Patents

Literature

236results about How to "Reduce apparent viscosity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Topical, non-cytotoxic, antimicrobial hydrogel with thixotropic properties

InactiveUS6333054B1Reduce apparent viscosityImprove distributionElectrolysis componentsInorganic active ingredientsCytotoxicitySodium hypochlorite solution

A thixotropic, non-cytotoxic, topical hydrogel that contains a proven safe and effective, broad spectrum, antimicrobial agent based on a unique electrolytically derived sodium hypochlorite solution.

Owner:AMUCHINA

Improved preparation of cellulose spinning solution with ion liquid as solvent

InactiveCN101476166AImprove solubilityReduced gel particle contentArtificial filaments from cellulose solutionsSpinning solutions preparationApparent viscosityDistillation

The invention provides a method for preparing an improved fibrino spinning original solution that ion liquid is used as solvent, which includes: two phases of swelling and dissolution, namely, placing dried fibrino dissolving pulp and 1-butyl-3-methyl imidazole villaumite with 1%-20% water ratio into a dissolution device for uniform mixing, firstly, leaving and swelling in 70-100 DEG. C, then stronger stirring for swelling to plasm shape without dissolution; secondly, raising temperature to 80-125 DEG. C slowly in stirring state, stirring and reducing pressure distillation for removing water component, fibrino can be dissolved completely after 2-8h; finally, reducing stirring speed, and reducing temperature of plasm to 90-100 DEG. C and keeping 30-60 min for obtaining straw yellow spinning original solution. The method provided by the invention has advantages that the spinning original solution is more uniform, dissolution is more fully, gelatin particle in the spinning original solution is reduced, the spinning original solution quality is increased; apparent viscosity of the spinning original solution is reduced, accordingly, solid content in the spinning original solution is increased further.

Owner:DONGHUA UNIV

High-fluidity PA10T polyamide resin and polyamide composition comprising same

The invention discloses a high-fluidity PA10T polyamide resin A. The relative viscosity of the PA10T polyamide resin A is 1.2-1.8 in 98% concentrated sulfuric acid at the temperature of 25 DEG C; the amino end group value of the PA10T polyamide resin A is 20-60mol / t and the carboxyl end group value is 70-130mol / t; and benzoic acid accounts for 2-20mol% of repetitive units in the PA10T polyamide resin A. A polyamide composition comprises the following components in percentage by weight: 5-29.8wt% of the PA10T polyamide resin A, 50-94wt% of PA10T polyamide resin B, 0.8-40wt% of mineral filler and 0.2-1wt% of other auxiliaries. The PA10T polyamide resin A disclosed by the invention has the advantages that the apparent viscosity is low and the fluidity is high under the melting condition; and when a certain proportion of the PA10T polyamide resin A is added in semi-aromatic polyamide, the obtained polyamide composition has high fluidity and basically-equal mechanical property and can be applied to occasions with high dimensional requirement on injection molding products.

Owner:KINGFA SCI & TECH CO LTD

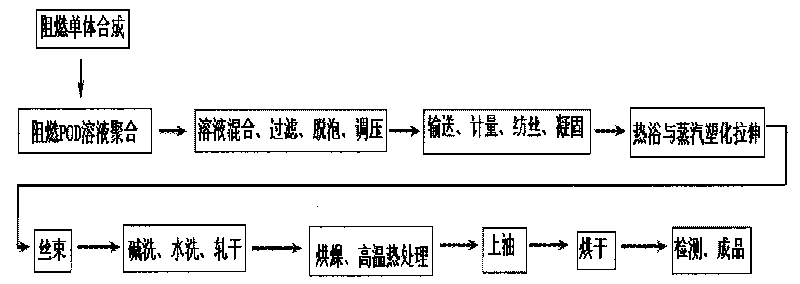

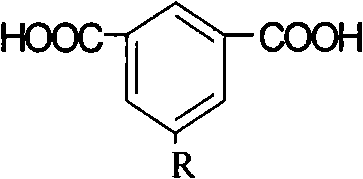

Method for preparing special aromatic polyoxadiazole and flame-retardant high-temperature resistant polyoxadiazole fiber thereof

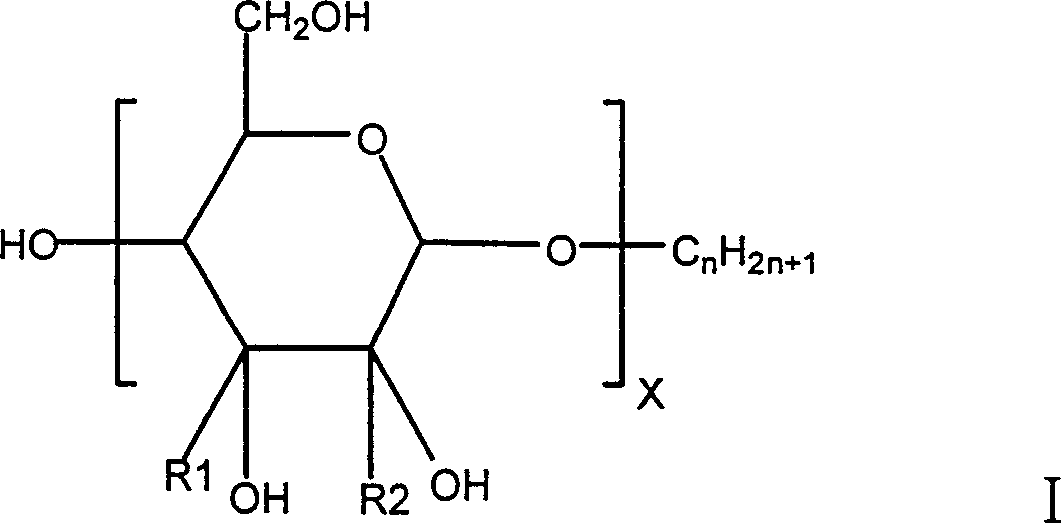

ActiveCN101735455ASingle structureEasy to synthesizeWet spinning methodsMonocomponent synthetic polymer artificial filamentChemistryDecomposition

The invention discloses a method for preparing special aromatic polyoxadiazole and flame-retardant high-temperature resistant polyoxadiazole fiber thereof. The special aromatic polyoxadiazole is prepared by the following method that the special aromatic polyoxadiazole is prepared from terephthalic acid, compound of which the structural general formula is expressed as formula I and hydrazine salt serving as monomers through condensation polymerization reaction. The polyoxadiazole fiber with high flame retardancy and high temperature resistance is prepared by using the special aromatic polyoxadiazole as a raw material. The fiber number of the prepared polyoxadiazole fiber is 1 to 20 dtex, the breaking strength is 2.5 to 5 cN.dtex-1, the elongation at break is 10 to 40 percent, the initial modulus is 50 to 250 cN.dtex-1, the moisture regain is 5.0 to 12.0 percent, the limited oxygen index is 30 to 38 percent, and the initial decomposition temperature is above 480 DEG C. The fiber can be widely used in the fields of protective products, filter materials, electric insulating materials, frictional sealed materials, various industrial textiles, high-temperature resistant paper, aviation and aerospace materials and the like.

Owner:JIANGSU BAODE NEW MATERIAL

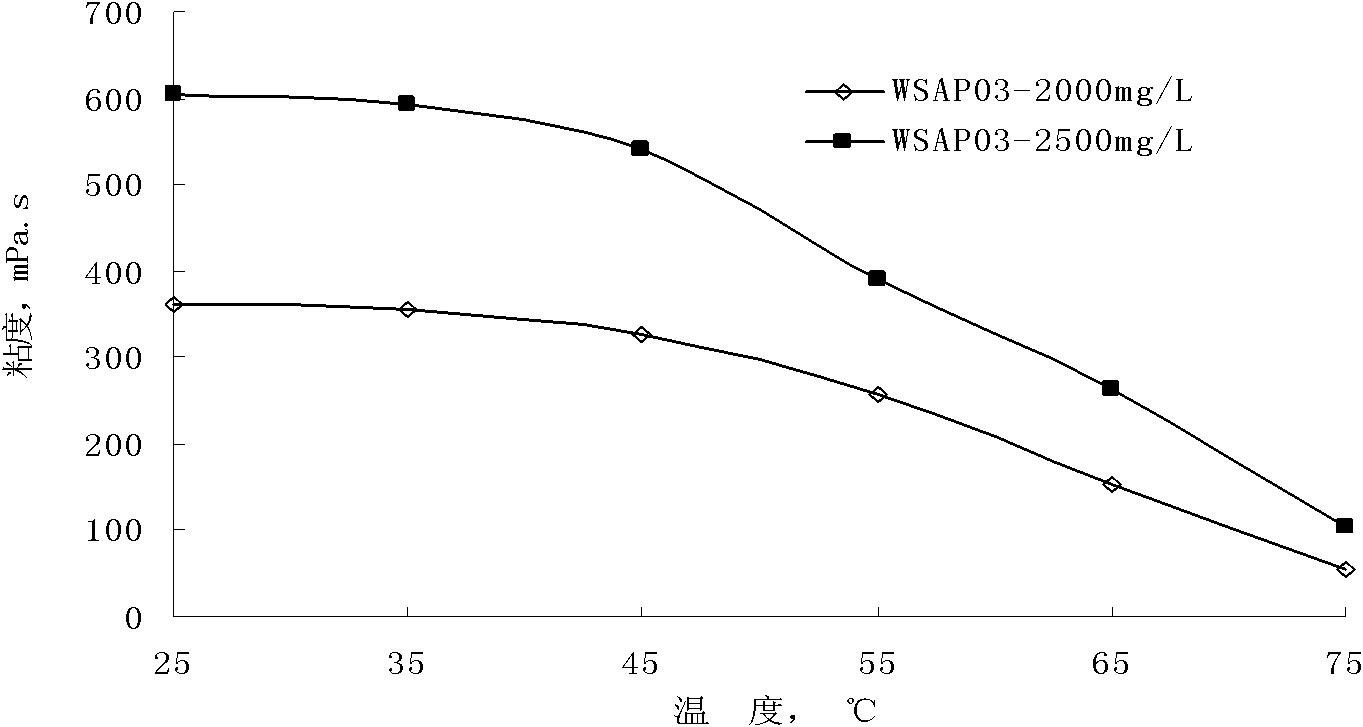

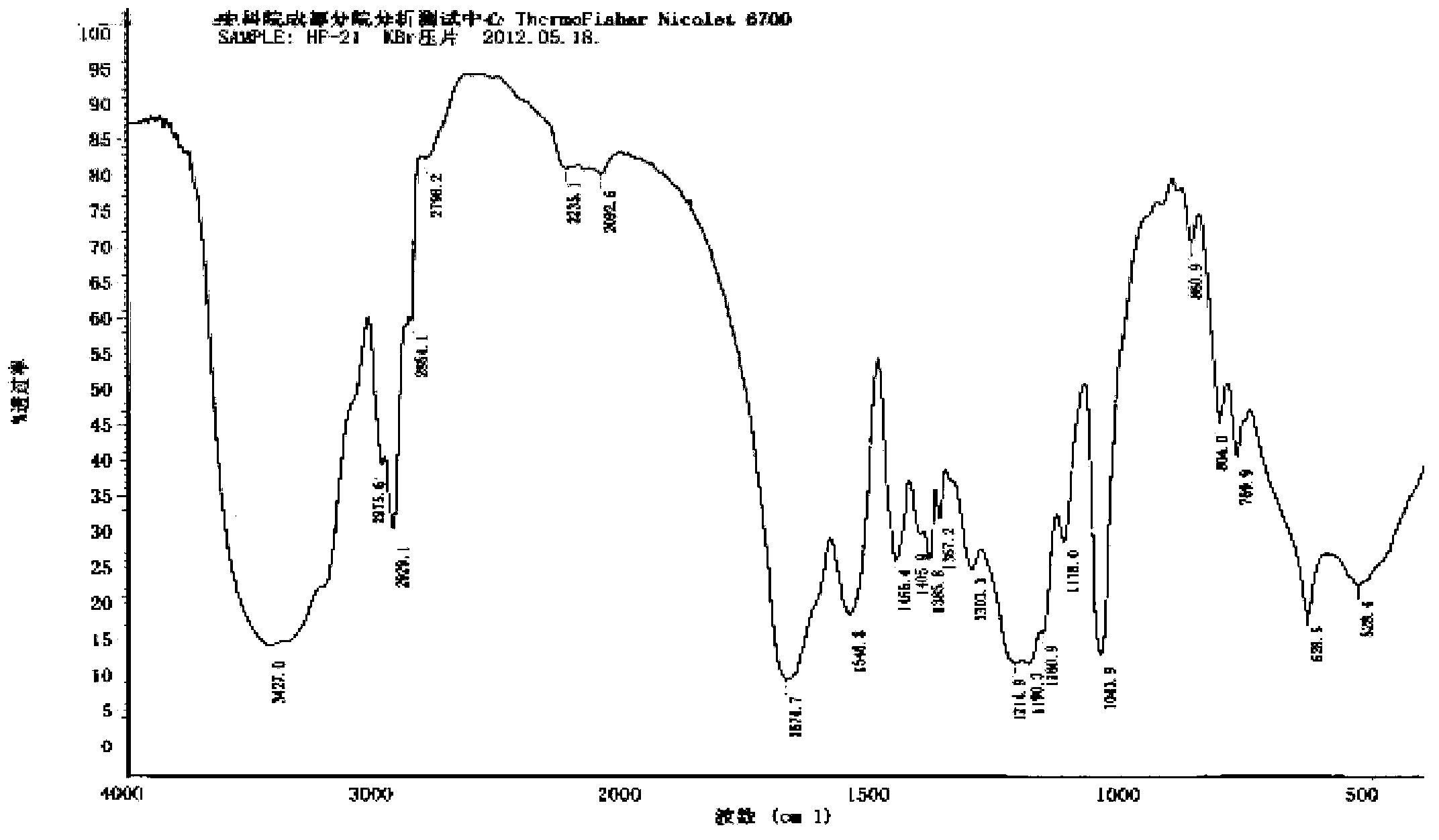

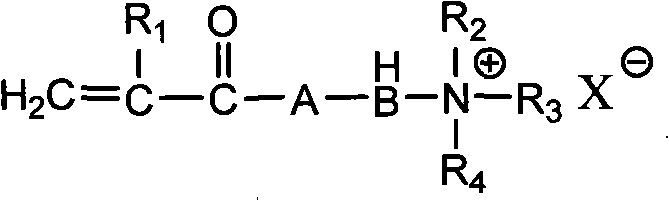

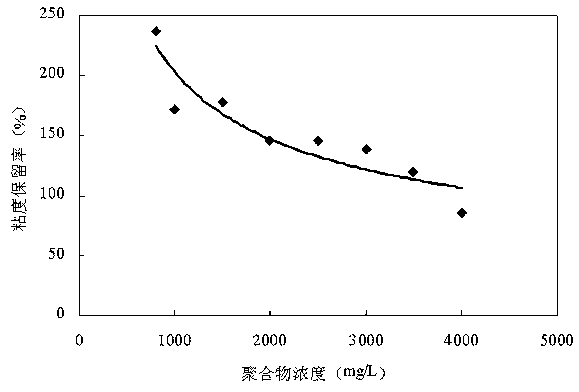

Novel polymeric oil-displacing agent for improving recovery ratio and application thereof

InactiveCN101798503AHigh viscosityGood temperature and salt resistanceDrilling compositionPolymer scienceEnhanced oil recovery

The invention relates to a novel polymeric oil-displacing agent for improving recovery ratio and application thereof. The polymeric oil-displacing agent is a novel association polymer which has different hydrophobic monomers in different contents and is synthesized through free radical polymerization method by taking acrylic amide (AM)-acrylic acid (AA)-hydrophobic monomers as the reactant monomers, wherein the hydrophobic monomers include dimethyl-allyl-p-alkyl-benzyl ammonium chloride. The polymeric oil-displacing agent presents high viscidity under high temperature and high hypersalinity, so the polymeric oil-displacing agent is suitable for high-temperature and high-hypersalinity oil deposits. The polymeric oil-displacing agent has good temperature tolerance, salt tolerance and resistance to shear, and good injectivity and transmissibility as well as the abilities to build up good resistance coefficient and residual resistance coefficient, and can effectively improve the recovery ratio of crude oil. The oil-displacing agent is widely applicable in tertiary oil extraction field and has good market prospect.

Owner:SOUTHWEST PETROLEUM UNIV +1

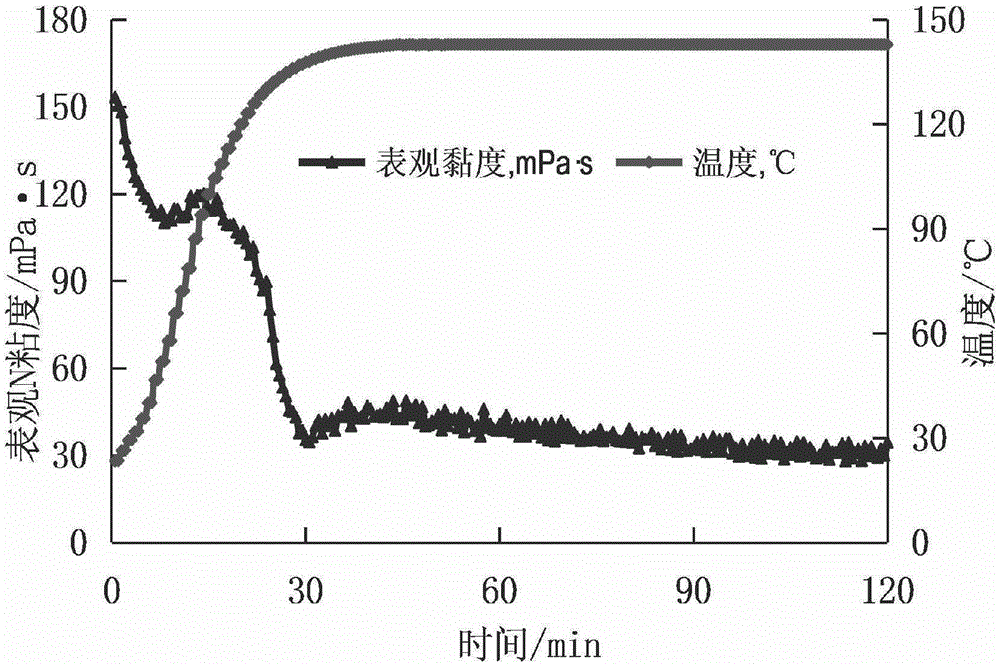

High temperature resistant cleansing emulsion or microemulsion fracturing fluid and preparation method thereof

ActiveCN102838980AIncrease contentReduce apparent viscosityProductsReagentsApparent viscosityPolymer science

The invention relates to a high temperature resistant cleansing emulsion or microemulsion fracturing fluid and a preparation method thereof. The emulsion fracturing fluid is composed of a continuous oil phase, a polymer (I)-containing dispersed water phase and an emulsifier. The preparation method of the emulsion fracturing fluid includes: preparing a mixed solution of the oil phase and the emulsifier, preparing a four-monomer containing water phase, conducting a polymerization reaction in the presence of an initiating agent, and other steps. The product provided in the invention has low apparent viscosity, and can dissolve rapidly. When the emulsion dissolves into gel, the emulsifier can have a synergistic effect with an association polymer, thus further improving and maintaining the viscosity, and helping to prevent leak-off and help flowback. An oxidation gel breaking way is employed for gel breaking, the gel can be completely broken, and the gel breaking solution has low viscosity and contains no residue. The emulsion fracturing fluid is easy to undergo flowback, and has low damage to the stratum.

Owner:CHINA PETROLEUM & CHEM CORP +1

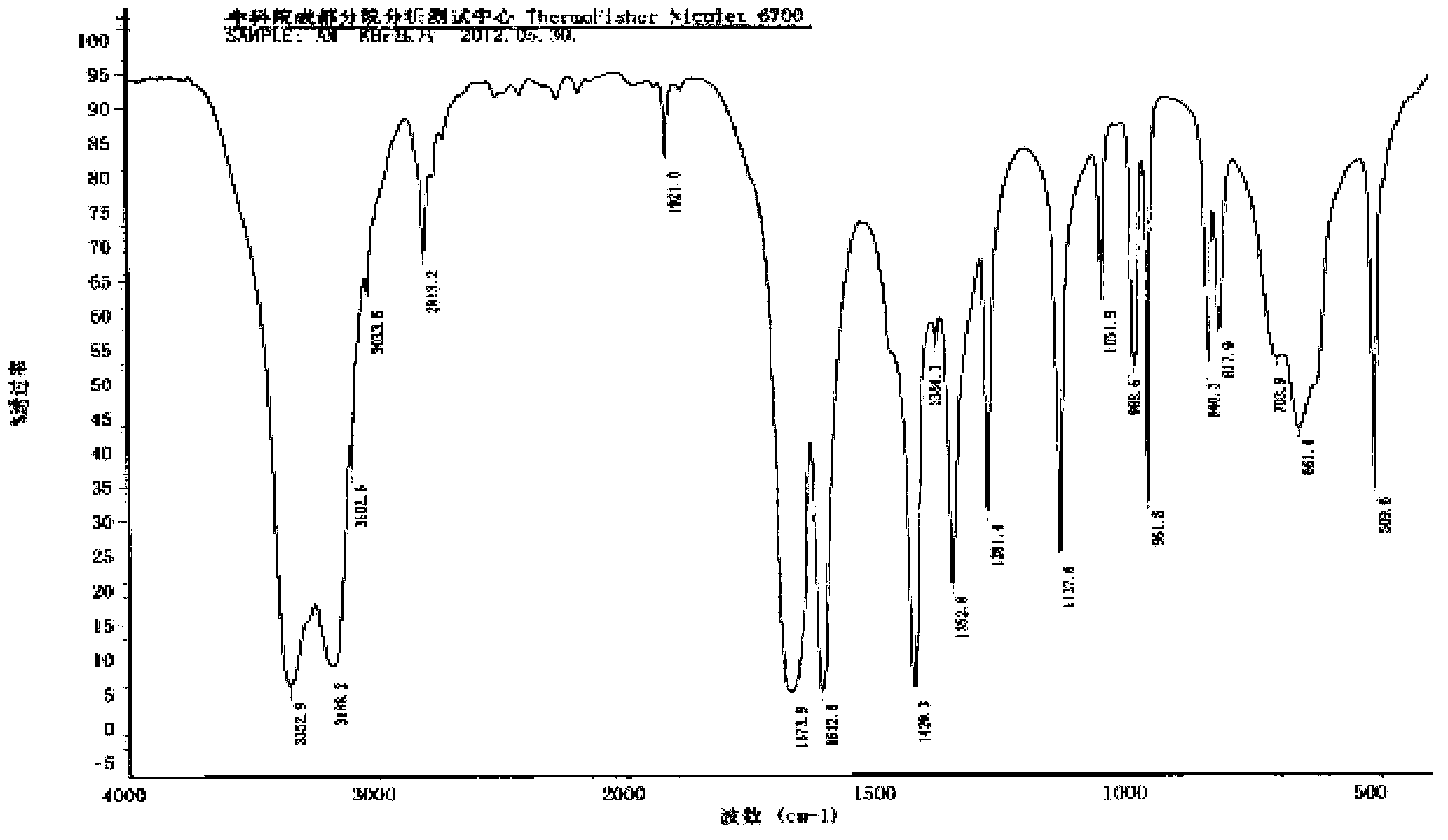

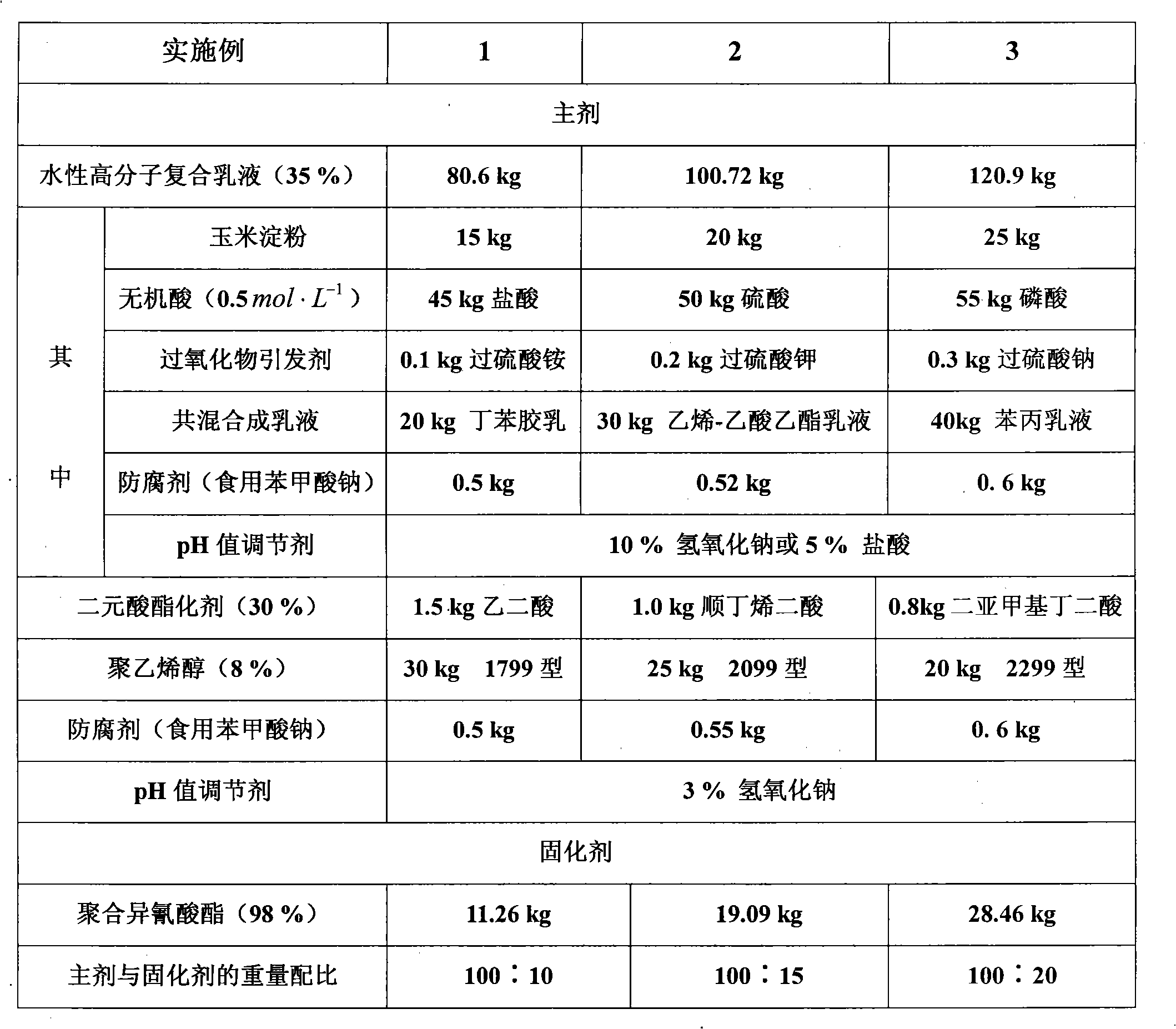

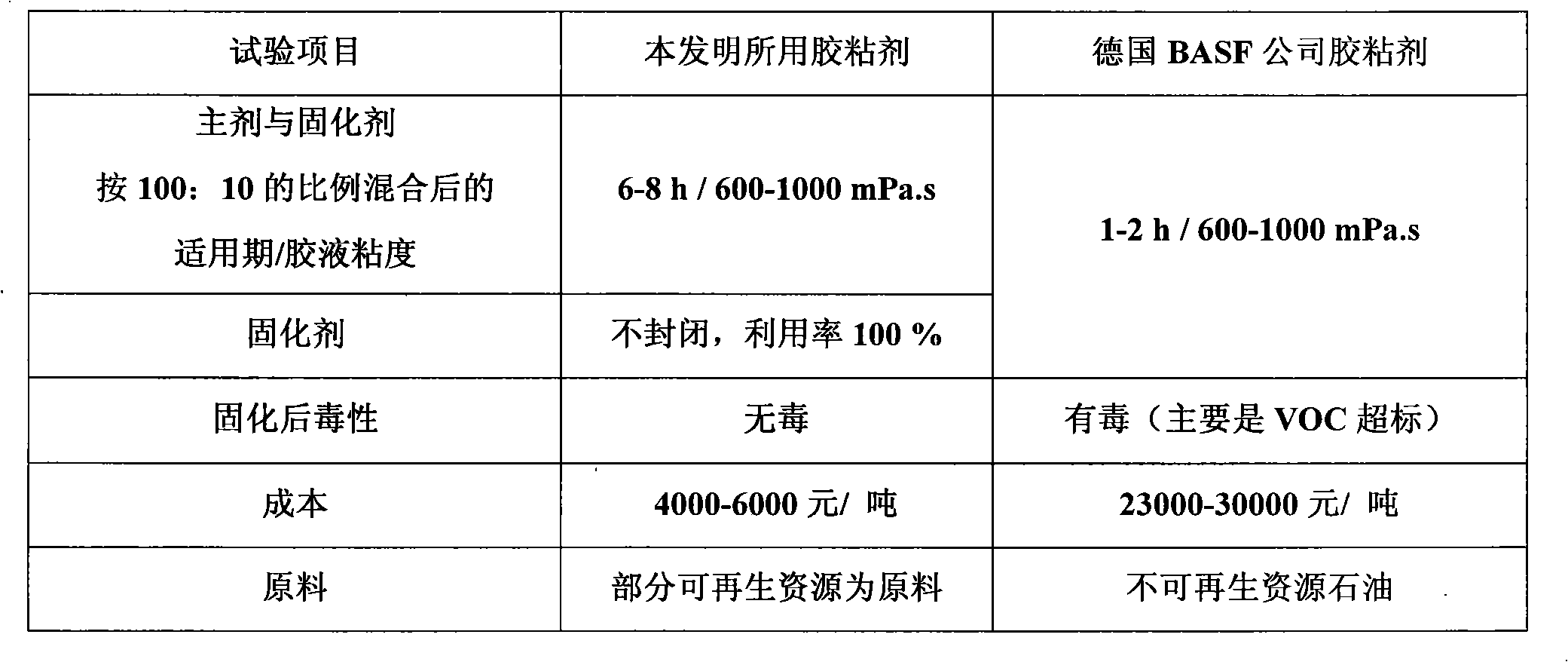

Aqueous macromolecule-isocyanic ester stalk artificial board and preparation thereof

ActiveCN101314235ARealize green productionGood workmanshipPolyureas/polyurethane adhesivesFlat articlesWater basedVolatiles

The invention relates to a water-based macromolecule-isocyanate straw hard board and a preparation method thereof. Straws of rice, wheat, corn or other crops, a water-based macromolecule-isocyanate adhesive and a straw interface performance modifying agent are used as raw materials, and the straws are treated by section cutting, kneading and modification, adhesive application and heat pressing to produce the water-based macromolecule-isocyanate straw hard board. A mixture ratio of the absolute dry straws to the water-based macromolecule-isocyanate adhesive to the straw interface performance modifying agent by weight is 100 to 10-16 to 0.05-0.15. The straw hard board uses the water-based macromolecule-isocyanate adhesive to replace a pure isocyanate adhesive, radically improves the problems of toxic organic volatiles, poor prepressing performance, adhesion on boards, etc., remarkably reduces cost and really realizes green production, and the raw materials after the treatment of kneading and modification have good prepressing and molding performances and high one-off qualified rate. The water-based macromolecule-isocyanate straw hard board has the characteristics of unique design, long active period, excellent aging, water and heat resisting performances, simple operation, easy availability of equipment, no environmental pollution, easy implementation, etc., and produces huge entironmental, social and economical benefits after the water-based macromolecule-isocyanate straw hard board is popularized.

Owner:BEIHUA UNIV

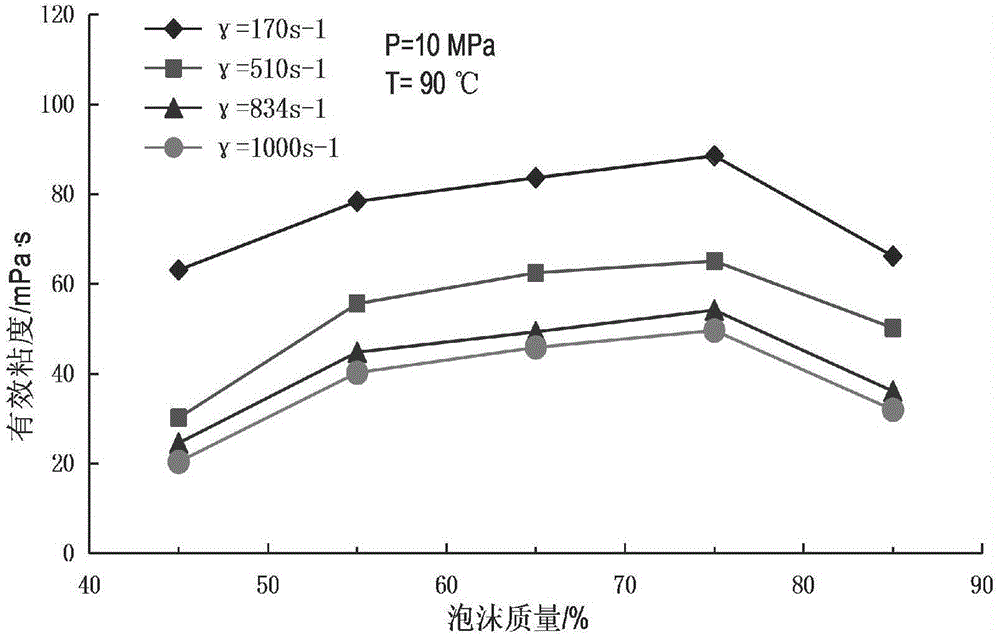

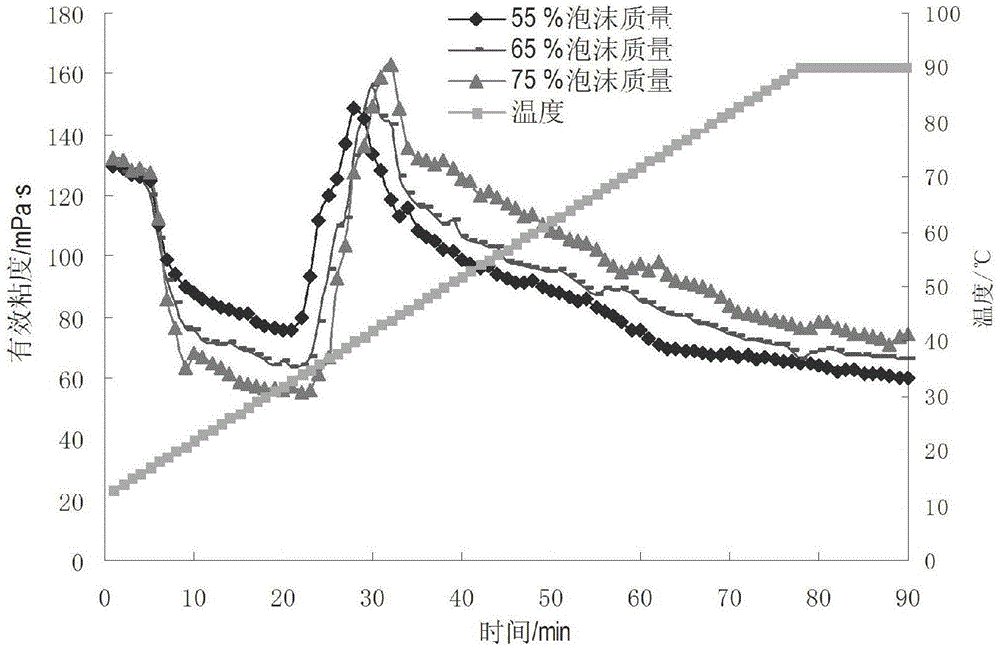

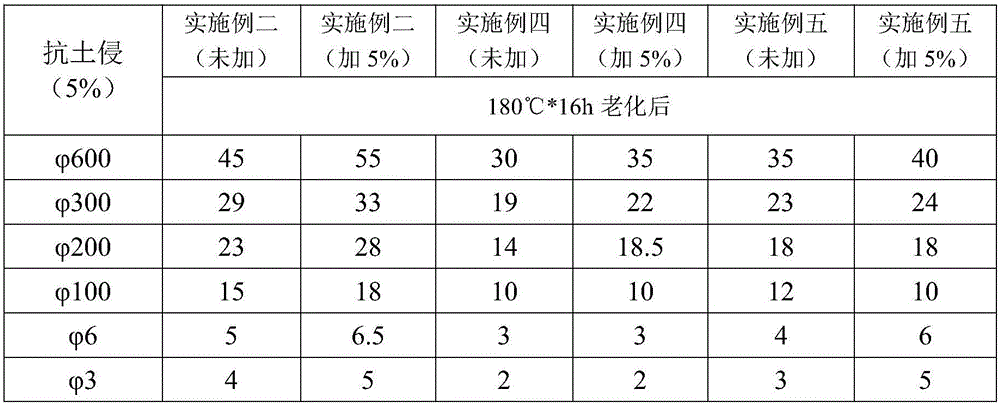

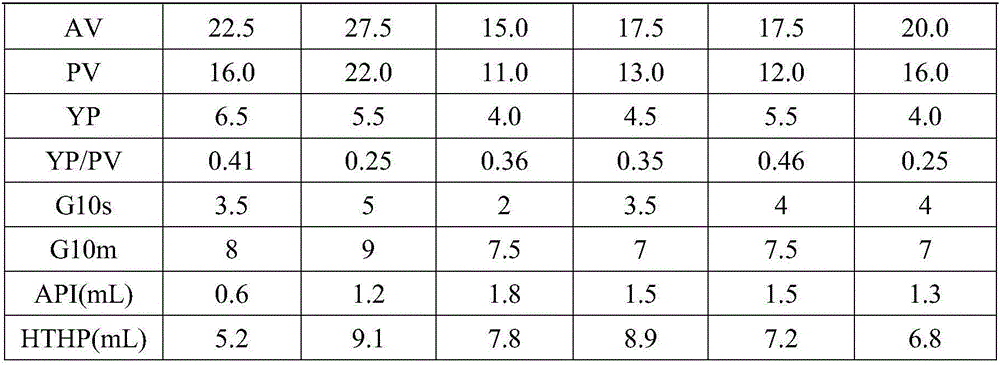

High temperature-resisting cleaning CO2 foam fracturing liquid suitable for unconventional oil and gas reservoir development

ActiveCN105567213ASolve the problem of water solubilityReduce or even eliminate residueDrilling compositionFunctional monomerGas phase

The invention discloses high temperature-resisting cleaning CO2 foam fracturing liquid suitable for unconventional oil and gas reservoir development. The high temperature-resisting cleaning CO2 foam fracturing liquid in gas phase is CO2; the high temperature-resisting cleaning CO2 foam fracturing liquid in liquid phase is high temperature-resisting cleaning fracturing liquid; the foam mass is 52 percent to 75 percent. The high temperature-resisting cleaning CO2 foam fracturing liquid is prepared from the following raw materials in percentage by weight: 0.3 to 0.65 percent of thickening agent, 0.2 to 0.5 percent of viscosity synergist, 0.2 to 0.3 percent of pH (Potential of Hydrogen) value modifier, 0 to 0.2 percent of high-temperature stabilizing agent, 0.01 to 0.1 percent of gel breaker and water, wherein the thickening agent is prepared from acrylamide, vinylpyrrolidone, maleic acid, anionic functional monomers, an initiating agent, inorganic salt and the like; the viscosity synergist is mainly prepared from an anionic surfactant; the pH value modifier is mainly prepared from an organic acid. According to the high temperature-resisting cleaning CO2 foam fracturing liquid disclosed by the invention, the temperature-resisting ability is up to 140 DEG C, the sand carrying performance is excellent, the frictional resistance is low, the foam stability is strong, the content of residual slag is extremely low, the stratum compatibility is good, back flowing is easy, the construction effect is quickly obtained, and important significances to effective development of an unconventional oil and gas reservoir and protection of a reservoir stratum are obtained.

Owner:CHENGDU BAICHUN PETROLEUM TECH

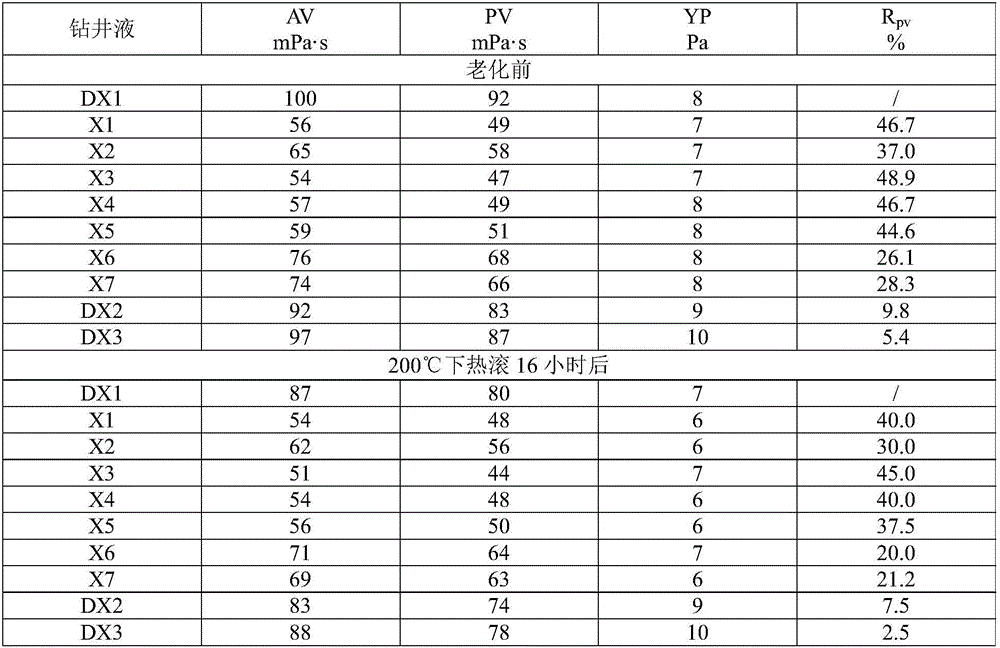

Ultralow-density oil-base drilling fluid and preparation method thereof

The invention relates to an ultralow-density oil-base drilling fluid. The invention is characterized in that the ultralow-density oil-base drilling fluid is prepared from the following raw materials: base oil, a density reducer, a suspension stabilizer, an emulsifier, a tackifier, a fluid loss additive, a flow pattern regulator, an alkalinity regulator and a calcium chloride water solution. The base mixed oil is prepared by the following steps: mixing 3# white oil, 5# white oil and natural gas prepared oil, adding a flash point enhancer while stirring, and standing for 0.5-1 hour; and stirring at low speed at the temperature of 30-40 DEG C, and slowly adding oil-soluble nano fumed silica while stirring, wherein the addition process is controlled at 2-3 hours. The ultralow-density oil-base drilling fluid has the advantages of favorable emulsifying stability, favorable rheological properties, high inhibition property for mud shale, high emulsion-breaking voltage, low filter loss, low density (0.75-0.90 g / cm<3>), and high sand carrying and pressure bearing capacities, is beneficial to cleaning the borehole and enhancing the mechanical drilling speed, solves the problem of severe lost circulation in the low-pressure formation and long-section shatter zone formation, and is especially suitable for low-pressure oil gas pools and depletion water-sensitive formations.

Owner:成都西油华巍科技有限公司 +1

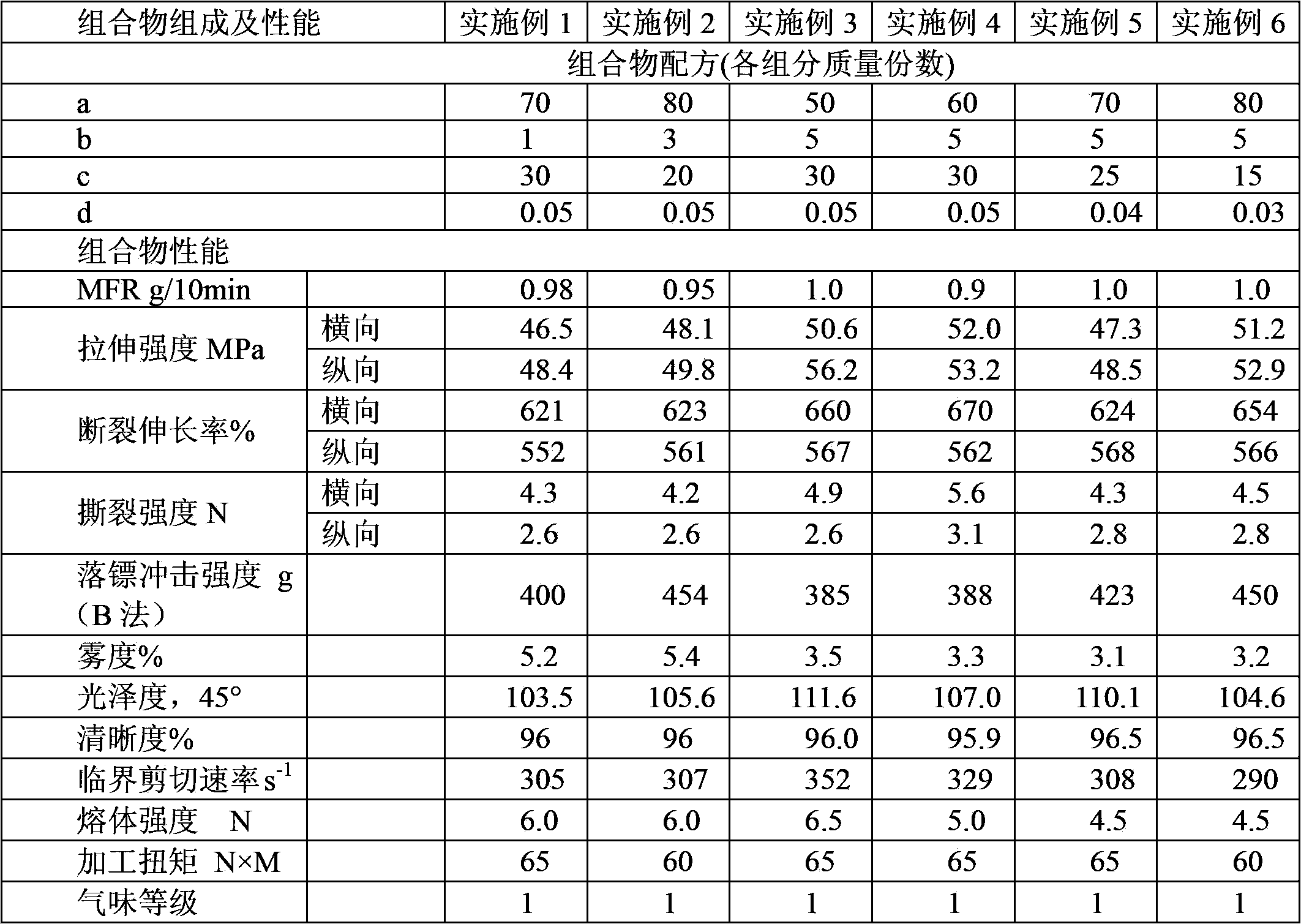

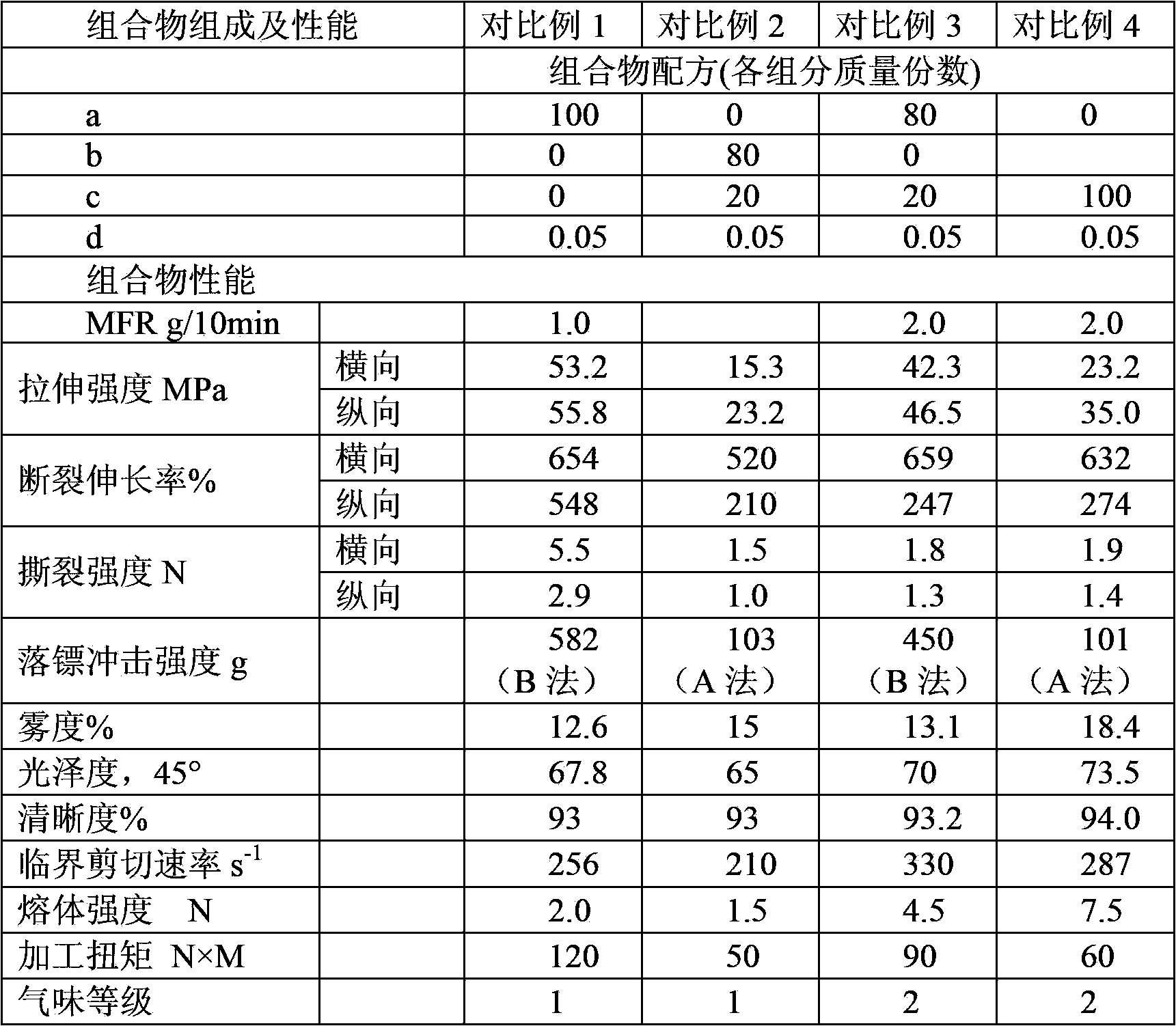

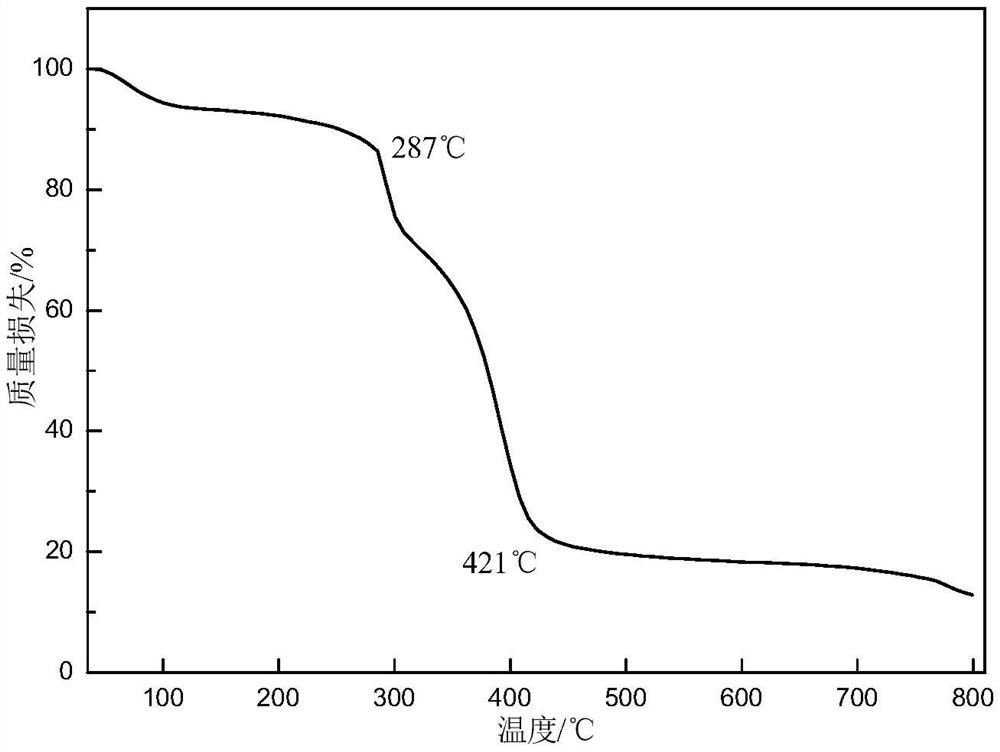

Highly-transparent polyethylene composition and preparation method thereof

The invention relates to a polyethylene composition, specifically to a highly-transparent polyethylene composition and a preparation method thereof. The highly-transparent polyethylene composition comprises a matrix resin and a processing auxiliary agent, wherein the matrix resin is prepared by co-mixing first mLLDPE, second mLLDPE and high pressure LDPE. The composition has characteristics of good strength, good flexibility, good processability, good aging resistance, low odor, excellent gloss, excellent impact strength, excellent tensile strength and excellent tear strength, can be used for preparing composite package films with excellent comprehensive performances, and can be provided for avoiding phenomena such as scratch, puncture and breaking by external force due to insufficient performances such as tear resistance and the like during the use process. In addition, after the mLLDPE resin and the normal resin are blended, the thickness of the film is reduced, the comprehensive performance is excellent, the product cost is reduced, and the processability of the composition is improved.

Owner:CHINA PETROLEUM & CHEM CORP

Salt-responsive high-temperature-resistant zwitterionic polymer filtrate reducer and preparation method and application thereof

ActiveCN112011318AImprove salt toleranceImprove temperature resistanceDrilling compositionPolyelectrolyteMeth-

The invention provides a salt-responsive high-temperature-resistant zwitterionic polymer filtrate reducer and a preparation method and application thereof. The filtrate reducer is prepared from the following raw materials in parts by mass: 2 to 40 parts of N, N-dimethylacrylamide, 2 to 20 parts of methacryloxyethyl trimethyl ammonium chloride, 2 to 20 parts of 2-acrylamide-2-methylpropanesulfonicacid, 4 to 8 parts of nano oxide, 1.0 to 1.5 parts of silane modifier and 0.3 to 0.4 part of an initiator. The salt-responsive zwitterionic polymer provided by the invention has a special polyelectrolyte resistance effect and positive response to salt, essentially realizes conversion from salt resistance to salt response, and is essentially compatible with salt, the obtained filtrate reducer has excellent salt resistance, temperature resistance and filtrate loss reduction performance, and also has shear dilutability.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

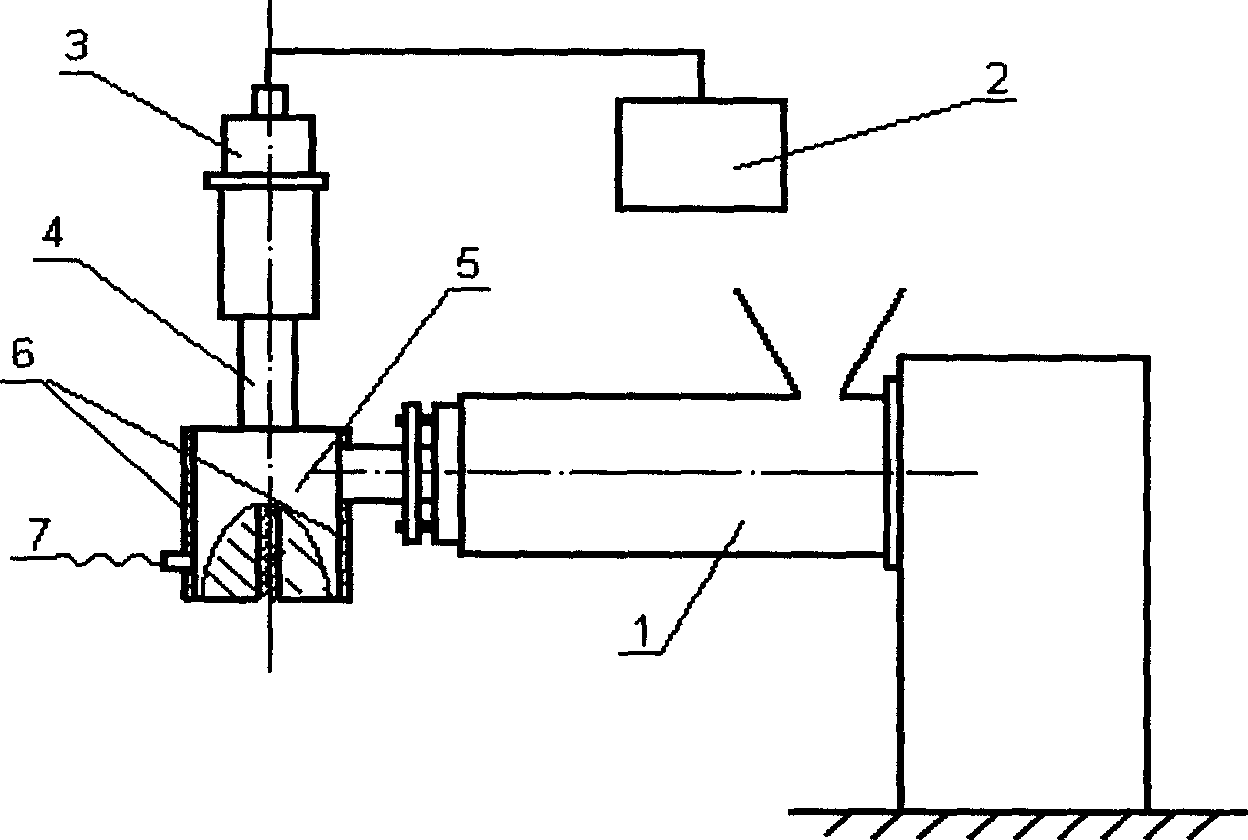

Continuous micro-reaction device and method for preparing meta-aramid resin and product

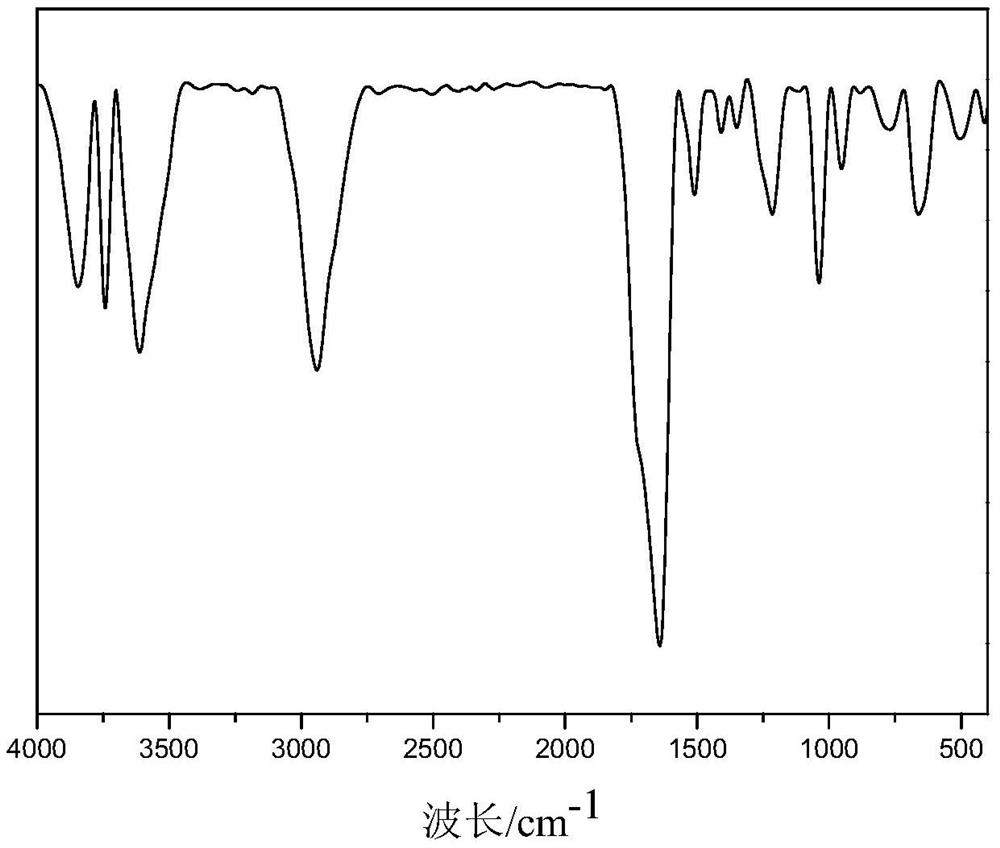

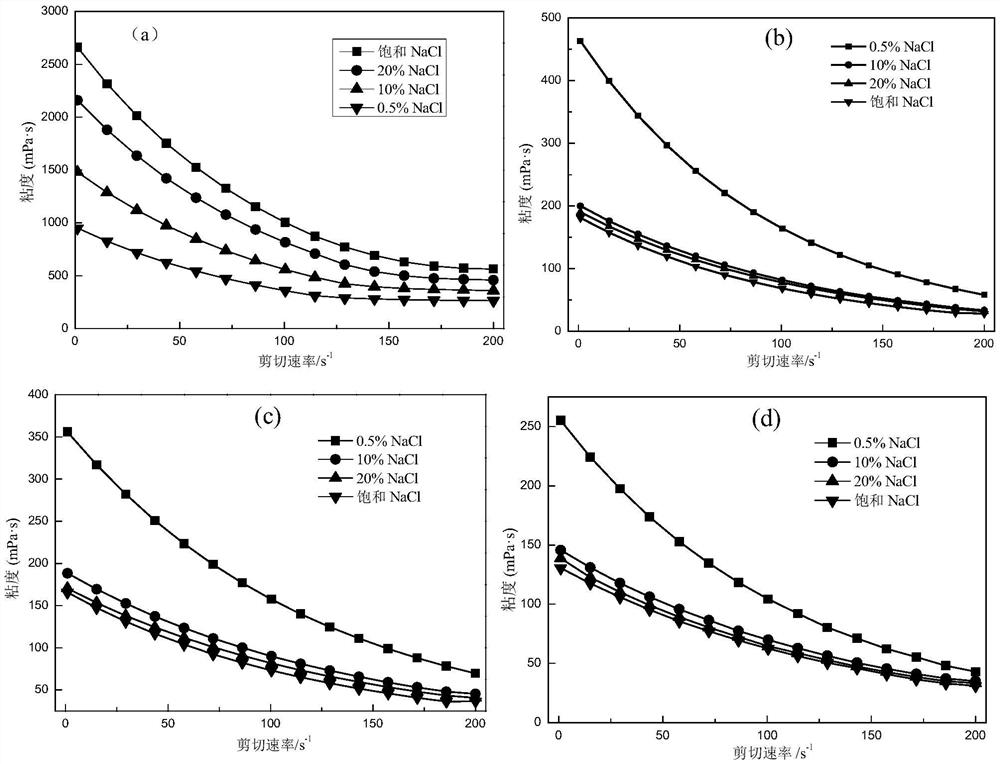

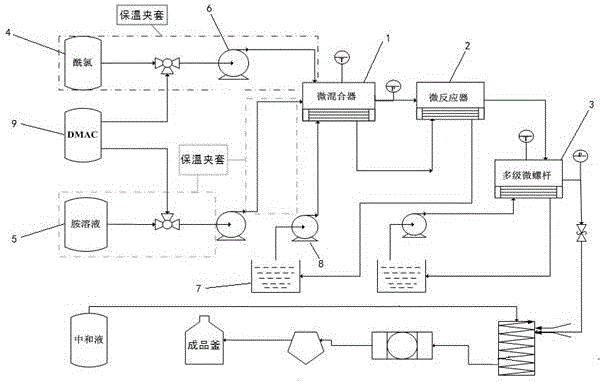

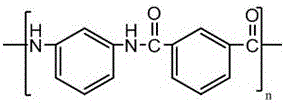

ActiveCN106478940AEasy transferReduce polydispersityChemical/physical/physico-chemical microreactorsMonocomponent polyamides artificial filamentAfter treatmentEngineering

A continuous micro-reaction device for preparing meta-aramid resin comprises a prepolymerization system, a polycondensation system, an after-treatment system and a heat exchange system, wherein the prepolymerization system, the polycondensation system and the after-treatment system are connected in sequence, and the heat exchange system is connected with the prepolymerization system and the polycondensation system to control temperatures of the prepolymerization system and the polycondensation system. The continuous micro-reaction device is characterized in that the prepolymerisation system comprises a raw material storage device, a micro-mixer and a micro-reactor which are connected in sequence; the polycondensation system comprises a multistage micro-screw device, and the micro-reactor is connected with multistage micro-screw device. The continuous micro-reaction device for preparing the meta-aramid resin improves the heat transfer effect at the polycondensation stage and the mass transfer effect at the polycondensation stage during preparation of the meta-aramid resin, and achieves the purpose of improving the performance of a meta-aramid resin product. The invention further provides a continuous micro-reaction method for preparing the meta-aramid resin and the product.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

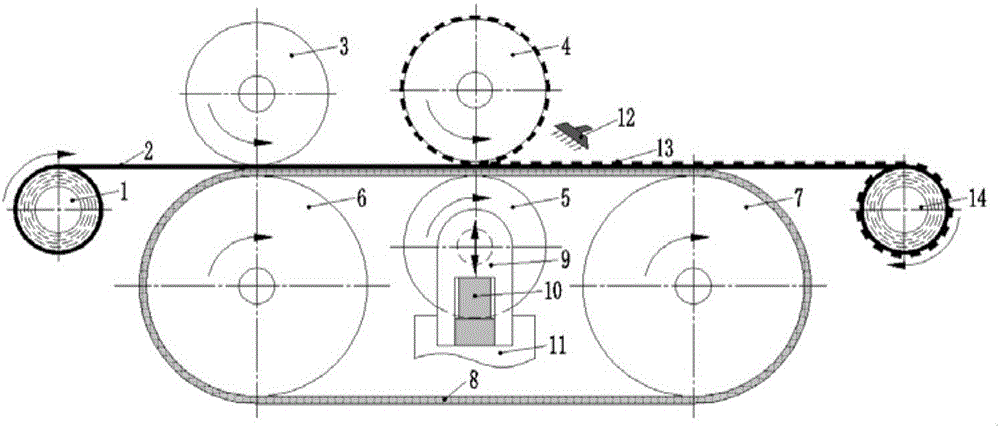

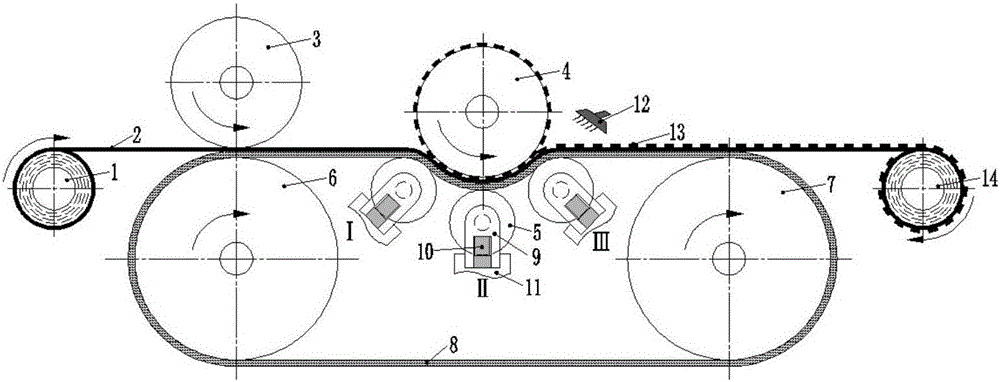

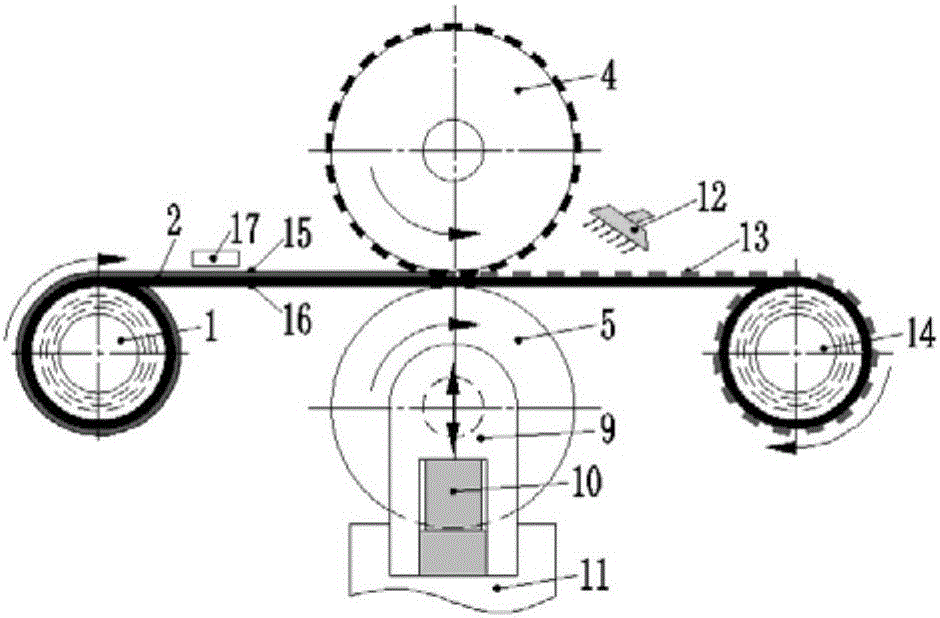

Reel-to-reel hot roller coining forming method for micro-nano structure on surface of polymer

The invention relates to a reel-to-reel hot roller coining forming method for a micro-nano structure on the surface of polymer. The reel-to-reel hot roller coining forming method comprises the steps that a polymer material is conveyed to a preheat roller from an unreeling device, preheated to the attaching temperature and attached to a base band in a hot pressing mode; the polymer material attached to the base band is conveyed to the position between a mold roller and a pressure roller and heated to the coining temperature through the mold roller heated in advance, and then a mold cavity is filled with the polymer material through the action of the pressure roller; mold filling and supersonic vibration assembly starting are conducted at the same time, and the reel-to-reel hot roller coining process is completed with assistance of supersonic vibration; the polymer material is conveyed out from the position between the mold roller and the pressure roller, and then cooled and separated from the position inside the mold roller; and after demolding is completed, a polymer product is continuously cooled, separation of the polymer product and the base band is achieved, and finally reeling is conducted. According to the reel-to-reel hot roller coining forming method for the micro-nano structure on the surface of the polymer, the reel-to-reel hot roller coining process is improved through supersonic vibration, the mold filling process is accelerated, the duplication precision is improved, and the demolding force and demolding deformation are reduced; and the reel-to-reel hot roller coining forming method is advanced.

Owner:SHANGHAI JIAO TONG UNIV

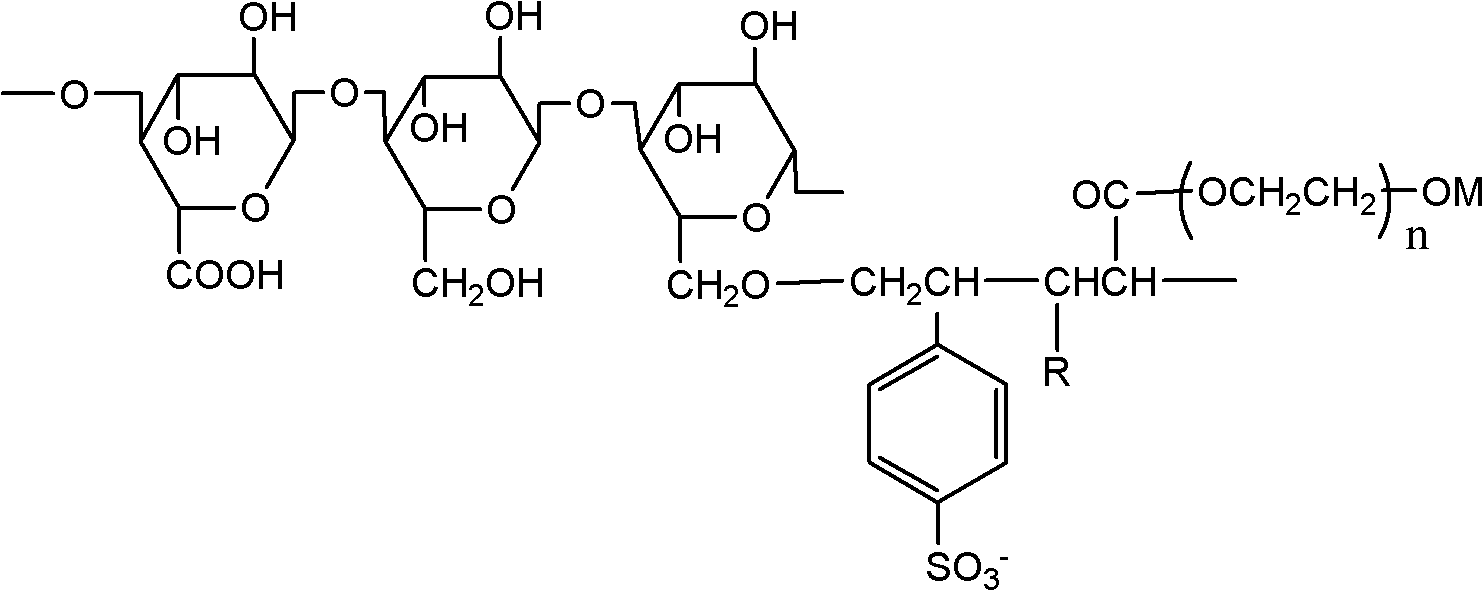

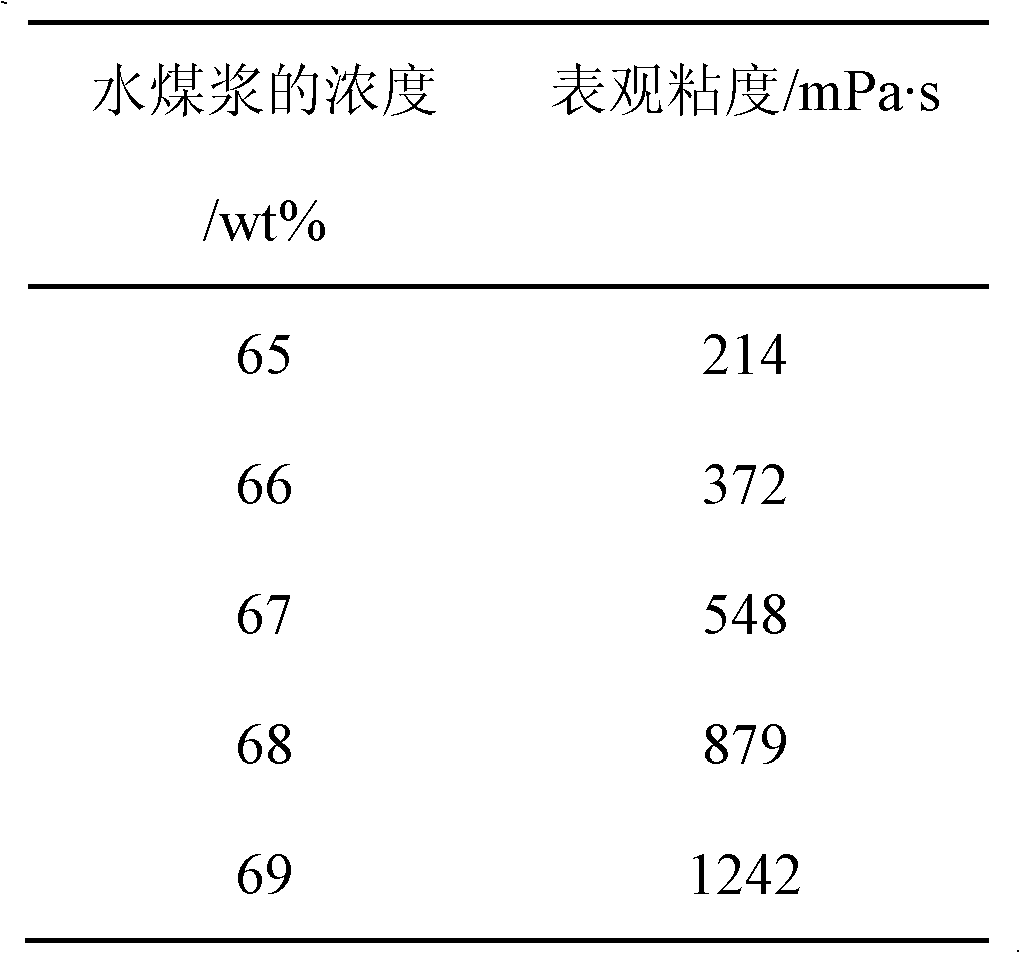

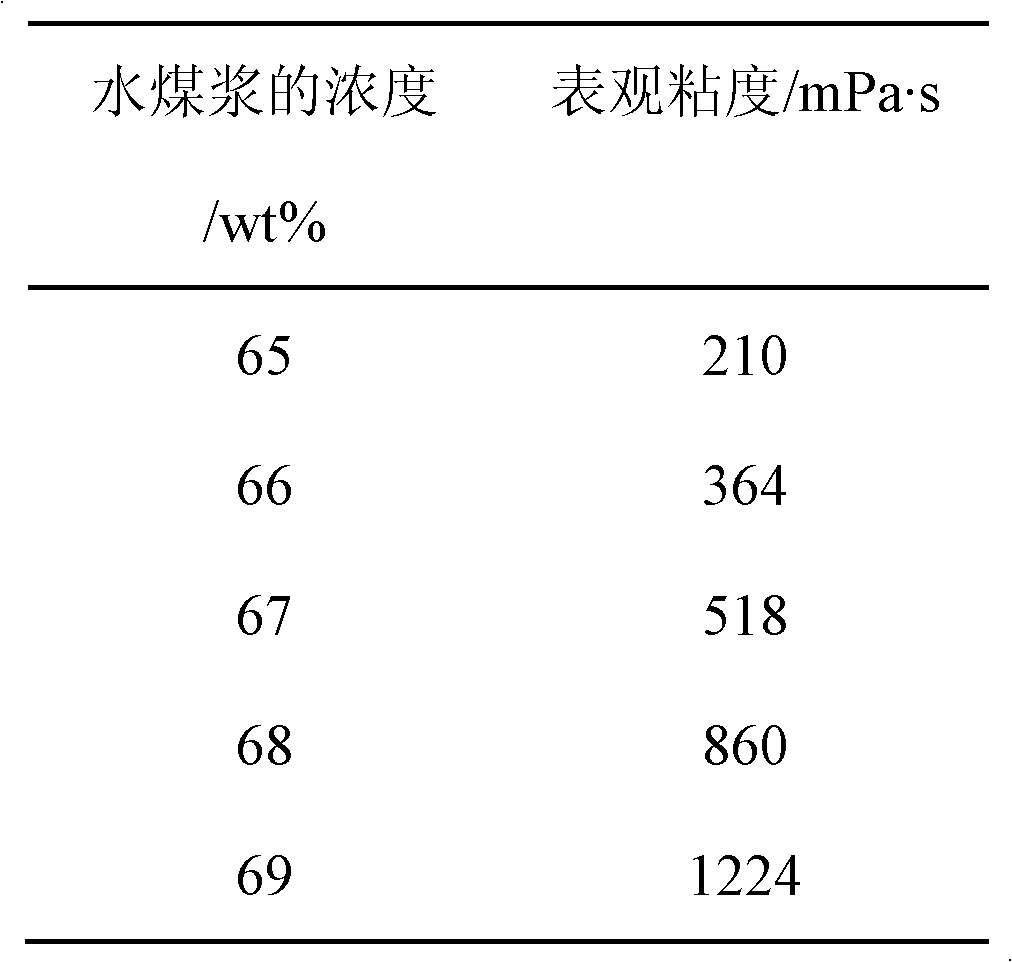

Starch graft copolymer coal-water slurry dispersants and preparation method thereof

InactiveCN102627729ALow toxicityWide variety of sourcesLiquid carbonaceous fuelsDispersityRaw material

The invention provides a preparation method of starch graft copolymer coal-water slurry dispersants. After oxidation modification of starch, in a redox system, sodium p-styrene sulfonate and a large monomer are introduced to a starch chain through free radical polymerization reaction to compound a series of coal-water slurry dispersants with excellent performance and unique characteristics. Chief constituents of the starch graft copolymer coal-water slurry dispersants are as follows, by mass: 8-20% of starch, 2-8% of oxidants, 10-30% of monomers and 2-4% of initiators. The starch graft copolymer coal-water slurry dispersants prepared by the method are brown sticky emulsion, the solid content is 26-38%, the pH value is 7-9, and the viscosity is 40-130mPa.s. The preparation method of the starch graft copolymer coal-water slurry dispersants exploits the advantages of strong dispersity of the sodium p-styrene sulfonate and carboxylate to the full and combines effects of hydrogen bond in water molecules and polyhydroxy on a starch straight chain and the space steric hindrance effect of a long chain of the large monomer to enable coal-water slurry to have good dispersion perfoamance and good storage stability. The dispersants can achieve biodegradation and have low toxicity, and raw materials of the dispersants are easy to obtain and low in cost.

Owner:SHAANXI UNIV OF SCI & TECH

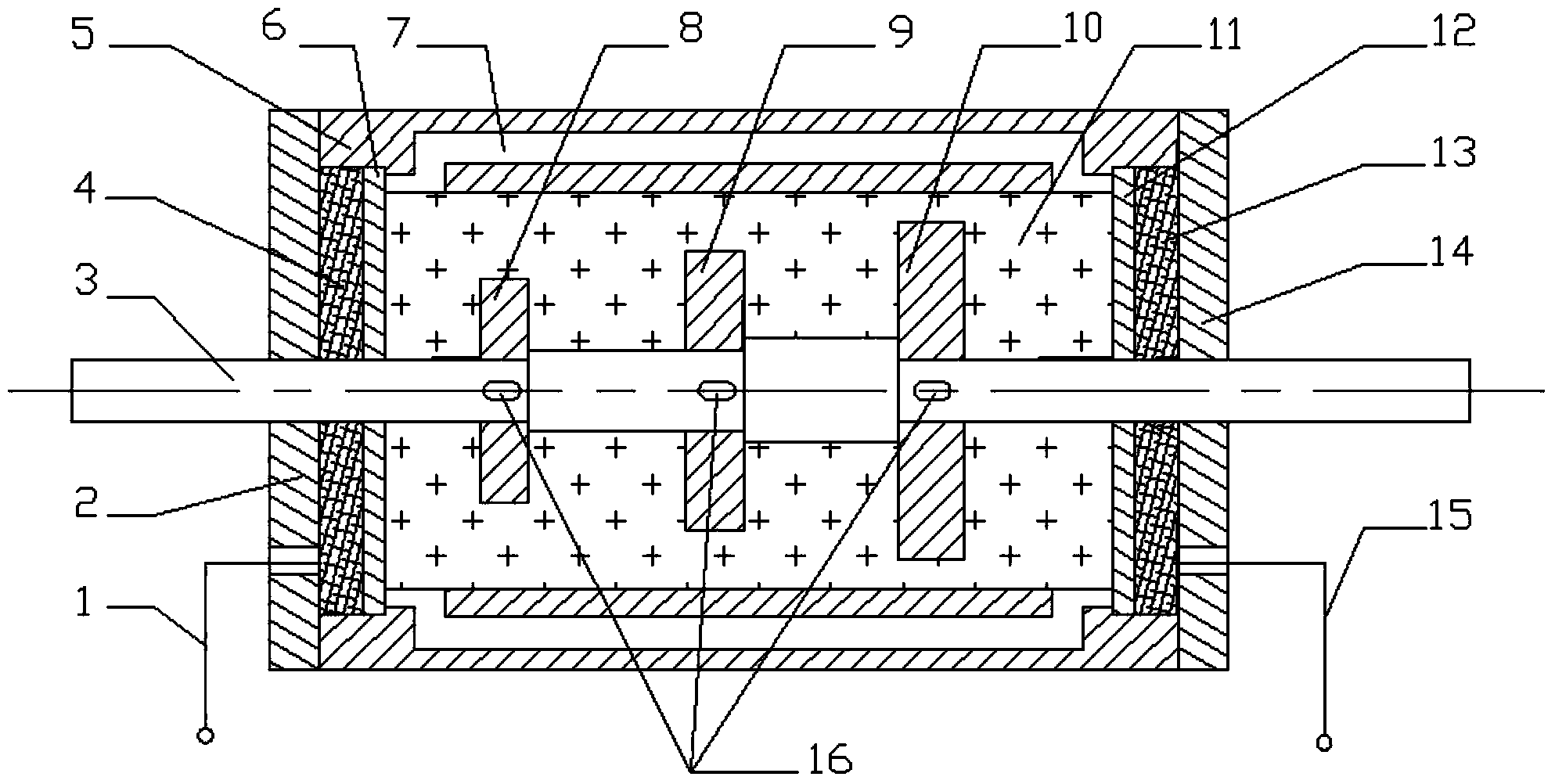

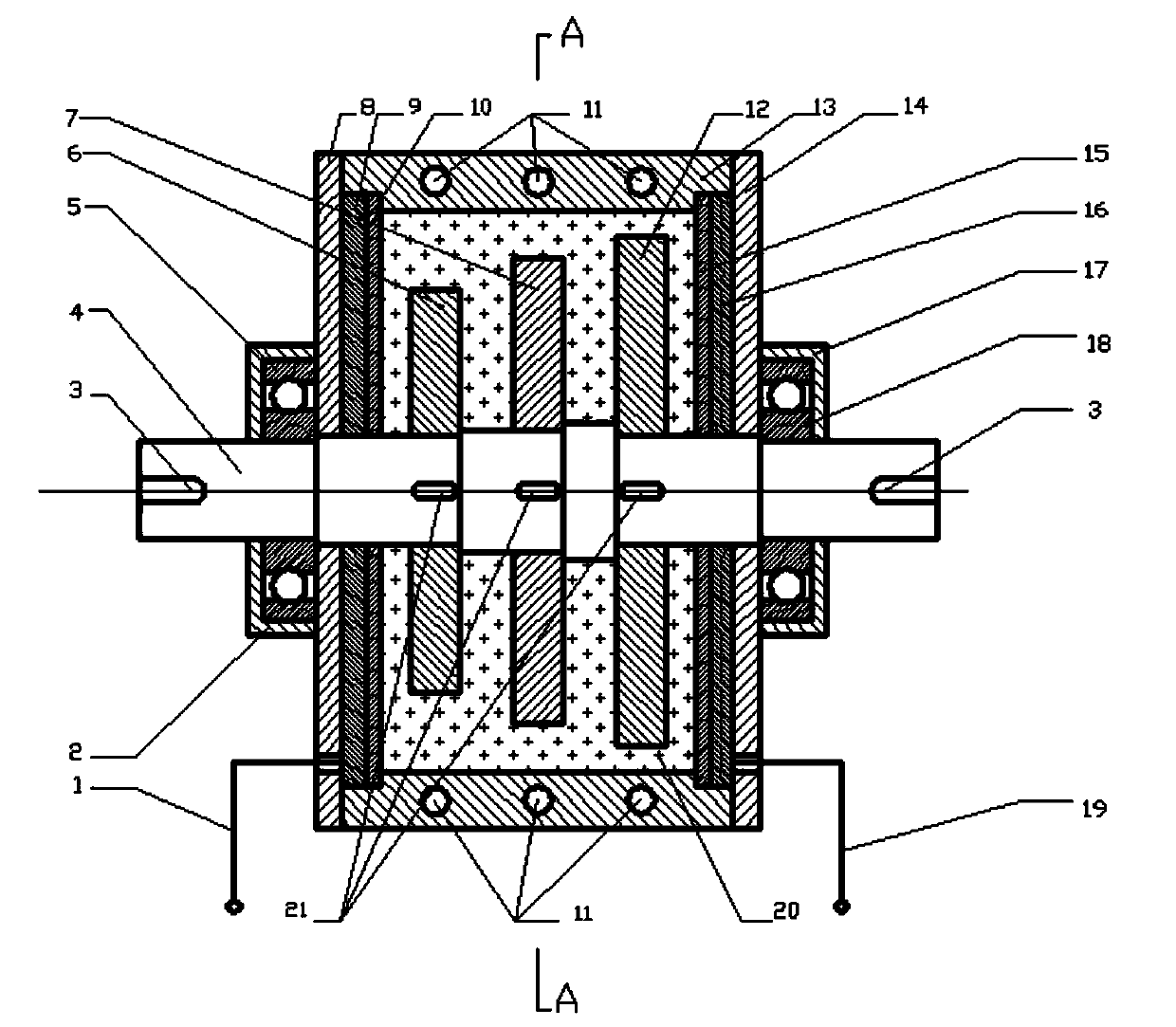

Seven-level adjustable reciprocating type electrorheological fluid damper

InactiveCN103591209AIncrease structural flexibilityLarge damping forceNon-rotating vibration suppressionLiquid based dampersThrottle controlApparent viscosity

A seven-level adjustable reciprocating type electrorheological fluid damper mainly comprises a positive-pole conducting wire, a negative-pole conducting wire, a positive-pole piston cylinder cover, a negative-pole piston cylinder cover, positive-pole conducting rubber, negative-pole conducting rubber, a piston rod, an insulating piston cylinder, a positive pole, a negative pole, a backflow control path, a small piston, a middle piston, a large piston and electrorheological fluid. The positive-pole conducting rubber and the negative-pole conducting rubber replace sealing materials and play a role in sealing and conducting. Installation forms of the small piston, the middle piston and the large piston are determined by borne damping force, wherein when the damping force is large, stress is not clear, and movement speed is high, the dual-piston or three-piston form is adopted; when the damping force is small, the single-piston form is adopted. The backflow control path replaces a throttling control valve, no external electric field exists, the electrorheological fluid bears the force and flows between the positive pole and the negative pole through the backflow control path, and the seven-level adjustable reciprocating type electrorheological fluid damper is a hydraulic damper; when an external electric field is applied and shearing efficiency is high, apparent viscosity of the electrorheological fluid of the backflow control path changes, the section area of the backflow control path becomes smaller, the backflow control path is even blocked completely, and the electrorheological fluid effectively controls an engineering system by proving shearing force and extruding force.

Owner:QINGDAO AGRI UNIV

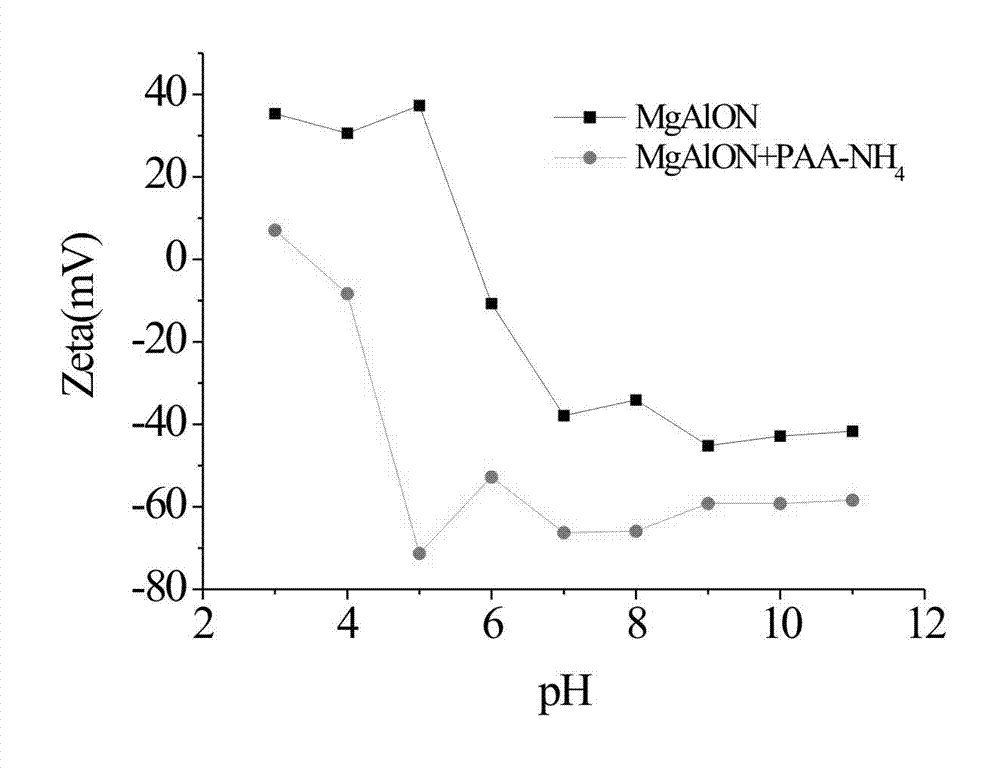

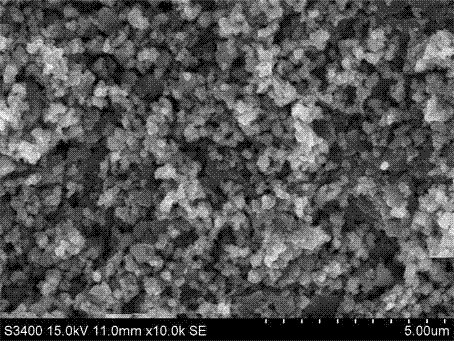

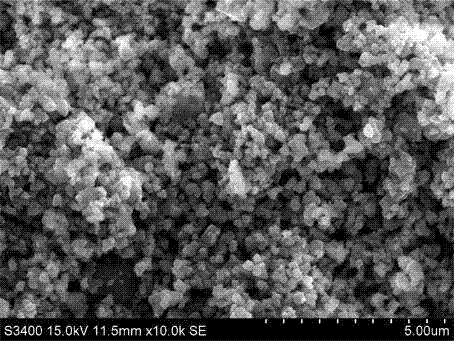

Method for preparing MgAlON transparent ceramic bisque by gel casting and molding

ActiveCN102825649AIn good shapeHomogeneous microstructureCeramic shaping apparatusFlexural strengthMicrostructure

The invention relates to a method for preparing an MgAlON transparent ceramic bisque by gel casting and molding. The method comprises the steps of: 1) preparing a pre-mixed solution; 2) preparing ceramic slurry; 3) casting and molding; 4) drying and degreasing a billet, and finally obtaining the MgAlON ceramic bisque. The MgAlON ceramic bisque prepared by the method is smooth in surface, intact in shape, and uniform in microscopic structure; the bending strength of a dried billet is greater than 10MPa, and the micro-structure and mechanical property of a sample are superior to those of the ceramic bisque prepared by the other traditional ceramic molding methods.

Owner:WUHAN UNIV OF TECH

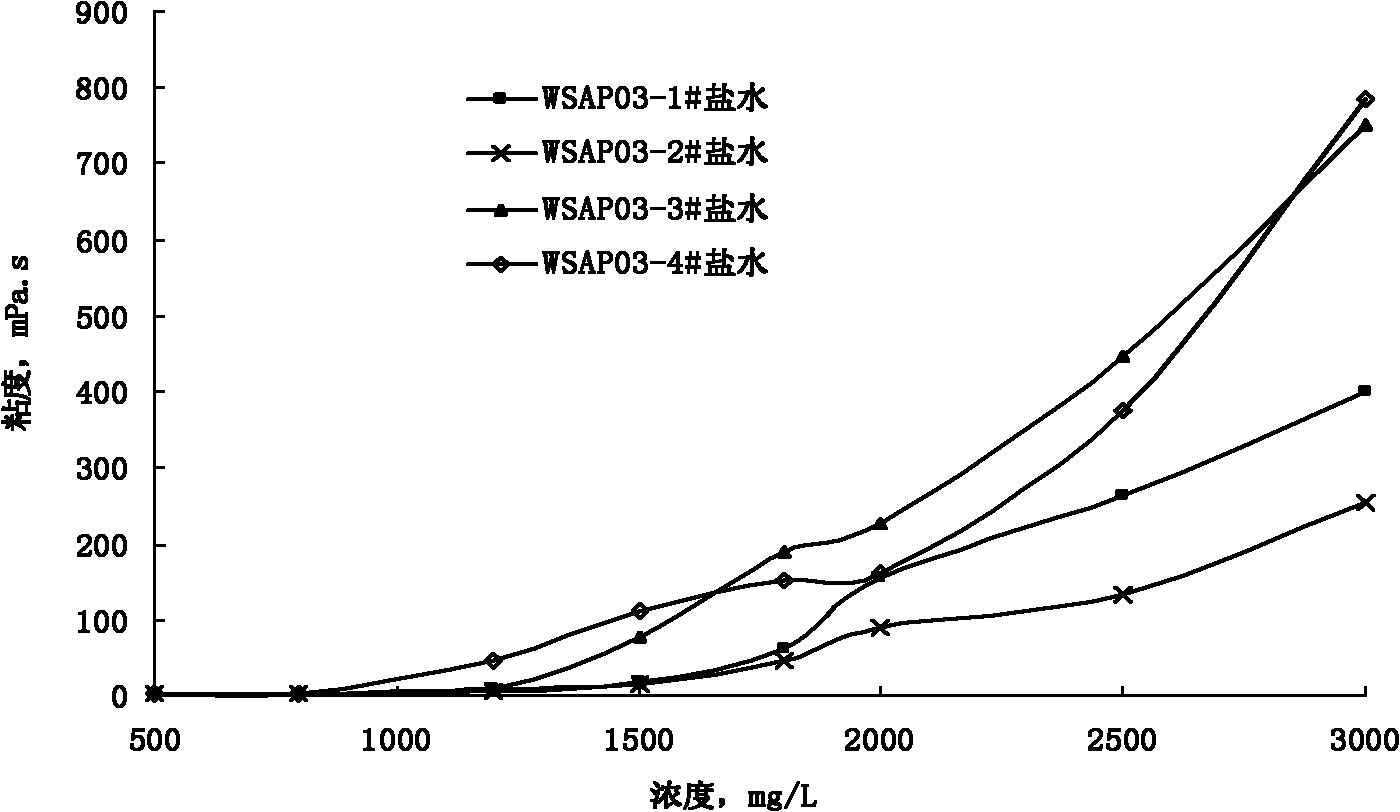

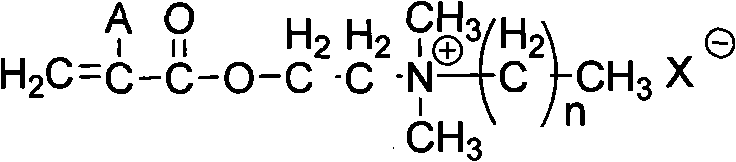

A Cationic Hydrophobic Association Polyacrylamide "Water-in-Water" Emulsion

InactiveCN102286128ASolve the problems of high cost, unsafe and environmental protectionReduce apparent viscositySaline waterInorganic salts

The invention relates to the synthesis of a hydrophobic association polyacrylamide "water-in-water" emulsion. Stable " "Water-in-water" emulsion has a small particle size and can be quickly dissolved in water, which solves the problem that the current hydrophobic association polyacrylamide dry powder is difficult to dissolve.

Owner:CHENGDU ORGANIC CHEM CO LTD CHINESE ACAD OF SCI

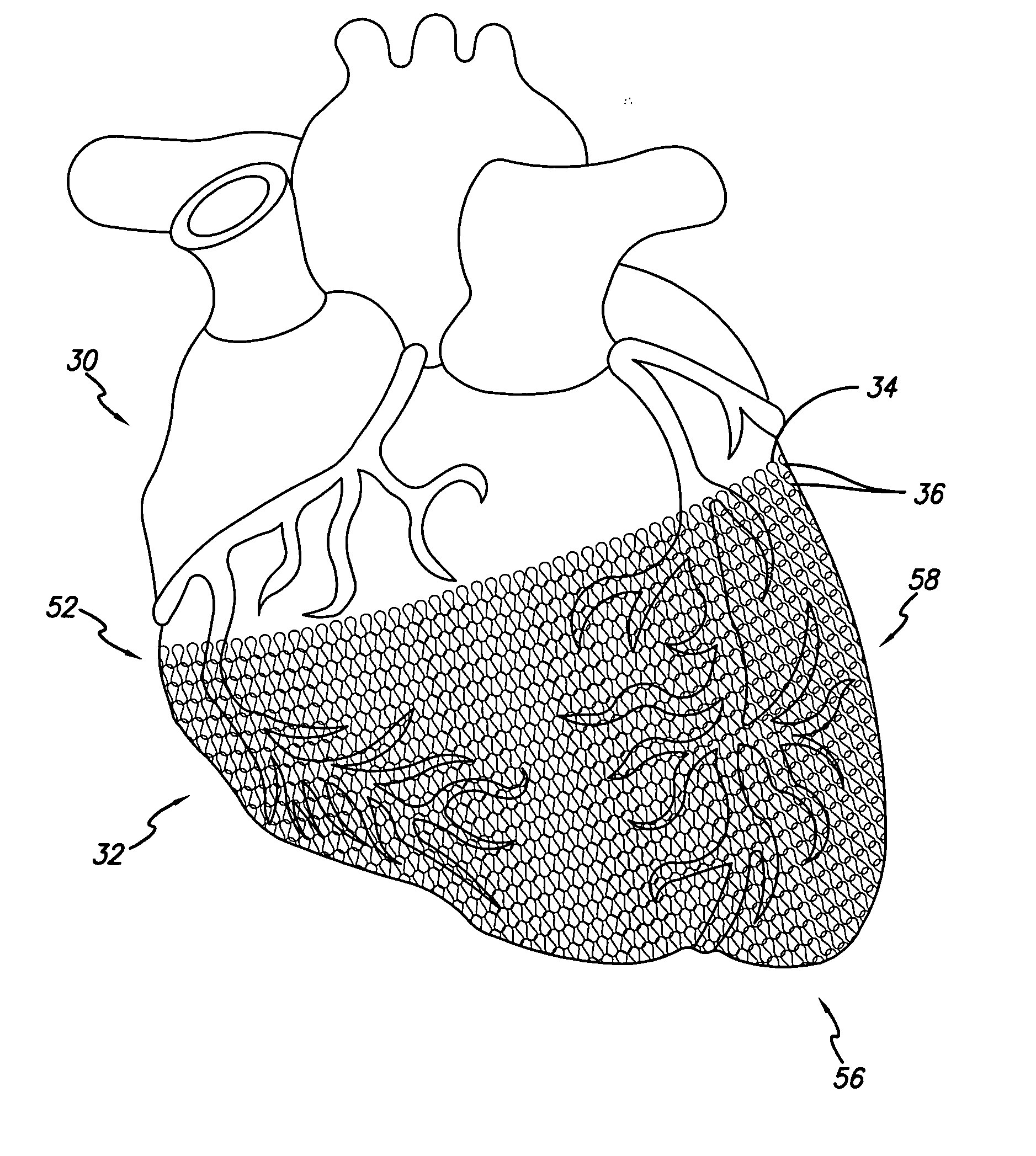

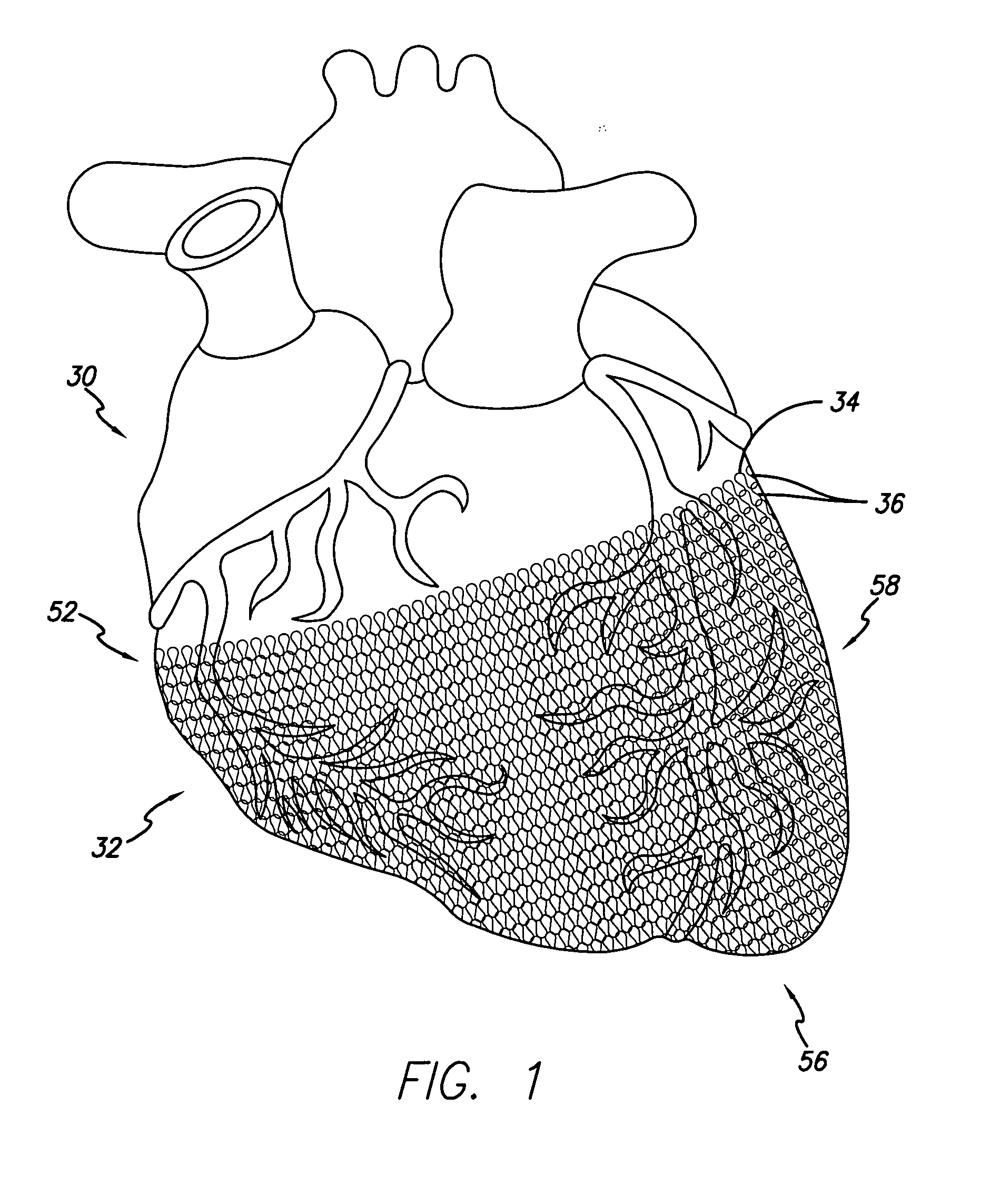

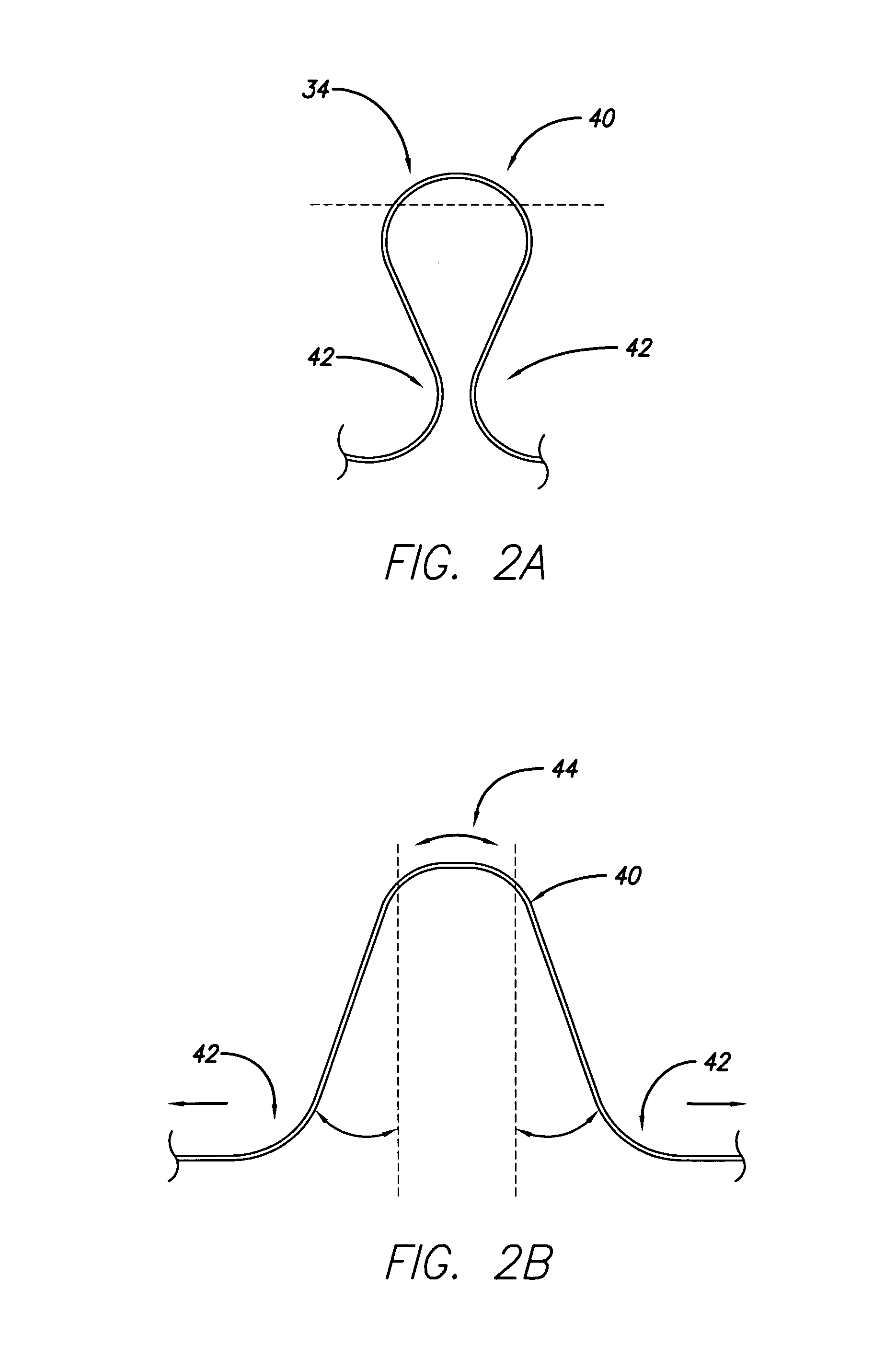

Apparatus and method of delivering biomaterial to the heart

InactiveUS20070100199A1Reduce apparent viscosityRelieve cardiac wall stressHeart valvesTissue regenerationCardiac cycleCardiac wall

A biomaterial for treating or preventing congestive heart failure is injected into the intrapericardial space of a patient's heart to apply a mild compressive force on the heart. A volume of biomaterial is placed in the intrapericardial space by an injection needle or catheter, adjacent at least the left ventricle, so that the biomaterial applies a compressive force on the myocardium to relieve cardiac wall tension during at least a portion of the cardiac cycle.

Owner:PARACOR MEDICAL

Amylose, polypeptide functional blueberry drink and production process

InactiveCN1620935AAbundant resourcesRaw materials are easy to getOrganic active ingredientsPeptide/protein ingredientsFood flavorPolysaccharide

The present invention discloses one kind of functional polysaccharide and polypeptide blue berry beverage. During preparing blue berry beverage, mycose, silk polypeptide powder and other nutritious reinforcing agent containing special function factor are added to make the beverage possess functions of preventing and treating diabetes, promoting intelligence growth, strengthening body's immunity, etc. The functional polysaccharide and polypeptide blue berry beverage is bluish, and has unique flavor.

Owner:辽宁省农业科学院食品与加工研究所

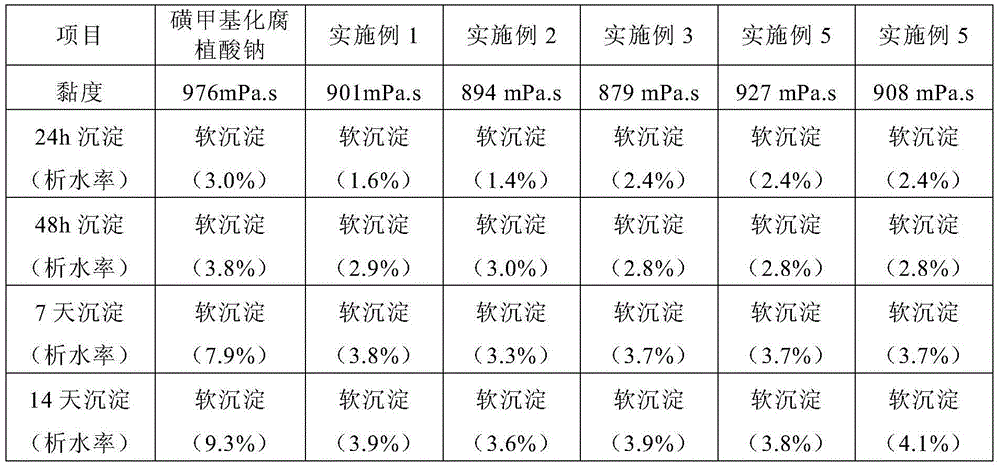

Amphoteric humate coal water slurry dispersant as well as preparation and application thereof

InactiveCN104152195APossesses both yin and yang characteristicsEvenly dispersedLiquid carbonaceous fuelsCoal waterCross linker

The invention discloses a preparation method of an amphoteric humate coal water slurry dispersant. The preparation method comprises the following steps: preparing sulfomethylated humic acid by reaction of humic acid, formaldehyde and a sulfonating agent; then further performing cationization reaction on sulfomethylated humic acid and a cationic etherifying agent and finally dropping a cross-linking agent to perform cross-linking reaction so as to obtain the novel amphoteric humate coal water slurry dispersant. The method for preparing the coal water slurry dispersant comprises three steps of sulfomethylation, cationization and cross-linking reaction, and anionic and cationic groups are introduced on a matrix of the humic acid, so that the relative molecular weight of the dispersant is also increased; by using the novel dispersant, the apparent viscosity of the coal water slurry can be effectively reduced and the stability of the coal water slurry can be also obviously improved.

Owner:SHAANXI UNIV OF SCI & TECH

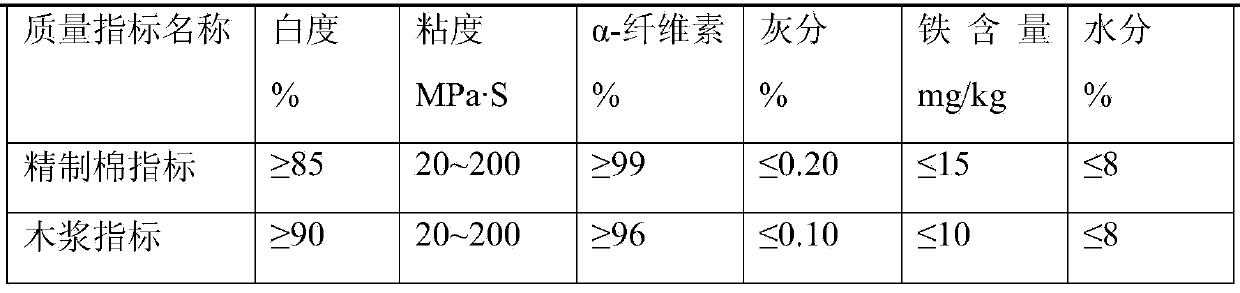

Production method of spherical cellulose acetate butyrate

The invention belongs to the technical field of organic acid ester cellulose preparation, in particular relates to a production method of spherical cellulose acetate butyrate, and solves the technical problem of low product yield. The production method comprises the following steps: a, treating velvet wood pulp or cellulose acetate grade refined cotton by acetic acid; b, mixing butyric anhydride, acetic anhydride and concentrated sulfuric acid, cooling to obtain cooled mixed liquid, adding the treated velvet wood pulp or cellulose acetate grade refined cotton into the cooled mixed liquid, and adding a solvent for acylation; c, adding hydrolysis liquid into acylation reaction liquid for hydrolysis, and neutralizing; d, precipitating, hardening, performing solid-liquid separation, washing, stewing, and drying to obtain a spherical cellulose acetate butyrate product. According to the method provided by the invention, the apparent viscosity of materials in reaction liquid can be effectively reduced, the mixing effect of the materials can be improved, the reaction performance of the materials can be improved, and the reaction yield of the materials can be increased.

Owner:SICHUAN NITROCELLULOSE CORP

Oil well plugging fluid

The invention provides an oil well plugging fluid. The oil well plugging fluid comprises, by weight parts, 10-20 parts of rigid leaking stoppage material, 20-35 parts of flexible leaking stoppage material, 1-5 parts of composite fiber material, 0.5-5 parts of strength regulator, 0.1-0.5 part of tackifier, 0.5-5 parts of surfactant and 45-55 parts of water. The oil well plugging fluid is simple in formula and small in viscosity, apparent viscosity is reduced to 35 mPa.s, the oil well plugging fluid is favorable for on-site preparation and construction, invasion of formation fluid can be effectively restrained; a very high strength can be achieved after injection of a leaking layer, heat resistance is high, and the pressure bearing capacity can reach 12 MPa when the oil well plugging fluid is at 150 DEG C. A loss problem of return loss type leaking well is solved, the one-time leaking stoppage can be improved, and the leakage rate is as low as 5%. A method for preparing the oil well plugging fluid is simple and convenient, and the oil well plugging fluid is suitable for large-scale industrial production.

Owner:JINGZHOU JIAHUA TECH

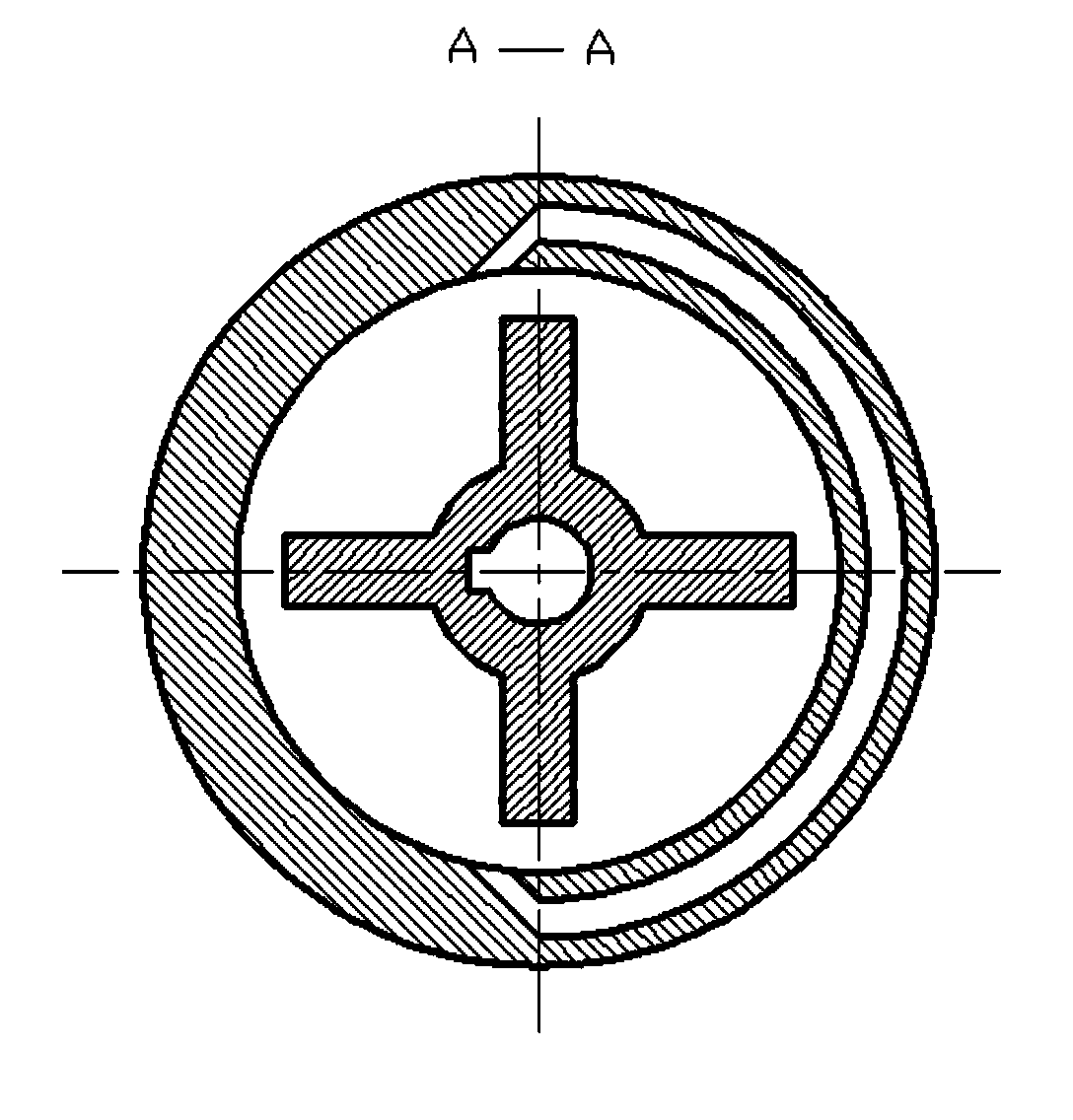

Seven-stage adjustable rotary type electrorheological fluid brake

InactiveCN103697090AIncrease structural flexibilityLarge braking forceLiquid resistance brakesBrake actuating mechanismsThrottle controlApparent viscosity

The invention provides a seven-stage adjustable rotary type electrorheological fluid brake. The seven-stage adjustable rotary type electrorheological fluid brake mainly comprises a positive pole conducting wire, a negative pole conducting wire, a bearing cap, a bearing, an end closure, conductive rubber, a half round key, a rotating shaft, an insulated shell, a positive pole, a negative pole, a backflow control channel, a small turntable, a middle turntable, a large turntable, electrorheological fluid and a flat key, wherein the installation type of the small turntable, the middle turntable and the large turntable is decided by suffered braking force, when the braking force is large, the stress is not clear and the rotating speed is high, the dual-turntable and three-turntable type is adopted; when the braking force is small, the single-turntable type is adopted; the backflow control channel is used for replacing a throttling control valve, an external electric field is not applied, and the electrorheological fluid is stressed, flows between the upper part and the lower part of the insulated shell through the backflow control channel and is a hydraulic brake; when the external electric field is applied and the high shear rate is adopted, the apparent viscosity of the electrorheological fluid of the backflow control channel changes, so that the sectional area of the electrorheological fluid becomes small till being completely closed; and the electrorheological fluid realizes the effective brake on an engineering system by providing shear force and extrusion force.

Owner:QINGDAO AGRI UNIV

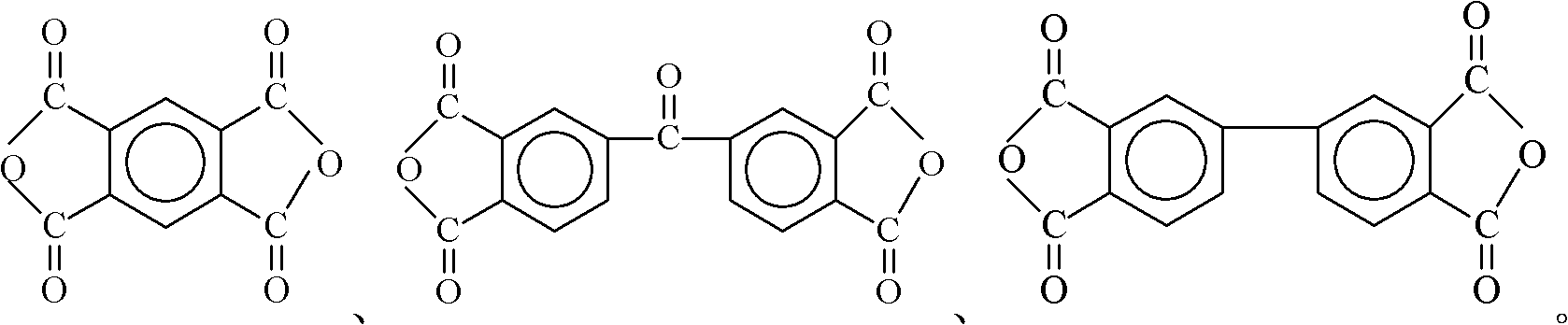

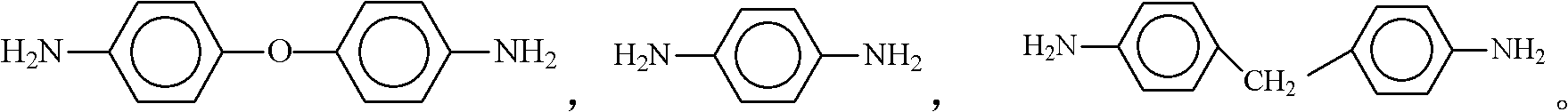

Method for improving spinnability and after processing characteristic of polyimide fiber

InactiveCN102242415ALow costImprove spinnabilityArtificial filament heat treatmentMonocomponent synthetic polymer artificial filamentFiberPolyamide

The invention relates to a method for improving spinnability and an after processing characteristic of a polyimide fiber. The method comprises the following steps: (1) adding a dianhydride monomer and two diamines monomers into a solvent, and forming a terpolymerization polyamide acids solution at a temperature of -5-20 DEG C; (2) adopting dry method spinning formation to carry out deaeration on the above polyamide acids solution in vacuum, entering a spinning channel through a spinning assembly, and carrying out winding shaping on the channel to obtain a polyamide acids fiber; (3) subjectingthe obtained polyamide acids fiber to a heat treatment and a heat stretching treatment. The method of the present invention has the characteristics of simple operation and low cost. The obtained polyimide fiber has good spinnability, good mechanical property, and soft handfeel of fiber. Maneuverability of the fiber in downstream product processing like braiding and nonwoven operations is improved. The polyimide fiber of the present invention can be widely applied to production of a composite material reinforcing fiber, a reinforcing core, a filtering material of high temperature substance, aninsulating material and the like.

Owner:DONGHUA UNIV

Coal gangue-based composite geopolymer grouting filling material and preparation method thereof

InactiveCN111018423AReduce bulk stackingWide variety of sourcesSolid waste managementCement productionSlagGeopolymer

The invention discloses a coal gangue-based composite geopolymer grouting filling material and a preparation method thereof. The preparation method comprises a step of weighing raw materials in partsby mass. According to the method, coal gangue powder and slag powder are used as main raw materials; a KOH solid and a water glass solution form an alkali solution; slag powder with good activation performance and ground coal gangue powder with insufficient activation performance are subjected to alkali-excited activation by adopting an alkali excitation technology, active glass bodies in the slagpowder and active components such as SiO2 and Al2O3 in the coal gangue powder are leached out in a strong alkali environment to form a grouting material with a gelling effect, and compared with a cement material, the grouting material is lower in manufacturing cost and wide in material source; meanwhile, comprehensive and effective utilization of coal gangue is improved, stacking of a large amount of coal gangue is reduced, and good environmental protection and social benefits are achieved. Compared with a cement grouting material, the grouting material prepared by the invention is lower in bleeding rate and higher in stone rate, has a rapid hardening effect, can reduce water damage caused by permeation of water into a roadbed in a non-setting stage of slurry, and effectively reduces airshrinkage and crack extension after slurry hardening.

Owner:CHANGAN UNIV +1

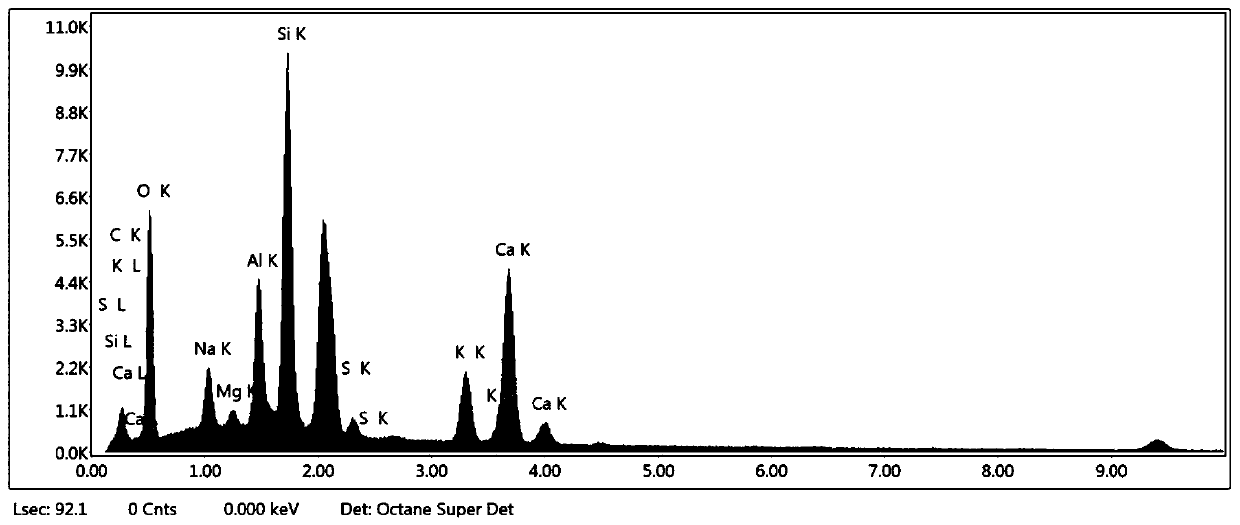

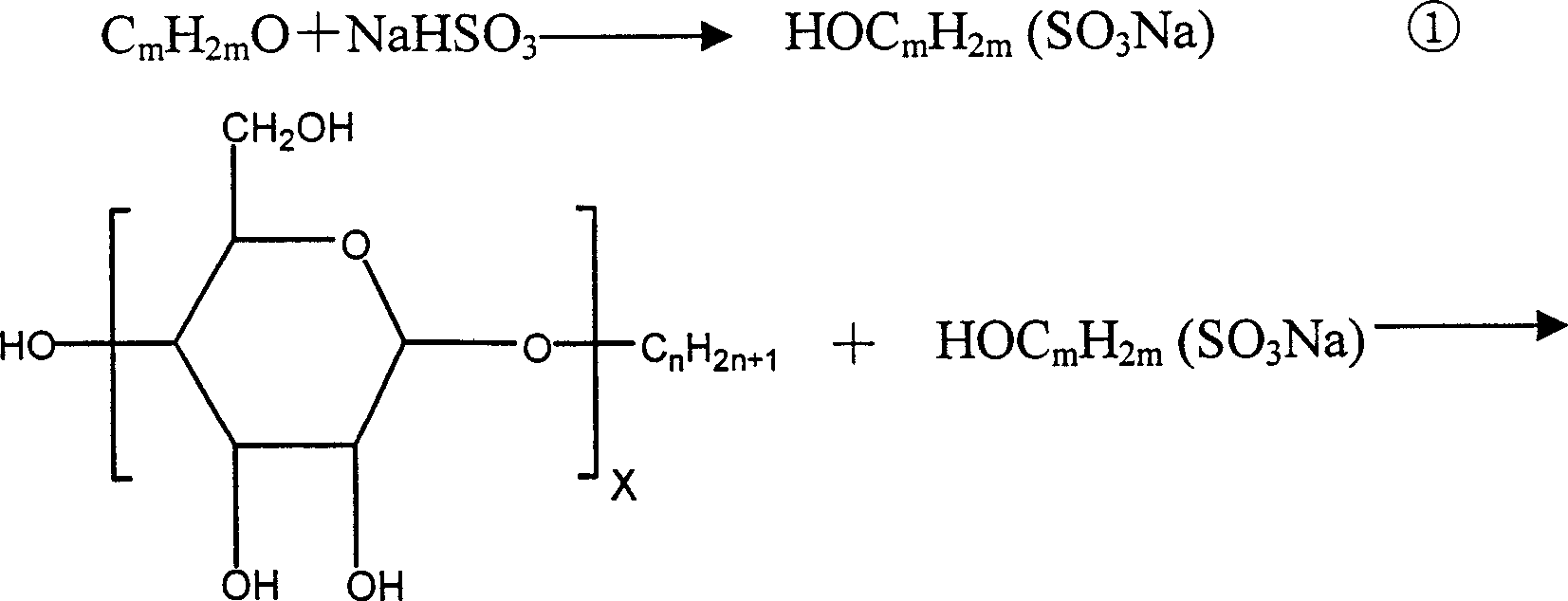

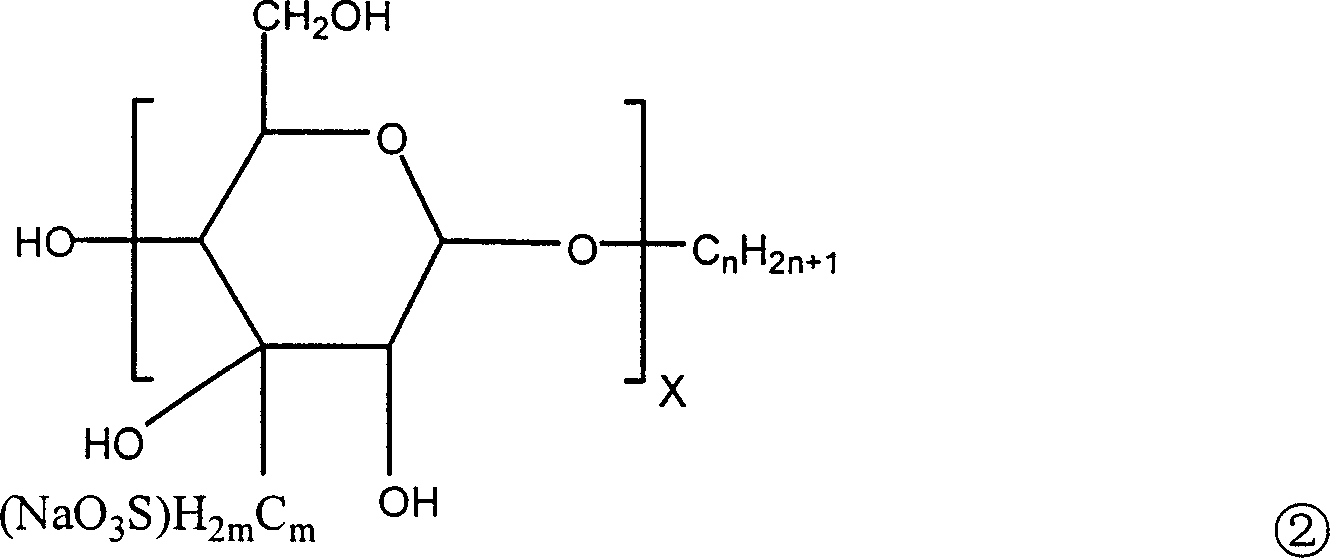

Low foamability drilling fluid and its preparation method

The invention relates to low-foamability drilling fluid as modified auxiliary agent composed of slurry and modified alkyl glycoside, wherein, the volume of modified auxiliary agent is 1-50% of slurry, and prepared by: mixing starch and low-carbon alcohol for glycosidation with catalyst to obtain material contained with low-carbon alkyl glycoside; adding sulphonating agent and aldehyde for further reaction at (50-100)+ / -5Deg to obtain the final product. The product has better adsorption, action ability with bentonite, and viscosity reduction ability, and fits to middle-deep well or ultradeep well.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method of preparing polymer / inorganic nanometer particle compesite

A process for preparing the polymer / inorganic nanoparticles composite includes such steps as proportionally mixing polymer with inorganic nanoparticles, loading the mixture in an extruder, fusing while plasticizing at 150-240 deg.C, and extruding out while ultrasonic radiation to improve its mechanical performance.

Owner:SICHUAN UNIV

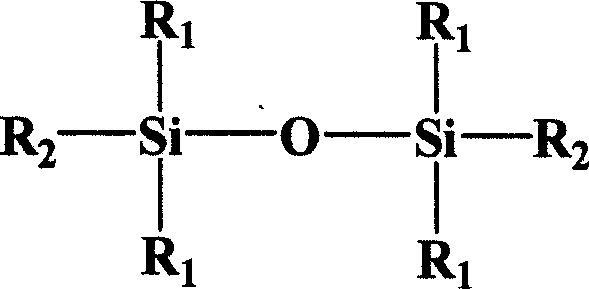

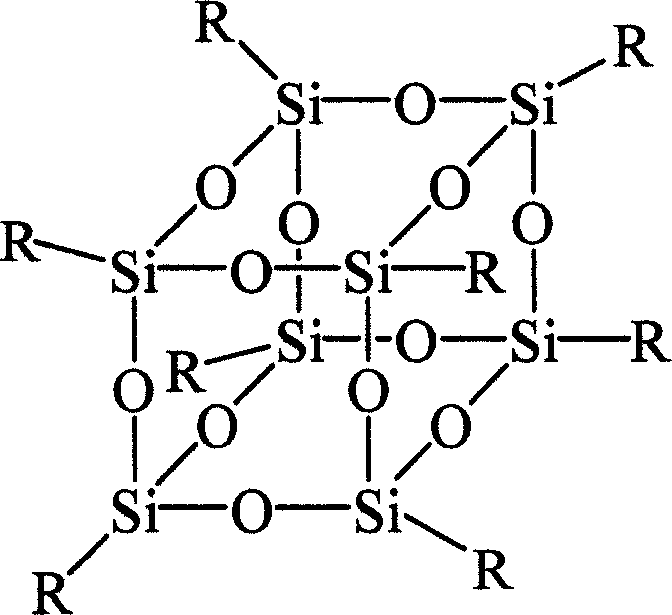

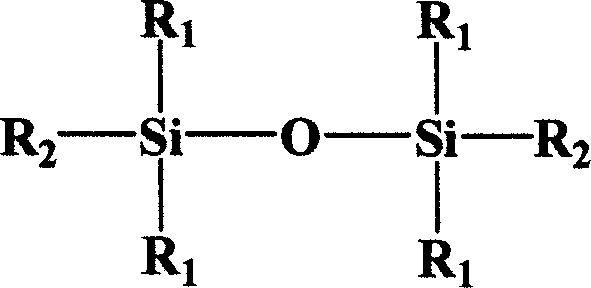

Method of preparing star-type multi-arm silicon oil

InactiveCN101016384AMolecular weight controllableReduce apparent viscosityApparent viscosityMethylamines

The invention discloses a preparing method of star type multi-armed silicon oil, which comprises the following steps: allocating 0.01-50.90% oxygenate four methylamine group cage model eight poly double half siloxane,16.90-99.99% ring type siloxane low-molecular polymer and 0-65.50% terminated agent with mass percent; controlling temperature at 20-130 deg.c; stirring under protection of air and inert gas; reacting at 10 min-48 h; rising temperature to 135-200 deg.c; disintegrating and removing oxygenate four methylamine group; getting end product.

Owner:NANJING UNIV

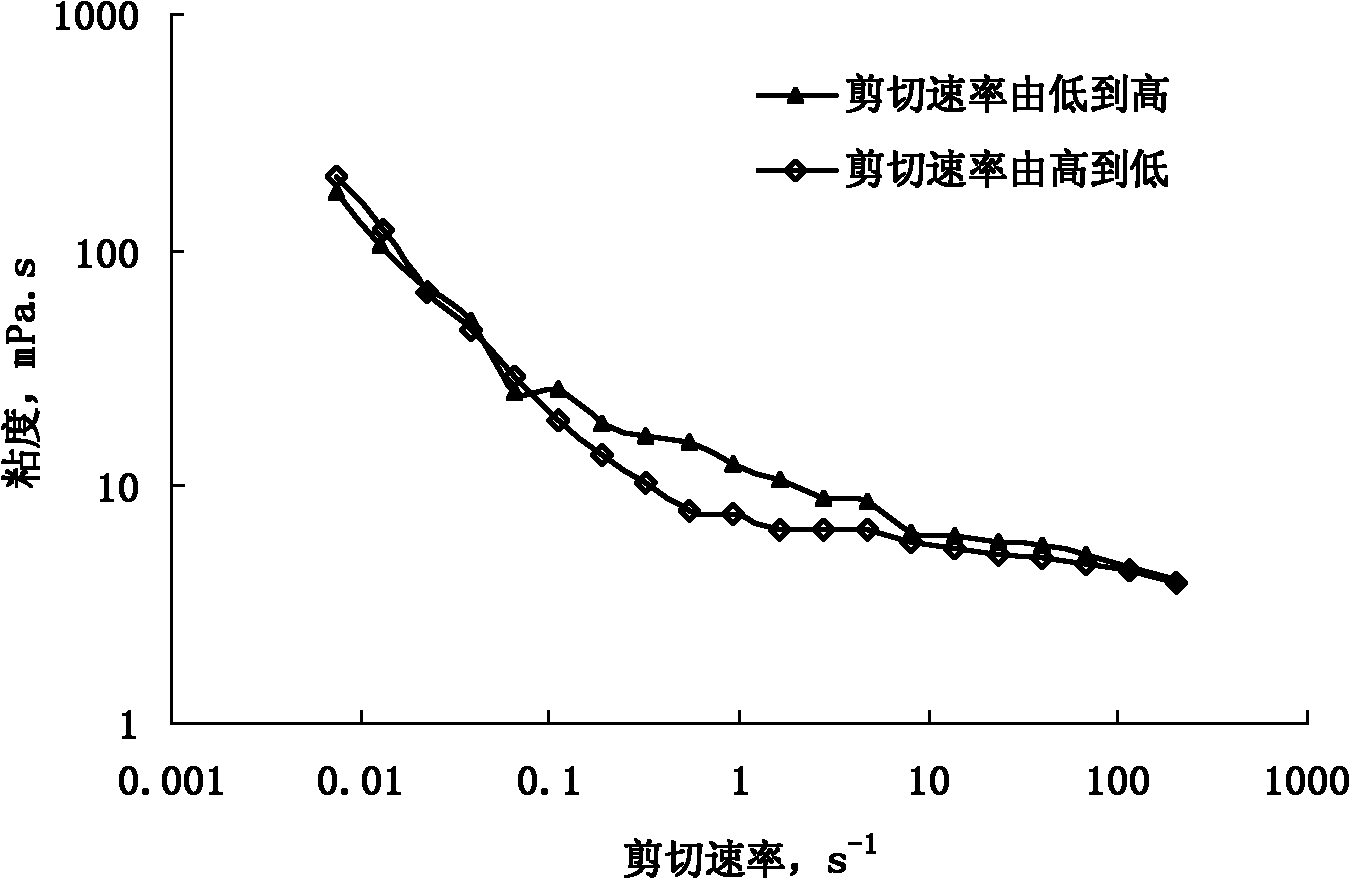

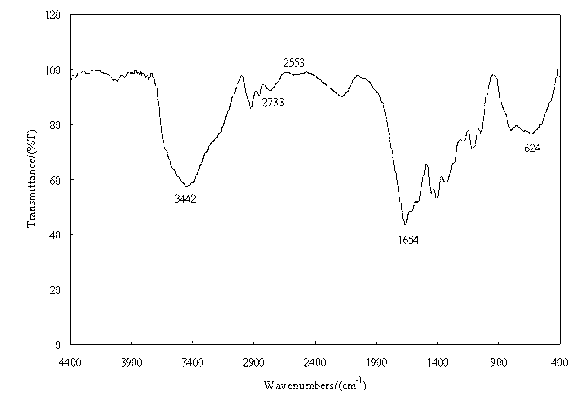

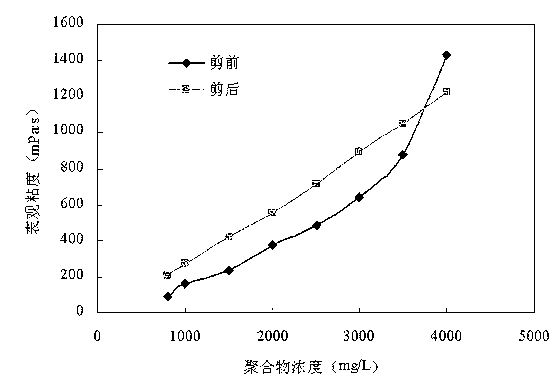

Novel anti-shearing branch polymer oil displacement agent and synthetic method thereof

InactiveCN103320112AHigh apparent viscosityExhibits lower apparent viscosity under high shear conditionsDrilling compositionPolymer sciencePolymer solution

The invention discloses a novel anti-shearing branch polymer oil displacement agent and a synthetic method thereof. According to the technical scheme, the following raw materials and monomers in mass percent are used: 73.5-84.95% of acrylamide (AM), 15-25% of sodium acrylate NaAA and 0.05-1.5% of polyamidoamine modified branch skeleton GA taking 1,3-propane diamine as a core. The synthetic method of the novel anti-shearing branch polymer oil displacement agent comprises the following steps of: adding NaAA into a reactor, adding pure water, regulating pH to be 6.5-7.5 with NaOH, stirring and adding AM and GA, preparing a solution with the concentration of 15-30%, introducing nitrogen for 20 minutes, then adding an initiating agent, continuously introducing the nitrogen for 10-20 minutes, and reacting for 3-10 hours at 30-60 DEG C; and finally washing, smashing and drying, thus an AM / NaAA / GA ternary polymer is obtained. The novel anti-shearing branch polymer oil displacement agent shows good shearing dilutability, the problem of injection of medium and low permeation oil reservoirs can be better solved, under lower shearing action, viscosity of the polymer can be rapidly restored, good fluidity control ability and aqueous phase permeability reducing capacity are realized, capacity of a polymer solution for expanding swept volume is improved, and simulated crude oil recovery ratio can be effectively increased by about 12.3%.

Owner:SOUTHWEST PETROLEUM UNIV

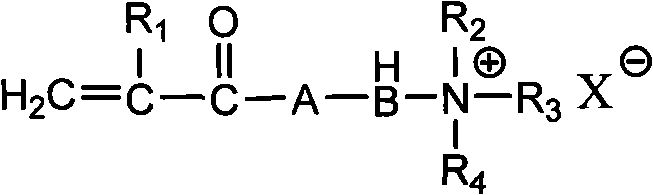

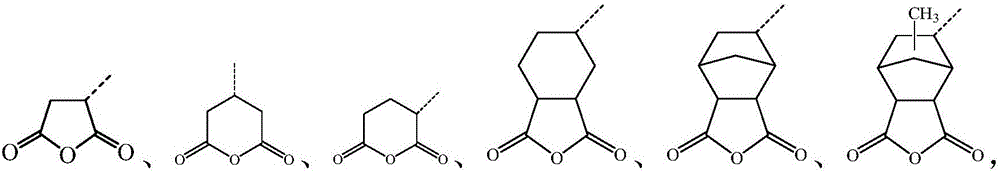

Diblock copolymer suitable for reducing viscosity of oil-based drilling fluid as well as preparation method and application thereof, and oil-based drilling fluid and application thereof

ActiveCN106220797AReduce apparent viscosityReduce drilling difficultyDrilling compositionApparent viscosityStructural unit

The invention relates to the well drilling field of petroleum industry, and concretely relates to a diblock copolymer suitable for reducing viscosity of oil-based drilling fluid as well as a preparation method and an application thereof, and oil-based drilling fluid and an application thereof. The diblock copolymer mainly comprises a block A and a block B, wherein the block A comprises a structural unit which is selected and shown in a formula (1), the block B comprises a structural unit which is selected and shown in the formula (2), and number-average molecular weight of the block A is 1500-10000. The diblock copolymer can be used as a viscosity reducer for oil-based drilling fluid, and especially can be used as a viscosity reducer which is applied to clay free phase oil-based drilling fluid with high density; in a stratum with high temperature and high pressure, a proper shearing force is guaranteed, apparent viscosity and plastic viscosity of the oil-based drilling fluid can be greatly reduced, in order to accelerate drilling speed and reduce well drilling difficulty.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com