Patents

Literature

1996results about "Carboxylic acid amide separation/purification" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

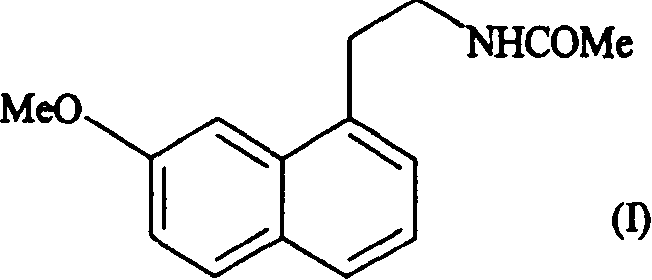

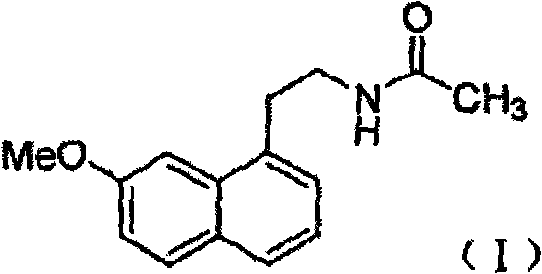

New crystalline form v of agomelatine, a process for its preparation and pharmaceutical compositions containing it

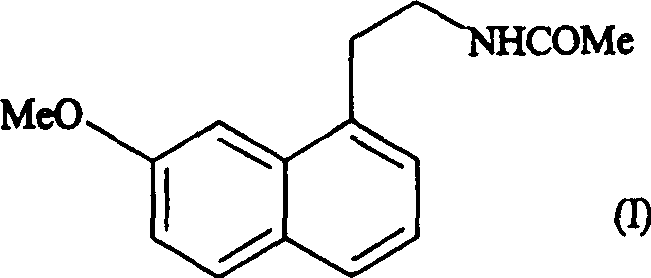

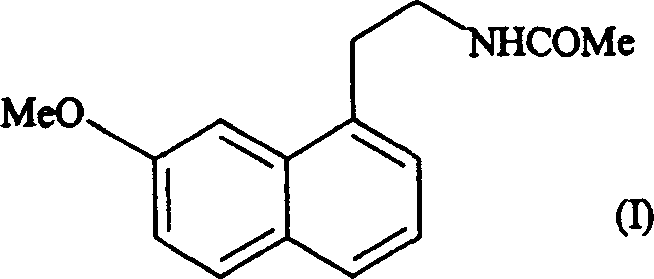

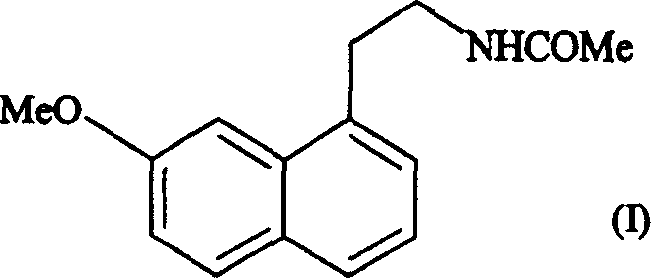

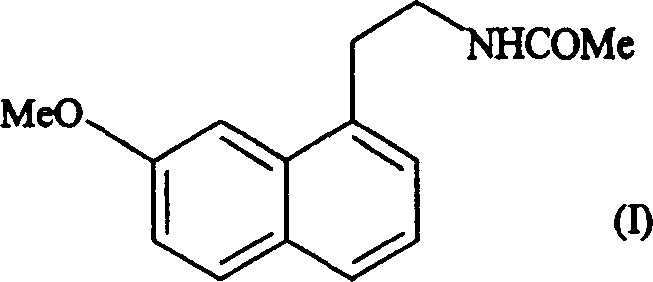

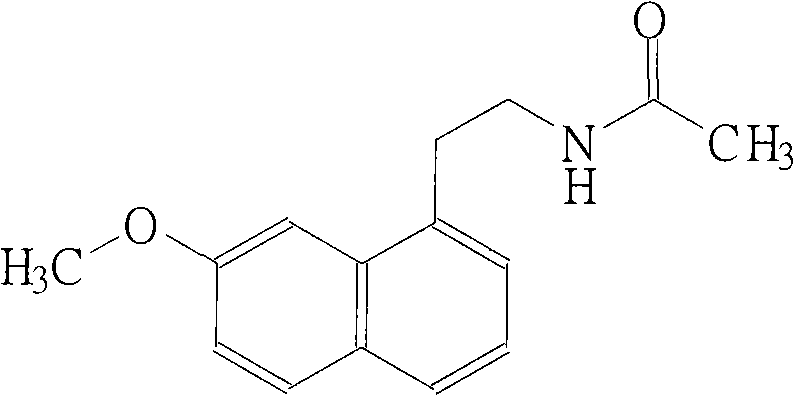

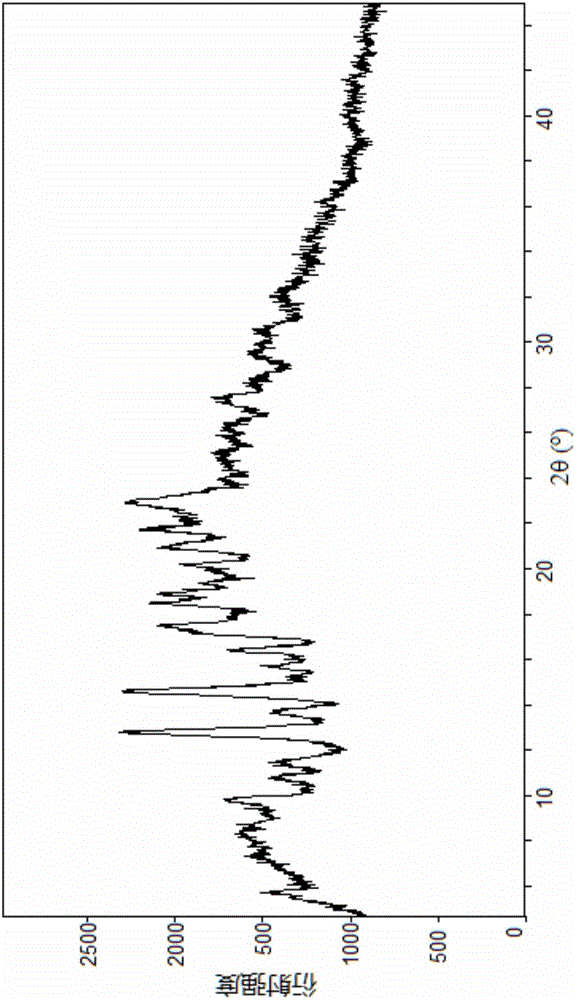

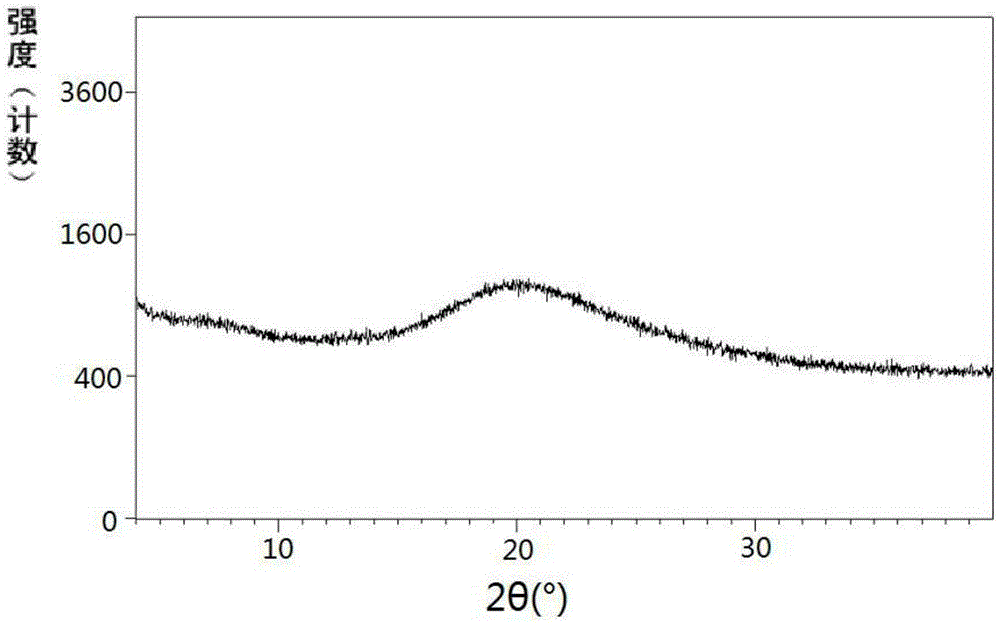

The crystalline form V of a compound of formula (I) is characterised by the X diffraction diagram thereof on a powder.

Owner:LES LAB SERVIER

Crystalline form iv of agomelatine, a process for its preparation and pharmaceutical compositions containing it

The crystalline form IV of a compound of formula (I) is characterised by the X diffraction diagram thereof on a powder.

Owner:SERVIER LAB

New crystalline form iii of agomelatine, a process for its preparation and pharmaceutical compositions containing it

The crystalline form III of a compound of formula (I) is characterised by the X diffraction diagram thereof on a powder, and the drugs contains it.

Owner:LES LAB SERVIER

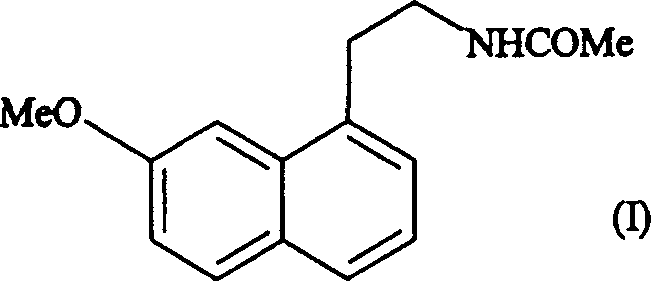

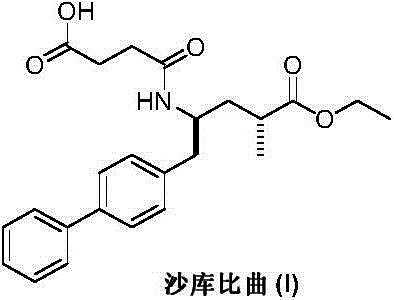

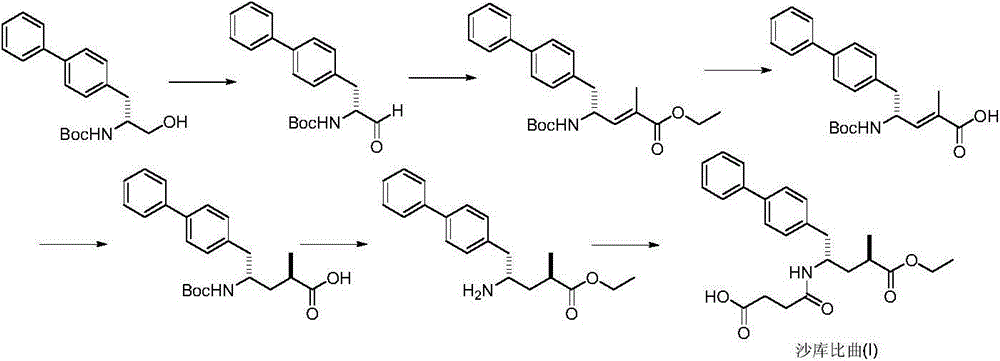

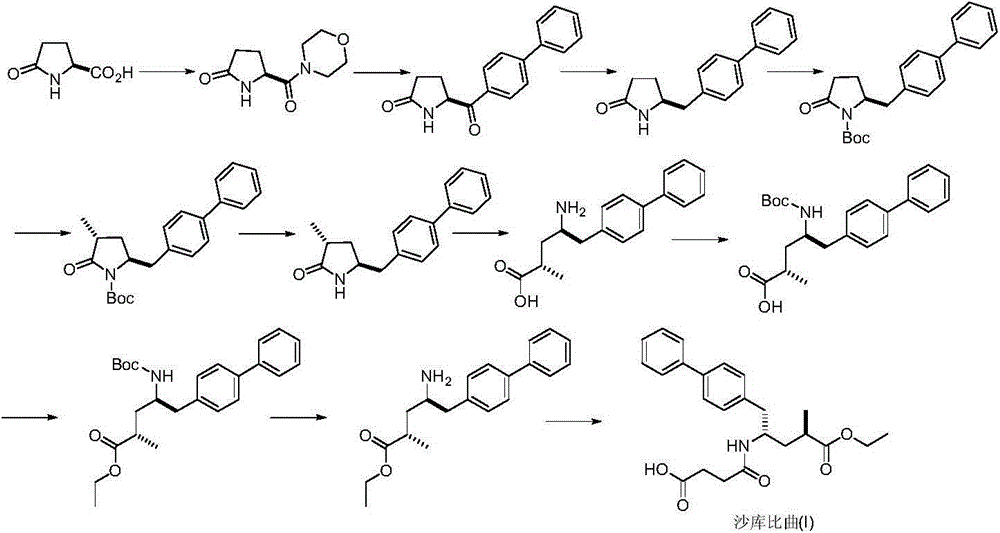

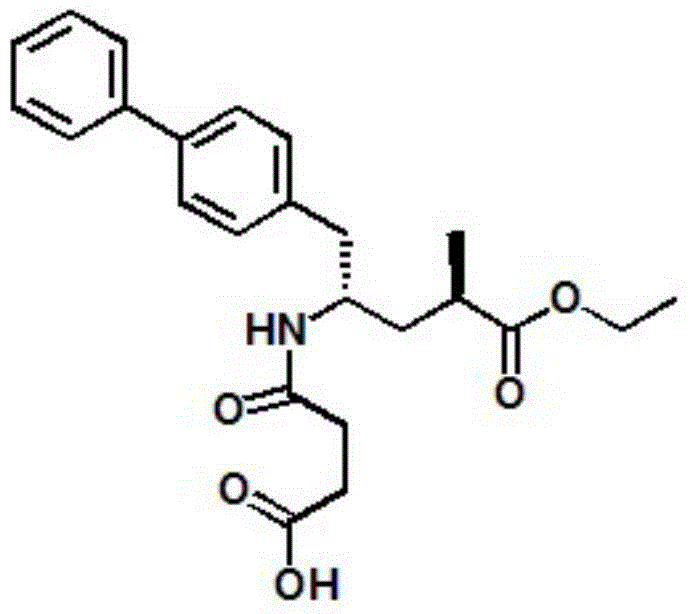

Preparation method of sacubitril

ActiveCN104557600AEase of industrial productionRaw materials are easy to getOrganic compound preparationCarboxylic acid amide separation/purificationSacubitril2-Naphthol

The invention discloses a preparation method of one of components of a novel antihypertensive drug LCZ696, namely, sacubitril (sacubitril, AHU-377, I). The method comprises the following preparation steps: carrying out cyclization, addition, debenzylation, ring opening, esterification, amidation and the like on a chiral induciton reagent (S)-1-(alpha-aminobenzyl)-2-naphthol (S-betti Base) and 2R-methyl-4-oxo-butyric acid to prepare the sacubitril (I). The preparation method is available in raw materials, concise in process, economic and environmentally friendly, and is suitable for industrial production.

Owner:广州博览咨询服务有限公司

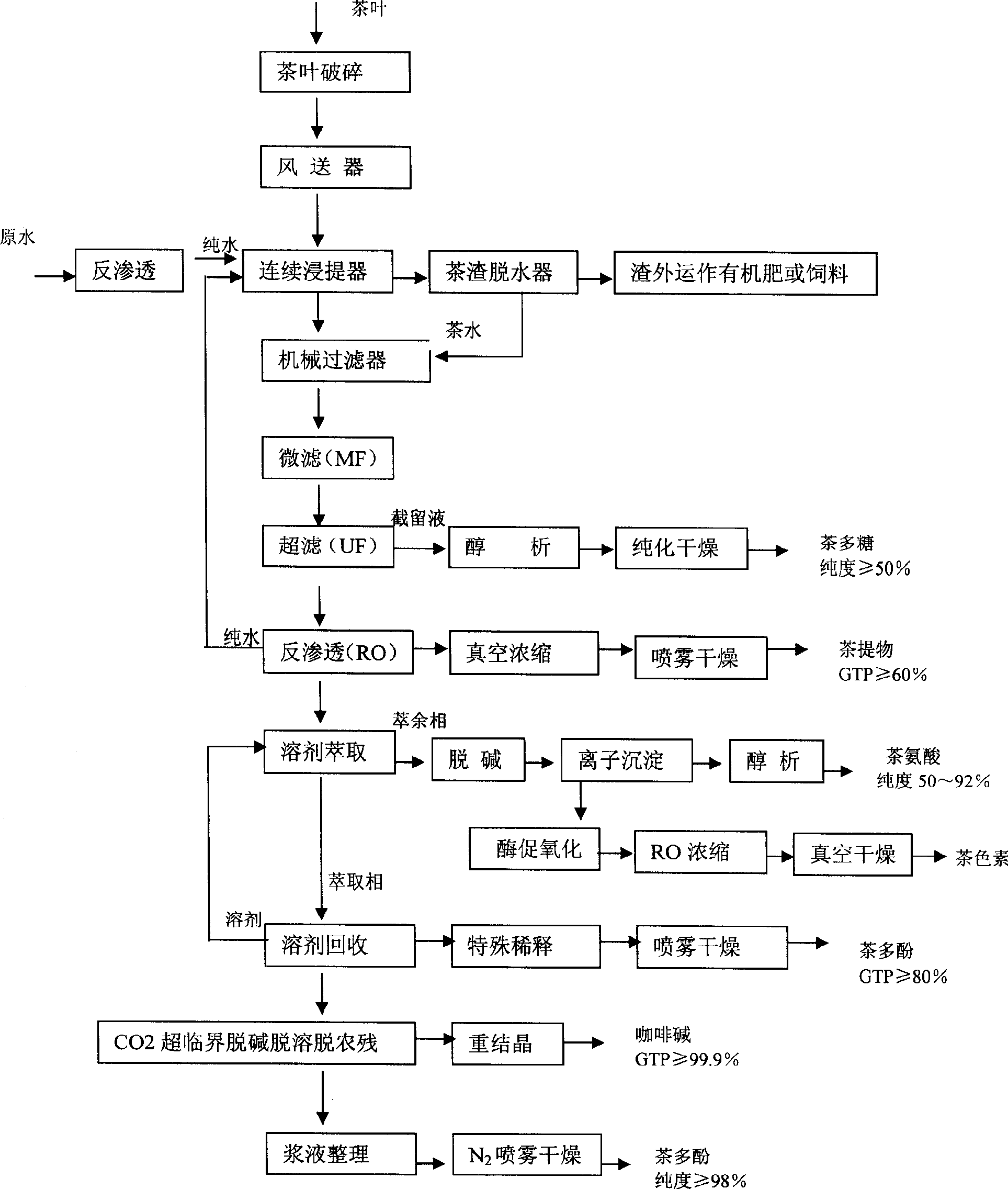

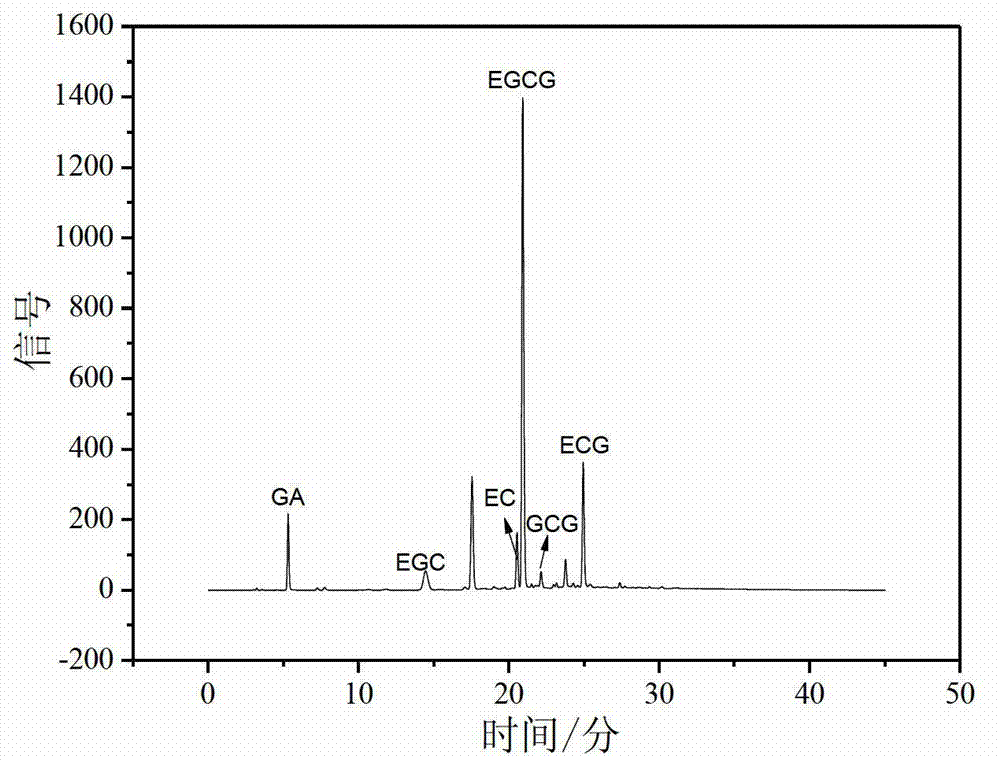

Process for extracting tea polyphenol, theanine, tea polysaccharide and tea pigment from tea

InactiveCN1837201AHigh purityReduce labor intensityCarboxylic acid amide separation/purificationBulk chemical productionForeign matterPhenolic content in tea

The invention discloses an extracting polyphenol, theanine, tea polysaccharide and tea pigment method from tea, which is characterized by the following: using deionized water for lixiviating tea at constant temperature with continuous flow upstream at multi-speed; adopting microstrainer to dislodge the foreign matter of raffinate; using hyperfiltration for putting-off pectin and protein; concentrating by hyperfiltration and dehydration; extracting tea polyphenol by acetic acid ethyl ester and recovering dissolvant; stripping caffeine of extracting extract phase, pesticide residue and dissolvant by CO2 supercritical fluid; getting tea polyphenol by low-temperature nitrogen spray-drying; using alcohol separation and low temperation vacuum drying by hyperfiltration trapped fluid to prepare tea polysaccharide; separating alcohol recrystallization by basic copper carbonate and hydrogen sulfide to get theanine; using enzymatic oxidation and alkaline air to oxygenate remain polyphenols substance of liquid phantom; getting tea pigment by hyperfiltration dehydration compression and vacuum drying; merging caffeine form carbon dioxide above-critical fluid and caffeine from carrene; recovering dissolvent; using deionized water for washing; obtaining caffeine by recrystallization vacuum drying.

Owner:张守政

Methods for producing nateglinide B-type crystals

Owner:AJINOMOTO CO INC

Preparation method of agomelatine I type crystal

The invention discloses a preparation method of an agomelatine I type crystal which is an anti-depressant. The preparation method comprises the following steps of: dissolving crude agomelatine in a hydrophily organic solvent, filtering, dropping the filtrate into water under stirring, separating out solids and drying; wherein the weight part ratio of the hydrophily organic solvent to the water is 1:2-50. The agomelatine I type crystal prepared by the invention has excellent quality, good reproducibility, and high purity of HPLC normalization method to be above 99 percent, and is more suitable for large-scale industrialization production.

Owner:TIANJIN TAIPU PHARMA SCI & TECH DEV

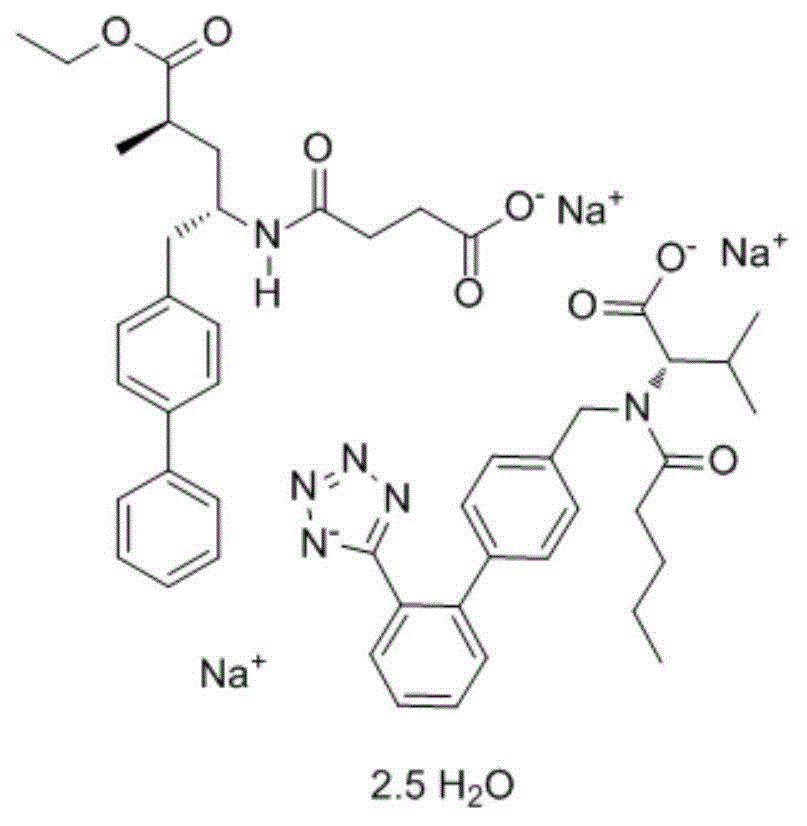

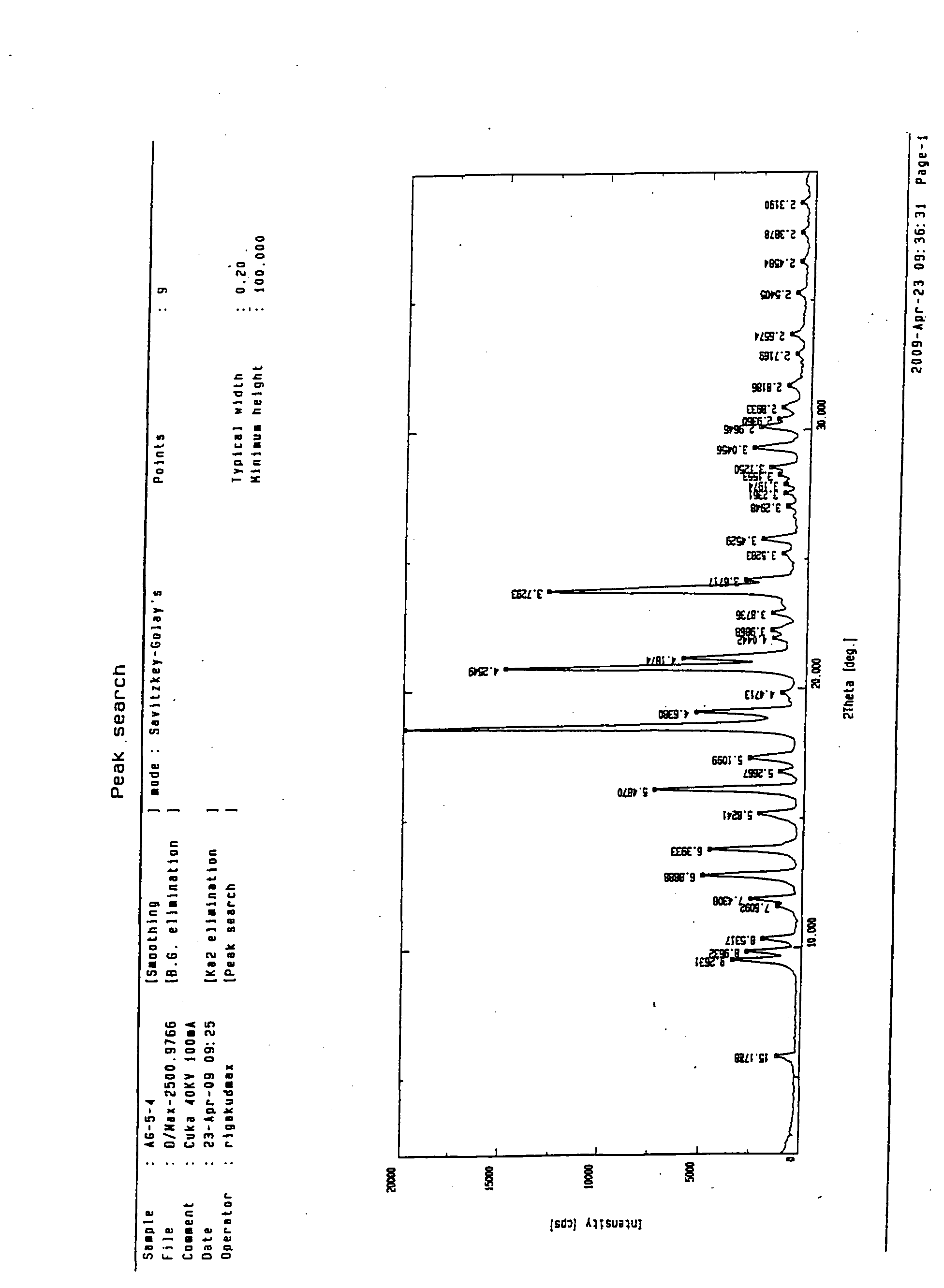

Novel crystalline form of angiotensin receptor antagonist and neutral endopeptidase inhibitor supramolecular complex

ActiveCN105037289AGood water solubilityImprove stabilityOrganic chemistry methodsCarboxylic acid amide separation/purificationSolubilityWater soluble

The present invention discloses a novel crystalline form of an angiotensin receptor antagonist and neutral endopeptidase inhibitor supramolecular complex. The novel crystalline form of the supramolecular complex has high water solubility and good stability. Experiments show that the moisture absorption and intrinsic dissolution extent and speed are superior to those of a conventional crystalline supramolecular complex.

Owner:EAST CHINA UNIV OF SCI & TECH

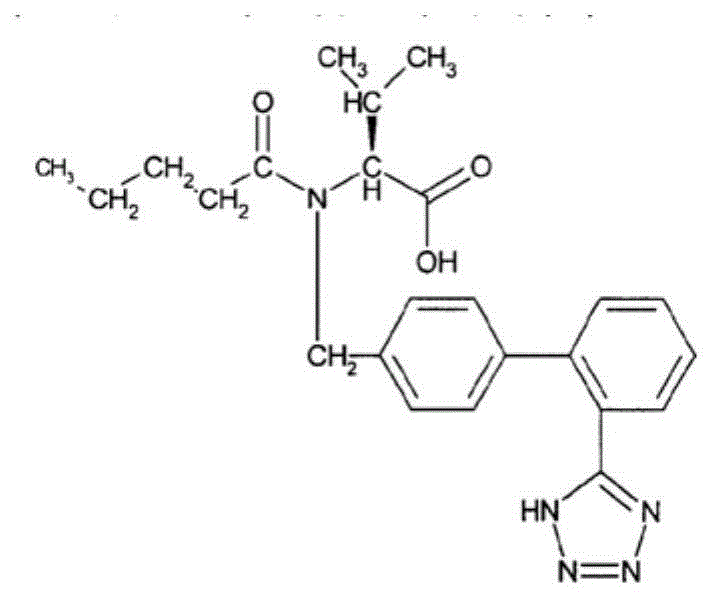

Method for preparing cardiotonic drug LCZ696

ActiveCN104860894ALow impurity contentImprove stabilityOrganic compound preparationCarboxylic acid amide separation/purificationDrug compoundMedicine

Owner:BEIJING BOQUANJIAN PHARMA TECH CO LTD

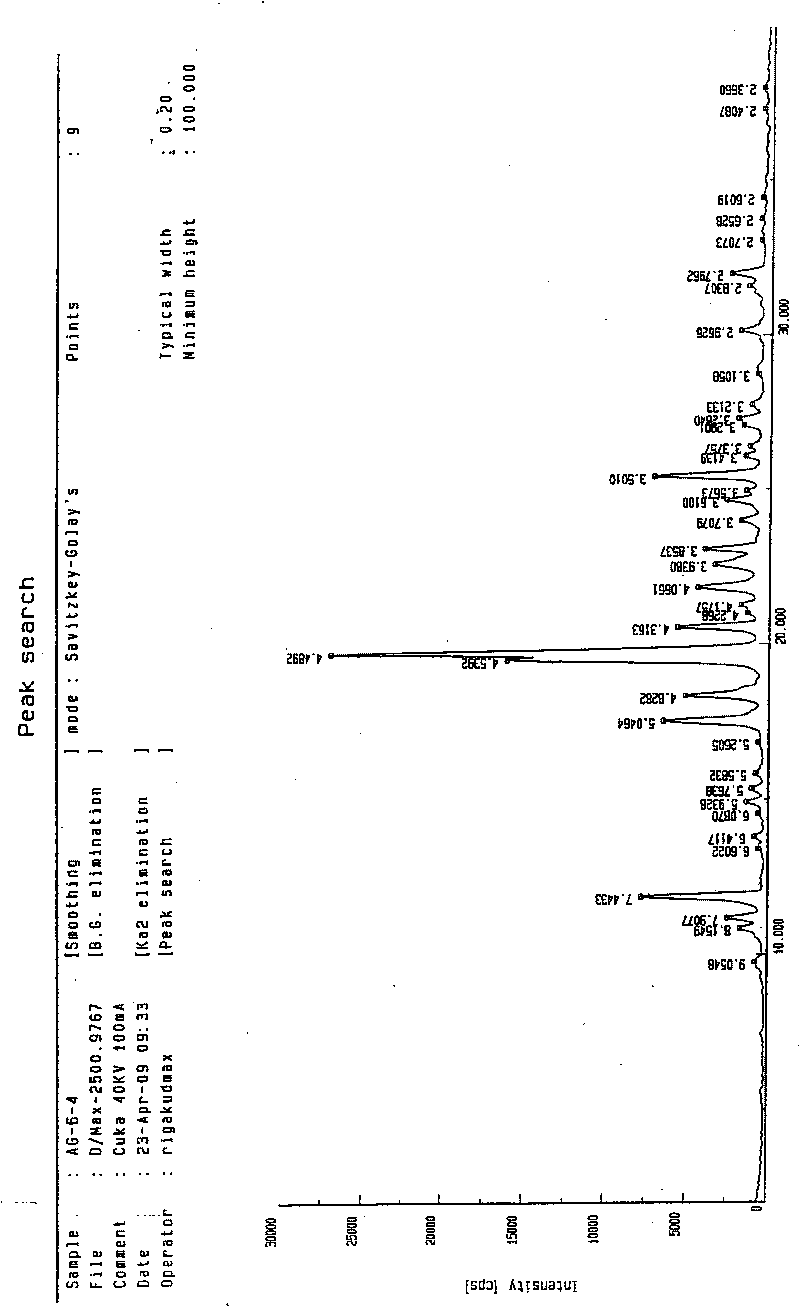

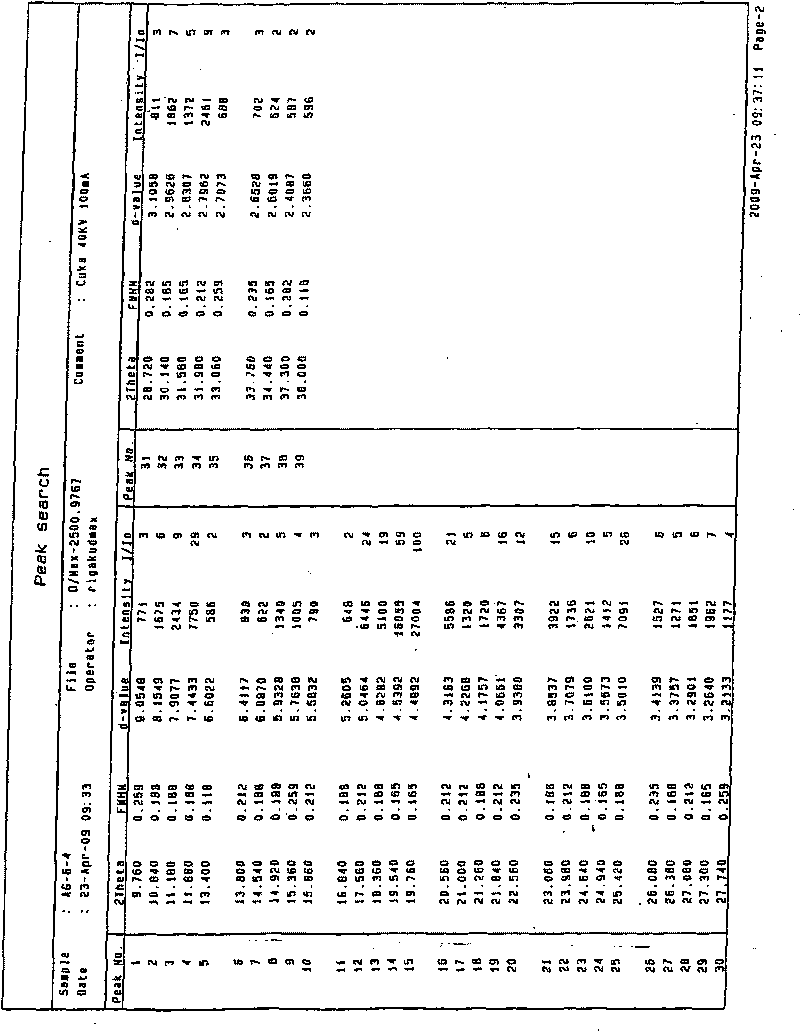

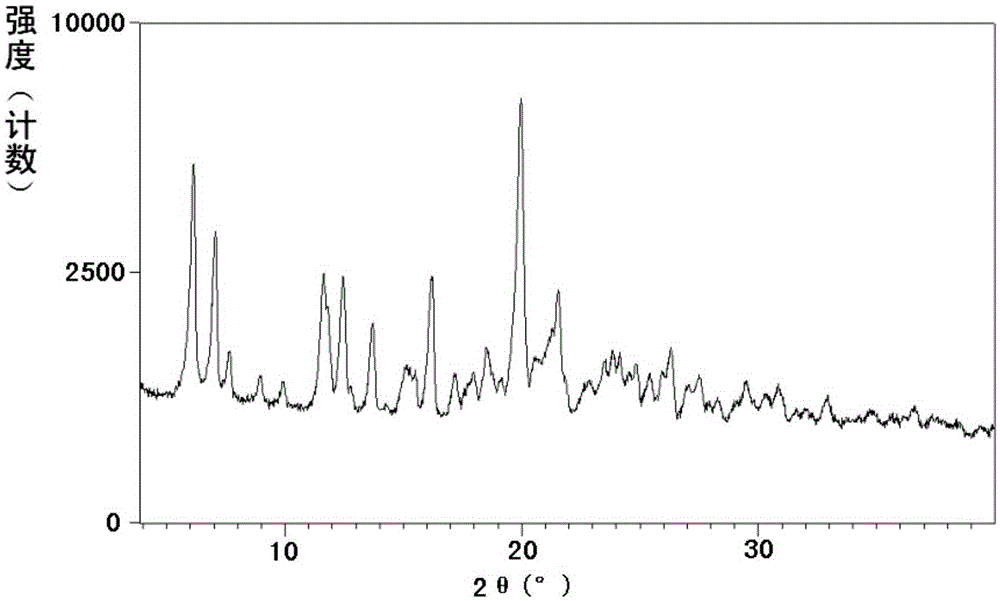

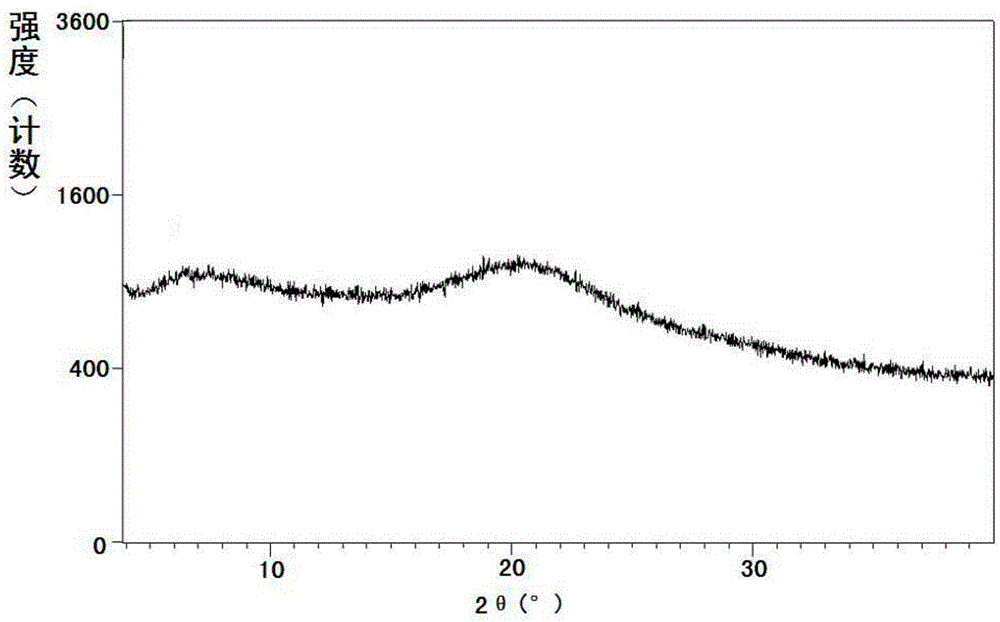

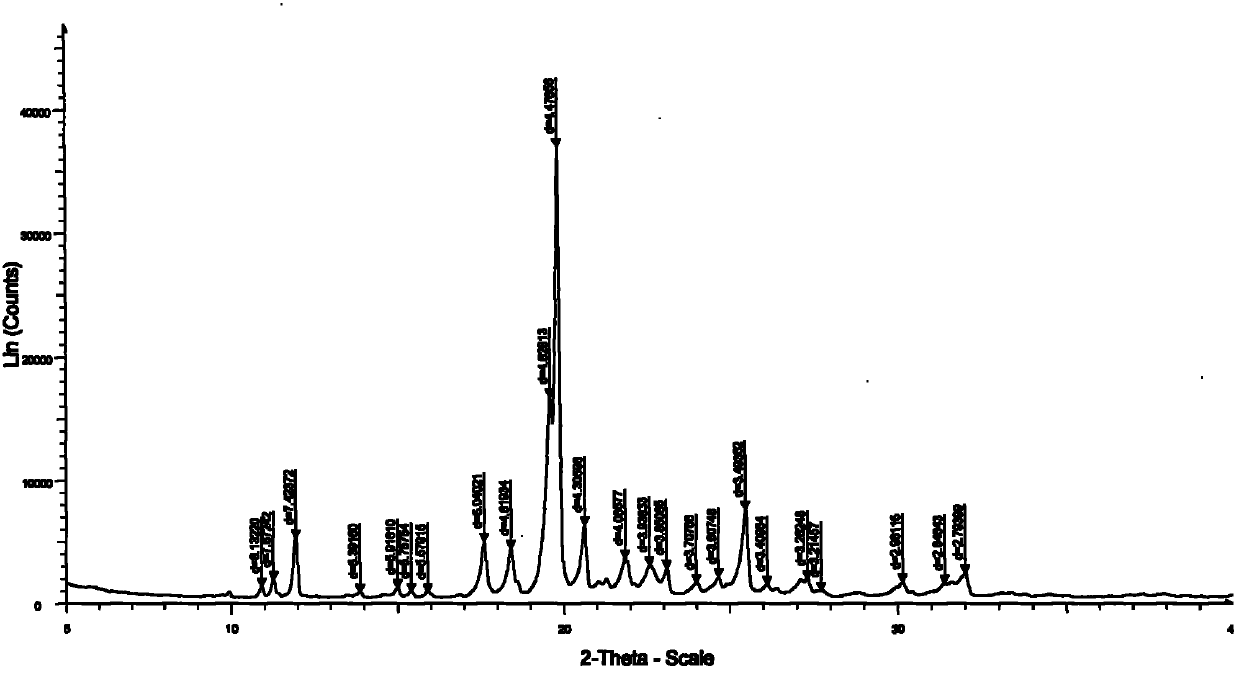

Agomelatine and medicine composition thereof

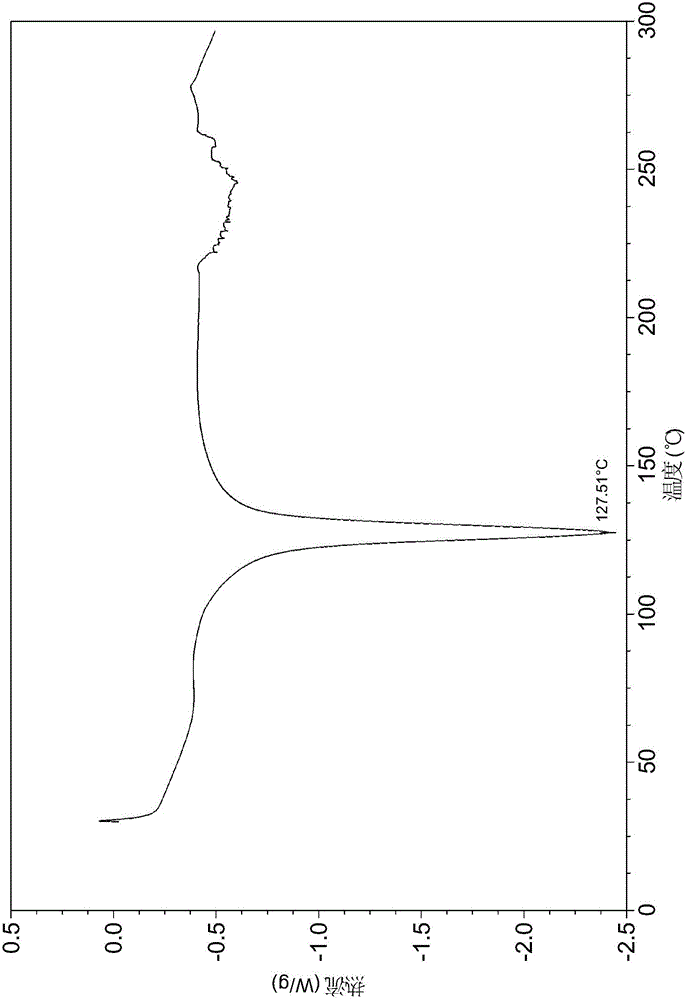

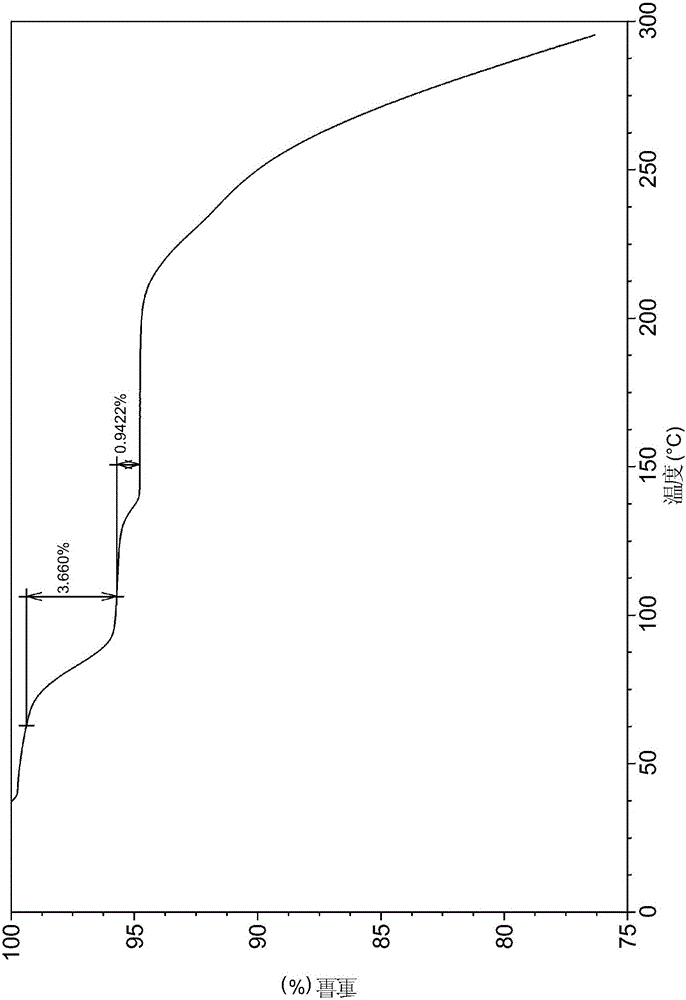

ActiveCN101781226AQuality improvementImprove solubilityOrganic active ingredientsNervous disorderK-alphaPowder diffraction

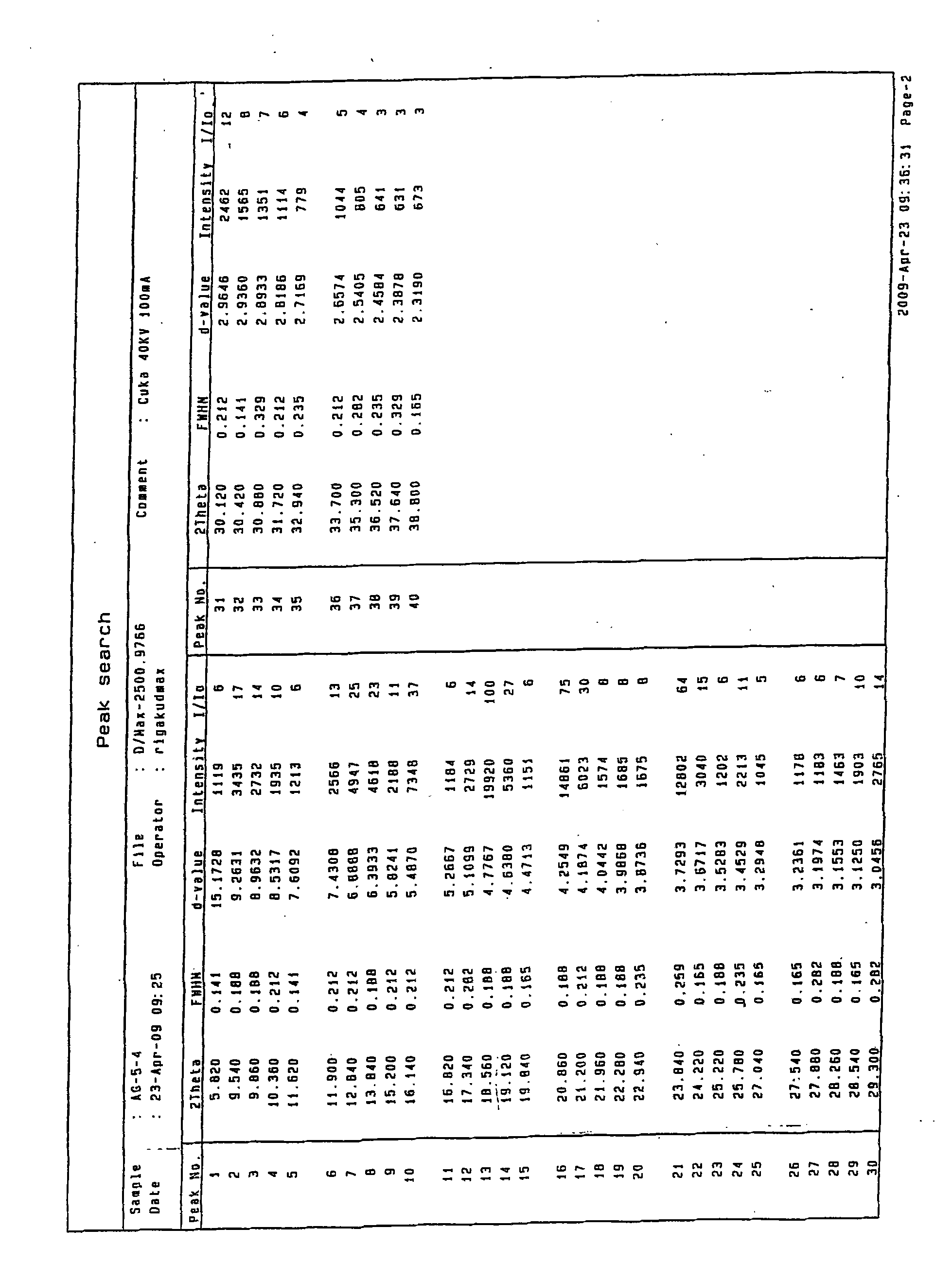

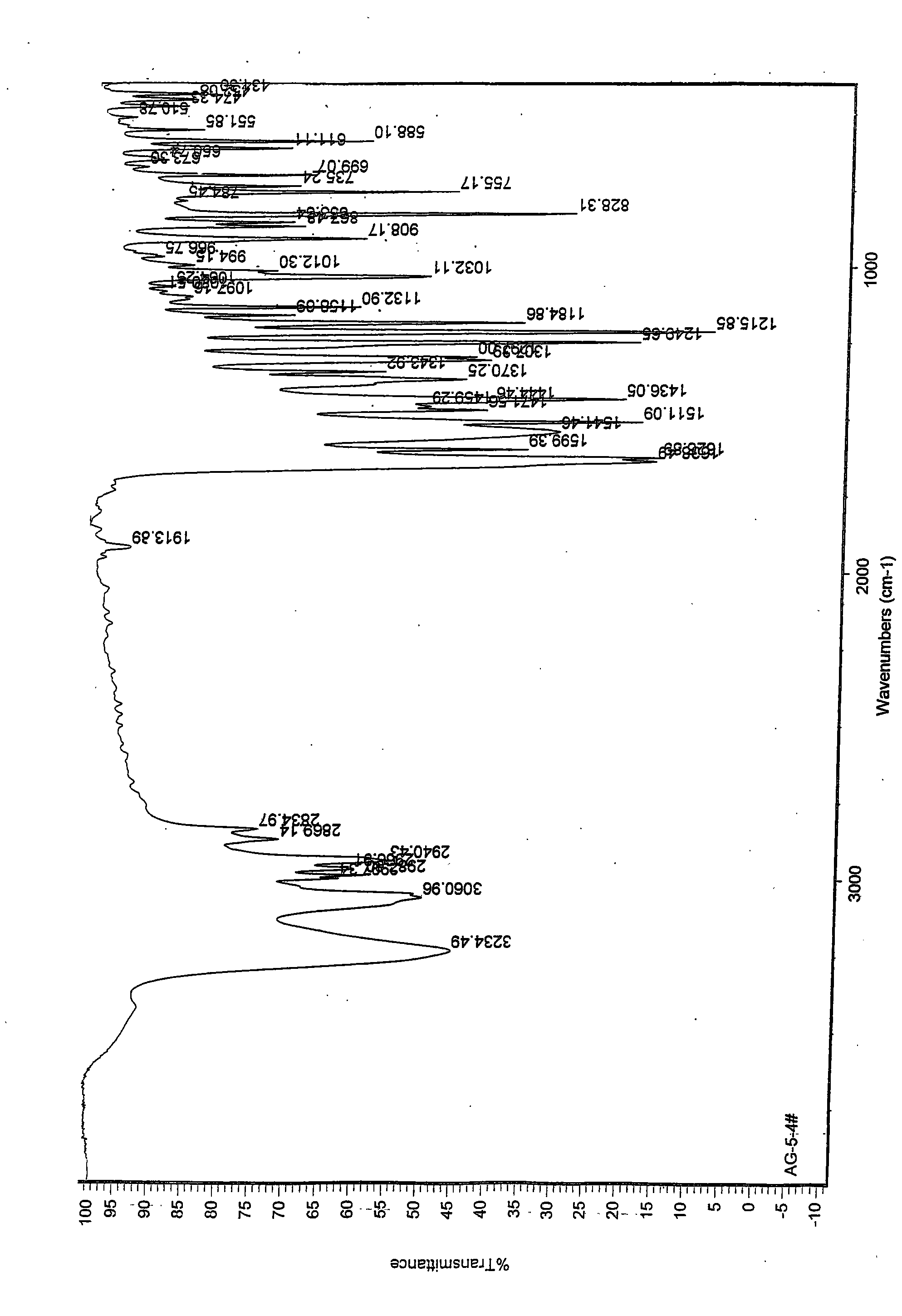

The invention discloses a medicine of Agomelatine for treating depression, in particular an Agomelatine crystal and a medicine composition thereof. The Agomelatine crystal is irradiated by using Cu-K alpha; and an X-ray powder diffraction spectrum expressed by the degree of 2theta of the Agomelatine crystal has characteristic diffraction peaks at positions of 12.84, 13.84, 16.14, 14.18, 18.56, 19.12, 20.86, 21.20 and 23.84, and an infrared absorption spectrum of the Agomelatine crystal has characteristic diffraction peaks approximately at position of 3234, 3060, 2940, 1638, 1511, 1436, 1249, 1215, 1184, 1032, 908, 828, 755 and 588cm-1. The DSP heat absorption transition is 97.6 DEG C. The invention further discloses application of the medicine composition containing the Agomelatine crystal as an active effective component to the preparation of medicines for treating the depression.

Owner:TIPR PHARM CO LTD

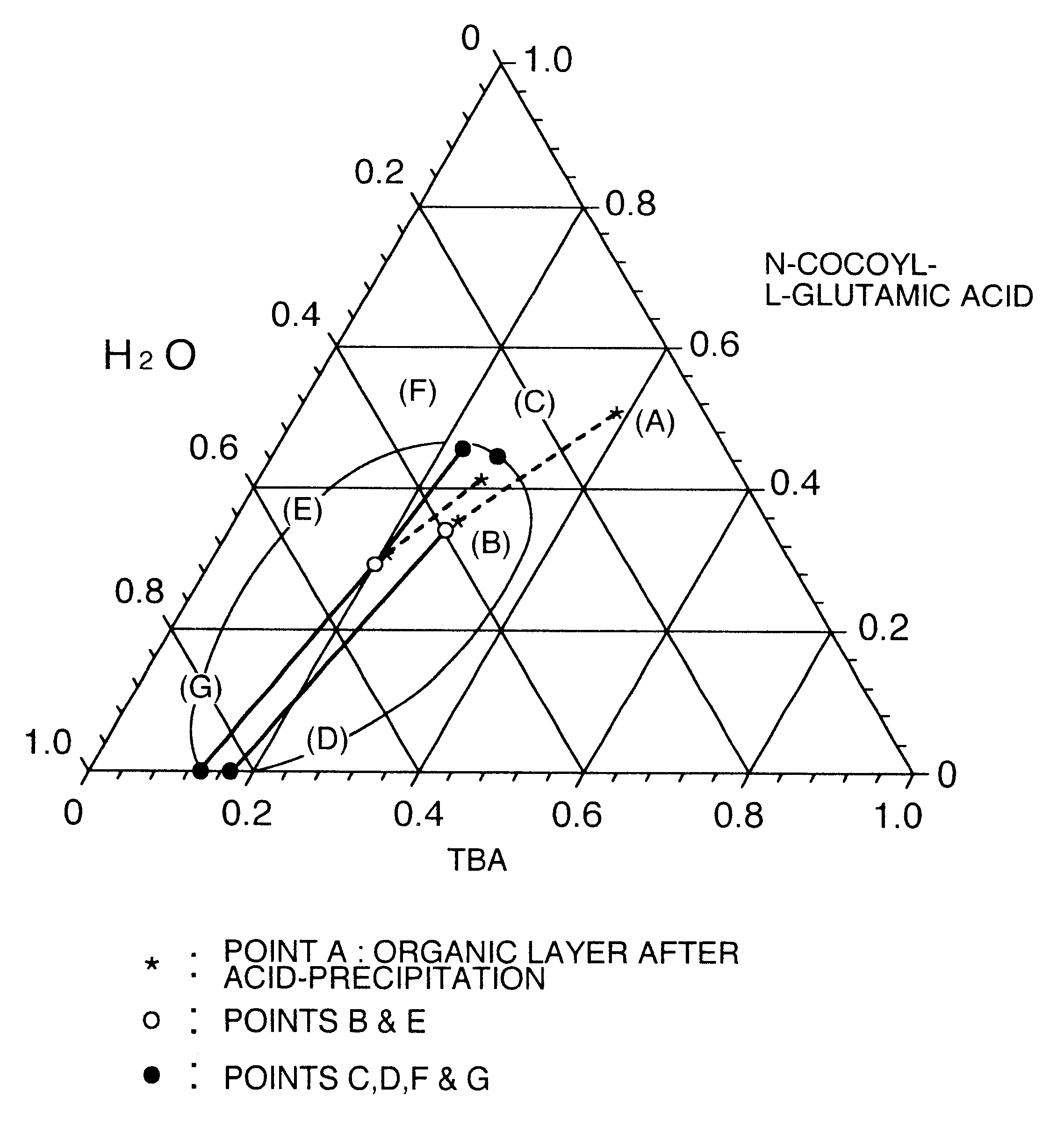

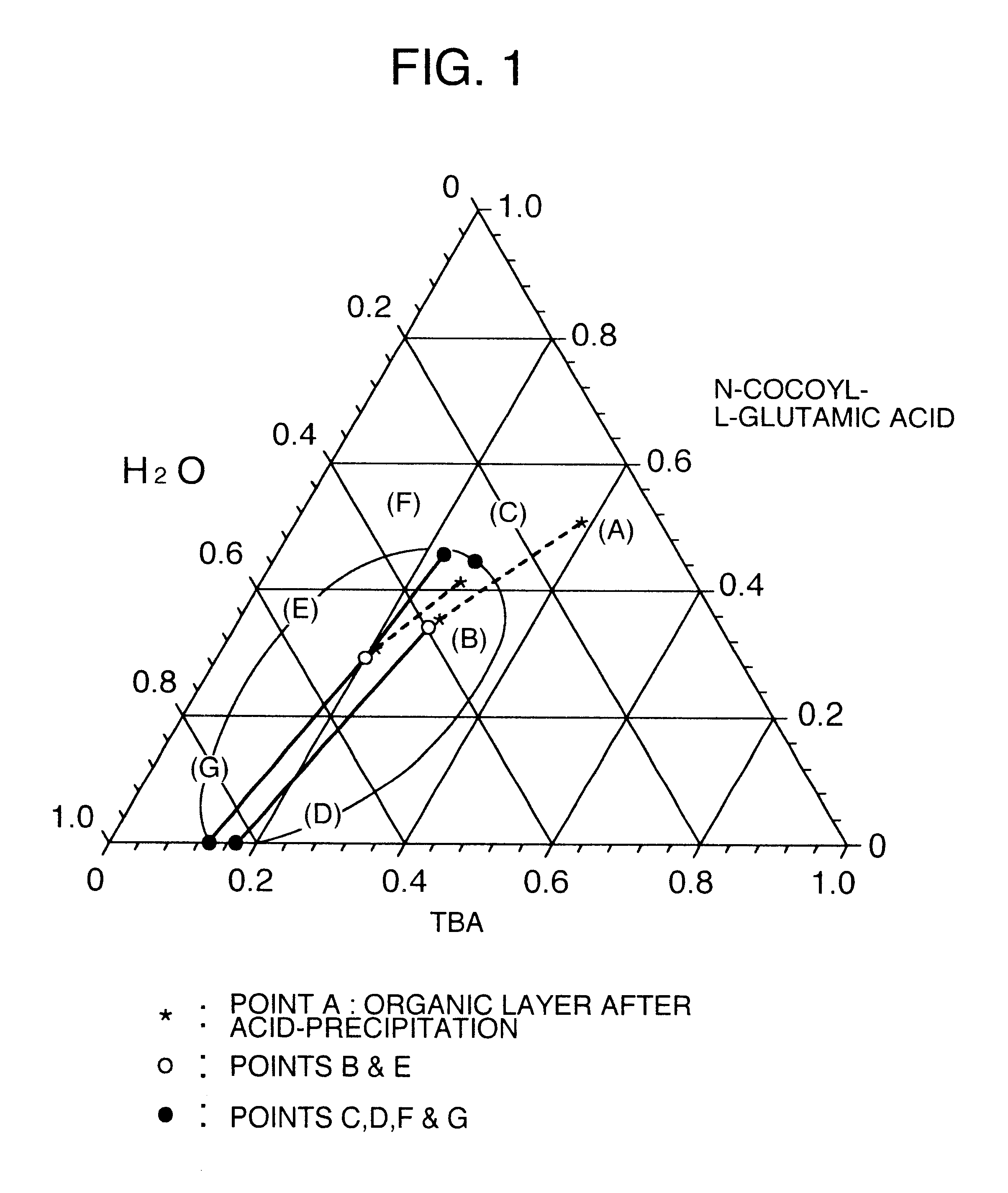

Process for producing long chain N-acyl acidic amino acid

A process for producing a long chain N-acyl acidic amino acid removes impurities by separating a mixture composed of a long chain N-acyl acidic amino acid containing an inorganic salt and a medium containing water and tertiary butanol into an aqueous layer and an organic layer containing the long chain N-acyl acidic amino acid at a temperature of from 35 to 80° C.

Owner:ASAHI KASEI FINECHEM CO LTD

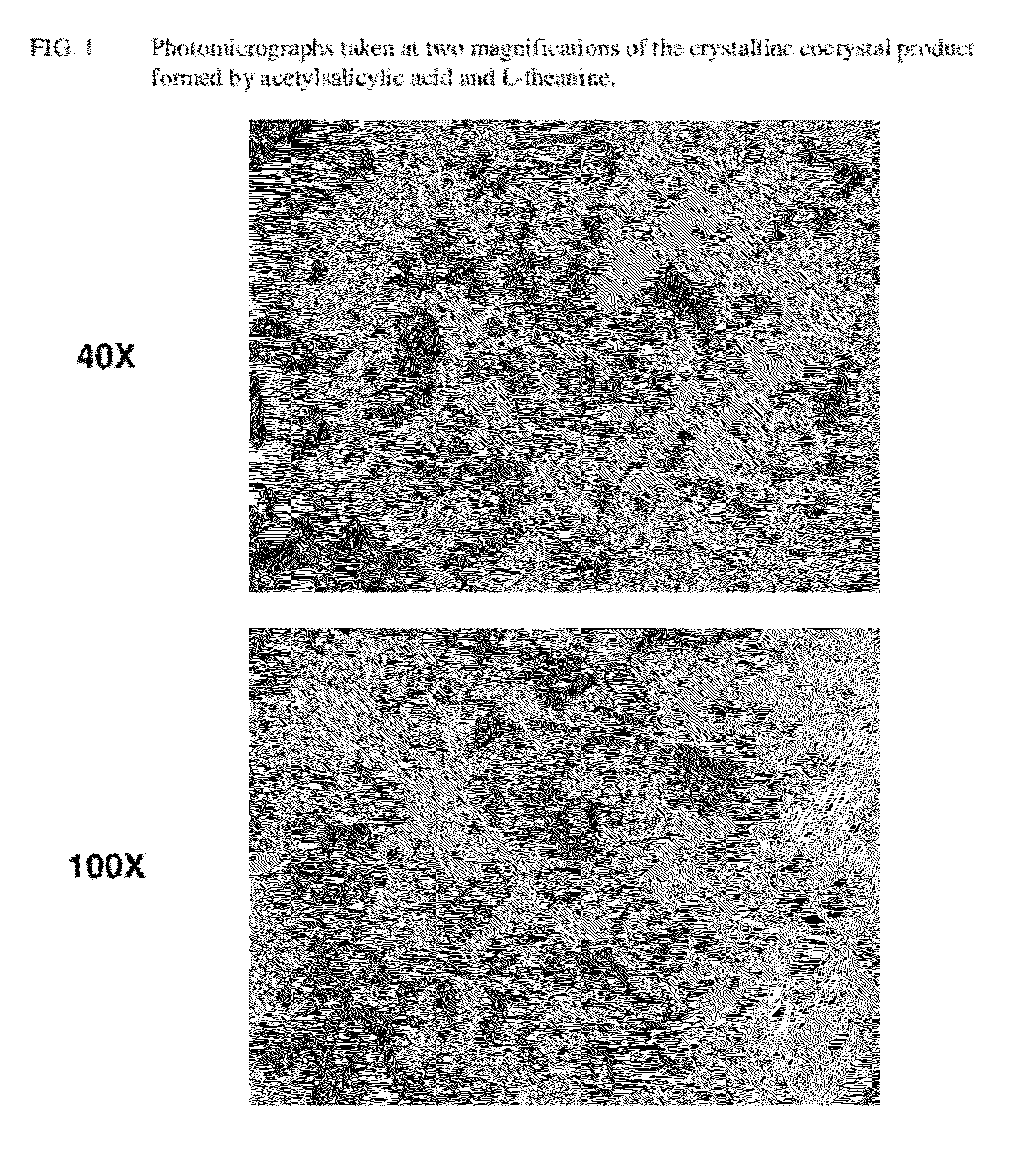

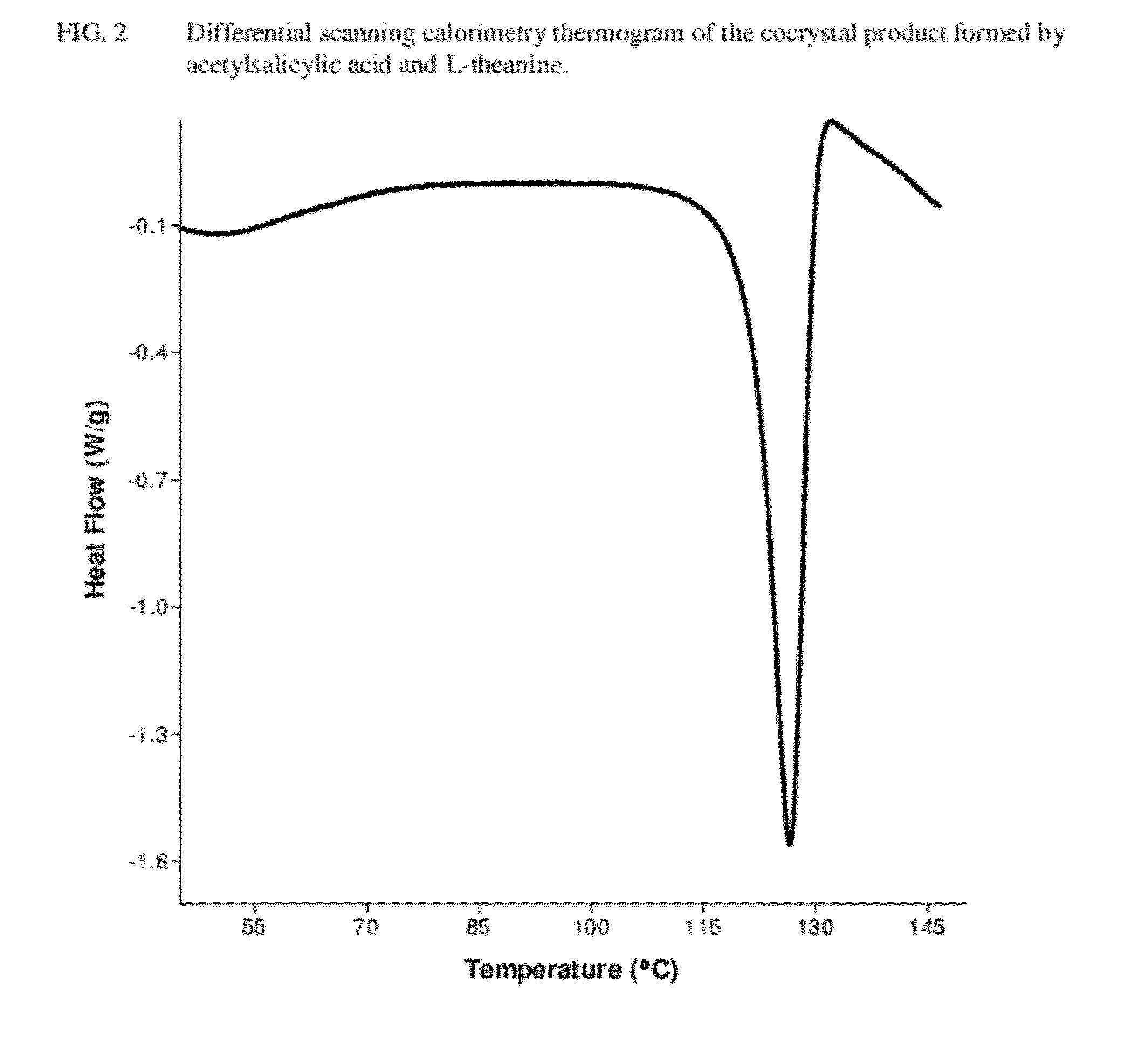

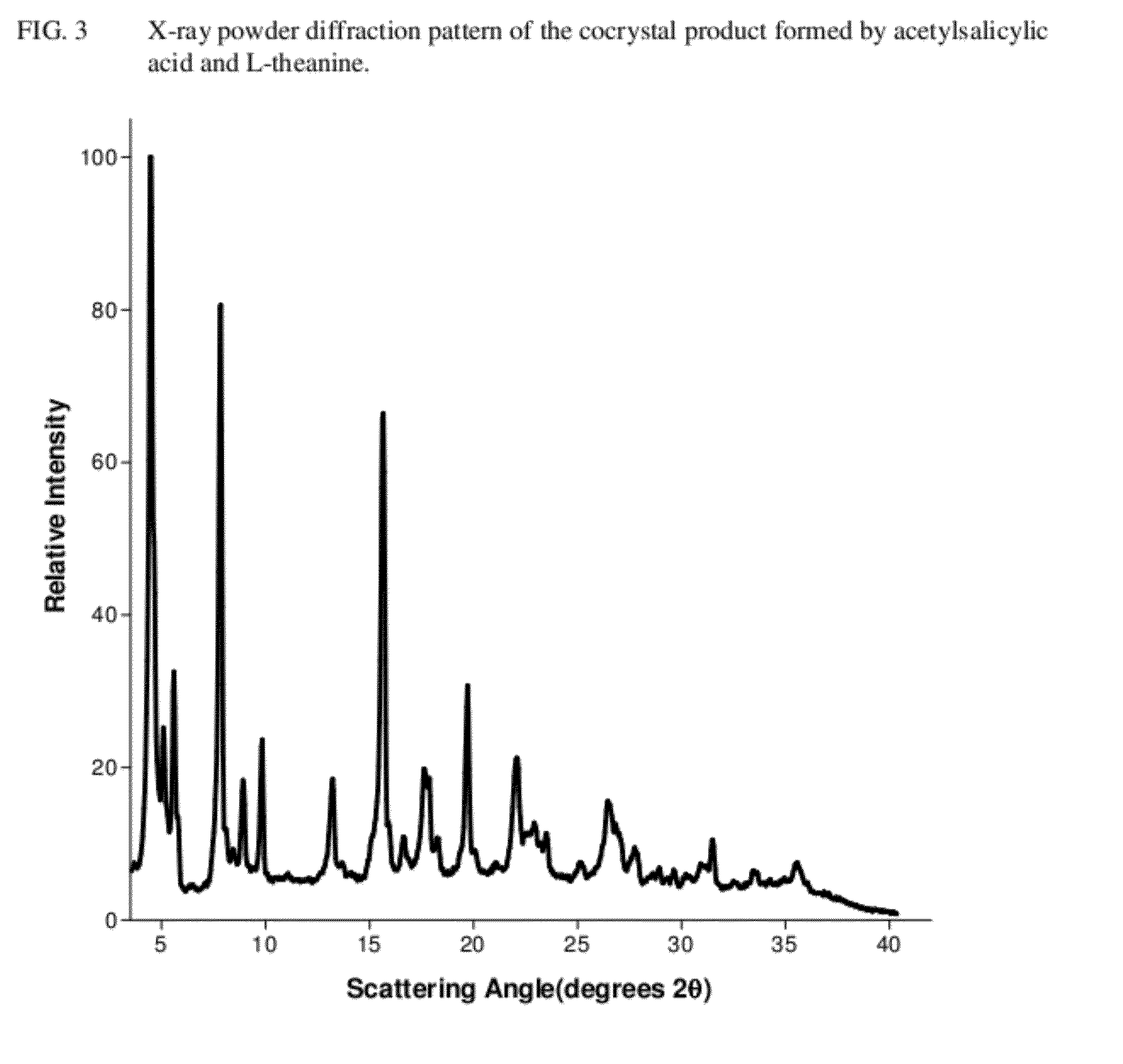

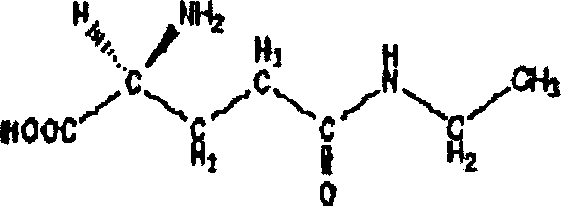

Intravenous formulation with water-soluble cocrystals of acetylsalicylic acid and theanine

A water-soluble aspirin-theanine cocrystal composition which includes a quantity of acetylsalicylic acid and a quantity of a theanine enantiomer associated with the quantity of acetylsalicylic acid. The composition may be created by a method including the steps of: (i) providing a quantity of acetylsalicylic acid; (ii) adding a quantity of a theanine enantiomer to the quantity of acetylsalicylic acid to form a mixture comprising the quantity of acetylsalicylic acid and the enantiomer of theanine; (iii) wetting the mixture; and (iv) grinding the mixture for a length of time sufficient to produce a dried crystalline mass. The water-soluble cocrystal composition is suitable for intravenous administration, preferably to humans.

Owner:THEAPRIN PHARMA

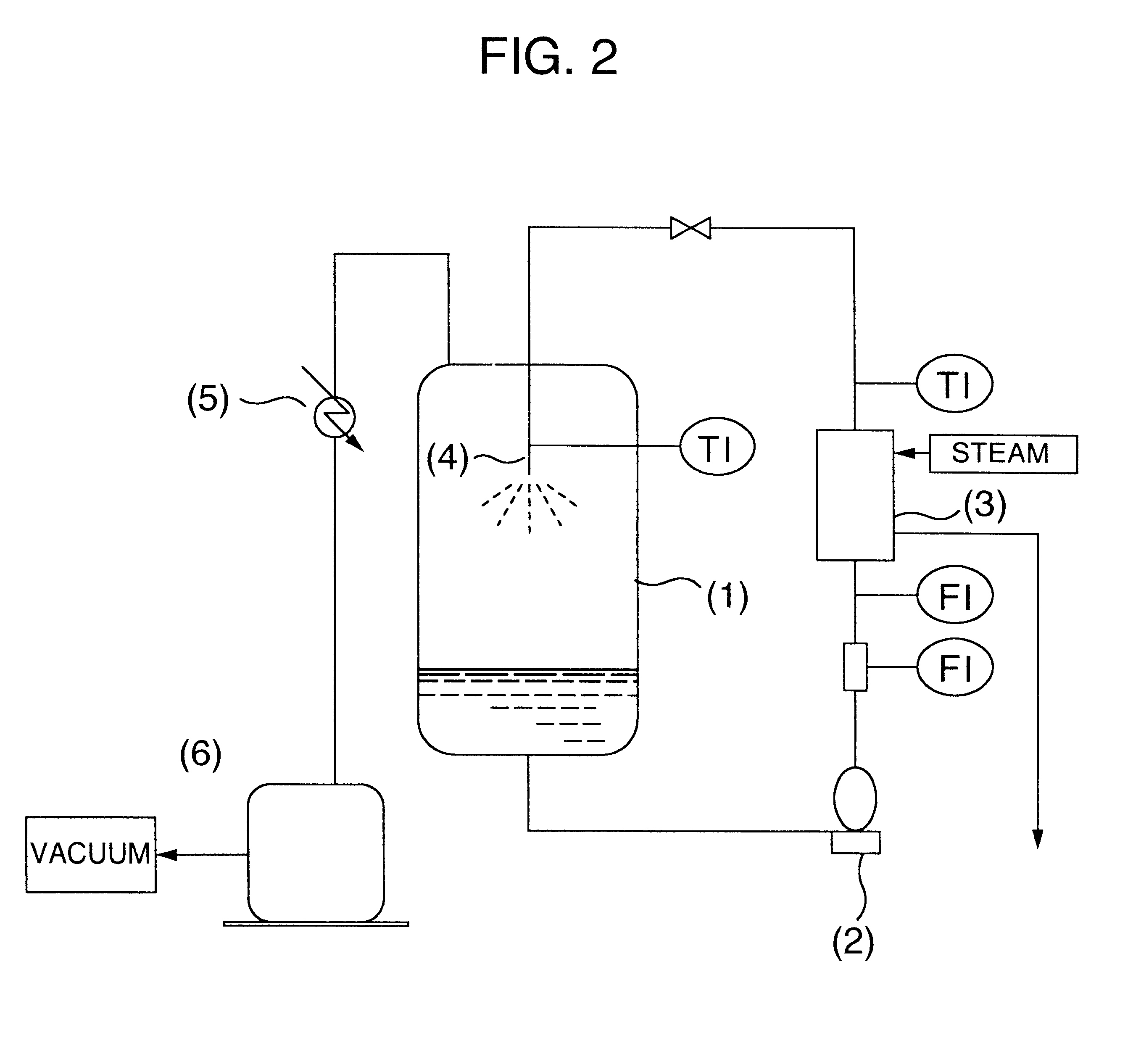

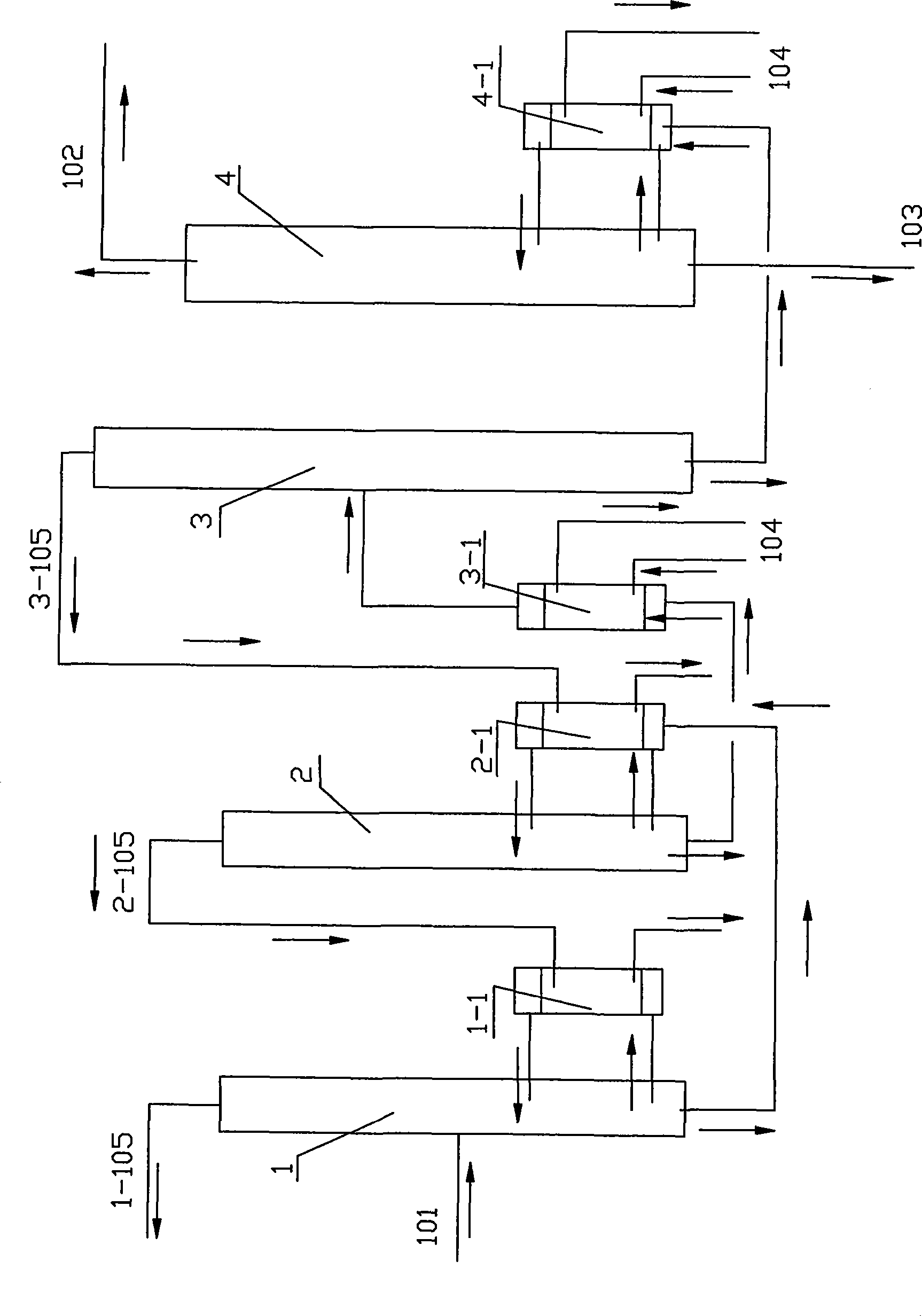

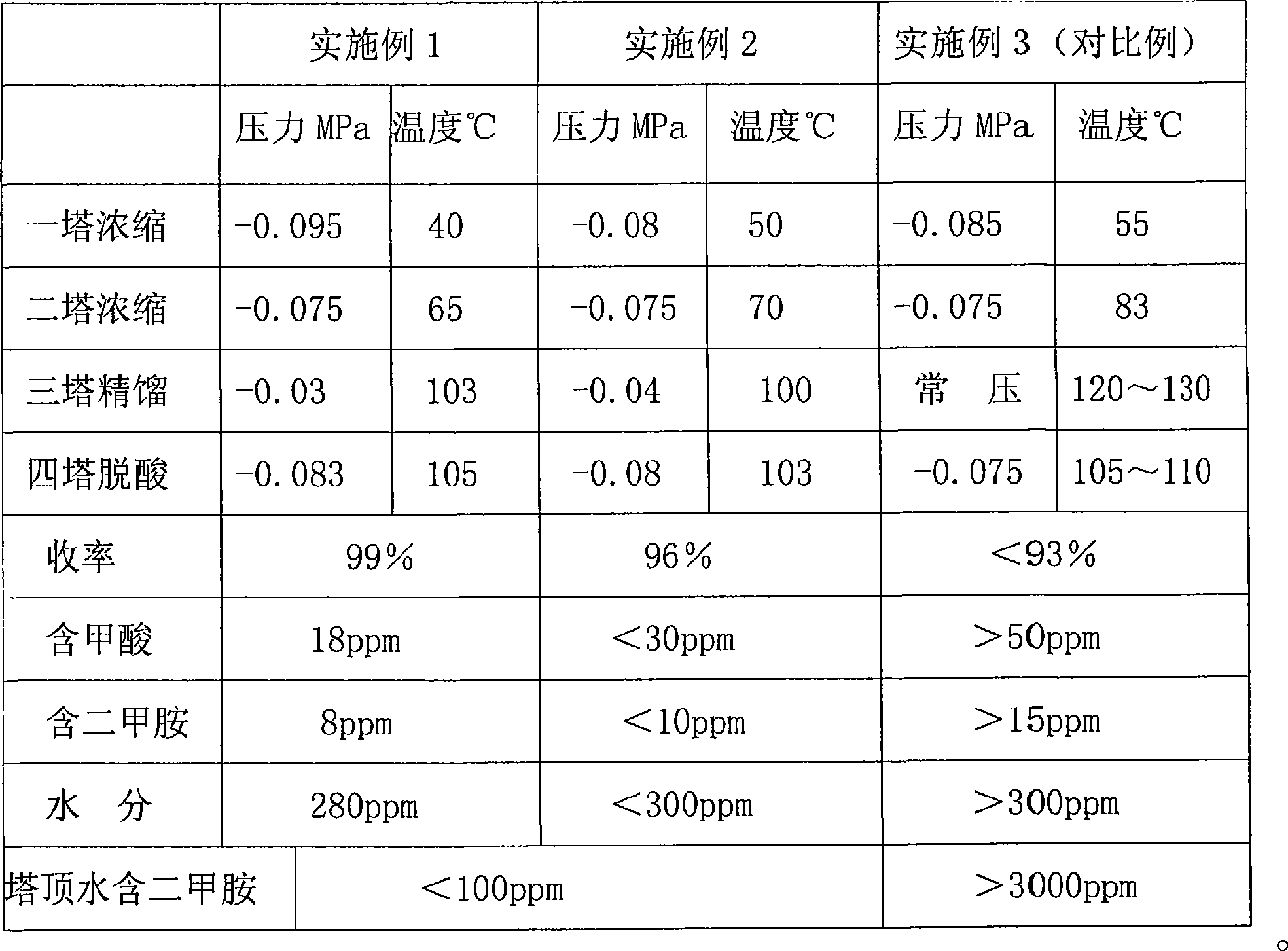

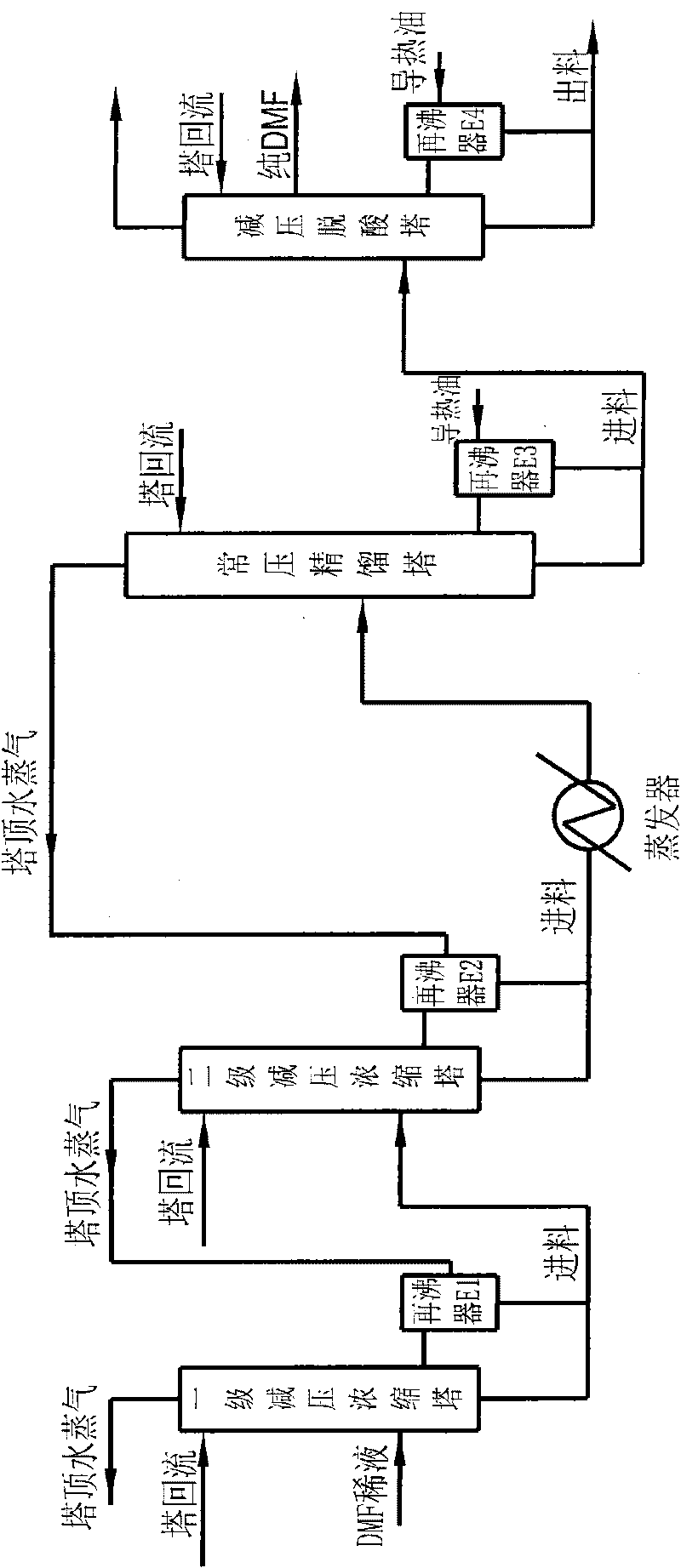

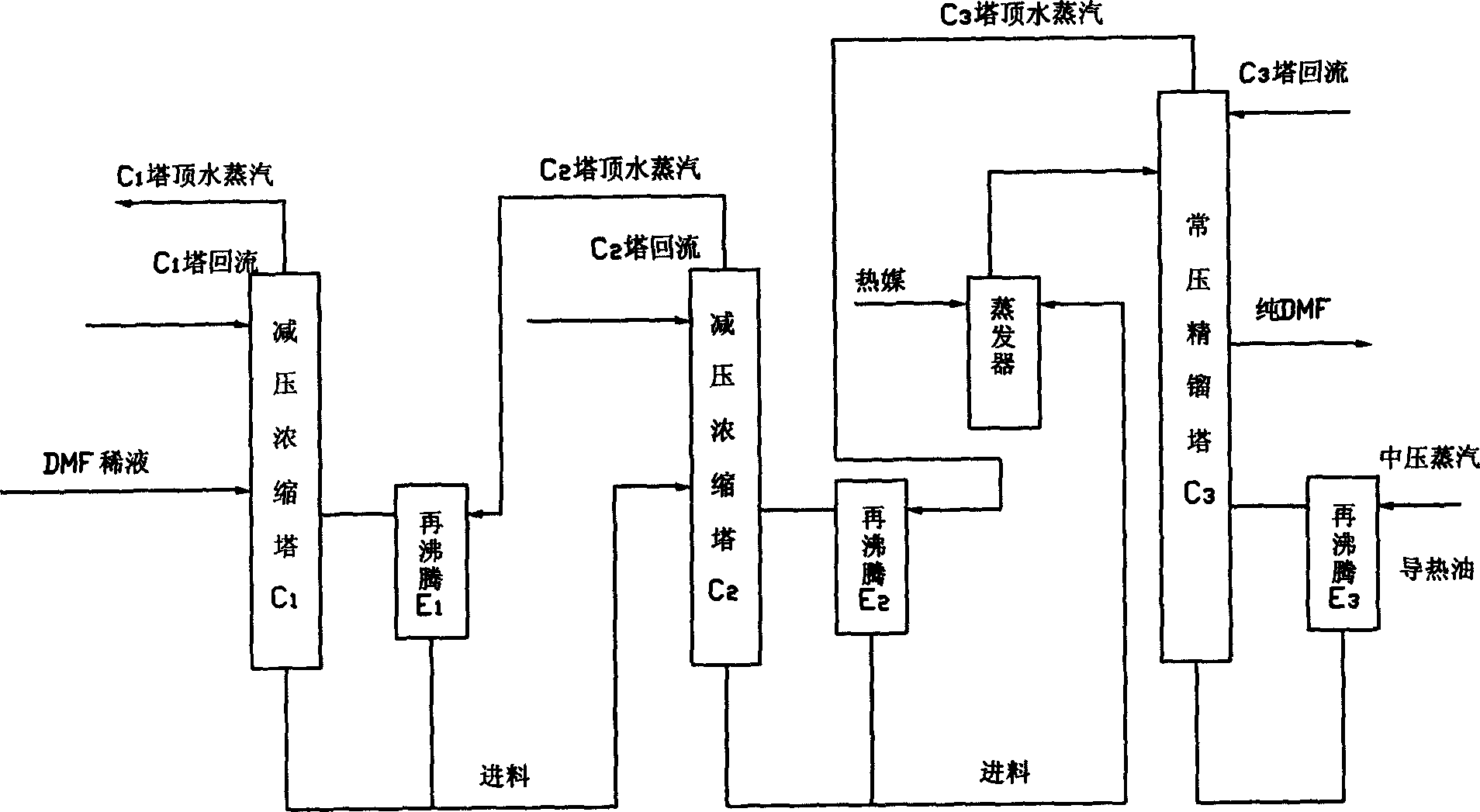

Method for recovering dimethyl formamide

ActiveCN101519362AReduce decomposition rateReduce return steam rateCarboxylic acid amide separation/purificationMultistage water/sewage treatmentDecompositionWastewater

A method for recycling dimethyl formamide relates to a method for recovering dimethyl formamide from waste water by an all-subpressure operation method. The method includes the steps of utilizing conduction oil or low-pressure steam as a heat source, sequentially leading the waste water containing DMF to four subpressure operation towers, and performing subpressure concentration in the first tower and the second tower, subpressure fractionating in the third tower and deacidification in the fourth tower, thereby obtaining finished DMF and methanoic acid. Due to the great decrease of stable operating temperature, the recovery rate of the DMF can reach over 99 percent, and the rate of purity reaches 99.99 percent; the resolution ratio of the DMF and the back evaporation rate of the peracid DMF are obviously reduced, a methanoic acid decomposition tower is cancelled, almost no DMF contains peracid, repeated rectification is not needed, and energy sources are saved by over 10 percent; and meanwhile, the dimethylamine quantity generated by decomposition is little and is completely absorbed by a boiler screen dust collection system without emission.

Owner:HUALUN LEATHER & PLASTIC SUZHOU

Sacubitril derivatives and medicine compositions, preparation methods and application thereof

ActiveCN105693543AEasy to prepareCrystal form controllableAmino compound purification/separationOrganic compound preparationEthylenediamineArginine

The invention provides sacubitril derivatives and medicine compositions, preparation methods and application thereof and belongs to the fields of medicine compounds and preparation thereof. The sacubitril derivatives comprise sacubitril lithium salt, sacubitril kali salt, sacubitril magnesium salt, sacubitril calcium salt, sacubitril strontium salt, sacubitril zinc salt, sacubitril ferric salt, sacubitril ammonium salt, sacubitril diethylamine salt, sacubitril ethylenediamine salt, sacubitril piperazine salt, sacubitril N-(2-ethoxyl)-pyrrolidine salt, sacubitril choline salt, sacubitril cholamine salt, sacubitril diethanol amine salt, sacubitril triethanolamine salt, sacubitril tromethamine salt, sacubitril meglumine salt, sacubitril diisopropylamine salt, sacubitril tert-butylamine salt, sacubitril N, N'-bis-benzyl ethylenediamine salt, sacubitril L-lysine salt, sacubitril L-arginine salt or sacubitril L-histidine salt.

Owner:SICHUAN HAISCO PHARMA CO LTD

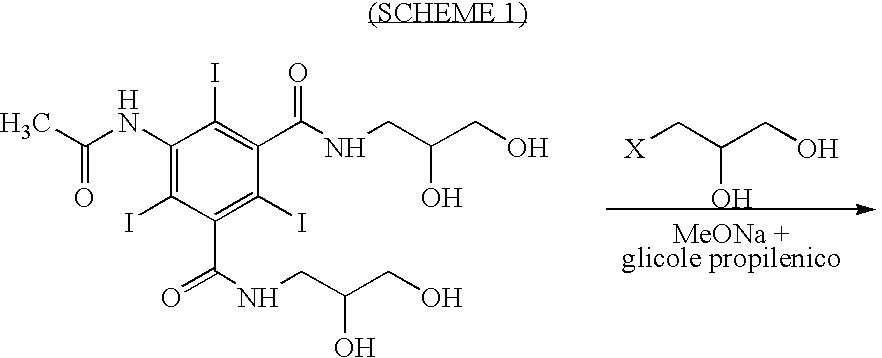

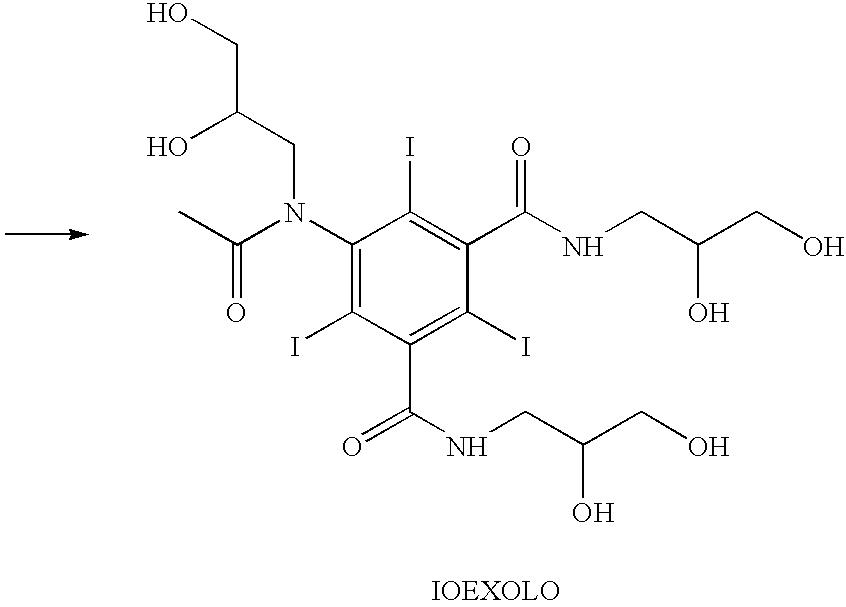

Process for the production of high purity iohexol

InactiveUS6897339B2Reduce impurityEliminate effectiveOrganic compound preparationCarboxylic acid amides optical isomer preparationPropanolPurification methods

Owner:CHEMI SPA

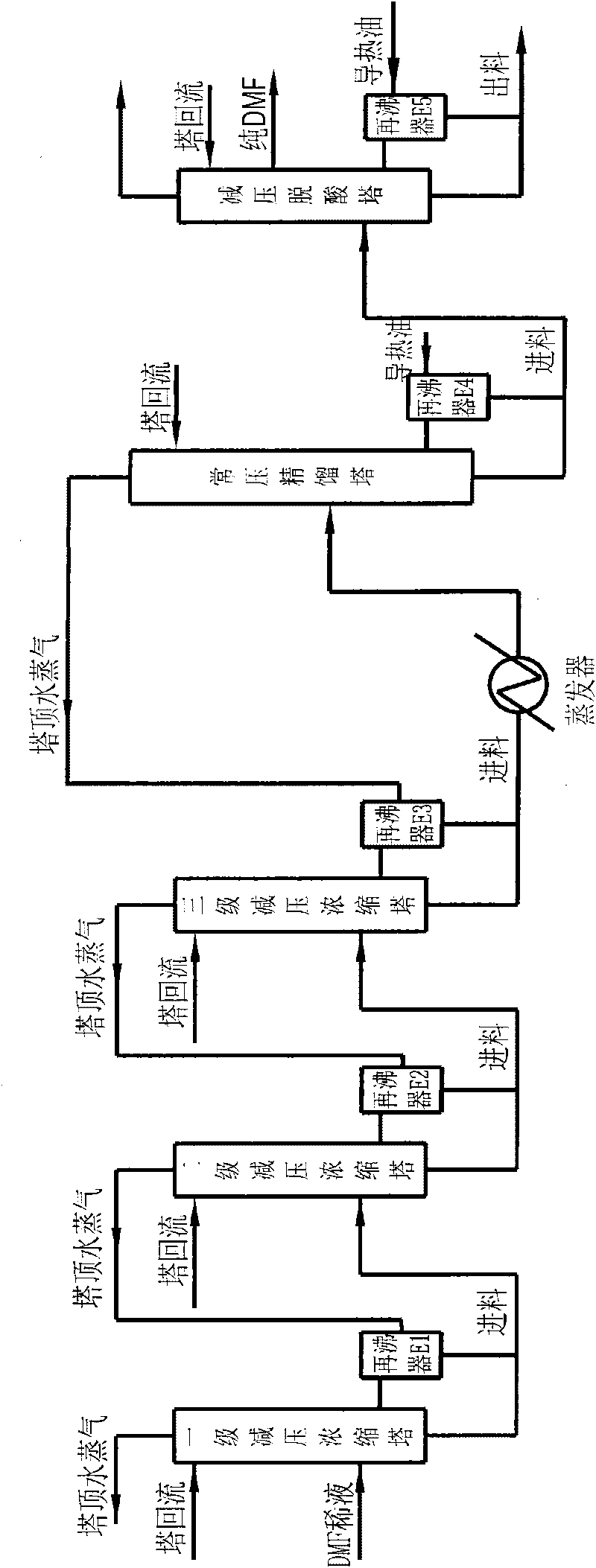

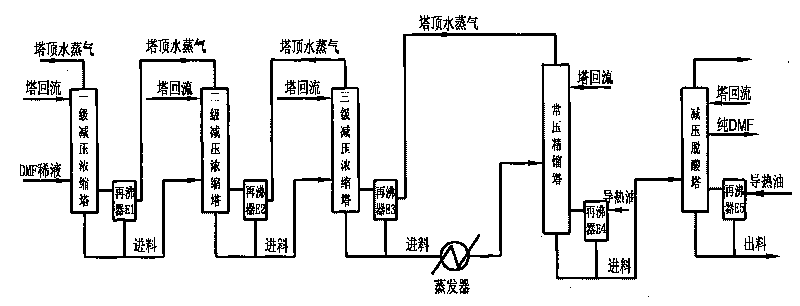

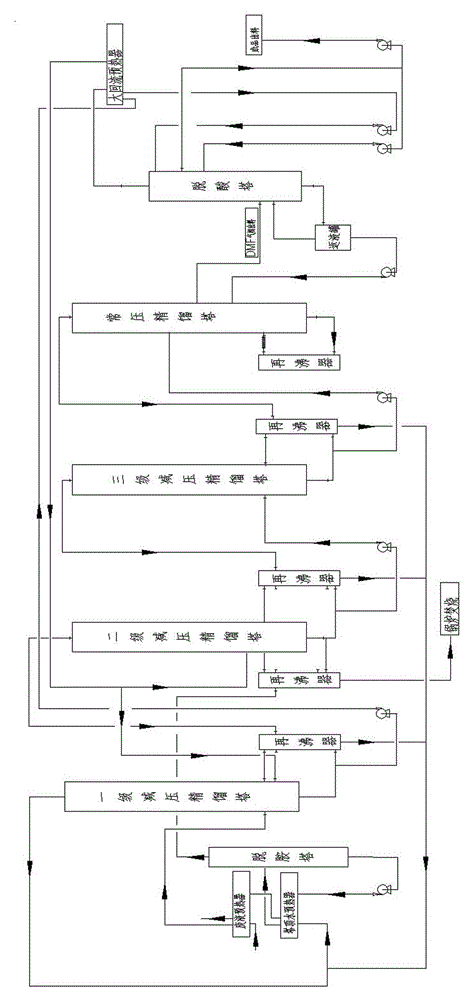

Four-effect rectification system for synthesizing leather dimethyl formamide solution by wet method and recovery method

InactiveCN101703840AImprove the level ofImprove heat utilizationCarboxylic acid amide separation/purificationFractional distillationRecovery methodThermal energy

The invention relates to a four-effect rectification system for synthesizing a leather dimethyl formamide solution by a wet method, and a recovery method. The four-effect rectification system comprises decompressing concentration towers, a normal-pressure rectification tower and a decompressing deacidification tower, wherein one decompressing concentration tower is added between two decompressing concentration towers in a three-effect rectification recovery system; the normal-pressure rectification tower adopts a filler tower. The process comprises the steps of feeding and preheating. By the concentration towers, the processes of one-stage decompressing concentration, two-stage decompressing concentration, three-stage decompressing concentration, normal-pressure rectification and decompressing deacidification are adopted, wherein the one-stage decompressing concentration tower, the two-stage decompressing concentration tower, the three-stage decompressing concentration tower, the normal-pressure rectification tower and the decompressing deacidification tower all adopt filler towers. The recovery technological procedure adopts a circulation process, and the generated heat energy is circularly used between the procedures of steaming at a tower top, heating by a tower kettle, feeding, preheating, condensing a finished product, preheating, rectifying and boiling again. Compared with a three-effect DMF recovery process which is widely applied at present, energy is at least saved by more than 20%; the purity of a recovered finished product DMF reaches 99.99%, the water content is below 200ppm, the acidity is below 20ppm, and the alkalinity is below 10ppm.

Owner:TIANJIN UNIV

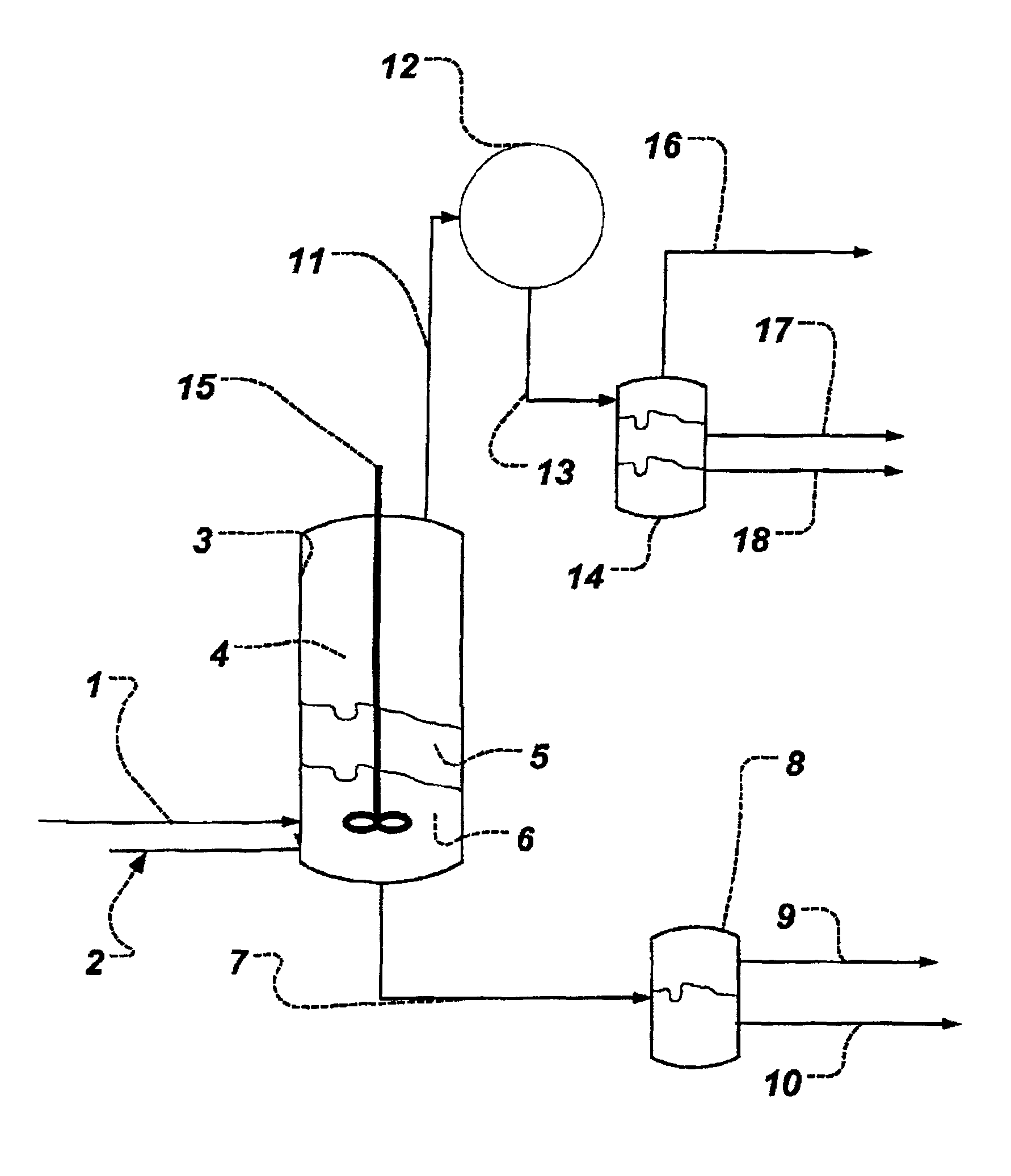

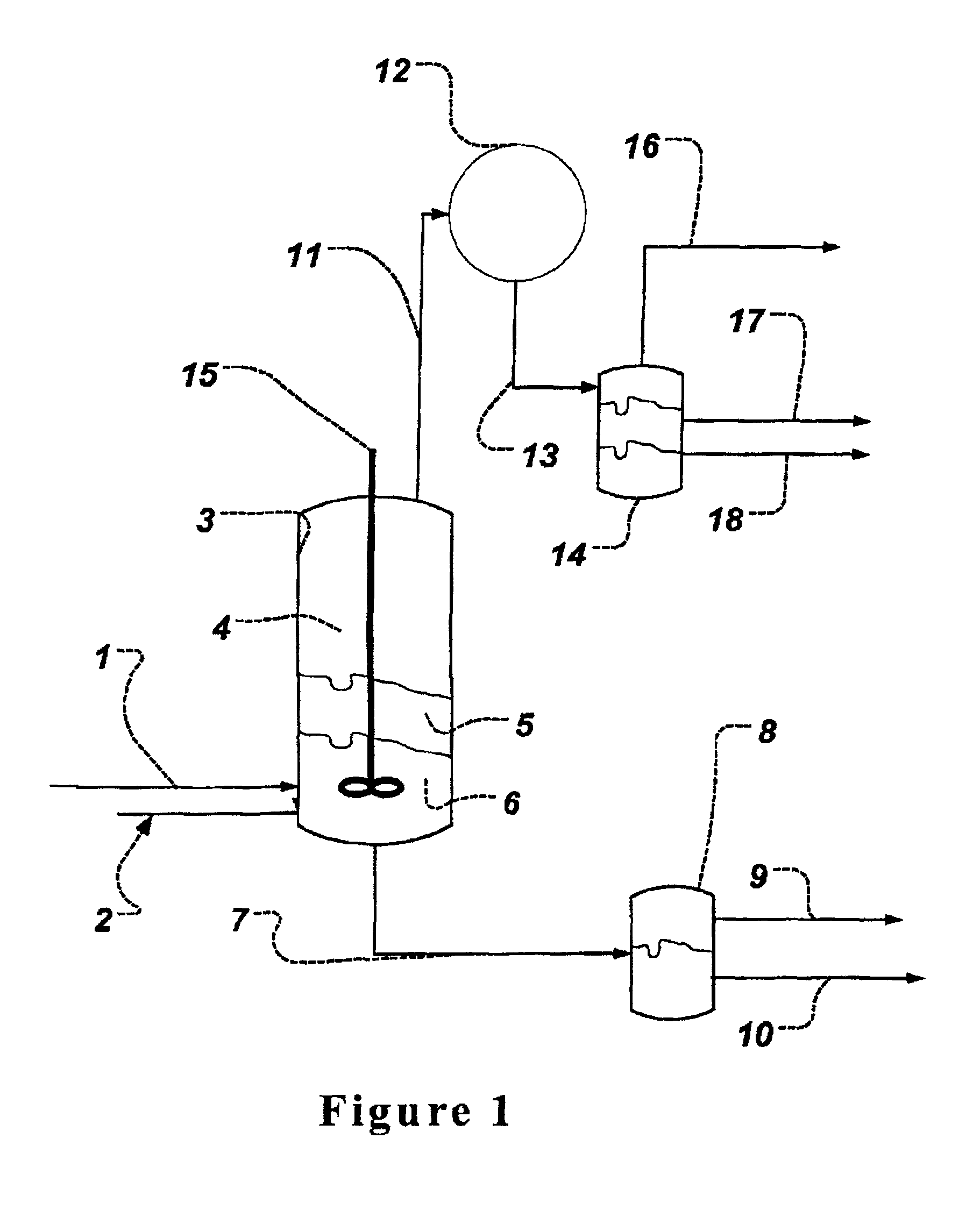

Process for obtaining an organic acid from an organic acid ammonium salt, an organic acid amide, or an alkylamine organic acid complex

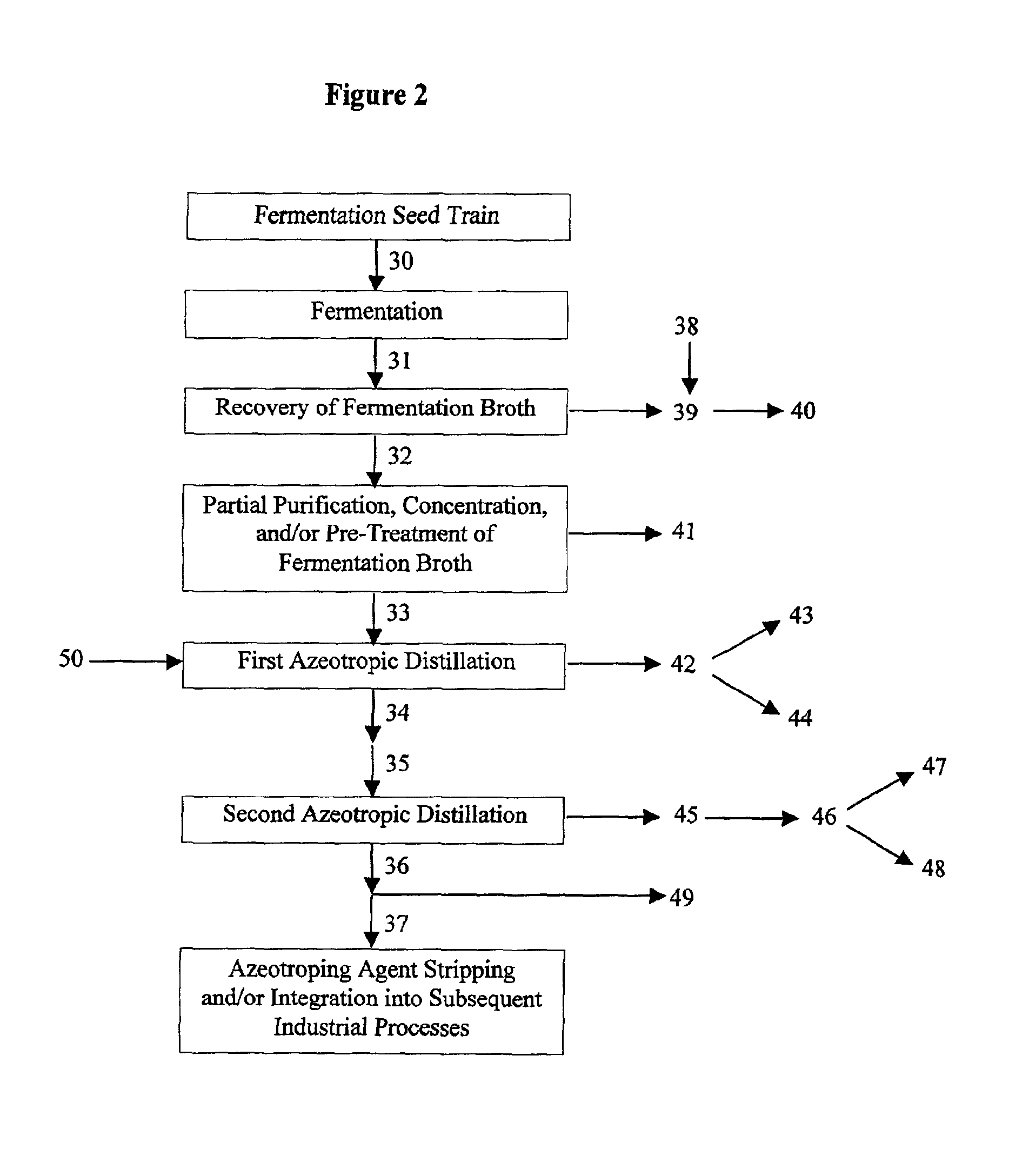

InactiveUS6926810B2Simple and cost-effective recoveryPreparation from carboxylic acid saltsOrganic compound preparationOrganic acidHeteroazeotrope

Disclosed herein are methods for the recovery of an organic acid, such as a heat stable lactic acid, from a feed stream which contains at least one of an organic acid amide, an organic acid ammonium salt, or an alkylamine-organic acid complex. The feed stream is mixed with at least one azeotroping agent. The azeotroping agent is a hydrocarbon capable of forming at least one azeotrope with the organic acid that is produced by the thermal decomposition of the amide, ammonium salt, or complex in the feed stream. Preferably the azeotrope is a heteroazeotrope. The mixture of the feed stream and the azeotroping agent is heated to produce a vapor stream. The azeotrope is a component of the vapor stream. The vapor stream can be condensed to a liquid stream, and the organic acid is recovered in the liquid stream that is produced. When the azeotrope is a heteroazeotrope, the vapor stream can be condensed into a liquid stream, which can be separated into a first phase and a second phase. The first phase contains the highest concentration of organic acid and the second phase contains azeotroping agent. The organic acid can be further purified and / or concentrated from the separated first phase or from the liquid stream.

Owner:TATE & LYLE INGREDIENTS AMERICAS INC

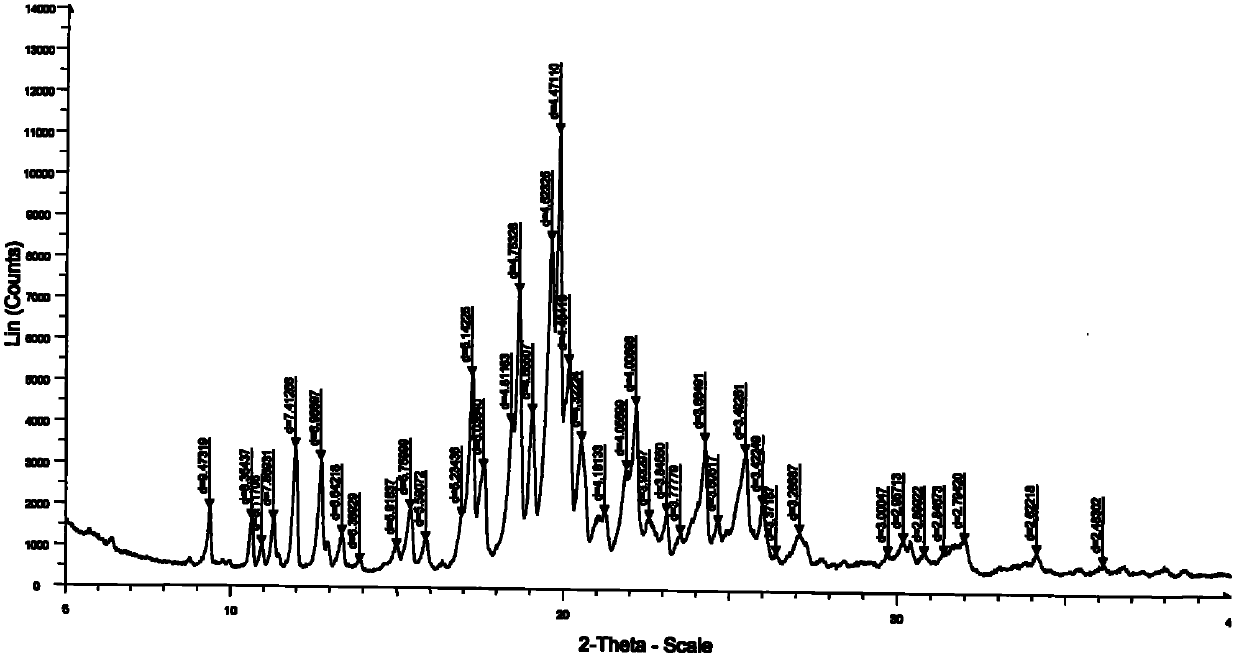

Preparation method of agomelatine I crystal form

ActiveCN101921205AHigh purityEasy to operateCarboxylic acid amide separation/purificationSingle crystalSolvent

The invention discloses a preparation method of an agomelatine I crystal form, which comprises the steps of: adding agomelatine into a mixed solvent of amide and water, heating for dissolving, then reducing the temperature and separating out crystals, and drying to obtain a solid. The agomelatine is dissolved in the heated mixed solvent of the amide and water, and separated out slowly in a cooled mixed solvent of the amide and water, and the high-purity I crystal form can be stably obtained. The method has the advantages of high purity of reaching above 99 percent of the single crystal form, simple operation and good repeatability, and the like and is suitable for industrialized production.

Owner:NHWA PHARMA CORPORATION

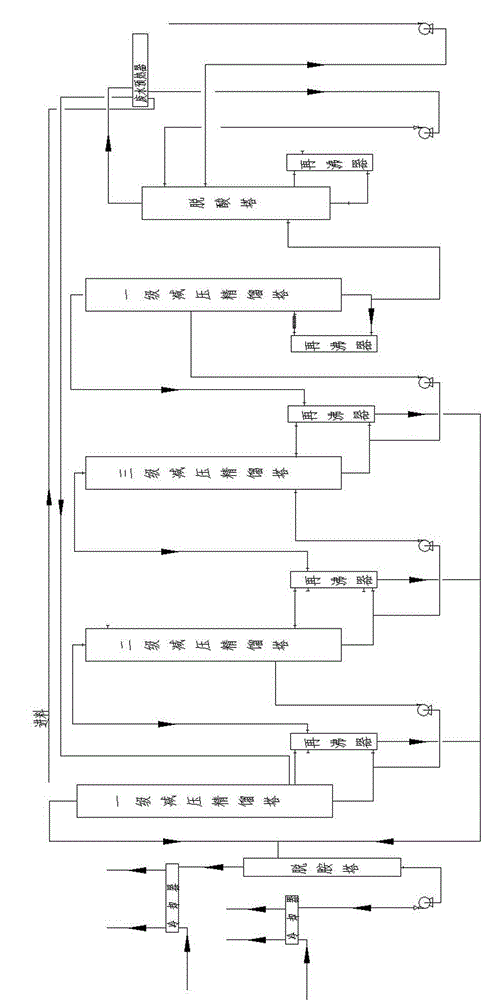

Quadruple-effect method for rectifying and recycling waste water containing DMF (dimethyl formamide)

InactiveCN103333080ASave energyReduce usageCarboxylic acid amide separation/purificationWastewaterProcess engineering

The invention discloses a quadruple-effect method for rectifying and recycling waste water containing DMF. The method comprises the steps as follows: utilization of heat of a deamination tower, a first-grade decompression rectifying tower discharging major cycle technology, normal-pressure rectifying tower gas-phase discharge to a deacidification tower and improvements and innovations on techniques such as up and down backflow of the deacidification tower and the like. According to the method, heat inside a system is fully used, the circulation volume of refrigerant recycled water is reduced, the consumption of a primary heat source is saved, the operation and running of the whole system is more stable and simpler, and the quality of a DMF finished product is easier to control. The technological process improvement method can be applied to a triple-effect DMF recycling system as well.

Owner:张瑞烟

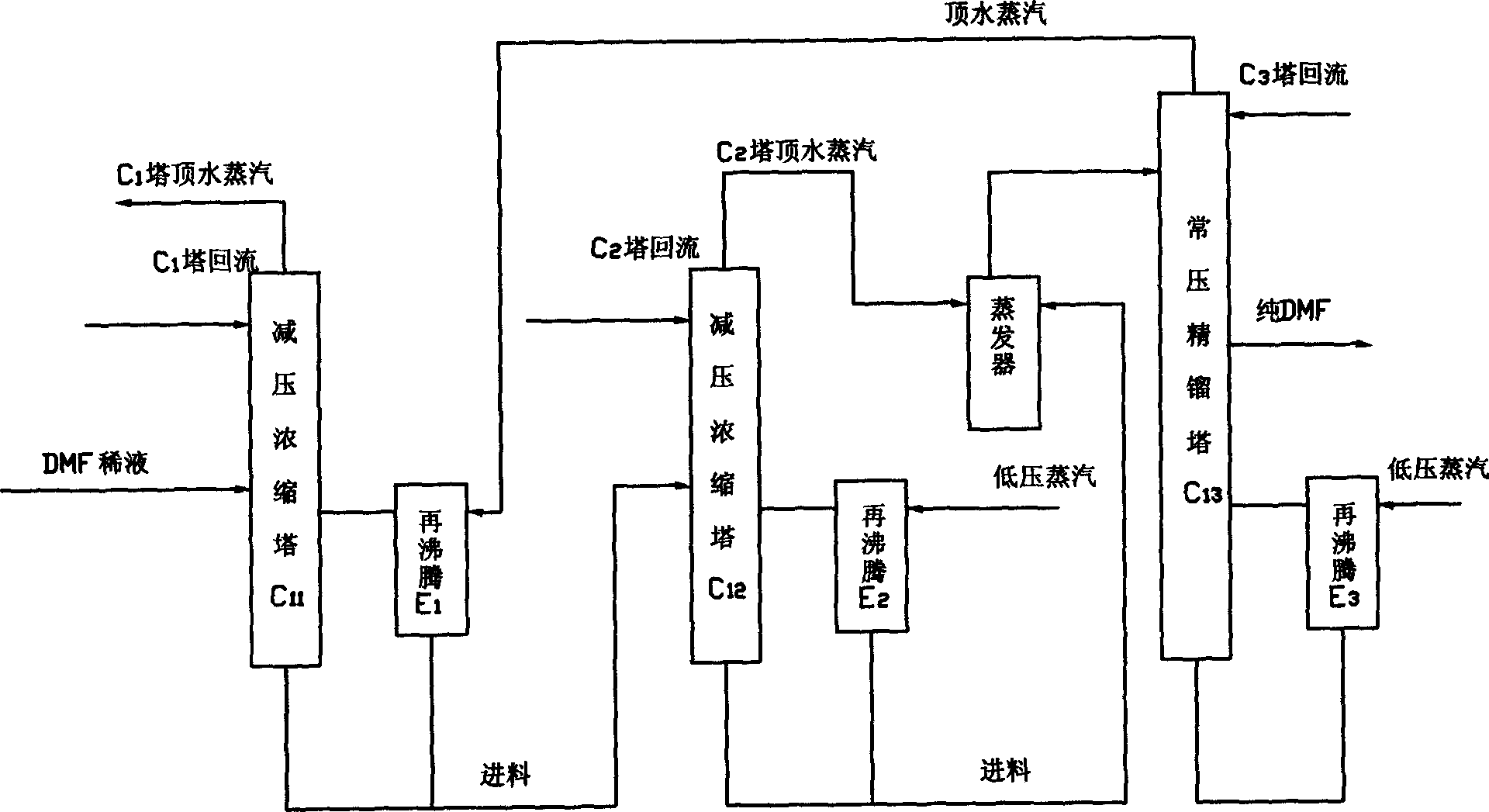

Dimethyl formylamine solution three-effect rectification recovery method for wet synthesis of leather

ActiveCN1891685AReduce consumptionAchieve consumptionCarboxylic acid amide separation/purificationThermal energyRecovery method

A triple-effect distillation and recovery method for wet synthetic leather dimethylformamide(DMF) solution includes: feeding, preheating, condensing and separating it by a concentration tower and a distillation tower to output it to complete the recovery process, in which, low-pressured steam is the heating media, using decompressed concentration for step I, atmospheric concentration for level II and vacuum distillation, the decompressed concentration processes in the packing tower, atmospheric concentration processes in the plate column, decompressed concentration processes in the combined packing and plate column. In the described cycle process, energy can be recycled between the steam in the top, heating at the bottom, feed preheating, preheating of finished condensation, distillation, reboilling processes.

Owner:ZHEJIANG HEXIN NEW MATERIAL CO LTD

Theanine extraction process

ActiveCN1546461APromote regenerationEfficient removalCarboxylic acid amide separation/purificationFlocculationAlcohol

A process for extracting theanine comprises the steps of chitosan rouging by flocculation, decolorizing by adsorption, adsorbing by cationic ion-exchange resin, ammonia eluation, decompression concentration, adsorbing and rouging by anion exchange resin, concentration alcohol depositing, and recrystallization. The process by the invention can effectively remove the impurity which influences the exchange adsorption function of the cationic ion-exchange resin.

Owner:TEA RES INST CHINESE ACAD OF AGRI SCI

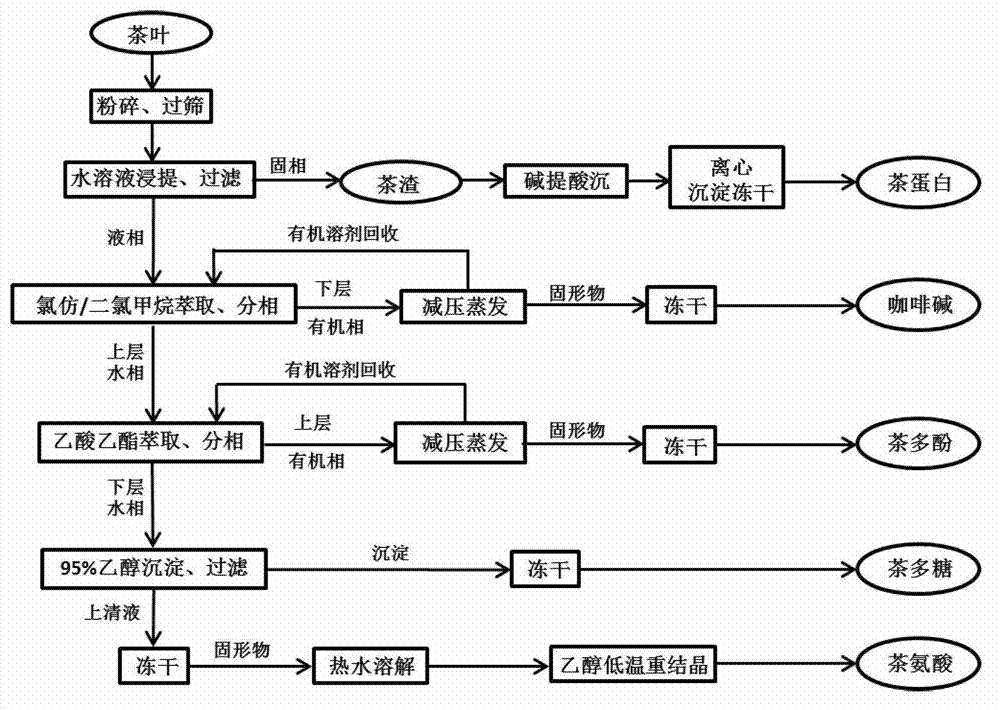

Method for comprehensively extracting effective ingredients in tea

ActiveCN103242314ALow costAvoid pollutionCarboxylic acid amide separation/purificationPeptide preparation methodsAdditive ingredientTheanine

The invention relates to a method for comprehensively extracting effective ingredients in tea. The method comprises the following steps of: with a faintly acidic water solution as a main extraction solvent and a certain amount of organic solvent as an auxiliary extraction solvent, carrying out step-by-step extraction on water extracts to obtain four effective ingredients, namely tea polyphenol, caffeine, tea polysaccharide and theanine; and meanwhile, extracting tea protein from tea residues by using an alkali dissolution and acid deposition method. According to the method, as water is used as the main solvent, the cost is low, the reactions are mild and active ingredients are favorably preserved; as a certain amount of organic solvent is used as the auxiliary extraction solvent, the problems of overhigh cost and product pollution caused by use of a large amount of organic solvents are solved; meanwhile, five effective ingredients, namely the tea polyphenol, the tea polysaccharide, the caffeine, the theanine and the tea protein are extracted, and therefore high extraction rate, high purity and high utilization rate of tea are achieved; the solvents are recycled in the extraction process, so that the preparation cost is reduced; and no alkali and acid waste liquor is discharged in the overall process, and therefore the method is environment-friendly. The overall preparation flow is high in efficiency and low in cost, and therefore the method has a favorable application value.

Owner:TIANJIN UNIV

Glutamine extracting process from fermented liquid

InactiveCN1432559AAvoid conversionReduce dosageCarboxylic acid amide separation/purificationStrong acidsImpurity

The present invention belongs to the field of medicine and health care article amino acid, and includes pre-treatment of the fermented liquid to eliminate thallus, partial protein, pigment and polysaccharide, controlling the pH value of the fermented liquid after pre-treatment; electrodialysis to eliminate inorganic salt and regulating pH value again; leading in processed OH type anionic exchangecolumn to adsorb impurities and separate glutamine; decoloring, vacuum concentration, isoelectric crystallization, washing coarse crystal in organic solvent and drying. The said process has low exchange resin consumption, no conversion of glutamine in strong acid and strong alkali environment, low production cost and high total glutamine extracting rate up to 70%, and is suitable for industrial production.

Owner:TSINGHUA UNIV

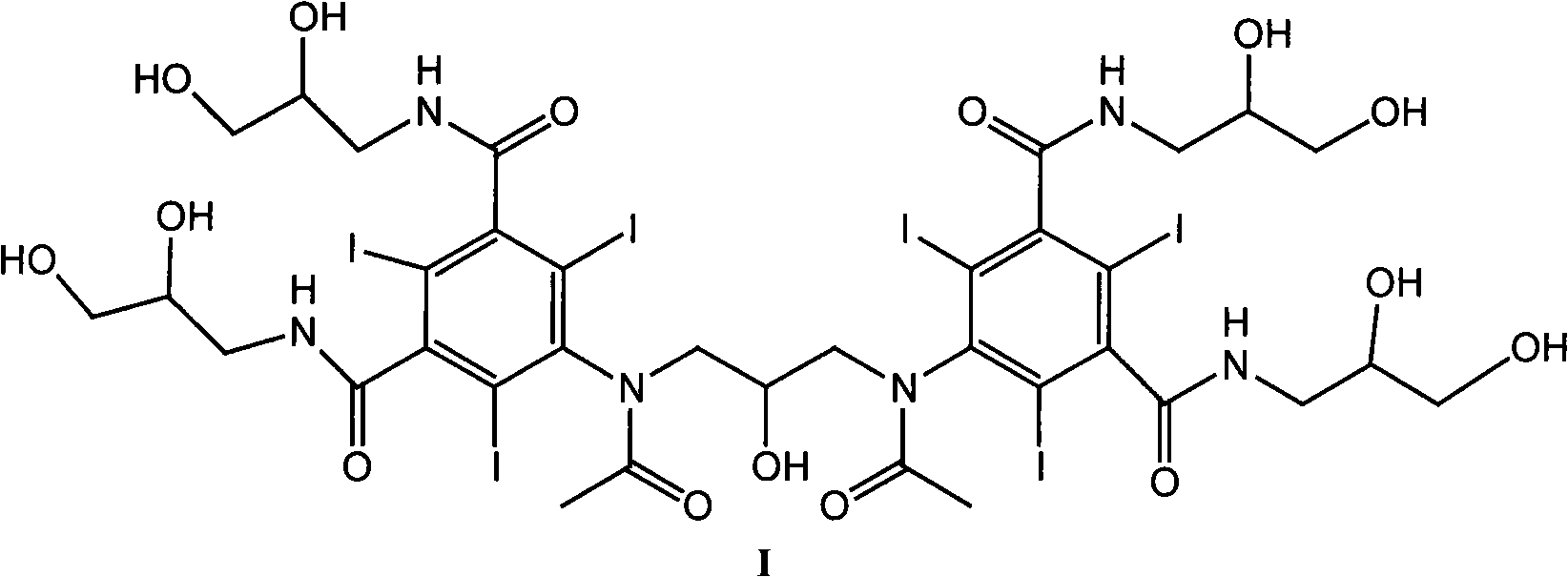

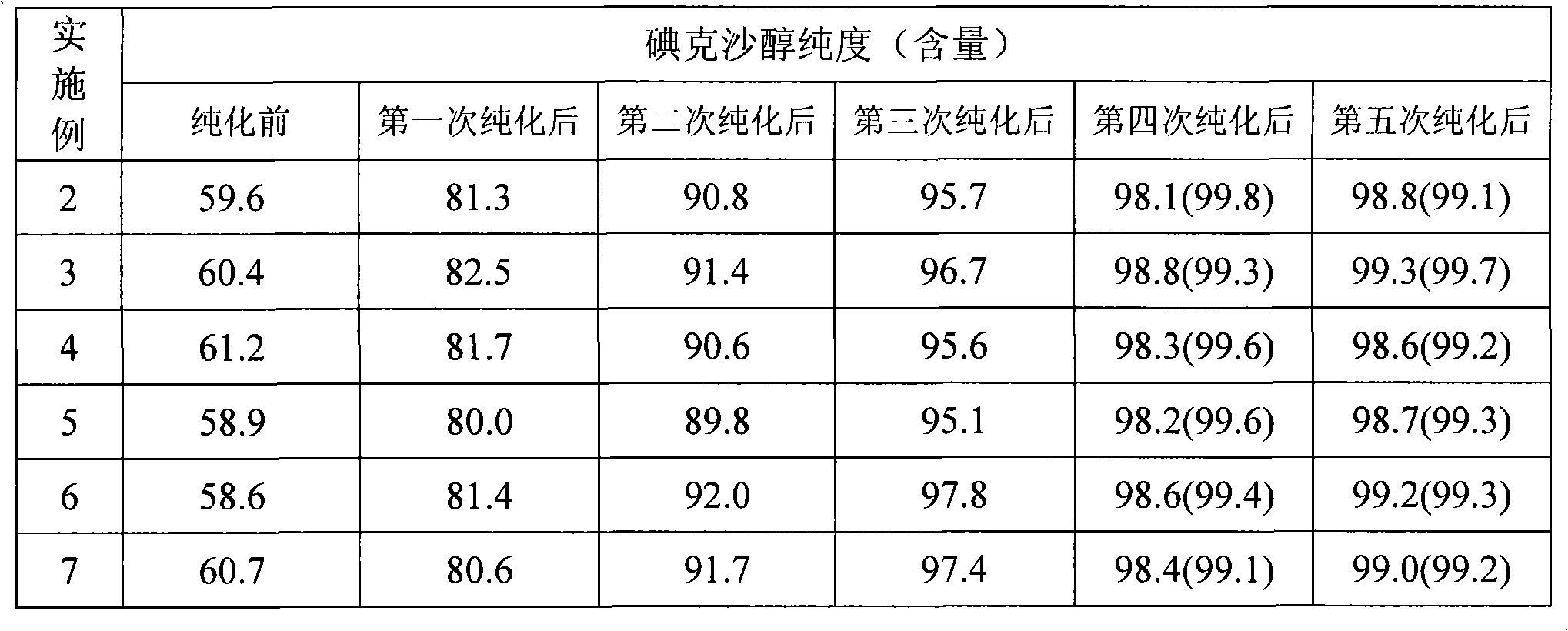

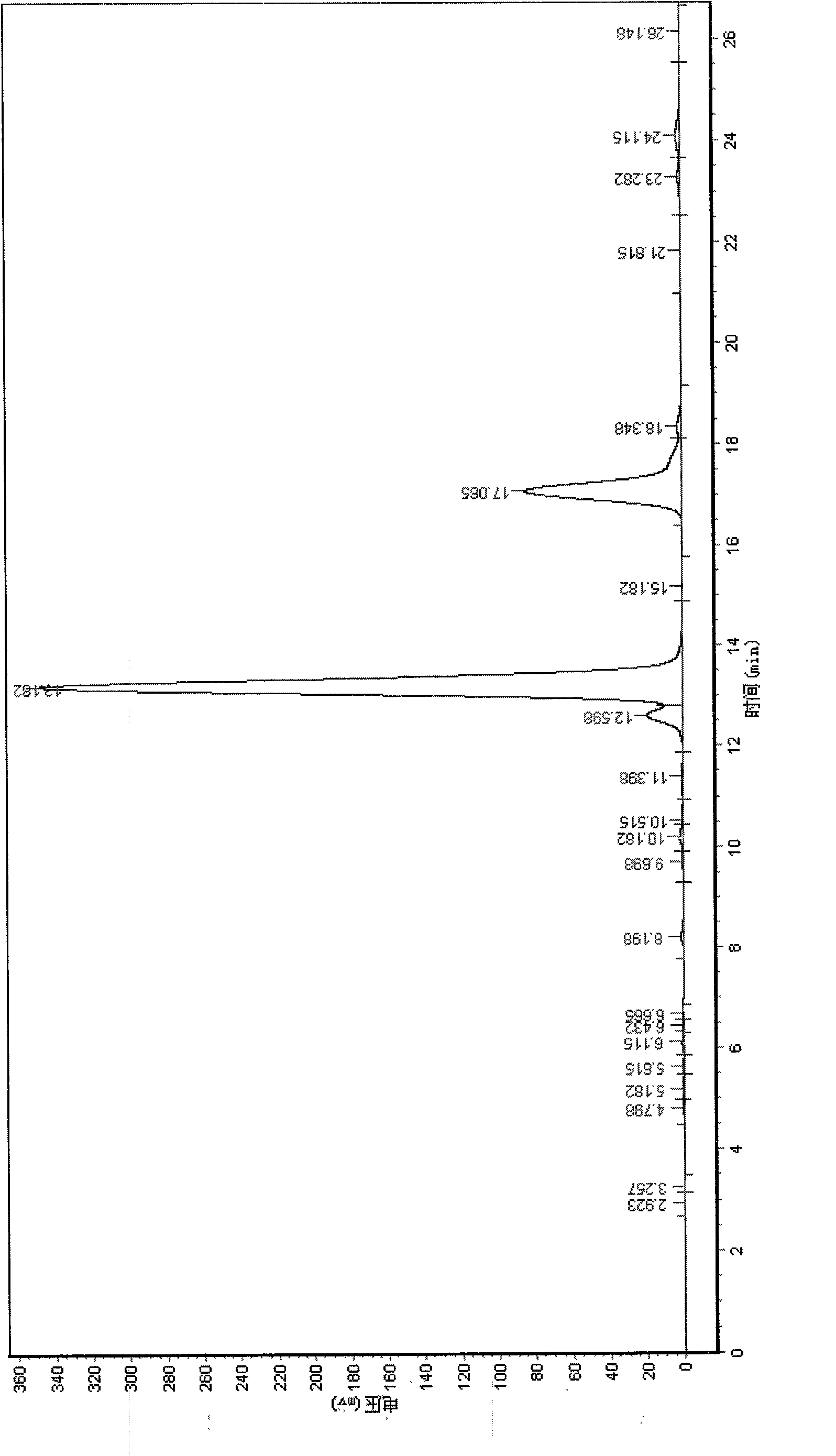

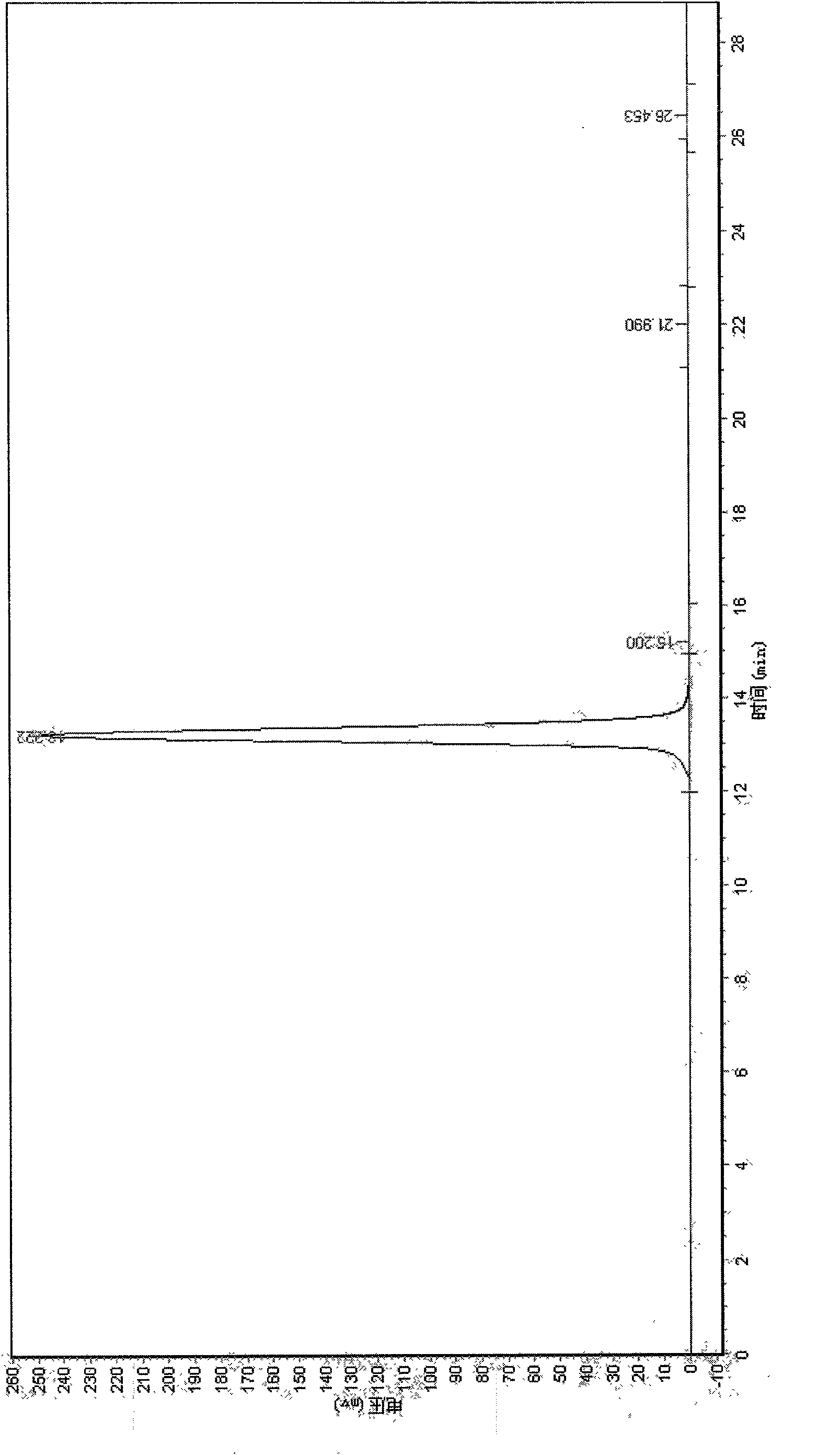

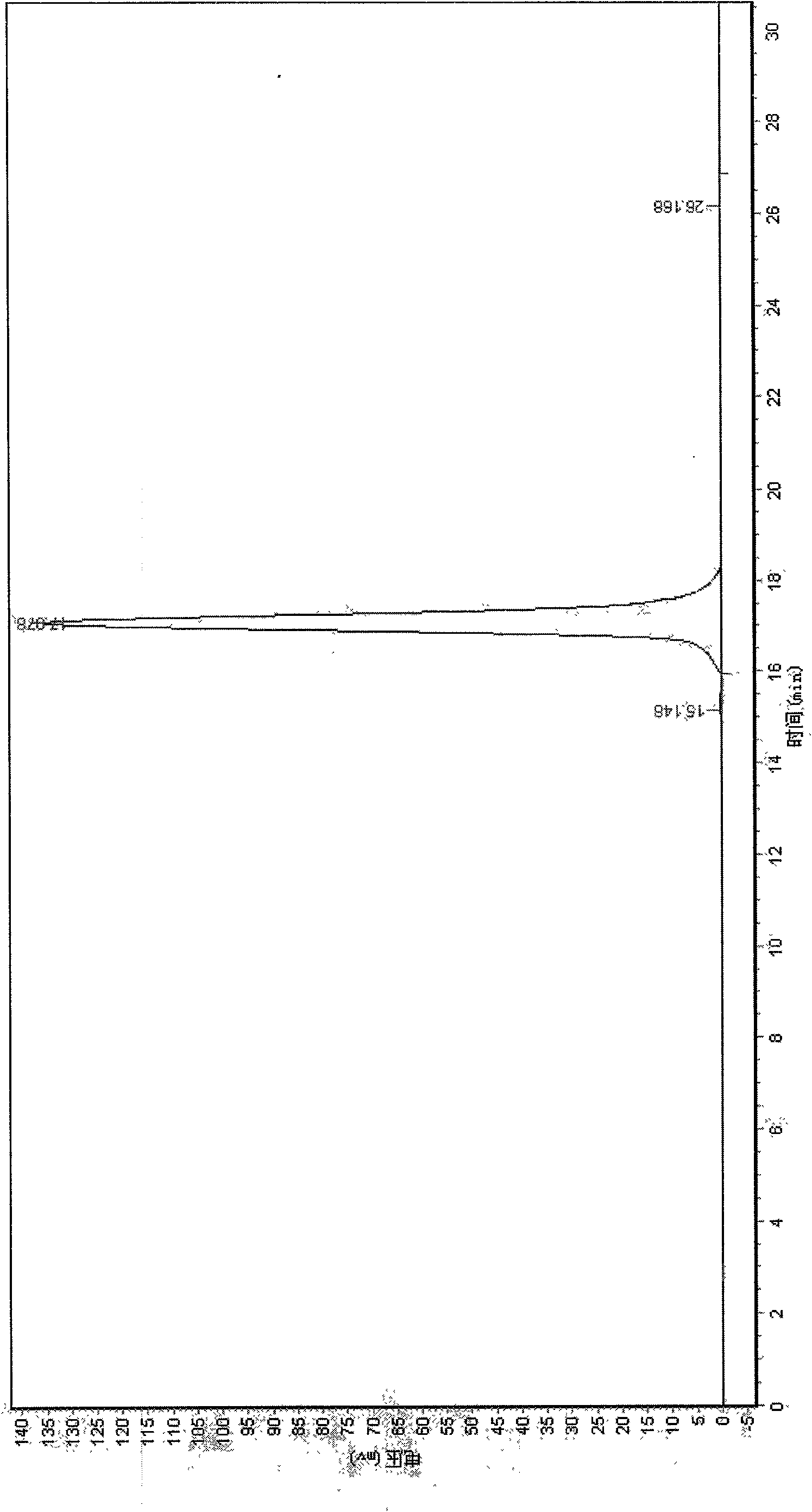

Purification process for Iodixanol

ActiveCN101293855ASuit one's needsFulfill the standardCarboxylic acid amide separation/purificationPurification methodsIodixanol

The invention provides a method for purifying iodixanol. The invention adopts a recrystallization method to purify crude iodixanol prepared from dipolymer of 5-acetamido-N,N'-bis(2,3-dihydroxypropyl)-2,4,6-triiodo isophthalamide, after several times of repeated purification, an iodixanol product qualified to Pharmacopoeia standards is obtained. The inventive purification method can be effectively used for purification of crude iodixanol prepared from dipolymer of 5-acetamido-N,N'-bis(2,3-dihydroxypropyl)-2,4,6-triiodo isophthalamide, and the used solvent has low cost, so as to remarkably reduce cost compared with the prior purification method. In addition, the inventive purification method is a non-chromatographic solvent purification method and can obtain iodixanol with high purity and high content after several times of repeated purification, so as to meet the industrial production requirements of iodixanol product, as well as Pharmacopoeia standards.

Owner:ZHEJIANG HAIZHOU PHARMA CO LTD

Method for preparing capsicine monomer

InactiveCN101619028AAchieve productionProduction operation safetyIon-exchange process apparatusIon-exchanger regenerationAlcoholOrganic solvent

The invention relates to a purifying method of natural functional components and provides a method for preparing capsicine monomers. The method for preparing capsicine monomers comprises the following technical steps of extracting capsicum essential oil or capsicum powder by alcohol, separating and purifying macroporous absorbent resin, recrystallizing a monomer crude product, and the like. The method for preparing a capsicine monomer extracts three capsicine monomers from the capsicum essential oil or the capsicum powder, has simple technology and low production cost, does not use a harmful organic solvent in a production process and is easy to realize industrialized production. The purity of capsicine, dihydrocapsaicine and a falling dihydrocapsaicine monomer which are produced by the method is larger than 98 percent, and the yield of the capsicine, the dihydrocapsaicine and the falling dihydrocapsaicine monomer are larger than 85 percent. The method for preparing capsicine monomers lays a solid foundation for the wide application of high-purity capsicine monomers.

Owner:厦门绿启源生物科技有限公司

Process for enriching extracts of natural theanine

A process for enhancing theanine extraction from plant material through a series of extraction, adsorption and filtration steps. More specifically, disclosed is a process for isolating theanine from a plant material, which includes the steps of: a) contacting the plant material with a solvent to obtain an extract comprising theanine; b) contacting the theanine extract with an adsorbent to obtain a theanine-containing eluate; and c) subjecting the theanine eluate to a filtration step to obtain a theanine-rich extract.

Owner:CIRCULAT BIOTECH +1

Method of making hydroxyalkyl amide containing reduced level of unreacted alkanolamine

ActiveUS20050107623A1Decrease in levelFatty acid chemical modificationOrganic compound preparationMetalAlkanolamine

A method for reacting alkanolamine with ester in the presence of a metal silicate compound and, optionally, a catalyst, to produce a hydroxyalkyl amide composition with a decreased level of alkanolamine and residual catalyst.

Owner:CHEMTURA CORP

Process of separating and purifying natural theanine

InactiveCN101020649APromote regenerationCarboxylic acid amide separation/purificationCelluloseAlcohol

The process of separating and purifying natural theanine belongs to the field of deep tea processing technology. The present invention uses the industrial waste liquid from tea polyphenol production as material to produce natural theanine through the steps of ultrafiltering, macroporous resin decolorizing, cationic exchange resin adsorption, ammonia water elution, microcrystal cellulose column chromatography and anhydrous alcohol crystallization. The present invention has theanine product purity over 95 % and total theanine recovering rate over 60 %, and is environment friendly.

Owner:JIANGNAN UNIV

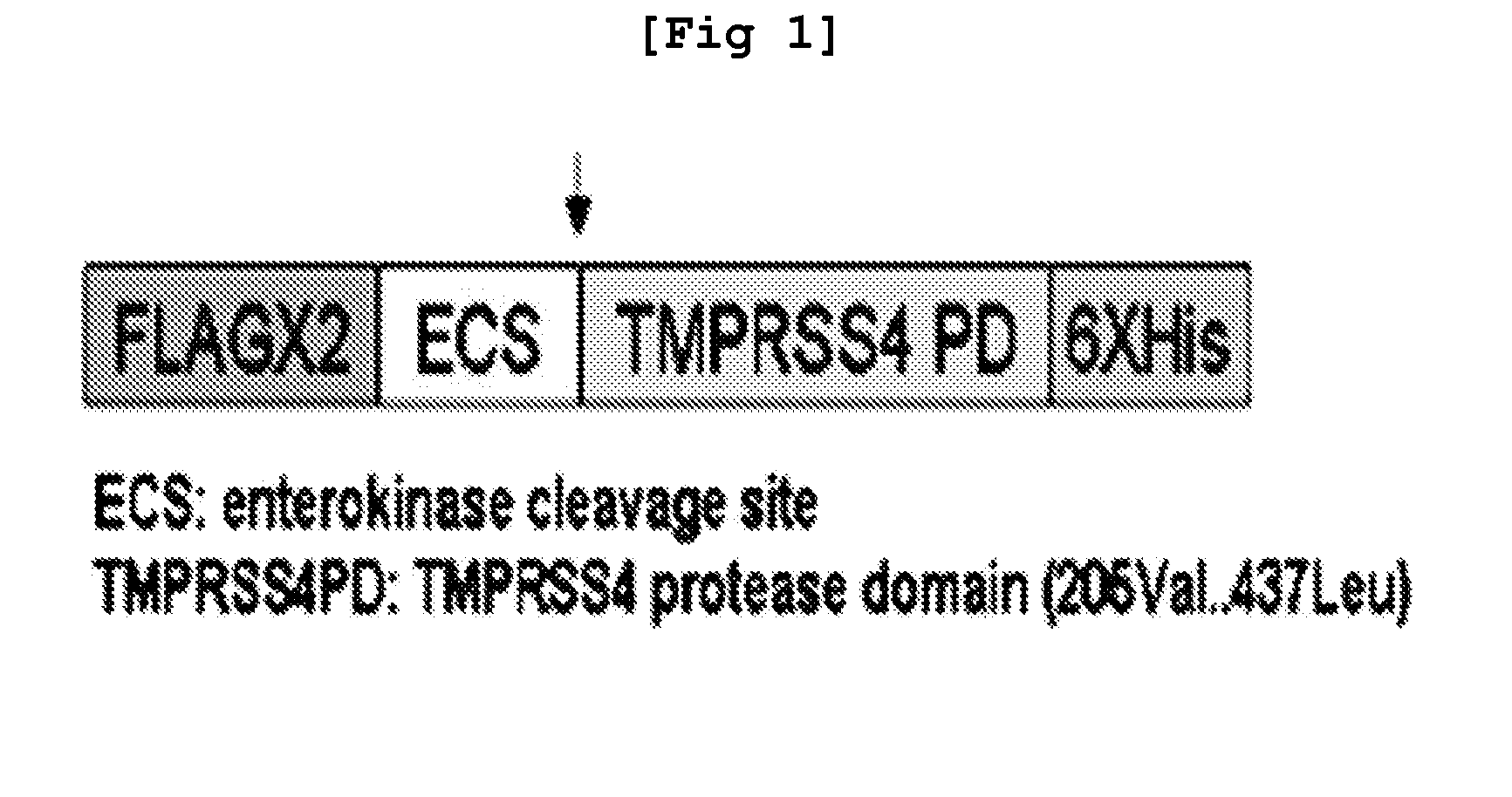

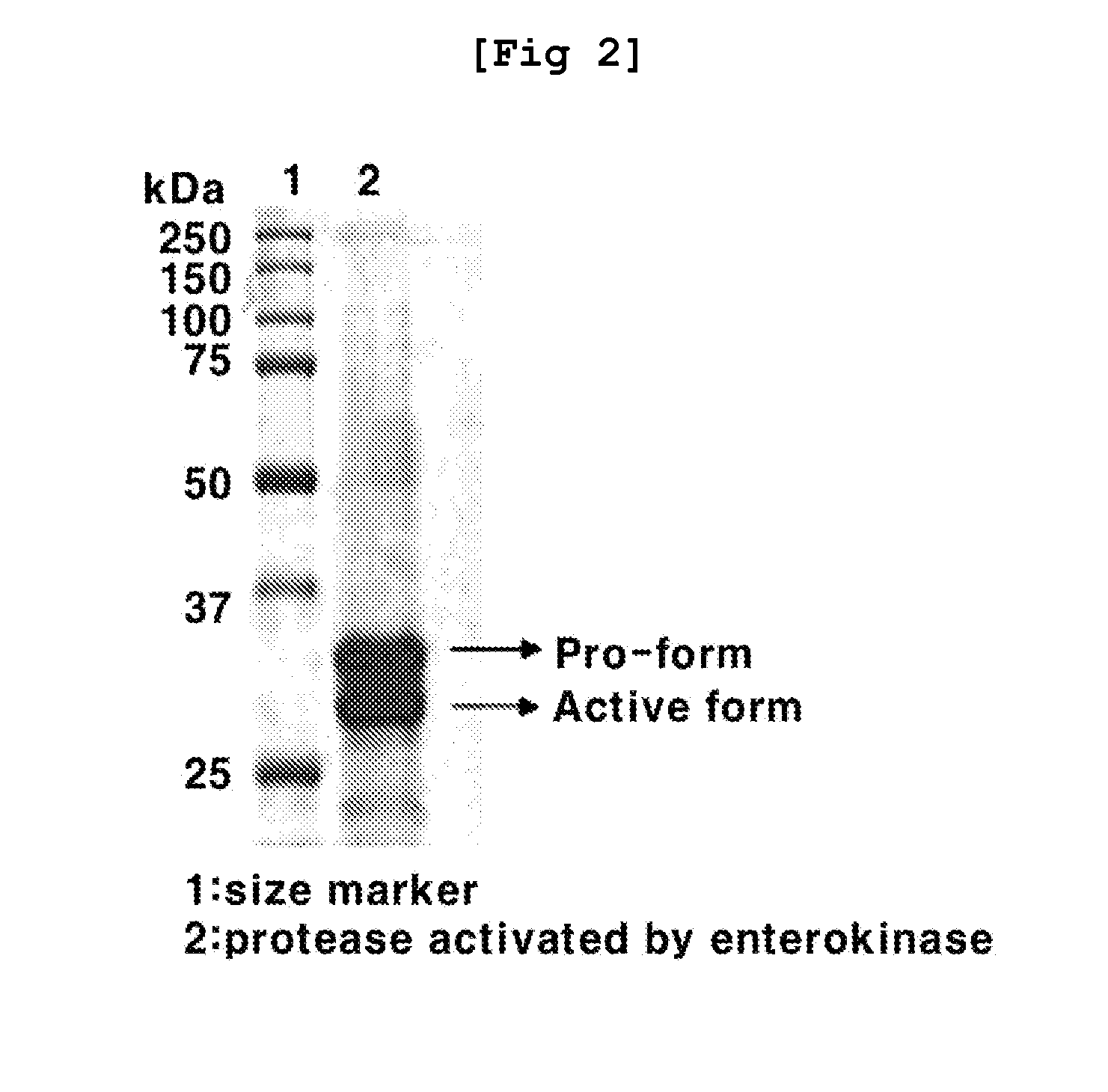

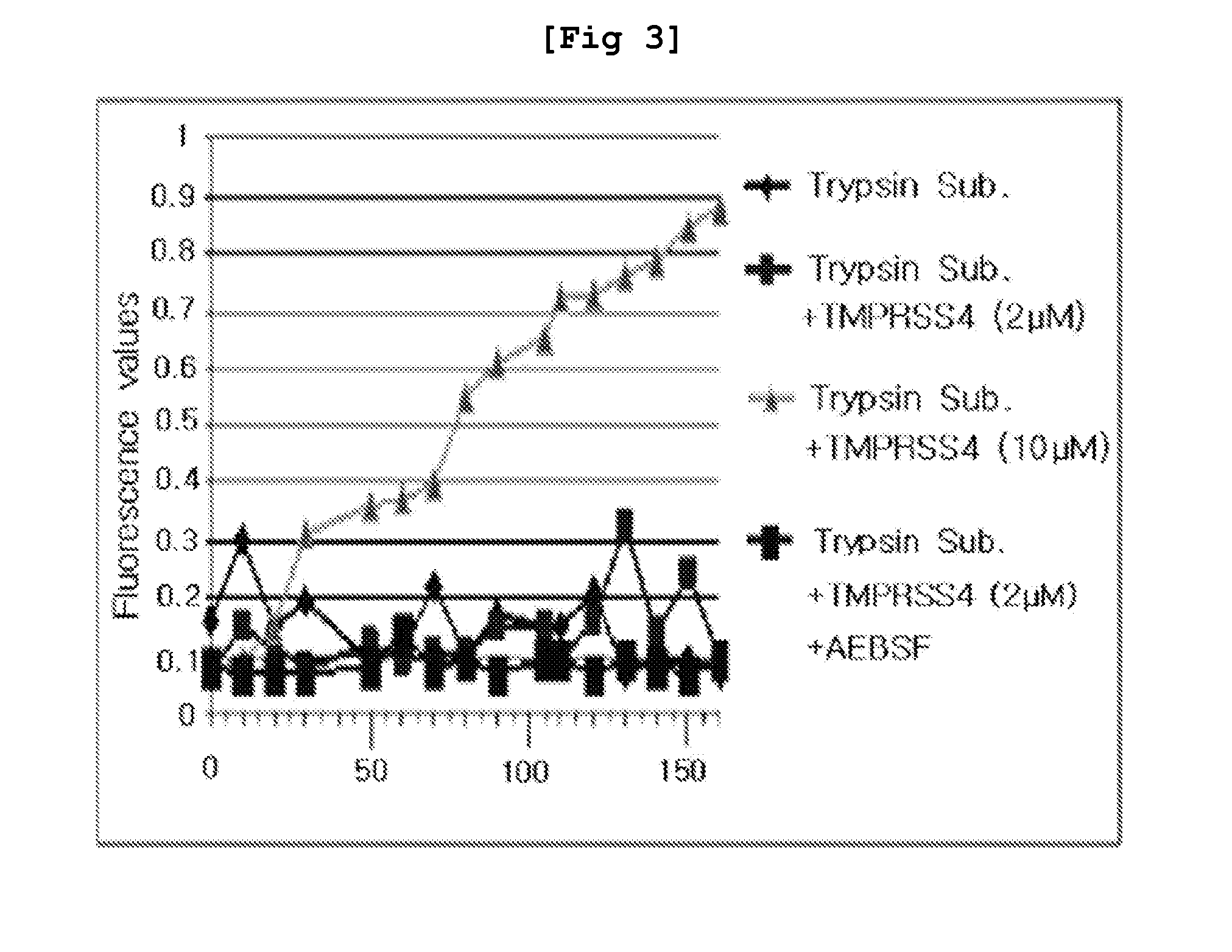

2-hydroxyarylamide derivative or pharmaceutically acceptable salt thereof, preparation method thereof, and pharmaceutical composition for preventing or treating cancer containing same as active ingredient

ActiveUS20140221411A1Inhibitory activityPrevent penetrationBiocideCarboxylic acid amide separation/purificationProstate cancerOncology

The present invention relates to a 2-hydroxyarylamide derivative or a pharmaceutically acceptable salt thereof, a preparation method thereof, and a pharmaceutical composition for preventing or treating cancer comprising the same as an active ingredient. The 2-hydroxyarylamide derivative prepared by the present invention is excellent in the inhibition of the activity of TMPRSS4 serine protease and the suppression of the infiltration of TMPRSS4-expressed cancer cells, and thus can be useful as a composition for preventing or treating cancer by inhibiting TMPRSS4 over-expressed in cancer cells, particularly, colorectal cancer, lung cancer, breast cancer, prostate cancer, ovarian cancer, pancreatic cancer, or stomach cancer cells.

Owner:KOREA RES INST OF BIOSCI & BIOTECH

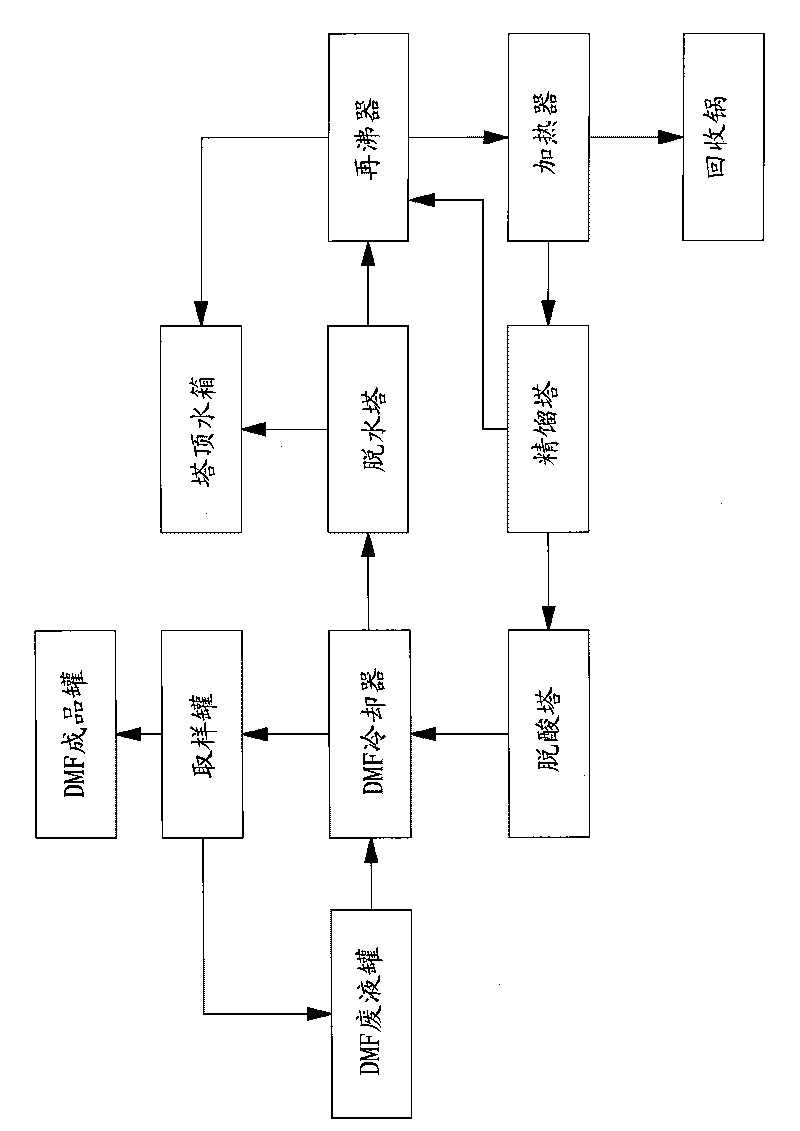

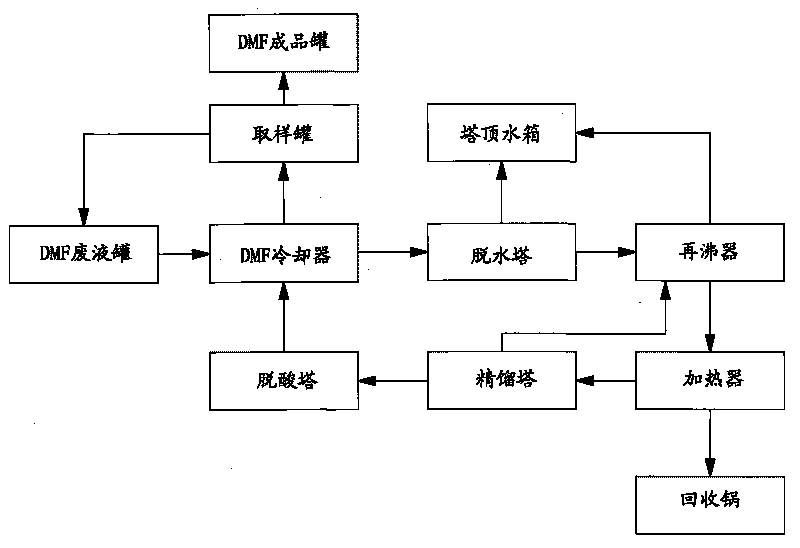

DMF recycling method

InactiveCN101759590AReduce manufacturing costReduce recycling costsCarboxylic acid amide separation/purificationLiquid wasteReboiler

The present invention provides a DMF recycling method with low recycling cost and high recycling rate. In the method, DMF is pumped to a DMF cooler from a waste liquid tank for preheating; then the preheated DMF waste liquid is pumped to a dewatering tower which is vacuumized by a vacuum motor to -0.078 plus or minus0.01 MPa to evaporate part of liquid water; the DMP waste liquid from the dewatering tower is pumped to a reboiler to be heated to 68 plus or minus3 DEG C and be further concentrated, thereby obtaining DMF waste liquid with the mass percentage concentration of 40-50%; next, the DMF waste liquid from the reboiler is pumped to a heater to be heated to 120 plus or minus5 DEG C; the waste liquid from the heater is pumped to a rectifying tower to evaporate and separate liquid water from the DMF recycling liquid; the DMF recycling liquid from the rectifying tower is deacidified in a deacidification tower; and then the deacidified DMF recycling liquid is inspected through a sampling can, if qualified, the DMF recycling liquid is delivered to a DMF tank of finished products.

Owner:石狮龙祥制革有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com