Purification process for Iodixanol

A technology of iodixanol and purification method, which is applied in the field of purification of iodixanol, and can solve problems such as difficult to handle, solvent residue, and slight toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

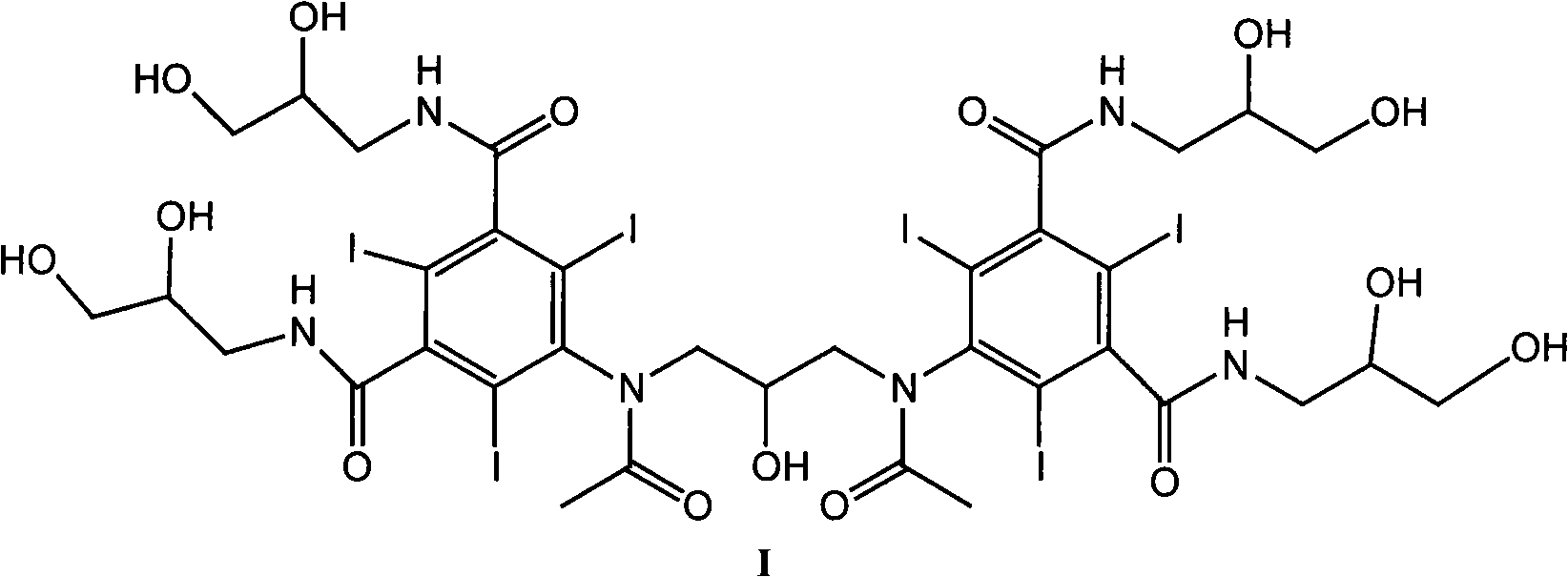

Image

Examples

Embodiment 1

[0018] Example 1 , the preparation of iodixanol crude product

[0019] The crude product of iodixanol was prepared according to the method in Chinese Patent Publication No. CN1340042.

[0020] Take 0.3 mol of raw compound A and dissolve it in 240 ml of 2-methoxyethanol containing 0.36 mol of sodium hydroxide at 50°C. After all the solids were dissolved, the temperature dropped below 15°C, and then 0.16mol of concentrated hydrochloric acid was added to the solution, and 0.086mol of epichlorohydrin was added at one time, and the reaction was tracked and monitored by HPLC.

[0021] After reacting for 46 hours, the content of iodixanol in the reaction mixture no longer increased, and 350ml of deionized water was added (the solution was clear at this moment, so it was unnecessary to add sodium hydroxide). After adjusting the pH to 10.8 with 18% hydrochloric acid, an appropriate amount (about 0.2 g) of compound A was added to the solution as a seed crystal, and the obtained suspen...

Embodiment 2~7

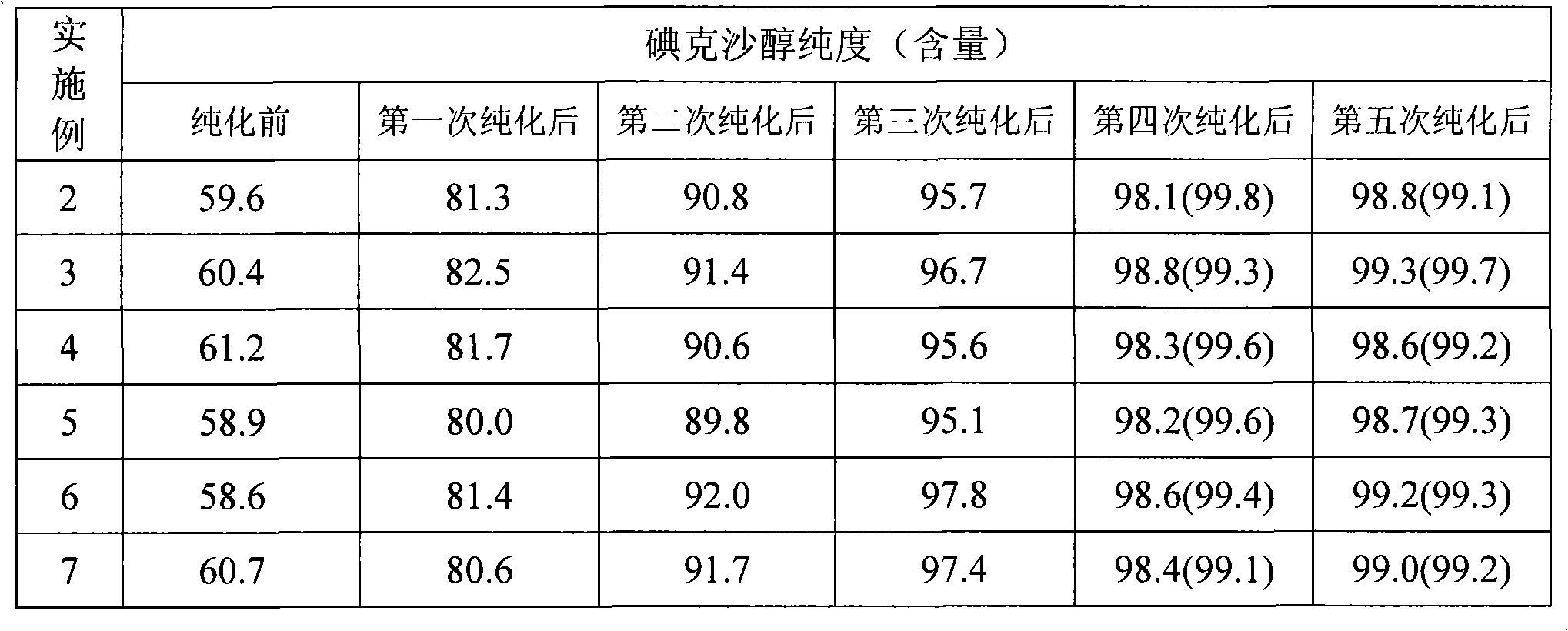

[0025] Embodiment 2~7, the purification of iodixanol

[0026] The HPLC method and chemical titration method used in the following examples are all carried out with reference to the method recorded in "Pharmacopia" (USP 29 edition).

[0027] Take about 135 g of the iodixanol crude product prepared in Example 1 respectively, add about 1000 ml of a large polar solvent as listed in Table 1, heat up to reflux, keep warm, and stir until the crude product is completely dissolved;

[0028] According to the color of the solution, selectively add an appropriate amount of activated carbon for decolorization, stir under reflux for 30 minutes, and filter while it is hot;

[0029] The filtrate was added dropwise with a small polar solvent (Table 1) under reflux until the system became turbid, then stopped the dropwise addition, and slowly cooled down until the crystallization was complete, then filtered, the filter cake was washed with an appropriate amount of cold methanol, and dried in va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com