Diblock copolymer suitable for reducing viscosity of oil-based drilling fluid as well as preparation method and application thereof, and oil-based drilling fluid and application thereof

A double-block copolymer and copolymerization technology, applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve the problem of unsatisfactory temperature resistance of high-density oil-based drilling fluids, reduce drilling difficulty and save drilling Cost, the effect of increasing the drilling speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The present invention also provides a kind of preparation method of diblock copolymer, this method comprises:

[0036] (1) In the presence of a chain transfer agent and the first azo initiator, in the first organic solvent, the compound represented by the formula (1') is prepared and polymerized to obtain a polymer with a number average molecular weight of 2000-10000 A; (2) in the presence of the second azo initiator, in the second organic solvent, polymer A and the compound shown in formula (2') are carried out copolymerization reaction;

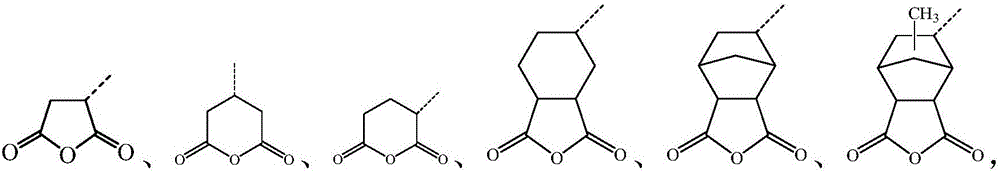

[0037] Formula 1') Formula (2')

[0038] Among them, R 1 , R 1' , R 4 , R 4' and R 6 each independently selected from H and C1-C6 alkyl; R 2 and R 2' each independently selected from H, C1-C6 alkyl, -O-C(O)-R 3 and-COOR 3 , and R 2 and R 2' At least one of -O-C(O)-R 3 or-COOR 3 ,R 3 Alkyl selected from C1-C6; R 5 selected from C1-C8 alkylene; X selected from -NH- or -O-; X' selected from halogen. In the present in...

preparation example 1

[0113] (1) The molar ratio of the reactants tetraethylenepentamine: linoleic acid=1:2.2 (that is, the molar ratio of the amount of tetraethylenepentamine in terms of primary amine groups to the amount of linoleic acid is 1:1.1) Mix and stir at 250r / min for 40min, then adjust the pH value of the resulting mixture to 9, then react at 230°C for 3 hours, while using a water separator to separate water, and then cool to room temperature; (2) the step The reaction product of (1) is mixed with malonic acid (the molar ratio of the amount of tetraethylenepentamine to the amount of malonic acid is 1:0.6), and then the pH value of the resulting mixture is adjusted to 8, followed by heating at 90° C. , and stirred at a speed of 400r / min for 6h to obtain emulsifier A1. According to infrared, hydrogen nuclear magnetic resonance and carbon spectrum analysis, the emulsifier A1 contains amide groups, unsaturated double bonds and carboxyl groups, and has a comb structure.

[0114] Cutting agen...

Embodiment 1

[0117] This example is used to illustrate the diblock copolymer of the present invention and its preparation method.

[0118] (1) Dissolve 12g (120mmol) of methyl methacrylate and 1.27g (3.49mmol) of chain transfer agent 2-(dodecyltrithiocarbonate)-2-methylpropionic acid (DMP) in 25mL In benzene, and pass into nitrogen 60min, then add initiator azobisisobutyronitrile 0.27g (1.65mmol) and react 4h at 60 ℃, underpressure distillation removes solvent and unreacted monomer, obtains 11.4g viscous liquid PMMA- 1. Its number average molecular weight was 3800, and its molecular weight distribution index was 1.2.

[0119] (2) Dissolve 23.4g (100mmol) of (3-acrylamidopropyl) trimethylammonium chloride and 11.4g of PMMA-1 in DMF of 70mL, and feed nitrogen gas for 60min, then add initiator azobis 0.08 g (0.49 mmol) of isobutyronitrile was reacted at 100° C. for 24 h, and cooled to room temperature (about 25° C.) to terminate the polymerization. The crude product was precipitated in anh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Flash point | aaaaa | aaaaa |

| Kinematic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com