Compound modification method for clay

A compound modification and clay technology, applied in chemical instruments and methods, silicon compounds, inorganic chemistry, etc., to achieve the effect of increasing layer spacing, improving modification effect, and reducing surface energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

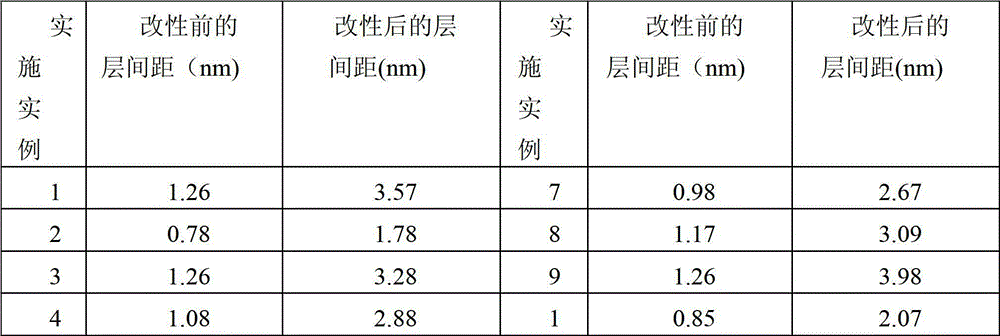

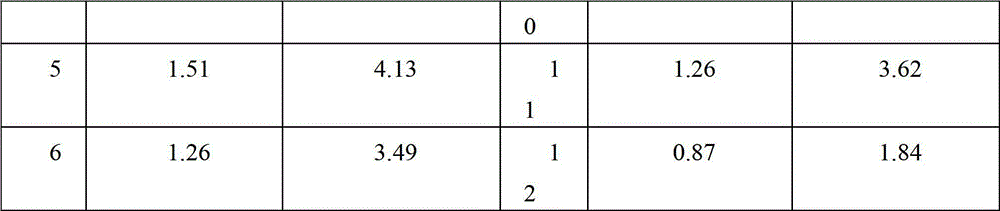

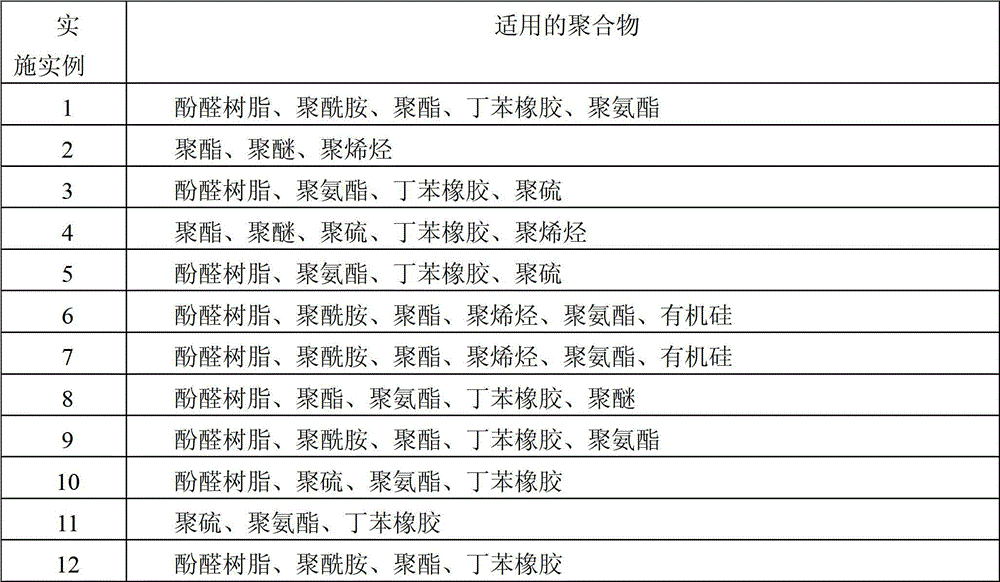

Examples

Embodiment 1

[0020] Dissolve 0.5g of γ-glycidyl etheroxypropyltrimethoxysilane in 20ml of water and methanol mixture, and keep the ratio of alcohol to water at 1:45. It was then stirred for 50 minutes on a magnetic stirrer. The clay is washed in water to skim off the impurities in the upper layer, and dried at 120°C. Then it is ground and passed through a 100-mesh sieve. Add 50 g of attapulgite into the stirring furnace, keep the stirring furnace at 60° C. and stir at a high speed, and the stirring rate of the stirring furnace is 350 rpm. Spray the above mixture into the clay, control the spraying time to about 2 minutes, and continue stirring for half an hour at 60°C. Then it was poured into a glass and heat-treated at 160°C for 2 hours. The above product was mixed with 0.5wt.% cetyltrimethylammonium bromide solution in an amount of 100ml, and a little acetic acid was added to adjust the pH to 3. Stir at 80°C for 2 hours. Then suction filter 5 times, heat treatment at 160°C for 5 hou...

Embodiment 2

[0022] Dissolve 1g of γ-(methacryloyloxy)propyltrimethoxysilane in 20ml of water and ethanol mixture, and keep the ratio of alcohol to water at 1:9. Then stir for 10 minutes on a magnetic stirrer. The clay is washed in water to skim off the impurities in the upper layer, and dried at 120°C. Then it is ground and passed through a 200-mesh sieve. Add 100 g of kaolin into the stirring furnace, keep the stirring furnace at 80° C. and the stirring rate of the high-speed stirring stirring furnace at 2000 rpm. , Spray the above mixture into the clay, control the spraying time to about 5 minutes at 80°C, and continue to stir for half an hour. Then it was poured into a glass and heat-treated at 120° C. for 1 hour. The above product was mixed with cetyltrimethylammonium bromide solution with a concentration of 0.25wt.% and an amount of 200ml, and a little acetic acid was added to adjust the pH to 3. Stir at 60°C for 2 hours. Then suction filter 3 times, heat treatment at 120°C for ...

Embodiment 3

[0024] Dissolve 0.5g of γ-glycidyloxypropyltrimethoxysilane and 0.5g of γ-mercaptopropyltriethoxysilane in 20ml of water and methanol mixture, and keep the ratio of alcohol to water at 1:5. It was then stirred for 25 minutes on a magnetic stirrer. The clay is washed in water to skim off the impurities in the upper layer, and dried at 120°C. Then it is ground and passed through a 250-mesh sieve. Add 20 g of attapulgite into the stirring furnace, keep the stirring furnace at 10° C. and stir at a high speed, and the stirring rate of the stirring furnace is 350 rpm. Spray the above mixture into the clay, the spraying time is controlled at about 10 minutes, and the stirring is continued for half an hour at 10°C. It was then poured into a glass and heat-treated at 80°C for 3 hours. The above product was mixed with a dodecyltrimethylammonium chloride solution with a concentration of 2wt.% and an amount of 25ml, and a little acetic acid was added to adjust the pH to 5. Stir at 80°...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com