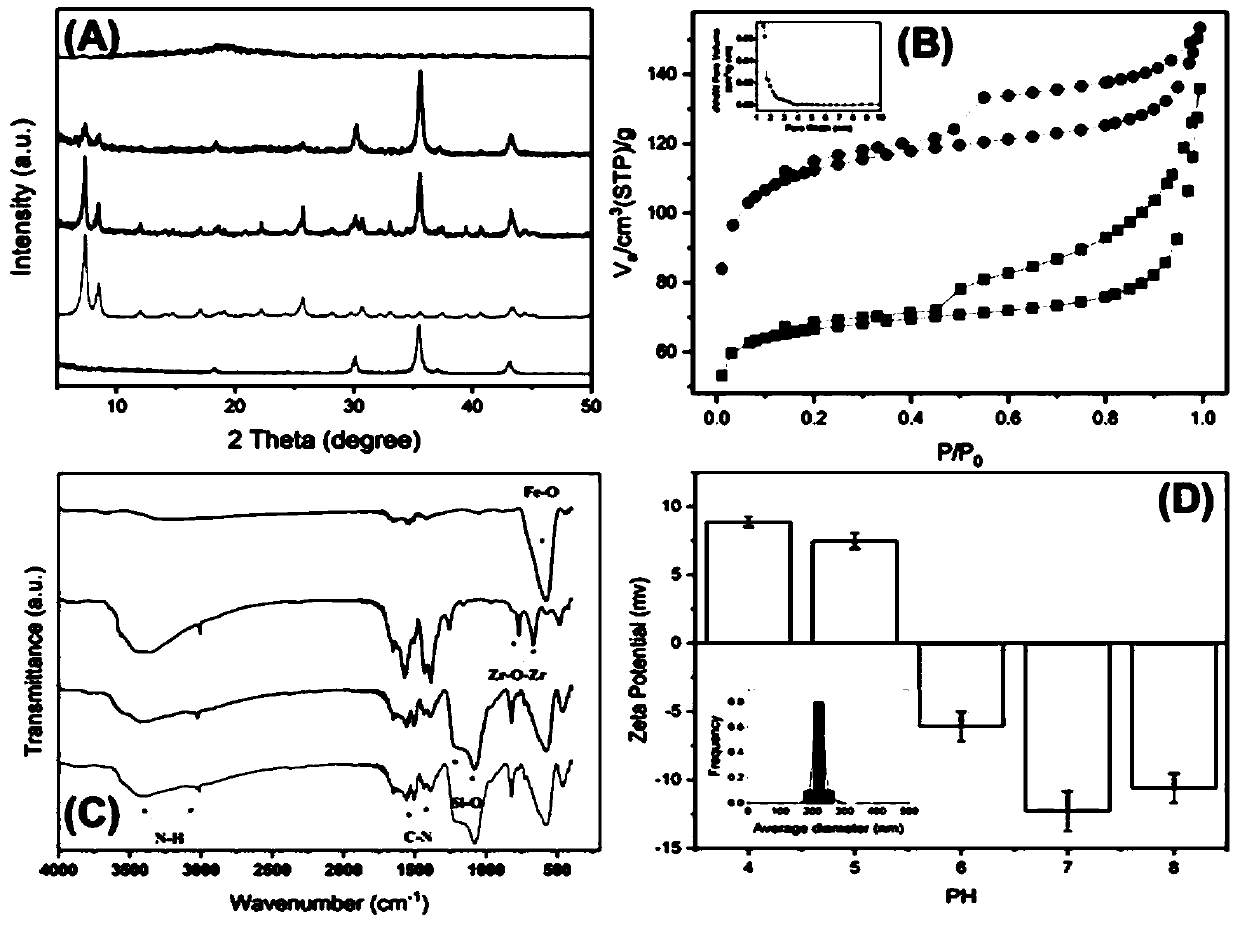

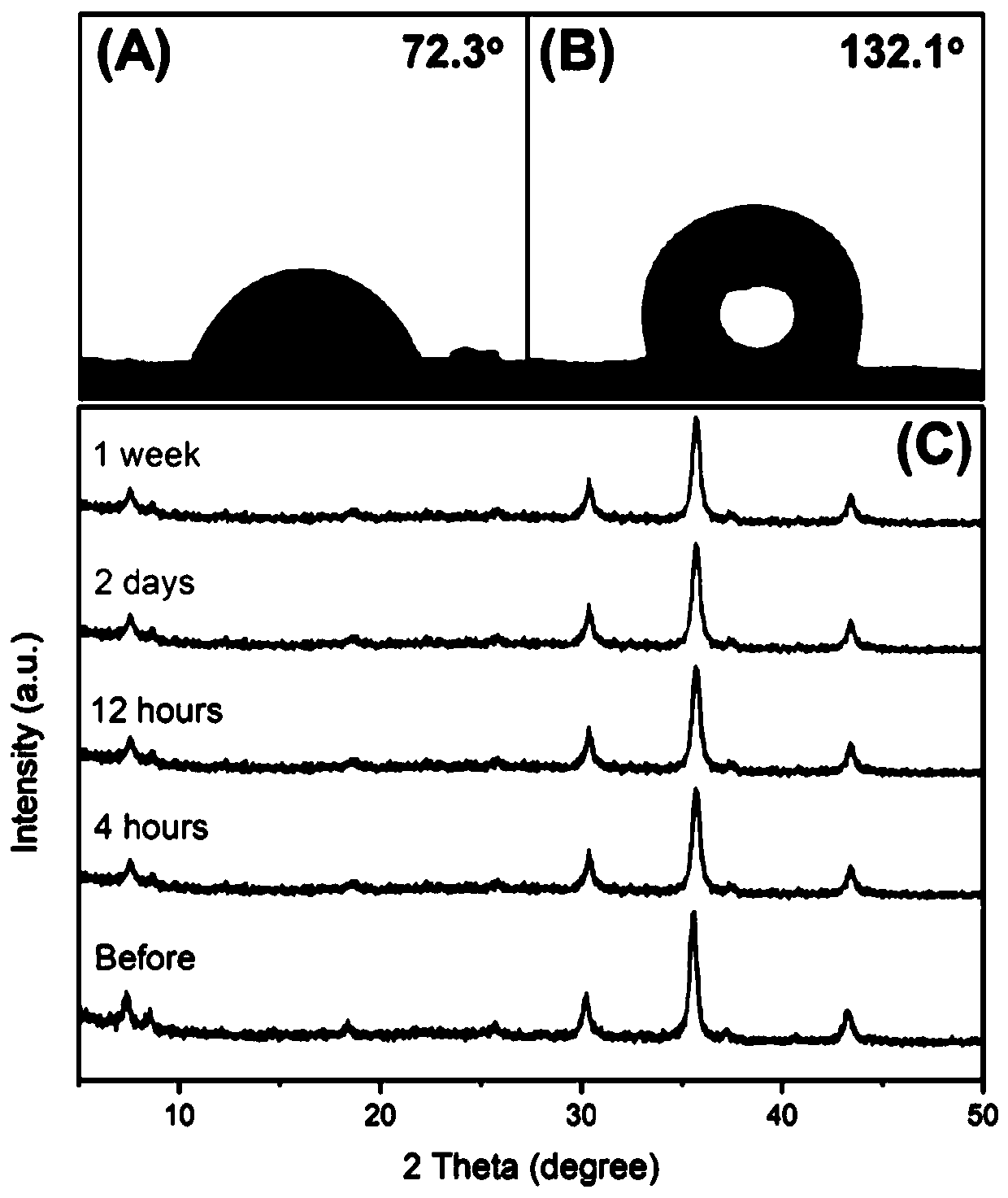

Synthesis method of magnetic metal organic framework composite material and application of material

InactiveCN103894161AGood magnetic responseImprove hydrophilicityOther chemical processesPreparing sample for investigationN dimethylformamideSynthesis methods

The invention discloses a synthesis method of a metal organic framework composite material which has a sandwich structure, comprises magnetic microsphere ferroferric oxide surface coating polydopamine and takes zirconium ion as central metal ion and application of the material. The synthesis method comprises the following steps: firstly synthesizing ferroferric oxide magnetic microspheres by using a hydrothermal synthesis method; dispersing the magnetic microspheres in an aqueous solution of polydopamine hydrochloride to coat the surfaces of the magnetic microspheres with polydopamine layers; dispersing the magnetic microspheres coated with the polydopamine in an N,N-dimethylformamide mixed solution of zirconium chloride and terephthalic acid to prepare the magnetic metal organic framework composite material with a sandwich structure. The synthesis method is simple and quick; the magnetic metal organic framework composite material obtained by synthesizing is high in specific surface area, good in biocompatibility and applicable to selective enrichment of phosphorylated peptide and MALDI-TOFMS detection in biological samples.

Owner:FUDAN UNIV

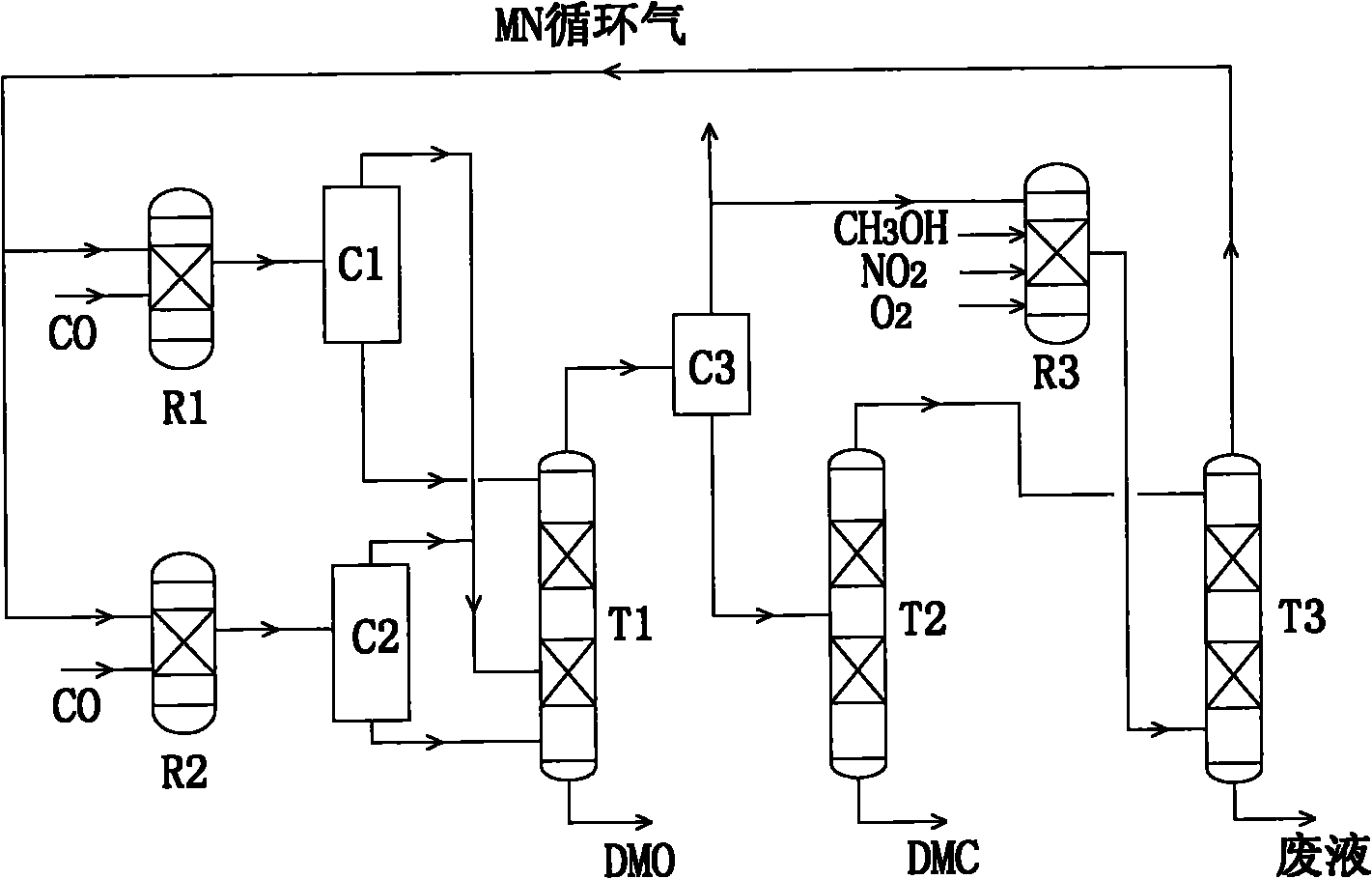

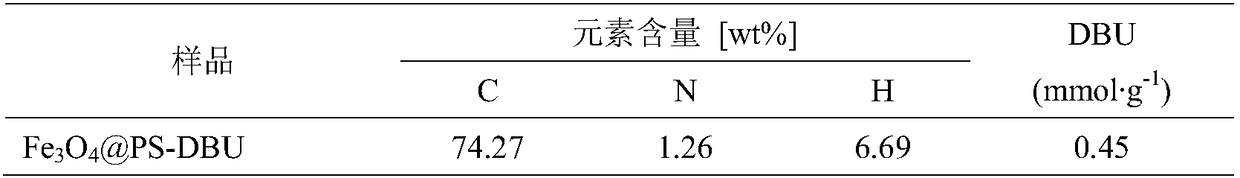

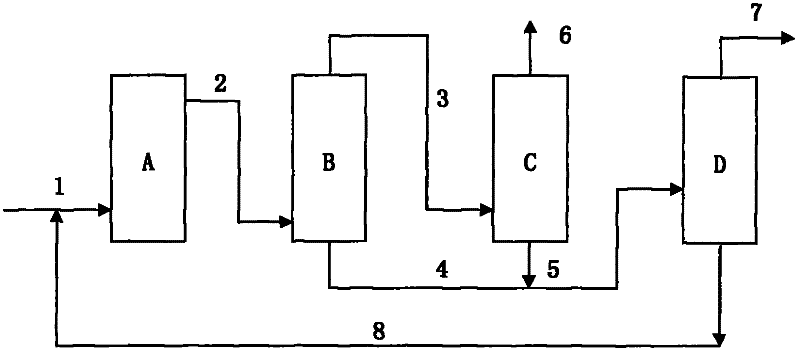

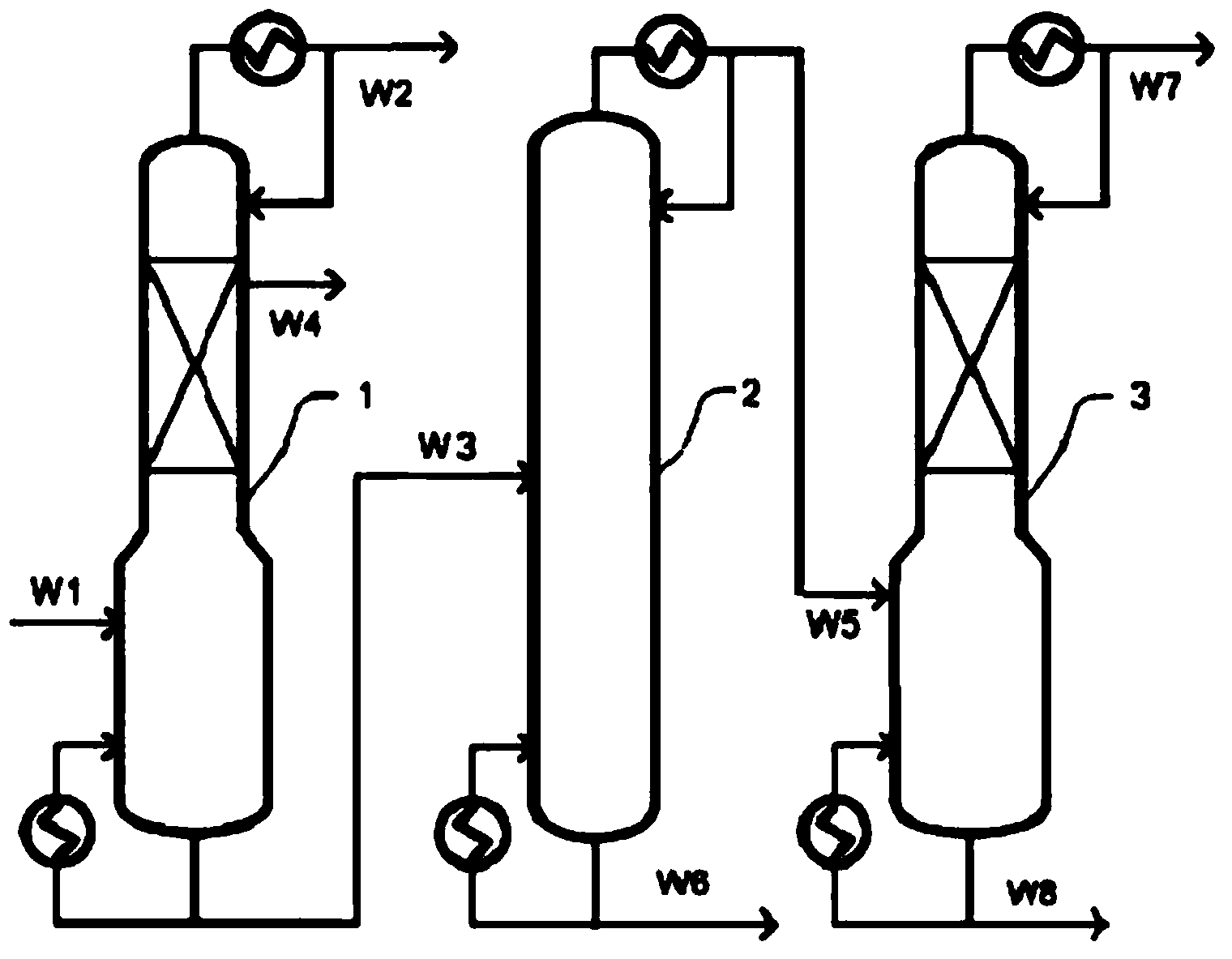

Method and device for co-producing dimethyl carbonate and dimethyl oxalate

ActiveCN101830806AReasonable deployment of productionLower energy requirementsOrganic compound preparationPreparation by carbon monoxide or formate reactionGas phaseTower

The invention discloses a method and a device for co-preparing di(C1-3) alkyl carbonate and di(C1-3) alkyl oxalate. The method comprises the following steps of: a) separating a product of a di(C1-3) alkyl carbonate synthesis reactor into a first liquid phase and a first gas phase; b) separating a product of a di(C1-3) alkyl oxalate synthesis reactor into a second liquid phase and a second gas phase; c) conveying the first liquid phase to a first rectifying tower from the tower top, conveying the combined first gas phase and second gas phase to the first rectifying tower from the middle lower part of the tower, conveying the second liquid phase to the first rectifying tower from the tower bottom, and generating basically pure di(C1-3) alkyl oxalate fraction from the bottom of the first rectifying tower during rectifying; d) separating the overhead fraction produced in the first rectifying tower into a third liquid phase and a third gas phase; and e) conveying the third liquid phase to a second rectifying tower from the middle part of the tower, and generating basically pure di(C1-3) alkyl carbonate from the bottom of the second rectifying tower. Only three rectifying towers are designed in the whole process through reasonable process design, so the energy requirement and operation expense are effectively reduced, and the equipment investment expense is saved.

Owner:PUJING CHEM IND SHA +1

Method for separating and culturing mouse primitive spermatogonia

The invention discloses a method for separating and culturing mouse primitive spermatogonia. In the method, the mouse primitive spermatogonia are separated by utilizing the characteristics of neutral protease, such as mild digestibility performance, high efficiency and small stimulation to cells; the step of enrichment and subculture of the mouse primitive spermatogonia are organically combined; and adherent mouse primitive spermatogonium colony is digested by utilizing the neutral protease, so a better enrichment effect is achieved. The method for separating and culturing the mouse primitive spermatogonia is characterized by simple separating and culturing operation, short period, good effect and low cost.

Owner:ANHUI AGRICULTURAL UNIVERSITY

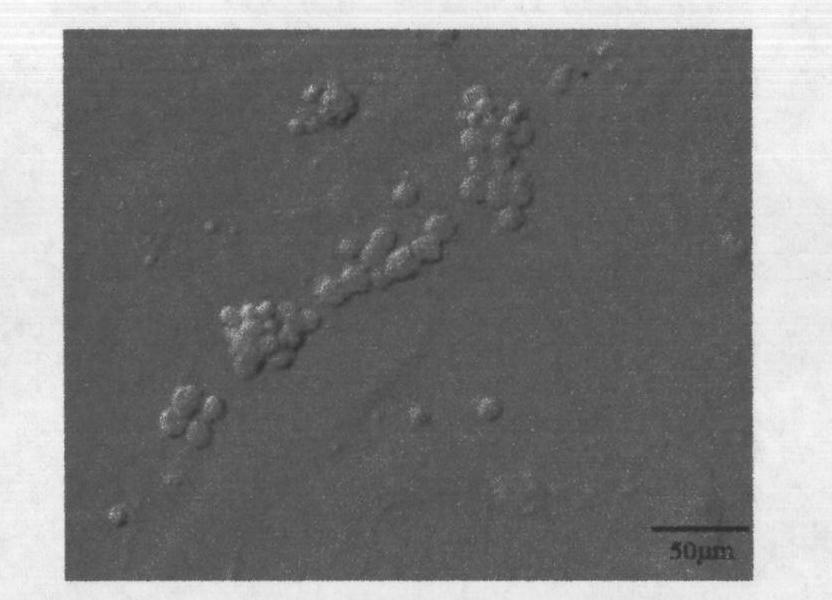

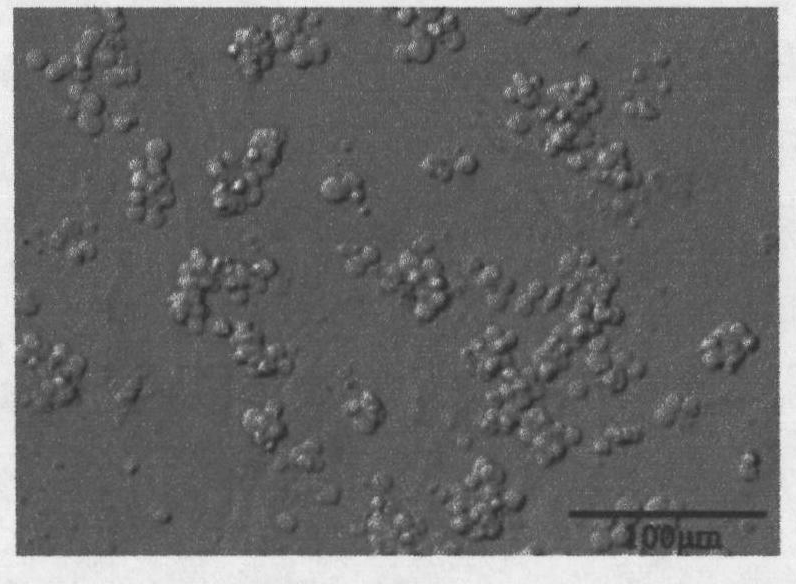

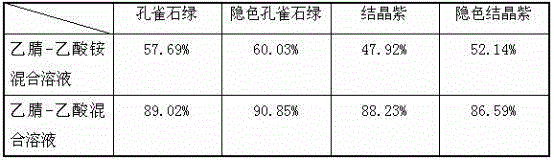

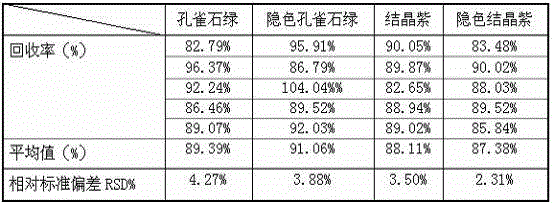

Pretreatment method of detection on malachite green, crystal violet and residues of malachite green and crystal violet in eels

The invention provides a pretreatment method of detection on malachite green, crystal violet and residues of malachite green and crystal violet in eels, belonging to the field of analytical chemistry. The method comprises the operations of weighing of a sample to be detected, homogenization, solid phase extraction, elution and the like; instruments used in the method comprise a constant temperature oscillator, a high speed dispersing homogenizer, a centrifugal machine and the like. A sample solution prepared by using the pretreatment method can be directly detected by using a liquid chromatogram-tandem mass spectrometry method; compared with the prior art, the pretreatment method has the advantages of simple and effective operation, less time consumption, low cost, good reproducibility and the like, and has very strong operability, so that the pretreatment method has the hope to be widely popularized and applied in a large scale in industries such as environment protection, commodity inspection, entry and exit inspection and quarantine and the like, with significant economic benefits.

Owner:FUZHOU UNIV

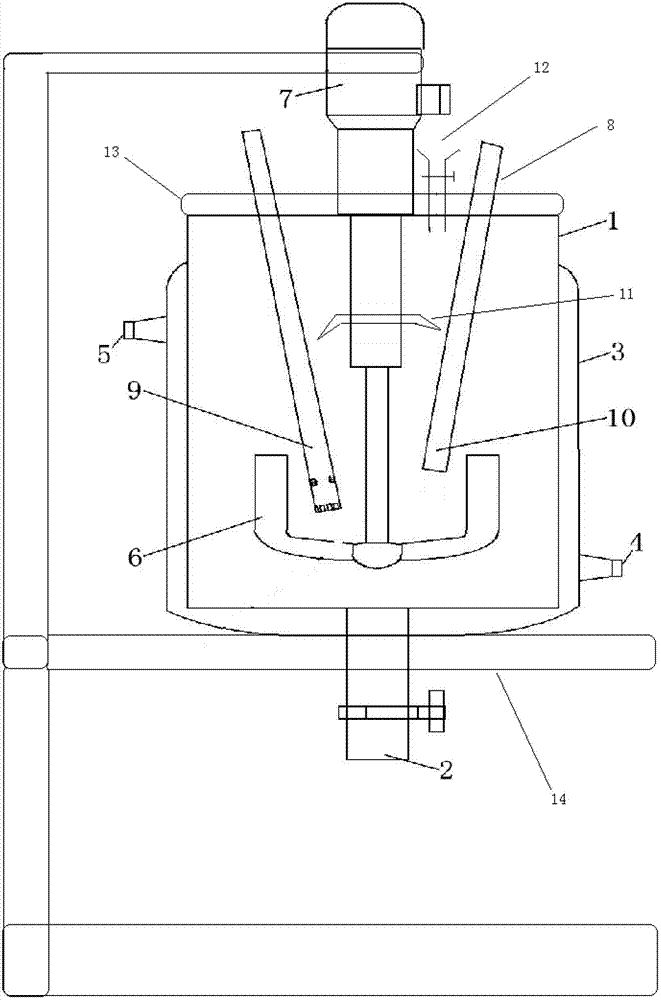

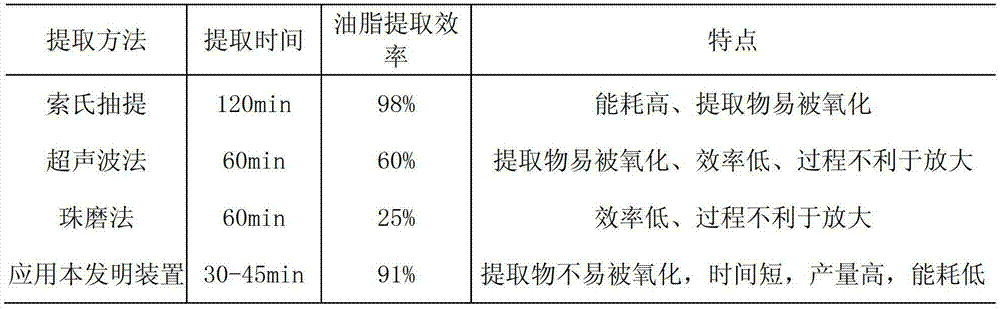

Extraction device of plant active ingredient

InactiveCN103111087AEasy to replaceEasy to cleanChemical/physical/physico-chemical stationary reactorsEnergy based chemical/physical/physico-chemical processesDrive shaftEngineering

The invention discloses an extraction device of a plant active ingredient. The device comprises a homogenate equipment tank body (1) and an end cover arranged at the upper end, wherein the end cover (13) and the homogenate equipment tank body (1) are sealed through a C-shaped clamp and a gasket; a feed funnel (12), an anchor agitator (6), a high-speed shearing agitator (9) and an ultrasonic generator (8) are mounted on the end cover (13); an agitating paddle of the anchor agitator (6), the high-speed shearing agitator (9) and a probe (10) of the ultrasonic generator all extend into a working cavity of the homogenate equipment tank body (1) from the end cover (13); the anchor agitator (6) comprises a motor (7) providing power, a rotation shaft and an agitating paddle; the high-speed shearing agitator (9) and the probe (10) of the ultrasonic generator are located between the agitating paddle and the rotation shaft; and a detachable blade (11) is mounted on the rotation shaft. The device disclosed by the invention has a simple structure and is easy to clean; and the working efficiency is high, and the operation range is wide.

Owner:EAST CHINA UNIV OF SCI & TECH

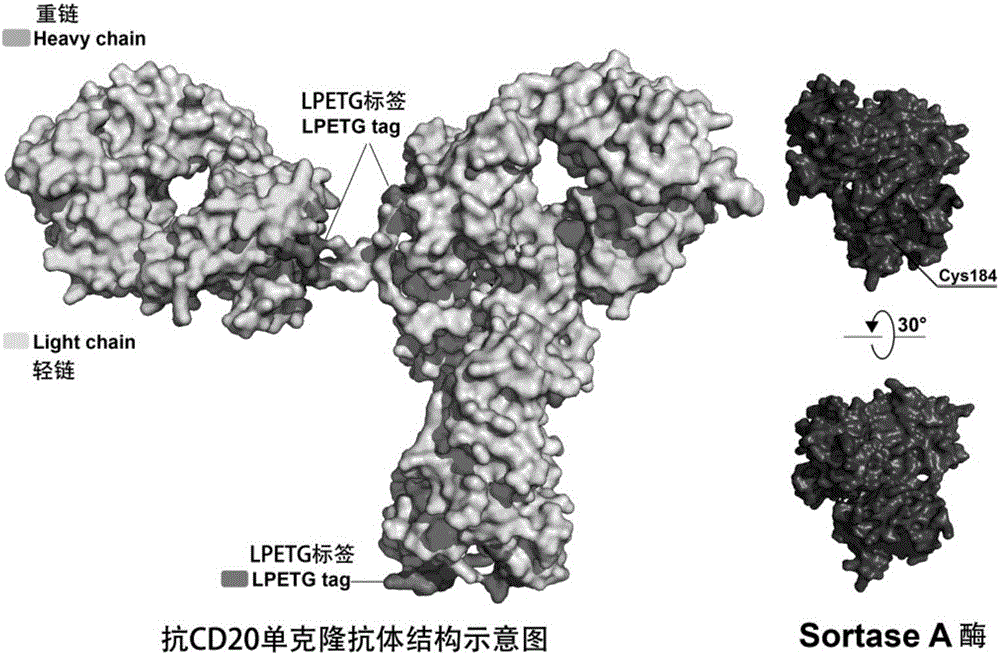

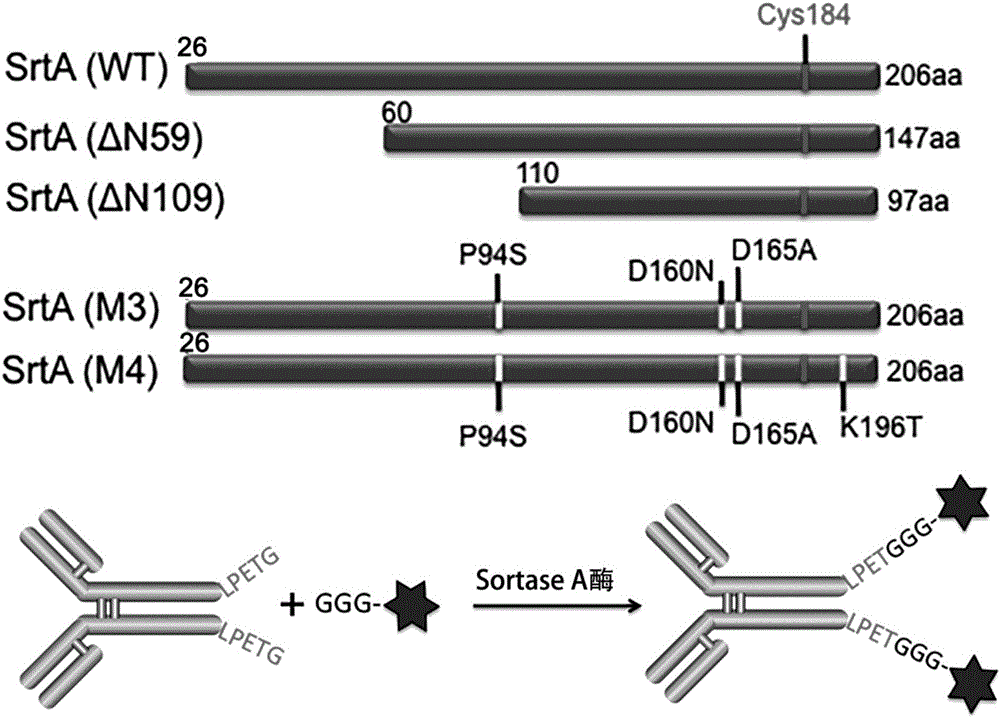

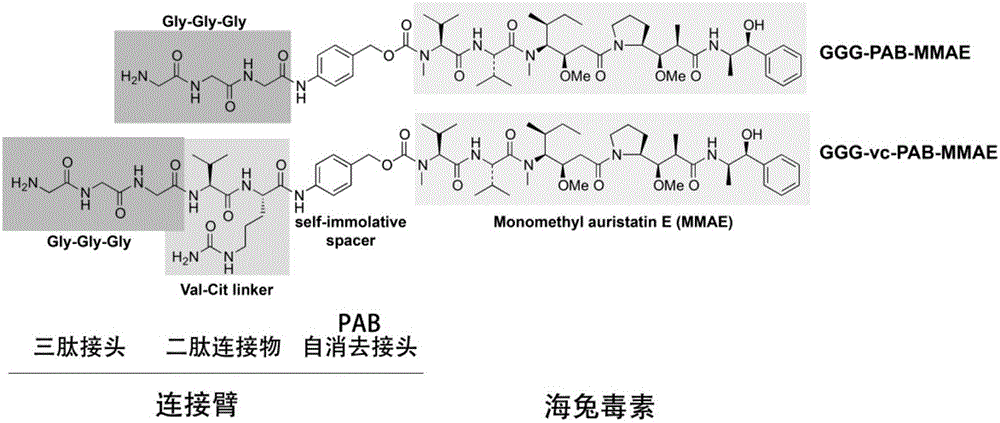

Antibody conjugated medicine and preparation method and application thereof

ActiveCN106237341AHigh anti-tumor activity in vitro and in vivoAvoid the use of organic reagentsPharmaceutical non-active ingredientsDepsipeptide ingredientsAnti cd20Drug

The invention discloses an antibody conjugated medicine and a preparation method and application thereof. The antibody conjugated medicine is formed by connecting an antibody and a medicine through a connecting arm. The antibody is an anti-CD20 monoclonal antibody with heavy chain containing LPXTG sequence. The medicine is aplysiatoxin or a derivative thereof. The connecting arm contains a short-peptide linker for connecting the antibody and a self-elimination linker for connecting the medicine. The short-peptide linker contains at least 1-3 continuous glycines. The antibody conjugated medicine has high uniformity and can achieve higher in-vitro and in-vivo antineoplastic activity with less drug loading capacity (DAR) than CD20 targeting ADC prepared by other chemical methods. IC50 (median inhibitory concentration) for Ramos cells can reach 0.005 nanogram / milliliter.

Owner:ZHEJIANG UNIV

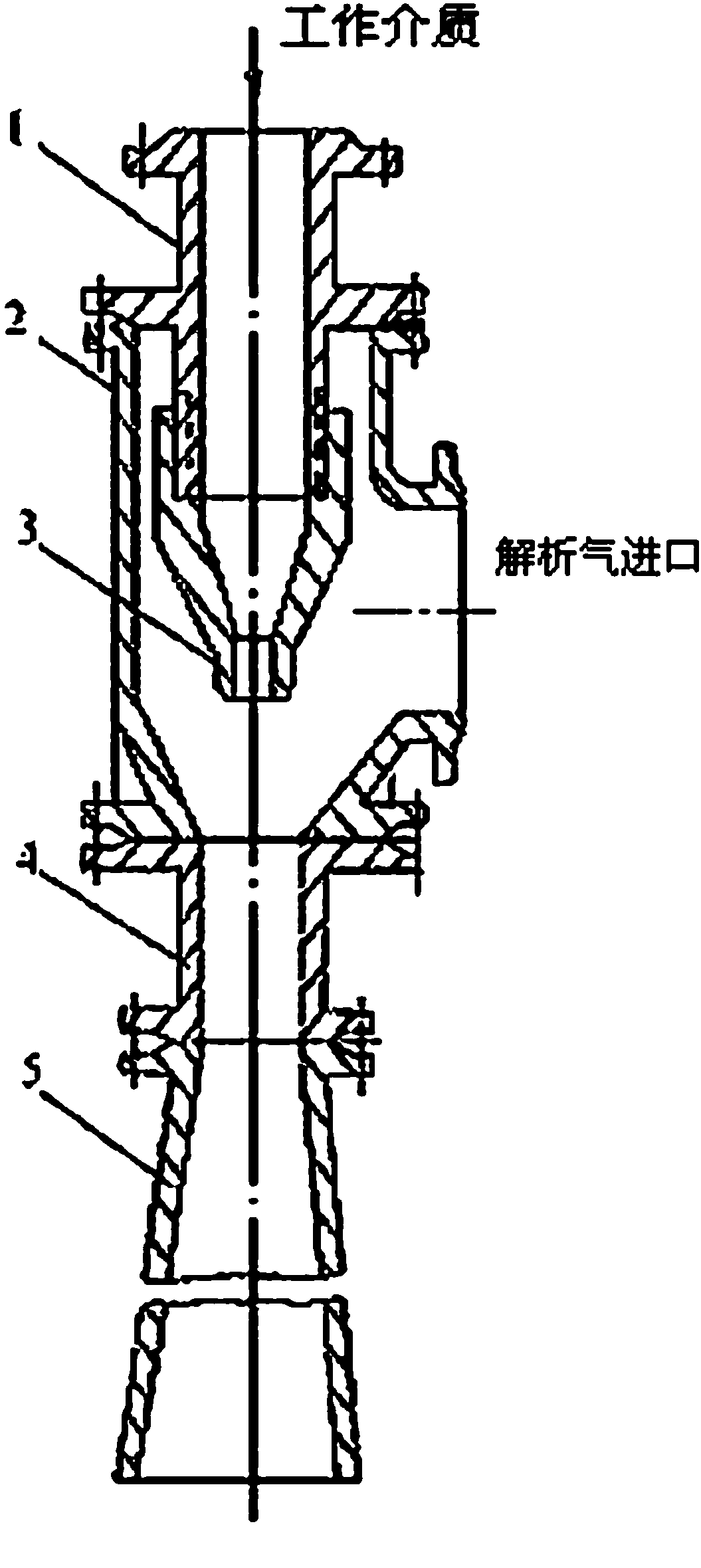

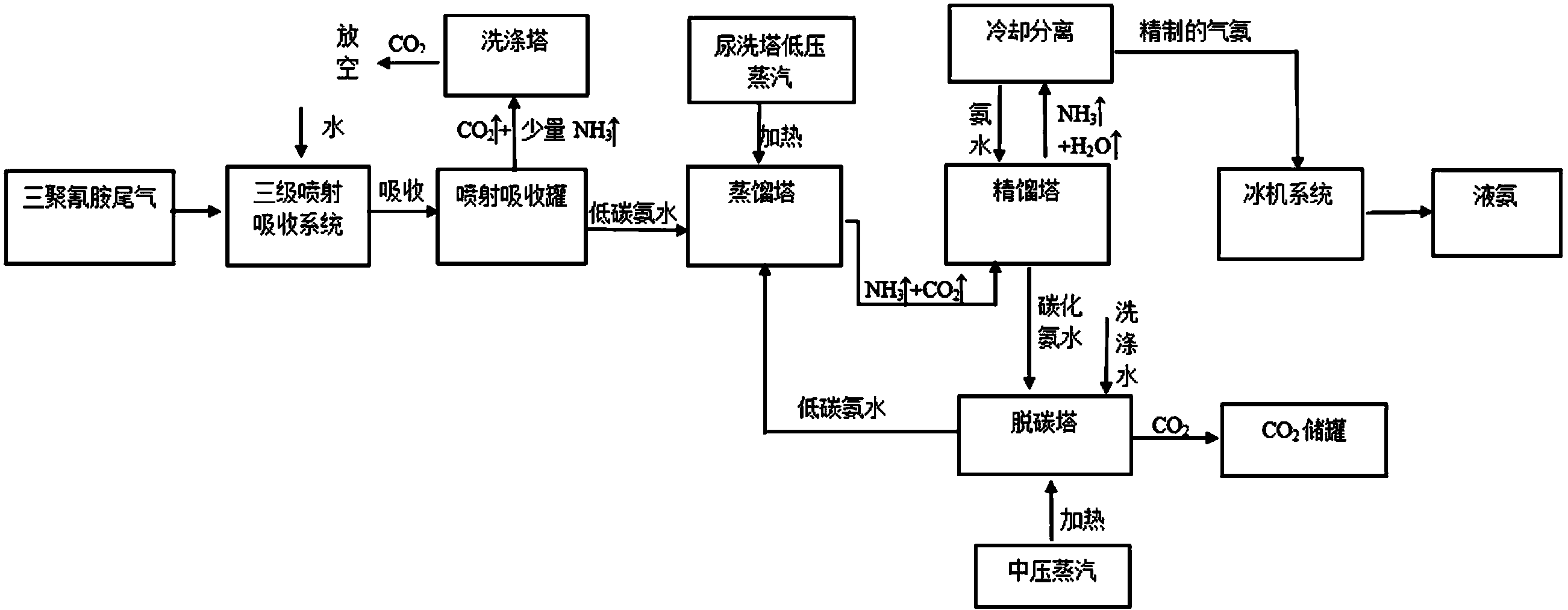

Method for separating ammonia carbon in melamine tail gas

The present invention relates to a method for separating ammonia carbon in melamine tail gas. The method is characterized by comprising absorption, distillation, rectification, decarbonization and other steps. The method has the following advantages that: the low pressure steam produced by the triamine urine washing tower is utilized at a maximum, and the heat of the urine washing tower is recovered by adopting the forced circulation way so as to reduce the steam consumption during the separation process; and the separated water is adopted to replace the desalted water and is supplemented into the urine washing tower steam chest so as to be recycled, such that the apparatus achieves no wastewater discharge so as to provide characteristics of water saving and environment protecting.

Owner:ANHUI JINGHE IND

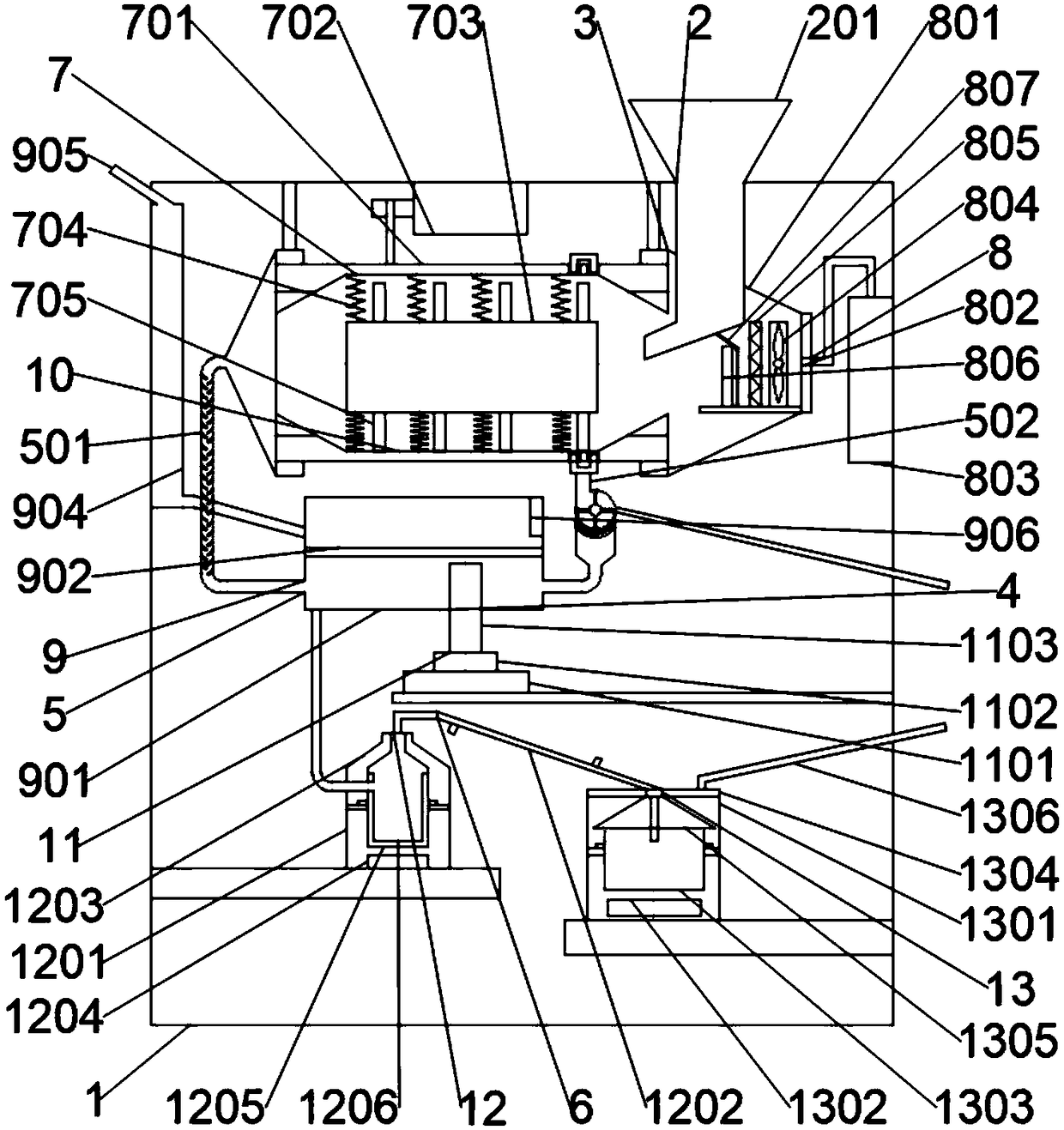

Plant effective component extraction equipment for medical material preparation

ActiveCN108525341AReduce lossHigh extraction rateVapor condensationSolution crystallizationMaterials preparationHas active ingredient

The invention discloses plant effective component extraction equipment for medical material preparation. An ultrafine grinding mechanism is arranged in a mounting case, and an effective component extraction mechanism is arranged on the lower portion of the ultrafine grinding mechanism and comprises a leacher and an efficient cleaning device. The leacher comprises a leaching vessel, the bottom of the leaching vessel is connected with a dry powder guide pipe and a water pulp guide pipe through pipes, and the upper portion of the leaching vessel is connected with a leach liquid adding box which is connected with a filling pipe. The efficient cleaning device comprises an ultrasonic wave generator, an ultrasonic transducer and an ultrasonic amplification rod. An output end of the ultrasonic wave generator is electrically connected with an input end of the ultrasonic transducer, an output end of the ultrasonic transducer is electrically connected with an electric energy input end of the ultrasonic amplification rod, and the ultrasonic amplification rod penetrates the lower bottom surface of the leaching vessel to extend into the leaching vessel. The plant effective component extraction equipment has advantages that separation of impurities and effective components in to-be-extracted plants is realized, and the step of subsequent separation of the effective components in the to-be-extracted plants is simplified.

Owner:南京泽朗医药技术有限公司

Harmless treatment method for dead animal bodies

InactiveCN106140798ASolve the costSolve complexitySolid waste disposalResource utilizationEngineering

The invention discloses a harmless treatment method for dead animal bodies, and relates to the technical field of animal harmless treatment. The harmless treatment method comprises the following steps of: conveying the dead animal bodies into a crushing and stirring device to crush; in a crushing process, starting a heating device on the bottom of the crushing and stirring device, heating and drying the dead animal bodies; when a heating temperature reaches a preset value, smelting out oil in the dead animal bodies; discharging grease and residues generated after dead animal body smelting into a spiral conveying device; and in a conveying process of the spiral conveying device, realizing separation of grease and residues. The harmless treatment method disclosed by the invention is relatively low in cost; and the residues subjected to harmless treatment can be used for preparing products capable of being recycled, so that a resource utilization rate is increased.

Owner:四川金逸智科技有限公司

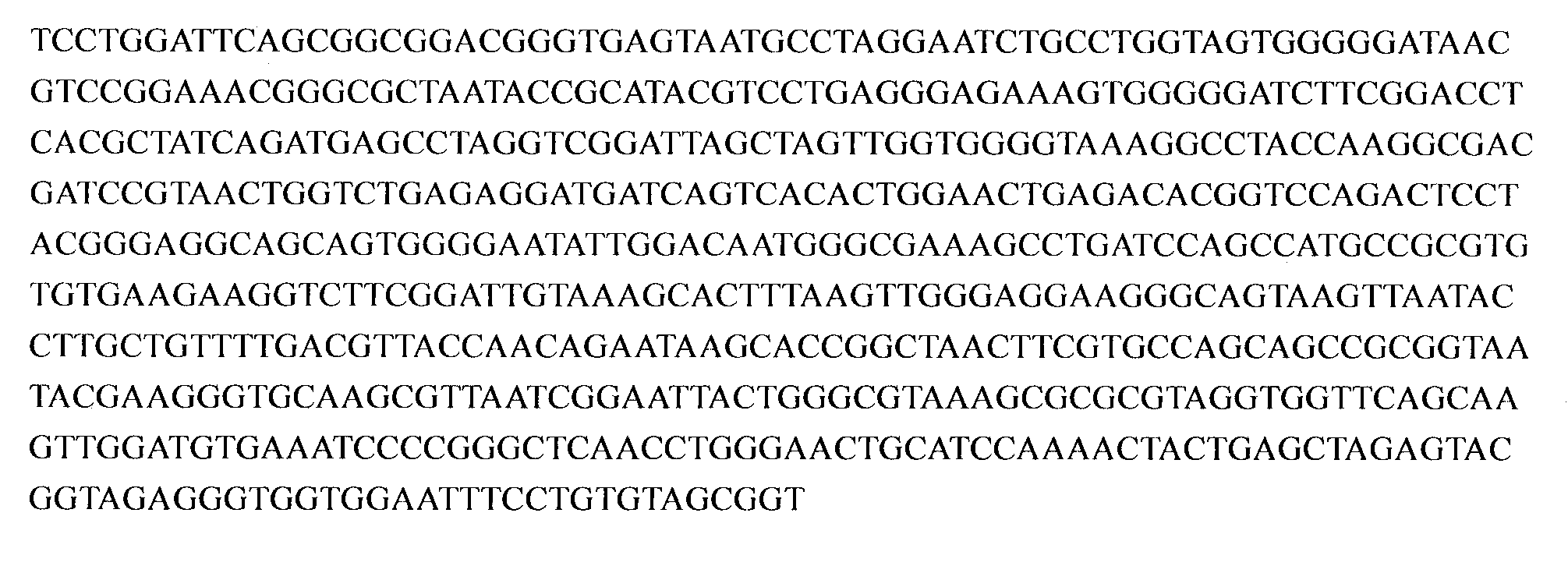

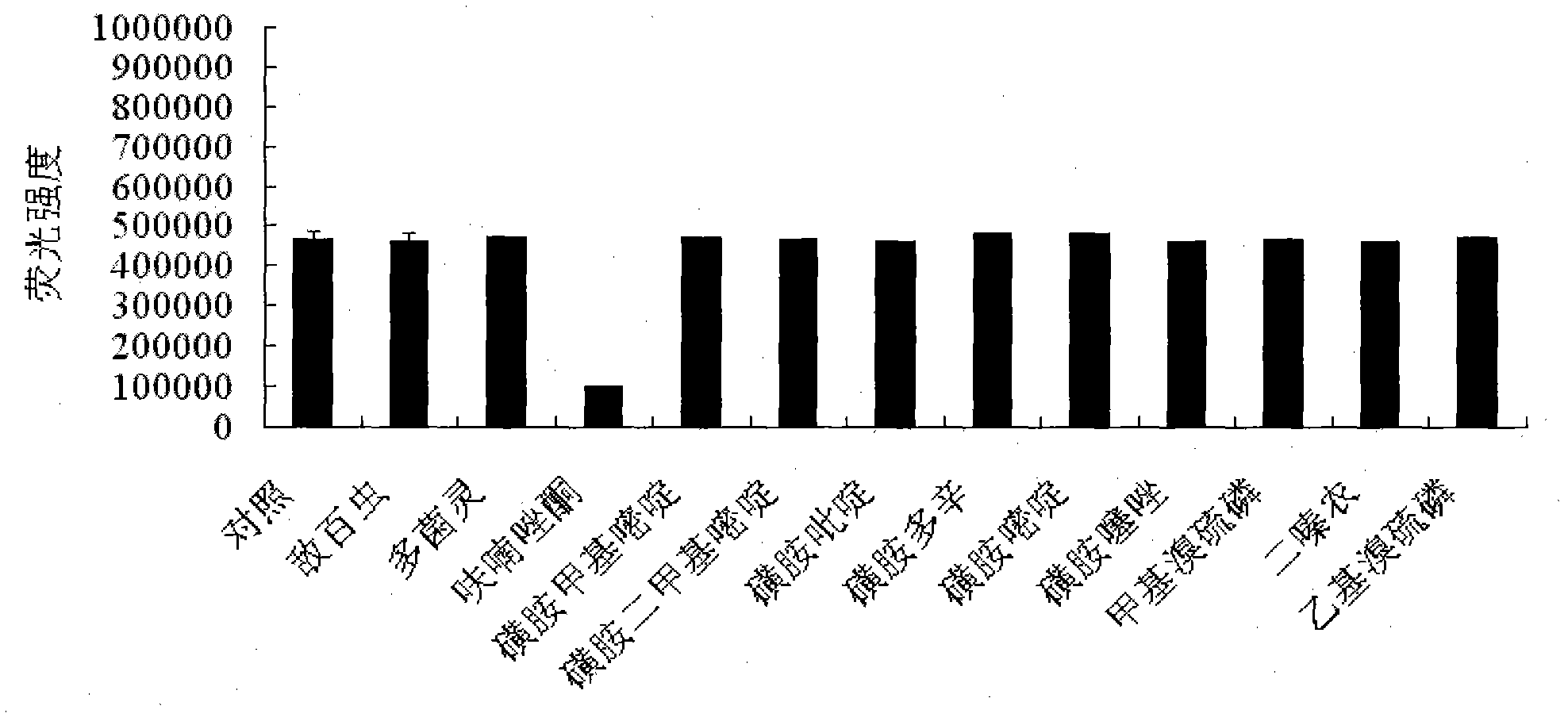

Pseudomonas aeruginosa capable of secreting fluorescent iron carrier and application thereof

InactiveCN102911891AEasy to trainSimplified separation stepsOrganic compounds purification/separation/stabilisationBacteriaMicroorganismFluorescence

The invention relates to application of a microorganism material in detection of environmental pollutants, in particular to a fluorescent iron carrier secreted by pseudomonas aeruginosa (Pseudomonas aeruginosa) PA1 and application thereof. The pseudomonas aeruginosa PA1 is registered and preserved in China General Microbiological Culture Collection Center (CGMCC); the preservation date is April, 28th, 2011; and the number is CGMCC No.4799. When the fluorescent iron carrier secreted by pseudomonas aeruginosa (Pseudomonas aeruginosa)PA1, related by the invention, is used for detecting furazolidone in the environment, the fluorescent iron carrier has the advantages of high specificity and fastness, and the furazolidone is quickly and sensitively detected on the basis of optimization of experimental conditions.

Owner:烟台海上传奇生物技术有限公司 +1

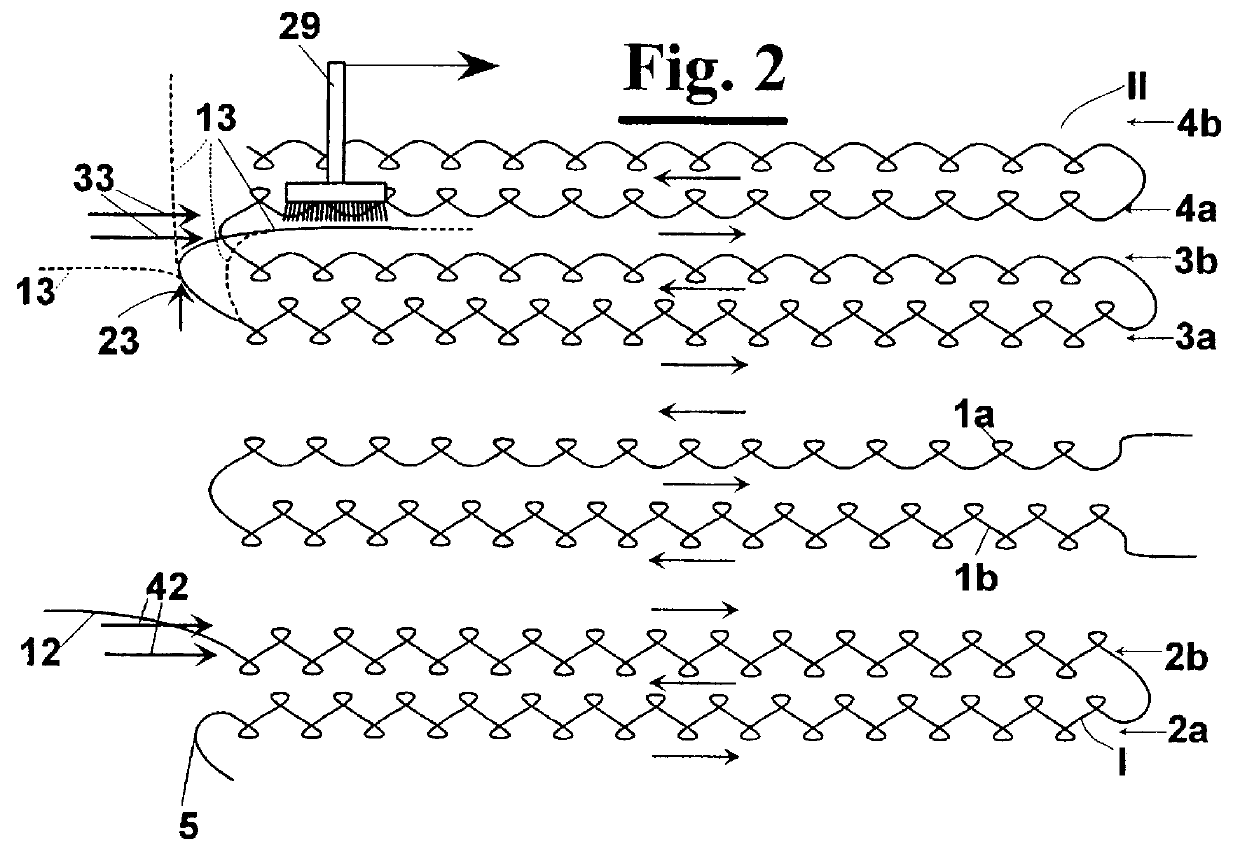

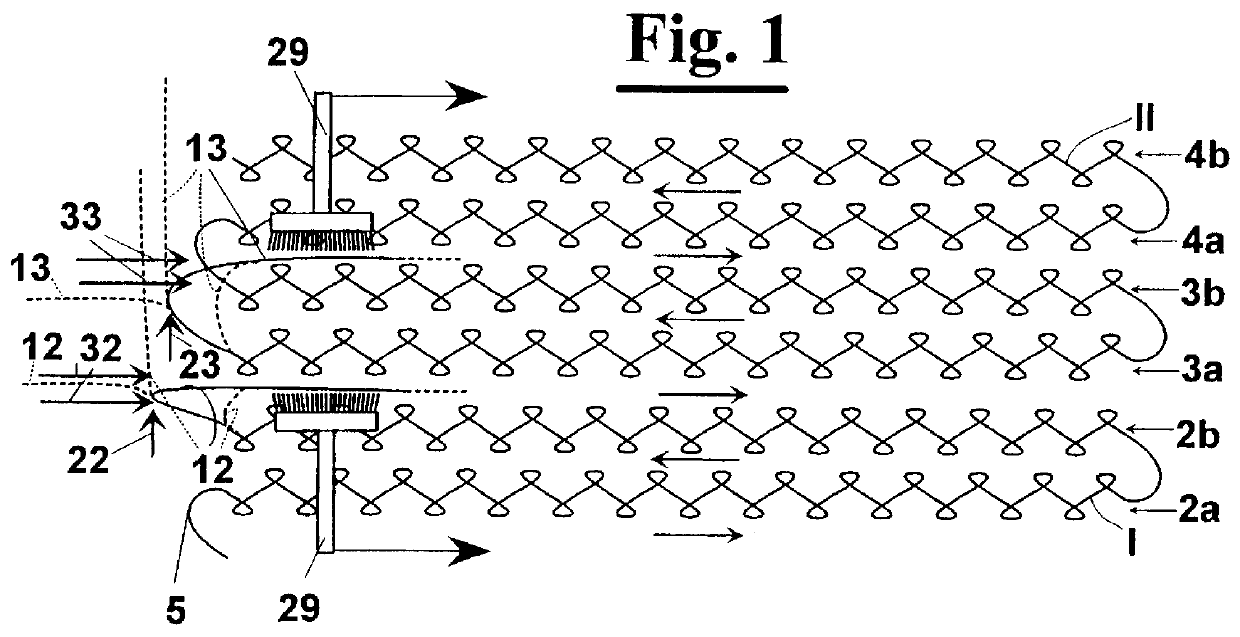

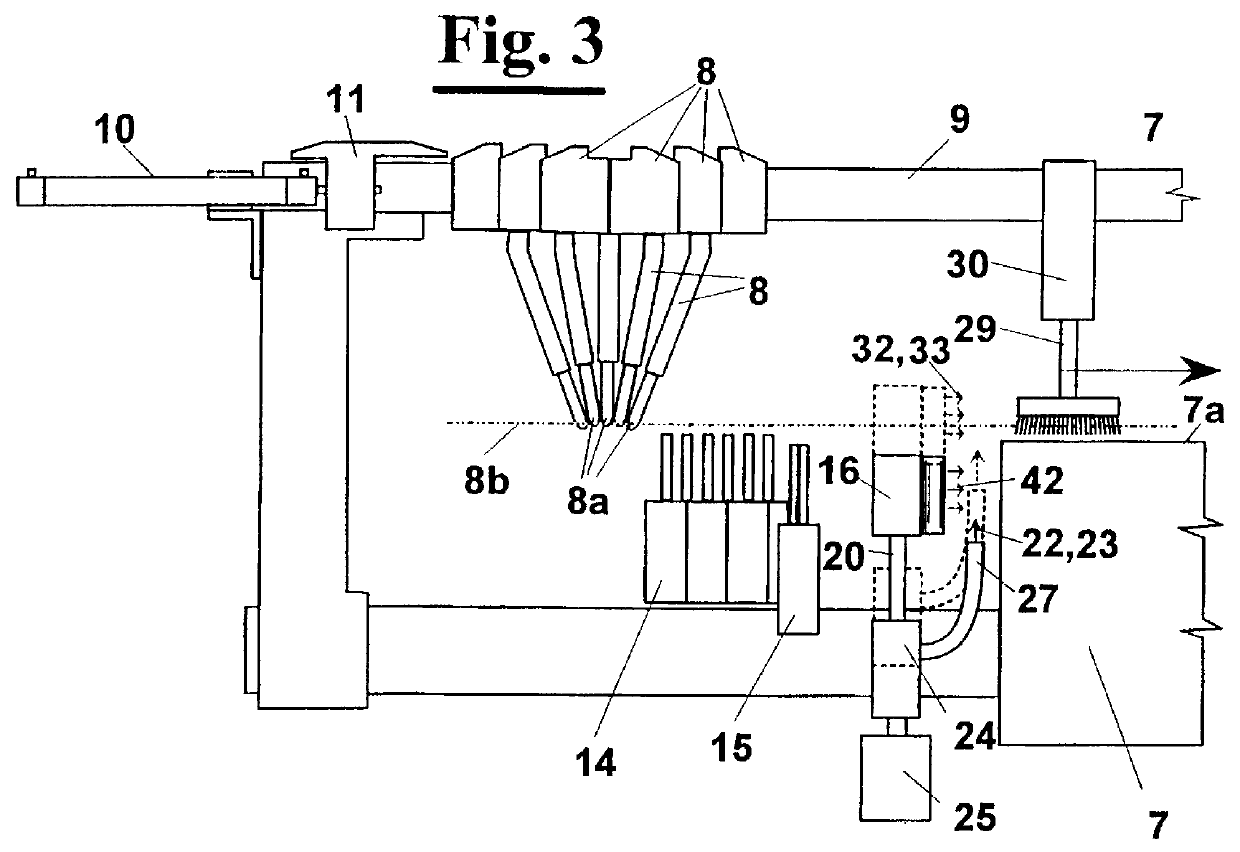

Method and equipment for restraining while knitting the end portions of cut thread protruding from collars for knit-wear articles and the like

InactiveUS6073466ASimplified separation stepsLoomsFlat-bed knitting machinesShaft collarScrew thread

PCT No. PCT / EP97 / 02859 Sec. 371 Date Nov. 23, 1998 Sec. 102(e) Date Nov. 23, 1998 PCT Filed Jun. 2, 1997 PCT Pub. No. WO97 / 45579 PCT Pub. Date Dec. 4, 1997A method and an apparatus, applicable to a knitting machine for the production of collars and the like, for restraining while knitting end portions of cut thread (12, 13) protruding from the edge (5) of said collars into the stitches that compose them. The means for introduction (16) of said thread ends (12, 13) among two next courses of stitches comprises fluid currents (22, 32) that catch the end portions and align them to the stitches while knitting. A combing step of the end portions and stretch them when passing may be provided for. A mobile blowing head (16) and a mobile nozzle (27) are provided for suited to produce said fluid currents (22, 32) while knitting and lower in order not to interfere with thread support means (8, 28). The and portions (12, 13) are restrained among the stitches of the collar without leaving portions or loops protruding from the edge. In order to make easier the separation of the collars, the thread of union of the collars is advantageously cut forming two thread ends which are restrained in turn among the stitches in the same way of the threads which form the collars.

Owner:A R M I ASSISTENZA RICAMBI MACHINE INDALI

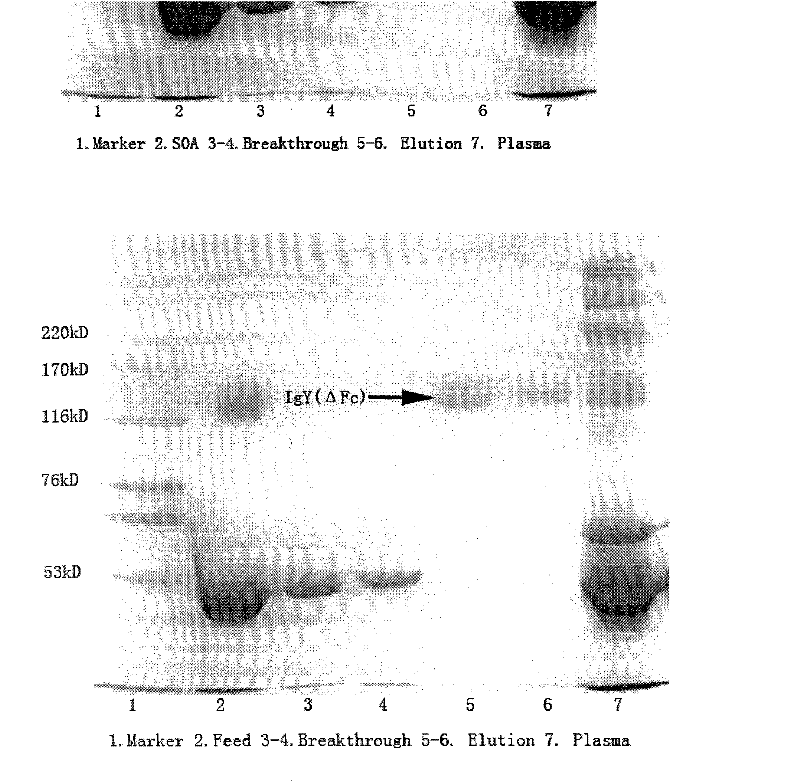

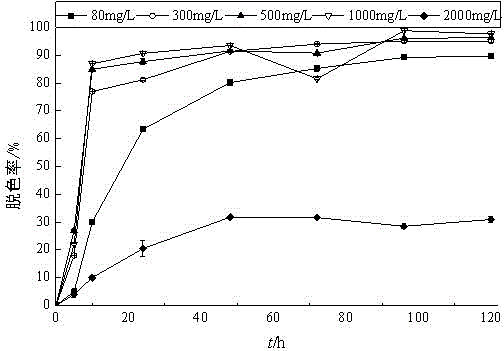

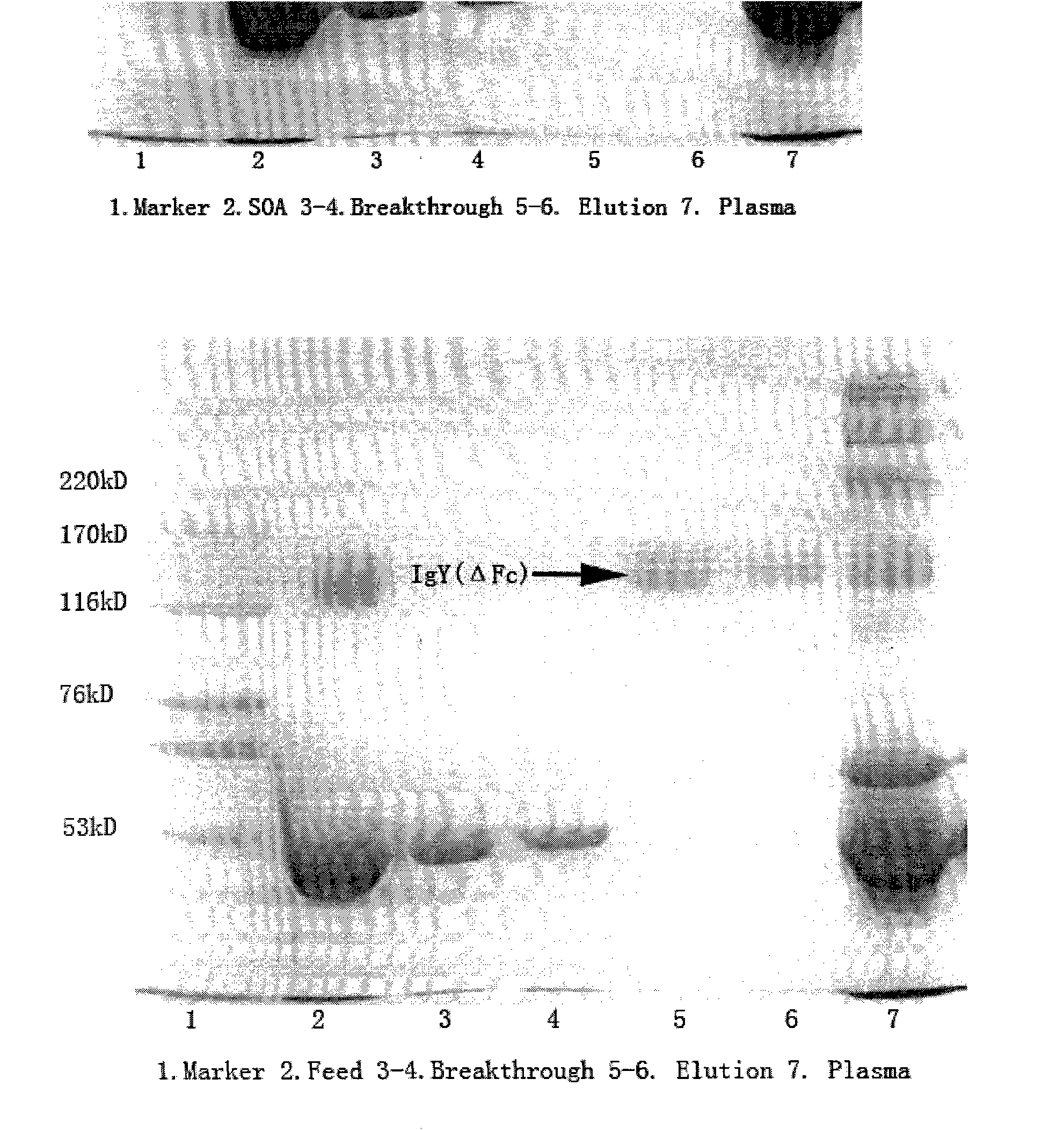

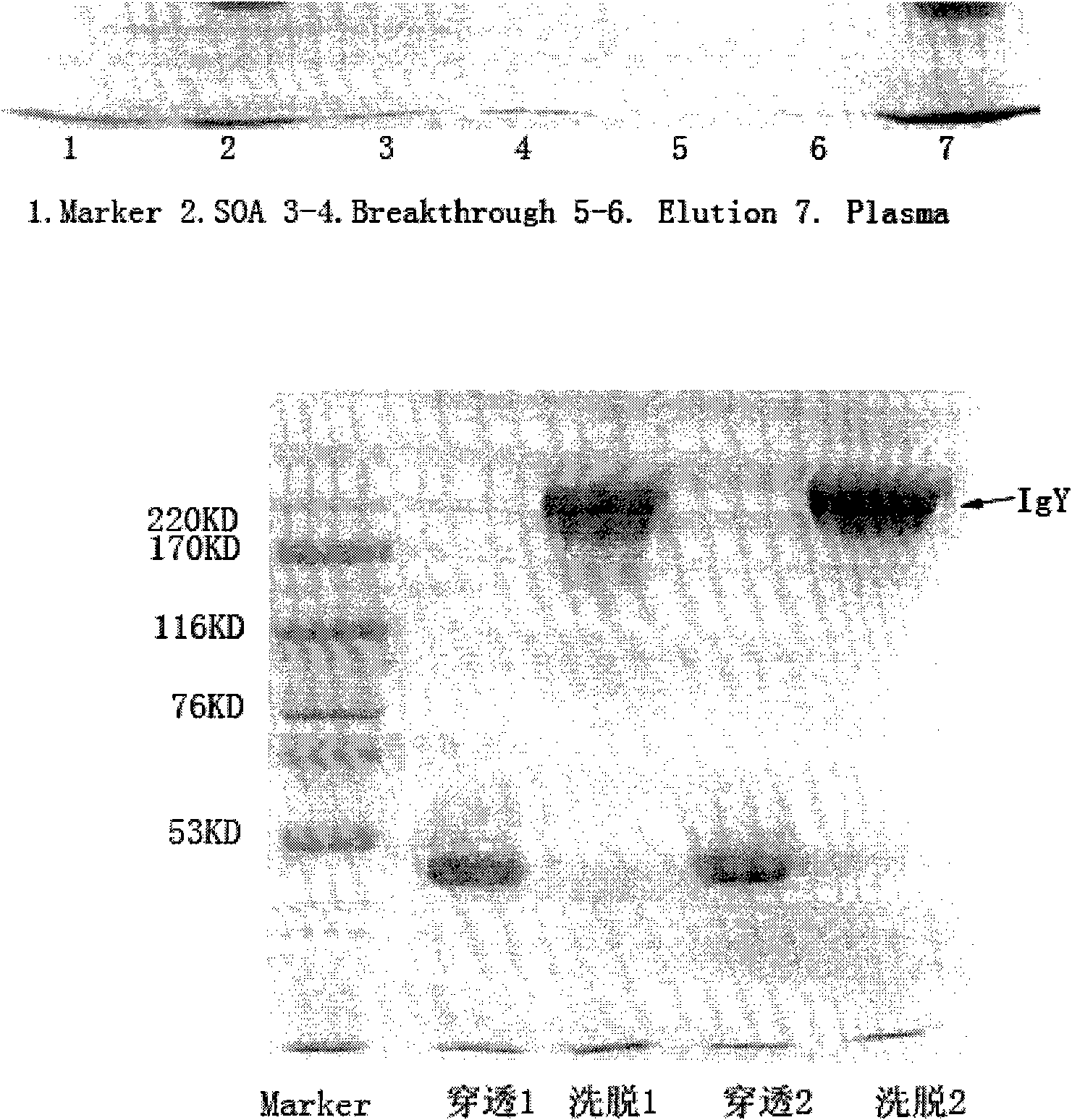

Method for separating immune globulin IgY(delta Fc) from goose blood

InactiveCN101899110BHigh purityImprove separation efficiencySerum immunoglobulinsPeptide preparation methodsOctanoic AcidsDesalination

The invention discloses a method for separating immune globulin IgY(delta Fc) from goose blood. The method comprises the following steps: 1) degreased plasm preparation, wherein fresh blood is selected to be centrifuged to remove erythrocyte, and then is degreased to obtain the degreased plasm; 2) octanoic acid precipitate, wherein octanoic acid is added to the plasm to reach a certain concentration, hybrid protein is precipitated and removed, and is centrifugally separated to obtain supernate; 3) column chromatography, wherein the supernate is separated by a chromatographic column which is filled with hybrid mode adsorbent to collect elution peak; and 4) desalination and drying, wherein the collected fluid is desalinated, refrigerated and dried to obtain the immune globulin IgY(delta Fc)with purity of over 95 percent. The method is characterized in that a new separation process is designed, the immune globulin IgY (delta Fc) can be separated from the goose blood; and the key of the method is that the immune globulin IgY (detal Fc) can be directly extracted from the supernate which is precipitated from the octanoic acid. The method has the advantages of simple operation steps andhigh separation and purification factors, and can be popularized and applied to treatment of blood of other waterfowls.

Owner:ZHEJIANG UNIV

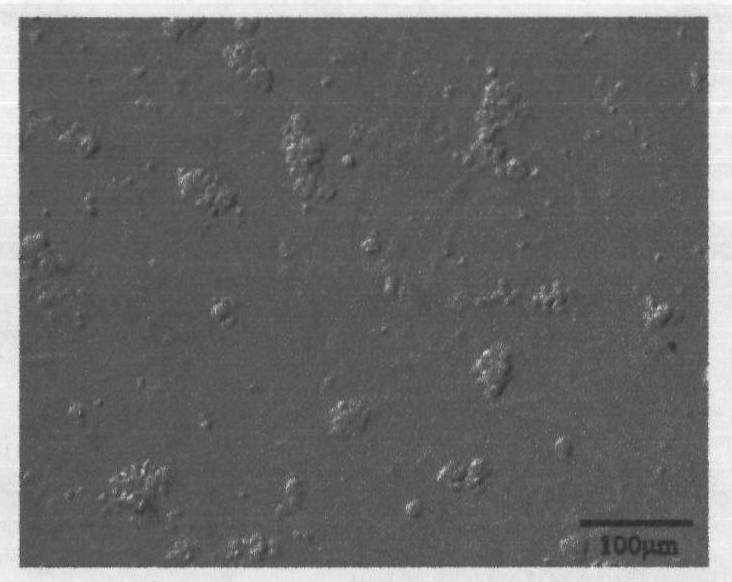

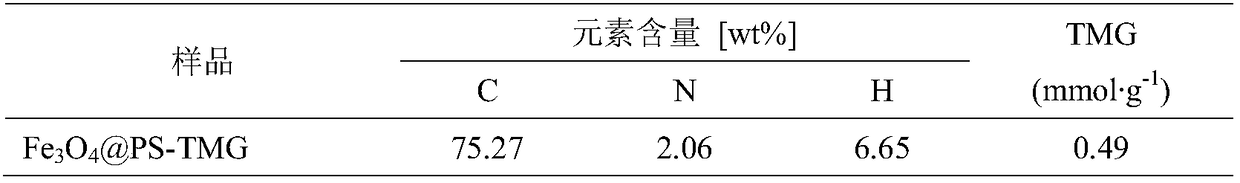

Magnetic organic solid base catalyst as well as preparation method and application thereof

InactiveCN108404977AImprove efficiencyExtended service lifeFatty acid esterificationOrganic-compounds/hydrides/coordination-complexes catalystsOrganic baseMicrosphere

The invention provides a magnetic organic solid base catalyst. Magnetic nanospheres with a uniform particle size are prepared by miniemulsion polymerization, and an organic base is supported on the microspheres to obtain the novel magnetic organic solid base catalyst. The method provided by the invention avoids the problem of loss of active sites of a conventional supported catalyst, maintains high efficiency of the catalyst, and effectively prolongs service life of the catalyst; at the same time, separation of the catalyst and a reaction system can be realized under an external magnetic field, and a separation step of the catalyst is greatly simplified; the magnetic organic solid base catalyst can be applied to a transesterification, esterification or aldol condensation reaction; and thepreparation method provided by the invention is simple, and the prepared catalyst has the characteristics of having high efficiency, saving energy, and being non-toxic, easy to separate and recyclable.

Owner:ZHEJIANG UNIV OF TECH

Catalyst for use in synthesis of methyl formate and preparation method and application thereof

ActiveCN102600847AEffective dispersionEffective anchoringOrganic compound preparationCarboxylic acid esters preparationPtru catalystMedicinal chemistry

The invention discloses a catalyst for used in synthesis of methyl formate. The molar ratio of Cu to Zr to K is 1:(0.3-12):(0.1-6). A precipitation method, a co-impregnation method and a stepwise soaking method are adopted for preparing the catalyst. The catalyst has the advantages of high stability and high selectivity of methyl formate.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

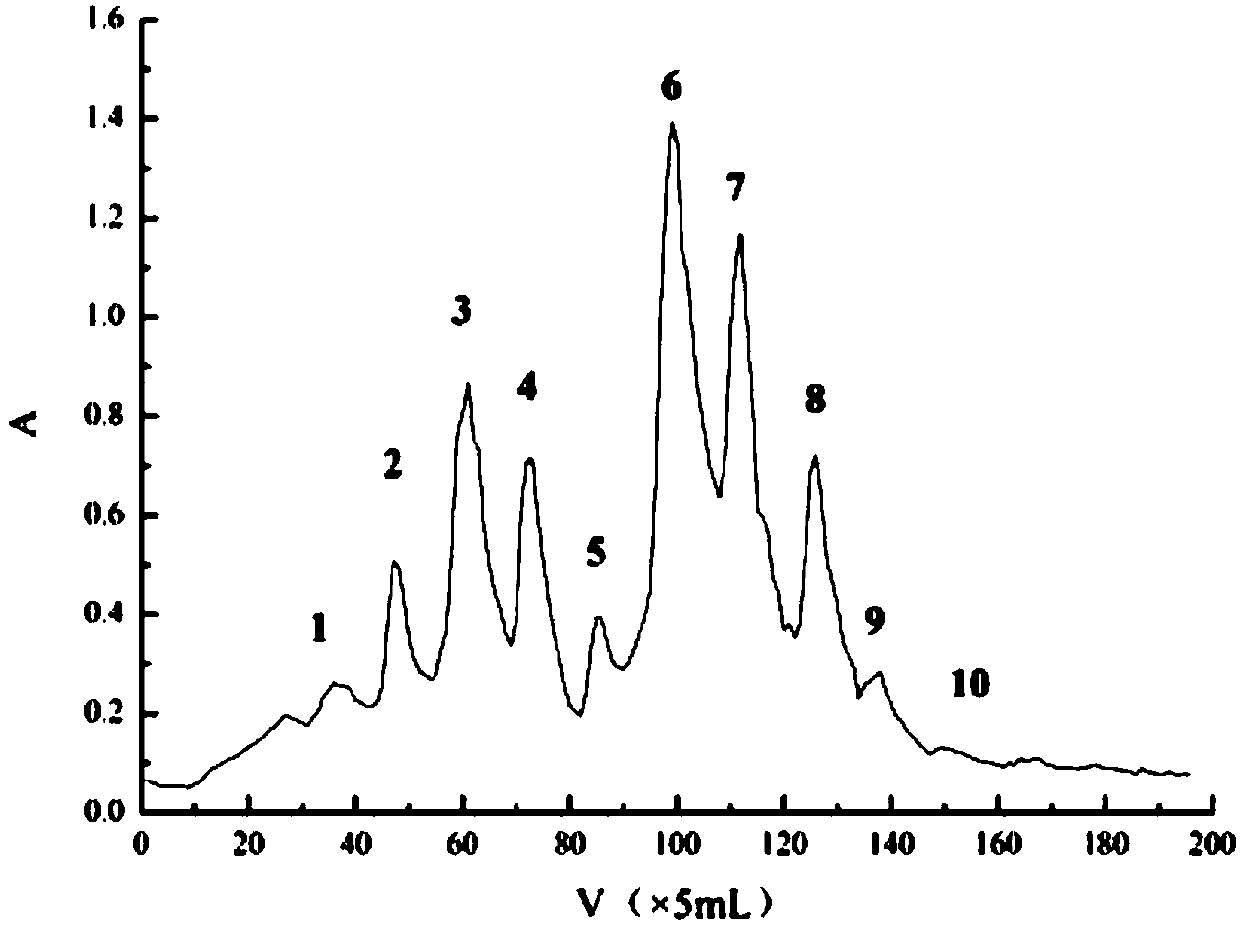

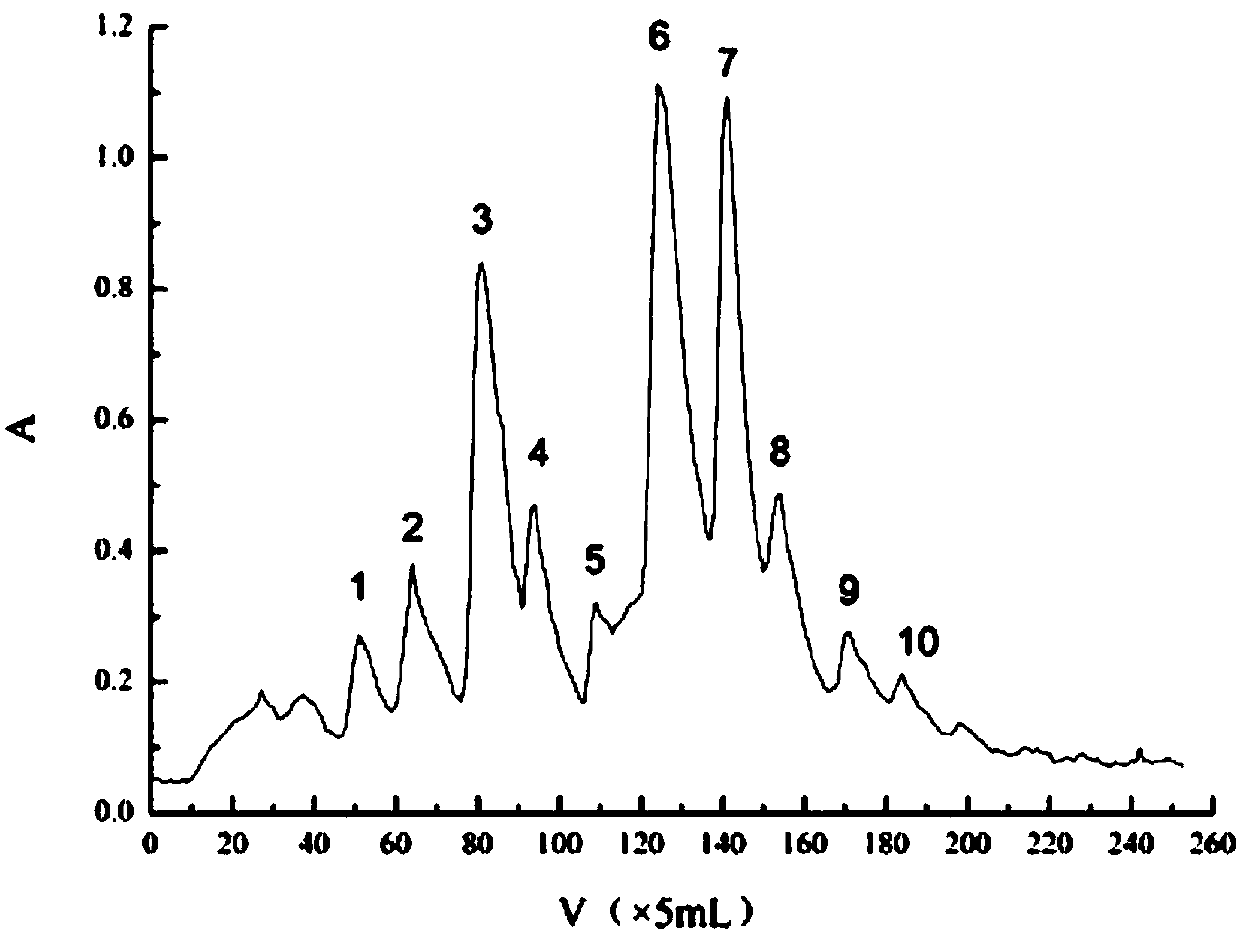

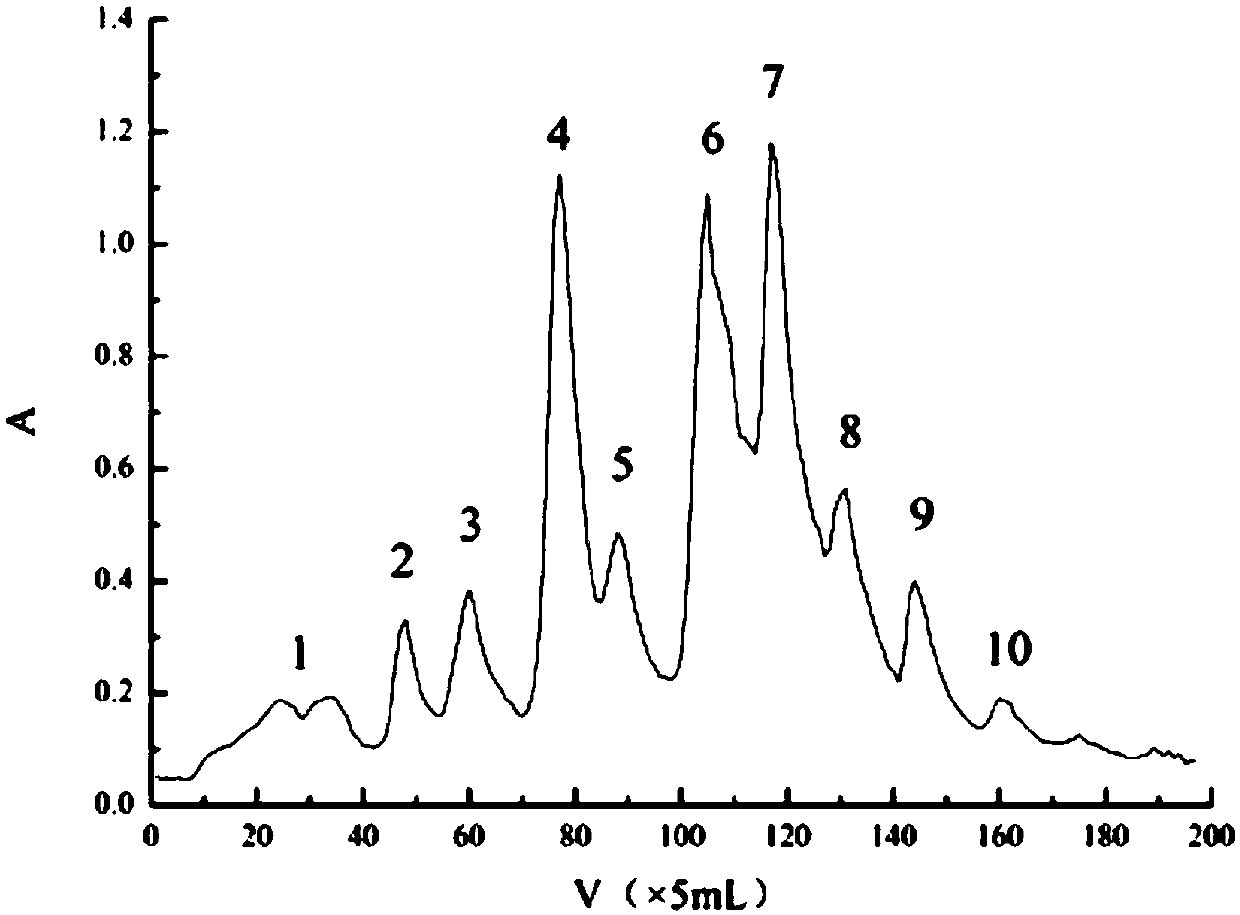

Method for simultaneously separating three main components of bovine milk casein

ActiveCN107840883ARealize industrial preparationSimple processPeptide preparation methodsAnimals/human peptidesBiotechnologyIon exchange

The invention discloses a method for simultaneously separating three main components of bovine milk casein, and aims to provide a method for separating the three main monomer components of casein, which adopts the bovine milk casein as a raw material, adopts a DEAE ion exchange column as separating equipment, and can simultaneously obtain alpha-casein, beta-casein and kappa-casein through one-timeseparation. According to the method provided by the invention, the three casein monomer components can be obtained through one-step separation, separation steps are less, a separation process is simple and easy to operate, a separation condition is mild and easy to implement, the separating equipment is simple and easy, the dosage of chemical reagents is less during a separation process, not onlyis the separation cost of the casein monomers reduced, but also the environment pollution is reduced, and the method meets a new concept on low carbon and environment protection; the average yield for separating the casein monomers is high, the average yield of the alpha-casein can reach 75 percent or more, the average yield of the beta-casein can reach 80 percent or more, and the average yield of the kappa-casein can reach 85 percent or more; the obtained three casein monomers have high purity which can reach to 95 percent or more; the method not only can meet the requirement on preparing the three high-purity casein monomer components in a laboratory, but also can be used for industrially preparing the main monomers of the casein, and is wide in application range.

Owner:GANSU AGRI UNIV

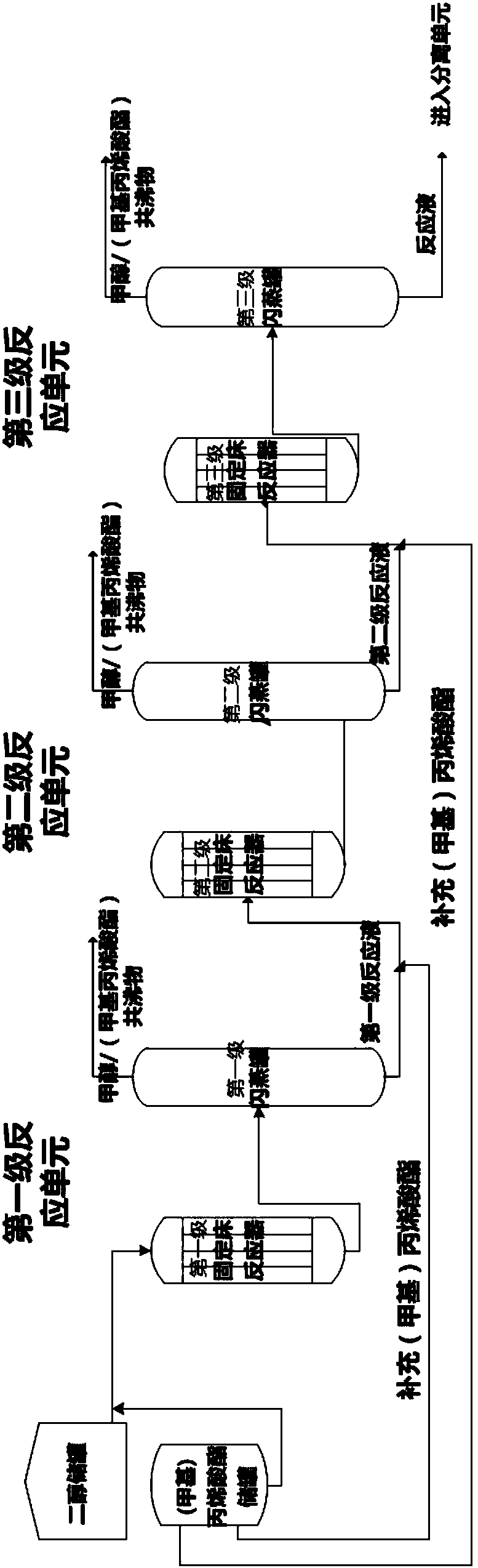

Method for continuously producing (methyl) hydroxyethyl acrylate and (methyl) diester acrylate and sulfoacid resin catalyst

ActiveCN107597187AEfficient productionIncrease productivityPreparation by ester-hydroxy reactionOrganic compound preparationContinuous productionAcrylate

The invention belongs to the technical field of a synthesis compound, and provides a sulfoacid resin catalyst and a method for continuously producing (methyl) hydroxyethyl acrylate and (methyl) diester acrylate. The continuous production method comprises the following steps of (1) contacting dihydric alcohol, (methyl) methyl acrylate and polymerization inhibitors to form reaction liquid; continuously injecting the materials into a reaction device containing the sulfoacid resin catalyst for reaction so as to obtain coarse reaction liquid; (2) injecting the coarse reaction liquid obtained in thestep (1) into a phase splitting tank; performing double-solvent extraction; respectively obtaining a water phase containing (methyl) hydroxyethyl acrylate and an oil phase containing (methyl) diesteracrylate; (3) respectively performing rectification on the water phase and the oil phase in the step (2) to obtain (methyl) hydroxyethyl acrylate and (methyl) diester acrylate products. The method has the advantages that the product separation step is simplified; the separation temperature is low and the product purity is high.

Owner:WANHUA CHEM GRP CO LTD

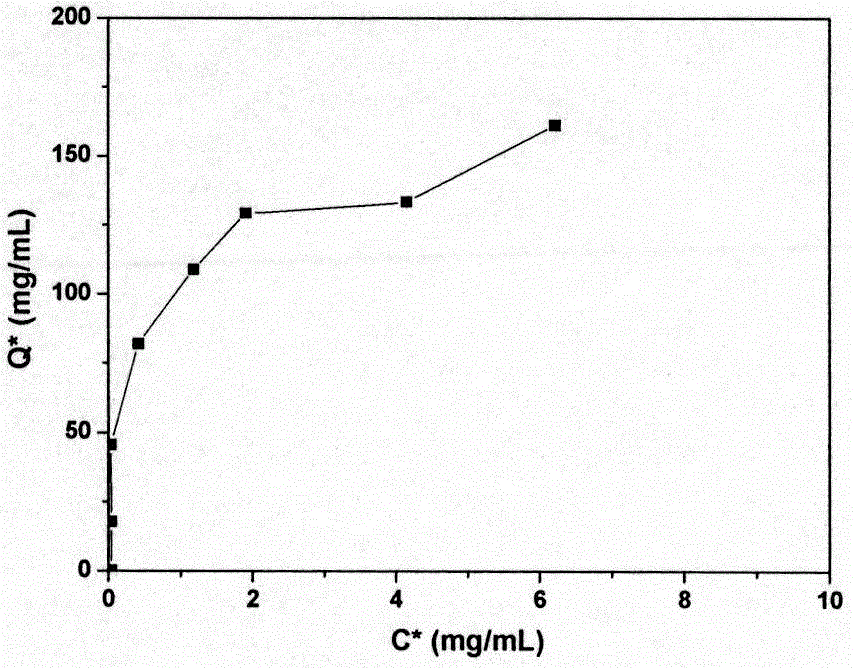

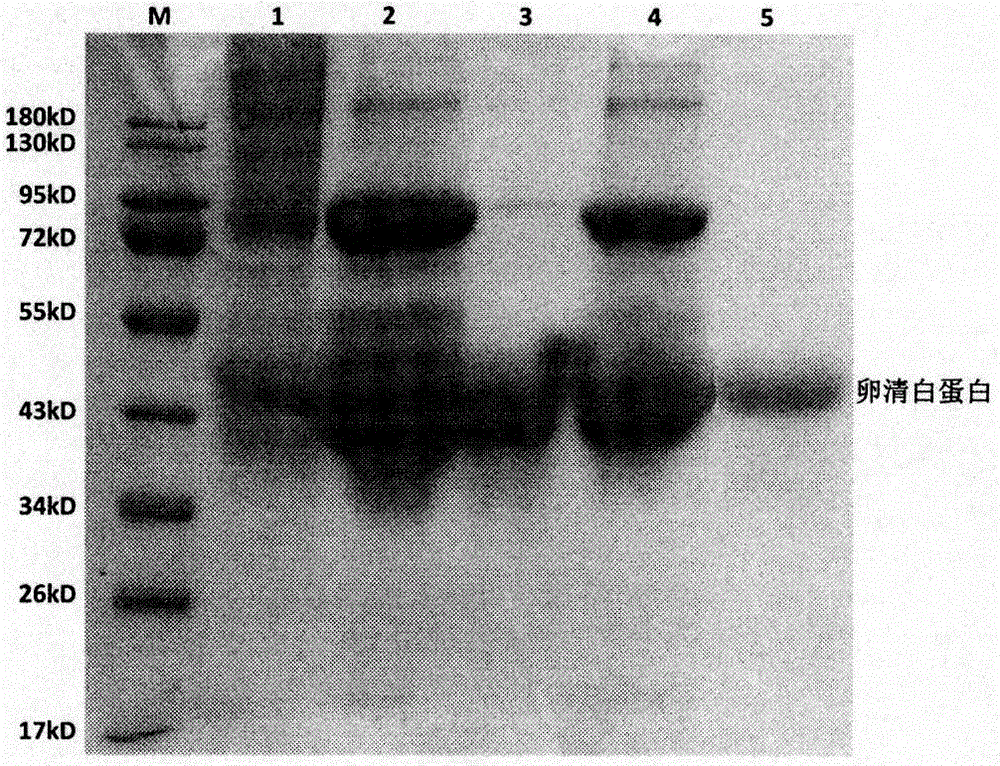

Method for separating ovalbumin from egg white

InactiveCN107434825AImprove separation efficiencySimplified separation stepsOvalbuminPeptide preparation methodsFreeze dryOctanoic Acids

The invention discloses a method for separating ovalbumin from egg white. The method comprises 1) taking fresh eggs and collecting an egg white stock solution, 2) adding a dilution buffer into the solution to obtain an egg white diluent A, 3) adding octanoic acid into the egg white diluent A and carrying out standing to obtain an egg white diluent B, 4) adding hydrophobic charge-induced agnetic beads into the egg white diluent B and carrying out shaking to adsorb ovalbumin, 5) washing the beads with the dilution buffer multiple times to obtain the hydrophobic charge-induced magnetic beads adsorbing the ovalbumin, 6) adding an elution buffer into the magnetic beads, carrying out shaking and collecting an ovalbumin solution, and 7) carrying out freeze-drying to obtain an ovalbumin solid product having purity greater than 98%. The method designs a simple and fast separation process, realizes separation of ovalbumin from egg white, is characterized by directly separating ovalbumin from egg white and has the advantages of simple operation processes and high separation efficiency.

Owner:HUZHOU TEACHERS COLLEGE

Preparation and applications of magnetic composite porous network adsorbing material

ActiveCN110586052AImprove uniformityImprove stabilityOther chemical processesAlkali metal oxides/hydroxidesOrganic solventSolid phase extraction

The invention relates to preparation and applications of a magnetic composite porous network adsorbing material, wherein the preparation method comprises: (a) preparing a magnetic porous organic framework material with strong adsorbability and large specific surface area by adopting an in-situ growth method, and (b) synthesizing a novel composite porous network adsorbing material with a core-shellstructure through a sonogashira coupling reaction so as to achieve the selective adsorption and efficient enrichment of food and environment pollutants. According to the present invention, the prepared magnetic composite porous network adsorbing material has good particle size uniformity and significantly efficient adsorption capacity on target pollutants, the separation step during solid-phase extraction is greatly simplified due to the magnetic characteristic of the material, and the microporous organic coating changes the hydrophobicity of the surface of the material, such that the material has high stability in a humid environment, can well play a role in an organic solvent, and is suitable for adsorption and enrichment of various food pollutants.

Owner:NANKAI UNIV

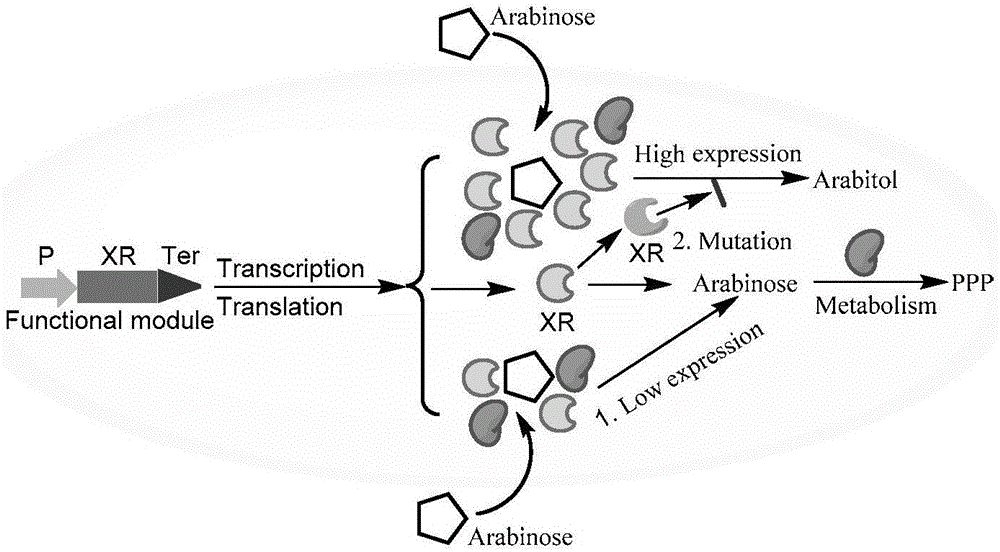

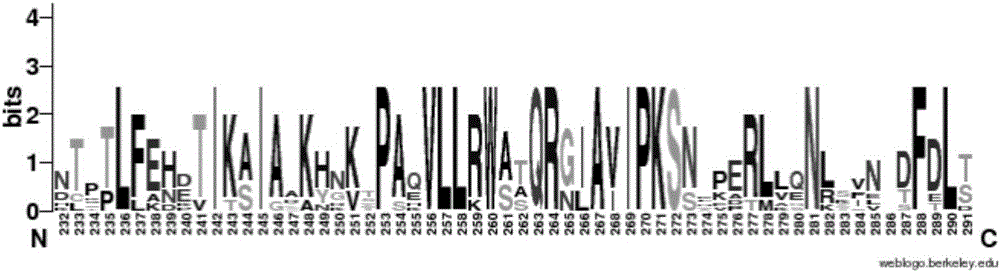

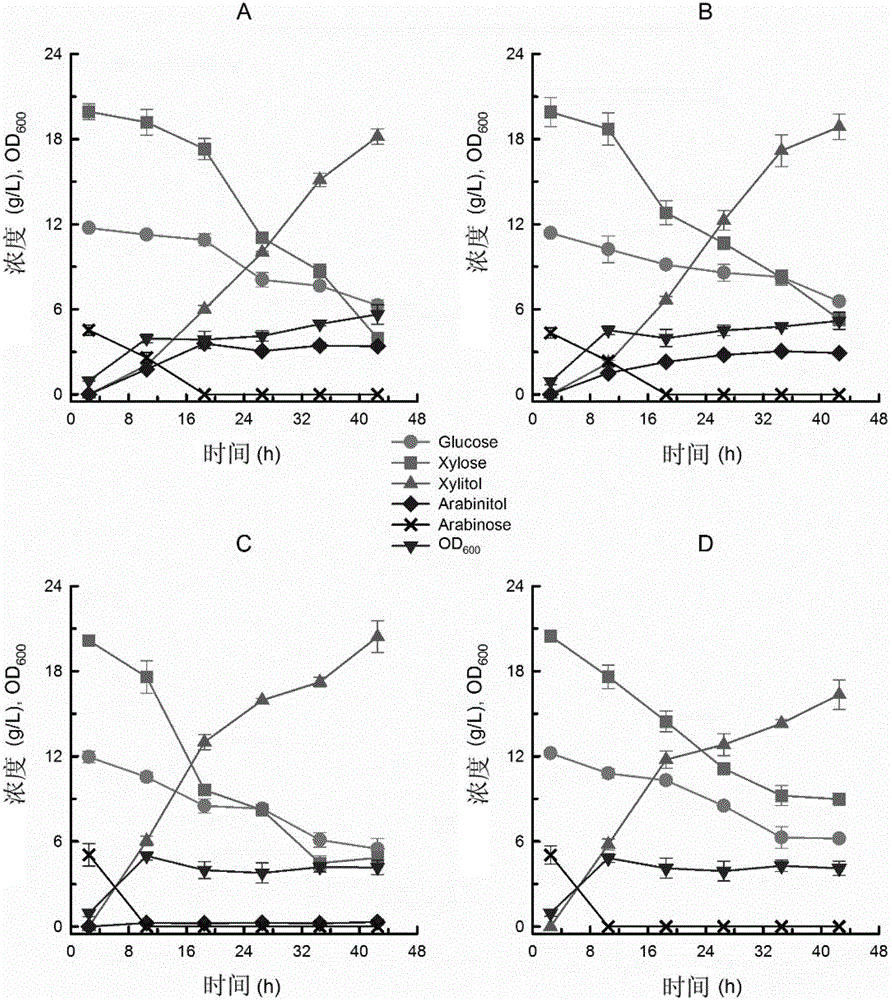

Xylose reductase mutant, genetically engineered bacteria and application in producing xylitol

ActiveCN105671013AHigh selectivityHigh purityBacteriaMicroorganism based processesD-arabitolArabinose

The invention discloses a xylose reductase mutant, genetically engineered bacteria and application in producing xylitol. The amino acid sequence of the xylose reductase mutant is shown in the SEQ ID No.1. Mutation of eight amino acid sites is carried out on xylose reductase, the activity of the xylose reductase mutant for catalyzing arabinose into arabitol is lowered, the selectivity of the xylose reductase mutant for converting xylitol is improved, and the by-product arabitol in the bioconversion product is not detected. The separation step of xylitol bioconversion production downstream can be simplified, the production cost is reduced, and the purity of the xylitol product is improved.

Owner:ZHEJIANG UNIV

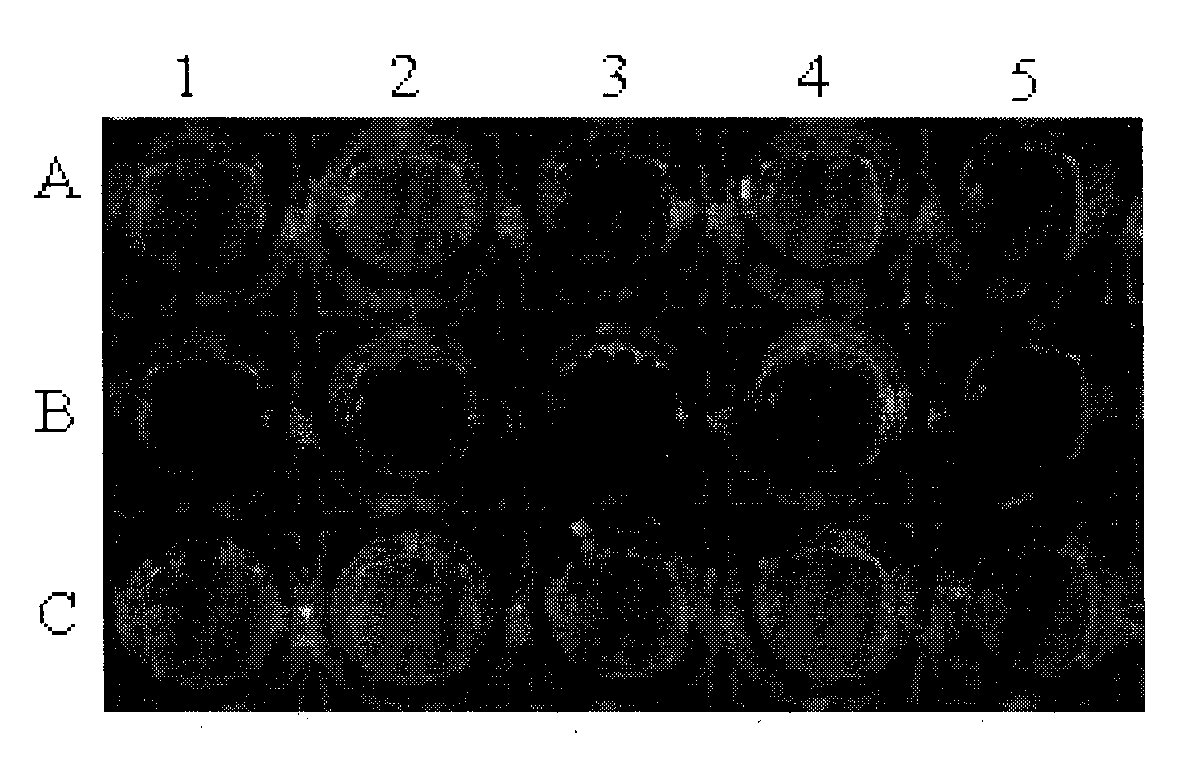

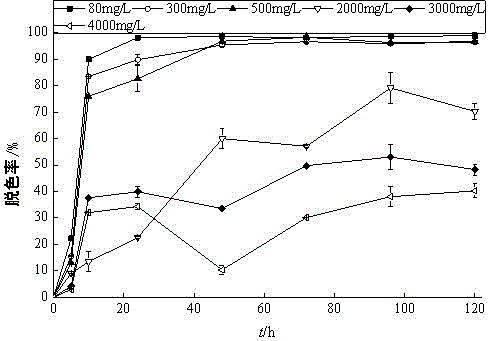

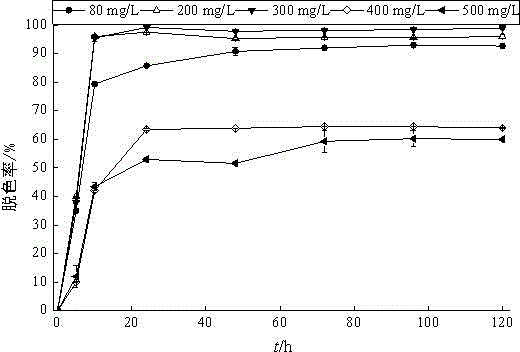

Bacterial strain for degrading dye with high efficiency

ActiveCN103937697APromote growthImprove environmental adaptabilityBacteriaMicroorganism based processesBiochemical engineeringDomestic technology

The invention discloses a bacterial strain for degrading dye with high efficiency. The bacterial strain is Lysinibacillussp ((i) Lysinibacillussp.( / i))FS1, and is preserved in the China Center for Type Culture Collection with the preservation number is CCTCC NO: M2013561 on Nov, 10th, 2013. The bacterial strain has the advantage of rapid growth and strong environment adaptability, has dye degradation capability with wide spectrum, and has good decolouring effect to a plurality of dyes, maximum decolourization percentage can be reached by culturing for 10 hours, the percent of decolourization can reach more than 90%, and the maximum decolouring concentration can reach 5000mg / L. The bacterial strain can be used for decolouring the printing and dyeing waste water and correlated dye waste water, can effectively avoid the dye molecules which are difficulty performed with natural degradation to directly enter in the water body for environment pollution, no secondary pollution is generated, and the bacterial strain has good ecology efficiency and application prospect. The Lysinibacillussp can be better used for degrading the dye, fills the blank of domestic technology, and provides a powerful technical base for solving the dye sewage treatment, especially the decolouring problem.

Owner:厦门众仁合美生物科技有限公司

Method for separating immune globulin IgY(delta Fc) from goose blood

InactiveCN101899110AHigh purityImprove separation efficiencySerum immunoglobulinsPeptide preparation methodsOctanoic AcidsDesalination

The invention discloses a method for separating immune globulin IgY(delta Fc) from goose blood. The method comprises the following steps: 1) degreased plasm preparation, wherein fresh blood is selected to be centrifuged to remove erythrocyte, and then is degreased to obtain the degreased plasm; 2) octanoic acid precipitate, wherein octanoic acid is added to the plasm to reach a certain concentration, hybrid protein is precipitated and removed, and is centrifugally separated to obtain supernate; 3) column chromatography, wherein the supernate is separated by a chromatographic column which is filled with hybrid mode adsorbent to collect elution peak; and 4) desalination and drying, wherein the collected fluid is desalinated, refrigerated and dried to obtain the immune globulin IgY(delta Fc) with purity of over 95 percent. The method is characterized in that a new separation process is designed, the immune globulin IgY (delta Fc) can be separated from the goose blood; and the key of the method is that the immune globulin IgY (detal Fc) can be directly extracted from the supernate which is precipitated from the octanoic acid. The method has the advantages of simple operation steps and high separation and purification factors, and can be popularized and applied to treatment of blood of other waterfowls.

Owner:ZHEJIANG UNIV

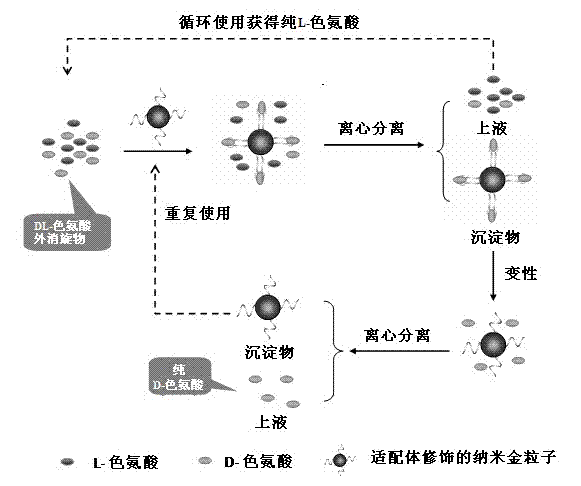

Chiral compound separation method based on nano gold modified by aptamer

InactiveCN102766005AGuaranteed binding siteTo achieve the purpose of chiral separationChemical recyclingOptically-active compound separationAptamerGold particles

The invention provides a chiral compound separation method based on nano gold modified by aptamer. The chiral compound separation method includes the following steps of firstly, modifying aptamer modified by mercapto onto the surfaces of nano-gold particles; secondly, adding chiral compounds to be separated, and centrifuging after incubating at room temperature to obtain supernatant which is a chiral compound of one configuration; and thirdly, dispersing the nano gold at the bottom of a centrifuge tube again, and denaturating and centrifuging the aptamer at 95 DEG C to obtain supernatant which is a chiral compound of another configuration. The nano gold modified by the aptamer serves as chiral selective reagent, the highly-selective and high-affinity characteristics are utilized, denaturation is performed at high temperature, the nano gold restores to the room temperature slowly and restores to the tertiary structure, and accordingly chiral separation of the chiral compounds is performed. A simple centrifuge is only needed for separation. In addition, targets of the aptamer are wide, so that the chiral compound separation method based on the nano gold modified by the aptamer is highly universal, operational and highly practical.

Owner:FUZHOU UNIV

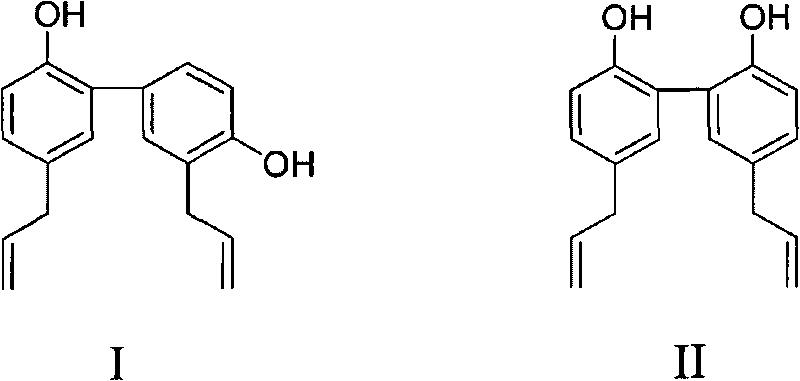

Method for extracting magnolol and honokiol from magnolia officinalis

ActiveCN101759532AResolve separabilityResolution timeOrganic chemistryOrganic compound preparationChemical reactionHonokiol

The invention discloses a method for extracting magnolol and honokiol from magnolia officinalis; the method includes that: magnolia officinalis powder and solid phase weak base reagent are mixed according to the weight ratio of 1:0.01-1, the mixture is grinded to obtain powder with granularity analysis result D90 of 10-200 um, and then water is added to the powder, the mixture is stirred sufficiently and is centrifuged to obtain sediment A and supernate A, acid X with pH value of 1.0-6.0 is added to the supernate A, then the supernate is centrifuged after standing to obtain sediment B as magnolol extractive. The invention firstly adopts mechanical chemical reaction technique to extract magnolol, and then adopts alkaline process to extract honokiol, has the advantages of high extraction rate, good separation effect of magnolol and honokiol, and short production cycle, and is the extraction and separation process with good popularization and application prospect.

Owner:ZHEJIANG UNIV OF TECH

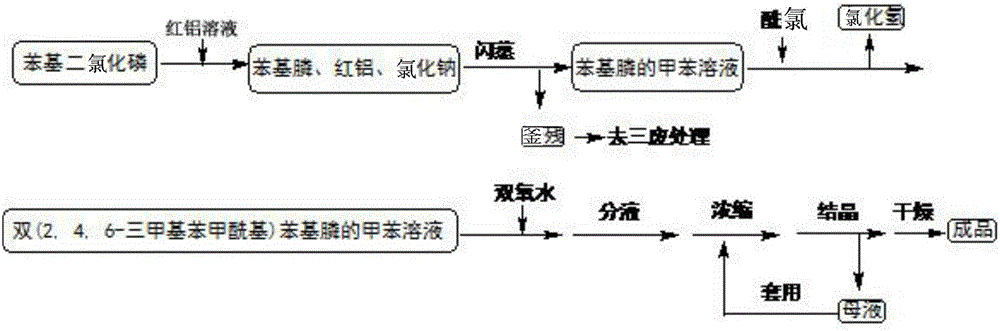

Preparation process of photo-initiator bis(2,4,6-trimethylbenzoyl)phenylphosphine oxide

InactiveCN105131036AImprove securityLow priceGroup 5/15 element organic compoundsAluminatePhenylphosphine

The invention discloses a preparation process of a photo-initiator bis(2,4,6-trimethylbenzoyl)phenylphosphine oxide, wherein the process comprises the following steps: 1) performing a reaction to phenyl phosphine dichloride and excessive sodium dihydro-bis-(2-methoxyethoxy)aluminate solution at -50 - 50 DEG C in inert gas, and after the reaction finished, removing a by-product sodium chloride and excessive sodium dihydro-bis-(2-methoxyethoxy)aluminate to obtain a methylbenzene solution of phenyl phosphine; 2) performing a reaction to the methylbenzene solution of phenyl phosphine with 2,4,6-trimethylbenzoyl chloride at -10 - 50 DEG C to obtain a methylbenzene solution of bis(2,4,6-trimethylbenzoyl)phenylphosphine after the reaction finished; and 3) oxidizing the methylbenzene solution of the bis(2,4,6-trimethylbenzoyl)phenylphosphine, and performing liquid separation, concentration and crystallization to the organic phase, and drying to obtain the target product, bis(2,4,6-trimethylbenzoyl)phenylphosphine oxide. The whole process is stable in raw material cost, is low in cost, is safe and easy-to-control in reactions and is easy to achieve large-scale production.

Owner:ZHANGJIAGANG JIMUTE CHEM TECH

Method for separating byproducts C9-C10 fractions in ethylene preparation through petroleum cracking and increasing yield

ActiveCN104276912AHigh yieldReduce lossesDistillation purification/separationHydrocarbon by depolymerisationDepolymerizationMixed materials

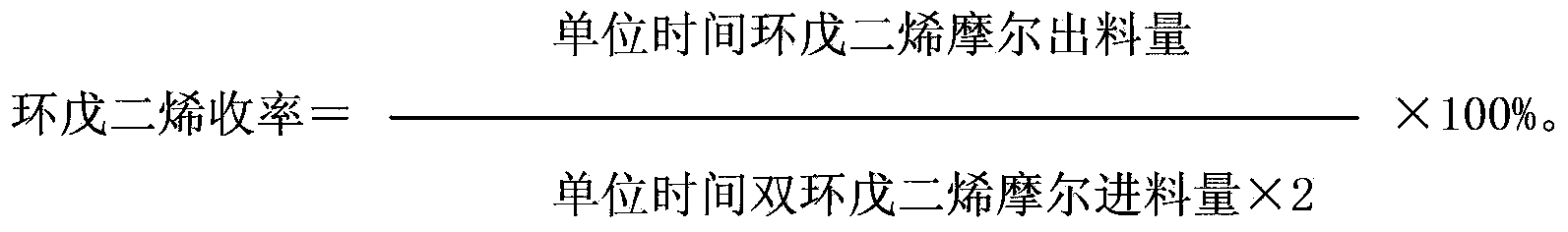

The invention relates to a method for separating and utilizing byproducts C9-C10 fractions in ethylene preparation through petroleum cracking. The method comprises the following steps: (1) carrying out depolymerization, rectification and separation on a raw material in a depolymerization and rectification tower to obtain a cyclopentadiene-enriched material on the tower top and a material of methyl cyclopentadiene from the siding; (2) feeding a bottom material in the step (1) into a decompression rectification tower for decompressed rectification so as to obtain styrene, methyl styrene, indene and remained dicyclopentadiene mixed fraction on the tower top and obtain heavy components and impurities at the bottom; (3) feeding the top mixed fraction in the step (2) into the depolymerization and rectification tower for depolymerizing and rectifying so as to obtain cyclopentadiene-enriched fraction on the tower top and obtain indene, styrene and methyl styrene mixed fraction at the bottom. According to the method, high-quality indene, styrene and methyl styrene raw materials can be obtained, and high-purity cyclopentadiene and methyl cyclopentadiene products are obtained at the same time; by adopting the process method of depolymerizing, separating and depolymerizing, the yield of dicyclopentadiene can be increased, and the indene, styrene and methyl styrene mixed material which can be directly utilized can be obtained.

Owner:CHINA PETROLEUM & CHEM CORP +1

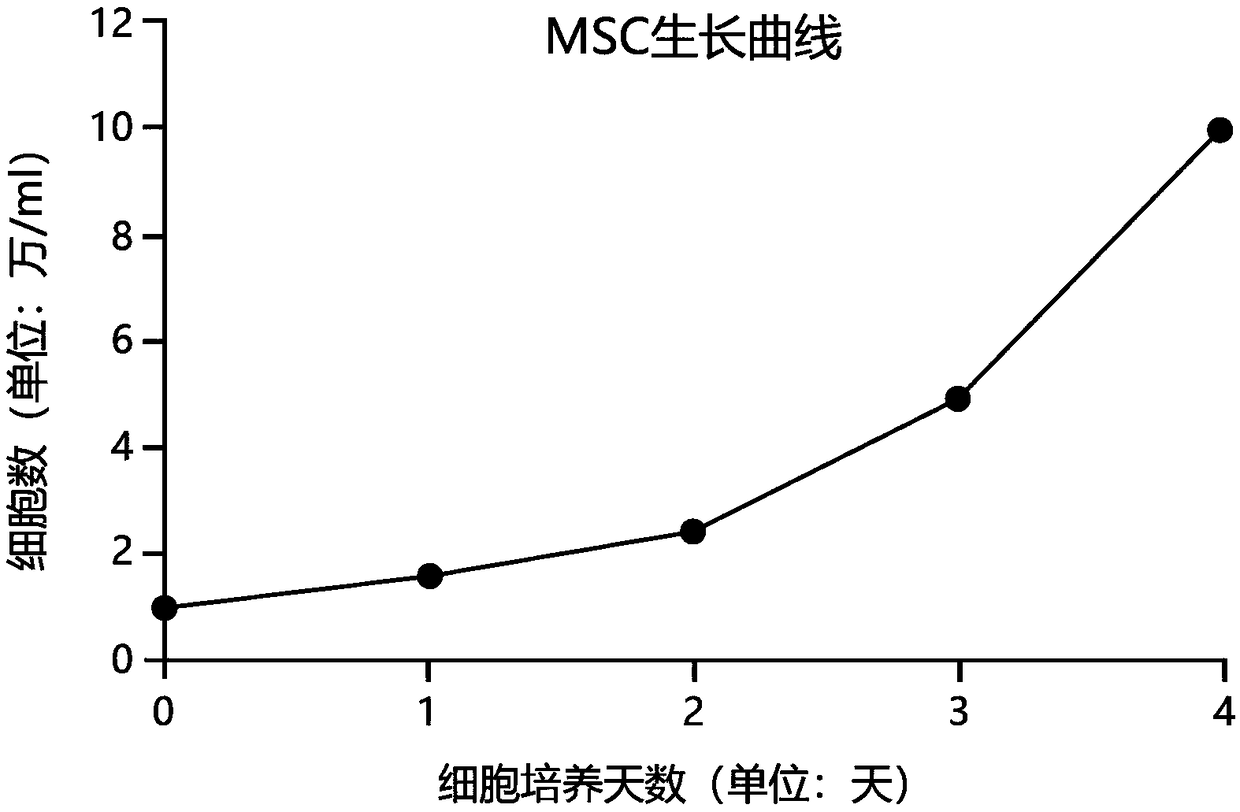

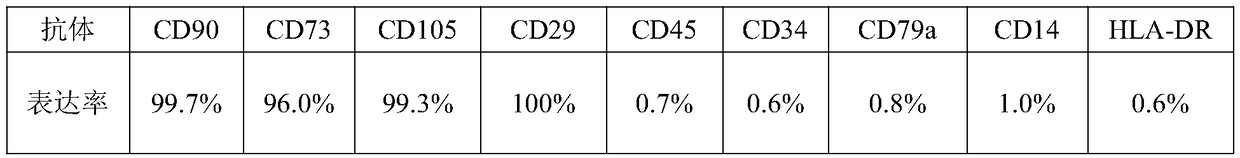

Serum-free medium for mesenchymal stem cells

InactiveCN109182262AReduce the risk of contaminationImprove efficiencyCulture processSkeletal/connective tissue cellsSerum free mediaCultured cell

The invention relates to the technical field of cell culture, and discloses a serum-free medium for mesenchymal stem cells, comprising a basic culture medium and an additive, wherein the additive comprises a serum substitute, other proteins and nutritional factors. The serum-free medium for mesenchymal stem cells has the following advantages: (1) the serum-free culture medium does not contain animal serum or other heterologous proteins, thereby reducing the risk of contamination of the cell preparation; (2), the serum-free culture medium arranged by the invention can reach the imported level in cell culture effect, and the source of the basic culture medium is sufficient and not influenced by the market; (3) Simplify the procedure of cell isolation; the digested cells can be directly usedin primary culture and ensure the specificity of the cultured cells; and (4), using the culture medium of the invention, the cells maintain good adherence, show fusiform fibroblast morphology, and atthe same time, the cells can still maintain a normal state after multiple passages of culture.

Owner:深圳市一五零生命科技有限公司

Method for extracting ceramide amphoteric lipid from agriculture-forestry byproducts

InactiveCN101591262ASimplified separation stepsDoes not affect useSugar derivativesCarboxylic acid amide separation/purificationChromatographic separationSolvent

The invention relates to a method for extracting ceramide amphoteric lipid from agriculture-forestry byproducts, which comprises the following steps: using waste materials of the processing of the agriculture-forestry byproducts of rice bran, wheat bran and corn as raw materials; adding protease which is 0.1 to 1.0 percent of the agriculture-forestry byproducts in weight and an amino acid chemical penetrating agent which is 0.01 to 0.1 percent of the agriculture-forestry byproducts in weight to the raw materials; extracting the raw materials for 3 times by using a mixed solvent of chloroform and methanol; performing column chromatographic separation; using a solvent to elute out lipid rich in ceramide; and after alkaline treatment, performing high-efficiency liquid phase chromatographic separation to obtain ceramide. The method has high extraction efficiency, simplifies the separation steps of other components, and obtains the ceramide lipid with different contents at the same time.

Owner:ZHEJIANG UNIV

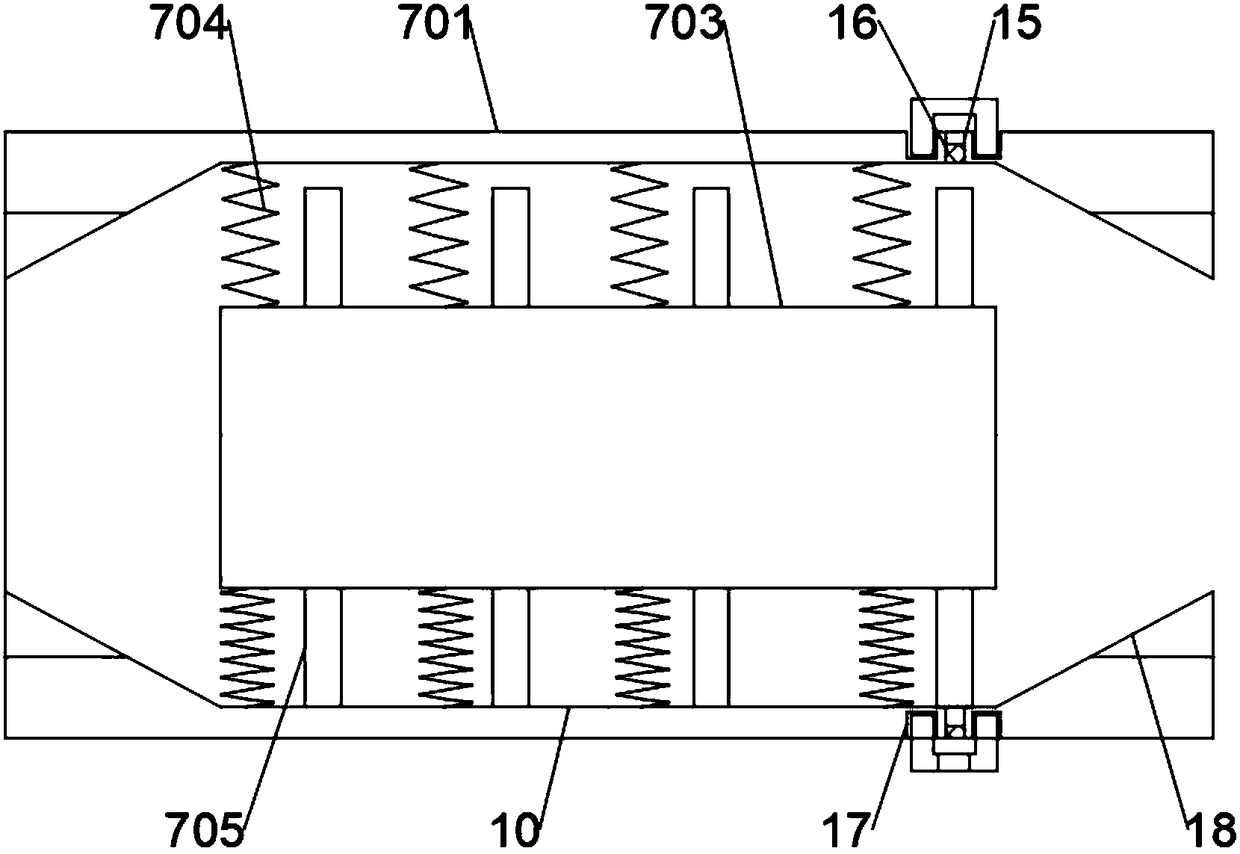

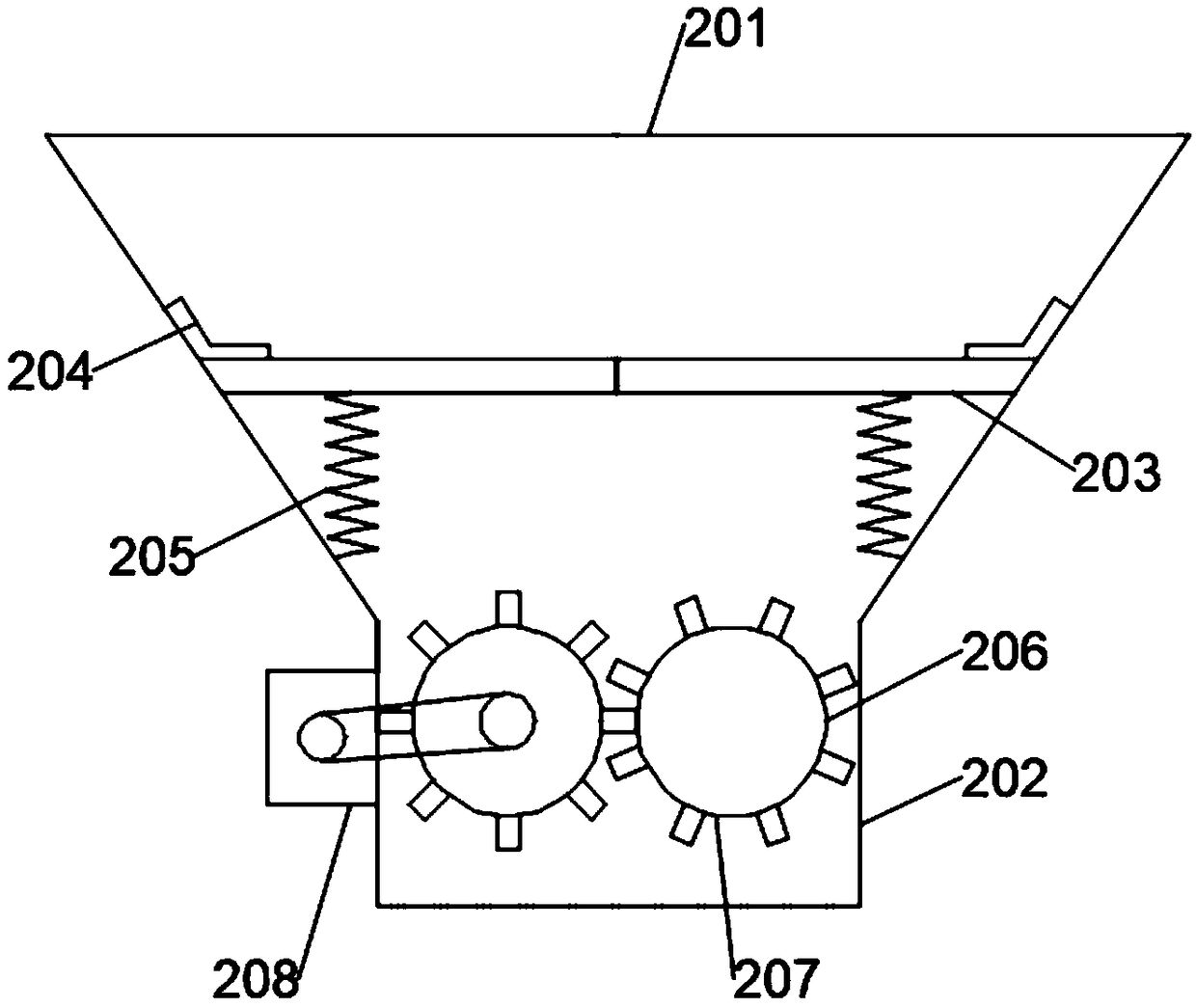

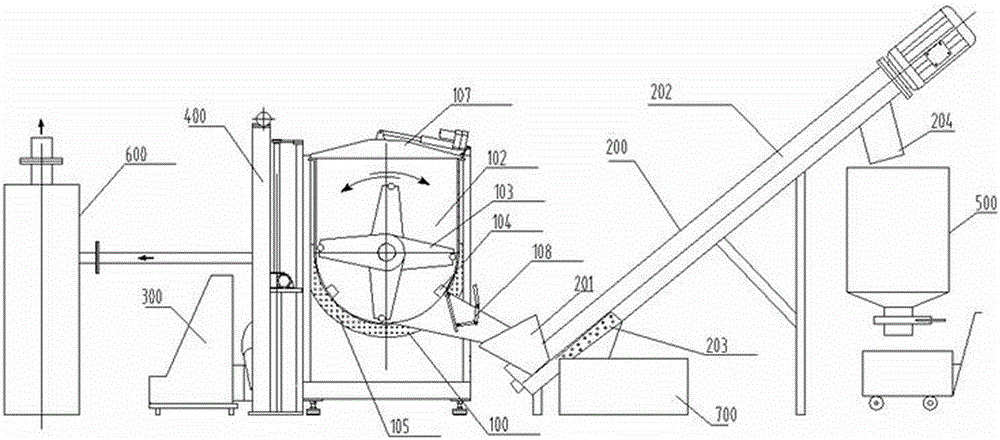

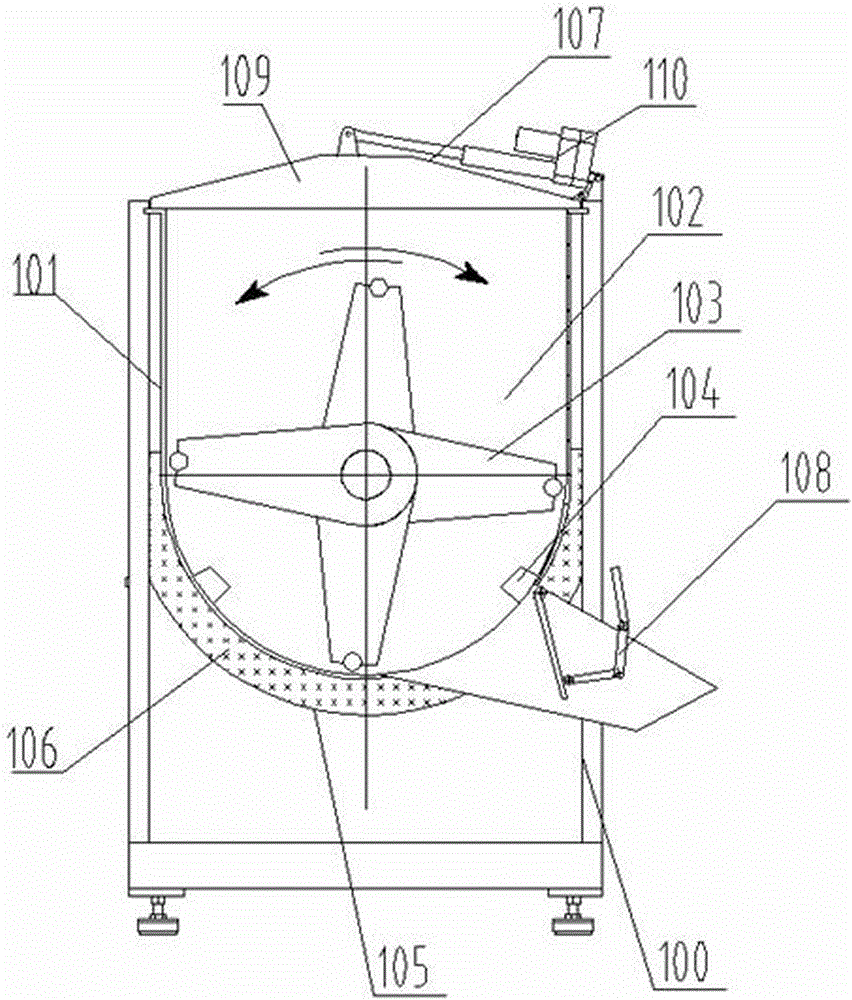

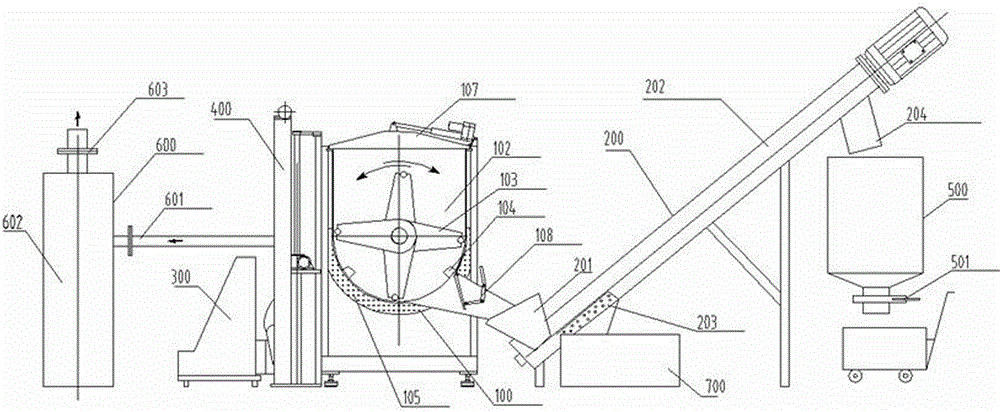

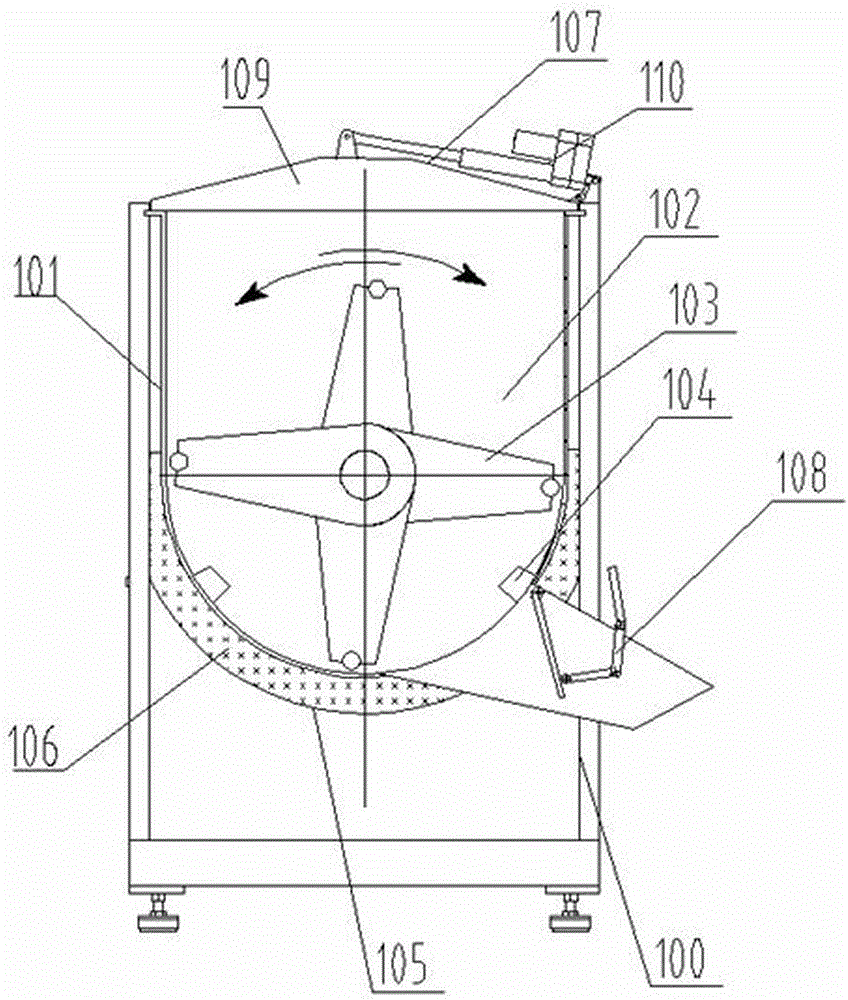

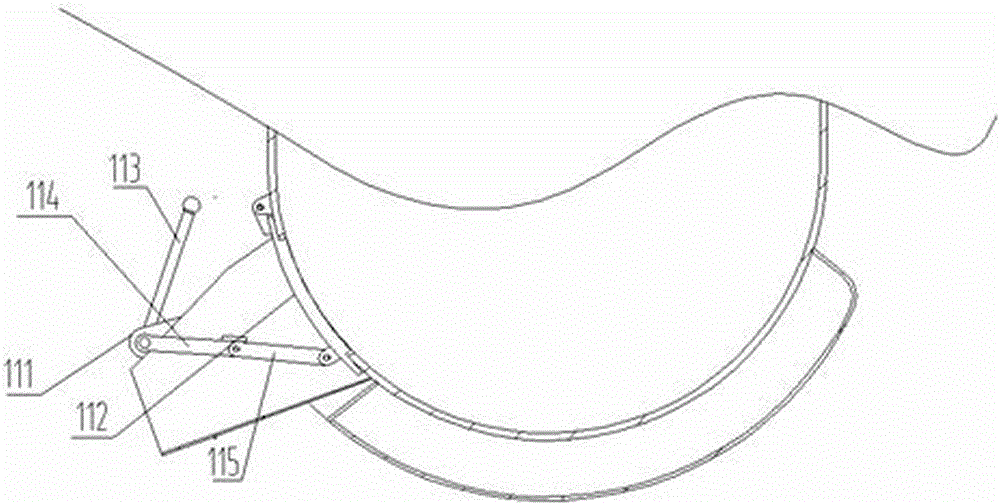

Livestock and poultry dead body innocent treatment system

InactiveCN106345789ARealize resource utilizationReduce deliverySolid waste disposalDispersed particle separationResource utilizationDead body

The invention discloses a livestock and poultry dead body innocent treatment system and relates to the technical field of livestock and poultry innocent treatment. The livestock and poultry dead body innocent treatment system comprises a crushing and stirring device and a spiral conveying device, wherein the crushing and stirring device is connected with the spiral conveying device; the crushing and stirring device is used for crushing livestock and poultry dead bodies, drying water in the livestock and poultry dead bodies in the crushing process and smelting grease from the livestock and poultry dead bodies; the spiral conveying device is used for conveying the crushed livestock and poultry dead bodies and separating the grease smelted from the livestock and poultry dead bodies in the conveying process into an oil storage tank. The livestock and poultry dead body innocent treatment system provided by the invention has low cost; furthermore, the residues after innocent treatment can be used for preparing reusable products, so the resource utilization rate is increased.

Owner:四川金逸智科技有限公司

Method for separating immunoglobulin IgY from chicken blood

InactiveCN101948535AHigh purityImprove separation efficiencySerum immunoglobulinsPeptide preparation methodsOctanoic AcidsSorbent

The invention discloses a method for separating immunoglobulin IgY from chicken blood. The method comprises the following concrete steps: 1) pretreating plasma, selecting fresh chicken blood, centrifuging, and removing erythrocyte to obtain plasma; 2) precipitating octanoic acid, adding the octanoic acid into the plasma to reach a certain concentration, removing foreign protein by precipitating, centrifugally separating, and taking the supernate; 3) carrying out column chromatography: separating the supernate by a chromatographic column filled with mixed adsorbent, and collecting elution peak; and 4) desalting and drying: desalting the collected solution, cooling and drying the desalted collected solution to obtain the high-purity immunoglobulin IgY. The method is characterized in that a new separation process, through which high-purity immunoglobulin IgY can be prepared by separating the chicken blood. The key point of the method is to directly extract the immunoglobulin IgY from the supernate of the octanoic acid, so the method has the characteristics of simple operation steps, high separation efficiency and low cost.

Owner:ZHEJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com