Method for preparing polymer/inorganic nano particle composite material

A technology of inorganic nanoparticles and composite materials, which is applied in the processing field of preparing polymer/inorganic nanoparticle composite materials, and can solve problems such as difficult to obtain composite materials with nanostructures, so as to broaden the scope of application, benefit environmental protection, and have a wide range of applications Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] A raw material of polypropylene / inorganic nanocomposite comprises the following components and their contents in parts by weight:

[0057] components weight ratio Isotactic polypropylene (PP, as a crystalline polymer matrix) 97 Montmorillonite (MMT, layered silicate nanofiller) 3

[0058] Note: The above components do not contain compatibilizers.

[0059] The first step, at first prepare raw materials by above-mentioned components;

[0060] In the second step, first place the nano-filled montmorillonite (MMT) in an oven at 120°C for 12 hours;

[0061] In the third step, the isotactic polypropylene obtained in the second step and the dry montmorillonite are placed in a high mixer and premixed for 6 minutes at a speed of 150 rpm to obtain the isotactic polypropylene / montmorillonite premix thing;

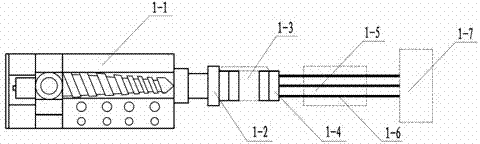

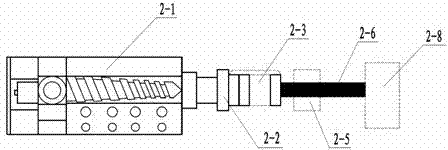

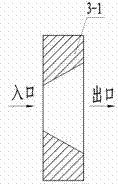

[0062] Then, put the obtained isotactic polypropylene / montmorillonite premix into a twin-screw extruder for melt blending, extruding, and granulat...

Embodiment 2

[0067] A raw material of polypropylene / inorganic nanocomposite comprises the following components and their contents in parts by weight:

[0068] components weight ratio Isotactic polypropylene (PP, as a crystalline polymer matrix) 90 Montmorillonite (MMT, layered silicate nanofiller) 5 Polypropylene grafted maleic anhydride (PP-MA, as compatibilizer) 5

[0069] The first step, at first prepare raw materials by above-mentioned components;

[0070] In the second step, the nano-filler montmorillonite (MMT) was first placed in a 120°C oven for 12 hours, and the compatibilizer polypropylene grafted maleic anhydride was placed in an 80°C oven for 12 hours;

[0071] In the third step, the isotactic polypropylene, dry montmorillonite and compatibilizer obtained in the second step are placed in a high mixer and pre-mixed for 5 minutes at a speed of 100 rpm to obtain isotactic polypropylene, montmorillonite The premix of declay and compatibilizer, nam...

Embodiment 3

[0077] A raw material of polypropylene / inorganic nanocomposite comprises the following components and their contents in parts by weight:

[0078] components weight ratio Isotactic polypropylene (PP, as a crystalline polymer matrix) 99.5 Graphene (R-GO, as a nanofiller) 0.5

[0079] Note: The above components do not contain compatibilizers.

[0080] The first step, at first prepare raw materials by above-mentioned components;

[0081] In the second step, the nano-filled graphene (R-GO) was dried in an oven at 80°C for 12 hours;

[0082] In the third step, the isotactic polypropylene obtained in the second step and the dry graphene are placed together in a high mixer and premixed for 5 minutes, and its rotating speed is 100 rpm to obtain an isotactic polypropylene / graphene premix;

[0083] Then, the obtained premix is put into a twin-screw extruder for melt blending, extruding and granulating to obtain isotactic polypropylene / graphene premixed com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Solution temperature | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com