Method of preparing polymer / inorganic nanometer particle compesite

A technology of inorganic nanoparticles and composite materials, which is applied in the field of preparation of polymer-based nanocomposites to achieve the effect of improving surface morphology, low production cost, and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

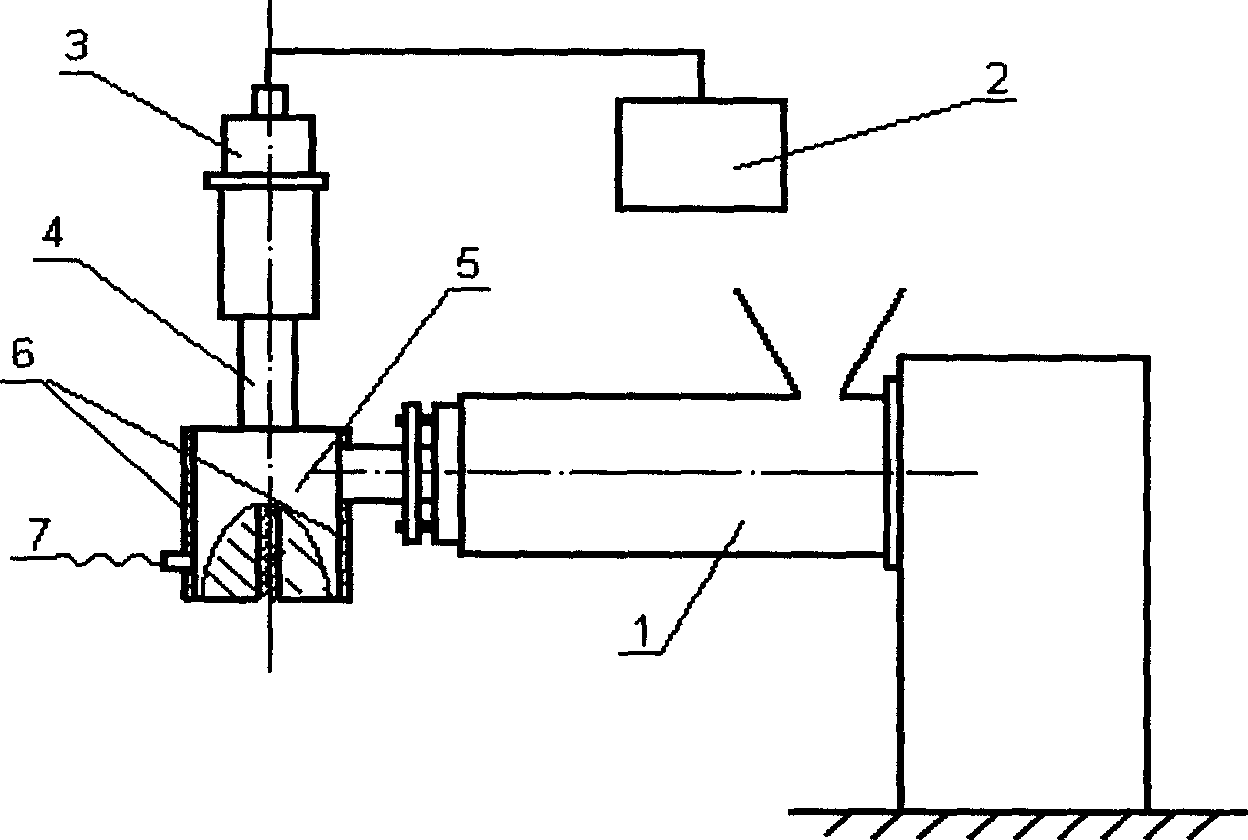

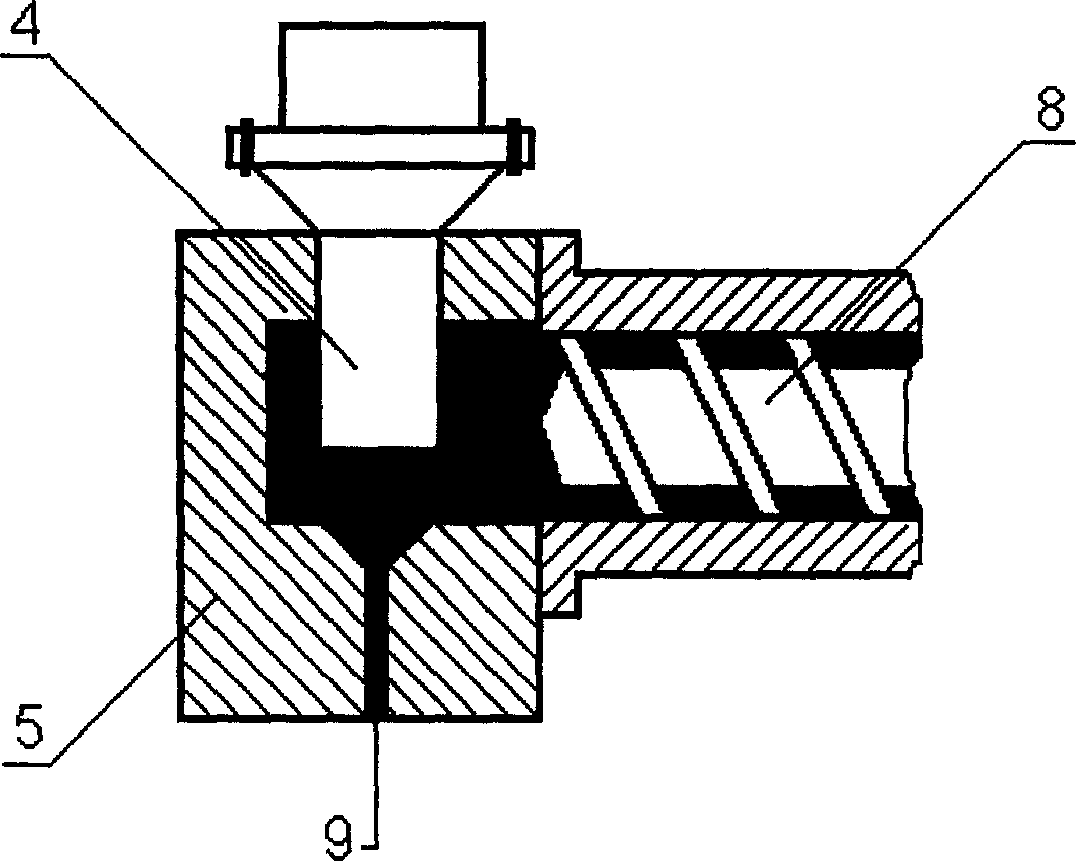

Method used

Image

Examples

Embodiment 1

[0038] Control the processing temperature of each section of the extruder to be 185 ° C, 195 ° C respectively, and the die temperature is 195 ° C. The raw materials are polypropylene (PP) and montmorillonite, and the content of montmorillonite is 3%, and the balance is polypropylene ( PP). After the PP and montmorillonite are dried, they are melt-mixed in an extruder and then granulated. The extruder rotates at 16 rpm. The blended pellets are extruded once through the extruder, and the extruder speed is 16rmp. At the same time, the ultrasonic irradiation with a power of 40W and a frequency of 20KHz is applied to the melt at the head and die of the extruder; Changes brought about by irradiation, prepare contrast samples that are not affected by ultrasound. The experimental results show that after ultrasonic irradiation, the modulus, elongation at break, and yield strength of the extrudate increase from 776MPa, 21.6%, and 22MPa to 1063MPa, 57.9%, and 22.9MPa, respectively, and th...

Embodiment 2

[0040] The processing temperature of each section of the extruder is controlled to be 185°C and 195°C respectively, and the die temperature is 195°C. The raw materials are polypropylene (PP), compatibilizer and montmorillonite. The content of montmorillonite is 3%, compatible The ratio of agent to montmorillonite is 3:1, and the balance is PP. After drying PP, compatibilizer (the compatibilizer is polypropylene grafted maleic anhydride) and montmorillonite, firstly knead the compatibilizer and montmorillonite in an internal mixer, and then extrude with PP after the pellets are obtained. After being melted and mixed in the extruder, it is granulated, and the rotation speed of the extruder is 16rmp. The blended pellets are extruded once through the extruder, the extruder speed is 16rmp, and at the same time, the ultrasonic irradiation with a power of 100W and a frequency of 20KHz is applied to the melt at the head and die of the extruder; Changes brought about by irradiation, p...

Embodiment 3

[0042] The processing temperature of each section of the extruder is controlled to be 185°C and 195°C respectively, the die temperature is 195°C, the raw material is PP, a compatibilizer (the compatibilizer is polypropylene grafted maleic anhydride) and montmorillonite, montmorillonite The content of exfoliated clay is 5%, the ratio of compatibilizer to montmorillonite is 2:1, and the balance is PP. After PP, compatibilizer and montmorillonite are dried, first knead the compatibilizer and montmorillonite in an internal mixer to obtain pellets, then melt and mix them with PP in an extruder, and then granulate. It is 16rmp. The blended pellets are extruded once through the extruder, the extruder speed is 16rmp, and at the same time, the ultrasonic irradiation with a power of 100W and a frequency of 20KHz is applied to the melt at the head and die of the extruder; Changes brought about by irradiation, prepare contrast samples that are not affected by ultrasound. The experimenta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com