Patents

Literature

86results about How to "Reduce drilling difficulty" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

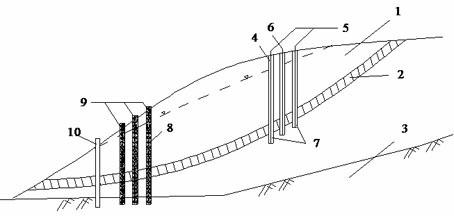

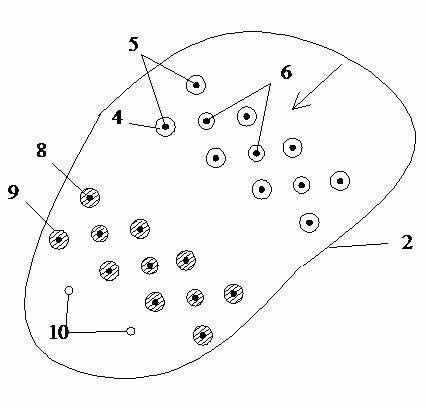

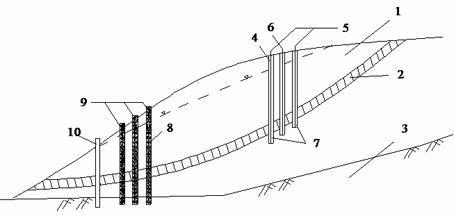

Method for treating landslide projects through combining chemical electroosmosis method with micro anti-slide piles

InactiveCN102322067AIncreased shear strength factorReduce processing costsClimate change adaptationExcavationsMetallic electrodeChemical solution

The invention relates to a method for treating landslide projects through combining a chemical electroosmosis method with micro anti-slide piles. The method comprises the following steps of: arranging metal electrodes and pouring different chemical solutions in boreholes and forming electroosmosis and chemical reaction under the action of a direct current field so as to enhance the shear strengthof potential failure surfaces of sliding zones; and then casting concrete in the boreholes and forming a micro reinforced concrete anti-slide pile system so as to provide a slide-resisting force. Themethod for treating the landslide projects through combining the chemical electroosmosis method with the micro anti-slide piles has the advantages and effects that: through carrying out electroosmosis reinforcement on the soft soil layers of potential landslide zones by using the chemical electroosmosis method, the coefficient of the shear strength of the potential landslide zones is remarkably increased, and the processing cost for the anti-slide piles or other treatment methods is effectively reduced; the bore diameter of the boreholes required by the micro anti-slide piles is small and themicro anti-slide piles are formed in identical boreholes to those for the chemical electroosmosis method through sequentially constructing, thus the difficulty and the cost for boring are low; and the shear strength and the slide-resisting force for landslide sliding zones are effectively enhanced. The method provided by the invention has the characteristics of simple construction technology, strong operability, convenience for quality control, obvious economic benefit and remarkable effect for treating landslides.

Owner:HOHAI UNIV

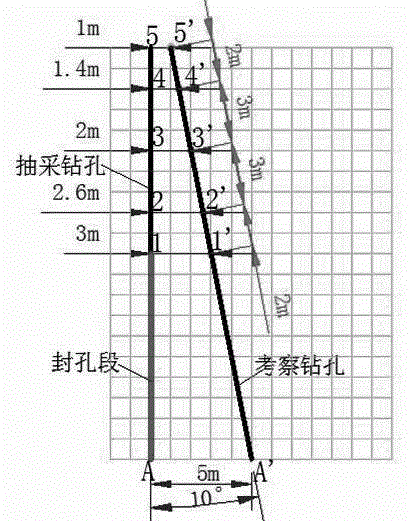

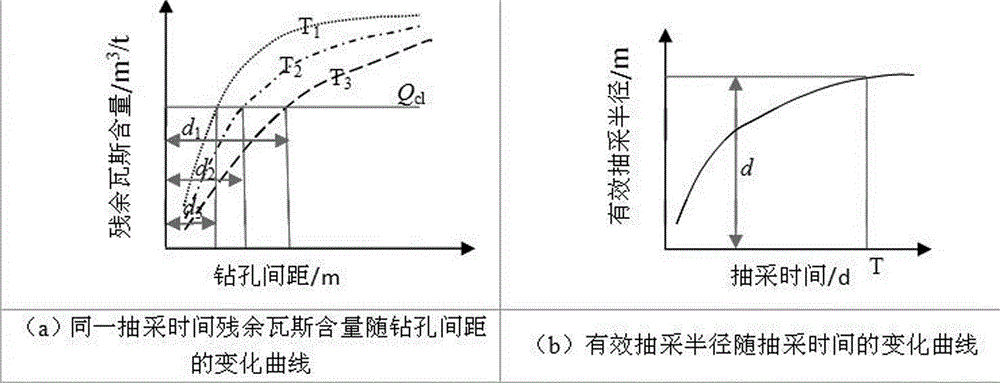

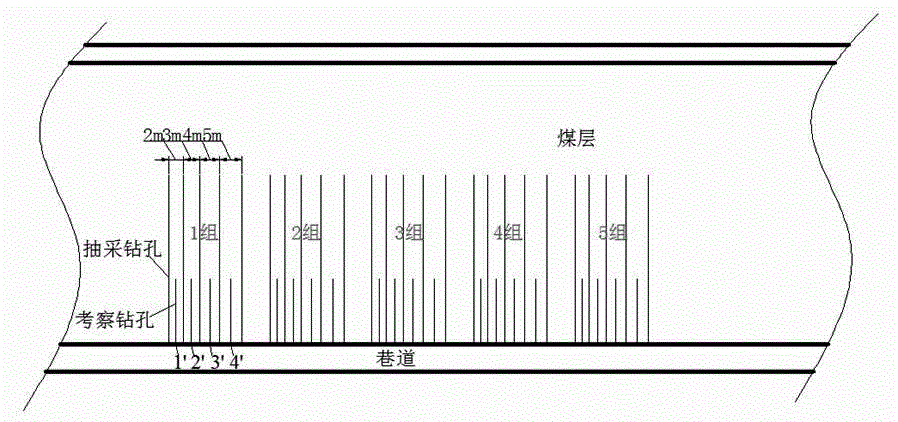

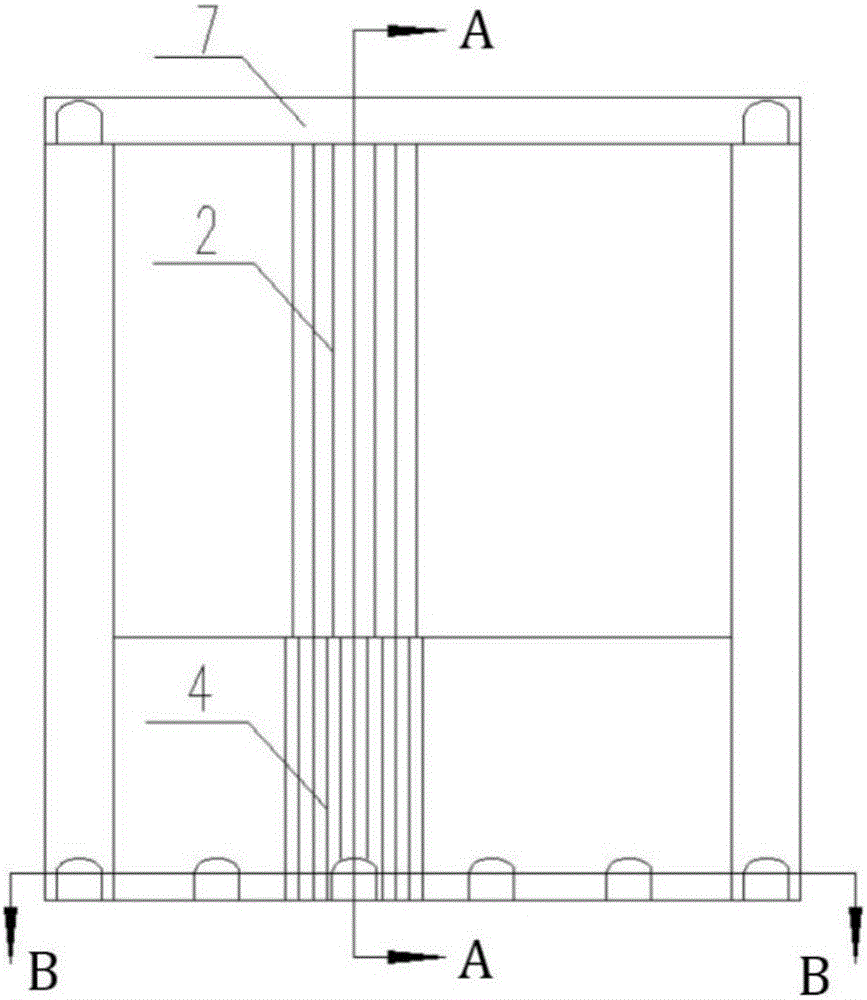

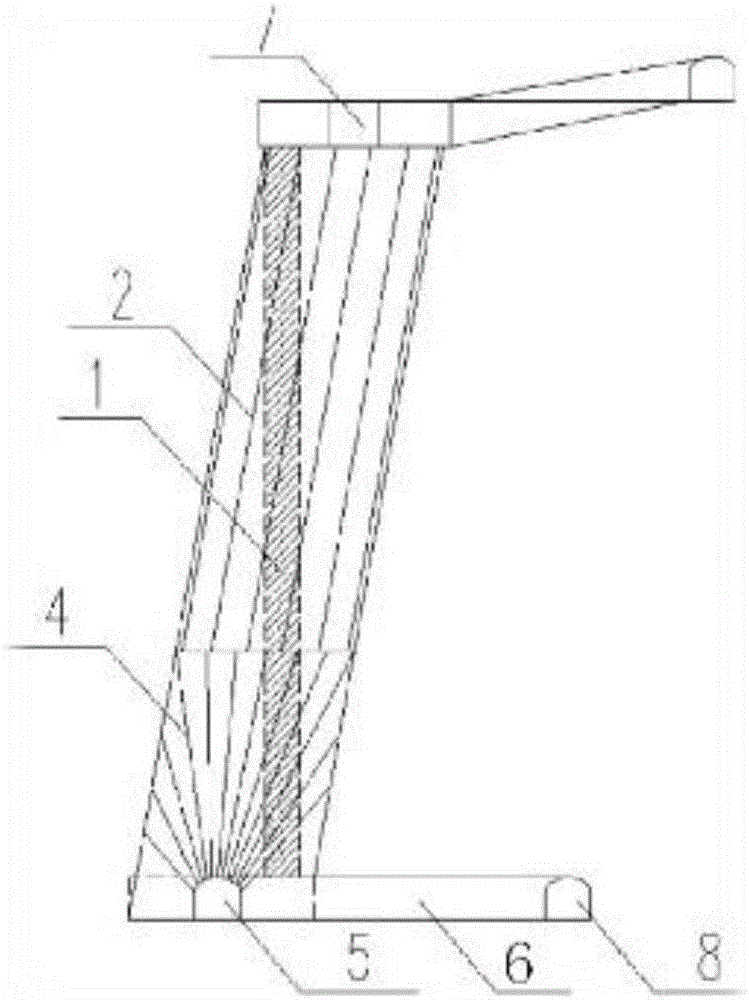

Measurement method of effective extracting radius of bedding boreholes based on content of residual gas

The invention relates to a measurement method of effective extracting radius of bedding boreholes based on the content of residual gas. The measurement method comprises a stepped measurement method of the content of residual gas and a grouping measurement method of the content of residual gas. The measurement method comprises the following steps: selecting districts which are simple in structure and stable in coal seam occurrence at districts to be pumped, and drilling holes; performing broaching and drilling on sampled drill holes so as to conform to stands of conventional bedding drill holes to be pumped; performing hole sealing and tube connecting extraction on drill holes to be pumped, continuously measuring extraction parameters, and after stable extraction is performed for 30 days, measuring the content of residual gas after extraction; repeating steps, measuring n groups of the content of residual gas; obtaining measurement results according to statistics, drawing a curve of results, and confirming the effective extracting radius. Through the adoption of the measurement method disclosed by the invention, the drilling difficulties are reduced, and the errors of measurement results are reduced, so that the measurement method is favorable for safety production of coal mines.

Owner:HENAN POLYTECHNIC UNIV

Full-staged combination drilling with blasting mining method

InactiveCN106761757AIncrease production capacityMaximum drilling efficiencyUnderground miningSurface miningEngineeringDeep hole

The invention discloses a full-staged combination drilling with blasting mining method. A stage haulage roadway, an ore drawing access road and a cutting undercut roadway are arranged at the bottom of a room. The ore drawing access road serves as a haulage channel of caved ores in the whole stage. The undercutting roadway serves as a construction space of a fan-shaped medium-depth hole on the lower portion, the fan-shaped medium-depth hole is drilled upwards, and after blasting, trench undercut is formed. A cut raise is formed through one-time blasting of a large-diameter deep hole, and then a cut groove is formed through the cut raise to serve as an ore caving compensation space. A drilling chamber or a roadway which communicates with a transverse drift is formed on the top of the room to serve as a construction space of the large-diameter deep hole on the upper portion. The large-diameter deep hole and the fan-shaped medium-depth hole at the lower portion are combined for drilling. After the large-diameter deep hole and the fan-shaped medium-depth hole drilling is finished, the cutting groove serves as a free face and combined, or separate charging is conducted to blast for lateral caving. The mining and cutting engineering quantity is small, the preparation time of stoping is reduced greatly, the production capacity of the room is large, and the investment cost is saved.

Owner:JIANGXI UNIV OF SCI & TECH +3

Laser rock breaking method and device applied to drilling

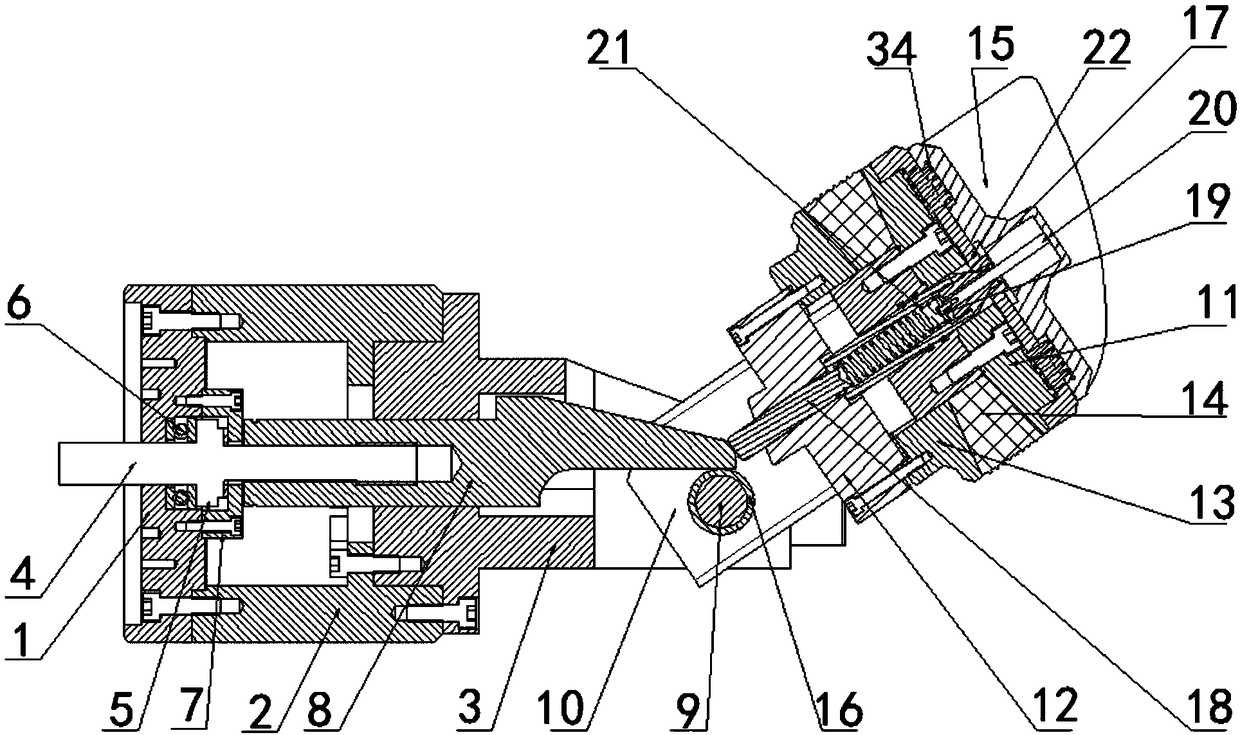

ActiveCN106837176AReduce secondary solidificationNo frequent replacementConstructionsThermal drillingLaser transmitterAtomizer nozzle

The invention relates to a laser rock breaking method and device applied to drilling. The device comprises a chip removing mechanism, an external drilling rod and an internal drilling rod, wherein the chip removing mechanism comprises a power supply, an electric wire, an air compressor, a sucker, a compression-resistance pipeline and a suction pump; a liquid nitrogen storage tank and an atomizing nozzle are arranged on the external drilling rod, a liquid nitrogen channel, an electric wire, a protection layer and a gas circulating area are arranged in the external drilling rod, and the external drilling rod does not rotate; the internal drilling rod comprises a down-hole motor, a down-hold power supply, a laser transmitter, a fiber-optical cable, a conical optical splitter, laser heads, a drilling head, laser holes and a temperature sensor; laser emitted by the laser transmitter can be transmitted by the fiber-optical cable, the fiber-optical cable is divided into four parts in the conical optical splitter, each divided fiber-optical cable is connected with one laser head, and laser can be transmitted out of the laser heads and shot out of the laser holes to heat and break rock. The laser rock breaking device disclosed by the invention has high work efficiency, reduces drilling difficulty and saves drilling cost.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

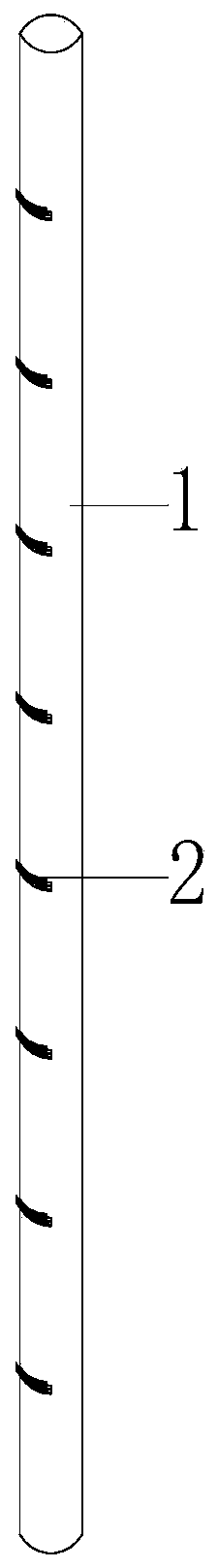

Self-drilling type spiral anchor rod and construction process using self-drilling type spiral anchor rod for grouting along with drilling, stirring and curing

InactiveCN102587366AGood effectImprove construction safetyExcavationsBulkheads/pilesHelical bladeEngineering

The invention discloses a self-drilling type spiral anchor rod and a construction process using the self-drilling type spiral anchor rod for grouting along with drilling, stirring and curing, which are suitable for support engineering of anchor-pulling slopes in weak soil regions. A paste outlet is arranged on a rod body of the spiral anchor rod, the front end of the rod body of the anchor rod is enclosed, a spiral vane is welded at the front end of the rod body of the anchor rod, and a stirring slice is welded behind the spiral vane on the rod body of the anchor rod. The construction process using the self-drilling type spiral anchor rod for grouting along with drilling, stirring and curing comprises the following steps of: injecting cement paste while drilling by rod body of the anchor rod, so that a paste body of the cement paste is ejected out of the paste outlet of the rod body of the anchor rod, mixing the paste body and a soil body cut by using the spiral vane on the front end, uniformly stirring the soil body and the cement paste by using the stirring slice arranged behind the spiral vane, forming an irregular anchor body after curing so that the anchoring force of the anchor rod is increased. Because the drilling and the grouting are integrated, the pressure influence of subsequent grouting on the side wall of a foundation pit is avoided; and meanwhile, the grouting pressure can be effectively controlled so that the grouting quality can be ensured.

Owner:中石化胜利建设工程有限公司

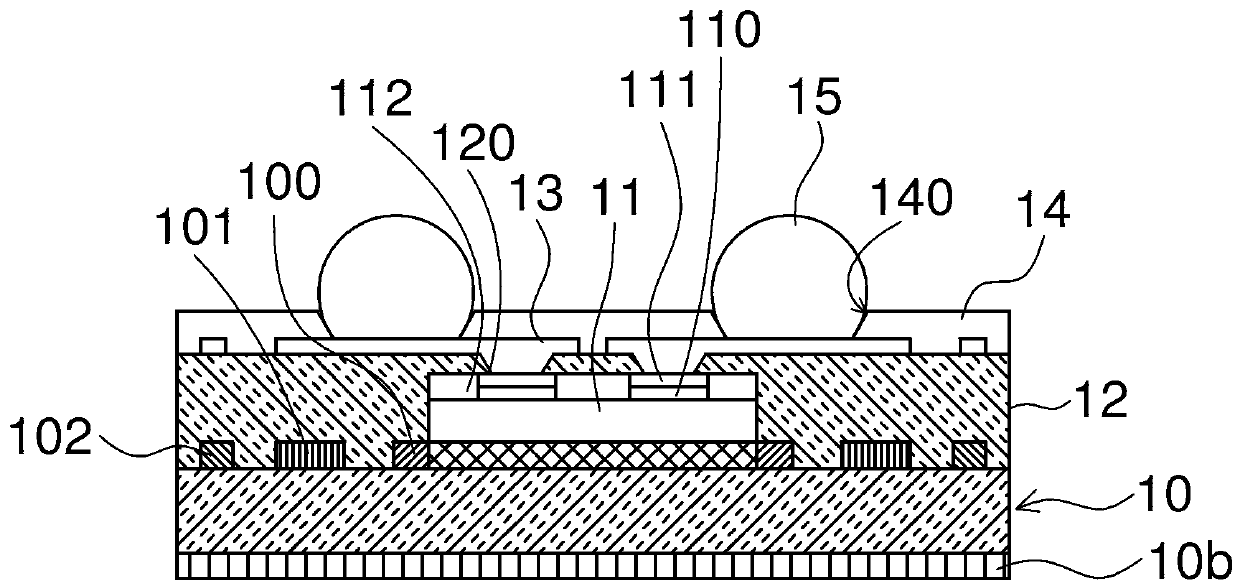

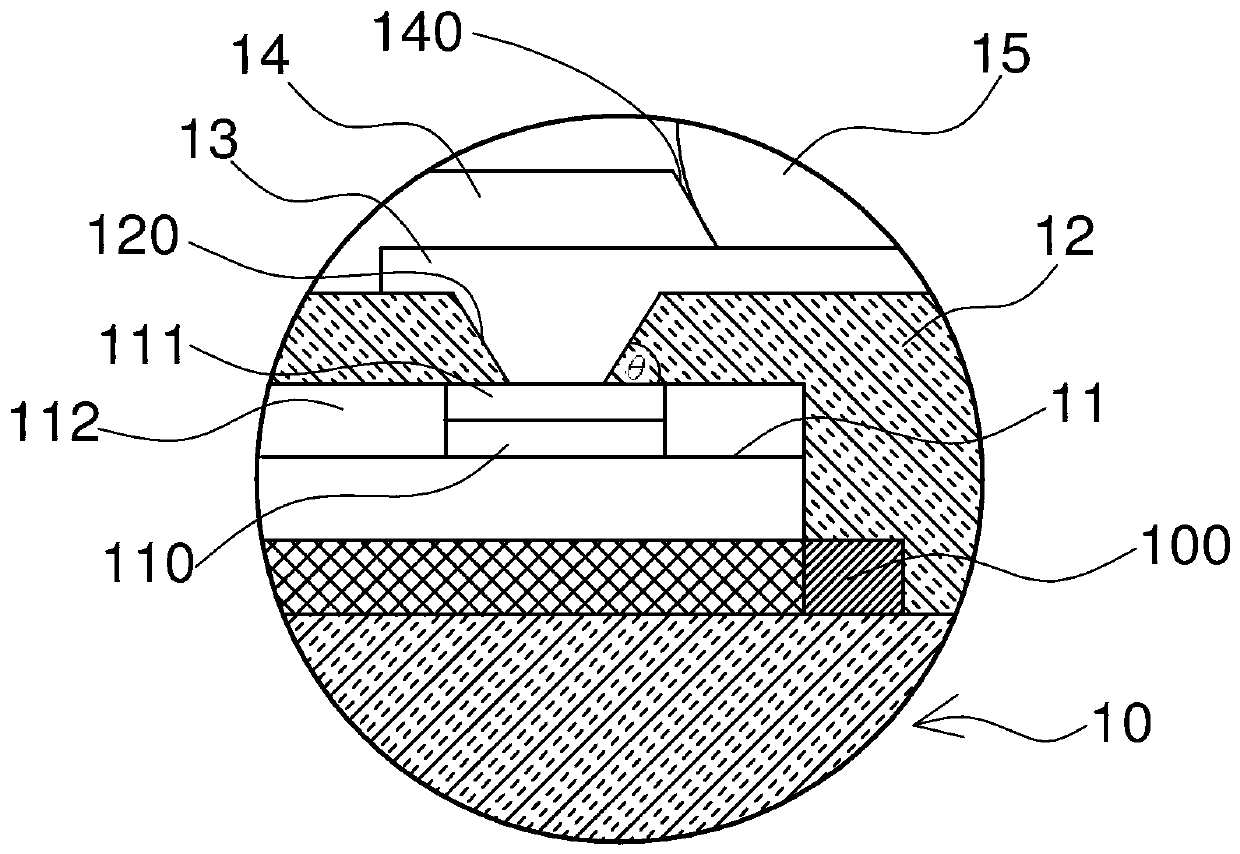

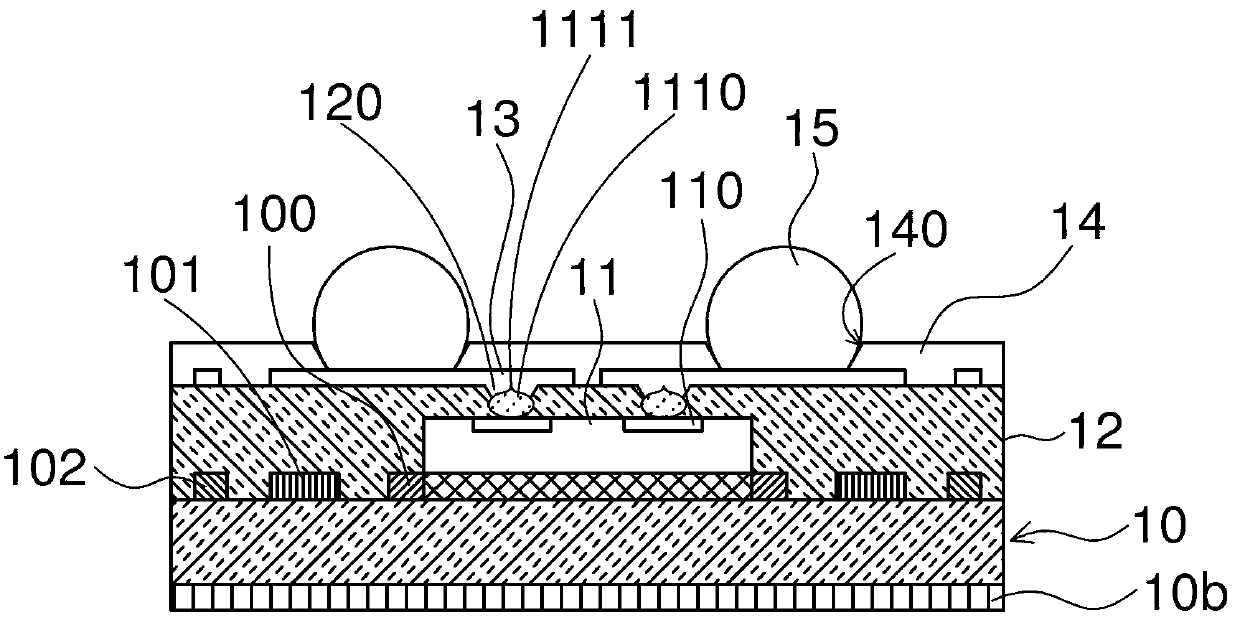

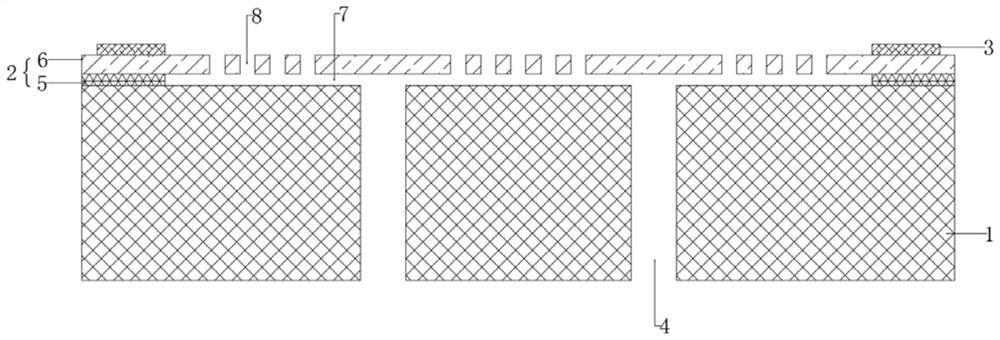

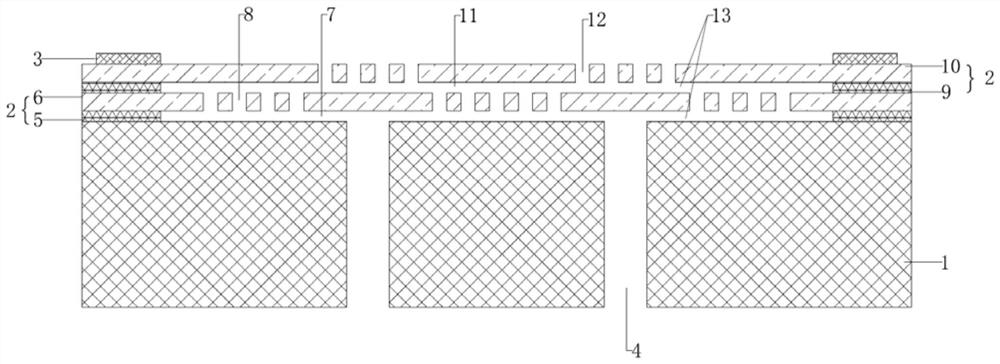

Wafer level packaging structure and manufacturing method thereof

InactiveCN103021984AReduce depthImprove plate yieldSemiconductor/solid-state device detailsSolid-state devicesEngineeringMetal

The invention discloses a wafer level packaging structure and a manufacturing method thereof. The wafer level packaging structure comprises a supporting layer, a chip, an insulating layer and a heavy wiring layer, the chip is arranged on the supporting layer and provided with an active surface which is opposite to the supporting layer and provided with multiple welding pads, each welding pad is provided with an incrassation metal object, the insulating layer is arranged on the chip and the supporting layer and provided with multiple blind holes which respectively correspond to and expose the incrassation metal objects on the welding pads, and the heavy wiring layer is arranged on the insulating layer and electrically connected with the welding pads through the blind holes and the chip. The incrassation metal objects can relatively reduce the depth of the blind holes and lower boring difficulty on the insulating layer.

Owner:ADVANCED SEMICON ENG INC

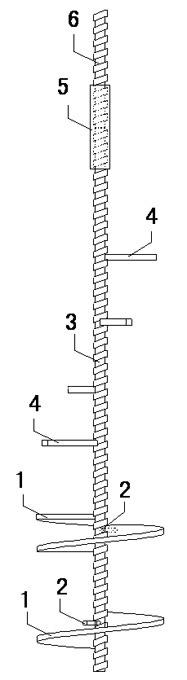

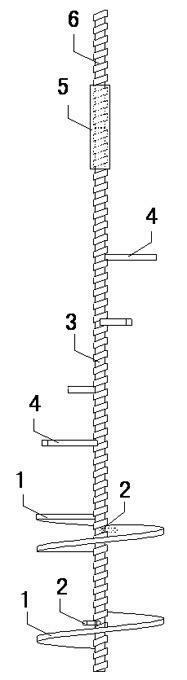

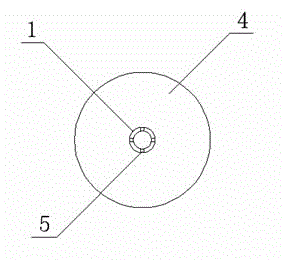

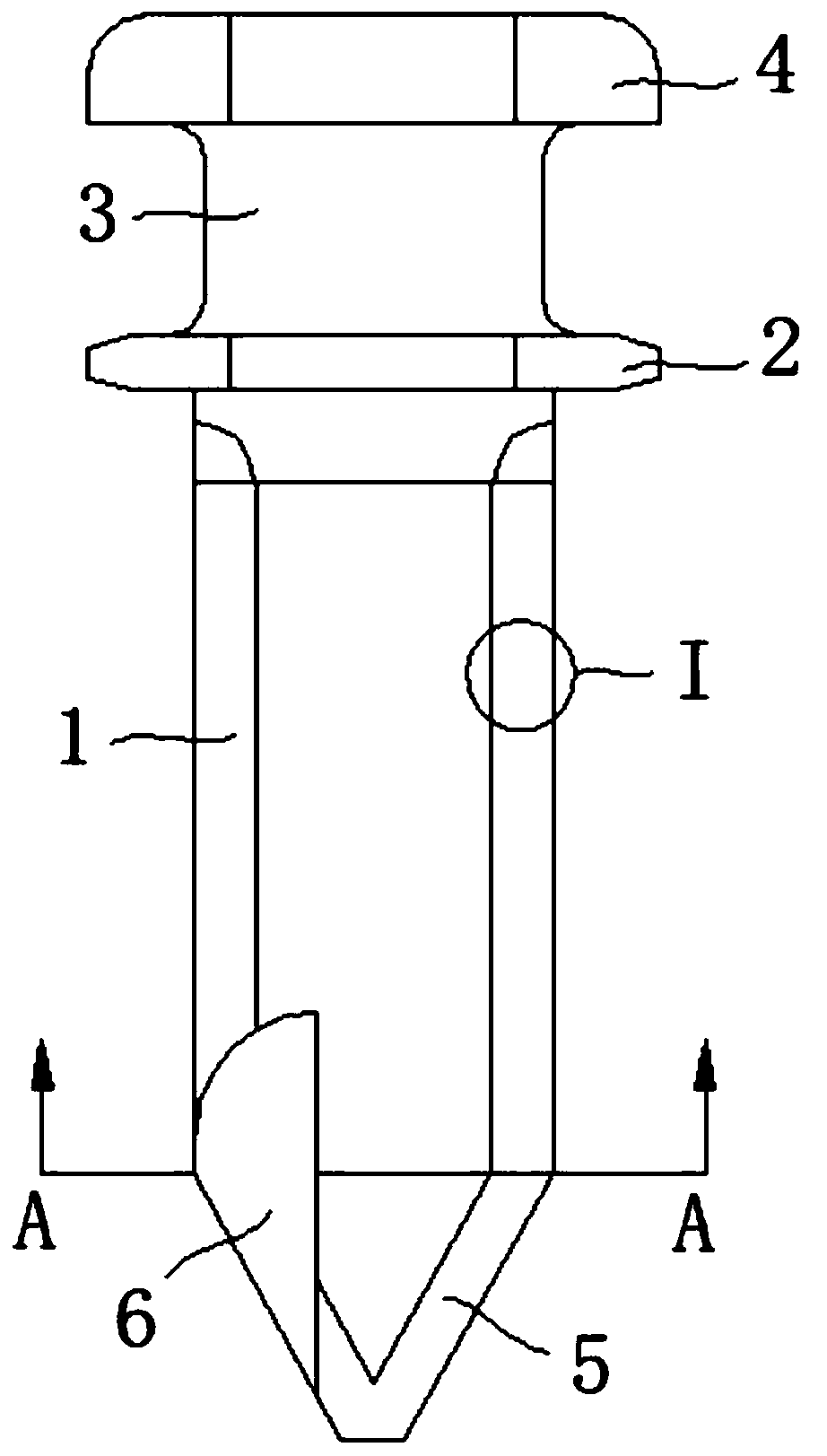

Multi-layer spiral blade self-drilling-type soil anchor rod and constructing method thereof

ActiveCN104141305AImprove drilling efficiencyStrong penetrating powerProtective foundationBulkheads/pilesSpiral bladeEngineering

The invention provides a multi-layer spiral blade self-drilling-type soil anchor rod and a constructing method of the anchor rod. The anchor rod comprises a front end anchor rod body (1), the outer surface of the end, close to the drill point, of the front end anchor rod body (1) is provided with front end spiral blades (4-1), grouting holes (5) are formed in the portion, near the front end spiral blades (4-1), of the side wall of the front end anchor rod body (1), the other end of the front end anchor rod body (1) is connected with one end of a middle-segment anchor rod body (2) through a thread connecting portion (6), the other end of the middle-segment anchor rod body (2) is connected with one end of a lengthened anchor rod (8) through a connecting sleeve (7), and spiral blades (4-2) are arranged on the outer surface of the middle-segment anchor rod body (2). The anchor rod is reasonable in structure, the blades have strong penetrating power in soft soil areas, the constructing technology is safe and reliable, the contact area is increased, the anchoring force is enhanced, the constructing efficiency and the constructing quality are improved, and it is guaranteed that the pulling resistance of the anchor rod in different soil layers can be improved more effectively.

Owner:WUDA JUCHENG STRUCTURE CO LTD

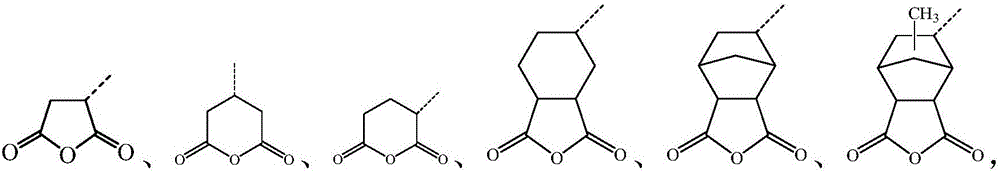

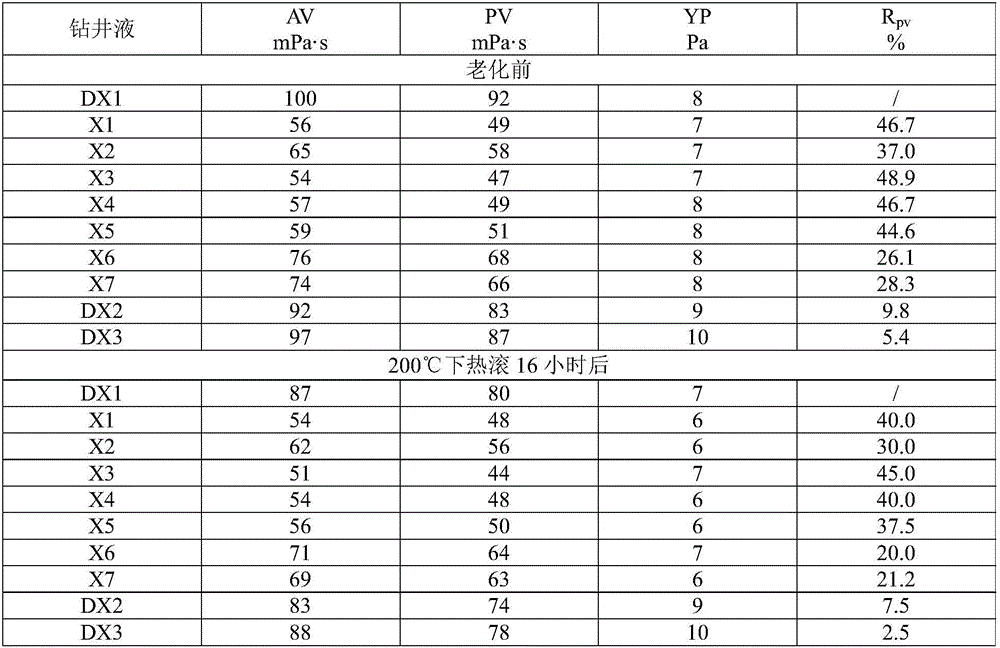

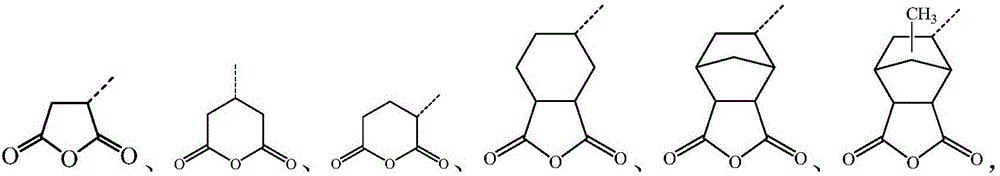

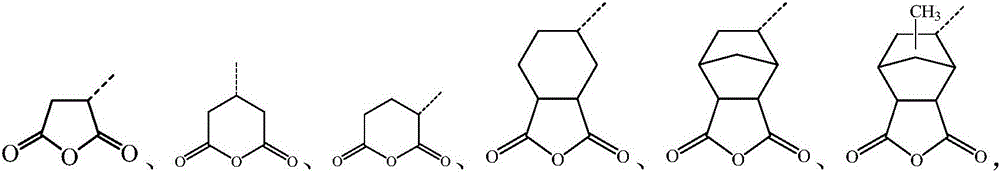

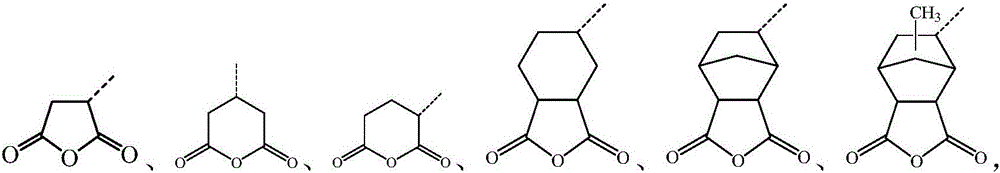

Diblock copolymer suitable for reducing viscosity of oil-based drilling fluid as well as preparation method and application thereof, and oil-based drilling fluid and application thereof

ActiveCN106220797AReduce apparent viscosityReduce drilling difficultyDrilling compositionApparent viscosityStructural unit

The invention relates to the well drilling field of petroleum industry, and concretely relates to a diblock copolymer suitable for reducing viscosity of oil-based drilling fluid as well as a preparation method and an application thereof, and oil-based drilling fluid and an application thereof. The diblock copolymer mainly comprises a block A and a block B, wherein the block A comprises a structural unit which is selected and shown in a formula (1), the block B comprises a structural unit which is selected and shown in the formula (2), and number-average molecular weight of the block A is 1500-10000. The diblock copolymer can be used as a viscosity reducer for oil-based drilling fluid, and especially can be used as a viscosity reducer which is applied to clay free phase oil-based drilling fluid with high density; in a stratum with high temperature and high pressure, a proper shearing force is guaranteed, apparent viscosity and plastic viscosity of the oil-based drilling fluid can be greatly reduced, in order to accelerate drilling speed and reduce well drilling difficulty.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

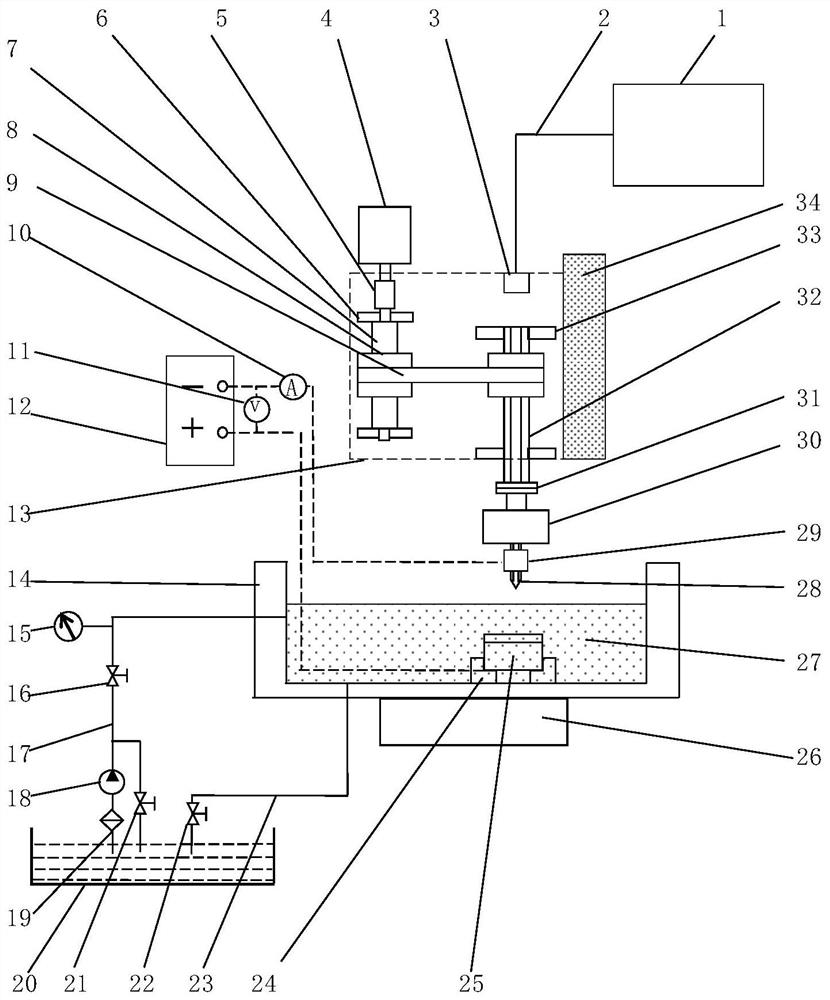

Combined machining method for blade air film holes and device thereof

ActiveCN112171184AReduce drilling difficultyImprove drilling efficiencyMetal working apparatusElectrolytic agentHeat-affected zone

The invention discloses a combined machining method for blade air film holes and a device thereof, and relates to the field of non-traditional machining. The combined machining method comprises the steps that the air film holes with the needed size are rapidly drilled in a thermal barrier coating high-temperature alloy matrix through laser heating auxiliary drilling; secondly, a drill bit rotatingat a high speed serves as a cathode, blades serve as an anode, the drill bit moves up and down, online electrolysis aftertreatment is conducted on part of the air film holes of the metal matrix, andthe defects of residual stress, a heat affected zone and the like in the drilling process are eliminated; and meanwhile, tiny abrasive particles are suspended in the electrolyte, tiny impact scratching is conducted on the hole wall under the driving of the drill bit rotating at a high speed, the similar grinding and polishing effect is achieved, and the quality of the whole inner wall of the air film holes including the thermal barrier coating is further improved. The method is simple and easy to implement, laser transmission is not affected by the surrounding environment, the environmental adaptability is high, repeated tool setting is not needed, and the defects that the thermal barrier coating cannot be machined through a conventional electric machining method, the single crystal alloylaser machining efficiency is low, and thermal damage is likely to be generated are overcome.

Owner:JIANGSU UNIV

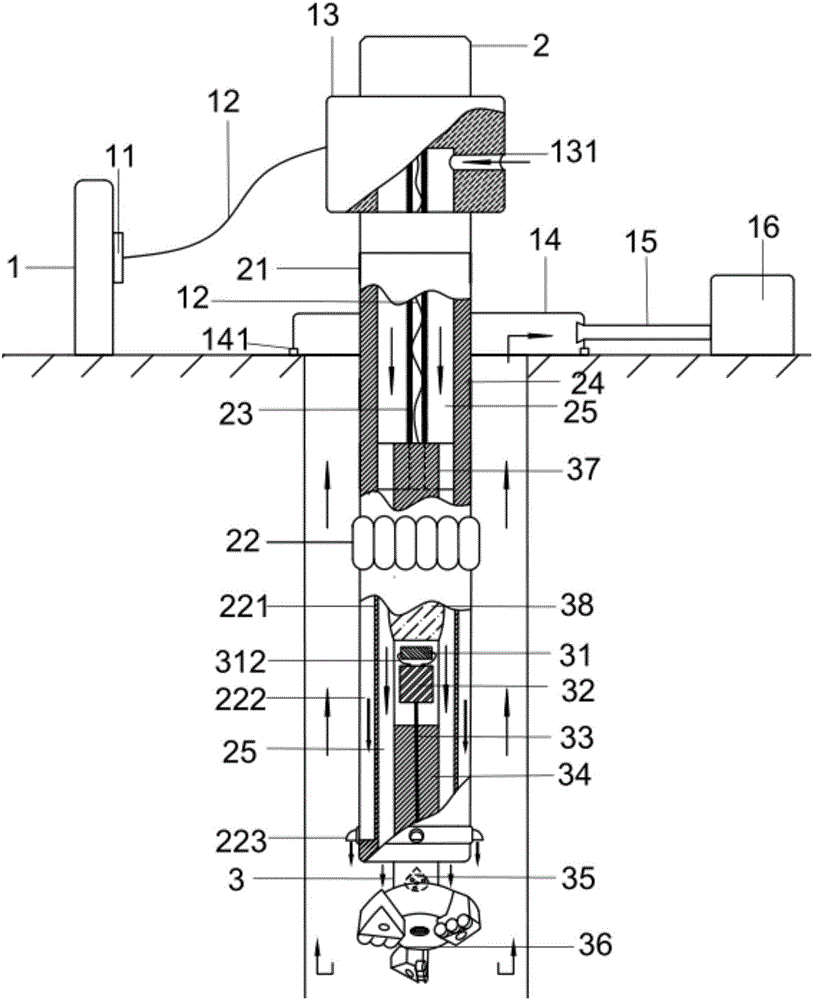

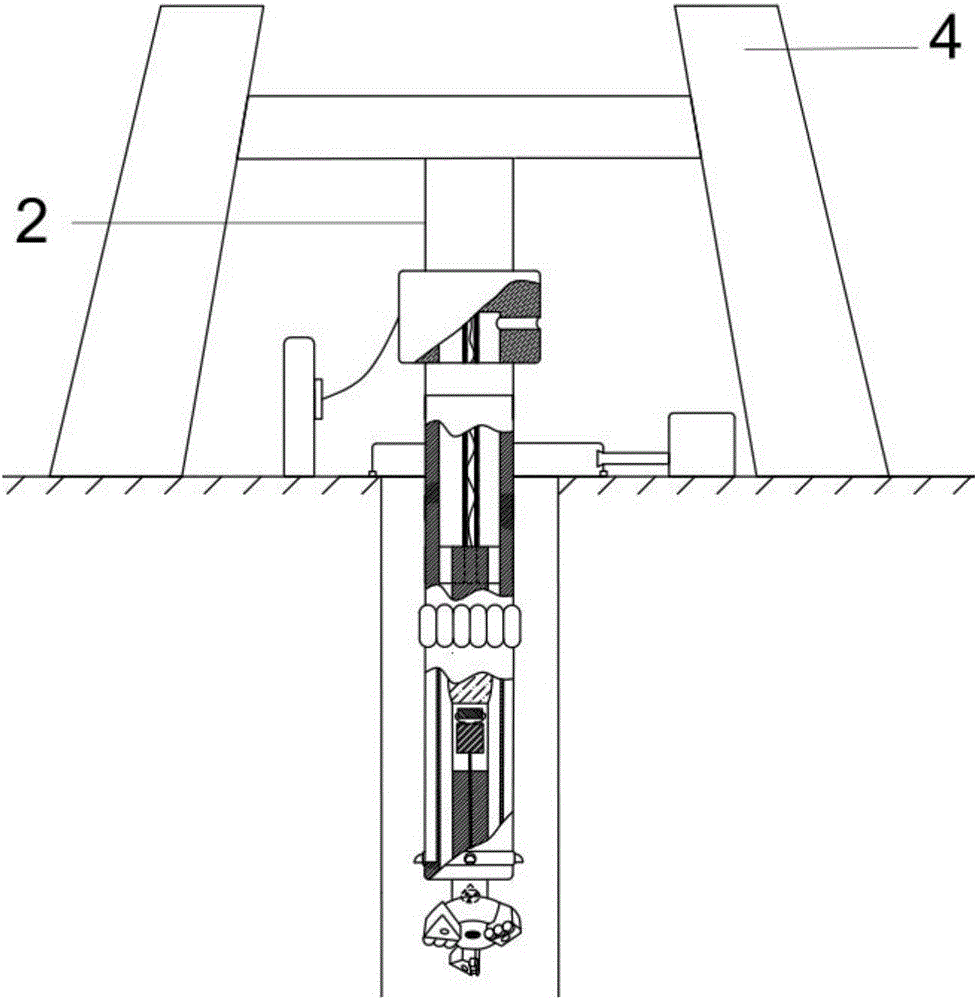

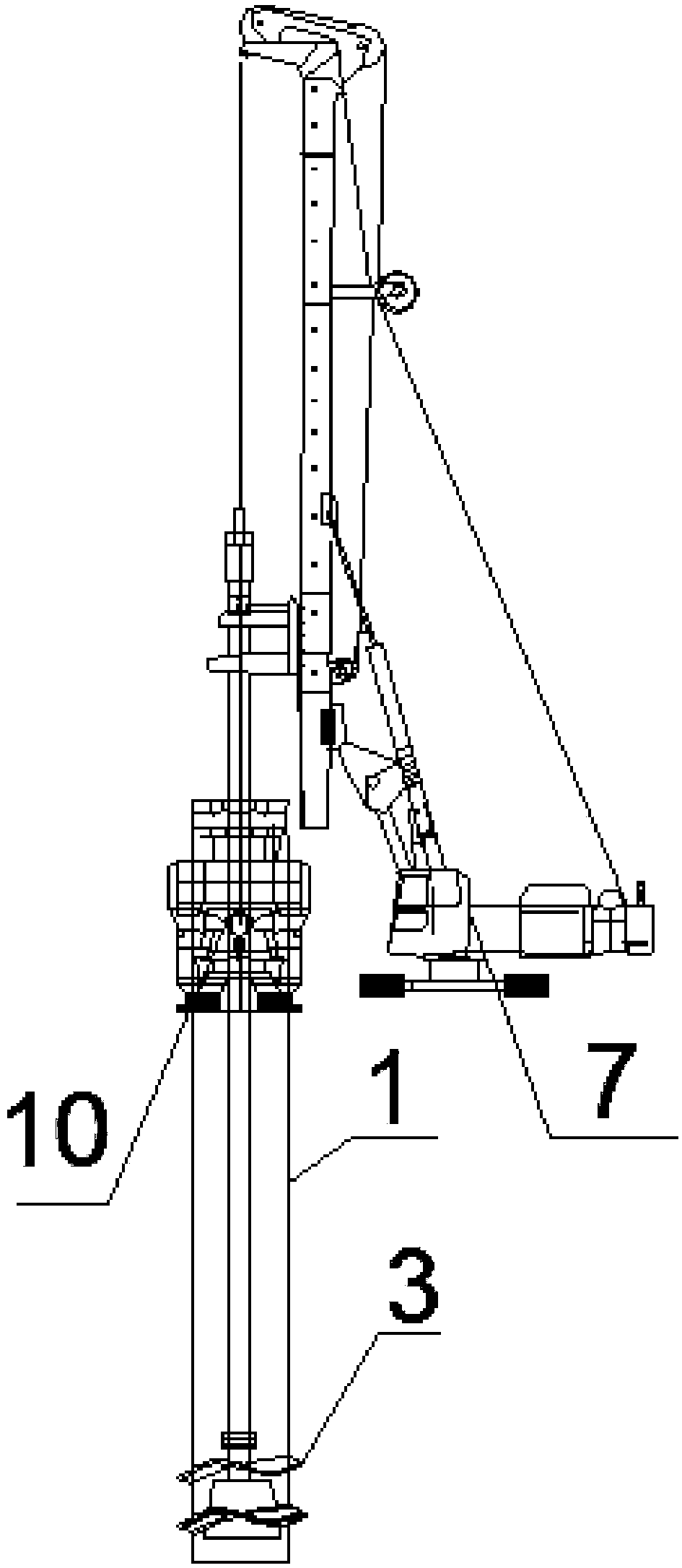

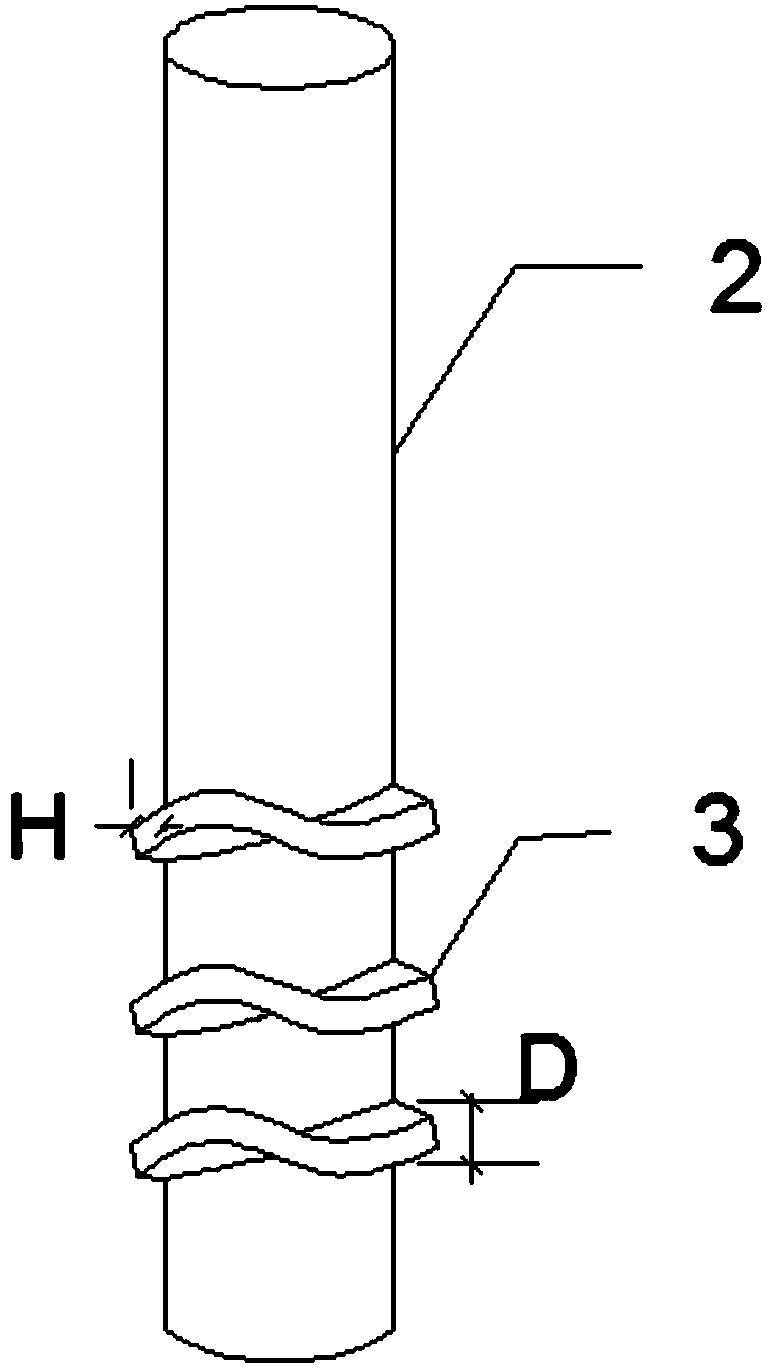

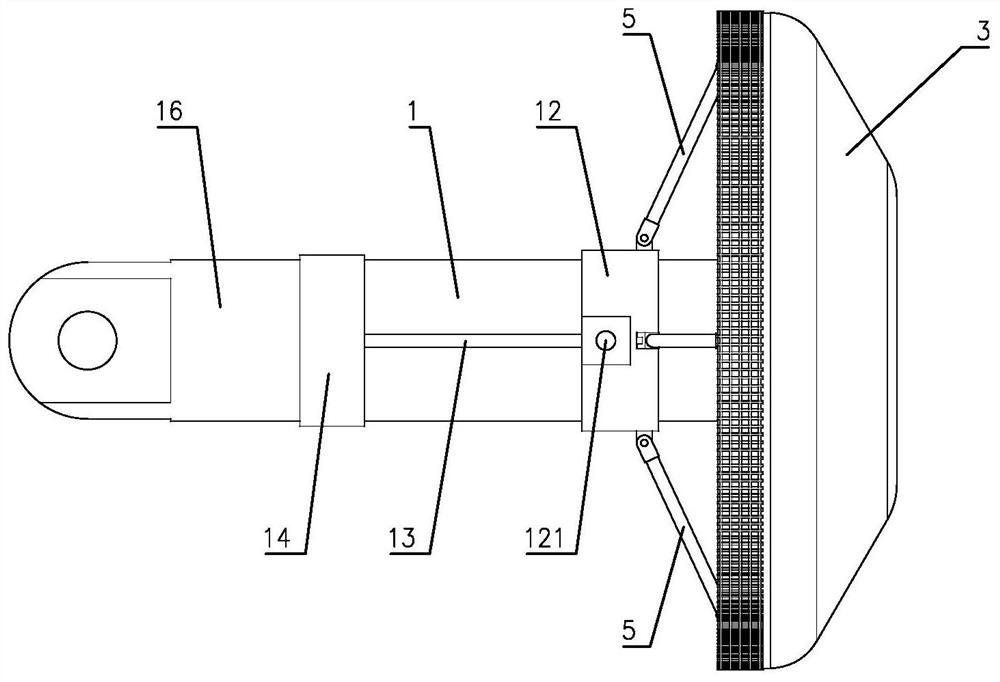

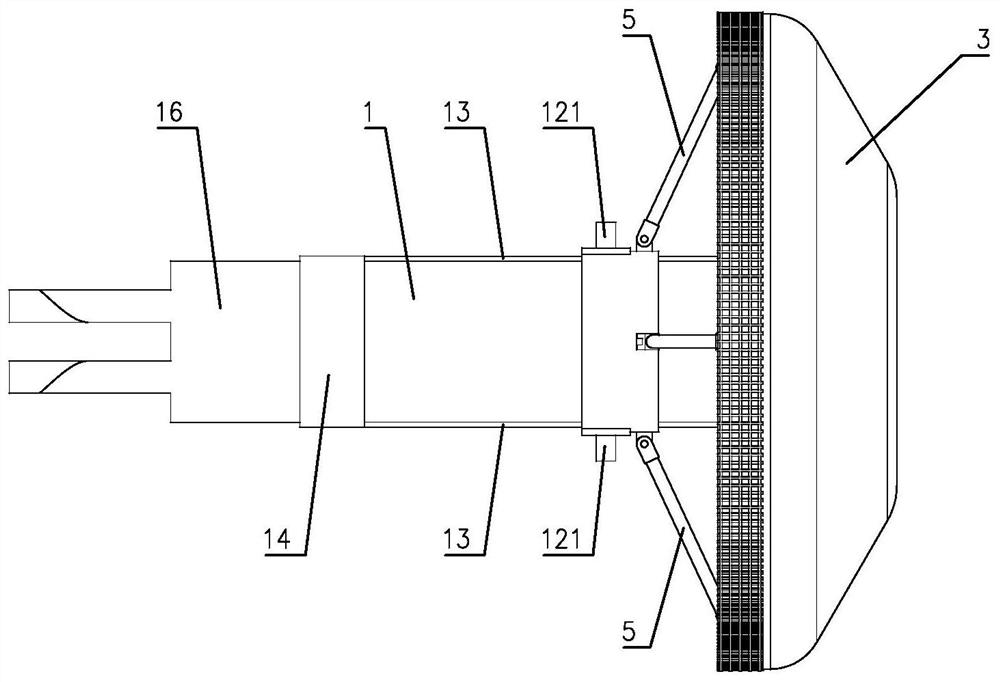

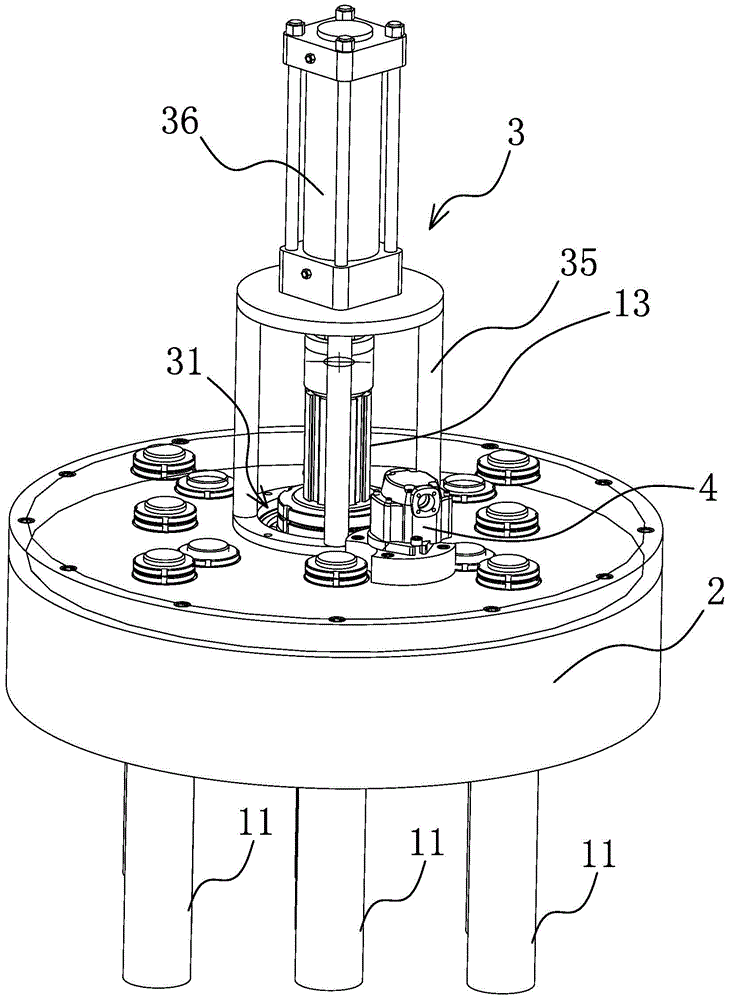

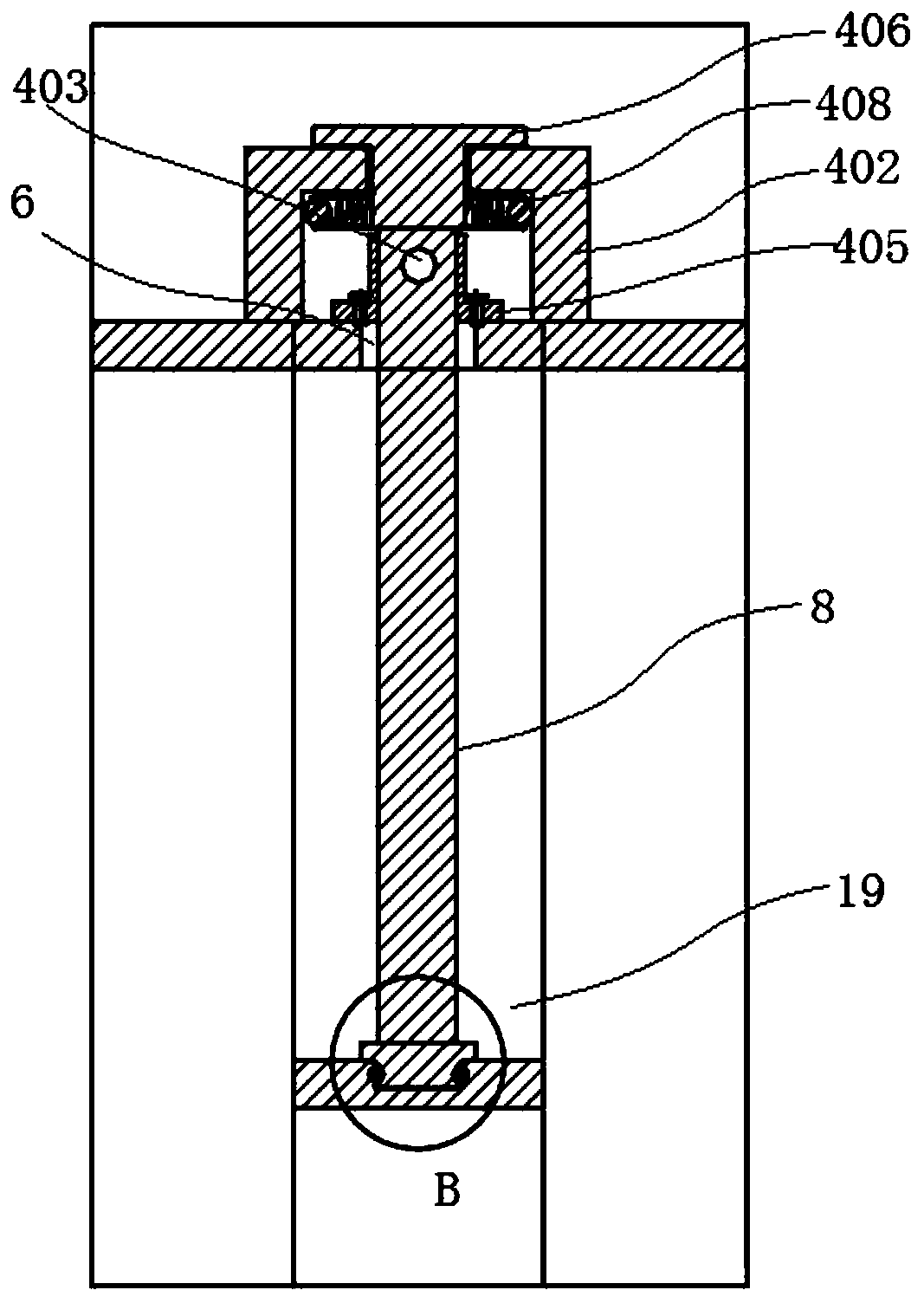

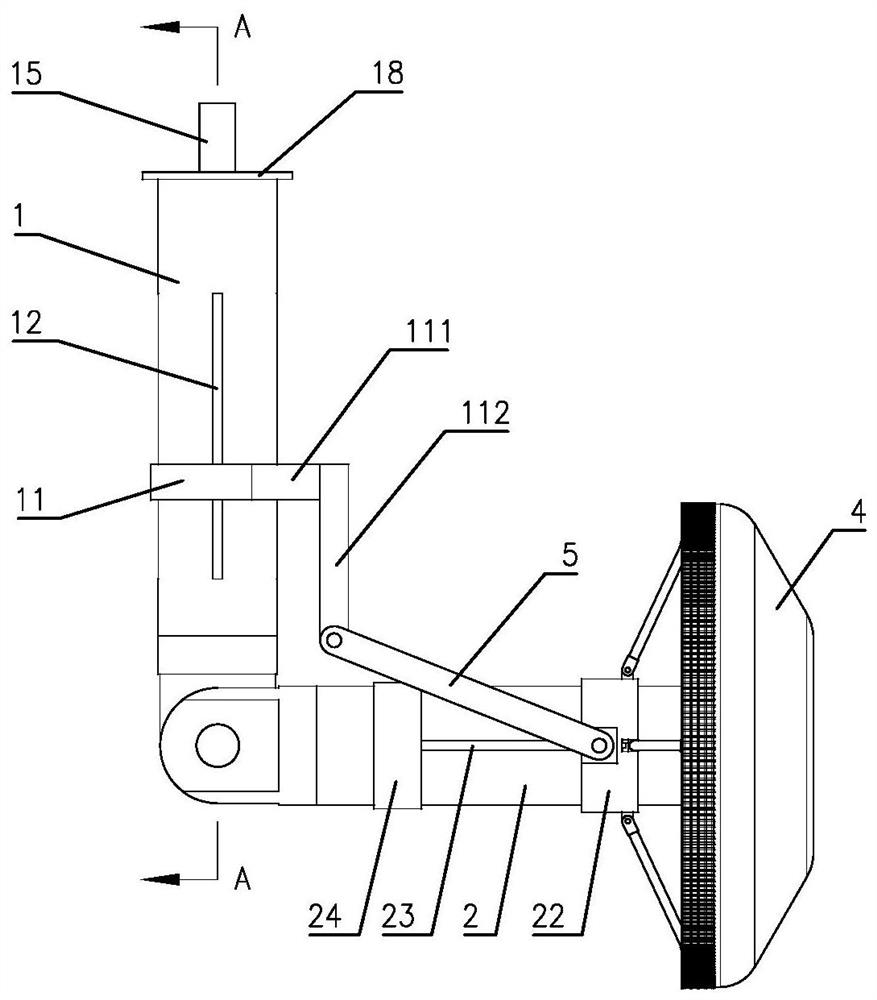

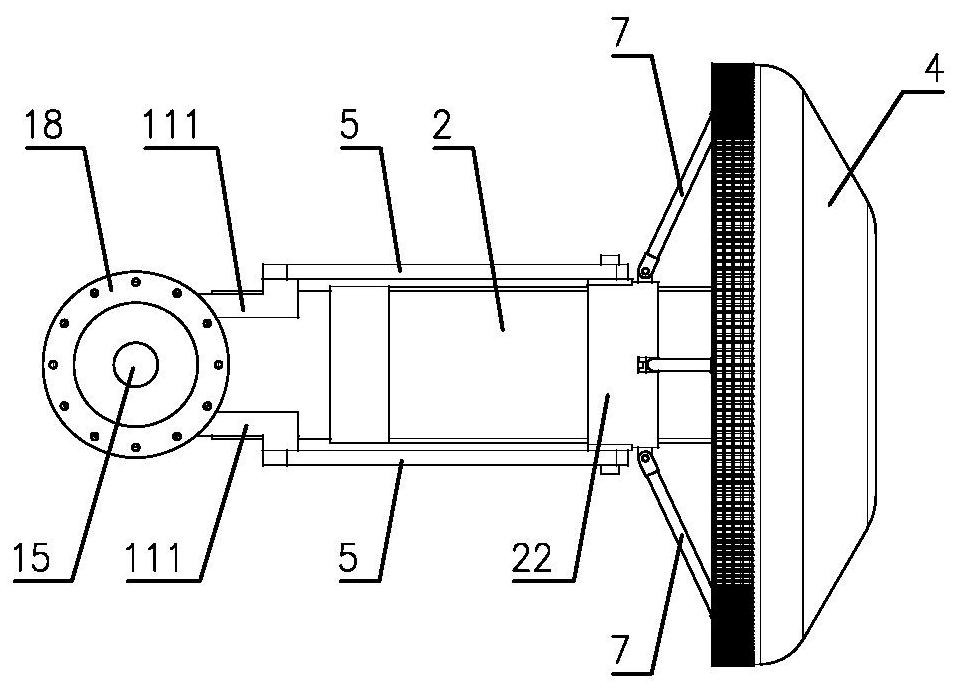

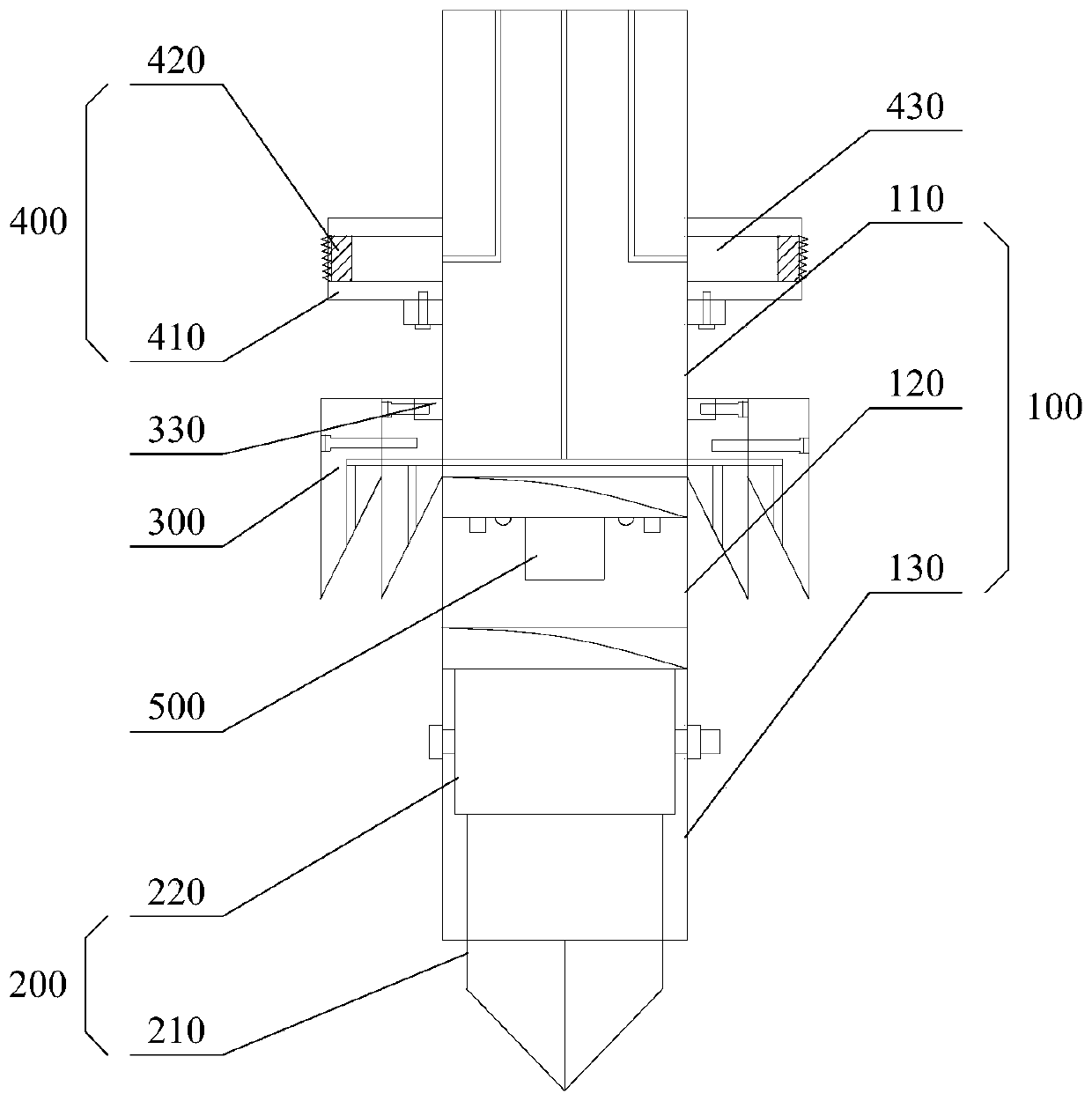

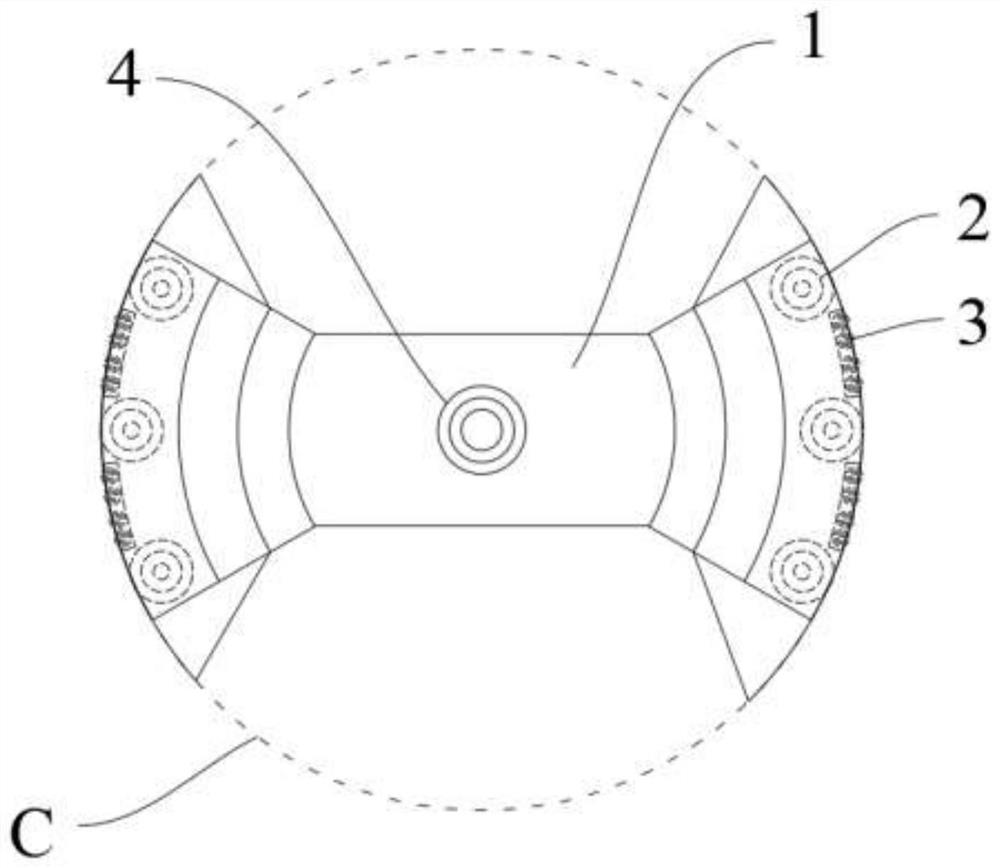

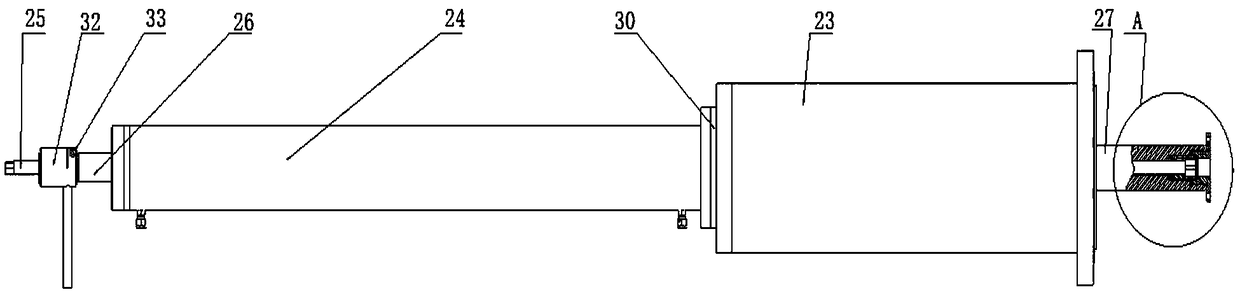

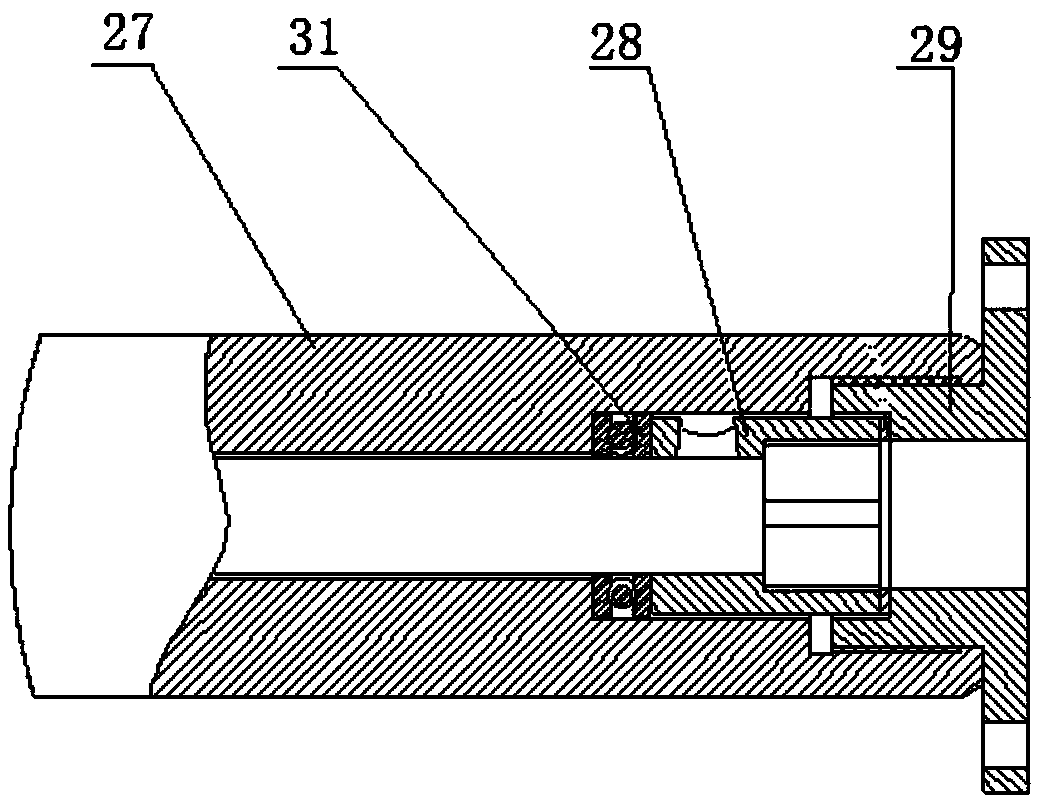

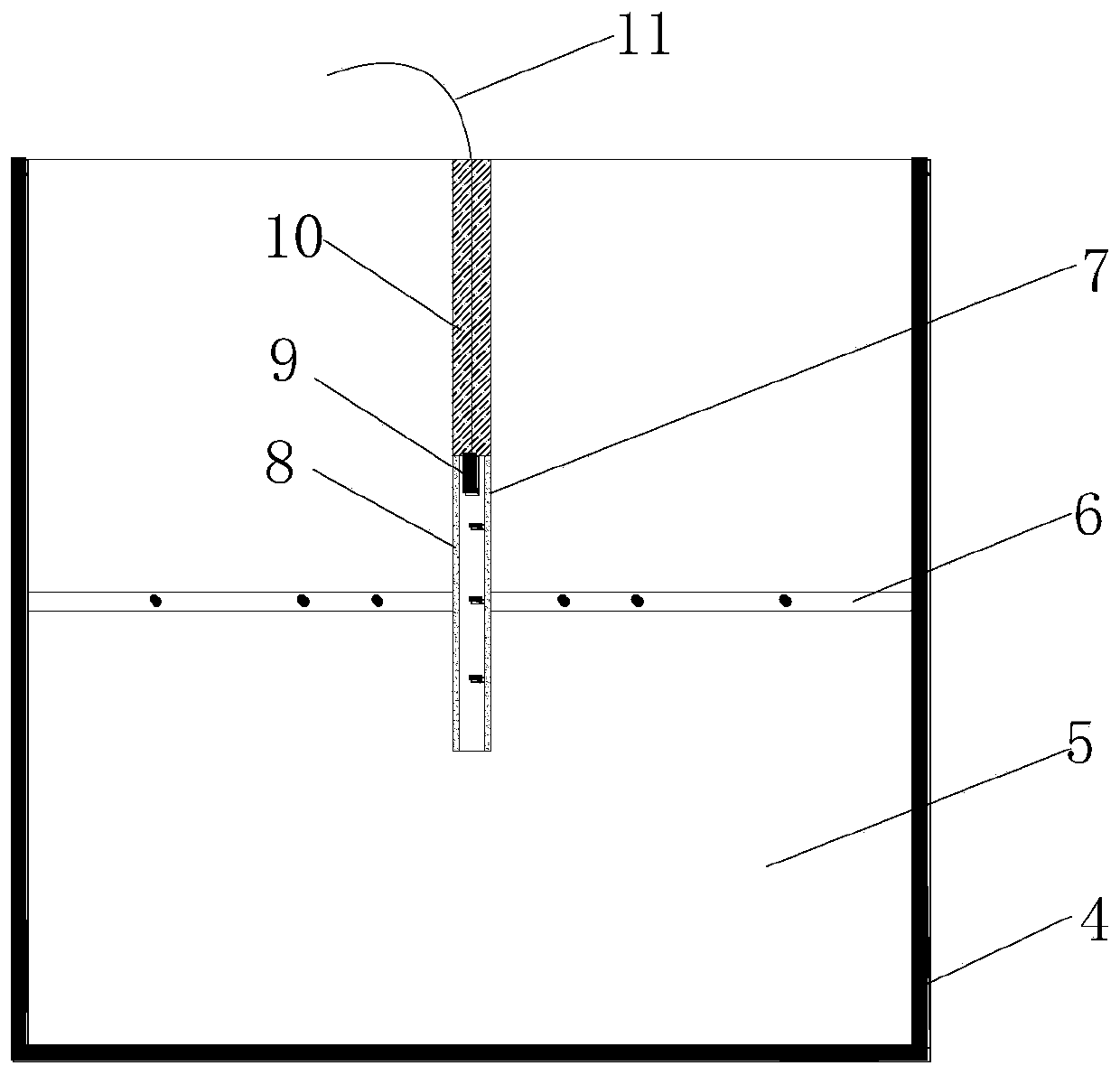

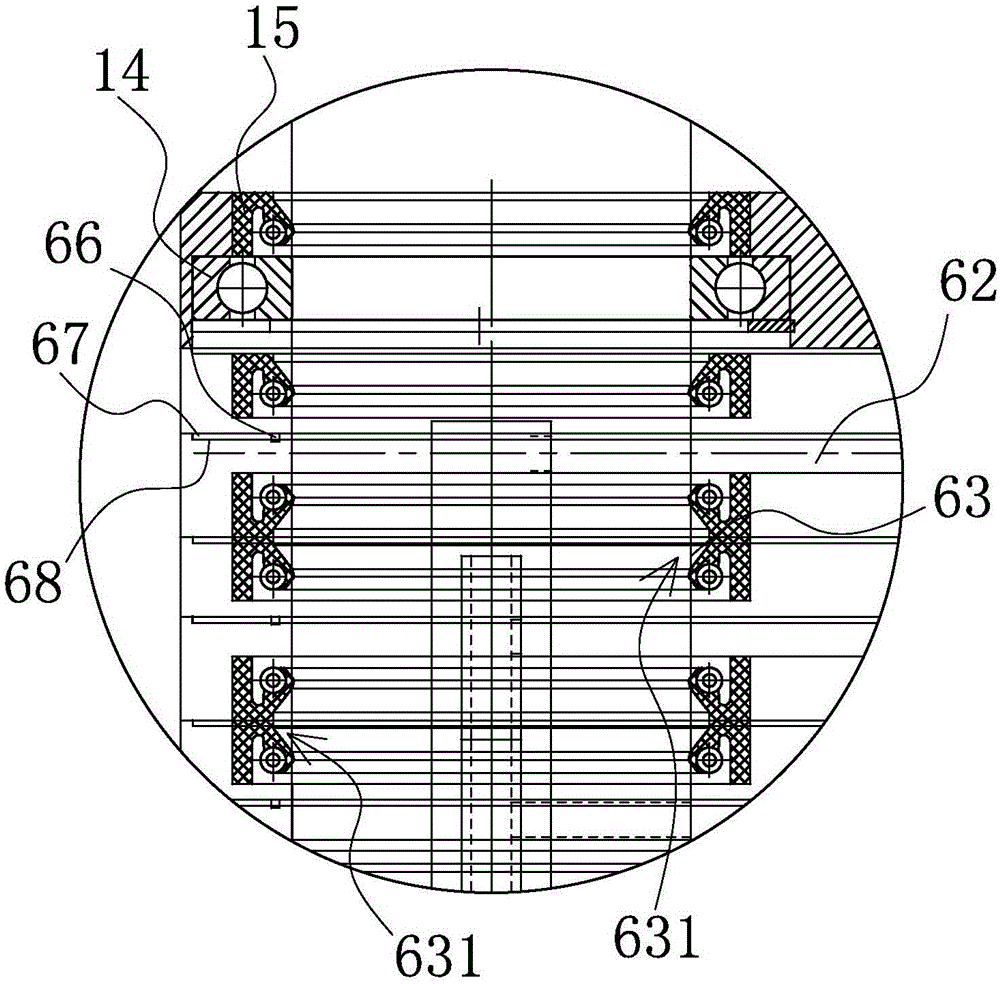

Improved structure of full casing spiral drilling machine and full casing threaded filling pile construction method

PendingCN109113566AQuality improvementReduce drilling difficultyDrilling rodsBorehole drivesEngineeringDrill pipe

The invention discloses an improved structure of a full casing spiral drilling machine and a full casing threaded filling pile construction method. The improved structure of the full casing spiral drilling machine includes a double power head spiral drilling machine (2). A casing (1) is mounted on the double power head spiral drilling machine (2). A lower power head (4) capable of making the sleeve tube rotate is detachably mounted on the casing. An upper power head (5) is arranged above the lower power head. A spiral drilling rod (6) capable of moving up and down in the casing is detachably connected to the upper power head. A drilling device capable of moving in the casing is connected to the lower end of the spiral drilling rod. A spiral member (3) is integrally formed on at least a part of the outer wall of the casing, wherein the spiral direction of the spiral member is opposite to that of the spiral drilling rod. The drilling machine improvement is simple and durable. the full casing spiral drilling machine with the structure and the construction method of the invention can be used to form threaded piles with medium and large diameter under conventional mechanical equipment dynamic conditions, and so threaded special-shaped piles are more in line with increasing demand of pile bearing capacity for structures at a current stage.

Owner:刘淼

Pipeline plugging device

ActiveCN111810762ATo achieve the purpose of blockingSimple structurePipe elementsStructural engineeringMechanical engineering

The invention relates to a pipeline plugging device. The pipeline plugging device comprises a supporting rod, an expansion ring and a sealing hood, wherein the right end of the supporting rod is provided with a fixed ring, and the middle portion of the supporting rod is provided with a sliding ring; the expansion ring comprises first arc-shaped parts and second arc-shaped parts which are alternately distributed in the circumferential direction, the first arc-shaped parts are provided with guiding portions, the side faces, corresponding to the two ends of the first arc-shaped parts, of the guiding portions are guiding faces, the guiding faces are provided with sliding grooves, the two side walls of the sliding grooves are provided with guiding holes, the guiding holes in the adjacent firstarc-shaped parts form shapes like a Chinese character 'ba', the second arc-shaped parts are provided with support lugs, the support lugs are correspondingly hinged to the fixed ring and the sliding ring through first connection rods and second connection rods, the two ends of the second arc-shaped parts are provided with sliding blocks located inside the sliding grooves correspondingly, and the two sides of the sliding blocks are provided with guiding columns located inside the guiding holes correspondingly; and the sealing hood is sleeved on the expansion ring from right to left and is fixedly connected with the first arc-shaped parts correspondingly. The pipeline plugging device has the advantages of being simple in structure, convenient to operate and control, reliable in plugging and high in adaptability, equal-diameter holes do not need to be arranged in a pipeline, and the operating efficiency is improved.

Owner:北京天兴燃气工程有限公司

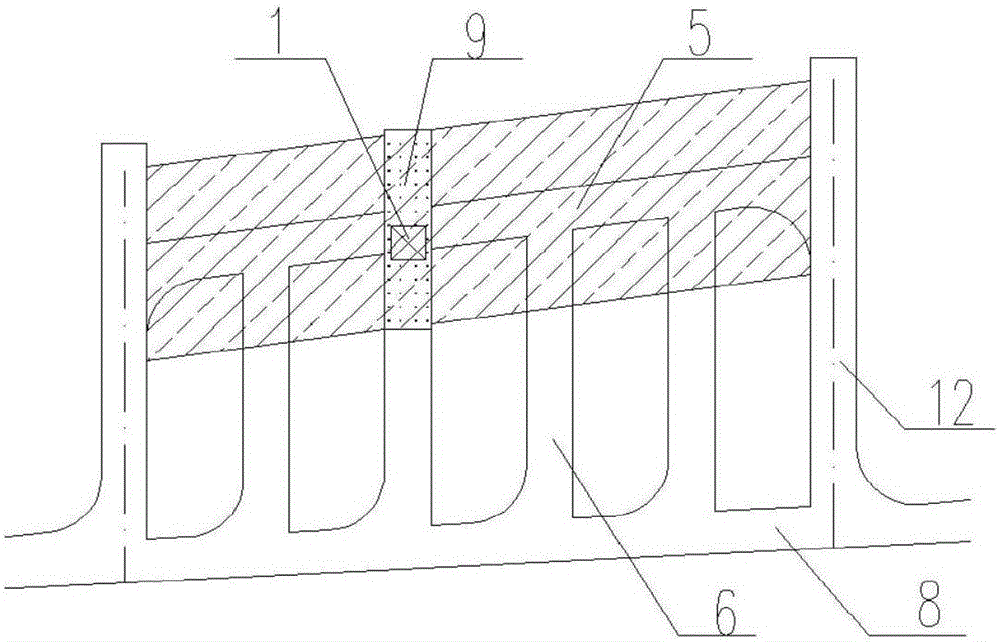

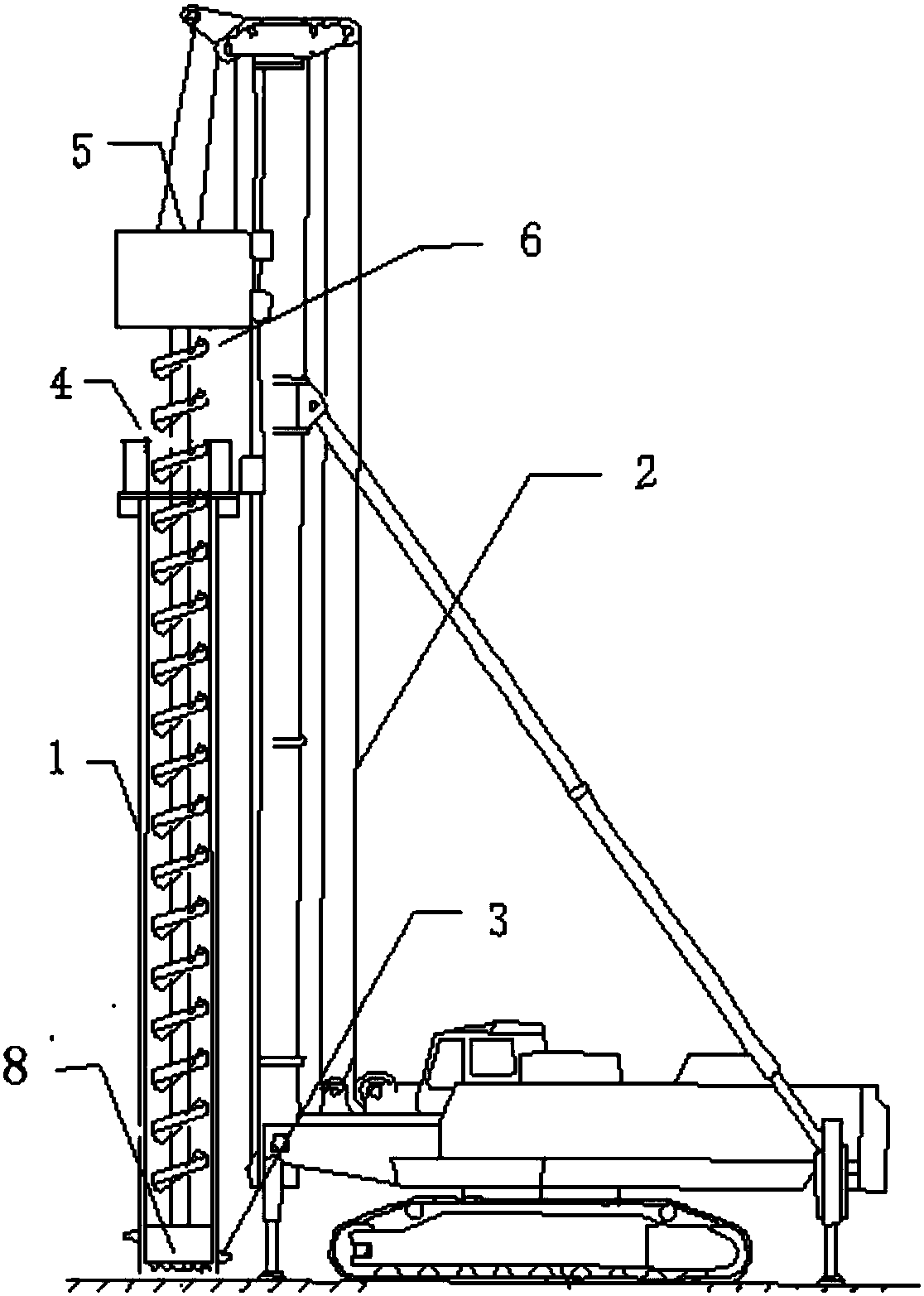

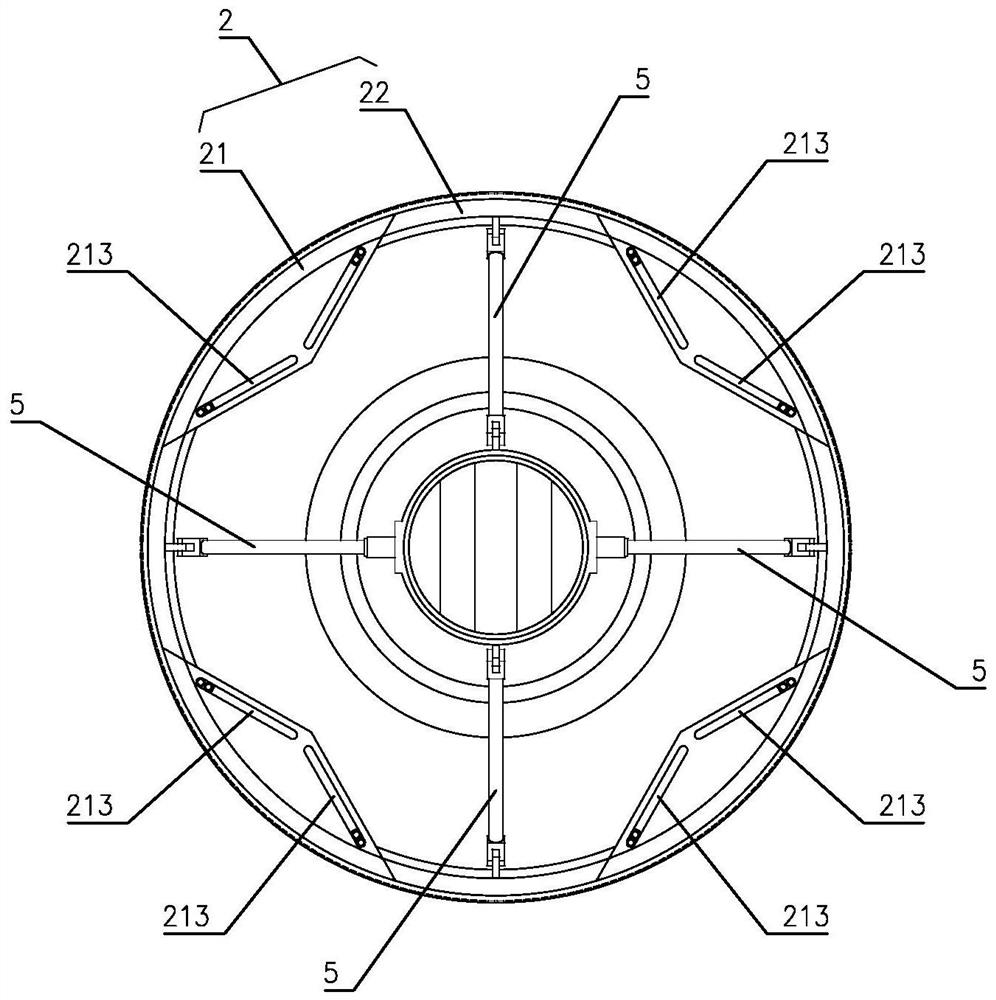

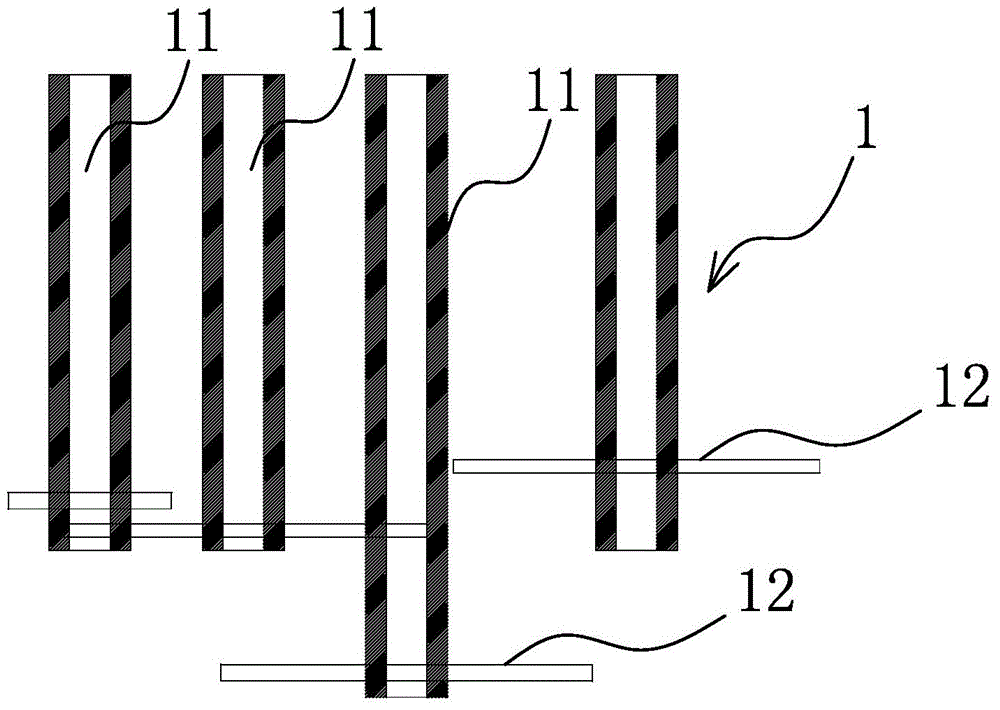

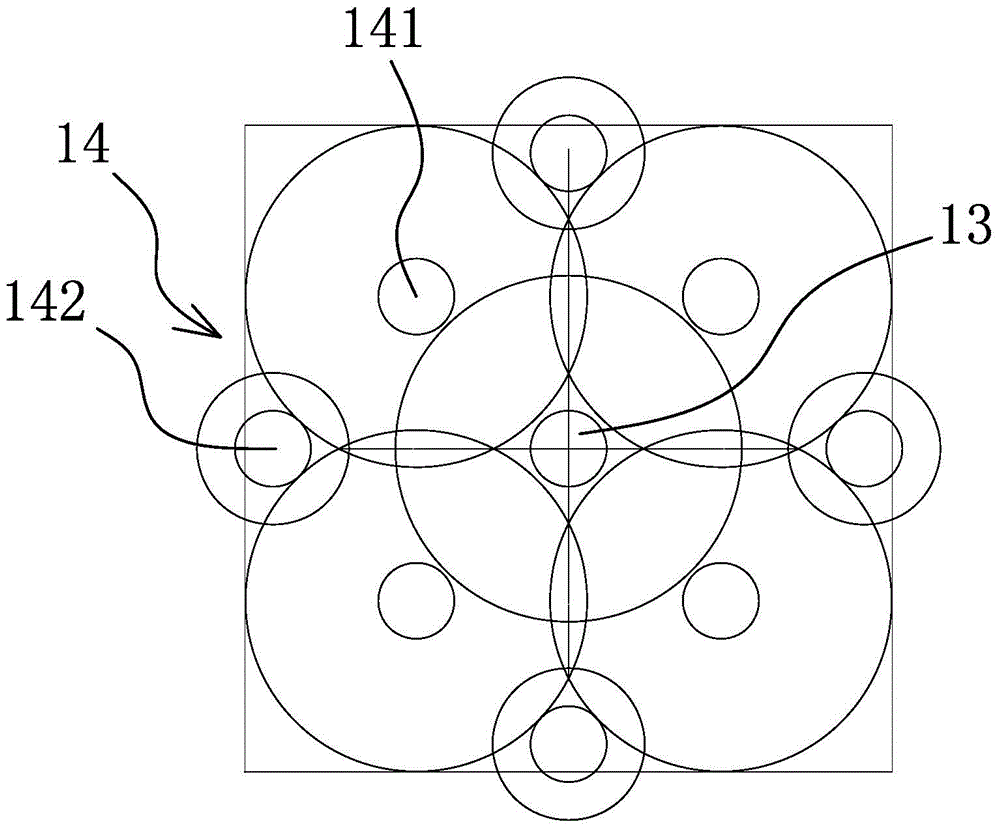

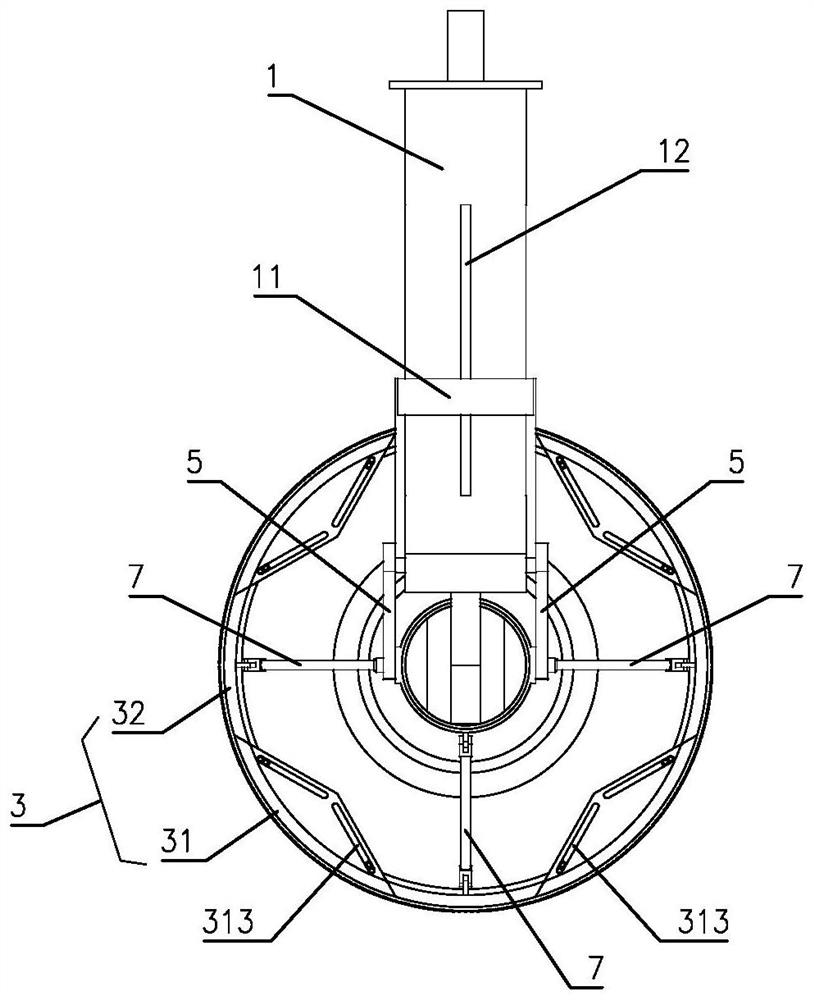

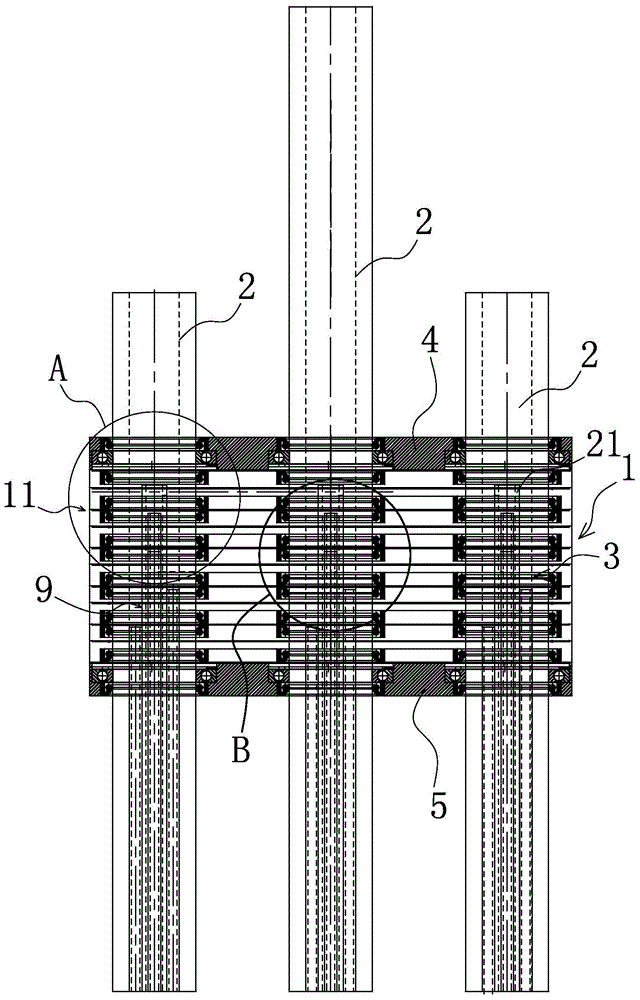

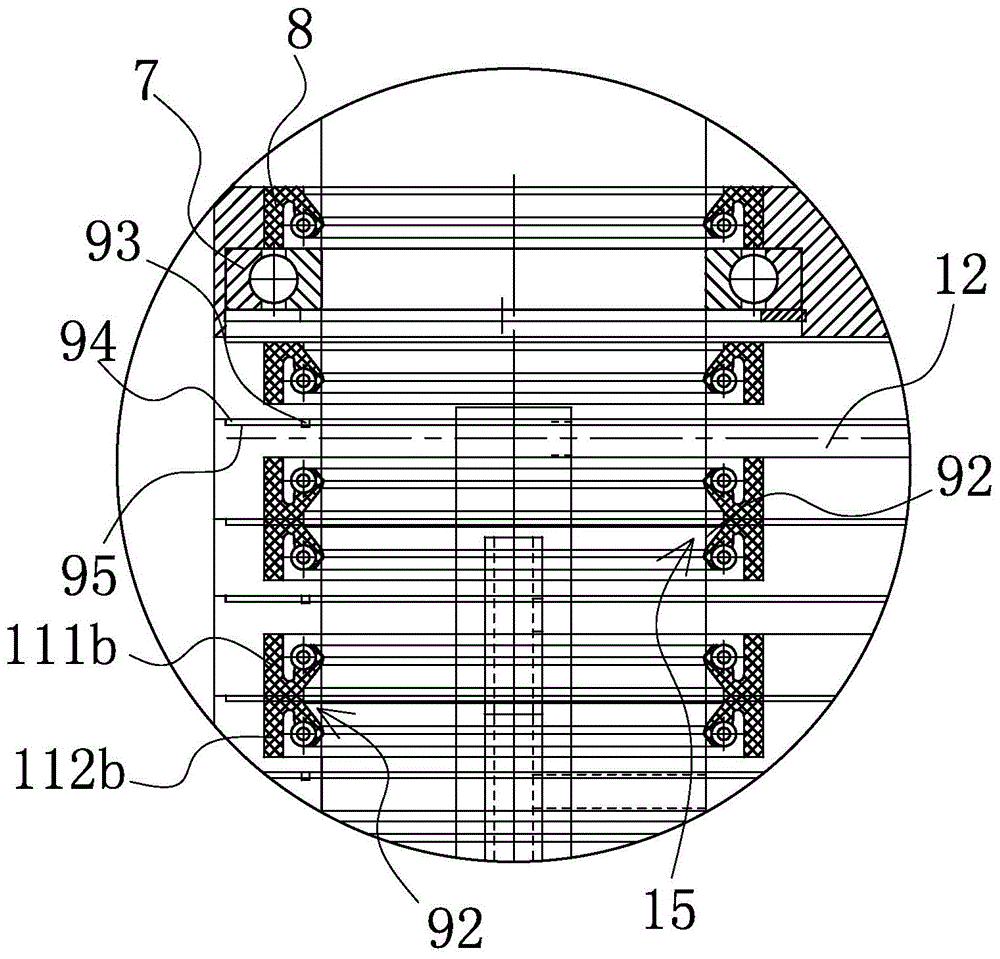

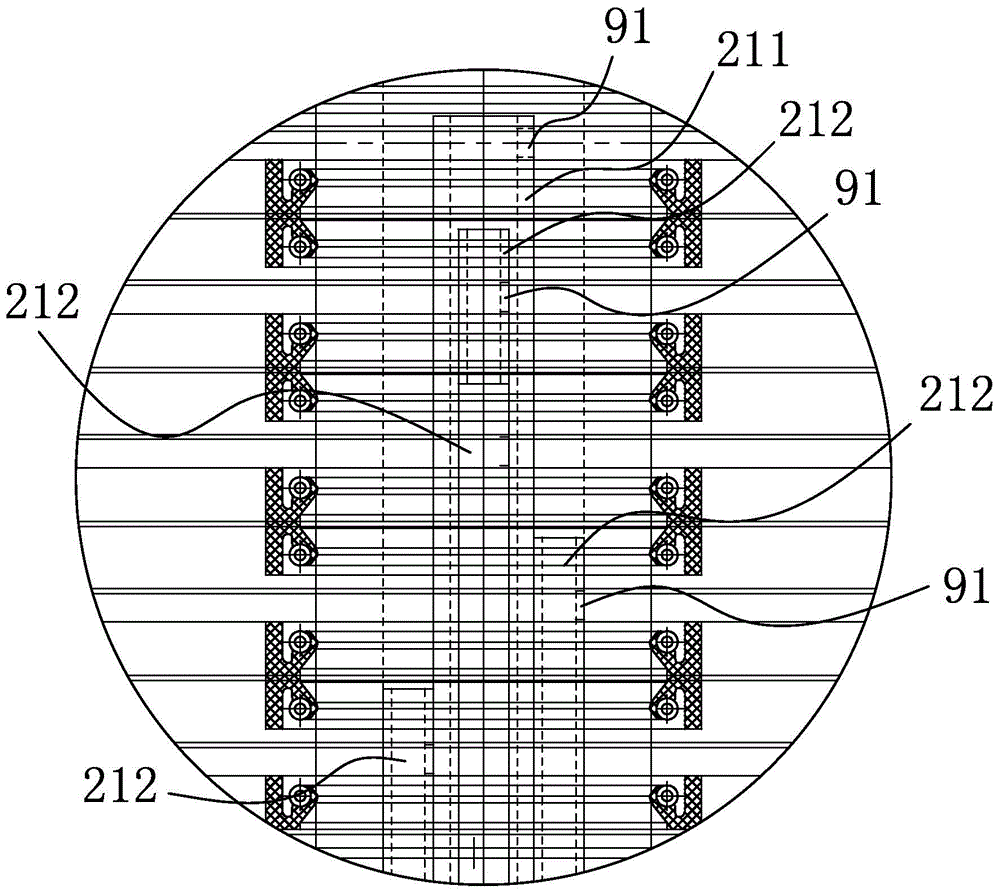

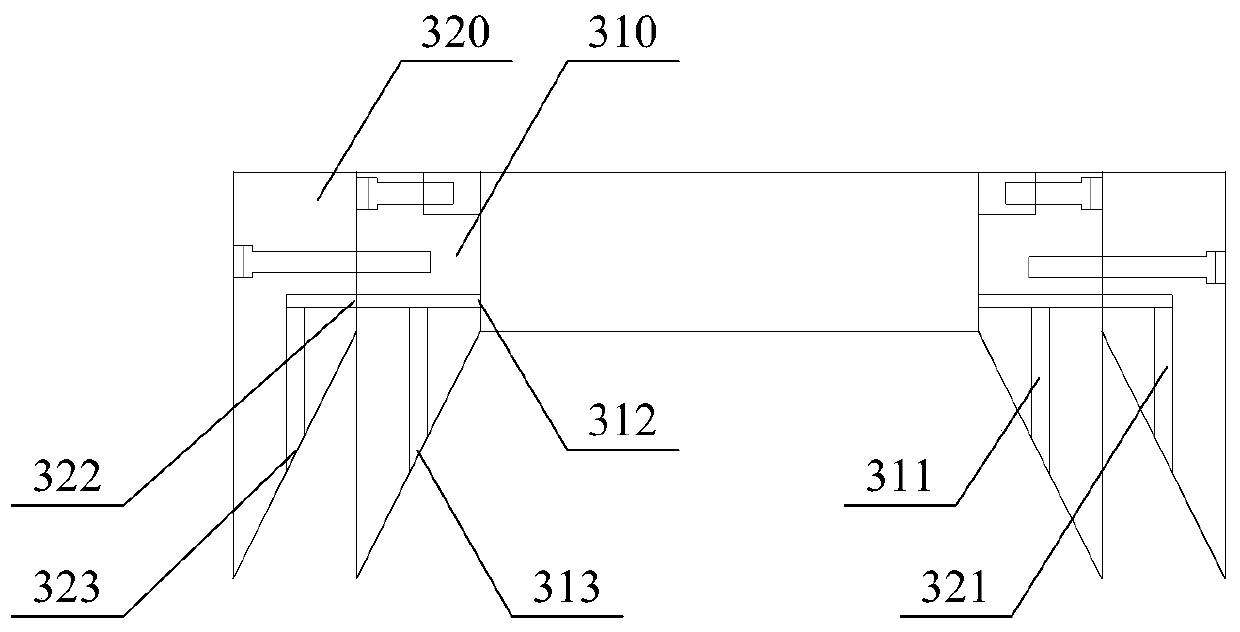

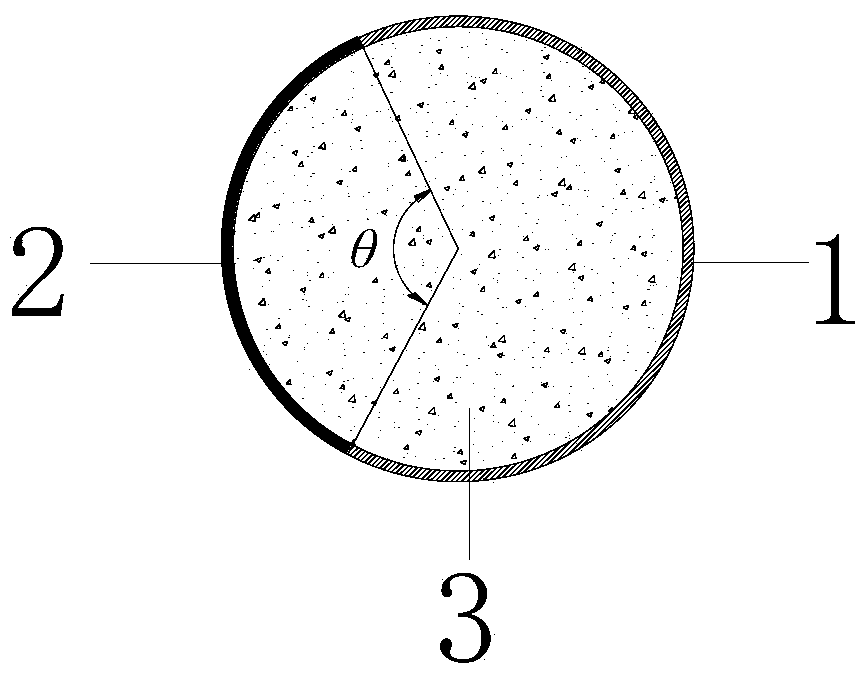

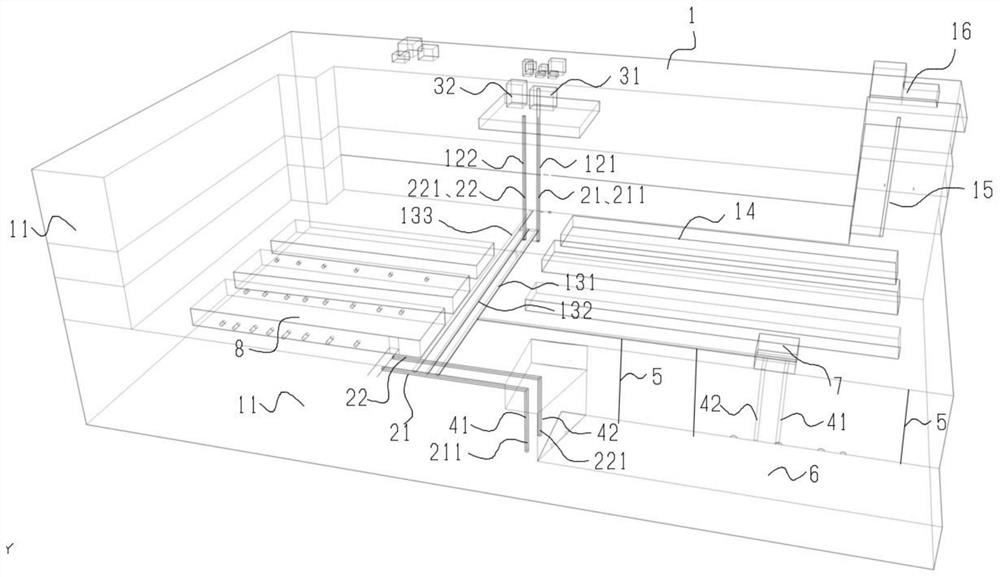

Drill rod distribution structure of cement soil mixing pile driver

ActiveCN105002896AStrong pull-out resistanceReduce drilling difficultyBorehole drivesBulkheads/pilesSoil mixingStructural engineering

The invention belongs to the technical field of construction equipment, and particularly relates to a drill rod distribution structure of a cement soil mixing pile driver. The drill rod distribution structure of the cement soil mixing pile driver solves the problem that an existing cement soil mixing pile driver is low in drilling efficiency and the like. The drill rod distribution structure of the cement soil mixing pile mixer comprises a drill rod assembly with at least three drill rod bodies which rotate in the circumferential direction and are arranged in the vertical direction; each drill rod body is provided with multiple stirring bodies; the projections of the center lines of the drill rod bodies in the drill rod assembly in the vertical direction are not located on the same straight line; the center lines of any three drill rod bodies, with the projections of the center lines in the vertical direction not located on the same straight line, of the drill rod assembly are sequentially connected to form a triangular structure; the drill rod bodies are arranged in the vertical direction in a one-to-one staggered mode. The drill rod distribution structure of the cement soil mixing pile driver has the advantages that stirring is uniform; a manufactured cement soil mixing pile is high in anti-pulling capacity; the drilling difficulty is low; drill holes in an approximate rectangle can be drilled at a time; machine movement or repeated drilling is not needed; the construction cost is saved; stability is good.

Owner:周兆弟

Additive composition applicable to viscosity reduction of oil-based drilling fluid and application thereof, and oil-based drilling fluid and application thereof

ActiveCN106634881AReduce apparent viscosityReduce drilling difficultyDrilling compositionApparent viscosityWell drilling

The invention specifically relates to an additive composition applicable to viscosity reduction of an oil-based drilling fluid and application thereof, and the oil-based drilling fluid and application thereof. The additive composition is a double block copolymer which is composed of a block A and a block B, wherein the block A is composed of a constitutional unit as shown in a formula (1) which is described in the specification and has a number-average molecular weight of 1500 to 10000, and the block B is composed of a constitutional unit as shown in a formula (2) which is described in the specification. The double block copolymer can be used as a viscosity reducer for the oil-based drilling fluid, especially as a viscosity reducer for a high-density clay-free oil-based drilling fluid; and the double block copolymer can greatly reduce the apparent viscosity and plastic viscosity of the oil-based drilling fluid in high-temperature high-pressure strata while guaranteeing proper shearing force, so drilling speed can be conveniently accelerated and difficulty in well drilling can be reduced.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

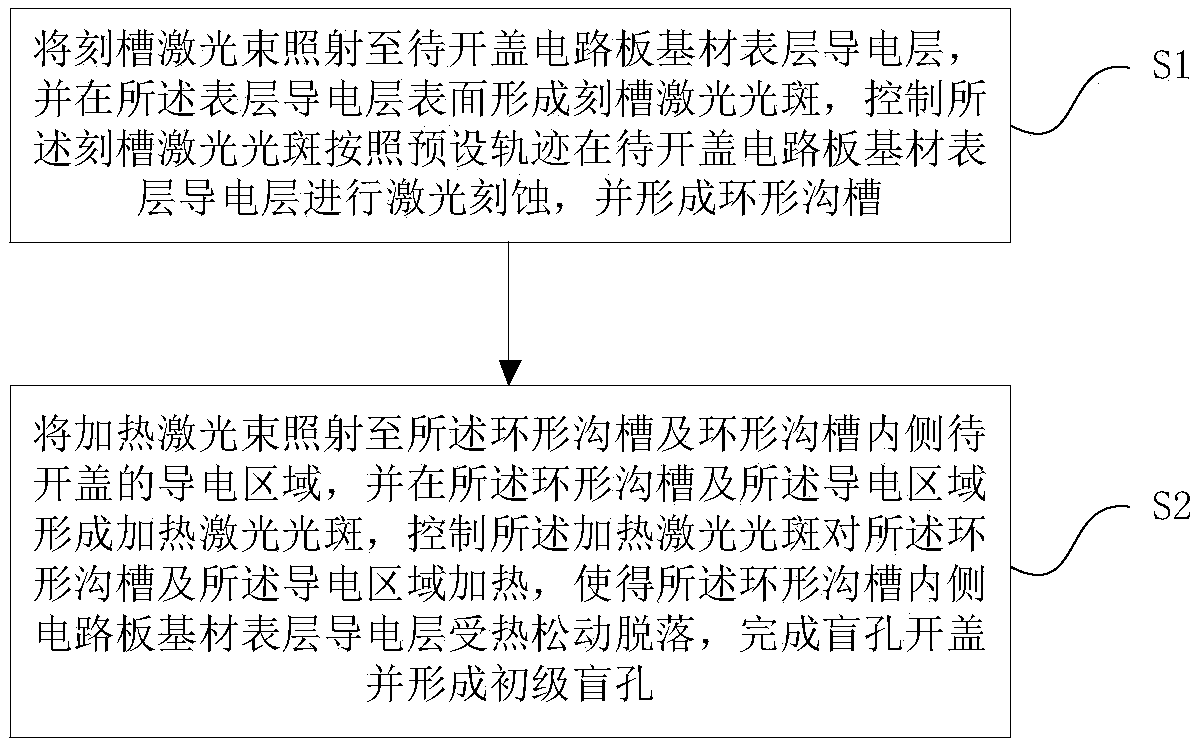

Blind hole uncapping method using laser

ActiveCN109640524AEasy to switchReduce processing timePrinted circuit manufactureLaser beam welding apparatusShock waveLaser etching

The invention relates to a blind hole uncapping method using laser. The blind hole uncapping method comprises the steps that grooving laser beams are irradiated to a surface layer conducting layer ofa to-be-uncapped circuit board substrate, laser etching is carried out on the surface layer conducting layer of the to-be-uncapped circuit board substrate according to a preset track, and an annular groove is formed; and heating laser beams are irradiated to the annular groove and a to-be-uncapped surface layer conducting layer area on the inner side of the annular groove, heating is carried out,the surface layer conducting layer of the circuit board substrate on the inner side of the annular groove becomes loose and drops off by heating, the blind hole uncapping is finished, and a primary blind hole is formed. According to the blind hole uncapping method using the laser, the surface layer conducting layer of a circuit board is subjected to closed-loop grooving using the grooving laser beams, the annular groove is obtained, the annular groove and a conducting area in the annular groove are heated using the heating laser beams, under the action of plasma shock waves generated by actionof heating laser light spots and substance in the groove, the surface layer conducting layer of a blind hole to-be-uncapped protecting area becomes loose and drops off, the blind hole uncapping is finished, the primary blind hole is formed, and the blind hole uncapping problem is ingeniously solved.

Owner:武汉铱科赛科技有限公司

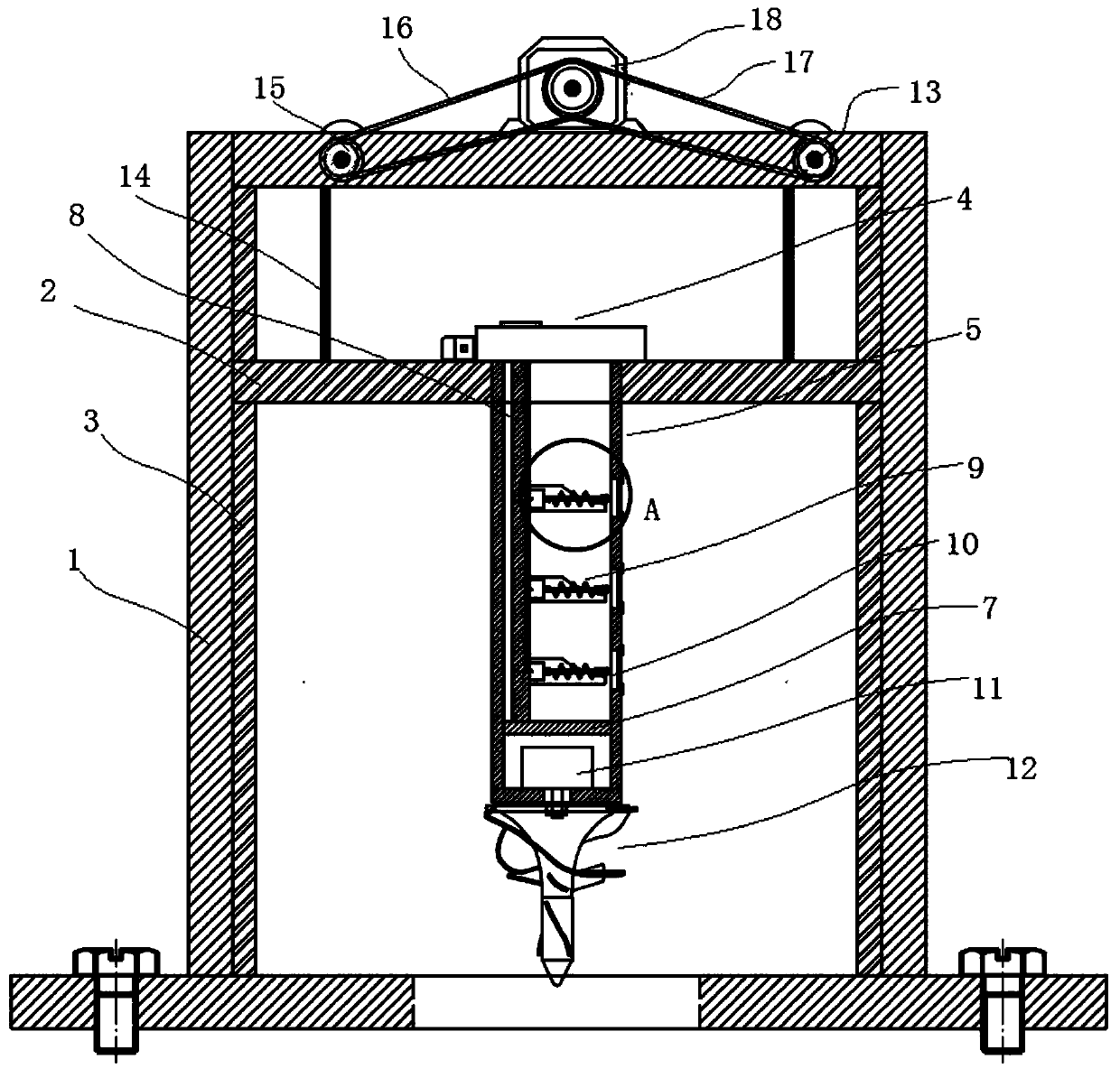

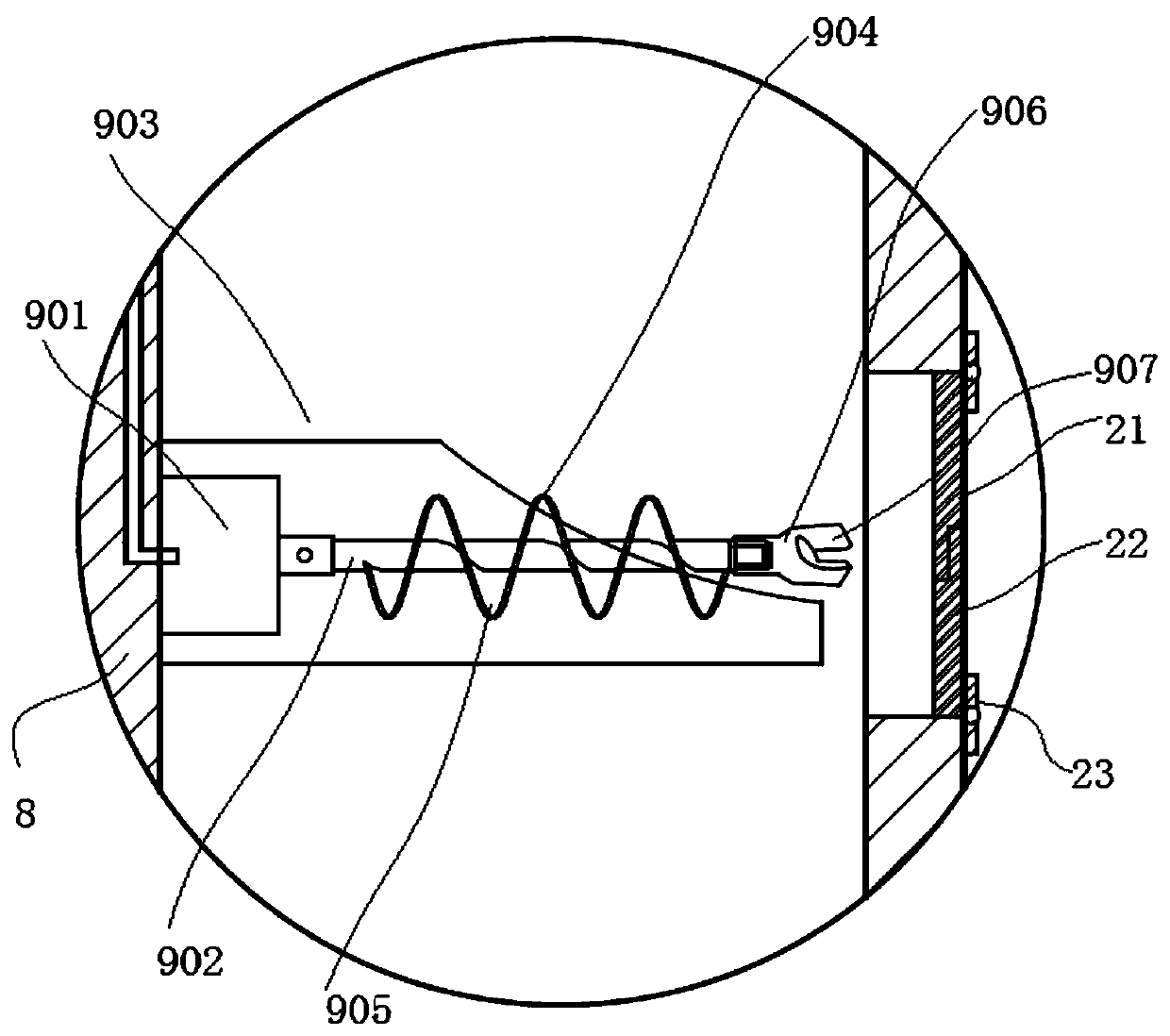

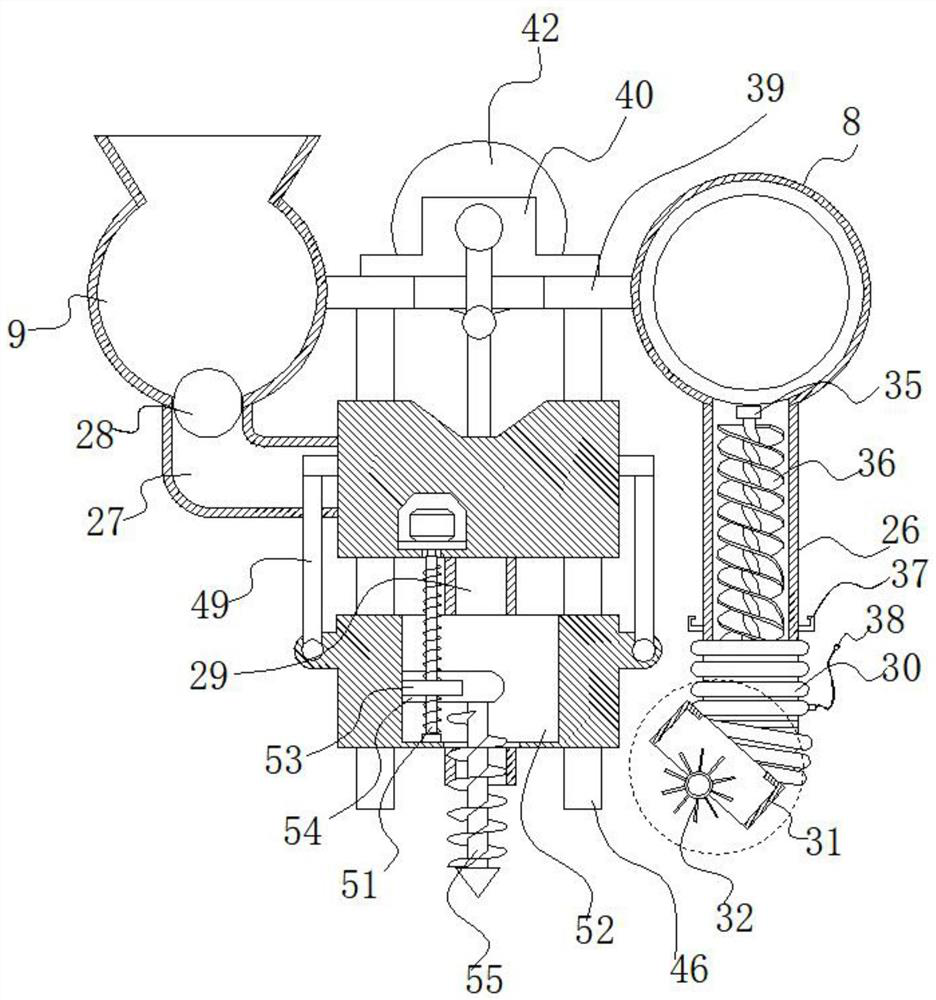

Rock-soil sampling mechanical device for civil engineering

ActiveCN111351681AReduce difficultyReduce drilling difficultyWithdrawing sample devicesPilot holeArchitectural engineering

The invention discloses a rock-soil sampling mechanical device for civil engineering, which comprises a mounting frame, a support plate and a vertical linear slide rail, and the support plate can slide along the vertical linear slide rail; the mechanical device also comprises a sliding mechanism which is arranged at the upper end of the supporting plate, and a drilling and sampling mechanism whichis arranged below the supporting plate. The drilling and sampling mechanism comprises a pile casing and a strip-shaped guide hole; the strip-shaped guide hole is communicated with the inner cavity ofthe pile casing; a baffle is arranged in the pile casing; the interior of the pile casing is divided into upper and lower cavities; a sliding rod is arranged in the upper cavity; the bottom of the sliding rod is in sliding connection with a baffle through a moving guide mechanism. The top of the sliding rod penetrates through the strip-shaped guide hole to be in sliding connection with the sliding structure, a plurality of sampling assemblies are arranged on the sliding rod in the height direction of the sliding rod, a plurality of sampling openings matched with the sampling assemblies are formed in the side wall of the pile casing in the height direction of the pile casing, and a first driving motor and a drill bit assembly are arranged in the lower cavity. Through cooperation of the sliding mechanism and the moving guide mechanism, sampling of different rock-soil layers is realized.

Owner:EAST CHINA UNIV OF TECH

Pipeline blocking device

The invention relates to a pipeline blocking device which comprises a first supporting rod, a second supporting rod, an expansion ring and a sealing cover. The first supporting rod is hinged to the second supporting rod. A drive ring, a support and a pull rod are arranged on the first supporting rod. A fixing ring and a sliding ring are arranged on the second supporting rod, and the sliding ring is connected with the pull rod through a transmission rod. The expansion ring comprises first arc parts and second arc parts, wherein the first arc parts and the second arc parts are distributed alternately. Symmetric guide faces are arranged on guide parts of the first arc parts, and sliding grooves and guide holes are formed in the guide faces. The guide holes in the adjacent first arc parts forma splay shape, and supporting lugs are arranged on the second arc parts. The supporting lugs are correspondingly hinged to the fixing ring and the sliding ring through first connecting rods and second connecting rods. Sliding blocks located in the sliding grooves are arranged at the two ends of the second arc parts, and guide pillars located in the guide holes are arranged on the two sides of thesliding blocks. The sealing cover is arranged on the expansion ring in a sleeving manner from right to left and is fixedly connected with the first arc parts. The pipeline blocking device has the beneficial effects that the structure is simple, control is convenient, adaptability is high, and blocking is reliable.

Owner:北京天兴燃气工程有限公司

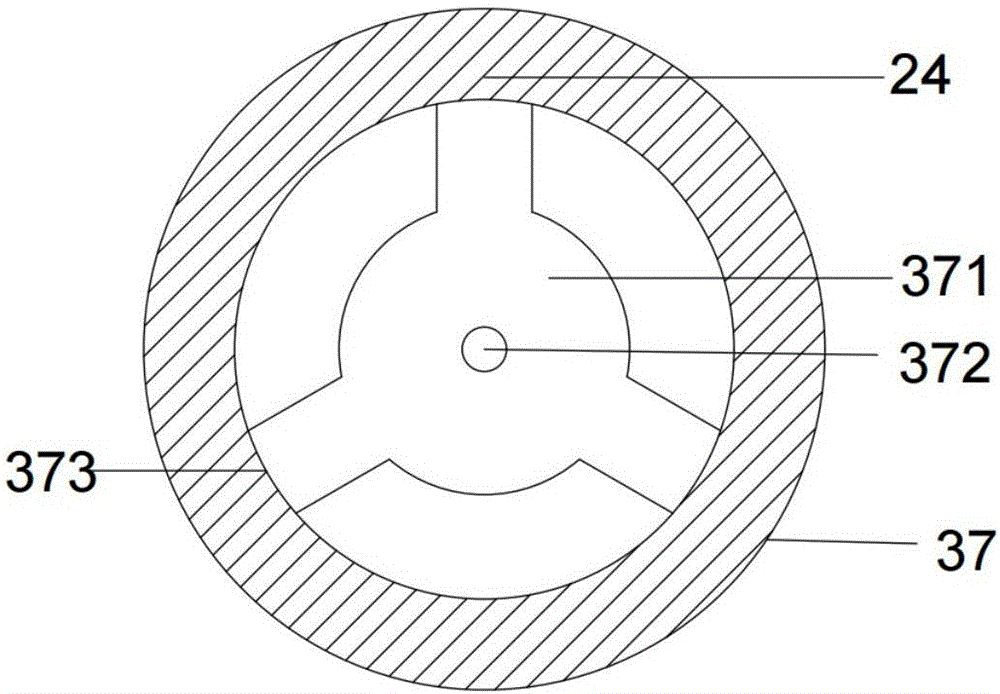

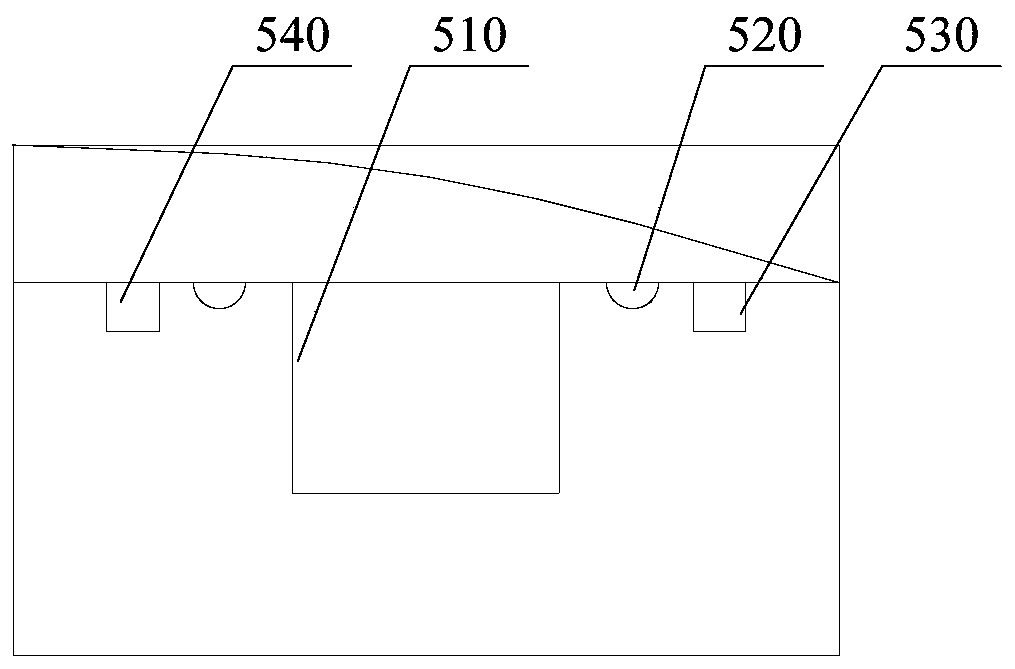

Drill rod feeding device of cement mixing pile driver

The invention relates to a drill rod feeding device of a cement mixing pile driver. By means of the drill rod feeding device, the problem that feeding is not even when an existing cement mixing pile driver drills holes is solved. The drill rod feeding device comprises a sealed distribution box, at least two distribution runners and at least two through holes. Each through hole is internally provided with at least two distribution holes. Drill rods capable of rotating in the circumferential direction are arranged in the through holes in a penetrating mode. Each drill rod is internally provided with at least two conveying pipes axially extending to a conveying pipe at the lower end of the drill rod. The conveying pipes are arranged in a staggered mode in the vertical direction and correspond to the distribution holes in a one-to-one mode. The conveying pipes are connected with the distribution runners through communicating structures. The drill rod feeding device has the advantages that additives can be conveyed to the conveying pipes in the multiple drill rods at the same time in the construction process and are distributed evenly; supply is even, and insufficient slurry supply is avoided; the drilling difficulty is reduced, and holes with larger cross sections can be drilled each time.

Owner:周兆弟

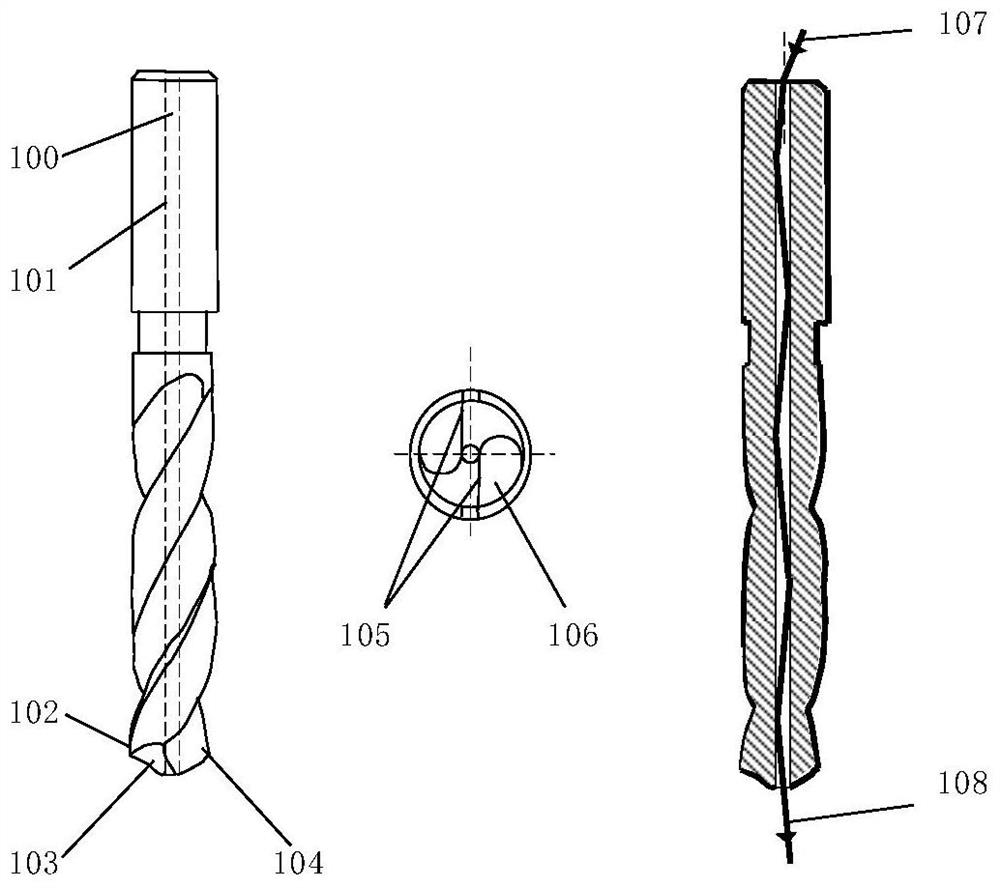

Drill bit for geological exploration

ActiveCN111550189APrimary Borehole ExpansionPowerfulDrill bitsDrilling rodsMining engineeringGeological exploration

Owner:SHENGLI OIL FIELD WANHE OIL CONSTR TECHN LIMITED LIABILITY

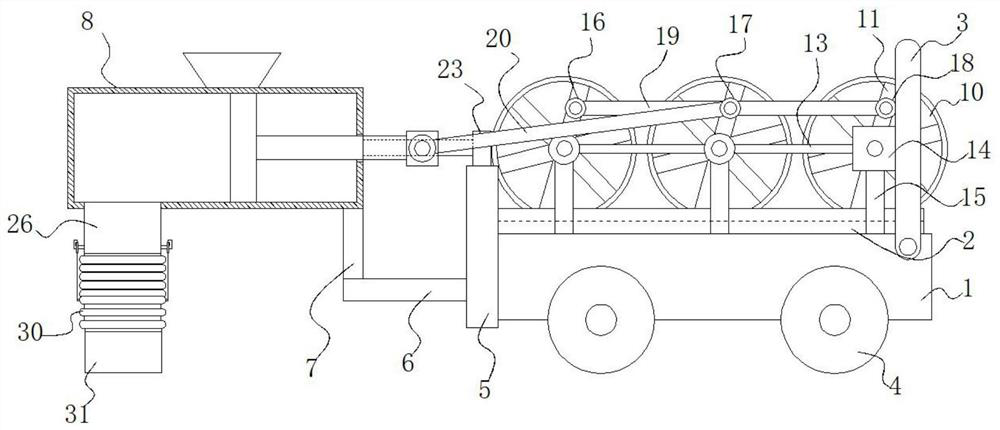

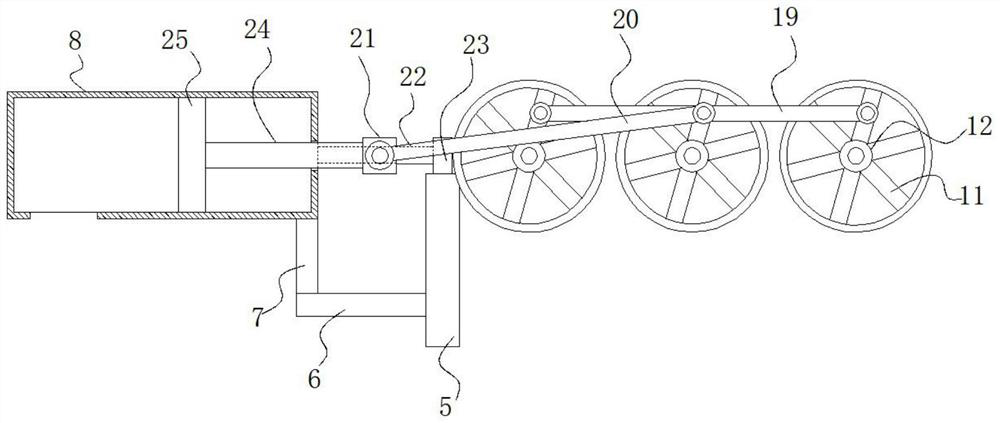

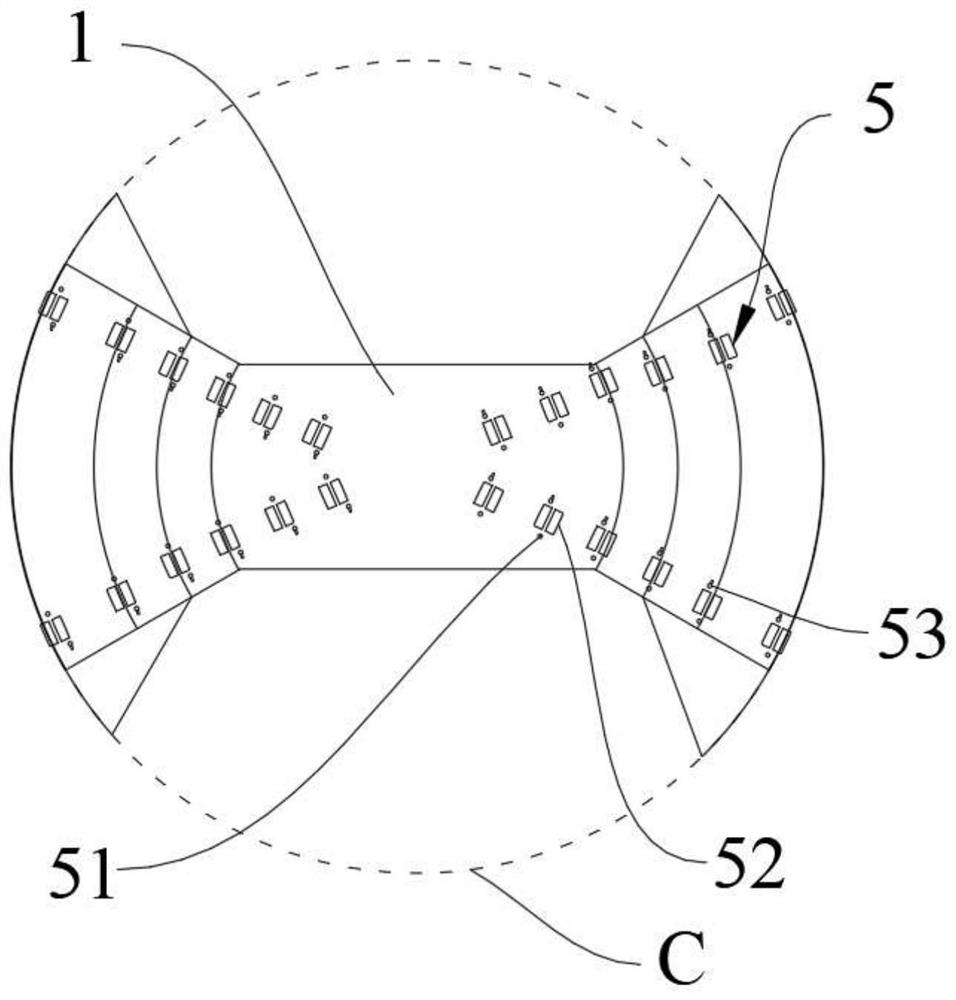

Wheel driving type discharging convertible dangerous solid waste landfill treatment device

InactiveCN113333457AAvoid affecting your healthImprove securityContaminated soil reclamationWaste collectionEnvironmental engineering

The invention discloses a wheel-driven discharging convertible dangerous solid waste landfill treatment device, and the device comprises a box body, a U-shaped tray is arranged at the center of the top of the box body, a driving part is arranged in the U-shaped tray, a U-shaped push rod is connected to one end of the box body in a clamped mode, a plurality of moving wheels are arranged at the bottom of the box body, a second supporting column is arranged on the side, away from the U-shaped push rod, of the box body, the top of the second supporting column is connected with the driving part, a supporting plate is arranged on the lower portion of the side, away from the box body, of the second supporting column, and first supporting columns are arranged at the two ends of the side, away from the second supporting column, of the top of the supporting plate; the top of each first supporting column is provided with a soil collecting bin and a waste collecting bin, and a landfill device is arranged between the soil collecting bin and the waste collecting bin. The invention has the beneficial effects that hazardous wastes are effectively buried in the ground, so that the influence on body health caused by hand contact in a manual operation process is avoided, and the safety performance is improved.

Owner:李帅

Integral rotary precession type rock roadway cutting machine

The invention relates to an integral rotary precession type rock roadway cutting machine. The integral rotary precession type rock roadway cutting machine comprises a rotary cutting platform; a first driving mechanism is arranged on the peripheral side of the rotary cutting platform, and the first driving mechanism is used for driving the rotary cutting platform to rotate and drill or retreat in the axial direction; a plurality of cutter groups are arranged on the front side of the rotary cutting platform; each cutter group at least comprises a first cutter and a second cutter; the first cutter is used for forming an annular drilling groove, and the second cutter is used for expanding the rear end of the annular drilling groove in the radial direction; a rock thin-wall ring is formed between the annular drilling grooves formed by the adjacent cutter groups; and each cutter group further comprises a third cutter used for cutting the corresponding rock thin-wall ring. The integral rotary precession type rock roadway cutting machine can be used for constructing all-directional and angular projects such as a patio, a gate way, an inclined shaft, a ground well and the like, and meanwhile, the machine is simple in structure, low in cost, high in mine underground adaptive capacity and high in cutting and drilling operation speed.

Owner:金色环掘(北京)科技有限公司

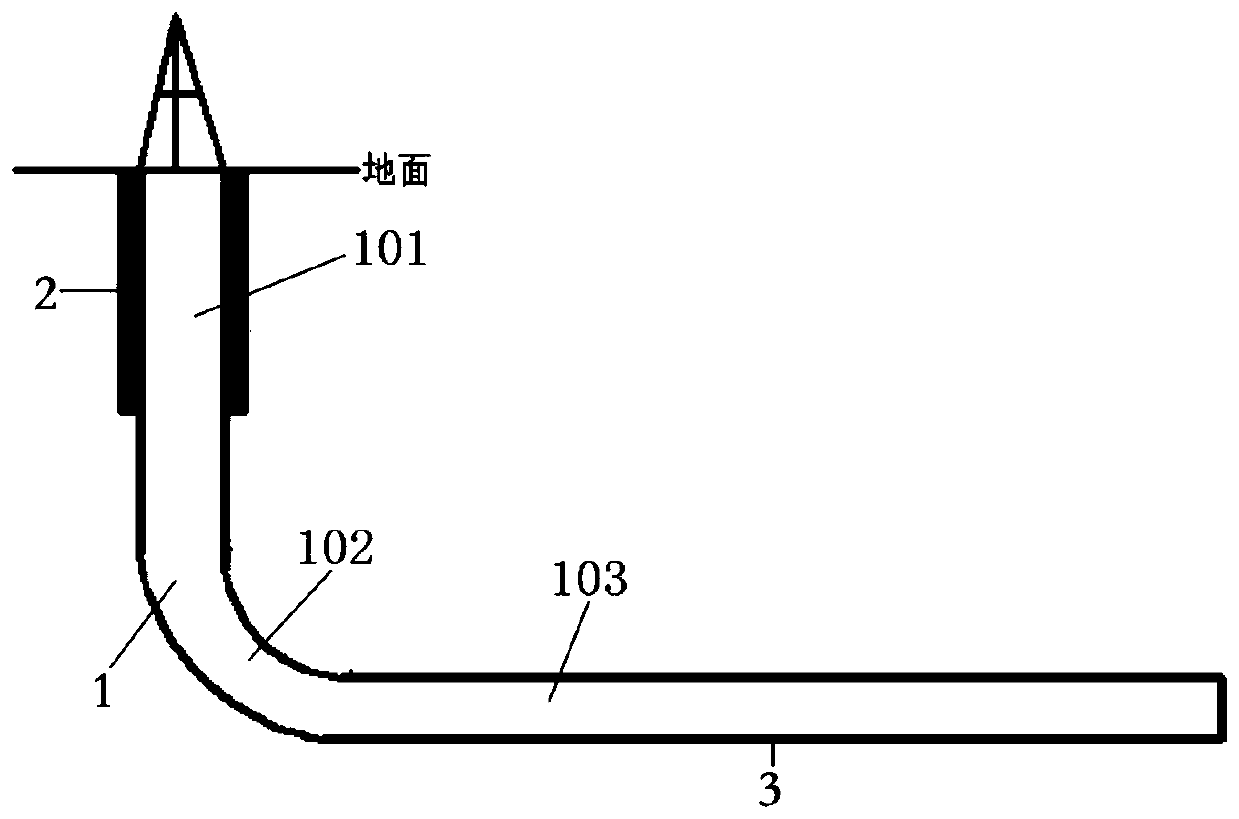

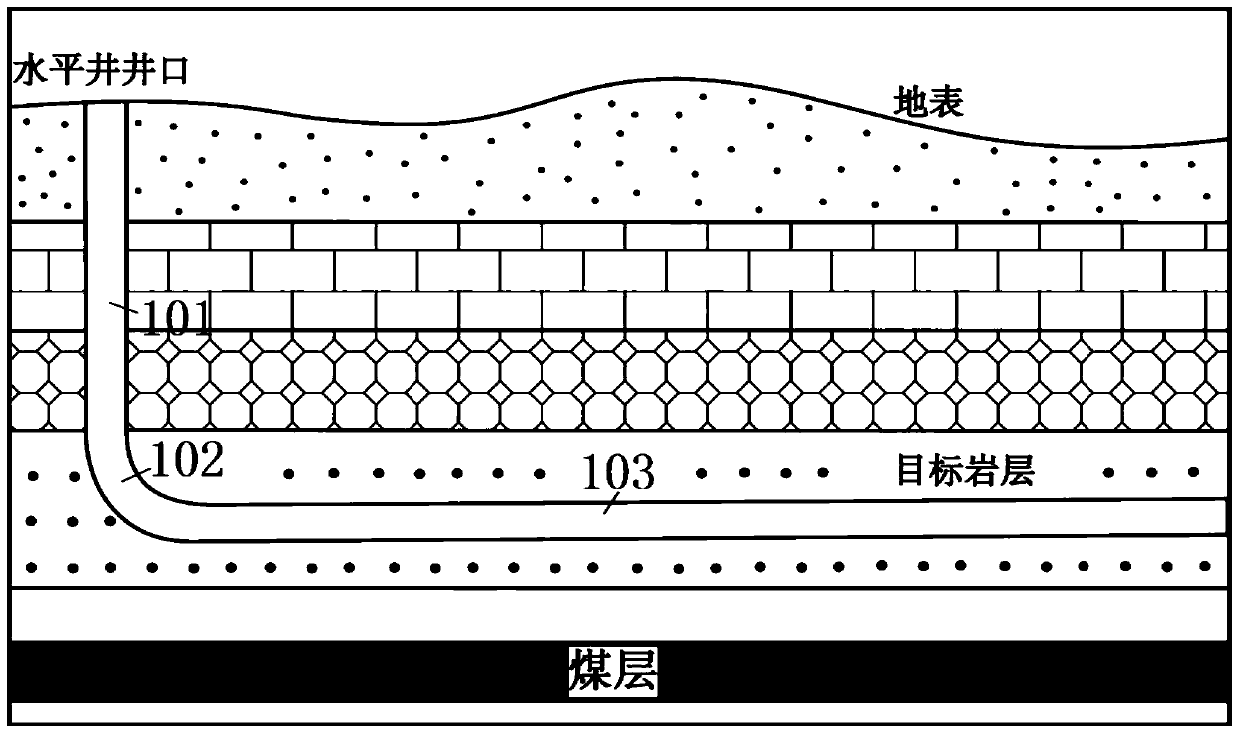

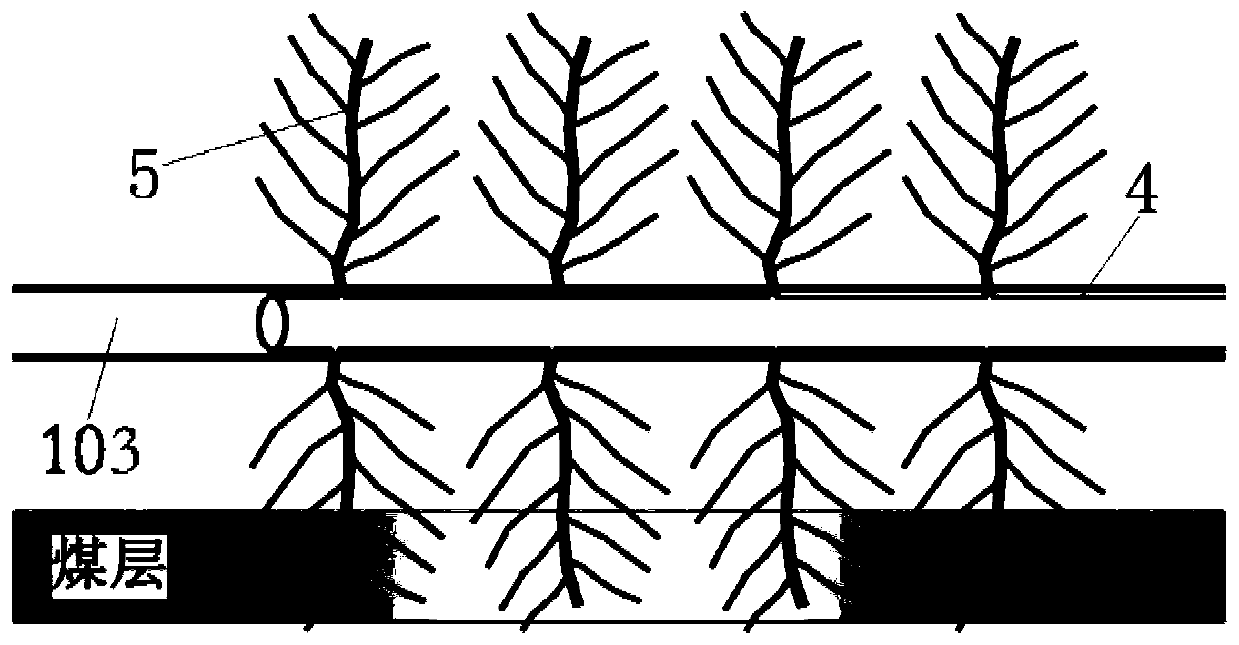

Coal mine impact ground pressure and harmful gas comprehensive prevention and treatment system and method

PendingCN111520184AReduce drilling difficultyRealize extractionFluid removalDirectional drillingLithologyMining engineering

The invention discloses a coal mine impact ground pressure and harmful gas comprehensive prevention and treatment system and method. Firstly, according to roof lithology and pressure characteristics of a coal mining work face, a target rock layer of horizontal well staged fracturing is determined, according to the target rock stratum and coal seam work face characteristics, a well spacing manner of a horizontal well is determined, the horizontal well is drilled, in the horizontal well, a target rock stratum and a coal seam are subjected to fracturing, through fracturing, the target rock stratum and the coal seam form an inter-communication net-shaped fracture, a ground pump drainage system is built, harmful gas in the coal seam is subjected to pump drainage, the horizontal well is mountedin the target rock stratum, in the horizontal well, the target rock stratum and the coal seam are subjected to fracturing, the inter-communication net-shaped fracture is formed in the target rock stratum and the coal seam, fracturing pressure relief of the target rock stratum is achieved, the stress state of a coal seam roof is changed, happening of an impact ground pressure accident is avoided, and meanwhile, release and pump drainage of harmful gas in the coal seam can be achieved.

Owner:陕西省煤层气开发利用有限公司

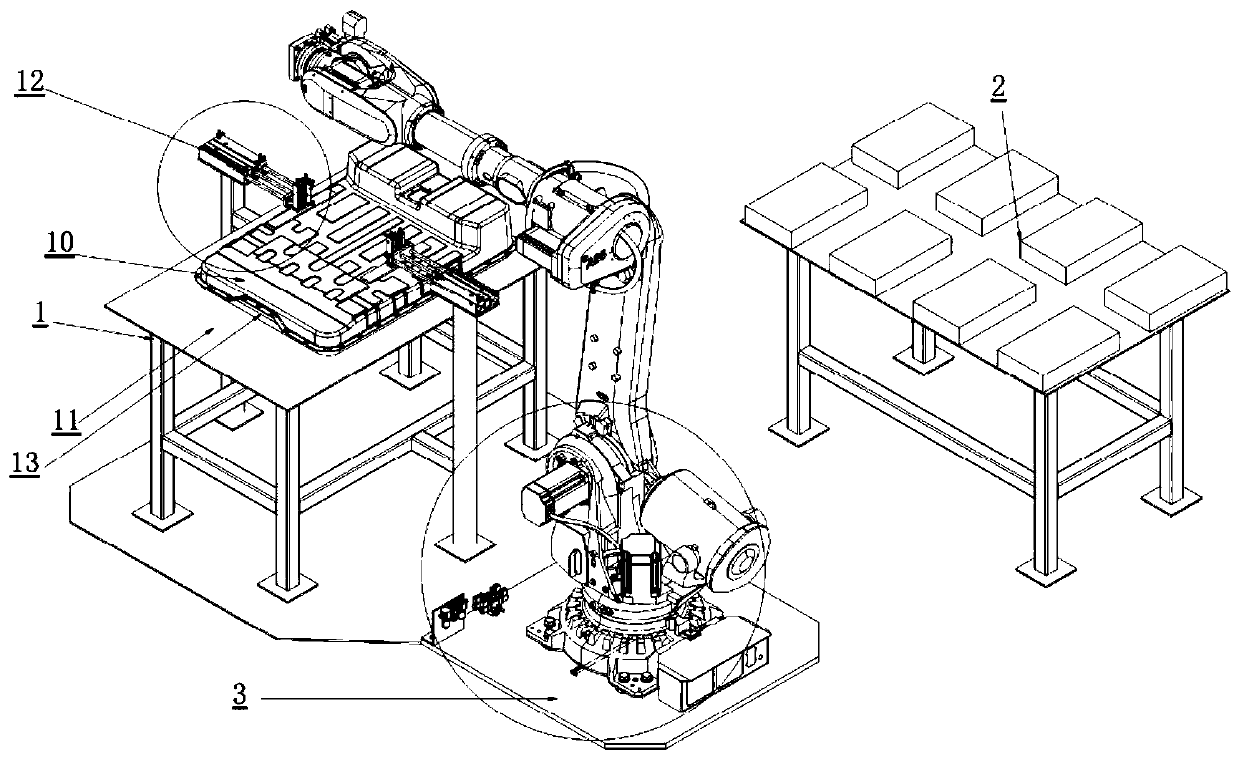

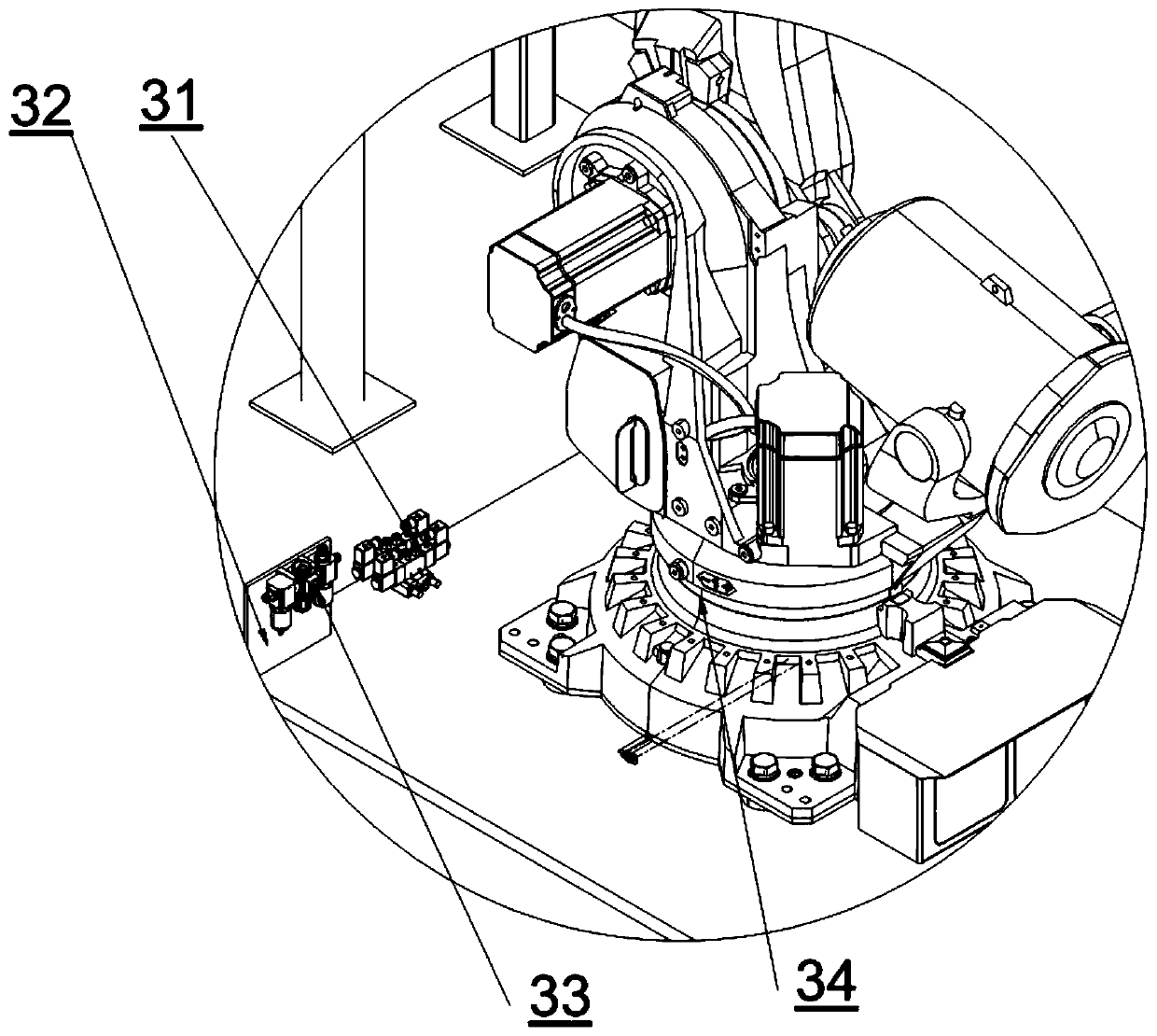

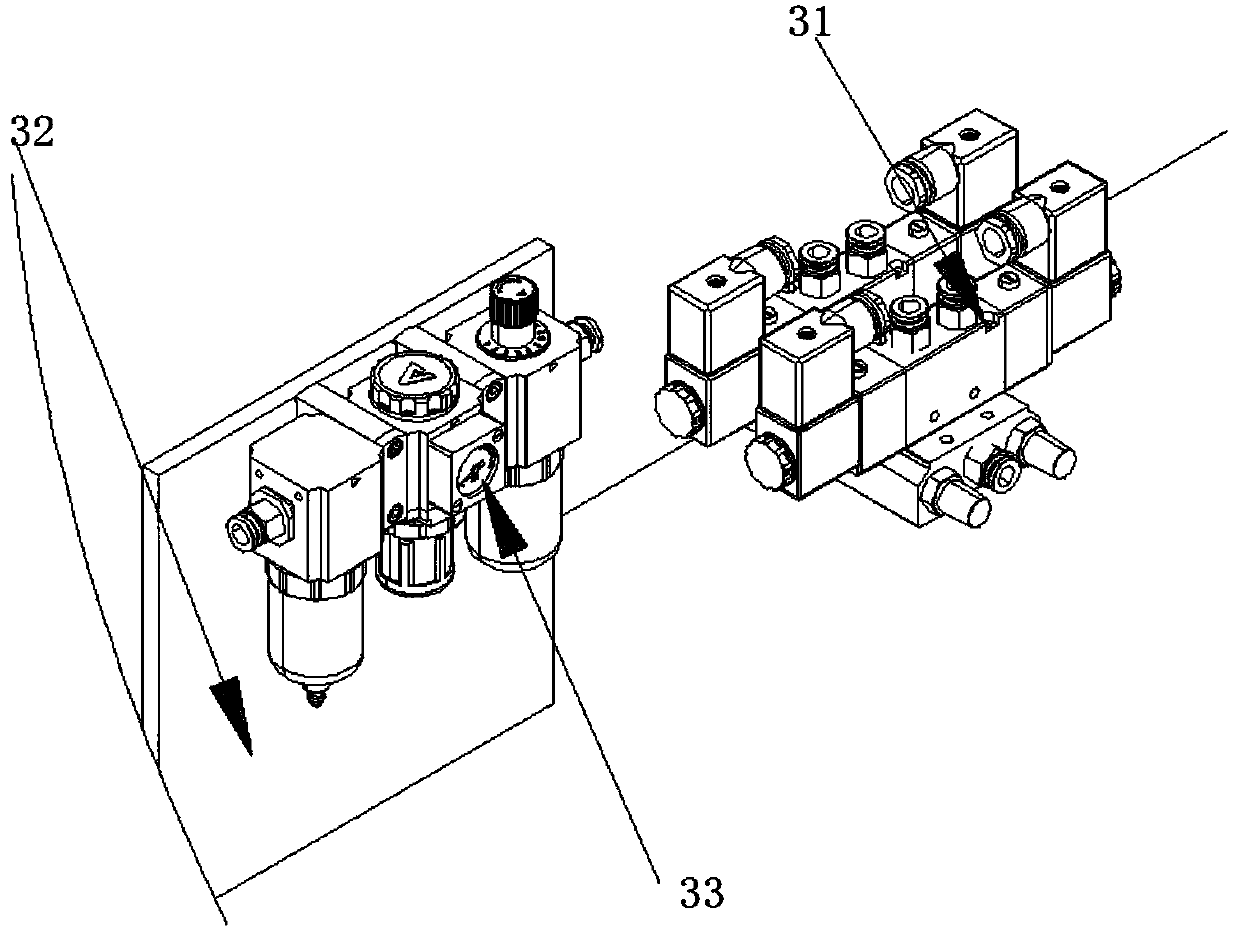

Composite material drilling and milling platform with robot

InactiveCN110340665AReduce the number of clampingReduce precision errorProgramme-controlled manipulatorOther manufacturing equipments/toolsEngineeringMechanical engineering

The invention provides a composite material drilling and milling platform with a robot. The composite material drilling and milling platform comprises a working table, a cutter switching platform, therobot and a cutter execution mechanism located at the tail end of an arm of the robot. The robot is fixed to a robot base. A supporting plate and a pneumatic clamping device are installed at the upper end of the working table. A locating die is arranged on the supporting plate. When a composite material is machined, composite material products needing to be machined are fixed to the working tablethrough the locating die and the pneumatic clamping device, and the robot automatically selects the needed cutter execution mechanism from the cutter switching platform to machine the composite material. The composite material drilling and milling platform with the robot can complete drilling and edge milling work of the composite material products automatically and efficiently, needed machiningcutters can be switched automatically, the production efficiency is improved, and precision errors caused by repeated locating are reduced.

Owner:泰安市复材装备有限公司

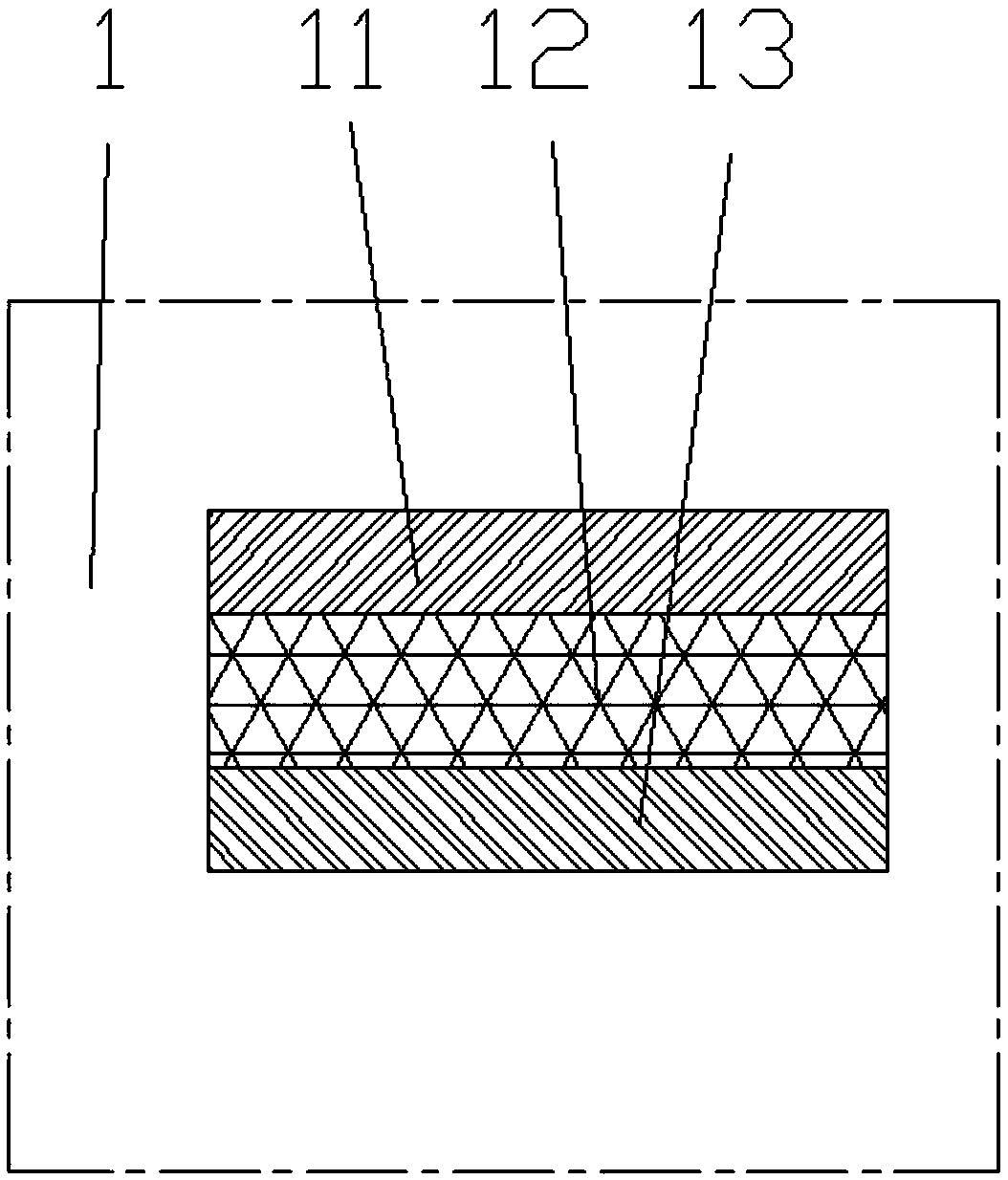

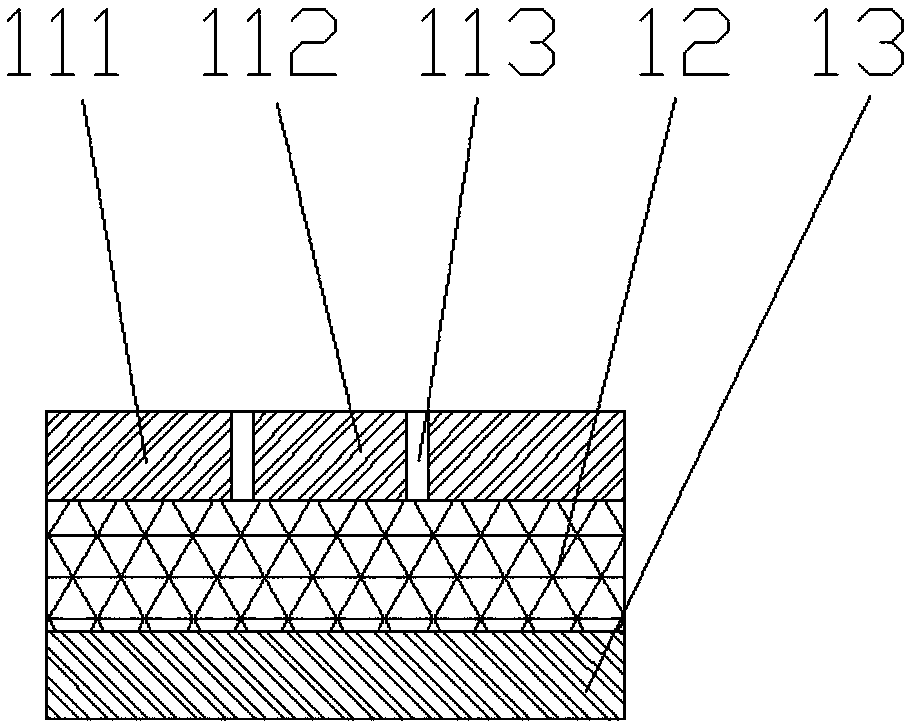

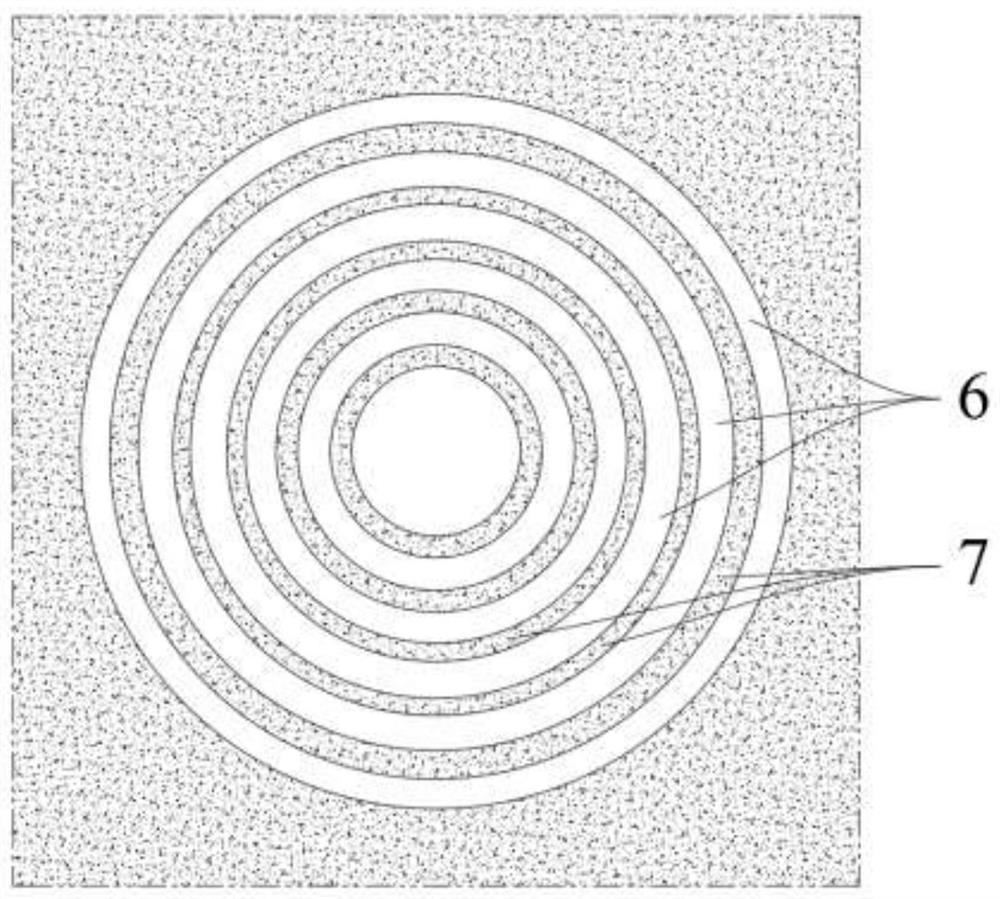

MEMS silicon-based membrane hole atomizing core and manufacturing method thereof

PendingCN113647696APromote decompositionHole thickness reducedTobaccoMultilayer membraneMetal electrodes

The invention discloses an MEMS silicon-based membrane hole atomizing core, and belongs to the technical field of liquid heating atomizing cores, the MEMS silicon-based membrane hole atomizing core comprises a silicon substrate slice, at least one layer of membrane hole mechanism and a metal electrode, the at least one layer of membrane hole mechanism is fixedly connected to the top surface of the silicon substrate slice, and the metal electrode is fixedly connected to the top of the membrane hole mechanism. At least one liquid guide hole is formed in the silicon substrate slice, and the liquid guide hole is communicated with the bottom of the silicon substrate slice and the top of the film hole mechanism; a multi-layer film hole mechanism is adopted, decomposition of the overall thickness is facilitated, the hole opening thickness of a first-stage atomization hole or a second-stage atomization hole is reduced, the hole opening difficulty of the atomization hole is reduced, small-aperture non-straight-through hole opening of the atomization hole is achieved, so that good liquid locking and storing functions are achieved; and the opening manufacturing process of the atomization holes is controllable, the consistency is high, the uniformity is good, and the problems of local overheating and dry burning carbonization are solved.

Owner:美满芯盛(杭州)微电子有限公司

Plugging device and plugging equipment

ActiveCN109282106AIncrease downforceIntegrity guaranteedPipe elementsHydro energy generationRubber ringMechanical engineering

The invention belongs to the technical field of fuel gas pipeline plugging, and more specifically relates to a plugging device and plugging equipment. The plugging device comprises a supporting cylinder, a sliding block screw rod and a sliding block are arranged in the supporting cylinder, the lower end of the sliding block can penetrate out of the supporting cylinder, the penetrating part is provided with a straight plane and a slope, the lower end of the supporting cylinder is connected with a plugging head through a pin shaft, and a rear cone plate sliding block, a rear cone plate, a rubberring, a front cone plate and a guide plate are arranged in the plugging head. According to the plugging device, the sliding block screw rod is driven so that the front cone plate and the rear cone plate can be used to extrude the rubber ring so as to complete plugging; and meanwhile, the plugging device can realize 90-degree steering in a pipeline through the guide plate. The invention further provides plugging equipment comprising the plugging device. The plugging equipment further comprises an inner rod used for driving the sliding block screw rod to rotate and a double-outlet-rod oil cylinder for driving the plugging head to move up and down and steer. The plugging equipment is long in service life, good in plugging effect and better in pipeline integrity keeping.

Owner:BEIJING SHILIXINDA INSTR EQUIP CO LTD

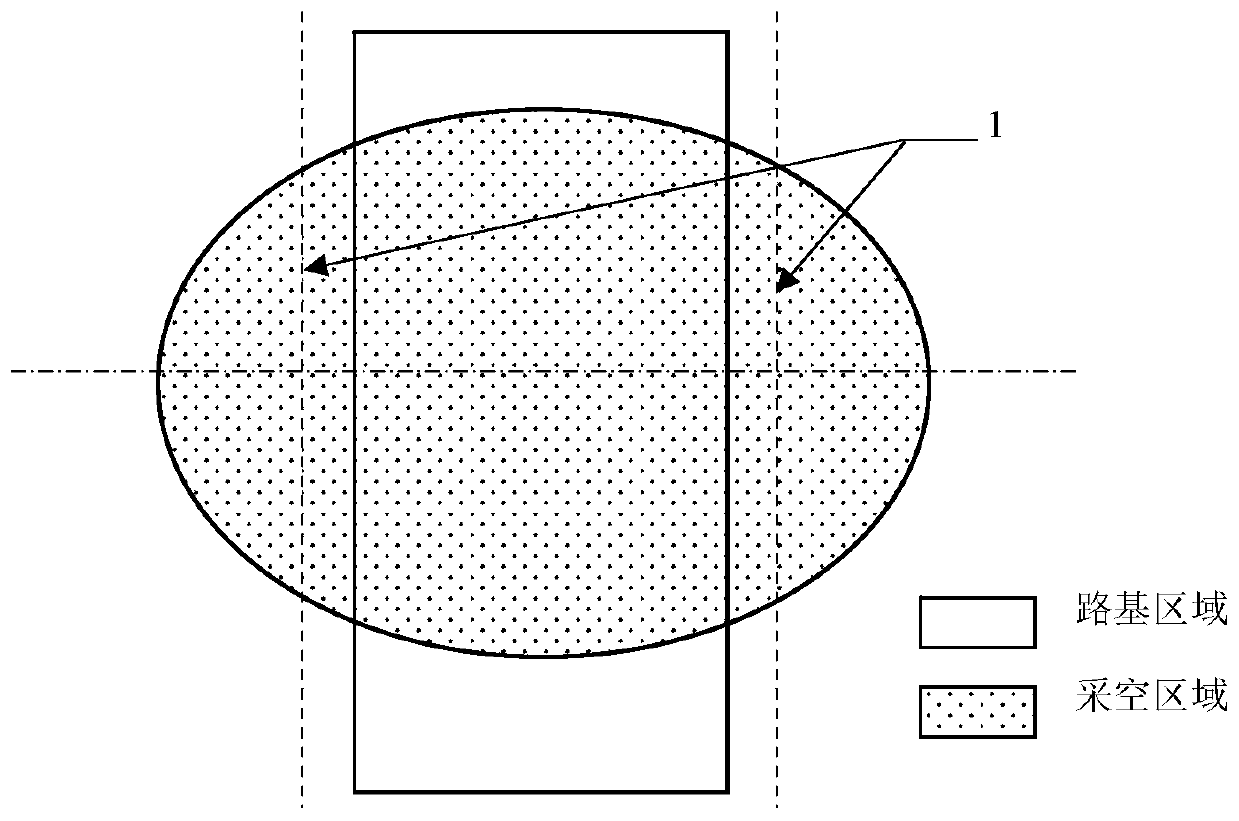

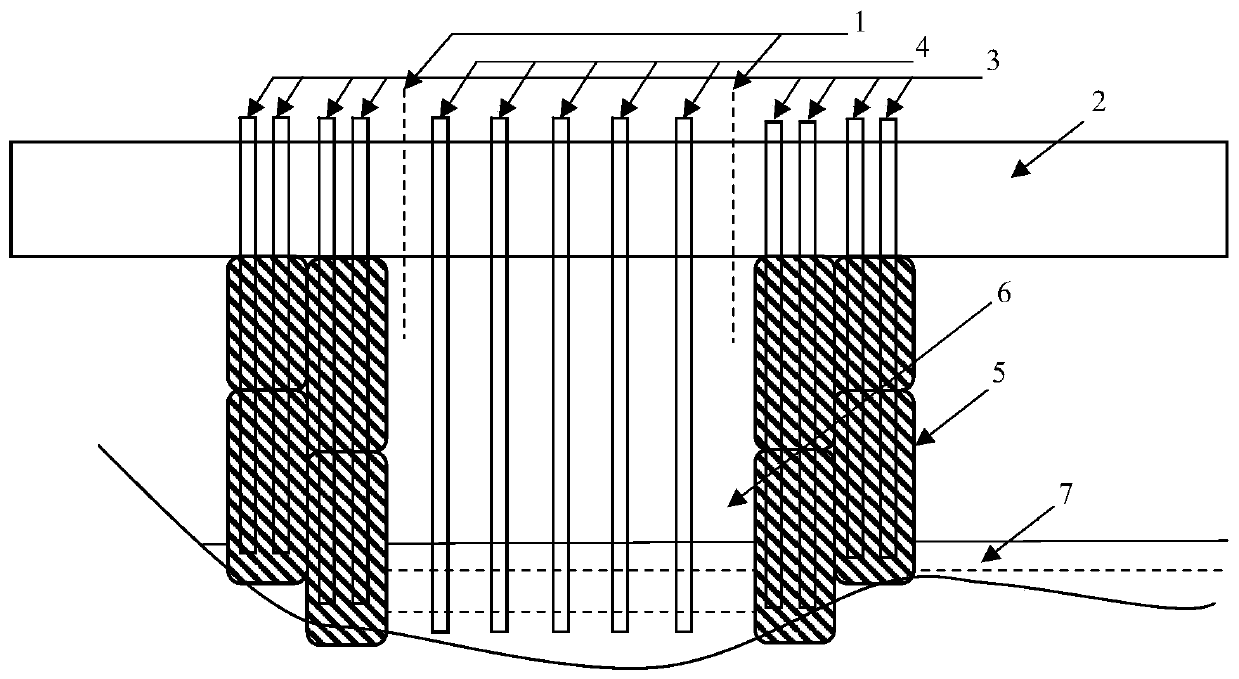

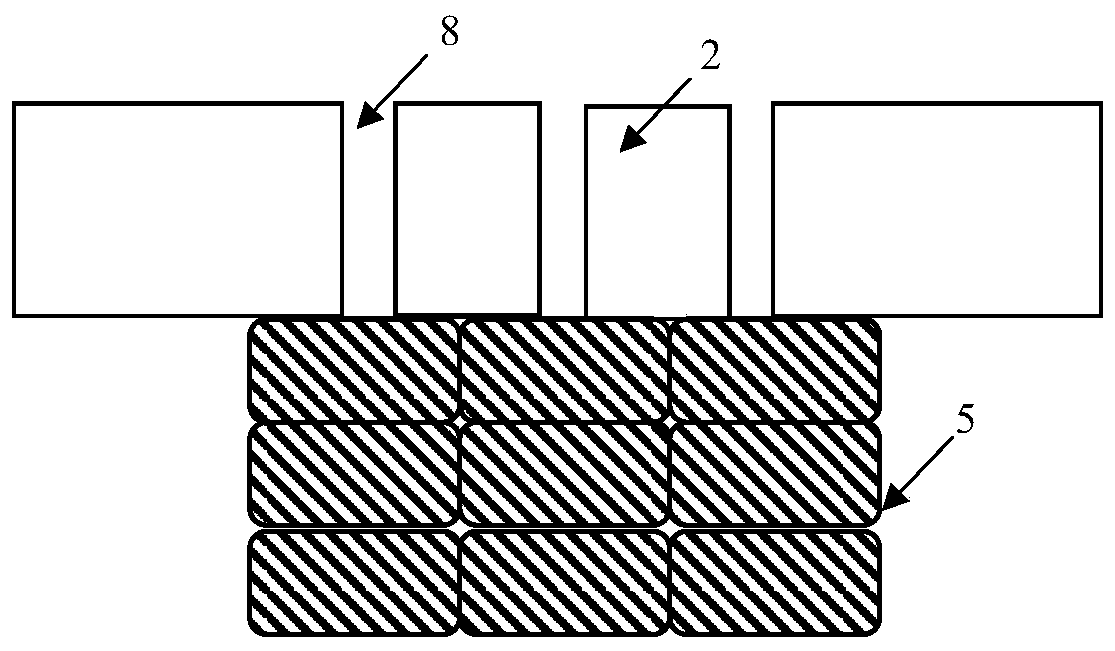

Controllable mould bag grouting method for reinforcing roadbed in underlying goaf

InactiveCN110644310AEasy to bundleIncrease contact areaRoadwaysSoil preservationArchitectural engineeringMaterial consumption

The invention relates to a controllable mould bag grouting method for reinforcing a roadbed in an underlying goaf. The method comprises a curtain wall and a grouting body, wherein the grouting body isfilled in the curtain wall; the curtain wall is formed by grouting a mould bag; the mould bag is formed by sewing hemp bags with thick threads; the mould bag has three sides with a width of 1.6m andan overall length of 6m; a galvanized pipe is arranged in the middle of the mould bag; a grouting pipe is arranged in the galvanized pipe; and the grouting pipe and the galvanized pipe are fixed by steel wires. According to the method, the goaf reinforcement grouting technology is controllable, the material consumption and the goaf treatment cost are reduced through the curtain wall, meanwhile, the reinforcement strength of the goaf is convenient to control, the pollution to the surrounding environment is greatly reduced, and the effective reinforcement of the hollow goaf can be realized.

Owner:SHANDONG UNIV

Single-sided annular kerf energy gathering grain, indoor test and application

PendingCN111504747AAvoid errorsImprove crushing effectPreparing sample for investigationFuel testingEngineeringStructural engineering

The invention discloses a single-face annular kerf energy gathering grain which comprises an explosive column shell and explosives, annular kerfs are cut in the explosive column shell every 2-3 timesof the inner diameter of the explosive column shell along the axial direction, the width of each annular kerf is 3-6 mm, the angle of each annular kerf is 120-180 degrees, and the explosive column shell is filled with the explosives. The invention further provides a laboratory test method and a field application technology of the single-sided annular kerf energy gathering grain. According to the laboratory test method, the distribution characteristics of the single-sided circumferential blasting cracks can be intuitively observed, the single-sided circumferential explosion stress field distribution can be accurately measured, and the single-face annular kerf energy gathering grain is applied to roadway tunneling blasting, and the result shows that the single-face annular kerf energy gathering grain can improve the groove cavity crushing effect, reduce the large block rate, improve the slotting blasting throwing effect, reduce the clamping effect of a ground stress clamp borne by rock,improve the blast hole utilization rate and the tunneling footage, shorten the tunneling operation time and save the economic cost.

Owner:ANHUI UNIV OF SCI & TECH +1

Novel anchoring nail

PendingCN110786922AEasy to drill throughReduce drilling difficultyFastenersInfection riskBone Cortex

The invention discloses a novel anchoring nail. The novel anchoring nail comprises a nail body, a stopper, a connecting column, a top button, a self-tapping tip end and a threaded cutting edge, wherein the stopper is arranged on the upper part of the nail body; and the upper part of the nail body is fixedly connected with the top button through the connecting column. According to the novel anchoring nail disclosed by the invention, through mutual cooperation among the nail body, threads, the stopper, the connecting column, the top button, the self-tapping tip end and the threaded cutting edge,the novel anchoring nail is realized. The design of an overflow groove is added in a threaded area, so that the tip end of a screw is sharper, and the self-tapping pressure intensity is increased, and thus, the anchoring nail passes through a cortical bone more easily in a drilling way; meanwhile, due to the overflow groove, bone chips can be discharged from the overflow groove, so that incrementof infection risk caused by accumulating the bone chips in bones is avoided, and the difficulty of drilling the anchoring nail into the bones is also reduced; and because of the design of thinner screwdriver buckle area, the exposure size of the anchoring nail outside the bones is reduced while the anchoring nail is stably clamped and self-tapping is carried out at the same time, and a discomfortsense of a patient caused by rubbing of muscles is reduced.

Owner:SHANGHAI NINTH PEOPLES HOSPITAL SHANGHAI JIAO TONG UNIV SCHOOL OF MEDICINE

A coal-thermal co-mining method based on high ground temperature mine

ActiveCN109057796BChange structureImprove heat extraction efficiencyLighting and heating apparatusUnderground miningEngineeringHeat energy

The invention discloses a coal-heat co-mining method based on a high ground temperature mine. The method uses a goaf formed after coal mining as a reservoir; at the same time, a geothermal well is excavated into a thermal reservoir in a roadway. Hot water is pumped out through a geothermal exploitation well, and cold water is recharged through a geothermal recharging well; at the same time, a WSHP(Water Source Heat Pump) heat exchange station and a wind source heat pump station are built on surface to recover heat energy in the hot water and the hot wind. Through the method, coal mining can effectively change structure of a underground rock stratum, and exert a certain pressure relief and anti-reflection effect on the thermal reservoir, thereby improving heat extraction efficiency of thegeothermal well; by the method, the waste high ground temperature mine can also be reused for reproduction; the extracted geothermal resources are energy-saving and emission-reducing; and the geothermal well is excavated in the mine, which greatly reduces mining depth of the geothermal well, reduces drilling difficulty, shortens drilling cycle and reduces mining cost.

Owner:CHINA UNIV OF MINING & TECH

Material conveying seal box for cement mixing pile driver

The invention relates to a material conveying seal box for a cement mixing pile driver. The material conveying seal box solves the problems that materials are unevenly fed when an existing cement mixing pile driver is used for drilling holes. The material conveying seal box comprises a main seal box body, a main rod penetrating hole, at least two auxiliary rod penetrating holes, a main drill rod, auxiliary drill rods, a movable seal box body and a main rod installation hole. At least two main rod conveying pipes are arranged in the main drill rod. At least two main rod feeding inlets are formed in the movable seal box body, and a main rod feeding mechanism is arranged in the movable seal box body. At least two auxiliary rod conveying pipes extending downwards in the axial direction are arranged in each auxiliary drill rod. At least two auxiliary rod feeding inlets are formed in the main seal box body, and an auxiliary rod feeding mechanism is arranged in the main seal box body. The material conveying seal box has the advantages that slurry is evenly distributed; a distributor does not need to be lifted up along with the drill rods which are lifted up; additives can be conveyed into the conveying pipes in the drill rods at the same time in construction, material feeding is smooth, and the additives in the conveying pipes in the drill rods are evenly distributed.

Owner:周兆弟

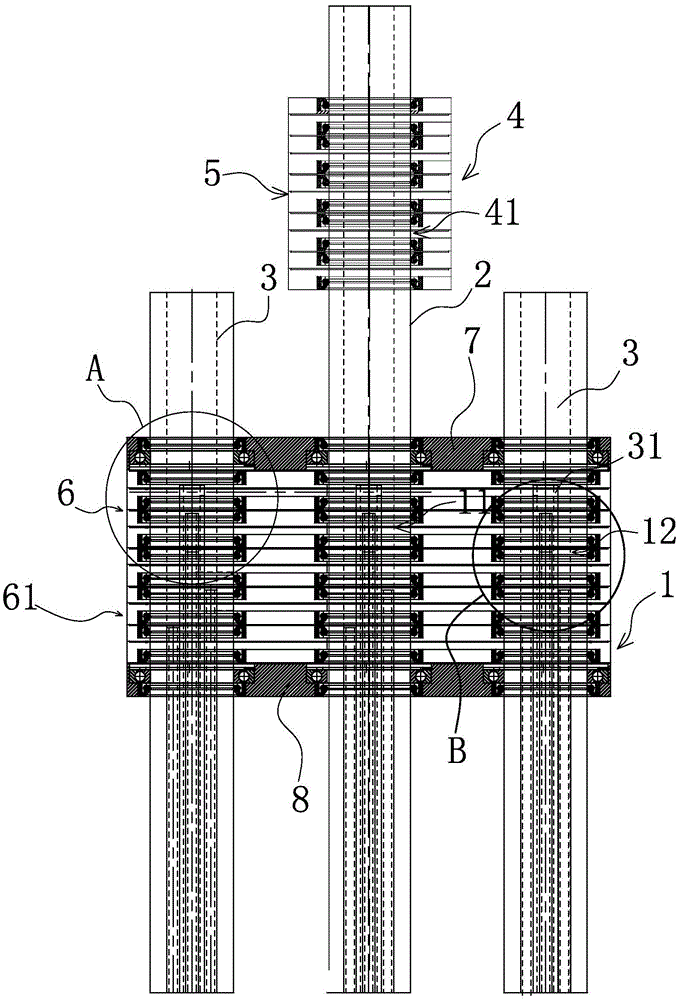

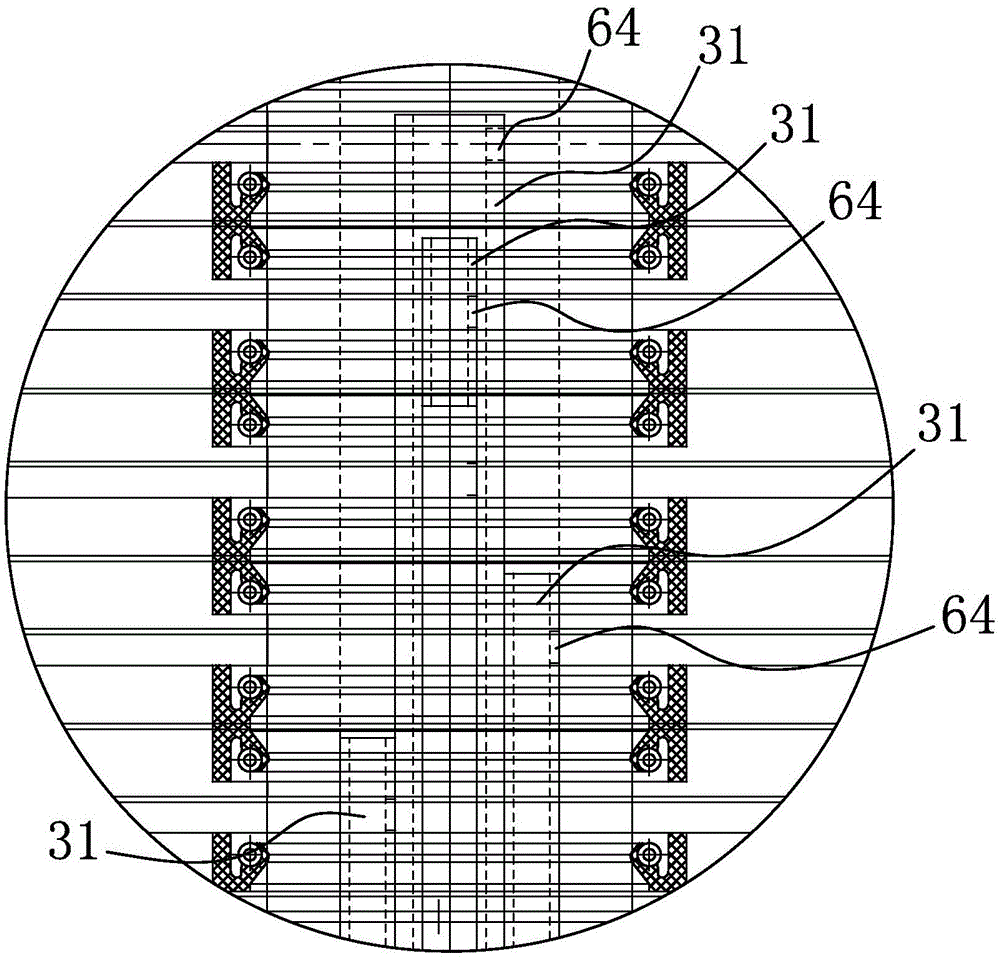

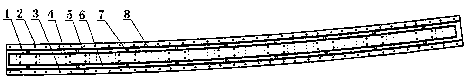

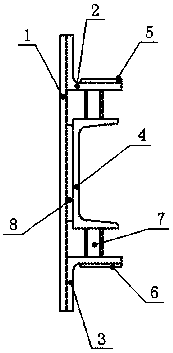

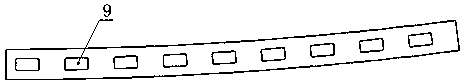

Distribution-drilling method for floating screen frame of banana-shaped flip-flow screen

ActiveCN110125449AImprove drilling accuracyReduce drilling difficultyDrill jigsBoring/drilling machinesNumerical controlCushion

The invention discloses a distribution-drilling method for a floating screen frame of a banana-shaped flip-flow screen. The method comprises the following steps: a, manufacturing a side square drill template; b, manufacturing an upper drill template; c, manufacturing a lower drill template; d, assembling a distribution-drilling part assembly; e, using a numerical-control drilling machine and a boring machine to drill upper support angle steel, lower support angle steel and the floating screen frame; and f, dismounting the distribution-drilling part assembly, accomplishing distribution-drillingof the floating screen frame once, and utilizing the side square drill template, the upper drill template, the lower drill template, a support block and an auxiliary cushion plate to perform distribution-drilling on next floating screen frame. The distribution-drilling part assembly consisting of the side square drill template, the upper drill template, the lower drill template, the auxiliary cushion plate and the support block, which can be used in a circulating mode, is adopted to perform all-around distribution-drilling on the upper support angle steel, the lower support angle steel and the floating screen frame, so that drilling difficulty is greatly reduced, drilling precision of the floating screen frame is improved, and smooth production is guaranteed.

Owner:TIANDI TANGSHAN MINING TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com